Patents

Literature

603results about "Other rubber adhesives" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

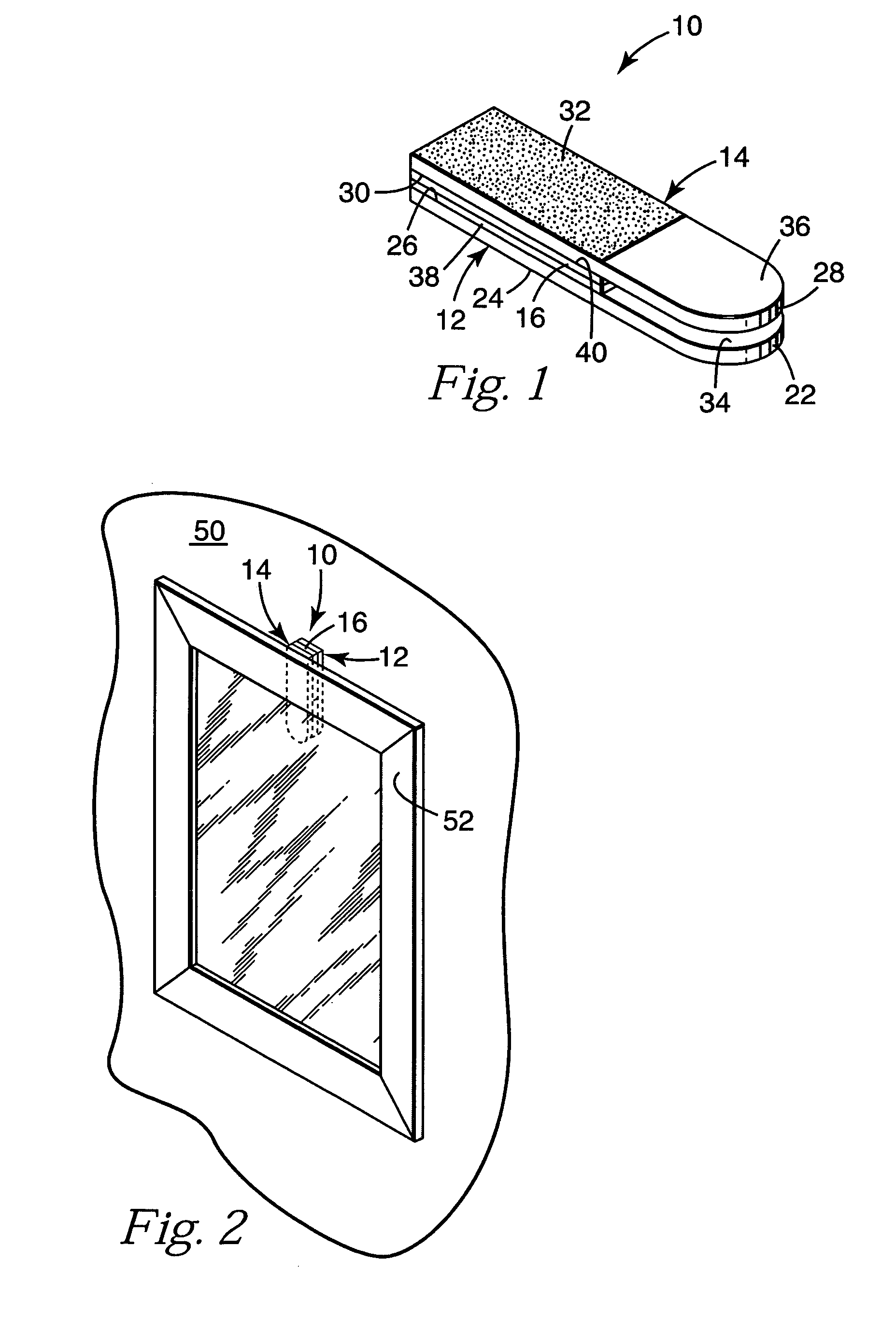

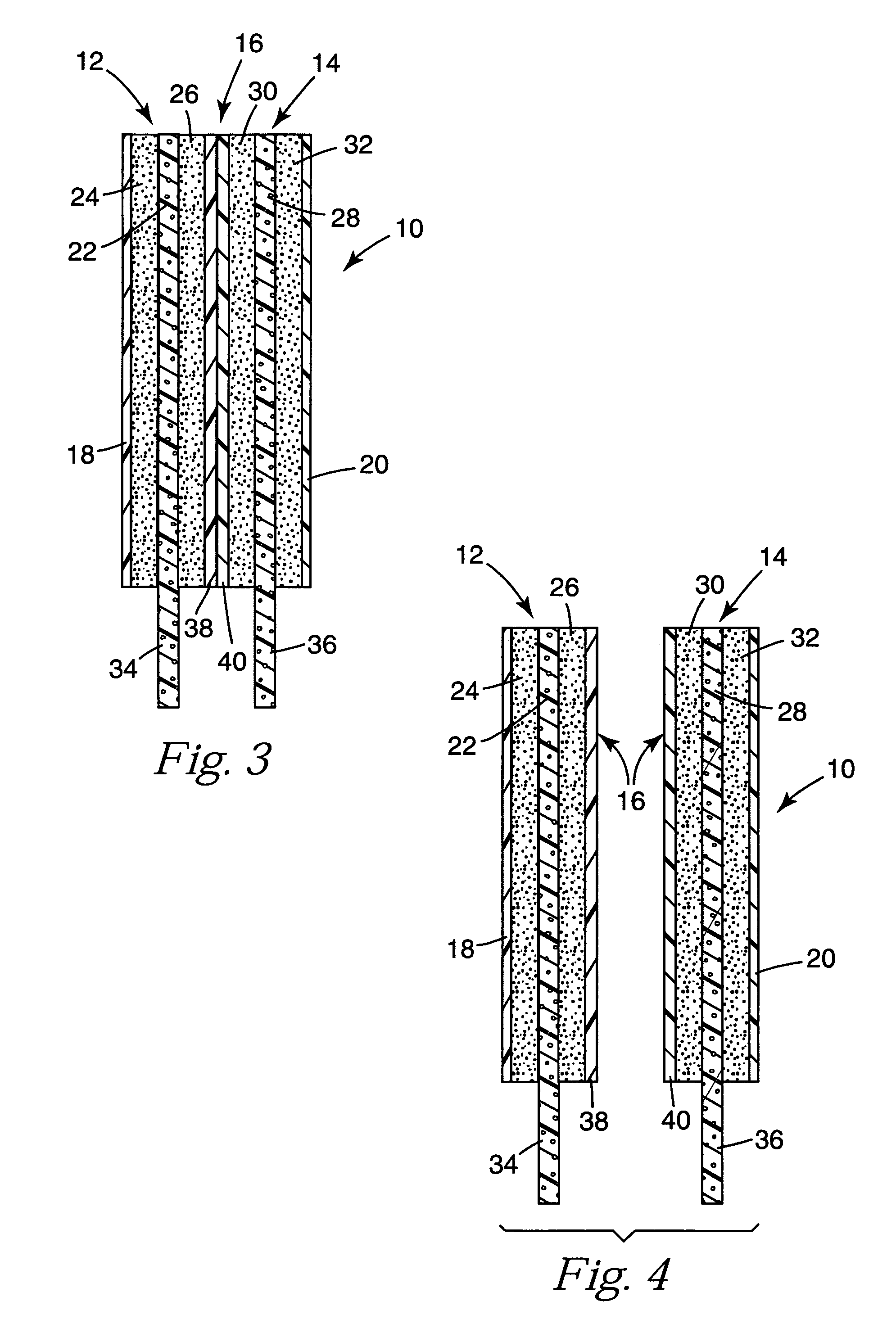

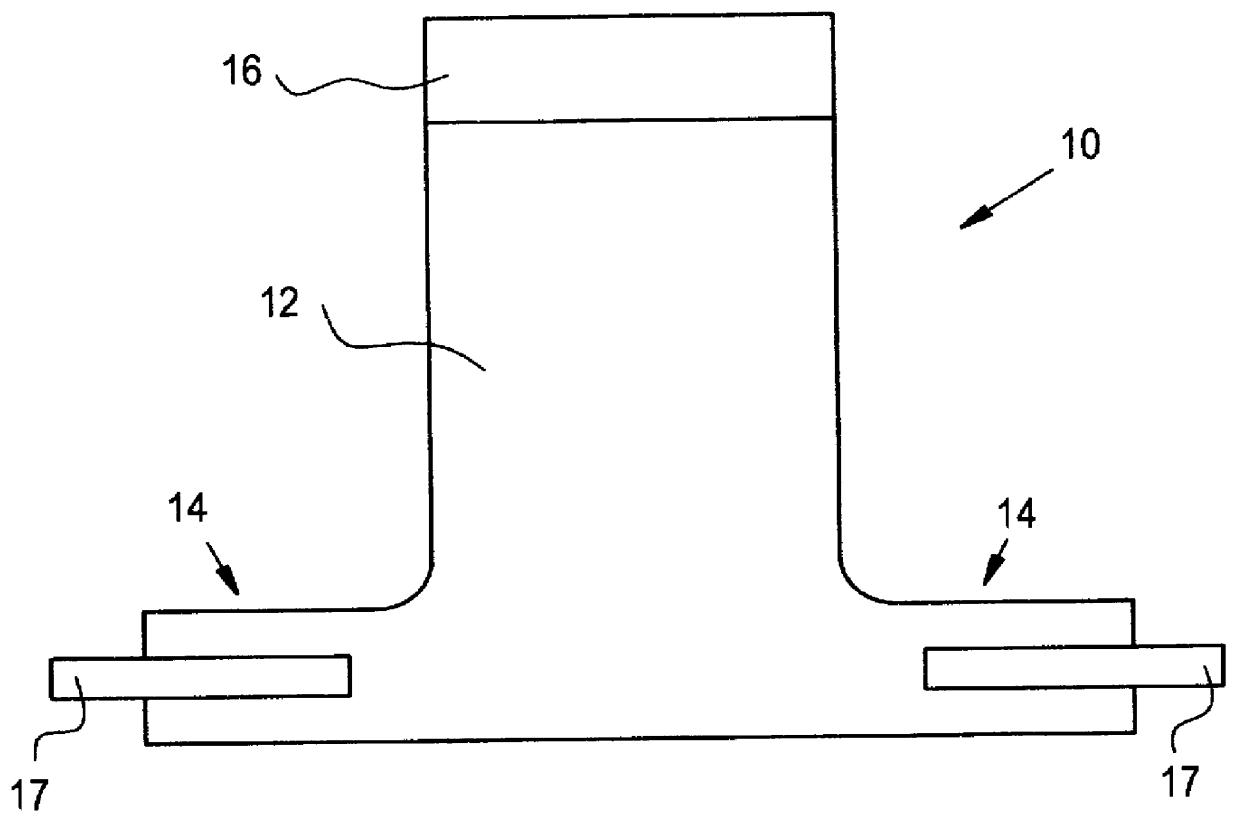

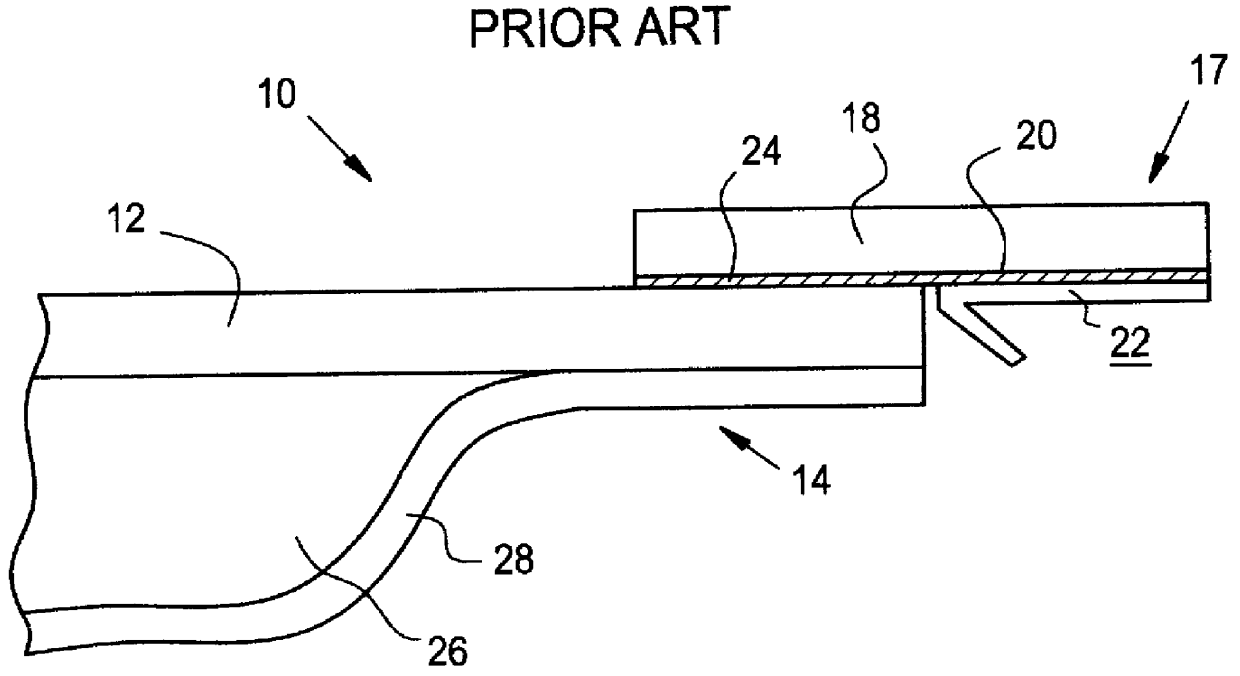

Removable adhesive tape laminate and separable fastener

An adhesive tape construction is removable from one or more objects to which it is adhered and which is reusably separable within its construction so that an object can be separated from another and subsequently reconnected with one another. The adhesive tape construction can be used to bond the other opposed surfaces of objects, including rigid objects such as a picture frame to a wall, where no portion of the adhesive tape construction projects from between the objects, and which subsequently affords easy separation of the objects without damage to either of them. More specifically, the adhesive tape construction includes a stretch release adhesive tape structure combined with a reusable connector surface.

Owner:3M INNOVATIVE PROPERTIES CO

TPE composition that exhibits excellent adhesion to textile fibers

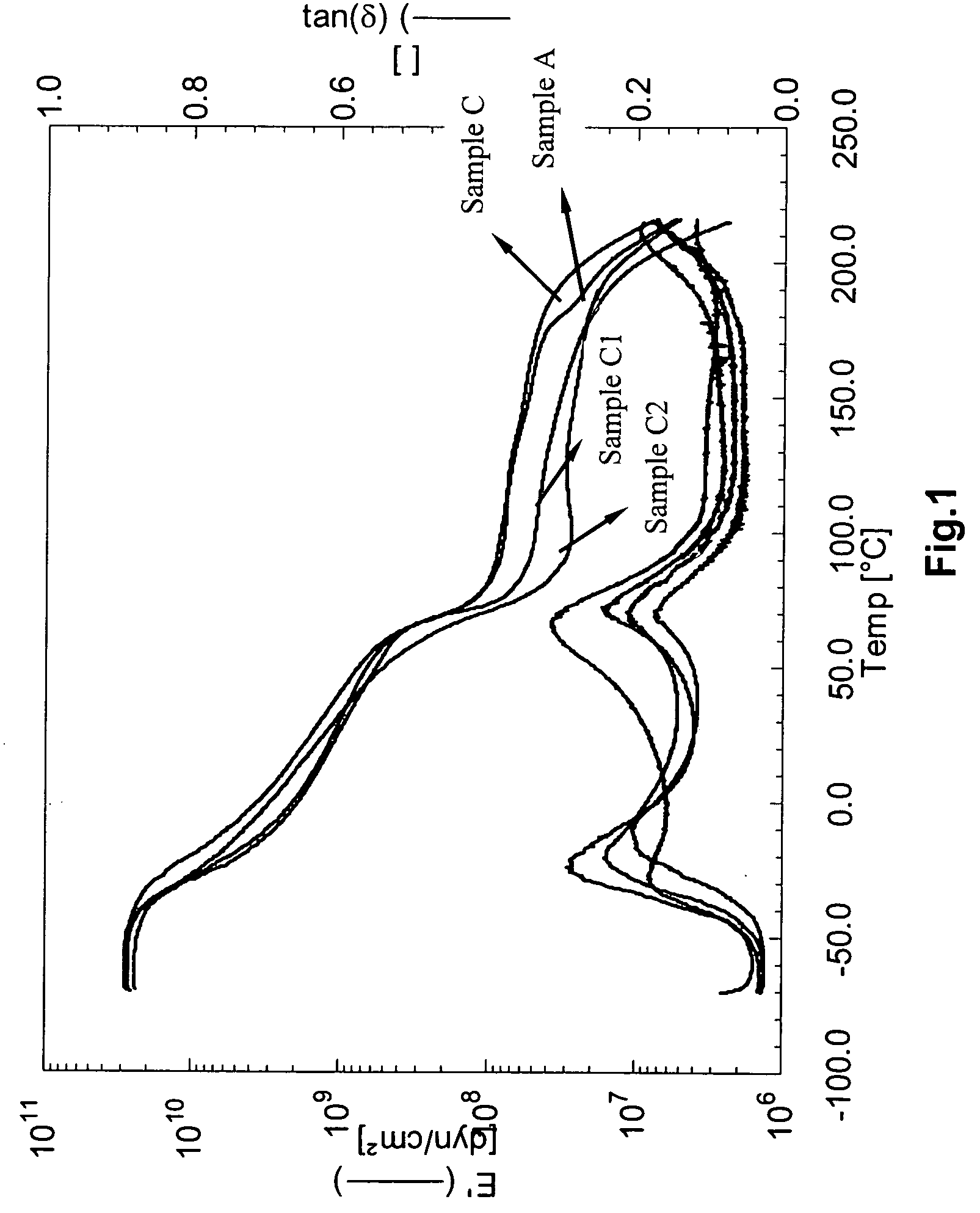

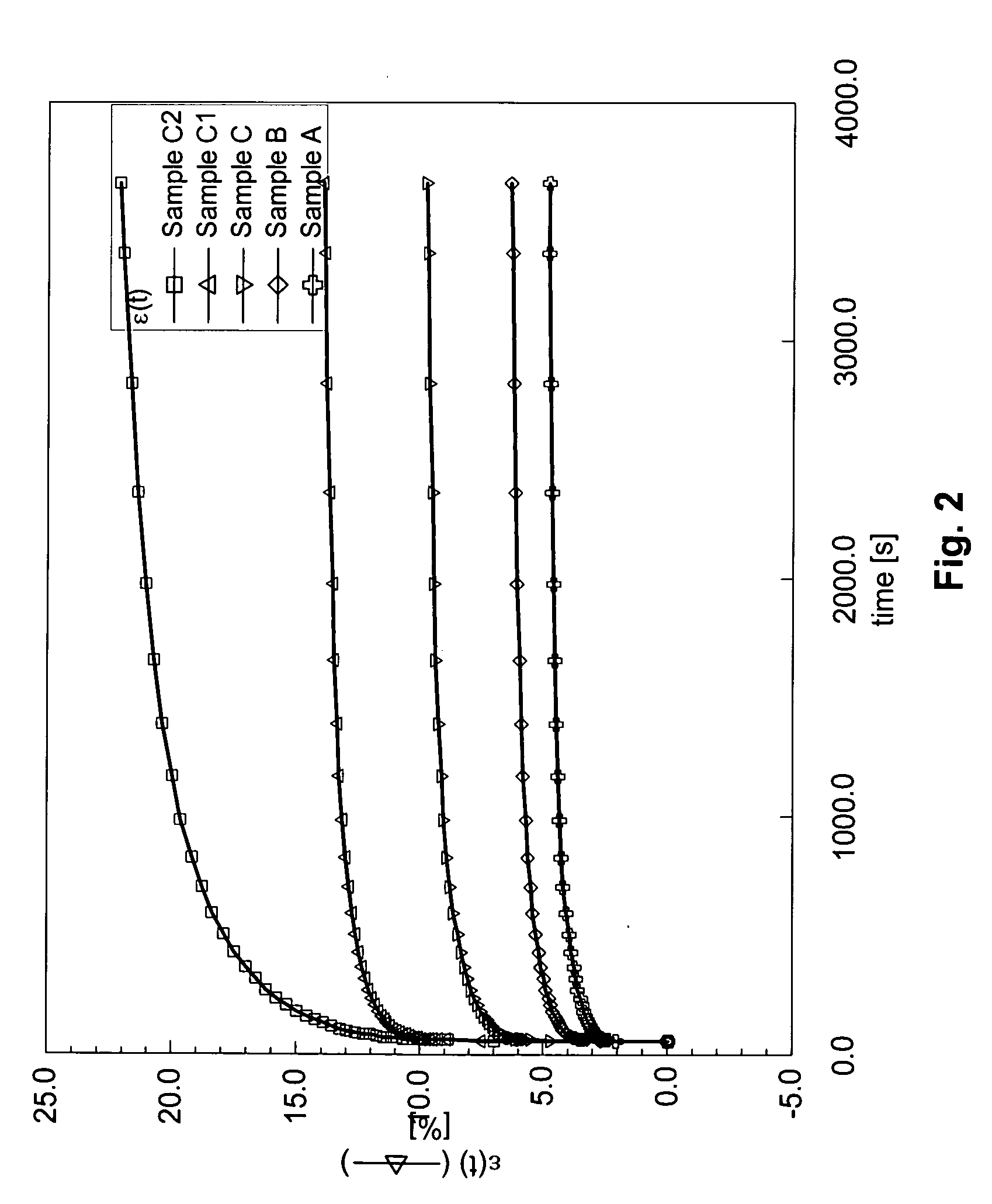

InactiveUS6503984B2Increase stiffnessHigh modulusFibre typesOther rubber adhesivesTextile fiberPolyester

A combination of a low flexural modulus and low crystallinity polyolefin and a functionalized polyolefin were found to result in an olefin composition with excellent adhesion to metals and polar polymers (e.g. polyesters, polyamides, etc) especially fibers therefrom. When these two polyolefins were added to a thermoplastic vulcanizate (e.g. used to partially or fully replace the semicrystalline polyolefin of a thermoplastic vulcanizate), the thermoplastic vulcanizate was found to have the necessary adhesion to form fiber reinforced thermoplastic vulcanizate.

Owner:EXXONMOBIL CHEM PAT INC

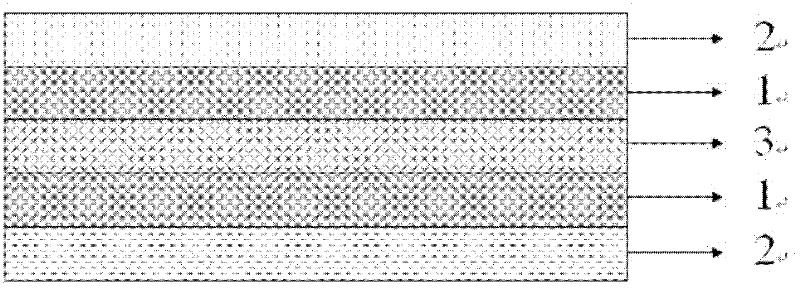

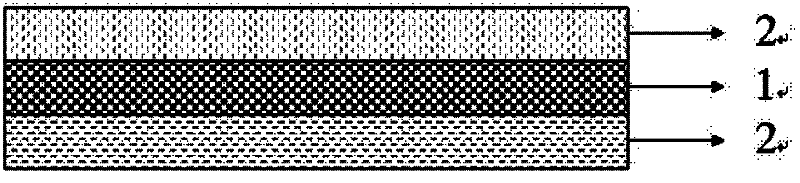

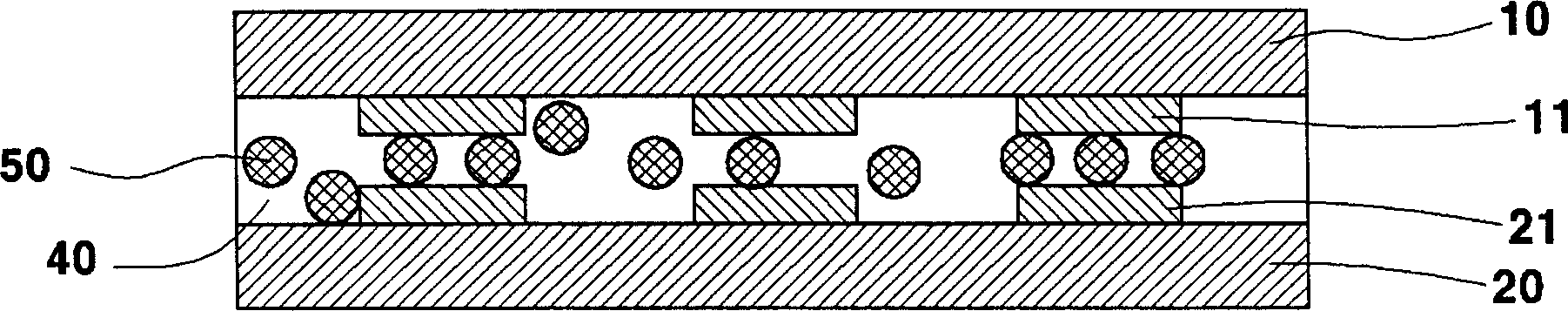

A kind of insulating and heat-conducting double-sided adhesive tape and preparation method thereof

InactiveCN102260466AImprove thermal conductivityGood thermal conductivity and electrical insulationFilm/foil adhesivesPolyureas/polyurethane adhesivesThermal insulationRoom temperature

The invention provides an insulating and heat-conducting double-sided adhesive tape and a preparation method thereof. In the insulating and heat-conducting double-sided adhesive tape, the outer layers on both sides are release paper, and a single layer of insulating and heat-conducting adhesive is arranged between the two layers of release paper. Or the outer layers on both sides are release paper, a single-layer substrate is arranged between the two layers of release paper, and an insulating and heat-conducting adhesive is arranged between the substrate and the release paper. The preparation method is as follows: mixing heat-conducting medium and solvent, adding insulating heat-conducting glue, stirring, coating and drying, and the preparation is completed. The adhesive tape of the invention has the advantages of good thermal conductivity, electrical insulation, stability at room temperature, easy die-cutting, reworkable characteristics, and easy operation.

Owner:ZHONGSHAN KINGLABEL ADHESIVE PRODS

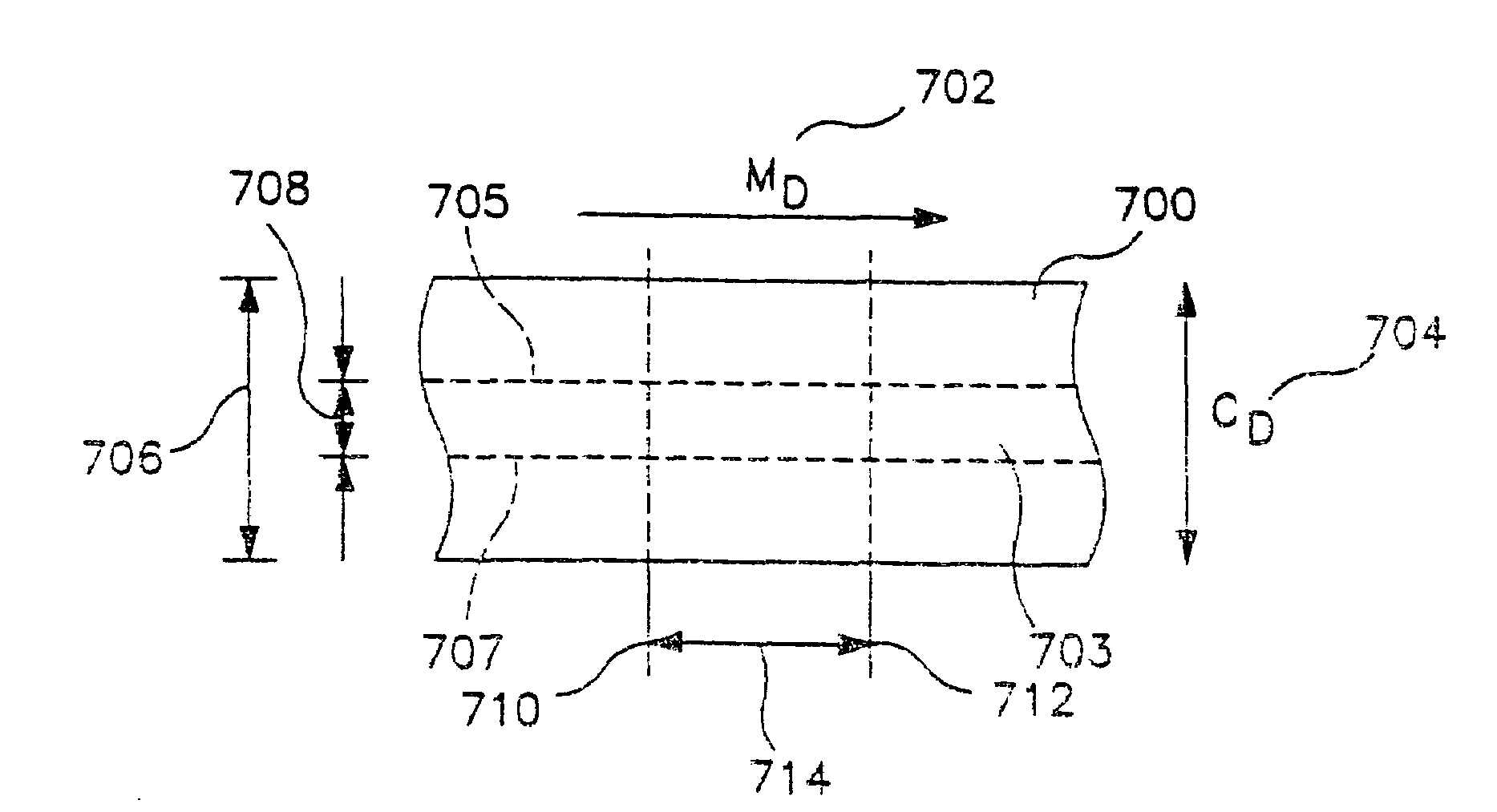

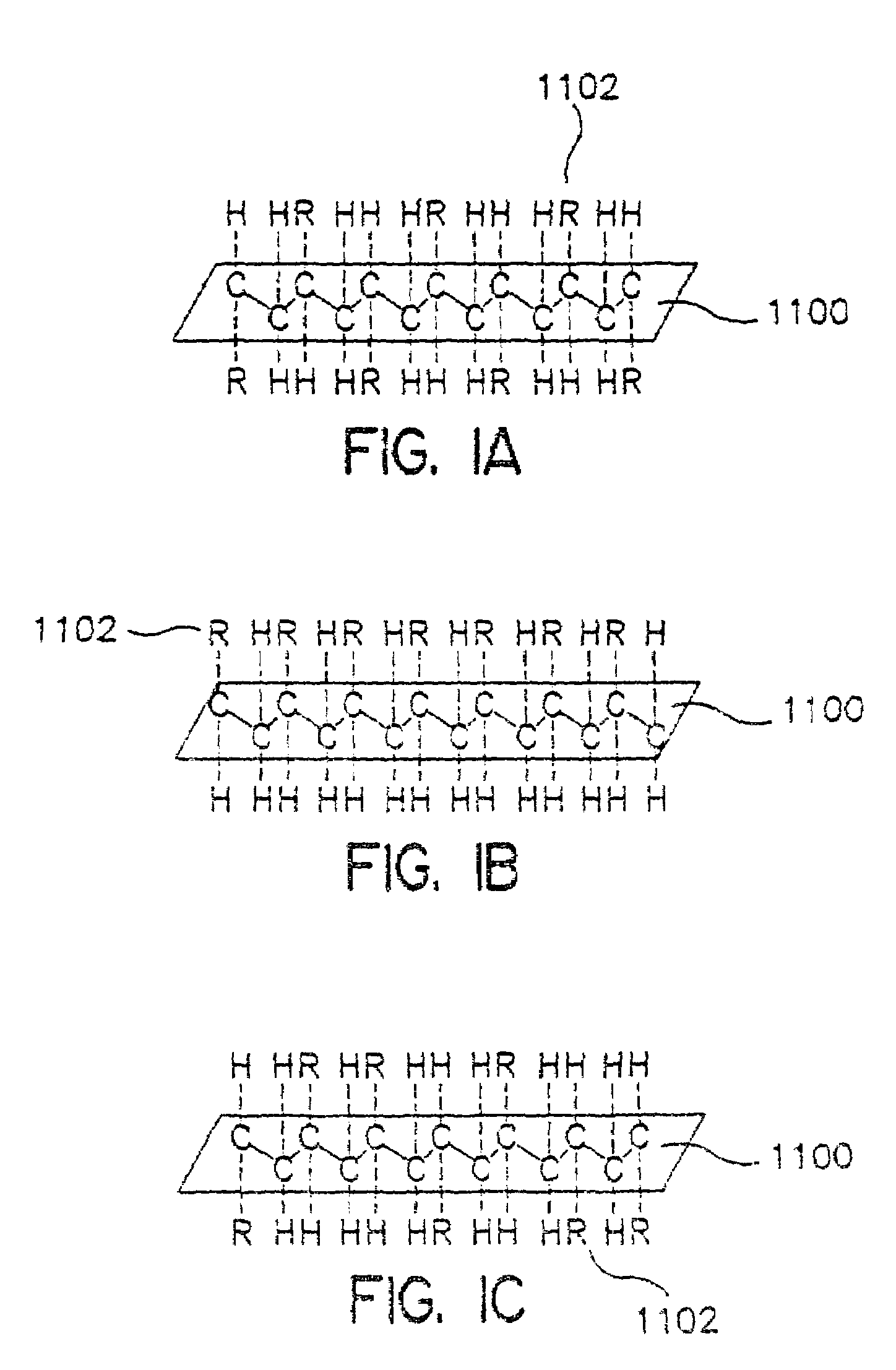

Thin plastic film

A covering for a portion of a body or an object, as well as improved, thin plastic films for use in such coverings, are disclosed. The covering comprises a thin plastic film and a pressure sensitive adhesive contacting at least a portion of, and forming a joint with, the thin plastic film. The plastic film comprises from about 85 to about 95 weight percent plastic, and from about 5 to about 15 weight percent tackifier. Such joints may be found in diapers, adult incontinent briefs, bandages, and other body coverings, as well as packagings for a variety of objects. Such joints exhibit unexpectedly high shear adhesion as compared to conventional joints.

Owner:TREDEGAR FILM PROD CORP

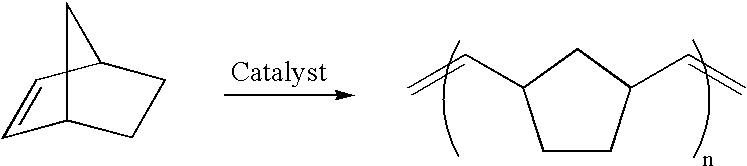

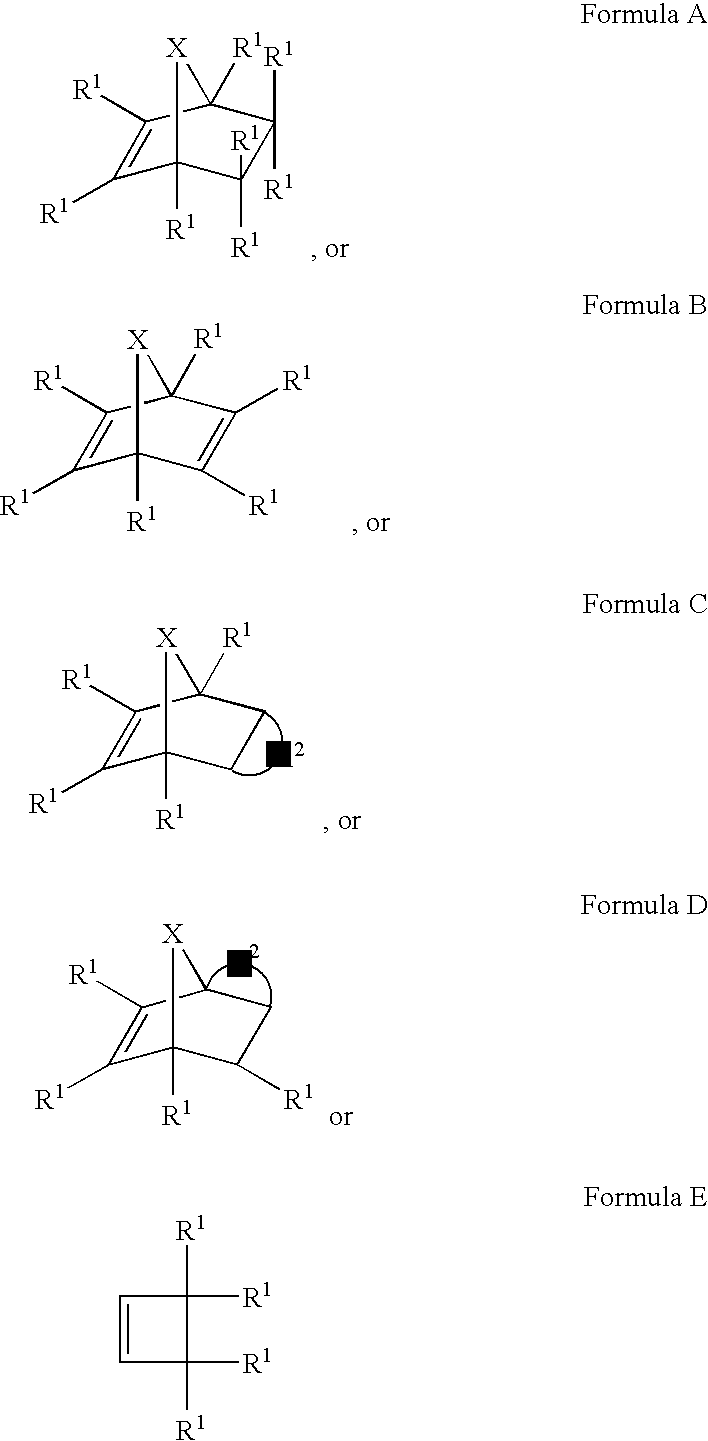

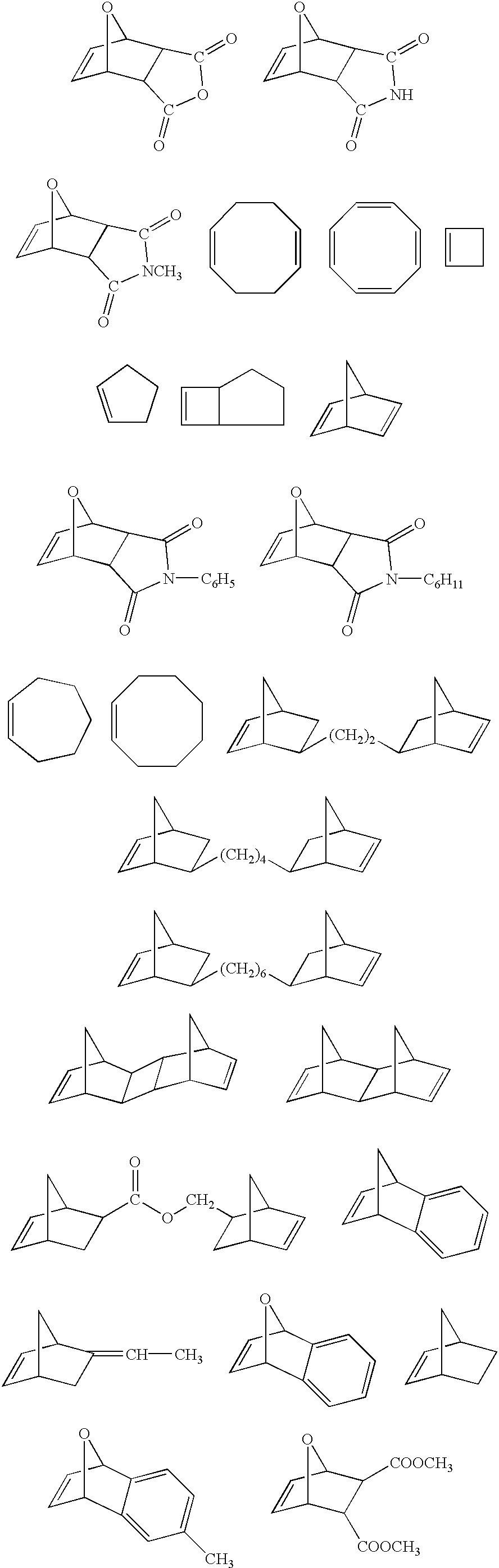

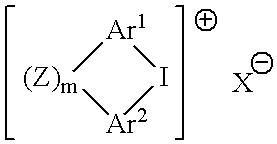

Metathesis polymerization adhesives and coatings

InactiveUS6800170B2Easy to useRemarkable strengthHydrocarbon purification/separationThickenersOligomerCoating system

An adhesive or coating composition prepared by mixing together at least one metathesizable highly-reactive cycloolefin (e.g., a norbornadiene) and a metathesis catalyst. The use of highly-reactive cycloolefins can provide exceptional adherence to a low-surface-tension substrate. Another embodiment is a two-part adhesive or coating system wherein the first part includes at least one first metathesizable material, and the second part includes at least one liquid metathesis oligomer or polymer and a metathesis catalyst.

Owner:LORD CORP

Tackified thermoplastic-epoxy pressure sensitive adhesives

InactiveUS7005394B1Retains porosityPoor extrusion propertySynthetic resin layered productsWoven fabricsEpoxyThermoplastic

A pressure sensitive adhesive composition comprised of: a) 75 to 99.9 weight percent of a tackified thermoplastic polymer component comprising 1) 1–99 weight percent of a thermoplastic polymer substantially without epoxy-binding or ester functions, and 2) 1–99 weight percent of a tackifier; and b) 0.1 to 25 weight percent of an epoxy component comprising a cured epoxy and non-woven webs made of this adhesive composition.

Owner:3M INNOVATIVE PROPERTIES CO

Optically clear and antistatic pressure sensitive adhesives

InactiveUS20070141329A1Natural rubber adhesivesNon-macromolecular adhesive additivesAntistatic agentPolymer chemistry

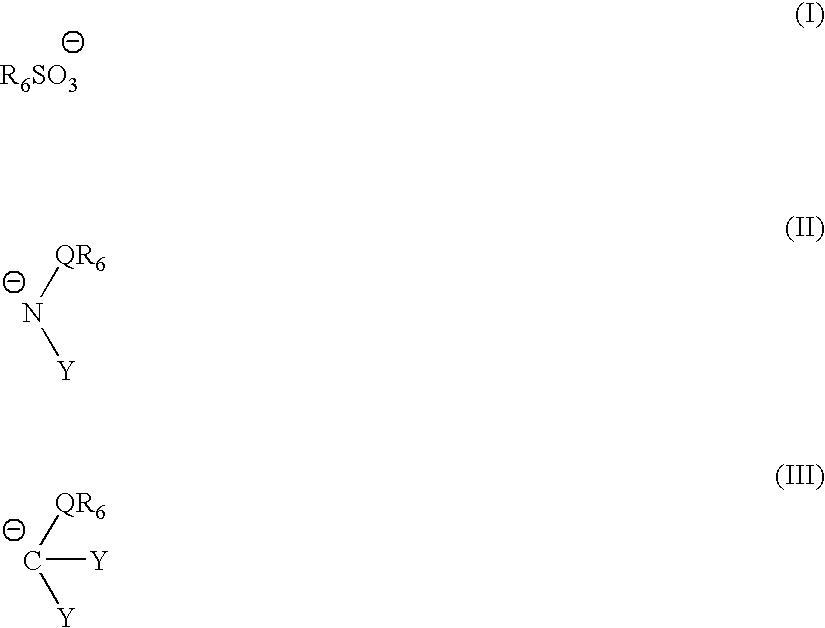

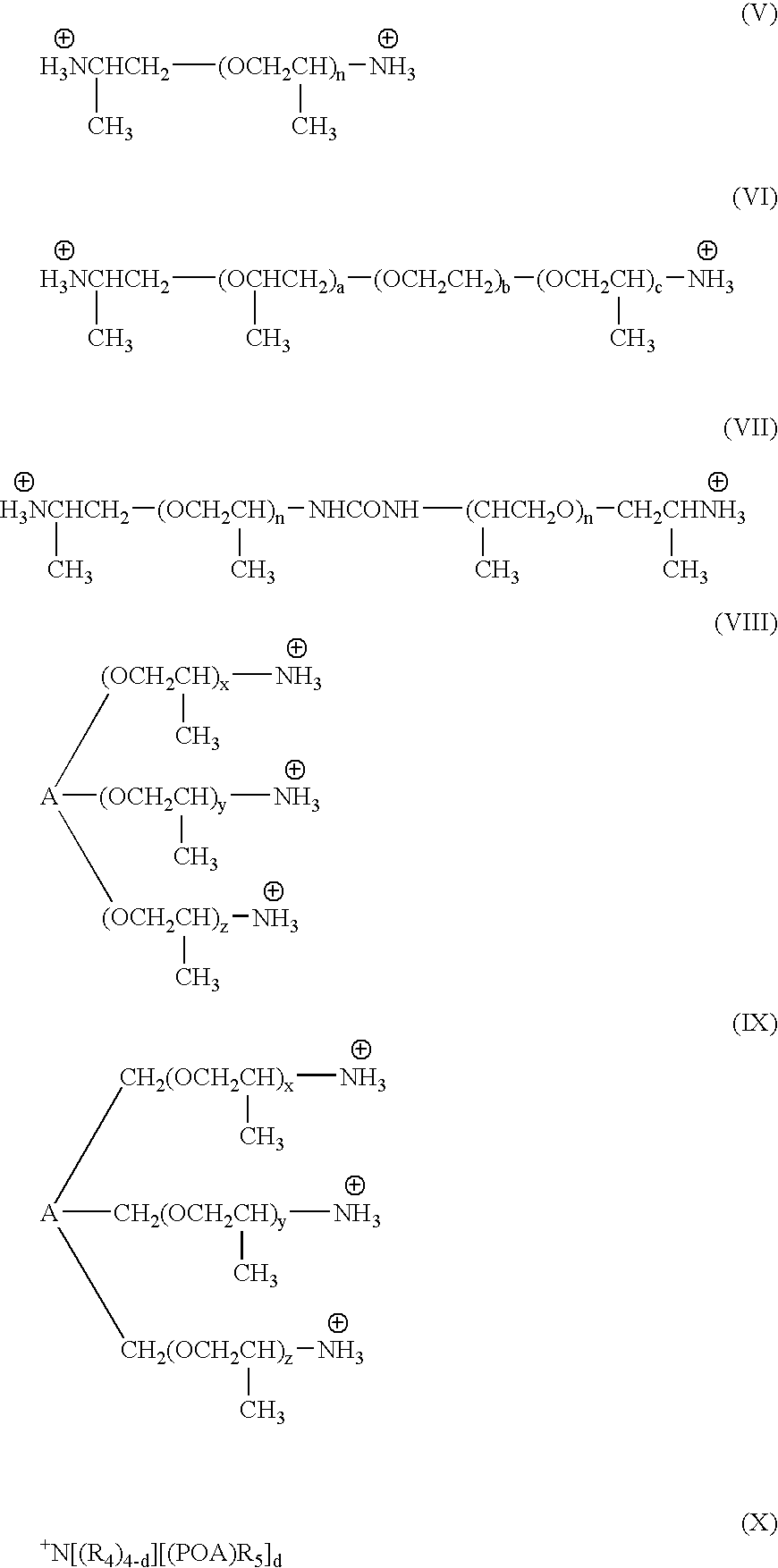

The present invention is directed to an antistatic pressure sensitive adhesive. The antistatic pressure sensitive adhesive comprises a pressure sensitive adhesive, and an antistatic agent comprising at least one organic salt. Certain embodiments of the antistatic pressure sensitive adhesive also have a luminous transmission of greater than about 89% according to ASTM D 1003-95. Additional embodiments of the antistatic pressure sensitive adhesive have a haze of less than about 5% according to ASTM D 1003-95, and in specific embodiments the haze is less than about 2% according to ASTM D 1003-95.

Owner:3M INNOVATIVE PROPERTIES CO

Thermal- and chemical-resistant acid protection coating material and spin-on thermoplastic adhesive

New compositions for use as protective coatings and / or adhesives are provided. The compositions comprise a hydrocarbon resin (e.g., terpene rosin) and a rubber (e.g., EPDM) dispersed or dissolved in a solvent system. The solvent system is preferably a single-solvent system, and the compositions are preferably free of surfactants, dyes, and chromophores. The compositions can be cured or dried to form layers or films that are chemically and thermally resistant, but that can be readily dissolved and removed at the appropriate stage in the fabrication process.

Owner:BREWER SCI

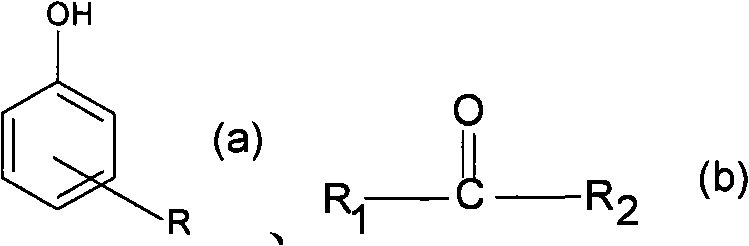

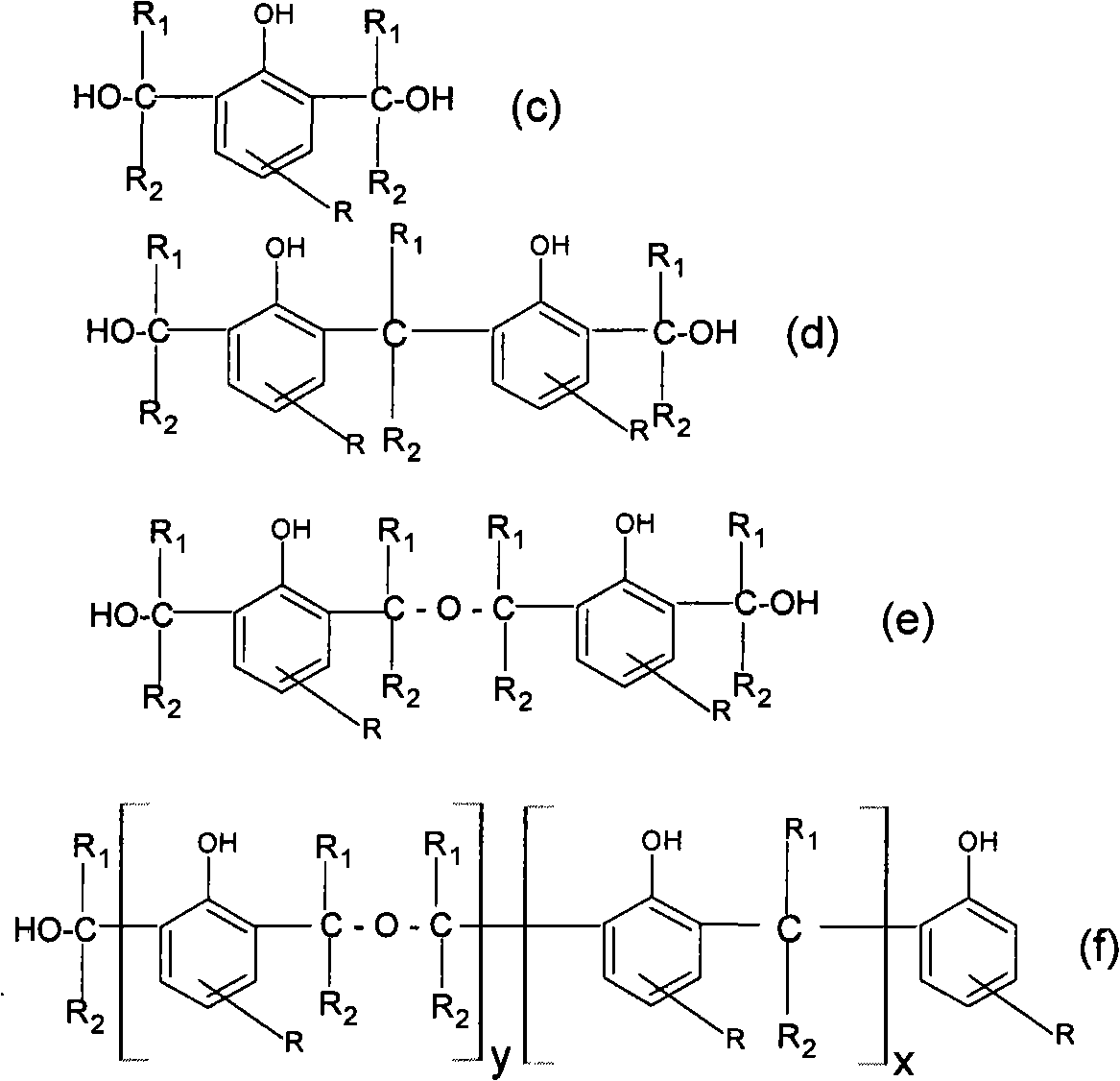

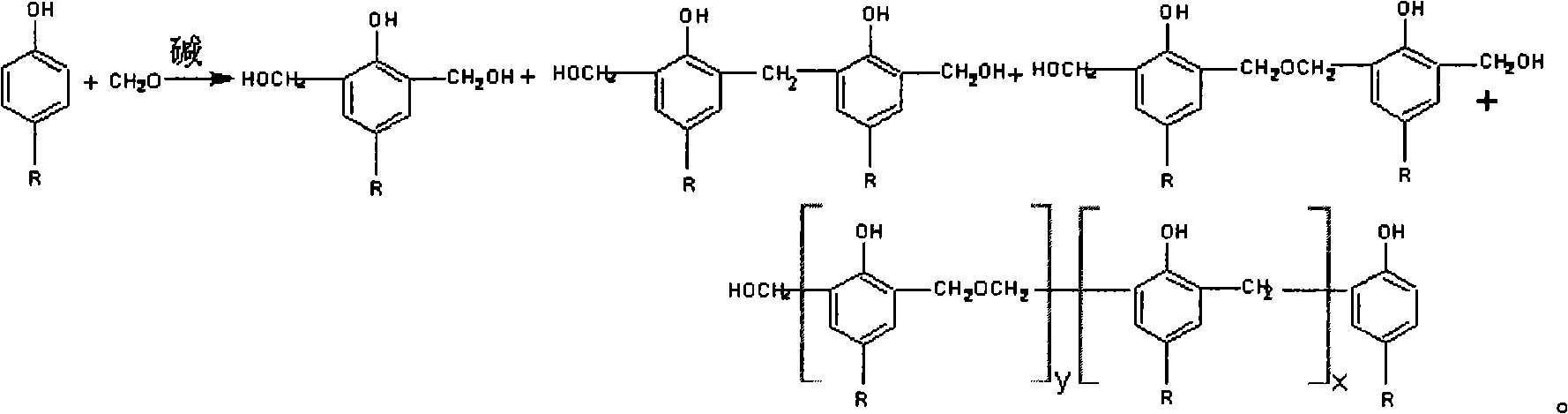

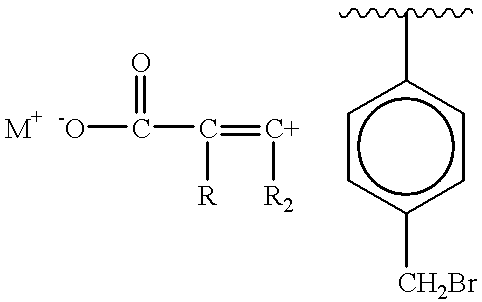

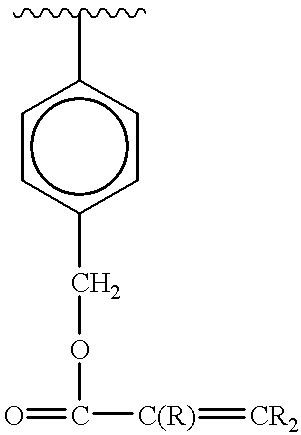

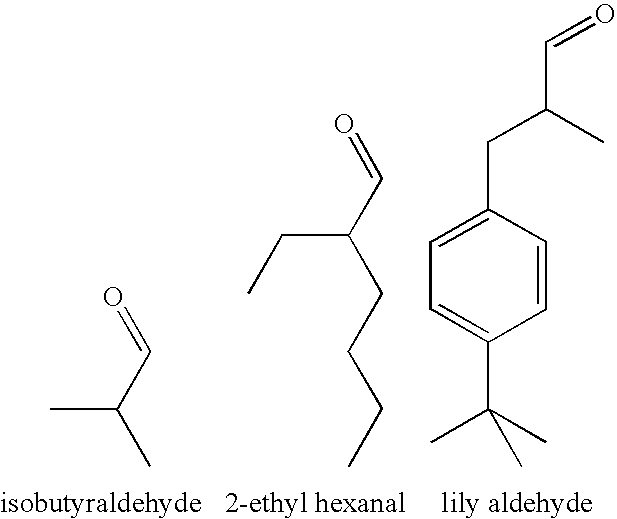

Modified phenolic tackifying resins for rubber compounding applications

This invention is related to modified alkylphenol aldehyde resins and a method for preparing them from the reactions of alkylphenols, aldehydes, amines, rosins and fatty acids. When used in rubber compounds, these modified alkylphenol aldehyde resins provide much improved tack properties.

Owner:SINO LEGEND CHINA CHEM

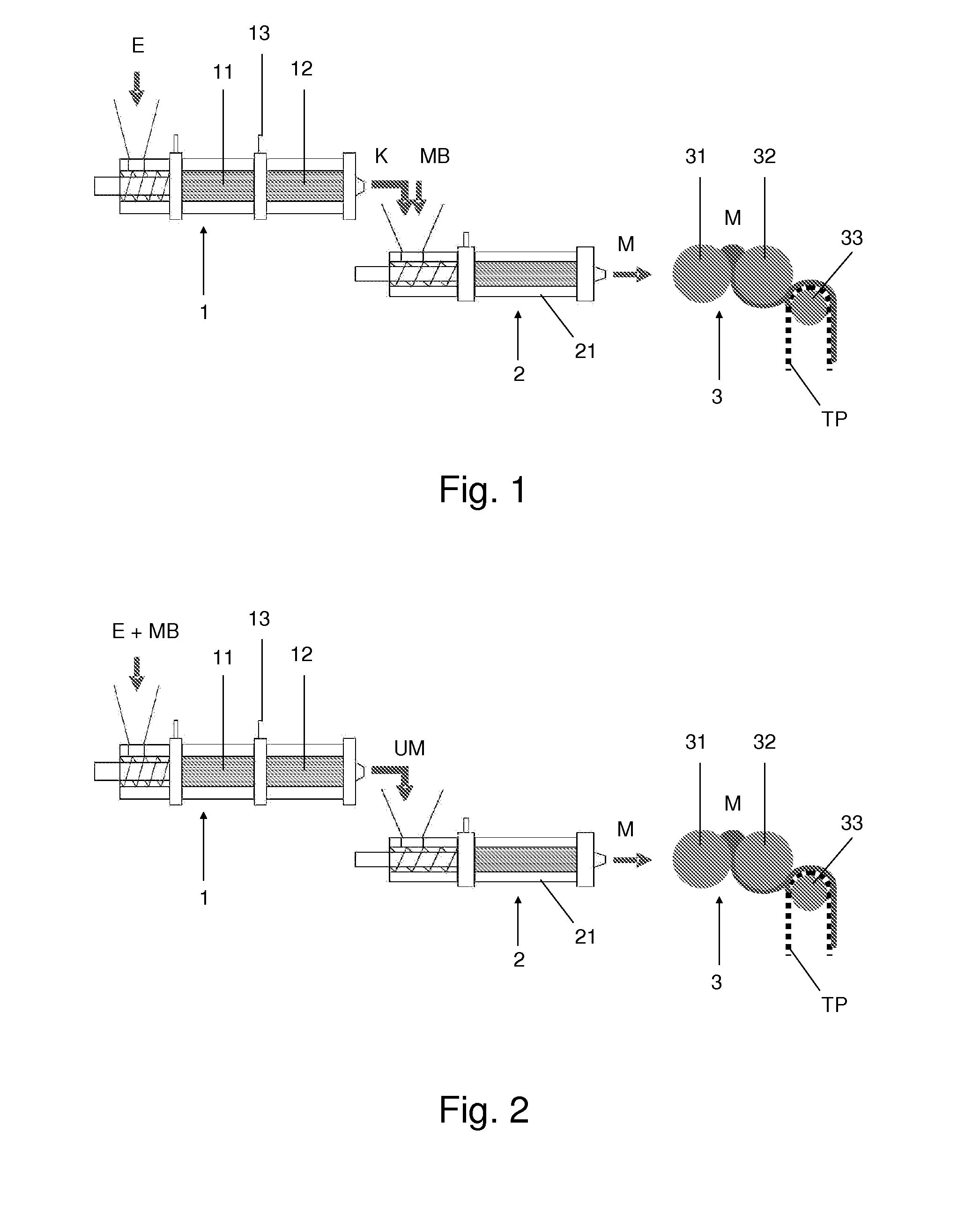

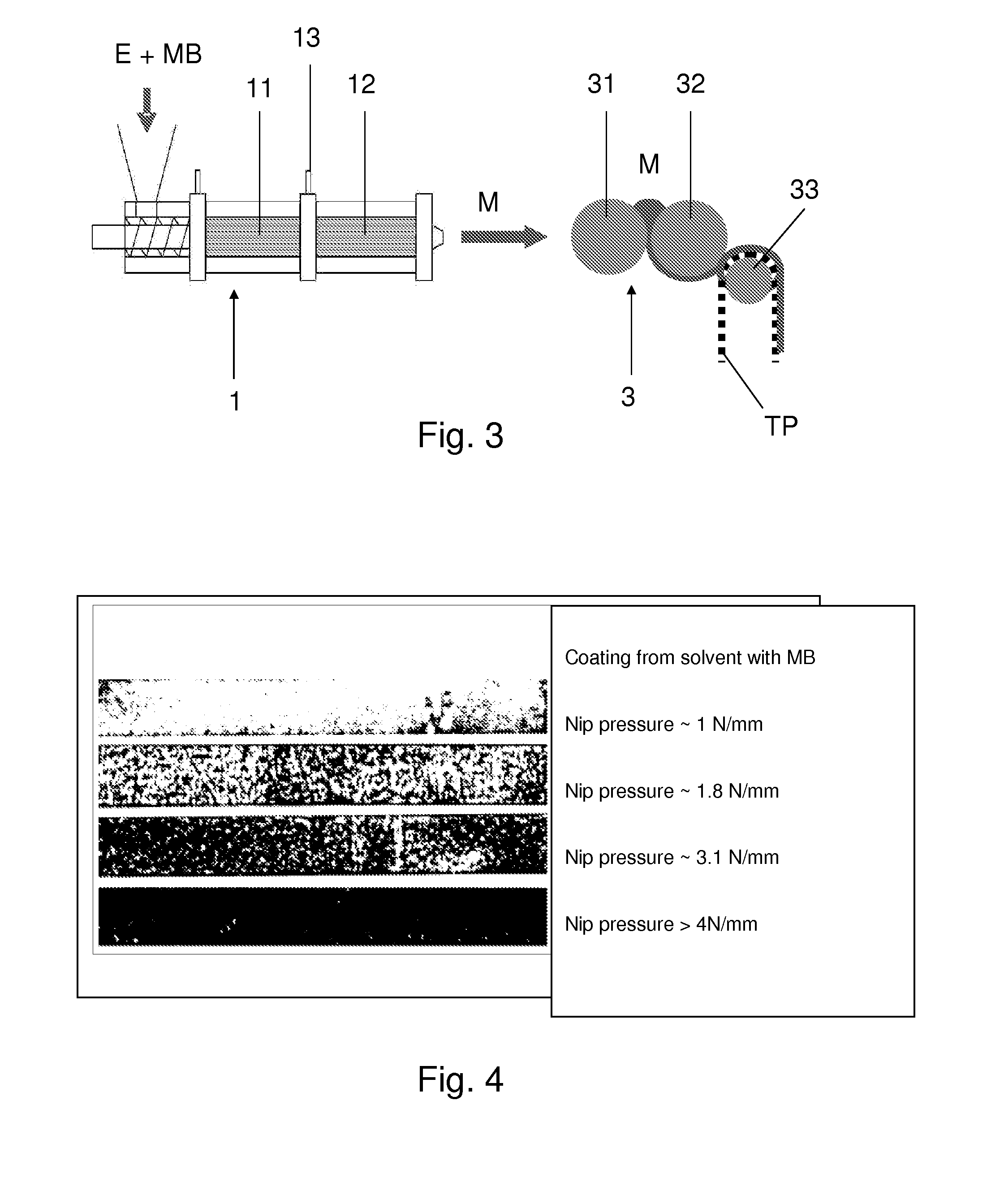

Foamed adhesive, more particularly pressure-sensitive adhesive, process for the production and also the use thereof

InactiveUS20090181250A1Natural rubber adhesivesMacromolecular adhesive additivesPolymer scienceMicrosphere

Adhesive, more particularly pressure-sensitive adhesive, which comprises expanded microballoons, the bond strength of the adhesive comprising the expanded microballoons being reduced by not more than 30%, preferably not more than 20%, more preferably 10%, in comparison to the bond strength of an adhesive of identical coatweight and formula which has been defoamed by the destruction of the voids produced by the expanded microballoons.

Owner:TESA SE

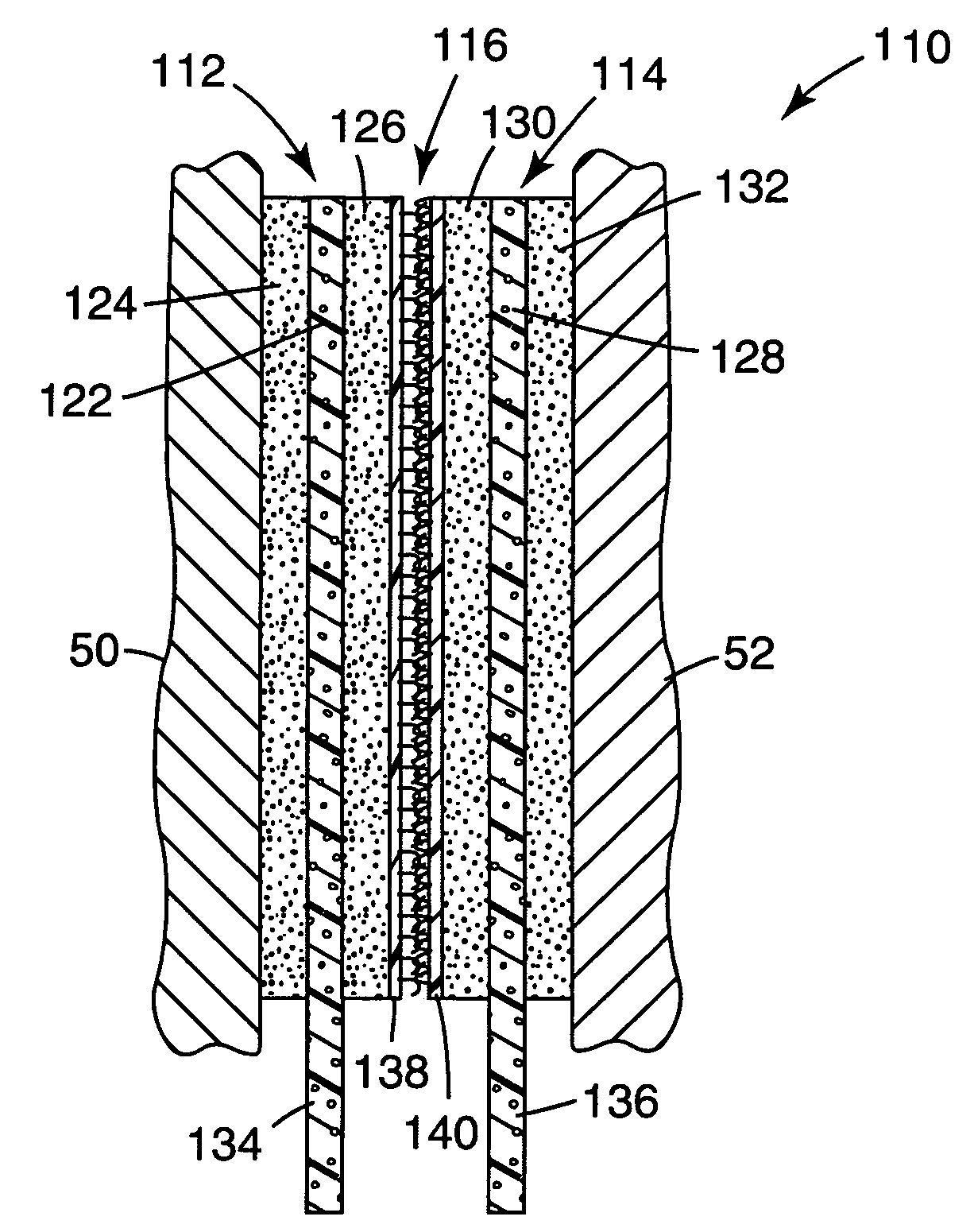

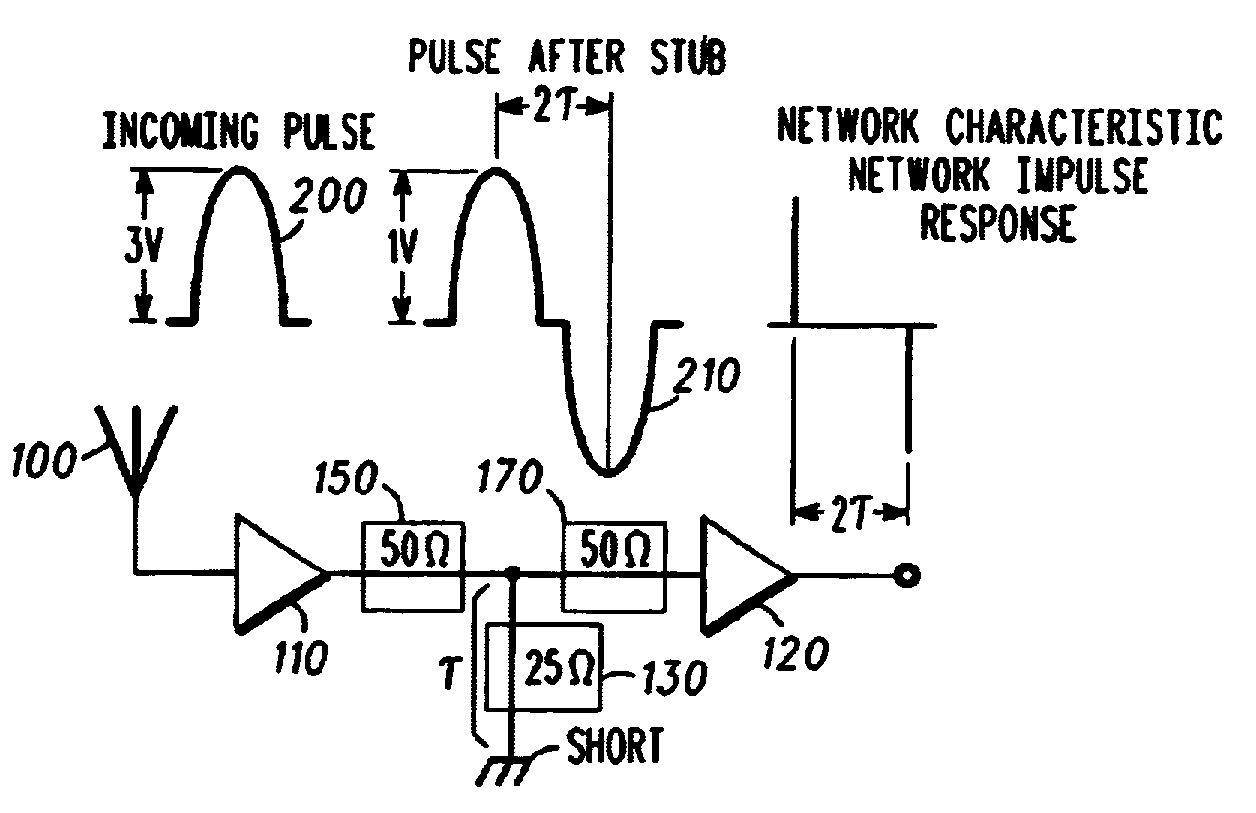

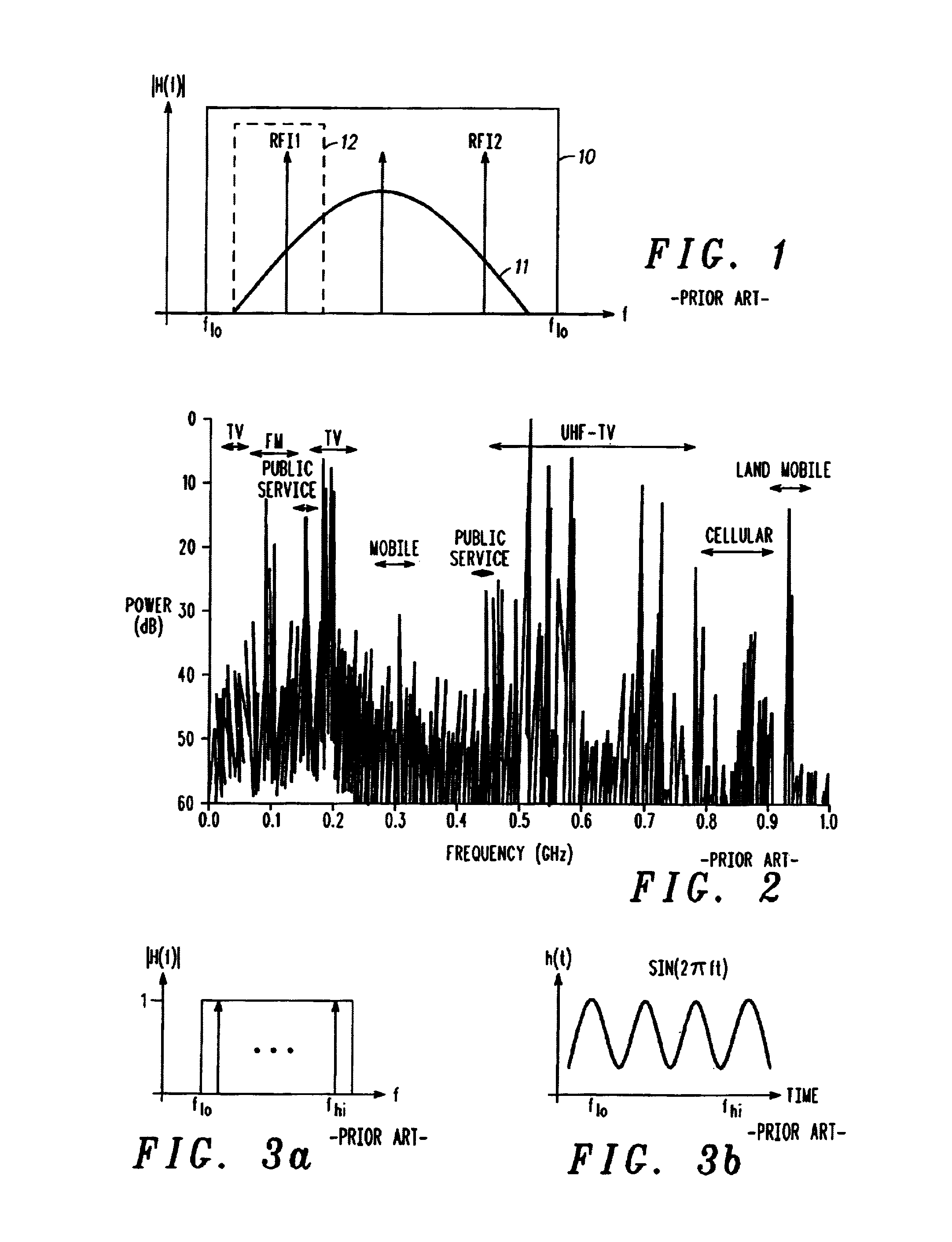

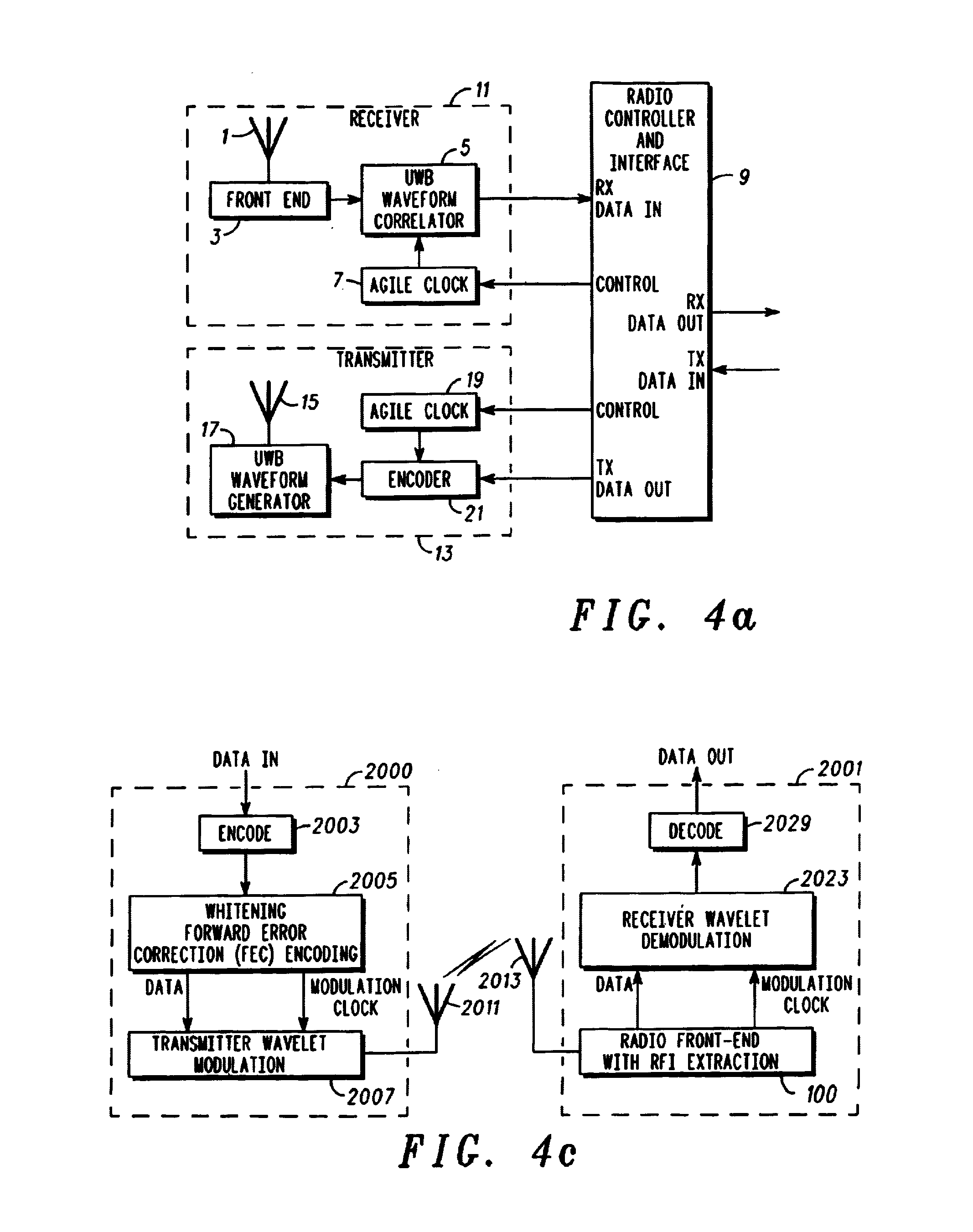

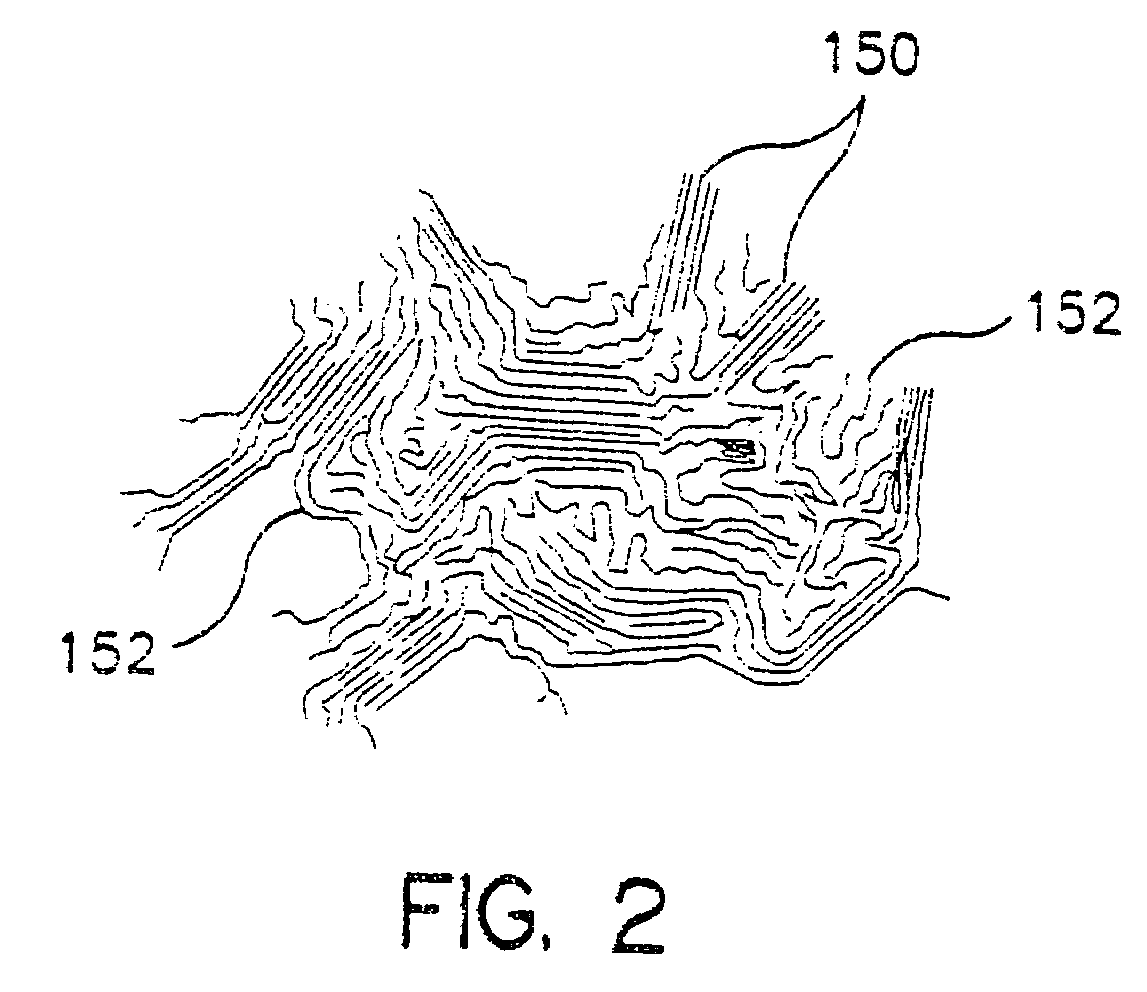

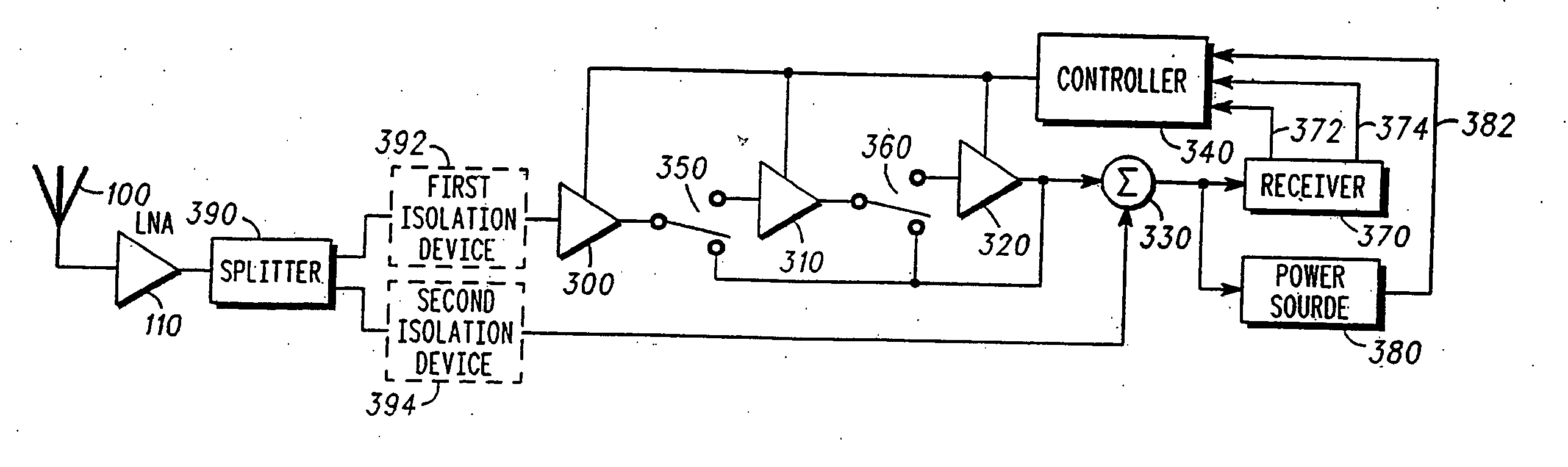

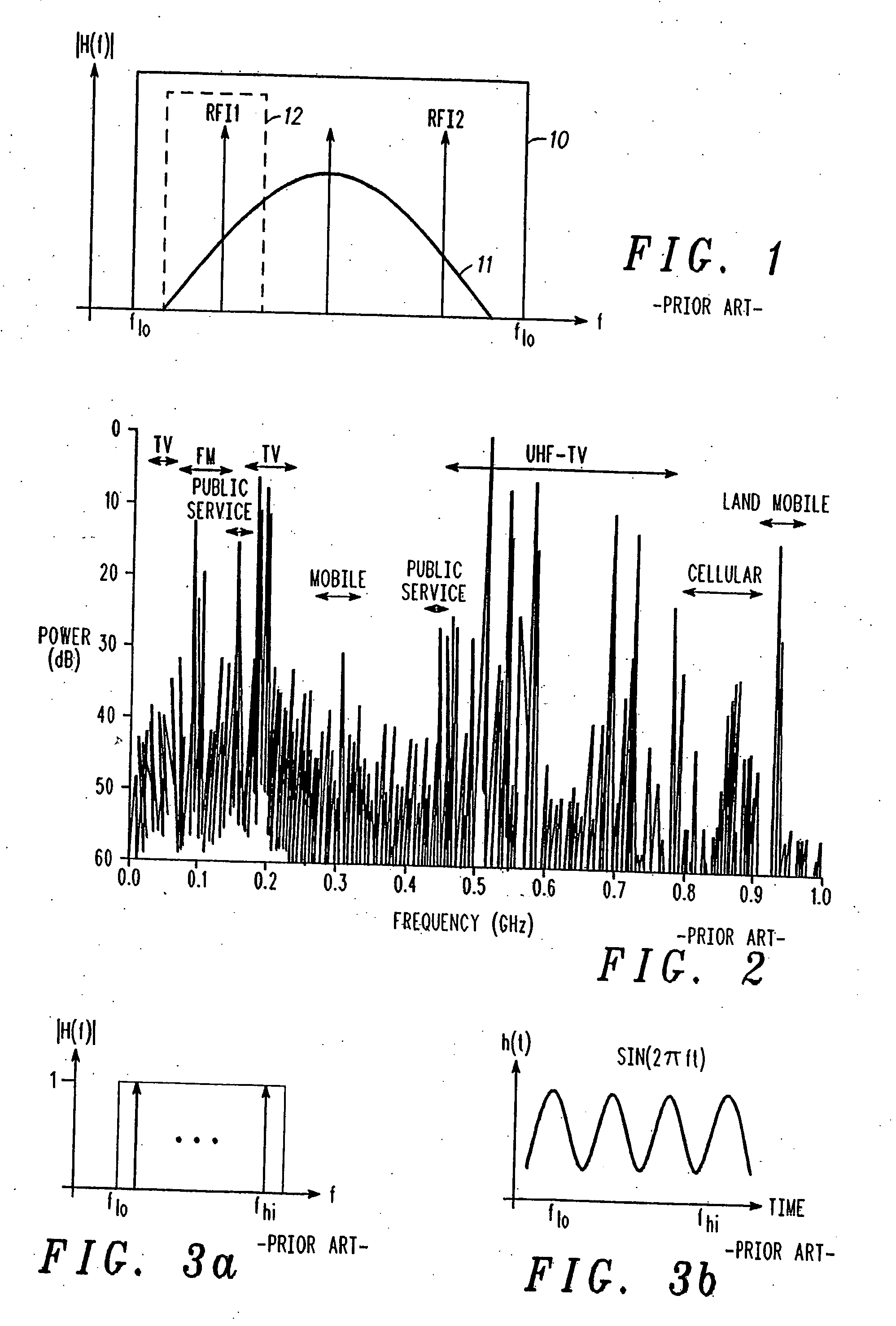

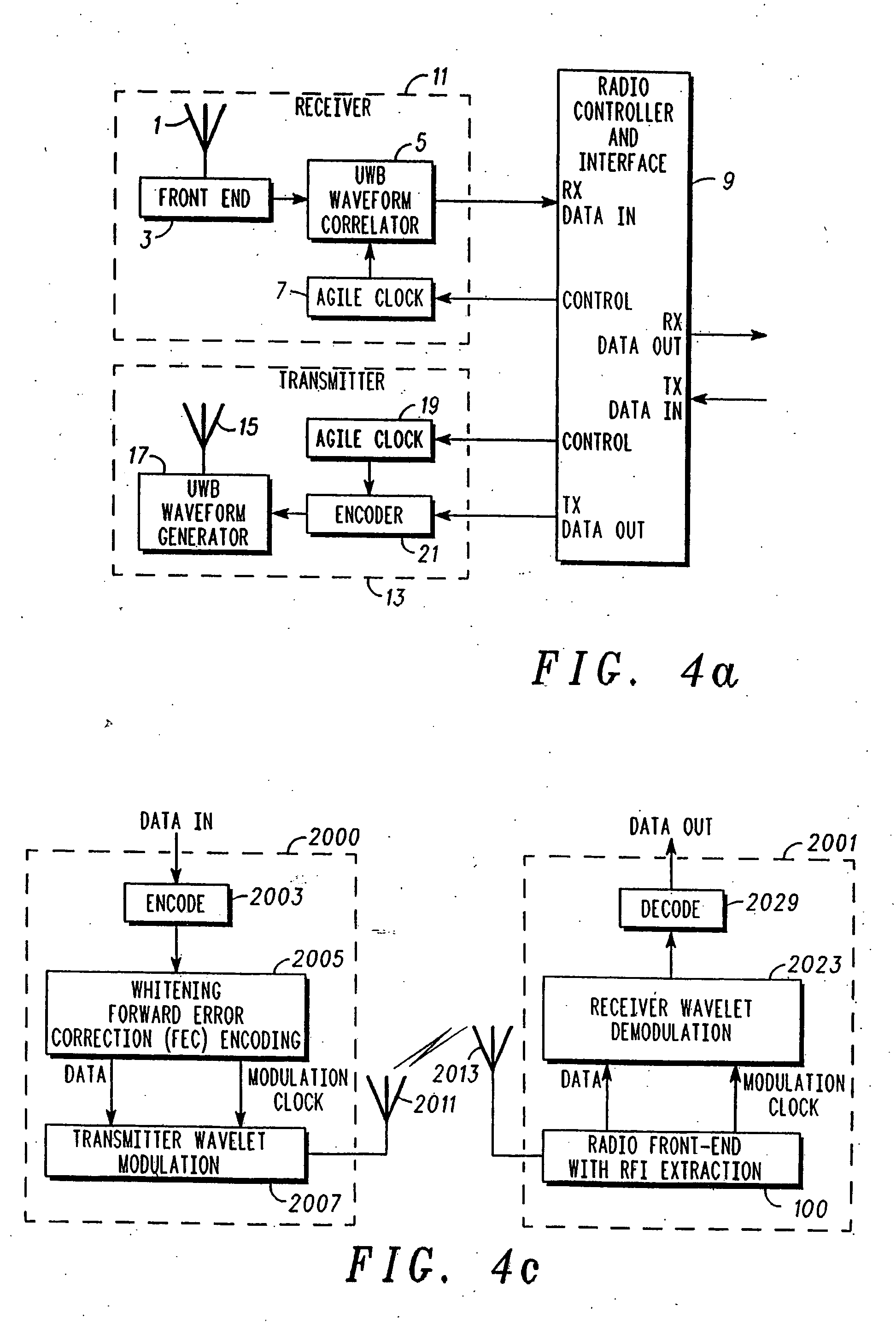

Analog signal separator for UWB versus narrowband signals

InactiveUS7006553B1Improve dynamic rangeAvoid saturationTyre partsTelevision system detailsFrequency spectrumContinuous tone

A system, method, and computer program product for removing “narrowband” interference from a broader spectrum containing a UWB signal, in a receiver of the UWB signal. The RFI is extracted from a broader spectrum to remove interference from the UWB signal, by employing an impulse response in a radio front-end of the UWB receiver that is matched with an incoming wavelet employed as part of a UWB signal to be received, matching the impulse response to the wavelet and its time-shifted and inverted versions, passing the wavelet unscathed through the receiver, and excising narrowband signals (continuous tones). Exemplary embodiments for the RFI extraction mechanism include a transmission line circuit, an active transmission line circuit, and an adaptable, controllable phase delay circuit.

Owner:NORTH STAR INNOVATIONS

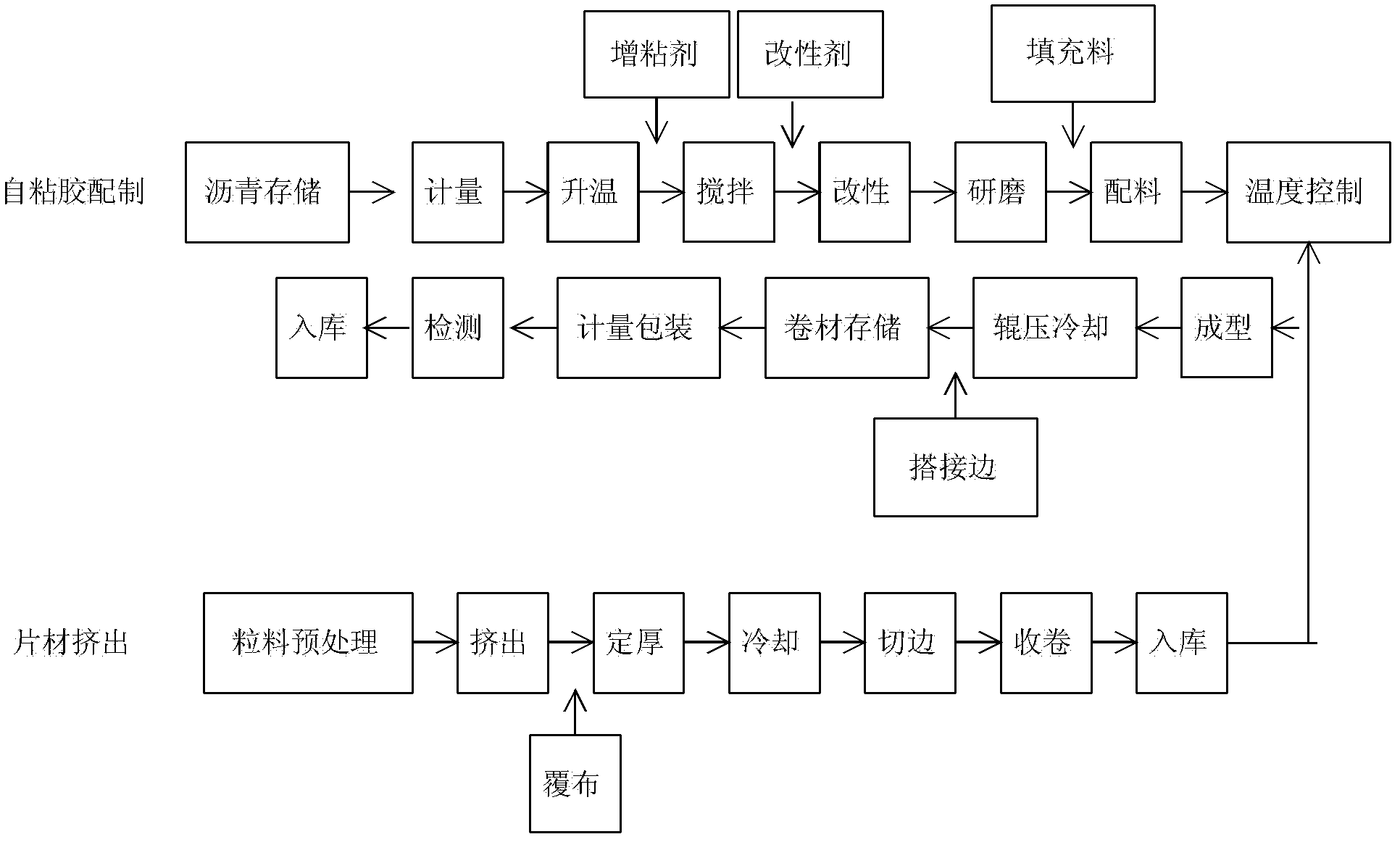

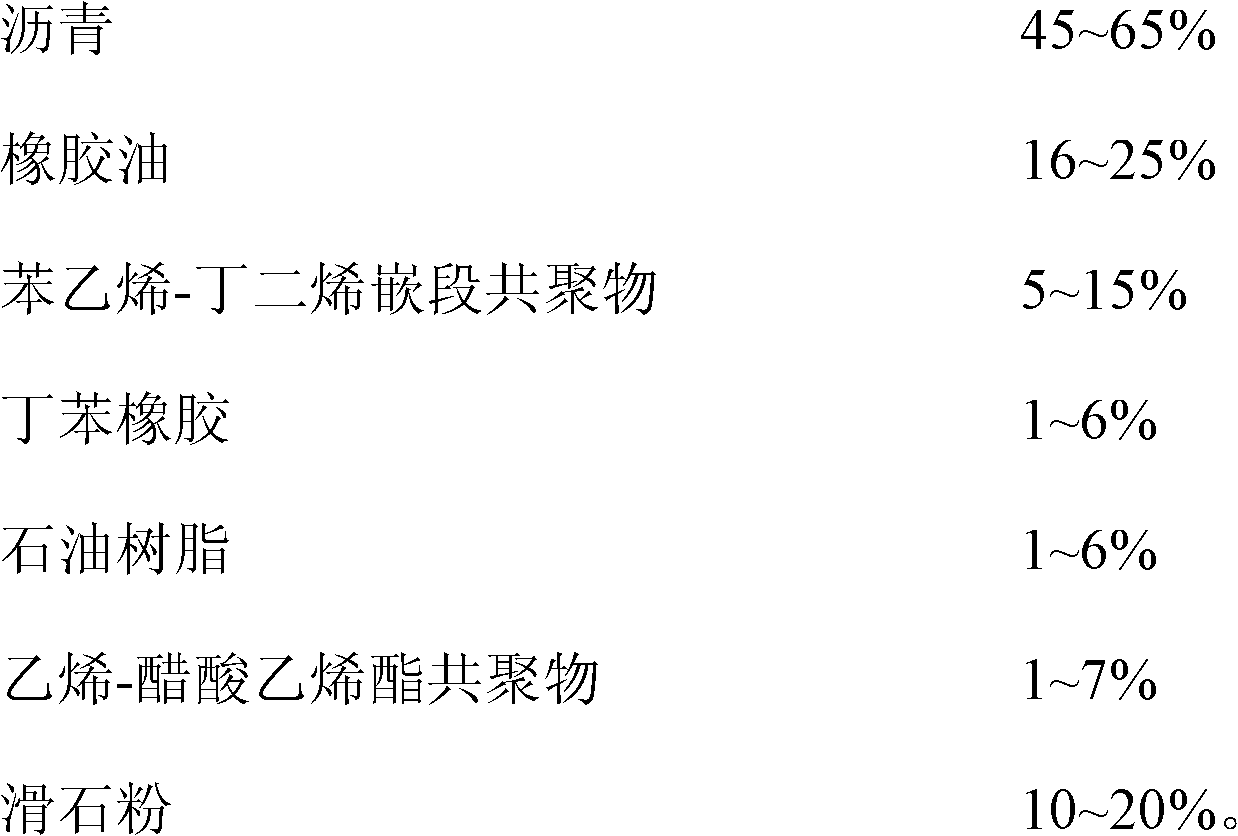

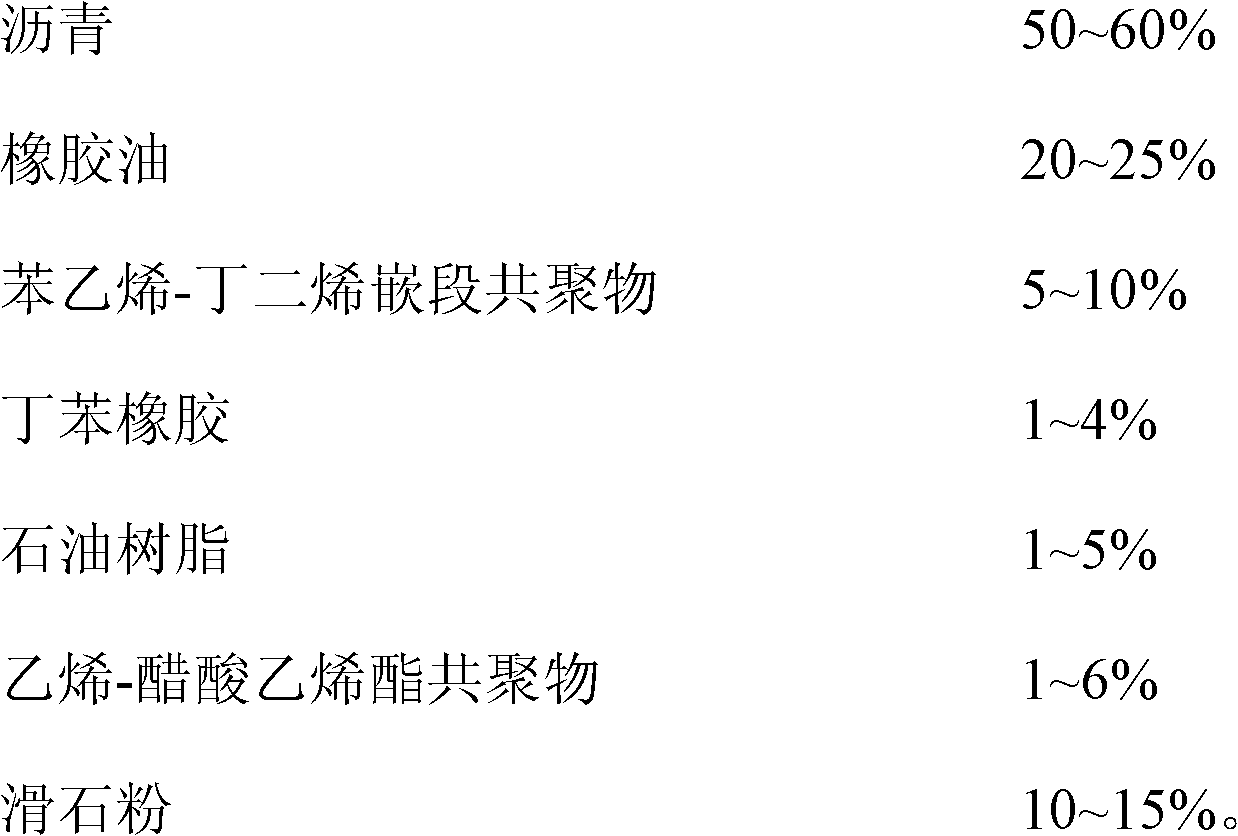

Asphalt self-adhesive and high-polymer self-adhesion rubber waterproof coiled material prepared from asphalt self-adhesive

InactiveCN102559135AGood compatibilityHigh composite strengthMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesUltimate tensile strengthButadiene-styrene rubber

The invention discloses asphalt self-adhesive. The asphalt self-adhesive comprises the following components in percentage by weight: 45 to 65 percent of asphalt, 16 to 25 percent of rubber oil, 5 to 15 percent of styrene butadiene styrene (SBS), 1 to 6 percent of styrene butadiene rubber (SBR), 1 to 6 percent of petroleum resin, 1 to 7 percent of ethylene vinyl acetate (EVA), and 10 to 20 percent of talcpowder. The invention also provides a high-polymer self-adhesion rubber waterproof coiled material which comprises a non-woven fabric coating, a high-polymer sheet coating, and an asphalt self-adhesive coating which consists of the asphalt self-adhesive from bottom to top. Two ends of the waterproof coiled material are provided with joint sides. The asphalt self-adhesive contains EVA, so the compatibility of the self-adhesive and a high-polymer sheet is improved, and compounding intensity of the high-polymer sheet coating is improved. The problem that the high-polymer sheets cannot be jointed reliably in a self-adhesion joint process is solved, so the coiled materials are jointed by the adhesive; and the coiled materials can be adhered firmly and reliably, and adjusted freely and flexibly.

Owner:SHENZHEN ZHUOBAO TECH

A tpe composition that exhibits excellent adhesion to textile fibers-

InactiveUS20020010265A1Increase stiffnessHigh modulusFibre typesOther rubber adhesivesTextile fiberPolyester

A combination of a low flexural modulus and low crystallinity polyolefin and a functionalized polyolefin were found to result in an olefin composition with excellent adhesion to metals and polar polymers (e.g. polyesters, polyamides, etc) especially fibers therefrom. When these two polyolefins were added to a thermoplastic vulcanizate (e.g. used to partially or fully replace the semicrystalline polyolefin of a thermoplastic vulcanizate), the thermoplastic vulcanizate was found to have the necessary adhesion to form fiber reinforced thermoplastic vulcanizate.

Owner:EXXONMOBIL CHEM PAT INC

Partially crosslinked microspheres

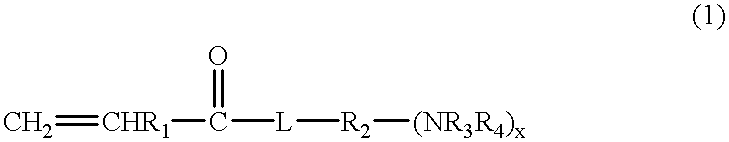

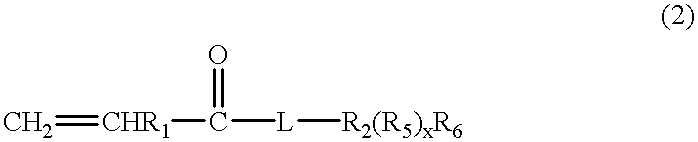

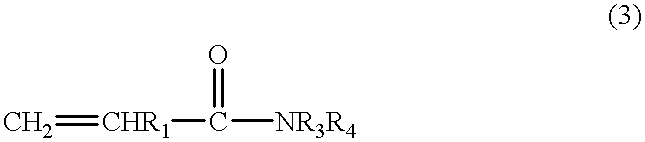

InactiveUSRE37563E1Improve adhesionEasy to disassembleLayered productsEster polymer adhesivesElastomerMeth-

An adhesive composition is provided comprising:(a) a plurality of polymeric, elastomeric microspheres wherein the microspheres are the reaction product of reactants comprising polymerizable starting materials comprising at least one C4-C14 alkyl (meth)acrylate monomer and optionally at least one comonomer and have a solvent soluble portion that is 30-98% of the microsphere.

Owner:3M INNOVATIVE PROPERTIES CO

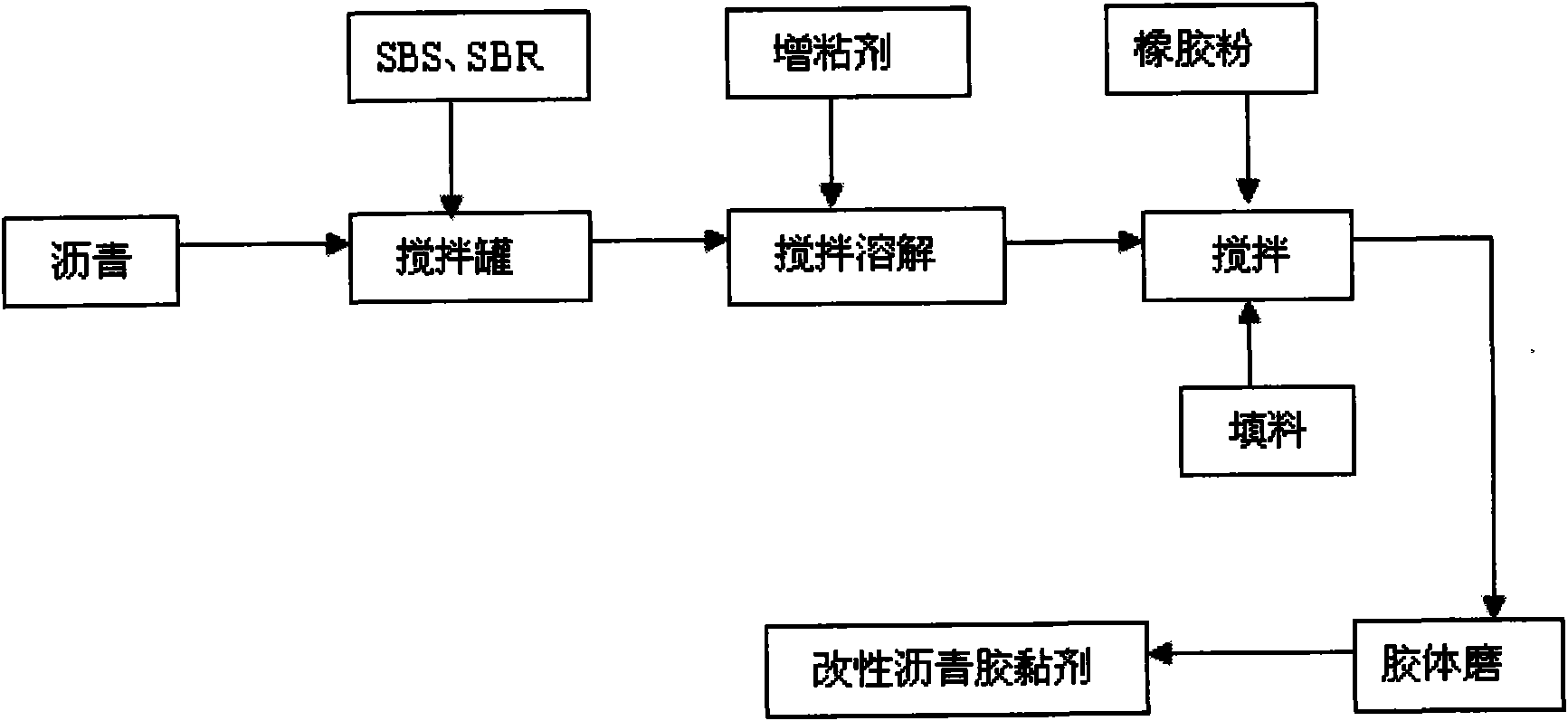

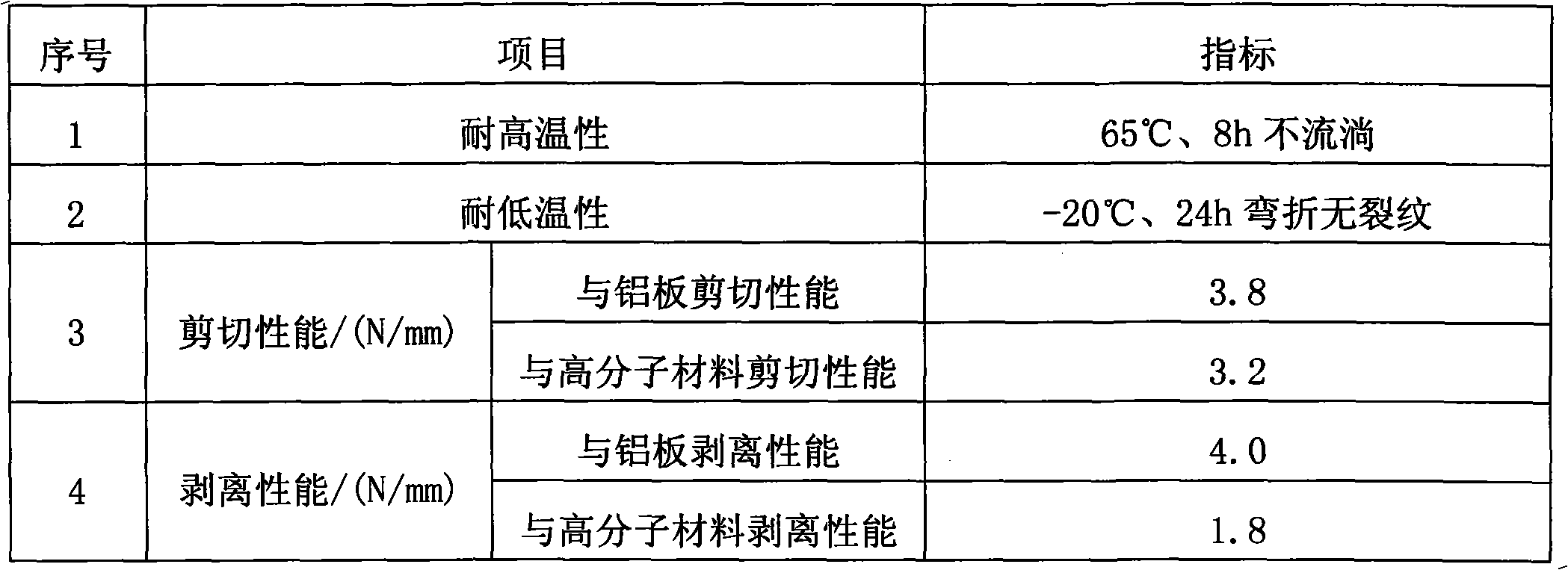

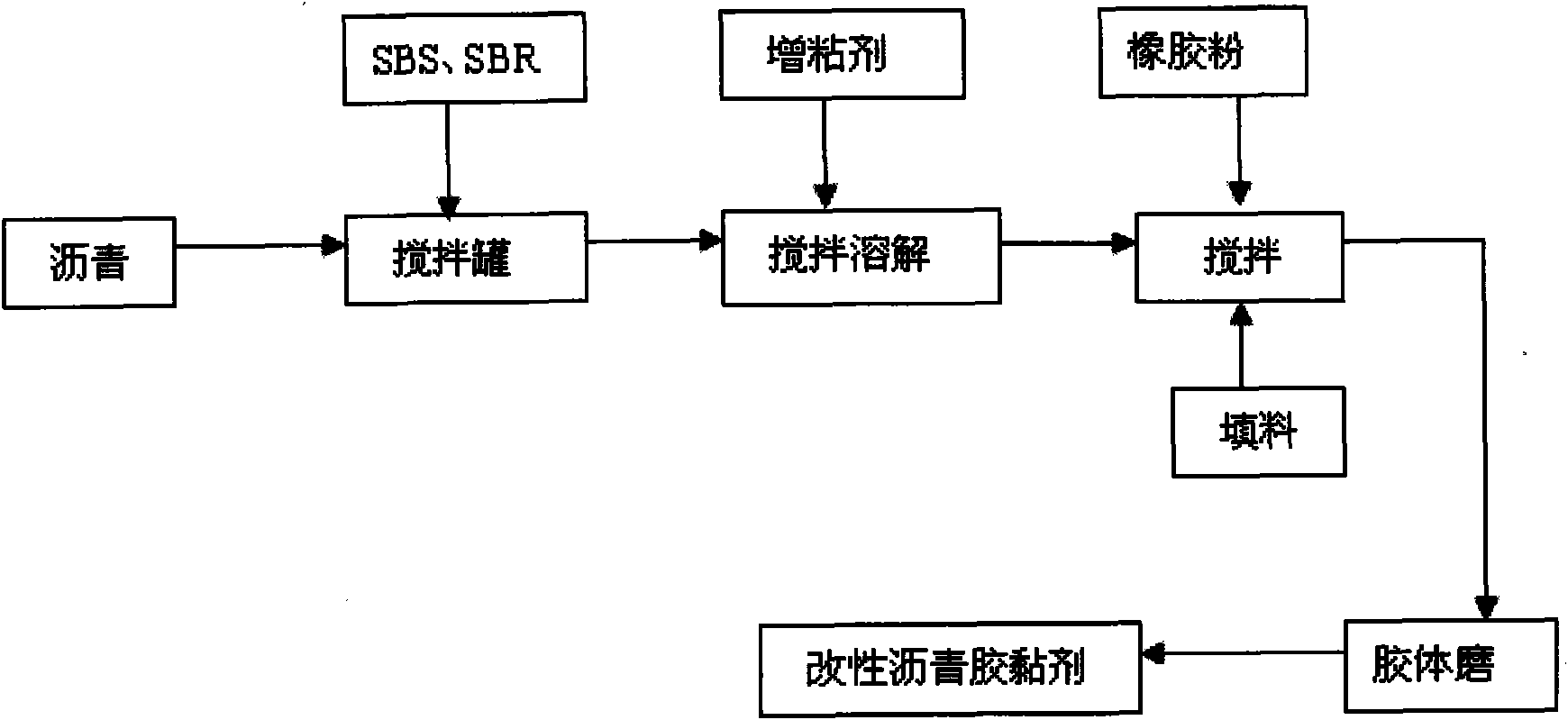

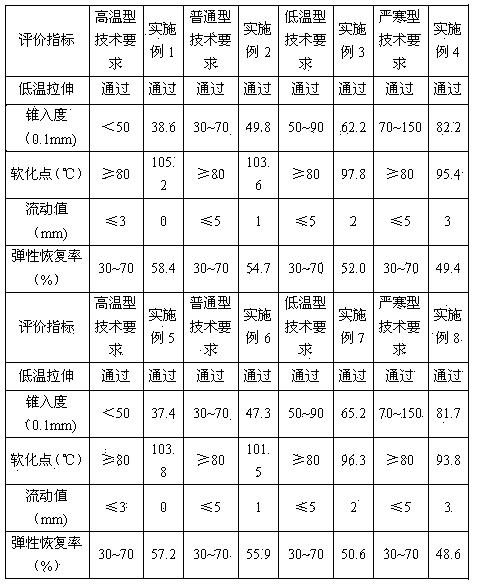

Modified asphalt adhesive and preparation method thereof

InactiveCN101982517AImprove adhesionImprove high temperature resistanceBituminous material adhesivesOther rubber adhesivesPolymer scienceAdhesive

The invention discloses a modified asphalt adhesive and a preparation method thereof. The preparation method comprises the following steps: pumping fused asphalt in a stirring kettle; starting a stirring paddle, wherein, the stirring speed is 60-200 revolutions / min, and the material temperature is 120-150 DEG C; stirring for 10-30min; adding styrene-butadiene block copolymer (SBS) and styrene butadiene rubber (SBR) and continuously stirring; heating to 160-180 DEG C; stirring for 1-2h; keeping the stirring temperature and the stirring speed; adding tackifier; continuously stirring for 30-60min; adding rubber powder and filler in sequence; continuously stirring for 30-60min; and grinding by a colloid mill to obtain the modified asphalt adhesive with good performance.

Owner:天津市耀新科技发展有限公司

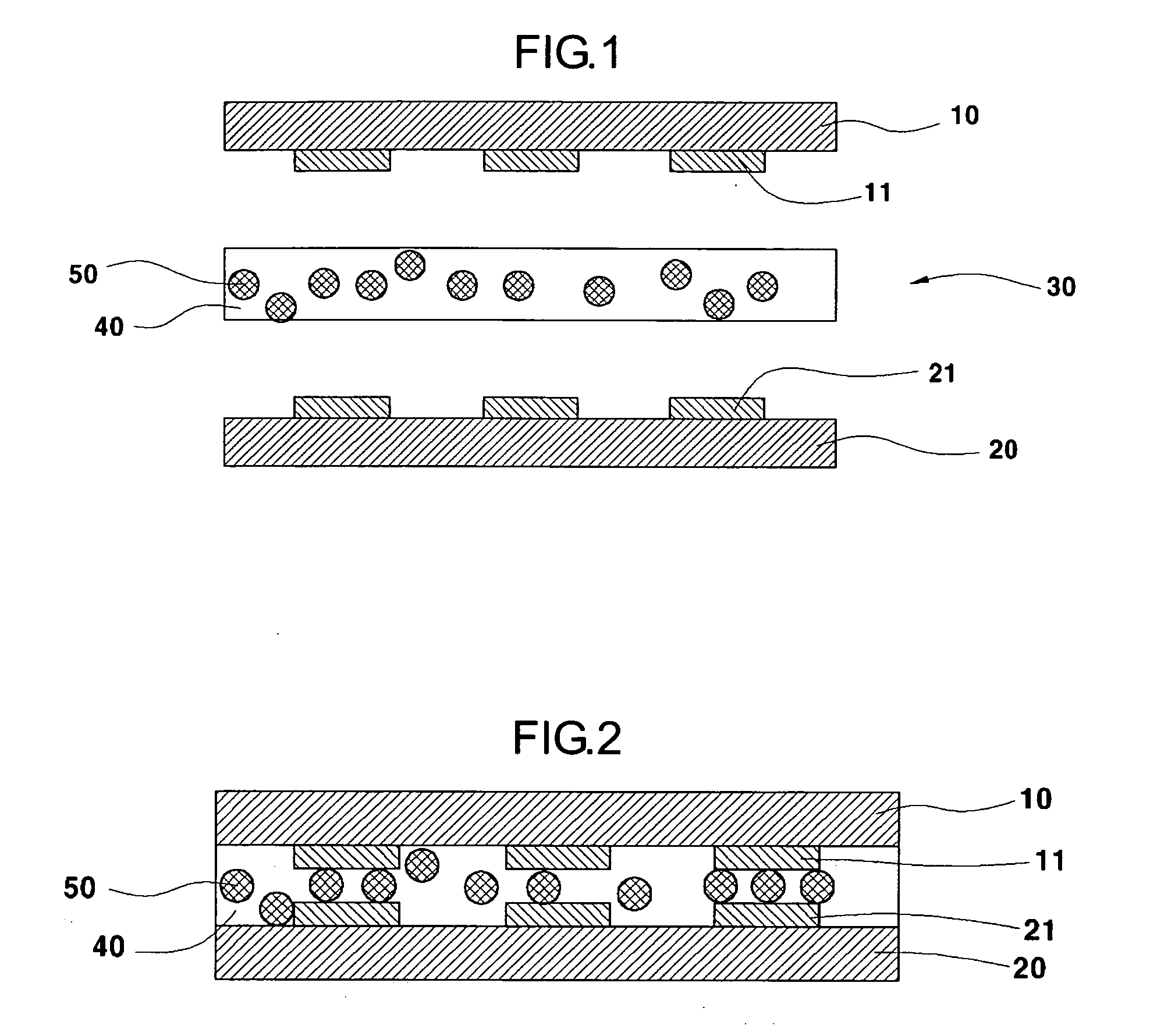

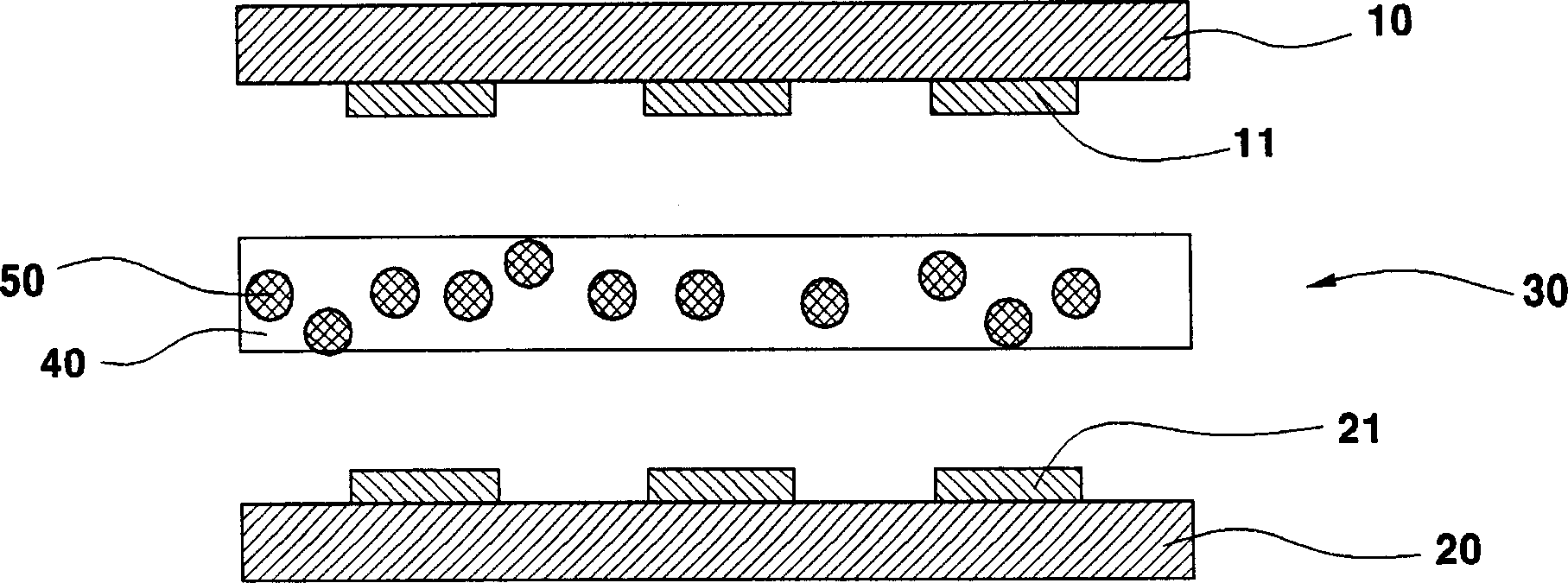

Isotropic conductive adhesive and adhesive film using the same

InactiveUS20050288427A1Minimizes its contractionImprove connection reliabilityImpression capsConductive materialAnisotropic conductive adhesiveIsotropic conductive adhesives

The present invention discloses an anisotropic conductive adhesive comprising an insulating adhesive component and a number of conductive particles dispersed in the insulating adhesive component, wherein the insulating adhesive component contains a crosslinked rubber resin. The anisotropic conductive adhesive of the present invention prevents exfoliation of an adhesive or reduction in adhesive strength of circuit by minimizing its the heat-contraction occurring in the process of a polymerization or a hardening reaction when connecting micro-circuits, whereby a short circuit between adjacent electrodes can be prevented when connecting the circuits, and excellent connection reliability according to a long-term use is achieved.

Owner:H&S HIGH TECH +1

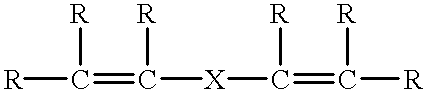

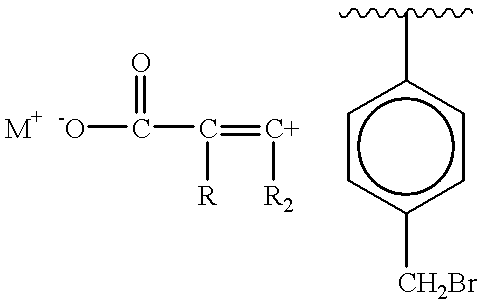

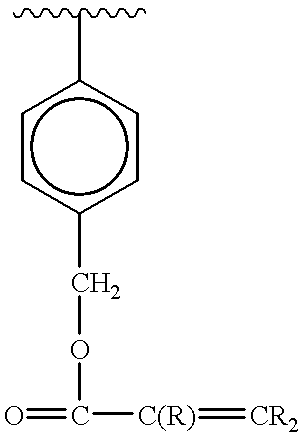

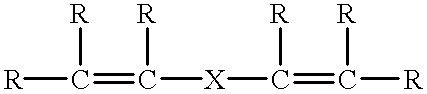

Fusible adhesives crosslinkable by radiation

To obtain an adhesive having both a high initial adhesive capacity and high heat resistance, a fusible adhesive which can be cross-linked by radiation and a low tendency to creep is provided. The adhesive contains 0 to 40 weight percent of at least one elastomer which cannot be cross-linked by radiation, 15 to 40 weight percent of at least one compound containing at least two olefinic double bonds, and 20 to 85 weight percent of at least one tackifier. The adhesive is especially suitable for use on high speed labeling machines.

Owner:HENKEL KGAA

Isotropic conductive adhesive and adhesive film using the same

InactiveCN1712483ASmall shrinkageAvoid short circuitPrinted circuit assemblingVinyl aromatic copolymer adhesivesAnisotropic conductive adhesiveIsotropic conductive adhesives

The present invention provides an anisotropic conductive adhesive comprising an insulating adhesive component and a large number of conductive particles dispersed in the insulating adhesive component, wherein the insulating adhesive component contains alternating Linked rubber resin. When connecting circuits, by minimizing the thermal shrinkage of the anisotropic conductive adhesive in the polymerization reaction or curing reaction, it is possible to prevent peeling of the adhesive or a decrease in the bonding strength of the circuit. It prevents short-circuit between adjacent electrodes and is excellent in long-term reliability.

Owner:H&S HIGHTECH

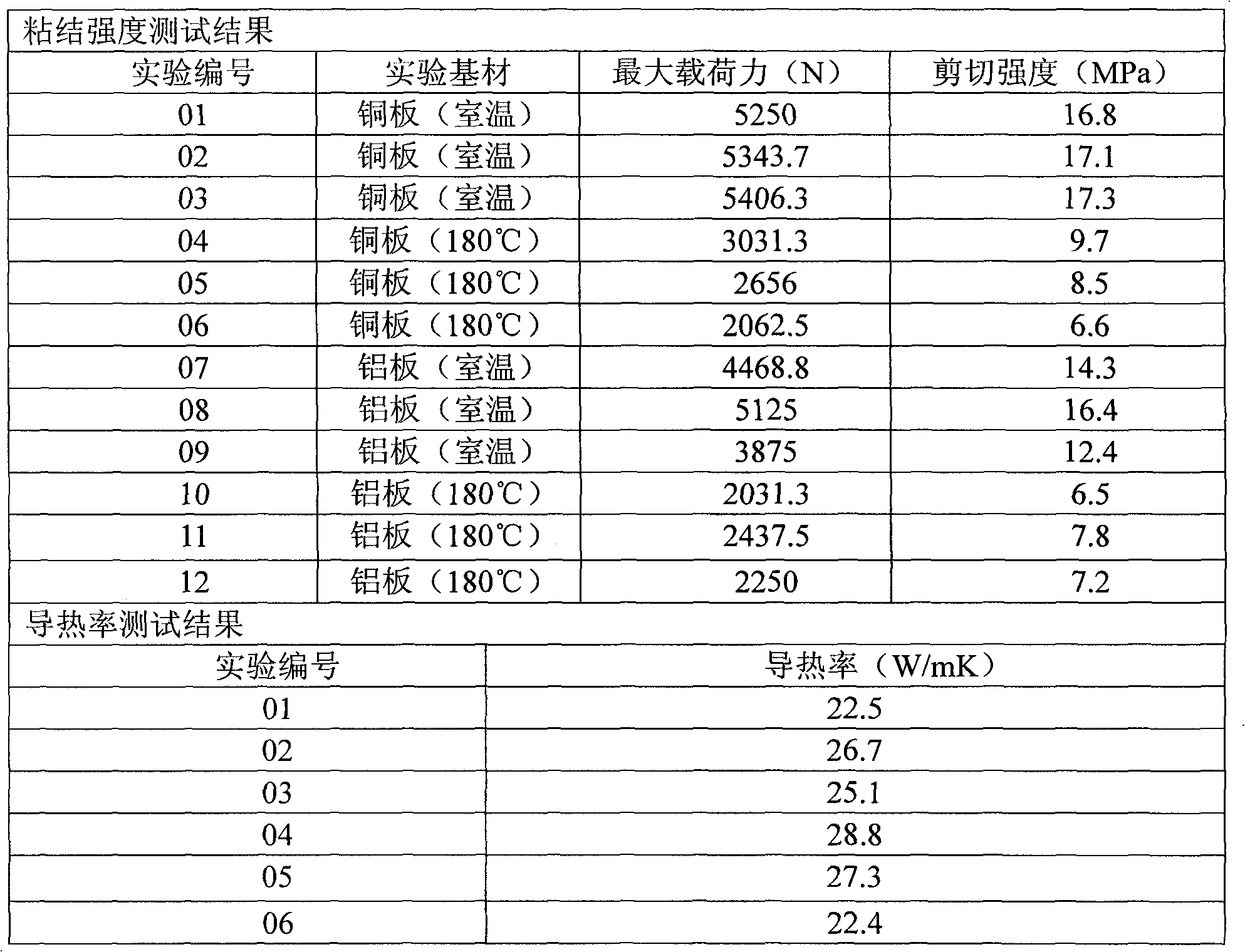

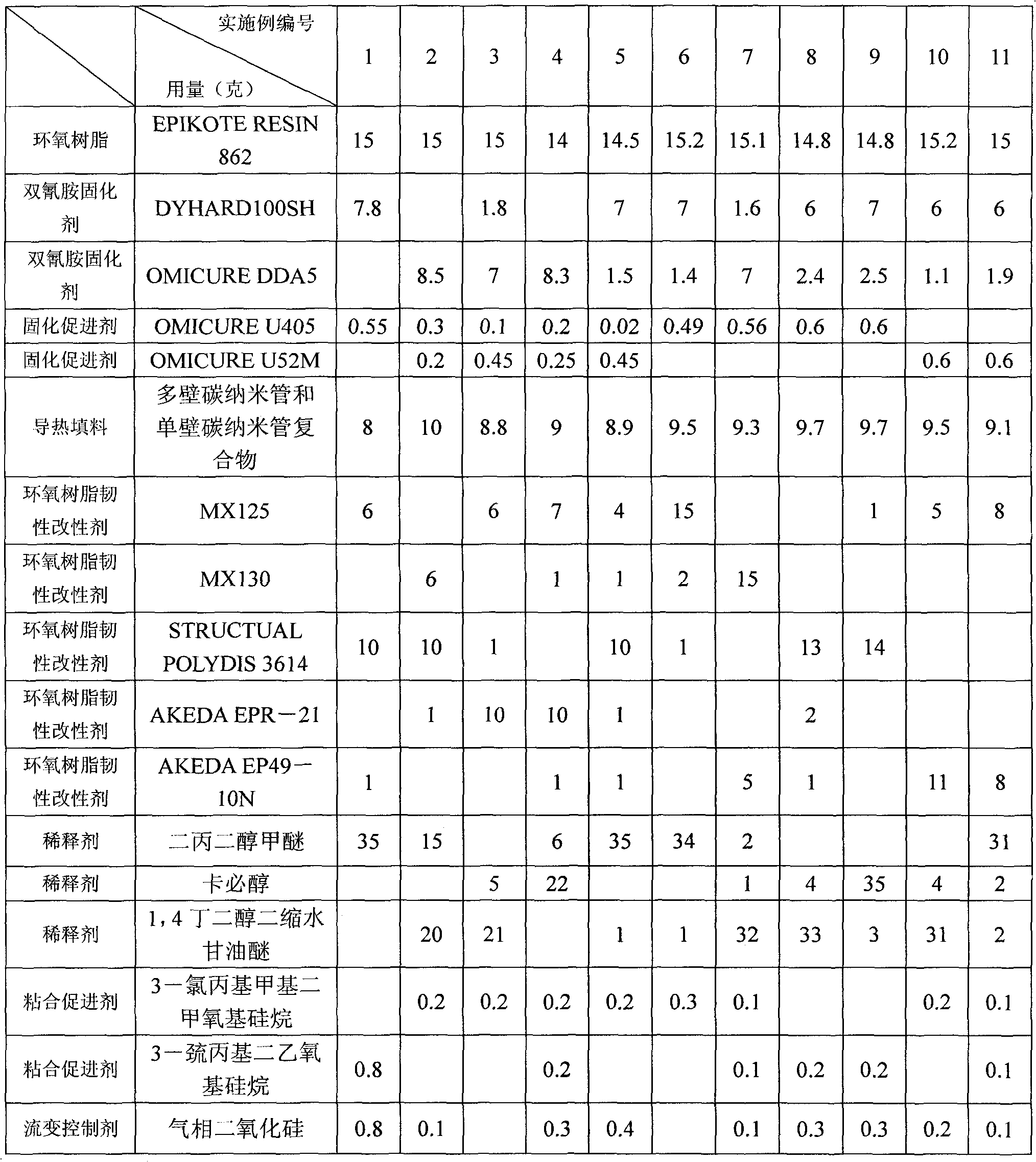

Isotropic high-performance thermal conductive adhesive for filling carbon nano tube

InactiveCN101831264AImprove thermal conductivityHigh bonding strengthNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEpoxyHigh energy

The invention discloses isotropic high-performance thermal conductive adhesive for filling a carbon nano tube, which belongs to the technical field of thermal conductive adhesive preparation. The thermal conductive adhesive comprises the following components in percentage by weight: 10 to 20 percent of at least one epoxy resin, 15 to 25 percent of epoxy resin toughness modifier, 6 to 11 percent of dicyandiamide, 0.1 to 1 percent of curing accelerator, 5 to 15 percent of thermal conductive filler, 30 to 40 percent of thinner, 0.5 to 0.8 percent of rheology controller, 0.5 to 0.8 percent of filler surface modifier, and 0 to 1 percent of flow additive and adhesive promoter. The thermal conductive adhesive has the advantages of high thermal conductivity, high adhesive strength, thermal resistance and the like, and has good adhesion to high-energy surfaces of metal, ceramic, glass and polymer.

Owner:CHANGZHOU HE RUN NEW MATERIAL TECH +1

Laminated structures having modified rubber-based adhesives

InactiveUS7241493B2Improve adhesionLess adhesivePersonal careSynthetic resin layered productsPolymer chemistryBond strength

Elastic attachment adhesive compositions of conventional rubber-based construction adhesive and a crystalline polymer have improved bond strength over conventional elastic attachment adhesives. The addition of a crystalline polymer to conventional rubber-based elastic attachment adhesive also results in elastic attachment adhesive compositions having improved bond strength. These elastic attachment adhesive compositions are particularly suitable for use in absorbent articles.

Owner:KIMBERLY CLARK WORLDWIDE INC

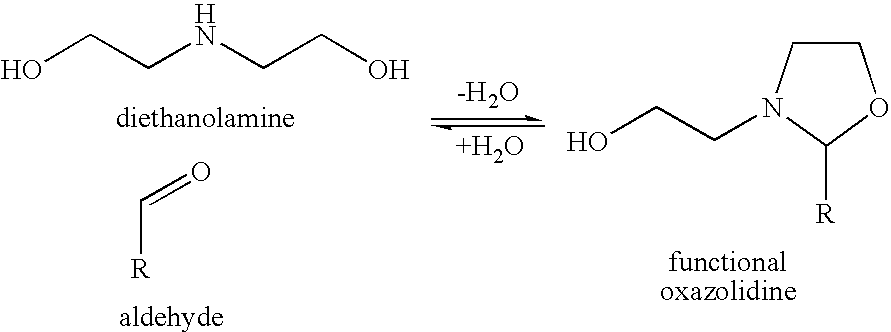

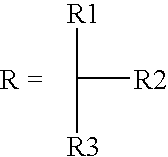

Reactive hot melt adhesive

ActiveUS20100152394A1Low volatile monomer contentImprove mechanical propertiesOrganic chemistryPolyureas/polyurethane adhesivesPolymer scienceOxazolidine E

Solvent free, moisture curable reactive hot melt adhesives are prepared using an oxazolidine functional prepolymer and a polyfunctional isocyanate.

Owner:HENKEL KGAA

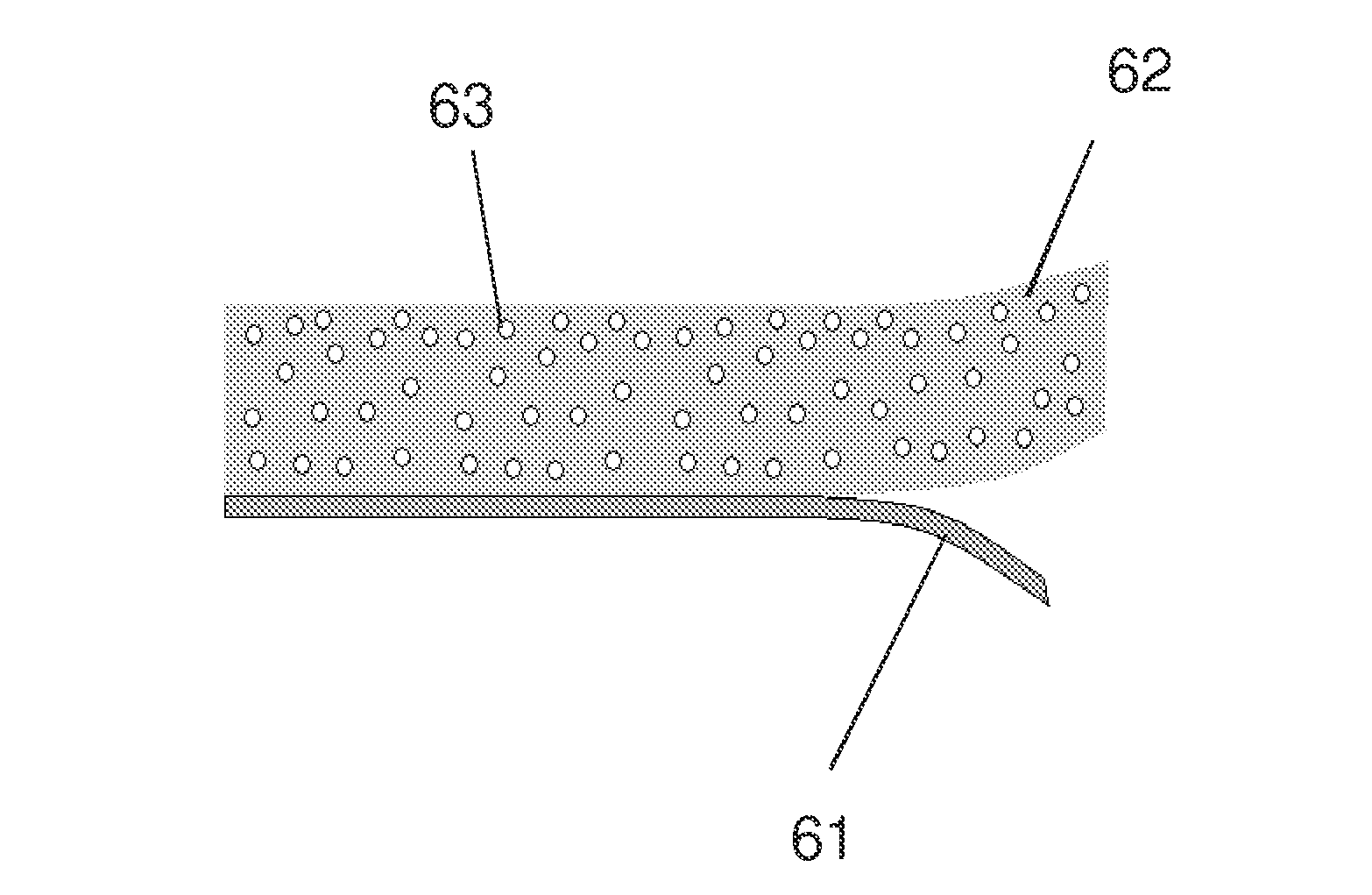

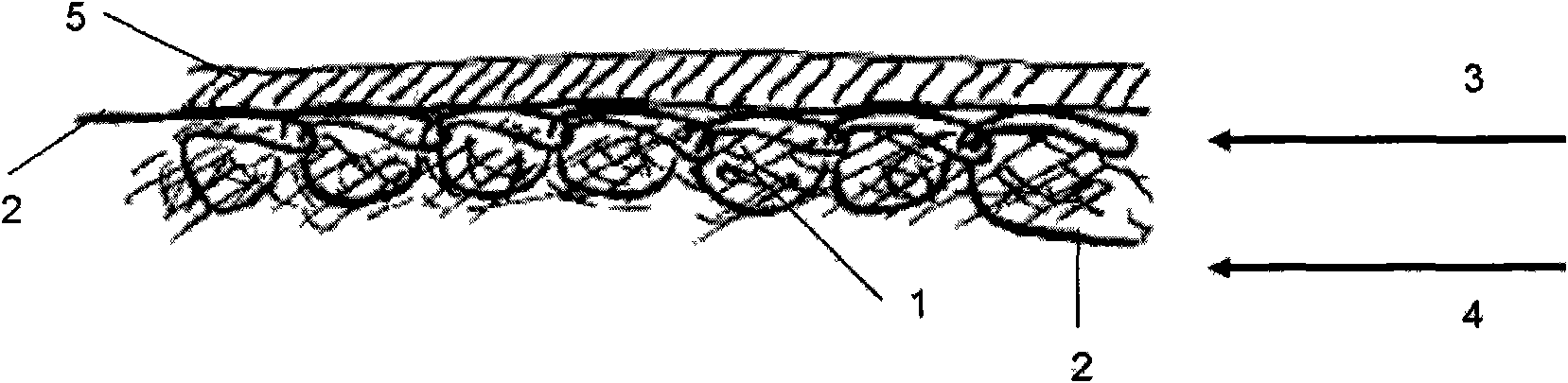

Adhesive tape with textile holder for cable bandaging

ActiveCN101586008AGood cross tearEffective knotNatural rubber adhesivesFilm/foil adhesivesYarnEngineering

The invention relates to an adhesive tape with textile holder for cable bandaging. The invention relates to an adhesive tape intended preferably for wrapping elongate material, such as lines or cable looms more particularly, having a textile carrier and having a pressure-sensitive adhesive coating applied at least to one side of the carrier. Adhesive tape for jacketing elongate material having a nonwoven-based carrier provided at least on one side with an adhesive coating, the carrier having a basis weight of 30 to 120 g / m2, and the carrier being composed of at least one ply of a preconsolidated nonwoven webfiber, specifically a spinning sticking webfiber, fusing spraying webfiber or mechanically reinforced short fibre webfiber that is overstitched with a multiplicity of threads, and has a thread density of less than 22 threads per 25 mm width of the carrier, preferably between 9-20 threads per 25 mm.

Owner:TESA SE

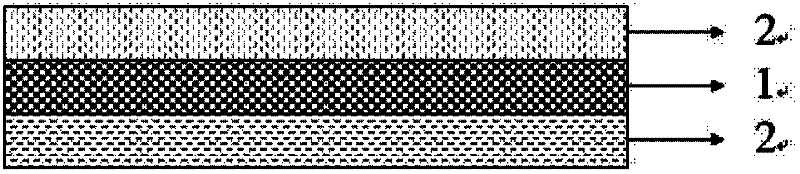

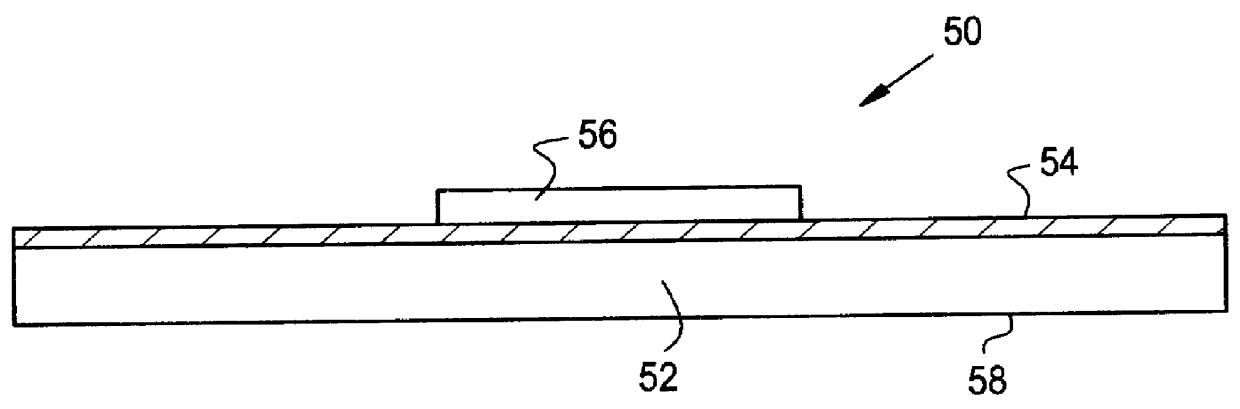

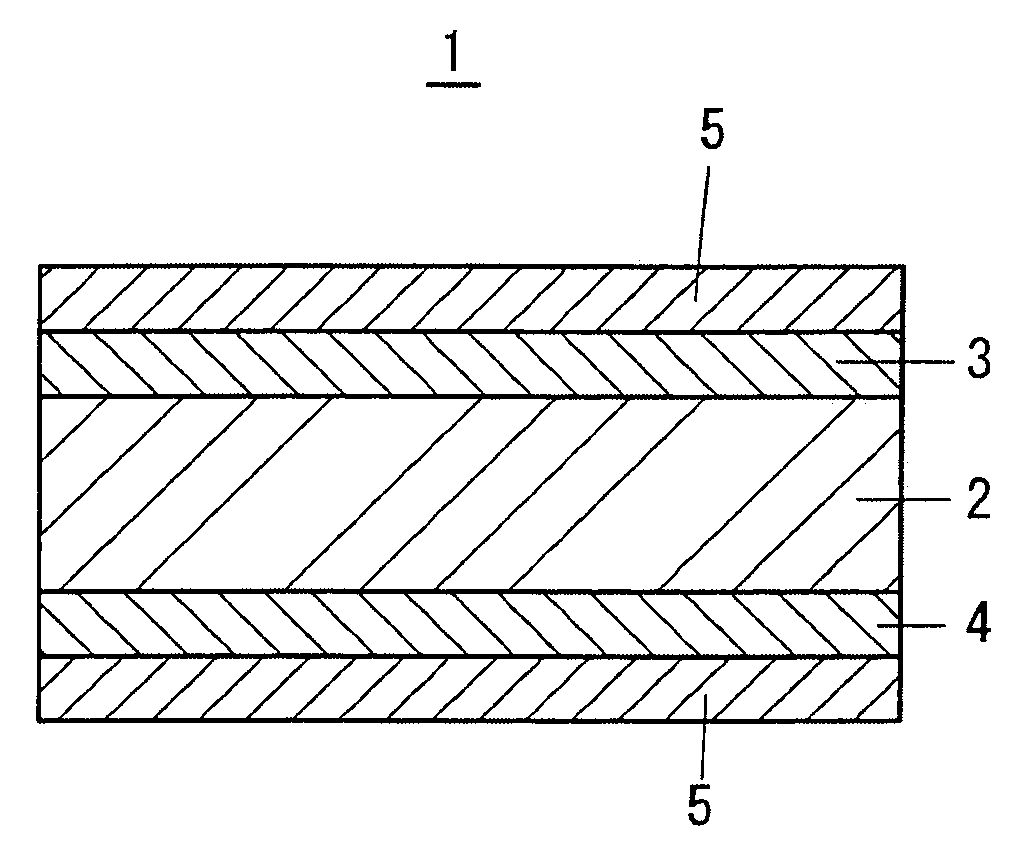

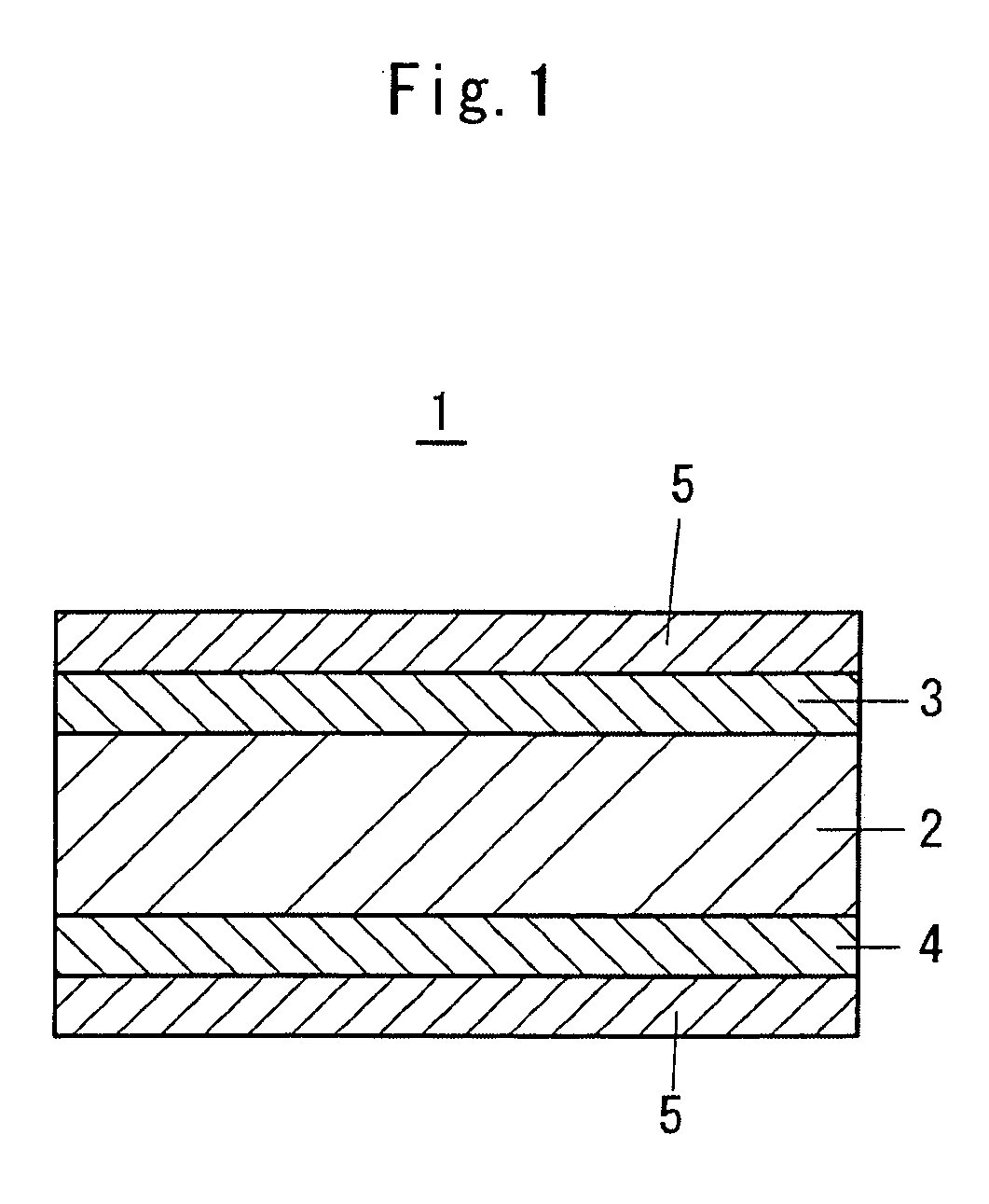

Double-Sided Adhesive Tape for Securing Polishing-Pad

InactiveUS20090098376A1High precisionReduce adverse effectsSynthetic resin layered productsLapping machinesPolyethylene terephthalateSolvent based

To provide a double-sided adhesive tape for securing a polishing-pad, the tape being capable of improving precision in polishing using a polishing-pad.The double-sided adhesive tape 1 for securing the polishing-pad includes a substrate 2 and adhesive layers 3 and 4, which are provided on both sides of the substrate 2, respectively. The substrate 2 is formed of a polyethylene terephthalate resin-film having a thickness of 150 to 300 μm, one of the adhesive layer 3 is formed of a synthetic rubber pressure sensitive adhesive, and the other adhesive layer 4 is formed of an acrylic solvent-based pressure sensitive adhesive.

Owner:SEKISUI CHEM CO LTD

Pipeline repairing carbon fiber composite material system and application thereof

ActiveCN102464861ASmall expansion coefficientGood resistance to cathodic disbondmentOther chemical processesSynthetic resin layered productsAdhesiveRoom temperature

The invention relates to a pipeline repairing carbon fiber composite material system and an application thereof. The pipeline repairing carbon fiber composite material system consists of a defect filling material, an anti-cathodic disbonding insulating primer and a carbon fiber composite material, wherein the defect filling material is used for overcoming pipeline defects; a pipeline defect reinforcing area is coated with the anti-cathodic disbonding insulating primer; an interlayer adhesive is used for coating and soaking carbon fiber cloth and paving a reinforced repairing area; a stainless steel tape is used for fastening and curing a composite material repairing layer; the repairing layer fastened by using stainless steel is cured at room temperature or heated and cured through an external heating belt; the repairing layer is subjected to external anti-corrosion treatment after a heating device and the stainless steel tape are removed; and the phenomena of debonding, lamination, hollowing, cracking, bubbling and the like of the repairing material and a pipe body occurring in the serving process of the repaired repair reinforcing layer can be avoided, construction effectiveness in a cold and wet severe environment is effectively increased, the repairing construction quality and reinforcing repair effect of the composite material are ensured, and the reliability of pipeline defect repairing construction is improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

High heat resistant adhesive and sealant compositions

ActiveUS20090242123A1Reduces and eliminates surface defectMaintain surface integrityOrganic non-macromolecular adhesiveCellulose adhesivesPolyesterCarbamate

The invention provides adhesive and sealant compositions prepared from urethane prepolymers. The urethane prepolymers are obtained by reacting the novel urethane diols, polyester polyols and polyether polyols with an excess of diisocyanate. The urethane diols are prepared by reacting excess low molecular weight diols and diisocyanates. The invention is particularly useful in end use applications such as panel lamination.

Owner:HENKEL KGAA

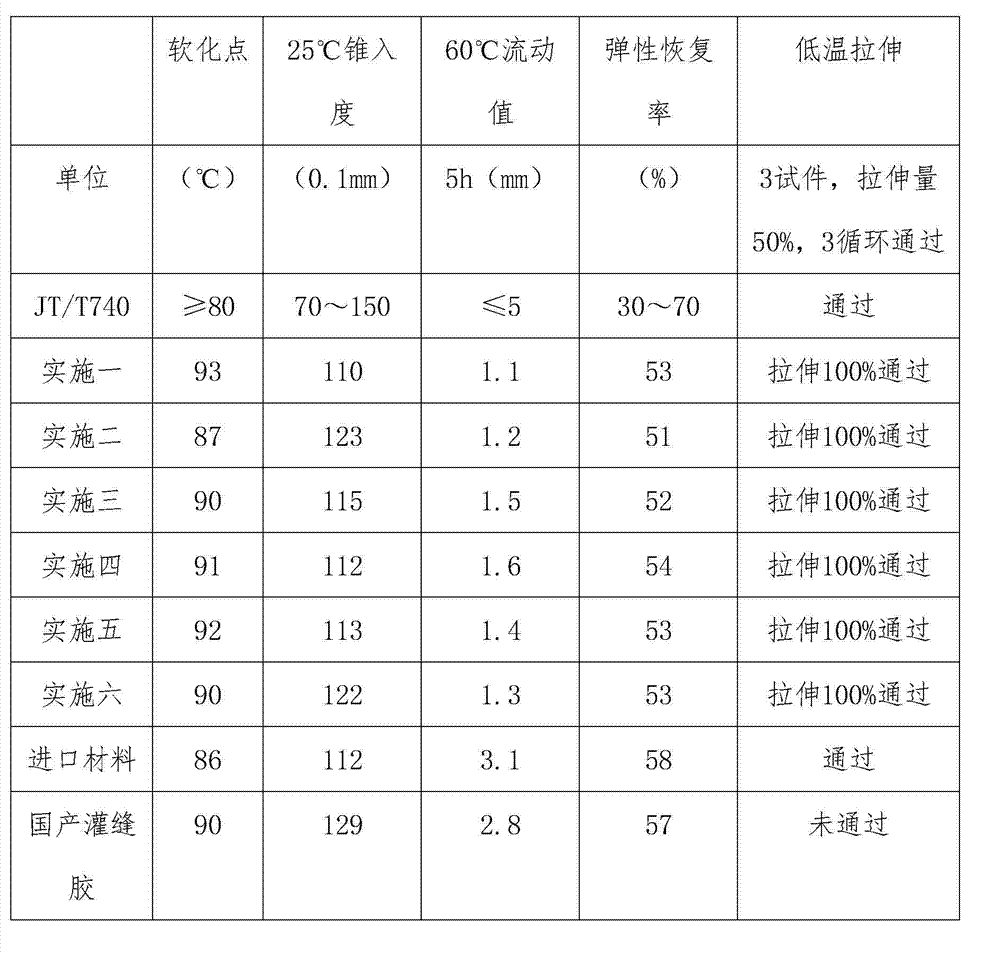

Pavement crack repairing material and preparation method

InactiveCN103589390AImprove adhesionSuitable for patchingIn situ pavingsNon-macromolecular adhesive additivesCrack resistancePolymer science

Provided is a pavement crack repairing material. The pavement crack repairing material comprises the following ingredients, by weight, 35-65% of asphalt, 6-12% of modifiers, 6-10% of special leftover material powder, 2-5% of plasticizers, 8-15% of softening oil, 10-25% of waste rubber power, and 3-10% of tackifiers or nano-oxides. The special leftover material powder is obtained after leftover materials of beef tendon sole rubber and chloroprene rubber at a weight ratio of 3:2.5 are ground by a grinding mill. The repairing material has good low-temperature crack resistance, high-temperature stability, interface binding property, ageing resistance and fatigue resistance. The repairing material is suitable for repairing of cracks and seams of asphalt or cement concrete pavements under extremely cold weather conditions.

Owner:GUANGDONG ESUN HEAVY IND CO LTD

Analog signal separator for UWB versus narrowband signals

InactiveUS20060078038A1Suppresses unwanted in-band RFI without adversely affecting the reception of the intended UWB signalTyre partsOther chemical processesFrequency spectrumContinuous tone

A system, method, and computer program product for removing “narrowband” interference from a broader spectrum containing a UWB signal, in a receiver of the UWB signal. The RFI is extracted from a broader spectrum to remove interference from the UWB signal, by employing an impulse response in a radio front-end of the UWB receiver that is matched with an incoming wavelet employed as part of a UWB signal to be received, matching the impulse response to the wavelet and its time-shifted and inverted versions, passing the wavelet unscathed through the receiver, and excising narrowband signals (continuous tones). Exemplary embodiments for the RFI extraction mechanism include a transmission line circuit, an active transmission line circuit, and an adaptable, controllable phase delay circuit.

Owner:NORTH STAR INNOVATIONS

High-performance rubber asphalt pouring sealant and preparation method thereof

InactiveCN103421467AReduce pollutionImprove performanceMineral oil hydrocarbon copolymer adhesivesOther chemical processesCrack resistanceProcess engineering

The invention discloses high-performance rubber asphalt pouring sealant and a preparation method thereof. The high-performance rubber asphalt pouring sealant is made from rubber powder, modifier, petroleum asphalt, tackifier, cosolvent, and stabilizer. The preparation method includes: heating the asphalt to 150-160 DEG C, adding the modifier, stirring to obtain liquid, adding the cosolvent and mixing for 30 minutes, heating to 190-200 DEG C, slowly adding the rubber powder, mixing for 30 minutes, adding the tackifier and the stabilizer, and mixing for 15 minutes to produce high-performance rubber asphalt pouring sealant. The rubber powder of waste tires is utilized, and accordingly product performance is improved, product cost is reduced and environmental pollution is reduced; the modifier, the rubber powder and the asphalt are mixed into stable, even mixture through the cosolvent, so that resin groups, rubber powder groups and asphalt groups can form a stable interlinked structure; through the modifier, route performance of the sealant can be improved, for example, softening point is increased and low temperature cracking resistance is improved; new cracks can be prevented effectively.

Owner:XIYUEFA INT ENVIRONMENTAL PROTECTION NEW MATERIALS CO LTD

Fusible adhesives crosslinkable by radiation

To obtain an adhesive having both a high initial adhesive capacity and high heat resistance, a fusible adhesive which can be cross-linked by radiation and a low tendency to creep is provided. The adhesive contains 0 to 40 weight percent of at least one elastomer which cannot be cross-linked by radiation, 15 to 40 weight percent of at least one compound containing at least two olefinic double bonds, and 20 to 85 weight percent of at least one tackifier. The adhesive is especially suitable for use on high speed labeling machines.

Owner:HENKEL KGAA

Adhesive and feeding material prepared thereby for metal powder injection molding

InactiveCN101235265AAvoid easy separationHigh strengthNon-macromolecular adhesive additivesWax adhesivesHigh densityVolumetric Mass Density

The invention relates to the metal powder injection forming field, in particular to binding agent and feeding which is used for the metal powder injection forming which is prepared. The binding agent comprises thermoplastic elastic compounded rubber, industrial paraffin, high density polythene HDPE, propene polymer PP and geoceric acid, and the feeding is prepared through procedures of mixing according to material ratio, heating extrusion, cooling disintegration and vacuum packaging and the like. And the effects of the invention are the the solid loadage of feeding is over 60%, liquid and solid are not easy to be separated when in forming, the sticky point technology is simple, cost is low, sticky blank point height is high, sintering blank density is high and the product price is lower.

Owner:王明喜

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com