Patents

Literature

1077results about "Control apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

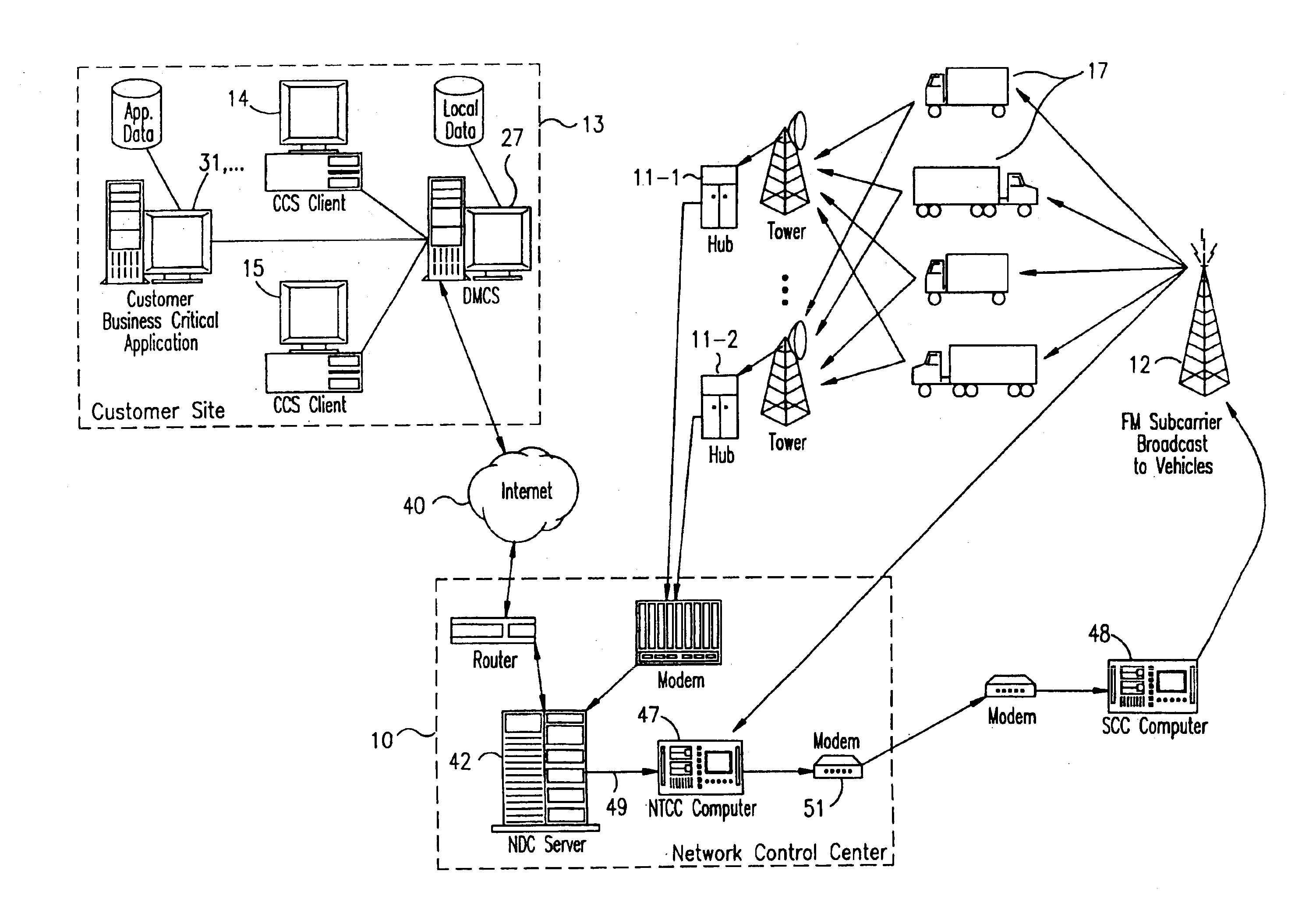

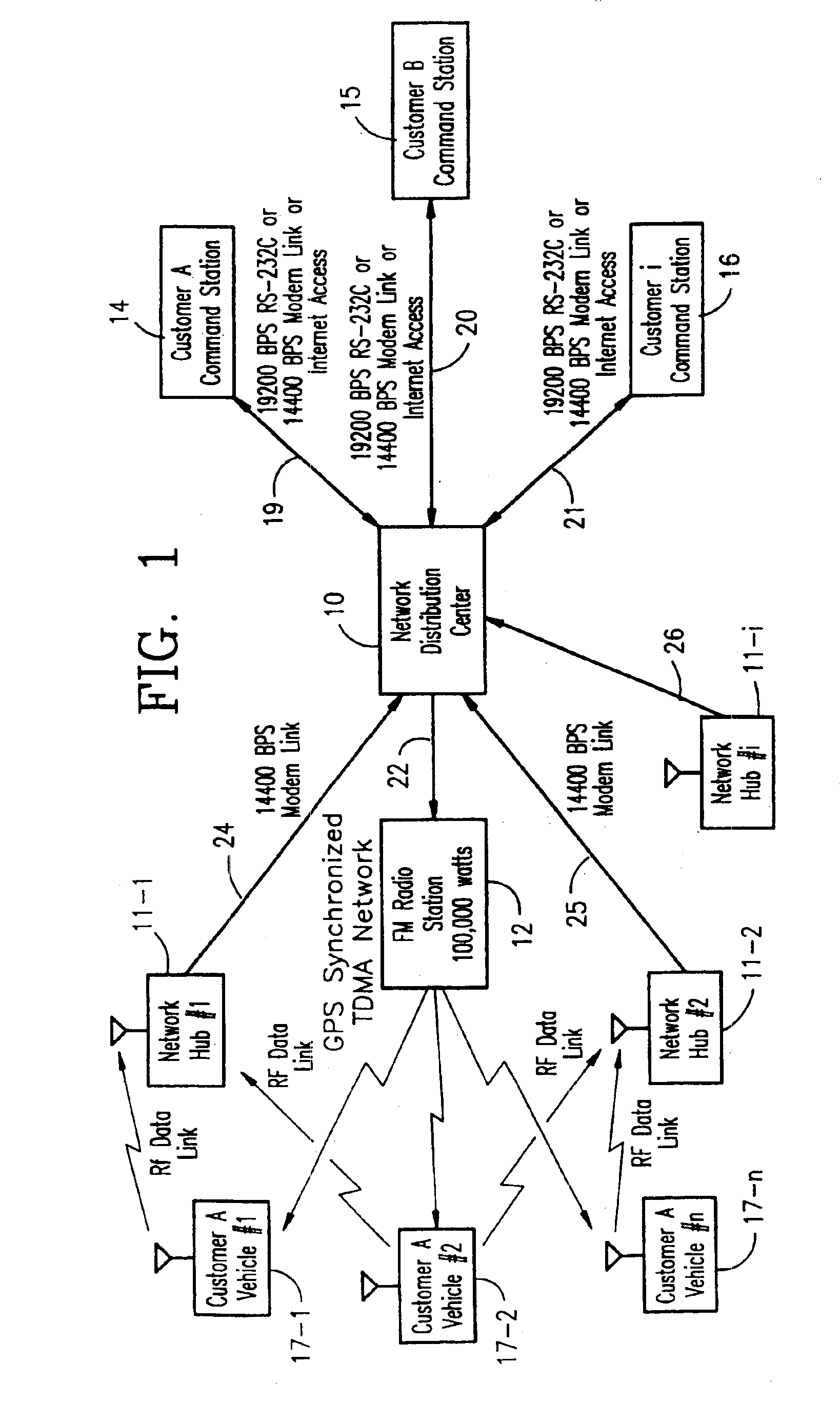

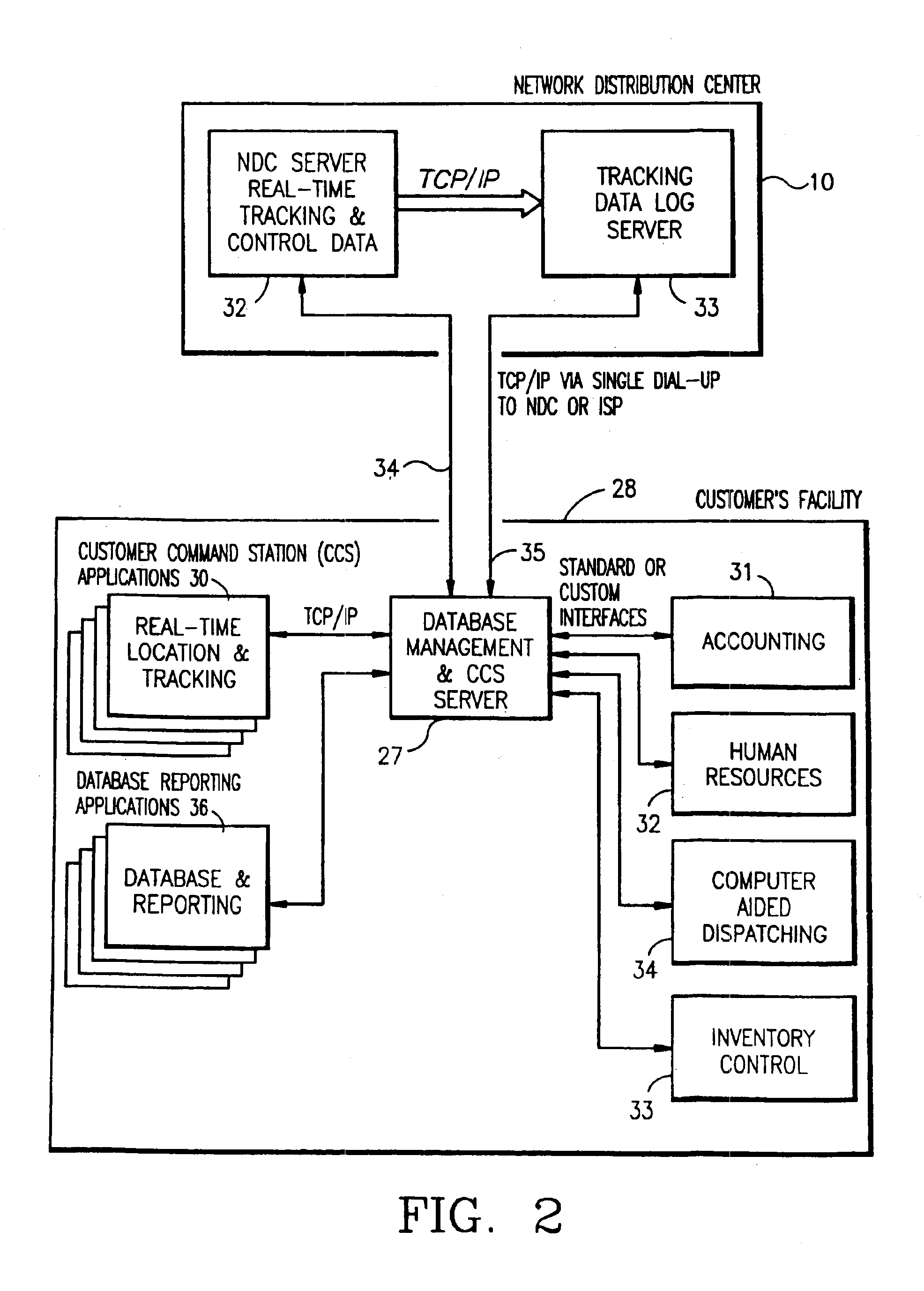

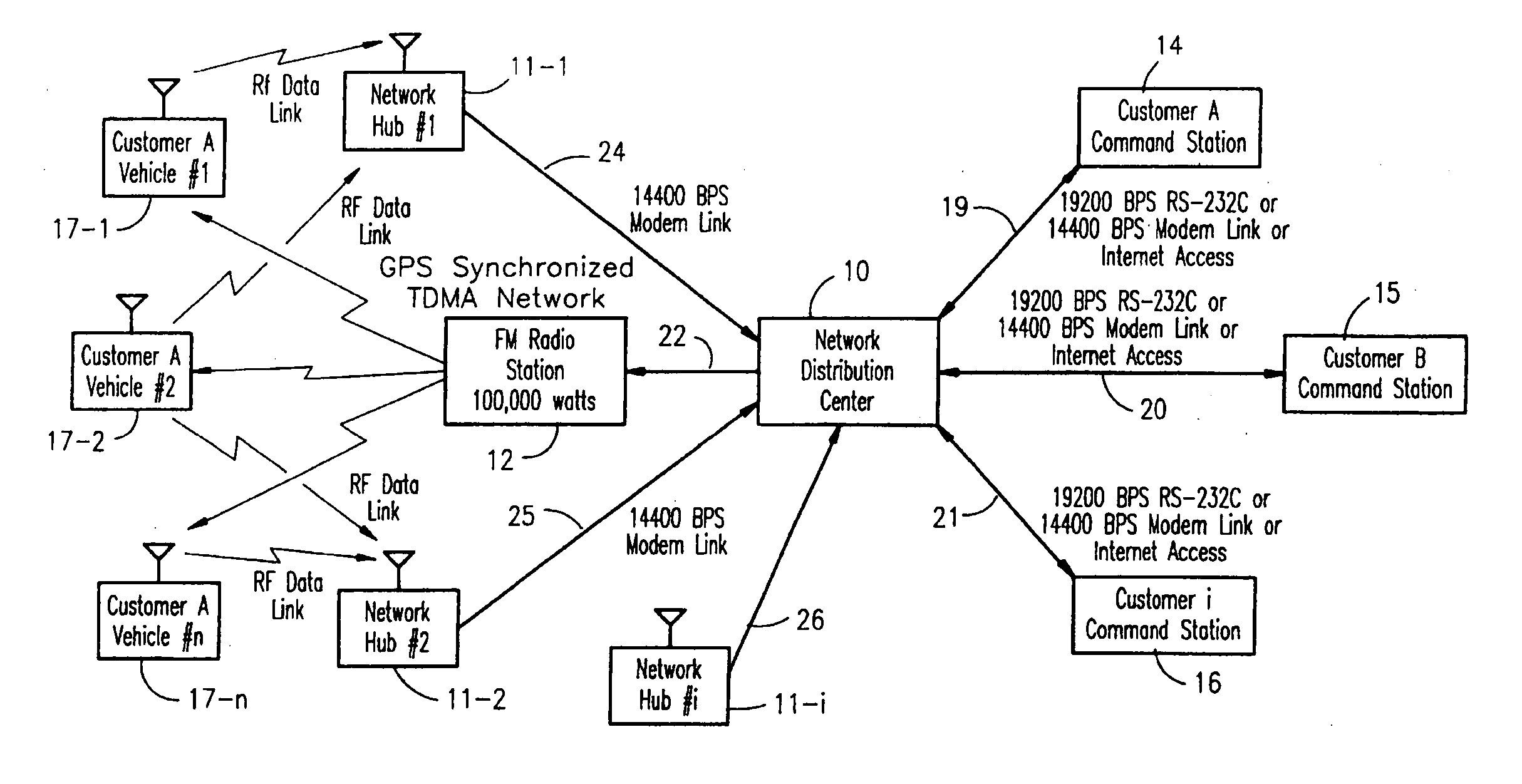

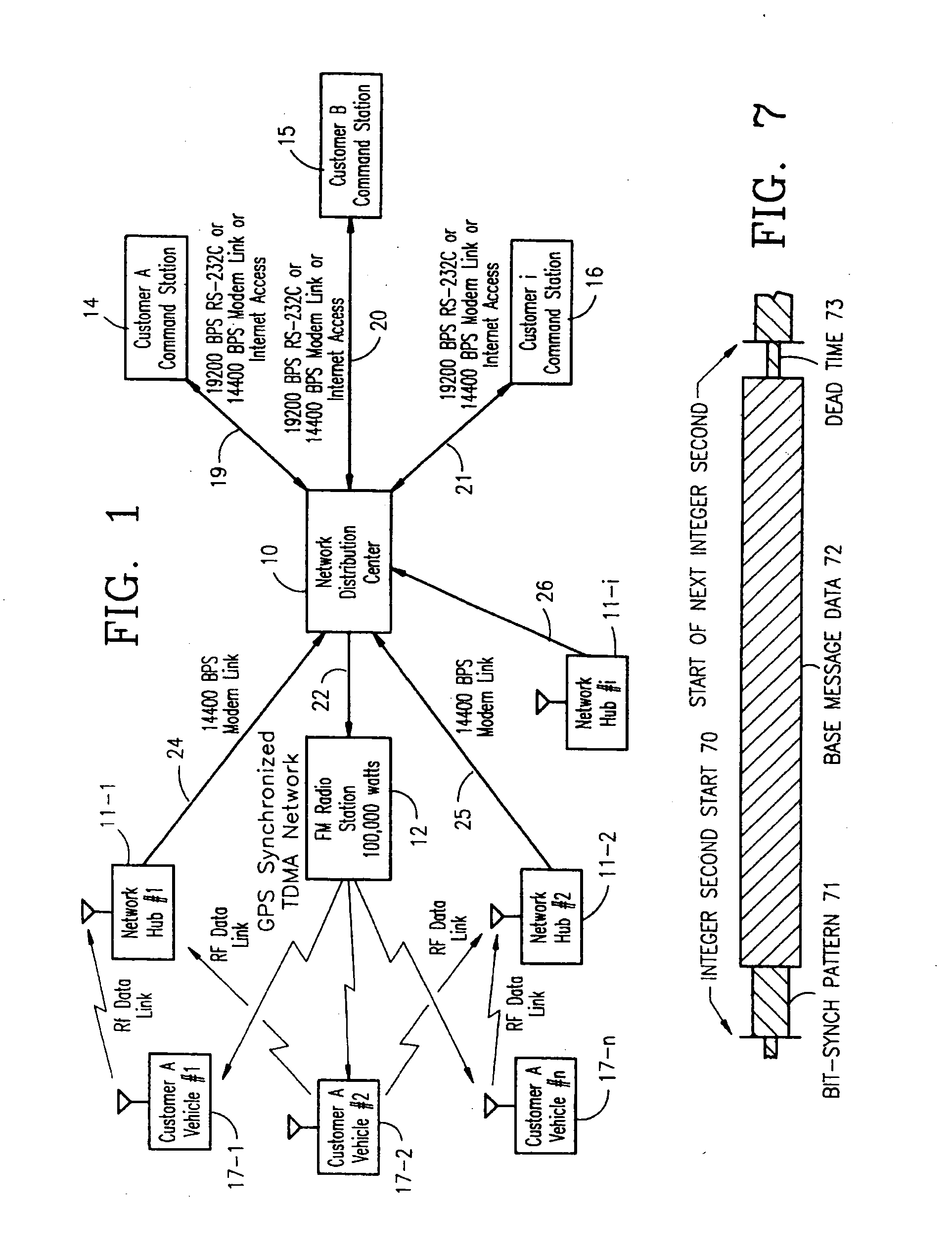

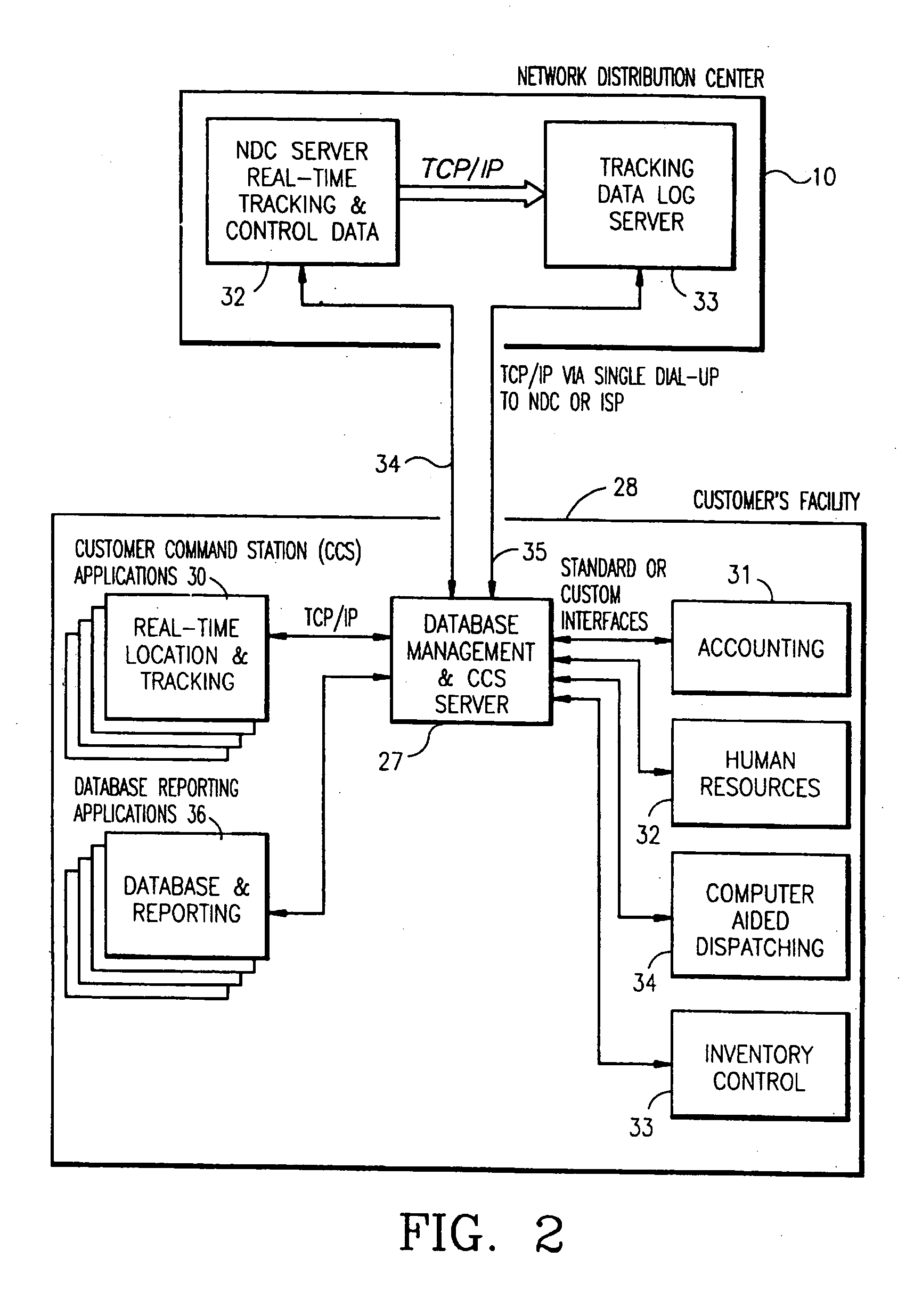

Vehicle tracking, communication and fleet management system

InactiveUS6892131B2Management moreEfficient and reliableVehicle testingRegistering/indicating working of vehiclesFleet managementTruck

A vehicle fleet management information system for identification of location and direction of movement of each vehicle in the fleet in real-time and automatic communication directly with management offices to report its location and heading, and status of predetermined events in which the vehicle may be engaged. One example is a cement delivery truck which monitors location, speed and status information such as start pour, pouring, end pour, wash and leave job, and automatically transmits this information with a management office without requiring affirmative action by the vehicle operator.

Owner:TRIMBLE NAVIGATION LTD

Vehicle tracking, communication and fleet management system

InactiveUS20060142913A1Management moreEfficient and reliableVehicle testingRegistering/indicating working of vehiclesFleet managementEngineering

A vehicle fleet management information system identifies location and direction of movement of each vehicle in a fleet in real-time, and automatically reports such information, as well as status of predetermined events in which the vehicle is engaged, directly to the fleet manager. Each fleet vehicle has an assigned time slot to transmit its reporting information over a communications network without interfering with transmissions from other vehicles in their own respective time slots. A timing control phase lock loop (PLL) provides precise time synchronization for timing corrections from a global positioning system (GPS) based time reference. A dual band full-duplex interface of the network has TDMA on one-half and broadcast on the other half. Microprocessor time processing units in components of the network perform precise clock synchronization. Space diversity performed on received vehicle transmitted messages avoids data corruption. Different vehicles have different periodic transmission intervals, by dynamically allocating the slots for various update rates. Auxiliary reporting slots enable prompt reporting of important data by the respective vehicle transmitters independent of the slower periodic transmission intervals.

Owner:TRIMBLE NAVIGATION LTD

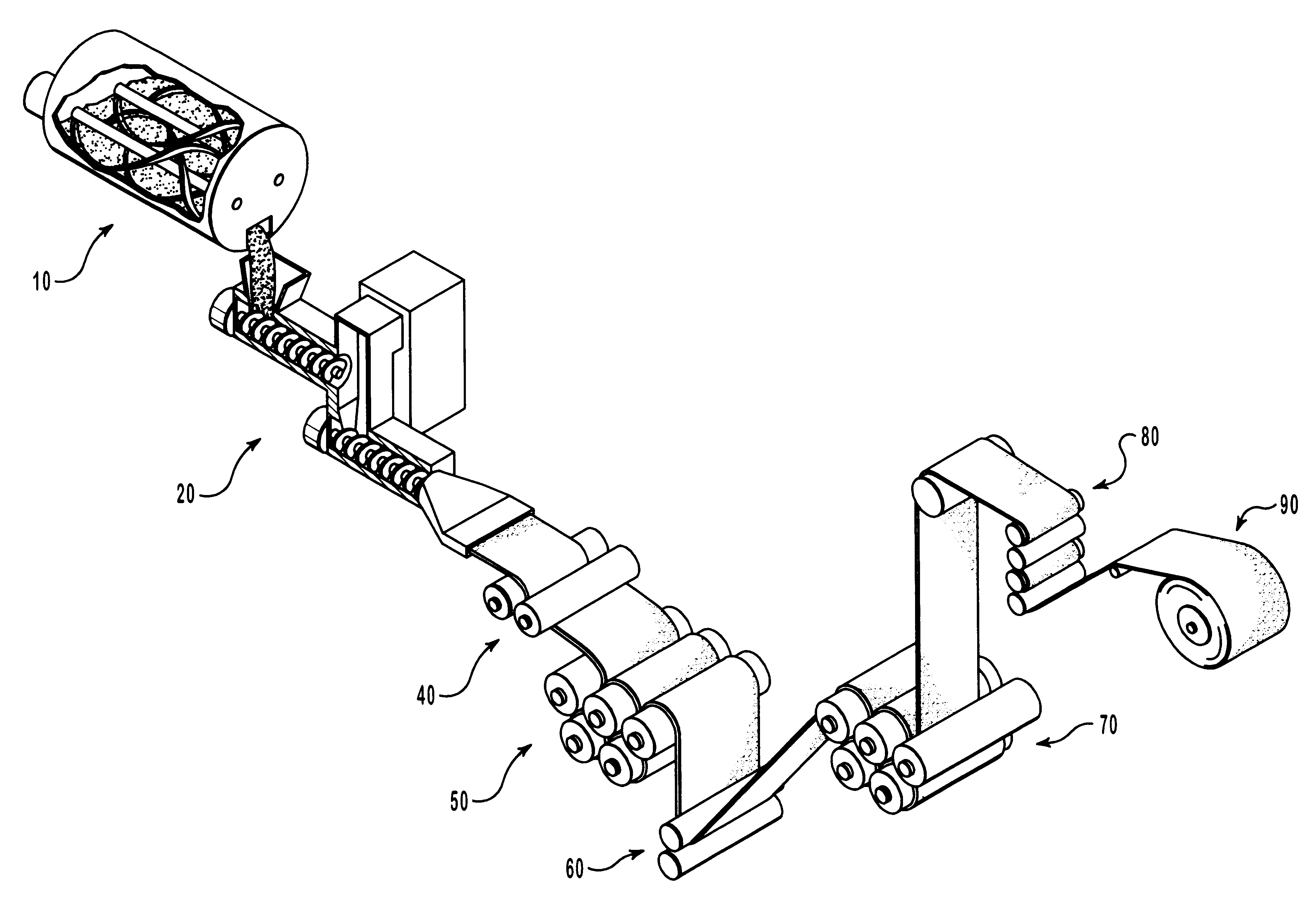

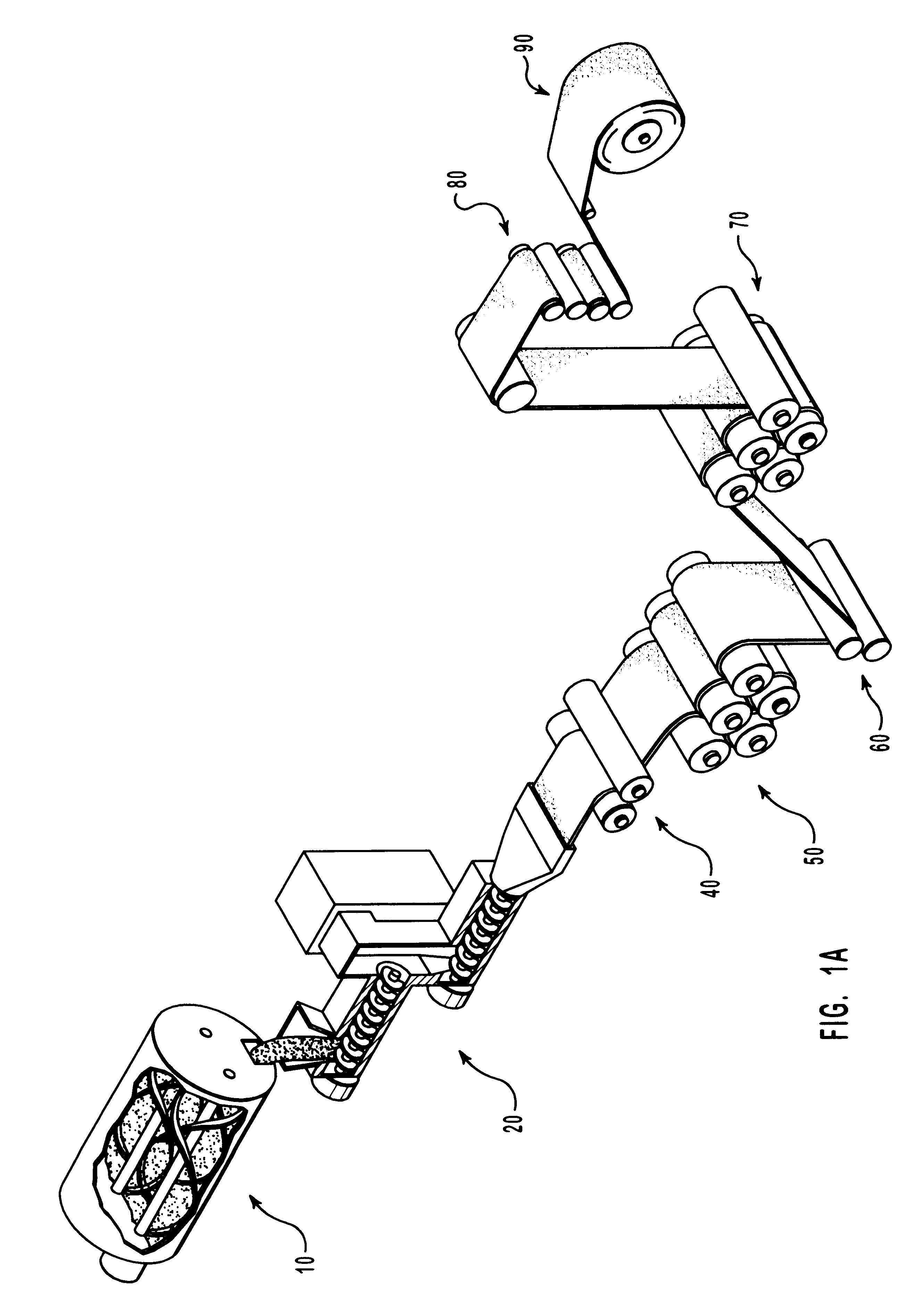

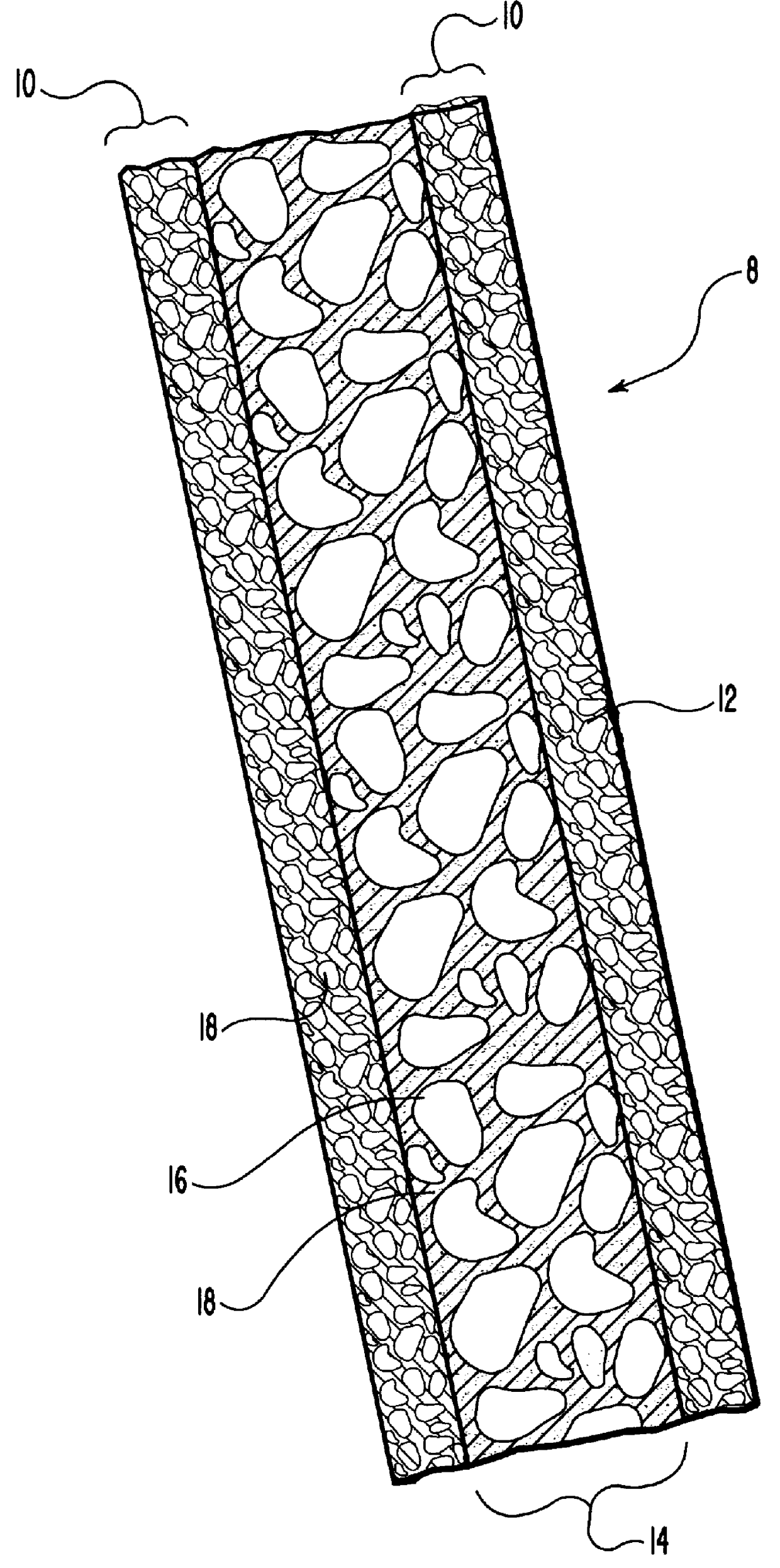

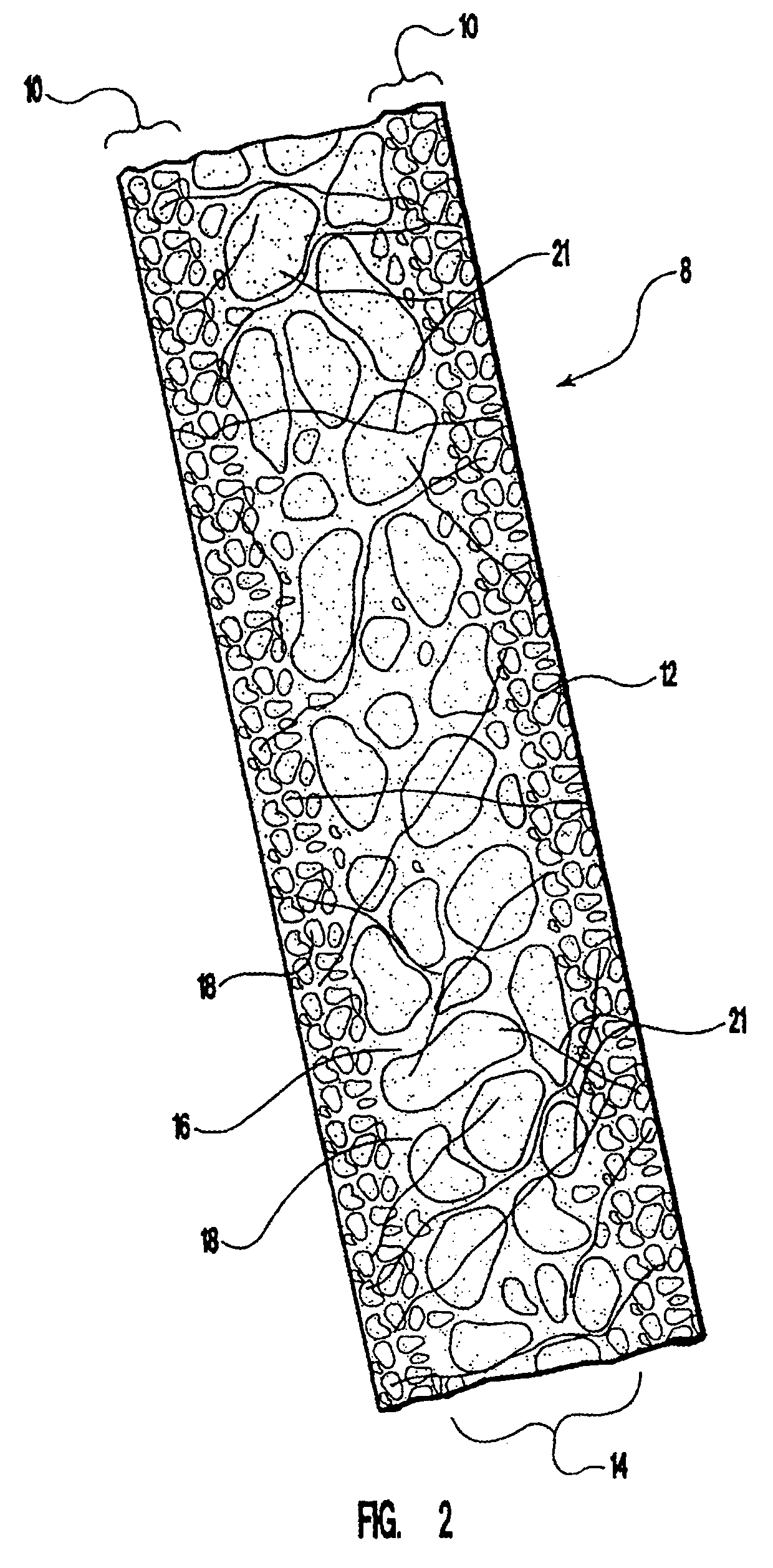

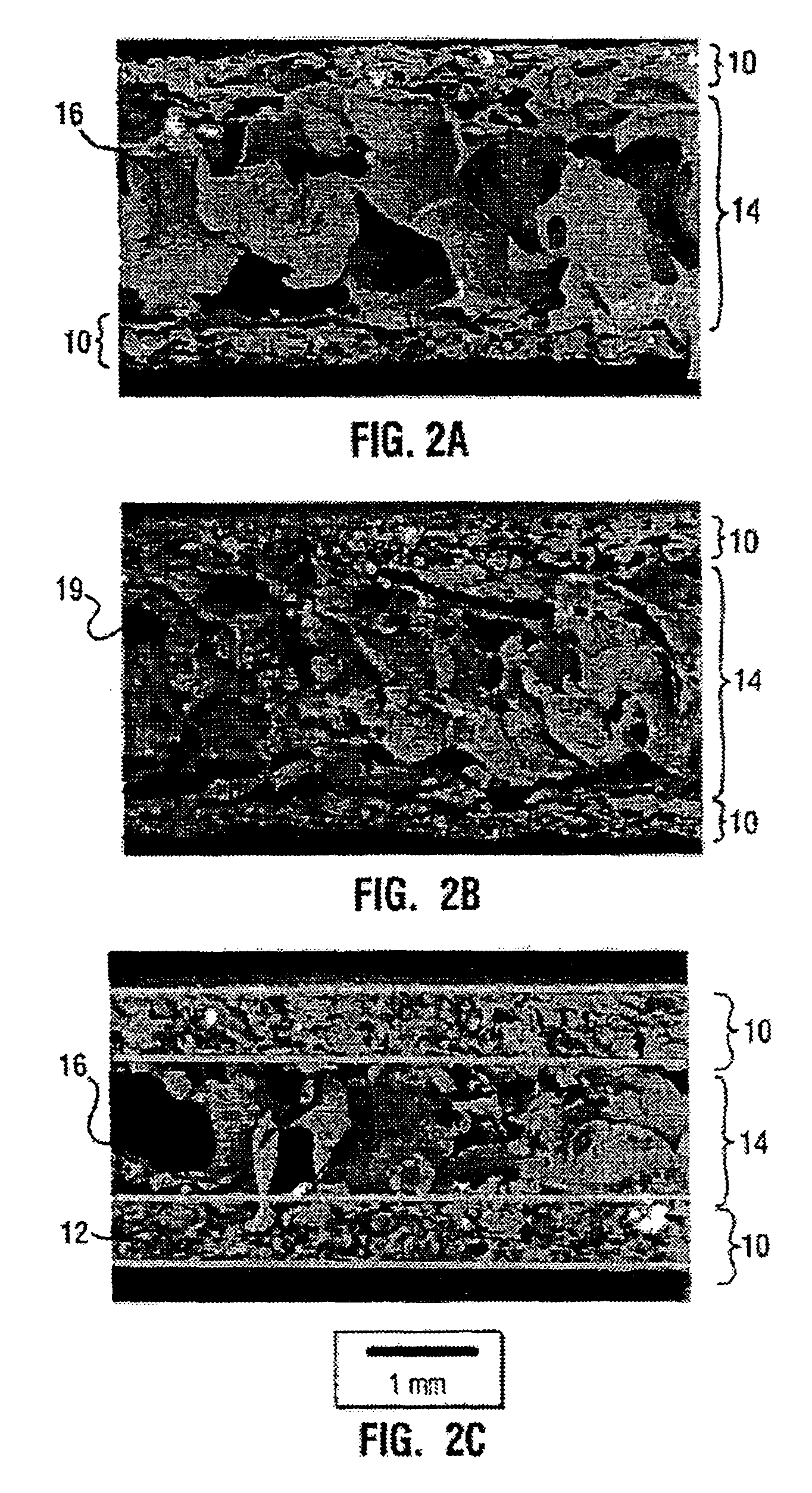

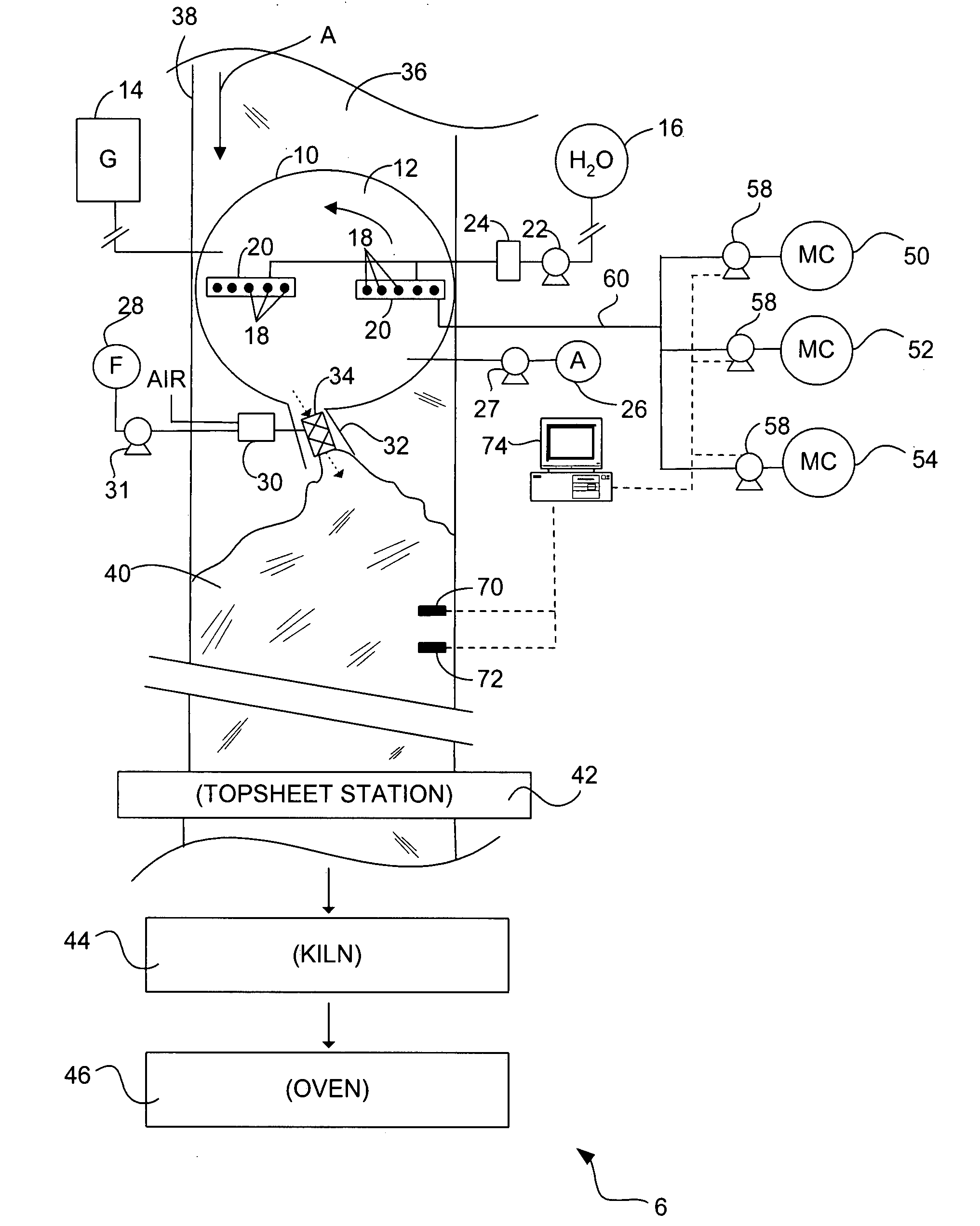

Methods for the manufacture of sheets having a highly inorganically filled organic polymer matrix

Compositions and methods for manufacturing sheets having a highly inorganically filled matrix. Suitable inorganically filled mixtures are prepared by mixing together an organic polymer binder, water, one or more inorganic aggregate materials, fibers, and optional admixtures in the correct proportions in order to form a sheet which has the desired performance criteria. The inorganically filled mixtures are formed into sheets by first extruding the mixtures and the passing the extruded materials between a set of rollers. The rolled sheets are dried in an accelerated manner to form a substantially hardened sheet, such as by heated rollers and / or a drying chamber. The inorganically filled sheets may have properties substantially similar to sheets presently made from traditional materials like paper, cardboard, polystyrene, plastic, or metal. Such sheets can be rolled, pressed, scored, perforated, folded, and glued. They have especial utility in the mass production of containers, particularly food and beverage containers.

Owner:E KHASHOGGI INDS

Molded starch-bound containers and other articles having natural and/or synthetic polymer coatings

Compositions, methods, and systems for manufacturing articles, particularly containers and packaging materials, having a particle packed, highly inorganically filled, cellular matrix are disclosed. Suitable inorganically filled mixtures are prepared by mixing together a starch-based binder, a solvent, inorganic aggregates, and optimal admixtures, e.g., fibers, mold-releasing agents, rheology-modifying agents, plasticizers, coating materials, and dispersants, in the correct proportions to form an article which has the desired performance criteria. The inorganically filled mixtures have a predetermined viscosity and are heated between molds at an elevated temperature and pressure to produce form-stable articles having a desired shape and a selectively controlled cellular, structure matrix. The molded articles may be placed in a high humidity chamber to obtain the necessary flexibility for their intended use. The articles may be manufactured to have properties substantially similar to articles presently made from conventional materials like paper, paperboard, polystyrene, plastic, or other organic materials. They have especial utility in the mass-production of containers, particularly food and beverage containers.

Owner:EARTHSHELL SPE

Compositions used in manufacturing articles having an inorganically filled organic polymer matrix

InactiveUS6090195AReadily and inexpensively mass producedHigh strengthClosure lidsWrappersFiberPolymer science

Compositions, methods, and systems for manufacturing articles, particularly containers and packaging materials, having a highly inorganically filled matrix. Suitable inorganically filled mixtures are prepared by mixing together an organic polymer binder, water, one or more aggregate materials, fibers, and optional admixtures in the correct proportions in order to form an article which has the desired performance criteria. The inorganically filled mixtures are molded to fashion a portion of the mixture into a form stable shape for the desired article. Once the article has obtained form stability, such as by heating to remove water by evaporation, the article is removed from the mold and allowed to harden to gain strength. The articles may have properties substantially similar to articles presently made from traditional materials like paper, paperboard, polystyrene, plastic, or metal. They have especial utility in the mass production of containers, particularly food and beverage containers.

Owner:EARTHSHELL SPE

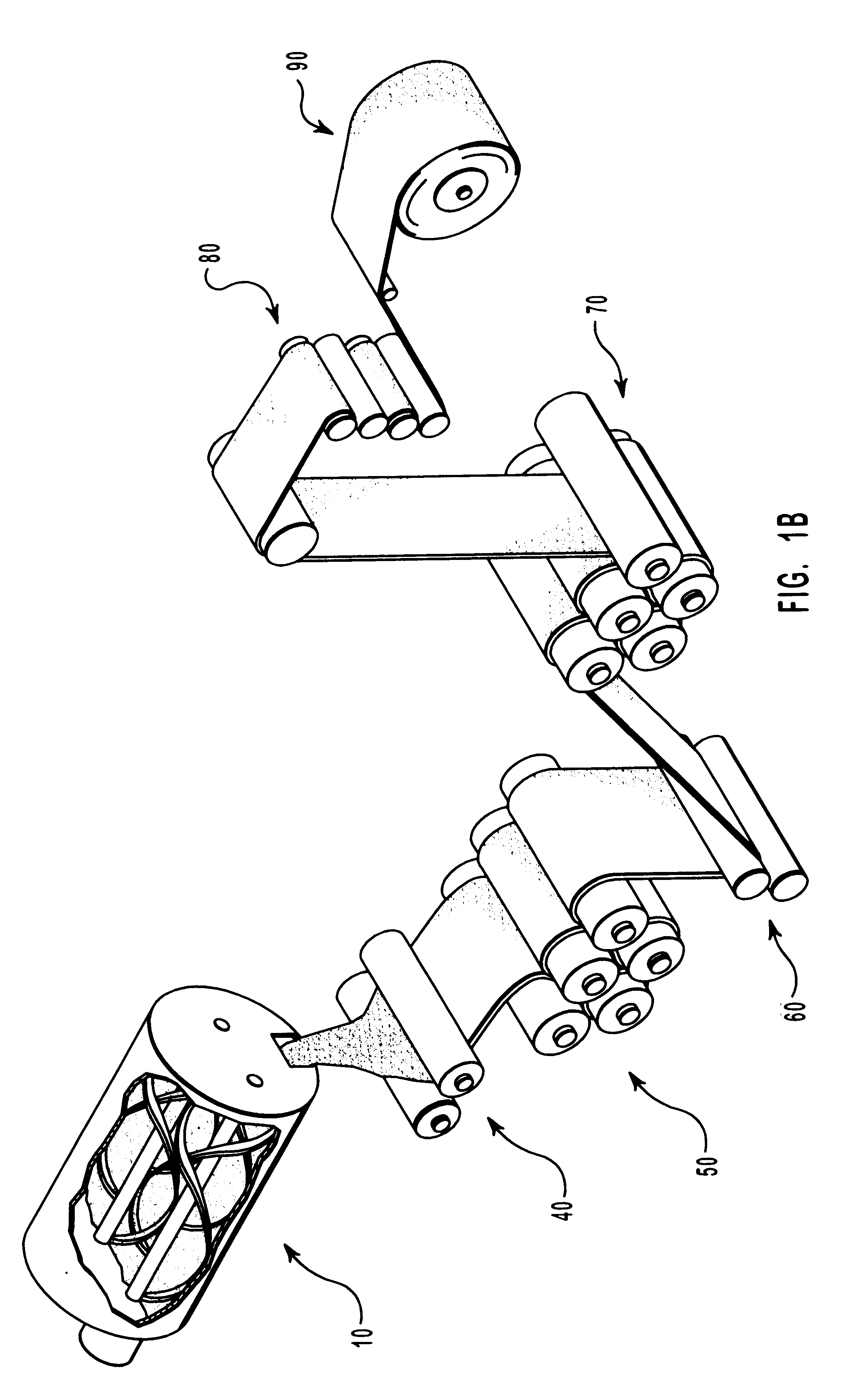

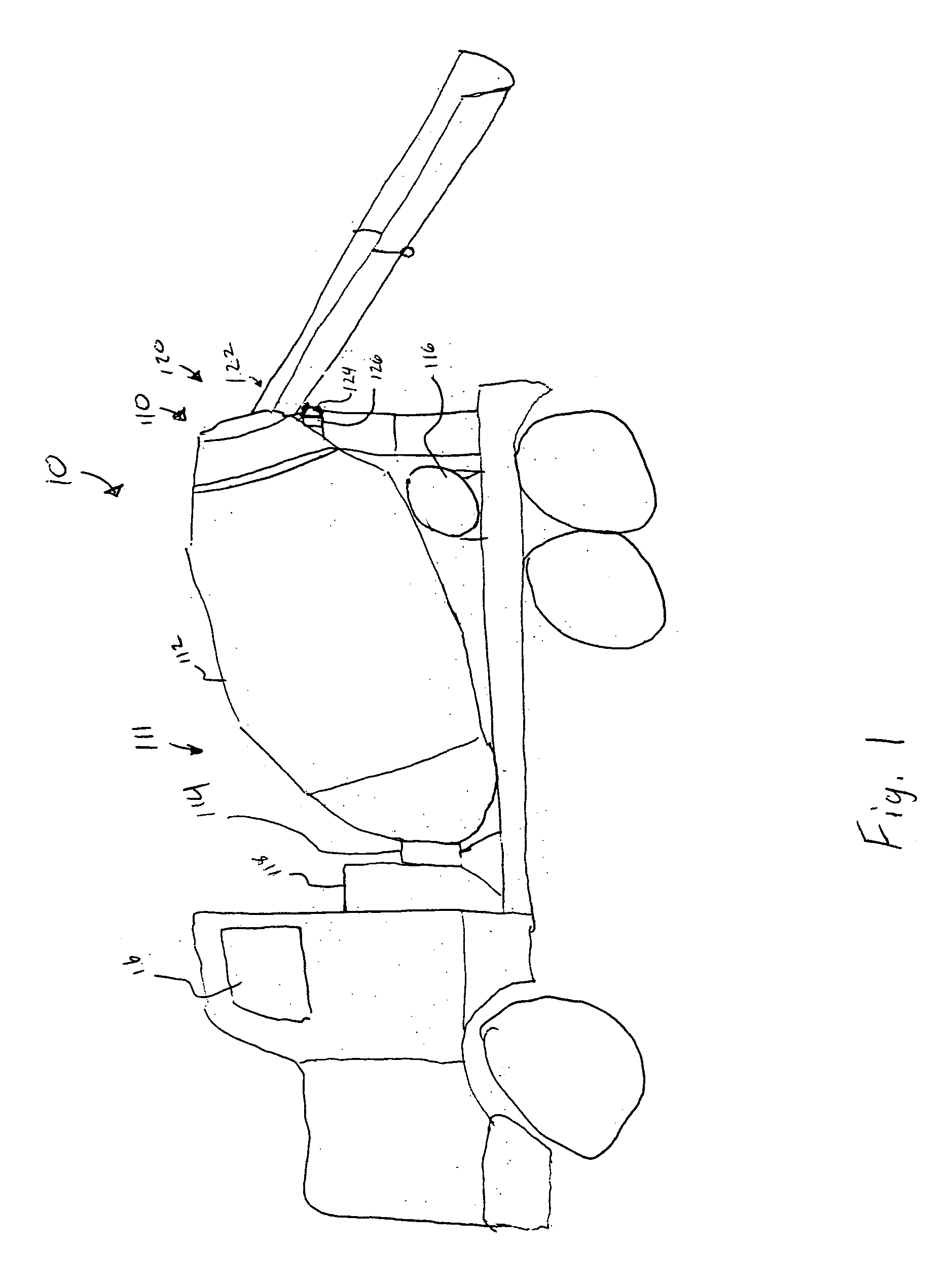

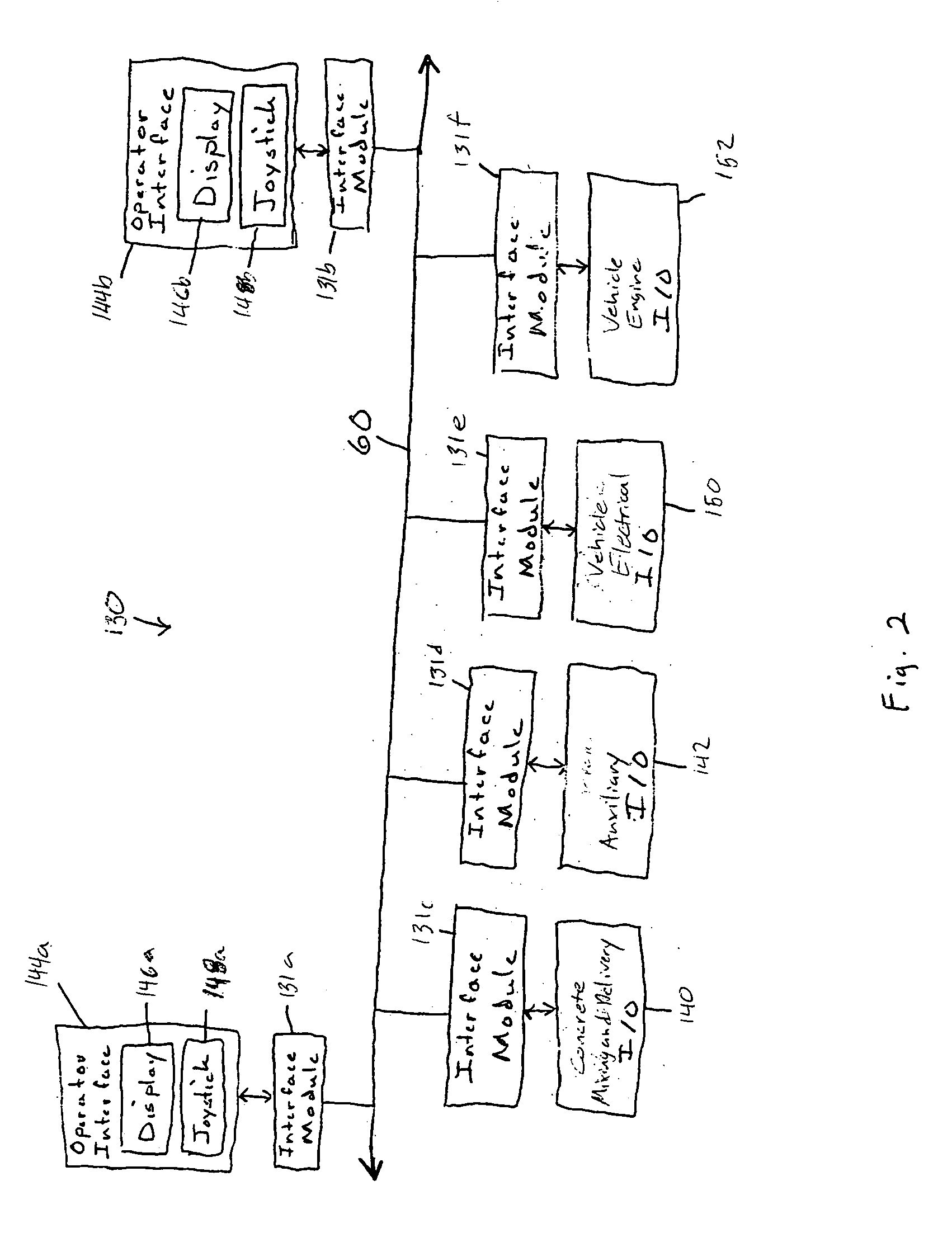

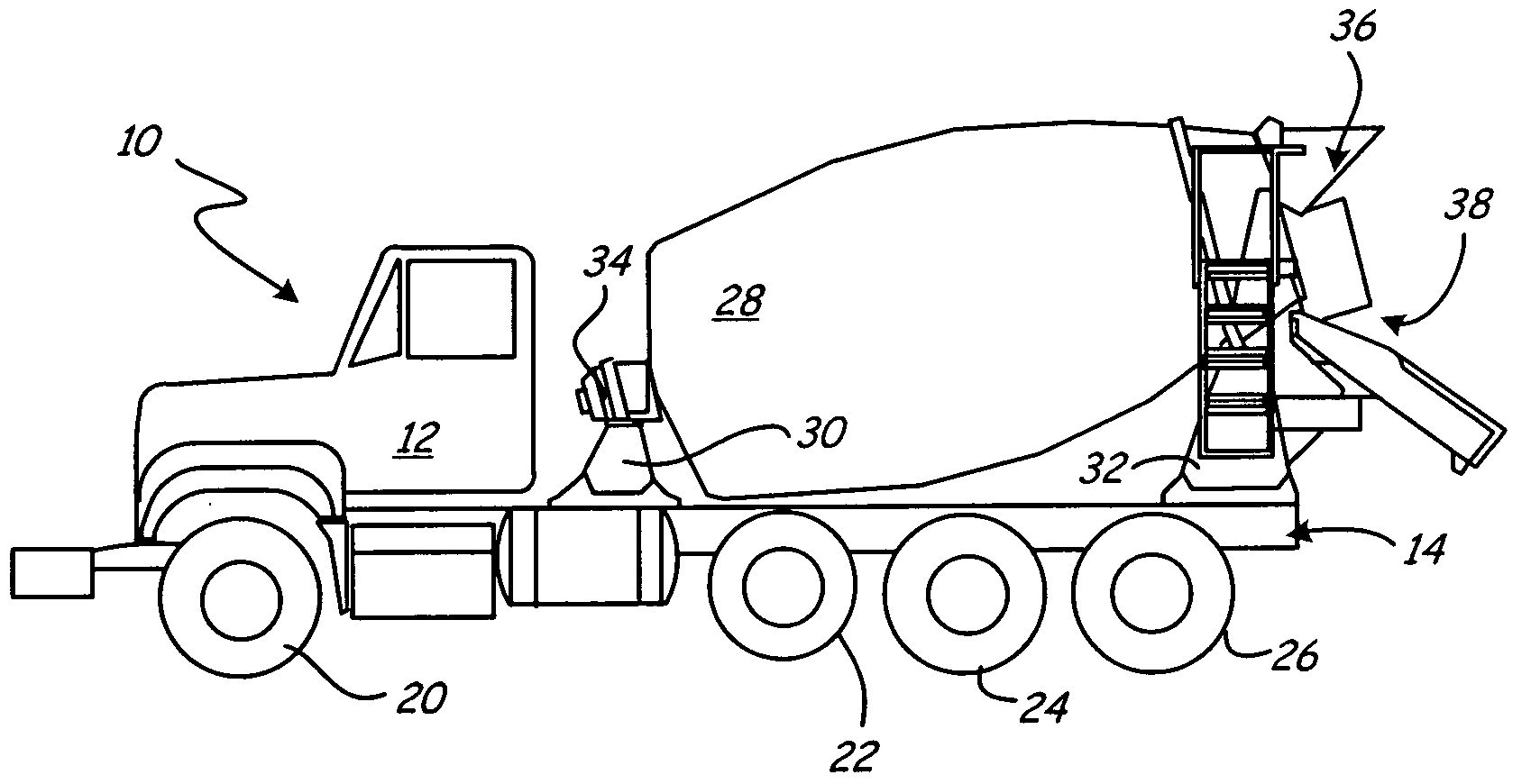

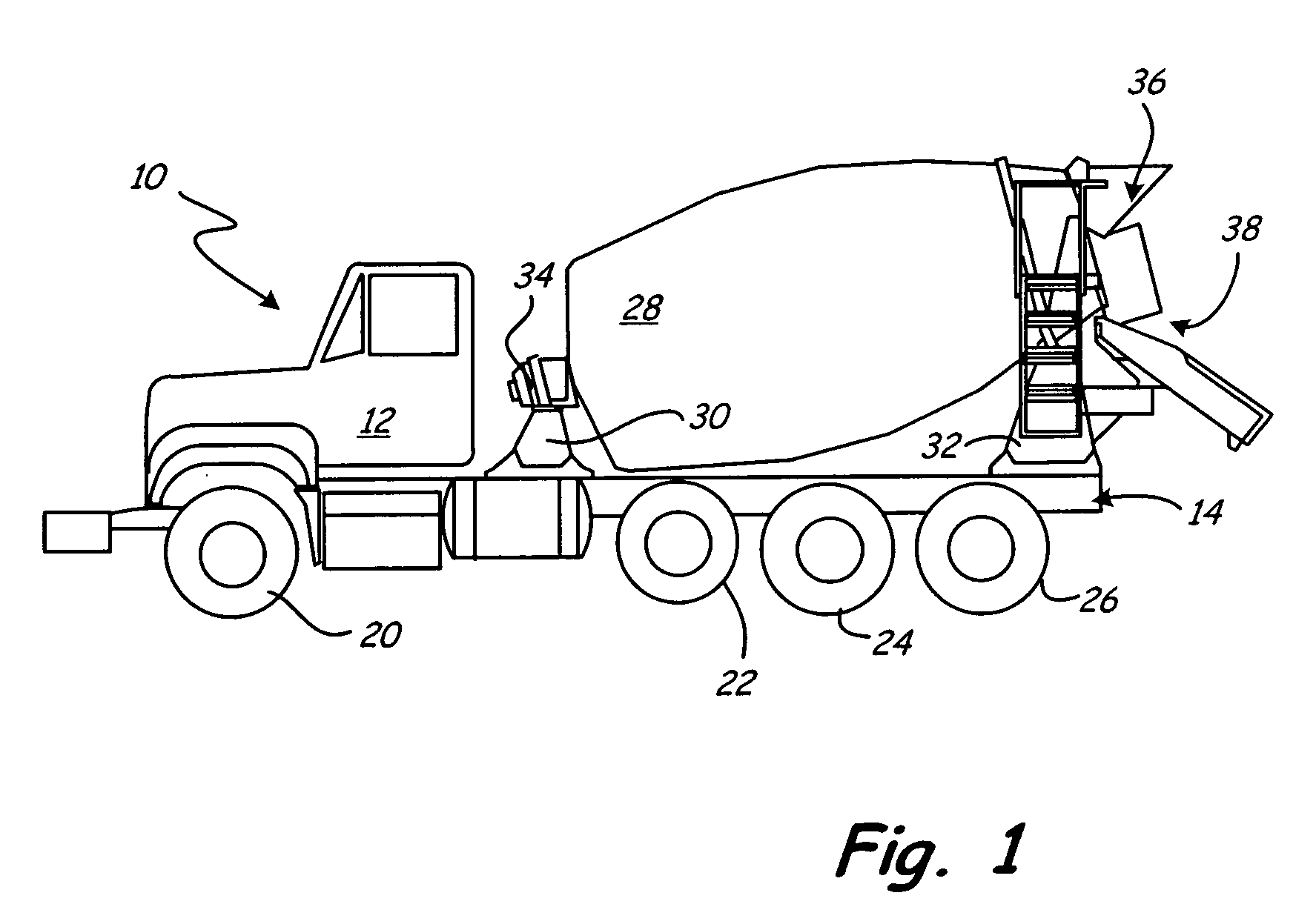

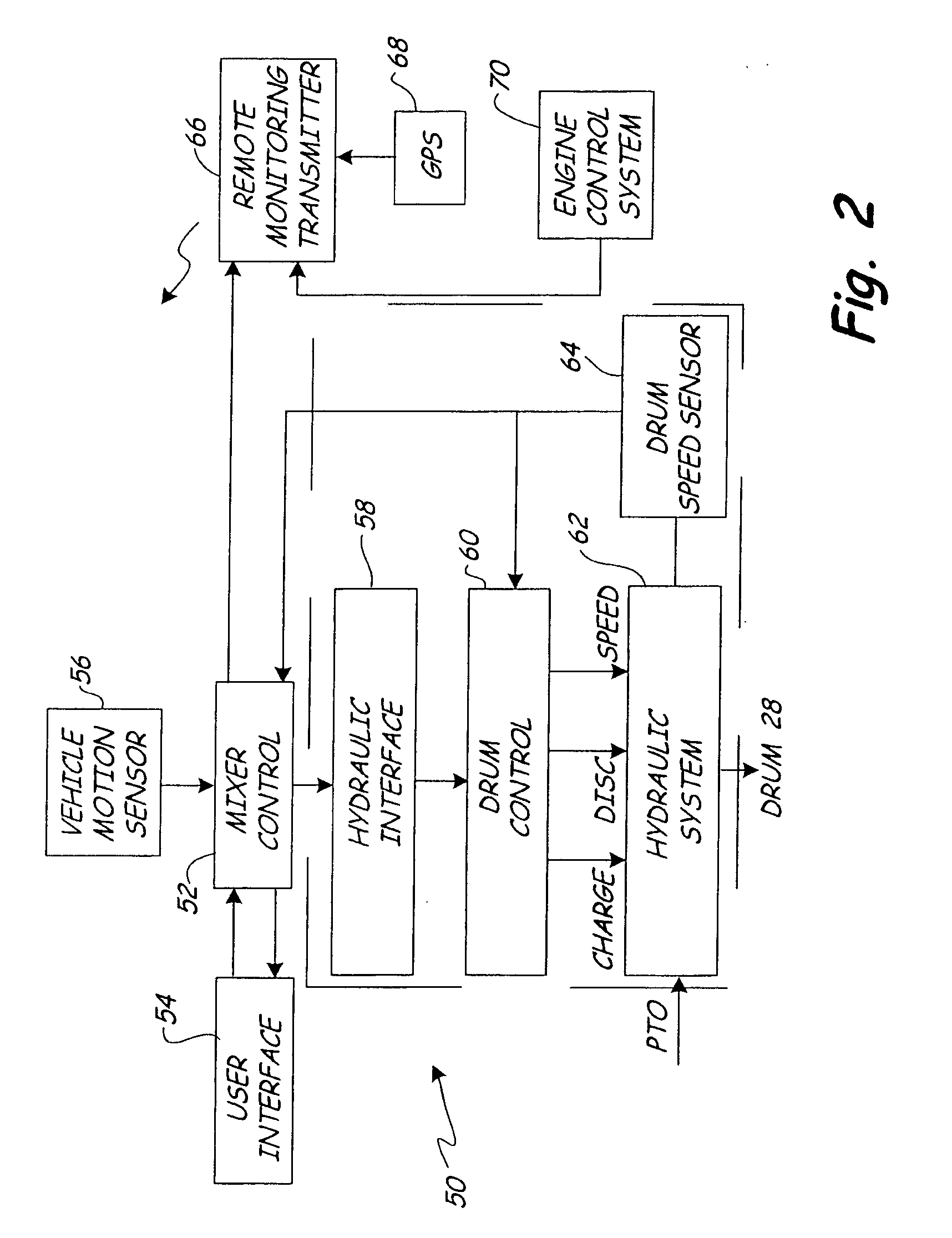

Concrete placement vehicle control system and method

ActiveUS20050004733A1Registering/indicating working of vehiclesRoad vehicles traffic controlControl systemVehicle control

A concrete placement vehicle. The concrete placement vehicle includes a concrete mixing and placement system, at least one vehicle sensor configured to monitor a characteristic of the concrete placement vehicle and at least one concrete system sensor configured to monitor a characteristic of the system for mixing and placing concrete. The vehicle further includes a control system configured to control the operation of the concrete placement vehicle and the concrete mixing and placement system based on inputs received from the at least one vehicle sensor and the at least one concrete system sensor.

Owner:OSHKOSH CORPORATION

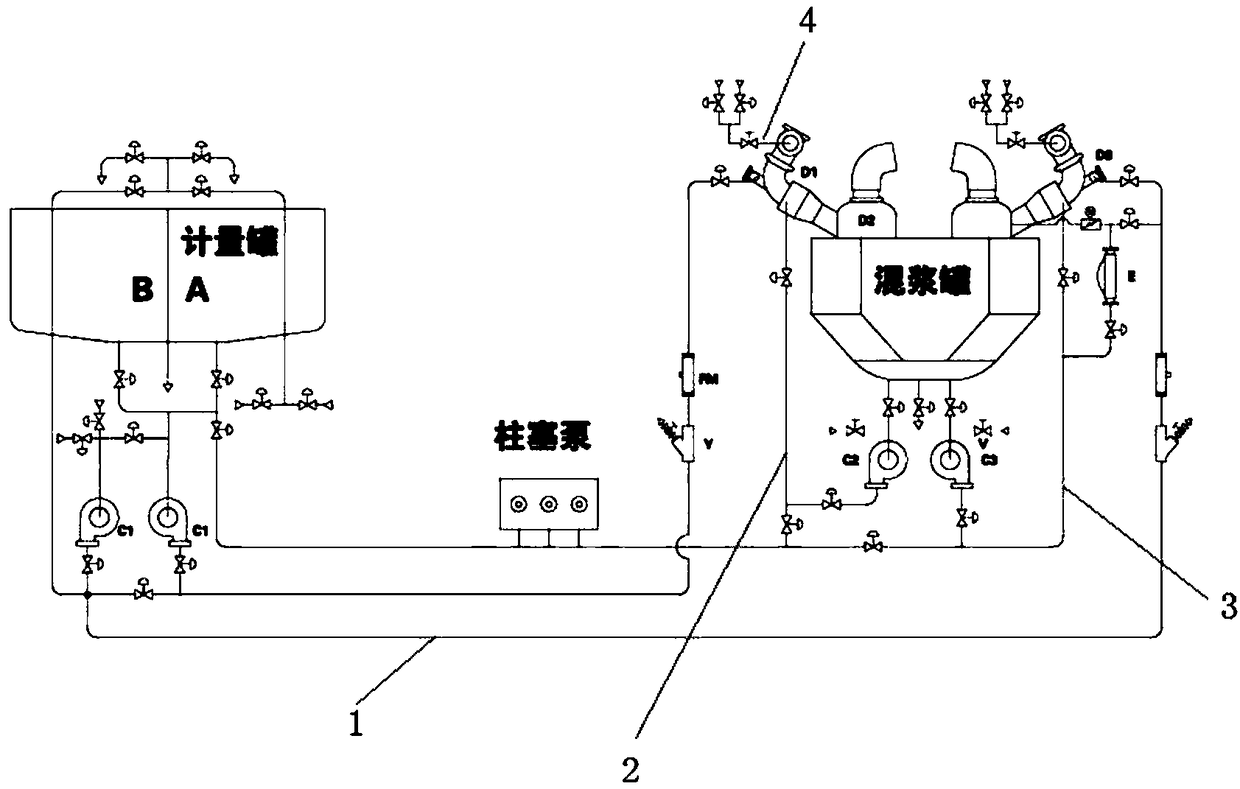

Efficient mixing system for well cementing operation

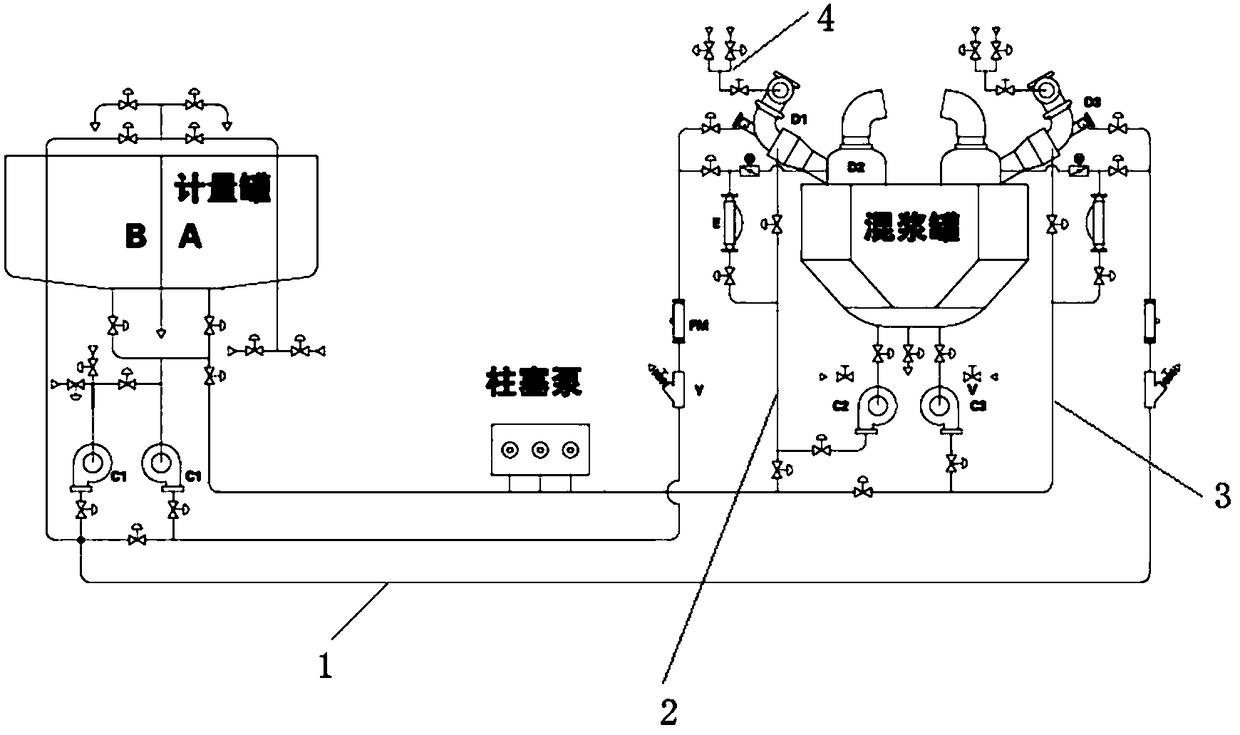

PendingCN108687954ARealize automatic controlEasy to operateCement mixing apparatusControl apparatusHybrid systemControl system

The invention relates to the technical field of petroleum equipment, in particular to an efficient mixing system for well cementing operation. The efficient mixing system comprises a measuring tank, aclear water manifold assembly, a cement grey feeding manifold assembly, high-energy mixers, a mud mixing tank and a mud manifold assembly. The mud mixing tank is at least connected with two high-energy mixers, and an inlet of the mud mixing tank is connected with diffusion boxes which are connected with the high-energy mixers. Discharged materials of the high-energy mixers are guided into the mudmixing tank through the diffusion boxes, and the at least one diffusion box is connected with a density control system. The multiple sets of mixers are integrated, and the large-discharge-capacity and efficient mixing effect can be achieved with existing operation conditions.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

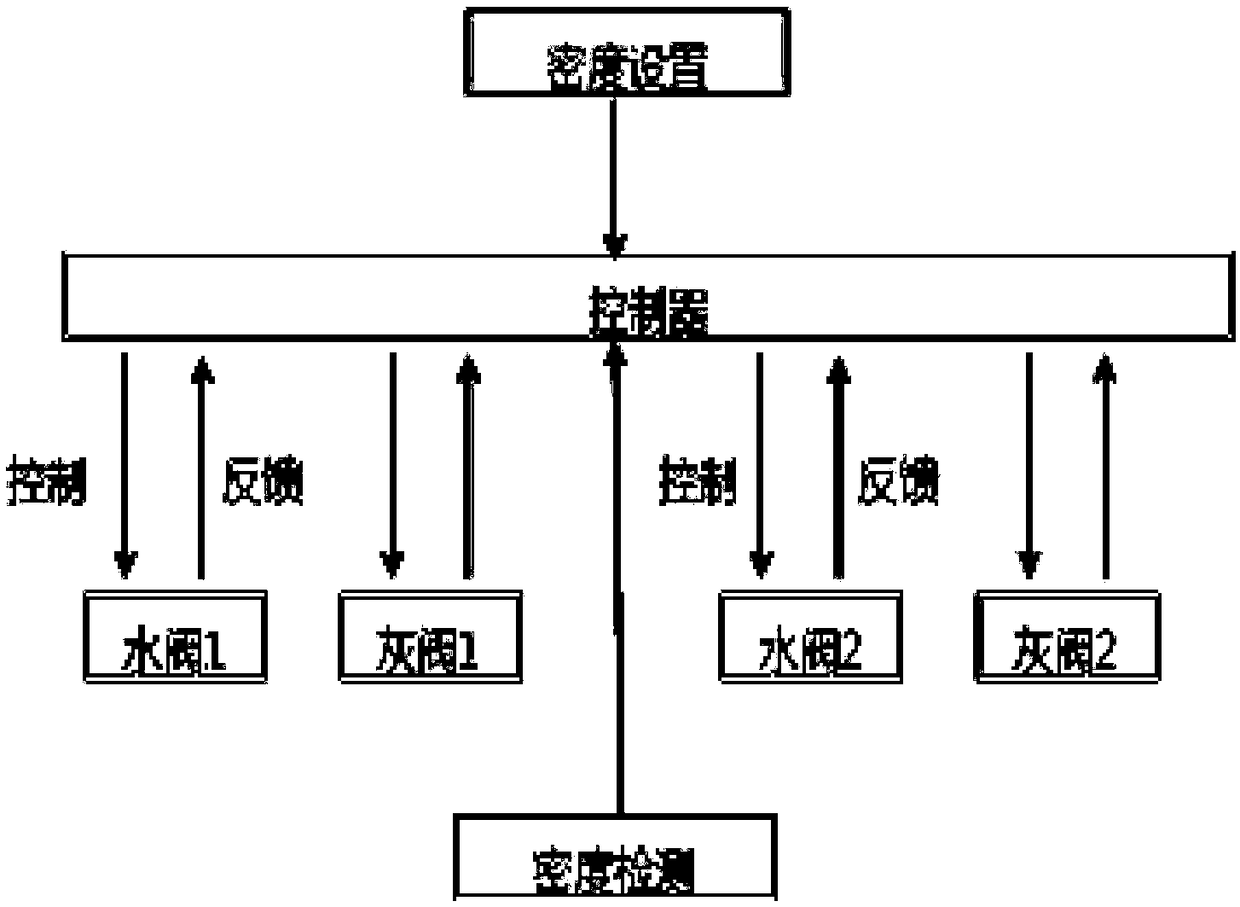

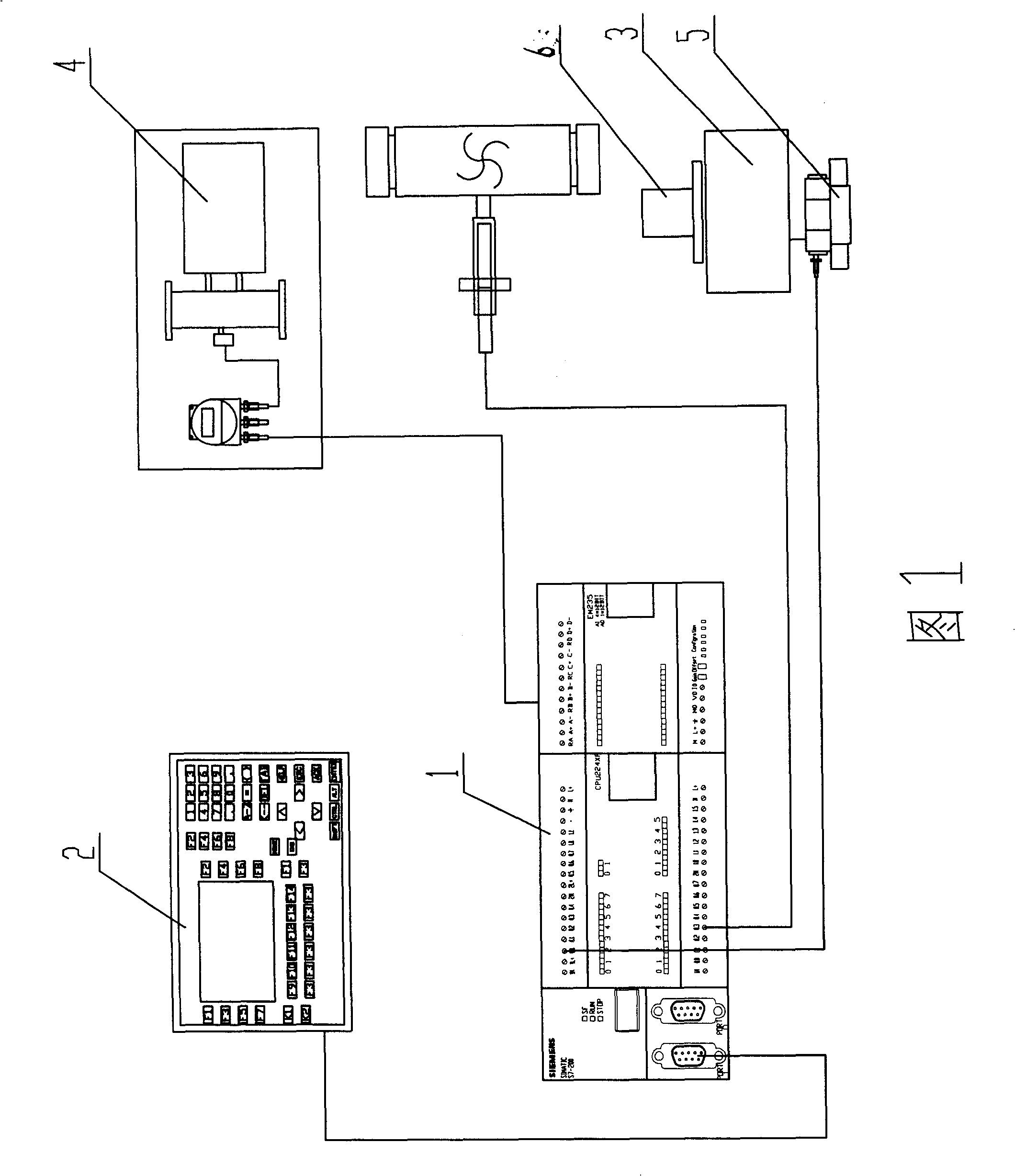

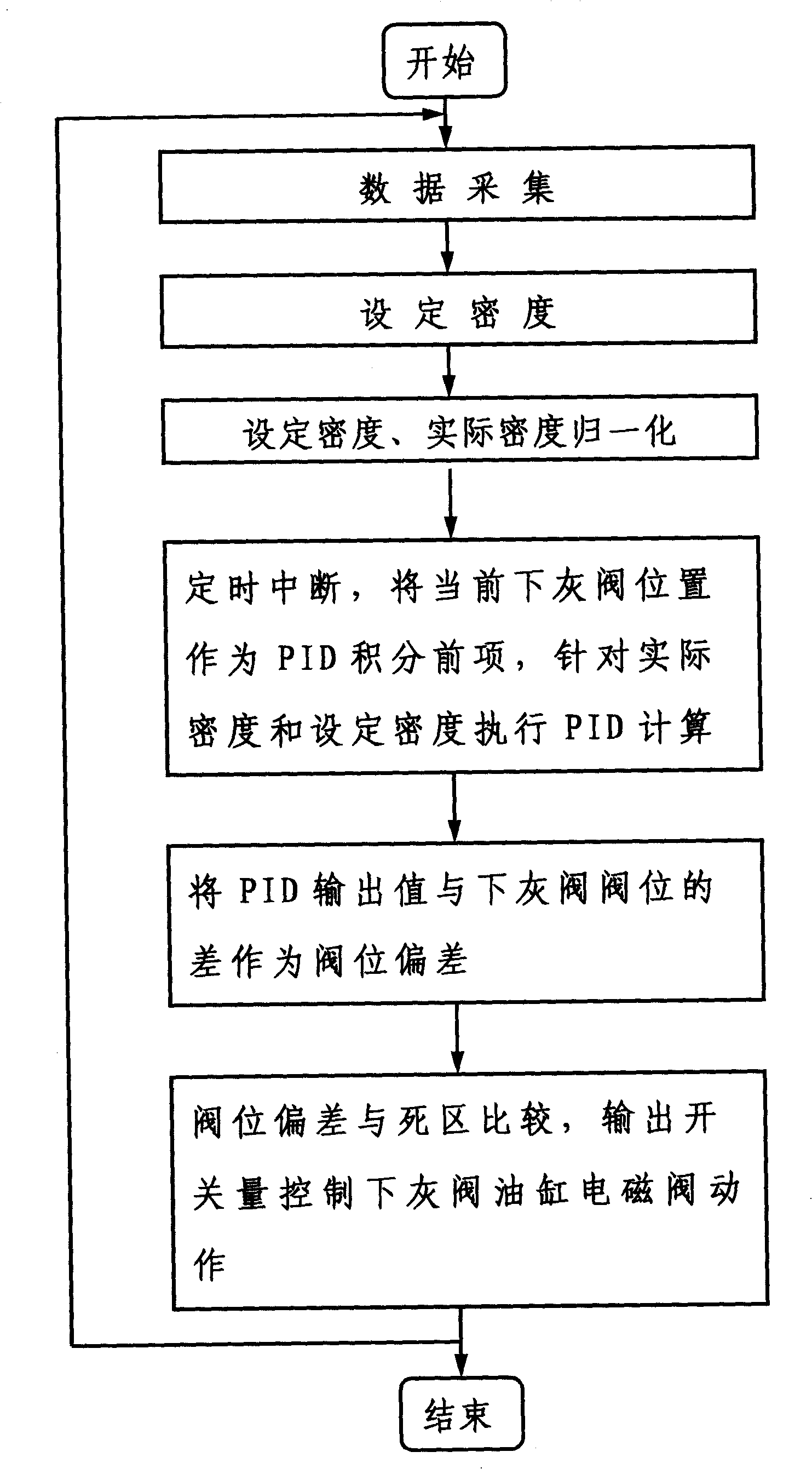

System and control method for automatically compounding cement paste

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

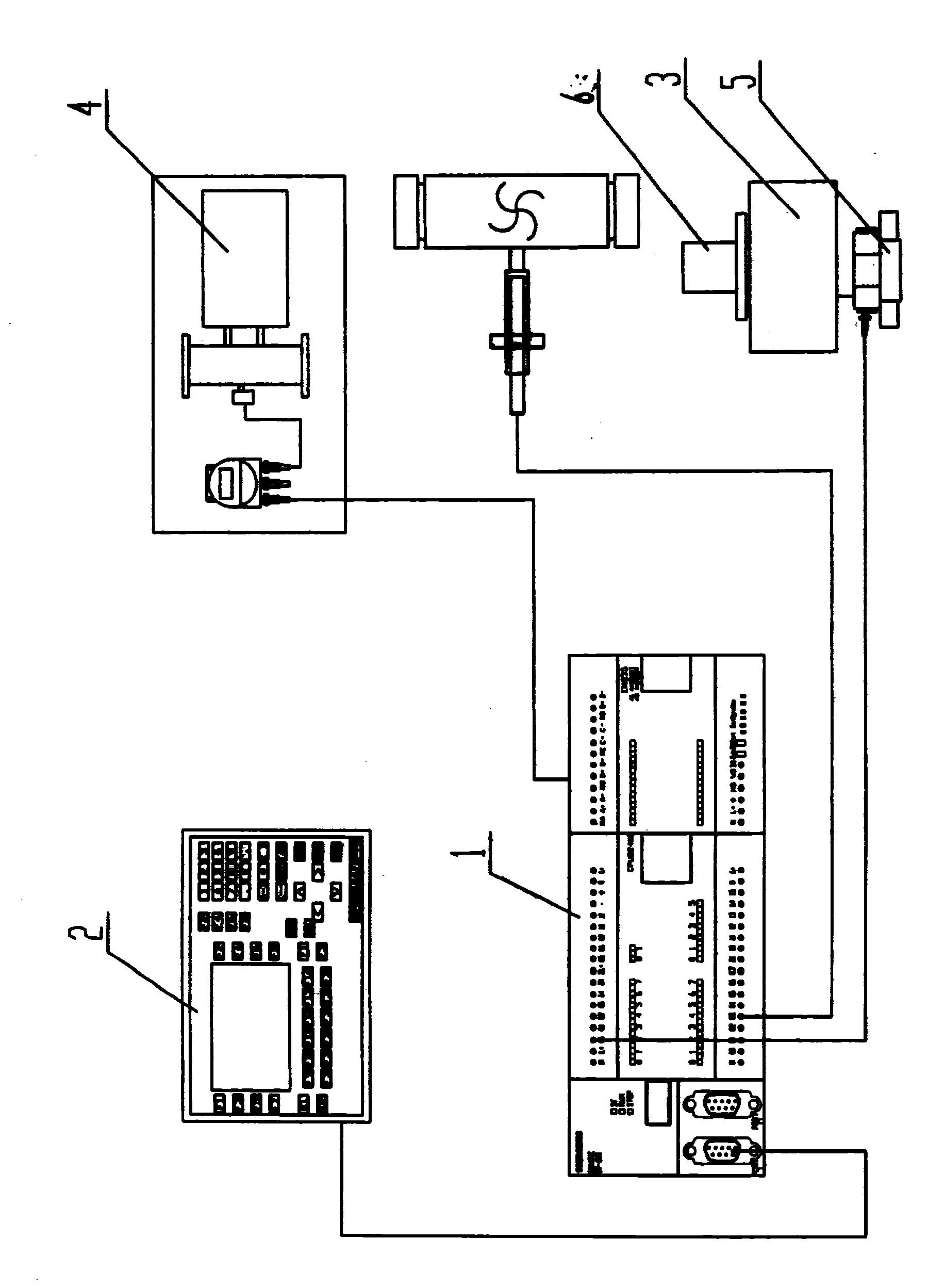

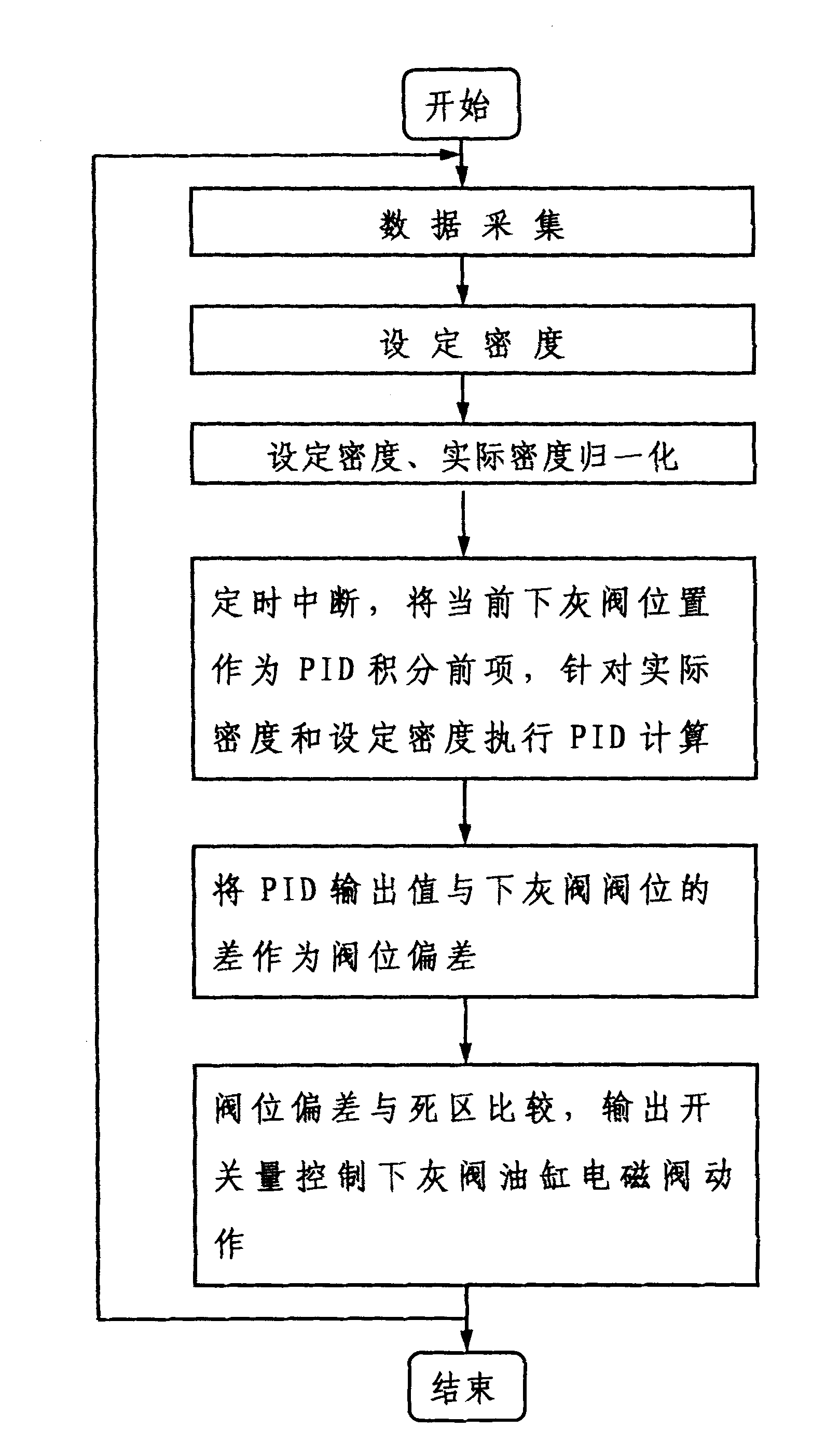

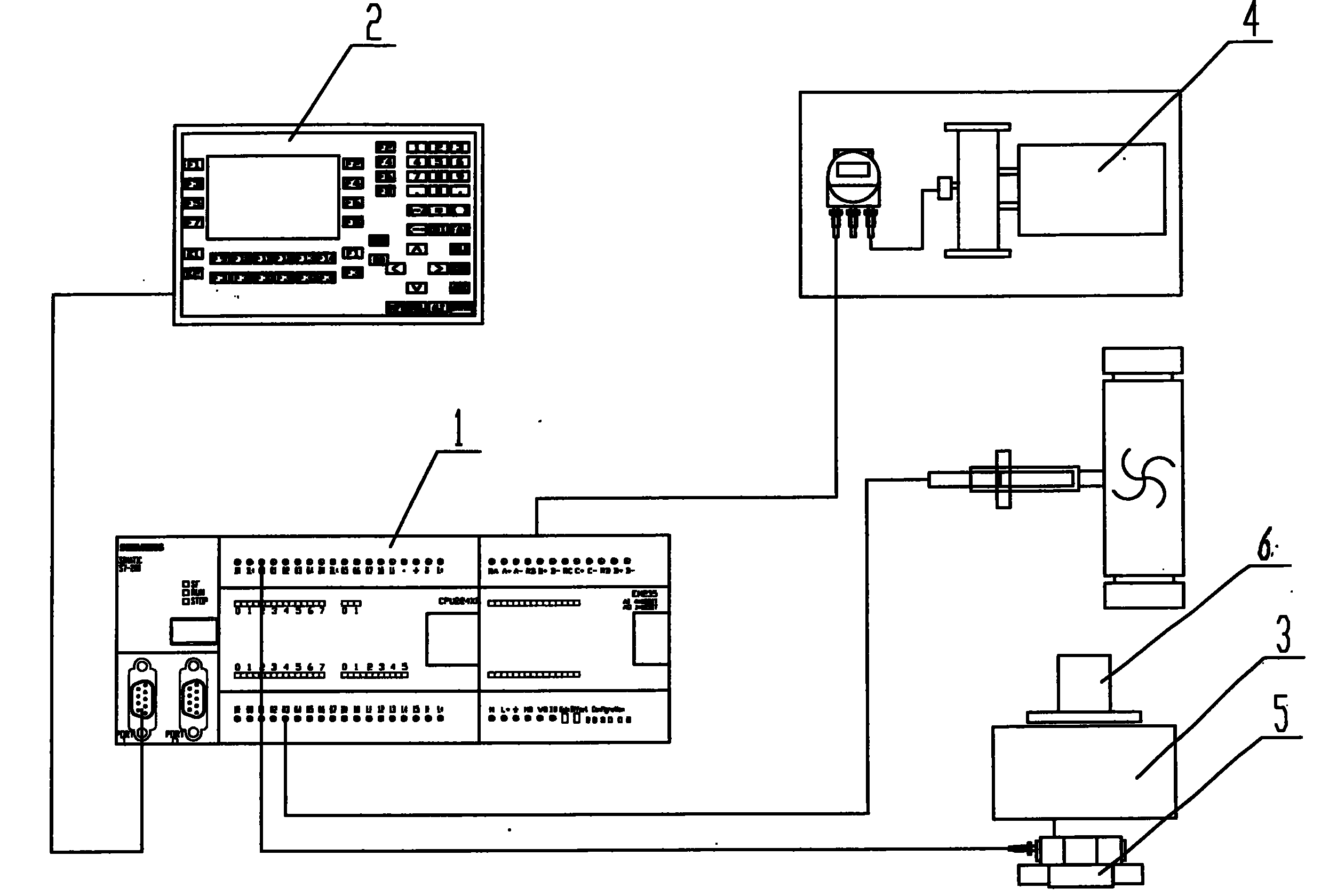

System and control method for automatically compounding cement paste

ActiveCN101323151AControl warp densityAutomatic and timely and accurate adjustmentControl apparatusAutomatic controlHuman–machine interface

The invention discloses an automatic grout mixing system and the control method thereof. The invention is characterized in that the system comprises a micro processor (1); the micro processor (1) is connected with a man-machine interface (2), a hydro cylinder magnetic valve for dust-discharging valve (5) and a densitometer (4) respectively over a wire. The hydro cylinder magnetic valve for dust-discharging valve (5) is connected with the dust-discharging valve (3). An angular displacement sensor for dust-discharging valve (6) is arranged on the dust-discharging valve (3). The density of the grout can be controlled in the following procedures of collecting data, setting density, normalizing set density and actual density, interrupting the timing, adopting the current valve location of the dust-discharging valve as the antecedent of PID integrate, calculating the PID based on the result of the normalization of the set and actual density; adopting the difference between PID output value and the valve location of the dust-discharging valve as valve location deviation, comparing the valve location deviation with a dead area and the action of flow control over the hydro cylinder magnetic valve of the dust-discharging valve performed by an output switch. Therefore, the density of the grout can be accurately controlled. The automatic grout mixing system is easy to operate and can automatically control the dynamic density.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH

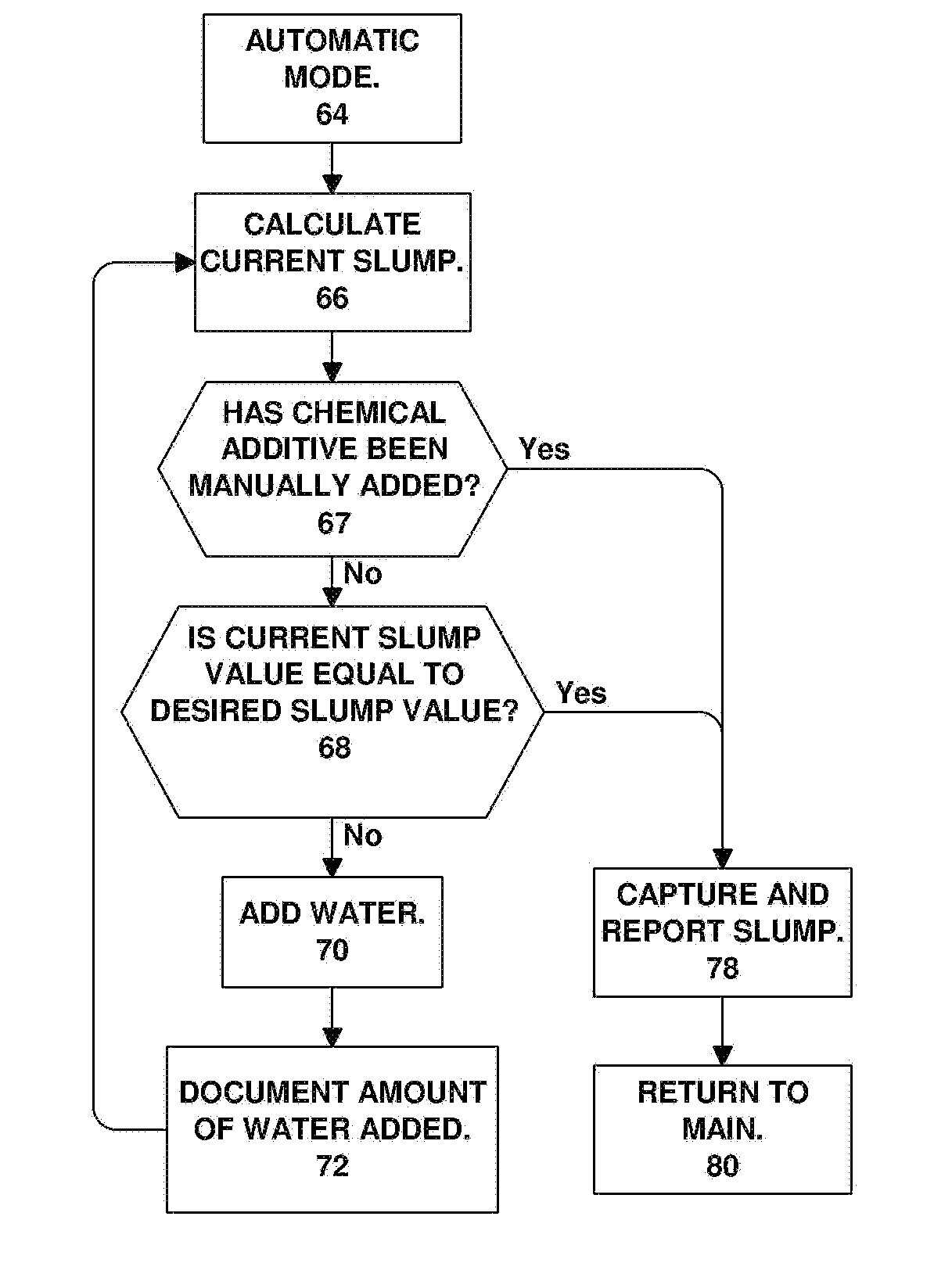

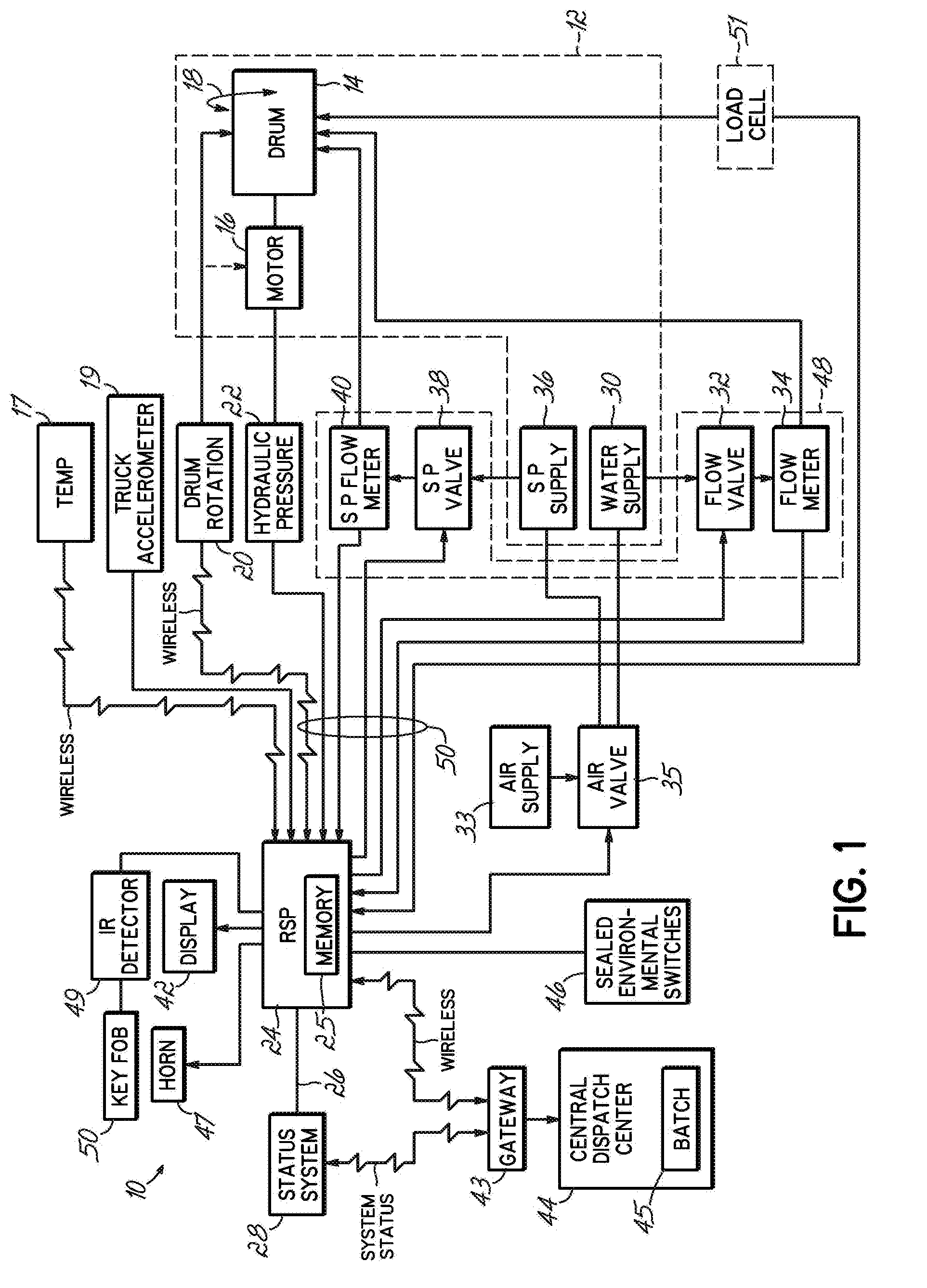

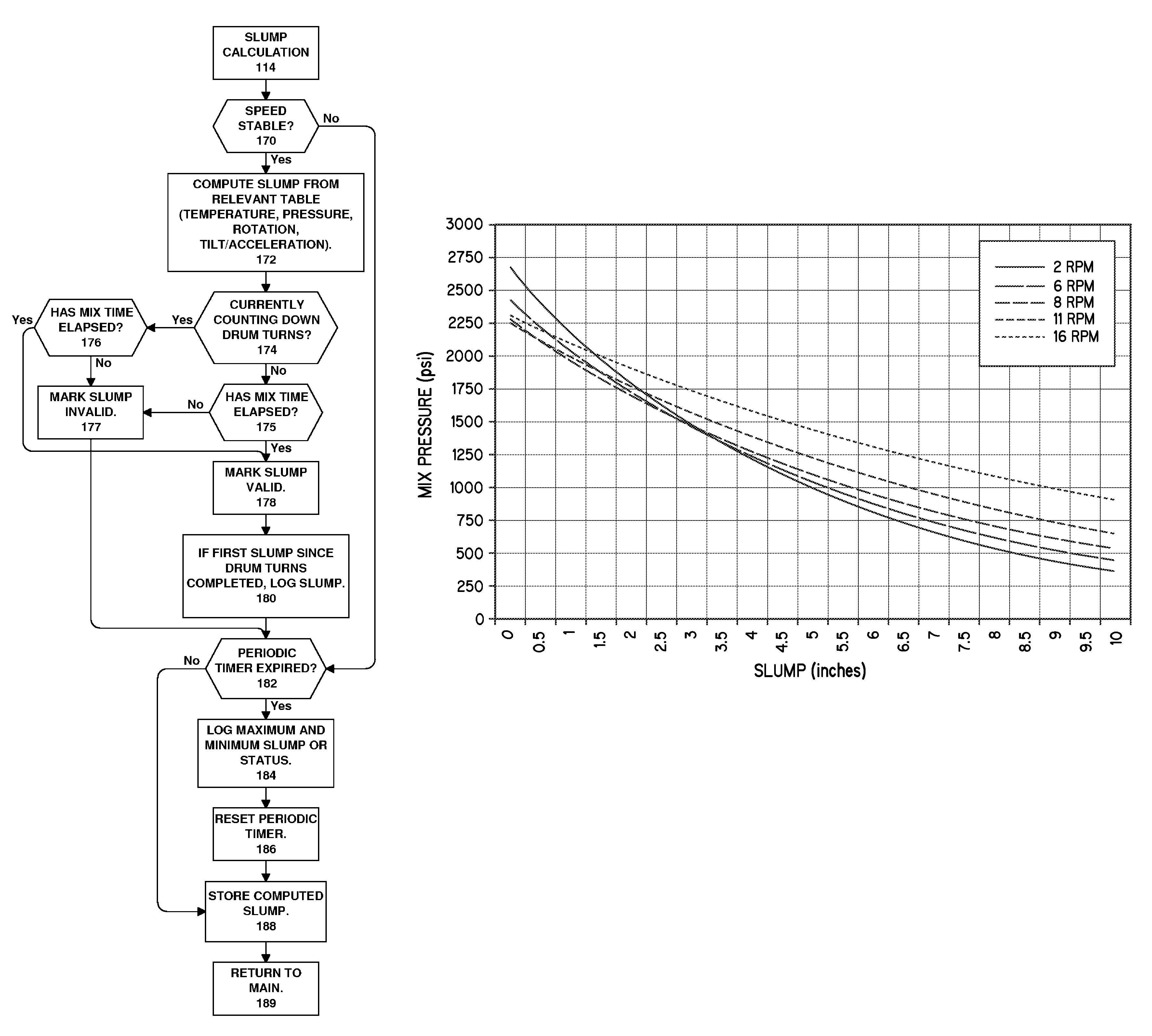

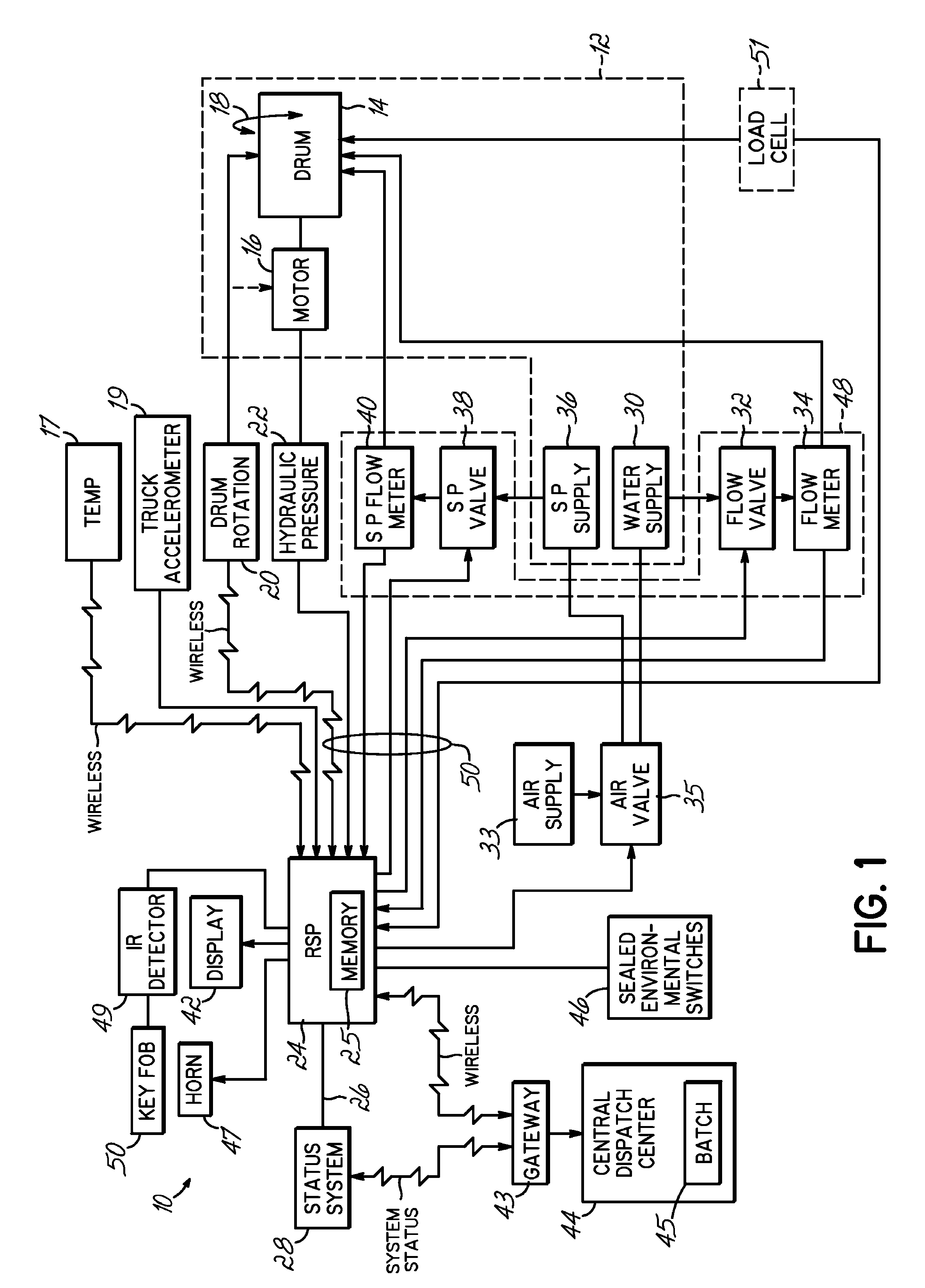

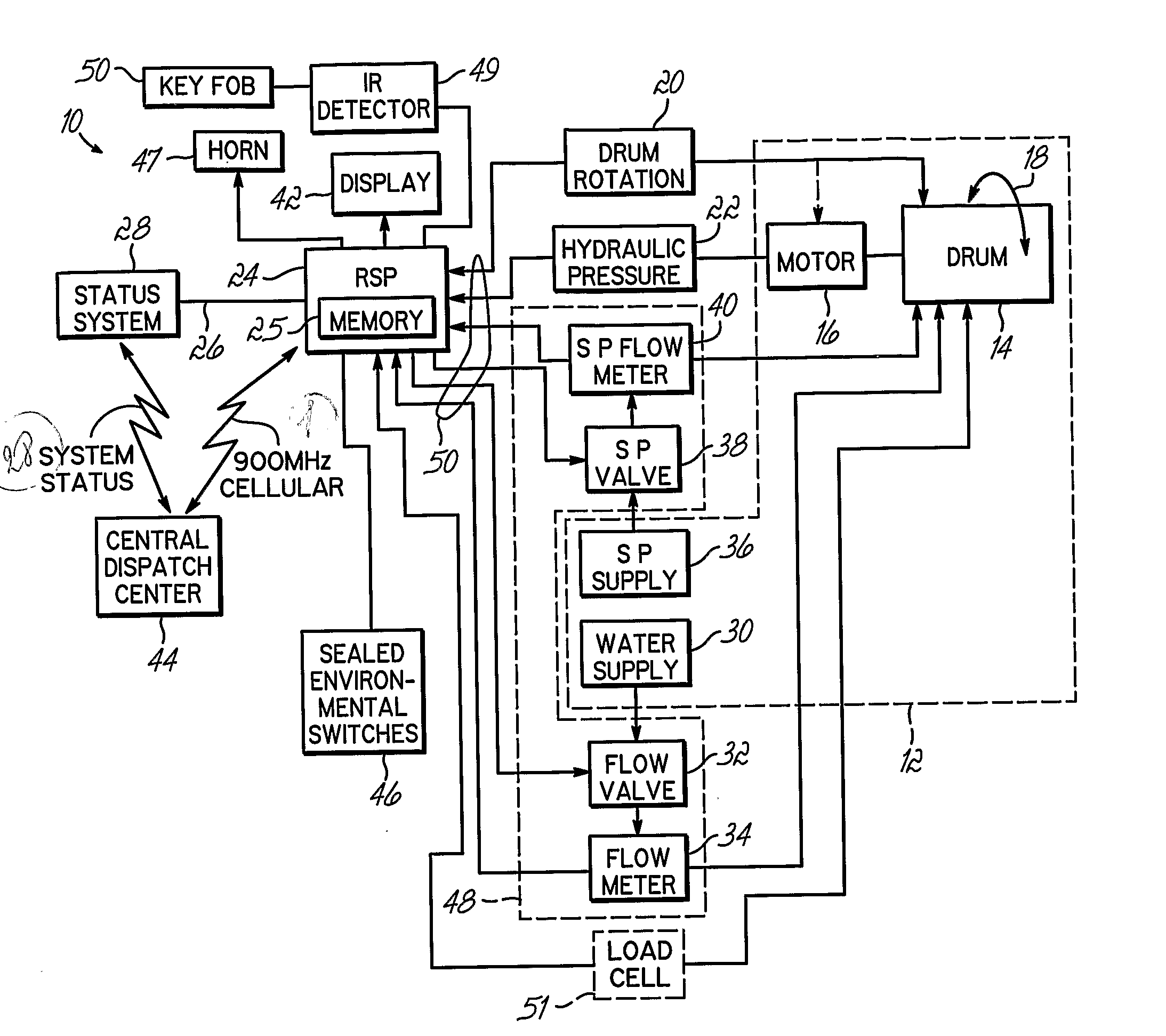

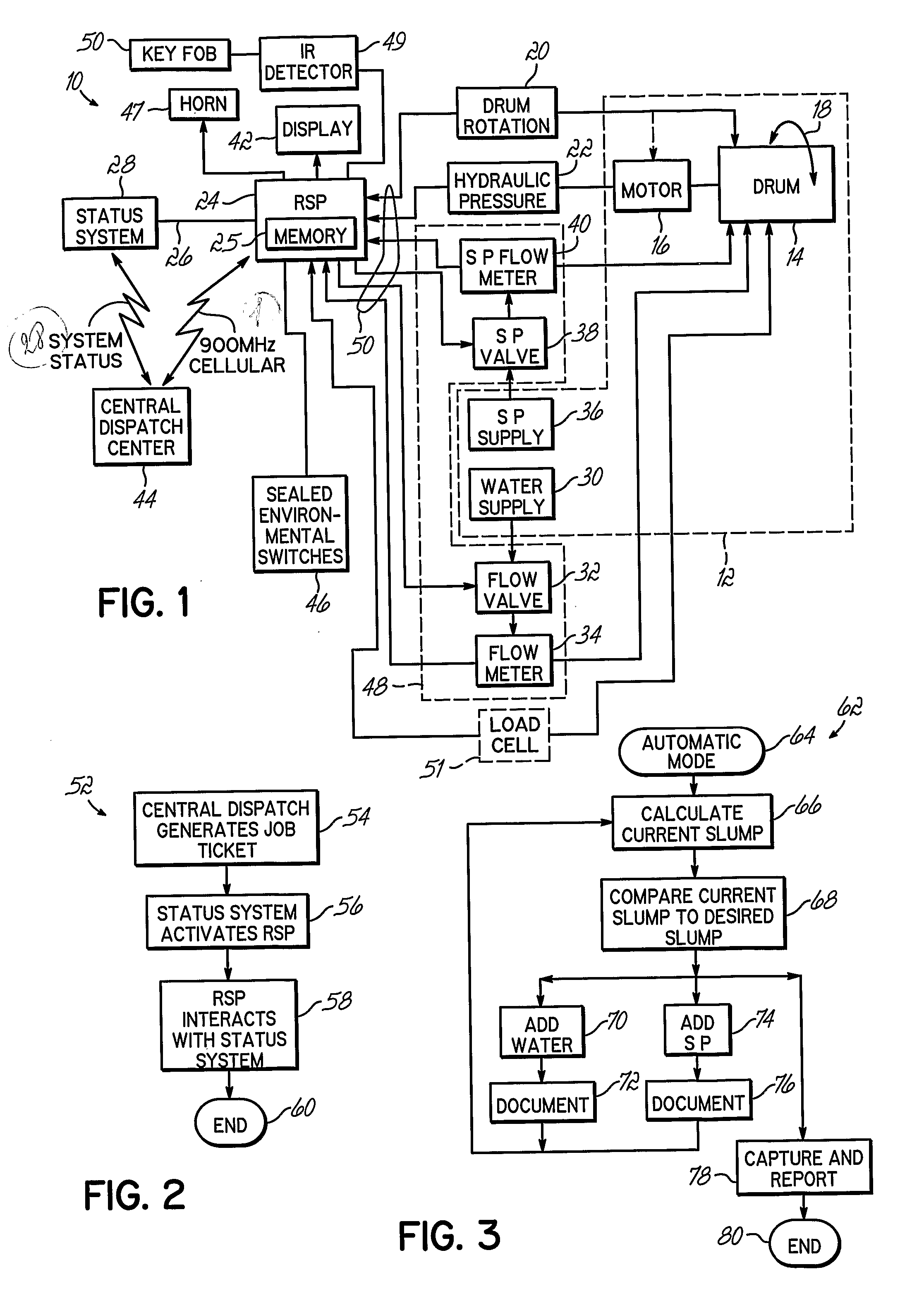

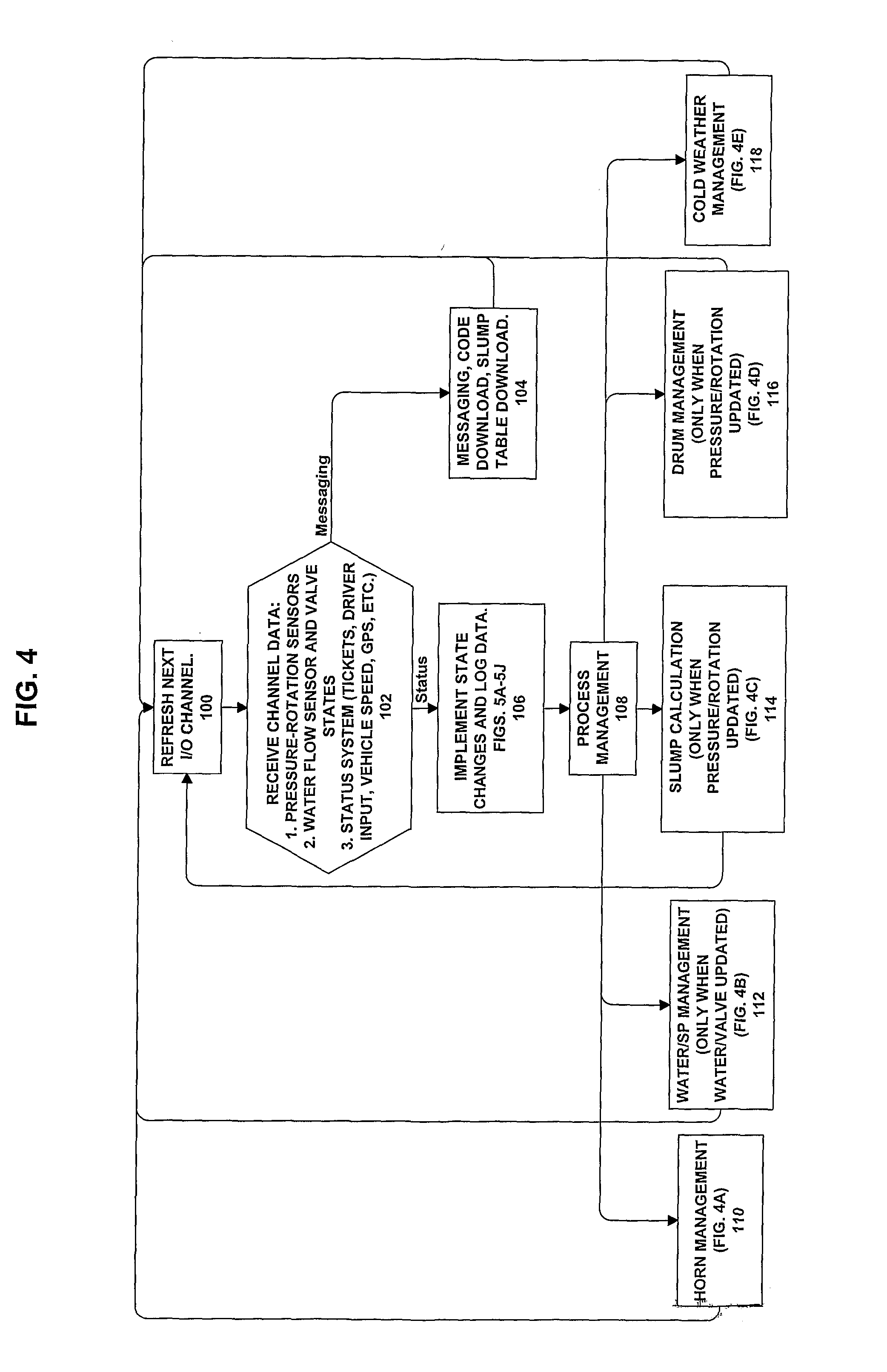

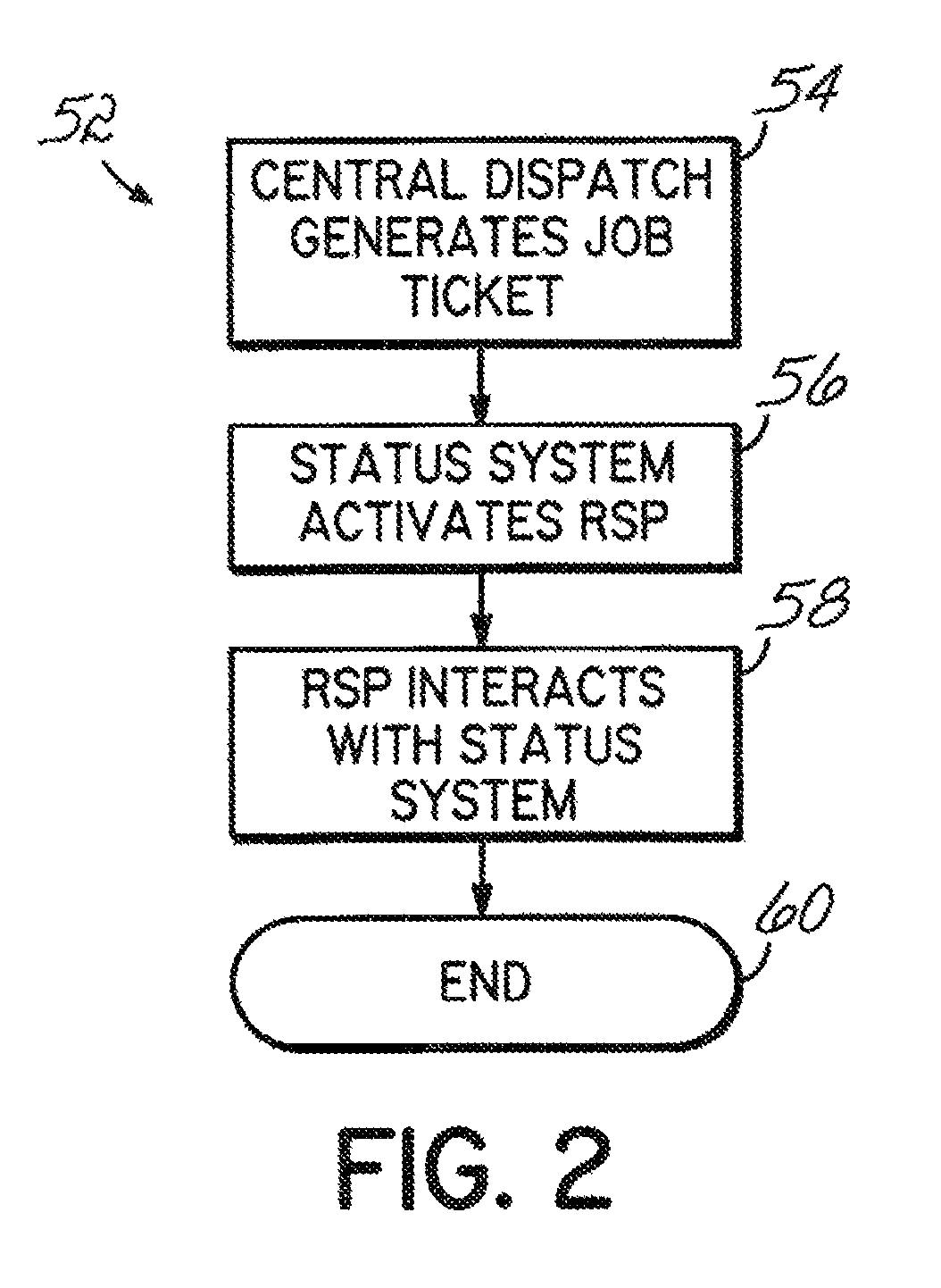

Method and System for Calculating and Reporting Slump in Delivery Vehicles

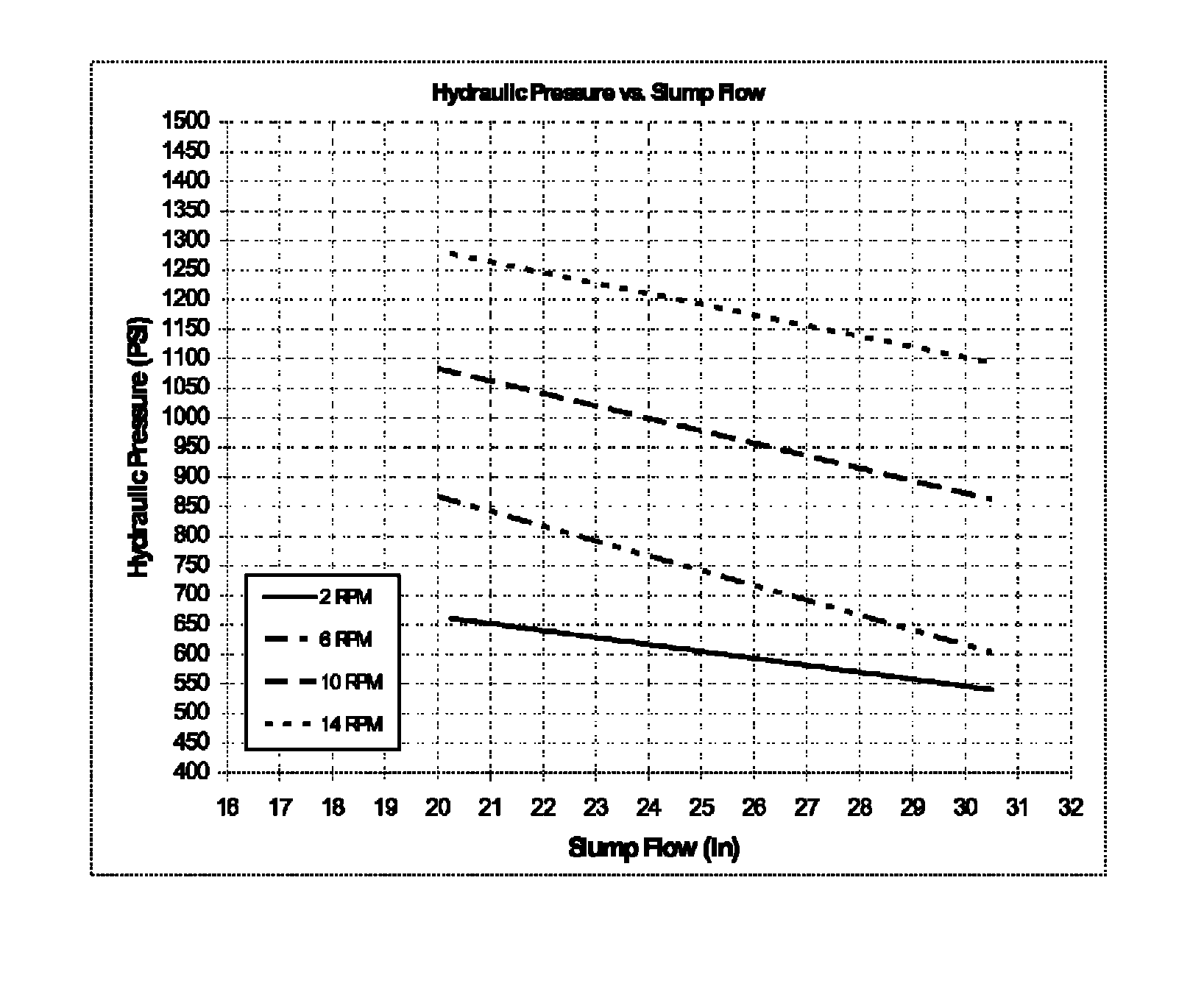

ActiveUS20090037026A1Easy to useThermometer detailsSampled-variable control systemsDelivery vehicleCold weather

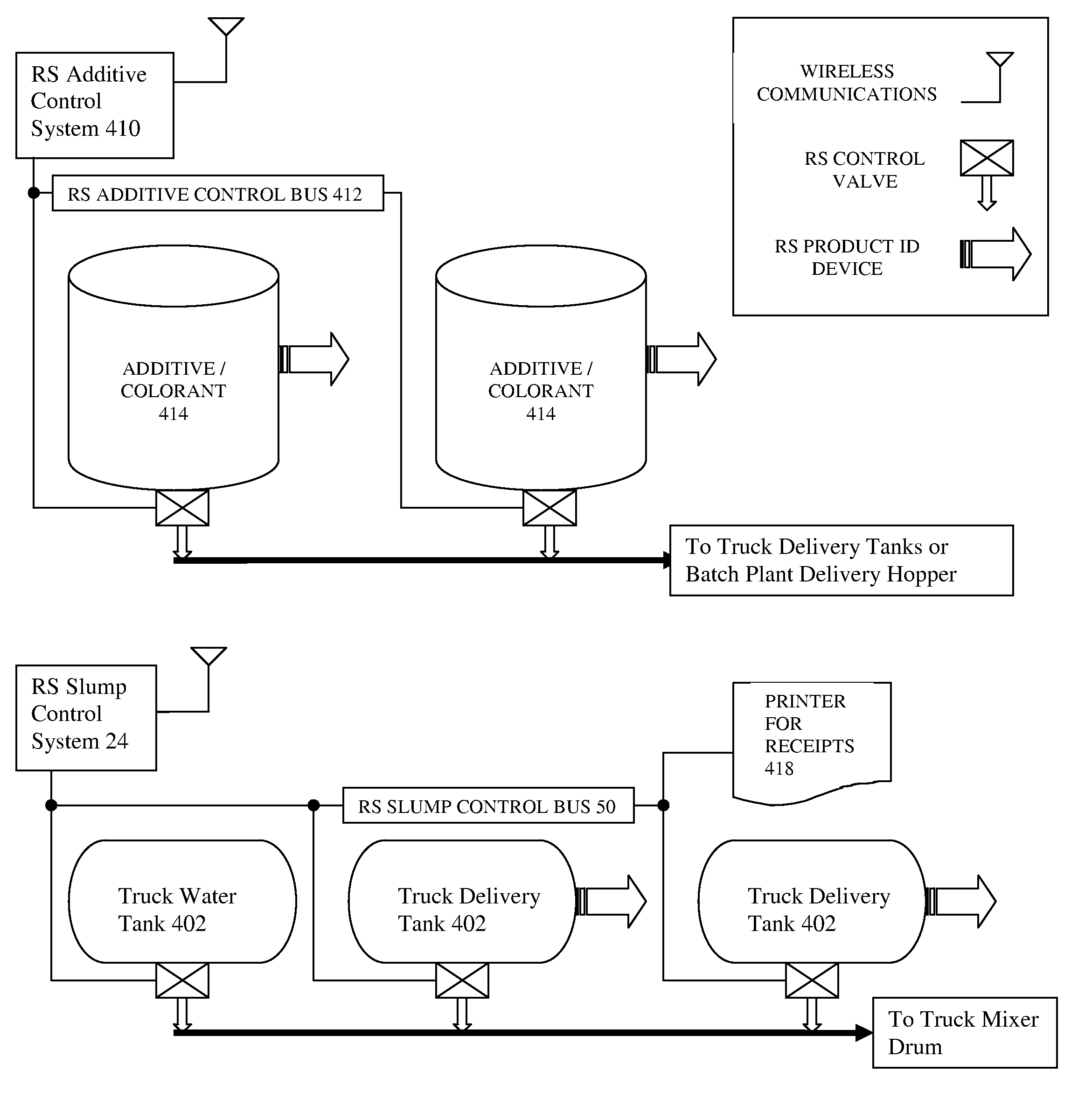

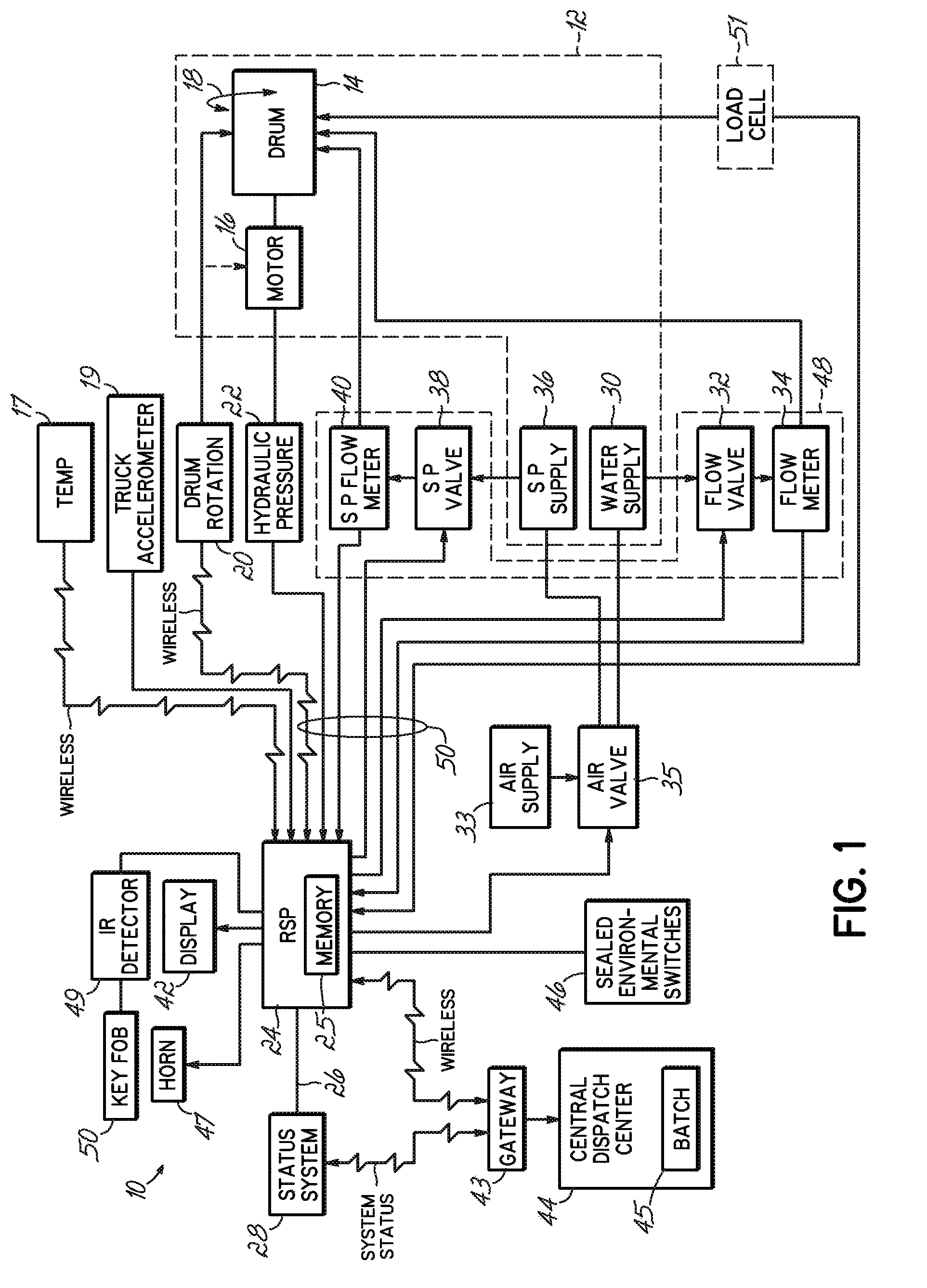

A system for managing a concrete delivery vehicle having a mixing drum 14 and hydraulic drive 16 for rotating the mixing drum, including a rotational sensor 20 configured to sense a rotational speed of the mixing drum, a hydraulic sensor 22 coupled to the hydraulic drive and configured to sense a hydraulic pressure required to turn the mixing drum, a temperature sensor for sensing temperature of the drum, and a communications port 26 configured to communicate a slump calculation to a status system 28 commonly used in the concrete industry, wherein the sensing of the rotational speed of the mixing drum is used to qualify a calculation of current slump based on the hydraulic pressure required to turn the mixing drum. Temperature readings are further used to qualify or evaluate a load. Also, water purge connections facilitate cold weather operation.

Owner:VERIFI

Method and system for calculating and reporting slump in delivery vehicles

A system for managing a concrete delivery vehicle having a mixing drum 14 and hydraulic drive 16 for rotating the mixing drum, including a rotational sensor 20 configured to sense a rotational speed of the mixing drum, a hydraulic sensor 22 coupled to the hydraulic drive and configured to sense a hydraulic pressure required to turn the mixing drum, a temperature sensor for sensing temperature of the drum, and a communications port 26 configured to communicate a slump calculation to a status system 28 commonly used in the concrete industry, wherein the sensing of the rotational speed of the mixing drum is used to qualify a calculation of current slump based on the hydraulic pressure required to turn the mixing drum. Temperature readings are further used to qualify or evaluate a load. Also, water purge connections facilitate cold weather operation.

Owner:VERIFI INC

Monolithic honeycomb structure made of porous ceramic and use as a particle filter

InactiveUS6582796B1Prevent the evaporation of the waterEasy curingInternal combustion piston enginesSilencing apparatusSodium BentoniteOxygen

A monolithic honeycomb-type structure useful in particular as a particle filter for exhaust gases from diesel engines has a number of passages that empty into the end faces of said monolith, but are alternately open and sealed. The monolith consists of a porous refractory material that comprises: 70 to 97% by mass of alpha and / or beta crystallographic-type silicon carbide that has at least one particle size and preferably at least two particle sizes, and 3 to 30% by mass of at least one bonding ceramic phase in the form of a micronic powder or particles that are obtained by atomization, comprising at least one simple oxide, for example, B2O3, Al2O3, SiO2, MgO, K2O, Li2O, Na2O, CaO, BaO, TiO, ZrO2 and Fe2O3 and / or at least one mixed oxide, for example, the alkaline aluminosilicates (of Li, Na, or K) or alkaline-earth aluminosilicates (of Mg, Ca, Sr or Ba), clays, bentonite, feldspars or other natural silico-aluminous materials. The production of the monolith comprises a calcination stage under an oxygen-containing atmosphere at a temperature up to 1650° C., but less than 1550° C.

Owner:INST FR DU PETROLE

Method and system for calculating and reporting slump in delivery vehicles

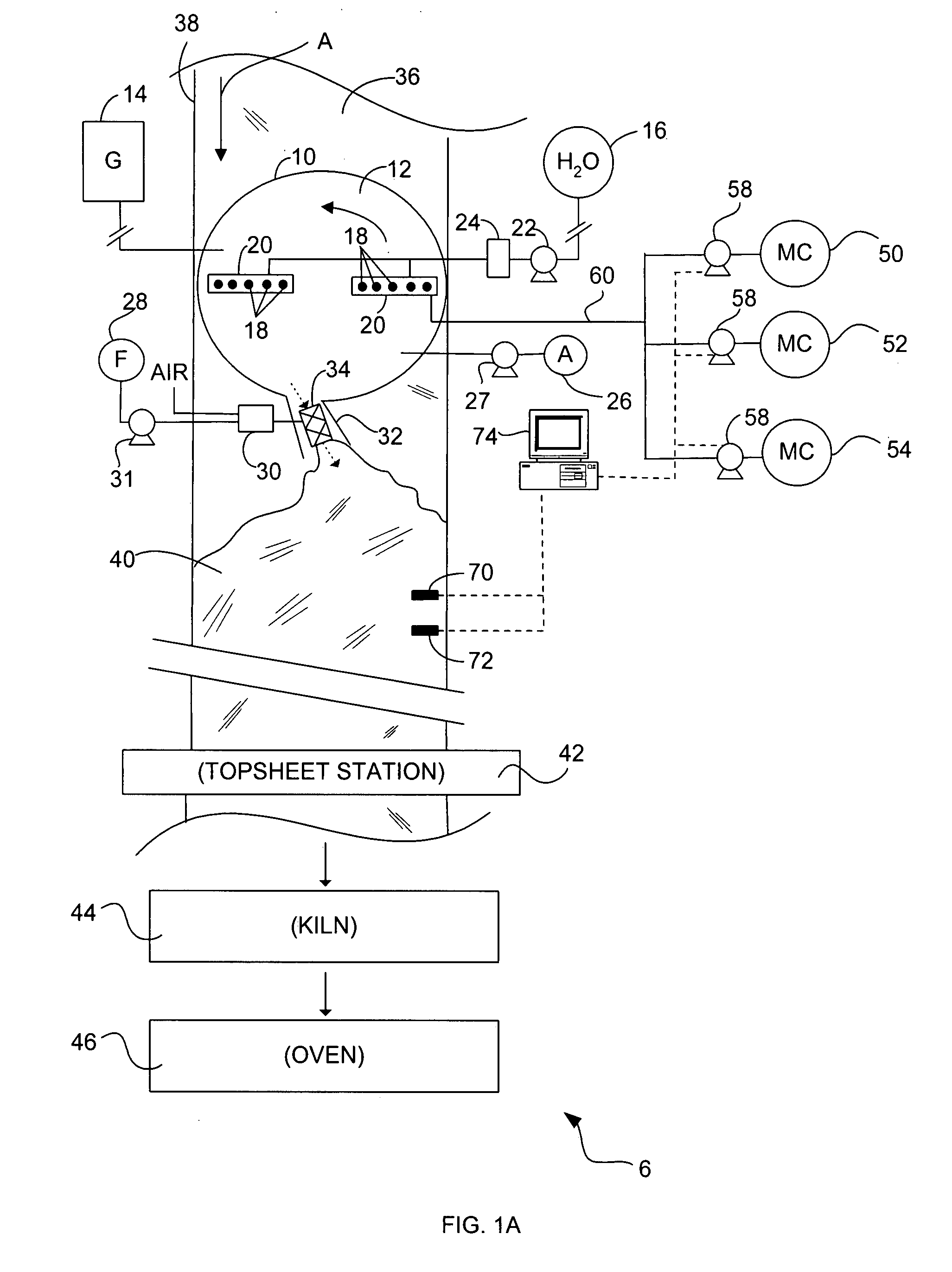

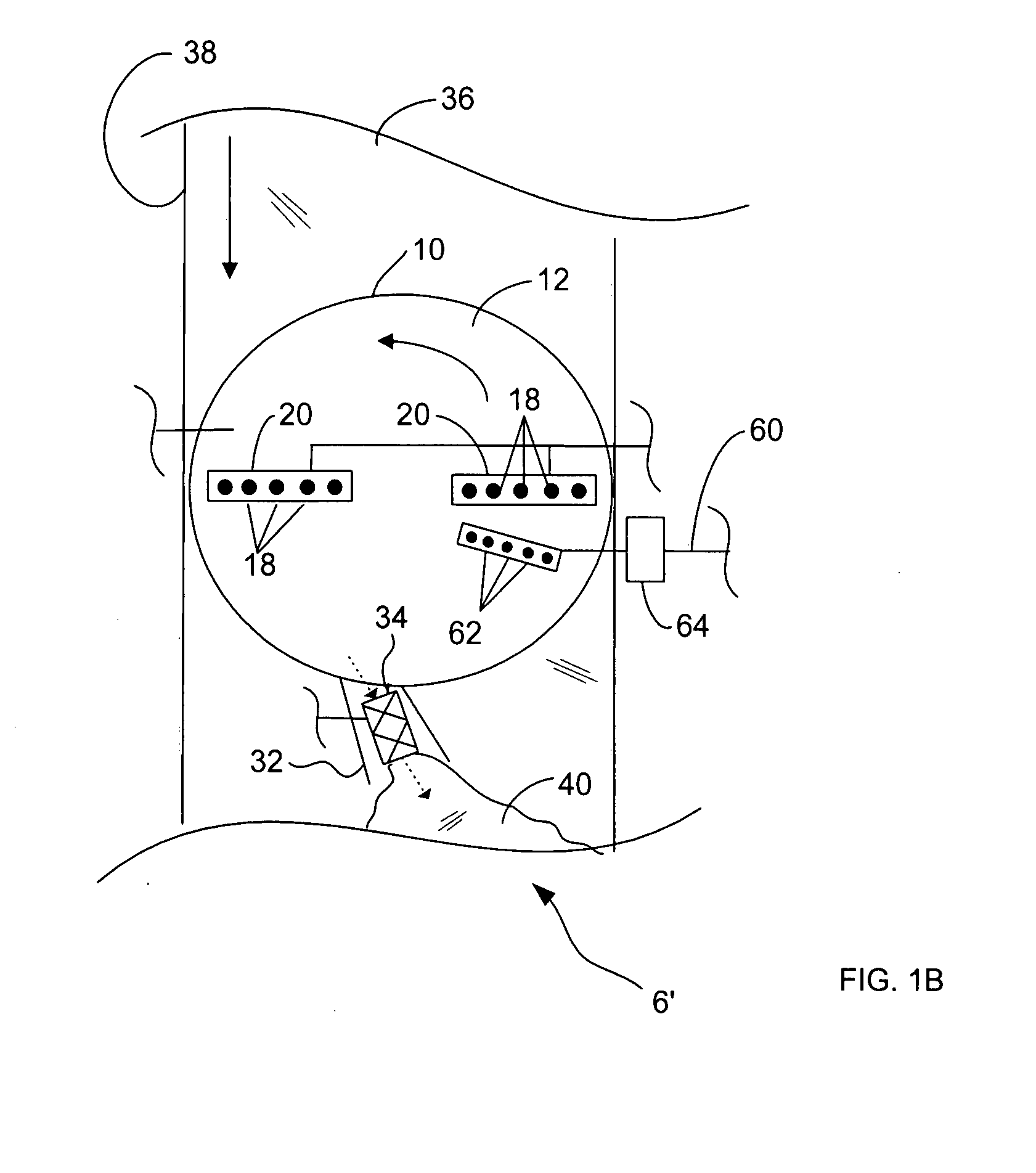

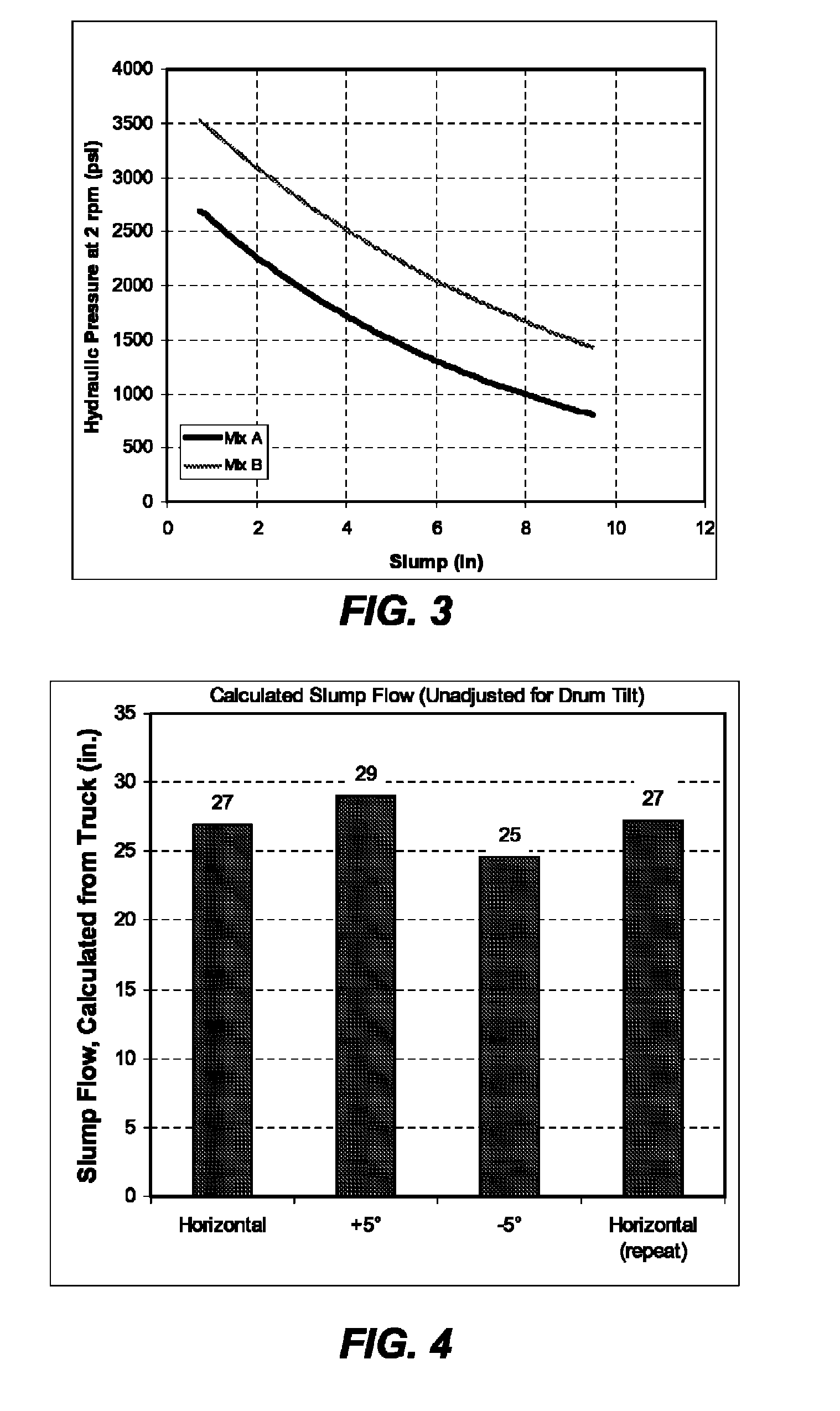

ActiveUS20070185636A1Amount be controlSampled-variable control systemsAnalogue computers for trafficDelivery vehicleControl theory

A system for calculating and reporting slump in a delivery vehicle having a mixing drum (14) and hydraulic drive (16) for rotating the mixing drum, including a rotational sensor (20) configured to sense a rotational speed of the mixing drum, a hydraulic sensor (22) coupled to the hydraulic drive and configured to sense a hydraulic pressure required to turn the mixing drum, and a communications port (26) configured to communicate a slump calculation to a status system (28) commonly used in the concrete industry, wherein the sensing of the rotational speed of the mixing drum is used to qualify a calculation of current slump based on the hydraulic pressure required to turn the mixing drum.

Owner:VERIFI

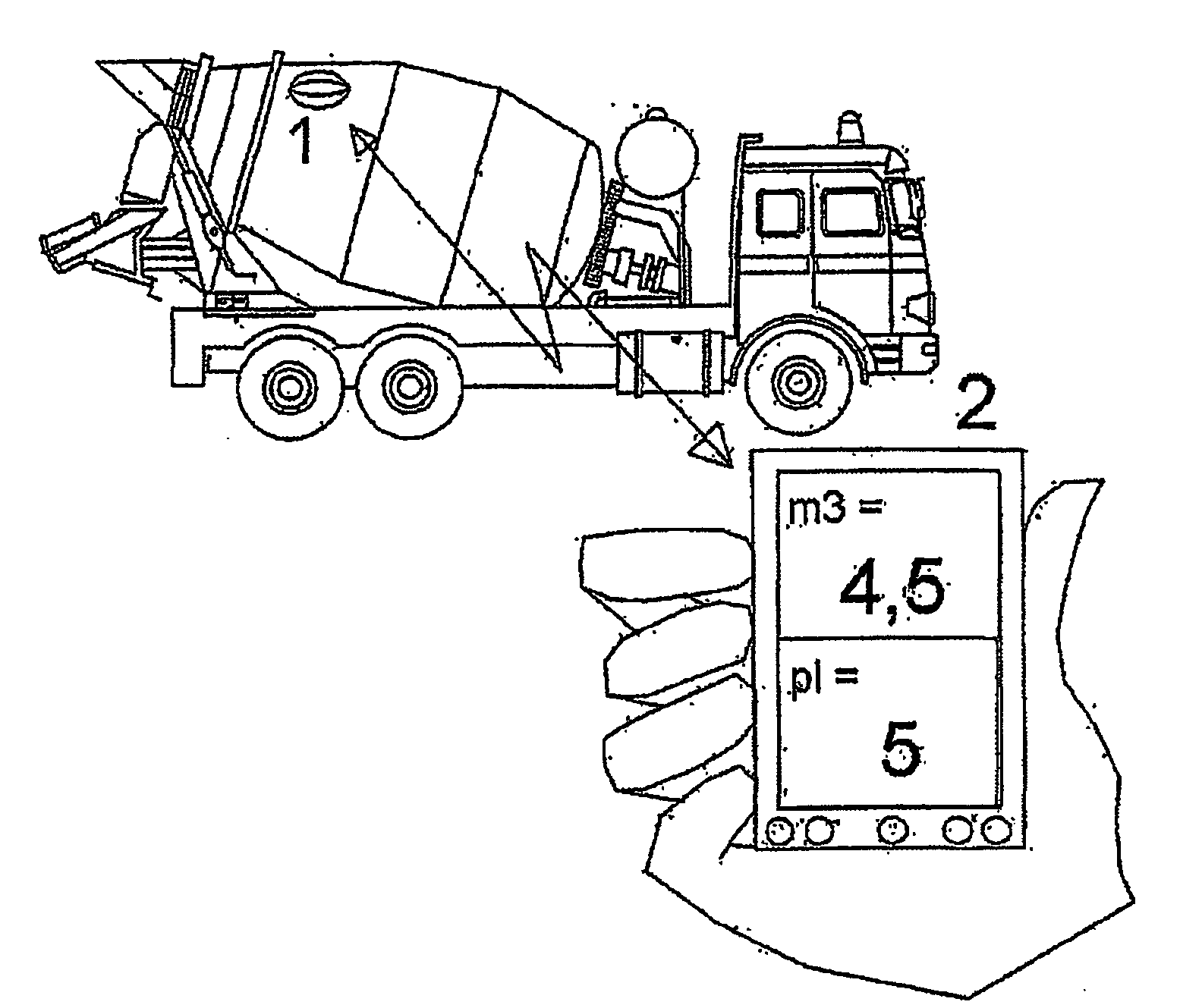

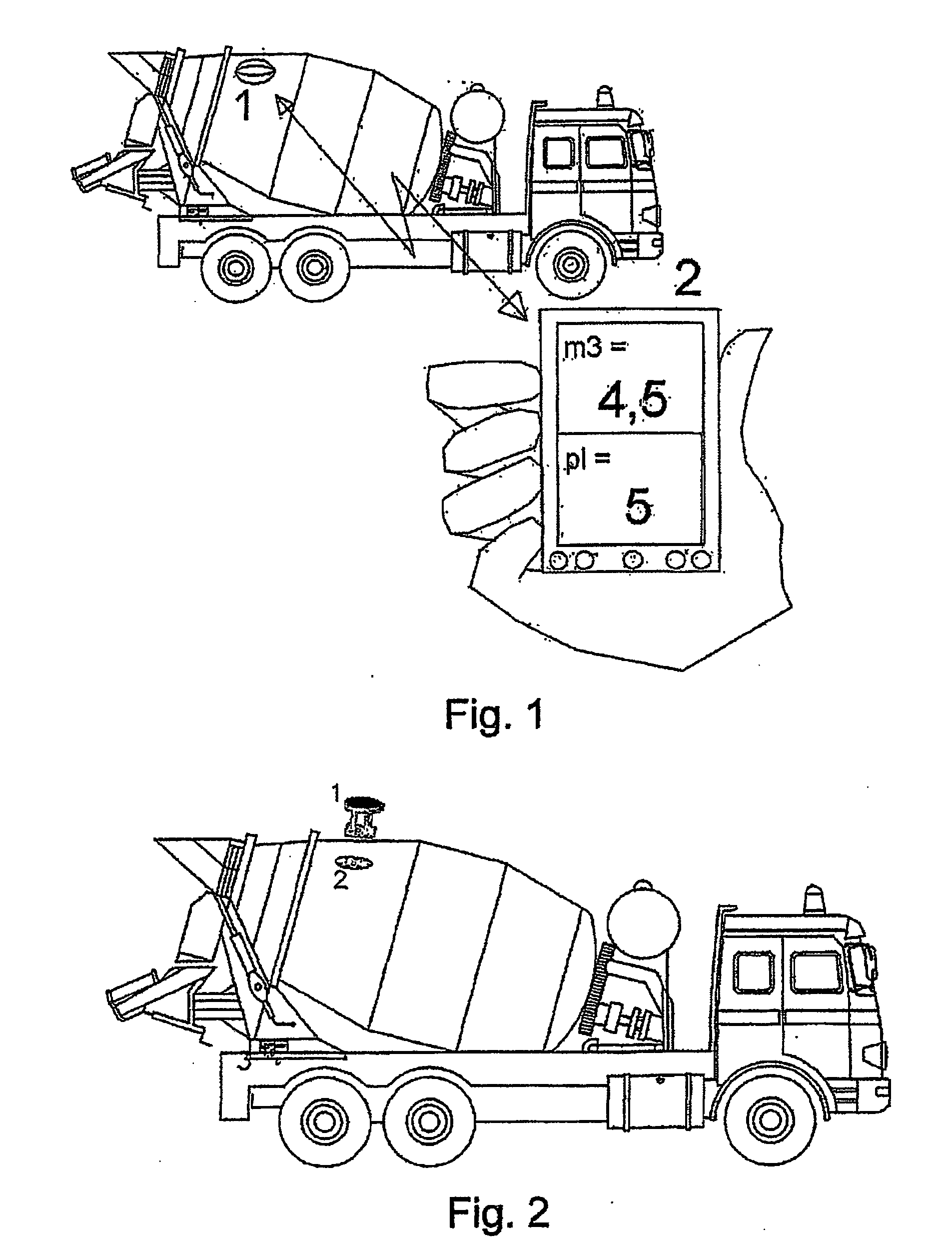

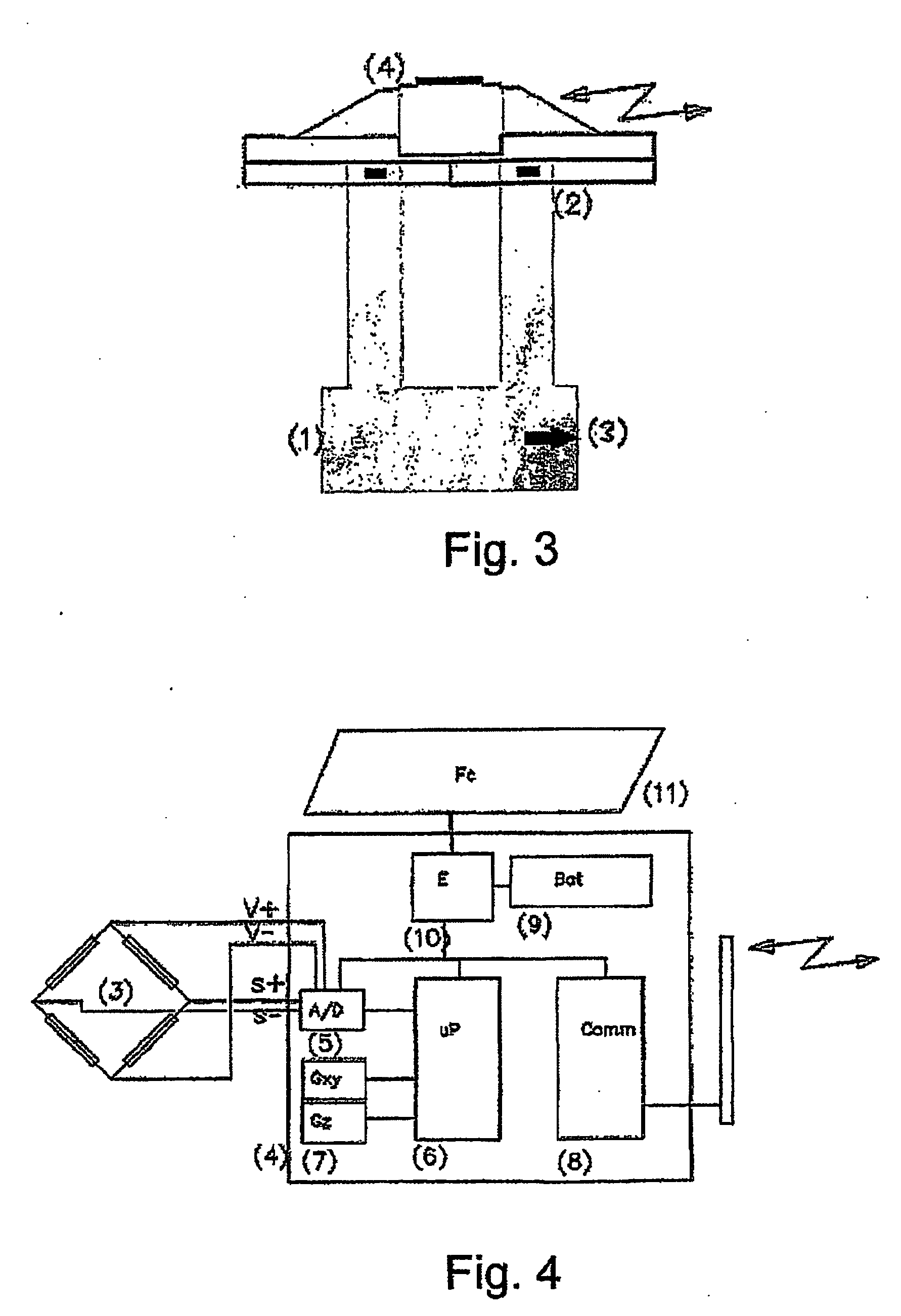

Automatic System for Monitoring the Mixing of Conglomerates

ActiveUS20090171595A1Force measurementAcceleration measurementTelecommunications equipmentBLENDER/MIXER

The invention relates to an automatic system for monitoring the mixing of conglomerates. The inventive system can be used to monitor and measure the volume of a conglomerate, i.e. a concrete, mortar or other similar product, and the conditions in which the conglomerate is being mixed inside a mixer. The invention is characterised in that the system is provided with a sensor which rotates integrally with the mixer and which is fitted with a blade that is sensitive to the stresses exerted by the conglomerate thereon. The invention is also characterised in that the aforementioned information is transmitted to one or more terminals, by means of radio communication or other similar wireless communication means, for use in industrial processes.

Owner:OZAMIZ TAPIA ANTONIO +1

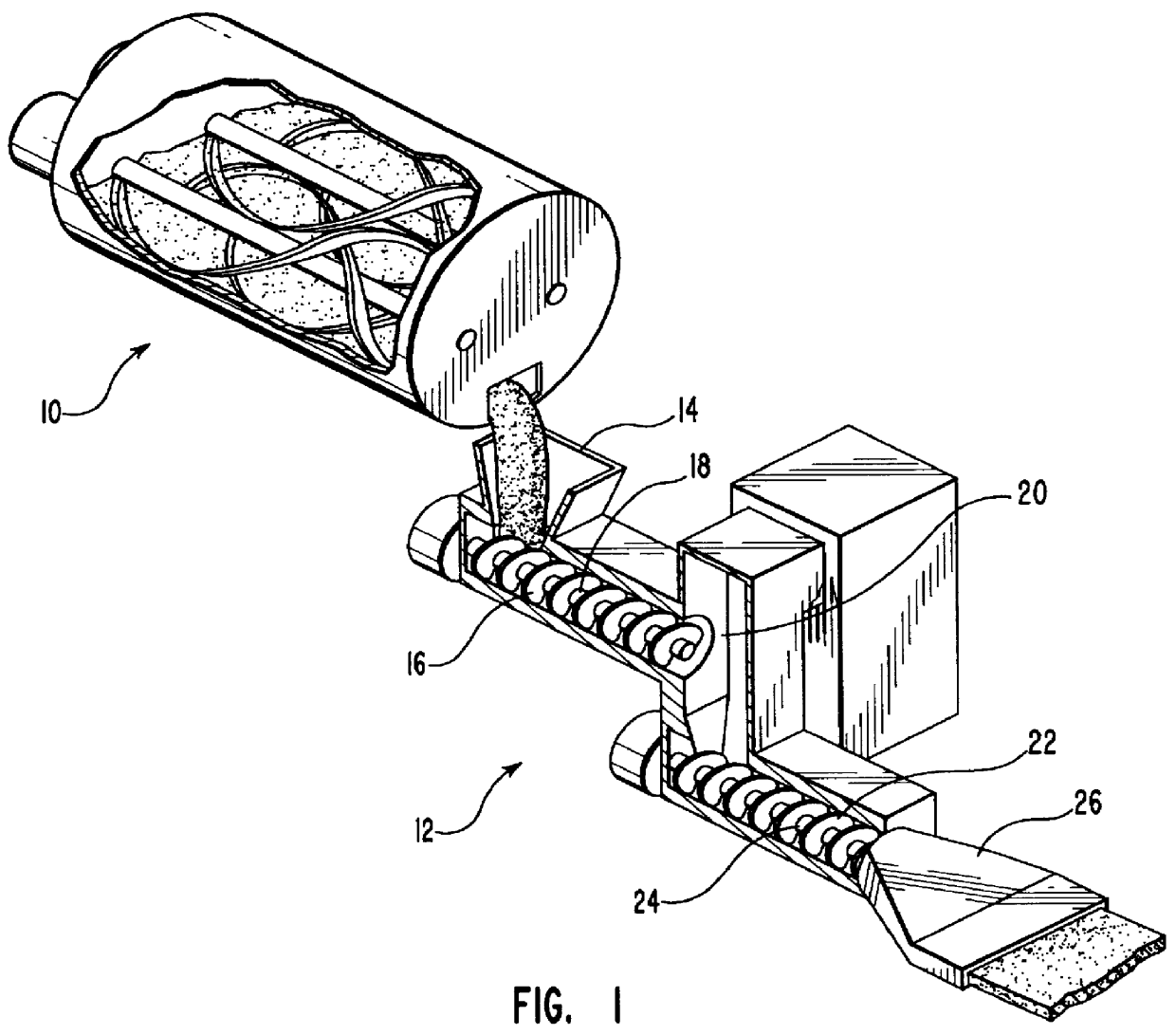

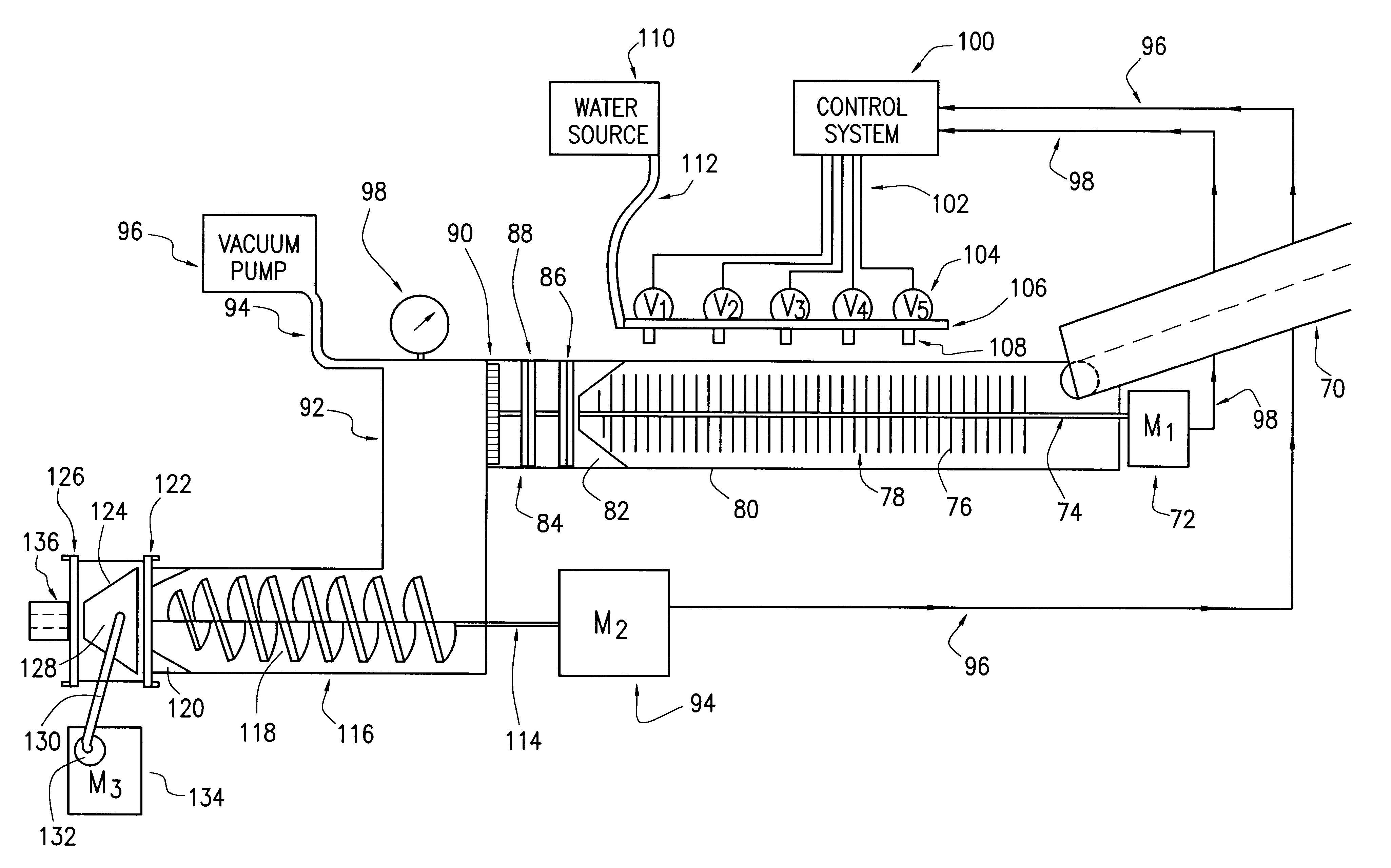

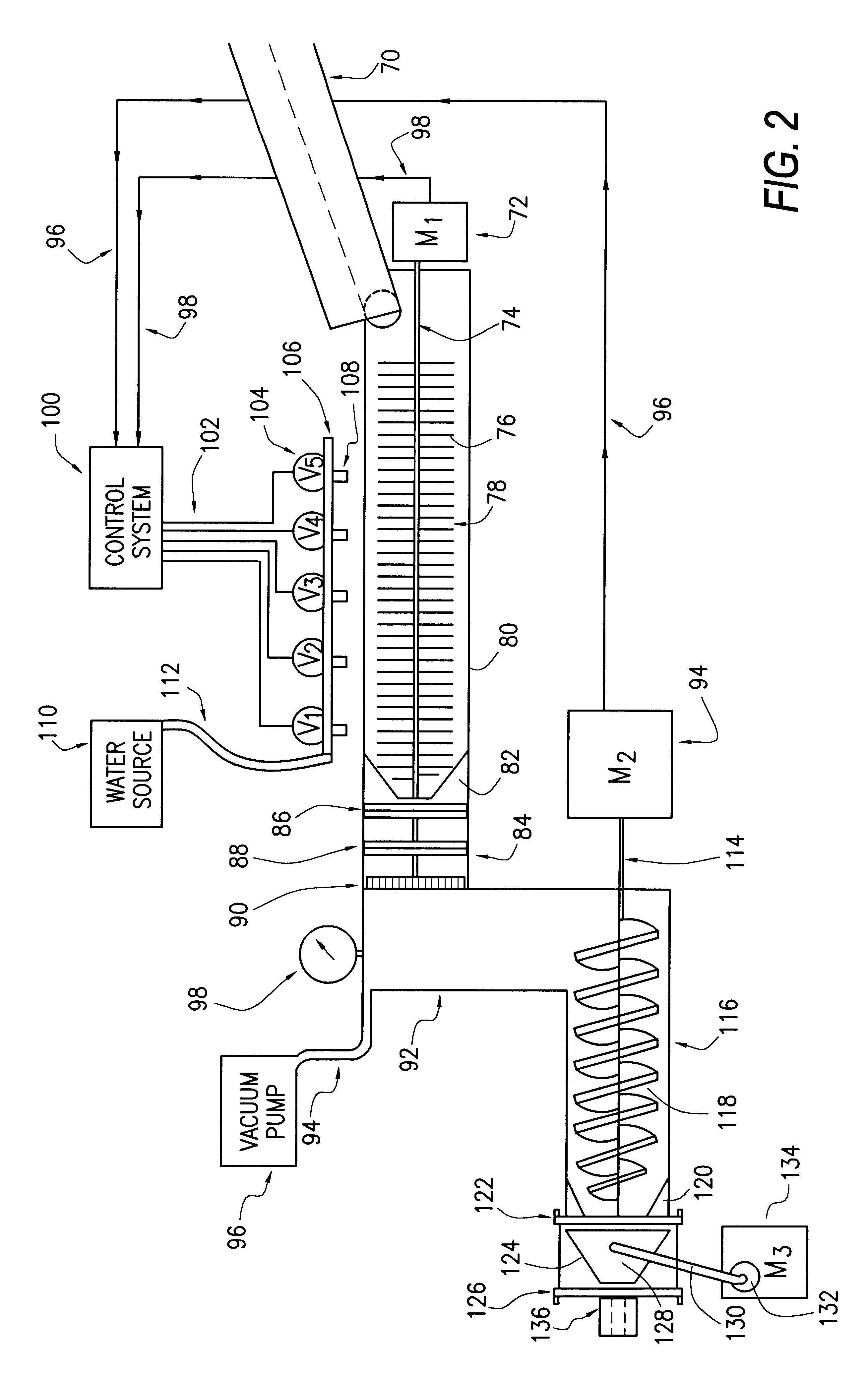

Vacuum extrusion system for production of cement-based articles

InactiveUS6309570B1Reduce frictionReduce the amount requiredFrozen sweetsConfectioneryMaterials scienceExcess water

A system for making extruded cement-based articles. The process can include forming a cement-based feed mixture including water, aggregate and binder and directing the feed mixture to a vacuum zone, wherein sufficient vacuum is maintained in the vacuum zone to remove entrained air and, preferably, excess water, from the feed mixture. The feed mixture is held in the vacuum zone at a negative pressure for a time sufficient to form a vacuum-treated or densified mixture. The vacuum-treated or densified mixture is passed through an extruder at an elevated pressure to provide an extruded cement-based article.

Owner:BLEECKER LEE M

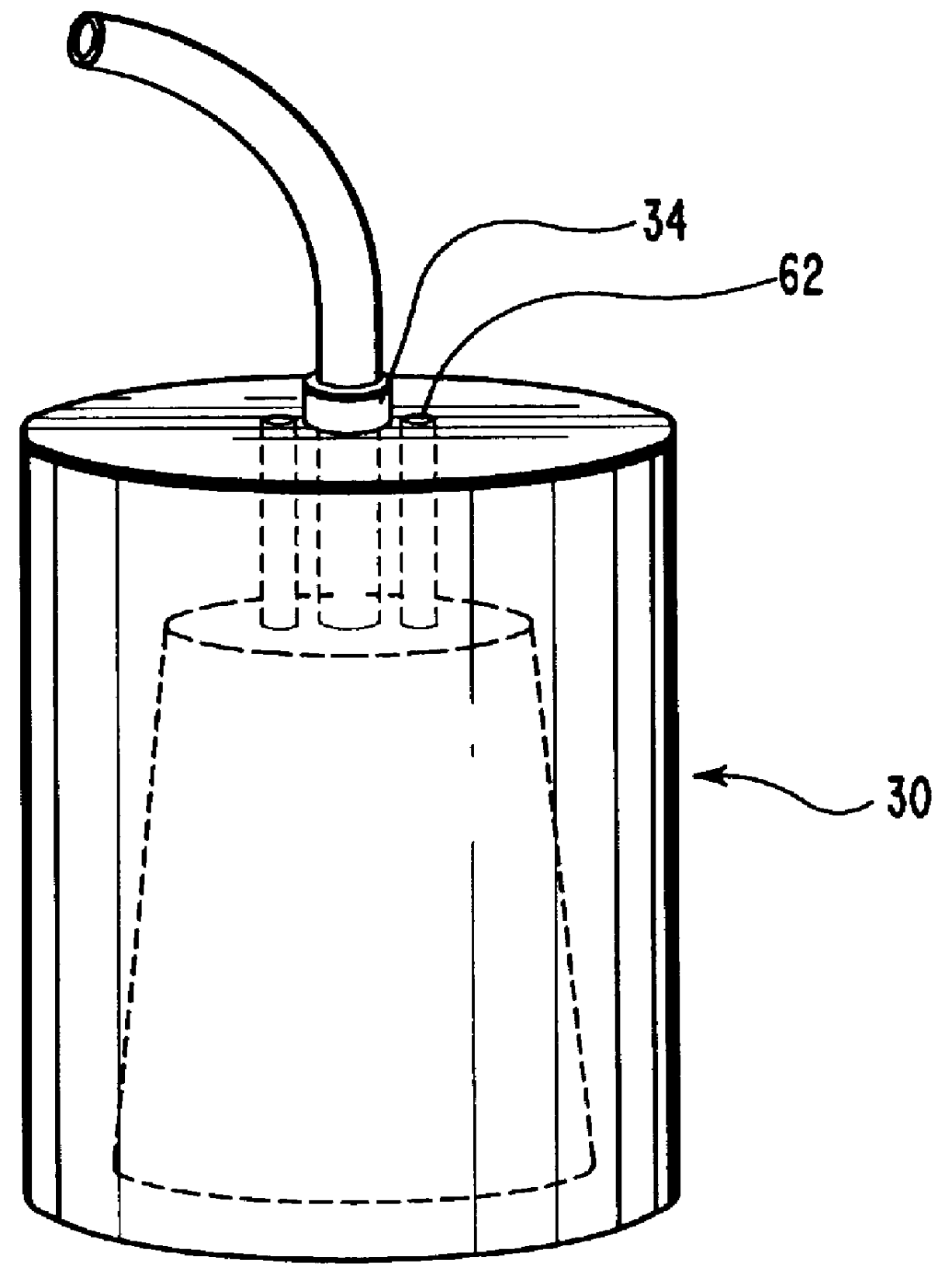

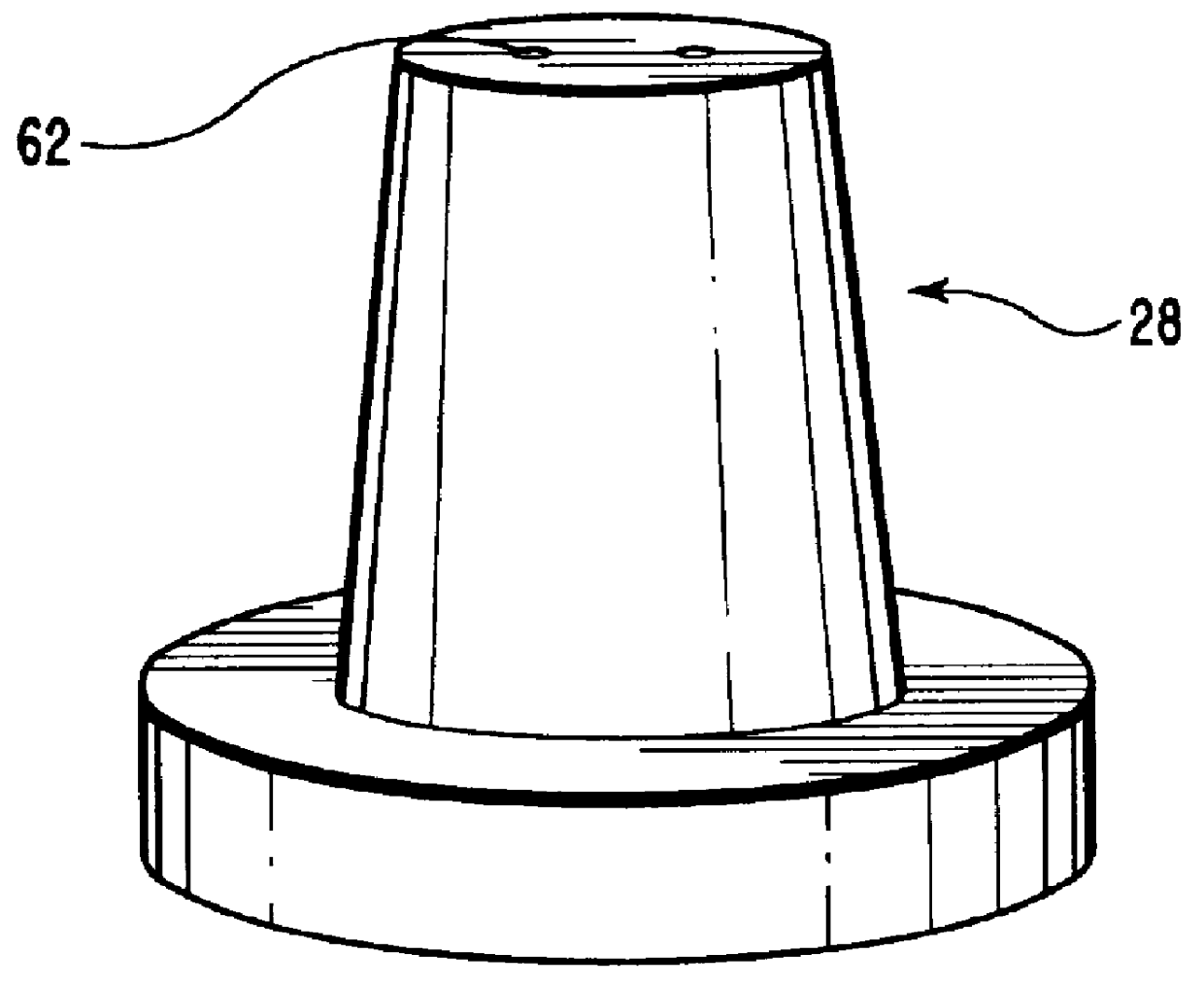

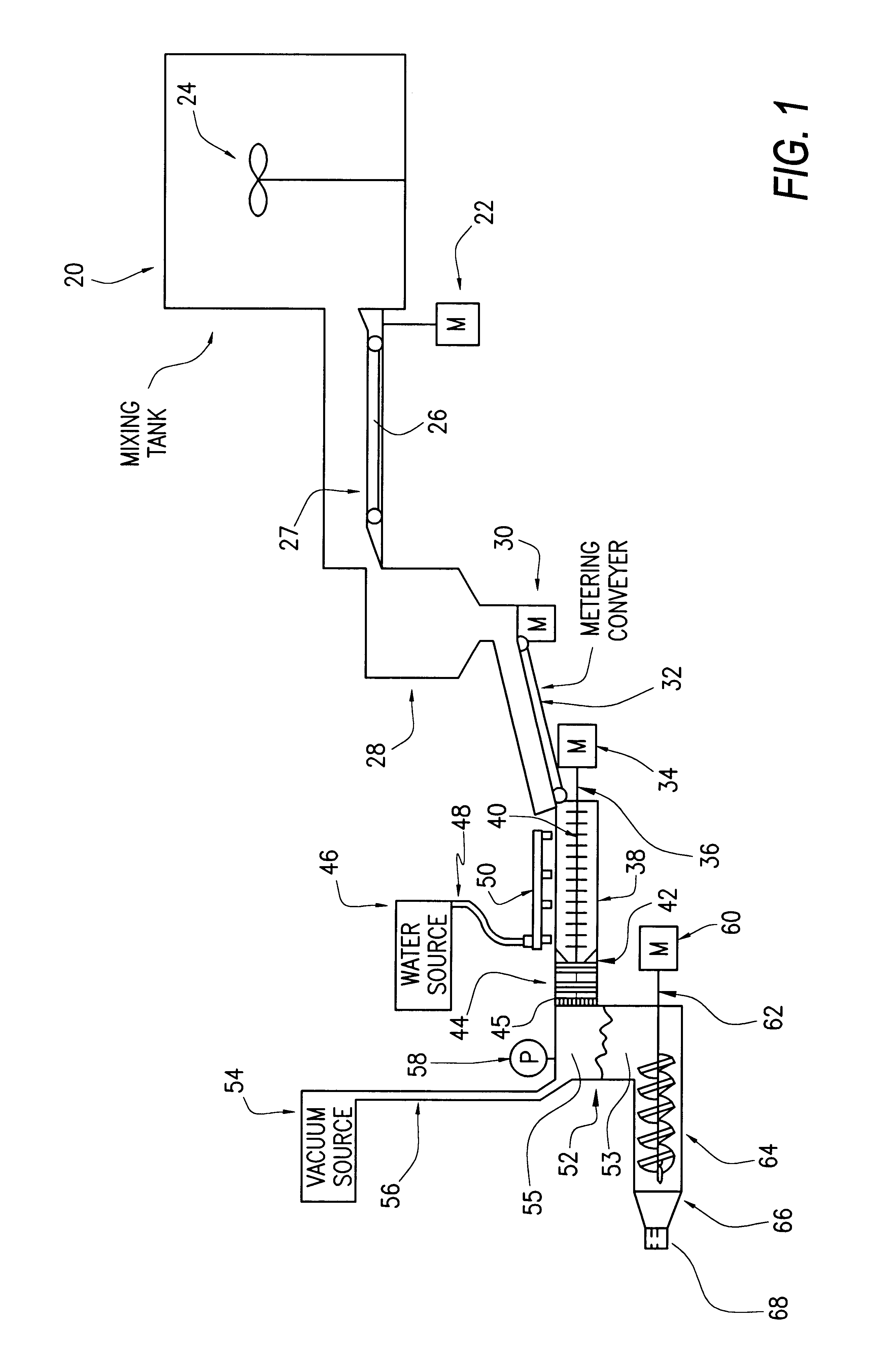

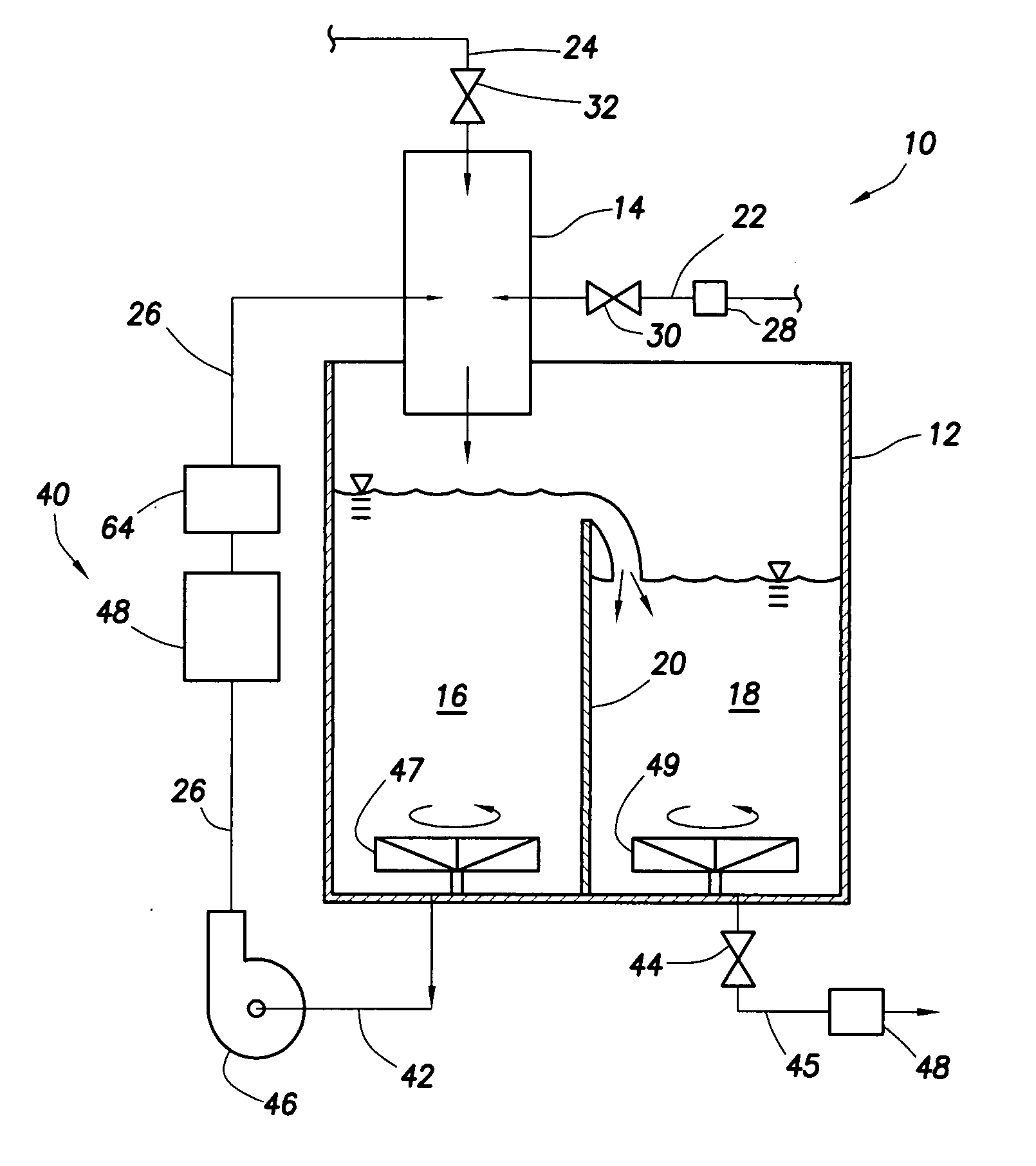

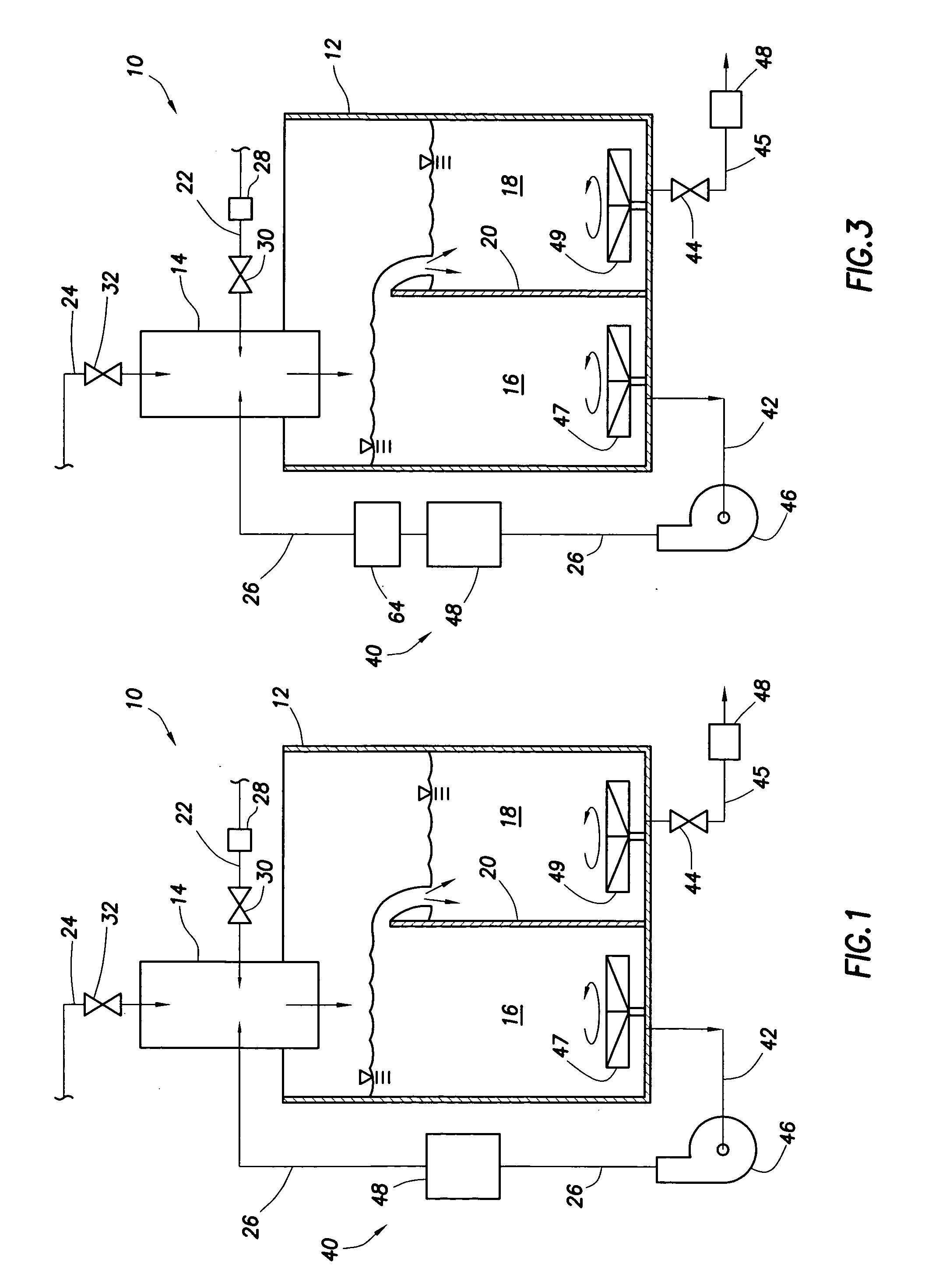

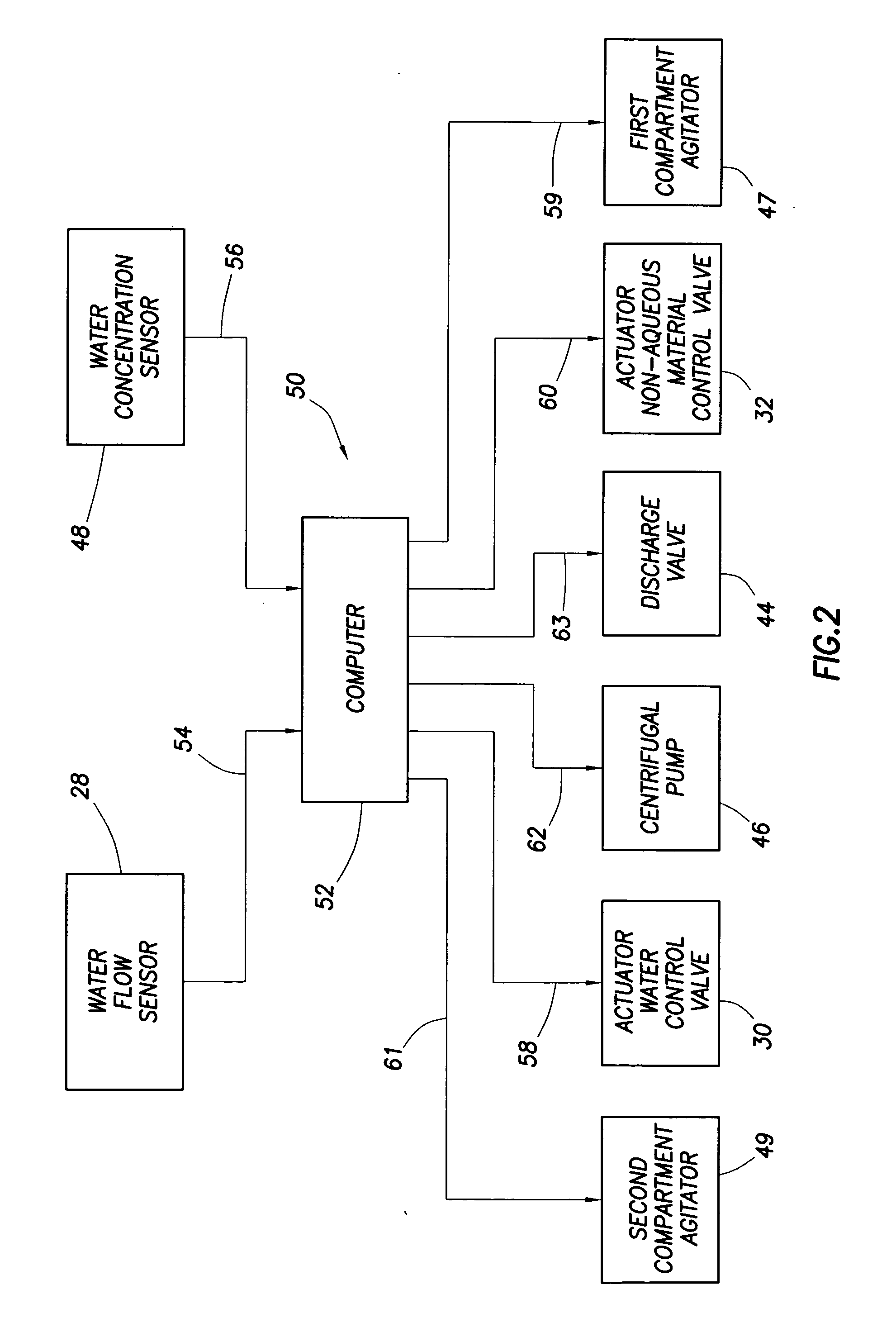

System and method for mixing water and non-aqueous materials using measured water concentration to control addition of ingredients

ActiveUS20050201197A1Eliminates and at least minimizes drawbackReduce stepsControlling ratio of multiple fluid flowsFlow mixersWater concentrationAdditive ingredient

The present invention is directed to a system and method for mixing a fluid comprising water and at least one non-aqueous material. The system comprises a mixing tub and mixing head adapted to inject the fluid into the mixing tub. It also includes a plurality of lines connected to the mixing head that supply the mixing head with water and the at least one non-aqueous material and a recirculation circuit that delivers the fluid from the mixing tub back to the mixing head. The system further includes a sensor connected to the recirculation circuit that measures the concentration of water in the fluid. An automatic controller uses the concentration measurement data to control the amount of each of the ingredients injected into the mixing tub.

Owner:HALLIBURTON ENERGY SERVICES INC

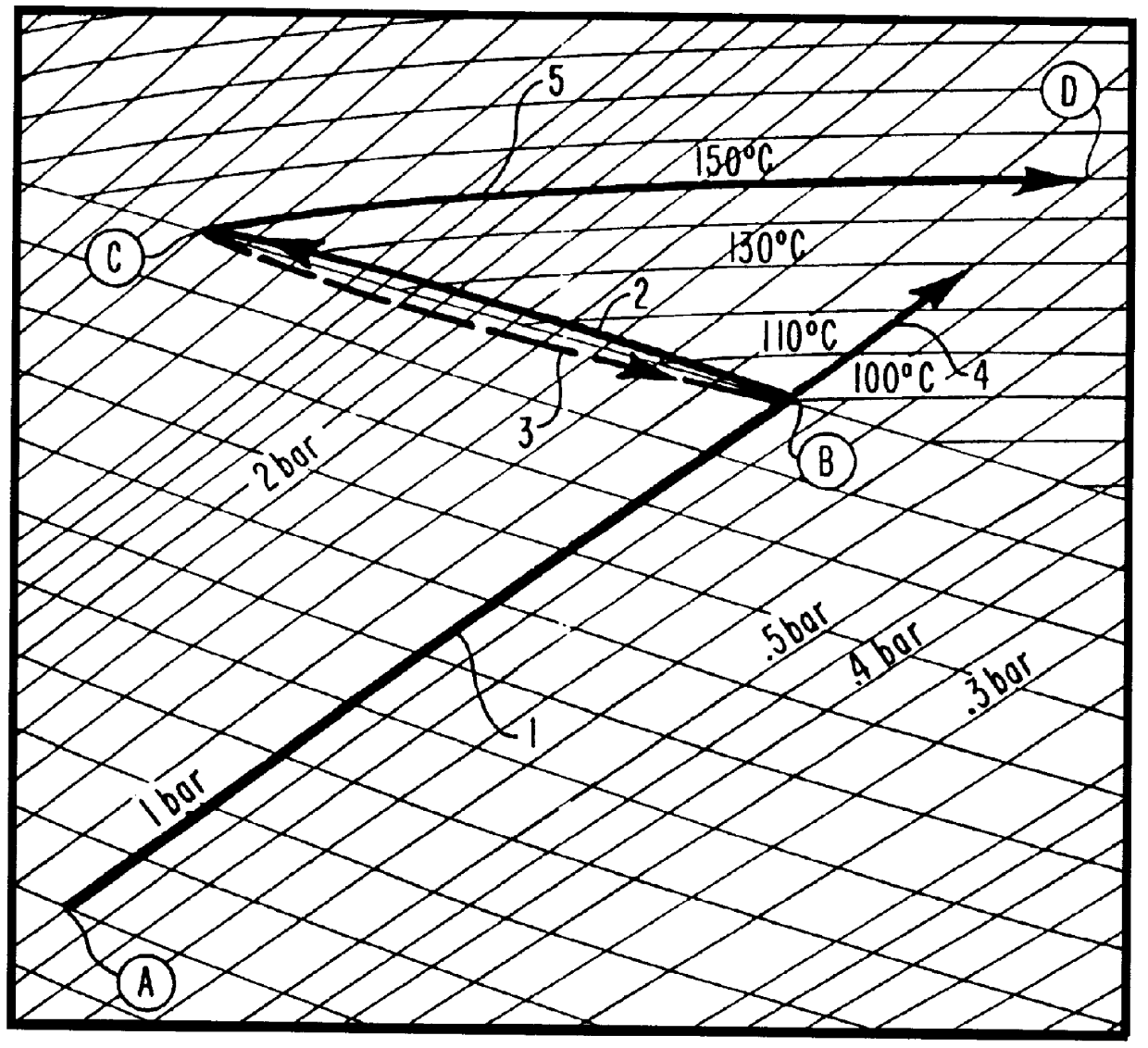

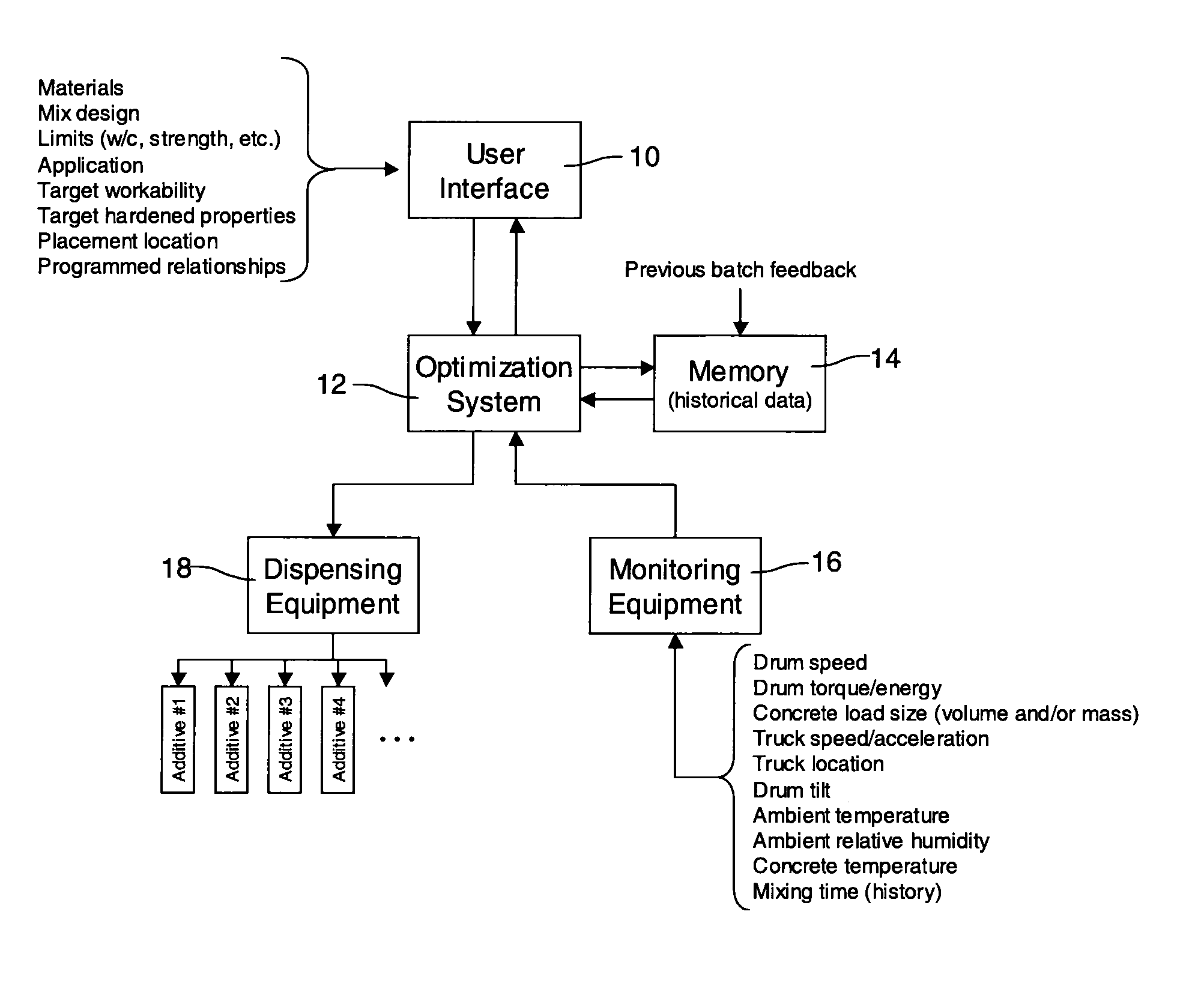

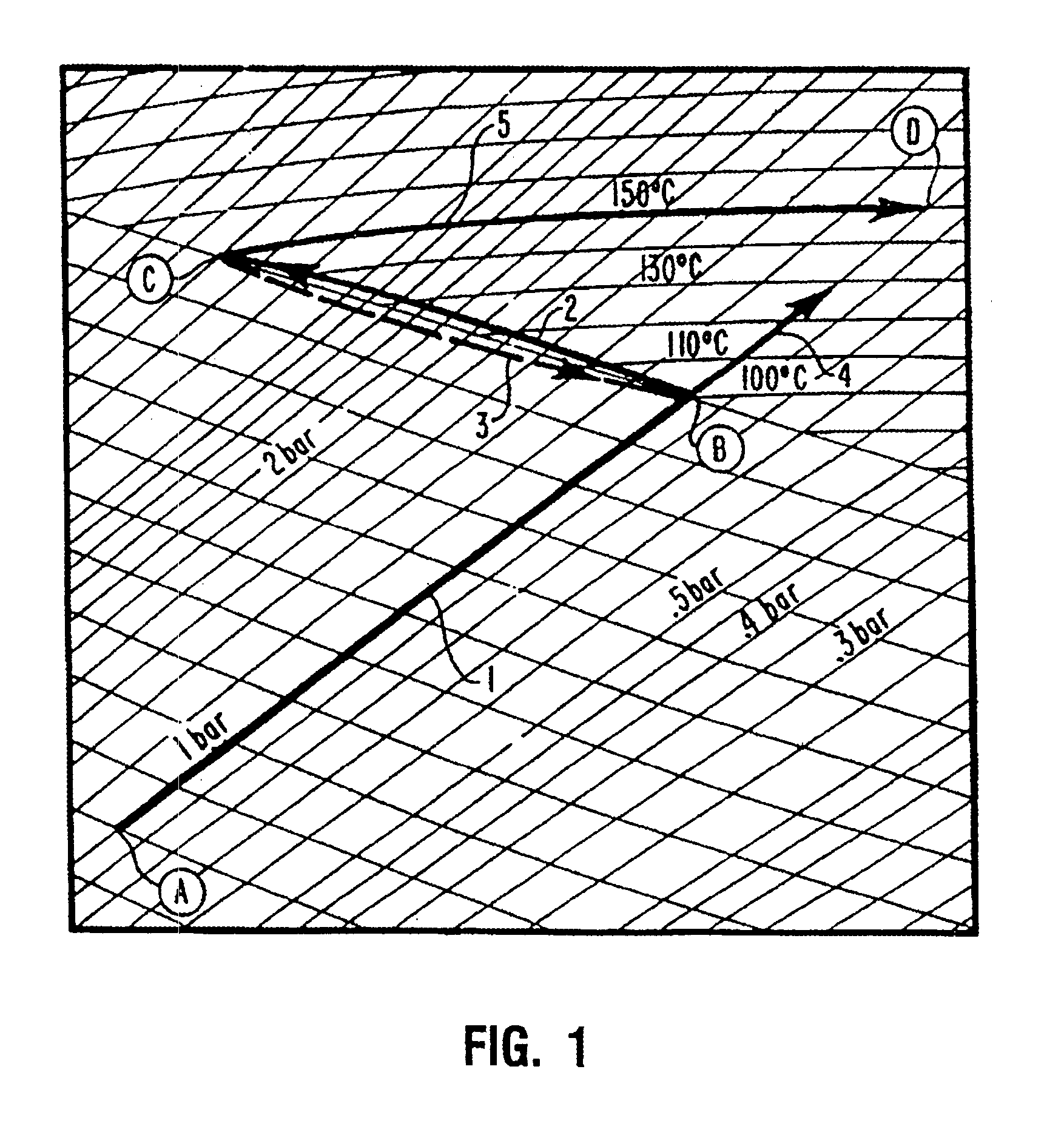

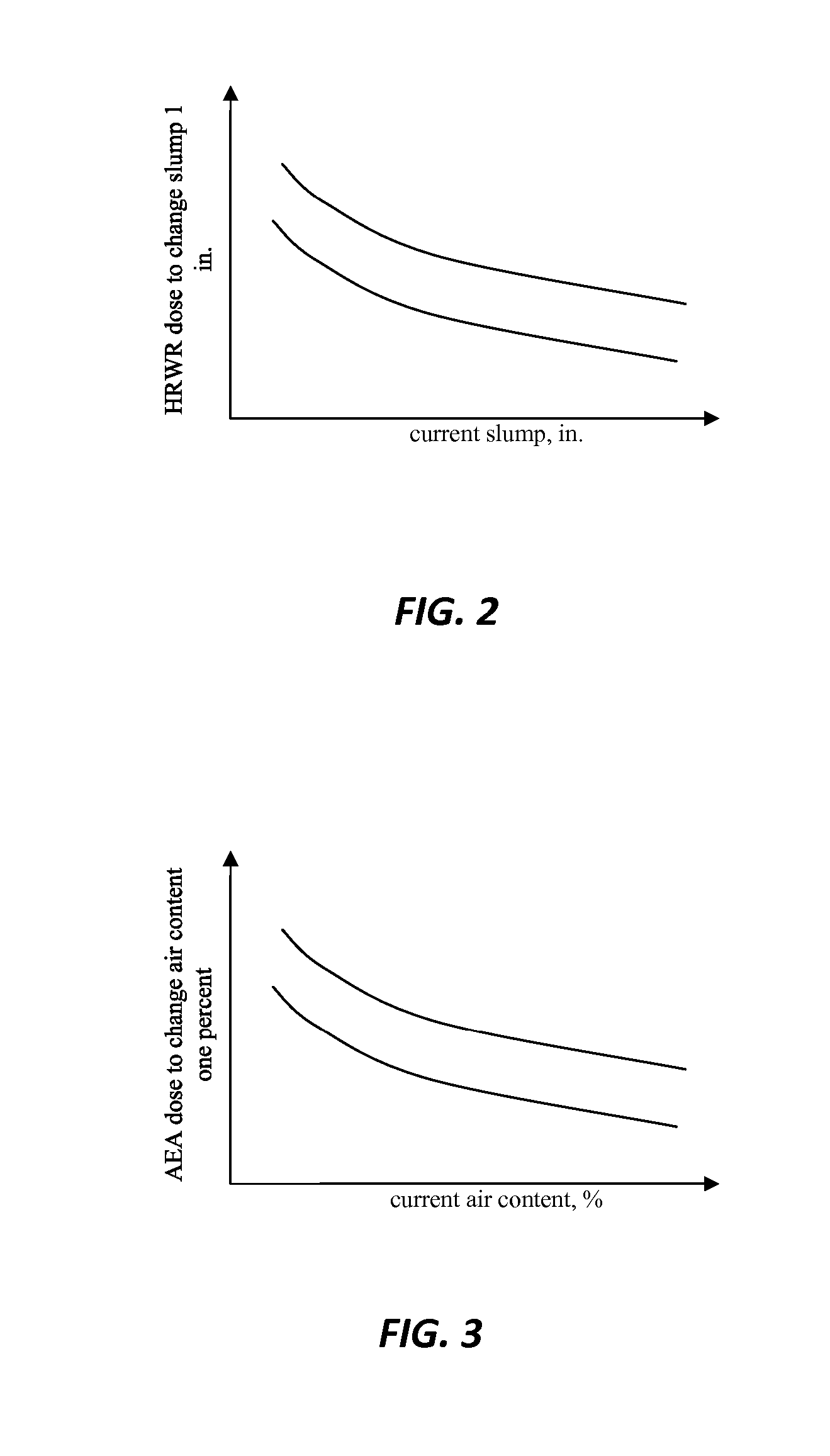

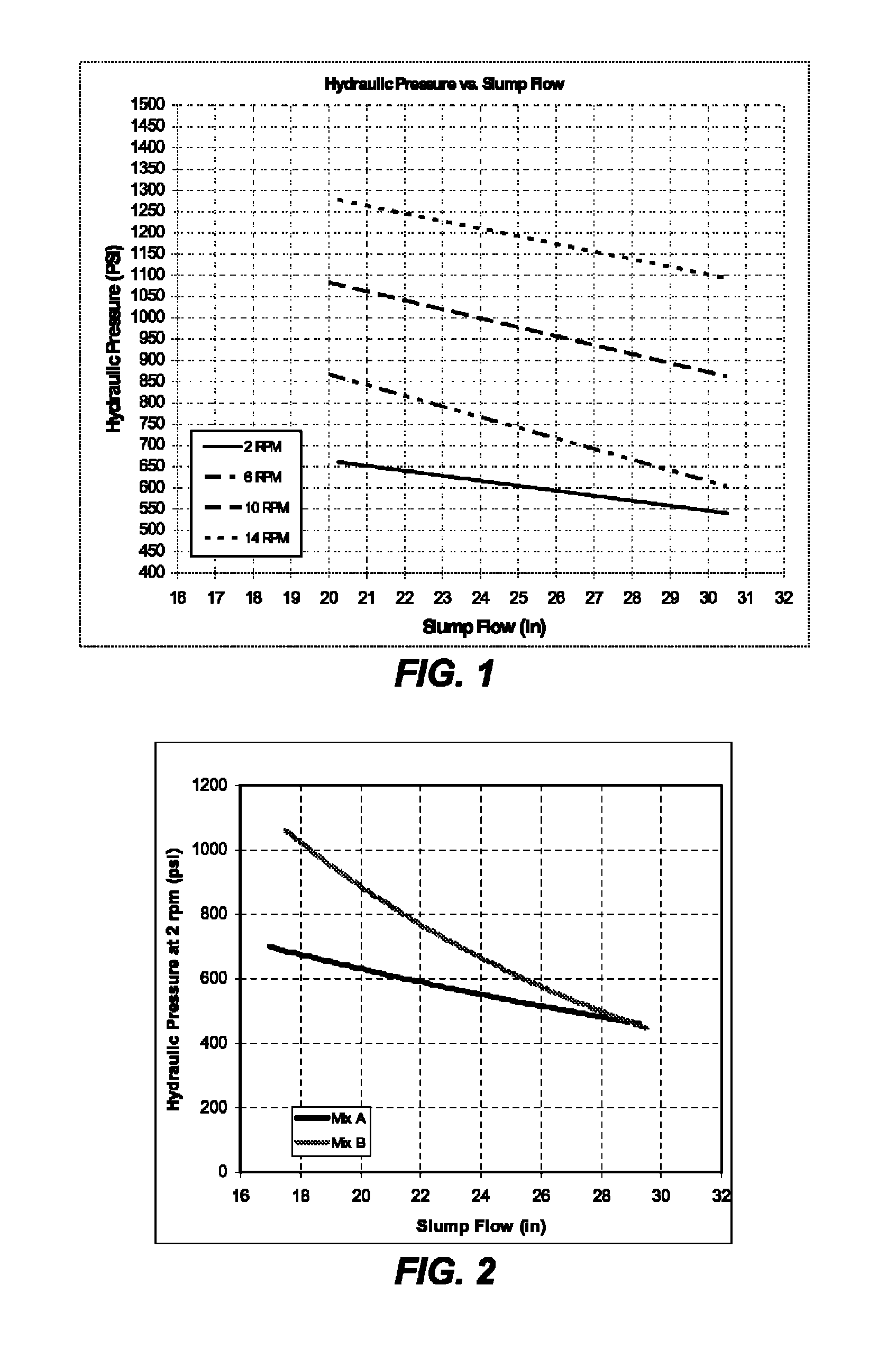

Method for adjusting concrete rheology based upon nominal dose-response profile

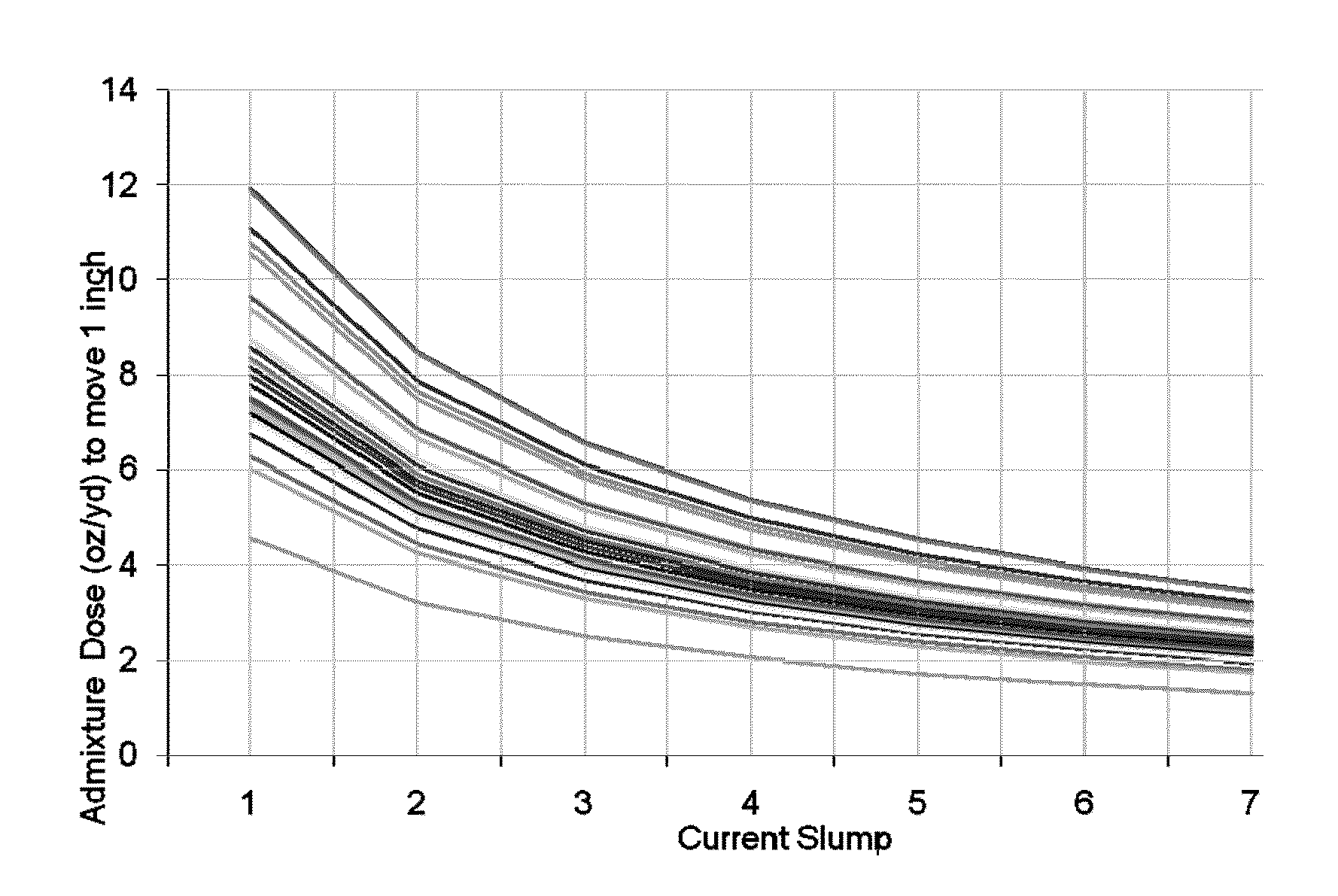

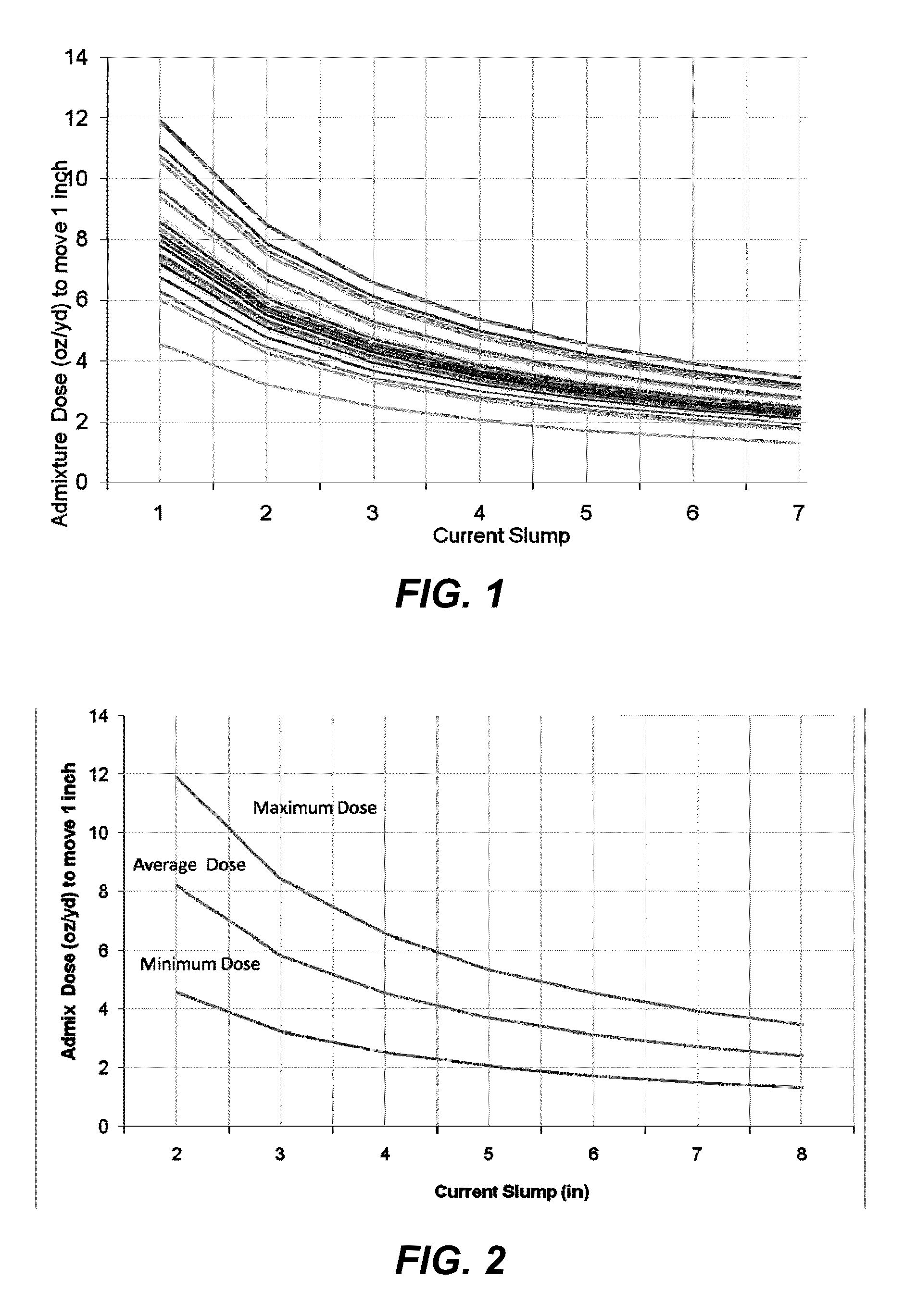

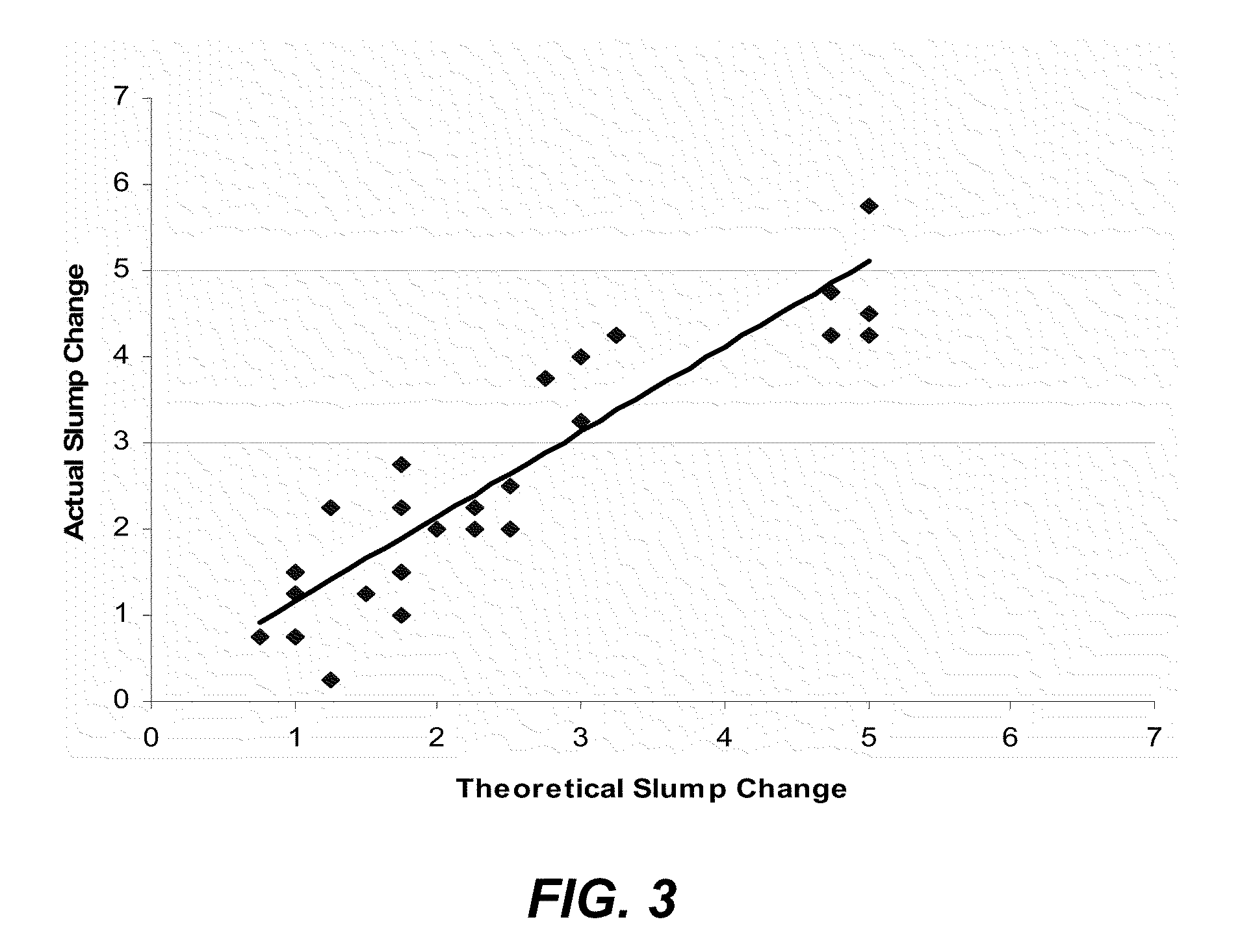

ActiveUS8311678B2Increased complexityAvoid overdoseSampled-variable control systemsControlling ratio of multiple fluid flowsEngineeringLookup table

The invention relates to a method for adjusting concrete rheology requiring only that load size and target rheology value be selected initially rather than requiring inputs into and consultation of a lookup table of parameters such as water and hydration levels, mix components, temperature, humidity, aggregate components, and others. Dosage of particular rheology-modifying agent or combination of rheology-modifying agents is calculated based on a percentage of a nominal dose calculated with reference to a nominal dose response (“NDR”) curve or profile. The NDR profile is based on a correlation between a rheology value (e.g., slump, slump flow, yield stress) and the rheology-modifying agent(s) dose required to change rheology value by one unit (e.g., slump change from 2 to 3 inches) such that exemplary methods can employ corrective dosing based on the NDR and the measured deviation by the system.

Owner:VERIFI INC

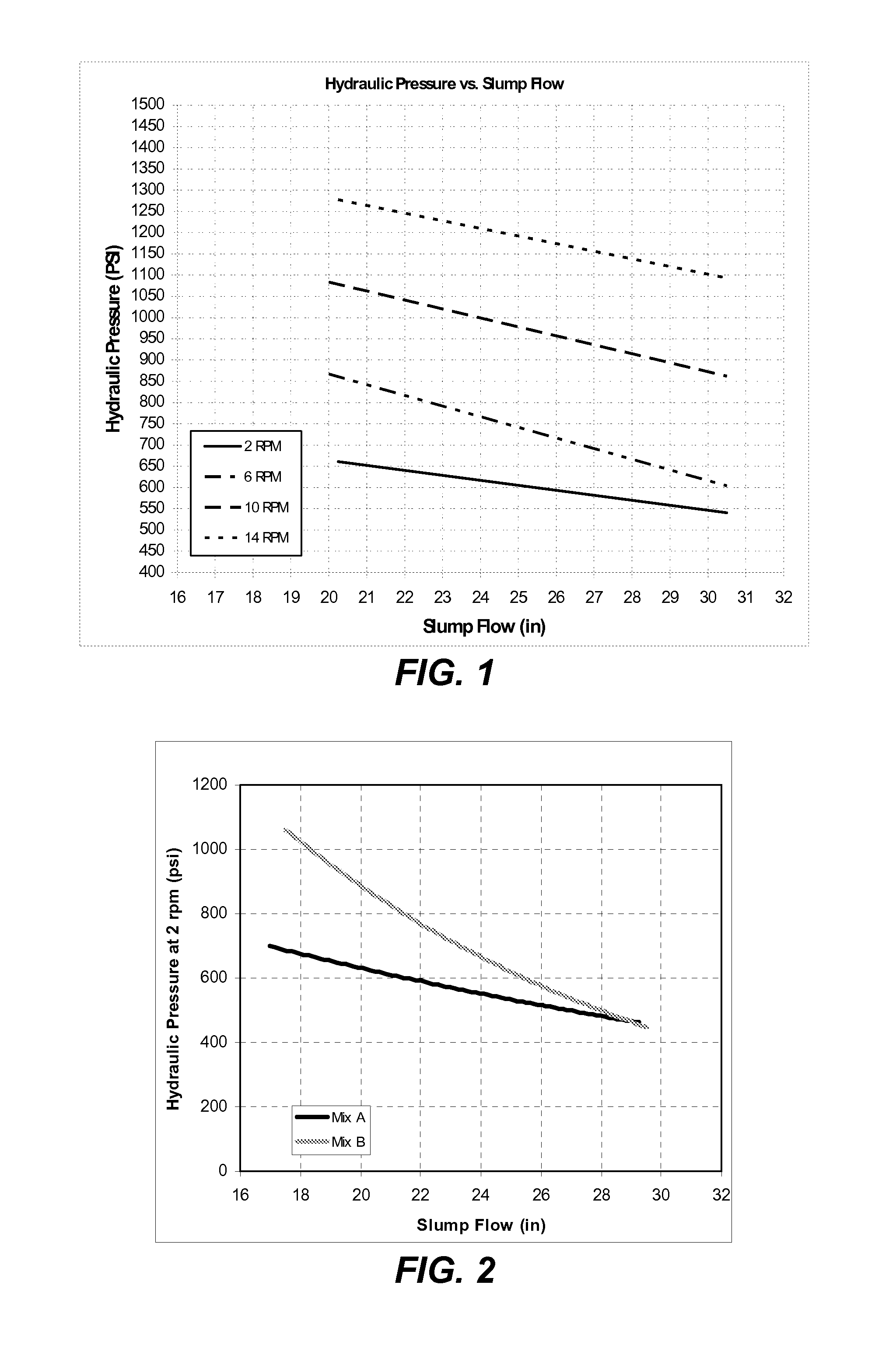

Slump Flow Monitoring

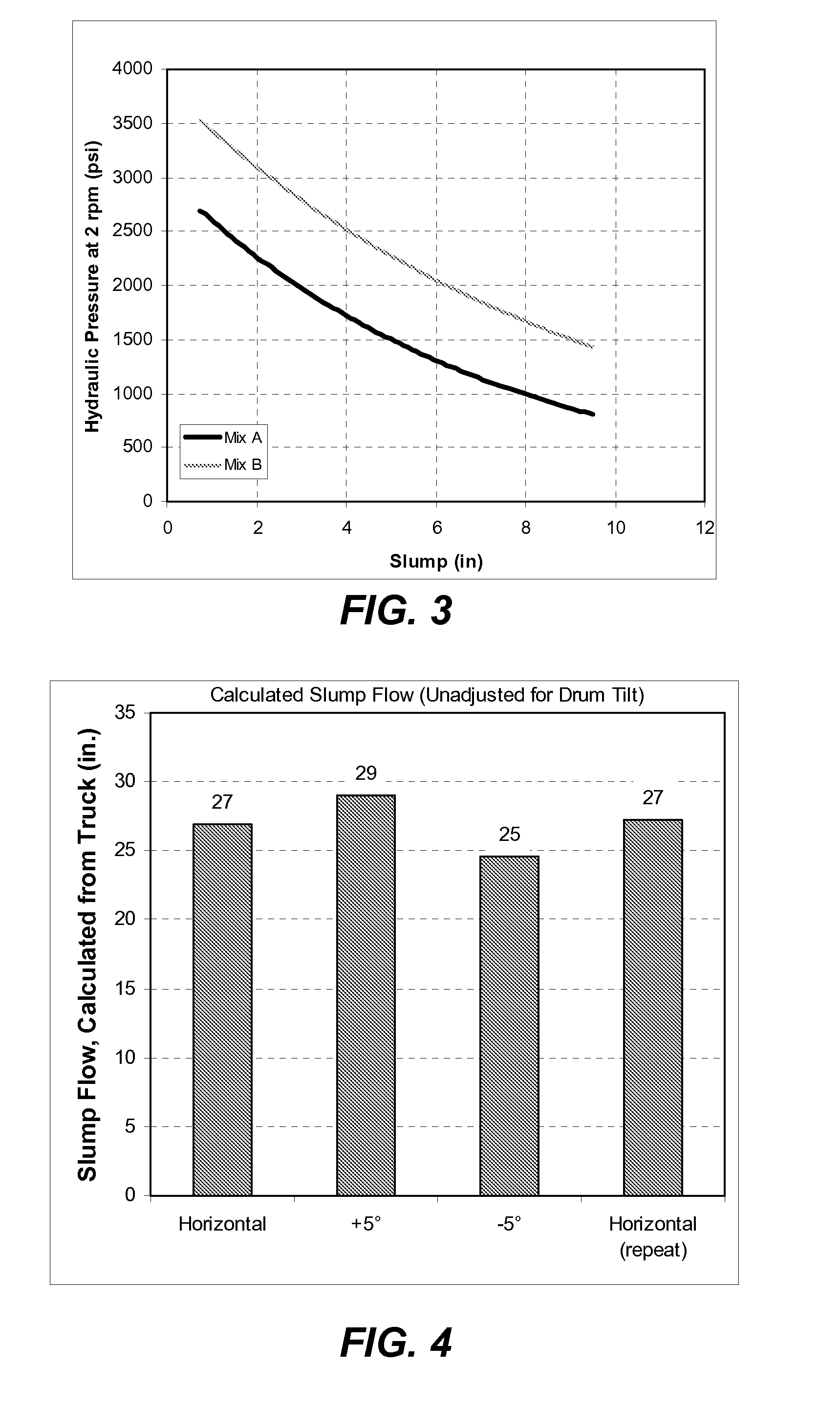

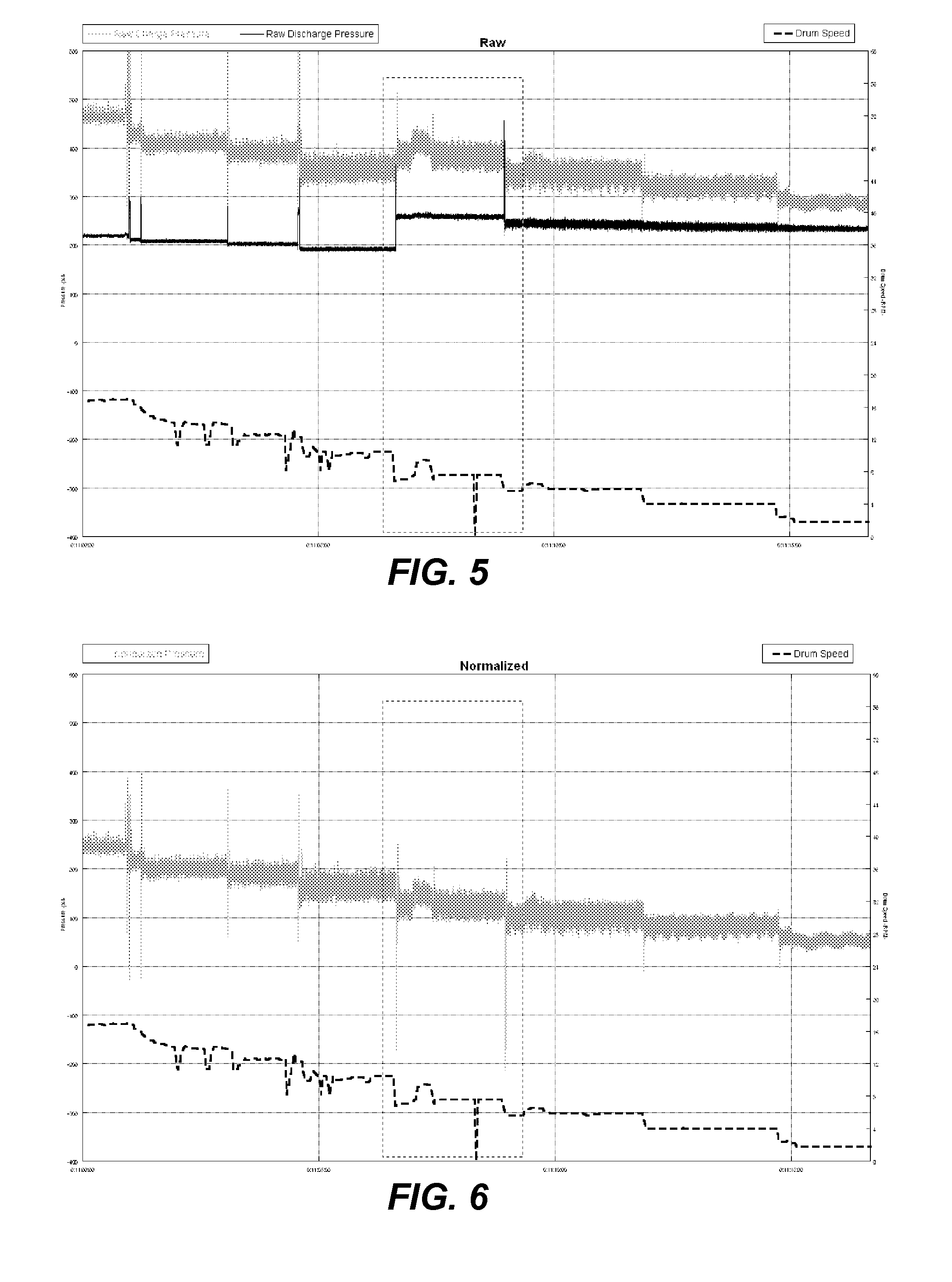

Method and system for monitoring slump flow of hydratable cementitious material such as wet concrete in a rotating mixing drum. Whereas prior art methods use a single value of the hydraulic pressure for turning the drum (such as the average value) and correlating with slump values using the vertical drop measurements of the standard slump test (e.g. ASTM C 143-05), the present invention involves analysis of values corresponding to slump flow of concrete samples, preferably having slump flow values of 16-36 inches when measured using standard slump flow tests (e.g., ASTM C1611-05).

Owner:VERIFI

Method and system for calculating and reporting slump in delivery vehicles

ActiveUS8989905B2Easy to useThermometer detailsTransportation and packagingDelivery vehicleCold weather

A system for managing a concrete delivery vehicle having a mixing drum 14 and hydraulic drive 16 for rotating the mixing drum, including a rotational sensor 20 configured to sense a rotational speed of the mixing drum, a hydraulic sensor 22 coupled to the hydraulic drive and configured to sense a hydraulic pressure required to turn the mixing drum, a temperature sensor for sensing temperature of the drum, and a communications port 26 configured to communicate a slump calculation to a status system 28 commonly used in the concrete industry, wherein the sensing of the rotational speed of the mixing drum is used to qualify a calculation of current slump based on the hydraulic pressure required to turn the mixing drum. Temperature readings are further used to qualify or evaluate a load. Also, water purge connections facilitate cold weather operation.

Owner:VERIFI INC

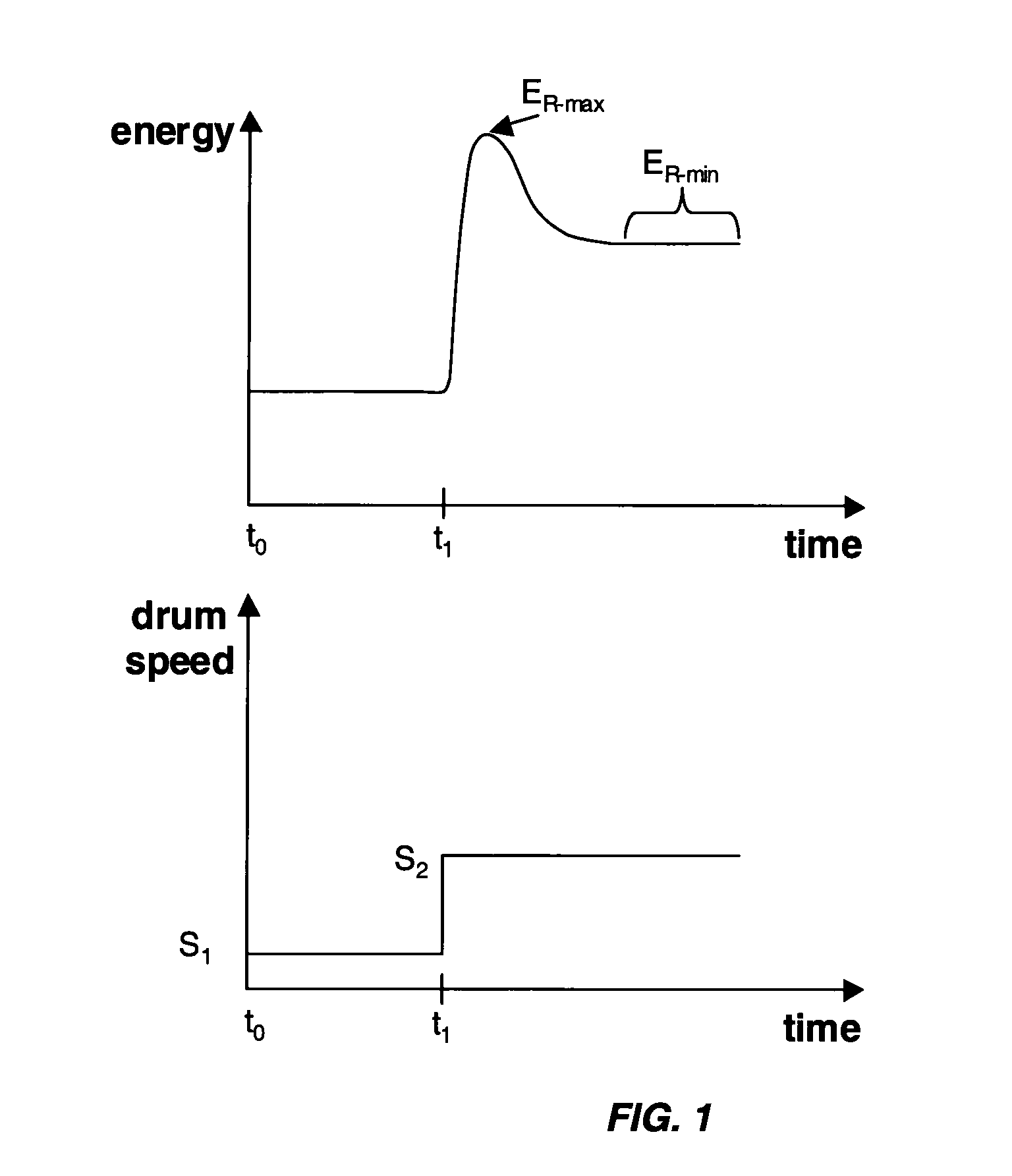

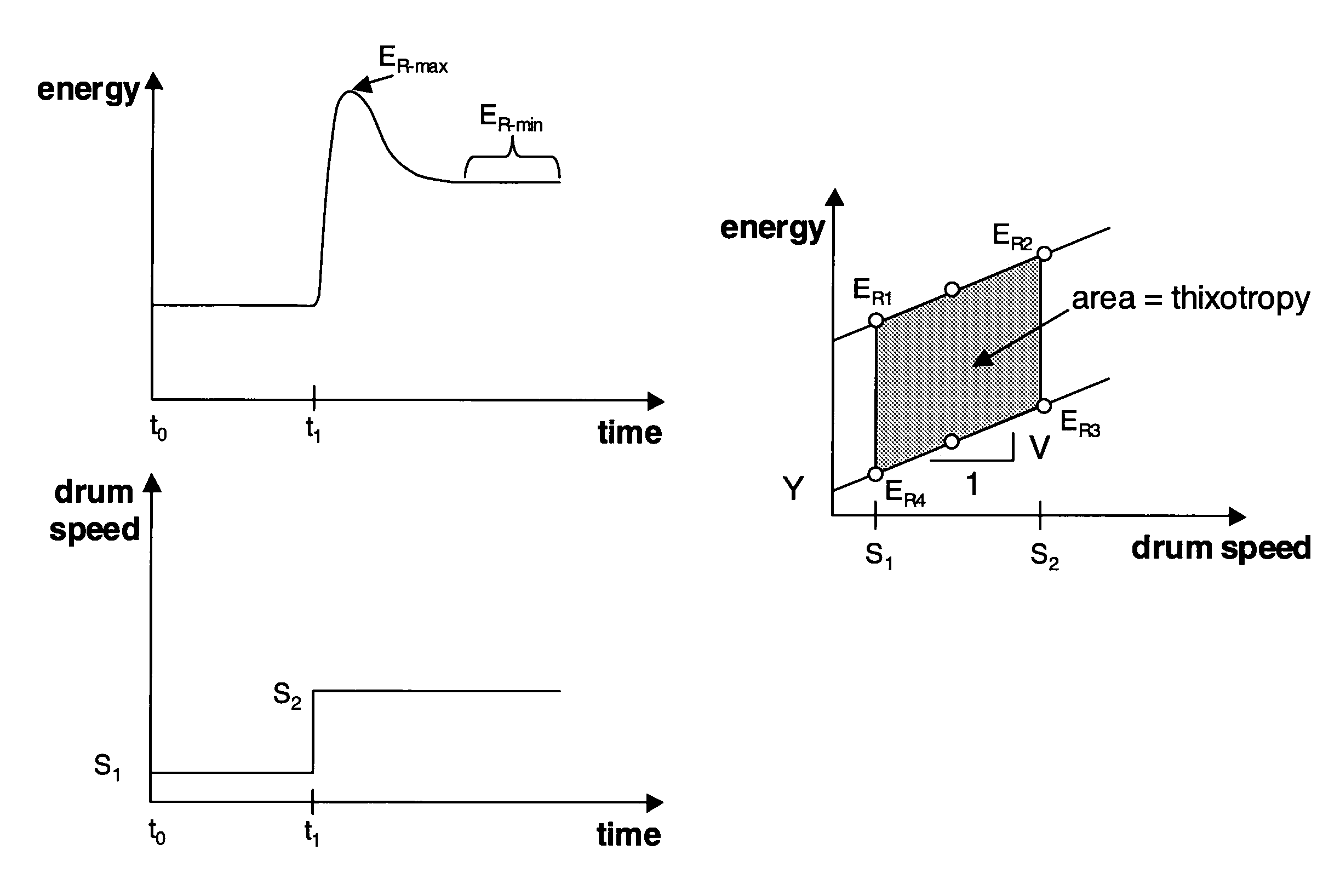

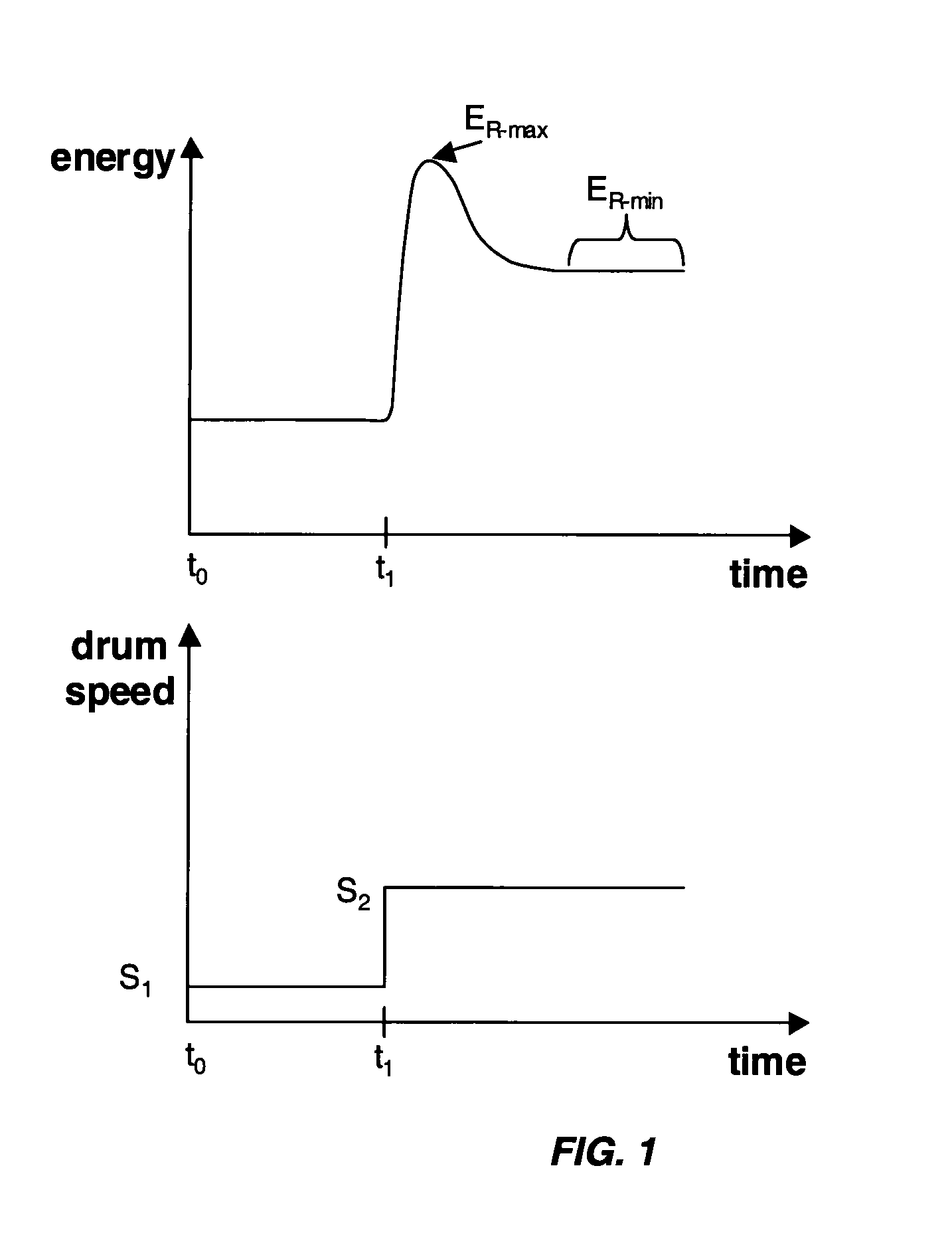

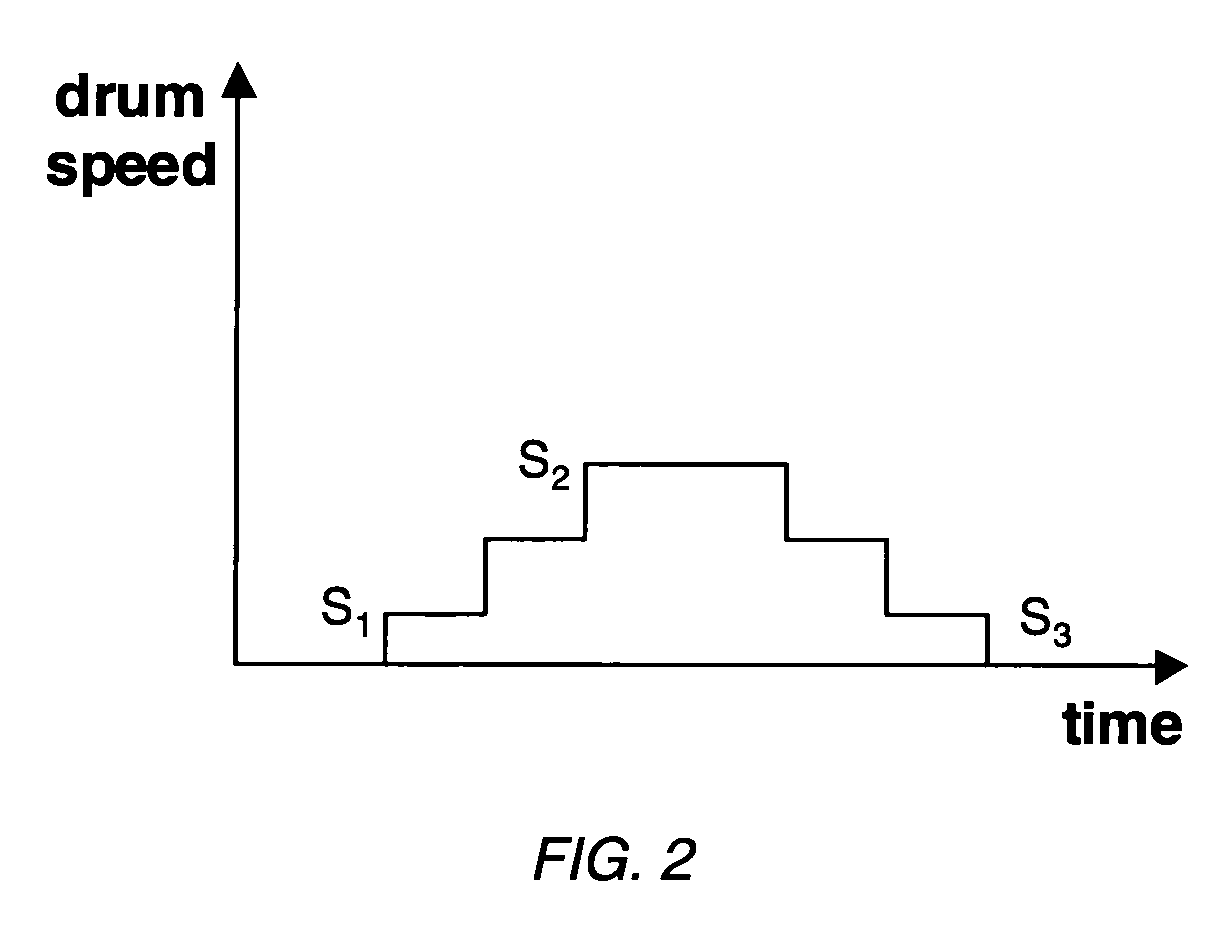

Method For Monitoring Thixotropy In Concrete Mixing Drum

The invention provides ‘thixotropy’ monitoring, by measuring the reversible, time-dependent reduction in viscosity occurring when concrete is subjected to mixing, and employs a mixing drum and conventional slump monitoring equipment as used on ready-mix trucks. In one embodiment, the drum is rotated until concrete is completely mixed; the speed is altered, such as by increasing it to a predetermined level; and the energy required to rotate the drum (ER) is monitored; the maximum (ER-MAX) and minimum (ER-MIN) values are recorded in computer memory; and these values are compared to pre-determined (target) values. Rheology factors (including viscosity, yield stress, and / or thixotropy) can be adjusted accordingly by adding liquid component(s) into the mix. This method, suitable for delivery of highly fluid concrete speed such as SCC, can involve transit and placement rheology targets during monitoring.

Owner:GCP APPL TECH INC

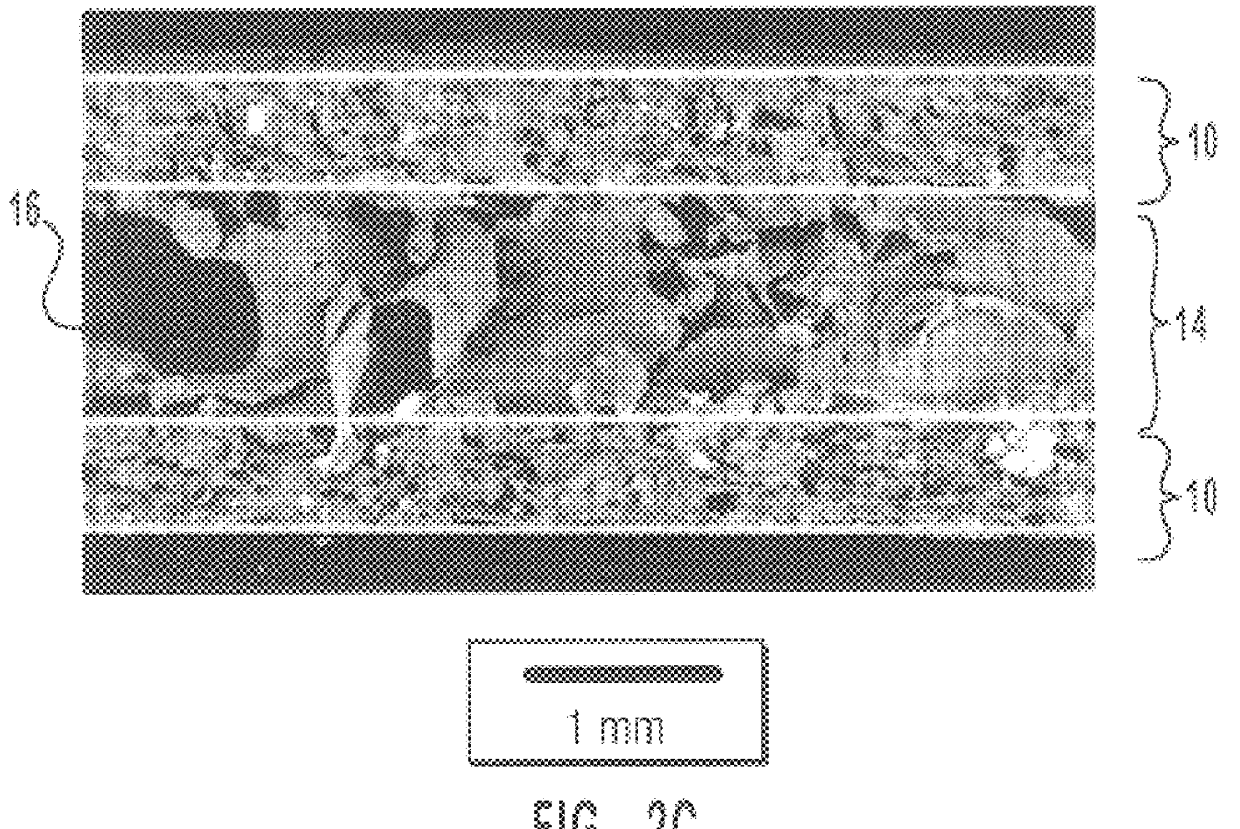

Compositions for manufacturing fiber-reinforced, starch-bound articles having a foamed cellular matrix

InactiveUSRE39339E1Avoid lack of toughnessHigh strengthClosure lidsSolid waste managementPolymer sciencePaperboard

Compositions, methods, and systems for manufacturing articles, particularly containers and packaging materials, having a fiber-reinforced, starch-bound cellular matrix. Suitable mixtures used to form the articles are prepared by first preparing a viscous preblended mixture comprising water, a gelatinized starch-based binder, and fibers having an average length greater than about 2 mm. The highly viscous preblended mixture effectively transfers the shearing forces of the mixer to the fibers. The final moldable mixture is then prepared by mixing into the preblended mixture the remaining starch-based binder, water, and other desired admixtures, e.g., mold-releasing agents, inorganic filler rheology-modifying agents, plasticizers, coating materials, and dispersants, in the correct proportions to form an article which has the desired performance criteria. The moldable mixtures are heated between molds at an elevated temperature and pressure to produce form-stable articles having a desired shape and a selectively controlled foamed structural matrix. The articles may be manufactured to have properties substantially similar to articles presently made from conventional materials like paper, paperboard, polystyrene, plastic, or other organic-based materials and have especial utility in the mass-production of containers, particularly food and beverage containers.

Owner:EARTHSHELL SPE

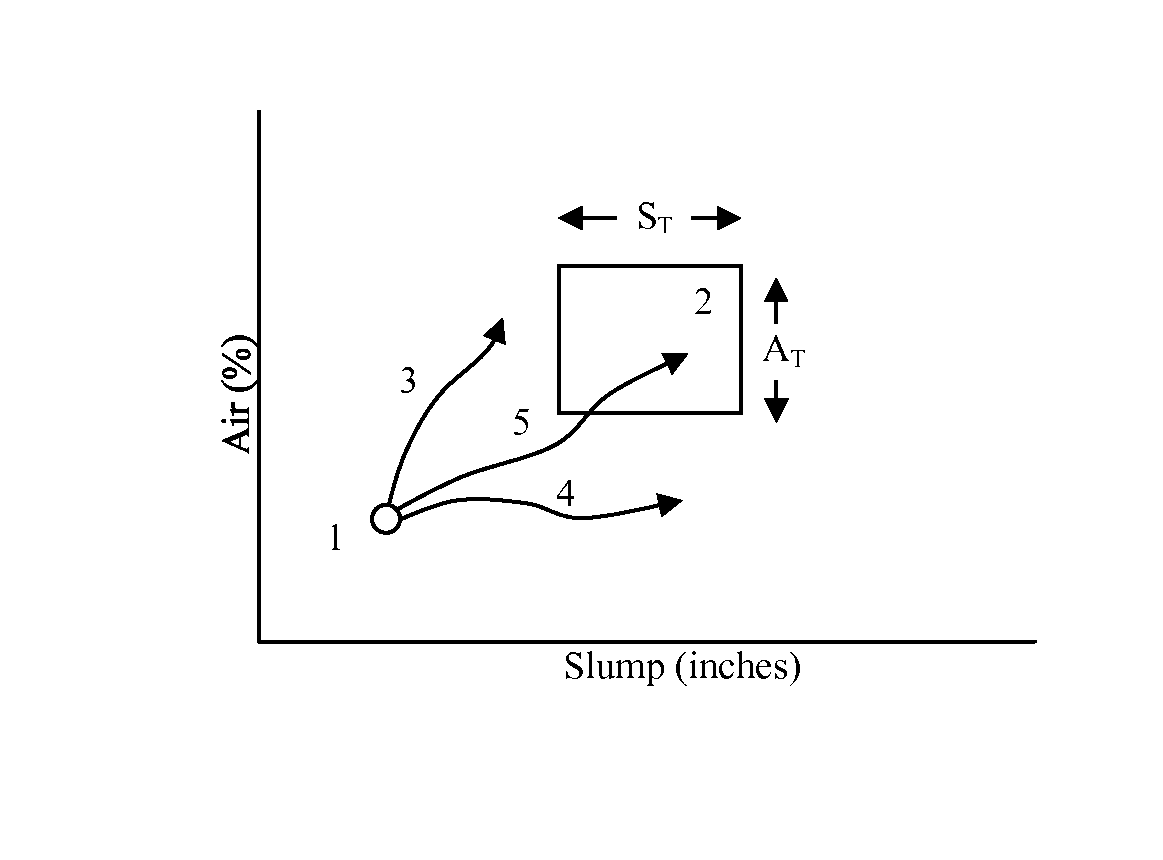

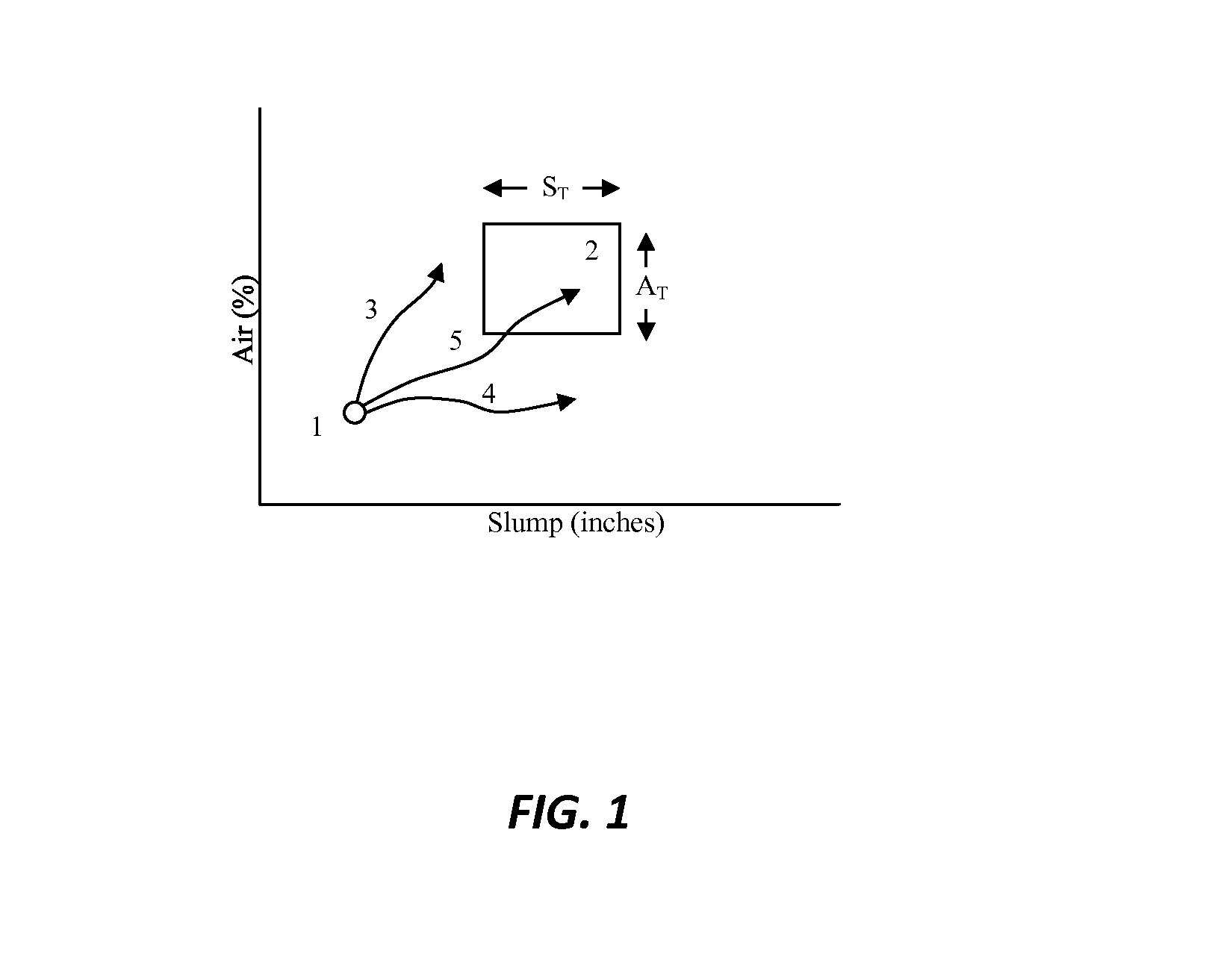

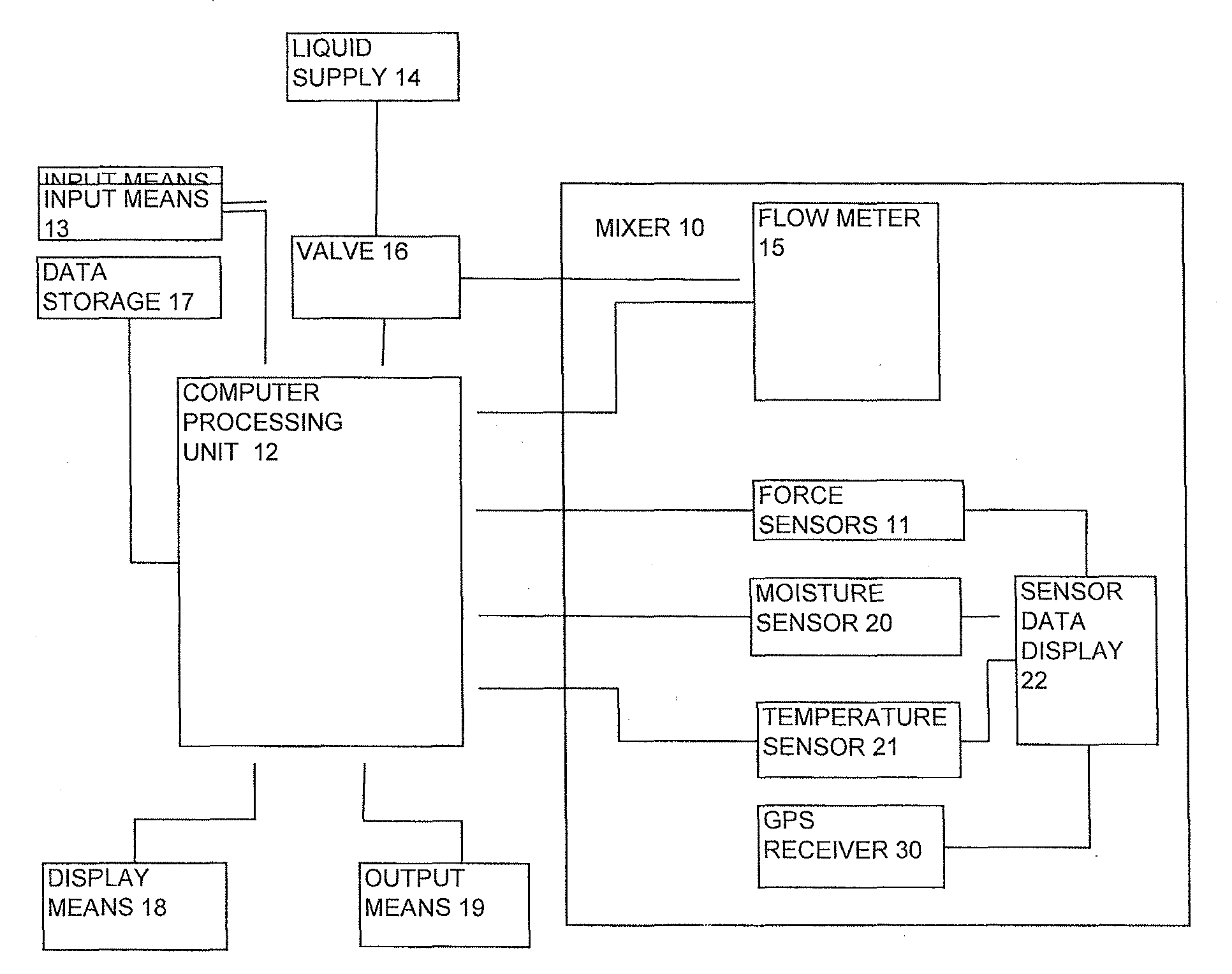

Multivariate management of entrained air and rheology in cementitious mixes

ActiveUS8491717B2Efficiently and accurately updatingHighly inventiveSampled-variable control systemsMixing operation control apparatusHydration reactionBLENDER/MIXER

The invention relates to a method and system for monitoring and adjusting both air content and rheology (e.g., slump, slump flow) properties of a hydratable concrete mix contained within a concrete mixer. The system simultaneously tracks dosage of both rheology-modifying admixture (e.g., polycarboxylate polymer cement dispersant) and air control agent or “ACA” (e.g., air entraining agent) by reference to at least four nominal dose response (“NDR”) curves or profiles, which at least four NDR profiles are based on the respective behaviors of each of the ACA and rheology-modifying agent on air content and rheology.

Owner:VERIFI INC

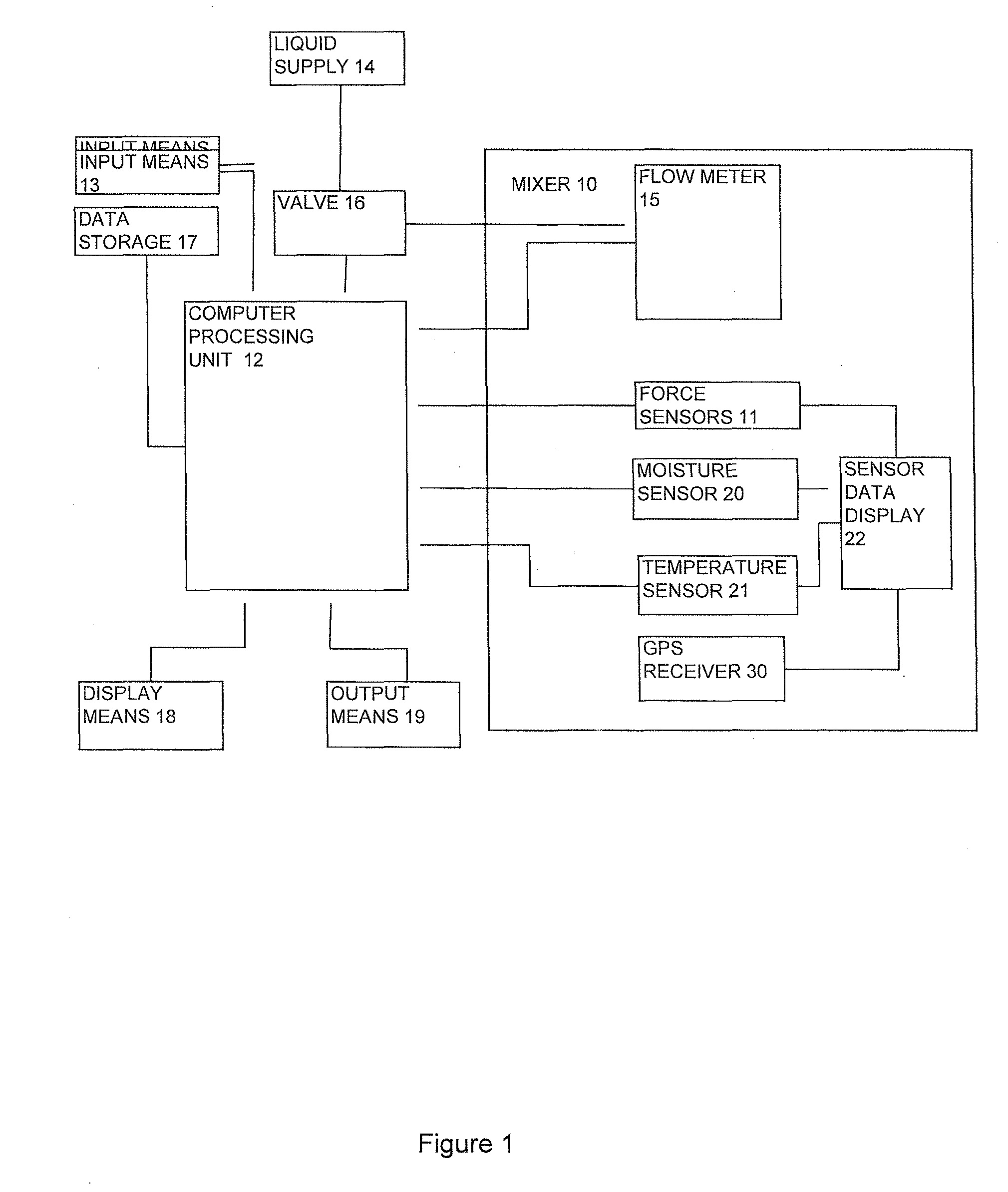

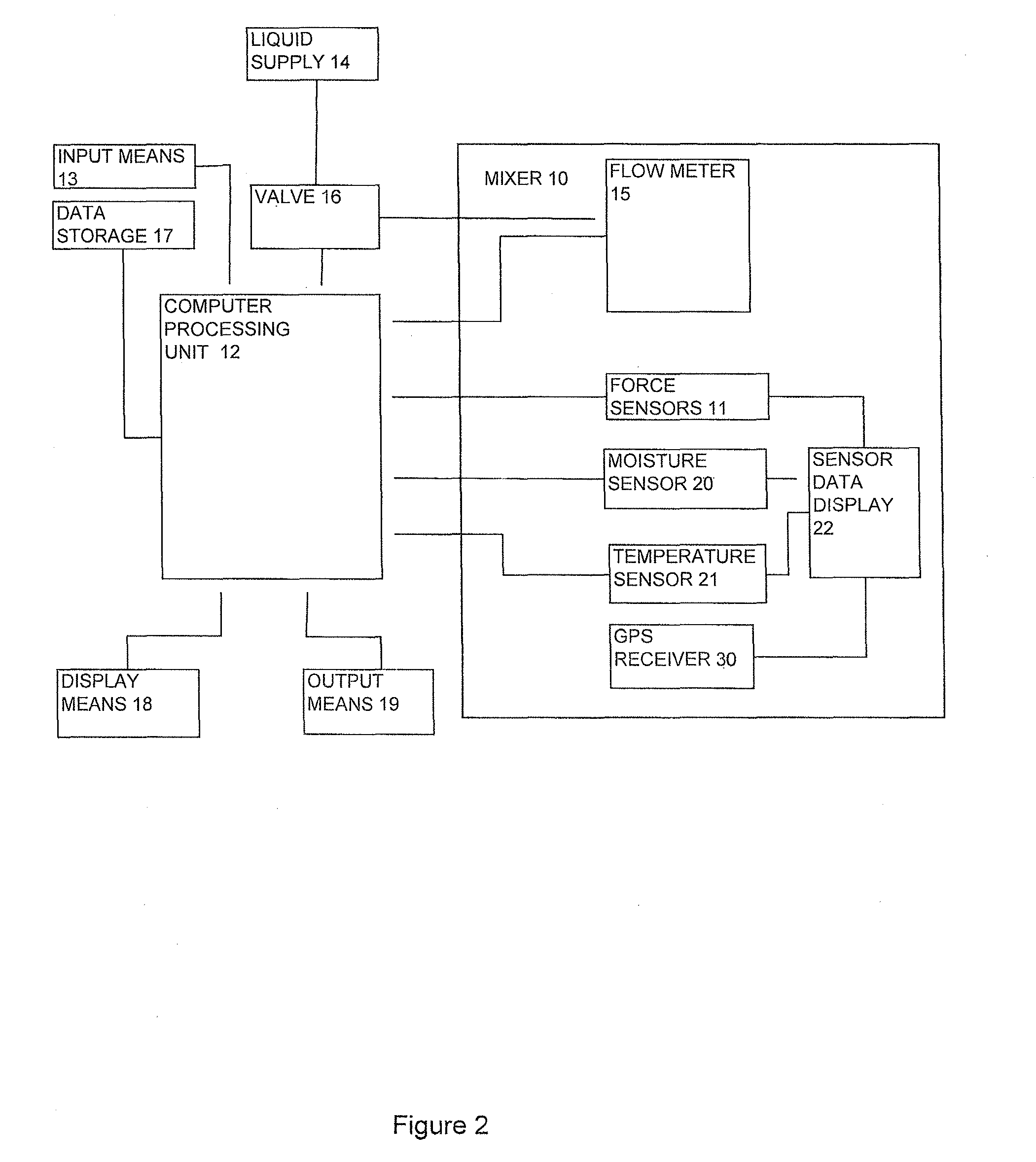

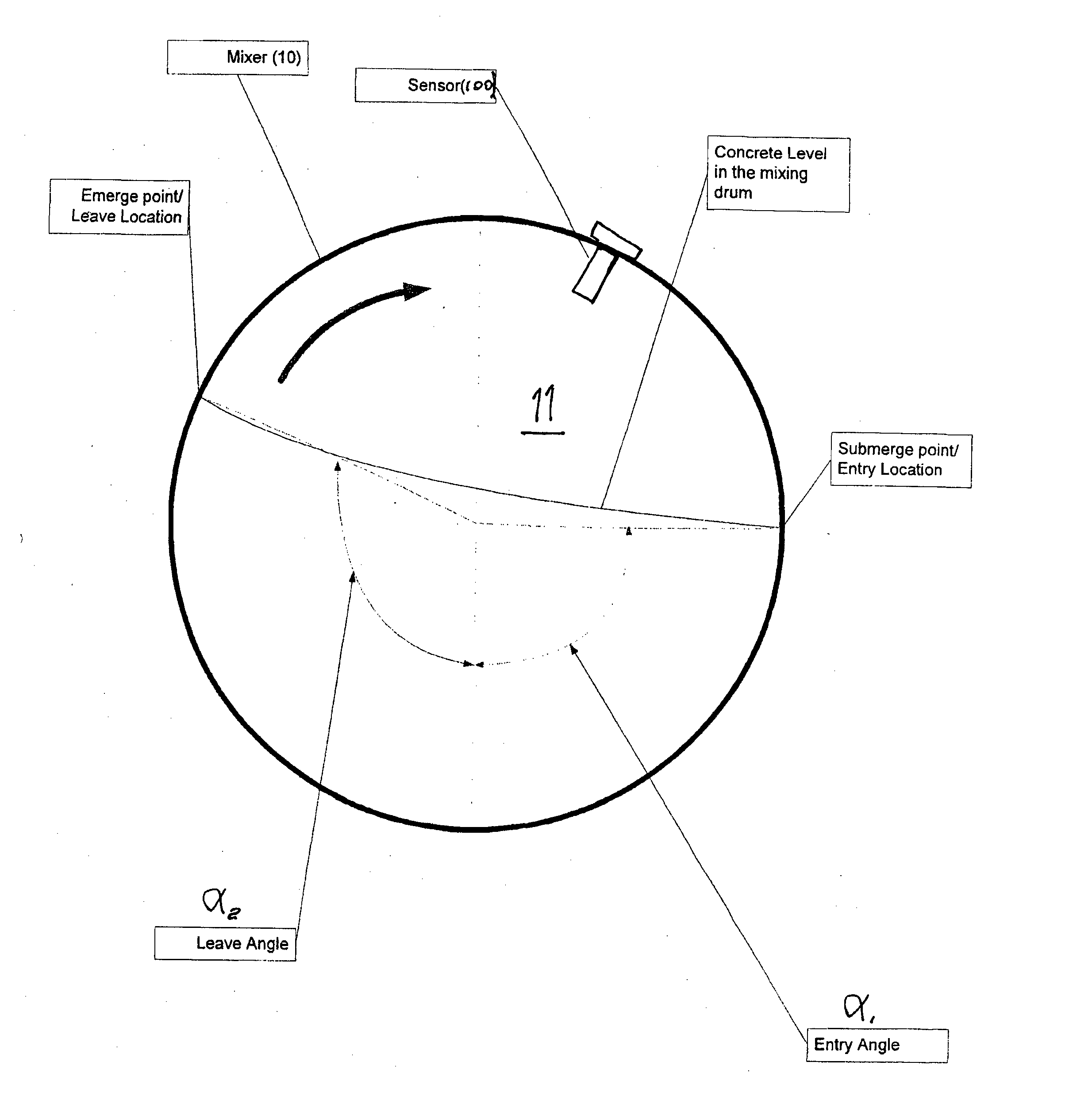

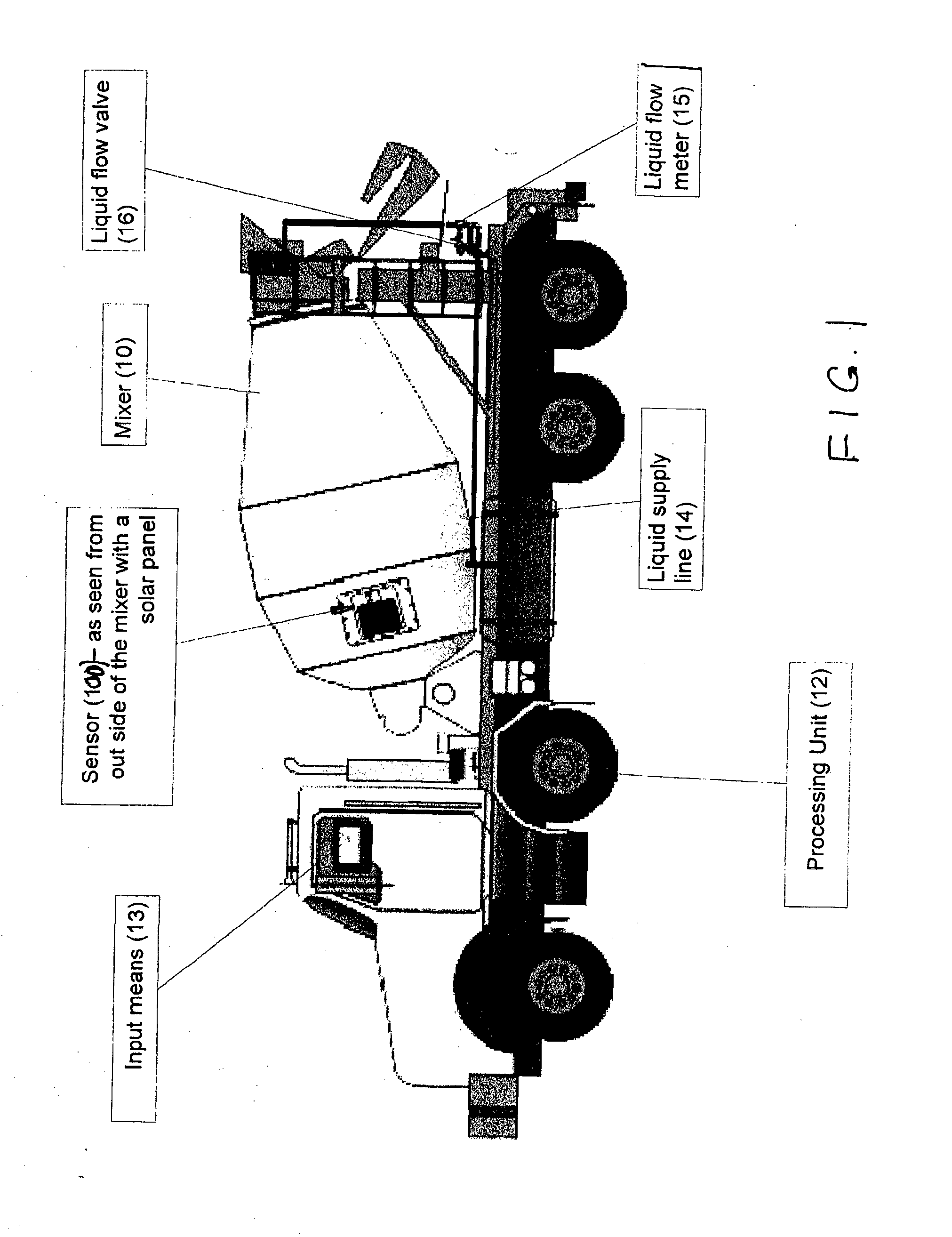

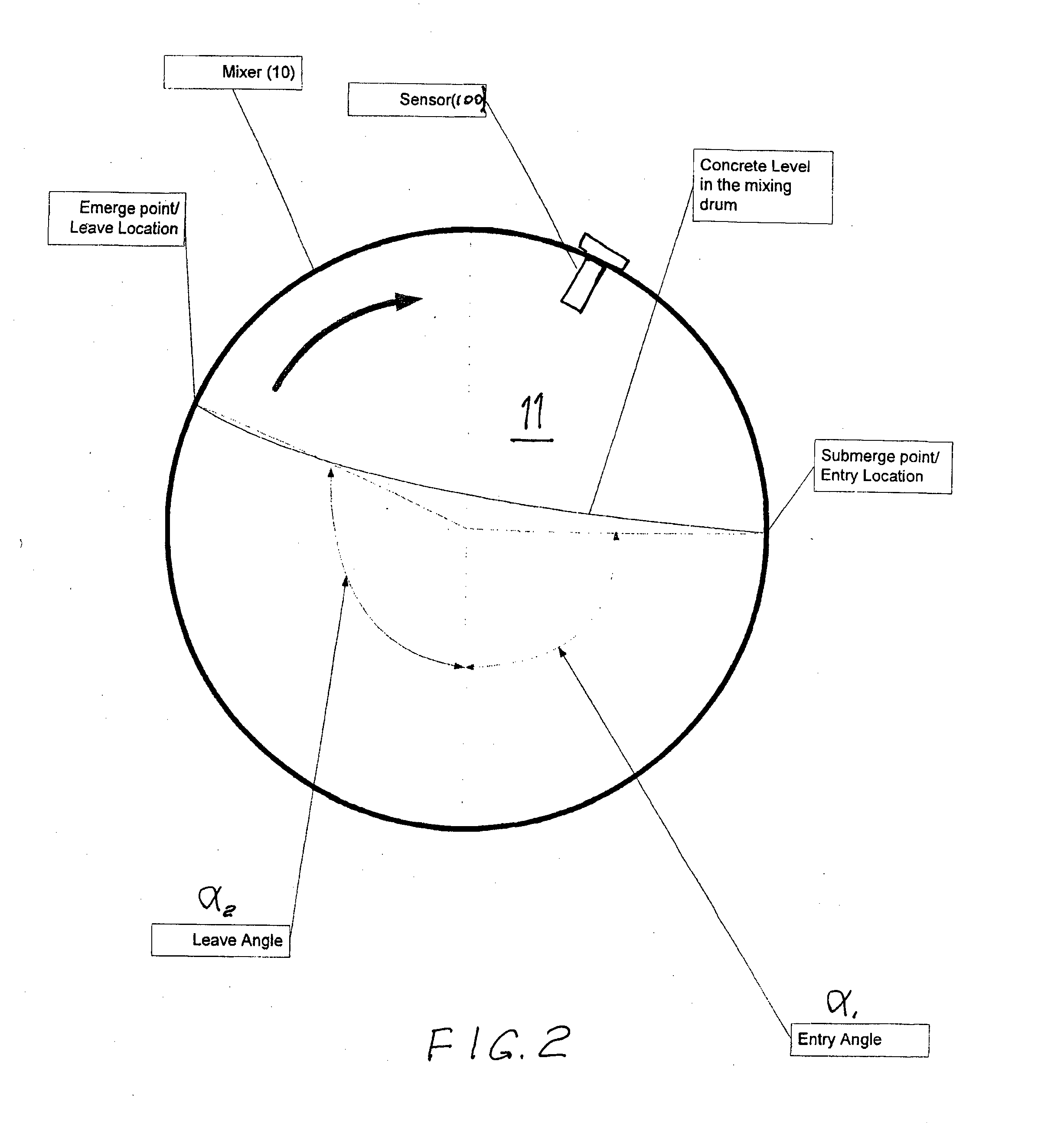

Concrete slump measurement and control system

ActiveUS20110077778A1Preventing loss through unauthorized poursSampled-variable control systemsRotating receptacle mixersControl systemEngineering

An apparatus and method to measure and control the slump of concrete by monitoring sensor within the interior surface of a concrete mixer and a liquid flow meter. Data is analyzed by a computer processing unit to determine the slump of the concrete, liquid needed the quantity of concrete within the mixer, the amount of concrete poured, and the starting and ending time of the pour.

Owner:GCP APPL TECH INC

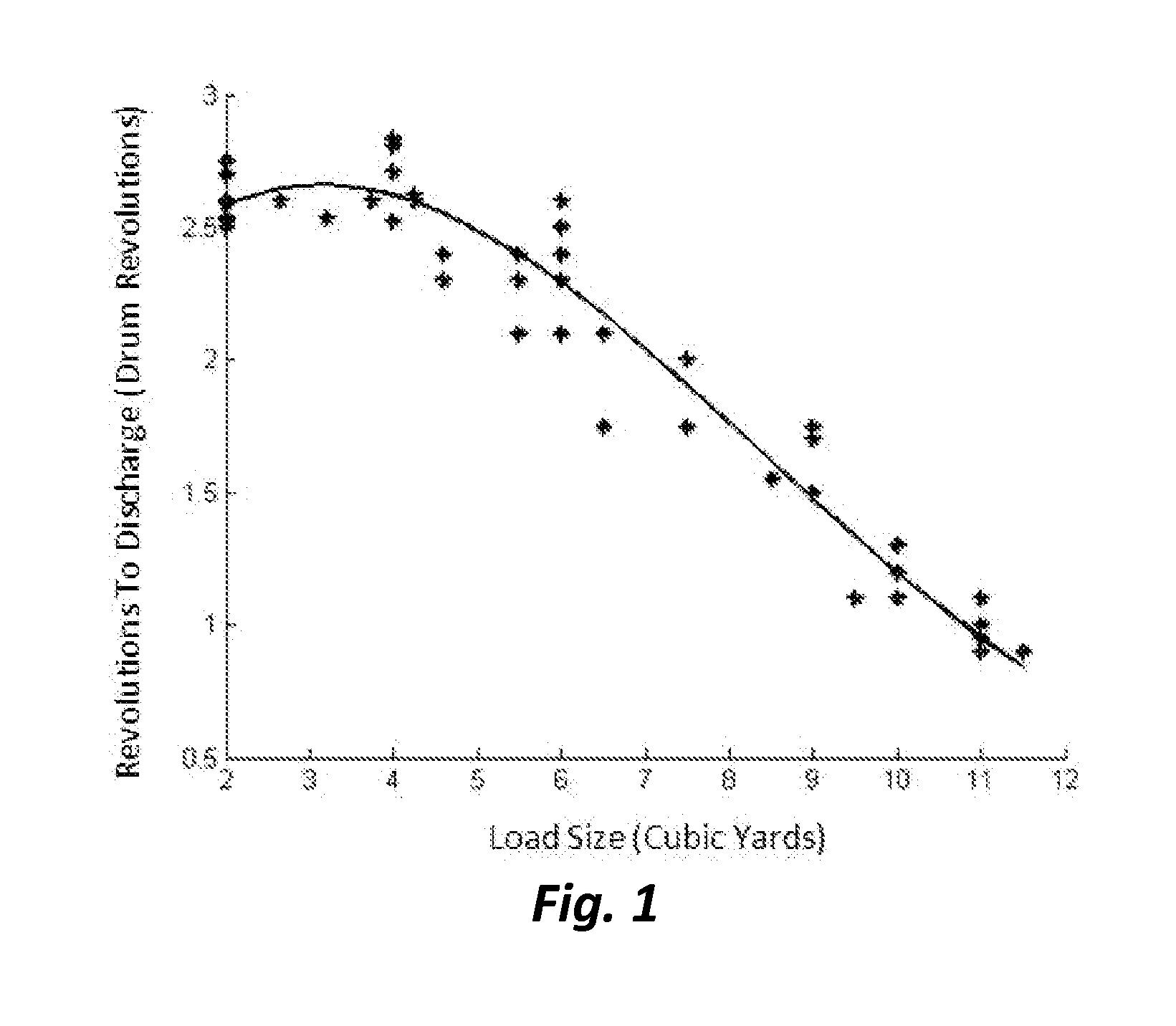

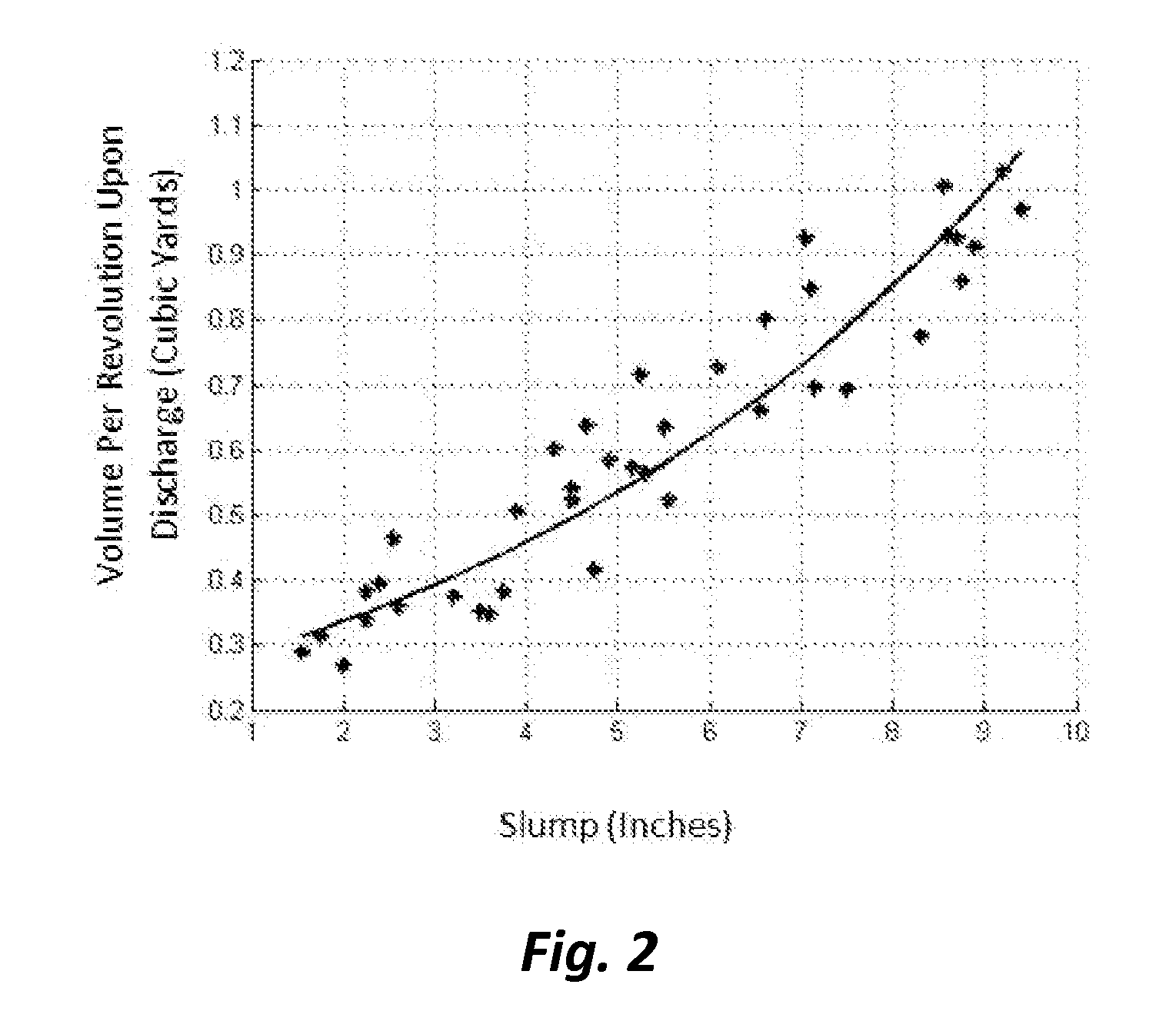

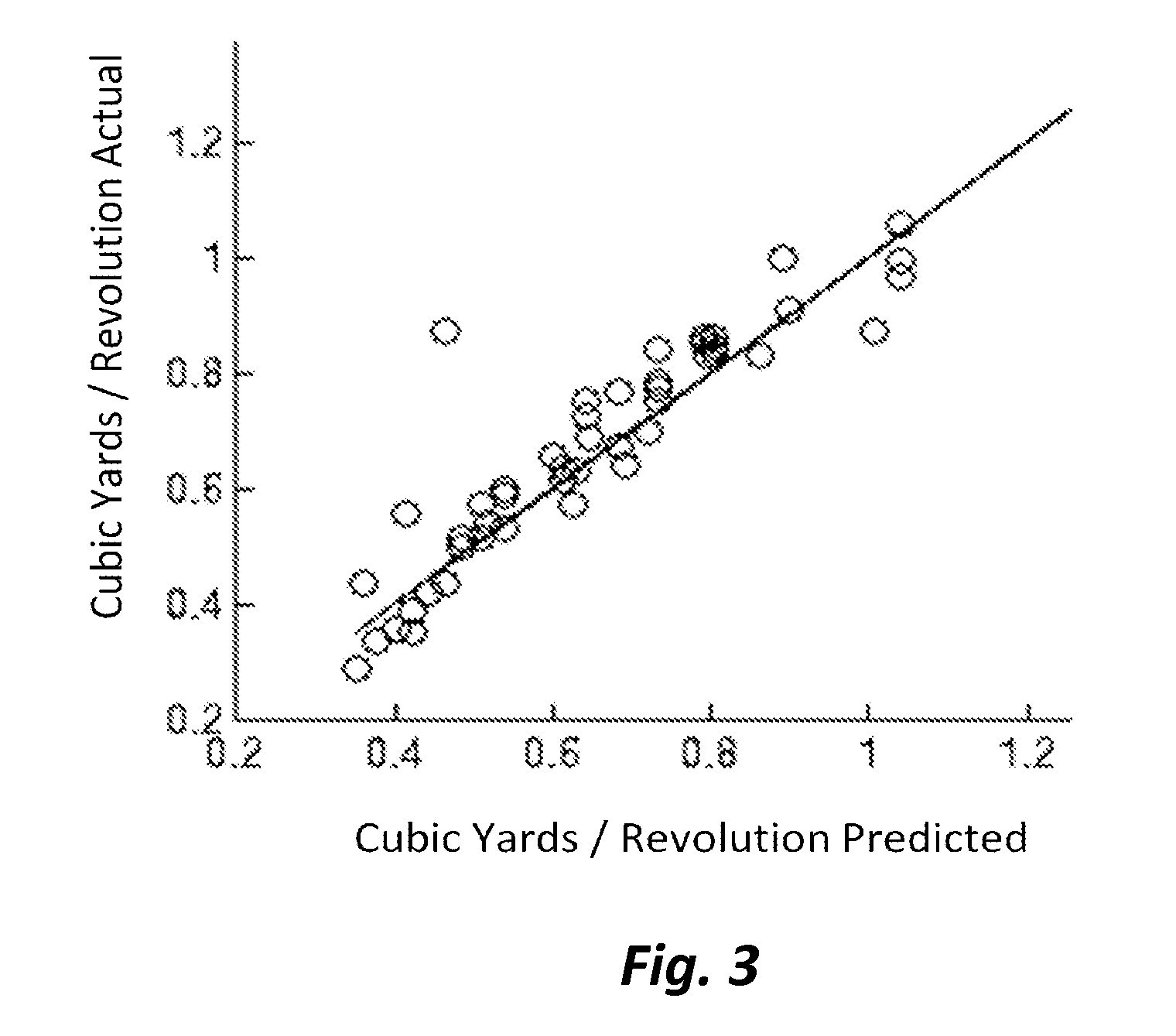

Treating and reporting volume of concrete in delivery vehicle mixing drum

ActiveUS20140104972A1Novel convenient highly accurate methodAccurate and convenient methodSampled-variable control systemsDischarging apparatusDelivery vehicleMonitoring system

Disclosed are method and system for treating concrete in mixing drums of delivery vehicles having automated rheology (e.g., slump) monitoring systems programmed to dose fluids into concrete based on the monitored rheology. The present invention takes into account a Revolution-To-Discharge value (“RTD”) which reflects drum rotations needed to move concrete towards and through the mixing drum opening from which concrete is discharged, and also takes into consideration a Volume-Per-Revolution-Upon-Discharge (“VPRUD”) value which reflects the relation between the rate of discharge and rheology (e.g., slump) of concrete upon discharge. The invention is especially useful for reclaiming concrete in the drum after delivery and can confirm rheology based upon peak (maximum) discharge pressure. The present inventors found surprisingly that discharge pressure readings are useful for recalibrating automated rheology monitoring systems as well as for reporting and / or treating the remainder concrete.

Owner:VERIFI

Concrete mixture measurement sensor, system and method

ActiveUS20150355160A1Reduce biasWell mixedFlow propertiesMaterial testing goodsEngineeringLife situation

A sensor measures slump and rheological characteristics of the concrete and is connected to a system that adjusts the slump by monitoring the sensor within the interior surface of a concrete mixer and controlling liquid additions. Data is analyzed by a computer processing unit to determine the slump and rheological characteristics of the concrete, liquid required to meet the slump requirements. The measurement done by the sensor is more accurate then the existing methods because it brings into consideration the effect of the helix inside the mixer on the movement of the concrete mixture inside the mixer. Furthermore, this method also allows the operation of the sensor in “real” life situations where the rotation speed of the mixer can't be maintained at a fixed value. The fact that the sensor rotates with the drum and that the concrete mixture is pushed to the bottom of the mixing drum guaranties that all the concrete is “sampled” by comparing results collected from each revolution of the mixing drum.

Owner:GCP APPL TECH INC

Methods and systems for addition of cellulose ether to gypsum slurry

An example system for making a gypsum board product comprises a container for containing a gypsum slurry, a moving receiver in communication with the container, wherein the container substantially continuously deposits the gypsum slurry on the moving receiver. A first and at least a second cellulose ether supply containing a first cellulose ether communicate with the container. The first and second supplies contain cellulose ethers having different physical or chemical properties. A controller is configured to change the amount of the first and second cellulose ethers delivered to the container in response to a change in at least one slurry physical property.

Owner:UNITED STATES GYPSUM CO

Slump flow monitoring

Method and system for monitoring slump flow of hydratable cementitious material such as wet concrete in a rotating mixing drum. Whereas prior art methods use a single value of the hydraulic pressure for turning the drum (such as the average value) and correlating with slump values using the vertical drop measurements of the standard slump test (e.g. ASTM C 143-05), the present invention involves analysis of values corresponding to slump flow of concrete samples, preferably having slump flow values of 16-36 inches when measured using standard slump flow tests (e.g., ASTM C1611-05).

Owner:VERIFI INC

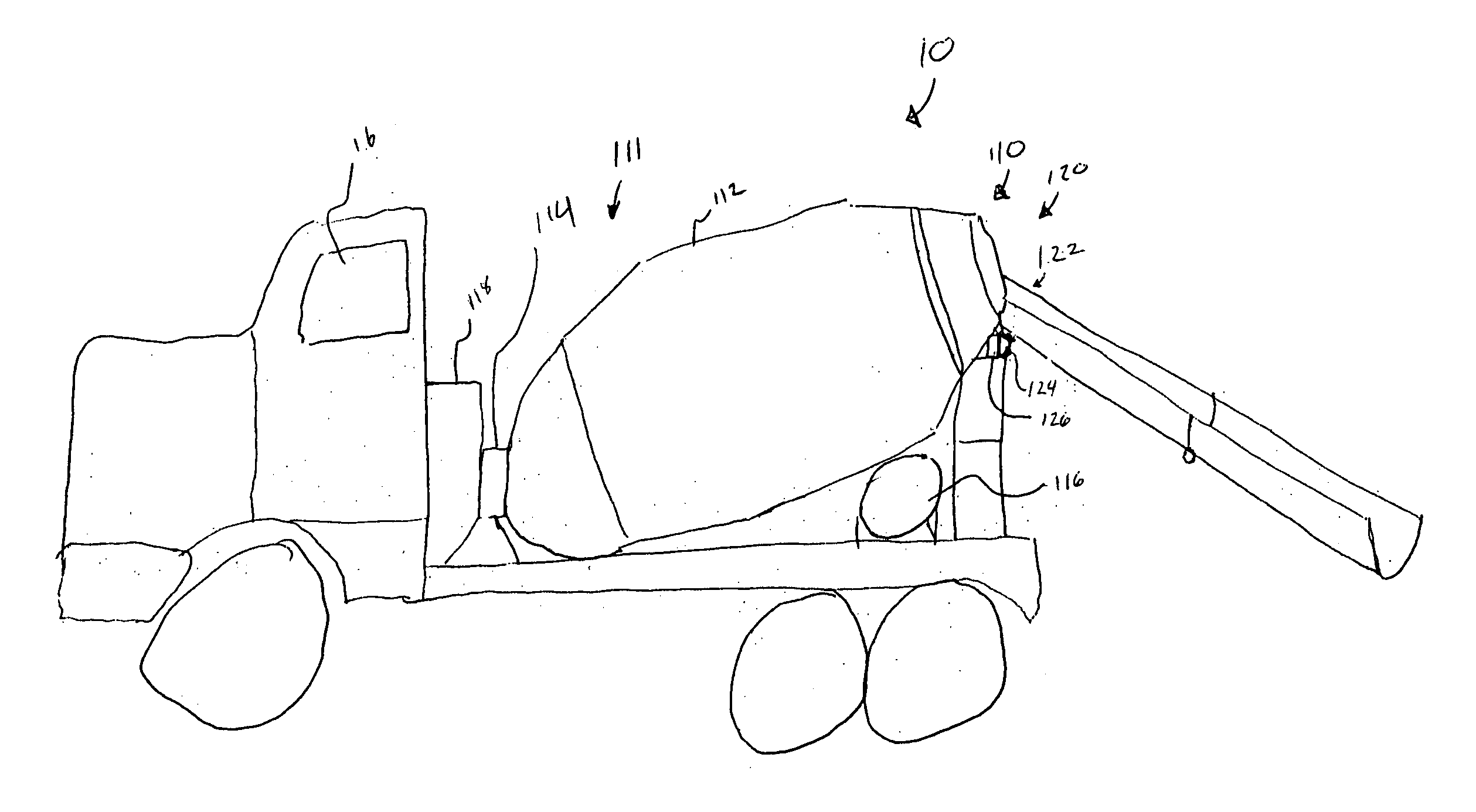

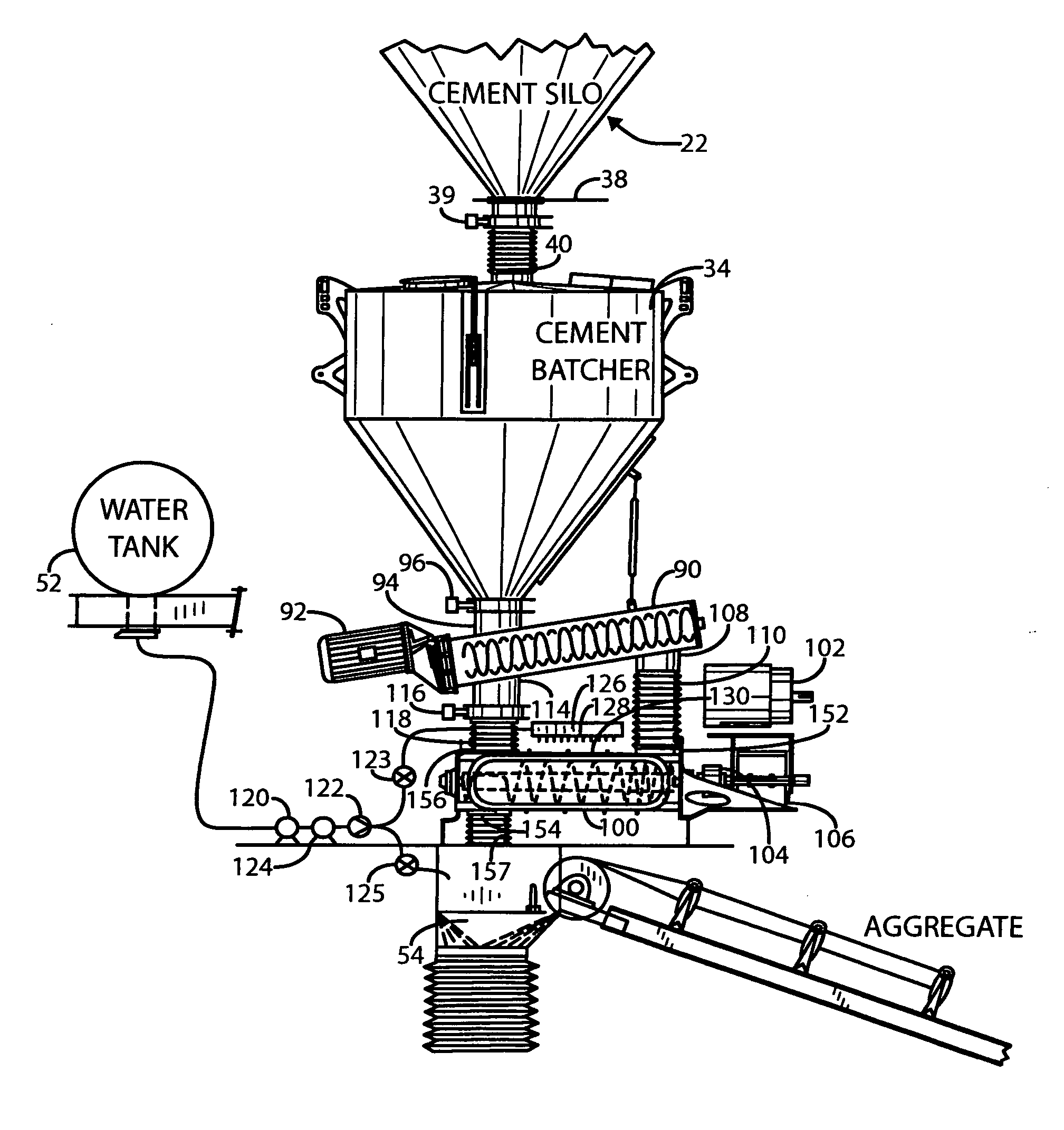

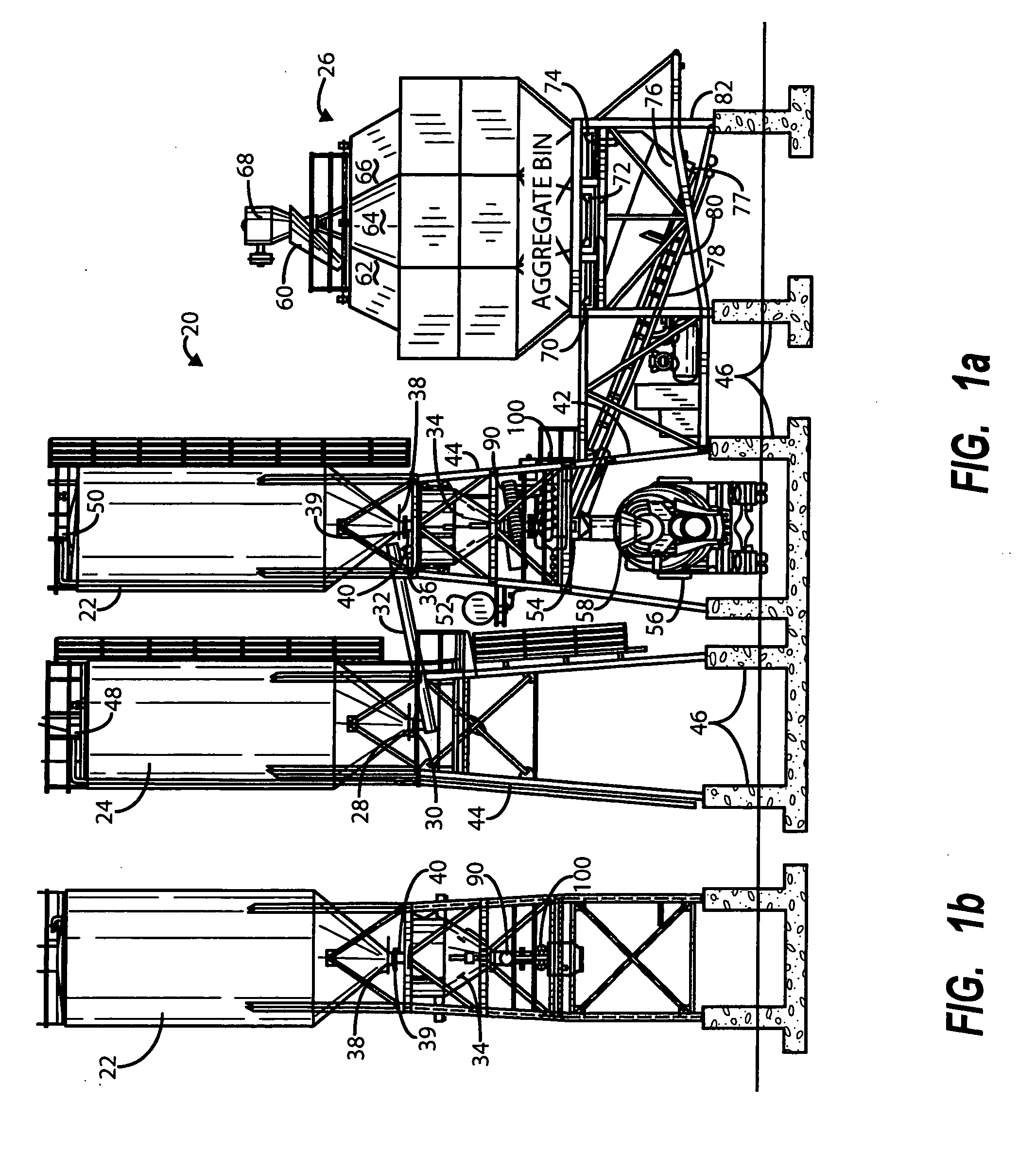

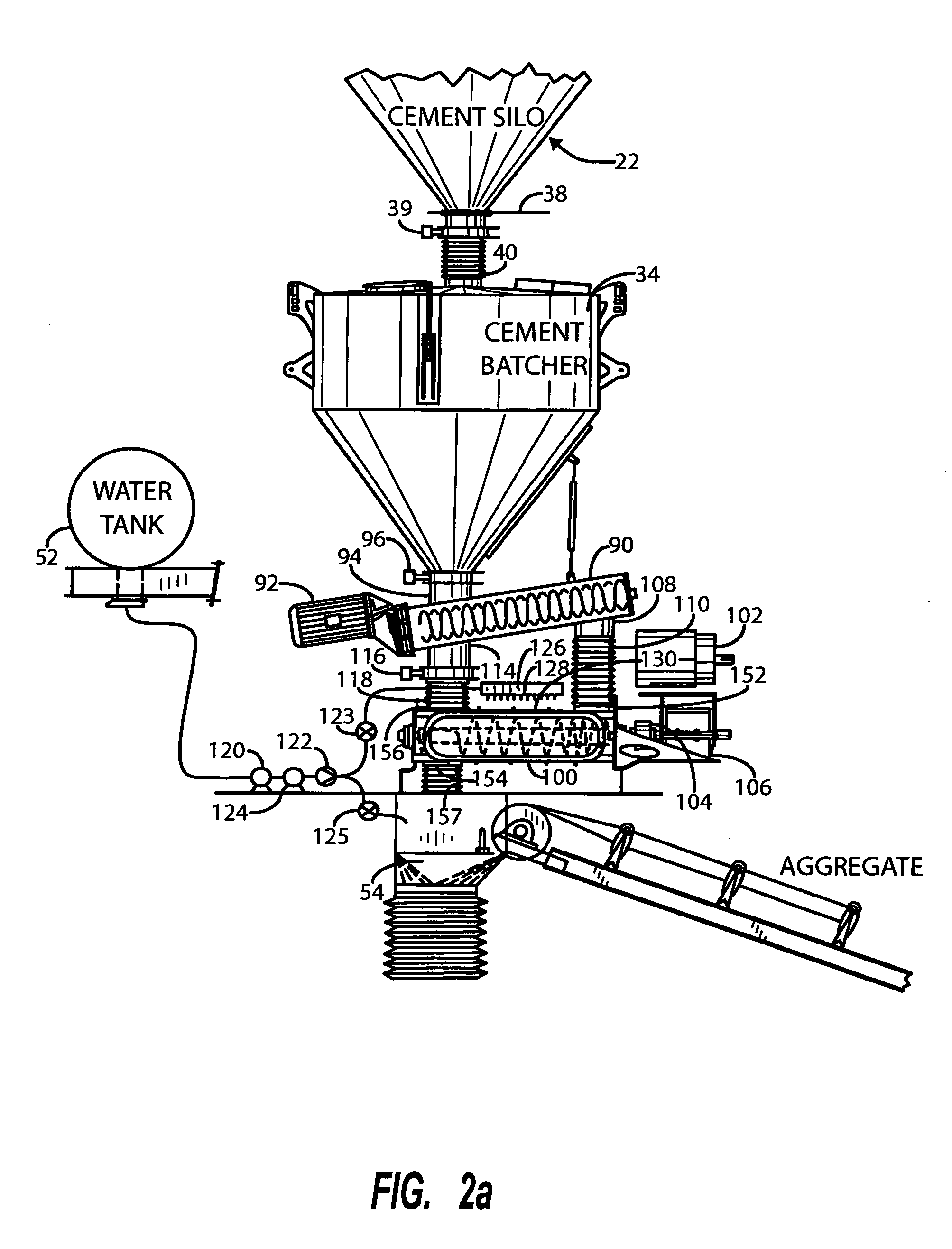

Concrete batching pre-mixer and method

InactiveUS20050219939A1Eliminate buildupWell mixedTransportation and packagingMixing operation control apparatusTruckMixed systems

A pre-mixer agglomerator and method of pre-mixing batching ingredients used to produce concrete mixes is disclosed. Specifically, this invention involves a pre-mix system which blends the wetting agents and the cementitious ingredients in relation to each other at any selected ratio in an adjustable and repeatable manner. The pre-mixer is a twin screw, preferably counter-rotating, pre-mixer agglomerator unit for pre-mixing these materials prior to combining them with aggregates in a drum of a transit mixer truck or other final mixing vessel.

Owner:MCNEILUS TRUCK & MFG INC

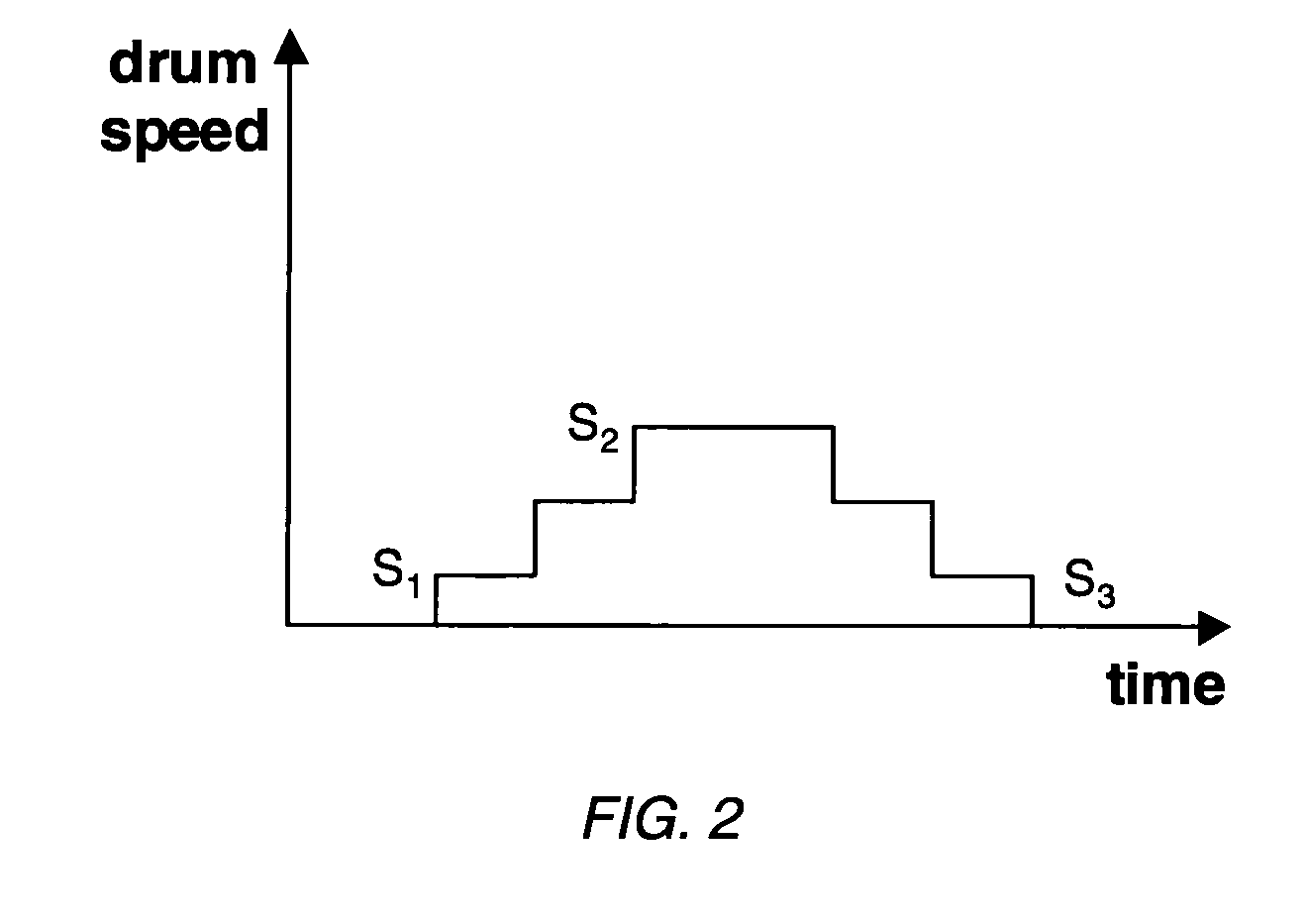

Automatic drum rotation control concrete transit mixer truck

A concrete transit mixer truck includes a control system that automatically controls rotation of the mixer drum at a constant drum speed when the mixer truck is traveling. When sensed speed of the truck exceeds a threshold, the control system automatically causes a hydraulic system to rotate the drum at a constant speed, regardless of the truck engine speed.

Owner:SCHWING AMERICA

Method for monitoring thixotropy in concrete mixing drum

The invention provides ‘thixotropy’ monitoring, by measuring the reversible, time-dependent reduction in viscosity occurring when concrete is subjected to mixing, and employs a mixing drum and conventional slump monitoring equipment as used on ready-mix trucks. In one embodiment, the drum is rotated until concrete is completely mixed; the speed is altered, such as by increasing it to a predetermined level; and the energy required to rotate the drum (ER) is monitored; the maximum (ER-MAX) and minimum (ER-MIN) values are recorded in computer memory; and these values are compared to pre-determined (target) values. Rheology factors (including viscosity, yield stress, and / or thixotropy) can be adjusted accordingly by adding liquid component(s) into the mix. This method, suitable for delivery of highly fluid concrete speed such as SCC, can involve transit and placement rheology targets during monitoring.

Owner:GCP APPL TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com