Patents

Literature

331results about How to "Reduce end break rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

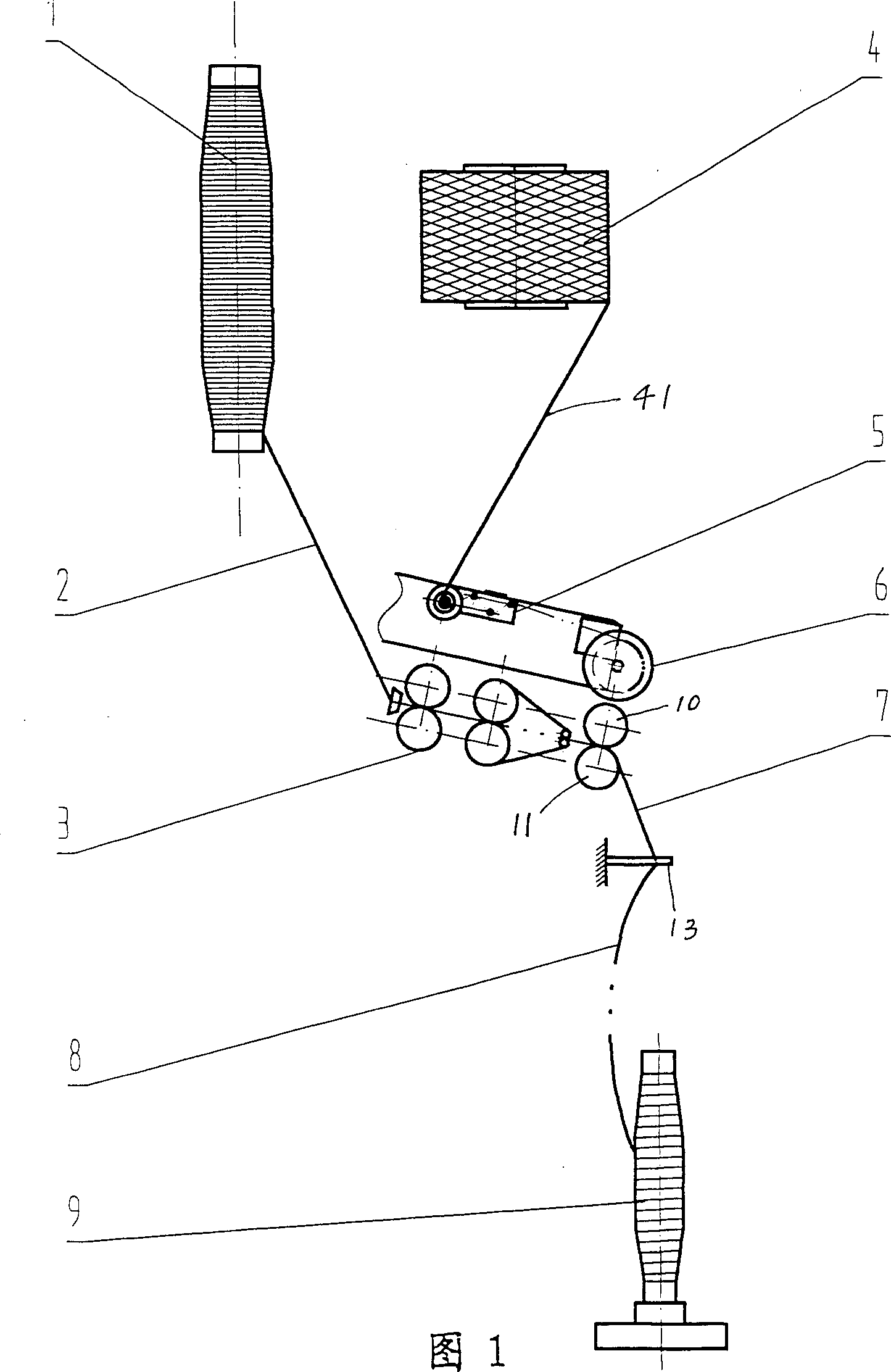

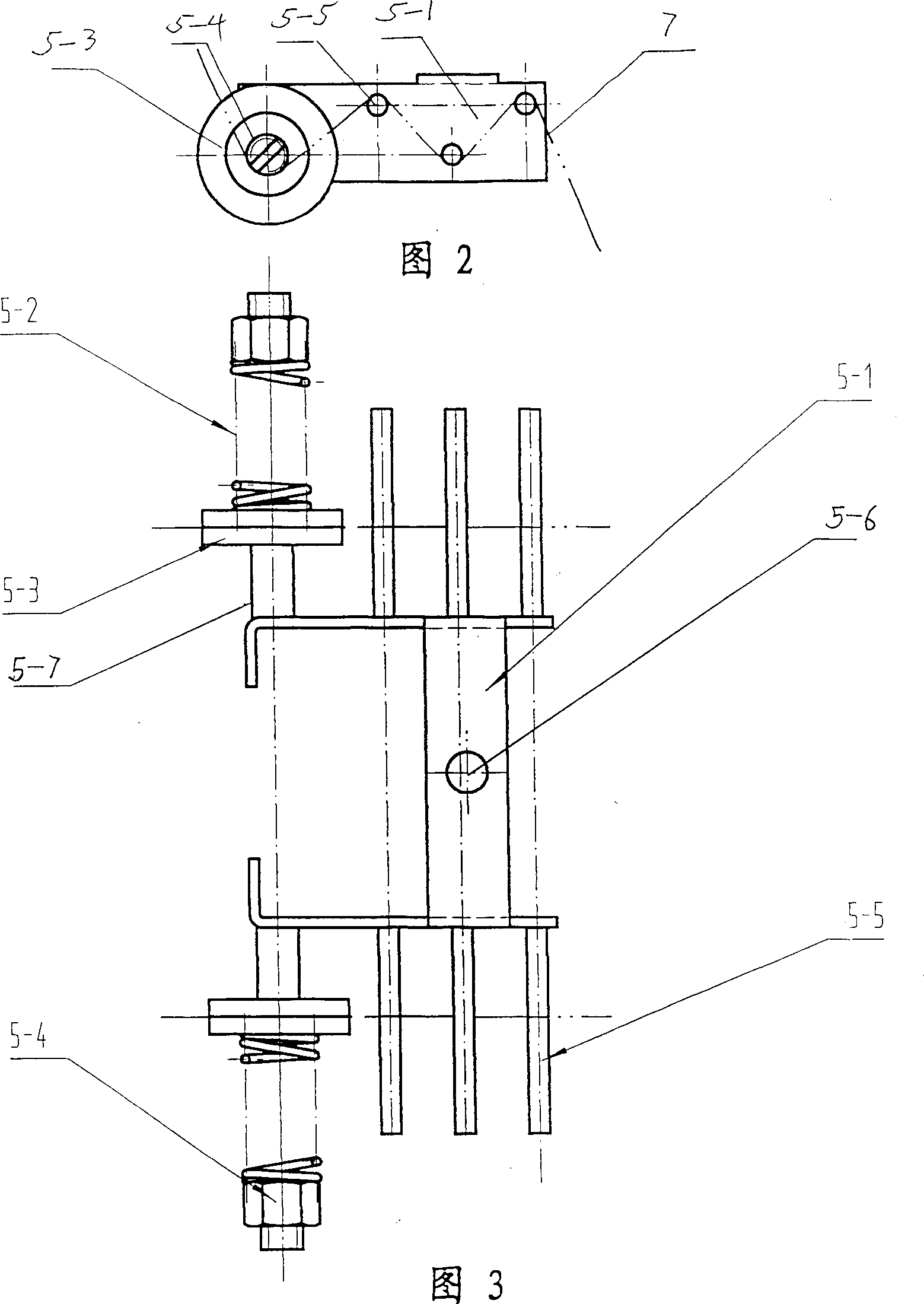

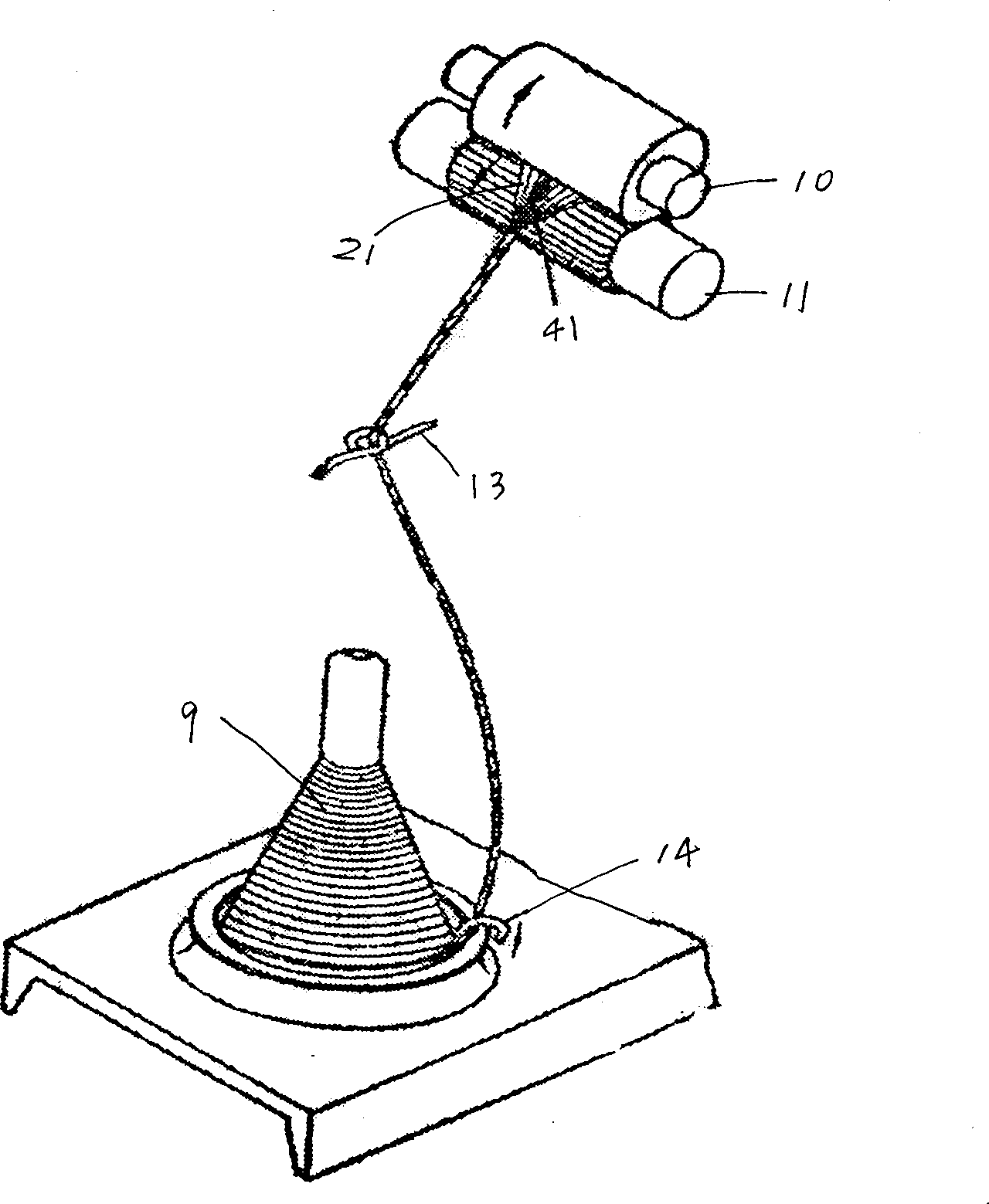

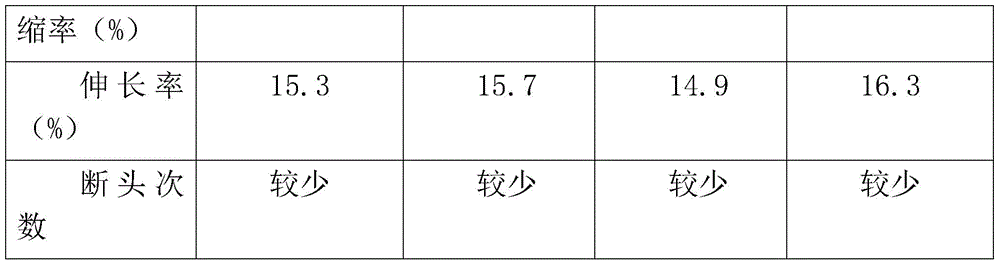

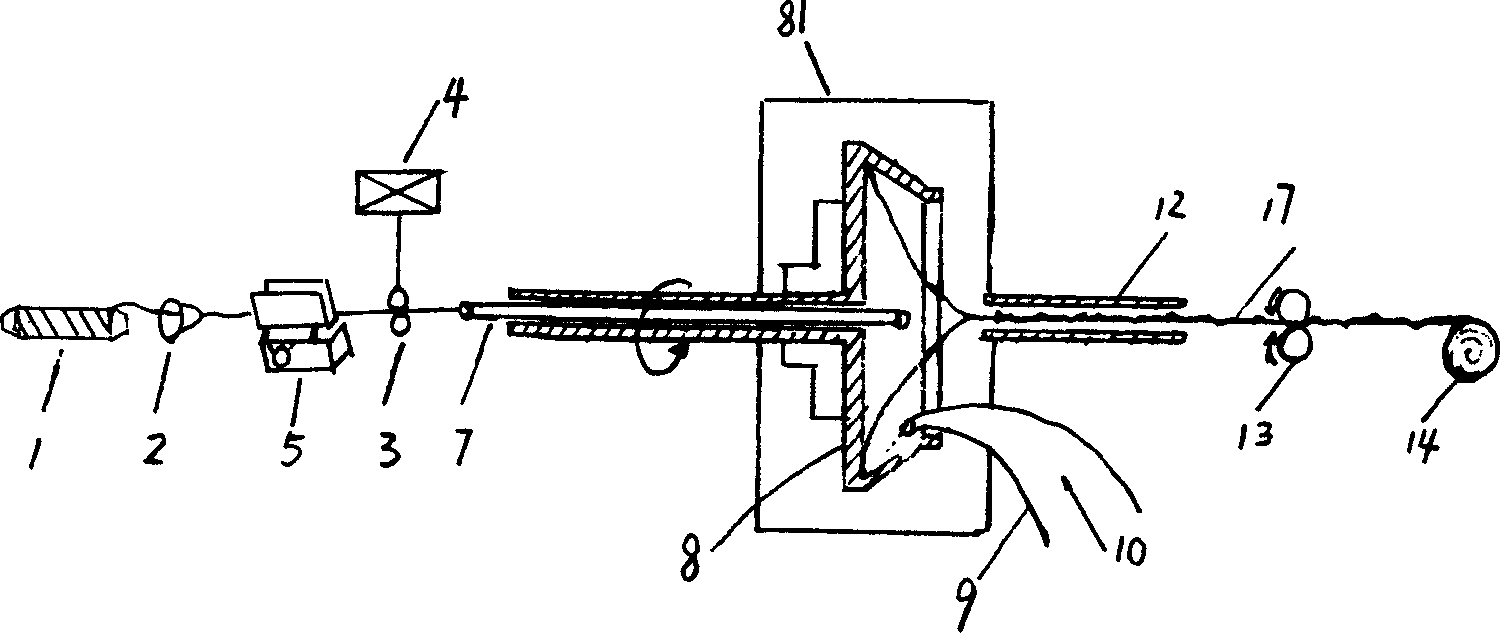

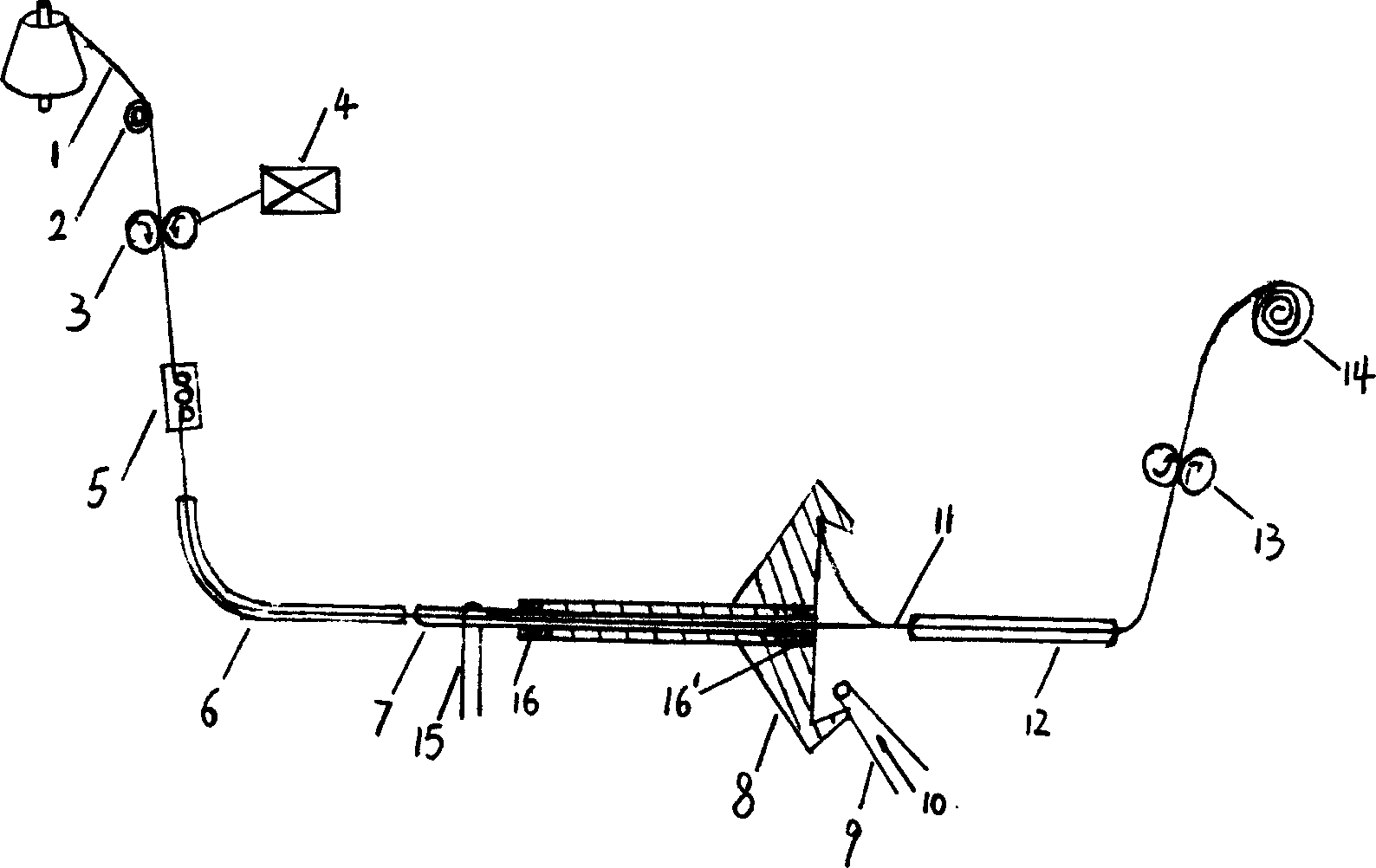

Method and apparatus for making core-spun yarn of steple-fibre covered filament

The present invention is characterized by that on the spinning machine it utilizes addition of a yarn tension control device and simple renovation of guide wheel to spin the invented core-spun composition yarn whose yarn is covered with staple fiber, and its covering rate is high. Said composite core-covered yarn not only has the appearance style, hand property, fluffy property and other advantages of staple fibre, but also possesses the strength and elongation, conformal property and drapping property, etc. of yarn.

Owner:薛元

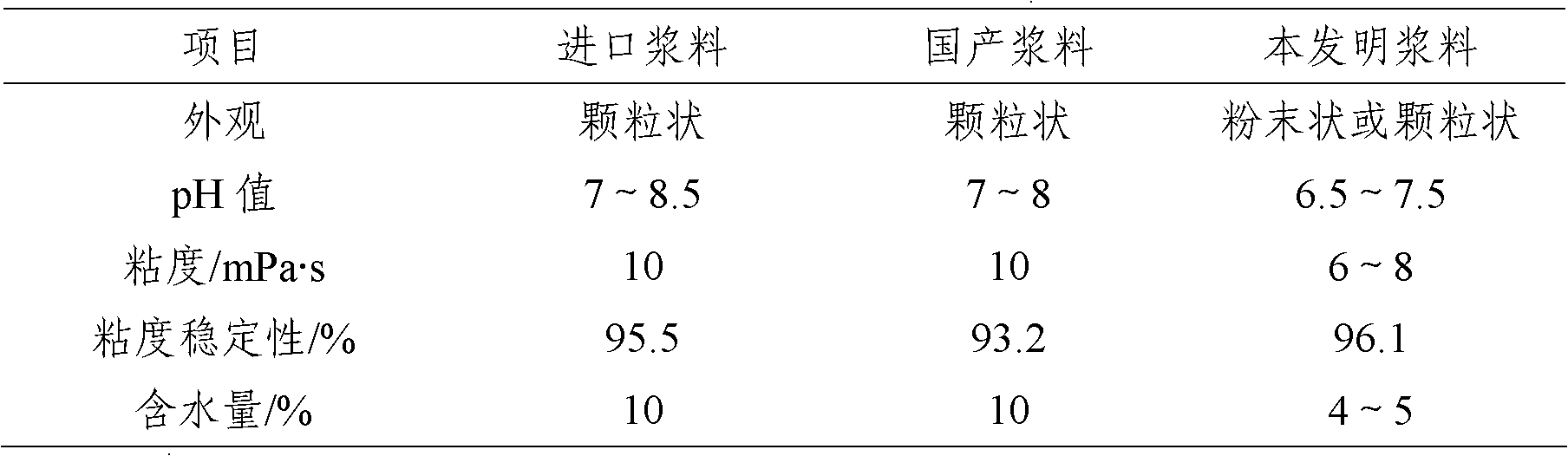

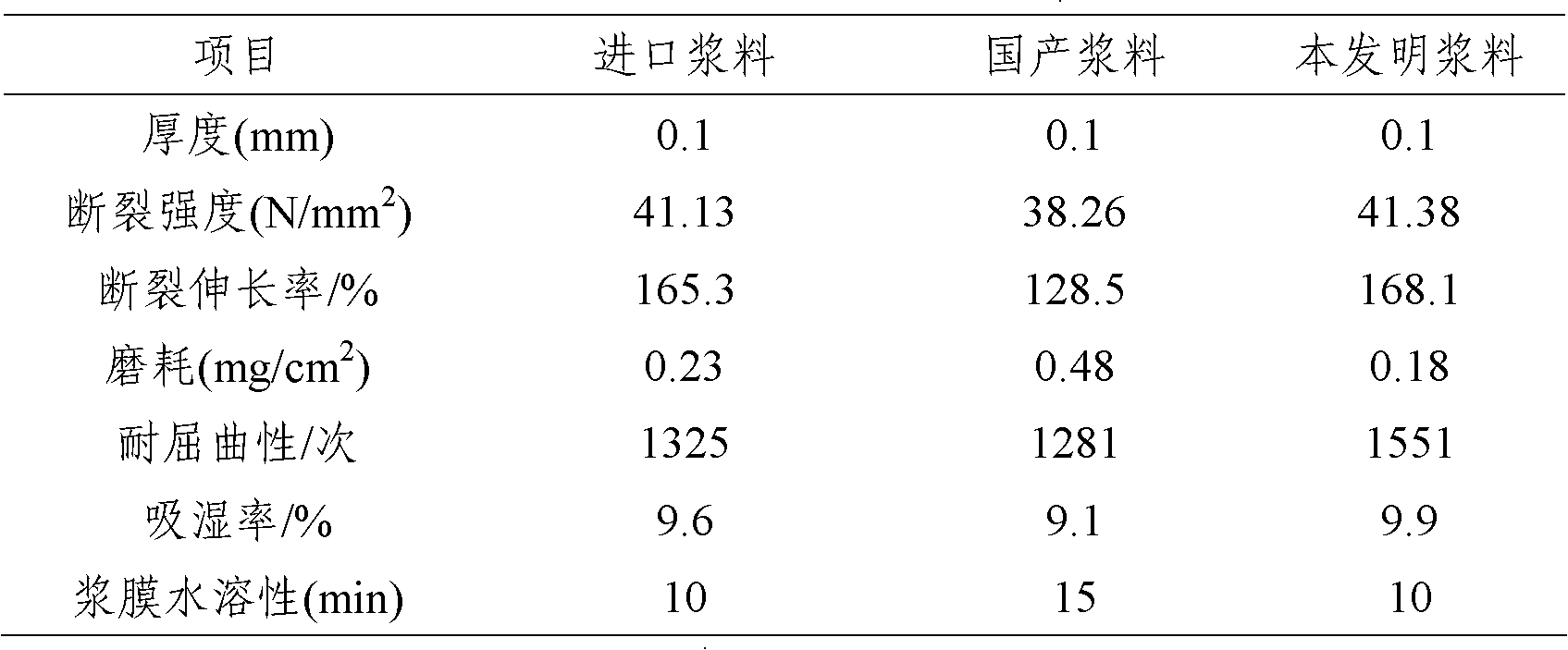

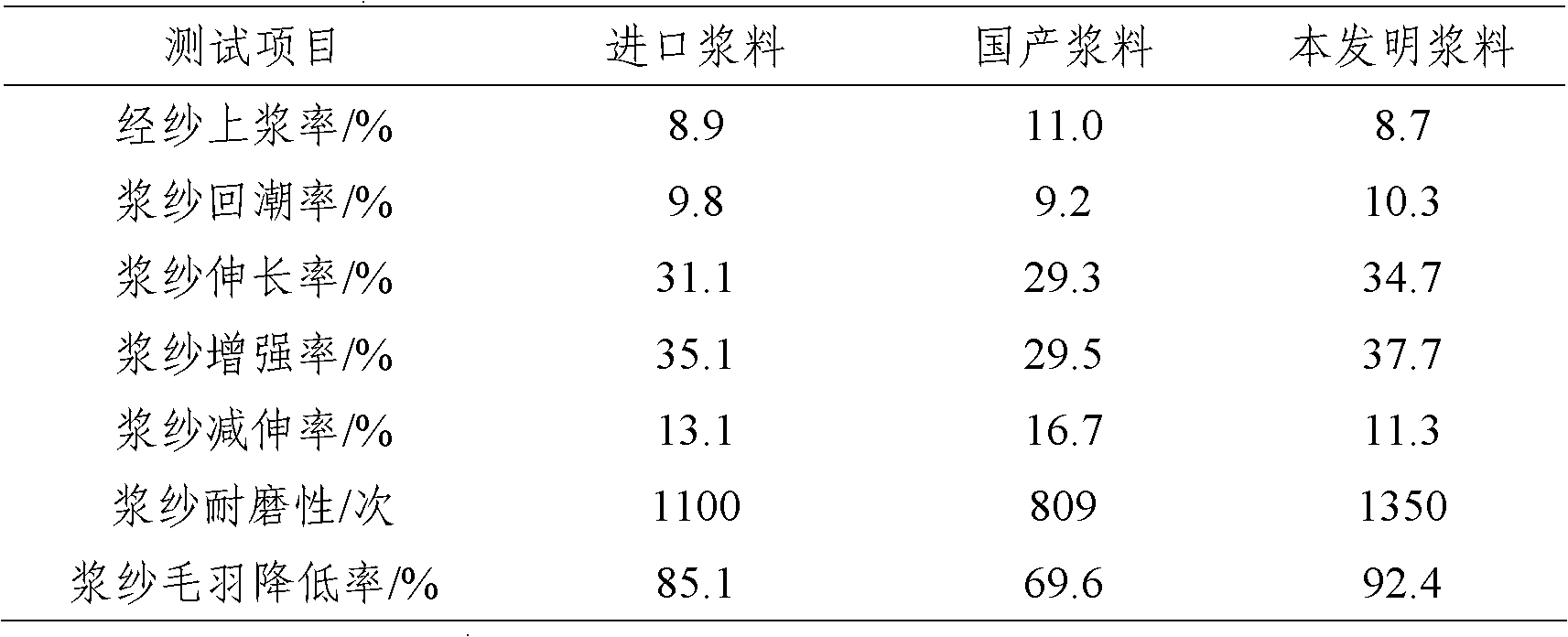

Textile size combination

The invention provides a textile size combination which is prepared by mixing solid acrylate with nano SiO2 compound modified starch in proportion, wherein the solid acrylate is prepared by the following steps: mixing acrylonitrile, methyl acrylate, butyl acrylate, methyl methacrylate, acroleic acid, methacrylic acid with acrylamide in proportion, and enabling the mixed solvent to be subject to internal polymerization under the action of compound initiator and chain transfer agent, neutralizing with sodium hydroxide and drying; and the nano SiO2 compound modified starch is prepared by the following steps: sequentially acidifying, crosslinking and oxidizing starch, introducing surface-modified nano-level SiO2 and carrying out ultrasonic dispersion. The size can obviously improve the warp sizing performance and improve the weaving efficiency, can be completely replace PVA and imported sizes in the same amount or partial amount, and is widely used for the warp sizing of purified cotton, terylens, novel fibers and mixed yarns of various counts.

Owner:HUBEI DAYA BIOLOGICAL TECH CO LTD

Liquid ammonia modified method of cotton fibriia and yarn

InactiveCN101413213AGood flexibilityImprove curling effectLiquid/gas/vapor removal by centrifugal forceTextile treatment by pouringYarnVegetable fibers

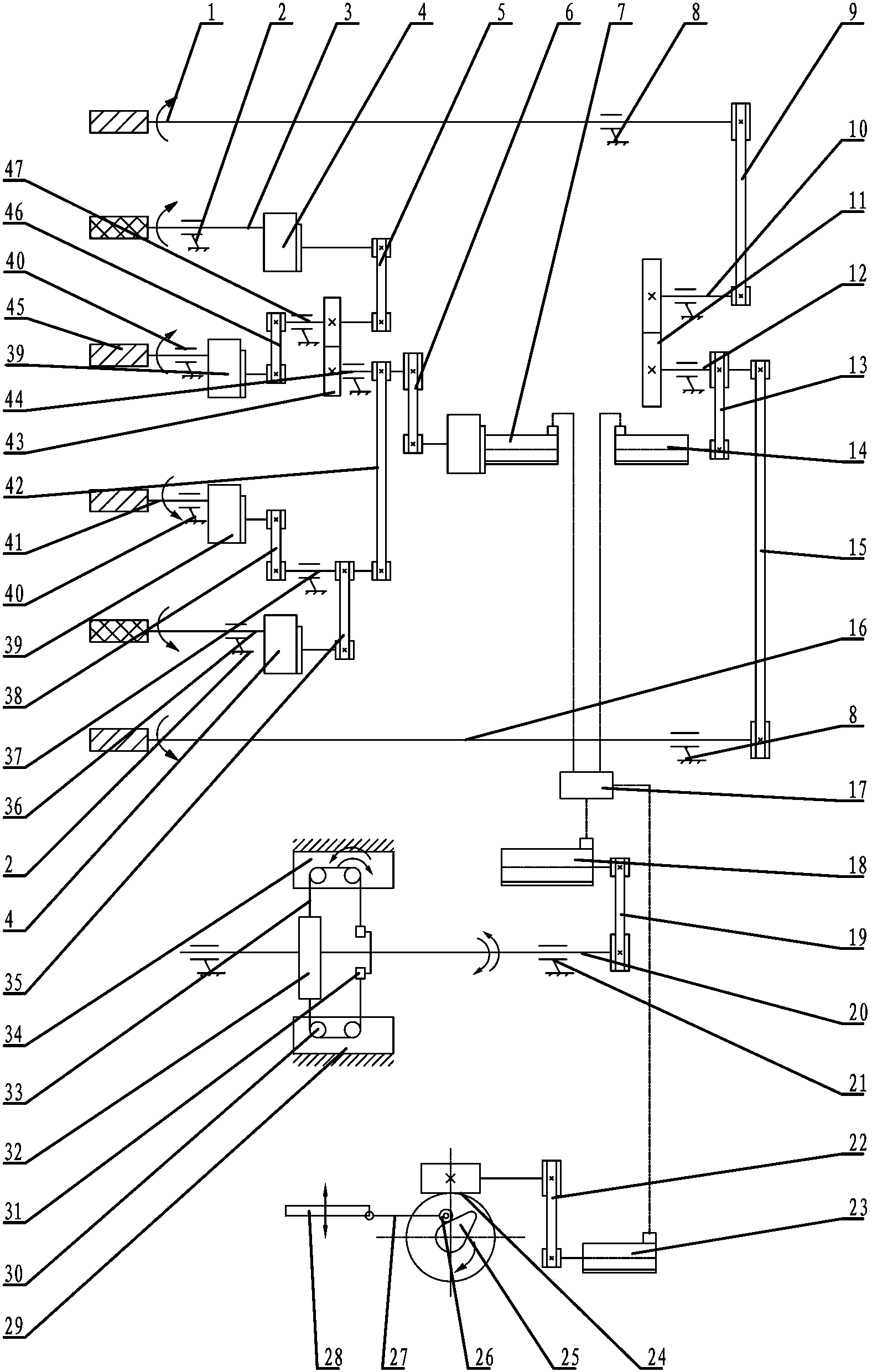

The invention provides a method for modifying cotton and long vegetable fiber or yarn by ammonia liquid, which comprises the following steps: firstly, drying pre-treatment of raw materials; secondly, ammonia leaching of the raw materials in a hermetical treatment tank; thirdly, spin-drying of the raw materials subjected to ammonia leaching when a creel is twirled; fourthly, drying of the raw materials subjected to spin-drying by ammonia flow when the creel rotates slowly; fifthly, flushing of the raw materials which are dried by the ammonia flow by airflow when the creel rotates slowly; and so on. The method keeps the inherent advantages of the cotton, the long vegetable fiber and the yarn, overcomes the defects of the cotton, the long vegetable fiber and the yarn, increases softness, crimp tendency and fluffiness of the cotton, the long vegetable fiber and the yarn, improves the dye-uptake rate, the leveling property and the showy dye level, and further solves the problems of energy conservation, efficiency improvement and environmental protection.

Owner:上海业安纺织科技有限责任公司

Polyester POY spinning finish and production method thereof

The invention discloses a polyester POY spinning finish, comprising 81-88% of lubricating agent, 3-5% of emulsifying agent, 4-7% of tow collecting agent, 3-5% of antistatic agent and 2-4% of additive by weight. The invention also discloses a production method of the polyester POY spinning finish. The product not only can endow the fibers with good processability but also is environment-friendly, overcomes the phenomenon that the finish corrodes equipment and can ideally solve the problem of easy cohesion on guide rolls during apparent cohesion and reduce fluff and broken yarns.

Owner:绍兴市上虞皇马化学有限公司

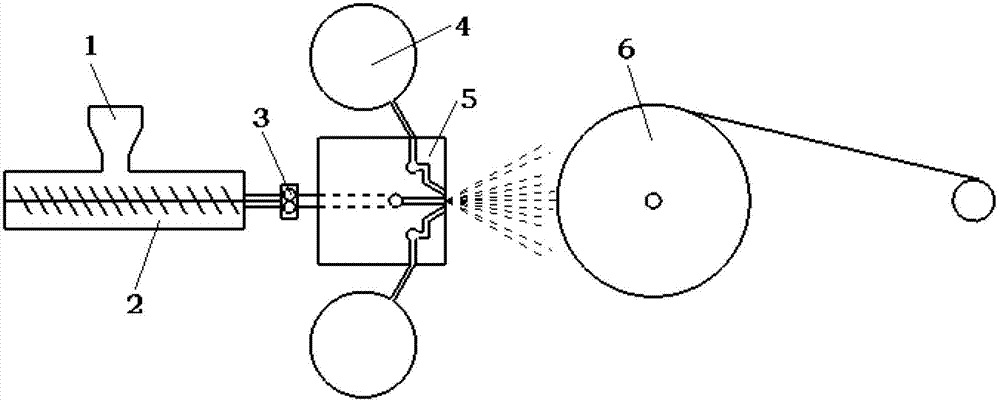

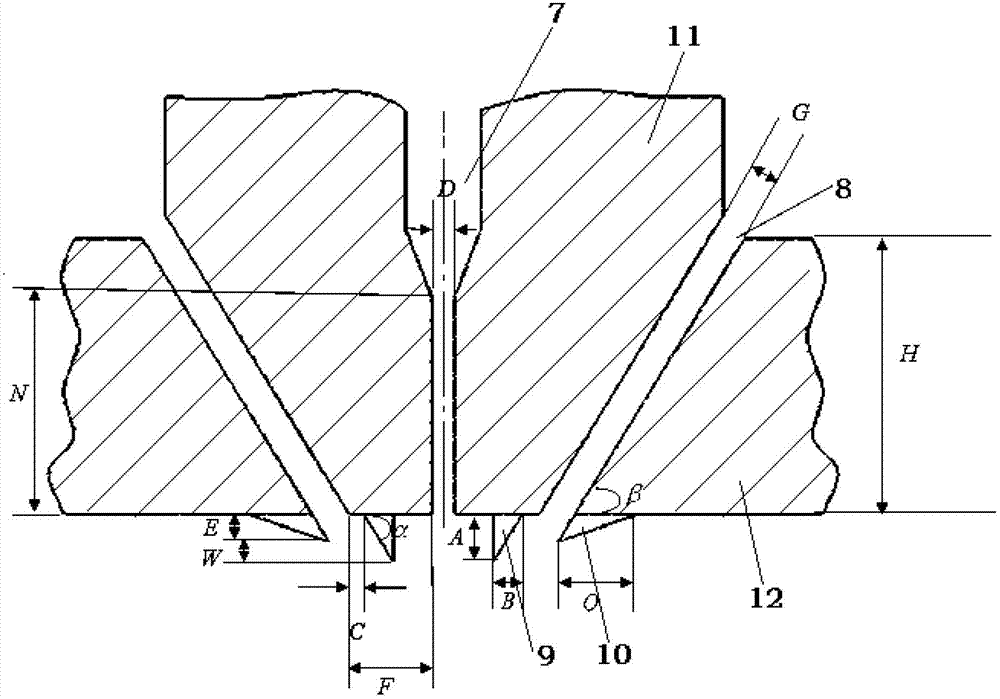

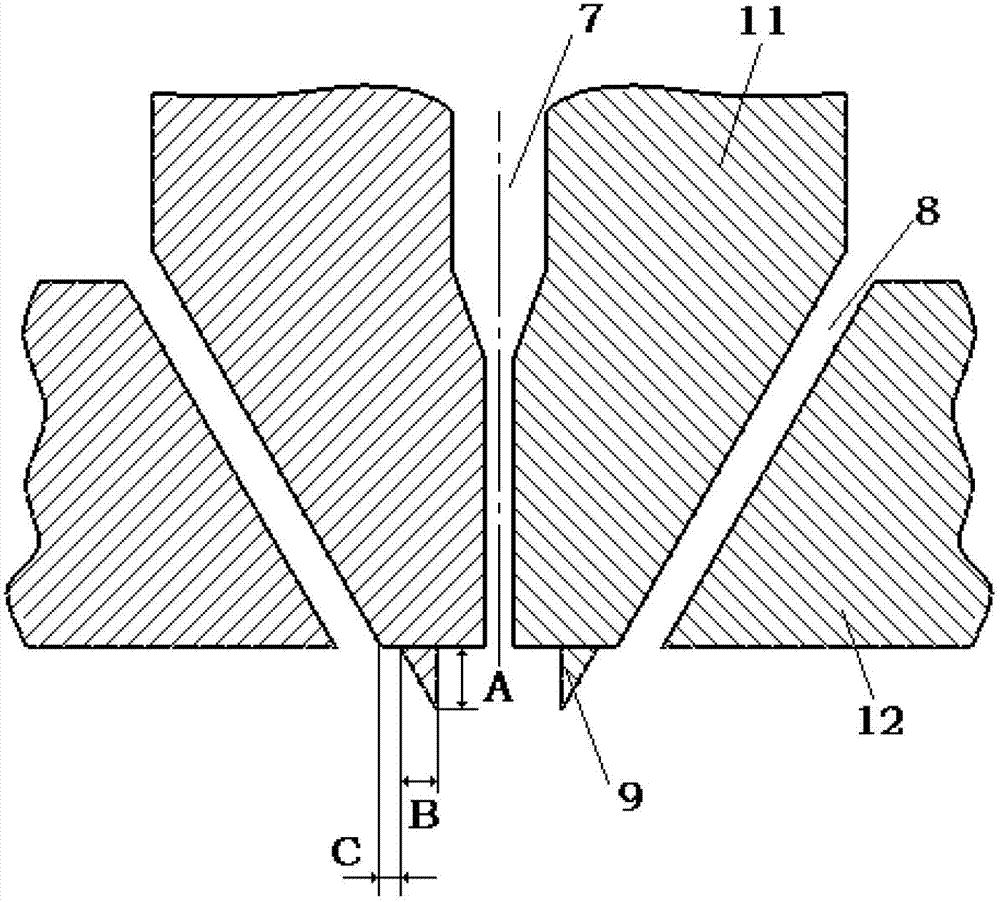

Meltblown mold head for preparing ultrafine fibers

ActiveCN102787374AReduce adverse effectsIncrease air velocitySpinnerette packsRight triangleBreakage rate

The invention relates to a meltblown mold head for preparing ultrafine fibers. The meltblown mold head comprises a spinning plate and an air plate, wherein the middle of the end surface of the spinning plate is provided with a spinning hole, a plurality of crack grooves are formed between the spinning plate and the air plate, the crack grooves are positioned around the spinning hole, slantwise point to the spinning hole and are in central symmetry on the end surface by the spinning hole as the symmetry center, a separation flow stabilizing element is fixedly connected between the spinning hole arranged on the end surface of the spinning plate and the crack grooves, the cross section of the separation flow stabilizing element is in a right-angled triangle shape, in addition, one edge in two right-angled edges is connected with the end surface of the spinning plate, the other right-angled edge is near a spraying opening, the inclination degrees of the inclined edge of the right-angled cross section of the separation flow stabilizing element and a conical bus of the spinning plate relative to the crack grooves are identical, and meanwhile, the outer sides of the crack grooves are selectively connected with external flow stabilizing elements. The meltblown mold head has the advantages that the reverse backflow region is reduced, the jet flow diffusion to two sides is inhabited, the turbulence intensity is reduced, the fiber end breakage rate is reduced, the melt body is prevented from gluing on the mold head, the air temperature at the nearby part of the mold head is improved, the meltblown nonwoven energy consumption is reduced, and the fiber diameter is further refined.

Owner:安徽深呼吸纺织科技有限公司

Spinning finish and preparation method thereof

ActiveCN103147168AIncrease molecular polarityLow smoke productionSynthetic polymer filament chemical after-treatmentFiberVegetable oil

The invention relates to a spinning finish and a preparation method thereof. The spinning finish is prepared from (a) 50-80 wt% of refined vegetable oil, (b) 20-40 wt% of polyglycerol fatty acid ester, (c) 5-20 wt% of antistatic agent and (d) 0.1-1 wt% of coking retarder. The preparation method comprises the following steps: accurately measuring the (a) refined vegetable oil, (b) polyglycerol fatty acid ester, (c) Gemini antistatic agent and (d) coking retarder according to the weight percents, sequentially adding the components while stirring, heating to 70-80 DEG C until the components are completely dissolved, continuing keeping the temperature and stirring for 15 minutes, cooling to 50 DEG C below within 1 hour, filtering, and packaging to obtain the required spinning finish. The spinning finish provided by the invention has excellent heat resistance, and is environment-friendly since the vegetable oil is used as the main component. In the spinning technique, the spinning finish has the advantages of low smoke, easily cleaned coking substances, and low waste fiber rate; the spinning finish improves the working environment of the spinning workshop, and enhances the work efficiency; the raw materials are accessible and cheap and have favorable biodegradability; and the spinning finish is free of PEG (polyethylene glycol) and APEO (alkylphenol ethoxylate), and thus, is environment-friendly.

Owner:安徽灵达高新材料有限公司

Spinning sizing agent

InactiveCN102926198AGood wear resistanceGood compatibility and stabilityFibre treatmentButyl acrylateEmulsion

The invention discloses a spinning sizing agent. The spinning sizing agent is formed by adopting the steps of: mixing crylic acid, butyl acrylate, an initiating agent, an emulsifying agent OP-10 and water according to a mass ratio of 10: 30: 0.2: 0.3: 100 for a reaction to obtain a polyacrylate emulsion; dispersing starch in water for heating to 40-45 DEG C, then adding a hypochlorous acid solution for a reaction for 20-30 min, then heating to 65-70 DEG C, and keeping the temperature for 30-40 min to obtain a hypochlorous acid modified starch size; and uniformly mixing the polyacrylate emulsion, the hypochlorous acid modified starch size and nanometer titanium dioxide according to a mass ratio of 1: (1-1.5): 0.1; heating to 50-60 DEG C, and keeping the temperature for 20-30 min. The spinning sizing agent disclosed by the invention has the advantages of being good in abrasive resistance, compatibility as well as stability, and easy to de-size, obtaining a pliable, tough as well as smooth size film, and being capable of replacing a PVA (Polyvinyl Acetate) sizing agent, reducing end breakage rate of yarns and increasing production efficiency.

Owner:WUXI YUTONG FABRIC IND

Preparation method of waterproof shell fabric

The invention discloses a preparation method of a waterproof shell fabric. The preparation method comprises the steps of examining precursor fiber, treating warp, weaving on a weaving machine and cropping; the warp treatment comprises six steps, namely hanging yarn, beaming, slashing, combining axles, leasing, as well as drafting and scrabbling reed. Starching is performed on warp, reasonable technological parameters are adopted, and specific sizing percentage control is performed, so that the inner layer of yarn is immersed in seriflux, cohesive force between fibers is increased, and breaking-resisting strength of yarn is improved; a layer of protective film is formed on the surface of the yarn, so that the yarn is smoother and wear-resisting, the warp can bear strong mechanical action of the weaving machine and repeated abrasion among yarns, the end breakage rate of the warp during weaving is reduced, and the weavability of the warp and the quality of the waterproof shell fabric are improved.

Owner:江苏晨越高新材料有限公司

Washing method for spinneret plate

The invention relates to a washing method for a spinneret plate, and mainly solves the technical problems in the prior art that the spinneret plate cannot be cleanly washed, gel is adhered to the surface of the spinneret plate, a spinning solution at the outlet of a spinneret hole overflows, and polyacrylonitrile protofilament has more broken filaments and more thin filaments and is high in fiber breakage rate. The washing method for the spinneret plate comprises the following steps of disassembling the spinneret plate from a spinning assembly; immersing the spinneret plate in a solvent in a container; then immersing the container in water bath; washing by adopting a mode of combining temperature rising with ultrasound; taking out the spinneret plate after the washing is completed; blowing the surface of the spinneret plate by gas which is precisely filtered after the spinneret plate is dried; completing the washing. According to the technical scheme, the problems are well solved, and the washing method can be used in a device washing process after the spinning of the polyacrylonitrile protofilament.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of high-quality wool heavy-twist and anti-wrinkle fabric

ActiveCN104397910AAvoid damageUniform dyeingLiquid/gas/vapor removalDyeing processEngineeringDesign methods

The invention provides a preparation method of high-quality wool heavy-twist and anti-wrinkle fabric. The high-quality wool heavy-twist and anti-wrinkle fabric is prepared by interweaving warps and wefts, wherein the warps and the wefts are respectively prepared by blending raw materials by weight percent, and the raw materials comprise 75% of 16.0 mu m Australasian wool and 25% of mulberry silk. The preparation method adopts an innovative easily-caring and anti-wrinkle fabric design method and an after-finishing technology; the prepared fabric is smooth in hand feeling, good in elasticity, excellent in draping property and good in wearability, and reaches the requirement of easy care, thus being very suitable for making a high-quality non-lining or semi-lining business and casual suit.

Owner:江苏纺谷科技有限公司

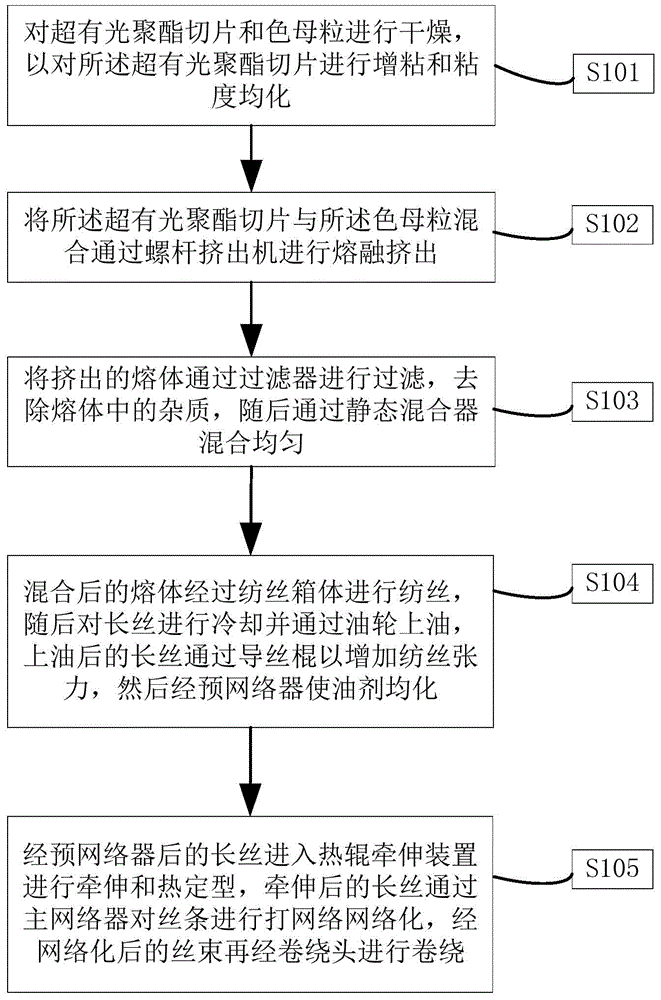

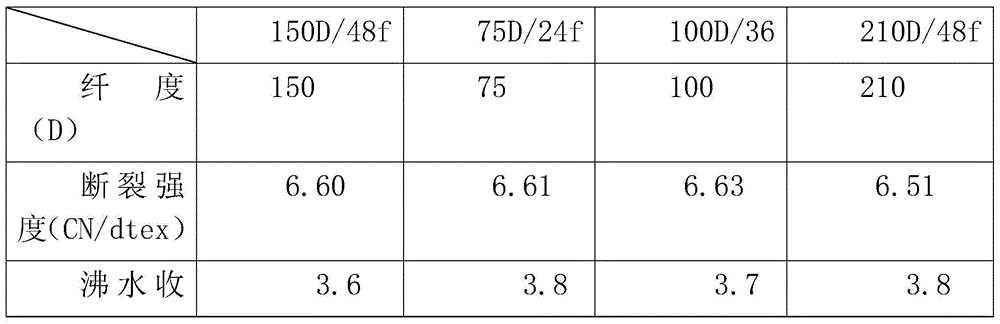

Special polyester filaments for black fine denier industry, and preparation method of special polyester filament

InactiveCN105648572AReduce manufacturing costShort processNew-spun product collectionMelt spinning methodsPolytetramethylene terephthalateYarn

The invention provides special polyester filaments for black fine denier industry, and a preparation method of the special polyester filaments. The special polyester filaments for the black fine denier industry comprise super bright polyester and black color masterbatch, wherein the black color masterbatch is prepared from the following materials by ratio: 30-50% of polyethylene glycol terephthalate, 30-50% of polybutylene terephthalate, 10-30% of carbon black and 0.4-12% of auxiliary additive. The preparation method of the special polyester filaments adopts a polyester chip with common viscosity and utilizes a melt spinning method, so that production cost is greatly saved from the raw material cost, a technological process is shorter, the energy consumption is low, end breakage rate is lower in the production process, and the produced filaments can meet the requirements of medium and high-strength sewing threads; furthermore, black fully drawn yarn (FDY) polyester filament sewing threads are prepared by directly adding the carbon black instead of firstly spinning and then dyeing, so that the phenomena such as environmental pollution, rinsing decoloration, light fugitive property, unstable chemical properties and the like which are caused by black dye dyeing are avoided.

Owner:NANTONG HUALUN CHEM FIBER

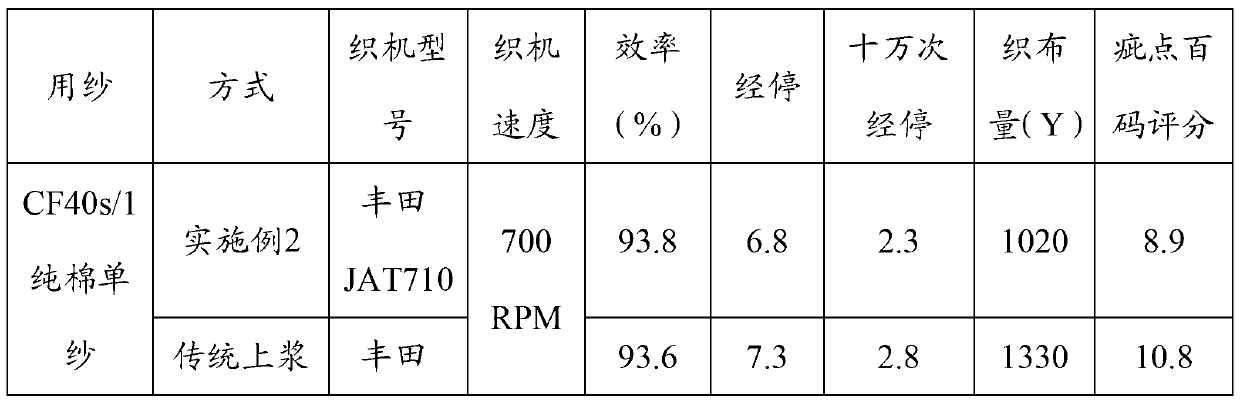

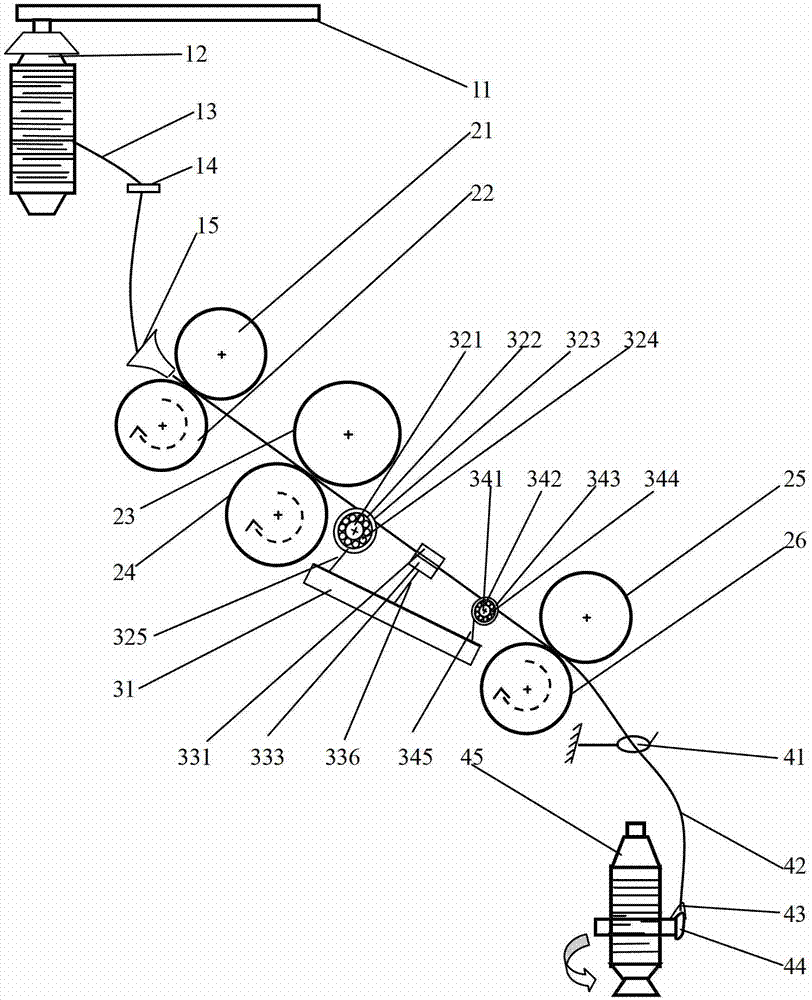

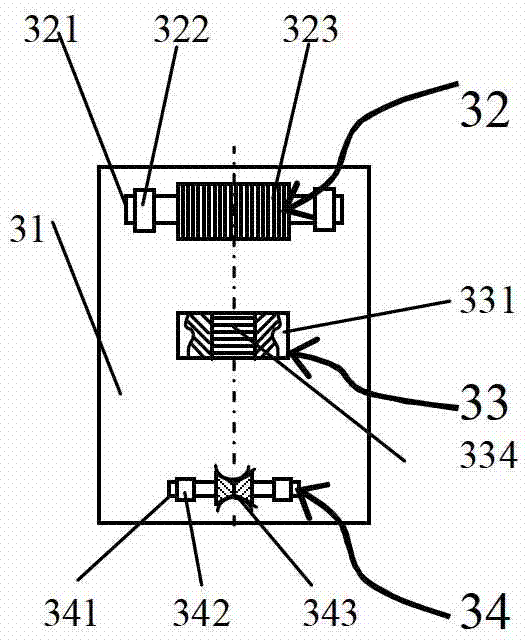

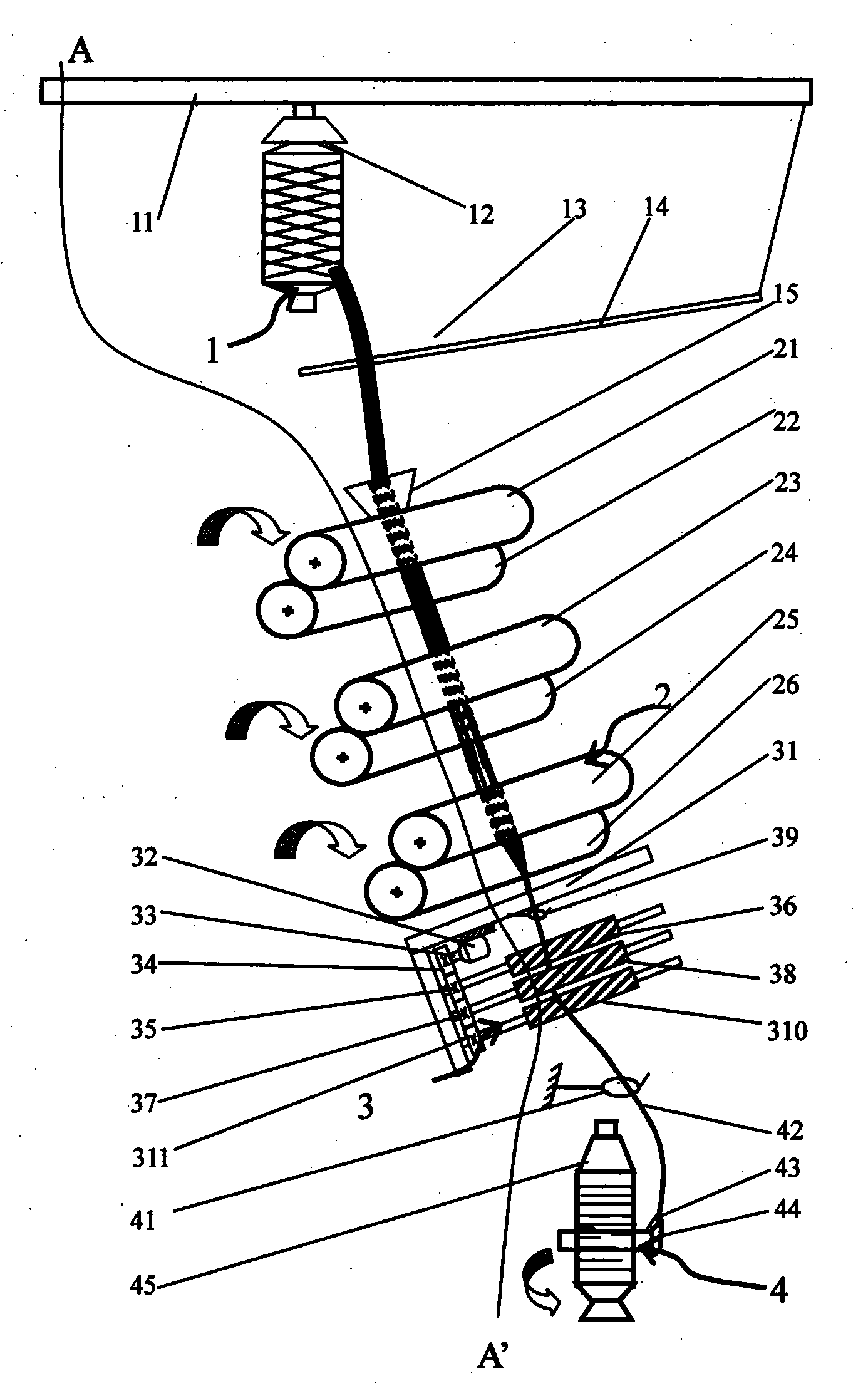

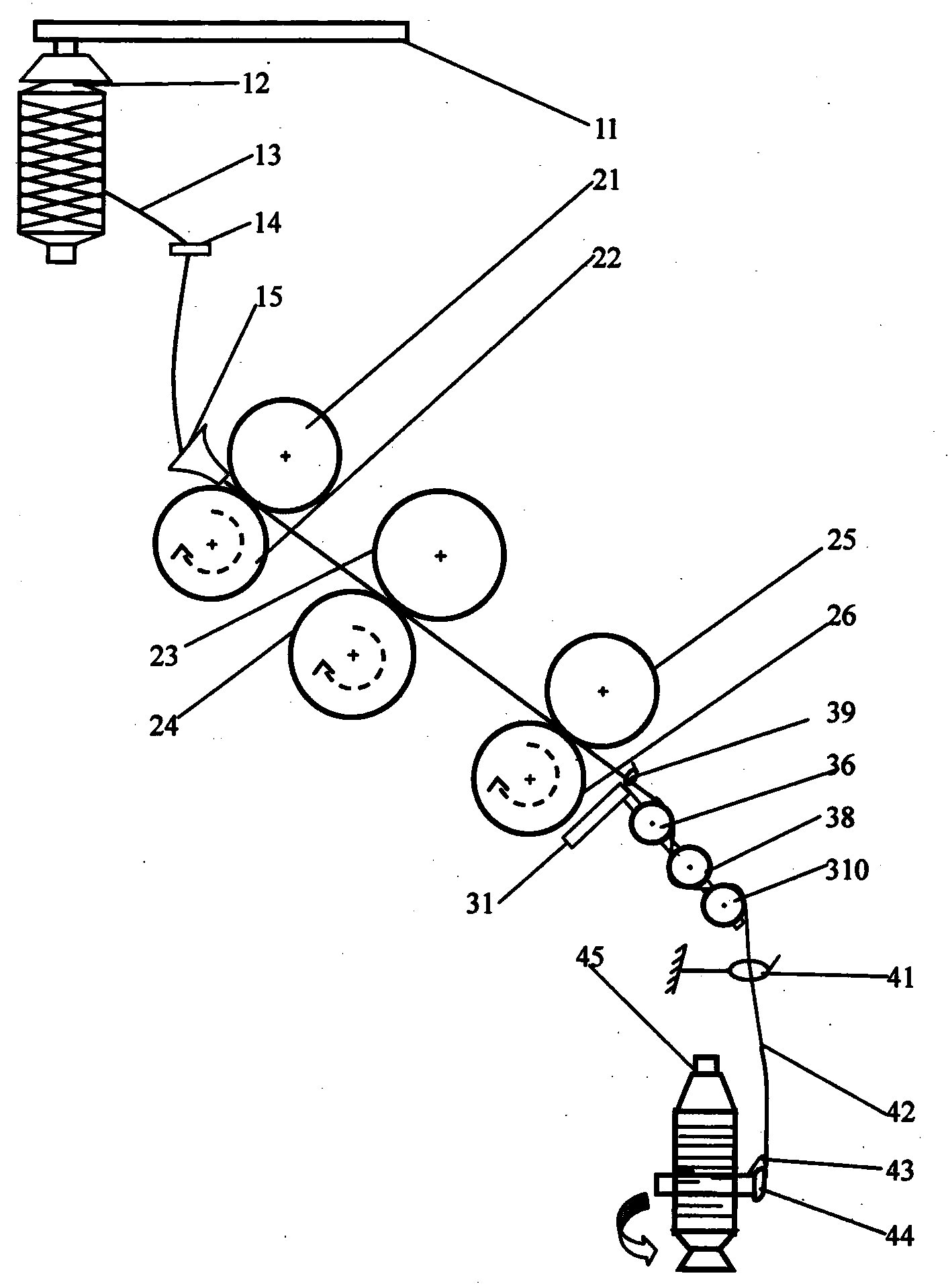

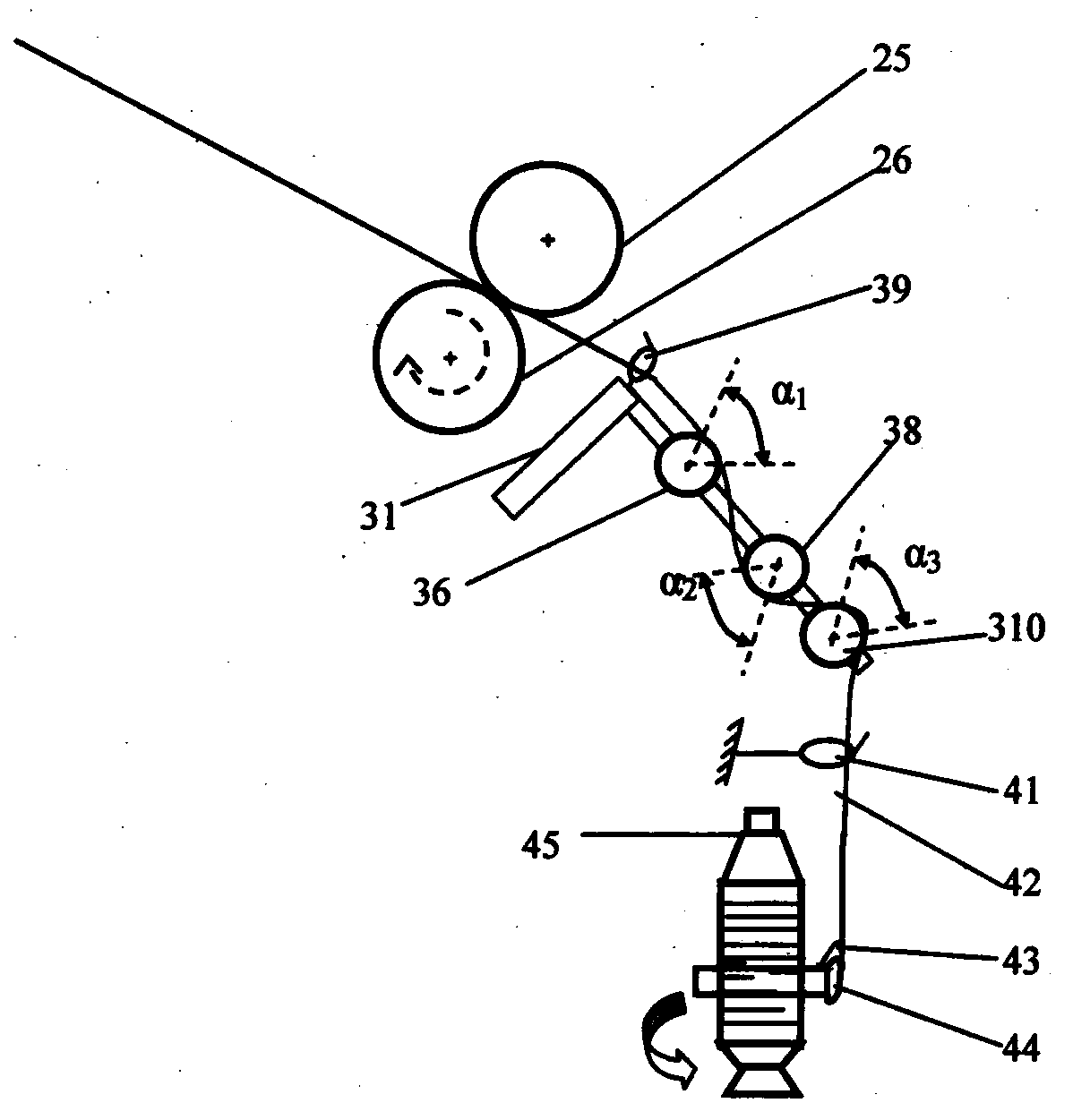

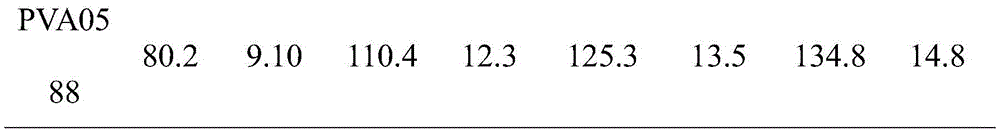

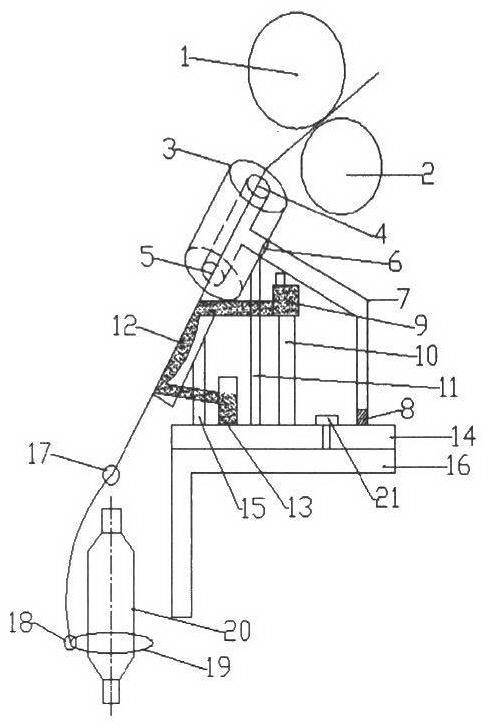

Spinning apparatus for rotor spinning composite yarn

InactiveCN1546760ARotor spinning high speedLow costContinuous wound-up machinesOpen-end spinning machinesTextile technologyYarn

The invention belongs to textile technology field; it discloses a kind of rotary cup compound yarn device, which includes a silk guiding device, feeding roller, gear device, rotary cup with middle hole, short fiber transmitting device, yarn leading pipe, yarn leading roller, twisting device. The character lies in: it includes a tension control device which is transferred to the feeding roller, L type yarn leading pipe, a hollow pipe, U type hole connection device, left and right high speed bearing. The invention has a high speed, good productivity, big coil package, low cost. The invention upgrades the producing efficiency.

Owner:DONGHUA UNIV

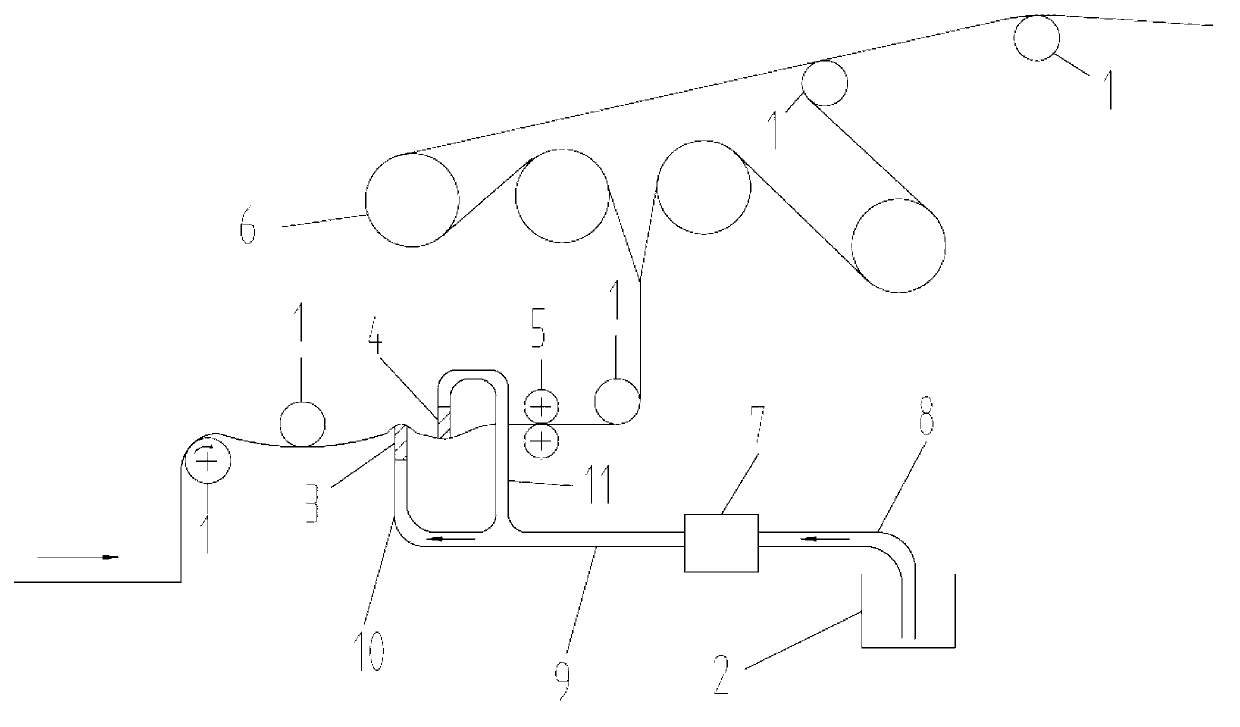

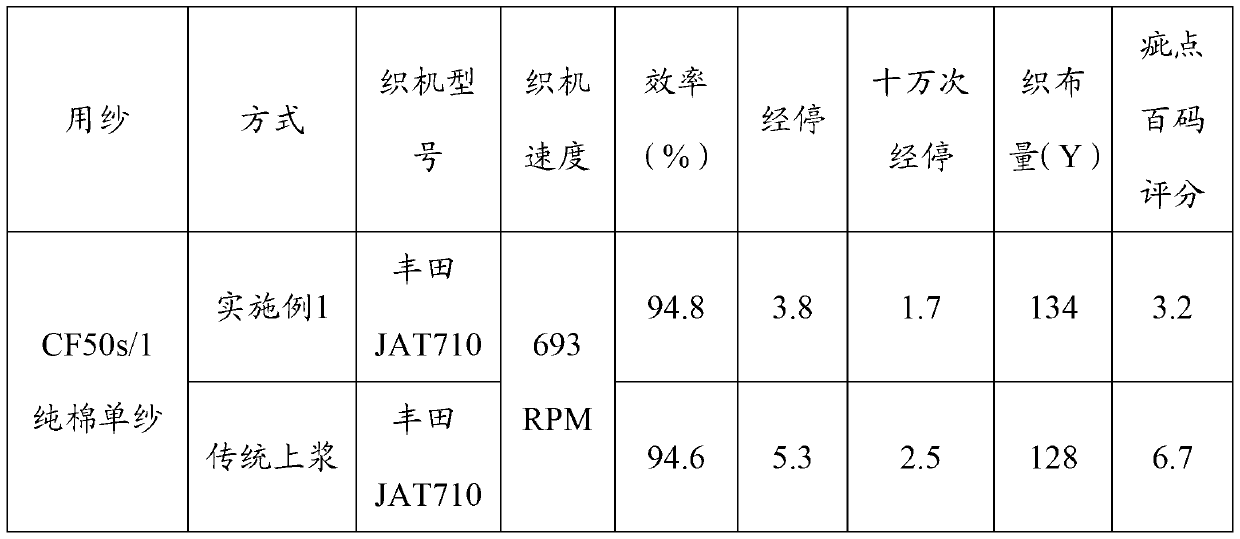

Warp sizing method and application thereof

ActiveCN103103710AEmission reductionReduce water consumptionFibre treatmentLiquid/gas/vapor textile treatmentYarnWastewater

The invention discloses a warp sizing method and an application thereof. The warp sizing method includes the following steps: preparing sizing agents, boiling the sizing agents, foaming, conducting foam sizing, rolling the sizing agents, drying and leasing; foaming ratio and applying amount are controlled by a foam producer in the step of foaming; the foaming ratio is 1:3-30, and the applying amount is 10%-50%; foam formed by the foam producer is instantly and entirely applied to warp yarn through a foam applicator in the step of conducting foam sizing; and the foam applicator is divided into an upper applying head and a lower applying head. The warp sizing method has the advantages of being low in water consumption, little in chemical and wastewater discharge, little in sizing amount, easy to desize, short in yarn drying time, capable of saving energy consumption by 50%-60%, high in production speed, low in cost, continuous in foam applying mode, capable of ensuring uniformity and stability of the applied foam, low in product breakage rate, high in efficiency and good in weaving effect.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

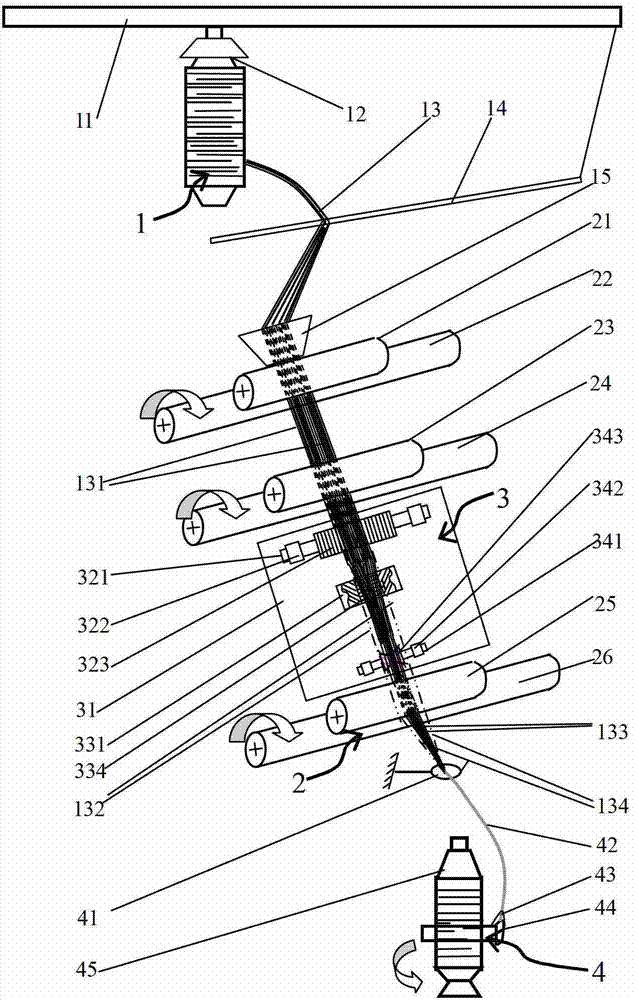

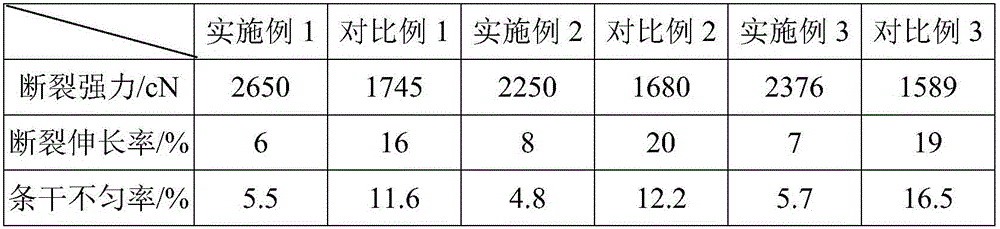

Bright yarn spinning device and application thereof

InactiveCN102965773AReduce spinning end break rateImprove spinning efficiencyDrafting machinesContinuous wound-up machinesCombingYarn

The invention discloses a bright yarn spinning device and an application thereof. The spinning device comprises a rough yarn feeding mechanism, a draft mechanism and a twisting and winding mechanism, and is characterized by further comprising a finishing mechanism which is composed of a fixed plate fixedly mounted on the draft mechanism, as well as a combing mechanism, a straight mechanism and a cluster mechanism all fixedly connected with the fixed plate; both the combing mechanism and the straight mechanism are provided with hairiness combing textures which are respectively used for combing and straightening cluttered hairiness and back curved hairiness projected from the bottom and periphery of the rough yarn; and the cluster mechanism is provided with a side horse-shaped surface and a symmetric V-shaped texture so as to complete rough yarn condensation and hairiness combing. The application of the spinning device is that the rough yarn fed by the rough yarn feeding mechanism is processed into the bright fine yarn after the procedures of drawing of the draft mechanism, combing and condensation of the finishing mechanism, and twisting and winding of the twisting and winding mechanism. The spinning device can also be used for bright spinning of cotton, mucilage and polyster fibre. According to the invention, the fine yarn is less in hairiness, and high in uniformity and strength; the preparation technology spinning septa is small; the end breakage rate and energy consumption are low; and the efficiency is high.

Owner:FUJIAN JINTAI TEXTILE

Steel wire connecting method

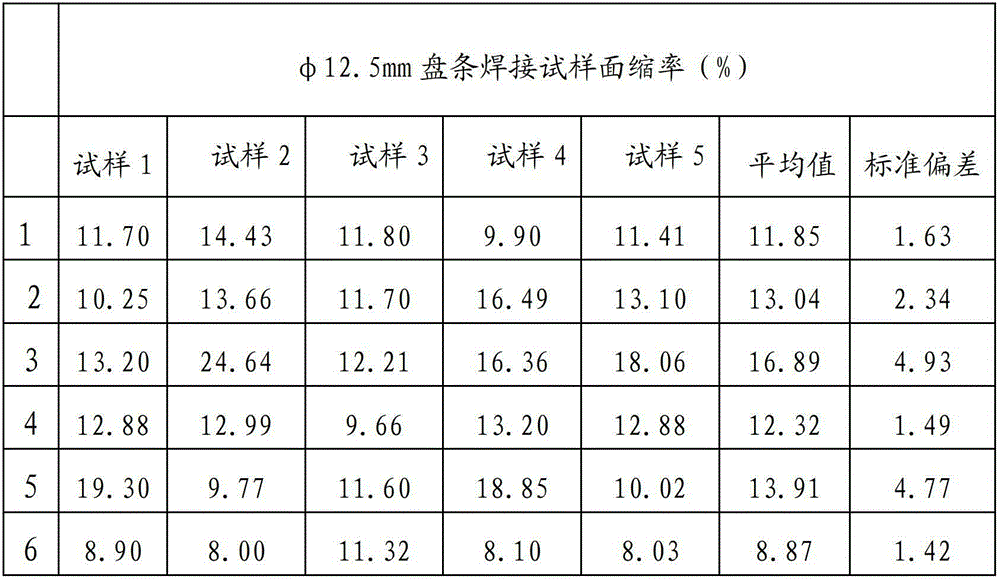

InactiveCN102873447AImprove toughnessGood elastic limitFurnace typesHeat treatment furnacesTwo temperatureFree cooling

The invention discloses a steel wire connecting method, and provides a steel wire connecting method capable of preventing end breakage of a welding position during a drawing process, and reducing end breakage rate. The method comprises the following steps of: clamping a polished welding seam at a tempering jaw, and raising the temperature intermittently for 4-5 times, with 1-2 seconds of interval between every two temperature rises, and stopping temperature rise when reaching 750-820 DEG C; continuously raising the temperature to 750-820 DEG C when naturally cooling to the temperature of 650 DEG C in the air, stopping temperature rise, repeating the above cooling-raising temperature process for three to four times, and then naturally cooling to 650 DEG C in the air; then continuously raising the temperature to 750-820 DEG C, and keeping the temperature for 1 minute through intermittent heating; and after naturally cooling to 570-590 DEG C, instantly electrifying and raising the temperature by 20-50 DEG C, and naturally cooling. The steel wire connecting method provided by the invention has the beneficial effects that through high temperature tempering processing at the weld part, the internal stress generated in welding is reduced, the tenacity of the welding part is improved, the phenomenon of end breakage at the welding position in the drawing process is prevented, and the end breakage rate is lowered.

Owner:天津市新天钢中兴盛达有限公司

China hemp cotton air vortex spinning product and preparing method thereof

InactiveCN103132208AGood moisture wicking effectMoisture absorption and quick dryingWoven fabricsYarnYarnCarding

The invention provides a China-hemp cotton vortex spun yarn product which has few feathers, is anti-pilling, has a soft and smooth yarn body and is good in hydroscopic and fast dry performance. Warps and wefts of the China-hemp cotton air vortex spinning product are China hemp fiber / cotton fiber vortex spun yarns, wherein the content of China hemp fibers occupies 60%, and the content of cotton fibers occupies 40%. The preparing method of the China-hemp cotton vortex spun yarn product comprises the following steps of a, preprocessing: the China hemp fibers are softened through emulgator before processing, the weight ratio of the emulgator, antistatic oiling agent and water satisfies the equation that ZY-06A:ZY-06B:water=1:0.5:5, and solution is prepared according to the ratio; the solution is evenly sprayed on the China hemp fibers according to 7% of the weight of the China hemp fibers; and the China hemp fibers are stored for 96 hours in the environment at the temperature of about 25 DEG C, and the China hemp fibers are turned over for a couple of times during storage; b, blending of the China hemp fibers and the cotton fibers: the China hemp fibers and the cotton fibers are mixed according to a portion inside a cotton box, and then blowing, carding, sliver lapping, combing and two combination processes are conducted; c, preceding spinning which comprises opening picking, cotton carding, combing and drawing; and d, vortex spinning: the temperature of a working workshop is 30 DEG C, and relative humidity is 65%.

Owner:JIANGSU YDTEX GRP LTD

Japanese banana fiber and its preparation method and uses

InactiveCN101187068AImprove qualityImprove spin performanceMechanical fibre separationYarnYarnRaw material

The invention relates to a musa fiber, which is prepared from stems of musa plants, which are used as raw materials, wherein the musa fiber comprises the following components: cellulose is 81-95 percent, hemicellulose is 1.0-5.0 percent, lignin is 1.0-2.8 percent, other components are pectin water soluble matter and is based on the dry weight of the musa fiber. The above musa fiber is prepared through the mechanical treatment, acid preimpregnation, washing, soda boil, washing, dehydration and oil supply, the above musa fiber is used to be spun into 10-60 single yarn, the process has low cost, compared with ancient process, the strength and the fineness of the made fiber are improved, and the process of preparing the musa fiber of the invention is also capable of being used to made mulberry fiber. The invention opens a new way for the development and utilization of phloem resources, has an important significance at the present that a part of prior fiber resources are run out, and accords with strategic demands of sustainable development.

Owner:吴苏明 +2

Polytetrafluoroethylene filament as well as preparation method and application thereof

InactiveCN107177893AImprove evennessImprove breaking strengthMonocomponent halogenated hydrocarbon artificial filamentStretch-spinning methodsFlue gasIncineration

The invention discloses a polytetrafluoroethylene filament as well as a preparation method and an application thereof. The preparation method comprises the following steps: (1) performing superposition and oil removal on a plurality of layers of single-layer polytetrafluoroethylene rolling base tapes so as to form a multilayer superposed base tape; (2) longitudinally heating and drafting twice; (3) slitting into ribbon-like filaments; (4) sintering and drafting the ribbon-like filaments; and (5) twisting the ribbon-like filaments to obtain round filaments, setting, and performing shock cooling so as to obtain the product; or setting the ribbon-like filaments, performing shock cooling, twisting, thereby obtaining the product. The filament made by the method disclosed by the invention is low in unevenness, high in breaking strength and low in elongation, the overall strength of a filter material can be improved, and the service life of the filter material is prolonged; meanwhile, the breakage can be reduced due to high strength, and the production efficiency is improved; the polytetrafluoroethylene filament can be directly produced by using the conventional production equipment, is low in production cost and smooth and even in filament surface and contributes to weaving, and the woven base cloth can be widely applied to framework materials of high-temperature flue gas dust-removing filter materials in industries such as steel, waste incineration, cement, power plants and the like.

Owner:上海灵氟隆新材料科技有限公司 +1

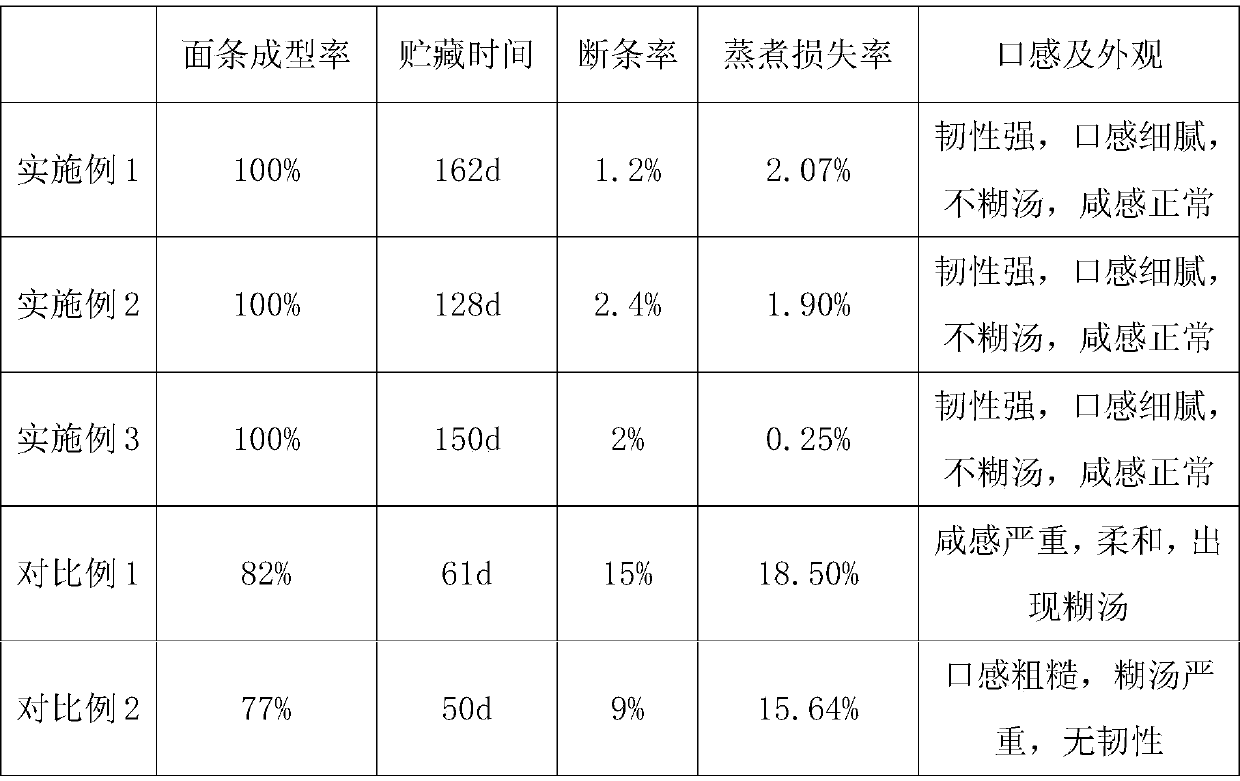

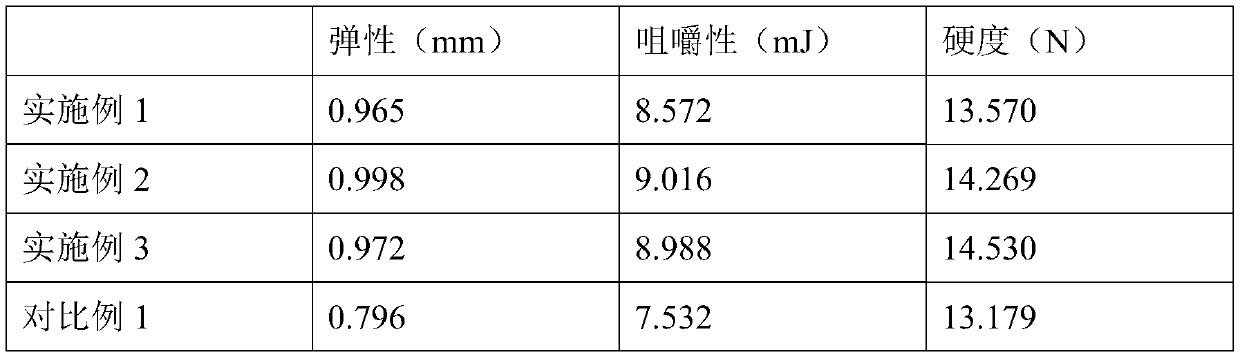

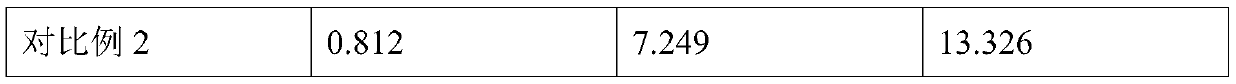

Mulberry leaf dried noodles

The invention discloses colorful dried noodles, in particular mulberry leaf dried noodles which are prepared by adding ultra-micro mulberry leaf powder, vitamin antioxidant and other functional nutrient components. The ultra-micro mulberry leaf powder with the fineness of over 300 meshes is uniformly dispersed so that the color of the mulberry leaf dried noodles is uniform and level. Vitamin type nutrient antioxidant sodium erythorbate is added so that light green color of the mulberry leaf dried noodles is constantly invariable. The high-grade wheat germ flour is adopted and can provide richer protein for the mulberry leaf dried noodles. Sodium alga acid is added in the formula so that the adhesiveness of the mulberry leaf dried noodle tissue can be improved, the mulberry leaf dried noodles have strong tension, high flexibility and chewier mouthfeel and the end breakage rate in the production process is lower, and more obvious effect can be achieved on flour with lower gluten content. The mulberry leaf dried noodles provide multiple nutrient components and health care functions, keep constantly invariable bright color and fresher taste simultaneously and promote the appetite of consumers.

Owner:QINGDAO RUIWENYUAN IND & TRADE

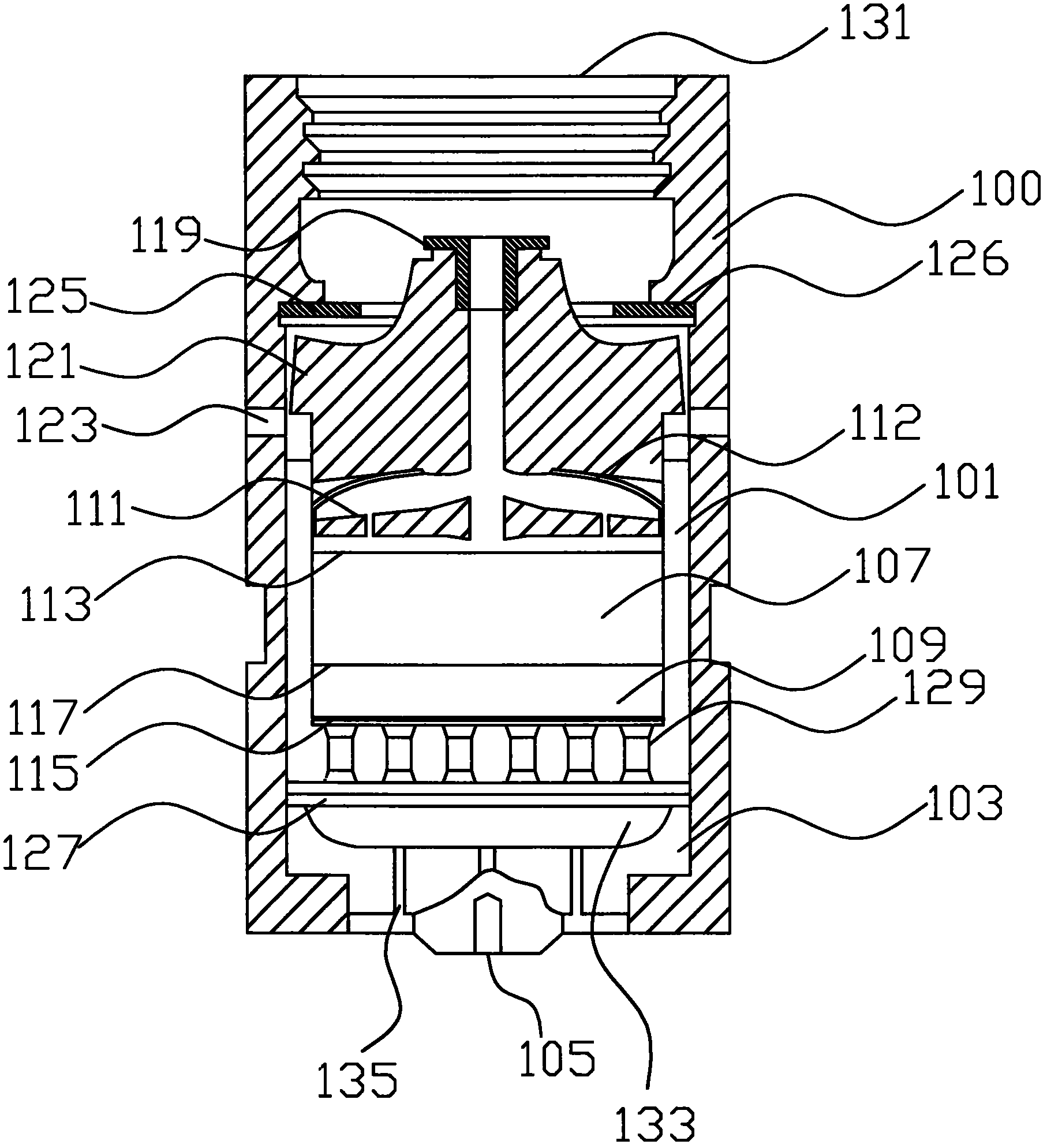

Melt spinning component device capable of improving quality of super fine-denier filament

ActiveCN103074691AAvoid disorderFully filteredSpinnerette packsFilament-forming treatmentEngineeringSand filter

The invention relates to the production field of synthetic fiber filaments and provides a melt spinning component device capable of improving the quality of a super fine-denier filament. The melt spinning component comprises a component casing, wherein a distributing cup mechanism is arranged in the component casing, and a spinneret plate and a screwing clamp slot are arranged at the lower end of the component casing. The distributing cup mechanism is divided into an upper layer and a lower layer, the upper layer is a coarse filtering sand layer, the lower layer is a fine filtering sand layer, a primary distributing plate is arranged above the coarse filtering sand layer, a bottom filtering screen is arranged at the lower end of the fine filtering sand layer, an isolation filtering screen is arranged between the coarse filtering sand layer and the fine filtering sand layer, and meanwhile, the upper opening of the spinneret plate of the melt spinning component is in the shape of a circular bowl bottom. The melt spinning component device has the beneficial effects that through the two filtering sand layers and the isolation filtering net additionally arranged between the two filtering sand layers, a melt in the pressurizing state is prevented from rushing to disorder the coarse and fine sand filtering layers, meanwhile the melt is filtered finely and uniformly, and the fineness and the uniform effect of a finished product are good; the spinneret plate of the component is easy to machine and convenient to assemble and operate; and besides, the micro melt is enabled to be smoothly redistributed under the state of no dead corners through the circular bowl bottom opening at the bottom, the uniformity of the melt is improved after the melt is precisely filtered, and the quality of each mono-filament extruded by the spinneret plate is guaranteed to be uniform and consistent.

Owner:JIANGSU WENFENG CHEM FIBER GROUP

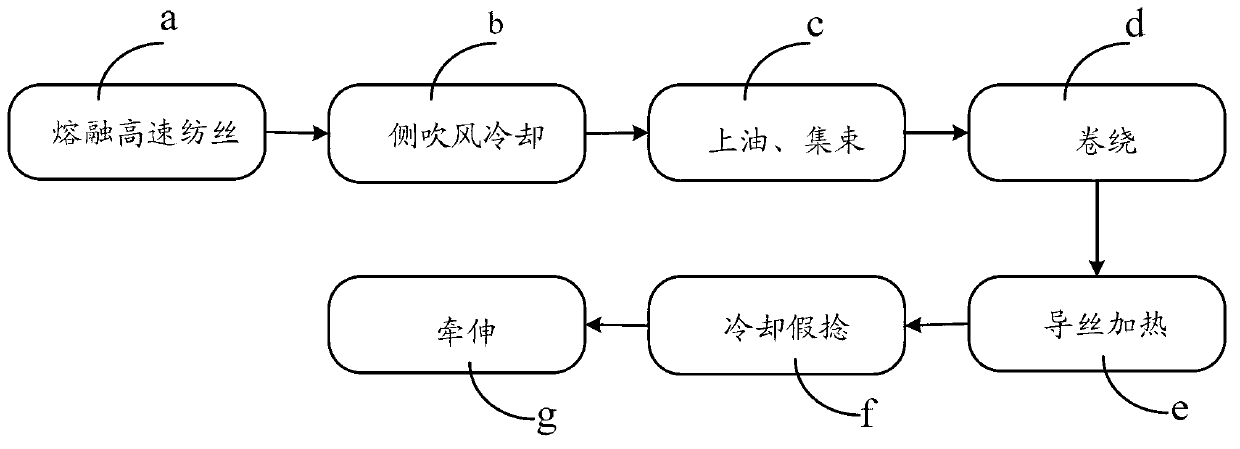

Manufacture method of ultrathin single-fiber polyamide drawn textured yarn (6DTY)

ActiveCN102995147AHigh degree of crystal orientationLow elongationSpinnerette packsFilament forming substance formingYarnSingle fiber

The embodiment of the invention discloses a manufacture method of an ultrathin single-fiber polyamide drawn textured yarn (6DTY), which comprises the following steps of: a, melting for high-speed spinning; b, laterally blowing air for cooling; c, oiling and bundling; d, winding; e, heating a conducting wire; f, cooling and false-twisting; and g, drafting to obtain the ultrathin single-fiber polyamide drawn textured yarn (6DTY) with yarn density of 0.40-0.55dtex. According to the invention, the method for manufacturing the ultrathin single-fiber polyamide drawn textured yarn (6DTY) by adopting a direct spinning method is formed through regulation and improvement of parameters such as a spinning assembly, spinning temperature, spinning speed, oiling, heat box temperature, D / Y ration, false twisting disk material and combination, roller speed ratio and the like, and thus the problem of end breaking, broken filaments and the like are solved, the production quality of the ultrathin single-fiber polyamide drawn textured yarn (6DTY) is stable, and the yield of the ultrathin single-fiber polyamide drawn textured yarn (6DTY) is increased.

Multi-group color separation spinning and crocheting wool yarn and manufacturing method thereof

The invention discloses multi-group color separation spinning and crocheting wool yarn and a manufacturing method of the multi-group color separation spinning and crocheting wool yarn. The manufacturing method comprises the steps that elastic nylon or filaments are crocheted to be net-shaped yarn, drafted multi-group color separation spinning short fiber thick yarn wool tops are fed and enter false twisting hooks of hook wood ingots under the traction of the nylon filaments or the elastic filaments, 10-20 false twists are added on strands and the nylon filaments or the elastic filaments to form thick yarn to be attached to the net-shaped yarn of the nylon filaments or the elastic filaments, and the multi-group color separation spinning and crocheting wool yarn is obtained after untwisting. As the tape yarn is of a drafting type, the yarn has the advantages of being soft, fluffy, high in strength and the like, wool does not fall off easily, the yarn is applicable to sweater yarn of autumn and winter clothes, and good moisture absorption performance, the heat retention performance and the air permeability are achieved. The manufacturing method overcomes the defect that a traditional twisting machine is single in fiber mode, enriches the characteristics of multiple components of the yarn, subsequent dyeing is avoided, and the yarn is an environmentally friendly product.

Owner:JIANGSU LUGANG SCI & TECH

Three-point mutual wrapping and winding type spun yarn evening and ordering device and method

The invention provides a three-point mutual wrapping and winding type spun yarn evening and ordering device and method. The three-point mutual wrapping and winding type spun yarn evening and ordering device comprises a three-point mutual wrapping and winding mechanism. The three-point mutual wrapping and winding mechanism comprises a fixing frame, a stepping motor, a worm, a drive gear, a first transmission gear, a first winding and pasting roller, a second transmission gear, a second winding and pasting roller, a third transmission gear, a third winding and pasting roller and a first yarn guiding hook. The worm on the stepping motor is coupled with the drive gear, and the first winding and pasting roller is sleeved with the first transmission gear. The second winding and pasting roller is sleeved with the second transmission gear. The third winding and pasting roller is sleeved with the third transmission gear. The drive gear drives the first transmission gear, the second transmission gear and the third transmission gear to rotate. The three-point mutual wrapping and winding mechanism is additionally arranged on a ring spinning frame, the fluctuation of an air ring is effectively controlled, a spun yarn is stabilized to be evenly output, the silver evenness is improved, and the yarn quality is improved.

Owner:DONGHUA UNIV

Convenient instant fresh wet noodle and preparation method thereof

The invention discloses a convenient instant fresh noodle and a preparation method thereof, and relates to the field of food processing. The convenient instant fresh wet noodle is mainly composed of high-gluten wheat flour, modified starch, vital gluten and salt. The addition of additives reduces indicator degradation of color, texture and microorganisms during storage. The noodle adopts an extrusion molding curing process to ensure long shelf life by pickling, modified atmosphere packaging and irradiation sterilization.

Owner:湖北戴氏食品科技股份有限公司

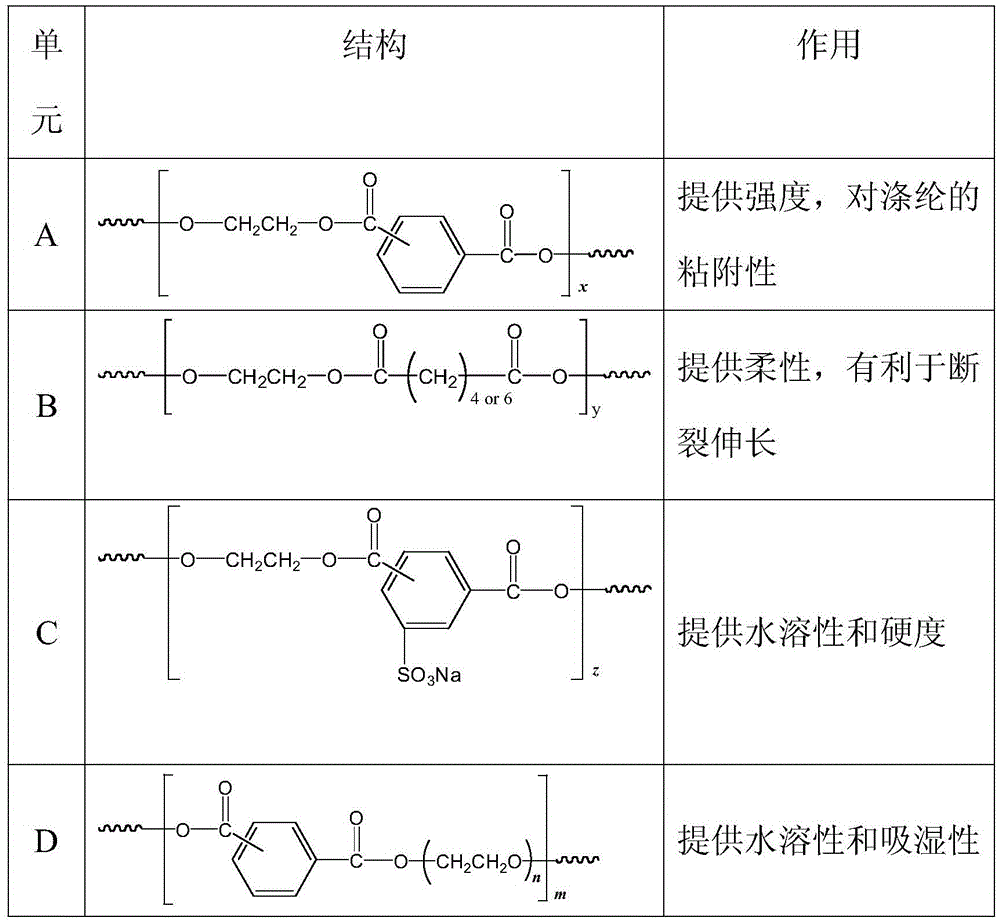

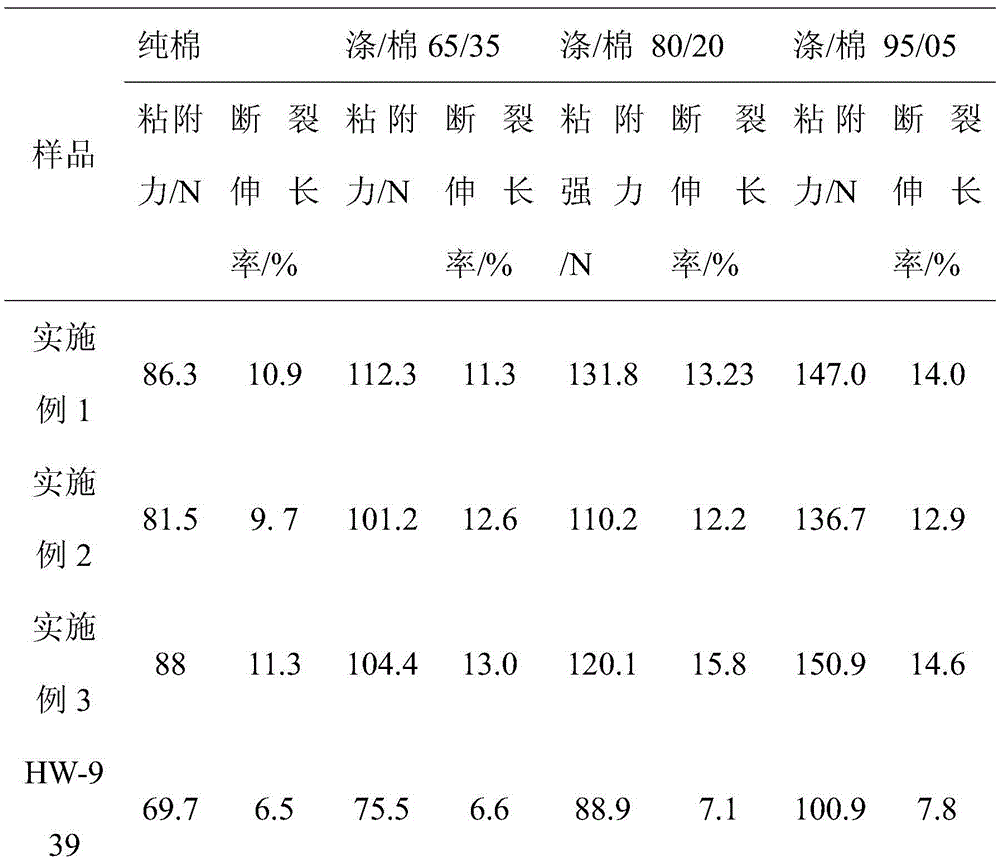

Polyester emulsion slurry and preparation method thereof

The invention discloses polyester emulsion slurry which is prepared from, by molar content, purified terephthalic acid, isophthalic acid, isophthalic acid-5-sodium sulfonate, aliphatic dicarboxylic acid, ethylene glycol and polyethylene glycol PEG, and the total molar weight ratio of carboxylic acid to dihydric alcohol is (1:1.2)-(1:1.4). The PET emulsion polyester glass transition temperature ranges from -10 DEG C to 0 DEG C and is much lower than that of slurry in the prior art. The slurry is soft and not adhesive on yarn and is better in softness and elasticity and good in adhesion. The slurry can be used for polyester cotton blending and pure cotton yarn sizing after being mixed with starch or modified starch, the end breakage rate can be greatly reduced, and efficiency of a loom is improved.

Owner:SICHUAN ZHUKANG NEW MATERIAL CO LTD

Special size composition for sizing hank yarns

The invention provides a special size composition for sizing hank yarns and application thereof and belongs to a hank yarn fiber spinning finishing agent. The special size composition is prepared from the following raw materials in part by weight: 50 to 60 weight parts of corn starch, 10 to 20 weight parts of polyvinyl alcohol, 10 to 15 weight parts of polyacrylic acid, 8 to 10 weight parts of sized yarn smooth paste, 3 to 6 weight parts of grease EL, 1 to 2 weight parts of DDF catalyst, 0 to 15 weight parts of bone glue, 1 to 2 weight parts of antistatic agent and a proper amount of water. The invention provides an ideal special size composition for sizing hank yarns, which has high yield, excellent yarn separability, low end breakage rate, no strip sticking nor sizing spot, and easy and complete de-sizing. As less polyvinyl alcohol (PVA) in adopted in formula, the ideal special size composition for sizing hank yarns is environment-friendly, diversified and suitable for small-batch production and can be mastered flexibly and operated conveniently. The composition of the invention solves the technical problem that no special size composition for sizing hank yarns exists in the prior art.

Owner:SHANDONG TIANDE IND & TRADE

Airflow gel spinning device

The invention disclose an airflow gel spinning device, which mainly comprises an airflow device and a gel lubricating device, wherein the airflow device consists of yarn lead and guide porcelain eyes, an air inlet, an airflow conveying pipe, an air valve switch and an airflow shell; and the gel lubricating device consists of a hydraulic device, a gel slot, a gel recovery bottle and gel. The airflow gel spinning device can be applied to the technical transformation of a spinning machine; an airflow plate and a gel lubricating plate are arranged on a table board of a machine, yarn is rotated by airflow, and a certain twist is applied to the yarn, so that hairiness of the yarn is reduced, and the uniformity of yarn levelness is improved; the yarn is docile after passing through the surface of the gel lubricating board, so that friction coefficient is decreased; and compared with the prior art, the airflow gel spinning device is easy and convenient to assemble and high in cost performance.

Owner:JIANGNAN UNIV

Wool/crotalaria sp./mulberry silk/cotton/polyester fiber blended fabric and preparation method thereof

The invention relates to a wool / crotalaria sp. / mulberry silk / cotton / polyester fiber blended fabric. The fabric comprises the following material components in percentage by weight: 28% of wool fiber, 35% of crotalaria sp. fiber, 17% of polyester fiber, 18% of cotton fiber and 3% of mulberry silk. The method includes the steps of: 1, top dying process of the cotton fiber and the crotalaria sp. Fiber; 2, dying and re-combing process of the wool fiber, the polyester fiber and the mulberry silk fiber; 3, spinning process; 4 weaving process; 5, dying and finishing process; the spinning process includes: mixing and performing primary gilling, secondary gilling, third gilling and fourth gilling on products prepared by the dying and re-combing process of the wool fiber, the polyester fiber and the mulberry silk fiber, then being subjected to primary roving, secondary roving and spinning processes together with yarn prepared by the top dying process of the cotton fiber and the crotalaria sp. Fiber, when a double-steel wire hook is adopted in the spinning process. The fabric achieves the purpose of being breathable, antibacterial and health-care, and meanwhile meets the requirements on various technical indexes of spring and summer fabrics.

Owner:江苏华西村纺织服装有限公司

Vortex spinning process

InactiveCN102719938ALow costQuality improvementContinuous wound-up machinesOpen-end spinning machinesYarnRecovery period

The invention relates to a vortex spinning process, belonging to the technical field of cotton spinning. The spinning process specifically comprises the process flows: raw cotton beating and impurity removal, combing treatment, pre-drawing treatment, lap forming and doubling treatment, fine combing, final drawing treatment, and vortex spinning to obtain purified cotton vortex yarn. Compared with the traditional ring spinning method, the method has the advantages of high yield, low energy consumption, short working time, little yarn filoplume, small occupied area, rapid starting and short investment recovery period, and is a first choice to replace ring spinning.

Owner:南昌凤凰纱业有限公司

Driving device for wool spinning machine

ActiveCN102704059BReduce labor intensityReasonable structureContinuous wound-up machinesGear driveGear wheel

The invention relates to a driving device for a wool spinning machine. After a front roller motor decelerates, one path of front roller motor subjected to deceleration is connected with a front-right roller through the driving of a first belt; the other path of front roller motor subjected to deceleration is connected with a front-left roller through driving of a first intermediate gear pair and a second belt; after a rear-middle roller motor decelerates, one path of rear-middle roller motor subjected to deceleration is connected with an intermediate roller gearbox through driving of a third belt and a fourth belt; the other path of rear-middle roller motor subjected to deceleration is connected with the intermediate roller gearbox through driving of a second intermediate gear pair and a fifth belt; left and right intermediate rollers are connected with the intermediate roller gearbox; the third belt drives to be connected with a rear roller gearbox through the driving of a sixth belt; the second intermediate gear pair is connected with a rear roller gearbox through driving of a seventh belt; left and right rear rollers are connected with the rear roller gearbox; after a main motor decelerates, the main motor subjected to deceleration is connected with a spindle through a spindle belt via a main shaft and a rolling disk; and a lifting motor subjected to deceleration is connected with a ring rail through a worm gear and worm transmission pair, a stroke cam, a cam roller and a swing rod. The driving device disclosed by the invention has the advantages of simple structure, reduced amount of driving mechanisms and reduction of production cost.

Owner:常州市同和纺织机械制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com