Low-shrinkage green UHPC (ultrahigh performance concrete) and preparation method thereof

A low-shrinkage, green technology, applied in the field of building materials, can solve problems such as structural durability problems, achieve the effects of reducing drying shrinkage, reducing engineering costs, and improving the ability to resist shrinkage and cracking at an early stage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

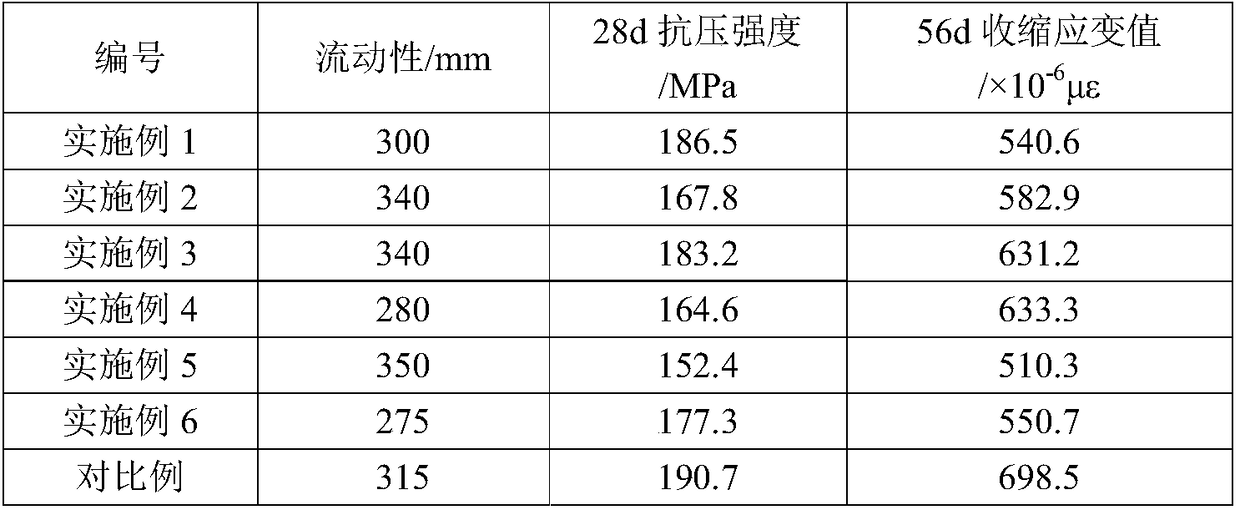

Examples

Embodiment 1

[0042] A kind of low-shrinkage green UHPC, by parts by weight, comprises the following components:

[0043] 720 parts of ordinary portland cement, 360 parts of superfine fly ash, 120 parts of silica fume, 4.8 parts of superabsorbent resin (SAP), 960 parts of aeolian sand, 239 parts of steel fiber, 60 parts of polycarboxylate superplasticizer , 180 parts of water.

[0044] Preparation:

[0045] (1) Weighing of powder, weigh cement, superfine fly ash, silica fume, SAP in proportion, put it in a standard cement mortar planetary mixer for dry mixing, stir at a slow speed for 2 minutes, and mix evenly to obtain mixed gelation Material;

[0046] (2) Add the aeolian sand evenly into the above-mentioned mixed material, and stir at a slow speed for 1 minute to obtain a homogeneous material;

[0047] (3) Add the uniformly stirred water and water reducing agent mixed solution to the above mixture to obtain a uniform mixed slurry. After stirring at a slow speed for 2 minutes, the effec...

Embodiment 2

[0050] A kind of low-shrinkage green UHPC, by parts by weight, comprises the following components:

[0051] 720 parts of ordinary portland cement, 360 parts of superfine fly ash, 120 parts of silica fume, 4.8 parts of super absorbent resin (SAP), 960 parts of aeolian sand, 239 parts of steel fiber, 60 parts of polycarboxylate superplasticizer , 192 parts of water.

[0052] Preparation:

[0053](1) Weighing of powder, weigh cement, superfine fly ash, silica fume, SAP in proportion, put it in a standard cement mortar planetary mixer for dry mixing, stir at a slow speed for 2 minutes, and mix evenly to obtain mixed gelation Material;

[0054] (2) Add the aeolian sand evenly into the above-mentioned mixed material, and stir at a slow speed for 1 minute to obtain a homogeneous material;

[0055] (3) Add the uniformly stirred water and water reducing agent mixed solution to the above mixture to obtain a uniform mixed slurry. After stirring at a slow speed for 2 minutes, the effec...

Embodiment 3

[0058] A kind of low-shrinkage green UHPC, by parts by weight, comprises the following components:

[0059] 720 parts of ordinary portland cement, 360 parts of superfine fly ash, 120 parts of silica fume, 6 parts of superabsorbent resin (SAP), 960 parts of aeolian sand, 239 parts of steel fiber, 60 parts of polycarboxylate superplasticizer , 192 parts of water.

[0060] Preparation:

[0061] (1) Weighing of powder, weigh cement, superfine fly ash, silica fume, SAP in proportion, put it in a standard cement mortar planetary mixer for dry mixing, stir at a slow speed for 2 minutes, and mix evenly to obtain mixed gelation Material;

[0062] (2) Add the aeolian sand evenly into the above-mentioned mixed material, and stir at a slow speed for 1 minute to obtain a homogeneous material;

[0063] (3) Add the uniformly stirred water and water reducing agent mixed solution to the above mixture to obtain a uniform mixed slurry. After stirring at a slow speed for 2 minutes, the effect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com