a catalytic reactor

A catalytic reactor and catalytic reaction technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve the problems of low usage of catalyst active components, low conversion rate of raw materials, low bed temperature, etc. Conversion rate, uniform bed temperature, and effect of reducing bed temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

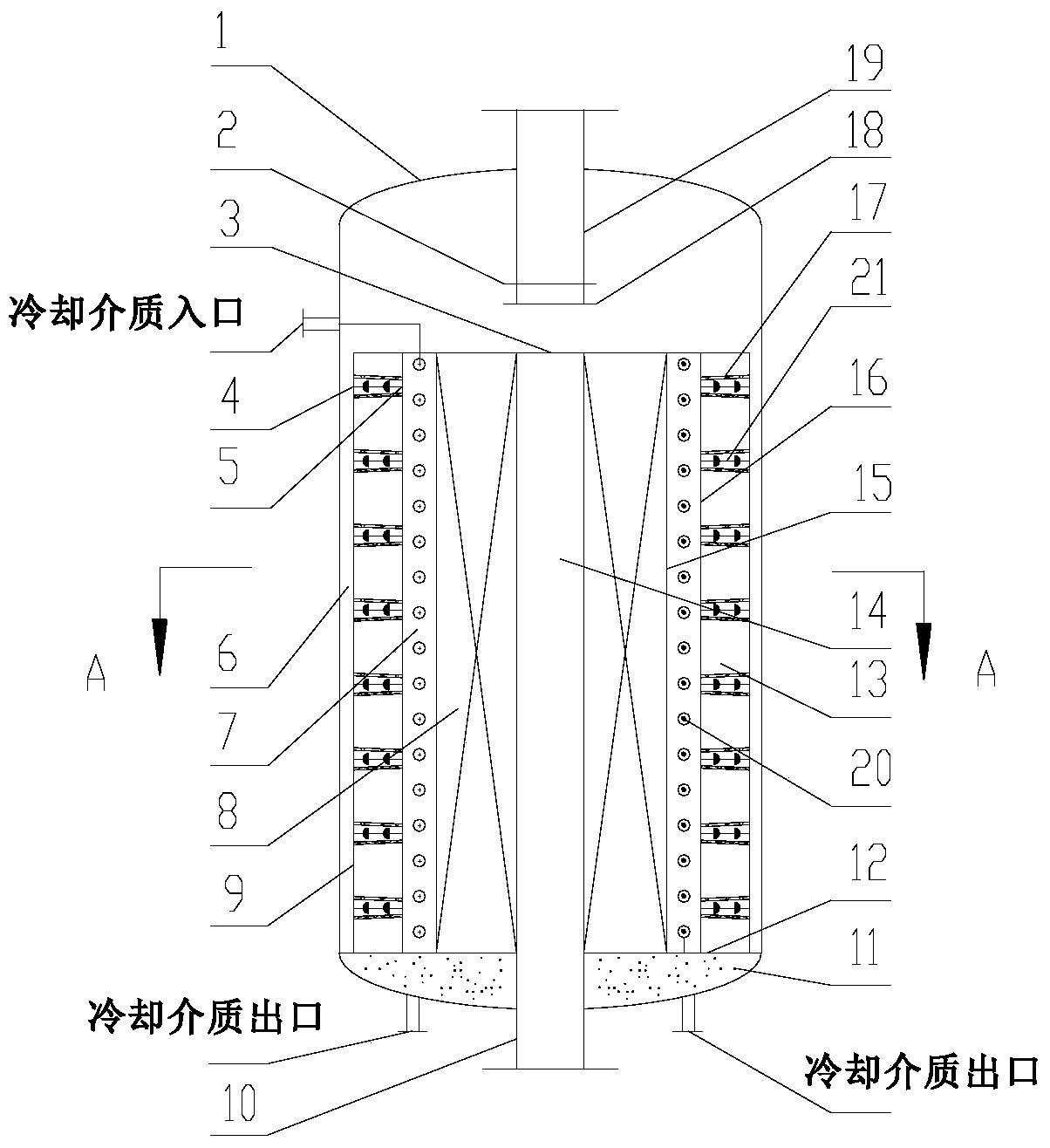

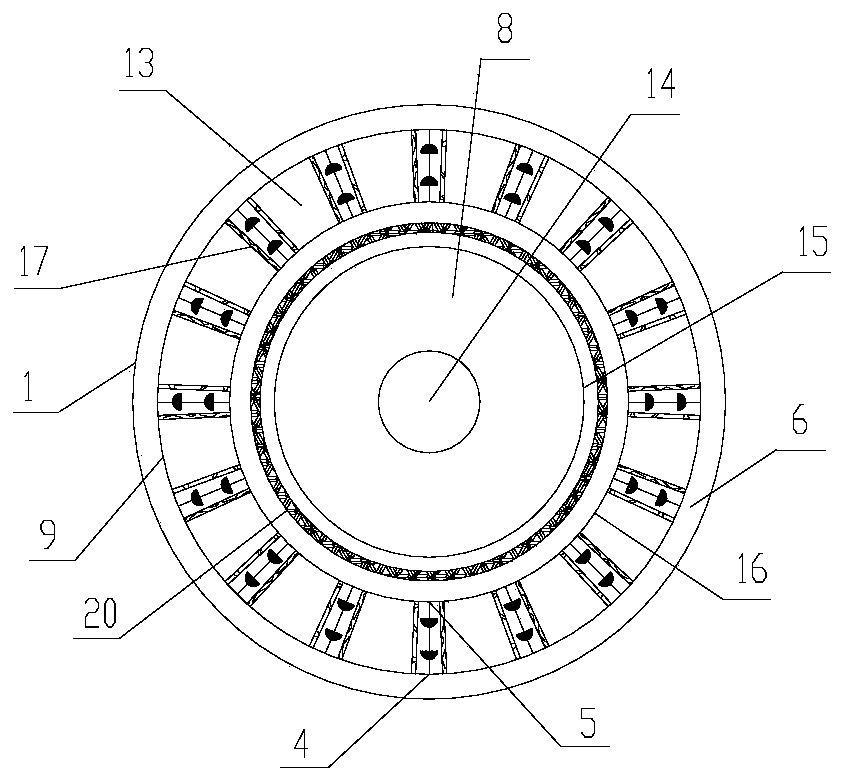

[0075] like figure 1 As shown, the catalytic reactor used in this embodiment includes a pressure housing 1 with a first straight pipe 19 at the upper end and a second straight pipe 10 at the lower end. The upper part of the first straight pipe 19 is provided with an air inlet The lower part is provided with a first gas distributor 2, and the lower part of the first gas distributor 2 is provided with a second gas distributor 18. The sleeve 13 made of microchannels arranged below the first straight pipe 19 in the housing 1 is filled with the central cylinder 8 of catalyst. The sleeve 13 shares the bottom sealing plate 12 and the top sealing plate 3 with the central cylinder 8 . All are hollow in the sleeve 13, as figure 2 shown. The sleeve 13 is provided with 99094 micro-reaction channels 17 (not all shown for clarity) arranged radially. The structure of the micro reaction channel 17, such as Figure 11 As shown, the two ends are sealingly connected with the sleeve inner w...

Embodiment 2

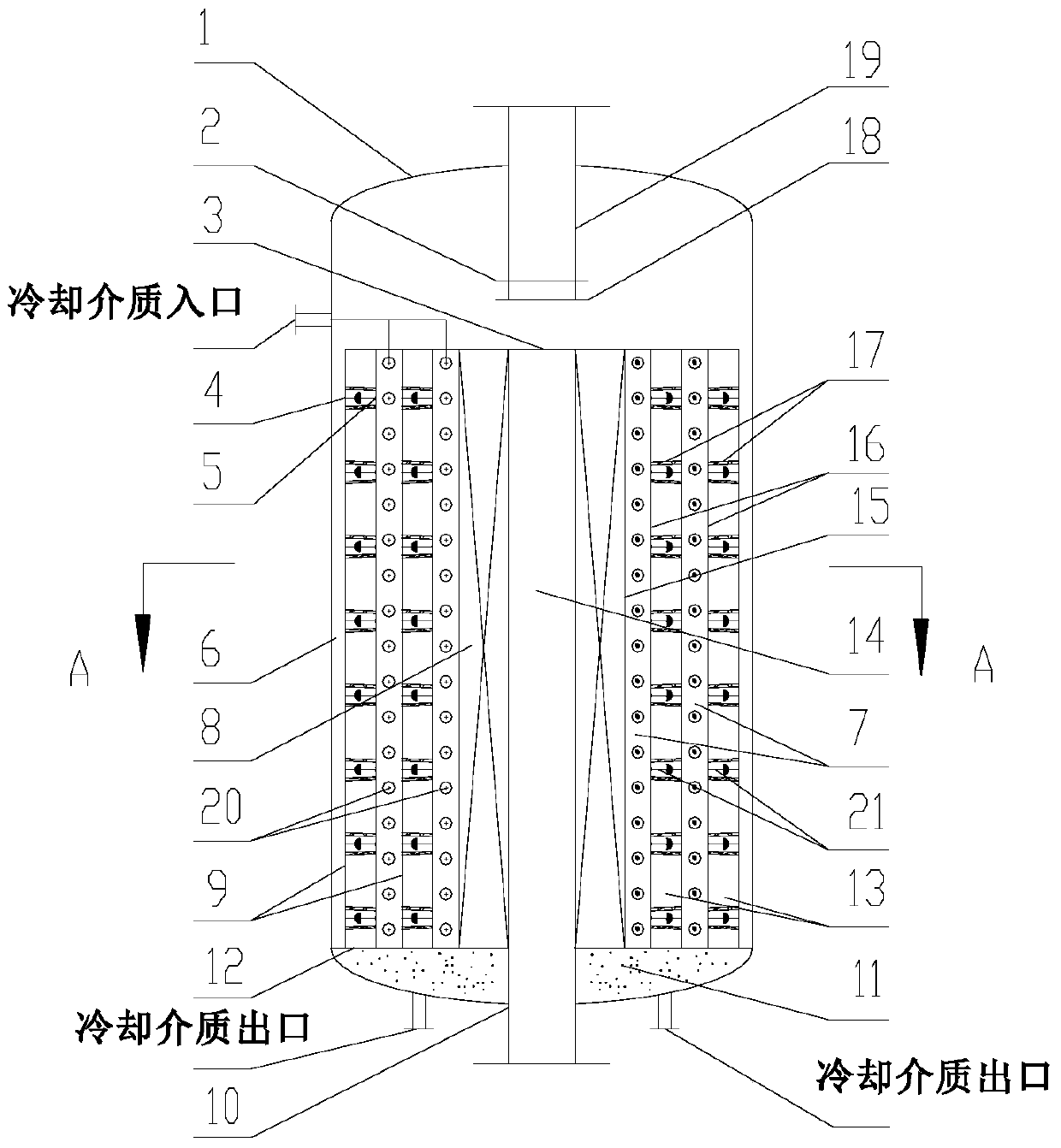

[0082] like image 3 , Figure 4 As shown, the catalytic reactor used in this embodiment has the same structural parameters as the catalytic reactor housing inner diameter and central cylinder of the first embodiment. The difference from Embodiment 1 is that in this embodiment, two sleeves are used, and cooling medium pipelines are arranged between the sleeves and between the sleeve and the central cylinder, the ring gap distance is still 30mm, and the gap distance is 10mm , the diameter of the central tube 14 is 150mm, the radial bed thickness of the central tube 8 is 175mm, the length of the micro-reaction channel of the tapered tube is 75mm, the diameter of the inlet of the tapered tube is 8mm, and the diameter of the outlet is 4mm. The total volume of all the tapered tubes accounts for The volume ratio of the sleeve 13 is 48.6%. The diameter of the bottom surface of the hemisphere of the flow guide element is 3mm, and the distance between adjacent flow guide elements is ...

Embodiment 3

[0085] like Figure 5 , Image 6 As shown, the catalytic reactor used in this embodiment has the same structural parameters as the catalytic reactor housing inner diameter, center tube, and sleeve in Example 1. The difference from Embodiment 1 is that no cooling medium pipeline is used in this implementation, and the cooling medium enters the casing 1 from the cooling medium inlet on the outside of the casing 1, and the cooling medium inlet is connected with the sleeve through the cooling medium pipeline. The inner wall of 13 is in fluid communication with the chamber formed by the outer wall of the micro-reaction channel 17, and the chamber is in fluid communication with the cooling medium outlet through two cooling medium pipelines passing through the heat insulating material area 11, and the cooling medium is sent out reactor.

[0086] The catalytic reactor used in this example can be applied to syngas synthesis of C in Fe-based catalysts 2 = 、C 3 = and other small mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com