Patents

Literature

42results about How to "No drift phenomenon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Washing method for spinneret plate

The invention relates to a washing method for a spinneret plate, and mainly solves the technical problems in the prior art that the spinneret plate cannot be cleanly washed, gel is adhered to the surface of the spinneret plate, a spinning solution at the outlet of a spinneret hole overflows, and polyacrylonitrile protofilament has more broken filaments and more thin filaments and is high in fiber breakage rate. The washing method for the spinneret plate comprises the following steps of disassembling the spinneret plate from a spinning assembly; immersing the spinneret plate in a solvent in a container; then immersing the container in water bath; washing by adopting a mode of combining temperature rising with ultrasound; taking out the spinneret plate after the washing is completed; blowing the surface of the spinneret plate by gas which is precisely filtered after the spinneret plate is dried; completing the washing. According to the technical scheme, the problems are well solved, and the washing method can be used in a device washing process after the spinning of the polyacrylonitrile protofilament.

Owner:CHINA PETROLEUM & CHEM CORP +1

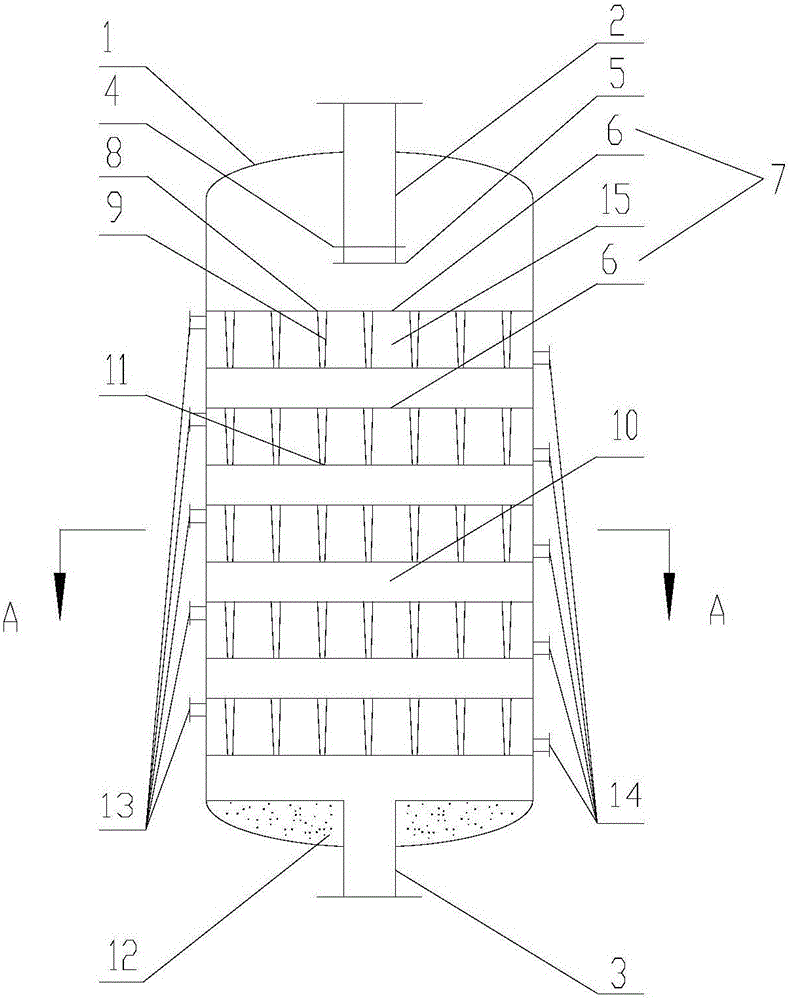

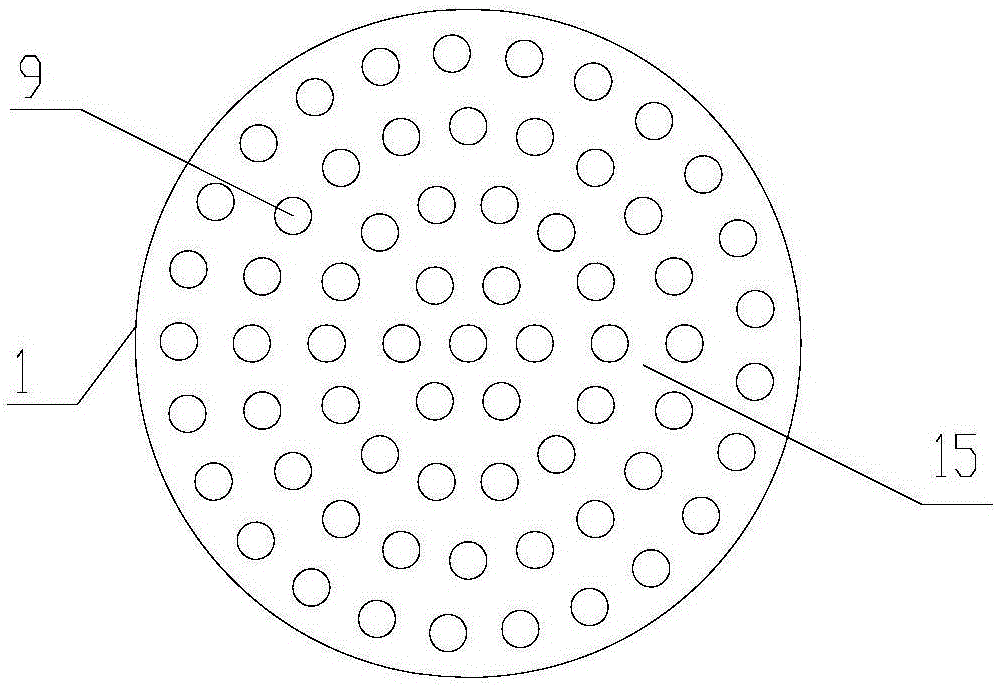

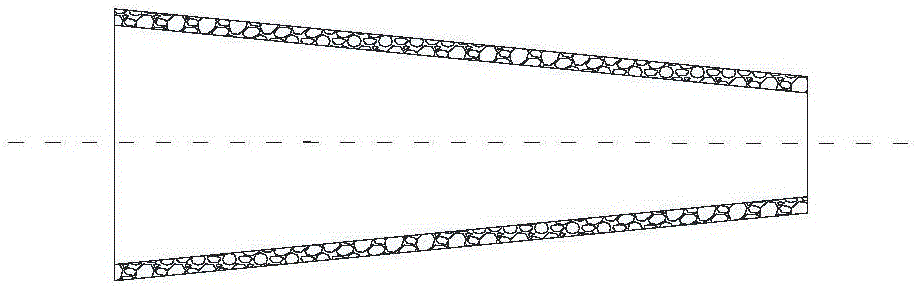

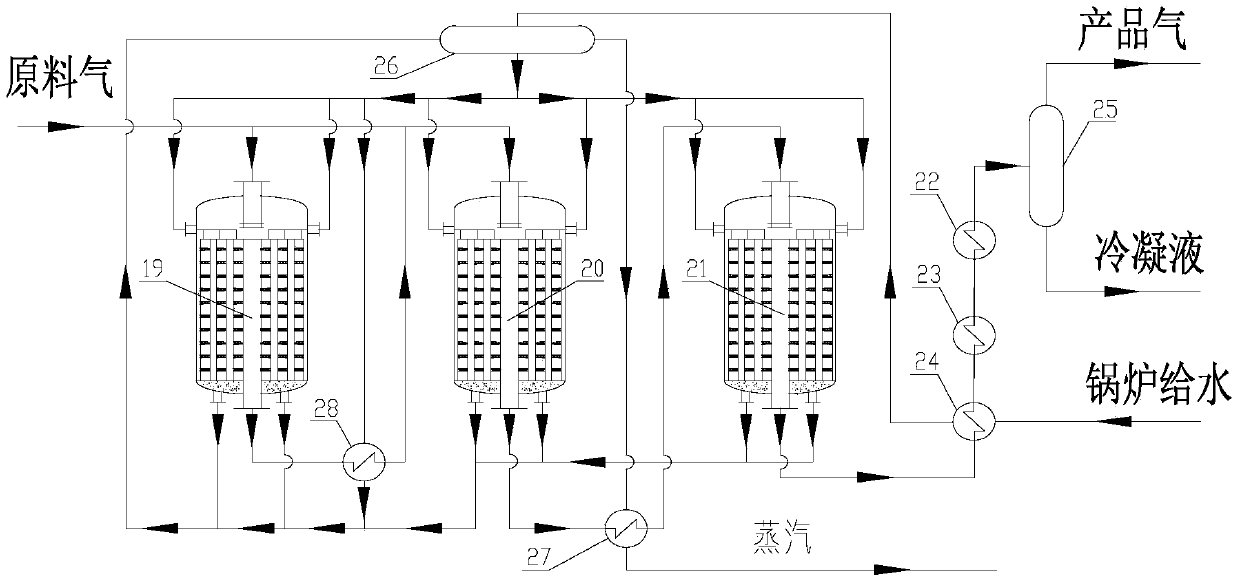

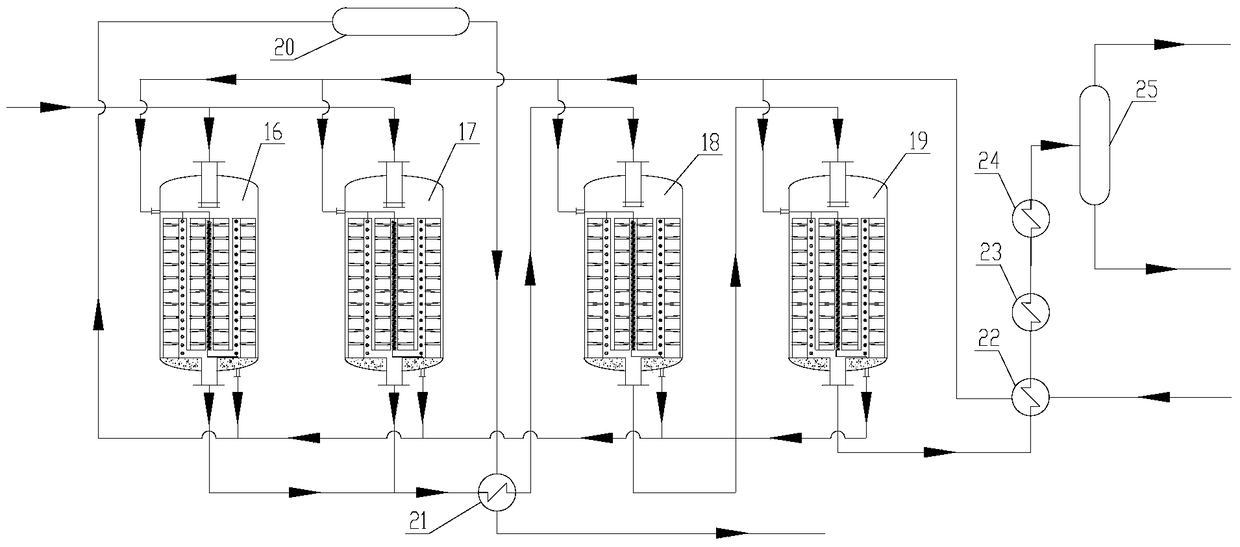

Methanation reactor and methanation process

ActiveCN107224940AIncreased turbulenceImprove conversion rateGaseous fuelsChemical/physical processesMethanationEconomic benefits

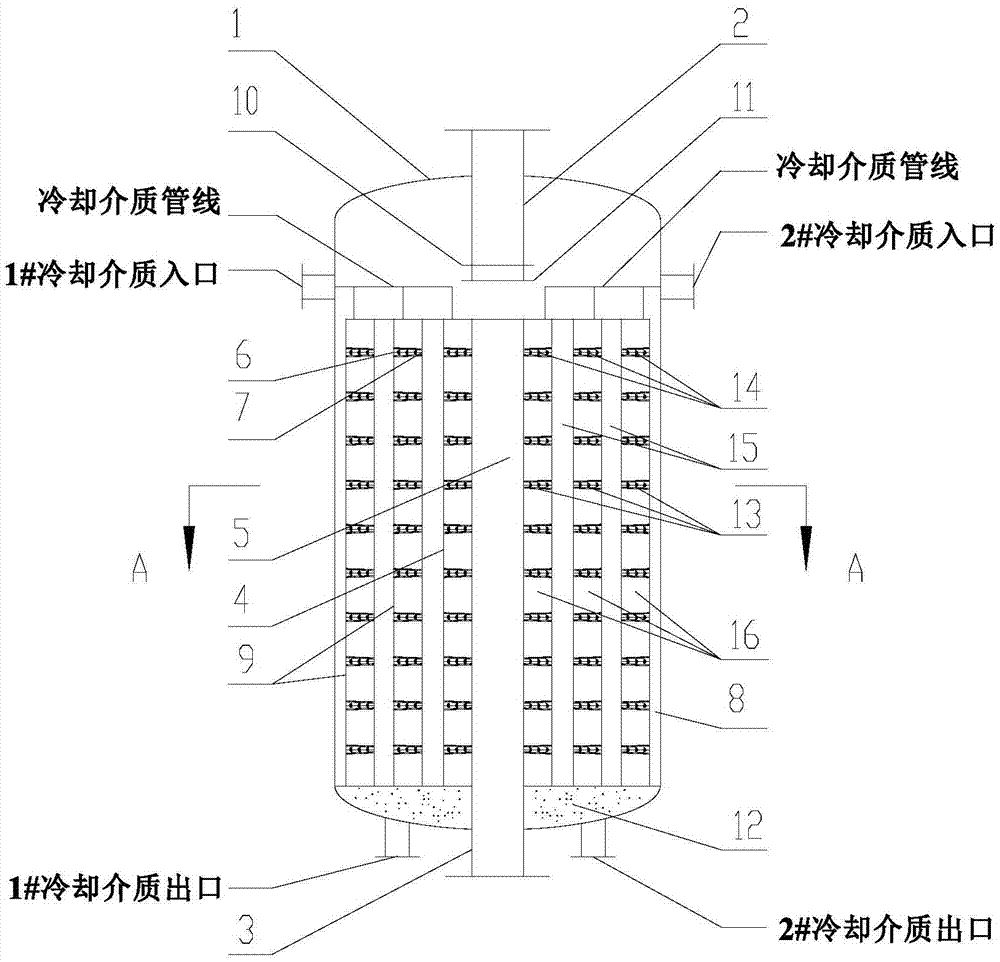

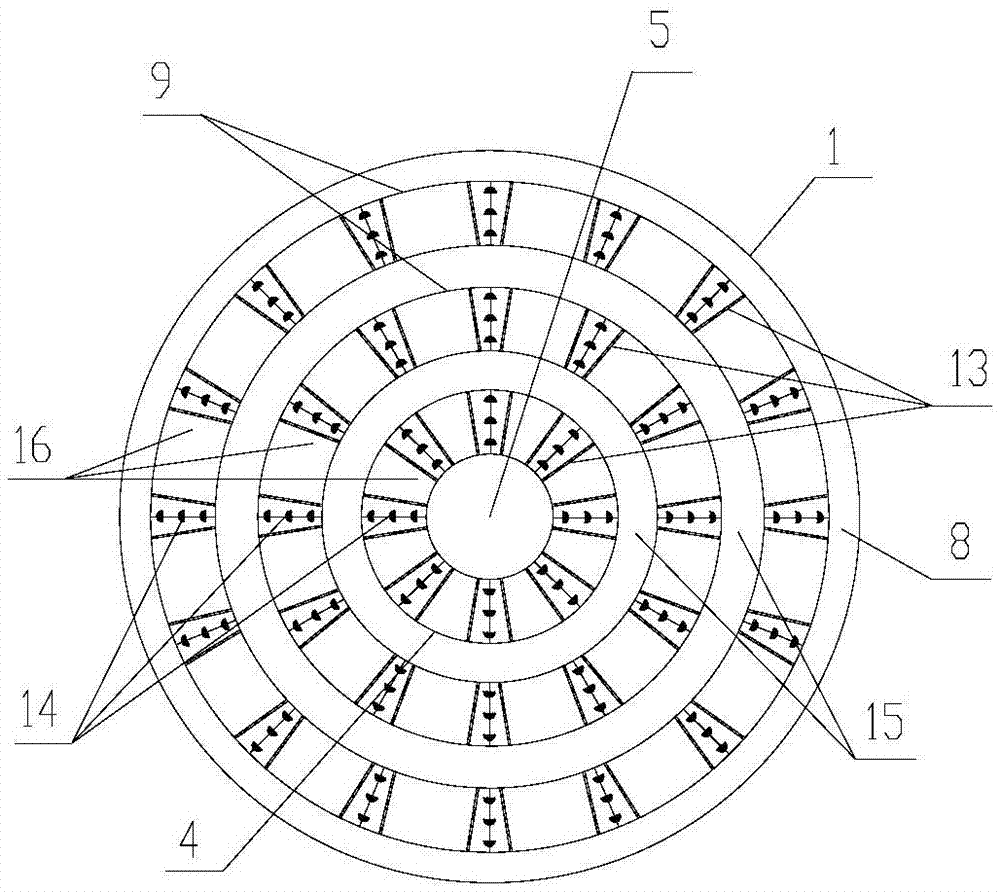

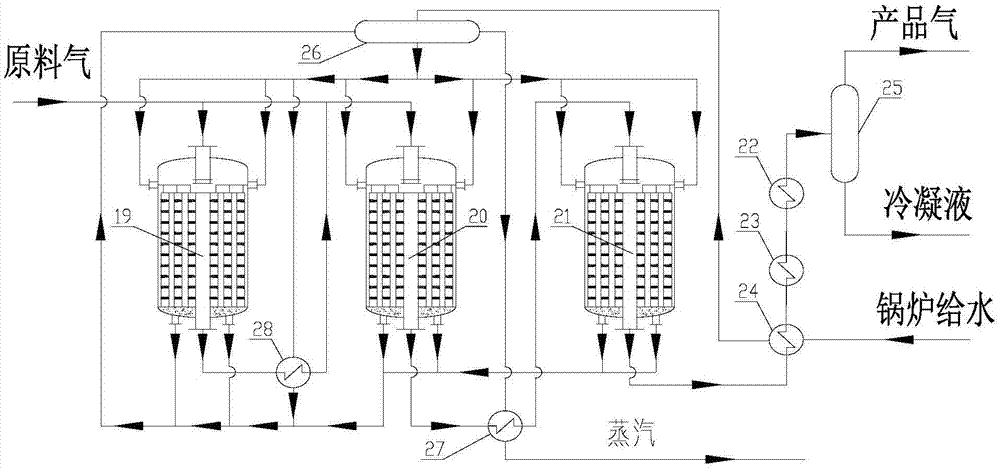

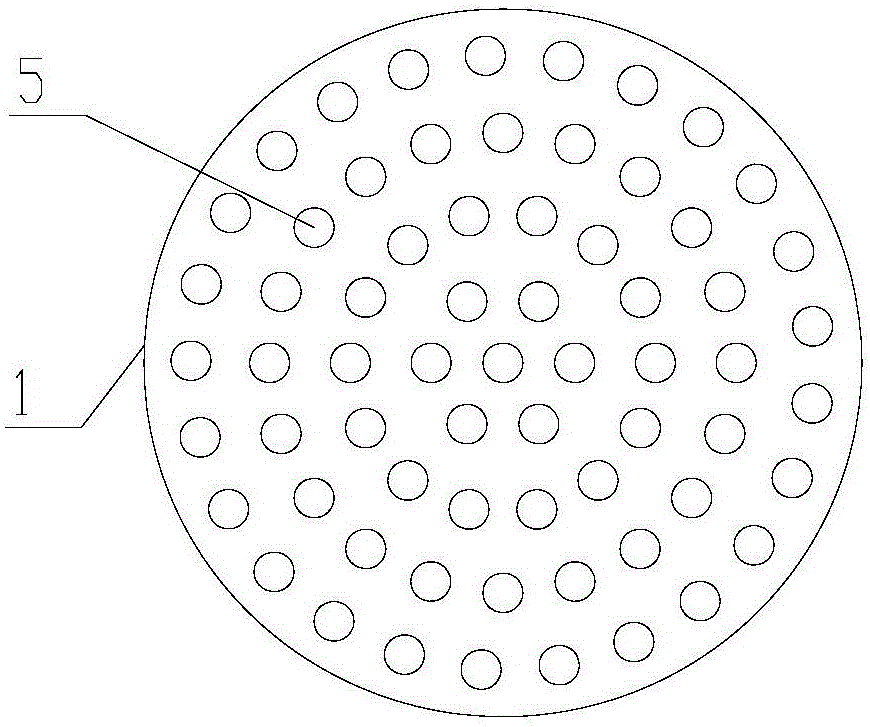

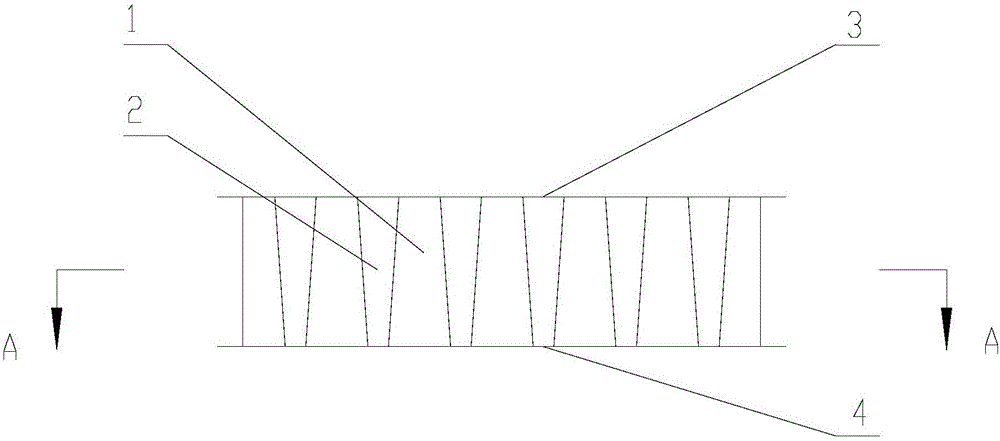

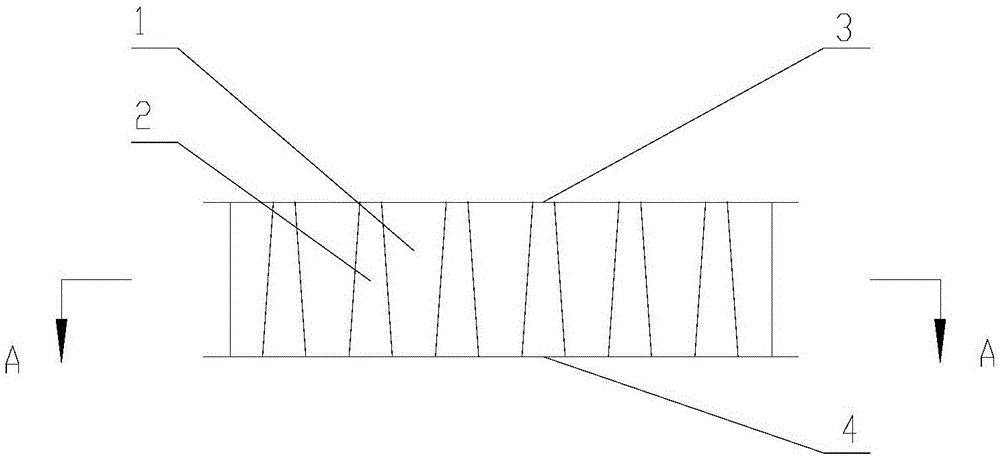

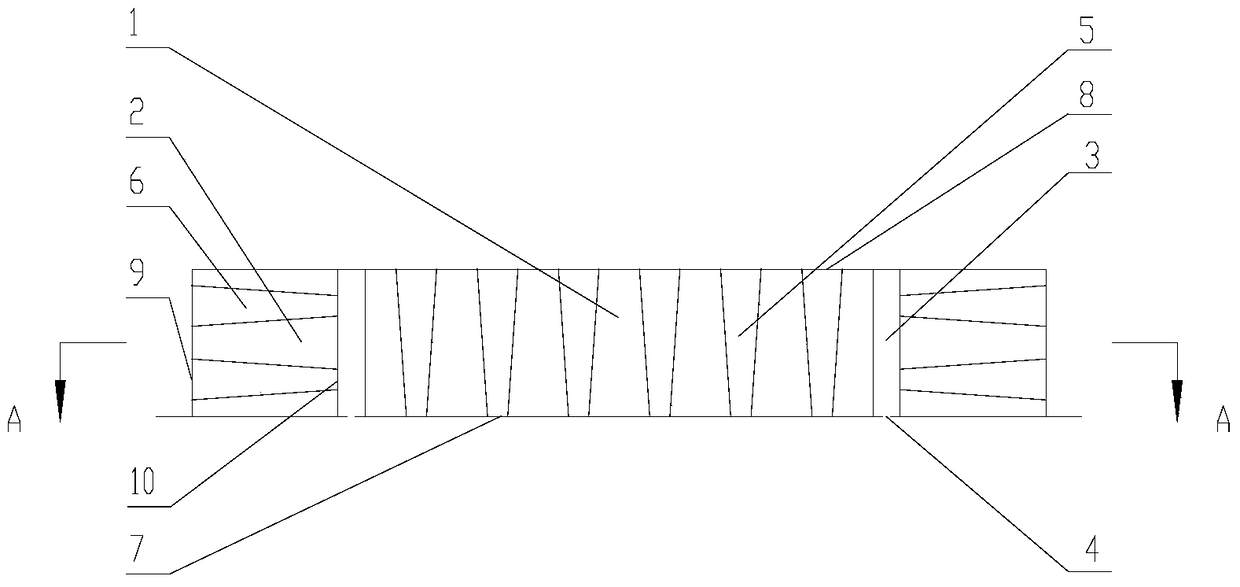

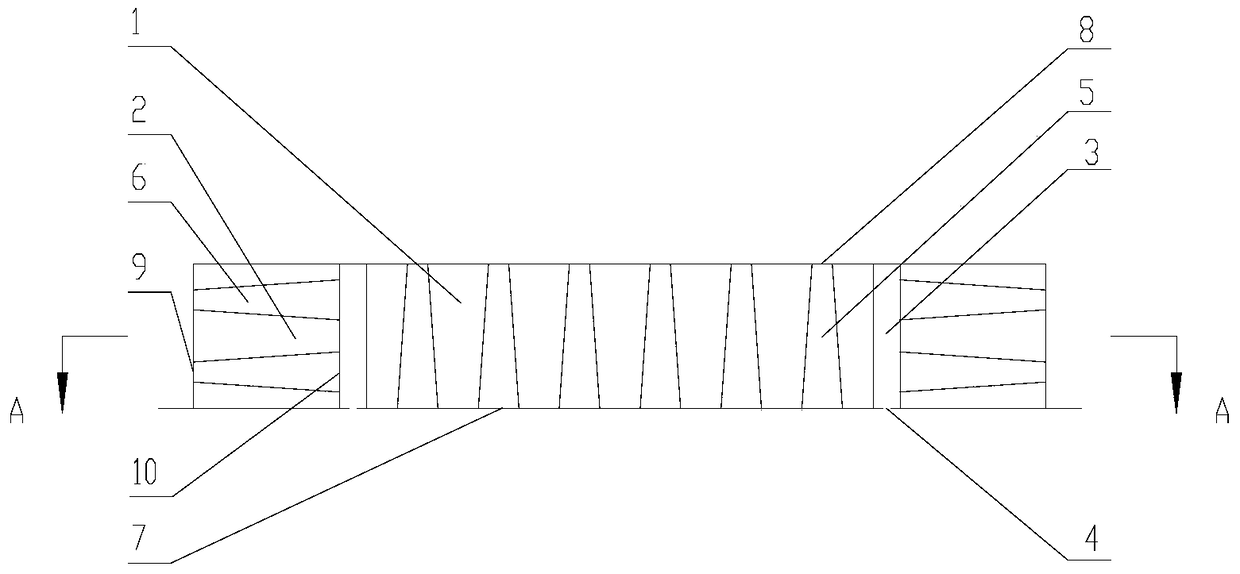

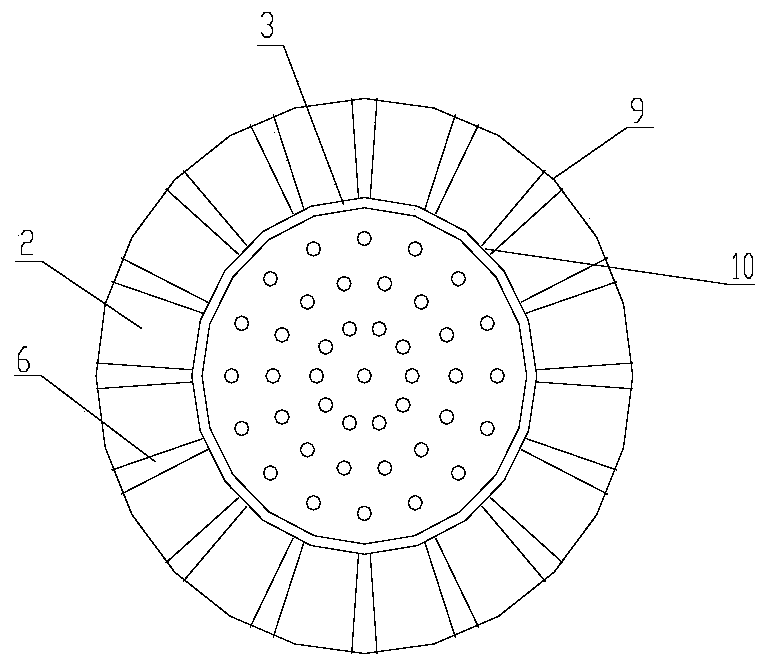

The invention discloses a methanation reactor and a methanation process. The reactor comprises a cylindrical sealed pressure-bearing shell body (1), a gas inlet pipe (2), a gas outlet pipe (3), a radial catalytic reaction zone and heating equipment, wherein the gas inlet pipe (2) extends inside the shell body from the top of the shell body (1), the gas outlet pipe (3) extends inside the shell body from the bottom of the shell body (1), and the radial catalytic reaction zone is formed in the shell body (1) below the gas inlet pipe (2) and above the gas outlet pipe (3) and comprises the heating equipment. Compared with the prior art, the methanation reactor and the methanation process have the advantages that the methanation reactor disclosed by the invention is low in active metal consumption and smaller in equipment size, and the methanation process adopting the methanation reactor is low in bed layer pressure drop and high in feedstock conversion ratio, is free of gas bias and short-circuit phenomena and has the characteristics of high economic benefit, low comprehensive energy consumption and the like.

Owner:SINOPEC ENG +1

Combined cleaning method for spinneret plate

The invention relates to a combined cleaning method for a spinneret plate with the aim of solving technical problems in the prior art such as long cleaning time, incomplete cleaning, high rate of plugged holes of the spinneret plate and many broken filaments of original filaments. The combined cleaning method for the spinneret plate is adopted and comprises following steps: detaching the spinneret plate on a spinning assembly, soaking the spinneret plate dipped with spinning solution to solidified solution, taking out the spinneret plate after spinning solution of the spinneret plate is solidified and tearing off solidified spinning solution on the spinneret plate; putting the spinneret plate into a container holding a cleaning solvent and putting the container into an ultrasonic water bath for cleaning; and putting the cleaned spinneret plate into an air-blast drying box for drying; and finally, utilizing gas filtered by a filter core of certain filter precision to blow and sweep the dried spinneret plate for less than 1min. The technical scheme of the combined cleaning method for the spinneret plate helps solve the problem and can be used for the equipment cleaning process following spinning of original filaments polyacrylonitrile.

Owner:CHINA PETROLEUM & CHEM CORP +1

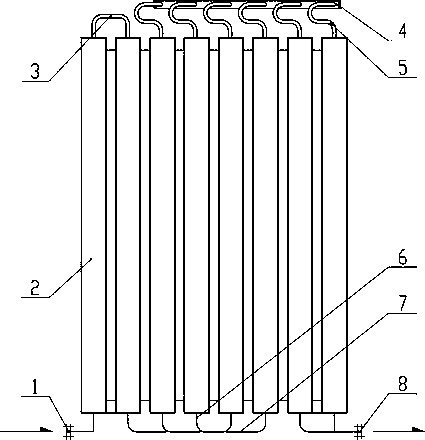

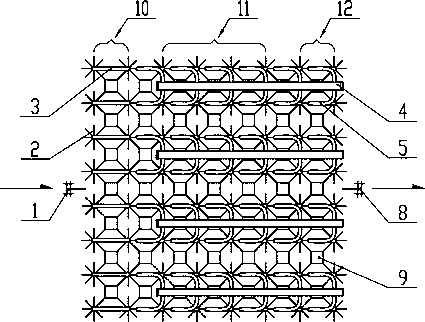

Large continuous air supply type air-heated vaporizer

InactiveCN103267430AReasonable arrangementCompact structureStationary conduit assembliesPressure vesselsEngineeringElectrical and Electronics engineering

The invention relates to a large continuous air supply type air-heated vaporizer. The large continuous air supply type air-heated vaporizer comprises a heat exchange fin tube bundle which is arranged between a liquid inlet and an air outlet and arranged in a matrix mode, the heat exchange fin tube bundle is divided into an undercooling section, an evaporation section and a heating section which are parallel from the liquid inlet to the air outlet, the undercooling section, the evaporation section and the heating section are connected between the liquid inlet and the air outlet in series, each of the undercooling section and the heating section comprises at least one row of heat exchange fin tubes, the evaporation section comprises a plurality of rows of heat exchange fin tubes which are connected in series. According to the air-heated vaporizer, the undercooling section, the evaporation section and the heating section of the heat exchange fin tube bundle are connected in series, the evaporation section comprises the plurality of rows of heat exchange fin tubes which are connected in series, the arrangement is reasonable, the structure is compact, the overall rigidity is high, the vaporizer is attractive and elegant in appearance, cryogenic fluids can be distributed to pipes evenly, bias current can be avoided, and requirements for high-flow continuous air supply are met.

Owner:无锡特莱姆气体设备有限公司

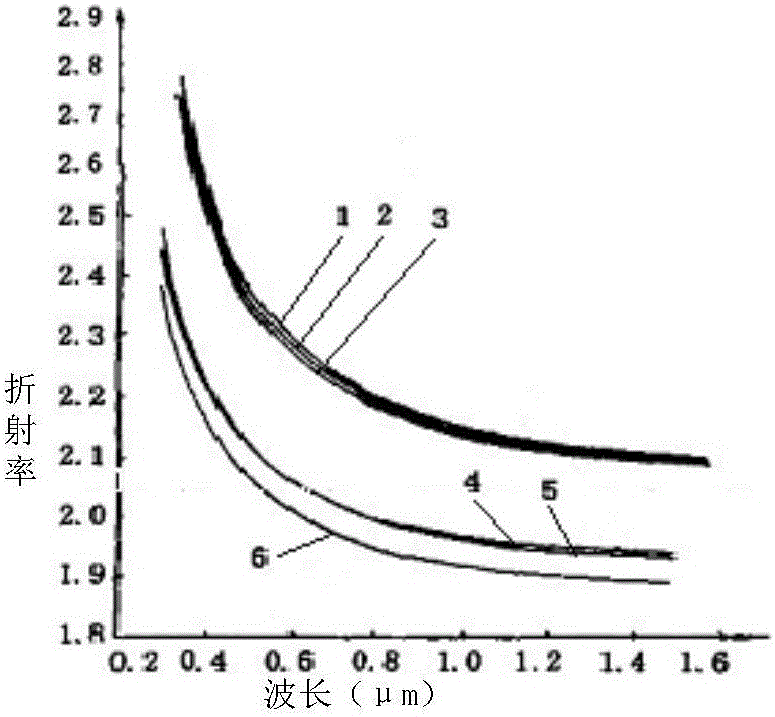

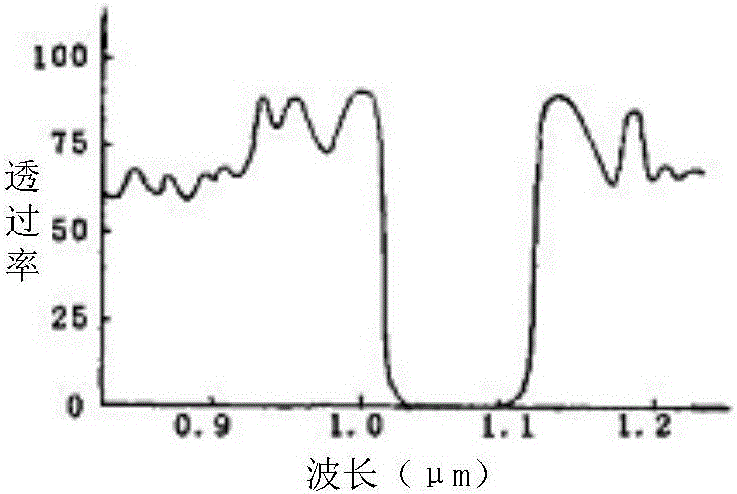

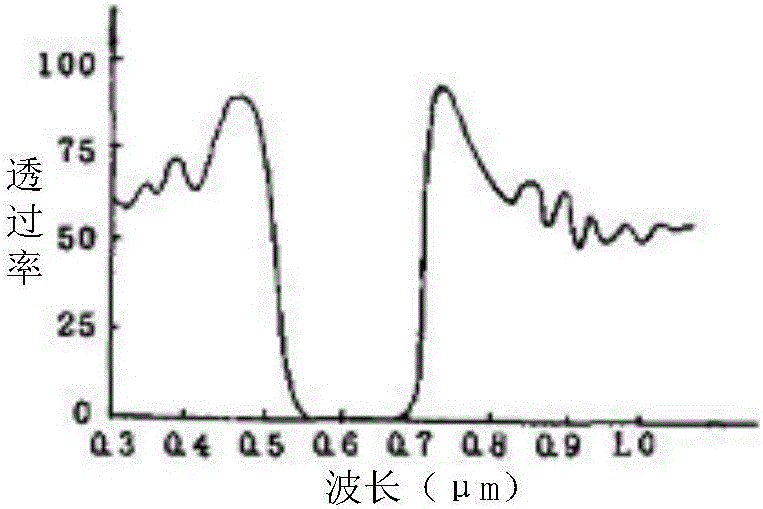

Plating method for laser high-reflective film

InactiveCN105132871ARaise the anti-damage thresholdImprove reflectivityVacuum evaporation coatingSputtering coatingRefractive indexLength wave

The invention discloses a plating method for a laser high-reflective film. Multiple commonly-used simple-substance film materials with high refractive indexes are mixed according to a certain proportion, and the mixed film materials are adopted for plating of a laser reflective film, so that the damage resistance threshold and the reflectivity of the laser reflective film are greatly improved. According to the laser reflective film formed by plating with such a series of mixed film materials as high-refractive-index materials and with SiO2 as a low-refractive-index film material, the damage resistance threshold is increased by 15%; the absorption is reduced; the mechanical strength is increased; and no wavelength drafting phenomenon is generated.

Owner:HEBEI HANGUANG HEAVY IND

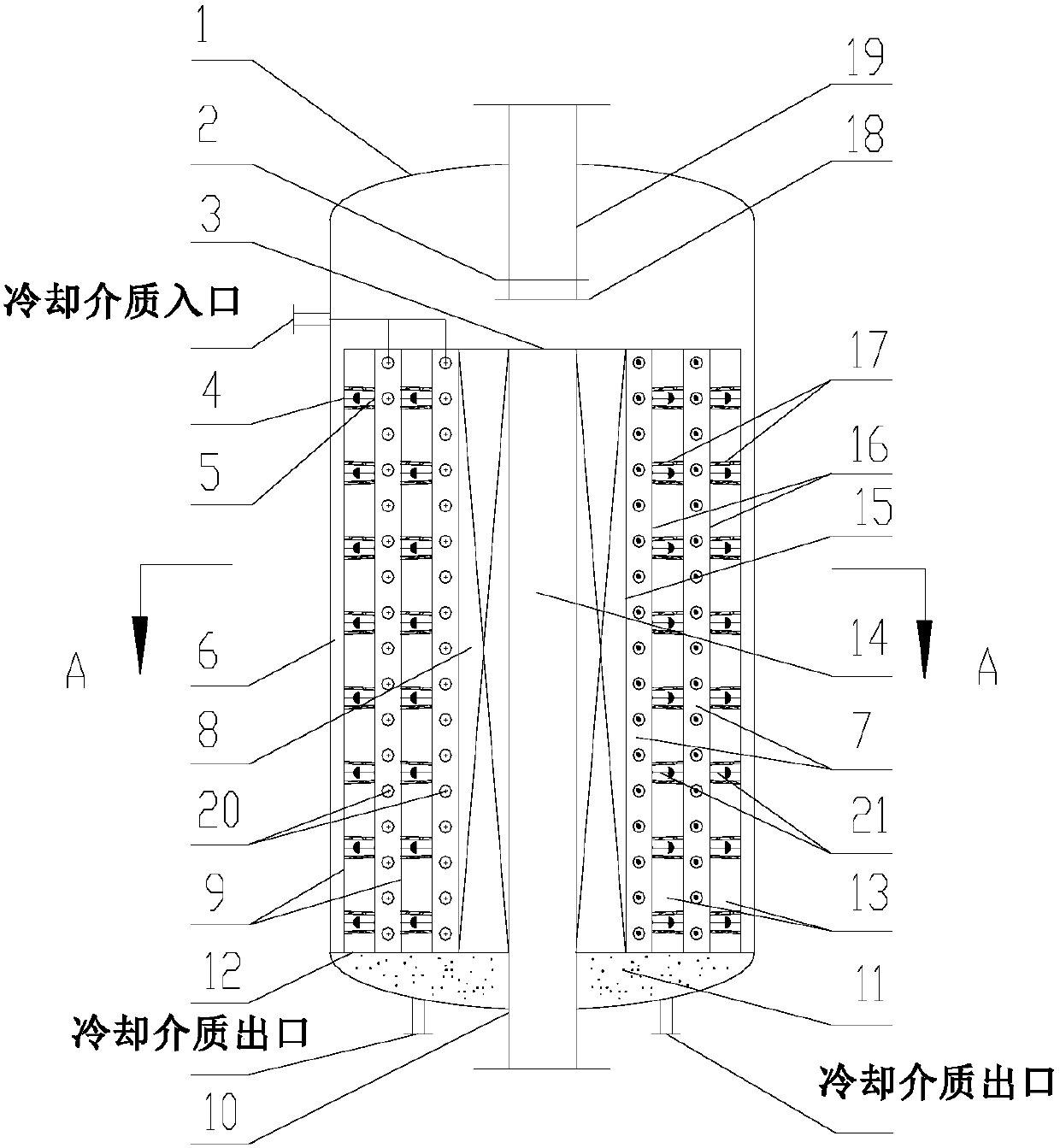

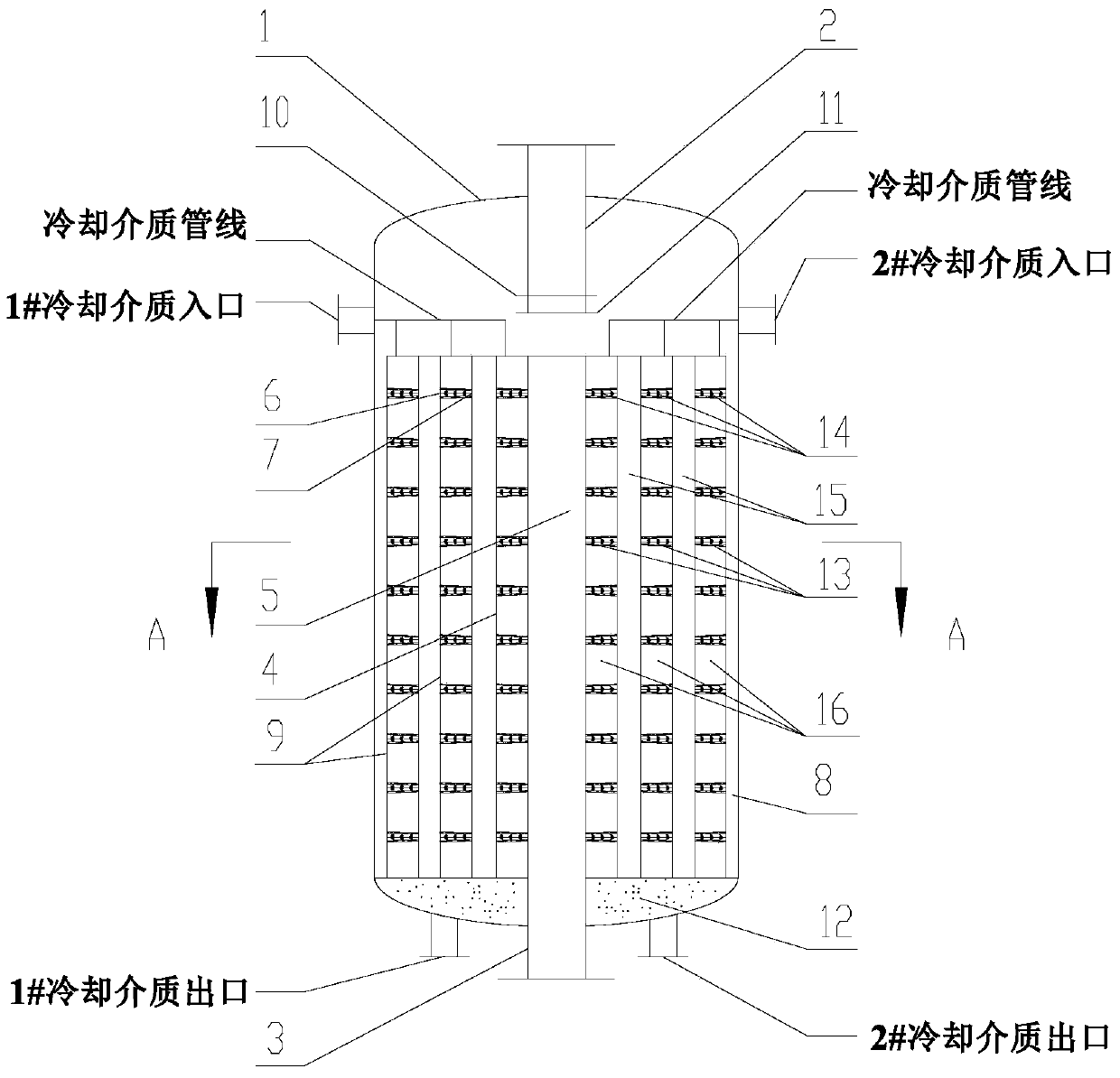

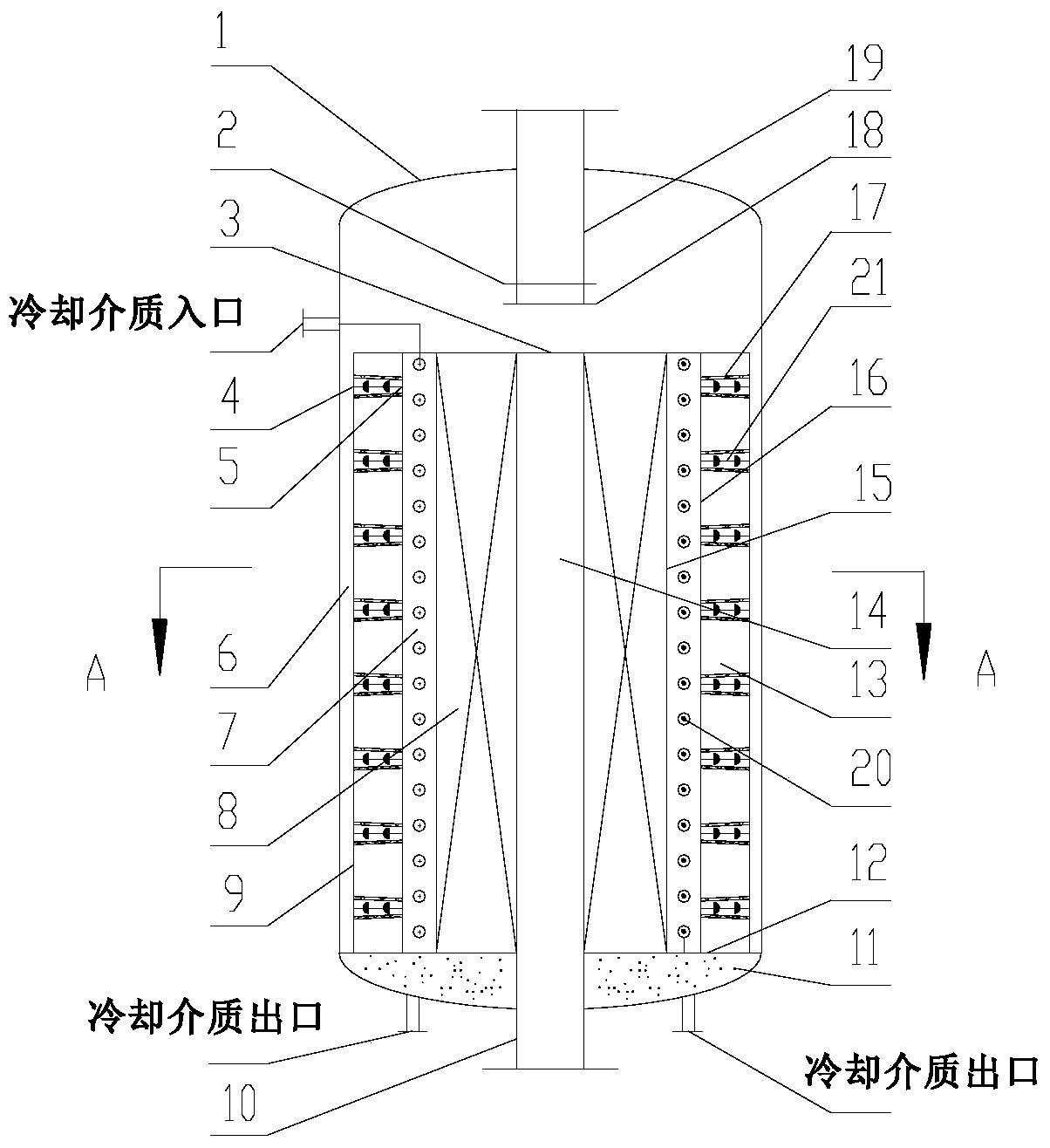

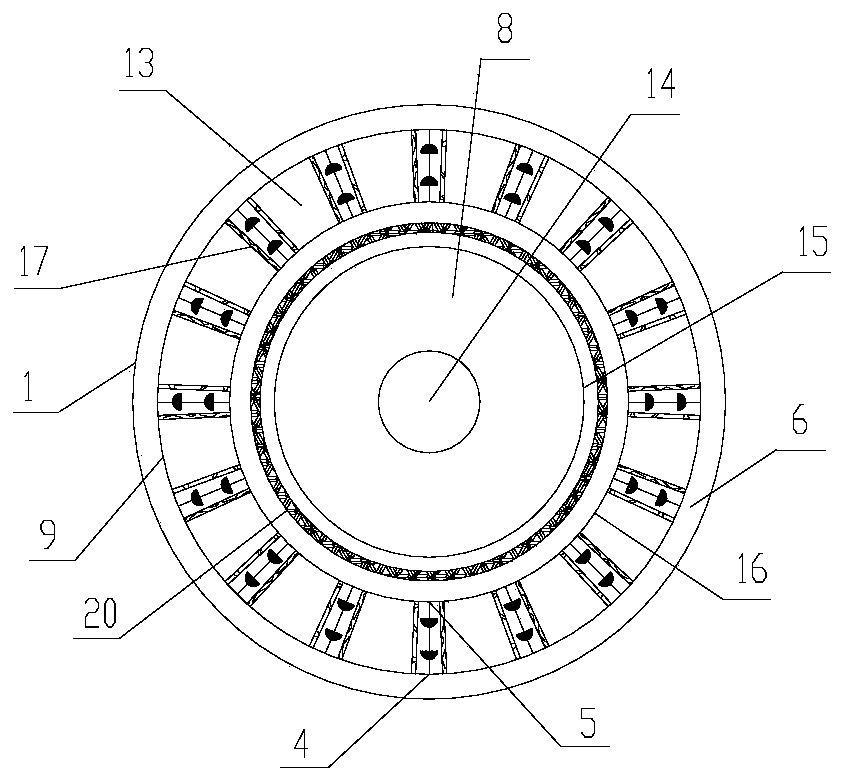

Methanation reactor and methanation process

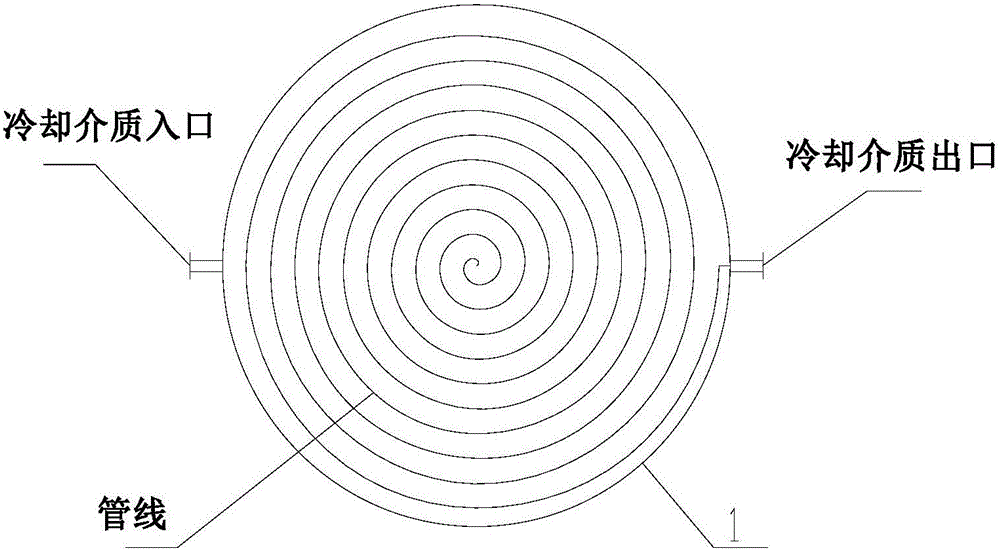

ActiveCN106693839AGreat driving forceShort stayHydrocarbon from carbon oxidesGaseous fuelsActive componentMethanation

The invention discloses a methanation reactor and a methanation process; the methanation reactor comprises a shell body, a gas inlet pipe, a central cylinder, a central pipe, a gas outlet pipe, a cooling medium inlet, a cooling medium outlet and a micro reaction channel, and includes or does not include a sleeve; the micro reaction channel can be internally loaded with a catalytic active component. Compared with the prior art, the methanation reactor has less catalyst use amount; according to the methanation process adopting the methanation reactor, the bed pressure is reduced, the gas residence time is short, the space utilization rate of a reaction bed is high, and gas bias current and short-circuit phenomena do not exist.

Owner:SINOPEC ENG +1

Methanation reactor and methanation technology

InactiveCN106693849AGreat driving forceShort stayGaseous fuelsChemical/physical/physico-chemical processesActive componentMethanation

The invention discloses a methanation reactor and a methanation technology. The methanation reactor comprises a shell, a gas inlet tube, a cylinder, a gas outlet tube and a micro-reaction channels, and a catalytic active component can be loaded in the micro-reaction channels. Compared with methanation reactors in the prior art, the methanation reactor disclosed in the invention has the advantages of small use amount of a catalyst, low bed pressure drop, short gas retention time, high reaction bed space utilization rate, no gas flow deflection and no short circuit in the methanation reaction process.

Owner:SINOPEC ENG +1

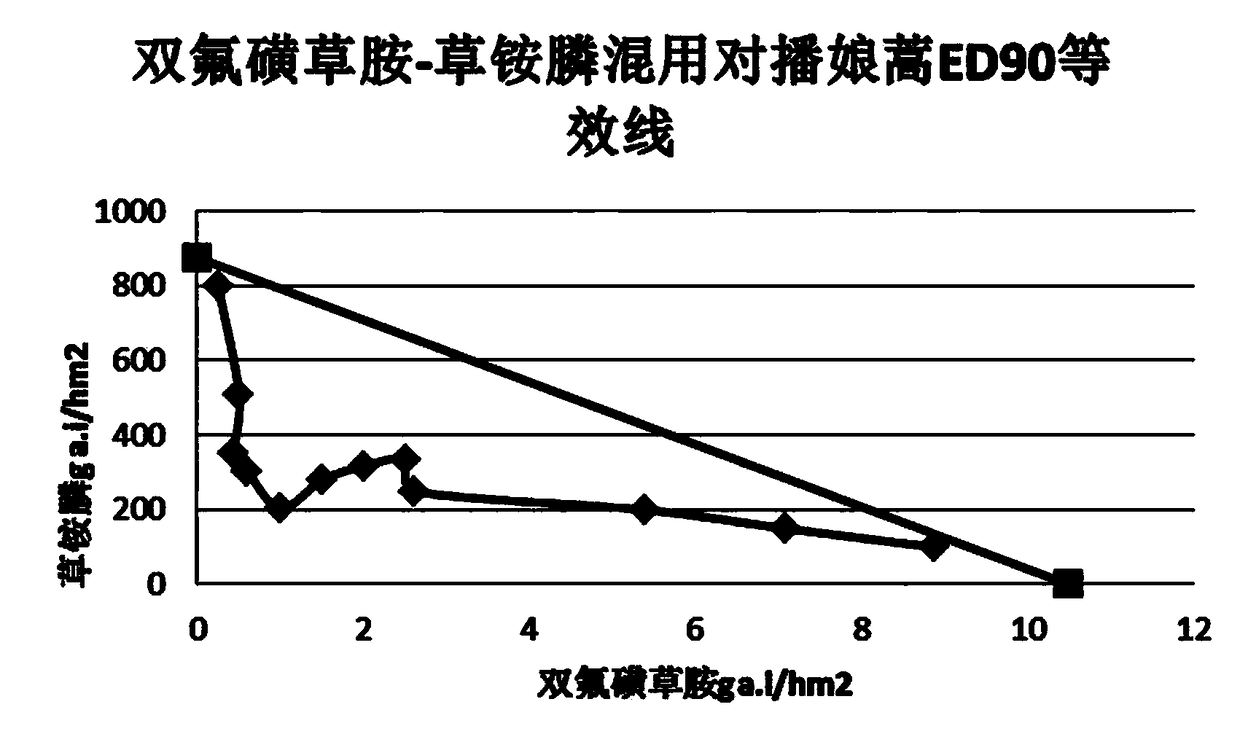

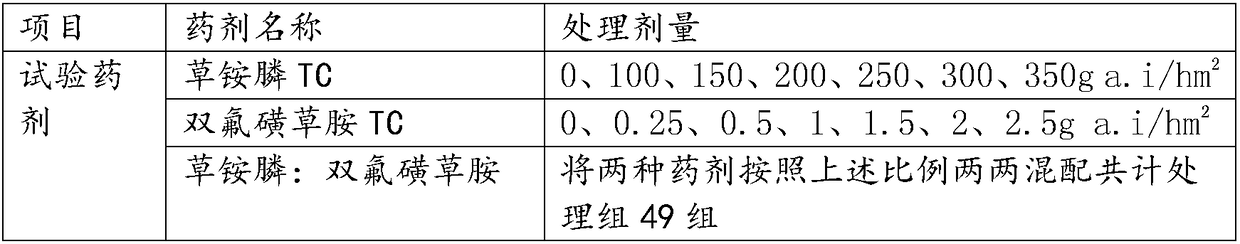

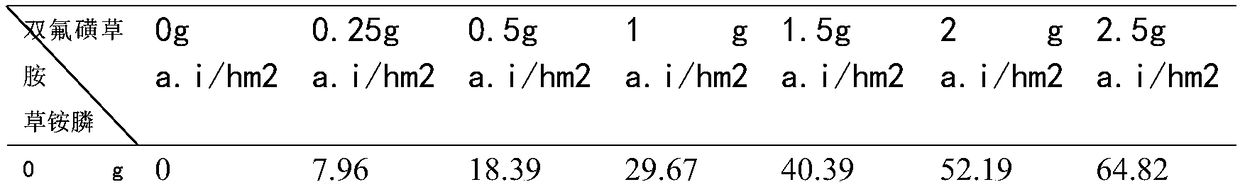

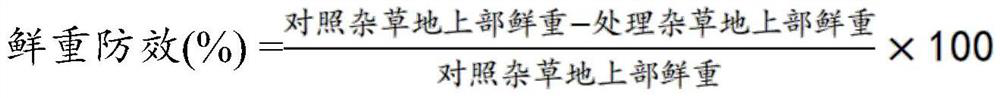

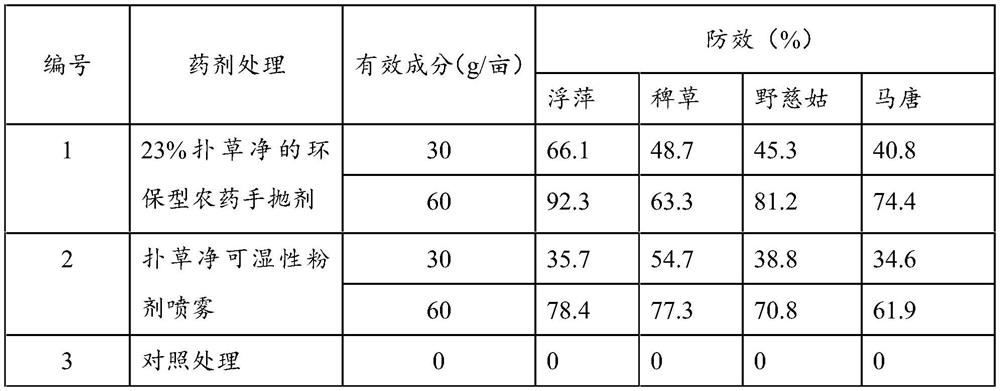

A compound herbicidal composition

ActiveCN105685094BGood synergyResidue reductionBiocideDead animal preservationSocial benefitsEcological environment

The invention discloses compound herbicide composition. The compound herbicide composition comprises effective components including glufosinate and florasulam in the weight ratio being (100-350) : (0.25-2.5). The compound herbicide composition belongs to a sterilant herbicide and can be used for controlling weeds in the uncultivated area, orchards, farmland and other areas. After mixed use of glufosinate and florasulam, the herbicide composition has a remarkable synergistic interaction function on descurainia Sophia and other broadleaf weeds and has the advantages of stable weeding effect at the low temperature, wide weed control spectrum and the like while compared with a single glufosinate agent. The use dosage of a pesticide can be effectively reduced, the adverse effect of the pesticide on the ecological environment is reduced, and the compound herbicide composition has a great significance in resistance comprehensive treatment of weeds and has huge economic benefits and social benefits.

Owner:ZHEJIANG TIANFENG BIOLOGICAL SCI

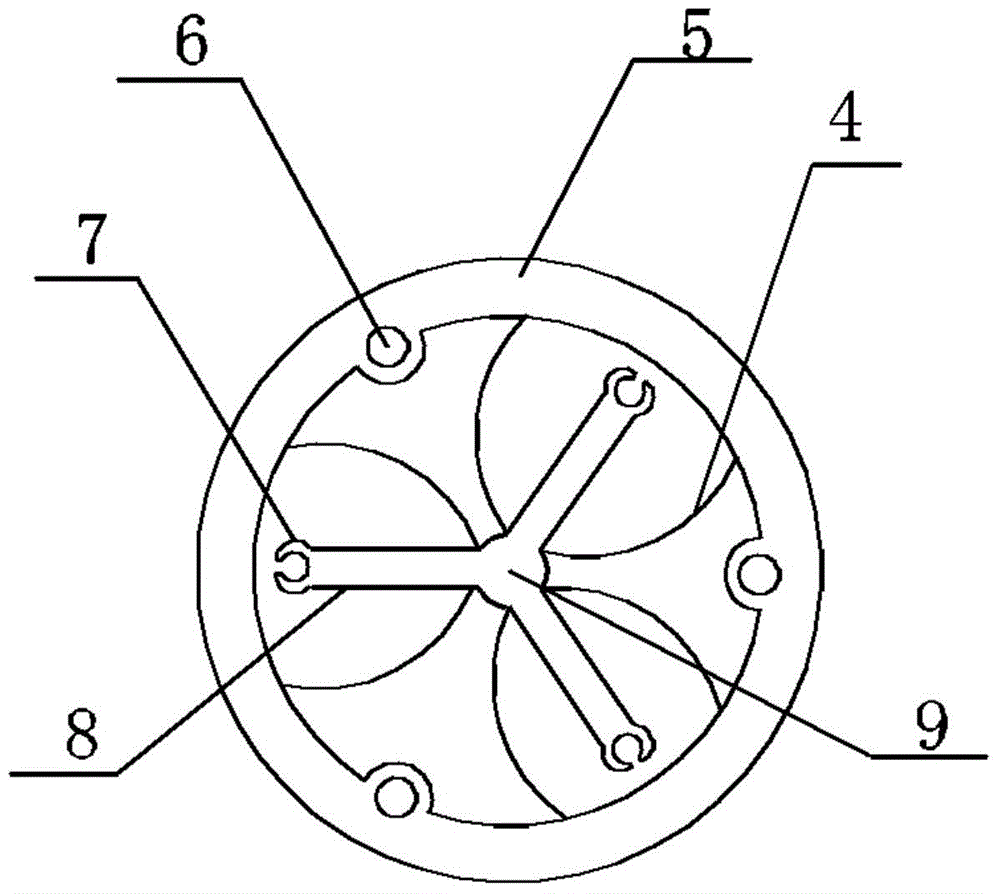

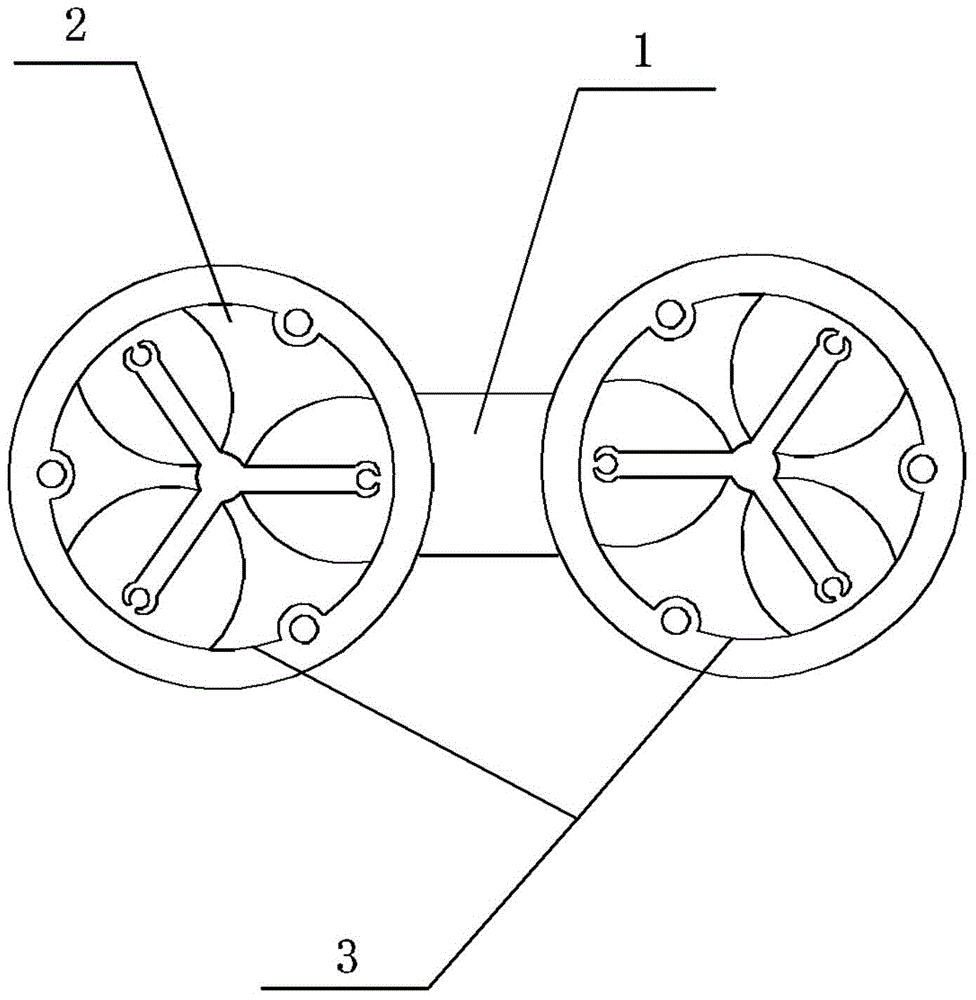

Large-deformation flexible mechanism

The invention provides a large-deformation flexible mechanism formed by connecting two large-deformation flexible hinges in series. Each large-deformation flexible hinge comprises six curve sheet flexible units, three inner arms and an outer ring, wherein one end of each curve sheet flexible unit is gathered on and fixed to a central point, the other ends of the six curve sheet flexible units are evenly distributed on and fixed to the outer ring, every two curve sheet flexible units are in axial symmetry to form a curve sheet flexible unit set, the three curve sheet flexible unit sets are in central symmetry about the central point, the three inner arms are located at the symmetry axis positions of the three curve sheet flexible unit sets respectively, one end of each inner arm is fixed to the central point, and the other ends of the inner arms are connected with mechanical input connectors. The curve sheet flexible unit sets are used for establishing the distributed-type blade-shaped rotary flexible hinges, when the centers of the hinges are subjected to the torque effect, the flexible hinges cannot generate the rotation center drifting phenomenon, under pure torque drive, the errors of the deformation positions of the hinges do not exceed 2%, and the rotation errors do not exceed 9%.

Owner:TIANJIN GUTE METAL PROD

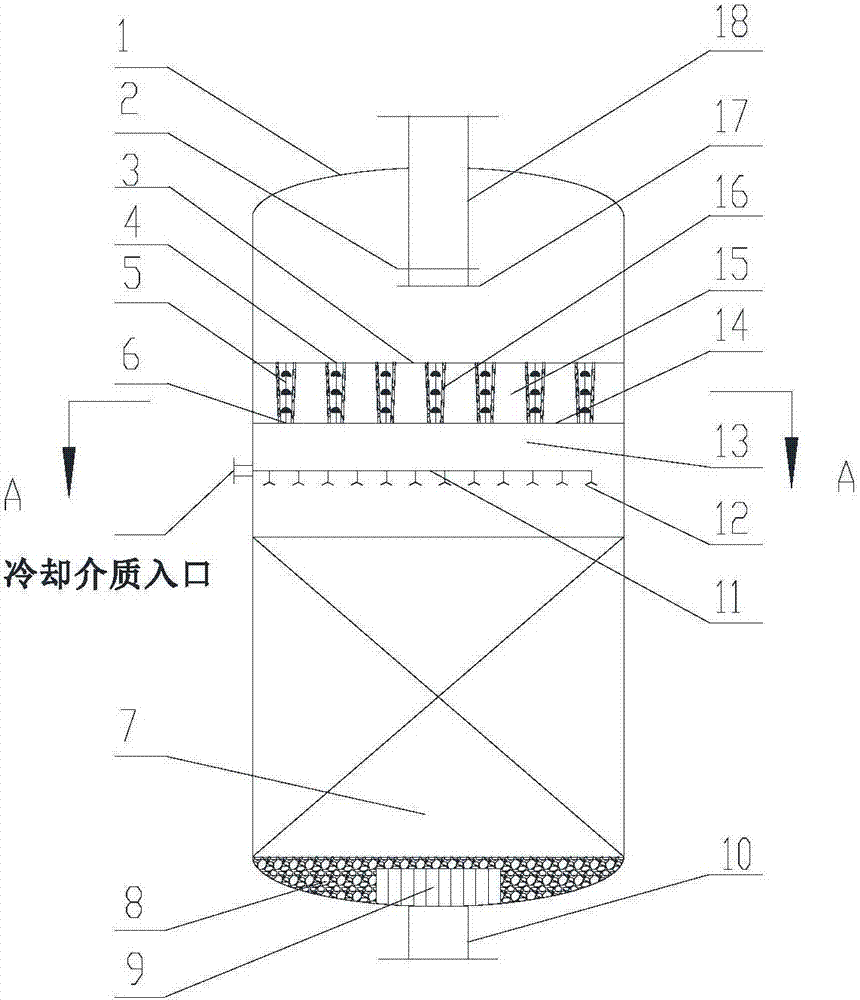

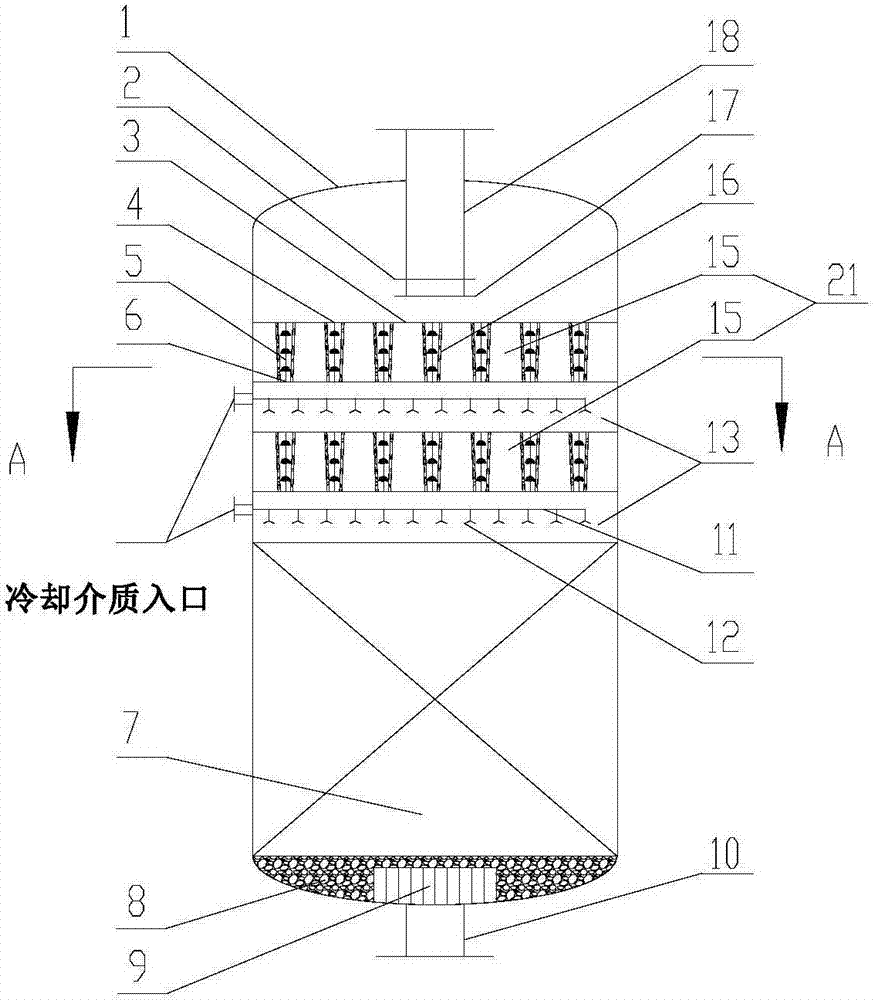

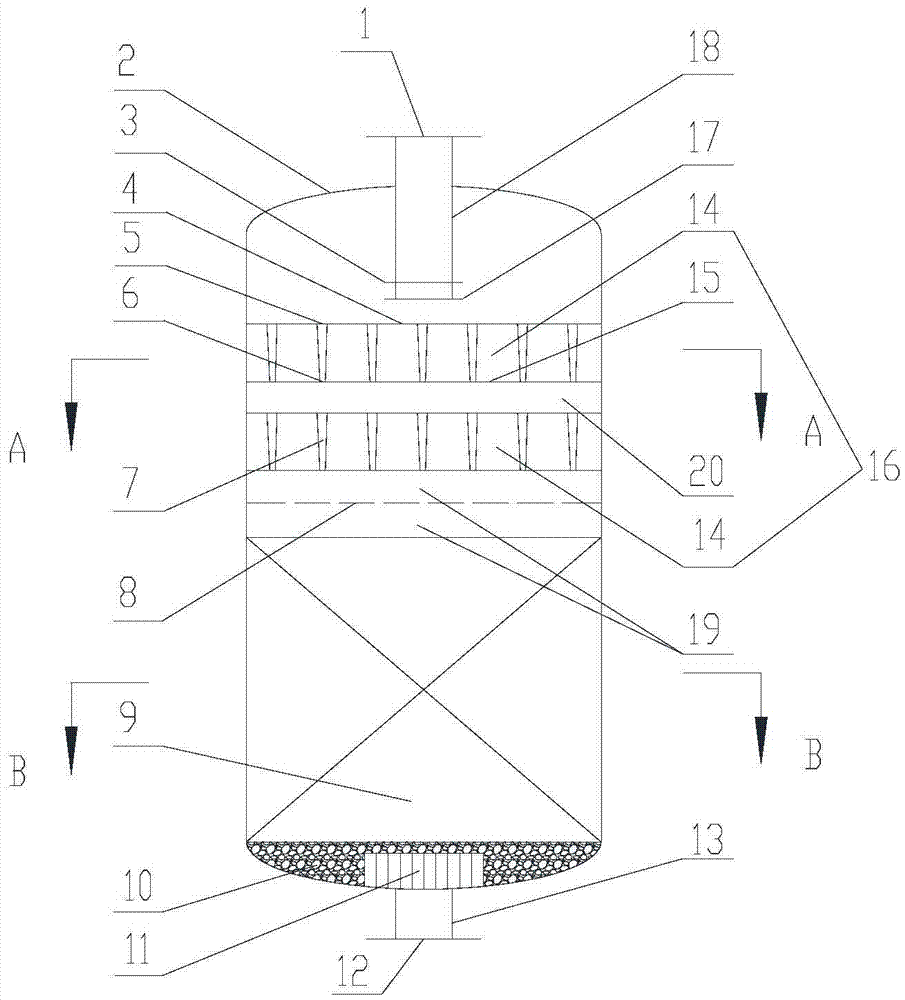

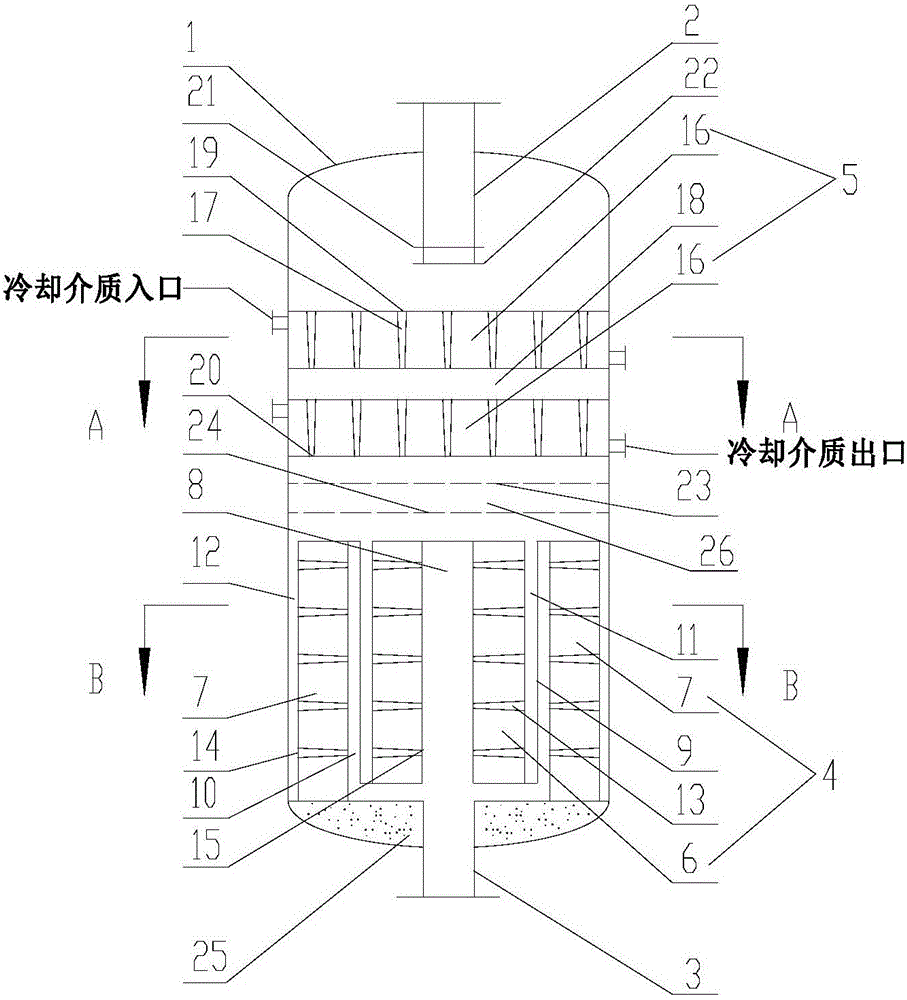

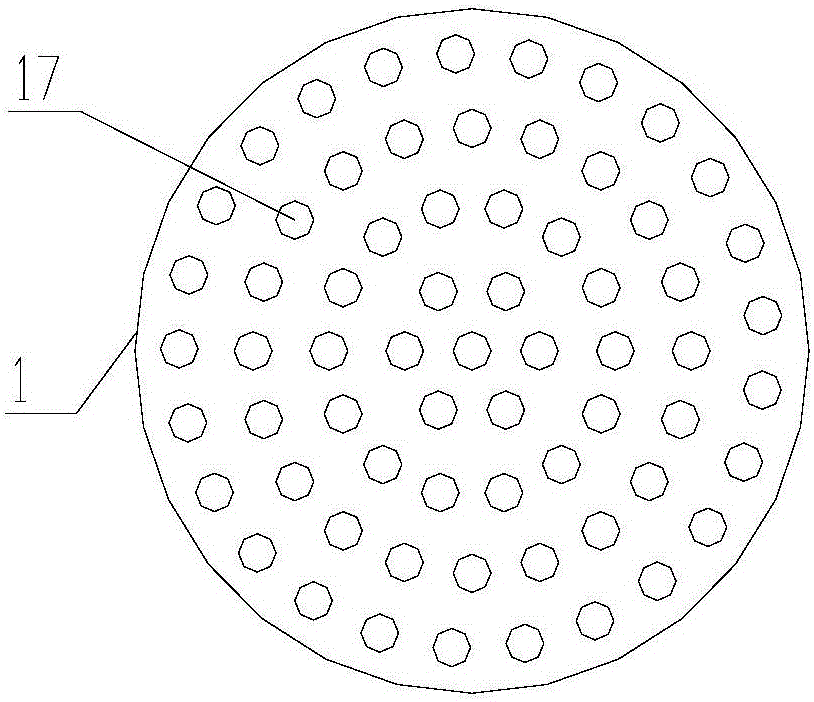

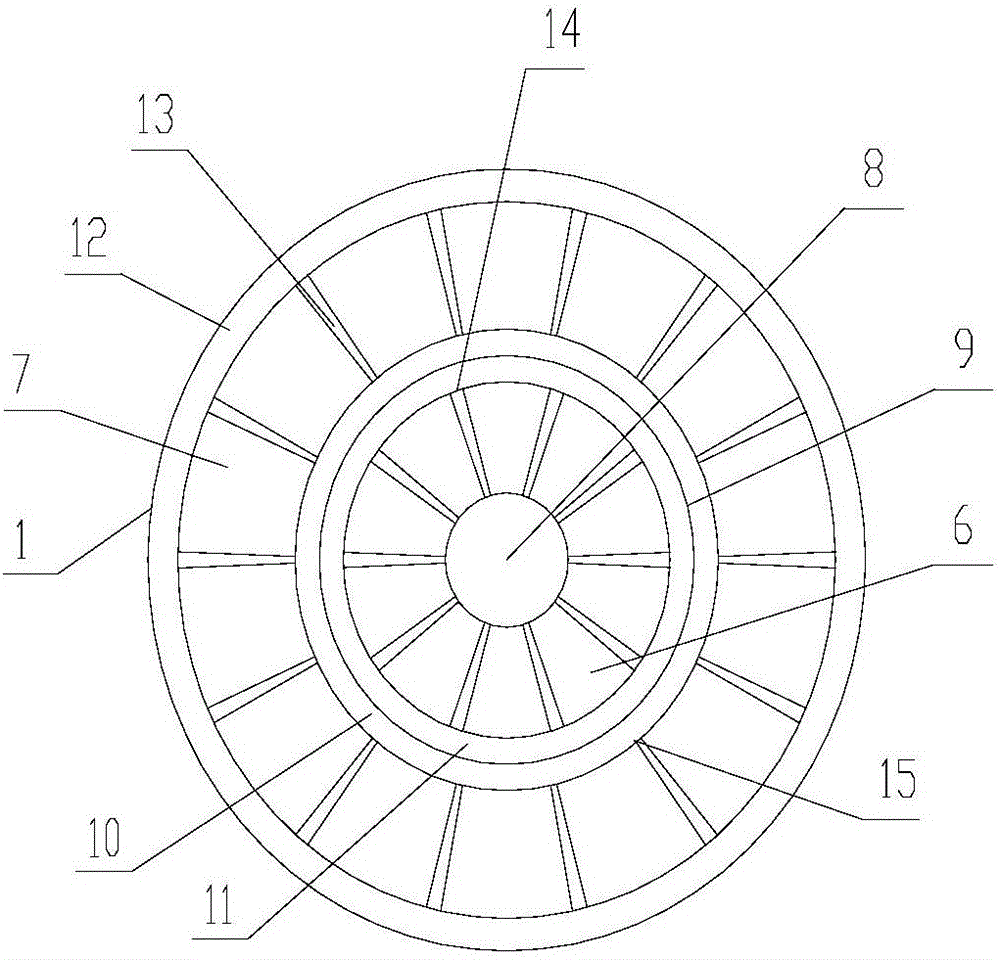

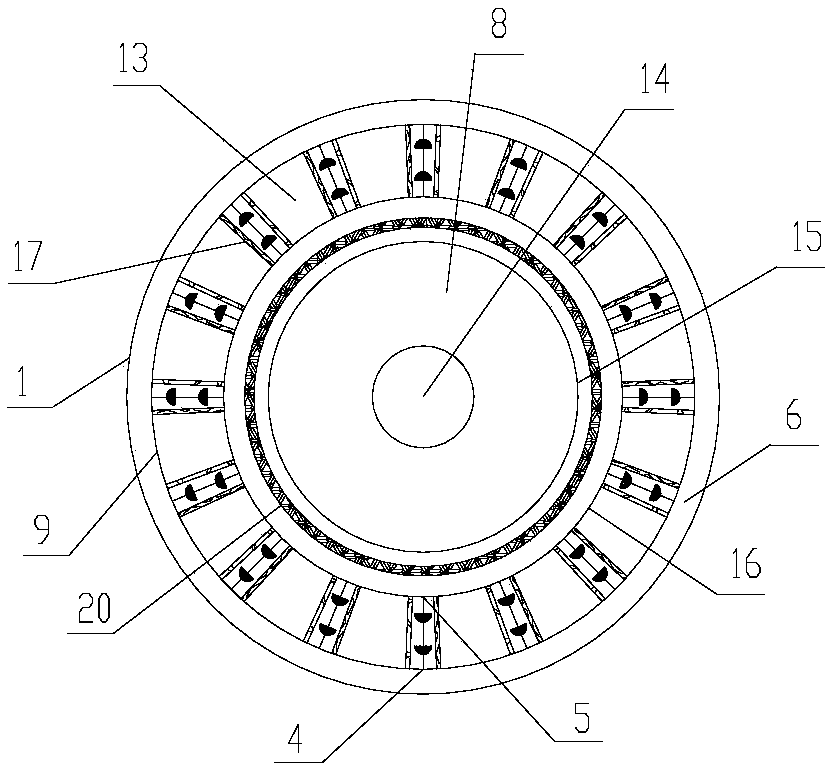

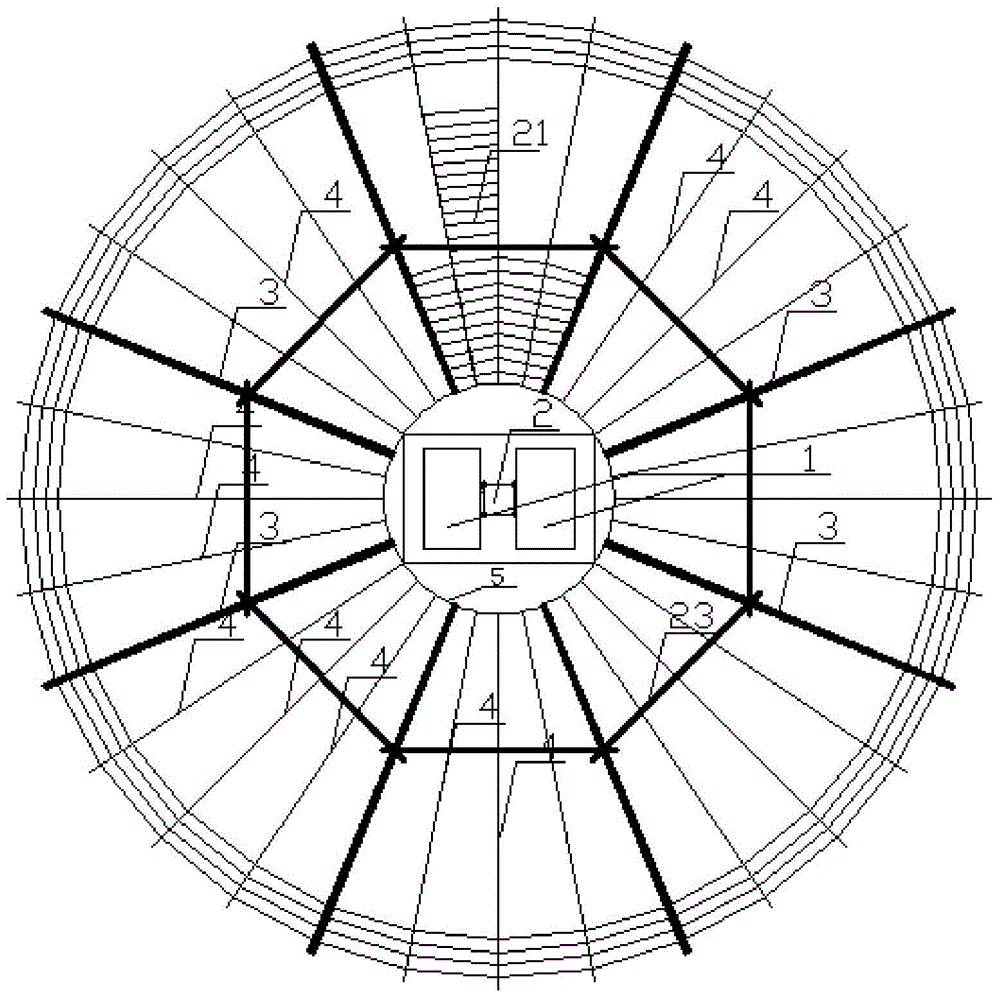

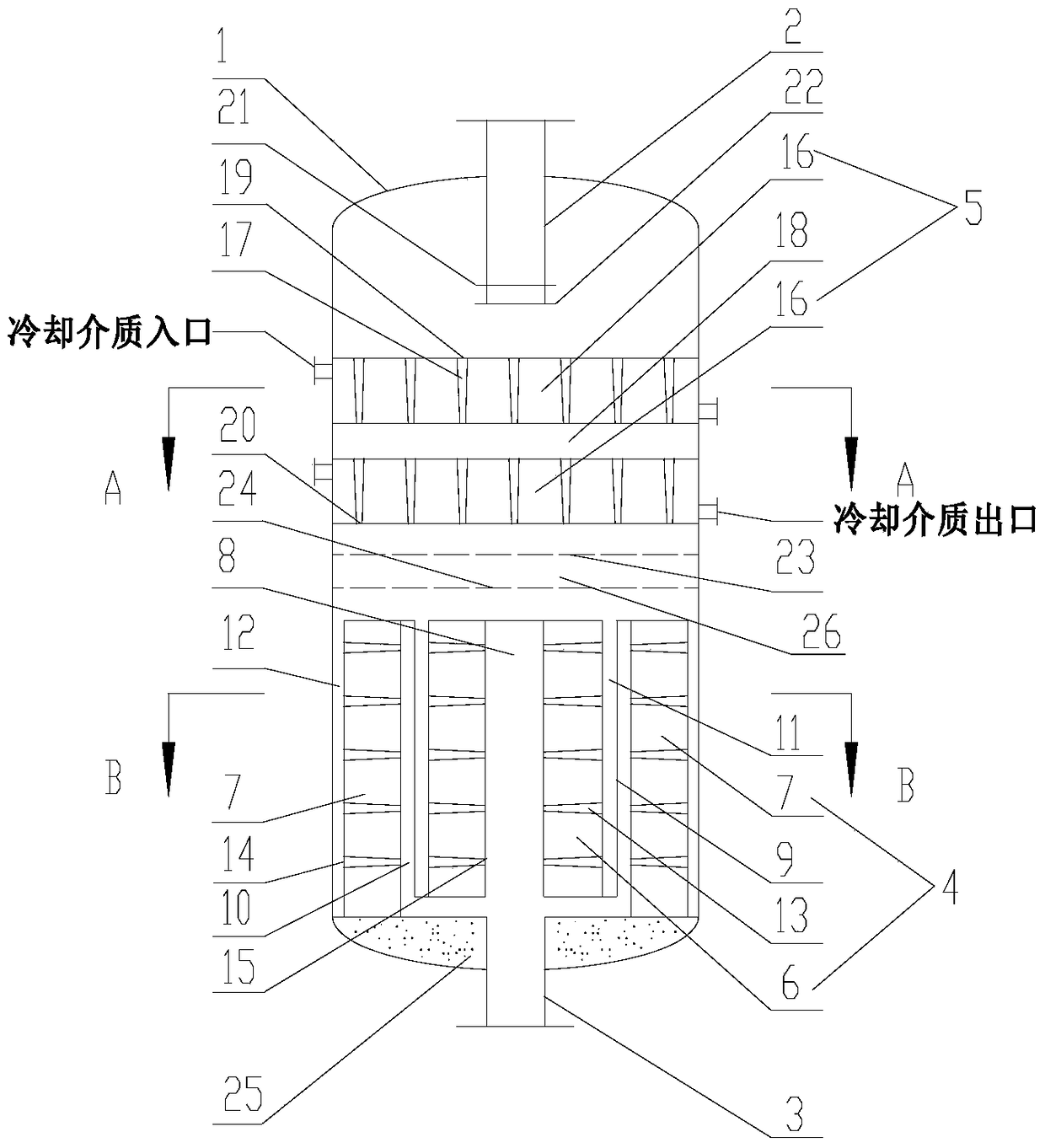

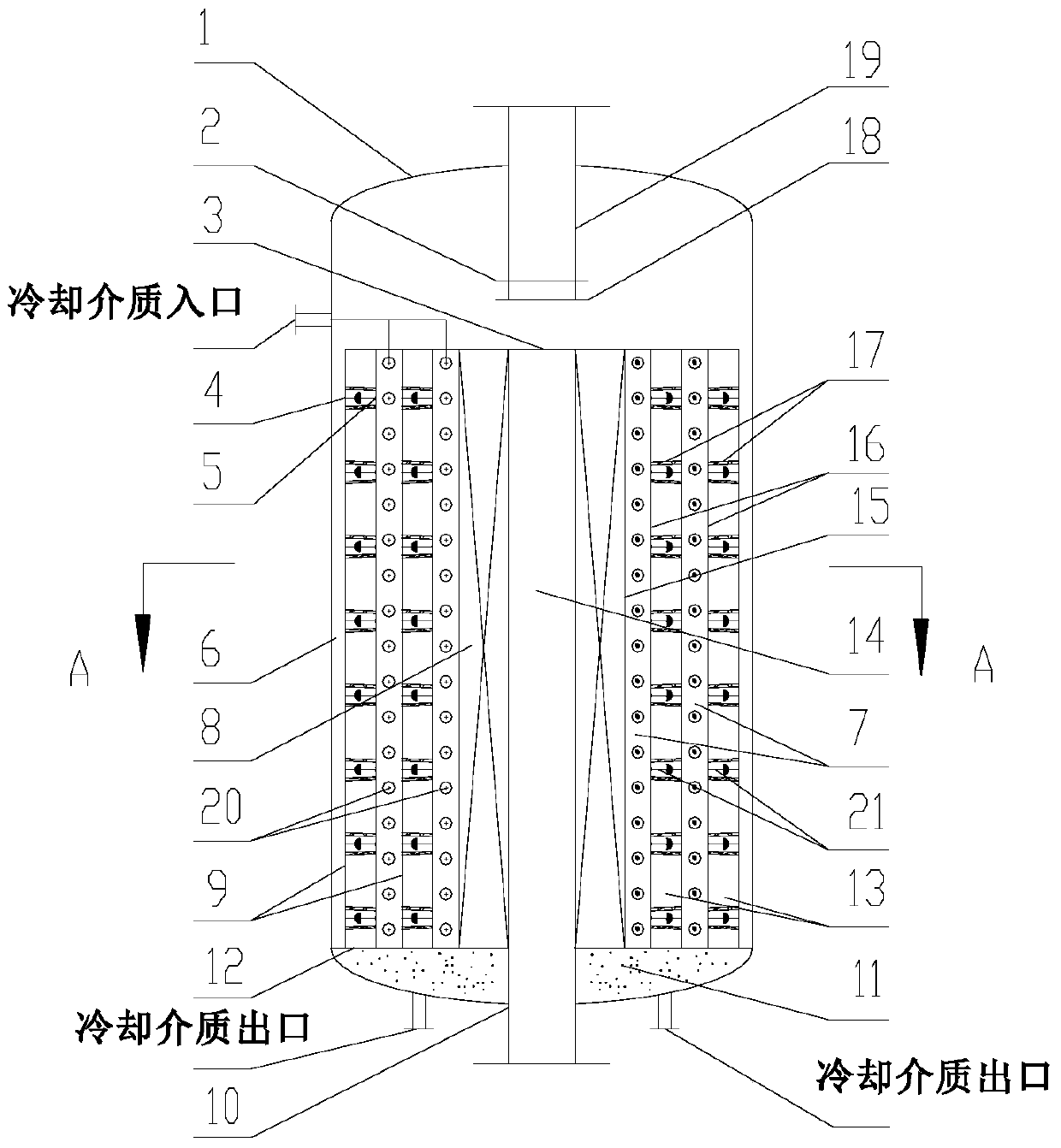

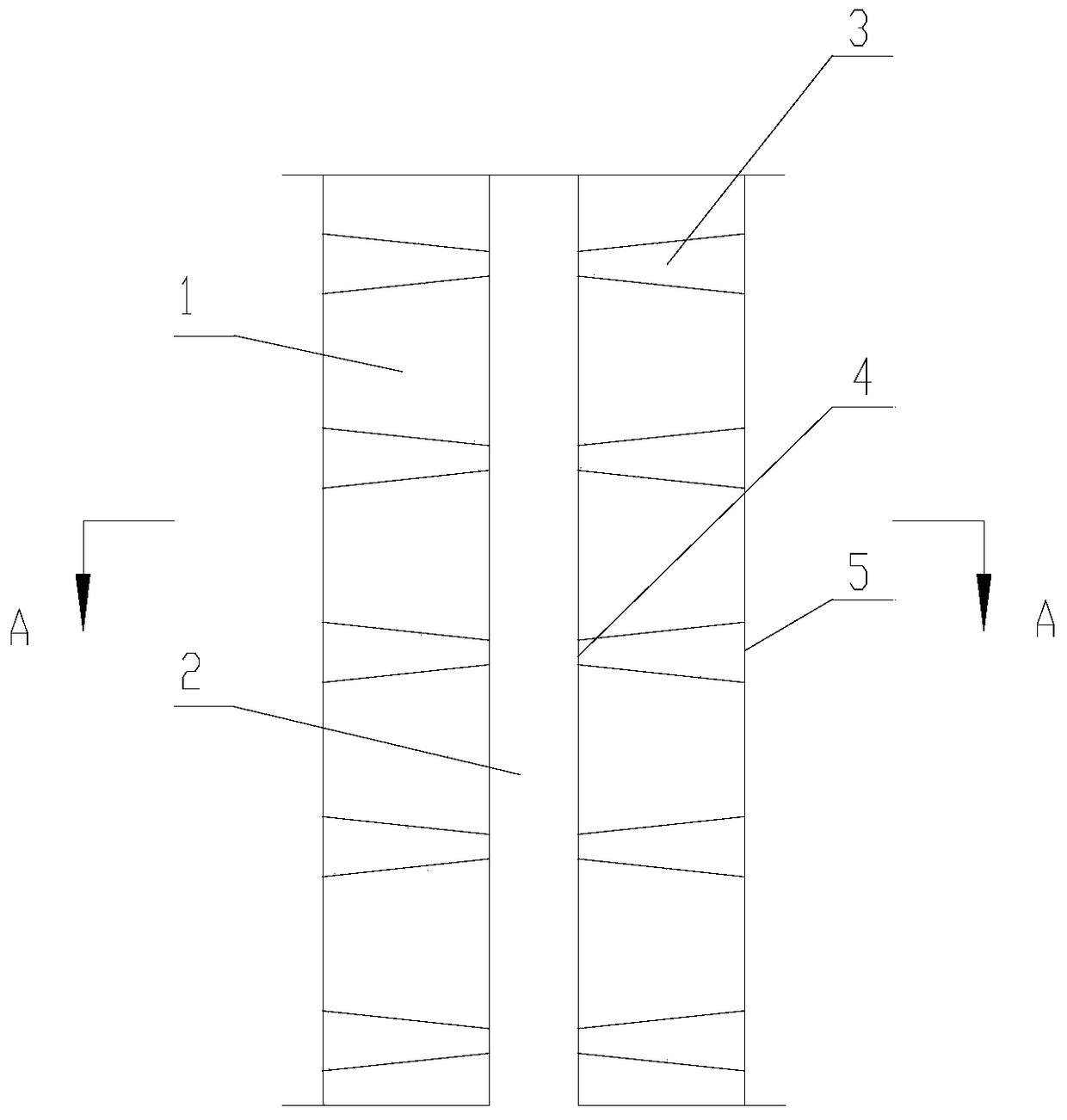

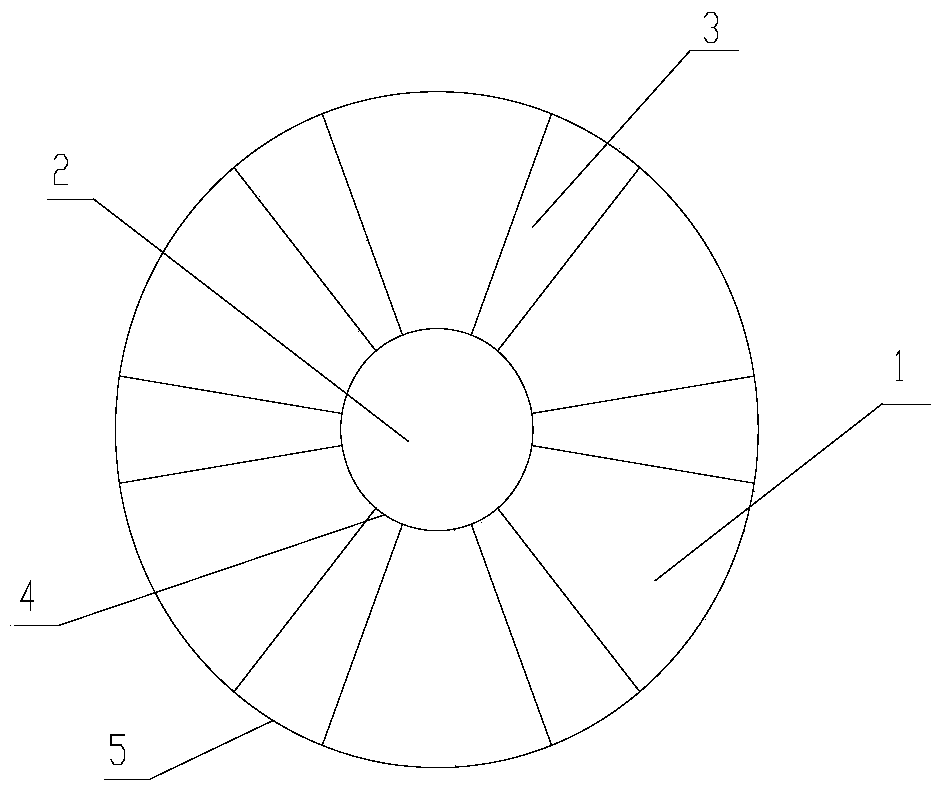

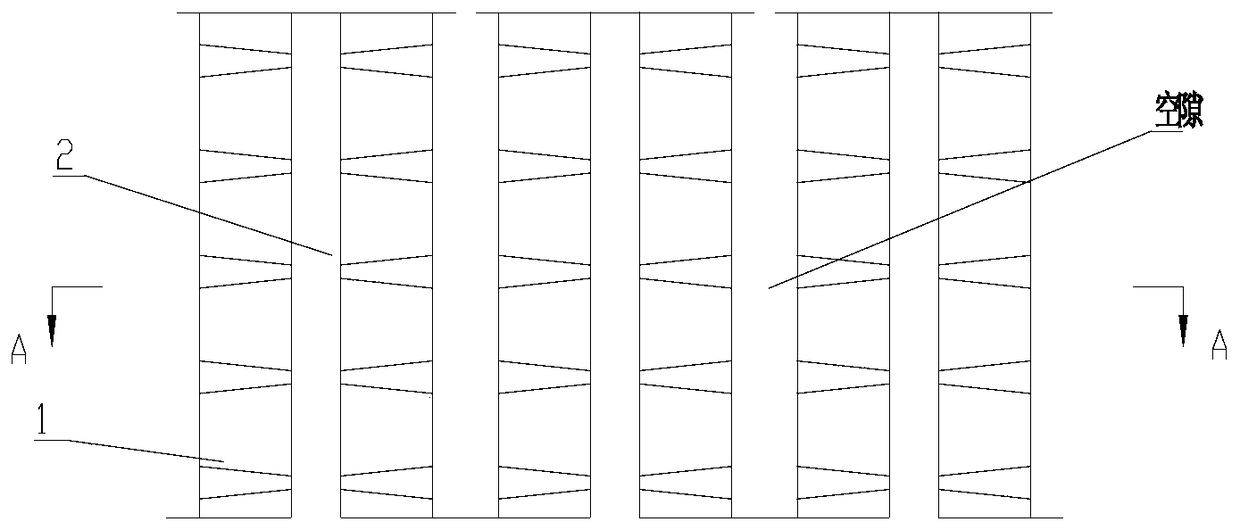

Quench-type reactor

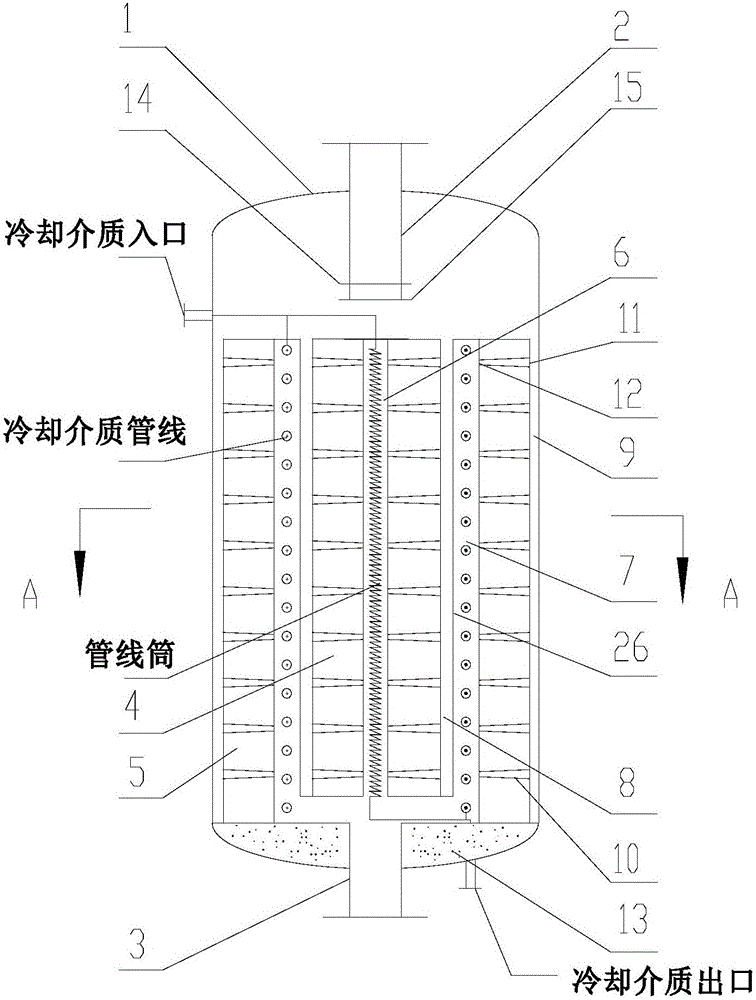

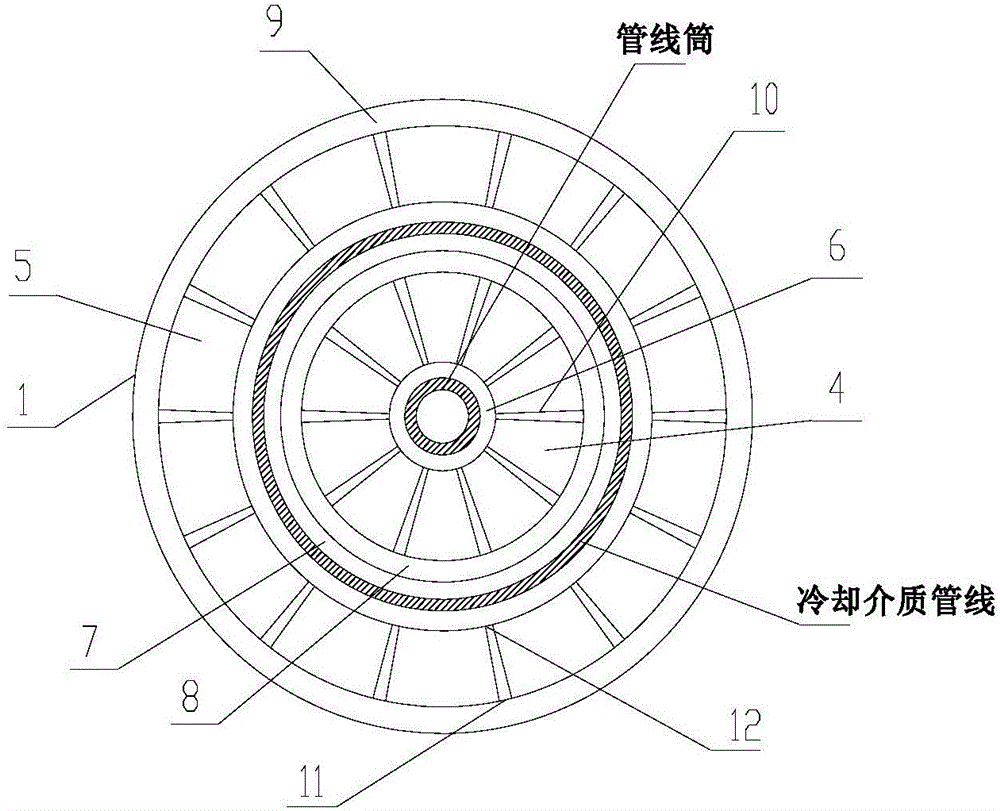

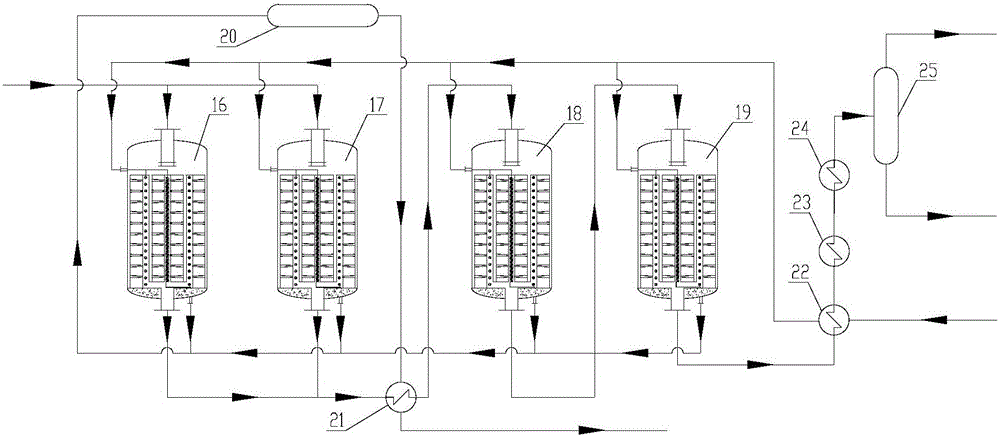

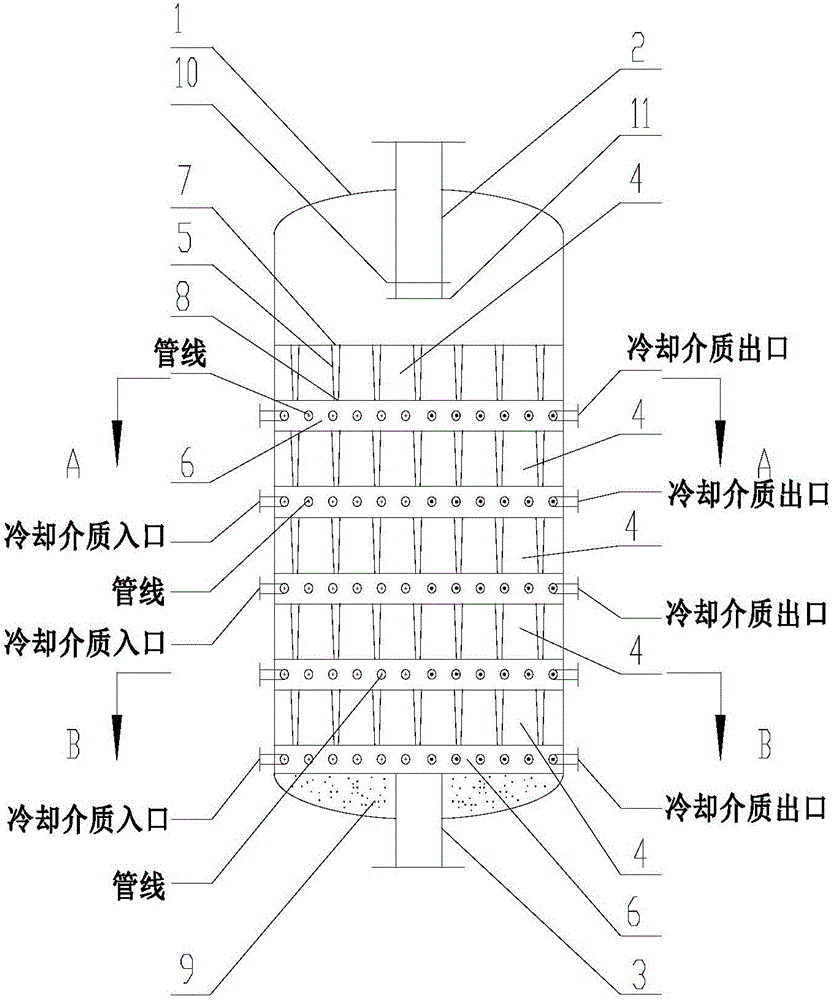

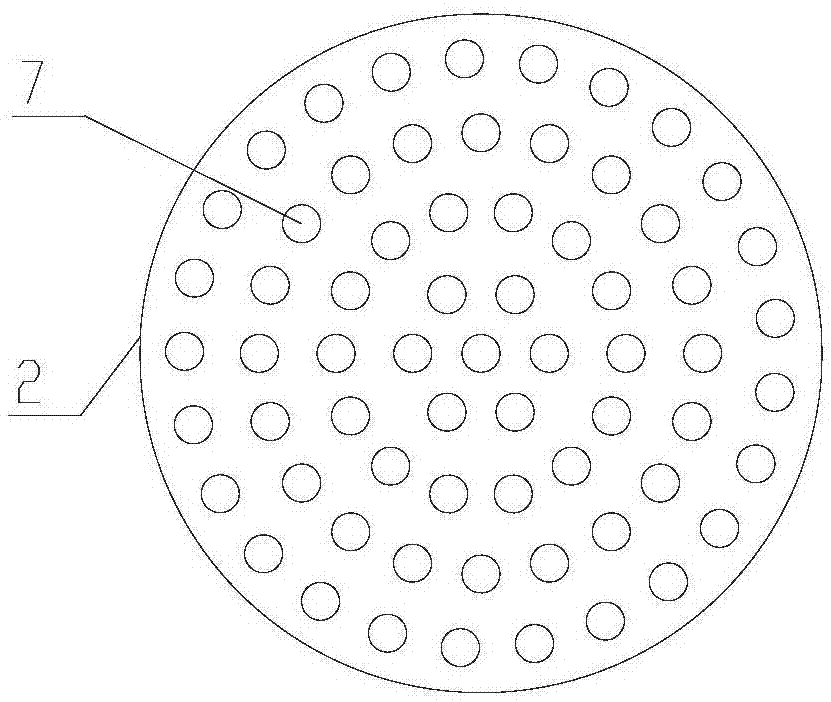

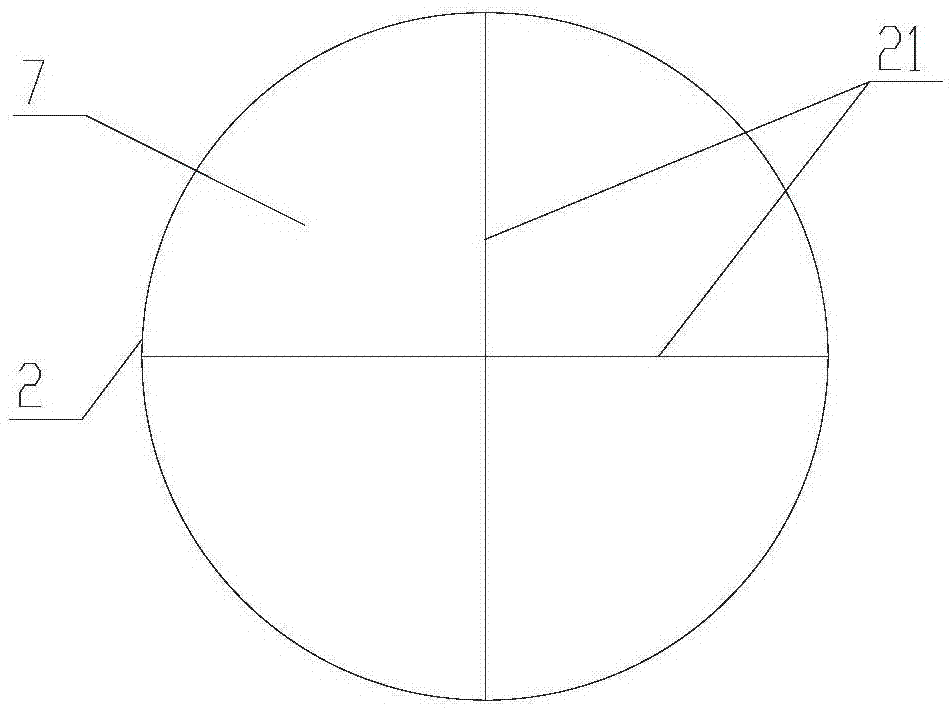

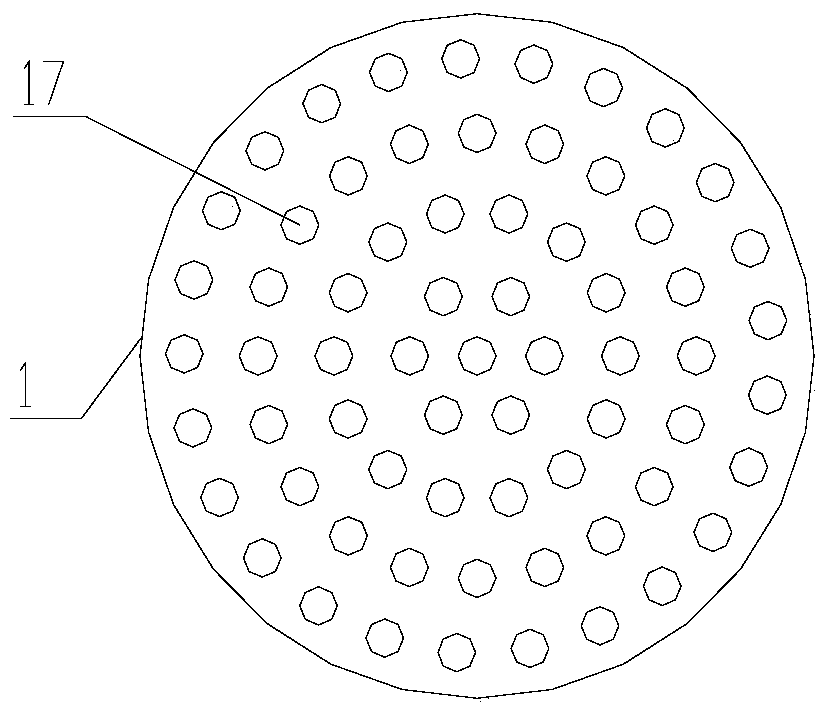

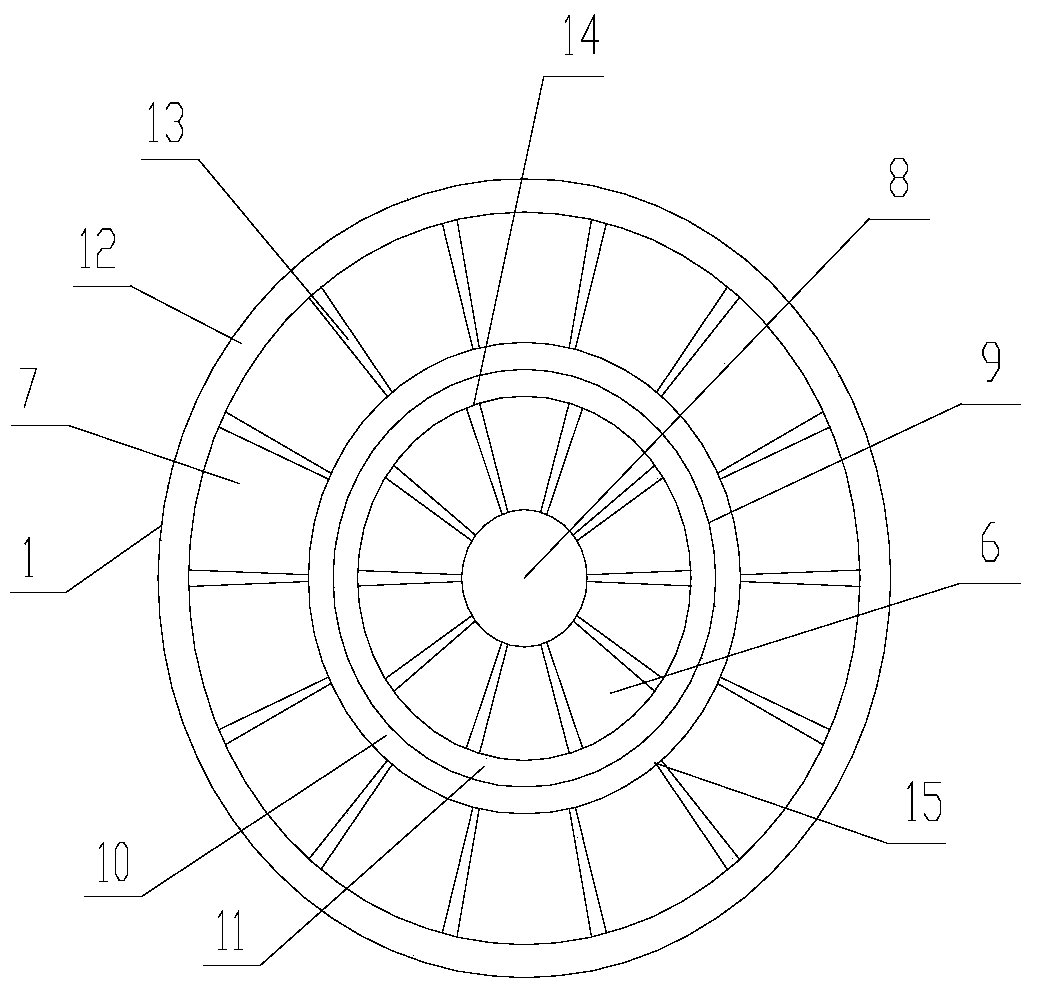

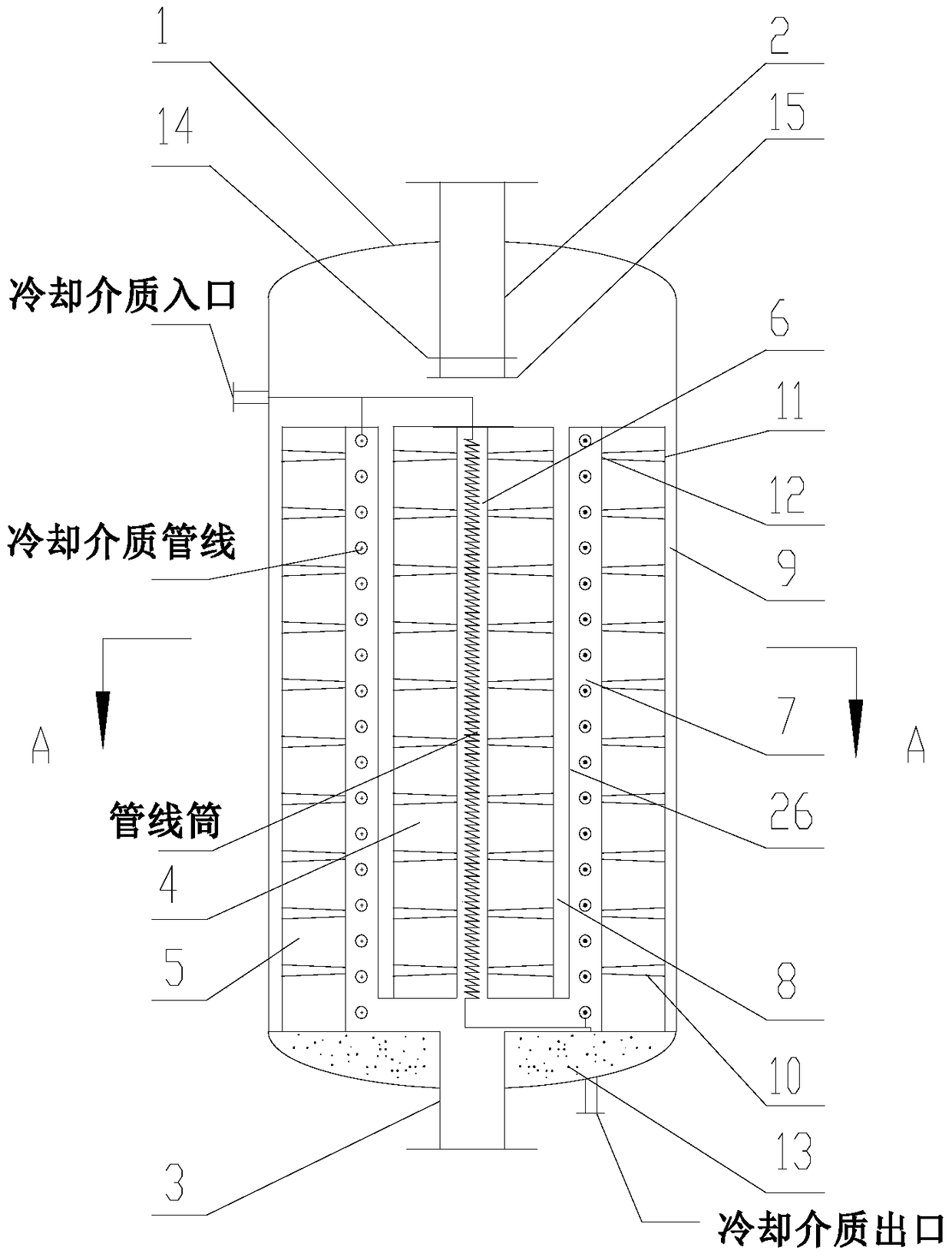

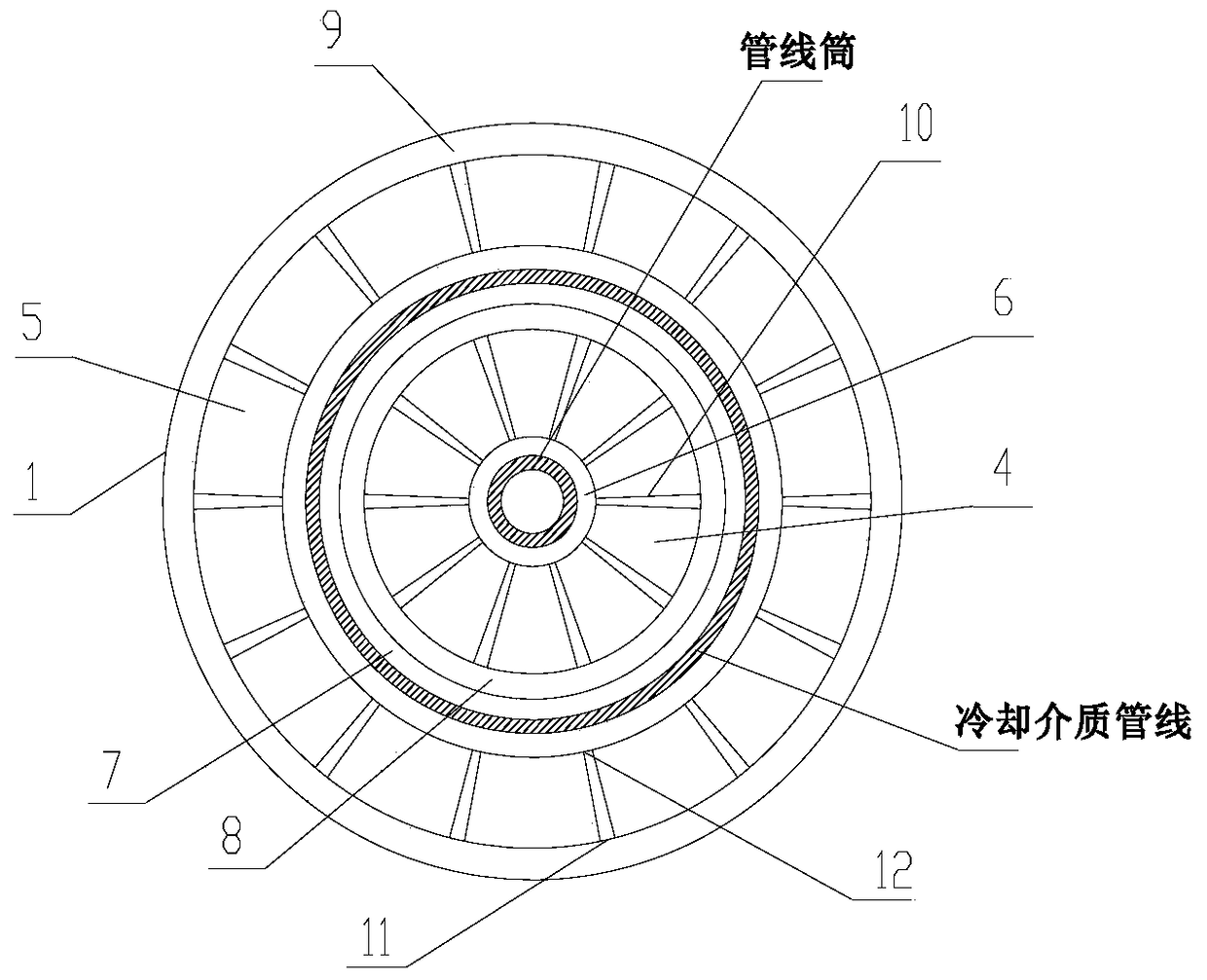

ActiveCN107398237APlay the role of distributing the reaction materialNo drift phenomenonChemical/physical/physico-chemical microreactorsLine tubingNuclear engineering

The invention discloses a quench-type reactor. The reactor comprises a radial cylindrical sealed pressure-bearing shell (1), an air inlet pipe (18), an air outlet pipe (10), as well as an axial micro-channel reaction zone (21) and an axial catalytic reaction zone (7), wherein gaps (13) are formed between the axial micro-channel reaction zone (21) and the axial catalytic reaction zone (7); cooling medium distributors (11) are arranged in the gaps (13); at least one cooling medium inlet is formed in the shell (1) corresponding to the side face of each gap (13); the cooling medium inlets are connected with the cooling medium distributors (11) through cooling medium pipelines. The reactor is small in usage amount of active ingredients of the catalyst, low in pressure drop and low in bed temperature and avoids a 'temperature runaway' phenomenon.

Owner:SINOPEC ENG +1

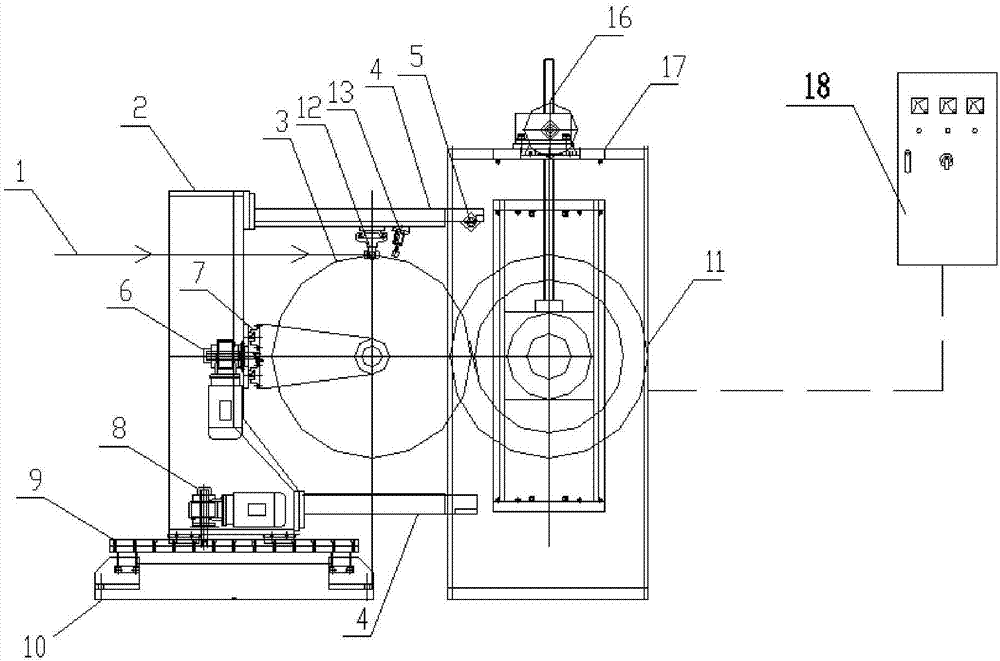

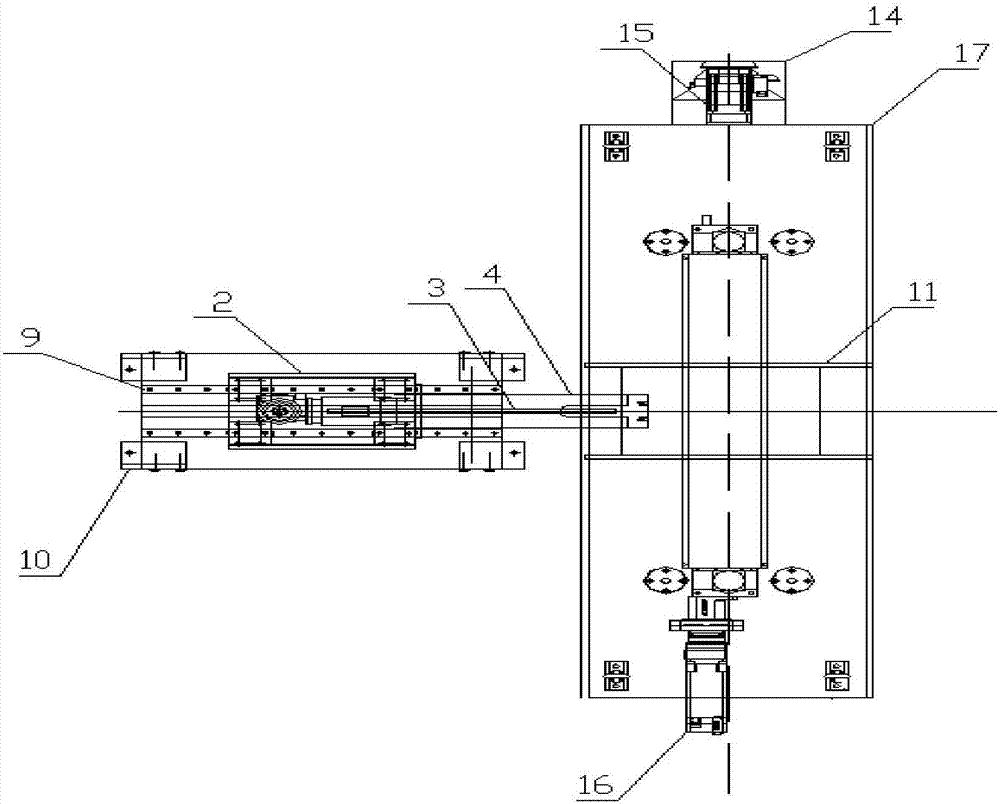

Wire winding machine precision wire winding device

ActiveCN107399637AImprove the wiring effectCable precisionFilament handlingWinding machinePhotoswitch

The invention relates to a wire winding machine precision wire winding device. The wire winding machine precision wire winding device comprises a wire winding device rack, a wire winding guide wheel, a photoelectric emission and receiving support, a photoelectric switch, a guide wheel left-right micro-motion motor reducer, guide wheel left-right micro-motion slide rails, a guide wheel front-back movement motor reducer, guide wheel front-back movement slide rails, a wire winding device base, a wire winding machine rack, a take-up reel, a guide wire left-right limiting retaining device, a pneumatic braking device, a take-up speed reducer motor, a wire winding speed reducer motor, a reel lifting motor and an external automatic power supply control system. Through cooperation of all the mechanisms, a flat winding wire is precisely coiled on the reel. By adopting the wire winding machine precision wire winding device provided by the invention, the wire winding precision is improved, and the phenomena that wire unwinding and clamping or wire surface scratches are caused due to the fact that a wire is arranged not to reach the edge, is overlapped and drifts are avoided.

Owner:WUXI TOLY ELECTRIC WORKS

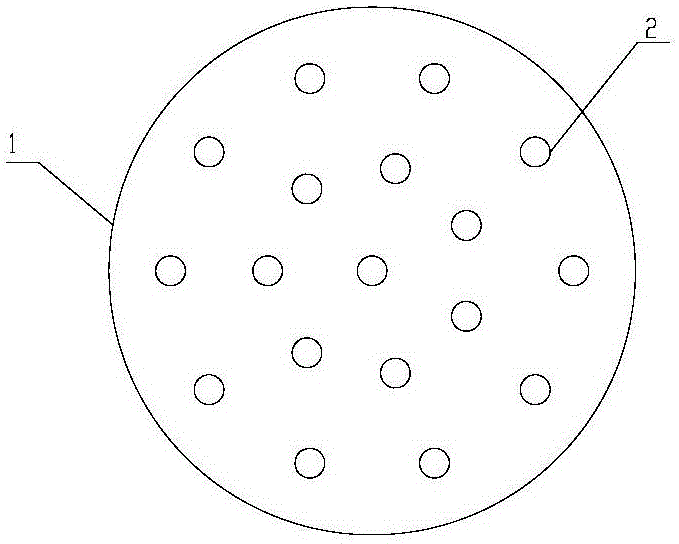

Axial micro-catalytic reaction unit and application thereof

ActiveCN106378067AGreat driving forceShort stayChemical/physical/physico-chemical processesRetention timeUtilization rate

The invention discloses an axial micro-catalytic reaction unit and application thereof. The axial micro-catalytic reaction unit is characterized in that the axial micro-catalytic reaction unit comprises a column and micro-reaction channels axially penetrating the column; the place above the column is communicated with a fluid below the column only through the micro-reaction channels; and the the micro-reaction channels are provided with upper micro-reaction channel openings and lower micro-reaction channel openings with different diameters. The axial micro-catalytic reaction unit provided by the invention can be applied to reactions with changes in reaction volume, enables the usage amount of a catalyst to be small, and is low in pressure drop, short in retention time, high in space utilization rate and free of the phenomena of bias current and short circuit of gas.

Owner:SINOPEC ENG +1

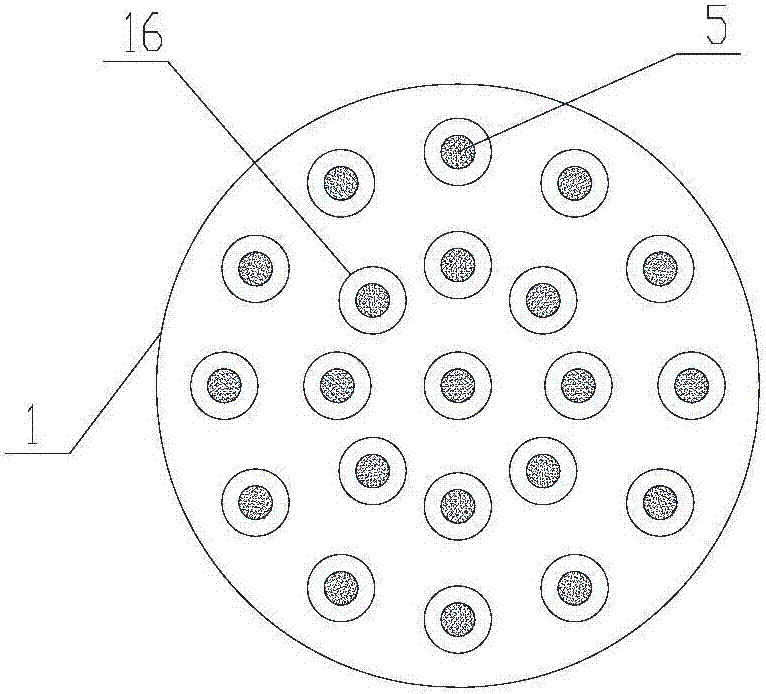

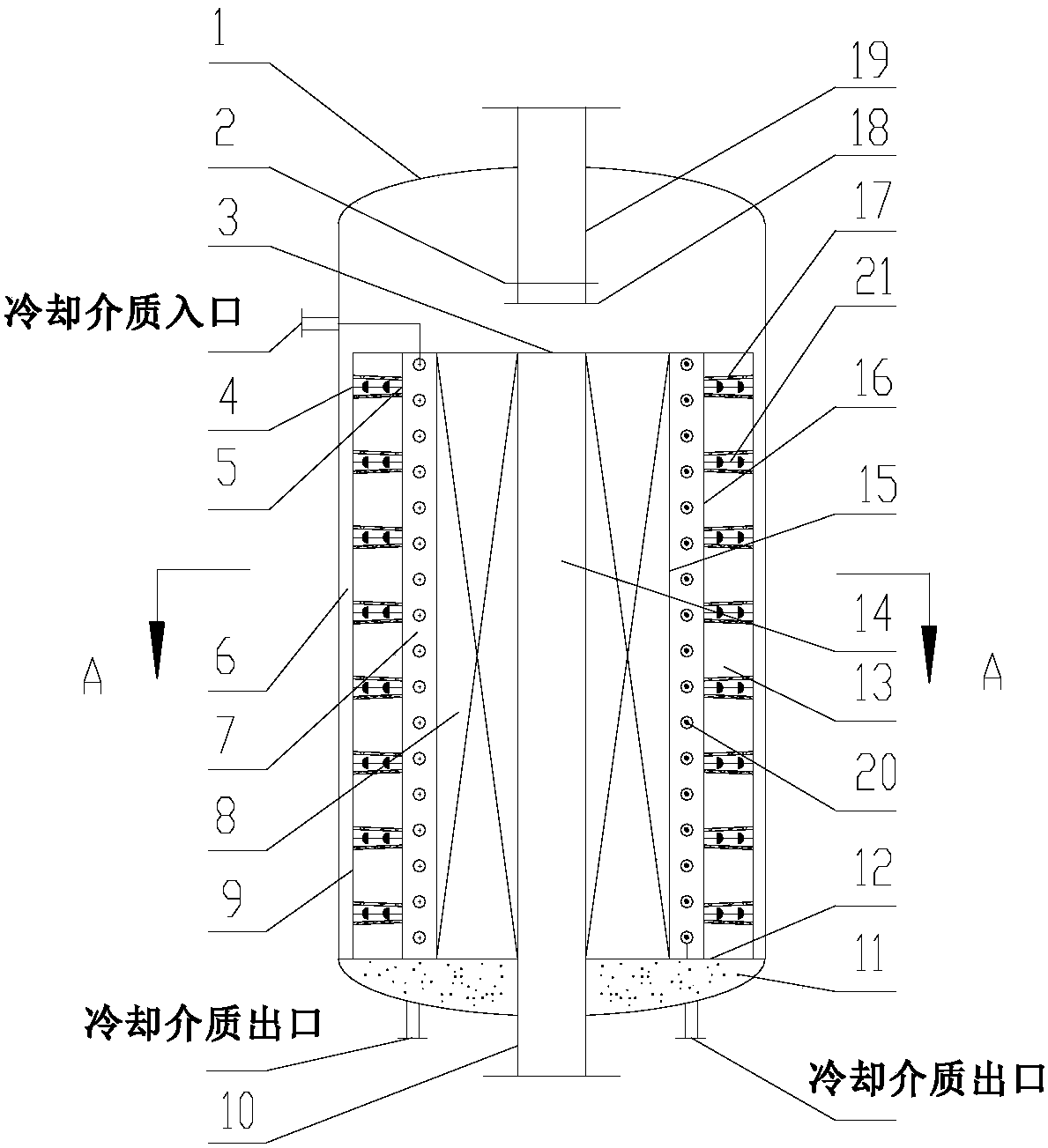

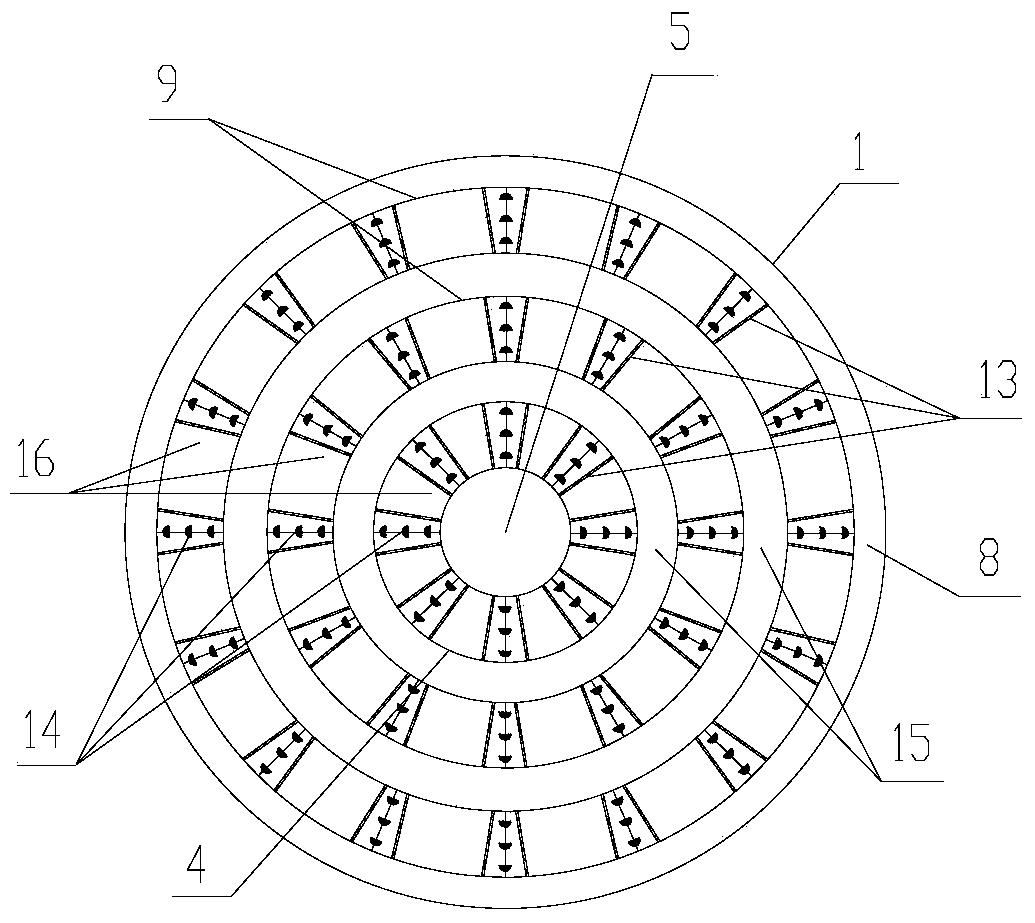

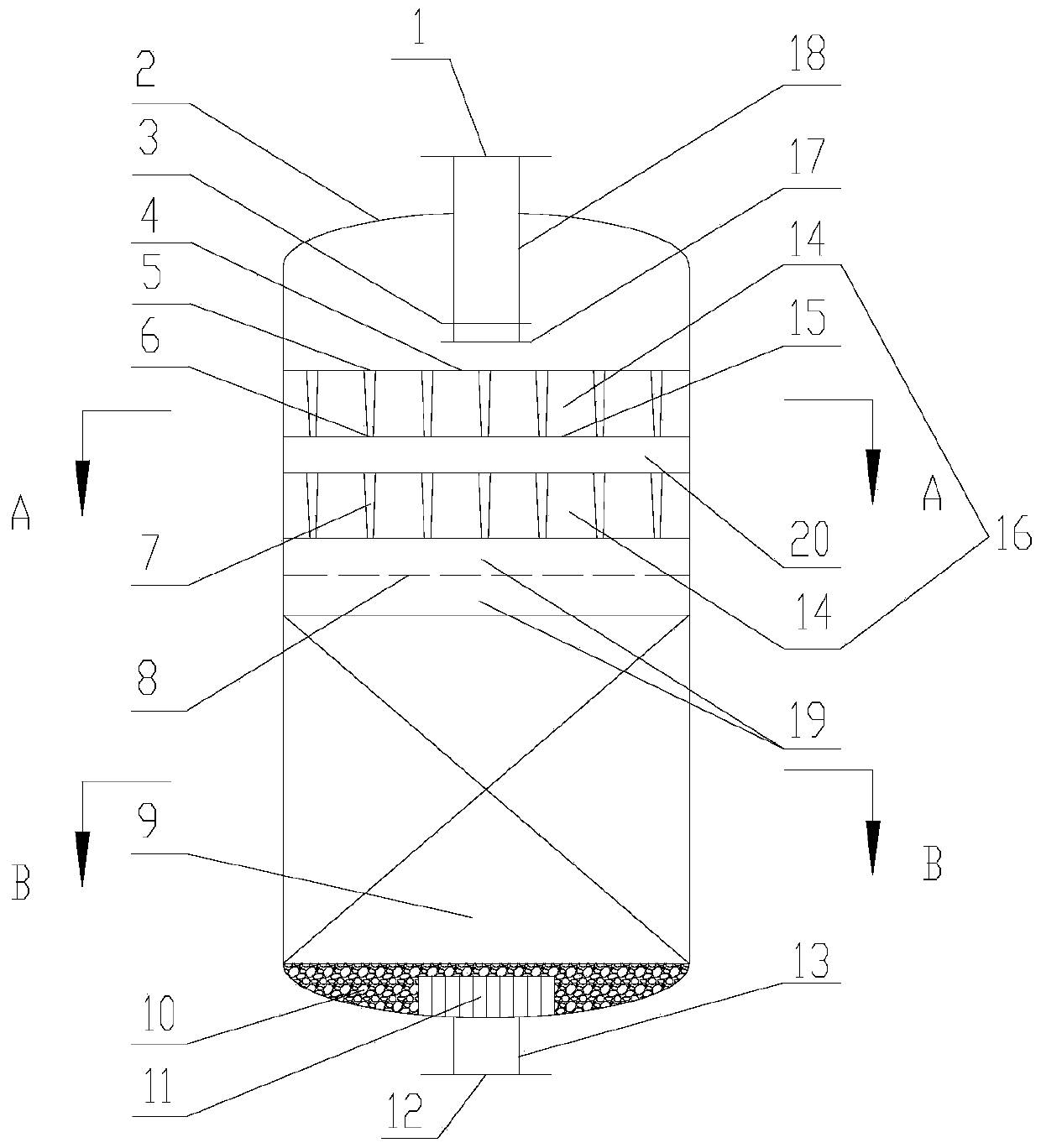

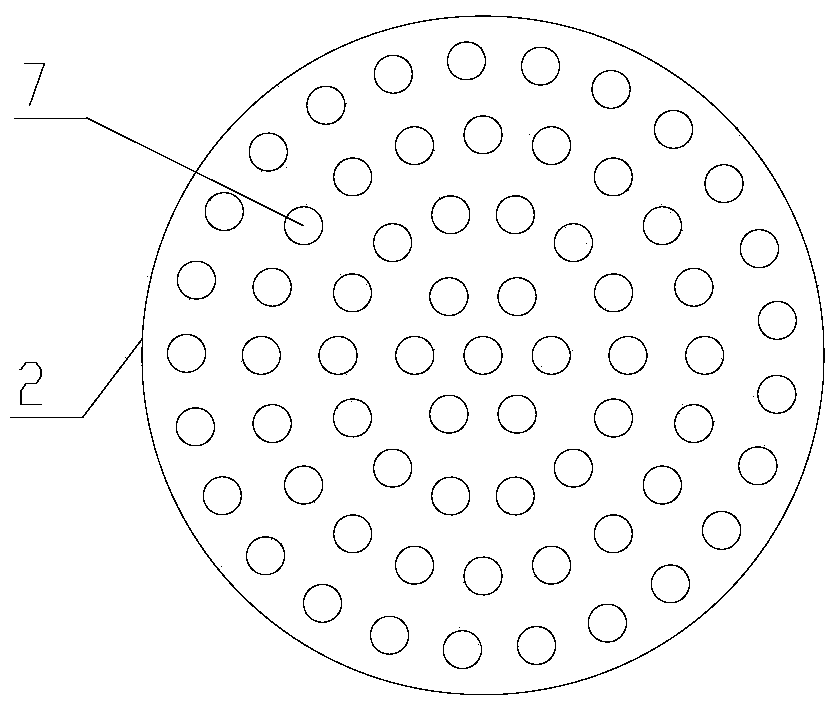

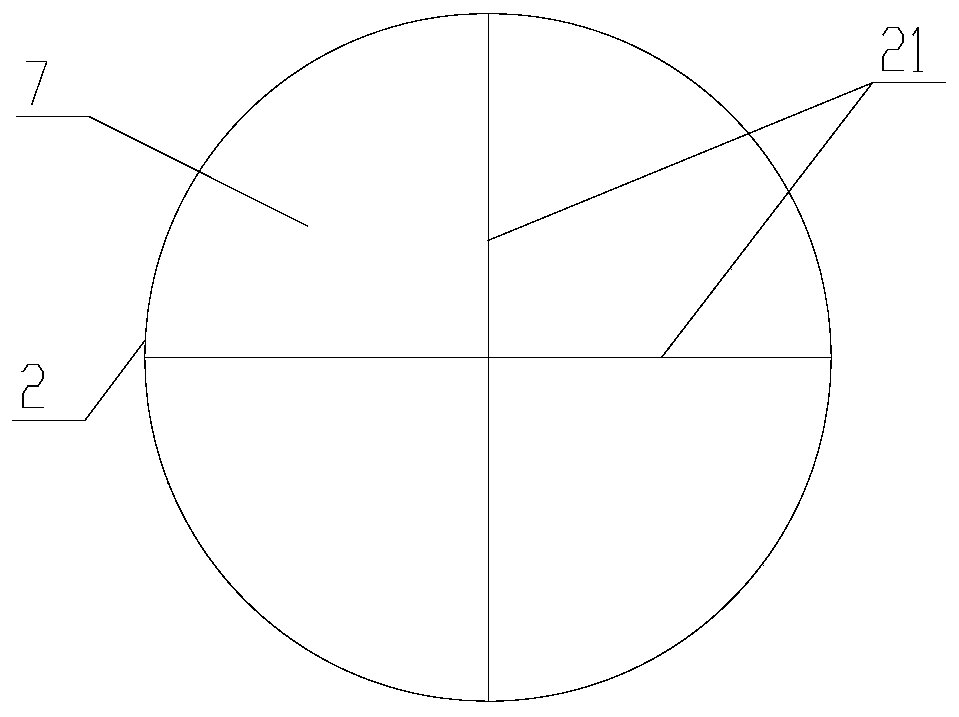

Axial reactor

ActiveCN107224939AImprove uniformityImprove conversion rateChemical/physical processesRetention timeProduct gas

The invention discloses an axial reactor. The reactor comprises a radial cylindrical sealed pressure-bearing shell body (2), a gas inlet pipe (18), a gas outlet pipe (13), an axial microchannel reaction zone (16) and an axial catalytic reaction zone (9), wherein the axial microchannel reaction zone (16) is located above the axial catalytic reaction zone (9); the axial microchannel reaction zone (16) comprises one or more disk-shaped axial microchannel reaction units (14) which are connected in series up and down; each axial microchannel reaction unit (14) has a plurality of axial microreaction channels (7); and the axial catalytic reaction zone (9) can contain at least one catalyst bed layer, and reactant fluid can flow through the catalyst bed layers from top to bottom for a catalytic reaction. Compared with the prior art, the reactor disclosed by the invention is compact in structure, low in active metal consumption, low in bed layer pressure drop, short in gas product retention time and high in bed layer space utilization ratio and is free of gas bias and short-circuit phenomena.

Owner:SINOPEC ENG +1

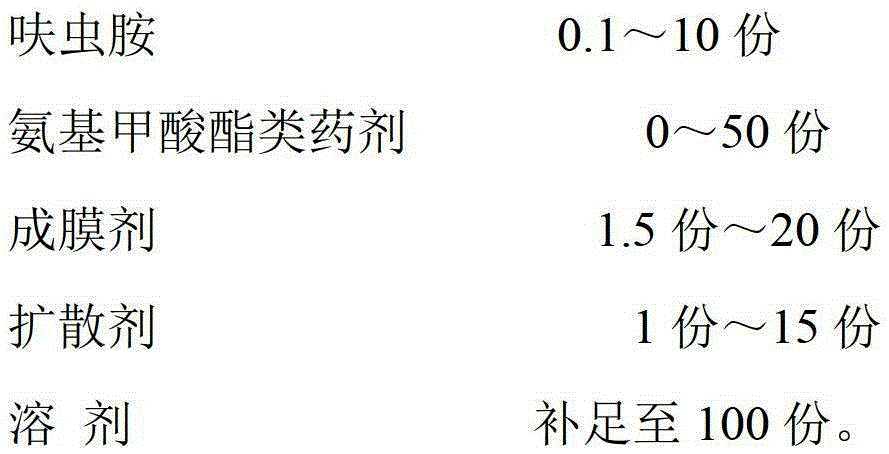

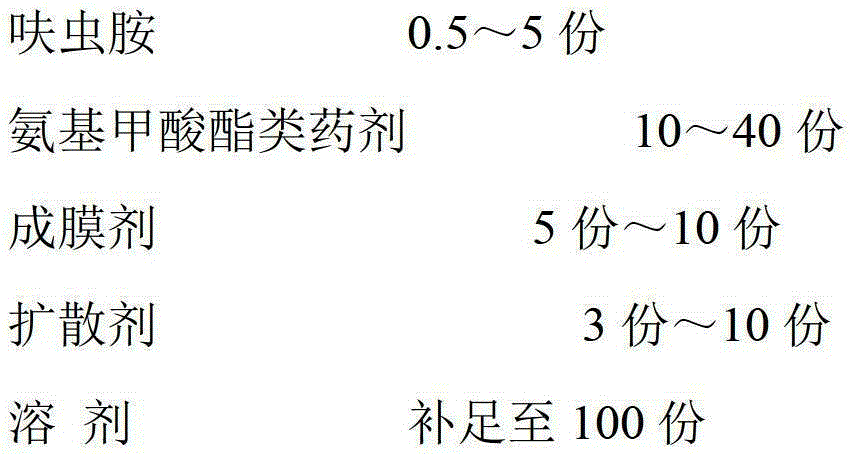

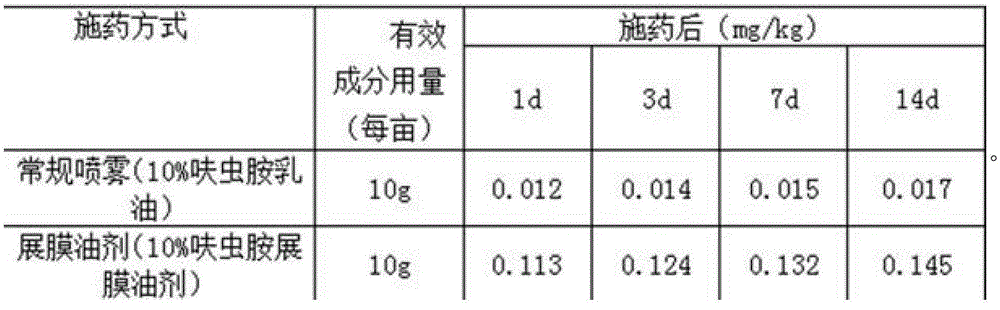

Film diffusing oil agent combined reagent for preventing and treating rice planthopper

ActiveCN103141505BSimple and fast operationReduce labor cost inputBiocideAnimal repellantsSolventBULK ACTIVE INGREDIENT

Owner:GAUNGXI TIANYUAN BIOCHEM

Axial micro-channel coupling reactor and applications thereof

ActiveCN106582468AGuaranteed conversion rateSimple processChemical/physical/physico-chemical processesNuclear engineeringHigh energy

The present invention discloses an axial micro-channel coupling reactor and applications thereof. The axial micro-channel coupling reactor comprises a cylindrical sealing pressure bearing shell, inlets and outlets for two kinds of raw material gases, and an axial catalysis reaction zone arranged in the shell, wherein the axial catalysis reaction zone comprises a plurality of axial micro-reaction channels coated with catalytic active components on the inner surface and the outer surface. According to the present invention, with the axial micro-channel coupling reactor, the two reactions such as heat release and heat absorption can be achieved in the one reactor, and particularly the reactor is suitable for one of the catalytic reactions having the significant volume change; the heat release reaction and the heat absorption reaction are integrally performed in the same reactor so as to simplify the original process and reduce the equipment cost; and the reactor has advantages of low catalyst active component consumption, high space utilization rate, high energy utilization rate, and high raw material conversion rate.

Owner:SINOPEC ENG +1

Methanation reactor and methanation process

ActiveCN106378063AGreat driving forceShort stayHydrocarbon from carbon oxidesGaseous fuelsMethanationProcess engineering

The invention discloses a methanation reactor and a methanation process. The methanation reactor comprises a shell, a gas inlet pipe, a transverse catalytic reaction unit, a longitudinal catalytic reaction unit, a gas outlet pipe, axial micro-reaction channels and radial micro-reaction channels, wherein a component with catalytic activity may be loaded in the axial micro-reaction channels and radial micro-reaction channels. Compared with the prior art, the invention has the advantages that the methanation reactor is reduced in the usage amount of a catalyst; and when the methanation reactor is used for methanation, pressure drop among beds is reduced, gas retention time is short, the utilization rate of the space of reaction beds is high, and the phenomena of bias current and short circuit of gas do not occur.

Owner:SINOPEC ENG +1

Catalytic reactor

ActiveCN107617392AImprove uniformityImprove conversion rateChemical/physical processesStraight tubeEngineering

The invention discloses a catalytic reactor. The reactor includes a cylindrical sealed pressure-bearing housing (1), a first straight tube (19) extending from the top of the housing (1) to the insideof the housing, a second straight tube (10) extending from the bottom of the housing (1) to the inside of the housing, and a catalytic reaction unit arranged inside the housing (1), below the first straight tube (19), and above the second straight tube (10). Compared with a catalytic reactor in the prior art, the catalytic reactor is compact in structure, less in active metal consumption, high intarget product selectivity, small in bed pressure drop, and low in temperature, and the phenomenon of temperature runaway isn't taken place in the bed.

Owner:SINOPEC ENG +1

A kind of methanation reactor and methanation process

ActiveCN107224940BIncreased turbulenceImprove conversion rateGaseous fuelsChemical/physical processesMethanationEconomic benefits

Owner:SINOPEC ENG +1

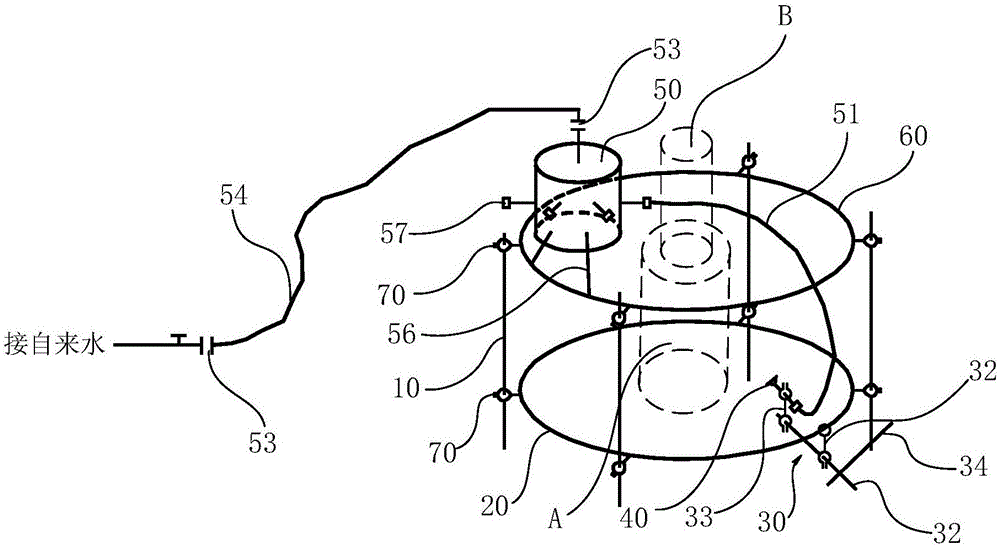

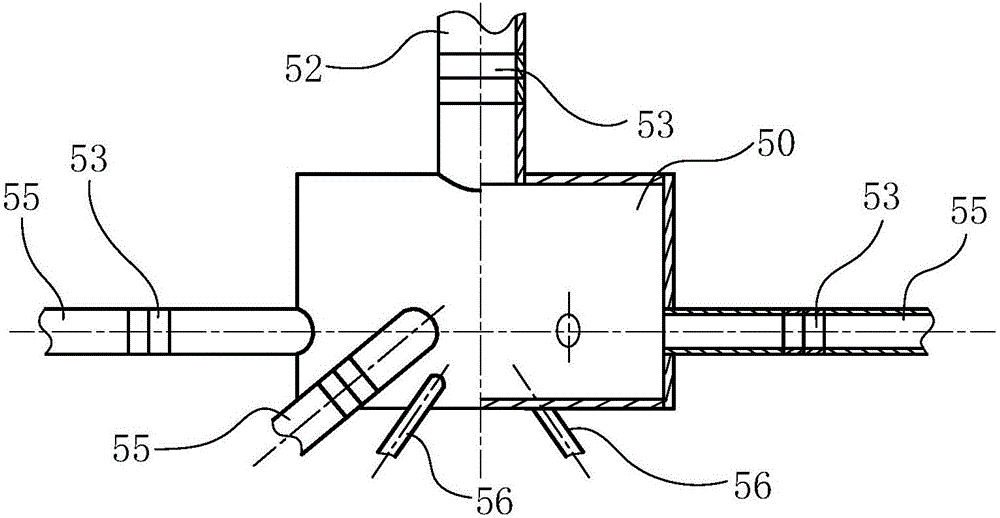

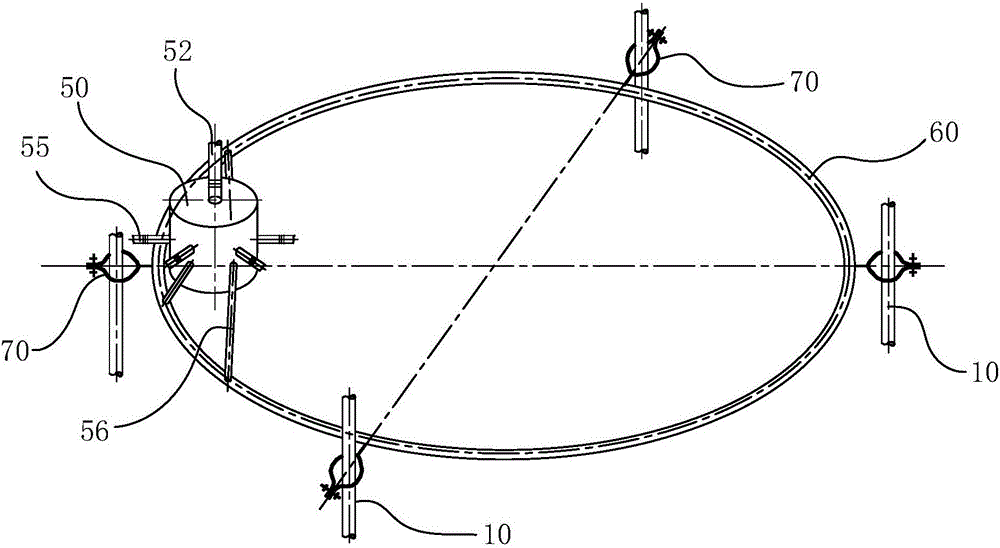

Water spraying and cooling system for bearing test of free high-temperature compression member

ActiveCN106595162AImprove running stabilityImprove cooling effectLighting and heating apparatusStructural/machines measurementSpray nozzleCooling effect

The invention relates to a water spraying and cooling system for a bearing test of a free high-temperature compression member. The water spraying and cooling system comprises metal supports arranged at the periphery of the compression member, wherein a lower fastening ring is arranged on the metal supports; the compression member is arranged at the central position of the lower fastening ring; the ring surface of the lower fastening ring is horizontal, and a plurality of free rocker arm assemblies are arranged on the ring surface at intervals; cooling water spraying nozzles are arranged at the overhanging ends of the free rocker arm assemblies; the spaces between water spraying heads of the cooling water spraying nozzles and the compression member are adjustable; and the cooling water spraying nozzles point to the center of the ring surface of the lower fastening ring and are obliquely arranged upwards. The water spraying and cooling system disclosed by the invention can be used for cooling a high-temperature cylindrical compression member and a high-temperature square compression member; cooling water uniformly distributes along the vertical wall surface, and the cooling effect is better; relative positions between the cooling water spraying nozzles and the compression member are controlled by using the free rocker arm assemblies, and the simplicity and the flexibility in operation are realized; the aim of meeting technical requirements of a cooling process test of the high-temperature square compression member is achieved; and in addition, the water spraying and cooling system has the advantages of simple structure, small size and convenience in disassembly and assembly.

Owner:SANHE TONGFEI REFRIGERATION

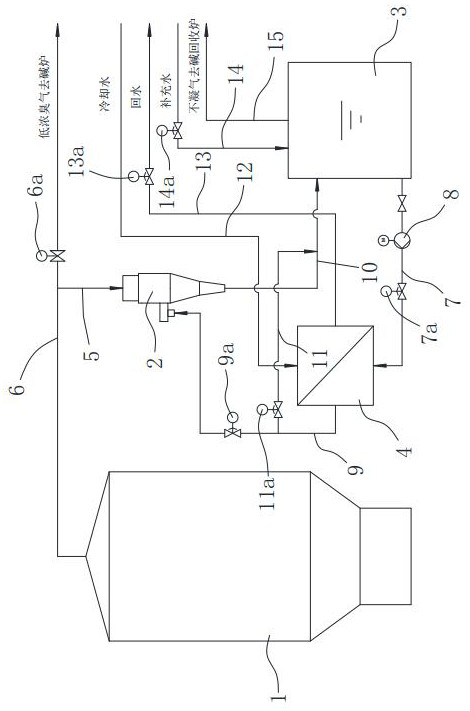

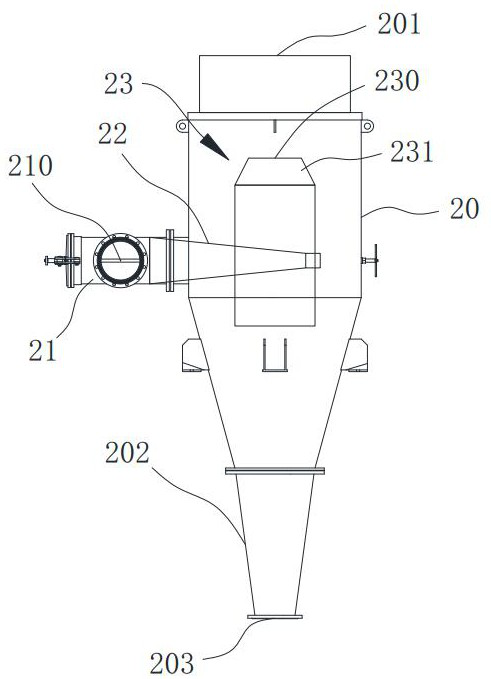

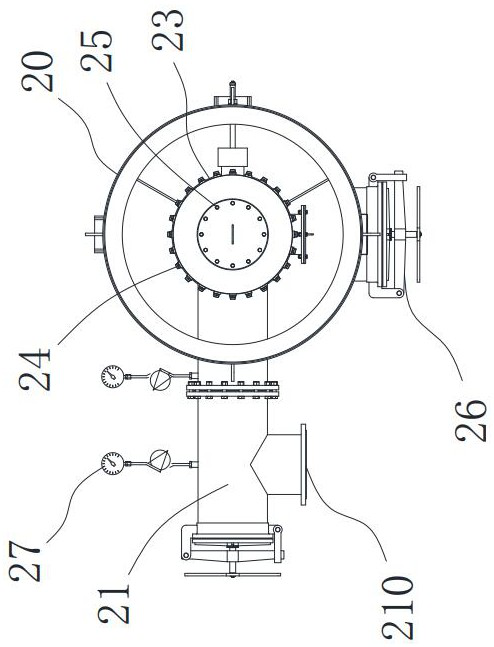

Blow tank odor treatment system and treatment method

PendingCN113893652AEasy to handleSmall footprintRecuperative heat exchangersDigestersEngineeringSlurry

The invention provides a blow tank odor treatment system and a treatment method, and aims to solve the technical problem of air pollution caused by direct emission of odor due to difficulty in treatment caused by large gas displacement during blowing of the blow tank. The treatment system comprises a condensation ejector connected with the blow tank and a dirty hot water tank connected with a water inlet of the condensation ejector, wherein an outlet of the dirty hot water tank is connected with a water inlet in one side of the condensation ejector after passing through a heat exchanger. The treatment method is carried out through the system and comprises the steps: S1, before blowing of the blow tank, water is supplied to the condensation ejector in advance for a certain time, and micro-negative pressure is established in the exhaust pipe; and S2, after the pressure of the system is stable, slurry pumping is started, water is continuously supplied to the condensation ejector, and water flow enters the condensation ejector at a certain pressure and temperature after heat exchange and is sprayed out in an atomized foam and high-speed jet flow mode. The problem that gas displacement is large and difficult to treat can be effectively solved, and it is avoided that odor is directly exhausted to pollute air.

Owner:四川永丰浆纸股份有限公司

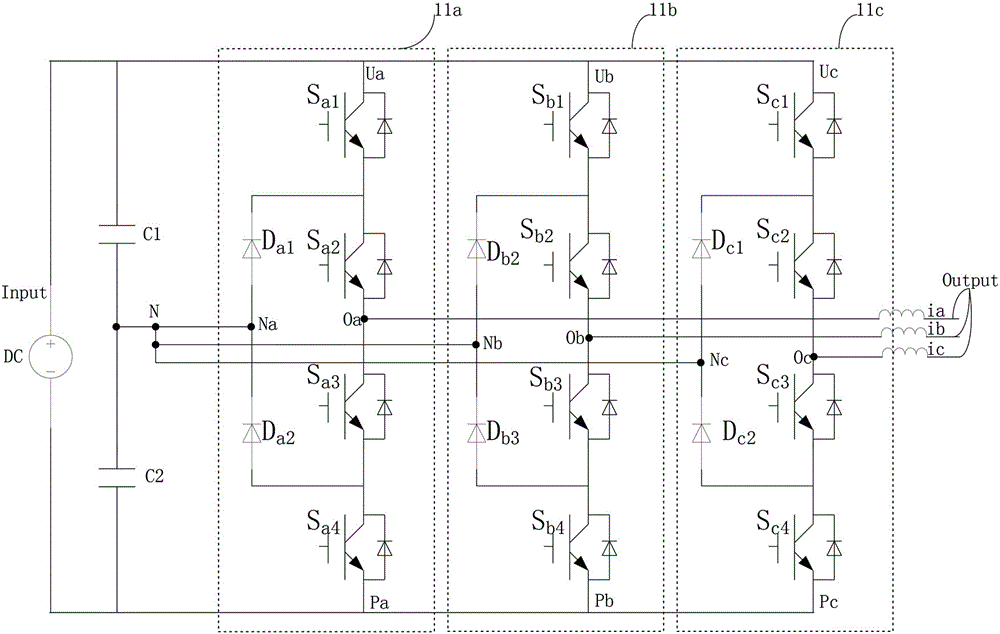

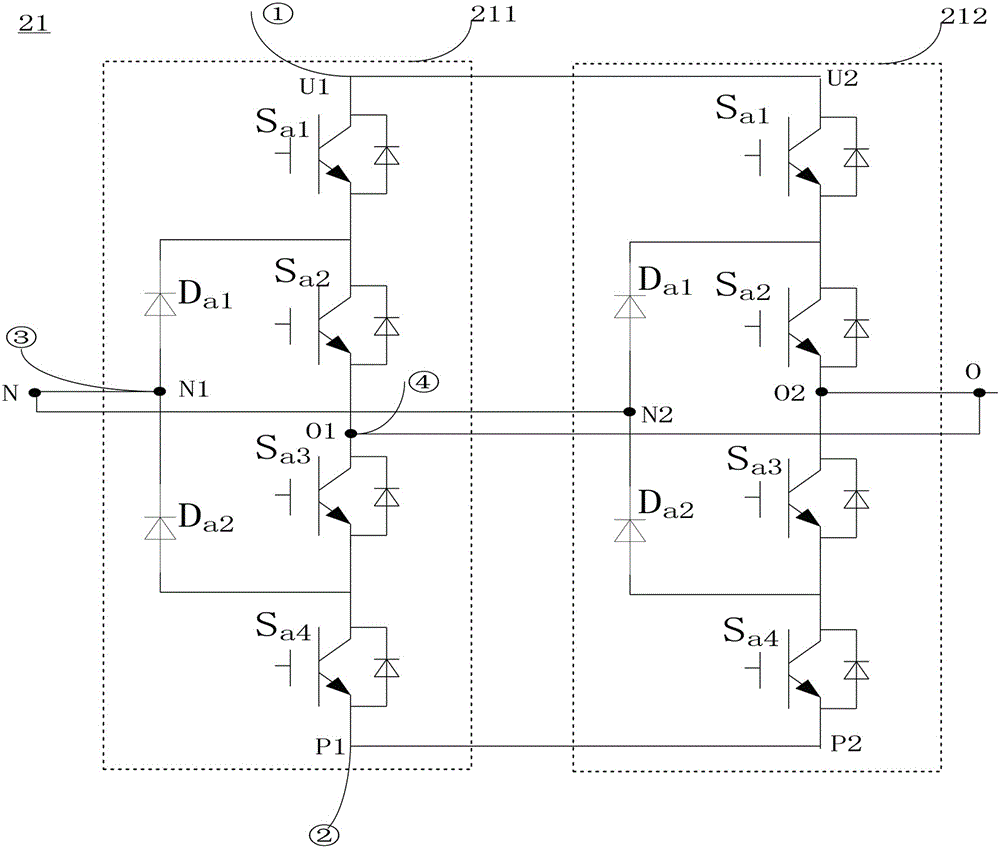

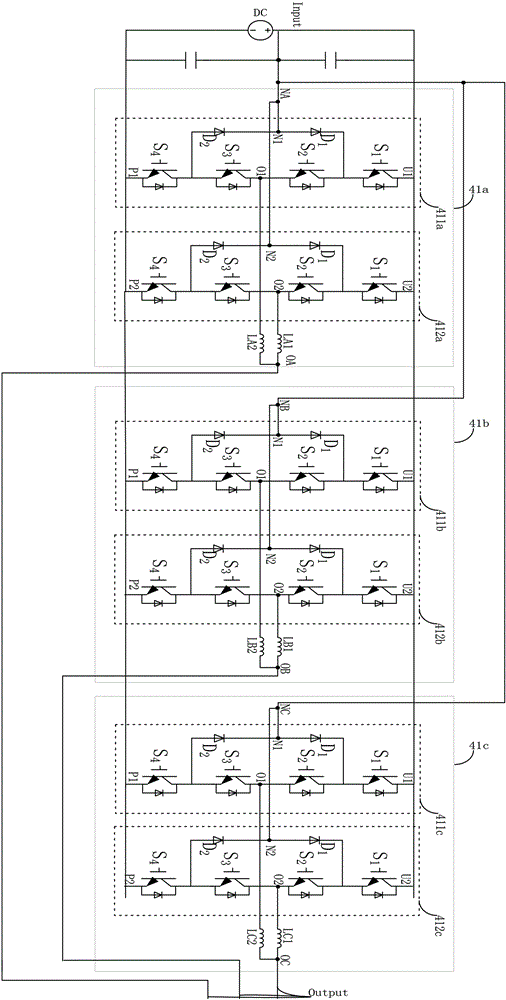

Three-level inverter

Provided in the invention is a three-level inverter comprising an A-phase high-power switch, a B-phase high-power switch, and a C-phase high-power switch. The high-power switches are connected in parallel. The A-phase high-power switch is formed by parallel connection of an A-phase first switch module and an A-phase second switch module; the B-phase high-power switch is formed by parallel connection of a B-phase first switch module and a B-phase second switch module; and the C-phase high-power switch is formed by parallel connection of a C-phase first switch module and a C-phase second switch module. Each switch module contains a current input terminal and a current output terminal; and one of the current input terminal and the current output terminal is connected in series with an inductor and then is connected in parallel. With the inductors, precise current equalization of each module is realized and the bias current phenomenon can be effectively avoided. The three-level inverter also has outstanding characteristics of simple structure, easy realization, and stable performance.

Owner:YANTAI DONGFANG WISDOM ELECTRIC +1

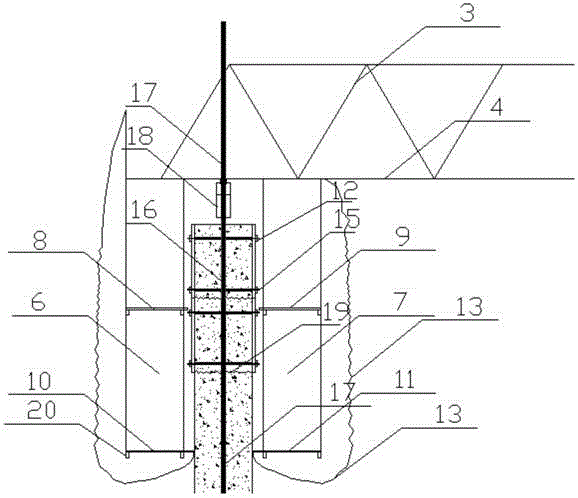

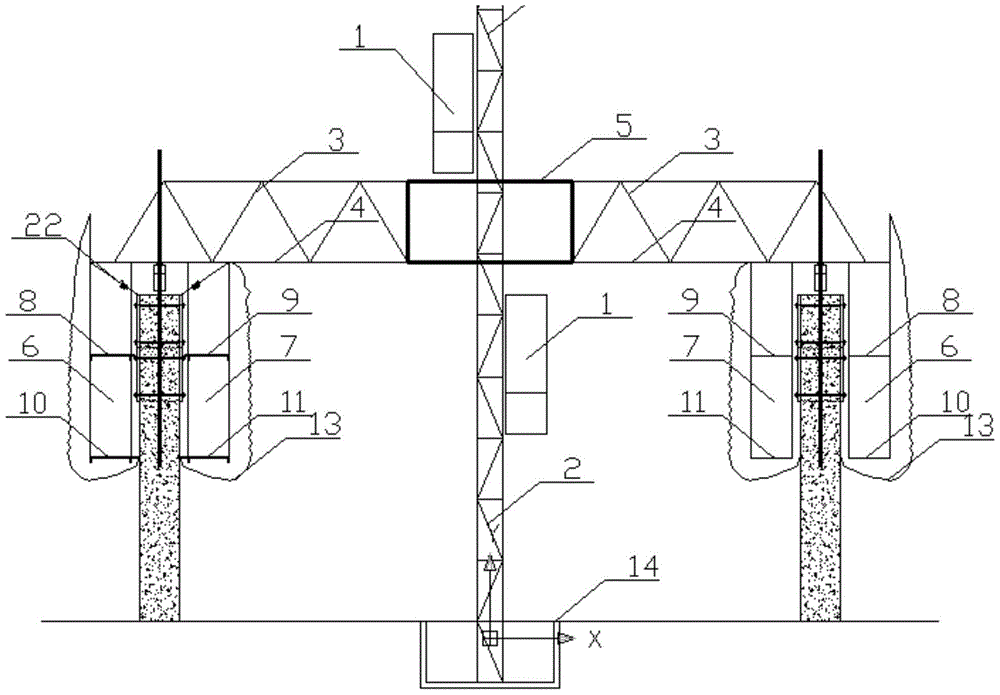

A construction method of circular reinforced concrete chimney wall inverted formwork

ActiveCN104712143BSolving the Recycling DilemmaModerate labor intensityForms/shuttering/falseworksBuilding material handlingFalseworkReinforced concrete

The invention relates to a reversed mould construction method for the circular reinforced concrete chimney wall. The method comprises the steps that a pre-embedded part is embedded; a scaffold is erected at the central position of the chimney wall, steel ring raw materials for connecting primary trusses and a secondary radiation beam are transported into the chimney, and steel rings are assembled on the ground; a central drum ring is installed; a cross-core jack is installed on a climbing rod, the cross-core jack is installed in a released state, and the cross-core jack is adjusted to the corresponding elevation; the primary trusses, the secondary radiation beam and forward-spin connecting rods of the primary trusses are installed, the assembled steel rings are lifted to the bottom of the secondary radiation beam, and the junctions of the secondary radiation beam and downward-spin rods of the primary trusses are connected through a stud and a clamp plate; a foot plank of an operation platform is paved; the normal operation of a chimney cylinder body is conducted. According to the reversed mould construction method for the circular reinforced concrete chimney wall, two formworks are adopted, and a layer of template is omitted compared with a normal condition; the labor intensity of the construction of a hydraulic reversed mould device is moderate, the lifting work of a railway mould is omitted, the labor intensity is reduced, the construction progress is obviously quickened through the dynamic and continuous operation, and the construction period is shortened obviously.

Owner:SEPCOIII ELECTRIC POWER CONSTR CO LTD

an axial reactor

ActiveCN107224939BImprove uniformityImprove conversion rateChemical/physical processesRetention timeProduct gas

The invention discloses an axial reactor. The reactor comprises a radial cylindrical sealed pressure-bearing shell body (2), a gas inlet pipe (18), a gas outlet pipe (13), an axial microchannel reaction zone (16) and an axial catalytic reaction zone (9), wherein the axial microchannel reaction zone (16) is located above the axial catalytic reaction zone (9); the axial microchannel reaction zone (16) comprises one or more disk-shaped axial microchannel reaction units (14) which are connected in series up and down; each axial microchannel reaction unit (14) has a plurality of axial microreaction channels (7); and the axial catalytic reaction zone (9) can contain at least one catalyst bed layer, and reactant fluid can flow through the catalyst bed layers from top to bottom for a catalytic reaction. Compared with the prior art, the reactor disclosed by the invention is compact in structure, low in active metal consumption, low in bed layer pressure drop, short in gas product retention time and high in bed layer space utilization ratio and is free of gas bias and short-circuit phenomena.

Owner:SINOPEC ENG +1

Axial radial micro-catalysis reaction unit and its application

ActiveCN106693848BGreat driving forceShort stayChemical/physical/physico-chemical processesRetention timeChemistry

The invention discloses an axial-radial micro-catalytic reaction unit and application thereof. The axial-radial micro-catalytic reaction unit contains a central column and a sleeve which coaxially sleeves the central column. The central column has axial micro-reaction channels which axially pass through the central column. Radial micro-reaction channels which pass through the sleeve are arranged in the radial direction of the sleeve. The axial-radial micro-catalytic reaction unit provided by the invention can be used for a reaction with reaction volume changing. In addition, use amount of a catalyst is small; pressure drop is low; retention time is short; utility rate of space is high; and there is no gas bias current or short circuit phenomenon.

Owner:SINOPEC ENG +1

A kind of methanation reactor and methanation process

ActiveCN106378063BGreat driving forceShort stayHydrocarbon from carbon oxidesGaseous fuelsMethanationProcess engineering

The invention discloses a methanation reactor and a methanation process. The methanation reactor comprises a shell, a gas inlet pipe, a transverse catalytic reaction unit, a longitudinal catalytic reaction unit, a gas outlet pipe, axial micro-reaction channels and radial micro-reaction channels, wherein a component with catalytic activity may be loaded in the axial micro-reaction channels and radial micro-reaction channels. Compared with the prior art, the invention has the advantages that the methanation reactor is reduced in the usage amount of a catalyst; and when the methanation reactor is used for methanation, pressure drop among beds is reduced, gas retention time is short, the utilization rate of the space of reaction beds is high, and the phenomena of bias current and short circuit of gas do not occur.

Owner:SINOPEC ENG +1

A kind of methanation reactor and methanation process

ActiveCN106693839BGreat driving forceShort stayHydrocarbon from carbon oxidesGaseous fuelsMethanationActive component

The invention discloses a methanation reactor and a methanation process; the methanation reactor comprises a shell body, a gas inlet pipe, a central cylinder, a central pipe, a gas outlet pipe, a cooling medium inlet, a cooling medium outlet and a micro reaction channel, and includes or does not include a sleeve; the micro reaction channel can be internally loaded with a catalytic active component. Compared with the prior art, the methanation reactor has less catalyst use amount; according to the methanation process adopting the methanation reactor, the bed pressure is reduced, the gas residence time is short, the space utilization rate of a reaction bed is high, and gas bias current and short-circuit phenomena do not exist.

Owner:SINOPEC ENG +1

a catalytic reactor

ActiveCN107617392BImprove uniformityImprove conversion rateChemical/physical processesStraight tubePhysical chemistry

Owner:SINOPEC ENG +1

A radial micro-catalytic reaction unit and its application

ActiveCN106693847BGreat driving forceShort stayGaseous fuelsChemical/physical/physico-chemical processesRetention timeEngineering

The invention discloses a radial micro-catalytic reaction unit and application thereof. The radial micro-catalytic reaction unit comprises a central cylinder having a central tube. One end of the central tube is an opening. The outboard of the central cylinder is in fluid communication with the central tube through micro-reaction channels which radially penetrate through the central cylinder. The micro-reaction channels have micro-channel inside openings and micro-channel outside openings which have different diameters. The micro-catalytic reaction unit can be used for a reaction with reaction volume changing. In addition, use amount of a catalyst is small; pressure drop is low; retention time is short; utility rate of space is high; and there is no gas bias current or short circuit phenomenon.

Owner:SINOPEC ENG +1

A kind of environment-friendly pesticide hand throw agent and preparation method thereof

The invention discloses an environment-friendly pesticide hand-throwing agent, which comprises a water-soluble film, the water-soluble film wraps oil-based pesticides, the thickness of the water-soluble film is 30-80um, and the oil-based pesticides include the following groups by mass percentage: Composition: 0.5-40% of active ingredients of pesticides, 0.5-5% of surfactants, 0-10% of co-solvents, and the balance is extensible plant essential oils. The environmental-friendly pesticide hand throwing agent of the present invention is convenient to use as a pesticide, and can be directly thrown in the field. After being thrown in the field, the oil-type pesticide in the water-soluble film is released, and the active ingredients of the pesticide are released on the water surface of the field along with the expansive plant essential oil. Diffusion enables the active ingredients of pesticides to be evenly distributed in the target application area, which not only exerts the effect of active ingredients of pesticides, but also does not cause pollution. The water-soluble film after use dissolves and degrades with water in the field, which is environmentally friendly and safe.

Owner:SOUTH CHINA AGRI UNIV

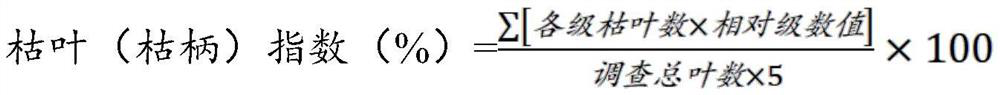

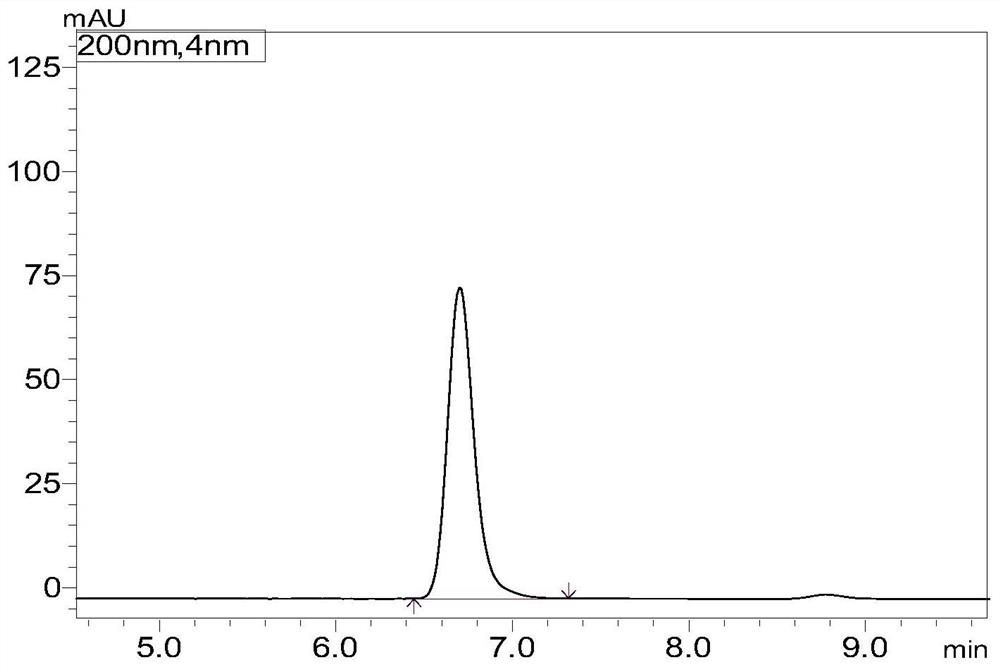

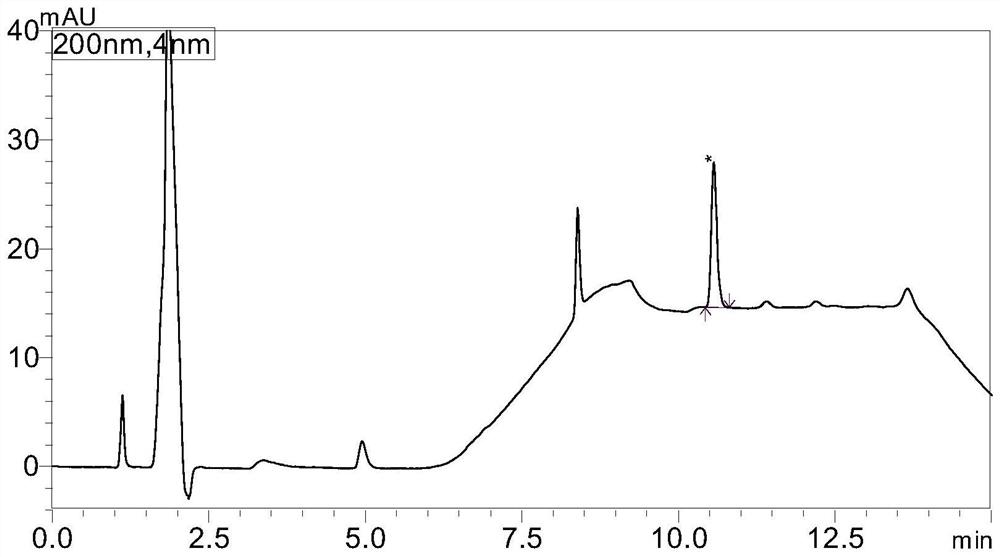

High performance liquid chromatography detection method for 9,9-bis(4-amino-3-chlorphenyl)fluorene in polyimide film

The invention relates to the field of chromatographic analysis, particularly to a high performance liquid chromatography detection method for 9,9-bis(4amino 3chlorphenyl) fluorene in a film. Accordingto the method, water and acetonitrile are selected as mobile phases to efficiently analyze the content of 9,9-bis(4amino 3chlorphenyl) fluorene in an extraction liquid obtained through extraction pretreatment so as to determine the content of a to-be-detected substance in a film; the obtained chromatographic peak is sharp in peak pattern, good in symmetry, small in baseline fluctuation and free of drifting phenomenon; and the proper detector wavelength is selected, the obtained chromatographic peak signal intensity is proper, analysis and calculation are facilitated, errors are reduced, and the accuracy is improved. The analysis method disclosed by the invention is high in sensitivity and accuracy, low in detection limit and quantification limit, early in chromatographic peak appearance retention time, high in analysis efficiency and capable of quickly obtaining an analysis result.

Owner:GUANGZHOU GRG METROLOGY & TEST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com