Patents

Literature

39results about How to "High peel strength between layers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

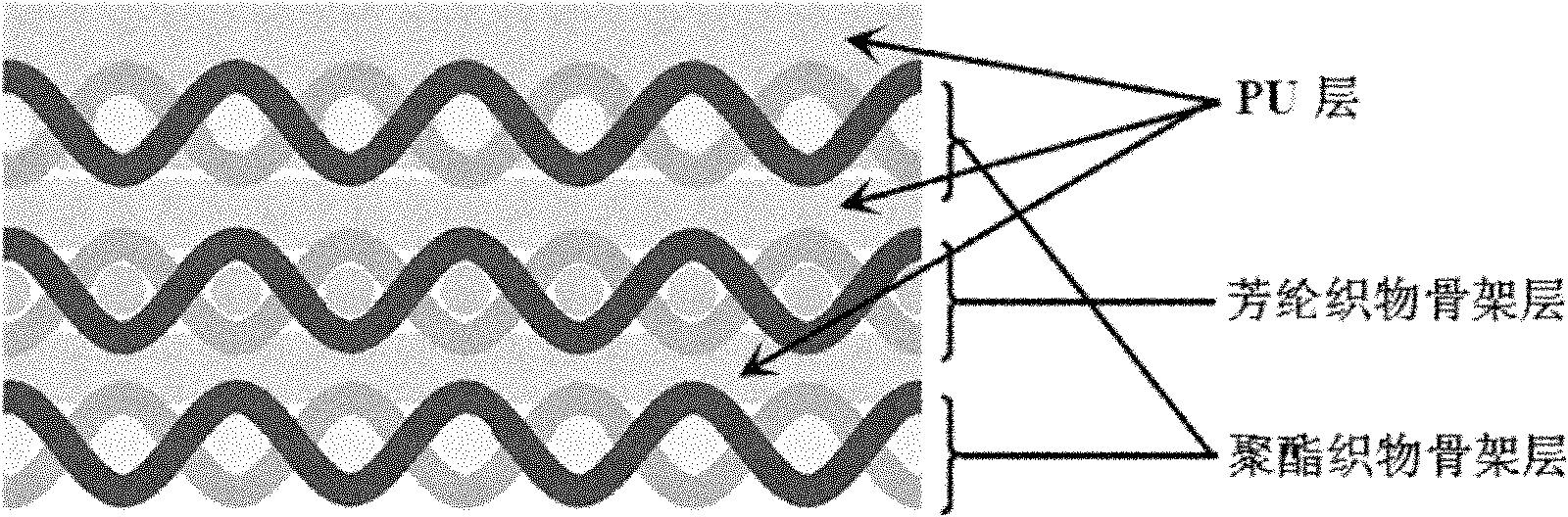

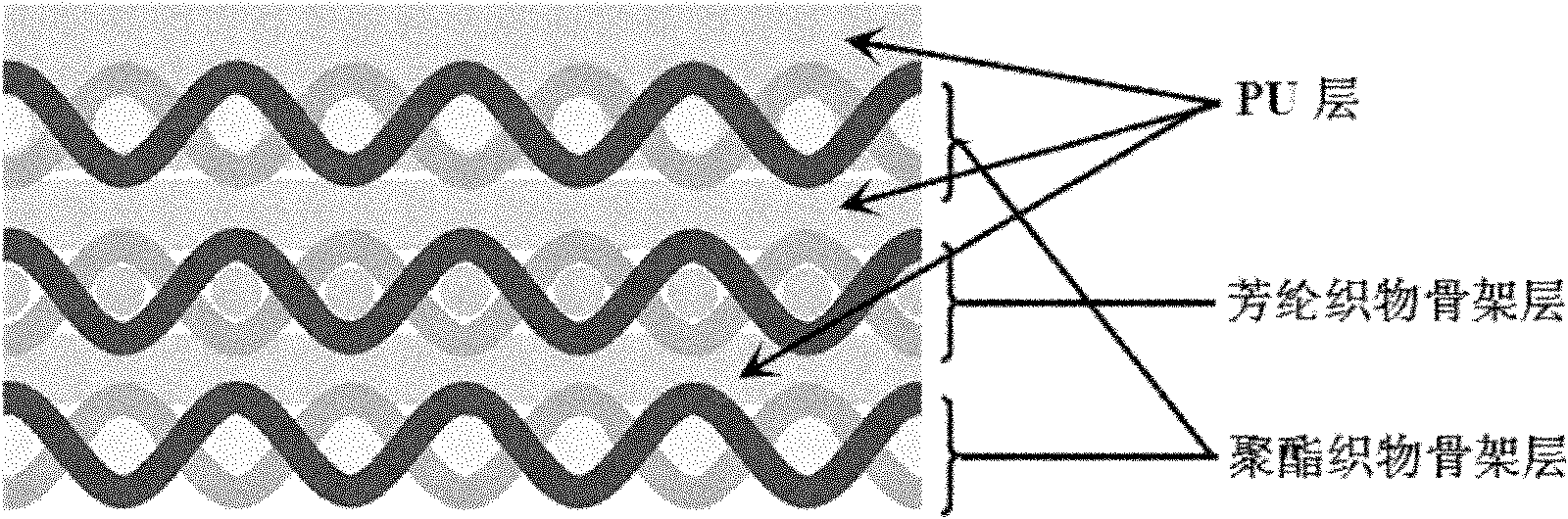

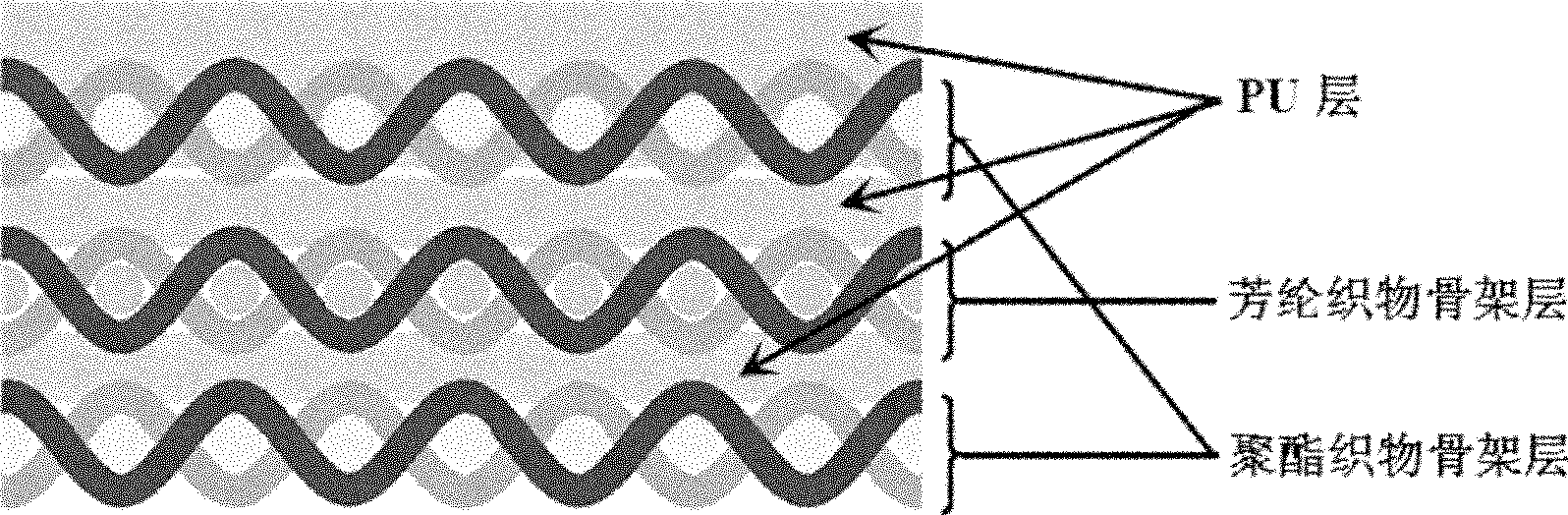

Light conveying belt and preparation method thereof

ActiveCN101979283AHigh warp strengthQuality assuranceConveyorsSynthetic resin layered productsPolyesterEngineering

The invention relates to a light conveying belt and a preparation method thereof. The conveying belt comprises a Kevlar woven fabric, polyester woven fabrics and a polyurethane covering adhesive layer, wherein the Kevlar woven fabric is used as a middle framework layer; two layers of the polyester woven fabrics are used as a framework material of an upper framework layer and a framework material of a bottom framework layer; and three framework layers are respectively laminated with conductive polyurethane so as to obtain the three-fabric three-adhesive light conveying belt. The preparation method comprises the following steps of: (1) adopting Kevlar as warps of the Kevlar woven fabric and adopting ultra low shrink polyester multifilament yarns as weft yarns of the Kevlar woven fabric, wherein the basic weave is plain weave; (2) gluing the fabric and then sizing the glued fabric; and (3) coating the materials. The conveying belt of the invention has high strength. The integral tensile strength and the peel strength of the conveying belt are greatly improved. The preparation method is simple, has low cost and is suitable for industrial production.

Owner:DONGHUA UNIV

Online double-layer composite plastic blow-molding film sheet and manufacturing method thereof

ActiveCN104527189AImproved material designReduce the temperatureSynthetic resin layered productsBoxesHot pressingMelting point

The invention discloses an online double-layer composite plastic blow-molding film sheet which is formed by softening inner layers of a plurality of layers membrane bubbles which are co-extruded and blow-molded, wherein the inner layers of the membrane bubbles consist of EVA, COC and SEBS; a melting point of materials of the outer layers of the membrane bubbles is higher than a Vica softening point of the materials of the inner layer of the membrane bubbles. By optimizing the materials of the inner layers of the membrane bubbles, sticking is inhibited when the hot-pressing effect is improved, the thickness uniformity, the transparency, the heat-sealing uniformity, and the like of the membrane sheet are improved, the prepared membrane sheet has extensive re-processing capacity; after being heat-sealed and thickened, the membrane sheet is stretched and thinned, so that the film sheet has the performances of a blow-molding material and a flow casting material, and can be used as a packaging box back seal strip on a high-speed packaging body production line. Besides, the invention further discloses a manufacturing method for the online double-layer composite plastic blow-molding film sheet.

Owner:JIANGYIN BAOBO PACKING

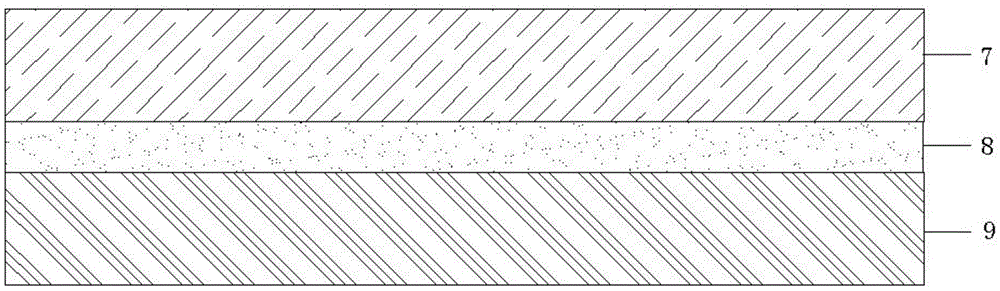

High sealing flexible composite film material for cold punching molding and its manufacturing method

InactiveCN103587165AHigh peel strength between layersImprove interlayer adhesionLamination ancillary operationsLaminationComposite filmPunching

The invention provides a high sealing flexible composite film material for cold punching molding. The composite film material comprises: a thermoplastic resin film inner layer, an aluminum foil metal core layer, and a heat resistant film outer layer. Specifically, the aluminum foil metal core layer is positioned between the thermoplastic resin film inner layer and the heat resistant film outer layer. The thermoplastic resin film inner layer is a multi-layer coextrusion layer containing at least two resin layers. The multi-layer coextrusion layer at least includes a surface heat seal layer and an inner composite layer, and the inner composite layer contacts the aluminum foil metal core layer. The surface heat seal layer contains a non-migrating inorganic additive with lubrication. The upper and lower surfaces of the aluminum foil metal core layer both undergo surface pretreatment. By adding the non-migrating inorganic additive with lubrication to the surface heat seal layer, the bonding problem caused by clinging of a composite material surface and a die can be prevented, and at the same time, air can permeate into the space between the composite material and the die along the gaps between tiny protuberances, so that the whole composite material is easy to undergo cold punching molding and die release. The invention also provides a preparation method of the flexible composite film material.

Owner:FSPG HI TECH

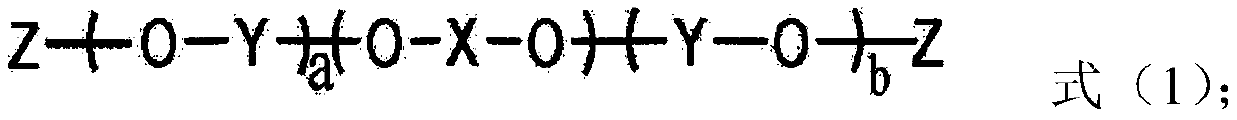

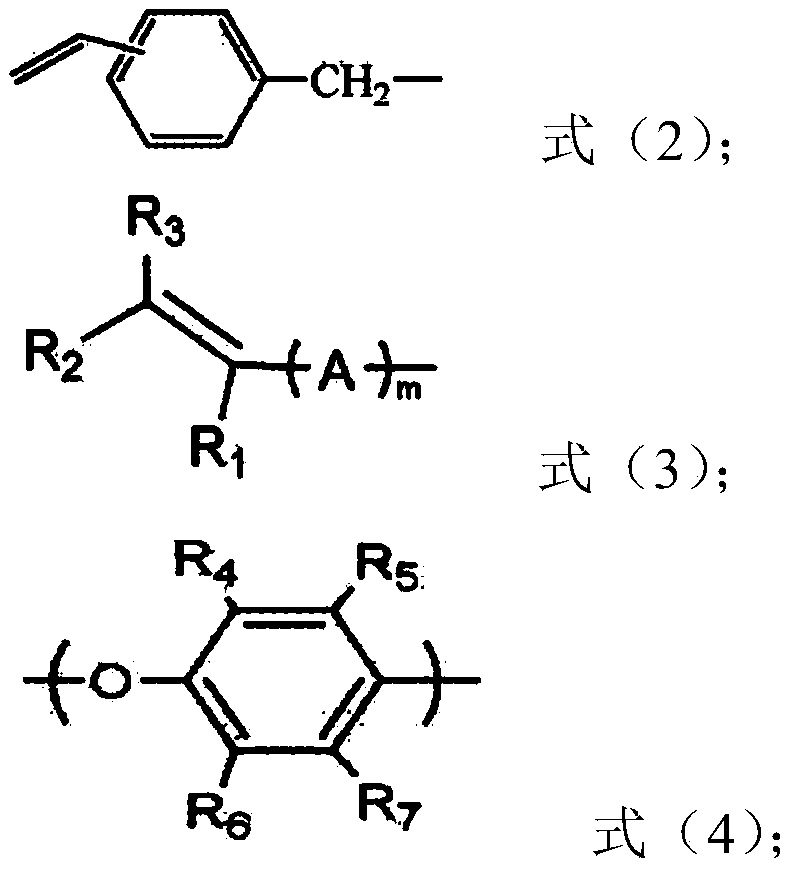

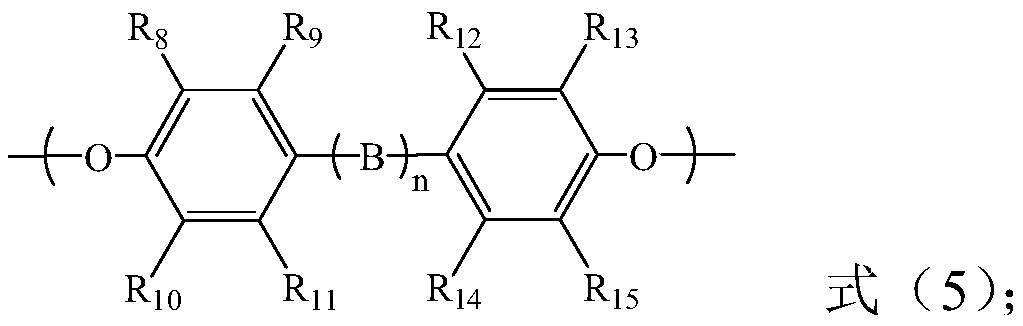

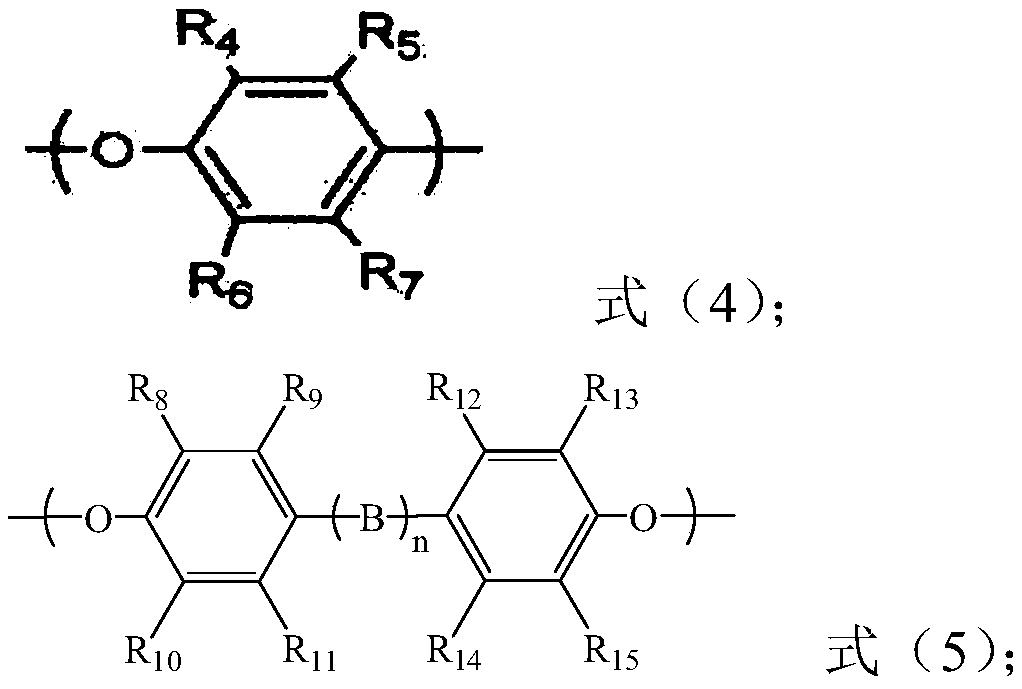

Resin composition and prepreg using same, and circuit material

ActiveCN111253702AGood film formingImprove adhesionPrinted circuit detailsPrinted circuit aspectsPolymer sciencePolyolefin

The invention provides a resin composition and a prepreg using the same, and a circuit material. The resin composition comprises unsaturated polyphenyl ether resin, polyolefin resin, terpene resin andan initiator, wherein the content of the terpene resin is 3-40 parts by weight based on the fact that the total weight of the unsaturated polyphenyl ether resin, the polyolefin resin and the terpeneresin is 100 parts by weight; and the polyolefin resin is one selected from a group consisting of unsaturated polybutadiene resin, SBS resin and styrene-butadiene resin or a combination of at least two selected from the group. Through mutual cooperation of the unsaturated polyphenyl ether resin, the polyolefin resin and the terpene resin, the obtained resin composition has good film-forming property, cohesiveness and dielectric property, and a circuit board adopting the resin composition has relatively high interlaminar strength and relatively low dielectric loss.

Owner:GUANGDONG SHENGYI SCI TECH

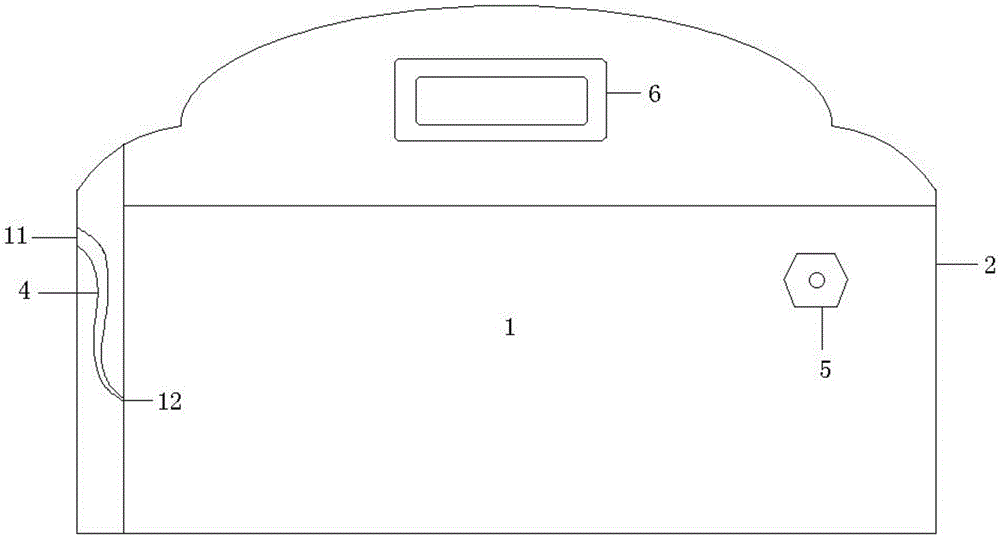

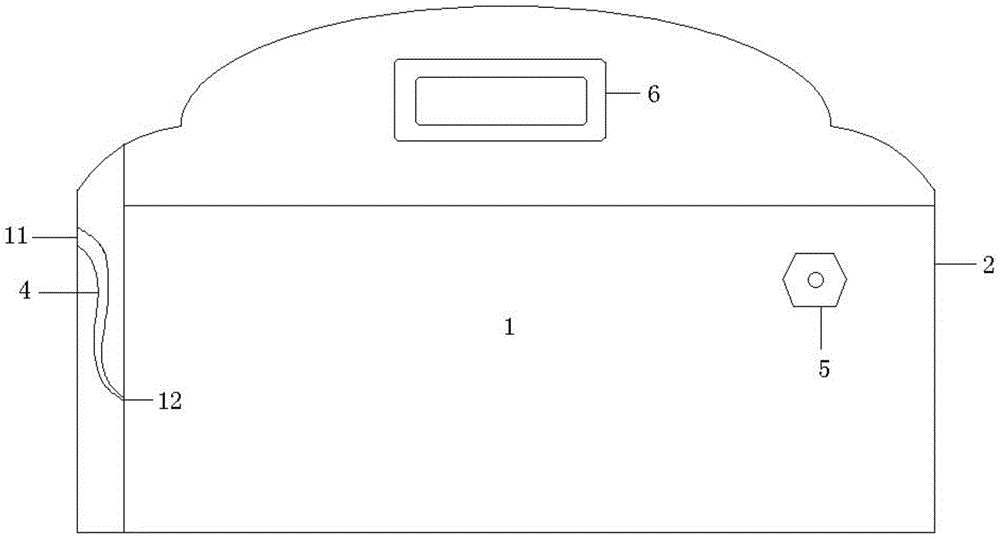

Transport packaging bag for live fish and manufacturing and using methods thereof

ActiveCN105475213AHigh gas storage efficiencyLight structurePisciculture and aquariaInlet channelExhaust valve

A transport packaging bag for live fish comprises a packaging bag body. An open part and a sealed part are arranged on the edge of the packaging bag body, a curve strip-shaped air inlet channel penetrating through the sealed part in the width direction is formed in the sealed part in a sandwiched mode, a first opening communicated with the external environment is formed in one end of the air inlet channel, a second opening communicated with an inner cavity of the packaging bag body is formed in the other end of the air inlet channel, and the width of the air inlet channel is gradually reduced from outside to inside. The transport packaging bag for live fish further comprises a one-way exhaust valve. The one-way exhaust valve is arranged on the side wall of the packaging bag body in a penetrating mode. The transport packaging bag for live fish is simple in structure, high in air storage capacity and not prone to breakage; besides, air in the bag can be replaced as needed, and the survival time of fish in the bag is long. The invention further provides manufacturing and using methods of the transport packaging bag for live fish. The manufacturing and using methods are easy and rapid to implement, low in cost and suitable for mass production.

Owner:罗鹏孩 +2

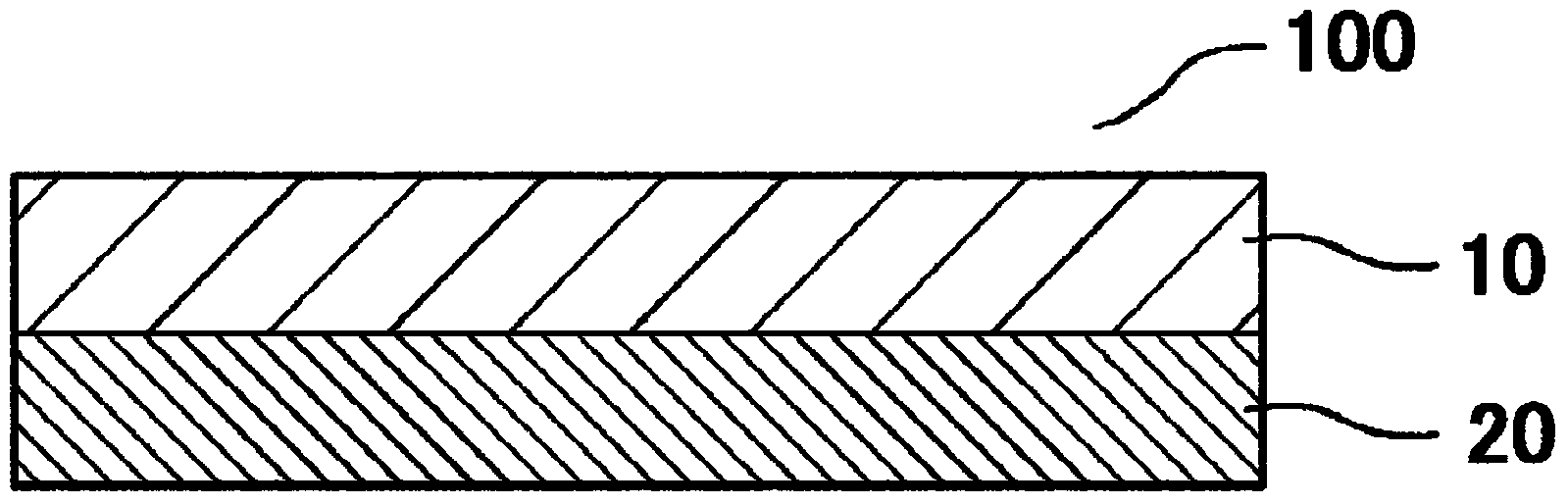

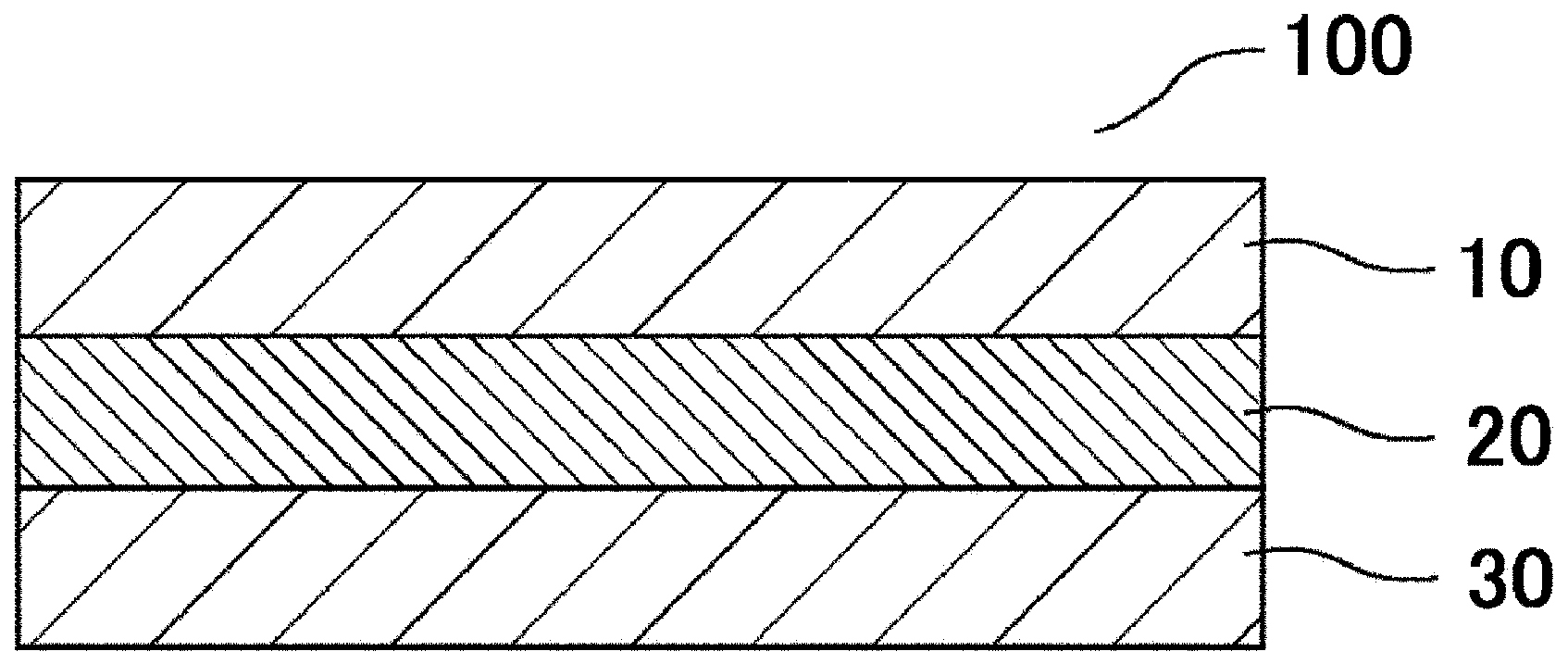

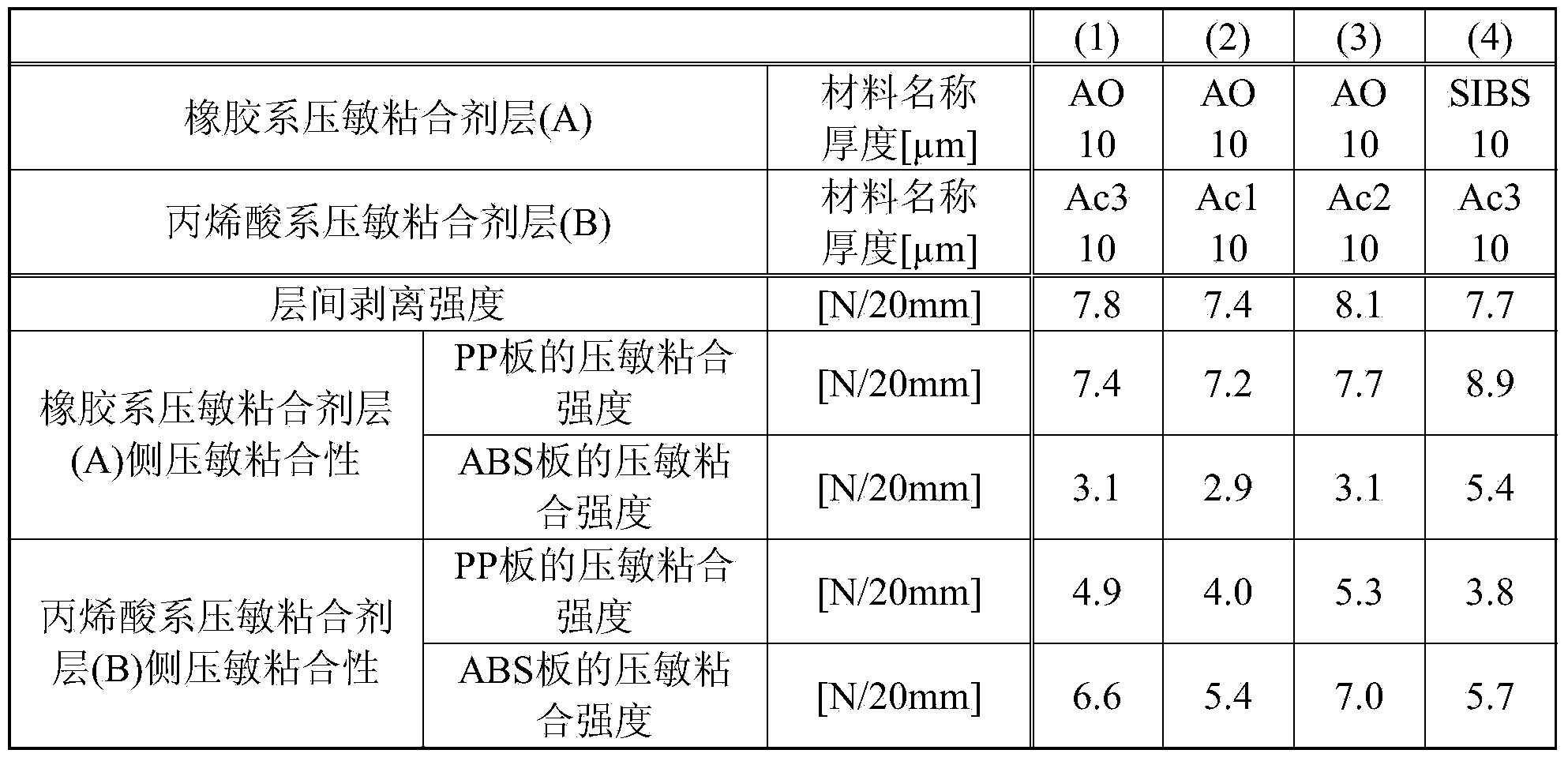

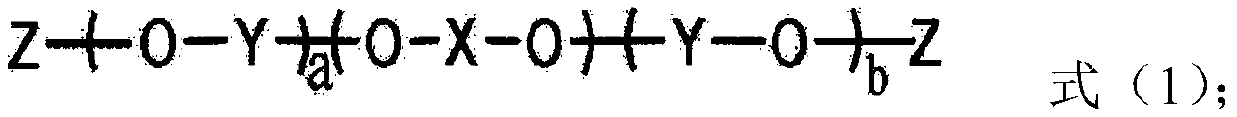

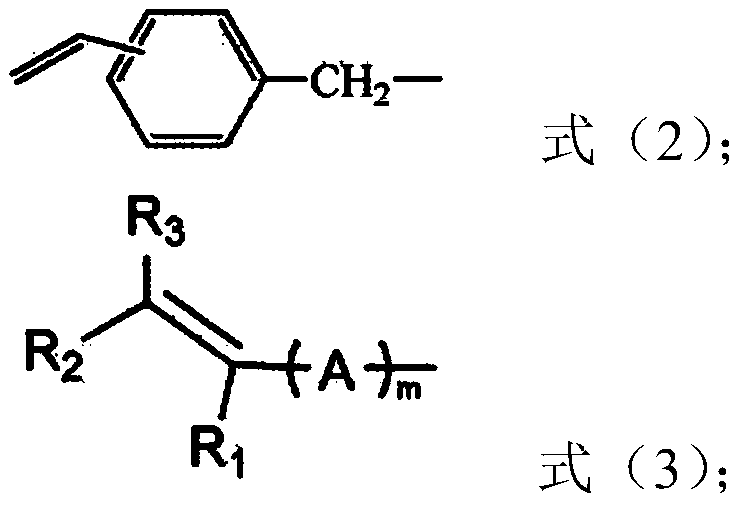

Adhesive sheet

InactiveCN103562330AHigh peel strength between layersVinyl aromatic copolymer adhesivesEster polymer adhesivesTwo layerPressure sensitive

Provided is a pressure-sensitive adhesive sheet formed of at least two layers, including a rubber-based pressure-sensitive adhesive layer (A) and an acrylic pressure-sensitive adhesive layer (B) that are directly laminated, in which the pressure-sensitive adhesive sheet has a large interlayer peel strength. The pressure-sensitive adhesive sheet is a pressure-sensitive adhesive sheet formed of at least two layers, including a rubber-based pressure-sensitive adhesive layer (A) and an acrylic pressure-sensitive adhesive layer (B) that are directly laminated, in which the pressure-sensitive adhesive sheet has an interlayer peel strength upon peeling of the acrylic pressure-sensitive adhesive layer (B) from the rubber-based pressure-sensitive adhesive layer (A) under conditions of a measurement temperature of 23° C., a tension speed of 0.3 m / min, and a peel angle of 180° C. of 2.0 N / 20 mm or more.

Owner:NITTO DENKO CORP

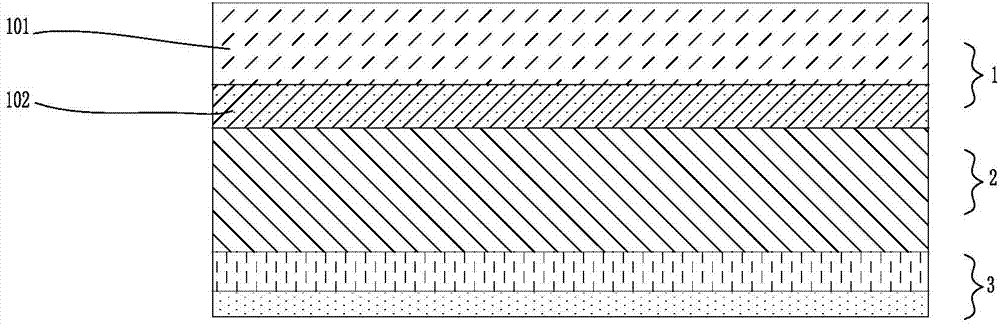

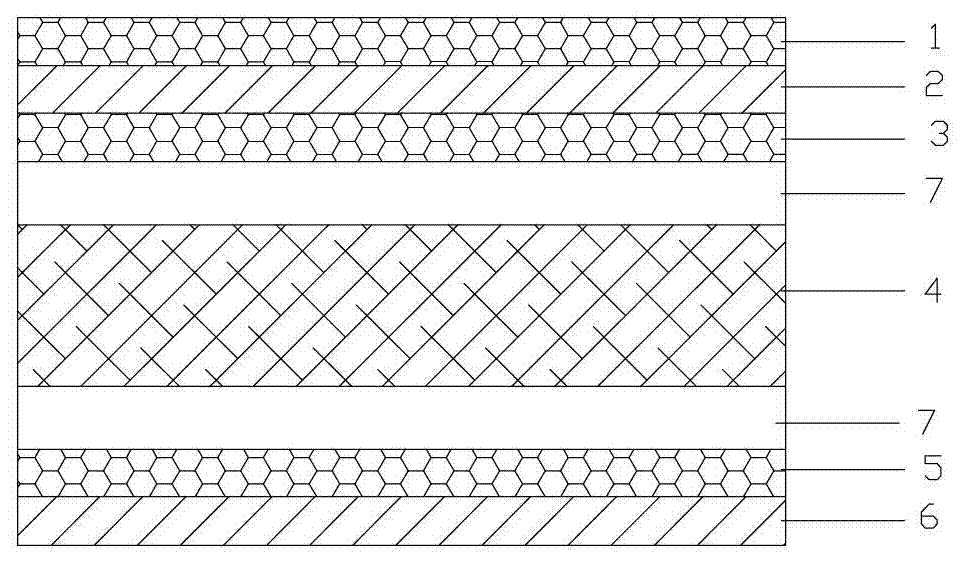

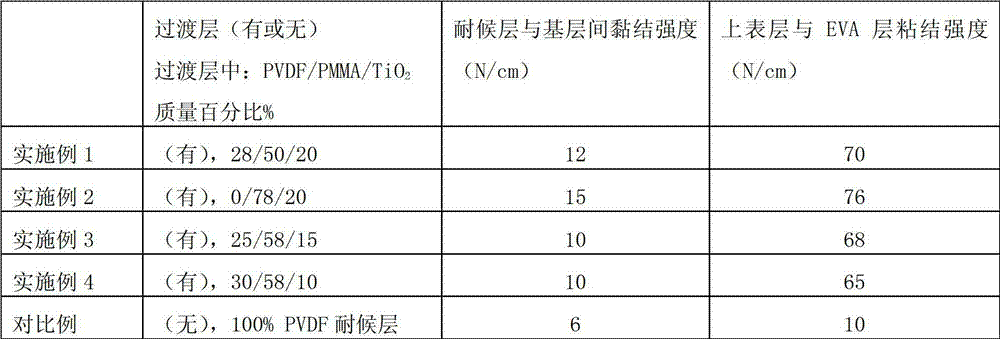

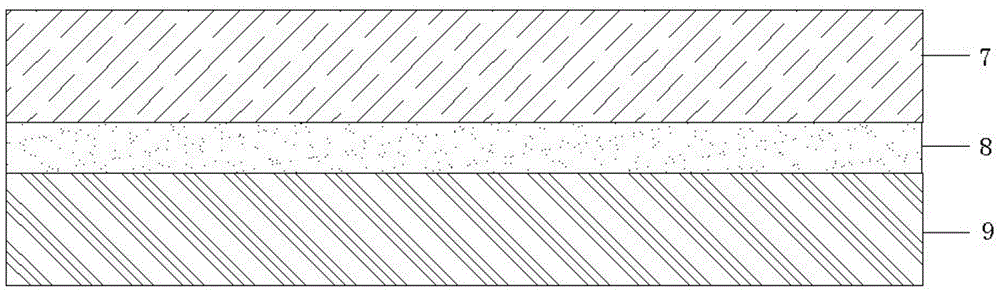

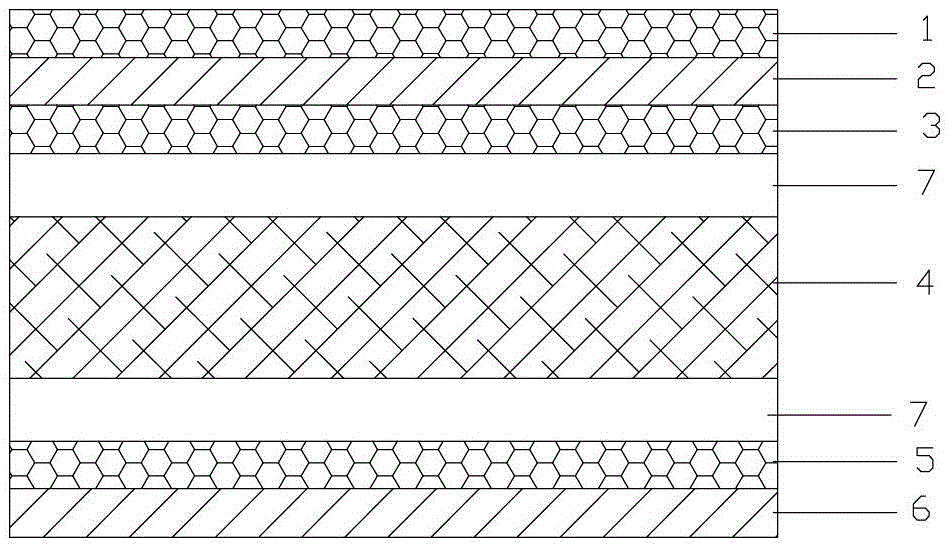

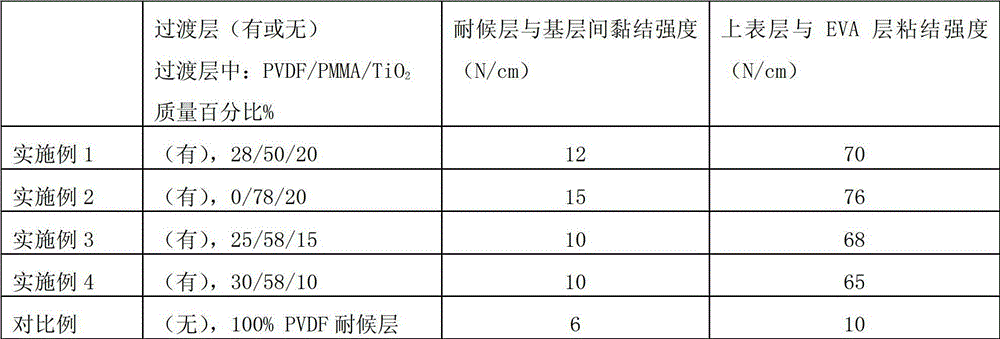

Solar cell back panel film and preparation method thereof

ActiveCN102922842AGood weather resistanceImprove adhesionSynthetic resin layered productsLaminationComposite filmWeather resistance

The invention relates to a solar cell back panel film and a preparation method thereof. The solar cell back panel film comprises a first transition layer, a first weather-resistant layer, a second transition layer, a substrate, a third transition layer and a second weather-resistant layer from top to bottom, wherein the substrate and the second and third transition layers are bonded by an adhesive layer; the first transition layer, the first weather-resistant layer and the second transition layer are three composite film layers prepared by way of coextrusion casting or film blowing; and the third transition layer and the second weather-resistant layer are two-layer composite films prepared by way of coextrusion casting or film blowing. The solar cell back panel film has the following beneficial effects that the solar cell back panel film has excellent weather resistance; introduction of the transition layers effectively improves the adhesiveness between the back panel film and the EVA adhesive layer as well as between the weather-resistant layers and the substrate; and meanwhile, the back panel film has tight structure, less production processes and low cost and does not cause solvent pollution.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

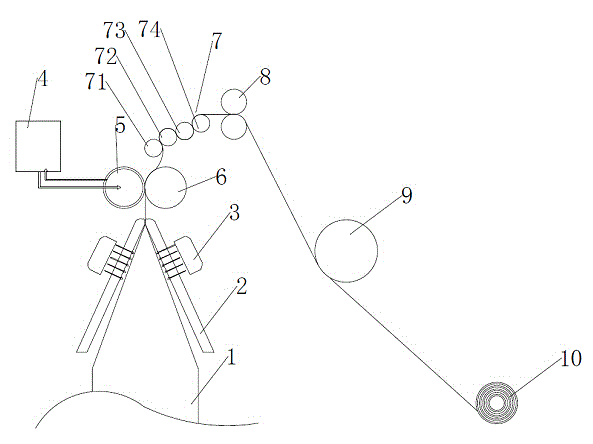

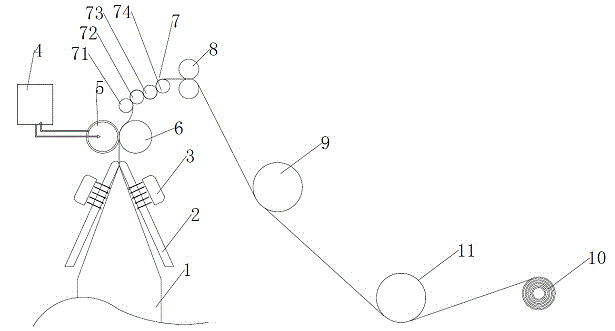

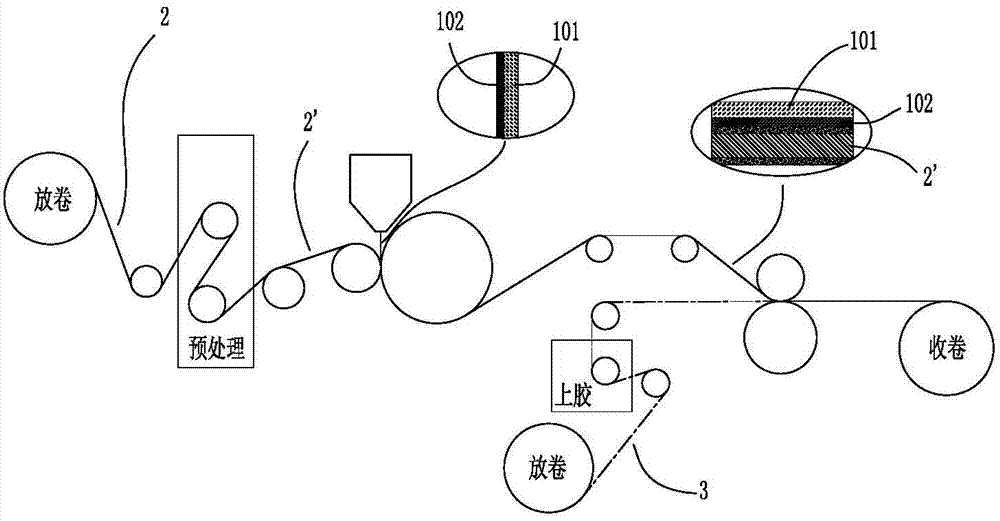

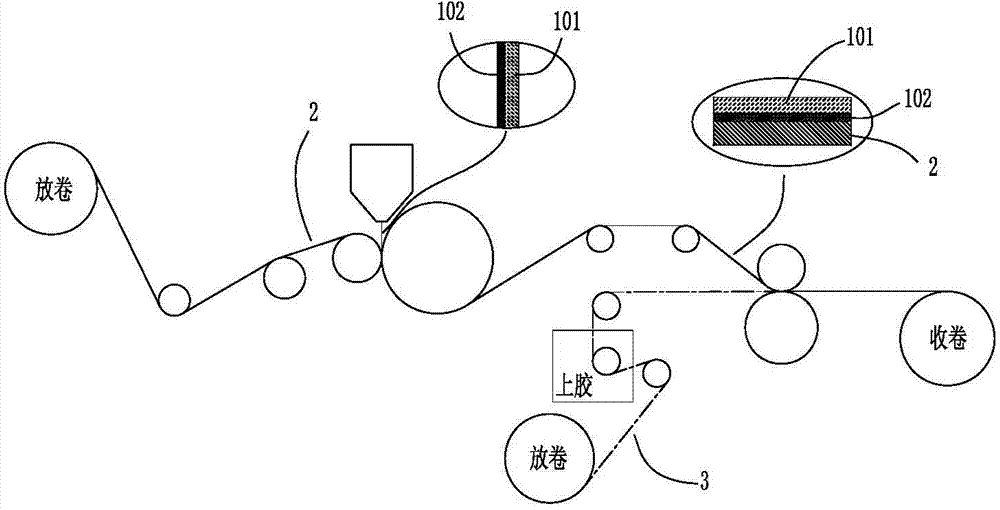

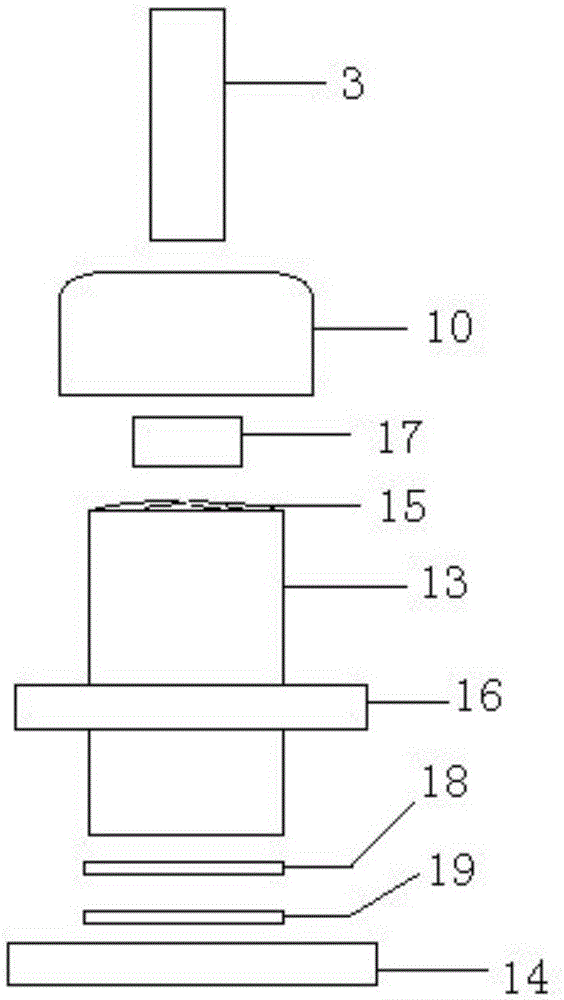

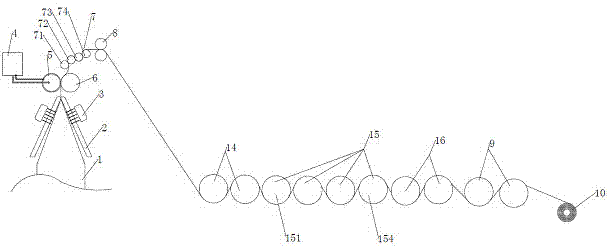

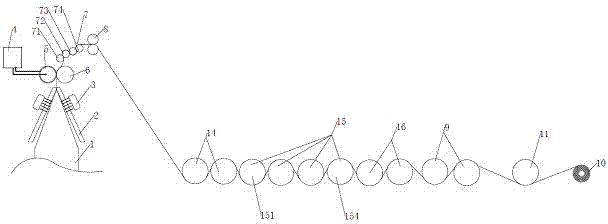

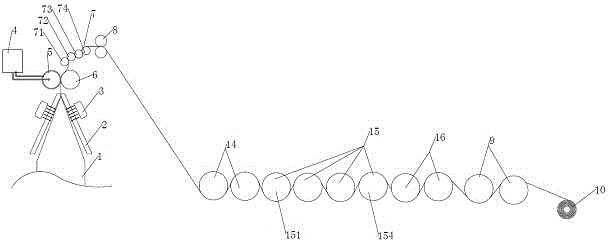

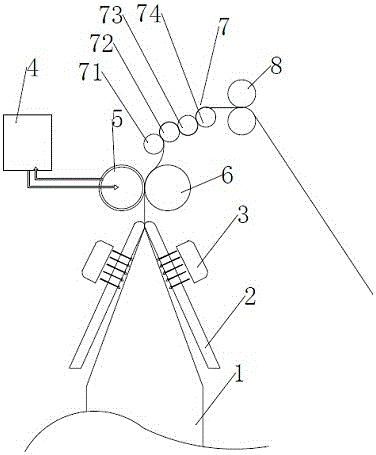

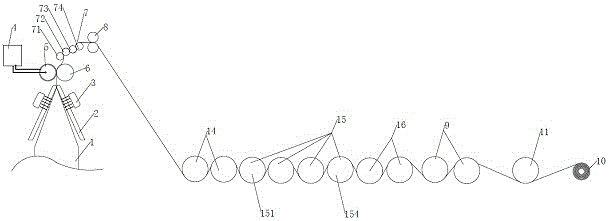

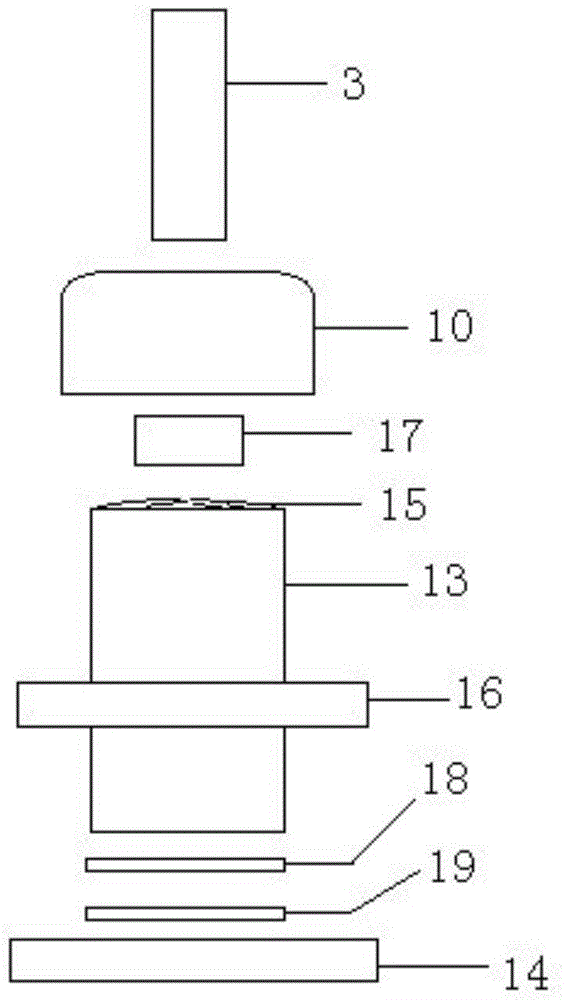

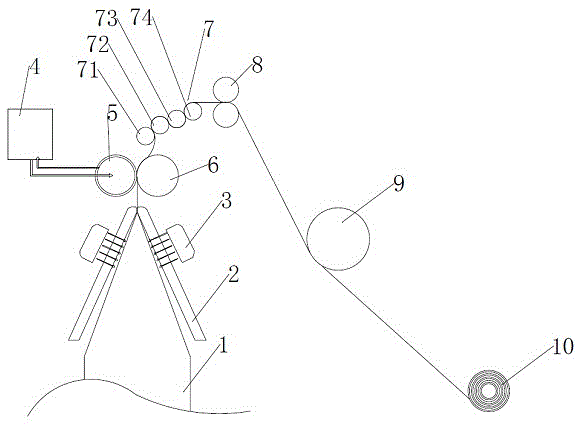

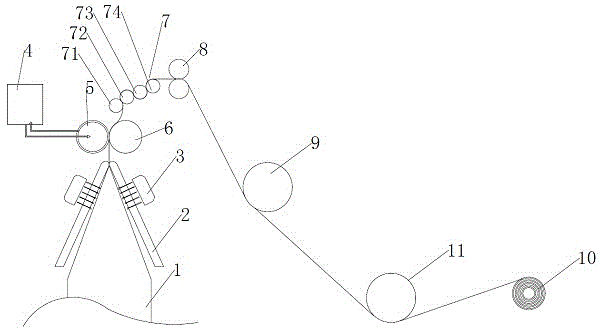

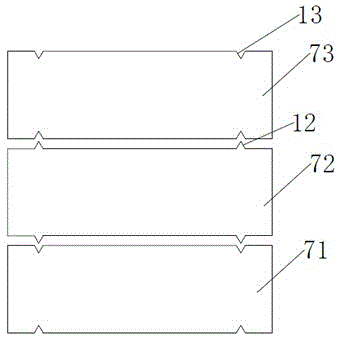

System for producing back sealing strips

ActiveCN104494177AEffective heat sealingAchieve stretch thinningFlat articlesEngineeringHeat resistant

The invention discloses a system for producing back seal strips. The system sequentially comprises an extruder, an extrusion mold, a herringbone frame, a traction roller group, a cooling roller group and a winding roller along the forwarding direction of materials, wherein the traction roller group comprises a heat-resistant rubber roller and a hollow steel roller internally filled with heating oil, and the hollow steel roller and a temperature controllable oil storage tank outside the hollow steel roller form a circulation circuit; a preheating device for preheating an inner layer of a film bubble is arranged at the herringbone frame at the front end of the traction roller group, a heat sealing roller group for heat sealing the compressed film bubble is arranged at the rear end of the traction roller group, the compressed film bubble winds the surface of the heat sealing roller group in an S shape to form a sheet, a shape setting roller group for setting the shape of the heat sealed sheet is arranged at the rear end of the heat sealing roller group, and the heat sealed sheet passes through gaps of the shape setting roller group in a line shape; and a one-way longitudinal drawing mechanism and a thickness detection mechanism are sequentially arranged between the shape setting roller group and the cooling roller group. The system for producing the back seal strips can be used for producing the high-strength back seal strips with low elongation at break.

Owner:JIANGYIN BAOBO PACKING

Circuit material and circuit board comprising same

InactiveCN111253888AGood film formingImprove adhesionNon-macromolecular adhesive additivesPrinted circuit detailsImidePolymer science

The invention provides a circuit material and a circuit board comprising the same. The circuit material comprises a conductive metal layer, a dielectric substrate layer, and an adhesive layer arrangedbetween the conductive metal layer and the dielectric substrate layer, wherein a material of the adhesive layer includes an adhesive composition; the adhesive composition comprises a resin componentand a non-resin component, the resin component is composed of unsaturated polyphenyl ether resin, SBS resin and maleimide resin, and the non-resin component comprises an initiator; and the adhesive layer is obtained by applying the adhesive composition dissolved in a solvent to the surface of the conductive metal layer or the dielectric substrate layer in the form of a solution, or obtained by applying the adhesive composition to a release material, partially or completely curing the adhesive composition and then removing the release material. According to the invention, the unsaturated polyphenyl ether resin, the SBS resin and the maleimide resin are matched with one another, so the obtained adhesive layer has good film-forming property, cohesiveness and dielectric property, and the circuit material has relatively high interlayer peel strength and relatively low dielectric loss.

Owner:GUANGDONG SHENGYI SCI TECH

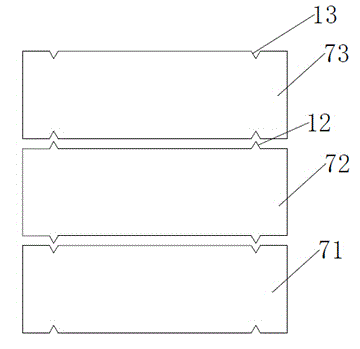

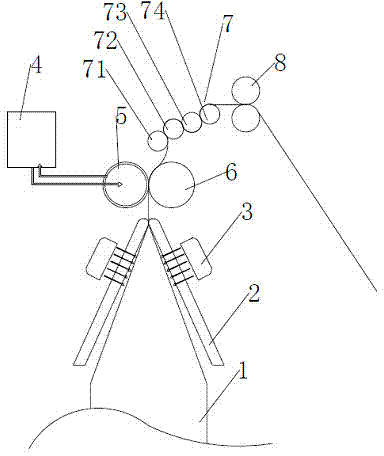

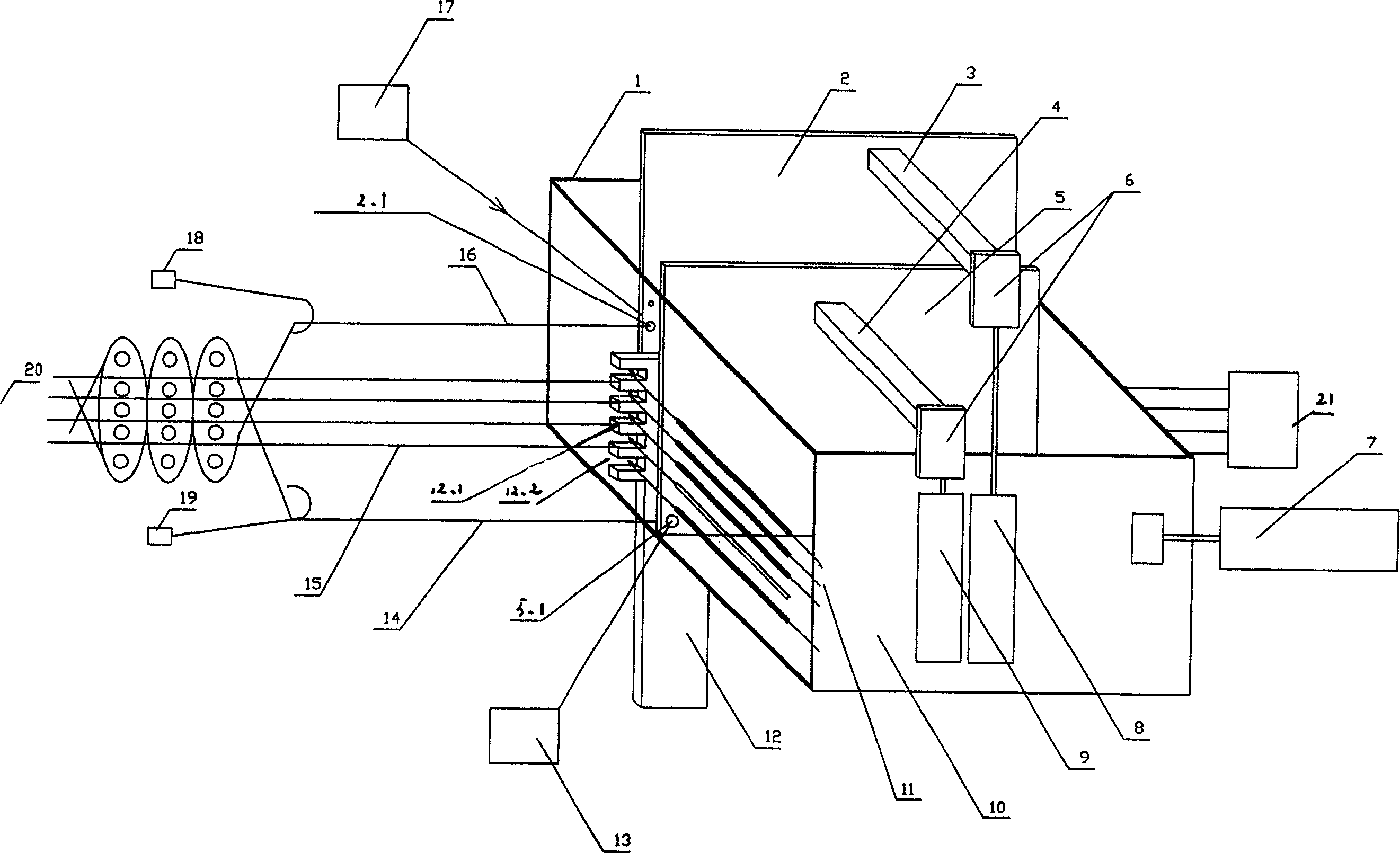

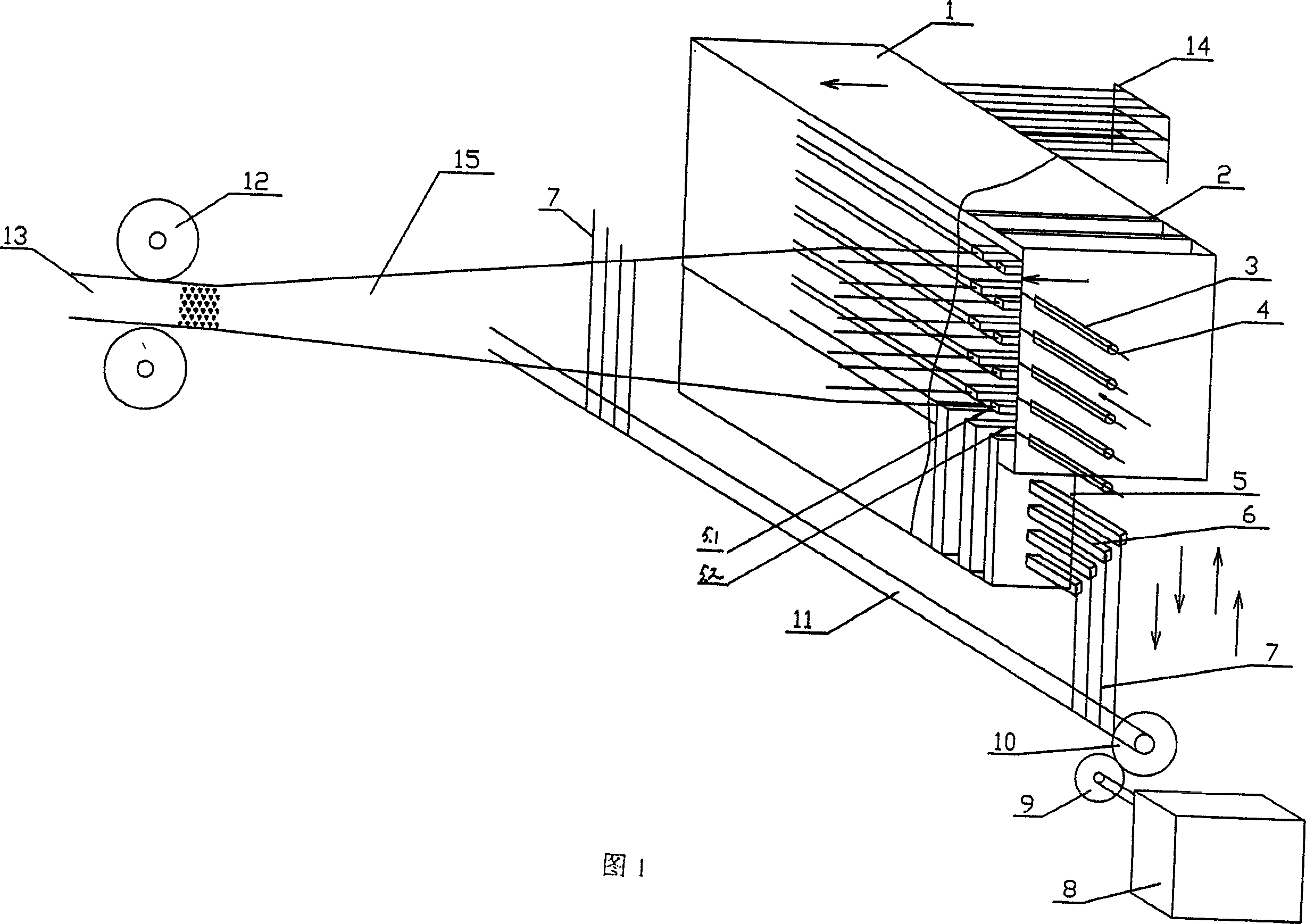

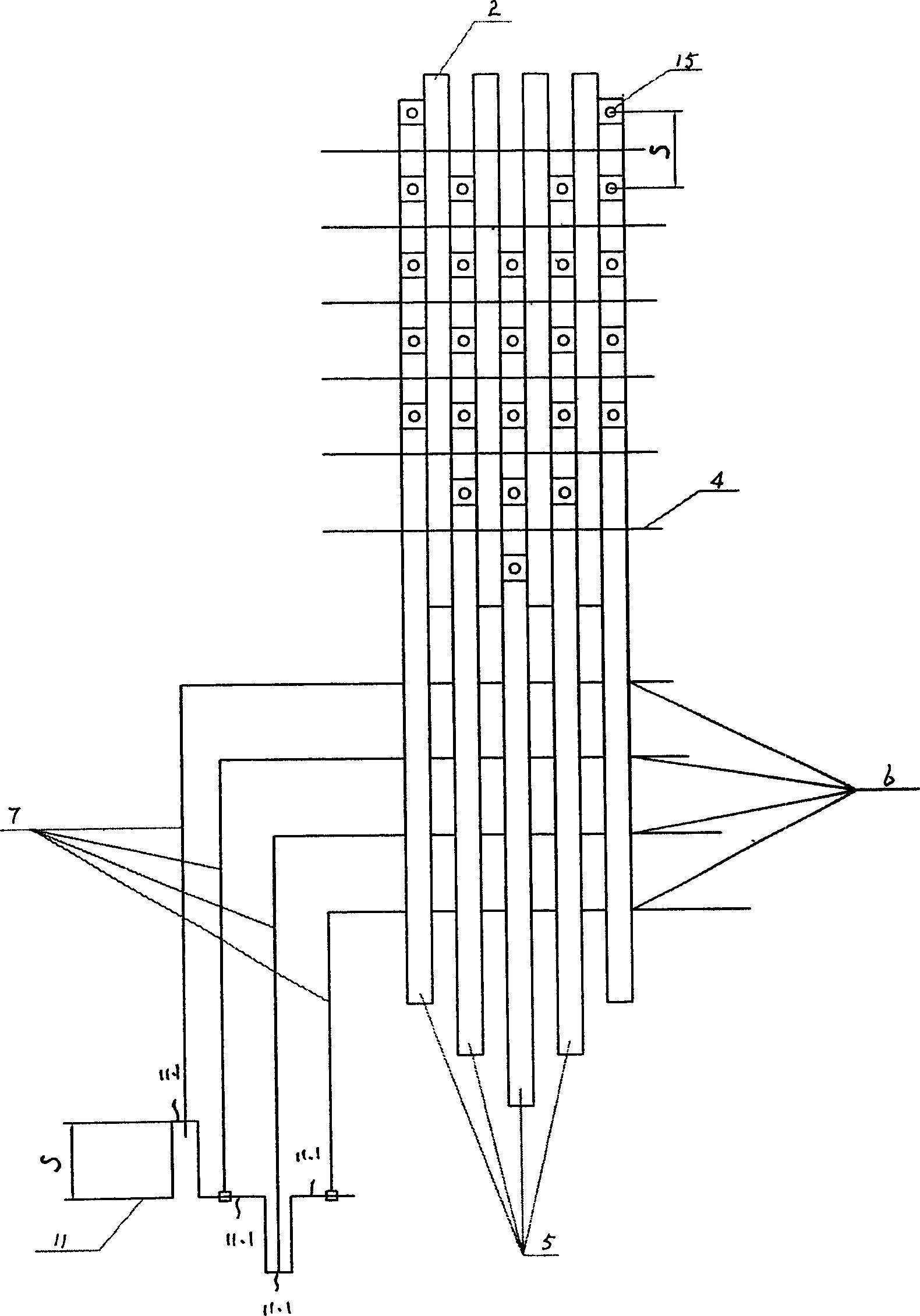

Loom with functions of warp-weft plain-weaving and z-directional yarn interweaving and weaving method thereof

The invention relates the interweave and Z yarn intertexture flat surface loom and weaving method, comprising steel frame(1), steel strap(2,5), palm strap(12), fistular rod gripper(11), beating-up cylinder(7), steel strap motion tip(3, 4), connecting lever(6), steel strap motion cylinder(8,9), up-down wire(18,19) on frame, and yarn hole(2.5, 2.1) on steel strap. The loom comprises the following structures: steel strap(2,5) having N+1 pieces, steel strap motion tip (3, 4) crossing the two steel straps, the up end of connecting lever(6) is connected with steel strap motion tip (3, 4), palm strap(12) having N pieces, them interval exists in steel strap(2,5), handing N palm root (5.1), handing opening used for fistular rod gripper(11) between two palm eyes(12.1). The method is Z fabric on the base of bidimensional flat surface crossing stereoscopic. The invention makes the Z fabric crosses in bidimensional level crossing stereoscopic, reducing hair.

Owner:赵祖良

Weatherproof high-barrier solar cell backboard and preparation method thereof

ActiveCN109605880ARaw materials are easy to getMild reaction conditionsSynthetic resin layered productsElectrical equipmentEpoxyWeather resistance

The invention discloses a weatherproof high-barrier solar cell backboard, which comprises a first weatherproof layer, a core layer and a second weatherproof layer sequentially from top to bottom. Thefirst weatherproof layer and the core layer, the core layer and the second weatherproof layer are all bonded by laminating through bonding layers, the first weatherproof layer and the second weatherproof layer are each independently formed by tetramethyl piperidine terminated poly2,3,5,6-tetrafluoroterephthalic acid 1,8-naphthalene dimethanol ester; the core layer is formed of a blend of nylon MXD6 and PET; the bonding layer is formed of a triazole tetramethylpiperidine co-modified epoxy resin. The invention also discloses a preparation method of the weatherproof high-barrier solar cell backboard. The weatherproof high-barrier solar cell backboard disclosed by the invention has more excellent weathering-resistance and high-barrier property, and other comprehensive properties are better.

Owner:徐州日托新材料科技有限公司

Heat-resistant fiber paper

InactiveUS6319605B1High tensile strengthLow bulk densityPaper/cardboardSynthetic cellulose/non-cellulose material pulp/paperFiberHigh humidity

A heat resistant fiber sheet composed of staple fibers consisting of a heat resistant organic high molecular polymer and fibrids consisting of a heat resistant organic high molecular polymer as main components, having excellent heat resistance, dimensional stability to heat, interlaminar peeling strength, electric insulation resistance under a high humidity, etc., and also good resin impregnating property in spite of having a high bulk density, and especially suitable for a base substrates for an electric insulating material and a laminate for an electric circuit, is obtained by setting the amount of the staple fibers occupying in the total amount of the sheet as 40 to 97% by weight and the amount of the fibrids as 3 to 60% by weight and partially softening and / or melting the fibrids so as to act as a binder.

Owner:TEIJIN LTD

Multilayer body, and flat cable and member for electrical wiring each using the multilayer body

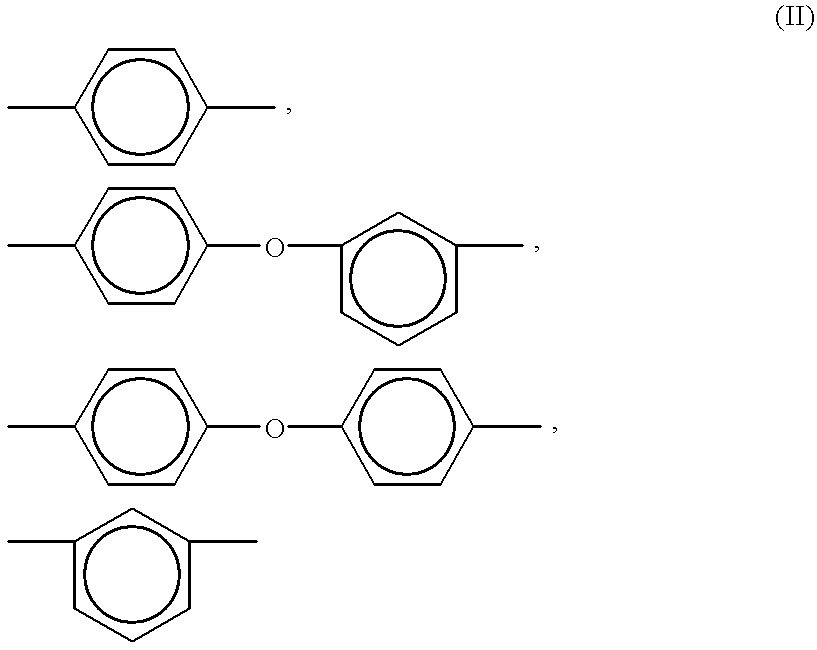

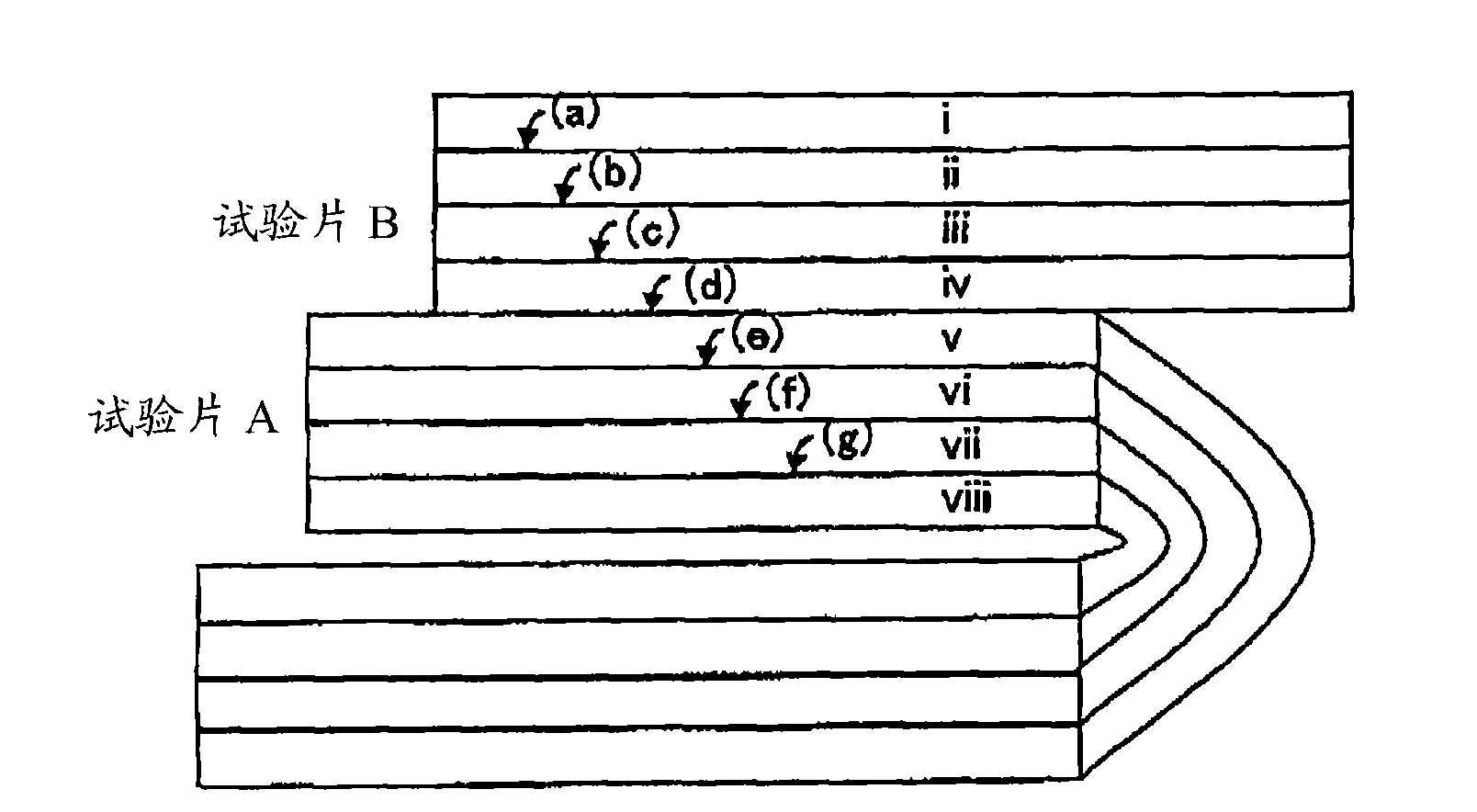

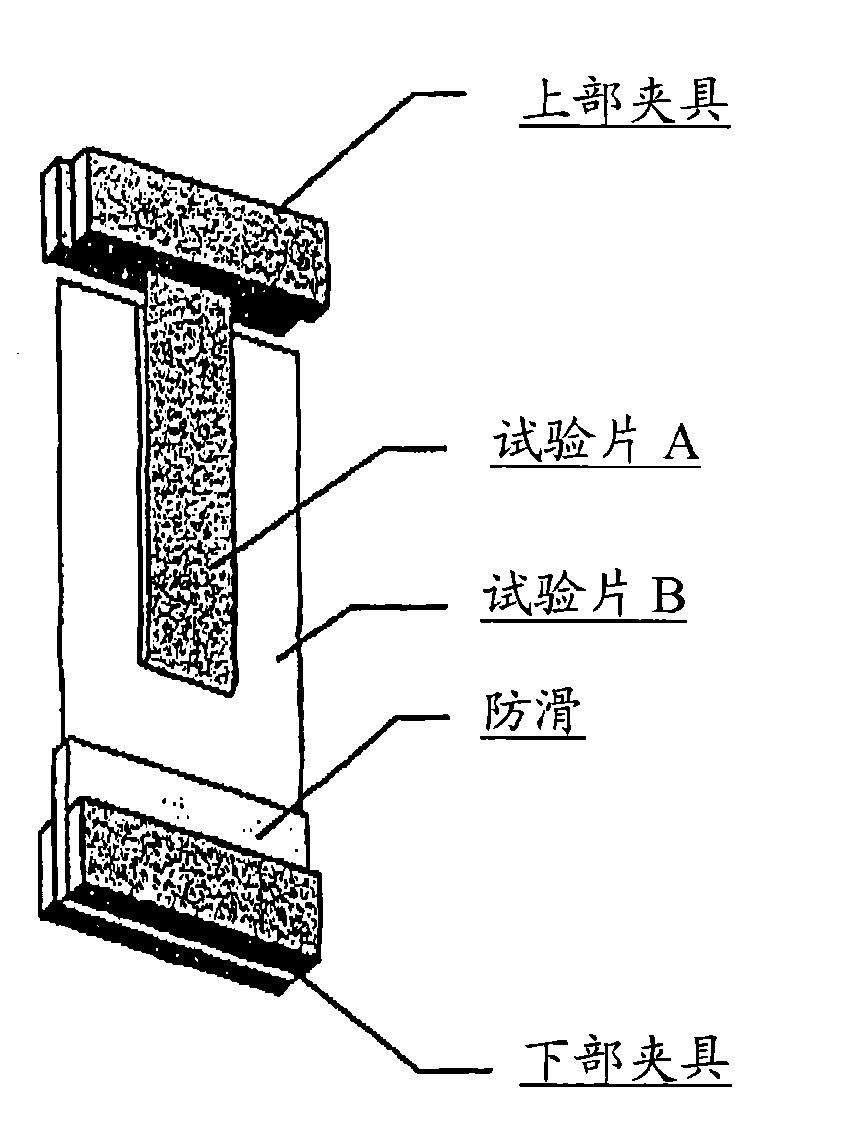

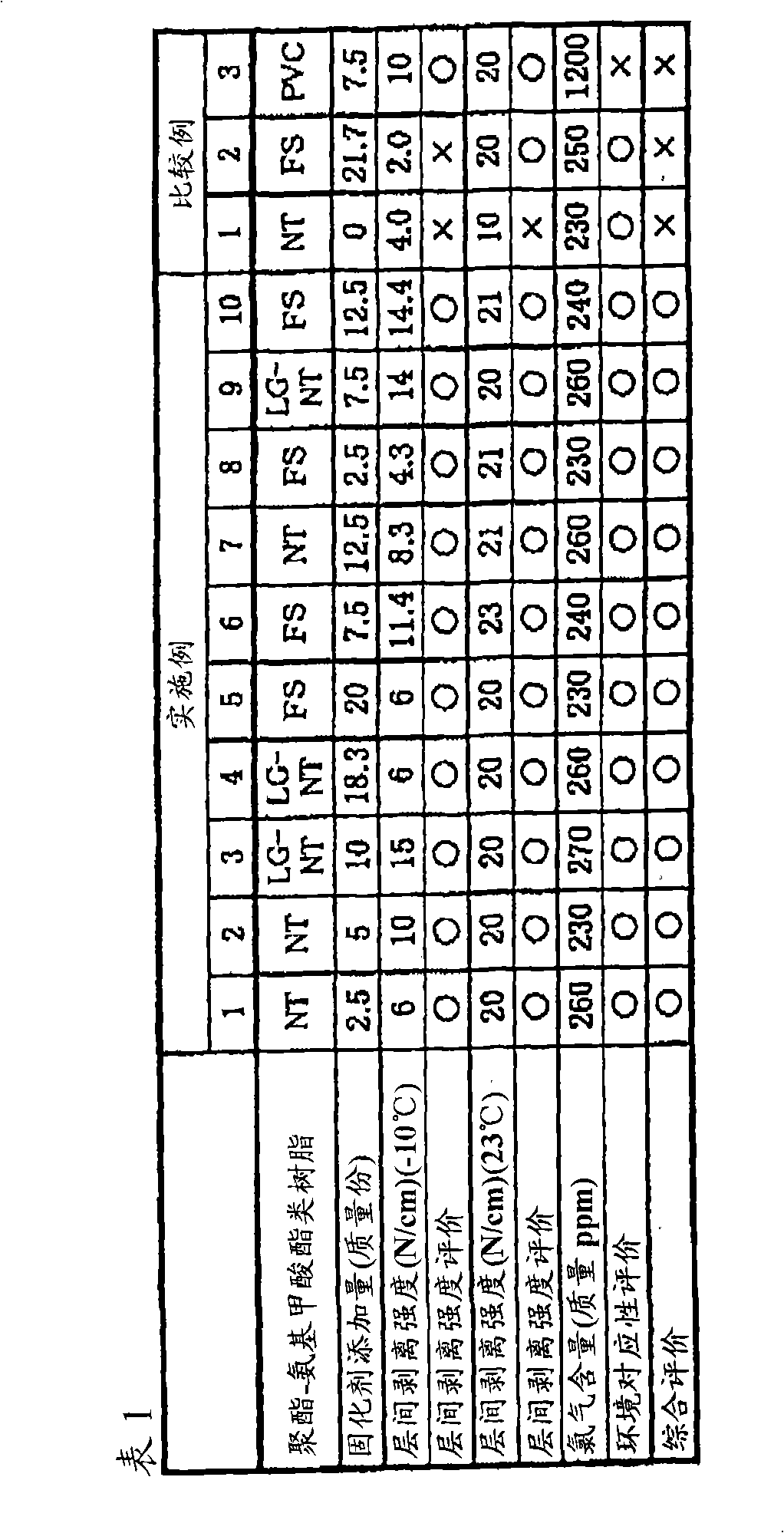

InactiveCN101687406AHigh peel strength between layersReduce chlorine contentPolyureas/polyurethane adhesivesSynthetic resin layered productsPolyesterElectrical wiring

Disclosed is (1) a multilayer body comprising a base layer, an anchor coat layer, a colored layer and an adhesive layer or (2) a multilayer body comprising a base layer, an anchor coat layer and an adhesive layer, wherein a resin contained in the anchor coat layer and the colored layer mainly contains a polyester-urethane resin and the delamination strength at -10 DEG C is not less than 4.2 N / cm.Such a multilayer body is excellent in adhesiveness and environmental friendliness. Also disclosed are a flat cable and a member for electrical wiring, each using such a multilayer body.

Owner:MITSUBISHI PLASTICS INC

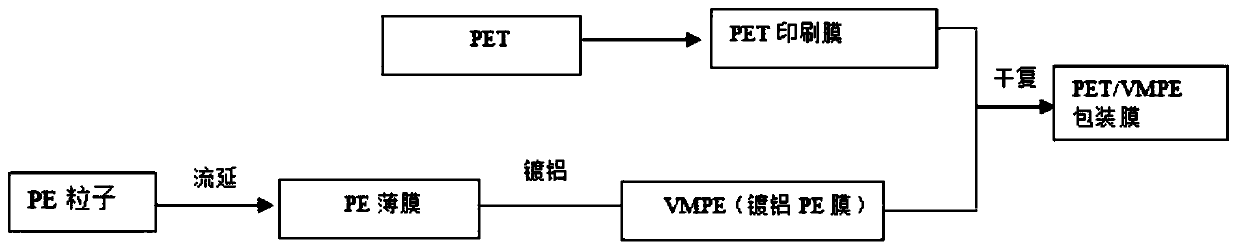

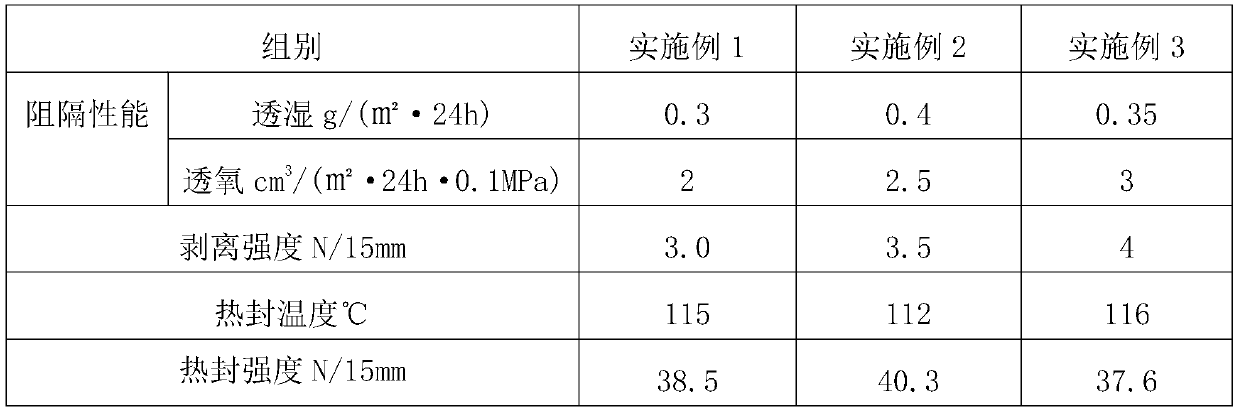

High-resistance high-speed auto-inflation food packaging film and production process thereof

PendingCN110065269AHigh barrierHigh peel strengthFlexible coversWrappersHigh resistanceLow-density polyethylene

The invention relates to a high-resistance high-speed auto-inflation food packaging film and a production process thereof. The packaging film is formed by compounding an aluminum-plated PE film and aPET printing film in a dry mode. The aluminum-plated PE film comprises a corona layer, a middle layer and a heat seal layer. The corona layer comprises linear low density polyethylene and polycycloolefin according to the mass ratio of (83-87):(13-17). The middle layer comprises linear low density polyethylene, low density polyethylene and high density polyethylene according to the mass ratio of (48-52):(23-27):(23-27). The heat seal layer comprises low density polyethylene, an olefin plastic body, linear low density polyethylene, silicone and a processing agent according to the mass ratio of (48-52):(23-27):(23-27):(1.3-1.7):(0.1-0.3). The packaging film is suitable for meeting the requirements of a high-speed packaging device and has high resistance, low heat seal temperature, high heat seal strength, high in pressure resistance and low in broken package air leakage rate.

Owner:HUANGSHAN NOVEL

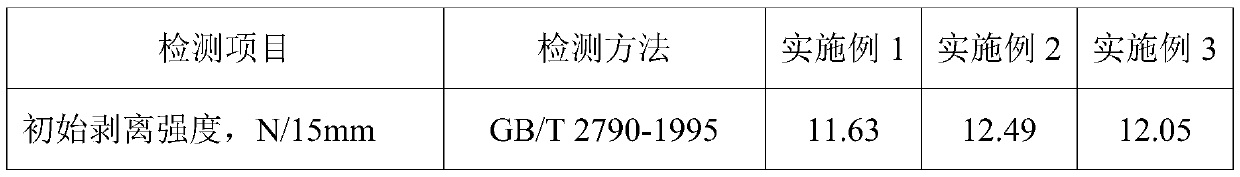

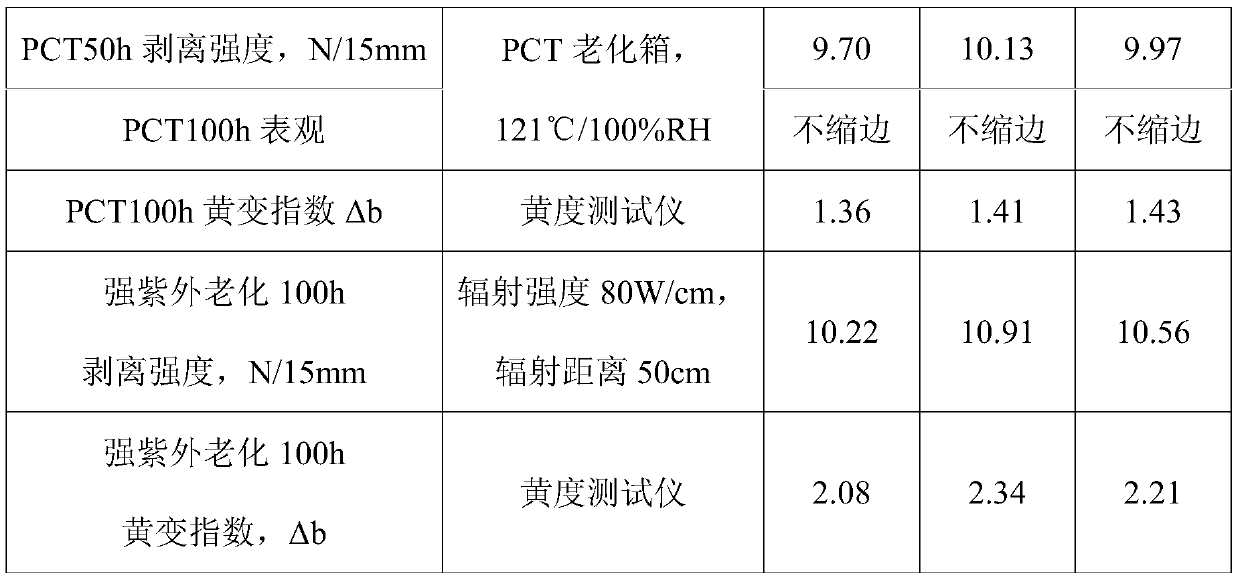

Adhesive for solar photovoltaic module back plate and preparation method of adhesive

InactiveCN110257000AImprove aging resistanceGood yellowing resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterPolyurethane adhesive

The invention relates to an adhesive for a solar photovoltaic module back plate and a preparation method of the adhesive. The adhesive is composed of a component A and a component B; the component A comprises a first isocyanate-terminated prepolymer and a second isocyanate-terminated prepolymer according to a mass ratio of (2.0-2.2):1; and the component B is mainly prepared by mixing the following raw materials in parts by weight: modified polyester polyol, polycarbodiimide resin, a silane coupling agent and a stabilizing assistant, wherein the molar ratio of -NCO in the component A to -OH in the component B is (2.6-2.8):1. The adhesive is a solvent-free double-component polyurethane adhesive and has excellent bonding performance. When the adhesive is used in the back plate interlayer combination process, the laminating defect caused by solvent volatilization can be avoided, and the rate of finished products is improved. A photovoltaic back plate prepared by using the adhesive has relatively high interlayer stripping strength, good ageing resistance and good yellowing resistance, and reliability and the service life of a solar photovoltaic module can be remarkably improved.

Owner:北京知淘科技有限责任公司

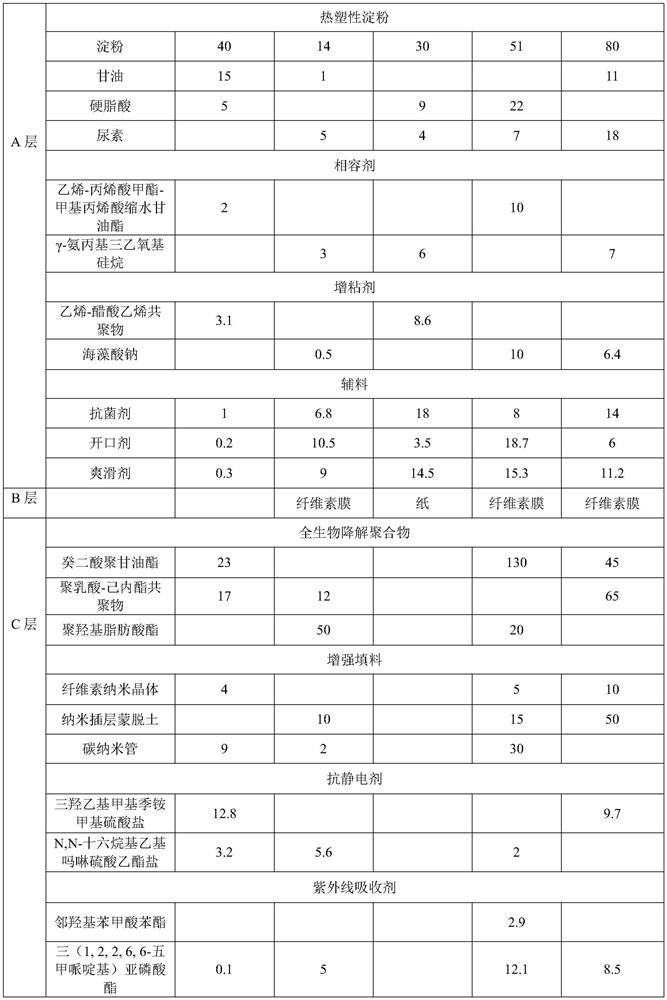

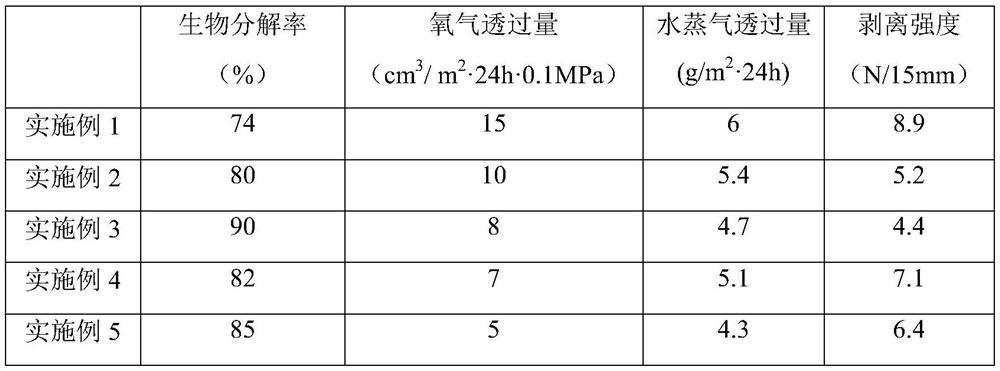

Degradable high-barrier composite film and preparation method thereof

PendingCN114211841AReduce manufacturing costHigh barrierSynthetic resin layered productsPaper/cardboard layered productsCellulosePolymer science

The invention discloses a degradable high-barrier composite membrane and a preparation method thereof.The composite membrane is of a layer structure of one of A / B, A / C, A / B / C and A / B / A / C. The layer A is a modified poly (butylene terephthalate)-adipate copolymer and comprises, by mass, 50-103 parts of poly (butylene terephthalate)-adipate copolymer, 20-109 parts of thermoplastic starch and 2-10 parts of compatilizer; 0.5 to 10 parts of a tackifier and 1.5 to 42 parts of an auxiliary material; the layer B is paper or a cellulose membrane; and the layer C is a composite material and comprises the following components in parts by mass: 40-150 parts of a full-biodegradable polymer, 12-60 parts of a reinforcing filler, 2-16 parts of an antistatic agent and 0.1-15 parts of an ultraviolet light absorber. The composite film disclosed by the invention has good barrier property and relatively high interlayer peel strength, and can be applied to the field of packaging of liquid and fresh foods.

Owner:RES INST OF ZHEJIANG UNIV TAIZHOU

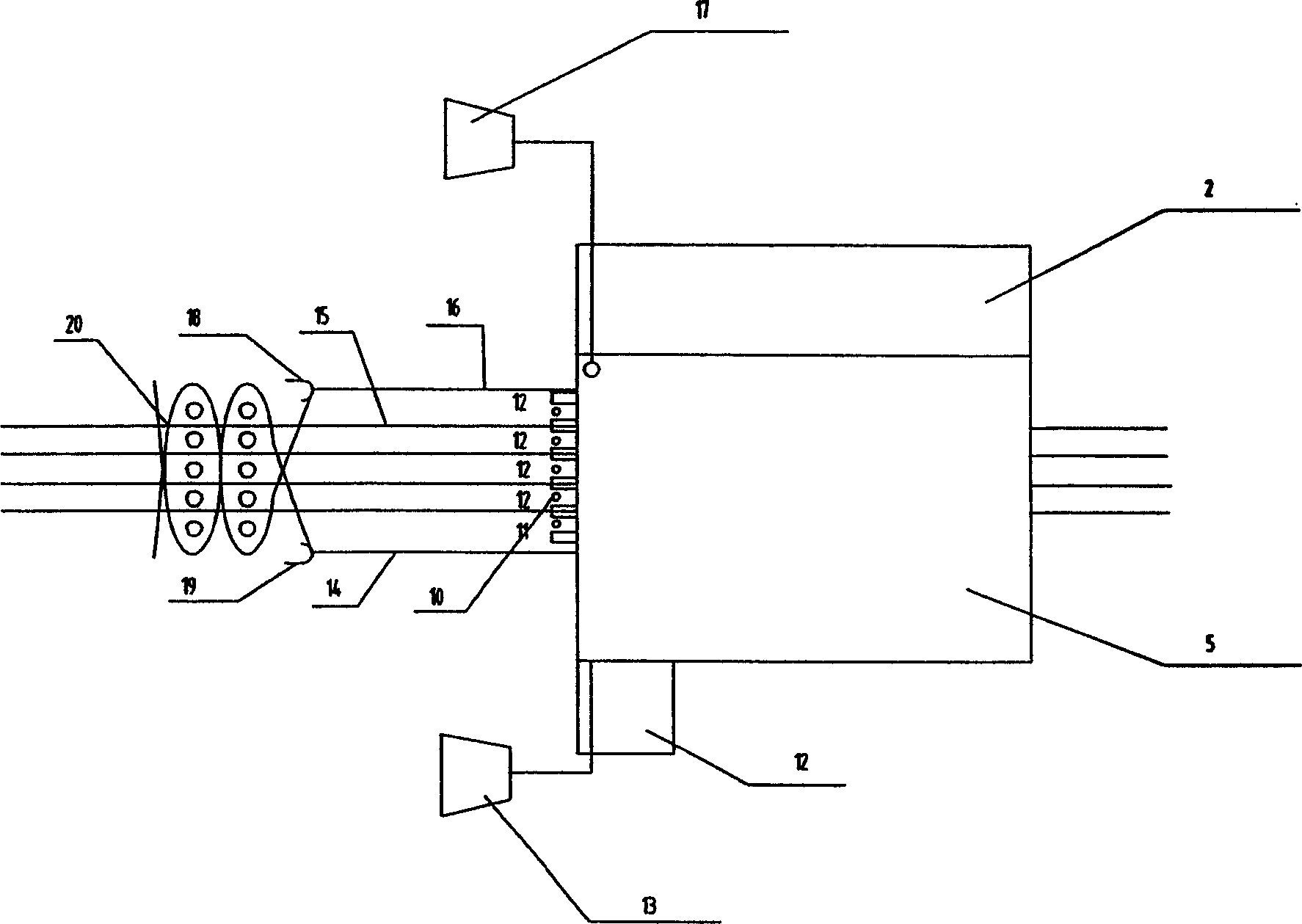

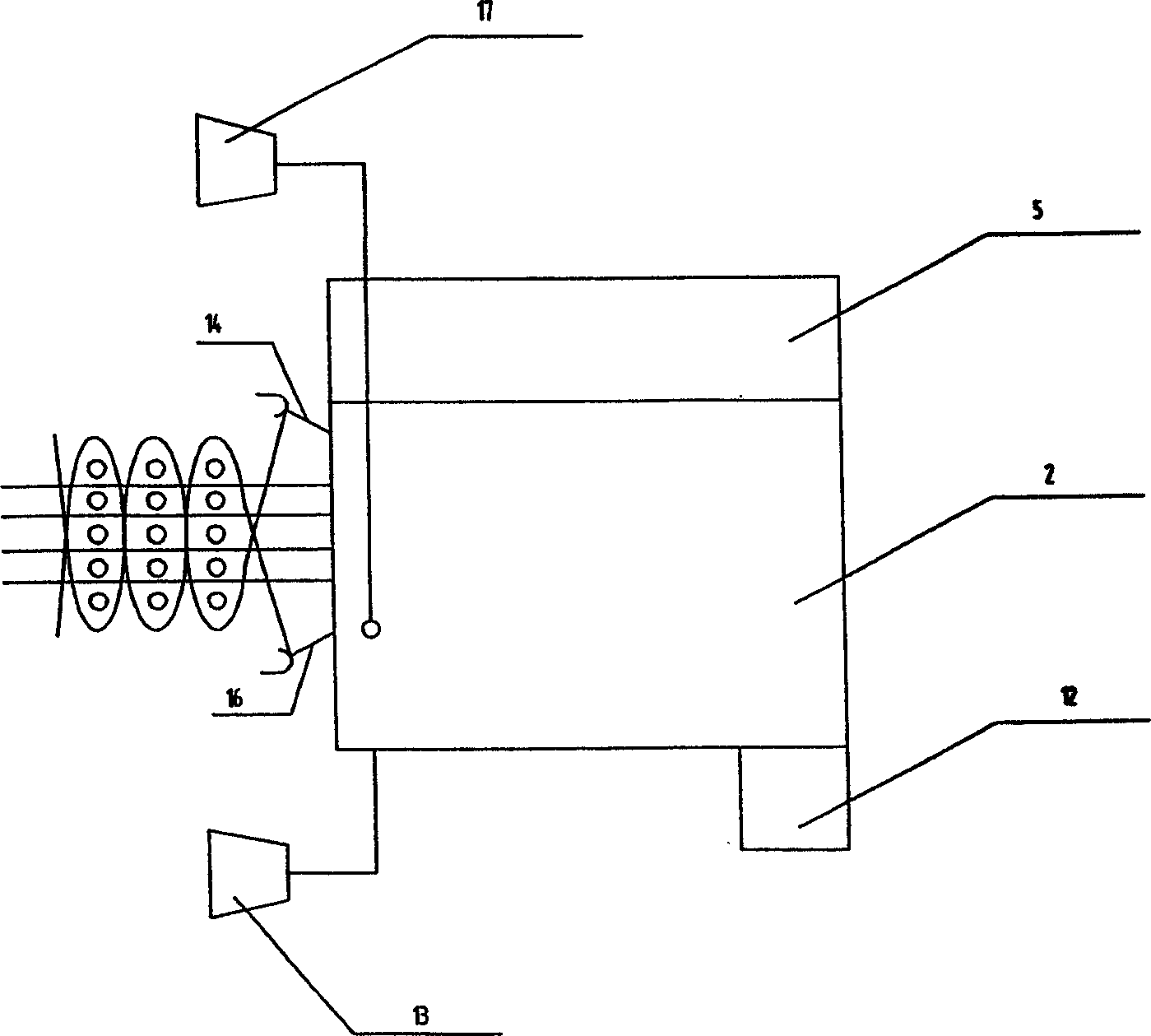

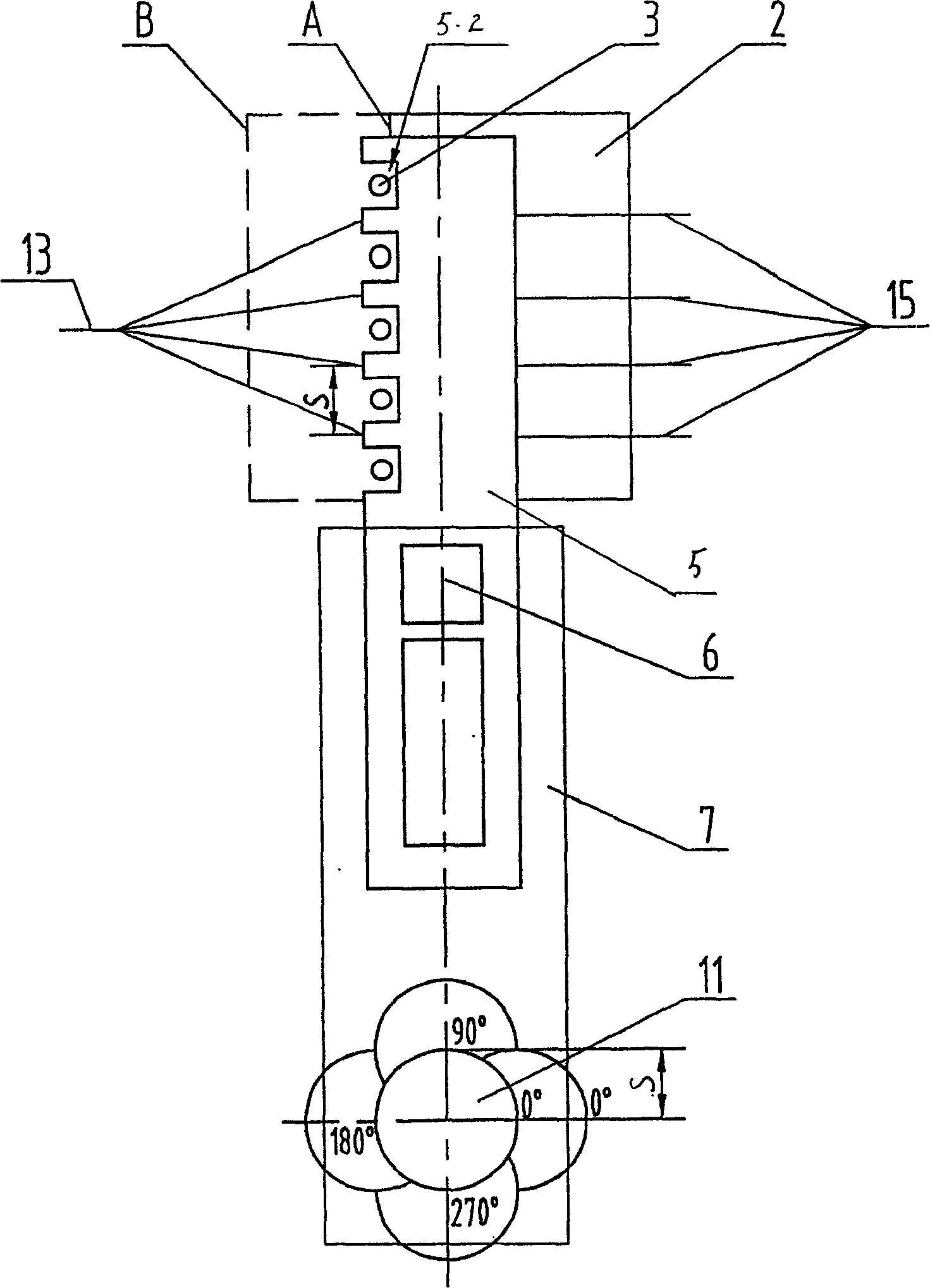

Warp-weft interleave interlayer penetration knitting machine and its weaving method

The invention relates to a chaine-latitude intercross penetrate loom and relative method. The loom comprises: a steel clamp frame (1), a steel clamp plate (2), a blade rod (3), a palm plate (5), a palm plate motion pin (6), a connection rod (7), a punch-imitation device (8), and a transmission shaft (11). It comprises several steel clamp plates (2) and several groups of palm plates (5), while N palm roots (5.1) is chaine mounted on the palm plates, and each palm eye (5.1) has a hole (5.2) through the blade rod (3) to form N+1 blade channels through N+1 blade rods; comprises four palm plate motion pins (6) through the palm plates (5); two ends of transmission shaft (11) have two groups of bent axle section, while the eccentric angle are 0, 90, 180, and 270 degrees; it comprises two groups of connection rods (7) while each group has four rods. The weaving method comprises: using palm plates to drive the chaine to operate several operation, to realize the intercross between each layer. The invention can intercross the chaine and latitude yarns without piles on the surface.

Owner:赵祖良

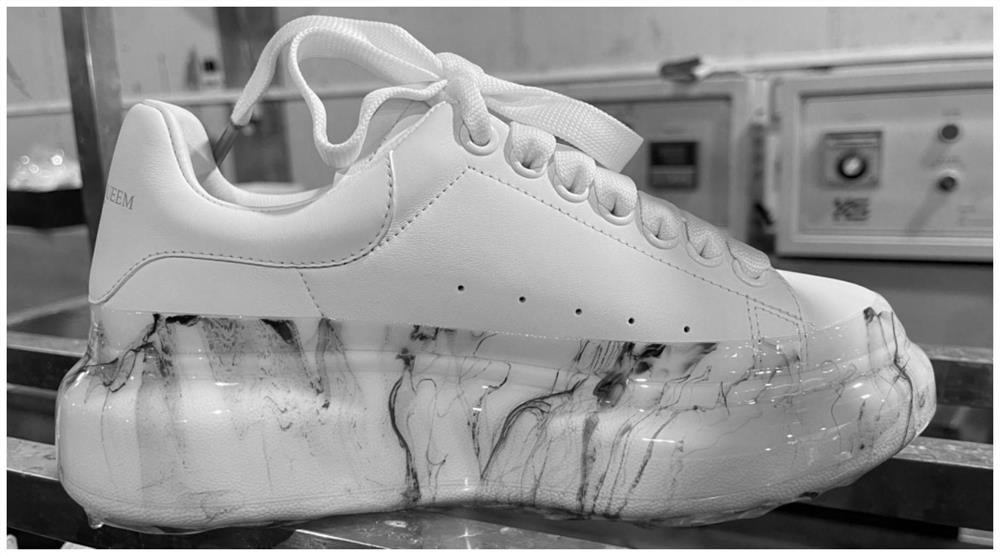

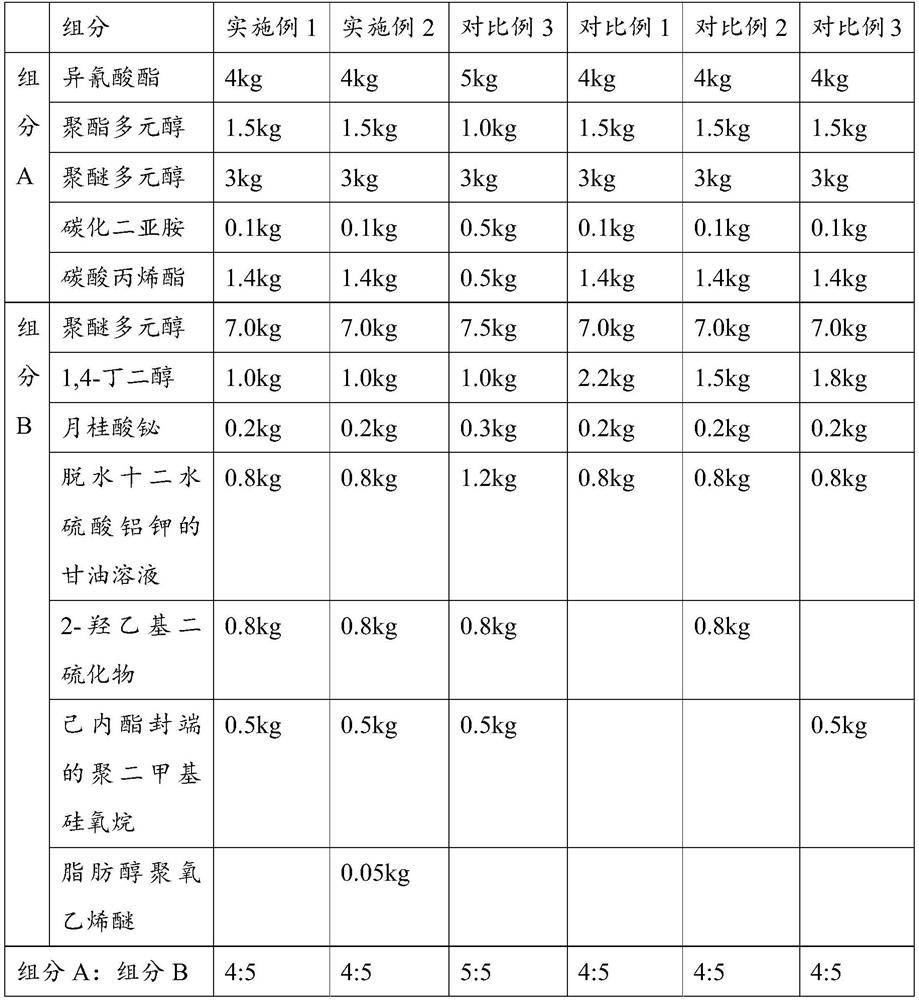

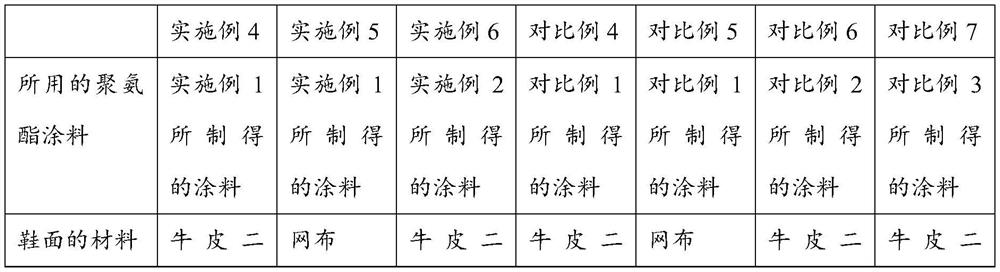

Polyurethane coating for shoes and manufacturing method of coating of polyurethane coating

ActiveCN114479628AImprove hydrophobicityHigh peel strengthPolyurea/polyurethane coatingsPolyesterPolymer science

The invention belongs to the technical field of polyurethane coatings, and particularly relates to a polyurethane coating for shoes and a manufacturing method of a coating of the polyurethane coating. The polyurethane coating is prepared from a component A and a component B, the component A is prepared from the following raw materials: isocyanate, polyester polyol, polyether polyol, a water removal agent and a diluent, and the component B is prepared from polyether polyol, 1, 4-butanediol, a catalyst, a glycerin solution of dehydrated aluminum potassium sulfate dodecahydrate, 2-hydroxyethyl disulfide and caprolactone-terminated polydimethylsiloxane. 2-hydroxyethyl disulfide and caprolactone-terminated polydimethylsiloxane are added, and the dosage and proportion of the 2-hydroxyethyl disulfide and caprolactone-terminated polydimethylsiloxane and a chain extender 1, 4-butanediol are regulated, so that the peel strength between the coating and the vamp is higher, the hydrophobicity is higher, and the coating is more durable. And bubbles in tiny holes at the edge of the vamp or the sole are prevented from expanding due to overheat chain extension.

Owner:FOSHAN NANHAI QIHONG SHOES MATERIAL CO LTD

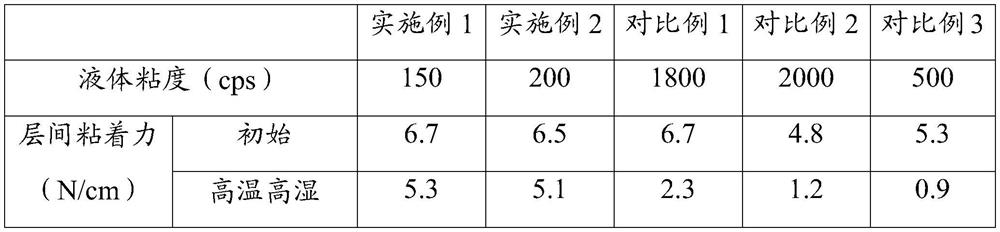

Polyurethane binder as well as preparation method and application thereof

ActiveCN112812728AIncrease moistureImprove adhesionPolyureas/polyurethane adhesivesPhotovoltaic energy generationPolymer sciencePolyol

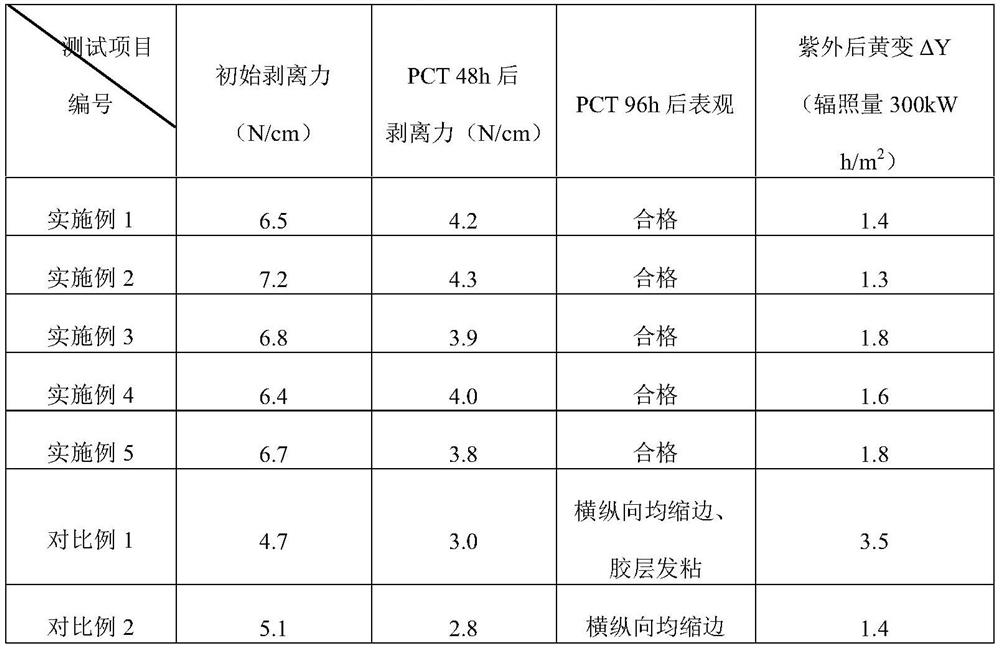

The invention discloses a polyurethane binder as well as a preparation method and application thereof. The polyurethane binder comprises polyol and diisocyanate, and the polyol comprises polyacrylate polyol, polyether glycol and polyfunctional polyether polyol. The polyurethane binder has the advantages of low viscosity, high peel strength and excellent damp-heat aging resistance, when the polyurethane binder is used in a solar back plate, the appearance defects such as edge shrinkage, blistering, layering and the like of the back plate after PCT for 96h are avoided, and the yellowing of the back plate after ultraviolet aging for 300 kWh / m<2> is less than 2, so that the use requirement of the back plate can be well met, the polyurethane binder does not contain a solvent, the binder does not cause air pollution when in use, has greater economic benefit than a commercially available solvent type binder, and can better meet the current environmental protection policy and the demand of the consumer market on environment-friendly products.

Owner:乐凯胶片股份有限公司

High-barrier aluminized composite film and preparation method thereof

ActiveCN114193879AGood heat sealing performanceHigh mechanical strengthPackage recyclingFlexible coversElastomerPolymer science

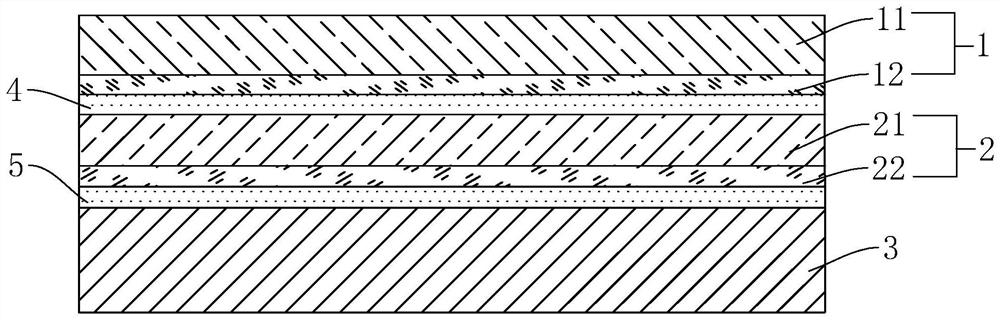

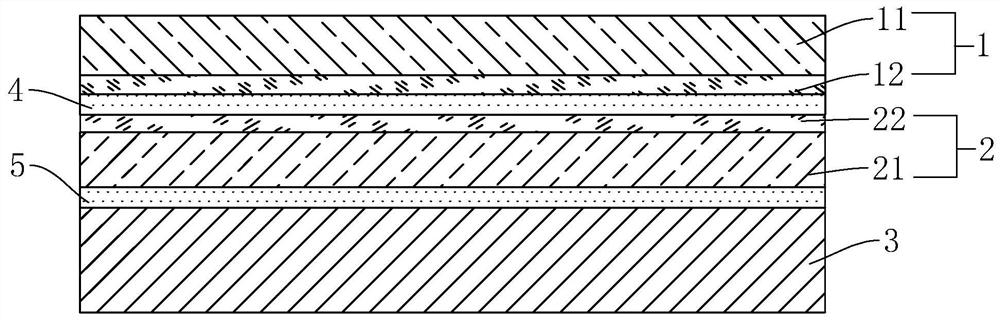

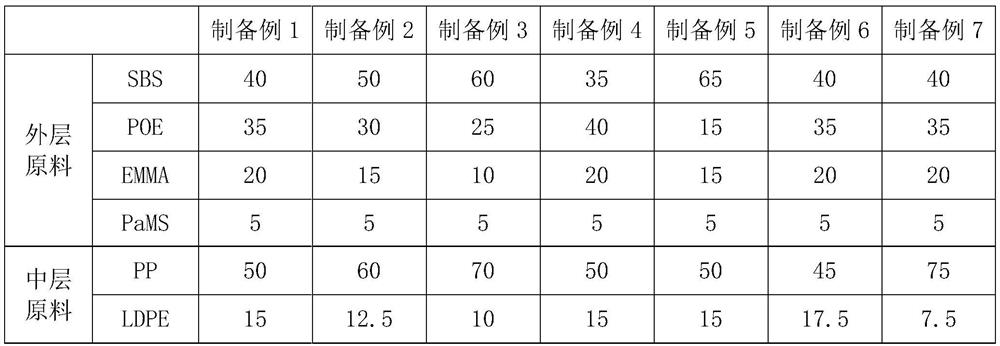

The invention relates to the field of packaging materials, and particularly discloses a high-barrier aluminized composite film and a preparation method thereof. A high-barrier aluminized composite film comprises a BOPP (biaxially-oriented polypropylene) printing film, an aluminized PET (polyethylene terephthalate) film and a PE (polyethylene) film, and the PE film comprises an outer layer, a middle layer and an inner layer; the aluminized surface of the aluminized PET film is compounded with the outer layer of the PE film through a second adhesive; the second adhesive is a solvent-free type polyurethane adhesive; the outer layer of the PE film is prepared from the following raw materials: a thermoplastic elastomer, POE (Polyolefin Elastomer), ethylene-methyl methacrylate copolymer and poly alpha-methylstyrene resin; the middle layer is prepared from copolymerized PP (polypropylene), LDPE (low-density polyethylene), LLDPE (linear low-density polyethylene), m-PE, an ethylene-methyl acrylate copolymer and a slipping agent; the raw materials of the inner layer comprise LDPE and m-PE. The high-barrier aluminized composite film can be used for food packaging and has the advantages of being good in barrier property, high in mechanical strength, not prone to stripping and layering and good in heat sealing property.

Owner:成都众恒印务有限责任公司

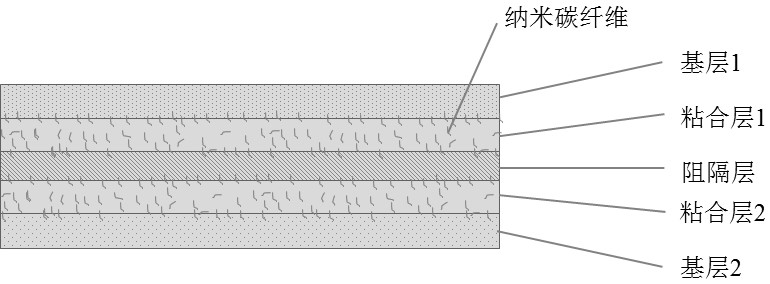

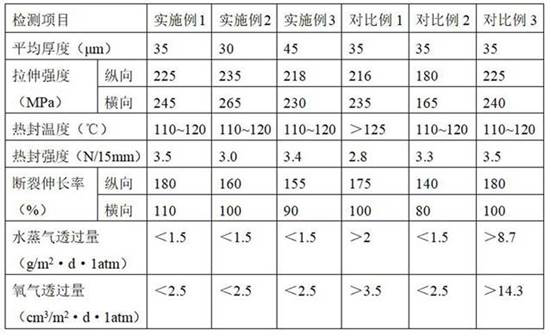

PETG/PET co-extrusion self-heat-sealing multilayer film and preparation method thereof

ActiveCN112848580AGood heat sealingLow mechanical strengthPackage recyclingFlexible coversMultilayer membranePolymer science

The invention belongs to the field of preparation of heat-sealing films, and particularly relates to a PETG / PET co-extrusion self-heat-sealing multilayer film and a preparation method thereof. The PETG / PET co-extrusion self-heat-sealing multilayer film provided by the invention comprises five film layers which sequentially comprise a base layer 1, a bonding layer 1, a barrier layer, a bonding layer 2 and a base layer 2, wherein the base layer 1 is a heat sealing layer and comprises metallocene PE and PETG; the base layer 2 is a lower surface layer and comprises PET, an anti-blocking agent and a slipping agent; the bonding layer 1 and the bonding layer 2 are the same in component and comprise maleic anhydride grafted polypropylene, PETG and carbon nanofibers; and the barrier layer is a middle layer and comprises PA and PETG. The film has the advantages of high heat sealing strength, moderate heat sealing temperature, improved toughness, improved elongation at break, improved interlayer peel strength and the like, and can be applied to the field of food packaging and the like.

Owner:河南银金达新材料股份有限公司

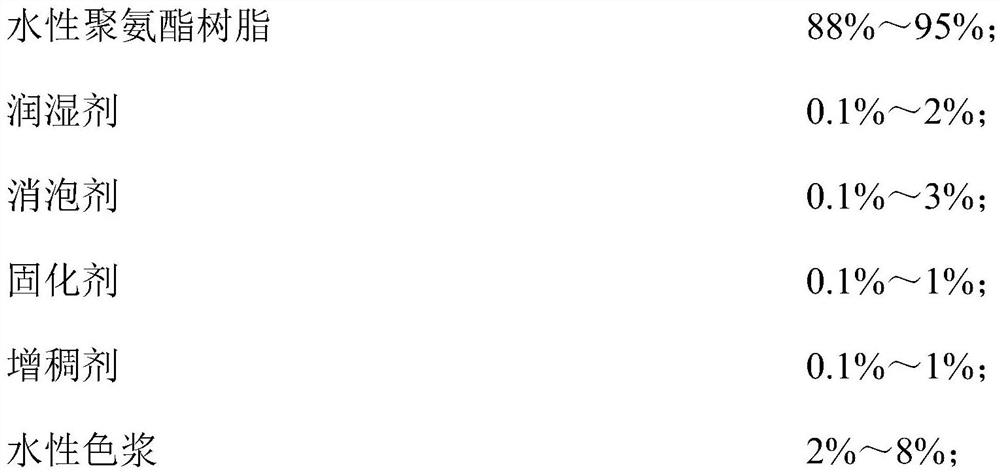

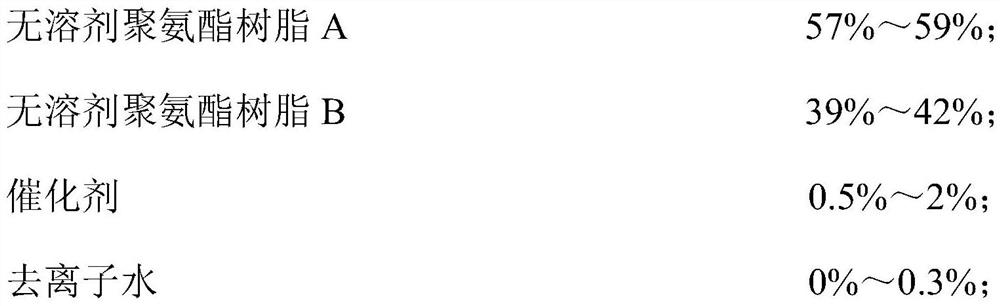

Environment-friendly space leather and preparation method and application thereof

PendingCN112761001AAvoid crackingImprove machinabilityFootwearTextiles and paperPolymer scienceSolvent free

The invention provides environment-friendly space leather and a preparation method and application thereof. The environment-friendly space leather sequentially comprises a waterborne polyurethane resin surface layer, a solvent-free polyurethane resin foaming layer and a waterborne polyurethane resin impregnation layer from top to bottom. The preparation method comprises the following steps that solvent-free polyurethane resin foaming layer slurry is coated on the waterborne polyurethane resin surface layer, drying is carried out to be half-dry, then the waterborne polyurethane resin impregnation layer is laminated, and drying is carried out to obtain the environment-friendly space leather. The environment-friendly space leather prepared by combining the waterborne polyurethane resin and the solvent-free polyurethane resin has high tear strength and high peel strength, is high in genuine leather feeling, full in hand feeling, fine in crease, good in folding fastness, good in wear resistance and good in hydrolysis resistance, and can be used for manufacturing high-end and environment-friendly sports shoe products.

Owner:SHANGHAI HUIDE TECH CO LTD

Adhesive for protective film on the back of a solar cell and application thereof

ActiveCN107903860BLow viscosityImprove hydrolysis resistanceFilm/foil adhesivesAldehyde/ketone condensation polymer adhesivesPolymer scienceElectrical battery

The invention belongs to the technical field of adhesives, and particularly relates to a water-resistant polyester resin adhesive for solar cell back surface protection films, and applications thereof, wherein the water-resistant polyester resin adhesive comprises, by weight, 100 parts of a polyester resin and 5-30 parts of a melamine formaldehyde resin, and the gelation rate of the adhesive is more than 50%. According to the present invention, the solar cell back surface protection film is formed by carrying out compound pressing on an electrical insulating layer, a moisture-resistant layer,a weathering-resistant layer and an adhesion layer, wherein the adhesion layer at least comprises the adhesive for the for solar cell back surface protection film; and with the technical scheme, the chelating system formed by adding the specific melamine formaldehyde resin can block the polar groups such as carboxyl, hydroxyl and the like on the branched chain so as to substantially reduce the viscosity of the system and substantially improve the hydrolysis resistance, such that the excellent processing construction performance is provided, the interlayer peel strength is high, and the servicelife is substantially prolonged.

Owner:SUZHOU GOLDEN TECH MATERIAL

A kind of light conveyor belt and preparation method thereof

ActiveCN101979283BHigh warp strengthQuality assuranceConveyorsSynthetic resin layered productsPolyesterPolymer science

Owner:DONGHUA UNIV

Weather-resistant and high-barrier solar cell back sheet and preparation method thereof

ActiveCN109605880BRaw materials are easy to getMild reaction conditionsSynthetic resin layered productsElectrical equipmentEpoxySolar battery

Owner:徐州日托新材料科技有限公司

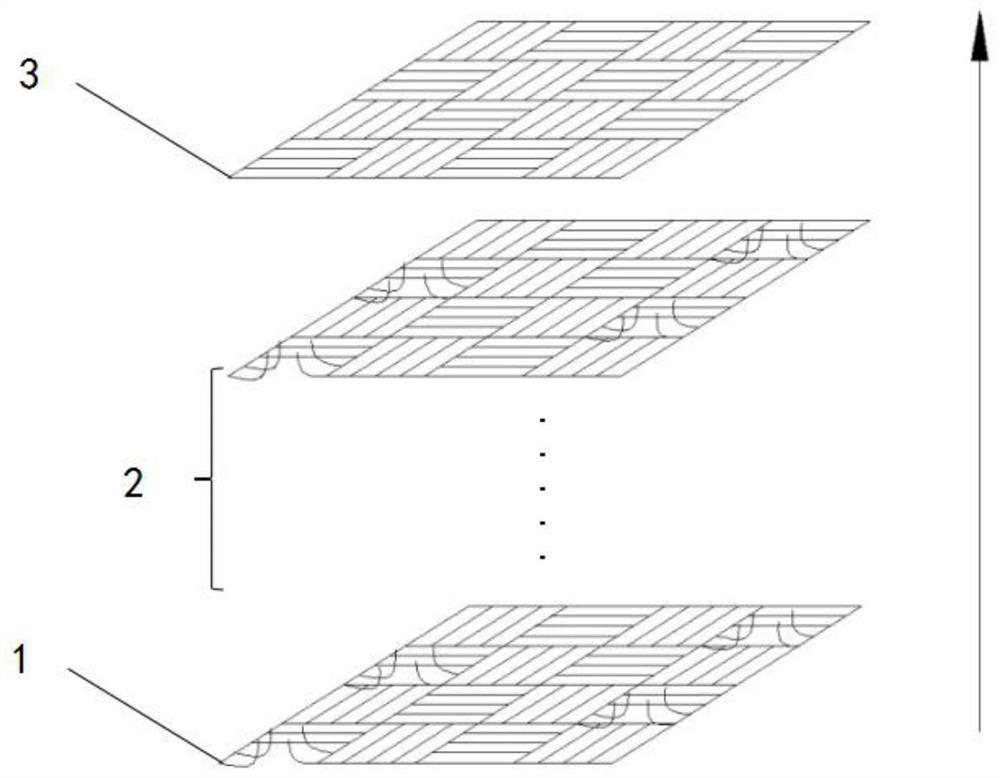

A composite material including anti-delamination wool fabric and its preparation method

ActiveCN110588092BAchieve enhanced effectHigh peel strength between layersLamination ancillary operationsLaminationFiberPolymer science

The invention provides a preparation method of an anti-delamination wool fabric composite material, comprising the following steps: (1) hooking part of the fibers on the surface of the fabric with a crochet roller to form a wool fabric; (2) using ordinary fabrics, single-face wool Layers of fabrics or double-sided wool fabrics are stacked, uniform pressure is applied, and the fabrics are combined to form an anti-delamination laminated fabric, wherein the order of laying is that one common surface and one wool surface are stacked in contact; (3) Step 2 The layered fabric is cut as required, impregnated in a mold with a polymer resin as a matrix, and then molded and hot-pressed to obtain the anti-delamination wool fabric composite material. The above-mentioned preparation method improves the interlayer peeling strength of the composite material, has better economic efficiency and product quality consistency, and is easy to standardize operations.

Owner:GUANGDONG YATAI NEW MATERIAL TECH CO LTD

A back seal production system

ActiveCN104494177BEffective heat sealingAchieve stretch thinningFlat articlesThermodynamicsEngineering

The invention discloses a back seal production system. The system sequentially includes an extruder, an extrusion die, a herringbone frame, a traction roller group, a cooling roller group, and a winding roller according to the advancing direction of materials. The traction roller group consists of It is composed of heat-resistant rubber roller and hollow steel roller with internal heating oil. The hollow steel roller and the temperature-controllable oil storage tank outside the hollow steel roller form a circulation loop; The preheating device for preheating the inner layer is installed at the rear end of the traction roller group so that the flattened film bubble is heat-sealed on the heat-sealing roller group, and the flattened film bubble bypasses the surface of the heat-sealing roller group in an S shape to form a sheet. At the rear end of the heat-sealing roller group, there is a shaping roller group to shape the sheet after heat-sealing, and the sheet after heat-sealing passes through the gap of the shaping roller group in a straight line; a unidirectional Longitudinal stretching mechanism and thickness detection mechanism. This production system enables the production of back seals with high strength and low elongation at break.

Owner:JIANGYIN BAOBO PACKING

A live fish transport packaging bag and its manufacturing and using methods

ActiveCN105475213BHigh gas storage efficiencyLight structurePisciculture and aquariaExhaust valveInlet channel

A transport packaging bag for live fish comprises a packaging bag body. An open part and a sealed part are arranged on the edge of the packaging bag body, a curve strip-shaped air inlet channel penetrating through the sealed part in the width direction is formed in the sealed part in a sandwiched mode, a first opening communicated with the external environment is formed in one end of the air inlet channel, a second opening communicated with an inner cavity of the packaging bag body is formed in the other end of the air inlet channel, and the width of the air inlet channel is gradually reduced from outside to inside. The transport packaging bag for live fish further comprises a one-way exhaust valve. The one-way exhaust valve is arranged on the side wall of the packaging bag body in a penetrating mode. The transport packaging bag for live fish is simple in structure, high in air storage capacity and not prone to breakage; besides, air in the bag can be replaced as needed, and the survival time of fish in the bag is long. The invention further provides manufacturing and using methods of the transport packaging bag for live fish. The manufacturing and using methods are easy and rapid to implement, low in cost and suitable for mass production.

Owner:罗鹏孩 +2

Solar cell back panel film and preparation method thereof

ActiveCN102922842BGood weather resistanceImprove adhesionSynthetic resin layered productsLaminationWeather resistanceComposite film

The invention relates to a solar cell back panel film and a preparation method thereof. The solar cell back panel film comprises a first transition layer, a first weather-resistant layer, a second transition layer, a substrate, a third transition layer and a second weather-resistant layer from top to bottom, wherein the substrate and the second and third transition layers are bonded by an adhesive layer; the first transition layer, the first weather-resistant layer and the second transition layer are three composite film layers prepared by way of coextrusion casting or film blowing; and the third transition layer and the second weather-resistant layer are two-layer composite films prepared by way of coextrusion casting or film blowing. The solar cell back panel film has the following beneficial effects that the solar cell back panel film has excellent weather resistance; introduction of the transition layers effectively improves the adhesiveness between the back panel film and the EVA adhesive layer as well as between the weather-resistant layers and the substrate; and meanwhile, the back panel film has tight structure, less production processes and low cost and does not cause solvent pollution.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

An online double-layer composite plastic blown film and its manufacturing method

ActiveCN104527189BSuppresses the effect of thickness variationImprove thickness uniformitySynthetic resin layered productsBoxesProduction lineBlow molding

The invention discloses an online double-layer composite plastic blow-molding film sheet which is formed by softening inner layers of a plurality of layers membrane bubbles which are co-extruded and blow-molded, wherein the inner layers of the membrane bubbles consist of EVA, COC and SEBS; a melting point of materials of the outer layers of the membrane bubbles is higher than a Vica softening point of the materials of the inner layer of the membrane bubbles. By optimizing the materials of the inner layers of the membrane bubbles, sticking is inhibited when the hot-pressing effect is improved, the thickness uniformity, the transparency, the heat-sealing uniformity, and the like of the membrane sheet are improved, the prepared membrane sheet has extensive re-processing capacity; after being heat-sealed and thickened, the membrane sheet is stretched and thinned, so that the film sheet has the performances of a blow-molding material and a flow casting material, and can be used as a packaging box back seal strip on a high-speed packaging body production line. Besides, the invention further discloses a manufacturing method for the online double-layer composite plastic blow-molding film sheet.

Owner:JIANGYIN BAOBO PACKING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com