Patents

Literature

51 results about "Silica dust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

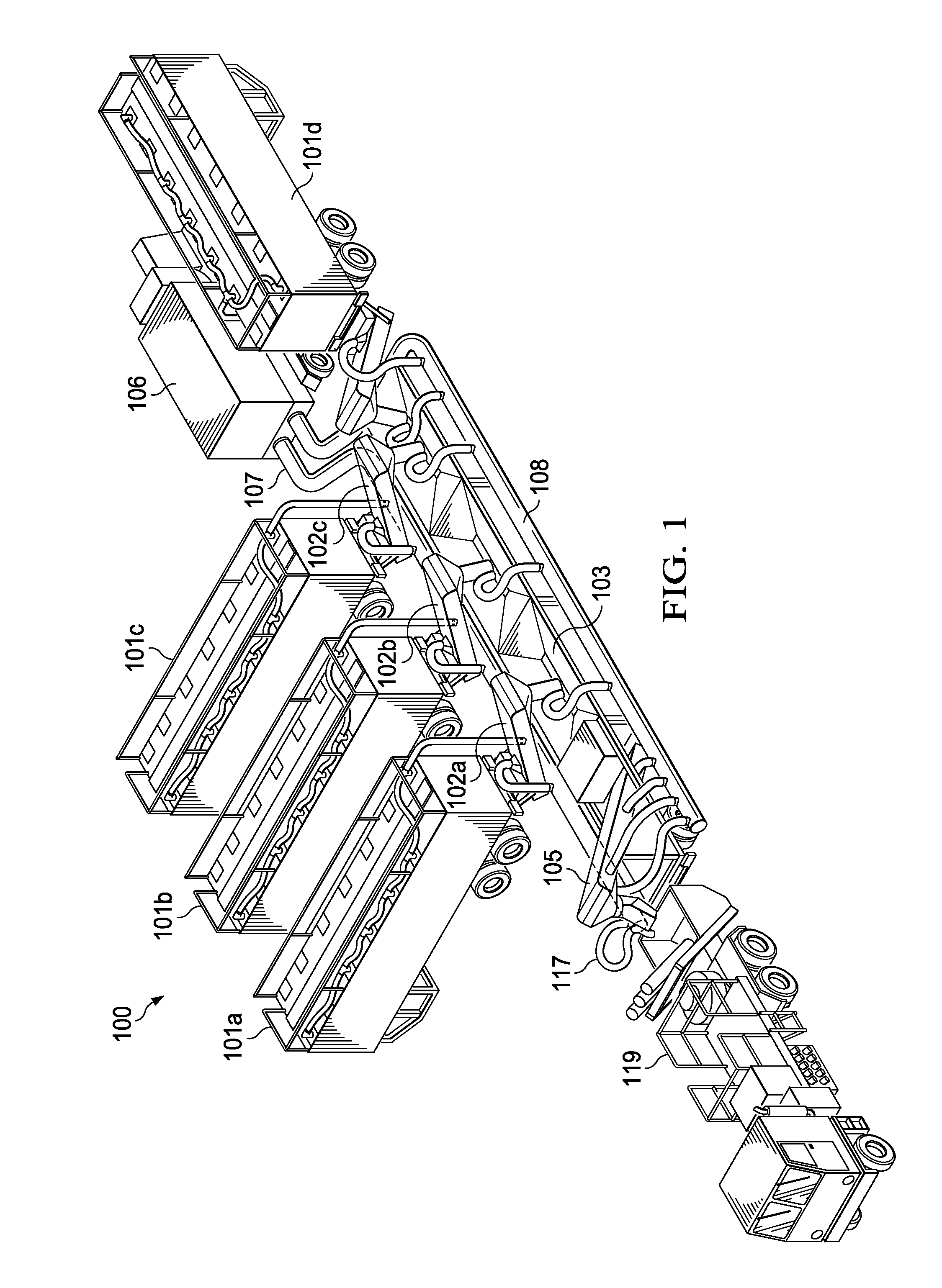

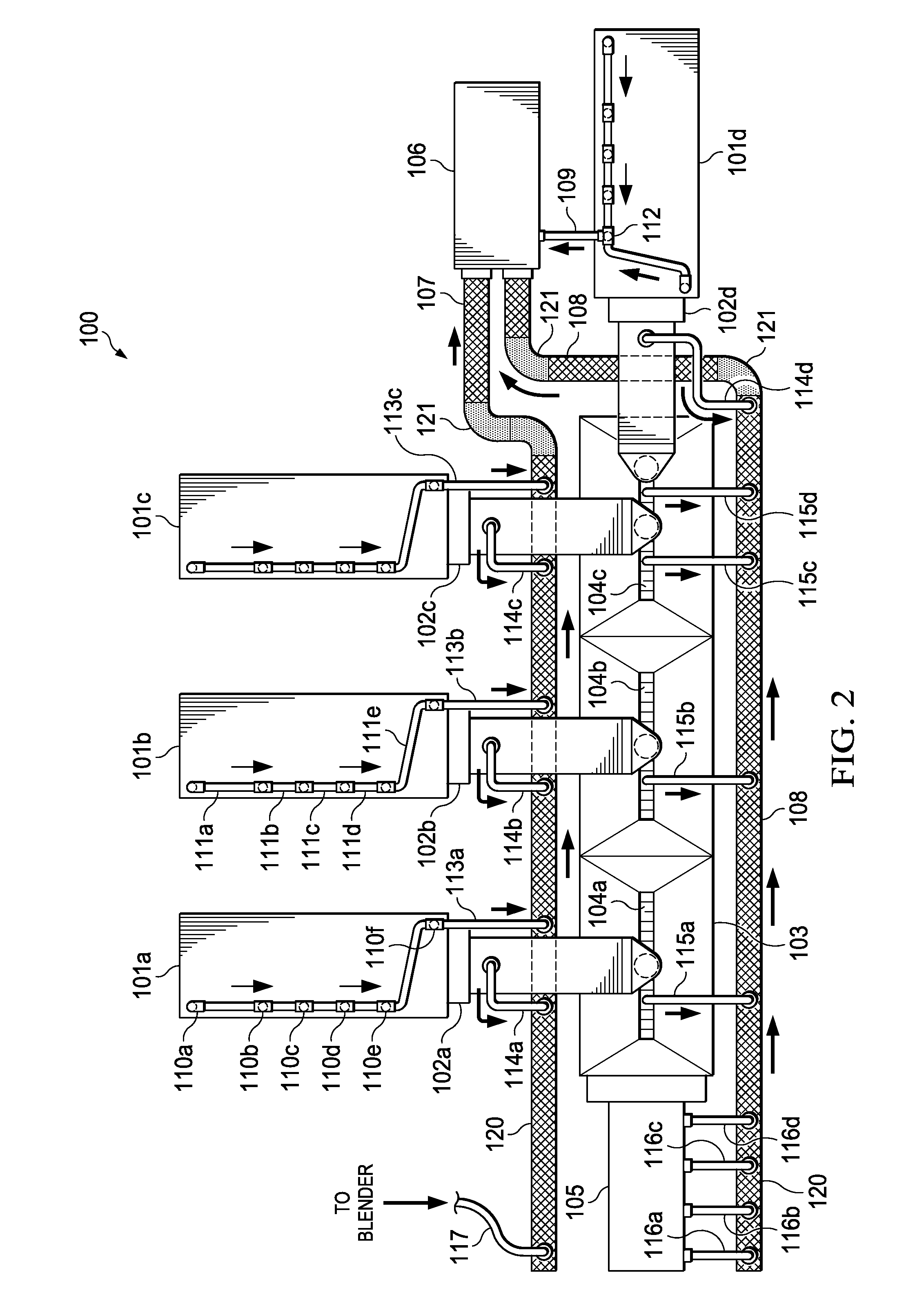

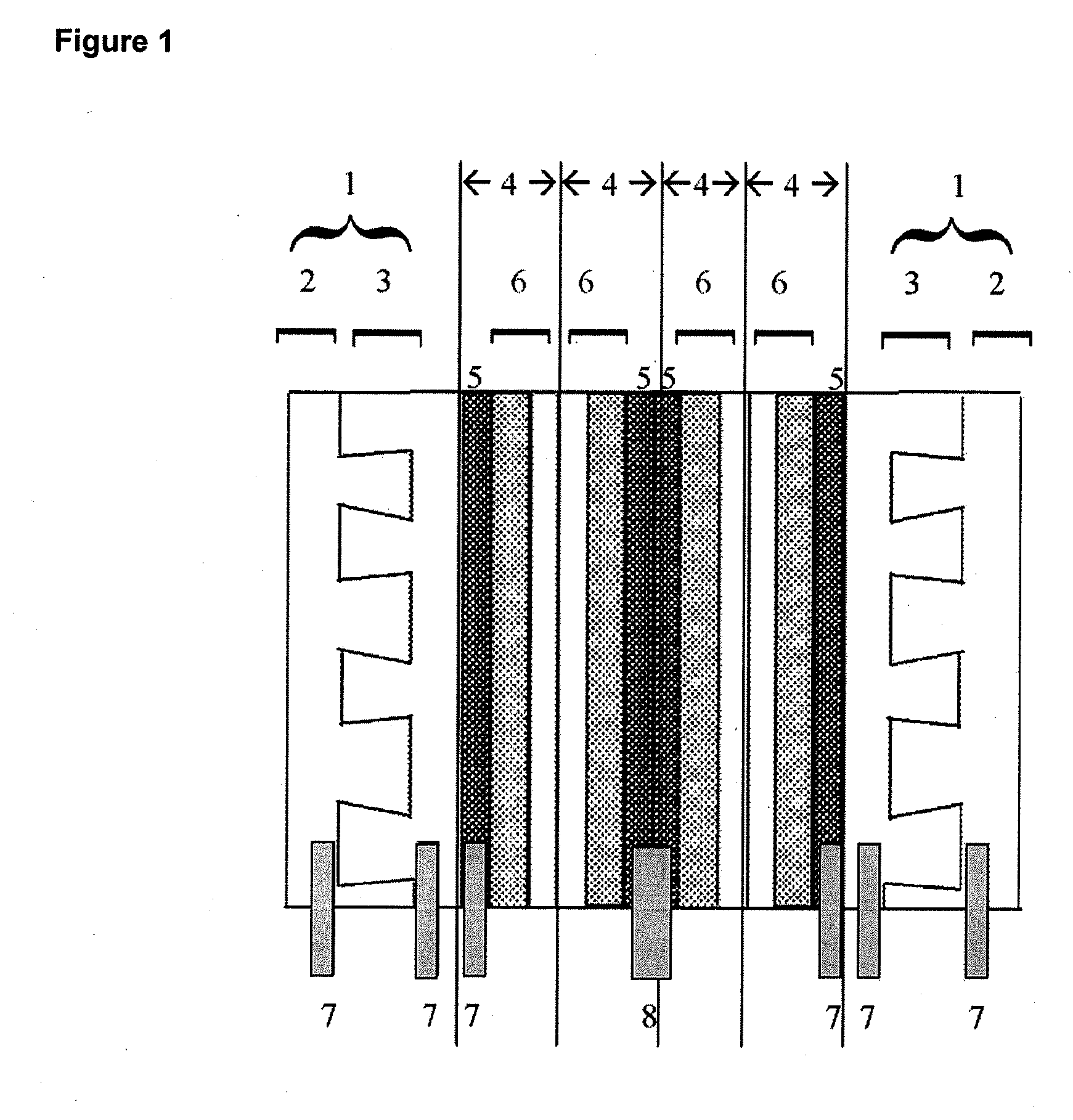

Systems and methods for controlling silica dust during hydraulic fracturing operations using an improved manifold

ActiveUS20160280480A1Simple apertureImprove efficiencyFouling preventionFluid removalHydraulic fracturingSilicon dioxide

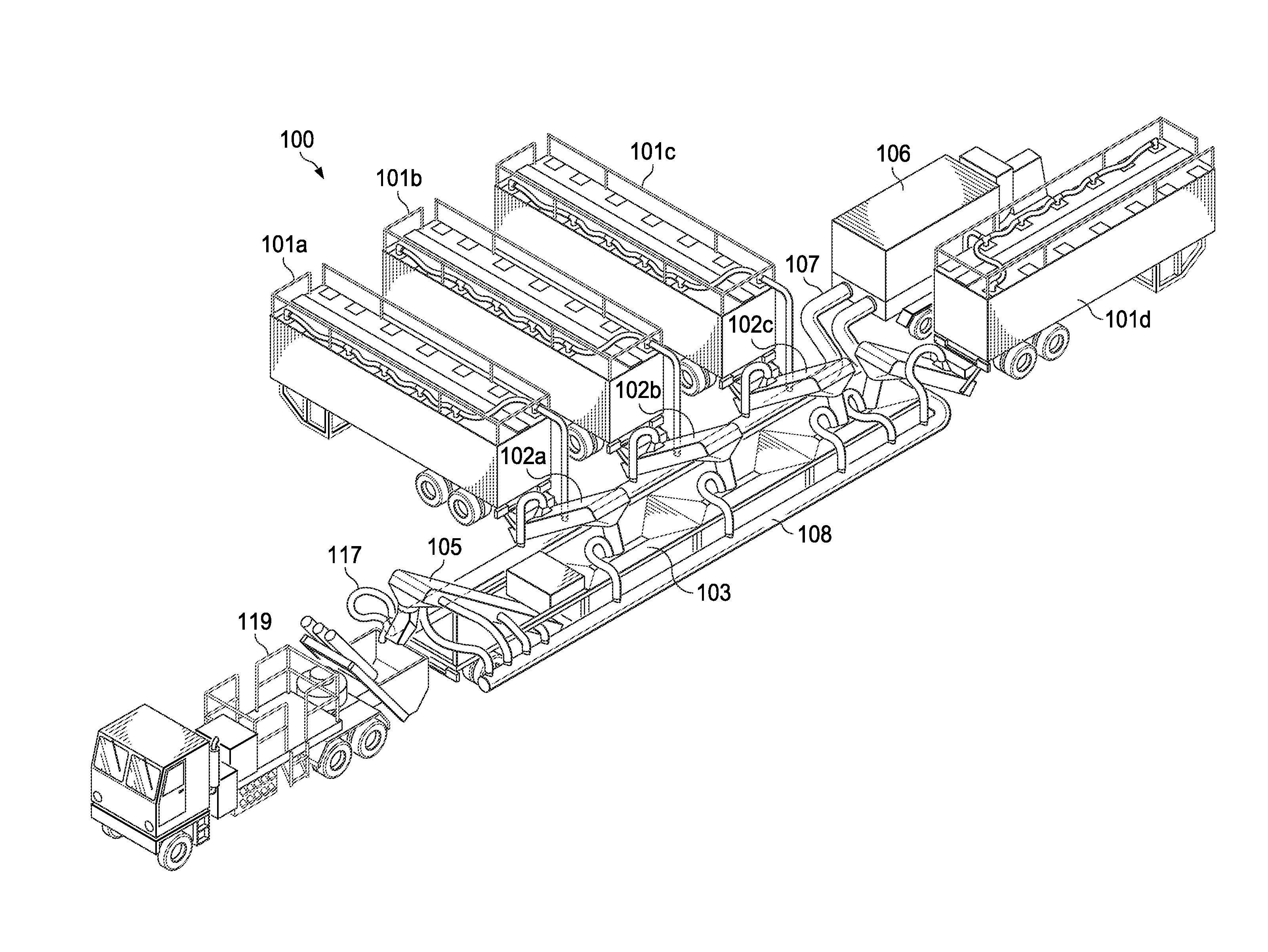

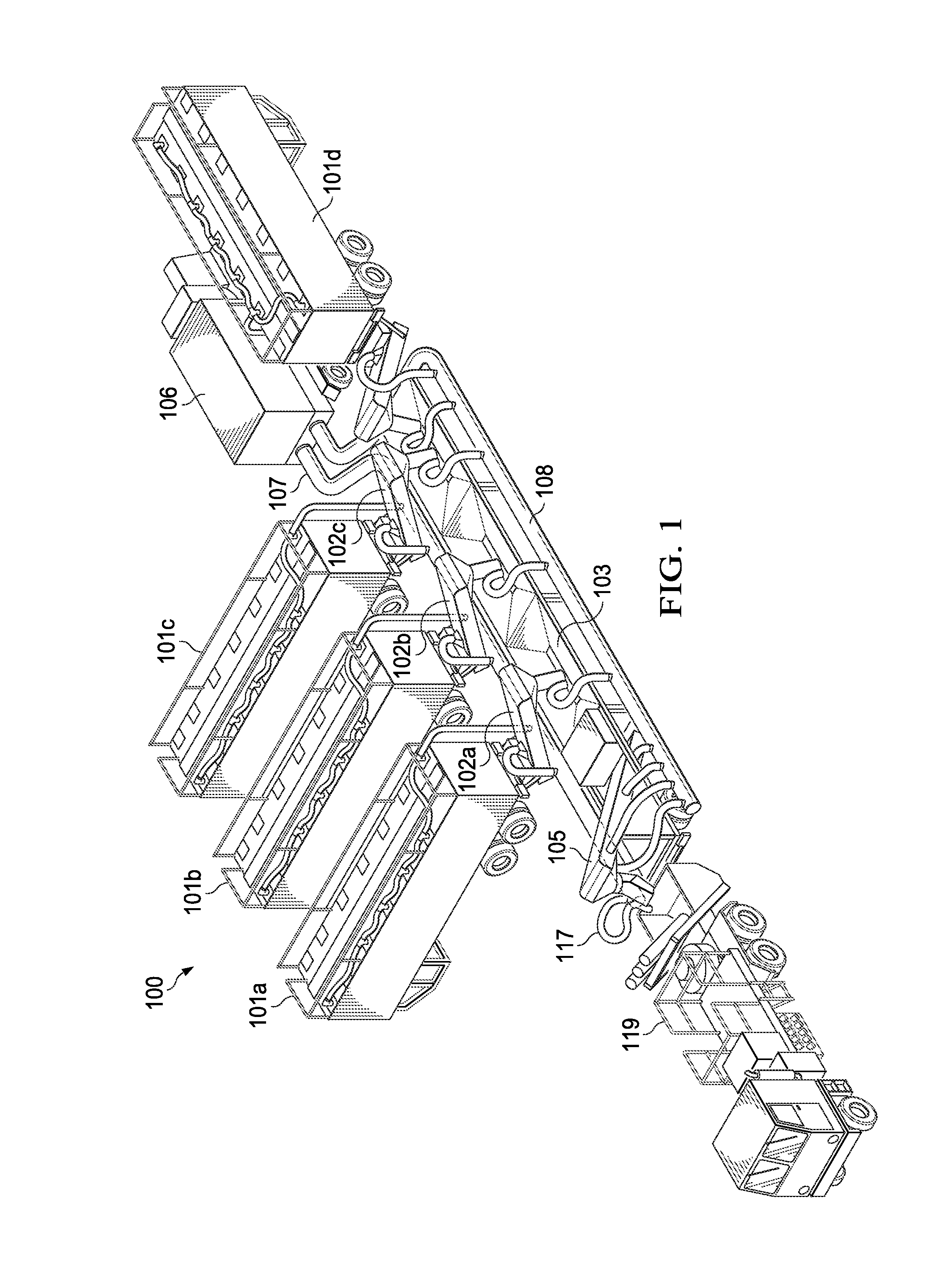

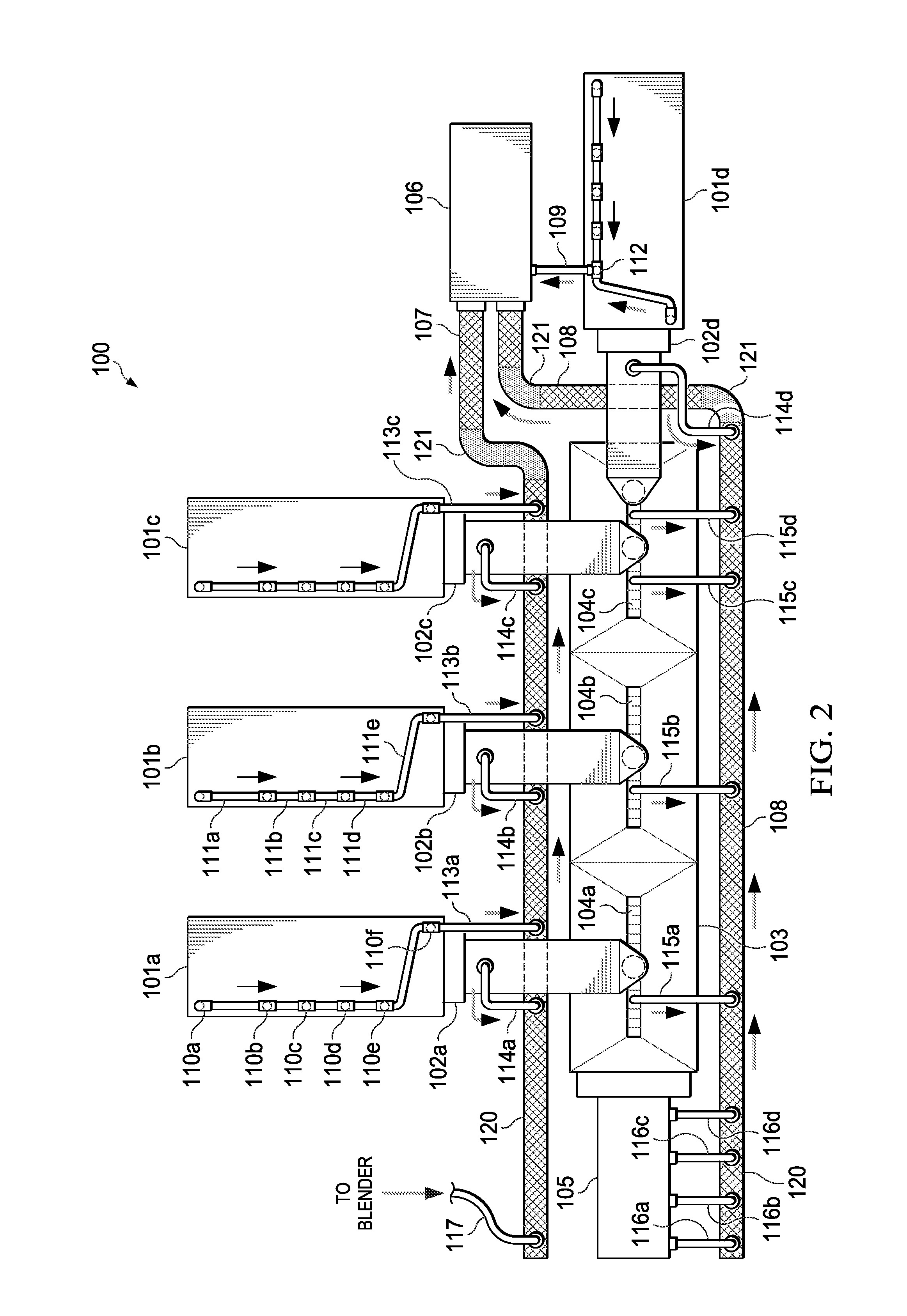

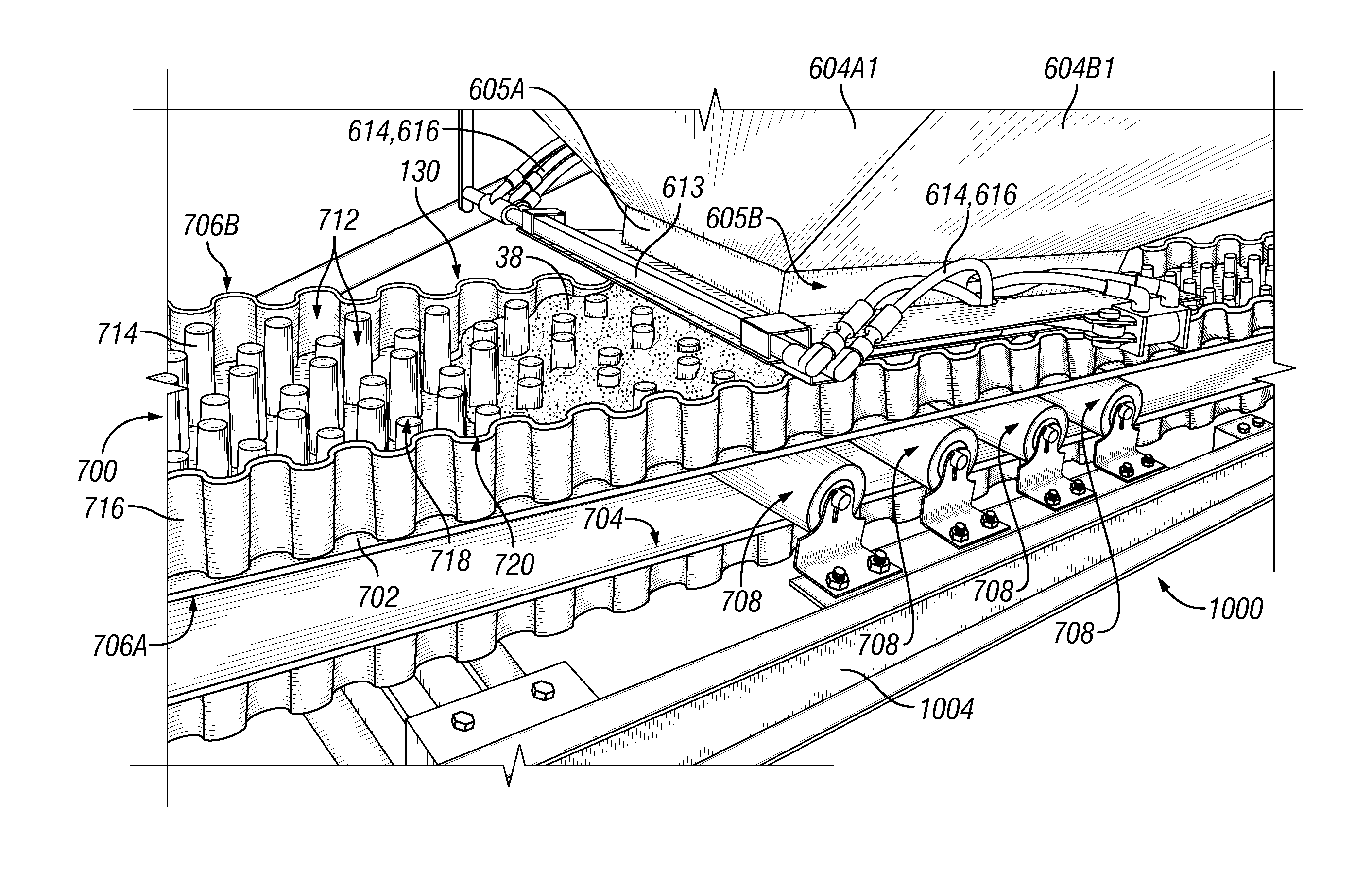

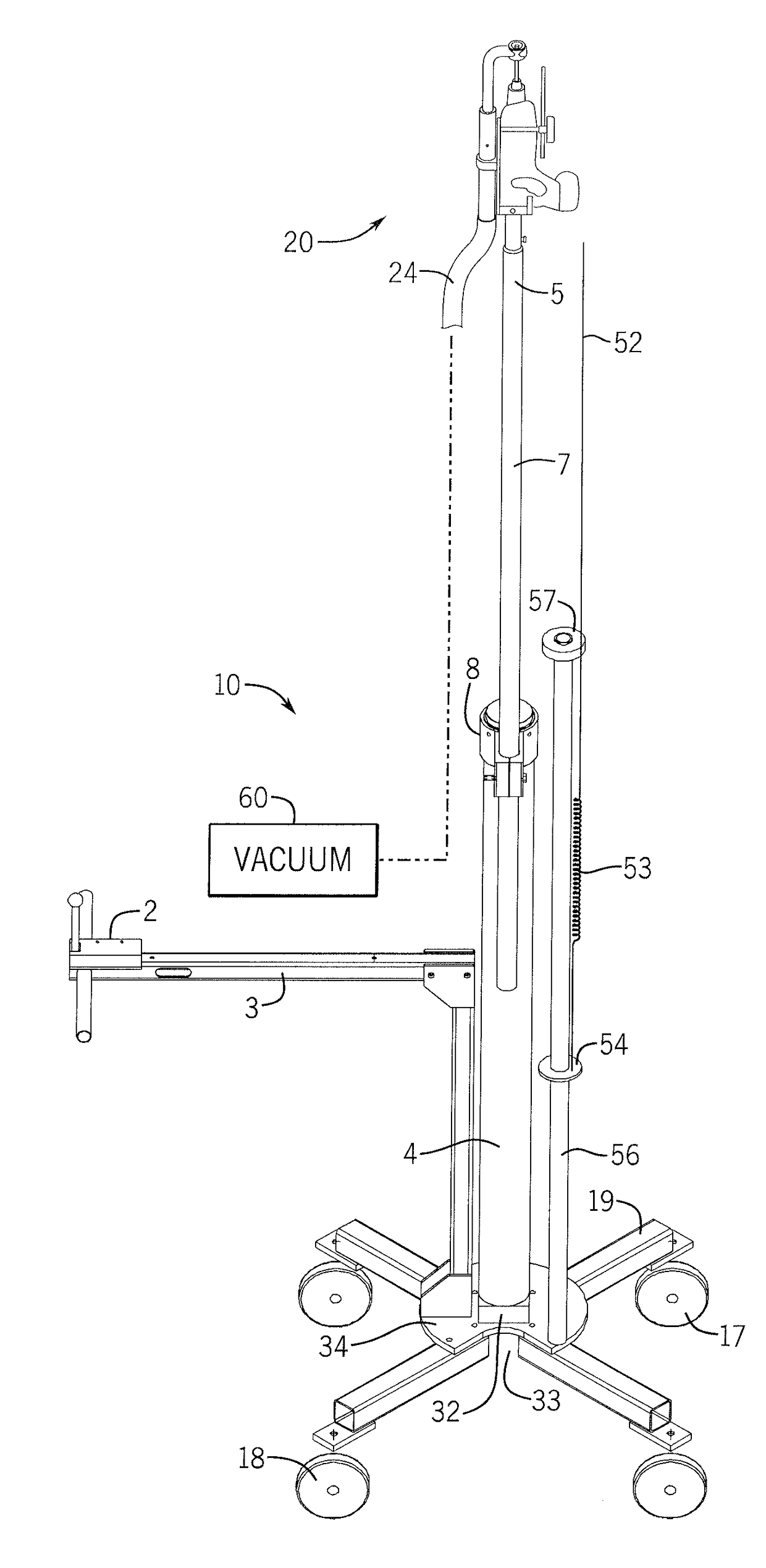

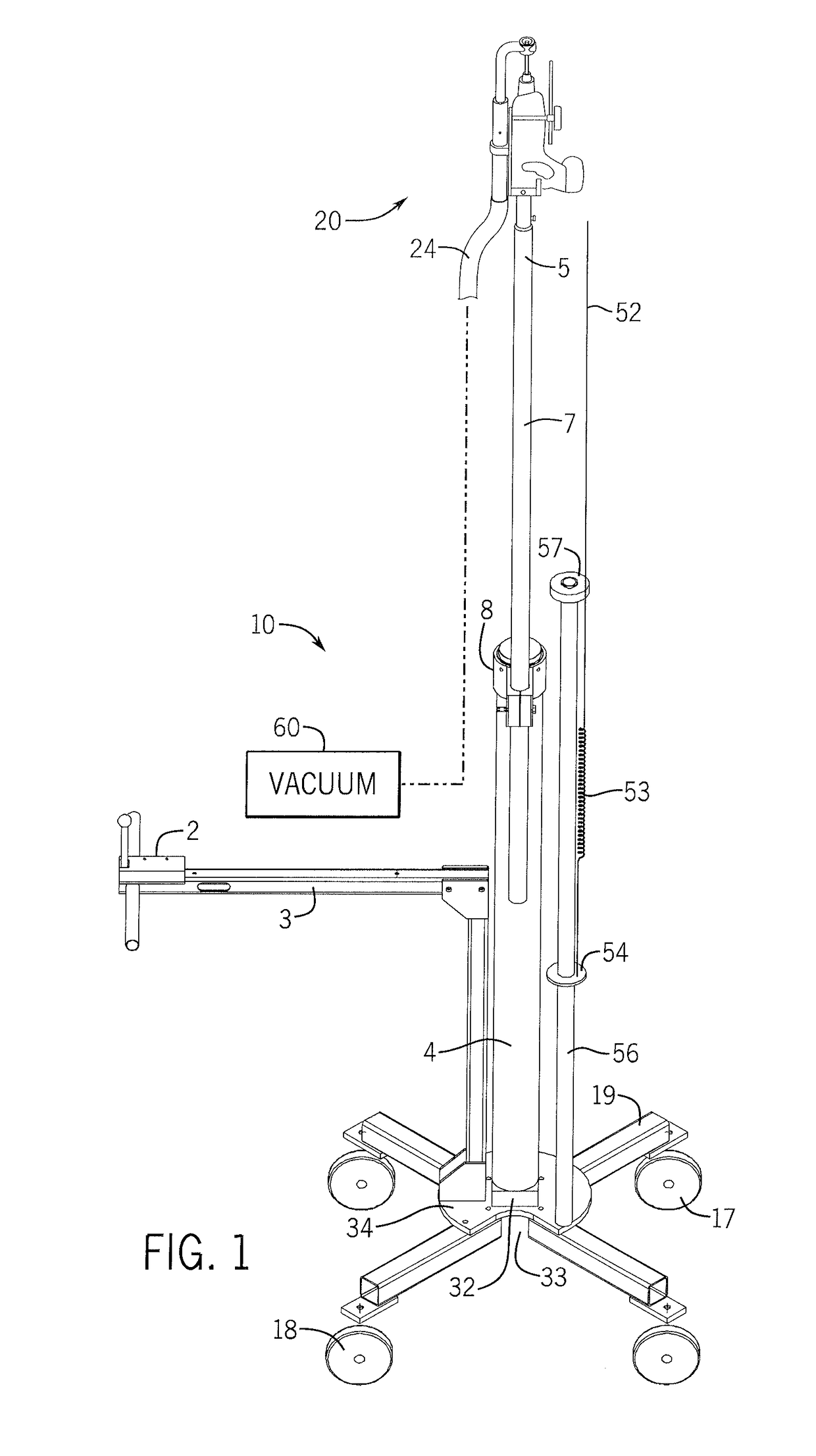

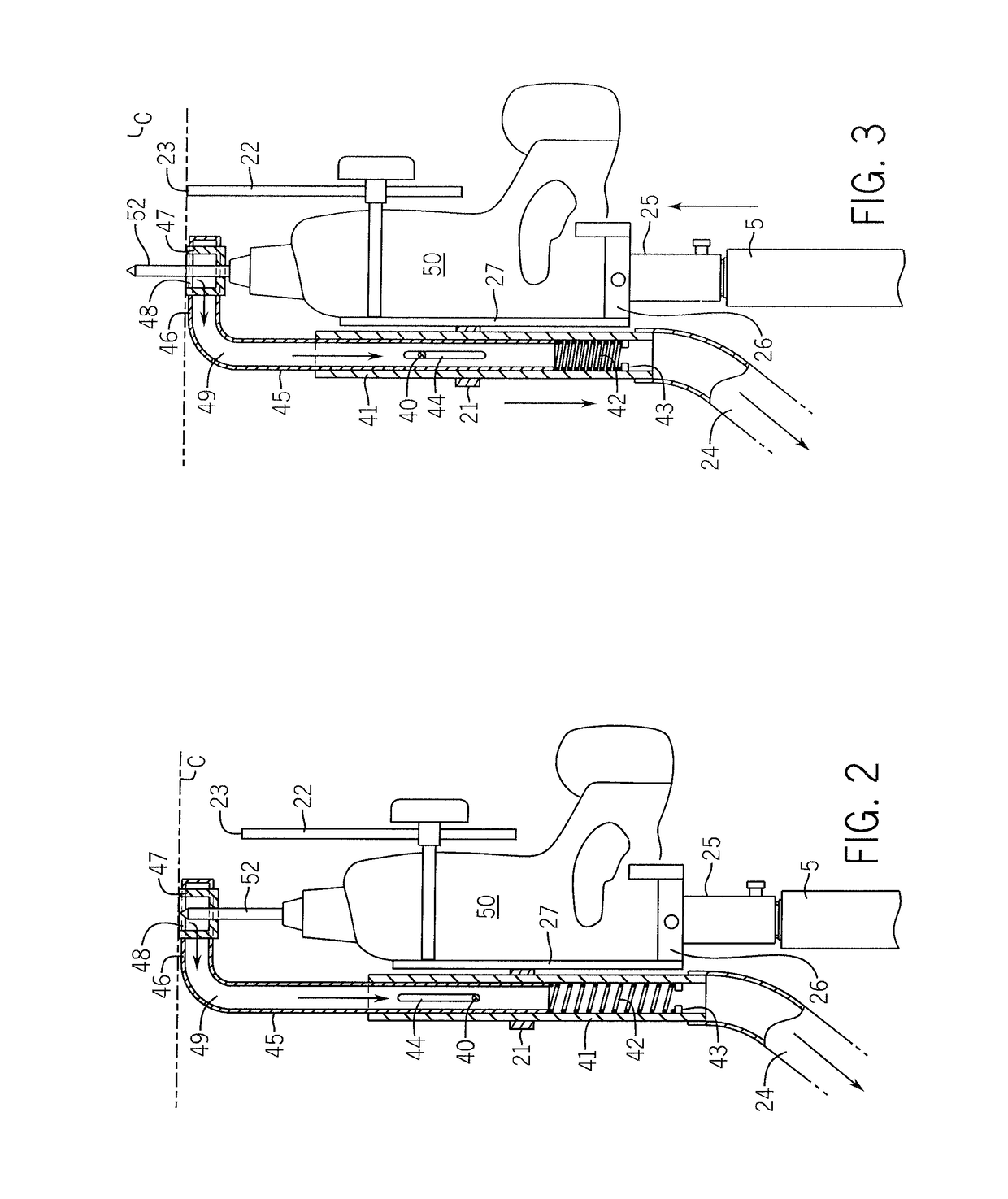

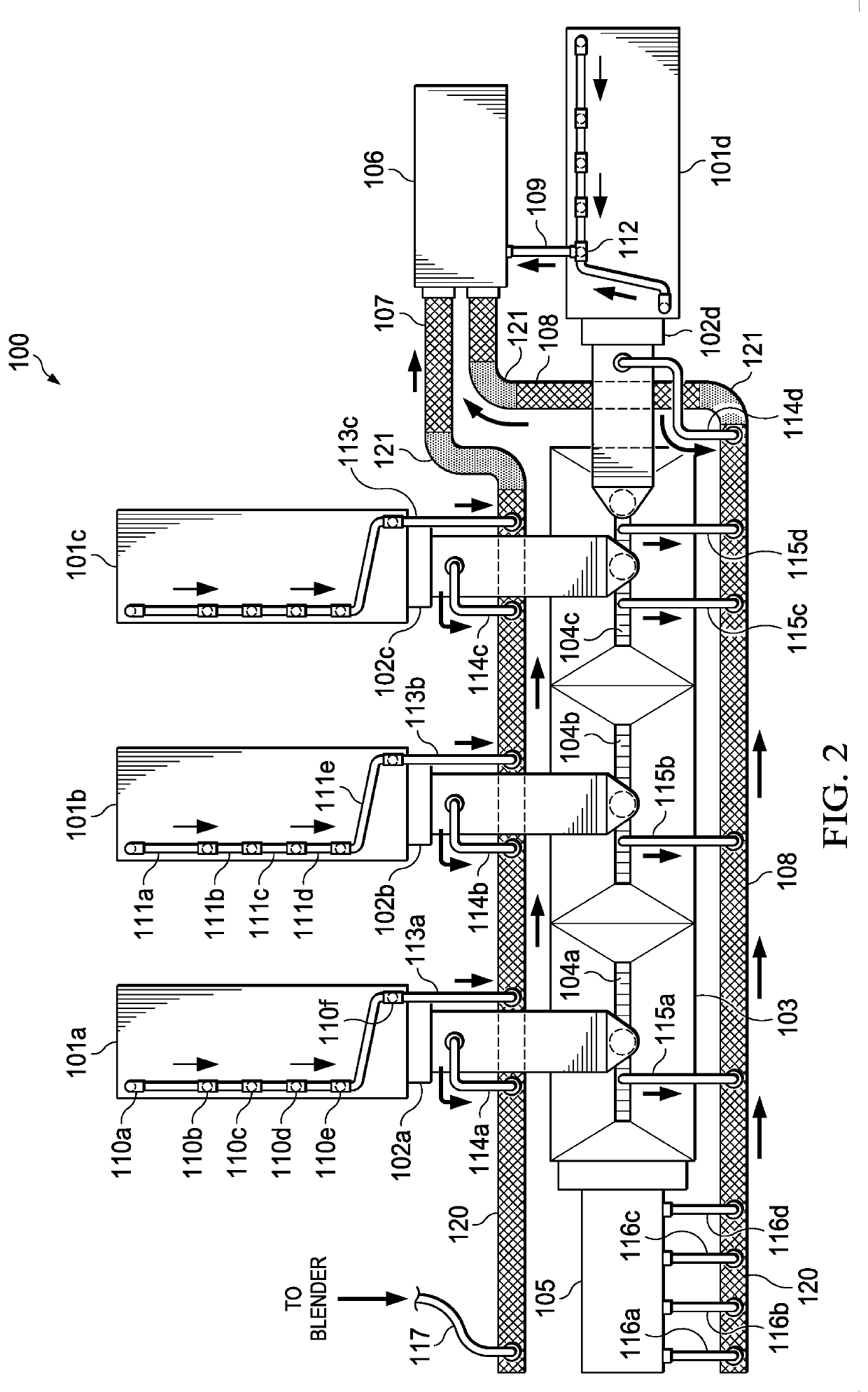

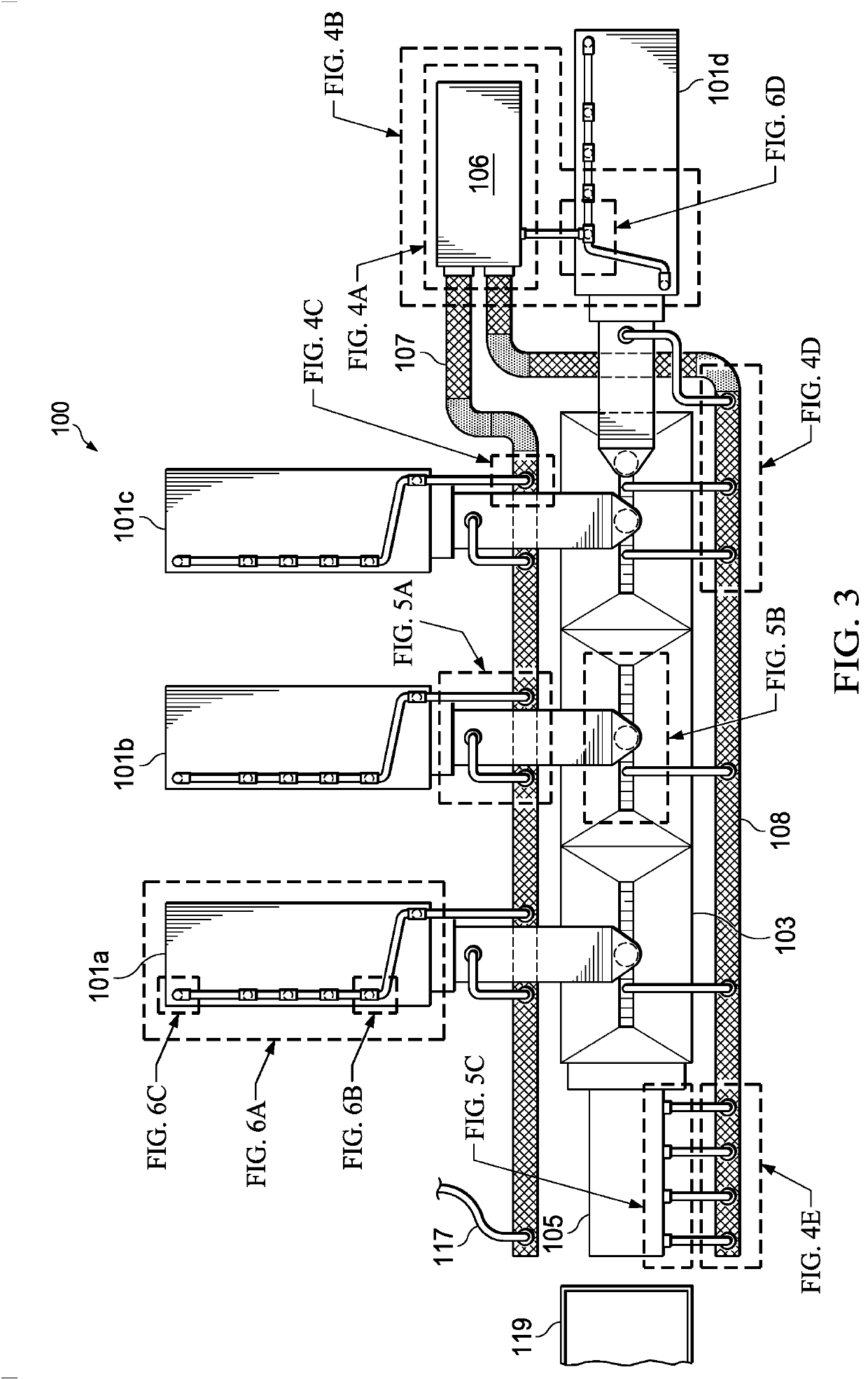

A system for controlling dust during hydraulic fracturing operations includes a manifold having a plurality of ports for capturing dust when negative air pressure is applied to the manifold. A support frame positions the manifold above a piece of hydraulic fracturing equipment receiving sand from a sand source.

Owner:SIERRA DUST CONTROL

Systems and methods for controlling silica dust during hydraulic fracturing operations

ActiveUS8881749B1Improve flexibility and efficiencyEfficient and flexible systemMechanical cleaningPressure cleaningEngineeringHydraulic fracturing

A system for controlling silica dust generated during the transfer of frac sand from a storage container through a conveyor system includes a system of conduits having a plurality of inlets for collecting silica dust generated at selected points along the conveyor system. An air system pneumatically coupled to the system of conduits generates a negative pressure at each of the inlets to induce the collection of silica dust at the selected points along the conveyor.

Owner:SIERRA DUST CONTROL

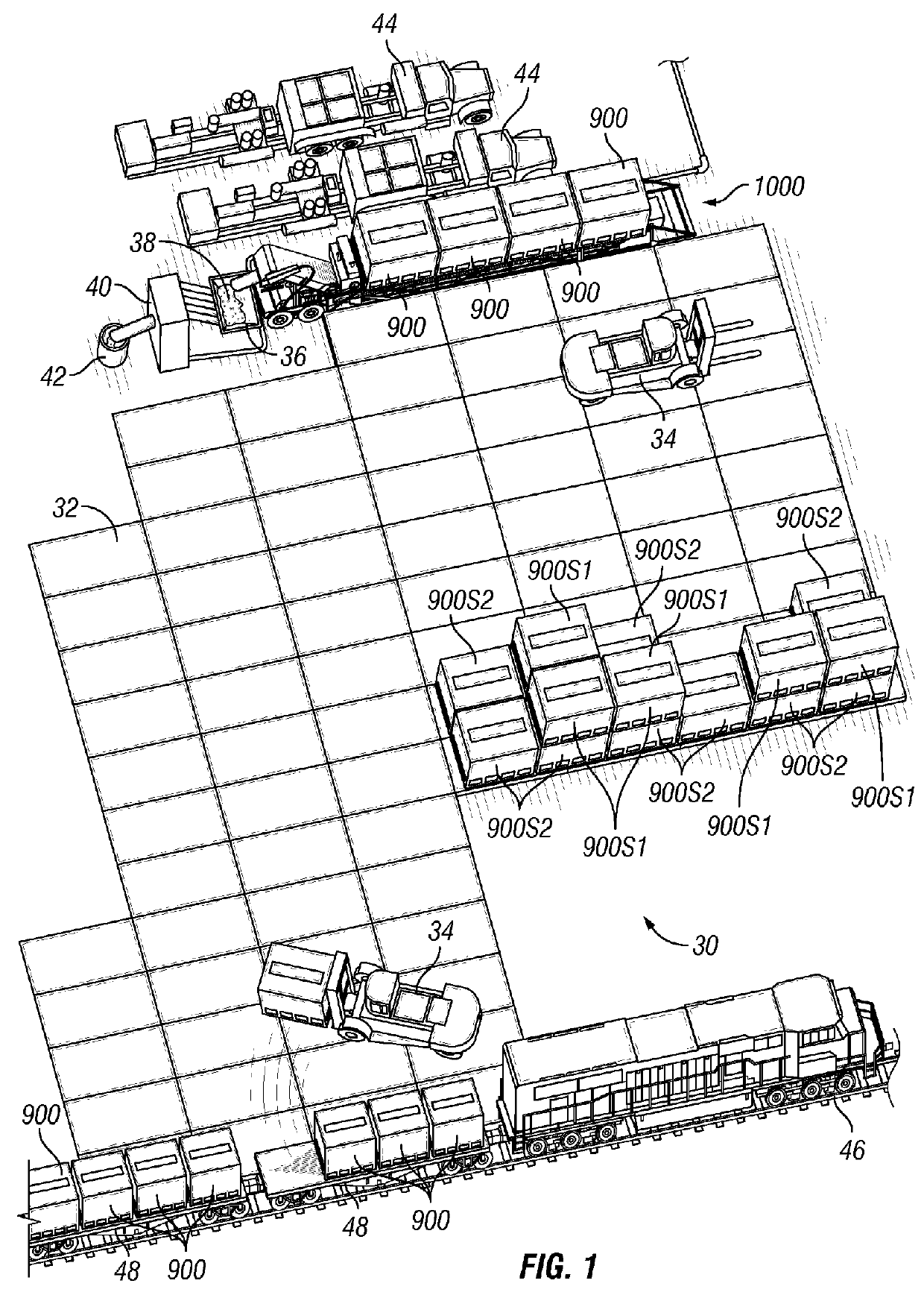

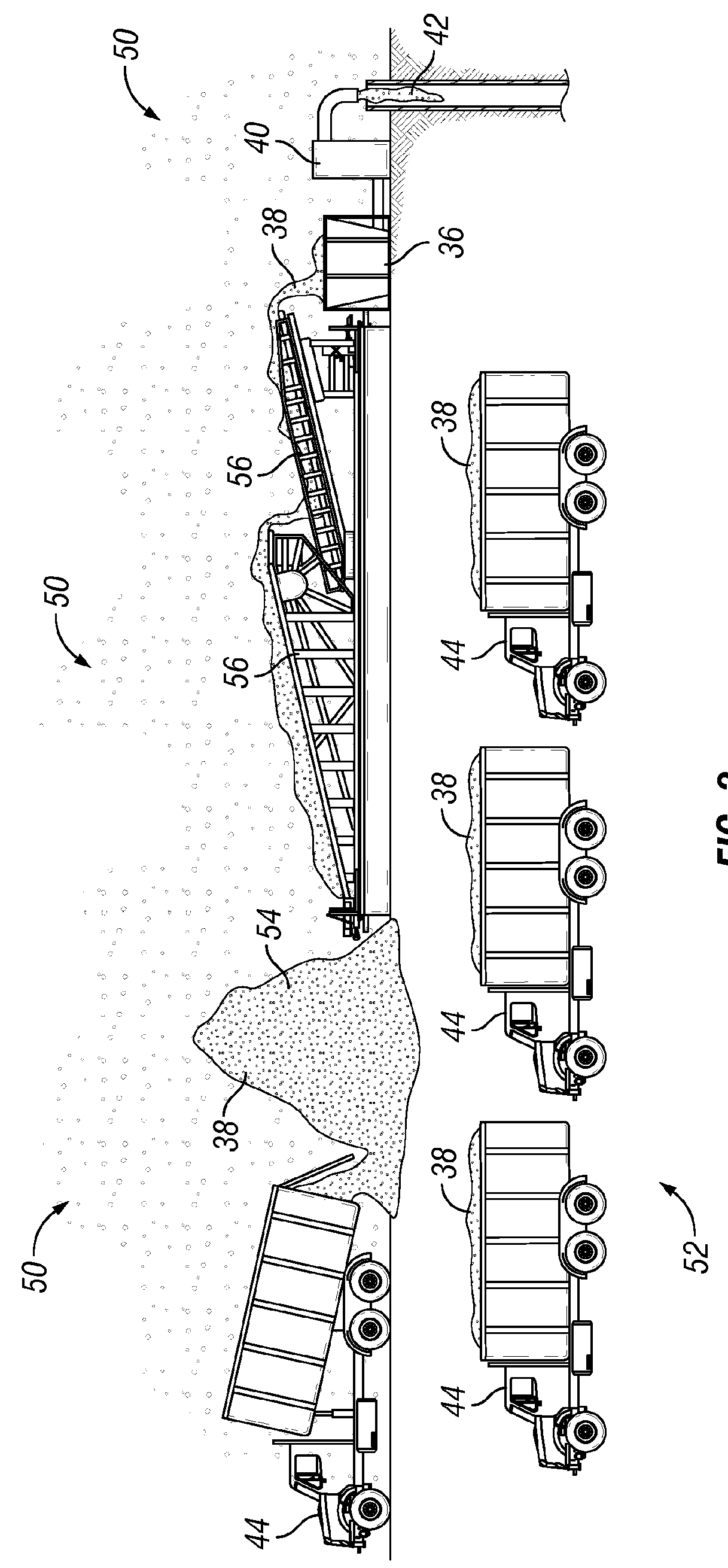

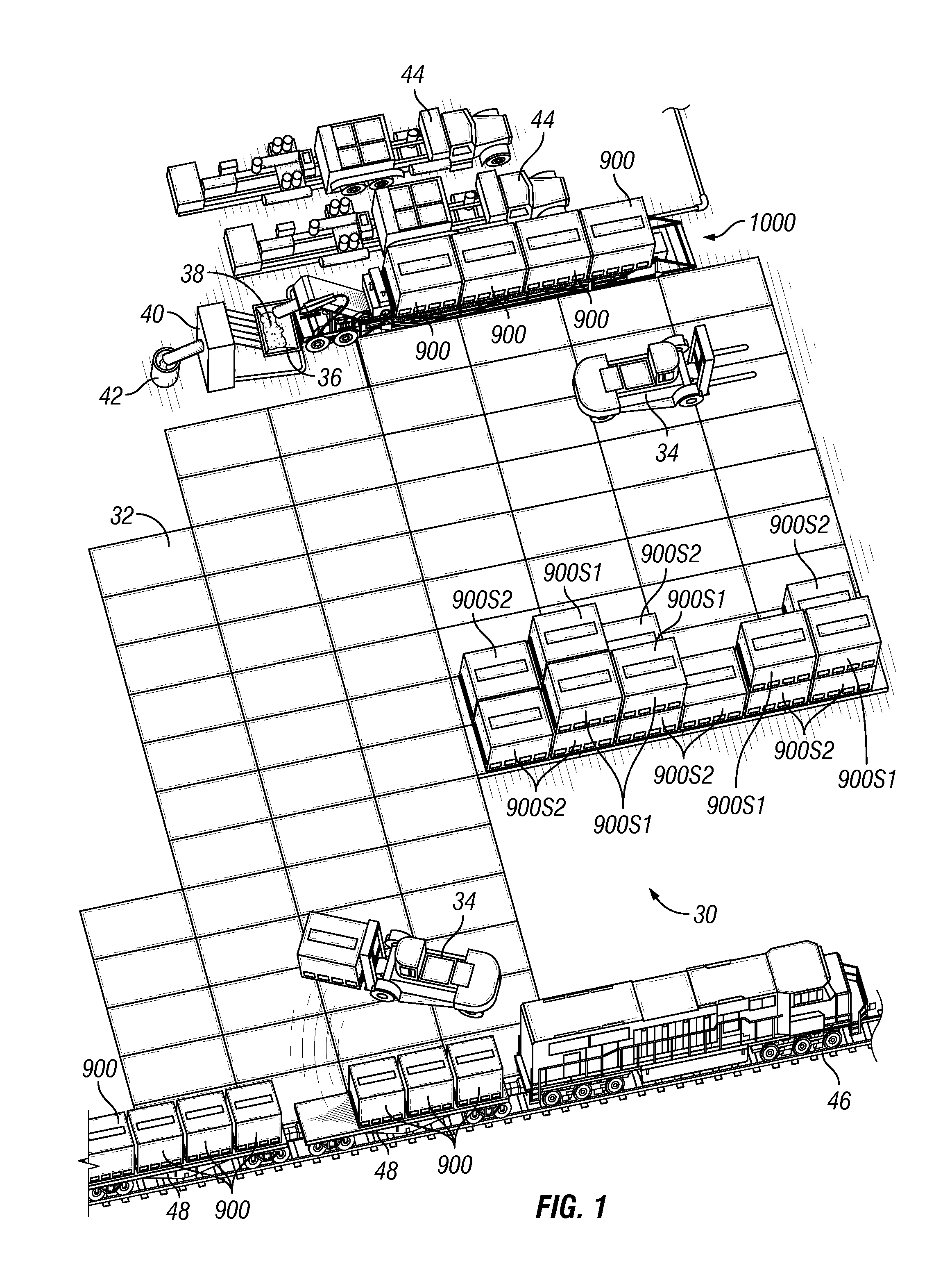

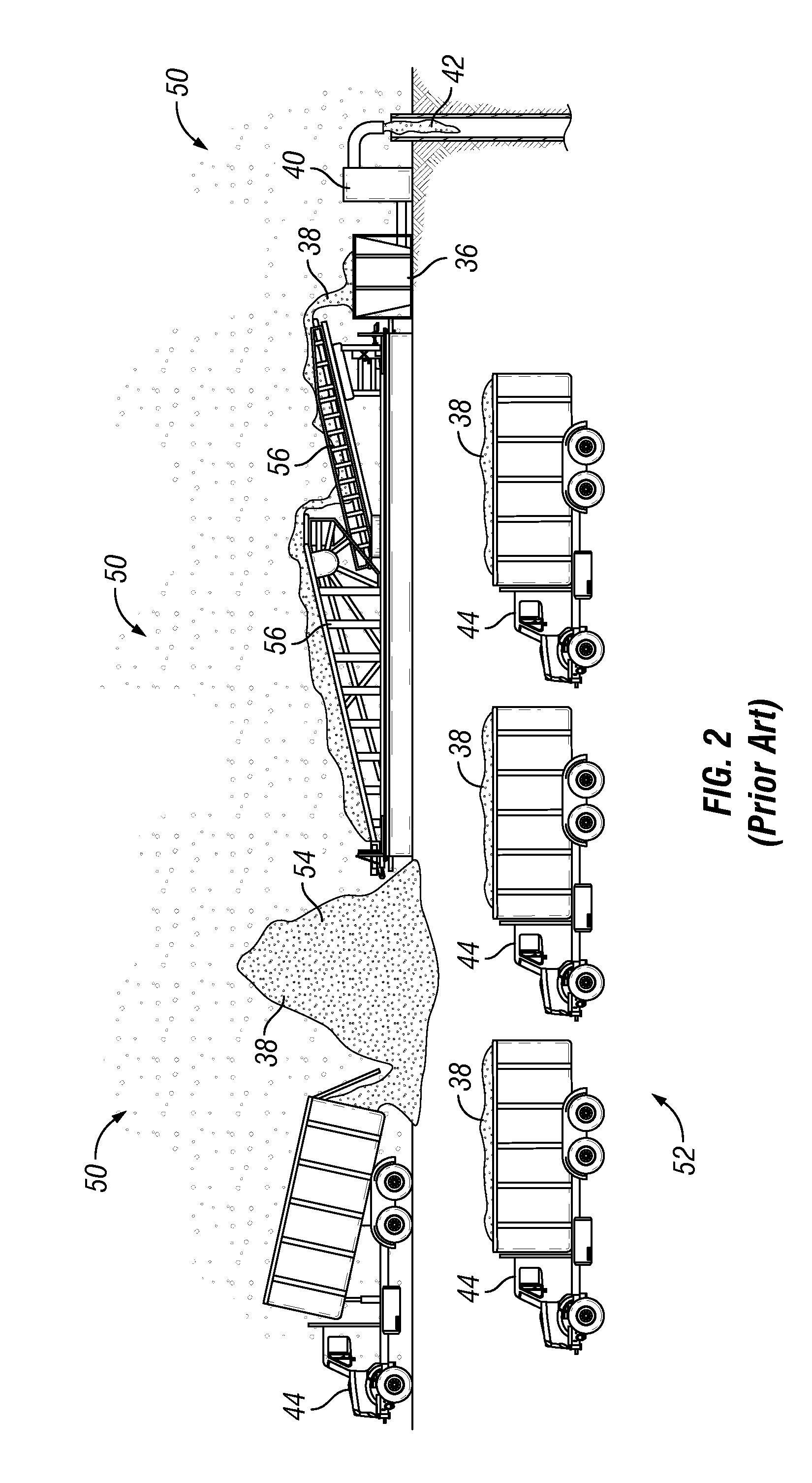

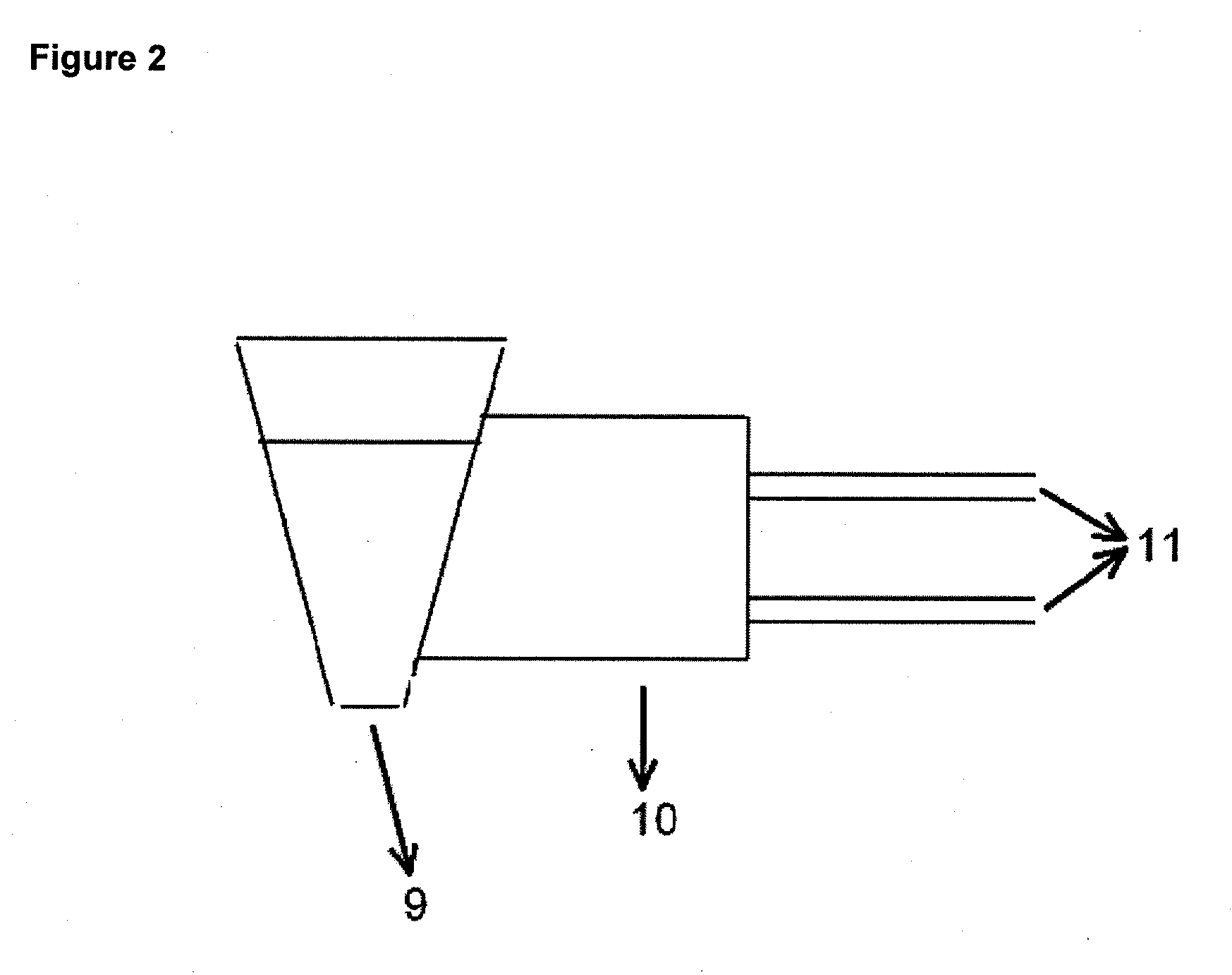

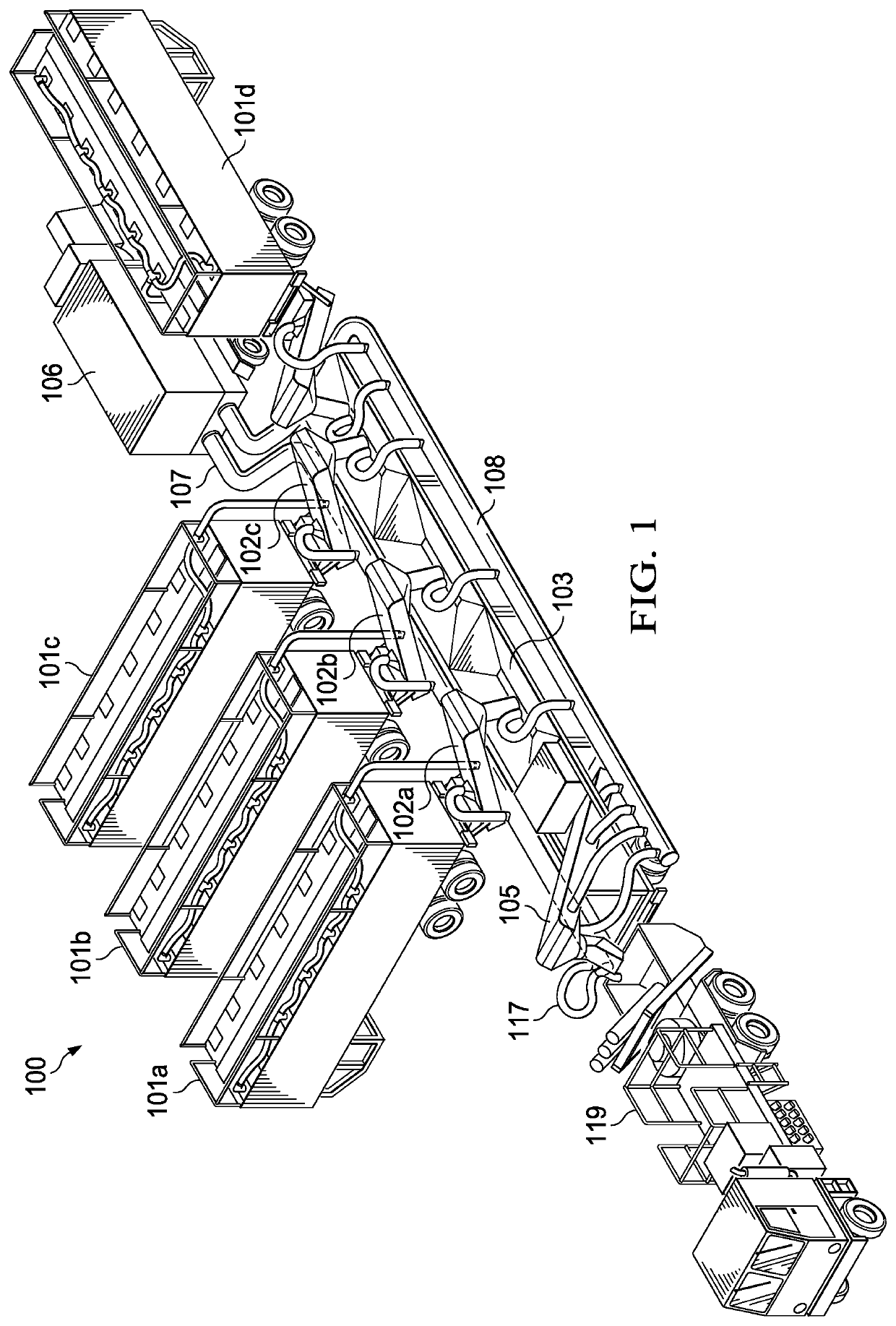

Proppant Discharge and Storage System

InactiveUS20160031658A1Reduce riskReduce productionConveyorsLarge containersEngineeringSilicon dioxide

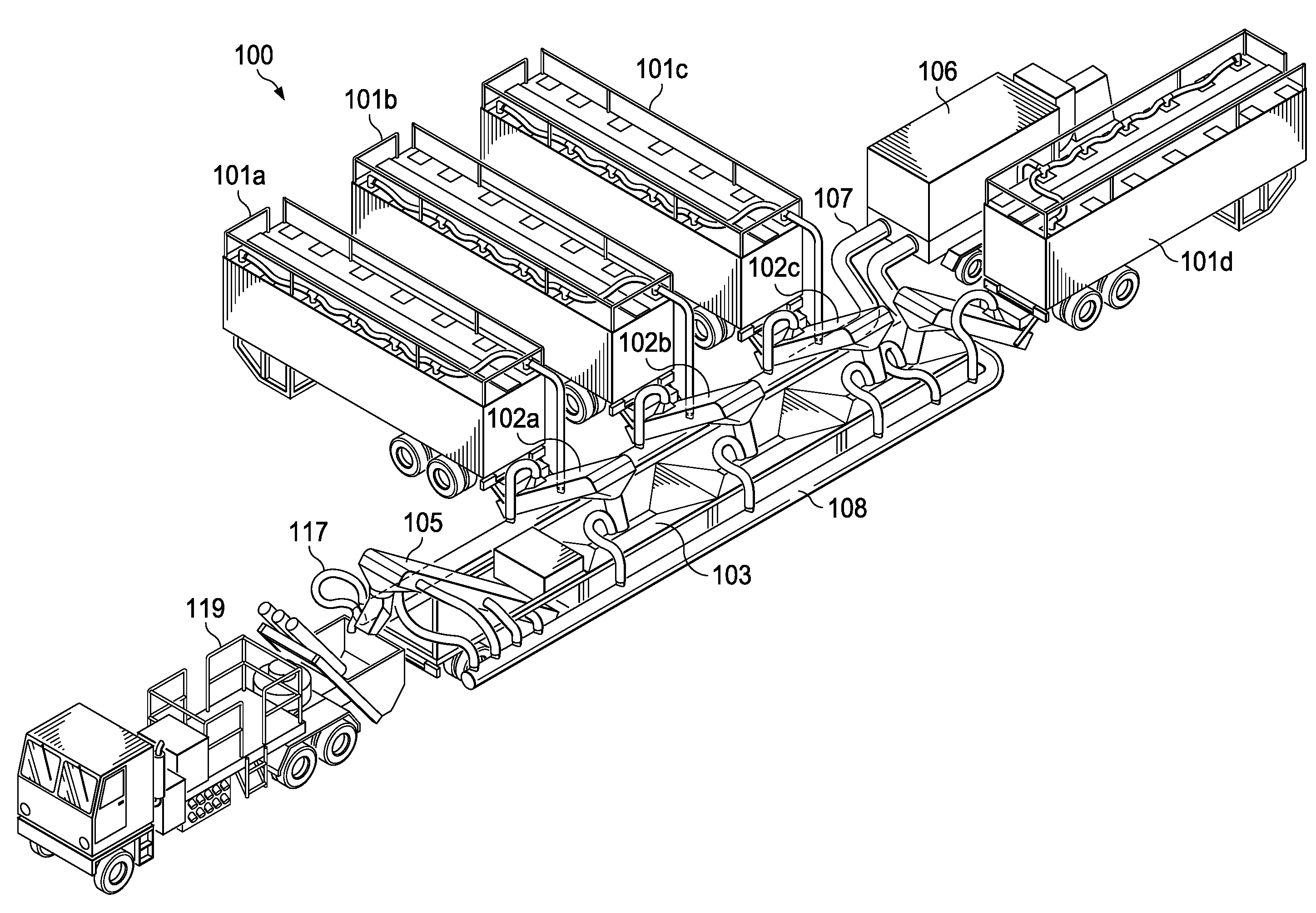

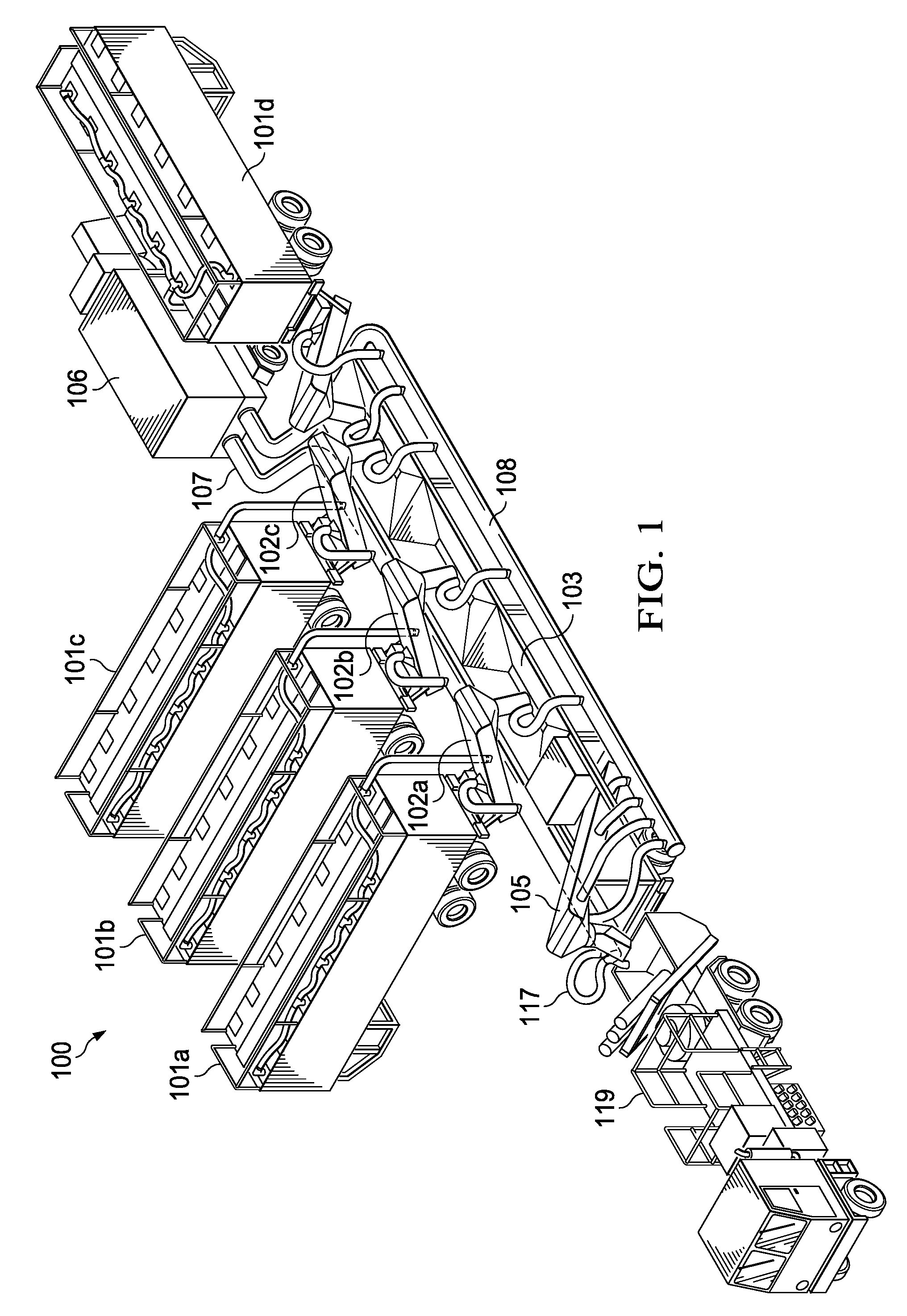

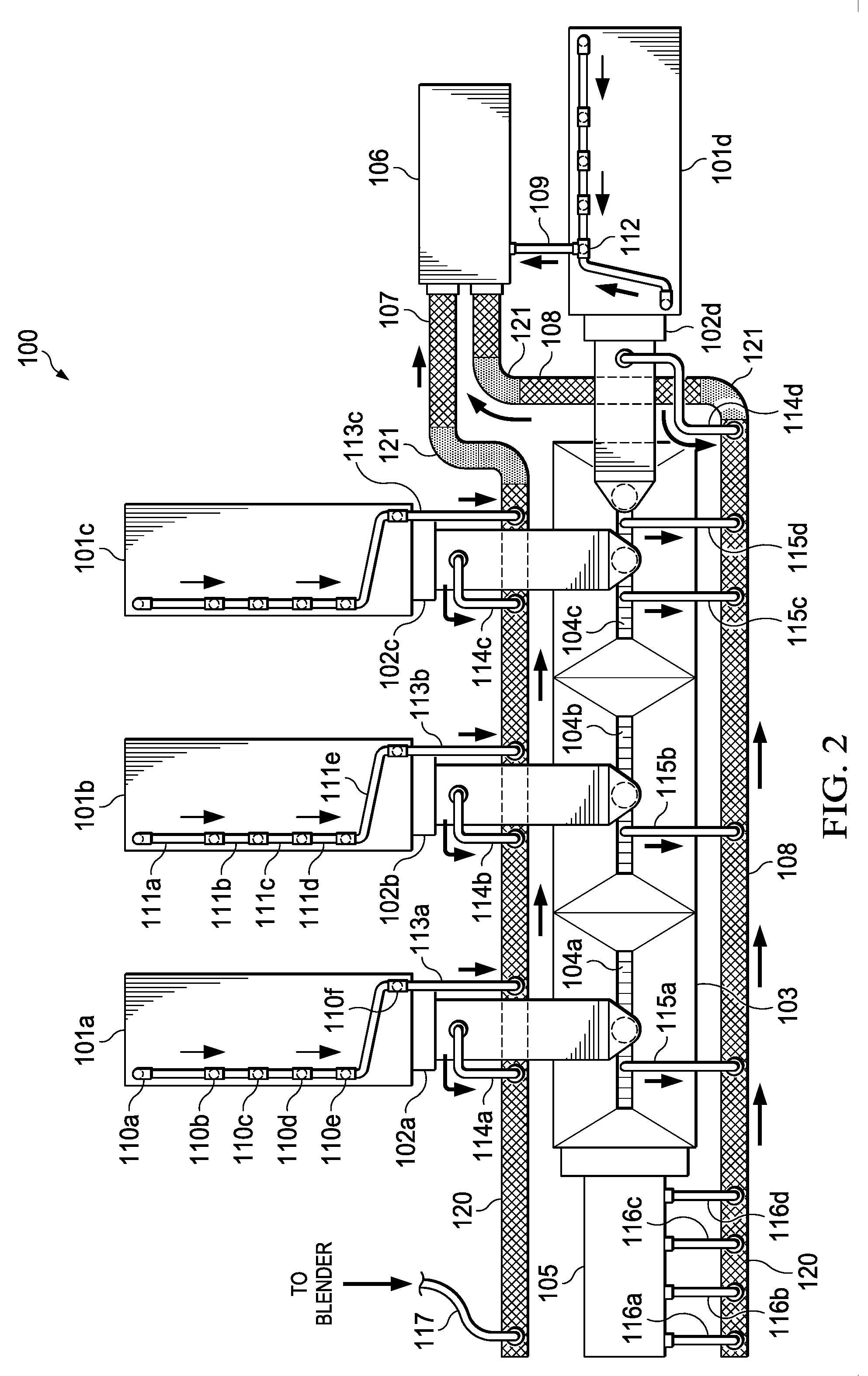

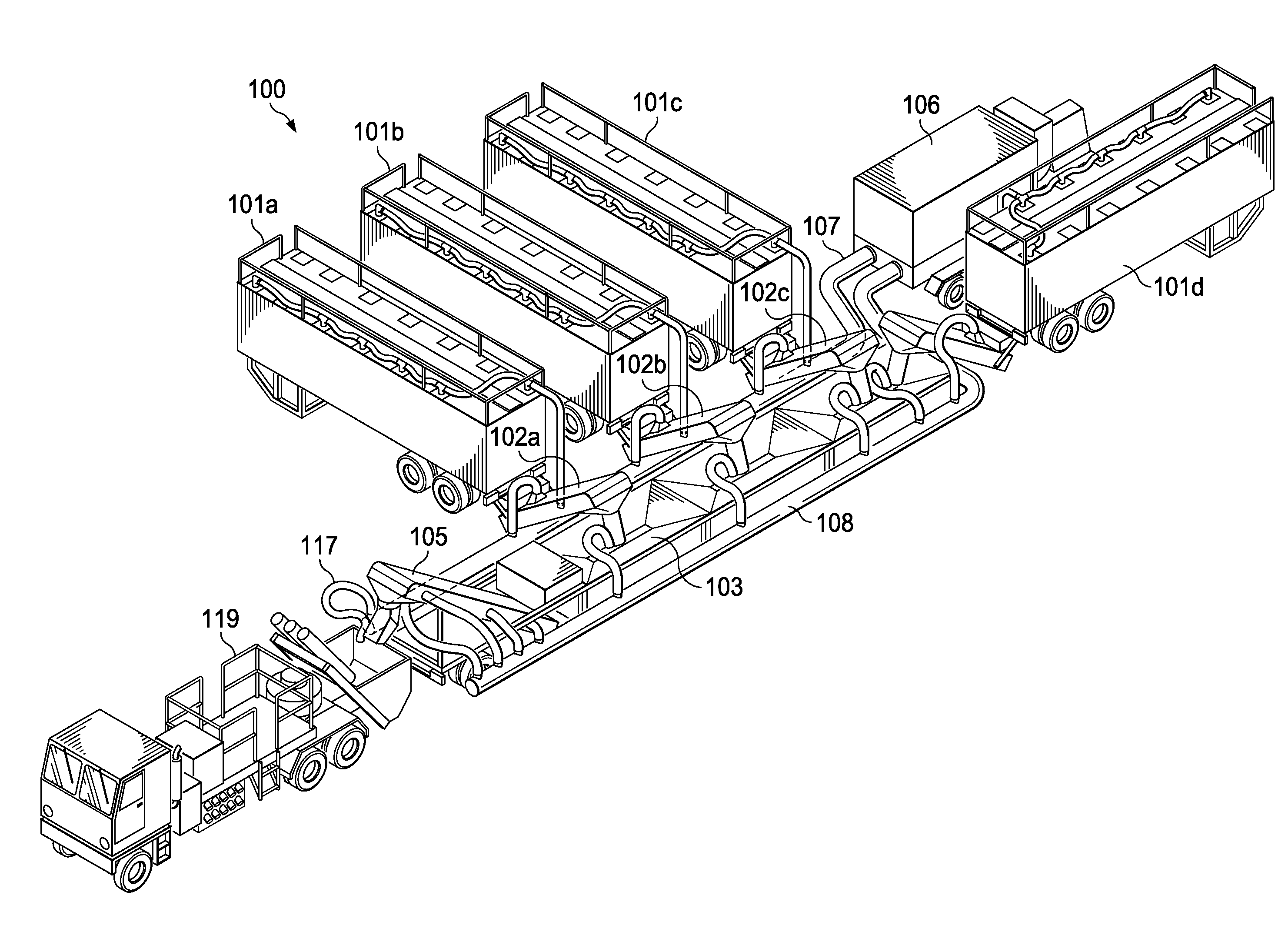

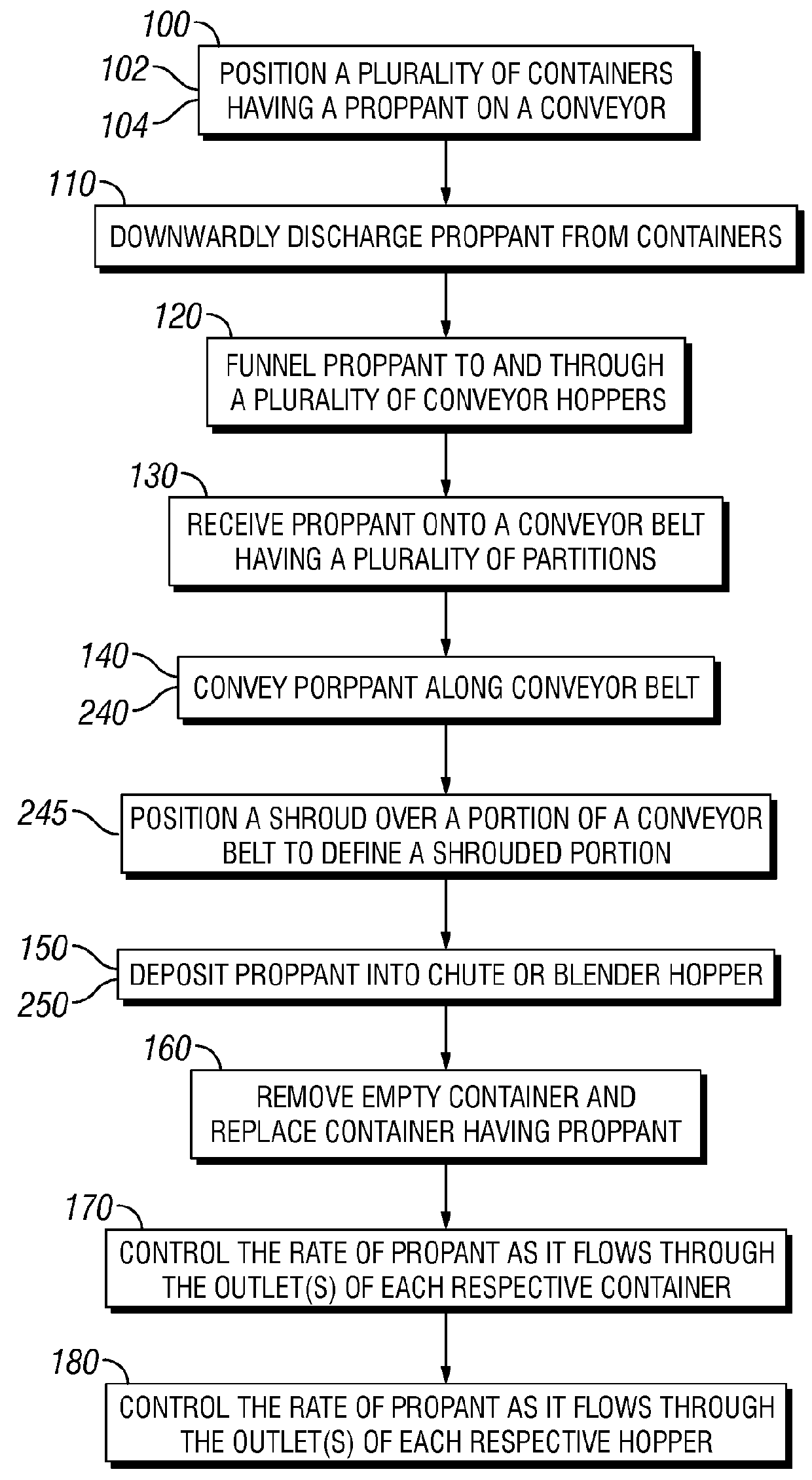

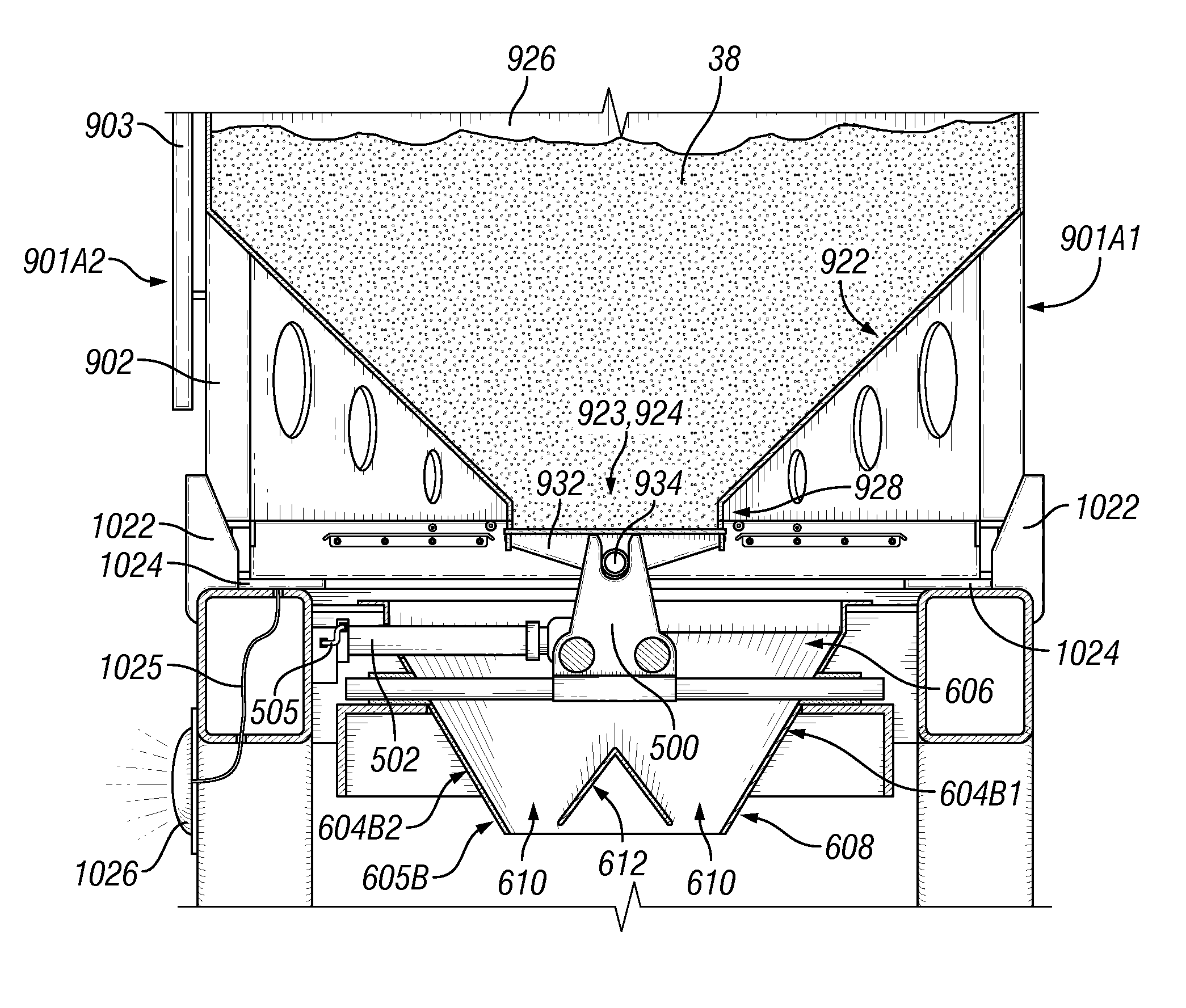

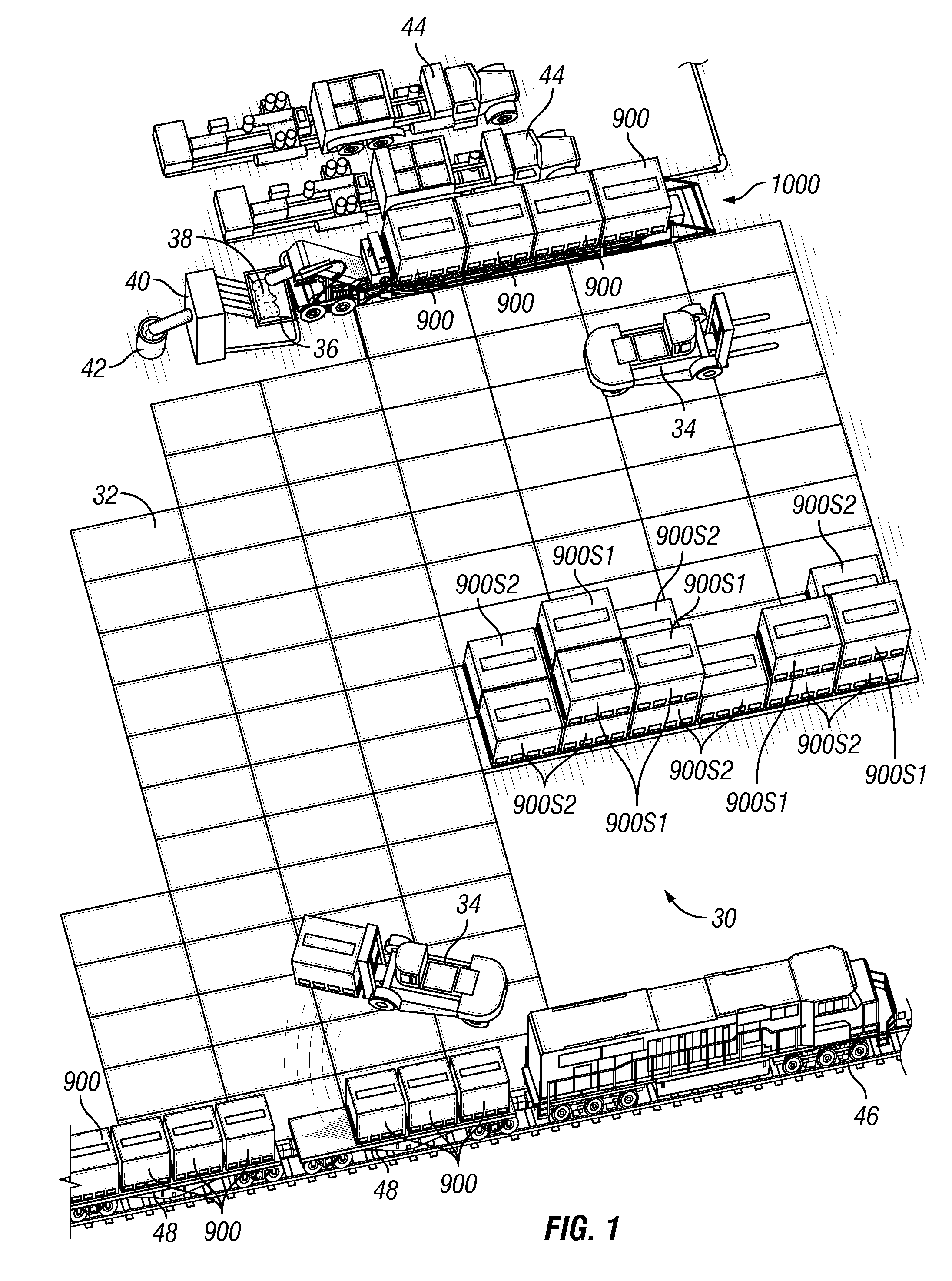

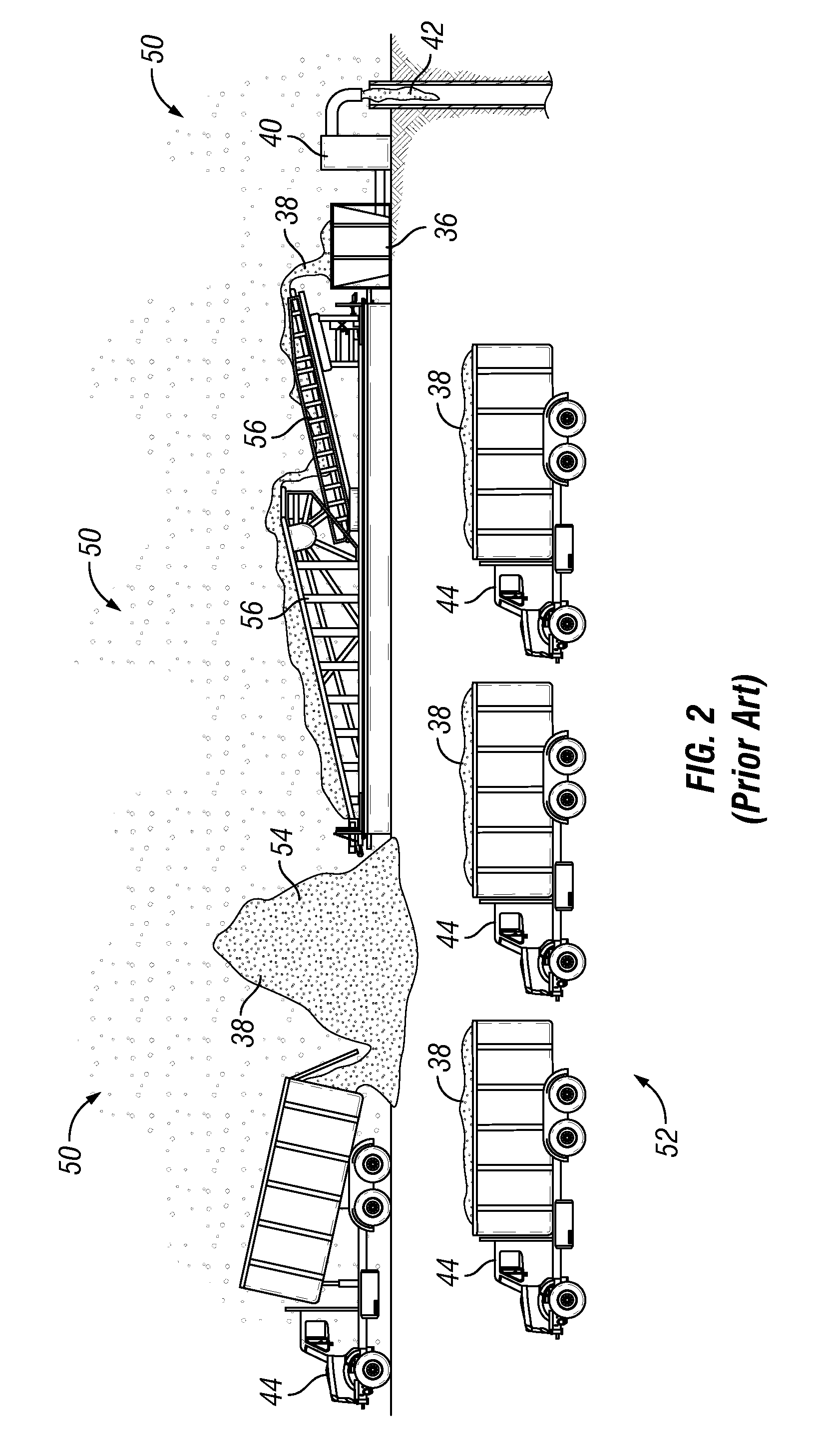

Embodiments of methods and systems of transferring proppant for fracking, to reduce risk of production and release of silica dust at a well site are provided. An embodiment of a method can include positioning a plurality of containers each having proppant for fracking contained therein onto a conveyor at a well site, downwardly discharging proppant from each respective container of the plurality of containers, funneling proppant from the one or more outlets of each of the plurality of containers through a plurality of conveyor hoppers, receiving proppant onto the conveyor belt, conveying proppant on the conveyor to a chute, and depositing the proppant into the chute for use in a blender or other location at the well site.

Owner:SANDBOX ENTERPRISES LLC

Methods and systems to transfer proppant for fracking with reduced risk of production and release of silica dust at a well site

ActiveUS20150360856A1Reduce riskEasy to liftPowdered material dispensingConveyorsEngineeringSilicon dioxide

Embodiments of methods and systems of transferring proppant for fracking to reduce risk of production and release of silica dust at a well site are provided. An embodiment of a method can include positioning a plurality of containers each having proppant for fracking contained therein onto a conveyor at a well site, downwardly discharging proppant from each respective container of the plurality of containers, funneling proppant from the one or more outlets of each of the plurality of containers through a plurality of conveyor hoppers, receiving proppant onto the conveyor belt, conveying proppant on the conveyor to a chute, and depositing the proppant into the chute for use in a blender or other location at the well site.

Owner:SANDBOX ENTERPRISES LLC

Systems and methods for controlling silica dust during hydraulic fracturing operations

ActiveUS9162261B1Improve flexibility and efficiencyEfficient and flexible systemFouling preventionFluid removalHydraulic fracturingSilicon dioxide

A system for controlling silica dust generated during the transfer of frac sand from a storage container through a conveyor system includes a system of conduits having a plurality of inlets for collecting silica dust generated at selected points along the conveyor system. An air system pneumatically coupled to the system of conduits generates a negative pressure at each of the inlets to induce the collection of silica dust at the selected points along the conveyor.

Owner:SIERRA DUST CONTROL

Methods and systems to transfer proppant for fracking with reduced risk of production and release of silica dust at a well site

ActiveUS20160046438A1Reduce riskReduce production and releasePowdered material dispensingConveyorsBLENDER/MIXERConveyor belt

Embodiments of methods and systems of transferring proppant for fracking to reduce risk of production and release of silica dust at a well site are provided. An embodiment of a method can include positioning a plurality of containers each having proppant for fracking contained therein onto a conveyor at a well site, downwardly discharging proppant from each respective container of the plurality of containers, funneling proppant from the one or more outlets of each of the plurality of containers through a plurality of conveyor hoppers, receiving proppant onto the conveyor belt, conveying proppant on the conveyor to a chute, and depositing the proppant into the chute for use in a blender or other location at the well site.

Owner:SANDBOX ENTERPRISES LLC

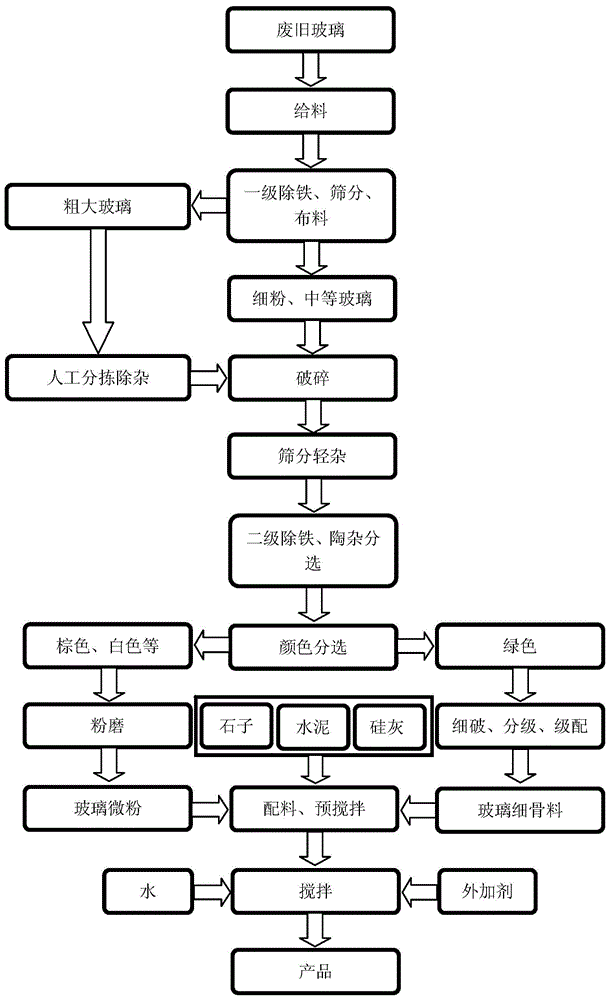

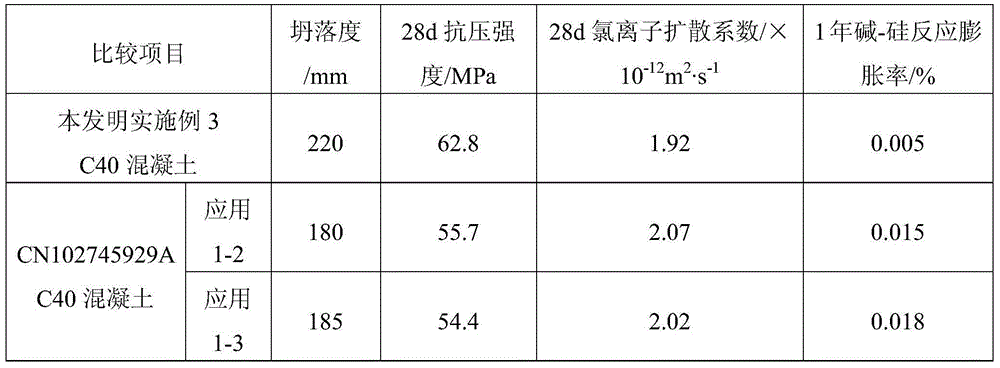

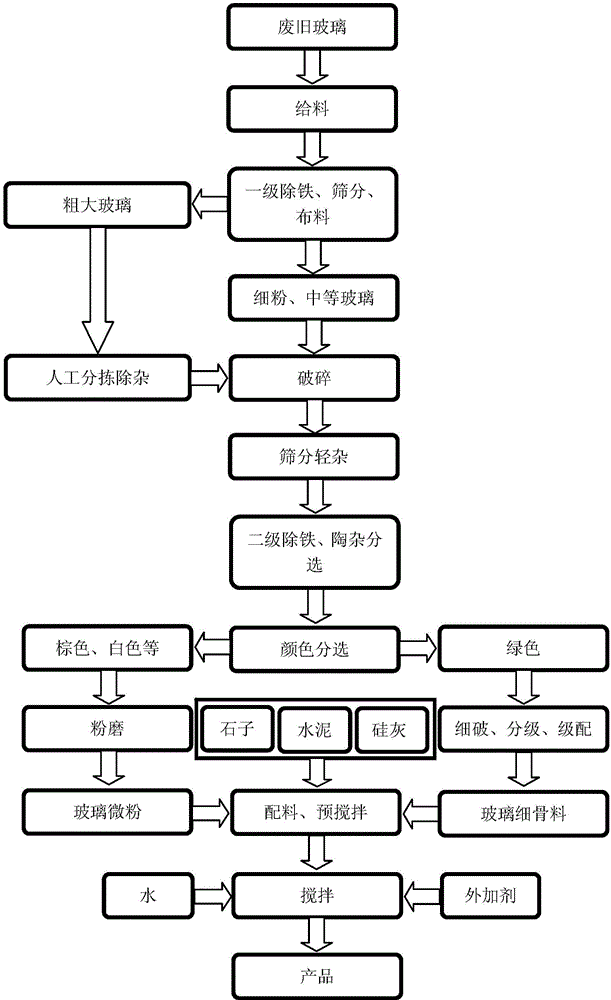

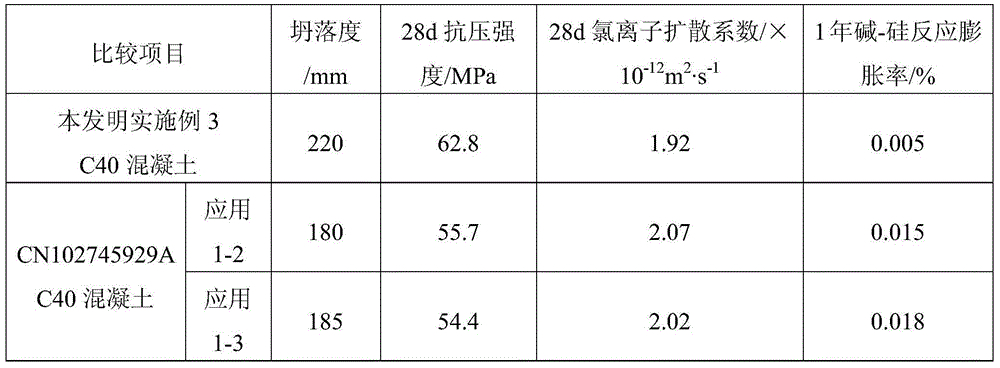

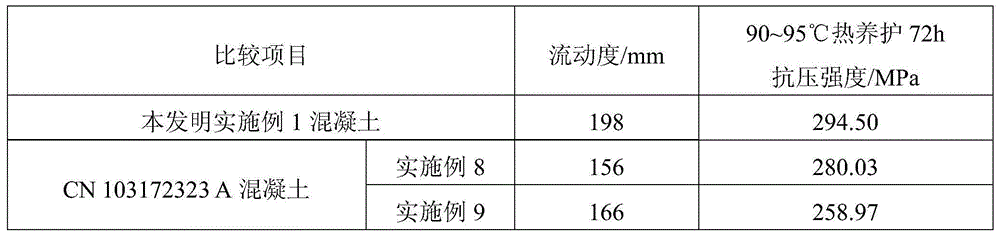

Concrete mainly prepared from waste glass and preparation method thereof

The invention discloses concrete mainly prepared from waste glass. The concrete is prepared from the following components in parts by weight: 10-30 parts of gel material, 30-40 parts of fine aggregate, 40-50 parts of coarse aggregate, 0.05-0.45 part of admixture and 3.8-16.5 parts of water, wherein the gel material comprises the following components in percentage by weight: 70-85wt% of cement, 10-20wt% of waste glass micropowder with the particle size being less than or equal to 30 micrometers and 5-10w% of silica dust; the fine aggregate is zone-II medium sand grading class waste glass powder, and the coarse aggregate is stones with the particle size being 5-16mm. The waste glass is utilized in the concrete to the maximum degree, and the cement has excellent compressive strength and mobility. The invention also provides a concrete preparation method.

Owner:北京元泰达环保科技有限公司

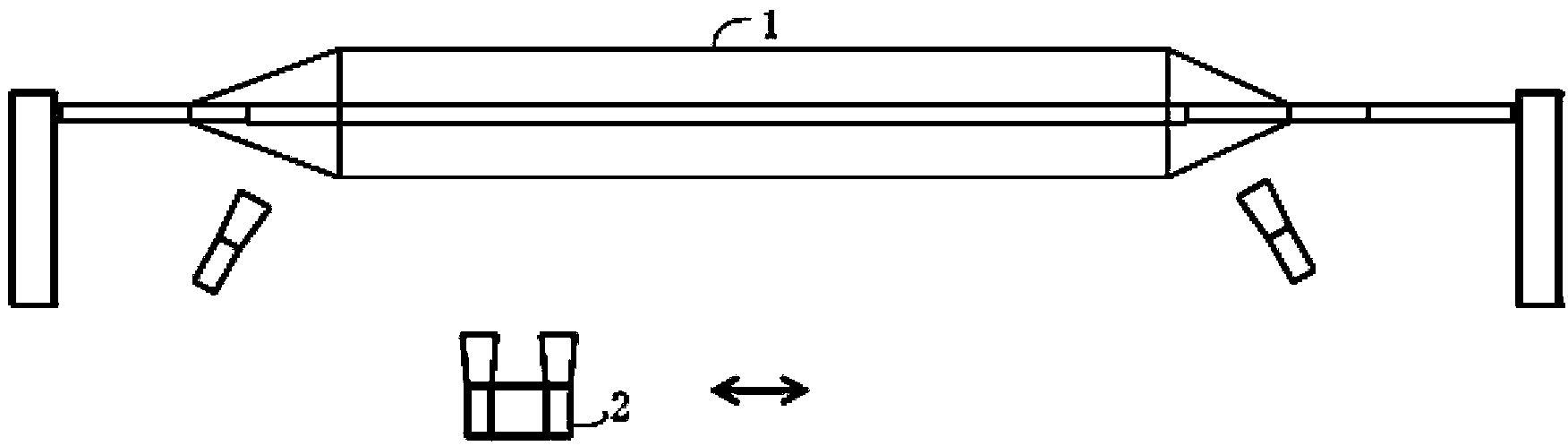

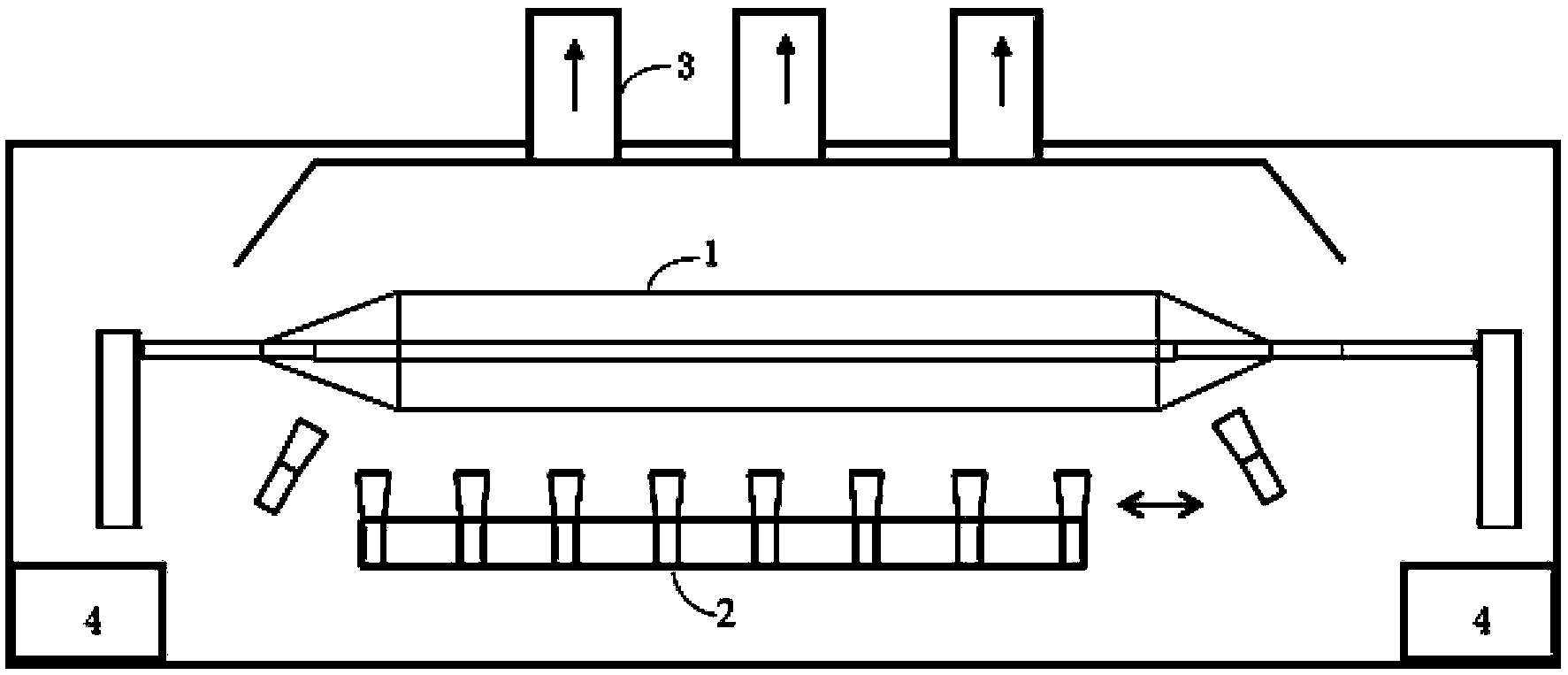

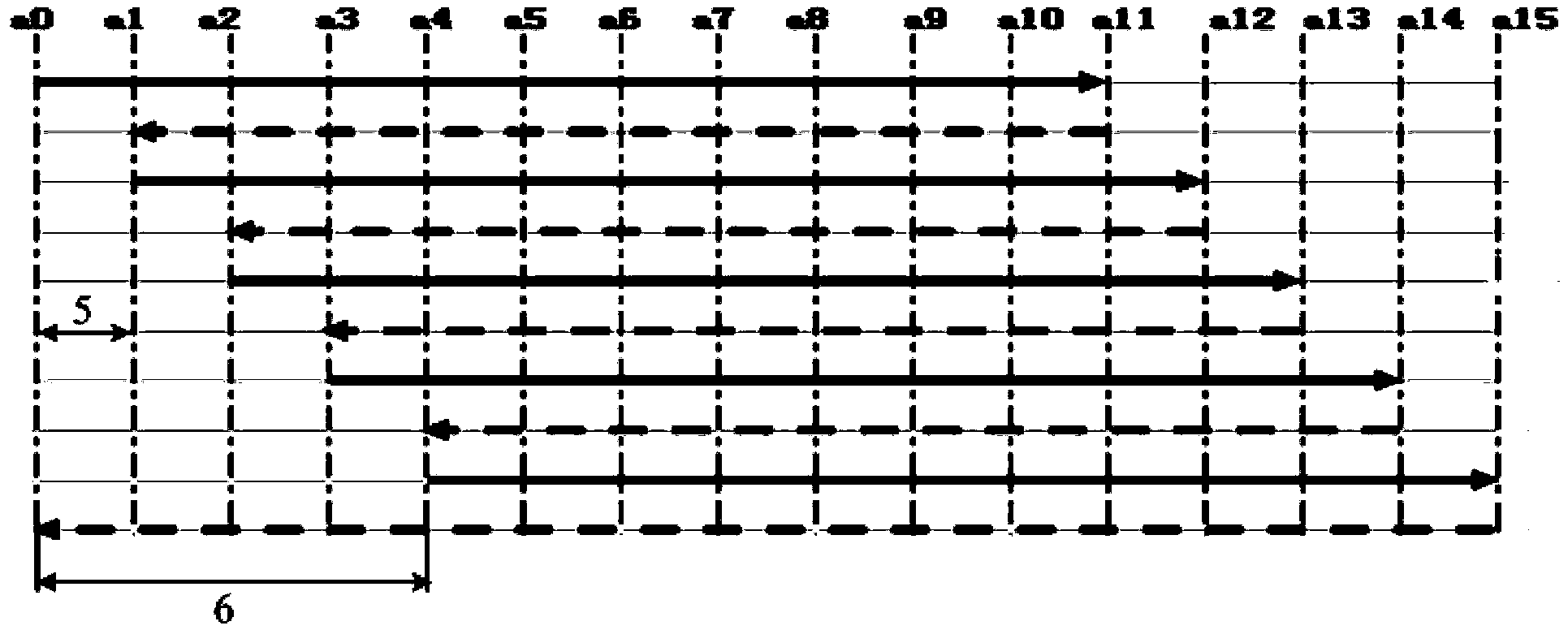

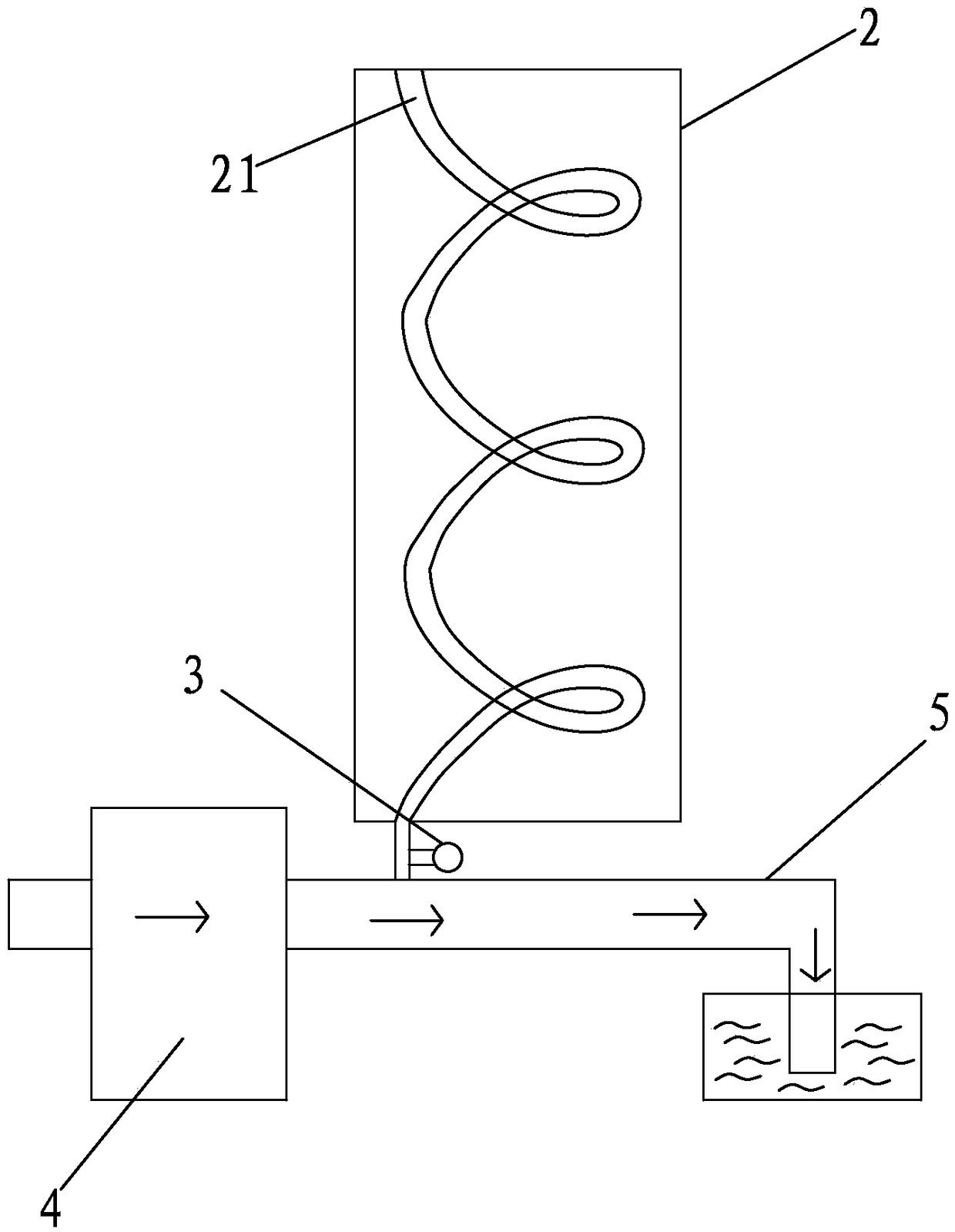

Method and apparatus for manufacturing optical fiber perform extramural cladding

InactiveCN103771696AIncrease deposition rateIncrease productivityGlass making apparatusGlass productionAir volumeReciprocating motion

The invention discloses a method for manufacturing an optical fiber perform extramural cladding, and the prior deposition method usually employs a double-lamp deposition, which has the disadvantages of long deposition time, reduced production efficiency and high cost. According to the invention, an external gas-phase deposition method is used for producing optical fiber perform, and multi-lamp deposition is employed; the quantity of the lamp is more than three times of that in the routine process, and lamps are horizontally and upwardly arranged in a straight line with a certain internal; center of lamp flames aligns to a cylindrical initial starting rod at a certain rotating speed, and carries out a reciprocating motion according to a certain rule relative to the initial starting rod, and thereby silica dust adheres to the surface of the initial starting rod. The invention employs a transverse deposition, controls of lamp moving mode, gas flow, deposition weight, reciprocating times, exhaust air quantity and two-end heat assisting lamp gas flow, which can effectively reduce fluctuation of external diameter of optical fiber perform, and the invention has the advantages of good reproducibility of external diameters between optical fiber performs, high production efficiency, low cost and high deposition speed which is increased by more than three times.

Owner:ZHEJIANG FUTONG OPTICAL FIBER TECH

Dust collection assembly for use with universal drill stand

The present invention is a dust collection assembly for capturing dust, debris and residue that is created during the process of drilling holes into a concrete ceiling. The dust collection assembly is used with a universal drill stand and a drill saddle which has an electric drill secured to it. The drill saddle further comprises a telescoping vacuum tube having a ceiling contact portion that encircles the drill bit at the portion of the drill bit where the drill bit enters the ceiling. As the drill bit begins to penetrate the ceiling, silica dust is generated and removed via the vacuum tube, which tube is connected to a vacuum source.

Owner:FELTON J REED +1

Bridge deck slab waterborne polyurethane polymer concrete and preparation method thereof

ActiveCN104876474ASusceptible to corrosion damage, the problem of low strength is solvedReduce repair costsSolid waste managementPolymer scienceSuperplasticizer

The invention provides bridge deck slab waterborne polyurethane polymer concrete and a preparation method thereof. The bridge deck slab waterborne polyurethane polymer concrete comprises the following raw material components: coarse aggregate, medium sand, coal ash, silica dust, a naphthalene water reducer, waterborne polyurethane and a silane coupling agent. The preparation method of the bridge deck slab waterborne polyurethane polymer concrete comprises the following steps: at room temperature, putting dried coarse aggregate, medium sand, coal ash and silica dust into a stirrer; then, adding waterborne polyurethane emulsion and stirring; and then adding the silane coupling agent and stirring; and finally adding the naphthalene water reducer and stirring. According to the preparation method, the waterborne polyurethane polymer is used for replacing concrete to serve as a cementing material, is mixed with aggregate and is added with coal ash, silica dust, the naphthalene water reducer and the silane coupling agent. The bridge deck slab waterborne polyurethane polymer concrete can be applied to a bridge deck structure which has a high requirement on durability or is difficult to repair and large in span.

Owner:HARBIN ENG UNIV

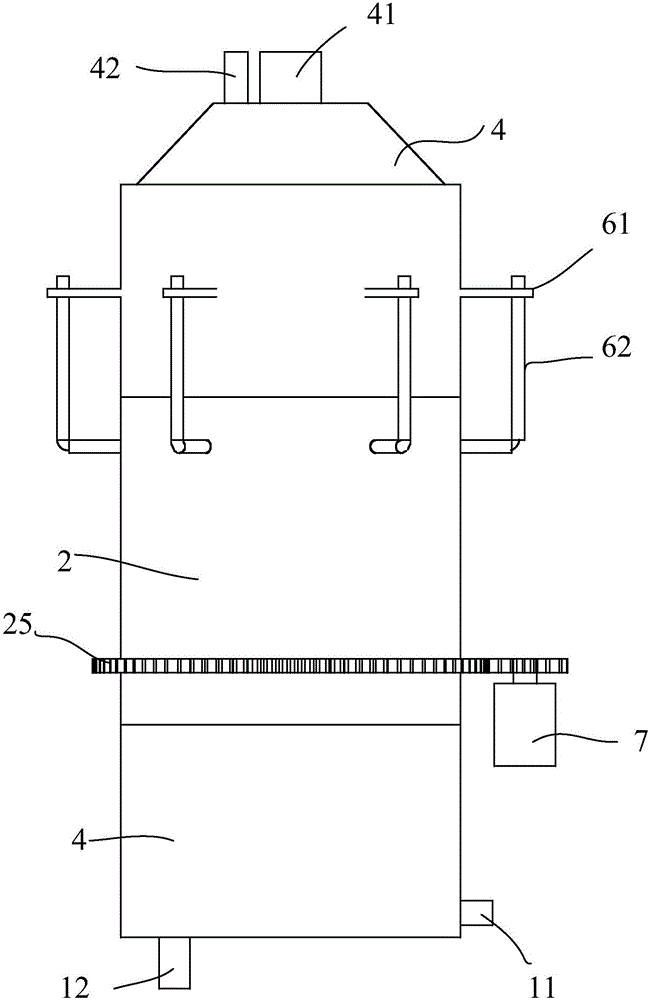

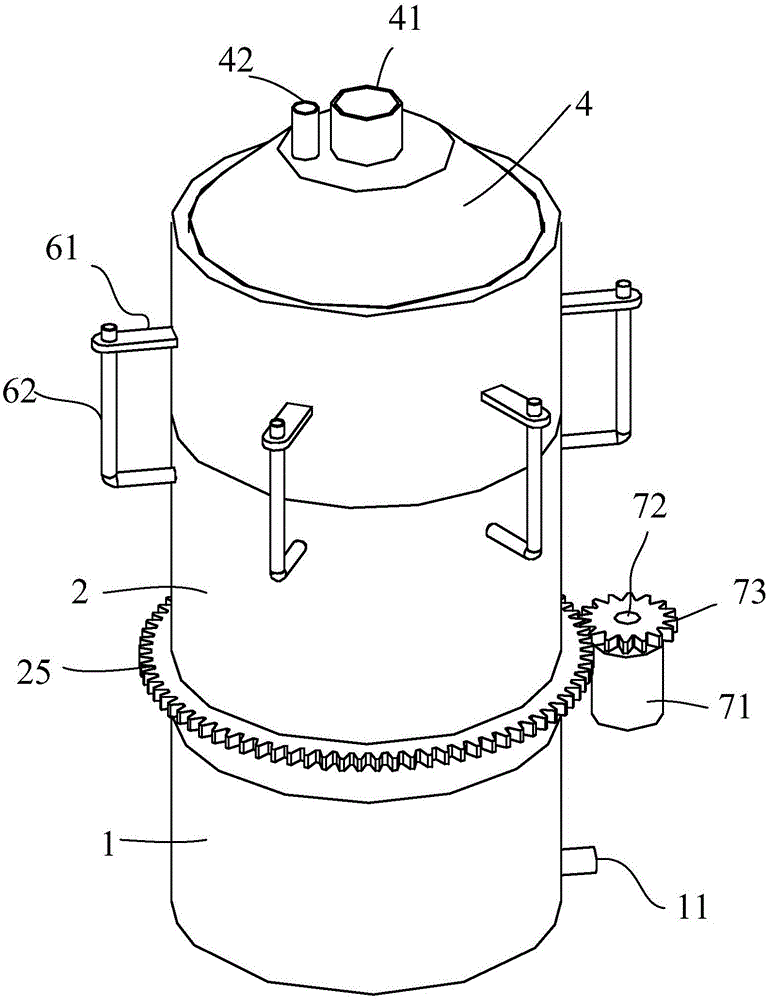

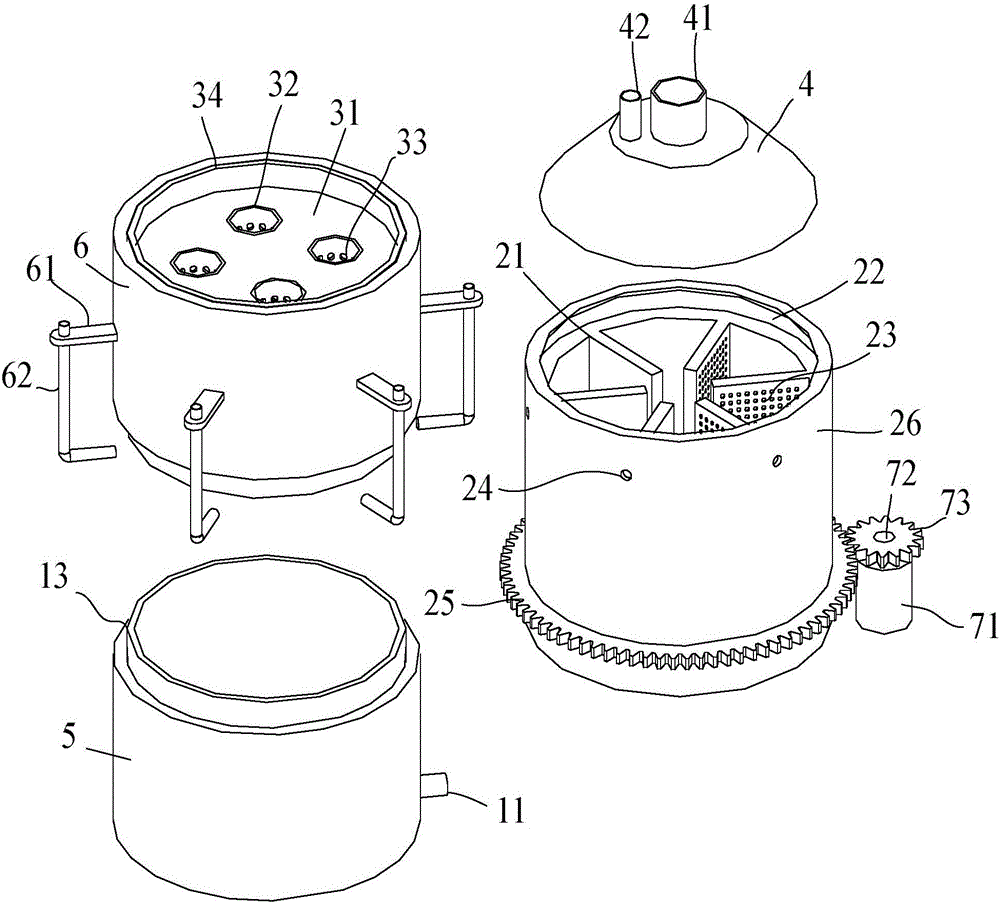

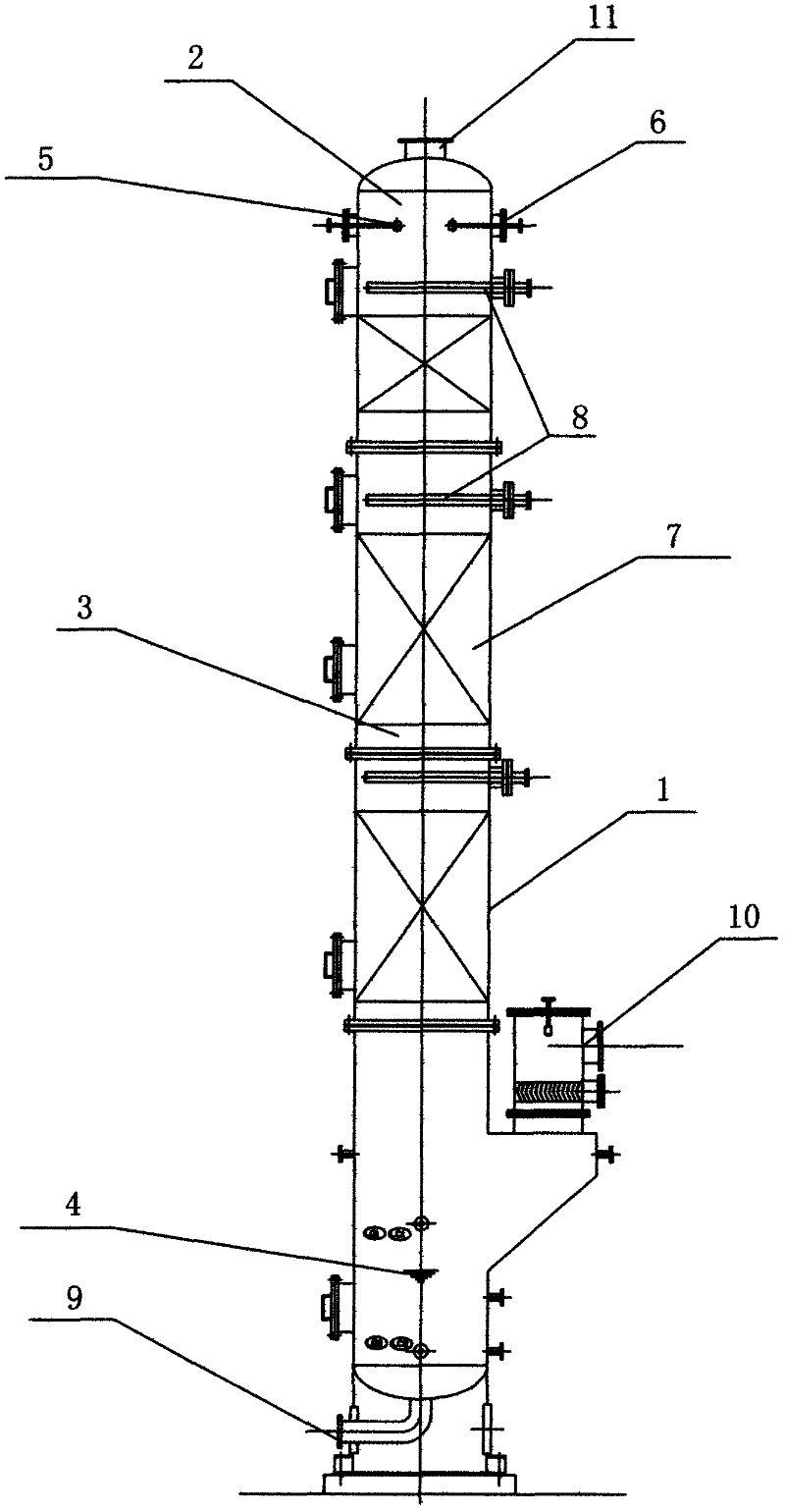

SiHCl3 synthetic tail gas treatment device

InactiveCN105797543AImprove adsorption capacityGas treatmentDispersed particle filtrationEngineeringSilica dust

The invention belongs to the field of SiHCl3 treatment devices and relates to SiHCl3 synthetic tail gas treatment equipment, in particular to a SiHCl3 synthetic tail gas treatment device.The SiHCl3 synthetic tail gas treatment device comprises a bearing device.The bearing device comprises a bearing shell, a second adsorption device is arranged above the bearing device, and a first adsorption device is arranged between the second adsorption device and the bearing device.Due to the fact that the first adsorption device is arranged between the second adsorption device and the bearing device, an adsorption plate is arranged in the first adsorption device, a rack wheel is arranged outside the first adsorption device, a drive mechanism is arranged on the rack wheel, the first adsorption device can well adsorb and filter solid silica dust and high-boiling residue dust in gas in the first adsorption device, the solid silica dust and the high-boiling residue dust in the gas can be well filtered out, and pure gas, pure solid silica dust and pure high-boiling residue dust can be obtained, utilized and recovered.

Owner:SHANDONG RUICHUAN SILICON IND

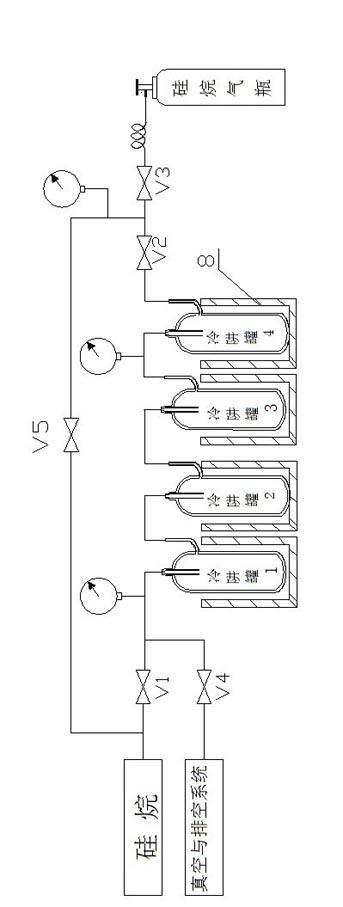

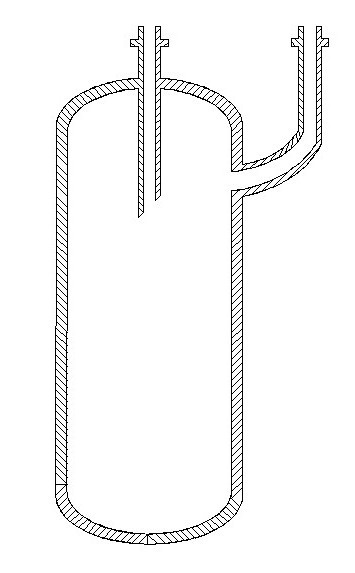

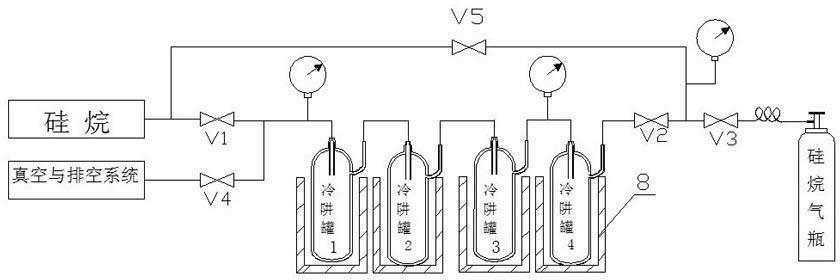

Cold trap system for purifying and filling silane

The invention discloses a cold trap system for purifying and filling silane. The cold trap system comprises a plurality of cold trap tanks and liquid nitrogen dewars in the same quantity as the cold trap tanks and is characterized in that: the cold trap tanks are provided with sealed tank bodies; the top parts of the tank bodies are provided with air inlet pipes; the lateral upper sides of the tank bodies are provided with outlet pipes; the outlet pipe of one cold trap tank is connected with the air inlet pipe of another cold trap tank, so that all the cold trap tanks are connected in series; and the cold trap tanks can be sleeved in the liquid nitrogen dewars. When the cold trap system is used, the air inlet pipe of the first cold trap tank is connected in parallel with two valves; one valve is a silane valve and is connected with a silane air source, and the other valve is a vacuumizing and venting valve and is connected with a vacuumizing and venting system; and the outlet pipe of the last cold trap tank is connected with a busbar; and all the outlets of the busbar are connected with silane cylinders to be filled with the silane. The cold trap system adopts the cold trap tanks connected in series, fills the silane at low temperature, has the function of purifying gas, can effectively purify silane gas, prevents silica dust, and ensures the safe and normal operation of filling systems.

Owner:NANJING SPECIAL GAS FACTORY

Preparation method of permanent layer castable and permanent layer for ferrovanadium smelting furnace

The invention belongs to the technical field of ferrovanadium smelting, and particularly relates to a preparation method of a permanent layer castable and a permanent layer for a ferrovanadium smelting furnace. The invention provides a castable production formula which realizes good using effect, long service life and low cost. The castable consists of the following components in percentage by weight: 67.5-68.5% of brown fused alumina, 19.5-20.5% of white corundum, 6.5-7.5% of fused magnesite, 2.5-3.5% of alumina powder and 2% of silica dust powder. The invention also provides a preparation method of a permanent layer for a ferrovanadium smelting furnace, which comprises the steps of mixing and stirring the production raw materials, pouring, forming and drying. The permanent layer for a ferrovanadium smelting furnace, provided by the invention, can effectively prevent the corrosion and scour of high-temperature molten steel, and can be used repeatedly.

Owner:PANZHIHUA GANGCHENG GROUP

Composition for building materials having improved freeze-thaw resistance and process for the production thereof

InactiveUS20130284071A1Improve freeze-thaw resistanceHydrophobic propertyPlastic/resin/waxes insulatorsSolid waste managementSilicon dioxideFly ash

A hydraulically curable composition, in particular for the production of concrete, mortar, screed, or render having improved freeze-thaw resistance, as well as a process for producing the composition. The composition includes the constituents cement, additional constituents, and organofunctional silicon compounds, and optionally aggregates and admixtures. The composition also contains the additional constituents fly ash and silica dust, in each case independently based on the weight of cement, in an amount of from 1 to 25% by weight and the organofunctional silicon compounds in an amount of from 0.1 to 5% by weight based on the weight of cement.

Owner:EVONIK DEGUSSA GMBH

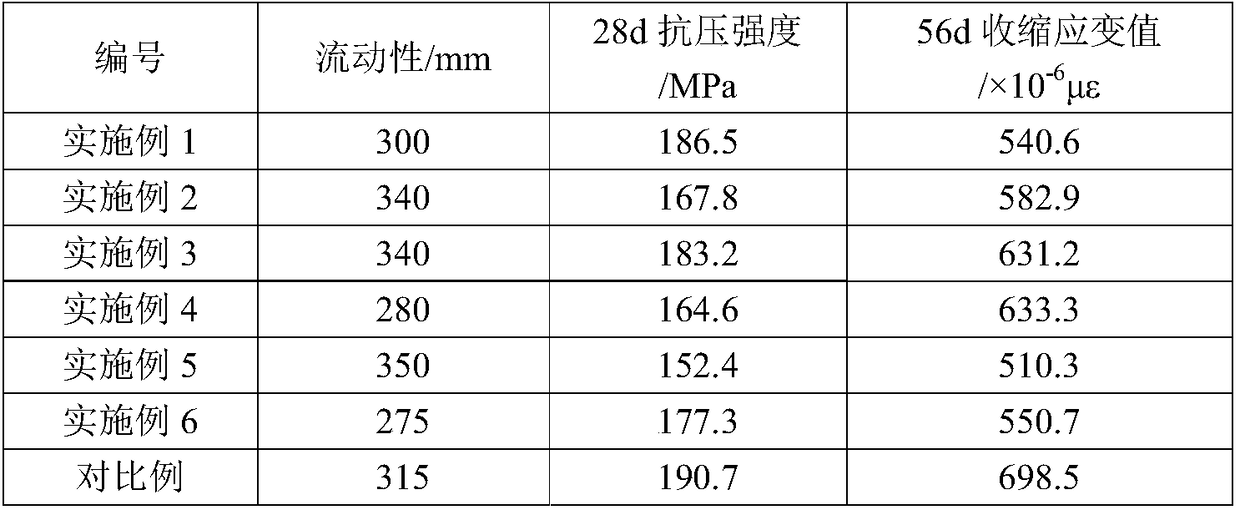

Low-shrinkage green UHPC (ultrahigh performance concrete) and preparation method thereof

The invention discloses a low-shrinkage green UHPC and a preparation method thereof. The low-shrinkage green UHPC is mainly prepared from the following raw materials including, by weight part, 700-750parts of ordinary Portland cement, 340-380 parts of ultrafine coal ash, 100-150 parts of silica dust, 4-8 parts of super absorbent polymer (SAP), 940-980 parts of Aeolian sand, 230-250 parts of steelfiber, 56-64 parts of polycarboxylate water-reducer and 180-200 parts of water. By the nature of ultralow porosity, UHPC can result in high shrinkage during hydration and hardening. According to thelow-shrinkage green UHPC, the Aeolian sand serves a UHPC fine aggregate; for reducing shrinkage, the SAP is doped during preparation. Results show that, with the SAP mixed, the low-shrinkage green UHPC is of little change in mechanical performance but reduces 56d drying shrinkage, thereby having a broad application prospect.

Owner:SOUTHEAST UNIV

Polycrystalline silicon and method for production thereof

Owner:WACKER CHEM GMBH

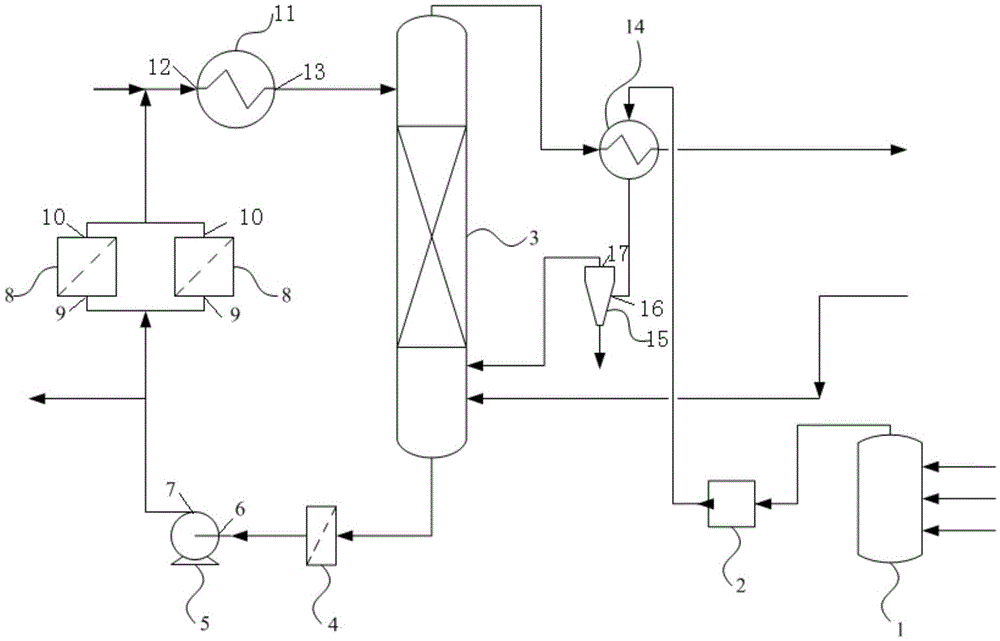

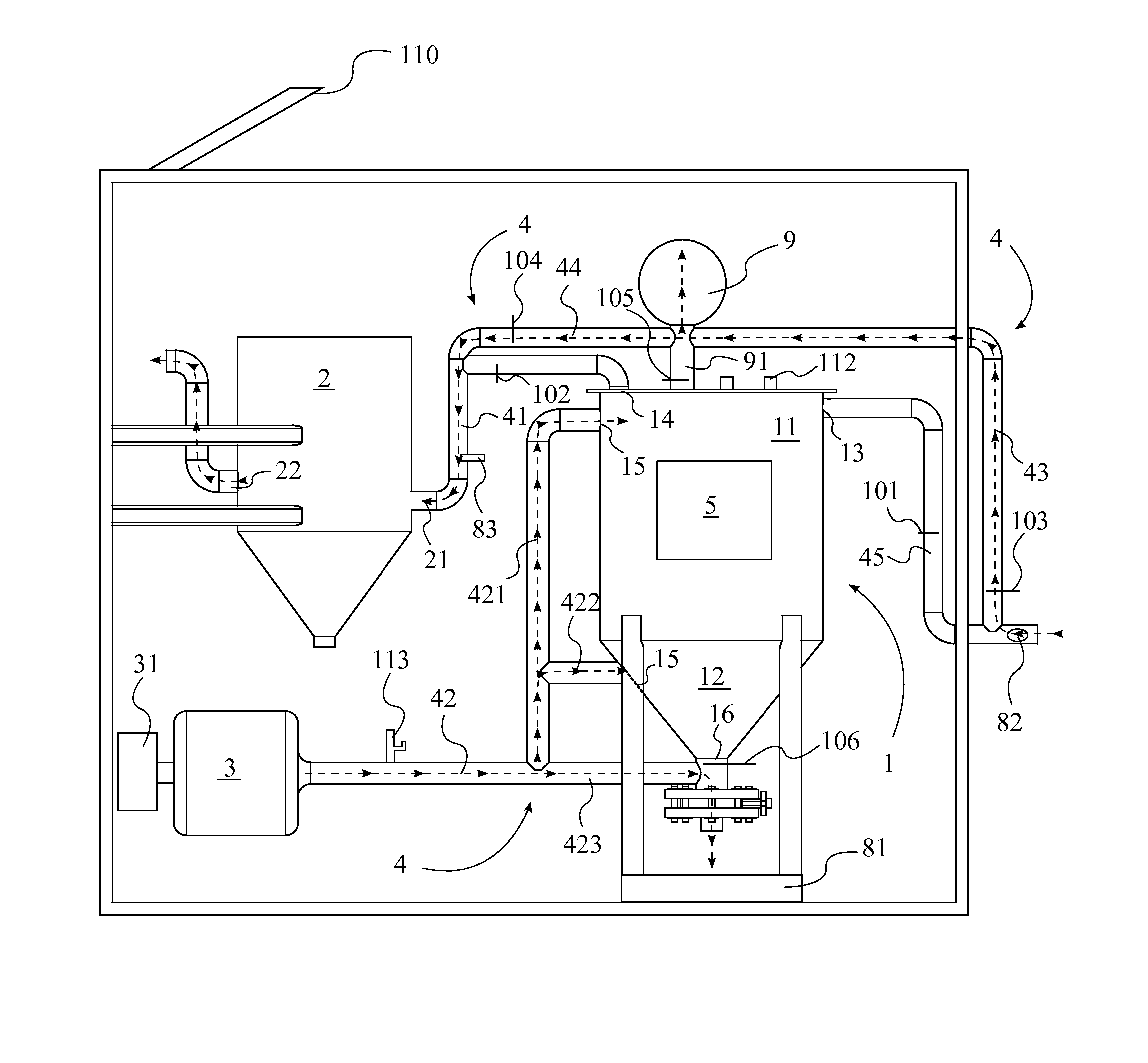

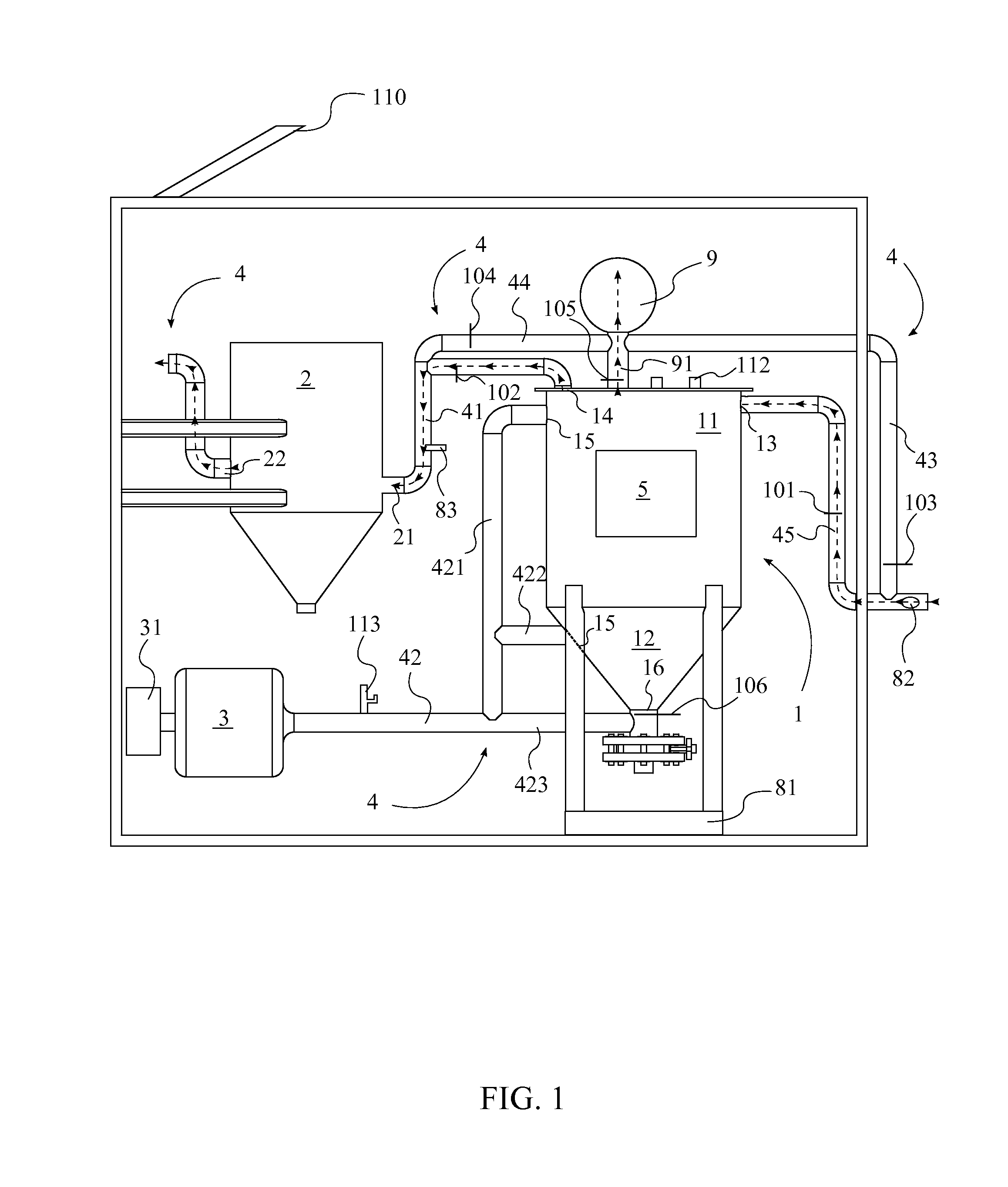

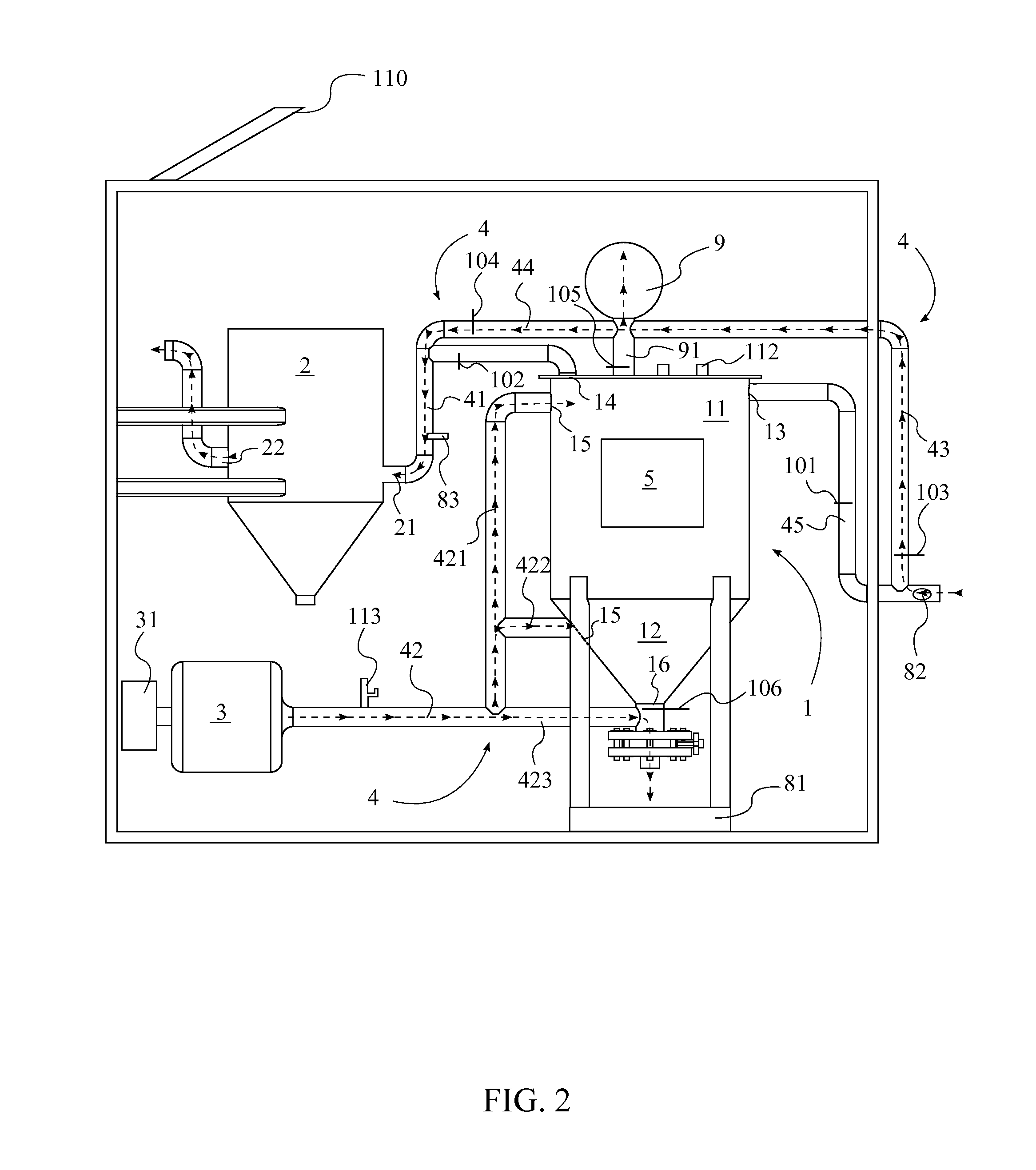

System for recycling hydrogen in production process of polycrystalline silicon

ActiveCN106829863AHigh purityReduce consumptionHydrogen separation using liquid contactHydrogen/synthetic gas productionHydrogenBuffer tank

The invention discloses a system for recycling hydrogen in the production process of polycrystalline silicon. The system comprises an oil-containing hydrogen buffer tank, a hydrogen compressor connected with the oil-containing hydrogen buffer tank, a hydrogen eluting column connected with the hydrogen compressor, a first filter connected with a column reactor of the hydrogen eluting column, wherein the hydrogen eluting column is further provided with an inlet to introduce dust-containing hydrogen produced in the production process of polycrystalline silicon and is used to elute by taking introduced chlorosilane as an eluent, and the first filter is used to filter to obtain filtered chlorosilane. The system avoids the abrasion damage of silica dust in the dust-containing hydrogen on the hydrogen compressor, and solves the problem of difficulty in maintenance of the hydrogen compressor after long-term operation; the system can treat the dust-containing hydrogen and the oil-containing hydrogen at the same time, the purity of the obtained recycled hydrogen is greatly improved, the loss of hydrogen and the number of electrolytic cells started are reduced, the system stability is improved, and the purity of the polycrystalline silicon prepared from the recycled hydrogen is further improved.

Owner:XINTE ENERGY

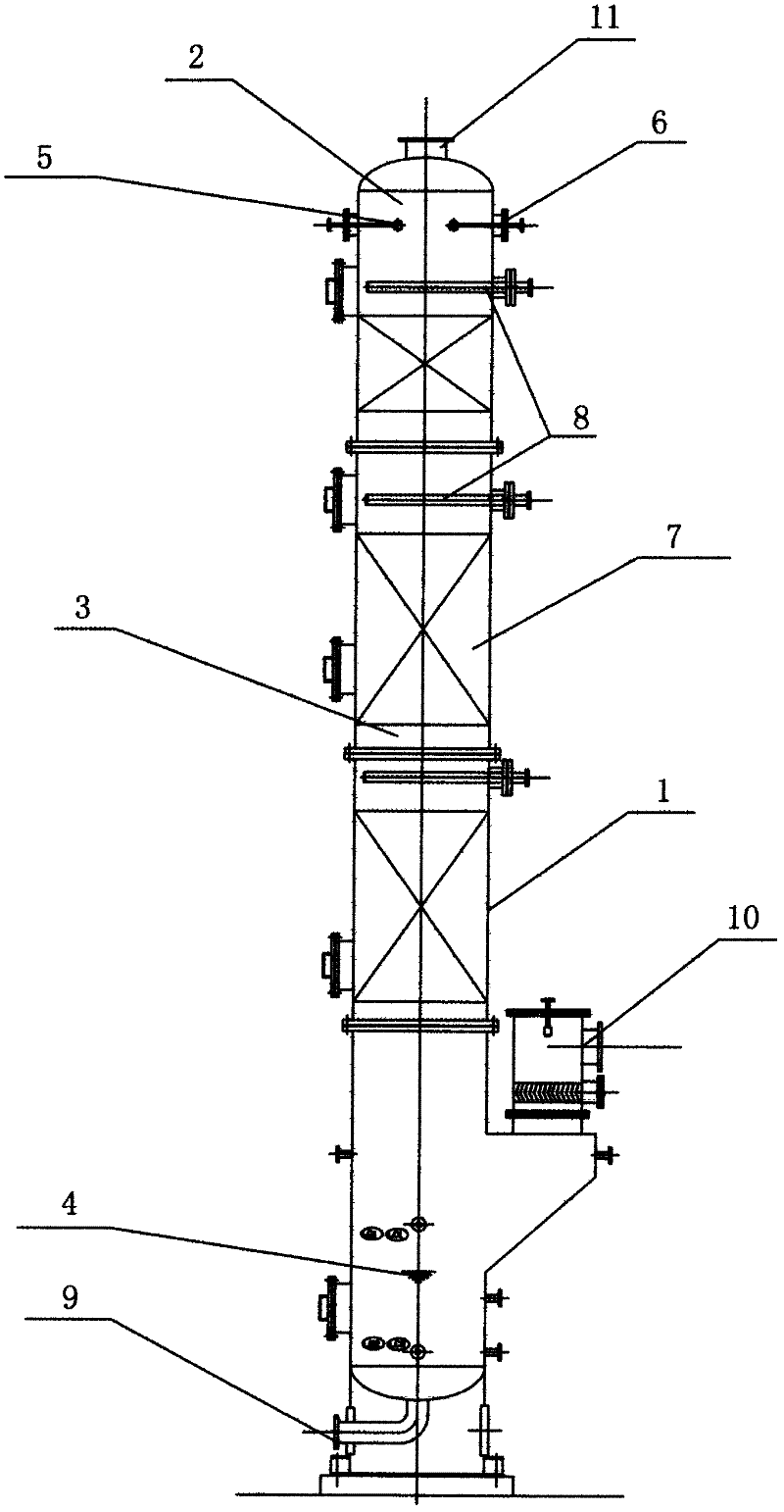

Dust Scrubber for Treatment of Fumed Silica Tail Gas

InactiveCN102284222AGood cleaning and dust removal effectGreat operating flexibilityUsing liquid separation agentAbsorption columnGas phase

The invention relates to a dust removal and washing tower for treating fume-phase silica tail gas, which includes a tower body, and the tower body is divided into a spray washing section, a packing absorption washing section and a liquid storage section from top to bottom. There are industrial primary water nozzles and dilute acid nozzles in the section; more than two grid fillers are arranged longitudinally in the filler absorption washing section, and concentrated acid distributors are respectively arranged above the grid fillers; concentrated acid distributors are installed at the bottom of the liquid storage section. The acid outlet, the side of the tower body between the liquid storage section and the packing absorption washing section is provided with a mixed gas outlet, and the top of the tower body is provided with a tail gas inlet. The gas-phase silica tail gas dedusting washing tower of the present invention has a good washing and dust removal effect, which can ensure that the subsequent hydrogen chloride absorption tower is not blocked; the tower has a large operating flexibility, which can reach 30% to 120%; the tower type and tower wall materials are respectively improved, Effectively guarantee the reliable operation of the tower; the processing capacity of a single tower is large, which can meet the processing requirements of 5000t / a fumed silica tail gas.

Owner:HANGZHOU ZHONGHAO TECH

Filtering system for dust material transfer

A filtering system for dust material transfer is a replacement for current practices at land drilling sites and other operations involving silica dust. While silica dust is being transferred from a delivery truck to a customer tank, the customer tank's vent is connected to a hopper tank inlet duct. The hopper tank outlet is connected to the inlet of a dust filter. An visual indicator bag provides a visual indication of pressure within the system. A plurality of sensors, a plurality of flow control valves, a processor, a power source and a control panel provide means for electronic operation. A blower is connected to a cleaning inlet of the hopper tank in order to clean the hopper tank. Bypass ducts are connected from the hopper inlet duct straight to the dust filter in order to bypass the hopper tank during tank cleaning.

Owner:GARZA JESUS JAIME

A kind of concrete with waste glass as main raw material and its preparation method

The invention discloses concrete mainly prepared from waste glass. The concrete is prepared from the following components in parts by weight: 10-30 parts of gel material, 30-40 parts of fine aggregate, 40-50 parts of coarse aggregate, 0.05-0.45 part of admixture and 3.8-16.5 parts of water, wherein the gel material comprises the following components in percentage by weight: 70-85wt% of cement, 10-20wt% of waste glass micropowder with the particle size being less than or equal to 30 micrometers and 5-10w% of silica dust; the fine aggregate is zone-II medium sand grading class waste glass powder, and the coarse aggregate is stones with the particle size being 5-16mm. The waste glass is utilized in the concrete to the maximum degree, and the cement has excellent compressive strength and mobility. The invention also provides a concrete preparation method.

Owner:北京元泰达环保科技有限公司

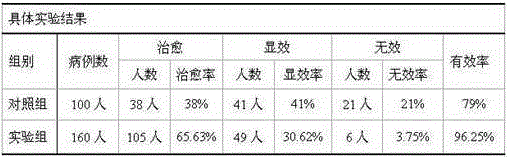

Yin and lung nourishing formula for treating silicosis and preparation method

InactiveCN105343344AReasonable drug compatibilityImprove immunityRespiratory disorderPlant ingredientsHouttuyniaRubus plicatus

The invention discloses a yin and lung nourishing formula for treating silicosis. The yin and lung nourishing formula mainly includes, by weight, 4-10 parts of loofah, 6-9 parts of lignum sappan, 7-11 parts of dwarf elm leaves, 9-12 parts of houttuynia cordata, 5-10 parts of Manchurian catalpa bark, 7-13 parts of kummerowia striata, 9-14 parts of vicia sativa, 6-11 parts of folium mori, 8-13 parts of roots and leaves of affined conehead, 7-12 parts of herba tripterospermi, 9-13 parts of bunge hackberry bark or stems, 5-12 parts of primrose roots, 4-9 parts of rhizoma atractylodis, 6-10 parts of fructus rubi, 8-12 parts of calceolaria crenatiflora and 7-10 parts of radix rubiae. The yin and lung nourishing formula has the advantages that raw materials in the yin and lung nourishing formula are reasonable in compatibility and supplement one another, accordingly, effects of promoting blood and qi circulation, clearing lung-heat, moistening dryness, eliminating phlegm by cooling and relieving cough and asthma can be realized, the immunity of organisms can be improved, silica dust in lungs can be effectively removed, and effects of improving pulmonary ventilation functions and delaying pulmonary fibrosis progress can be realized.

Owner:赵连祺

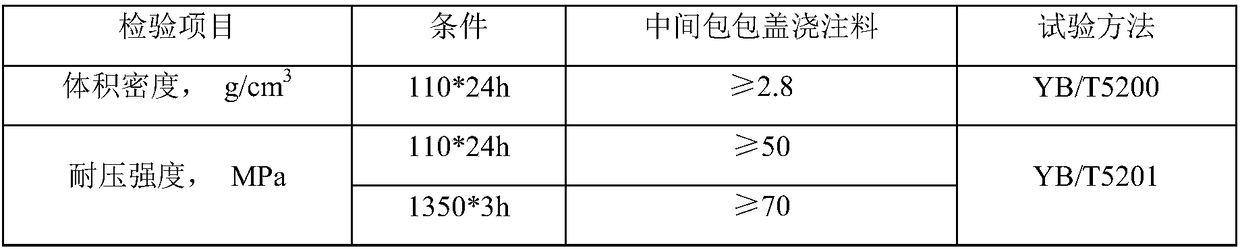

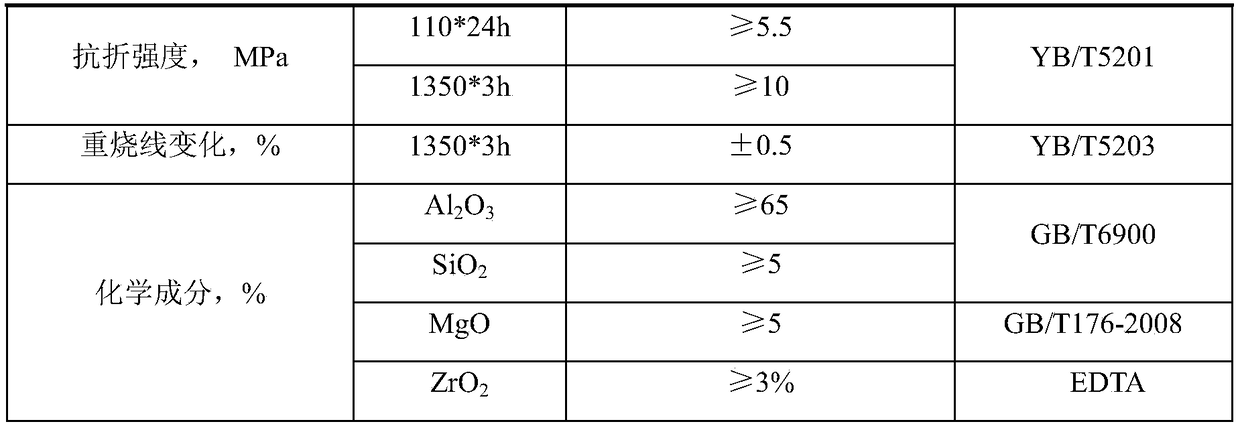

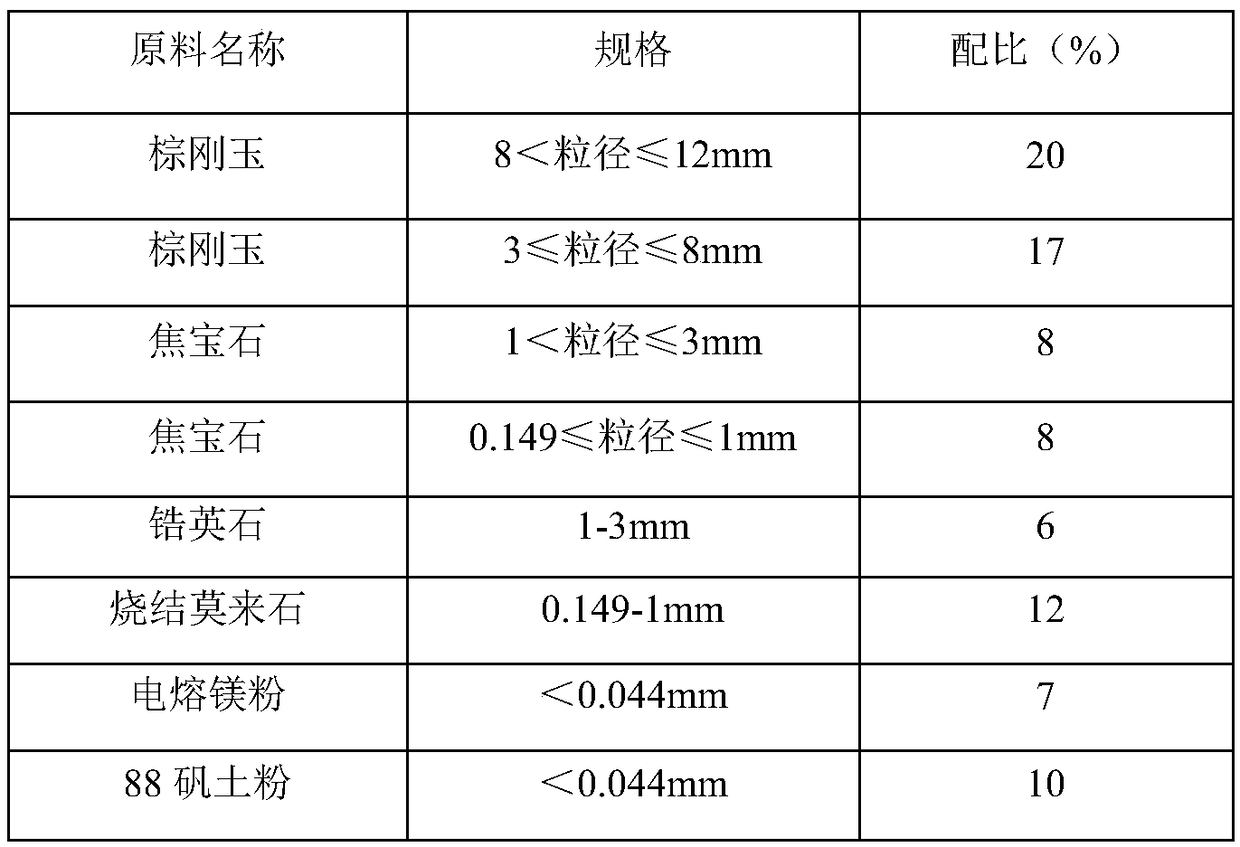

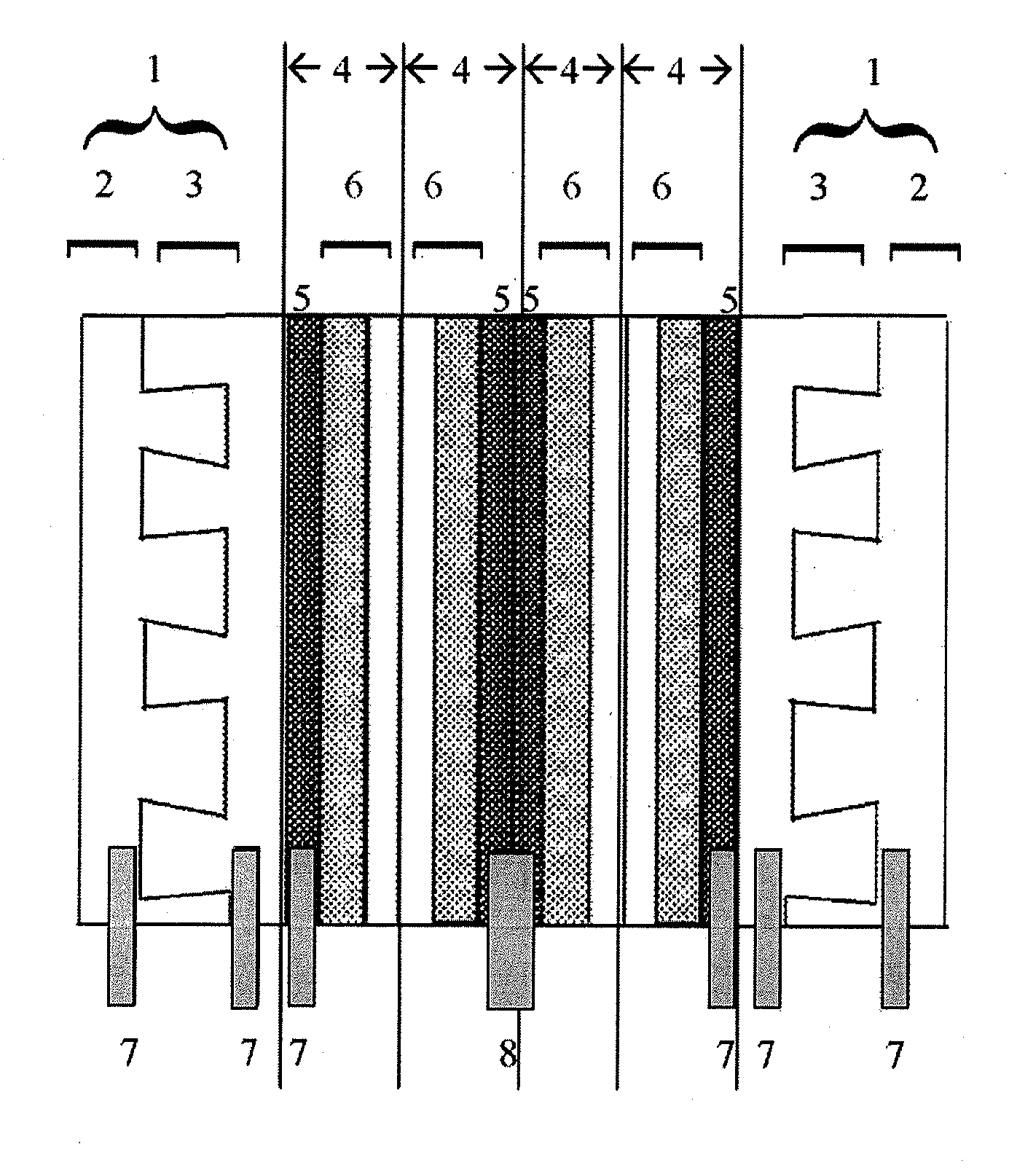

Tundish cover castable

ActiveCN109369160APouring construction performance is goodImprove thermal shock resistanceRefractoryMullite

The invention belongs to the technical field of tundish refractories, and particularly relates to a tundish cover castable. According to the tundish cover castable, the tundish cover castable is prepared from the following raw materials and components in percentage by weight: brown fused alumina, hard clay, electro-fused magnesite powder, zirconite, sintered mullite, alumina powder, aluminum oxidemicro powder, silica dust powder and cement, and additionally prepared from a water reducer, explosion-proof fibers and stainless steel fibers. The tundish cover castable has the advantages of beinggood in casting construction property, excellent in thermal shock resistance, resistant to structural peeling and the like.

Owner:GANGCHENG GRP LIANGSHAN RUIHAI IND

Distortion Resistant Roofing Material

InactiveUS20100055399A1Excessive distortionRoof covering using tiles/slatesProjectorsFixed positionTalc

A roofing material, such as laminated shingles, comprising fines deposited on an upper surface of the roofing material, particularly on one or more non-weathering regions, such as on the headlap region, and / or shim layer. The fines may be deposited, for example, as a strip from about 0.5 inches to about 2.5 inches in width and extend the length of the roofing material at a fixed position from one edge of the roofing material to the opposite edge of the roofing material. The fines may comprise mica flakes, copper slag, coal slag, sand, talc, expanded clay, slate flour, powdered limestone or silica dust.

Owner:BUILDING MATERIALS INVESTMENT

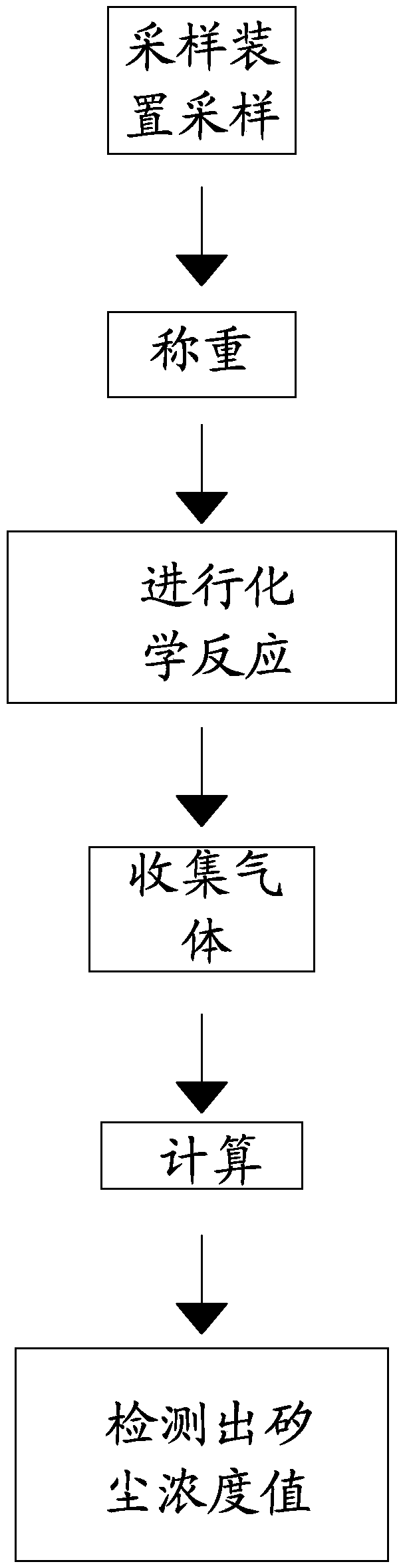

Detection method for concentration of silica dust in workplace

ActiveCN108776091AReduce contentJudging the degree of harmParticle suspension analysisChemical reactionSilicon dioxide

The invention discloses a detection method for the concentration of silica dust in a workplace. According to the invention, dust in the air is sampled and collected through a sampling device; collected dust is weighed and measured; a corresponding chemical reaction is performed so as to obtain the corresponding mass of silicon dioxide; then whether the dust in the air is silica dust or not is determined; and the concentration of the silica dust in the workplace is judged. Compared with the prior art, the detection method provided by the invention has the following advantages: the detection accuracy of the concentration of the silica dust is greatly improved; meanwhile, the content of the silicon dioxide in the silica dust is detected, so the current harm extent of the silica dust is more effectively judged; and the safety of a worker is protected to a greater extent.

Owner:福建拓普检测技术有限公司

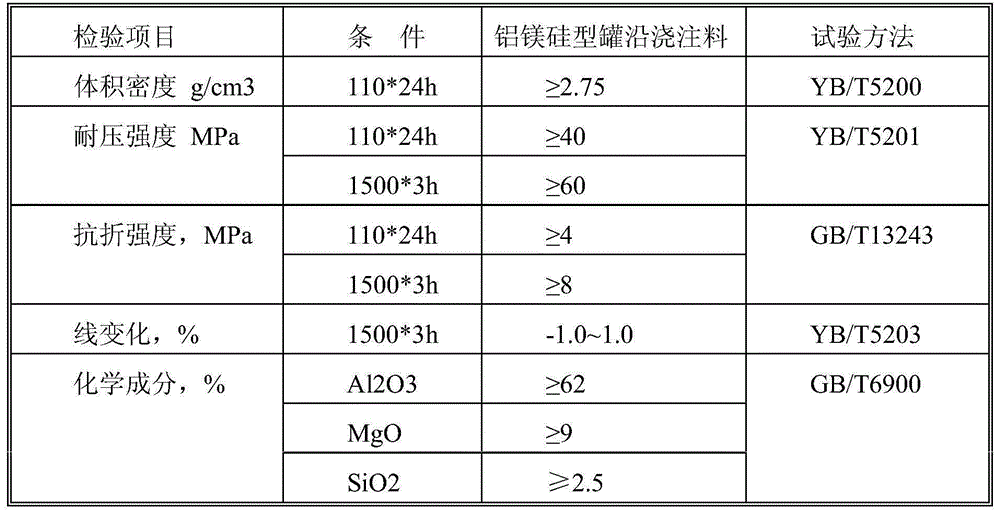

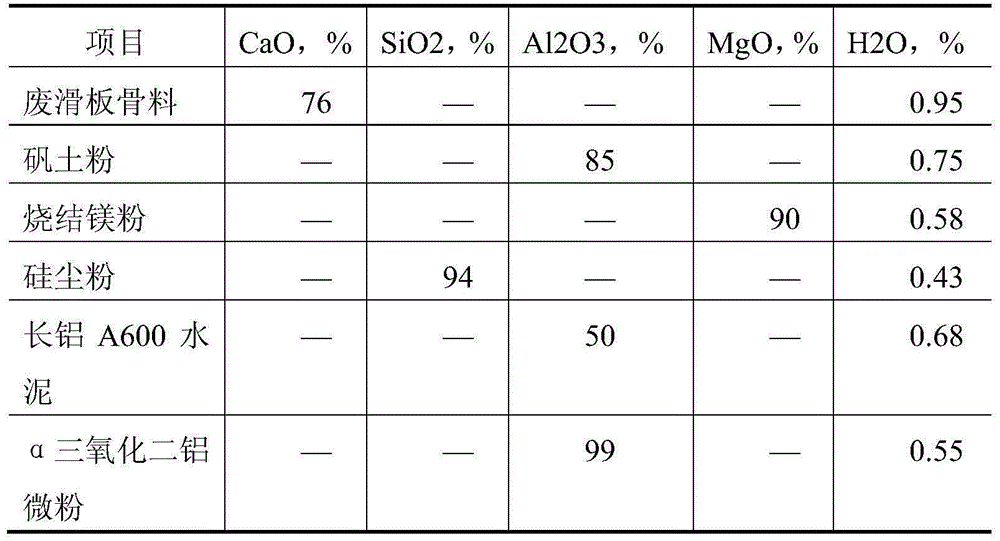

Aluminum-magnesium-silicon pot edge castable and preparation method thereof

The invention relates to the field of steel-making steel ladle refractory materials, in particular to an aluminum-magnesium-silicon pot edge castable and a preparation method thereof and provides an aluminum-magnesium-silicon pot edge castable capable of solving the technical problems of difficult steel ladle pot edge slag treatment, cracks produced in the baking process, poor heat stability in the high-temperature using process and the like of steel ladle pot edges and a preparation method. The castable is prepared from, by weight, 20-25% of 3-8 mm waste sliding plate aggregate, 45-50% of 0-3 mm waste sliding plate aggregate, 5-8% of alumina powder, 9-12% of sintered magnesium powder, 3-7% of long aluminum A600 cement, 3-5% of silica dust, 5-7% of alpha aluminum oxide micro powder, 0.015%-0.02% of explosion-proof fiber and 0.2-0.3% of admixture sodium hexametaphoshpate. The aluminum-magnesium-silicon pot edge castable can effectively solve the problems of poor steel ladle pot edge application property, cracks, low strength, poor heat stability, difficult steel ladle pot edge slag treatment and the like and is especially suitable for preparation of aluminum-magnesium-silicon pots.

Owner:PANZHIHUA GANGCHENG GROUP

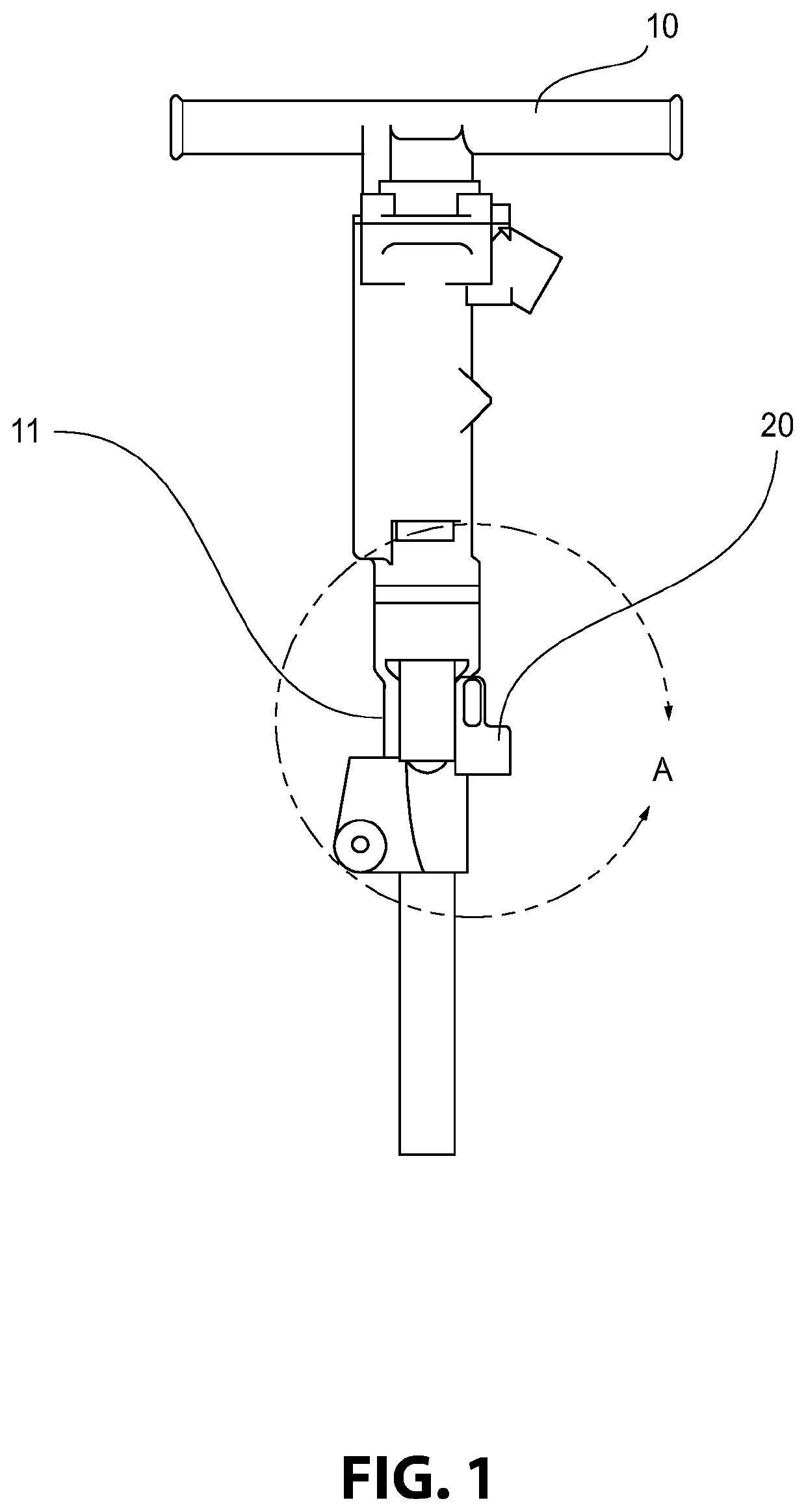

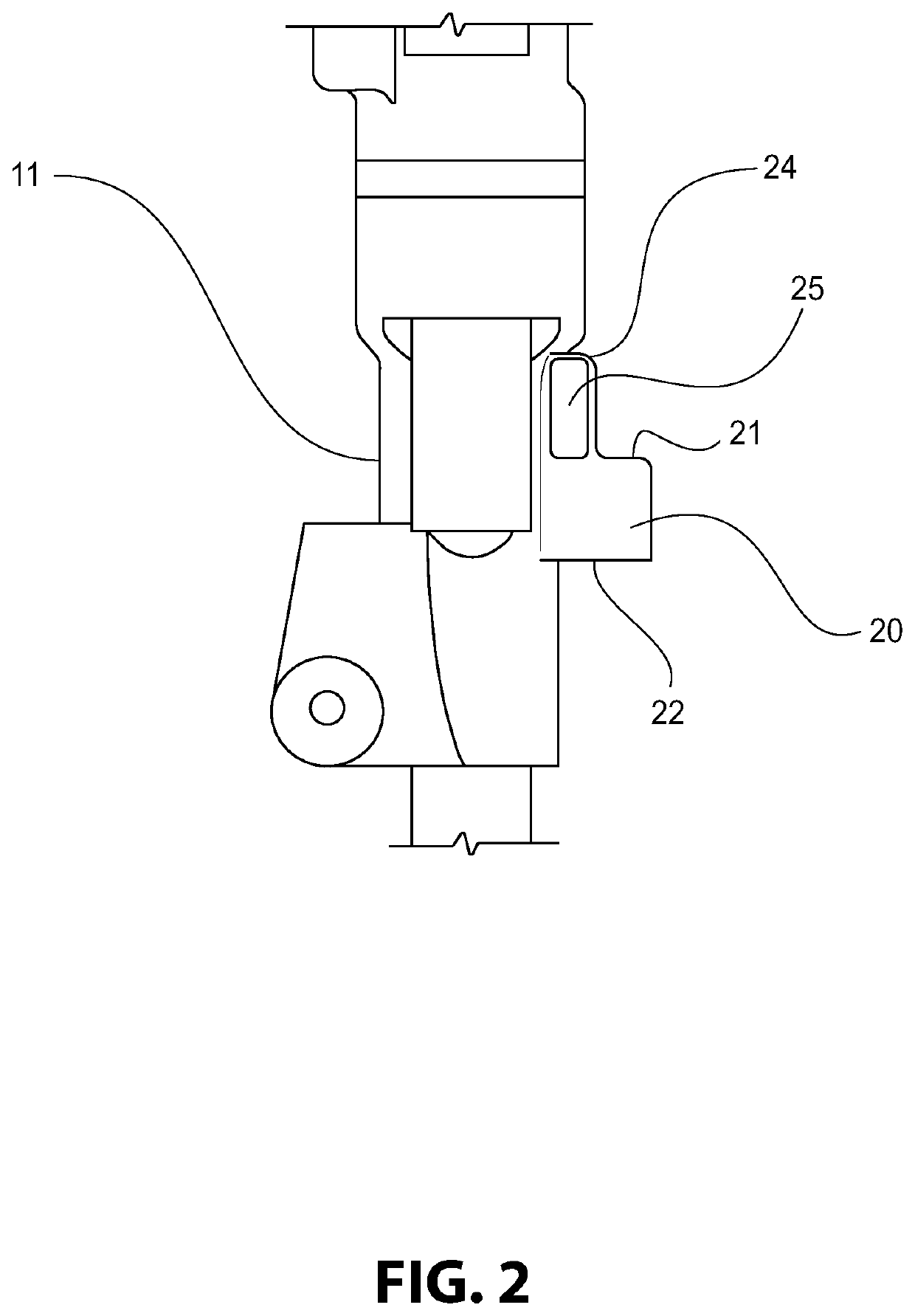

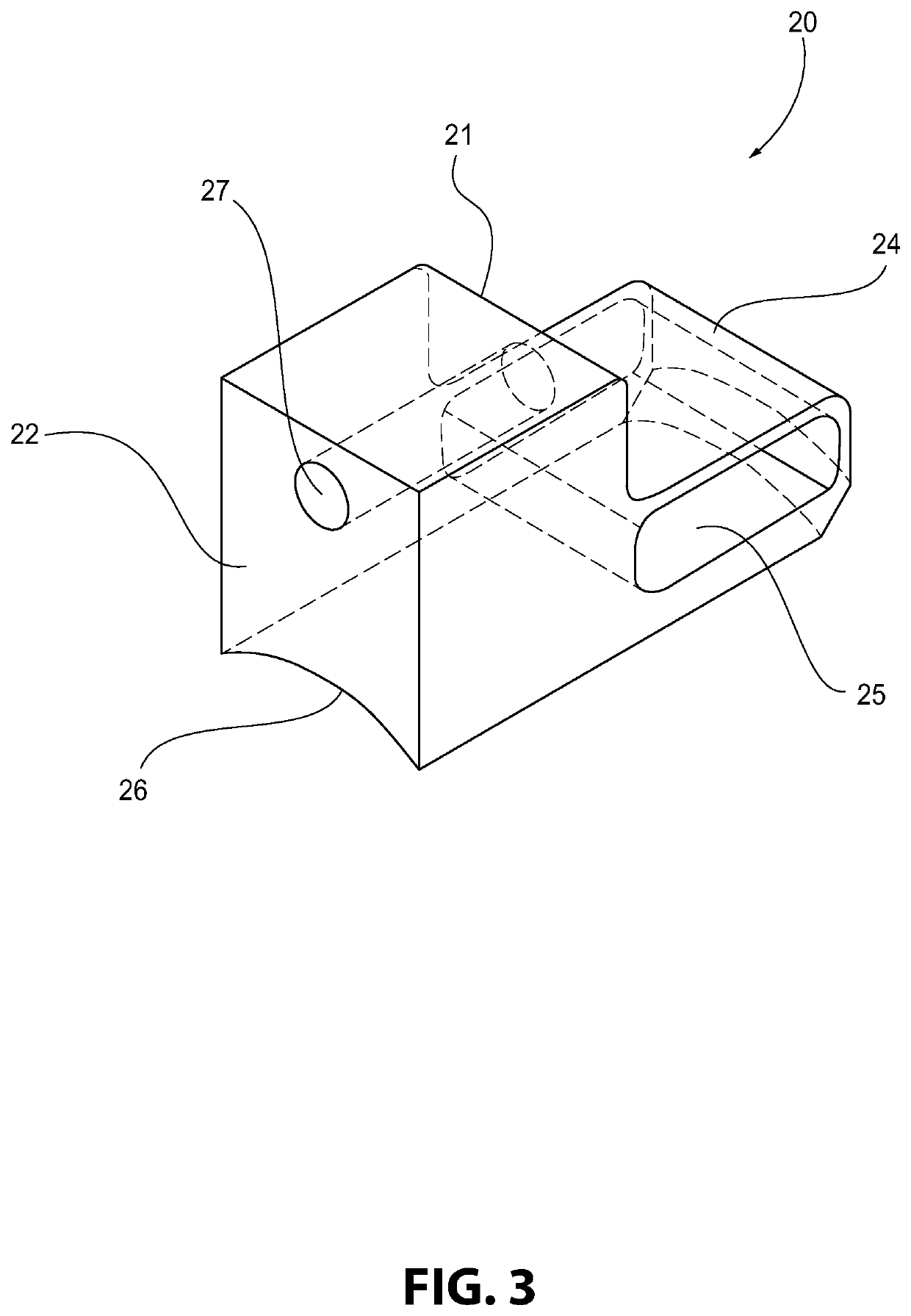

Jack hammer silica dust suppression system

ActiveUS11103988B2Easy and quick connectionFouling preventionPortable percussive toolsEngineeringMechanical engineering

A dust suppression system for a jack hammer includes a spraying device that applies a fluid spray to an area surrounding the jack hammer. The spraying device includes a bracket connected to the jack hammer and a nozzle that creates the fluid spray. The system also includes a fluid source and a pump in fluid communication with the fluid source and the spraying device. The pump directs fluid from the fluid source to the spraying device. The bracket directs fluid from the pump and the fluid source to the nozzle.

Owner:CJ&S INC

Raw material formula and method for preparing porous ceramics by using silicon micronized quartz powder of iron alloy plant

The present invention provides one kind of porous ceramic prepared with micro silica dust from ferroalloly works and its material recipe and preparation process. The material recipe includes micro silica dust and additive. The preparation process includes the steps of: mixing material and adding water to form slurry, dewatering the slurry to form powder, forming biscuit, stoving biscuit to water content lower than 1 %, sintering in a kiln for 30 min, and naturally cooling to room temperature to obtain the porous ceramic. The product has simple production process, low sintering temperature, great specific surface area, small and narrowly distributed pore size, excellent sound isolating, heat insulating, adsorbing and filtering performance.

Owner:FUZHOU UNIV

Castable for ferrovanadium smelting furnace and preparation method of cast permanent layer

The invention discloses a castable for a ferrovanadium smelting furnace and a preparation method of a cast permanent layer. The castable is prepared from components in percentage by weight as follows:67.5%-68.5% of brown fused alumina, 19.5%-20.5% of white fused alumina, 6.5%-7.5% of fused magnesia, 3% of alumina powder, 2% of silica dust powder as well as a binder, stainless steel fiber and anti-explosion fiber, wherein the binder accounts for 0.2% of the total weight of above components, the stainless steel fiber accounts for 0.5% of the total weight of the above components and the anti-explosion fiber accounts for 0.03% of the total weight of above components. The prepared cast permanent layer has higher strength and can effectively prevent corrosion and washing of high-temperature molten steel in a steelmaking ferrovanadium smelting process; the usable times through one-time casting is far higher than that of a magnesia brick permanent layer, collapse can be avoided, so that frequent replacement is not required, consumption is effectively reduced, the service life is further prolonged, the production cost is lower, moreover, the cost for replacement of the permanent layer is saved, and the production cost can be further saved.

Owner:PANZHIHUA GANGCHENG GROUP

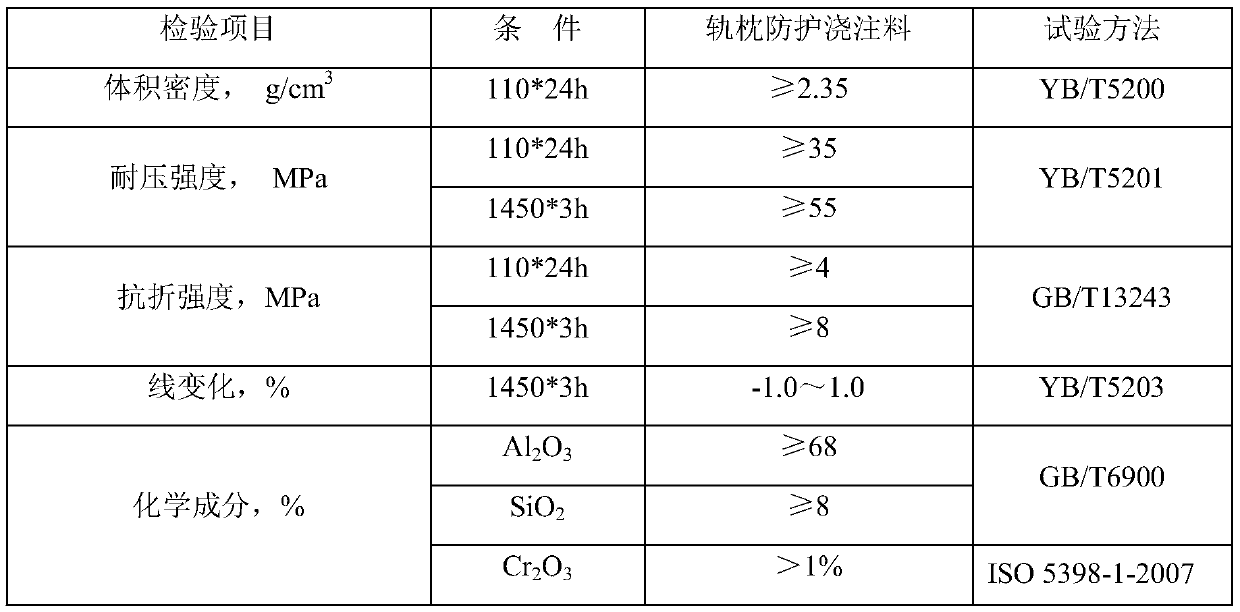

High-temperature-resistant and anti-burn sleeper protective castable

InactiveCN110790580ASolve scourSolve the phenomenon of high temperature burningSodium phosphatesSlag

The invention belongs to the technical field of refractory materials, in particular relates to high-temperature-resistant and anti-burn sleeper protective castable and aims to solve the technical problem of providing castable. Raw materials of the castable comprise the following components in percentage by weight: 18-22% of corundum slag of which the particle size is 3-8mm, 16-30% of corundum slagof which the particle size is 2-5mm, 8-20% of flint clay of which the particle size is 1-3mm, 8-13% of flint clay of which the particle size is 0.074-1mm, 9-15% of alumina powder, 1-4% of Guangxi white clay, 4-8% of aluminum oxide micro powder, 5-13% of CA-60, 1-3% of silica dust powder and 4-8% of magnesite-chrome brick powder, and sodium hexametaphosphate which accounts for 0.1-0.4% of the total weight of the raw materials, stainless steel fiber which accounts for 0.3-0.6% of the total weight of the raw materials, and anti-explosion fiber which accounts for 0.03-0.06% of the total weight ofthe raw materials are additionally added. The sleeper protective castable provided by the invention has the advantages of being good in high temperature resistance, good in impact resistance, stablein thermodynamic property, and the like.

Owner:GANGCHENG GRP LIANGSHAN RUIHAI IND

Systems and methods for controlling silica dust during hydraulic fracturing operations using an improved manifold

ActiveUS11185900B2Improve accessibilityEfficient and flexible systemFluid removalDirt cleaningThermodynamicsEngineering

A system for controlling dust during hydraulic fracturing operations includes a manifold having a plurality of ports for capturing dust when negative air pressure is applied to the manifold. A support frame positions the manifold above a piece of hydraulic fracturing equipment receiving sand from a sand source.

Owner:SIERRA DUST CONTROL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com