Patents

Literature

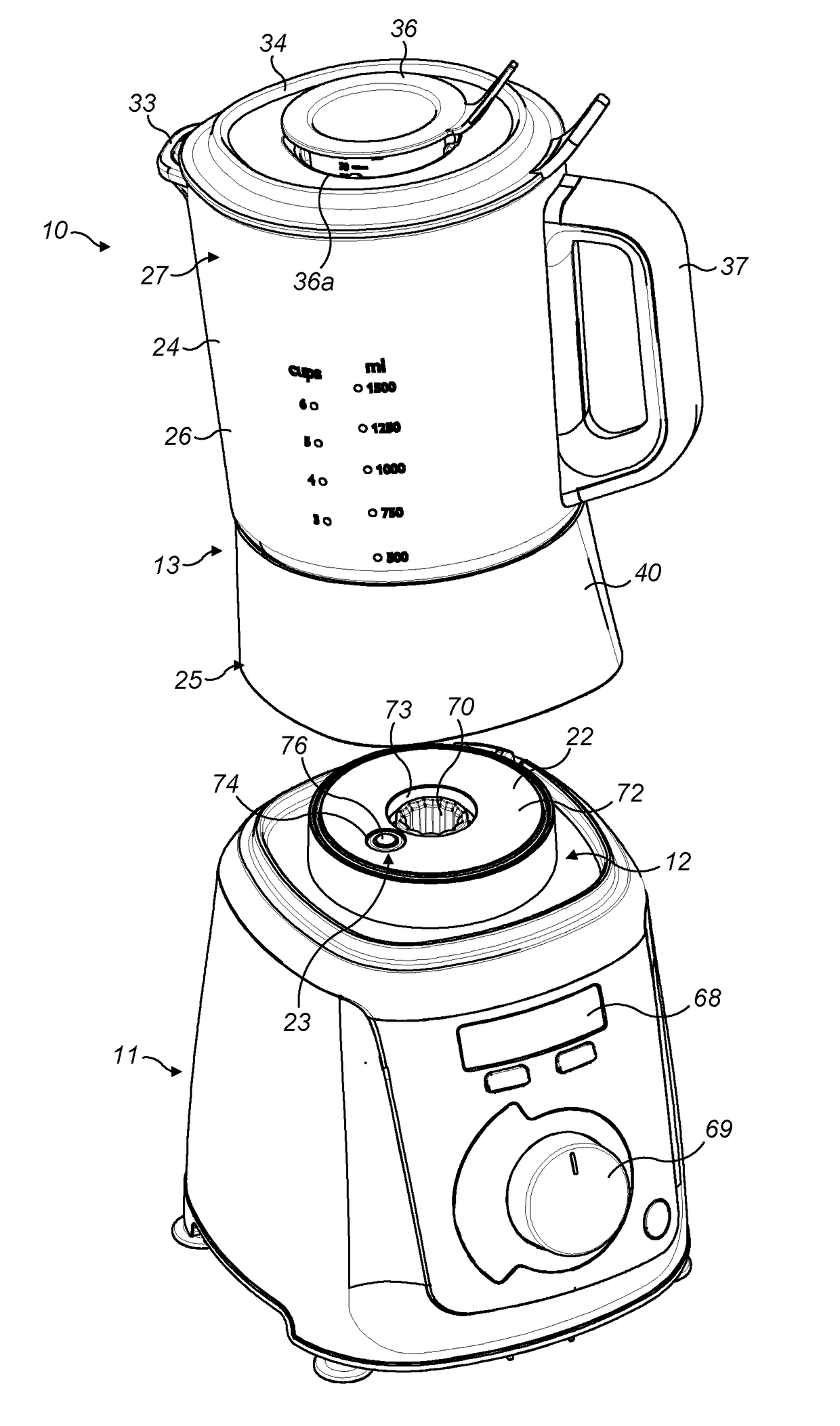

1525 results about "BLENDER/MIXER" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

General purpose laboratory equipment labeled or promoted for a specific medical use is a device that is intended to prepare or examine specimens from the human body and that is labeled or promoted for a specific medical use.

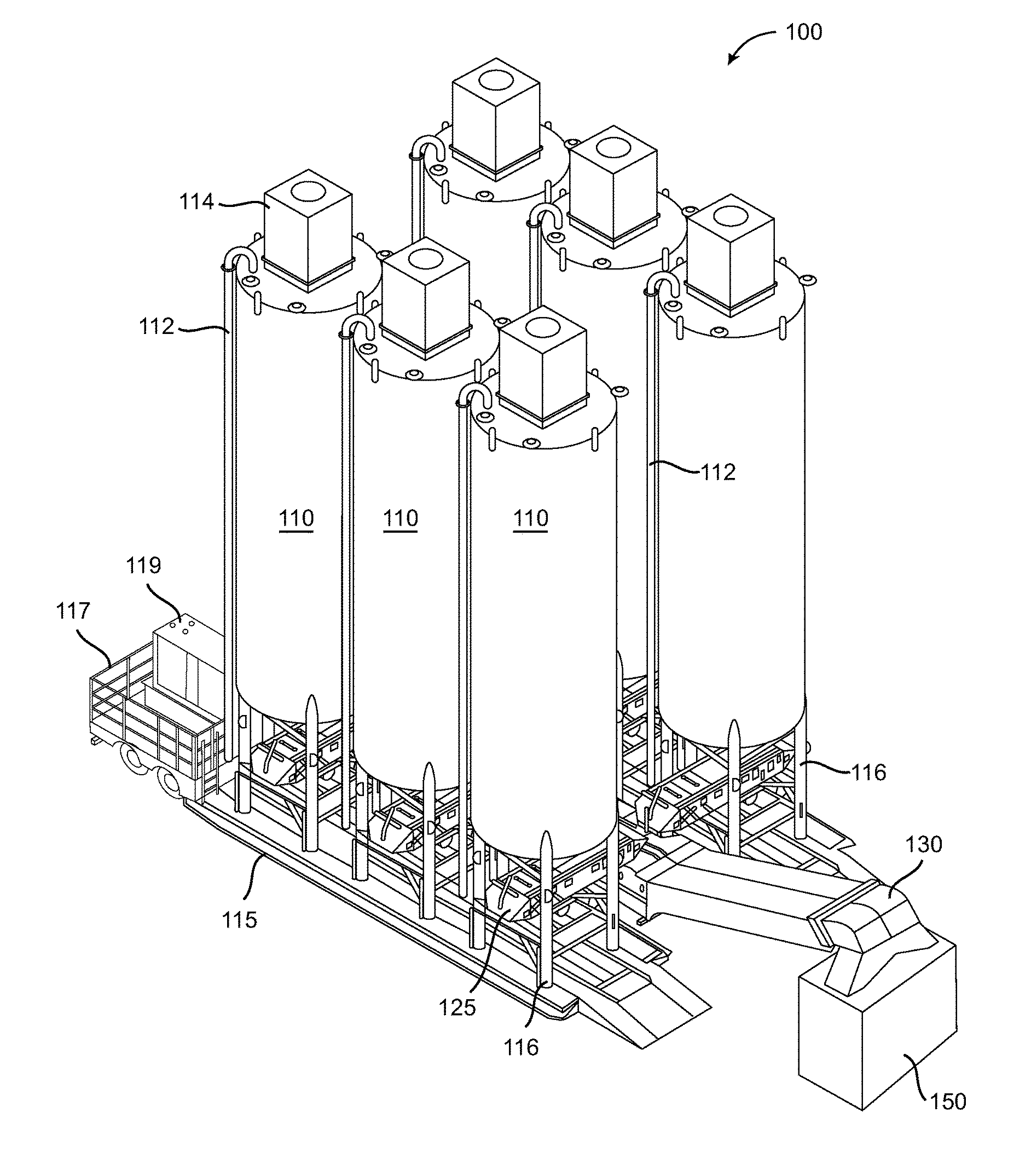

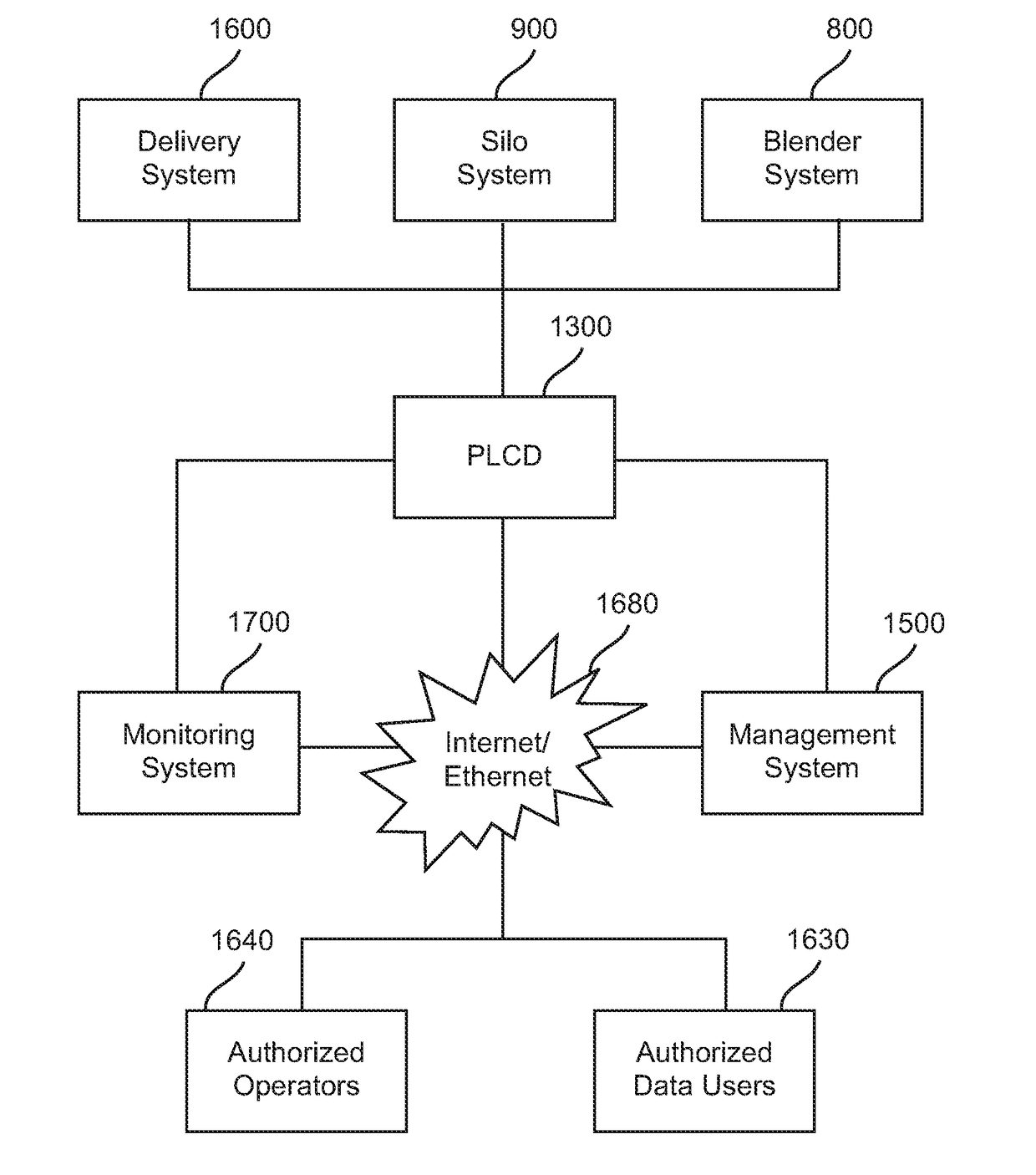

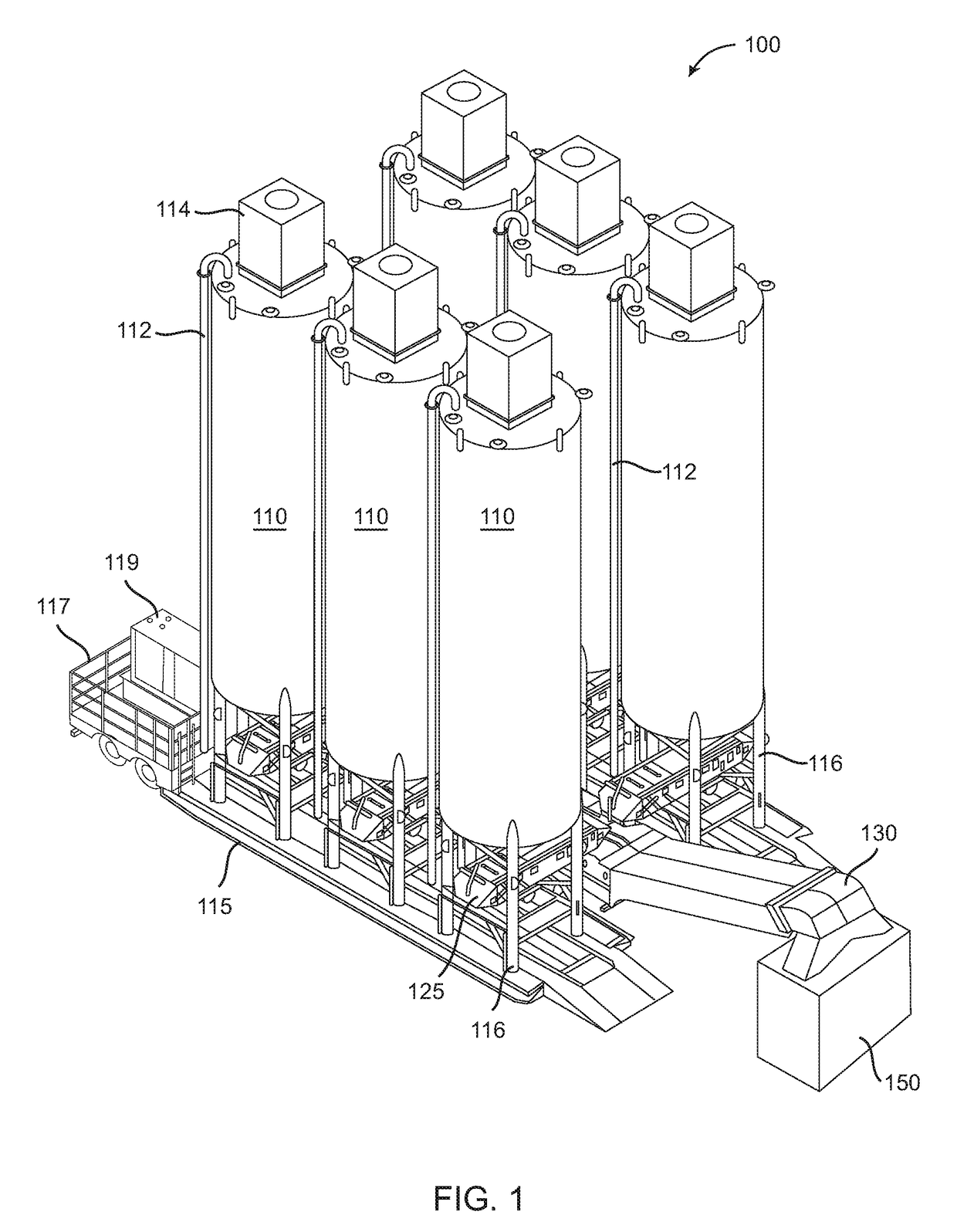

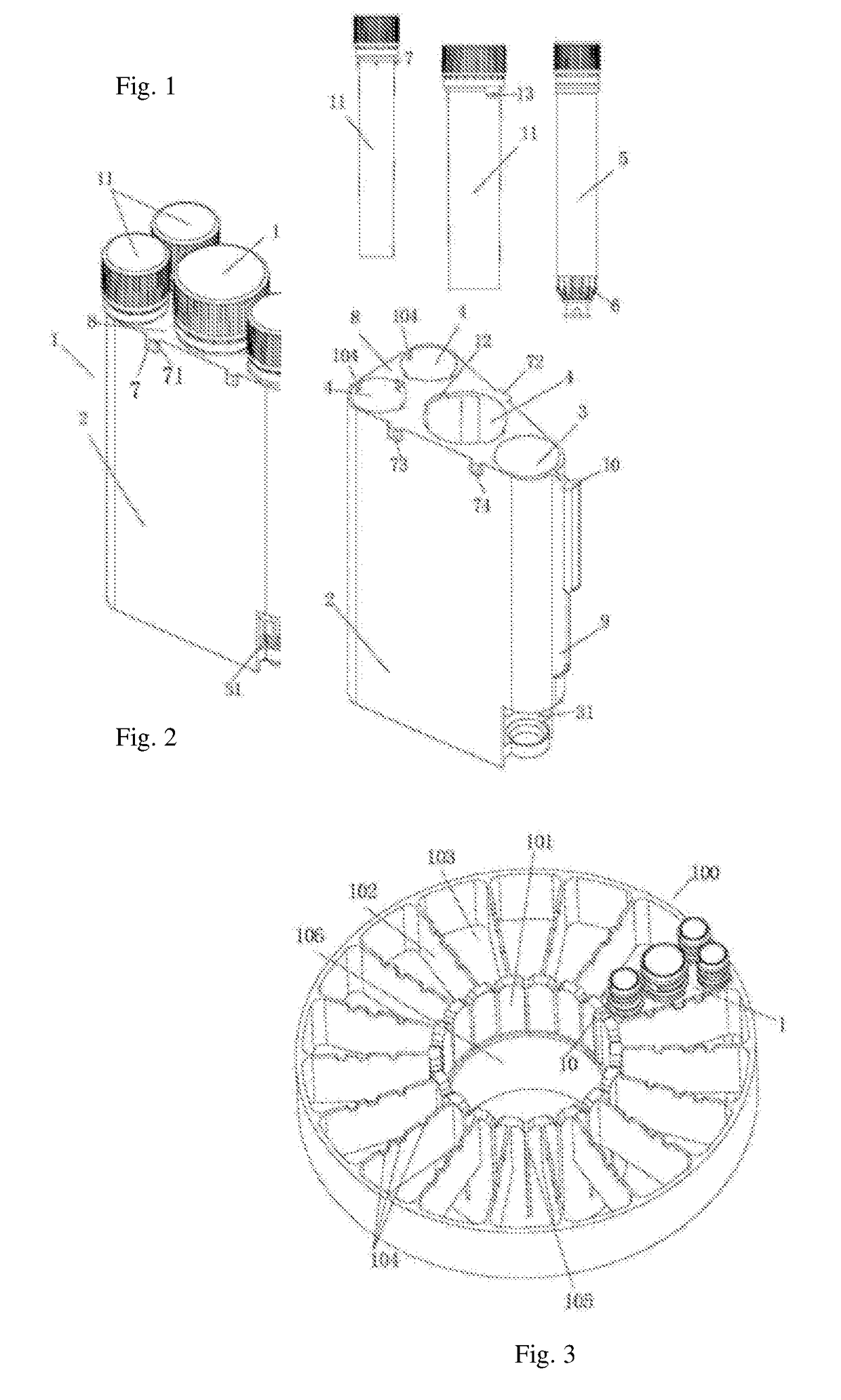

Storage and blending system for multi-component granular compositions

Embodiments of the present invention include a method and system for blending multi-component granular compositions such as proppant used in hydraulic fracturing in well drilling. The system includes the control and management of an on-site storage system for each of the components, regulating the delivery of specified quantities of each component to a blender, and coordinating the flow of materials into and out of the blender.

Owner:SOLARIS OILFIELD SITE SERVICES OPERATING

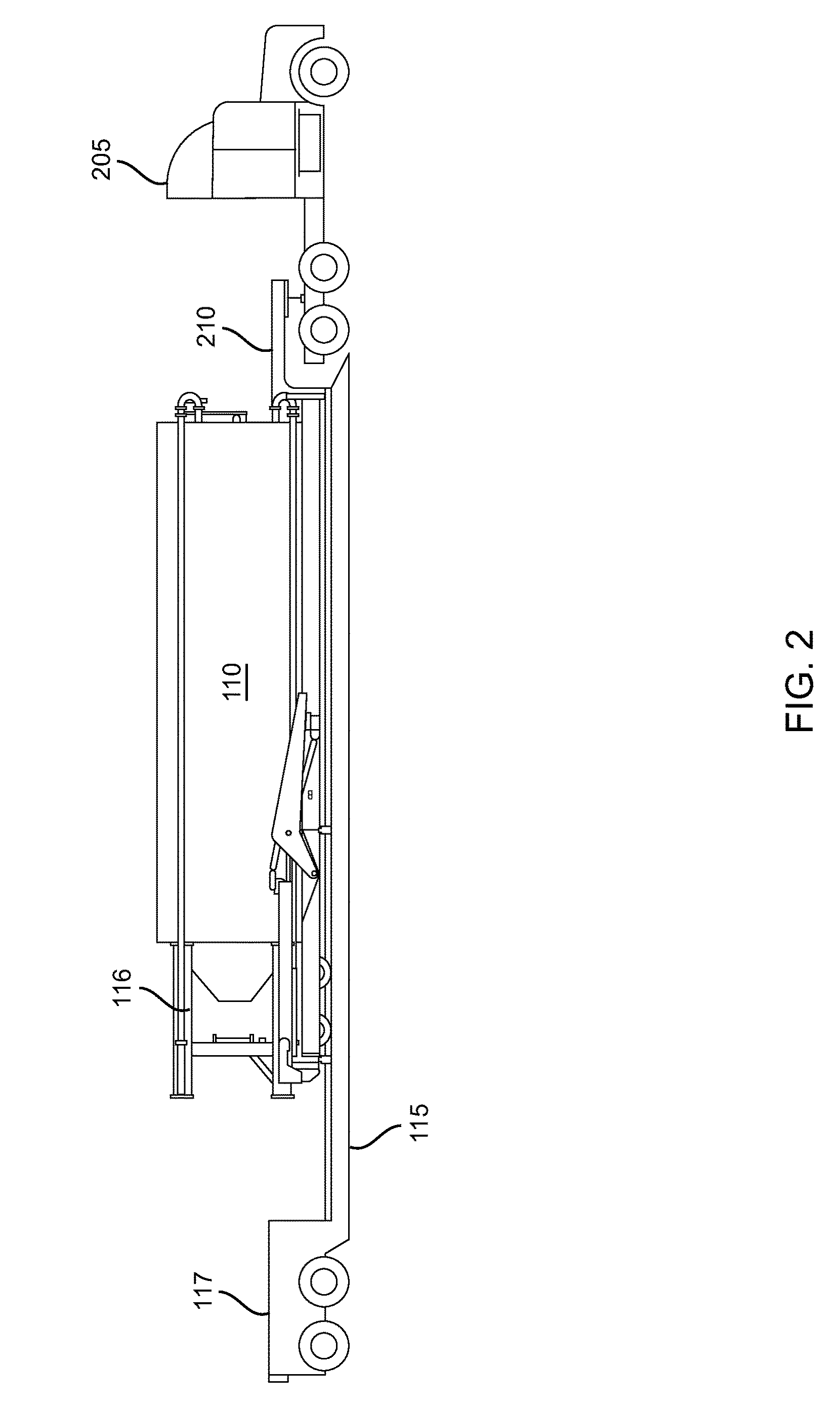

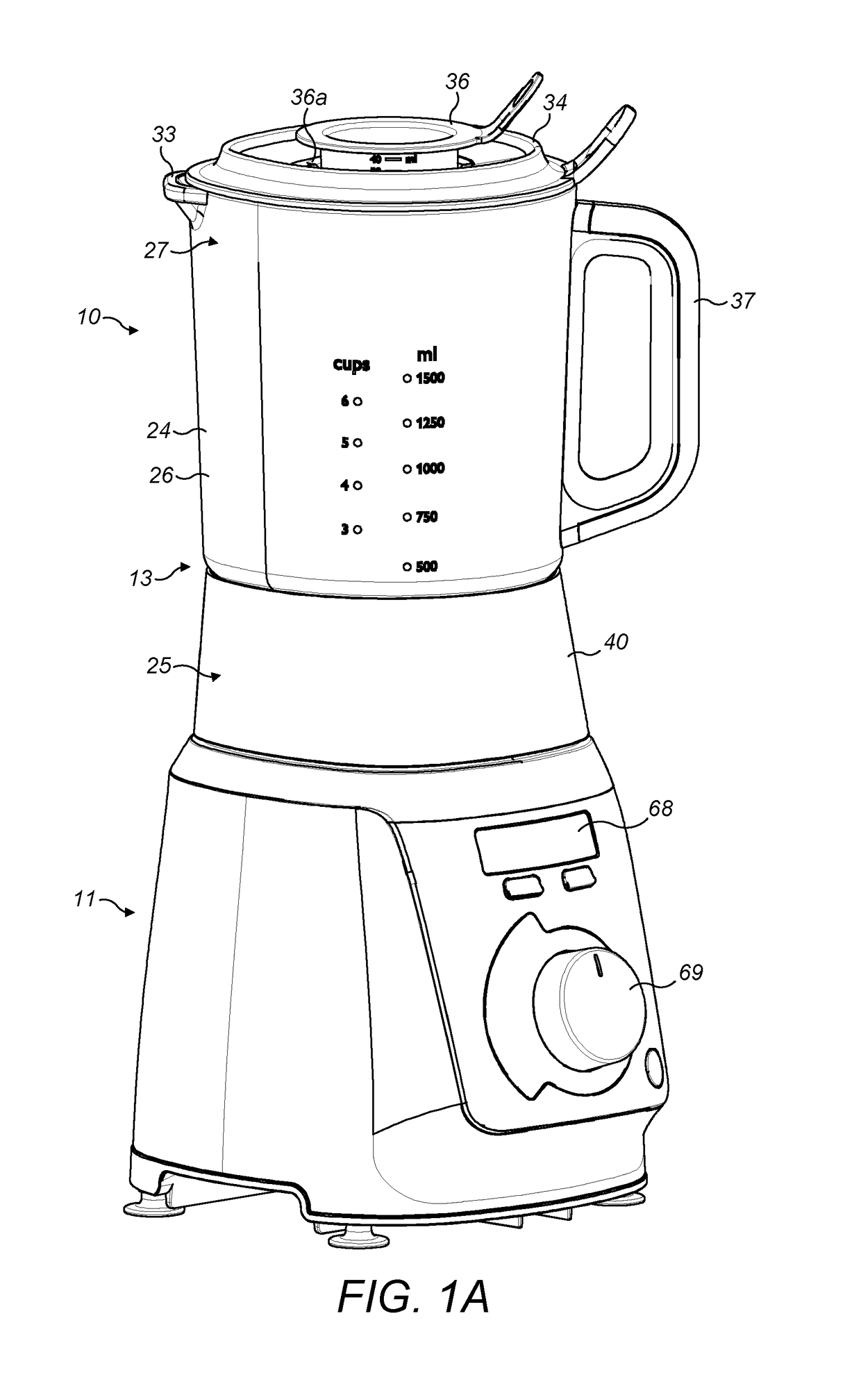

Blender with temperature sensor

ActiveUS20180206677A1Improve temperature sensing accuracyAccurate inductionTransportation and packagingRotary stirring mixersAdditive ingredientEngineering

Owner:VERSUNI HLDG BV

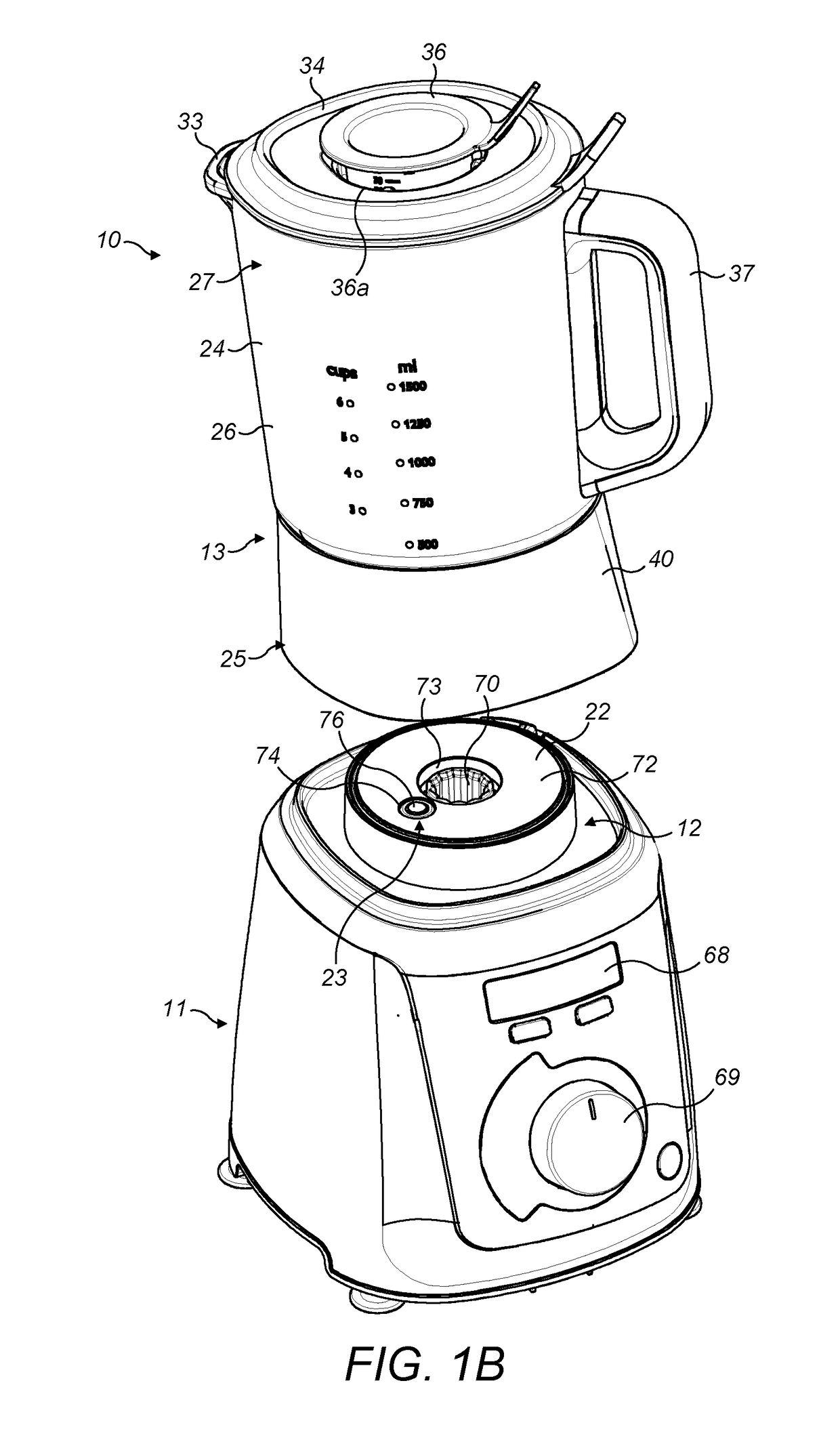

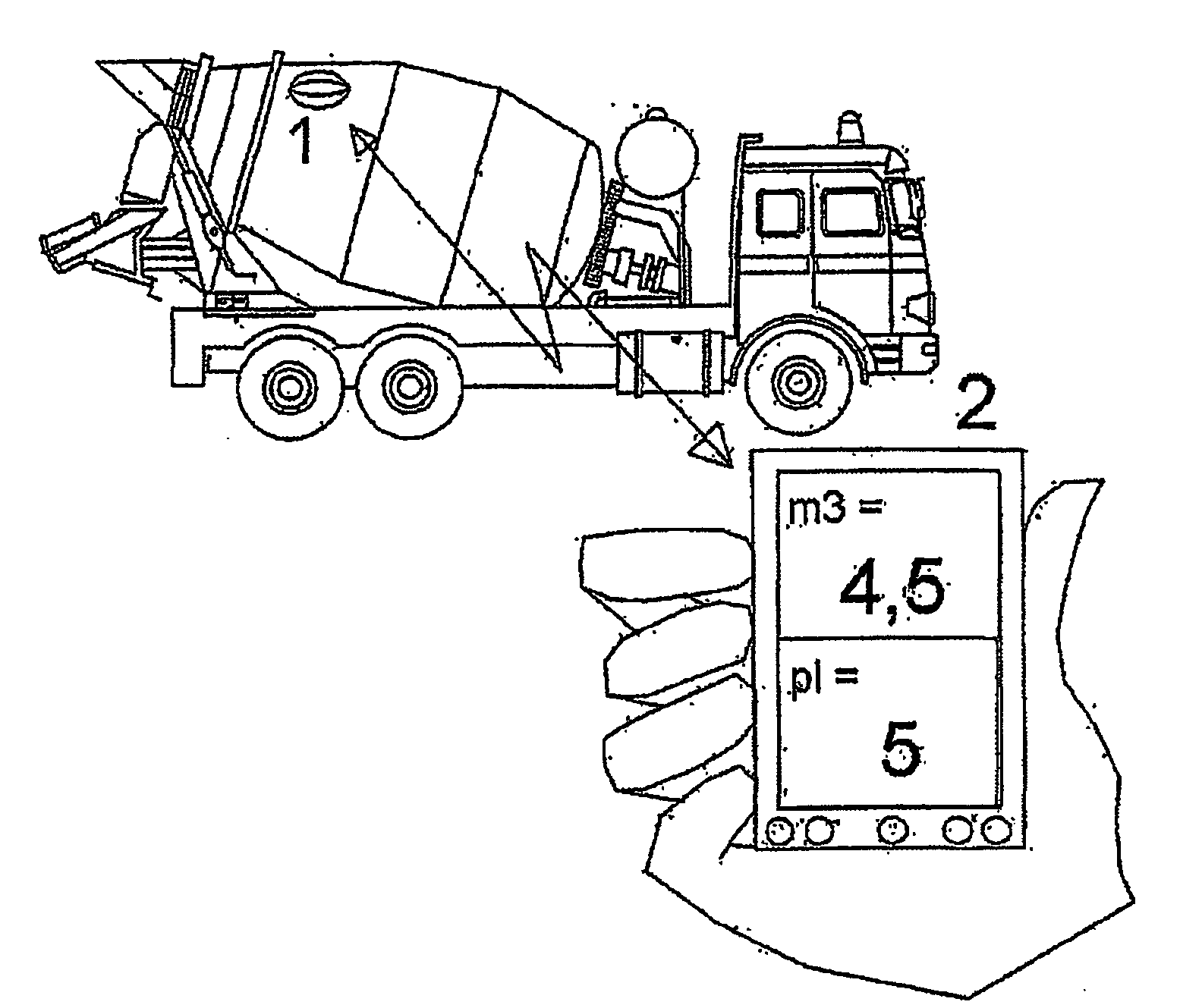

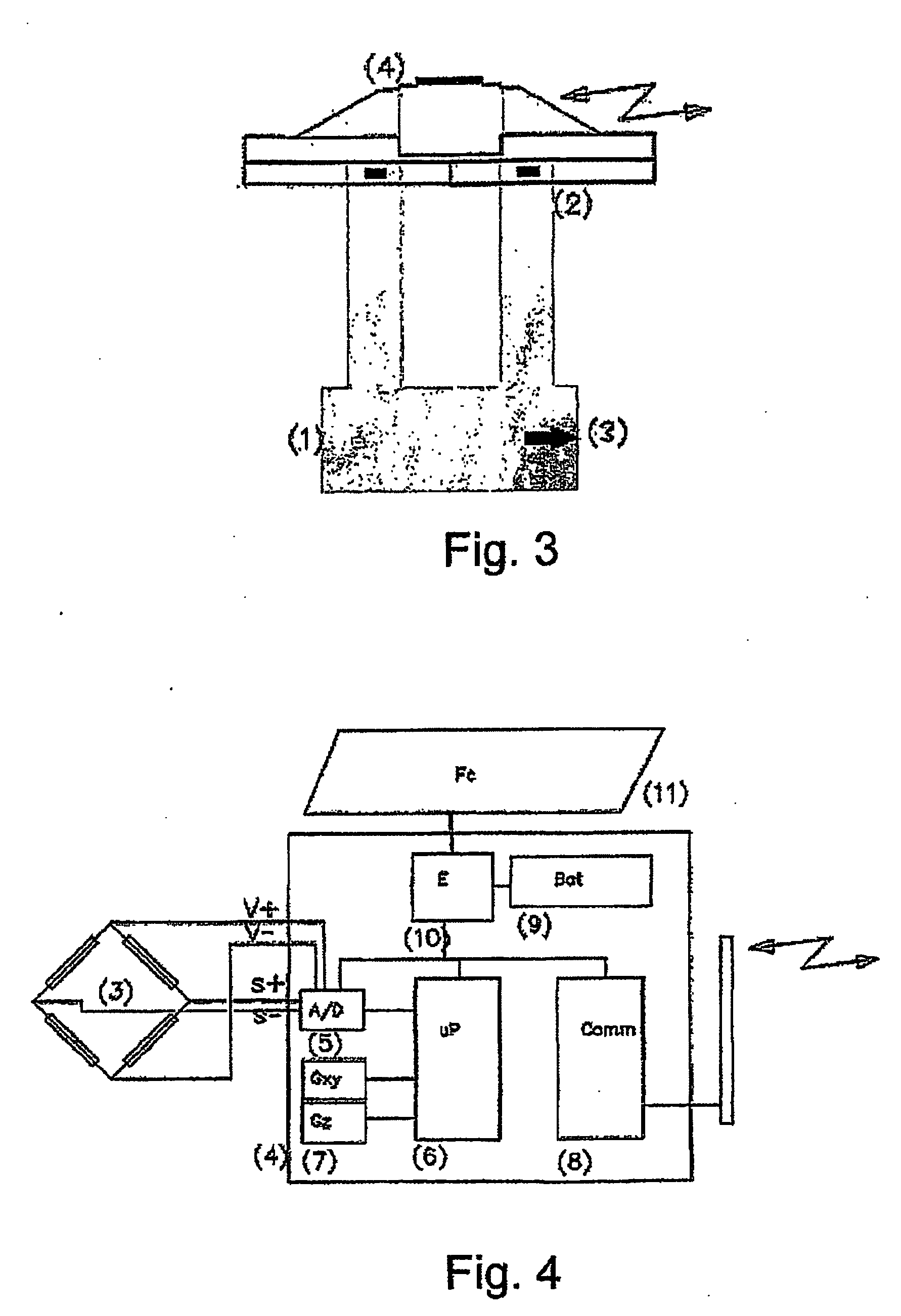

Automatic System for Monitoring the Mixing of Conglomerates

ActiveUS20090171595A1Force measurementAcceleration measurementTelecommunications equipmentBLENDER/MIXER

The invention relates to an automatic system for monitoring the mixing of conglomerates. The inventive system can be used to monitor and measure the volume of a conglomerate, i.e. a concrete, mortar or other similar product, and the conditions in which the conglomerate is being mixed inside a mixer. The invention is characterised in that the system is provided with a sensor which rotates integrally with the mixer and which is fitted with a blade that is sensitive to the stresses exerted by the conglomerate thereon. The invention is also characterised in that the aforementioned information is transmitted to one or more terminals, by means of radio communication or other similar wireless communication means, for use in industrial processes.

Owner:OZAMIZ TAPIA ANTONIO +1

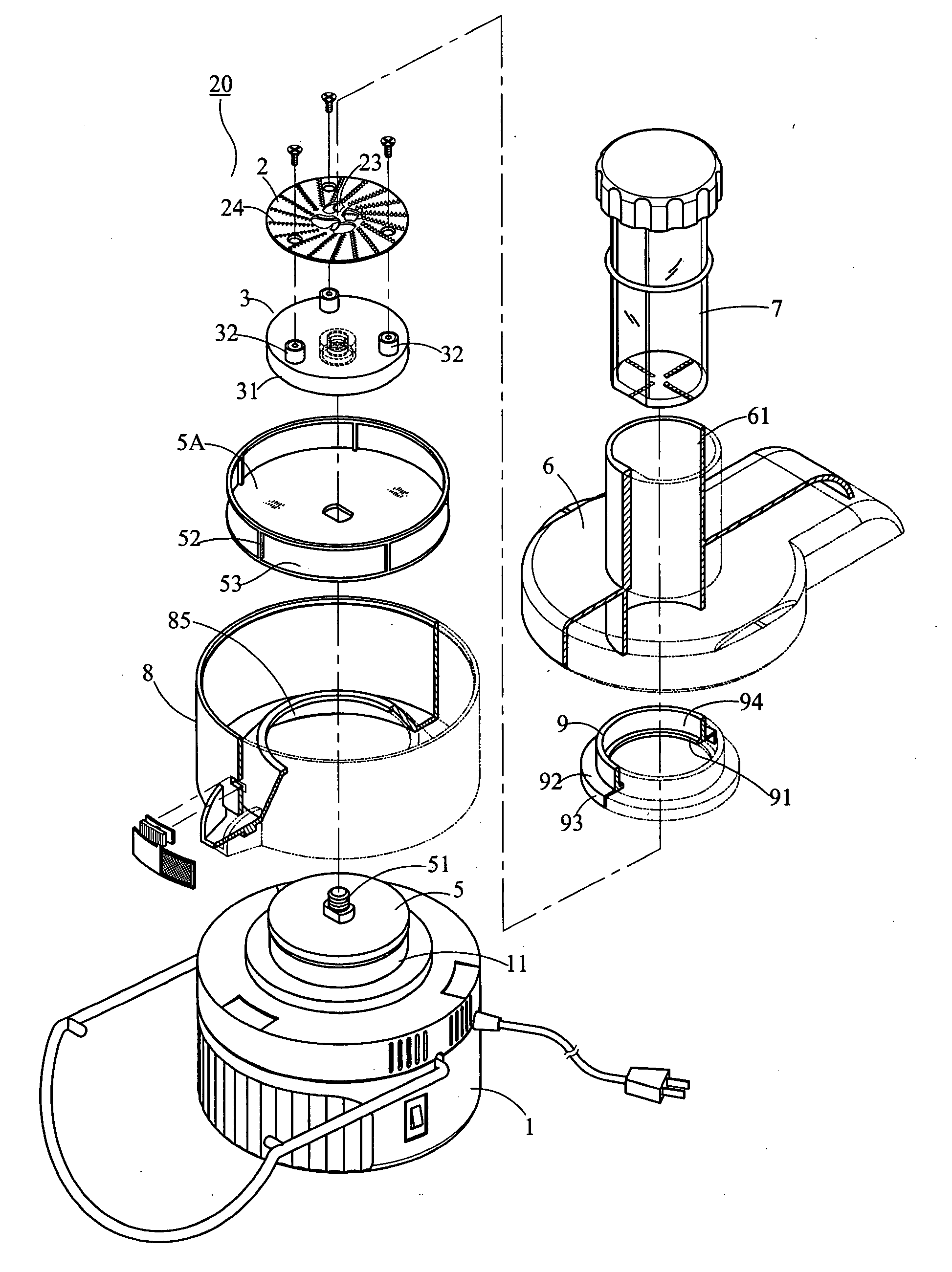

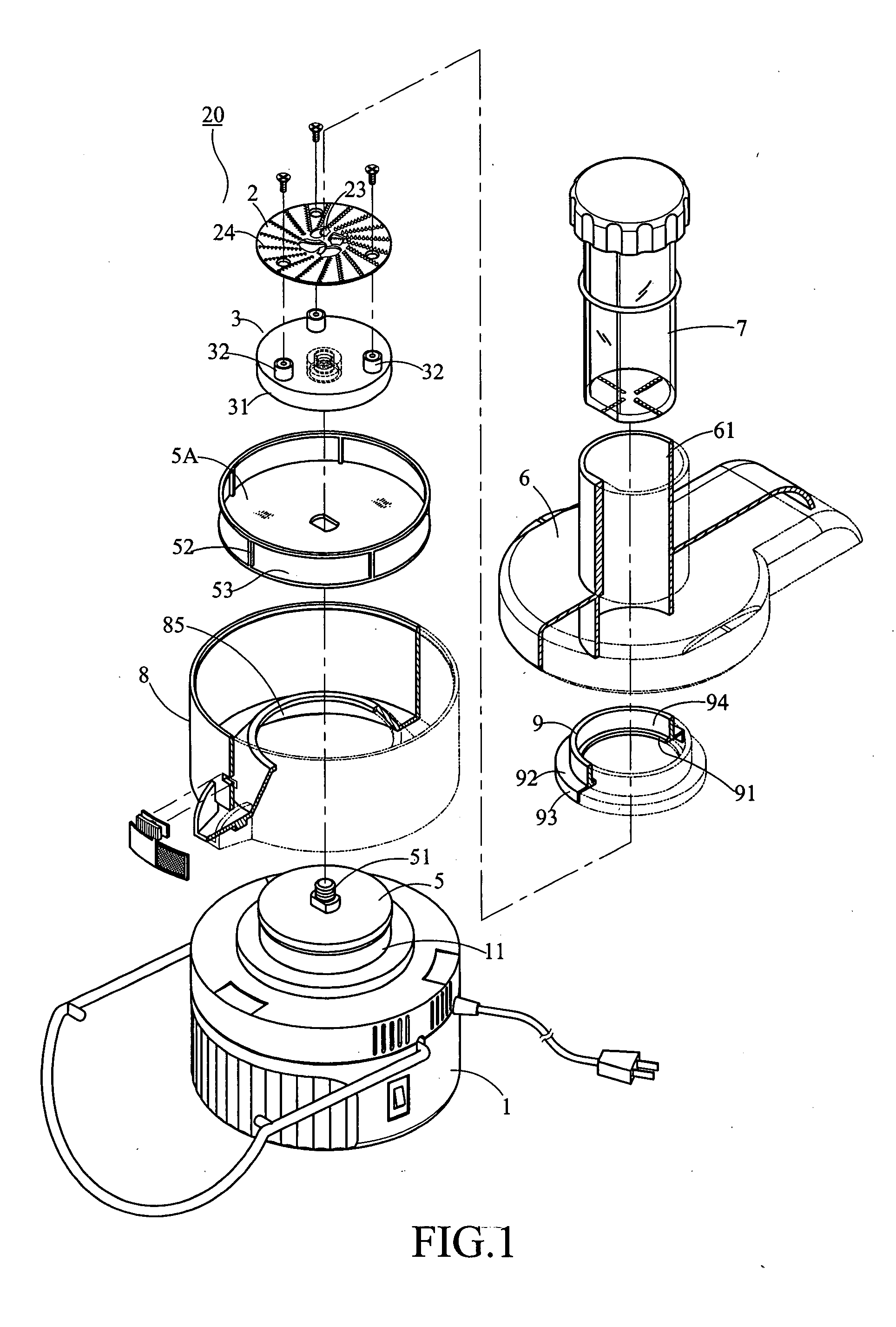

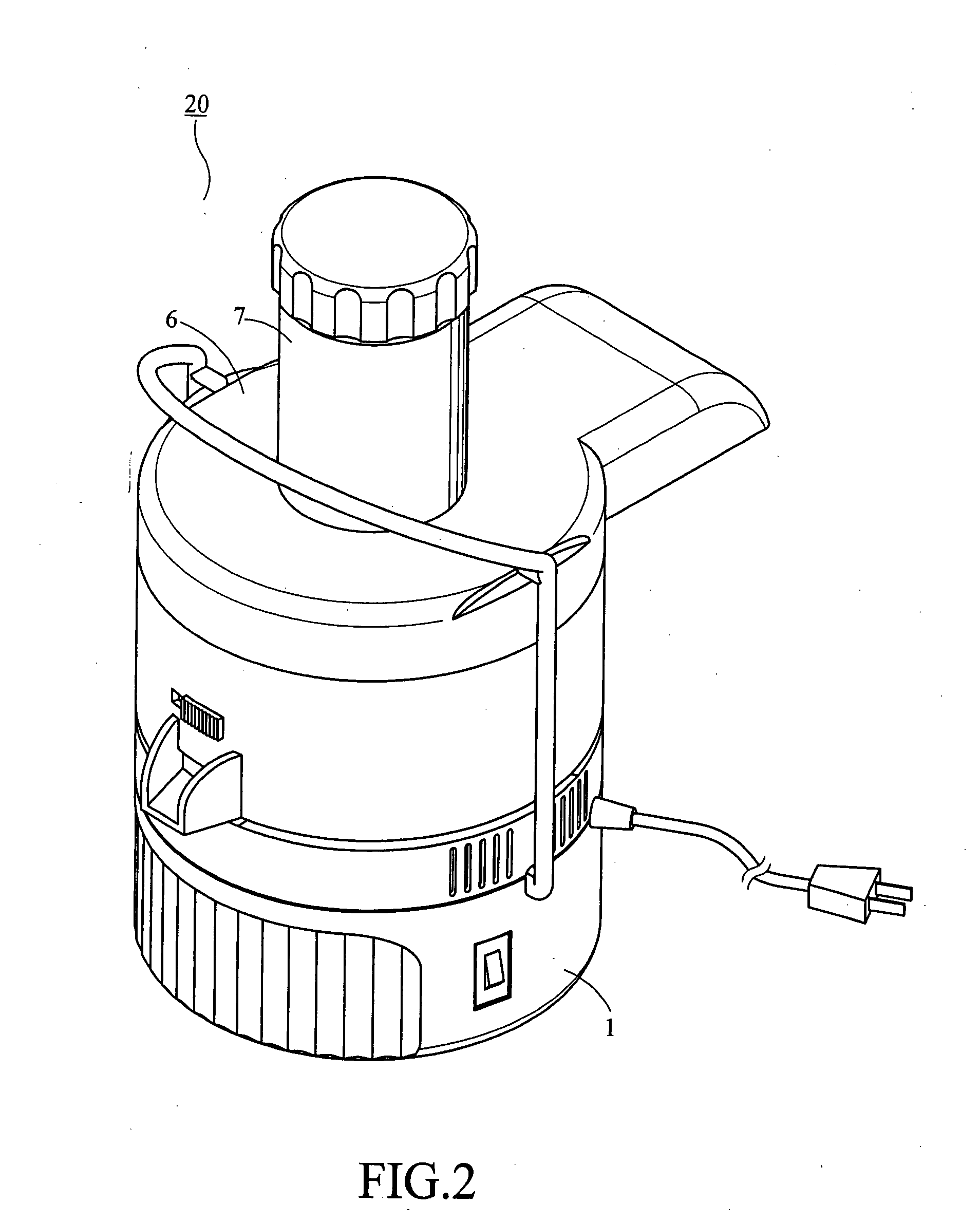

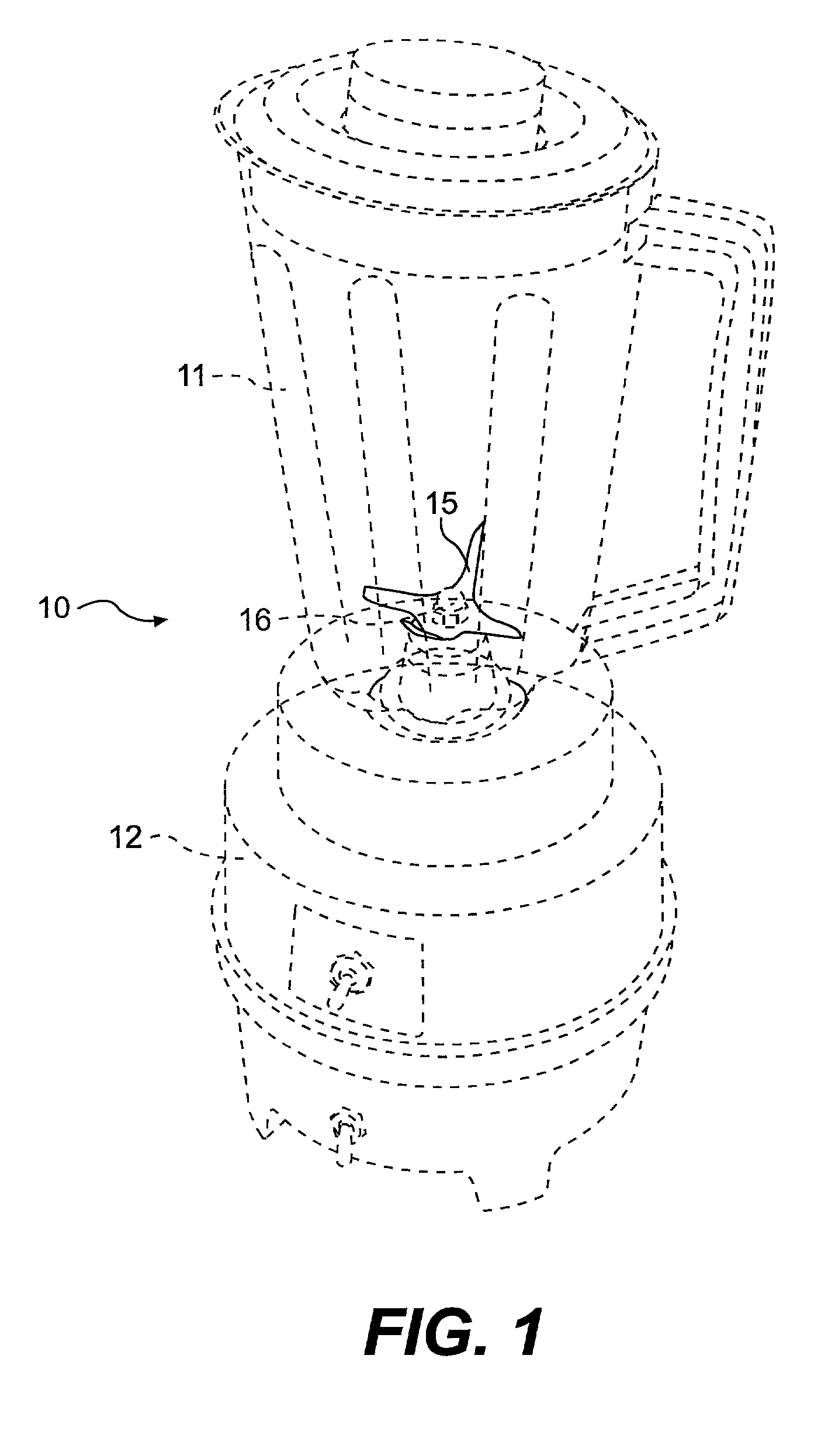

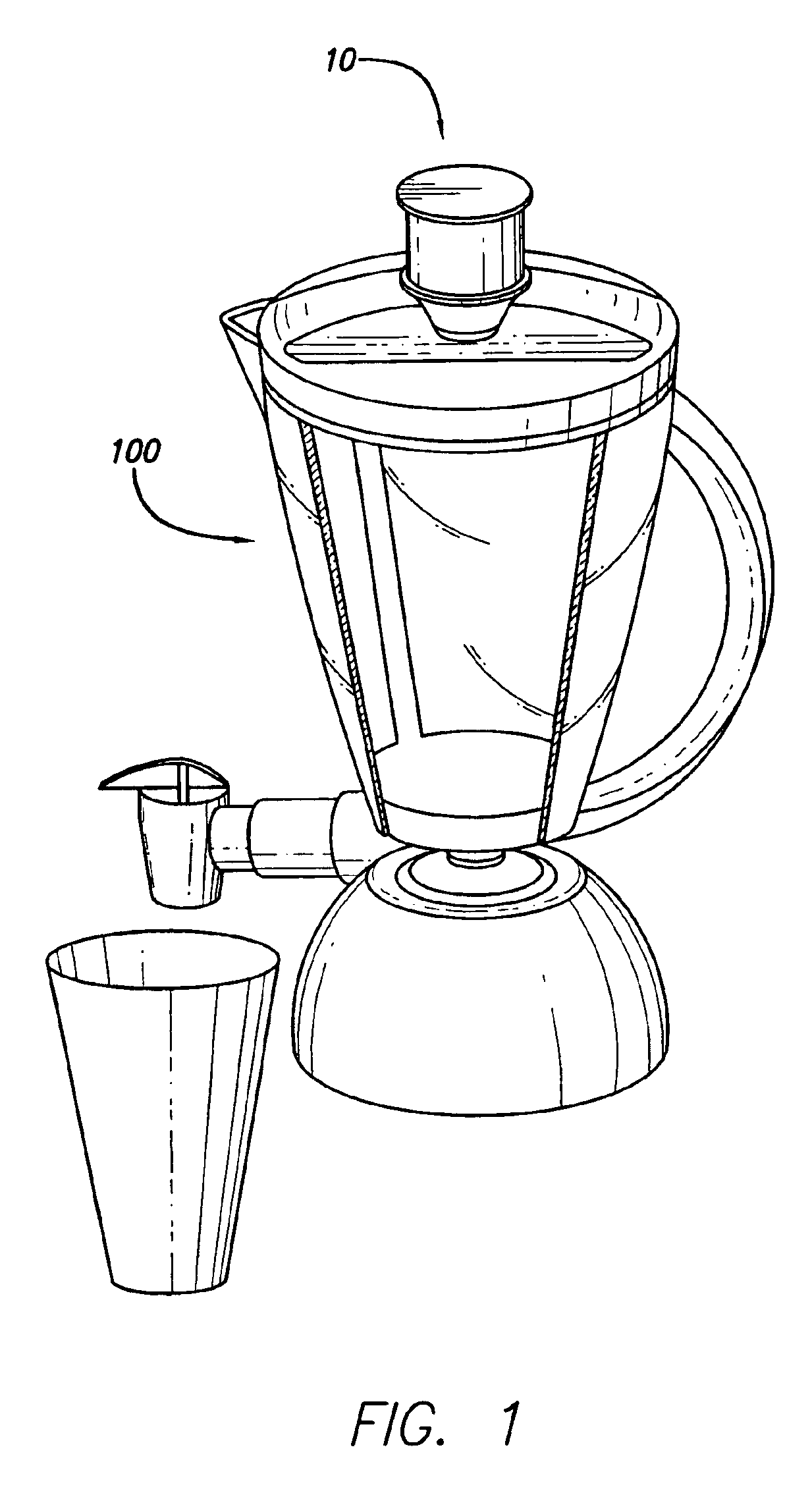

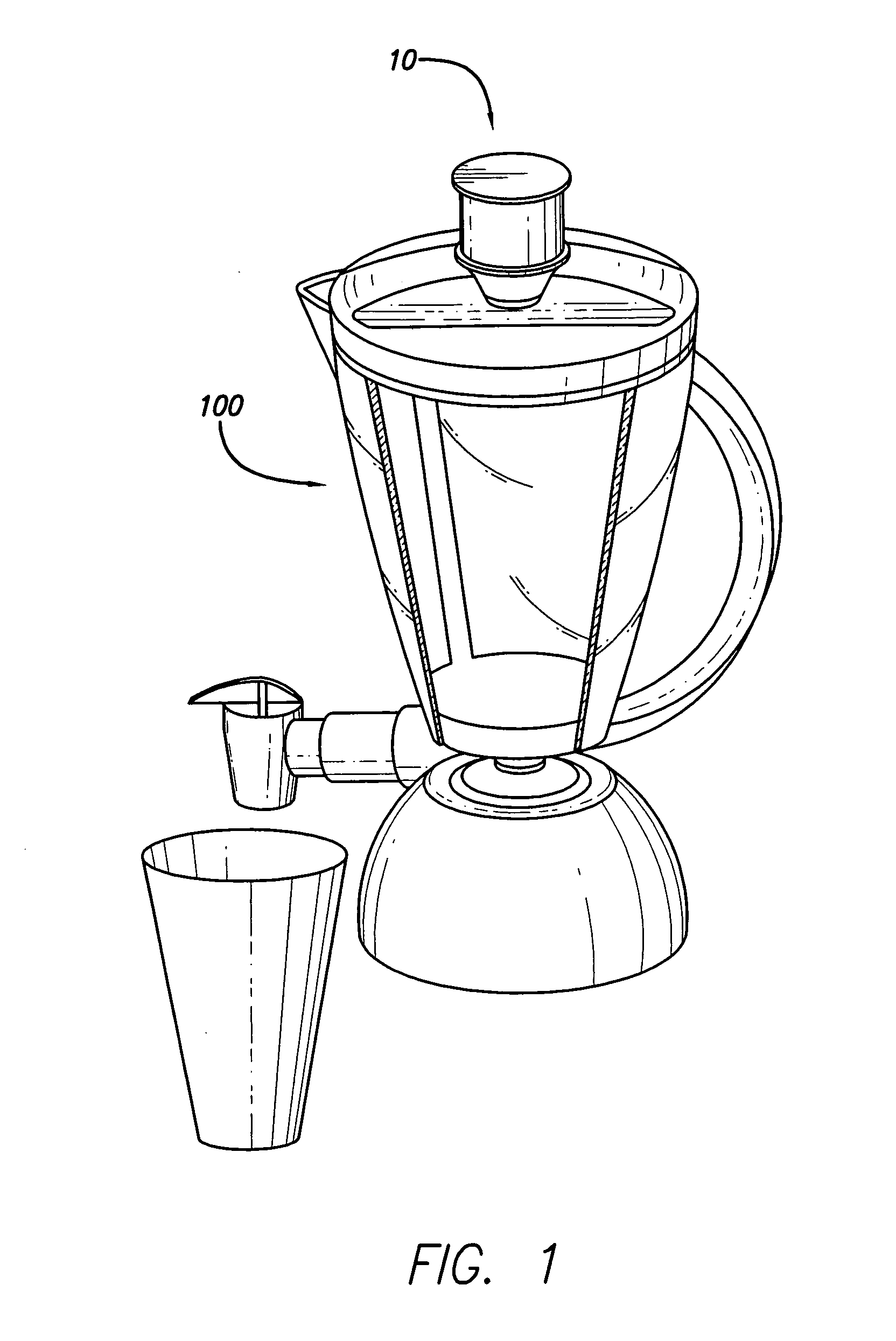

Blender

InactiveUS20070209528A1Efficient productionSufficient supplyJuice extractionCentrifugesBLENDER/MIXEREngineering

The present invention is related to a blender, particularly to a blender having a blade disk formed with dreg-expel holes in front of leading edges of blades of inner circle, and a ring-typed cover added below a feed chute as well as being hung over the blade disk to keep gaps in between, thereby it can get pulp contained with juice; which introduces less air thereinto, further enzymes found in raw vegetables and fruits may not be destroyed.

Owner:CHANG MING SHIH

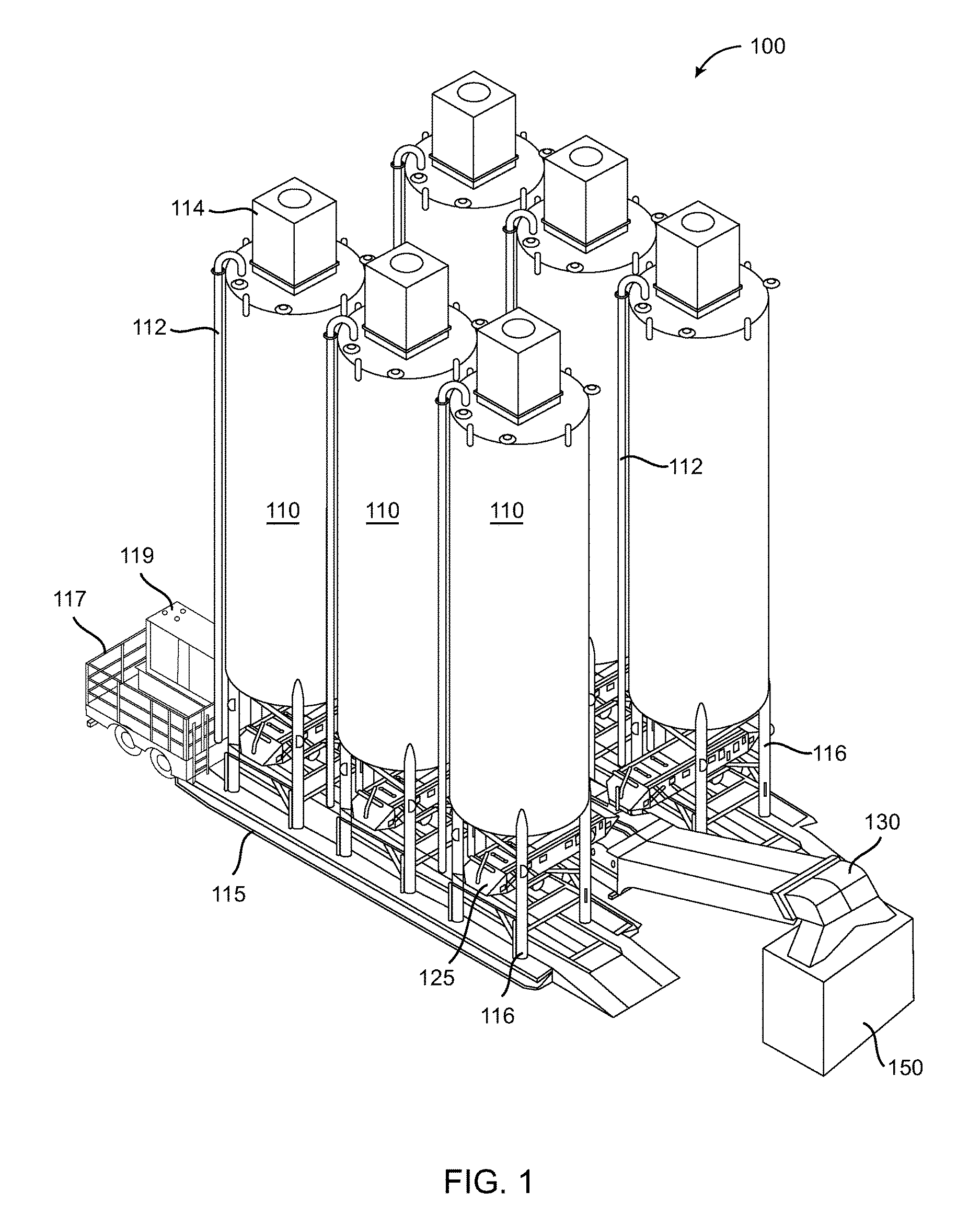

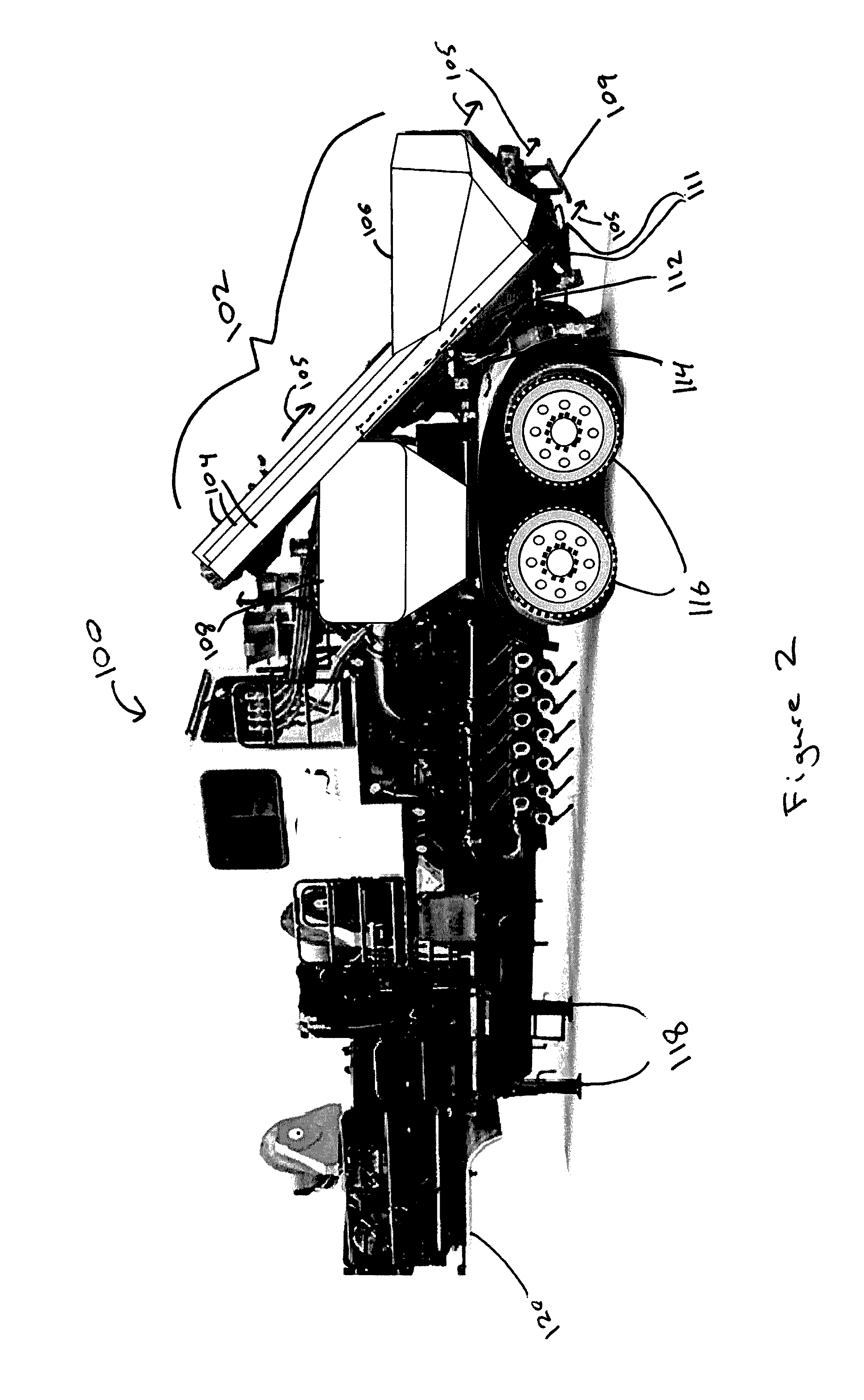

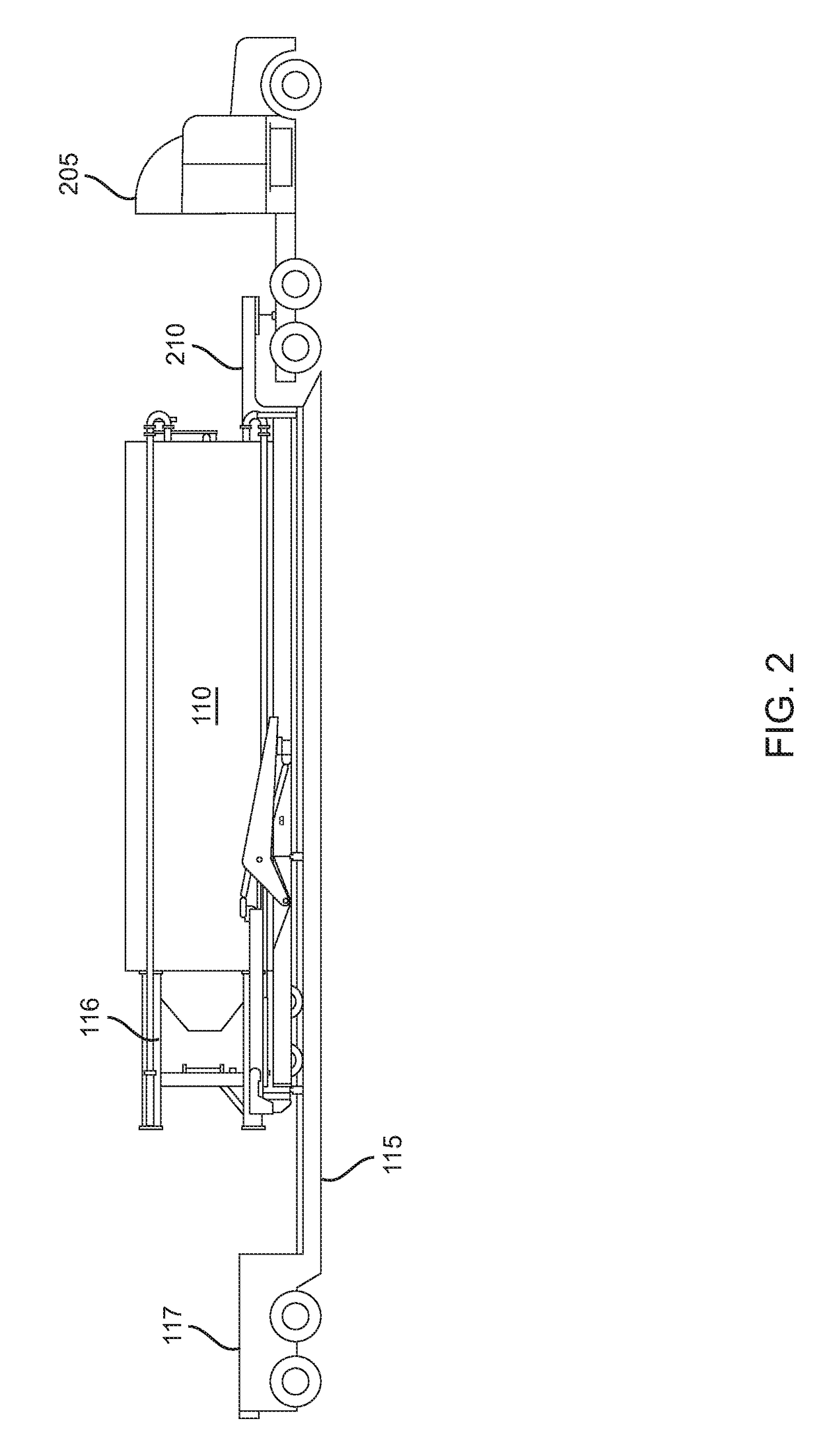

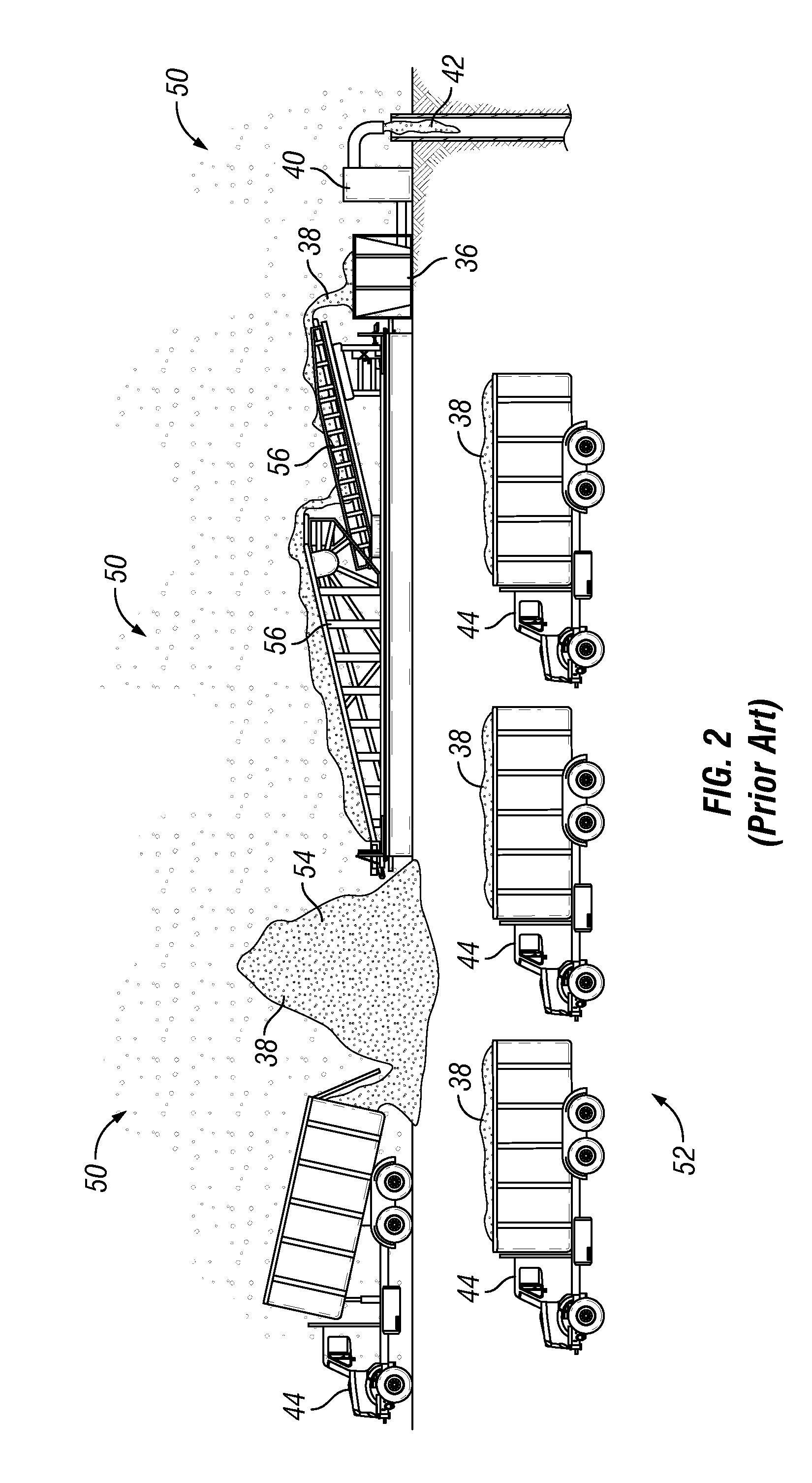

Mobile dry material storage

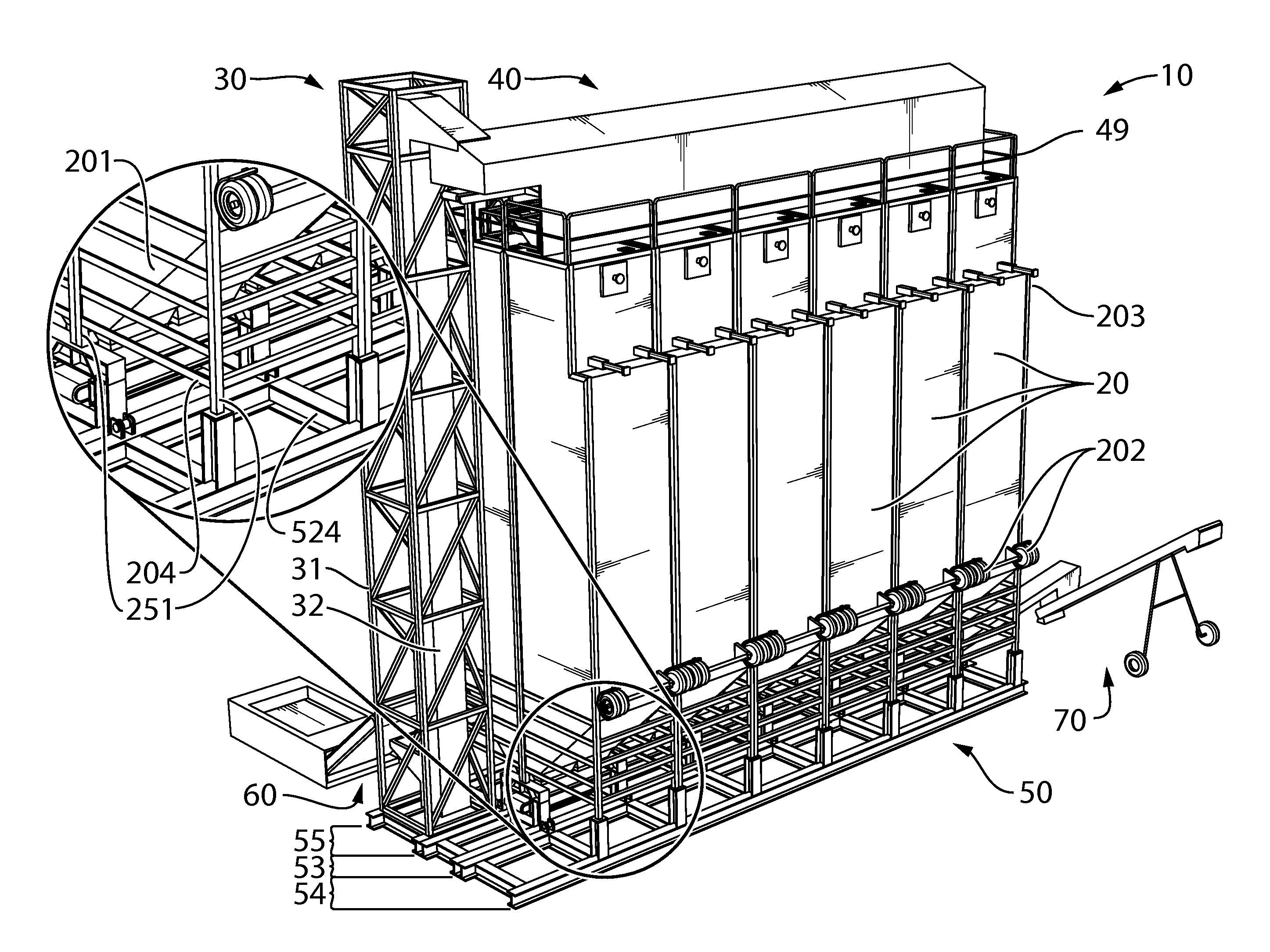

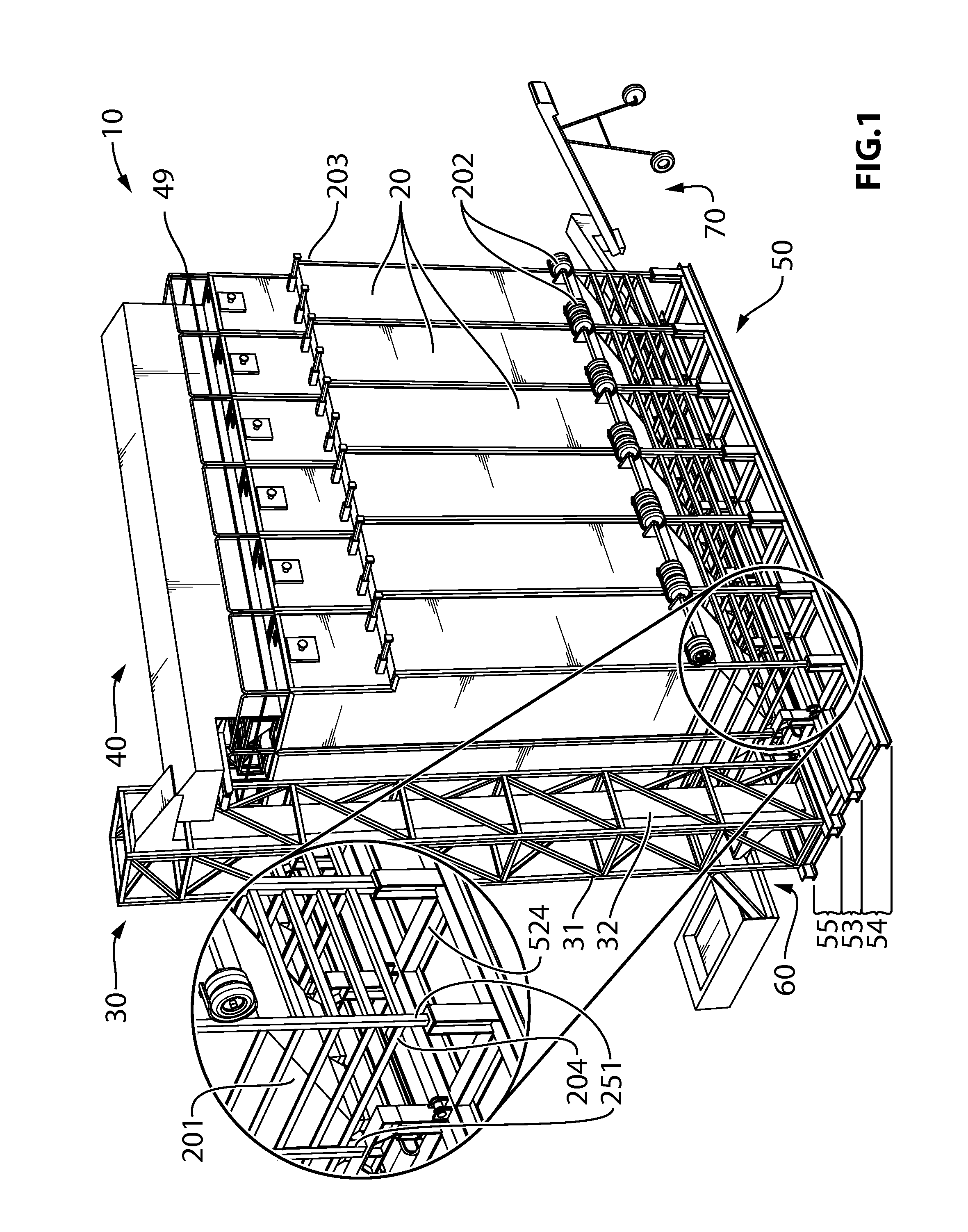

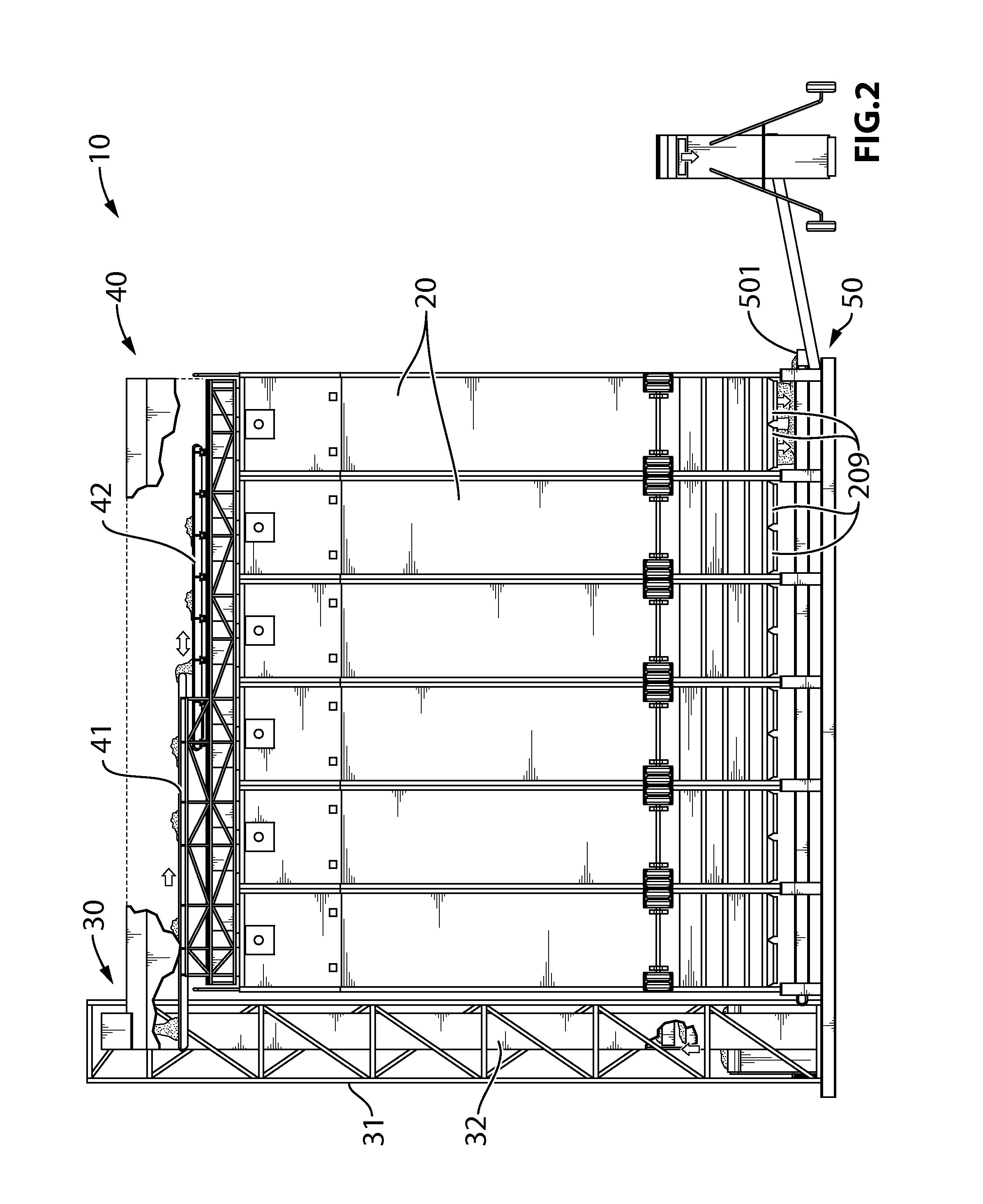

ActiveUS20140377042A1Avoid accidental damageIncrease volumeTractor-trailer combinationsKitchen equipmentWell drillingBucket elevator

A system that can be assembled at a well drilling or other site for storing bulk material such as sand includes a plurality of storage bins configured as trailers, a skid that includes a lower conveyor, a bucket elevator and a top conveyor system. At the site, the bins and the elevator are vertically oriented and stood on the skid, resulting in discharge outlets on the bins becoming positioned over the lower conveyor. The top conveyor is installed on top of the bins. In operation, the elevator lifts the material and discharges it onto the top conveyor system. The top conveyor system discharges the material into the bins for storage. The stored material is controllably discharged from the discharge outlets of the bins onto the lower conveyor from which the material is conveyed to one end of the skid for transport to a new location or directly into a blender.

Owner:SOURCE LOGISTICS LTD O A AMMOS FIELD SOLUTIONS +1

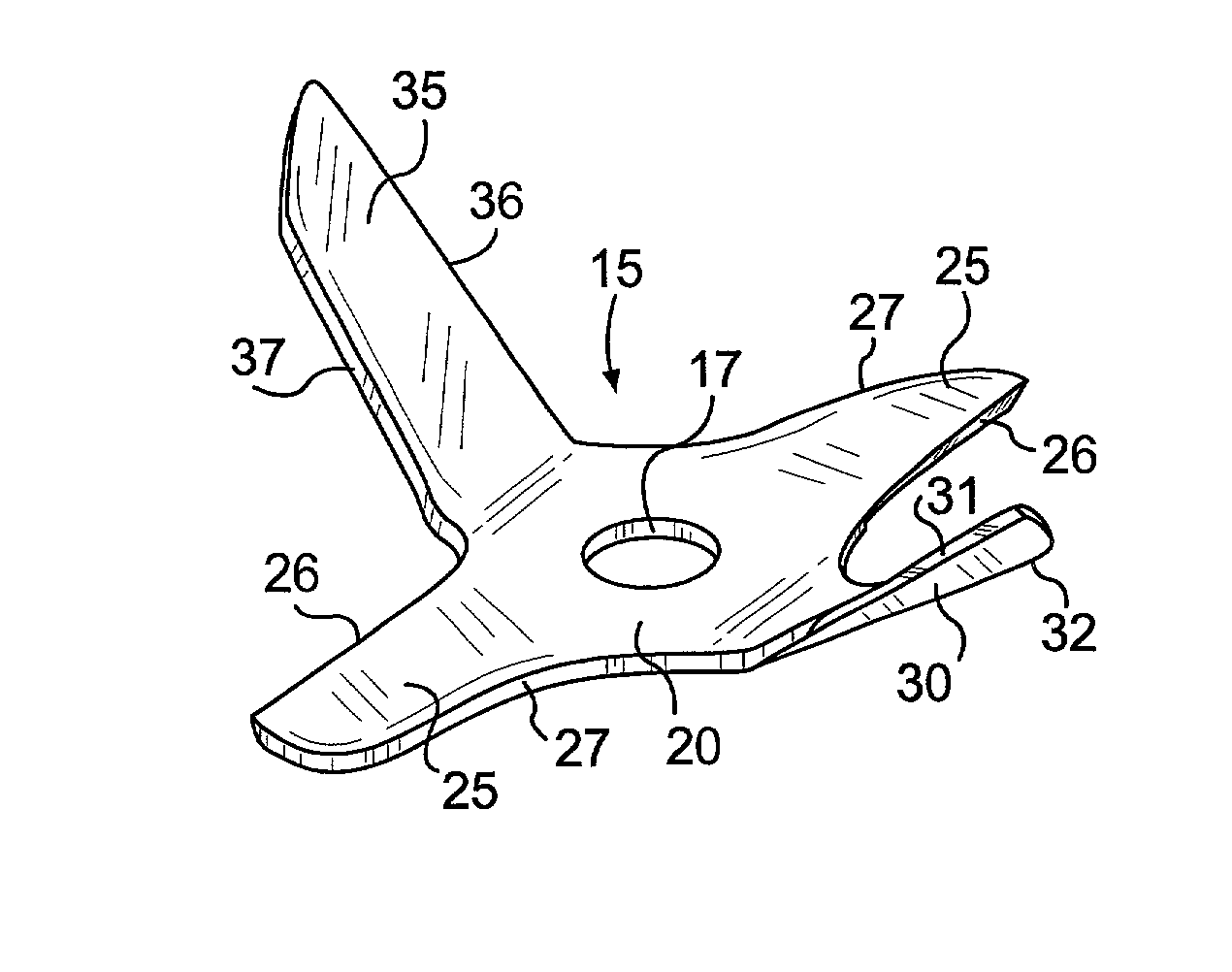

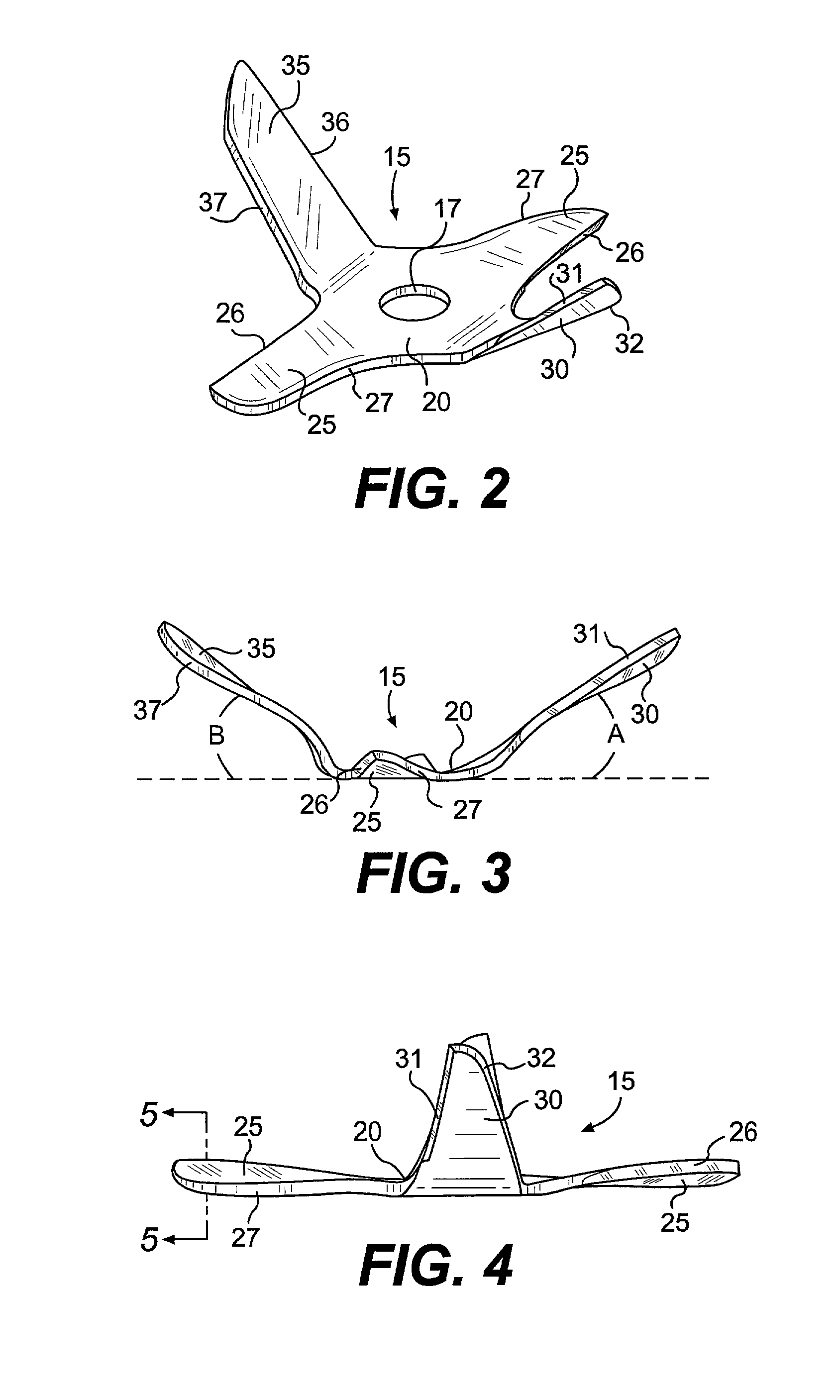

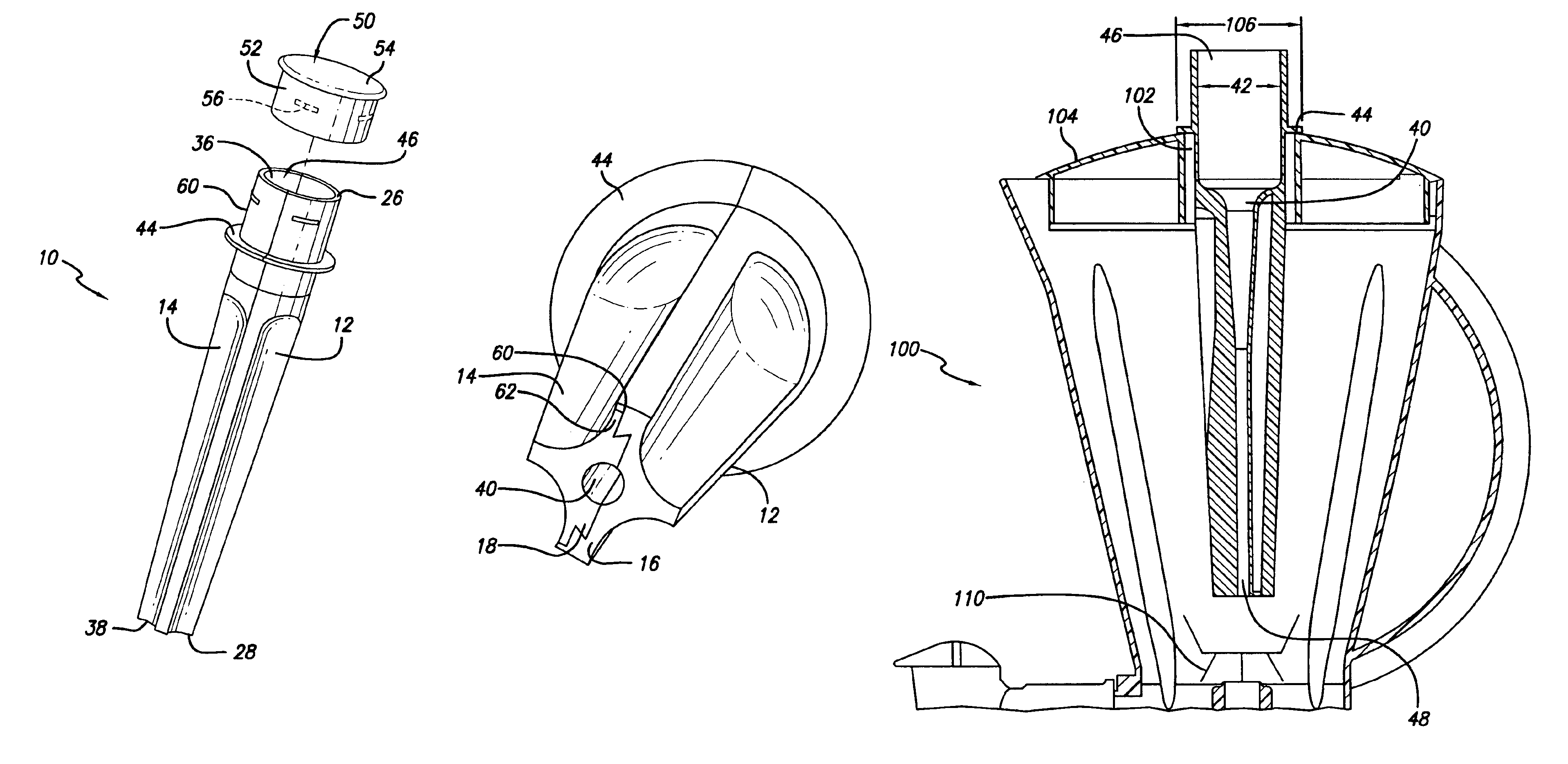

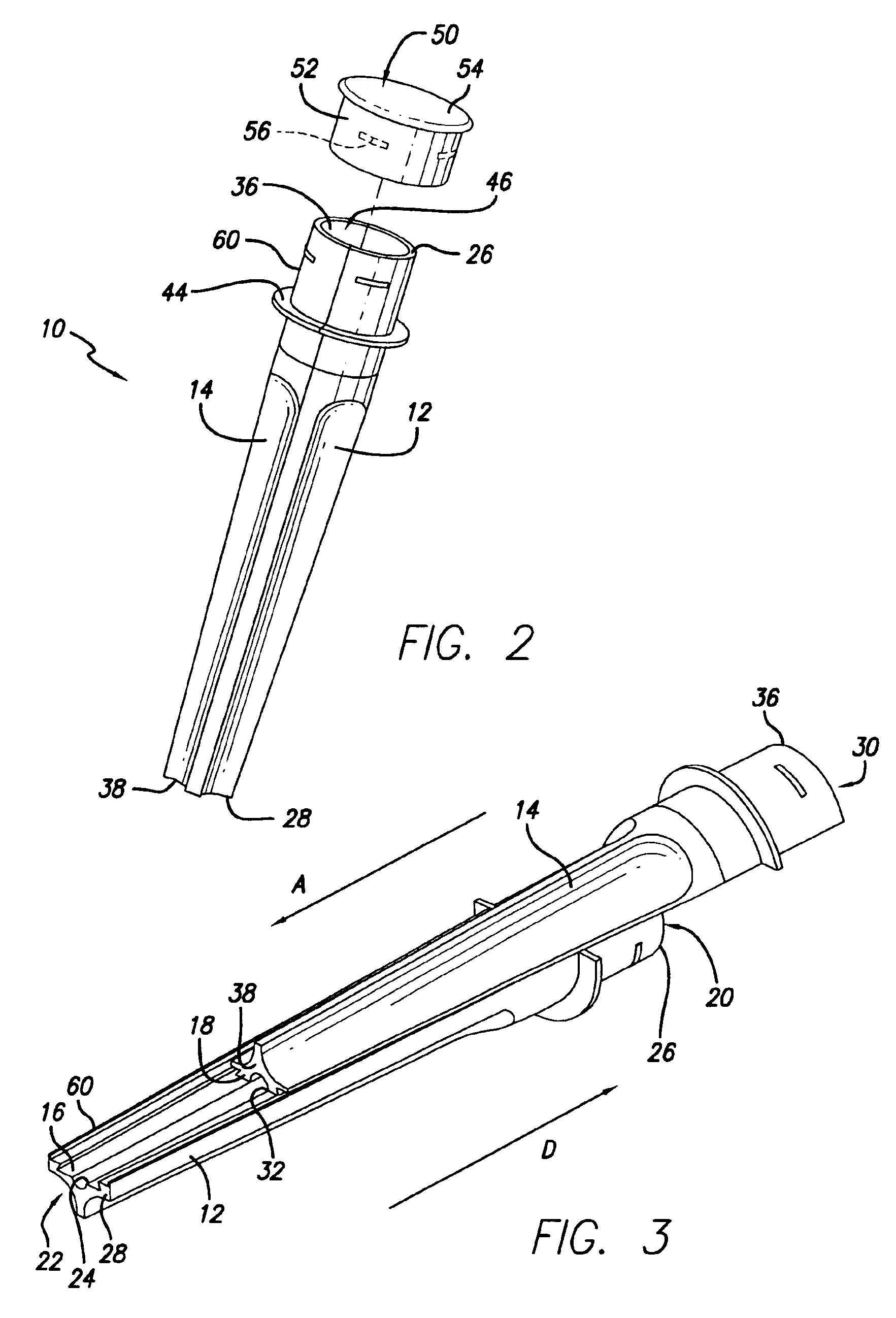

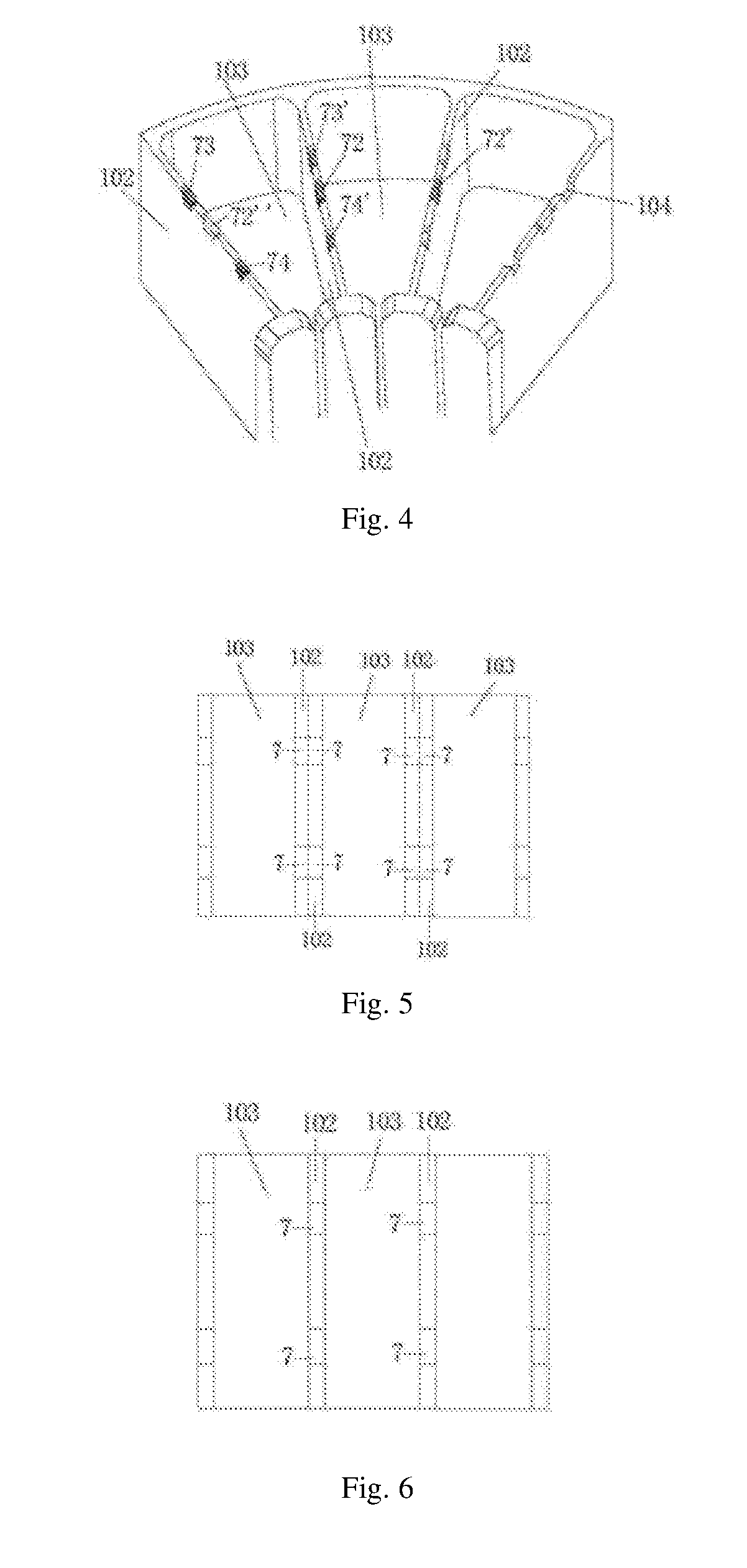

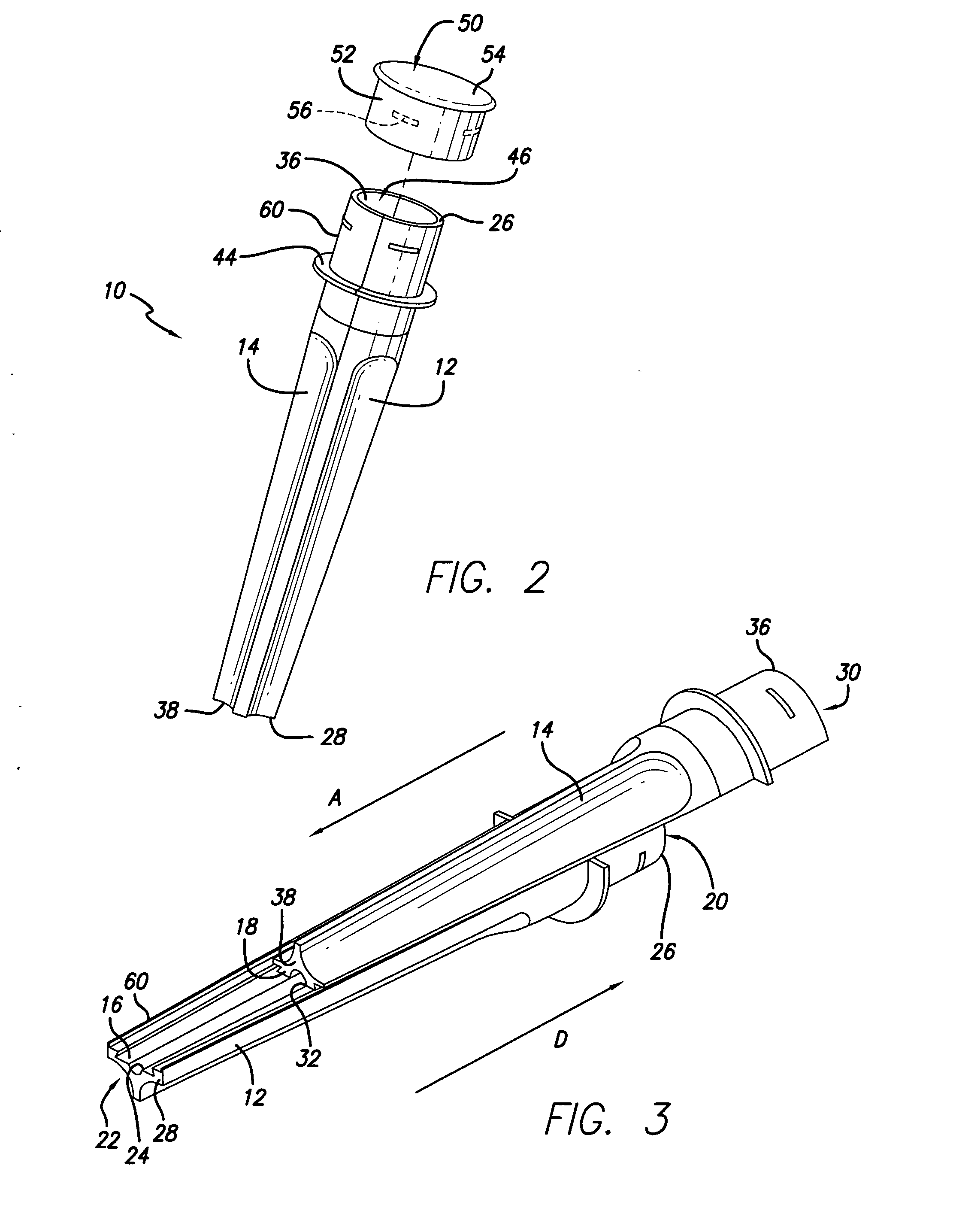

Blender cutter

A cutter for use in a blender includes a central hub portion defining a horizontal plane. First and second pairs of blades extend outwardly from the hub portion. The first pair of blades is oriented on opposite sides of the hub portion and the blades lie in substantially the same horizontal plane as the hub portion. The second pair of blades is oriented on opposite sides of the hub portion and the blades extend upwardly from the horizontal plane of the hub portion, and further wherein the angles of upward extension of each of the second pair of blades is asymmetric. Further, each blade of the first set of blades has a cutting edge and trailing edge, and each blade of the first set of blades is pitched so that there is a downward slope from the cutting edge to the trailing edge.

Owner:HAMILTON BEACH BRANDS

Independent control of auger and hopper assembly in electric blender system

Embodiments relate to a hydraulic fracturing system that includes a blender unit. The system includes an auger and hopper assembly to receive proppant from a proppant source and feed the proppant to the blender unit for mixing with a fluid. A first power source is used to power the blender unit in order to mix the proppant with the fluid and prepare a fracturing slurry. A second power source independently powers the auger and hopper assembly in order to align the hopper of the auger and hopper assembly with a proppant feed from the proppant source. Thus, the auger and hopper assembly can be stowed or deployed without use of the first power source, which is the main power supply to the blender unit.

Owner:US WELL SERVICS LLC

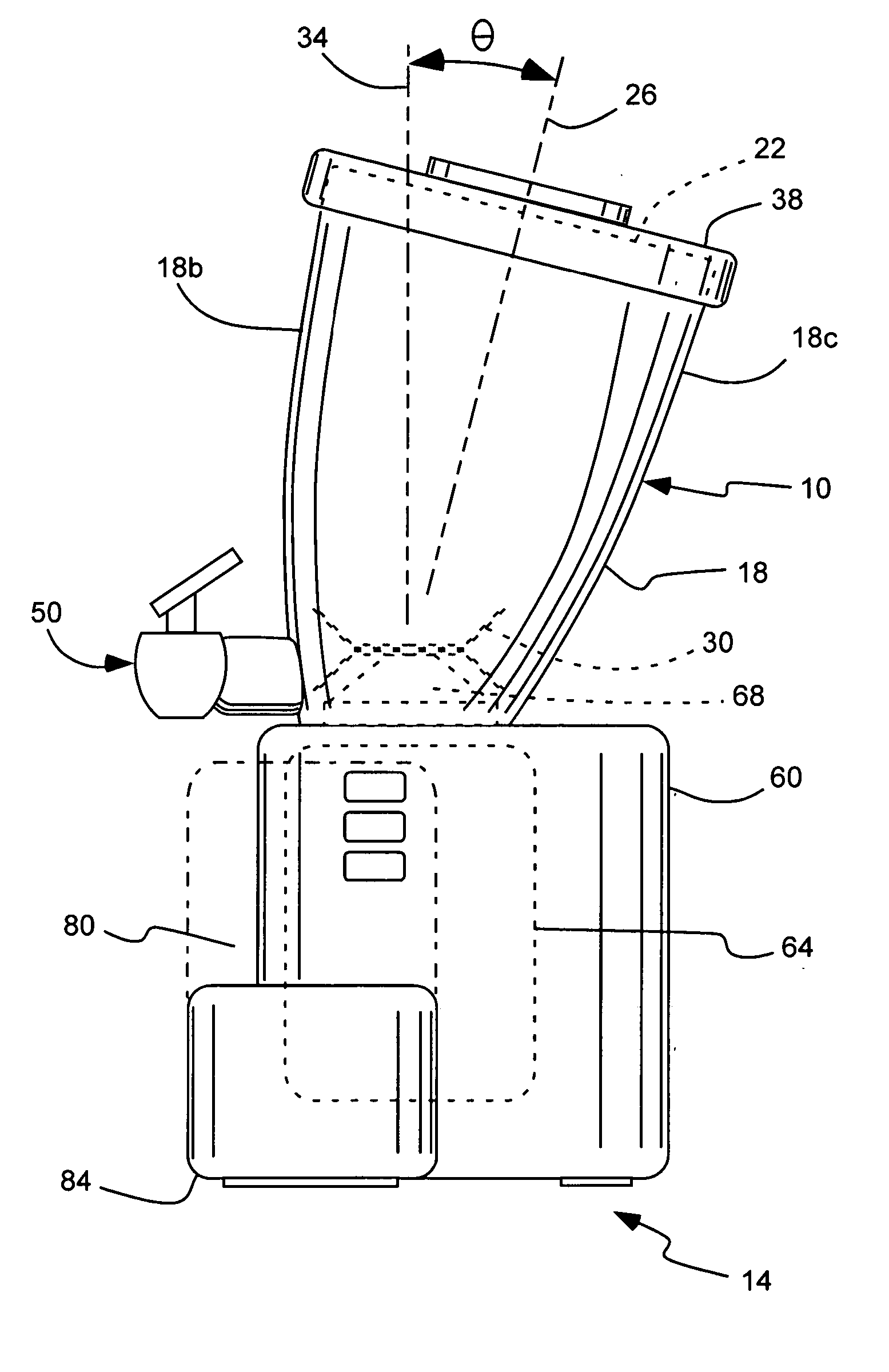

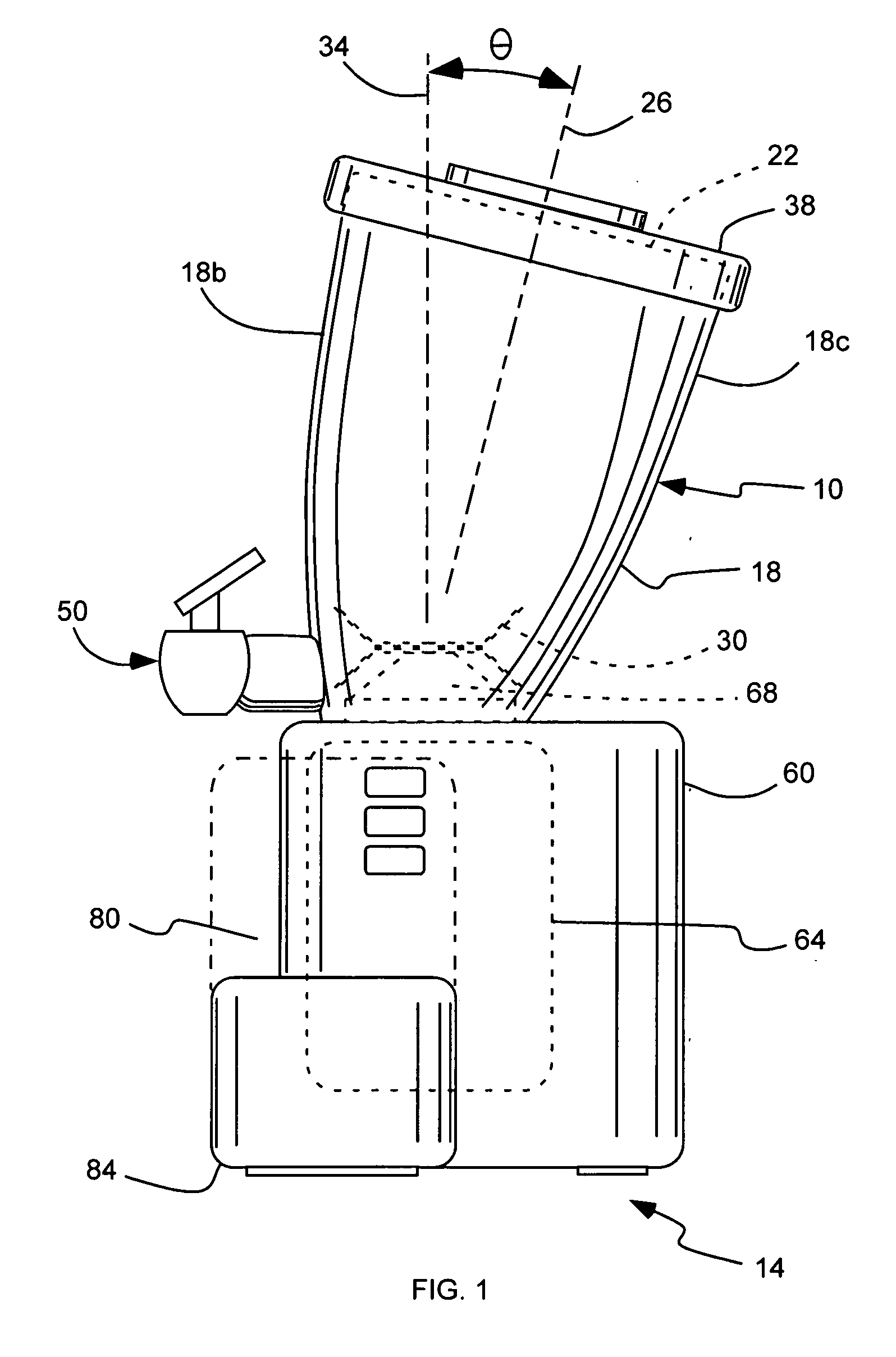

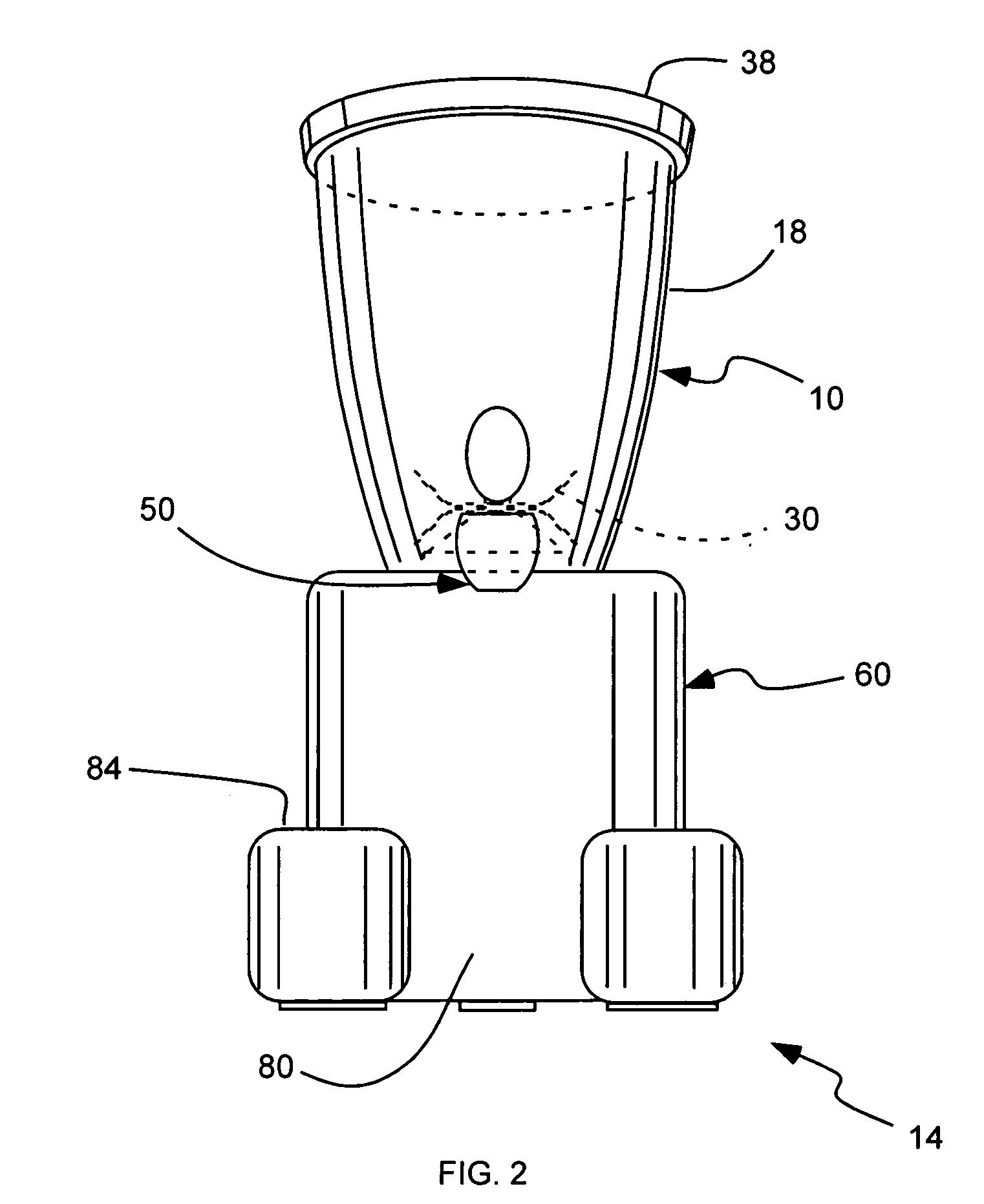

Off-axis goblet for food mixer

InactiveUS20050207270A1Improve abilitiesFacilitate dispensing contentRotary stirring mixersTransportation and packagingBLENDER/MIXERRotational axis

An off-axis goblet or container for a food or beverage mixer has a longitudinal axis centered therein. A mixing assembly is disposed in the goblet or container and has a rotational axis. The longitudinal and rotational axes of the goblet and mixing assembly are different and non-collinear.

Owner:FOCUS PROD GRP INT

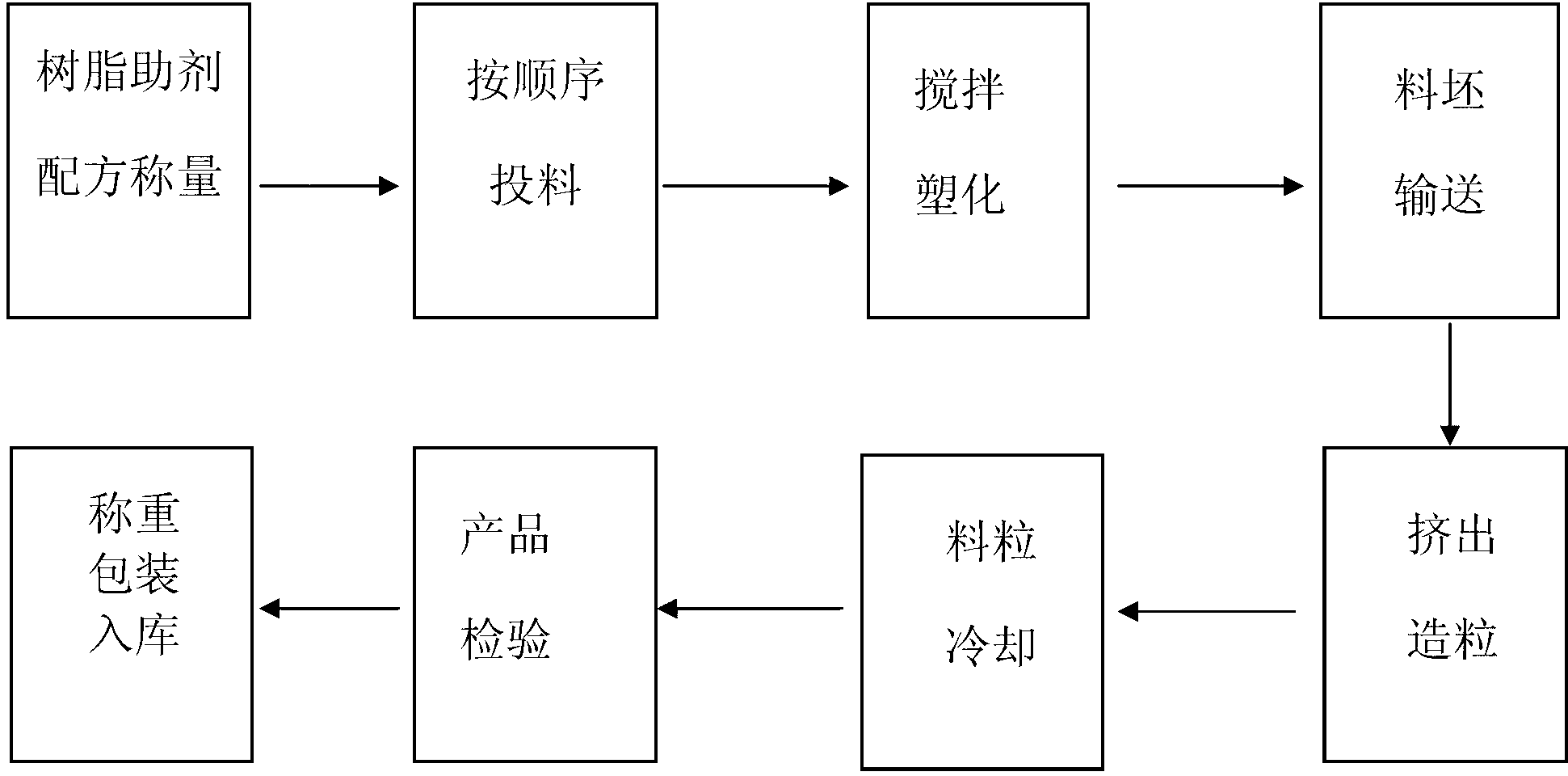

Macromolecule heat conduction and dissipation blended composite material and automatic preparation method

The invention discloses a macromolecule heat conduction and dissipation blended composite material. The macromolecule heat conduction and dissipation blended composite material is prepared from, by mass, 35-75 parts of matrix resin, 0-10 parts of flexibilizer, 20-50 parts of heat conduction filler, 0.2-1.0 part of antioxidant 1010, 0.2-1.0 part of phosphite ester antioxidant 168, 0.5-1.5 parts of powder surface activation treating agents and 0.5-1.5 parts of lubricant. An automatic preparation method of the macromolecule heat conduction and dissipation blended composite material includes the steps of firstly, conducting surface treating on heat conduction filler for 20 min through powder surface activation treating agents in a high-speed stirring machine; secondly, making the heat conduction filler enter another high-speed stirring machine through an automatic conveying device to be evenly mixed with other materials; thirdly, automatically conveying the mixture obtained in the second step to an internal mixer to be mixed and kneaded for 15 min; fourthly, making the obtained mixture directly enter a double-screw extruder to be extruded and granulated. The prepared heat conduction and dissipation material has the high mechanical property and heat conduction performance, automatic and continuous production is achieved, a large amount of labor is saved, the production period is greatly shortened, the production cost is greatly reduced, and the macromolecule heat conduction and dissipation blended composite material can be widely applied to the fields of LED illumination, electronic electrical appliances, automobiles and the like where good heat conduction and dissipation performance is required.

Owner:东莞市万江明冠实业有限公司

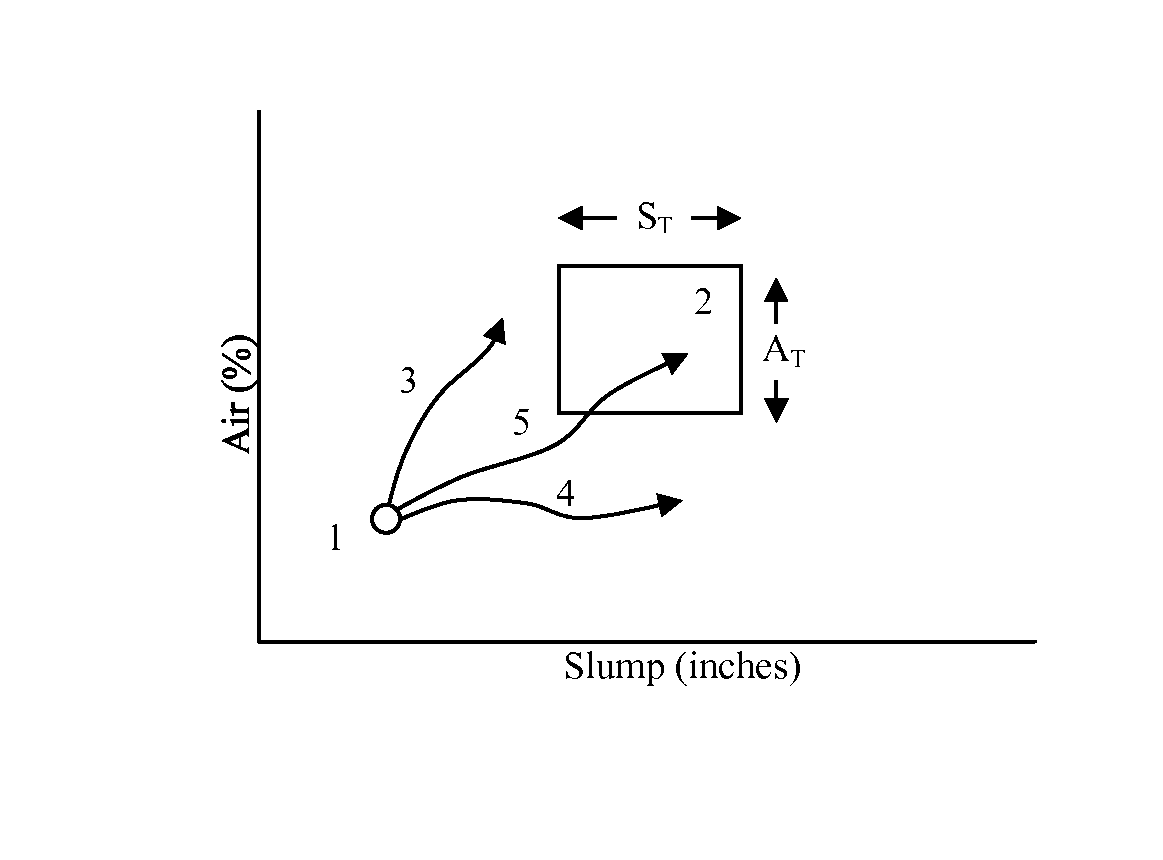

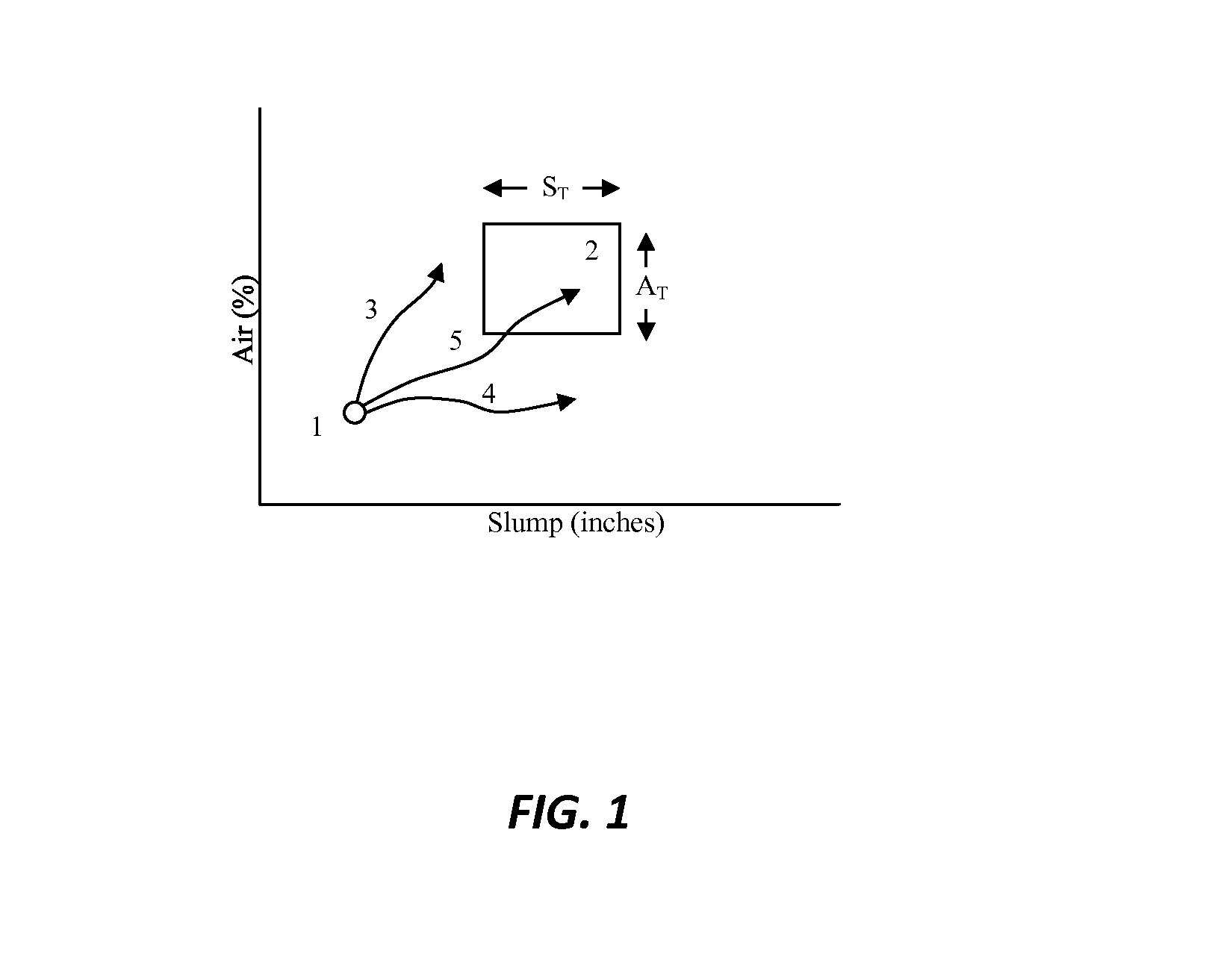

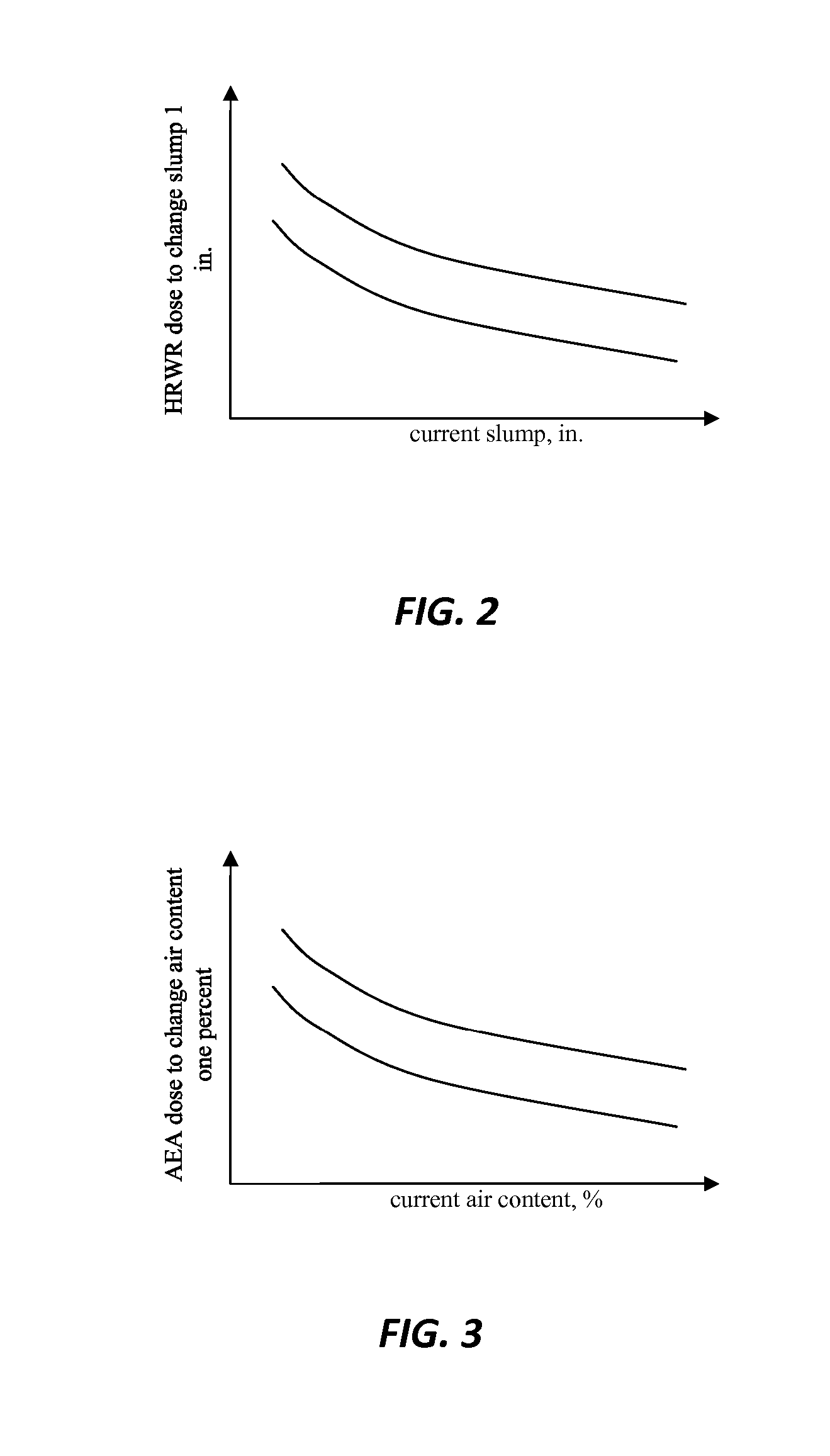

Multivariate management of entrained air and rheology in cementitious mixes

ActiveUS8491717B2Efficiently and accurately updatingHighly inventiveSampled-variable control systemsMixing operation control apparatusHydration reactionBLENDER/MIXER

The invention relates to a method and system for monitoring and adjusting both air content and rheology (e.g., slump, slump flow) properties of a hydratable concrete mix contained within a concrete mixer. The system simultaneously tracks dosage of both rheology-modifying admixture (e.g., polycarboxylate polymer cement dispersant) and air control agent or “ACA” (e.g., air entraining agent) by reference to at least four nominal dose response (“NDR”) curves or profiles, which at least four NDR profiles are based on the respective behaviors of each of the ACA and rheology-modifying agent on air content and rheology.

Owner:VERIFI INC

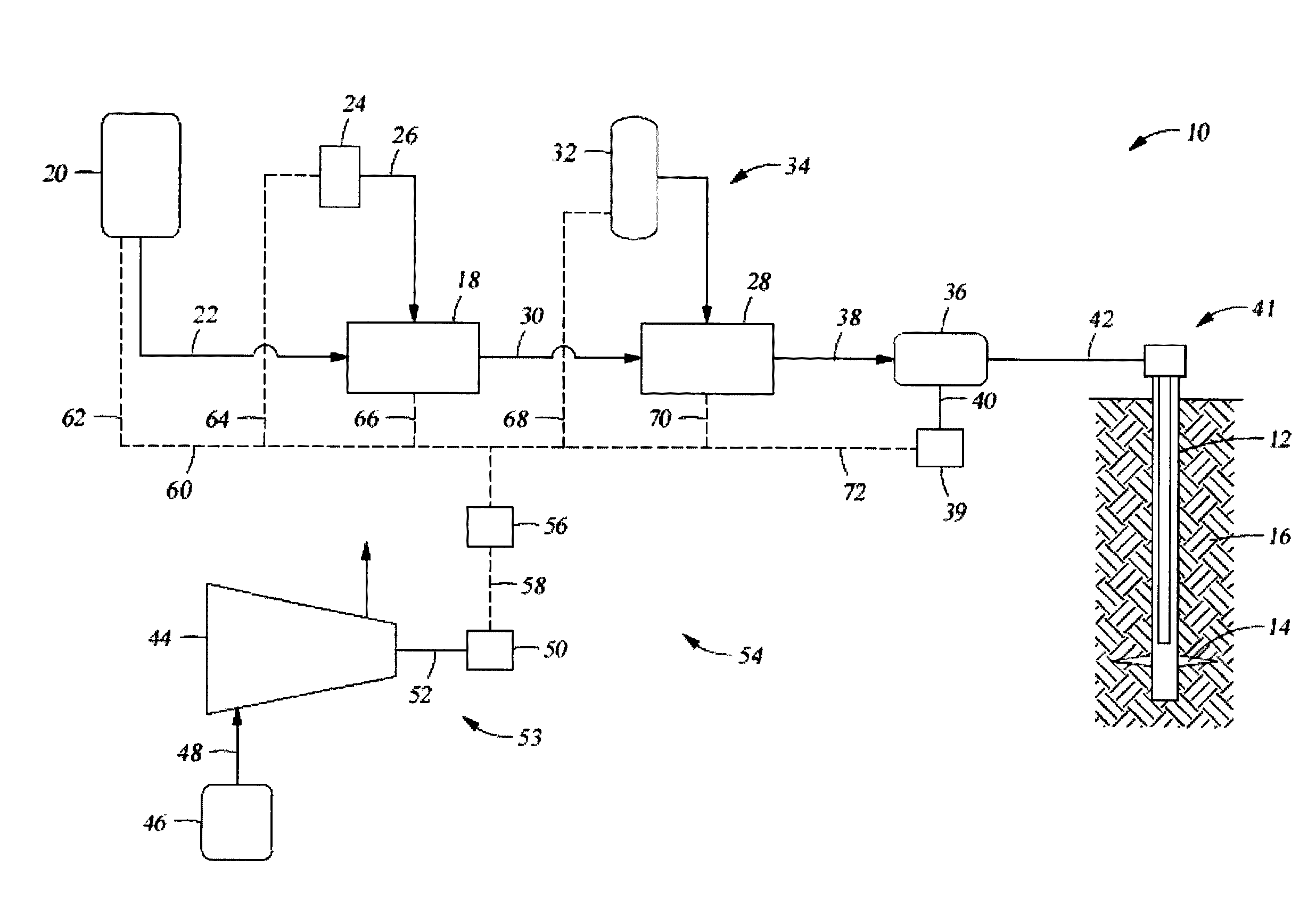

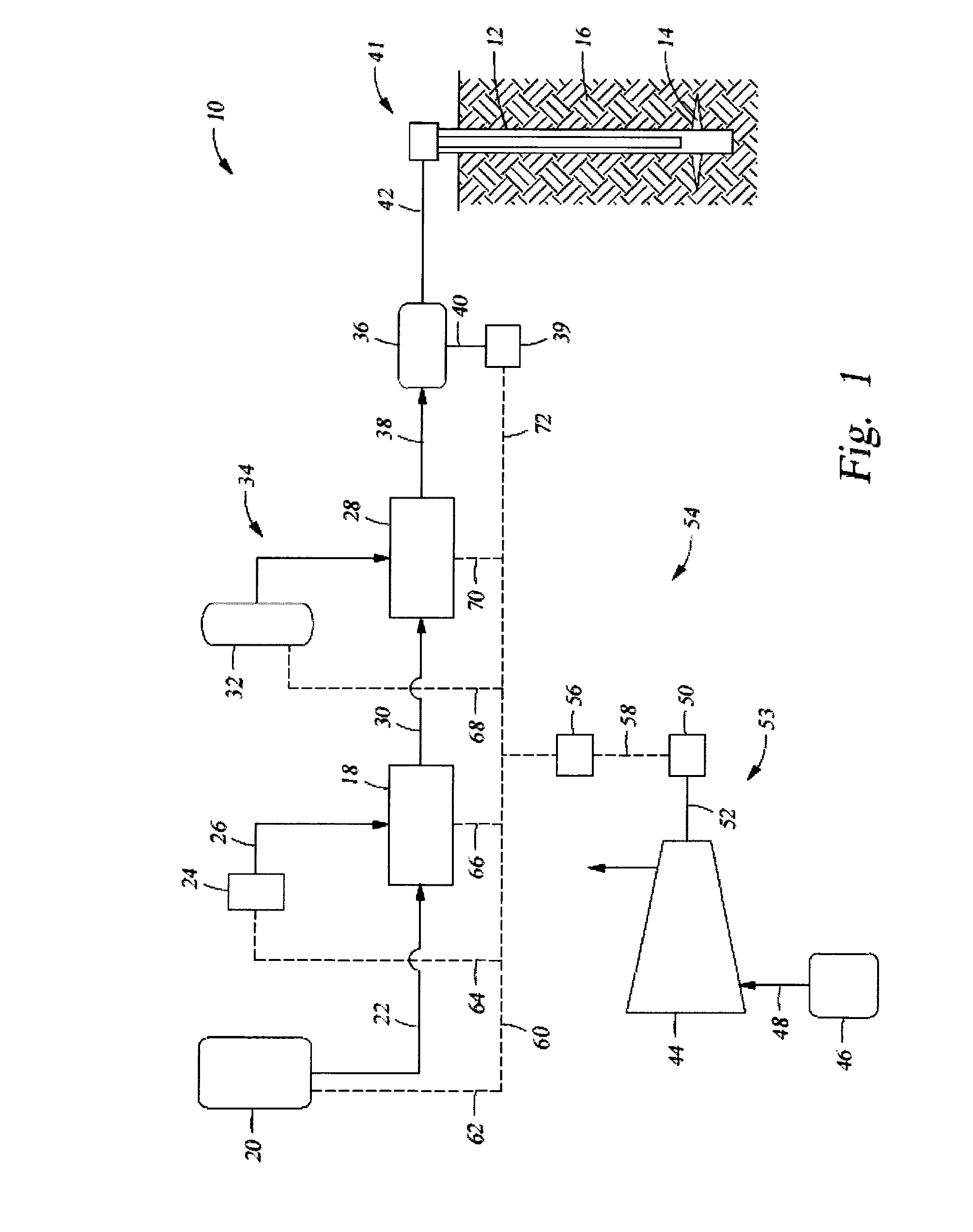

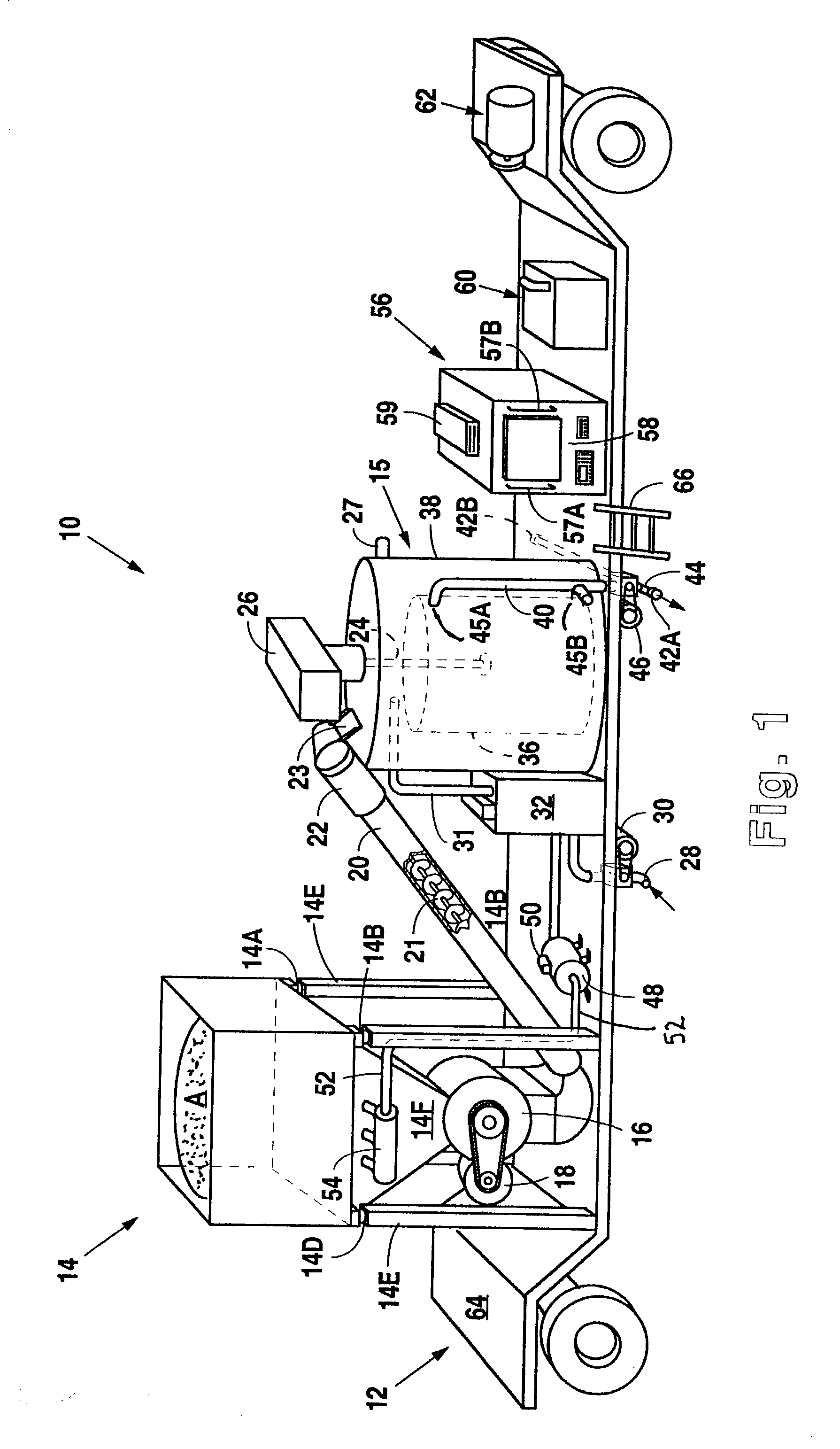

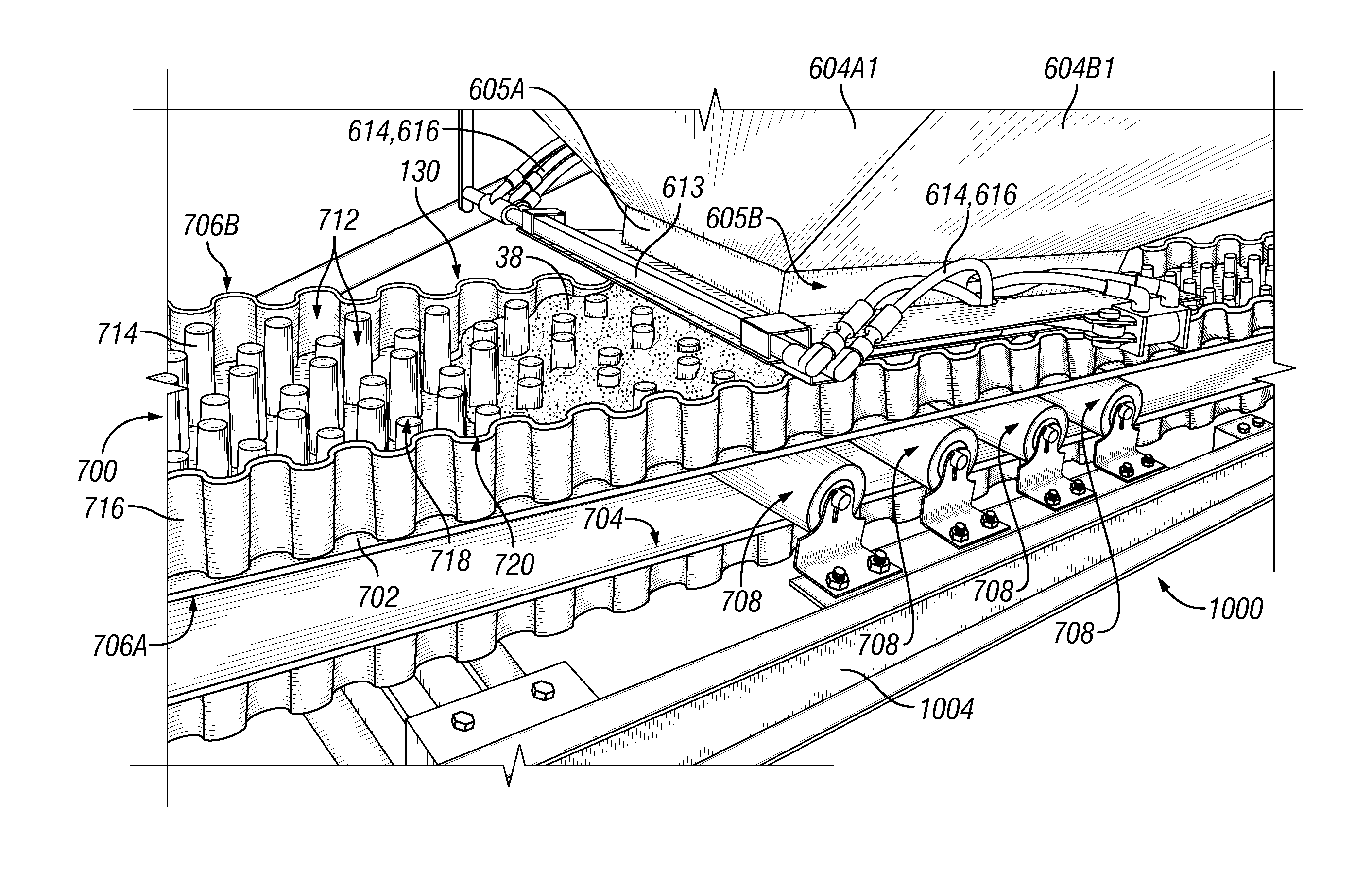

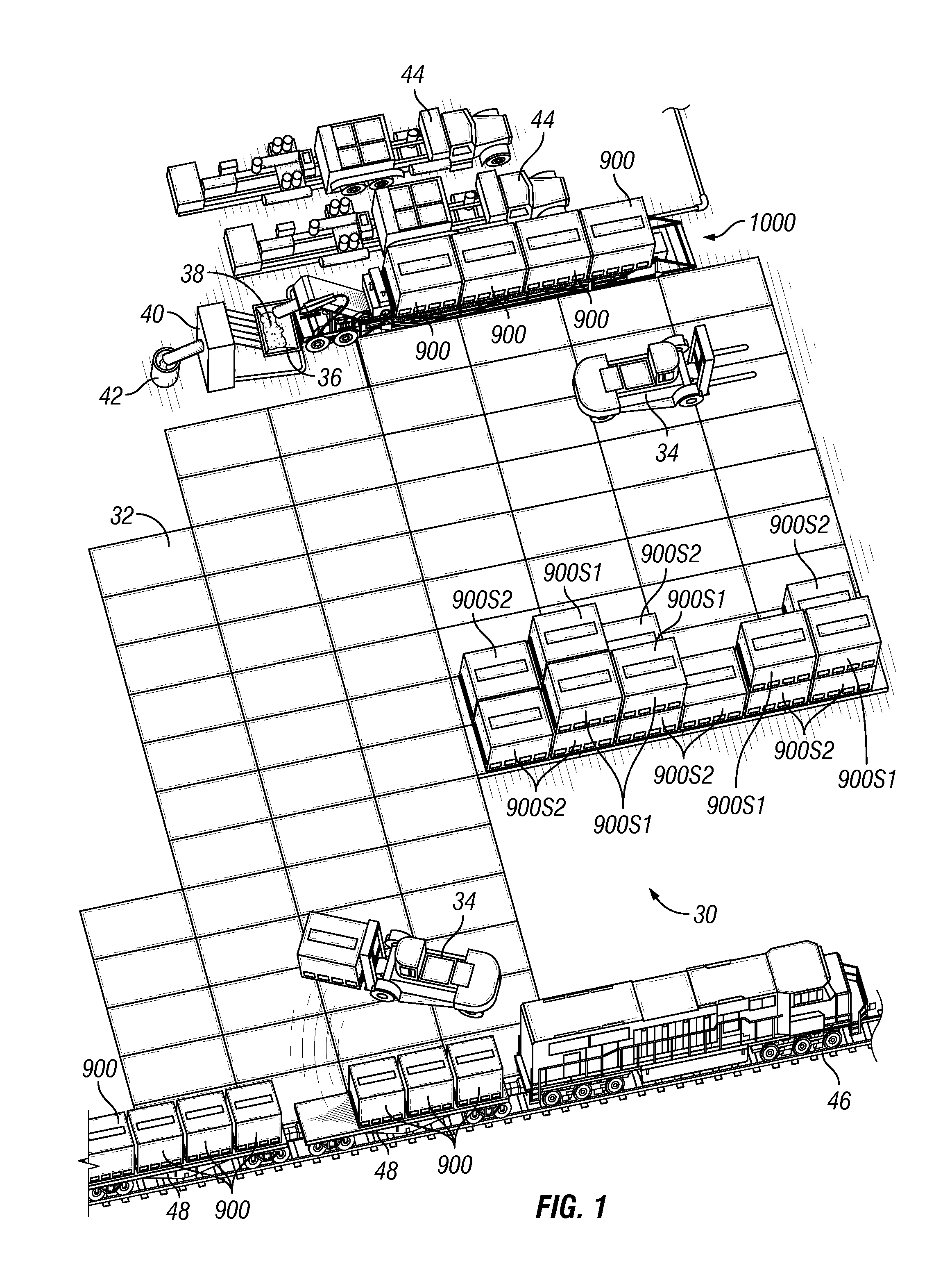

Delivery, storage and blending system for multi-component granular compositions

Embodiments of the present invention include a method and system for blending multi-component granular compositions such as proppant used in hydraulic fracturing in well drilling. The system includes the control and management of an on-site storage system for each of the components, regulating the delivery of specified quantities of each component to a well site, and coordinating the flow of materials into and out of the blender.

Owner:SOLARIS OILFIELD SITE SERVICES OPERATING

Stir stick assembly for blender apparatus

Owner:IDEAL LIVING HLDG

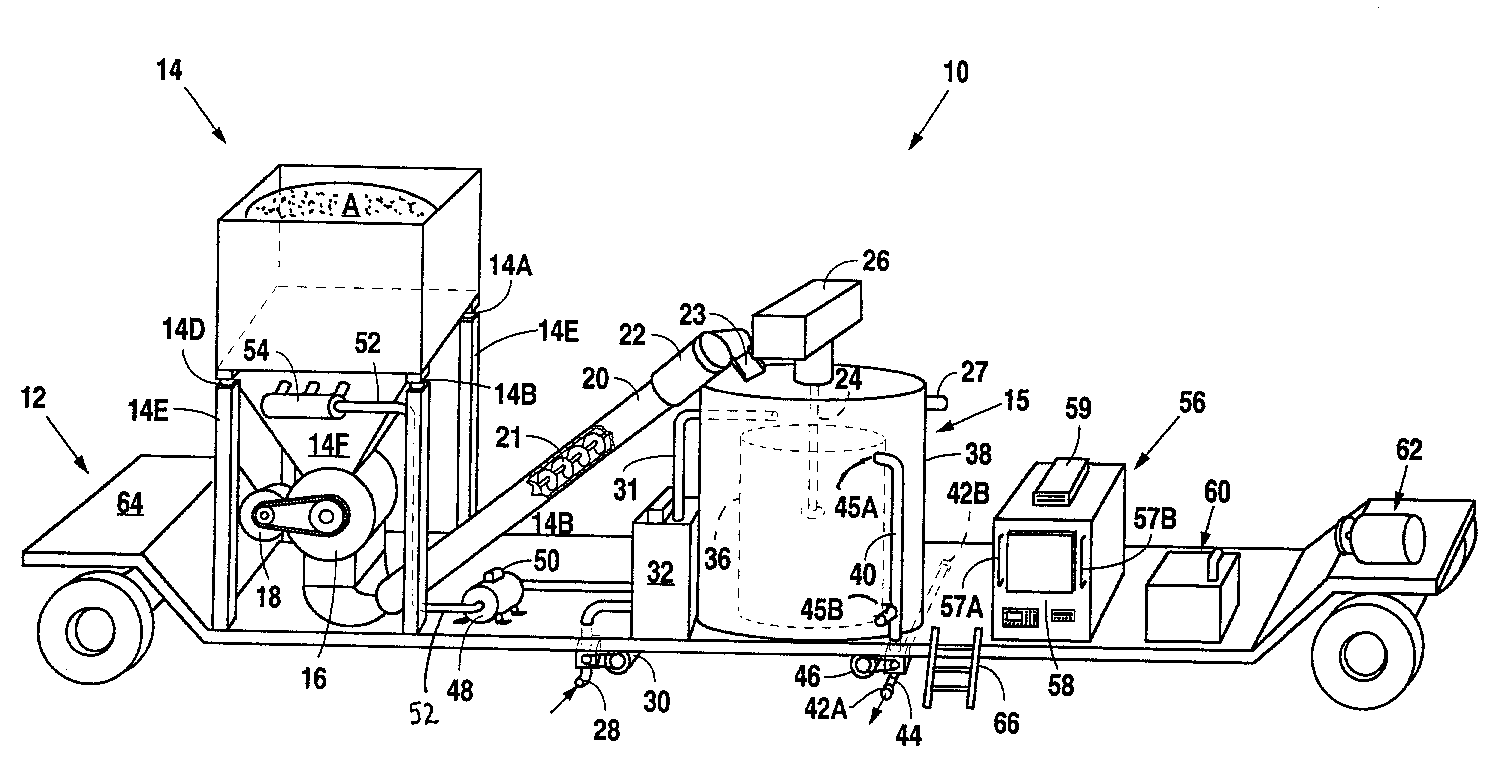

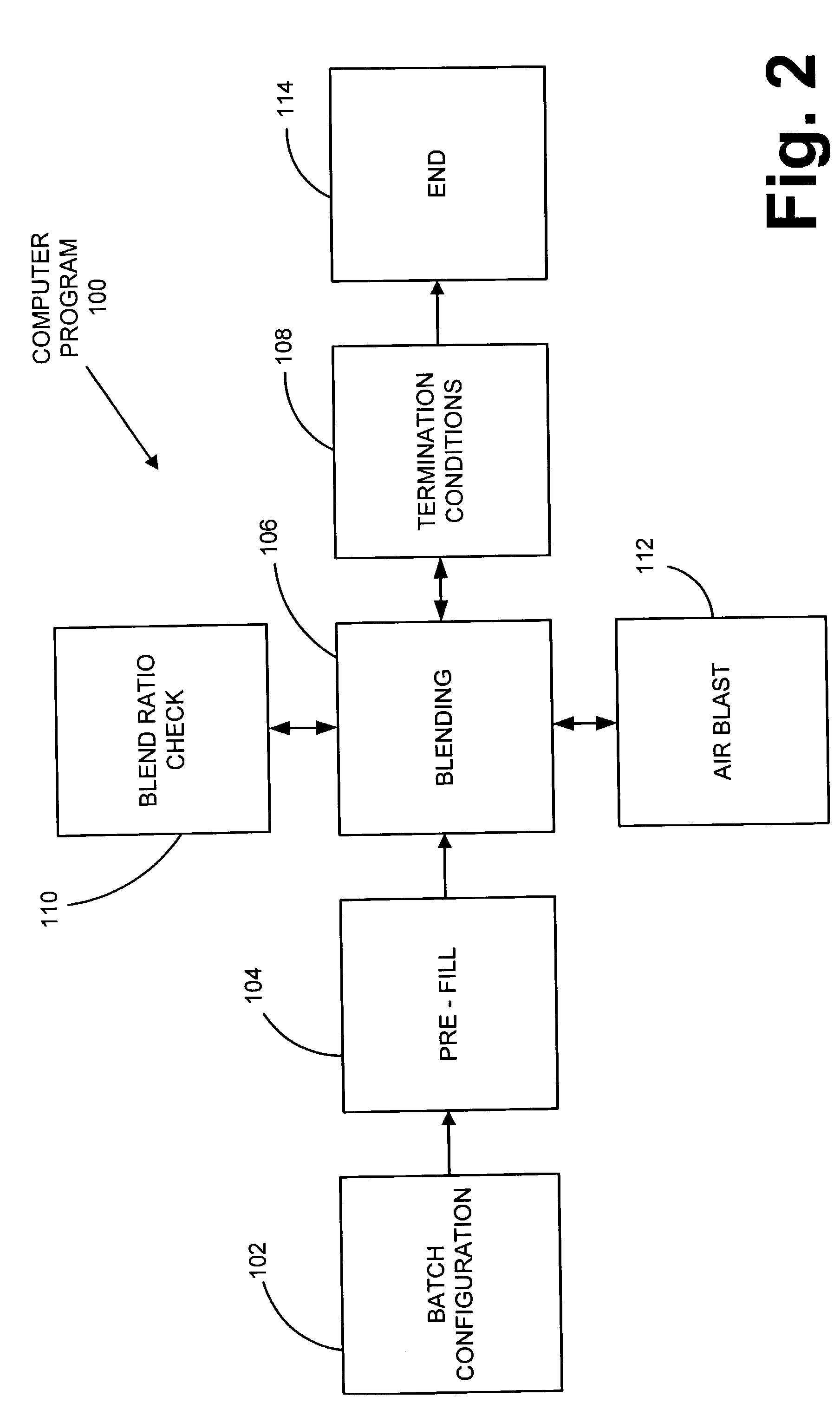

Portable plant for mixing asphalt and rubber

InactiveUS20020191481A1Sampled-variable control systemsTransportation and packagingMotor driveControl system

The present invention to provides for a novel asphalt mixing plant which is portable, that is, capable of being transported from one site to another. The portable asphalt mixing plant has a control system that adjusts the rate at which crumb rubber is added to oil so as to maintain a constant oil / rubber ratio in a mixer. The blending control process has a CPU to control the rate at which asphalt is pumped into a mixer and the rate at which crumb rubber is fed to the same mixer so as to maintain a constant asphalt rubber ratio in the produced asphalt. The main components of the portable asphalt mixing plant are located on a flatbed trailer and include the following: a hopper for storing loose crumb rubber; a crumb rubber delivery system for delivery of the crumb rubber from the hopper to the mixing chamber; a mixing chamber for the mixing therein; a delivery system for the delivery of asphalt (from a tank off the trailer) to the mixing chamber; a control system including motors, motor drives, a central processing unit, sensors, and computer program for the controlled delivery of crumb rubber and asphalt to the mixing chamber; a crumb rubber and asphalt mixing means including a motor and a onboard generator for powering the electrical elements of Applicant's system.

Owner:COX PAVING

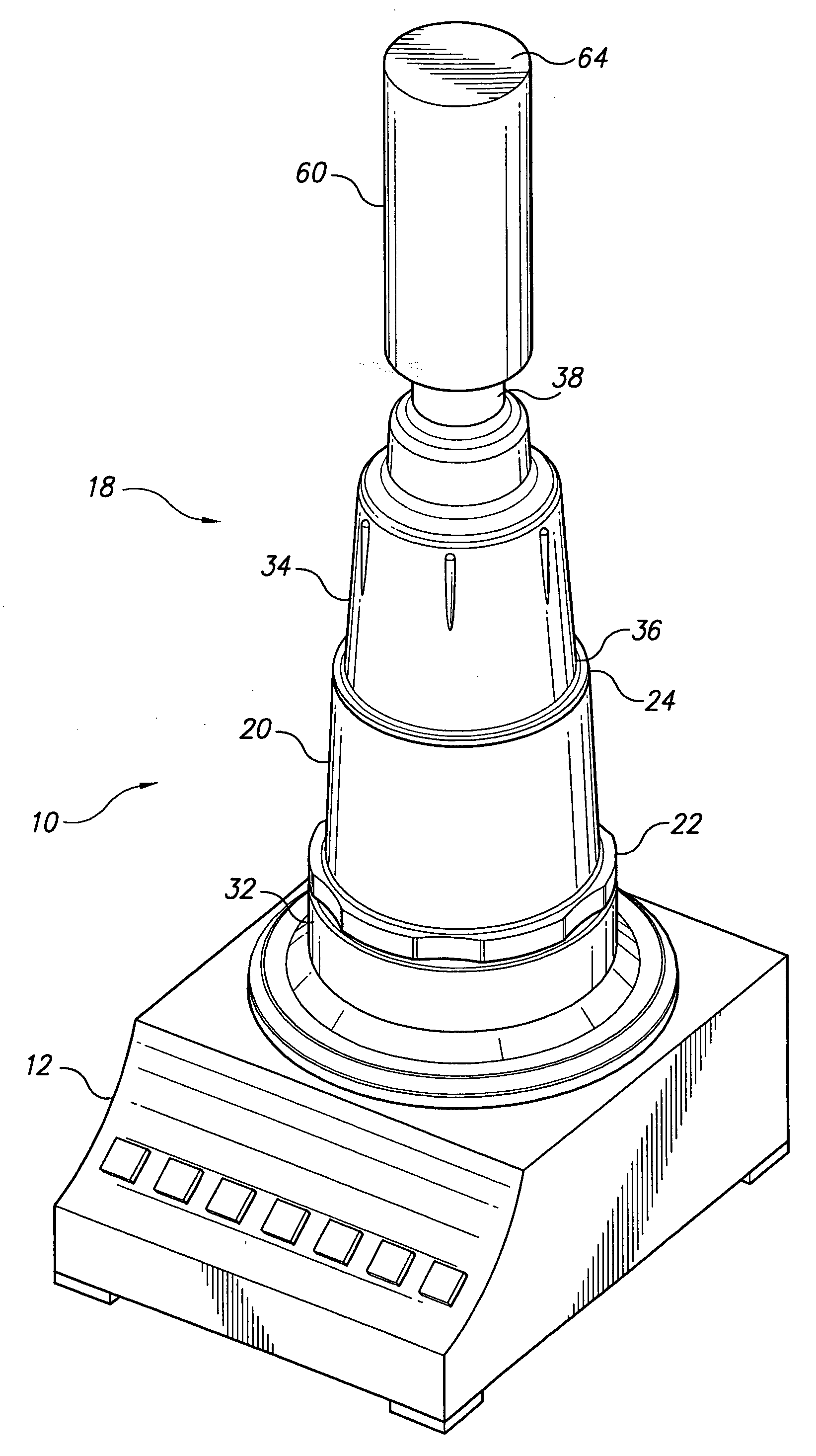

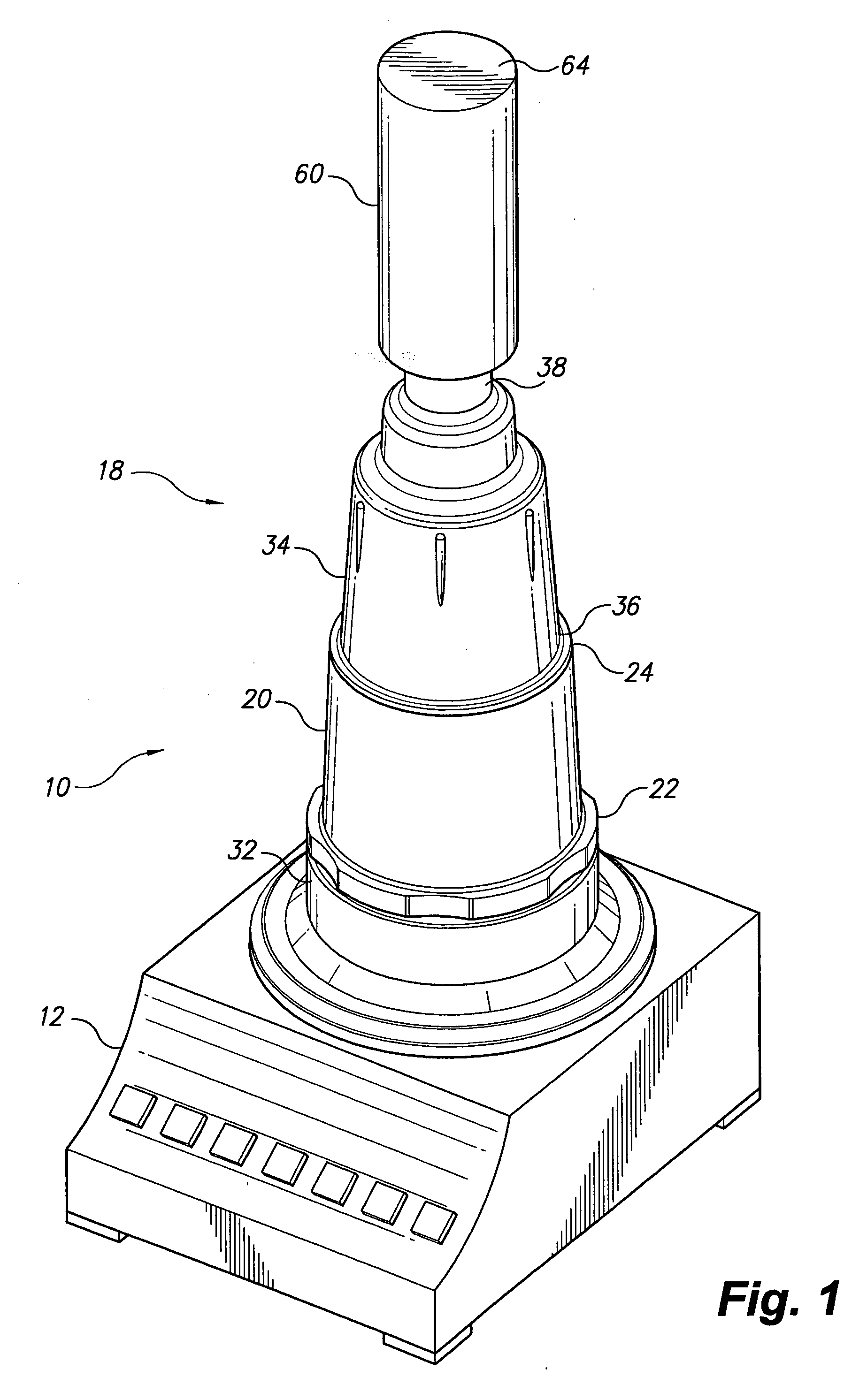

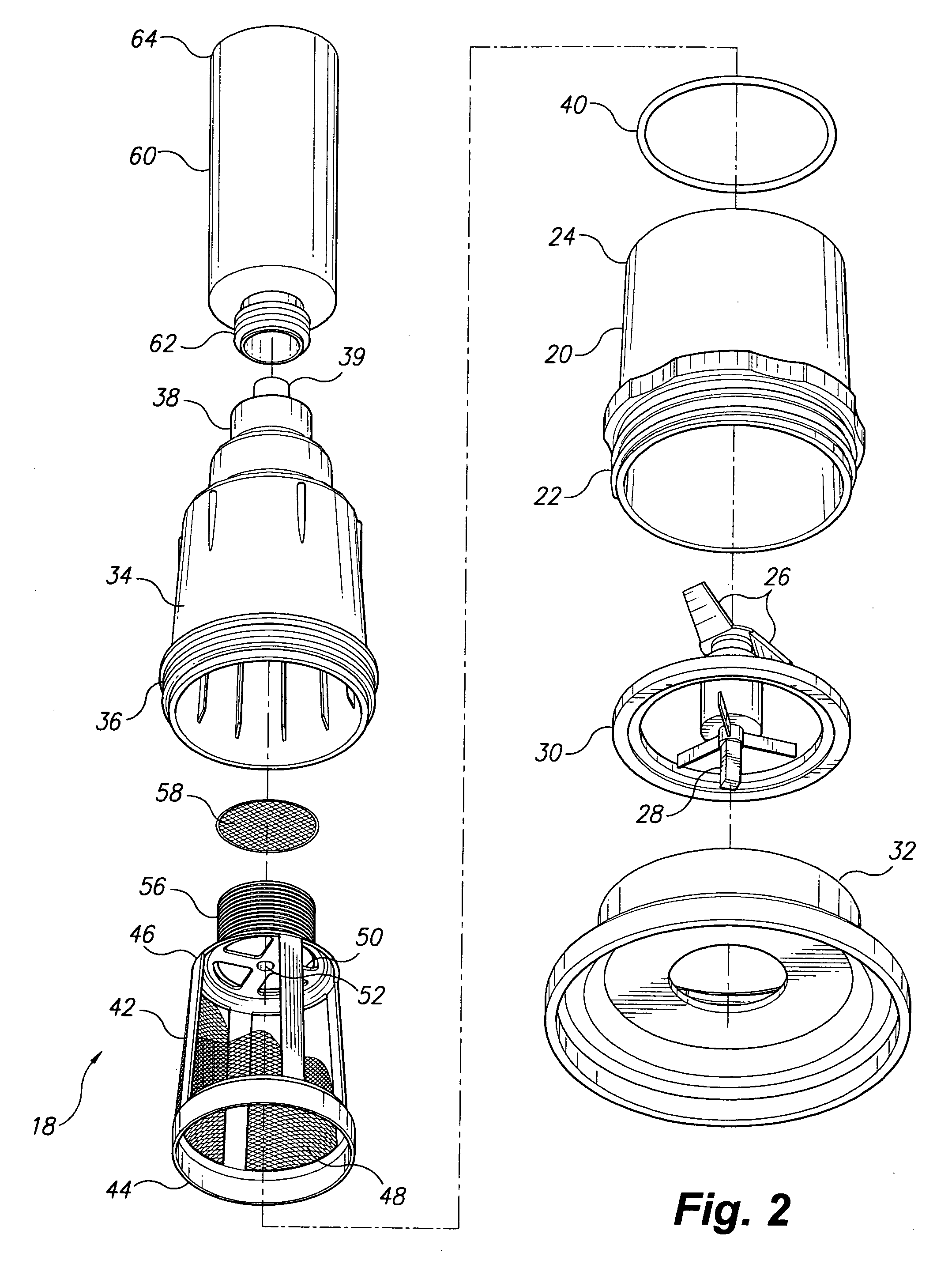

Blender for production of scented materials

The blender for production of scented materials has mutually connecting containers or chambers that attach to a conventional motorized blender base. The chambers include a mixing chamber having a removable blade assembly and base attachment mount, a filtration chamber installed upon the mixing chamber, and a collection chamber installed upon the filtration chamber. The filtration chamber may include one or more scent absorbent pads removably installed in the neck thereof. The blender is used by assembling the mixing chamber upon the blender base, adding ingredients and liquid, installing the filtration and collection chambers, and operating the blender. When the ingredients have been mixed and comminuted, the chamber assembly is removed from the base and inverted to drain the liquid mixture through the scent absorbent discs and into the collection bottle. The discs and collection bottle are then removed for use in distributing the scent.

Owner:SANFORD SAMUEL A

Reagent mixing and conveying device and reagent mixing method

ActiveUS20180252707A1Small sizeSmart structureRotating receptacle mixersTransportation and packagingMechanical engineeringChemiluminescence immunoassay

The present invention provides a reagent mixing device, which comprises a driving device, a transport device and a rotating part, wherein the transport device comprises a conveying mechanism for conveying a reagent kit and a mixing mechanism for mixing a reagent; the conveying mechanism is driven by the driving device to move relative to the mixing mechanism; the rotating part and mixing mechanism are in transmission matching; the conveying mechanism and the mixing mechanism are sleeved with each other to form a bearing structure. The present invention further provides a reagent mixing method. The reagent mixing device is small in size, smart in structure, easy to assemble and low in manufacturing cost. The reagent mixing method provided by the present invention is simple and reliable, high in overall operation reliability, and has very high application values in such analysis and test fields as full-automatic chemiluminescence immunoassay analyzers and biochemical analyzers.

Owner:LEADWAY HK

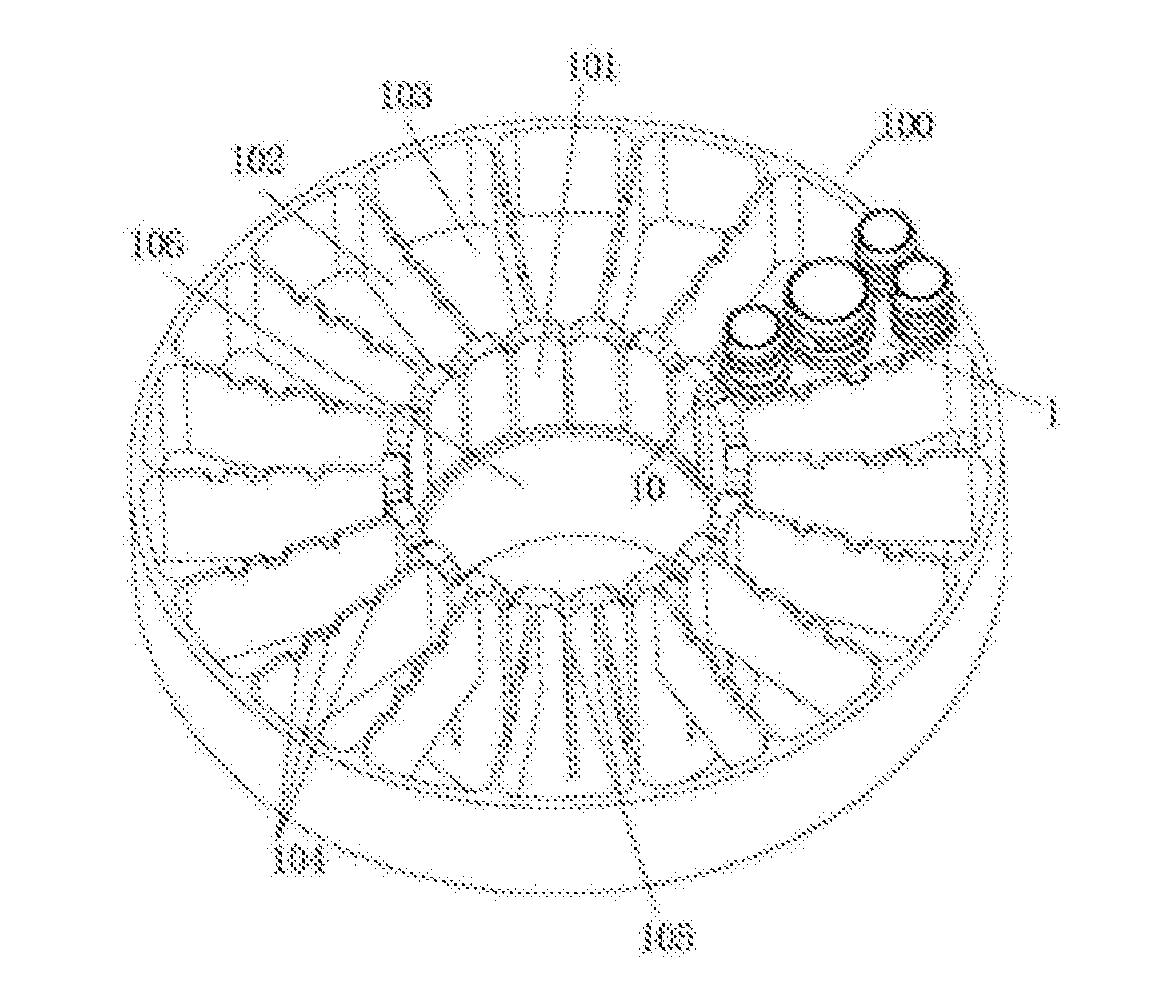

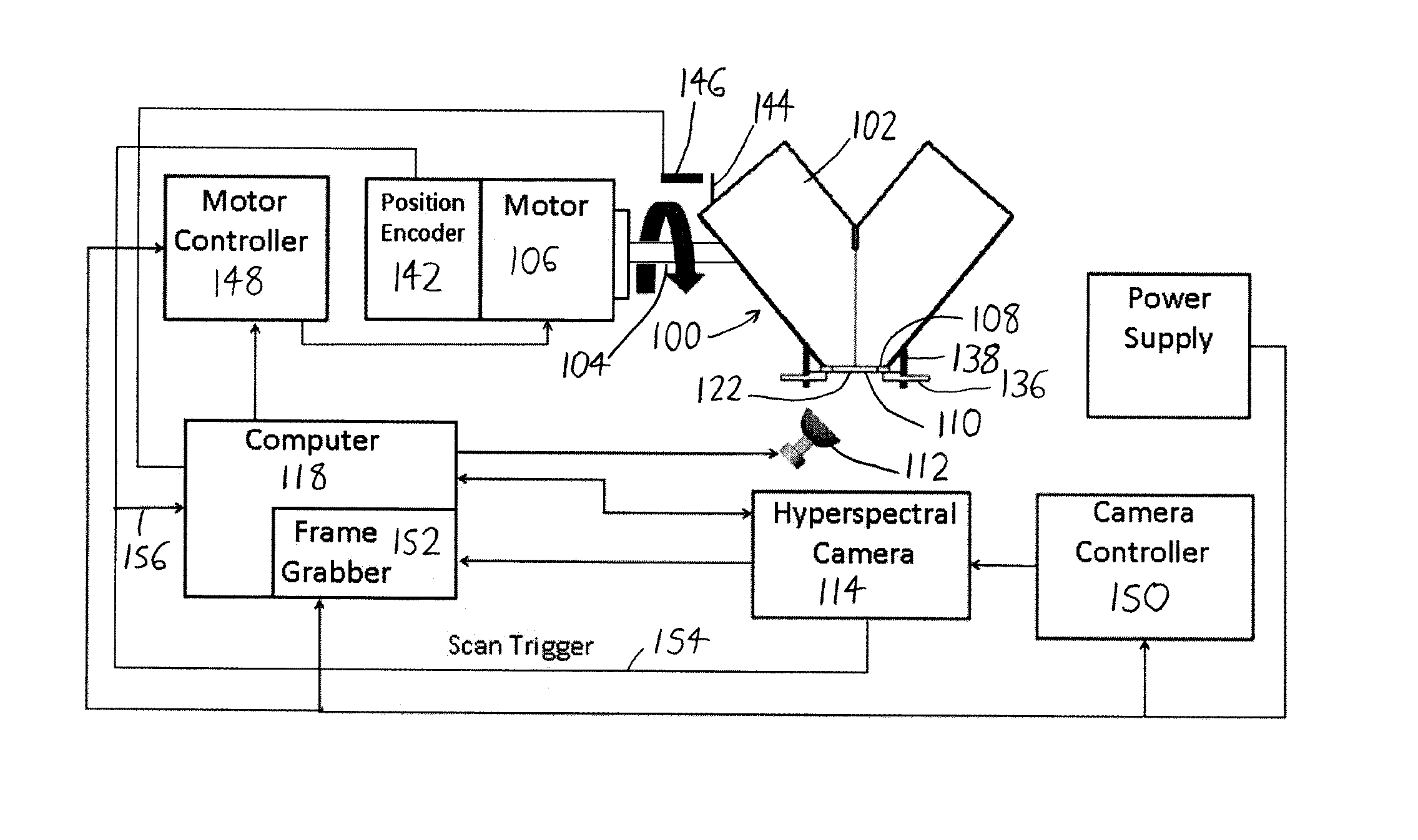

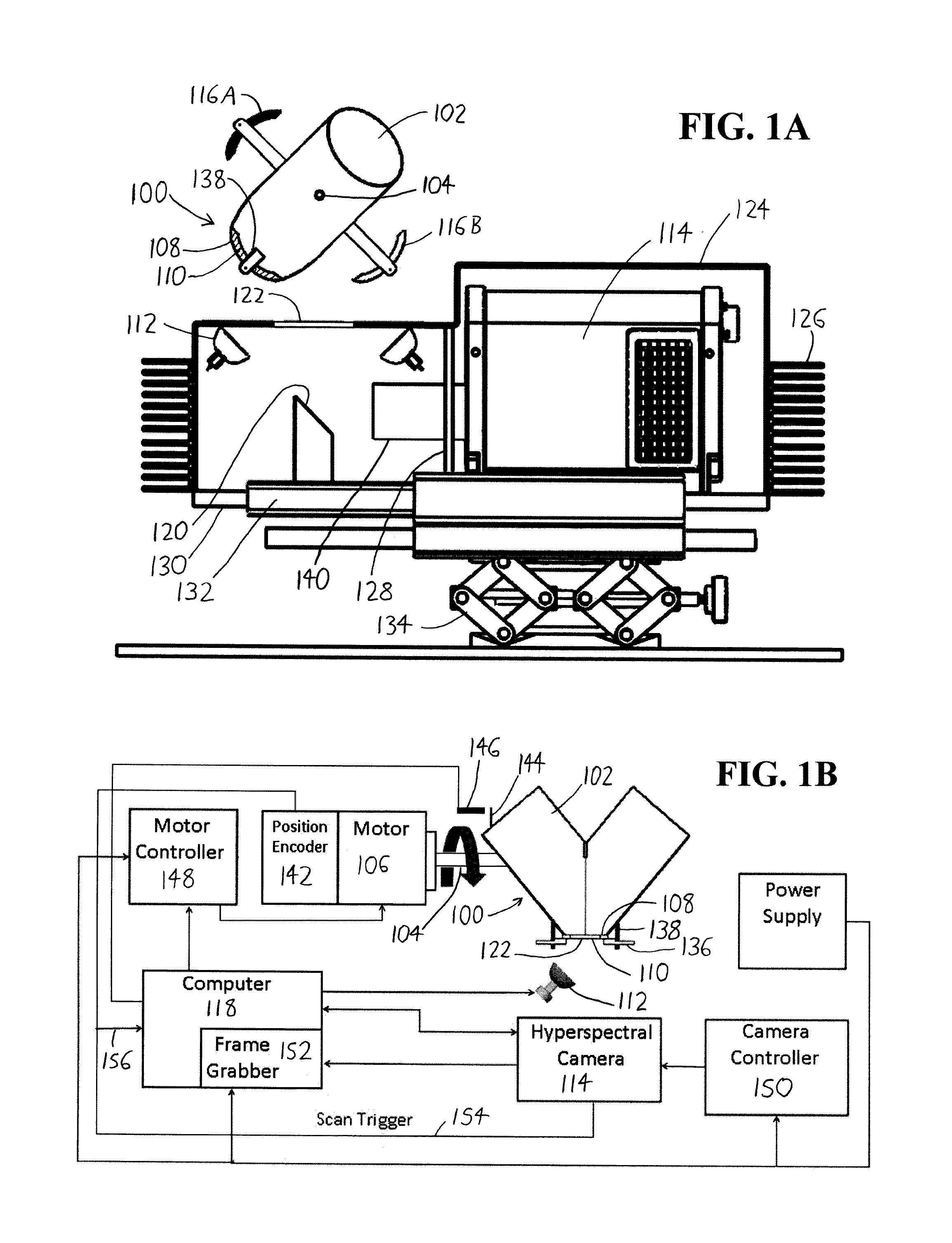

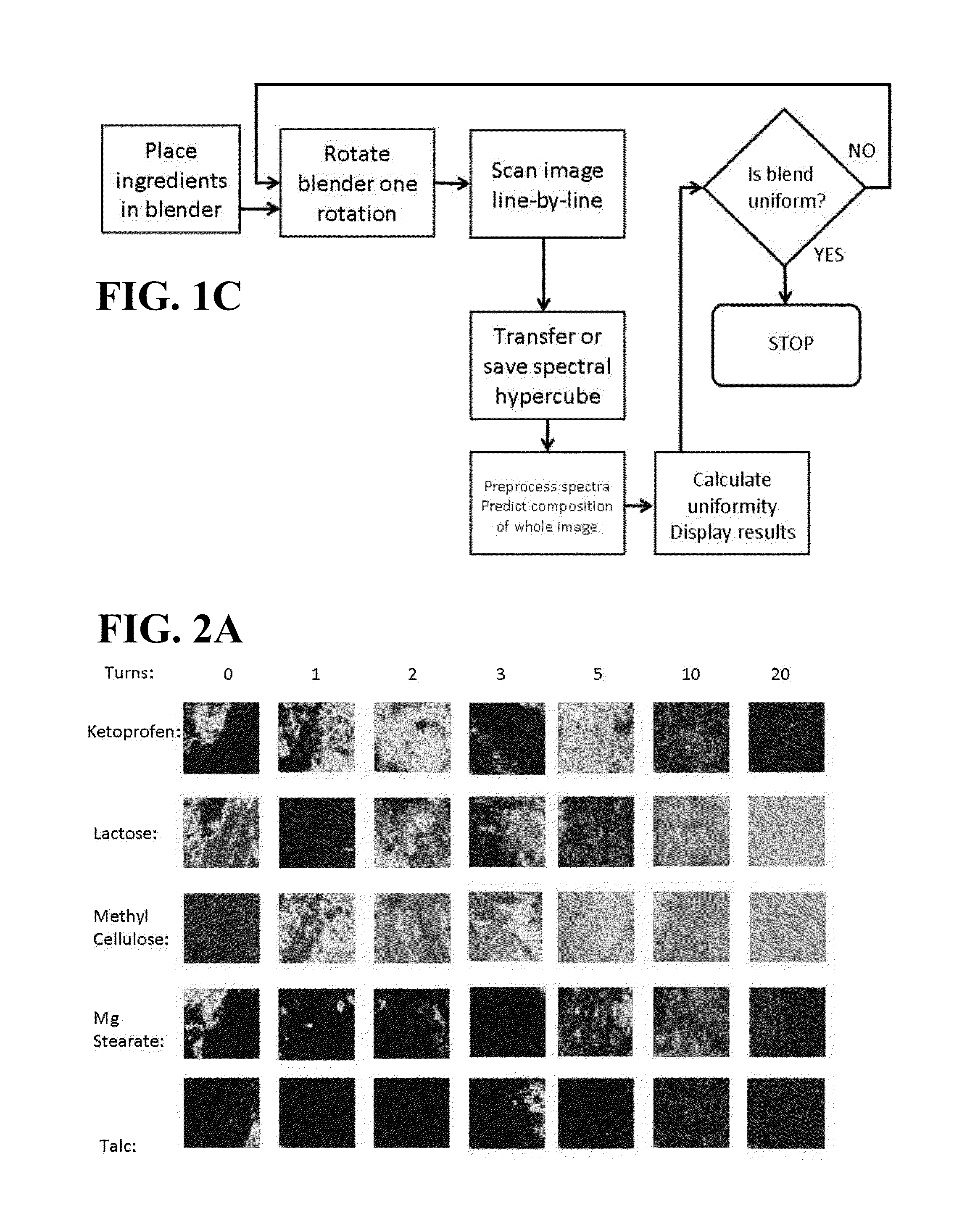

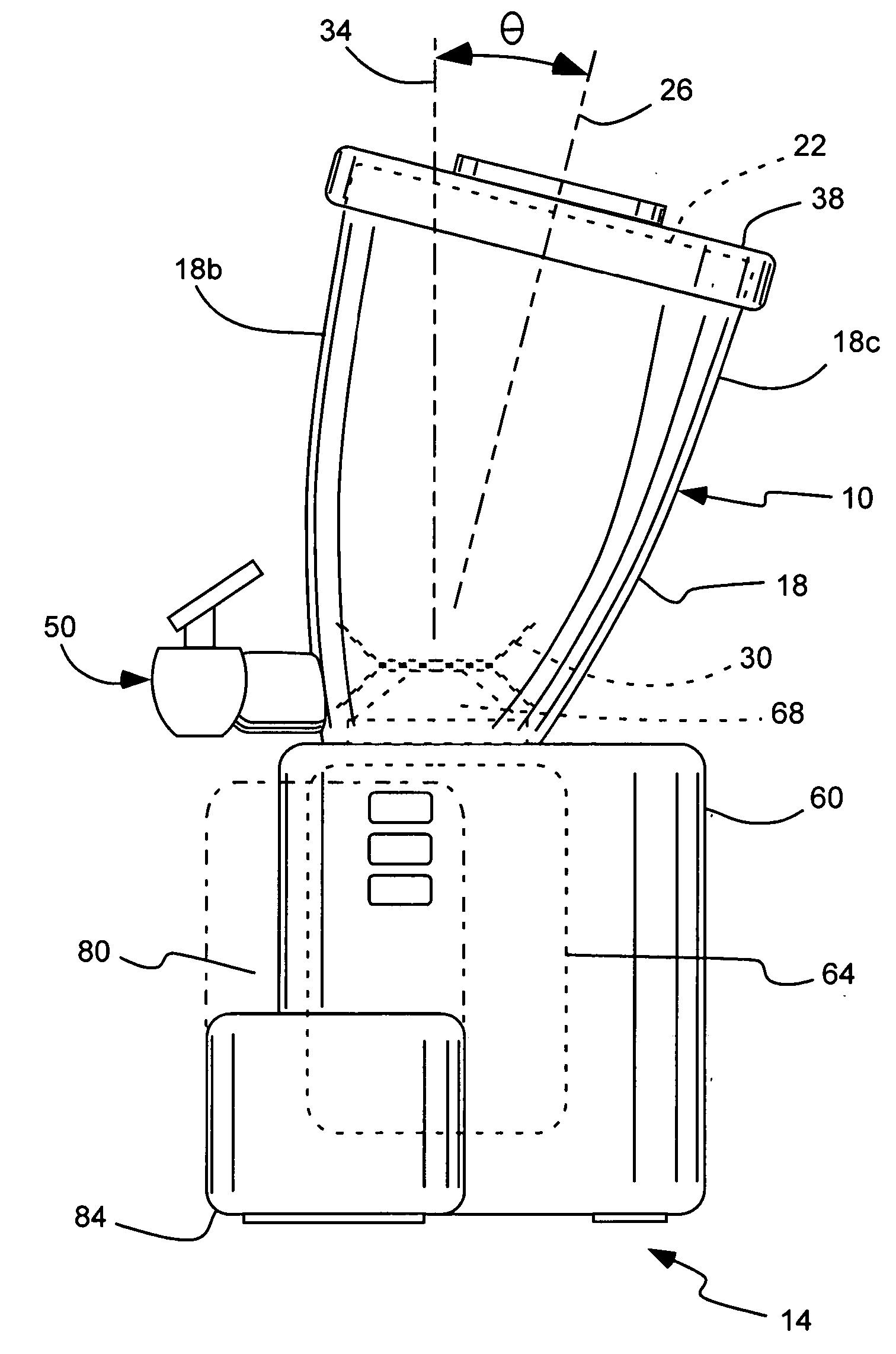

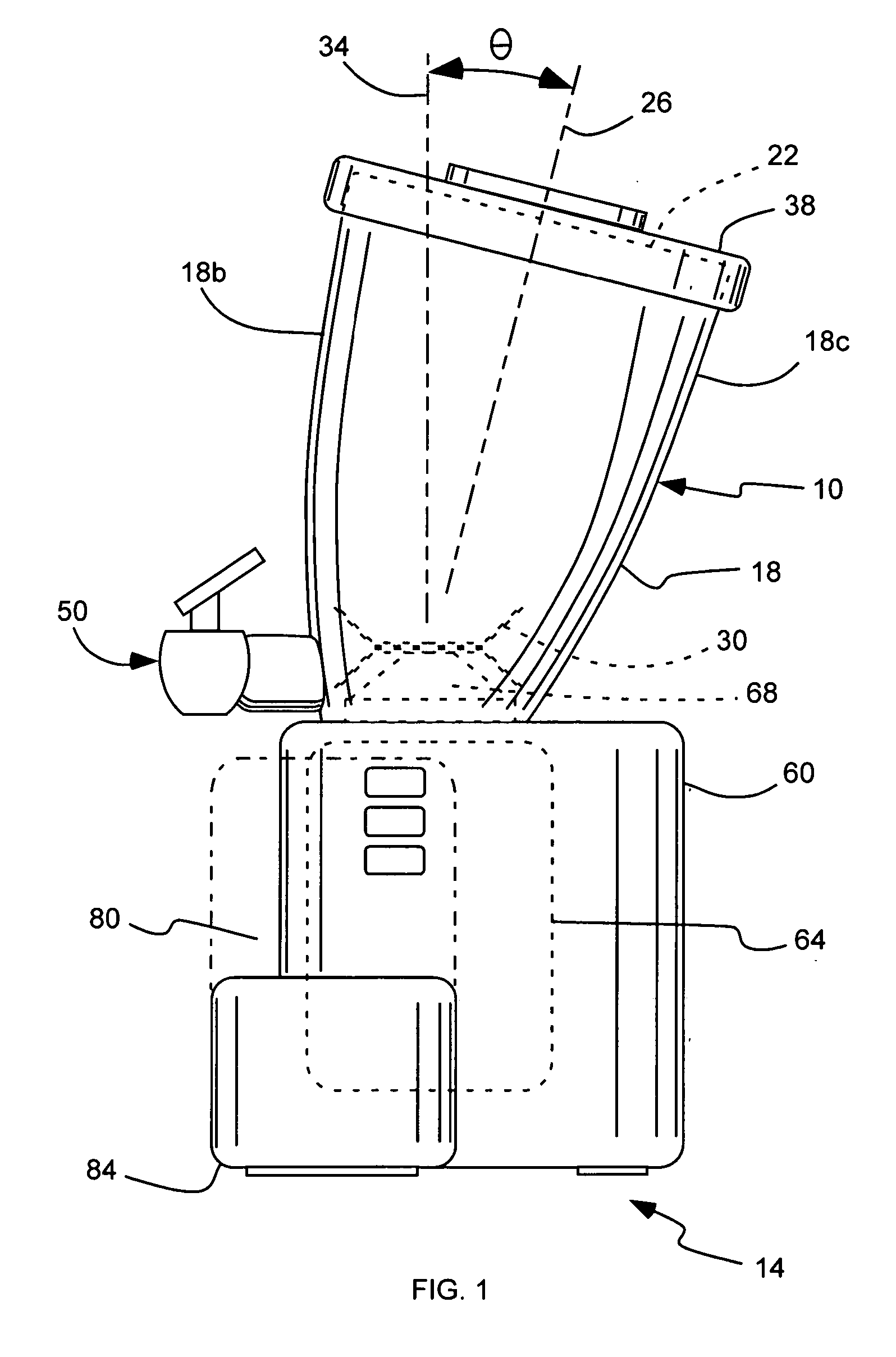

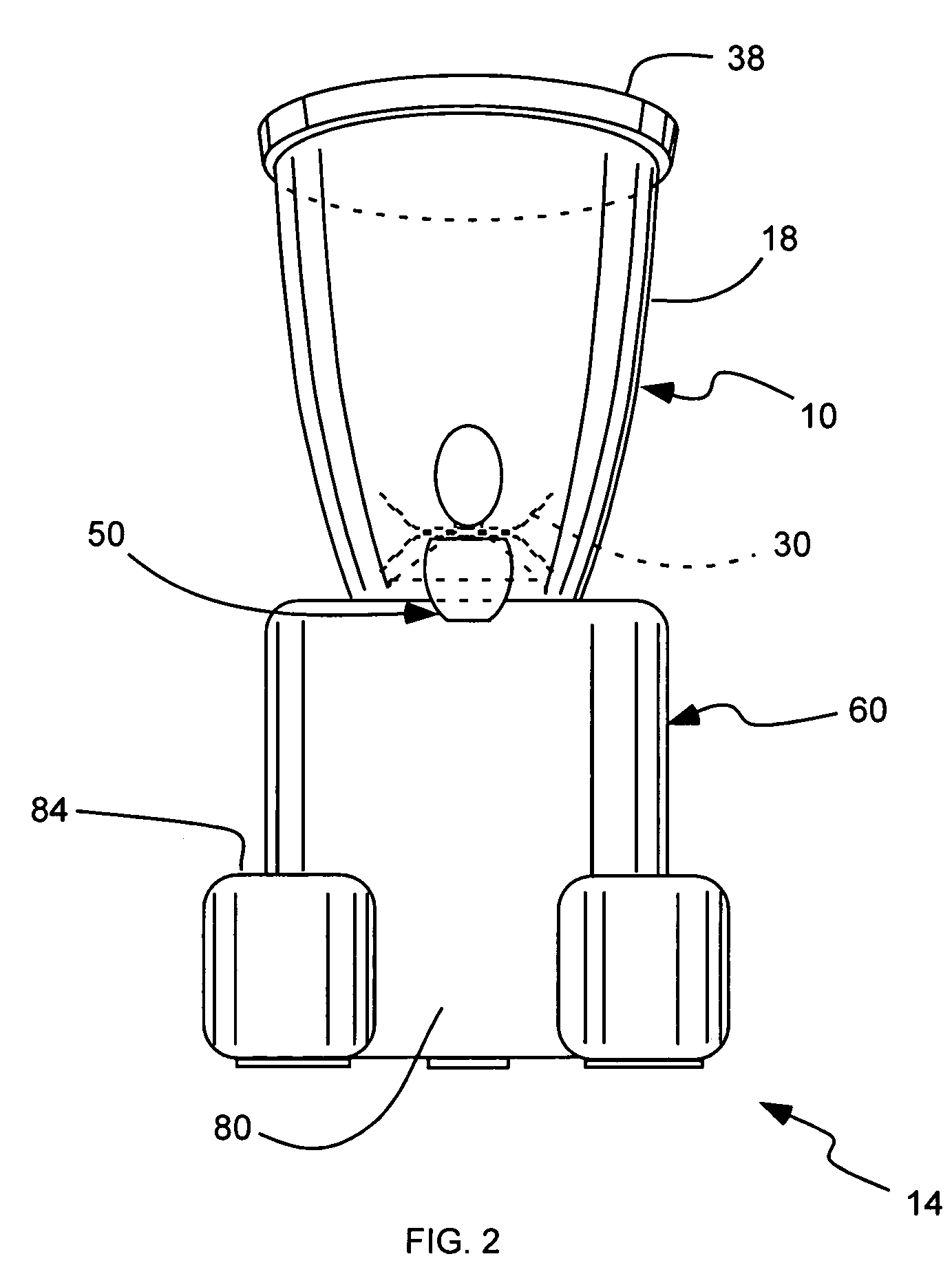

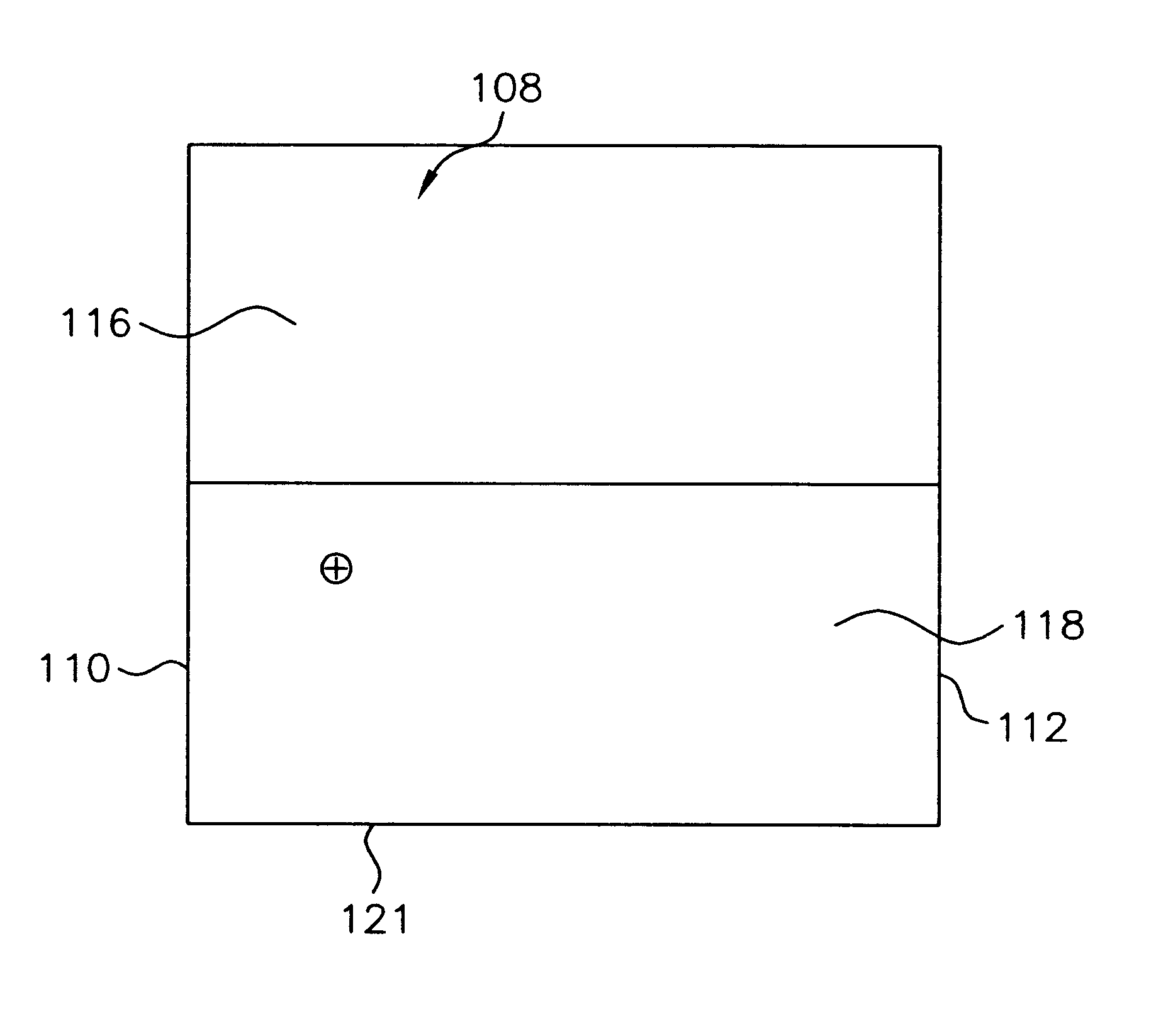

Spectral monitoring of ingredient blending

Spectral and hyperspectral imaging systems allow monitoring of pharmaceutical or other industrial blending processes to establish the characteristics of the blend. To illustrate, a batch type blender may be equipped with a computer controlled drive mechanism that is slowed down at a predetermined point during rotation to assess the progress of the blending through an imaging window mounted on the blender. A fast hyperspectral imaging device can be provided directly on the blender to view the blend through the imaging window, or can be placed in a fixed position relative to the rotating blender. The image of the blend is preferably captured line-by-line at a location at or near the bottom of the blender synchronously with the blender's rotation. The spectral information acquired from the blend at each rotation can be used to assess whether the nominal blend composition is achieved, or to reveal uniformity of the blend.

Owner:KEMENY ASSOC LLC

Off-axis goblet for food mixer

InactiveUS7217028B2Improve abilitiesFacilitate dispensing contentRotary stirring mixersTransportation and packagingRotational axisEngineering

Owner:FOCUS PROD GRP INT

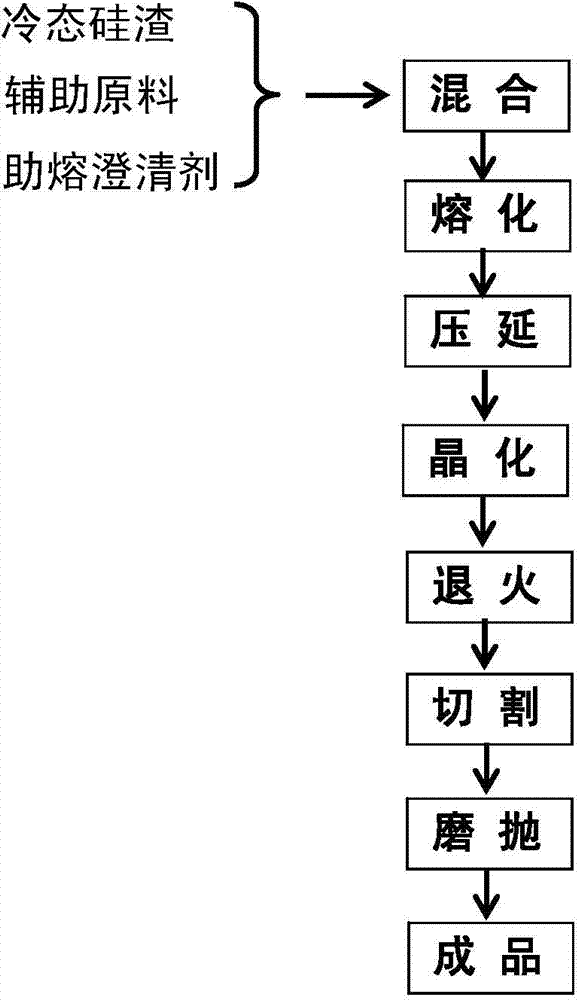

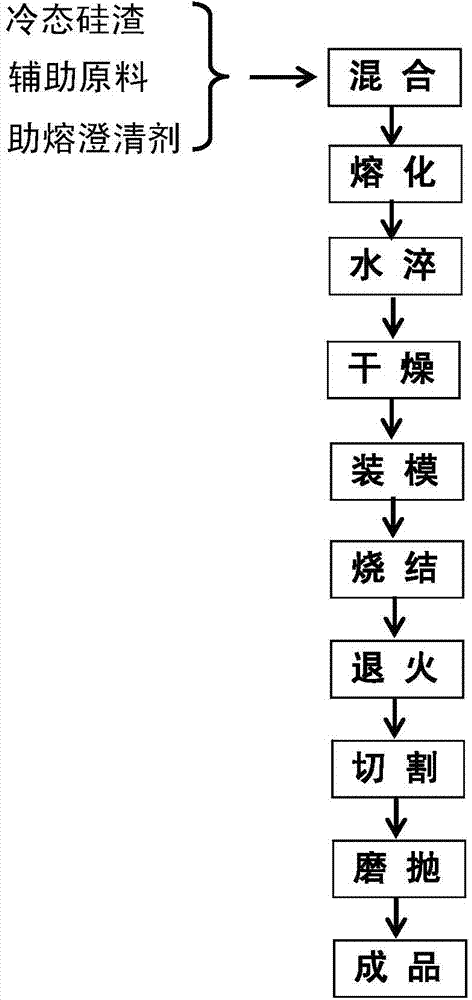

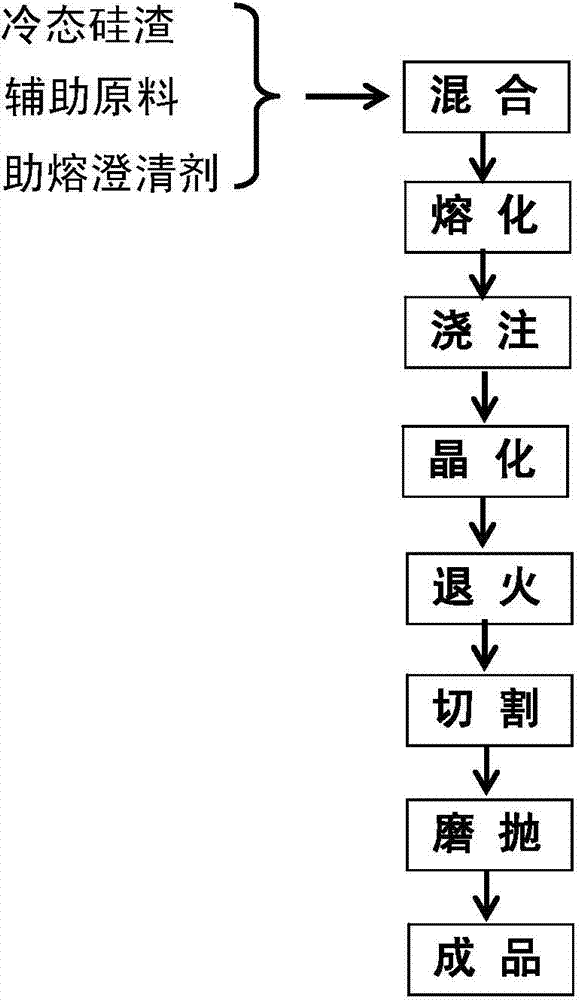

Silicon-slag microcrystalline glass and preparation method thereof

The invention relates to silicon-slag microcrystalline glass and a preparation method thereof. Silicon smelting waste slag is taken as a major raw material, and silicon dioxide or silica sand (SiO2), fluorite (CaF2), limestone or calcite (CaCO3), industrial sodium carbonate (Na2CO3), zinc oxide (ZnO) and potassium carbonate (K2CO3) are taken as auxiliary raw materials, wherein the dosage of the silicon smelting waste slag in the raw materials of the microcrystalline glass is 26.0-75.0wt%. The preparation method specifically comprises the following steps of: evenly mixing cold-state silicon slag with other auxiliary raw materials in a blender mixer to obtain a basic mixed batch, melting the basic mixed batch into qualified glass liquid in a melting furnace, and then performing calendering, casting or water quenching on the glass liquid to form a basic glass plate or granules; finally, subjecting the basic glass plate to crystallization heat treatment to obtain the microcrystalline glass. The density of the microcrystalline glass is 2.5-2.8 g / cm<3>, the rupture strength of the microcrystalline glass is 30.0-103.5 MPa, the compressive strength of the microcrystalline glass is 70.0-903.0 MPa, the Moh's hardness of the microcrystalline glass is 5-8 and the abrasive resistance of the microcrystalline glass is 0.063-0.15 g / cm<2>; the silicon-slag microcrystalline glass can be widely applied to the fields such as chemical engineering, metallurgy, architectural ornament, petroleum, mine and machinery.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Methods and systems to transfer proppant for fracking with reduced risk of production and release of silica dust at a well site

ActiveUS20160046438A1Reduce riskReduce production and releasePowdered material dispensingConveyorsBLENDER/MIXERConveyor belt

Embodiments of methods and systems of transferring proppant for fracking to reduce risk of production and release of silica dust at a well site are provided. An embodiment of a method can include positioning a plurality of containers each having proppant for fracking contained therein onto a conveyor at a well site, downwardly discharging proppant from each respective container of the plurality of containers, funneling proppant from the one or more outlets of each of the plurality of containers through a plurality of conveyor hoppers, receiving proppant onto the conveyor belt, conveying proppant on the conveyor to a chute, and depositing the proppant into the chute for use in a blender or other location at the well site.

Owner:SANDBOX ENTERPRISES LLC

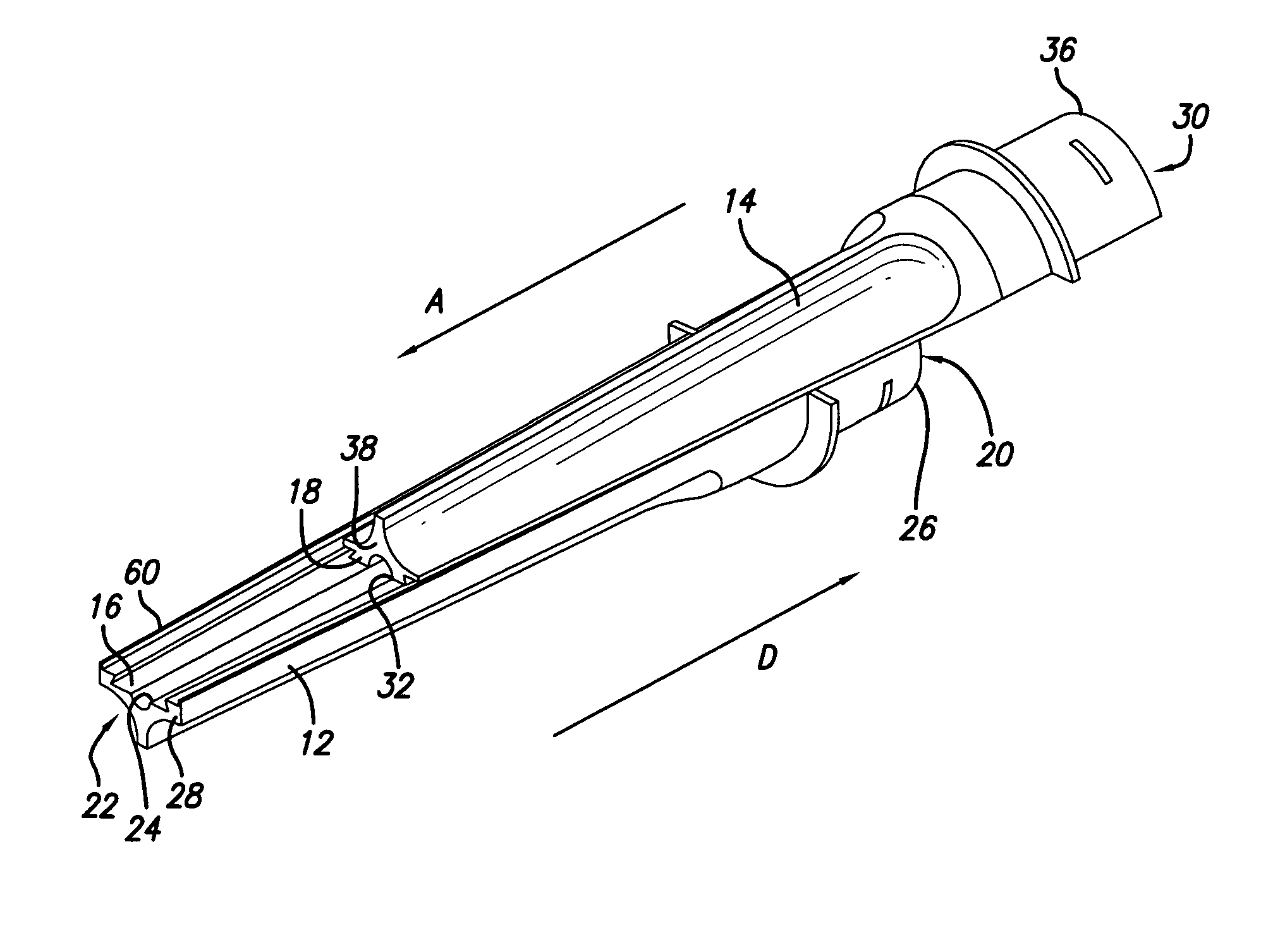

Stir stick assembly for blender apparatus

InactiveUS20050018532A1Easy to addRotary stirring mixersFrozen sweetsEngineeringMechanical engineering

A stir stick assembly is disclosed having a stir stick body with a control end and a stirring end, opposite the control end. The stir stick body includes a plurality of sections that are detachably mated together. The stir stick body further defines a passageway extending from the control end to the stirring end.

Owner:IDEAL LIVING HLDG

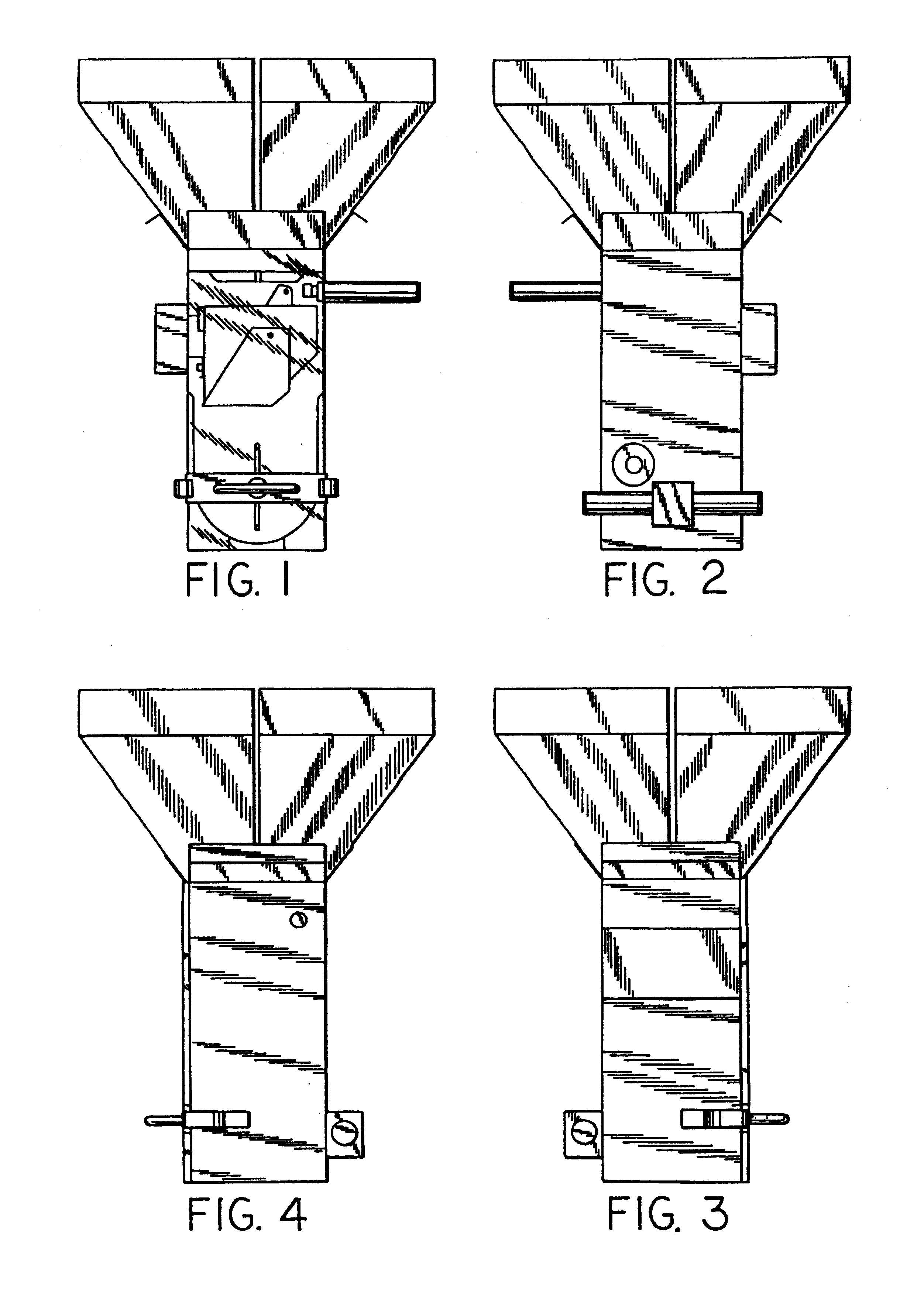

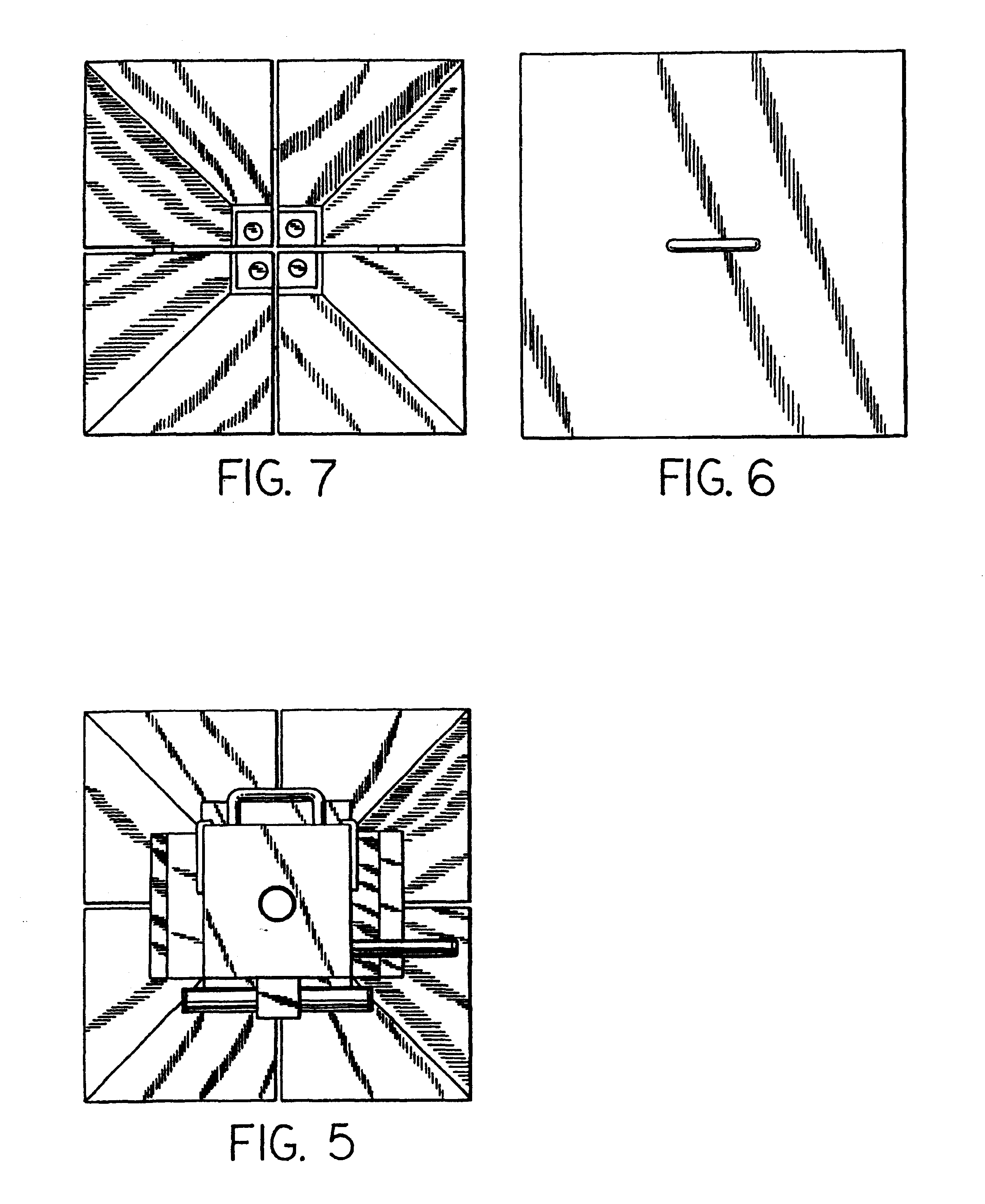

Reduced size gravimetric blender

InactiveUS6467943B1Controlling ratio of multiple fluid flowsRotary stirring mixersMolding machineReduced size

A gravimetric blender of a reduced size mounted to be directly over the feed trough of small molding machines or extruders. The blender has an upright hollow rectangular frame with a transparent panel. The top of the frame forms a cradle for removably supporting a plurality of hoppers having a bottom discharge controlled by a valve mechanism. The valve mechanism is mounted on each hopper and is connected to a control station having a quick-disconnect fitting on the hopper. The hoppers discharge sequentially into a weigh bin supported on a load cell connected to the control station of the blender. The weigh bin has an openable bottom portion pivotally mounted thereon for actuation by the control station when the appropriate weight is registered by the load cell. The weigh bin discharges into a mixing chamber having an agitator or mixer removably mounted therein. The mixer is journaled for rotation in the transparent panel which is removable so that when the panel is removed, the mixer agitator is disengaged from its drive and removed with the panel.

Owner:MAGUIRE PROD

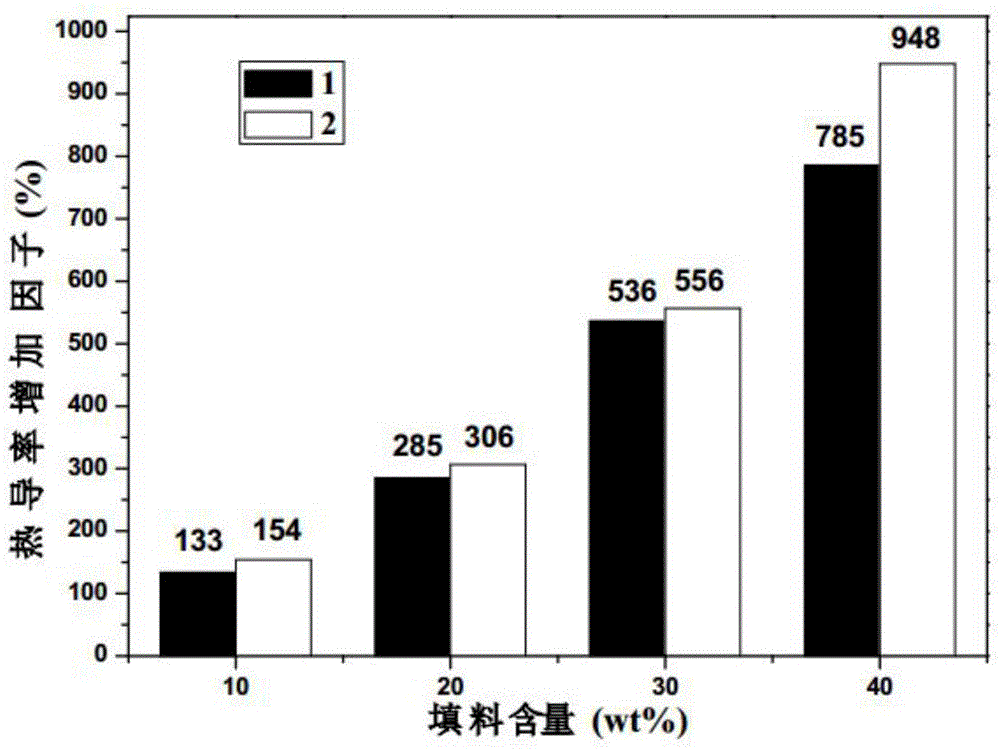

High thermal conductive and insulating polymer composite and preparing method and application thereof

The invention discloses a high thermal conductive and insulating polymer composite and a preparing method and application thereof. The preparing method is characterized in that 0.1-1.0 part of hexagonal boron nitride is evenly stirred and mixed with 50-1000 parts of organic solvent, and is added into an ultrasonic cleaner with the power ranging from 100 w to 1000 w or an ultrasonic cell disruptor, ultrasonic treatment is carried out for 4 hours to 72 hours, and mixed liquor is obtained; standing is carried out on the mixed liquor for 24 hours to 72 hours, after filtering or rotary evaporating is carried out, a product is cleaned for twice to five times by using acetone, and a boron nitride nano-sheet with the higher yield is obtained; 60-90 parts of a polymer matrix and 40-10 parts of the boron nitride nano-sheet are added into a high-speed blender mixer, the temperature ranges from 200 DEG C to 300 DEG C, the rotary speed ranges from 30 rpm to 60 rpm, mixing is carried out for 5 minutes to 10 minutes, and granulates are extruded by a screw extruder; the high thermal conductive and insulating polymer composite can be obtained through smelting and forming. According to the high thermal conductive and insulating polymer composite, the mechanical property can be maintained, and meanwhile the thermal conductivity is improved maximally.

Owner:SICHUAN UNIV

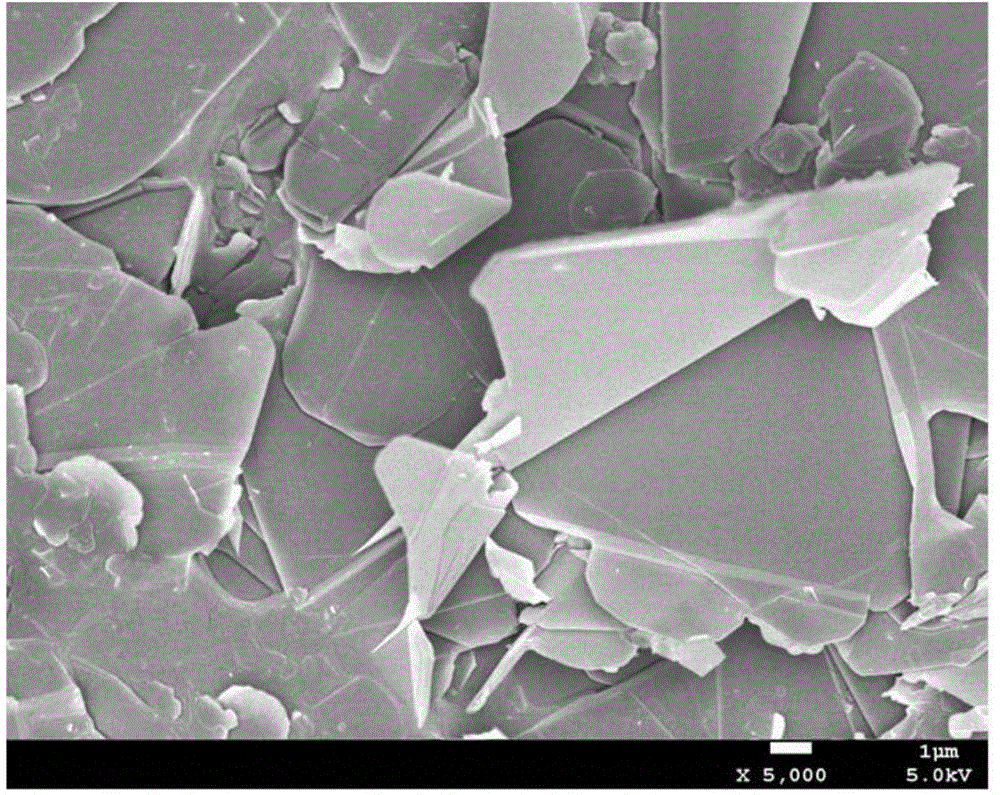

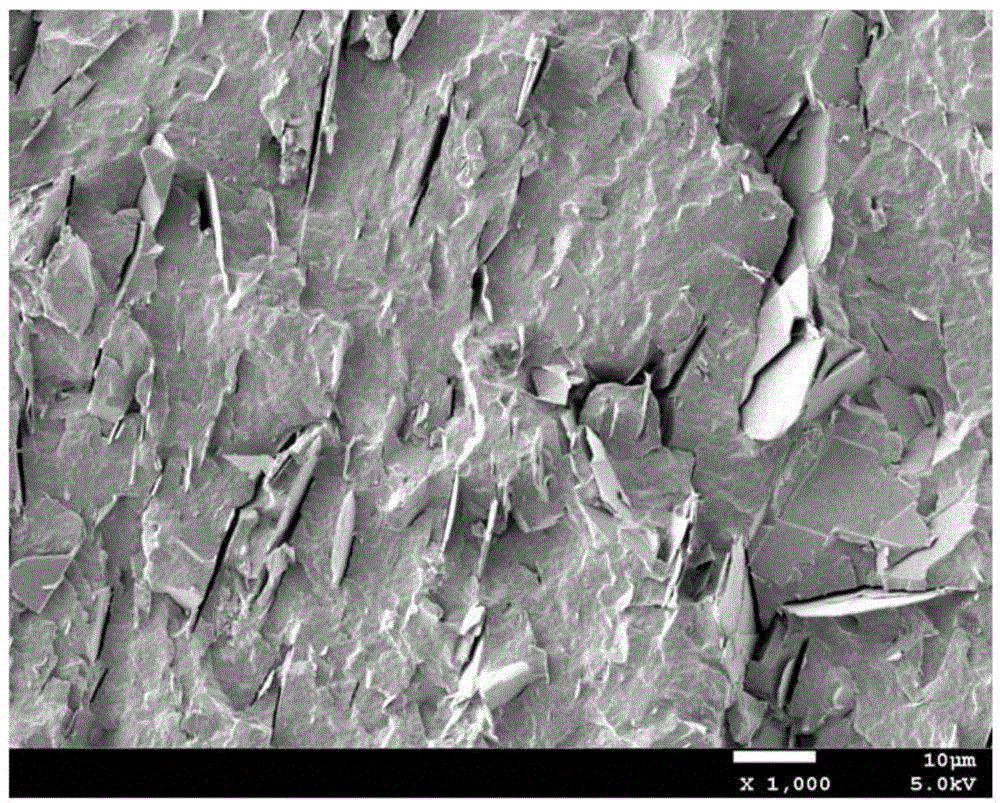

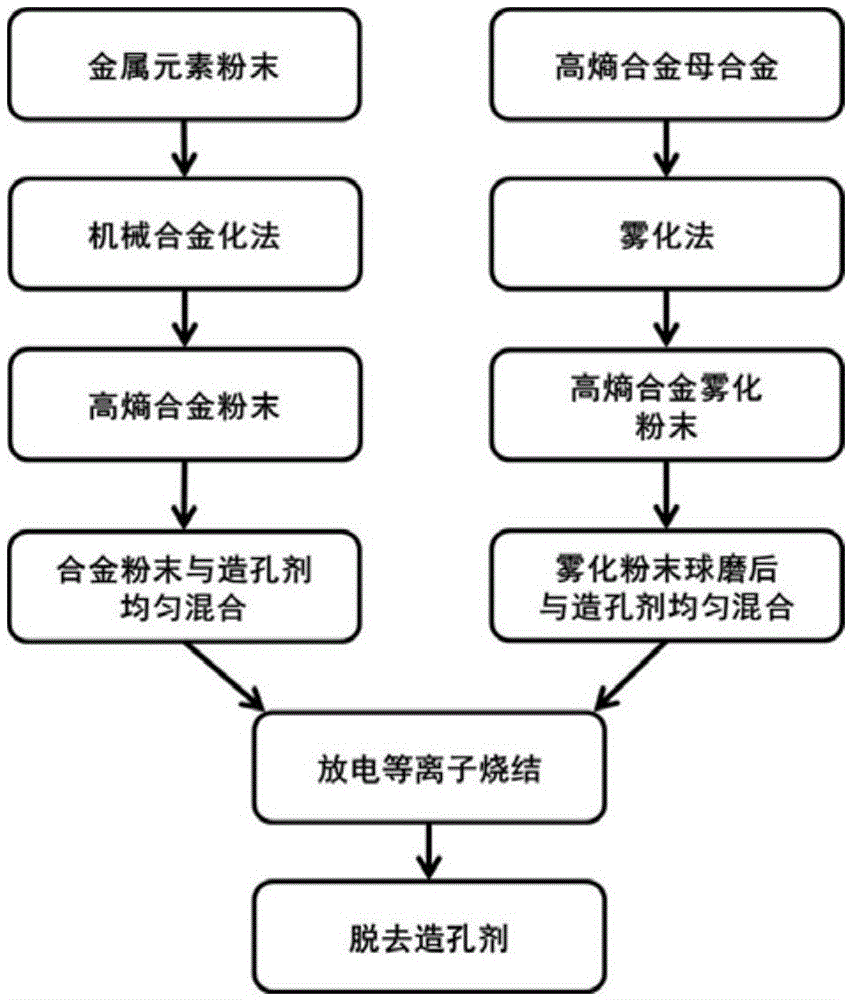

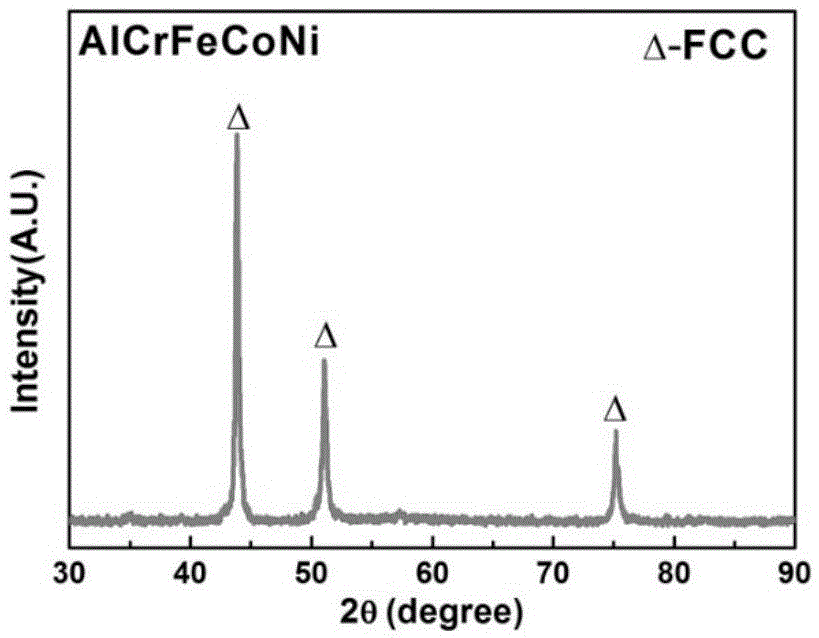

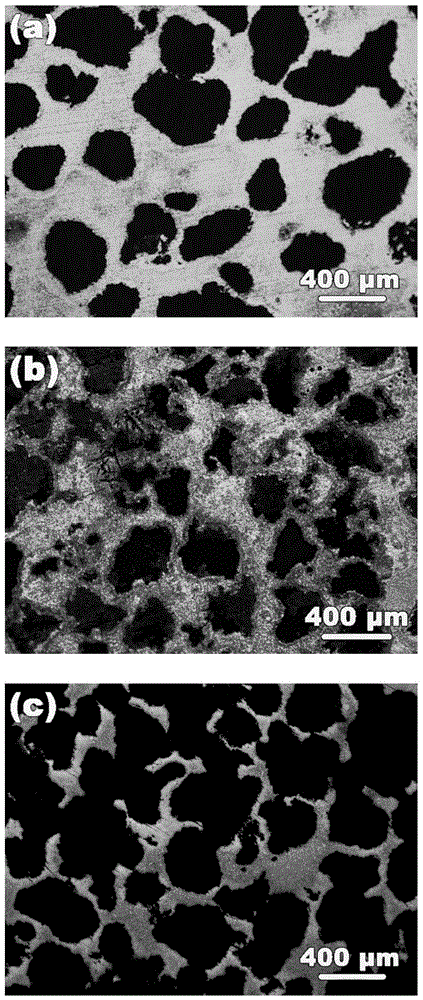

Porous high-entropy alloy and preparation method thereof

The invention discloses porous high-entropy alloy and a preparation method thereof and belongs to the field of porous foam metal. The preparation method of the porous high-entropy alloy specifically comprises the steps that high-entropy alloy powder and screened pore-forming agents are mixed proportionally according to the requirements for the porosity and the pore size, and the high-entropy alloy powder and the screened pore-forming agents are sintered through spark plasma sintering (SPS) directly after being uniformly mixed by a blender mixer; after sintering is completed, a sintered sample is put into deionized water to be subjected to ultrasonic cleaning, and particles of the pore-forming agents are removed by using the characteristic that the pore-forming agents are soluble in water; and finally the porous high-entropy alloy is obtained. The preparation method is simple in process, particularly, the preparation time is shortened greatly through the SPS method, and the efficiency is improved. The prepared porous high-entropy alloy has the characteristics of being high in porosity, uniform in pore size distribution, controllable in porosity and pore size and the like and has potential application prospects in the fields of biology, petroleum, metallurgy, chemical industry and the like.

Owner:UNIV OF SCI & TECH BEIJING

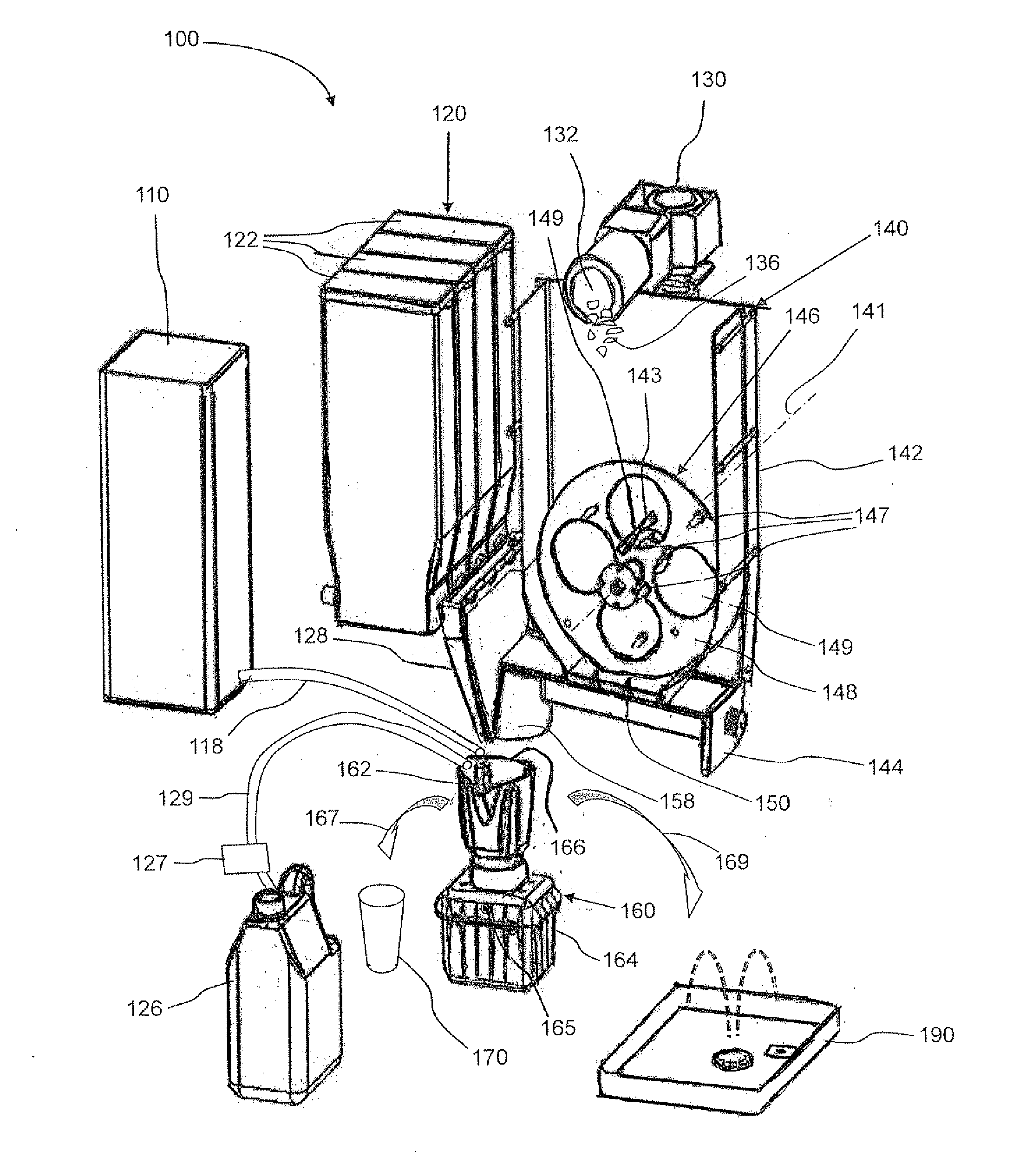

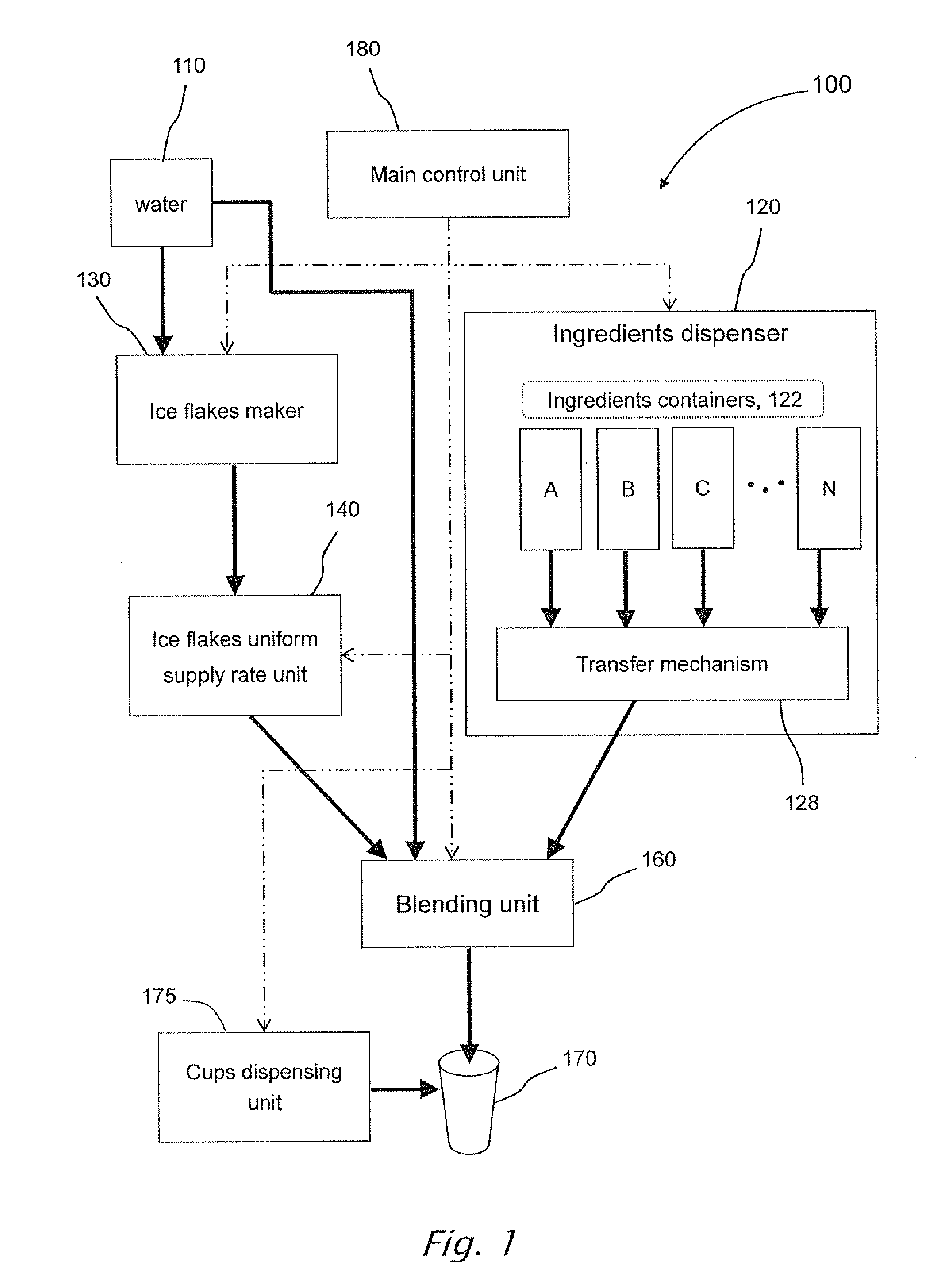

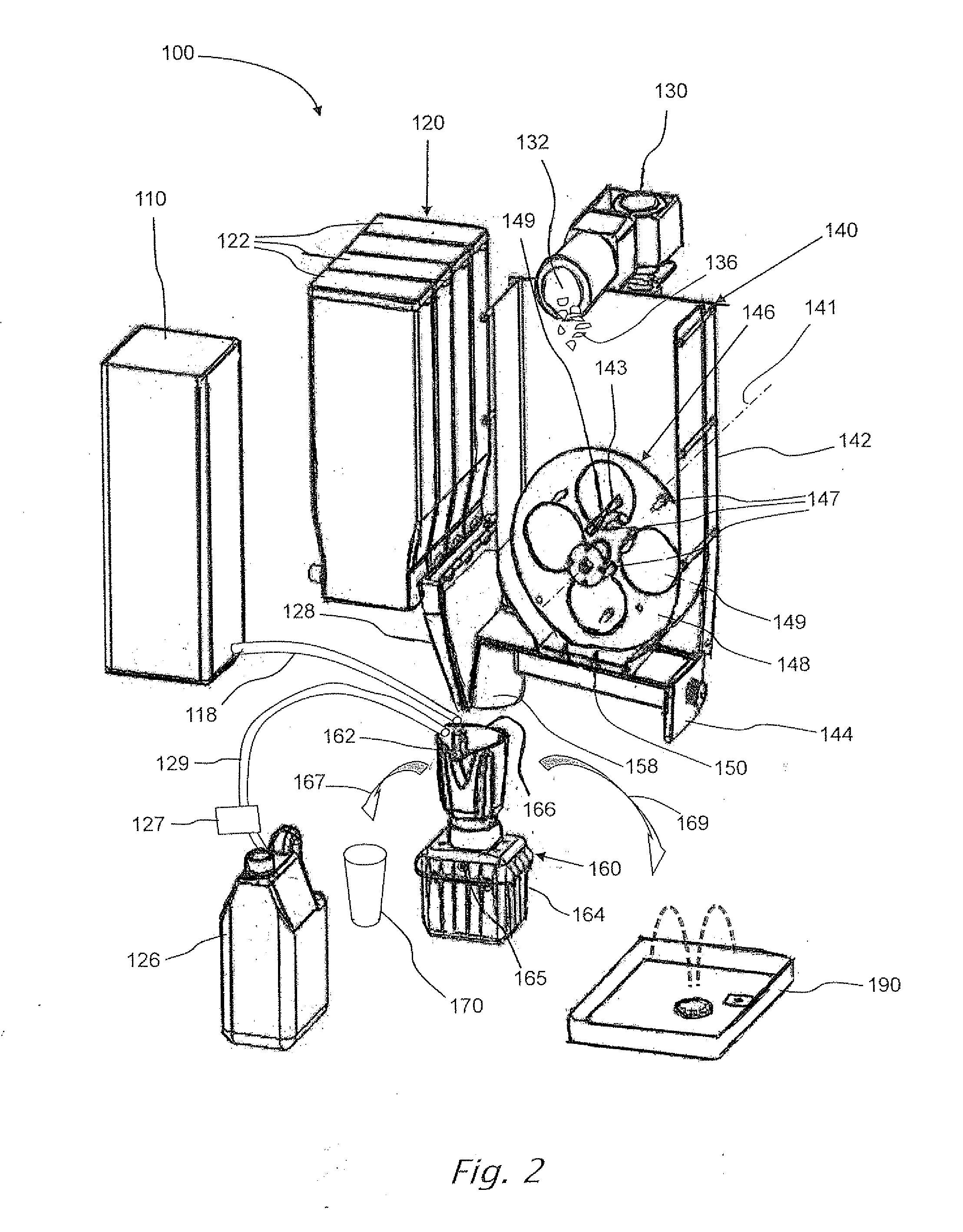

Apparatus for dispensing made to-order frozen beverage

ActiveUS20100151083A1Easy to movePromotes relative motionOpening closed containersBottle/container closureAdditive ingredientEngineering

An apparatus for preparing and dispensing a flavored ice beverage and a method of using thereof. The apparatus includes at least one container for holding flavor ingredients, a blending unit including a blender container and a blending mechanism, an ice flakes supplying unit, a mechanism for transferring the flavor ingredients to the blender container and a computerized control unit for controlling one or more aspects of the process of producing the ice beverage. The flavor ingredients can be in grain form, powder form or in liquid form.

Owner:NICEVEND

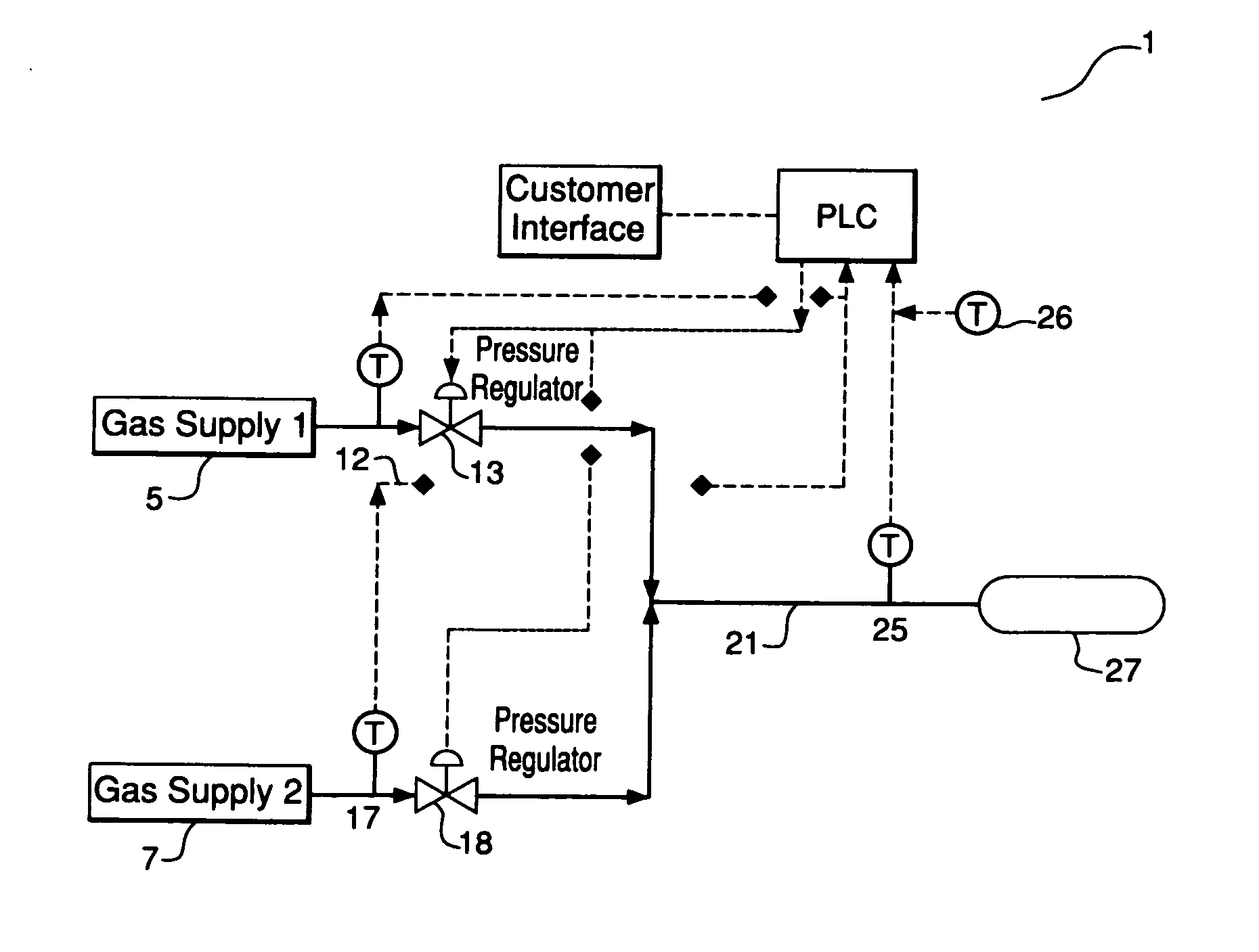

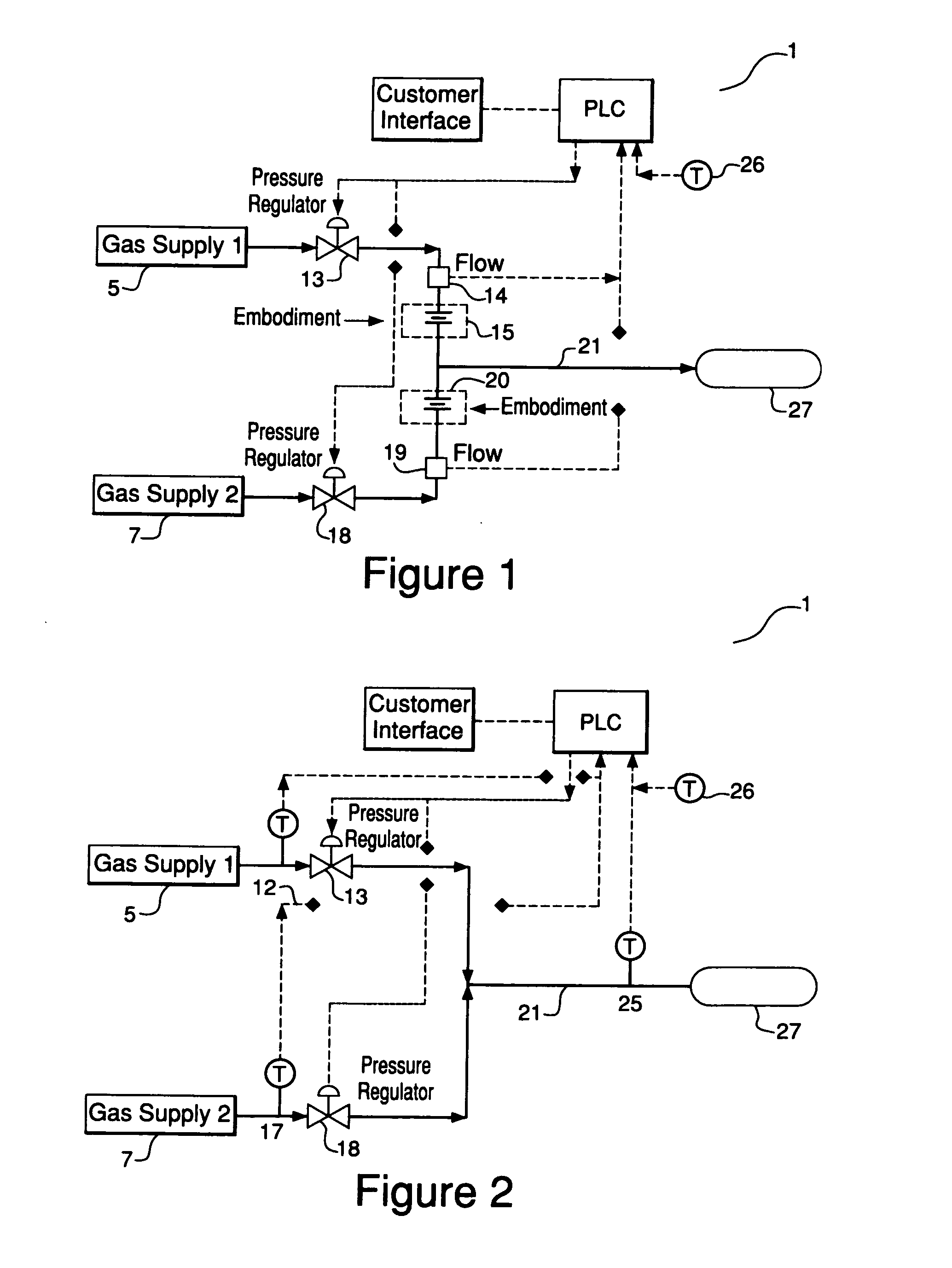

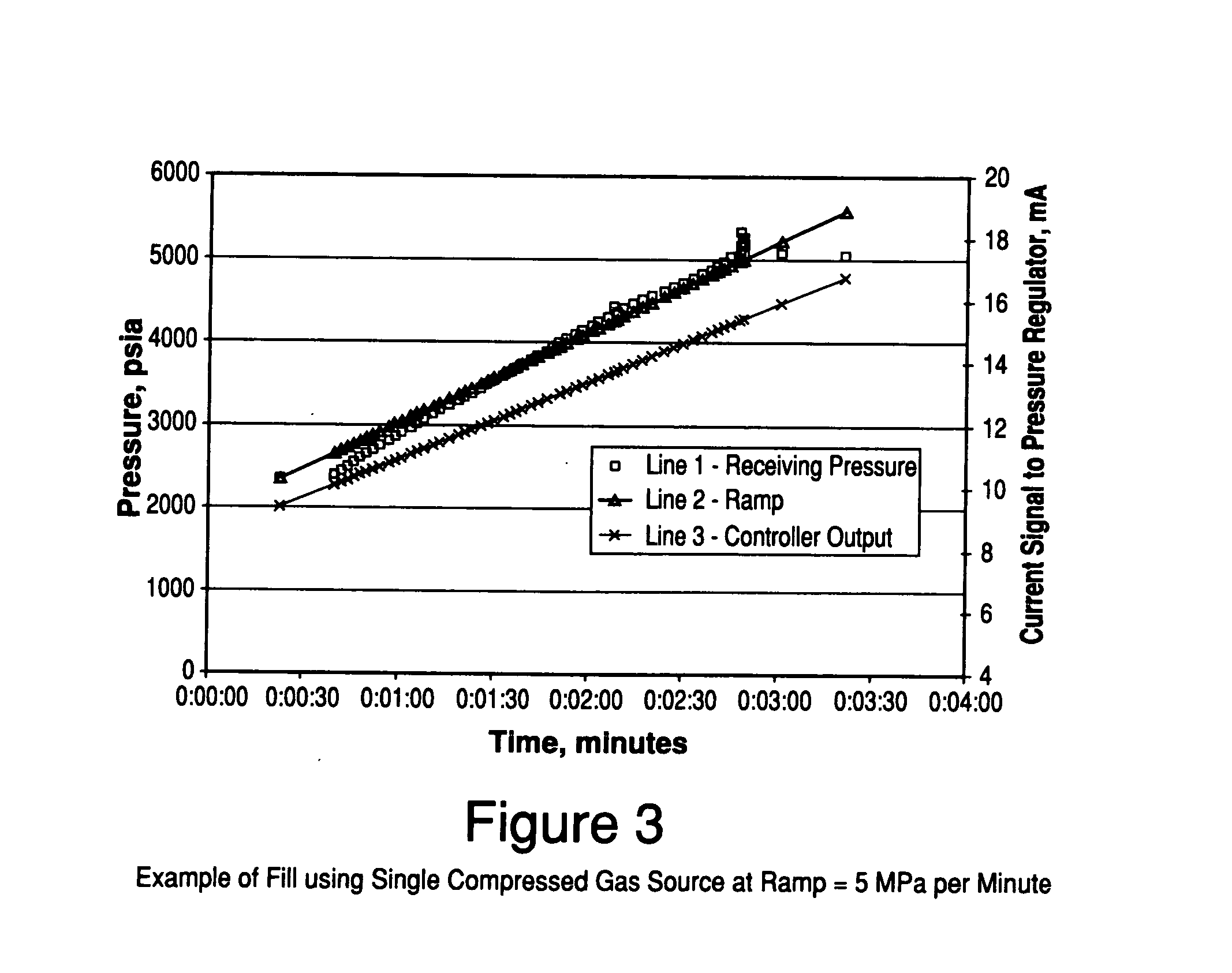

Ramp rate blender

InactiveUS20070169837A1Easy to controlClean burningLiquid fillingTemperatue controlEngineeringElectrical and Electronics engineering

Owner:AIR PROD & CHEM INC

Treatment method capable of achieving stabilization and curing of electroplating sludge

InactiveCN102514079AImprove stabilityEasy to fixSludge treatmentCeramic shaping apparatusSludgeElectroplating

The invention relates to a treatment method capable of achieving stabilization and curing of electroplating sludge, which belongs to the technical field of environmental engineering. The treatment method comprises the following steps of (1) dewatering and drying the electroplating sludge at the temperature of 105 DEG C, grinding, crushing and screening the electroplating sludge for standby application; (2) mixing the electroplating sludge, stabilizer and curing agents according to a certain weight percentage at the temperature within a range of 25-50 DEG C, adding water with a certain proportion into the mixture, and strongly blending the mixture through a blender; (3) moulding the mixture and curing the mixture into building blocks; and (4) conserving and drying the building blocks through air. A toxic leaching test is carried out on a building block sample according to GB 5085.3 2007, the building block sample accords with state environmental protection requirements, and physical properties of the building block sample accord with national building materials secondary standards.

Owner:YANCHENG INST OF TECH

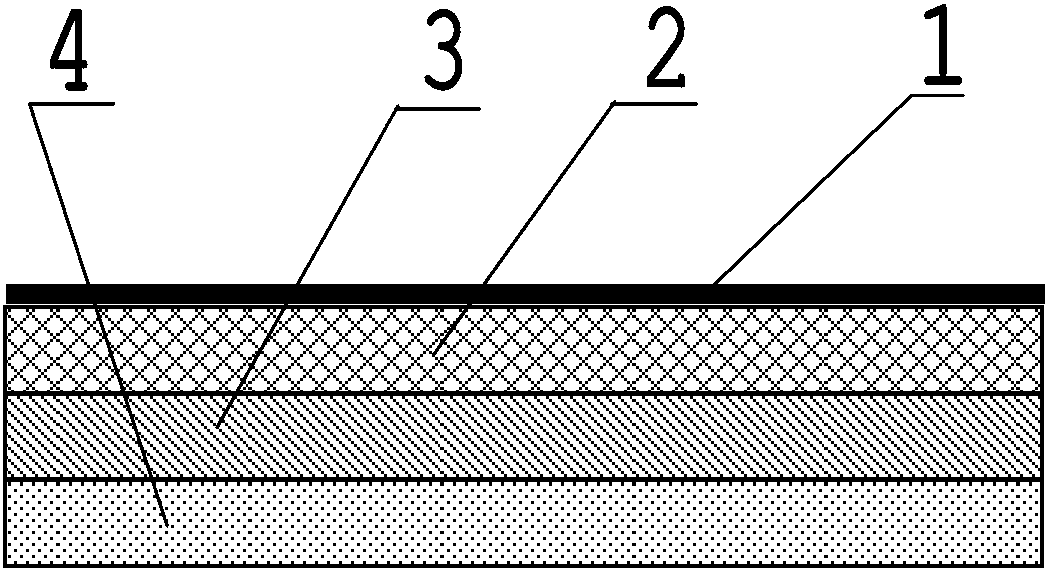

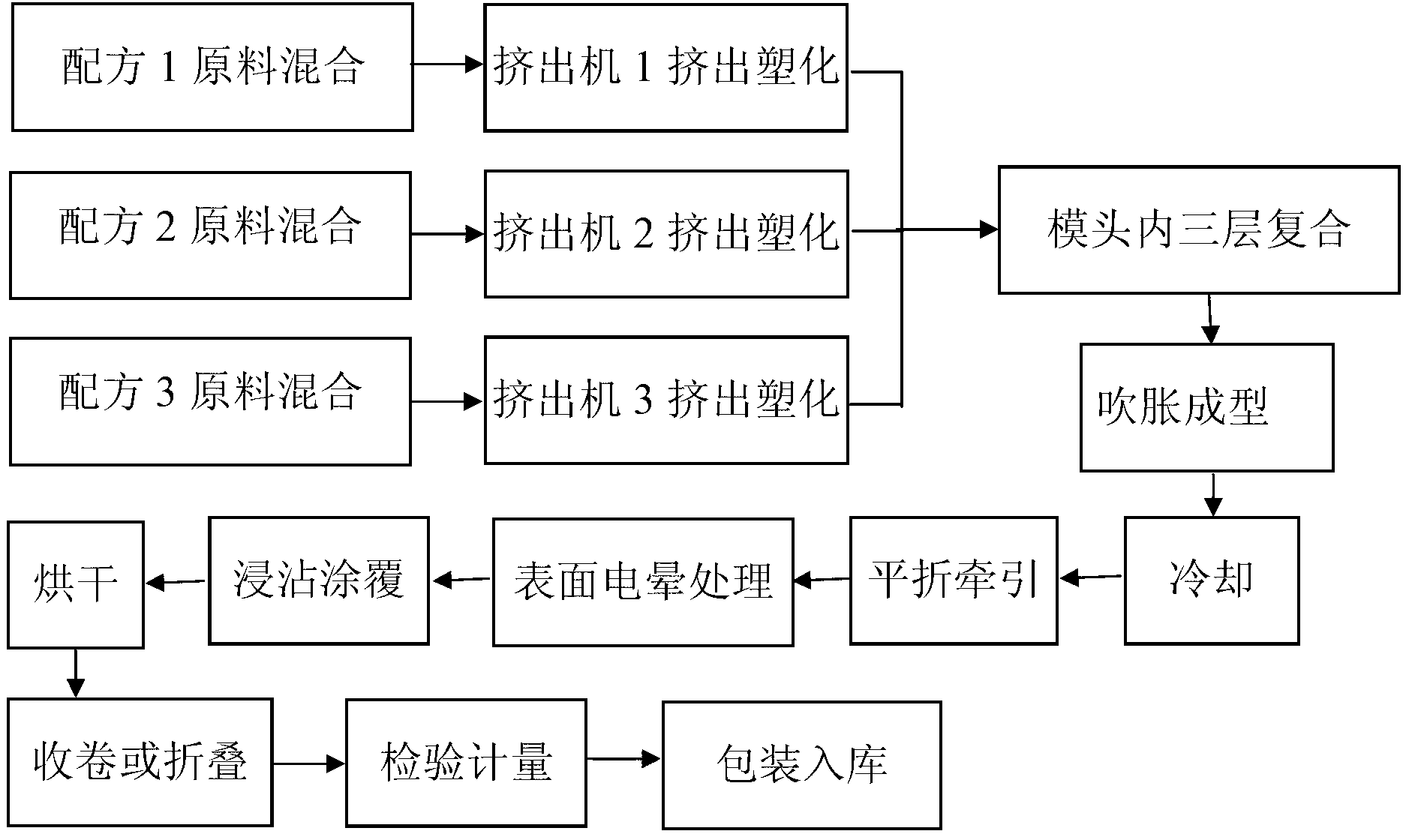

Coating-type light conversion film and preparation method thereof

InactiveCN102848683AAvoid degradationHas acid resistanceClimate change adaptationSynthetic resin layered productsCooking & bakingMechanical property

The invention relates to a coating-type light conversion film and a preparation method of the coating-type light conversion film. The invention belongs to the technical field of an agricultural film. An inner layer of the coating-type light conversion film is a mechanical property layer; a middle layer is a heat-insulating light conversion layer; a secondary outer layer is a coating carrier layer, and the outer layer is a film coating layer. The preparation method of the coating-type light conversion film comprises the following steps of: (1) preparing a multifunctional master batch with a long service life, heating an internal mixer, charging and agitating, discharging and pelletizing; (2) preparing the master batch with the long service life and efficient light conversion, heating the internal mixer, charging and agitating, discharging and pelletizing; (3) manufacturing the coating light conversion film, weighing the inner layer, the middle layer and the secondary outer layer according the prescription, respectively adding to a blender mixer to agitate and extrude, wherein a die head is of a three-layer composite center feeding form; the material is fused and plastified by three extruders, and coextruded by a round opening die; carrying out corona treatment on the film surface, coating on line, baking and sizing. The coating-type light conversion film has the advantages that the coating-type light conversion film is high in strength, high in impact resistance, high in tear resistance, high in light conversion, high in heat preservation, high in light transmittance, and long in lasting period of drip fog dissipation and the like.

Owner:TIANJIN TIANSU SCI & TECH GROUP

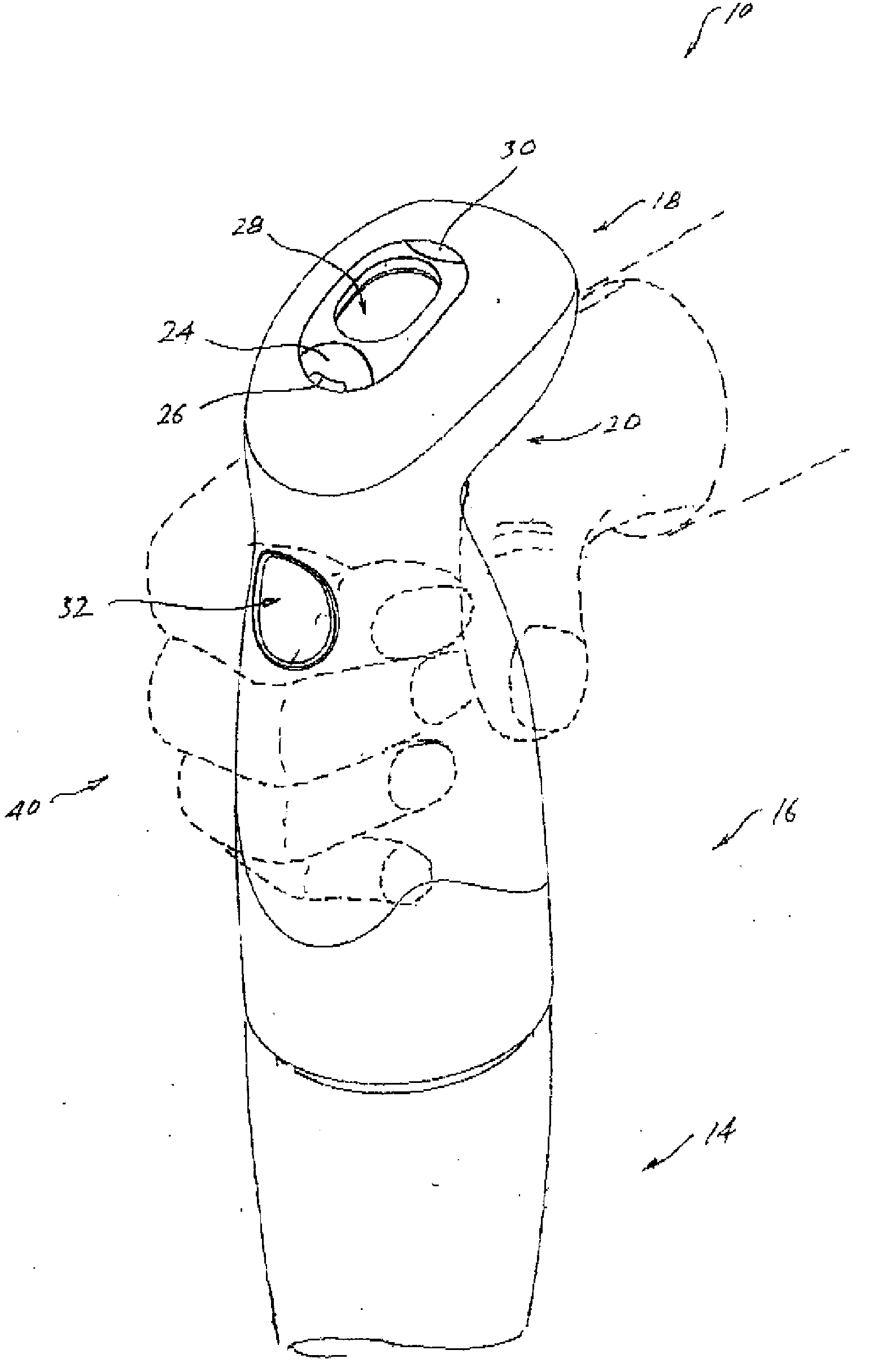

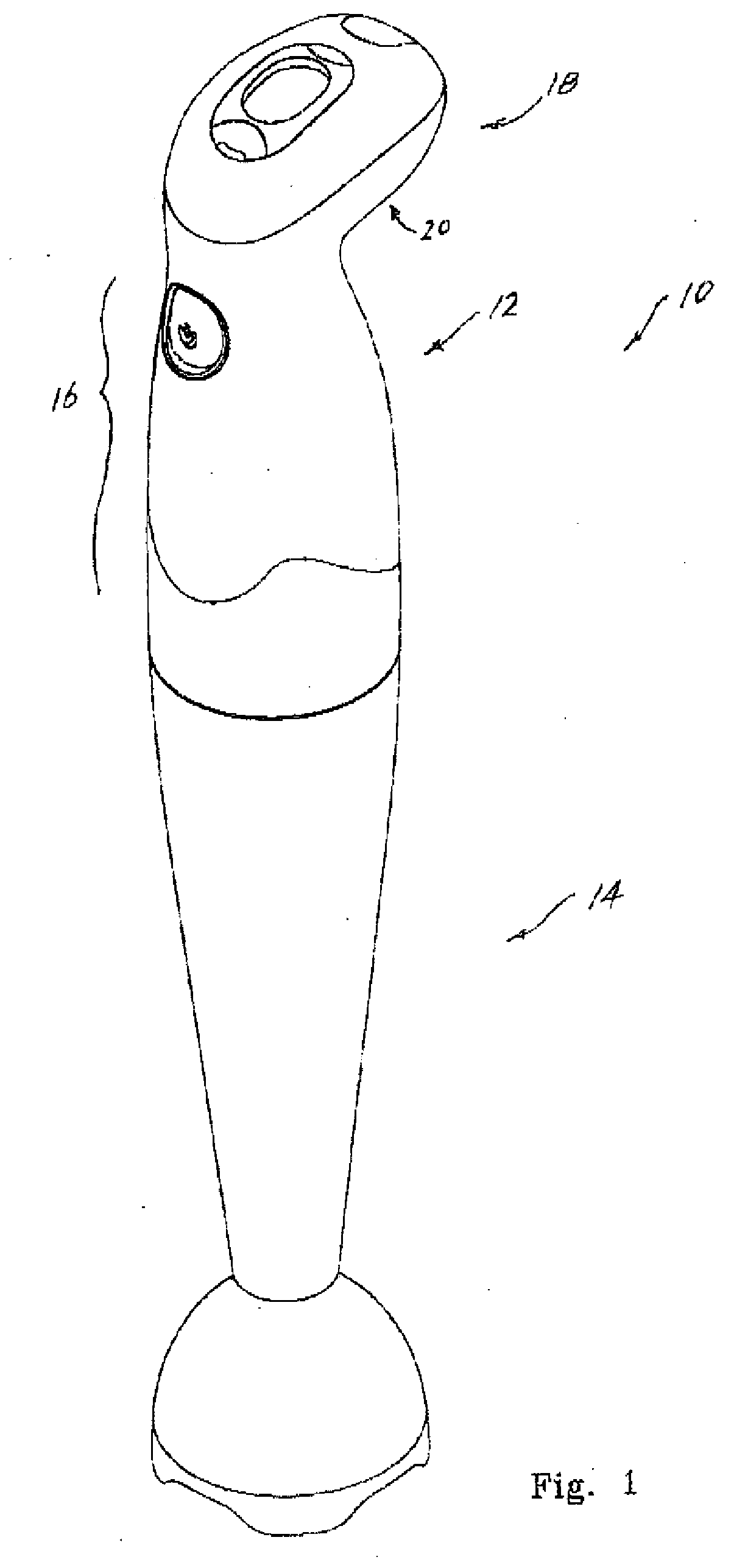

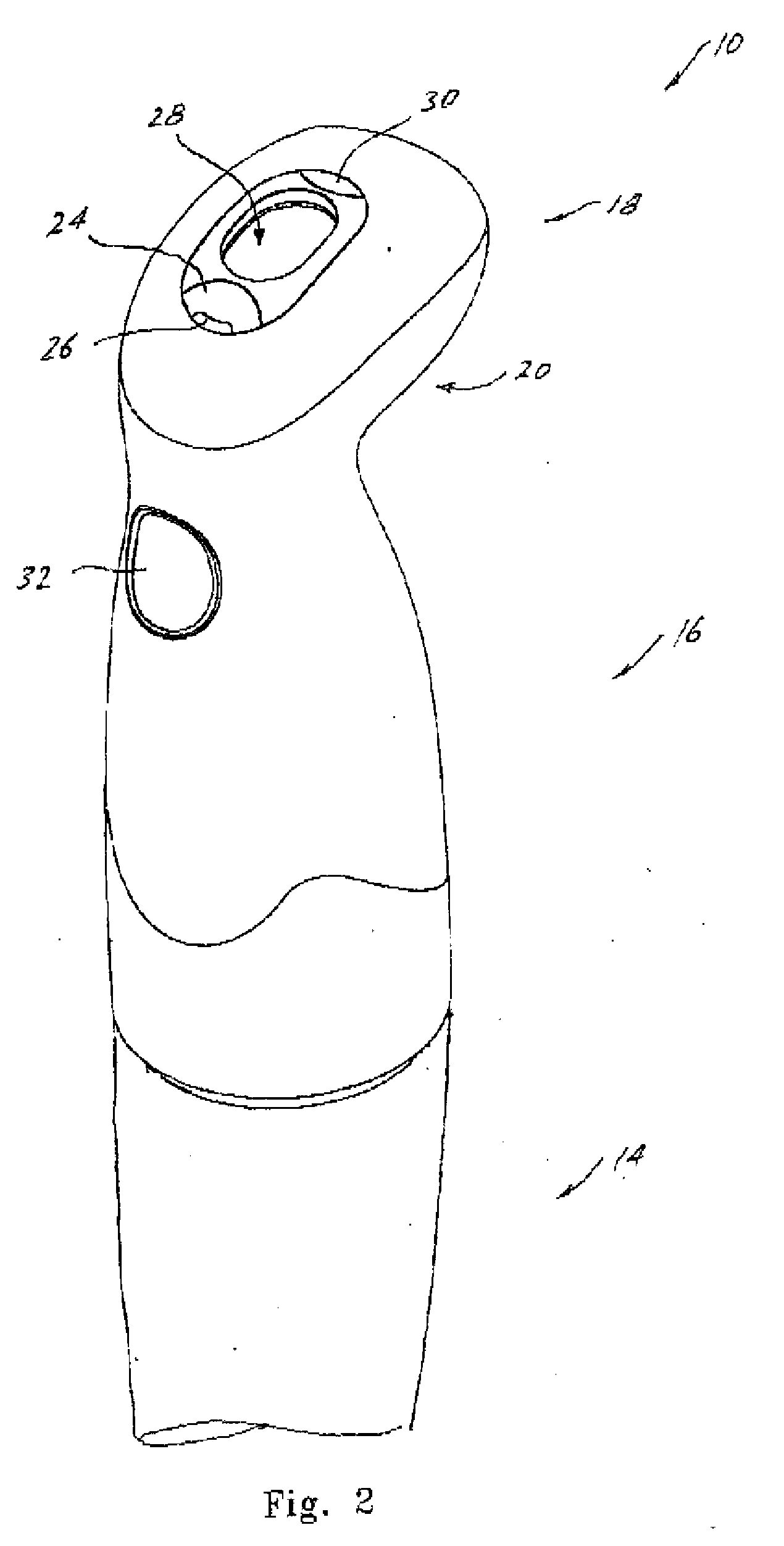

Hand blender switch

InactiveUS20090303830A1Easy to operateTransportation and packagingMixer accessoriesHand heldEngineering

A hand blender switch arrangement on a hand-held food blender; said switch arrangement including a first activation switch and a second operating switch; said first activation switch located in an upper surface of an upper body portion of a power unit of said blender; said second operating switch located in a front surface of a hand grip portion of said blender remote from said first activation switch such that said first activation switch cannot be readily operated by a hard gripping said hand blender for use.

Owner:WILSON CO INC

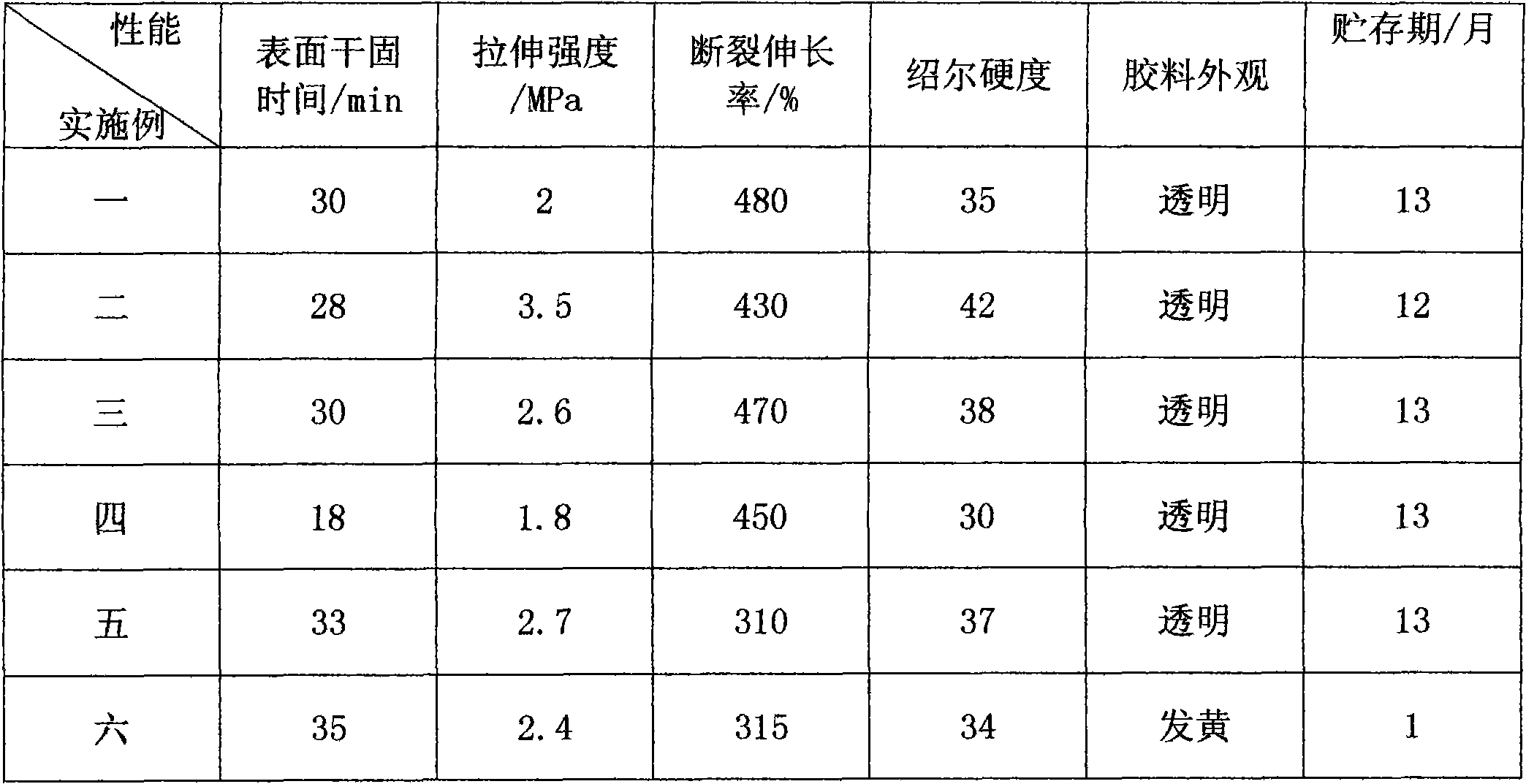

Method for preparing transparent dealcoholized single-component room temperature vulcanized silicone rubber

ActiveCN102146208AAvoid yellowingSolve the problem of short storage periodNon-macromolecular adhesive additivesOther chemical processesAlkanePolymer science

The invention discloses a method for preparing transparent dealcoholized single-component room temperature vulcanized silicone rubber. The method is characterized by comprising the steps of mixing 80-90% of alpha, omega-dihydroxydimethylpolysiloxane, 1-15% of white carbon black reinforcing filler and 5-10% of alkane mixture plasticizer in a blender in a vacuum state at a room temperature; and then adding 1-5% of siloxane crosslinking agent to be mixed in a vacuum state; adding 0.01-2% of siloxane titanate TiOSi catalyst, 0.01-3% of organic tin catalyst and 0.01-5% of silane coupling agent to be mixed in a vacuum state; and discharging out and packaging. Through the method disclosed by the invention, rubbers can be effectively prevented from yellowing on the basis of keeping the catalytic efficiency, and the problem of short storage life of the rubber can be effectively solved.

Owner:GUANGZHOU GLORYSTAR CHEM +1

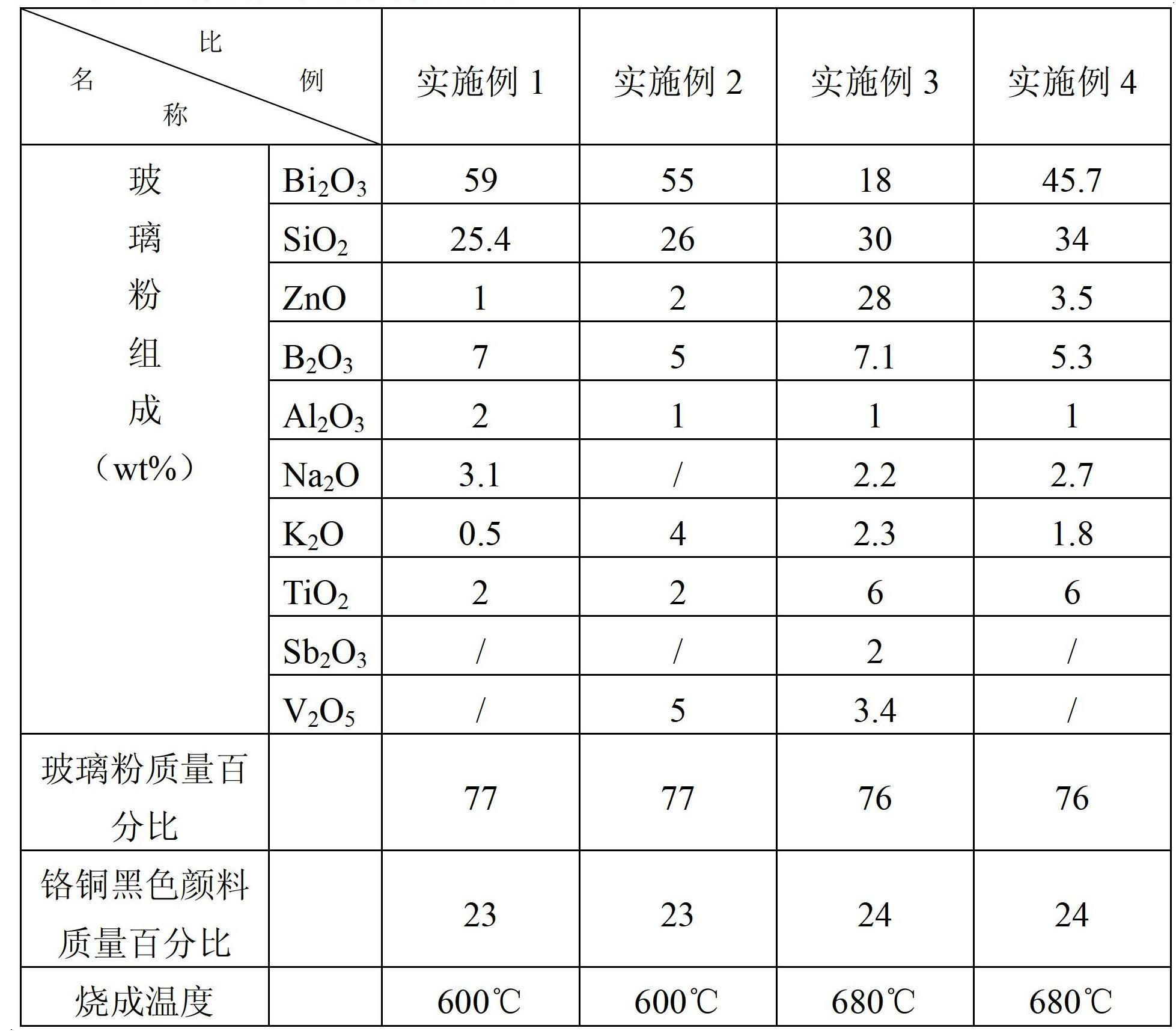

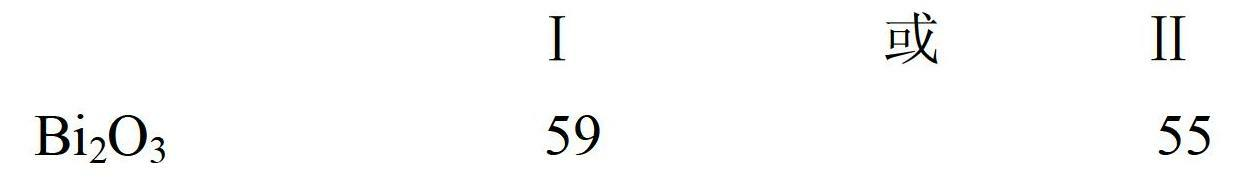

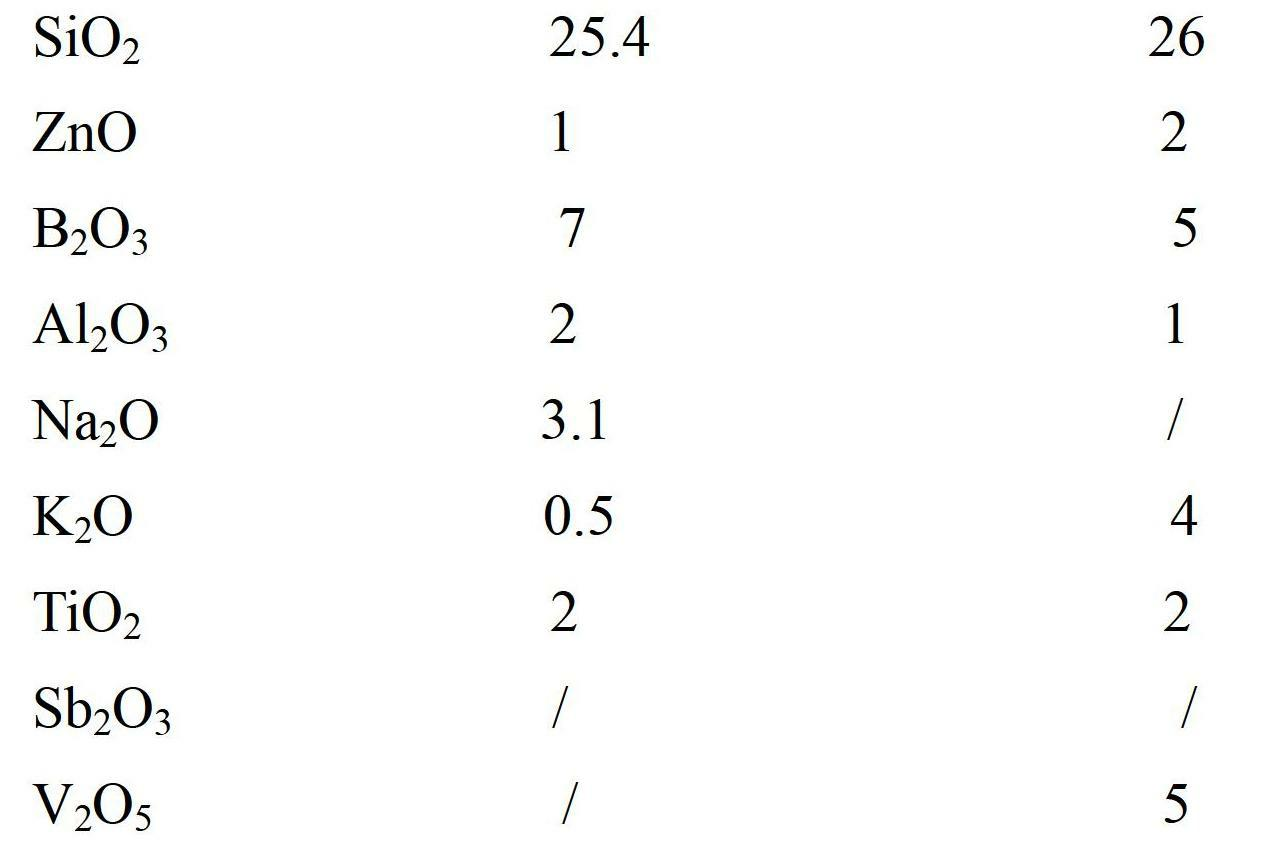

Environmental-friendly black glaze for automotive glass and preparation method of black glaze

The invention relates to a high-performance environmental-friendly black glaze for automotive glass and a preparation method of the black glaze. The invention is characterized in that the high-performance environmental-friendly black glaze for the automotive glass comprises the following compositions in percentage by weight: 75-80% of bismuth series low-melting- point glass powder and 20-25% of inorganic black pigment. The bismuth series glass powder contains ZnO without rare-earth oxides; the grain size of the glass powder is 0.5-3 um; and the inorganic black pigment is iron-chromium-nickel-manganese black pigment or chromium-copper black pigment. The glass powder and the inorganic pigment are added to a V-shaped blender mixer to be mixed in proportion, so that the black glaze for the automotive glass is obtained. And then the black glaze is blended into slurry by organic carrier, and is coated at the edge of the automotive glass through screen printing. a black framework of the automotive glass is formed through the processes such as low-temperature drying, hard fire and the like. The blackness value L is less than 7, and the shielding property Delta L is less than 1.

Owner:JIANGXI SUNFLEX LIGHT RETROREFLECTIVE MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com