Patents

Literature

2152 results about "Cover glass" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

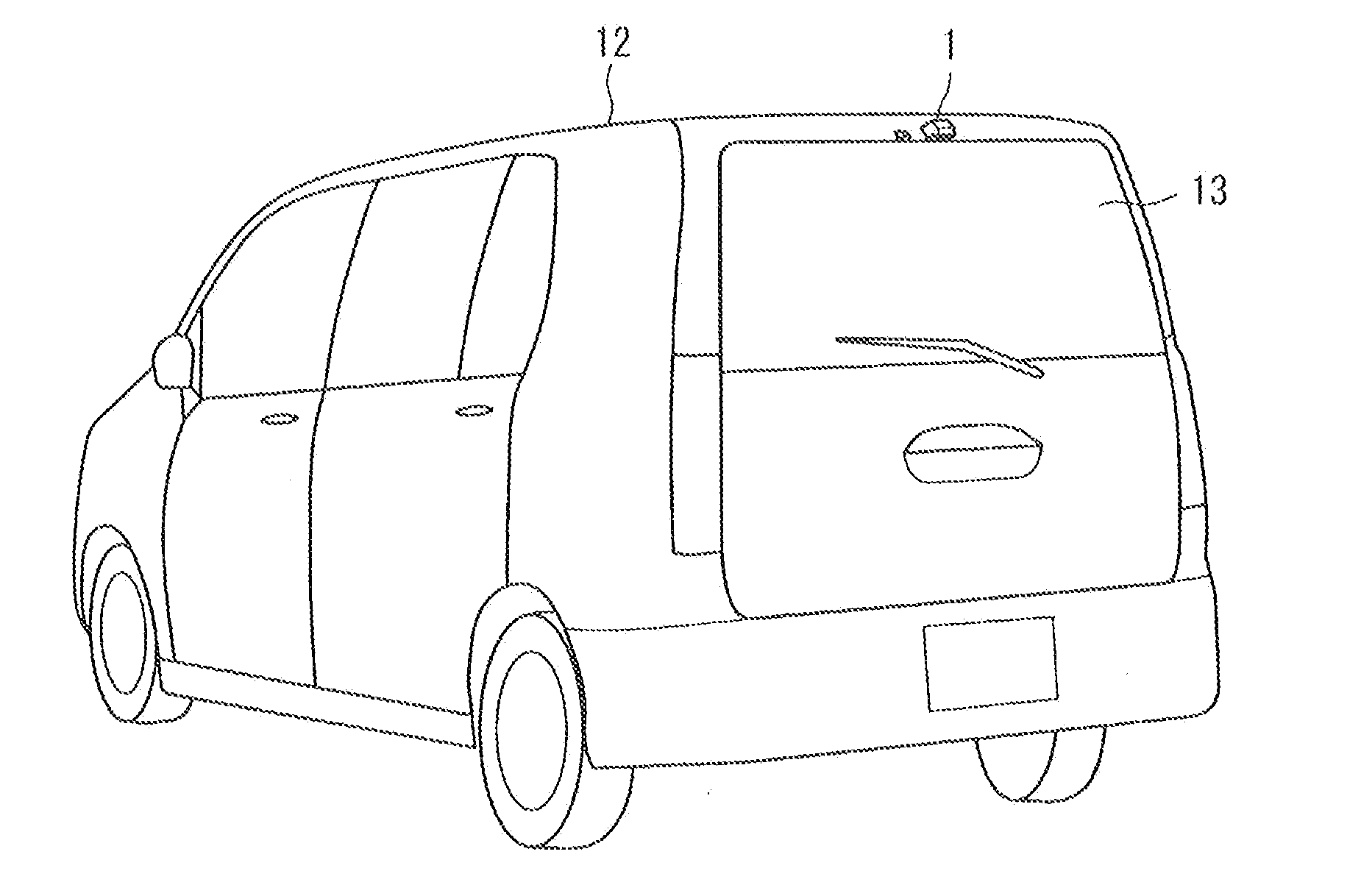

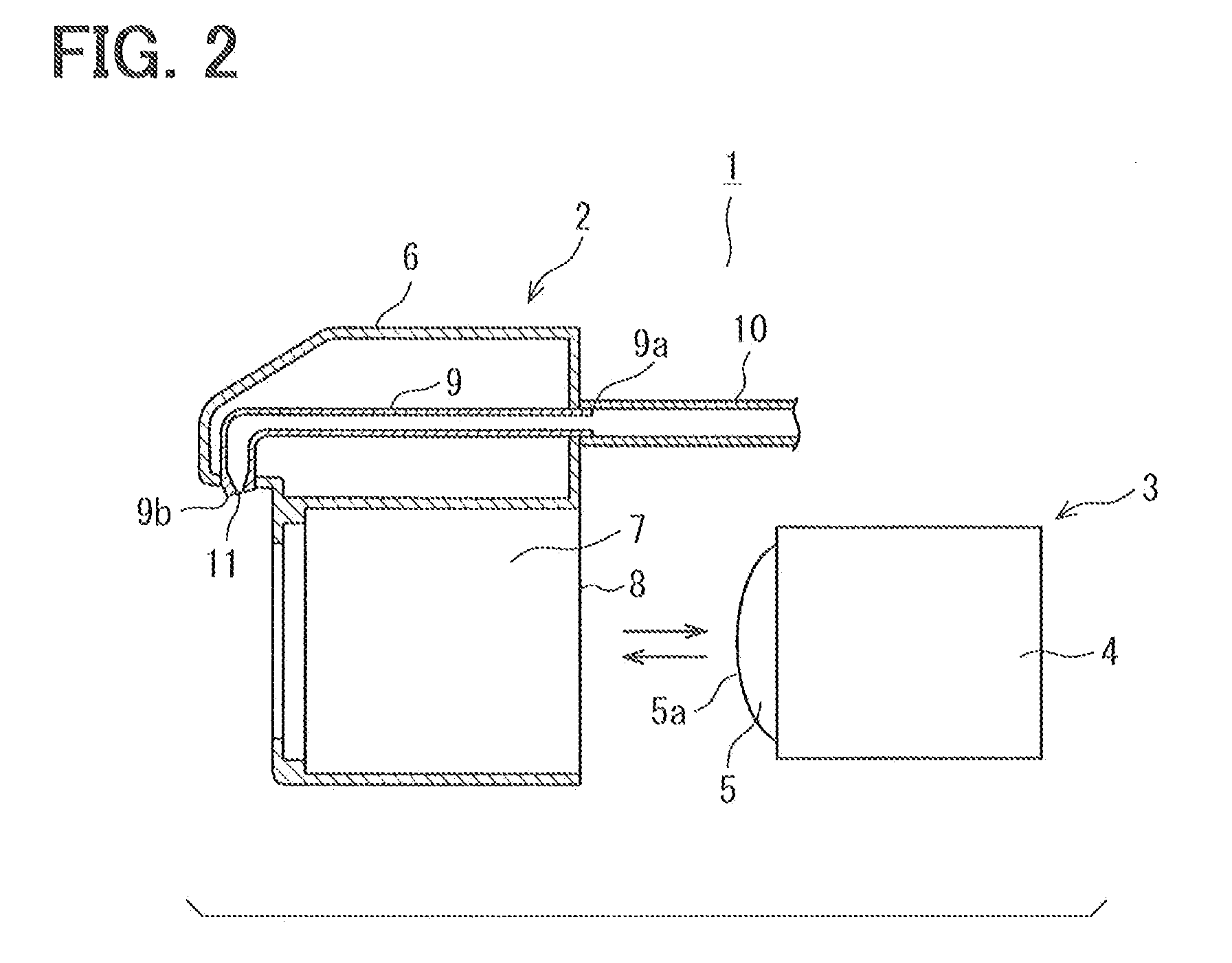

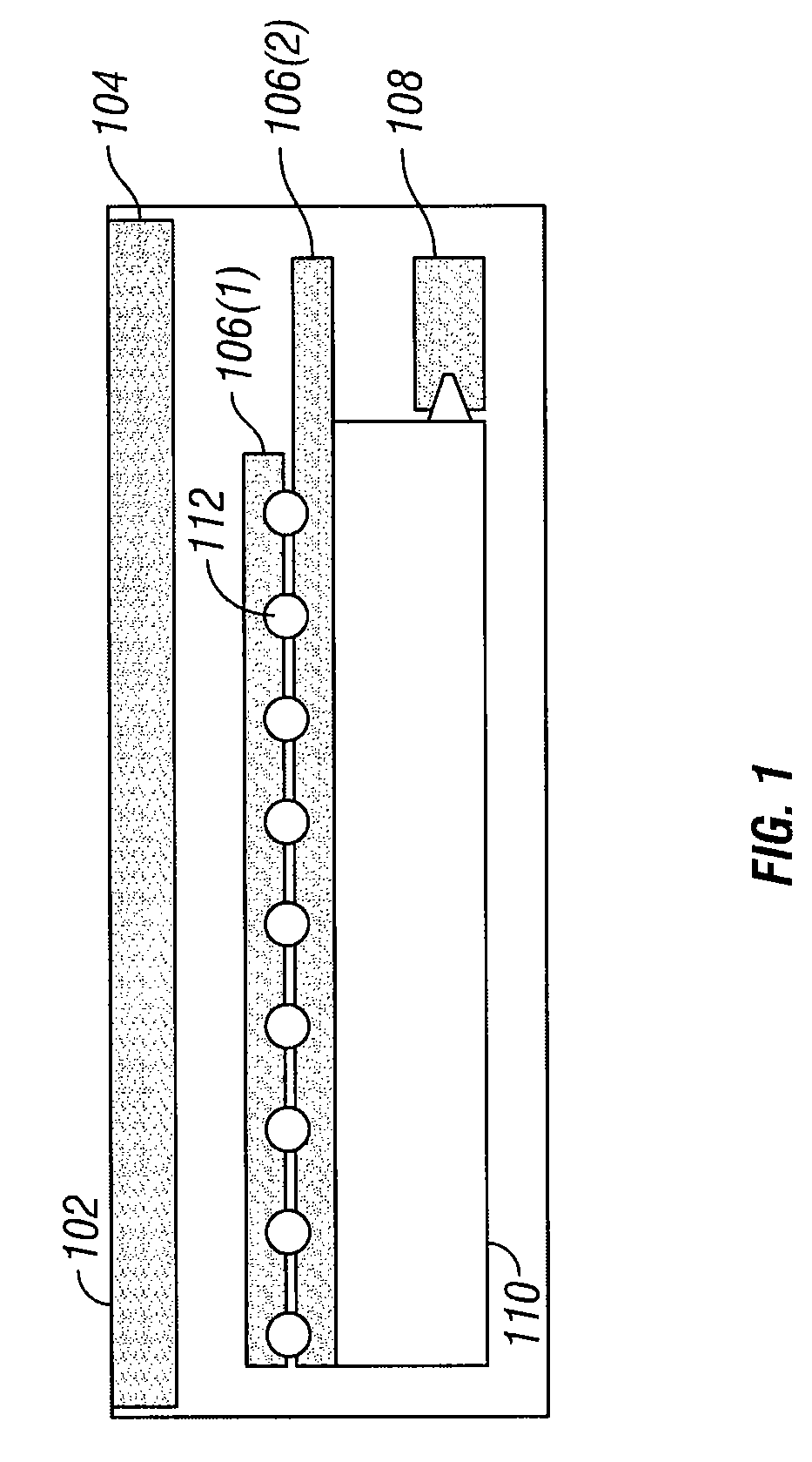

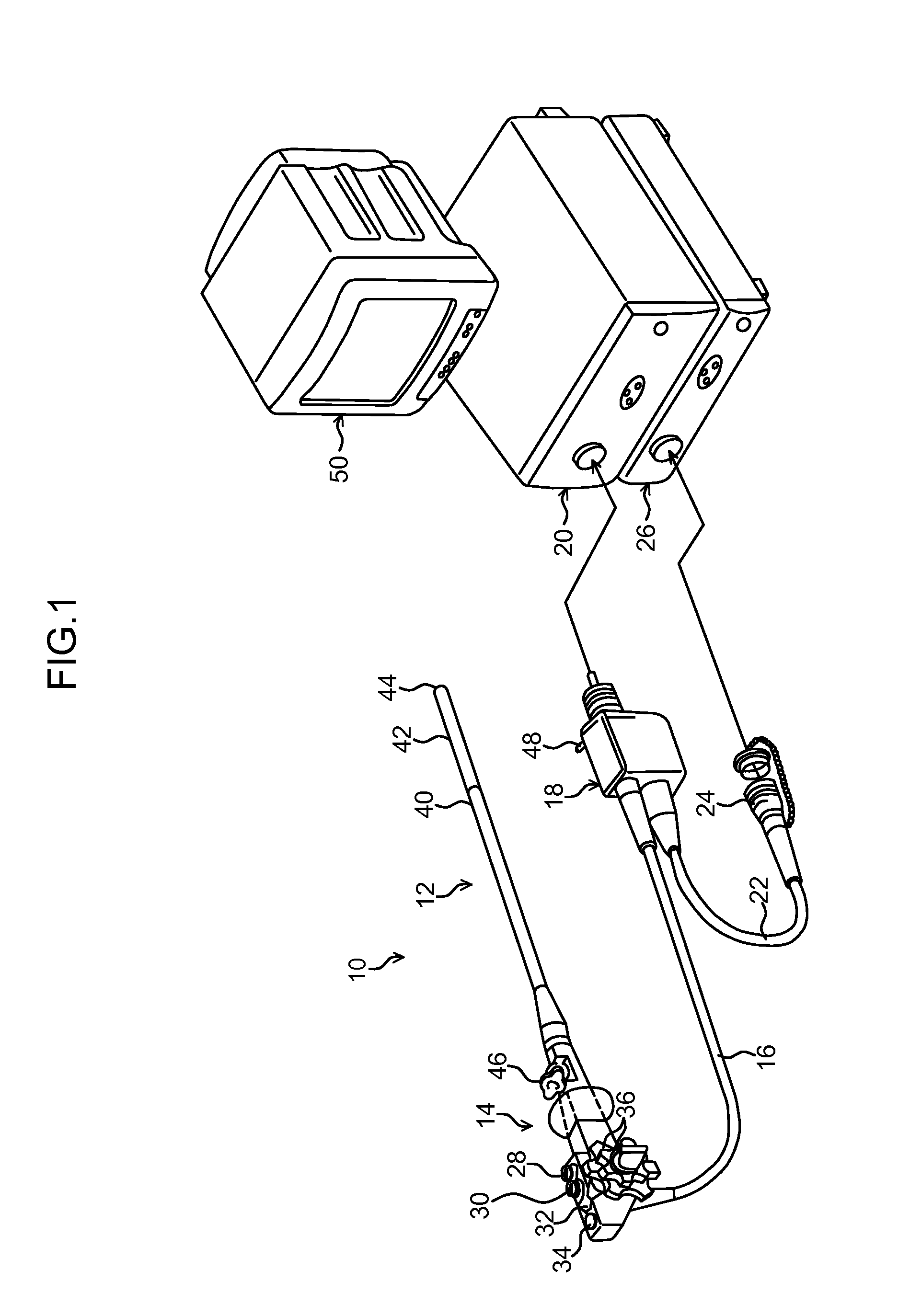

On-board optical sensor cover and on-board optical apparatus

An on-board optical sensor apparatus includes an optical sensor, an optical sensor cover, and a controller. The optical sensor has a lens. The optical sensor cover includes a holder and a washer nozzle. The holder holds the optical sensor. The washer nozzle performs a washing operation to wash a lens surface of the lens of the optical sensor or a glass surface of a cover glass located facing the lens by spraying a washer fluid, supplied from a washer fluid tank, onto the lens surface or the glass surface. The controller controls the washing operation of the washer nozzle.

Owner:DENSO CORP

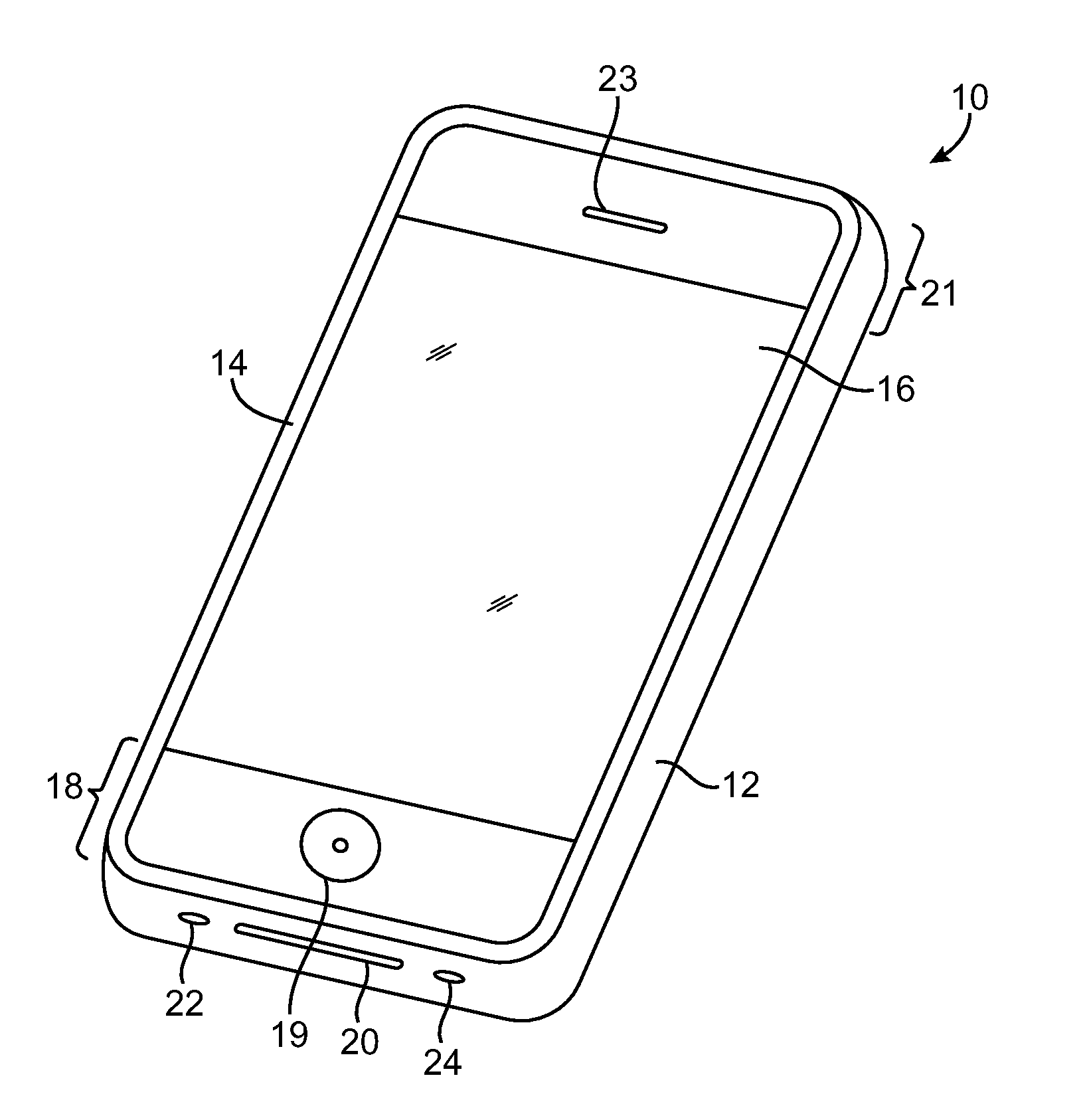

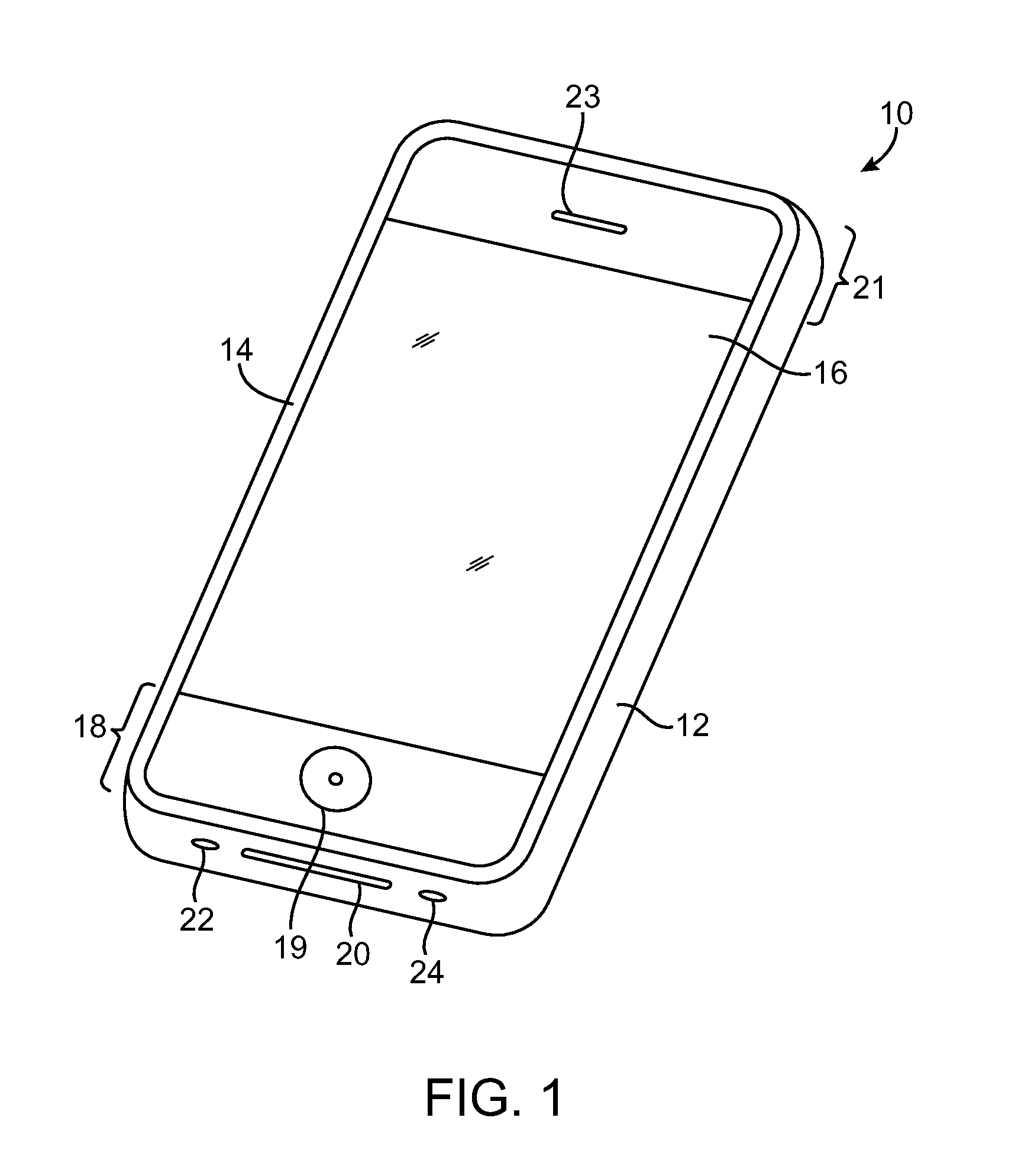

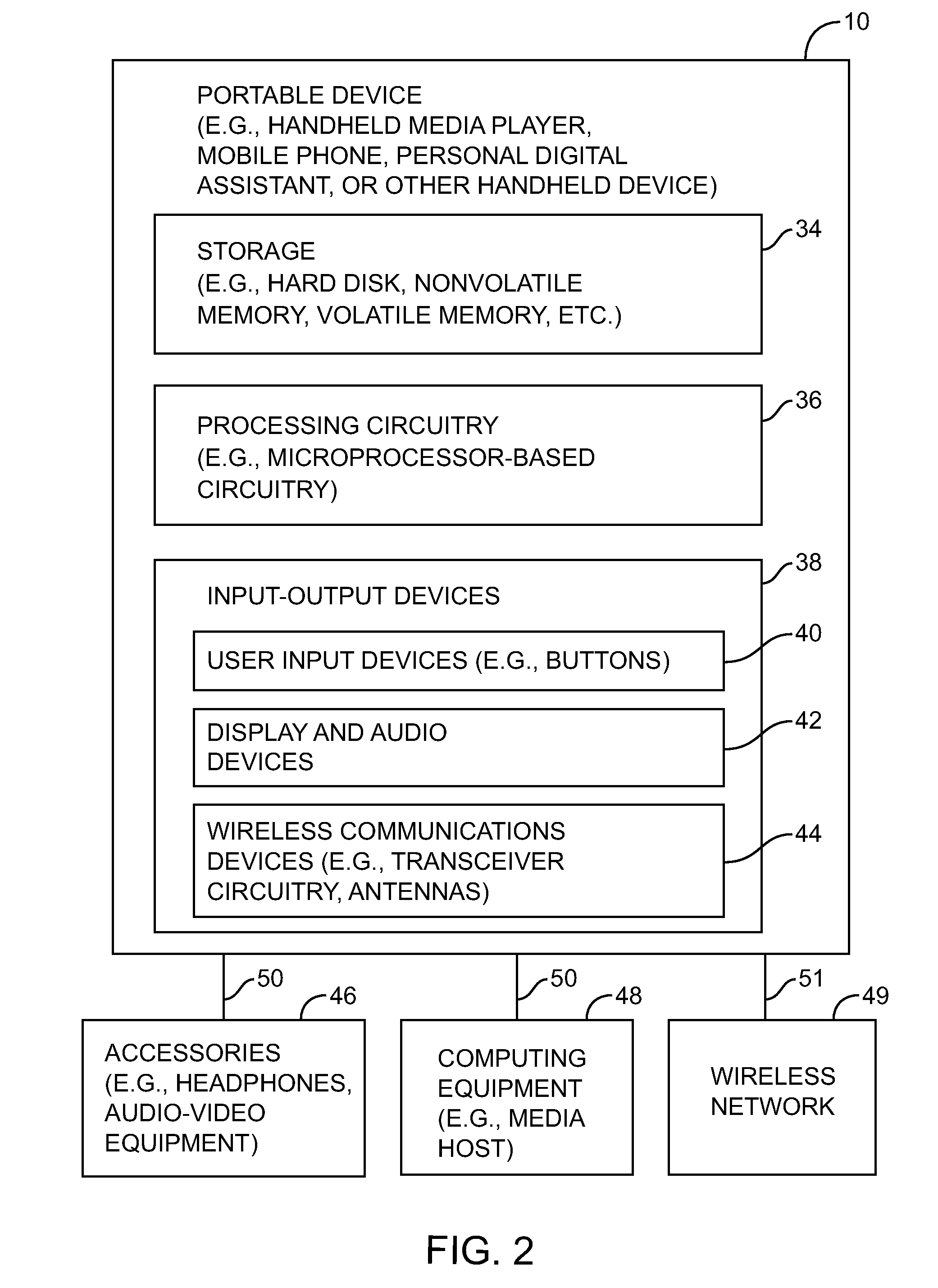

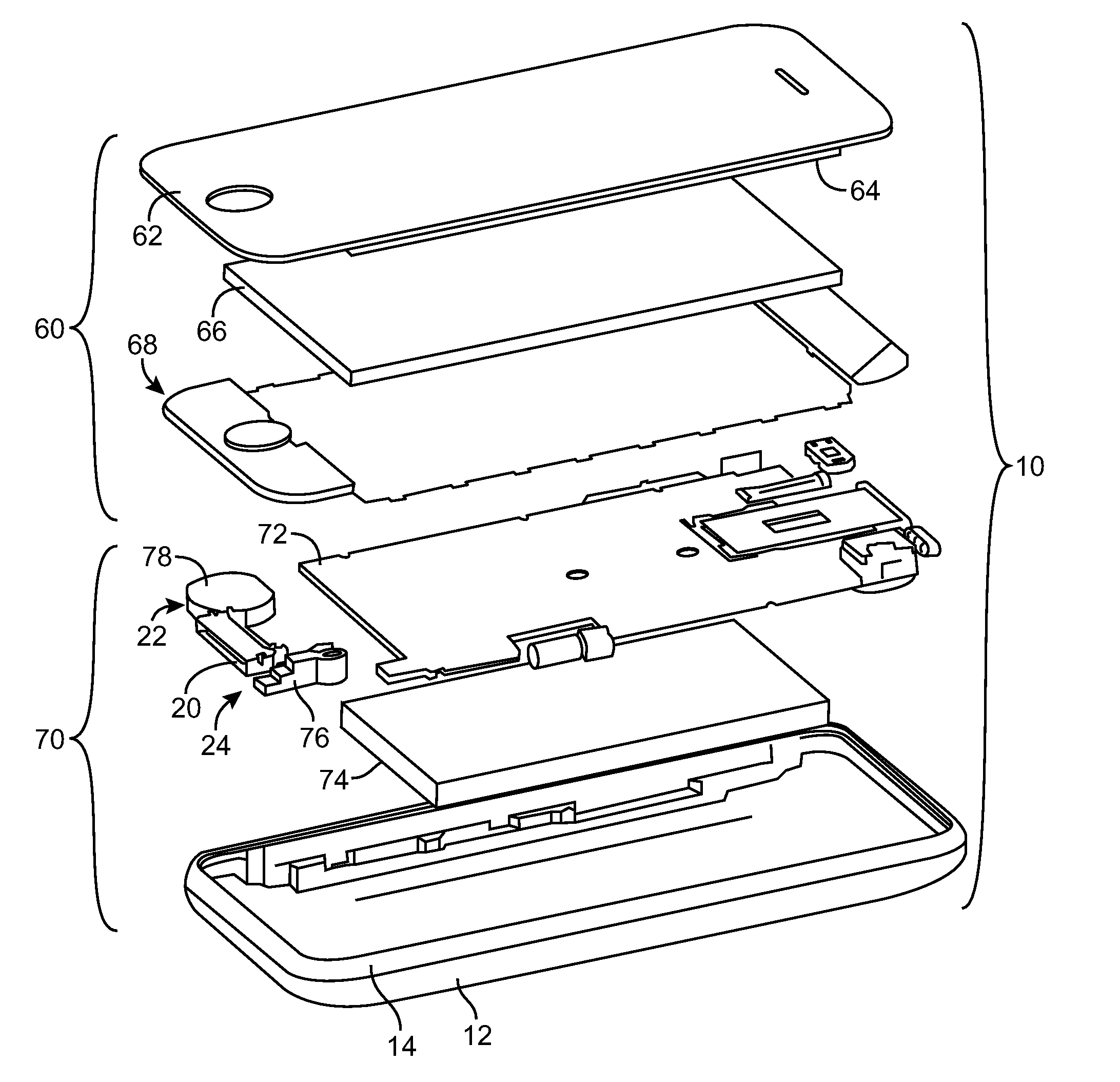

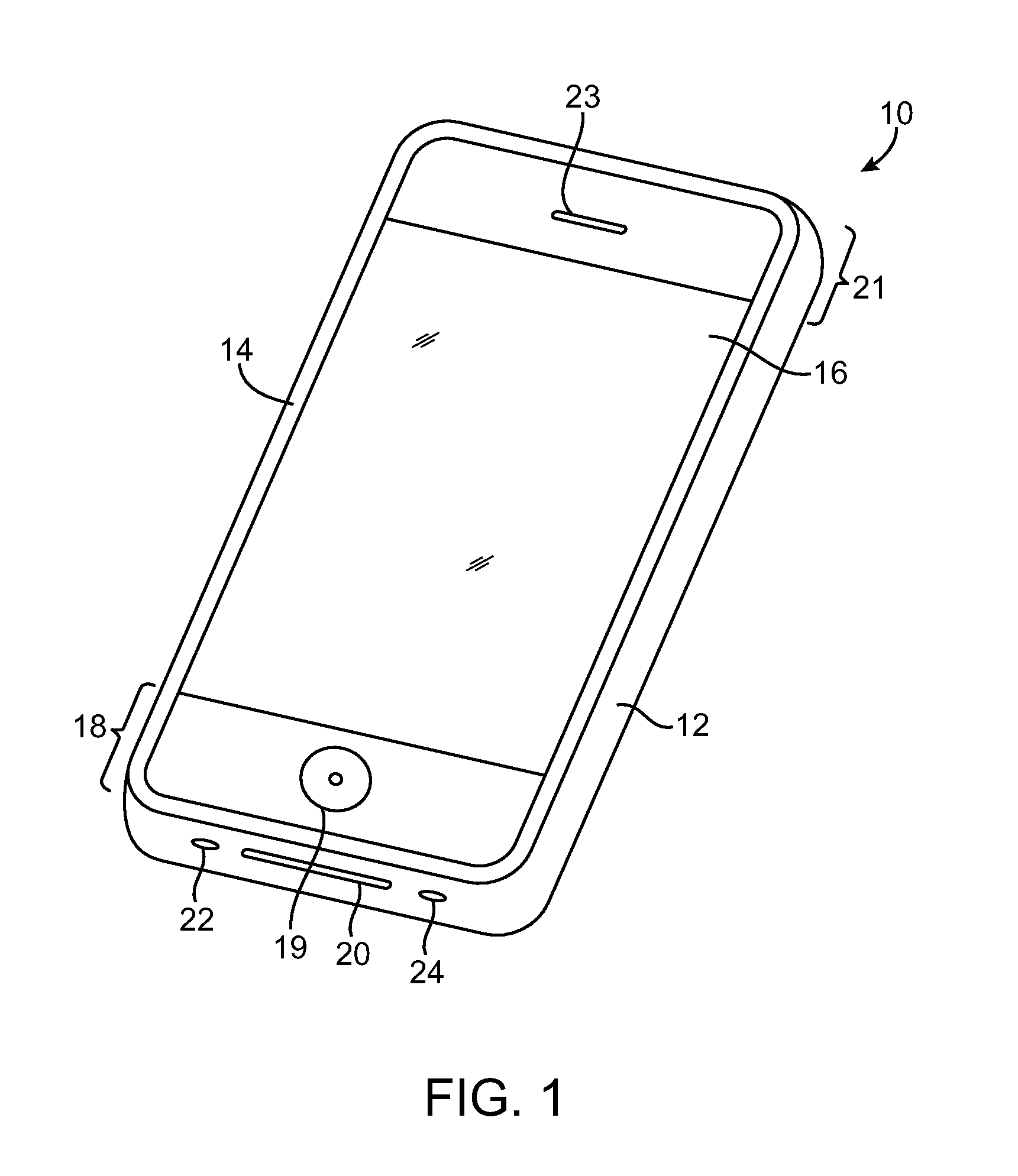

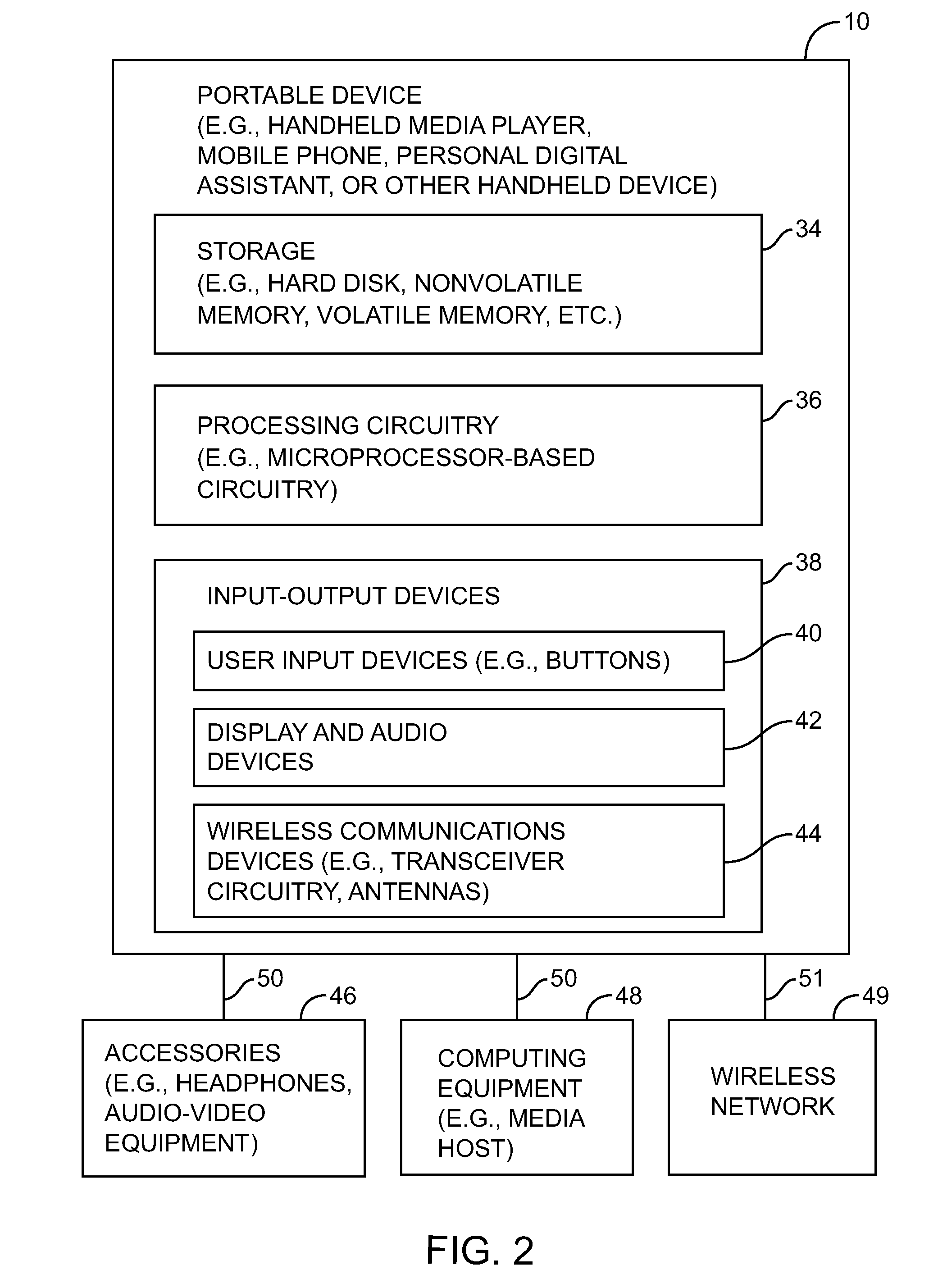

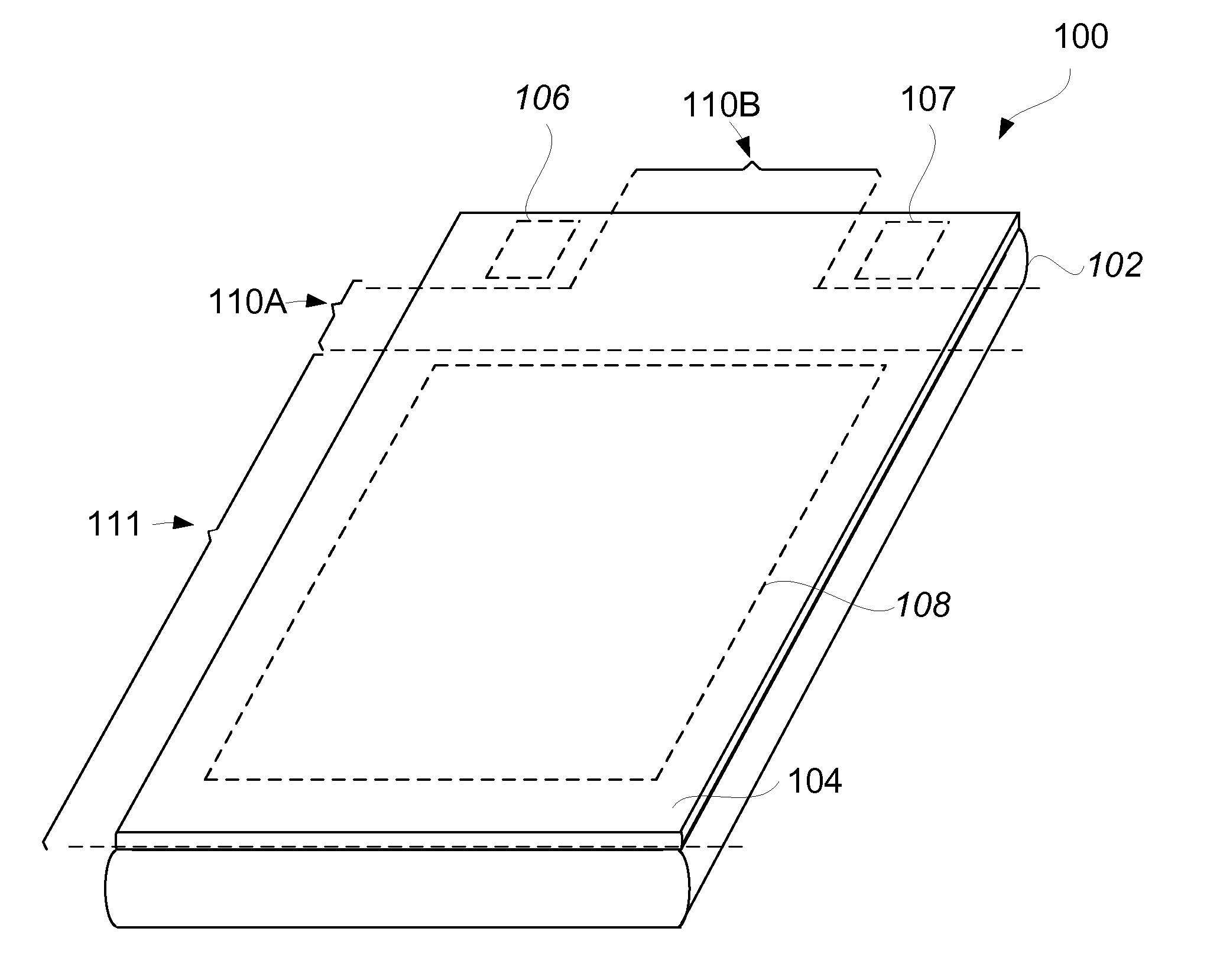

Portable electronic device with two-piece housing

ActiveUS20090257207A1Avoid scratchesDisassembled for rework or repair operationsWave amplification devicesMagnetic/electric field screeningDisplay deviceEngineering

Portable electronic devices are provided. Each device may be formed from two parts. A first part may be provided with components such as a display, a touch screen, a cover glass, and a frame. A second part may be provided with a plastic housing, circuit boards containing electrical components, and a bezel. Engagement members may be connected to the first and second parts. The engagement members may be formed from metal clips with holes and springs with flexible spring prongs that mate with the holes in the clips. The metal clips may be welded to frame struts on the frame and the springs may be welded to the bezel. During assembly, the first part may be rotated into place within the second part. Retention clips attached to the frame may be used to secure the two parts together. Assembly instructions and associated connector numbers may be provided within the devices.

Owner:APPLE INC

Reduced reflectance polarized display

A method and apparatus according to various aspects of the present invention provides a polarized display exhibiting reduced reflectances. A polarizer is disposed adjacent to a cover glass in front of the display. Light intended to be transmitted by the display is transmitted by the polarizer. Light reflected after passing through the polarizer reverses polarization, and is absorbed as it intercepts the polarizer following reflection.

Owner:HONEYWELL INC

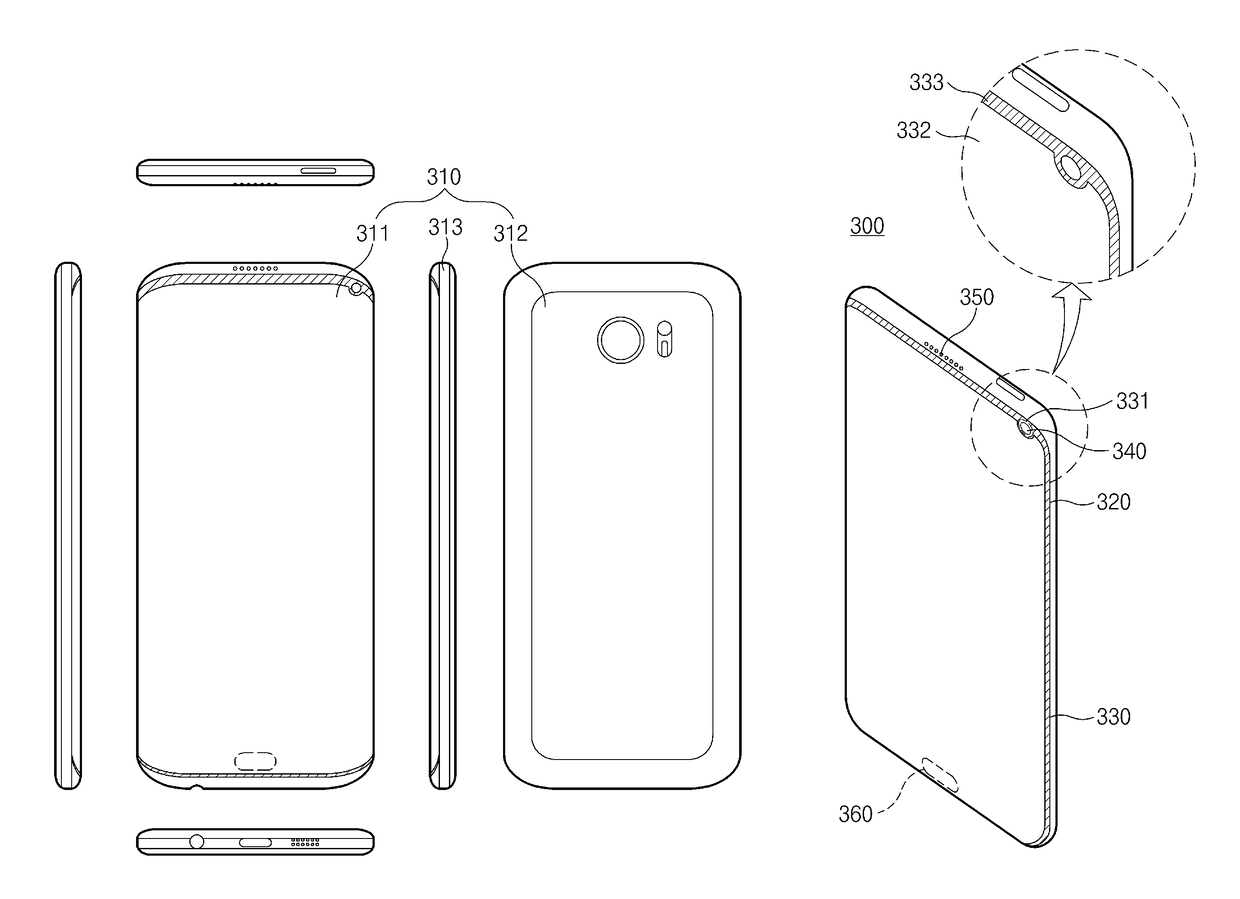

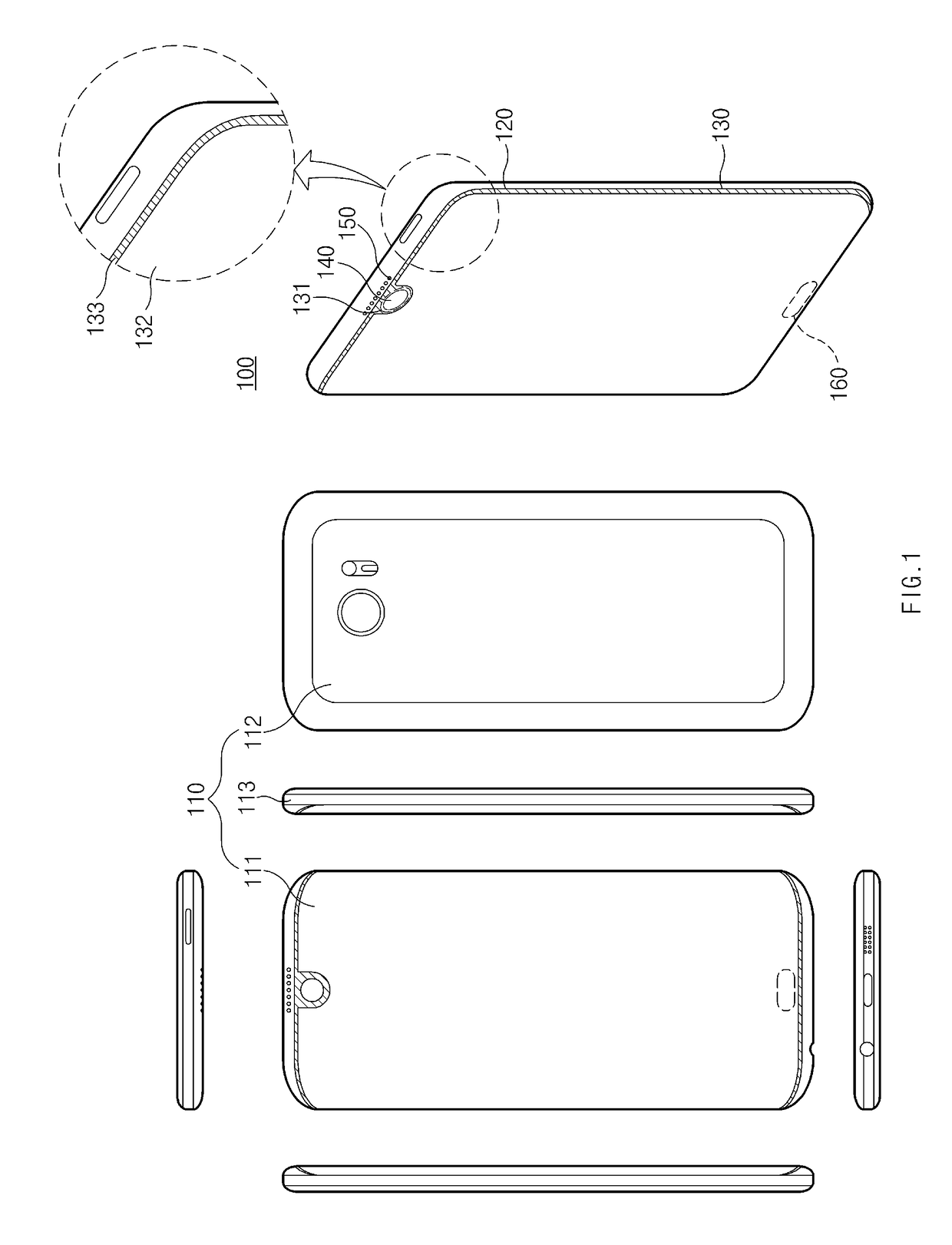

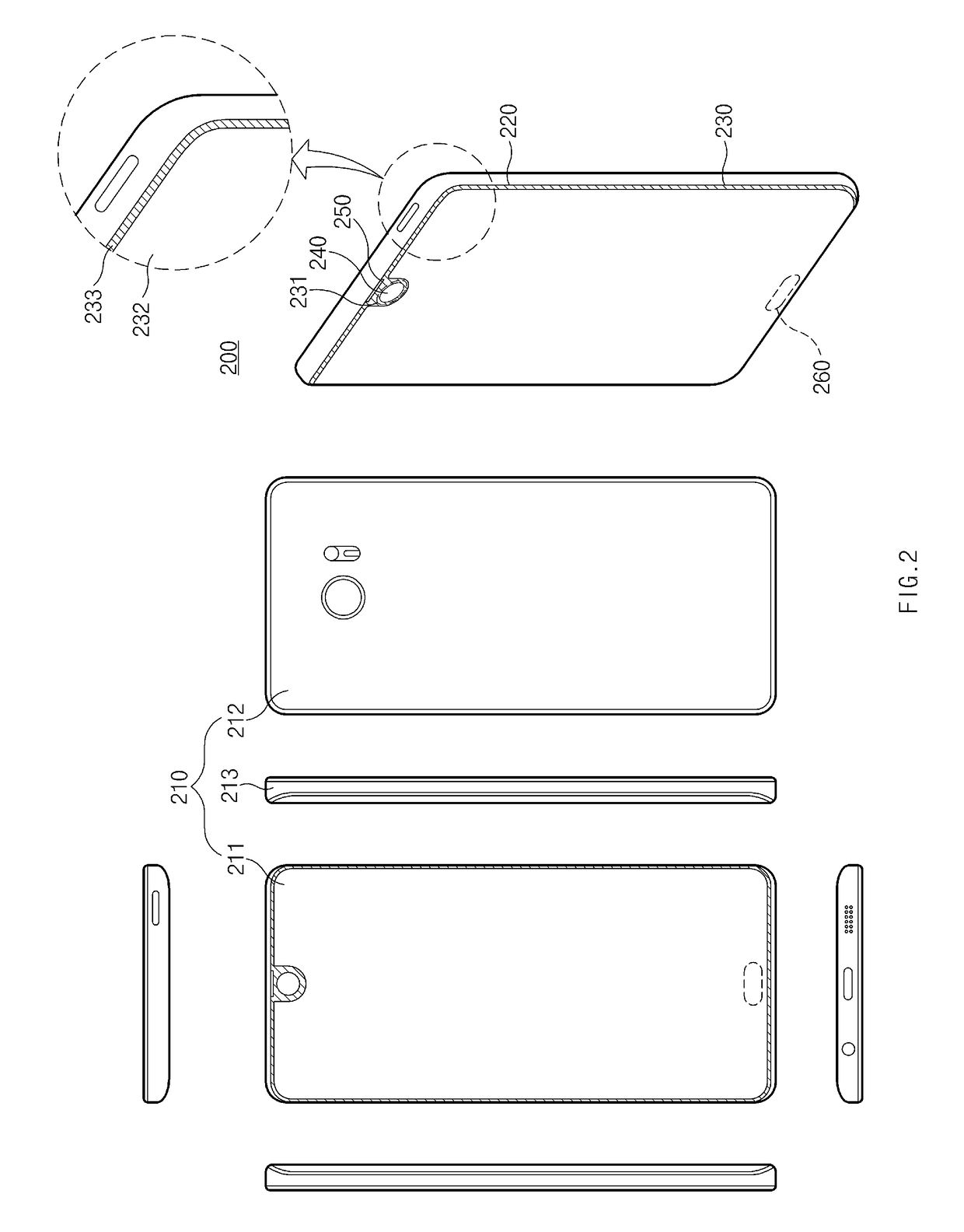

Electronic device including display

An electronic device is provided. The electronic device includes a housing including a first surface facing a first direction, a second surface facing a second direction opposite to the first direction, and a side surface extending between and along a perimeter of the first surface and the second surface, a cover glass corresponding to at least the first surface, a display panel disposed under the cover glass and including an active area exposed through the cover glass, an inactive area surrounding the active area, and a printed circuit board connection portion connected to one end of the inactive area, wherein at least one opening or at least one cutaway portion is formed in the display panel, and a camera module disposed in a space formed by the at least one opening or the at least one cutaway portion and exposed through the cover glass.

Owner:SAMSUNG ELECTRONICS CO LTD

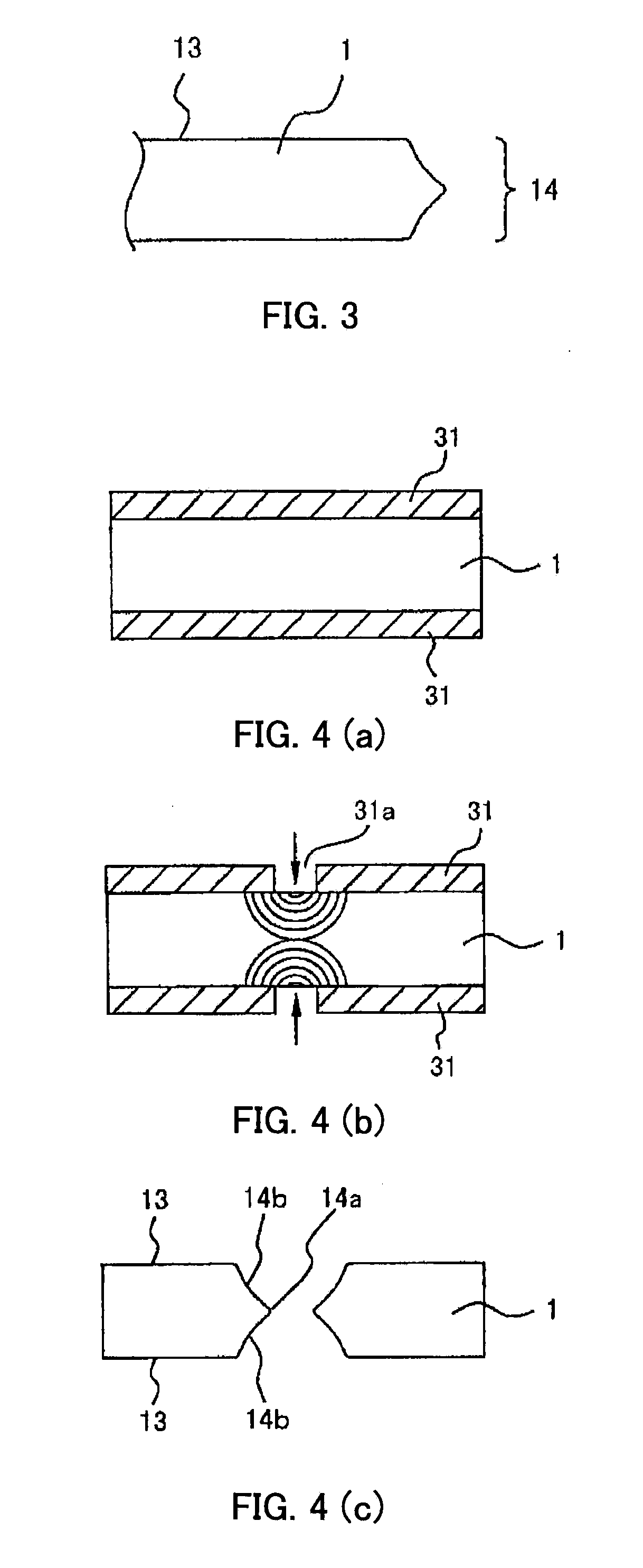

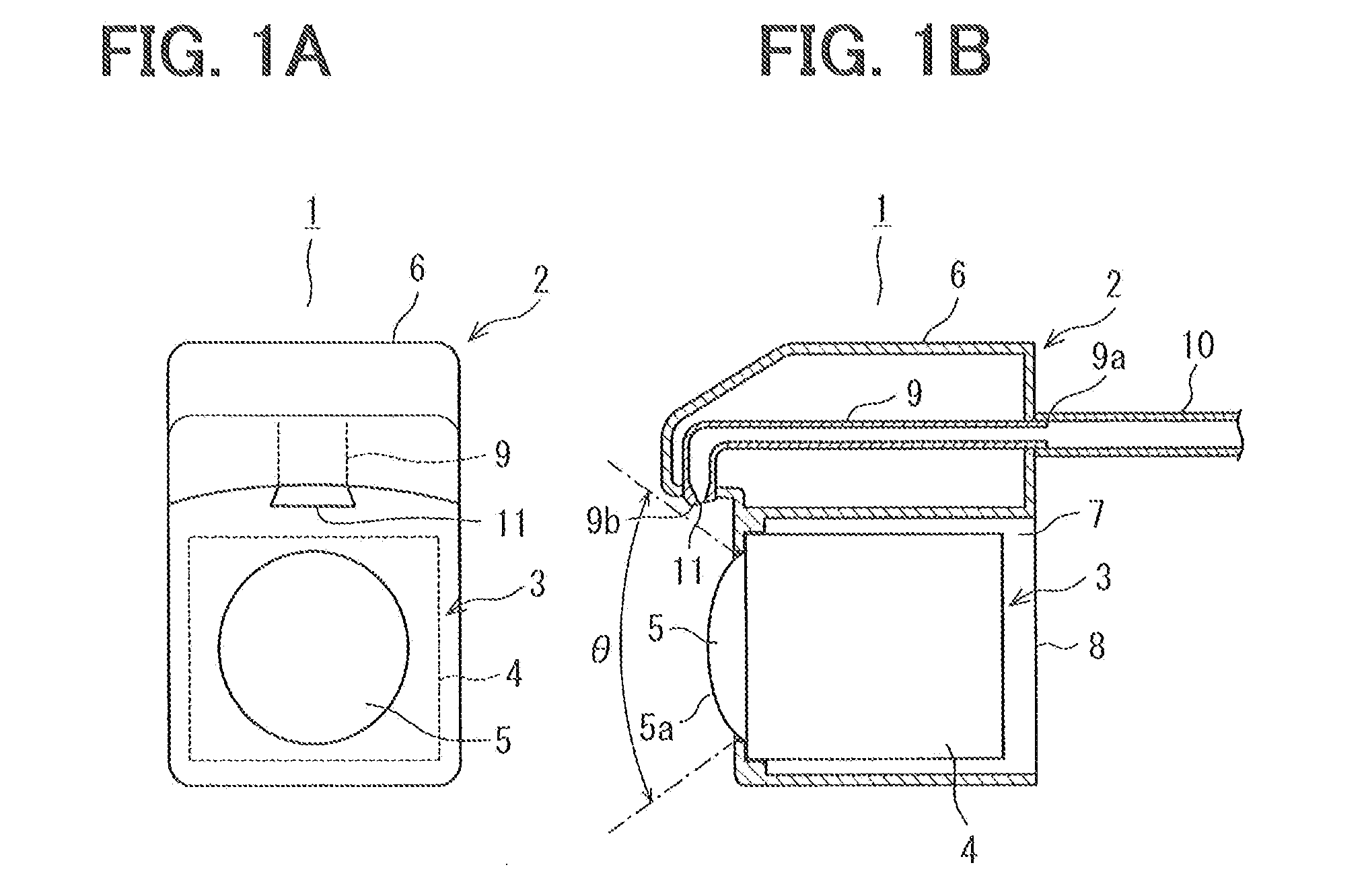

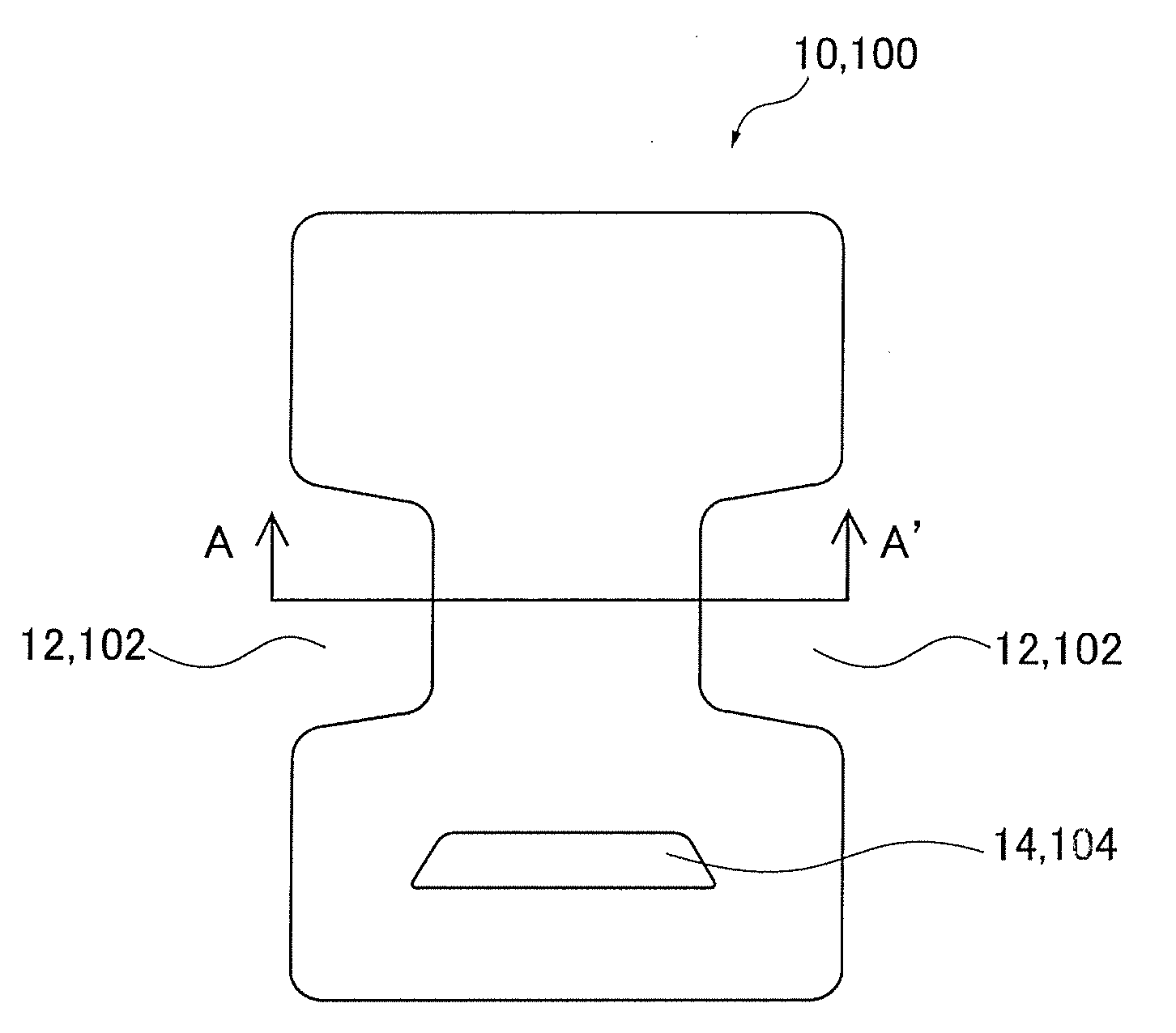

Cover glass for mobile terminals, manufacturing method of the same and mobile terminal device

To provide cover glass for mobile terminals exhibiting high strength in a thin plate thickness state to enable reductions in thickness of apparatuses when inserted in the apparatuses, cover glass (1) for a mobile terminal of the invention is cover glass (1) that is obtained by forming a resist pattern on main surfaces of a plate-shaped glass substrate, then etching the glass substrate with an etchant using the resist pattern as a mask, and thereby cutting the glass substrate into a desired shape and that protects a display screen of the mobile terminal, where an edge face of the cover glass (1) is formed of a molten glass surface, and as surface roughness of the edge face, arithmetic mean roughness Ra is 10 nm or less.

Owner:HOYA CORP

Portable electronic device with two-piece housing

ActiveUS7933123B2Avoid scratchesDisassembled for rework or repair operationsDigital data processing detailsSubstation equipmentEngineeringCover glass

Owner:APPLE INC

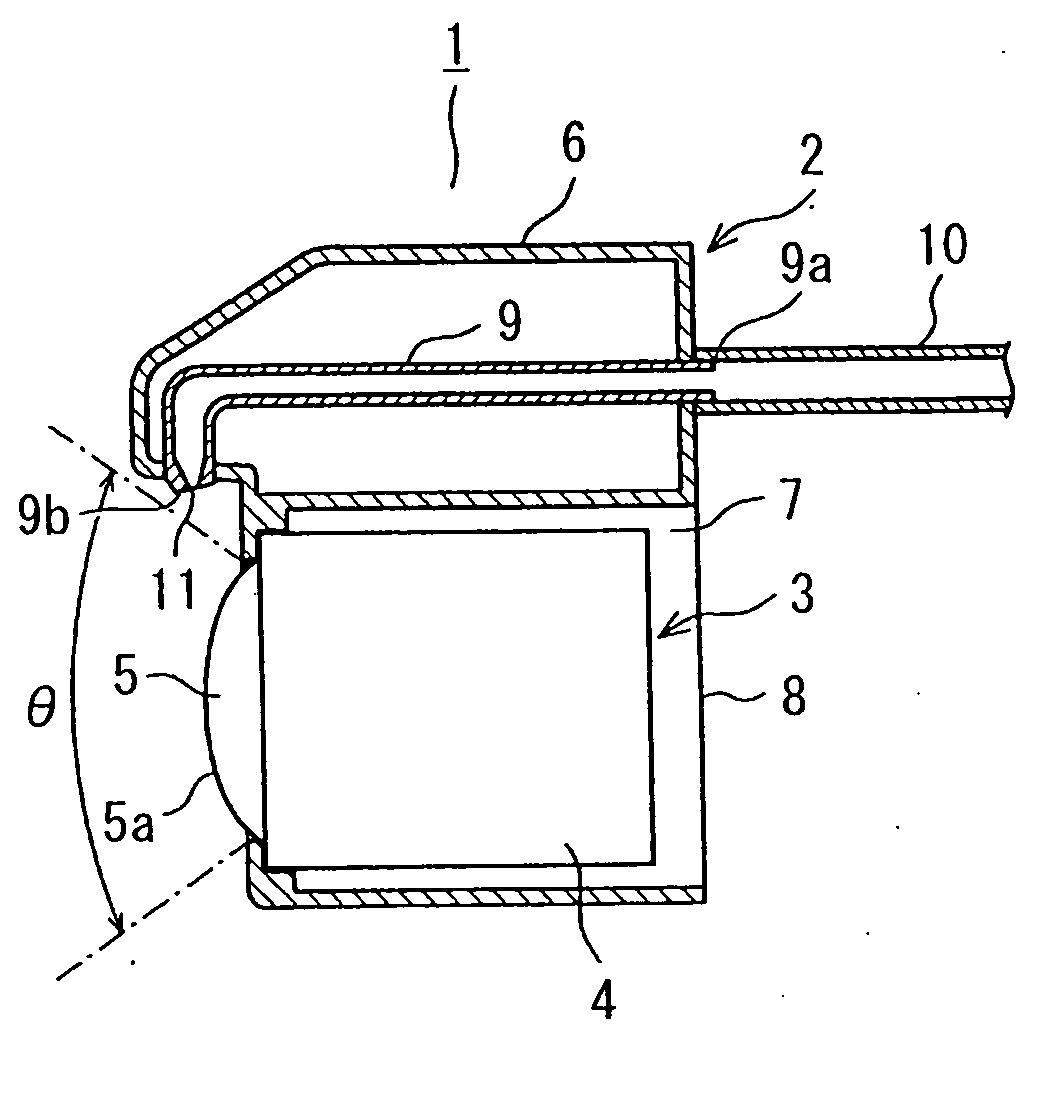

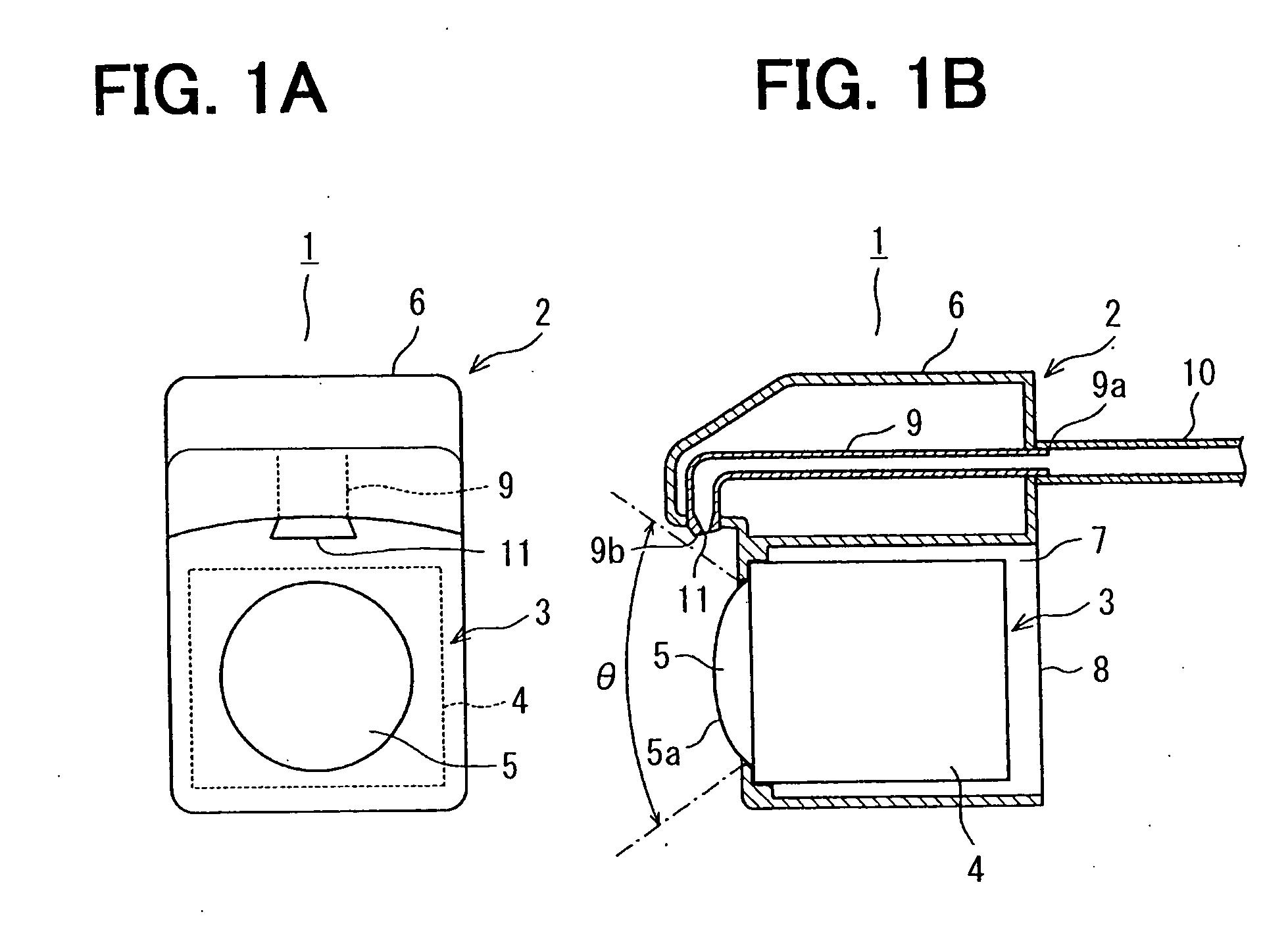

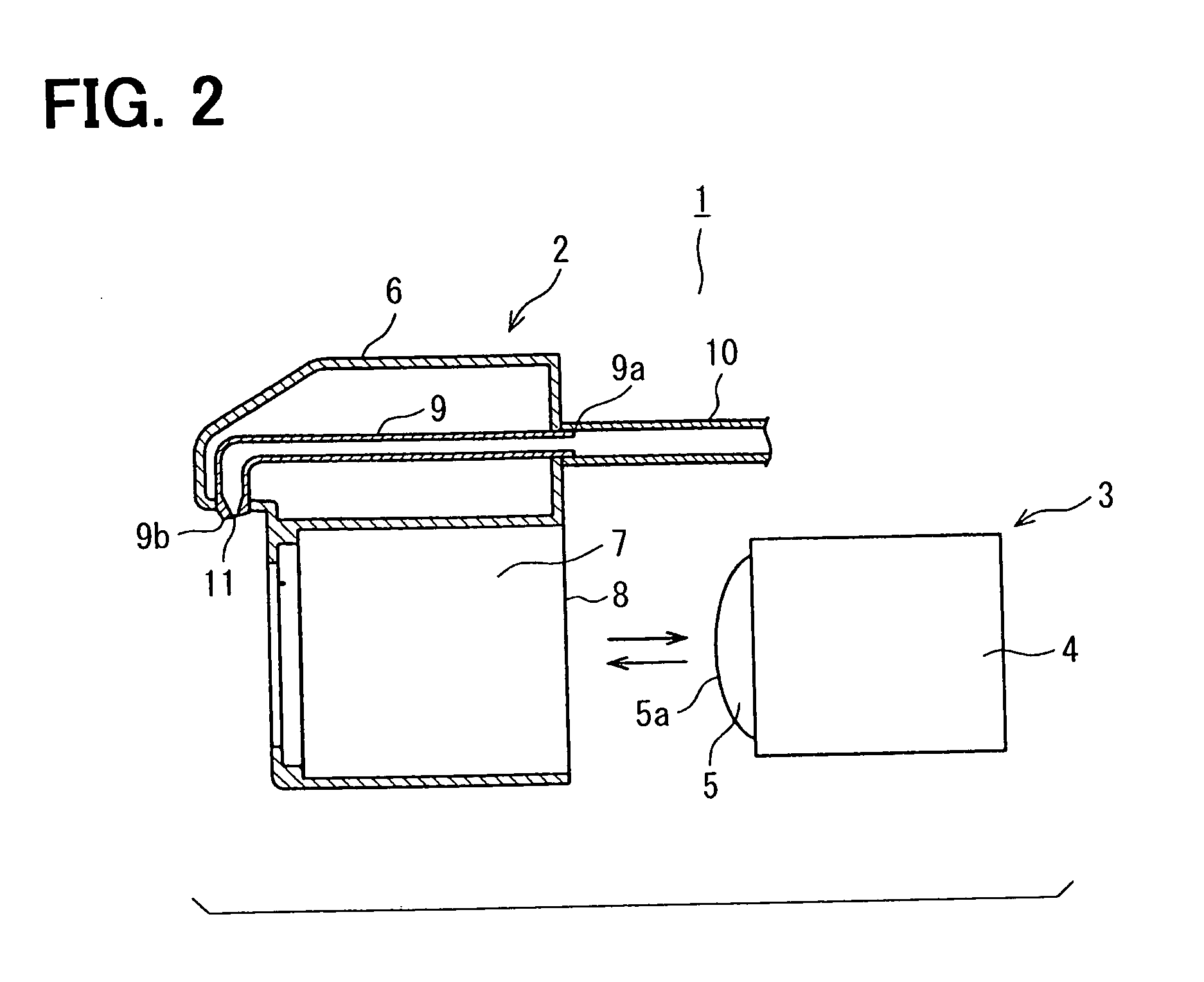

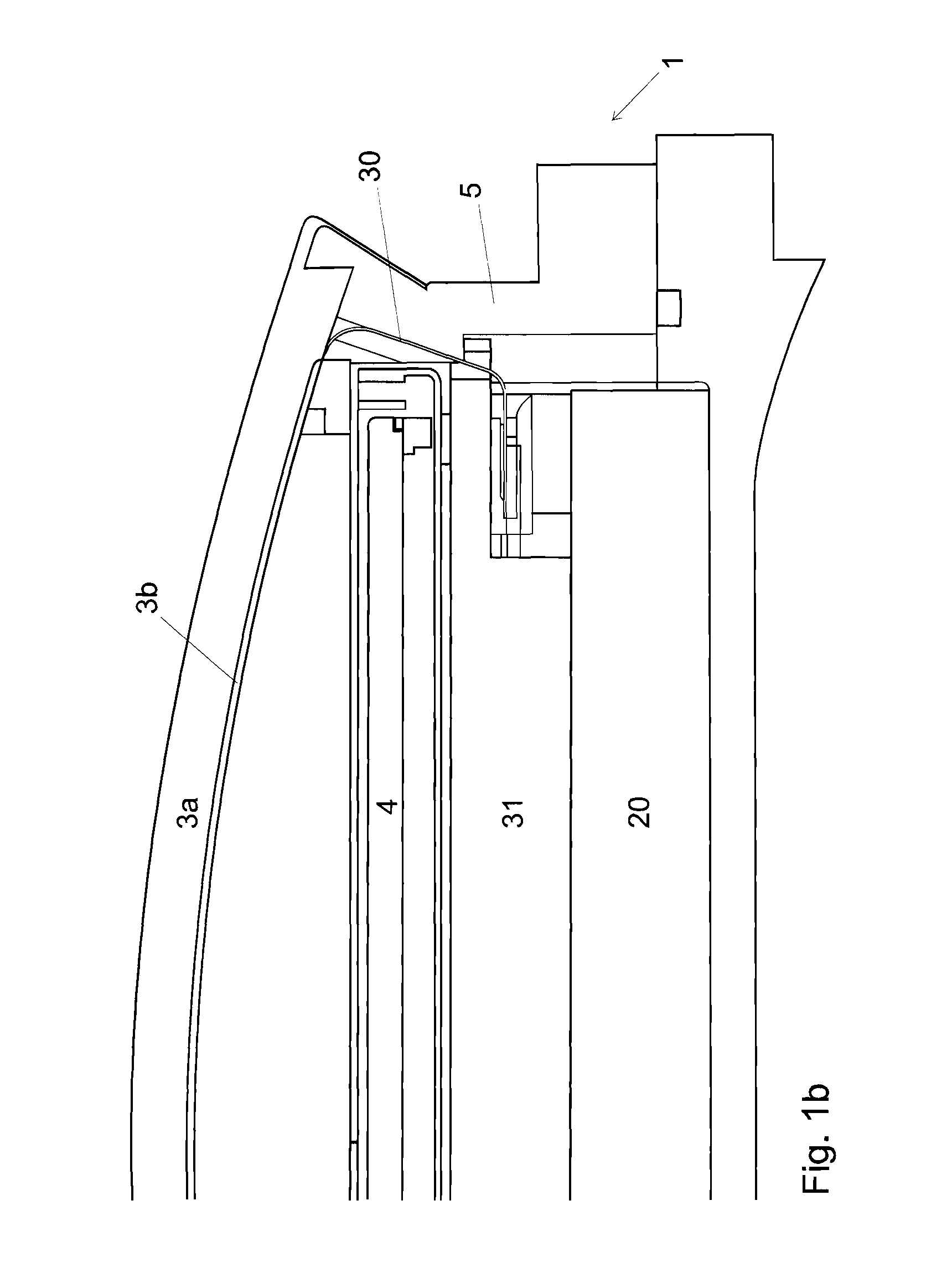

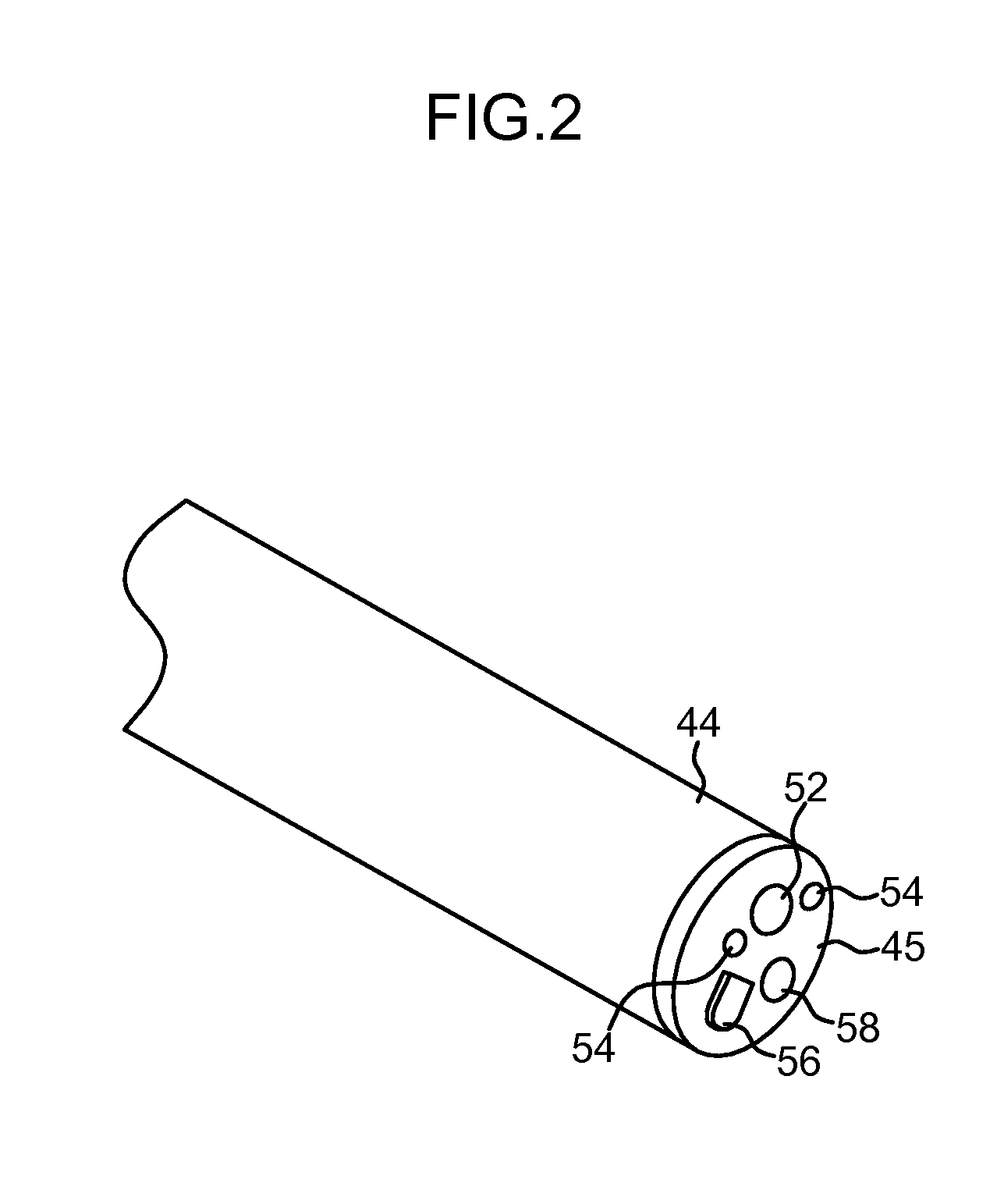

On-board optical sensor cover and on-board optical sensor apparatus

An on-board optical sensor cover includes a holder and a washer nozzle. The holder holds an optical sensor. The optical sensor has a lens and is mounted above a window of a vehicle outside the vehicle. The washer nozzle performs a washing operation to wash a lens surface of the lens of the optical sensor held in the holder or a glass surface of a cover glass located facing the lens if the cover glass exists by spraying a washer fluid, supplied from a washer fluid tank, onto the lens surface or the glass surface. The optical sensor cover is located above the window outside the vehicle so that the washer fluid spayed from the washer nozzle flows to a window surface of the window after washing the lens surface or the glass surface.

Owner:DENSO CORP

Touch Panel Structure

InactiveUS20100164881A1High touch sensing sensitivityImprove reliabilityNon-linear opticsInput/output processes for data processingTouchscreenCover glass

A touch panel structure is provided. The touch panel structure comprises a cover glass, a first transparent electrode and a light shielding element. The cover glass has a touch surface, a sensing surface corresponding to the touch surface, wherein the sensing surface is defined with a center area and a peripheral area surrounding the center area thereon. The first transparent electrode is formed on the cover glass, comes into contact with the sensing surface and is disposed in the center area correspondingly. The light shielding element is formed on the cover glass, comes into contact with the sensing surface and is disposed in the peripheral area correspondingly.

Owner:AU OPTRONICS CORP

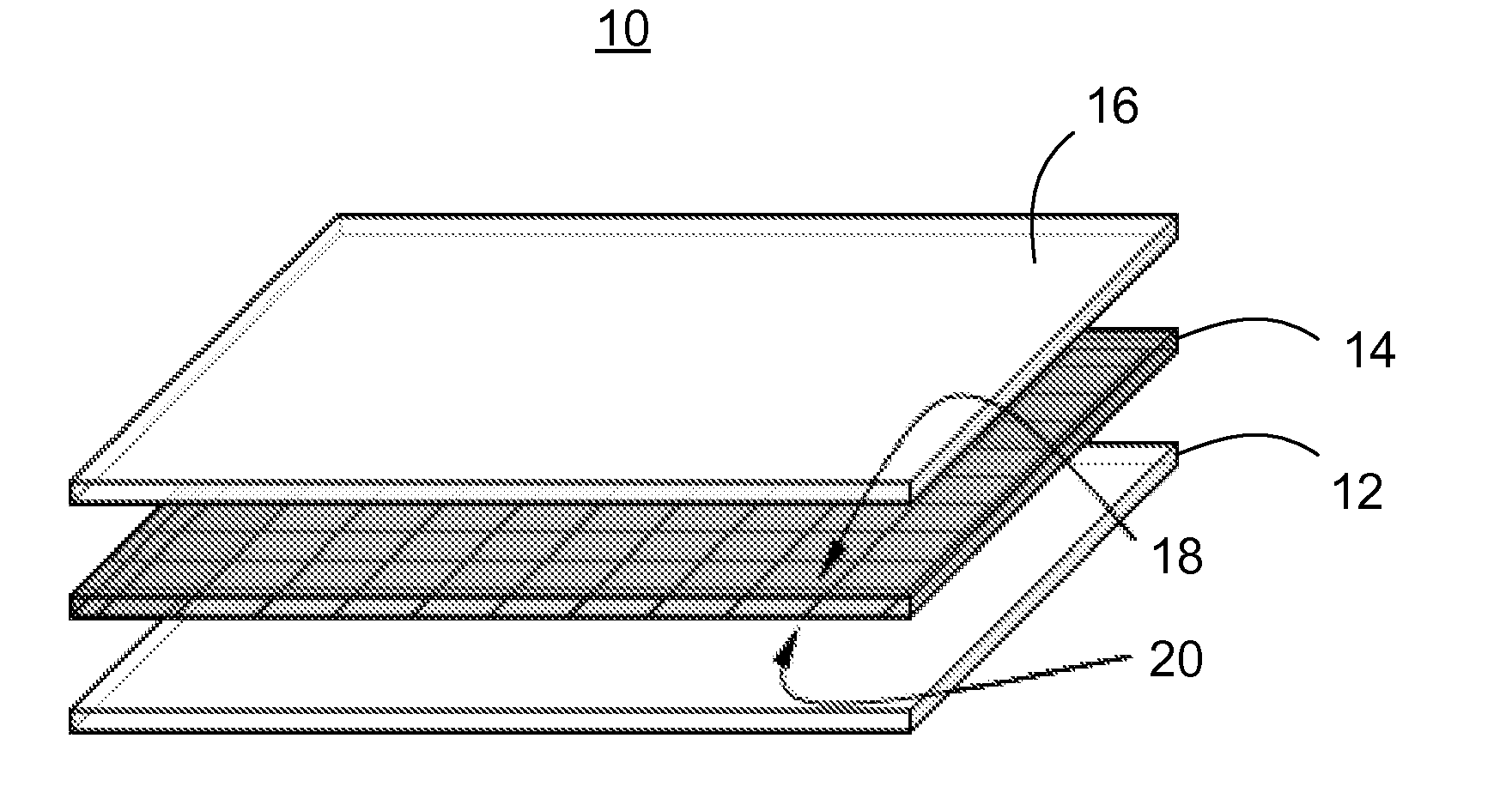

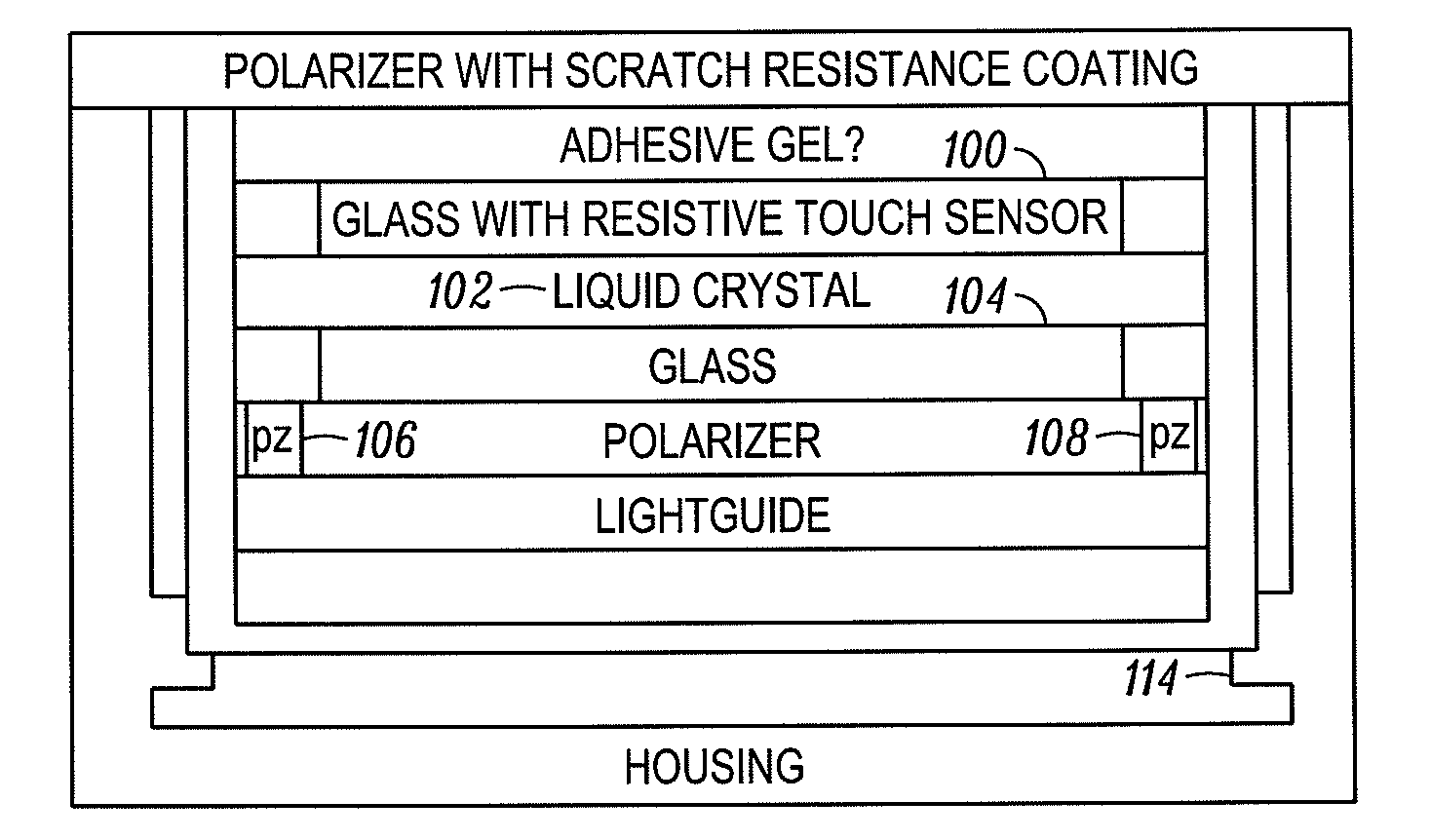

Methods and apparatus for providing touch sensitive displays

InactiveUS20110102346A1Lamination ancillary operationsStatic indicating devicesCover glassDistortion

Methods and apparatus provide for a touch sensitive display, which may include: a display layer; a cover glass layer formed from ion exchanged glass; and an optional touch glass layer, where, either on a first side of the touch glass or on a first side of the cover glass, a grid of electrode traces is disposed, which is sensitive to distortions of a local electrostatic field caused by a touching event, and the grid may be positioned between the display layer and the cover glass layer.

Owner:CORNING INC

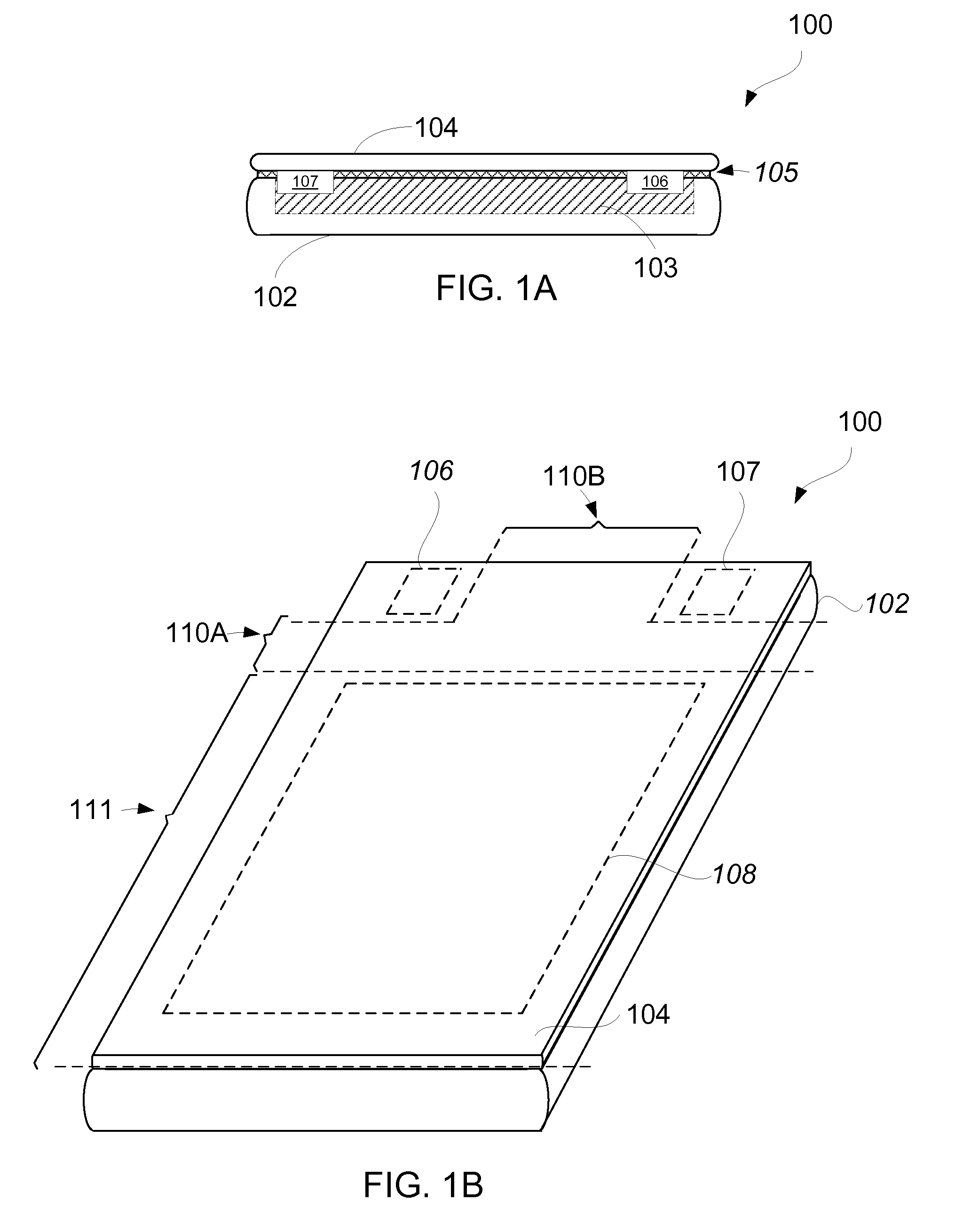

Glass substrate for display cover glass and its production process

ActiveUS20120219792A1High strengthImprove antibacterial propertiesRecord information storageMagnetic recordingTransmittanceDisplay device

To provide a glass substrate for a display cover glass not only having excellent strength and antibacterial properties but also having a high transparency and a high visible transmittance suitable as a cover glass for a display device. A glass substrate for a display cover glass, which comprises a surface compressive stress layer and an antibacterial substance-containing layer formed on the glass substrate surface, characterized by having a ratio (T1 / T2) of the transmittance T1 at a wavelength of 428 nm to the transmittance T2 at a wavelength of 650 nm of the glass substrate of at least 0.95, and a transmittance at a wavelength of 428 nm of at least 86% when the thickness of the glass substrate is from 0.1 to 3.0 mm.

Owner:ASAHI GLASS CO LTD

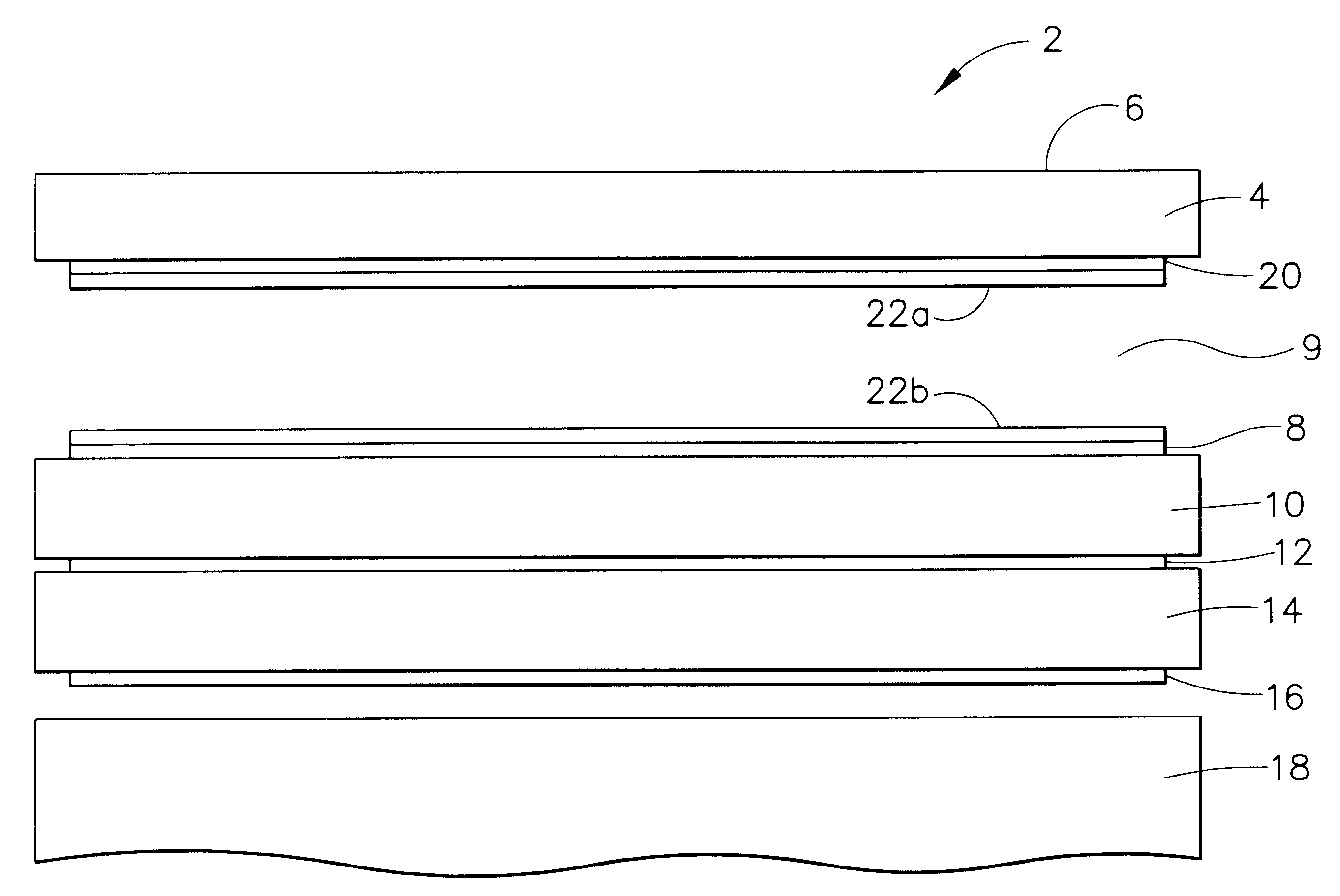

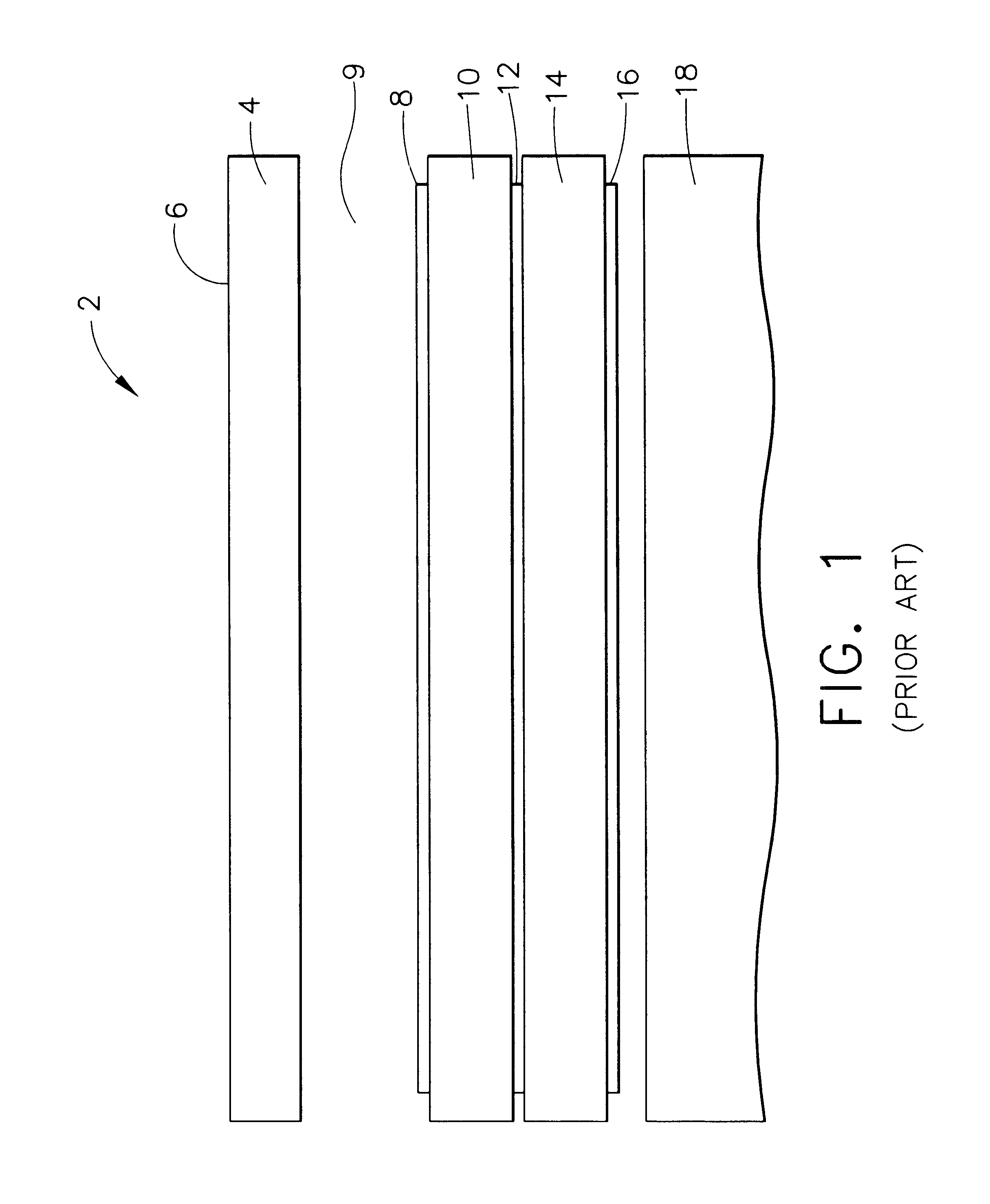

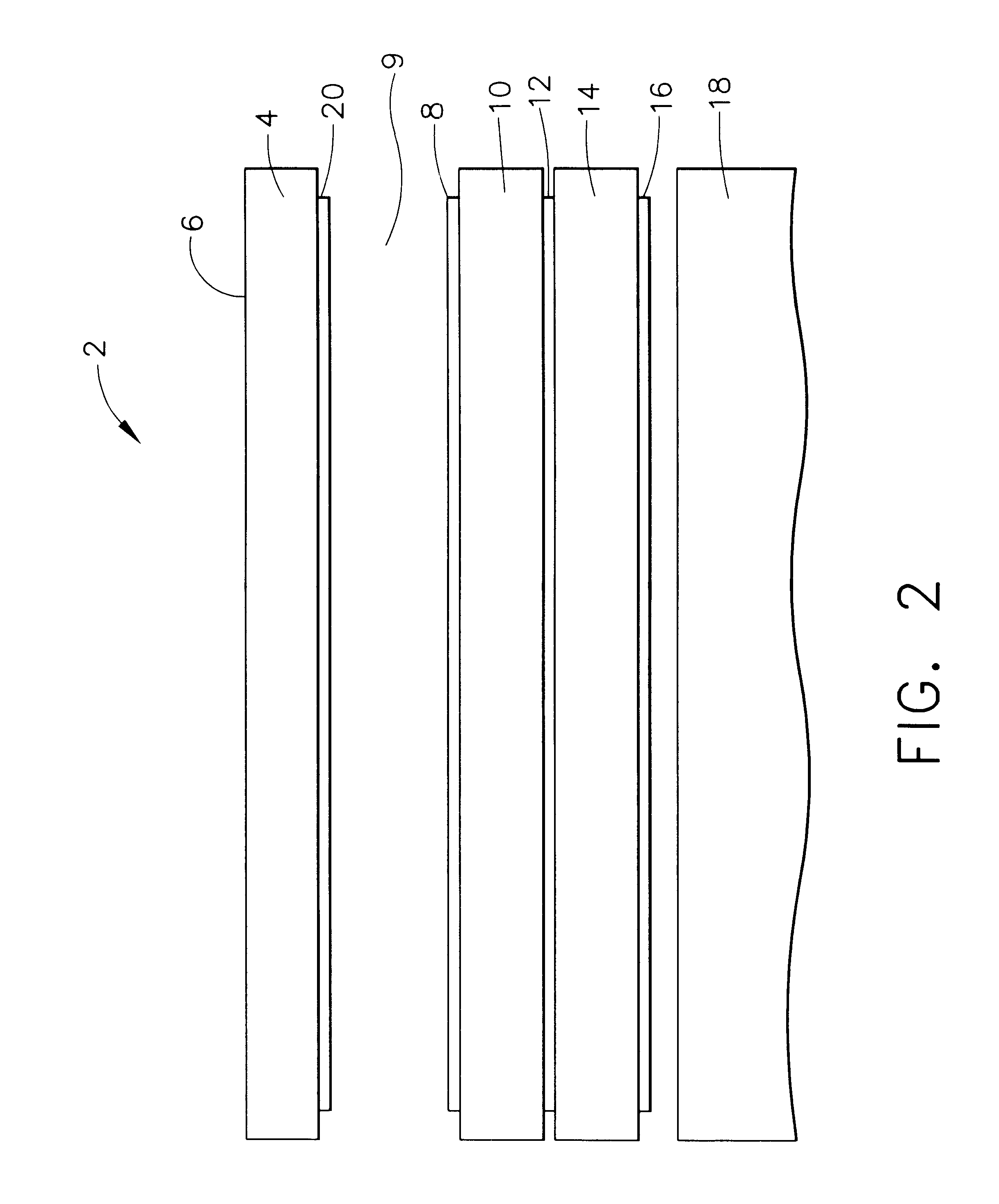

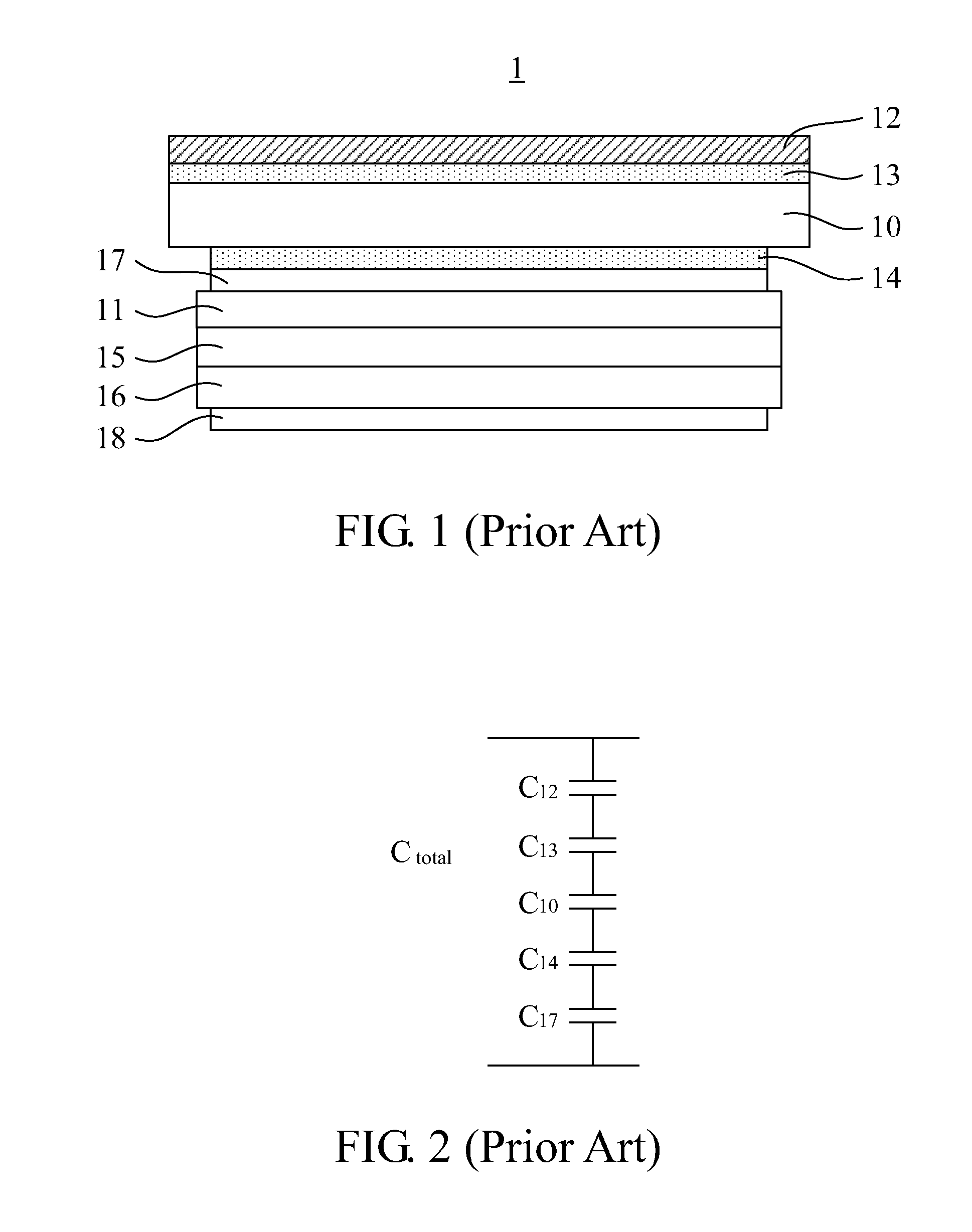

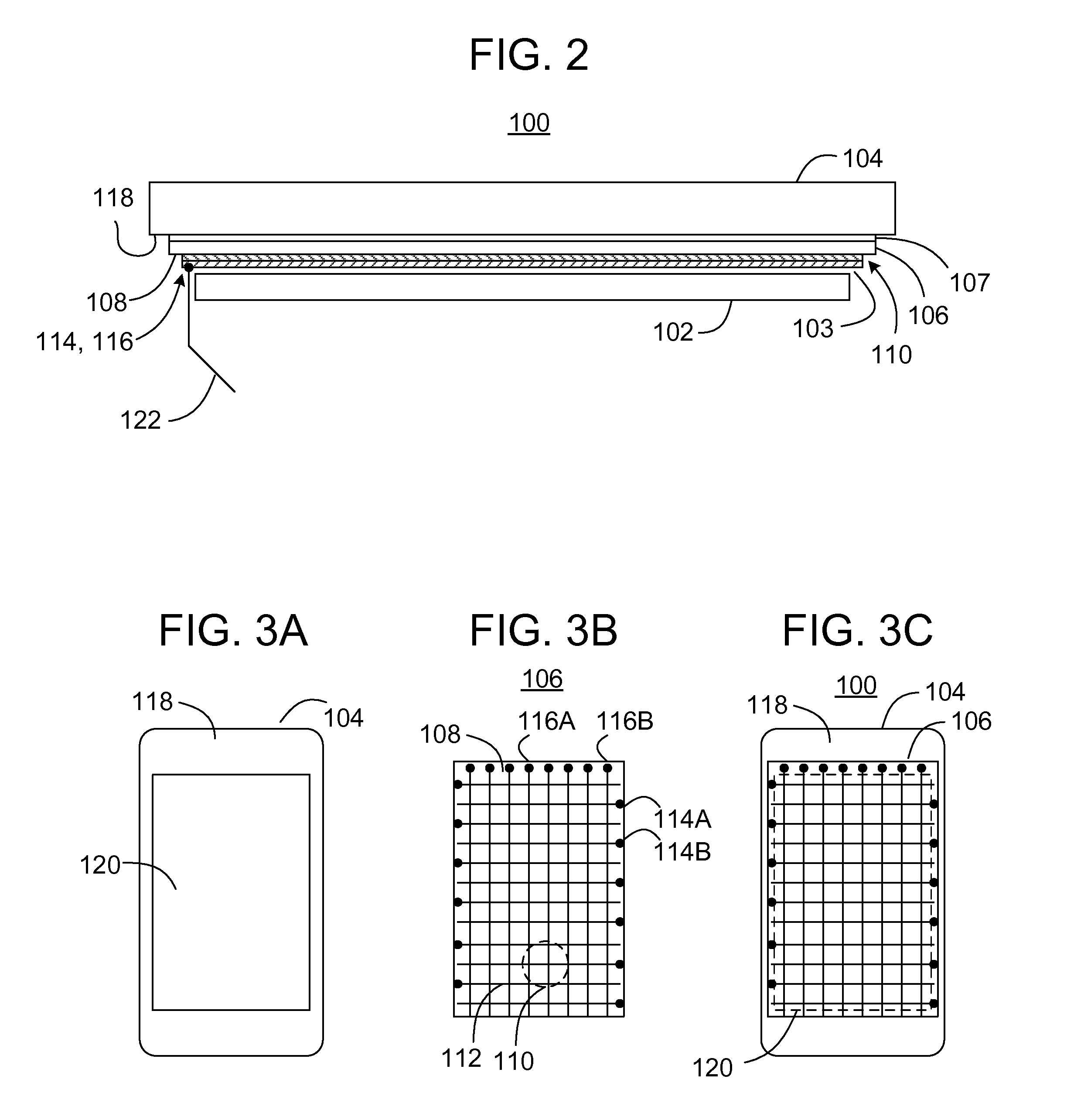

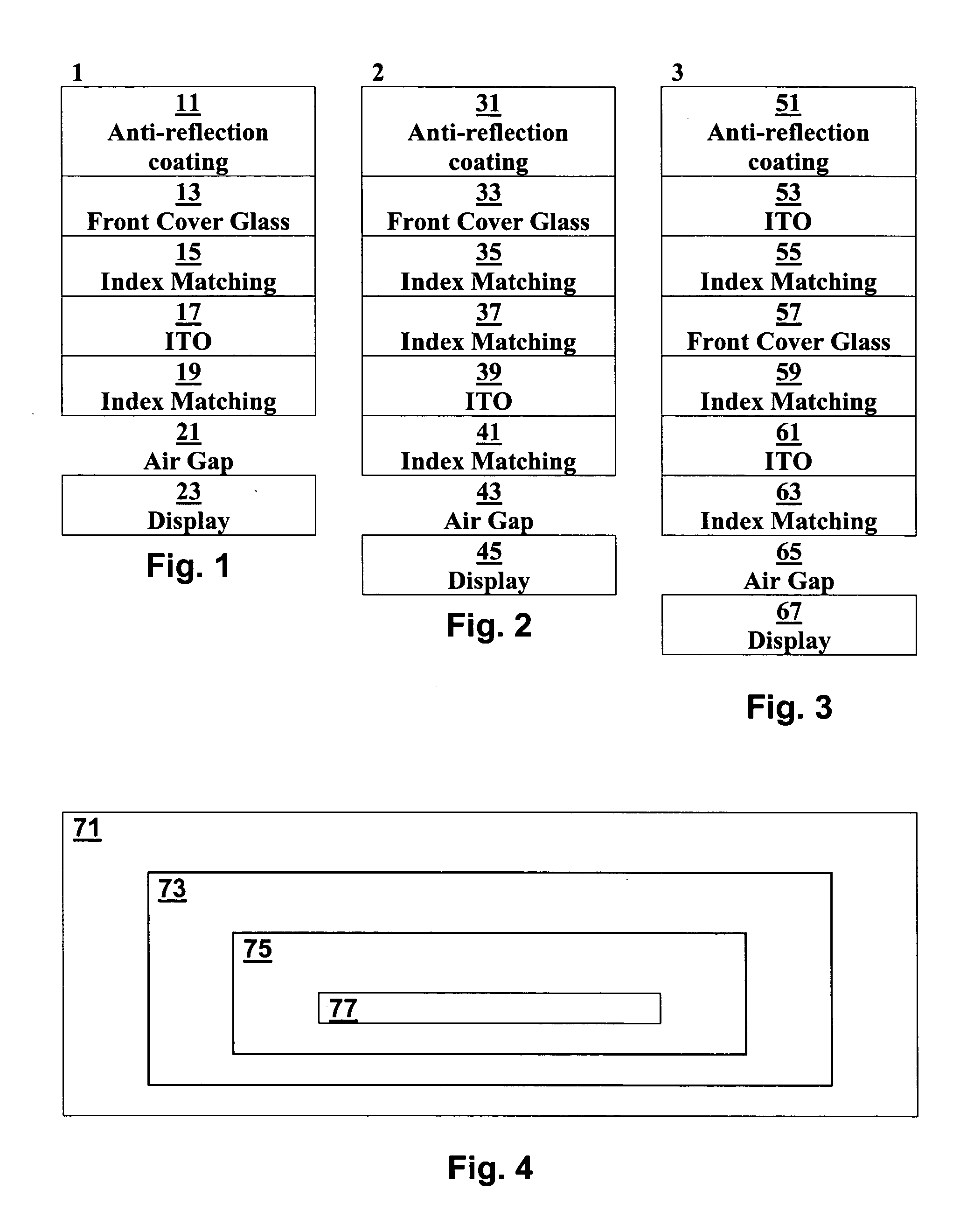

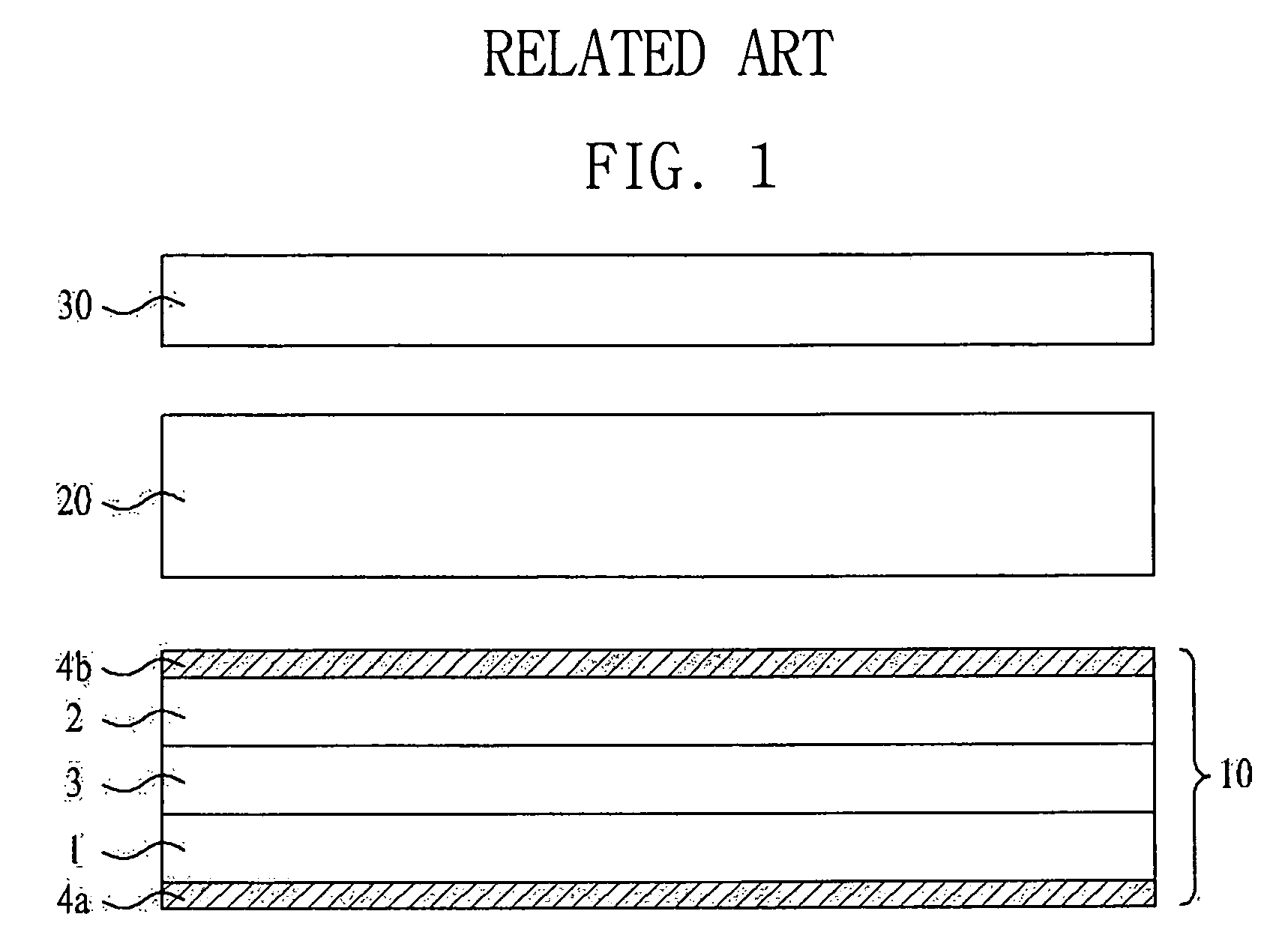

Optical compensation of cover glass-air gap-display stack for high ambient lighting

Apparatus and methods relating to display stacks wherein one or more index matching layers are utilized to minimize reflectance at the boundaries of otherwise adjacent layers. More particularly, the present invention is directed to methods and apparatus relating to a multilayer display stack comprising a glass layer, a first index matching layer, a first intermediate layer, a second index matching layer, a second intermediate layer, and a light emitting display panel wherein: the glass layer, first index matching layer, first intermediate layer, second index matching layer, and second intermediate layer are each transparent or translucent, and comprise an index of refraction; the index of refraction of the first index matching layer is between the index of refraction of the glass layer and the first intermediate layer; and the index of refraction of the second index matching layer is between the index of refraction of the first intermediate layer and the second intermediate layer. Alternative embodiments may comprise additional index matching layers, additional non-index matching layers, as well as layers other than those described herein.

Owner:NORTHROP GRUMMAN SYST CORP +1

Shaping a cover glass

ActiveUS20090090694A1Pleasing shapeTransmission systemsDecorative surface effectsEngineeringAnisotropic etching

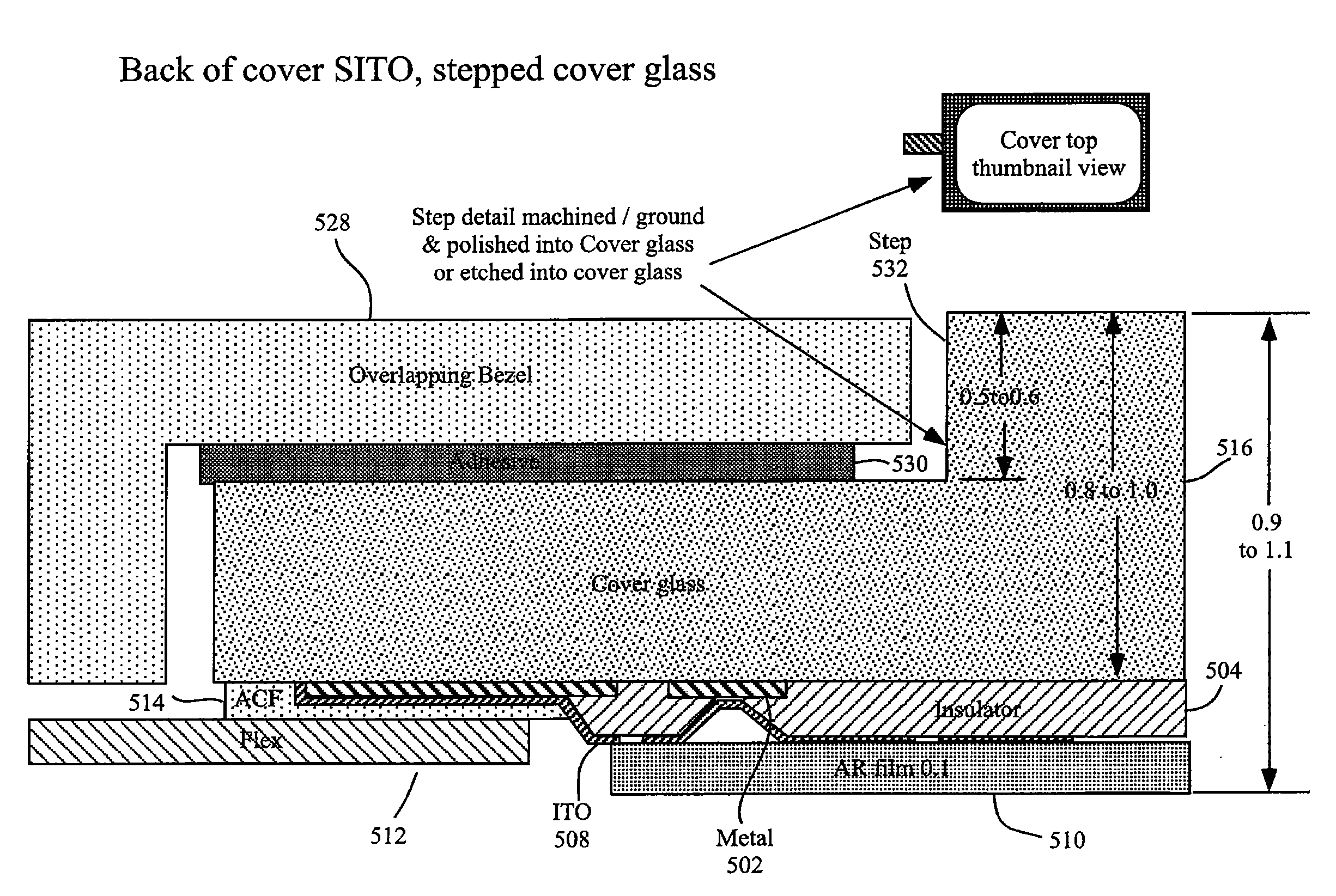

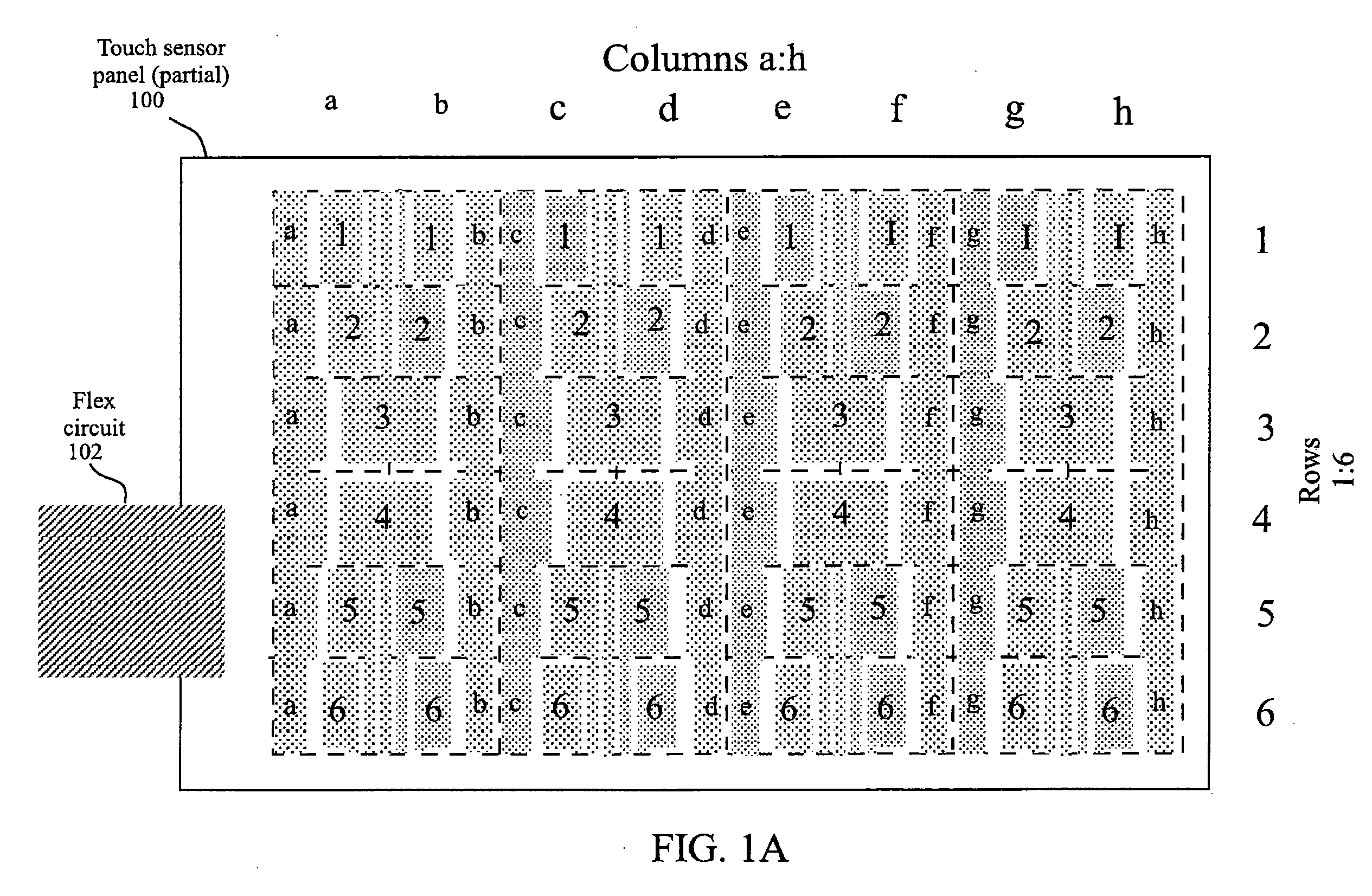

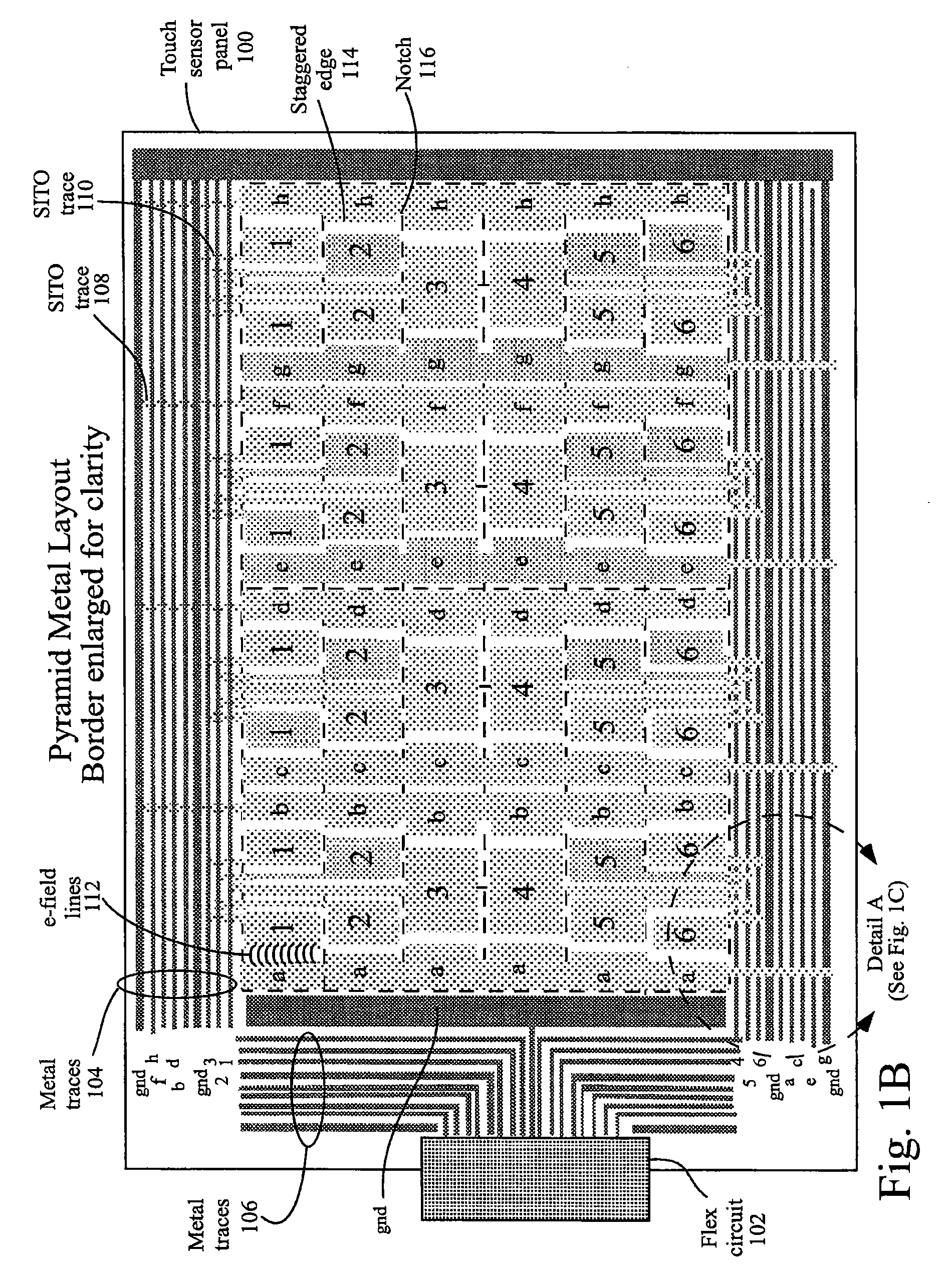

The fabrication of a touch sensor panel having co-planar single-layer touch sensors fabricated on the back side of a cover glass is disclosed. It can be desirable from a manufacturing perspective to perform all thin-film processing steps on a motherglass before separating it into separate parts. To perform thin-film processing on a motherglass before separation, a removable sacrificial layer such as a photoresist can be applied over the thin-film layers. Next, the motherglass can be scribed and separated, and grinding and polishing steps can be performed prior to removing the sacrificial layer. In alternative embodiments, after the protective sacrificial layer is applied, the bulk of the coverglass can be dry-etched using a very aggressive anisotropic etching that etches primarily in the z-direction. In this embodiment, the etching can be patterned using photolithography to create rounded corners or any other shape. The photoresist can then be removed.

Owner:APPLE INC

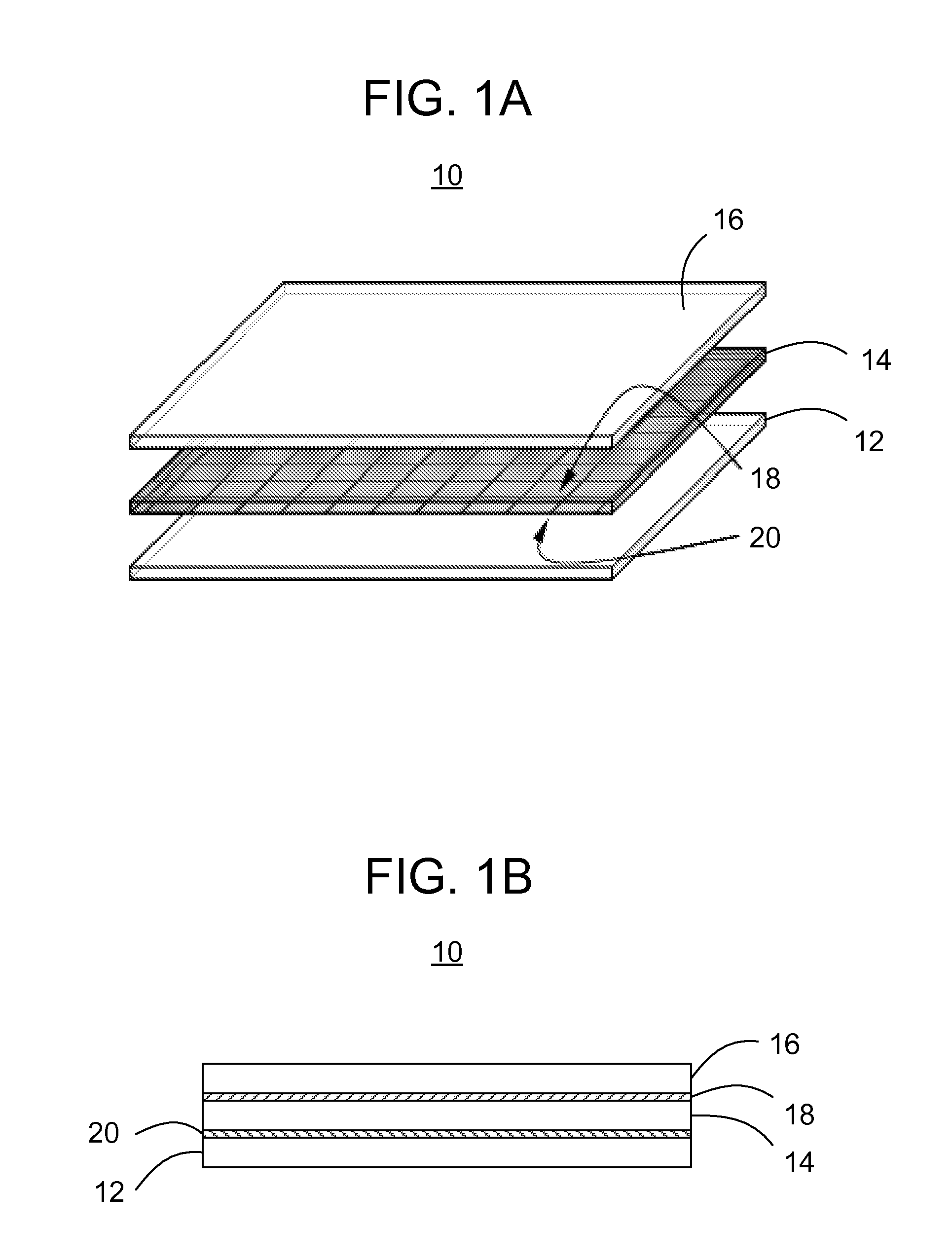

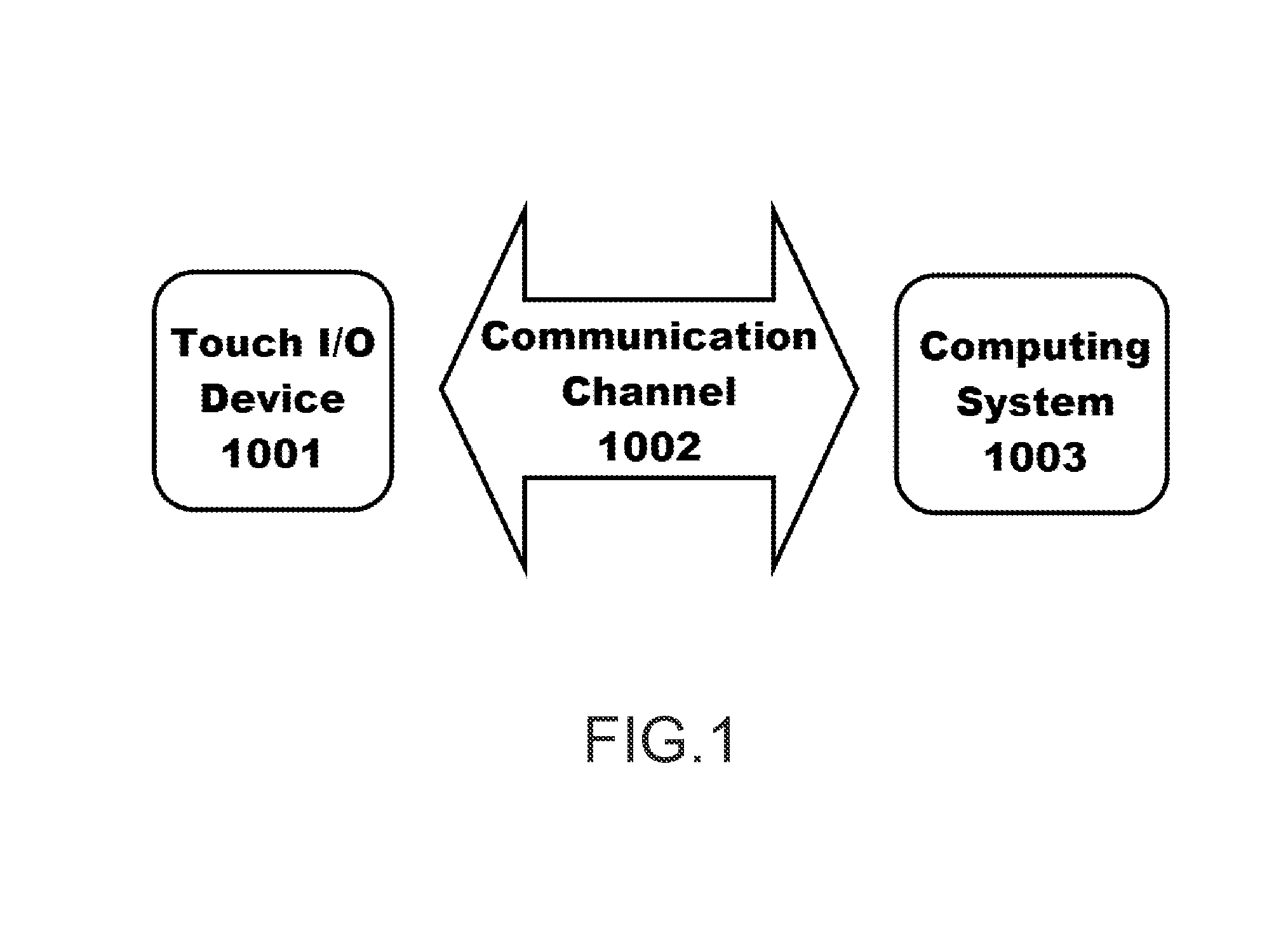

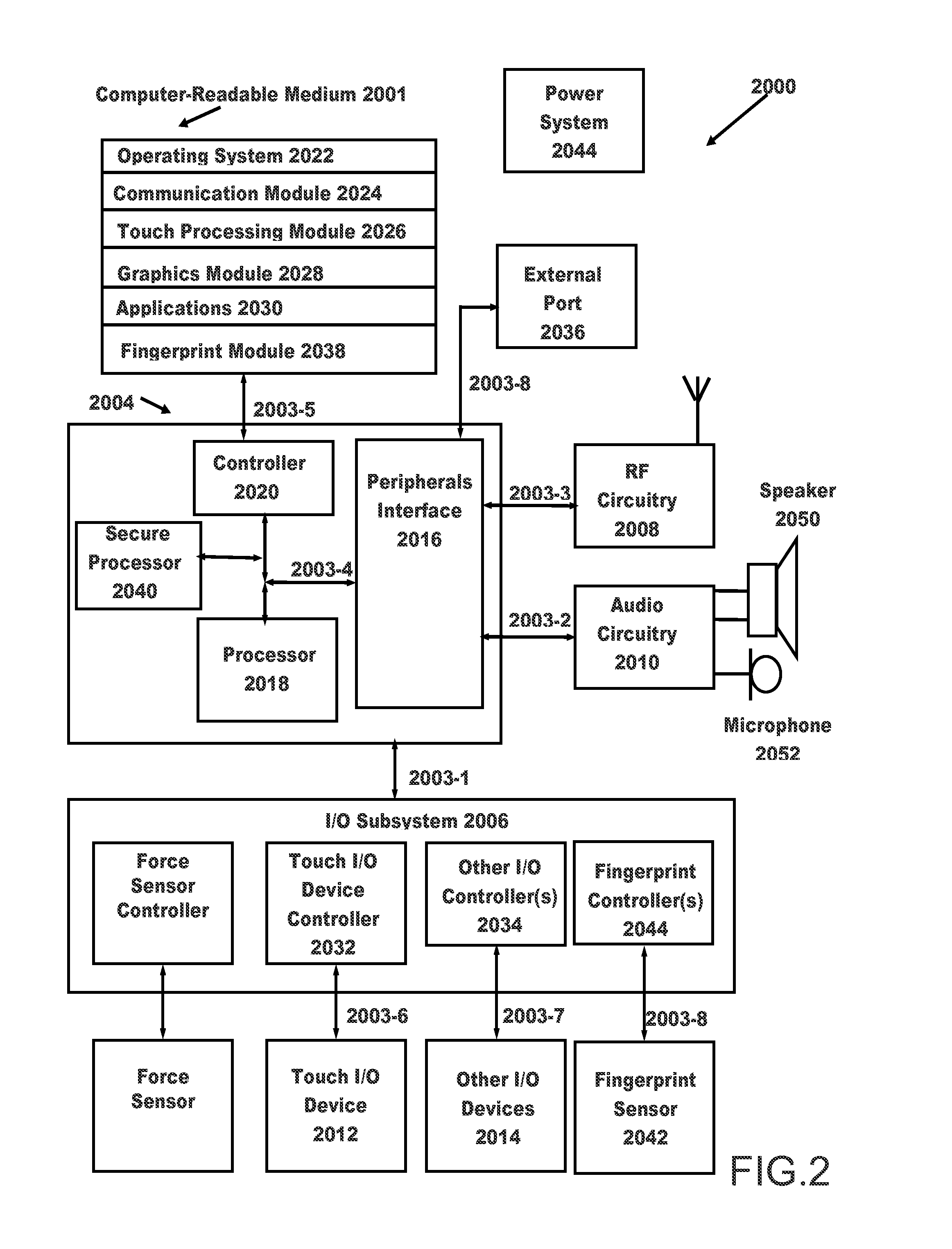

Force Sensing Using Bottom-Side Force Map

A force sensor incorporated into a touch device, measuring deflection in a device stack, including compressible elements disposed between the device stack and the frame element. When the device stack is deformed, applied force is measured using the compressible elements, using capacitive sensing or strain measurements. The force sensitive sensor provides an applied force image for the touch device's surface. The applied force location [X, Y] can be determined from measures of cover glass tilt, force at particular points, and capacitive sensing of touch location.

Owner:APPLE INC

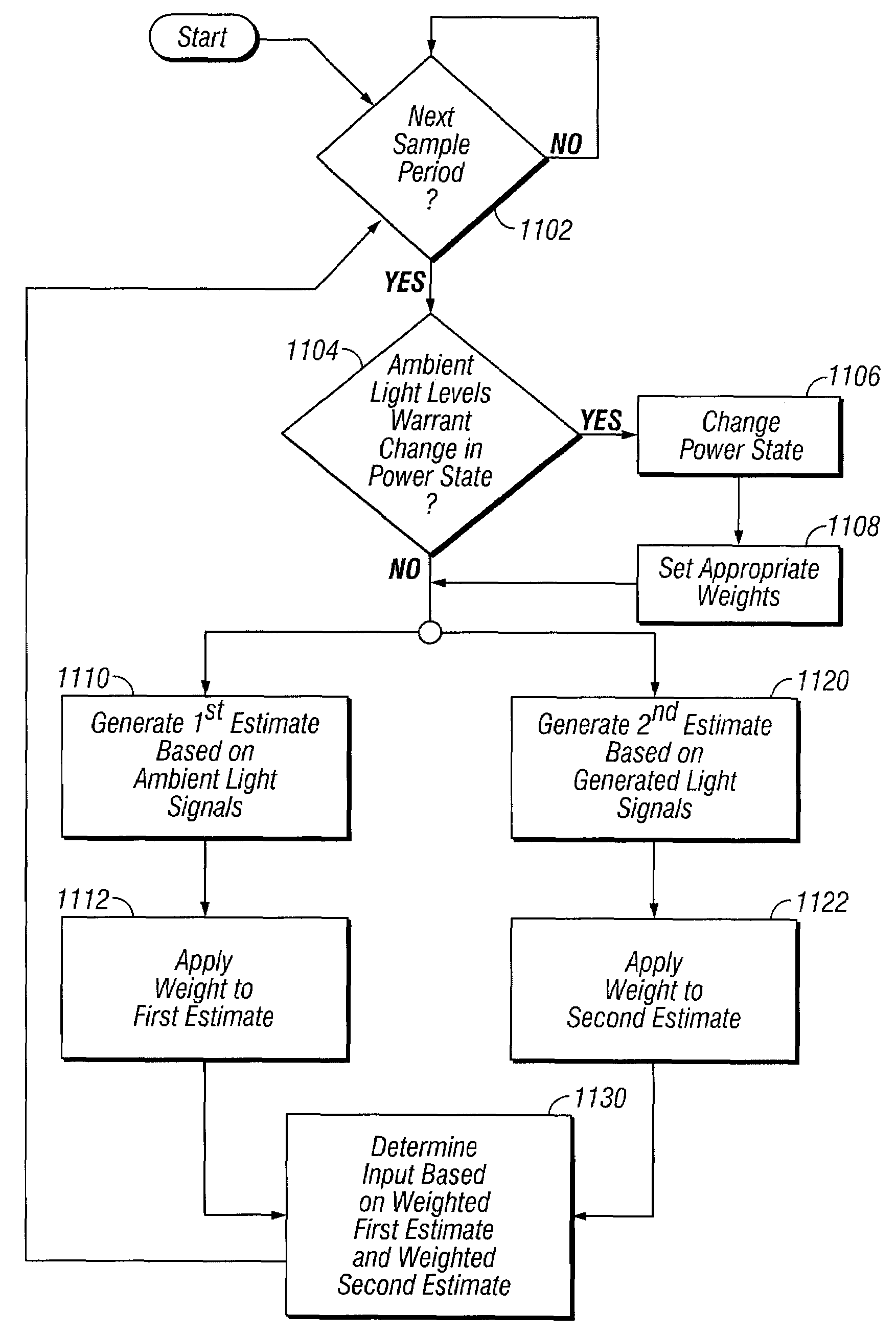

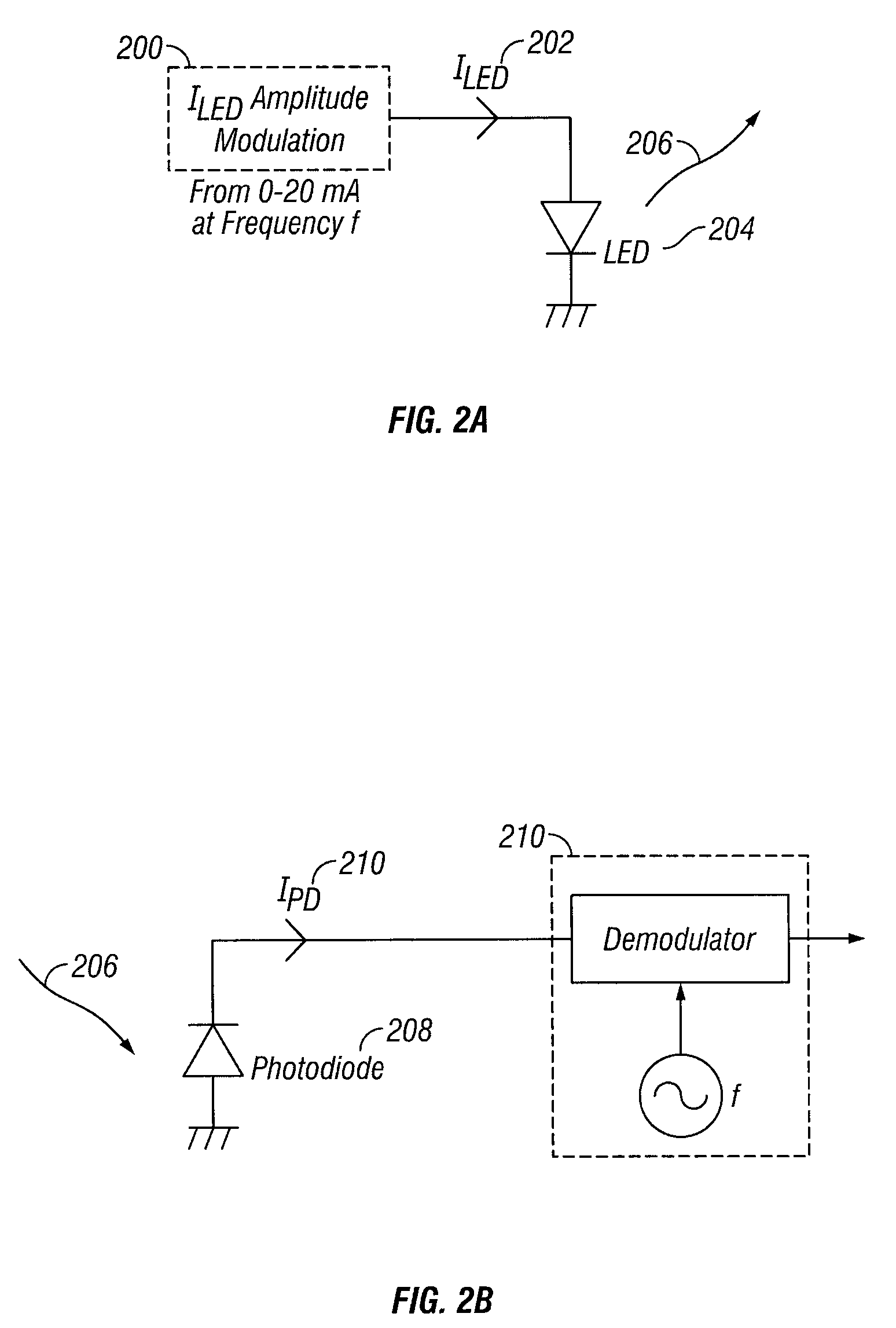

Ambient light interference reduction for optical input devices

InactiveUS20100001978A1Avoid volatilityReduce lightInput/output processes for data processingDisplay deviceEngineering

Methods and apparatus for preventing fluctuations in ambient light from affecting the optical input mechanism of a liquid crystal display device. In one embodiment, an independent light source is adapted to generate electromagnetic signals through the cover glass of the display device. When the user's finger is proximate to a certain region of the touch panel, the electromagnetic signals reflect off of the user's finger and back through the cover glass. One or more photosensors monitoring the presence of these reflected signals service the various regions on the touch panel where input may be detected. Thus, when the reflected signals are detected at a certain region, the user's finger may be assumed to be present.

Owner:APPLE INC

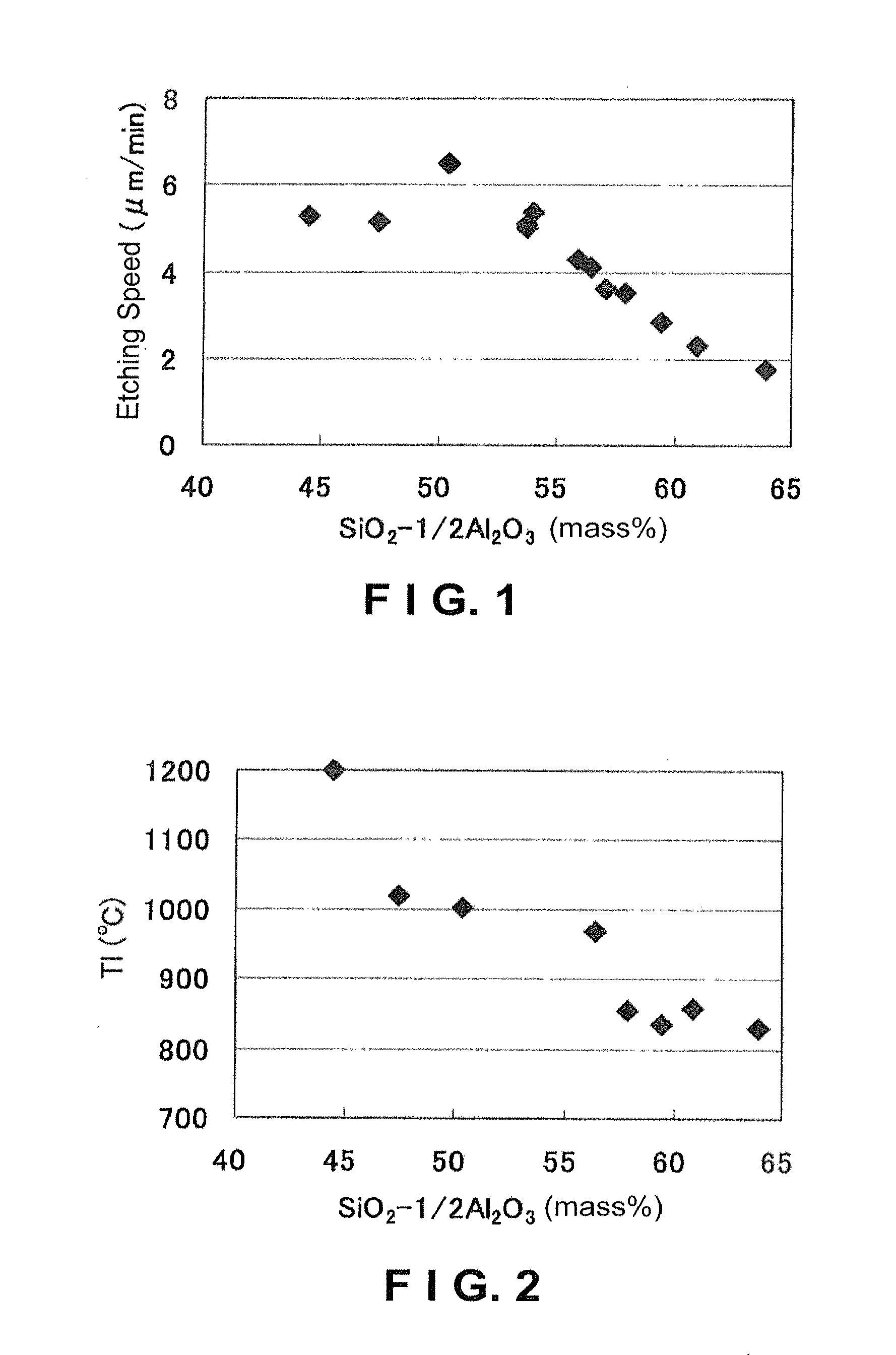

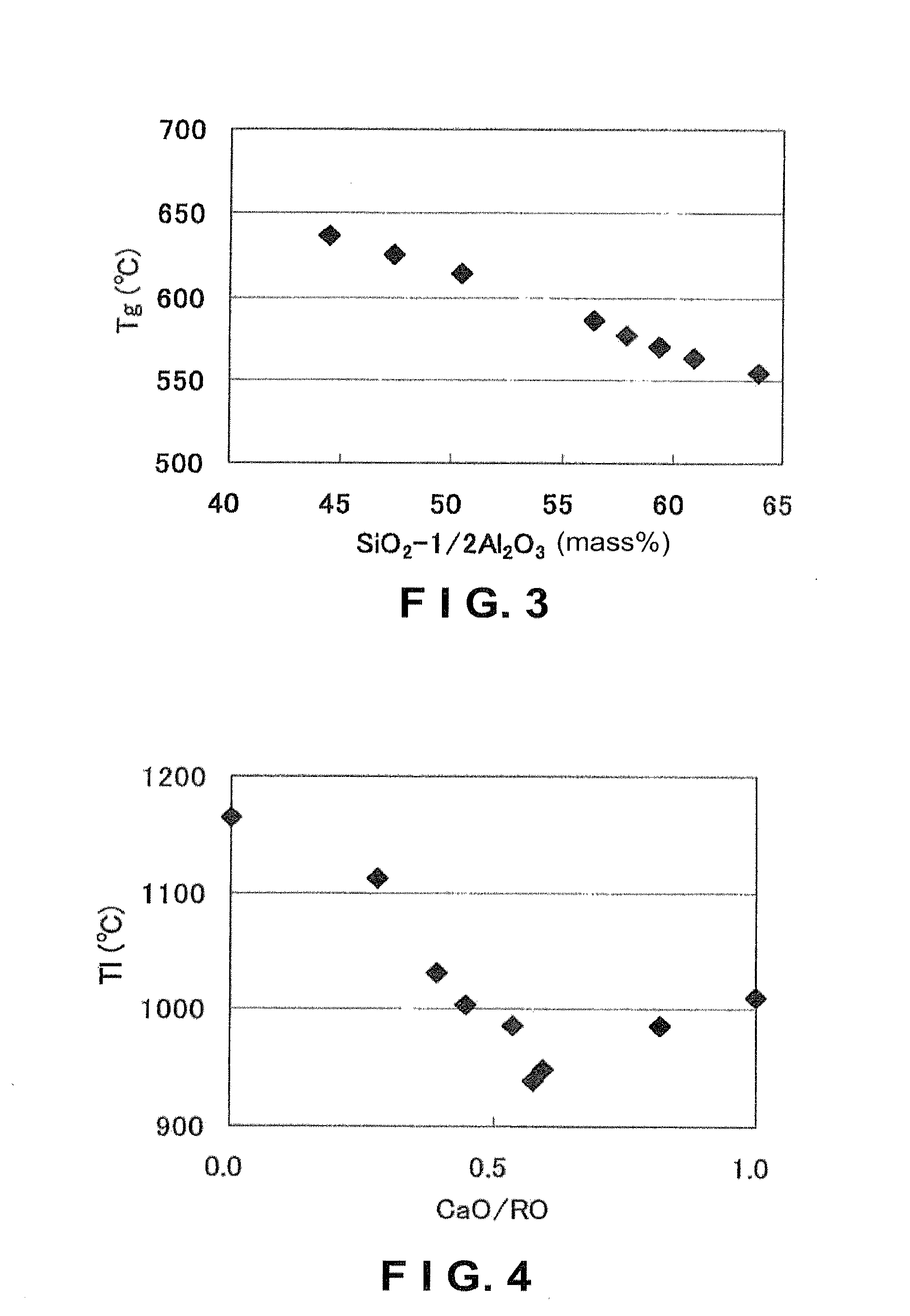

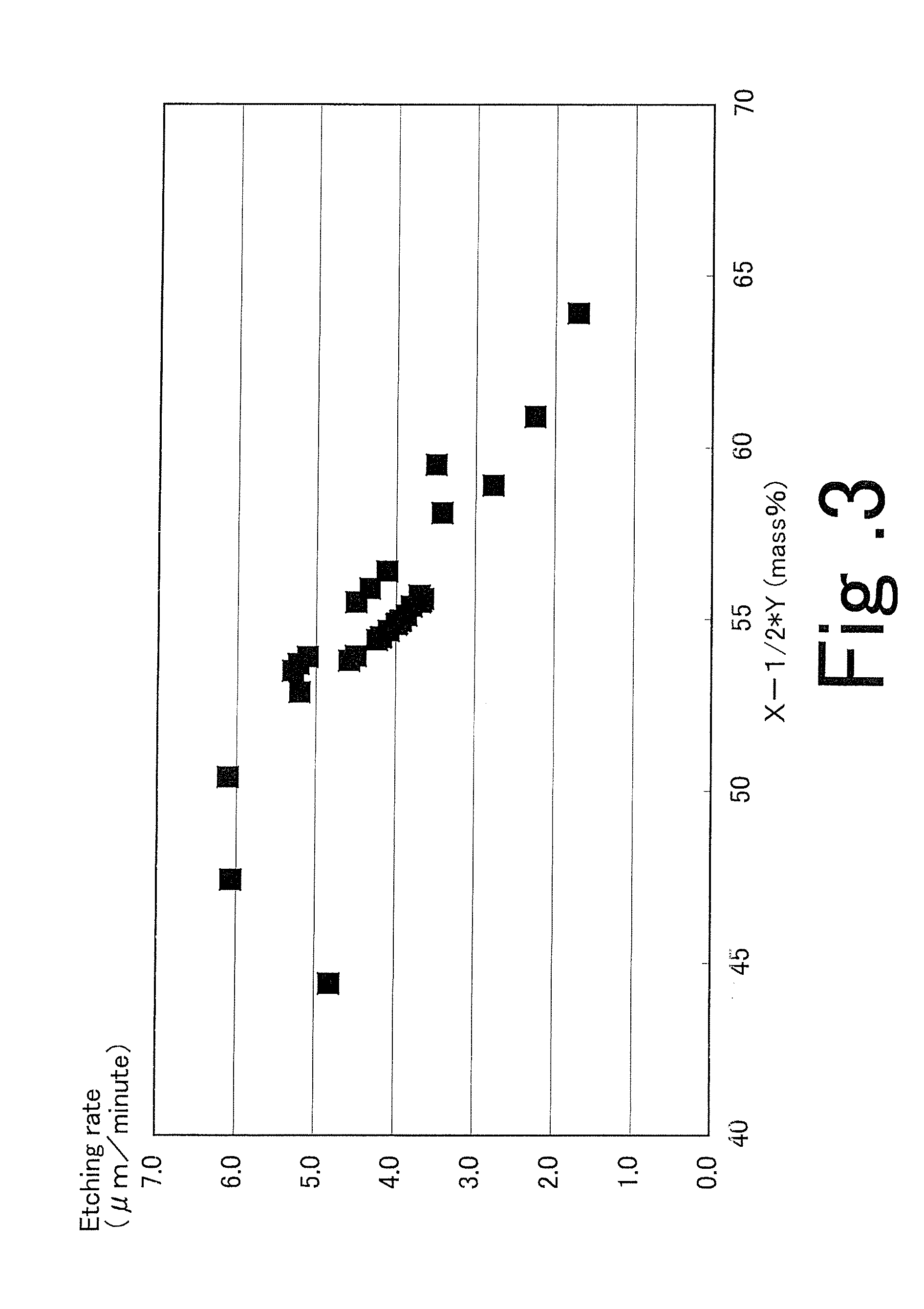

Glass substrate, chemically strengthened glass substrate and cover glass, and method for manufactruing the same

InactiveUS20120052275A1Etching speed is fastIncrease productionGlass drawing apparatusGlass forming apparatusCover glassChemistry

Provided is a cover glass having a down-drawable composition including, in mass percent: 50%-70% SiO2, 5%-20% Al2O3, 6%-20% Na2O, 0%-10% K2O, 0%-10% MgO, above 2%-20% CaO, and 0%-4.8% ZrO2 wherein, (i) 46.5%≦(SiO2−½Al2O3)≦59%, (ii) 0.3<CaO / RO, where RO represents a total mass percent of one or more compounds selected from the group consisting of MgO, CaO, SrO and BaO included in the glass substrate, (iii) SrO+BaO<10%, (iv) 0≦(ZrO2+TiO2) / SiO2)<0.07, and (v) 0≦B2O3 / R12O<0.1, where R12O represents a total mass percent of one or more compounds selected from the group consisting of Li2O, Na2O and K2O included in the glass substrate.

Owner:HOYA CORP +1

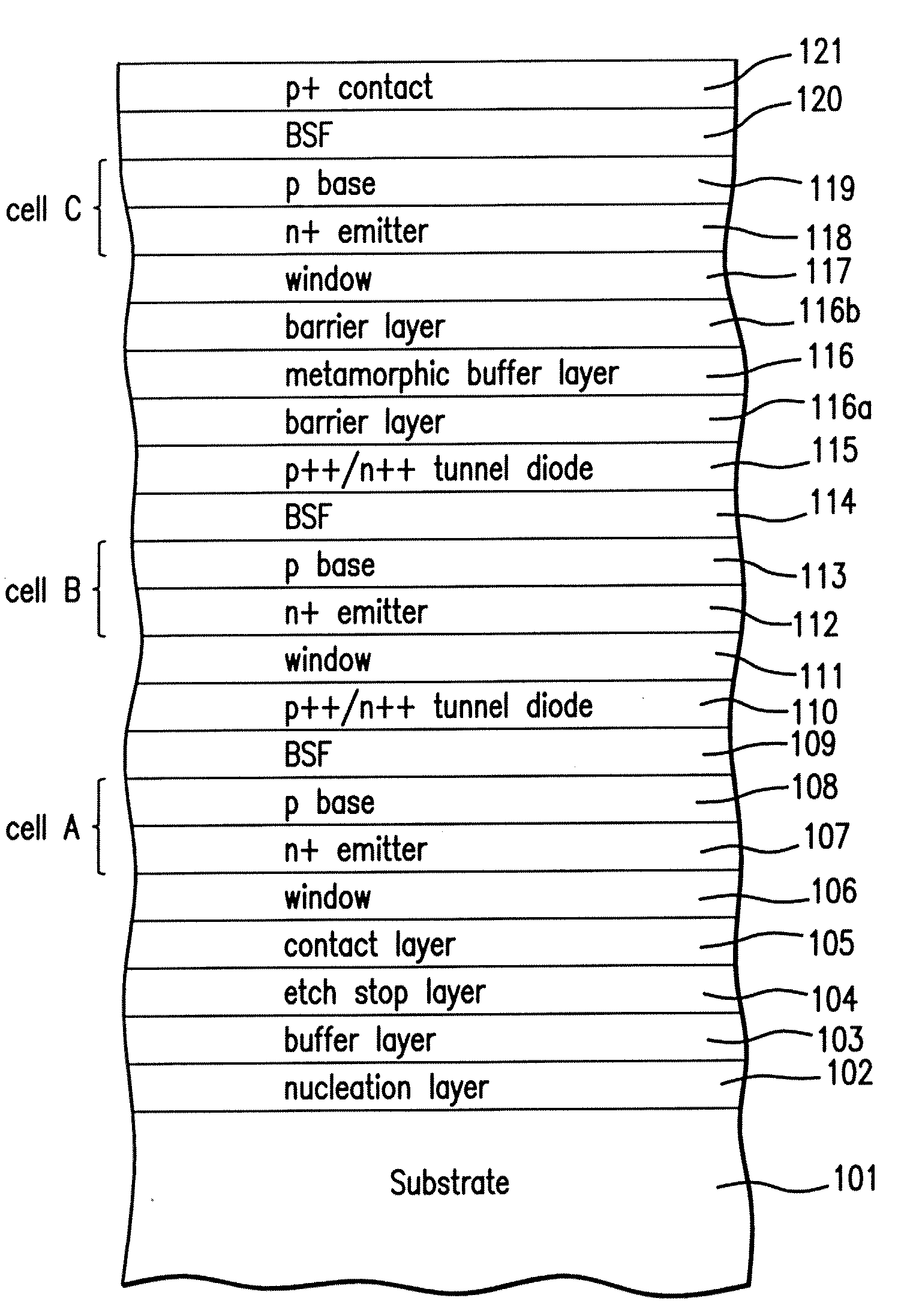

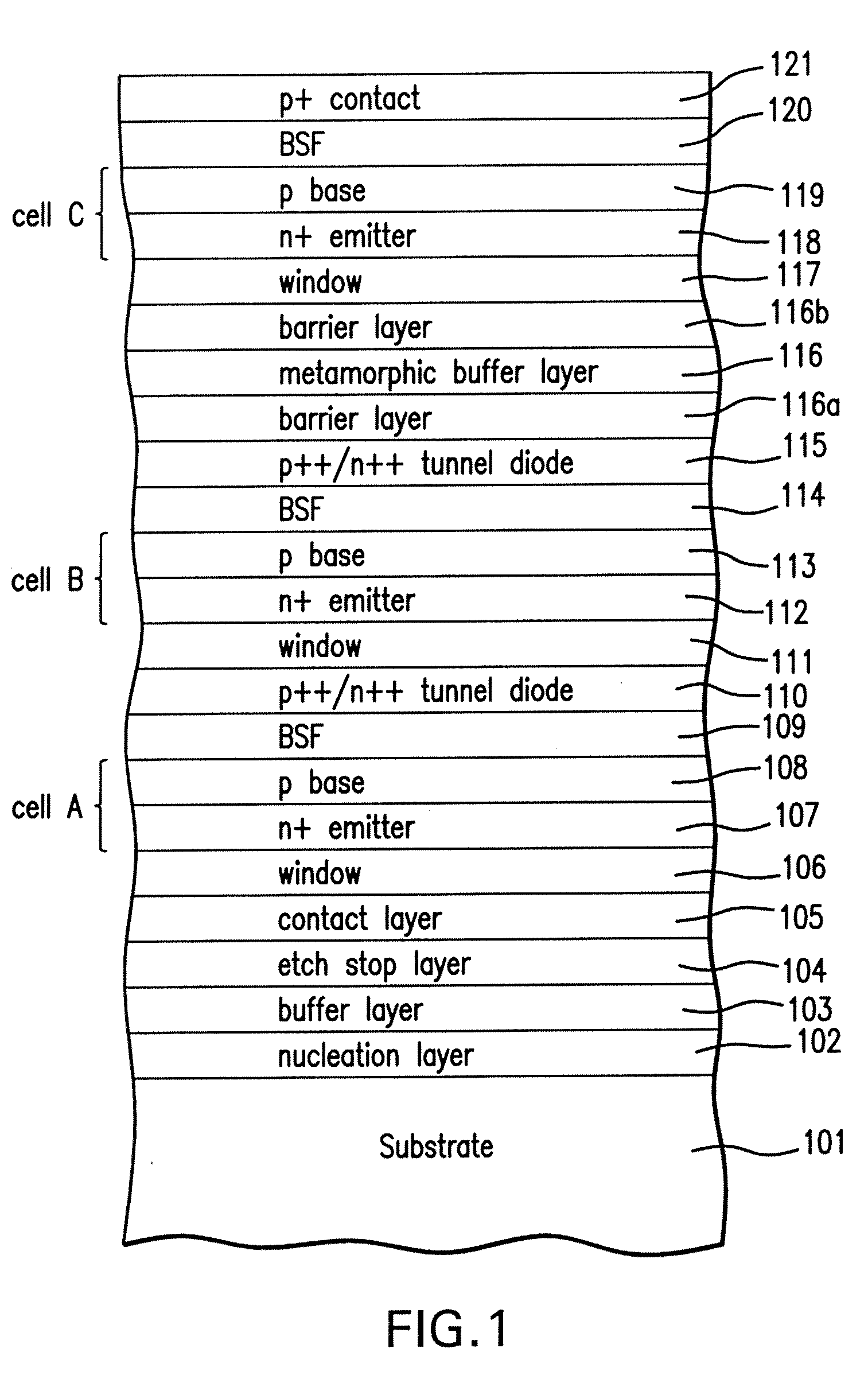

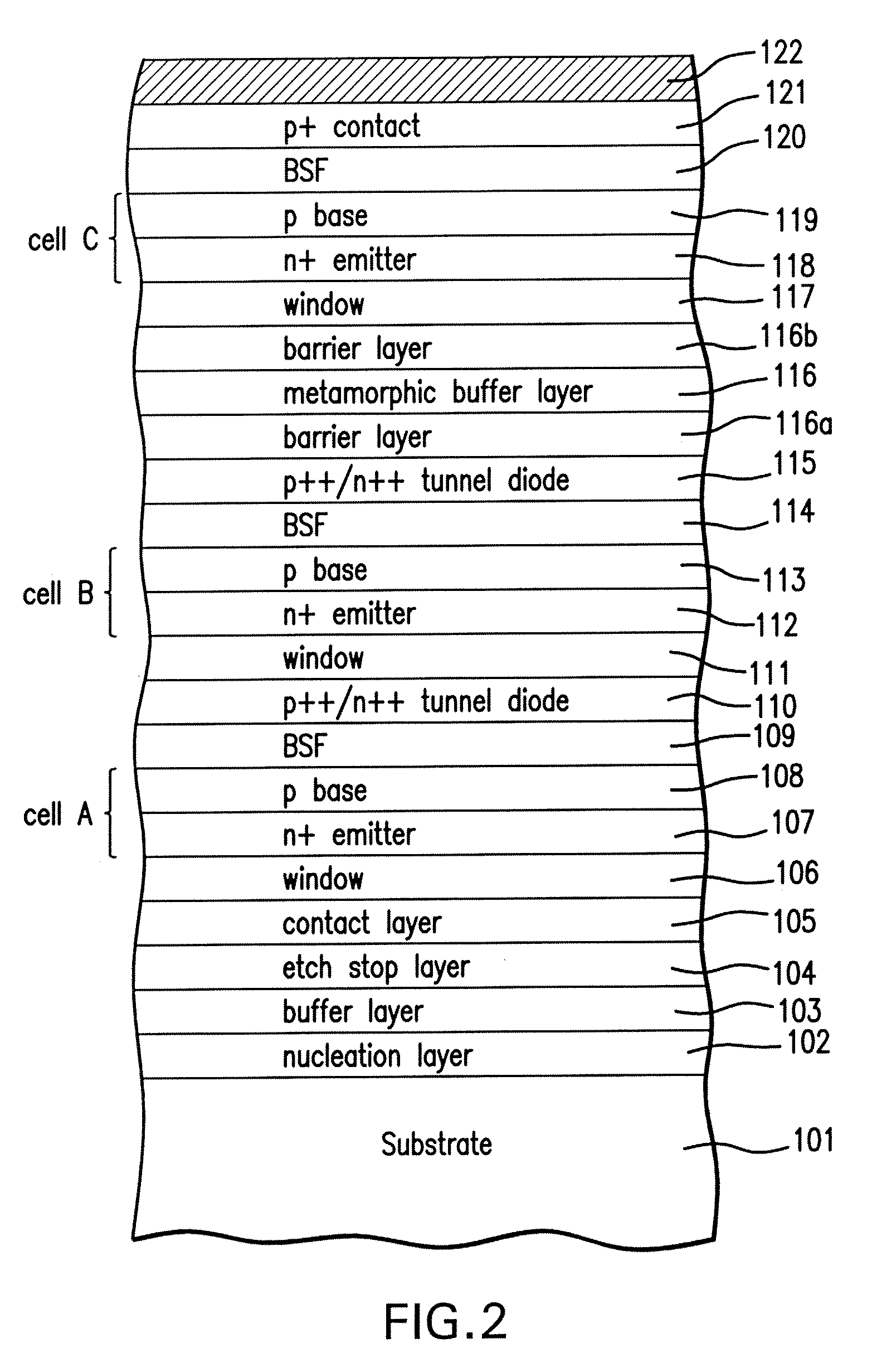

Thin Inverted Metamorphic Multijunction Solar Cells with Rigid Support

InactiveUS20090078308A1Multifunctional and convenientFinal product manufactureSemiconductor/solid-state device manufacturingSolar cellEngineering physics

A multijunction solar cell including a first solar subcell having a first band gap; a second solar subcell disposed over the first subcell and having a second band gap smaller than the first band gap; a grading interlayer disposed over the second subcell and having a third band gap greater than the second band gap; a third solar subcell disposed over the interlayer that is lattice mismatched with respect to the middle subcell and having a fourth band gap smaller than the second band gap; and either a thin (approximately 2-6 mil) substrate and / or a rigid coverglass supporting the first, second, and third solar subcells.

Owner:EMCORE SOLAR POWER

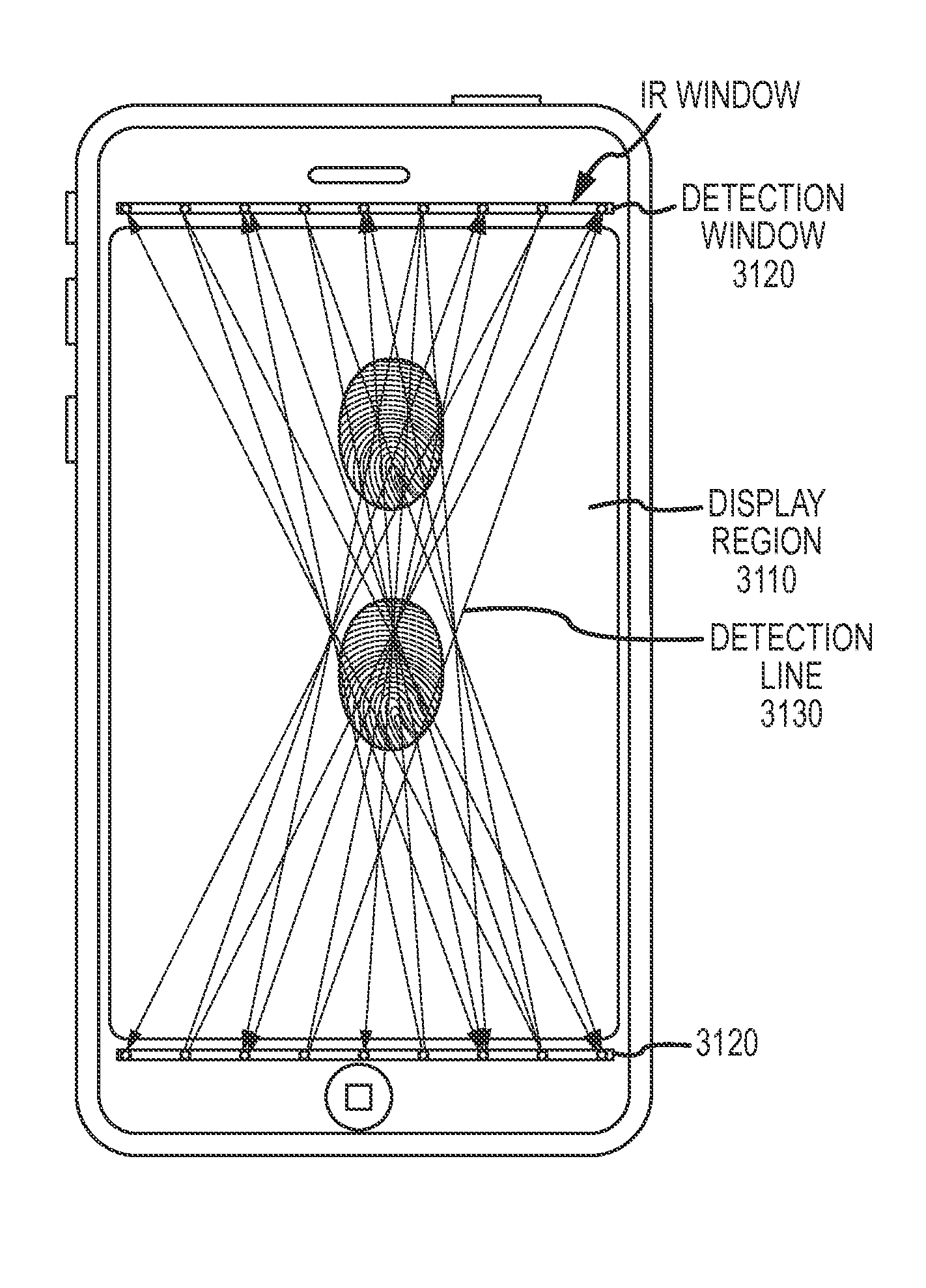

Frustrated Total Internal Reflection and Capacitive Sensing

ActiveUS20140092052A1Accurate measurementLarge amount of appliedInput/output processes for data processingCapacitanceTotal internal reflection

Detecting force and touch using FTIR and capacitive location. FTIR determines applied force by the user's finger within infrared transmit lines on a touch device. A pattern of such lines determine optical coupling with the touch device. Capacitive sensing can determine (A) where the finger actually touches, so the touch device more accurately infers applied force; (B) whether finger touches shadow each other; (C) as a baseline for applied force; or (D) whether attenuated reflection is due to a current optical coupling, or is due to an earlier optical coupling, such as a smudge on the cover glass. If there is attenuated reflection without actual touching, the touch device can reset a baseline for applied force for the area in which that smudge remains. Infrared transmitters and receivers are positioned where they are not visible to a user, such as below a frame or mask for the cover glass.

Owner:APPLE INC

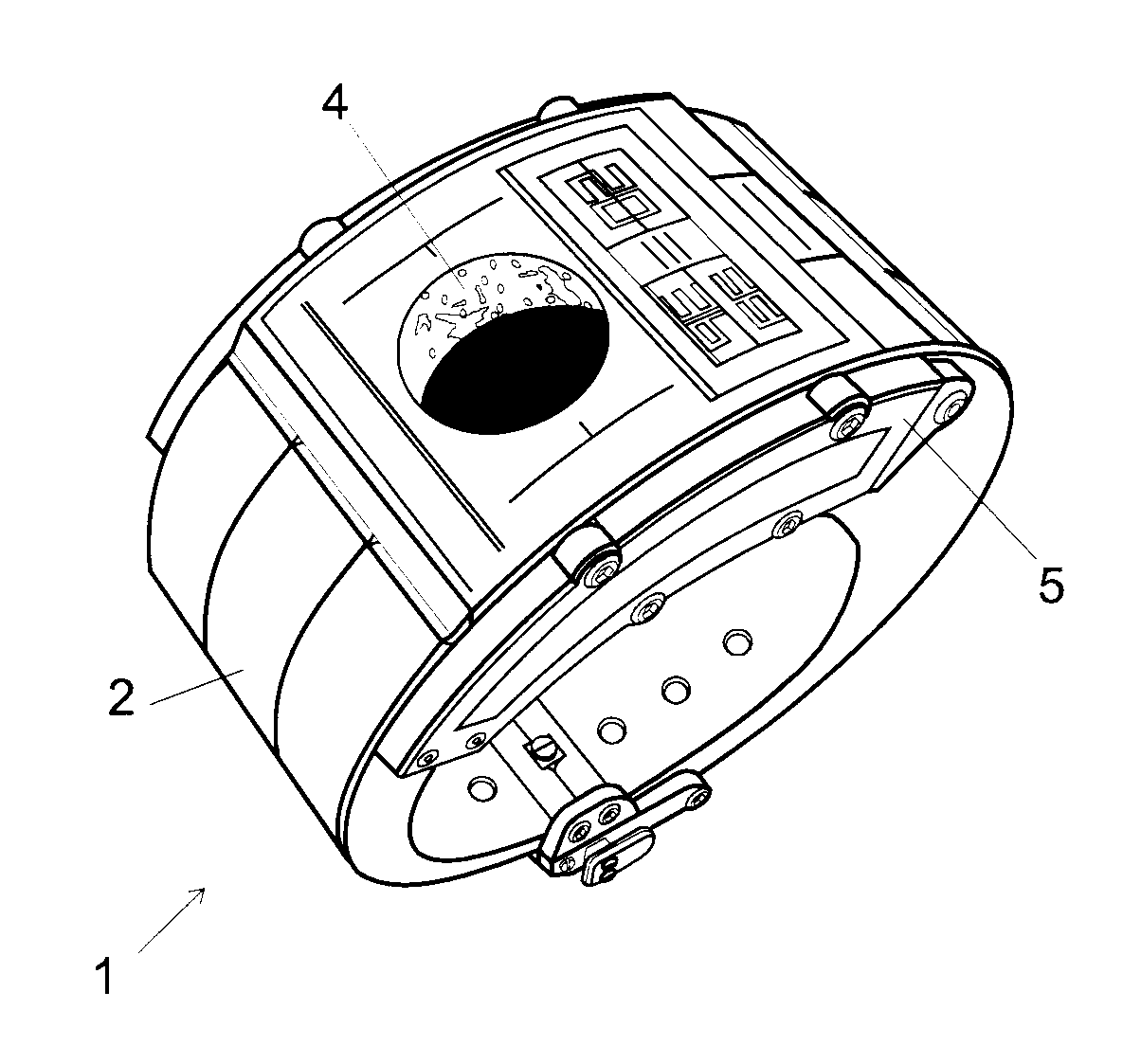

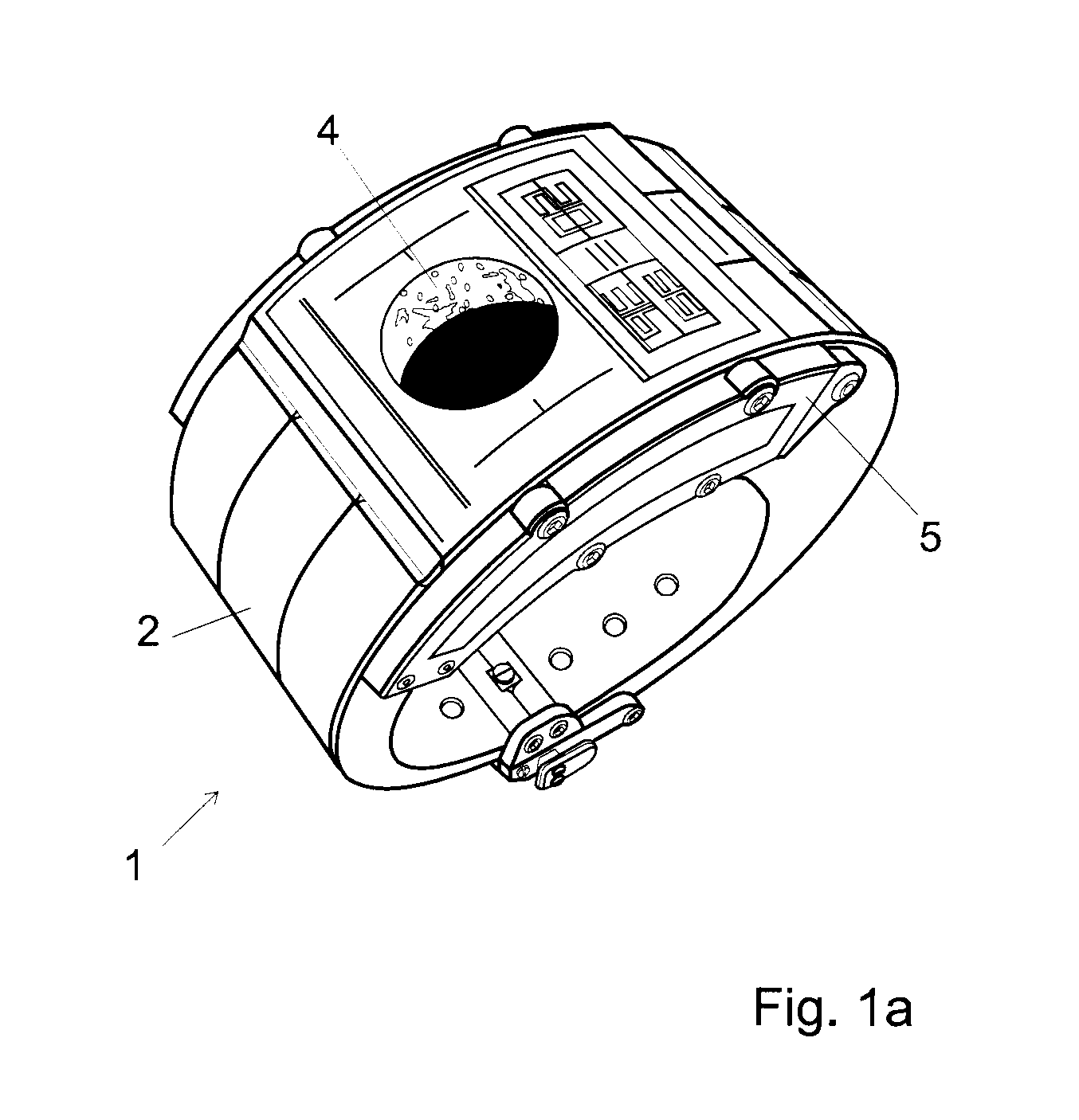

Method and circuit for switching a wristwatch from a first power mode to a second power mode

ActiveUS20140253487A1Easy to switchSimple methodInput/output for user-computer interactionElectronic time-piece structural detailsPower modeTouchpad

An electronic wristwatch operable in two power modes. The wristwatch has an inertial sensor for detecting a gesture on a cover glass of the wristwatch. A touch panel is provided underneath the cover glass for detecting the gesture. Gesture detection by the inertial sensor is combined with gesture detection by the touch panel for triggering a switch from a first power mode to a second power mode.

Owner:SLYDE ANALYTICS LLC

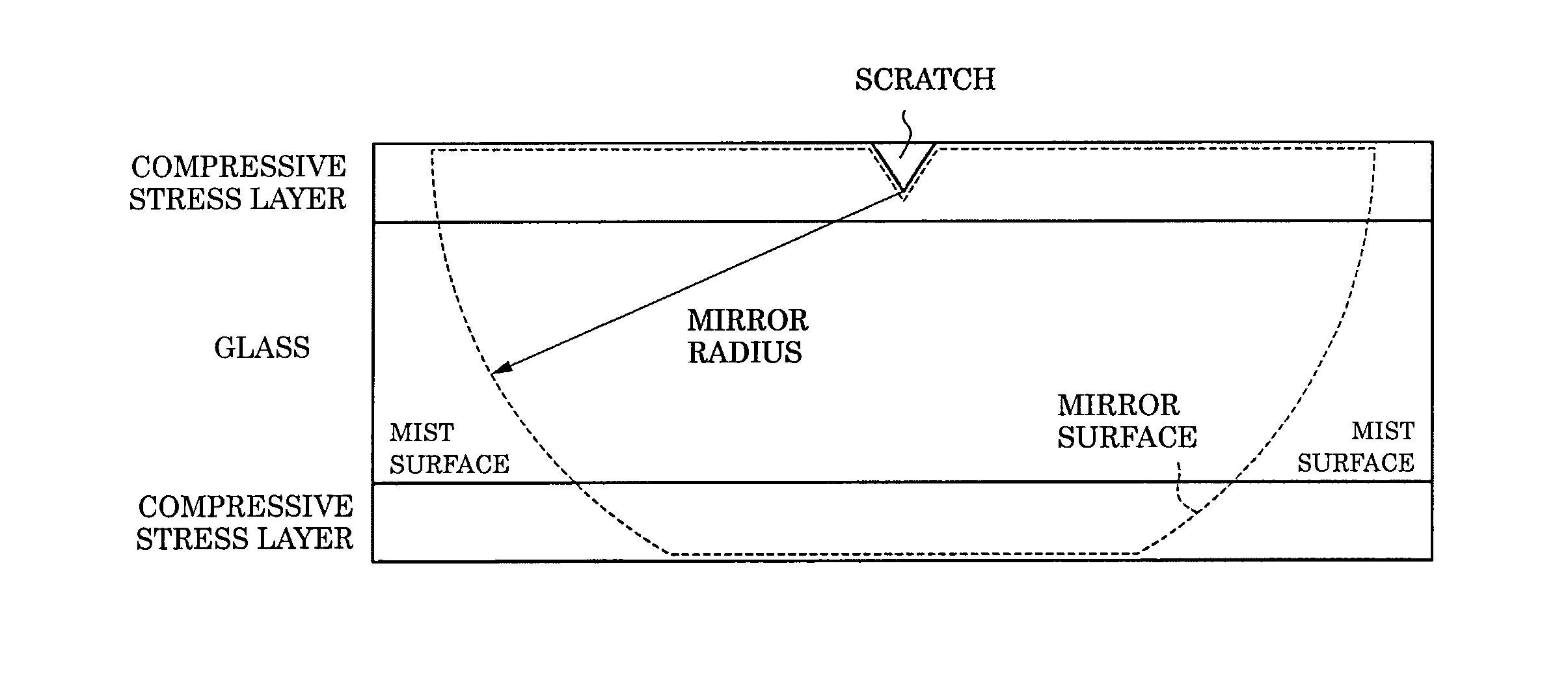

Display cover glass and display cover glass fabrication method

ActiveUS20140370264A1Increase the surface compressive stressGood wear resistanceDigital data processing detailsSynthetic resin layered productsDisplay deviceCompressive strength

The present invention provides a cover glass for a display, having high durability to slow cracking and strong abraded strength even though a compressive stress is large and a depth of a compressive stress layer is deep. The present invention relates to a cover glass for a display, in which a depth of a compressive stress layer (DOL) is 30 μm or more, a surface compressive stress is 300 MPa or more, a position (HW) at which a compressive stress is half of a value of the surface compressive stress is a position of 8 μm or more from a glass surface, and the depth of the compressive stress layer (DOL) and the position (HW) at which the compressive stress is half of the value of the surface compressive stress satisfy the following formula:0.05≦HW / DOL≦0.23 (1).

Owner:ASAHI GLASS CO LTD

Cover glass and method for producing cover glass

The disclosed cover glass is produced by etching a glass substrate that has been formed by a down-drawing process, and chemically strengthening the glass substrate to provide the glass substrate with a compressive-stress layer on the principal surfaces thereof. The glass substrate contains, as components thereof, 50% to 70% by mass of SiO2, 5% to 20% by mass of Al2O3, 6% to 30% by mass of Na2O, and 0% to less than 8% by mass of Li2O. The glass substrate may also contain 0% to 2.6% by mass of CaO, if necessary. The glass substrate has an etching characteristic in which the etching rate is at least 3.7 μm / minute in an etching environment having a temperature of 22° C. and containing hydrogen fluoride with a concentration of 10% by mass.

Owner:AVANSTRATE INC +1

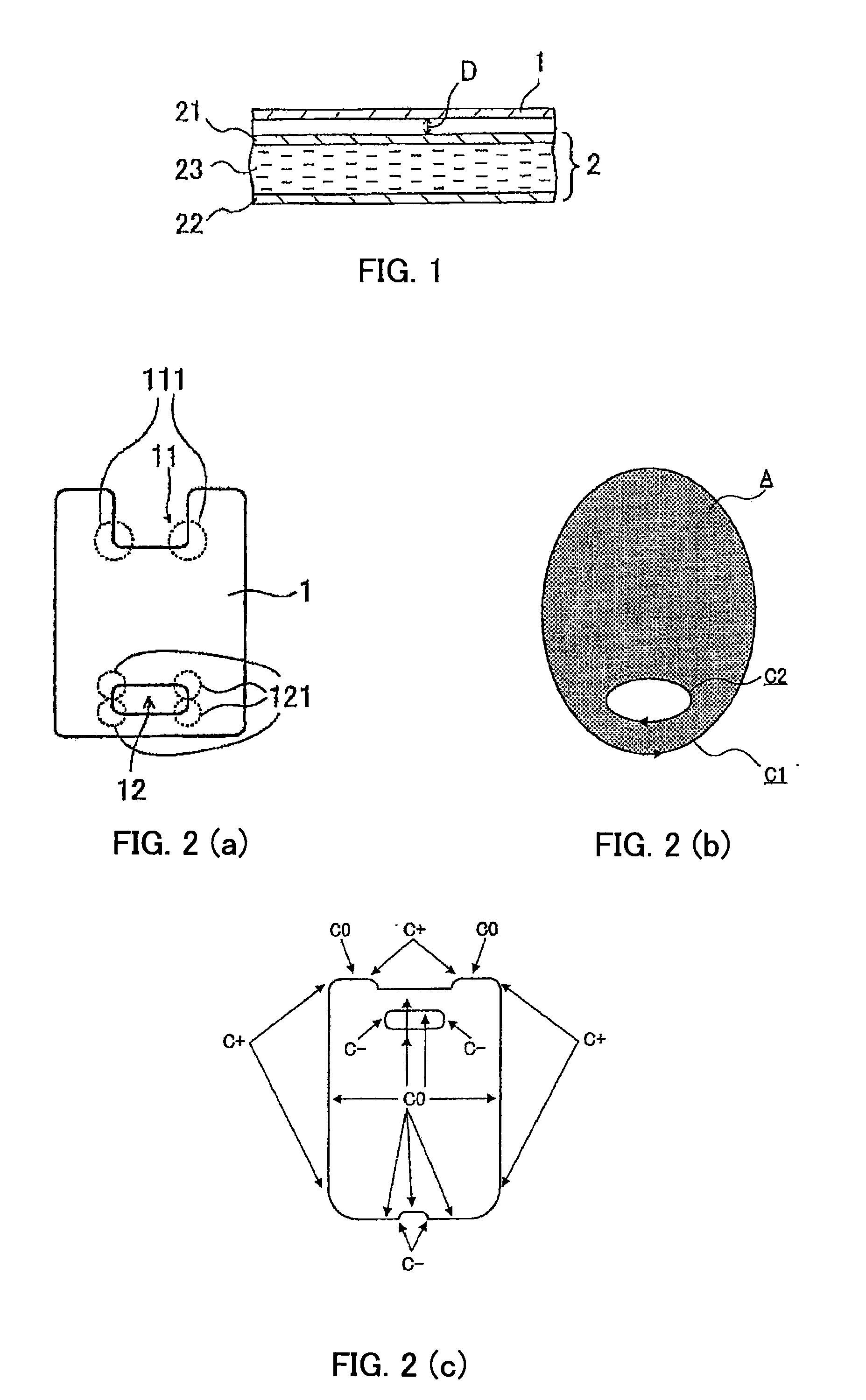

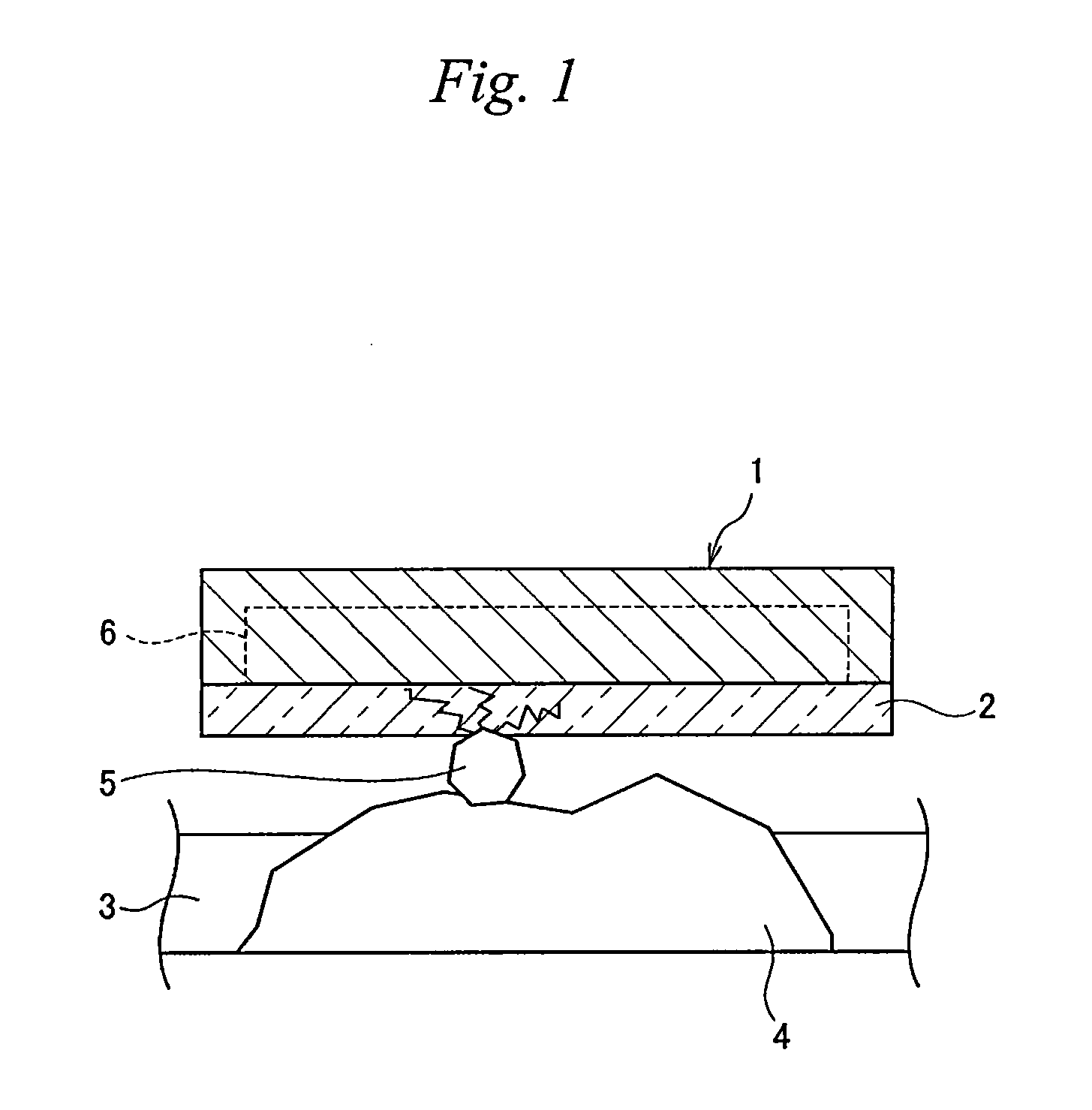

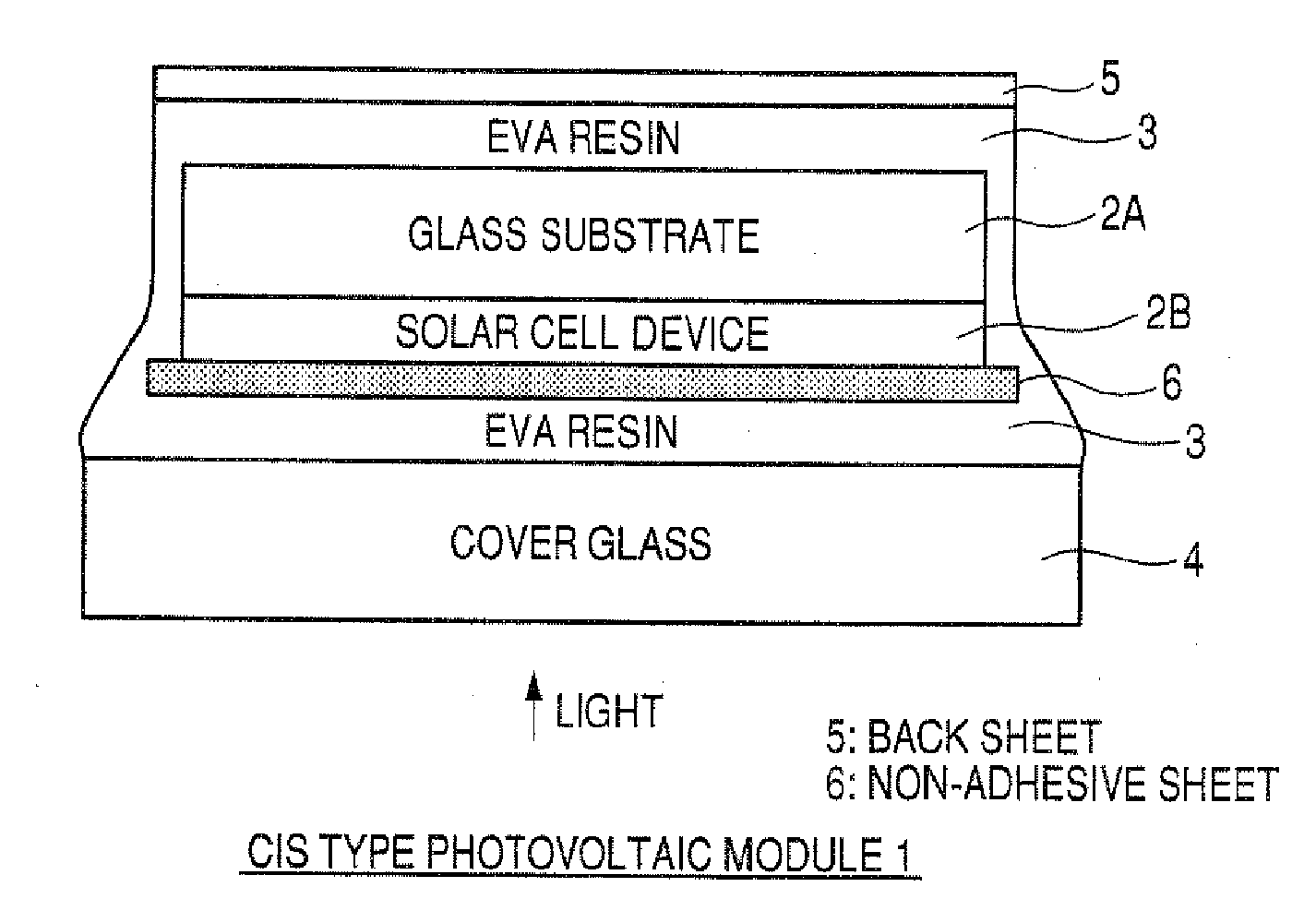

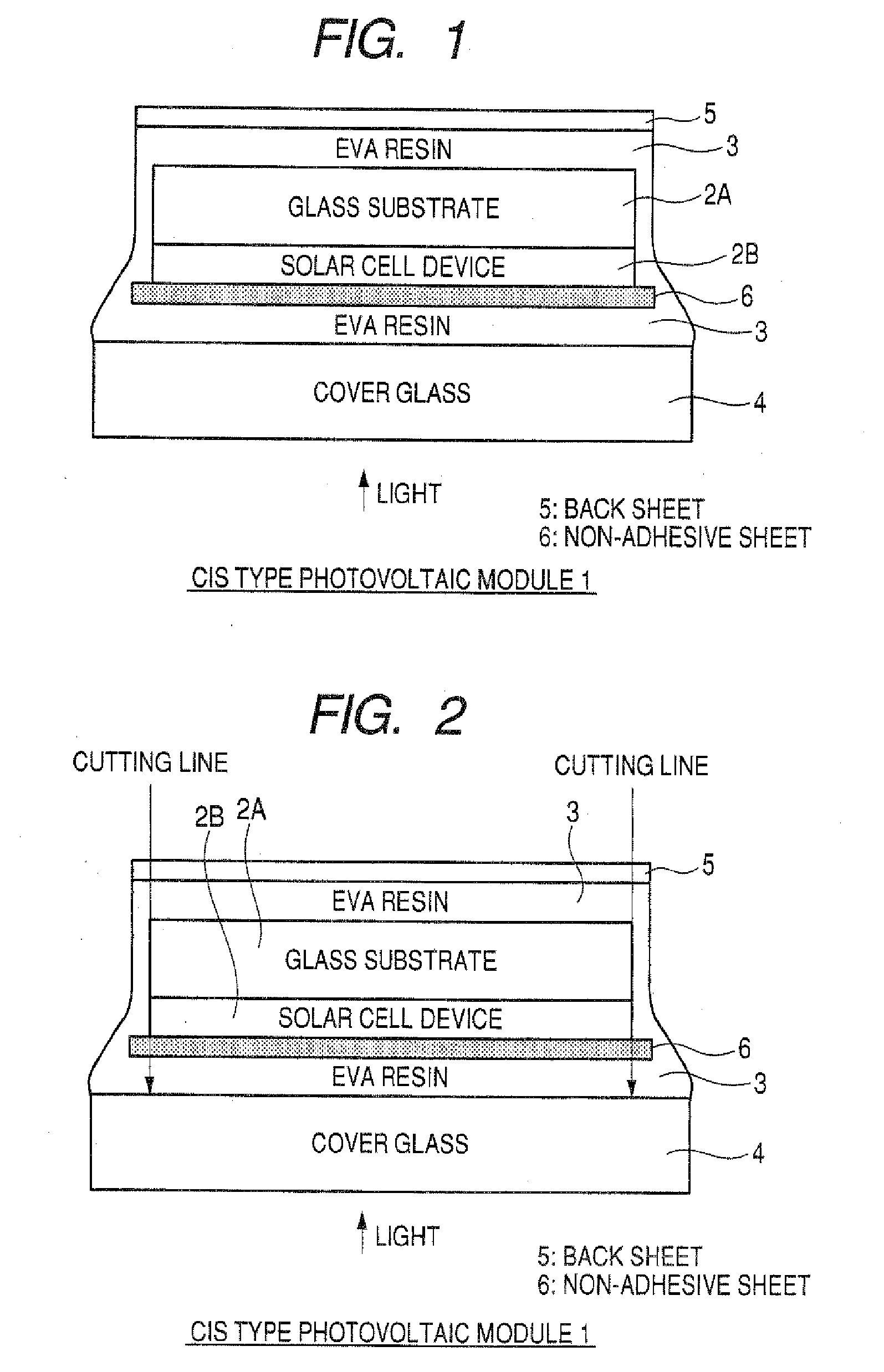

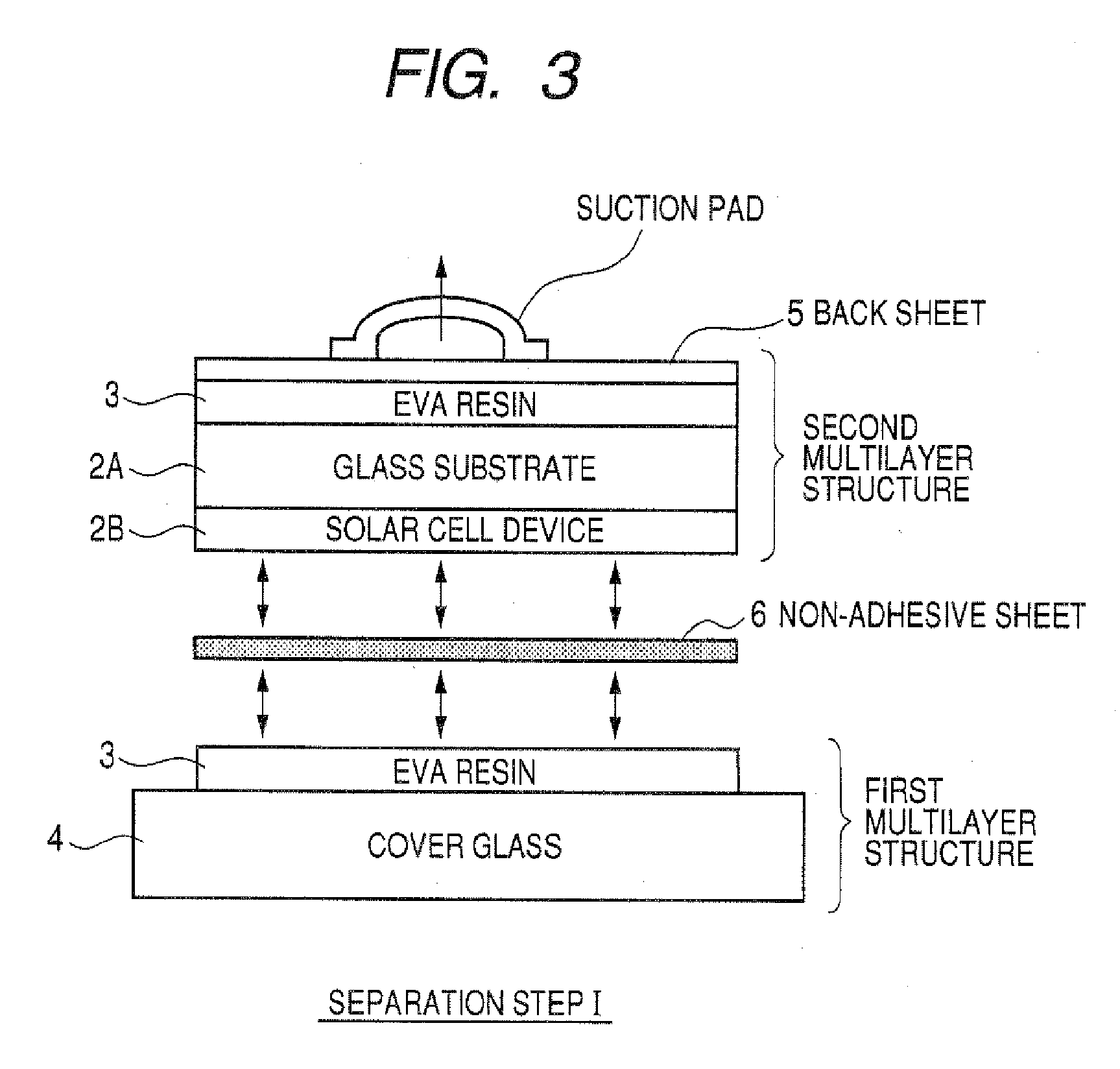

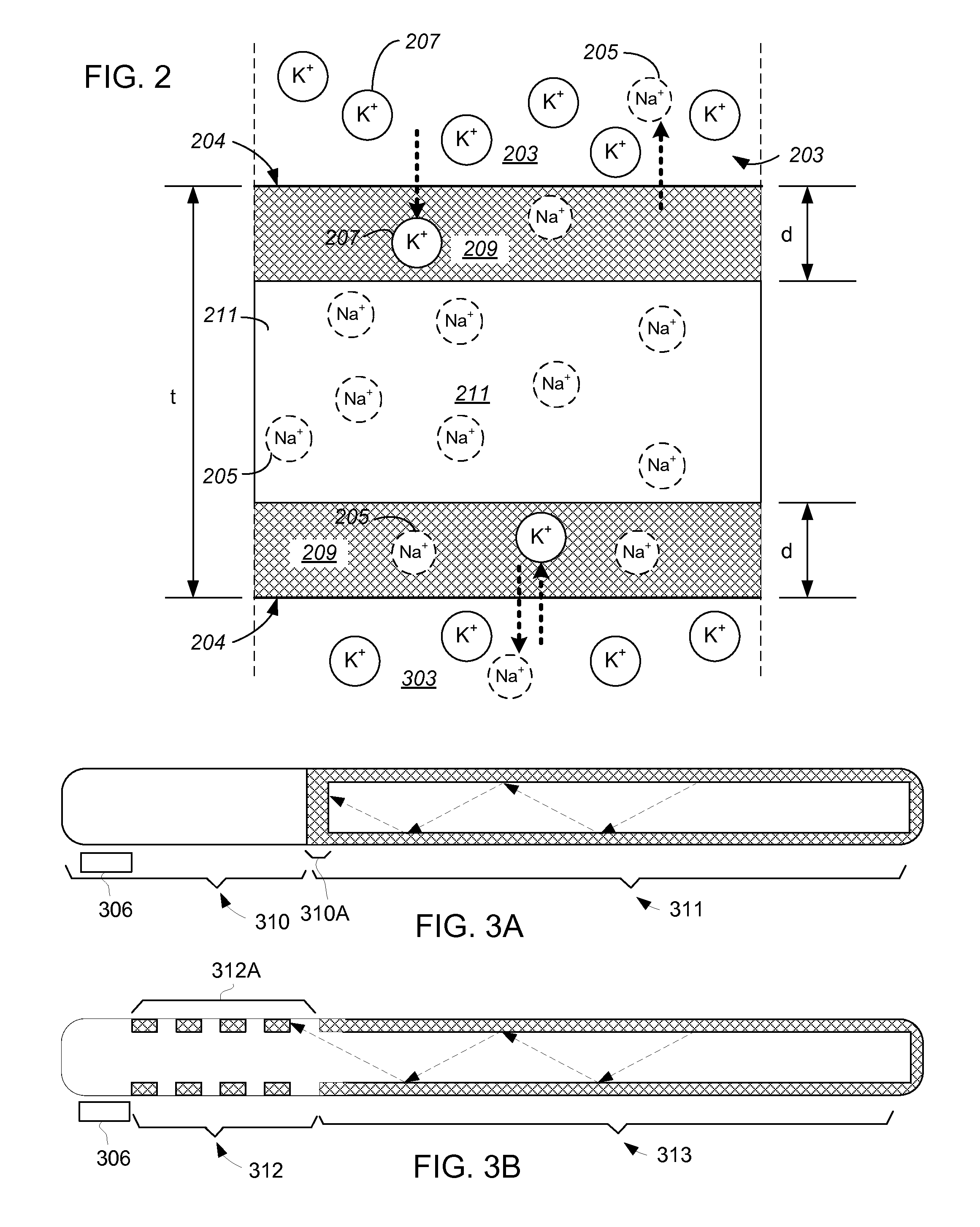

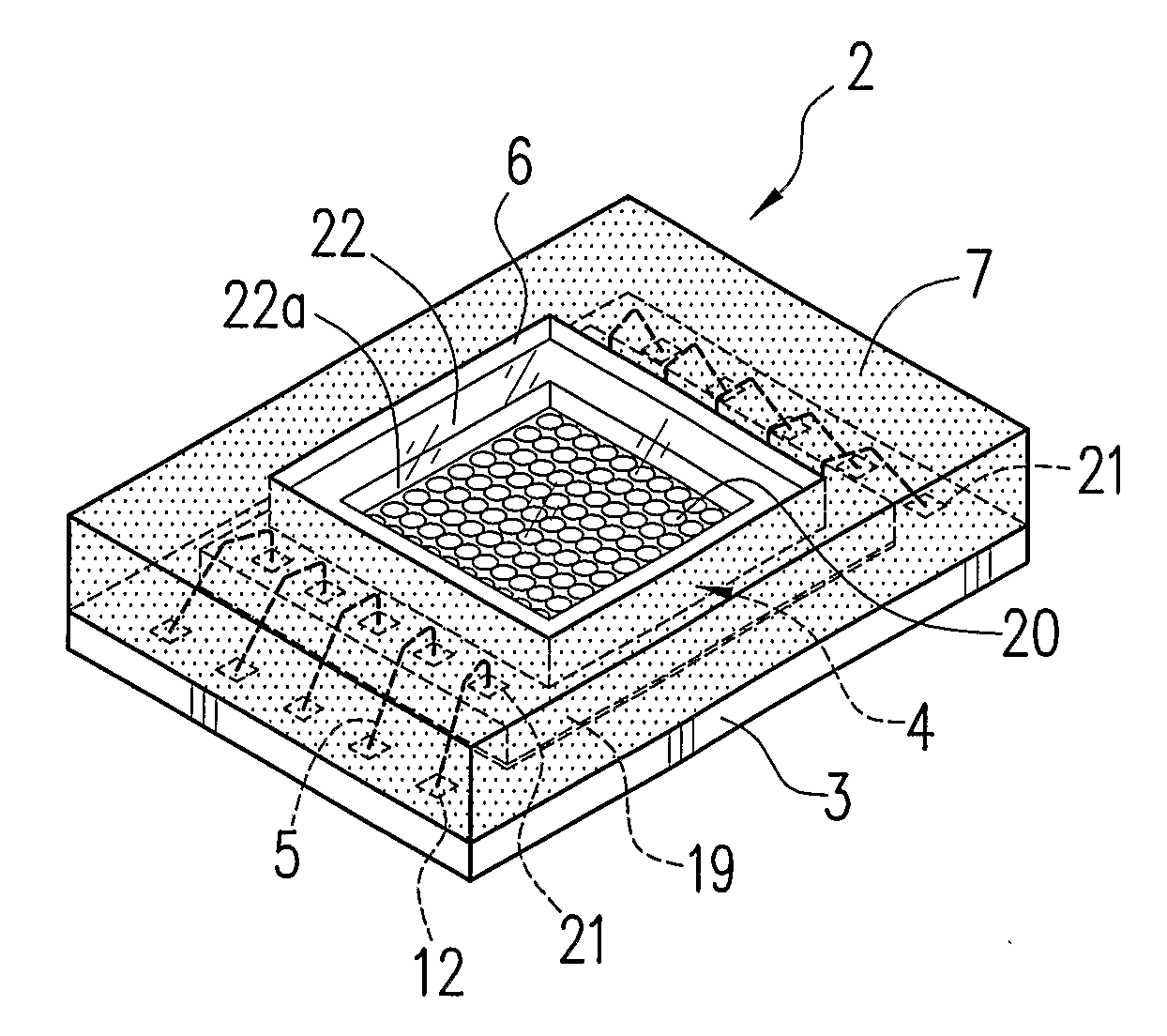

Cis Type Thin-Film Photovoltaic Module, Process for Producing the Photovoltaic Module, and Method of Separating the Module

InactiveUS20080105294A1Reducing output characteristicReducing durabilityLamination ancillary operationsFinal product manufacturePolyesterAdhesive

Constituent materials of a CIS type thin-film photovoltaic module are made separable and recyclable without reducing output characteristics and durability.A thin-film photovoltaic module 1 having a substrate structure comprising a CIS type thin-film solar cell device 2 and a cover glass 4 bonded to the light incidence side of the device 2 with a thermally crosslinked EVA resin or the like 3 as an adhesive is made to include a non-adhesive plastic (e.g., polyester) resin 6 sandwiched between the solar cell device 2 and the EVA resin 3. Thus, the constituent materials are separable. Through later simple separation steps, the constituent materials are separated and recovered.

Owner:SHOWA SHELL SEKIYU KK

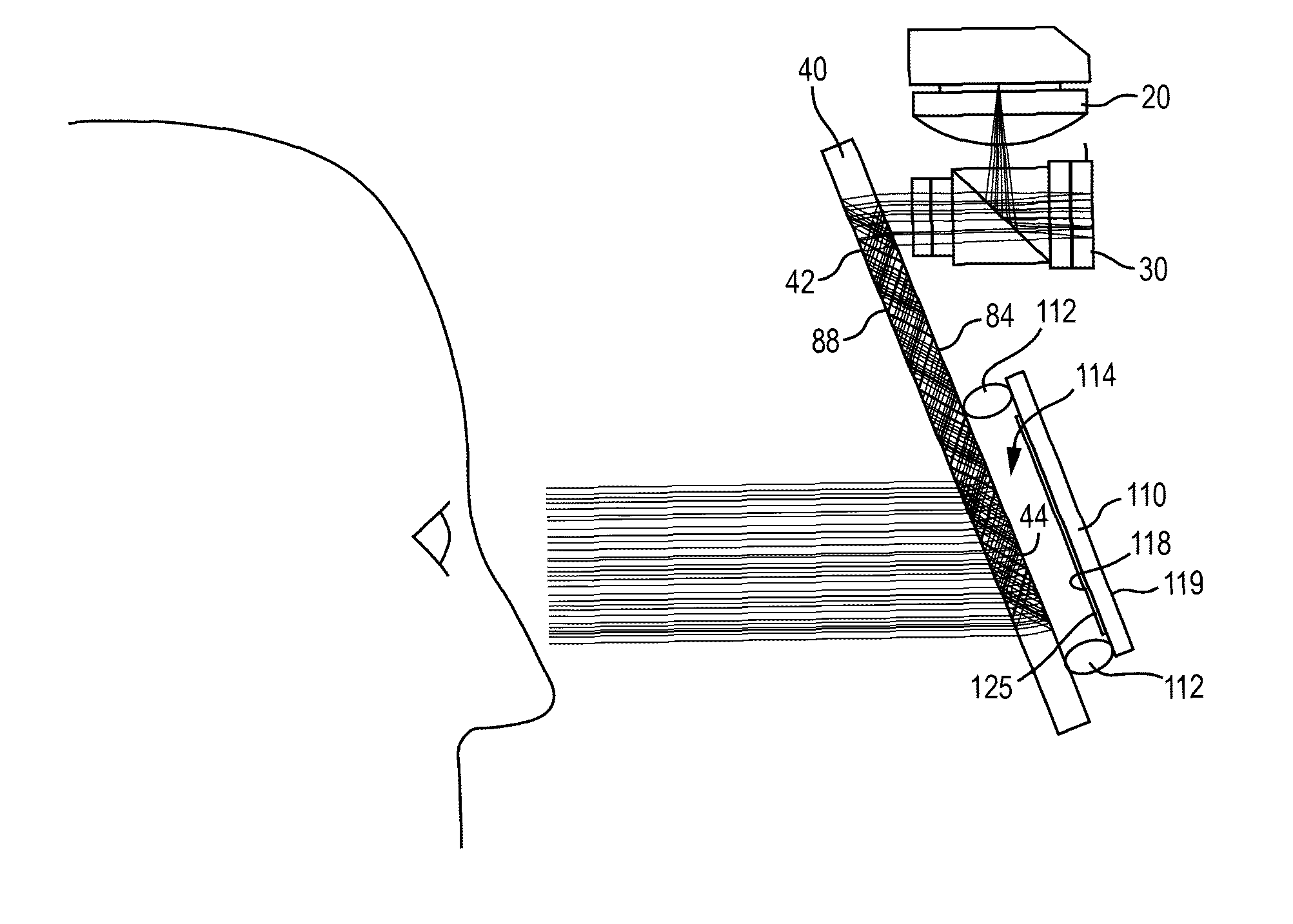

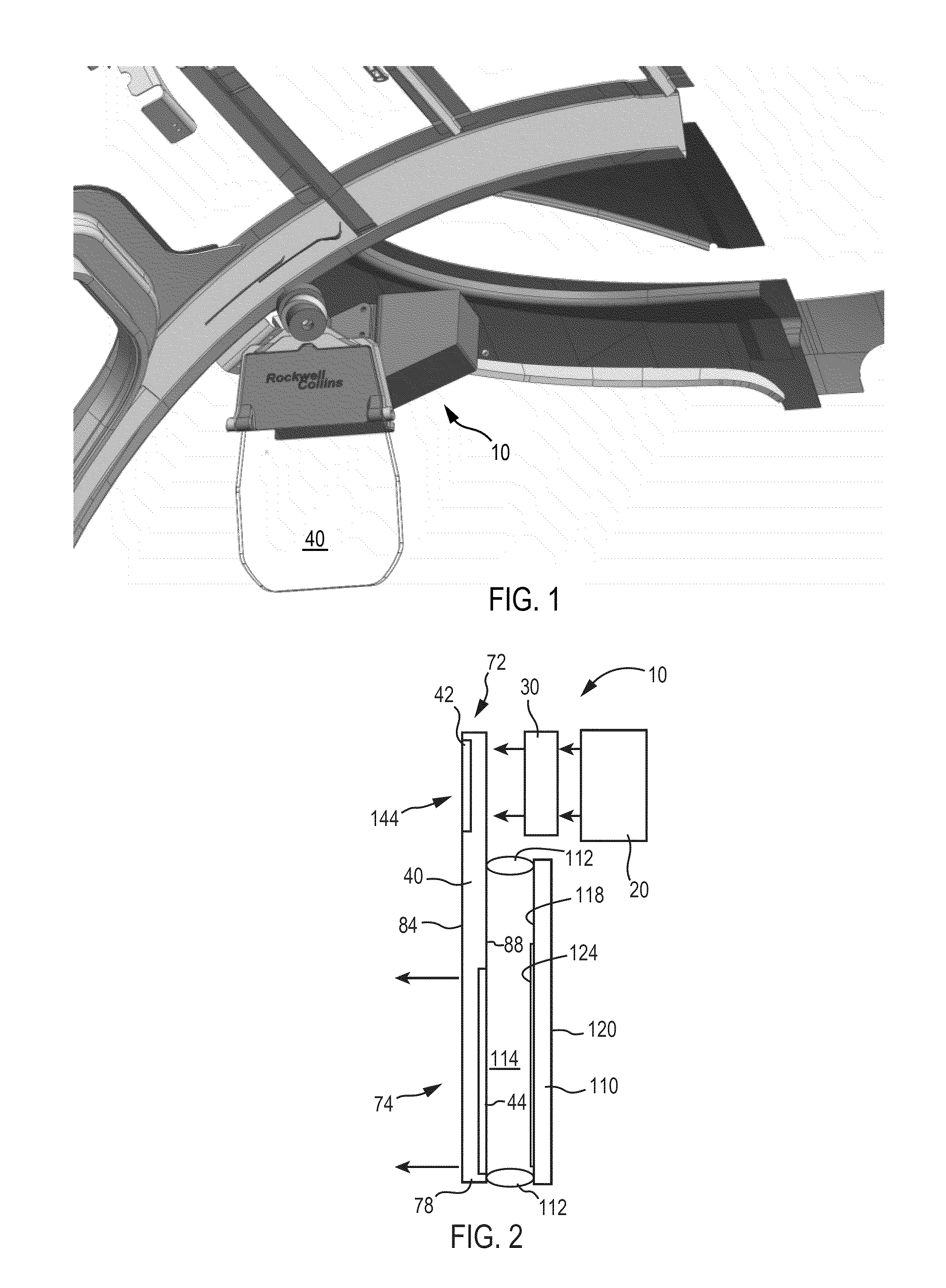

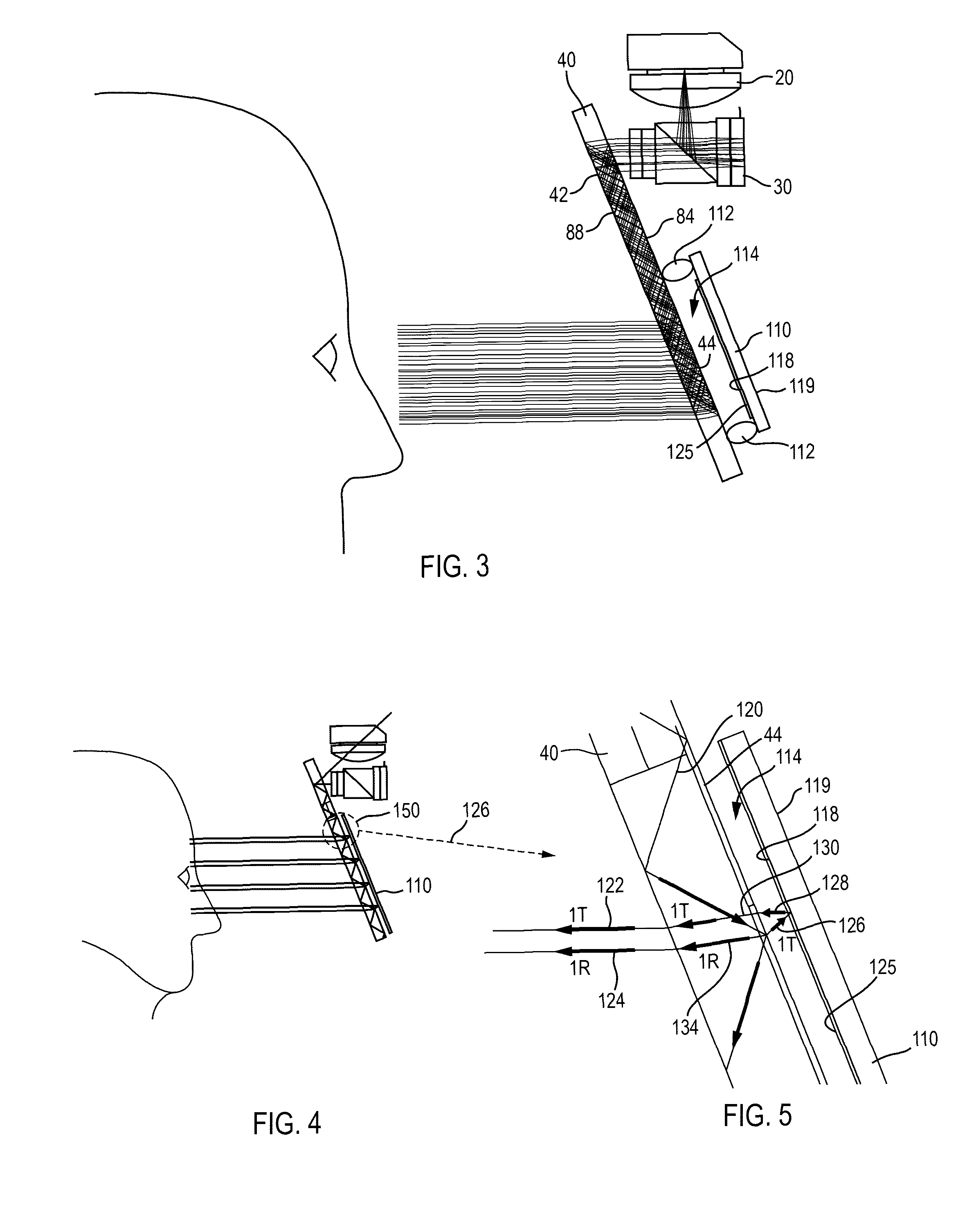

Reflector and cover glass for substrate guided HUD

A display (for example, a head up display (HUD)) includes a substrate waveguide. The substrate waveguide can act as a combiner. The substrate waveguide receives collimated light an input and provides the collimated light to an output. The collimated light travels from the input to the output within the substrate waveguide by total internal reflection. An input diffraction grating is disposed in the first area at the input and an output diffraction grating is disposed in the second area at the output. A plate covers at least a portion of the second area. The plate can protect the diffraction grating and reflect transmitted order light from the diffraction grating to improve efficiency.

Owner:ROCKWELL COLLINS INC

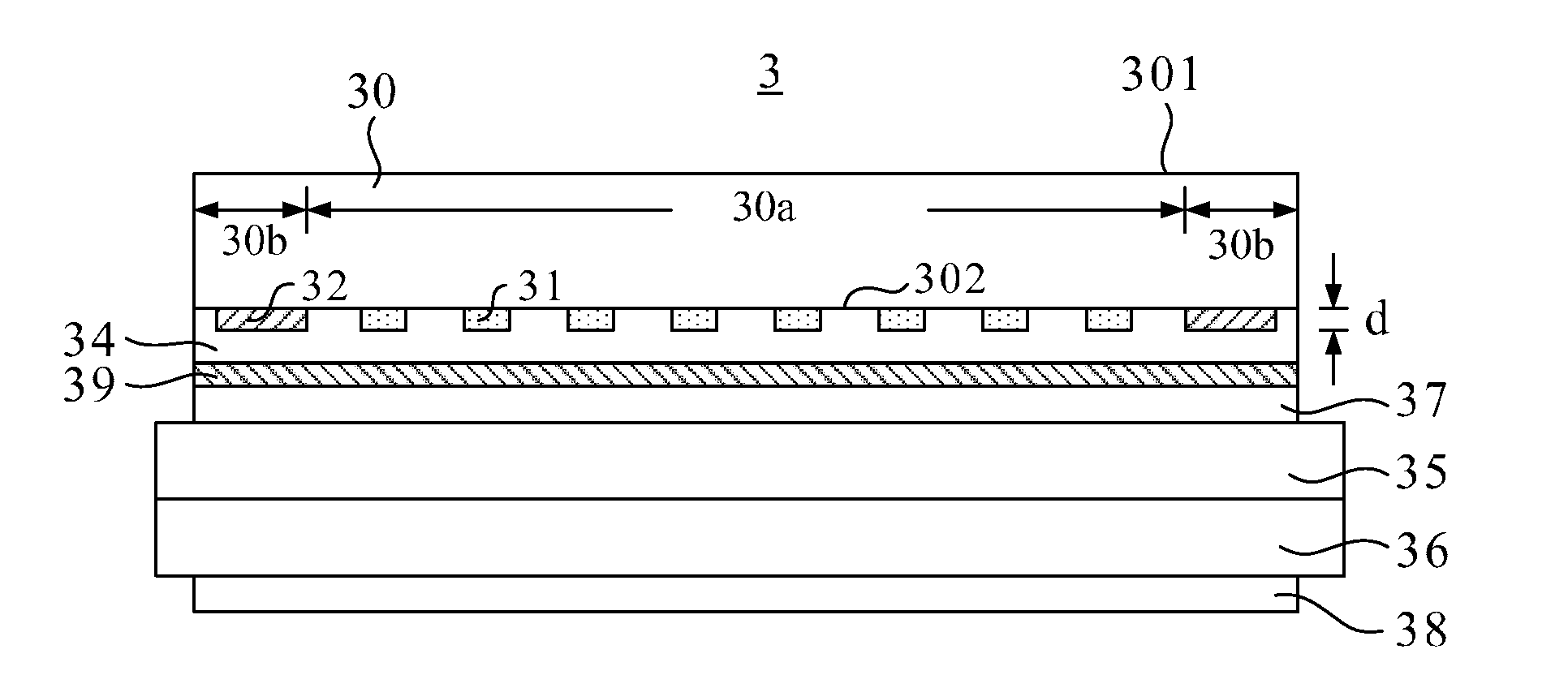

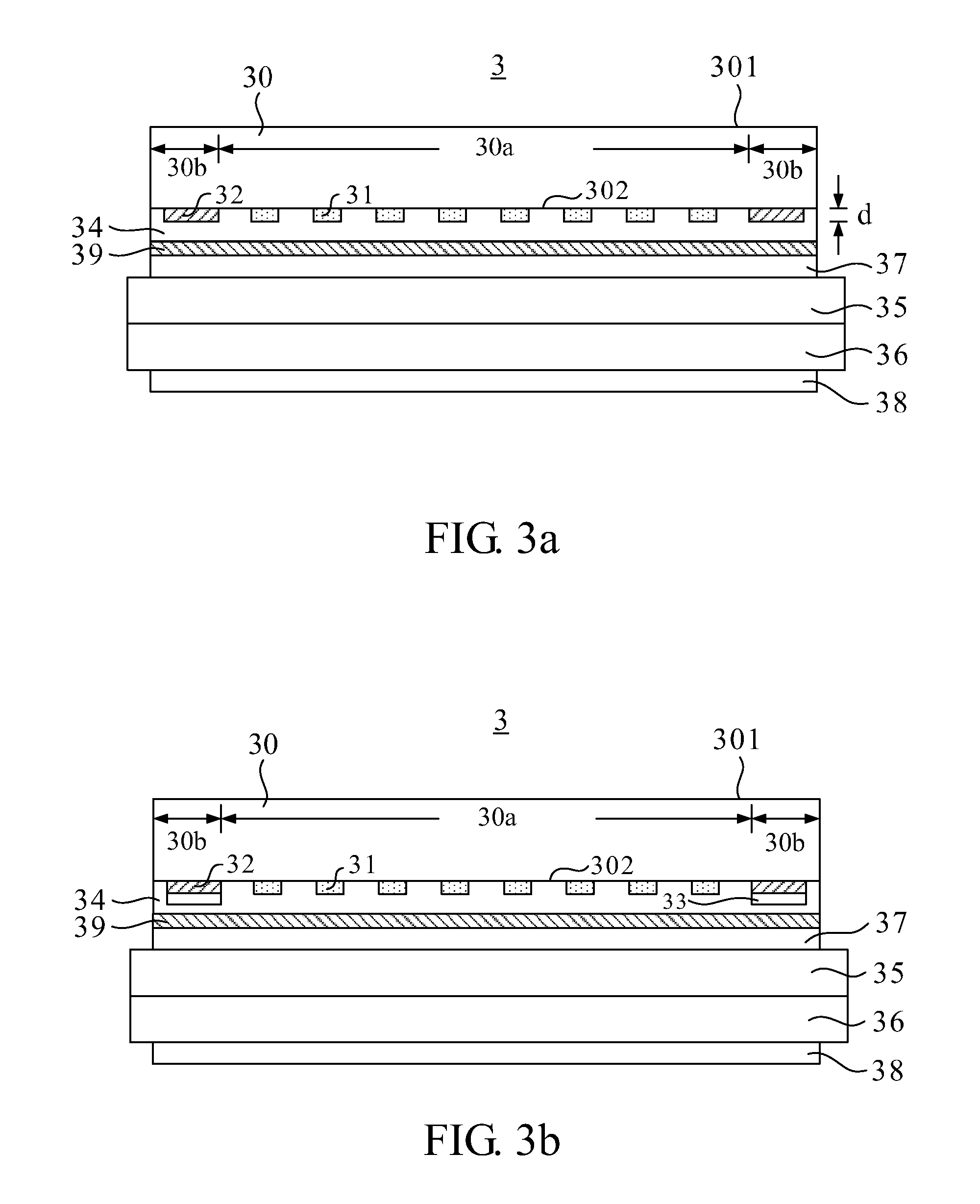

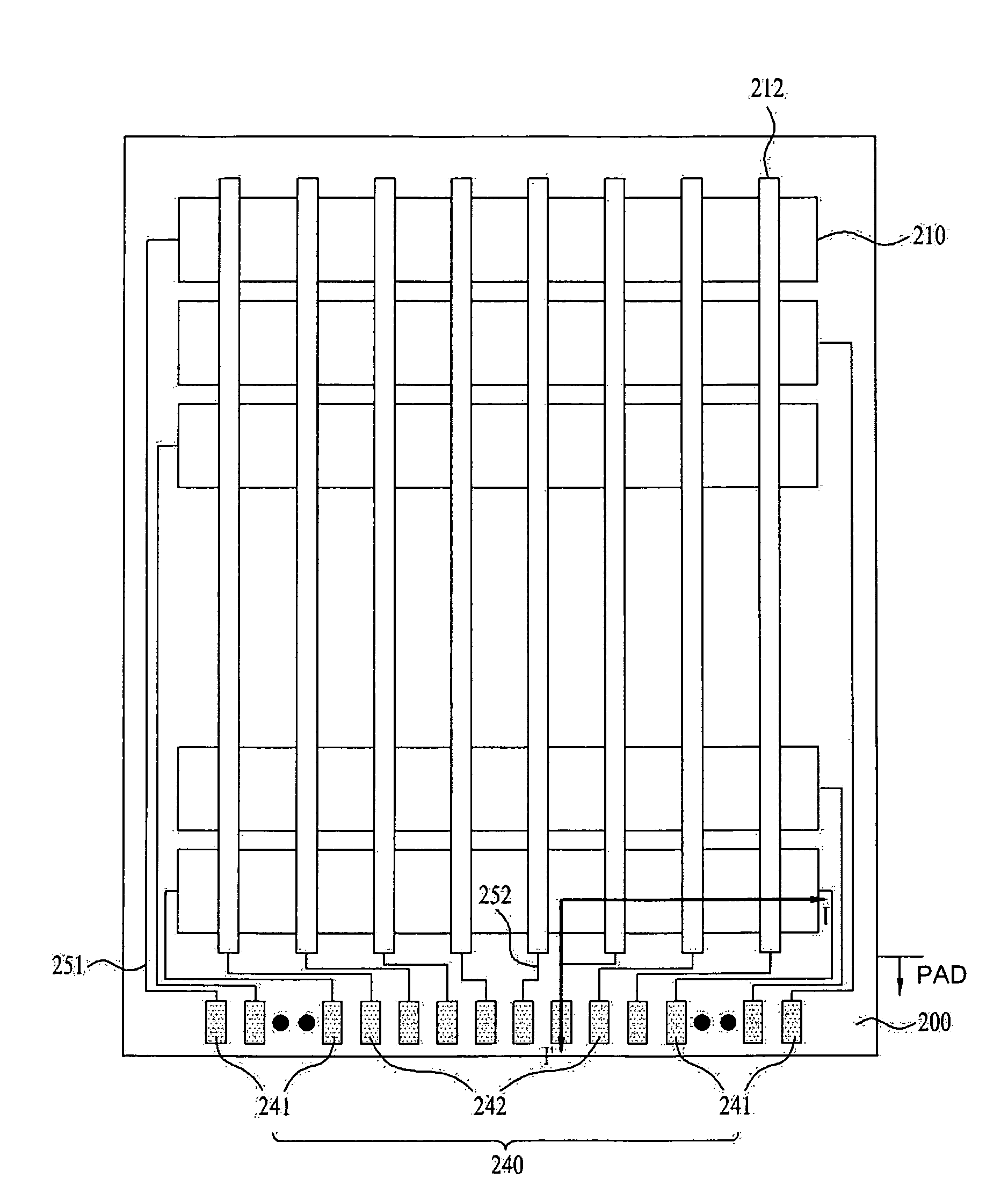

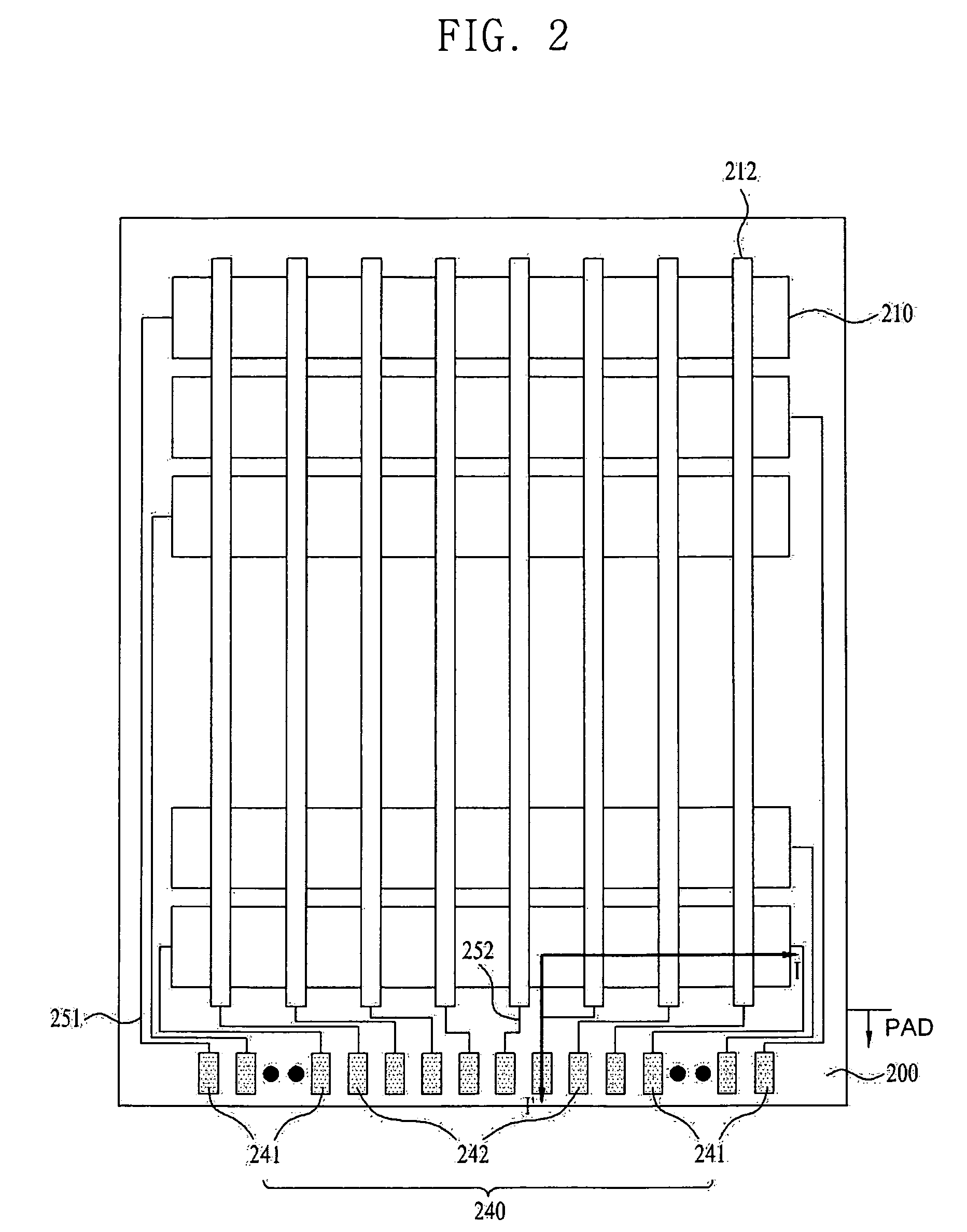

Liquid crystal display device and method of manufacturing thereof

ActiveUS8111248B2Reduce in quantityEasy to assembleStatic indicating devicesNon-linear opticsLiquid-crystal displayEngineering

A liquid crystal display device includes: a liquid crystal panel including first and second substrates facing each other and a liquid crystal layer between the first and second substrates, each of the first and second substrates defining a central display region and a peripheral non-display region; a cover glass integrated touch sensor on the liquid crystal panel, the touch sensor including a plurality of transparent first electrodes and second electrodes formed on a surface of the cover glass facing the liquid crystal panel, wherein the first electrodes and second electrodes cross each other; and a touch signal applicator at a side of the cover glass away from the display region of the liquid crystal panel.

Owner:LG DISPLAY CO LTD

Electronic Device Having Selectively Strengthening Glass Cover Glass

ActiveUS20120027399A1Reduce glareReducing glare at the cameraWave amplification devicesDiffusing elementsGlass coverOptical barrier

Embodiments disclosed therein generally pertain to selectively strengthening glass. More particularly, techniques are described for selectively strengthening cover glass, which tends to be thin, for electronic devices, namely, portable electronic devices. In certain embodiments, selectively strengthening glass, such as cover glass, can be used to provide optical barriers (or channels) internal to the glass. The electronic devices can also provide for camera integration behind the cover glass.

Owner:APPLE INC

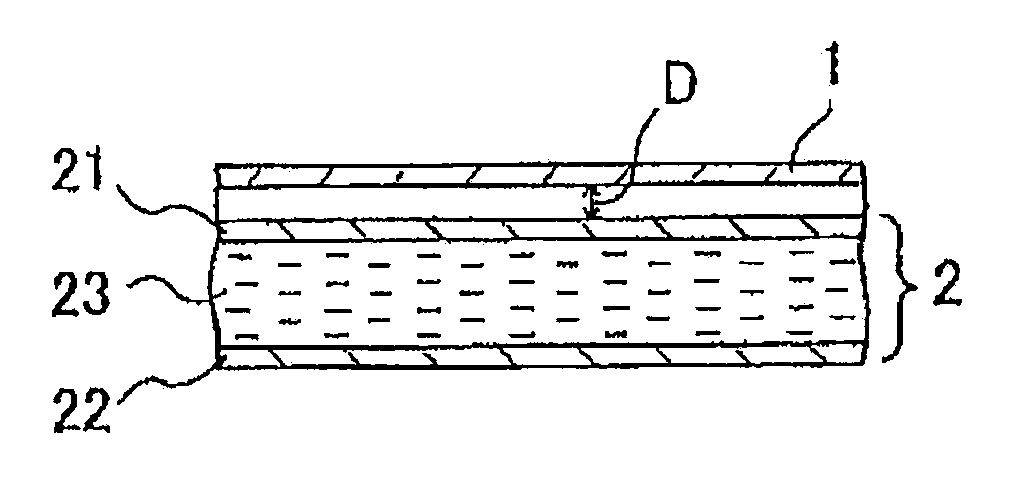

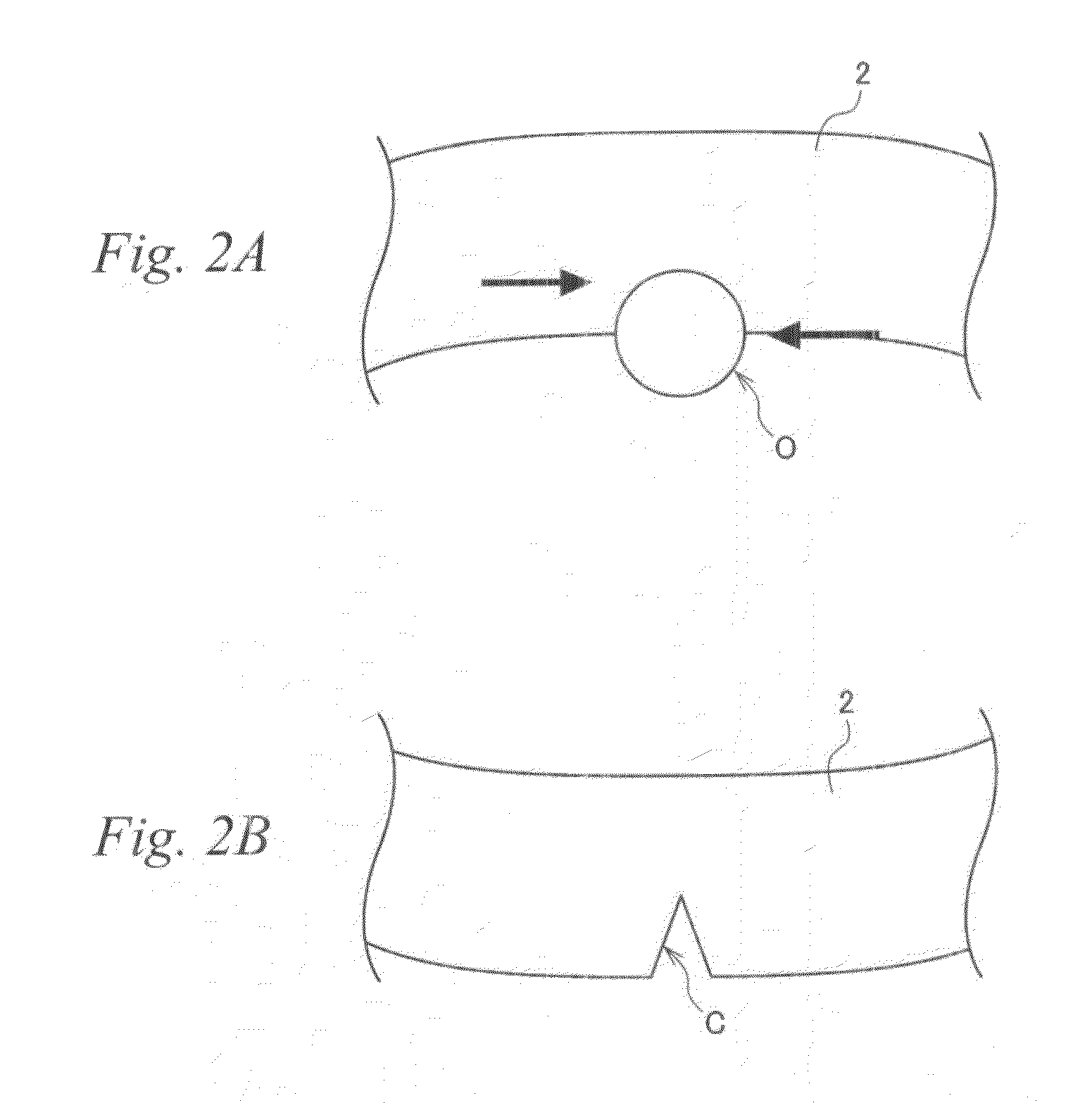

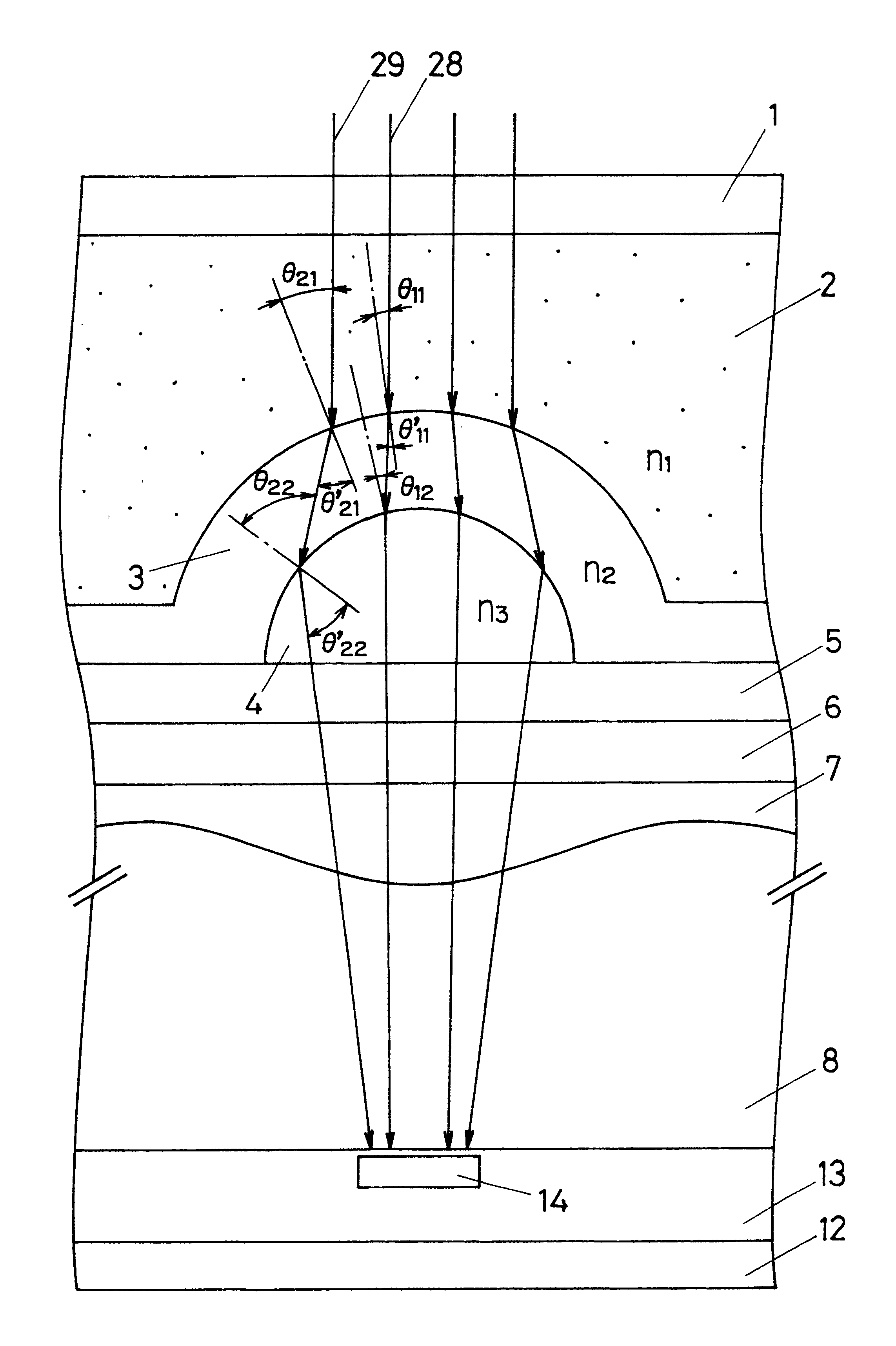

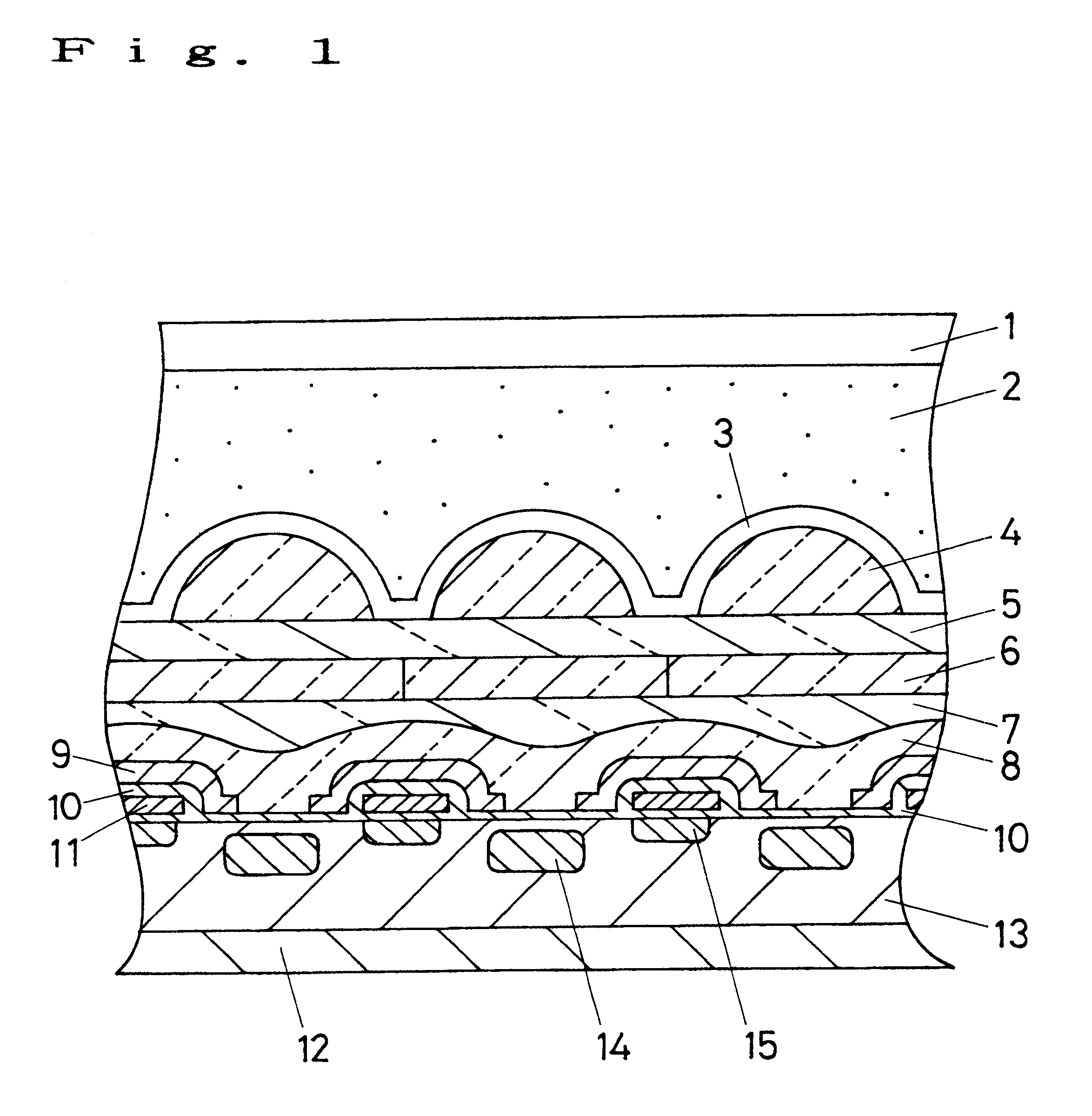

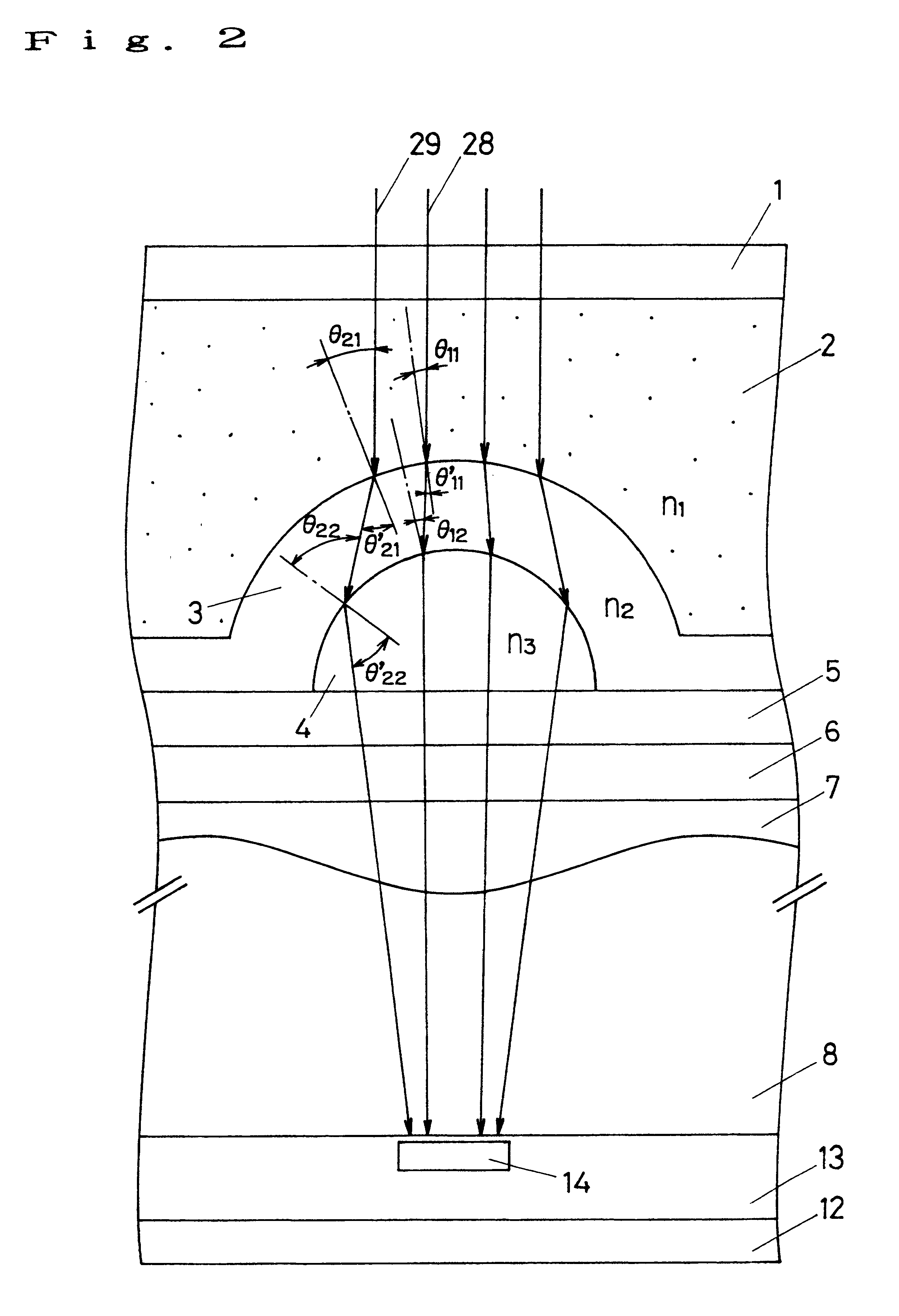

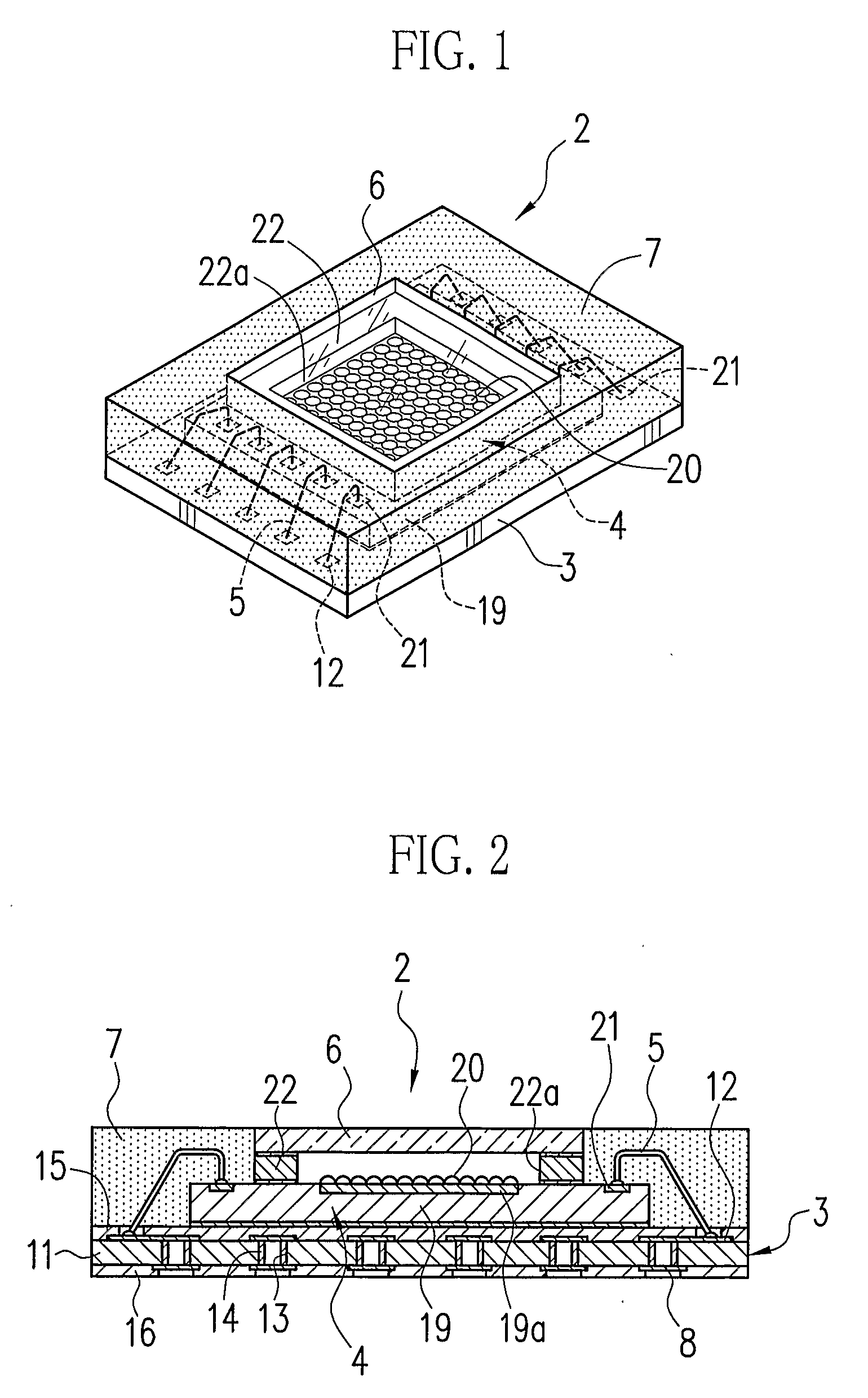

Solid-state imaging device

A conventional solid-state imaging device in which a sealing resin is applied onto a microlens has a low condensing efficiency. There are provided a photodiode 14 for receiving light, a microlens 4 made of a resin set on the photodiode 14 and having a refractive index of n3, a thin-film lens 3 formed on the microlens 4 and having a refractive index of n2, a sealing resin 2 formed on the thin-film lens 3 and having a refractive index of n1, and cover glass 1 formed on the sealing resin 2 to seal the sealing resin 2. The refractive index n2 of the thin-film lens 3 is set to a value smaller than n1 and n3. In this case, it is assumed that values of n1 and n3 are substantially equal to each other and the thin-film lens 3 is made of fluoride and / or oxide.

Owner:SOVEREIGN PEAK VENTURES LLC

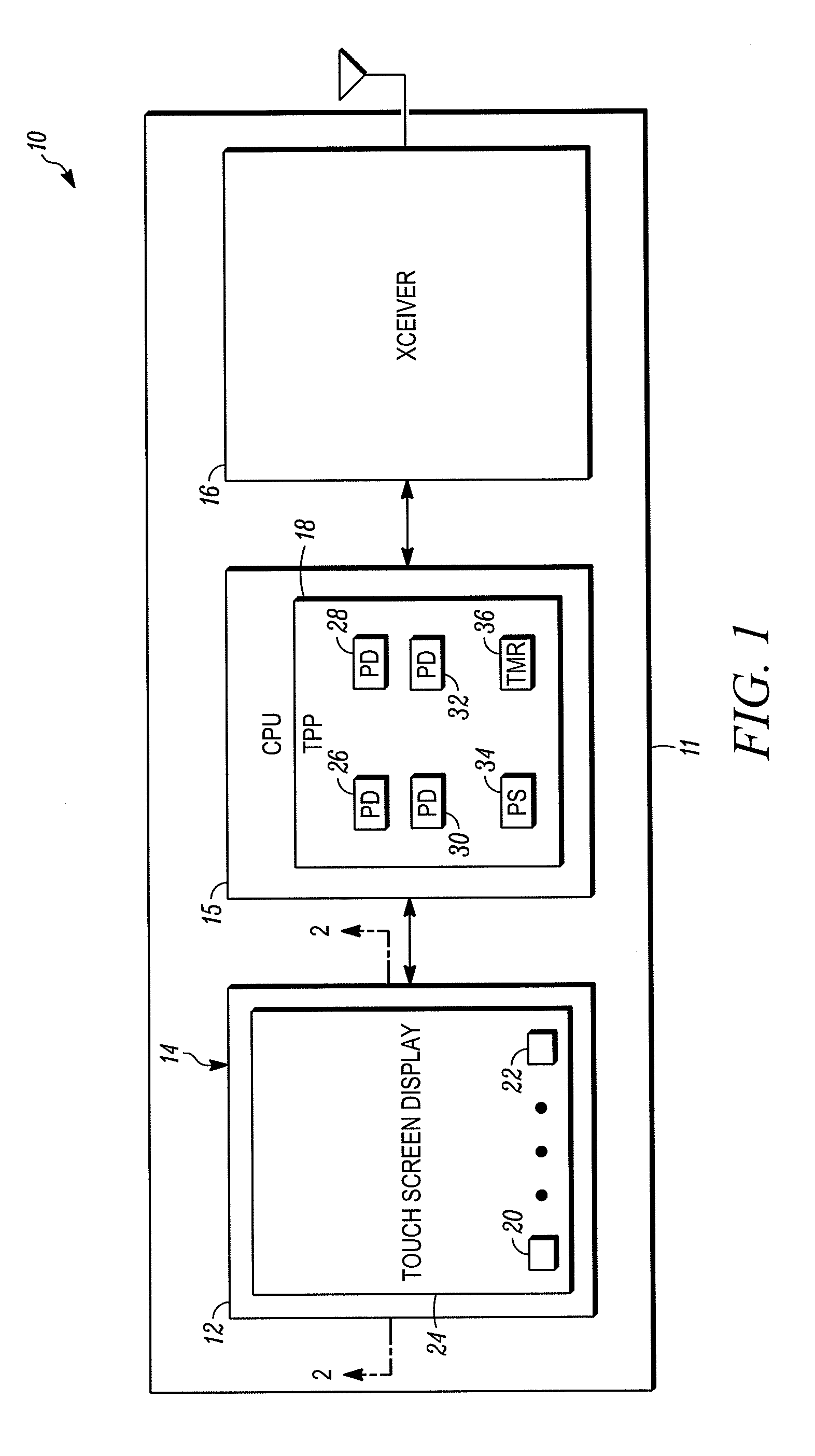

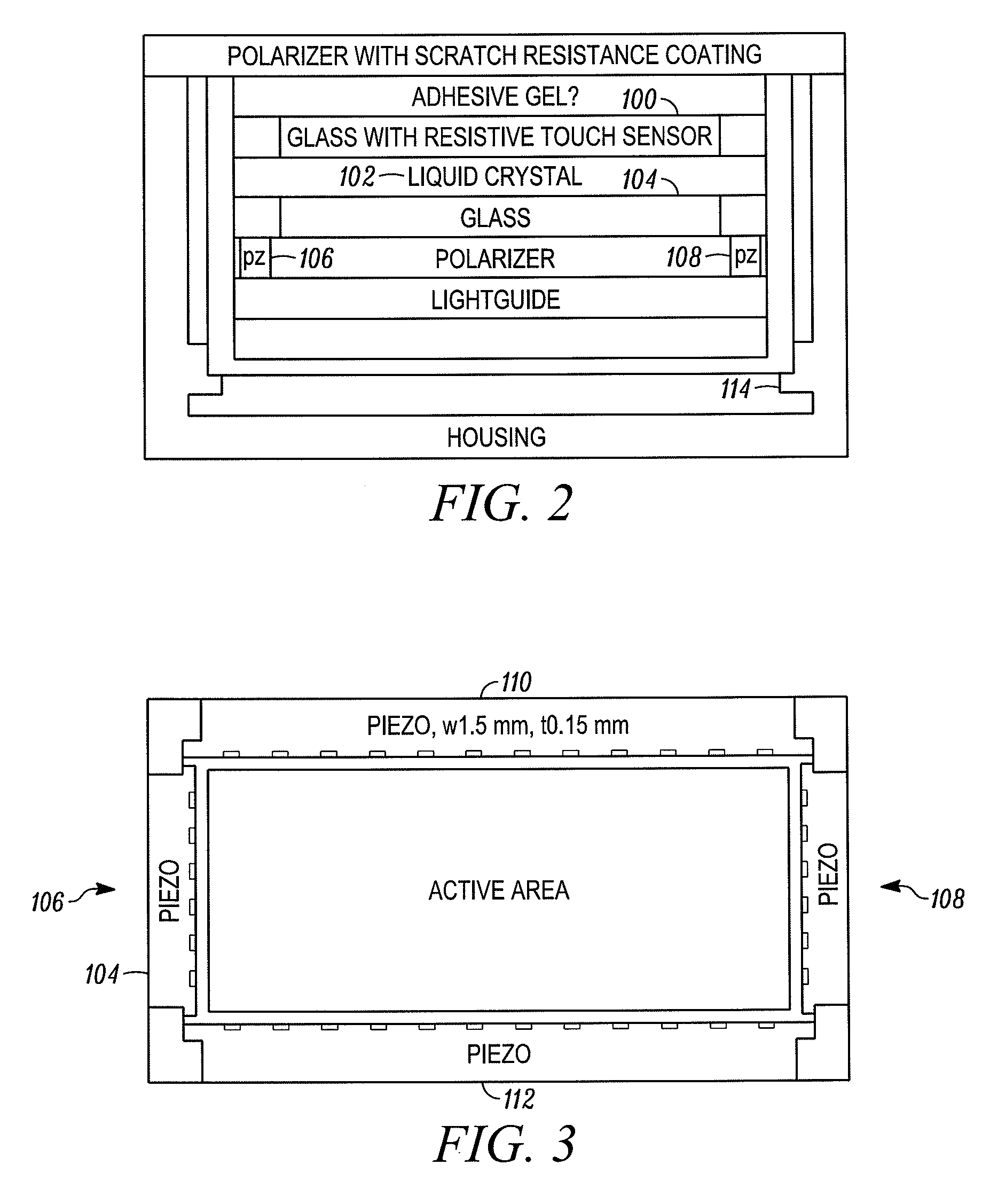

Display module with piezoelectric haptics

InactiveUS20100117809A1Digital data processing detailsRepeater circuitsLiquid-crystal displayBiological activation

A mobile communication terminal (10) is provided. The mobile communication terminal (10) includes a touch sensitive liquid crystal display (LCD) module (12) having a predetermined plurality of touch sensitive areas (20, 22) and a plurality of piezoelectric elements (106, 108, 110, 112) disposed along a periphery of a cover glass of the display module (12) wherein activation of the piezoelectric elements provides tactile feedback to a user of activation of a portion of the touch sensitive LCD module (12) by the user.

Owner:MOTOROLA MOBILITY LLC

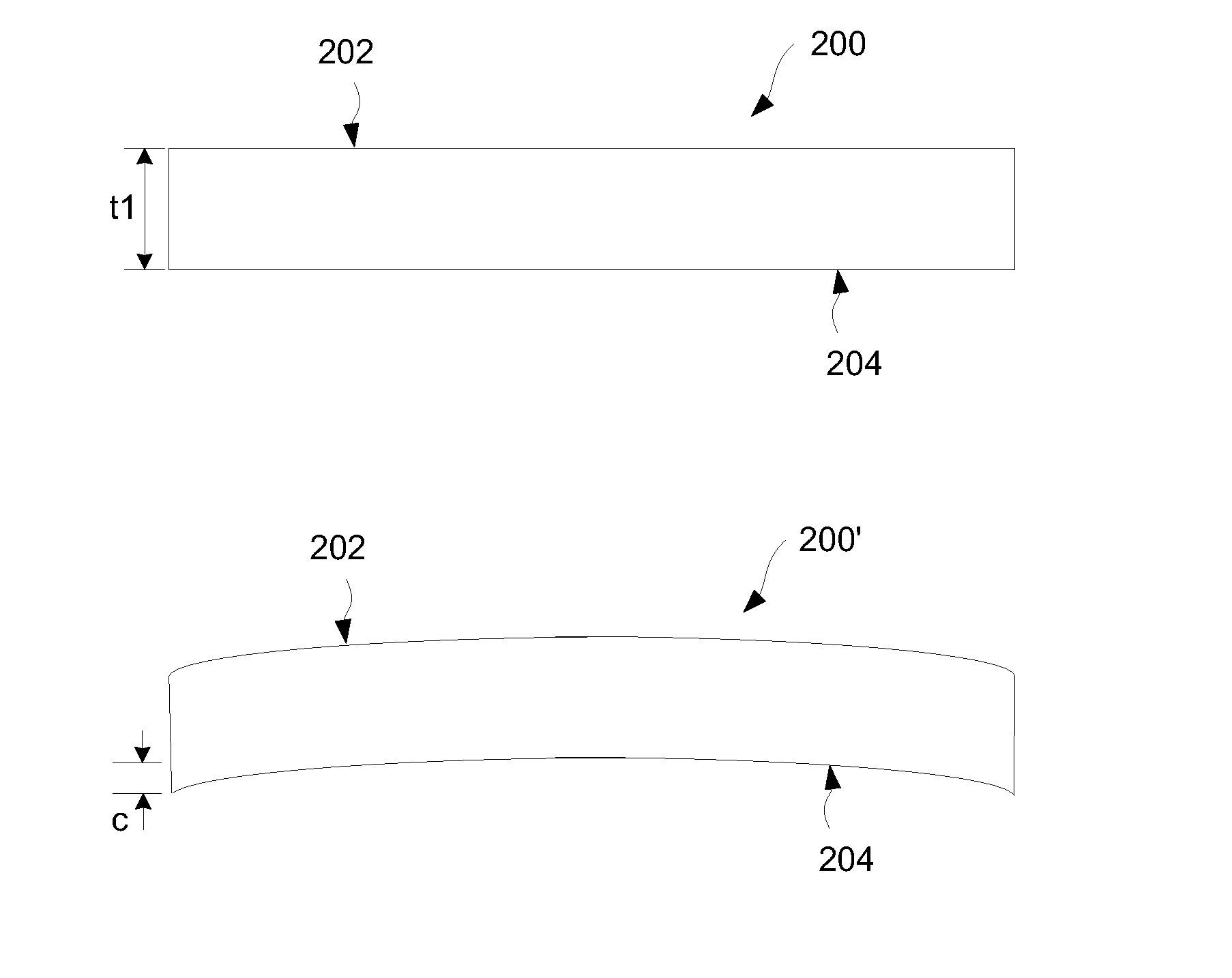

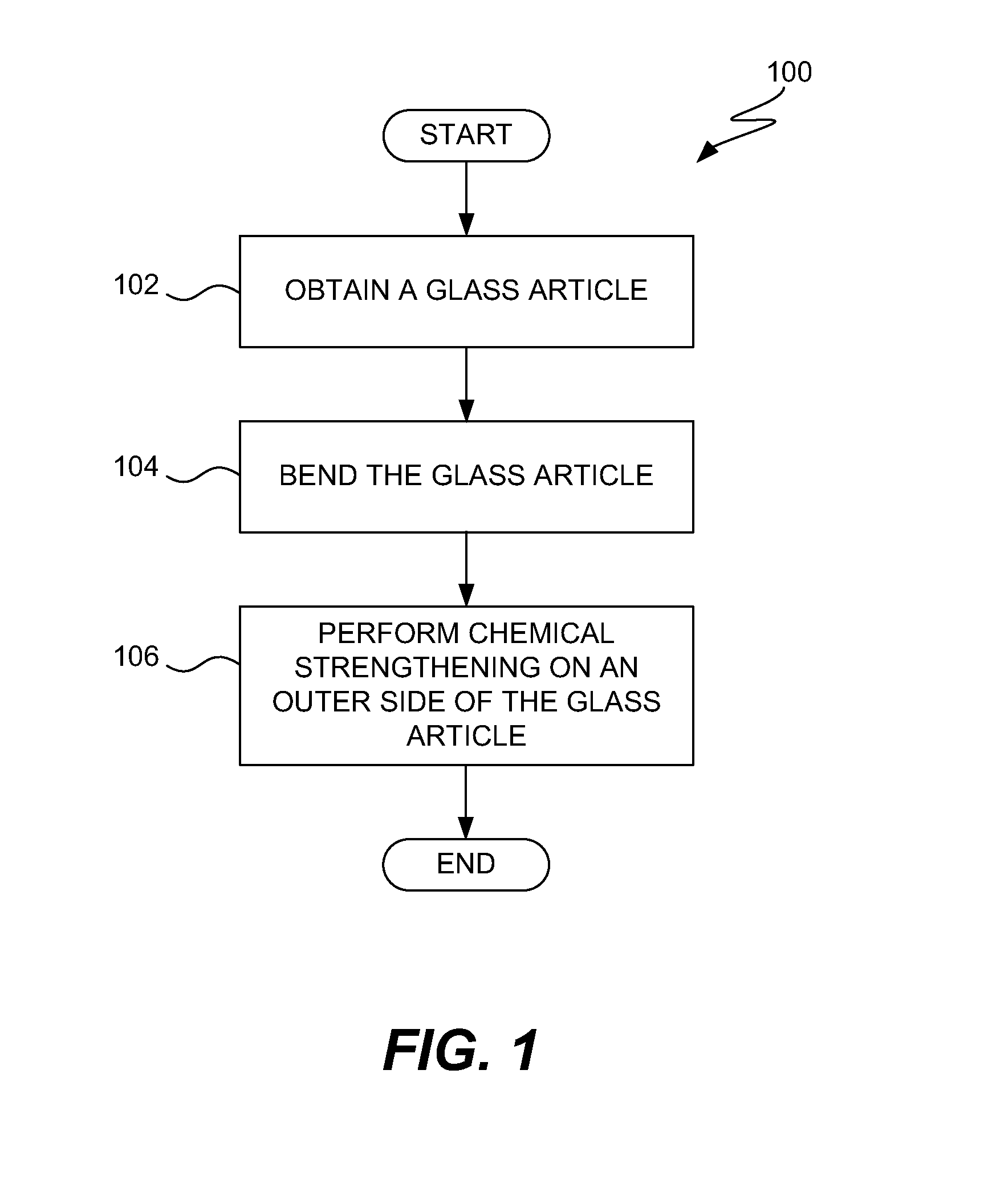

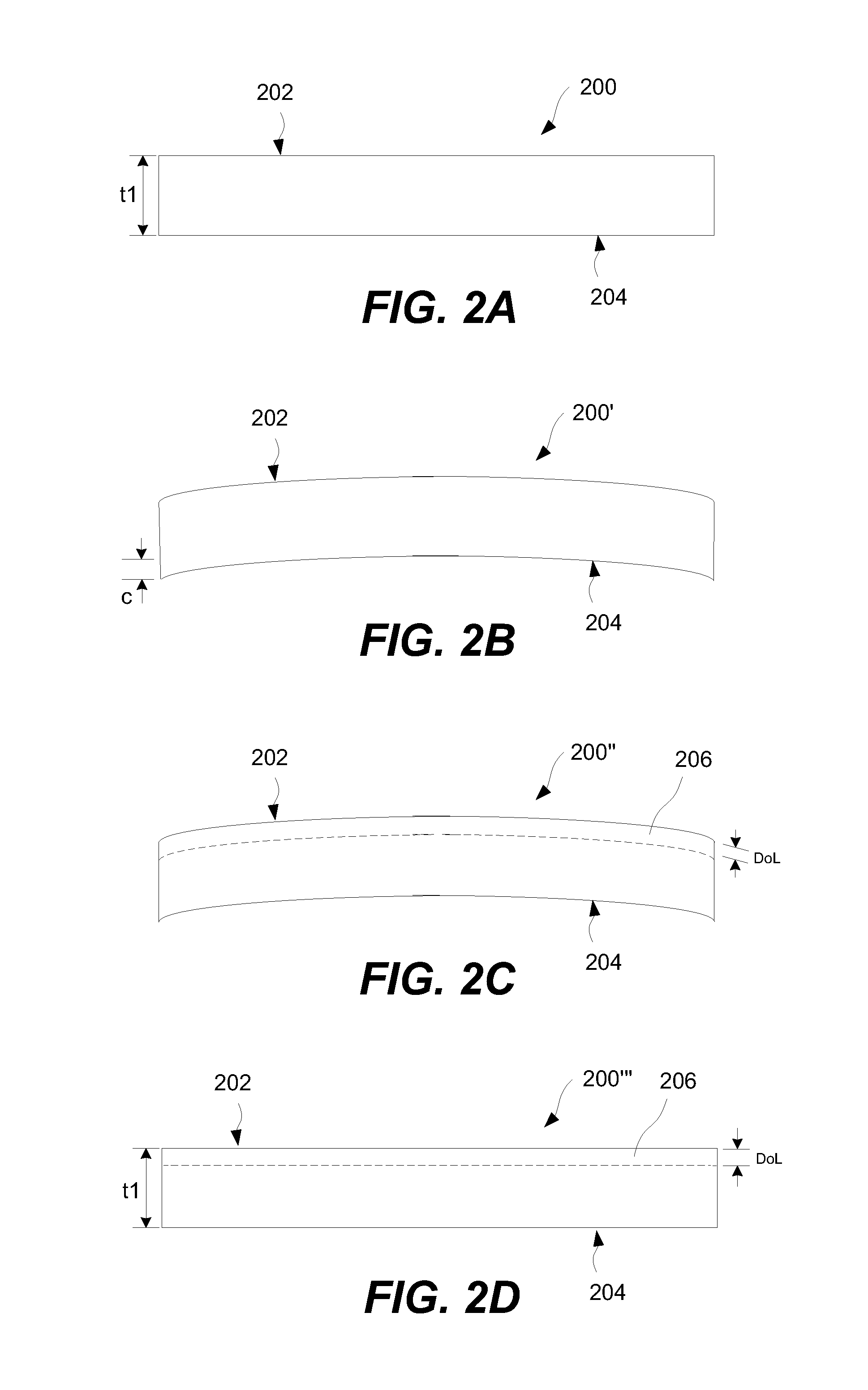

Asymmetric chemical strengthening

InactiveUS20150274585A1Improve glass strengthReduce distortion problemsDigital data processing detailsElectrical apparatus contructional detailsPHYSICAL MANIPULATIONSUltimate tensile strength

Apparatus, systems and methods for increasing the strength of glass are disclosed. The strengthening of one portion of the glass article can be performed to a greater degree than another portion. Additionally, to mitigate against any distortion, such as warpage, physical manipulation of the glass article can be performed prior to or during strengthening, namely chemical strengthening. For example, in accordance with one embodiment, an outer surface of a glass article (e.g., cover glass) can be chemically strengthened to a greater degree than an inner surface of the glass article, yet the asymmetric strengthening does not induce distortion of the glass article because the glass article was physically manipulated, such as being bent, to counter any such distortion. Accordingly, glass articles that have undergone chemical strengthening processing are able to be not only thin and undistorted but also sufficiently strong and resistant to damage. The strengthened glass articles are well suited for use in consumer products, such as consumer electronic devices (e.g., portable electronic devices).

Owner:APPLE INC

Glass substrate and method for manufacturing the same, cover glass and method for manufacturing the same, personal digital assistant, and display device

ActiveUS20160357294A1Flatness of thinExcellent surface appearanceDevices with sensorCharacter and pattern recognitionDisplay deviceEngineering

In a glass substrate for extracting therefrom a plurality of cover glasses to protect a protection object, plural concave portions are provided in a front surface or back surface of the glass substrate. The glass substrate includes plural thin portions formed by providing the plural concave portions and a thick portion connecting to the thin portion, and a haze value of the thin portion is 8% or less.

Owner:ASAHI GLASS CO LTD

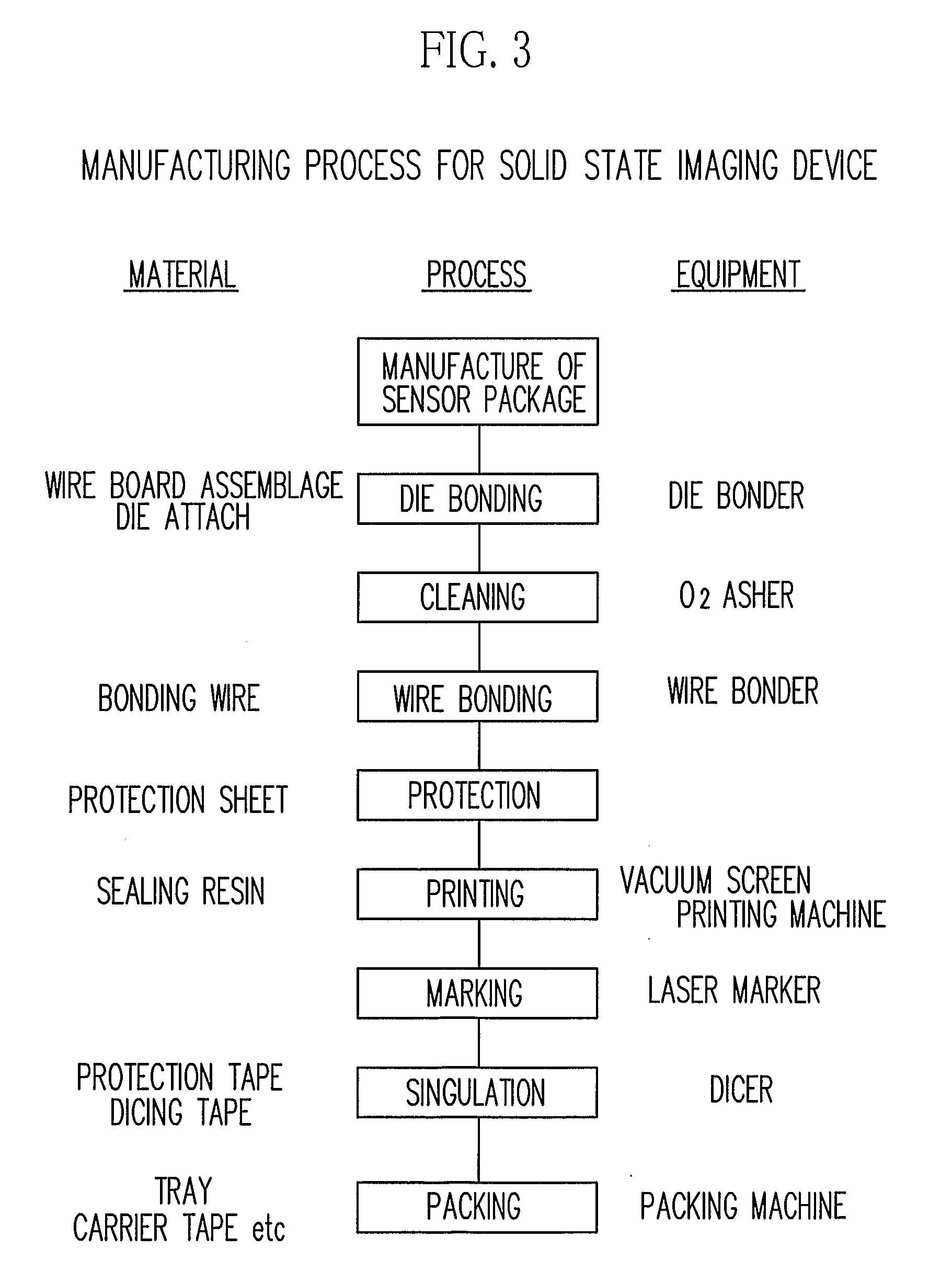

Method of manufacturing solid state imaging device

InactiveUS20090053850A1Avoid corrosionIncrease manufacturing costSolid-state devicesSemiconductor/solid-state device manufacturingCover glassSilk-screen printer

A mask (68) is attached to a circuit assembly board (47) on which a plurality of sensor packages (4) are adhered. An upper face of a cover glass (6) of each sensor package (4) is protected by a mask section (68b) of the mask (68). The circuit assembly board (47) is set in a vacuum screen printing machine and paste of sealing resin (7) is supplied to it. The circuit assembly board (47) is moved in a horizontal direction on a stage with a squeegee (65) pressed onto an upper face of the mask (68). The squeegee (65) presses to fill the sealing resin (7) around each of the sensor packages (4).

Owner:FUJIFILM CORP

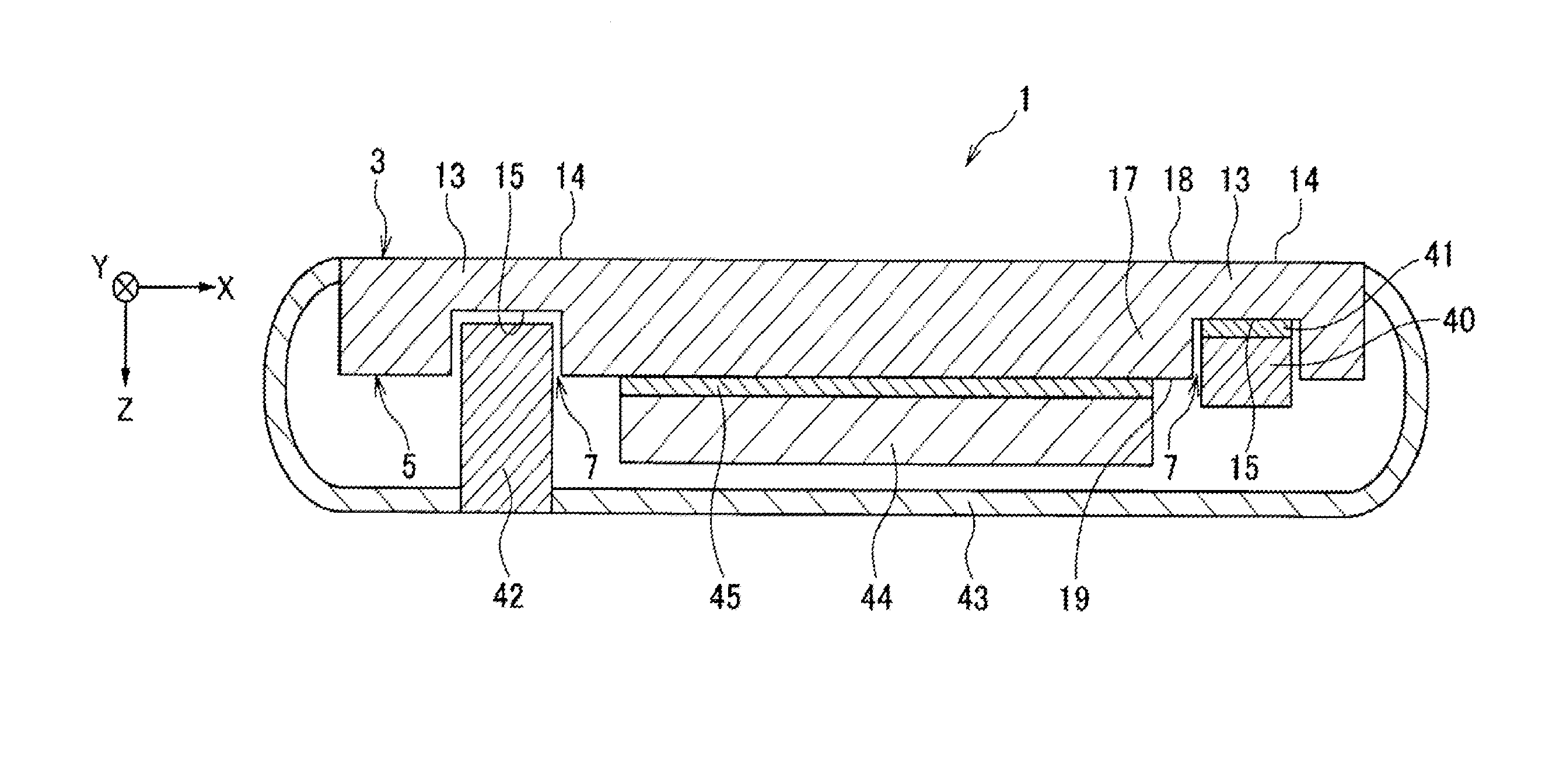

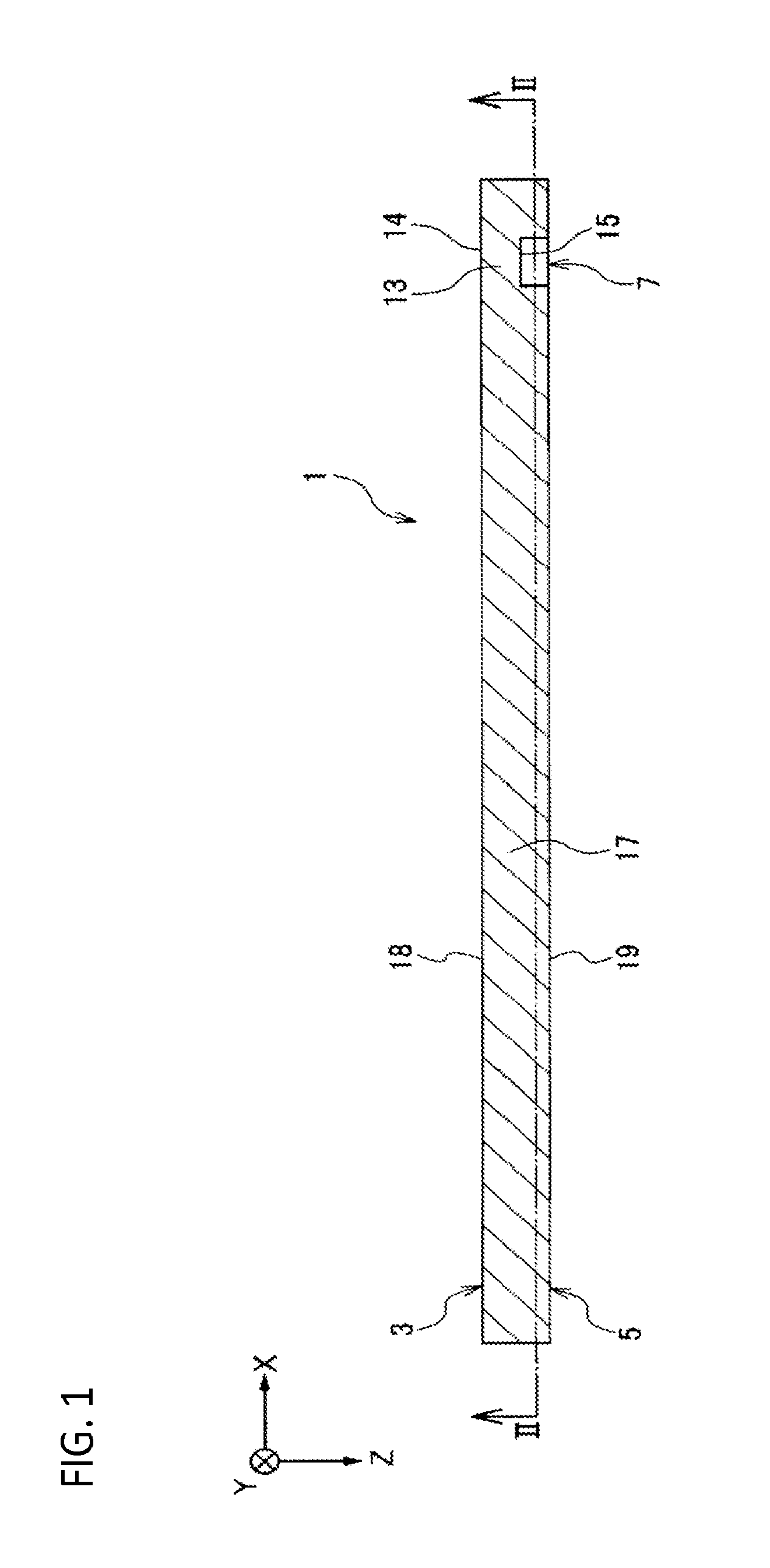

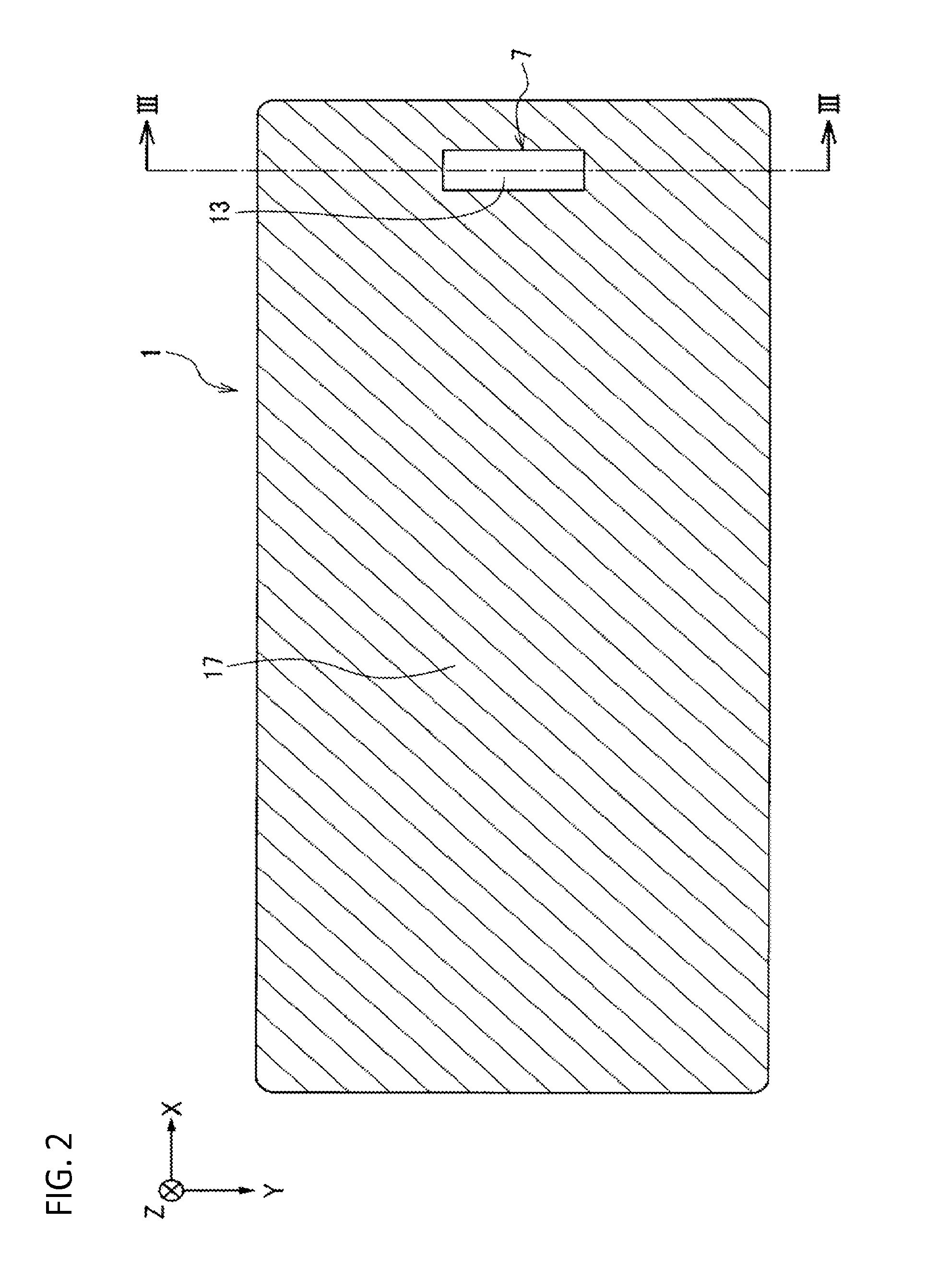

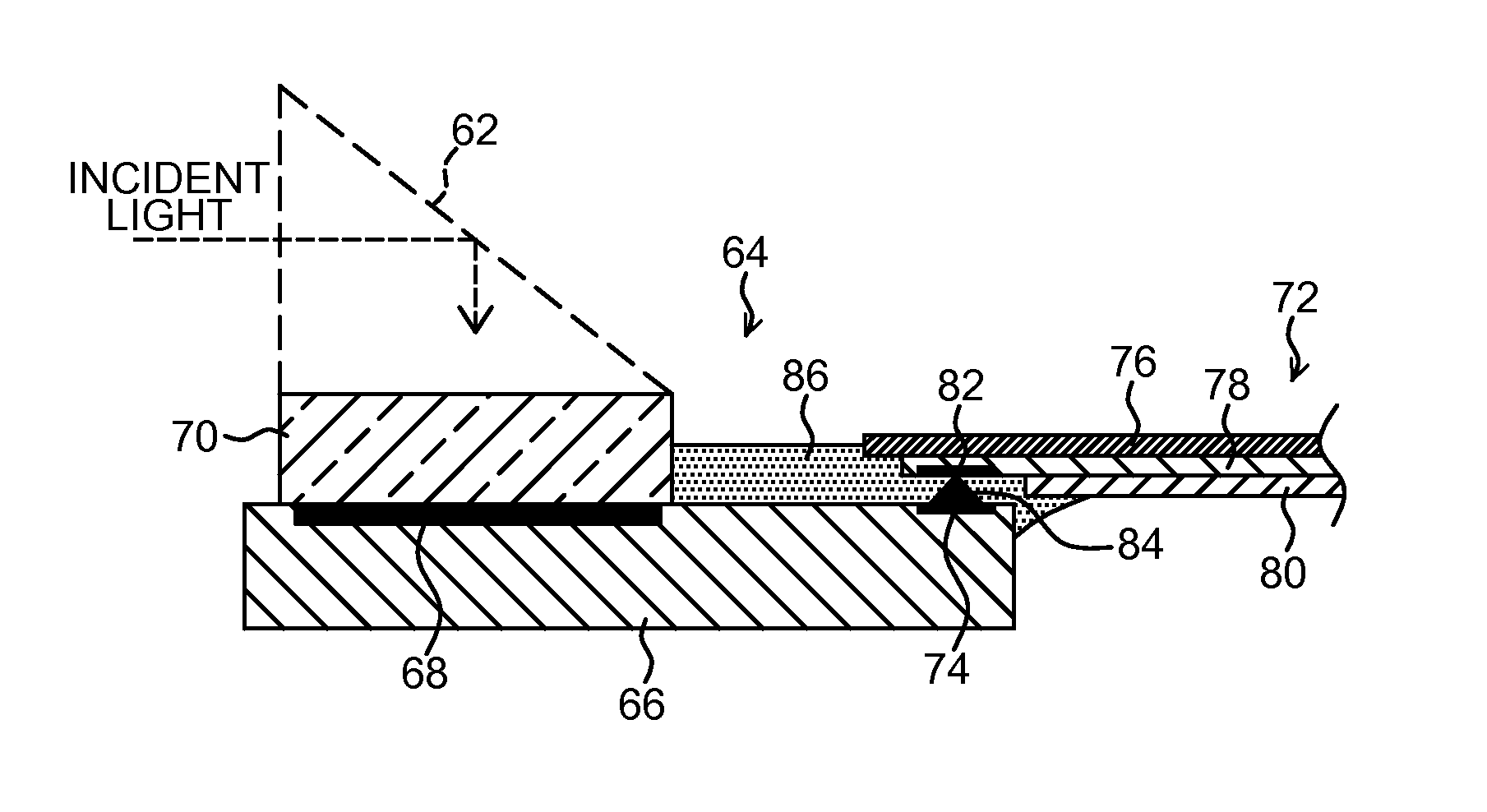

Image pickup module, manufacturing method thereof, and endoscopic device

InactiveUS20110224487A1Improve workabilityConnection strengthSurgeryEndoscopesComputer moduleEndoscope

Size reduction of an image pickup module is promoted, and reliability of electric connection and electric noise resistance are improved by decreasing the numbers of components and connection spots. The problems are solved by providing an image pickup module including a solid-state image pickup element chip having an image pickup surface, a cover glass that covers the image pickup surface, and a wiring board on which the solid-state image pickup element chip is mounted, in which the solid-state image pickup element chip and the wiring board have an overlap structure in which end portions thereof are overlapped with each other, and a first electrode portion formed on the end portion of the solid-state image pickup element chip and a second electrode portion formed on the end portion of the wiring board are electrically connected through a bump.

Owner:FUJIFILM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com