High-performance flame-retardant cable material and preparation method thereof

A fuel-resistant, high-performance technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the decline of thermal stability of materials, the decline of water resistance of flame-retardant substrates, and the decline of mechanical properties such as impact strength and tensile strength, etc. problem, to achieve the effect of good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The implementation of the present invention will be described in detail below in conjunction with the examples, so as to fully understand and implement the implementation process of how to apply technical means to solve technical problems and achieve technical effects in the present invention.

[0030] The embodiment of the present invention raw material:

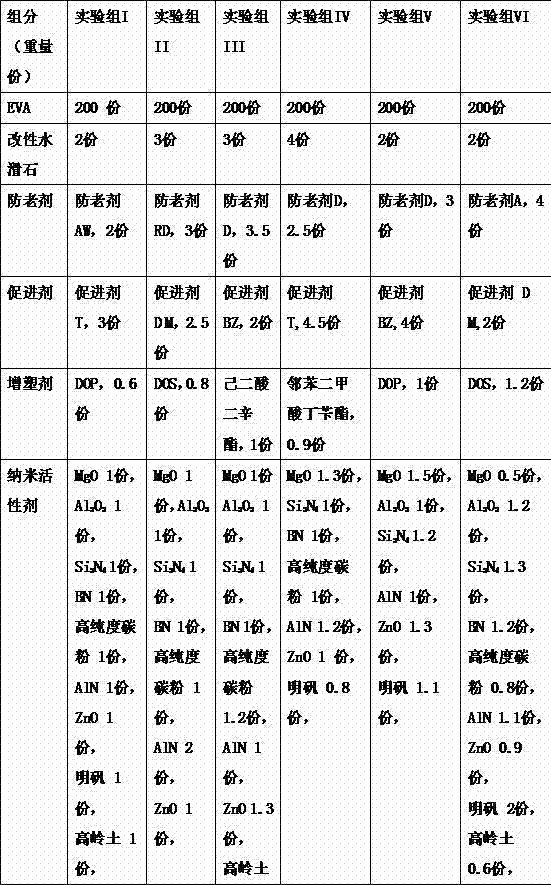

[0031] EVA (Elvax 360) 100 parts, American DuPont, melt flow rate is 2 g / 10 min, density is 0.948g / cm 3 ; 2-4 parts of modified hydrotalcite, 2-9 parts of anti-aging agent, 2-10 parts of accelerator, 0.8-1.8 parts of plasticizer, 6-12 parts of nano active agent;

[0032] Preparation method of modified hydrotalcite LDHs

[0033] Dispersion of magnesium aluminum hydrotalcite in CO removal 2 After making a slurry in deionized water, the NaH 2 PO 4 2H 2 Dissolve O in water to form a supersaturated solution and slowly pour it into the slurry, heat and stir, adjust the pH to 4.2~4.3 with dilute nitric acid, and reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The melt flow rate | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com