Patents

Literature

560results about How to "Good heat resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

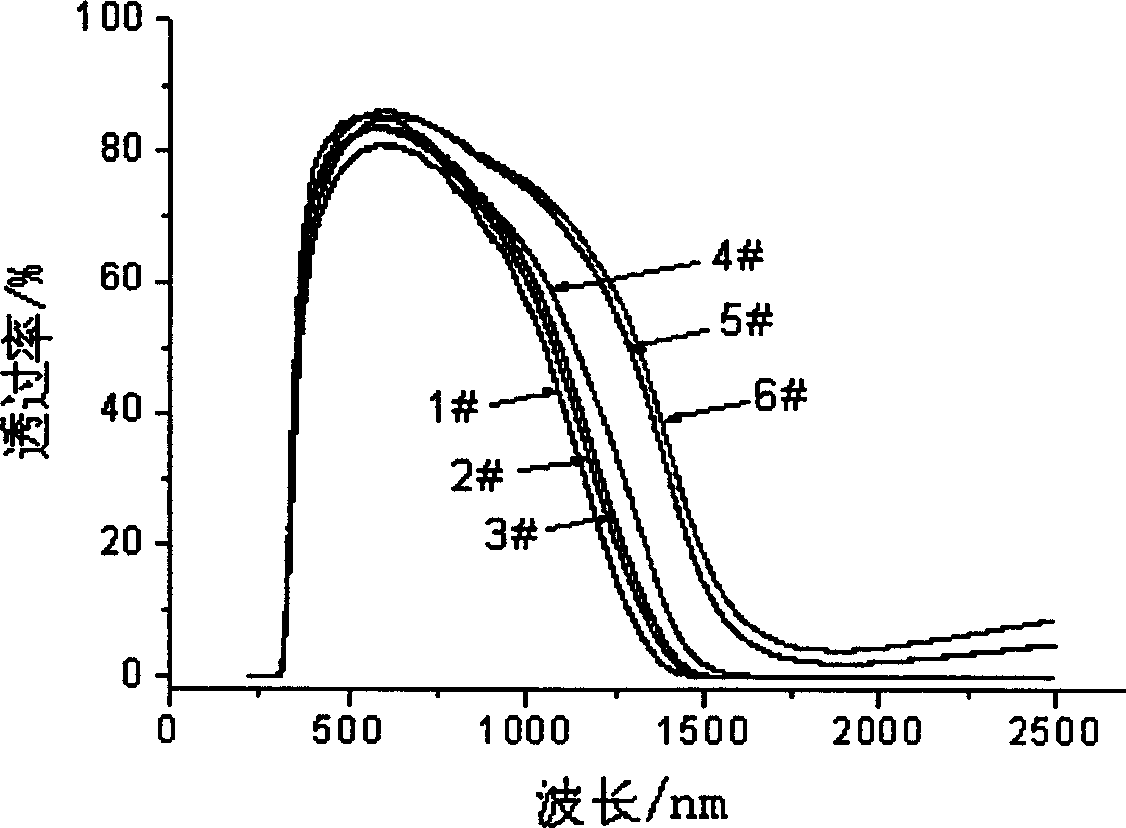

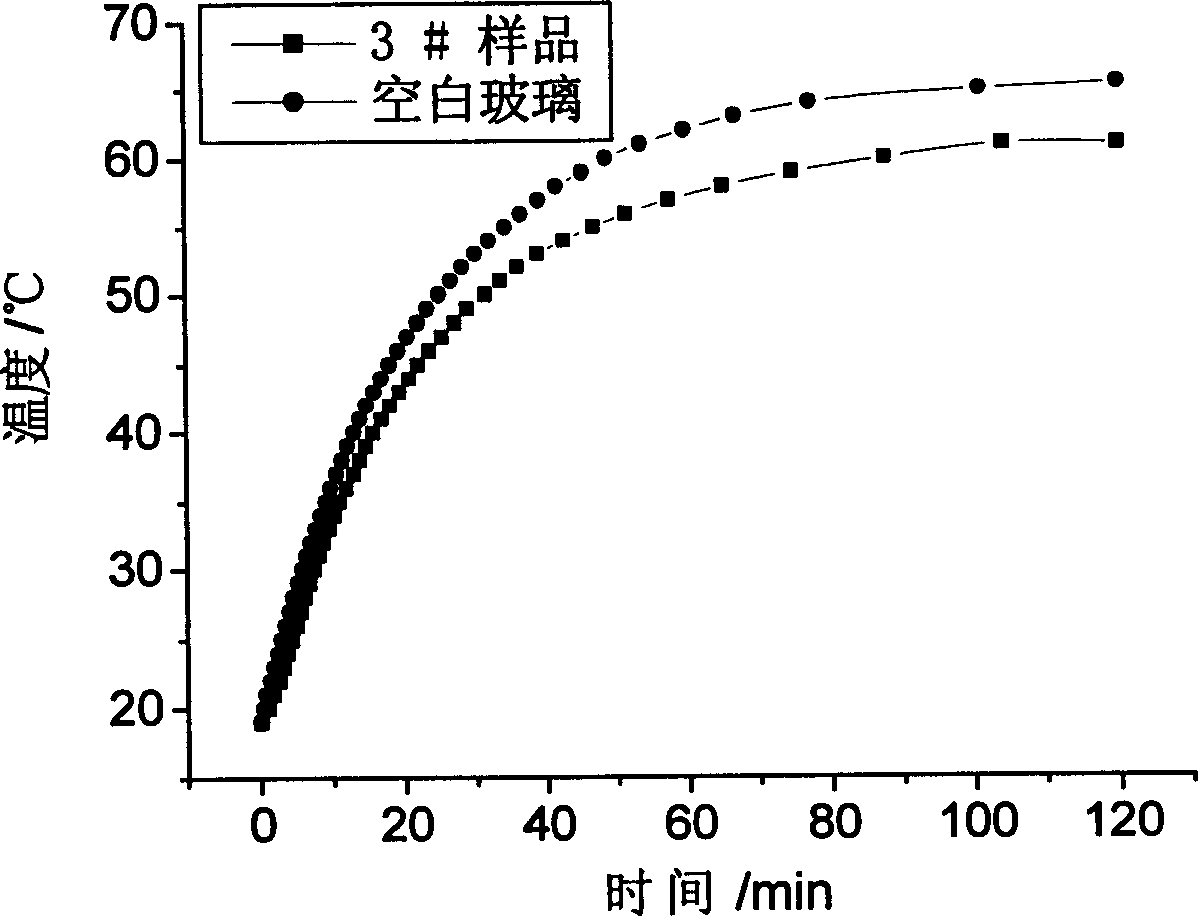

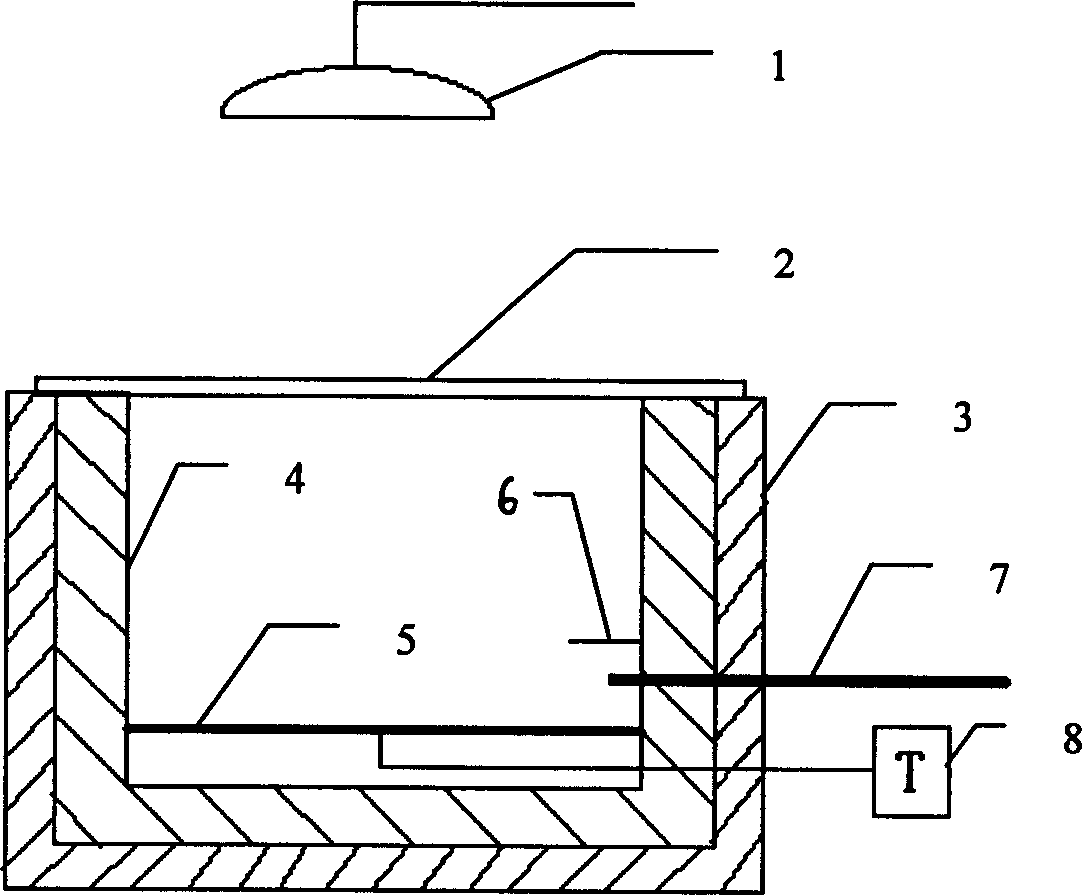

Nano transparent heat insulated composite coating material and equipment for testing effect of heat insulation for the material

InactiveCN1563231AGood heat resistanceStrong adhesionPolyurea/polyurethane coatingsThermal insulationNanometre

A nanotransparent and insulated composite coating material which can be coated on glass, transparent resin, metal and cement surface is prepared from polyurethane resin, polysiloxane resin, polyacrylic acid, nano-ITO powder, nano-ATO powder, coating material assistant and thinner. The unit for testing insulation result of the coating material is also disclosed by the present invention.

Owner:NANJING UNIV OF TECH

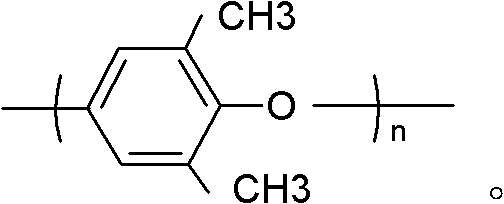

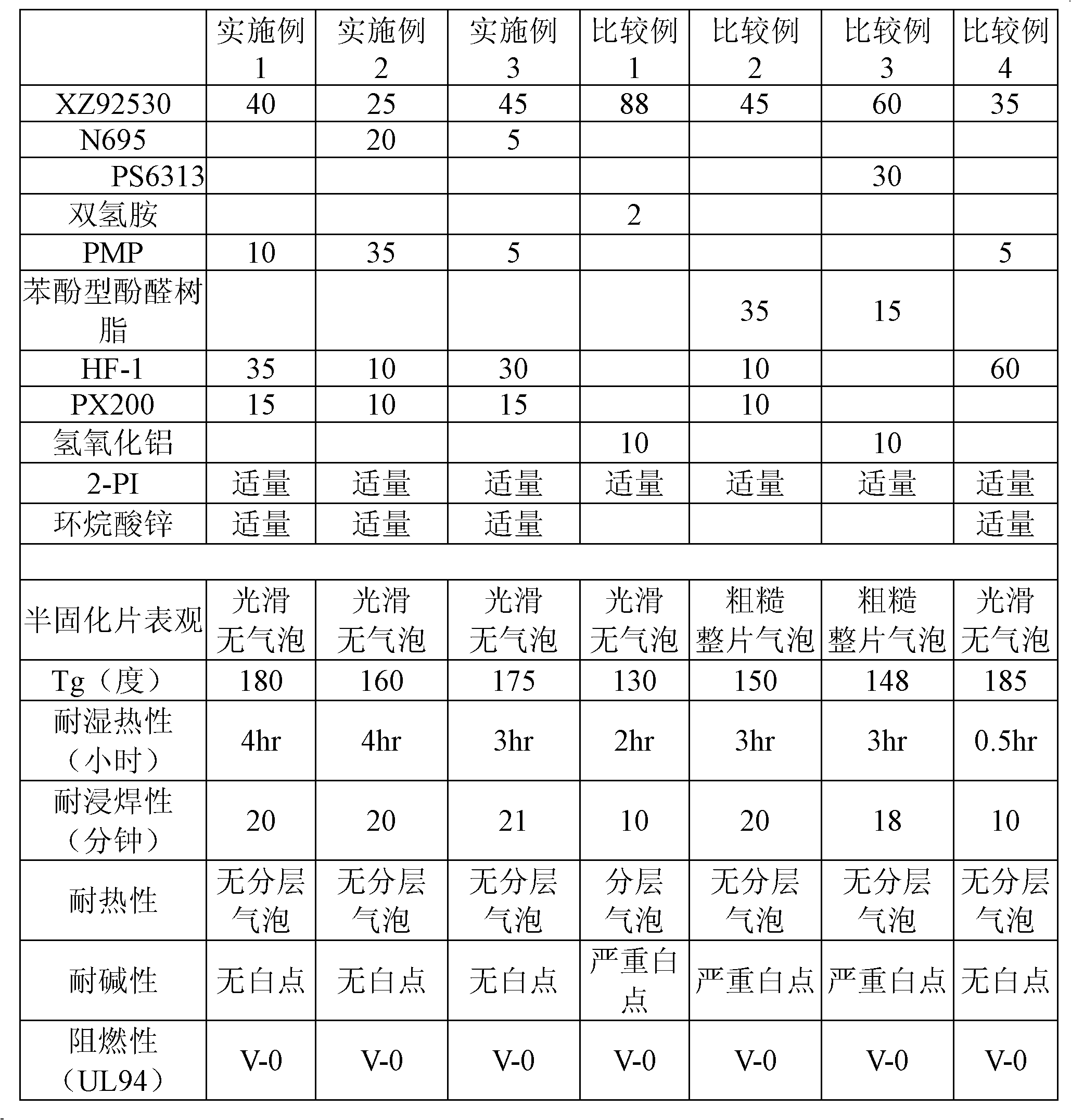

Epoxy resin composition as well as prepreg and laminated board made of same

InactiveCN102051022AGood heat resistanceLow water absorptionSynthetic resin layered productsCircuit susbtrate materialsDielectric lossChemistry

The invention relates to an epoxy resin composition as well as a prepreg and a laminated board made of the same. The epoxy resin composition comprises the following components in parts by weight: 1-50 parts of modified polyphenylene oxide resin, 30-80 parts of epoxy resin, 20-60 parts of active ester curing agent, 0-50 parts of filler and 1-20 parts of assistant. The prepreg made of the epoxy resin composition comprises a base material and the epoxy resin composition which is attached to the base material through soaking and drying. The laminated board made of the epoxy resin composition comprises a plurality of laminated prepregs, wherein each prepreg comprises a base material and the epoxy resin composition which is attached to the base material through soaking and drying. The invention has the advantages of high heat resistance, high fire retardancy, low dielectric constant, low dielectric loss, excellent high-frequency dielectric properties and the like, and is suitable to be used as a high frequency circuit substrate material.

Owner:GUANGDONG SHENGYI SCI TECH

Heat-resistant polylactic acid composite material and preparation method thereof

The invention provides a heat-resistant polylactic acid composite material and a preparation method thereof, which belong to the technical field of polymer materials. The preparation method solves the technical problems of low product biodegradability, high cost, poor mechanical performance and the like of the prior method for preparing polylactic acid crosslinking materials and polymer crosslinking materials. The heat-resistant polylactic acid composite material comprises the following components in portion by weight: 50 to 99 portions of polylactic acid resin with an oligomerization-D lactic acid content, 0.1 to 15 portions of nucleating agent and 1 to 50 portions of starch or modified starch, wherein the content of a poly-D lactic acid in the poly-lactic acid resin with the oligomerization-D lactic acid content is less than 5 weight percent. The preparation method for the composite material comprises the following steps: a, mixing and pelleting; b, injection molding; and c, heat treatment. The composite material has the advantages of high mechanical and heat-resistant performance. The preparation method for the composite material is simple in technical process, high in processability and low in cost and can realize large-scale industrial production.

Owner:ZHEJIANG HISUN BIOMATERIALS

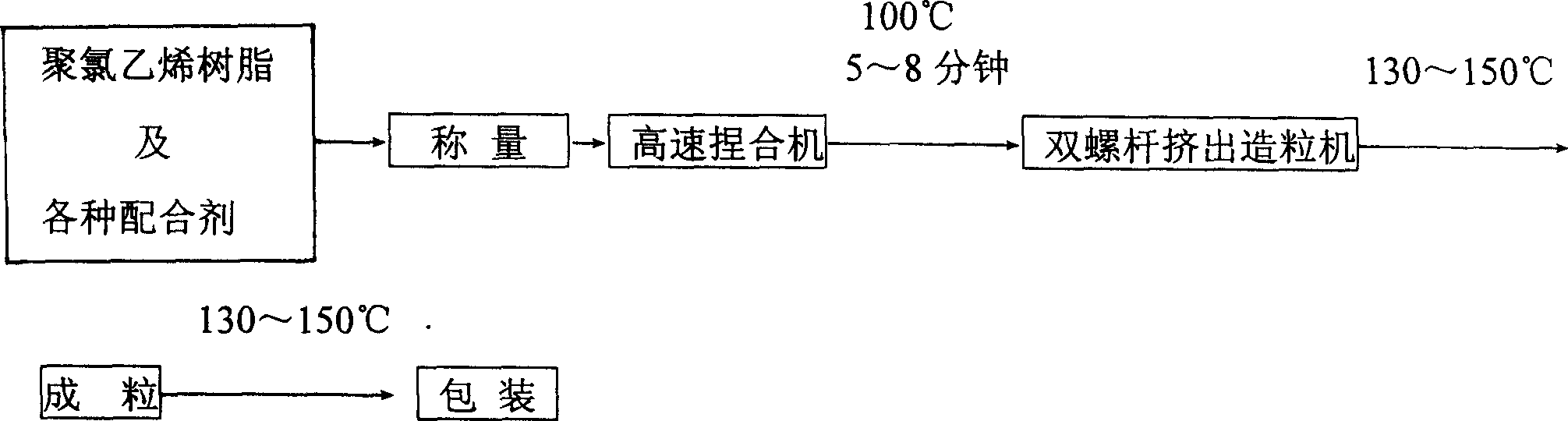

Flexible vinyl dedicated to wire and cable

ActiveCN1760258AGood heat resistanceLow volatilityPlastic/resin/waxes insulatorsTransmission linePlasticizer

A soft polyviny chloride plastic for electric transmission line or cable is proportionally prepared from PVC resin, refractory plasticizer, stabilizer, antioxidizing agent, filler and lubricant. Its advantages are high refractory class (120deg.C), long high-temp stabilizing duration (300 min), and low high-temp volatilization.

Owner:CHANGSHU ZHONGLIAN PHOTOELECTRICITY NEW STUFF +1

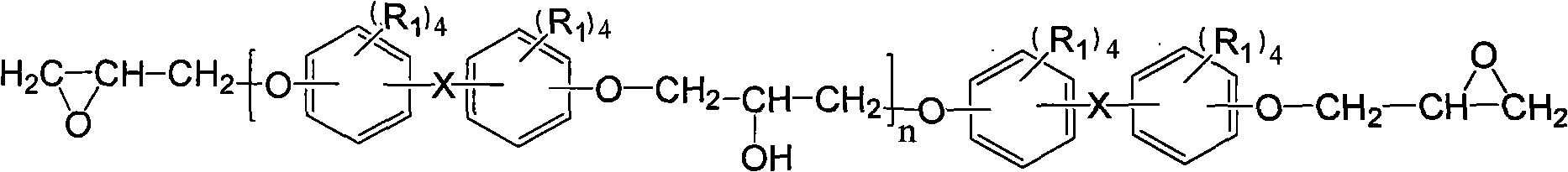

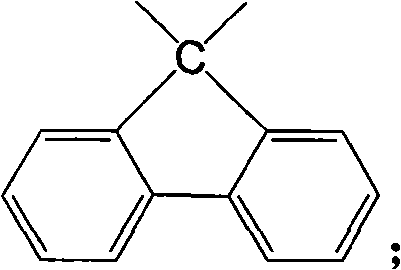

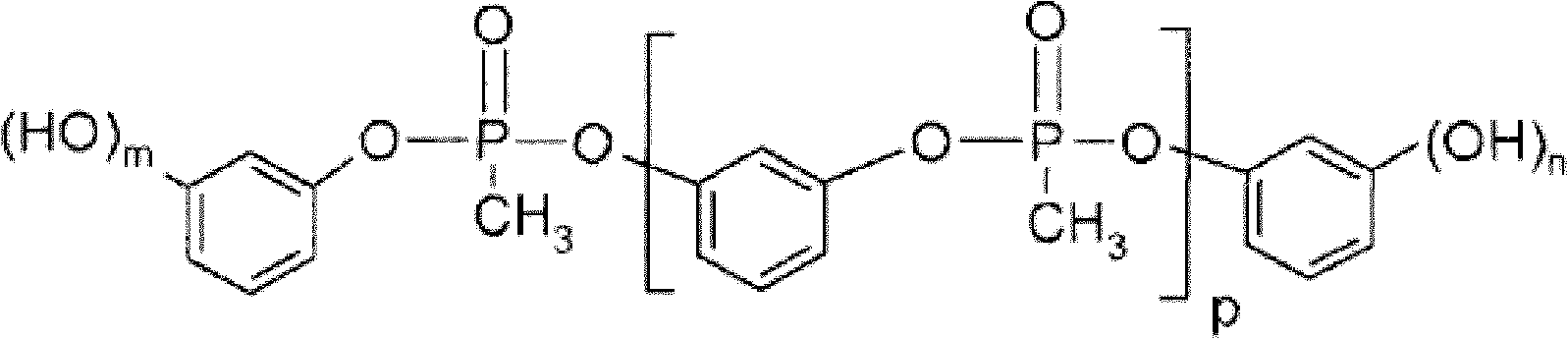

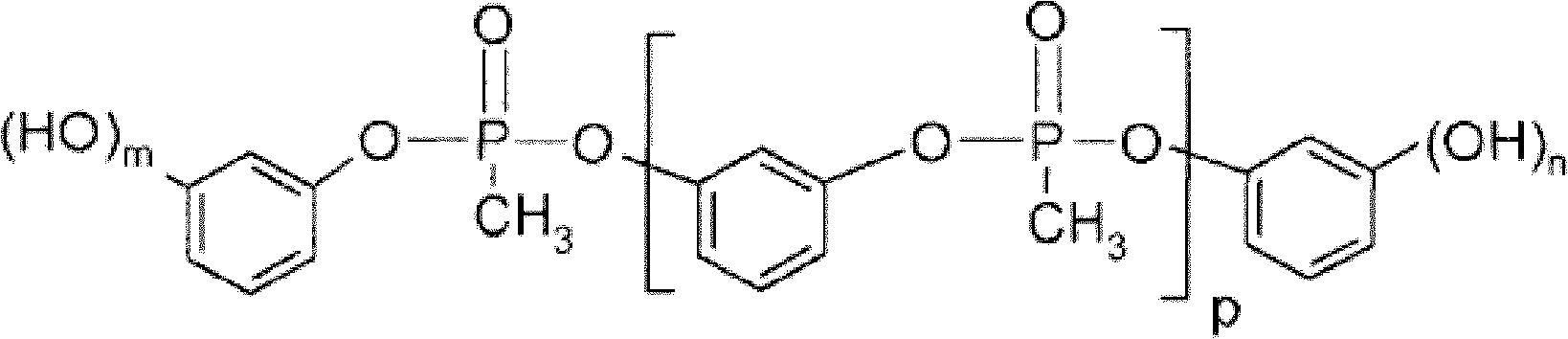

Resin composition for embedded capacitor, and dielectric layer and metal foil-clad plate manufactured by using same

InactiveCN101974205AGood heat resistanceLow water absorptionFixed capacitor electrodesFixed capacitor dielectricMetal foilChemistry

The invention relates to a resin composition for an embedded capacitor, and a dielectric layer and a metal foil-clad plate manufactured by using the same. The resin composition for the embedded capacitor comprises the following components in percentage by weight: 5 to 60 percent of epoxy resin, 5 to 45 percent of at least one of phenoxy resin and carboxyl-terminated nitrile butadiene rubber, 2 to 45 percent of biphenyl phenolic resin or naphthalene phenolic resin and 5 to 85 percent of high-dielectric constant fillers. The dielectric layer manufactured by using the resin composition for the embedded capacitor is a resin sheet or resin composite metal foil; the resin sheet comprises a carrier film and the resin composition for the embedded capacitor coated on the carrier film; and the resin composite metal foil comprises metal foil and the resin composition for the embedded capacitor, which is coated on the metal foil.

Owner:GUANGDONG SHENGYI SCI TECH

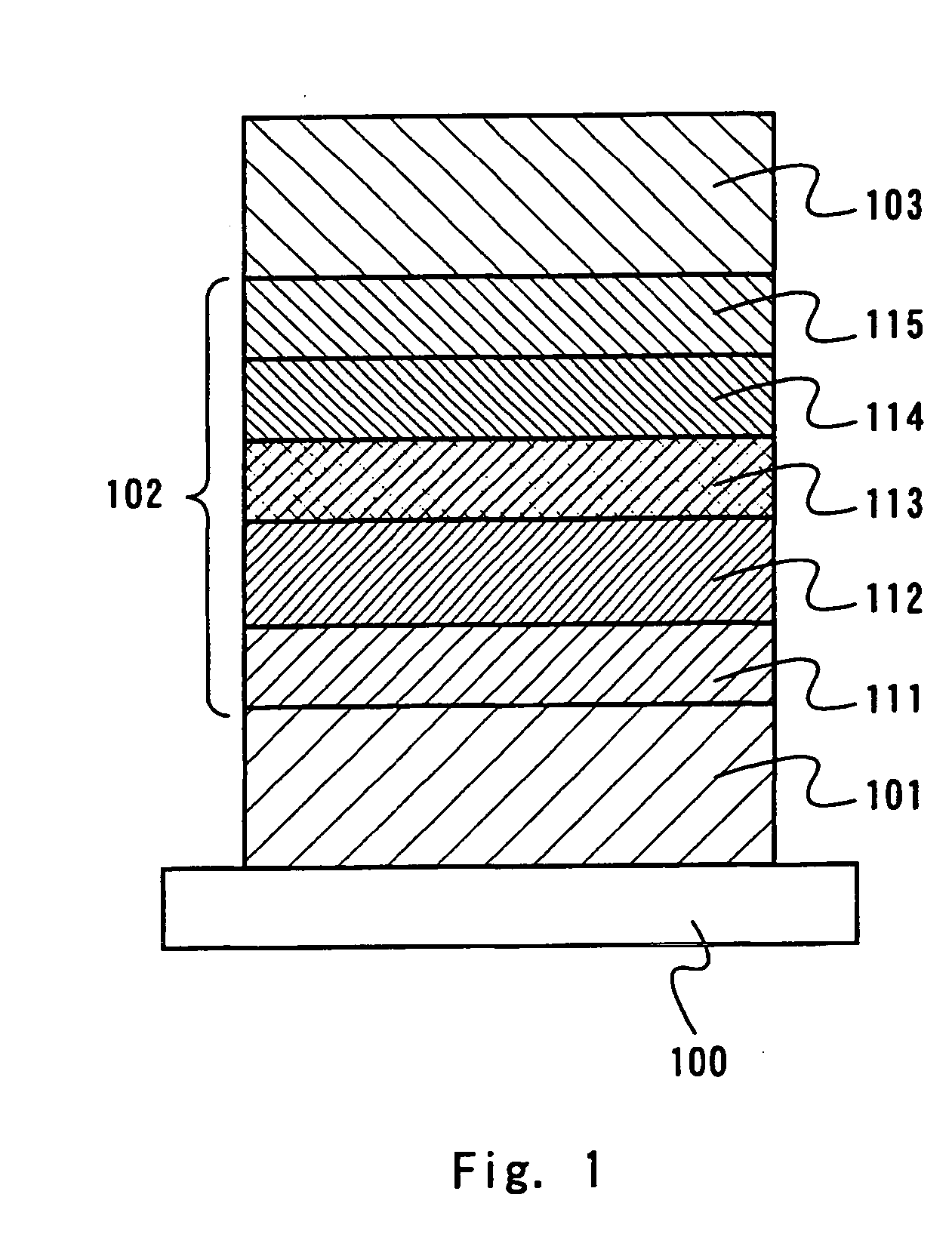

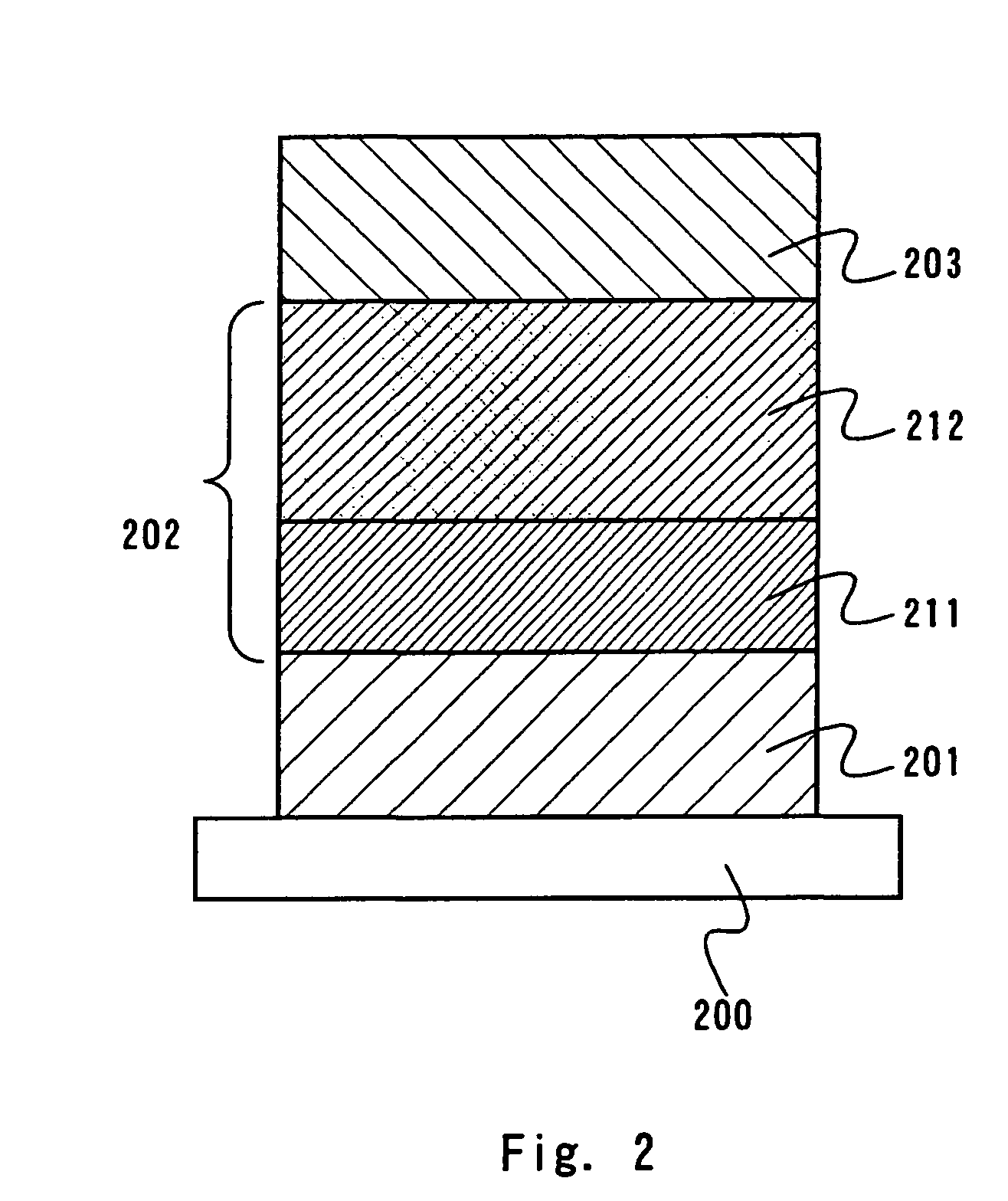

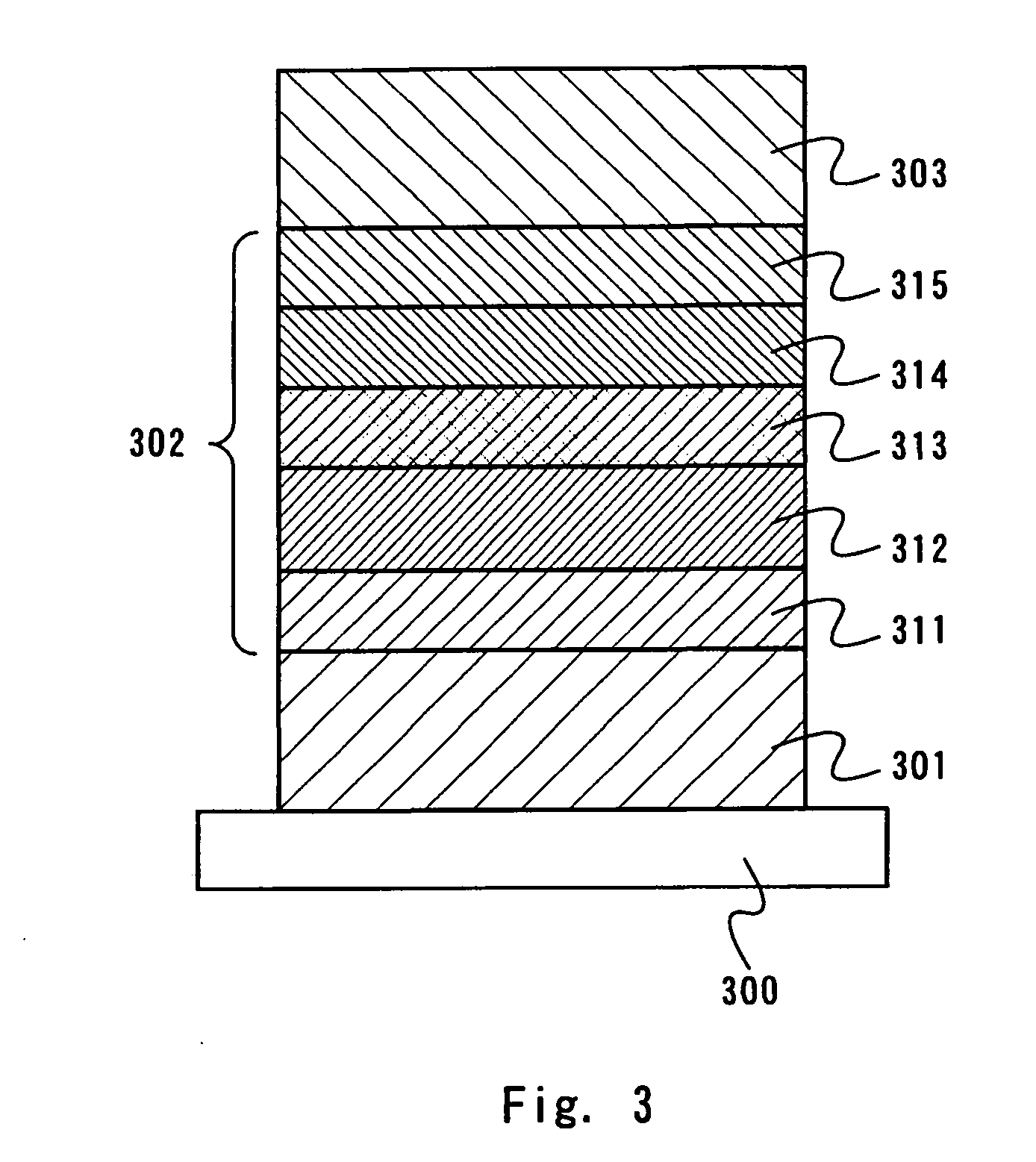

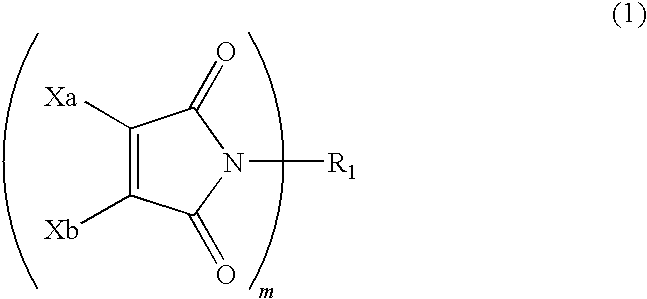

Organometal complex and light-emitting element using the same

ActiveUS20050242715A1Low power consumptionGood heat resistanceGroup 5/15 element organic compoundsSolid-state devicesHalogenAryl

An organometallic complex according to the present invention comprises a structure represented by the following general formula (1). In the formula, R1 to R5 are any one selected from the group consisting of hydrogen, a halogen element, an acyl group, an alkyl group, an alkoxyl group, an aryl group, a cyano group, and a heterocyclic group, Ar is an aryl group having an electron-withdrawing group or a heterocyclic group having electron-drawing group, and M is an element of Group 9 or an element of Group 10.

Owner:SEMICON ENERGY LAB CO LTD

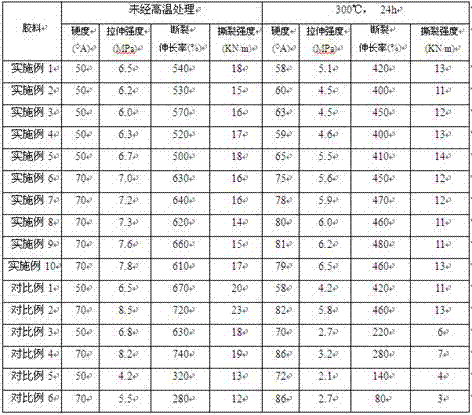

Heat-resistant high-temperature vulcanized silicone rubber and preparation method thereof

The invention relates to heat-resistant high-temperature vulcanized silicone rubber. The heat-resistant high-temperature vulcanized silicone rubber is prepared from, by weight, 100 parts of crude rubber, 10-100 parts of a reinforcing filler, 1-100 parts of a nano-scale heat-resistant filler, 1-100 parts of a micron-scale heat-resistant filler, 0.5-20 parts of a small-molecular heat-resistant agent, 3-15 parts of a structurized control agent, 1-10 parts of a surface-treated agent, 0.1-10 parts of a heat-resistant surface-treated agent and 0.1-10 parts of an internal deformable auxiliary. The heat-resistant high-temperature vulcanized silicone rubber is suitable for multiple product molding processes of mold pressing, extruding, injecting and the like, and high-temperature working devices of various shapes can be molded; the product is good in heat-resistant effect after vulcanization, hardness can be adjusted by synchronous adjustment of formulas and processes, use of different environments is met, good mechanical performance in long-time high-temperature environment can be sustained, working environment is protected, and stable operation of equipment is maintained.

Owner:浙江恒业成有机硅有限公司

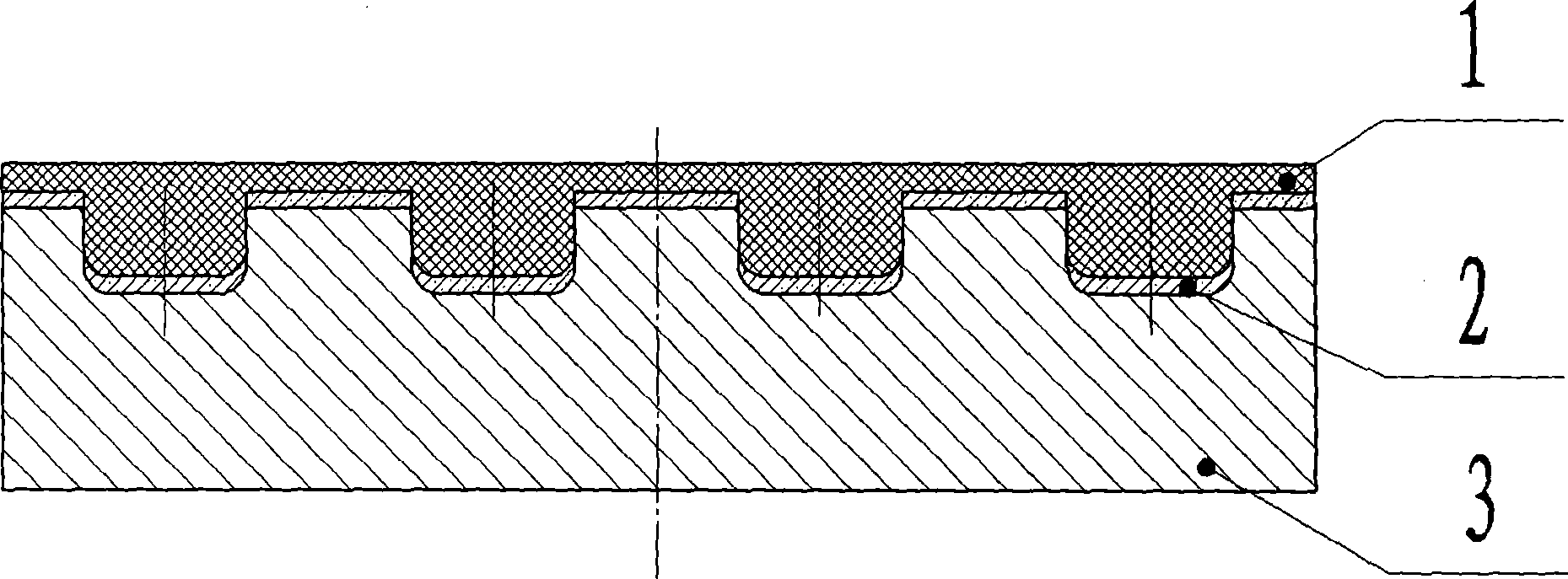

Metal and plastic composite self-lubricating material and preparation method thereof

ActiveCN101544080AHigh bonding strengthGood heat resistanceLiquid surface applicatorsLaminationThioetherPolyether ether ketone

The invention discloses a metal and plastic composite self-lubricating material and a preparation method thereof. The metal and plastic composite self-lubricating material comprises a metal layer, a plastic binding layer and a plastic working layer, wherein the plastic binding layer binds the metal layer and the plastic working layer together through a chemical bond of a molecule; one part of theplastic working layer is embedded in a drop pit of the metal layer; the plastic working layer includes the material components according to the mass percent as follows: 60-90 of polyether-ether-ketone, 5-20 of polyfluortetraethylene, 7 of graphite, 1 of MoS2 and 5-10 of aluminium oxide; and the plastic binding layer includes the material components according to the mass percent as follows: 70-90 of polyether-ether-ketone, 5-20 of polyphenyl thioether and 5-10 of aluminium oxide. By adding the plastic binding layer between the metal layer and the plastic working layer, the invention further improves the binding strength of metal and plastic, has favorable heat resistance and resistance to chemical corrosion, no environment pollution, low noise and energy saving; in addition, the usage temperature is -60 DEG C to 250 DEG C, the friction coefficient is 0.08-0.32 and the wear rate is 0.8-3.5*10<-6>mm<3> / N. m.

Owner:JIANGSU UNIV

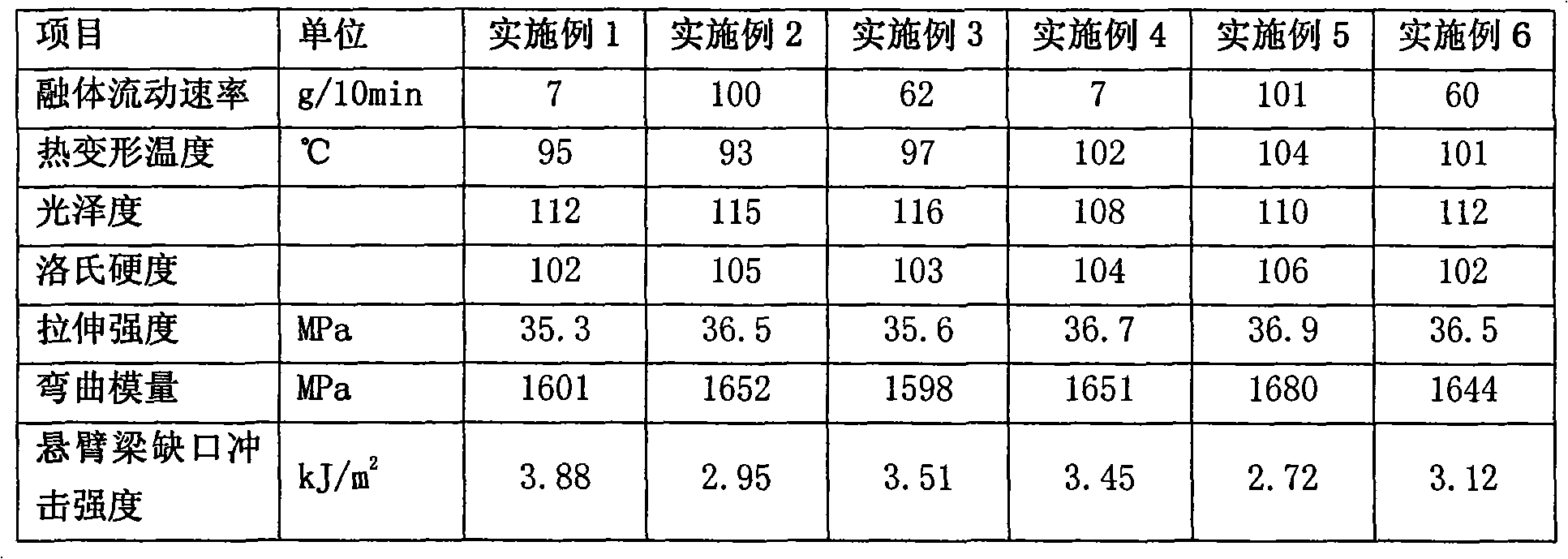

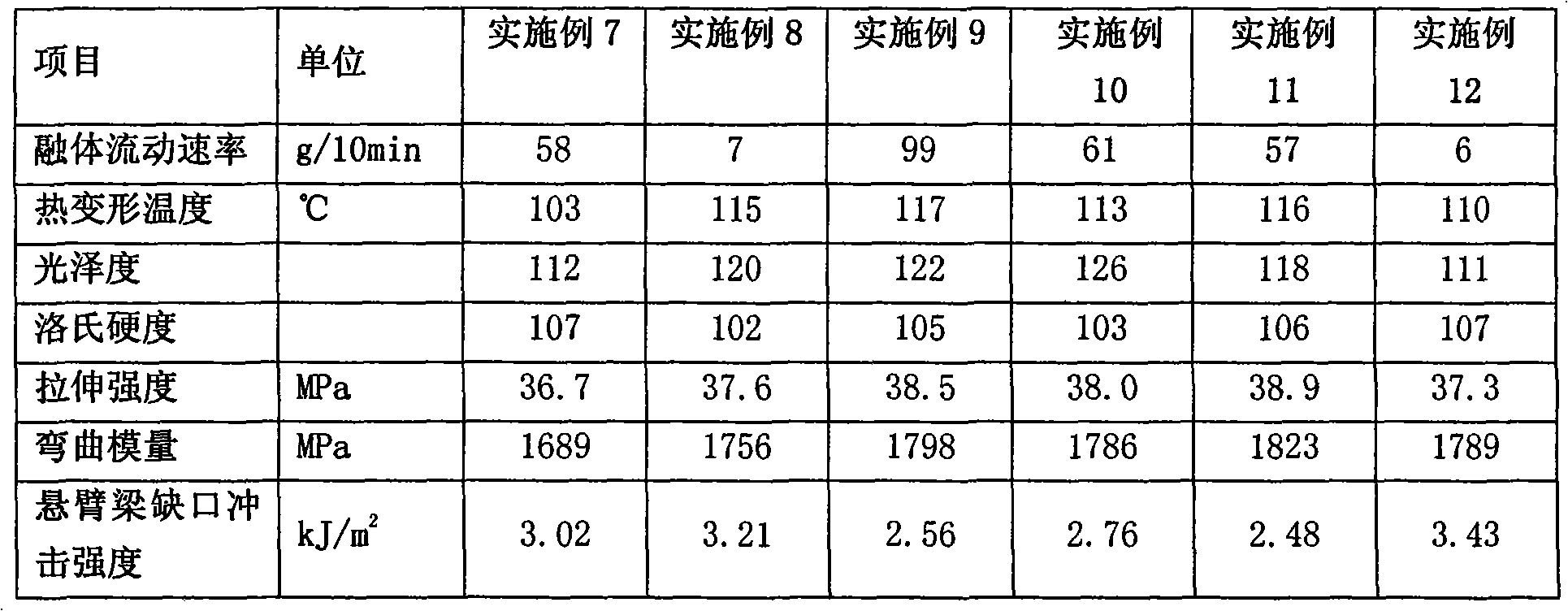

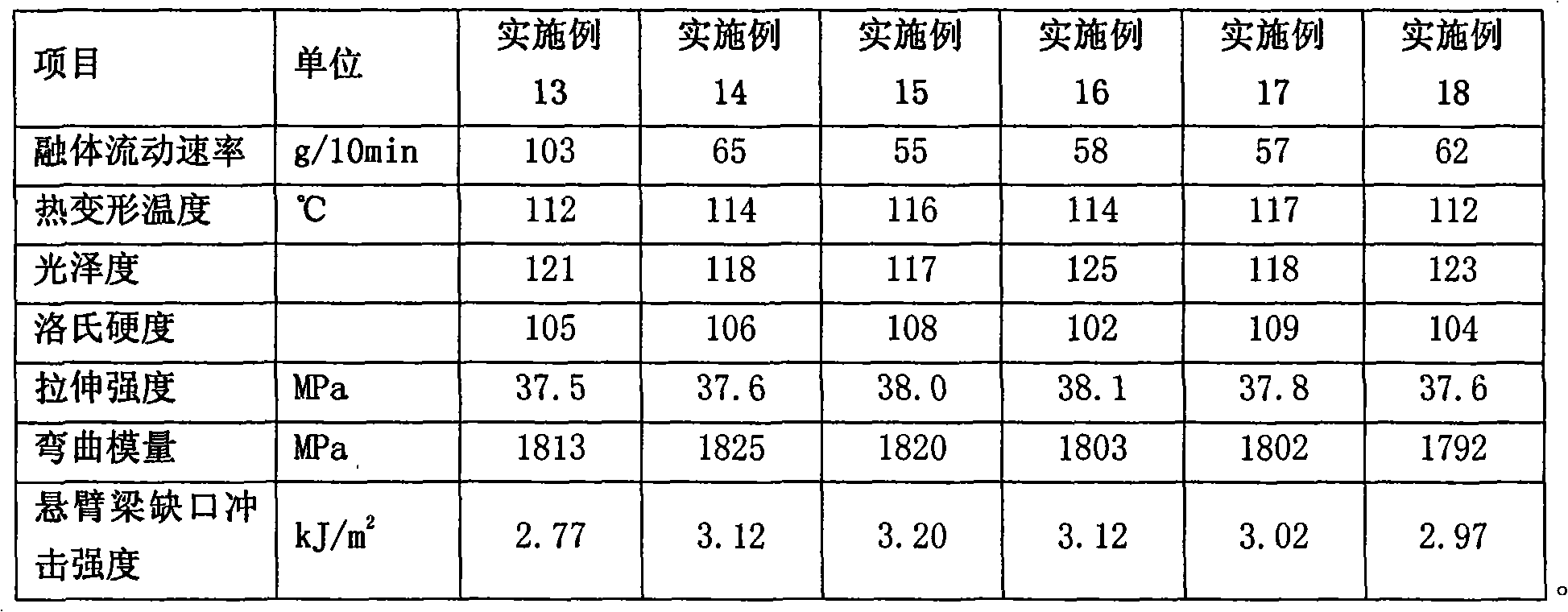

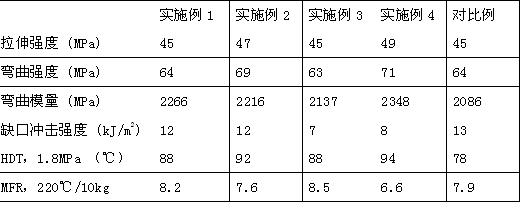

Controllable rheological high-gloss polypropylene resin and preparation method thereof

The invention discloses a controllable rheological high-gloss polypropylene resin which is composed of the following components in parts by weight: 100 parts of homo polypropylene as a base material, 0.1-0.25 part of processing agent, 0.15-0.2 part of nucleating agent, 0-1.5 parts of hardness regulator, 0.05-0.1 part of glossiness regulator and 1-12 parts of oxide master batch, wherein the number-average molar mass of the homo polypropylene is 61235-65210; the oxide master batch is formed by mixing 100 parts of homo polypropylene and 0.1-0.65 part of peroxide. Thus, the rheological behaviour of the resin can be changed by regulating the additive amount of the peroxide master batch. The controllable rheological high-gloss polypropylene resin of the invention has favourable heat resistance (heat distortion temperature is more than or equal to 110 DEG C) and higher rigidity (bending modulus is more than or equal to 1800 MPa). Because of adopting the controllable rheological technology, the invention can flexibly regulate the melt flowing rate of the material, and the material has excellent processability, heat-resistant quality and mechanical property.

Owner:CHINA PETROLEUM & CHEM CORP +1

Diaphragm, preparing method of diaphragm and lithium ion battery

ActiveCN104078633AGood heat resistanceImprove heat resistanceCell seperators/membranes/diaphragms/spacersSecondary cellsCeramic particlePolymer substrate

The invention provides a diaphragm, a preparing method of the diaphragm and a lithium ion battery comprising the diaphragm. The diaphragm comprises a polymer substrate and slurry layers positioned at the inside and on the surface of the substrate; each slurry layer comprises ceramic particles and curing resin; the curing resin is obtained through performing cross-linking and curing reaction on curing agents or initiating agents positioned inside the substrate and cross-linking resin positioned in the slurry layers; the high-temperature-resistant performance of the diaphragm is excellent; a heat-resistant layer cannot easily fall; and the winding, the preparation and the practical application are easier.

Owner:BYD CO LTD

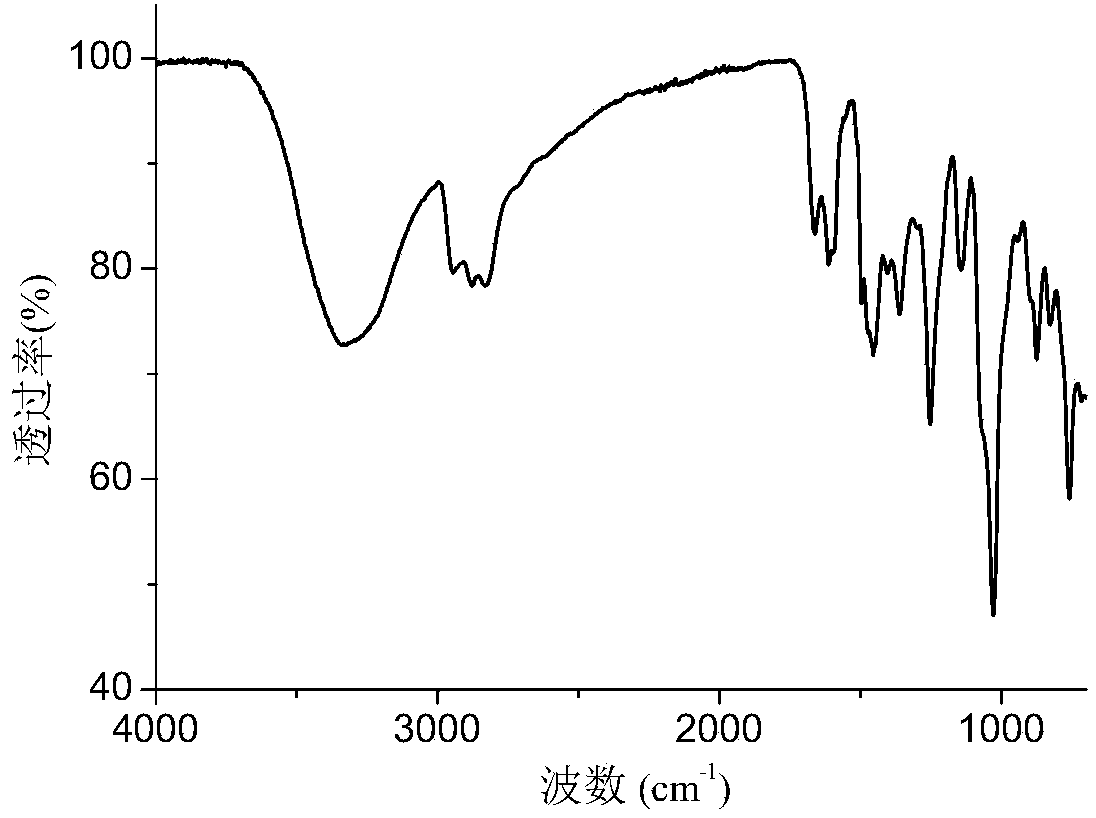

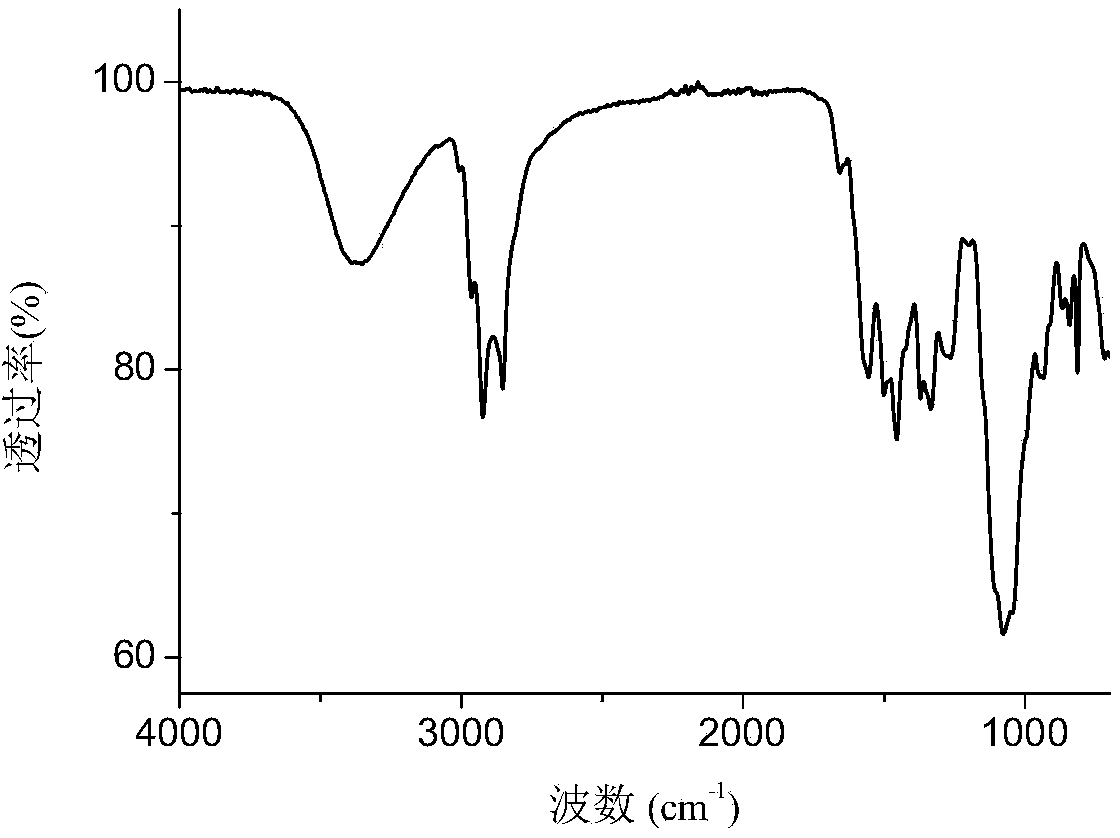

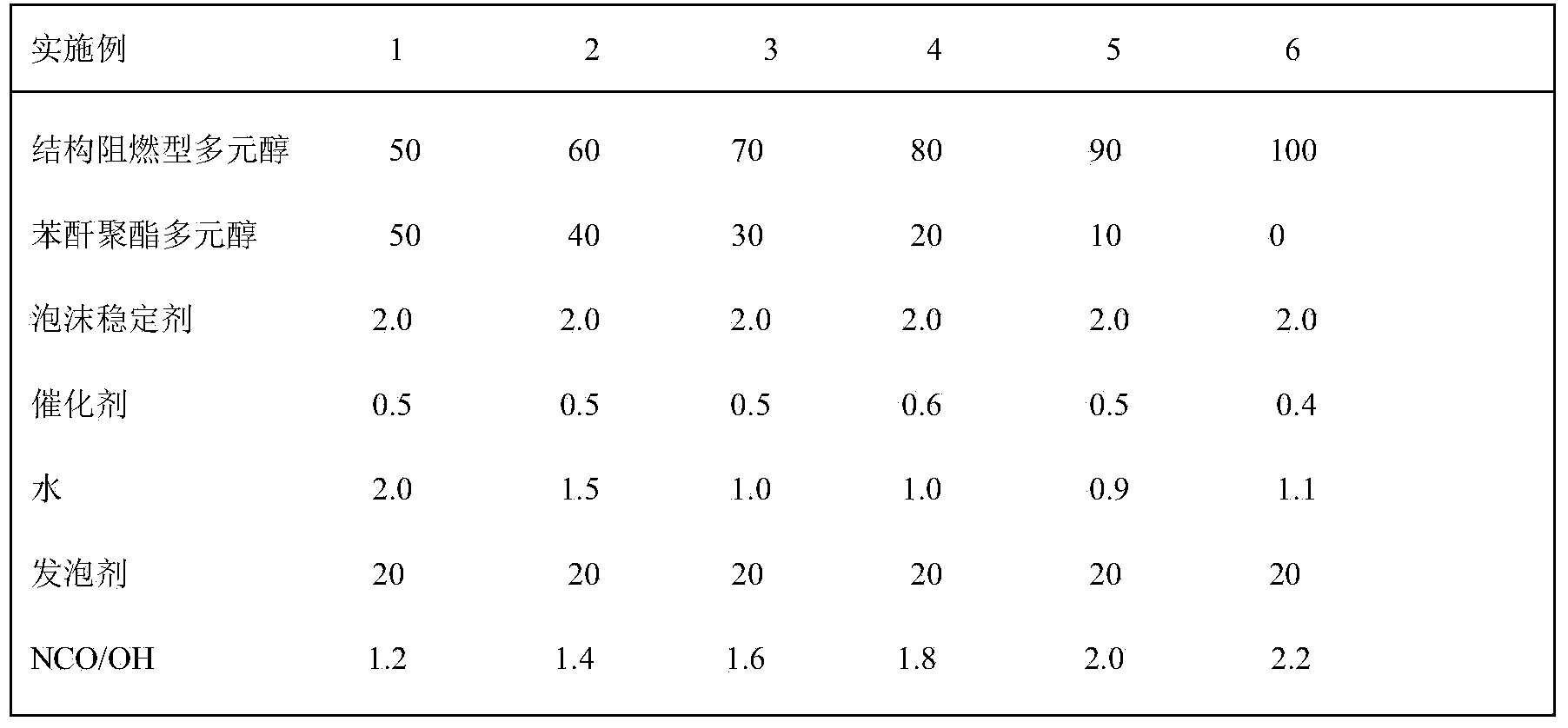

Biomass base structure flame retardant polyol and preparation method and application thereof

The invention discloses biomass base structure flame retardant polyol and a preparation method and an application thereof. An intermediate is obtained by utilizing the Mannich reaction of biomass anacardol, diethanolamine, melamine or urea, and formaldehyde, and the biomass base structure flame retardant polyol can be prepared through further alkoxylation with epoxy ethane and epoxy propane, with a hydroxyl value of 200-500mg / gKOH, moisture being less than or equal to 1.0%, and viscosity of 2000-10000mPa.s (25 DEG C), and the biomass base structure flame retardant polyol is applied in polyurethane foam as a polyol component. According to the biomass base structure flame retardant polyol as well as the preparation method and the application, an intermediate process does not need separation, the cost is low, the process is easy, and the prepared polyurethane foam is good in flame retardance, has the advantages that a product does not drip liquid, the shape is kept, the smoke density is low and the like, and can be used in construction, heat preservation and some special fields.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Heat resistant ASA (Acrylonitrile-Styrene-Acrylic ester) resin composition and preparation method thereof

InactiveCN102030958AGood heat resistanceOvercome the disadvantage of low heat distortion temperatureComposite materialPolymer chemistry

The invention relates to a heat resistant ASA (Acrylonitrile-Styrene-Acrylic ester) resin composition and a preparation method thereof. The ASA resin composition is prepared from ASA high rubber powder, SAN (Styrene Acrylonitrile) resin with different melt indexes, a heat resistant modifier, an inorganic additive and a proper quantity of antioxidant and light stabilizer which are sufficiently mixed and then melted, blended and extruded by a double-screw extruder at 170-240 DEG C. The prepared ASA resin composition has the advantages of high heat resistance and weather resistance and good comprehensive mechanical property and processability and is particularly suitable for auto exterior part products such as a radiator grid, an exterior mirror shell, and the like.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

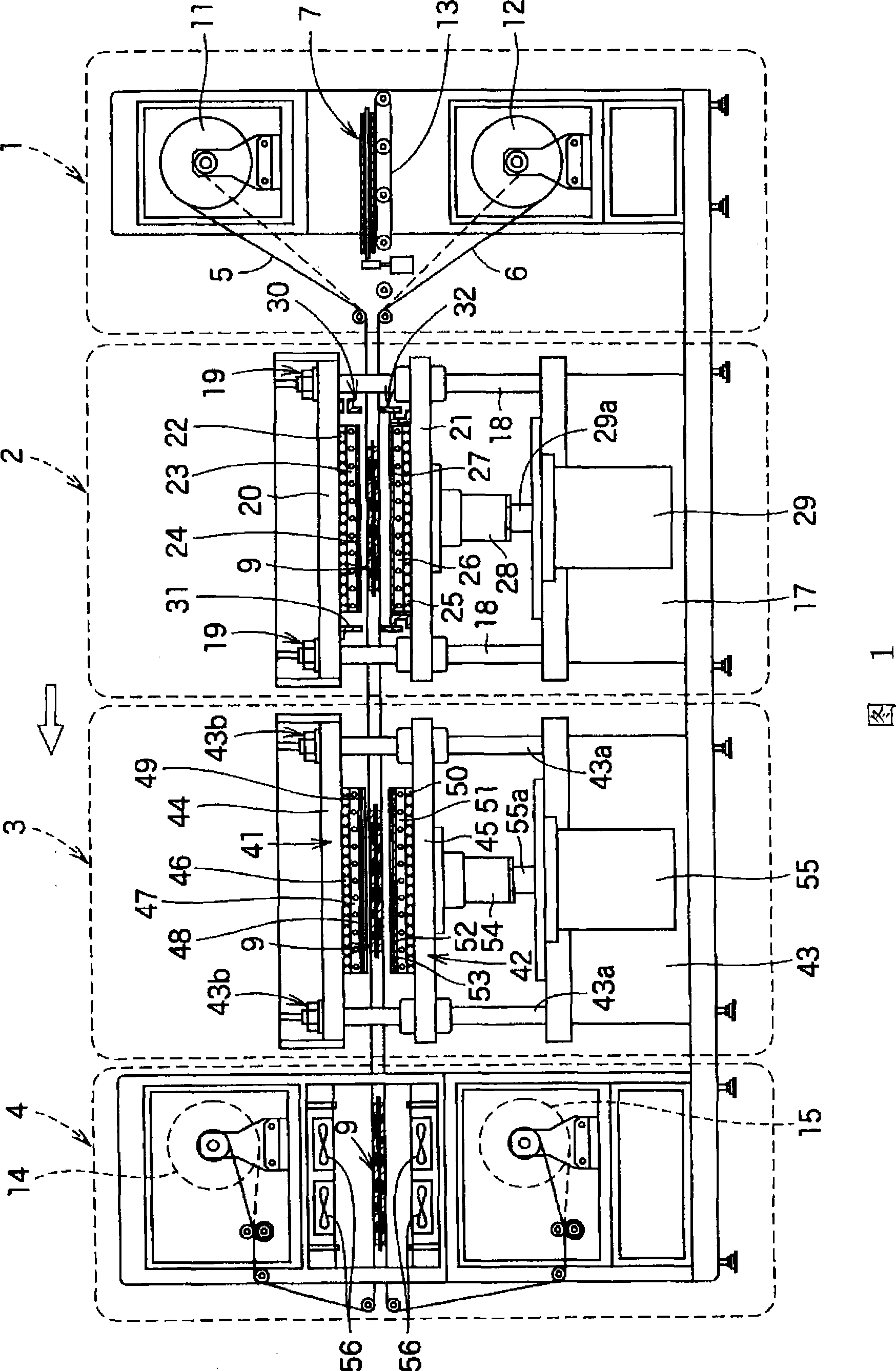

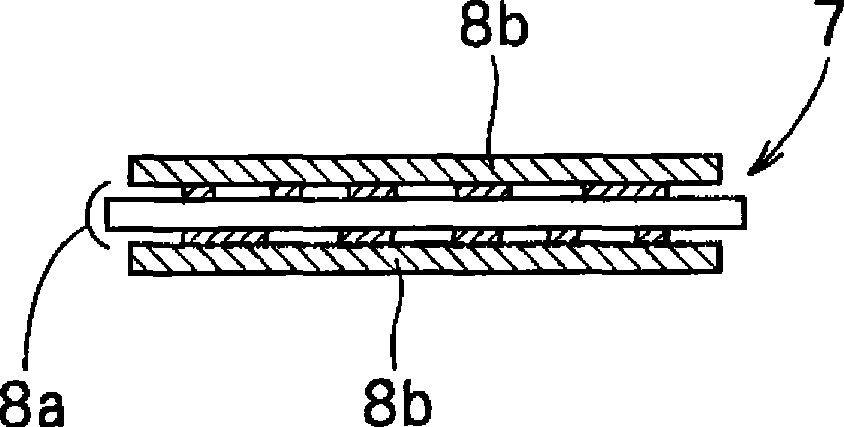

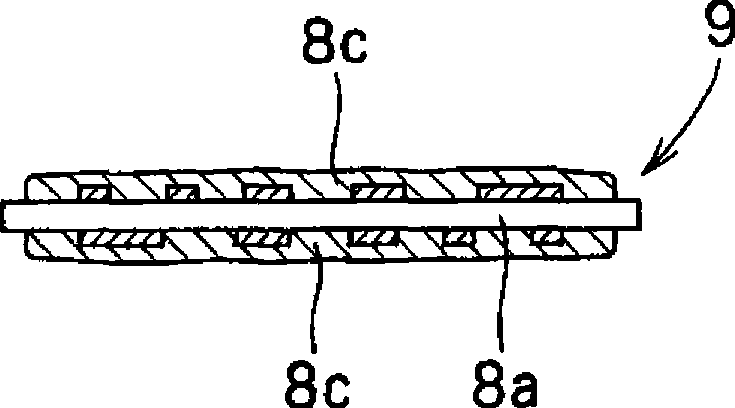

Laminating apparatus, and laminating method using it

ActiveCN101384416AGood heat resistanceImproves closeness and followabilityLamination plant layoutLayered product treatmentEngineering

Owner:NIKKO MATERIALS CO LTD

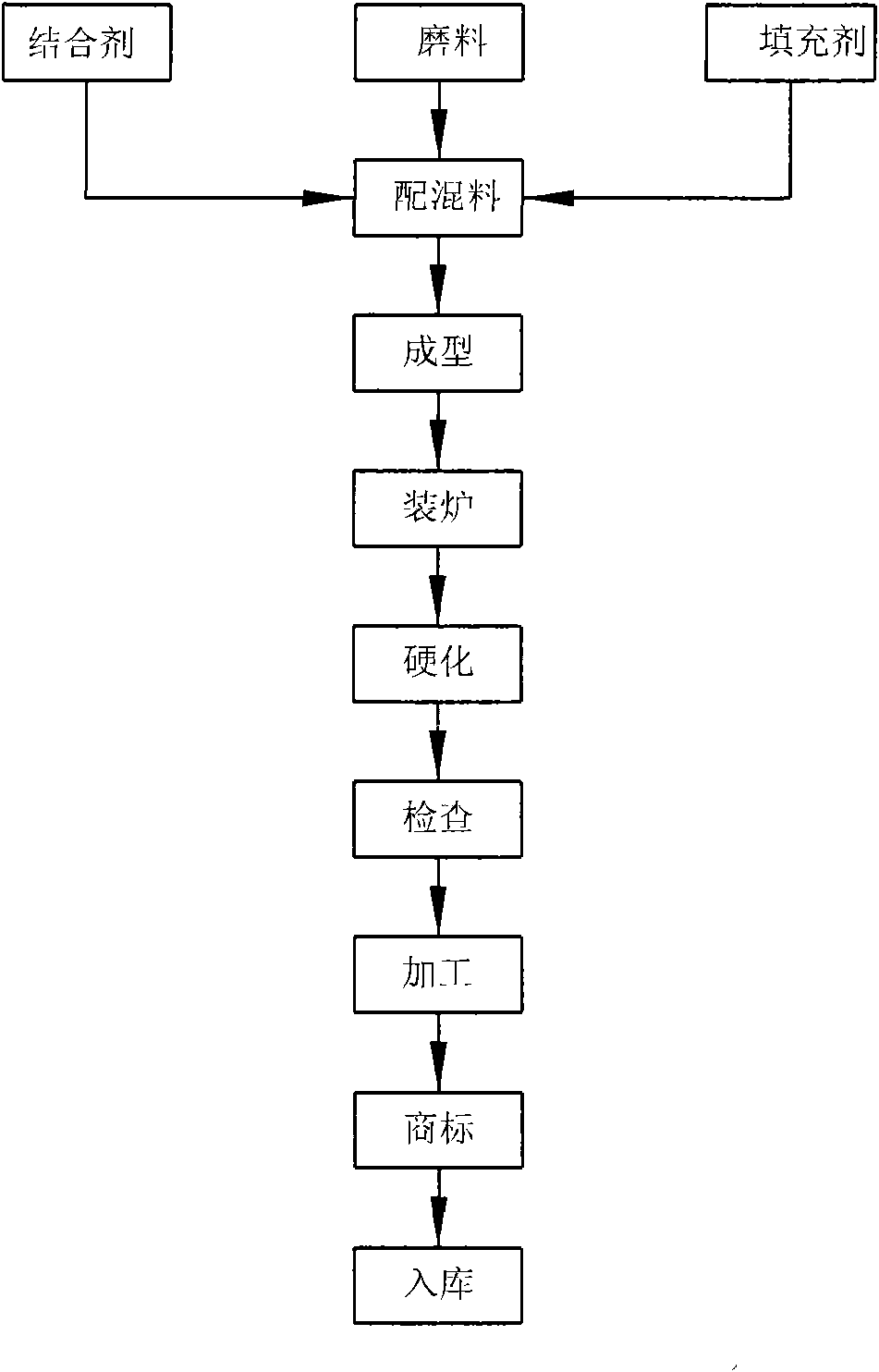

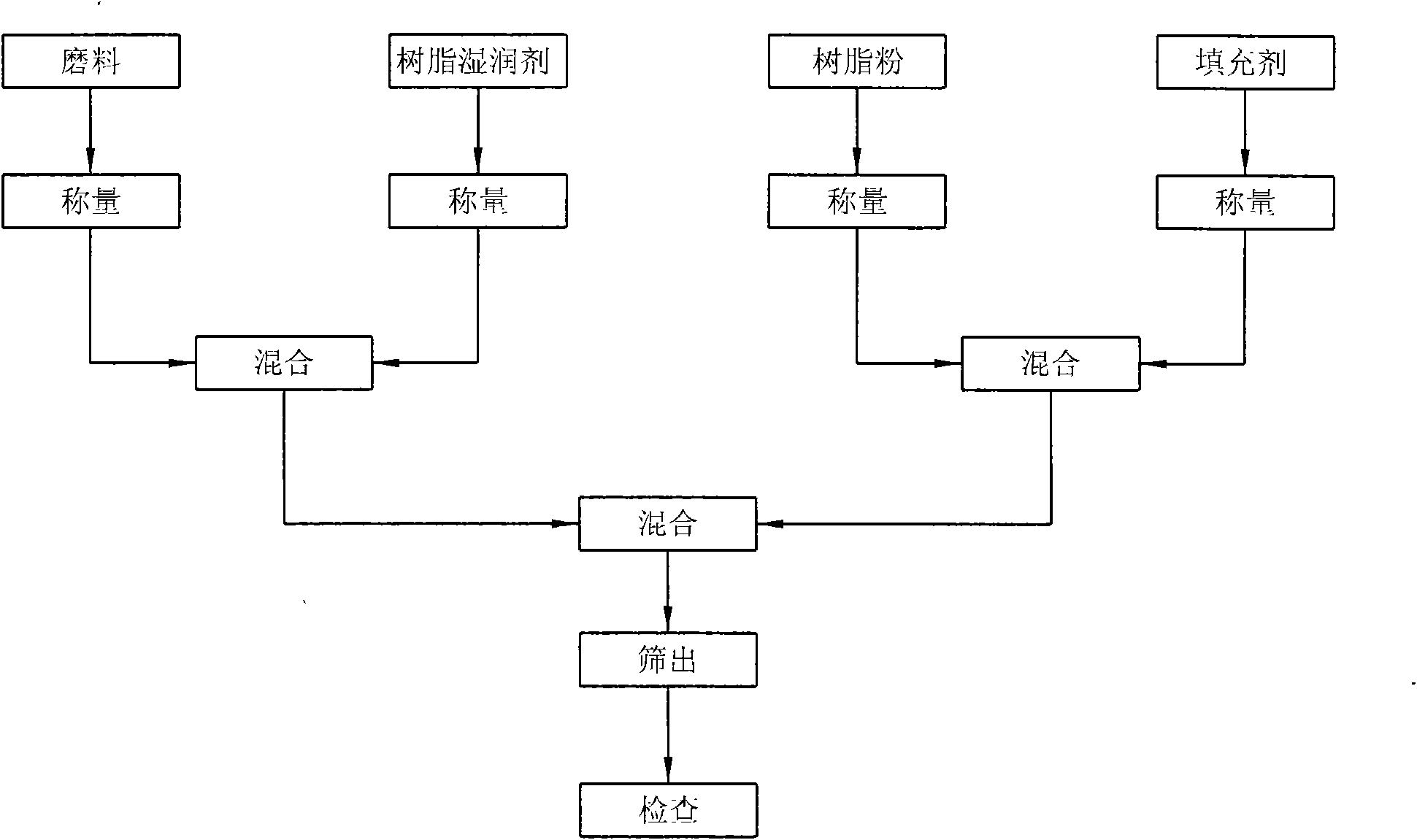

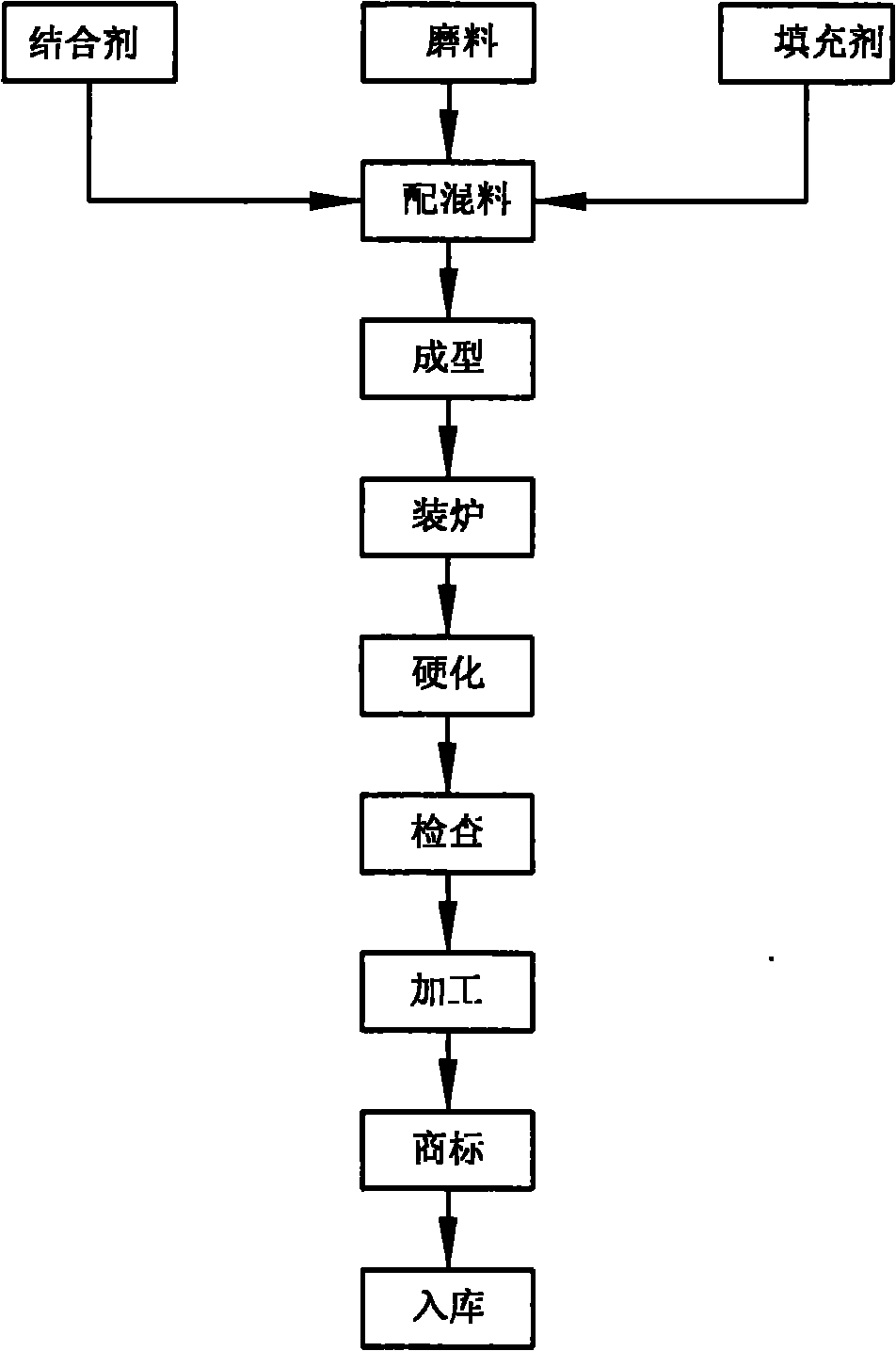

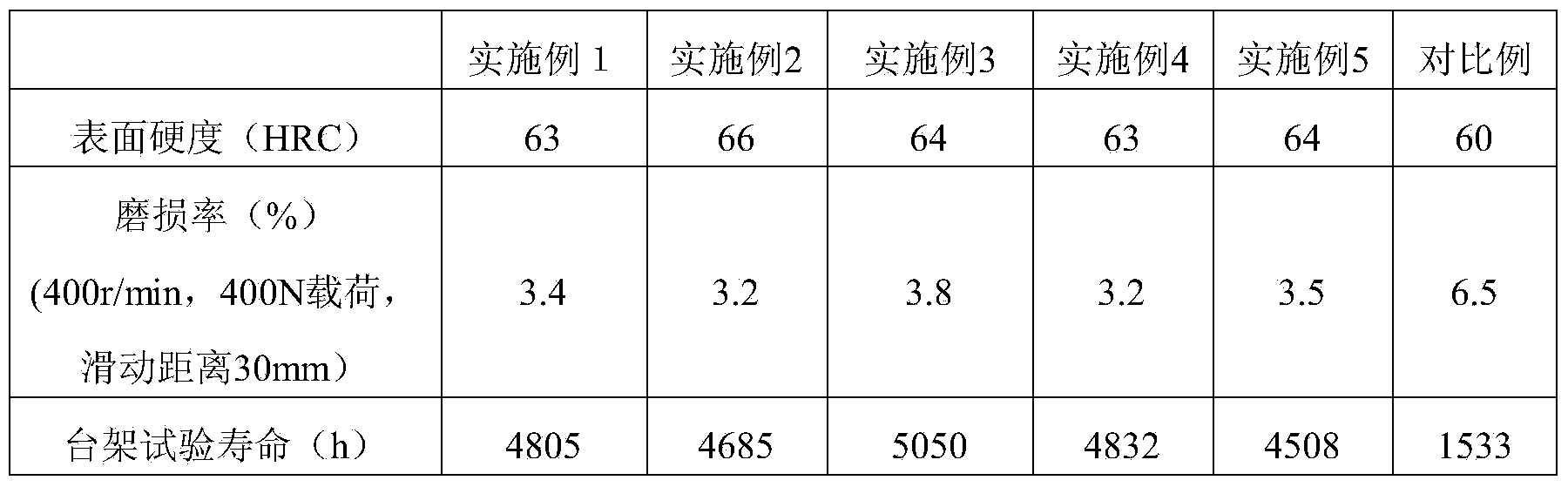

Fiber-reinforced resin heat-resistant high-speed abrasive cutting wheel and processing method thereof

ActiveCN101966693AGood heat resistanceGood wear resistanceAbrasion apparatusGrinding devicesWear resistantTitanium dioxide

The invention belongs to the field of abrasive wheels, and in particular relates to a fiber-reinforced resin heat-resistant high-speed abrasive cutting wheel with a large diameter and a flake structure and a processing method thereof. In the invention, the abrasive wheel is divided into a center reinforced part and a cutting part which adopt different formulas, wherein the formula of the center reinforced part has the advantages of high strength and good cohesiveness with a fiber glass reinforced net, and because the center reinforced part does not use zirconia alumina and other materials with a relatively higher price, the cost is saved. By adding iron sulfide powder, cryolite powder and titanium dioxide fine powder to the cutting part, and optimizing the respective proportion, the heat resistance and wear resistance of the cutting part are enhanced and the cutting ratio is improved. The abrasive wheel of the invention has the advantages of good heat-resistant property, good wear-resistant property, high cutting ratio and low cost.

Owner:山东鲁信四砂泰山磨具有限公司

Fluorocopolymer and its applications

ActiveCN1765982AGood heat resistanceGood adhesion between layersSynthetic resin layered productsVehicle componentsWeather resistanceRepeat unit

A fluorine-containing copolymer comprising a repeating unit (a) based on tetrafluoroethylene and / or chlorotrifluoroethylene, a repeating unit based on a cyclic hydrocarbon monomer comprising a dicarboxylic anhydride group and a bridging ring polymerizable unsaturated group (b) and recurring units (c) based on other monomers (excluding tetrafluoroethylene, chlorotrifluoroethylene and said cyclic hydrocarbon monomers), with said recurring units (a), (b) and (c) Based on the total molar weight, the content of repeating unit (a) is 50-99.89 mol%, the content of repeating unit (b) is 0.01-5 mol%, and the content of repeating unit (c) is 0.1-49.99 mol%. , the volume flow rate of the fluorine-containing copolymer is 0.1-1000 cubic millimeters per second, and the present invention also relates to a laminate and a coated product. The fluorocopolymer has excellent adhesion, heat resistance, weather resistance, stress crack resistance and fuel barrier properties. The laminates have excellent interlayer adhesion and fuel barrier properties. The coated product has excellent heat resistance, chemical resistance, oil resistance, weather resistance, abrasion resistance and lubricity.

Owner:ASAHI GLASS CO LTD

Anti-aging high-flame-retardance natural rubber composite

InactiveCN105754155AGood heat resistanceExcellent weather and oil resistanceMaleic anhydrideDicumyl peroxide

The invention discloses an anti-aging high-flame-retardance natural rubber composite.The composite is prepared from natural rubber, ethylene-propylene-diene monomer rubber, polychloroprene, polyvinyl chloride, natural rubber grafting maleic anhydride, carboxyl liquid nitrile rubber, polypropylene carbonate, zinc oxide, stearic acid, sulphur, dicumyl peroxide, nanosilicon dioxide, kieselguhr, nano-microcrystalline cellulose, medium super abrasion furnace black, cerium oxide, silane coupling agent, accelerant, anti-aging agent, silicon phosphorus flame retardant, HAPCP, aluminum diethylhypophosphite and zinc borate.The composite is high in strength, good in aging resistance, excellent in flame retardance, capable of meeting use requirements of various fields of cables, electric appliances and the like and long in service life.

Owner:宿州学院

Wear-resistant intake valve and preparation method thereof

InactiveCN103627956AGood heat resistanceGood fatigue performanceMachines/enginesLift valveZirconium alloyWear resistant

The invention discloses a wear-resistant intake valve and a preparation method thereof. The intake valve adopts the following alloying constituents by weight percent: 0.32-0.40 percent of C, 0.17-0.27 percent of Si, 0.5-1.2 percent of Mo, 0.50-0.80 percent of Mn, 0.2-0.5 percent of Nb, 0.80-1.10 percent of Cr, 0.50-1.0 percent of W, no more than 0.030 percent of Ni, no more than 0.015 percent of S, no more than 0.010 percent of Cu and the balance of Fe. The intake valve is processed by the processes of surface nanocrystallization, low-temperature nitridation, build-up welding of tungsten zirconium alloy and the like and has the advantages of high surface strength and rigidity, good wear-resisting property and long service life.

Owner:JIANGSU UNIV OF SCI & TECH

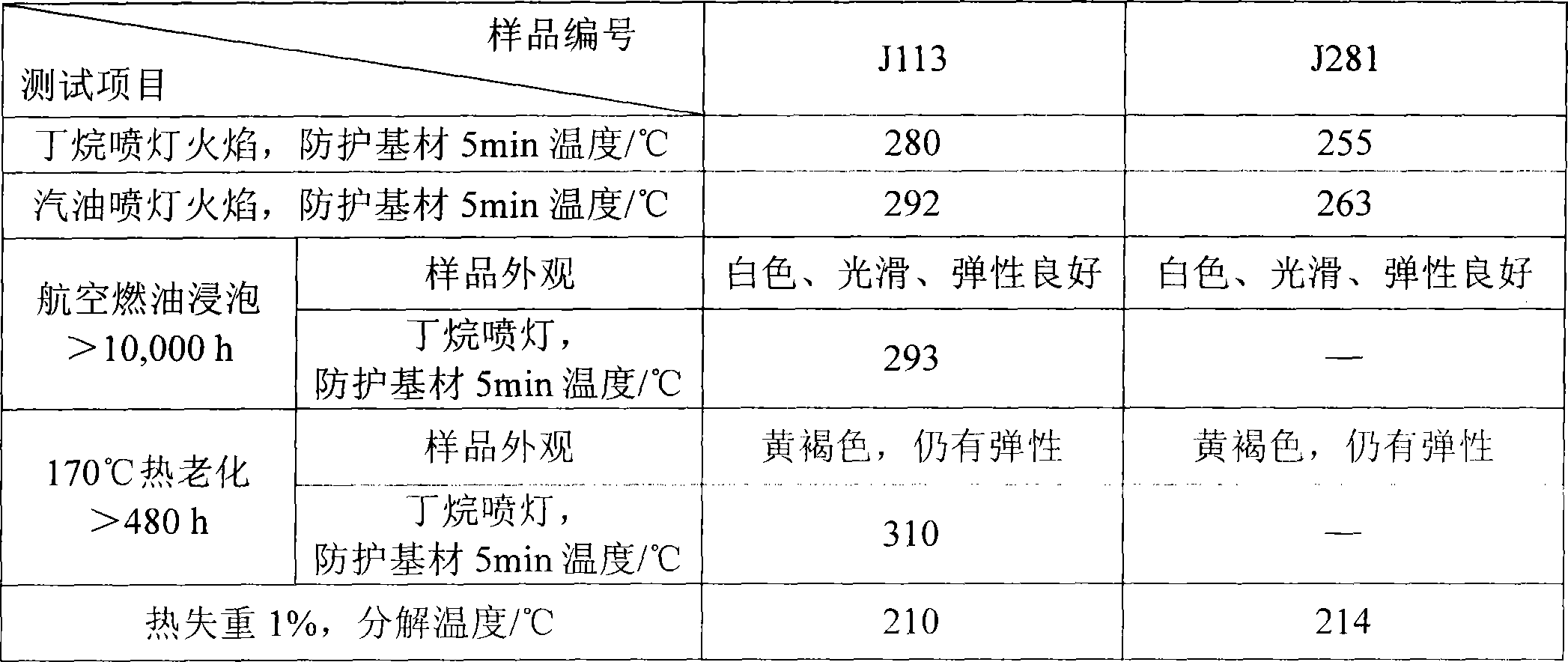

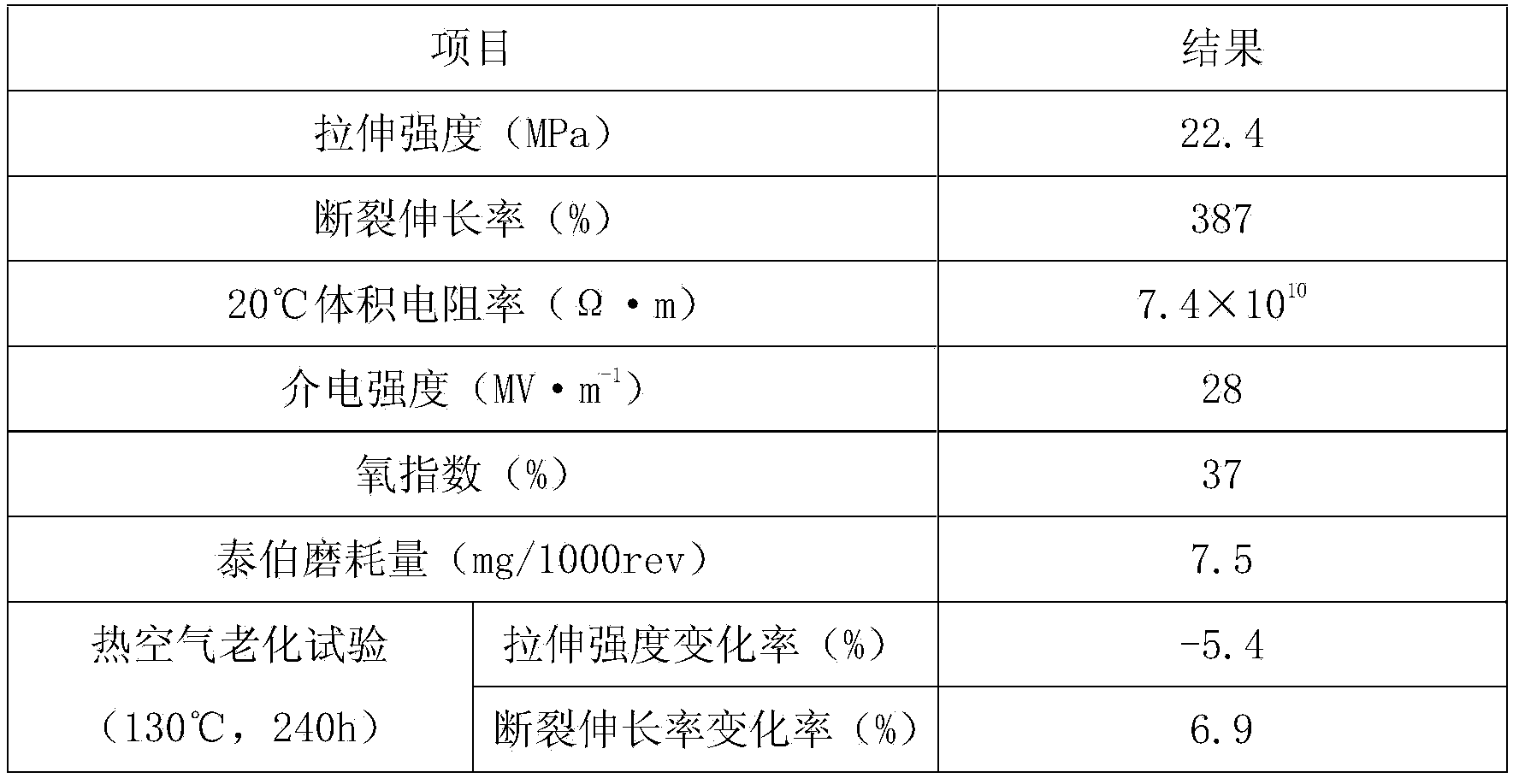

Grease-proof, heat-resistant expansion type flame-proof rubber

This invention discloses an expansion fire-retardant rubber with resistance to oil and heat, particularly being applicable to fire safety protection of conductor bundles in all enclosed spaces, and relates to the technical field of the fire-retardant rubber which is composed by the components with the following portions by weight: 40 to 60 percent of oil-resistant rubber, 5 to 10 percent of resin viscosity regulator, 20 to 40 percent of ammonium polyphosphate, 3 to 10 percent of melamine, 2 to 8 percent of zinc borate, 5 to 20 percent of nano-inorganic and 1 to 5 percent of silica white. The fuel immersion swelling rate of the fire-retardant rubber is zero; when the rubber thickness is less than or equal to 1.0mm, the fire resistance duration is more than or equal to 5 min with the flame temperature of 1200 DEG C and the protected substrate temperature of being less than or equal to 300 DEG C. The fire-retardant rubber of the invention has resistance to heat and ageing, and flexibility and can be used for the fire safety protection of various the conductor bundles.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Heat resistance stainless steel and smelting method thereof

Heat resisting stainless steel and its smelting process are both disclosed herewith. It comprises (wt%): C 0.05-0.10, Si 1.40-2.00, Ce 0.03-0.08, Cr 20.0-22.0, Ni10.0-12.0, N 0.14-0.20, and Mn 0.4-0.80, with impurities of P not more than 0.040 and S 0.030. It is produced by: (1) pouring mother liquid of stainless steel with C (1.2-2.5) into AOD furnace, (2) decarbonizing to C (0.05-0.10), (3) reducing steel liquid and desulfurizing, (4) floss removing and regulating components of steel liquid, (5) pouring out and adding B-iron and Al cakes, (6) feeding Ce wires, (7) regulating temperature and controlling impurities, and (8) continuously casting. It costs low and has good performance at high temperature.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

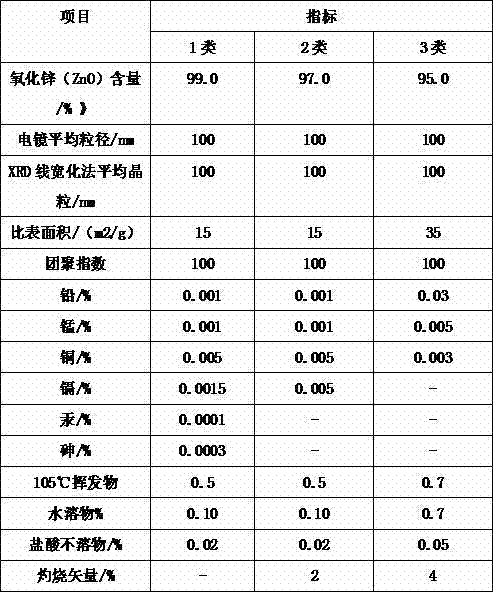

High-wearability insulating cable material and preparation method thereof

InactiveCN103881359AExcellent wear resistanceGood heat resistancePlastic/resin/waxes insulatorsDiamineChemistry

The invention discloses a high-wearability insulating cable material and a preparation method thereof. The high-wearability insulating cable material is prepared from the following raw materials in parts by weight: 70 to 90 parts of polyurethane rubber, 15 to 20 parts of polytetrafluoroethylene, 10 to 15 parts of nylon 6, 10 to 15 parts of polypropylene glycol adipate, 5 to 10 parts of dipropylene glycol dibenzoate, 5 to 10 parts of trel-butylphenyl diphenyl phosphate, 7 to 13 parts of antimonous oxide, 5 to 10 parts of decabromodiphenylethane, 4 to 8 parts of zinc borate, 2 to 3 parts of tert-butyl peroxybenzoate, 1.5 to 2 parts of zinc oxide, 2 to 3 parts of stearic acid, 3 to 6 parts of chlorcosane, 1 to 2 parts of accelerant ZDMC (Zinc Dimethyldithiocarbamate), 1 to 2 parts of accelerant CZ (N-cyclohexylbenzothiazole-2-sulphenamide), 15 to 20 parts of fumed silica, 10 to 15 parts of attapulgite nanoocomposites, 5 to 10 parts of nano zeolite, 10 to 15 parts of precipitated barium sulphate, 1.5 to 2.5 parts of antioxidant 1010, 2 to 3 parts of anti-aging agent TPPD (N-(p-toluene-sulphonylamido-N'-phenylene diamine)), and 3 to 6 parts of composite filler. The cable material is outstanding in wearability, particularly, the wearability is always several times and even dozen times that of the common electrical material under a terrible working condition in the presence of water, oil and other wetting medias; the cable material is also remarkable in heat resistance, flame resistance, ageing resistance, oil resistance, warping strength, impact resistance and tear resistance.

Owner:ANHUI WANGDA COPPER DEV

Method for preparing high solid content aqueous polyurethane emulsion by continuous process

The invention provides a method for preparing water-borne polyurethane emulsion with high solid content by the continuous method. The method comprises the following steps that: oligomer polylol after vacuum dehydration, isocyanate, a chain extender, a solvent and a catalyst are added into a reactor at a time under the protection of dry nitrogen; the mixture is mechanically stirred and simultaneously controlled at a certain temperature for reaction to a certain degree; the system temperature is reduced to between 20 and 50 DEG C; the hydrophilic chain extender is slowly dripped into a prepolymer which is then added with the solvent so as to prevent gel coagulation caused by overlarge viscosity; the isocyanate-based NCO content in the prepolymer which is generated through reaction is not changed again; and the prepolymer is added with water again to perform emulsion dispersion and undergoes vacuum distillation to remove the solvent, and then the water-borne polyurethane solution is prepared. The water-borne polyurethane solution prepared by the method has high solid content, low viscosity, large initial bonding strength, and good heat resistance, can be used as textile fabric coating agent, shoe coating agent, leather finishing agent, and adhesives used in the fields of wood, architecture, automobile, paper-making, electronics and so on.

Owner:ANHUI UNIVERSITY +1

High temperature resistance precoated sand

InactiveCN103231008AGood heat resistanceReduce roughnessFoundry mouldsFoundry coresWater soluble polymersRosin

The invention discloses high temperature resistance precoated sand, which comprises base sand, a binder, hexamethylenetetramine, a phenol formaldehyde resin, a silane coupling agent and an additive A, wherein the base sand comprises, by weight, 55-60 parts of iron ore sand, 60-70 parts of forsterite sand, and 7-10 parts of diatomite, a particle size of the base sand is 100-150 mesh, 3-5 parts by weight of boric acid, 1-2 parts by weight of water-soluble polymer glue powder, 3-5 parts by weight of starch, 0.5-0.8 part by weight of rosin, 4-5 parts by weight of dextrin and 4-6 parts by weight of water are subjected to a reaction and drying to obtain the binder, 4-6 parts by weight of a straw powder material, 2-4 parts by weight of sepiolite and 5-8 parts by weight of water are subjected to a mixing calcination treatment to obtain the additive A, a particle size of the straw powder material is 0.5-0.8 mm, and the obtained calcined product, 2-4 parts by weight of montmorillonite powder and 3-4 parts by weight of water glass are subjected to mixing granulation. The high temperature resistance precoated sand has the following characteristics that: moisture absorption resistance is good, roughness is low, high temperature resistance is provided, and sand sticking on a cast is not easily generated.

Owner:FANCHANG COUNTY HENGXIN AUTO PARTS

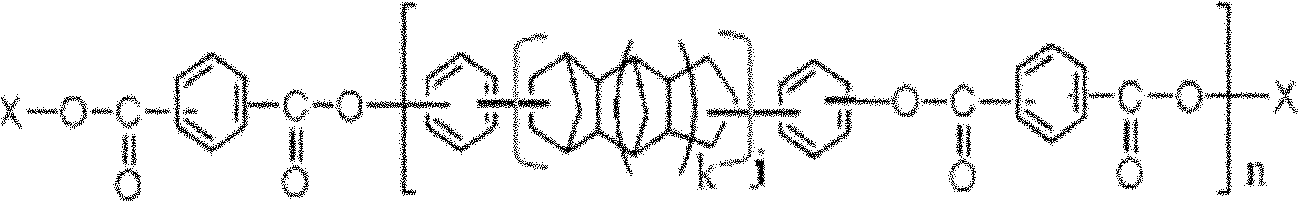

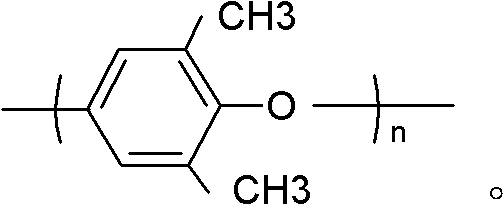

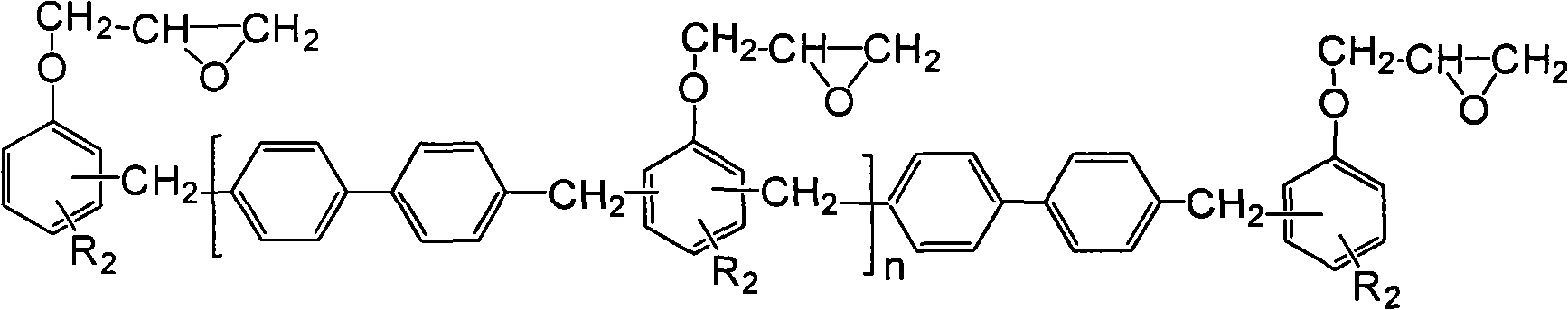

Thermosetting Resin Composition of Semi-IPN Composite, and Varnish, Prepreg and Metal Clad Laminated Board Using the Same

ActiveUS20100233495A1Good high-frequency propertyGood heat resistanceSynthetic resin layered productsPrinted circuit aspectsPrepolymerMetal foil

Provided is a thermosetting resin composition which can be used for the production of printed circuit boards, having good dielectric properties in high frequency bands so that transmission loss can be significantly lowered, having excellent heat resistance after moisture absorption and thermal expansion properties, and satisfying peeling strength between the resin composition and metal foil.The present invention relates to a thermosetting resin composition of a semi-IPN composite, comprising (A) a polyphenylene ether, and a prepolymer formed from (B) a chemically unmodified butadiene polymer containing 40% or more of a 1,2-butadiene unit having a 1 2,-vinyl group in a side chain of a molecule and (C) a crosslinking agent, in a compatibilized and uncured state; and a resin varnish, a prepreg and a metal clad laminated board using the same.

Owner:RESONAC CORP

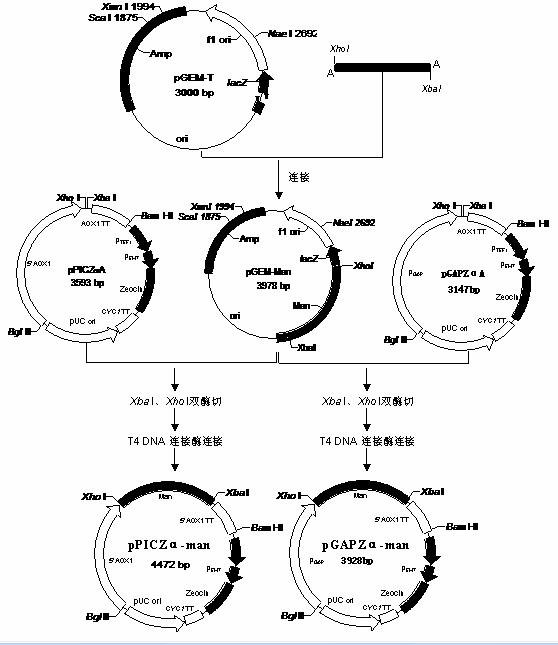

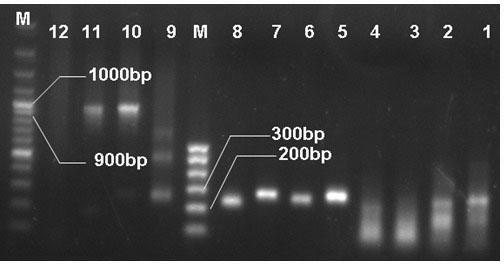

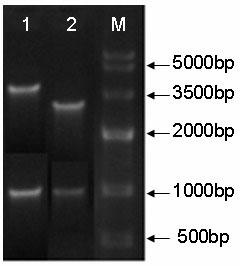

Transformation of acidic beta-mannase gene and construction of engineering bacteria of acidic beta-mannase gene

The invention discloses transformation, synthesis and splicing of acidic heat-resistant beta-mannase gene and construction of engineering bacteria containing the acidic heat-resistant beta-mannase gene. An encoding gene has a nucleotide sequence shown as SEQIDNO.3 or SEQIDNO.4; and the acidic beta-mannase obtained by encoding has an amino acid sequence shown as SEQIDNO.1 or SEQIDNO.2. According to the construction of the engineering bacteria, the engineering bacteria are obtained by introducing Pichia pastoris constitutive expression vector (pGAPZalpha-man) into Pichia pastoris. The acidic heat-resistant beta-mannase gene disclosed by the invention has the following properties that the optimum action pH is 5.0, the optimum action temperature is 40DEG C, the structure is favorable and the properties are stable when the pH value is in a range of 3.0 to 7.0 and the remained enzyme activity is over 70 percent after an enzyme liquid is treated at high temperature of 90 DEG C for 5 minutes; meanwhile, the acidic heat-resistant beta-mannase gene has high specific activity and better proteinase resistance; and the engineering bacteria realize high-level expression of the acidic heat-resistant beta-mannase gene and has the advantages of simple fermentation process, low extraction cost, suitability for large-scale industrial production and wide application prospect.

Owner:JINANBESTZYME BIO ENG CO LTD

Halogen-free fire resistance resin composite and application thereof

InactiveCN102020830AGood heat resistanceSmall water absorptionPrinted circuit aspectsPrinted circuit manufactureMetal foilFlame resistance

The invention relates to a halogen-free fire resistance resin composite and application thereof. The halogen-free fire resistance resin composite comprises the following components: bifunctional or multifunctional halogen-free epoxy resin, reactive polyphosphonate and cyanate resin. The halogen-free fire resistance resin is applied to a prepreg; the prepreg comprises a base material and the halogen-free fire resistance resin composite attached to the base material after being impregnated and dried. The halogen-free fire resistance resin composite is applied to a plyboard for a printing circuit; the plyboard for the printing circuit comprises a plurality of stacked prepregs and single-surface or double-surface metal foil arranged on the stacked prepregs; each prepreg comprises the base material and the halogen-free fire resistance resin composite attached to the base material after being impregnated and dried. The halogen-free fire resistance resin composite has high heat resistance, fire resistance and dip soldering resistance, and thereby, the halogen-free fire resistance resin composite can be used for manufacturing the resin sheet, the resin composition metal foil, the prepreg, the plyboard and the printed wiring board.

Owner:GUANGDONG SHENGYI SCI TECH

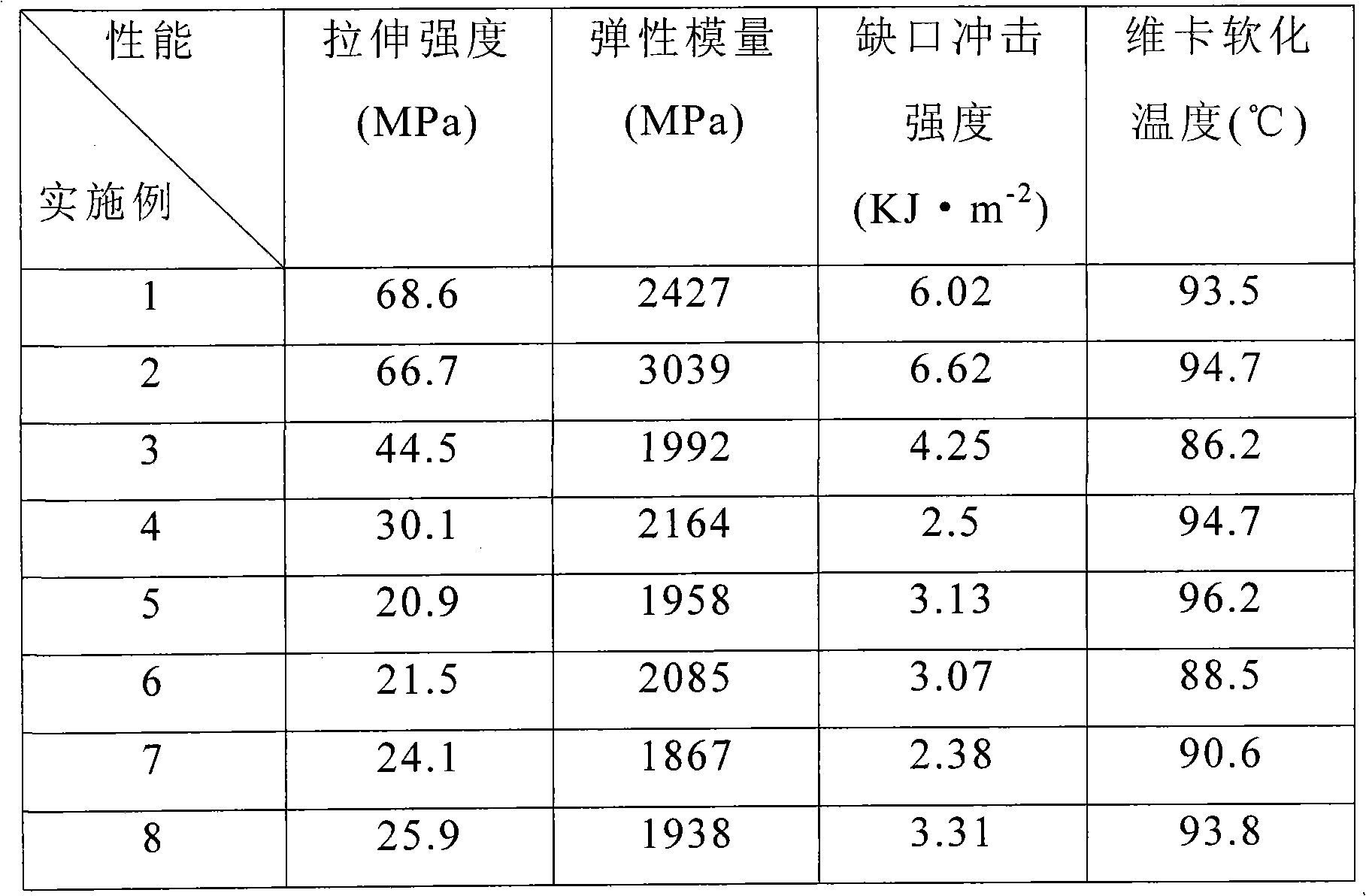

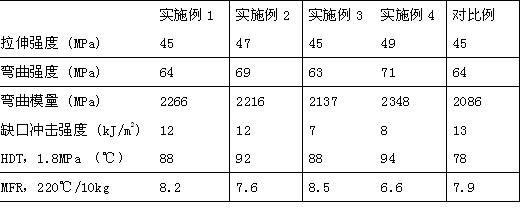

Reinforced polyester alloy composite material and preparation method thereof

The invention discloses a reinforced polyester alloy composite material and a preparation method thereof. By weight proportion, the reinforced polyester alloy composite material comprises the following components: 5 percent to 80 percent of PC resin, 5 percent to 80 percent of PET resin, 5 percent to 80 percent of PBT resin, 5 percent to 50 percent of glass fibers, 0.5 percent to 10 percent of PA6 oligomer and 0.5 percent to 10 percent of other additives. The method includes the following steps that: the materials, except the glass fibers and the PA6 oligomer, are weighed and prepared according to the proportion, and are mixed in a high-speed mixer for 3 to 5 minutes. The uniformly mixed materials are fed into a double-screw extruder, wherein the glass fibers are fed via a first exhaust port, temperatures from a feed inlet to an extrusion mold are respectively 200 DEG C to 230 DEG C, 220 DEG C to 250 DEG C, 240 DEG C to 260 DEG C, 240 DEG C to 270 DEG C and 250 DEG C to 280 DEG C. Therotation speed of a main unit is 20Hz to 60Hz, and a plastic injection molding machine is then used for sampling. The composite material has the advantages of high hardness, high rigidity, each machining, good evenness and high glossiness.

Owner:CHONGQNG PRET NEW MATERIAL +2

Cobalt salt adhesive in use for bonding rubber - metal in high tenacity, and preparation

This invention discloses modification of Co salt binder for high-strength rubber-metal binding. The Co salt binder comprises components A and B. Component A comprises: Co salt binder 0.5-8 wt.%, rubber 35-60 wt.%, anti-aging agent 0.5-3 wt.%, plasticizer 0.5-15 wt.%, reinforcer 5-50 wt.%, HRH binder 0-6 wt.% and accelerator 0-2 wt.%. Component B comprises curing agent, and is 4-12 wt. % of component A. The modified Co salt binder retains its previous excellent properties, while can be used by coating like Chemlok binder. The modified Co salt binder can be widely used for high-strength binding of majority rubbers and metals. Besides, the modified Co salt binder has such advantages as high heat resistance (with higher than 95% binding efficiency above 100 deg.C), and low cost (30% lower than Chemlok binder), and can be used in middle- and small-scale rubber industries as well as retreading of meridian tires.

Owner:严忠庆 +3

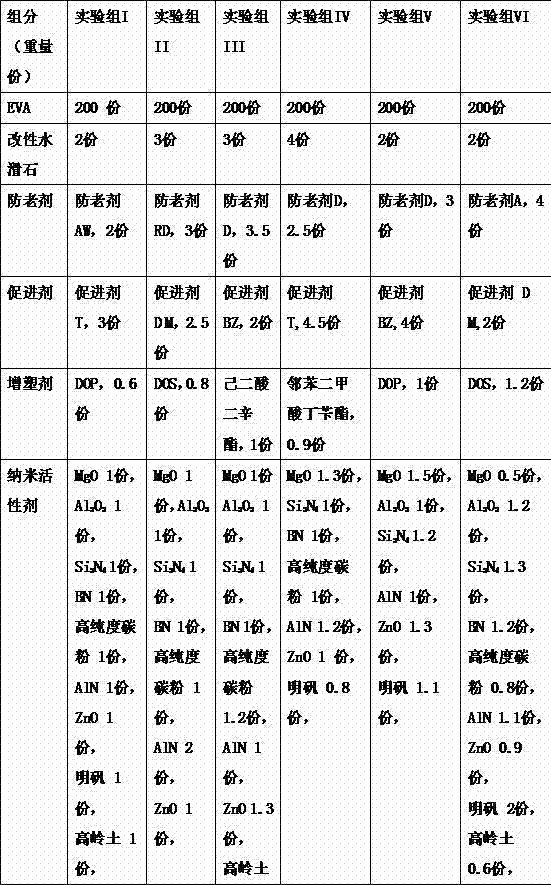

High-performance flame-retardant cable material and preparation method thereof

ActiveCN104774372AGood heat resistanceImprove mechanical propertiesInsulated cablesInsulatorsPlasticizerHydrotalcite

The invention discloses a high-performance flame-retardant cable material. The high-performance flame-retardant cable material comprises the following raw materials: 200 parts of EVA, 2 to 4 parts of modified hydrotalcite, 2 to 9 parts of an antioxidant, 2 to 10 parts of a promoter, 0.8 to 1.8 parts of a plasticizer and 6 to 12 parts of a nanometer activator. The invention further discloses a preparation method for the flame-retardant cable material. Through usage of nanometer synergistic modification flame-retardation EVA, the cable material has good mechanical properties, flame retardation and heat resistance.

Owner:安徽国信电缆科技股份有限公司

Epicoccum nigrum DB3 bacterial strain as well as preparation and application thereof

InactiveCN102329738AExtensive culture conditionsGood heat resistanceFungiMicroorganism based processesSea grassEpicoccum nigrum

The invention relates to an epicoccum nigrum DB3 bacterial strain as well as a preparation and an application thereof. The preparation method comprises the steps of: 1, placing rotten sea grass in an enrichment culture medium, standing and culturing at room temperature, then coating the enrichment culture medium in a separation culture medium, standing and culturing at a temperature of 30 DEG C for 1-4 days to obtain a wild type flax biological treatment bacterial strain; 2, inoculating the bacterial strain obtained from the step 1 into a flax lignin nutrition culture medium, culturing at a temperature of 28 DEG C for 72 hours; and 3, selecting the bacterial strain with the capacity of degrading the lignin from the flax lignin nutrition culture medium to obtain the epicoccum nigrum DB3 bacterial strain. The epicoccum nigrum DB3 bacterial strain can be applied to a process for preparing spinning flax, hemp, jute or red ramie fibers through peroxide degumming. The epicoccum nigrum DB3 bacterial strain has the characteristics of short growth period, low possibility of being polluted, low treatment cost, mild reaction conditions, strong pollution resistance capacity, good heat-resistant performance, no environment pollution and good quality of the treated fibers. The preparation method has a simple process and is suitable for large-scale industrial production.

Owner:DONGHUA UNIV

Die casting aluminium alloy water-based release agent and preparation method thereof

ActiveCN107999692AGood heat resistanceCasting surface smoothFoundry mouldsFoundry coresOLEYL ETHERTriethanolamine

The invention discloses a die casting aluminium alloy water-based release agent and a preparation method thereof, and relates to release agents and preparation methods thereof. The preparation methodcomprises the steps that engine oil, beewax, organic molybdenum compounds and silicone oil are placed in a water bath kettle to be mixed and heated to be 50 DEG C to 80 DEG C, the materials are stirred with an electric stirring machine, polyoxyethylene aliphatate and polyoxyethylene oleyl ether are slowly added after uniform stirring, hot water is added while stirring, and the materials are emulsified into an emulsion, wherein hot water is tap water or purified water, and the heating temperature is 50 DEG C to 80 DEG C; when the emulsion is cooled to the room temperature, silicon dioxide is added while stirring, and then, stearic acid, ethyl alcohol, triethanolamine, an organosilicone wetting agent, sodium benzoate, sodium phosphate, a thickening agent, sodium nitrite and sorbic acid are added. The release agent prepared through the preparation method contains ultrafine silicon dioxide, silicone oil, and the like, heat resistance is excellent, the surface of a casting is smooth, mold sticking, strain damage or deformation defects are effectively prevented, the lubricating property of the water-based release agent is remarkably improved through lubricating oil, beewax, the organic molybdenum compounds, and the like, and the demolding property is remarkably improved.

Owner:SHENYANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com