Patents

Literature

2835results about How to "Reduce risk of damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

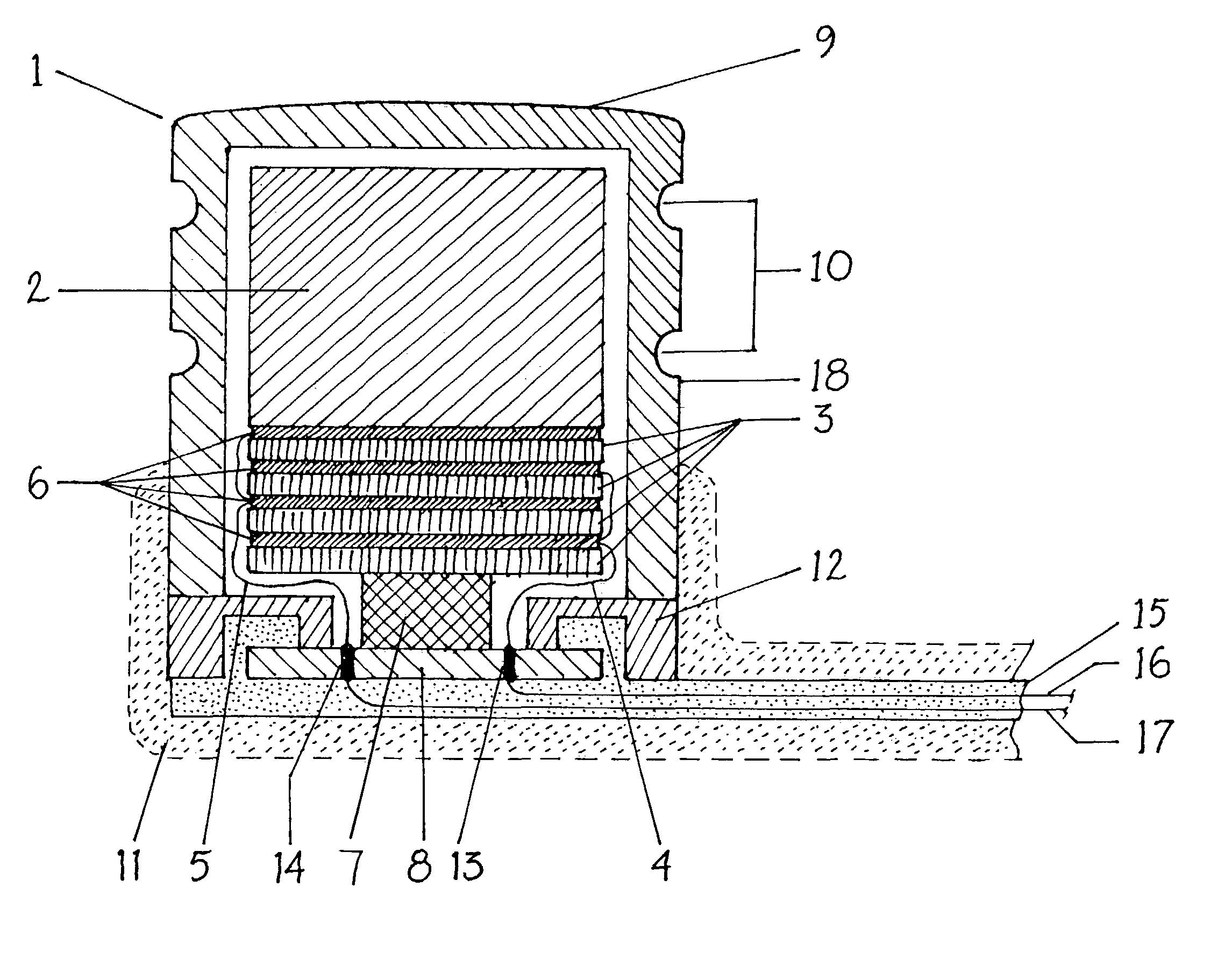

Heart valve prosthesis and methods of manufacture and use

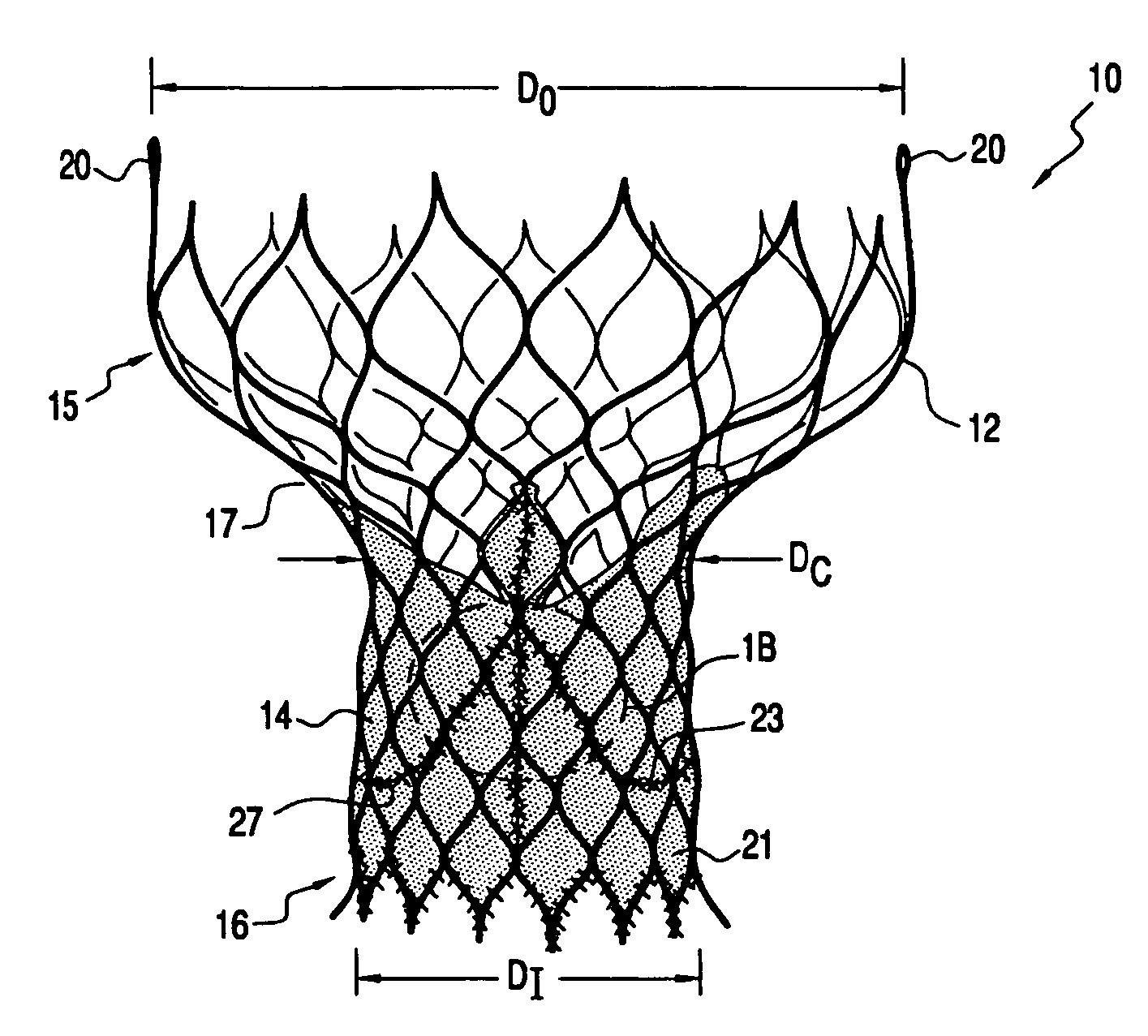

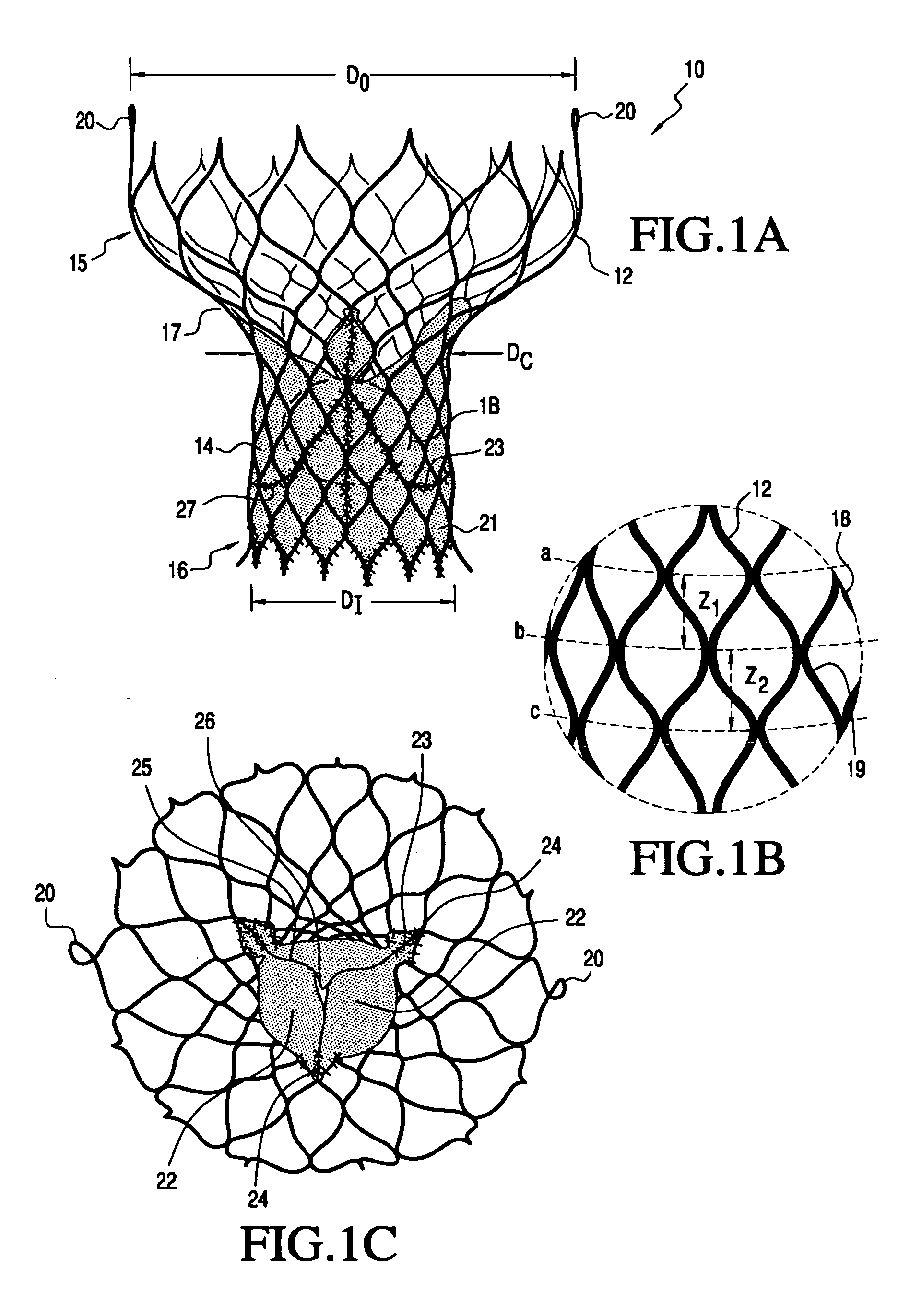

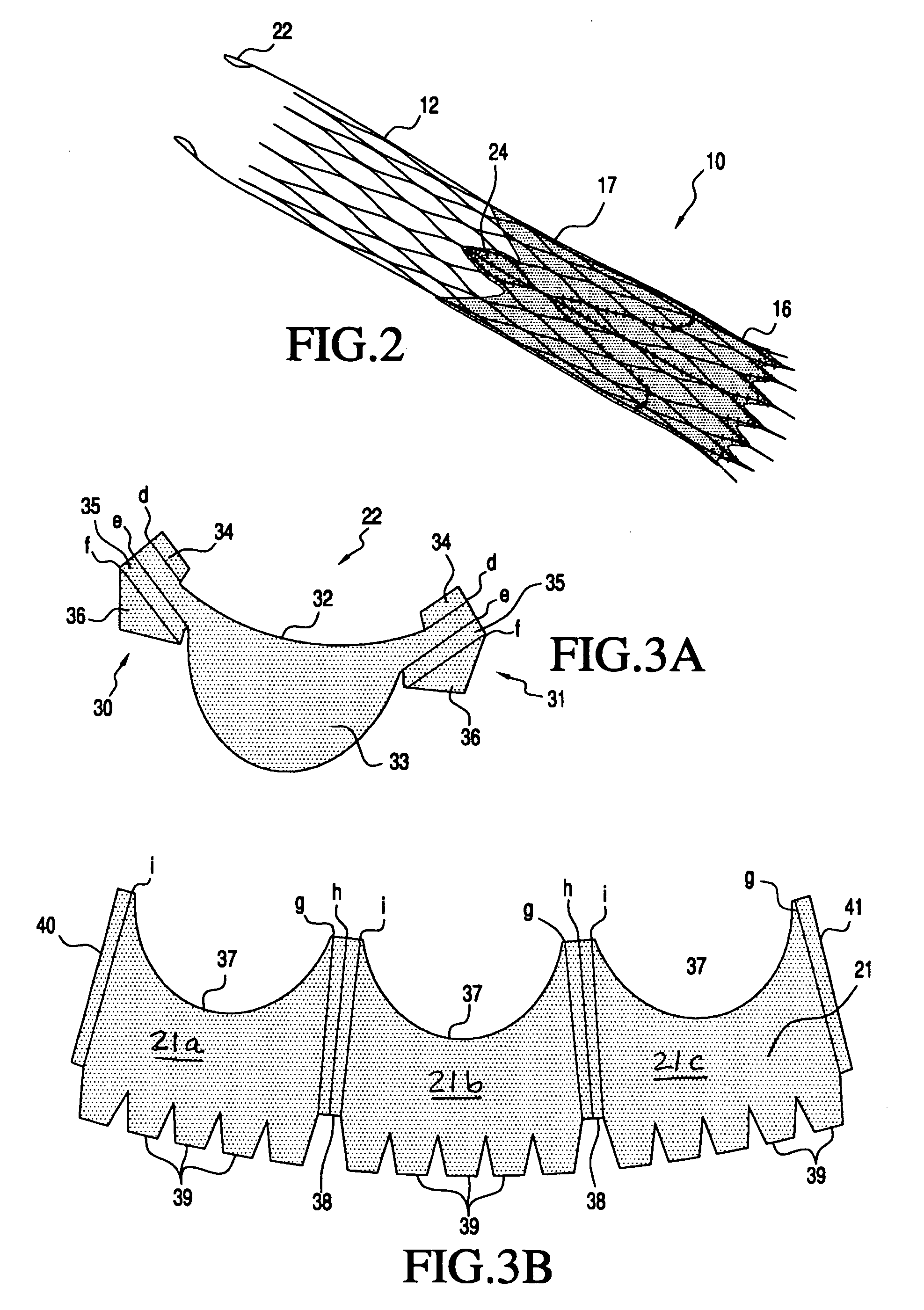

ActiveUS20060265056A1Reduce risk of damageEfficient configurationHeart valvesHorizontal forceHourglass

A heart valve prosthesis is provided having a self-expanding multi-level frame that supports a valve body comprising a skirt and plurality of coapting leaflets. The frame transitions between a contracted delivery configuration that enables percutaneous transluminal delivery, and an expanded deployed configuration having an asymmetric hourglass shape. The valve body skirt and leaflets are constructed so that the center of coaptation may be selected to reduce horizontal forces applied to the commissures of the valve, and to efficiently distribute and transmit forces along the leaflets and to the frame. Alternatively, the valve body may be used as a surgically implantable replacement valve prosthesis.

Owner:MEDTRONIC ARDIAN LUXEMBOURG SARL

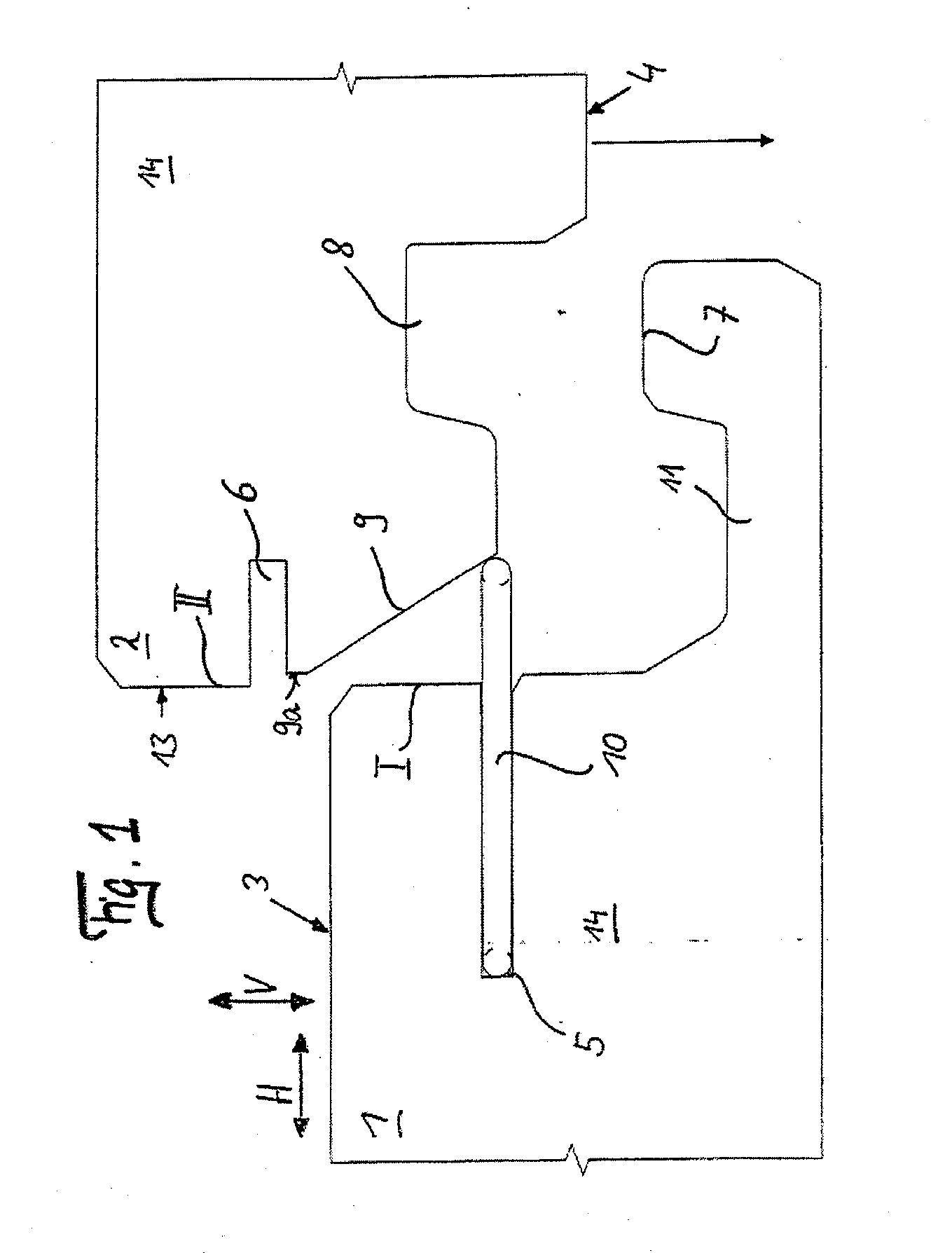

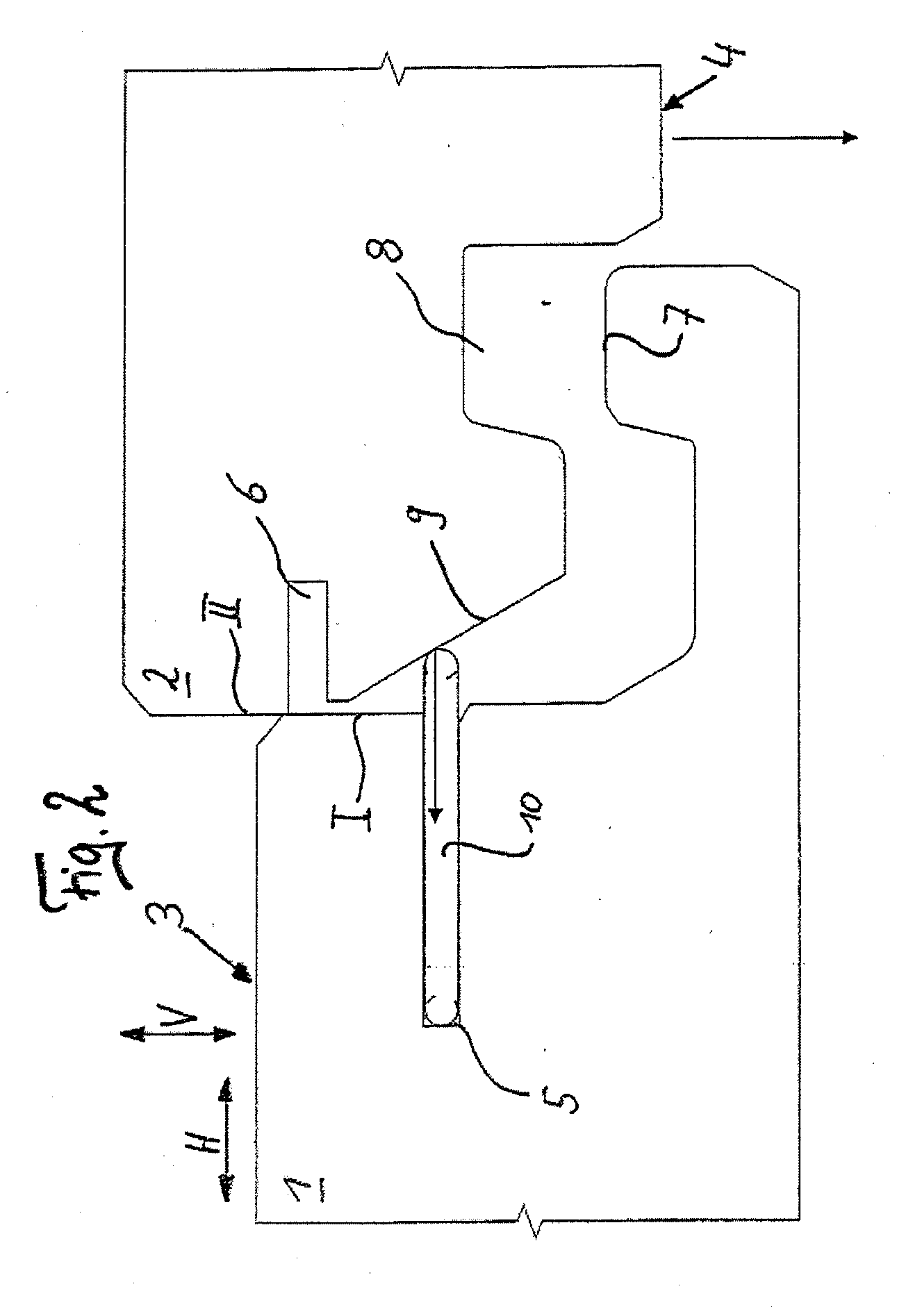

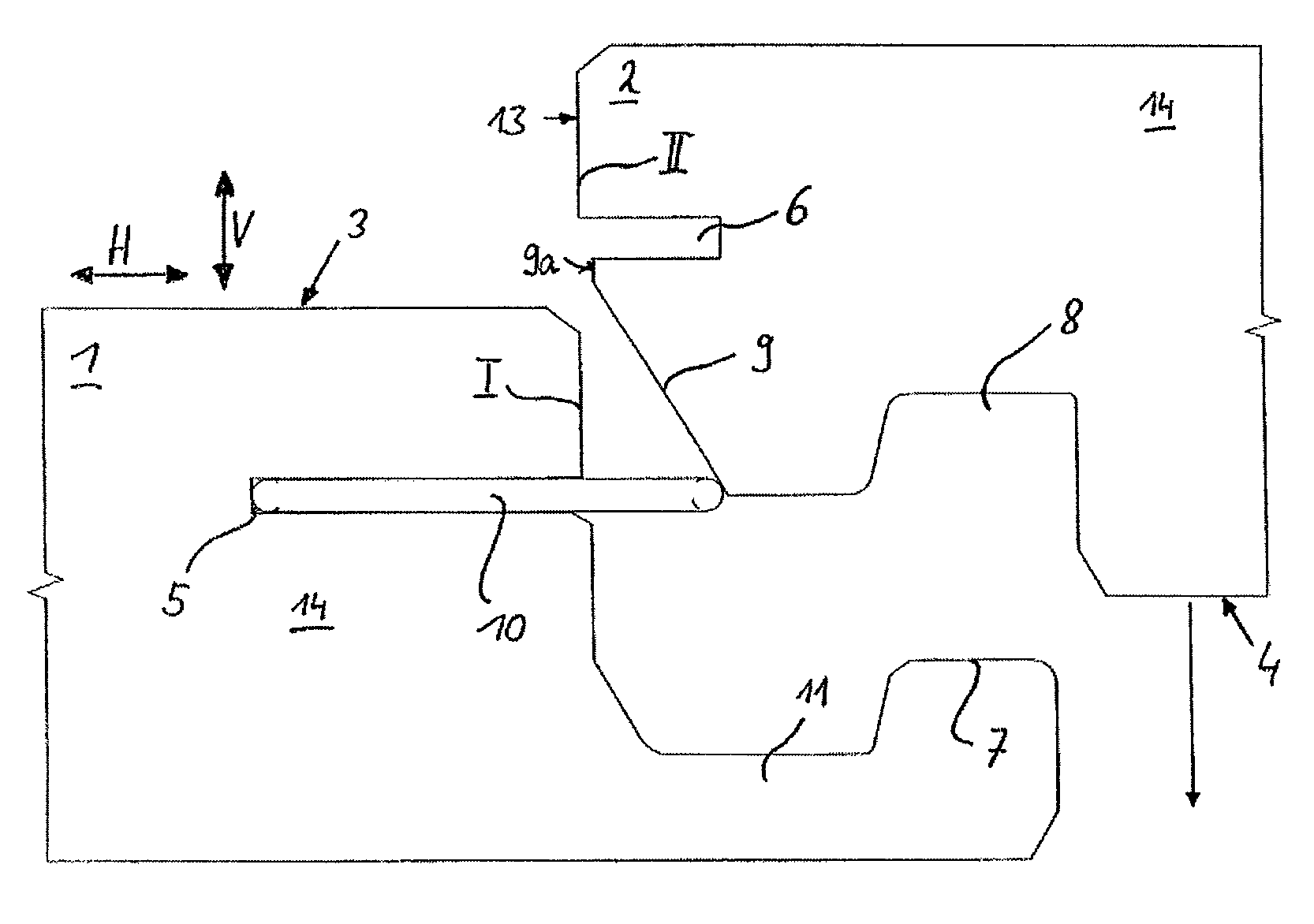

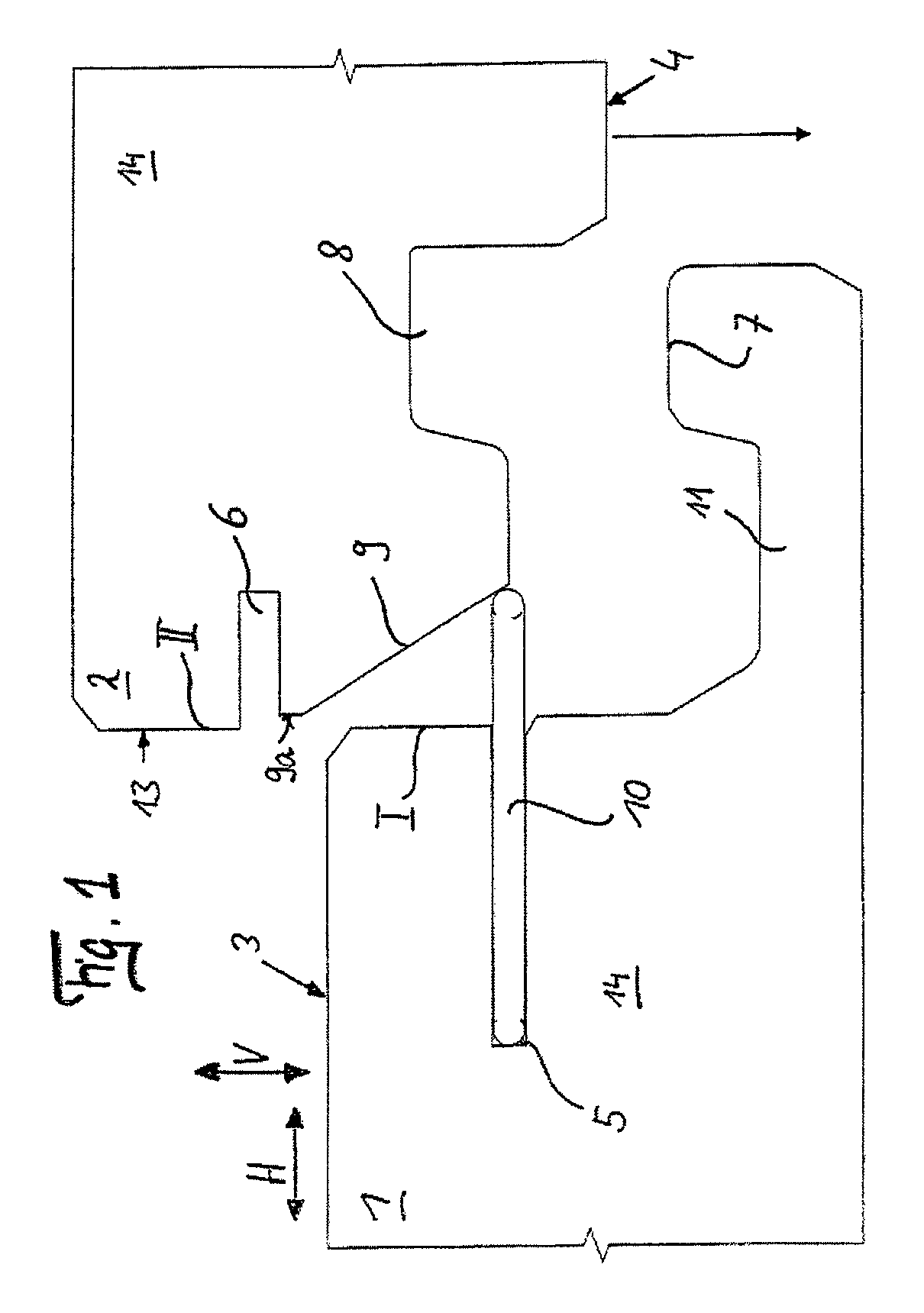

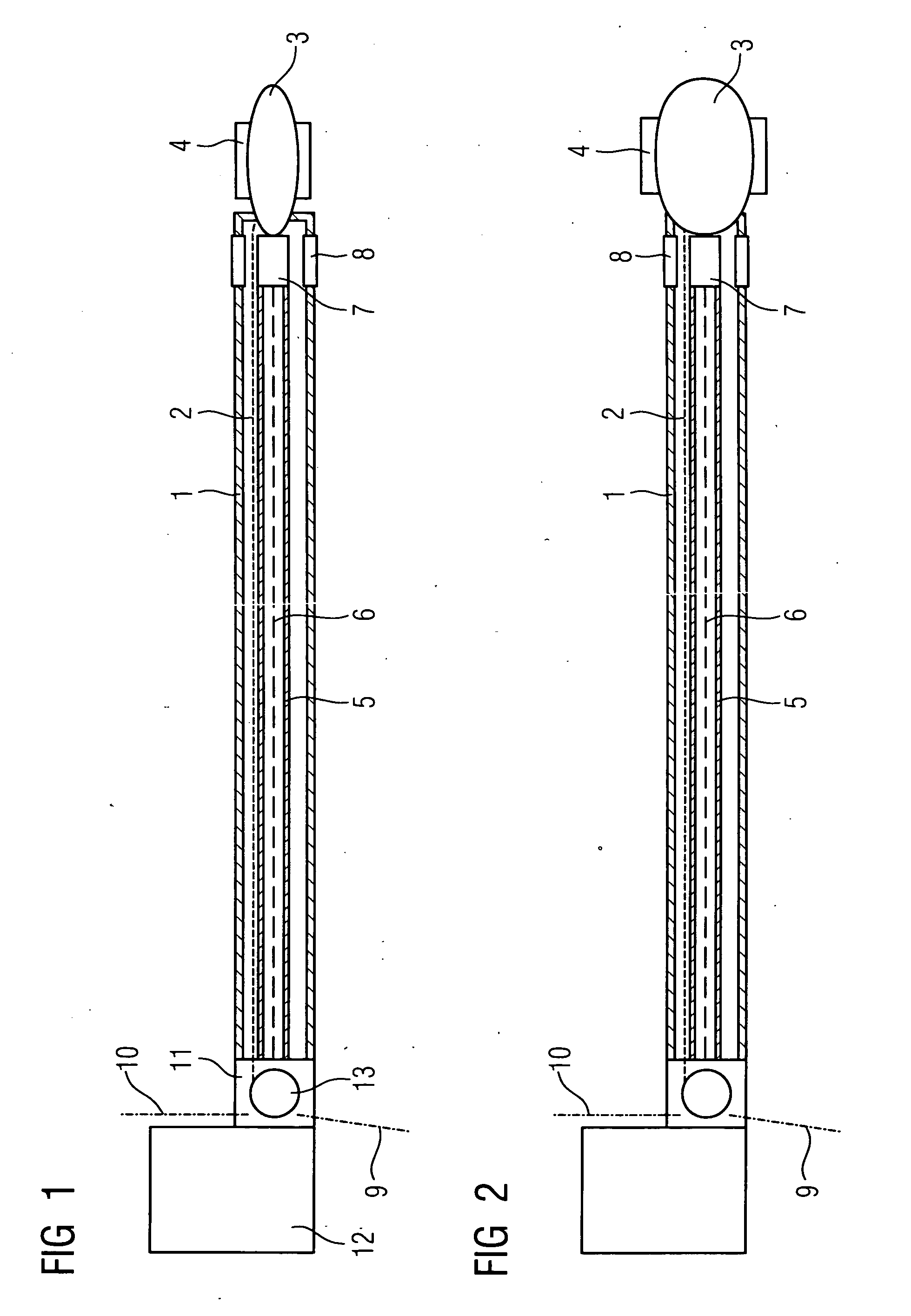

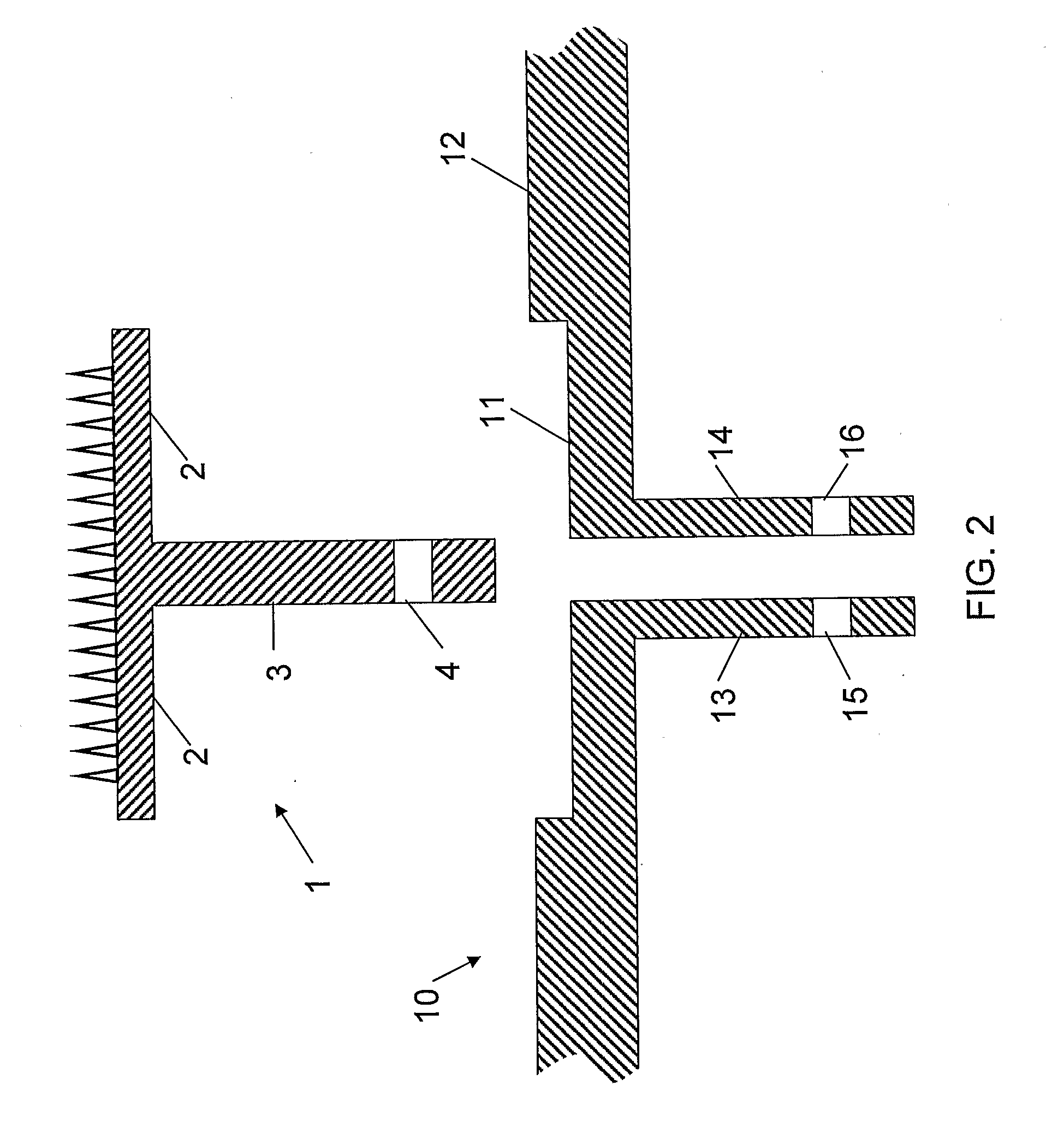

Device and method for locking two building boards

Owner:FLOORING TECH

Device and method for locking two building boards

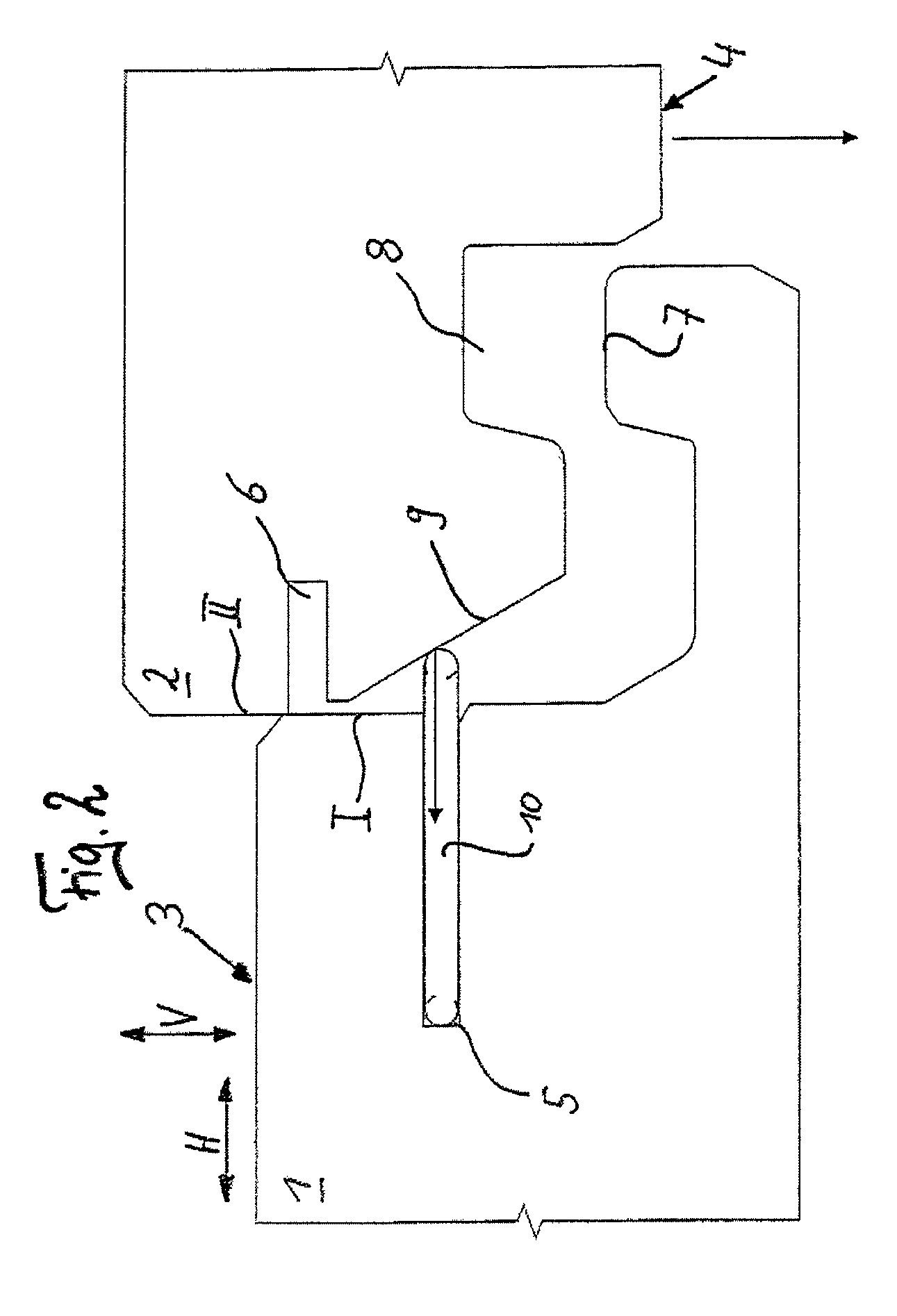

InactiveUS7621092B2Easy to manufactureMore cost-effectiveWallsSheet joiningArchitectural engineeringEngineering

Owner:FLOORING TECH

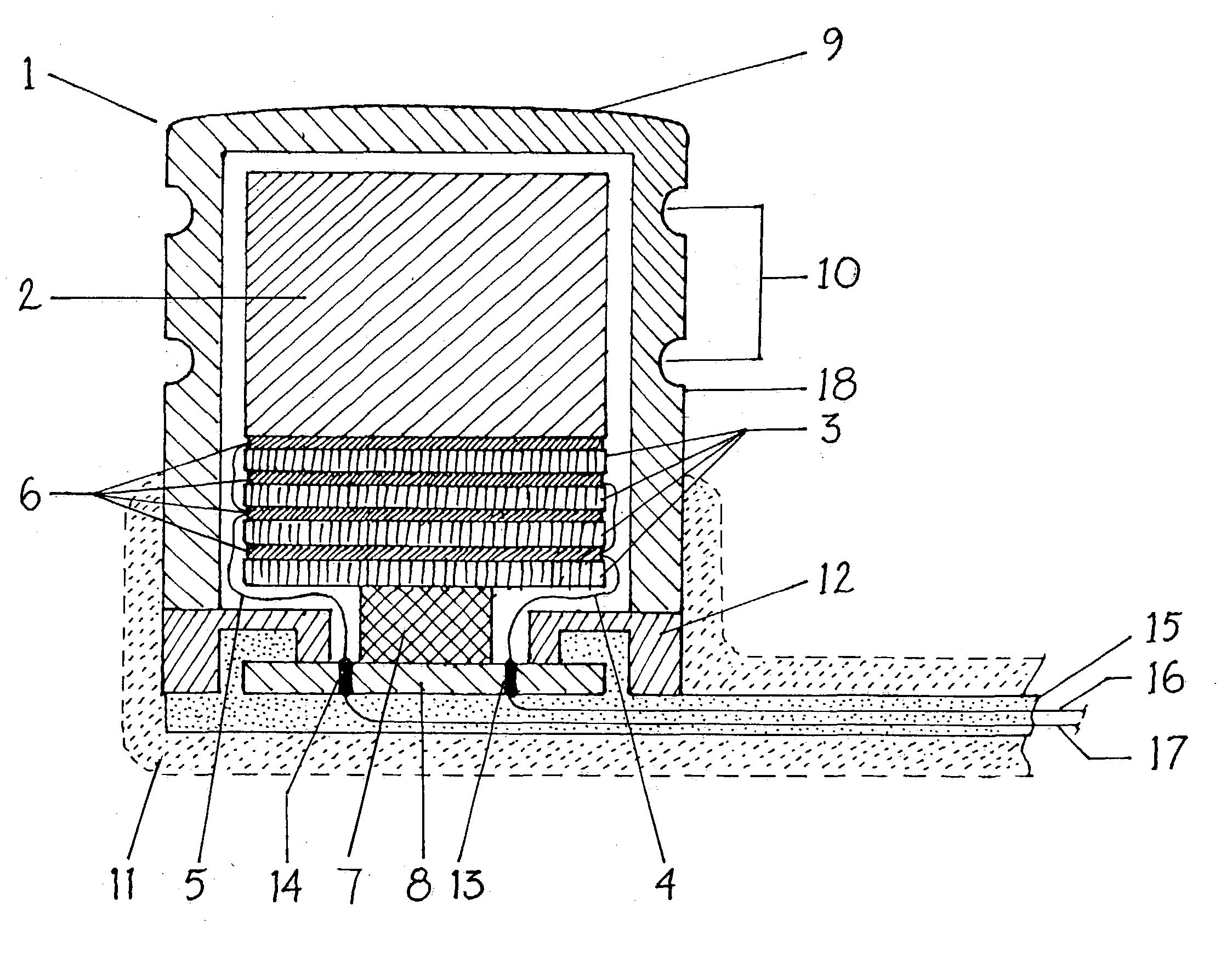

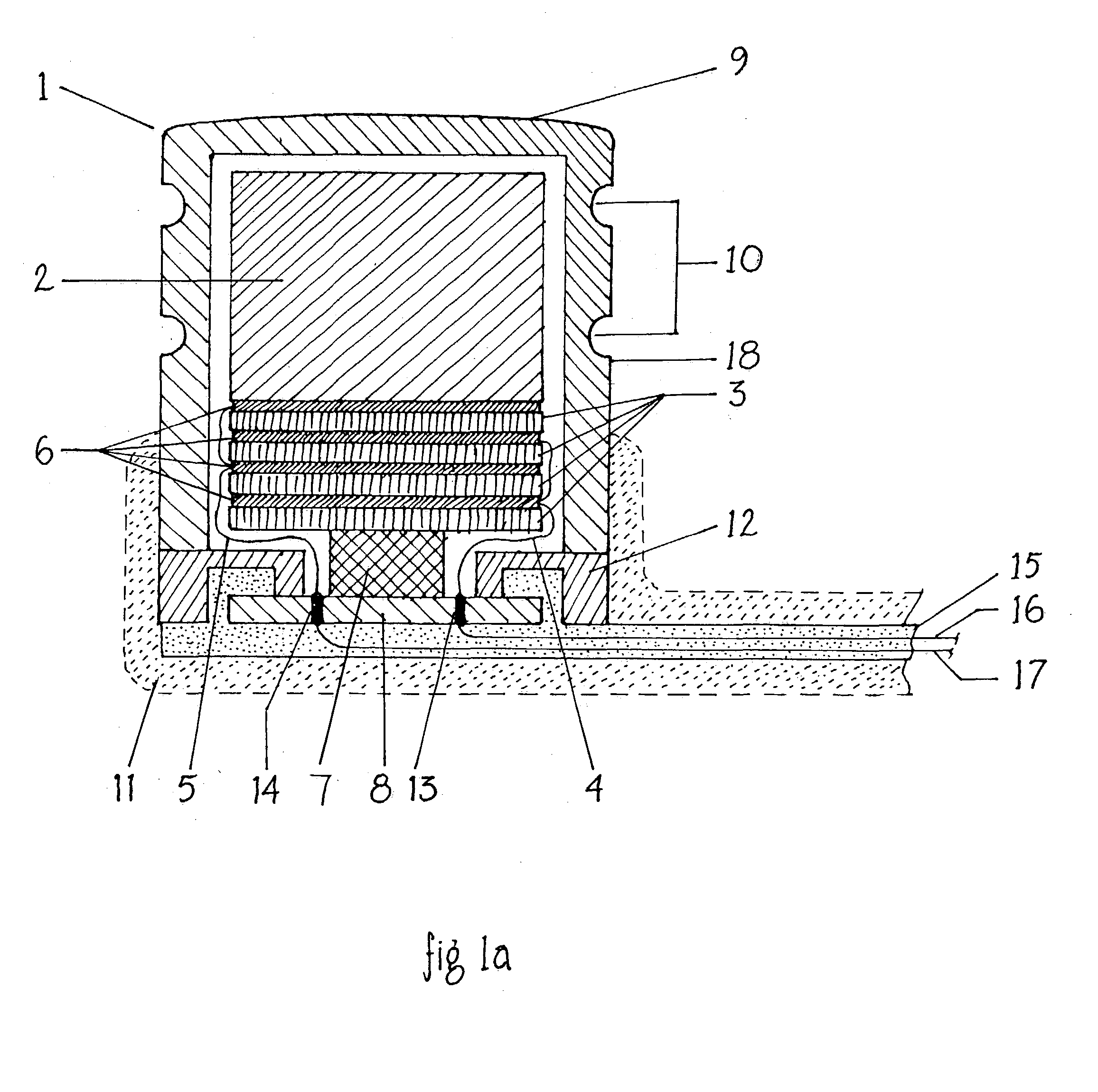

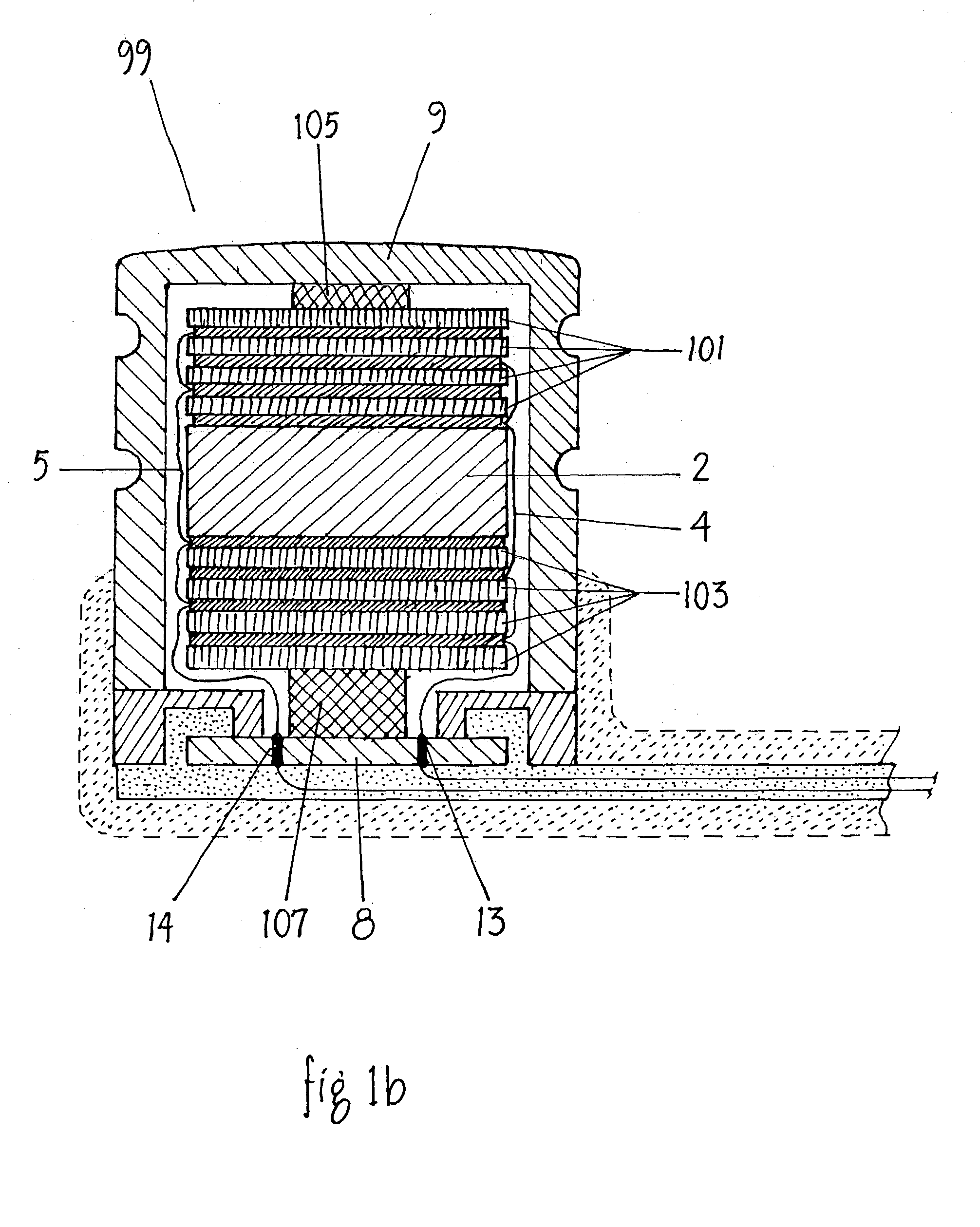

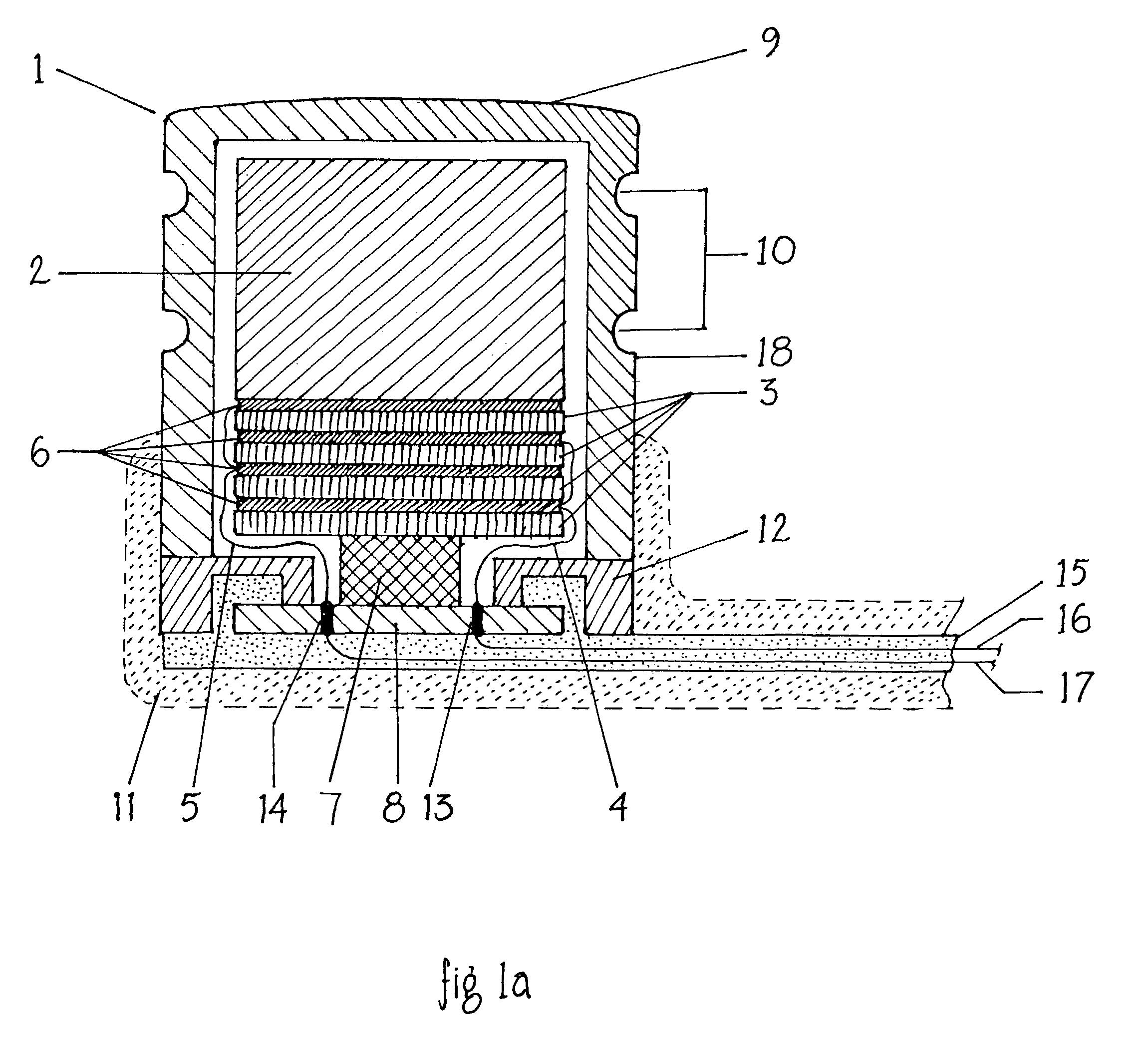

Totally implantable hearing prosthesis

ActiveUS20050020873A1Easy and safe to implantIncrease powerElectrotherapyImplantable hearing aidsCochlear implantationProsthesis

The invention comprises a totally implantable hearing prosthesis for hearing impaired persons. An inertial vibrational element is hermetically sealed and implanted in bone between the lateral and superior semicircular canals without breaching the integrity of the canals. The vibrational element is adapted to vibrate the walls of the canals and the fluids contained therein, thereby vibrating contiguous fluids within the cochlea thus stimulating hair cells and creating a hearing percept. The invention can also be adapted to be a tinnitus masking system, and / or used in combination with a coehlear implant hearing system.

Owner:MED EL ELEKTROMEDIZINISCHE GERAETE GMBH

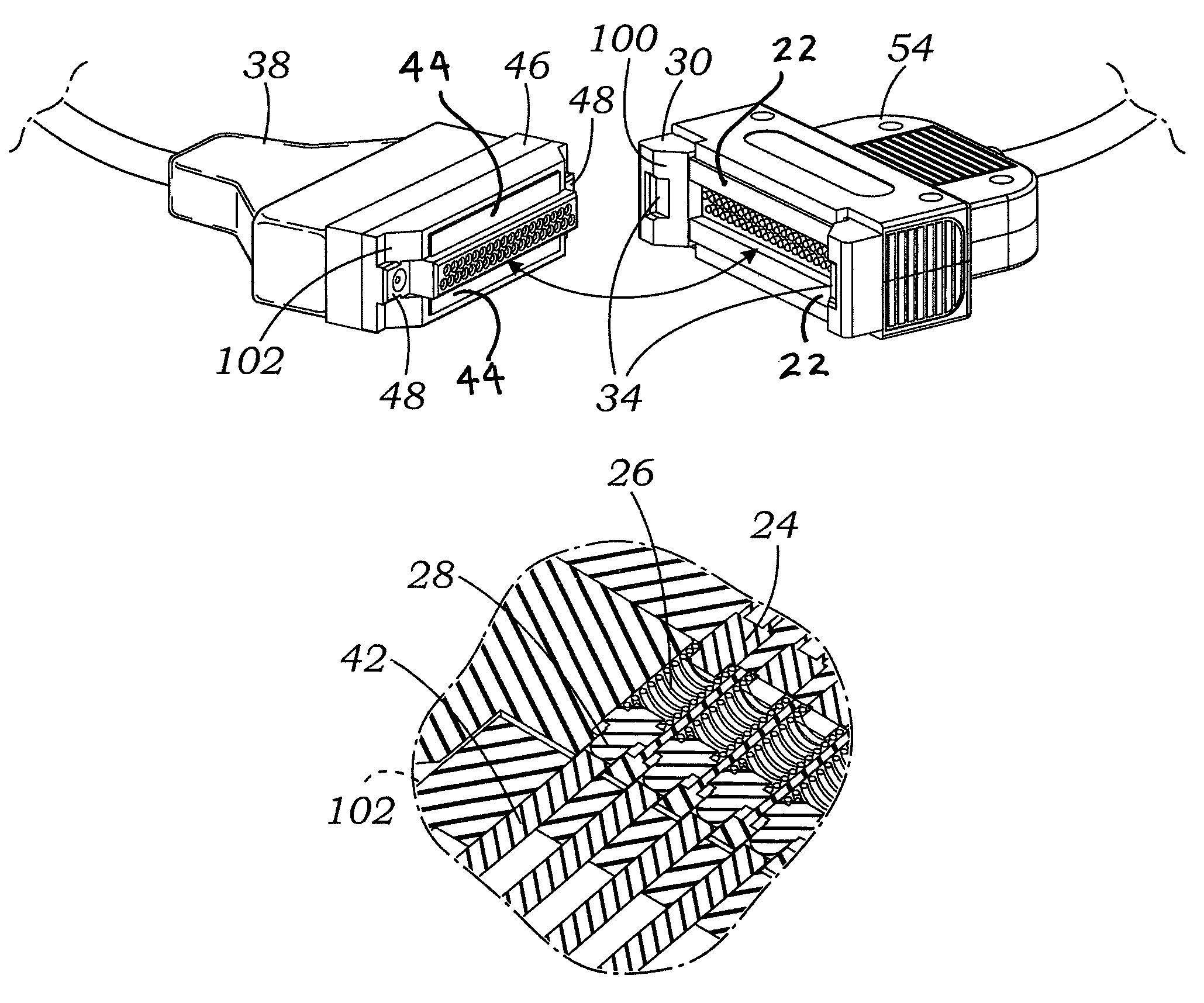

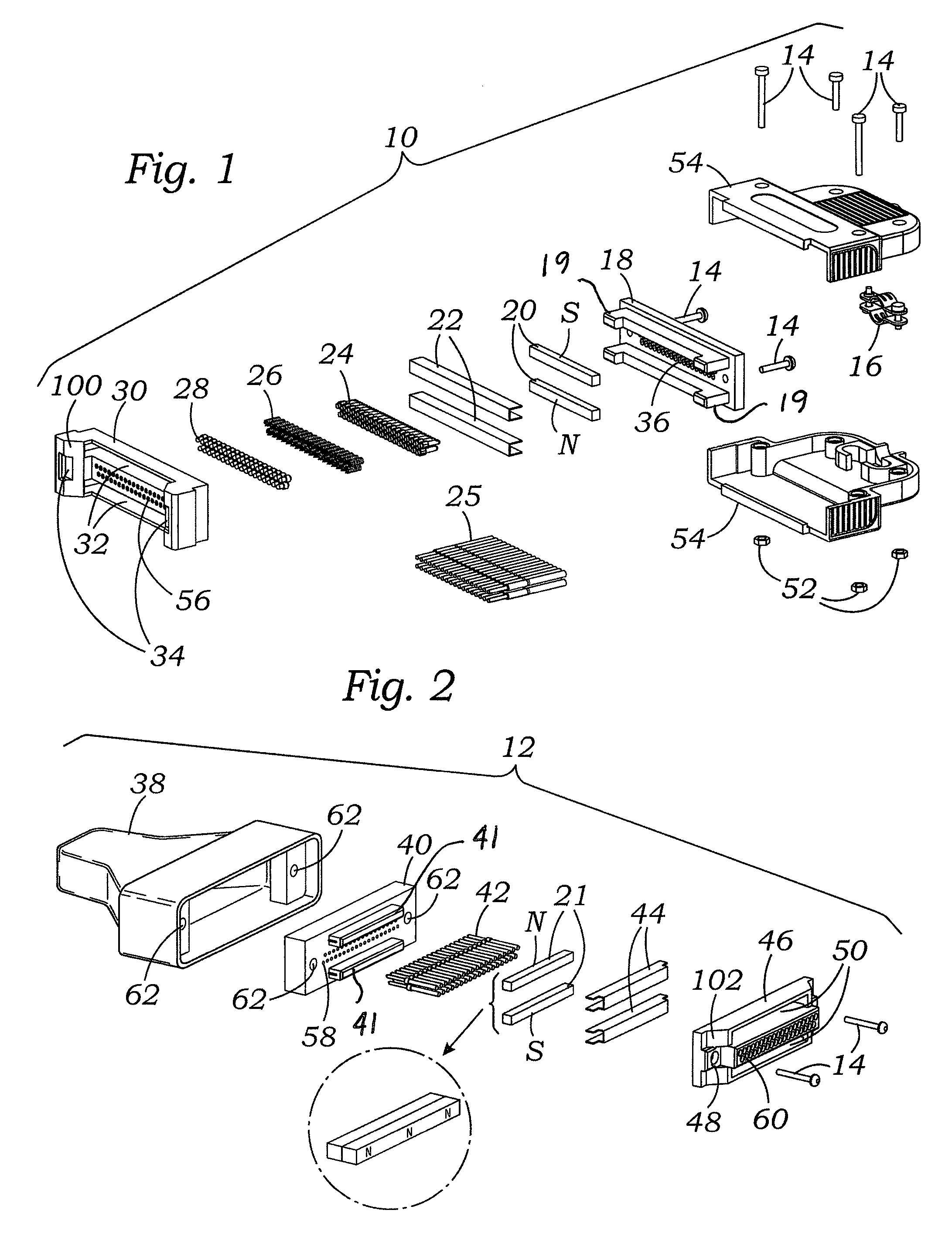

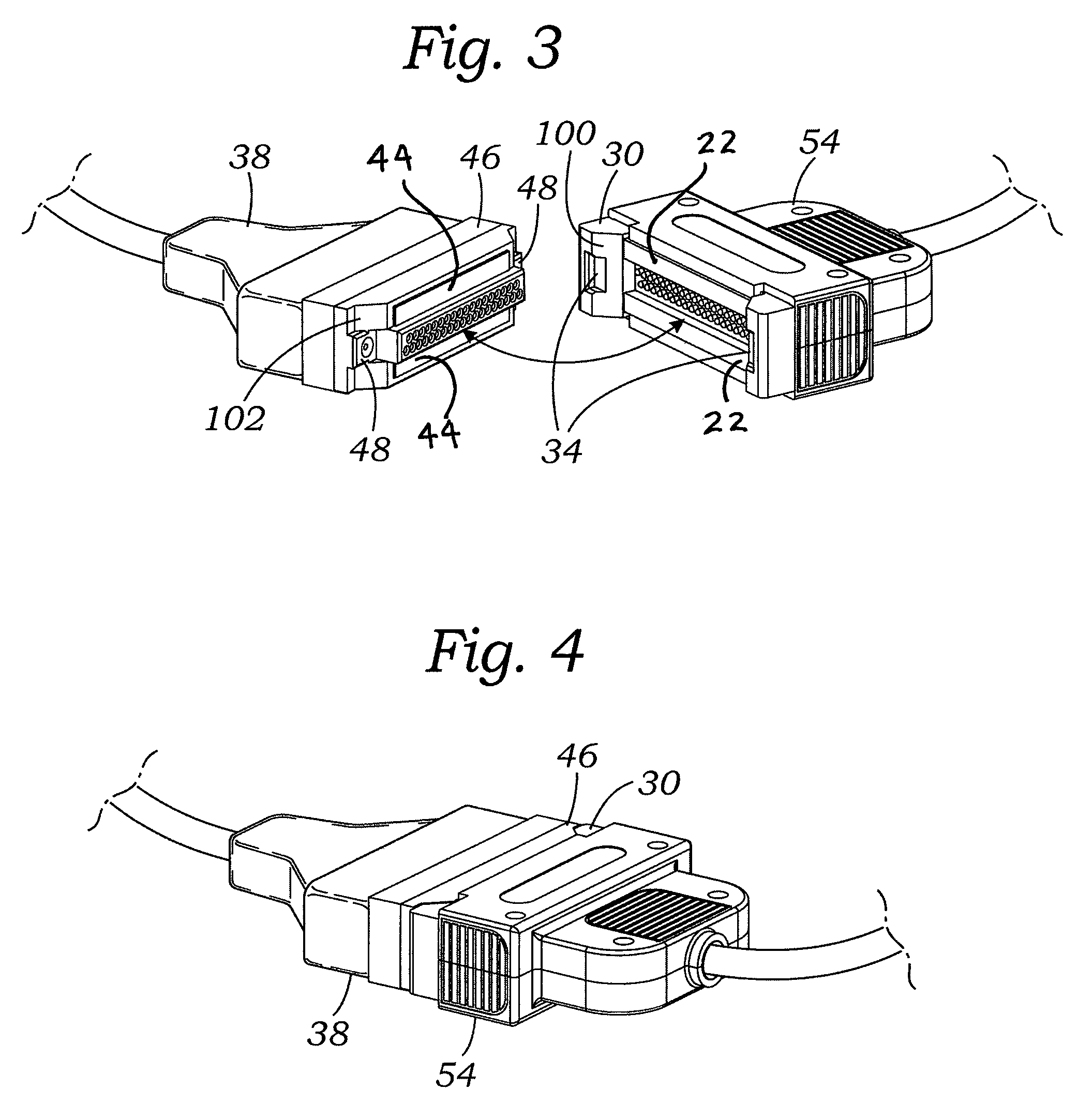

Magnetic-enabled connector device

ActiveUS9147965B2Connected quickly and preciselyAvoid connectionEngagement/disengagement of coupling partsCoupling contact membersElectricityNon magnetic

An electrical connector, which may be a multi-pin connector, includes magnetic elements and mechanical alignment elements which provide connective forces and precision alignment and orientation. The magnetic elements permit a user to bring male and female connector portions only into “rough” alignment before magnetic forces bring the portions into the correct position. Pin contacts on the connector portions extend only a small amount beyond respective protective annular openings and are thereby protected. Spring-biased pin elements may be included on one of the connector portions to bias the contact pins into engagement and create conductive paths when the portions are in a connected position. Paramagnetic or non-magnetic sheaths may surround the magnetic elements to focus, or distribute, magnetic forces.

Owner:KC MAGCON

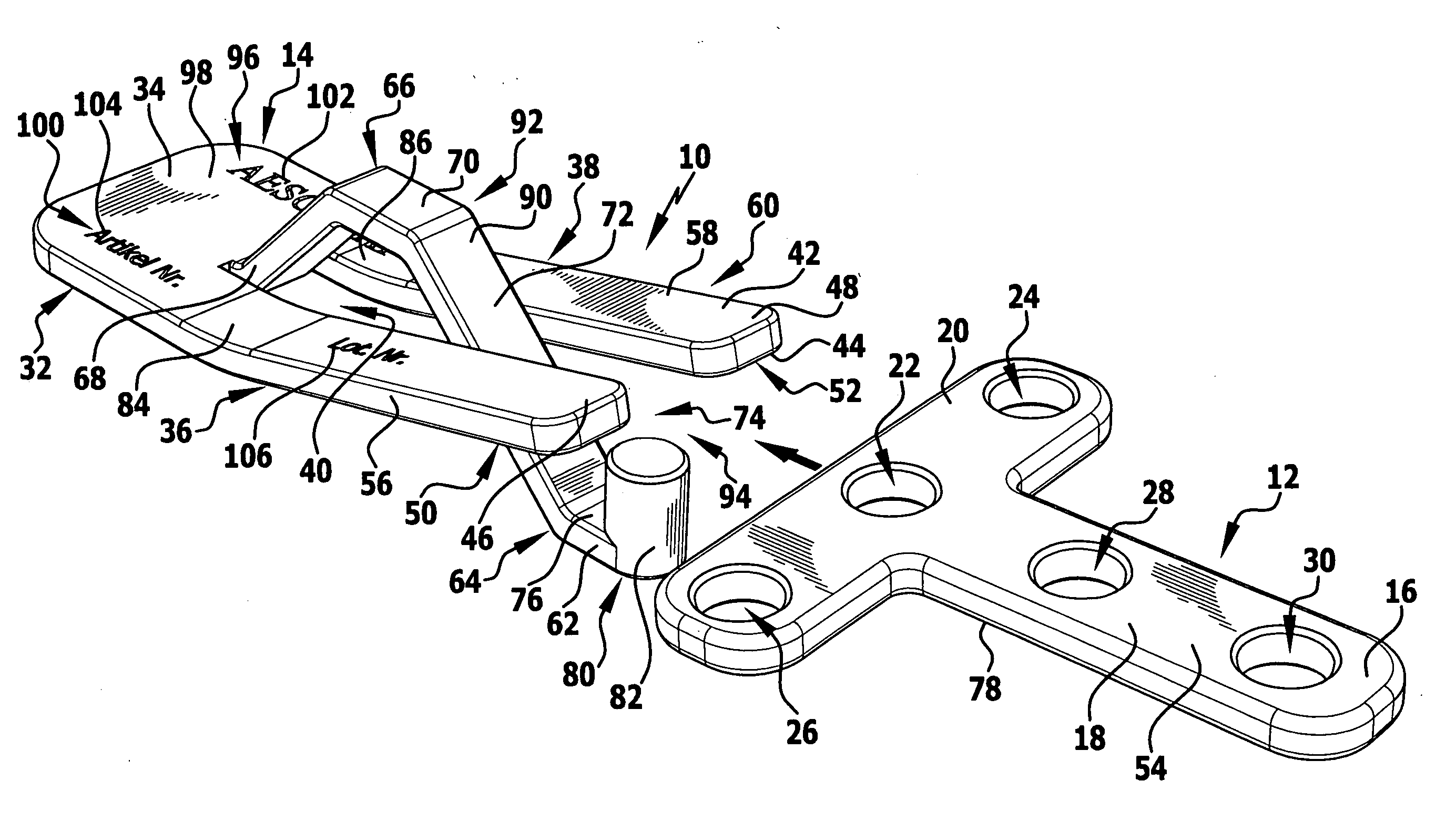

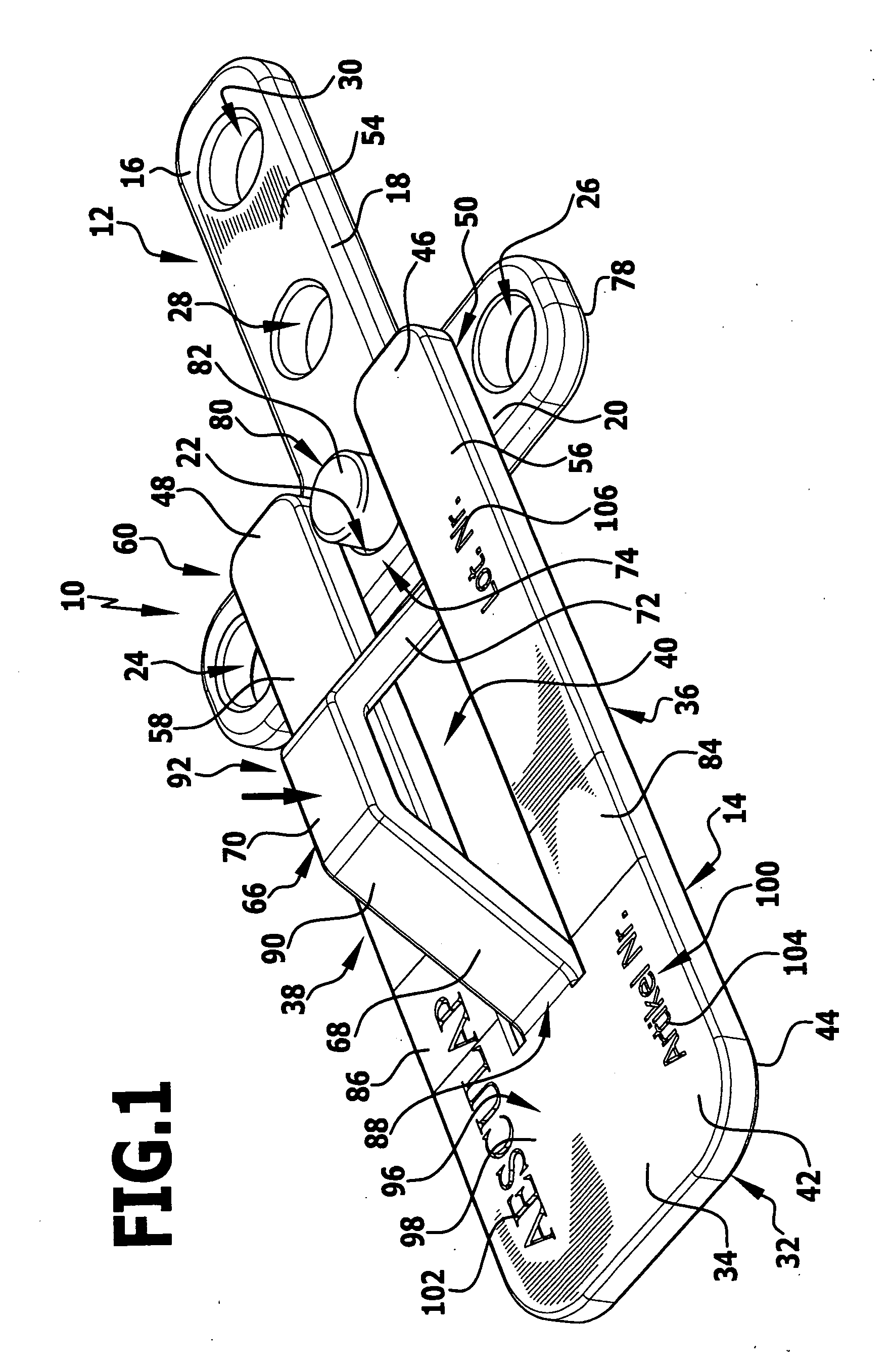

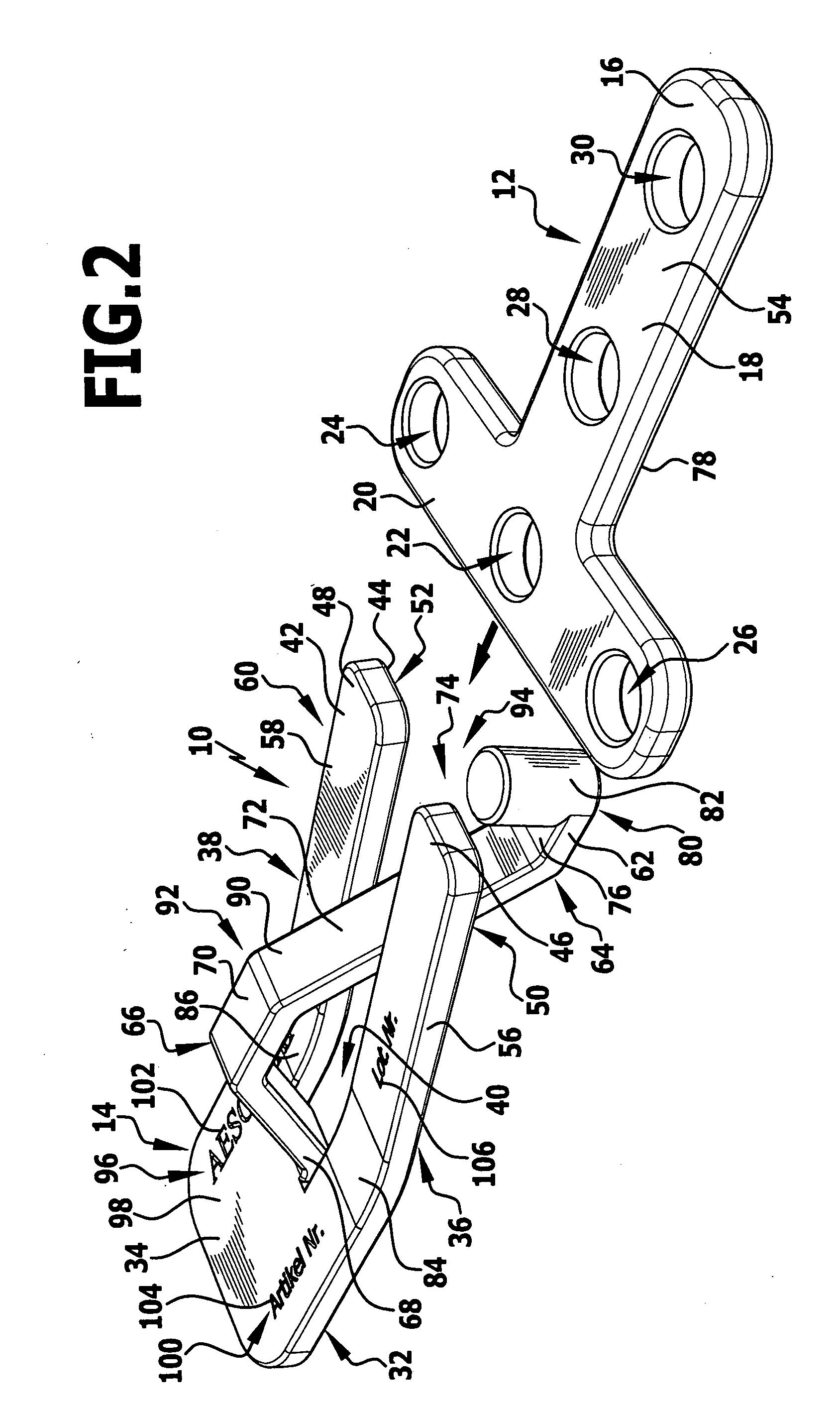

Surgical data carrier

InactiveUS20080230422A1Risk of infectionAdvantageously producedDiagnosticsSurgical needlesBone fragmentBiomedical engineering

The invention relates to a surgical data carrier for the identification of a medical implant, in particular, a surgical plate for the fixing of bones or bone fragments, wherein the data carrier has a carrier element and a connecting device which comprises a receptacle for the insertion of at least part of the implant. In order to make such a surgical data carrier available which has an improved handling capability, it is suggested in accordance with the invention that the data carrier have an actuating device which can be actuated by a user and with which the connecting device can be transferred from a connecting position, in which the implant is held in the receptacle, into a release position, in which the data carrier can be detached from the implant. The invention relates, in addition, to a surgical implantation system.

Owner:AESCULAP AG

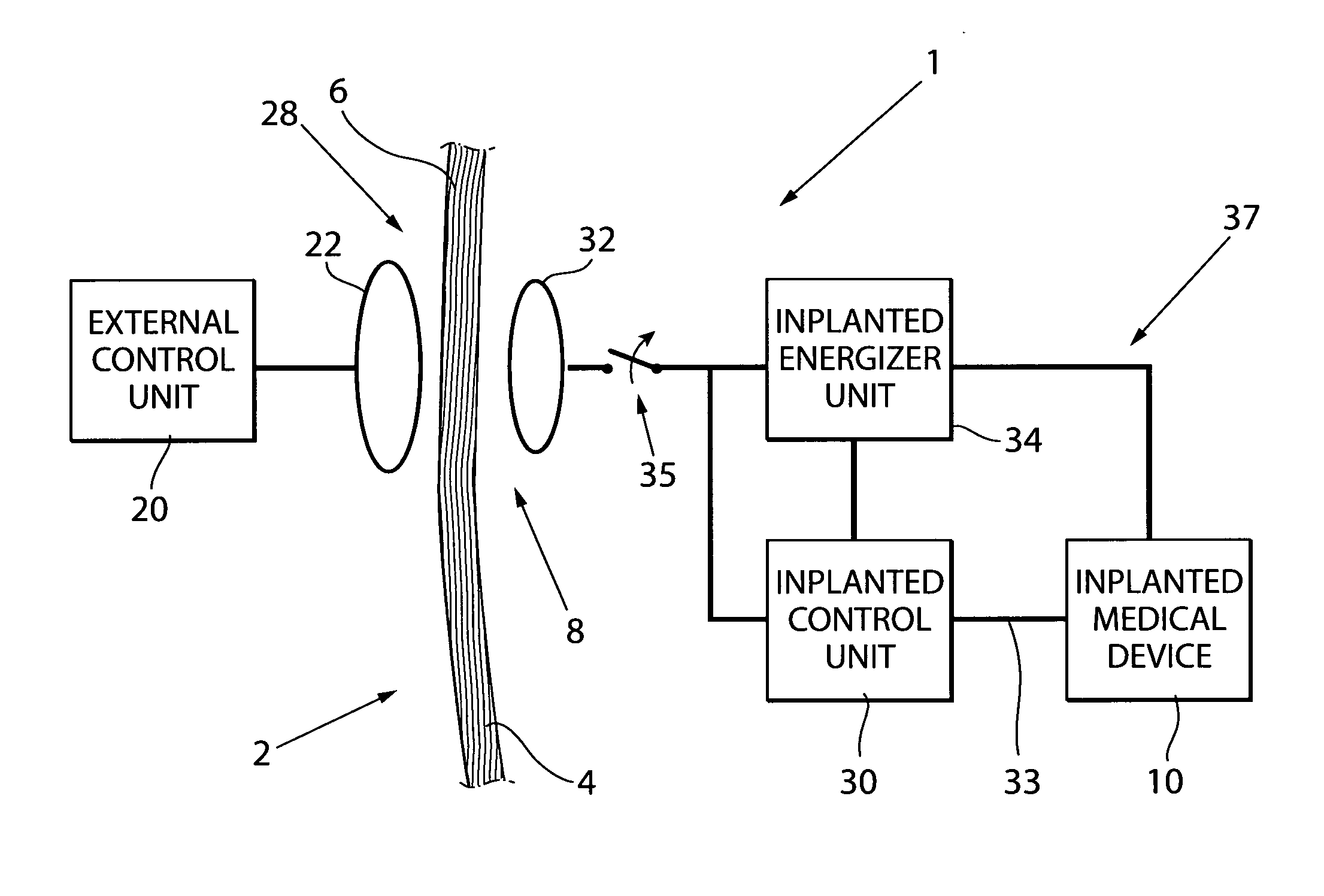

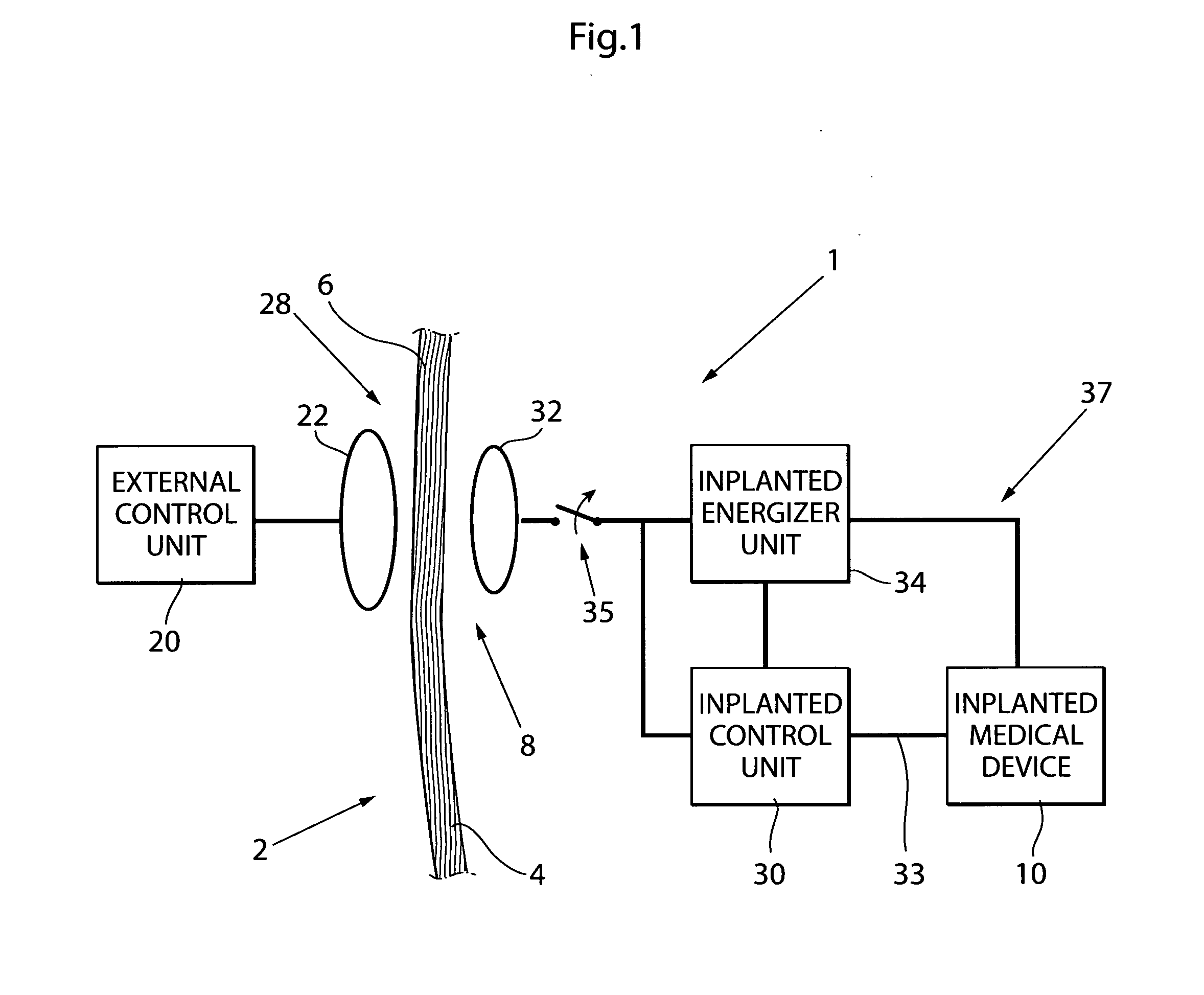

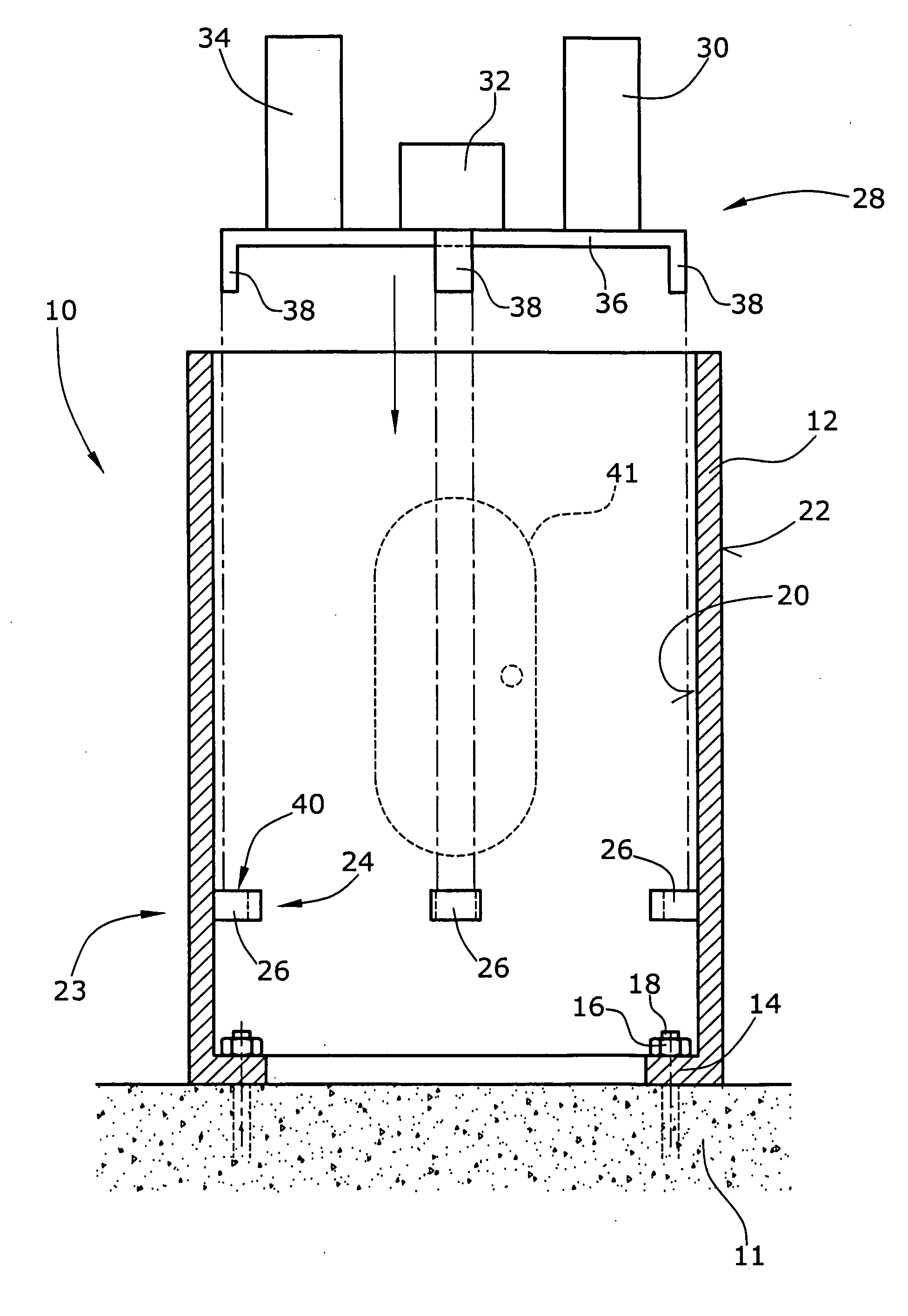

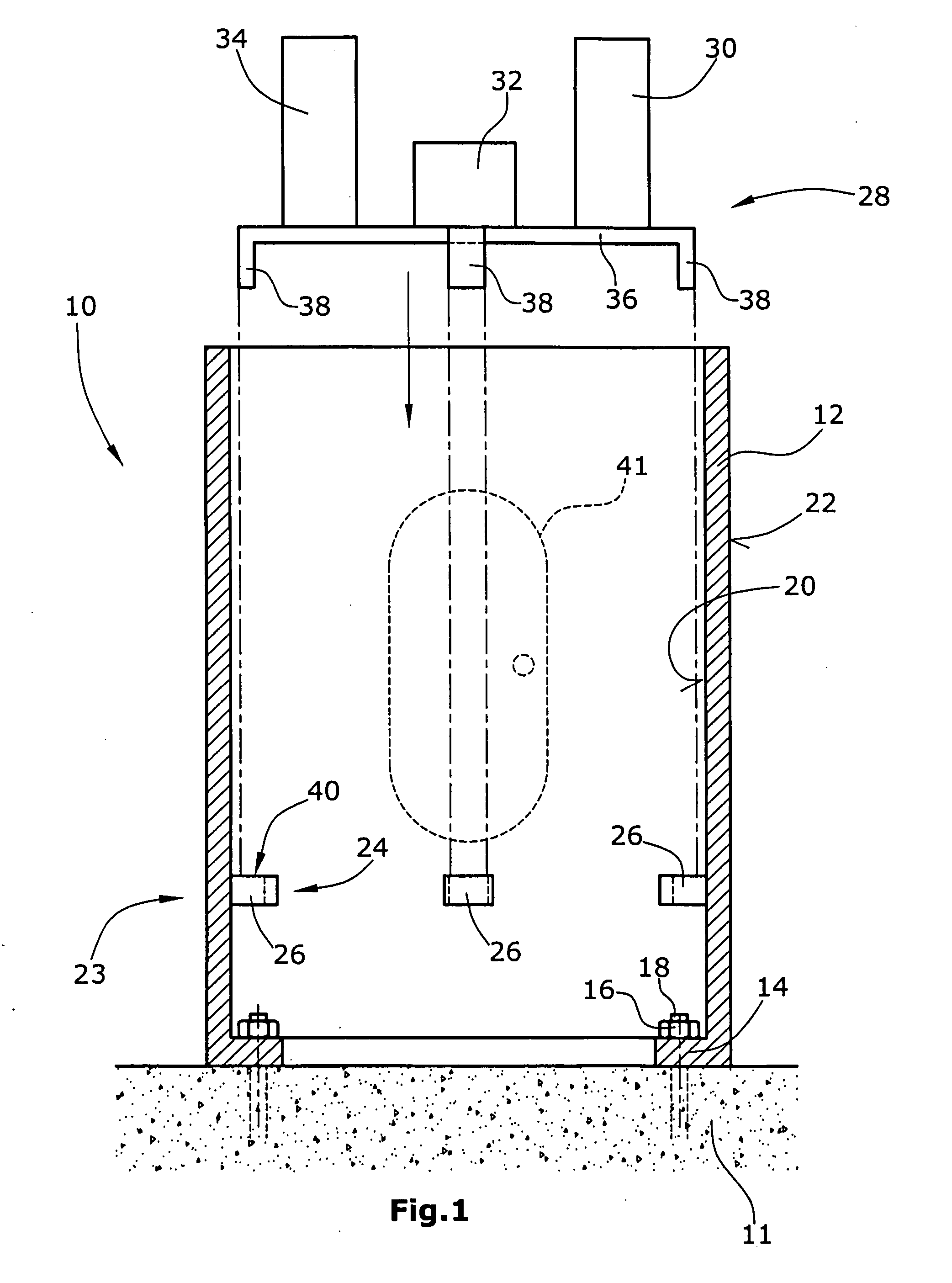

System for supplying energy

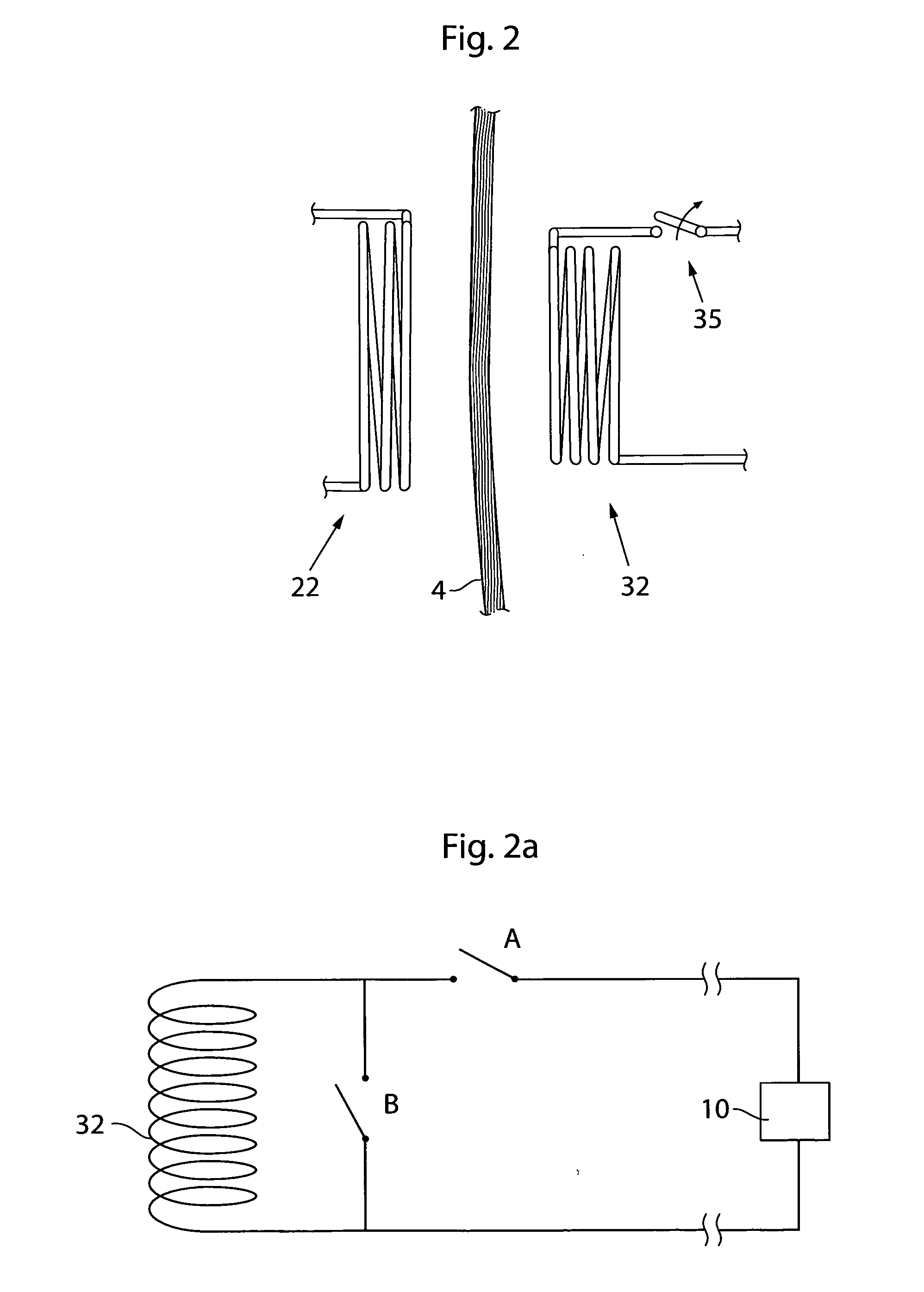

InactiveUS20110278948A1Reduce risk of damageGuaranteed uptimeElectrotherapyElectromagnetic wave systemControl signalEngineering

A coil arrangement supplies energy or control signals to, or provides information from, a medical device implanted in a human or animal patient. The coil arrangement includes an external coil that is larger than an implanted coil so as to reduce the risk of damage to circuitry in an energy transmitter attached to the external coil that results from a low impedance at the external coil when a switch in an over-voltage protection circuit is opened to protect circuitry in a medical device attached to the implanted coil from being damaged by a too high voltage induced across the implanted coil.

Owner:FORSELL PETER

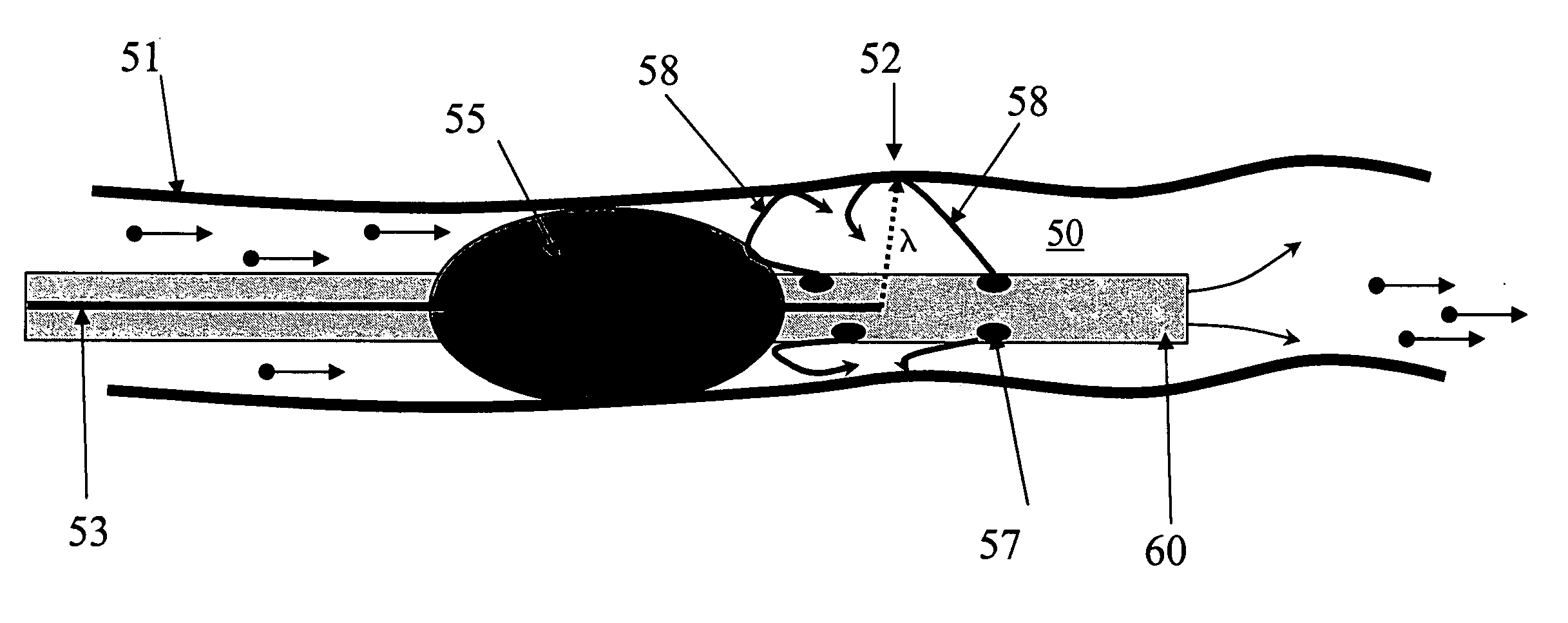

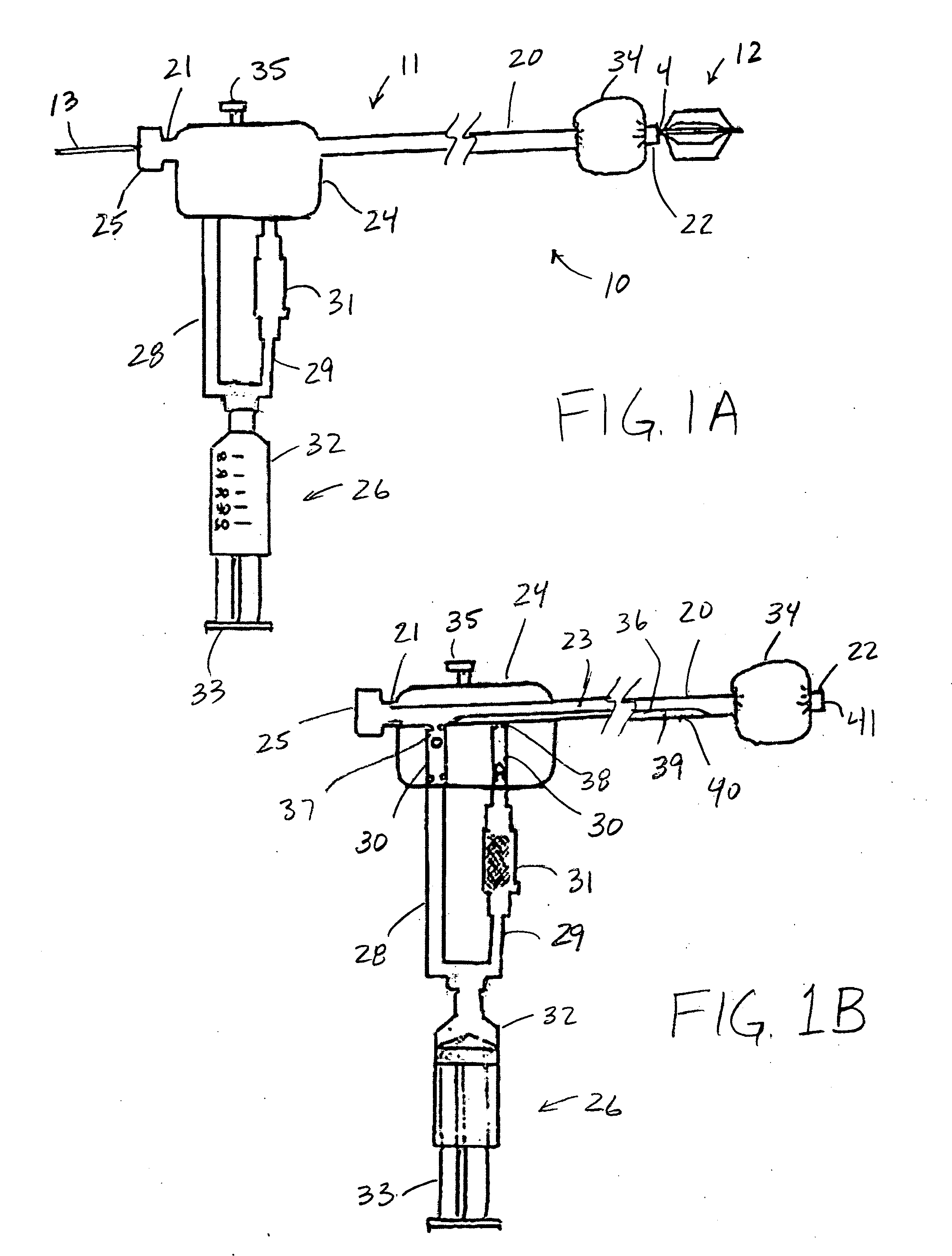

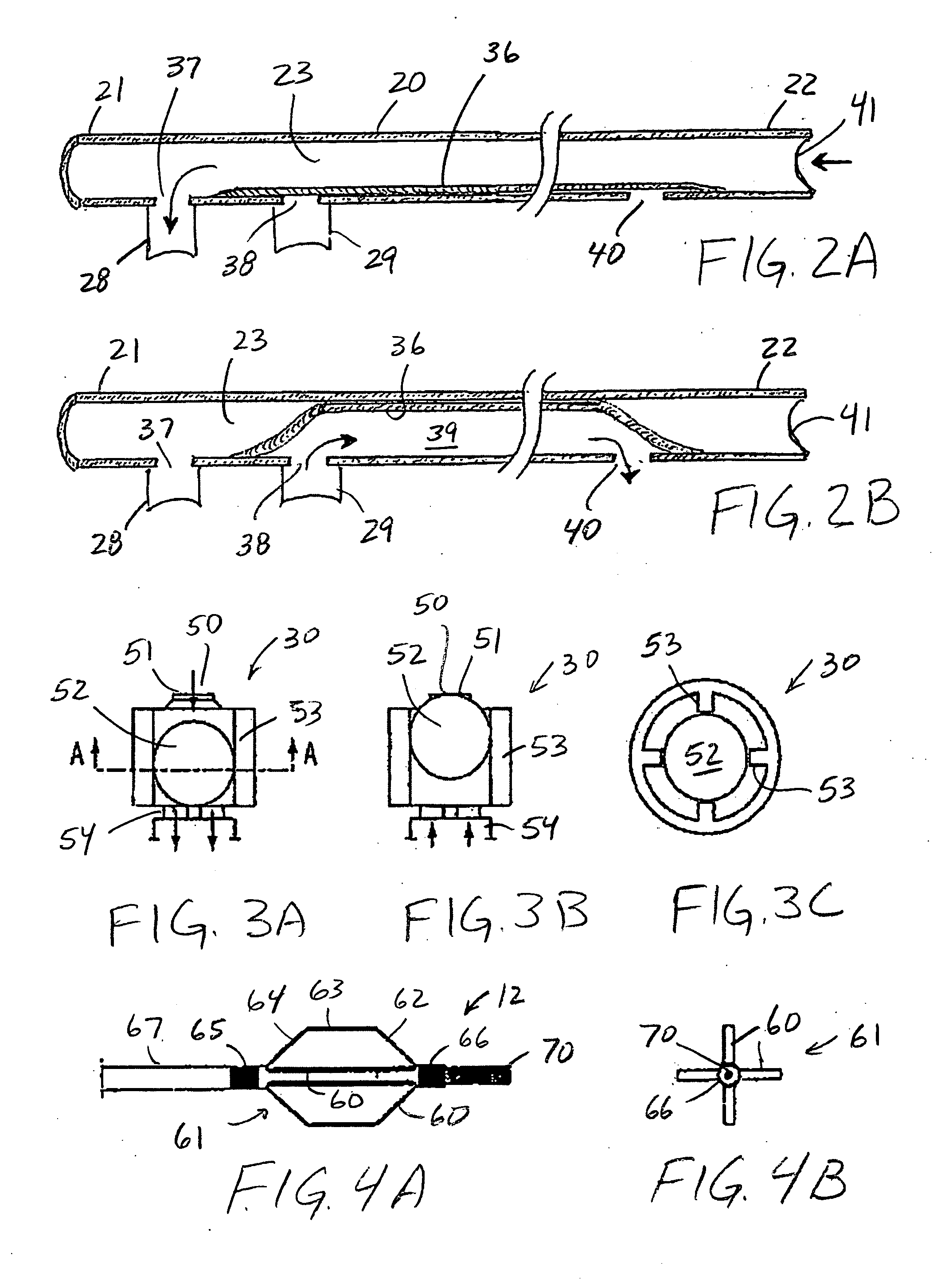

Fluid occluding devices and methods

InactiveUS20060095065A1Reduce risk of damageIncrease pressureStentsBalloon catheterRadiologyThree vessels

In one aspect, the invention relates to a method of occluding blood in a blood vessel during the imaging of a portion of the blood vessel. The method includes the steps of selecting an inflatable element such that diameter of the inflated inflatable element is greater than the diameter of the blood vessel being imaged, introducing the inflatable element into the blood vessel and underinflating the inflatable element such that the vessel wall is not substantially deformed by the inflatable element, the inflatable element substantially occluding the blood vessel to reduce imaging distortion resulting from vessel fluids.

Owner:LIGHTLAB IMAGING

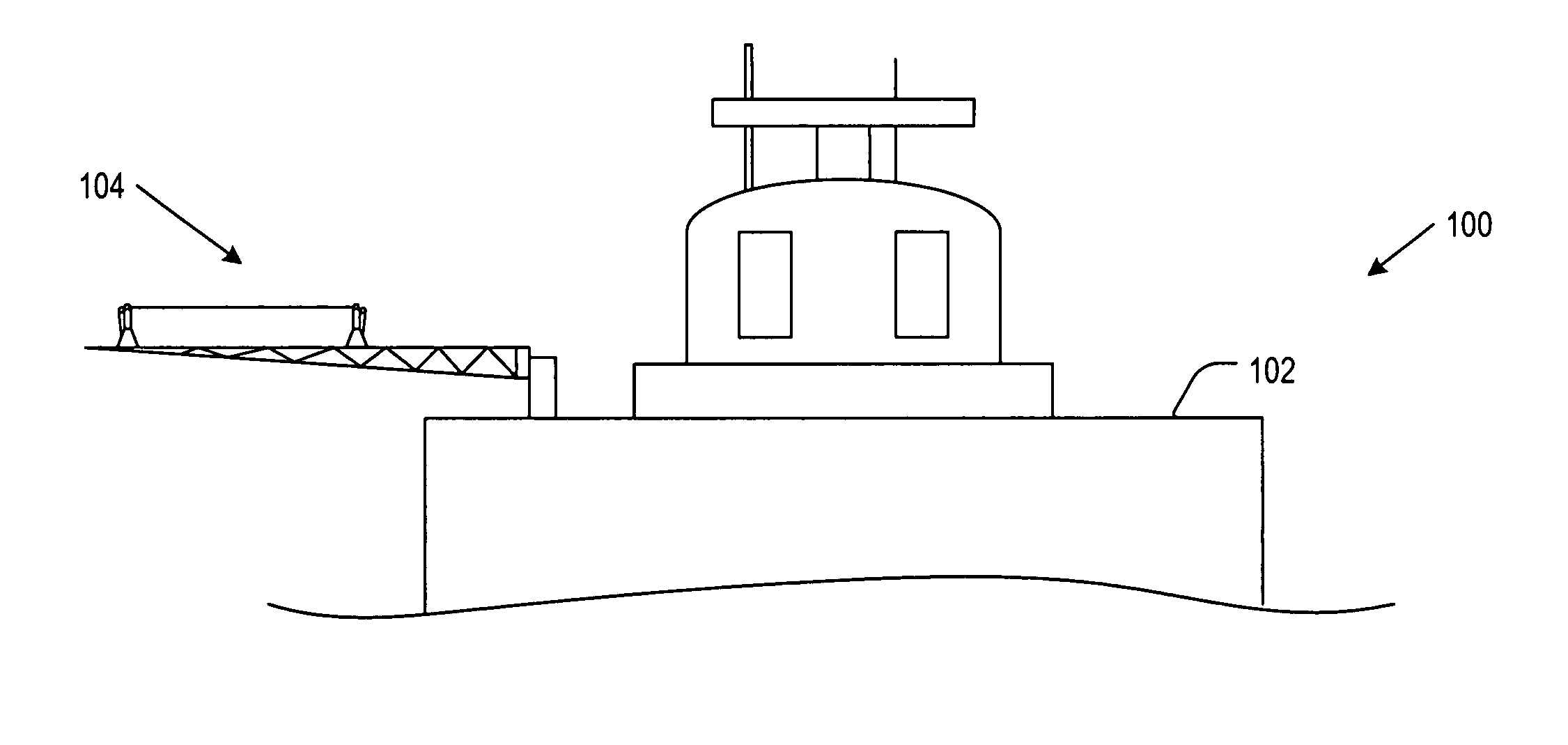

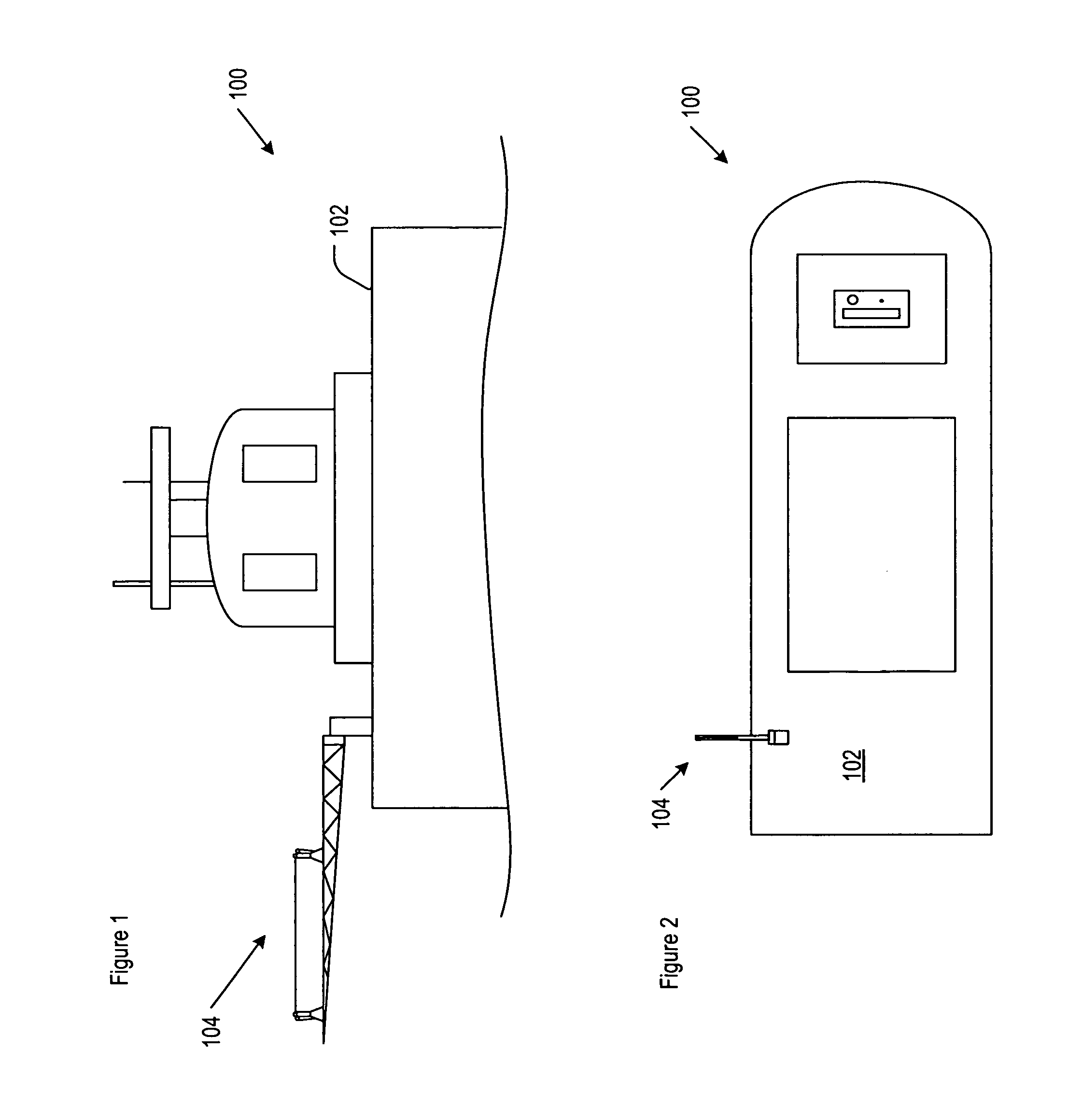

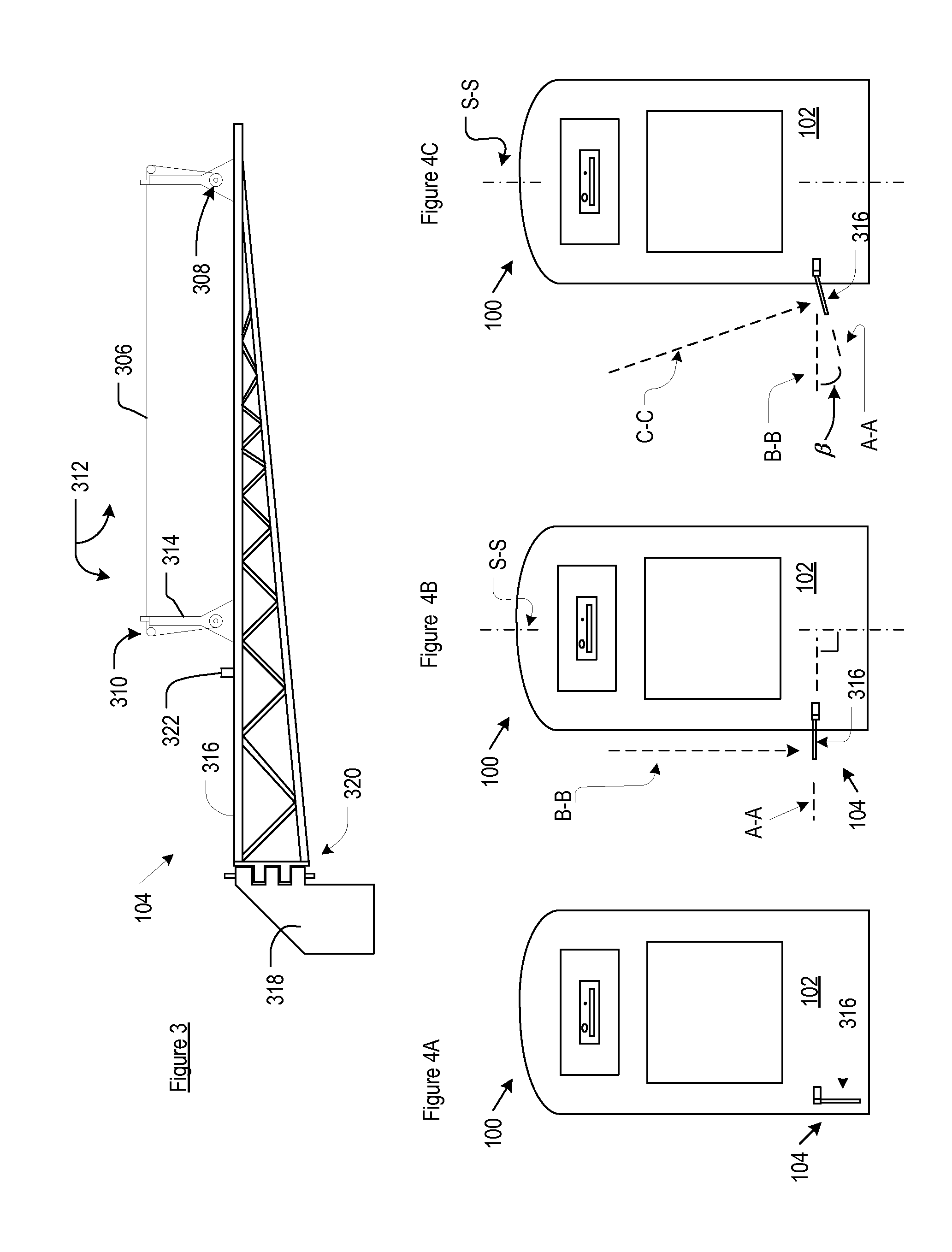

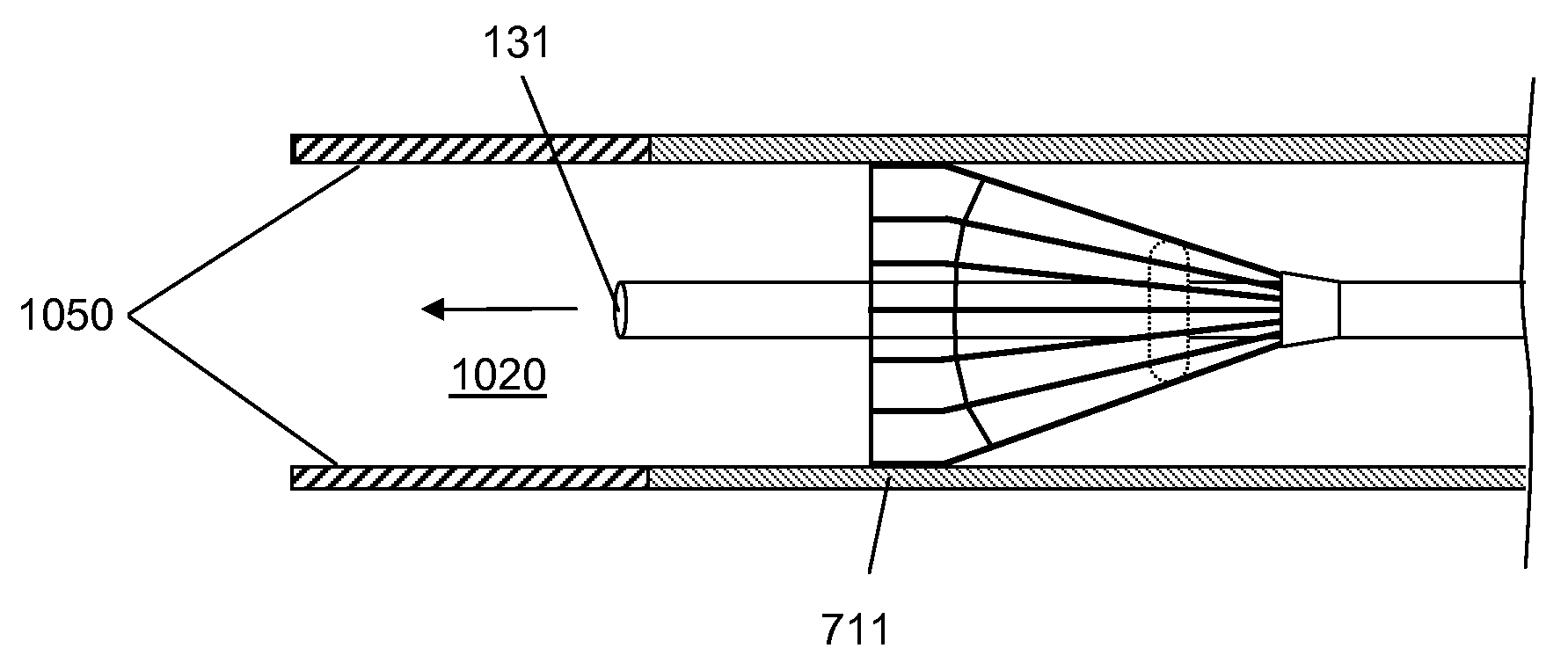

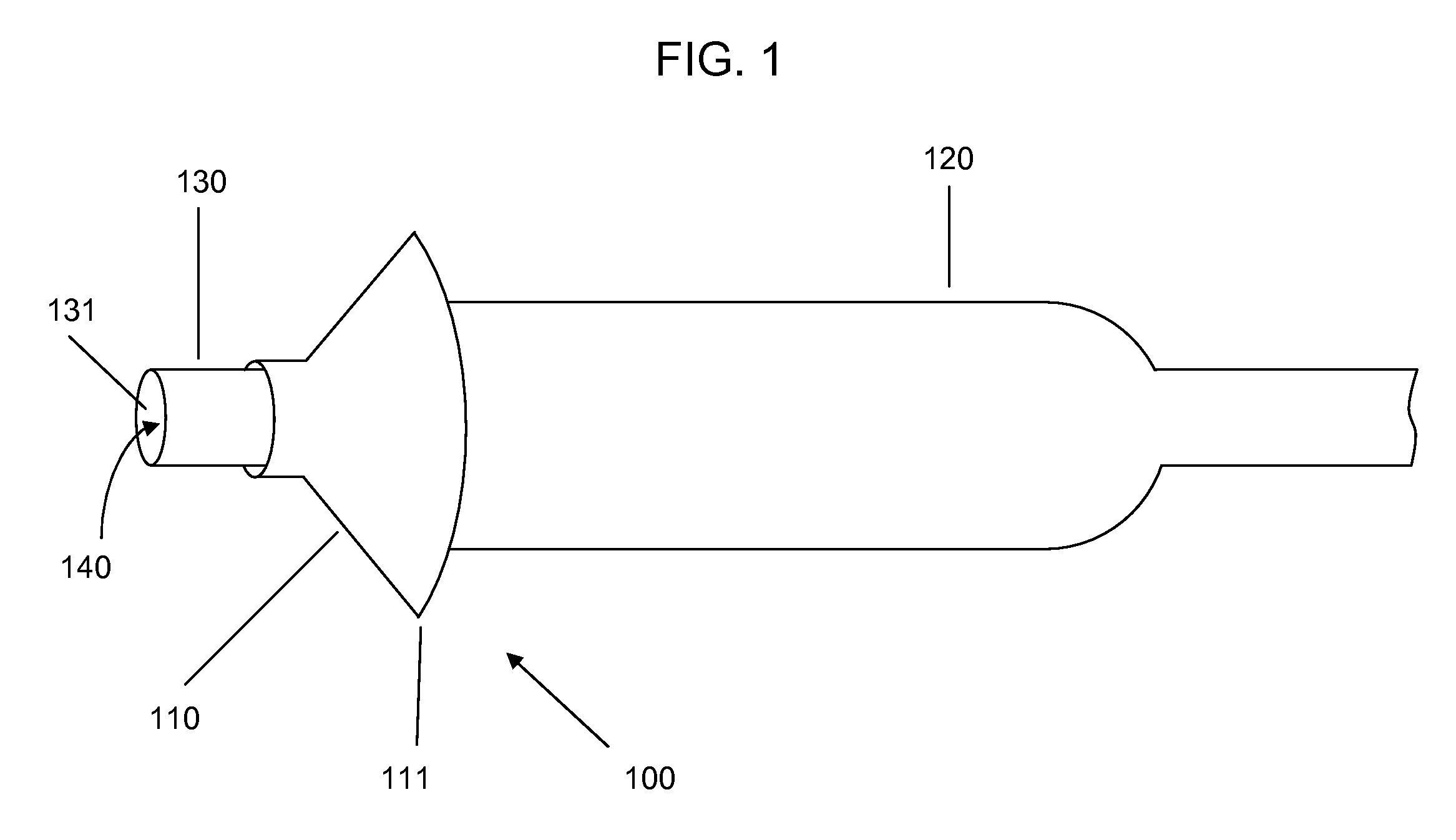

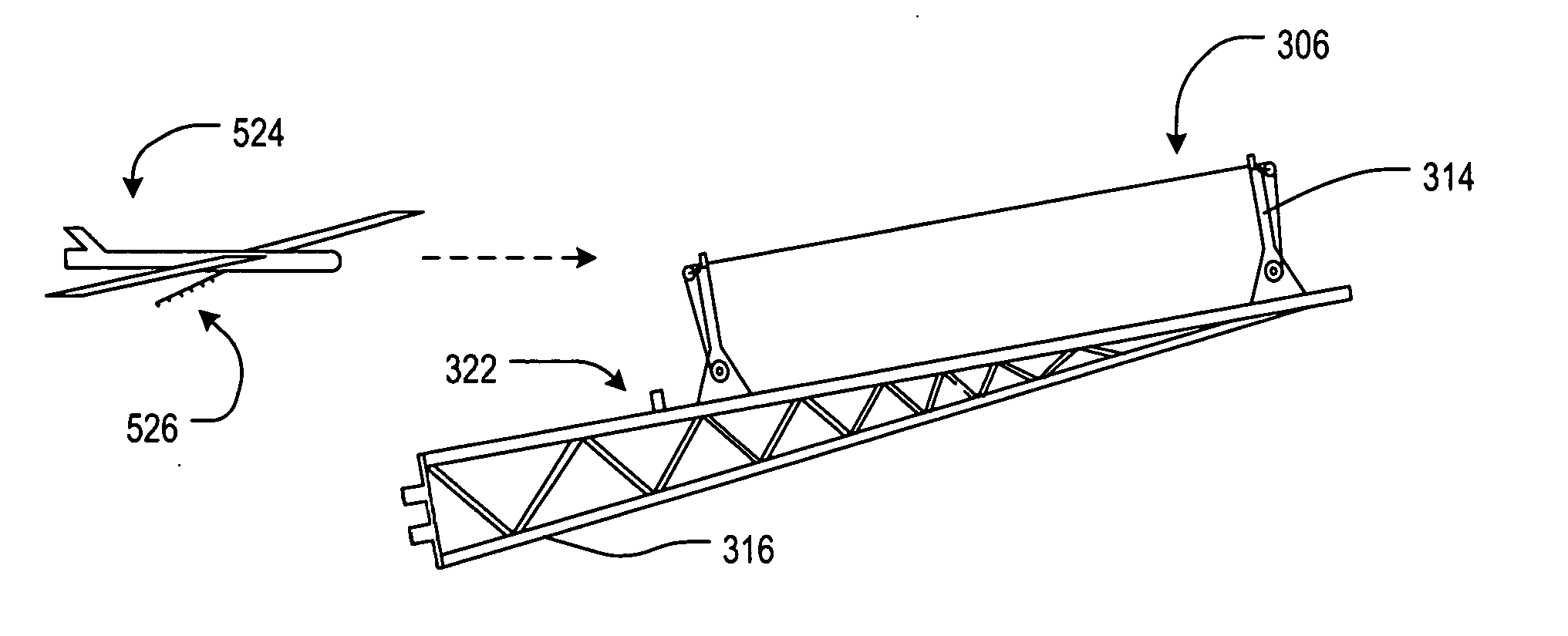

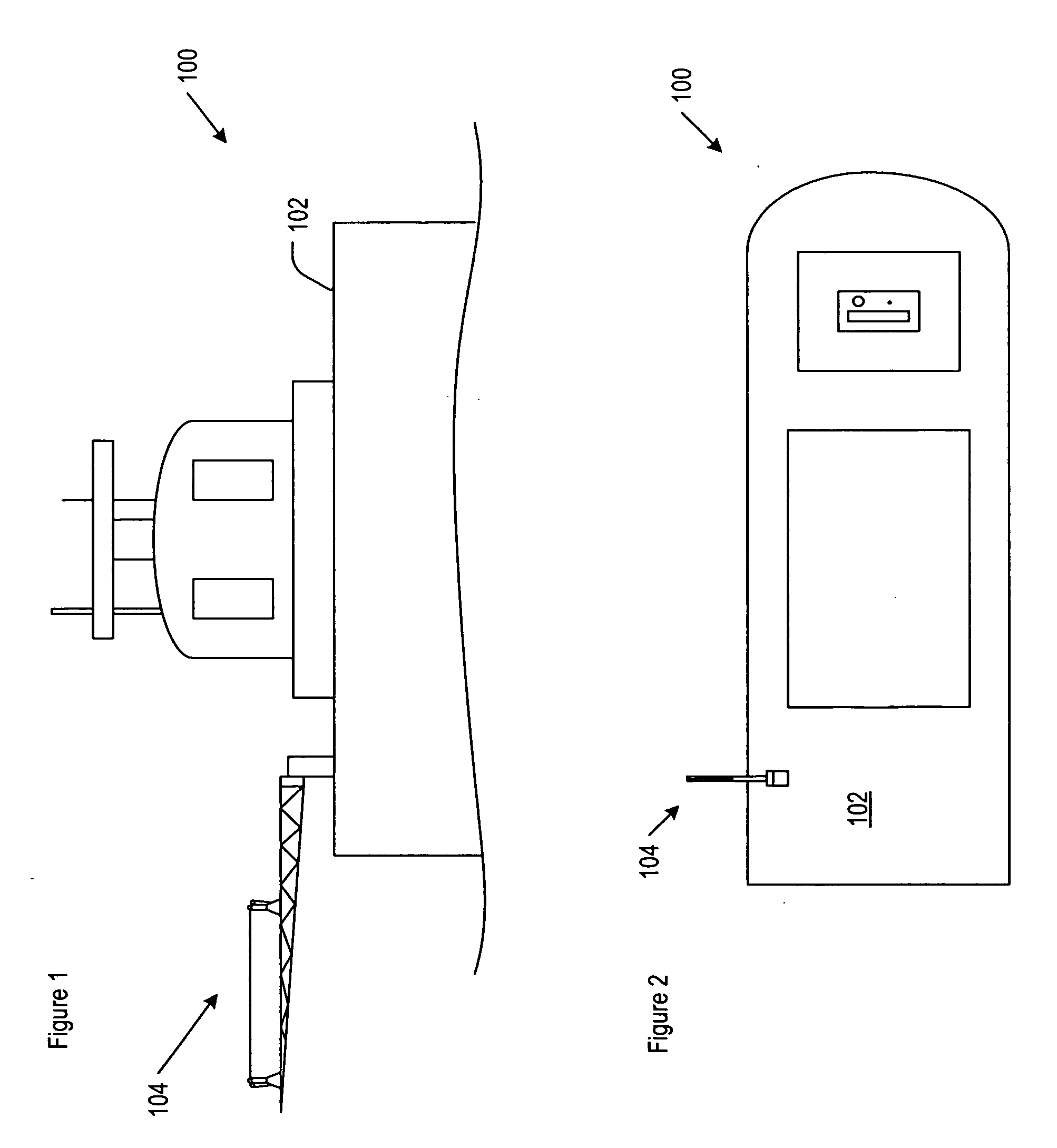

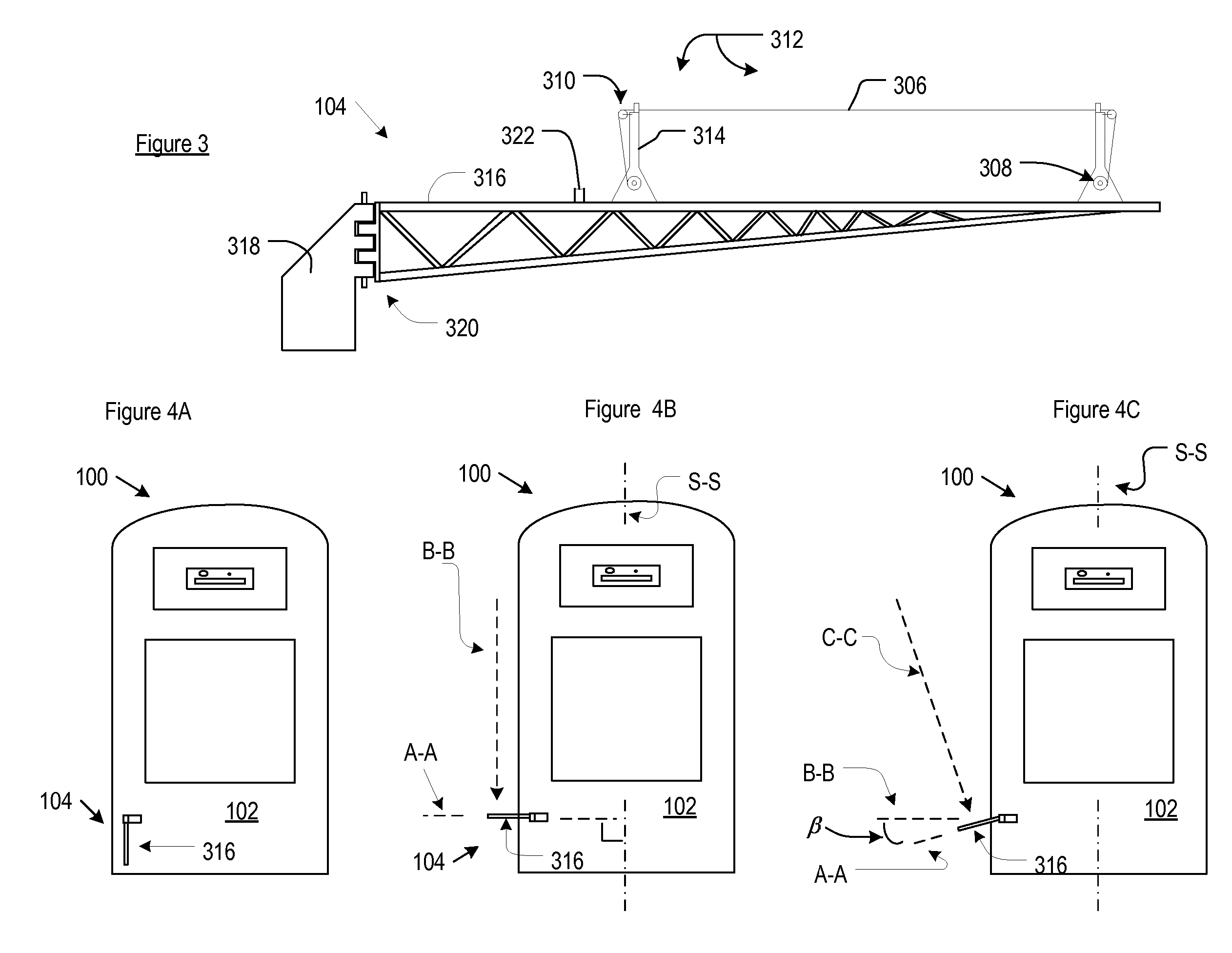

UAV recovery system

ActiveUS7219856B2Avoid contactReduce risk of damageArresting gearUnmanned aerial vehiclesAerospace engineering

A UAV capture system is disclosed. In the illustrative embodiment, the UAV capture system is coupled to the deck of a sea-faring vessel. The UAV capture system includes a single arresting line that is supported by a stanchion. In the illustrative embodiment, the stanchion is disposed on a rotatable boom.

Owner:LOCKHEED MARTIN CORP

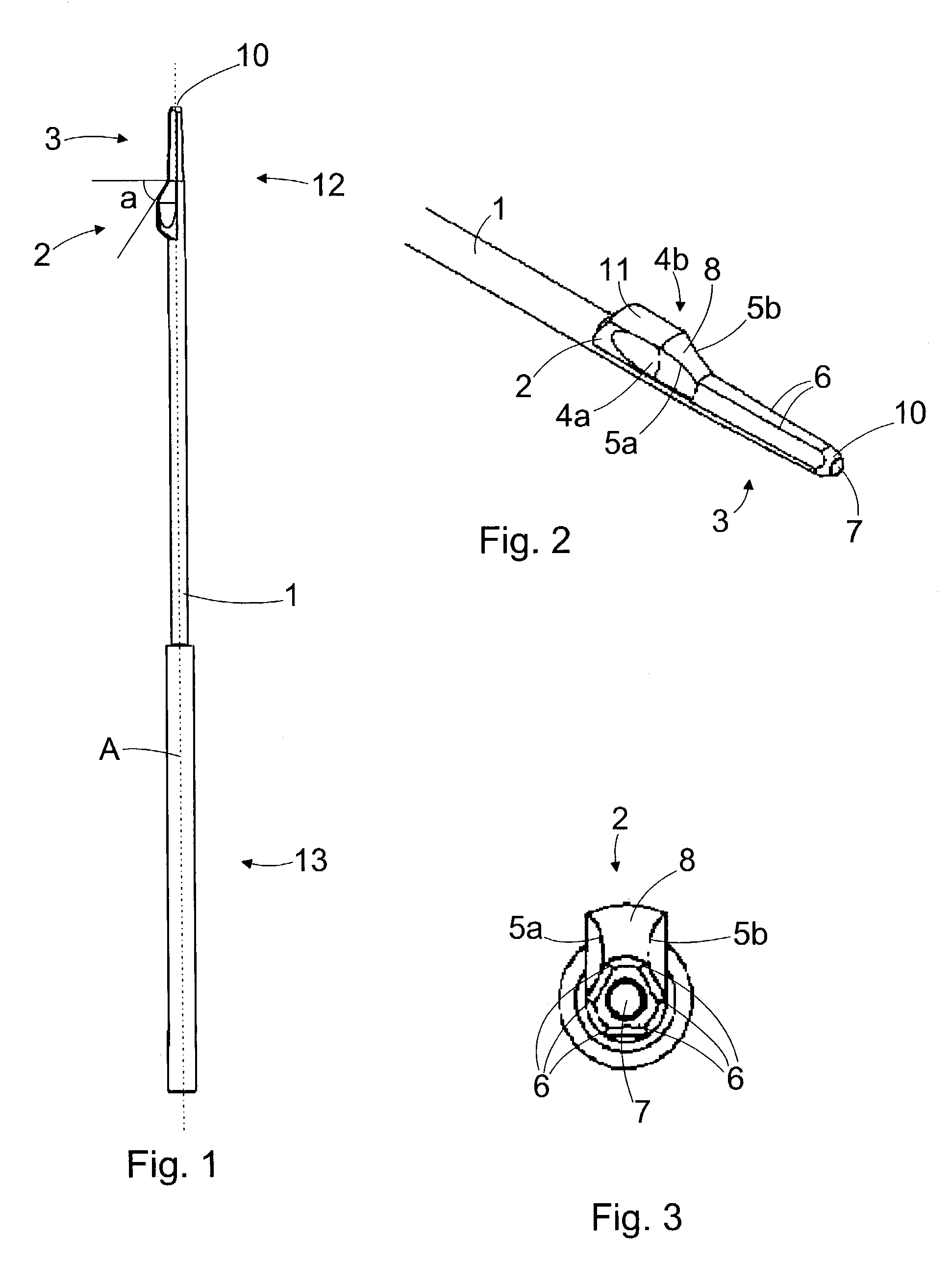

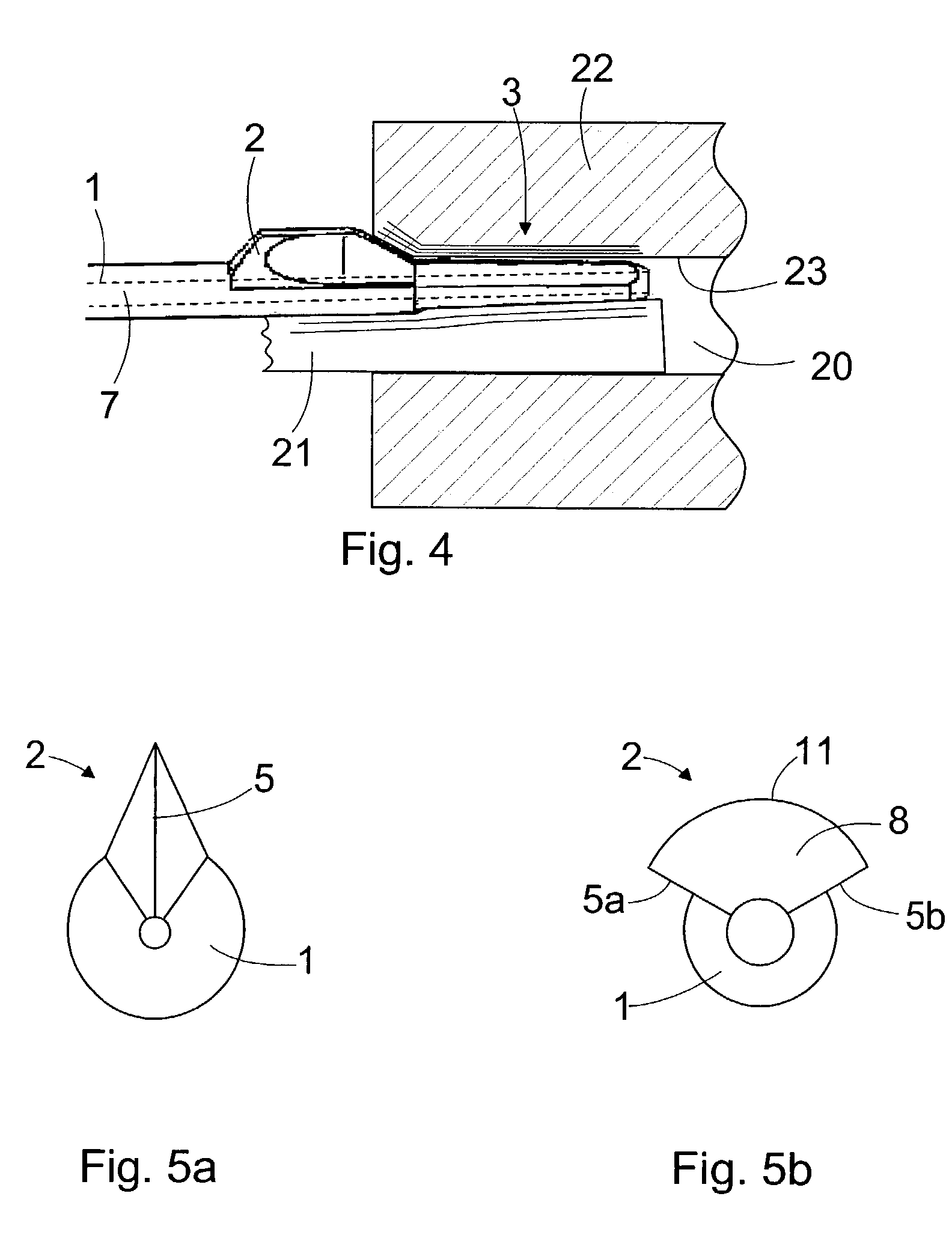

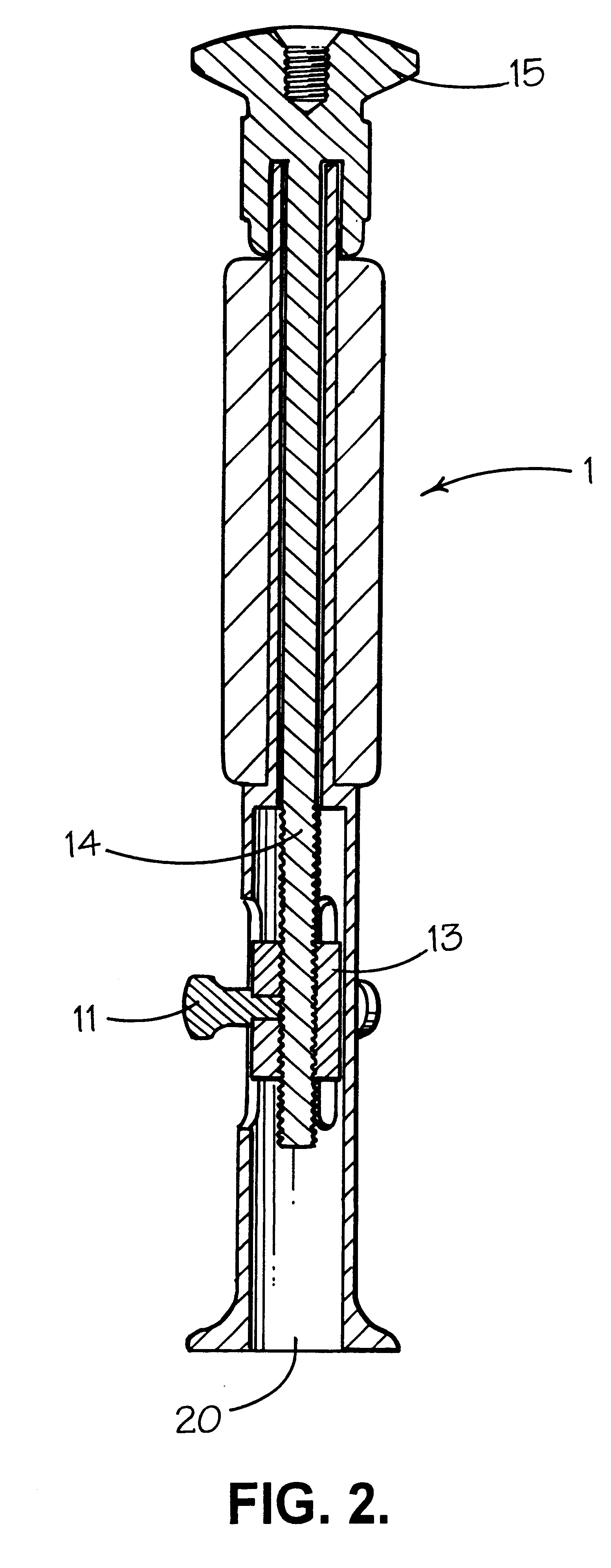

Instrument

InactiveUS7041107B2Reduce risk of damageReduce in quantityProsthesisOsteosynthesis devicesTurn angleEngineering

An instrument for shaping a mouth part of a drilled tunnel provided in a bone. The instrument includes a shaft having a longitudinal axis and a first and a second end. The first end of the shaft is provided with a projection, which includes a blade for shaping the mouth part of the drilled tunnel when the instrument is turned around the longitudinal axis of the shaft. The instrument is asymmetric at an intersecting surface perpendicular to the longitudinal axis and intersecting with the blade, the instrument thus shaping the surfaces surrounding the first end only substantially within an area corresponding with a turning angle of such a turning movement.

Owner:INION

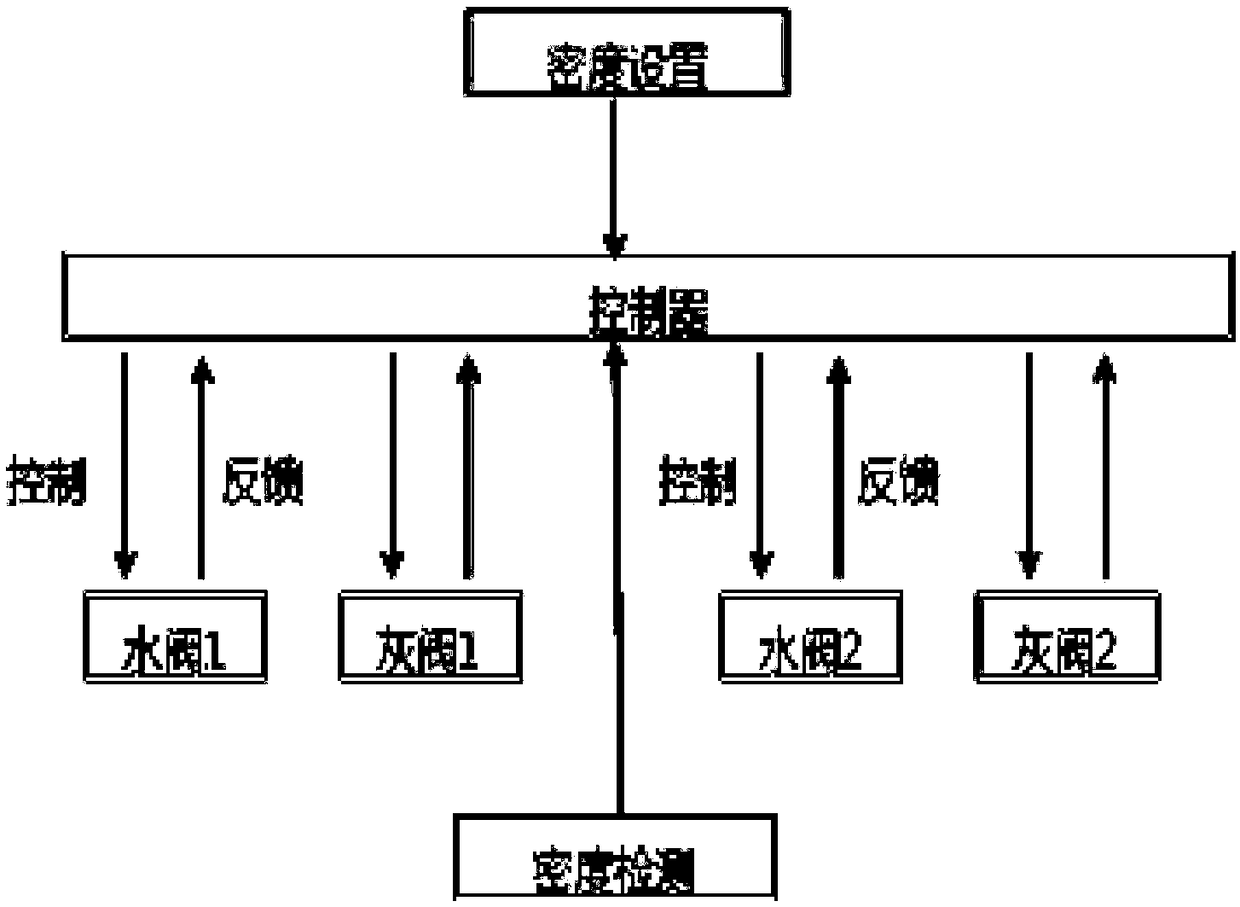

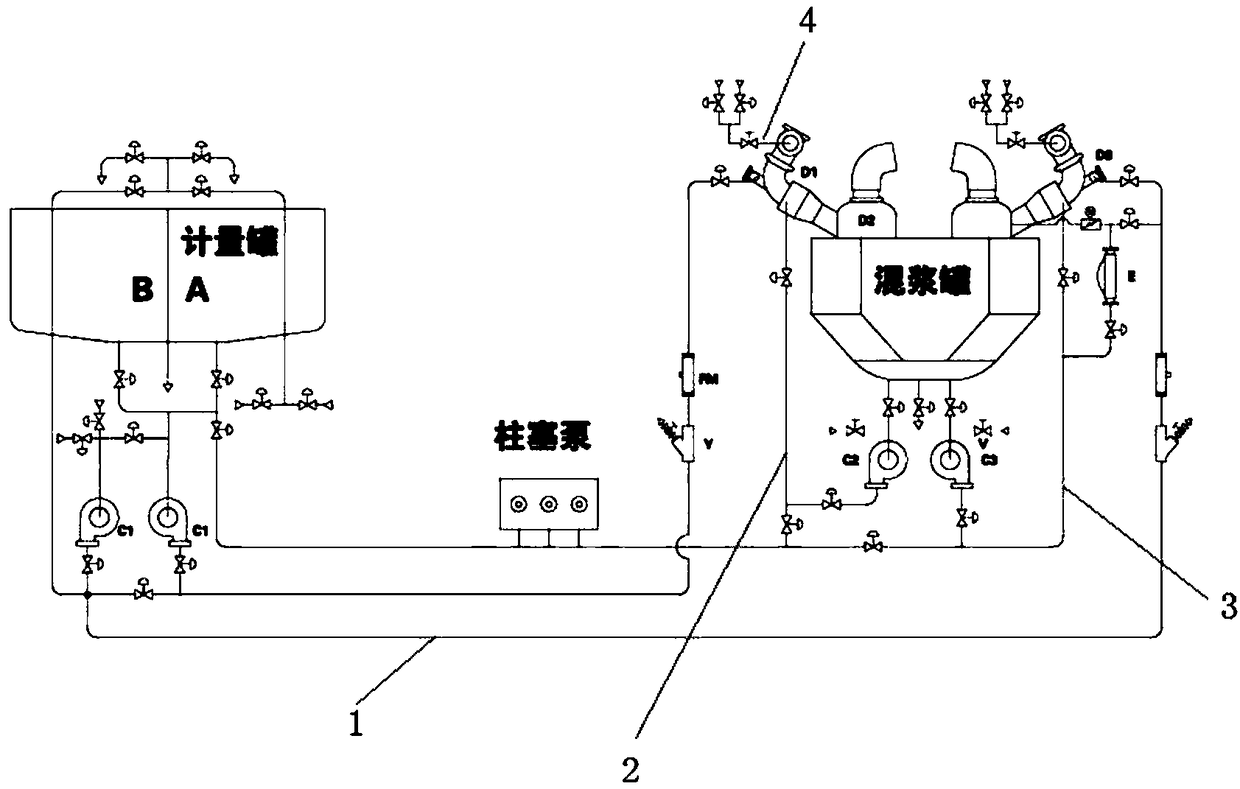

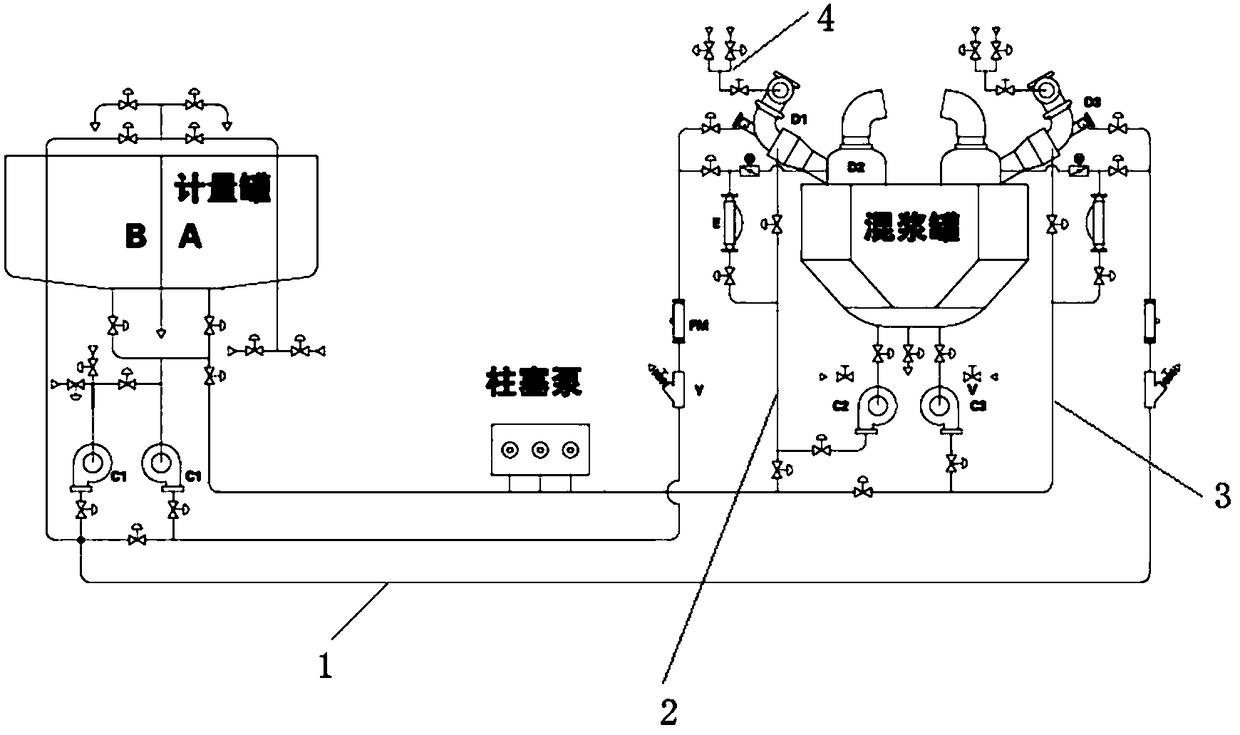

Efficient mixing system for well cementing operation

PendingCN108687954ARealize automatic controlEasy to operateCement mixing apparatusControl apparatusHybrid systemControl system

The invention relates to the technical field of petroleum equipment, in particular to an efficient mixing system for well cementing operation. The efficient mixing system comprises a measuring tank, aclear water manifold assembly, a cement grey feeding manifold assembly, high-energy mixers, a mud mixing tank and a mud manifold assembly. The mud mixing tank is at least connected with two high-energy mixers, and an inlet of the mud mixing tank is connected with diffusion boxes which are connected with the high-energy mixers. Discharged materials of the high-energy mixers are guided into the mudmixing tank through the diffusion boxes, and the at least one diffusion box is connected with a density control system. The multiple sets of mixers are integrated, and the large-discharge-capacity and efficient mixing effect can be achieved with existing operation conditions.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

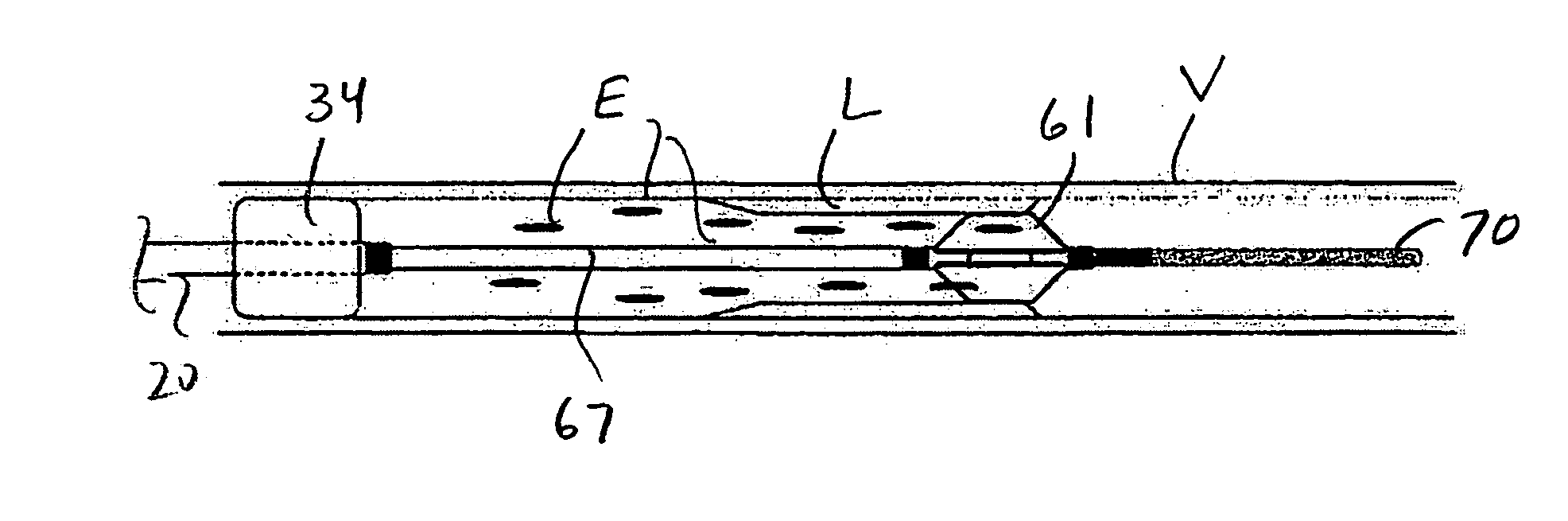

Embolic protection and plaque removal system with closed circuit aspiration and filtering

InactiveUS20070021774A1Avoid mixingReduce risk of damageOperating means/releasing devices for valvesBalloon catheterSurgeryBlood vessel

Embolic protection and plaque removal apparatus and methods are provided wherein an aspiration device aspirates, filters and reperfuses blood using a closed fluid circuit having a bi-directional working lumen. The plaque removal device includes a plurality of self-expanding cutting elements that form cage that self-centers within the blood vessel to reduce the risk of trauma to the vessel lining.

Owner:NOVOSTENT CORP

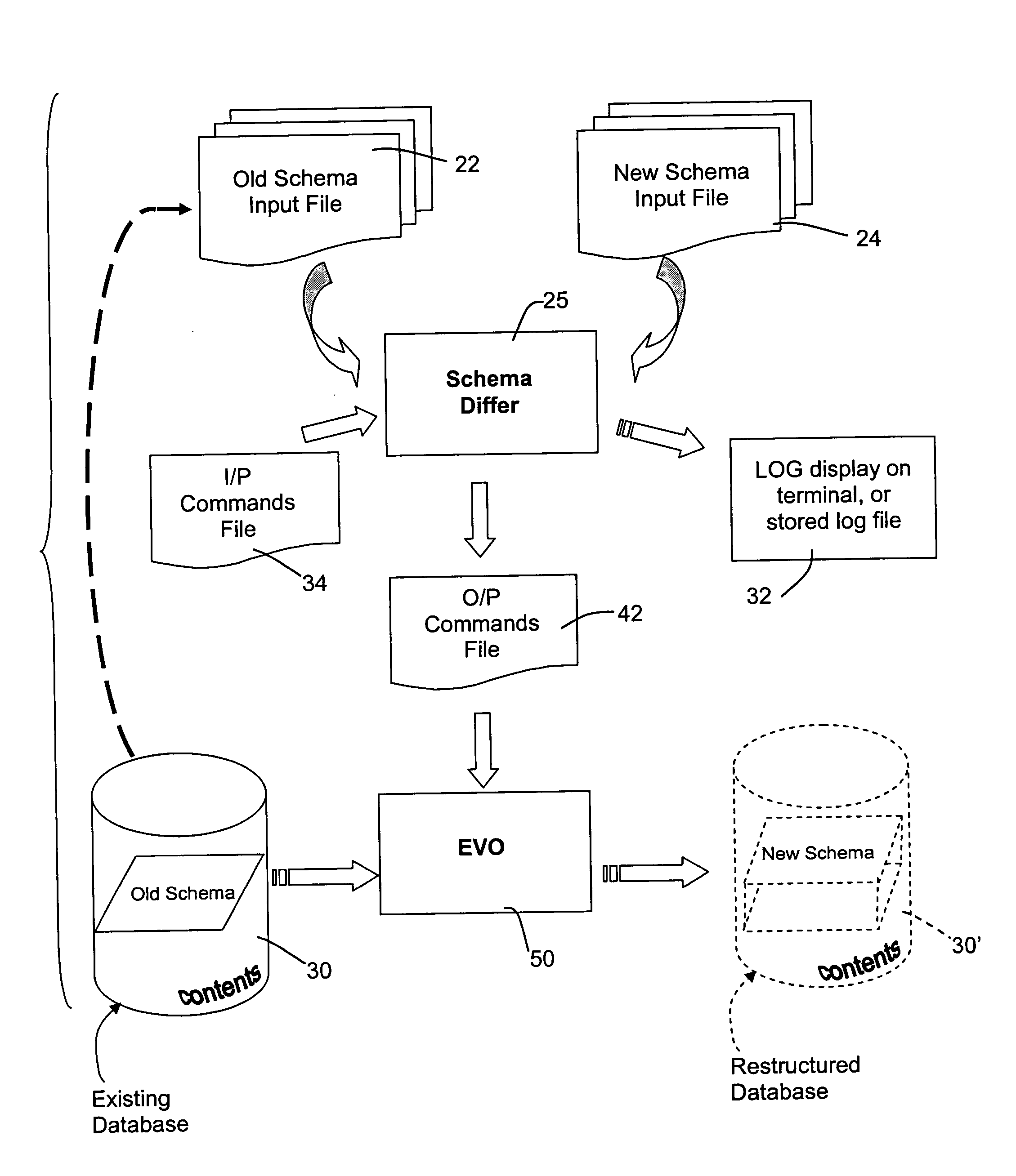

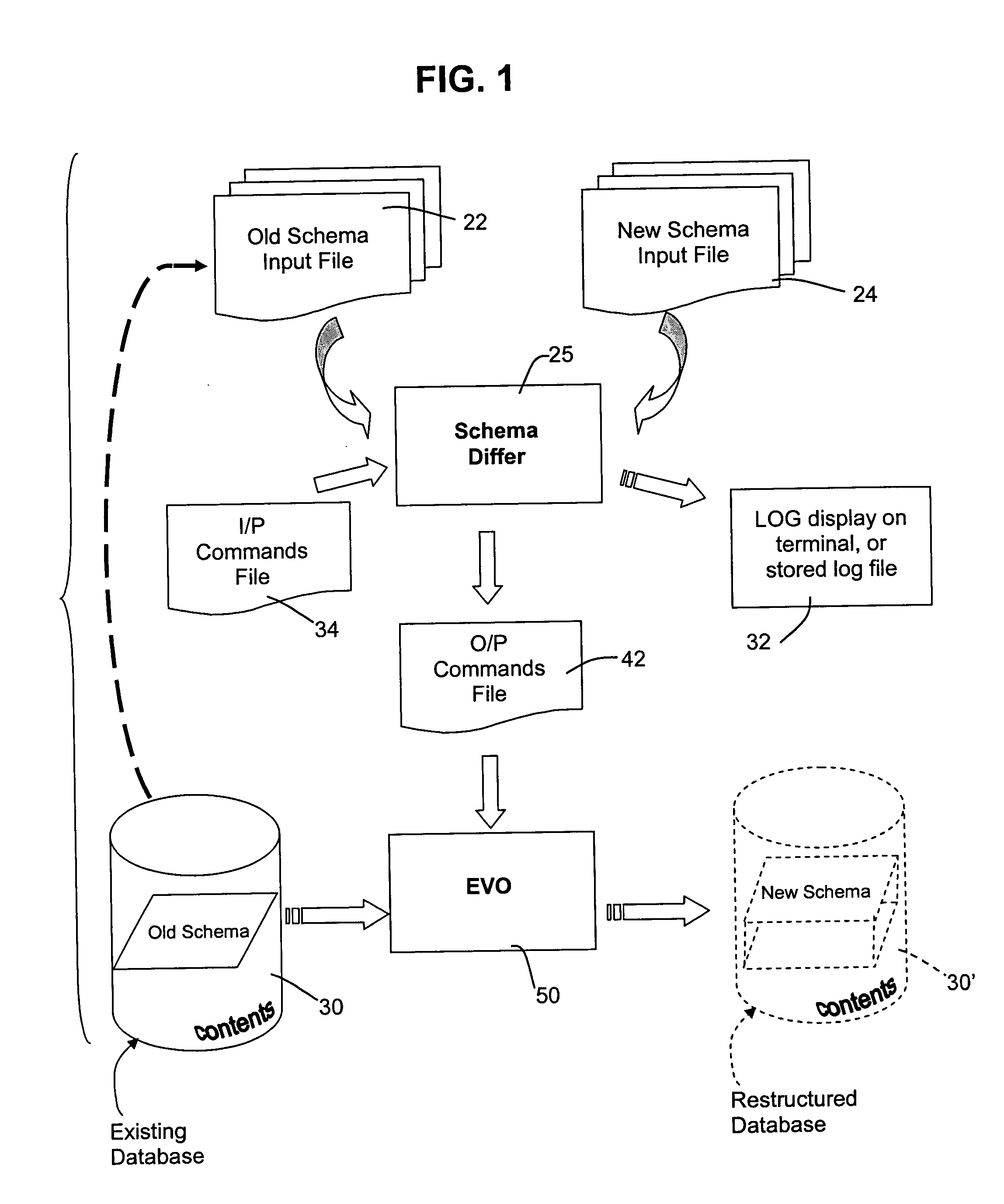

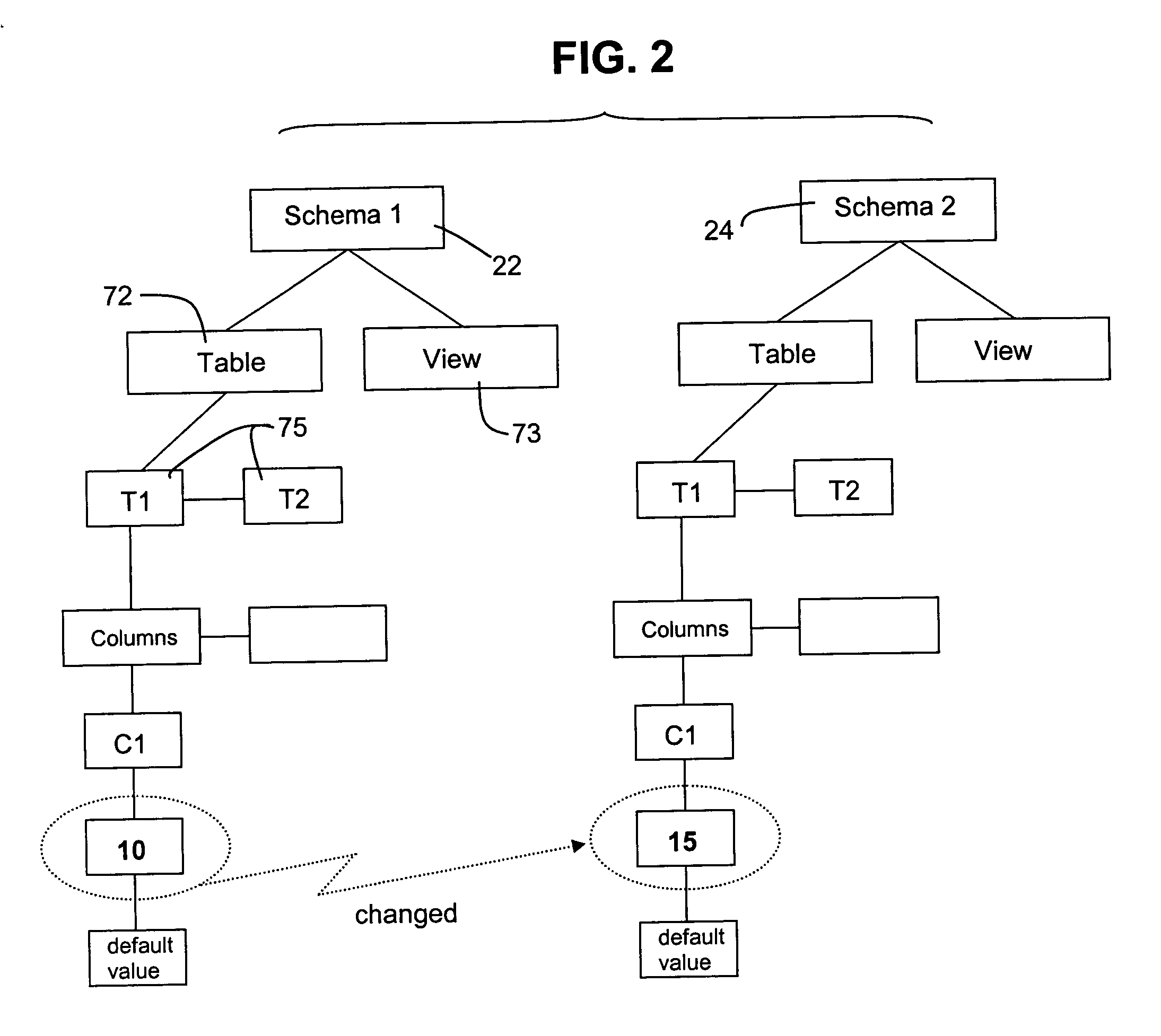

Method for automated database schema evolution

InactiveUS20050071359A1Easy to changeMinimal impactDigital data information retrievalSpecial data processing applicationsSchema for Object-Oriented XMLAutomated database

A database structure of a sort defined by an access and query language that defines tables of variables having labels and field characteristics, such as ANSI structured query language (SQL), is modified by determining the structural differences between an existing schema and a new schema, independent of database contents. The differences are processed to generate commands that are then applied to evolve an existing database from the old schema or structure to the new one. This avoids the need to dump and restructure the contents of the old database for reload into an empty new database that has been prepared to meet the new schema.

Owner:LUCENT TECH INC

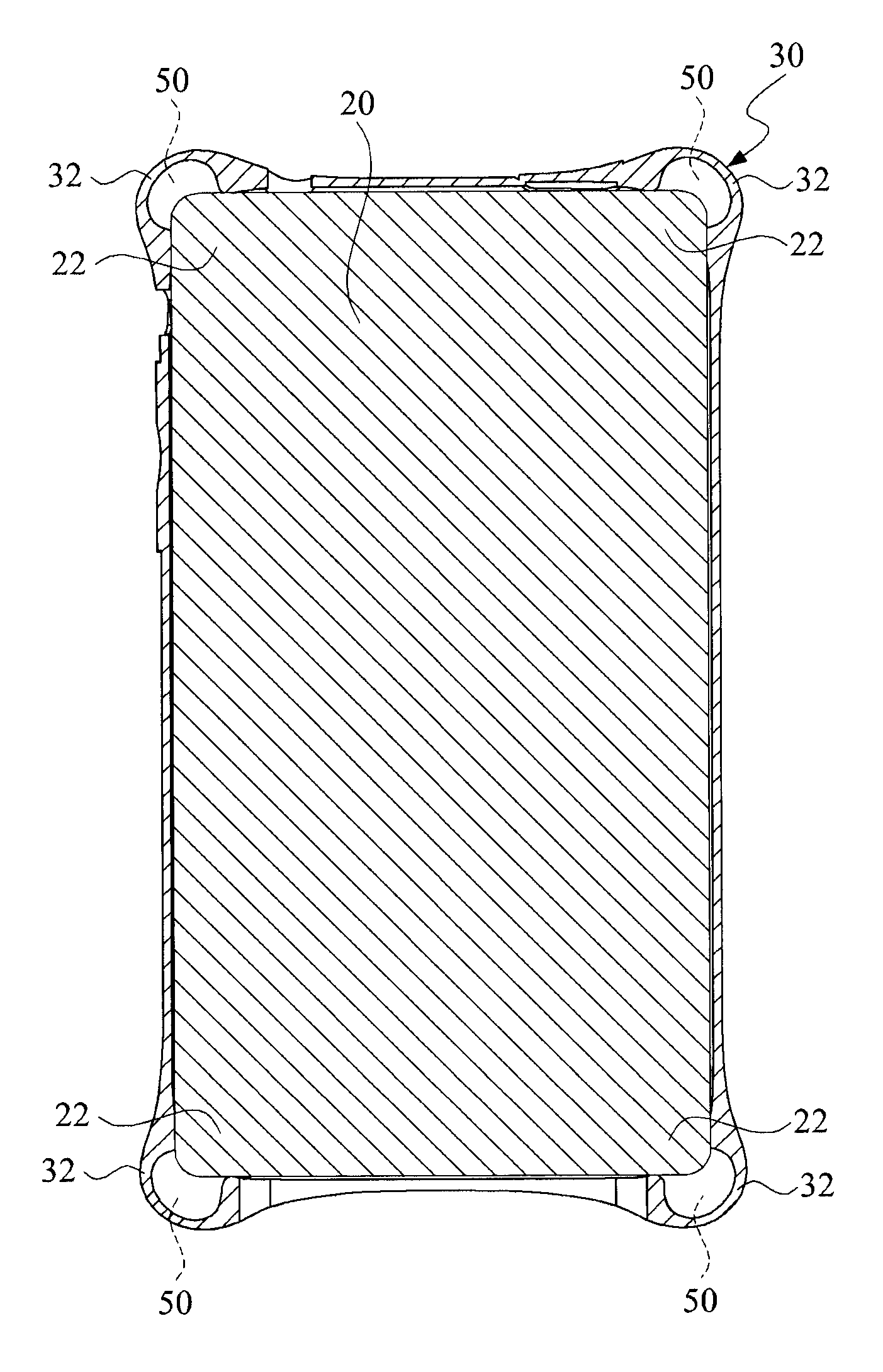

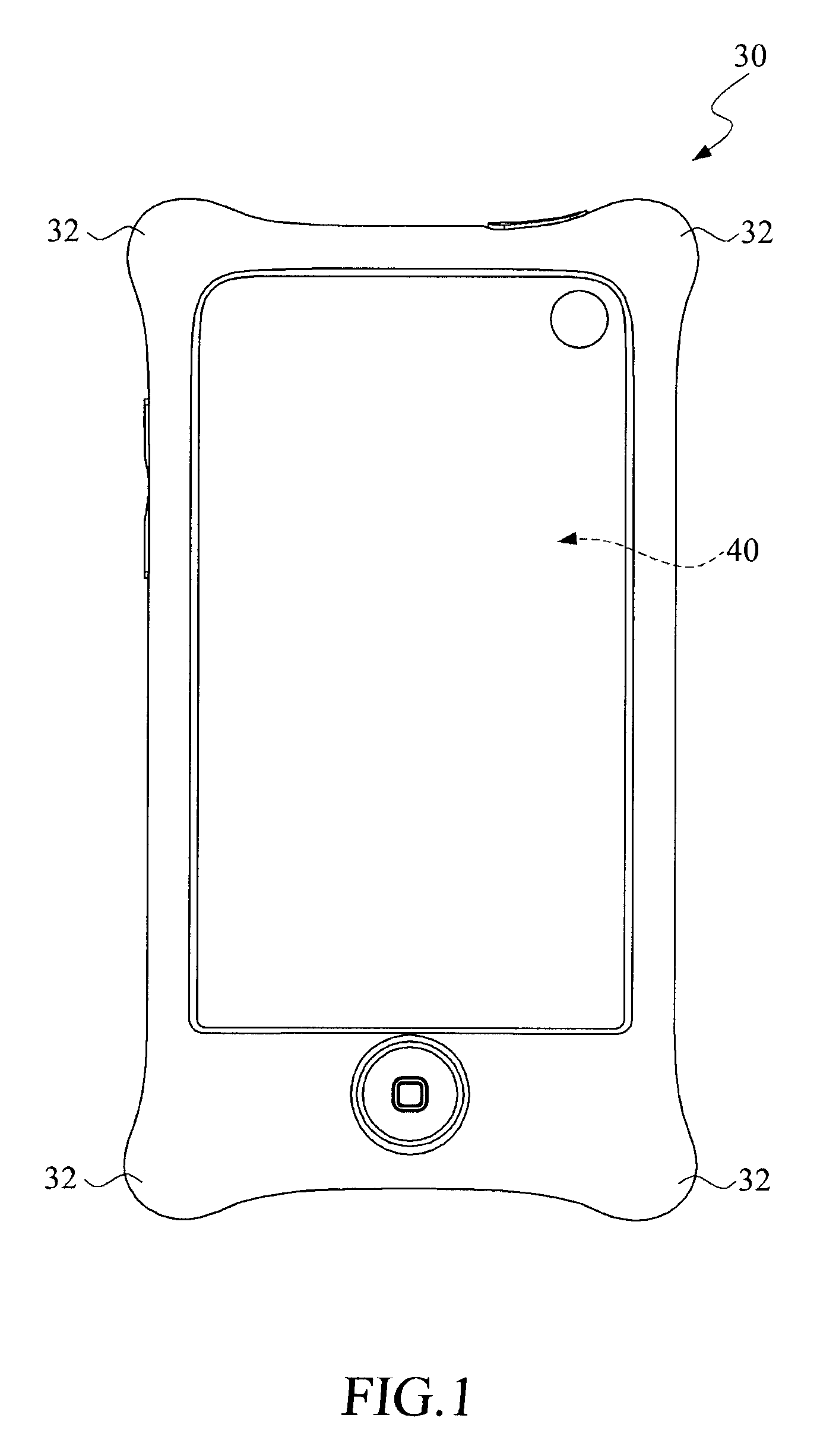

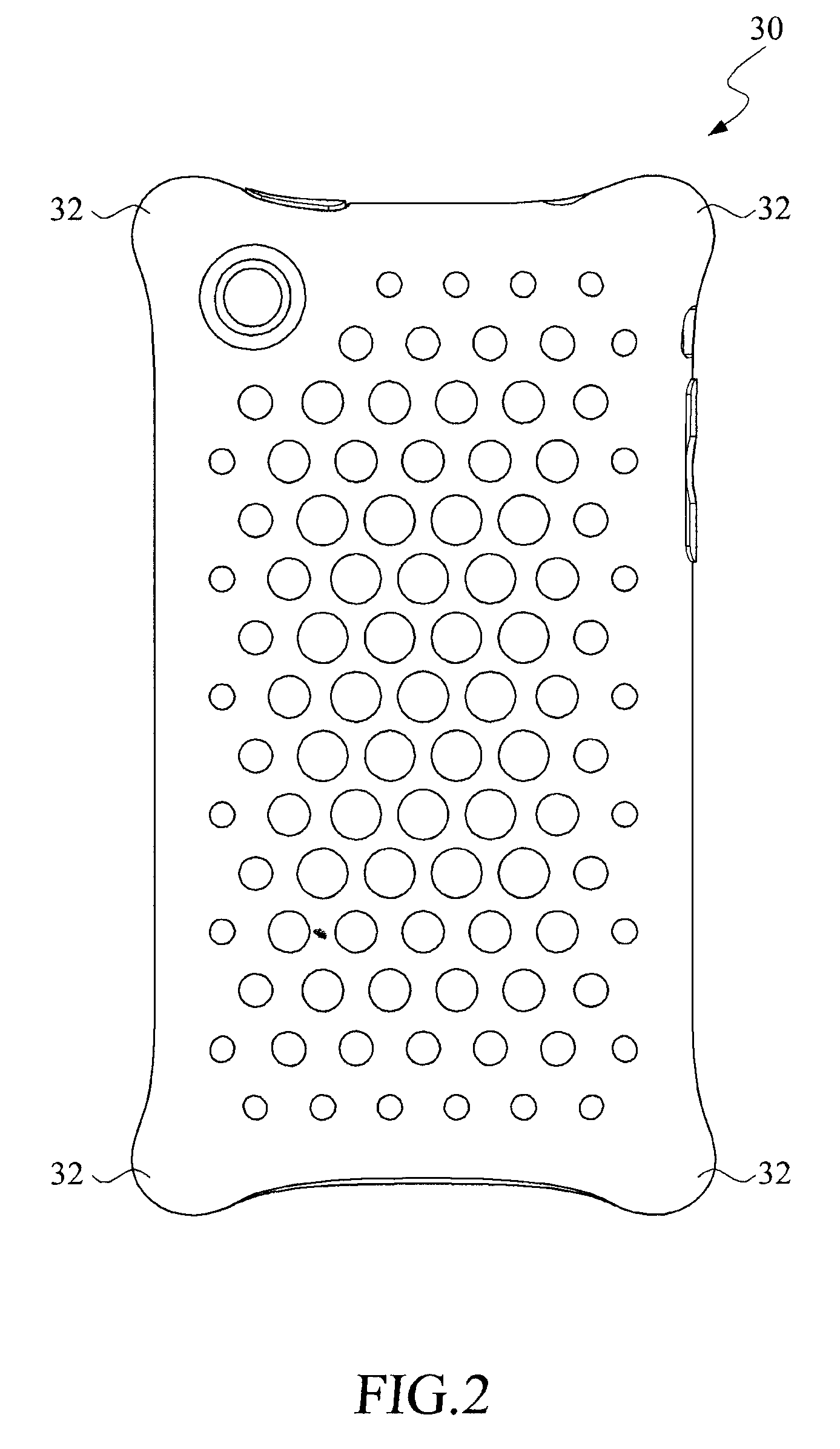

Shock-absorbing protection cover for a portable product

InactiveUS7938260B2Reduce risk of damageAvoid scratchesPortable framesSubstation equipmentEngineeringInternal zone

A protection cover is used for sleeving over a portable product so as to help protect the product from being scratched. The protection cover includes a shock-absorbing structure for shielding and concealing a corner of the portable product. The shock-absorbing structure is formed with an air chamber bulging outwardly from the corner of the portable product. The shock-absorbing structure further has an inner region that defines an opening for access into the air chamber and that abuts tightly and sealingly against the corner of the portable product so as to convert the air chamber into an air-trapped chamber when the protection cover is sleeved over the portable product.

Owner:FRUITSHOP INT

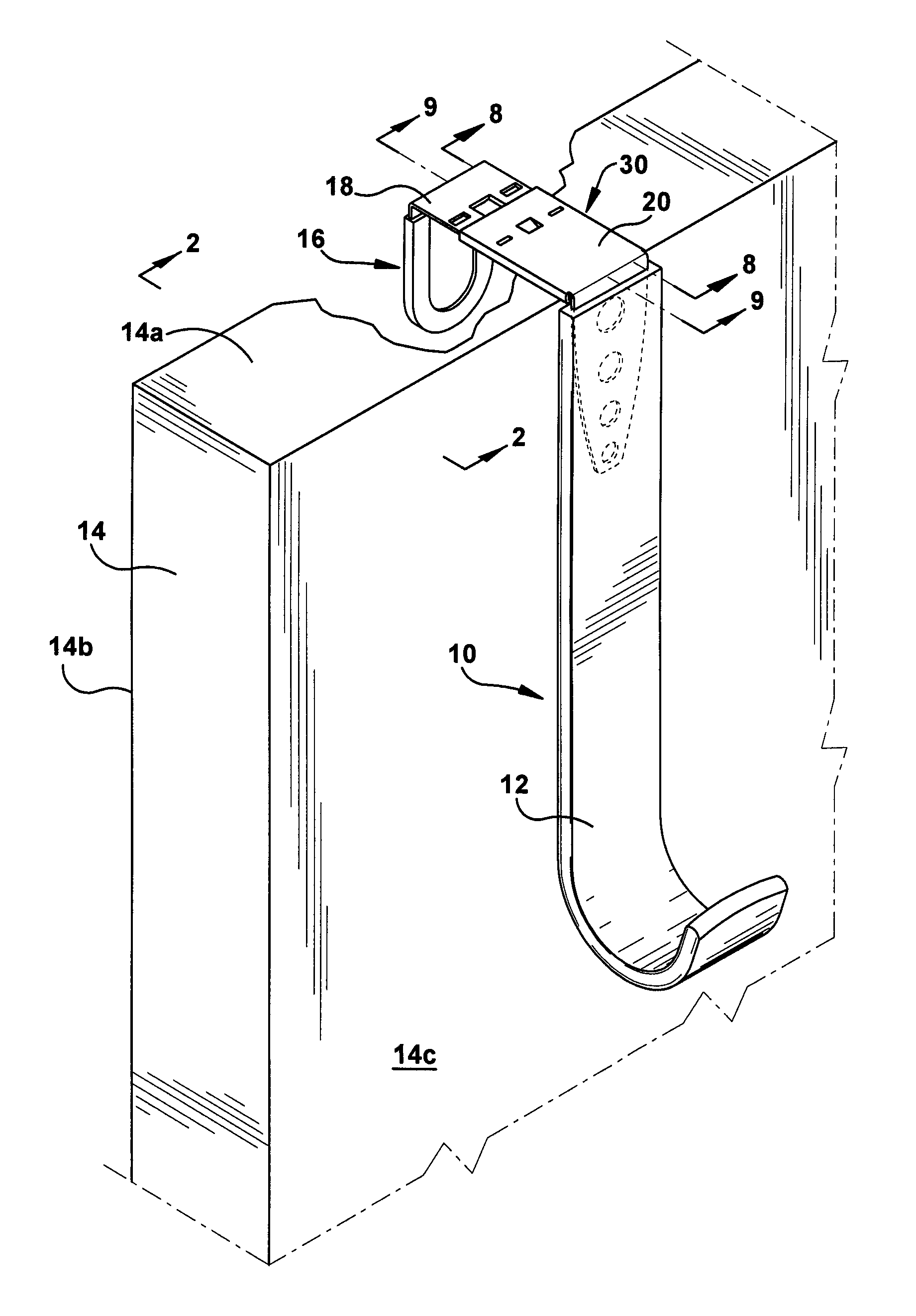

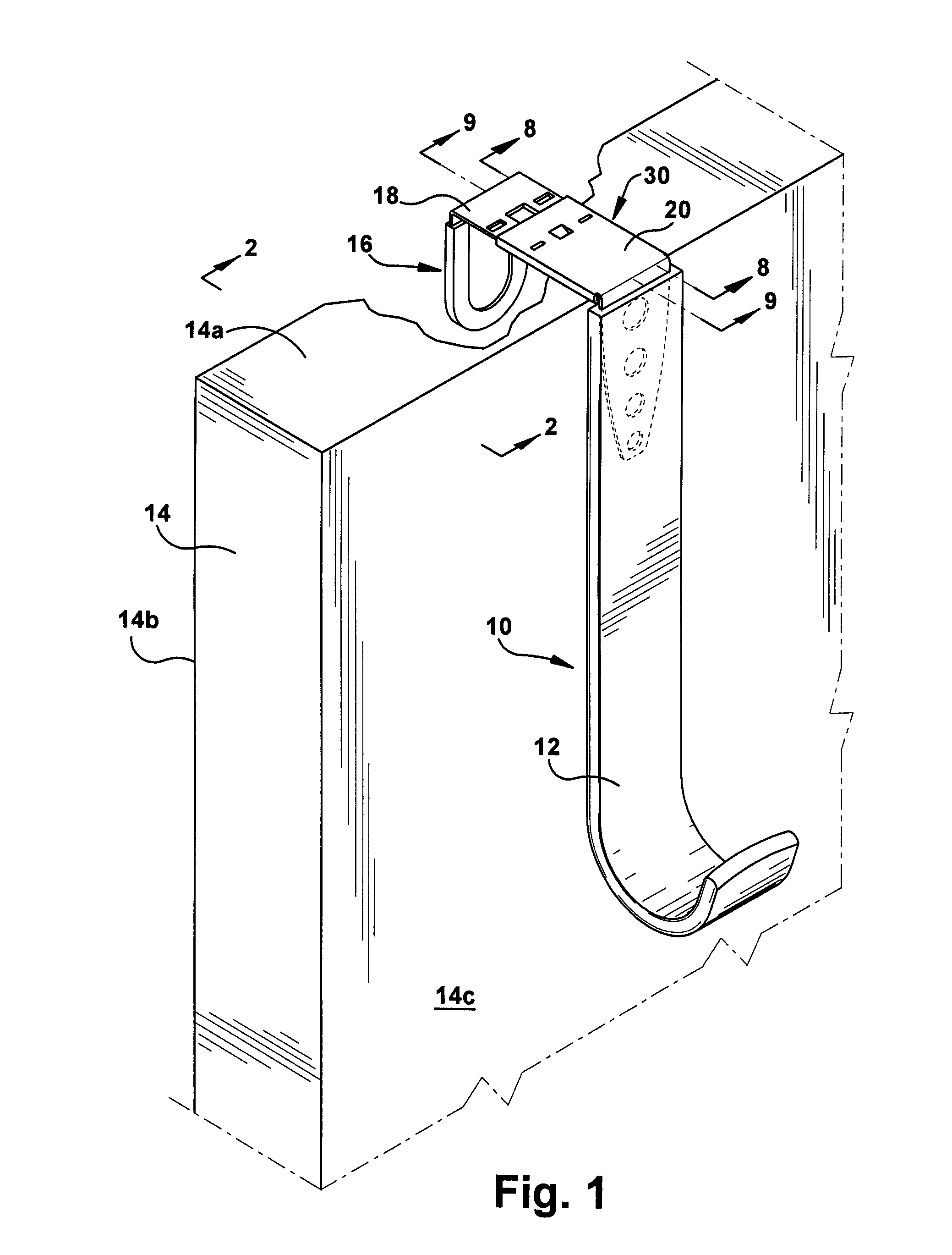

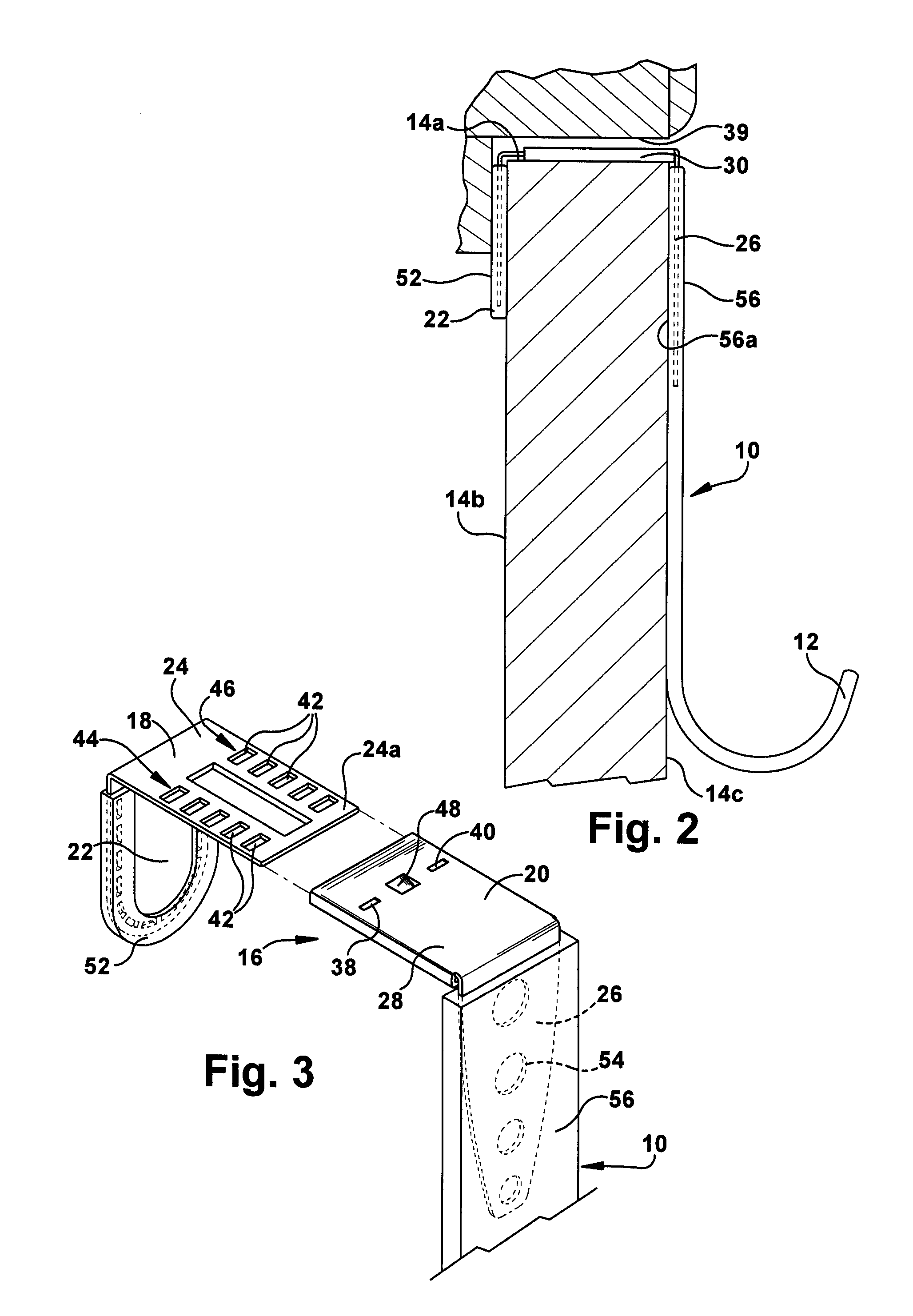

Adjustable hanger device

InactiveUS7992833B1Formed relatively economicallyReduce risk of damageApparel holdersCurtain suspension devicesEngineeringUltimate tensile strength

An adjustable hanger device includes an adjustable mounting bracket that may be sized for mounting the hanger to support members of various dimensions. The hanger device has a composite structure including both metallic and polymeric components. The mounting bracket is formed of primarily metallic components to provide adequate hang strength, and a thin profile for use in so-called over-the-door hanger devices supported on the top edge of a door below the lintel or frame member when the door is in the closed position.

Owner:SPECTRUM DIVERSIFIED DESIGNS

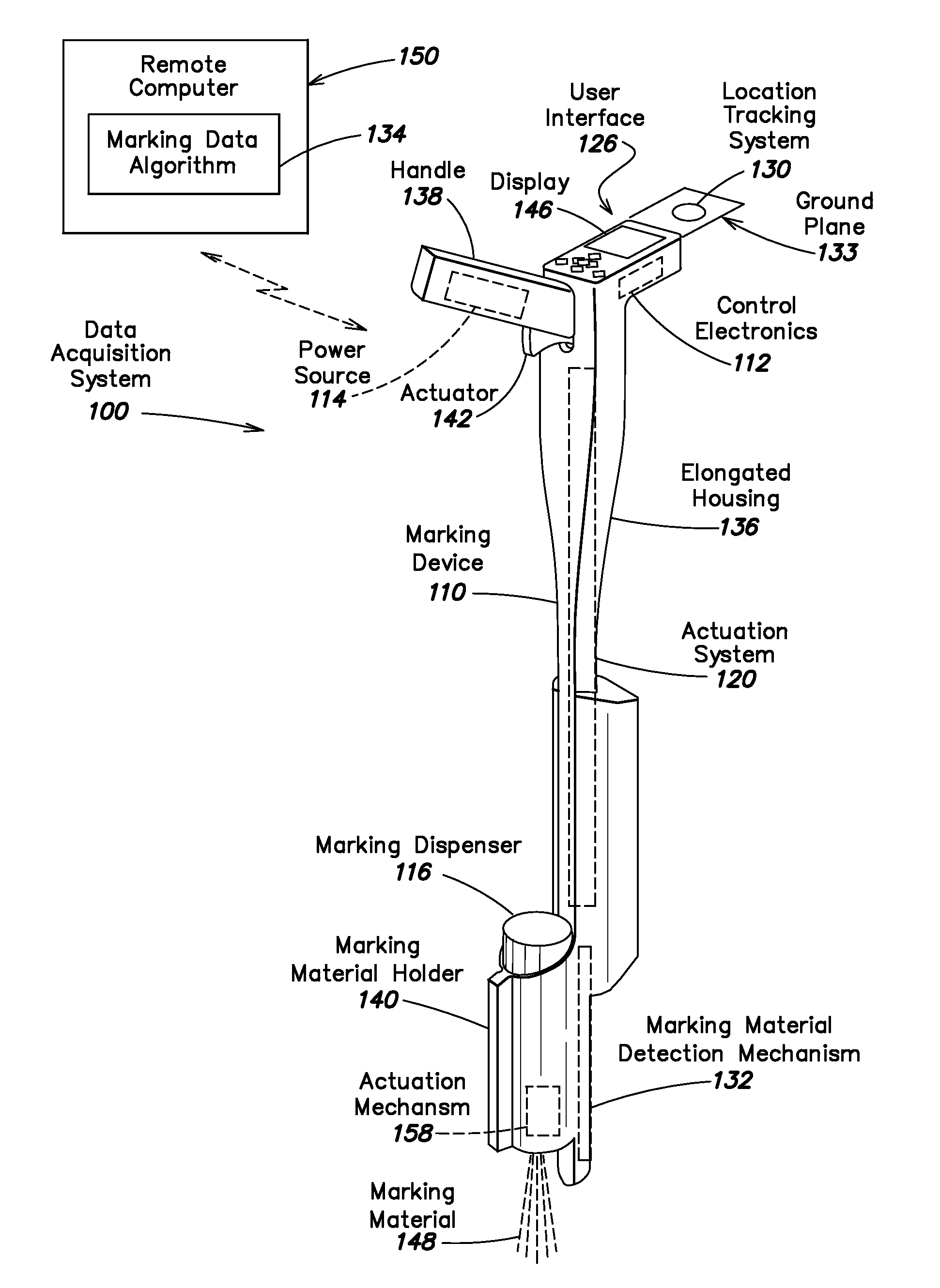

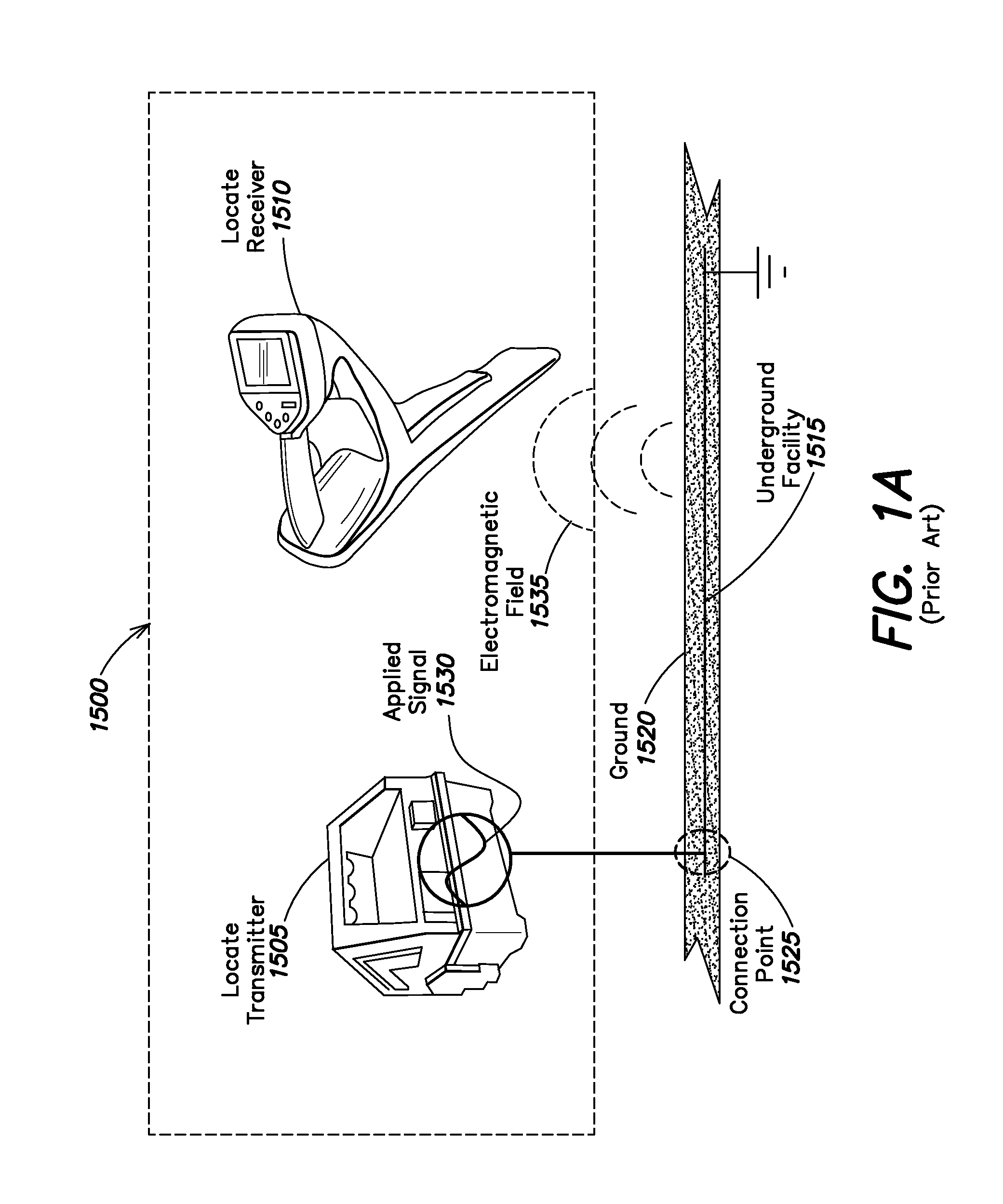

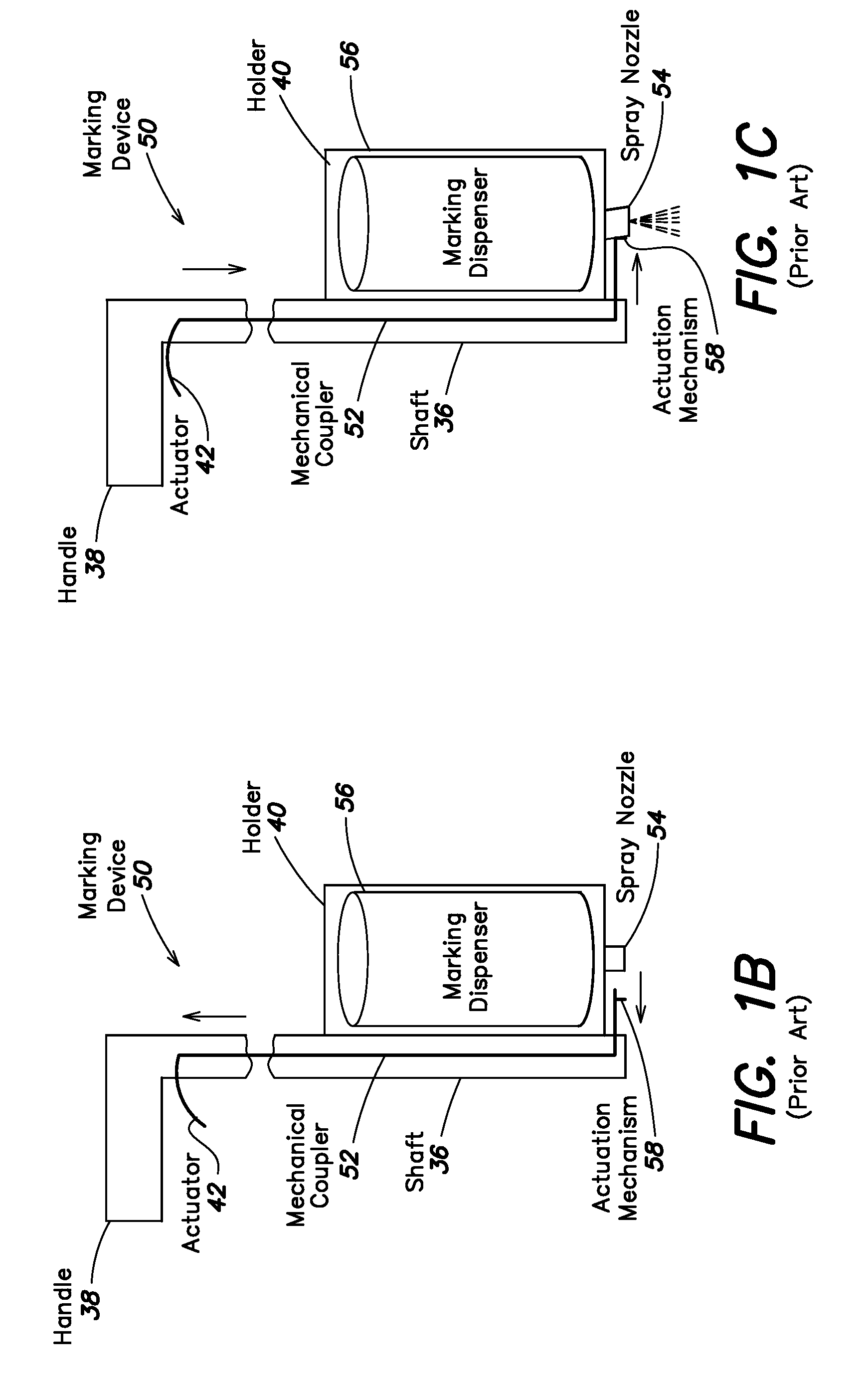

Locating equipment communicatively coupled to or equipped with a mobile/portable device

ActiveUS20110191058A1Reduce risk of damageReduce the risk of injuryThermometer detailsDispensing apparatusEngineeringRemote computer

Locating and / or marking equipment, such as a locate transmitter or locate receiver, a marking device, or a combined locate and marking device, may be communicatively coupled to and / or equipped with a mobile / portable device (e.g., a mobile phone, personal digital assistant or other portable computing device) that provides processing, electronic storage, electronic display, user interface, communication facilities and / or other functionality (e.g., GPS-enabled functionality) for the equipment. A mobile / portable device may be mechanically and / or electronically coupled to the equipment, and may be programmed so as to log and generate electronic records of various information germane to a locate and / or marking operation (e.g., locate information, marking information, and / or landmark information). Such records may be formatted in various manners, processed and / or analyzed on the mobile / portable device, and / or transmitted to another device (e.g., a remote computer / server) for storage, processing and / or analysis. The mobile / portable device also may provide redundant, shared and / or backup functionality for the equipment to enhance robustness.

Owner:CERTUSVIEW TECH LLC

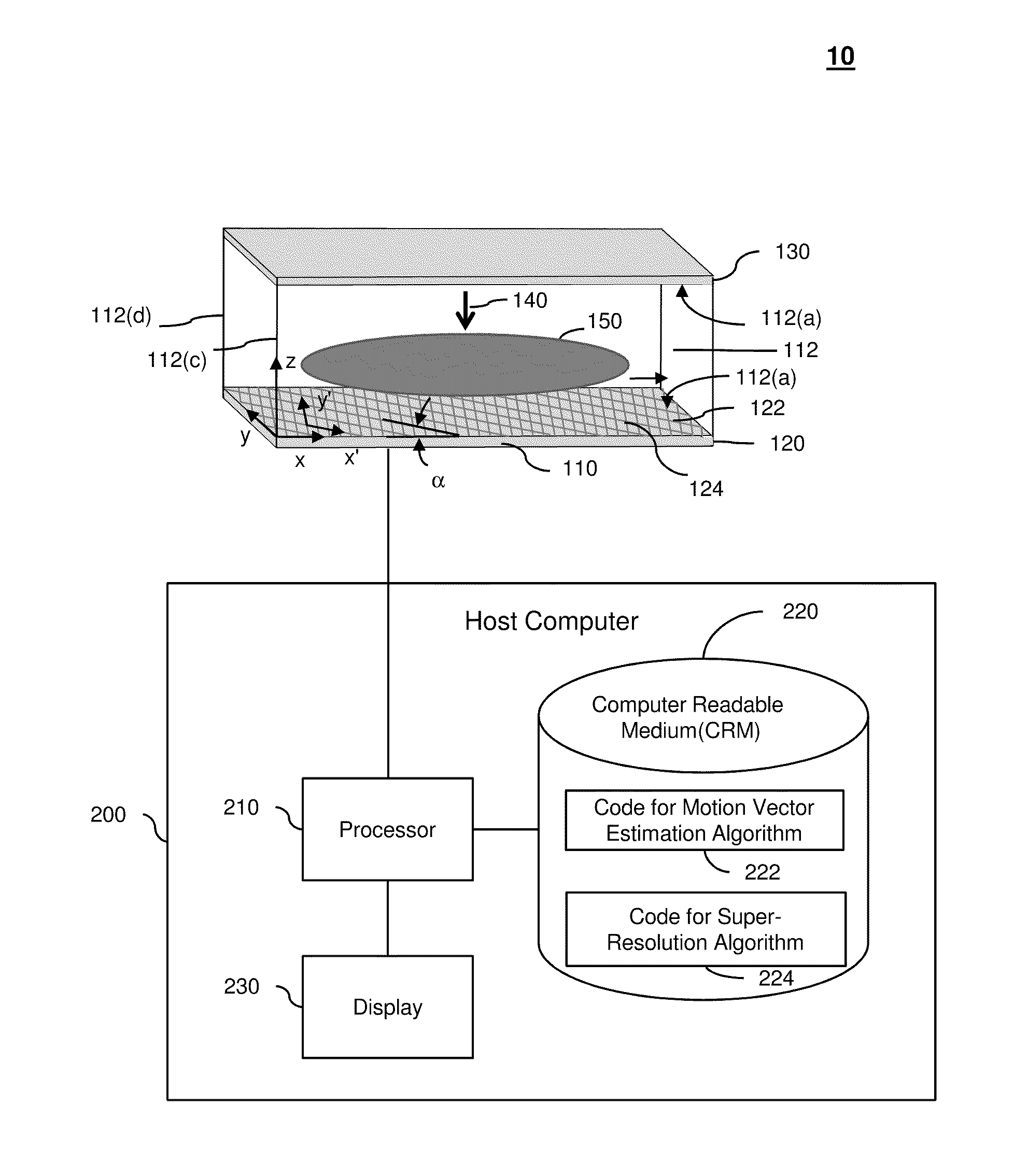

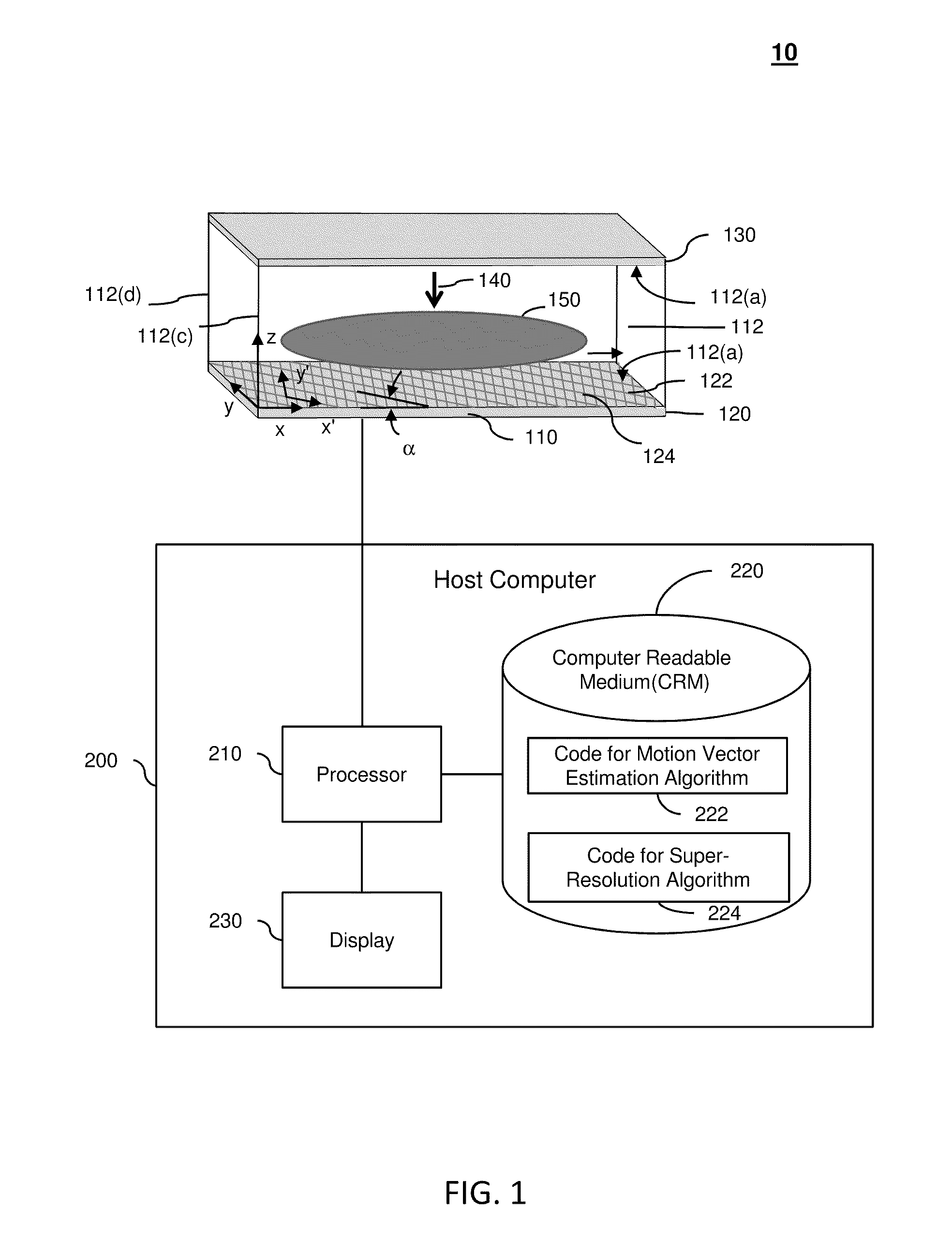

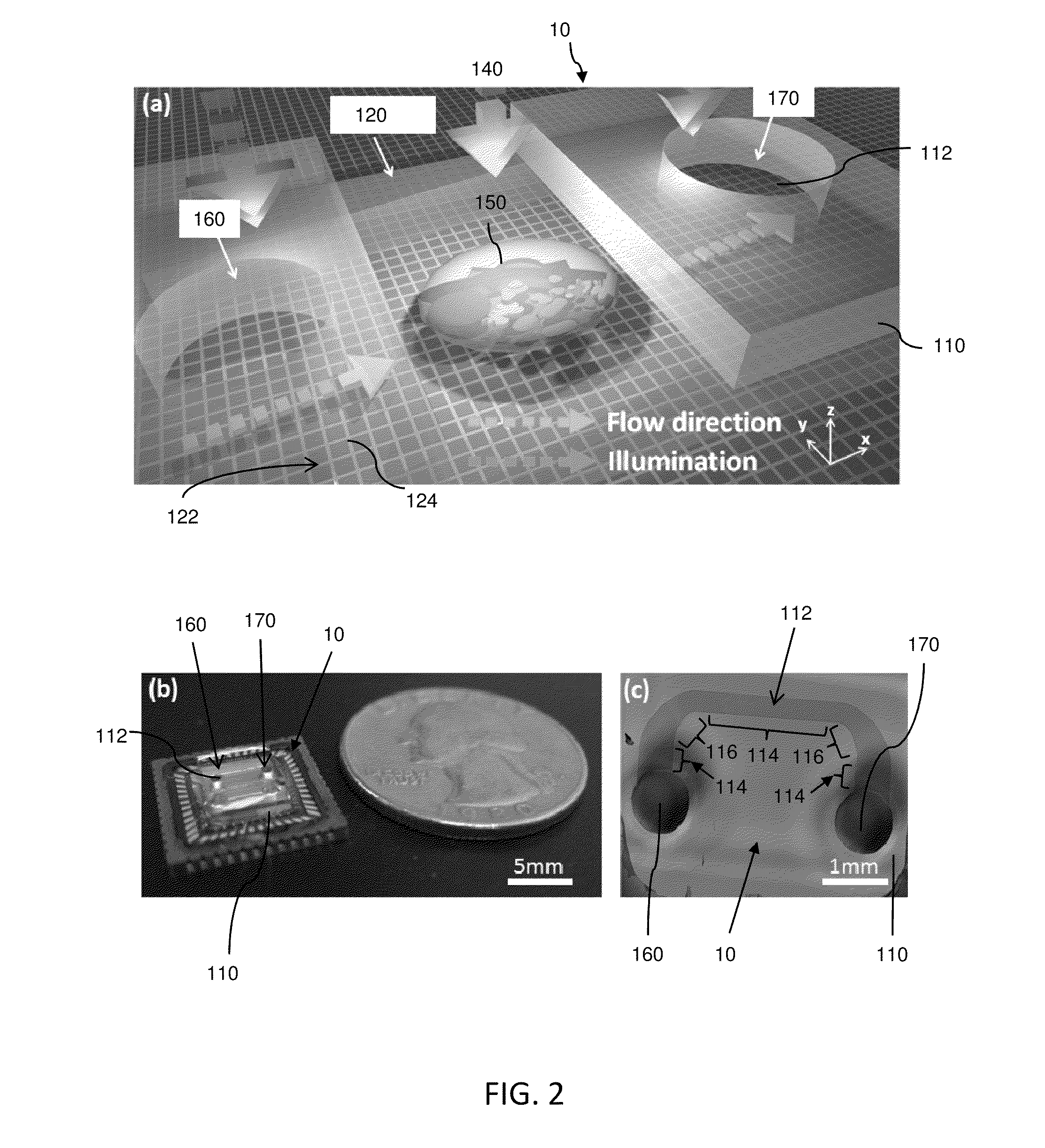

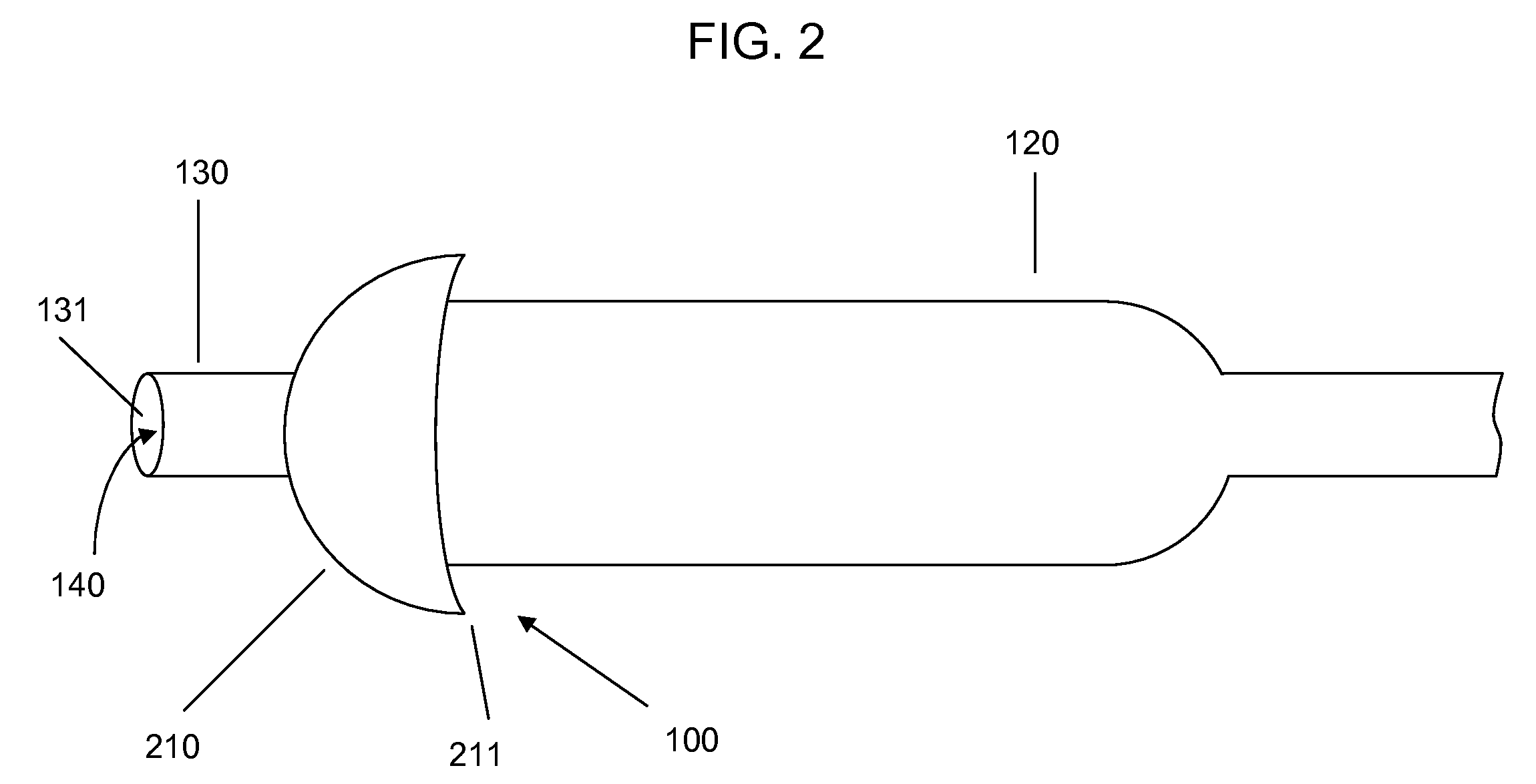

Super resolution optofluidic microscopes for 2d and 3D imaging

ActiveUS20110234757A1High resolutionHigh resolution imagingTelevision system detailsGeometric image transformationSurface layerElectronic communication

A super resolution optofluidic microscope device comprises a body defining a fluid channel having a longitudinal axis and includes a surface layer proximal the fluid channel. The surface layer has a two-dimensional light detector array configured to receive light passing through the fluid channel and sample a sequence of subpixel shifted projection frames as an object moves through the fluid channel. The super resolution optofluidic microscope device further comprises a processor in electronic communication with the two-dimensional light detector array. The processor is configured to generate a high resolution image of the object using a super resolution algorithm, and based on the sequence of subpixel shifted projection frames and a motion vector of the object.

Owner:CALIFORNIA INST OF TECH

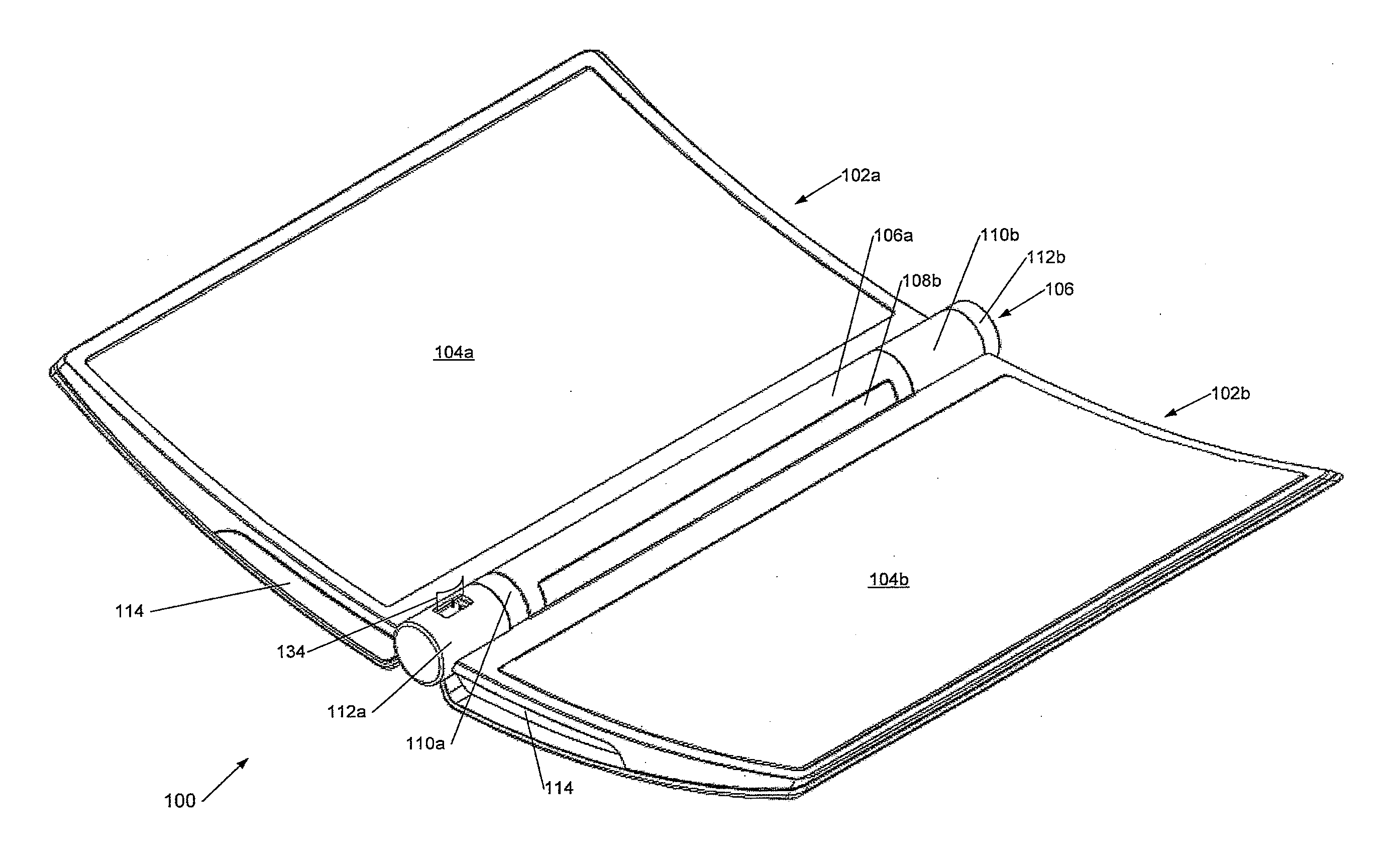

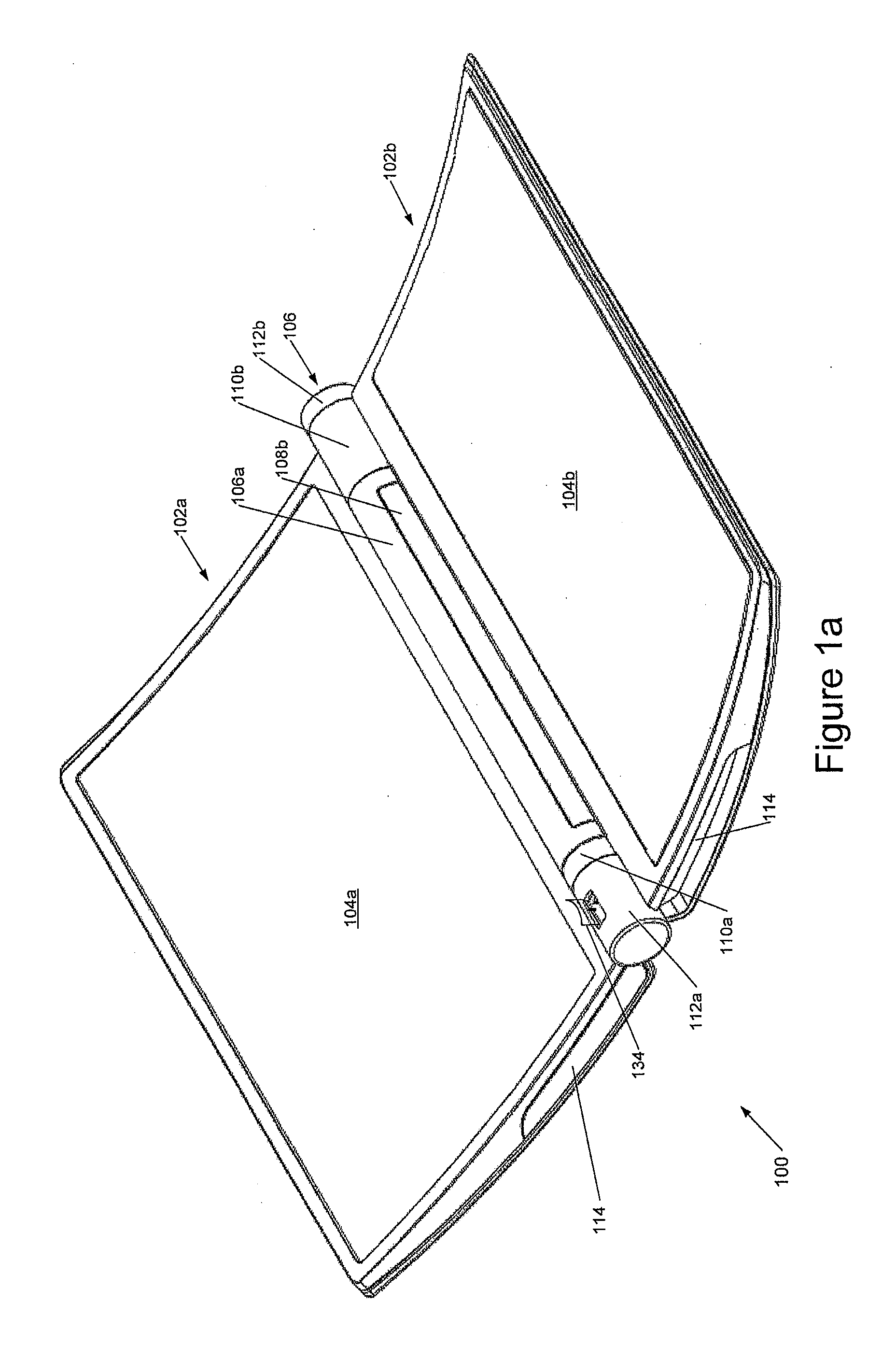

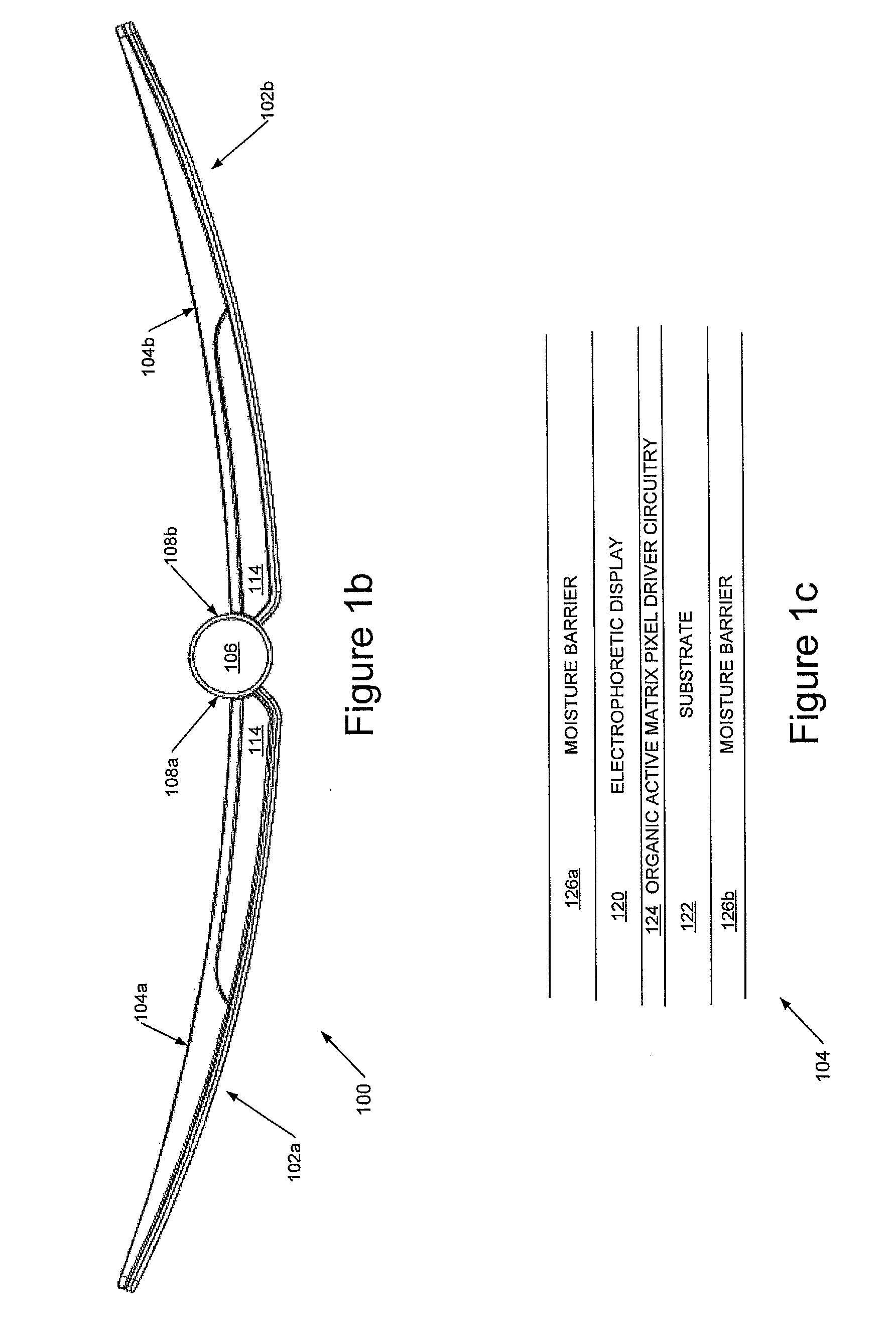

Electronic reading devices

InactiveUS20080298083A1Reduce risk of damageEasy to insertMechanical apparatusVisual presentationElectronic documentDisplay device

The invention relates to electronic devices, in particular consumer electronic devices, including an electrophoactive display, as well as to electronic document reading devices, sometimes called e-readers, such as electronic books. We describe an electronic device including an electroactive display and a light to illuminate said display, wherein said display has a viewing surface, and wherein said light is configured to illuminate said display from in front and to one side of an edge of said viewing surface, across said viewing surface and through a front-most surface of said display.

Owner:FLEHKSENEHBL LTD

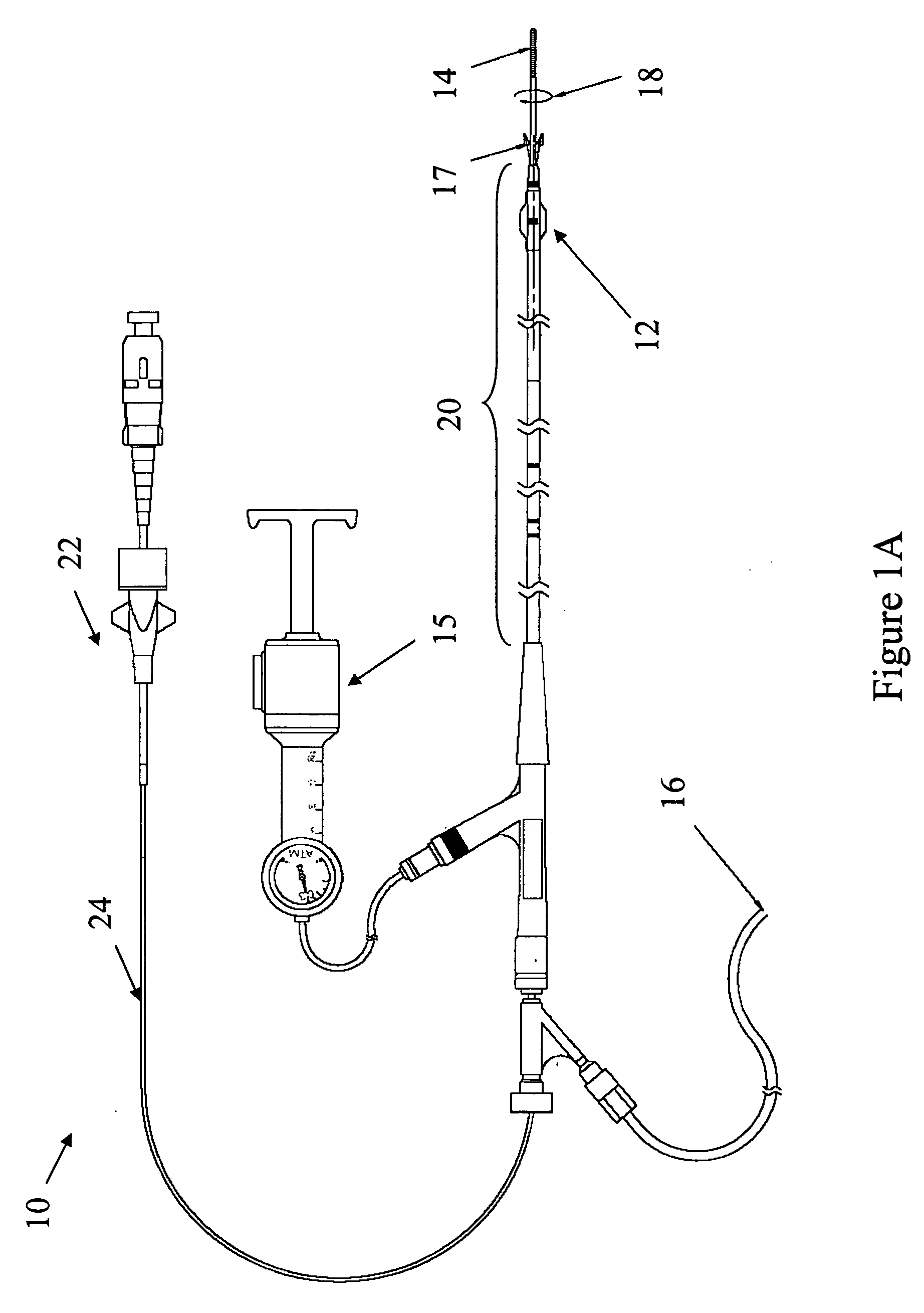

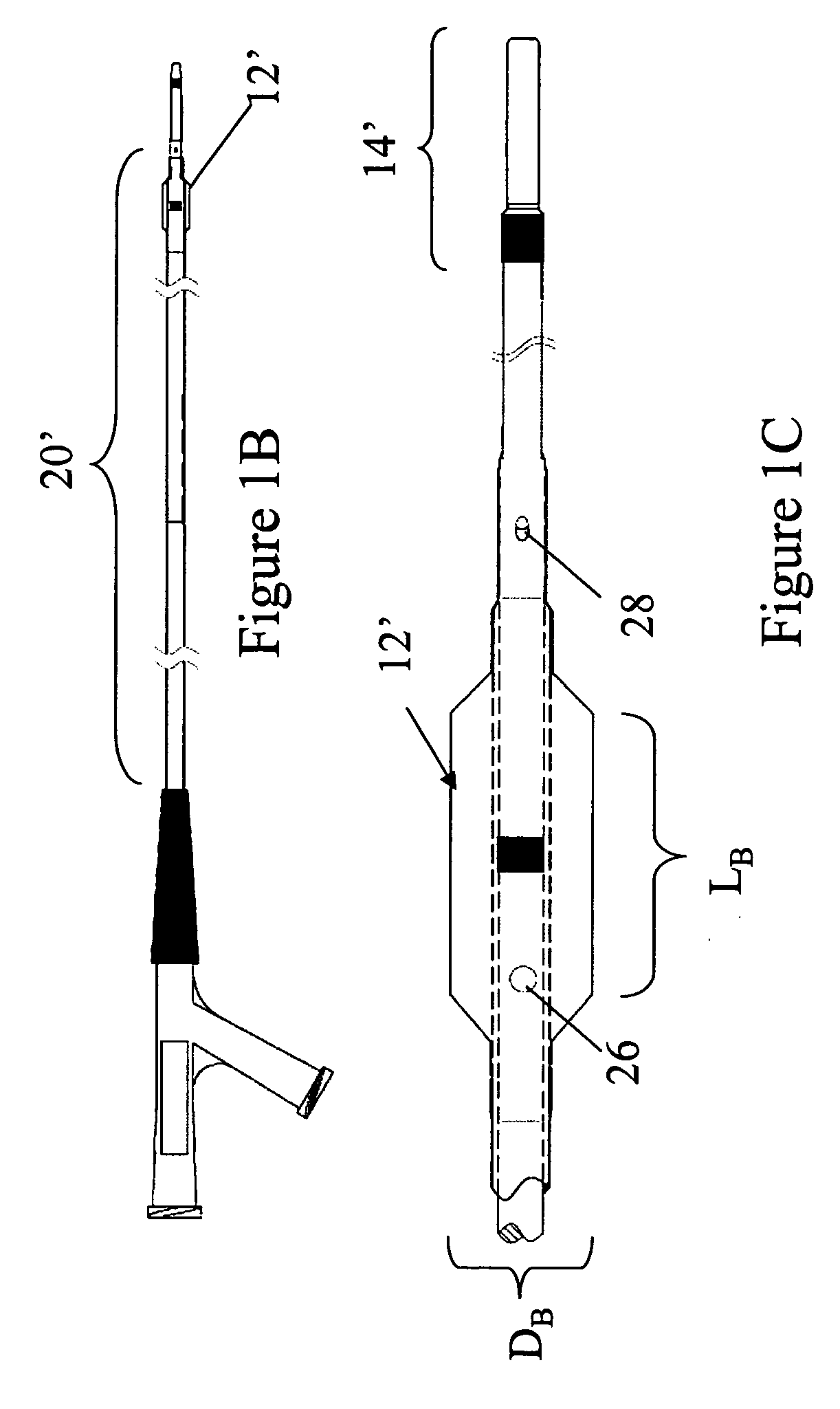

Medical device for vessel compatibility during high pressure infusion

The invention provides devices that can be used to deliver a therapeutic agent to a treatment site within the vessel of a patient at increased pressure, while limiting the contact with and pressure placed on the vessel walls. Devices according to the invention include an expandable structure arranged around and on a tube having a lumen. The expandable structure may include a sealing ring that makes contact with the interior surface of a vessel to prevent or decrease fluid flow during delivery of a therapeutic agent. This allows delivery of a therapeutic agent with decreased risk of injury to the treatment site. The invention also provides for large lumen diameters, preventing shearing stress on therapeutic agents such as cell slurries.

Owner:BOSTON SCI SCIMED INC

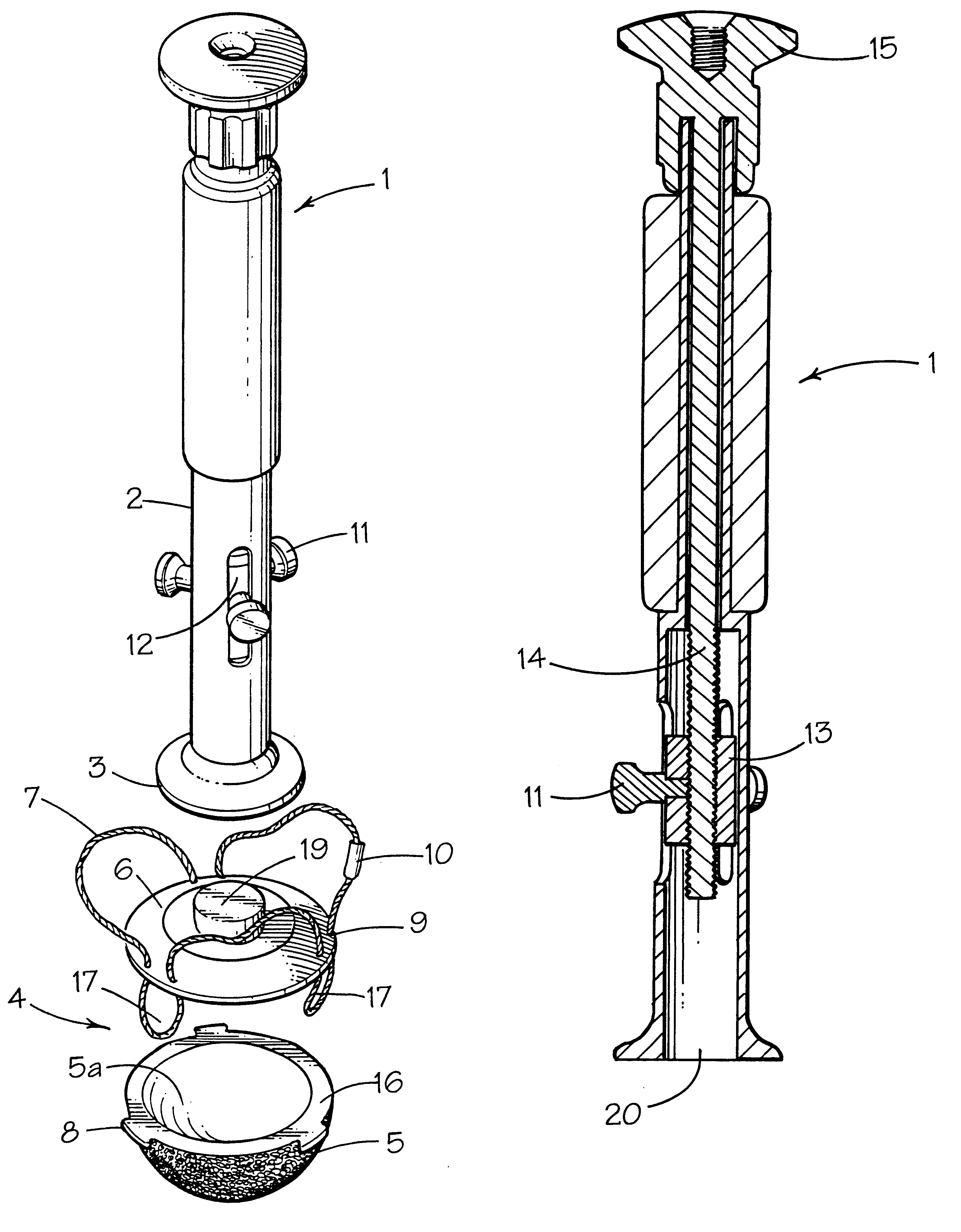

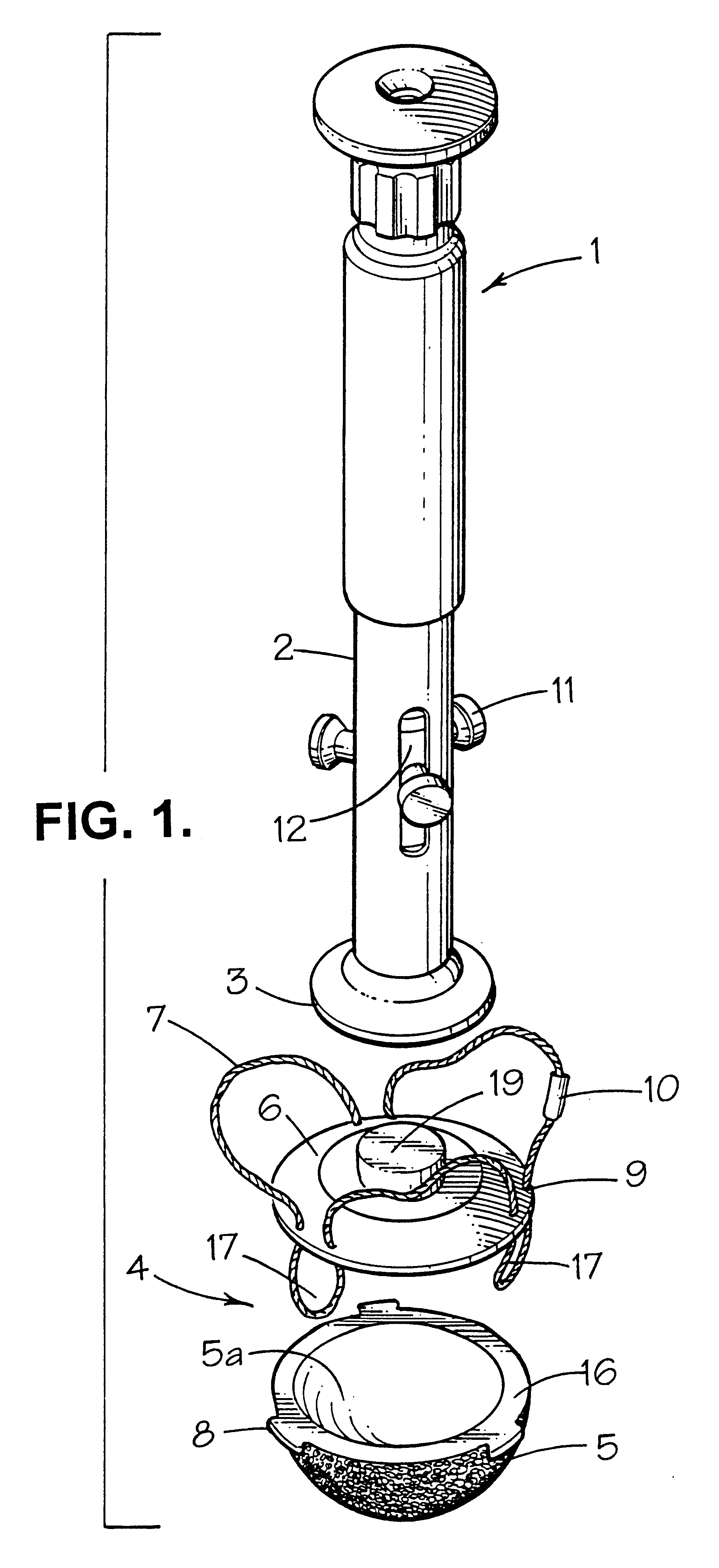

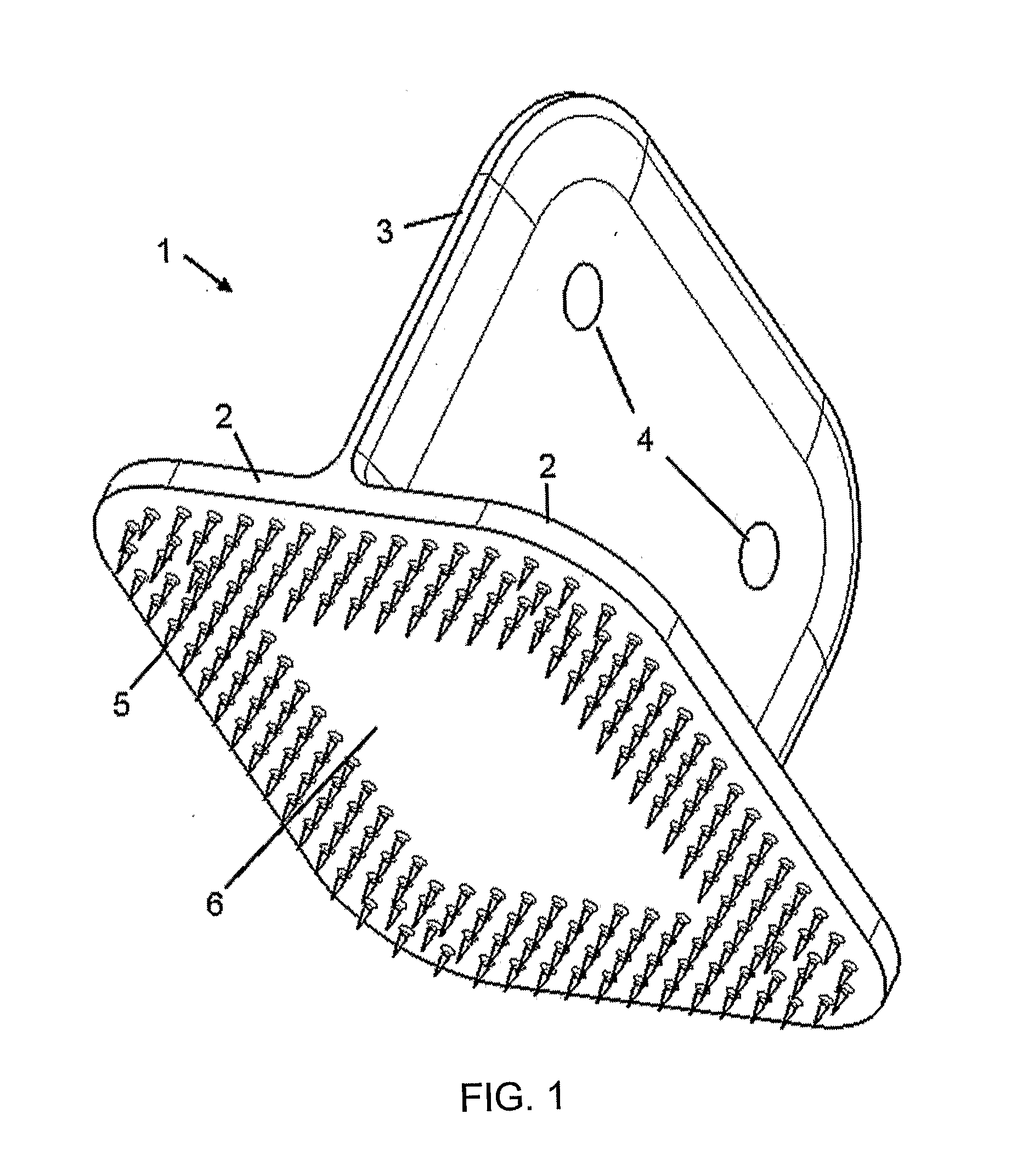

Prosthetic implant and surgical tool

InactiveUS6746452B2Promote ingrowthCompromise integrityJoint implantsCoatingsProsthesisSurgical department

Owner:T J SMITH & NEPHEW

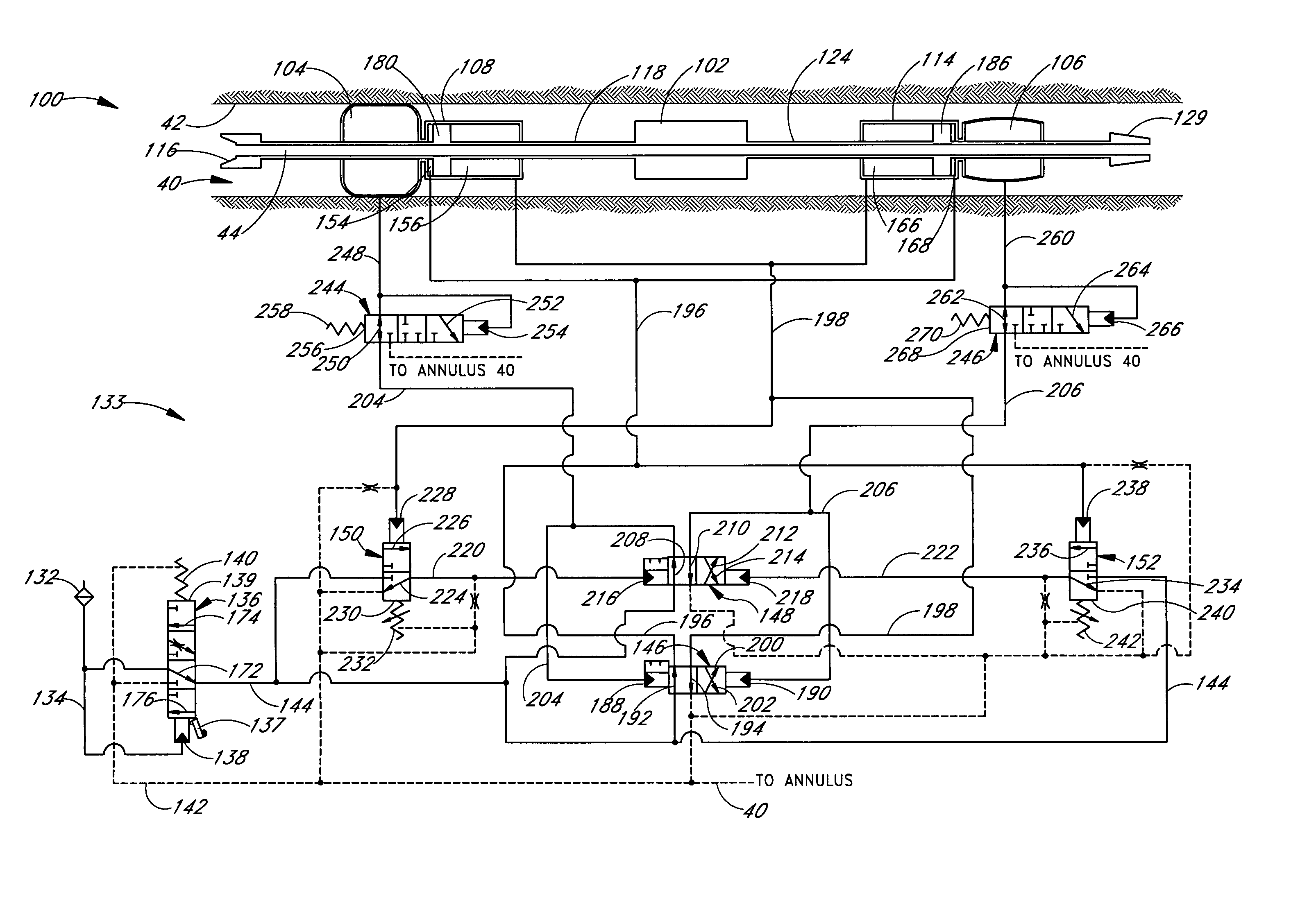

UAV recovery system

ActiveUS20070051849A1Reduce risk of damageLittle deck spaceArresting gearUnmanned aerial vehiclesAerospace engineering

A UAV capture system is disclosed. In the illustrative embodiment, the UAV capture system is coupled to the deck of a sea-faring vessel. The UAV capture system includes a single arresting line that is supported by a stanchion. In the illustrative embodiment, the stanchion is disposed on a rotatable boom.

Owner:LOCKHEED MARTIN CORP

Totally implantable hearing prosthesis

ActiveUS7442164B2Easy and safe to implantMinimize power consumptionElectrotherapyImplantable hearing aidsHermetic sealProsthesis

The invention comprises a totally implantable hearing prosthesis for hearing impaired persons. An inertial vibrational element is hermetically sealed and implanted in bone between the lateral and superior semicircular canals without breaching the integrity of the canals. The vibrational element is adapted to vibrate the walls of the canals and the fluids contained therein, thereby vibrating contiguous fluids within the cochlea thus stimulating hair cells and creating a hearing percept. The invention can also be adapted to be a tinnitus masking system, and / or used in combination with a cochlear implant hearing system.

Owner:MED EL ELEKTROMEDIZINISCHE GERAETE GMBH

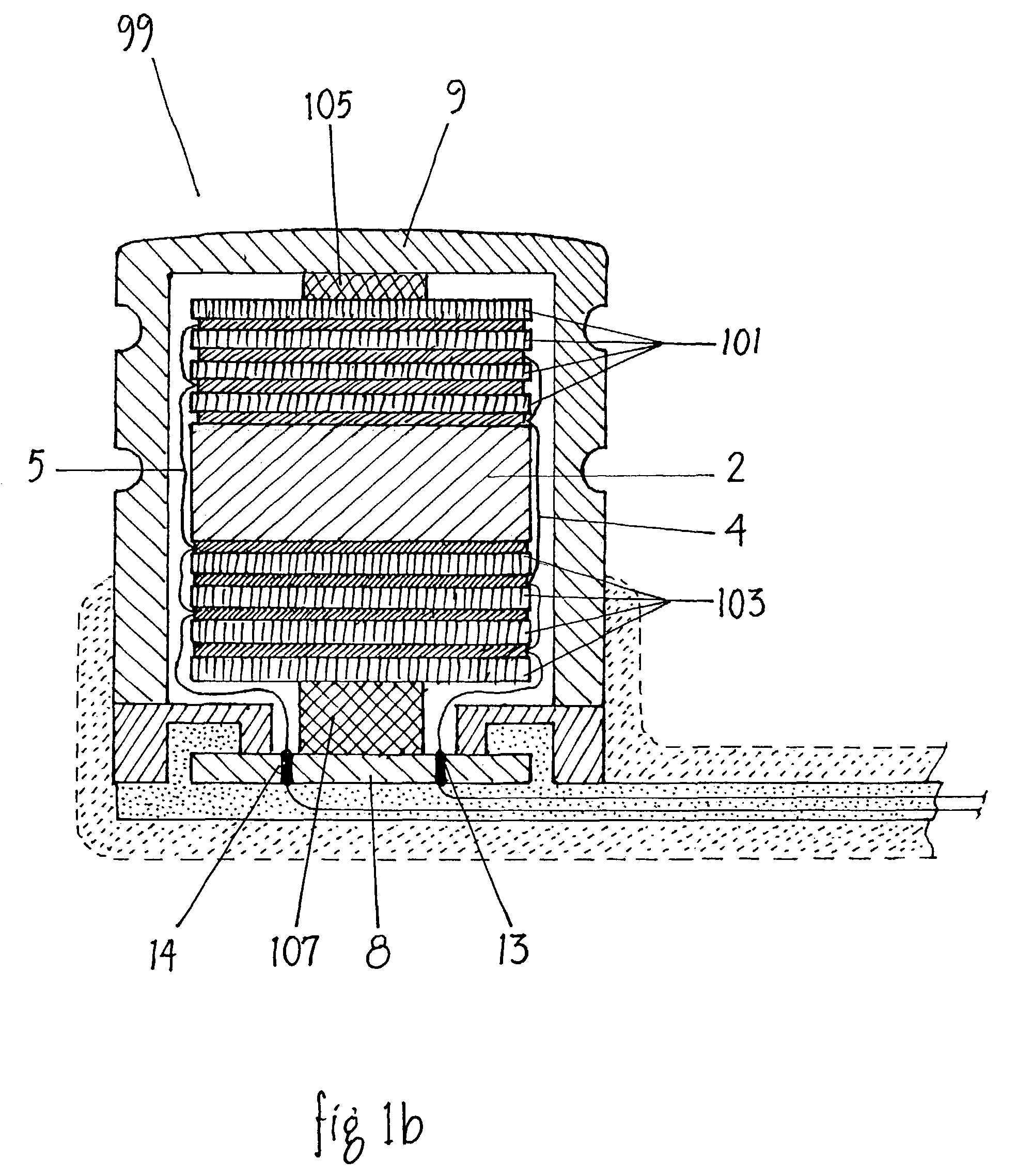

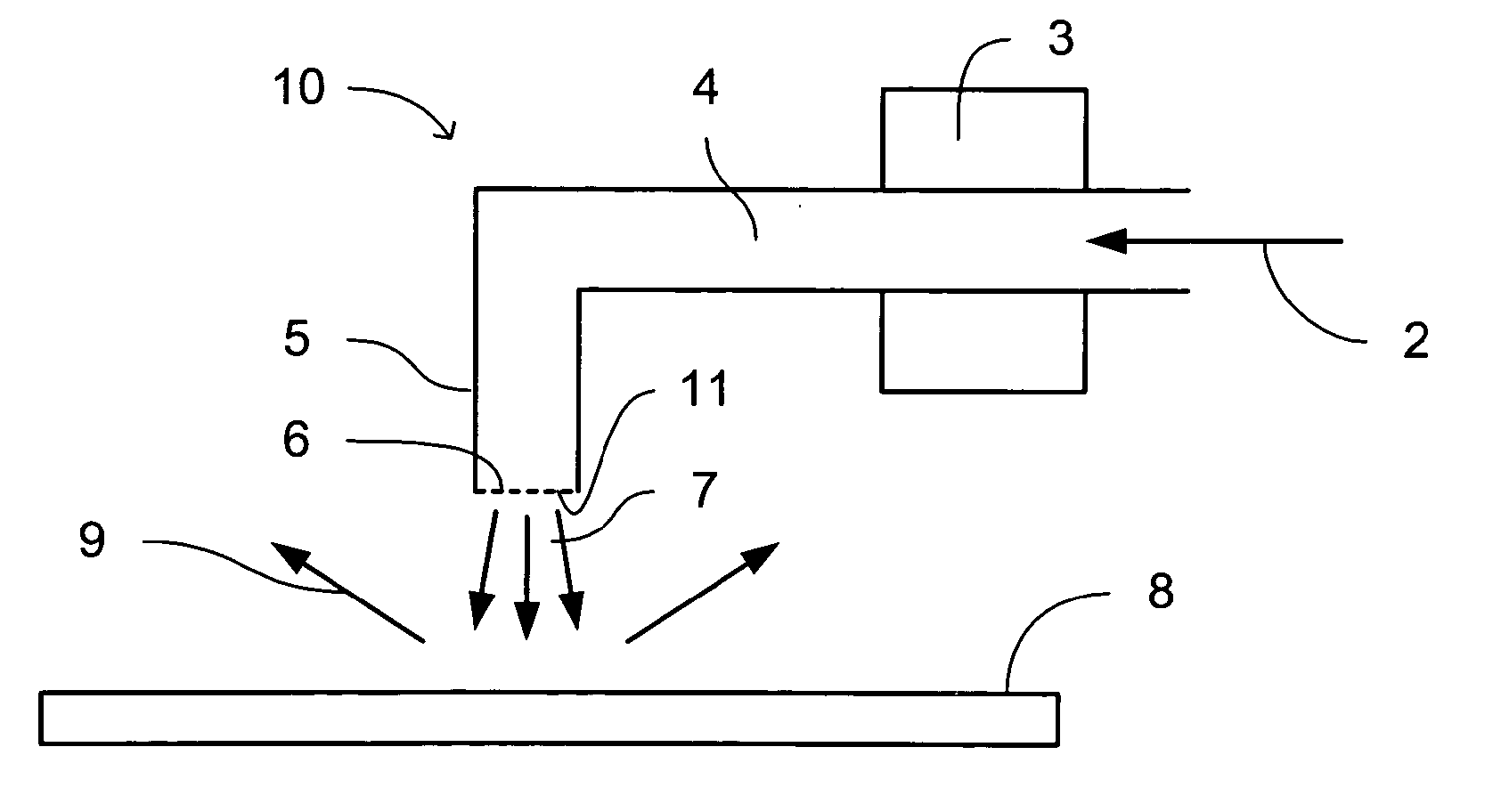

Lithographic apparatus and device manufacturing method

InactiveUS20040165160A1Reduce component countMinimizes cost of apparatusHandling using diffraction/refraction/reflectionSemiconductor/solid-state device manufacturingLight beamEngineering

A lithographic projection apparatus is disclosed. The apparatus includes a support structure constructed to support a patterning structure. The patterning structure is adapted to pattern a beam of radiation according to a desired pattern. The apparatus also includes a substrate holder that is constructed to hold a substrate, a projection system that is constructed and arranged to project the patterned beam onto a target portion of the substrate, and a downstream radical source that is connected to a gas supply and is configured to provide a beam of radicals onto a surface to be cleaned.

Owner:ASML NETHERLANDS BV

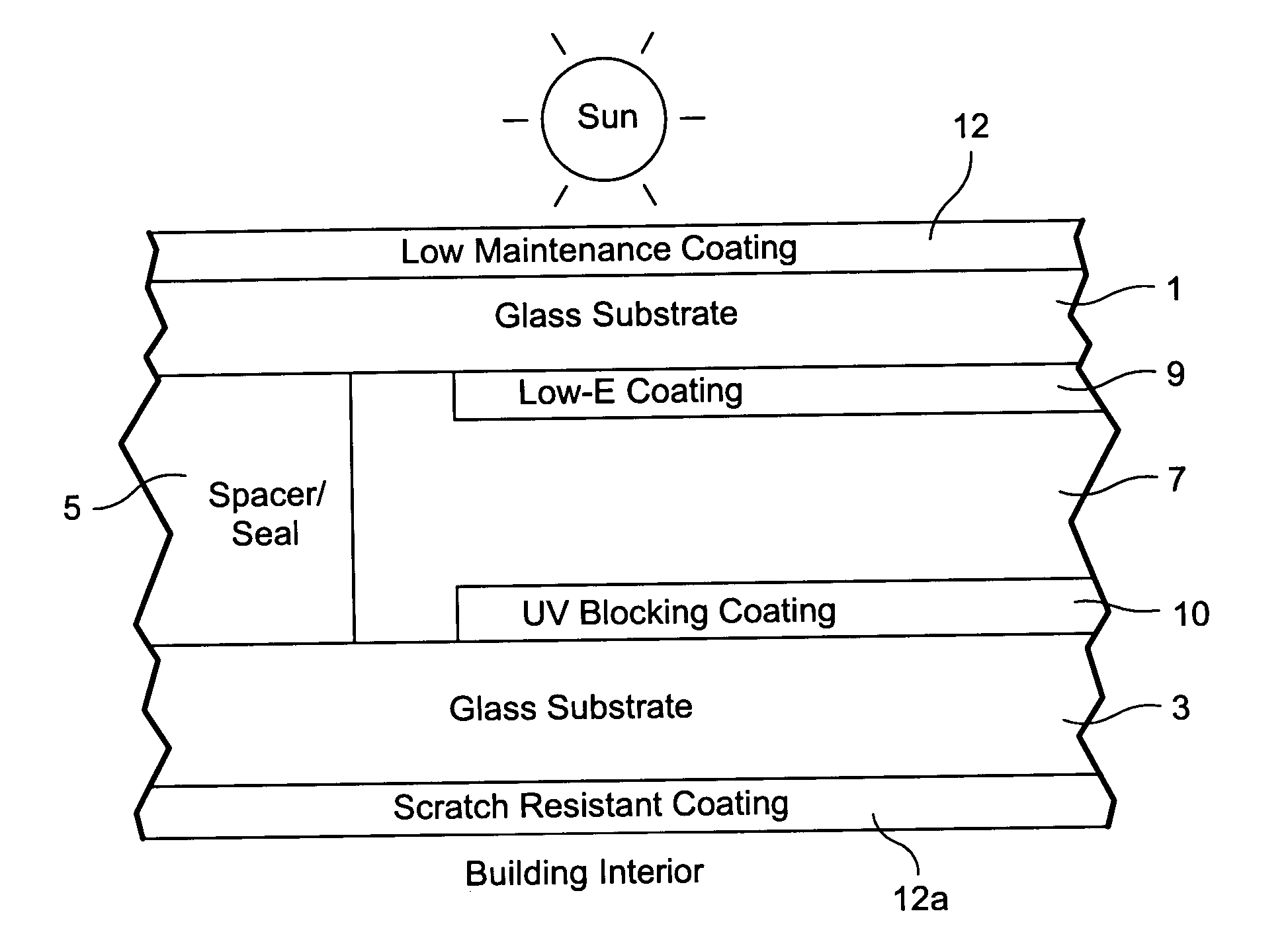

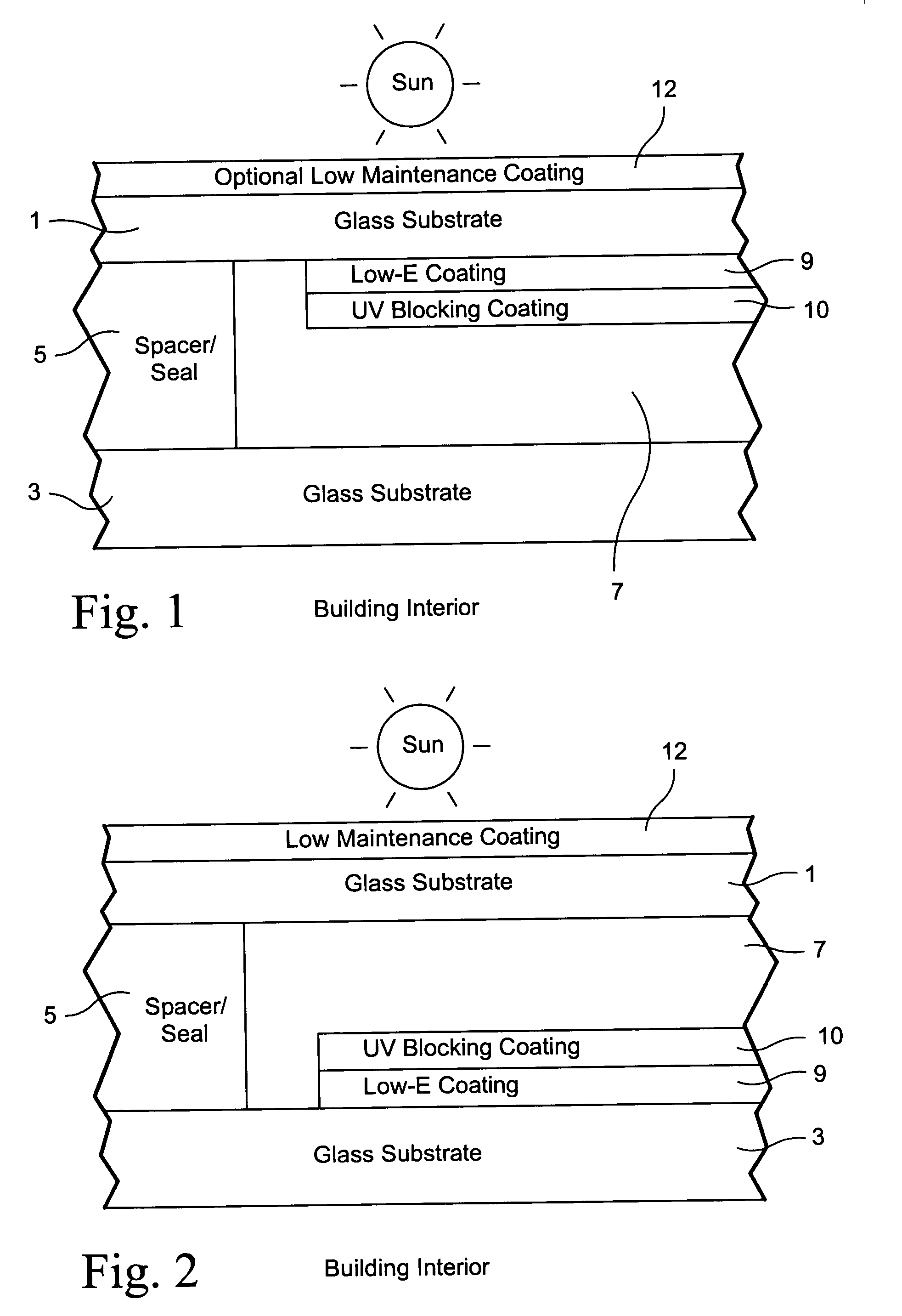

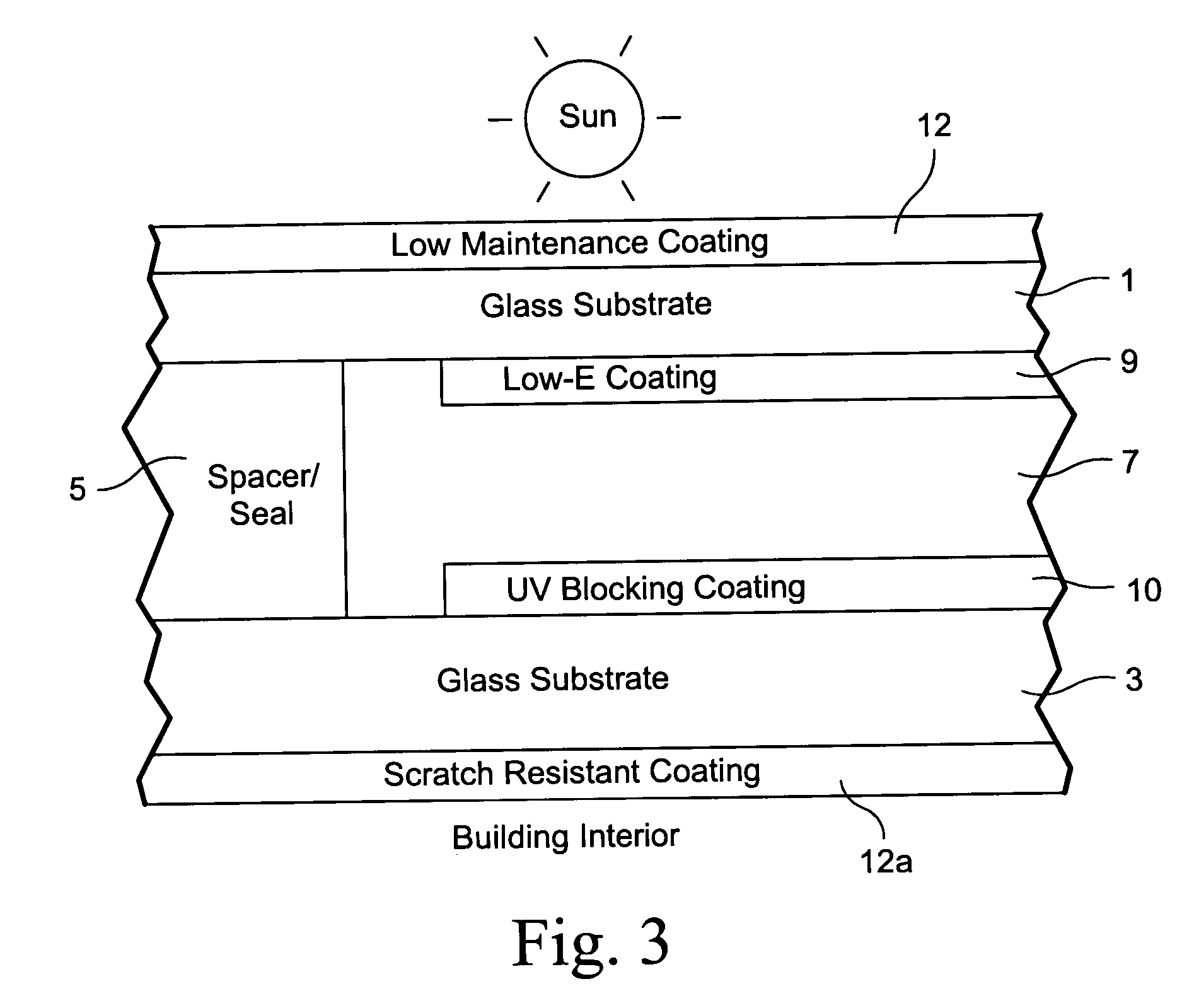

IG window unit and method of making the same

InactiveUS20070128449A1Reduce risk of damageDoors/windowsGlass/slag layered productsInsulated glazingUltraviolet

An insulating glass (IG) window unit, and / or a method of making the same is / are provided. The IG window unit includes two spaced apart substrates that are separated from one another by at least one seal and / or spacer. One of the substrates supports both a solar management coating for blocking significant amounts of infrared (IR) radiation and a coating for blocking amounts of ultraviolet (UV) radiation.

Owner:GUARDIAN GLASS LLC

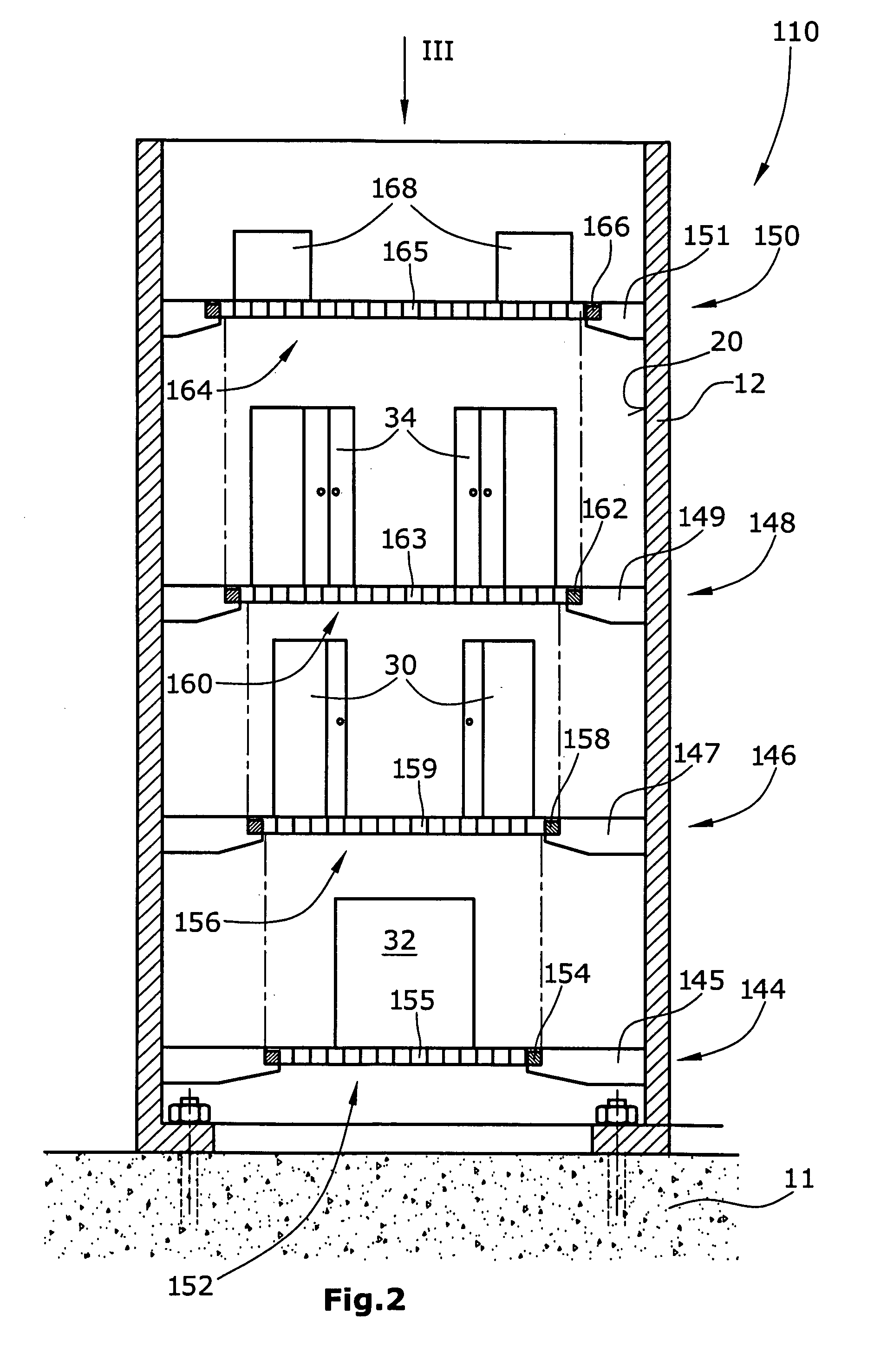

Segment for a tower of a wind energy turbine and method for arranging operating components of a wind energy turbine in a tower thereof

The segment for a tower of a wind energy turbine comprises a tubular section having a longitudinal axis and inner and outer sides, and at least one group of supporting elements arranged at the inner side of the tubular section. The segment further comprises at least one platform supportable by the supporting elements of the at least one group of supporting elements.

Owner:GENERAL ELECTRIC CO

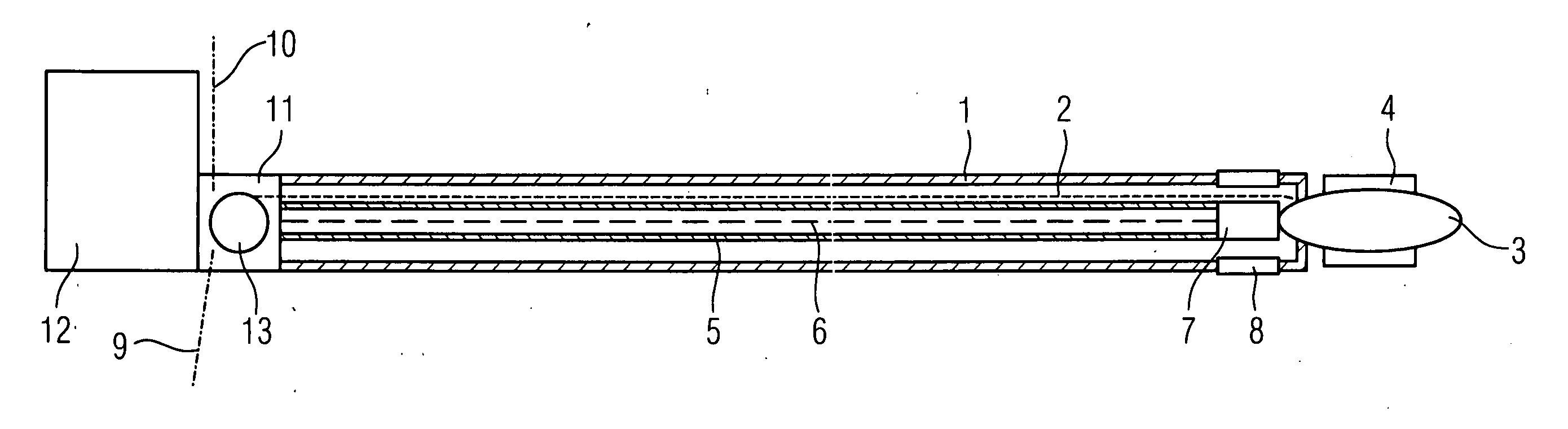

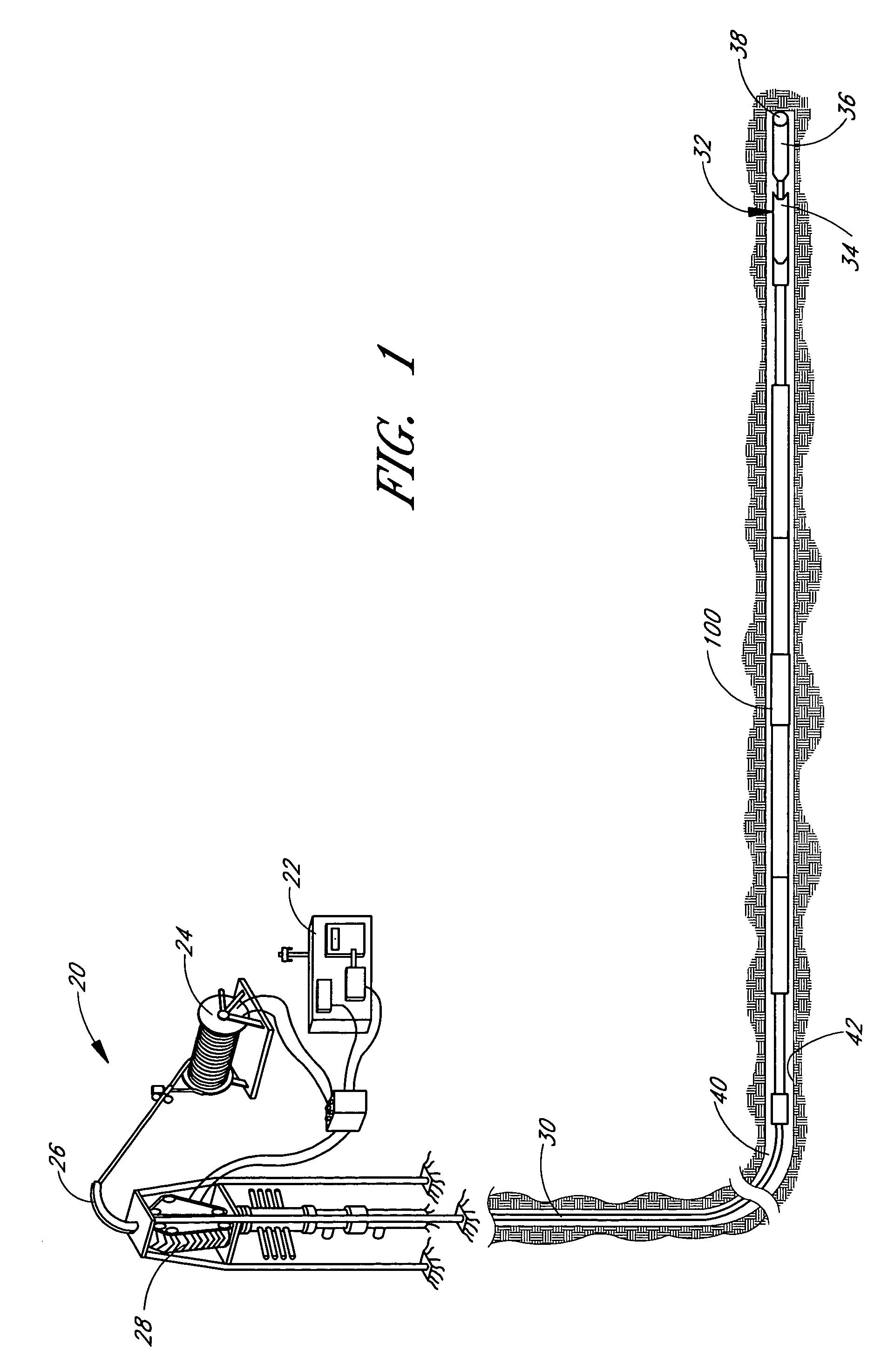

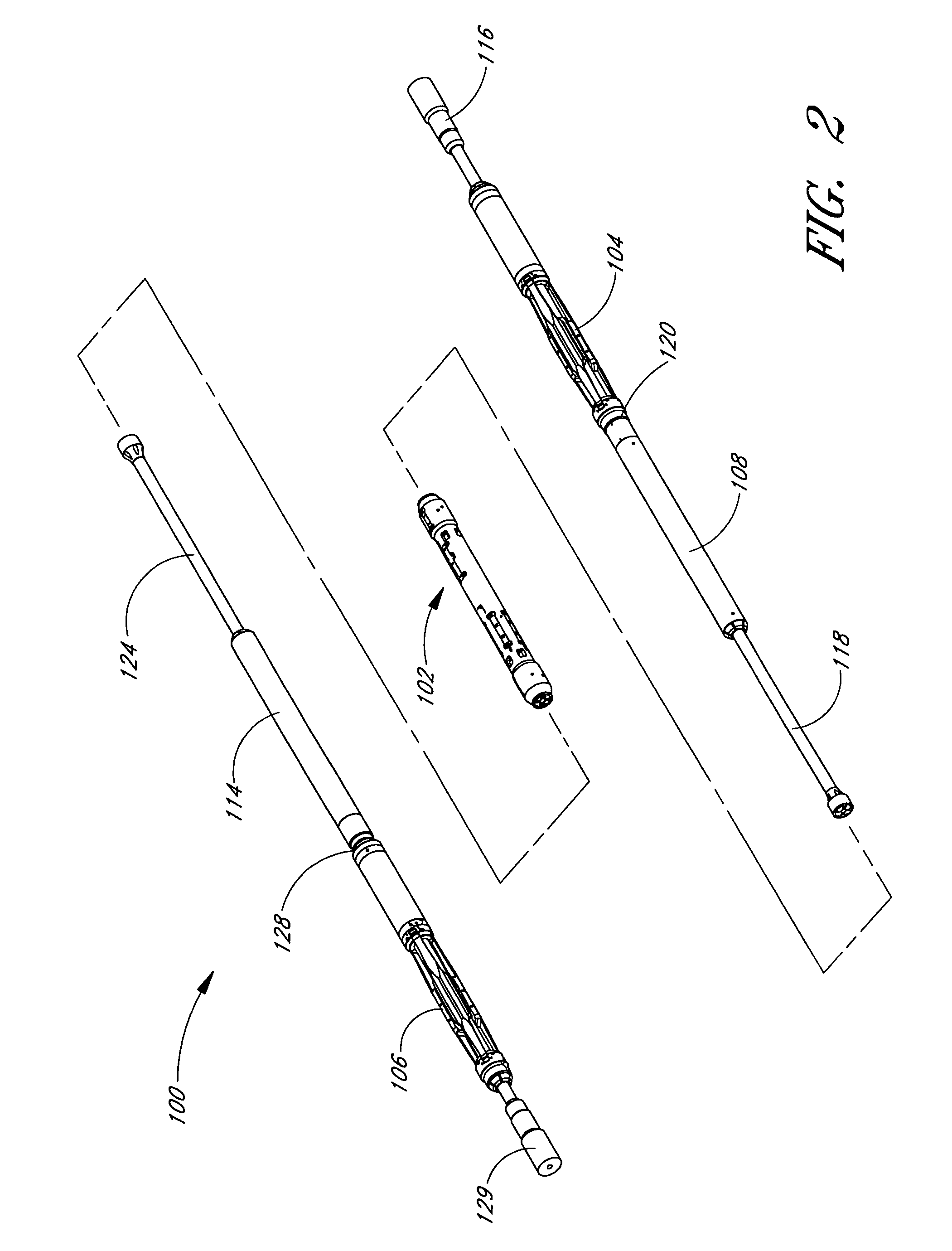

Device for implementing a cutting balloon intervention with IVUS monitoring

Device for implementing a cutting balloon intervention by means of a “cutting balloon” catheter, at the distal end of which is disposed an inflatable balloon with axially running blades mounted thereon, and which has IVUS monitoring, whereby the cutting balloon catheter is combined with an IVUS catheter to form an integrated module.

Owner:SIEMENS HEALTHCARE GMBH

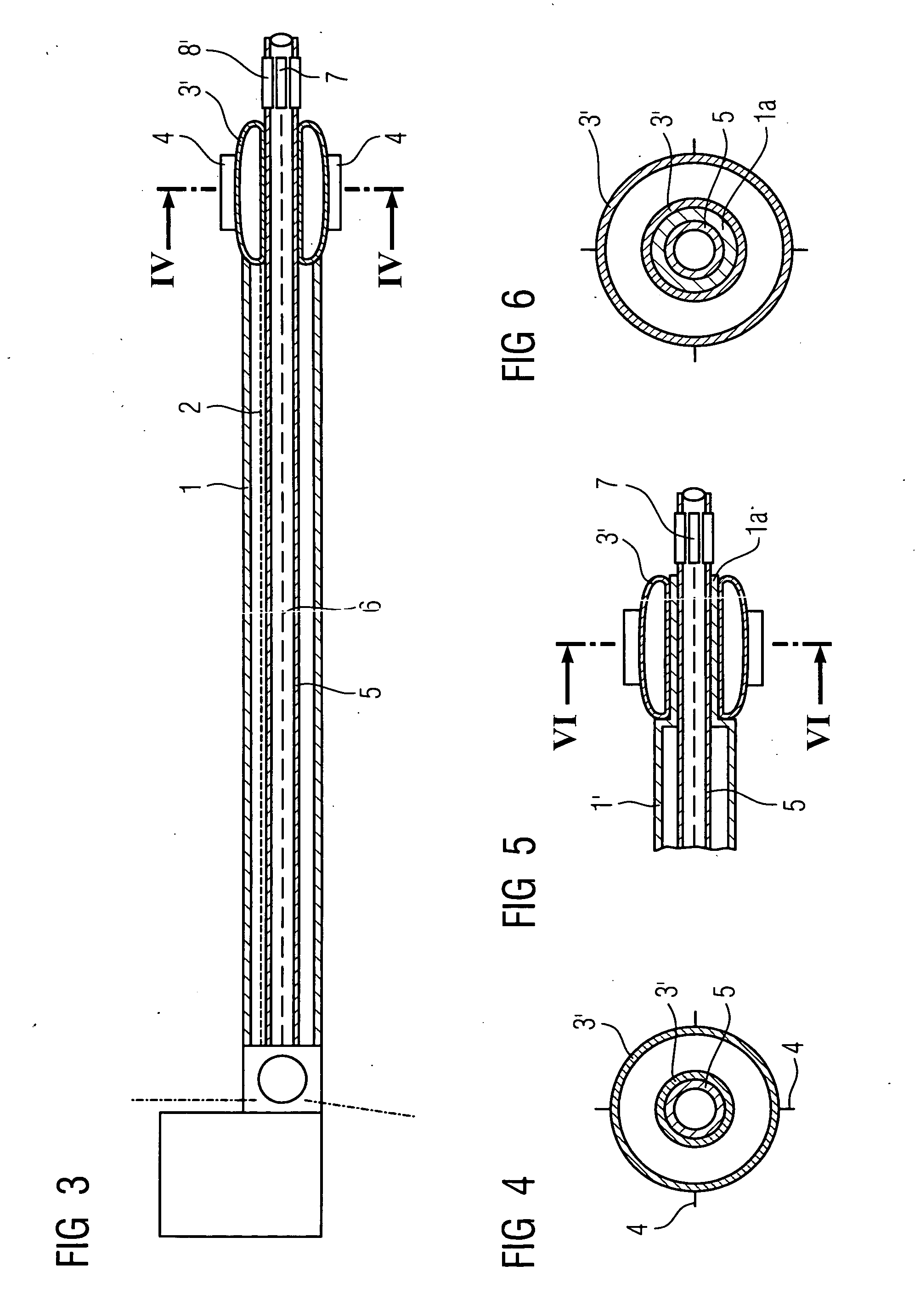

Tractor with improved valve system

InactiveUS7080700B2Long time lagBetter shiftingDrilling rodsReciprocating drilling machinesWorking fluidDetent

A hydraulically powered tractor includes an elongated body, two gripper assemblies, at least one pair of aft and forward propulsion cylinders and pistons, and a valve system. The valve system comprises an inlet control valve, a two-position propulsion control valve, a two-position gripper control valve, two cycle valves, and two pressure reduction valves. The inlet control valve spool includes a hydraulically controlled deactivation cam that locks the valve in a closed position, rendering the tractor non-operational. The propulsion control valve is piloted on both ends by fluid pressure in the gripper assemblies. The propulsion control valve controls the distribution of operating fluid to and from the propulsion cylinders, such that one cylinder performs a power stroke while the other cylinder performs a reset stroke. Each end of the gripper control valve is piloted by a source of high-pressure fluid selectively admitted by one of the cycle valves. The gripper control valve controls the distribution of operating fluid to and from the gripper assemblies. The cycle valves are spring-biased and piloted by fluid pressure in the propulsion cylinders, so that the gripper control valve shifts only after the cylinders complete their strokes. The pressure reduction valves limit the pressure within the gripper assemblies. These valves are spring-biased and piloted by the pressure of fluid flowing into the gripper assemblies. Some or all of the valves include centering grooves on the landings of the spools, which reduce leakage and produce more efficient operation. The propulsion control and gripper control valves include spring-assisted detents to prevent inadvertent shifting.

Owner:WWT NORTH AMERICA HLDG

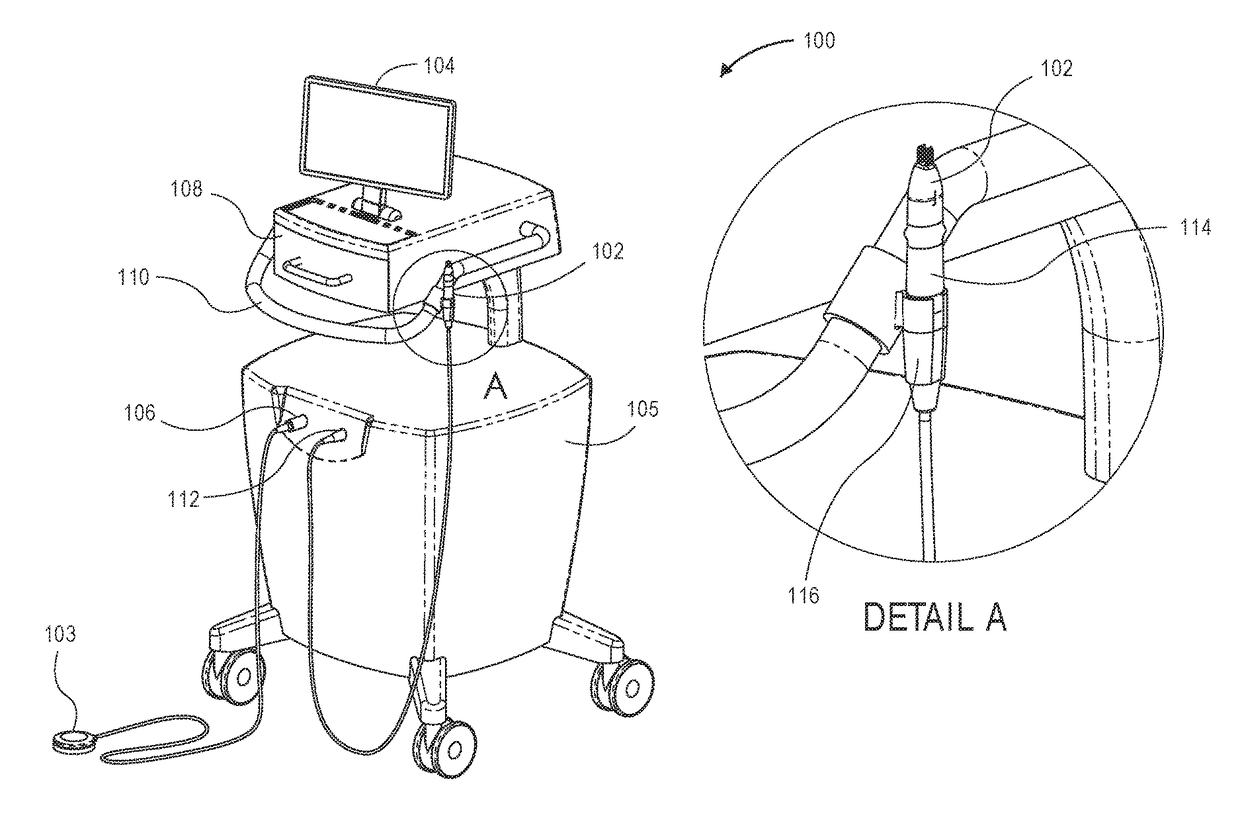

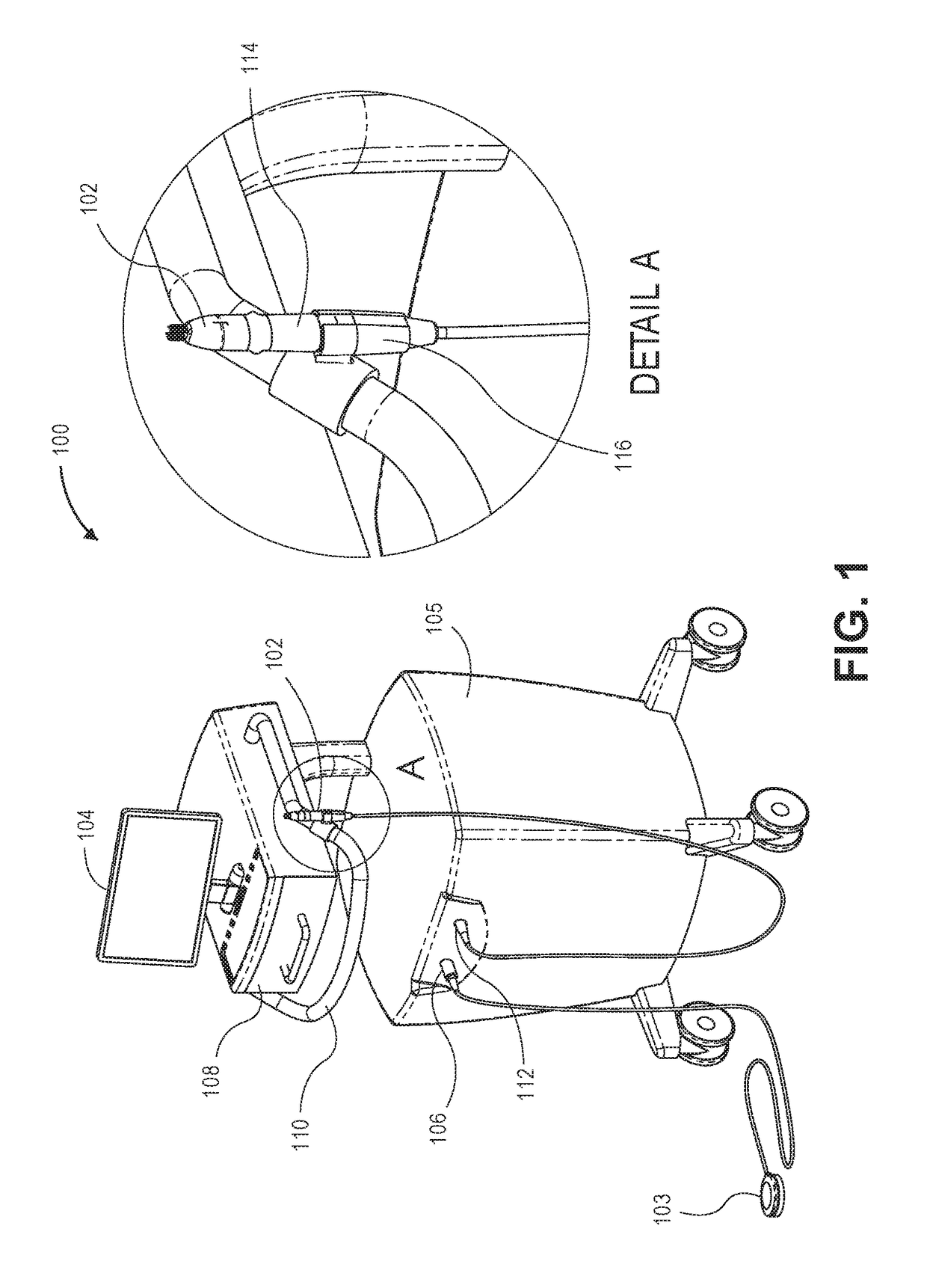

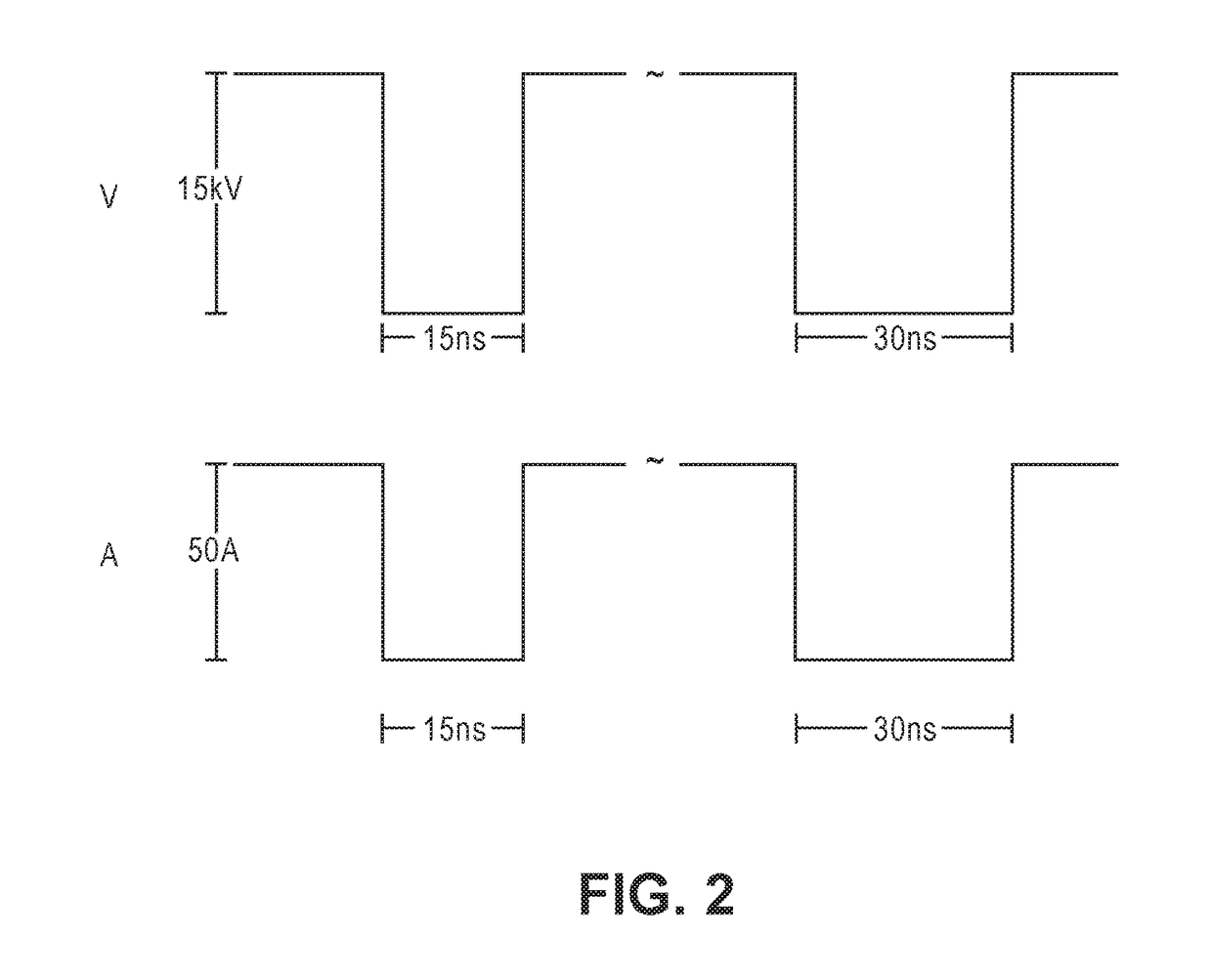

High-voltage analog circuit pulser and pulse generator discharge circuit

ActiveUS20170246455A1Reduce risk of damageEasy to controlElectrotherapyPulse generation by energy-accumulating elementElectricityControl signal

A pulse generator discharge circuit is disclosed. The circuit includes one or more discharge stages, each discharge stage including a plurality of control input terminals. The circuit also includes first and second discharge terminals, and a plurality of serially connected switches electrically connected between the first and second discharge terminals, where a conductive state of each of the switches is controlled by a control signal. The circuit also includes a plurality of inductive elements configured to generate the control signals for the serially connected switches, where each inductive element is configured to generate a control signal for one of the serially connected switches in response to one or more input signals at one or more of the control input terminals, and where each of the serially connected switches is configured to receive a control signal from a respective one of the inductive elements.

Owner:PULSE BIOSCI INC

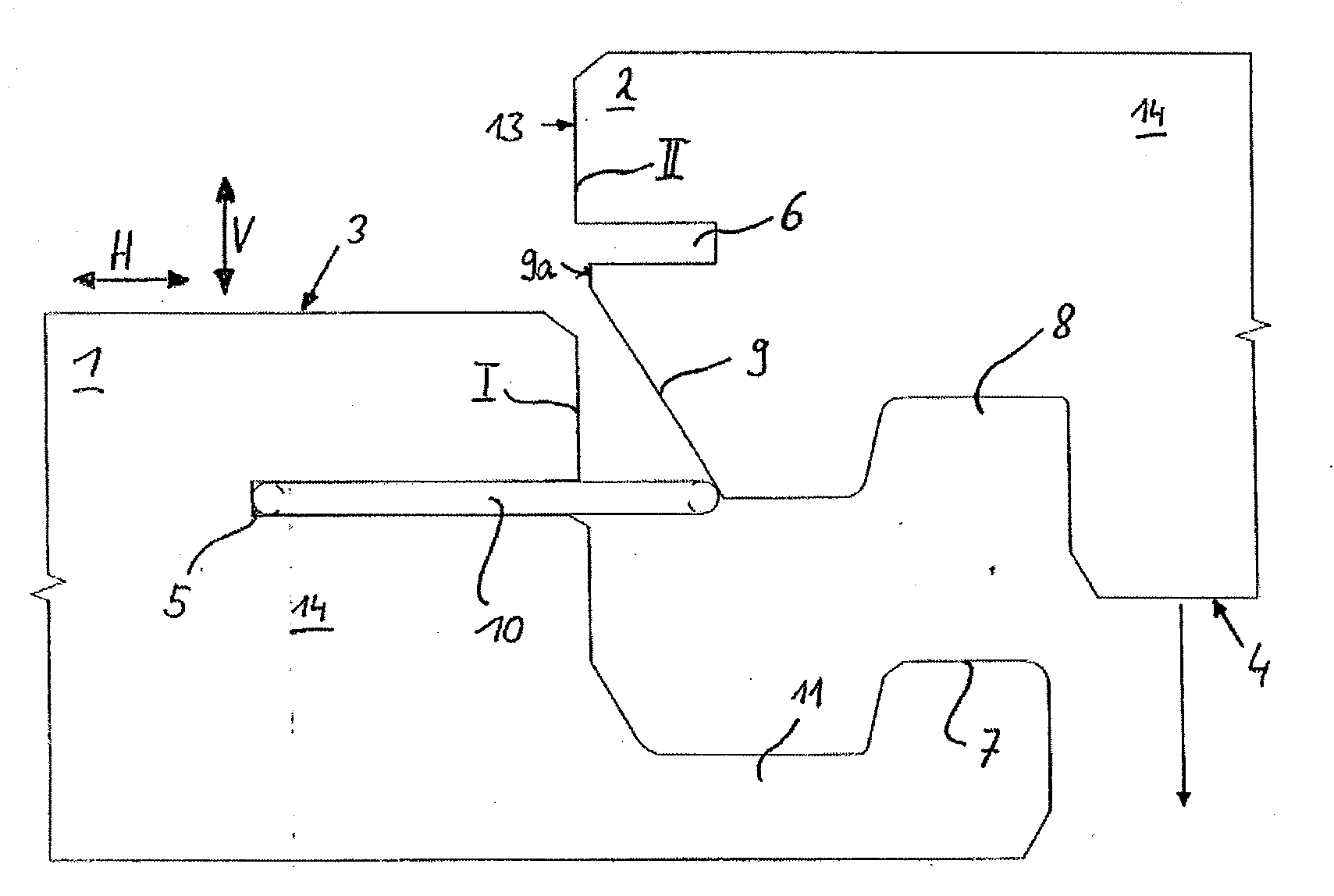

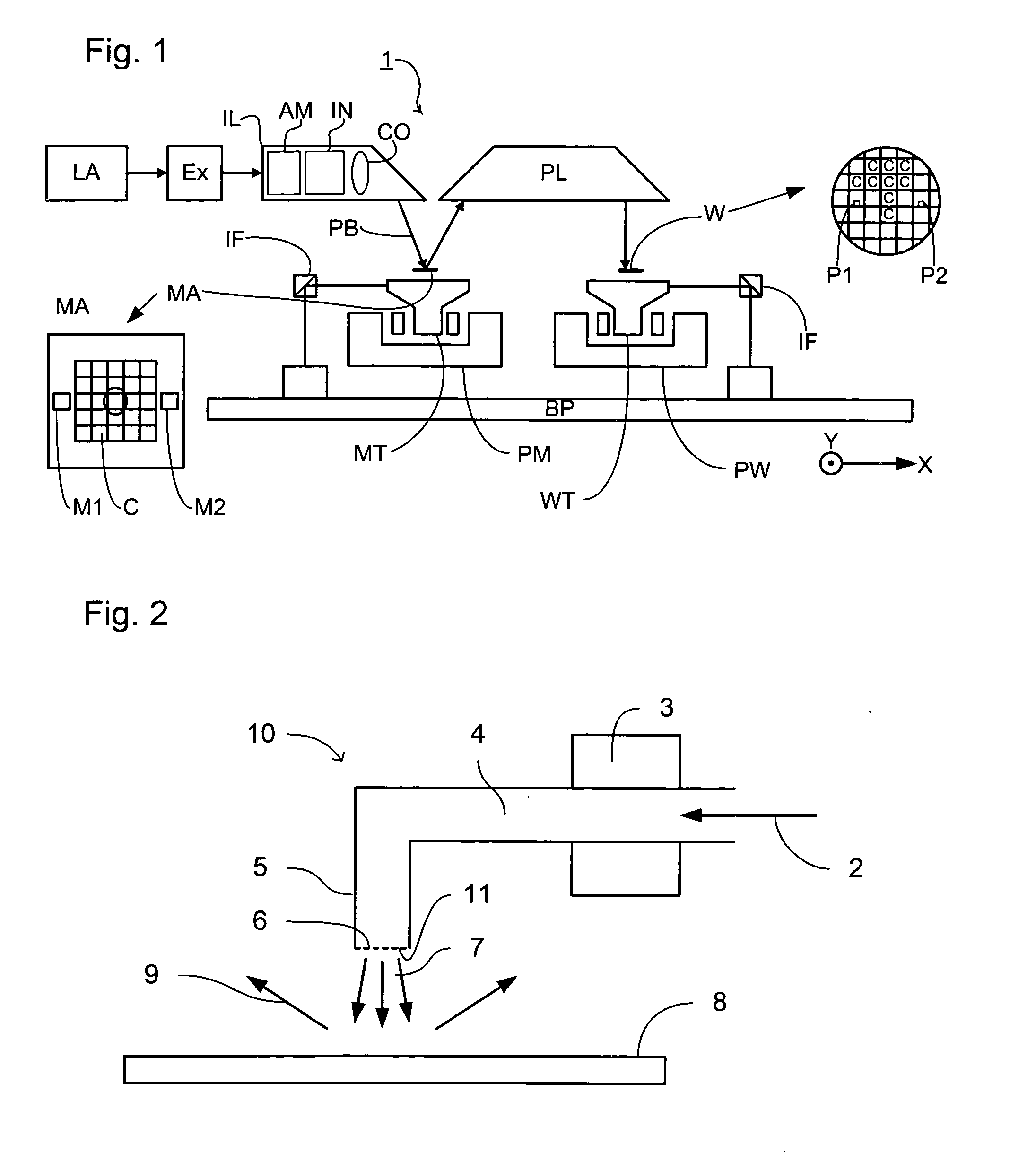

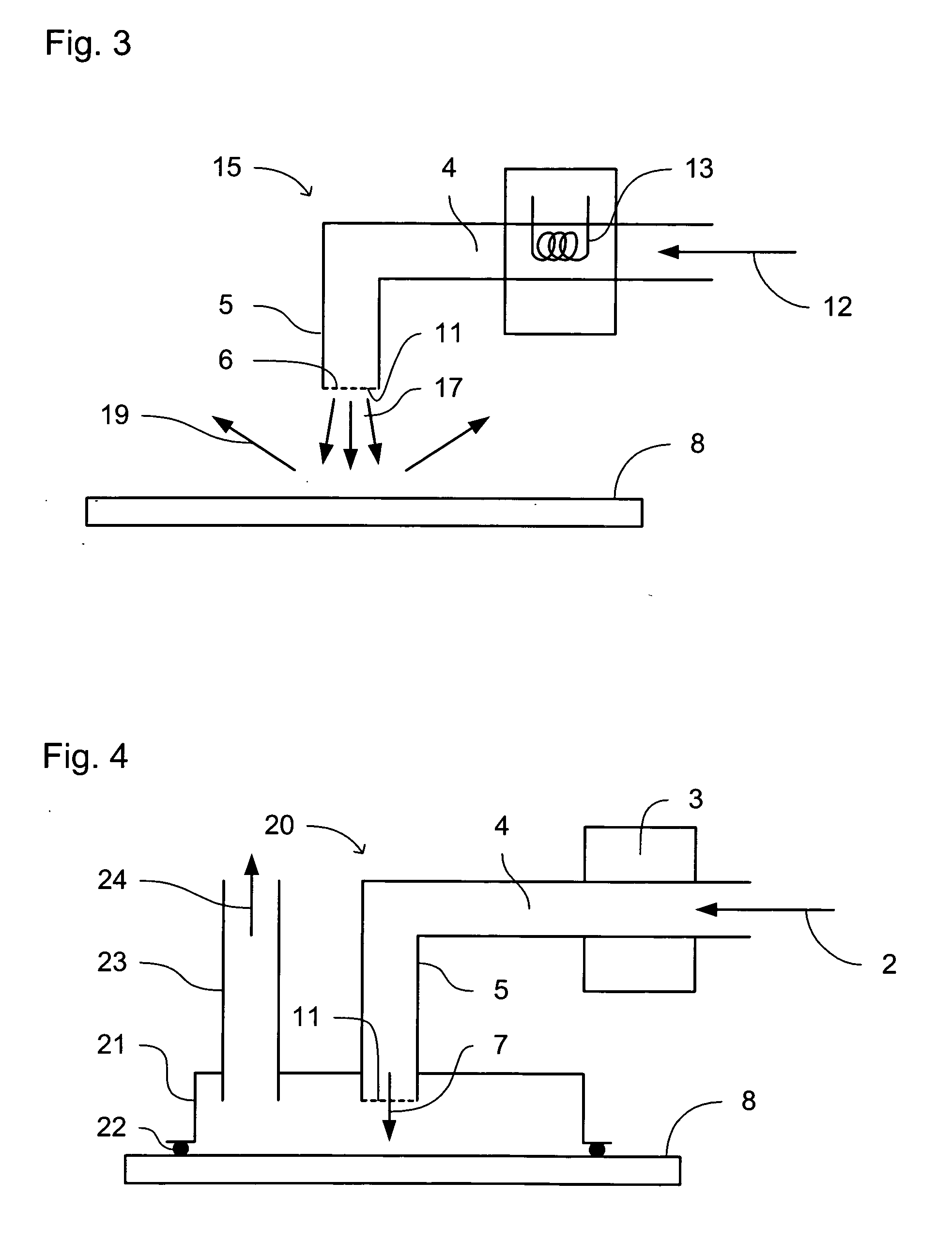

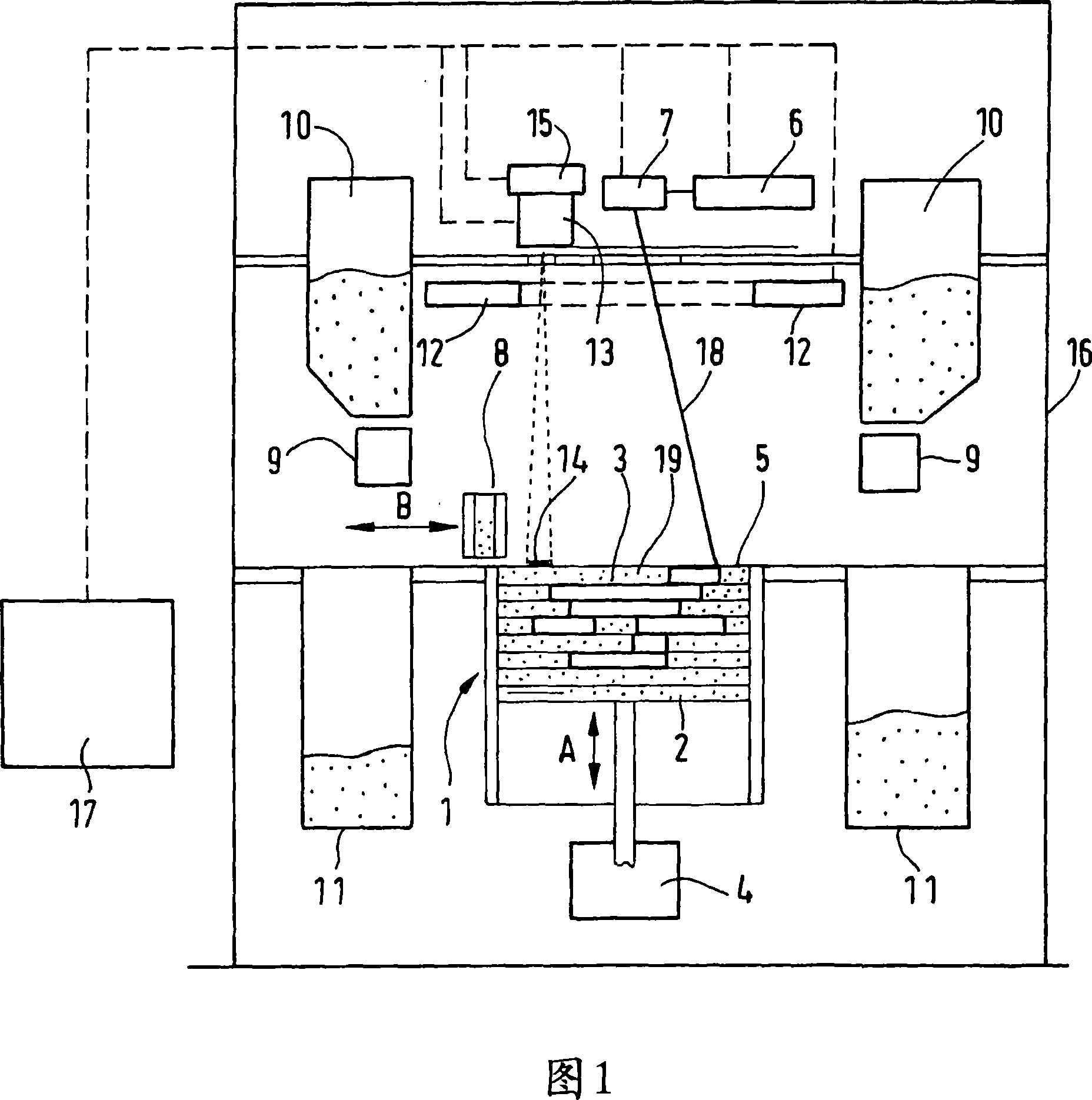

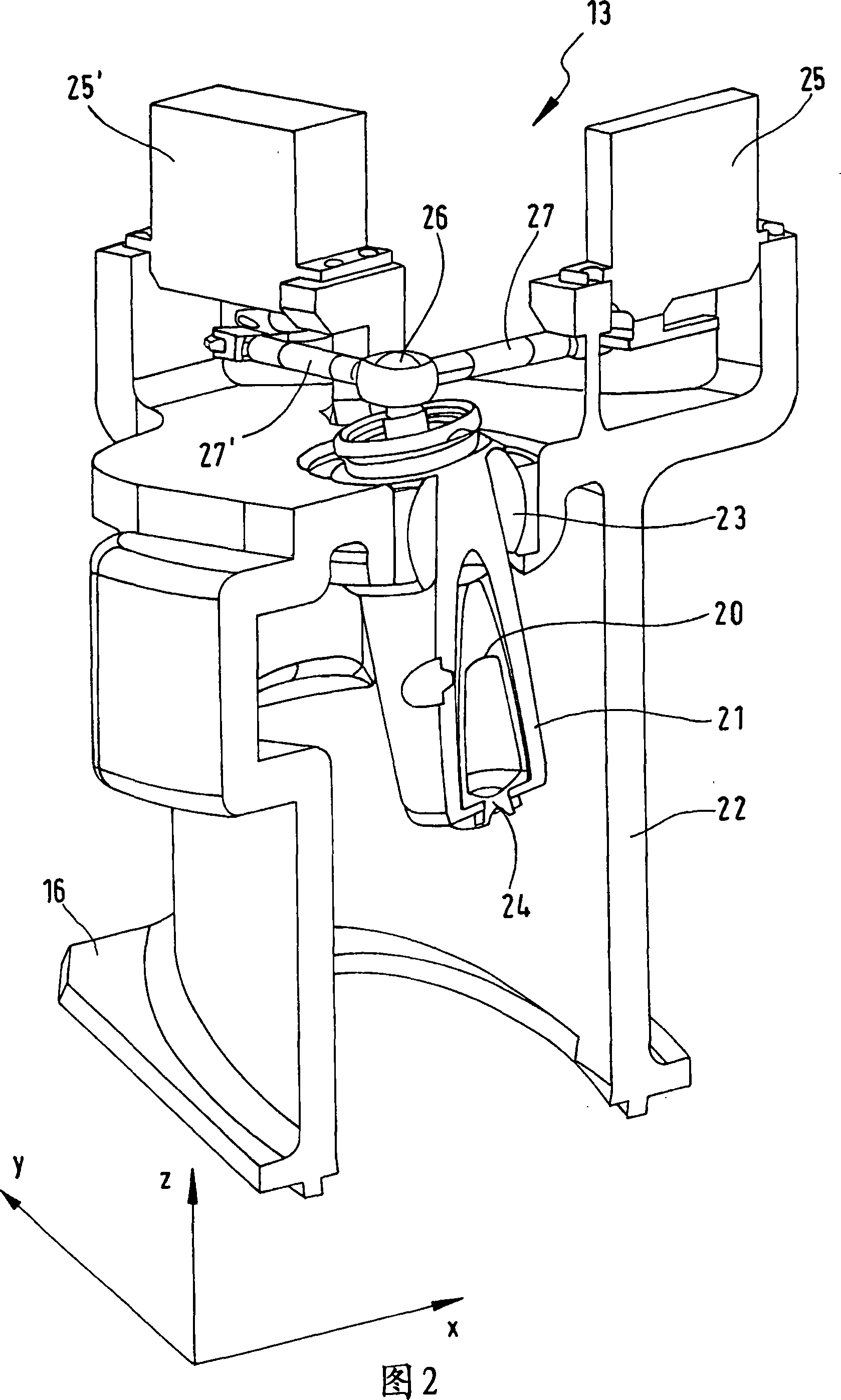

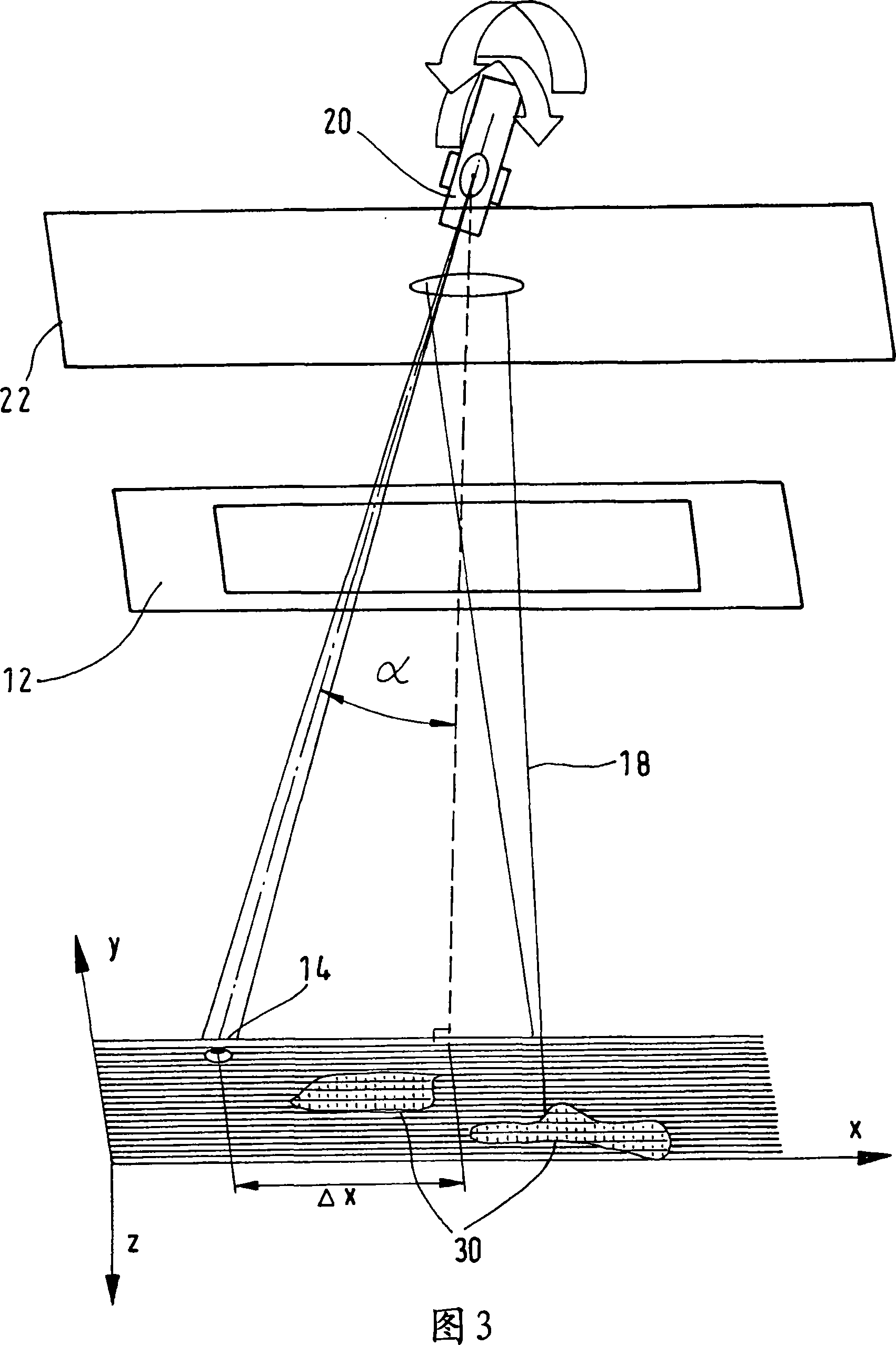

Device and method for the production of a three-dimensional object

InactiveCN1976800AEasy to controlAccurate adjustment effectAdditive manufacturing apparatusIncreasing energy efficiencyStructural materialPhysics

Disclosed are a device and a method for producing three-dimensional objects (3) by locally solidifying layers of a structural material at the points corresponding to the respective cross-section of the object (3) under the effect of electromagnetic or corpuscular radiation. The inventive device comprises a temperature measuring apparatus (13) for the contactless measurement of the temperature of the structural material in a measuring area (14) that is a subarea of the layer of the structural material as well as a position adjusting mechanism (15) for modifying the position of the measuring area (14) of the temperature measuring apparatus (13) regardless of the change in position of the zone upon which the radiant energy acts. Said device allows a non-illuminated area of the surface to be actively triggered for measuring the temperature of each layer while making it possible to detect a temperature distribution by modifying the position of the measuring area (14) in a layer.

Owner:EOS ELECTRO OPTICAL SYST

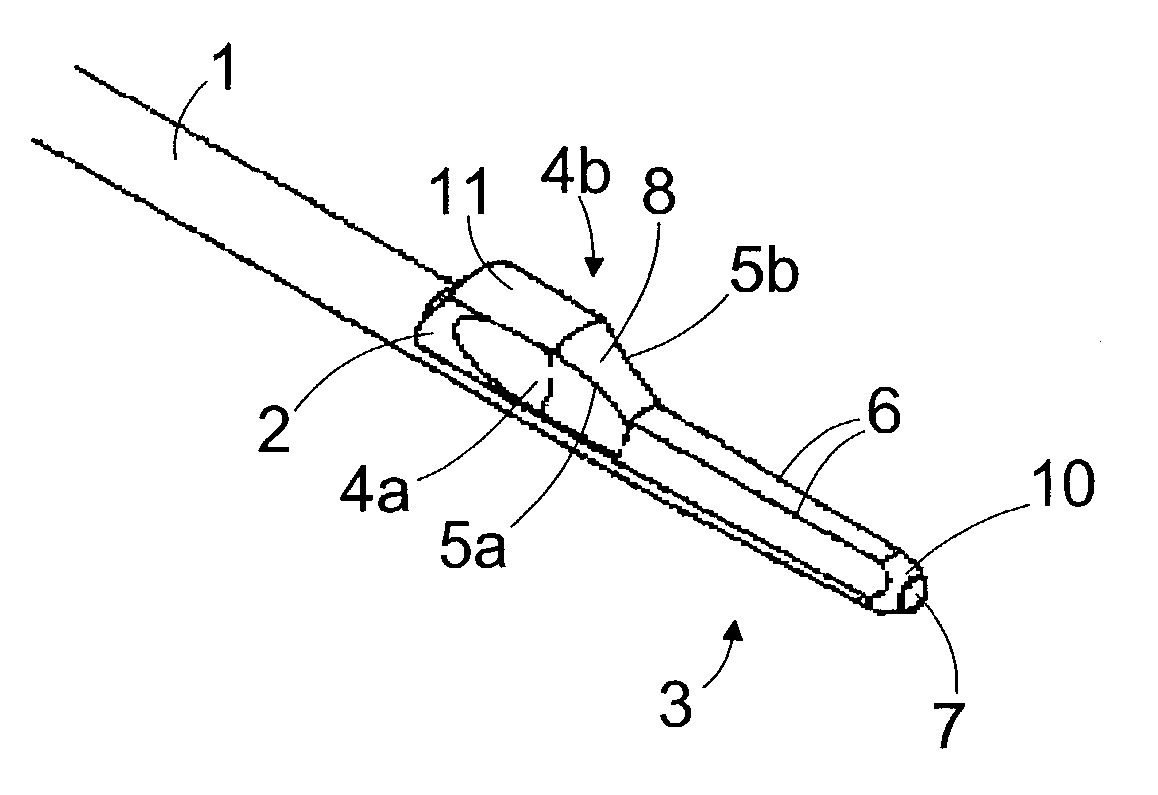

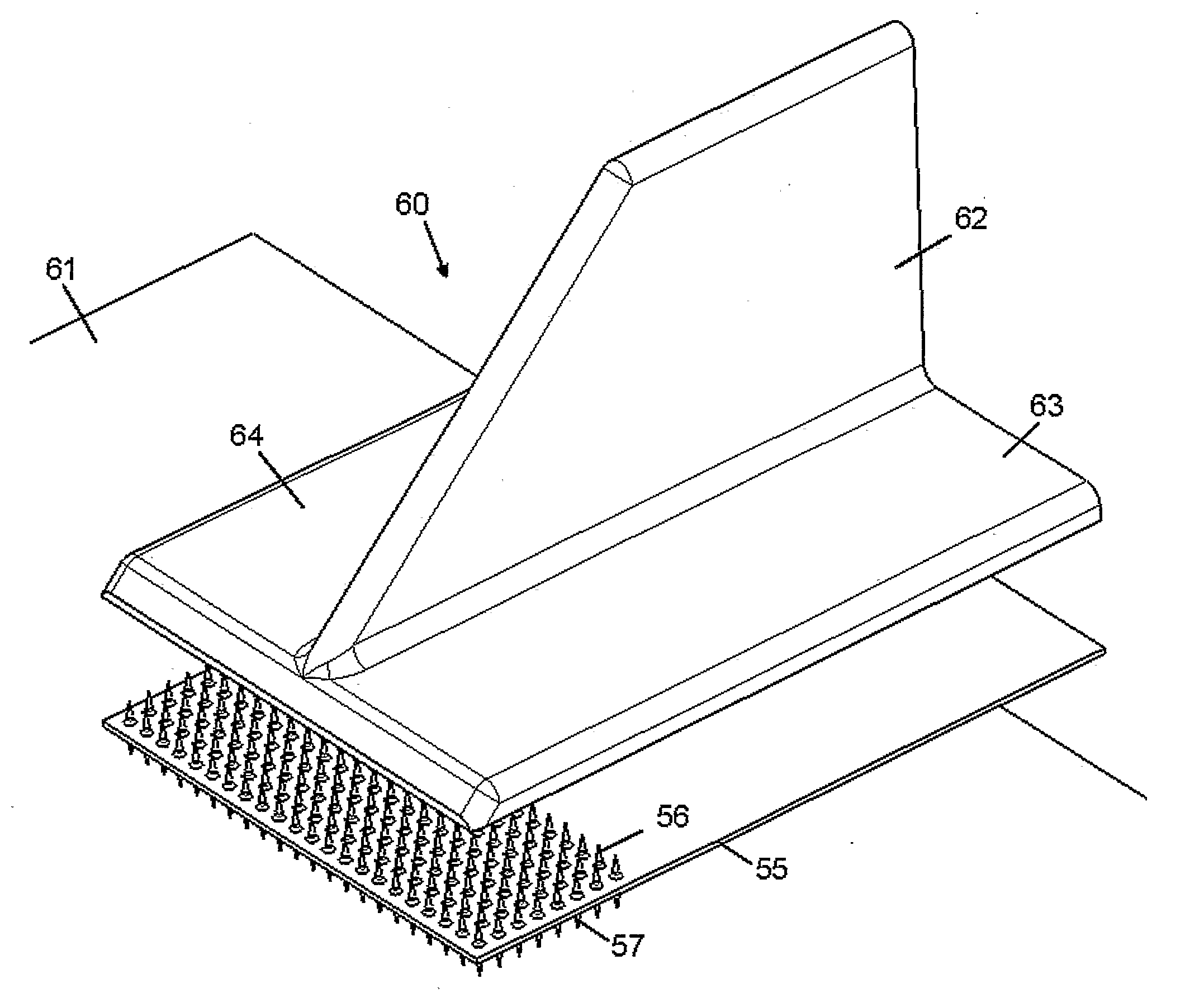

Preparation of a component for use in a joint

ActiveUS20100068464A1Reduce riskReduce risk of damageCeramic layered productsAdditive manufacturing with solidsEngineeringFuselage

A method of preparing a component (60) to be joined to another component (55). The method comprises growing an array of projections (56, 57) on a bond region of the component (55) in a series of layers, each layer being grown by directing energy and / or material from a head to selected parts of the bond region. The joint may be used to join a pair of structural components, for instance in an aerospace application. For instance the joint may be used to join a reinforcing plate, floating rib foot, or stringer to a panel such as a wing or fuselage cover. Alternatively the joint may be used to join adjacent layers in a laminate structure.

Owner:AIRBUS OPERATIONS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com