Patents

Literature

97results about "Vinyl aromatic copolymer adhesives" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plasticized acrylics for pressure sensitive adhesive applications

InactiveUS6624273B1High TgHigh modulusMonocarboxylic acid ester polymer adhesivesSurgical adhesivesMeth-Ethylene Homopolymers

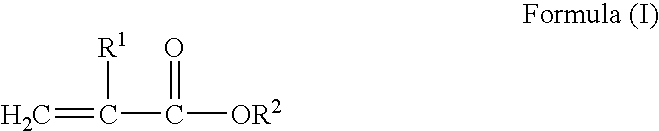

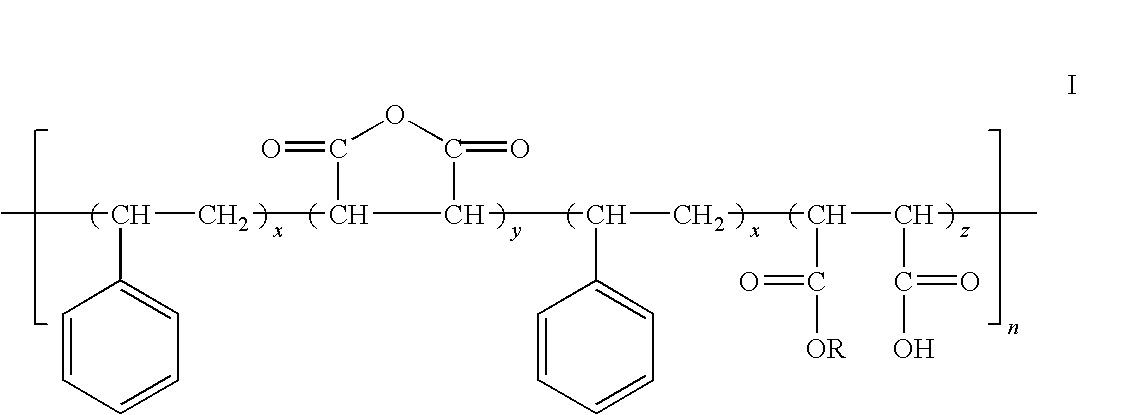

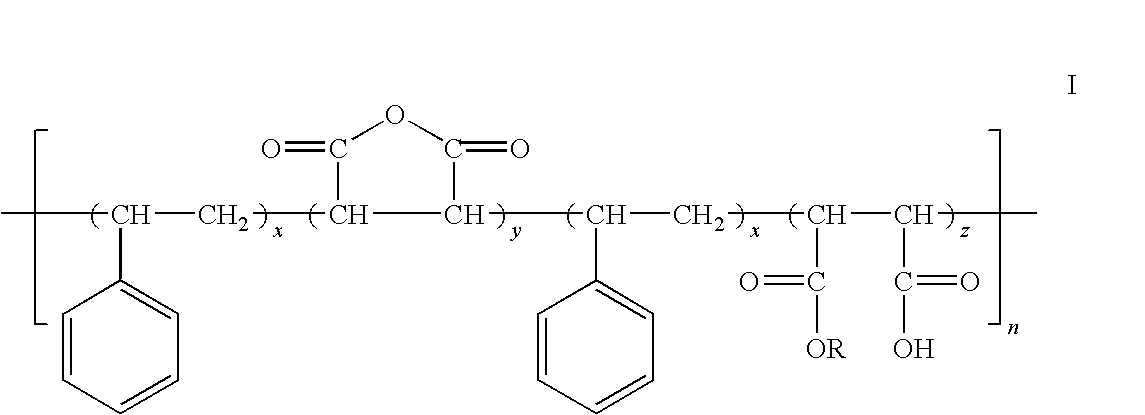

Non-tacky, base polymers are plasticized into pressure-sensitive adhesives and comprise: a) about 100 parts by weight of a base copolymer having a Tg greater than about 0° C., wherein the base copolymer is formed from and comprises: (1) about 50 to 70% by weight of a high Tg comonomer component, wherein the homopolymer formed from the high Tg comonomer component has a Tg of at least about 20° C.; (2) optionally, up to about 20% by weight based on the total weight of the base copolymer of an acidic comonomer; and (3) about 30 to 50% by weight of one or more low Tg (meth)acrylate comonomer, wherein the Tg homopolymer of the low Tg comonomer is less than about 20° C., and b) about 1 to about 100 parts based on the base copolymer of a nonreactive, non-volatile, non-acrylic-based plasticizing agent.

Owner:3M INNOVATIVE PROPERTIES CO

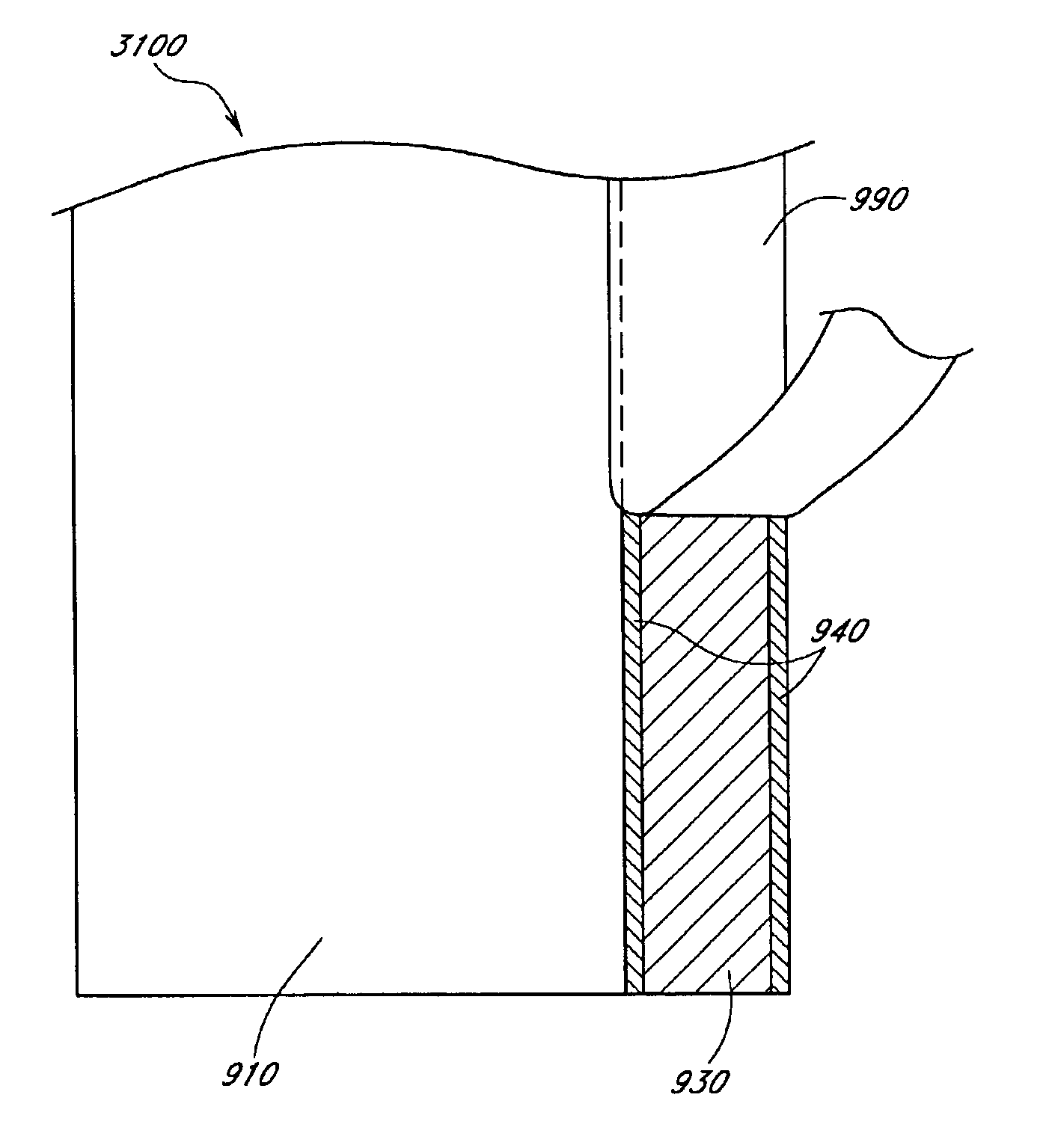

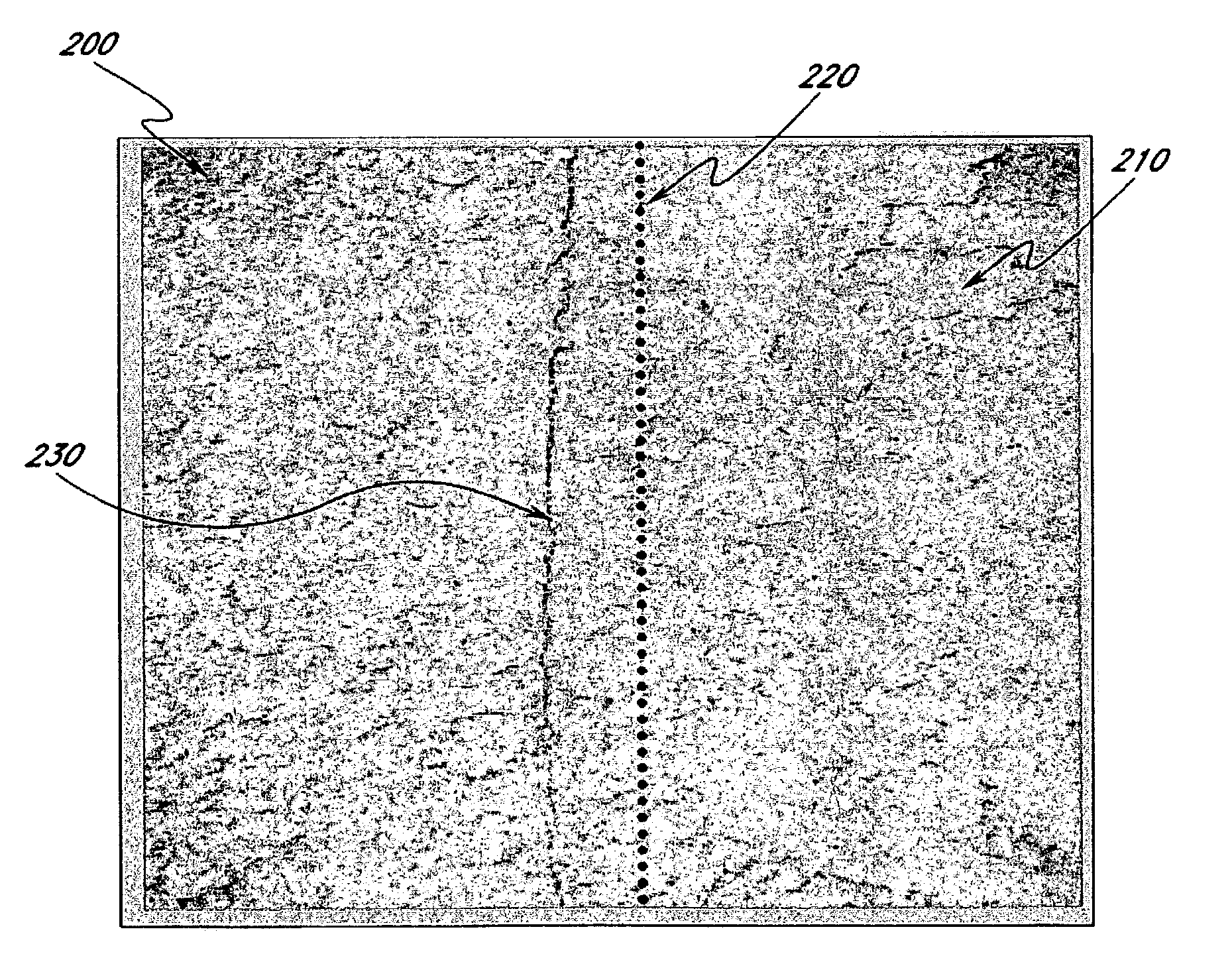

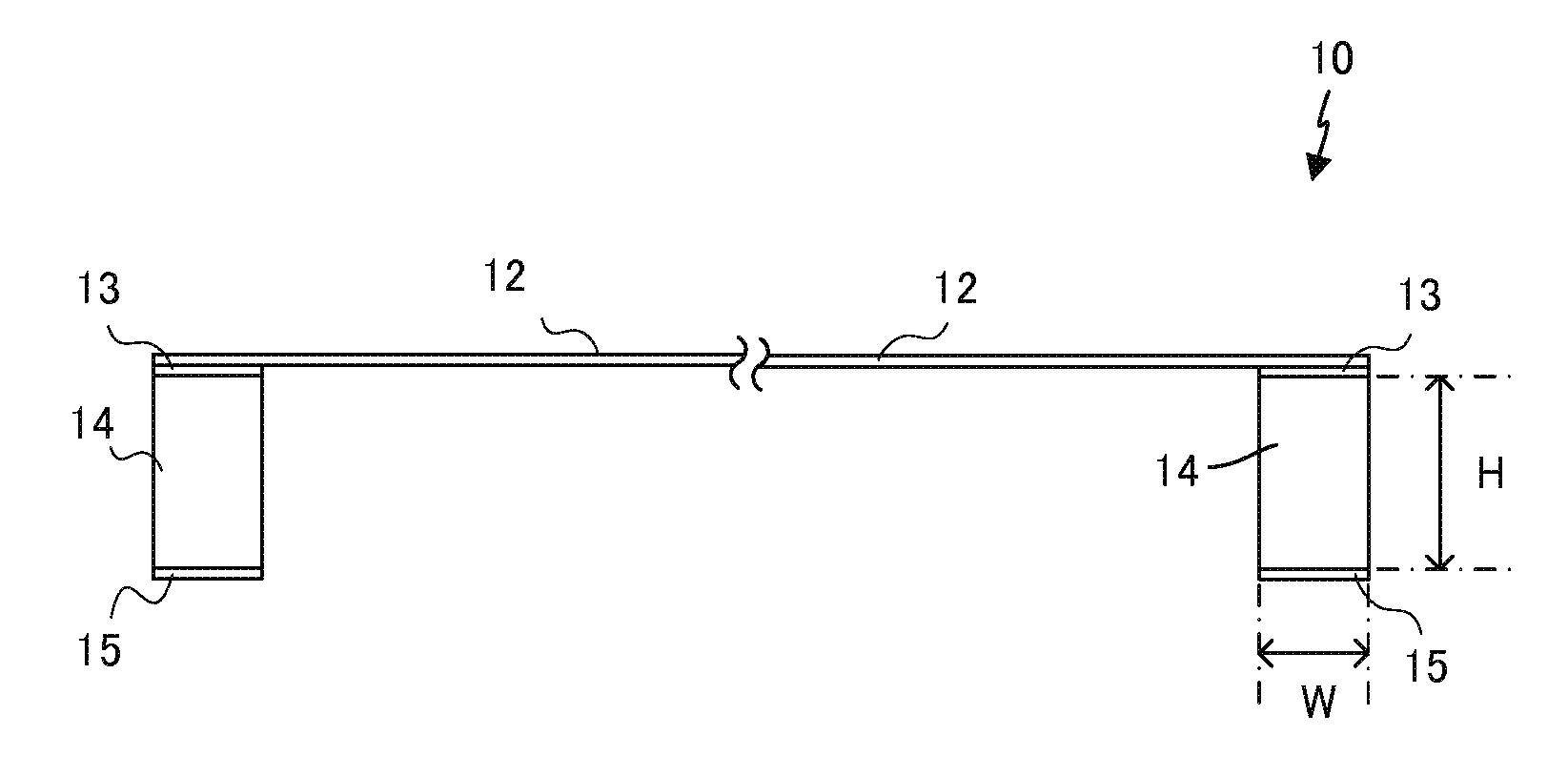

Panelized wall system utilizing trough-edge building panels

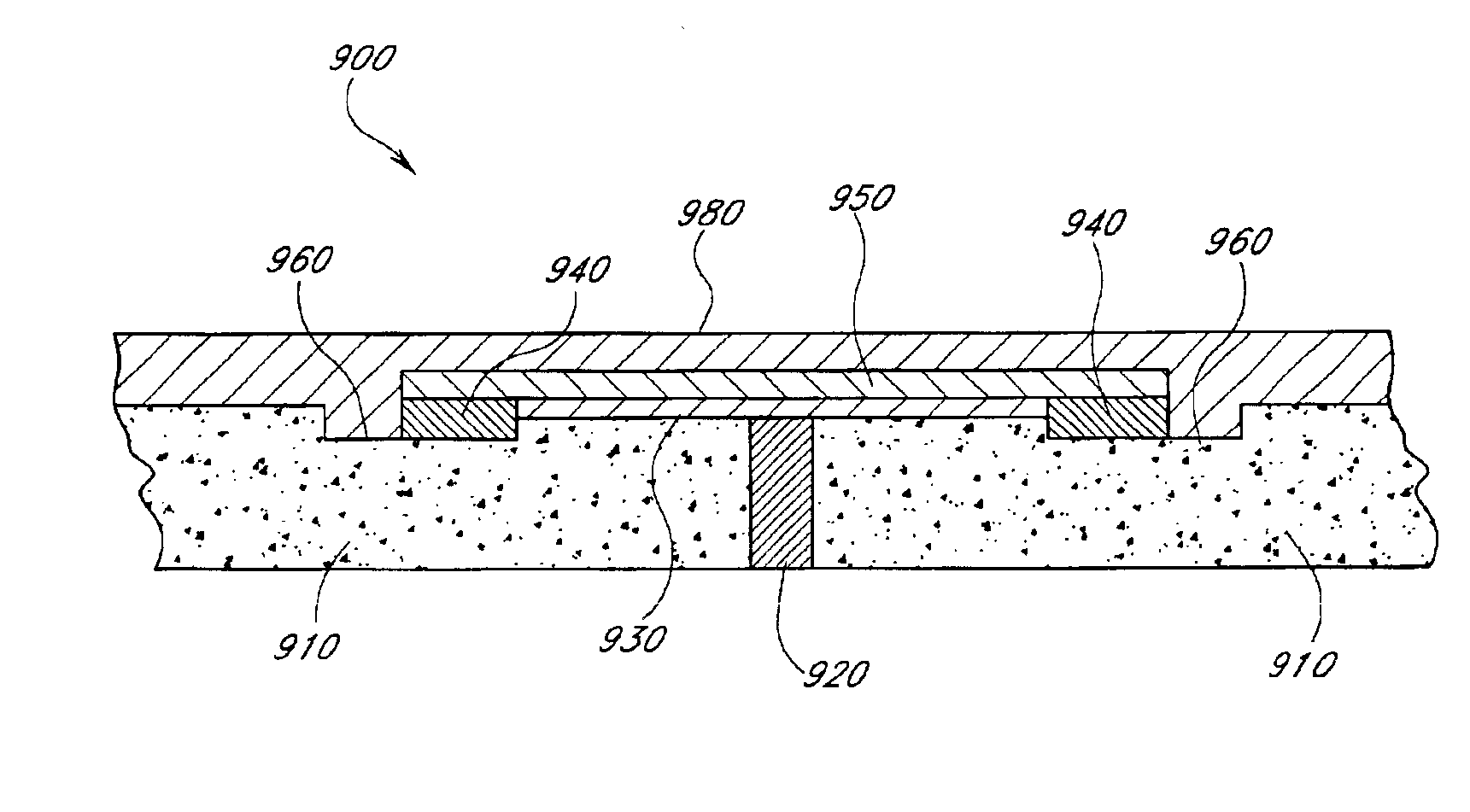

Disclosed herein are panelized wall systems and methods for their construction, wherein the wall systems have elastomeric joints that are resistant to cracking. The walls are constructed with trough-edge building panels. The trough-edge building panels are preferably fiber cement. The front surface of each panel has a trough adjacent to an edge of the panel. Panels are fastened to a frame with the trough-edges adjacent to each other. A joint tape is applied to the seam between the panels such that the edges of the joint tape fall within the troughs of the adjacent panels. The wall is then finished with an elastomeric finish.

Owner:JAMES HARDIE TECH LTD

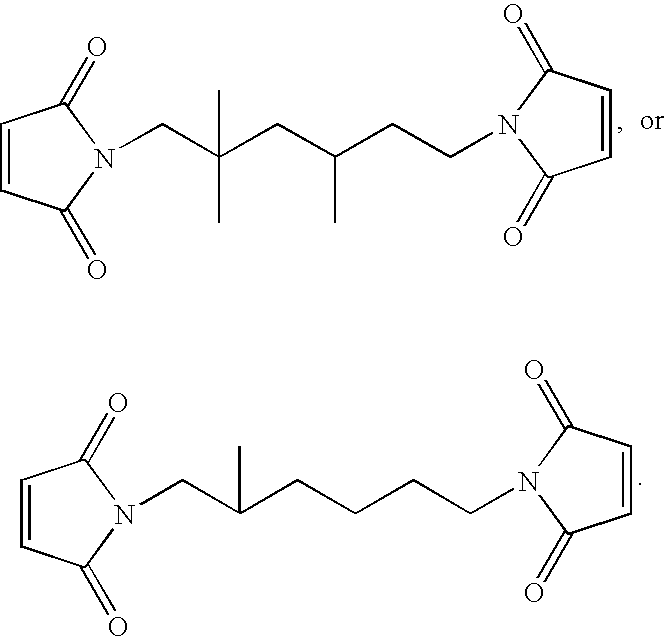

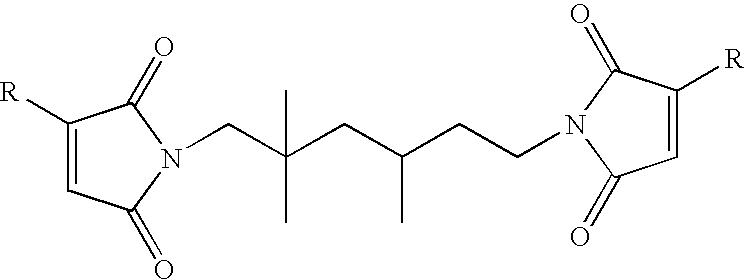

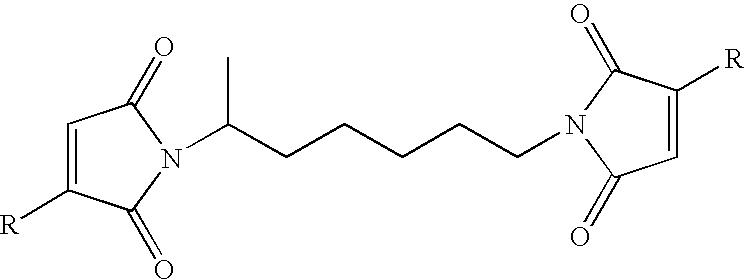

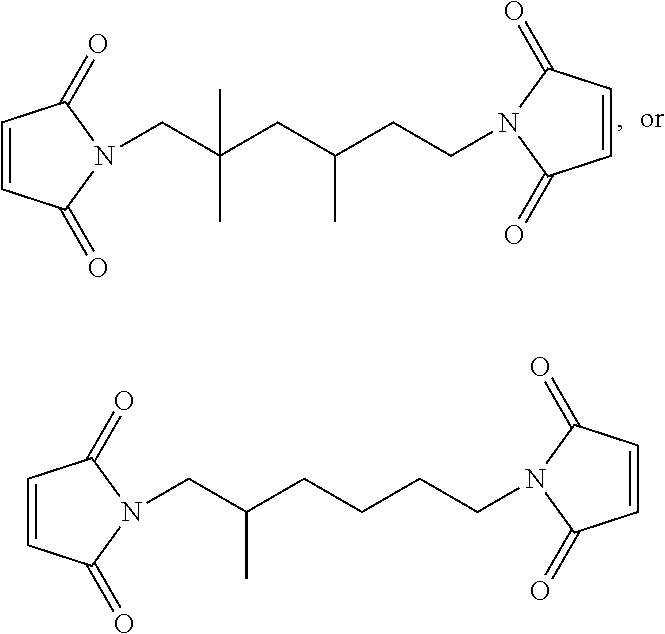

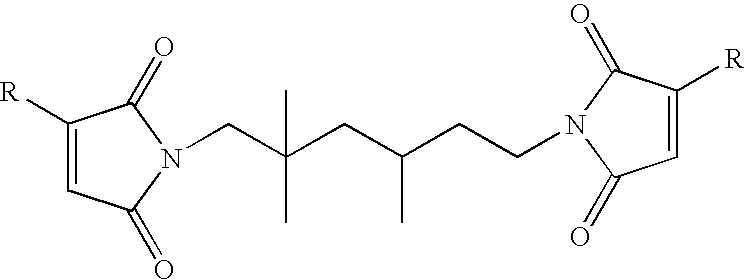

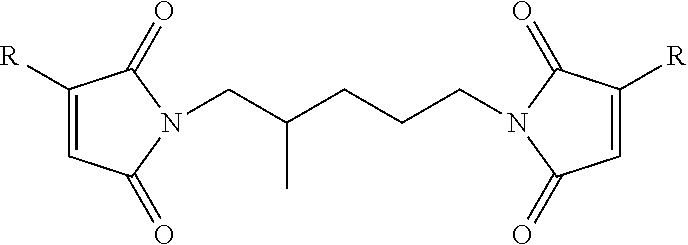

Low temperature curing acrylate and maleimide based formulations and methods for use thereof

ActiveUS20100063184A1Non-fibrous pulp additionFilm/foil adhesivesLow temperature curingElectronic packaging

The present invention is based on the discovery that certain electron poor olefins combined with nucleophiles and a base catalyst are useful as adhesive compositions for the electronic packaging industry. In particular, the adhesive formulations set forth herein are useful as low temperature curing formulations with high adhesion to a variety of substrates. Invention formulations typically cure at about 80° C. and have a potlife of about 24 hours. The formulations cure by the well-known Michael addition reaction.

Owner:DESIGNER MOLECULES

Panelized wall system utilizing adhesive-edge building panels

Disclosed herein are panelized wall systems and methods for their construction, wherein the wall systems have elastomeric joints that are resistant to cracking. The walls are constructed with adhesive-edge building panels. The adhesive-edge building panels are preferably fiber cement. The front surface of each panel has an adhesive preapplied to an edge of the panel. Panels are fastened to a frame with the adhesive-edges adjacent to each other. A joint tape is applied to the seam between the panels such that the edges of the joint tape adhere to the adhesive-edges of the adjacent panels. The wall is then finished with an elastomeric finish.

Owner:JAMES HARDIE INT FINANCE BV

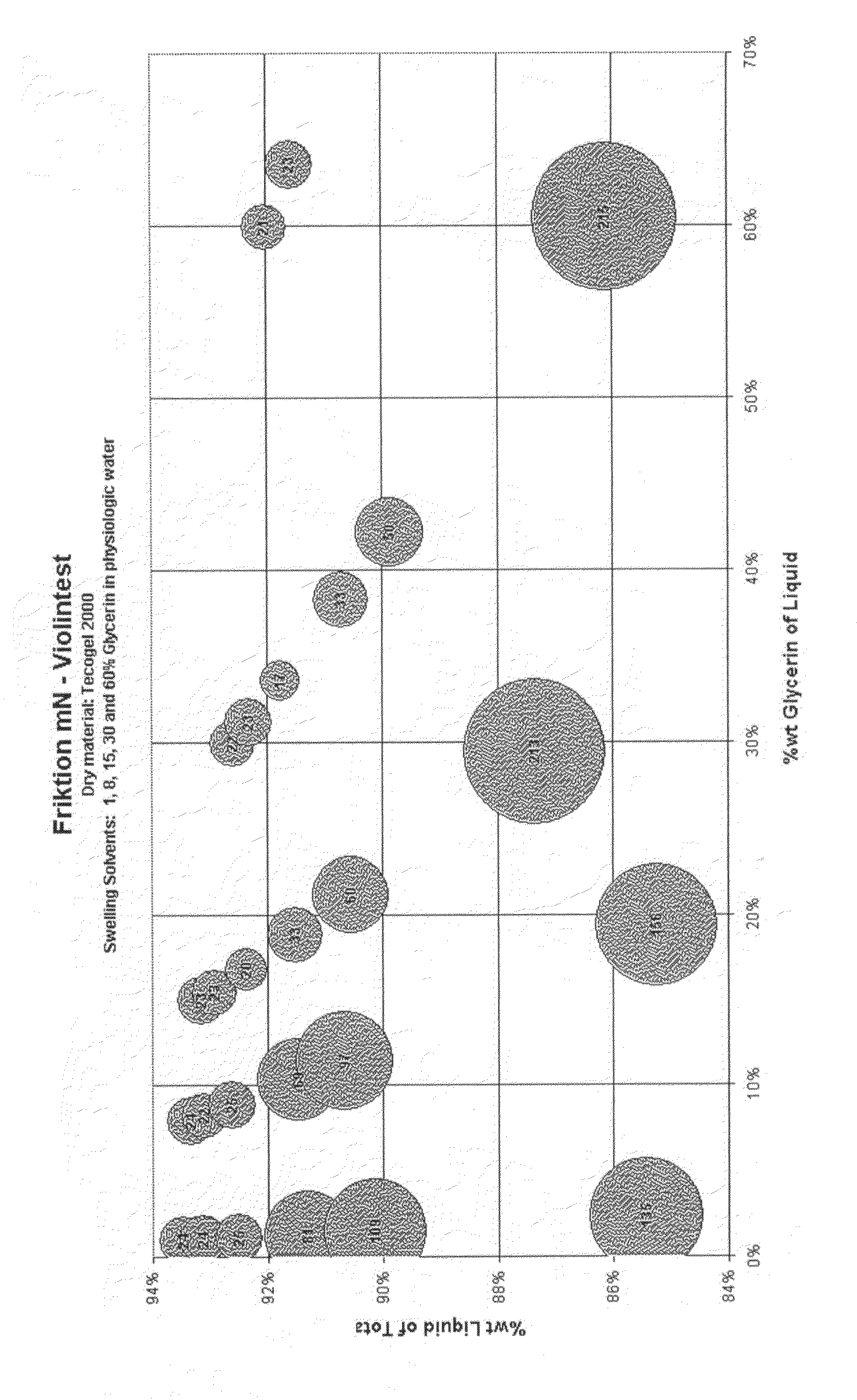

Medical Device Having a Wetted Hydrophilic Coating

InactiveUS20090012208A1Reduce frictionExtended maintenance periodSurgical adhesivesVinyl aromatic copolymer adhesivesHydrophilic coatingHydrophilic polymers

The present invention relates to a medical device having a wetted hydrophilic coating comprising:a coating composition containing a hydrophilic polymer anda wetting agent comprising water and one or more lubricant(s).

Owner:COLOPLAST AS

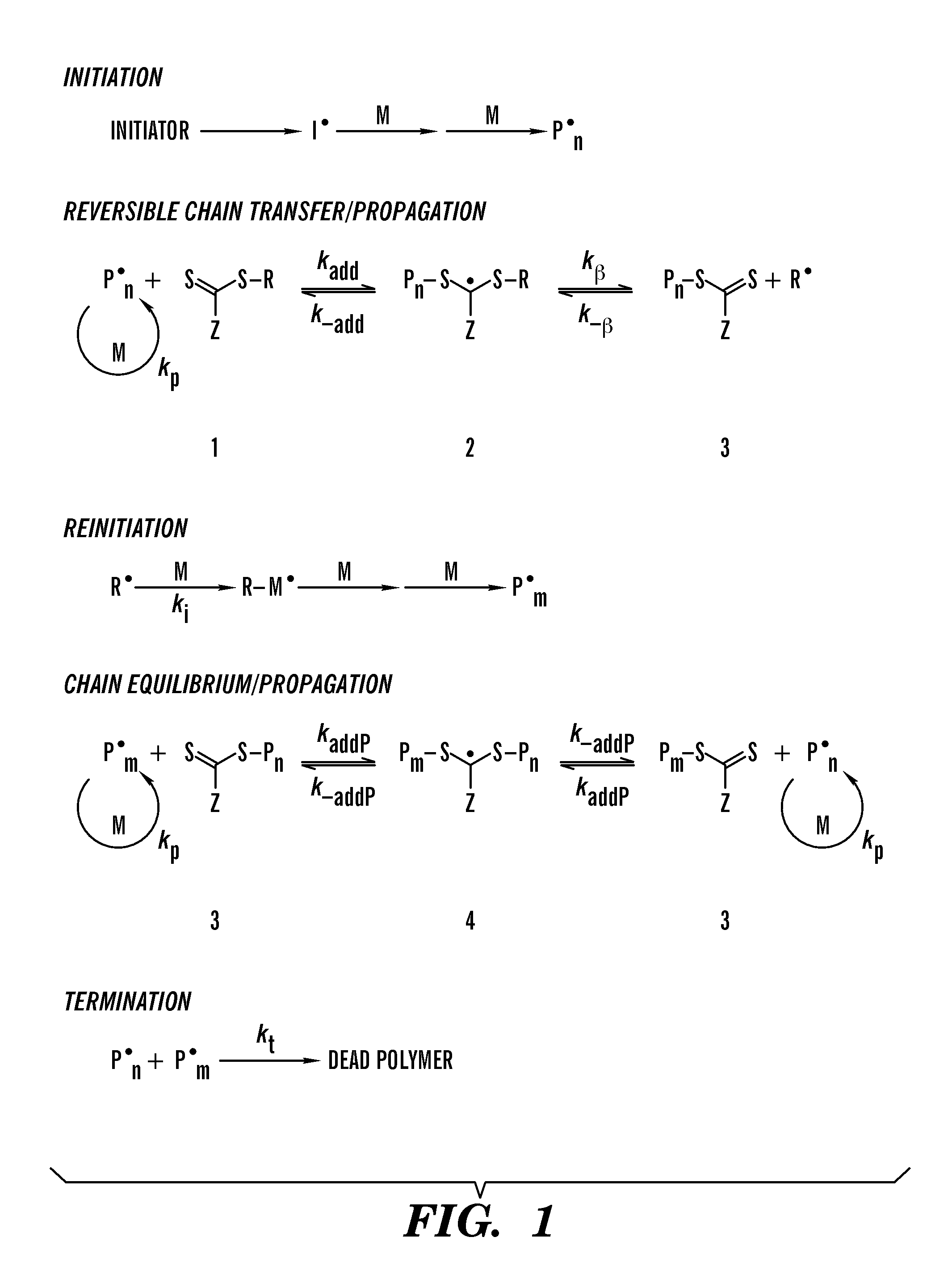

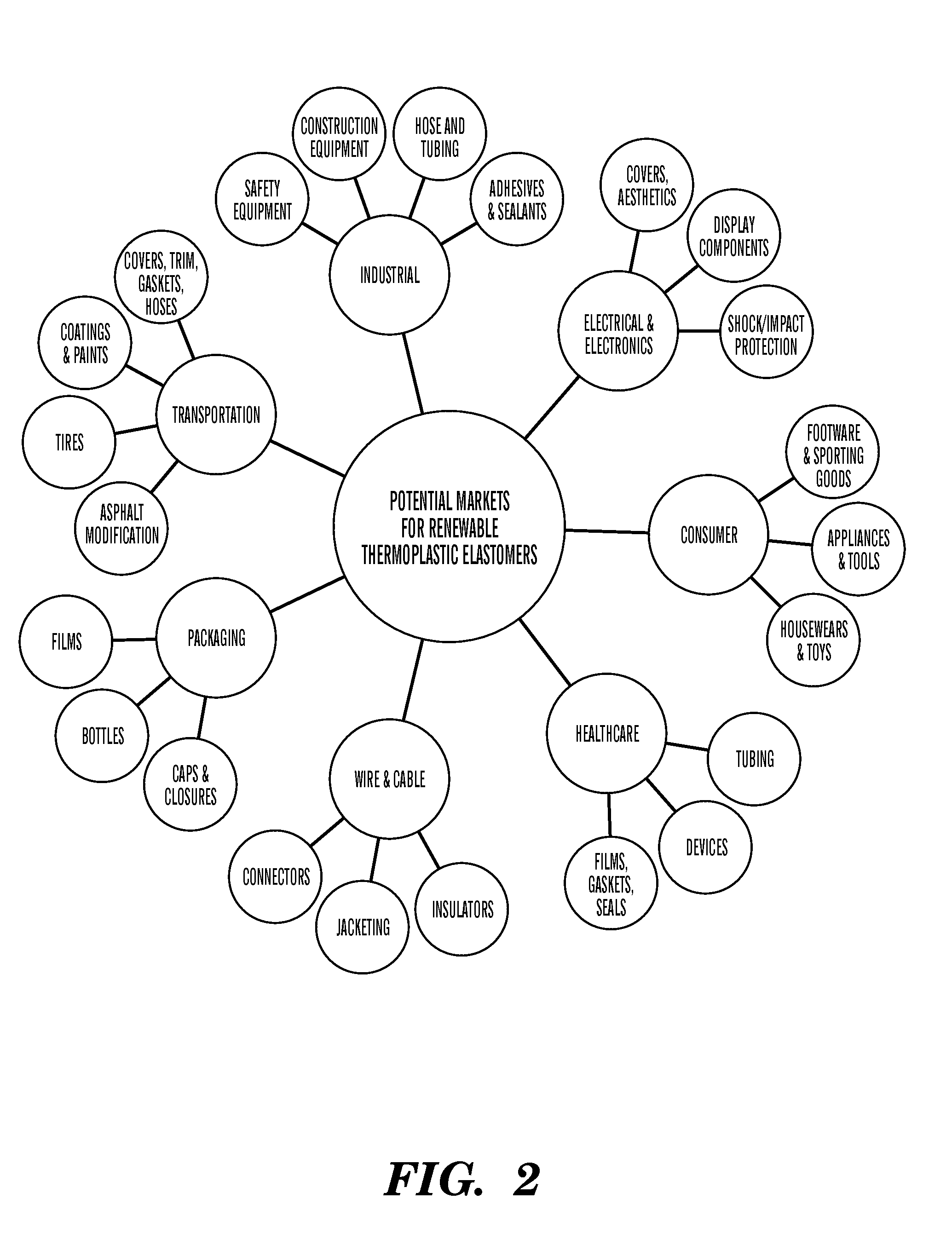

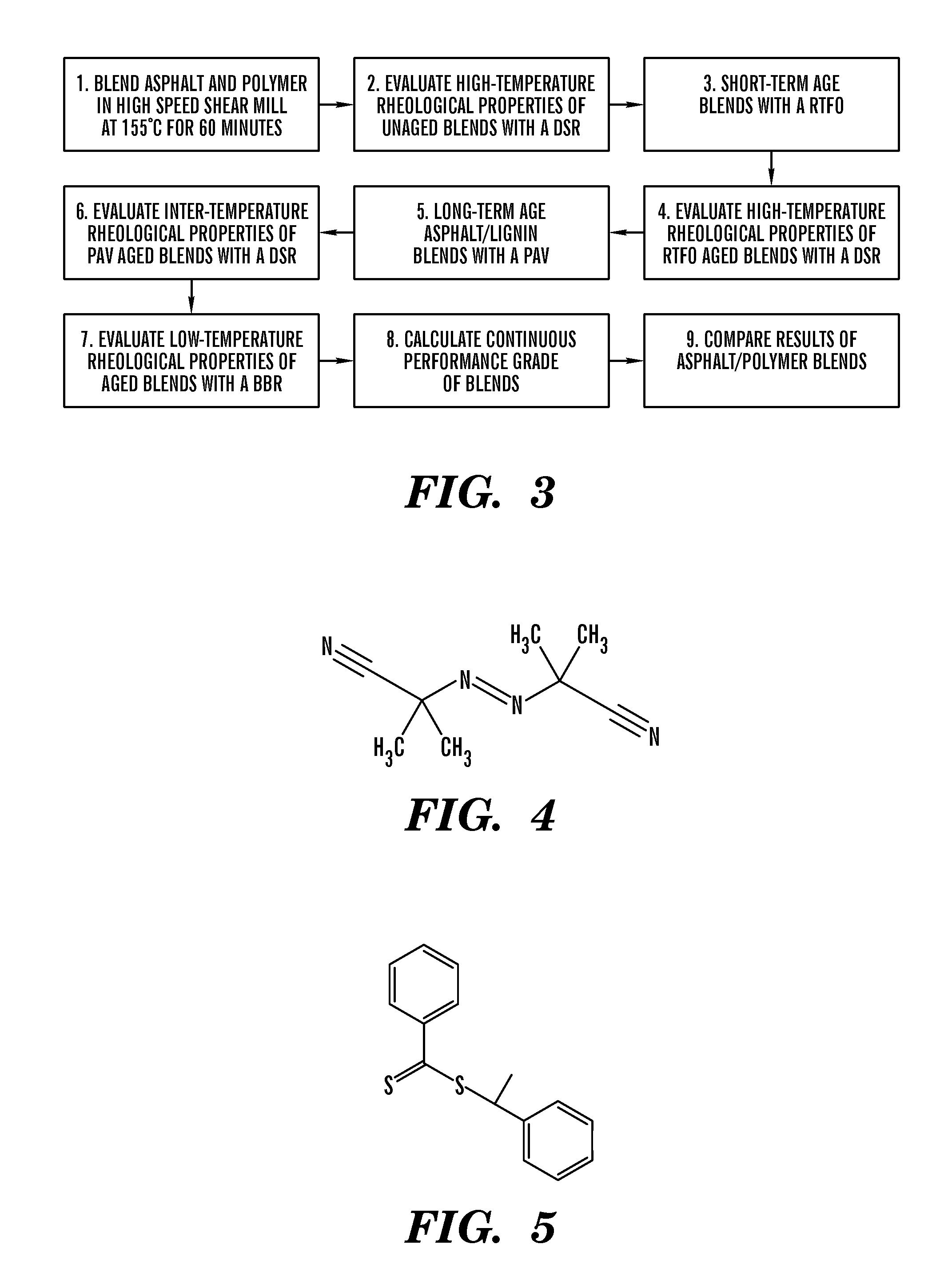

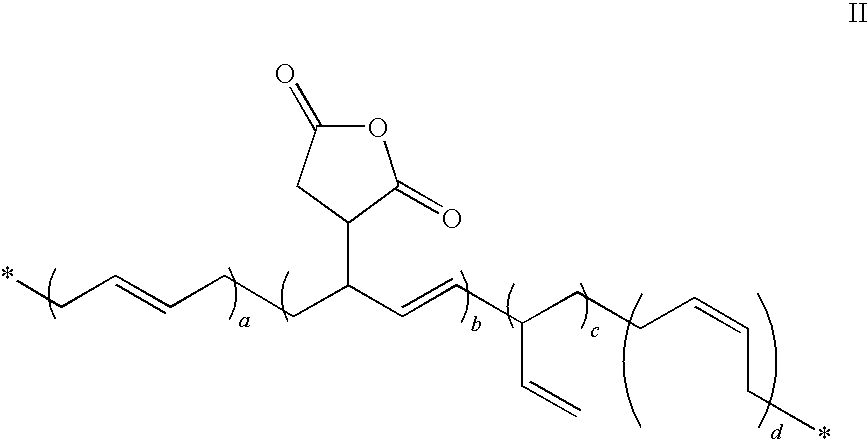

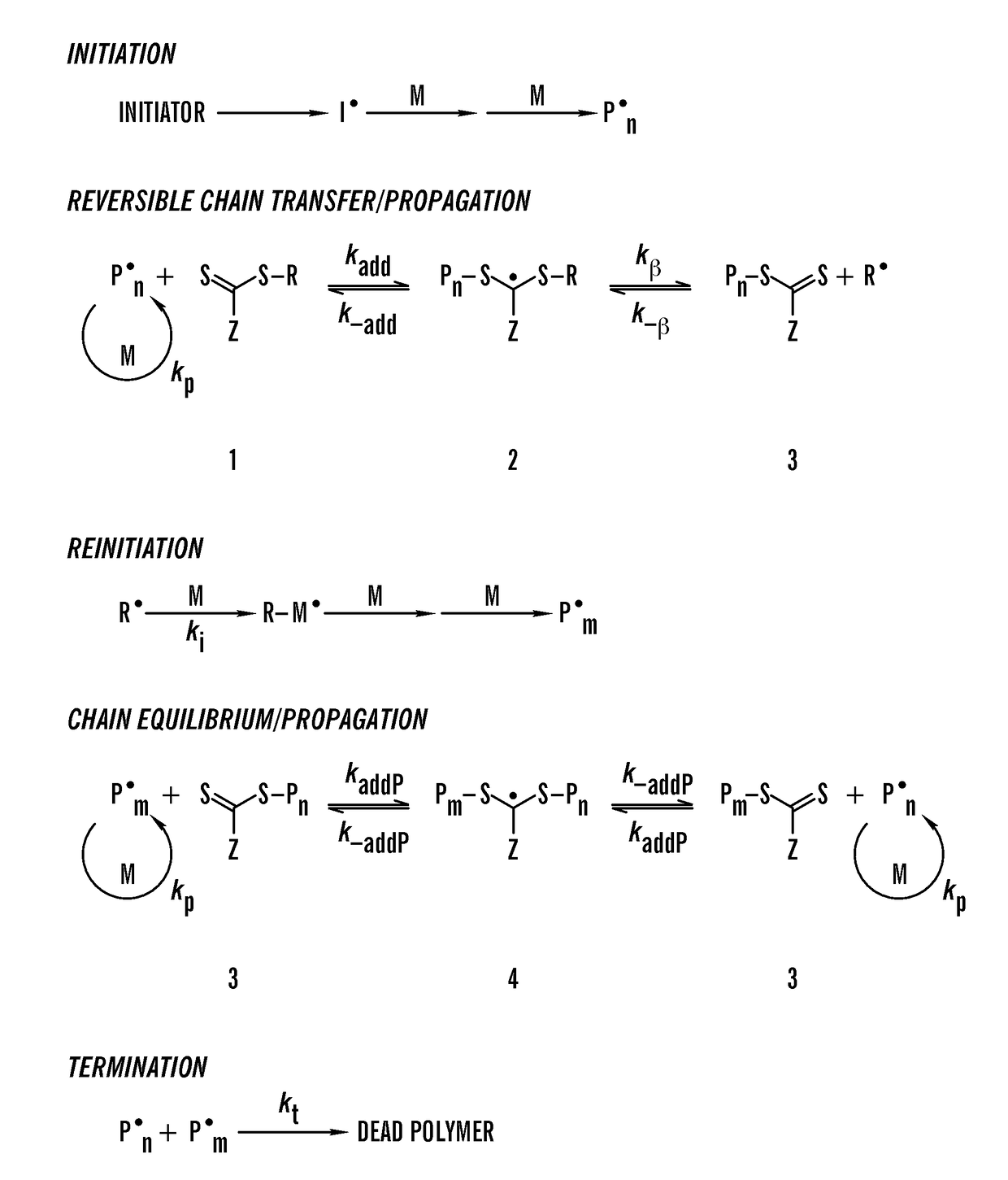

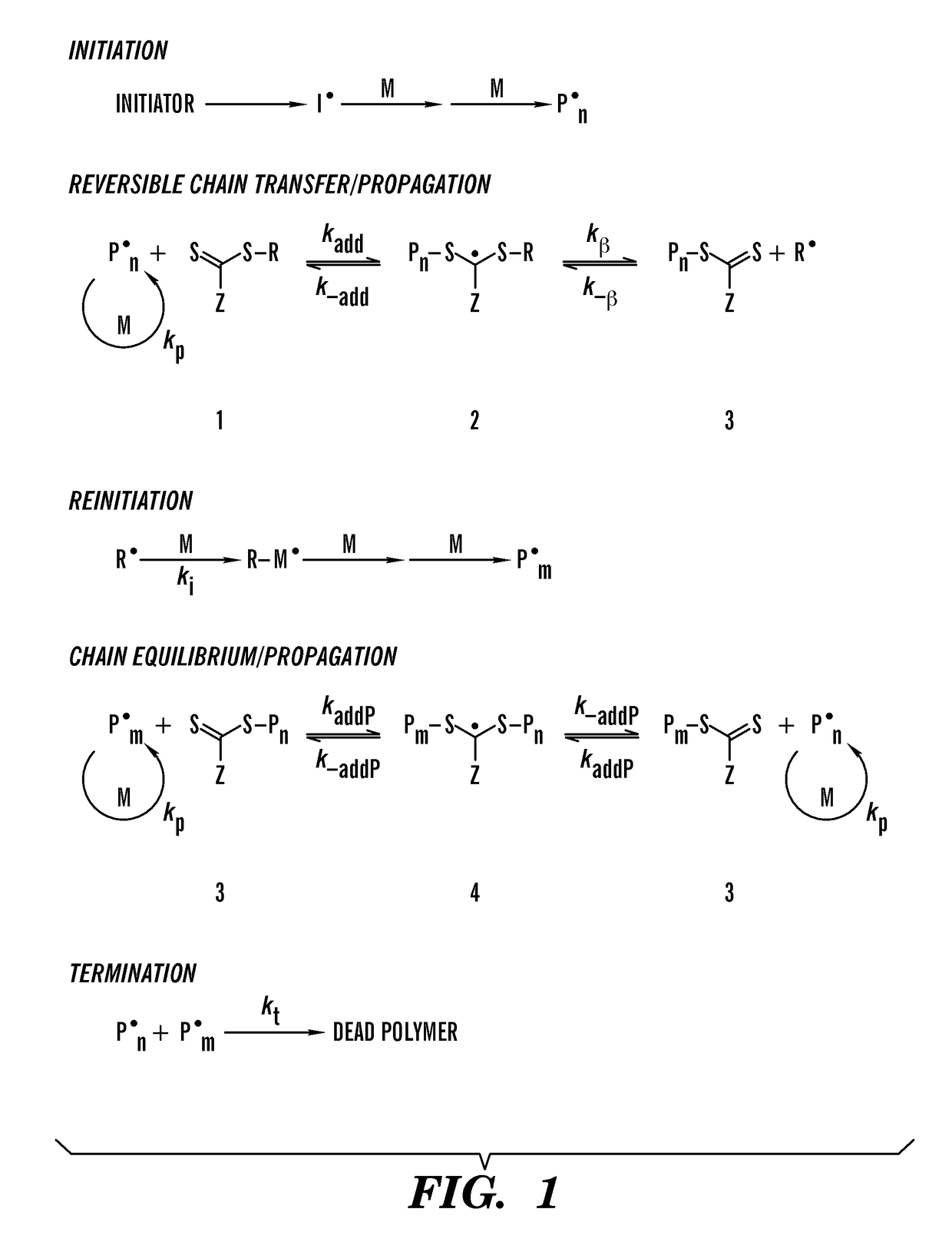

Thermoplastic elastomers via reversible addition-fragmentation chain transfer polymerization of triglycerides

ActiveUS20140343192A1Convenience to mergeCompetitive costVinyl aromatic copolymer adhesivesBituminous coatingsPolymer scienceThermoplastic elastomer

The present invention relates to a thermoplastic block copolymer comprising at least one PA block and at least one PB block. The PA block represents a polymer block comprising one or more units of monomer A, and the PB block represents a polymer block comprising one or more units of monomer B. Monomer A is a vinyl, acrylic, diolefin, nitrile, dinitrile, acrylonitrile monomer, a monomer with reactive functionality, or a crosslinking monomer. Monomer B is a radically polymerizable triglyceride or mixtures thereof, typically in the form of a plant or animal oil. The present invention also relates to a method of preparing a thermoplastic block copolymer or novel thermoplastic statistical copolymers by polymerizing a radically polymerizable monomer with a radically polymerizable triglyceride or mixtures thereof via reversible addition-fragmentation chain-transfer polymerization (RAFT), in the presence of an free radical initiator and a chain transfer agent.

Owner:IOWA STATE UNIV RES FOUND

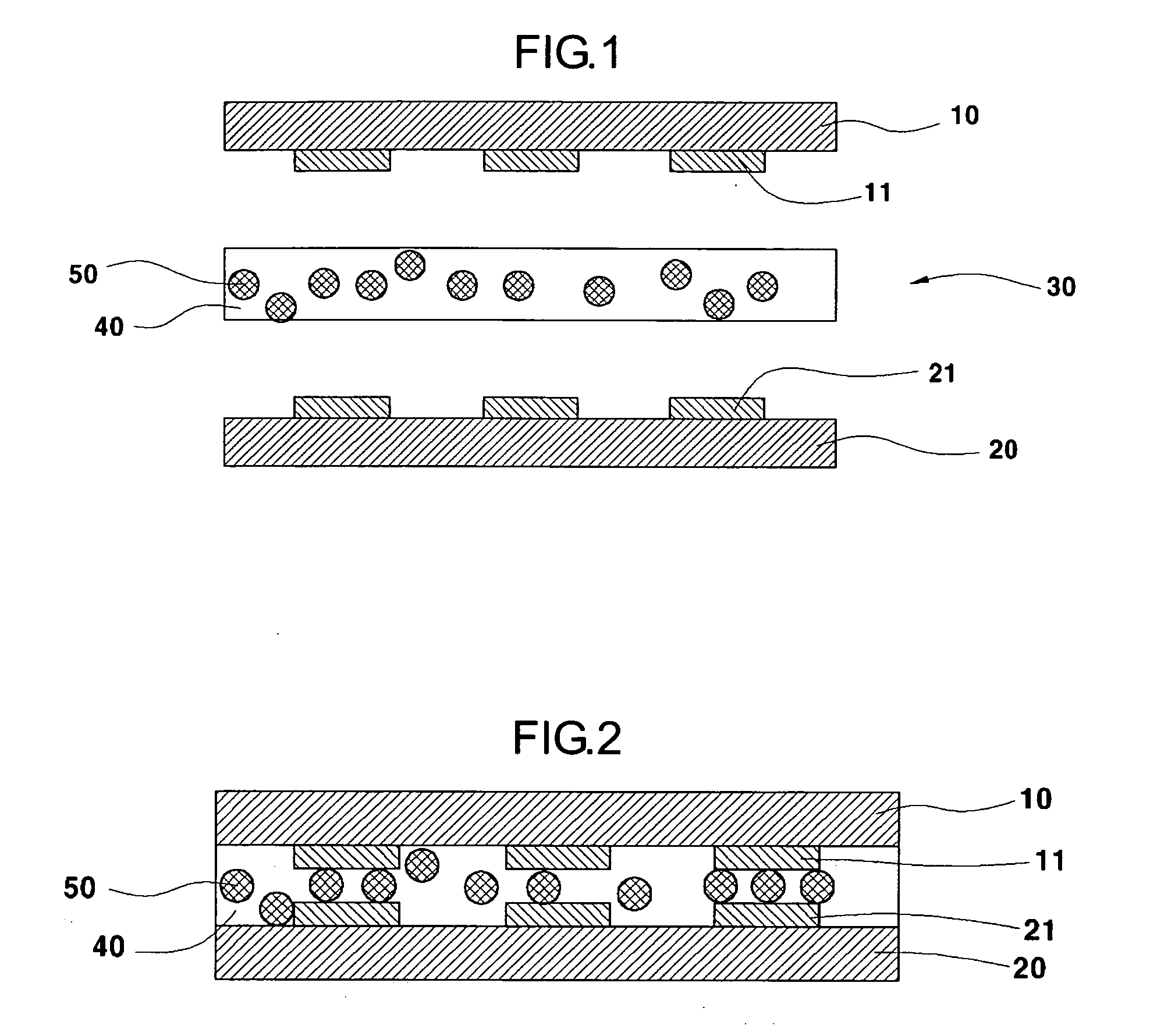

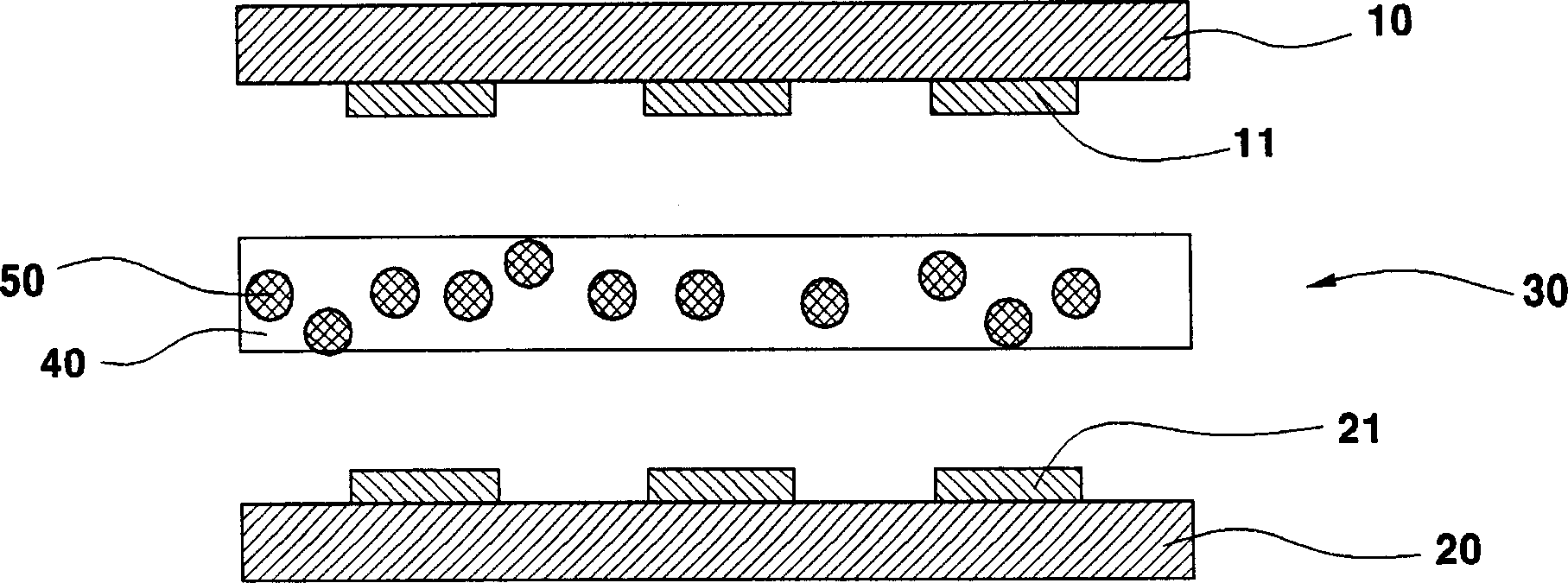

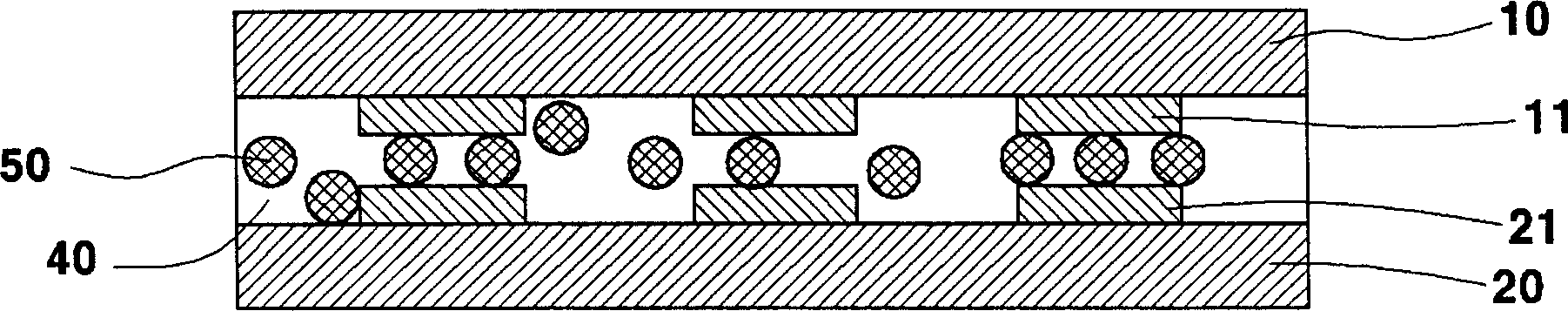

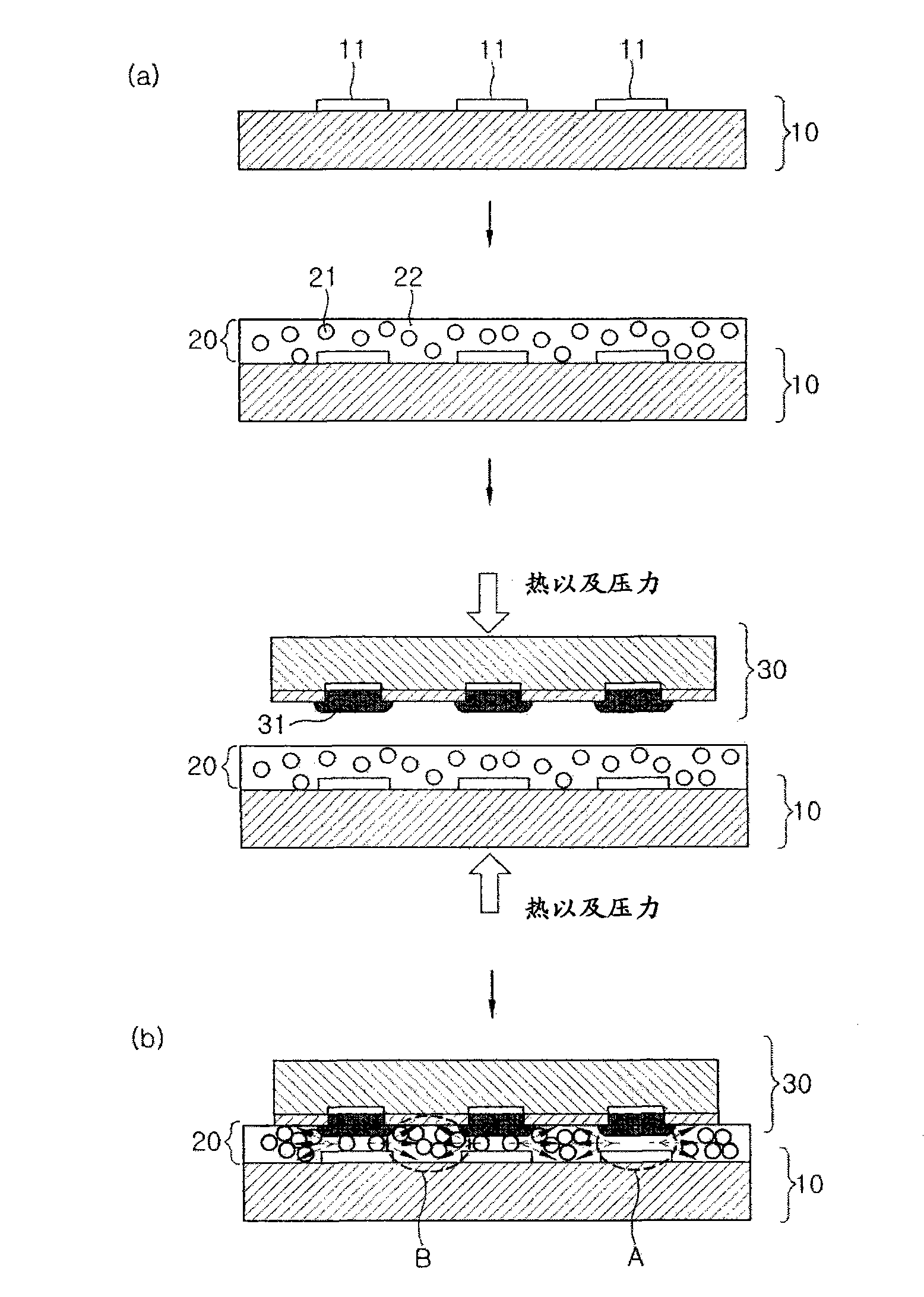

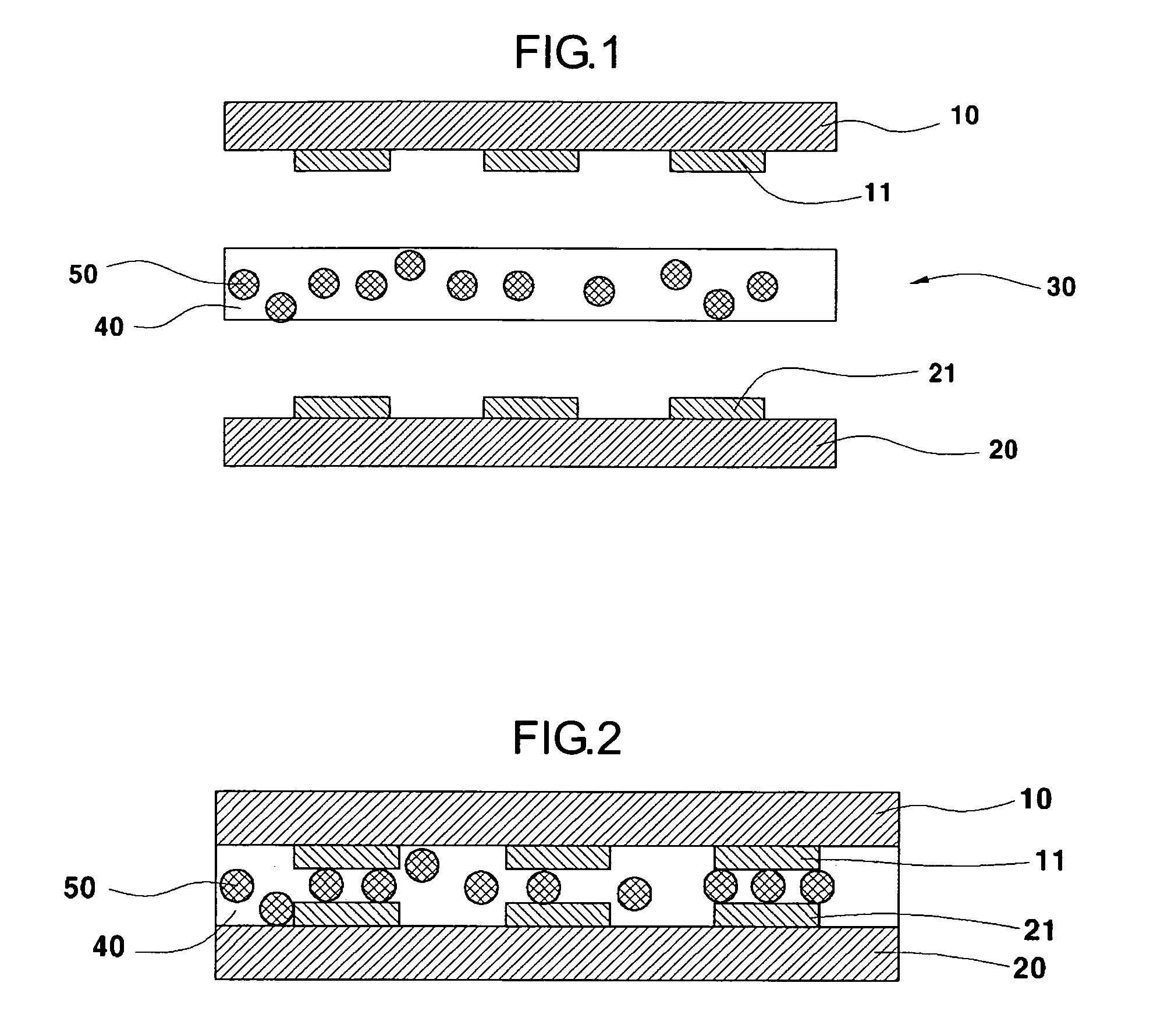

Isotropic conductive adhesive and adhesive film using the same

InactiveUS20050288427A1Minimizes its contractionImprove connection reliabilityImpression capsConductive materialAnisotropic conductive adhesiveIsotropic conductive adhesives

The present invention discloses an anisotropic conductive adhesive comprising an insulating adhesive component and a number of conductive particles dispersed in the insulating adhesive component, wherein the insulating adhesive component contains a crosslinked rubber resin. The anisotropic conductive adhesive of the present invention prevents exfoliation of an adhesive or reduction in adhesive strength of circuit by minimizing its the heat-contraction occurring in the process of a polymerization or a hardening reaction when connecting micro-circuits, whereby a short circuit between adjacent electrodes can be prevented when connecting the circuits, and excellent connection reliability according to a long-term use is achieved.

Owner:H&S HIGH TECH +1

Self-associating low adhesion backsize material

A low adhesion backsize (LAB) material made by mixing together materials, which self-associate. The mixtures can be waterbased and have high solids levels. The release is provided by functional groups such as silicones, fluorocarbons or long chain hydrocarbons. Release level can be tailored with release levels as low as the 0.5 gram / cm range to microsphere adhesives.

Owner:3M INNOVATIVE PROPERTIES CO

Isotropic conductive adhesive and adhesive film using the same

InactiveCN1712483ASmall shrinkageAvoid short circuitPrinted circuit assemblingVinyl aromatic copolymer adhesivesAnisotropic conductive adhesiveIsotropic conductive adhesives

The present invention provides an anisotropic conductive adhesive comprising an insulating adhesive component and a large number of conductive particles dispersed in the insulating adhesive component, wherein the insulating adhesive component contains alternating Linked rubber resin. When connecting circuits, by minimizing the thermal shrinkage of the anisotropic conductive adhesive in the polymerization reaction or curing reaction, it is possible to prevent peeling of the adhesive or a decrease in the bonding strength of the circuit. It prevents short-circuit between adjacent electrodes and is excellent in long-term reliability.

Owner:H&S HIGHTECH

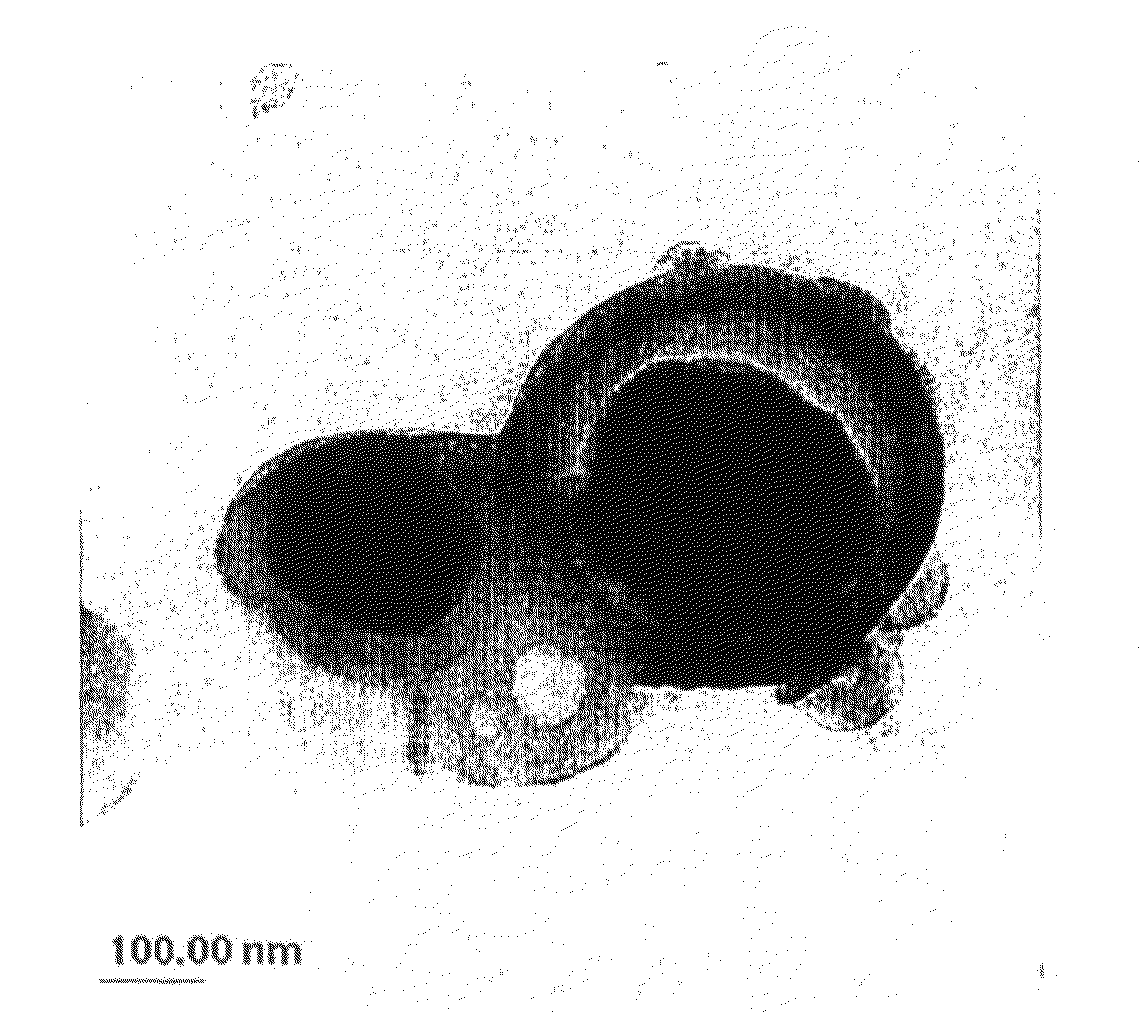

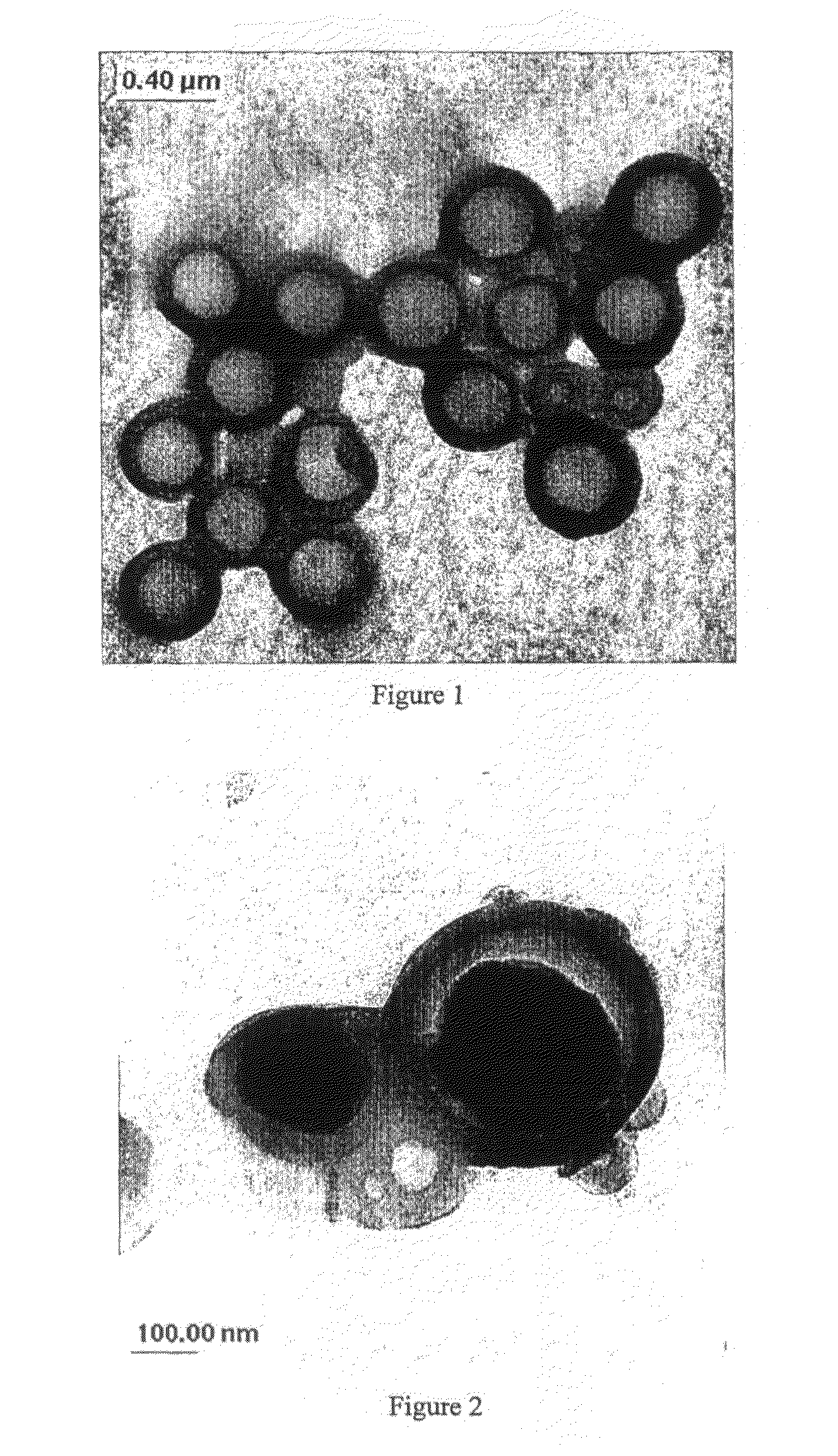

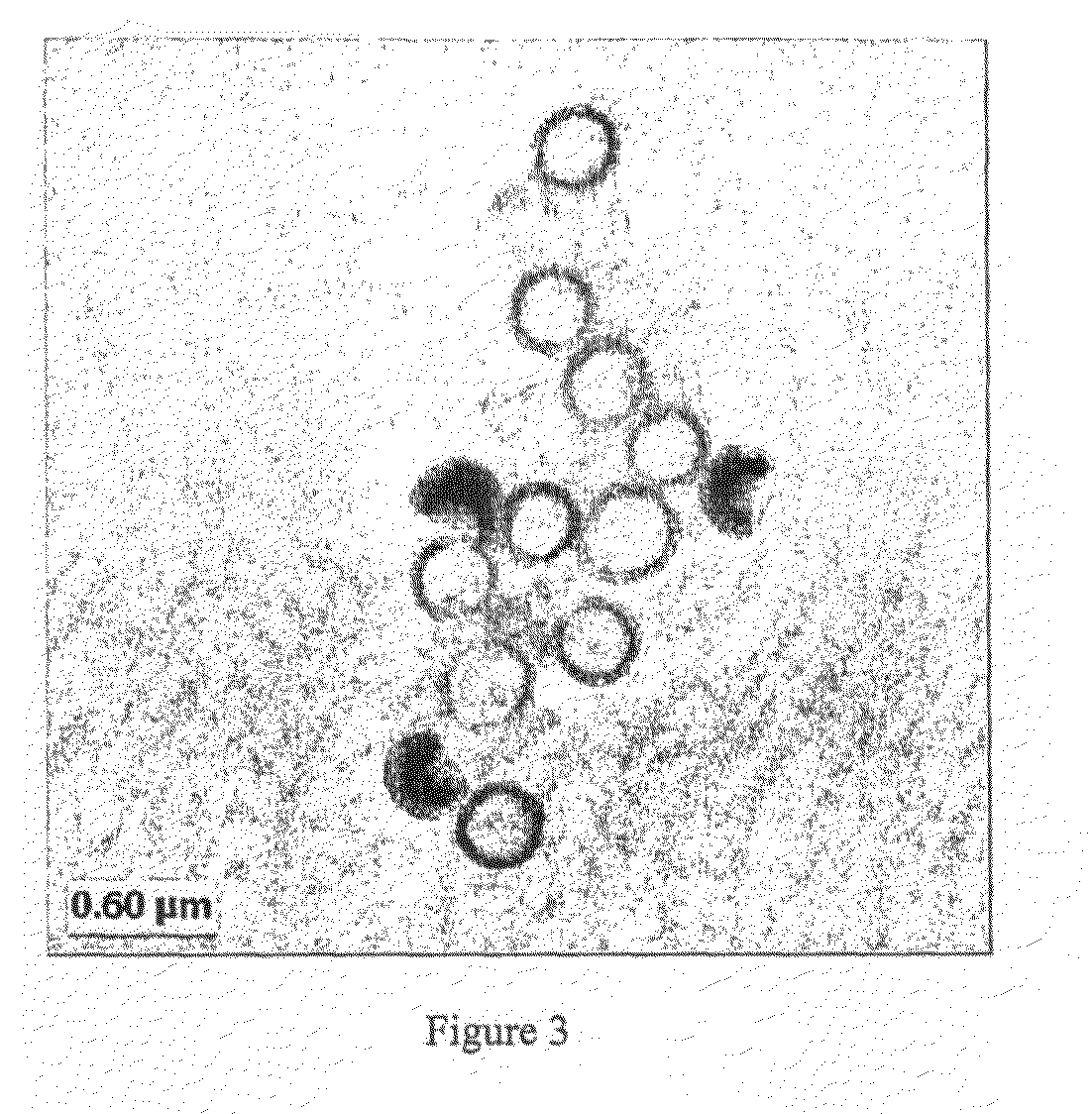

Vesiculated polymer particles

InactiveUS20100048750A1Presence undesirableSmall sizeVinyl aromatic copolymer adhesivesInksUnsaturated monomerAqueous dispersion

The invention provides a method of preparing an aqueous dispersion of vesiculated polymer particles, the method comprising: preparing a dispersion of polymerisable particles within a continuous aqueous phase, the polymerisable particles having a structure that is defined by an outer organic phase that comprises one or more ethylenically unsaturated monomers and surrounds an inner aqueous phase, said inner aqueous phase defining a single void within the polymerisable particle, wherein a RAFT agent functions as a stabiliser for the outer organic phase within the continuous aqueous phase, and wherein a RAFT agent functions as a stabiliser for the inner aqueous phase within the outer organic phase; and polymerising the one or more ethylenically unsaturated monomers under the control of a RAFT agent functioning as said stabiliser to form the aqueous dispersion of vesiculated polymer particles.

Owner:THE UNIV OF SYDNEY

Binding of fibrous material utilizing a crosslinked polyamic acid

Improved binder technology for use with fibrous materials is provided whereby the adjoining fibers of a fibrous material are bound in the absence of a phenol-formaldehyde reaction product. A curable binder composition is provided which comprises a water-soluble polyamic acid and an organic crosslinking agent capable of undergoing a covalent crosslinking reaction with the polyamic acid. The polyamic acid is formed by the reaction of a polycarboxylic acid and / or polyanhydride having a molecular weight of at least 150 with ammonia and / or amine compound. The binding composition is coated on a fibrous material and is heated to achieve crosslinking of the polyamic acid to form a cured water-resistant binder in association with the fibrous material wherein adjoining fibers are bound at cross-over points.

Owner:JOHNS MANVILLE CORP

Aqueous Resin Dispersion for Adhesive and Composition Thereof

ActiveUS20070225442A1Good dry adhesionSacrificing pot lifePolyureas/polyurethane adhesivesVinyl aromatic copolymer adhesivesWater basedMethacrylate

To provide a water-based polymer dispersion for isocyanate-crosslinked adhesives comprising a polymer (1) which is obtained by emulsion polymerization of a monomer composition comprising at least one monomer selected from the group consisting of an aromatic vinyl monomer and a (meth)acrylate monomer, a crosslinkable monomer, and a different monomer, in respective predetermined amounts; and a polymer (2) which is obtained by emulsion polymerization of a monomer composition comprising at least one monomer selected from the group consisting of an aromatic vinyl monomer and a (meth)acrylate monomer, a hydroxyl group-containing vinyl monomer, an ethylenically unsaturated carboxylic acid monomer, and a different monomer, in respective predetermined amounts, wherein the polymers (1) and (2) have a Tg difference of 20 to 80° C.

Owner:ASAHI KASEI CHEM CORP

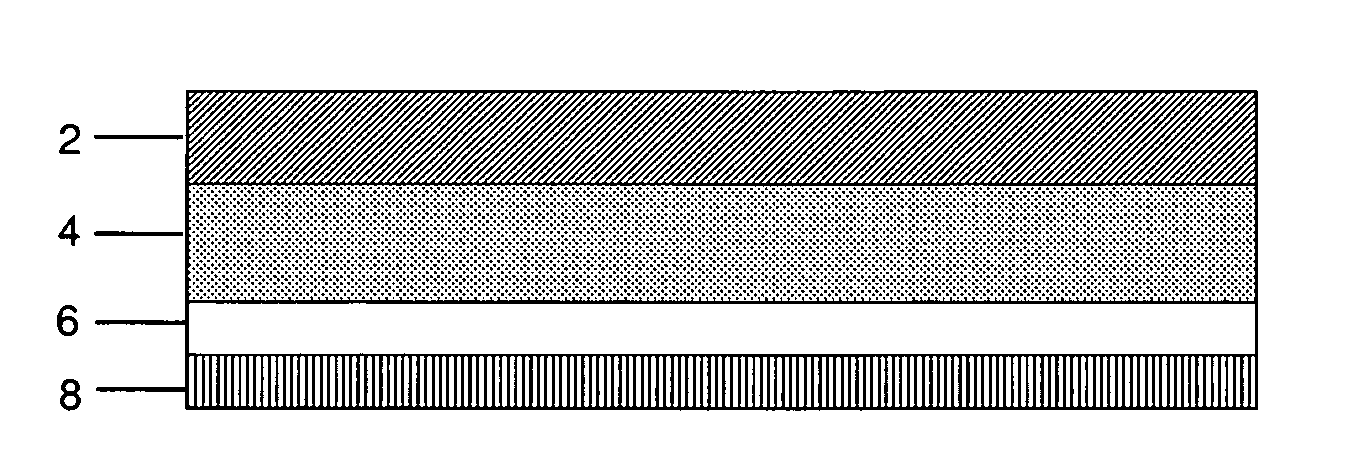

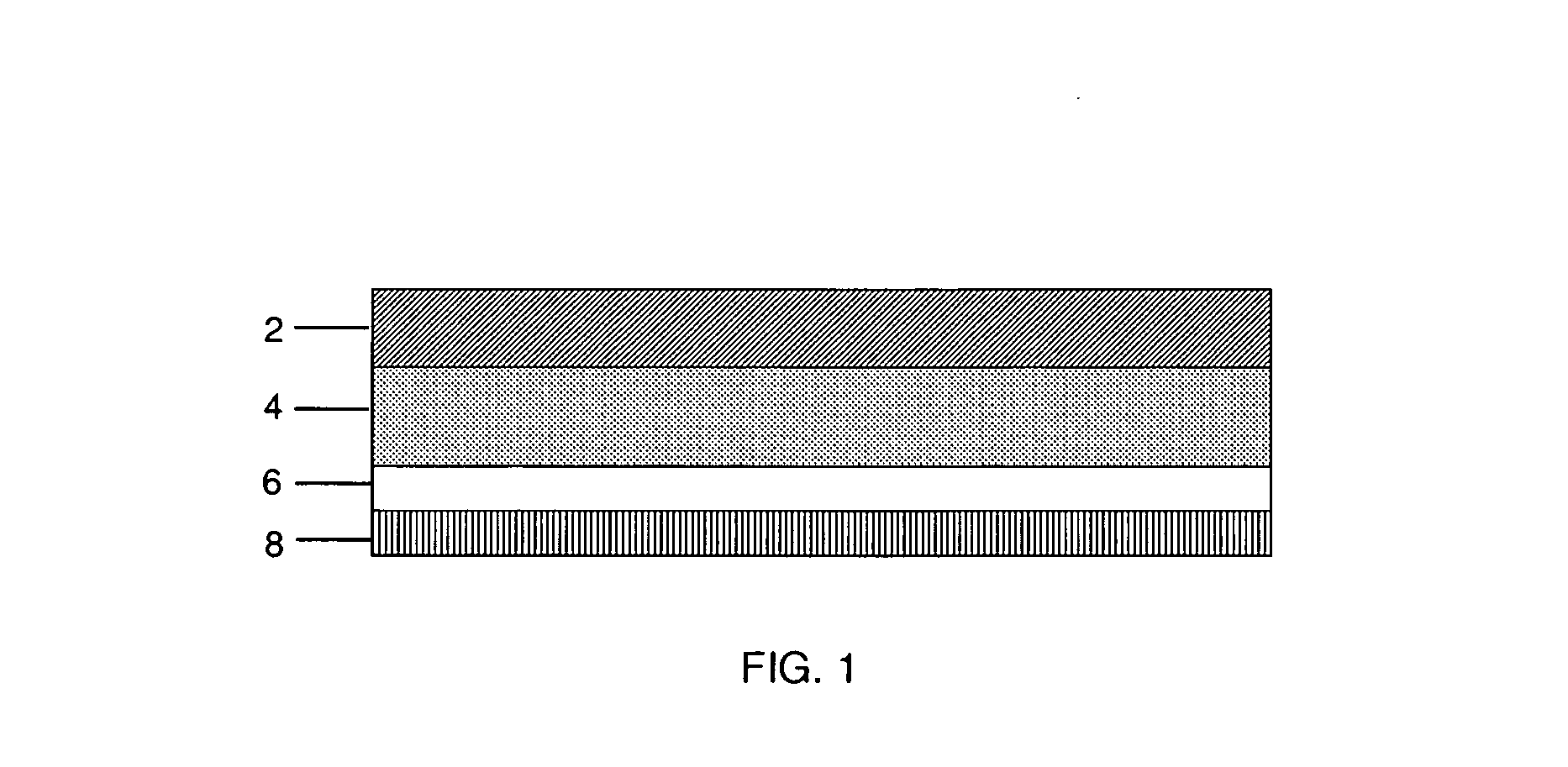

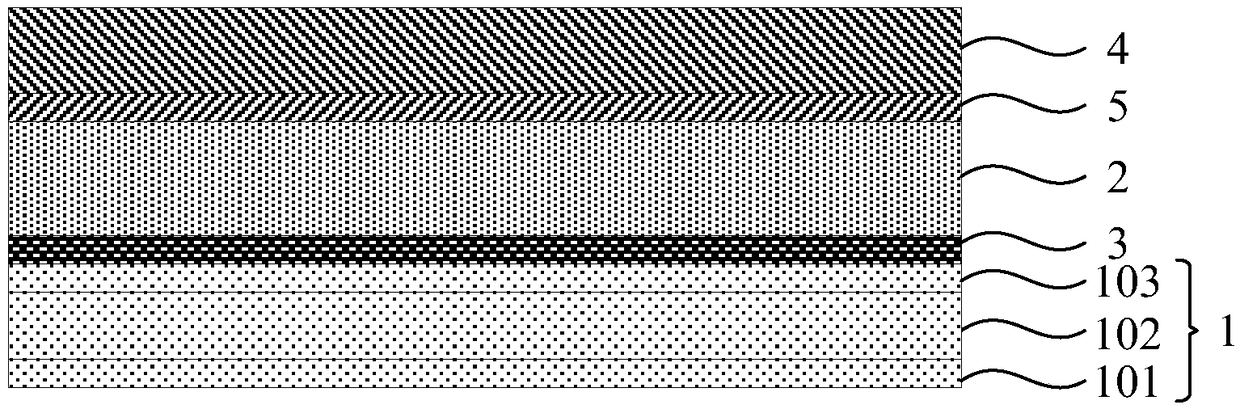

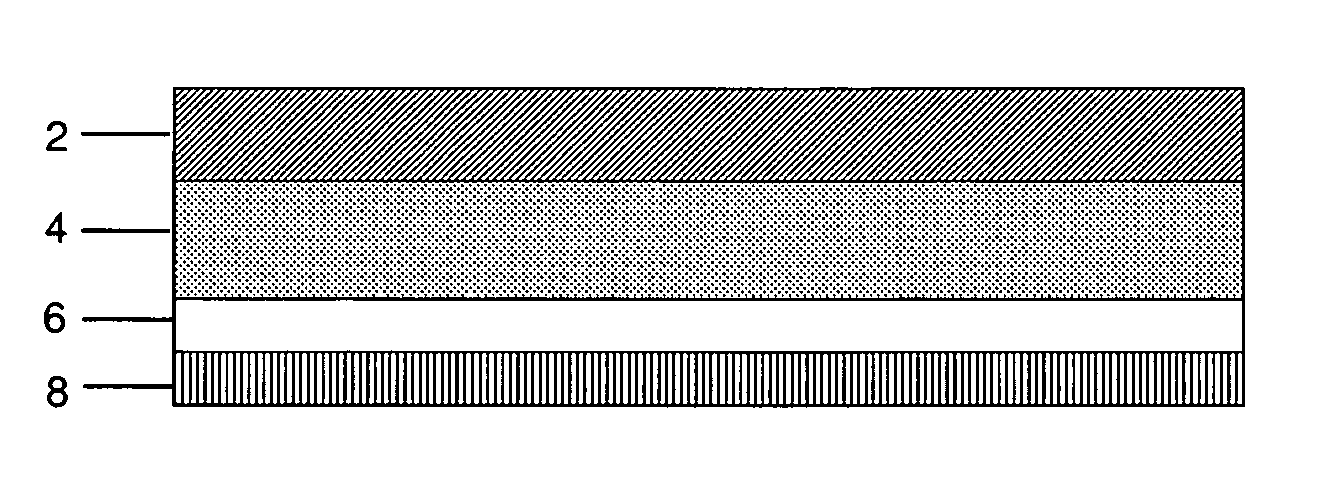

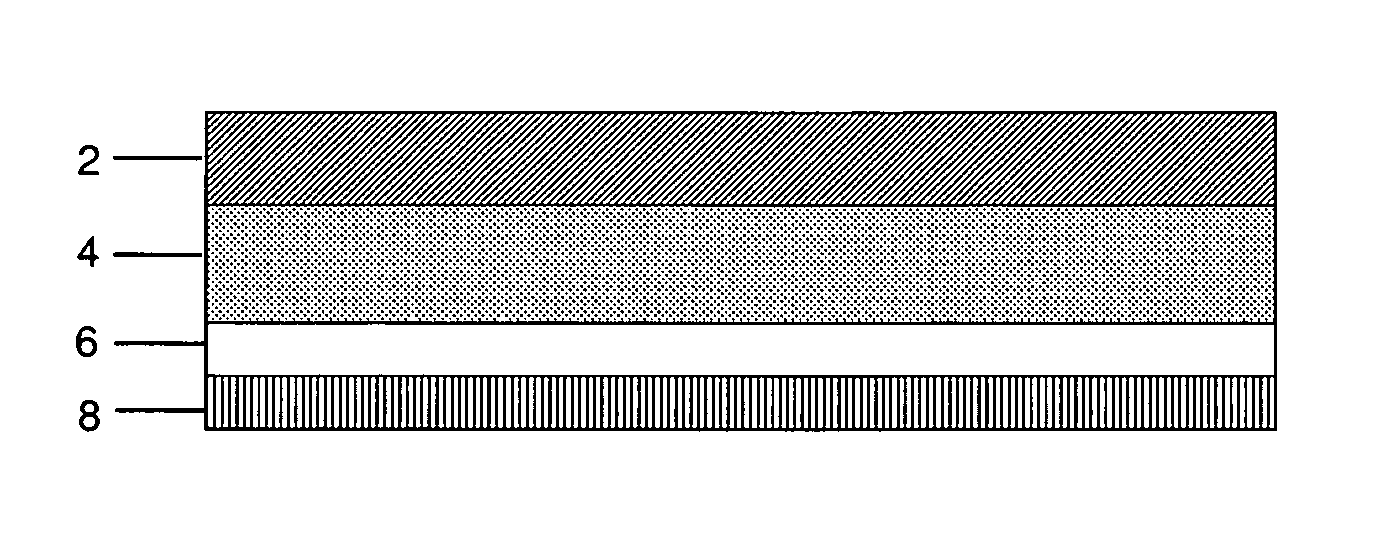

Waterproofing membrane

ActiveUS20150052847A1Vinyl aromatic copolymer adhesivesEster polymer adhesivesUltravioletSurfactant free

Disclosed is a waterproofing membrane that comprises a carrier sheet (layer A); a waterproofing adhesive (layer B); a protective coating (layer C), wherein the protective coating is substantially free of surfactant and comprises an acrylic or methacrylic polymer or copolymer, an inorganic filler and a white pigment; and a releasable material (layer D), wherein the releasable material comprises amorphous nanoscale silica and a polymeric binder. The waterproofing membrane does not require a release liner, binds strongly to concrete cast against it (even after UV exposure), tolerates foot traffic, and withstands immersion in water over an extended period.

Owner:GCP APPL TECH INC

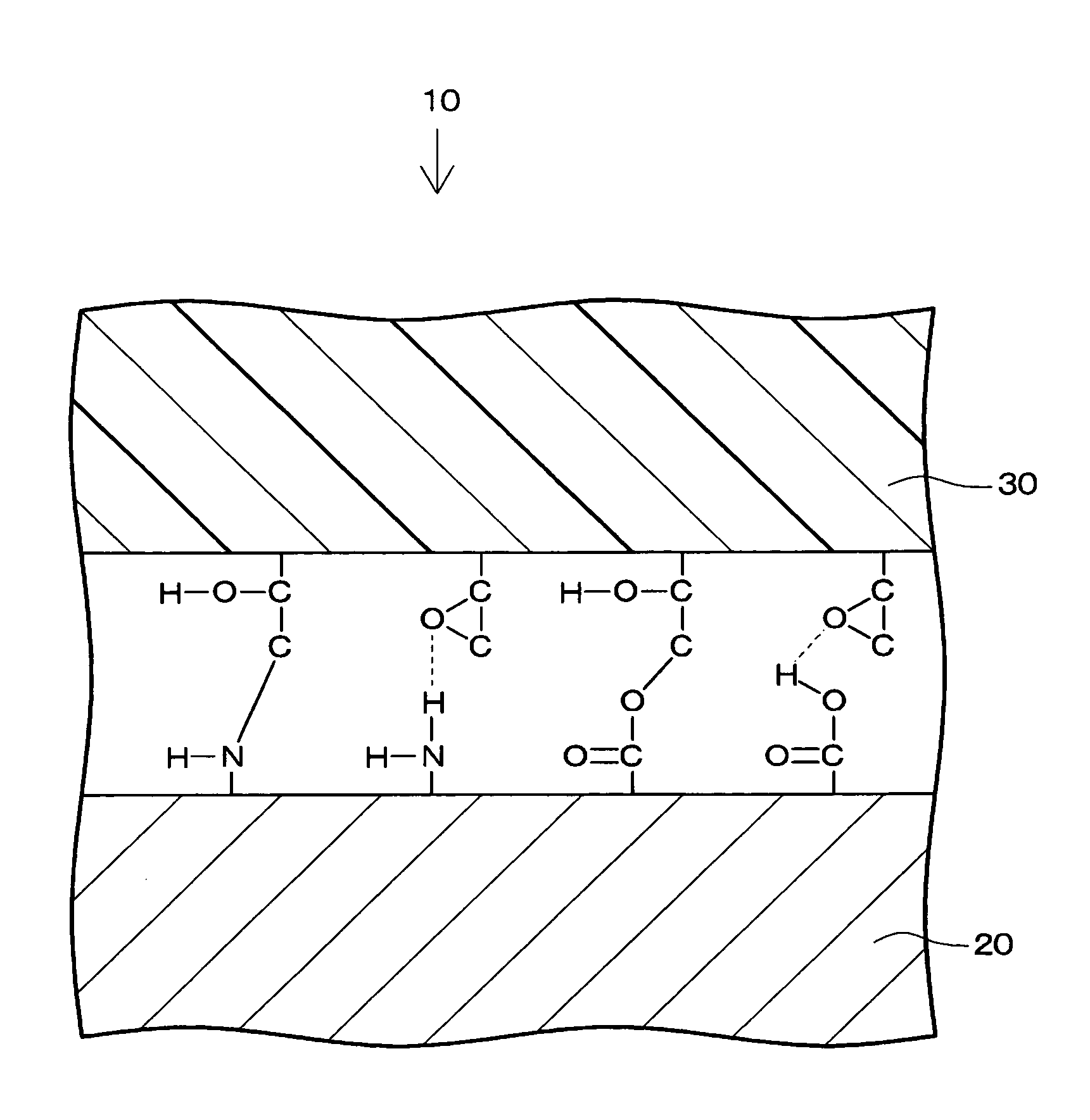

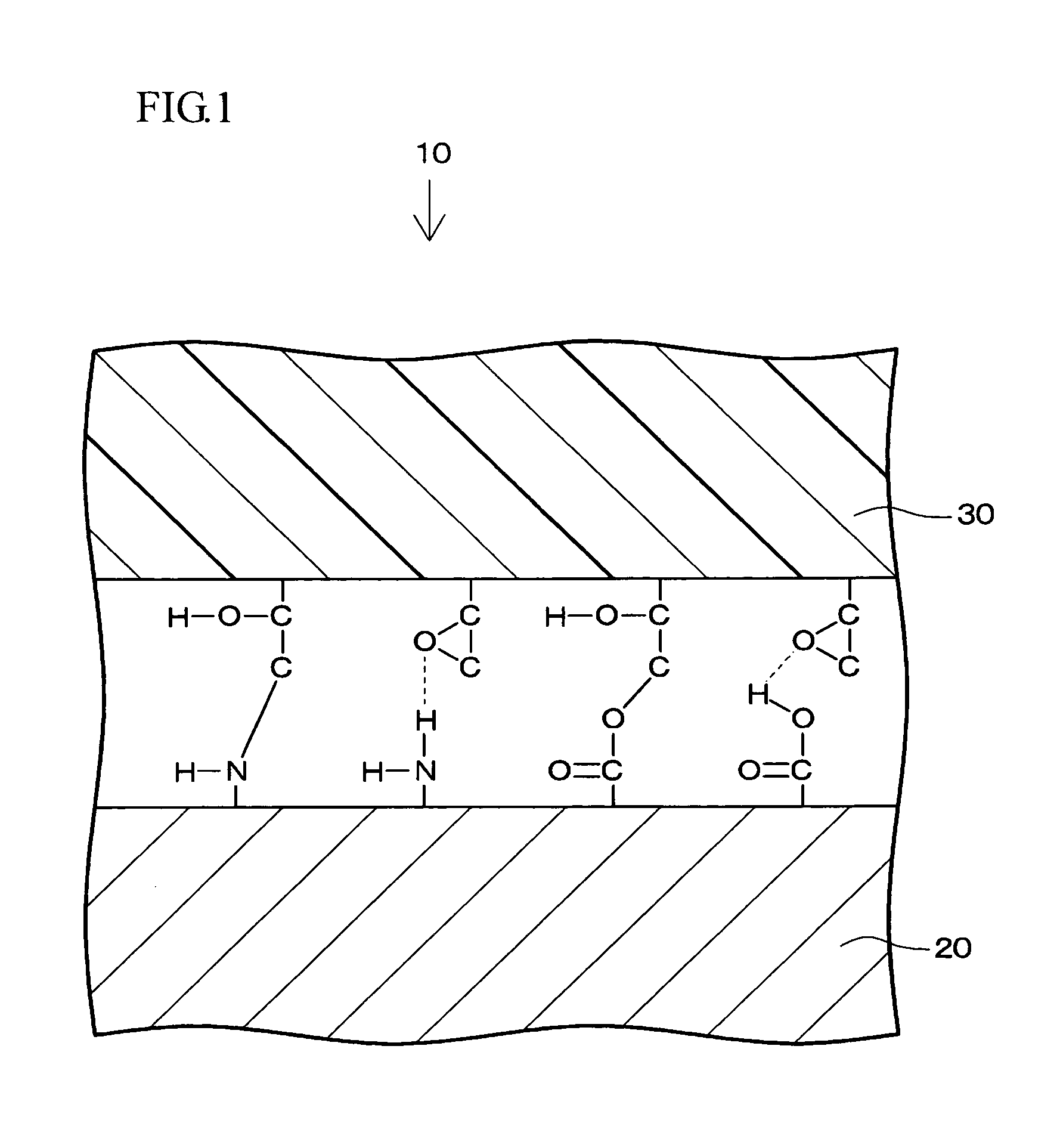

Composite material engineered from metal and resin and production method thereof

InactiveUS20100197882A1Easily and uniformly mixedReduce in quantityAgricultural articlesDomestic sealsPolyresinMetal

A composite material engineered from metal and resin and a production method of the composite material. The composite material includes a metal portion composed of metal; a resin portion composed of resin; a polar functional group imparted to a surface of the metal portion; and an adhesion modifying agent mixed in the resin and including an adhesive functional group which interacts with the polar functional group. The metal portion and the resin portion are bonded by the interaction between the polar functional group and the adhesive functional group.

Owner:TOYODA GOSEI CO LTD

Trough-edge building panel and method of manufacture

Disclosed herein is a trough-edge building panel used in the fabrication of panelized wall systems with elastomeric joints that are resistant to cracking. The panels are preferably fiber cement. The front surface of each panel has a trough adjacent to an edge of the panel. Panels are fastened to a frame with the trough-edges adjacent to each other. A joint tape is applied to the seam between the panels such that the edges of the joint tape fall within the troughs of the adjacent panels. The wall is then finished with an elastomeric finish. Also disclosed is a method of manufacturing the trough-edge panels.

Owner:JAMES HARDIE TECH LTD

Caustic removable hot melt adhesive formulations

ActiveUS20100255228A1Imparts caustic removabilityClean removabilitySynthetic resin layered productsVinyl aromatic copolymer adhesivesPolymer sciencePolyolefin

An additive composition for imparting caustic removability to a hot melt adhesive comprises a low molecular weight α,β ethylenically unsaturated anhydride-containing or acid-containing polymer. The polymer is selected from the group consisting of a low molecular weight carboxylic anhydride homo-polymer or the at least partial ester thereof, a low molecular weight carboxylic anhydride copolymer or the at least partial ester thereof, a low molecular weight carboxylic anhydride polyolefin, a low molecular weight carboxylic anhydride vinyl aromatic copolymer, and a low molecular weight carboxylic anhydride grafted copolymer, or the combination or mixtures thereof. A caustic removable hot melt adhesive composition comprises a hot melt adhesive additive and a conventional hot melt adhesive resin. A caustic removable adhesive label comprises a substrate and a caustic removable hot melt adhesive composition which includes an additive composition. The caustic removable hot melt adhesives can be used on labels for articles, such as glass bottles.

Owner:FINA TECH

Pellicle and mask adhesive agent for use in same

ActiveUS20130101927A1Easy plastic deformationEasy to operateVinyl aromatic copolymer adhesivesOriginals for photomechanical treatmentThermoplastic elastomerPlastic property

A pellicle which has a mask adhesive layer that can be plastic-deformed readily particularly at a temperature at which exposure to light is carried out, rarely provides a residue of an adhesive agent upon the removal of the mask adhesive layer from a mask and has good handling properties, and which can prevent the position gap of a pattern. The pellicle comprises a pellicle frame, a pellicle membrane and a mask adhesive layer containing a mask adhesive agent. The mask adhesive agent comprises 100 parts by mass of a thermoplastic elastomer (A) having a tan δ peak temperature of −20 to 30 DEG C and 20 to 150 parts by mass of an adhesiveness-imparting resin (B).

Owner:MITSUI CHEM INC

Fast response photochromic composition and device

InactiveUS20130242368A1Quick changeQuick responseNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesOptical powerEngineering

The present invention relates to optical power-limiting device, and more particularly, to an optical power-limiting passive device and to a method for limiting optical power transmission in lenses and windows, using absorption changes in a photochromic material with a fast response, featuring under a millisecond rise time and one to five seconds return / decay time.

Owner:KILOLAMBDA TECH

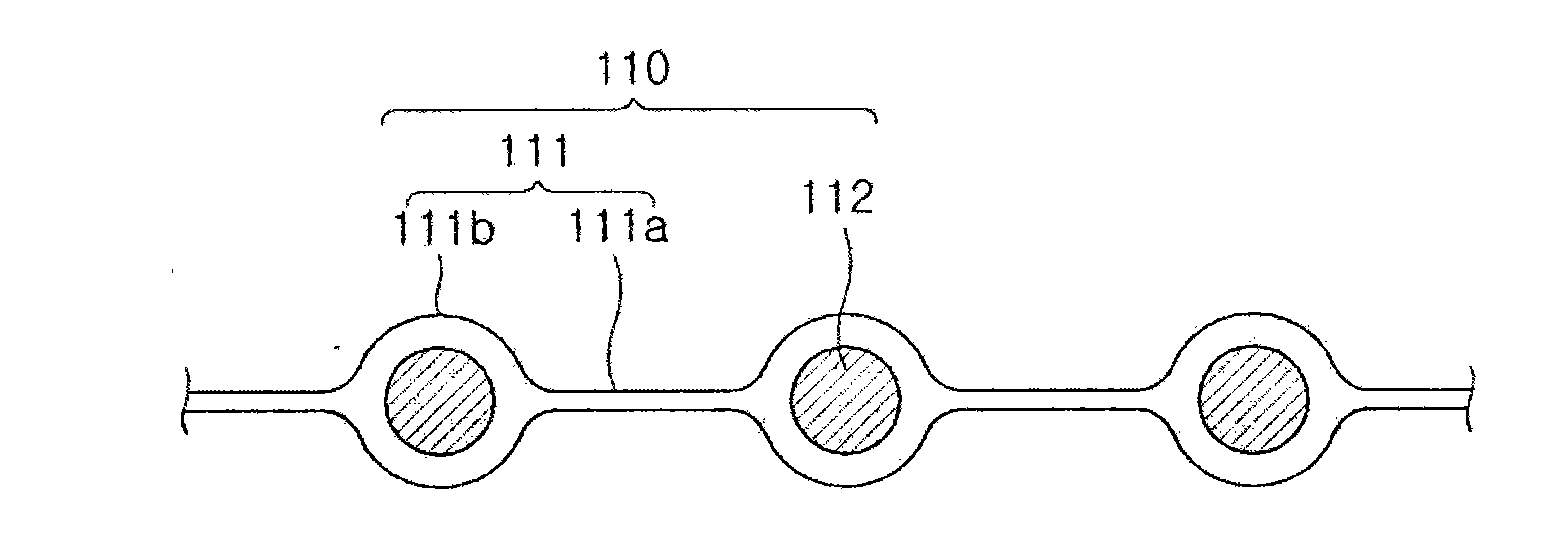

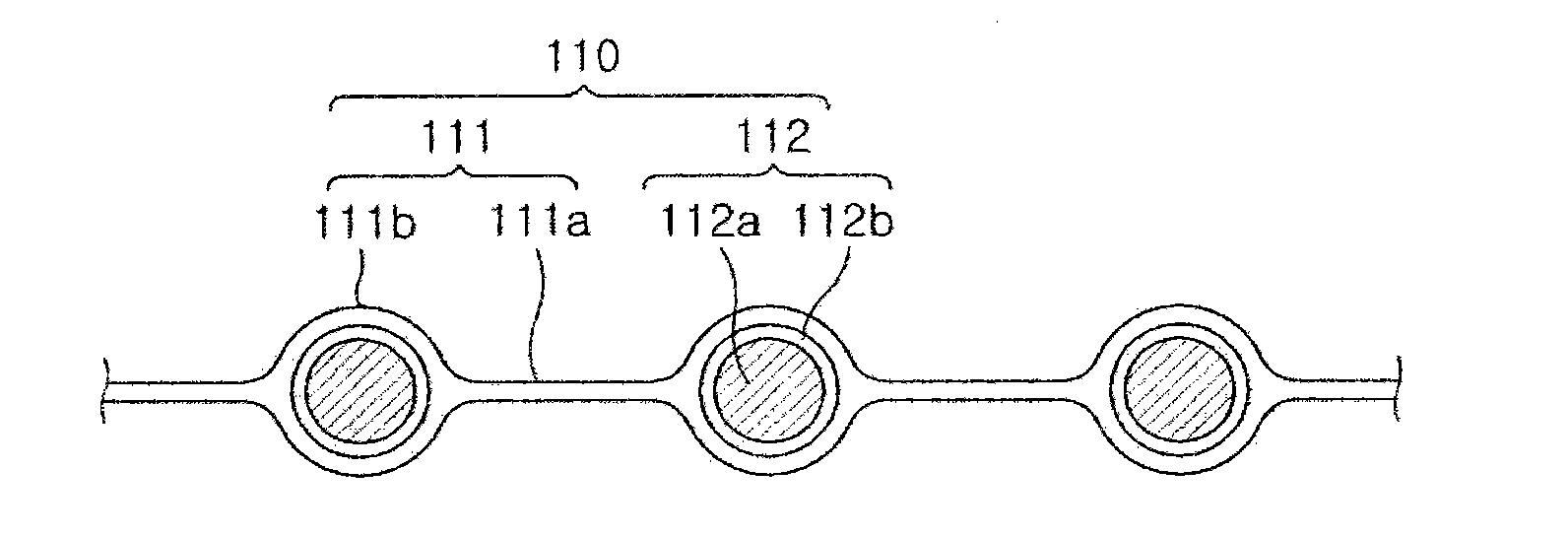

Fiber, fiber aggregate and adhesive having the same

Provided is a functional fiber and a fiber aggregate for realizing various functions, an adhesive for easily bonding electronic components, and a method for manufacturing the same. Particularly, a fiber extended in a length direction includes a carrier polymer and a plurality of functional particles, wherein the plurality of functional particles are embedded in the carrier polymer and physically fixed to the carrier polymer to be integrated.

Owner:OPTOPAC +2

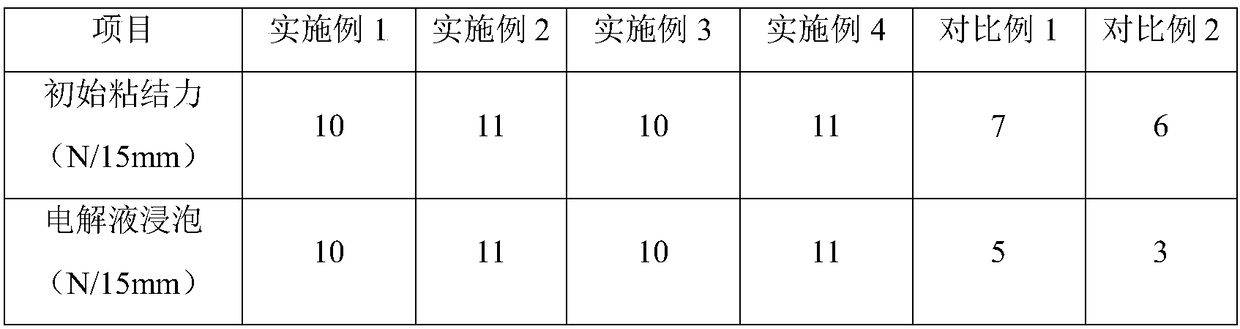

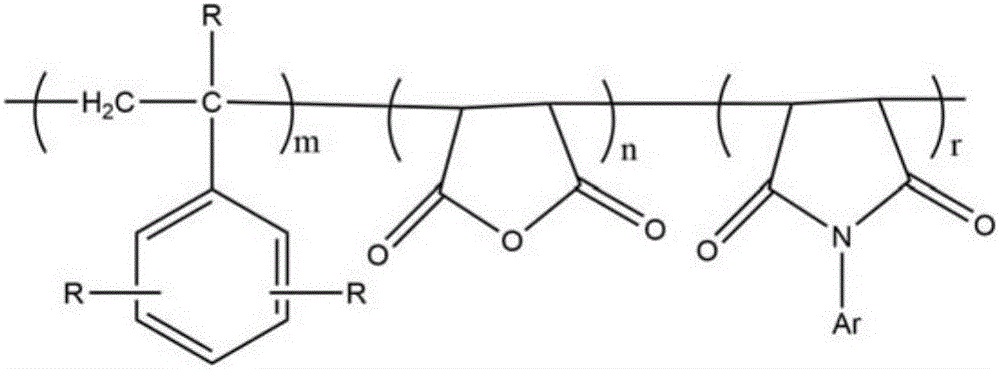

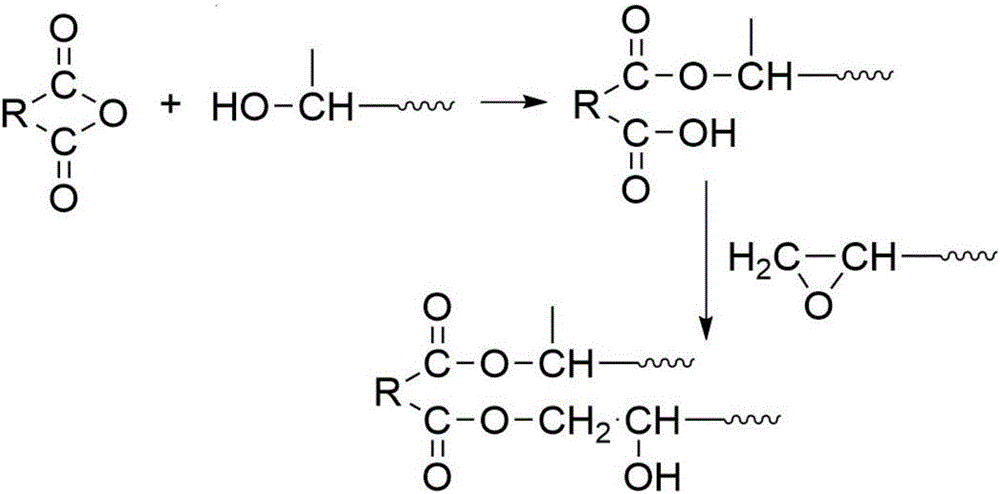

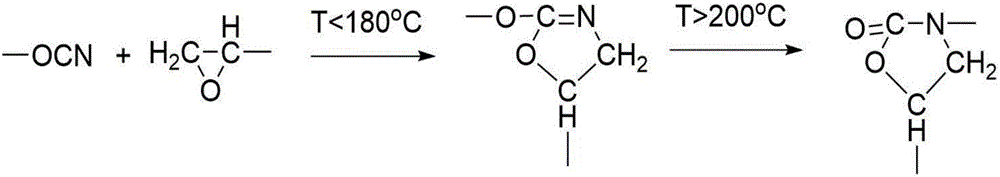

Adhesive for aluminum battery packaging aluminum plastic film, aluminum plastic film and preparation method of aluminum plastic film

InactiveCN109337620AGood solvent resistanceImprove acid resistanceNon-macromolecular adhesive additivesVinyl aromatic copolymer adhesivesElastomerEpoxy

The invention provides an adhesive for an aluminum battery packaging aluminum plastic film, the aluminum plastic film and a preparation method of the aluminum plastic film. The adhesive at least comprises the following components in percentage by mass: 10-15% of a main resin, 1-3% of a curing agent, 0.5-1%of a tackifying resin, 0.1-0.5% of an anti-hydrolysis agent and 65-90% of a solvent, whereinthe main resin comprises one or more of maleic anhydride modified styrene, polypropylene and a polyolefin elastomer; the curing agent comprises a mixture of one or more polymers in an epoxy resin system. In the aluminum plastic film, the adhesive is coated on the surface of an adhesive layer of a cast polypropylene film, and dried to serve as an inner adhesive layer. The inner adhesive layer is used for dry compounding of an aluminum foil layer of the aluminum battery packaging aluminum plastic film and the cast polypropylene layer, so that aluminum plastic film products have high adhesion andelectrolyte resistance; in addition, the adhesive has a relatively long storage cycle.

Owner:JIANGXI RUIERGY NEW MATERIAL TECH CO LTD

Adhesive used for high-heat resistance leadless low-dielectric copper-clad plate and preparation method thereof

InactiveCN106381113AImprove performanceImprove heat resistanceNon-macromolecular adhesive additivesVinyl aromatic copolymer adhesivesAdhesiveSilanes

The invention relates to an adhesive used for a high-heat resistance leadless low-dielectric copper-clad plate and a preparation method thereof. The adhesive comprises the following components in parts by weight: 15-70 parts of low dielectric epoxy resin, 15-40 parts of modified polymerized acid anhydride, 5-40 parts of a cyanate esters curing agent, 2-40 parts of an active esters curing agent, 10-50 parts of a bromine-containing fire retardant, 0.05-1.000 parts of silane, 0.001-0.1 parts of a metals curing accelerator, 0.001-0.1 parts of an amines promoter, 0.005-0.1 parts of an imidazoles promoter, 10-60 parts of an inorganic filling material, and 1-8 parts of a flexibilizer. Compared with the prior art, the copper-clad plate has the advantages of high heat resistance, low water absorption, low dielectric loss and excellent resistance to heat and humidity.

Owner:NANYA NEW MATERIAL TECH CO LTD

Anisotropic conductive adhesive

InactiveUS7452923B2Minimizes its contractionPreventing a short circuitImpression capsConductive materialAnisotropic conductive adhesivePolymerization

The present invention discloses an anisotropic conductive adhesive comprising an insulating adhesive component and a number of conductive particles dispersed in the insulating adhesive component, wherein the insulating adhesive component contains a crosslinked rubber resin. The anisotropic conductive adhesive of the present invention prevents exfoliation of an adhesive or reduction in adhesive strength of circuit by minimizing its the heat-contraction occurring in the process of a polymerization or a hardening reaction when connecting micro-circuits, whereby a short circuit between adjacent electrodes can be prevented when connecting the circuits, and excellent connection reliability according to a long-term use is achieved.

Owner:H&S HIGH TECH +1

Low temperature curing acrylate and maleimide based formulations and methods for use thereof

ActiveUS8063161B2Non-fibrous pulp additionFilm/foil adhesivesLow temperature curingElectronic packaging

The present invention is based on the discovery that certain electron poor olefins combined with nucleophiles and a base catalyst are useful as adhesive compositions for the electronic packaging industry. In particular, the adhesive formulations set forth herein are useful as low temperature curing formulations with high adhesion to a variety of substrates. Invention formulations typically cure at about 80° C. and have a potlife of about 24 hours. The formulations cure by the well-known Michael addition reaction.

Owner:DESIGNER MOLECULES

Thermoplastic elastomers via reversible addition-fragmentation chain transfer polymerization of triglycerides

ActiveUS9650463B2Reduce probabilityShort timeVinyl aromatic copolymer adhesivesBuilding insulationsThermoplastic elastomerTriglyceride

The present invention relates to a thermoplastic block copolymer comprising at least one PA block and at least one PB block. The PA block represents a polymer block comprising one or more units of monomer A, and the PB block represents a polymer block comprising one or more units of monomer B. Monomer A is a vinyl, acrylic, diolefin, nitrile, dinitrile, acrylonitrile monomer, a monomer with reactive functionality, or a crosslinking monomer. Monomer B is a radically polymerizable triglyceride or mixtures thereof, typically in the form of a plant or animal oil. The present invention also relates to a method of preparing a thermoplastic block copolymer or novel thermoplastic statistical copolymers by polymerizing a radically polymerizable monomer with a radically polymerizable triglyceride or mixtures thereof via reversible addition-fragmentation chain-transfer polymerization (RAFT), in the presence of an free radical initiator and a chain transfer agent.

Owner:IOWA STATE UNIV RES FOUND

Adhesive composition for patch and use thereof

InactiveUS20100092544A1Improve skinImprove cohesionFilm/foil adhesivesVinyl aromatic copolymer adhesivesElastomerPolymer science

The present invention provides an adhesive composition for patch, containing a rubber elastomer and a tackifier having a weight average molecular weight of 1200-2500, a patch having a support and an adhesive layer containing the composition, which is provided on at least one surface of the support, and a patch preparation having an adhesive layer containing a percutaneously absorbable drug (excluding bisoprolol).

Owner:NITTO DENKO CORP

Modifier for resins, adhesive compositions, and thermoplastic resin compositions

InactiveUS20110288208A1Improve propertiesGood groomingNon-macromolecular adhesive additivesVinyl aromatic copolymer adhesivesPolymer resinGas chromatography–mass spectrometry

The present invention provides a resin modifier comprising as an active ingredient a hydrogenated rosin ester in which a component having a molecular weight of 320 of a methylation product of a hydrolyzate of the hydrogenated rosin ester as measured by gas chromatography-mass spectrometry accounts for 95 wt % or greater of the total amount of the components having a molecular weight of 314 to 320; a modifier that is an optical embrittlement inhibitor for use in an adhesive polymer resin; an adhesive composition comprising the optical embrittlement inhibitor; a modifier that is a melt fluidity and adhesion improver for a thermoplastic resin; and a thermoplastic resin composition comprising the melt fluidity and adhesion improver.

Owner:ARAKAWA CHEM IND LTD

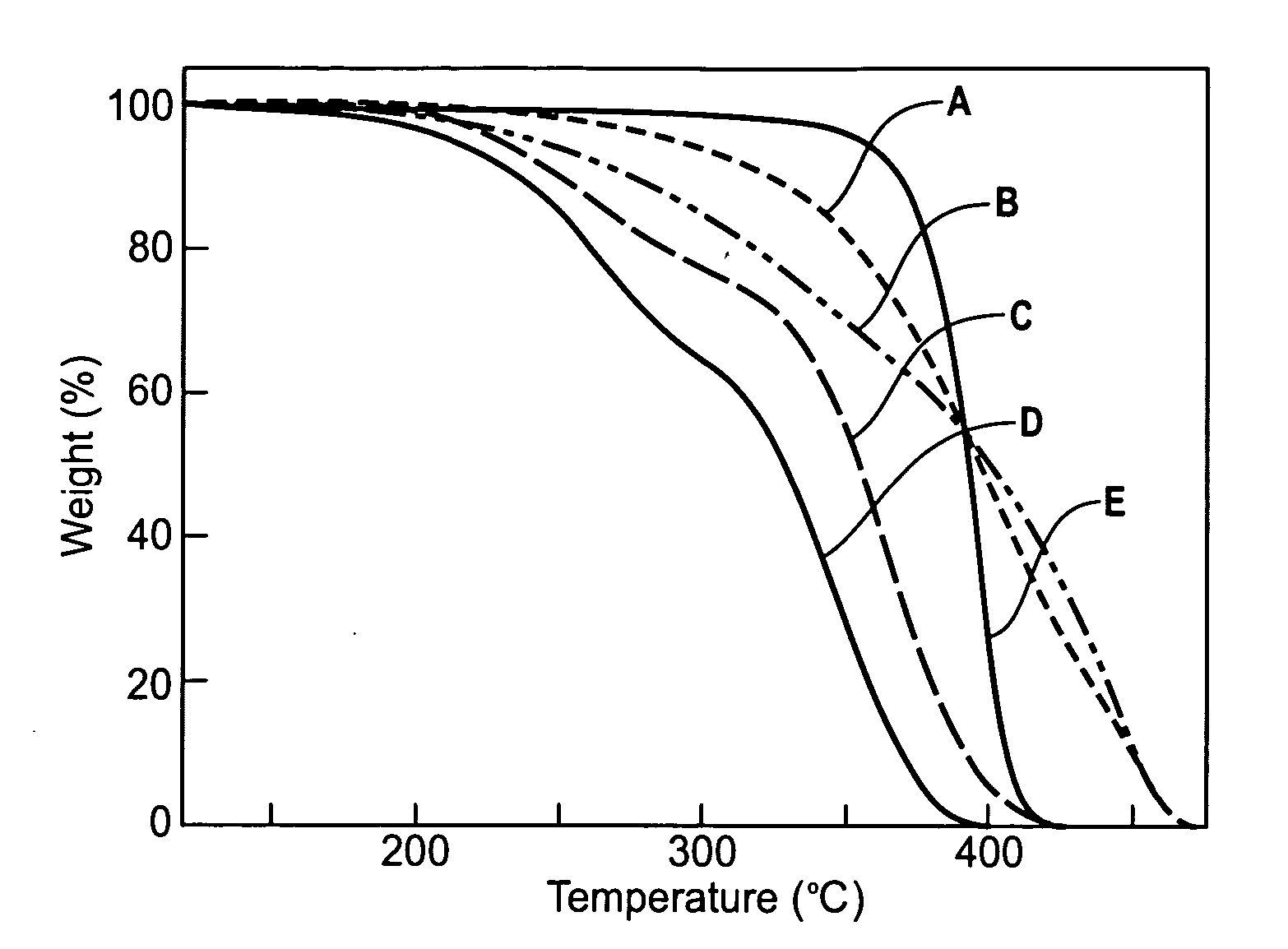

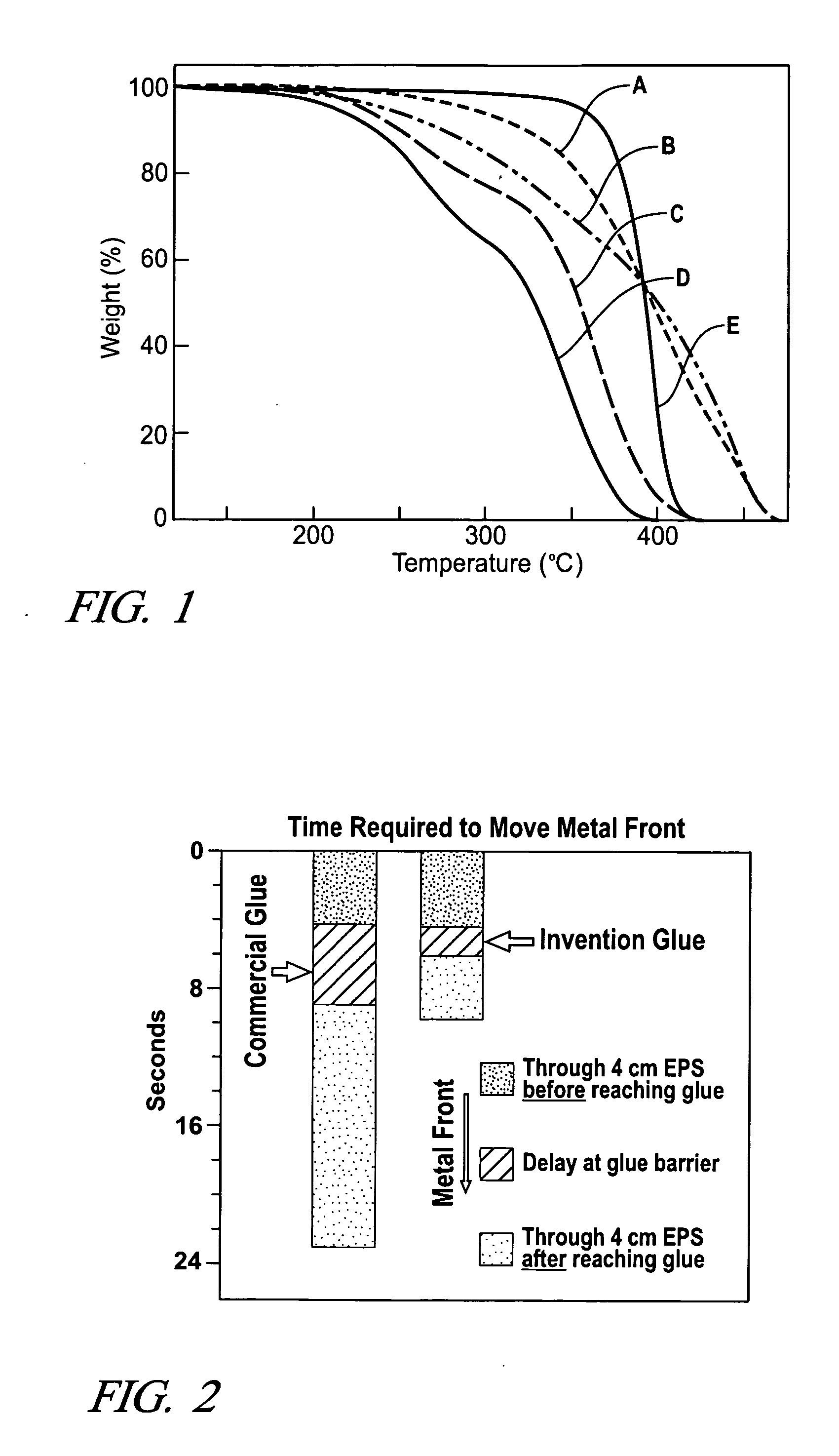

Glued lost foam casting pattern assembly

InactiveUS20060254740A1Reduce formationPoor miscibilityFoundry mouldsVinyl aromatic copolymer adhesivesPlasticizerPolystyrene

Lost foam pattern assemblies formed by gluing together a plurality of EPS foam pattern segments with a polystyrene-like glue comprising an aromatic resin that has a molecular weight less than 10,000 and thermally degrades at temperatures no greater than said EPS. The glue contains sufficient first plasticizer, miscible with the resin, to impart a viscosity of about 0.1 to 5 PaS @ about 100-135° C. to the glue. The glue may optionally include a second, limited-miscibility, plasticizer to accelerate the hardening rate and increase the ultimate rigidity of the glue.

Owner:GM GLOBAL TECH OPERATIONS LLC

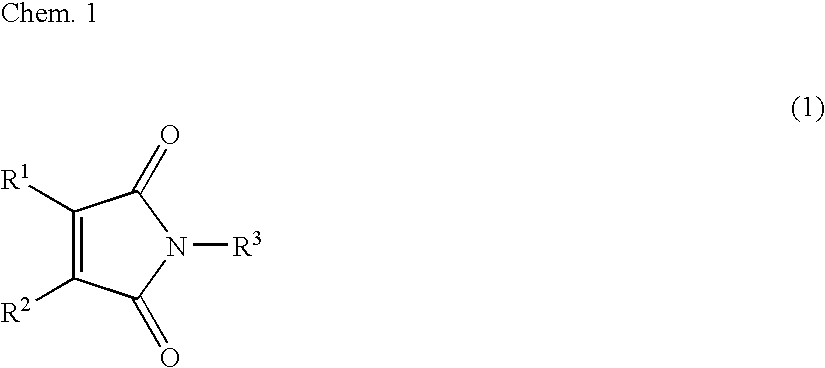

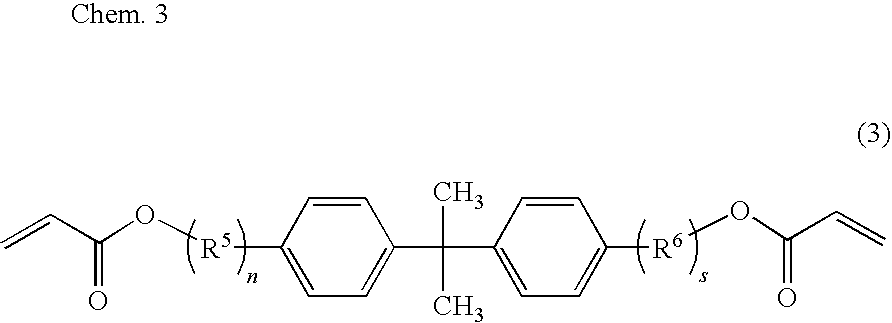

Adhesive composition, film adhesive, and heat treatment method

ActiveUS20090311526A1High bonding strengthEasy to peelFilm/foil adhesivesVinyl aromatic copolymer adhesivesMonomer compositionPolymer science

An adhesive composition of the present invention contains, as a main composition, a polymer obtained by copolymerizing a monomer composition containing a monomer having a maleimide group, and further contains a thermal polymerization inhibitor. As a result, it is possible to provide an adhesive composition that allows forming an adhesive layer that is excellently dissolved after the adhesive layer has been subjected to a high-temperature process.

Owner:TOKYO OHKA KOGYO CO LTD

Waterproofing membrane

ActiveUS9476196B2Vinyl aromatic copolymer adhesivesEster polymer adhesivesUltravioletSurfactant free

Disclosed is a waterproofing membrane that comprises a carrier sheet (layer A); a waterproofing adhesive (layer B); a protective coating (layer C), wherein the protective coating is substantially free of surfactant and comprises an acrylic or methacrylic polymer or copolymer, an inorganic filler and a white pigment; and a releasable material (layer D), wherein the releasable material comprises amorphous nanoscale silica and a polymeric binder. The waterproofing membrane does not require a release liner, binds strongly to concrete cast against it (even after UV exposure), tolerates foot traffic, and withstands immersion in water over an extended period.

Owner:GCP APPL TECH INC

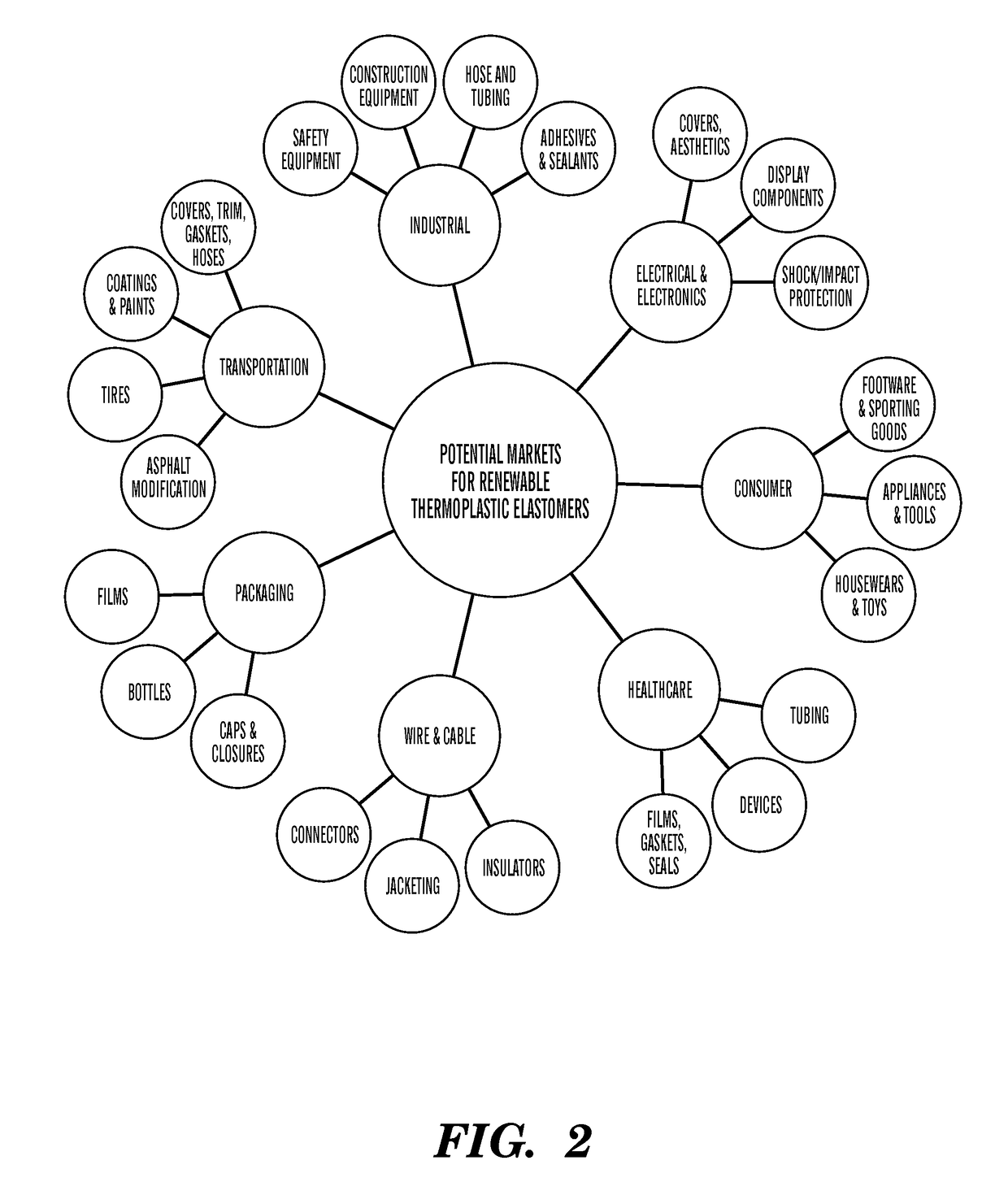

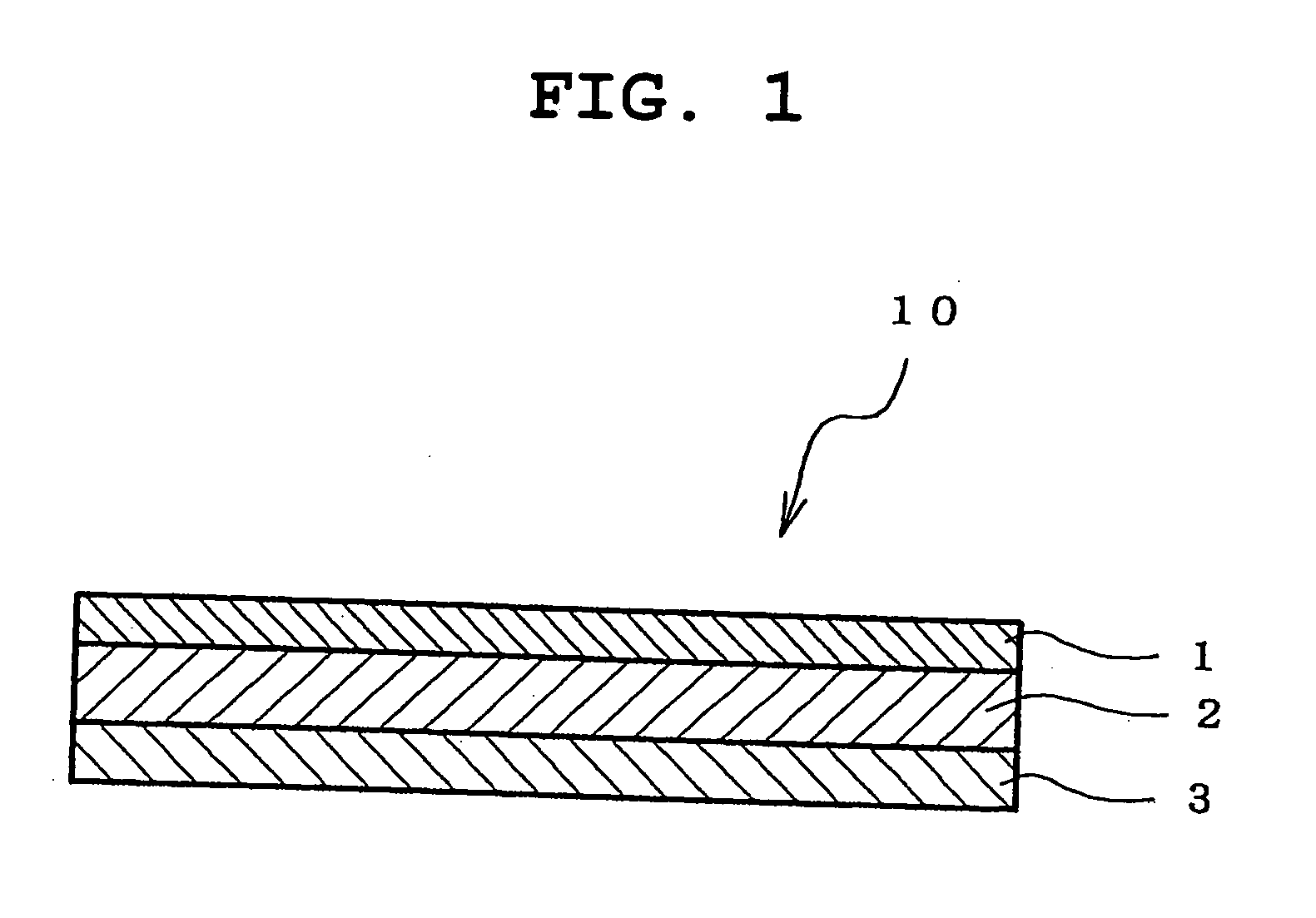

Adhesive sheet

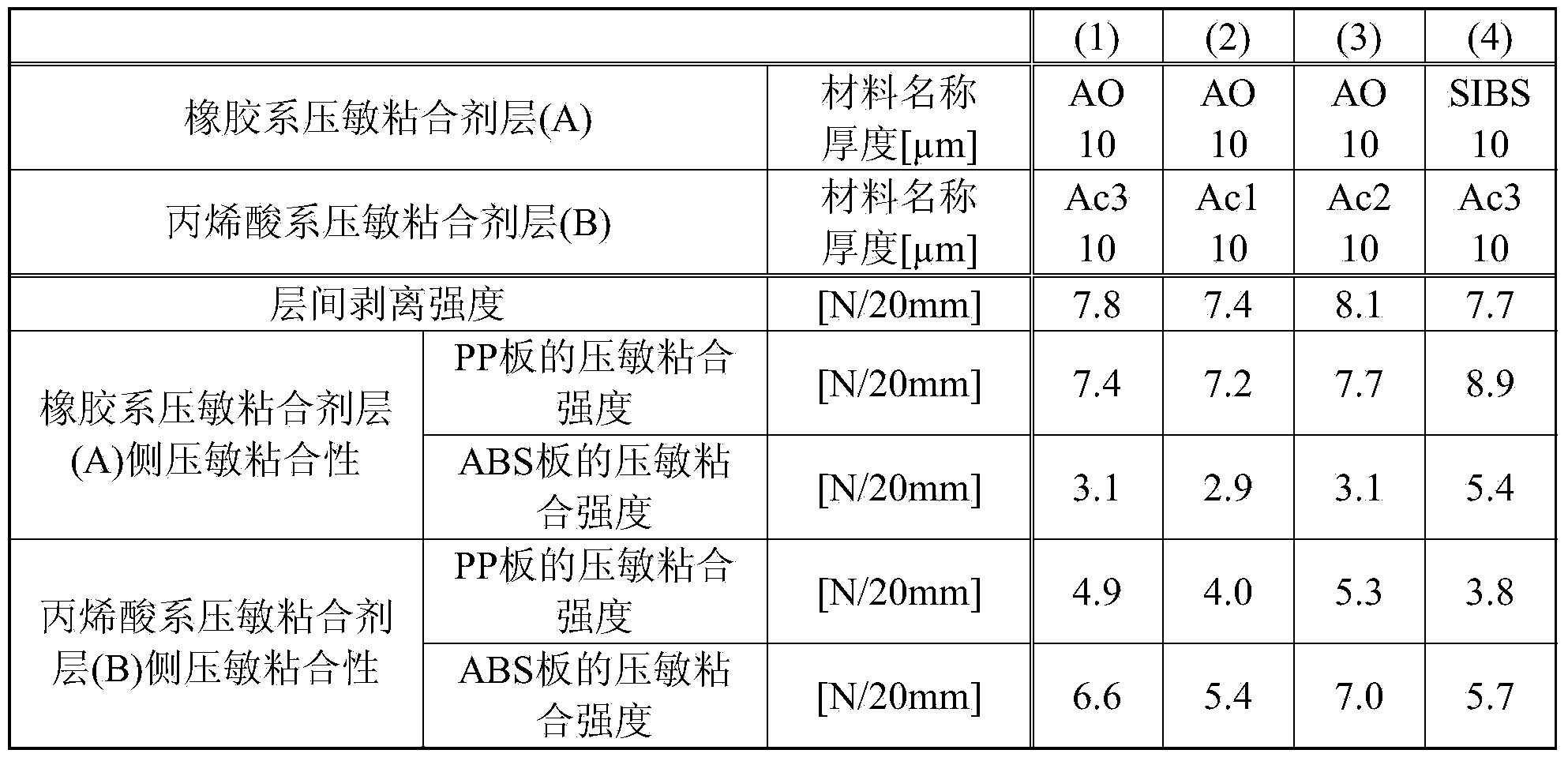

InactiveCN103562330AHigh peel strength between layersVinyl aromatic copolymer adhesivesEster polymer adhesivesTwo layerPressure sensitive

Provided is a pressure-sensitive adhesive sheet formed of at least two layers, including a rubber-based pressure-sensitive adhesive layer (A) and an acrylic pressure-sensitive adhesive layer (B) that are directly laminated, in which the pressure-sensitive adhesive sheet has a large interlayer peel strength. The pressure-sensitive adhesive sheet is a pressure-sensitive adhesive sheet formed of at least two layers, including a rubber-based pressure-sensitive adhesive layer (A) and an acrylic pressure-sensitive adhesive layer (B) that are directly laminated, in which the pressure-sensitive adhesive sheet has an interlayer peel strength upon peeling of the acrylic pressure-sensitive adhesive layer (B) from the rubber-based pressure-sensitive adhesive layer (A) under conditions of a measurement temperature of 23° C., a tension speed of 0.3 m / min, and a peel angle of 180° C. of 2.0 N / 20 mm or more.

Owner:NITTO DENKO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com