Patents

Literature

1805results about How to "Increased turbulence" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

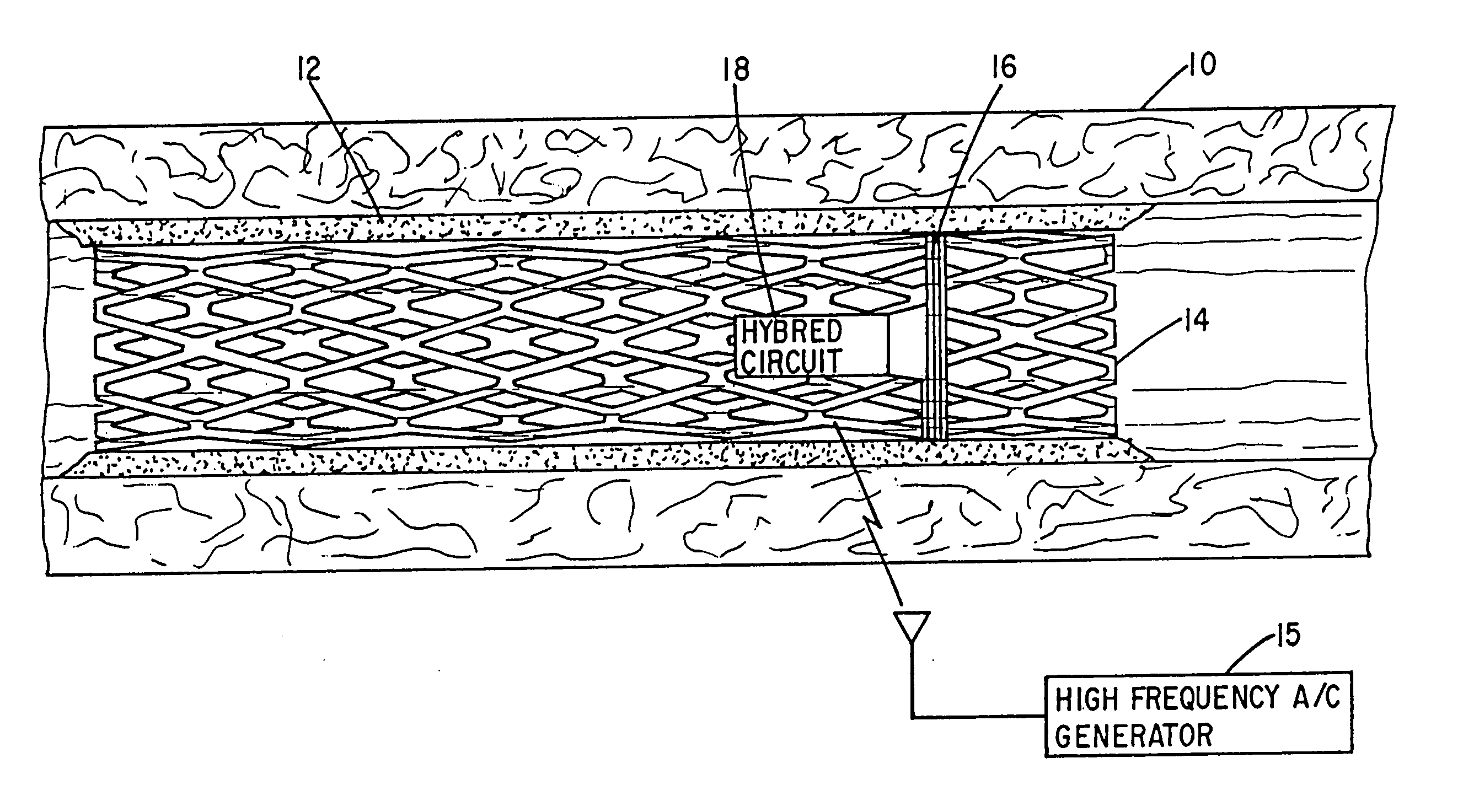

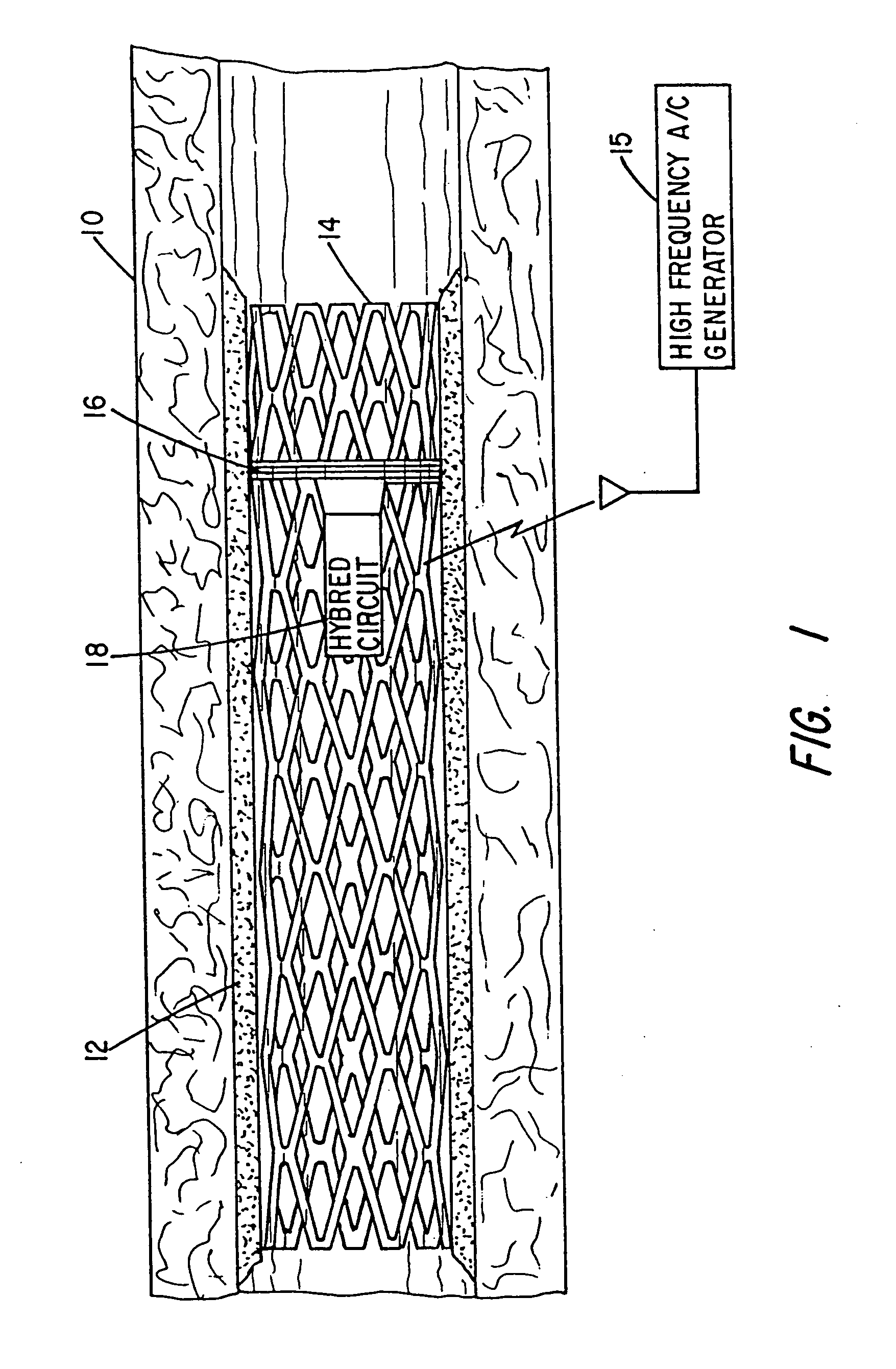

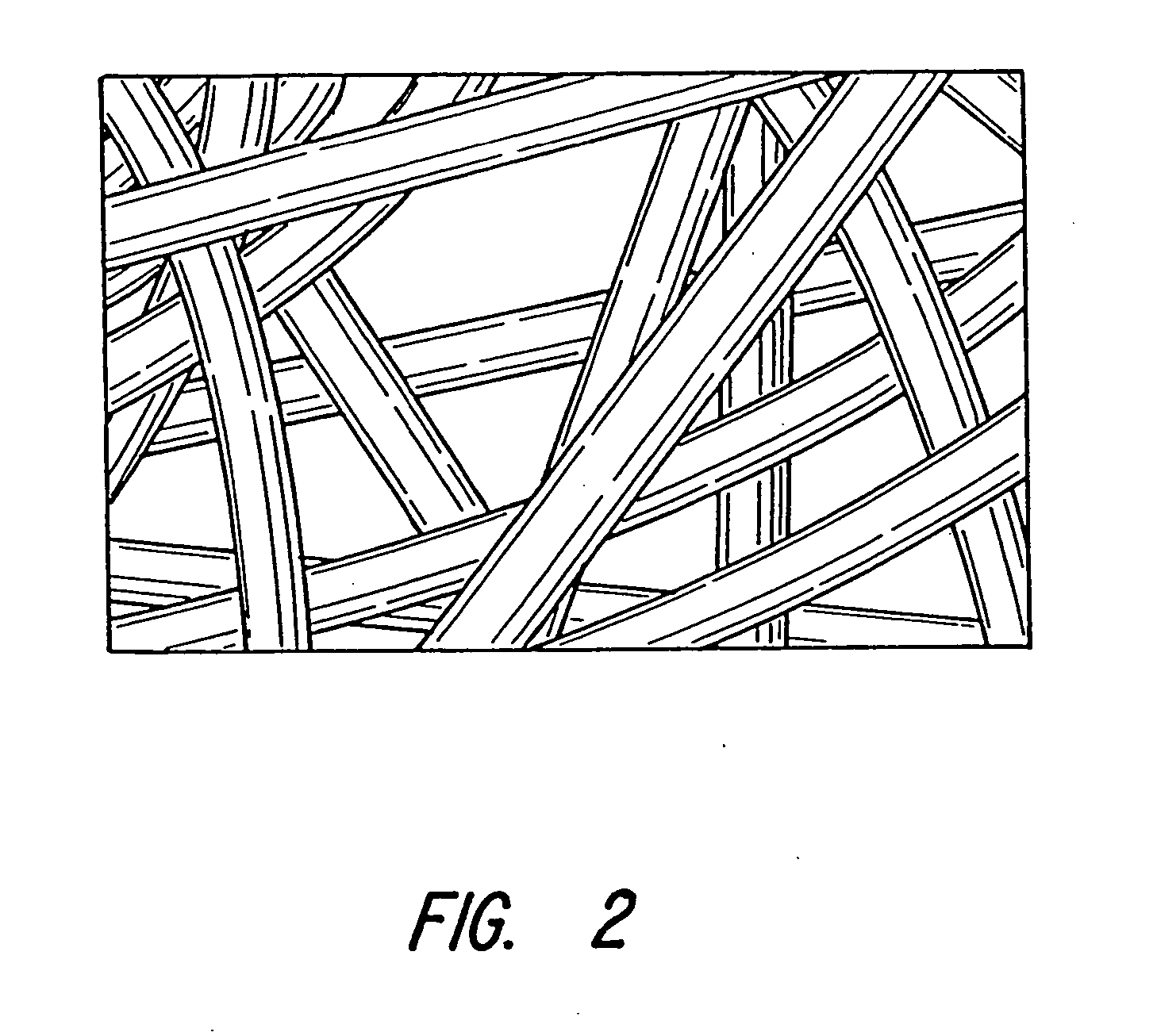

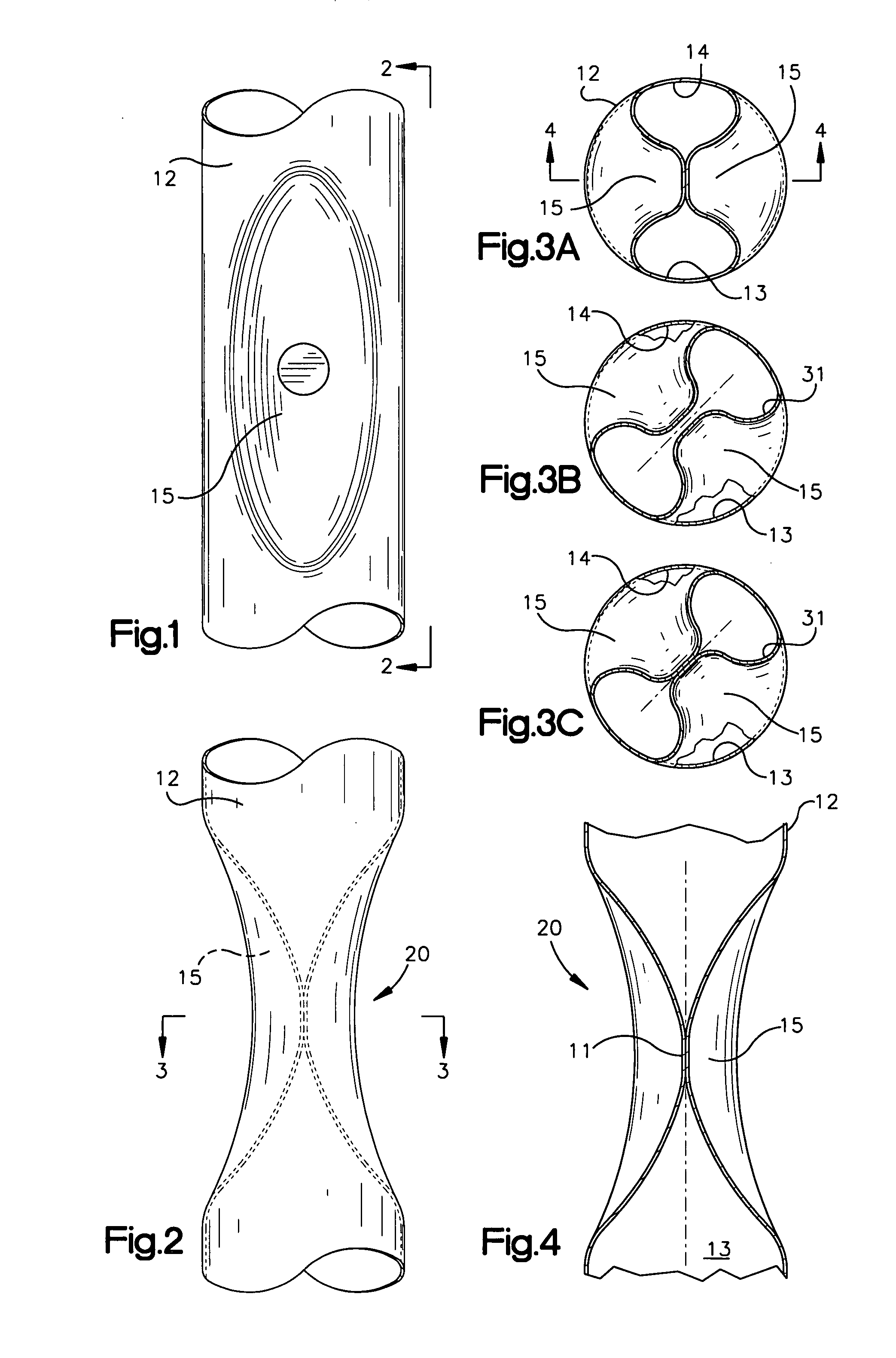

Implantable device for promoting repair of a body lumen

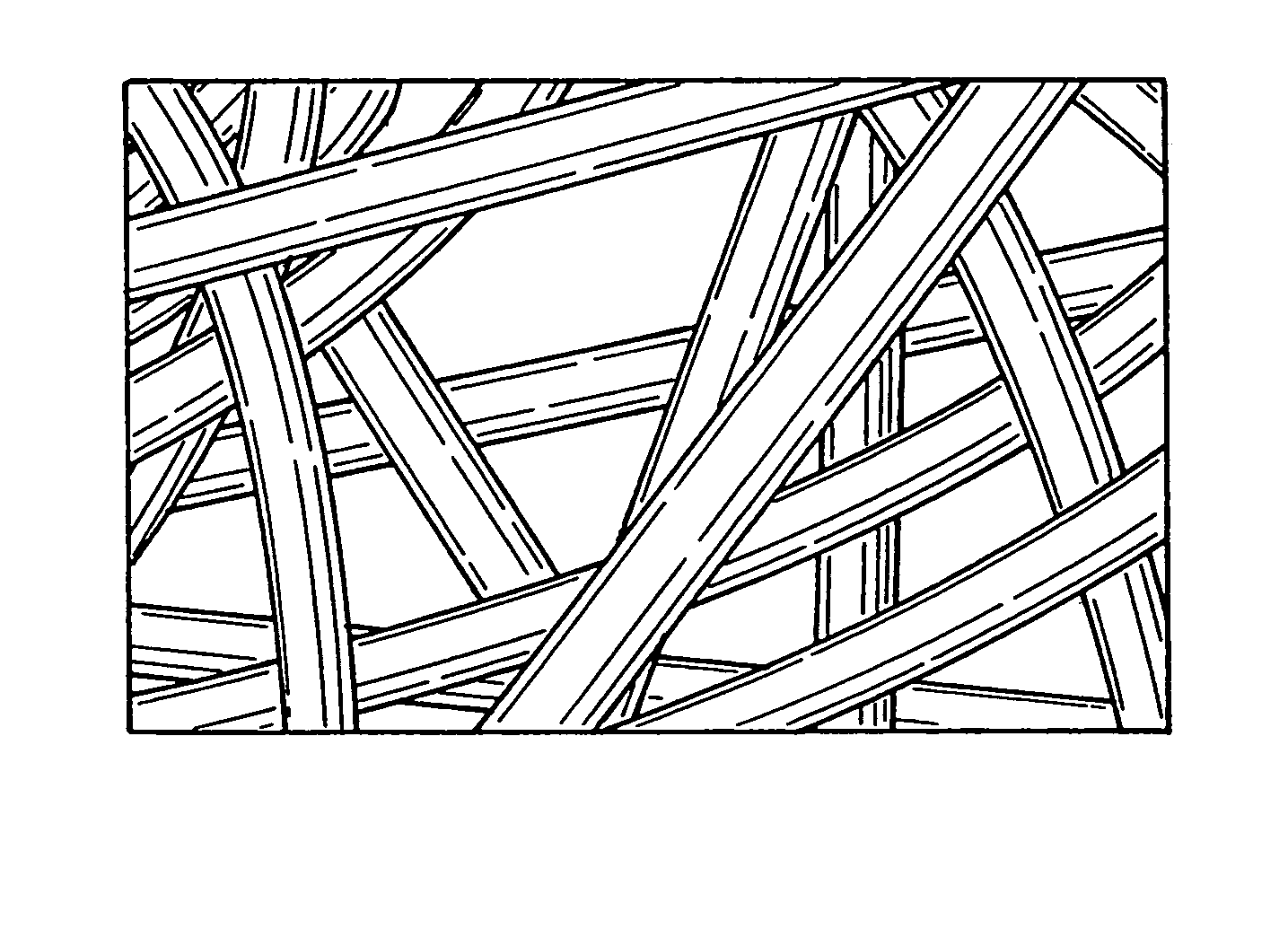

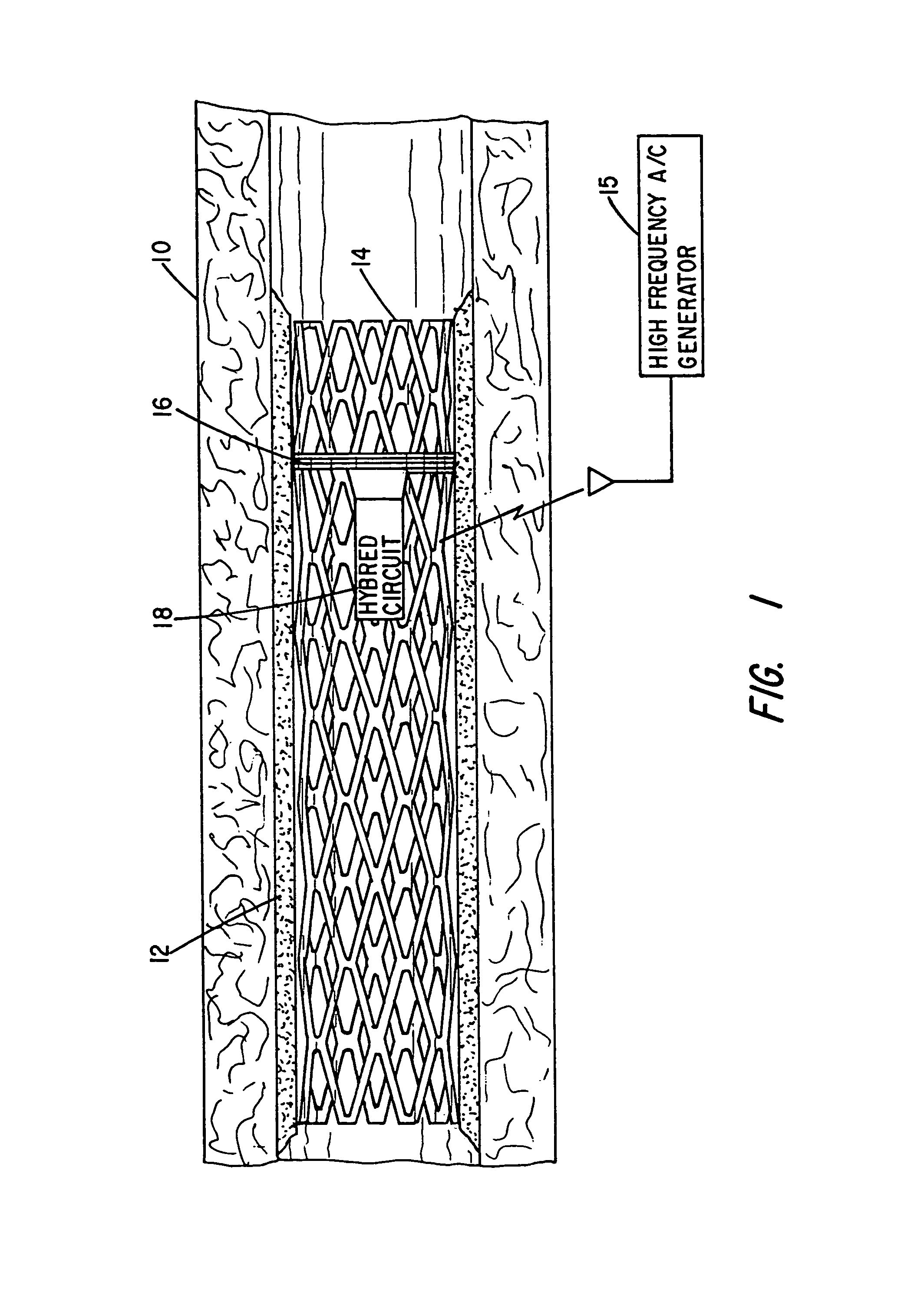

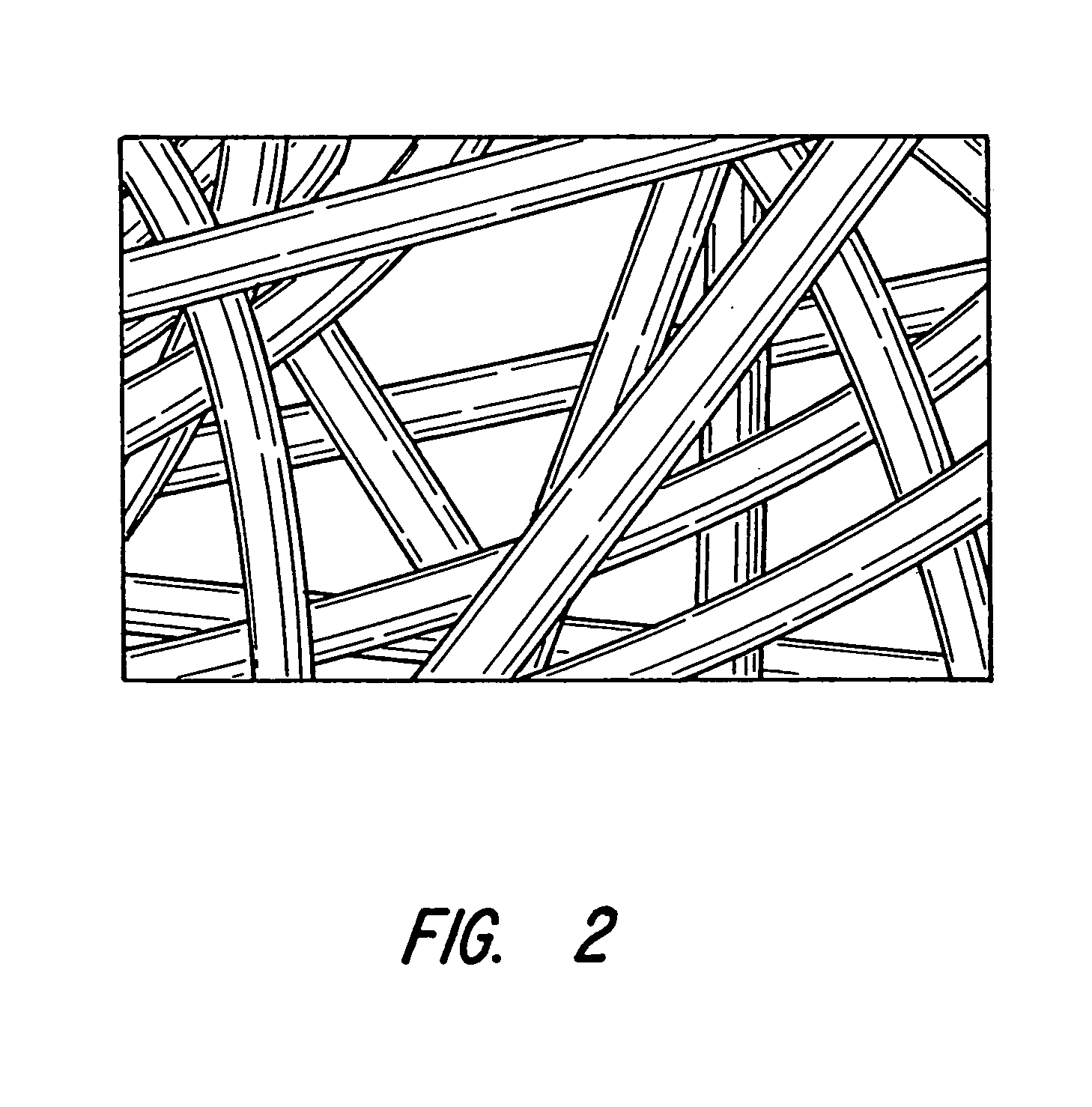

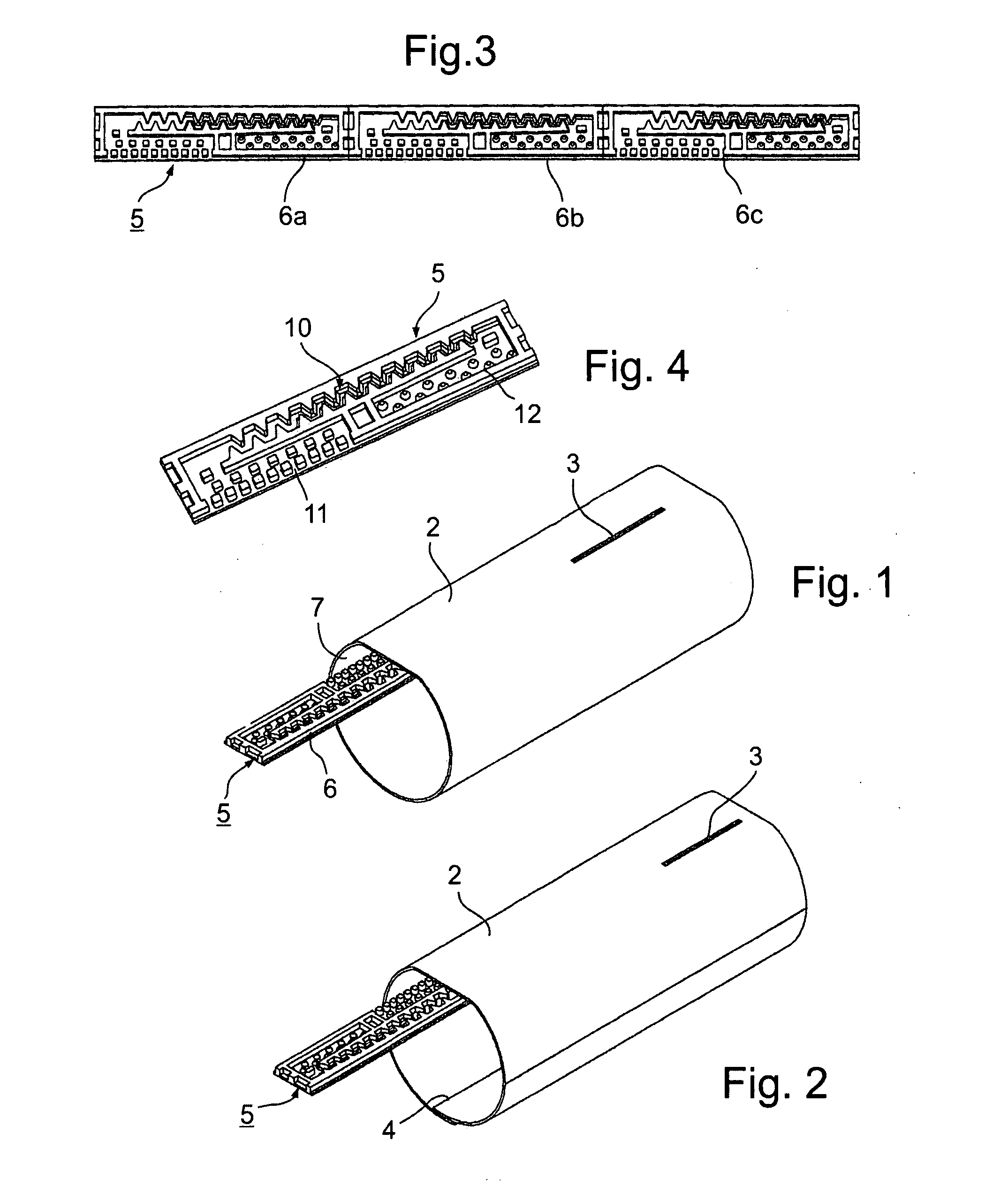

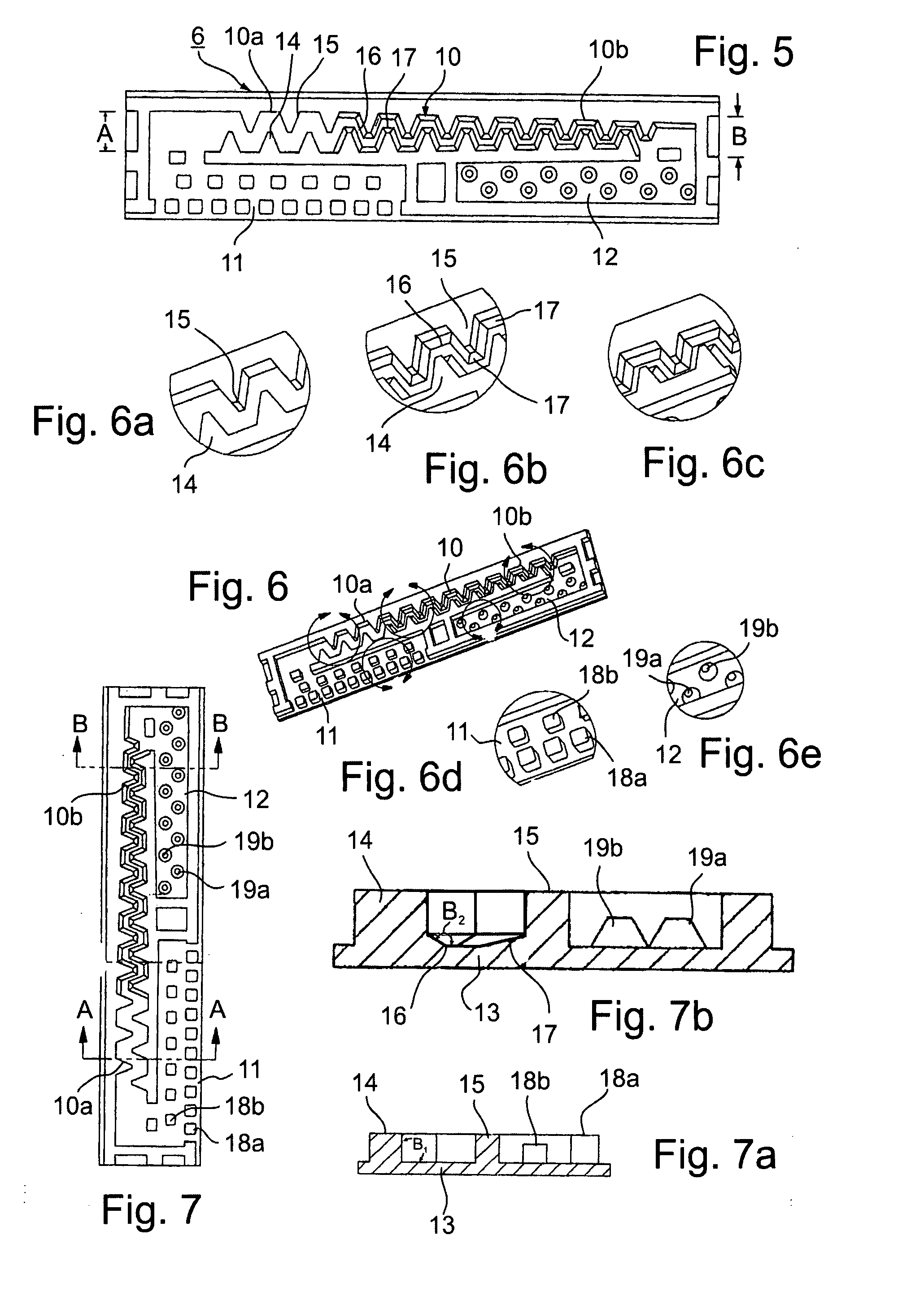

An implantable stent having surface features adapted to promote an organized growth pattern of infiltrating cells when implanted in a tubular organ is provided. The surface features comprise depressions, pores, projections, pleats, channels or grooves in the stent body and are designed to increase turbulence or stagnation in the flow of a liquid, such as blood through the stent, and / or to promote the growth of infiltrating cells in an organized pattern. Alternatively, the invention stent can be populated with living cells prior to implant and can be heatable from an external source of energy, thereby inducing production of therapeutic bioactive agents from ingrowing cells. The invention also provides an implantable heatable stent for transcutaneously monitoring the flow of fluid through a lumen into which the stent is implanted by measuring the rate at which the heated stent cools in response to blood flow when the source of heat is removed.

Owner:TRICARDIA

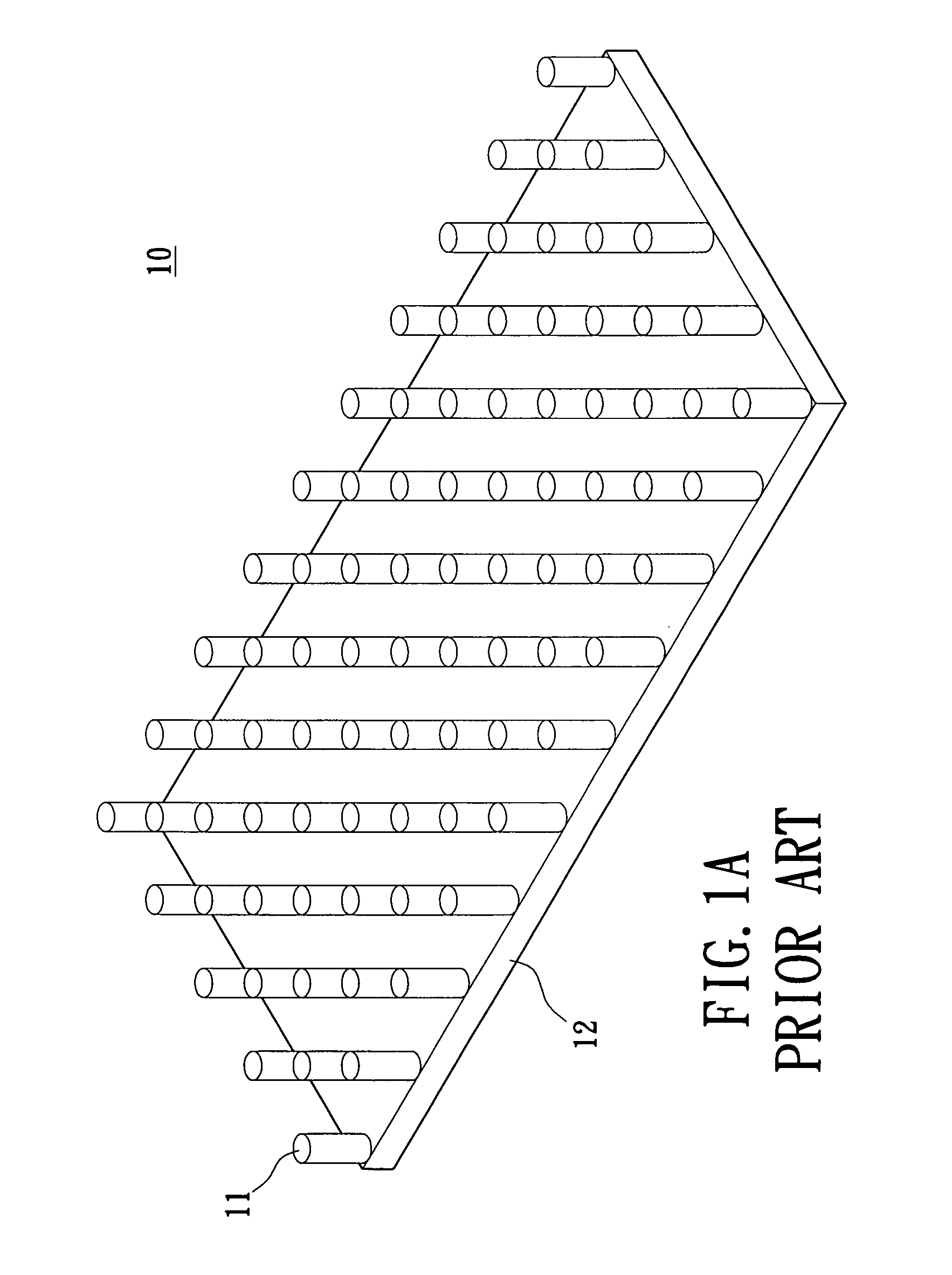

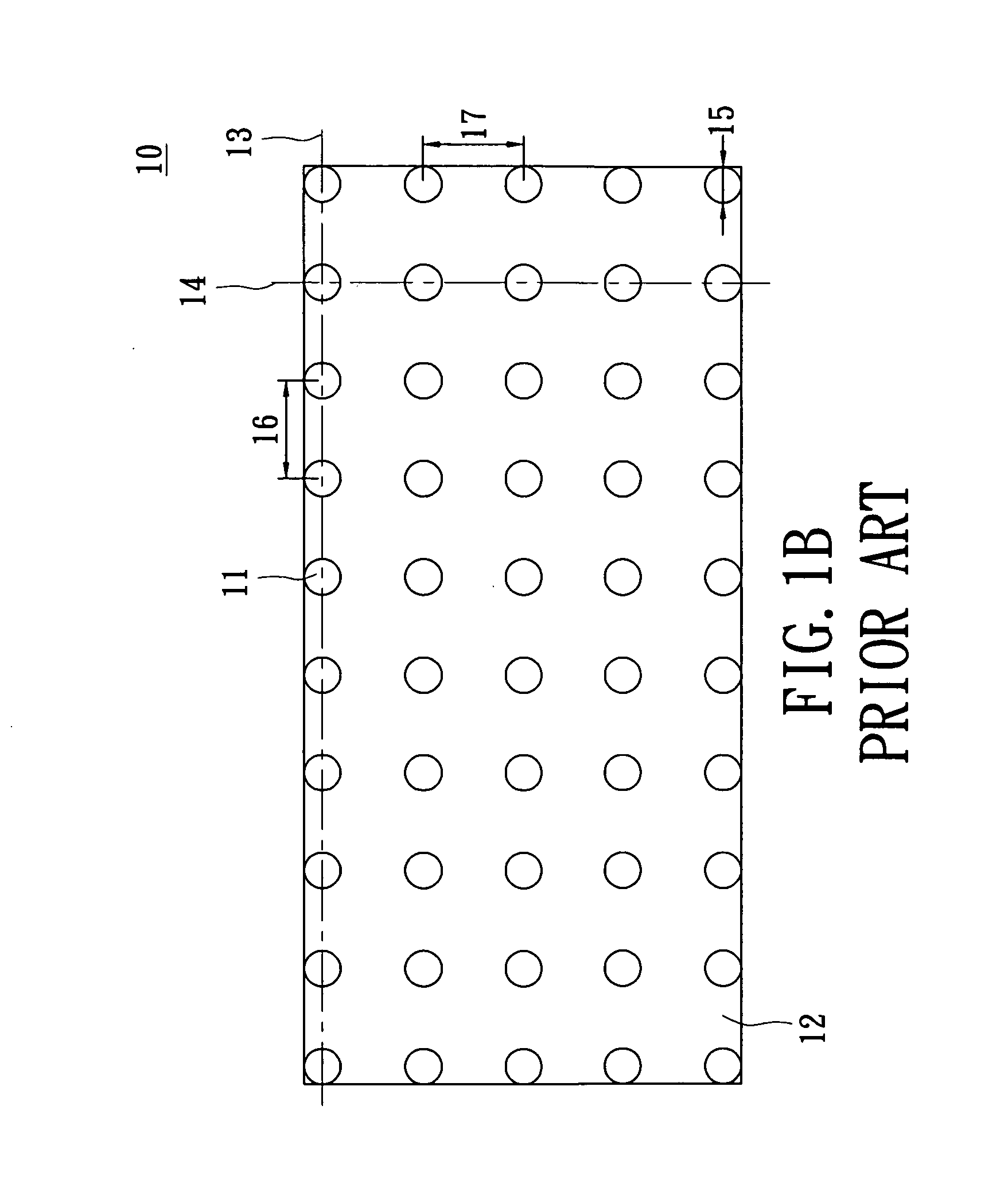

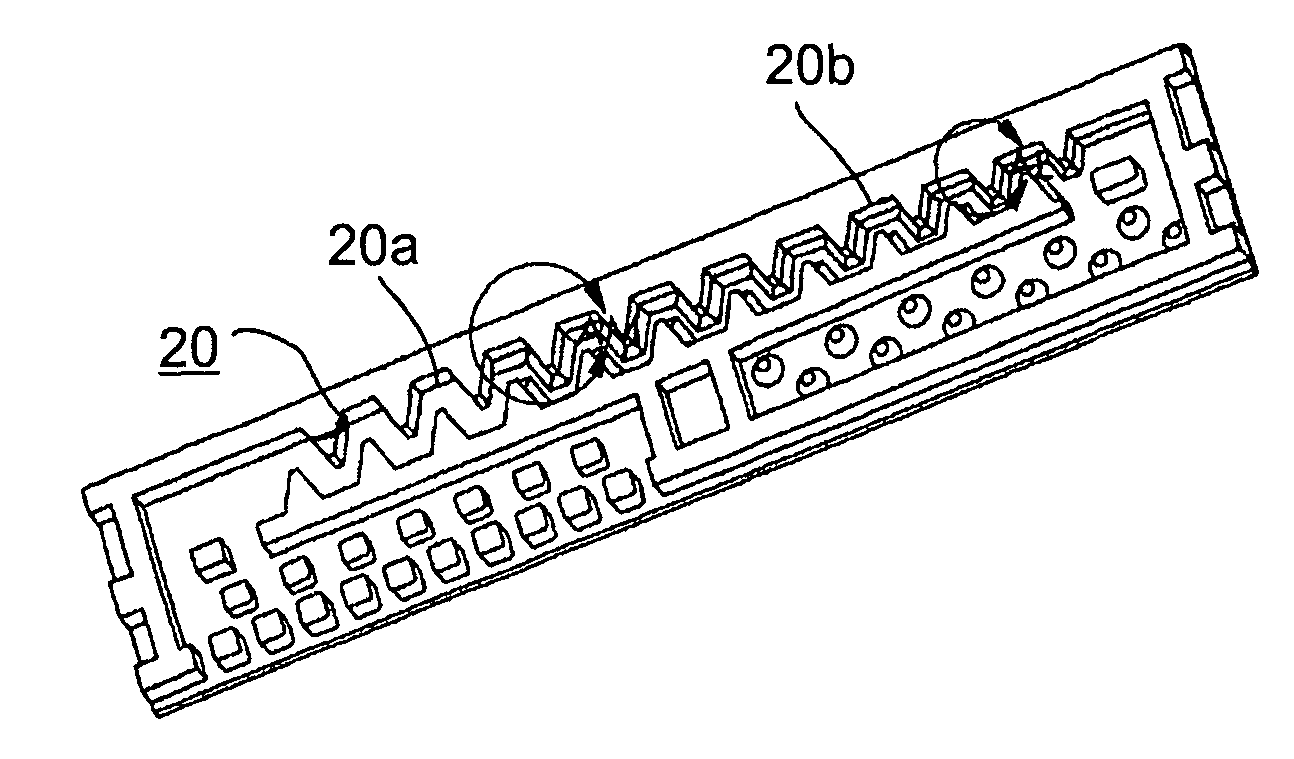

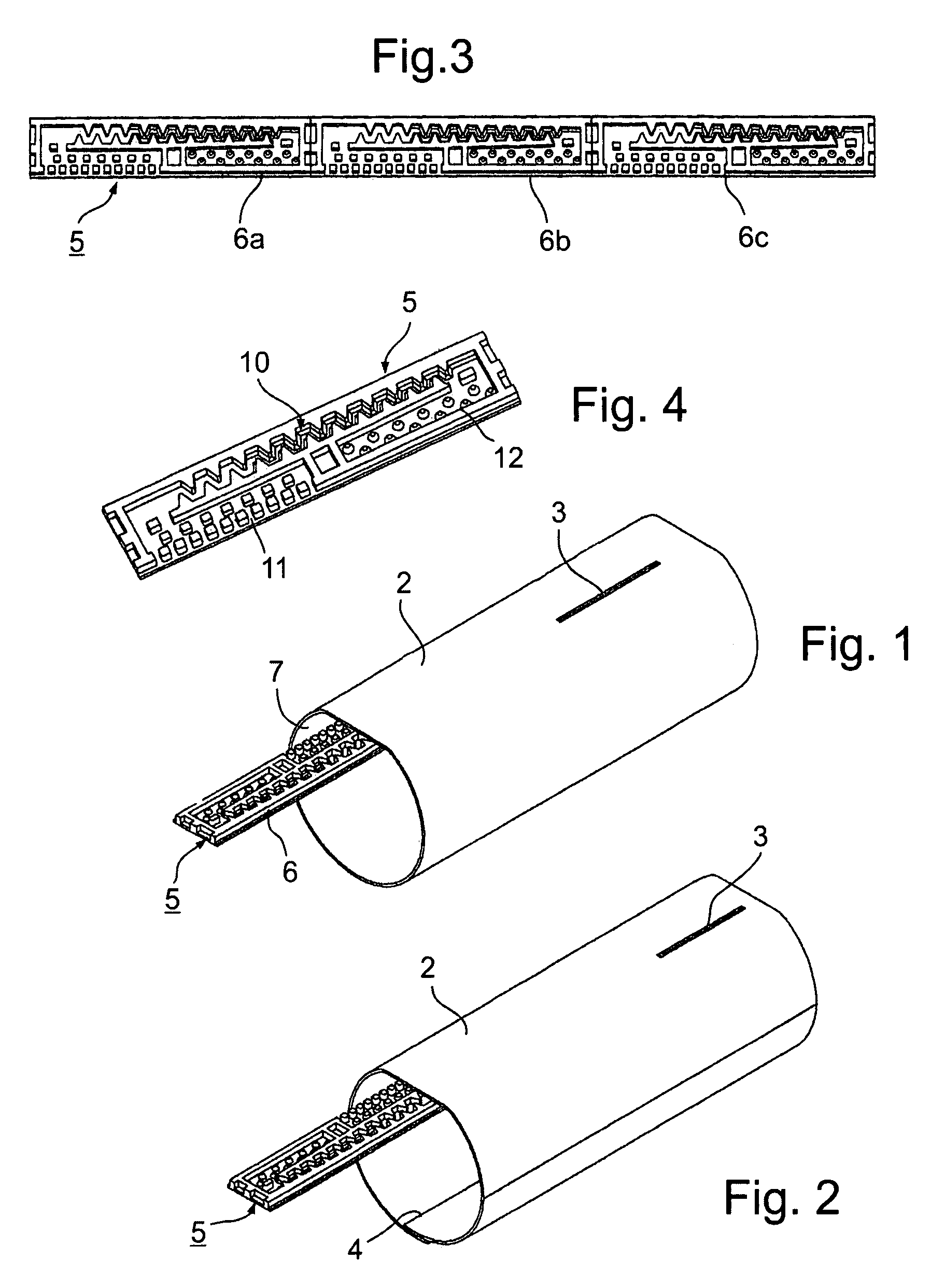

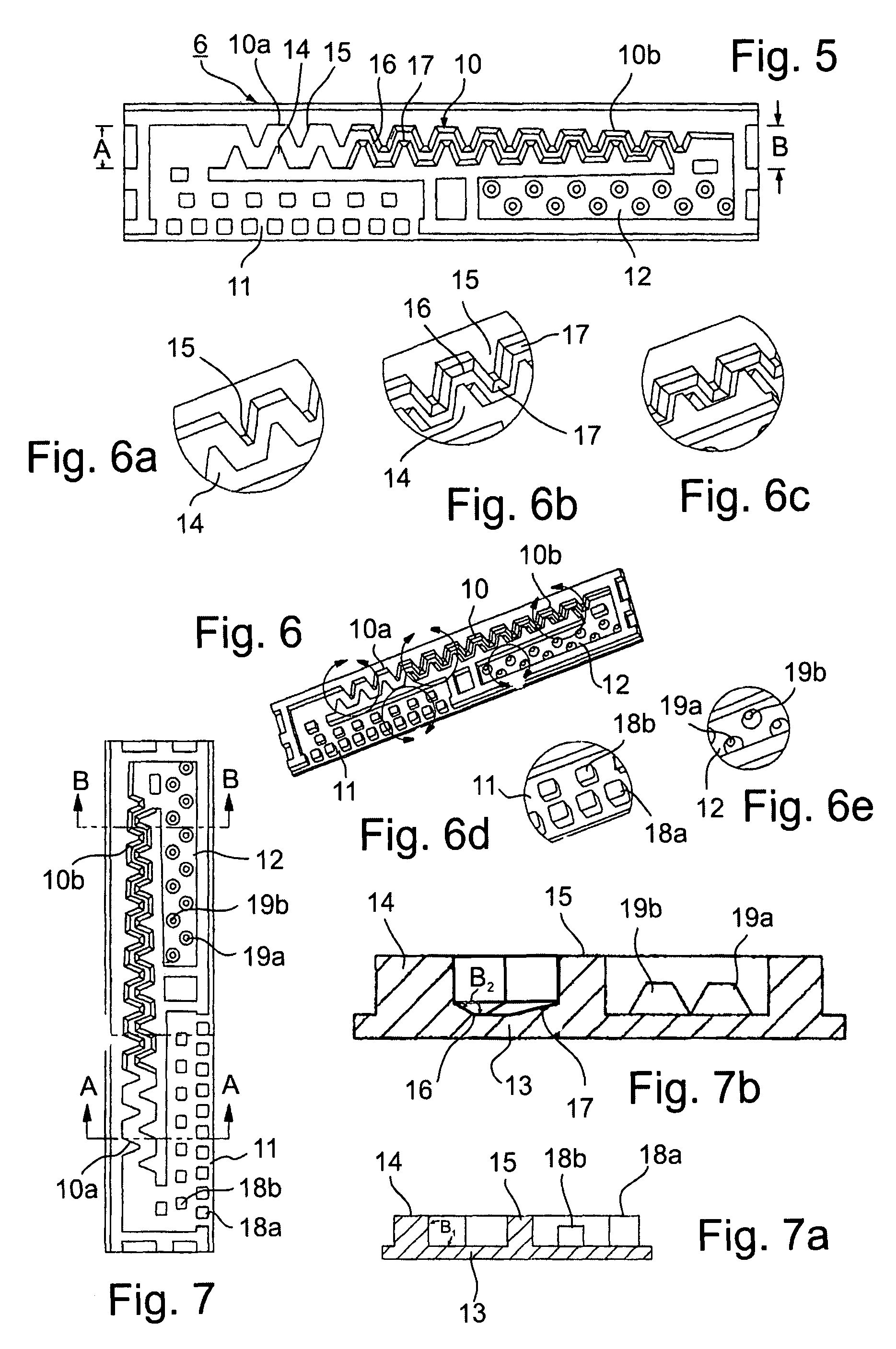

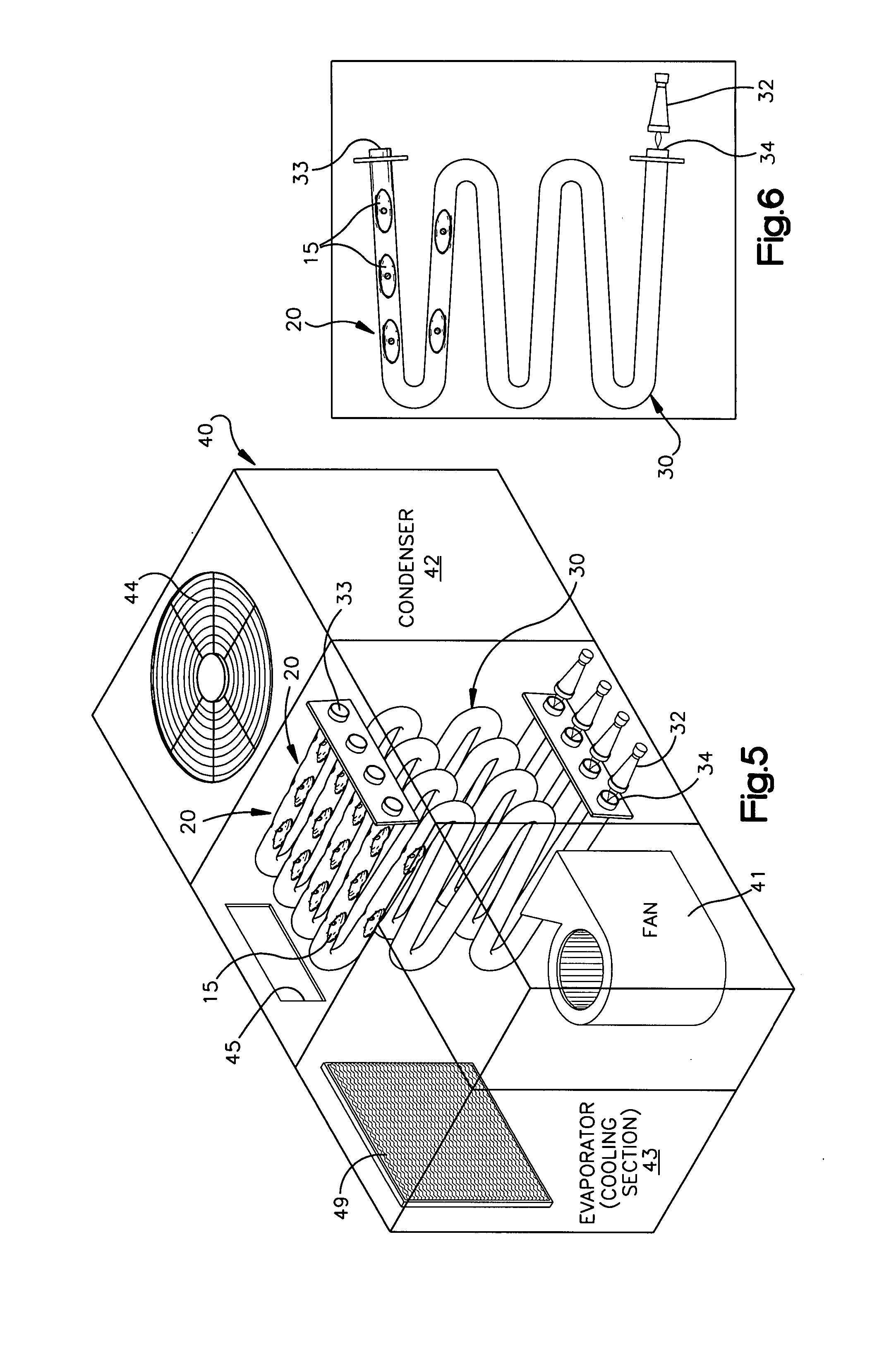

Non-linear fin heat sink

InactiveUS20090145581A1Improve power densityDissipating/removing heatSemiconductor/solid-state device detailsSolid-state devicesCoolant flowEngineering

A non-linear fin heat sink is provided for dissipating / removing heat uniformly from a device, where the heat generation is non-uniform over that device, while also providing a small and relatively lightweight heat sink. The heat sink has extended surface protrusions that are optimally shaped in recognition of convective heat transfer, conductive heat transfer, and flow resistance allowing the heat sink to offset the temperature rise of a coolant media and provide enhanced cooling for the coolant temperature, deliver optimized cooling efficiency per the local physical properties of the coolant media, be used with a fluid for effectuating heat transfer; either liquid coolant, gas coolant or a combination thereof. Furthermore the heat sink features turbulence enhancement of the coolant stream by a pin array through which coolant stream passes, such fin array featuring a non-linear shape, spacing, and height pattern to provide optimal cooling while simultaneously reducing volume and flow resistance.

Owner:THERMAL TECH

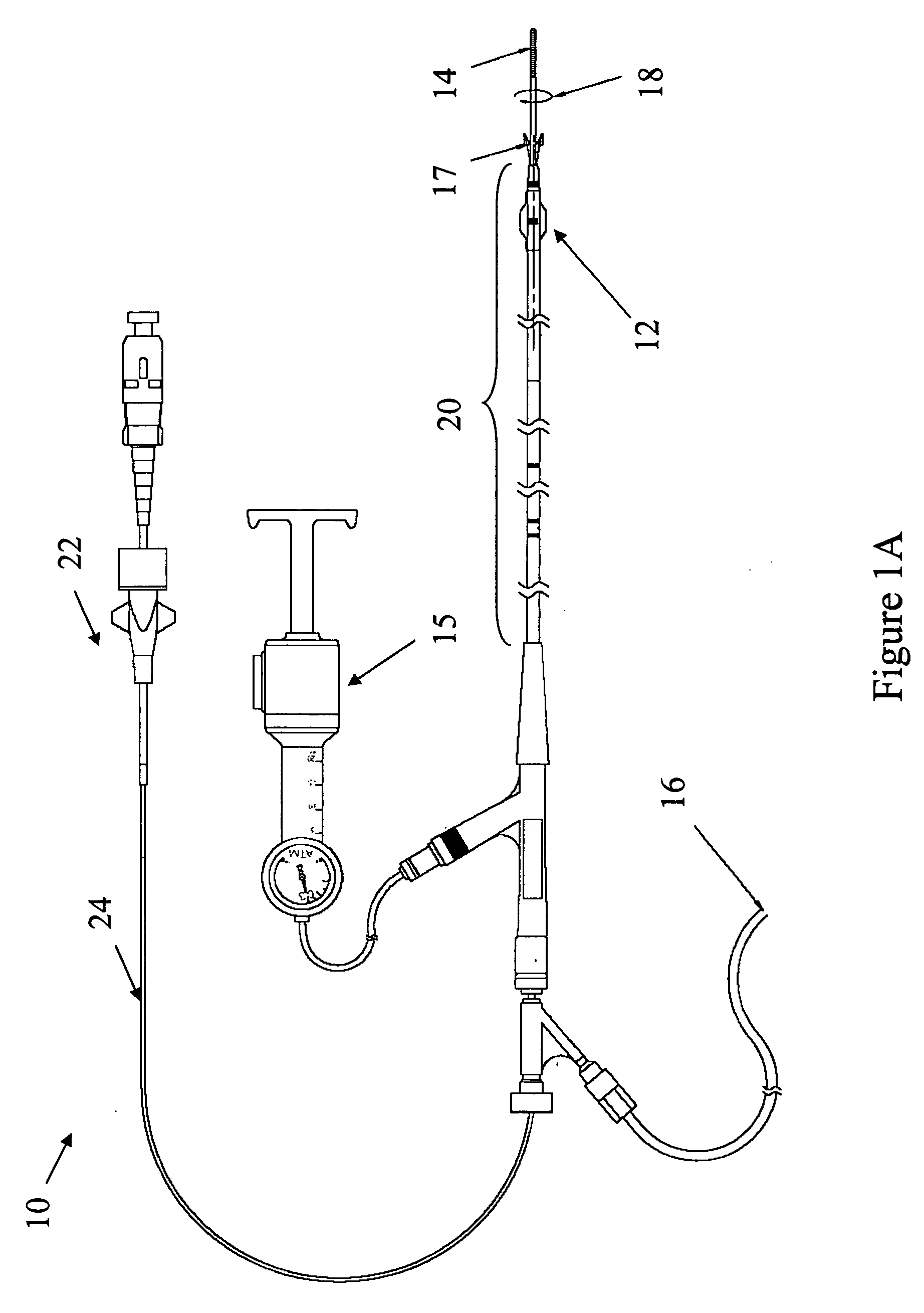

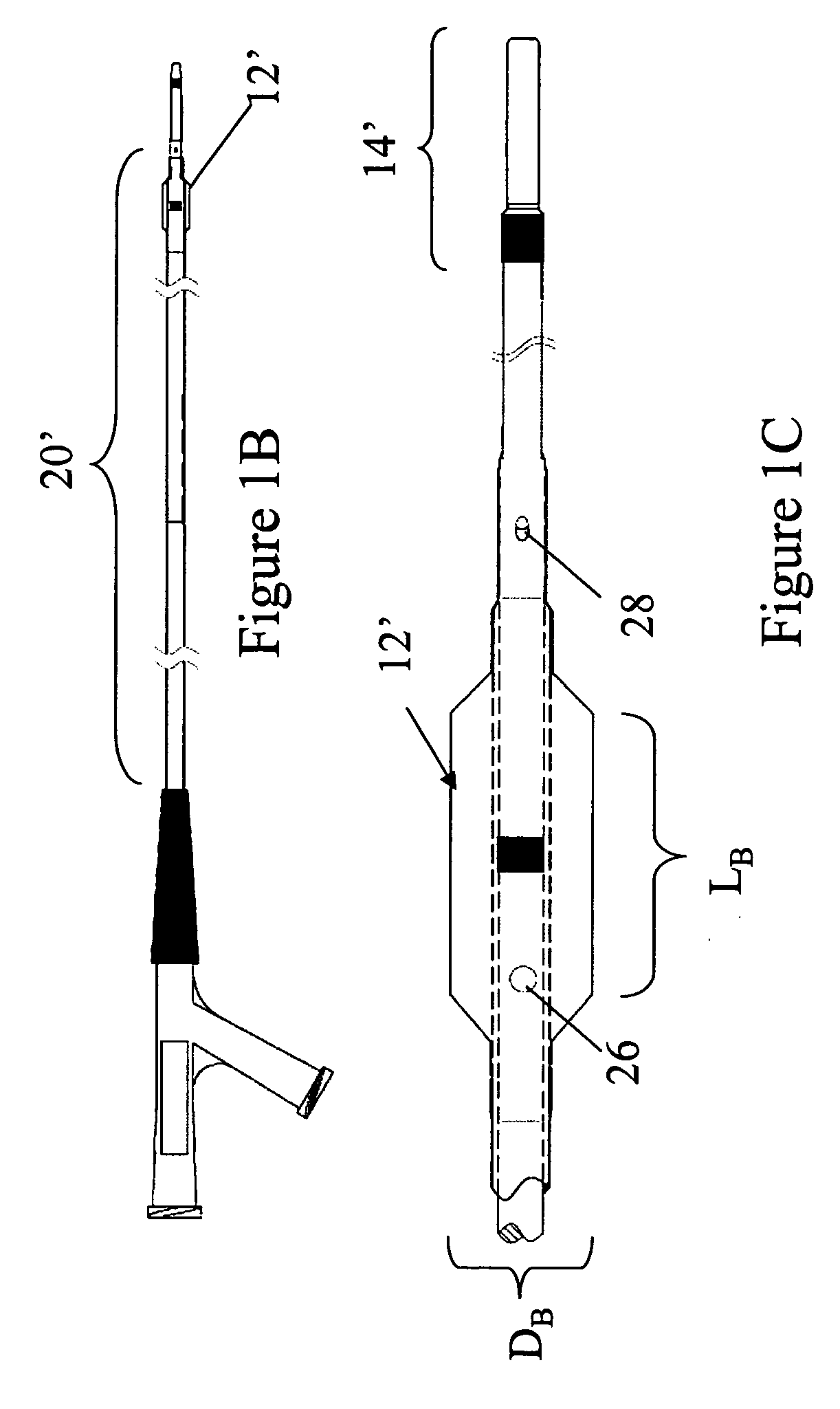

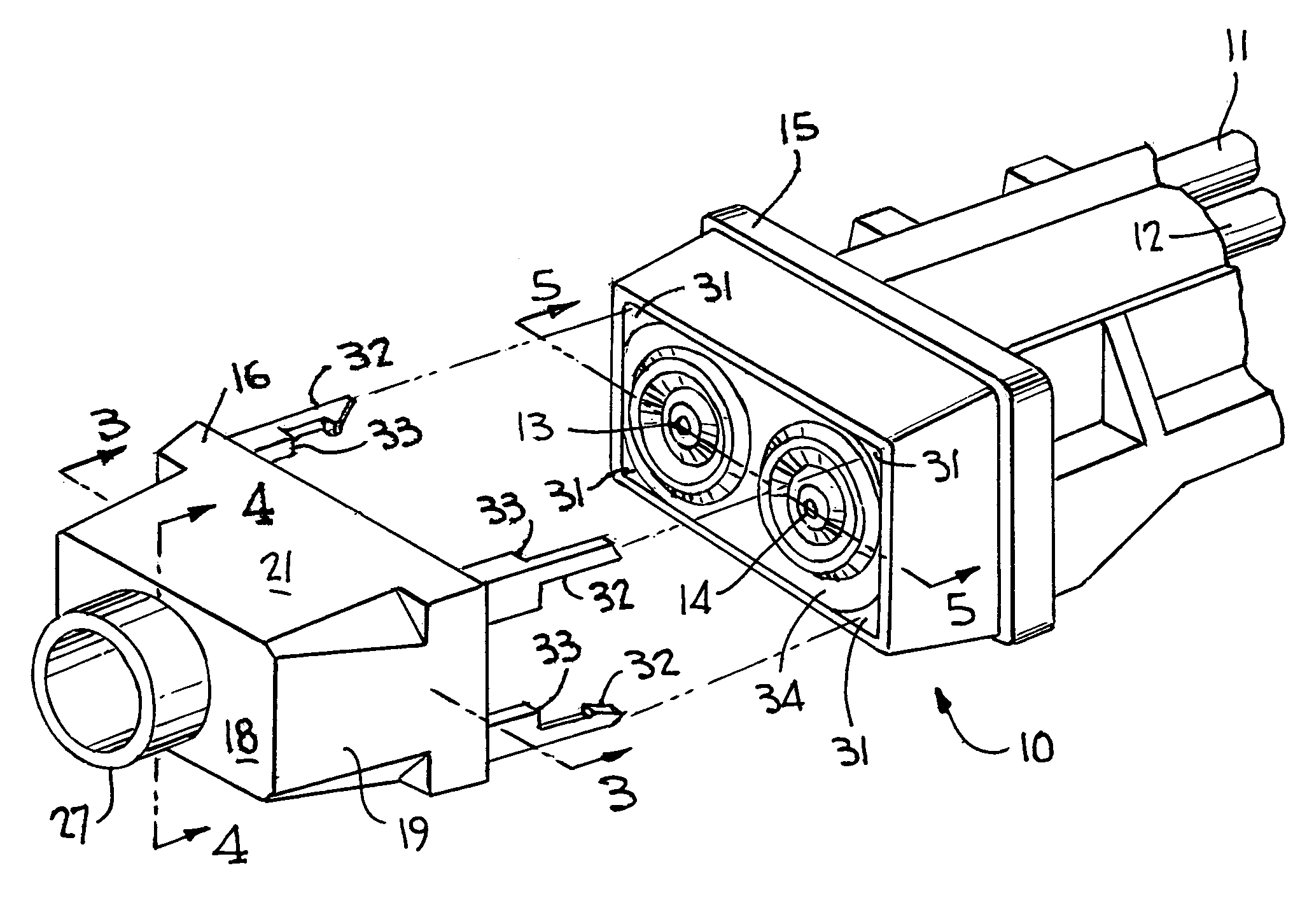

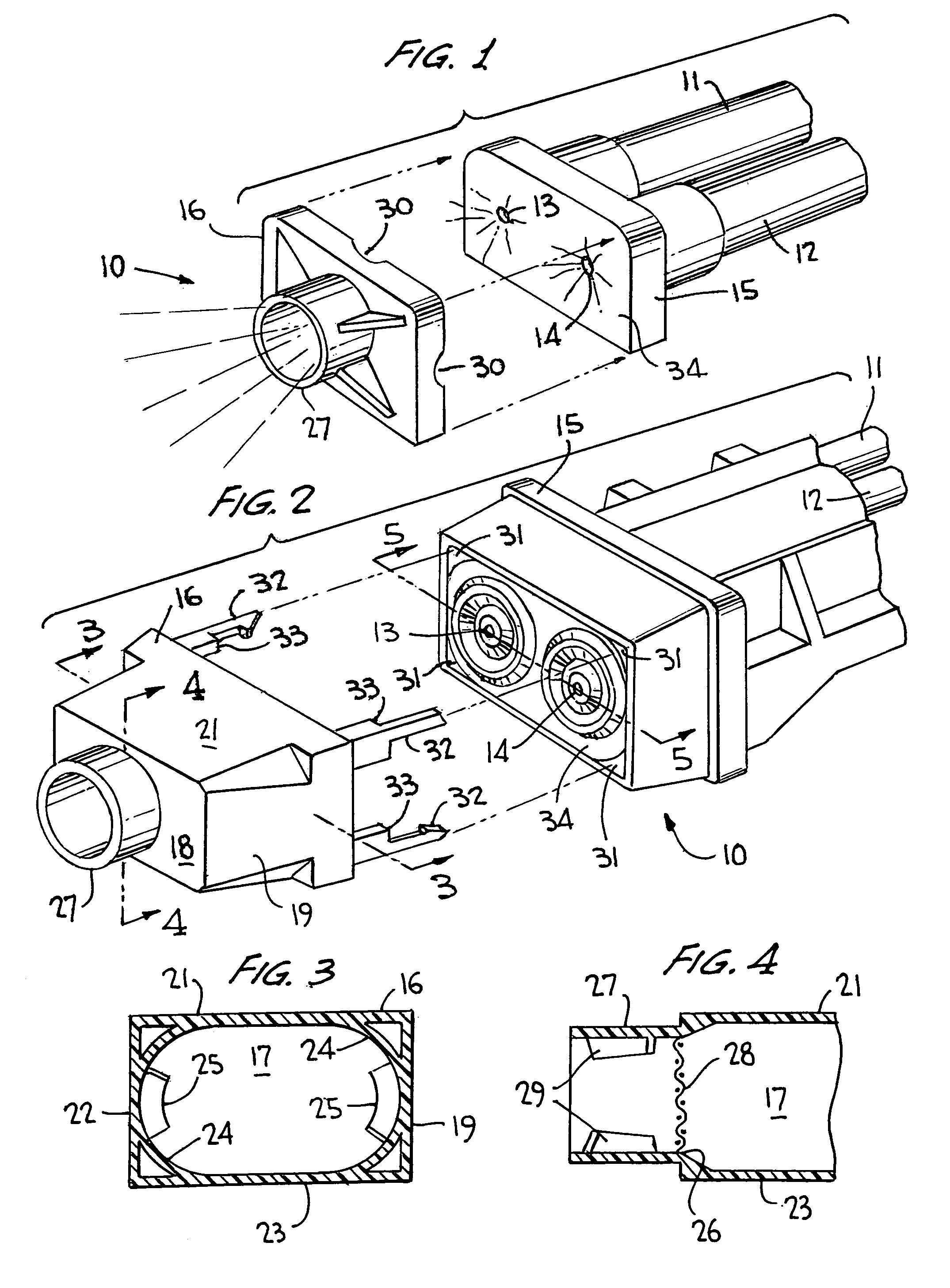

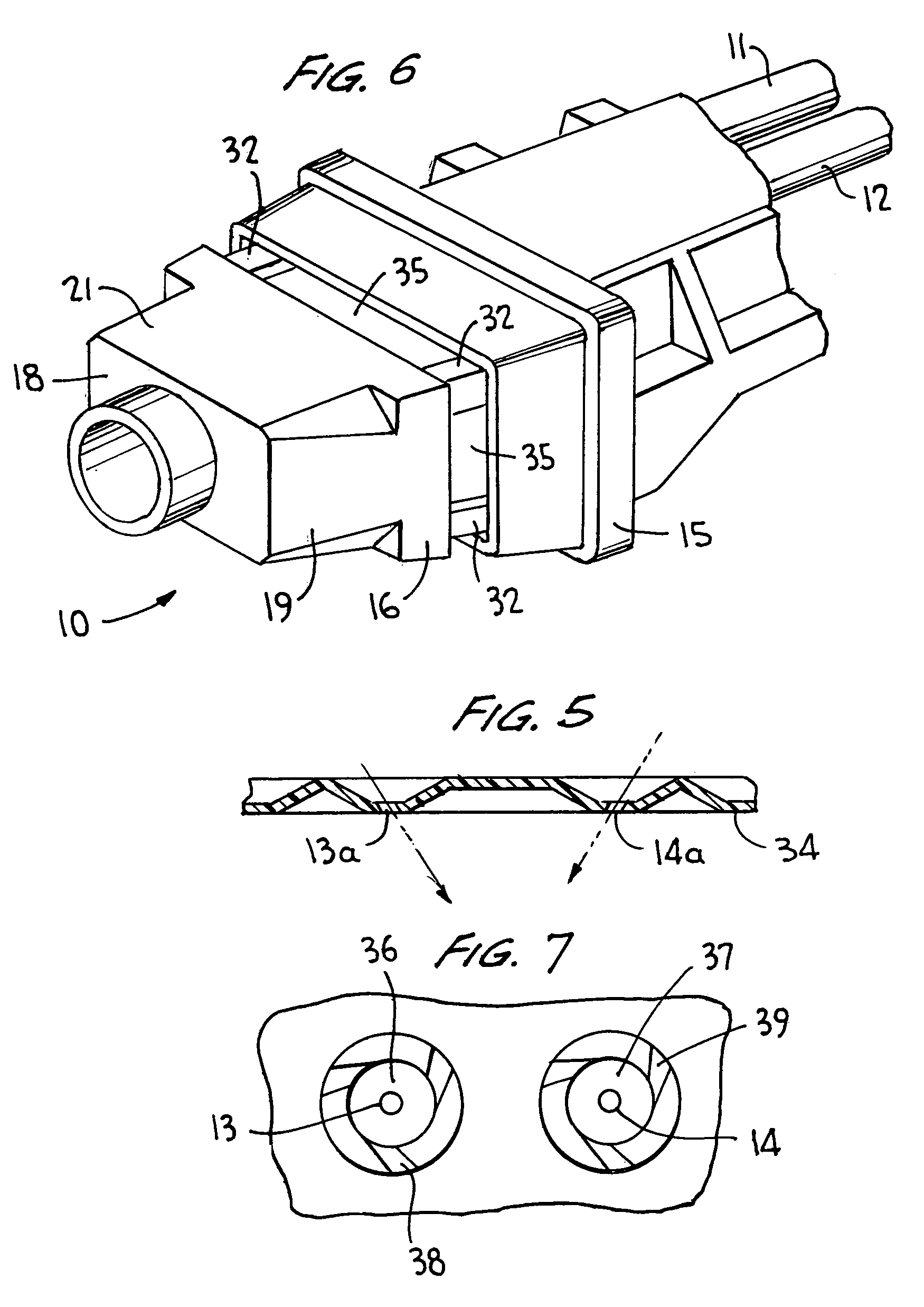

Fluid occluding devices and methods

InactiveUS20060095065A1Reduce risk of damageIncrease pressureStentsBalloon catheterRadiologyThree vessels

In one aspect, the invention relates to a method of occluding blood in a blood vessel during the imaging of a portion of the blood vessel. The method includes the steps of selecting an inflatable element such that diameter of the inflated inflatable element is greater than the diameter of the blood vessel being imaged, introducing the inflatable element into the blood vessel and underinflating the inflatable element such that the vessel wall is not substantially deformed by the inflatable element, the inflatable element substantially occluding the blood vessel to reduce imaging distortion resulting from vessel fluids.

Owner:LIGHTLAB IMAGING

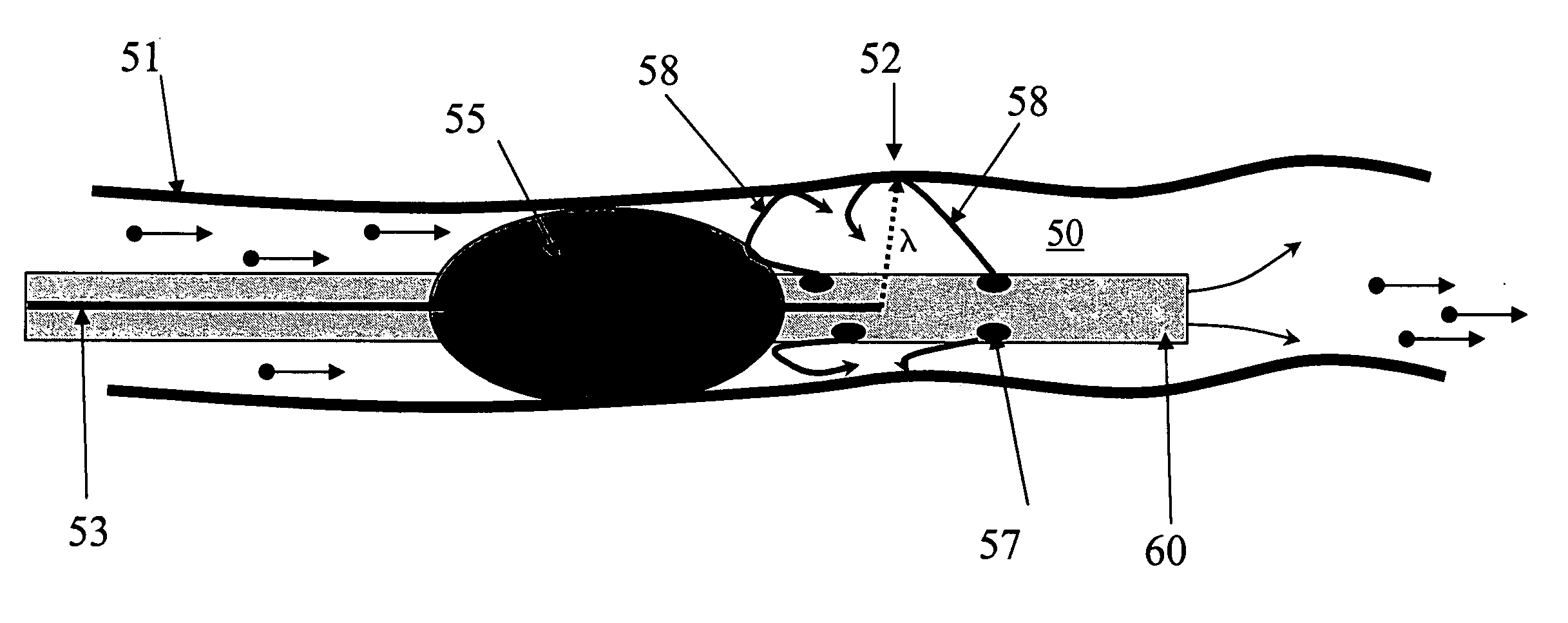

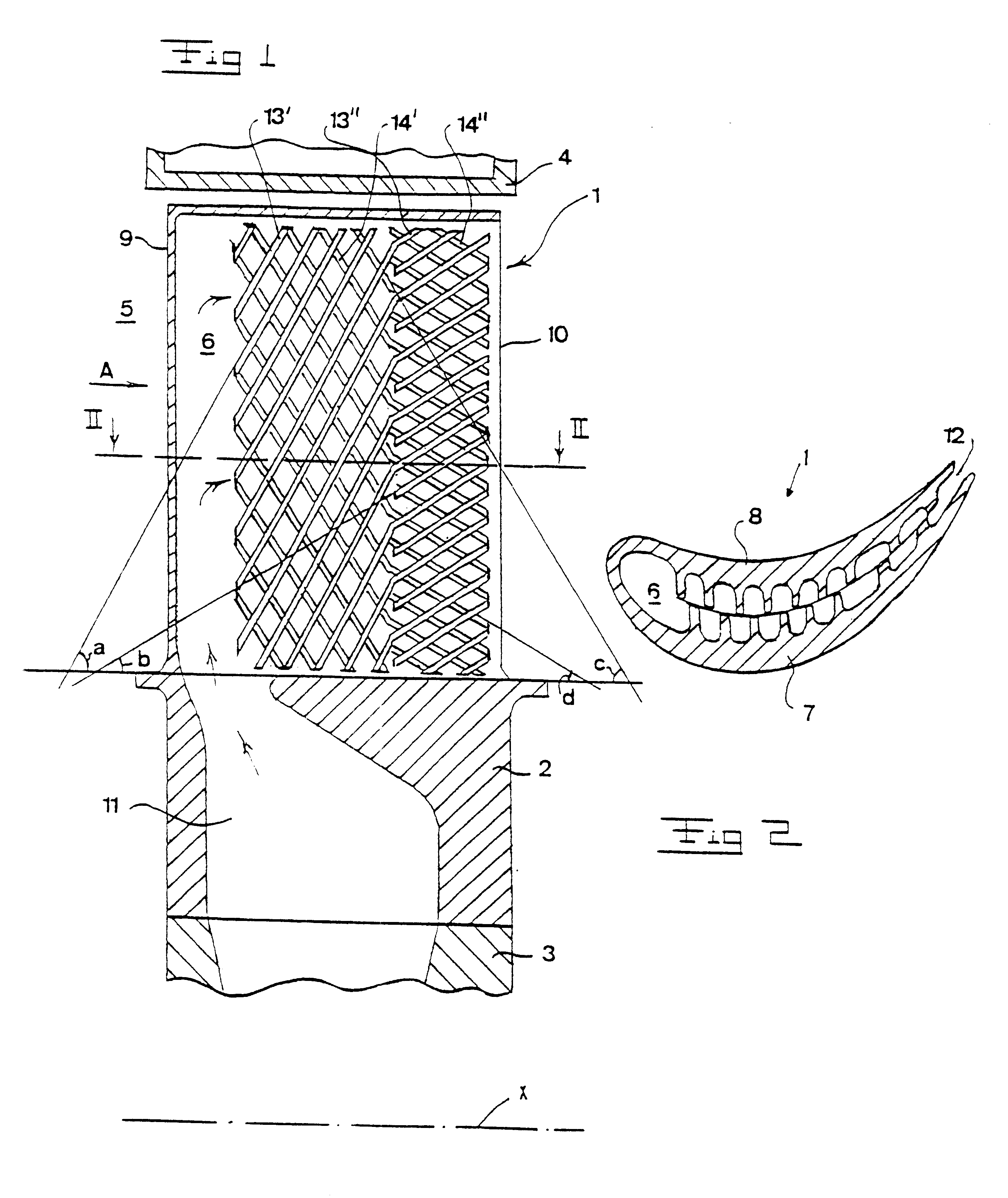

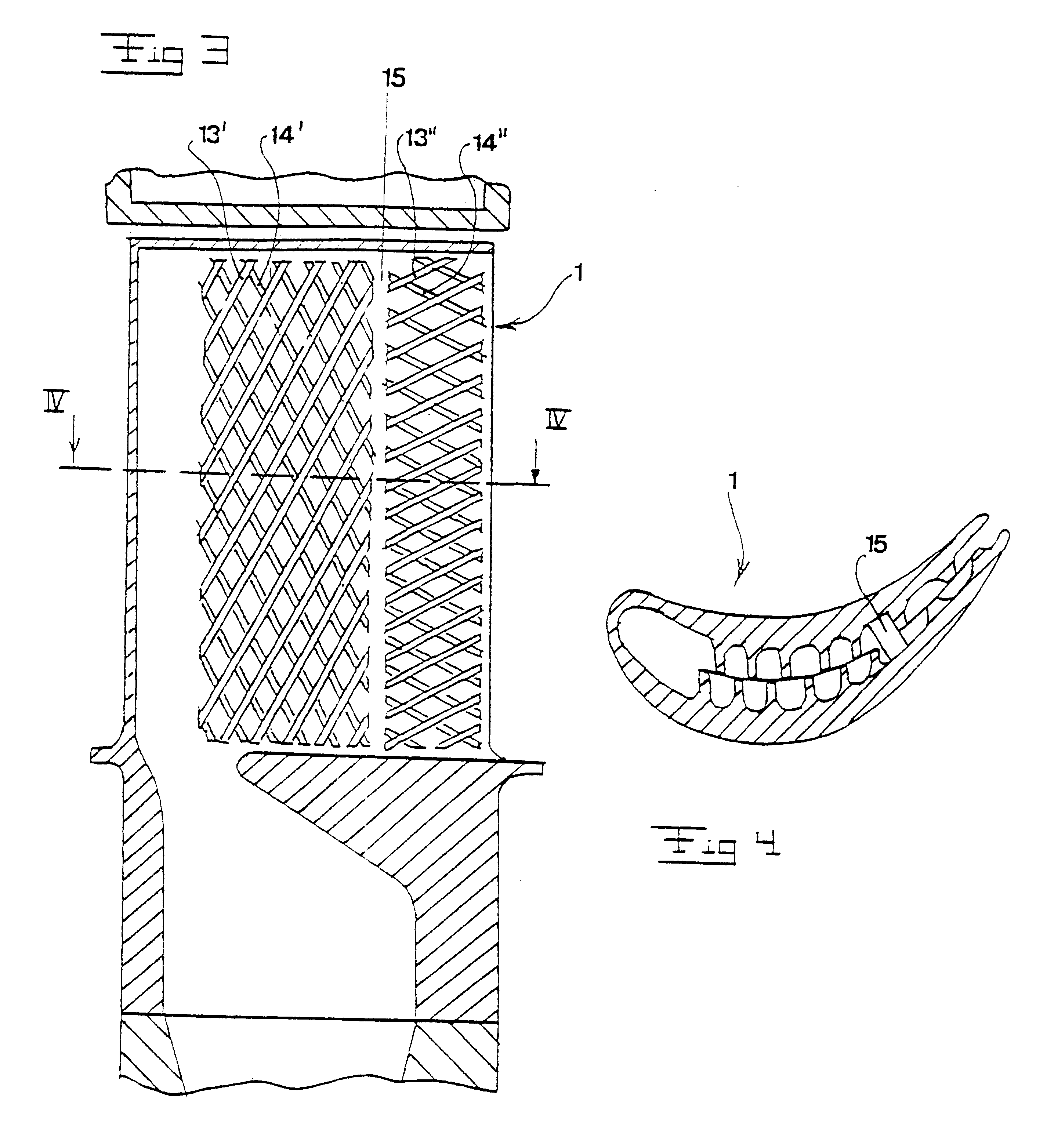

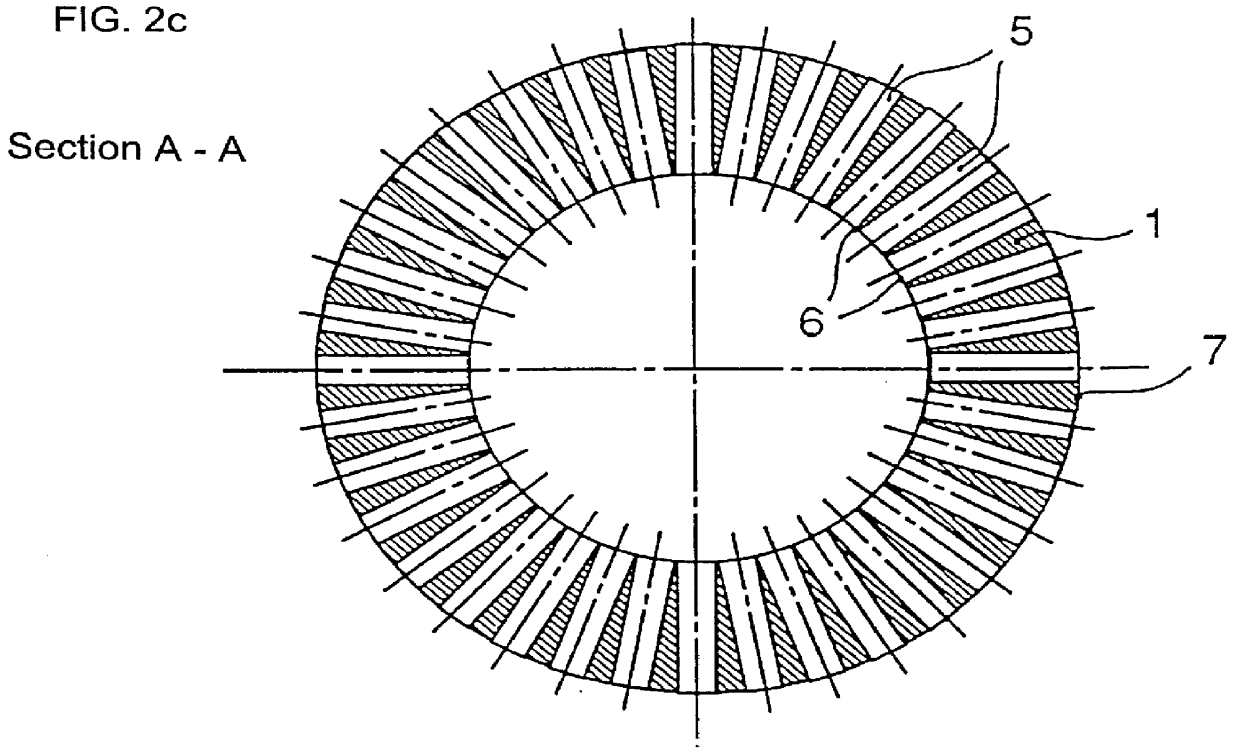

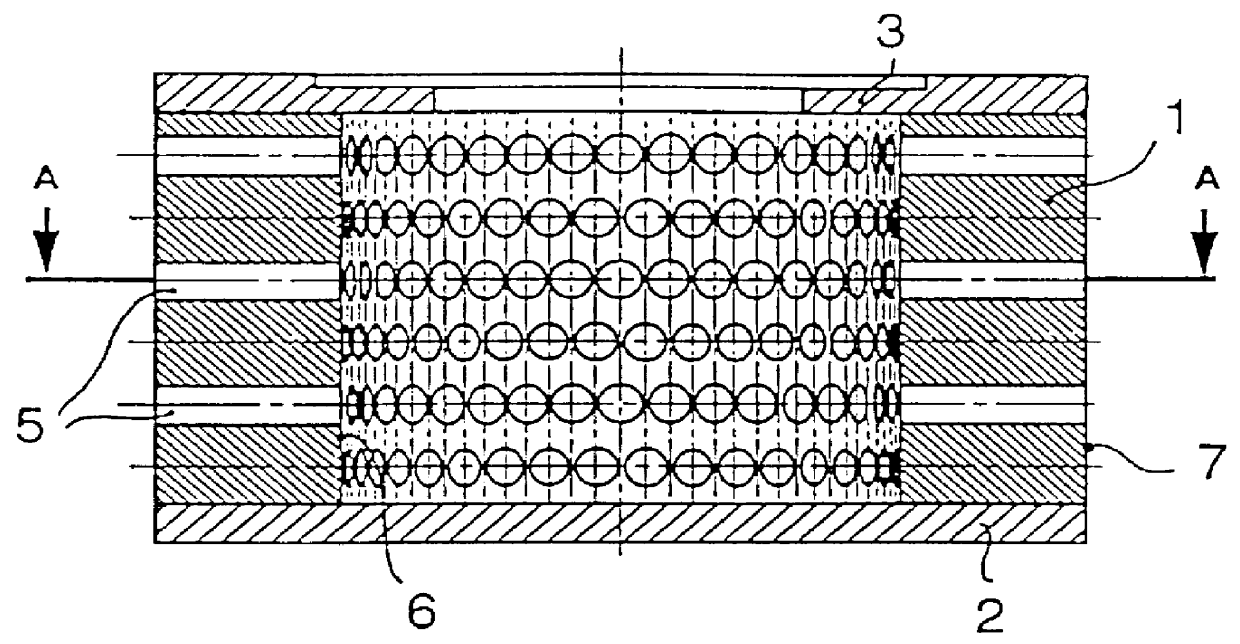

Implantable device for promoting repair of a body lumen

InactiveUS20050149170A1Promote growthPromoting angiogenesisStentsSurgeryActive agentImplanted device

An implantable stent having surface features adapted to promote an organized growth pattern of infiltrating cells when implanted in a tubular organ is provided. The surface features comprise depressions, pores, projections, pleats, channels or grooves in the stent body and are designed to increase turbulence or stagnation in the flow of a liquid, such as blood through the stent, and / or to promote the growth of infiltrating cells in an organized pattern. Alternatively, the invention stent can be populated with living cells prior to implant and can be heatable from an external source of energy, thereby inducing production of therapeutic bioactive agents from ingrowing cells. The invention also provides an implantable heatable stent for transcutaneously monitoring the flow of fluid through a lumen into which the stent is implanted by measuring the rate at which the heated stent cools in response to blood flow when the source of heat is removed.

Owner:TASSEL ROBERT A VAN +2

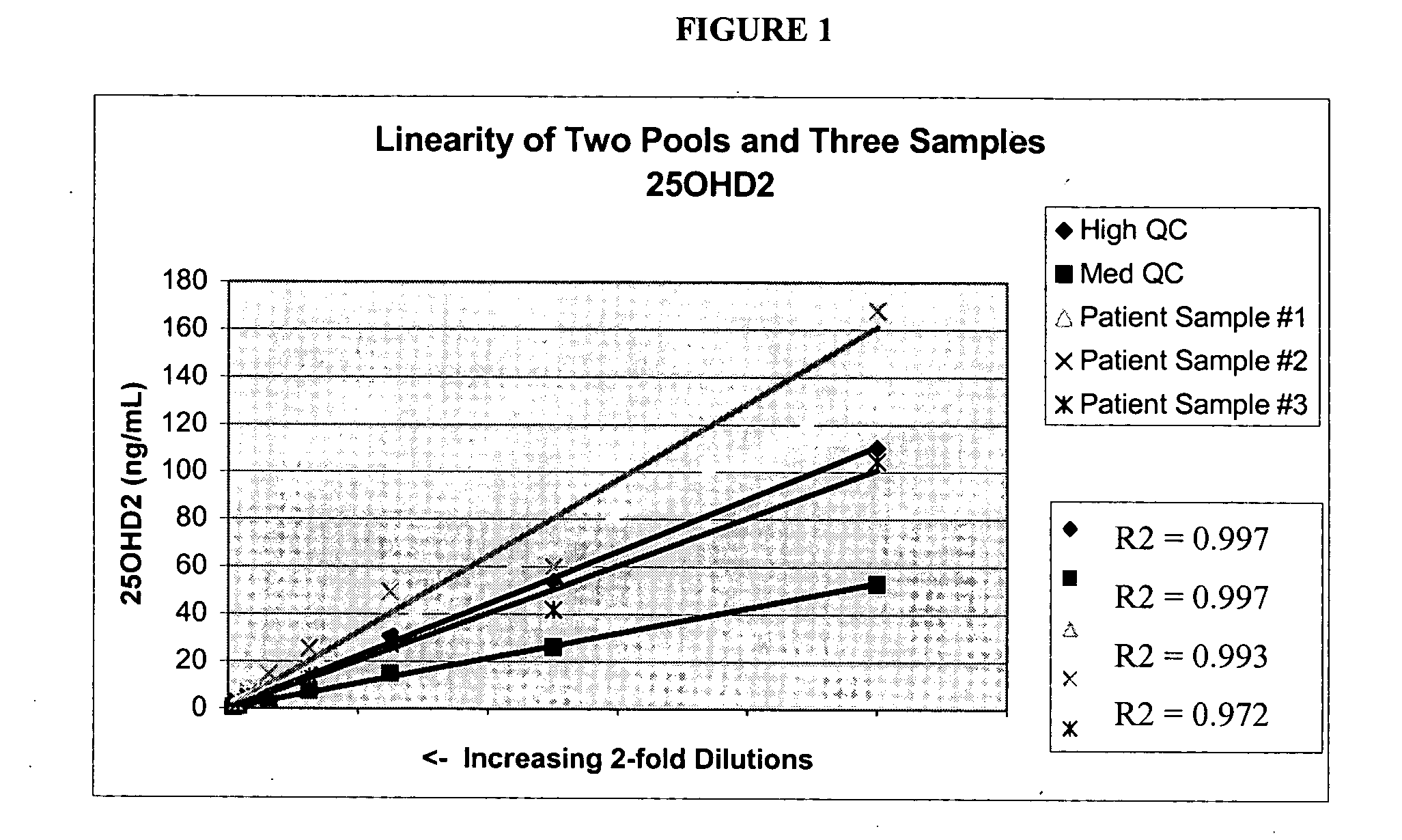

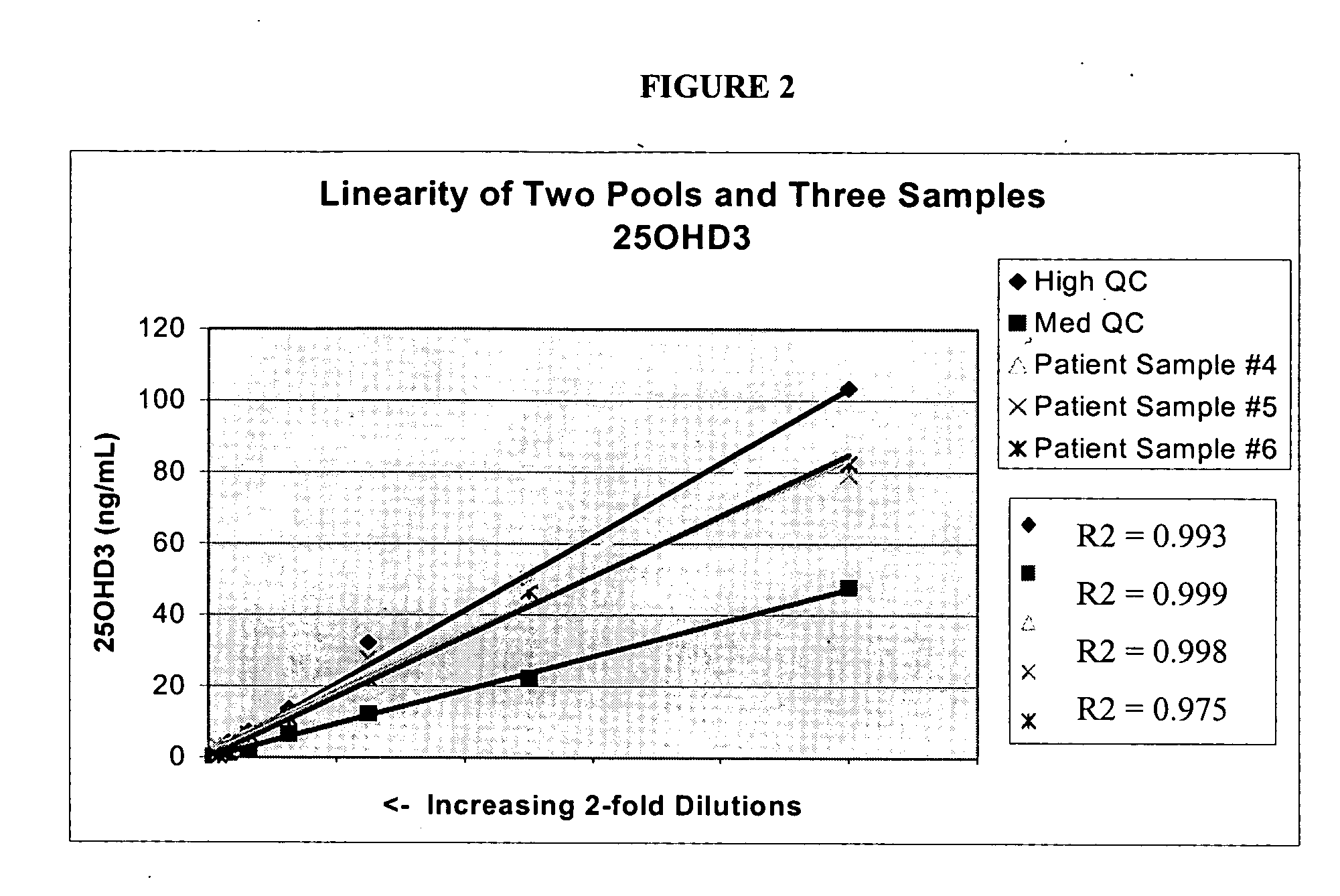

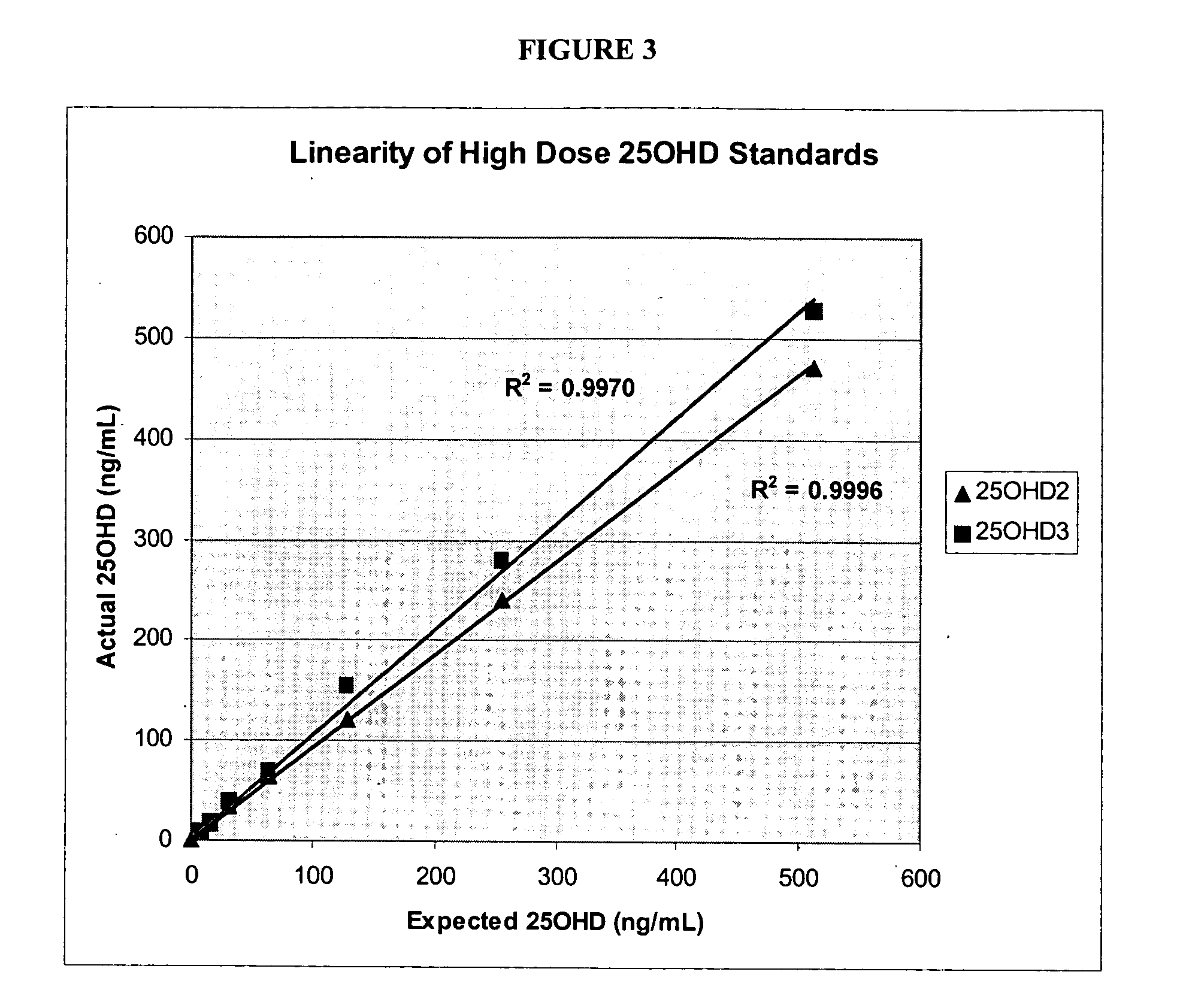

Methods for detecting vitamin D metabolites

ActiveUS20060228808A1Increased turbulenceEasy to separateComponent separationMass spectrometric analysisMetaboliteMass Spectrometry-Mass Spectrometry

Provided are methods of detecting the presence or amount of a vitamin D metabolite in a sample using mass spectrometry. The methods generally comprise ionizing a vitamin D metabolite in a sample and detecting the amount of the ion to determine the presence or amount of the vitamin D metabolite in the sample. Also provided are methods to detect the presence or amount of two or more vitamin D metabolites in a single assay.

Owner:QUEST DIAGNOSTICS INVESTMENTS INC

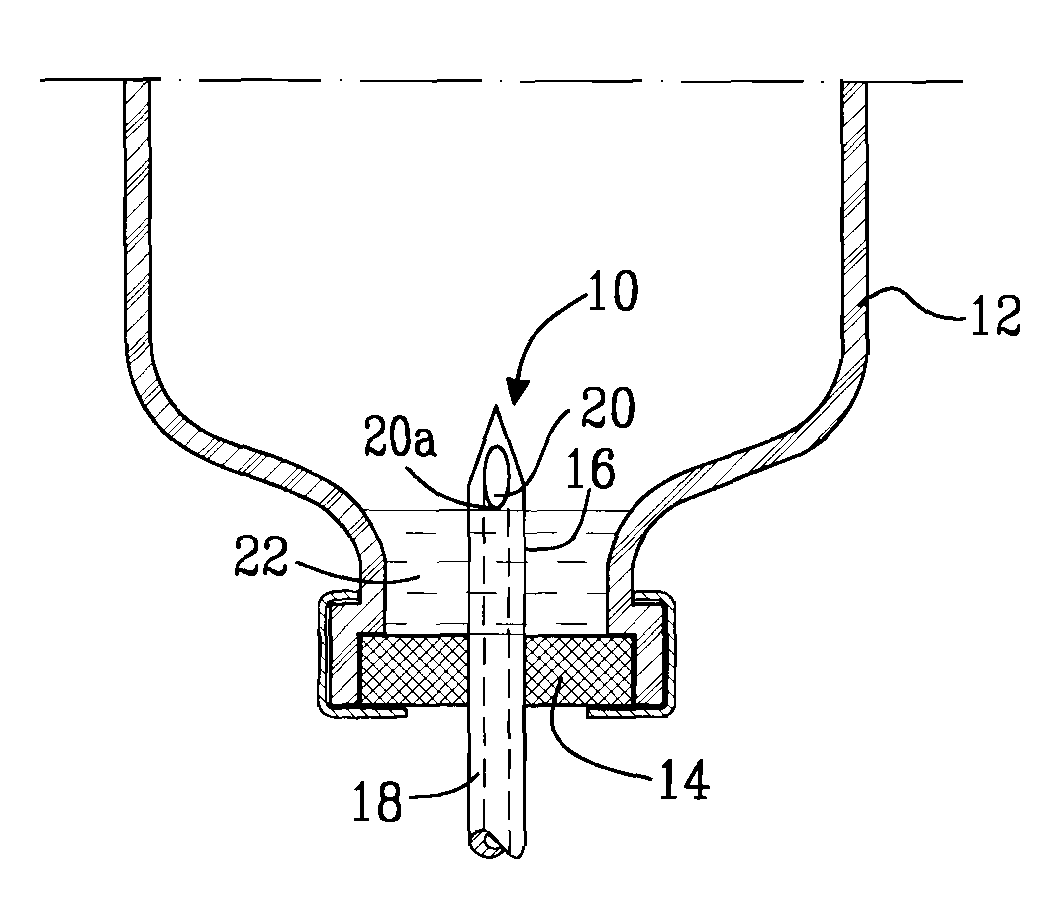

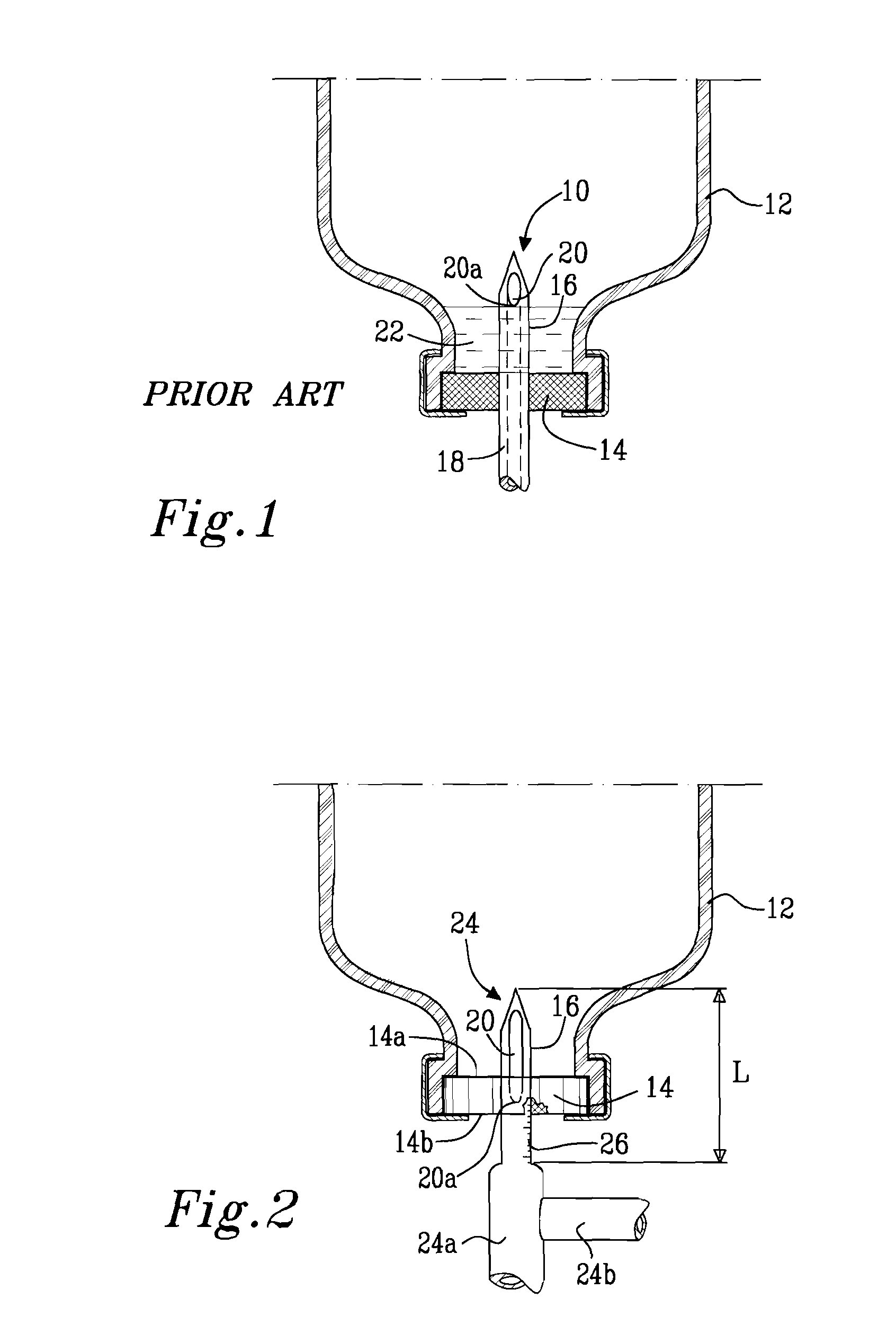

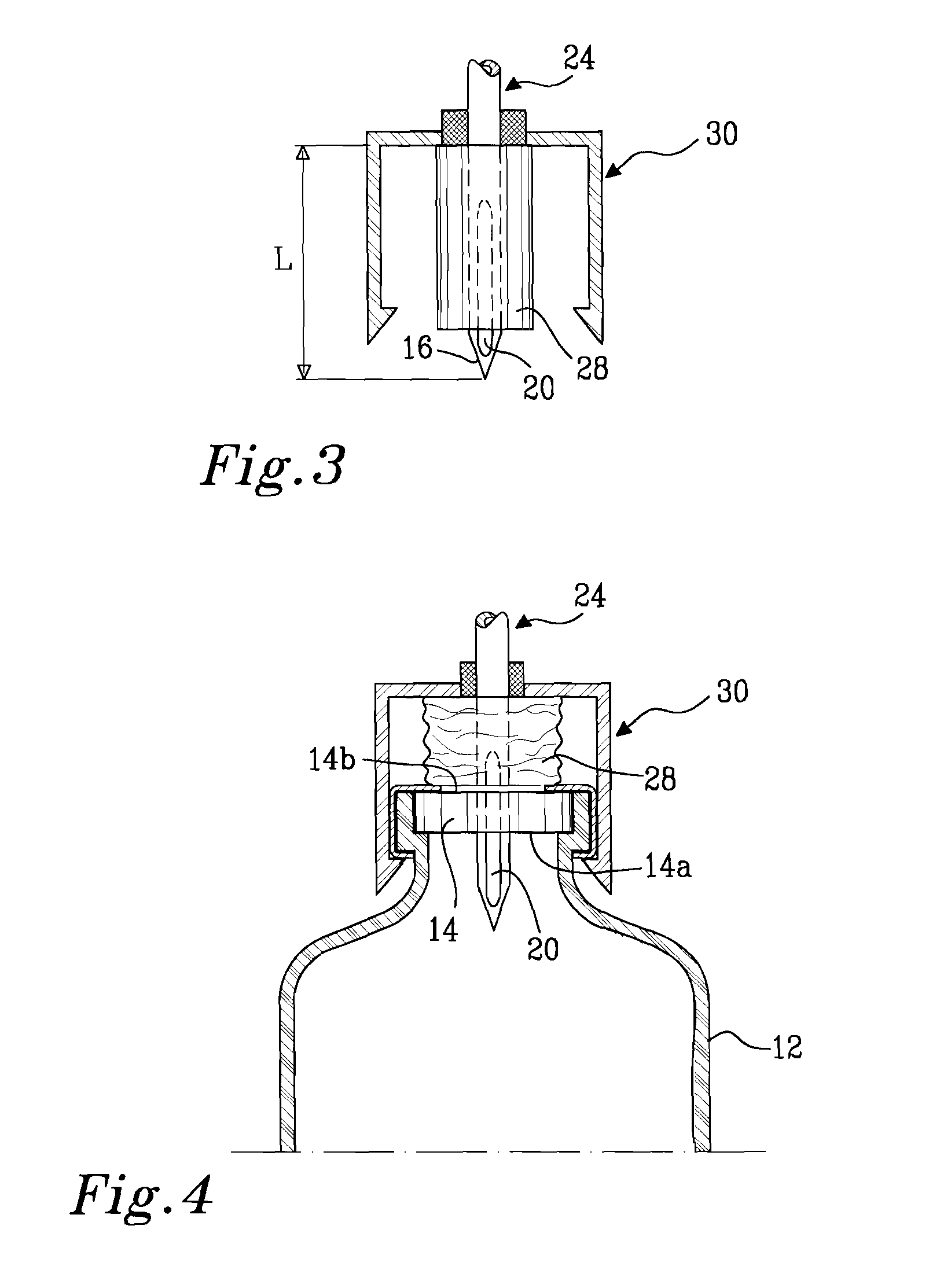

Device, Sealing Member and Fluid Container

ActiveUS20090057258A1Efficient transferWell mixedCapsClosure using stoppersEngineeringMechanical engineering

Owner:CARMEL PHARMA

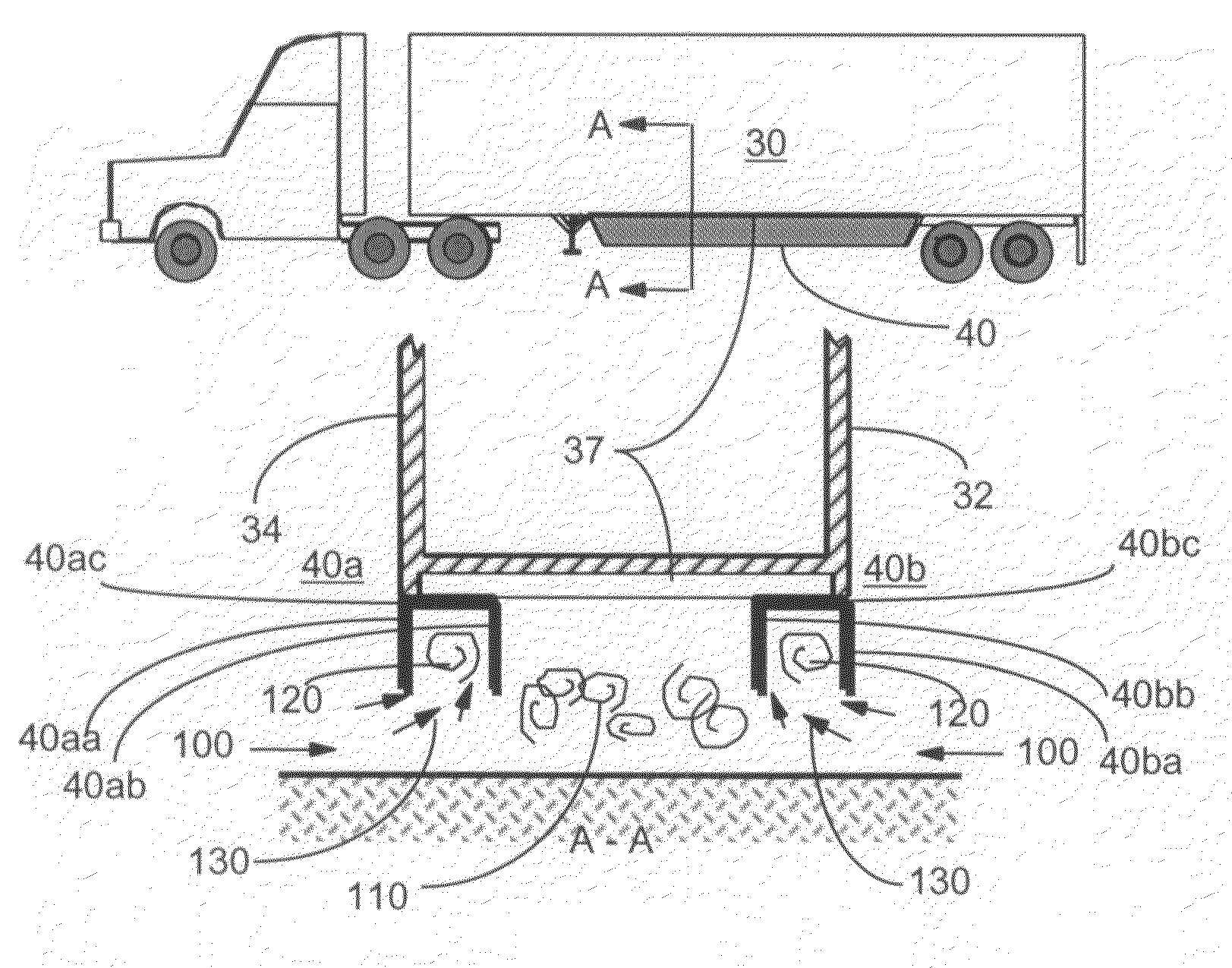

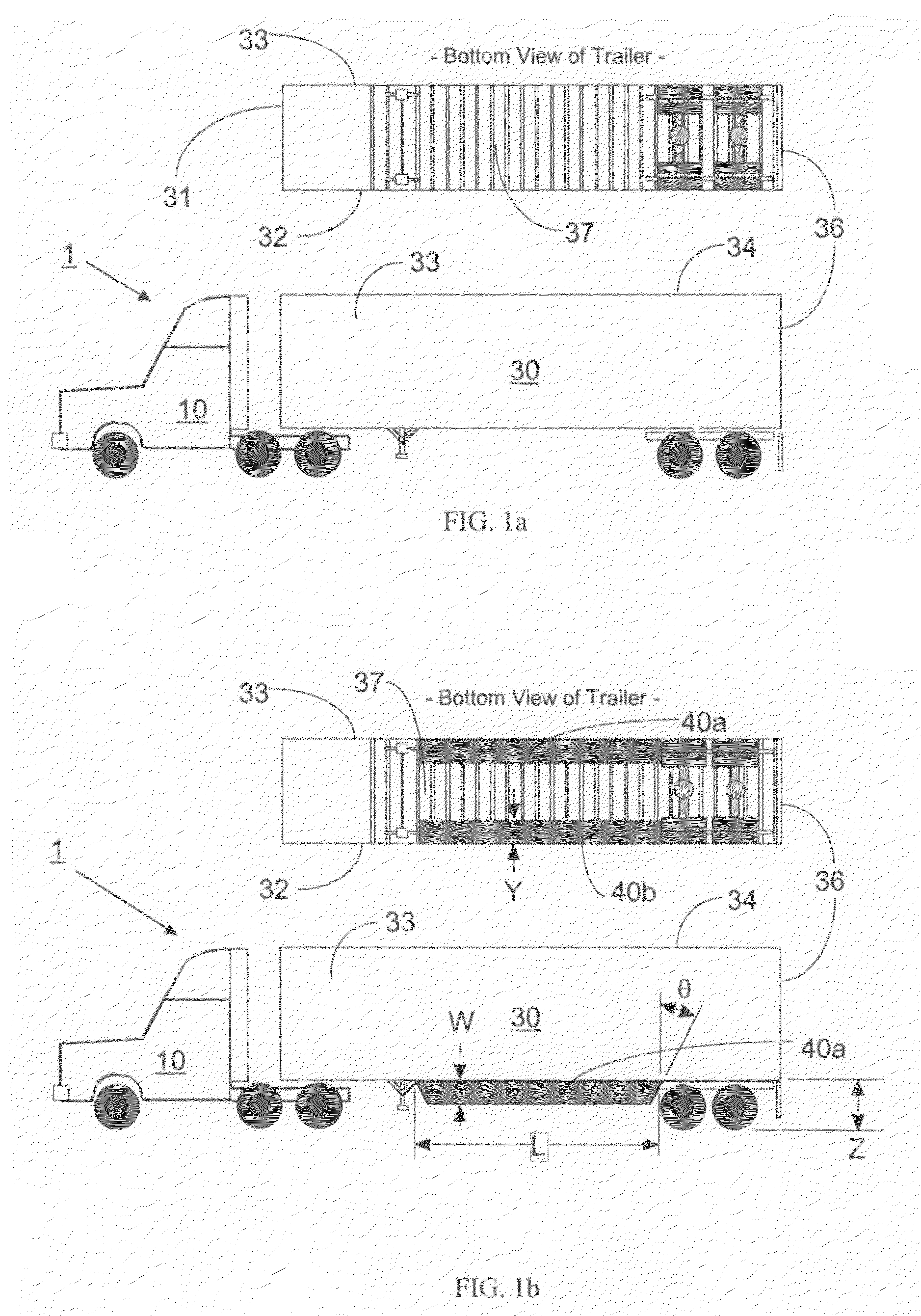

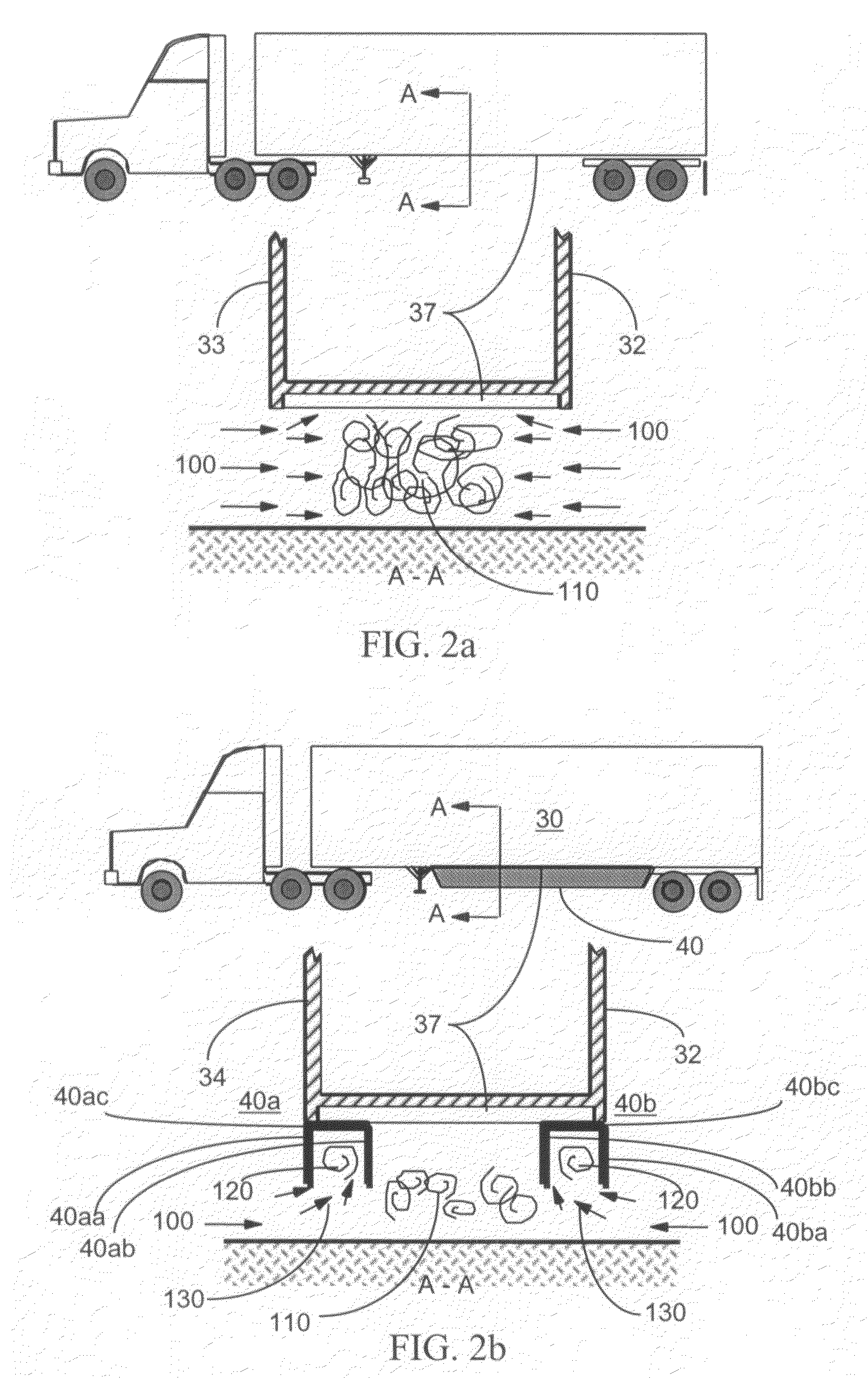

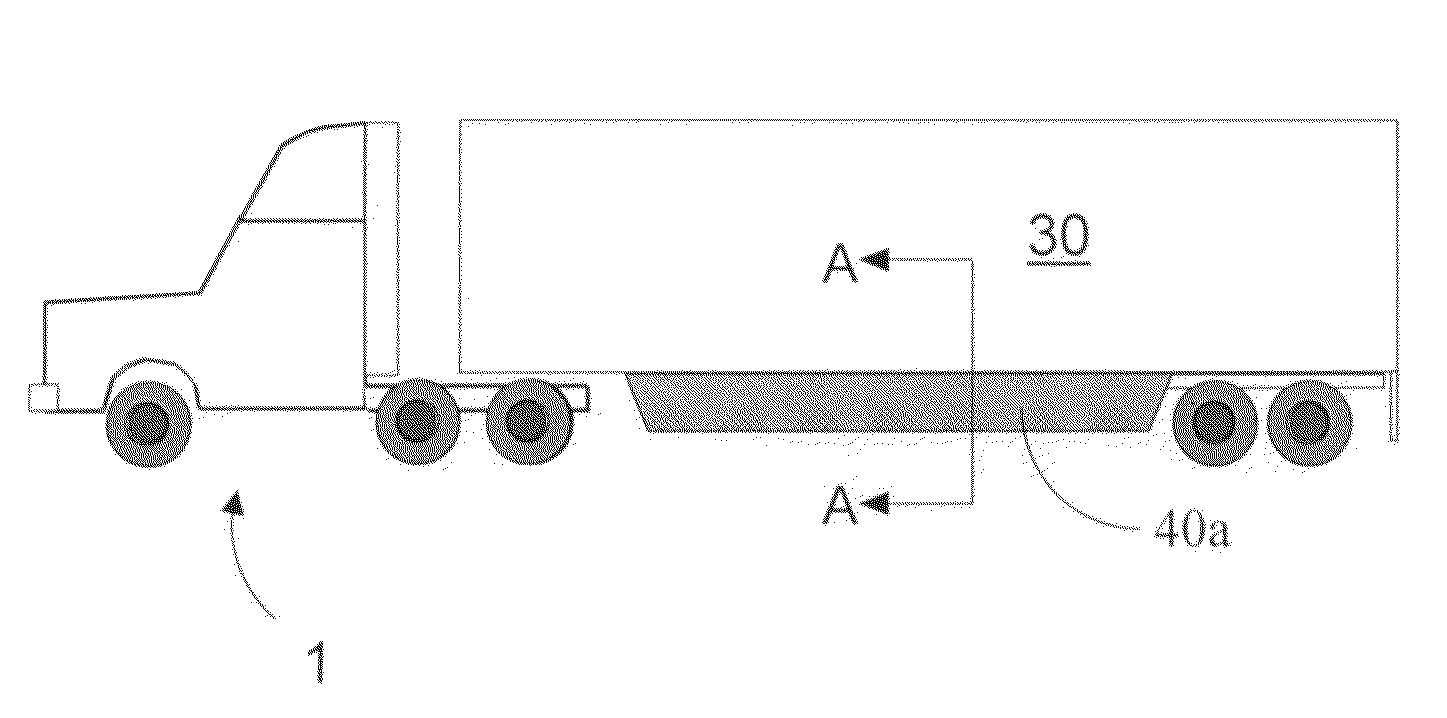

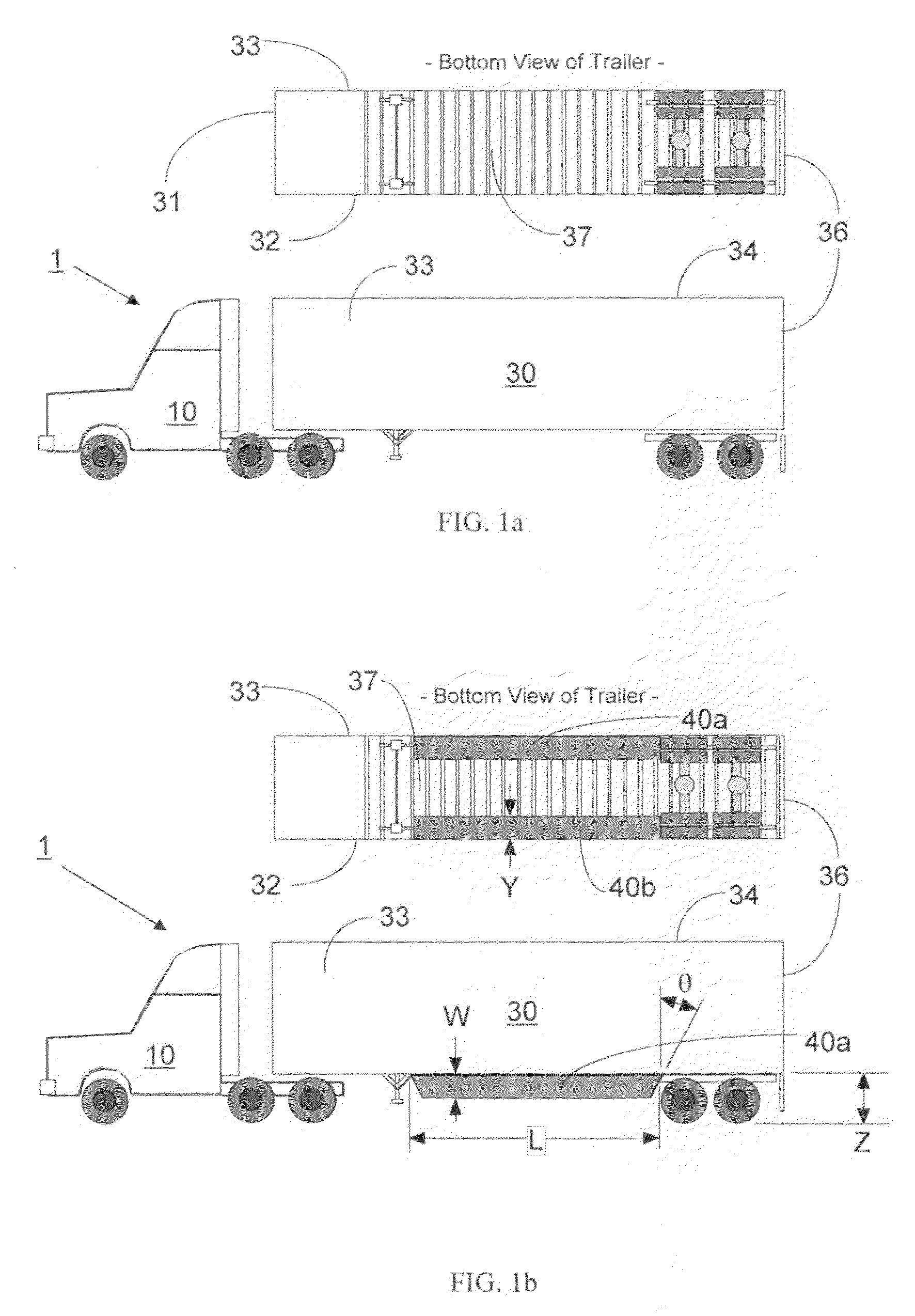

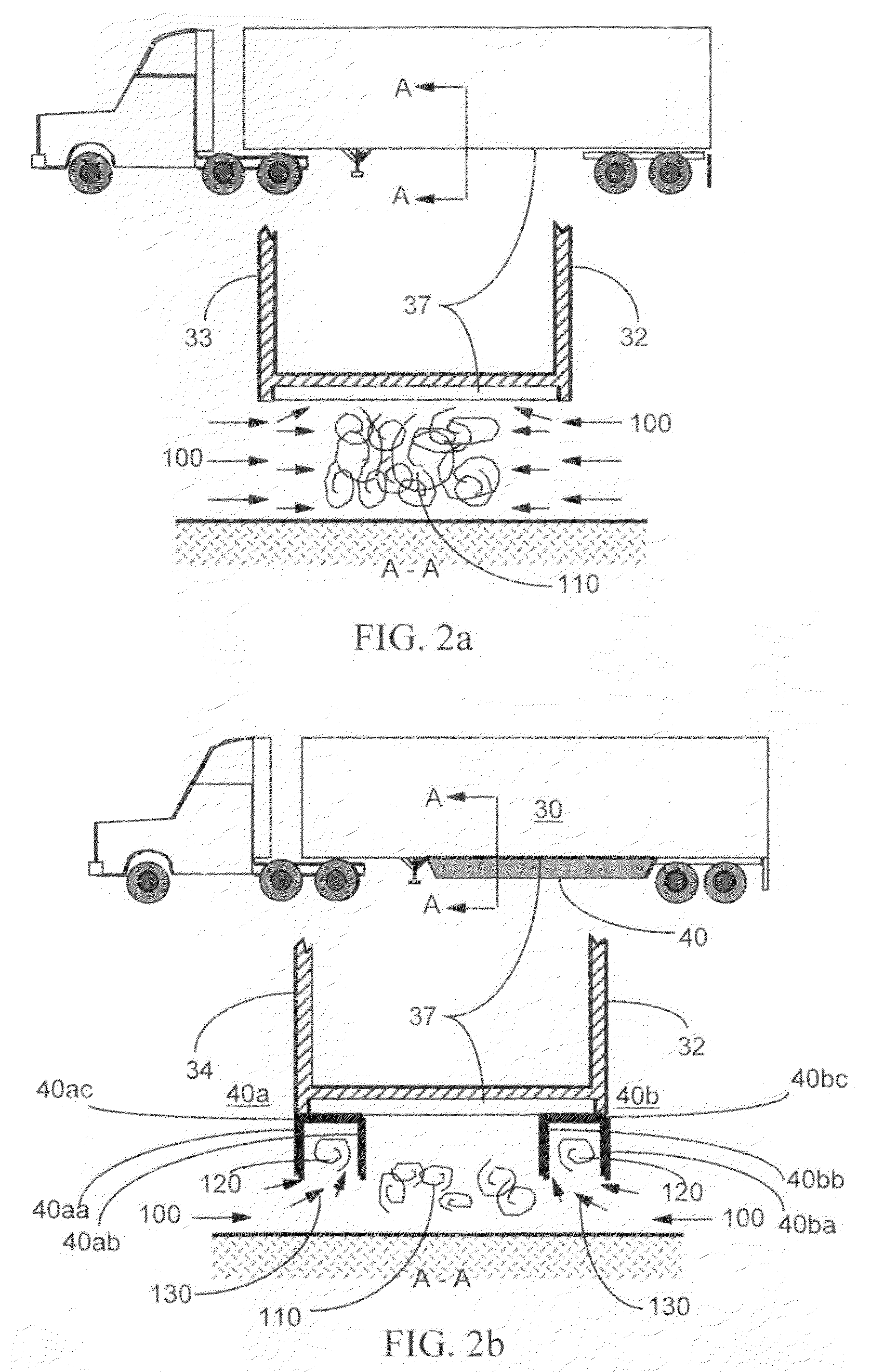

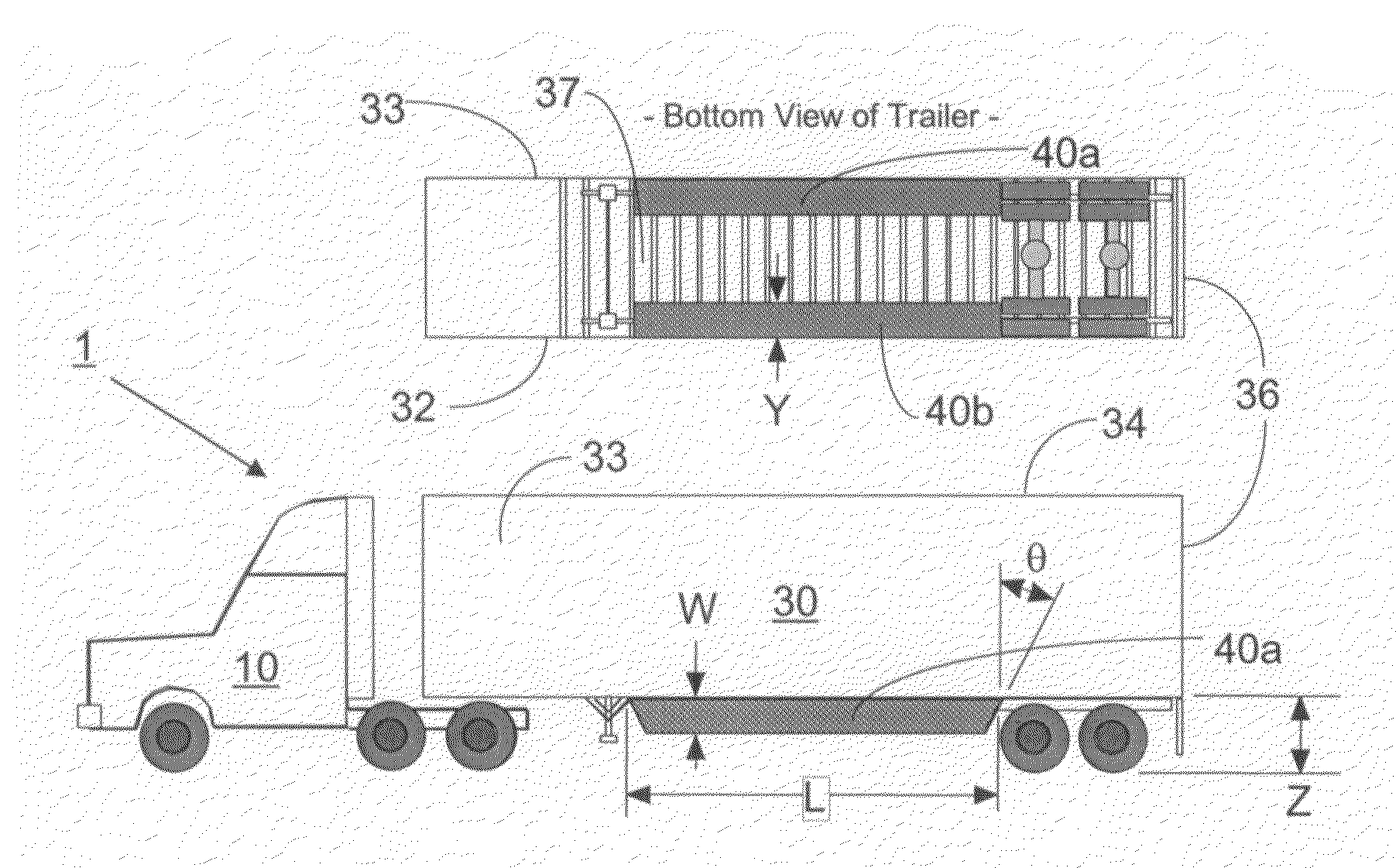

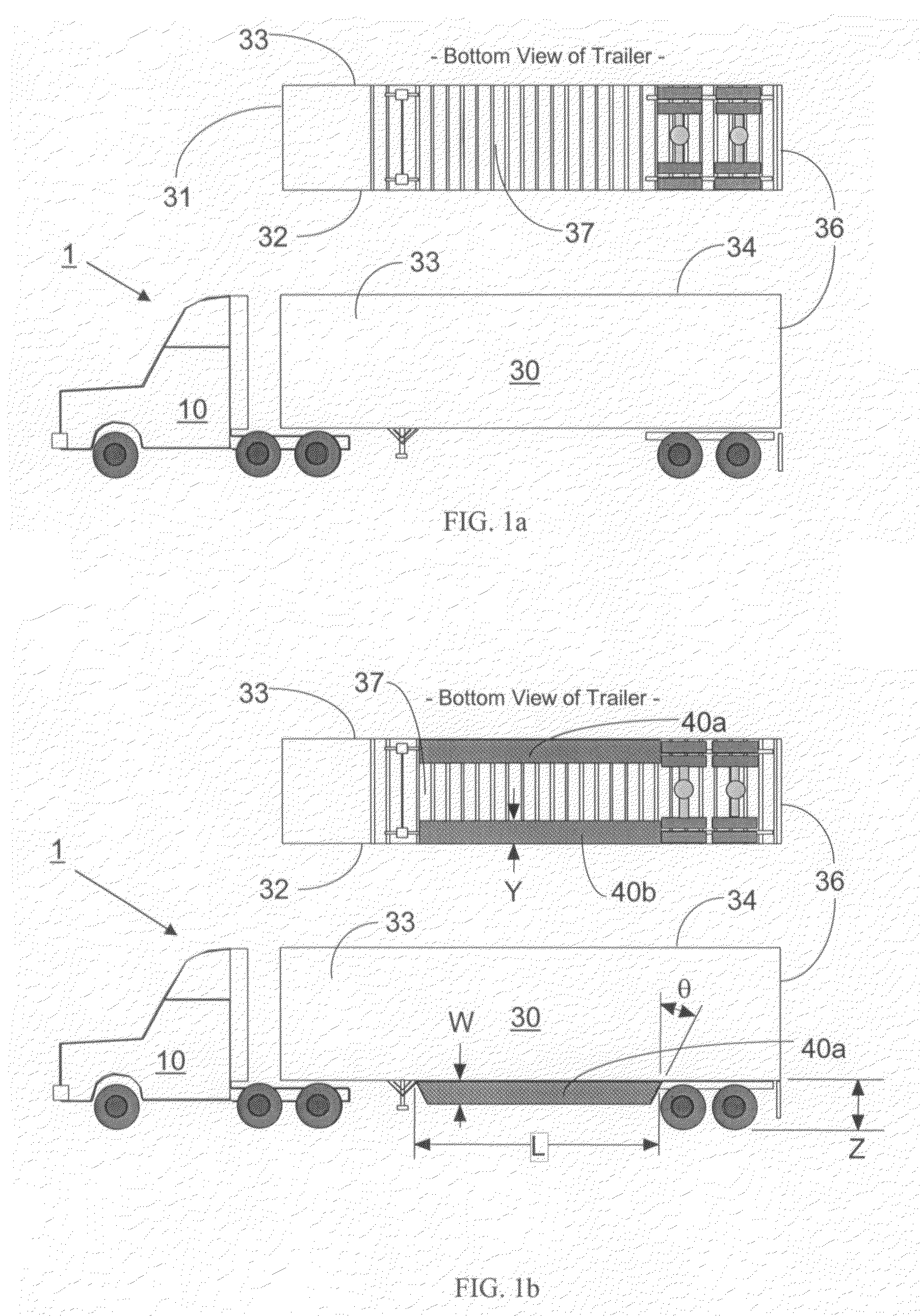

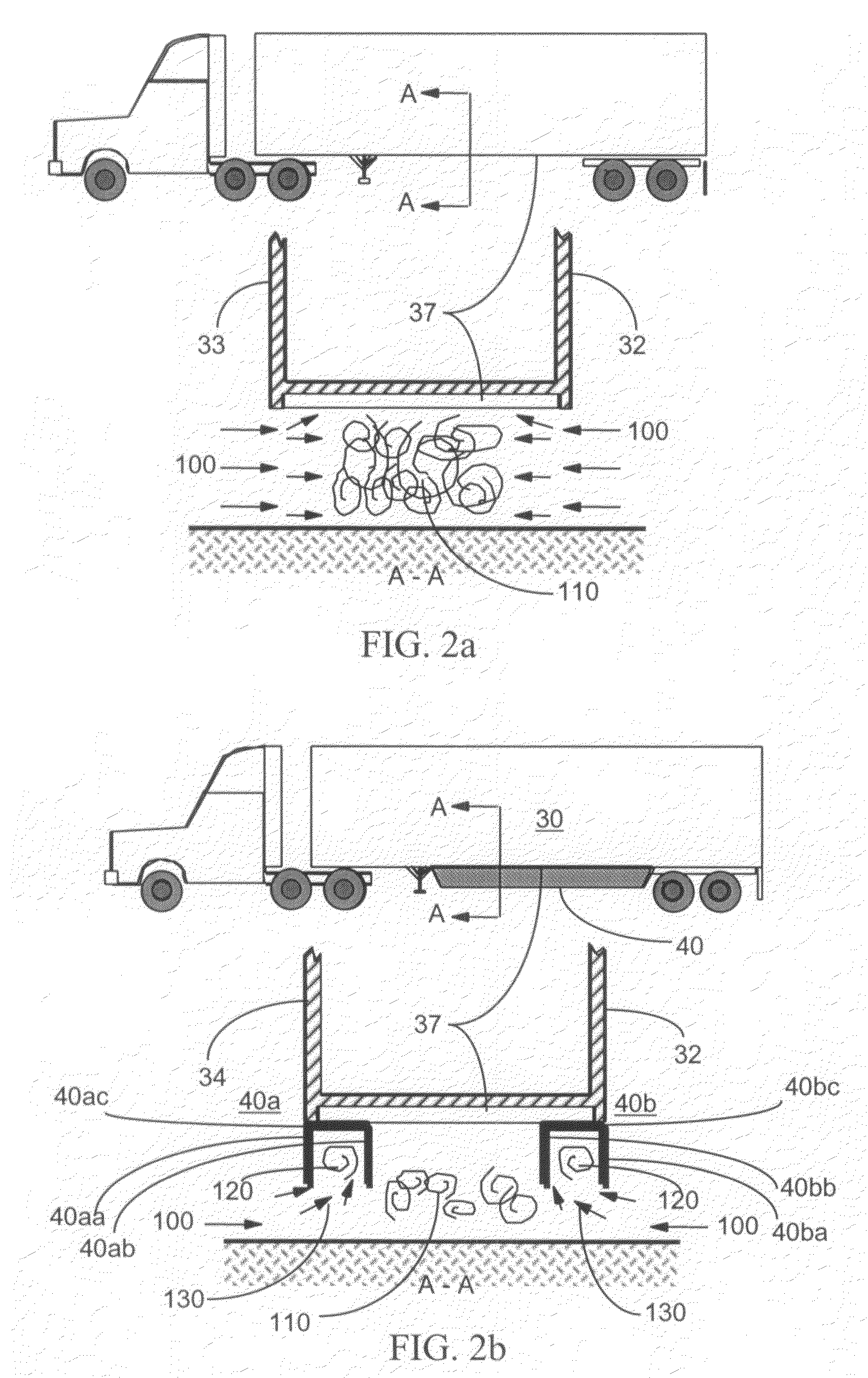

Mini skirt aerodynamic fairing device for reducing the aerodynamic drag of ground vehicles

InactiveUS7497502B2High trafficGood blocking performanceVehicle seatsWindowsMobile vehicleAerodynamic drag

A device for the reduction of aerodynamic drag and for improved performance and stability of ground vehicles by reducing the mass and velocity of the flow passing under a vehicle is described. The device is particularly suited for a tractor-trailer truck system that includes a motorized lead vehicle pulling one or more non-motorized vehicles. The device is designed to control the flow from entering the undercarriage region from the side of a trailer of a tractor-trailer truck system.

Owner:SOLUS SOLUTIONS & TECH

Mini skirt aerodynamic fairing device for reducing the aerodynamic drag of ground vehicles

InactiveUS7740303B2High trafficGood blocking performanceVehicle seatsWindowsMobile vehicleAerodynamic drag

A device for the reduction of aerodynamic drag and for improved performance and stability of ground vehicles by reducing the mass and velocity of the flow passing under a vehicle is described. The device is particularly suited for a tractor-trailer truck system that includes a motorized lead vehicle pulling one or more non-motorized vehicles. The device is designed to control the flow from entering the undercarriage region from the side of a trailer of a tractor-trailer truck system.

Owner:WOOD RICHARD

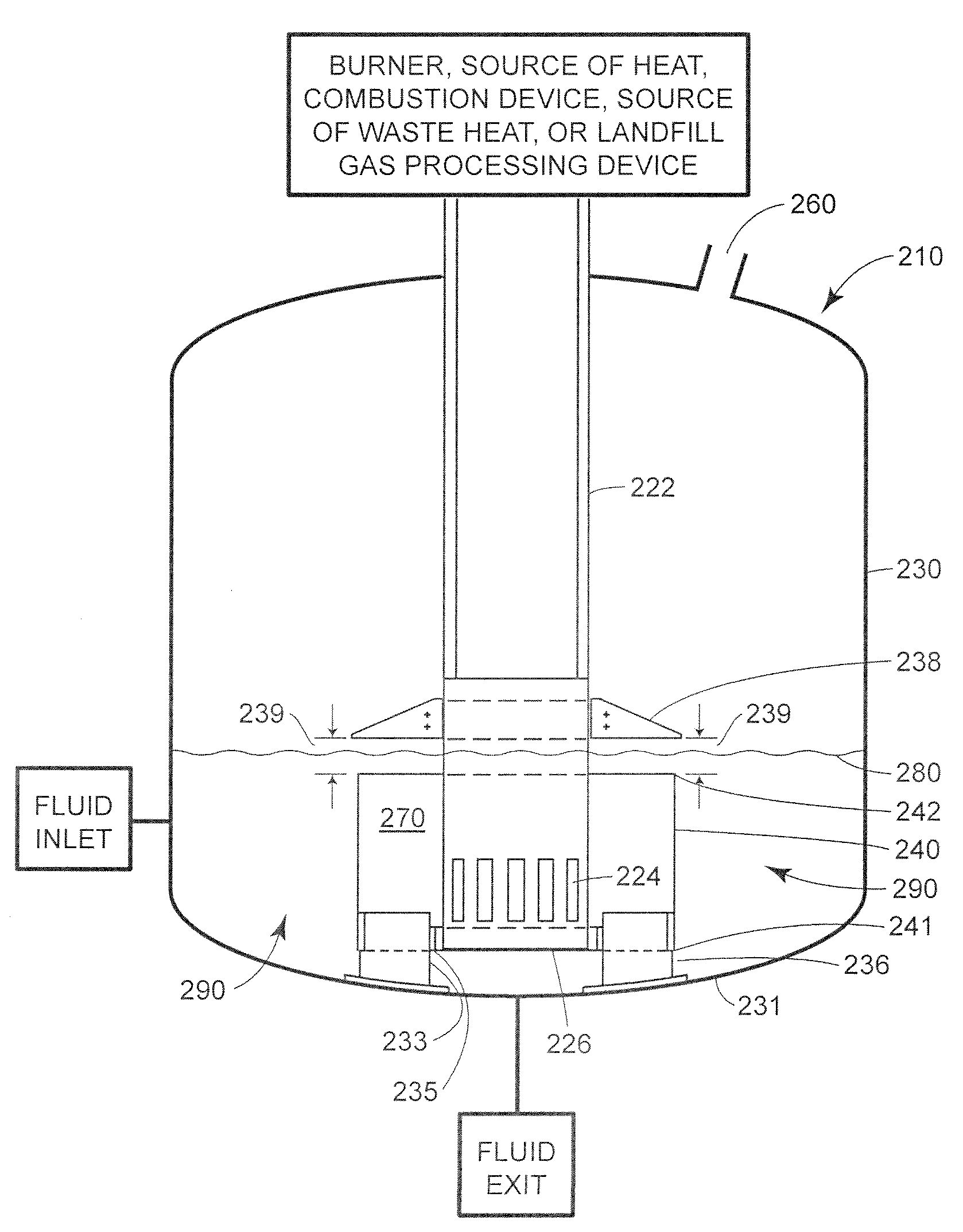

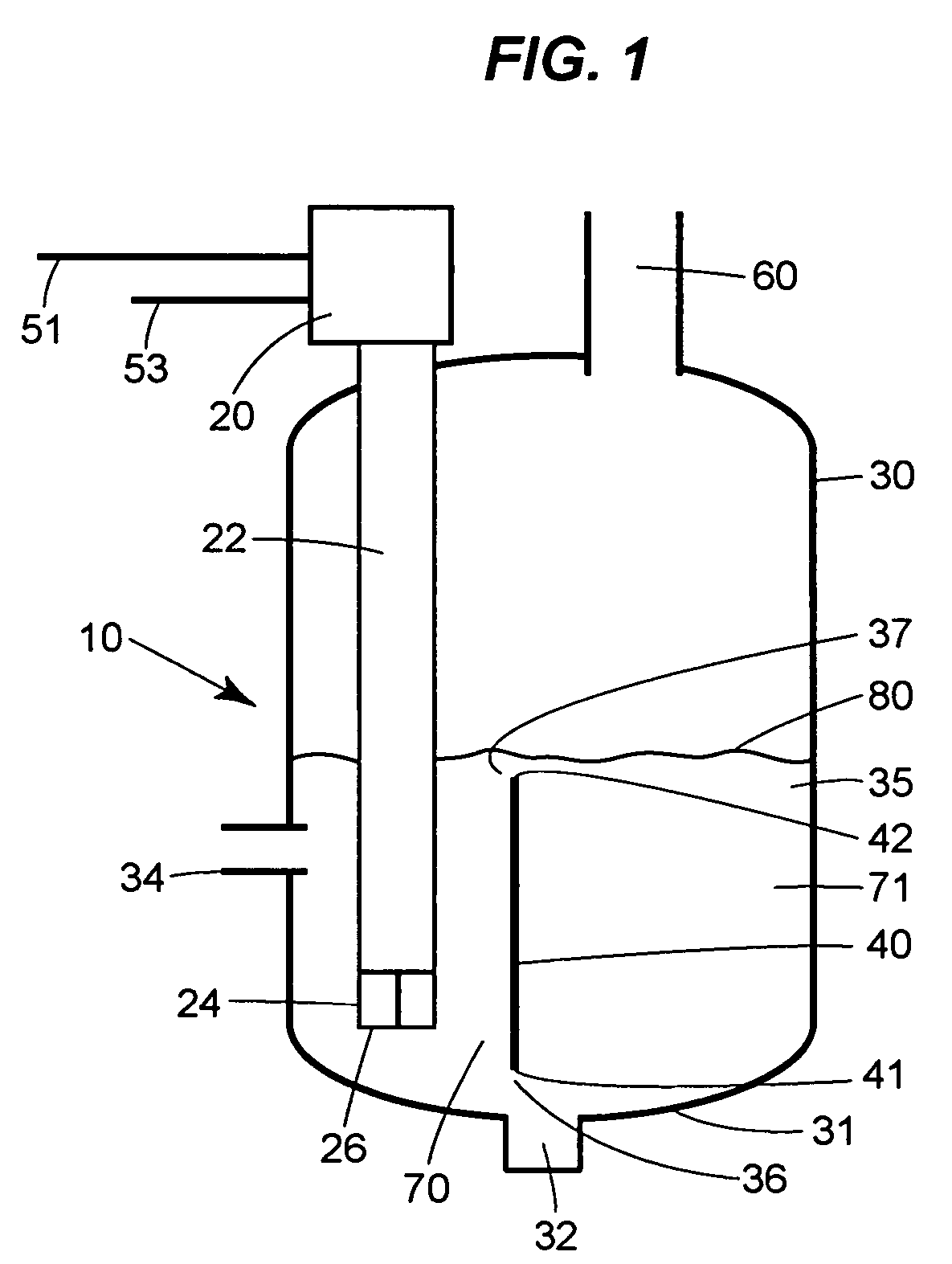

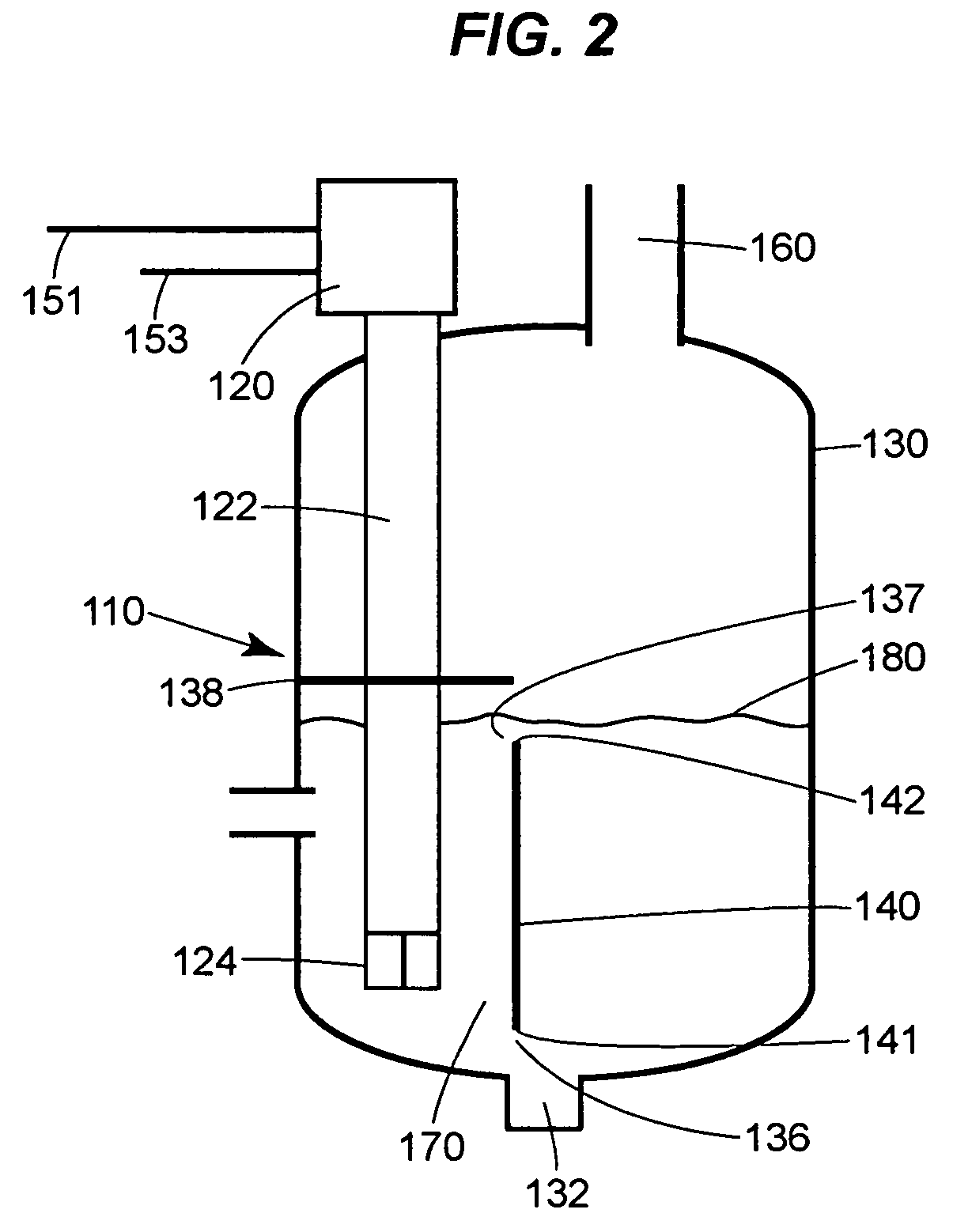

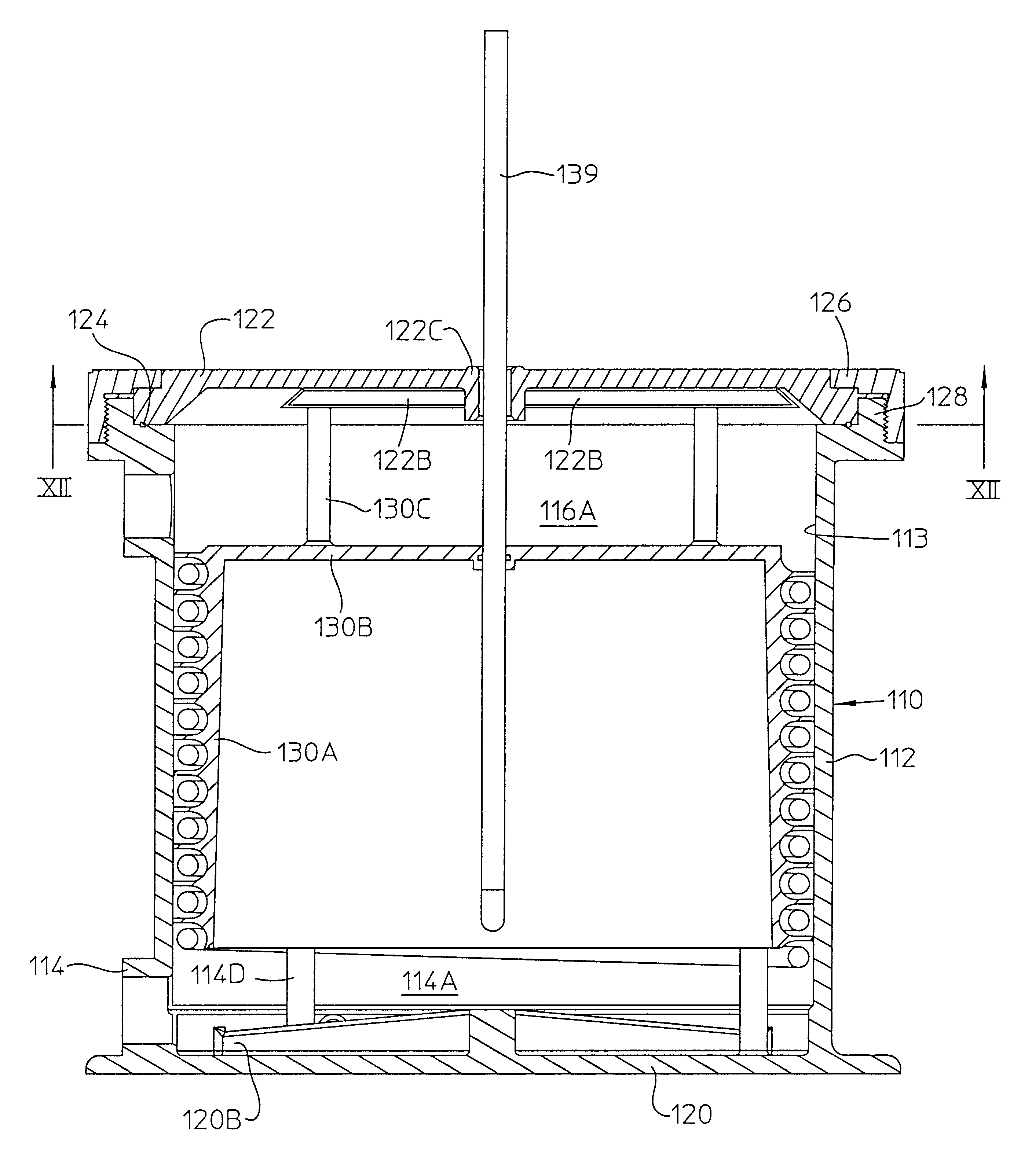

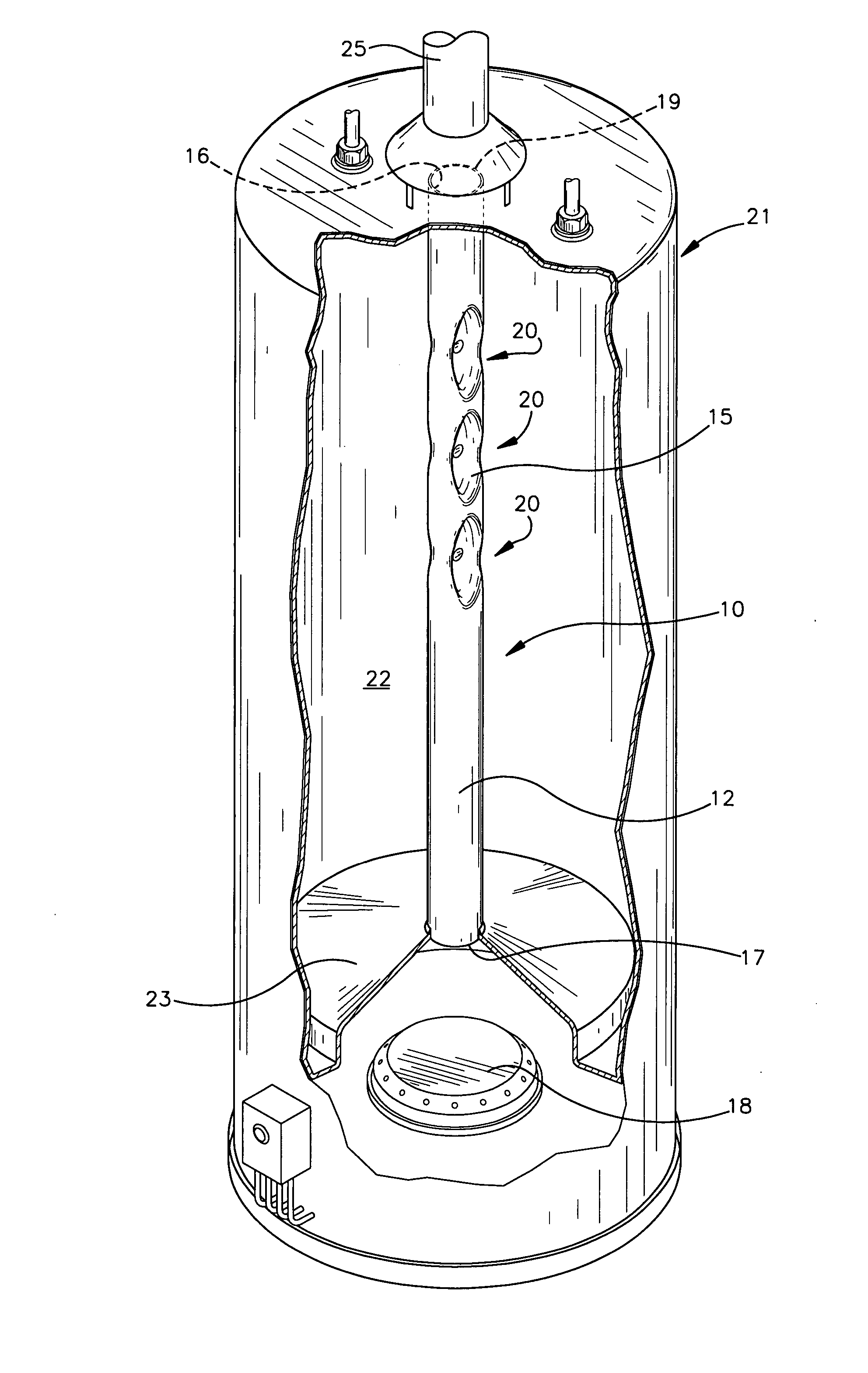

Submerged gas evaporators and reactors

ActiveUS7416172B2Increased turbulenceEnhanced mixing processCarburetting airUsing liquid separation agentChemical reactionHigh rate

A submerged gas processor in the form of an evaporator or a submerged gas reactor includes a vessel, a gas delivery tube partially disposed within the vessel to deliver a gas into the vessel and a process fluid inlet that provides a process fluid to the vessel at a rate sufficient to maintain a controlled constant level of fluid within the vessel. A weir is disposed within the vessel adjacent the gas delivery tube to form a first fluid circulation path between a first weir end and a wall of the vessel and a second fluid circulation path between a second weir end and an upper end of the vessel. During operation, gas introduced through the tube mixes with the process fluid and the combined gas and fluid flow at a high rate with a high degree of turbulence along the first and second circulation paths defined around the weir, thereby promoting vigorous mixing and intimate contact between the gas and the process fluid. This turbulent flow develops a significant amount of interfacial surface area between the gas and the process fluid resulting in a reduction of the required residence time of the gas within the process fluid to; achieve thermal equilibrium and / or to drive chemical reactions to completion, all of which leads to a more efficient and complete evaporation, chemical reaction, or combined evaporation and chemical reaction process.

Owner:SHAW INTPROP HLDG INC

Mini skirt aerodynamic fairing device for reducing the aerodynamic drag of ground vehicles

InactiveUS20080093887A1Promote upwashIncreasing effective blocking areaVehicle seatsWindowsMobile vehicleAerodynamic drag

A device for the reduction of aerodynamic drag and for improved performance and stability of ground vehicles by reducing the mass and velocity of the flow passing under a vehicle is described. The device is particularly suited for a tractor-trailer truck system that includes a motorized lead vehicle pulling one or more non-motorized vehicles. The device is designed to control the flow from entering the undercarriage region from the side of a trailer of a tractor-trailer truck system.

Owner:SOLUS SOLUTIONS & TECH

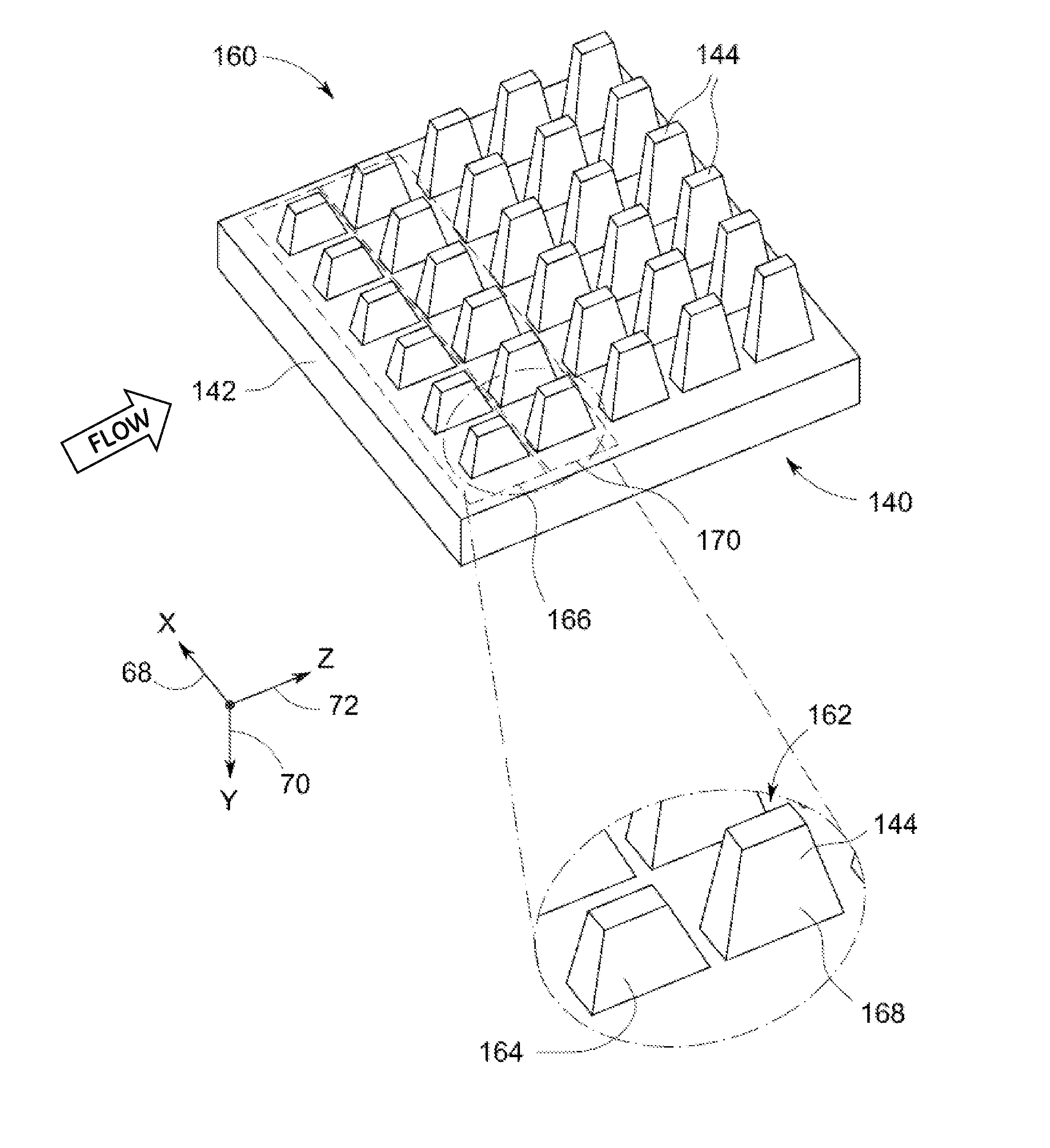

Air-cooled engine surface cooler

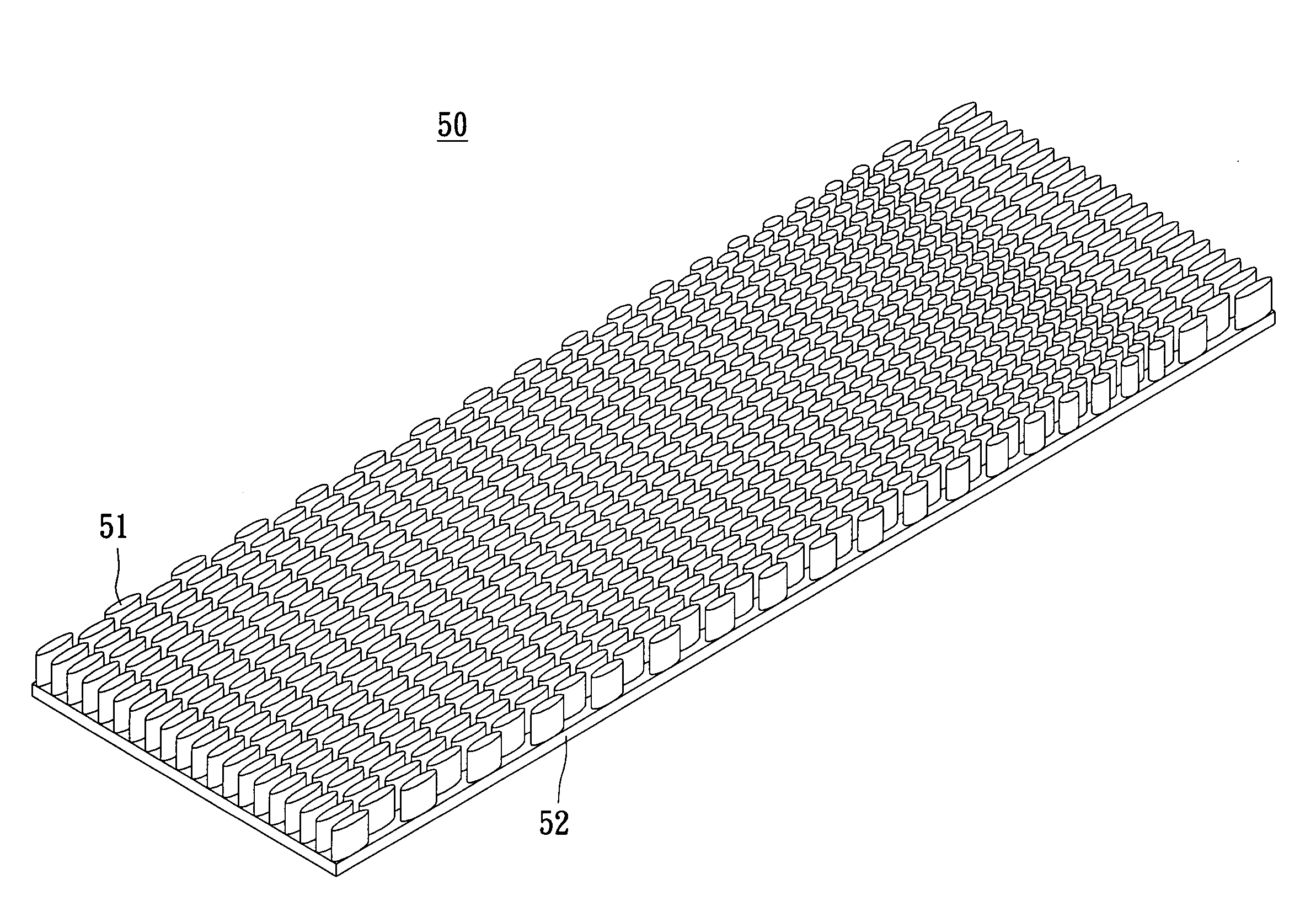

ActiveUS20140027102A1Improve heat transfer performanceIncreasing turbulence levelEngine fuctionsTurbine/propulsion engine coolingSurface coolingEngineering

A surface cooler comprises a plate-like layer and a plurality of spaced-apart fins extending substantially perpendicular from an uppermost layer of the plate-like layer. The plurality of fins defining a plurality of air flow paths. The plurality of spaced-apart fins are configured to augment heat transfer of the surface cooler by increasing the turbulence levels of a fluid flowing through the airflow paths by promoting increased mixing with a resulting increase in the heat transfer coefficient of the surface cooler. A method of forming the surface cooler and an engine including the surface cooler.

Owner:GENERAL ELECTRIC CO

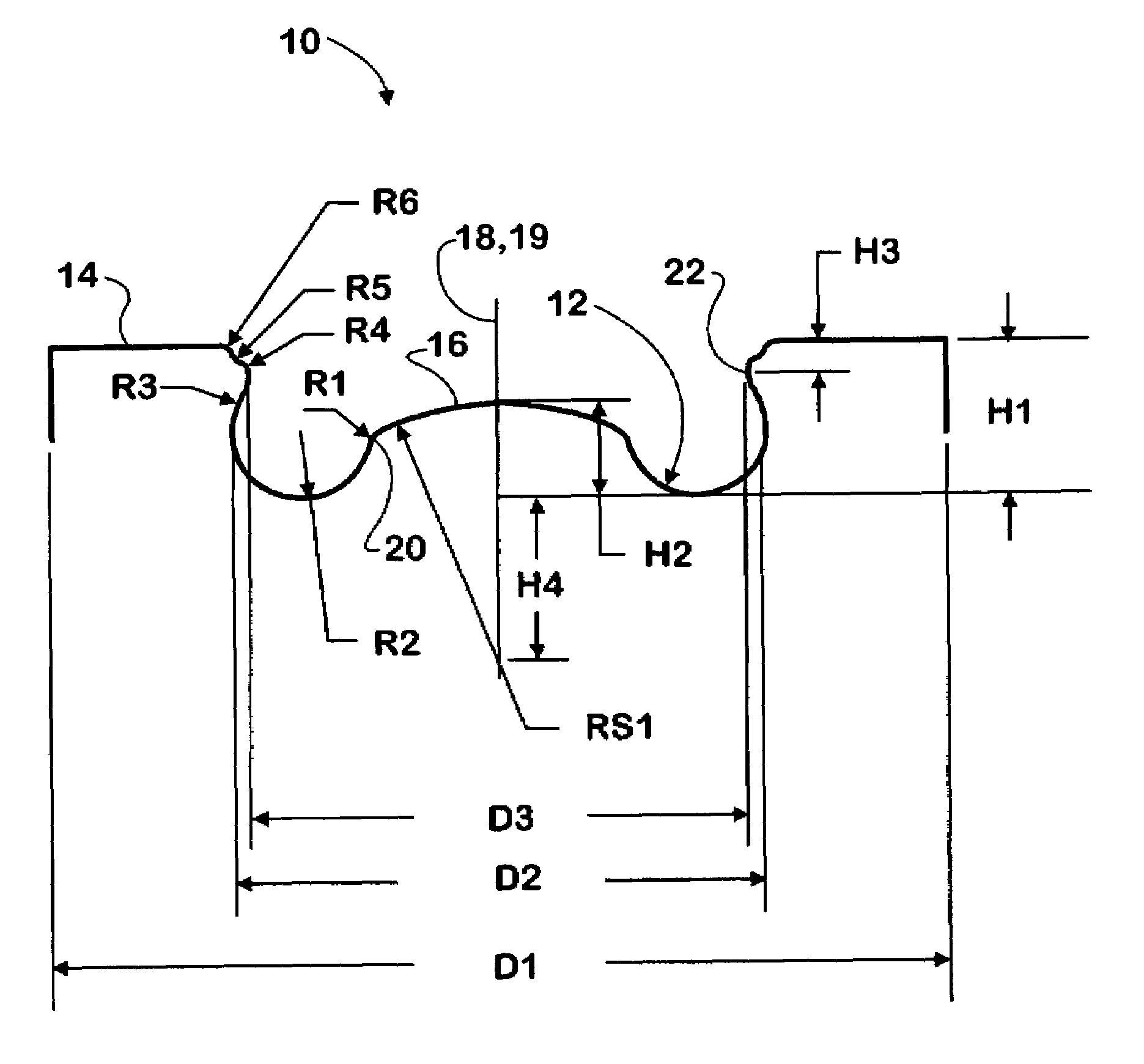

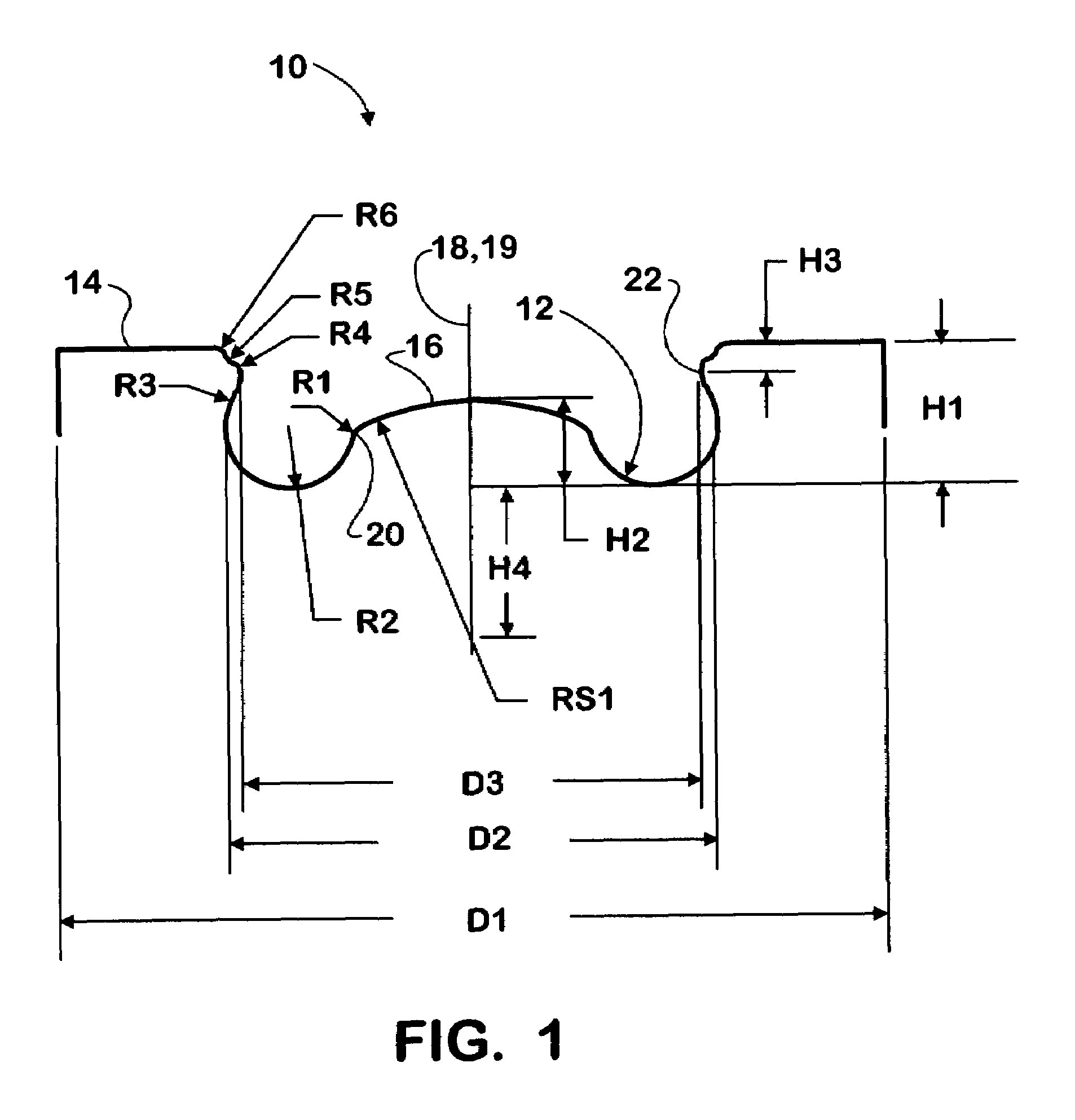

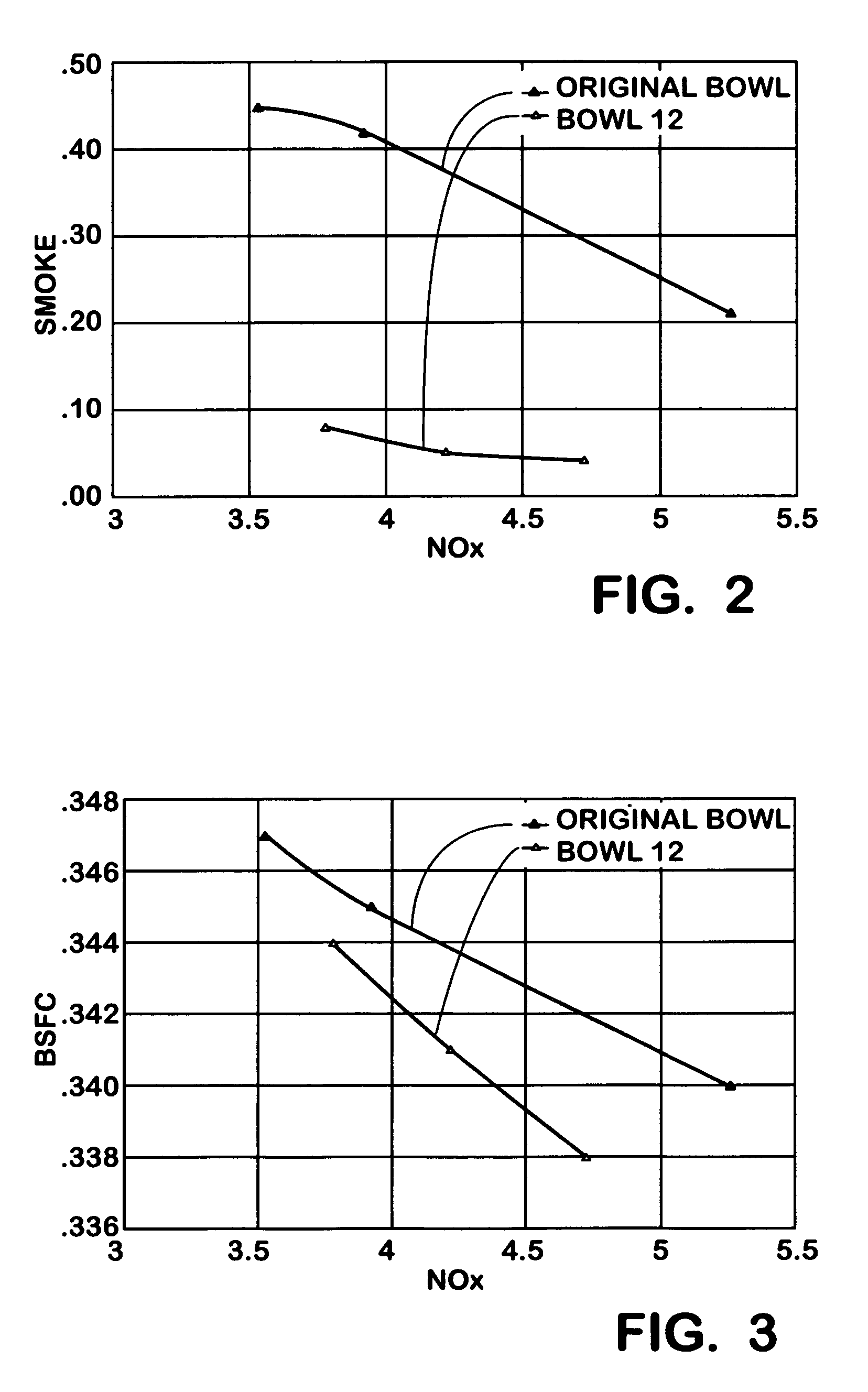

Diesel combustion chamber

ActiveUS6997158B1Increase kinetic energyEasily formInternal combustion piston enginesPistonsPistonCombustion chamber

Owner:INT ENGINE INTPROP CO LLC

Exhaust gas catalyst

InactiveUS6180075B1Favorable degree of conversionExceptional heat and aging resistanceNitrogen compoundsInternal combustion piston enginesZirconium hydrideCerium(IV) oxide

A single-layered three-way catalytic converter containing palladium as the only catalytically active noble metal, with high activity and heat resistance. The catalyst contains, in addition to finely divided, stabilized aluminum oxide, at least one finely divided cerium / zirconium mixed oxide and optionally finely divided nickel oxide as well as highly dispersed amounts of cerium oxide, zirconium oxide and barium oxide. The palladium is distributed largely uniformly throughout the entire catalyst.

Owner:DMC2 DEGUSSA METALS +1

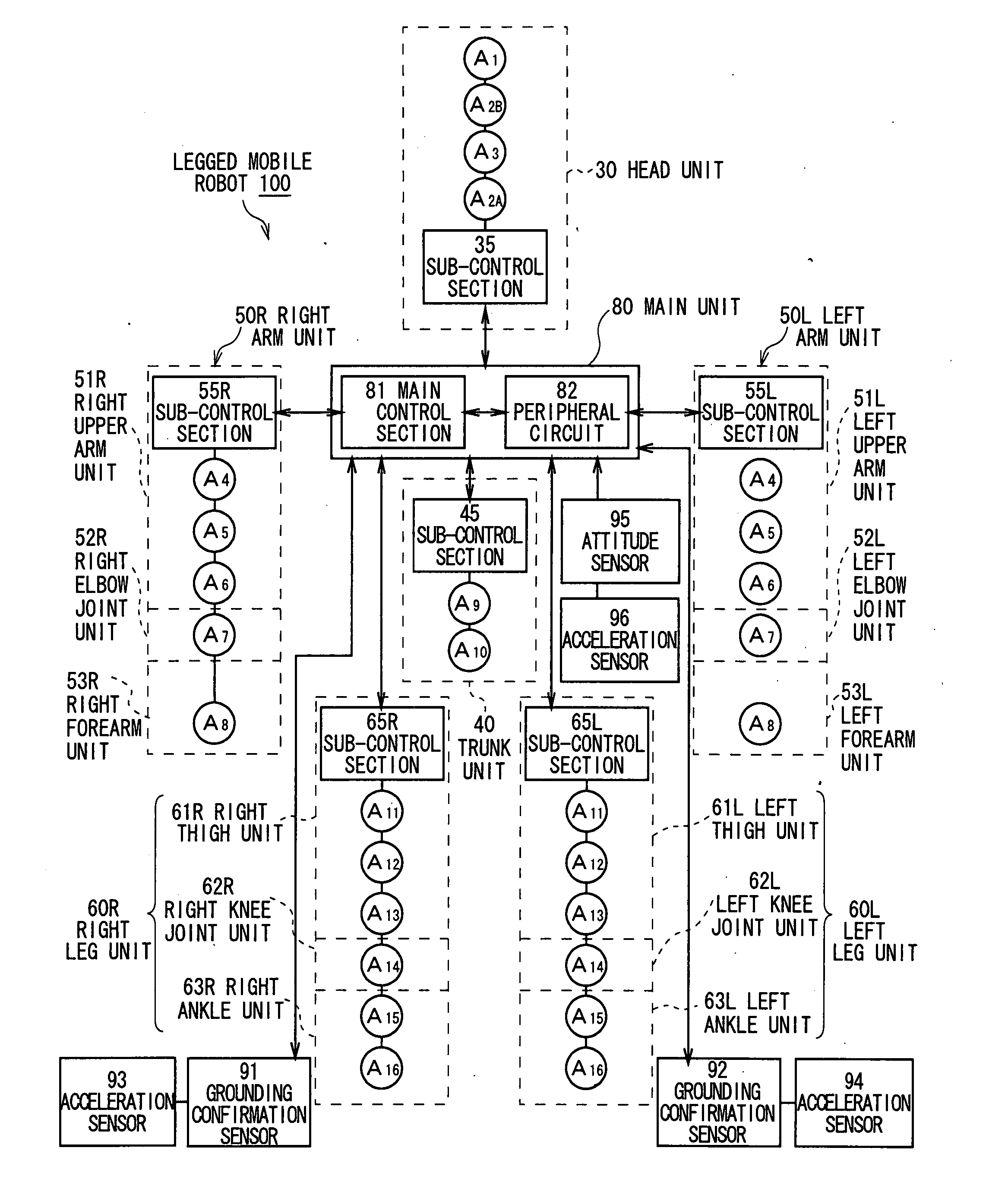

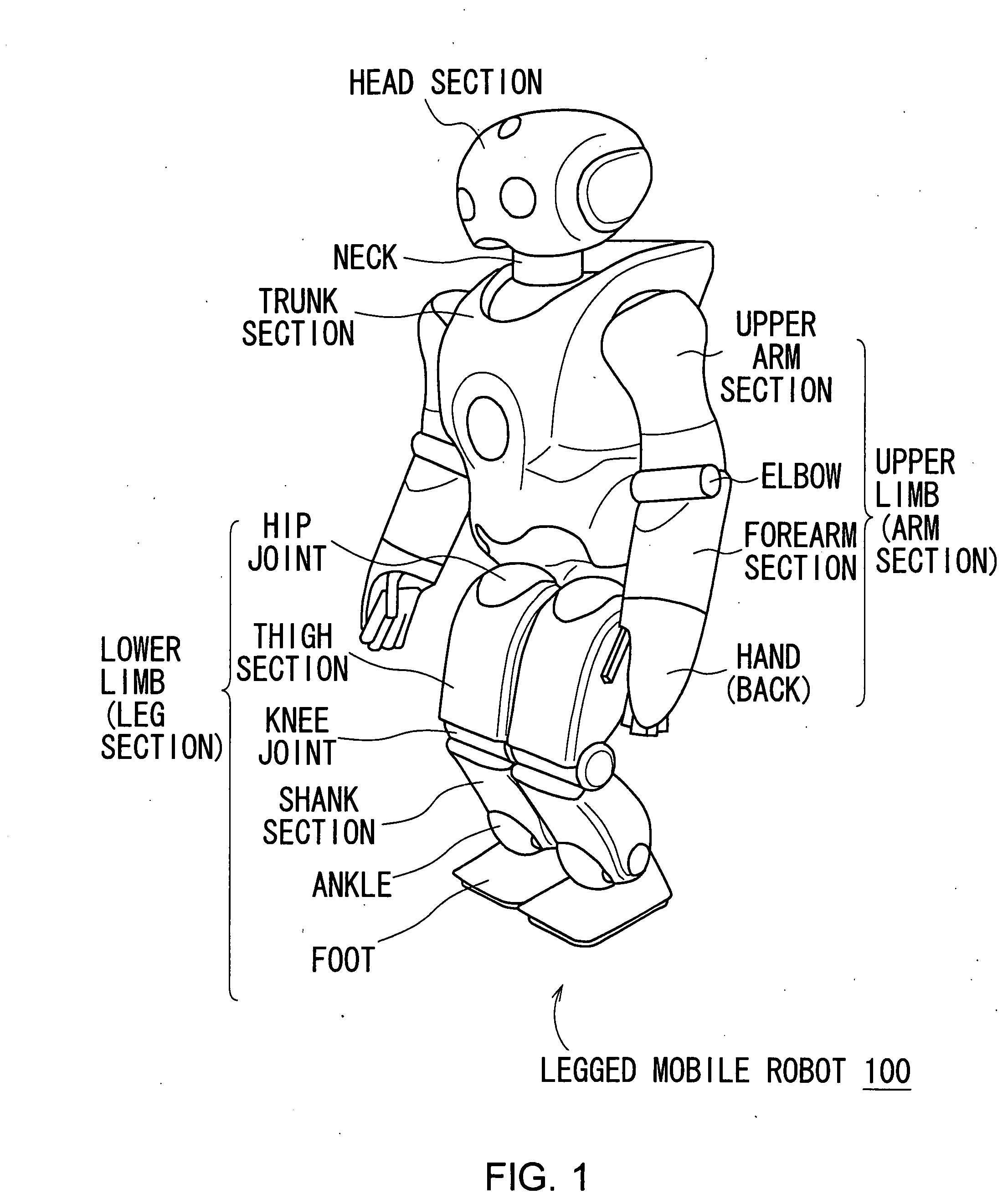

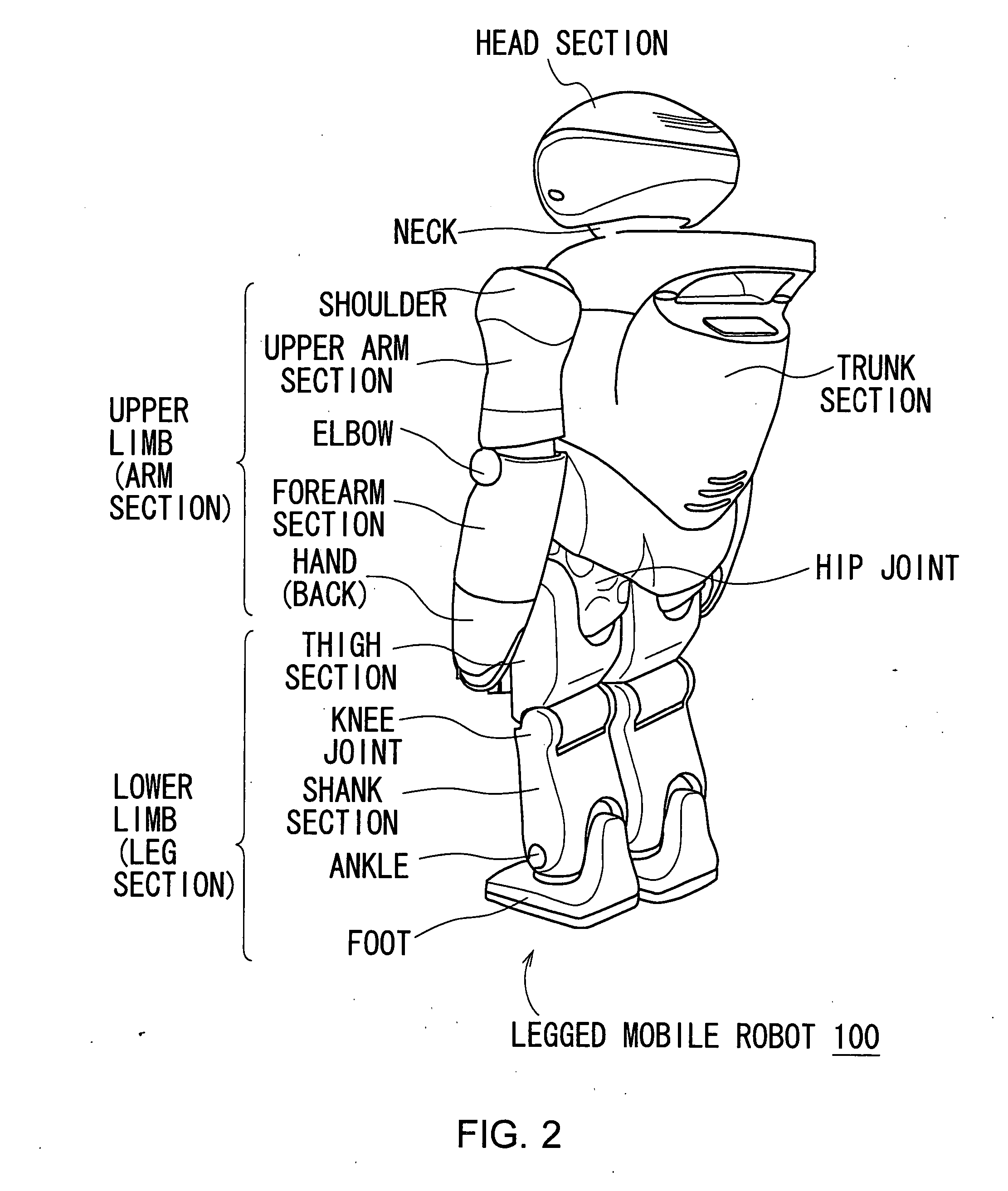

Robot apparatus and method of controlling the same

InactiveUS20070220637A1Improve the immunityImprove noiseProgramme-controlled manipulatorComputer controlControl signalSelf-oscillation

A robot apparatus having a plurality of movable sections includes a motion control section that generates a control signal for the periodic motion of at least part of the movable sections according to the output of an oscillator showing self-oscillation and entrainment characteristics, an environment measuring section that measures the motion according to the control signal for the movable sections or the physical environment at the time of the motion of the movable sections, a periodic oscillator control section that inputs a periodic signal to the oscillator as feedback according to the outcome of the measurement by the environment measuring section and generates an entrainment phenomenon and a non-periodic oscillator control section that inputs a non-periodic or temporary feedback signal to the oscillator.

Owner:SONY CORP +2

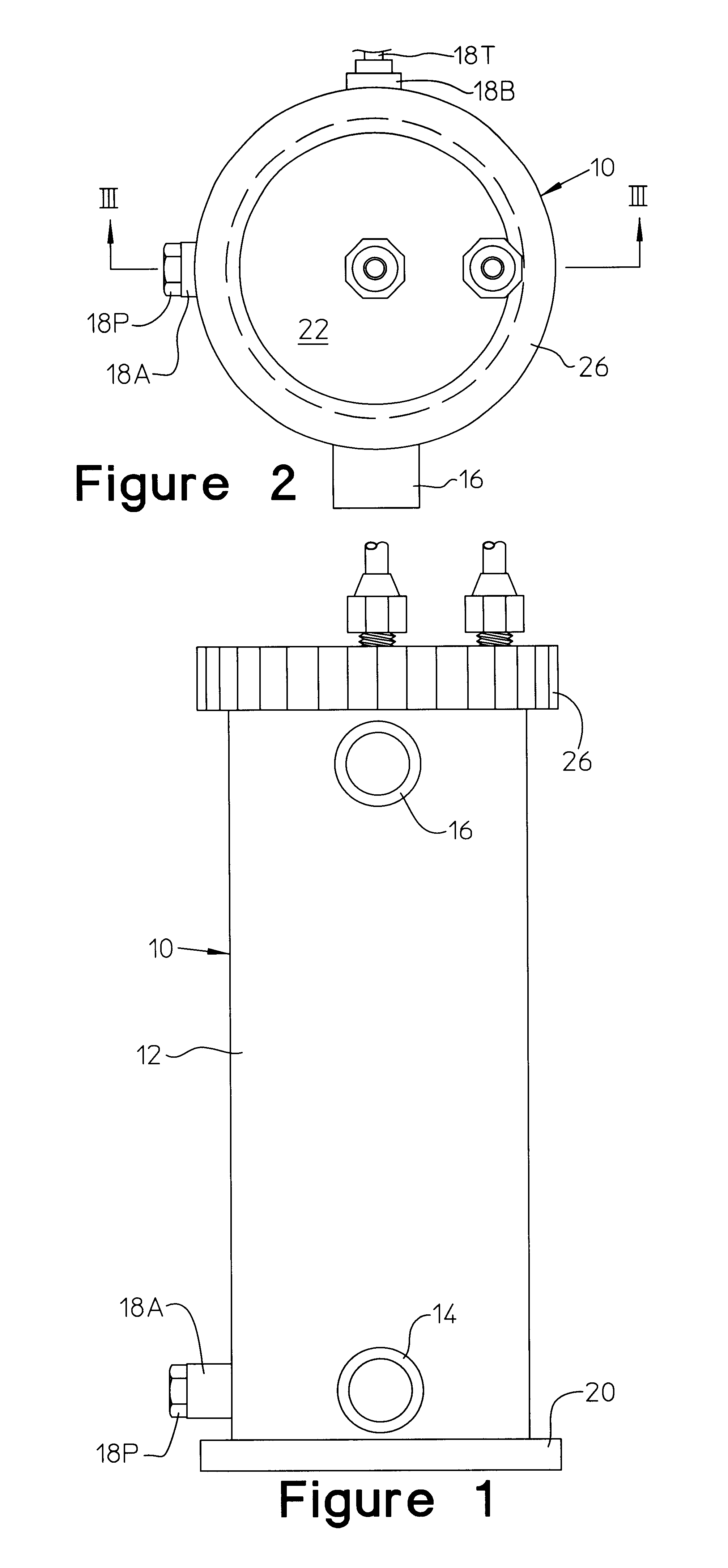

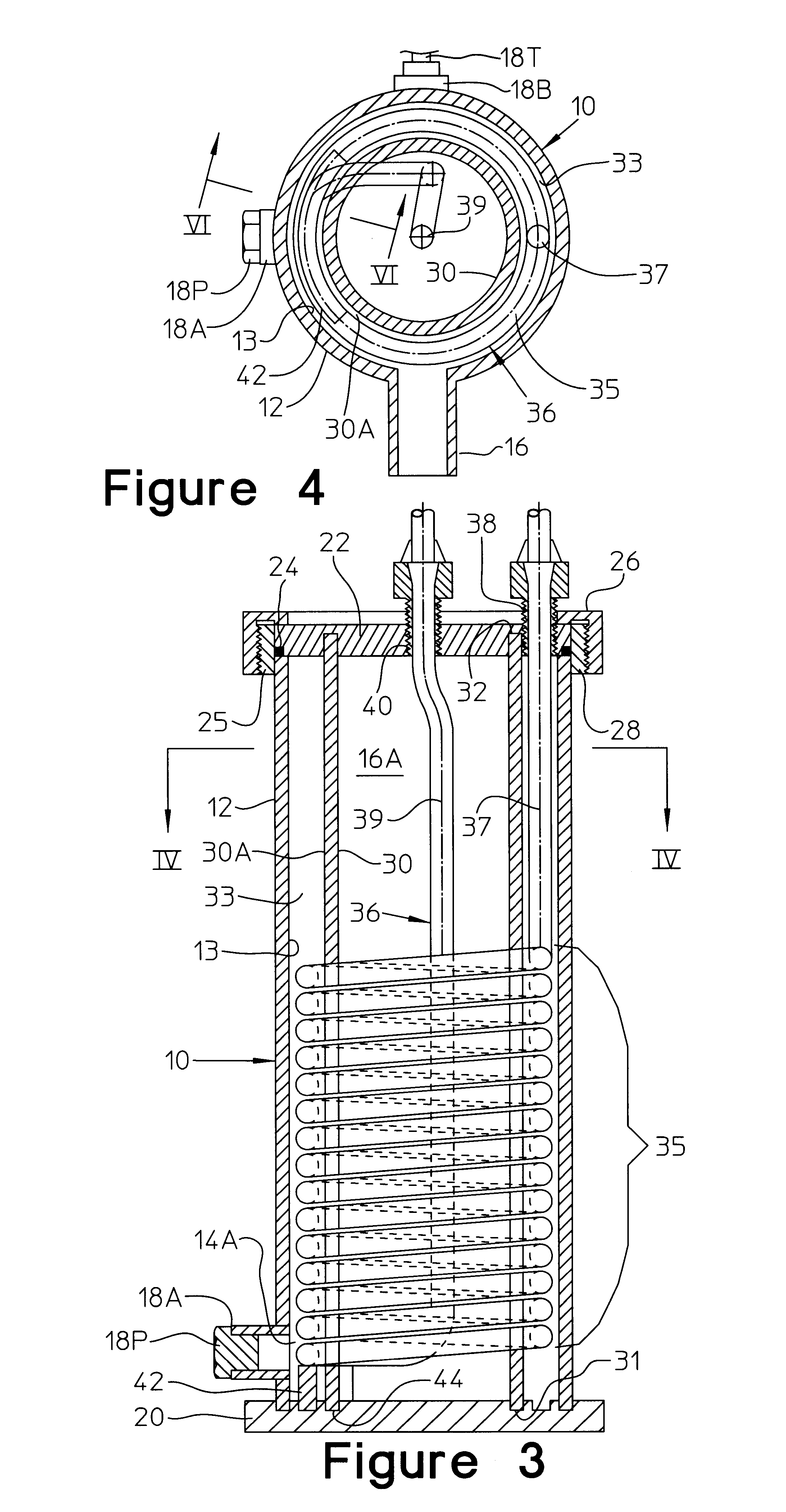

Method and apparatus for optimizing heat transfer in a tube and shell heat exchanger

InactiveUS6293335B1Increased turbulenceMaximize heat transferHeat exchanger casingsStationary tubular conduit assembliesPlate heat exchangerShell and tube heat exchanger

A tube and shell heat exchanger having a transversely oriented inlet port and a spirally coiled heat transfer tube contained within an arcuate chamber created by an internal baffle in which the water to be conditioned travels along a helical pathway in which the flow has minimized water depth and high turbulence. The tube and shell heat exchanger maximizes heat transfer capability in a relatively easy to assemble design to make feasible the use of a higher cost material for the tubing such as titanium in a wide range of applications.

Owner:AQUACAL

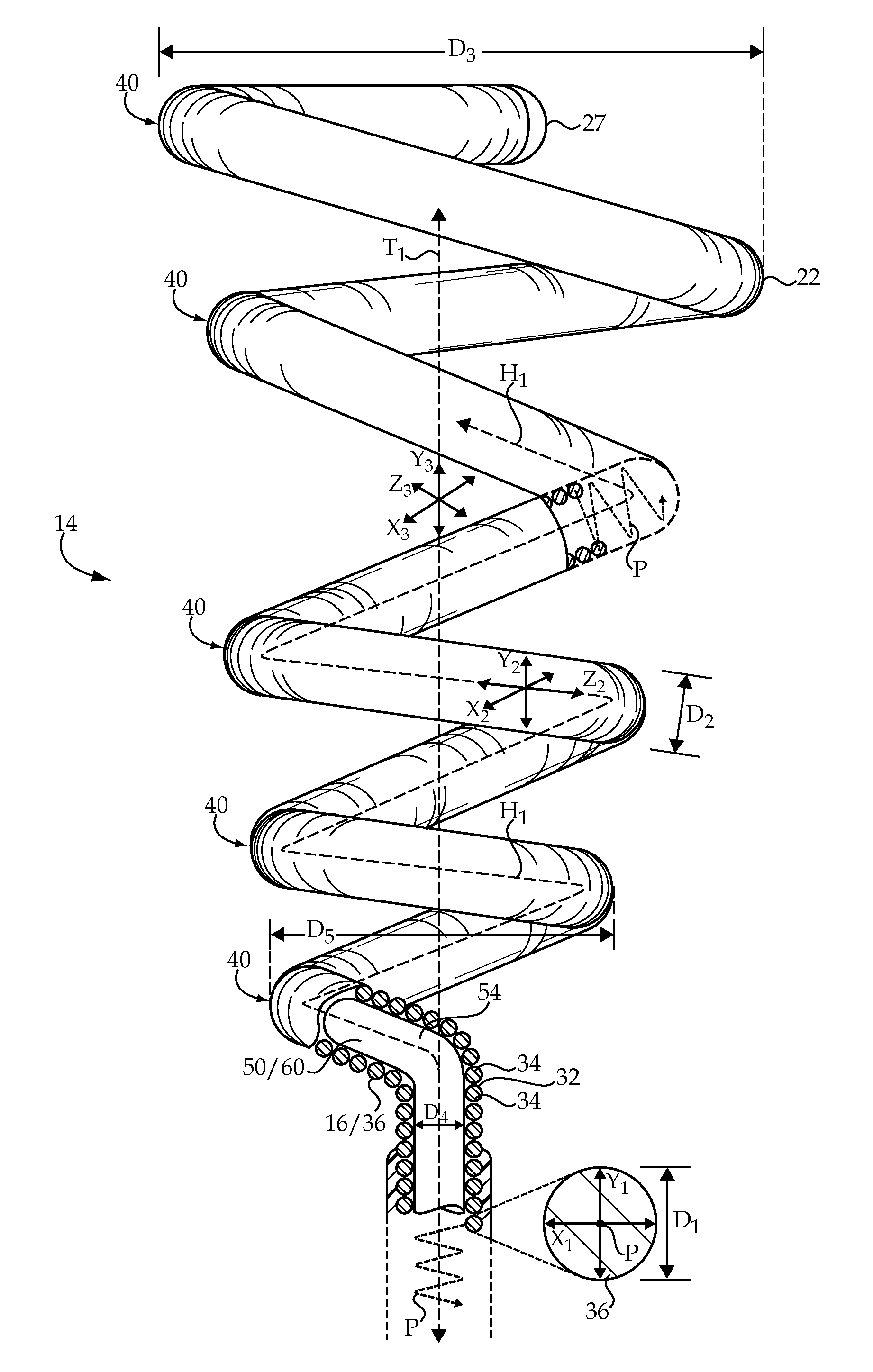

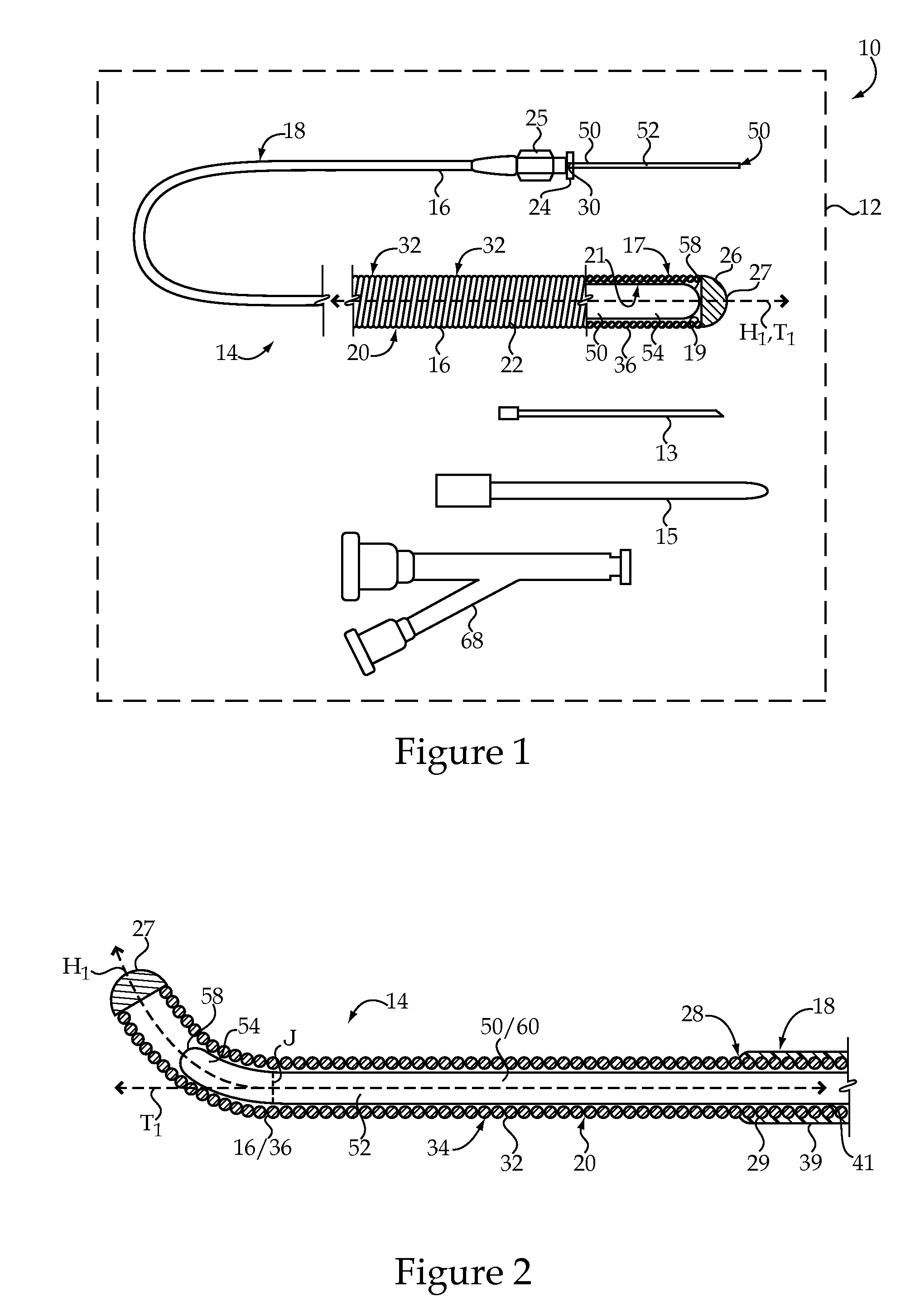

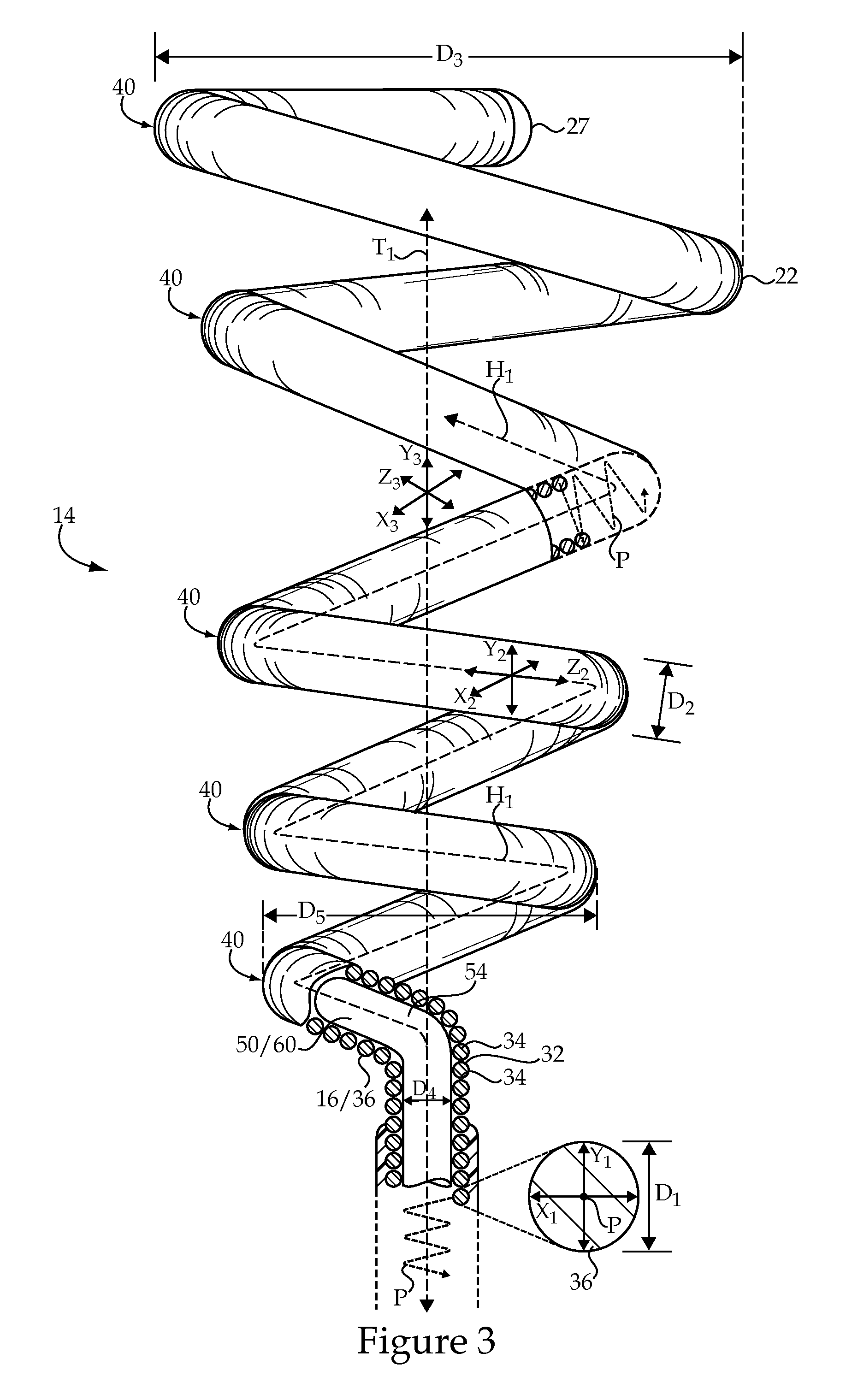

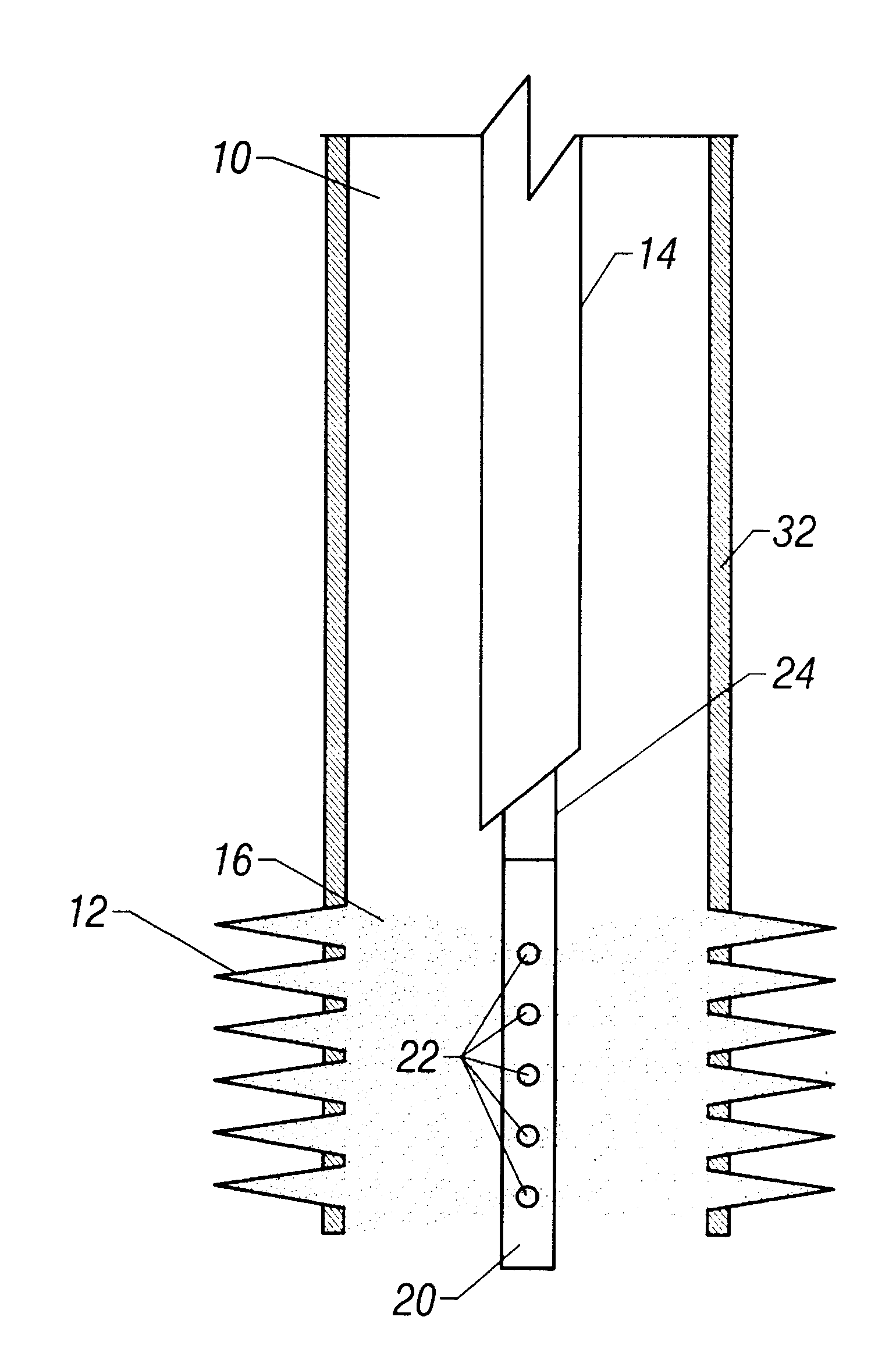

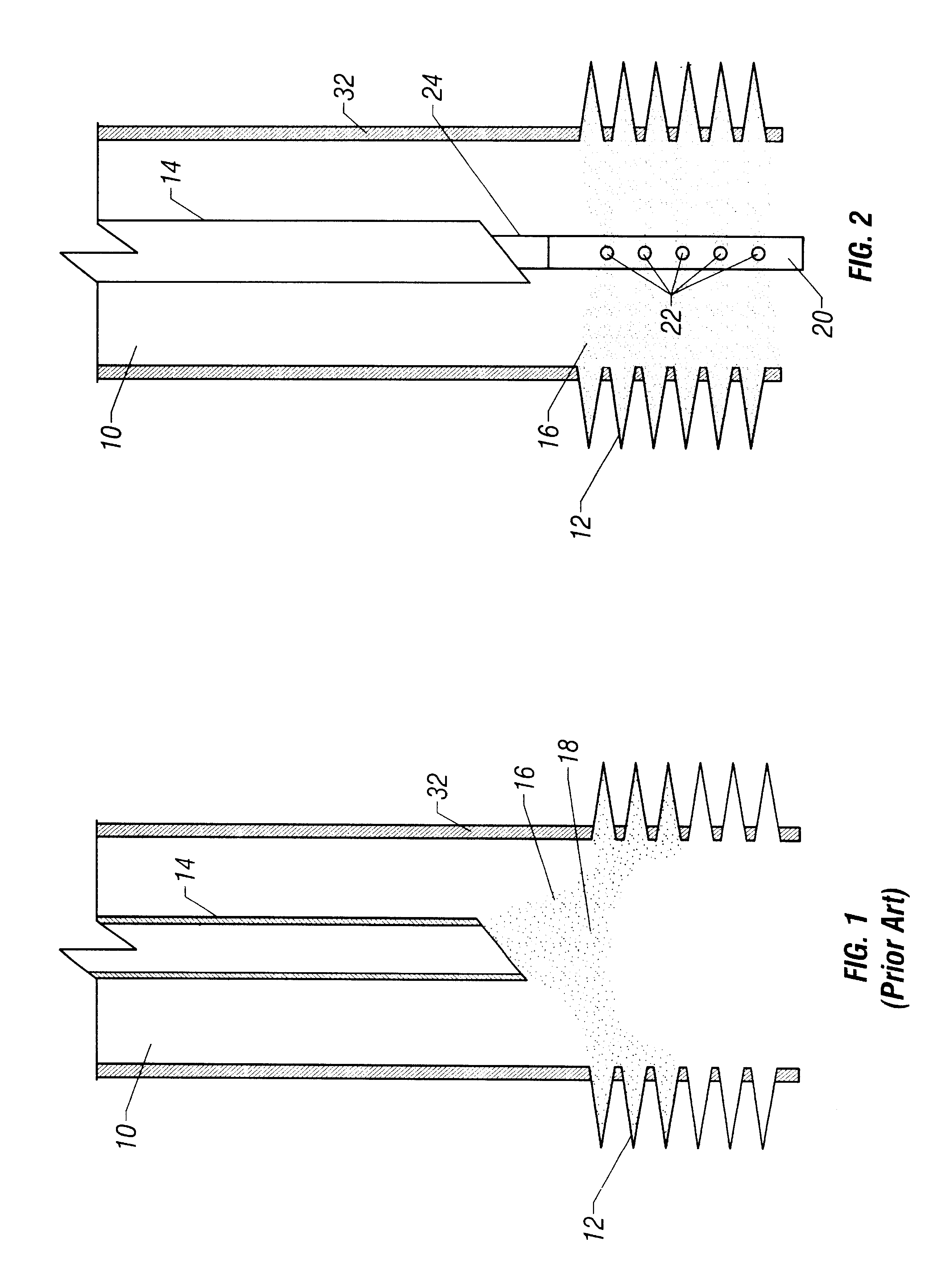

Treatment Fluid Delivery Method, And Turbulator For Promoting Uptake Of A Treatment Agent

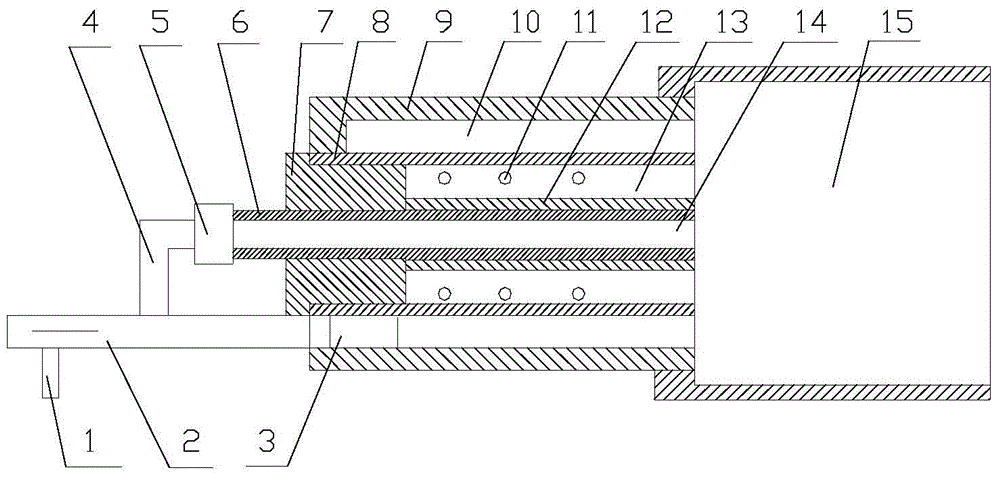

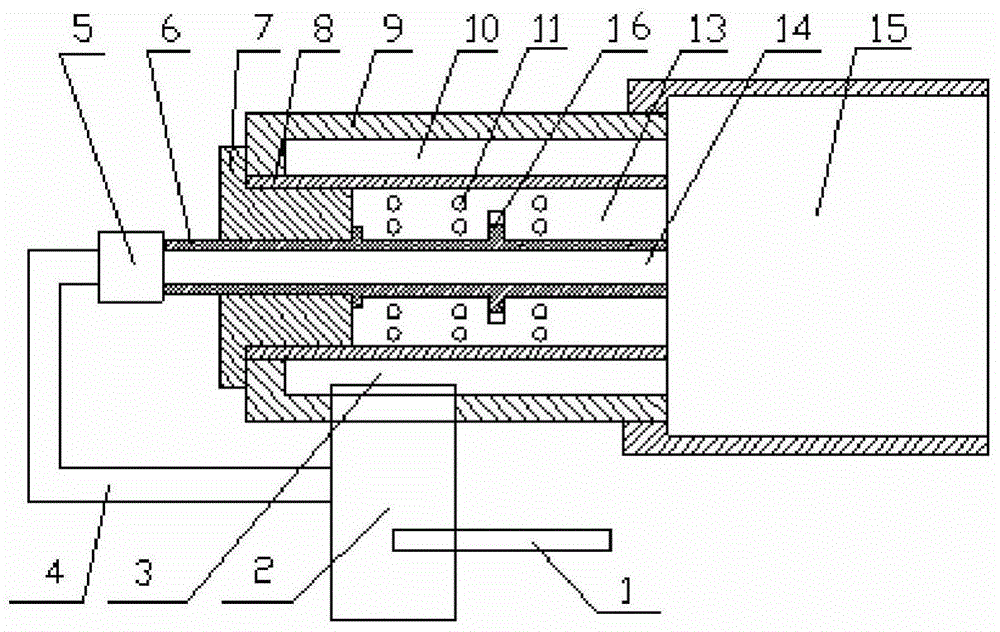

ActiveUS20110276024A1Well mixedConvenient treatmentSurgeryMedical devicesBody fluidBiomedical engineering

A turbulator for promoting mixing of fluids passing through a body lumen includes an elongate flow perturbing component and an elongate shape controlling component freely slidable within the flow perturbing component. The turbulator is adjustable from a low profile, lumen access configuration to a deployed configuration via sliding the shape controlling component within the flow perturbing component. Adjusting the turbulator within a body lumen of a patient induces turbulence within a flow of fluid passing through the body lumen to increase mixing of a treatment fluid with the body fluid by way of the induced turbulence.

Owner:COOK MEDICAL TECH LLC

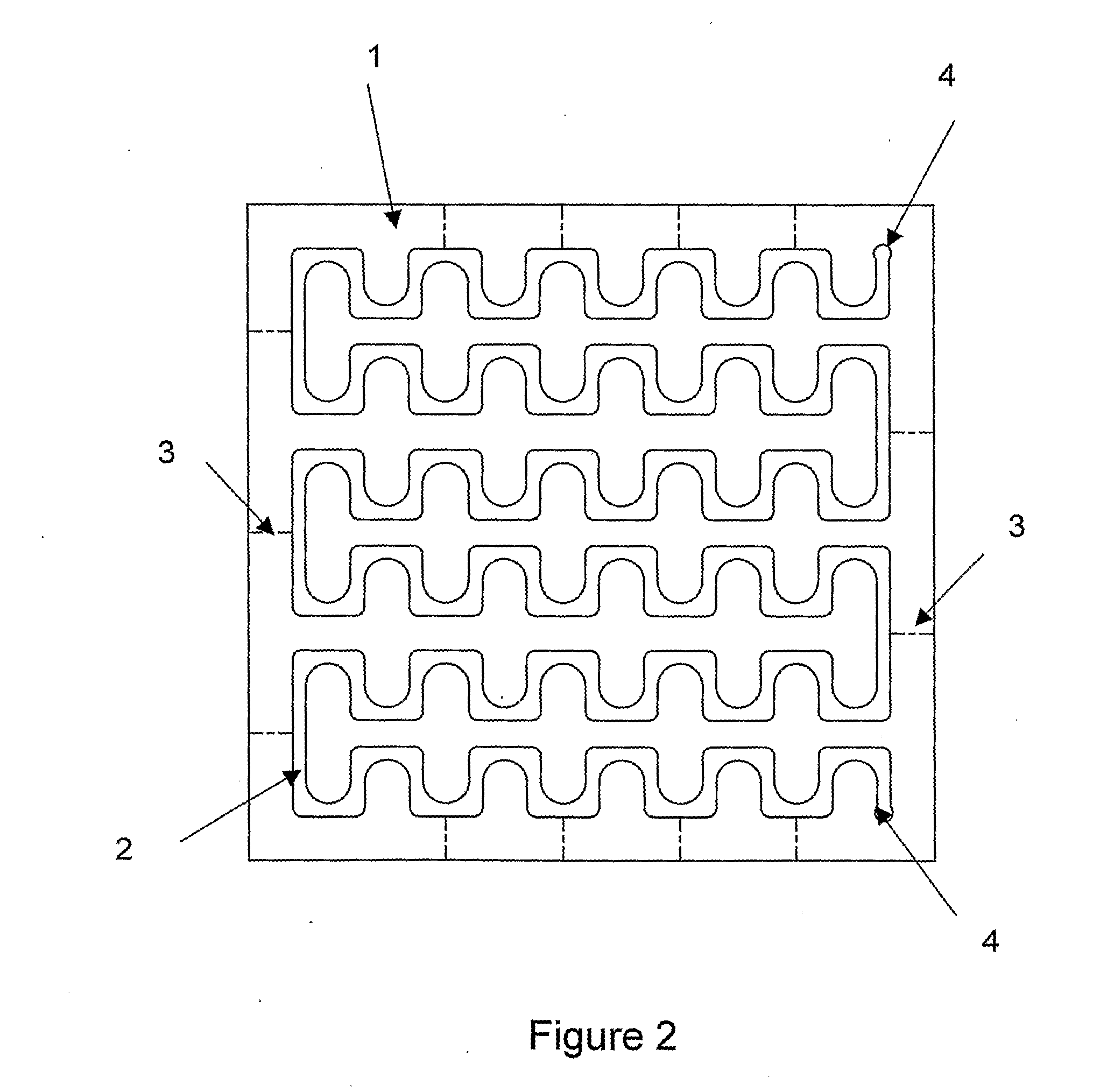

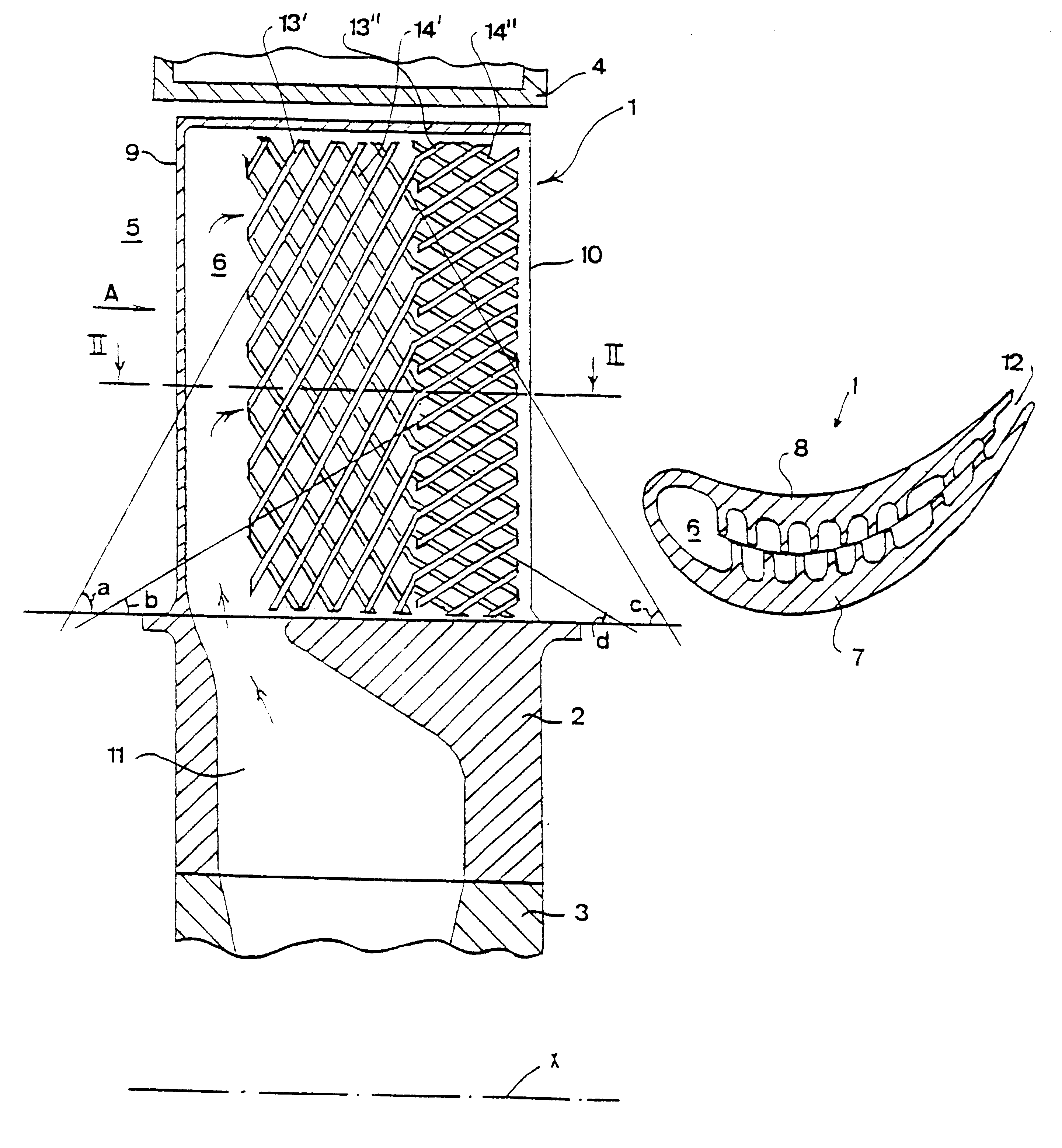

Drip irrigation hoses of the labyrinth type and flow-control elements for producing such hoses

InactiveUS7735758B2Increased turbulenceLarge heightClimate change adaptationWatering devicesDrip irrigationWater flow

A drip irrigation hose includes a tube for conducting pressurized water through its interior and formed with a plurality of outlets for emitting water at longitudinally-spaced locations along the length of the tube; and a plurality of flow-control elements fixed with respect to the inner surface of the tube at longitudinally-spaced locations thereof to define, with the inner surface, a plurality of labyrinths each having an inlet communicating with the interior of the tube and an outlet communicating with a tube outlet for emitting water there from at a slow rate. The labyrinth includes a bottom wall constructed to produce, adjacent to the bottom wall, a significant laminar flow of water in which the laminar flow decreases, and thereby turbulent flow increases, with an increase in the water pressure within the tube to thereby provide pressure-compensation for the water flow through the respective tube outlet.

Owner:COHEN

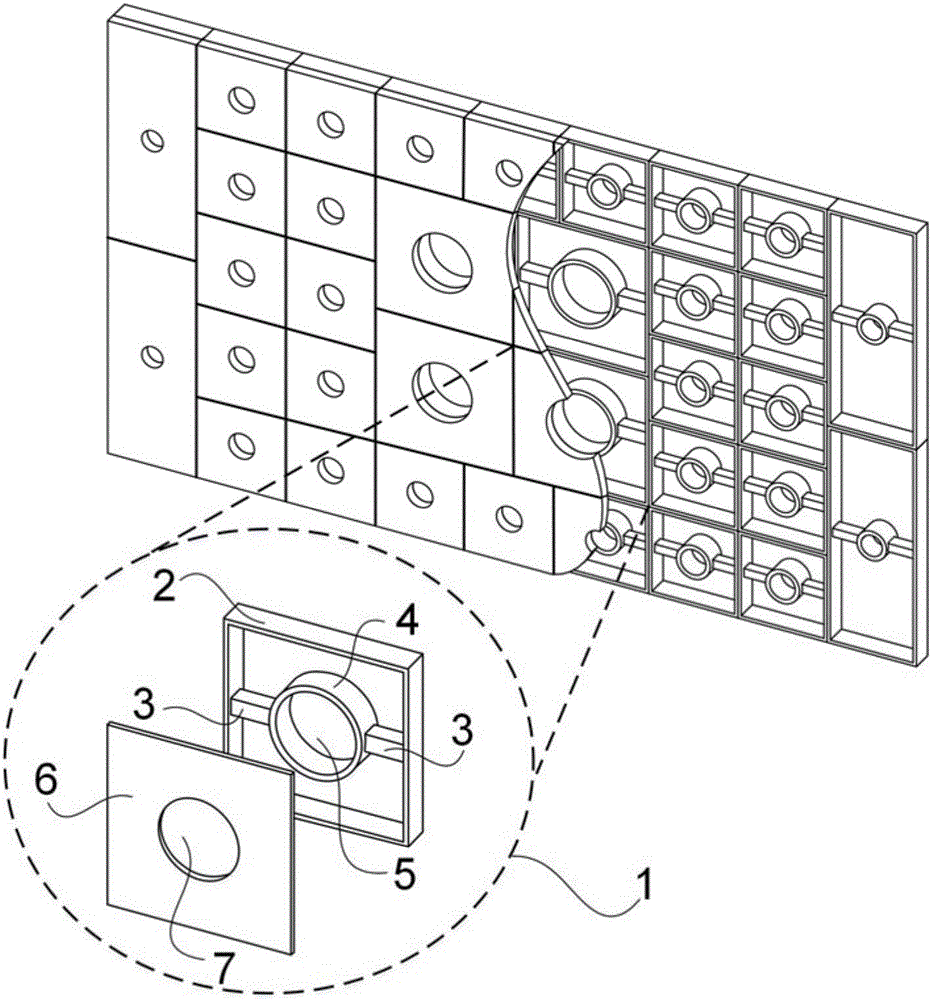

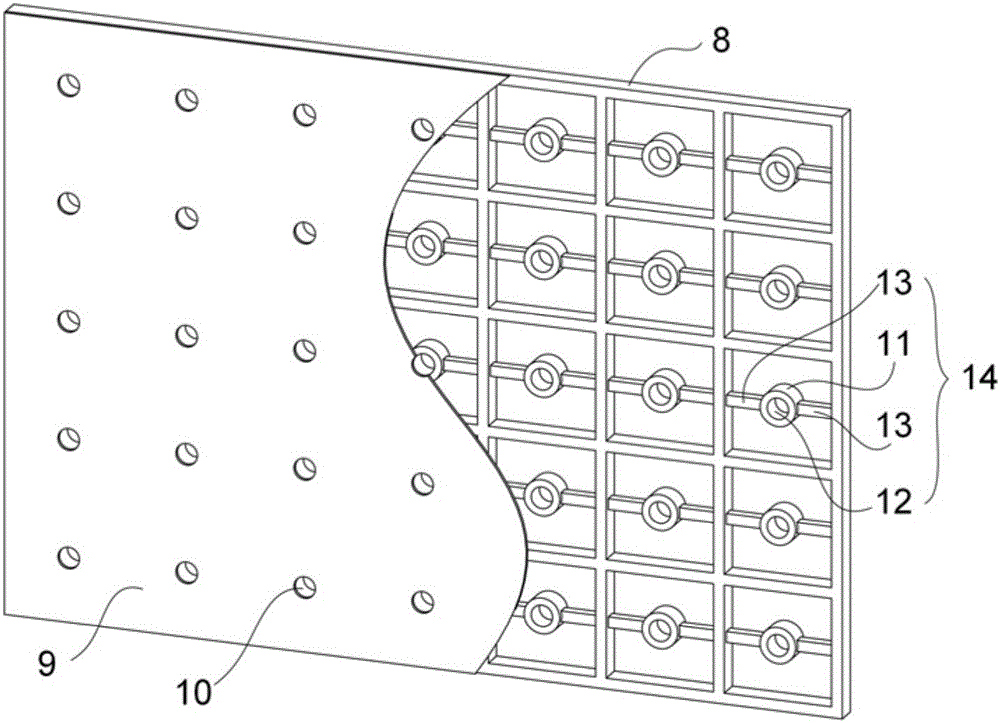

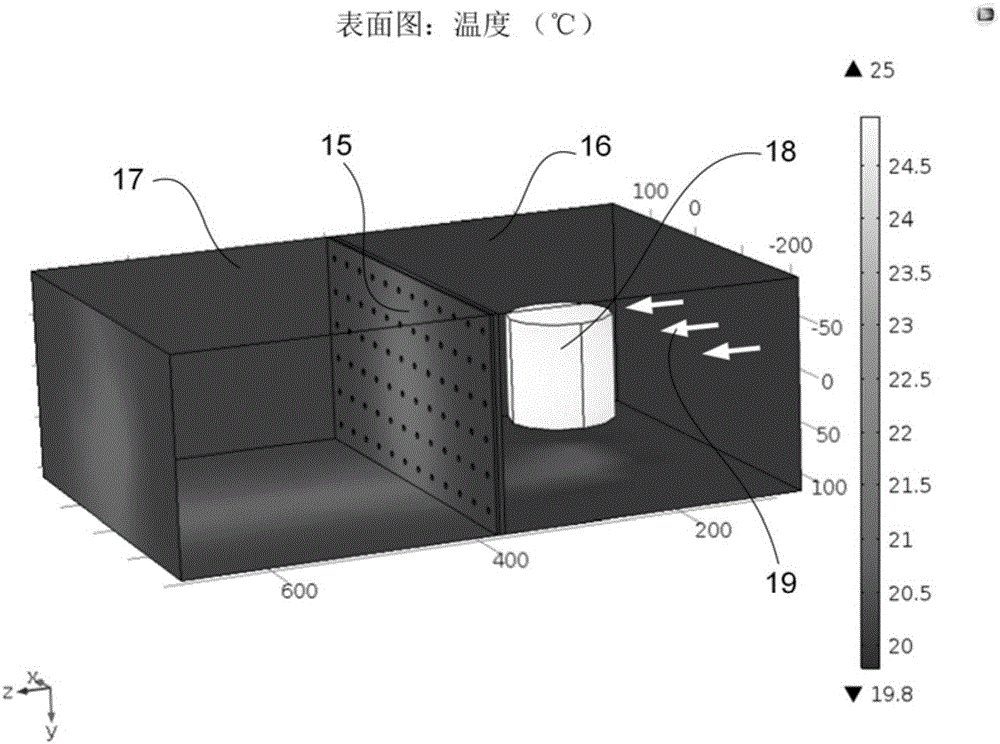

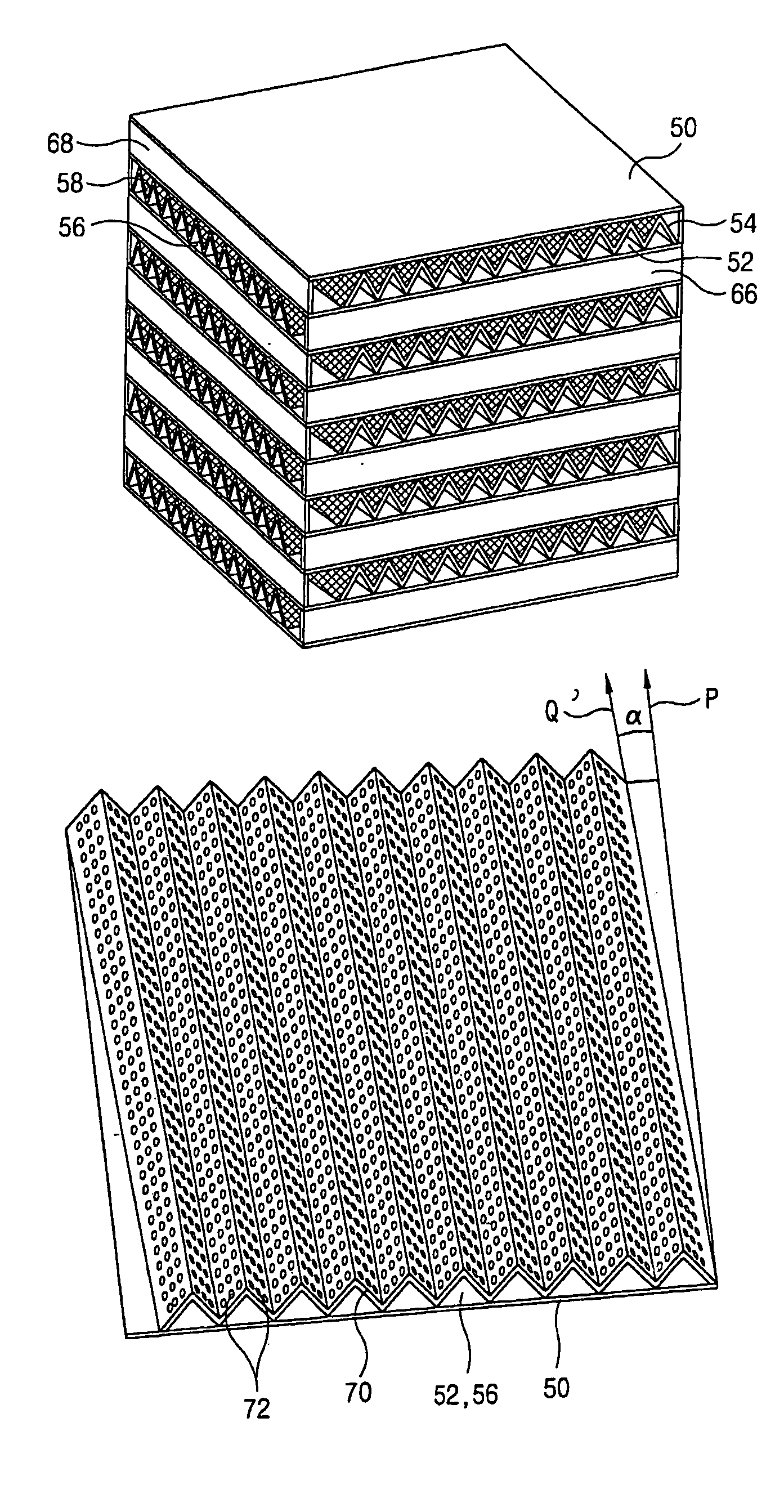

Sound-insulating, ventilating and heat transfer enhancing acoustic metamaterial unit, composite structure and preparation method

ActiveCN105845121AWorking frequency bandwidthImprove sound insulationStringed musical instrumentsSound producing devicesEngineeringComposite plate

The invention relates to a sound-insulating, ventilating and heat transfer enhancing acoustic metamaterial structural unit, which comprises a frame, wherein a restraining body is arranged inside the frame, and at least one of the upper and lower surfaces of the frame is coated with a thin film; and at least one hole is formed in the restraining body and the thin film. In addition, the invention provides an acoustic metamaterial composite plate and an acoustic metamaterial composite structure comprising the acoustic metamaterial structural unit, as well as a frequency modulation method and an assembly method. The acoustic metamaterial structural unit has sound insulation capability superior to that of an ordinary perforated plate or micro-perforated plate within a broadband, can ensure that sufficient heat flow, air flow or liquid flow can pass through smoothly, and increases heat diffusion rate of fluid media on both sides of holes and accelerates heat convection efficiency through unit localized vibration generated by the structure under excitation of acoustic waves. The acoustic metamaterial structural unit and the array composite structure have the advantages of simple assembly technology and stable working performance.

Owner:黄礼范

Multipurpose Flow Module

InactiveUS20080267845A1Prevent leakageSufficient contact pressureFlow mixersChemical/physical/physico-chemical microreactorsEngineeringHeat exchanger

The present invention relates to a multipurpose flow module comprising flow plates and / or heat exchanger plates stacked together, which flow plate having a flow channel and one or more connection ports. To each flow plate or heat exchanger plate one or more barrier plates may be attached. The present invention further relates to a method for extraction, for reaction, for mixing, or combinations thereof in the multipurpose flow module, and to uses of the multipurpose flow module.

Owner:ALFA LAVAL CORP AB

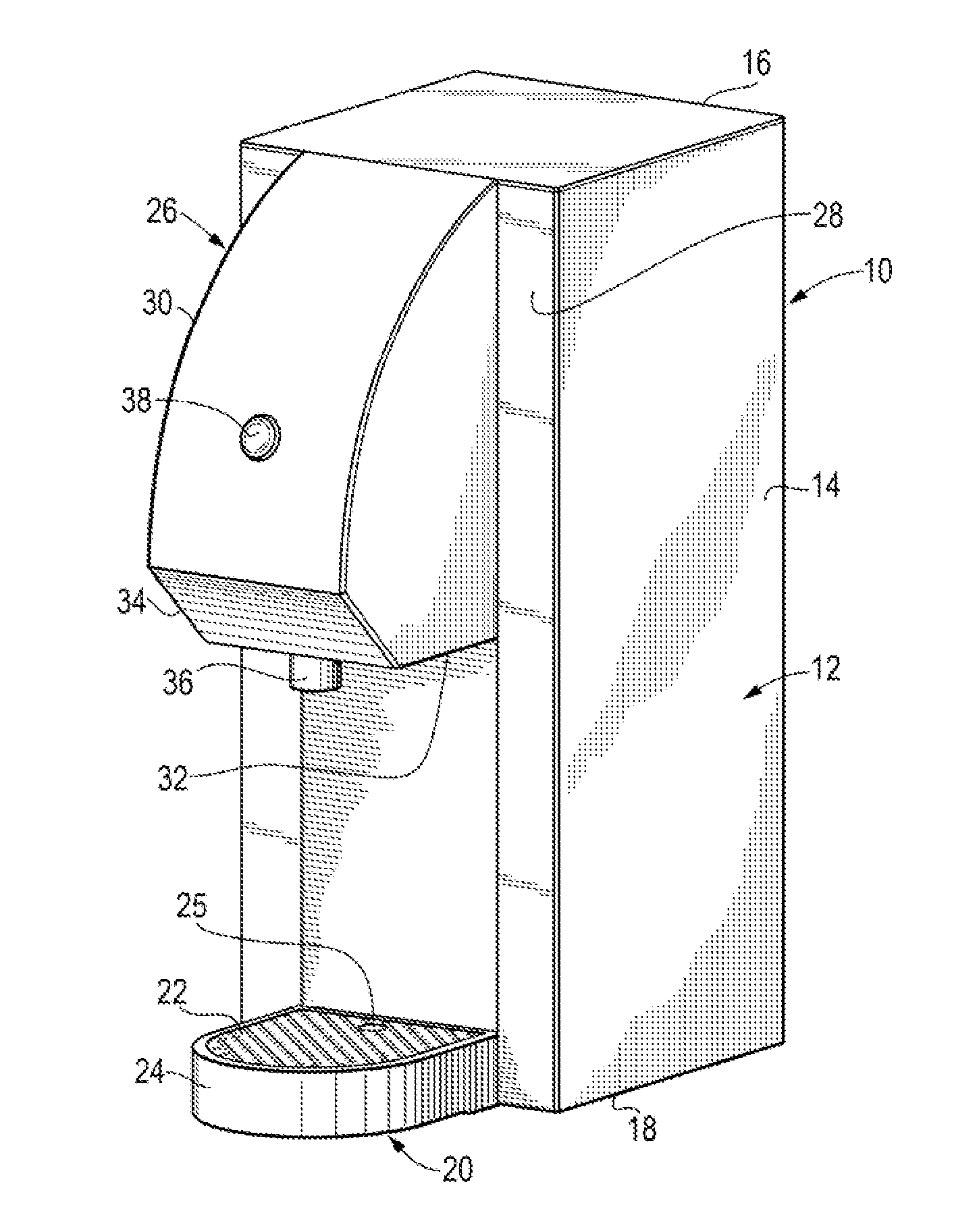

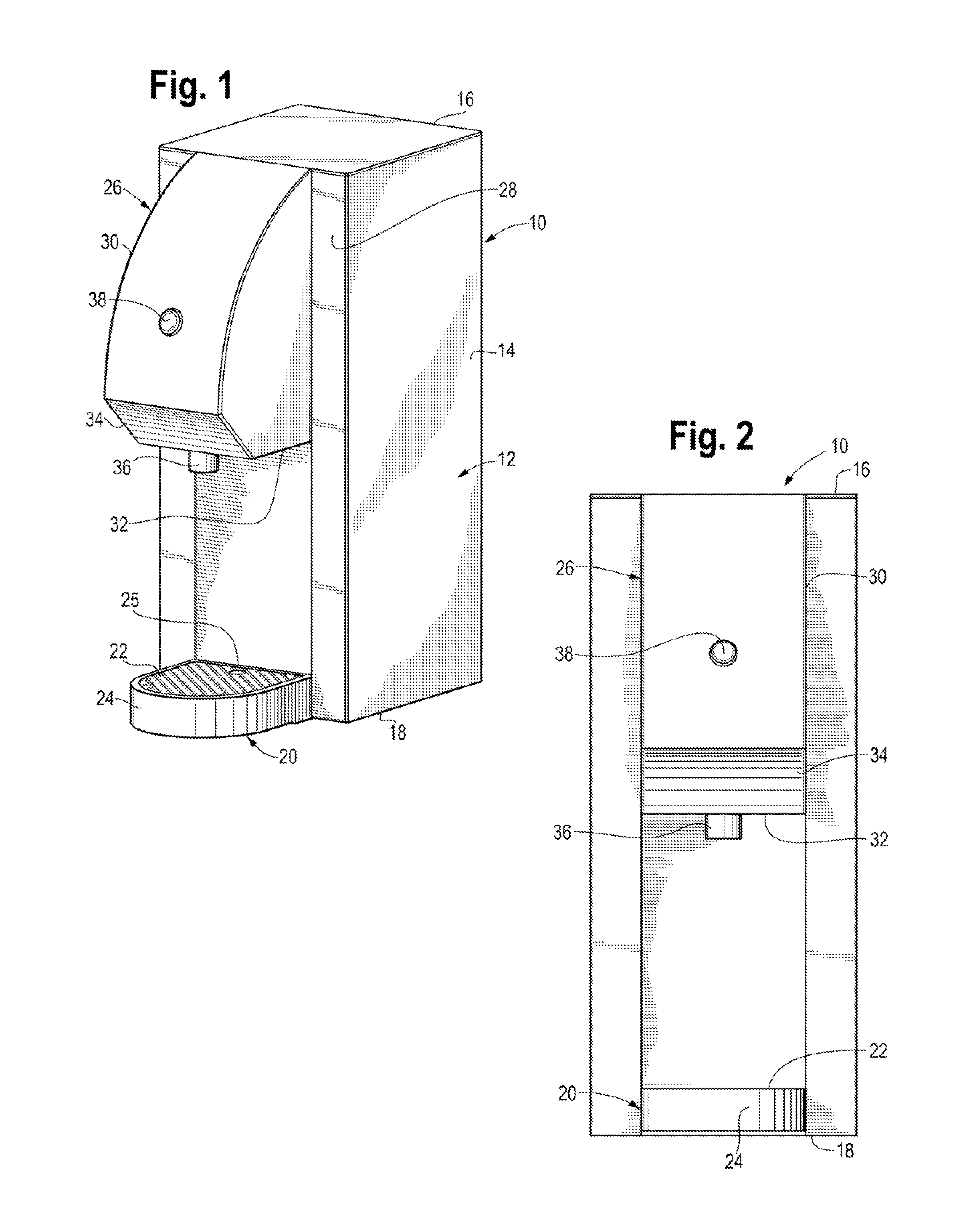

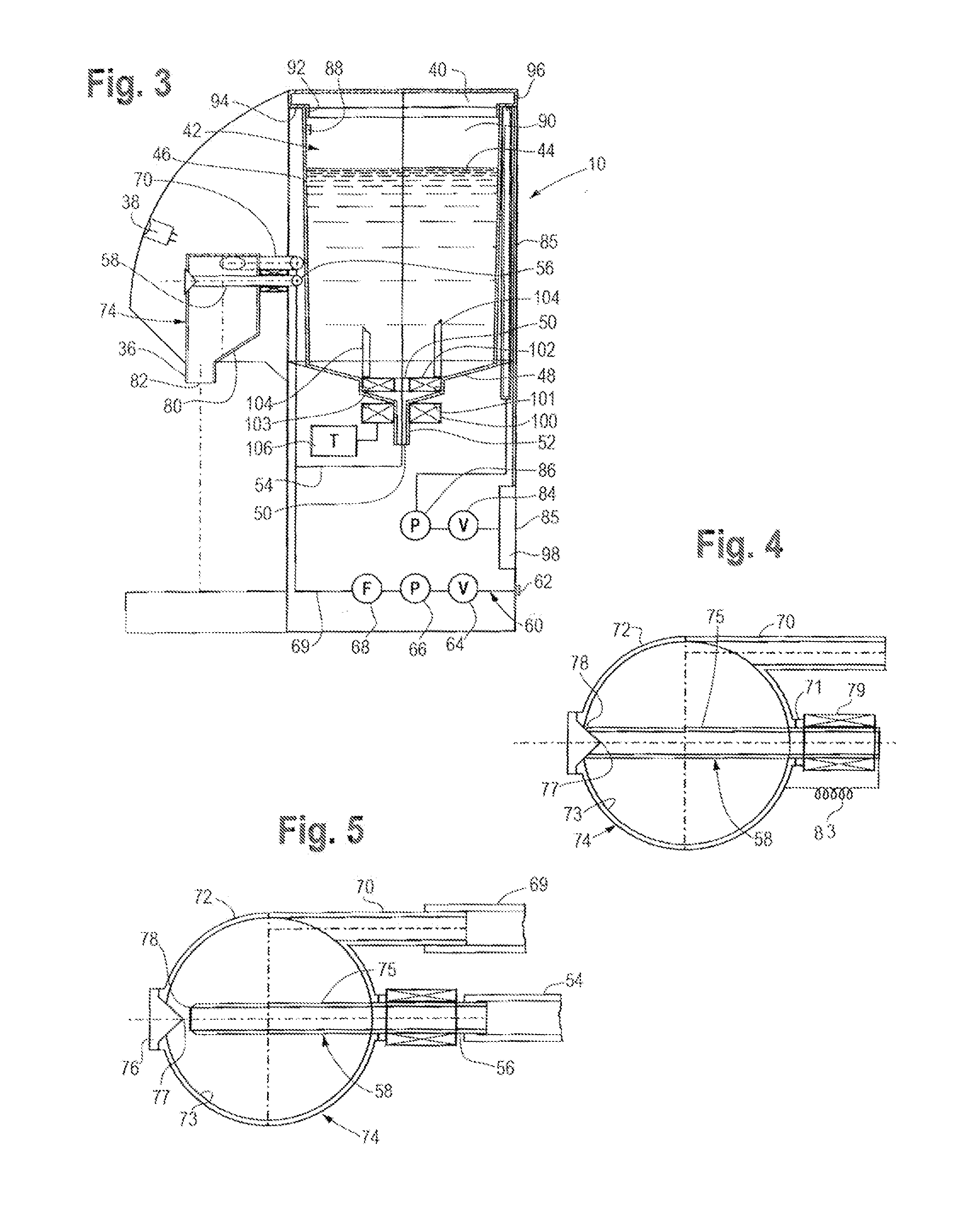

Liquid beverage concentrate mixing beverage dispenser and method

ActiveUS8881948B1Easy maintenanceUniform viscosityBeverage vesselsLiquid transferring devicesNitrogenEngineering

An automated mixing drink dispenser (10) establishes a preselected feed rate of concentrate from a concentrate hopper (42) and ratio of concentrate to mixing water fed into a mixing chamber (42) through the Venturi effect created by swirling water fed into a mixing chamber (42) at a preselected water pressure (66) and preselected regulated flow rate (68) associated with the preselected feed rate of the concentrate. Concentrate is fed to a mixing chamber (42) from a concentrate hopper (42) having an open drain hole (50) openly connected to the mixing chamber (42). A stirring mechanism (106, 100, 101, 102, 104) mechanically mixes the concentrate within the concentrate hopper (42) to maintain a uniform density and viscosity and a gas pressure mechanism (92, 94, 96, 86) maintains a uniform head pressure of concentrate to facilitate maintenance of the preselected concentrate flow rate over time. Nitrogen gas in air is pumped through a nitrogen passing filter to fill the space (90) above the concentrate to both maintain head pressure and to reduce deterioration of the concentrate due to interaction with oxygen.

Owner:FOOD EQUIP TECH

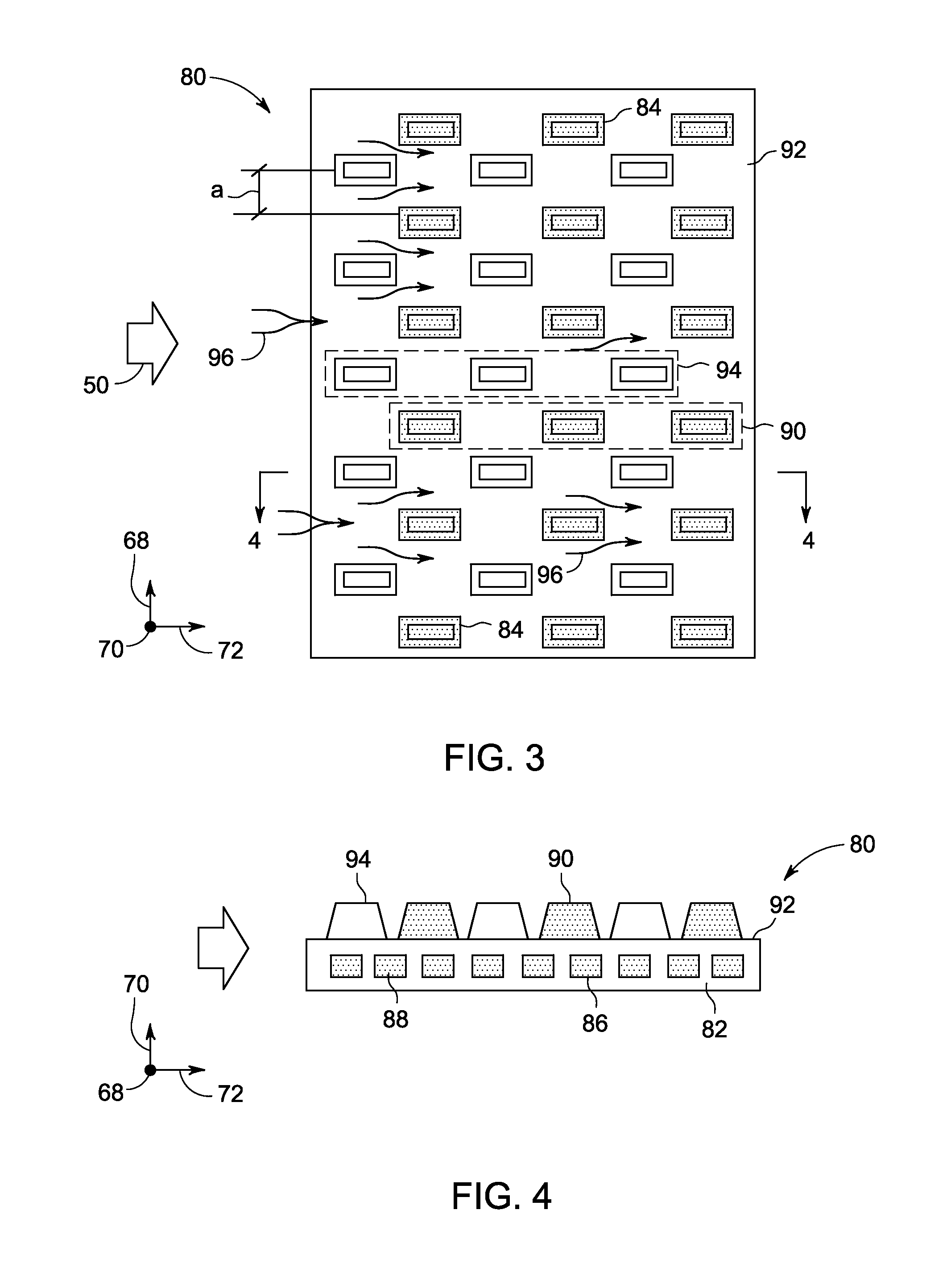

Heat exchanger tube with integral restricting and turbulating structure

InactiveUS20080029243A1Reduce possibilityEffective structureRecuperative heat exchangersAir heatersCHEEK DIMPLESMechanical engineering

A heat exchanger tube having an integral restricting and turbulating structure consisting of dimples formed by confronting indentations pressed into the sides of the heat exchanger tube. The dimples are comprised of indentations disposed in pairs which extend into the tube to such a depth as is necessary to significantly reduce the cross sectional area of the heat exchanger tube. The dimples of a pair are staggered or offset, longitudinally with respect to each other such that a restrictive passage is defined between each pair of offset dimples. The turbulence characteristics of the tube can be controlled by varying the depth to which the dimples project into the tube and the longitudinal spacing between the dimples that comprise the pair. Adjacent pairs of dimples may be rotated 90° with respect to each other or alternately can be arranged in a helix pattern.

Owner:BECKETT GAS

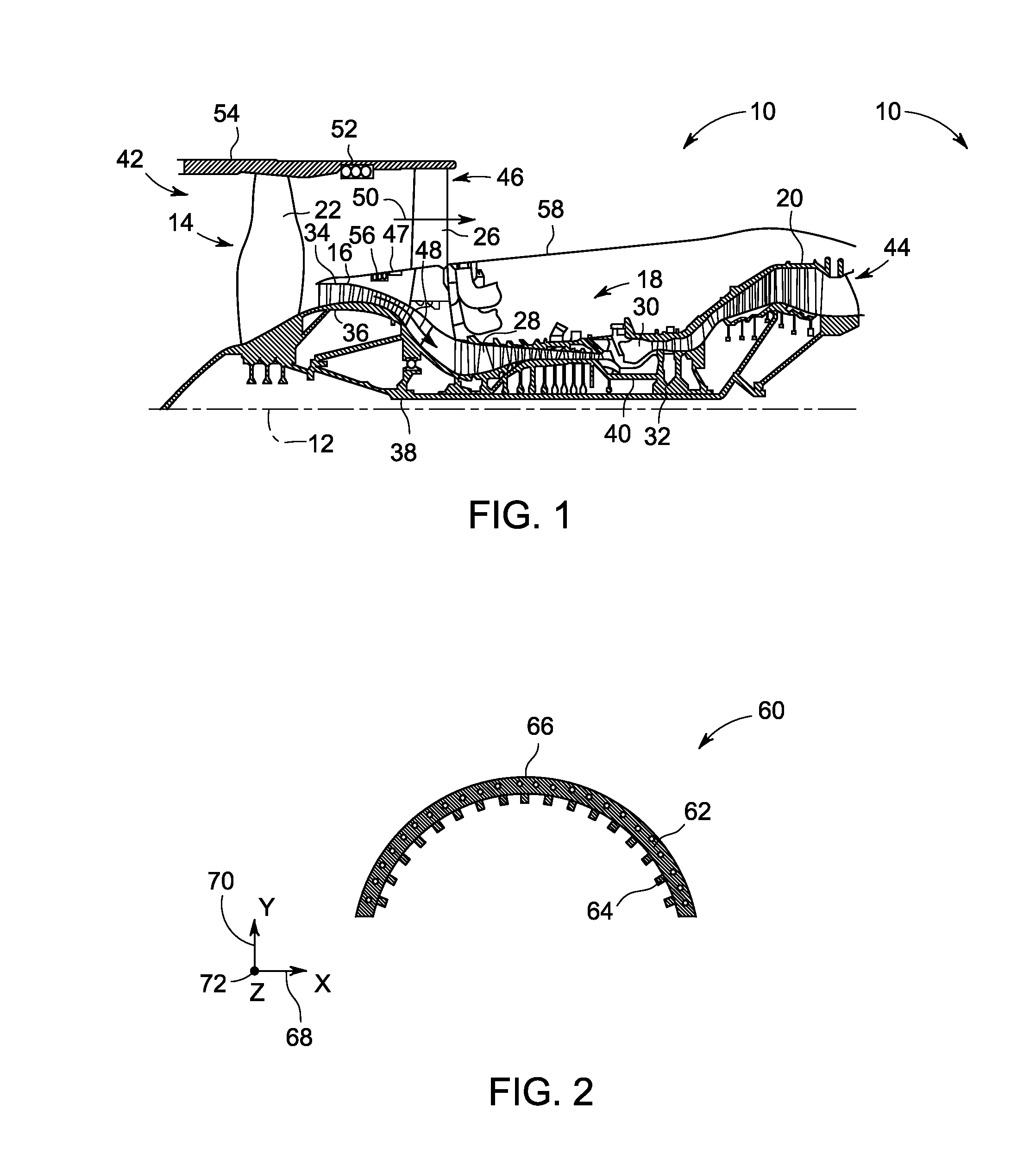

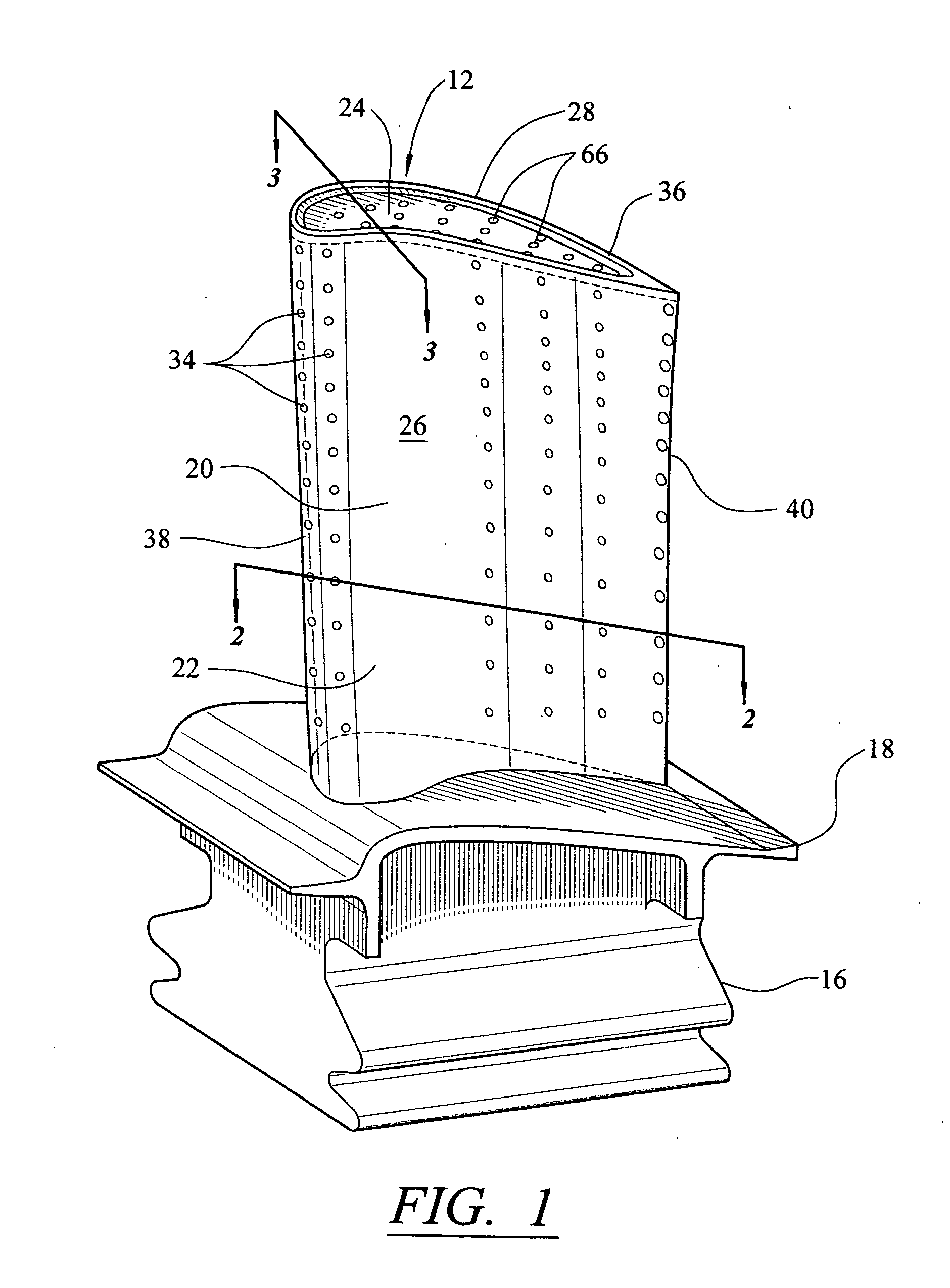

Component for a gas turbine

InactiveUS6382907B1Improve cooling effectIncreases stiffness thus strength reliabilityPump componentsEngine fuctionsRotary machineInterior space

The invention refers to a component defining a blade or a vane for a rotary machine having a rotor rotatable about an axis. The component includes an inner space forming a passage for a cooling fluid between first and second walls. First ribs project from the fist wall and extend essentially in parallel to each other to form fist channels for the fluid from a leading part of the inner space to a trailing part of the space. The first ribs extend in a first direction forming a first angle of inclination to the axis in the leading part and in a second direction forming a second angle of inclination to the axis in the trailing part. The first angle is greater than the second angle.

Owner:SIEMENS AG

Sand control method and apparatus

InactiveUS6752206B2Reduce the possibilityIncrease pressureFluid removalDrinking water installationControl treatmentCoiled tubing

Owner:SCHLUMBERGER TECH CORP

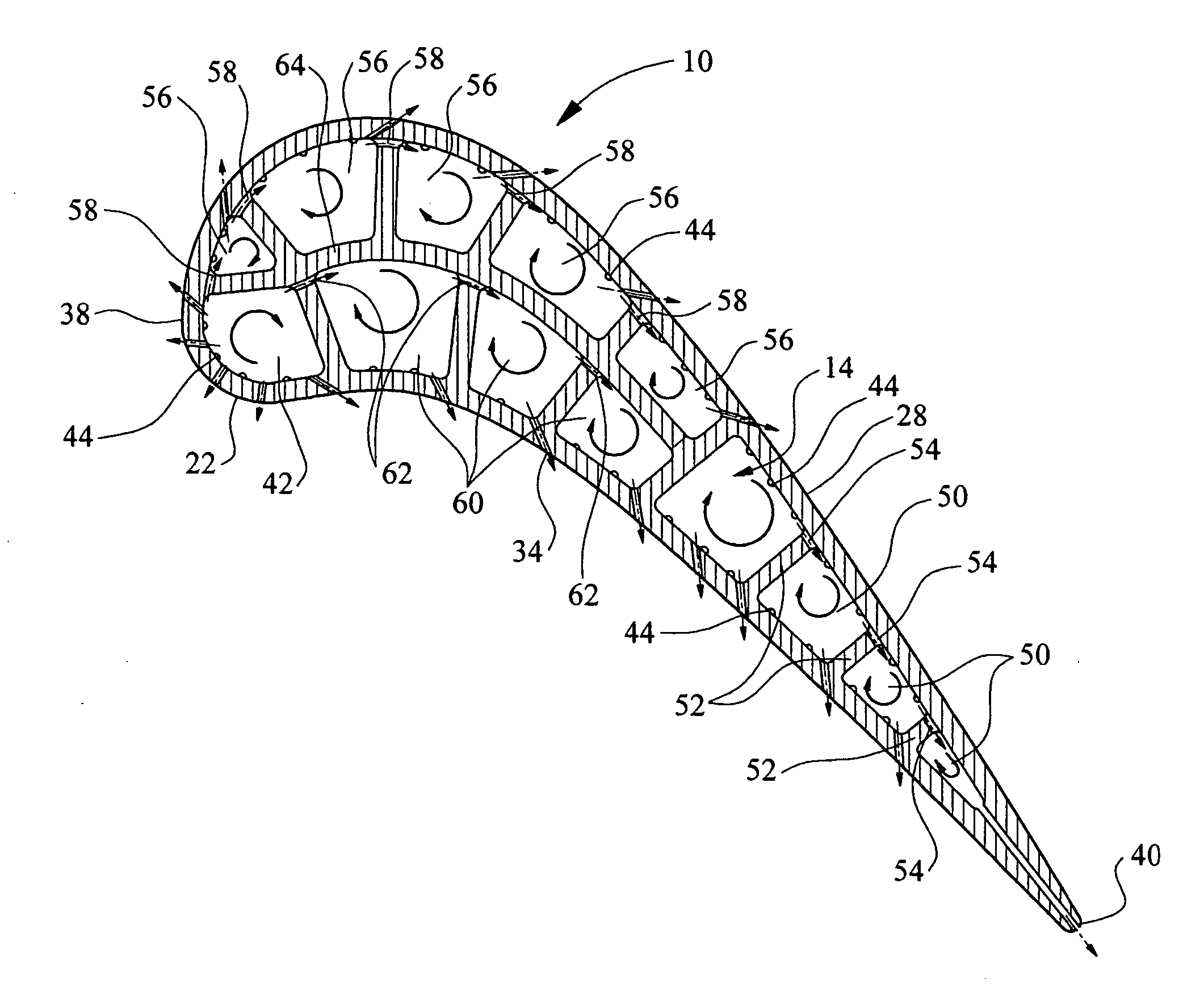

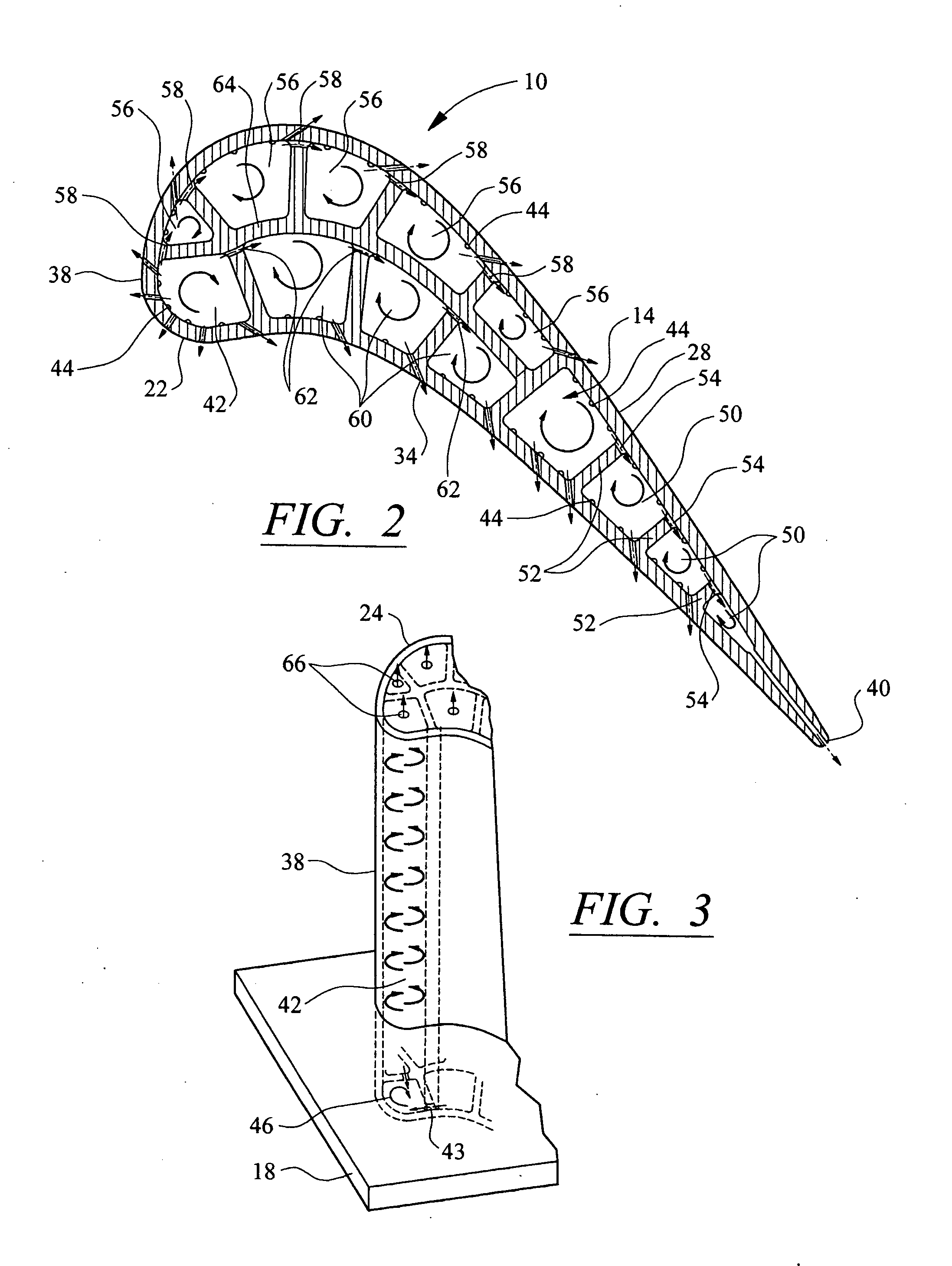

Vortex cooling system for a turbine blade

ActiveUS20060056967A1Heat dissipationIncrease heat heat removalEngine fuctionsBlade accessoriesLeading edgeTurbine blade

A turbine blade for a turbine engine having an internal cooling system formed from a plurality of cooling chambers extending radially in the blade and configured to create vortices within the chambers. In at least one embodiment, the cooling system may be formed from leading edge cooling chambers, trailing edge cooling chambers, suction side mid-chord cooling chambers, and pressure side mid-chord cooling chambers that are configured to receive cooling fluids from supply channels in a root of the blade and to create vortices in the cooling chambers. The vortices of cooling fluids increase heat removal from the turbine blade. The cooling fluids may be exhausted from the turbine blade through film cooling orifices.

Owner:SIEMENS ENERGY INC

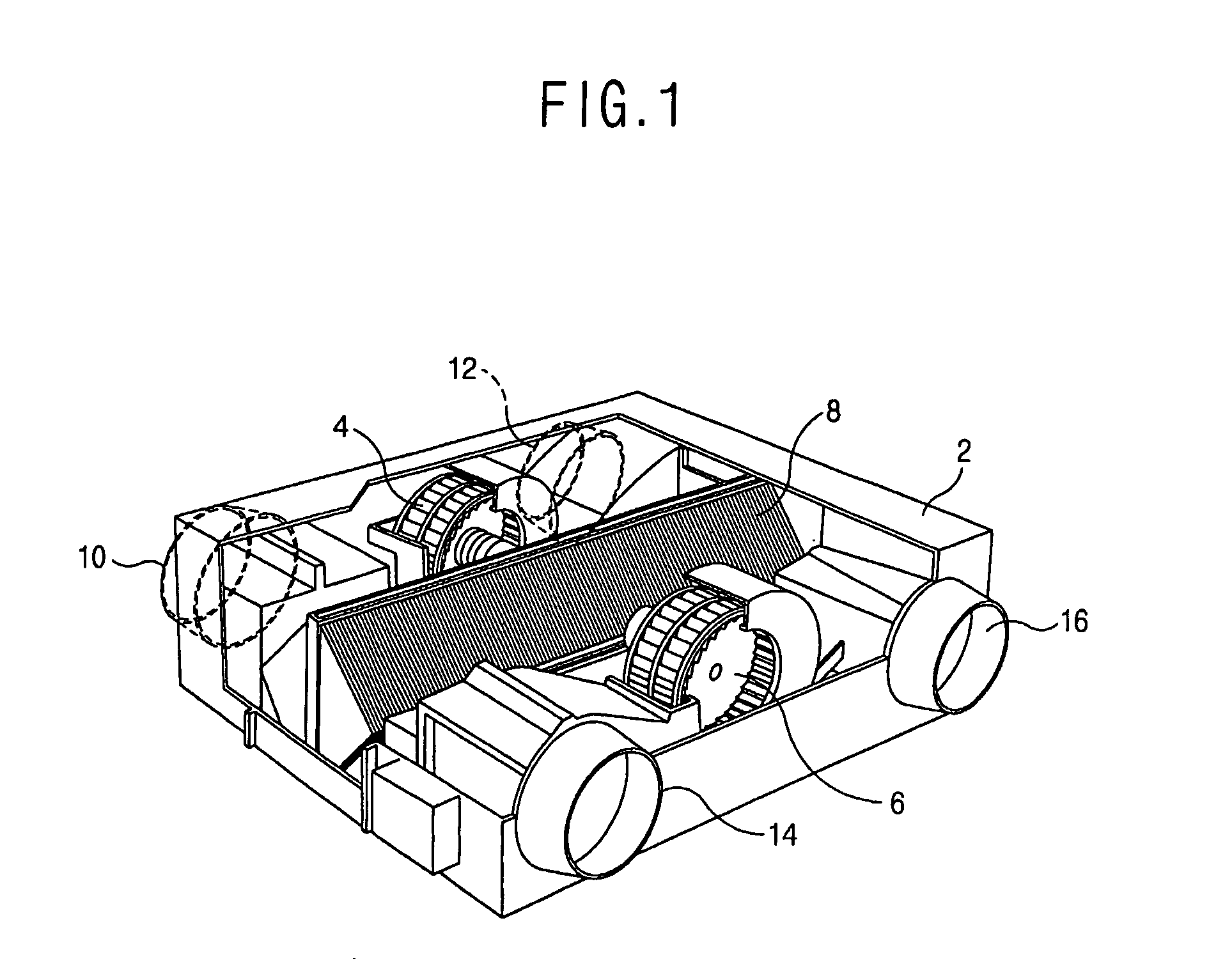

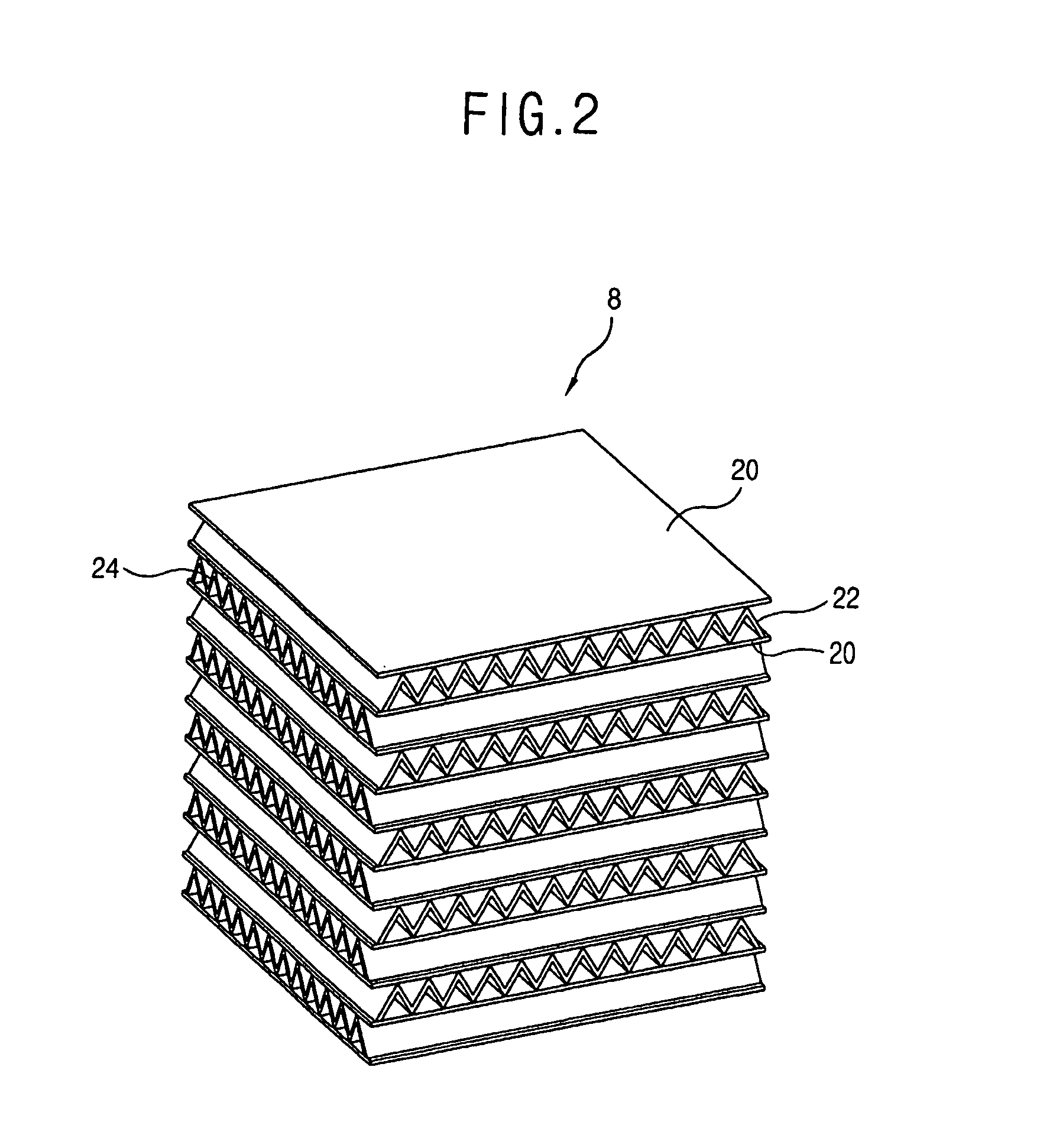

Heat exchanger of ventilating system

InactiveUS7228891B2Improve heat transfer performanceIncreased air turbulenceEnergy recovery in ventilation and heatingHeat recovery systemsPlate heat exchangerEngineering

A heat exchanger of a ventilating system, including a plurality of heat exchanging plates which are laminated at a predetermined interval, a first heat exchange member which is laminated among the heat exchanging plates and is formed in a mesh type to increase turbulence of the outdoor air which flows while being attached on a first air path through which outdoor air passes and a second heat exchange member which is laminated among the heat exchanging plates crossed with the first heat exchange member and is formed in a mesh type to increase turbulence of indoor air which flows while being attached on a second air path through which the outdoor air passes can improve heat transfer performance by increasing turbulence of air by positioning a mesh type heat exchange in a air path through which outdoor and indoor air passes.

Owner:LG ELECTRONICS INC

Drip irrigation hoses of the labyrinth type and flow-control elements for producing such hoses

InactiveUS20080067266A1Large heightReduce thicknessClimate change adaptationWatering devicesDrip irrigationWater flow

A drip irrigation hose includes a tube for conducting pressurized water through its interior and formed with a plurality of outlets for emitting water at longitudinally-spaced locations along the length of the tube; and a plurality of flow-control elements fixed with respect to the inner surface of the tube at longitudinally-spaced locations thereof to define, with the inner surface, a plurality of labyrinths each having an inlet communicating with the interior of the tube and an outlet communicating with a tube outlet for emitting water there from at a slow rate. The labyrinth includes a bottom wall constructed to produce, adjacent to the bottom wall, a significant laminar flow of water in which the laminar flow decreases, and thereby turbulent flow increases, with an increase in the water pressure within the tube to thereby provide pressure-compensation for the water flow through the respective tube outlet.

Owner:COHEN

Multichannel plasma area igniting burner

ActiveCN104879780AAct as ignition sourceFlame stabilityGas turbine plantsCombustion ignitionCombustion chamberLow speed

The invention discloses a multichannel plasma area igniting burner. The igniting burner comprises a plasma power supply, a nozzle, an air inlet fish nozzle, a tangential air hole, an air pipe, a hollow insulator, a high-voltage electrode, an insulation piece, a low-voltage electrode, a housing, a swirl chamber, air vents, barrier mediums, a low-speed area, center jet flow and a flame stabilization chamber. Fuel oil is atomized by the use of a splash plate disposed inside the air inlet pipe, mixed gas composed of high-speed rotation air-flow and direct current jet flow is disposed inside the igniting burner, and the two flows cool the igniting burner. The space between the high-voltage electrode and the low-voltage electrode is filled with the inflammable mixed gas flowing at a low speed, so that multi-point discharge and ignition can be carried out in a low-speed mixed gas area inside the igniting burner; and an on-duty high-temperature combustion thermonuclear area and the flame stabilization chamber have ignition source and flame stabilization functions and form a miniature high-speed combustion chamber, so that the combustion chamber can efficiently and reliably ignite and keep flames stable under poor conditions such as high-speed, low-temperature, low-pressure, coal firing and the like.

Owner:PEKING UNIV

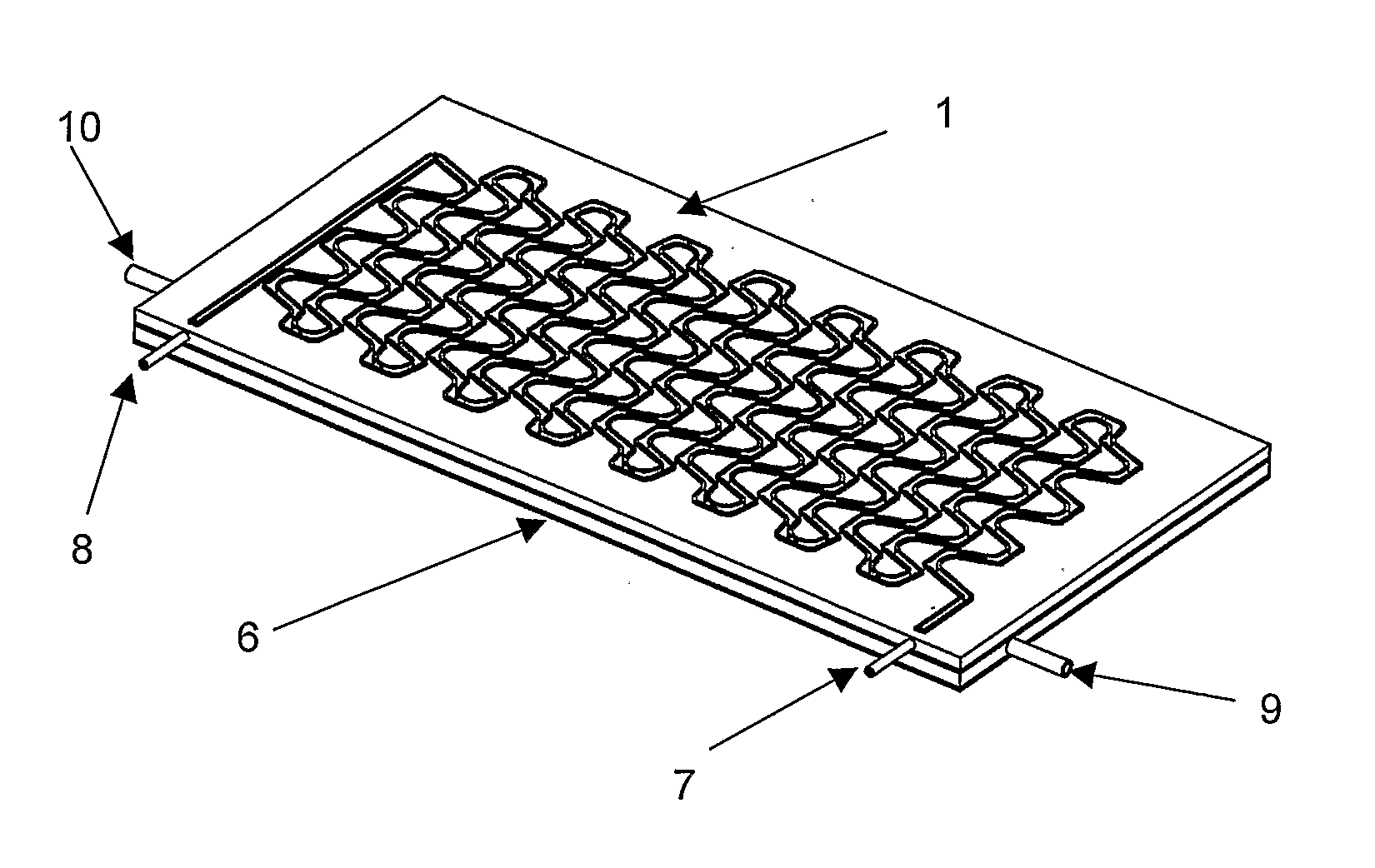

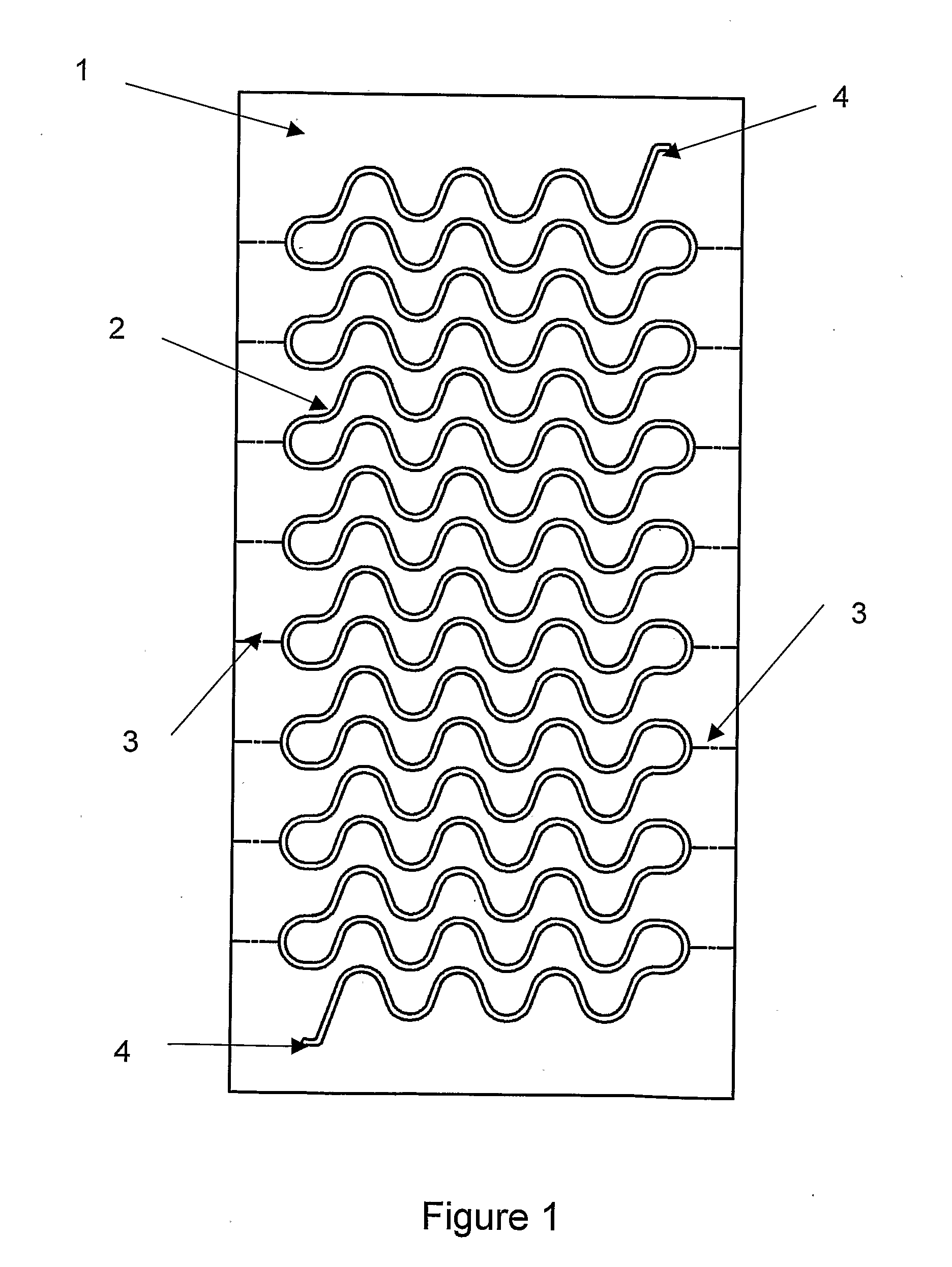

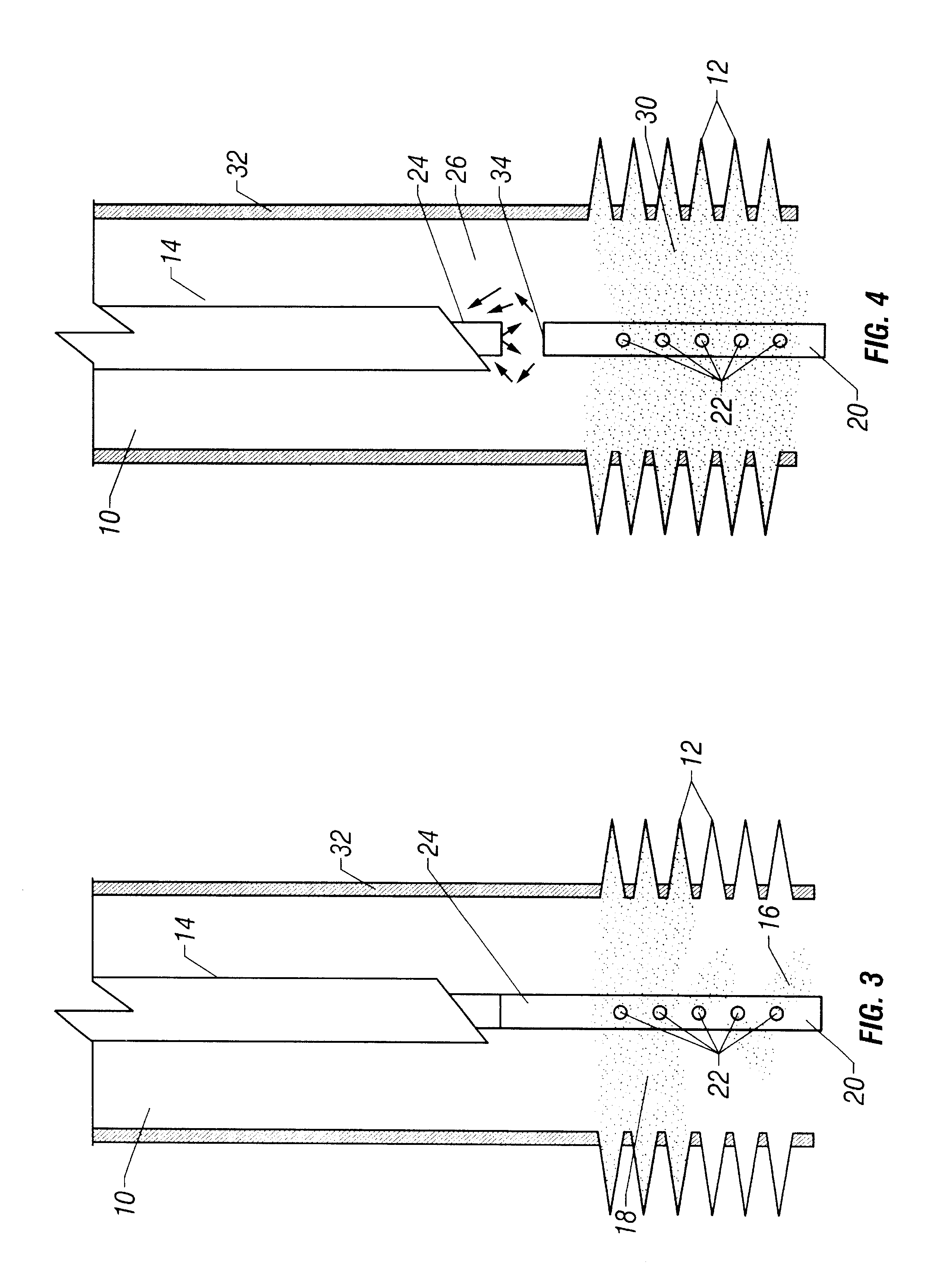

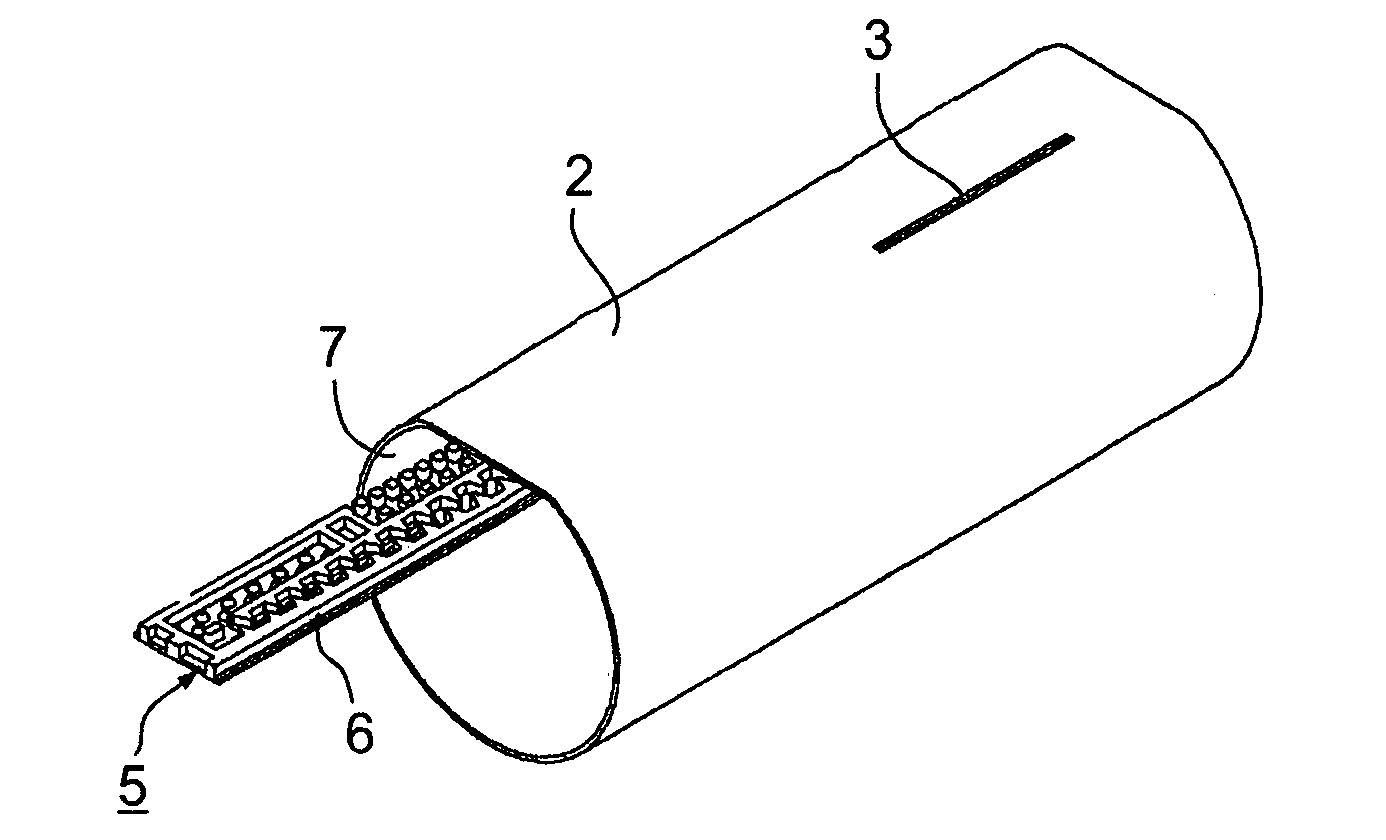

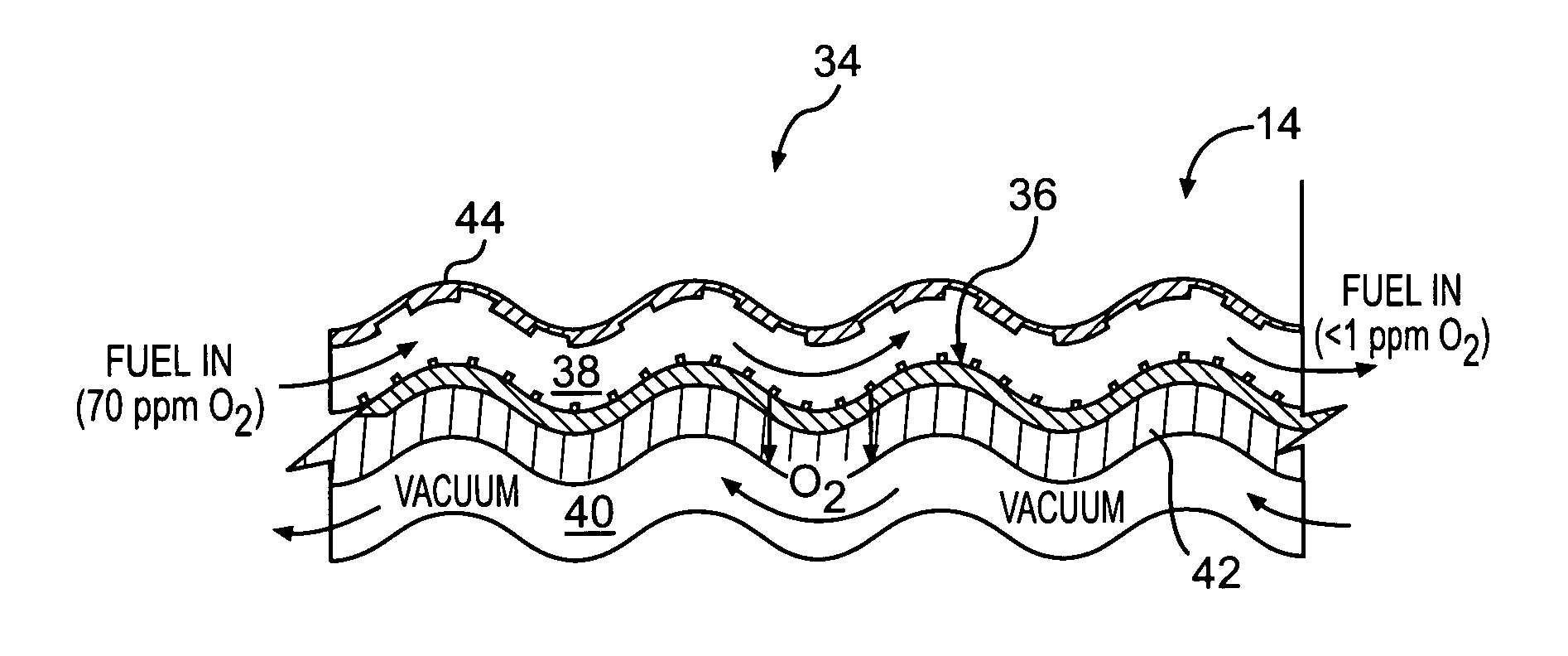

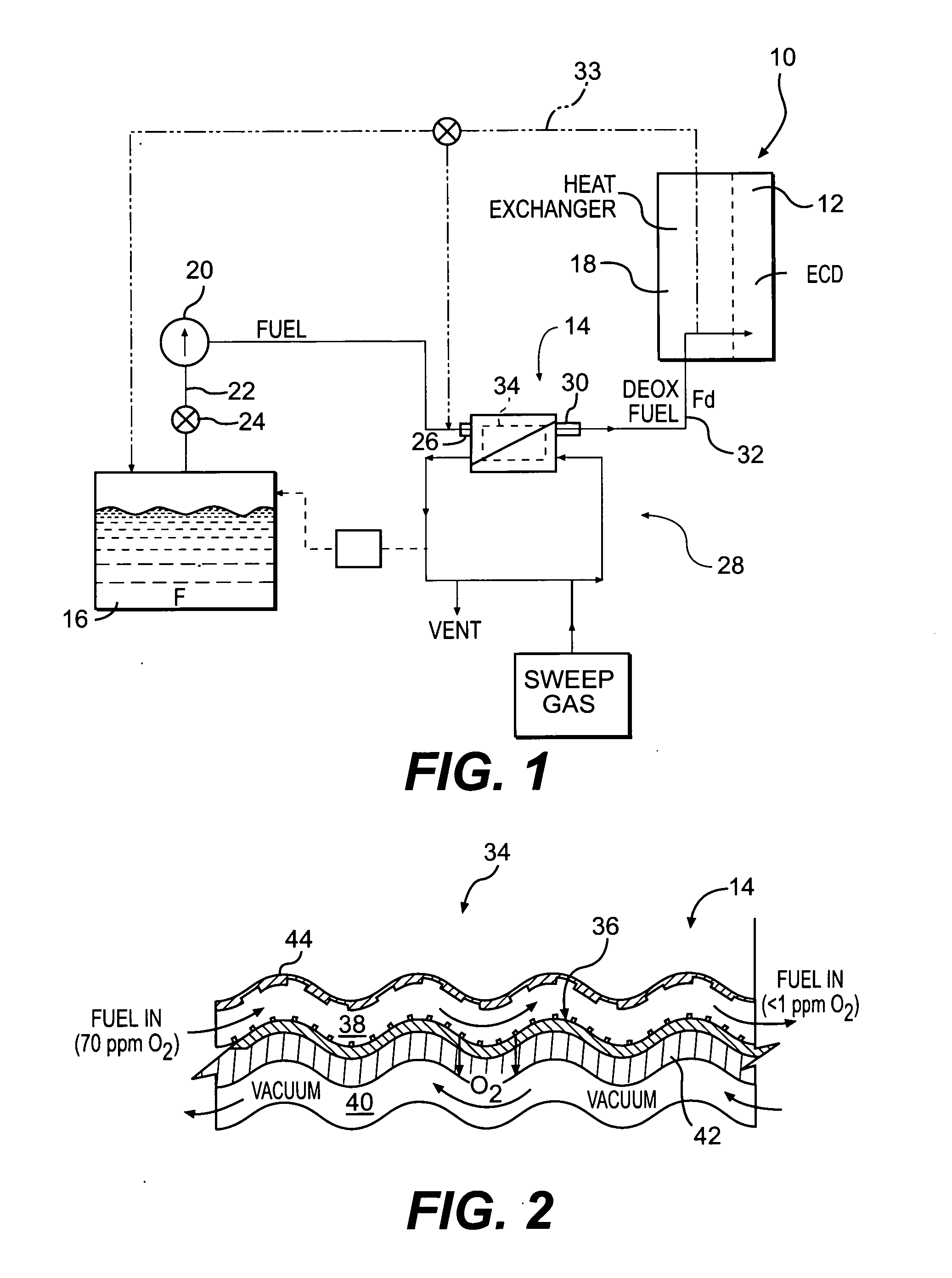

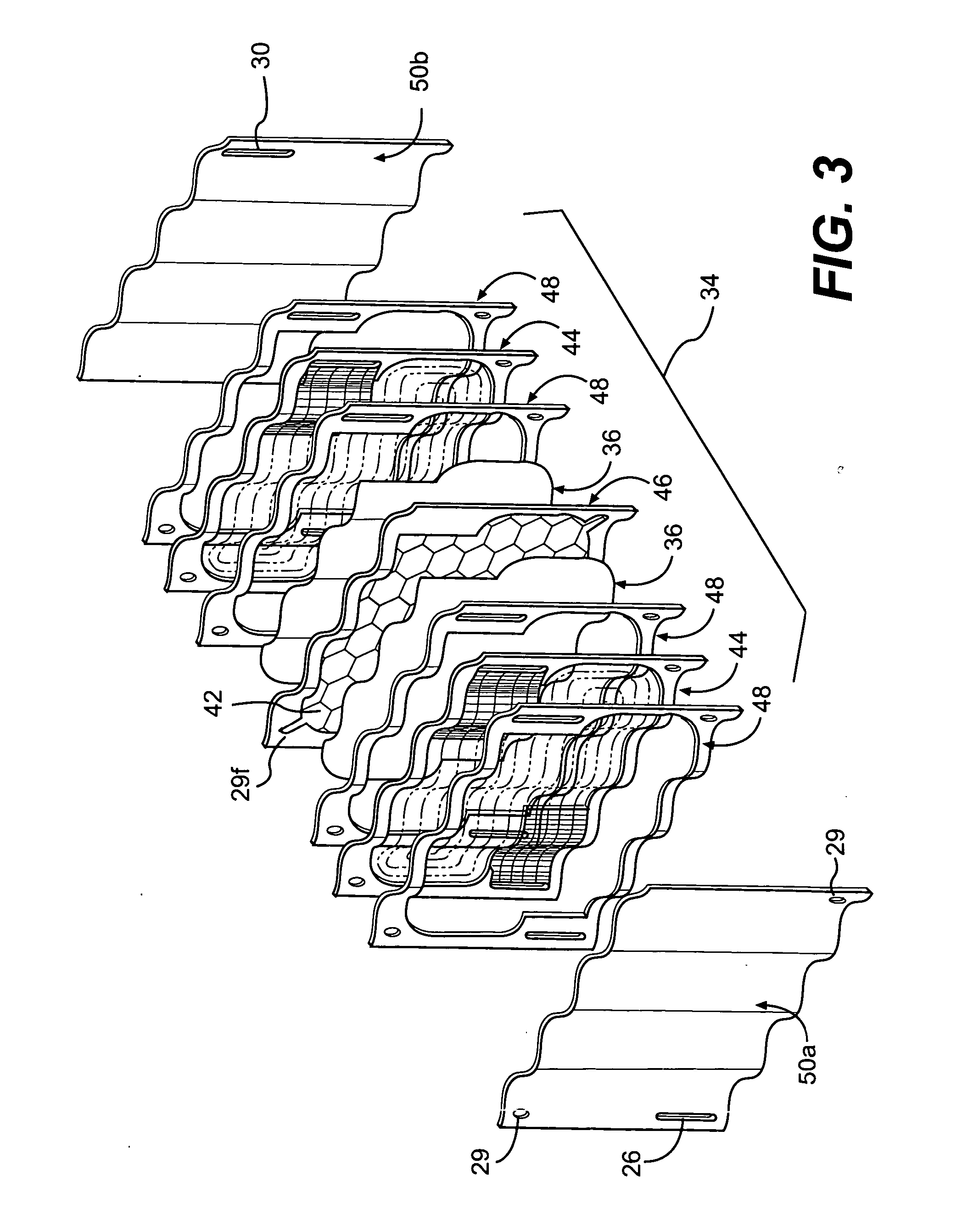

Fuel deoxygenation system with non-planar plate members

ActiveUS20060278073A1Enhances deoxygenationImprove efficiencyPower plant fuel tanksIsotope separationPorous substrateEngineering

A fuel system for an energy conversion device includes a multiple of fuel plates, oxygen permeable membranes, porous substrate plates, and vacuum frame plates which define a wave pattern configuration. The wave configuration enhances deoxygenation by increasing the efficiency and integrality due to higher surface volume ration, increase of flow turbulence, and minimal sharp edges which may otherwise damage the oxygen permeable membranes compared to other configurations.

Owner:RAYTHEON TECH CORP

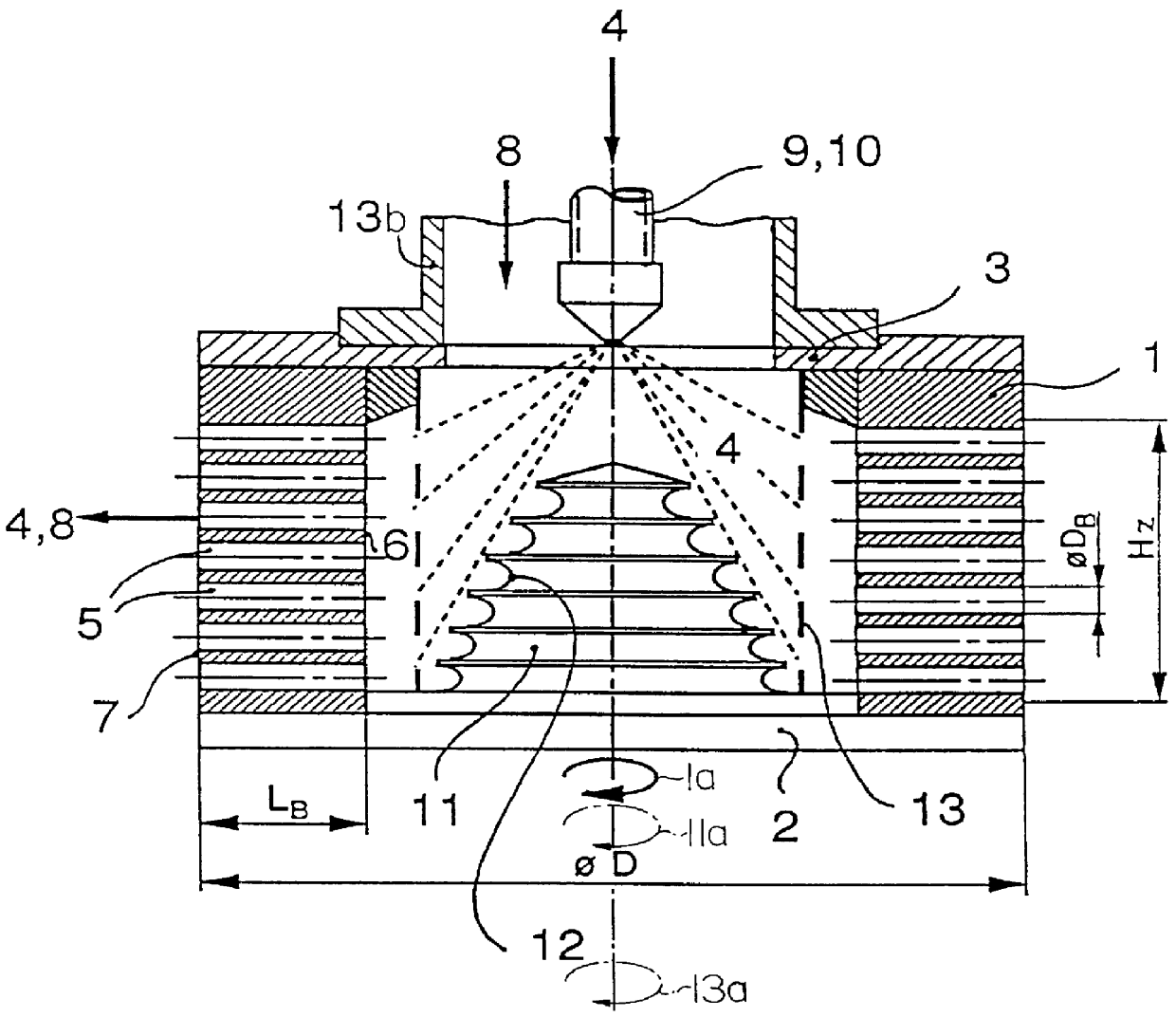

Process and a device for atomizing liquids

InactiveUS6098895ALarge caliberAvoid easy cloggingBurnersMovable spraying apparatusDecompositionEngineering

The liquid to be atomized is uniformly sprayed on the inner surface of a hollow rotating cylinder, for example by means of one- or two-fluid-nozzles and is thus distributed on bores provided in the cylinder wall. The rotation of the cylinder causes the liquid to flow outwards through the bores. Droplets are generated when the liquid flows out of the bores by laminary decomposition of the jet. The flow rate in each bore lies in the range 1.0<+E,dot V+EE B (a3 rho 5 / sigma 5)0.25<16 to prevent the droplets from becoming too large and to satisfy the condition of an adequate flow laminarity, i.e. for the value of the Reynolds number for the continuous liquid flow in the boress not to exceed Re delta 400. +E,dot V+EE B represents the flow rate of the liquid in each bore, a represents the centrifugal acceleration at the outer surface of the cylinder, rho represents the density of the liquid and delta indicates the surface tension of the liquid. The large number N>200 of bores having the diameter DB in the cylinder wall causes the flow rate of liquid through each bore to be relatively low, so that a continuous laminary flow in each bore is ensured even at low viscosities and technically useful total flow rates. Preferably cylindrical bores with a minimum length at least three times larger than the bore diameter are provided in the cylinder wall, with a narrow spacing in the range defined by 1.1<t / DB<5, so that a number of bores as large as possible may be arranged in the wall of the cylinder.

Owner:NIRO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com