Adhesive for solar photovoltaic module back plate and preparation method of adhesive

A solar photovoltaic and adhesive technology, which is applied in the direction of adhesives, adhesive additives, adhesive types, etc., can solve the problem that the performance quality and service life of solar photovoltaic modules are greatly affected, the dilution solvent performance is greatly affected, and the adhesive performance Decrease and other issues, to reduce the risk of hydrolysis aging, improve reliability and service life, improve the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

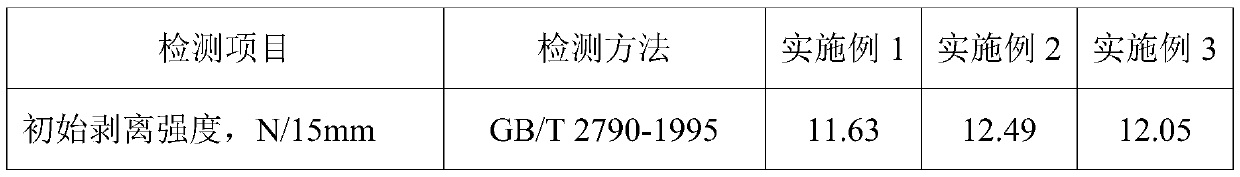

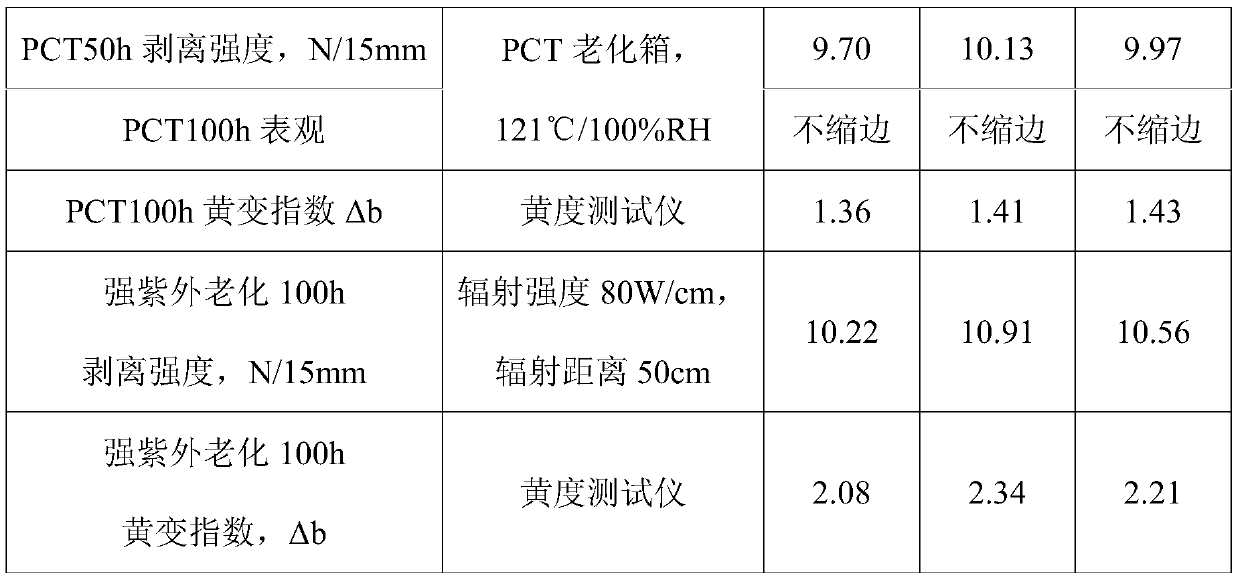

Embodiment 1

[0036] The adhesive for the solar photovoltaic module back sheet of this embodiment is prepared by the following method:

[0037] 1) According to the molar ratio of polypropylene glycol in terms of -OH and diphenylmethane diisocyanate in terms of -NCO being 1:3.5, dehydrated polypropylene glycol is slowly added to liquefied diphenylmethane diisocyanate; under nitrogen protection, The temperature of the system was raised to 80°C for 2 hours of heat preservation reaction, and then cooled to room temperature to obtain the first isocyanate-terminated prepolymer; the mass content of -NCO in the obtained first isocyanate-terminated prepolymer was 8.84%;

[0038] According to the molar ratio of polytetramethylene ether glycol in terms of -OH and polymethylene polyphenyl polyisocyanate in terms of -NCO is 1:4.5 ratio, dehydration polytetramethylene ether glycol is slowly added to polytetramethylene ether glycol In methylene polyphenyl polyisocyanate; under the protection of nitrogen, ...

Embodiment 2

[0045] The adhesive for the solar photovoltaic module back sheet of this embodiment is prepared by the following method:

[0046] 1) According to the molar ratio of polypropylene glycol in terms of -OH and diphenylmethane diisocyanate in terms of -NCO being 1:3.8, slowly add dehydrated polypropylene glycol dropwise to liquefied diphenylmethane diisocyanate, under nitrogen protection , raising the temperature of the system to 85°C for 2 hours of heat preservation reaction, and then cooling to room temperature to obtain the first isocyanate-terminated prepolymer; the mass content of -NCO in the obtained first isocyanate-terminated prepolymer is 9.60%;

[0047] According to the molar ratio of polytetramethylene ether glycol in terms of -OH and polymethylene polyphenyl polyisocyanate in terms of -NCO is 1:4.7 ratio, dehydration polytetramethylene ether glycol is slowly added to polytetramethylene ether glycol In methylene polyphenyl polyisocyanate; under the protection of nitrogen...

Embodiment 3

[0054] The adhesive for the solar photovoltaic module back sheet of this embodiment is prepared by the following method:

[0055] 1) According to the molar ratio of polypropylene glycol in terms of -OH and diphenylmethane diisocyanate in terms of -NCO being 1:4.0, slowly add dehydrated polypropylene glycol dropwise into liquefied diphenylmethane diisocyanate, under nitrogen protection , heating the system to 85°C for 2.5 hours, then cooling to room temperature to obtain the first isocyanate-terminated prepolymer; the mass content of -NCO in the obtained first isocyanate-terminated prepolymer is 10.1%;

[0056] According to the molar ratio of polytetramethylene ether glycol in terms of -OH and polymethylene polyphenyl polyisocyanate in terms of -NCO, the ratio of 1:5.0 is slowly added to the polytetramethylene ether glycol. In methylene polyphenyl polyisocyanate; under the protection of nitrogen, keep warm at 75°C for 2h, and then cool to room temperature to obtain the second i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

| yellowness index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com