Patents

Literature

39 results about "Film processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Film forming method and processing system

ActiveUS20110163451A1Improve barrier propertiesImprove adhesionLiquid surface applicatorsSemiconductor/solid-state device detailsEngineeringFilm processing

Provided is a film-forming method for performing a film-forming process on a surface of a target substrate to be processed in an evacuable processing chamber, a recessed portion being formed on the surface of the target substrate. The method includes a transition metal-containing film processing process in which a transition metal-containing film is formed by a heat treatment by using a source gas containing a transition metal; and a metal film forming process in which a metal film containing an element of the group VIII of the periodic table is formed.

Owner:TOKYO ELECTRON LTD

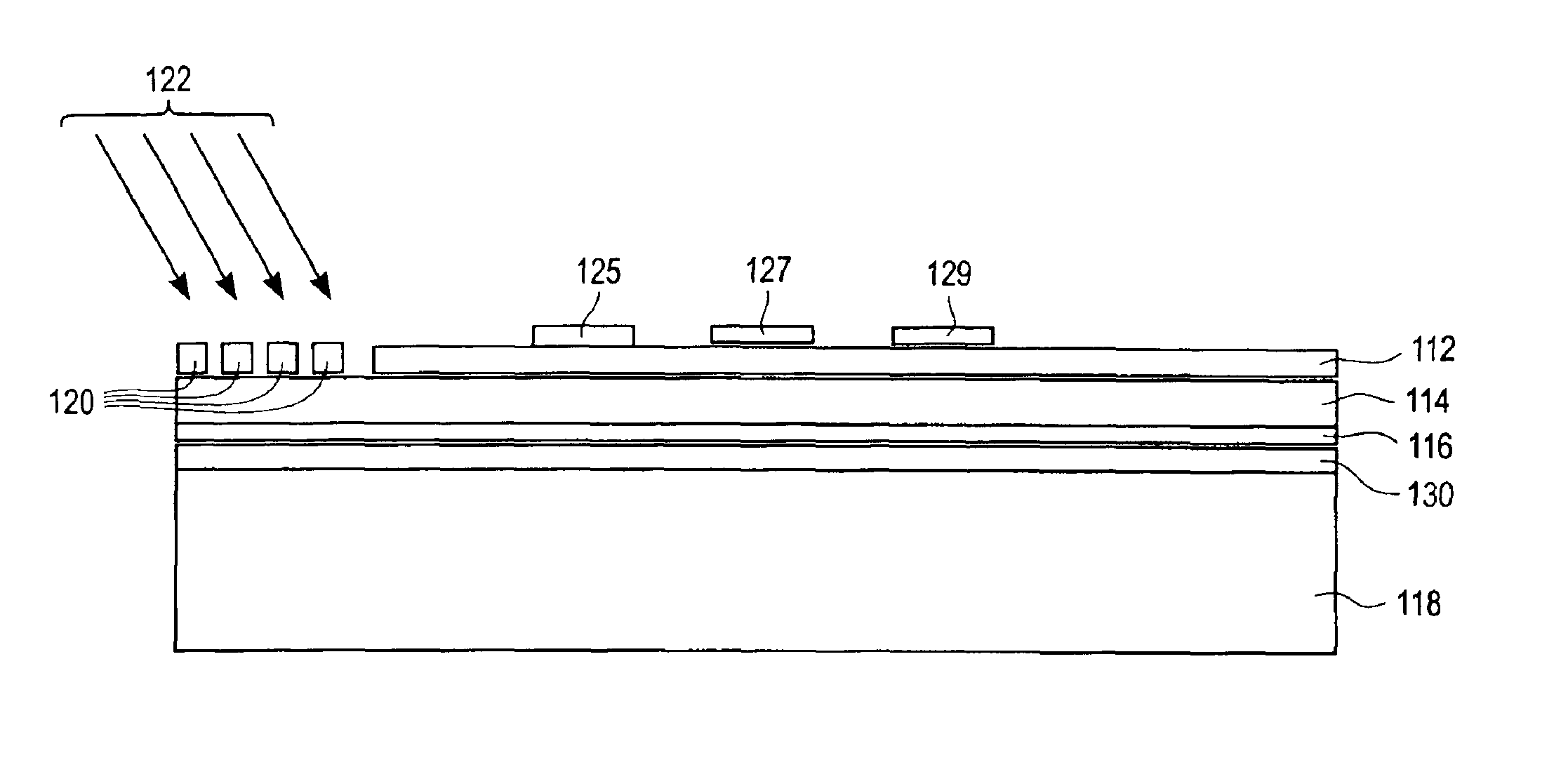

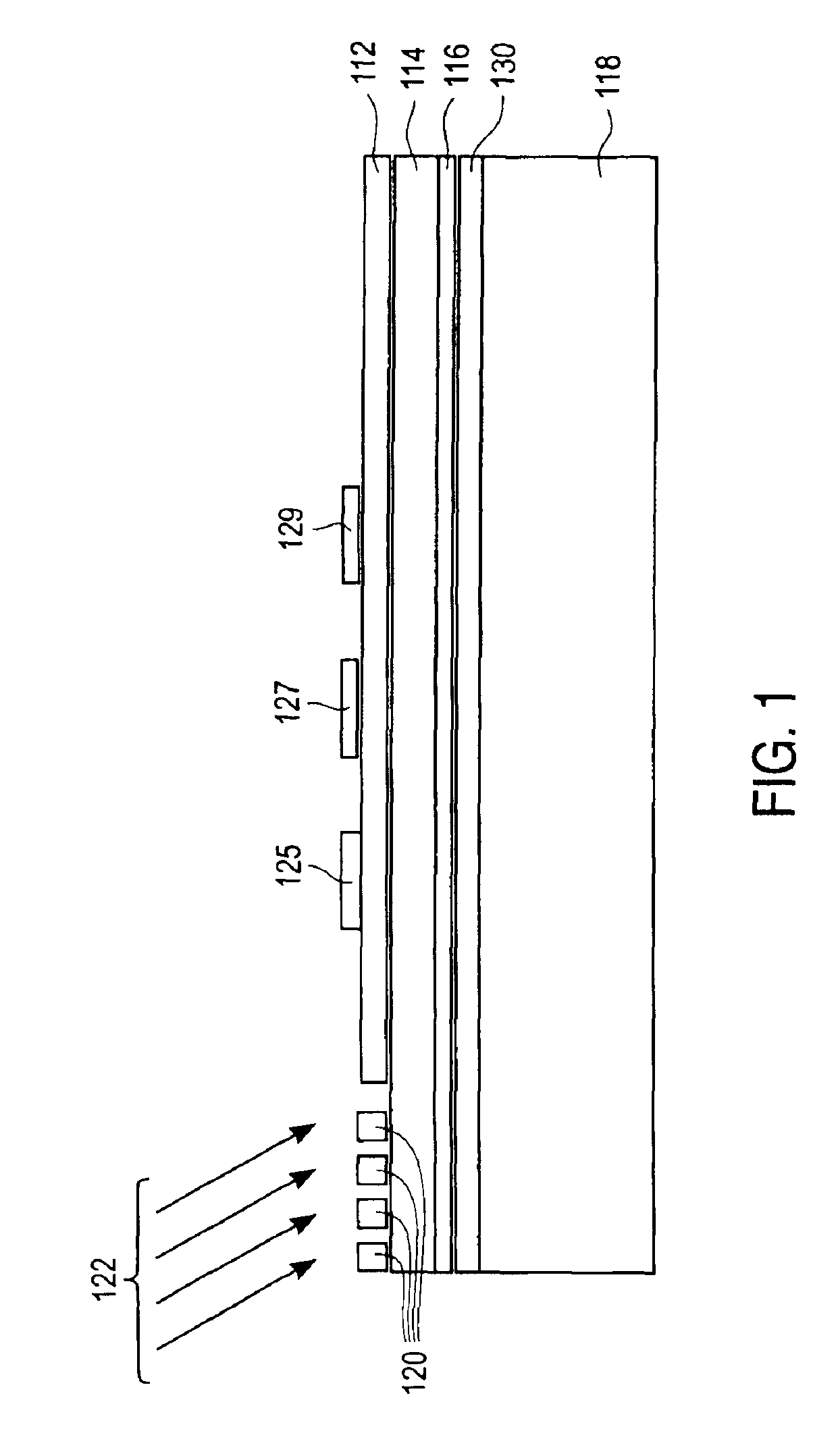

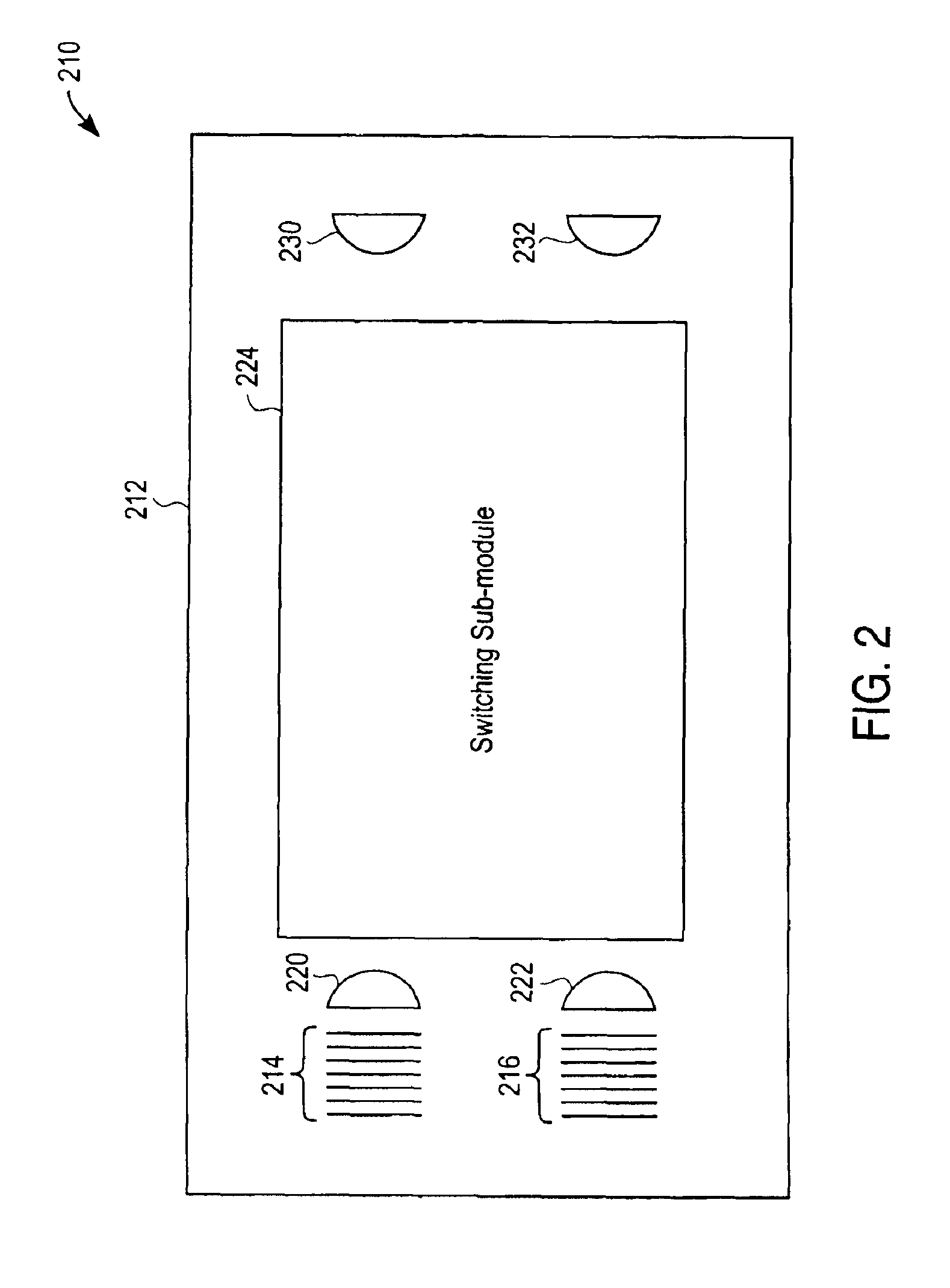

Optical switch fabricated by a thin film process

InactiveUS6885789B2Easy to takeSemiconductor/solid-state device manufacturingCoupling light guidesWaveguideFilm processing

An electro-optical switch is provided, that includes: a single mode optical waveguide having a thin ferroelectric oxide film for propagating a single mode of light; a coupler adjoining the single mode optical waveguide for coupling a part of the single mode of light from an optical fiber to the single mode optical waveguide; an electrically formed lens in the single mode optical waveguide for collimating the single mode of light from the coupler; and a switching module comprising another electrically formed lens in the single mode optical waveguide, for switching the single mode of light.

Owner:FUJITSU LTD

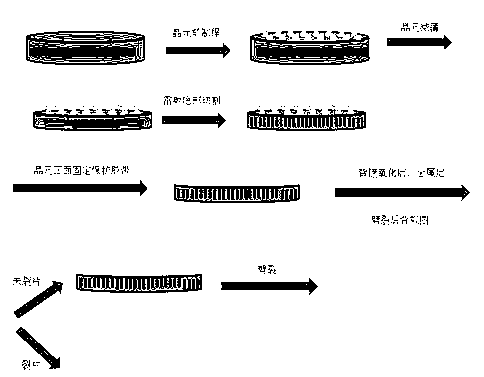

Semiconductor component coating film processing method

InactiveCN103258773ASolve processingSolve the problem of fragile piecesSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringLaser cutting

The invention discloses a semiconductor component coating film processing method which includes a first step of conducting thinning on a wafer before conducting back coating on a reflective layer, a second step of conducting invisible laser cutting on the wafer, a third step of enabling the wafer which the invisible laser cutting is conducted on to be attached and bonded to a firm substrate, a fourth step of conducting the back coating on an oxidized layer or a metal layer, a fifth step of conducting peeling on the attached and bonded substrate after the back coating is completed, and a sixth step of conducting separation. Through addition of the process that the wafer is attached and bonded to the firm substrate, the semiconductor component coating film processing method solves the problems that in the prior art, the wafer is fragile and difficult to process and is easily broken when attached through only one adhesive tape after the invisible cutting.

Owner:合肥彩虹蓝光科技有限公司

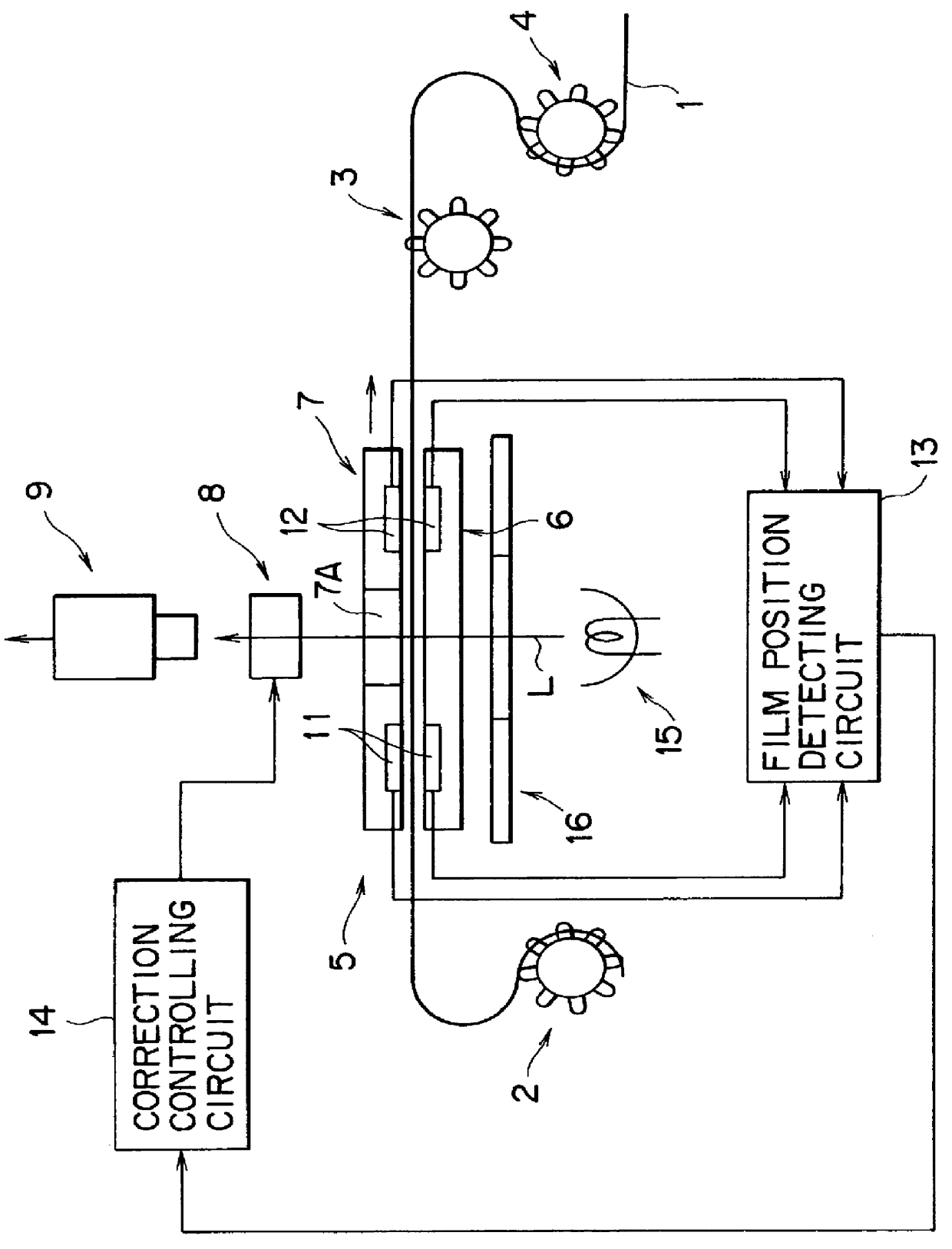

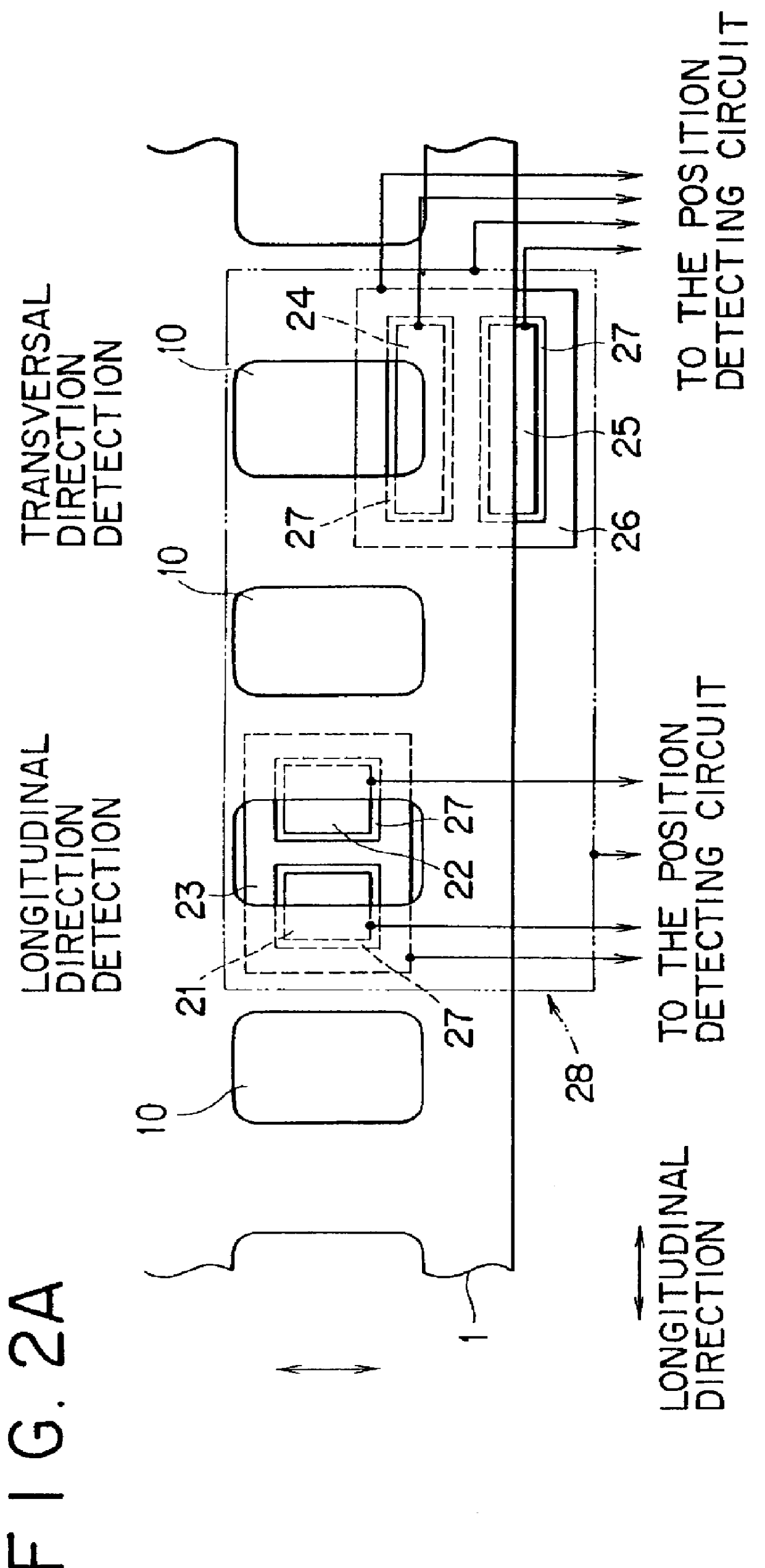

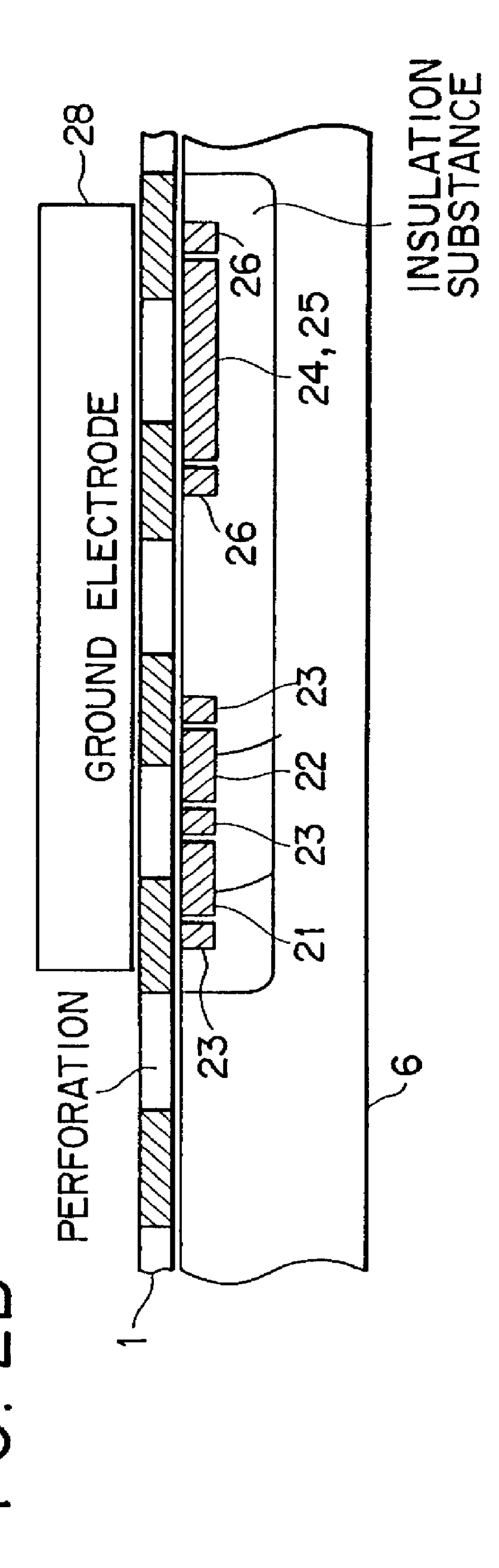

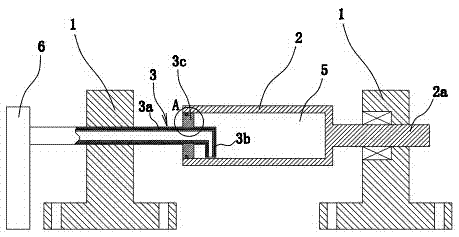

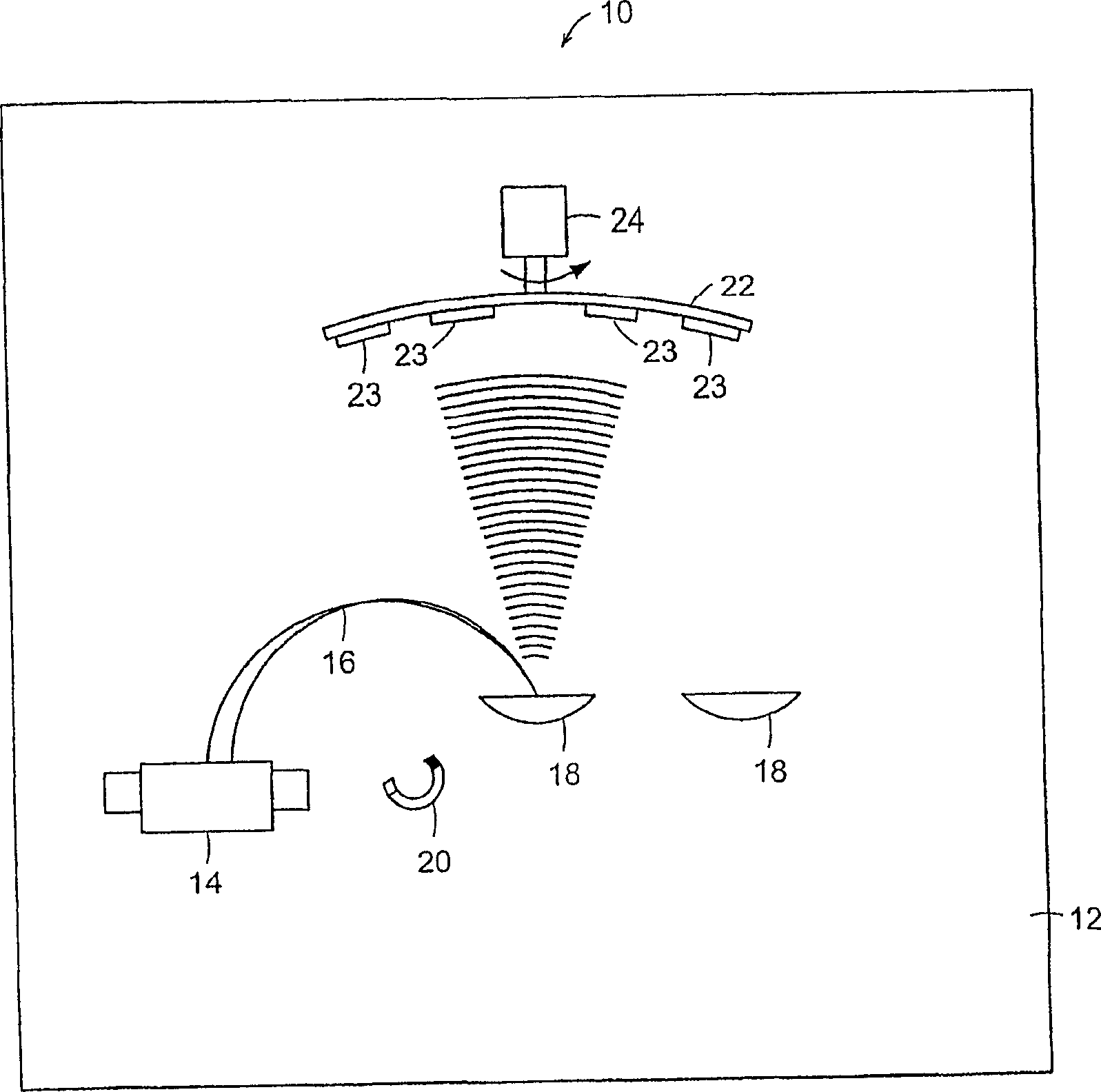

Film processing apparatus and film processing method

InactiveUS6048066AProjector film strip handlingCamera film strip handlingAnomaly detectionOptical axis

A movie film image projecting device wherein a movie film is intermittently stopped in a manner synchronized with rotation of a sprocket by means of travel-synchronizing holes which have been formed longitudinally with respect to the movie film and a light from a light source is projected on a stated region of the movie film at a stopped base position. Detectors for detecting at a plurality of locations the displacement of the film from the base position at the time the movie film has stopped, on the basis of the travel-synchronizing holes, output a different position detection signal corresponding to the deviation of the film from the base position at each of the plurality of locations. An abnormality judging circuit supplied with the position detection signals determines whether or not the position detection signals are abnormal and outputs an abnormality detection signal for each of the position detection signals which is determined to be abnormal. An optical axis correcting unit supplied with the position detection signals and the abnormality detection signals then corrects the optical axis of light transmitted through the movie film on the basis of the position detection signals which are judged by the abnormality judging means to be not abnormal.

Owner:SONY CORP

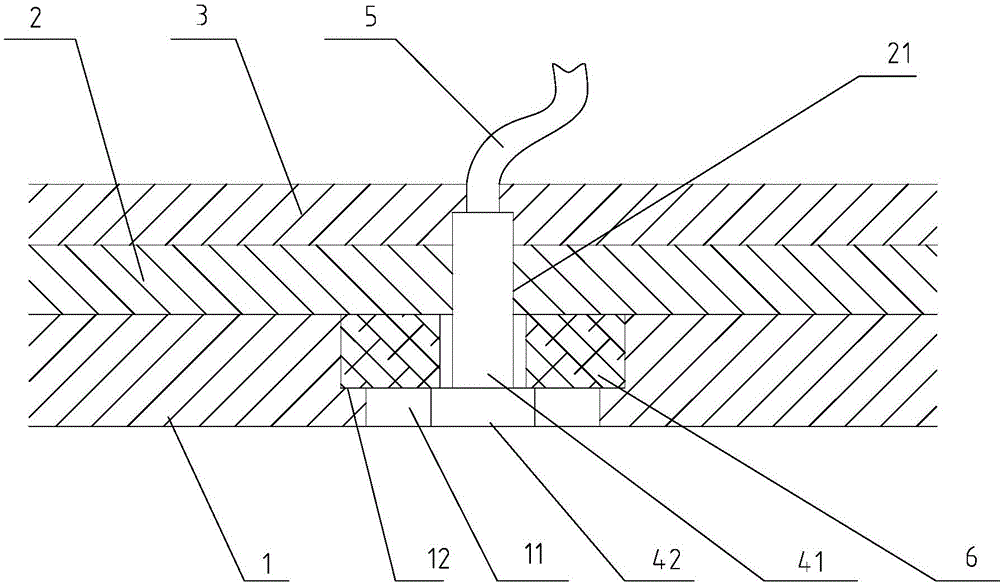

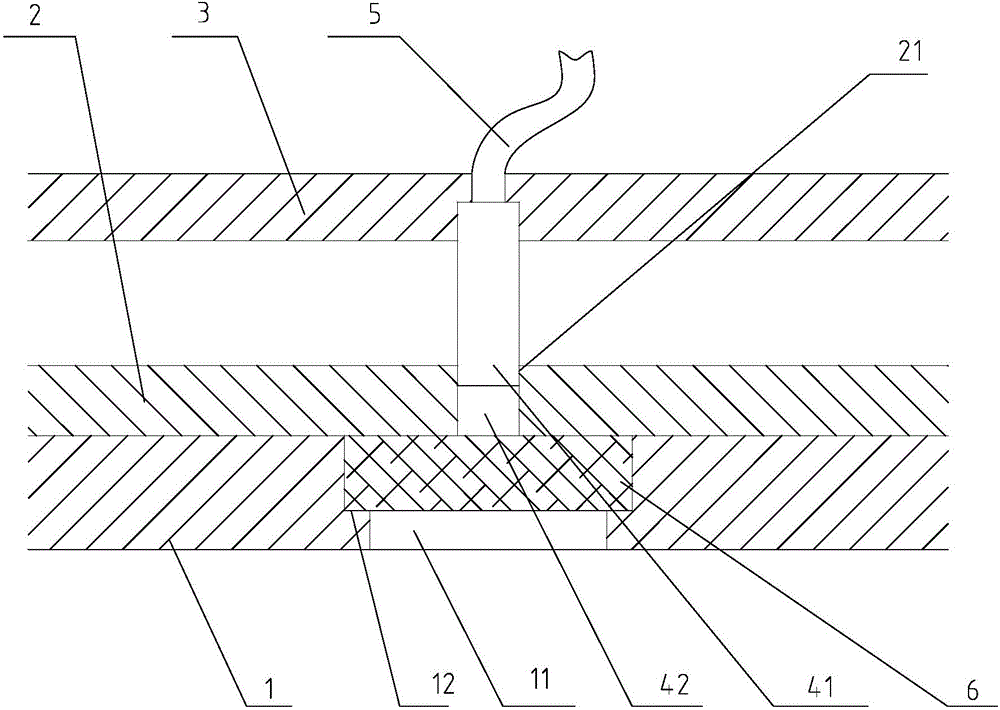

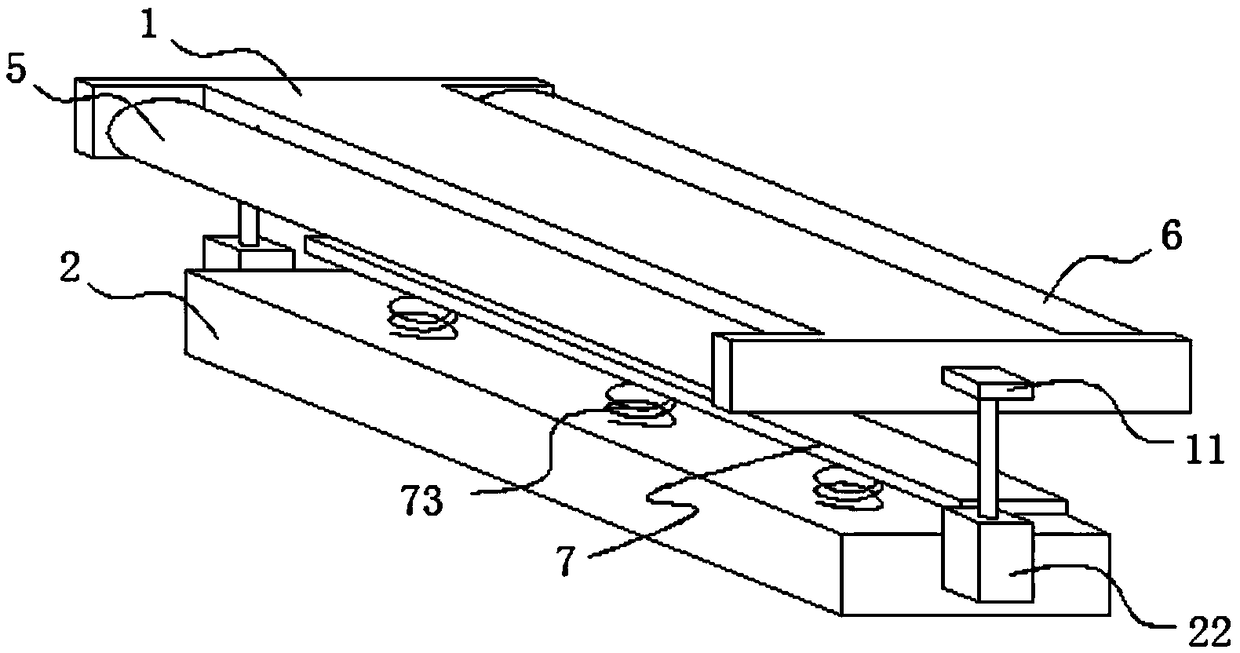

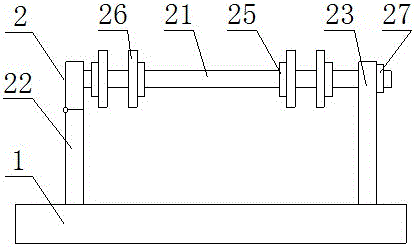

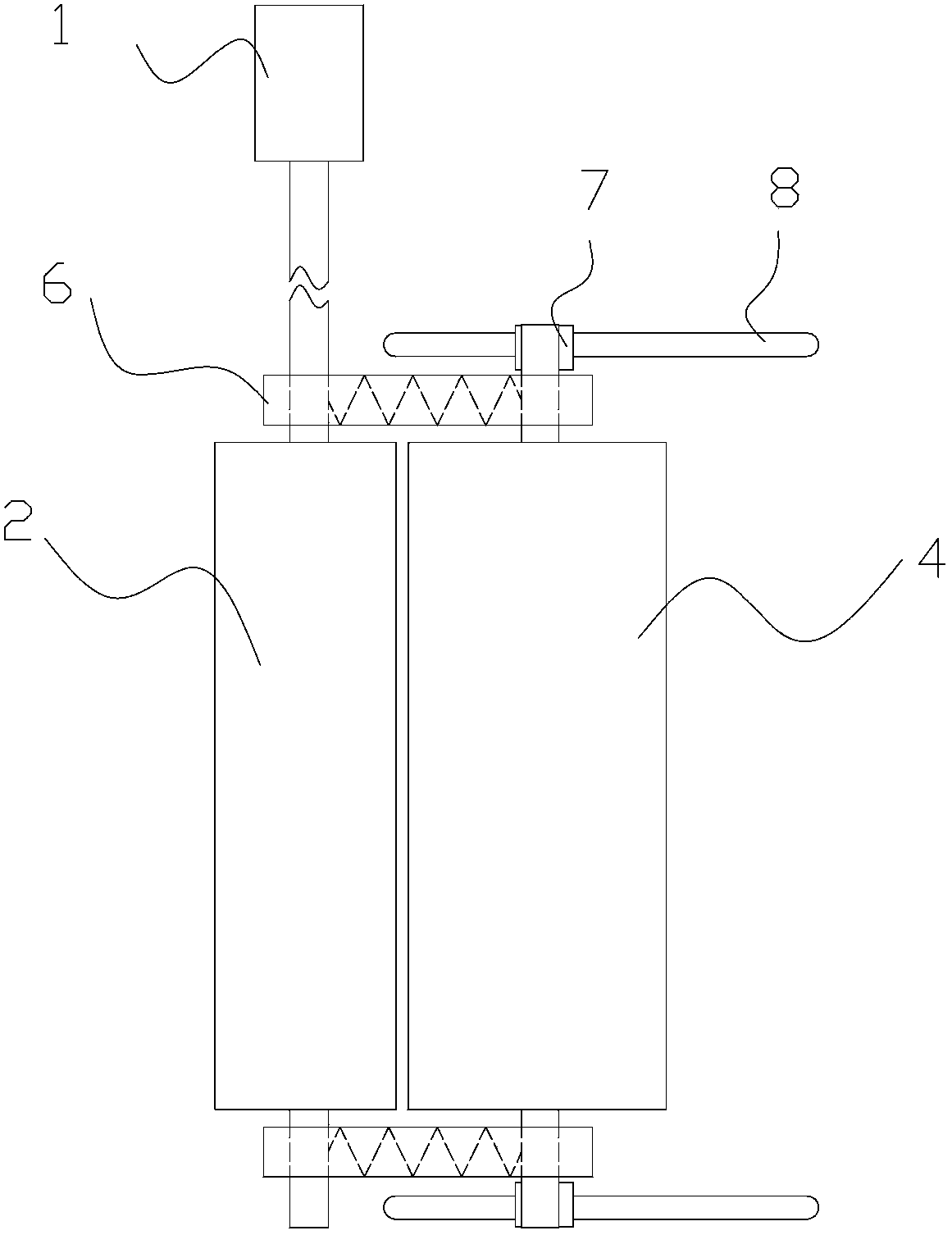

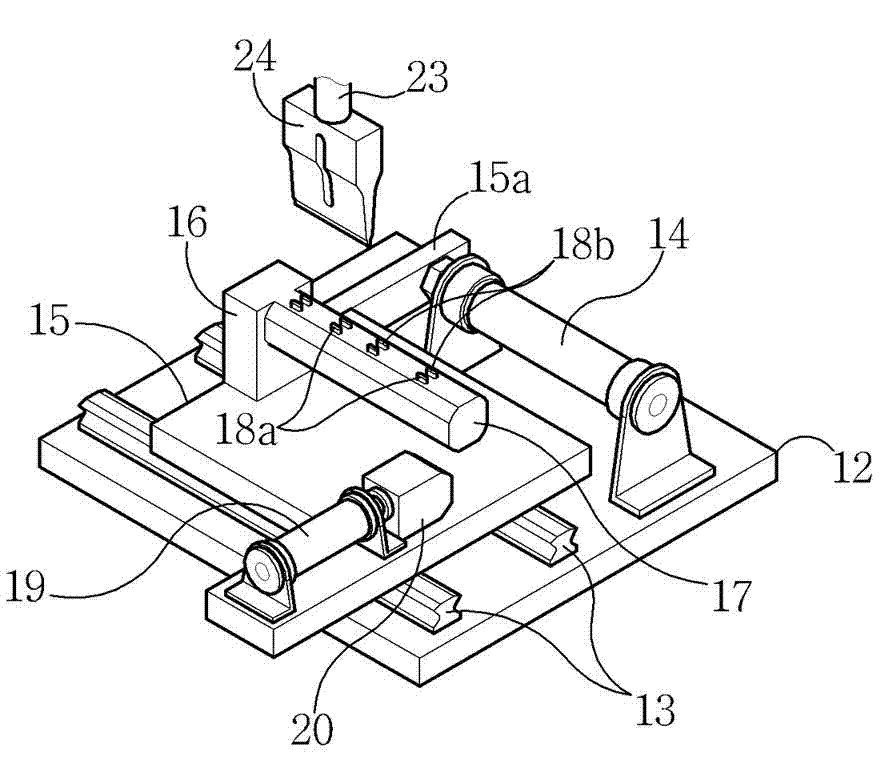

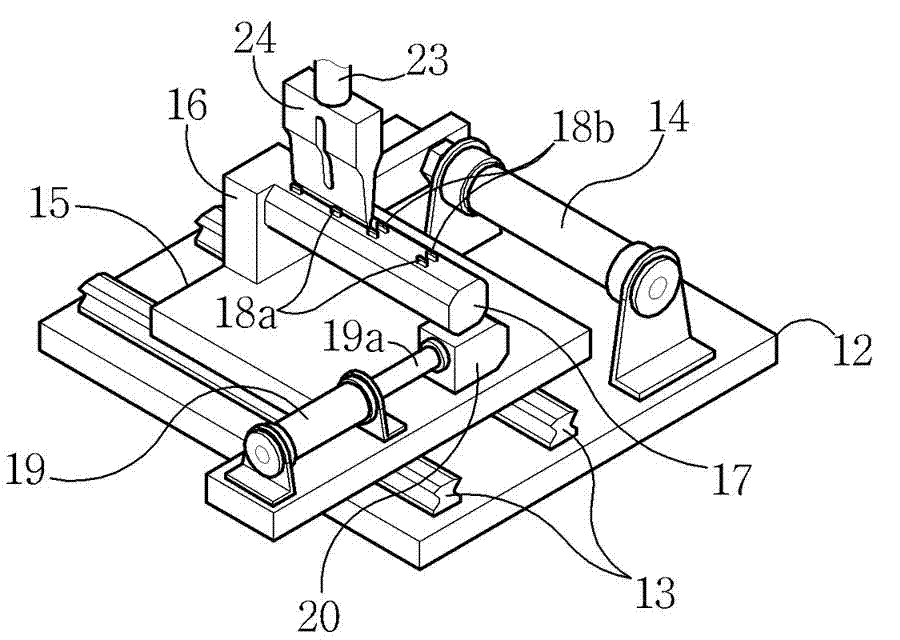

Cooling device of plastic thin film processing device

The invention provides a cooling device of a plastic thin film processing device and belongs to the technical field of machinery. The cooling device solves the problem of complex operation of a cooling roller in a thin film processing line. The cooling device includes two pedestals and a roller arranged therebetween. One end of the roller is sealed while the other one end is opened. A rotational portion is arranged on the sealed end and is axially fixed to the corresponding pedestal. A liquid inlet pipe is installed in the opened end and comprises a liquid inlet portion, which is axially arranged along the roller, and a liquid outlet portion, which is arranged in the radial direction of the roller. The outer end of the liquid inlet portion is stretched out from the opened end and is fixed to the corresponding pedestal. A ring-shaped connection portion is arranged on the edge of the inner end of the liquid inlet portion. A sealing ring is arranged between the connection portion and the roller. A refrigerating chamber is formed between the connection portion and the inner wall of the roller. The liquid inlet portion is communicated with a refrigerating system. The refrigerating system works so that a refrigerant cyclically flows in the refrigerating chamber. The cooling device is convenient to operate.

Owner:TIANJIN KAKA TECH CO LTD

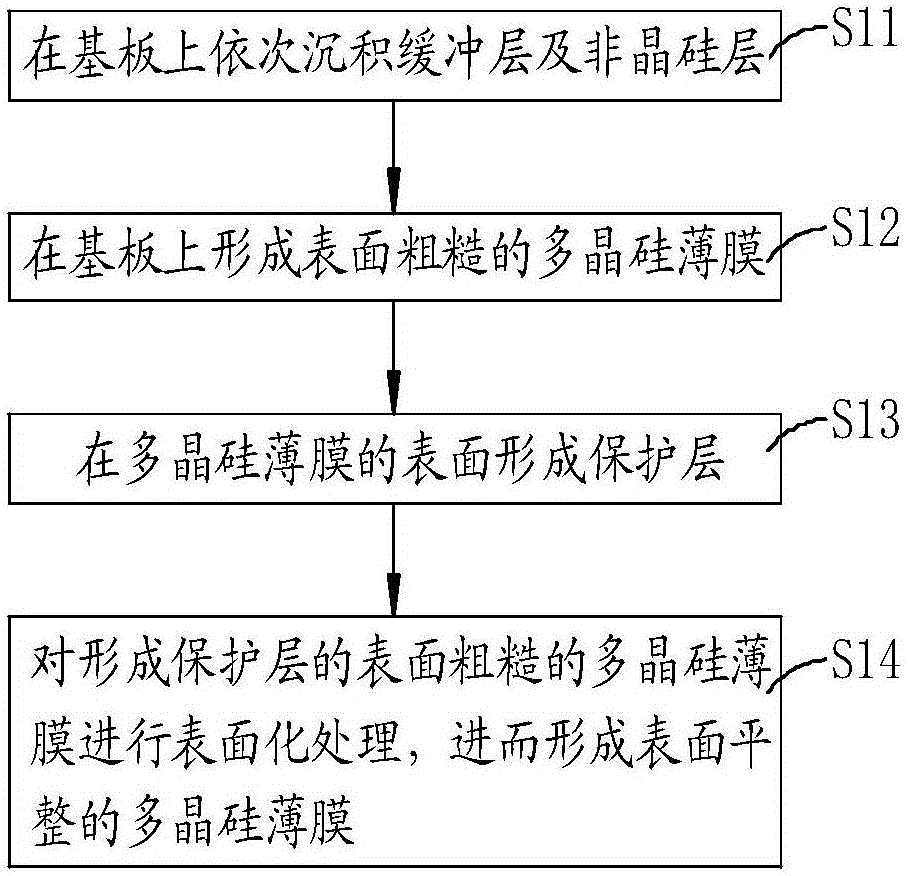

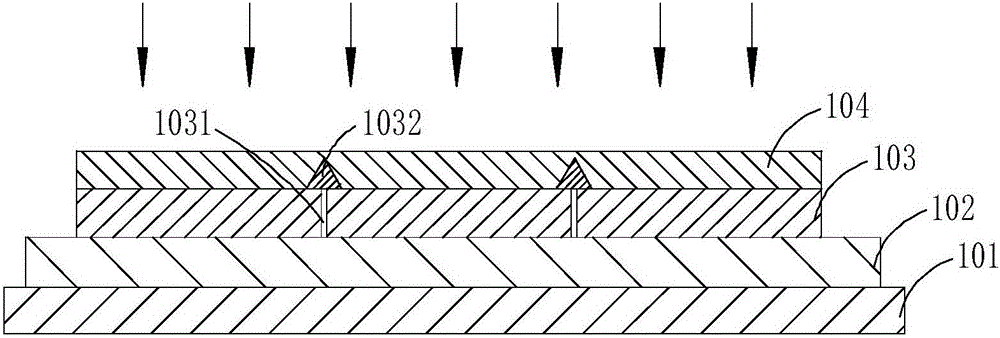

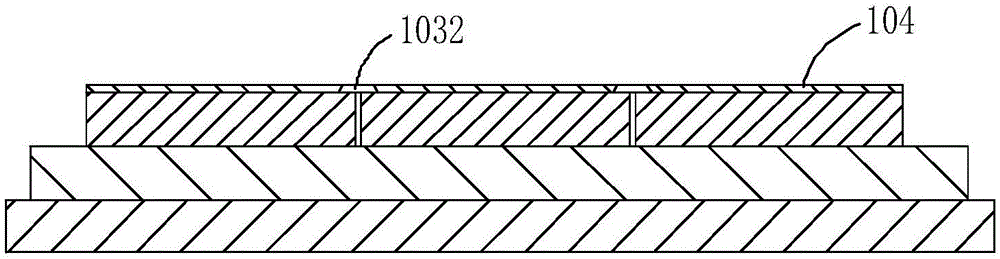

Polycrystalline silicon thin film processing method, thin film transistor, array substrate and display panel

ActiveCN106783582AAvoid tip discharge phenomenonImprove leakage currentTransistorSemiconductor/solid-state device manufacturingOptoelectronicsFilm processing

The invention provides a polycrystalline silicon thin film processing method, a thin film transistor, an array substrate and a display panel. The method comprises the following steps: forming a polycrystalline silicon thin film with a coarse surface on a substrate; forming a protective layer on the surface of the polycrystalline silicon thin film; carrying out surface processing on the polycrystalline silicon thin film with the coarse surface on which the protective layer is formed, and then forming a polycrystalline silicon thin film with a smooth surface. Through the method, the polycrystalline silicon thin film with the smooth surface can be formed, and then relatively large leakage current generated by a point discharge phenomenon caused by the coarse polycrystalline silicon thin film is avoided in the corresponding array substrate and display panel, so that the product quality is improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

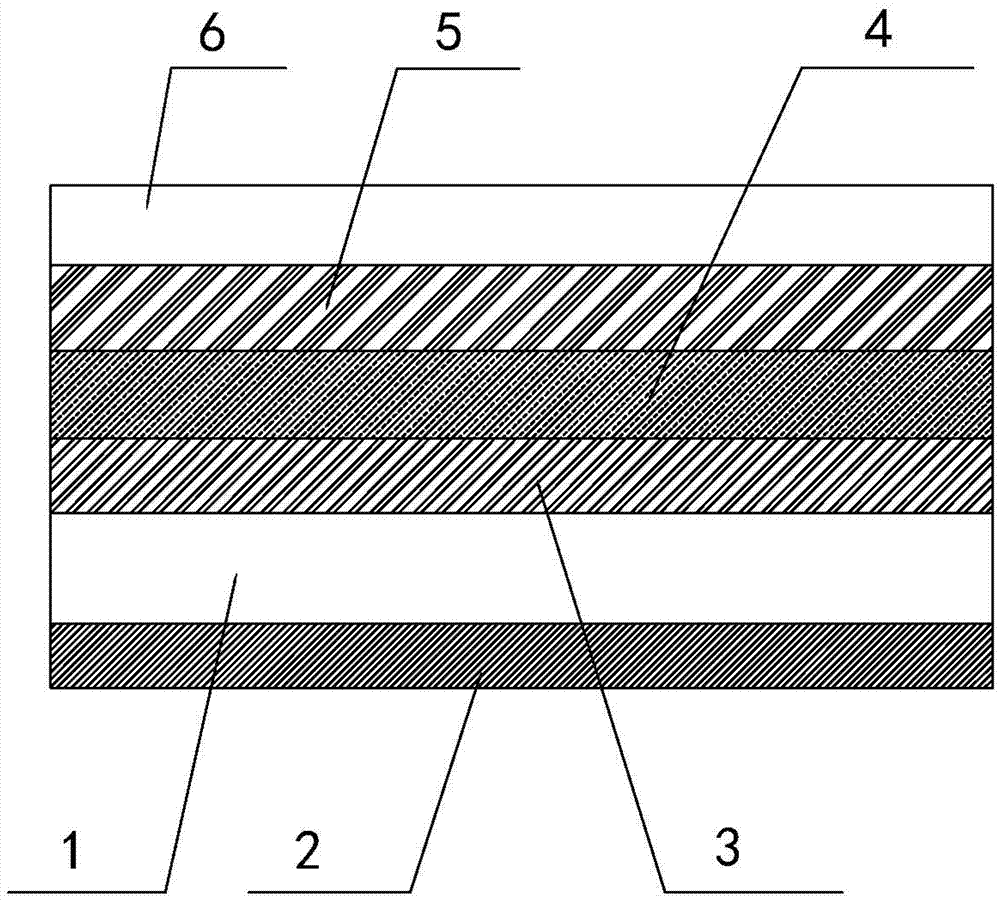

BOPP film for leather printing transfer and manufacturing method thereof

InactiveCN101774290ALow heat shrinkageEasy to prepareSynthetic resin layered productsPolyethylene terephthalate glycolEthylene Homopolymers

The invention discloses BOPP film for leather printing transfer and a manufacturing method thereof which belong to the technical field of BOPP film processing; the film comprises an upper surface layer, a core layer and a lower surface layer; the upper surface layer is prepared from the following components by weight percentage: 98 to 99 percent of homopolymer polypropylene and 1 to 2 percent of anti-adhesive; the core layer is prepared from the following components by weight percentage: 87.5 to 93.2 percent of homopolymer polypropylene, 0.8 to 1.5 percent of antistatic agent, 2 to 3 percent of transfer agent and 4 to 8 percent of nucleating agent; and the lower surface layer is prepared from the following components by weight percentage: 97 to 98 percent of homopolymer polypropylene and 2 to 3 percent of anti-adhesive. Compared with traditional BOPP film, the BOPP film for leather printing transfer has higher elastic modulus and lower heat shrinkage rate, and can replace bi-oriented polyethylene terephthalate film and be applied to the field of printing transfer.

Owner:ZHEJIANG KINLEAD PACKAGING MATERIAL

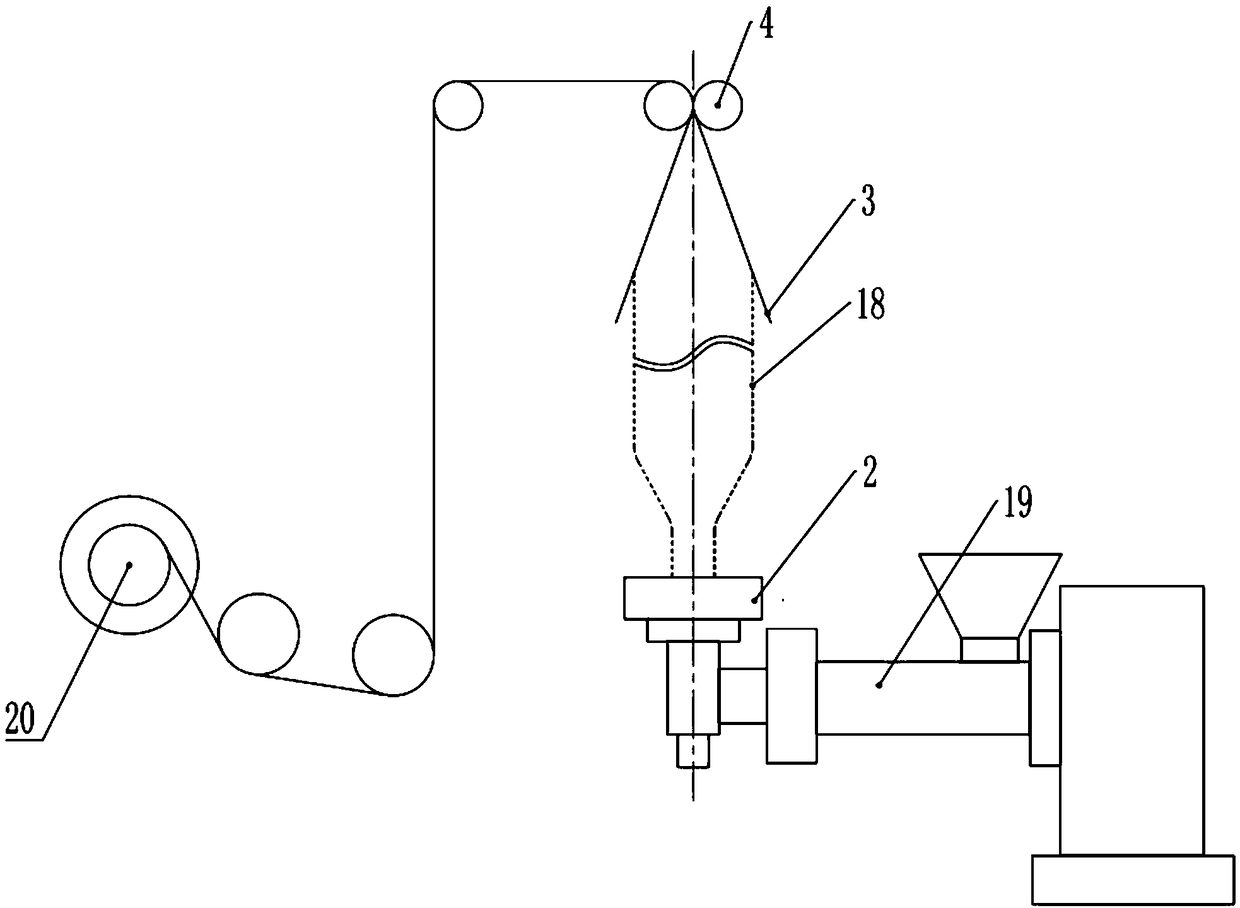

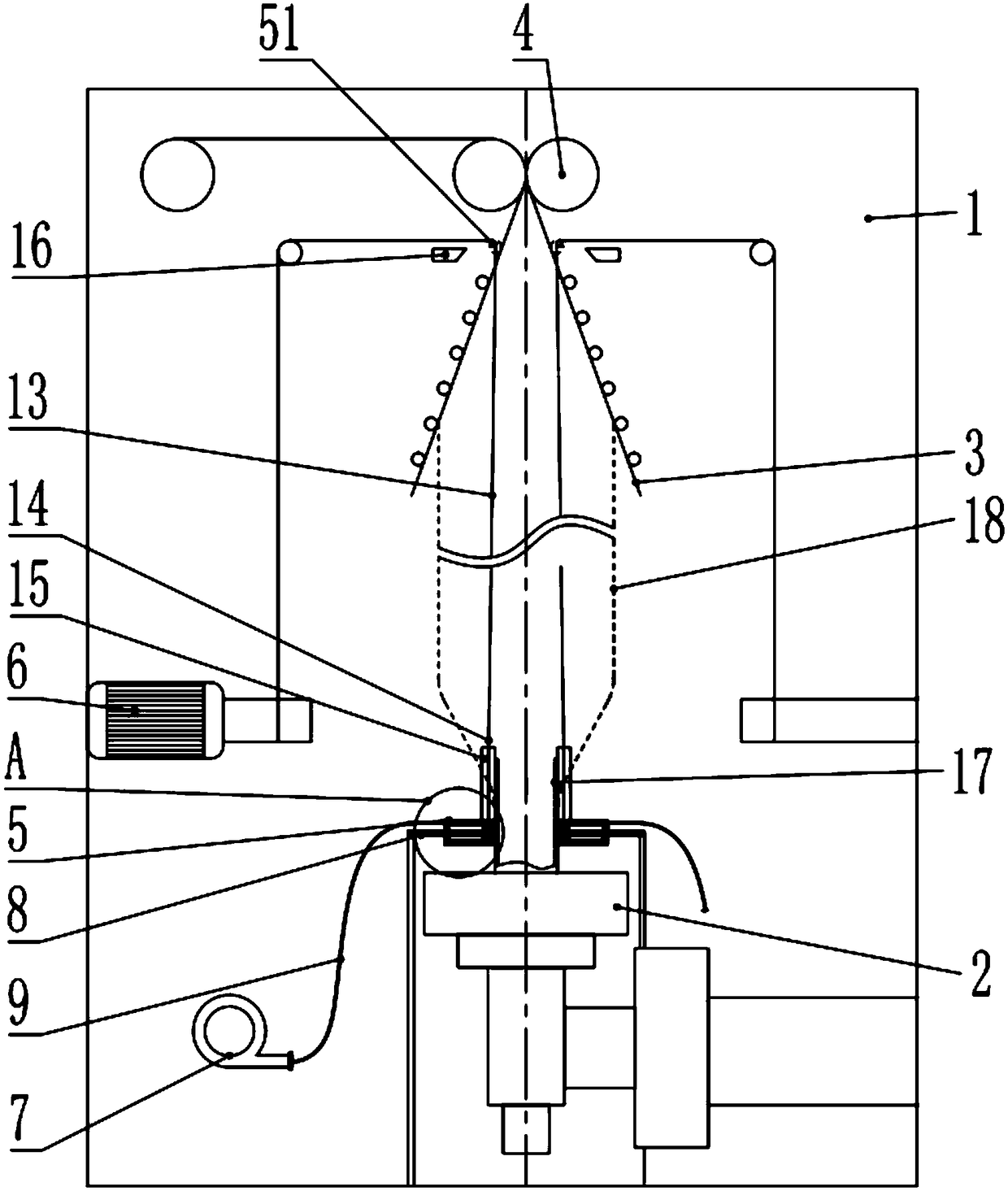

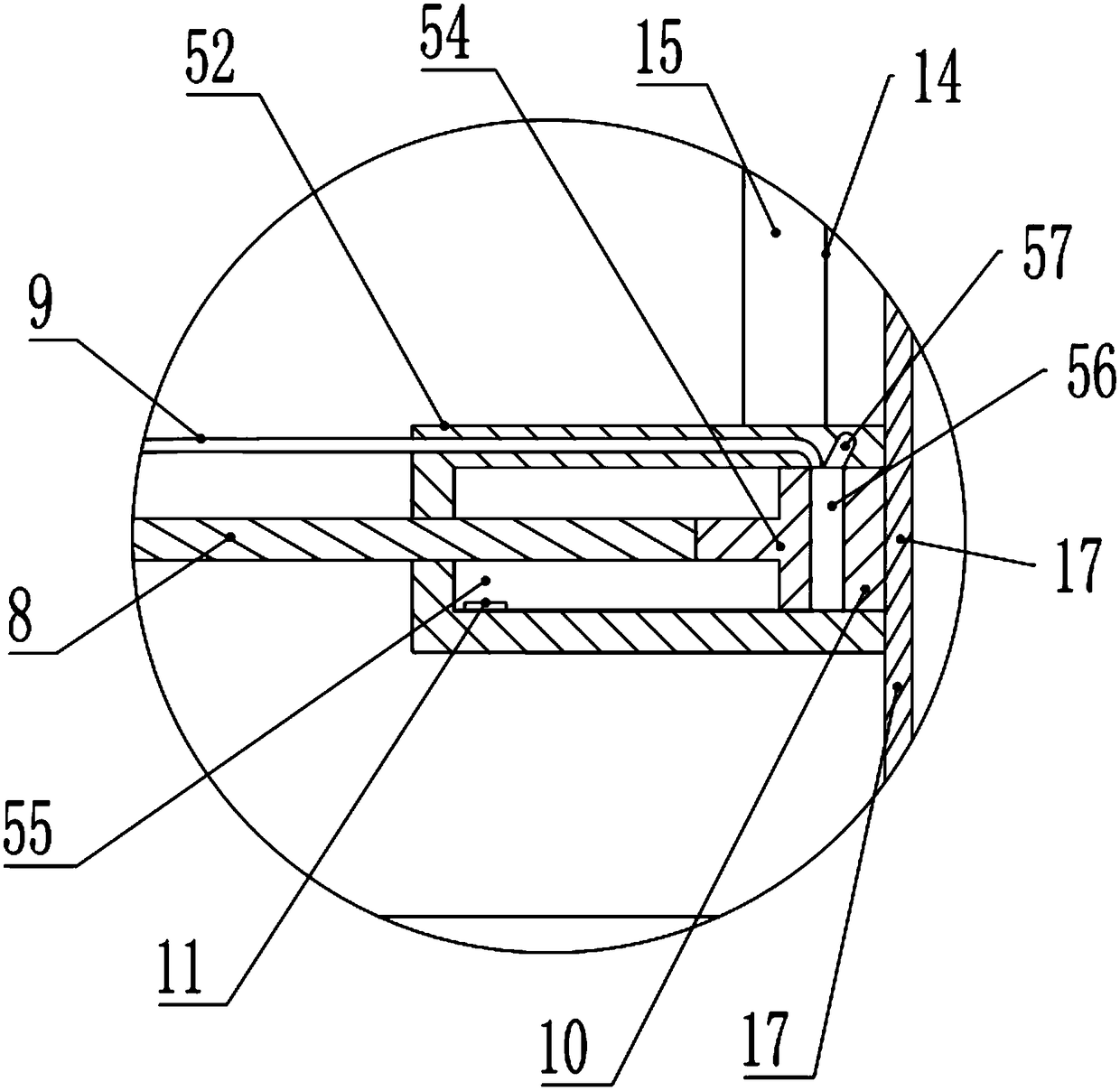

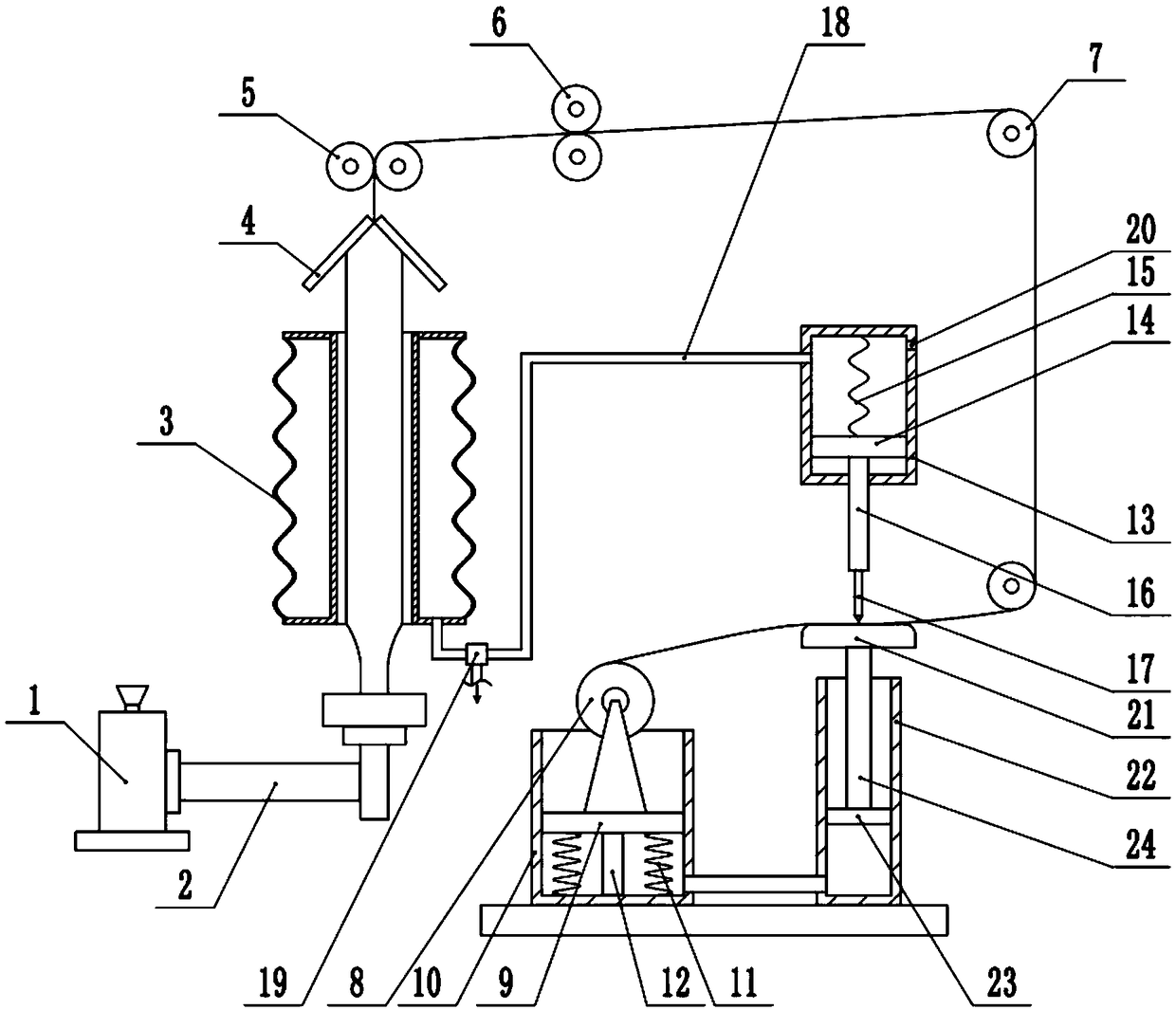

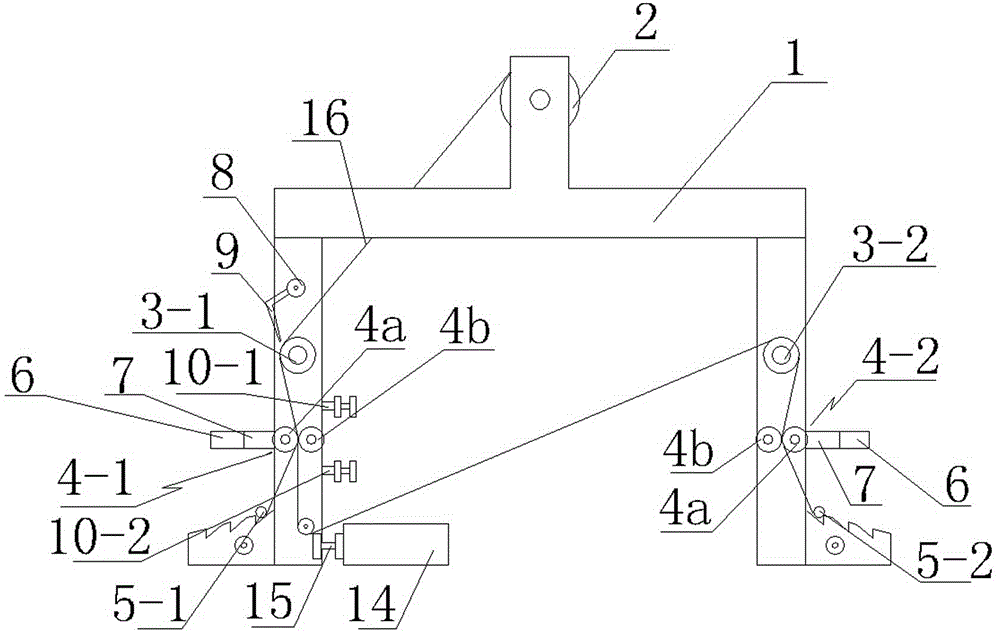

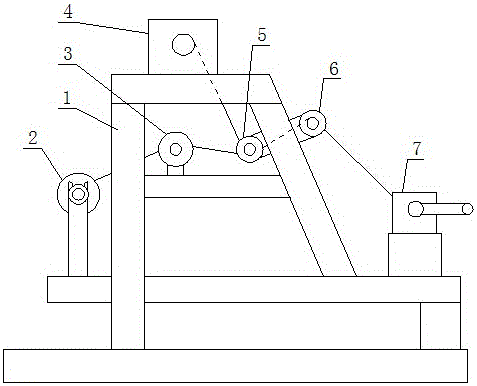

Blow molding machine for PE thin film processing

The invention relates to the field of production of plastic thin film, in particular to a blow molding machine for PE thin film processing. The blow molding machine includes a rack, a machine head, aninversely Y-shaped plate, a traction roller and a material picking device. The material picking device includes material picking rollers, left material picking blocks and right material picking blocks, wherein the left material picking blocks and the right material picking blocks are symmetric in structure and are connected with the material picking rollers through traction ropes respectively, hung above the machine head through the traction ropes and both internally provided with a sealed cavity; a piston is slidably connected into each sealed cavity and divides the sealed cavity into a rodcavity body and a rodless cavity body; piston rods are fixedly connected to the rack, penetrate through the corresponding rod cavity bodies and abut against the corresponding pistons; the sliding direction of each piston is perpendicular to the middle axis of the corresponding traction roller, and air pipes are arranged in the peripheries of the sealed cavities of the left and right material picking blocks respectively and communicated with the rodless cavity bodies. The blow molding machine is used for solving the problem that during formation of PE thin film in the prior art, manual materialsealing, material picking and roller feeding are likely to cause danger to personnel safety.

Owner:CHONGQING RUITING PLASTIC

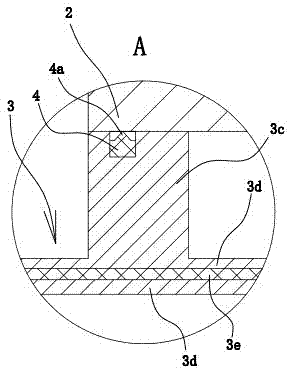

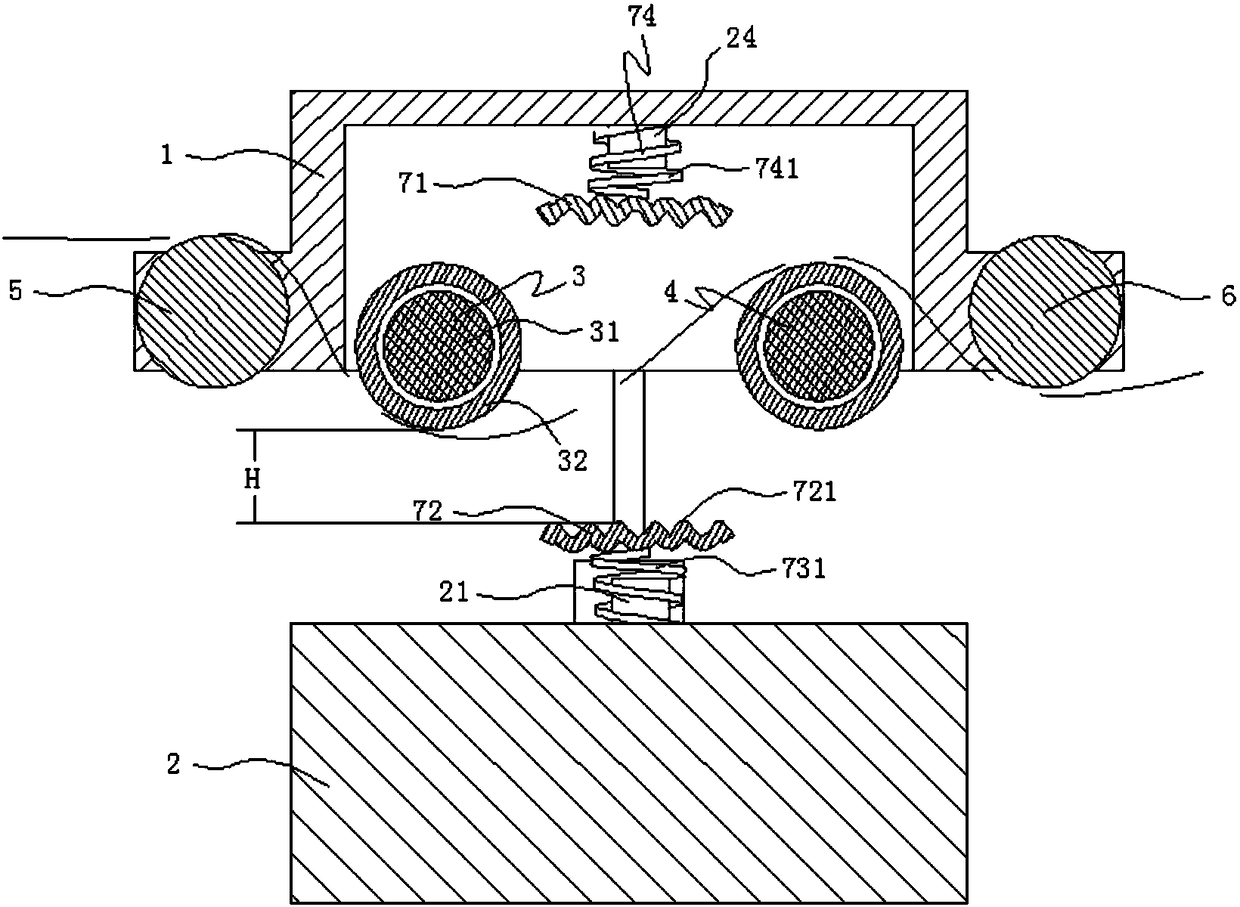

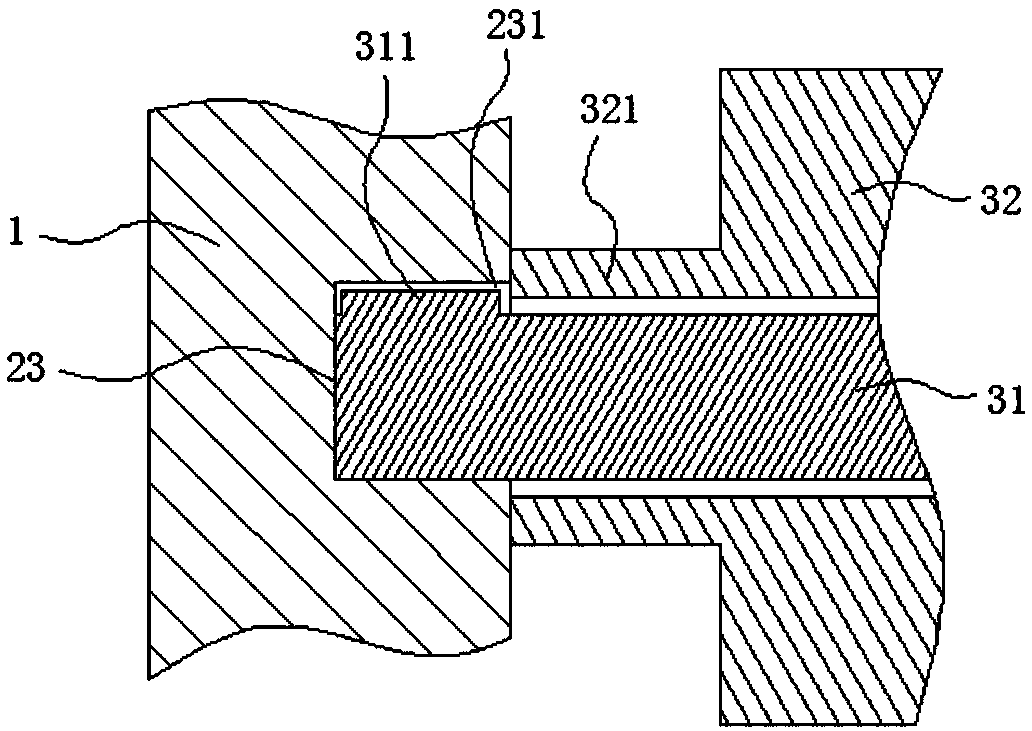

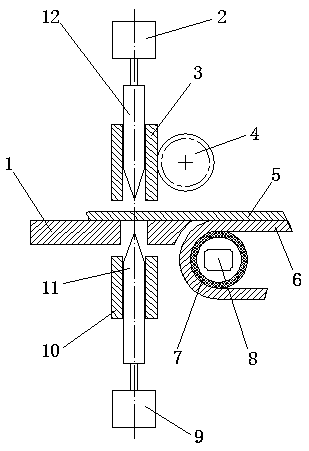

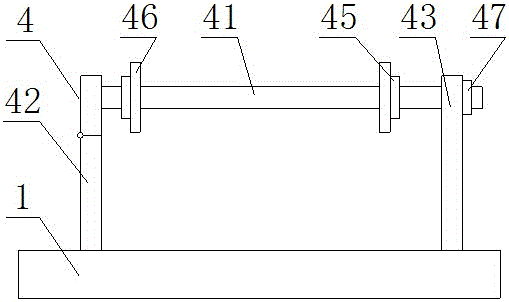

Coating film fixture for coating film substrate

InactiveCN104313547AEasy to installImprove work efficiencyVacuum evaporation coatingSputtering coatingEngineeringFilm processing

The invention discloses a coating film fixture for a coating film substrate, relates to the field of coating films and aims at solving the technical problems that an inner ring of the substrate is unblocked, a processing effect is poor and efficiency is low in the prior art. The coating film fixture for the coating film substrate comprises an upper clamping plate and a lower clamping plate, wherein a mounting hole is formed in the lower clamping plate, a positioning step is formed on the mounting hole, the substrate is compacted between the upper clamping plate and the positioning step, the upper clamping plate is connected with a protective cap opposite to the mounting hole, the protective cap comprises a hollow supporting column, an expansion sleeve is arranged at the bottom of the supporting column, the top of the supporting column is connected with a gas injecting pipe, and the expansion sleeve props against the bottom of the substrate after being aerated and expanded. The coating film fixture for the coating film substrate is applied to coating film processing of the substrate.

Owner:董新妹

Film forming method and processing system

ActiveUS8440563B2Improve barrier propertiesImprove adhesionLiquid surface applicatorsSemiconductor/solid-state device detailsEngineeringFilm processing

Owner:TOKYO ELECTRON LTD

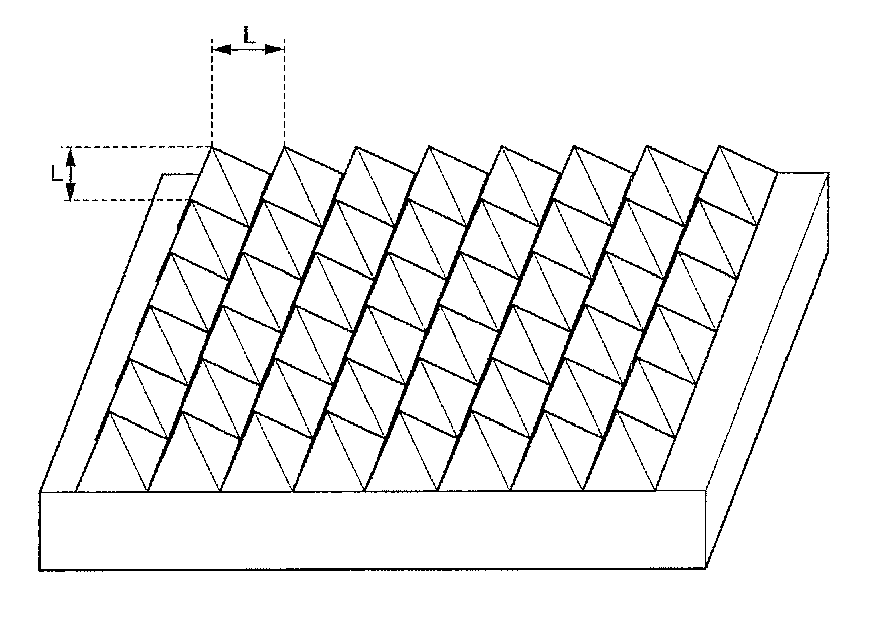

Film and method of film processing

ActiveUS20110052873A1Superior in hand tearabilitySuperior in linear cutting efficiencyLayered productsFilm/foil adhesivesSheet filmFilm processing

[PROBLEMS] To provide a film superior in hand tearability and linear cutting efficiency that can be produced without need for a complicated blending of resin raw materials and high-grade processing facilities.[MEANS OF SOLVING PROBLEMS] There is provided a film having an average distance between the local apexes in any one direction of 8 μm or less.

Owner:DENKA CO LTD

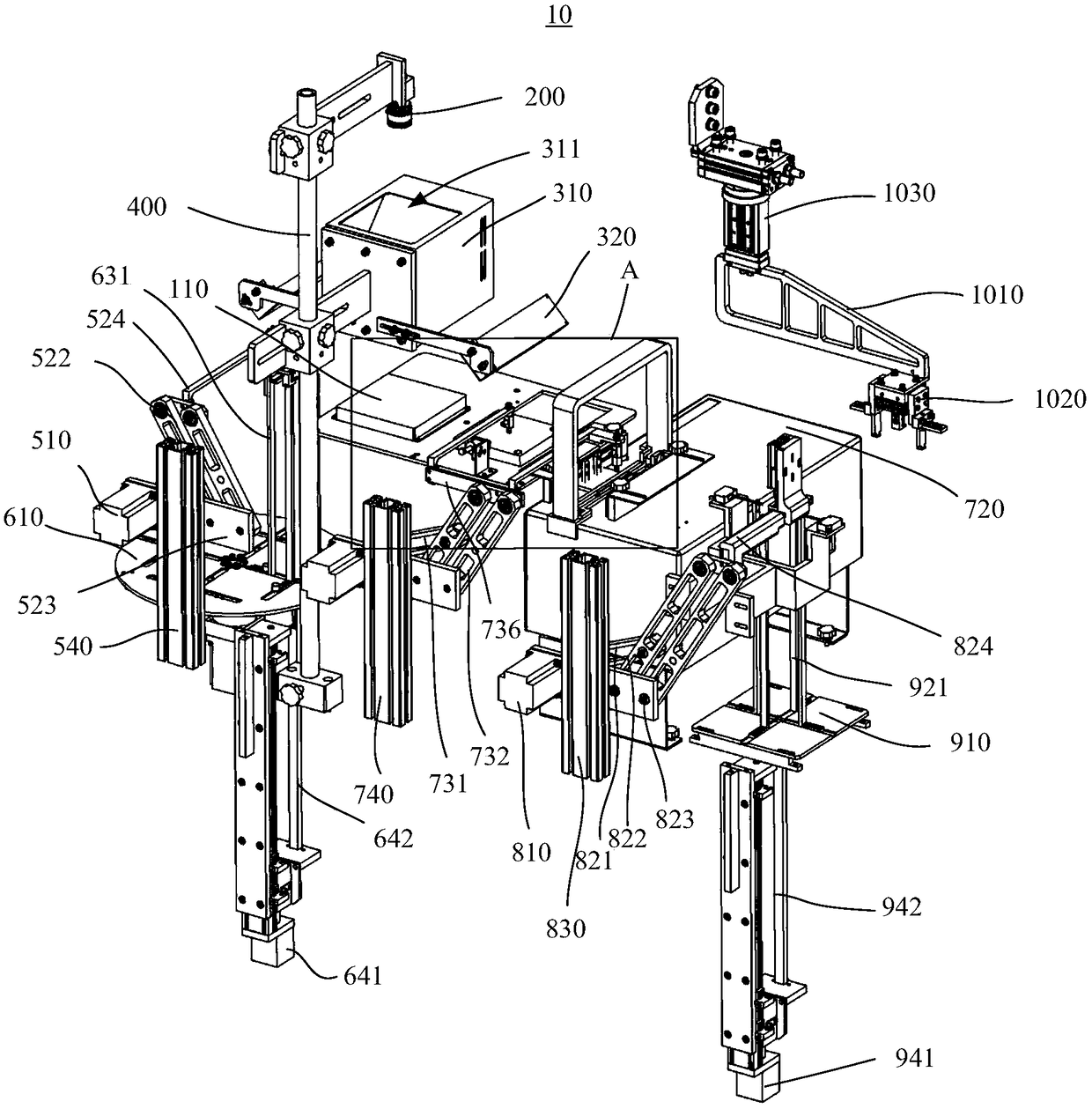

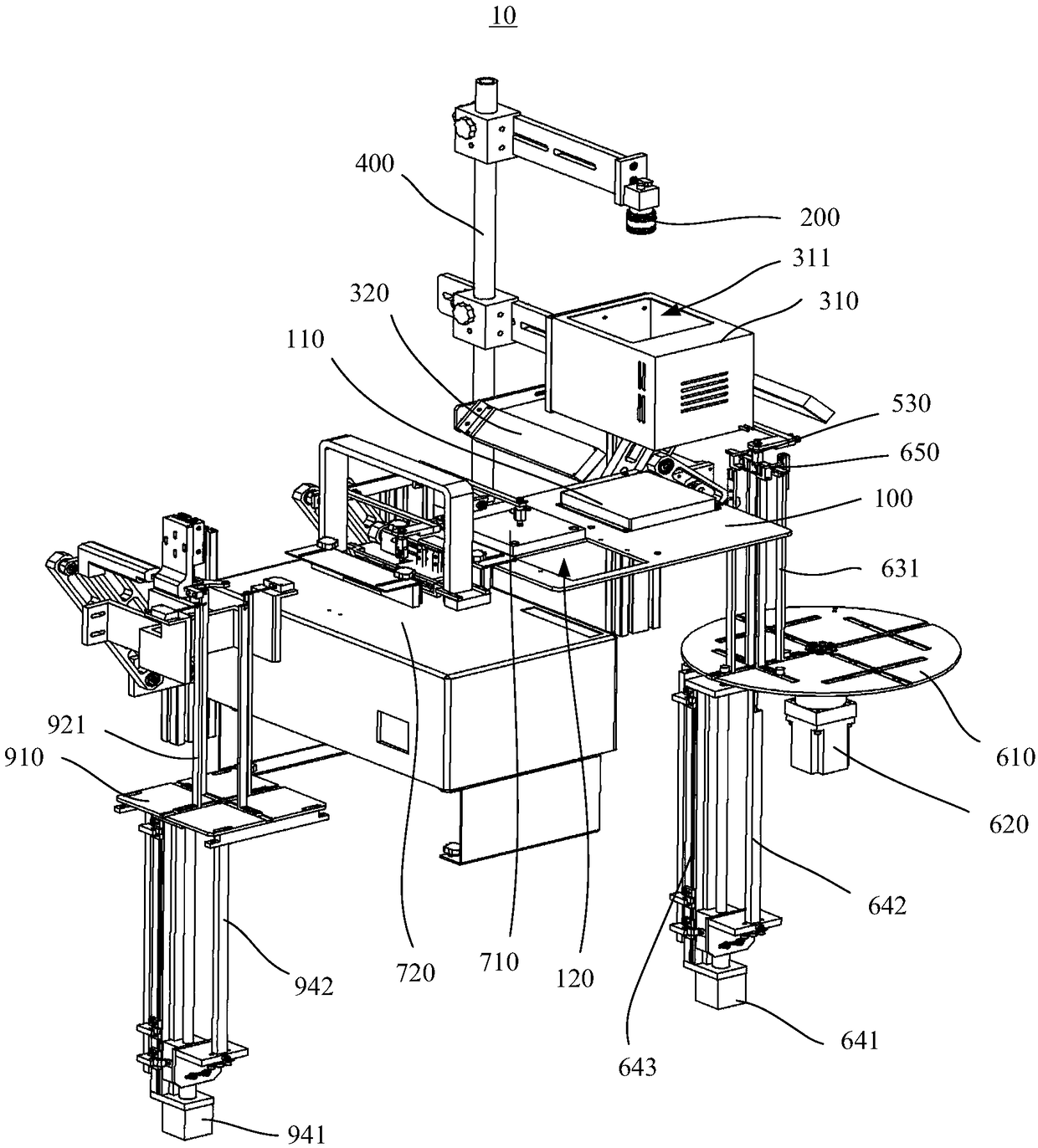

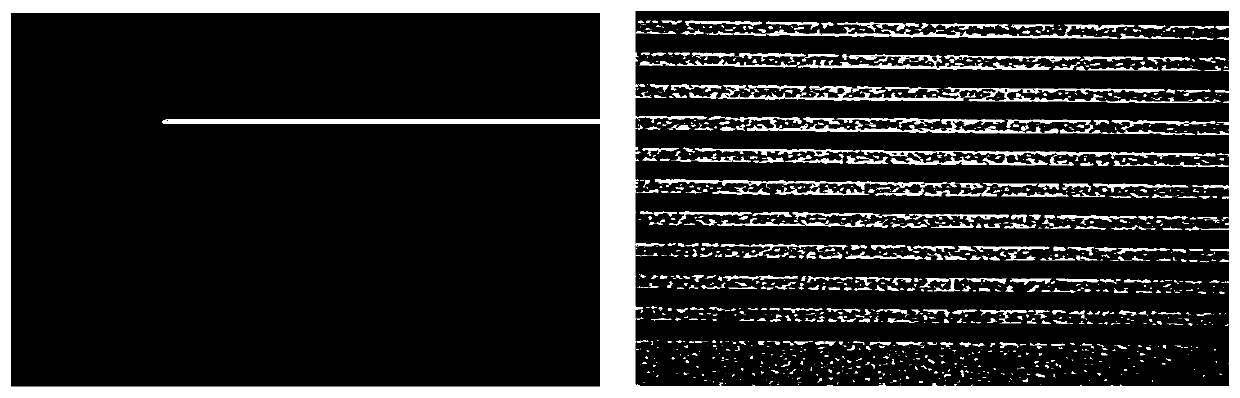

Heat transfer printing film detection system

The invention relates to a heat transfer printing film detection system. The heat transfer printing film detection system comprises a machine base, a light source assembly, an image acquisition device, an image analysis device and a film processing device, wherein a detection platform on which a to-be-detected film is placed is arranged on the machine base; the light source assembly is used for lighting the film placed on the detection platform; the image acquisition device is used for performing image acquisition on the film placed on the detection platform; the image analysis device can be used for analyzing the quality of the film according to the film image acquired by the image acquisition device and is electrically connected with the image analysis device; and the film processing device is used for performing classification processing on the film according to a quality analysis result. According to the heat transfer printing film detection system and method, image acquisition, quality analysis and automation of classification processing of the heat transfer printing film can be realized, so that the labor force can be reduced, the production efficiency is improved, the production cost is reduced and occurrence of situations such as missing detection and fault detection is avoided.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD +1

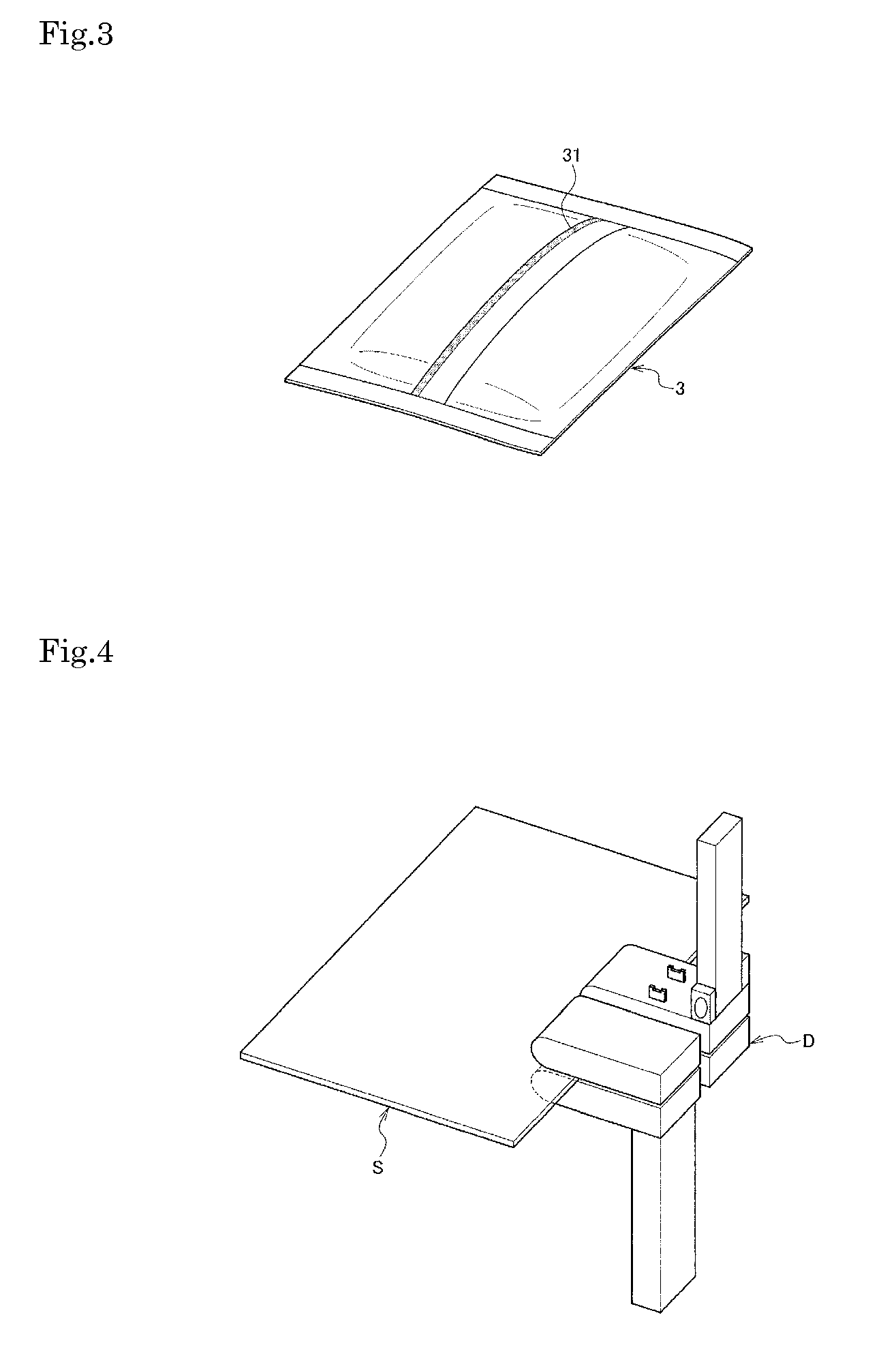

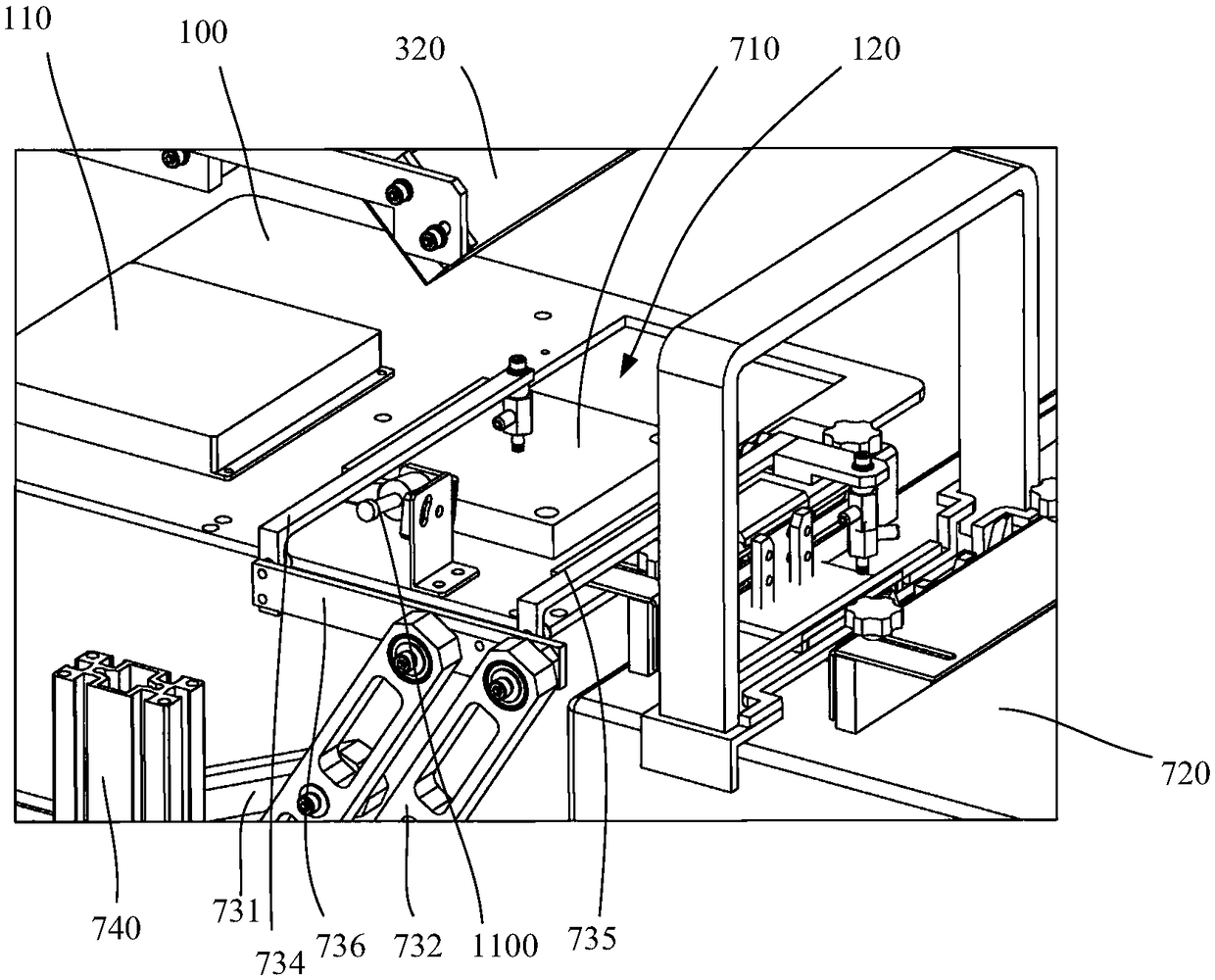

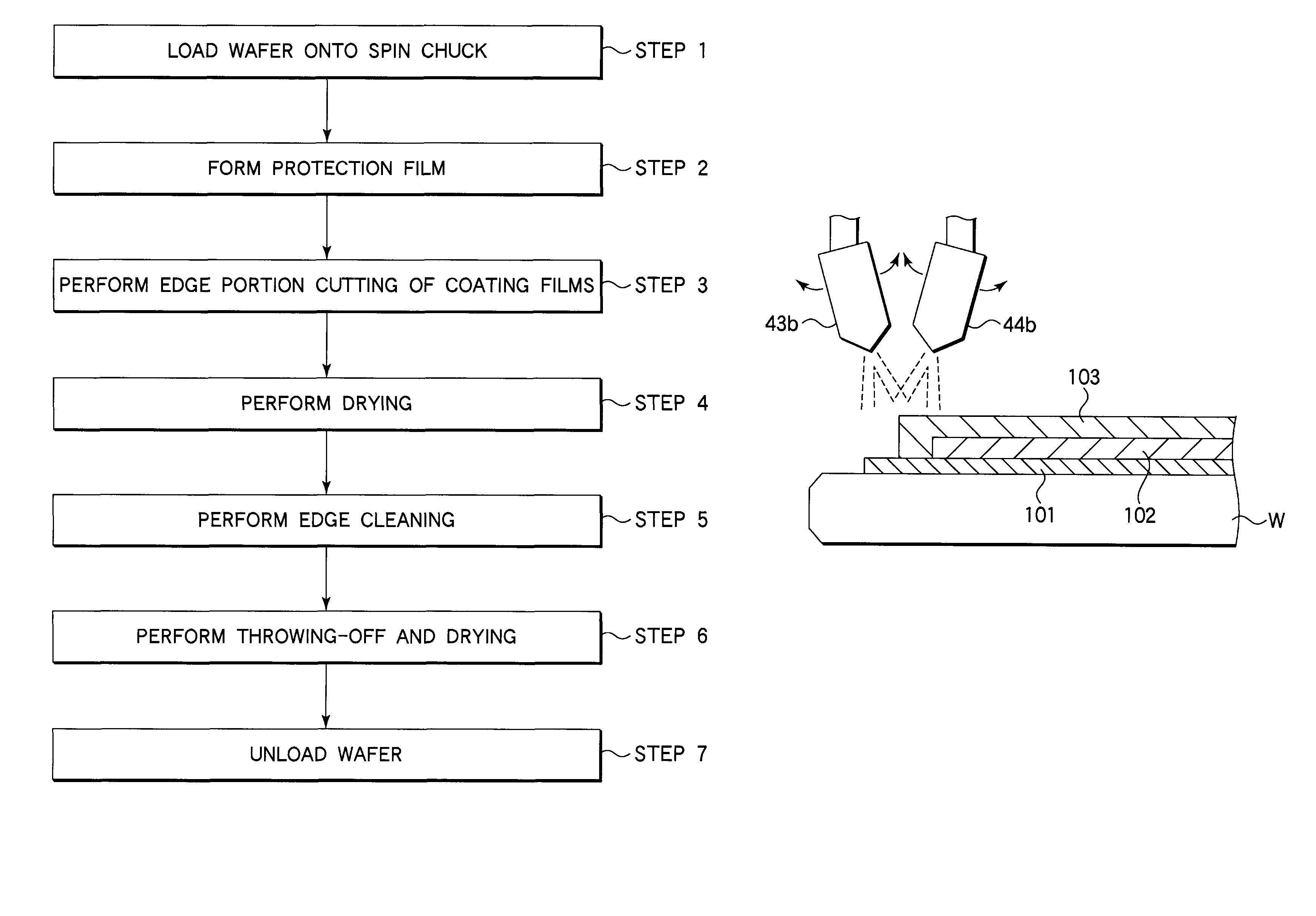

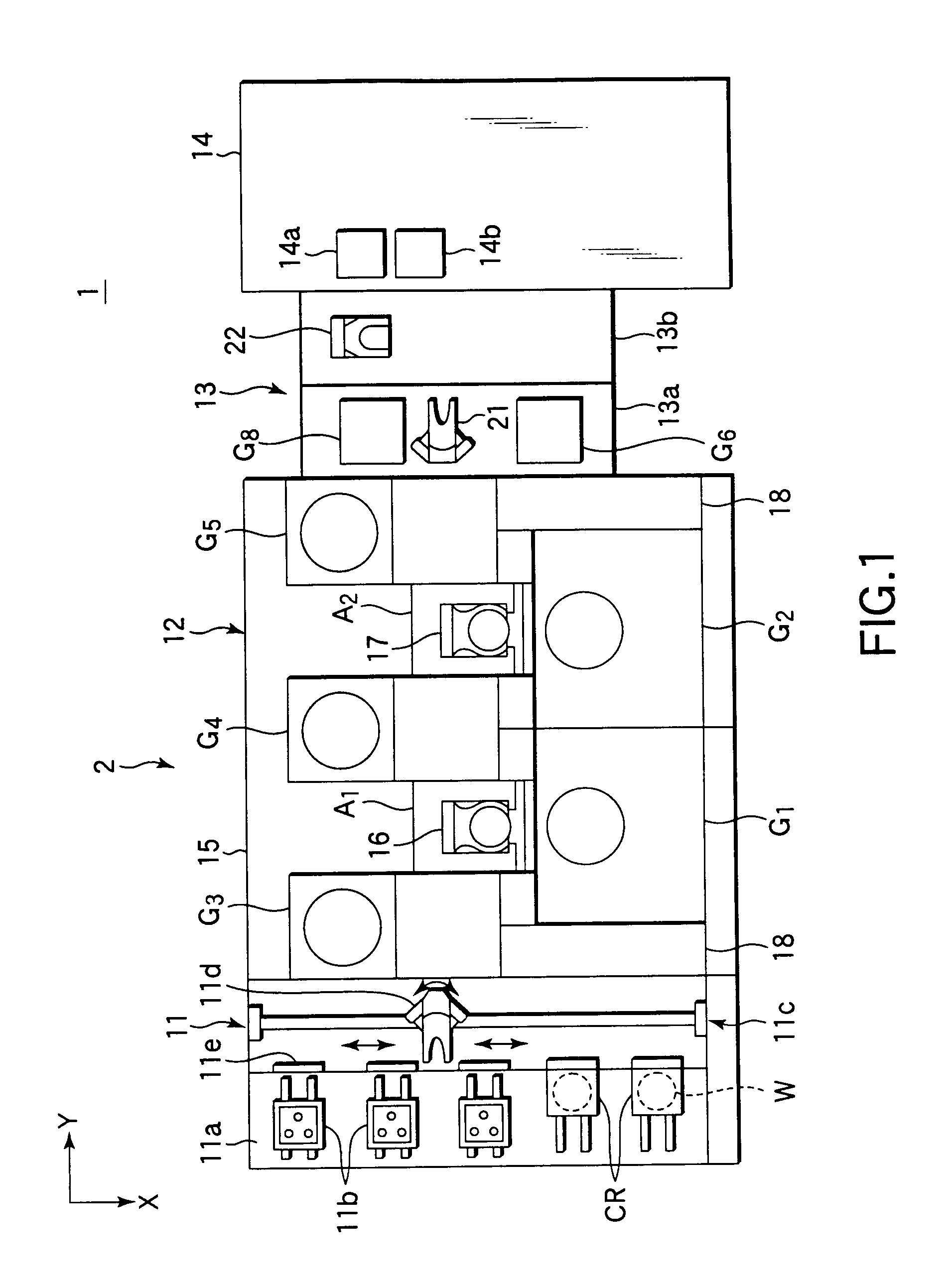

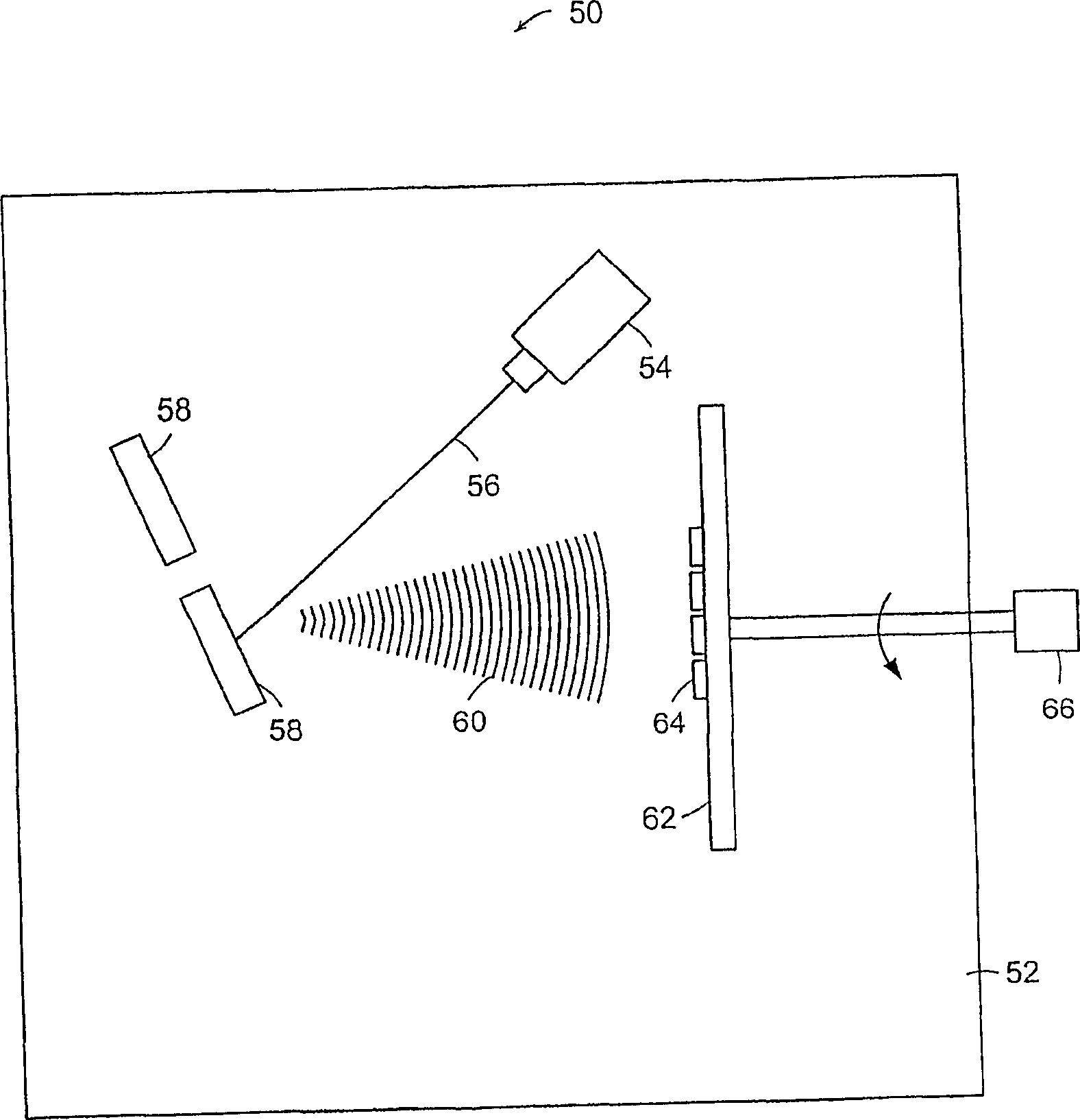

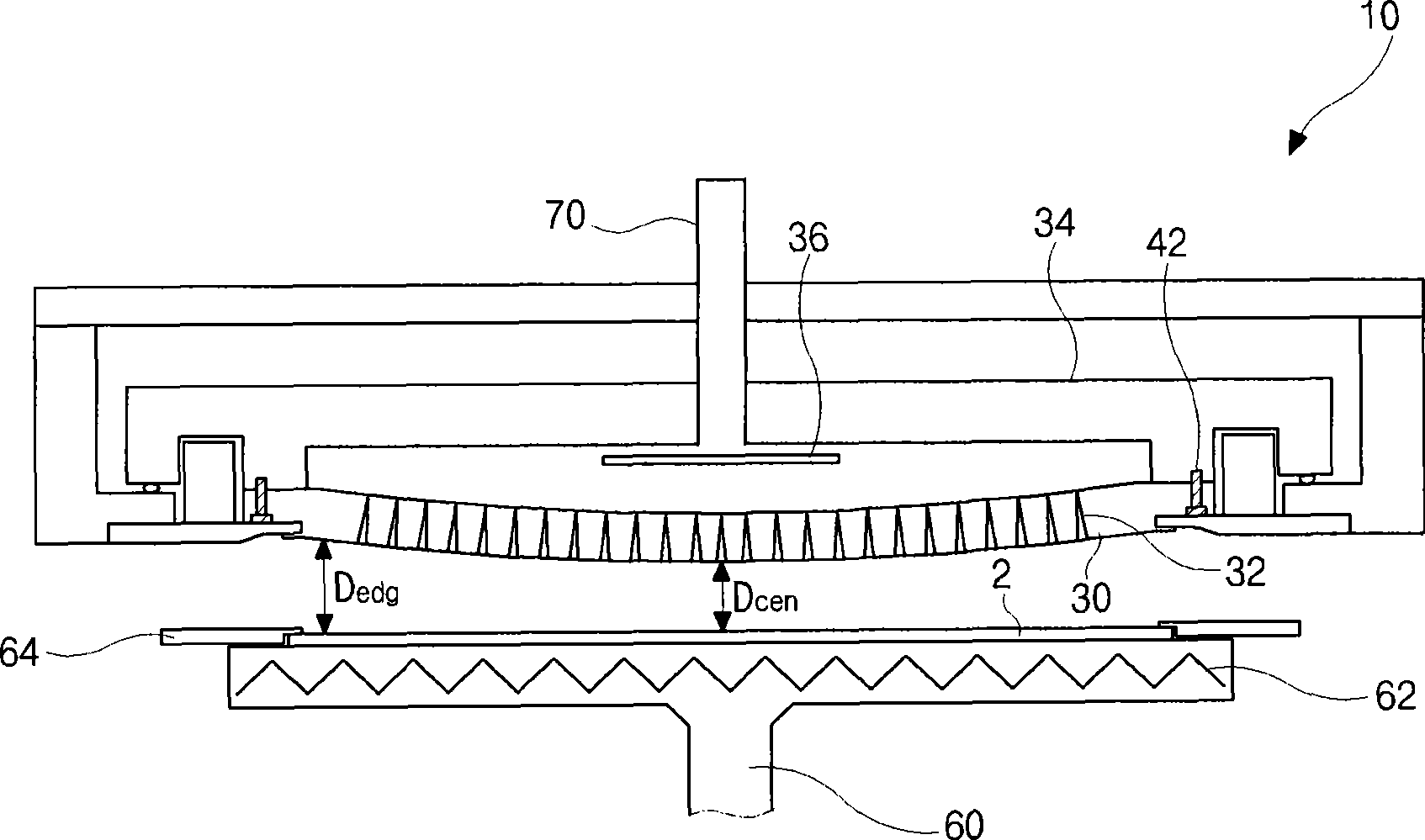

Coating film processing method and apparatus

ActiveUS8069816B2Without complicating apparatus structure and process stepPrevent peelingLiquid surface applicatorsLiquid processingLight exposureEngineering

A coating film processing method is used for processing a coating film formed on a surface of a substrate to prepare for an immersion light exposure process arranged to perform light exposure through a liquid. The method includes supplying a solvent-containing liquid comprising a combination of a solvent and a solvent-ability decreasing agent for decreasing solvent ability, or a diluted solvent, onto an edge portion of the coating film, thereby performing edge portion cutting; and supplying a cleaning liquid onto the edge portion of the coating film, thereby performing edge portion cleaning, subsequently to the edge portion cutting.

Owner:TOKYO ELECTRON LTD

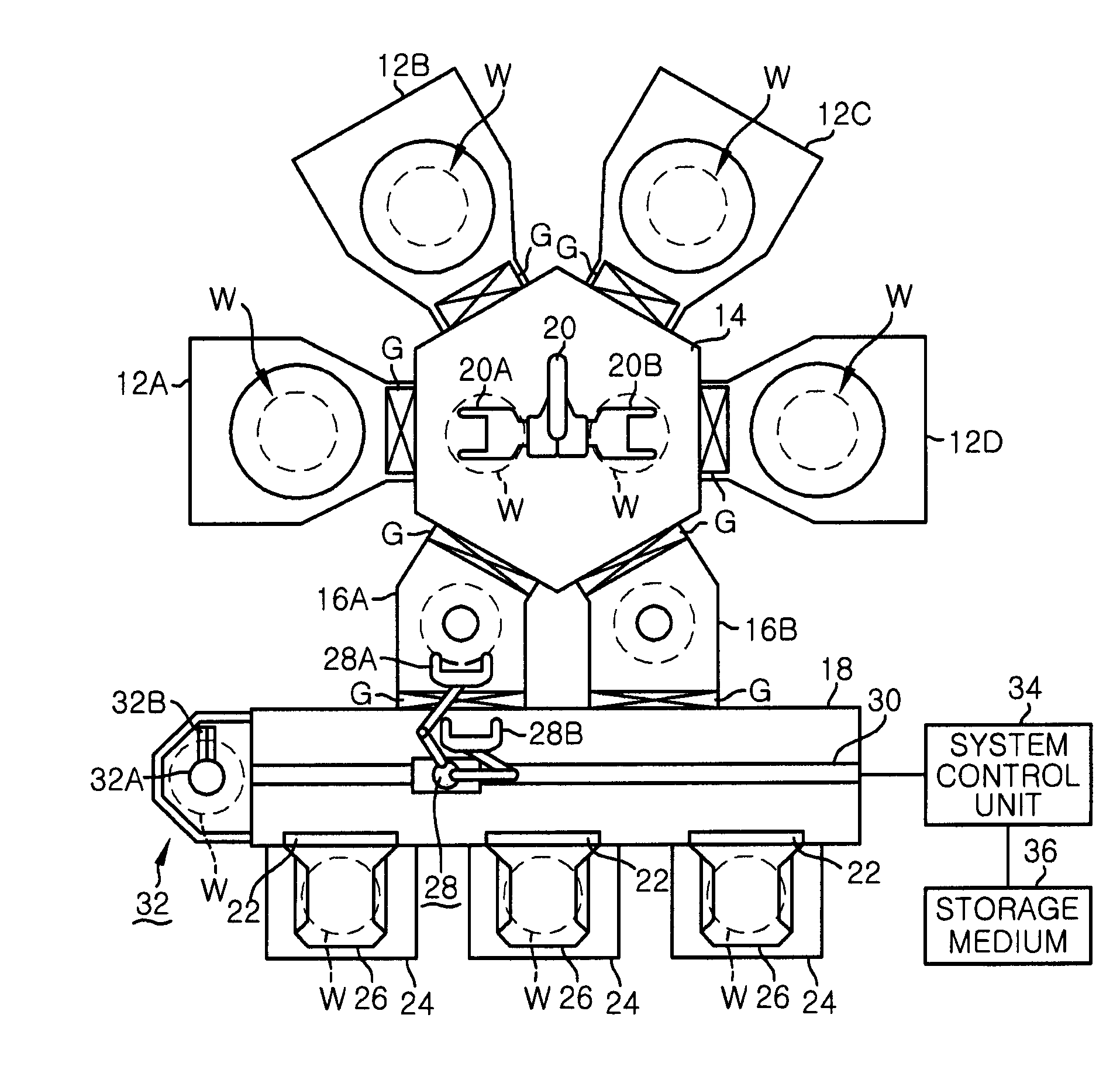

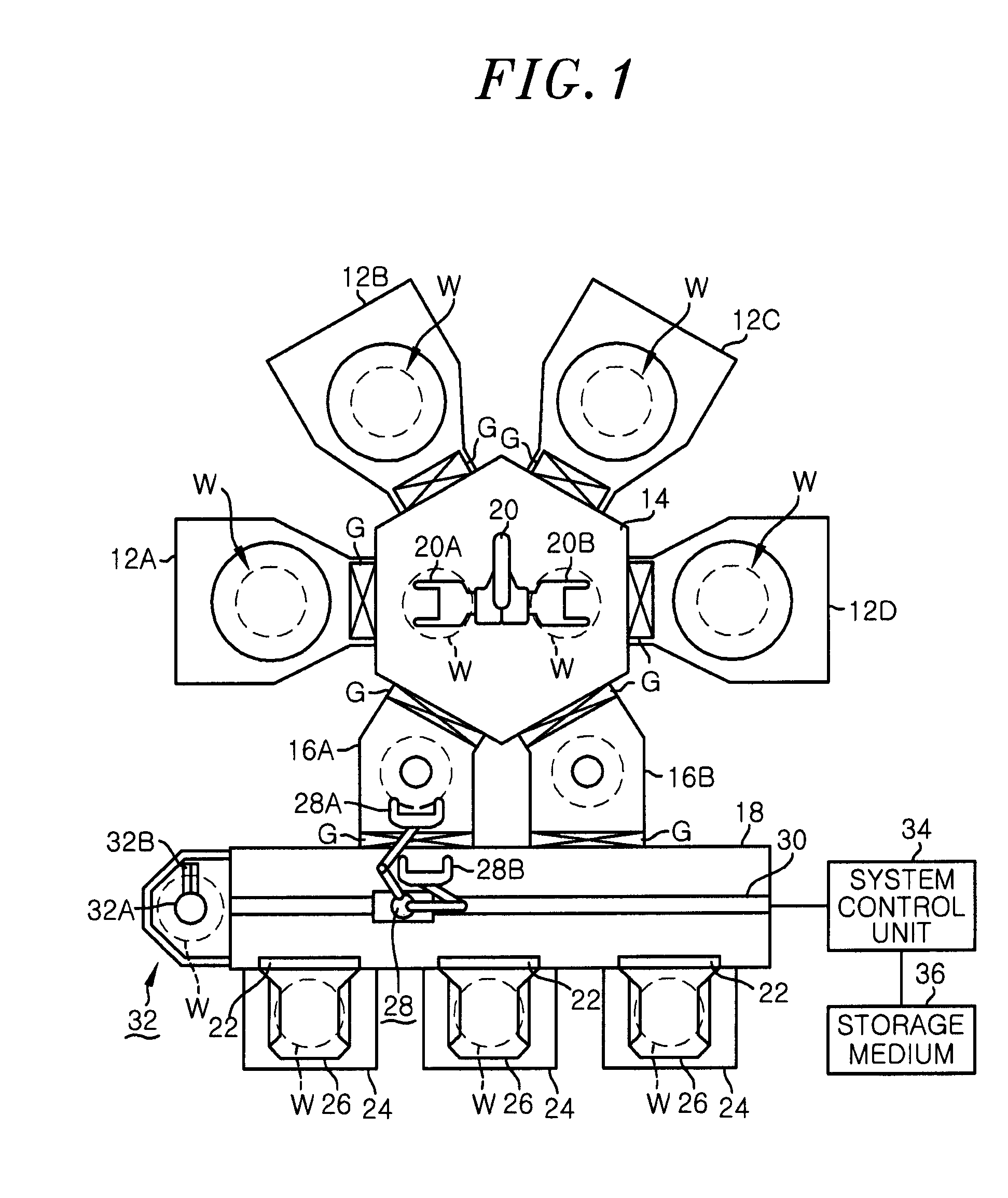

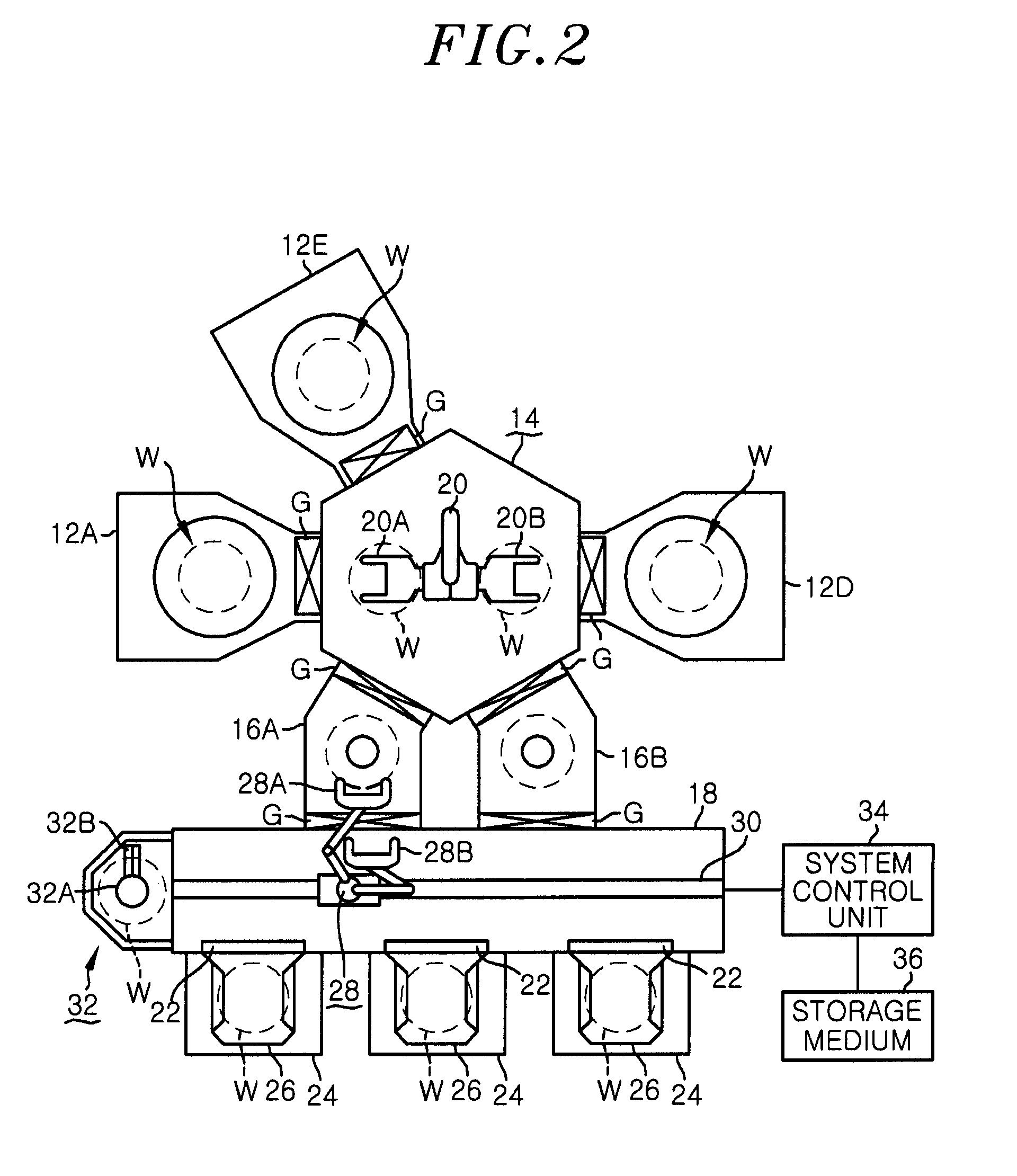

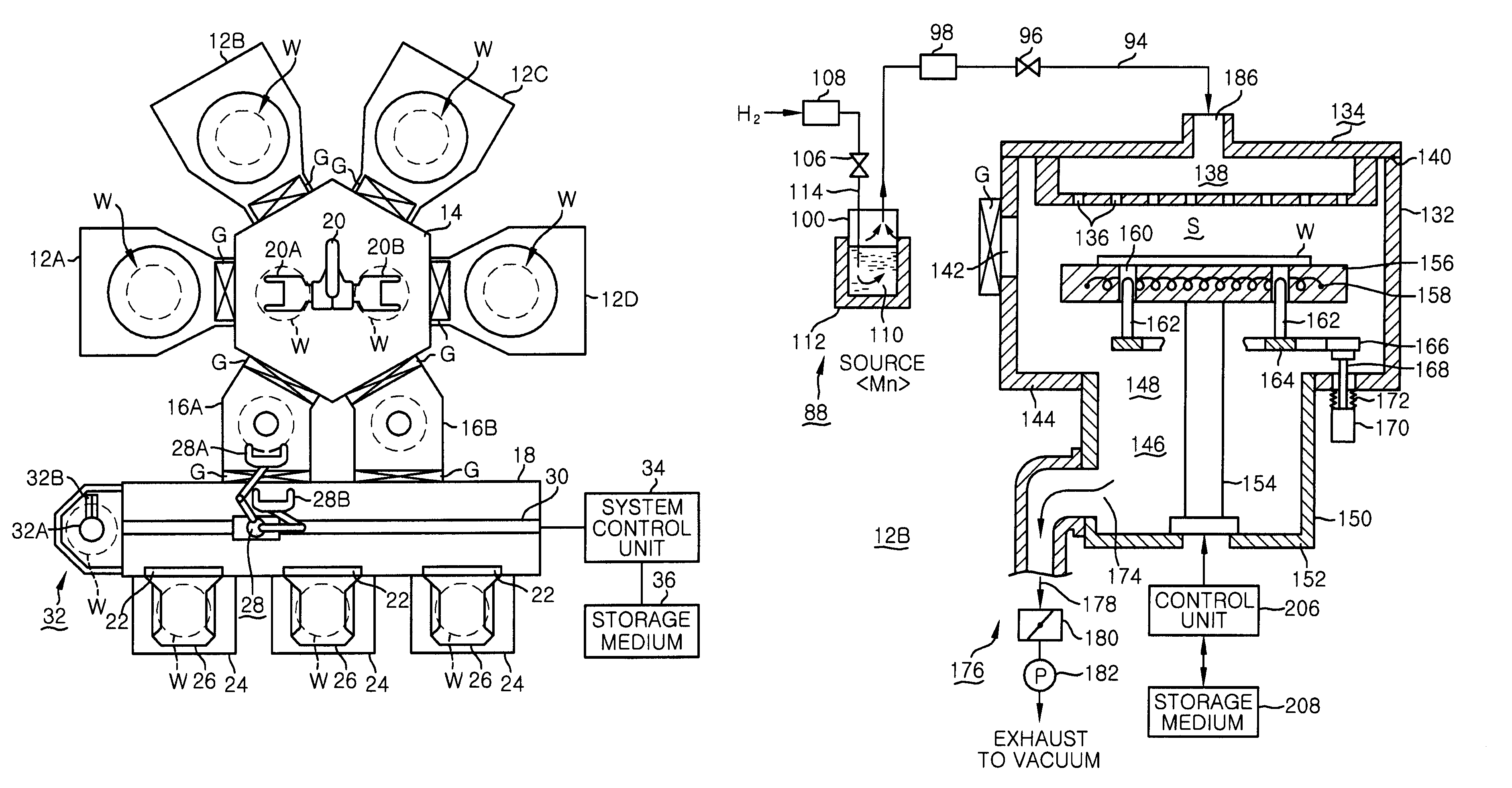

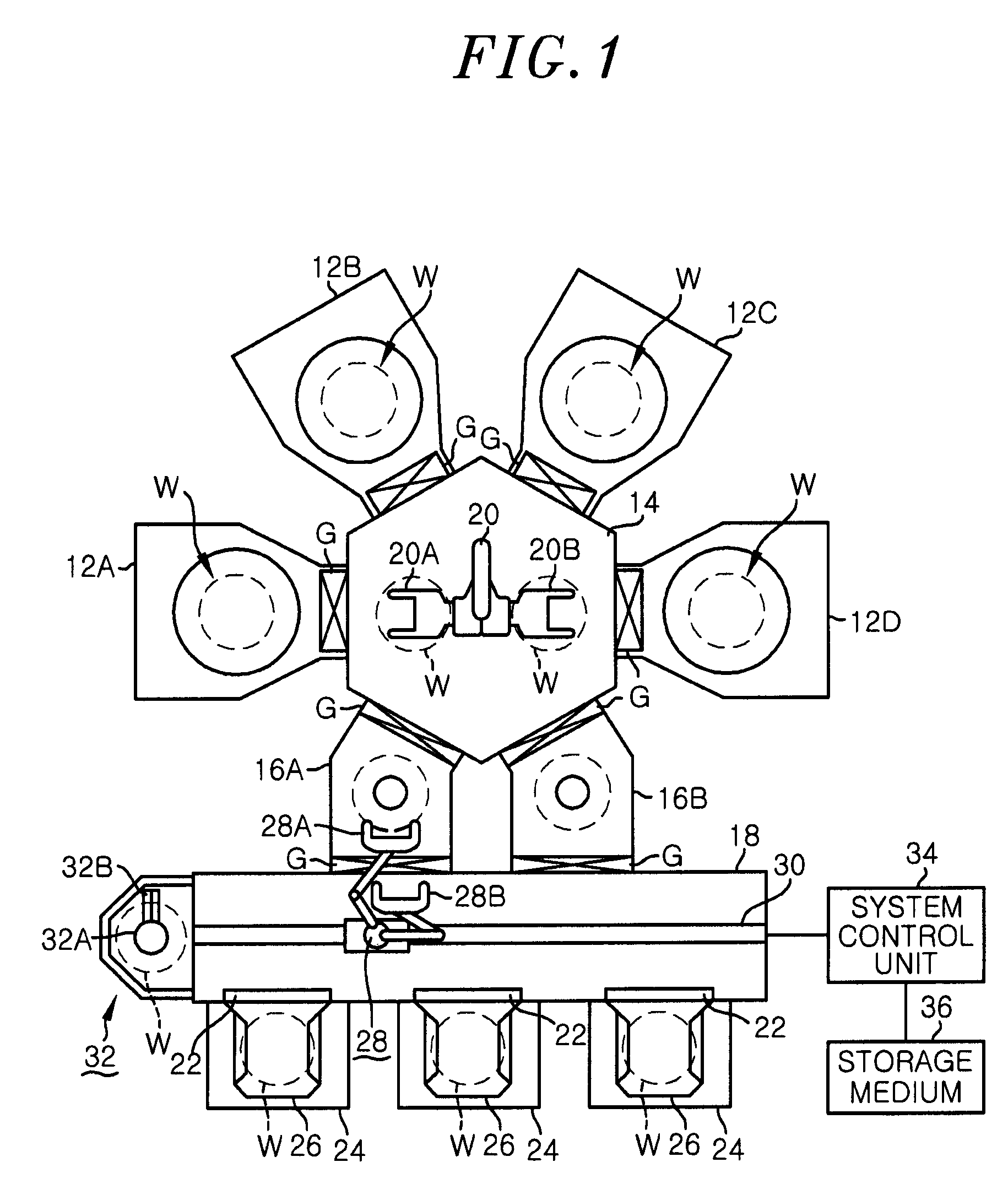

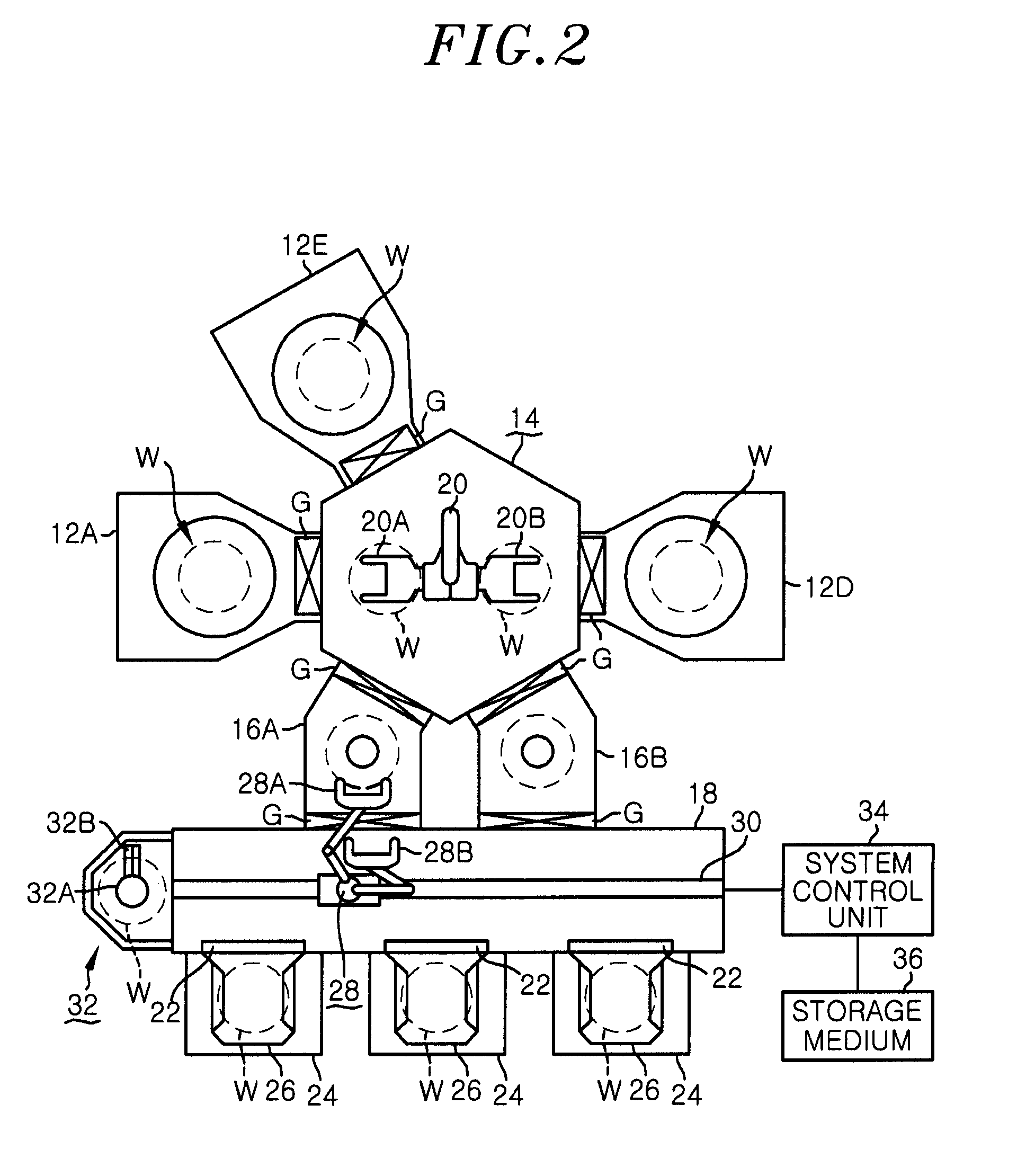

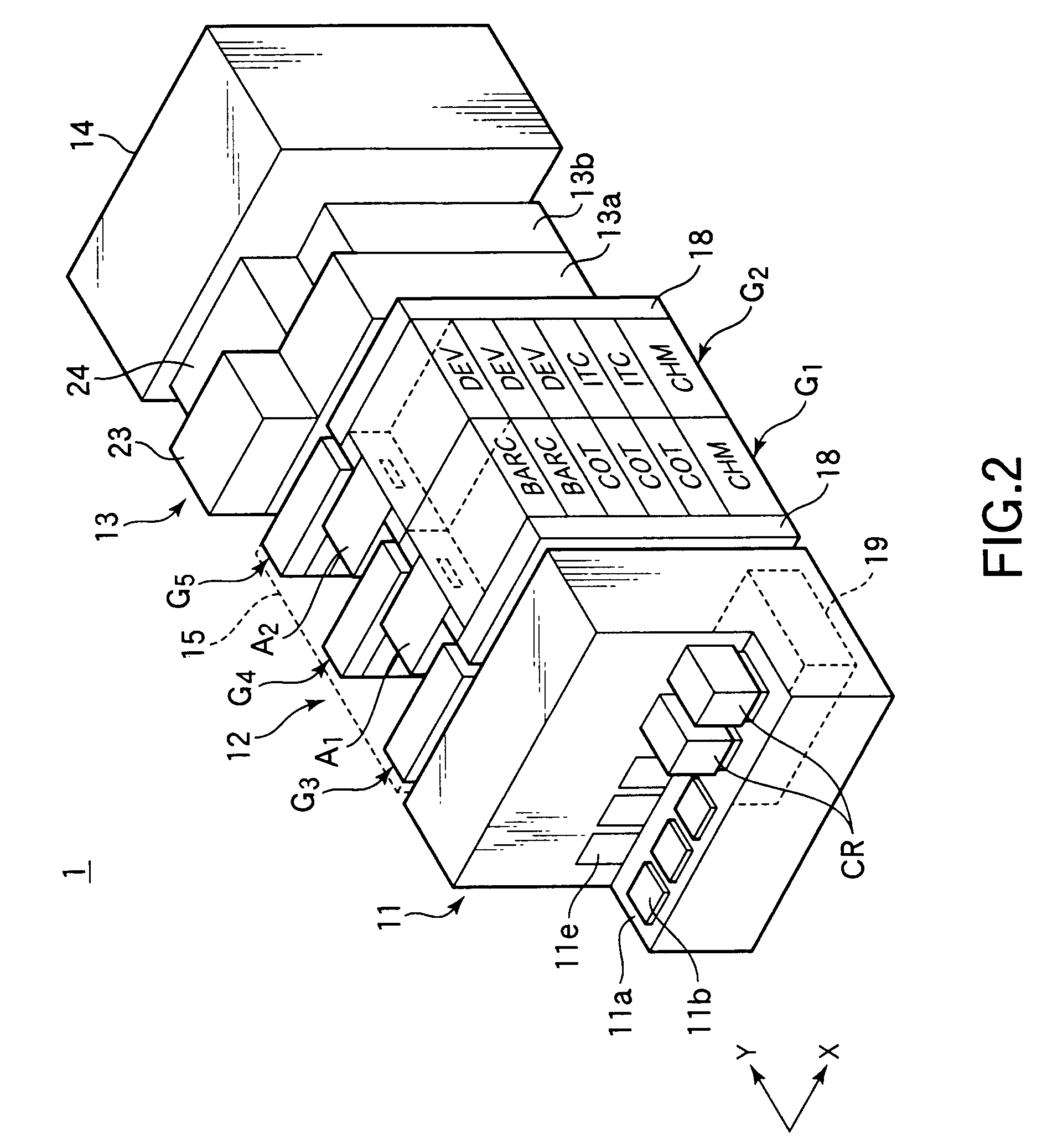

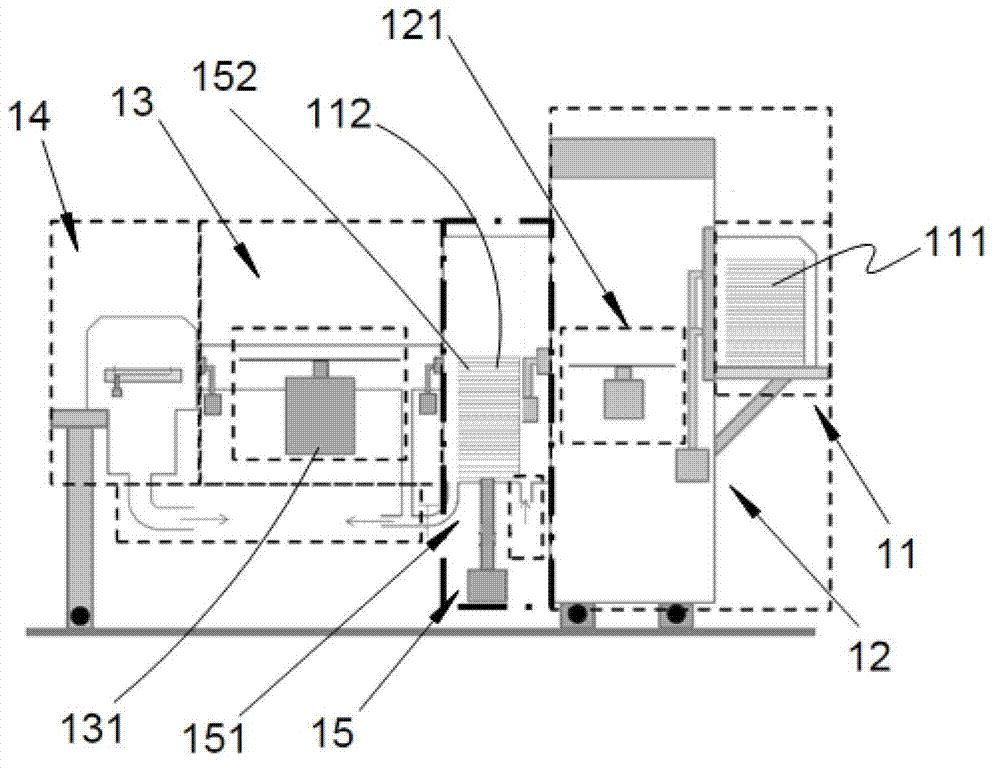

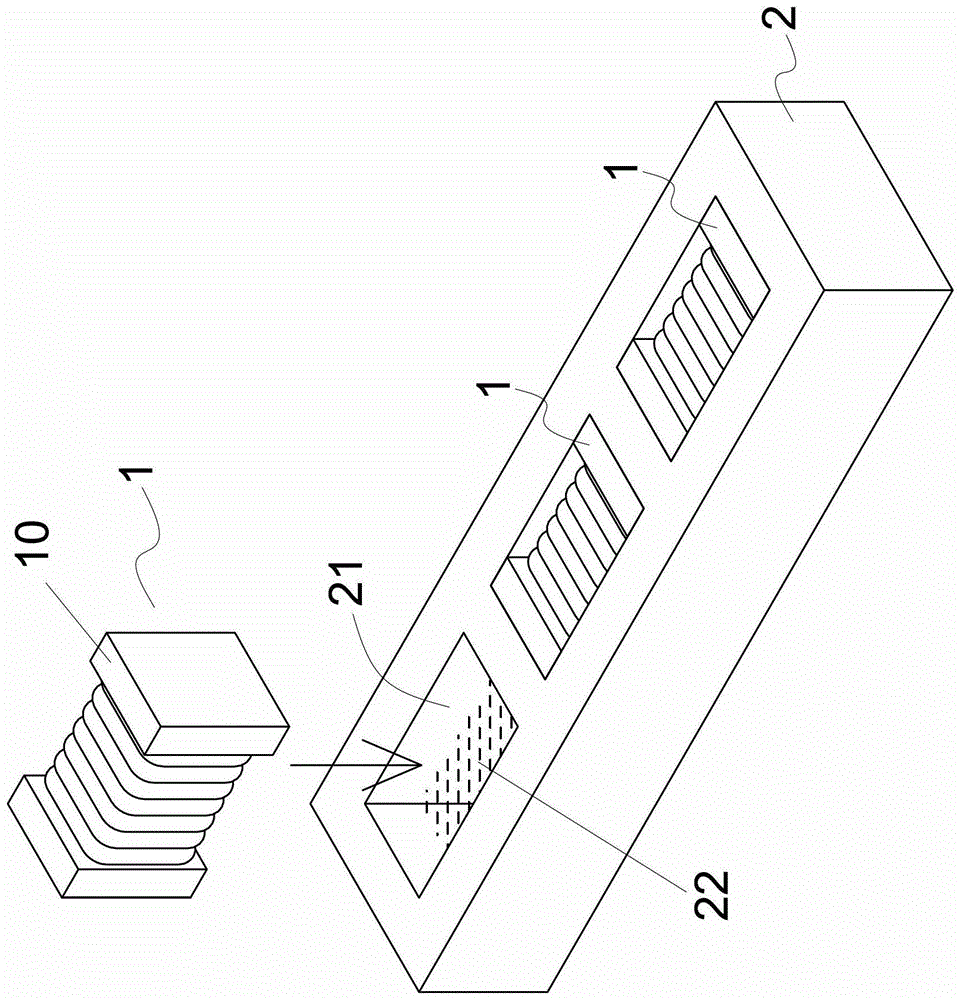

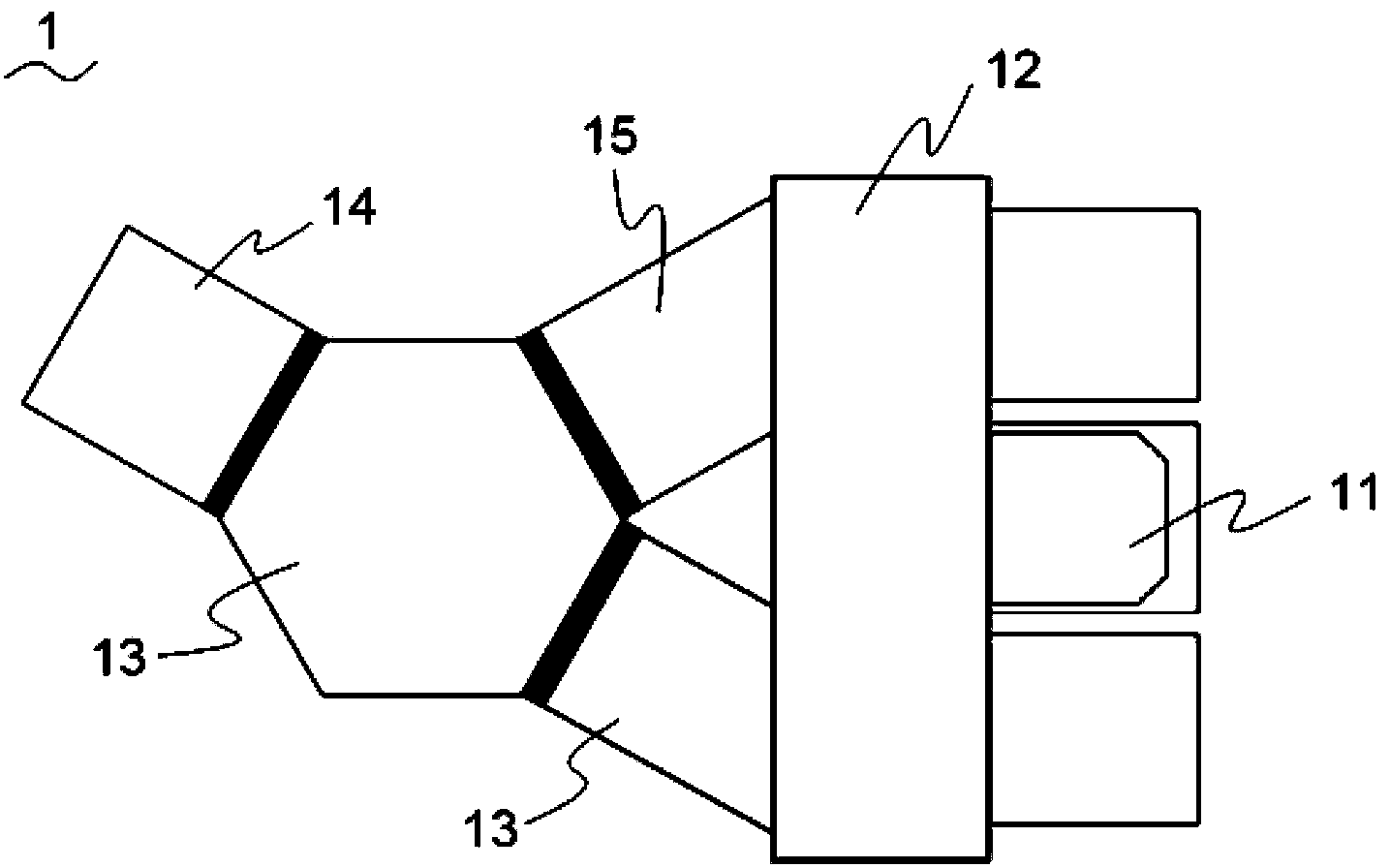

Thin-film process system with wafer storage groove and wafer accessing method thereof

ActiveCN102820245AReduce waiting timeAvoid interactionSemiconductor/solid-state device manufacturingConveyor partsProcess systemsAir atmosphere

The invention relates to a thin-film process system with a wafer storage groove. The system comprises a wafer storage unit, a wafer transfer cavity, a vacuum wafer conveying cavity, a process cavity and a vacuum wafer storage cavity arranged between the wafer conveying cavity and the vacuum conveying cavity connected in sequence successively. The vacuum wafer storage cavity further comprises a pumping unit communicated with the vacuum wafer storage cavity. The pumping unit is used to provide a vacuum atmosphere or an air atmosphere for the vacuum wafer storage cavity. The wafer storage groove is moveably arranged in the vacuum wafer storage cavity. According to the thin-film process system with the wafer storage groove provided by the invention, the vacuum wafer storage cavity with the moveably arranged wafer storage groove is additionally arranged so that not only the waiting time of risk of processed wafers is effectively reduced, but also mutual influence between wafers after thin-film process and wafers to be processed is avoided, and potential risks are avoided and the performance and quality of products are improved.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

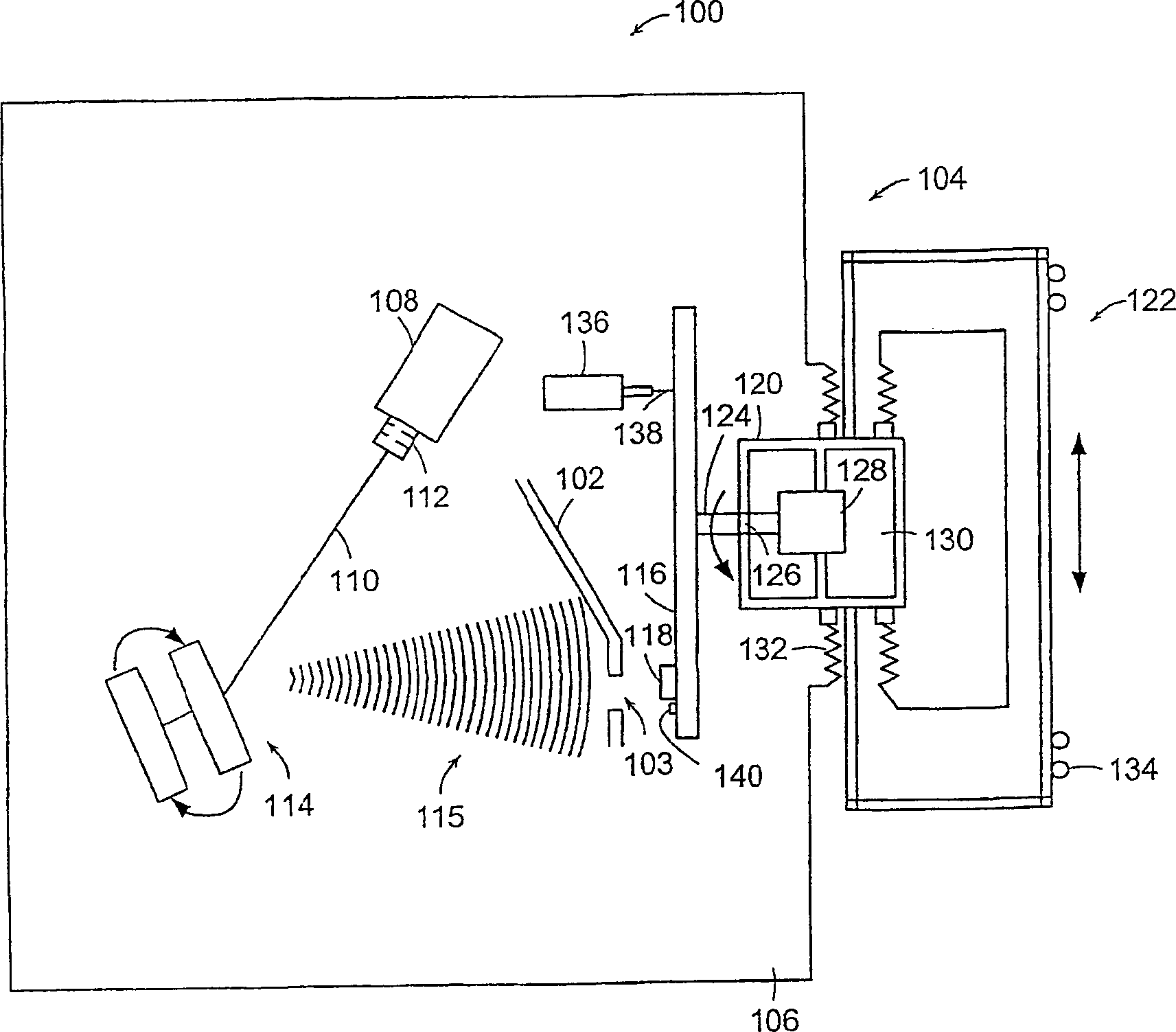

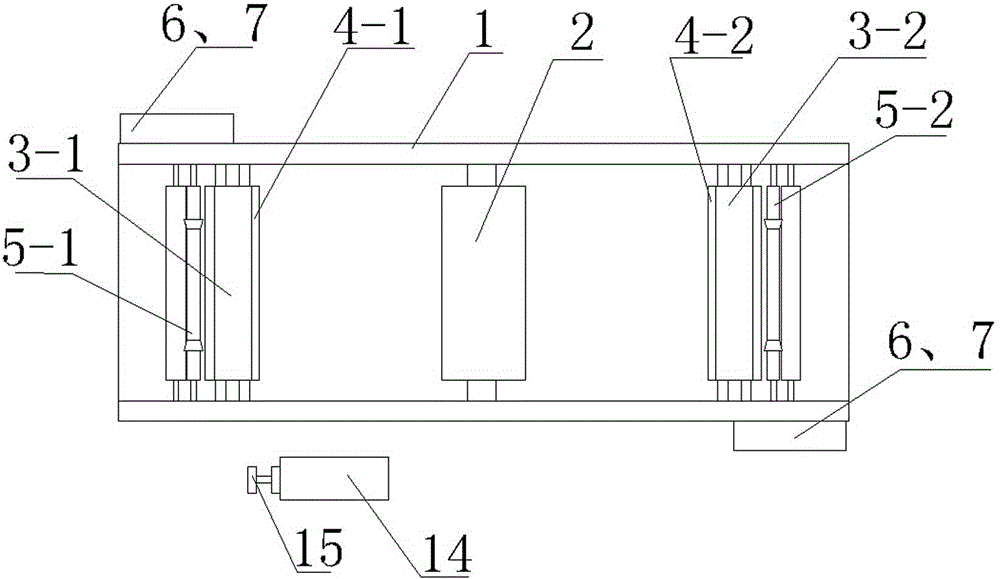

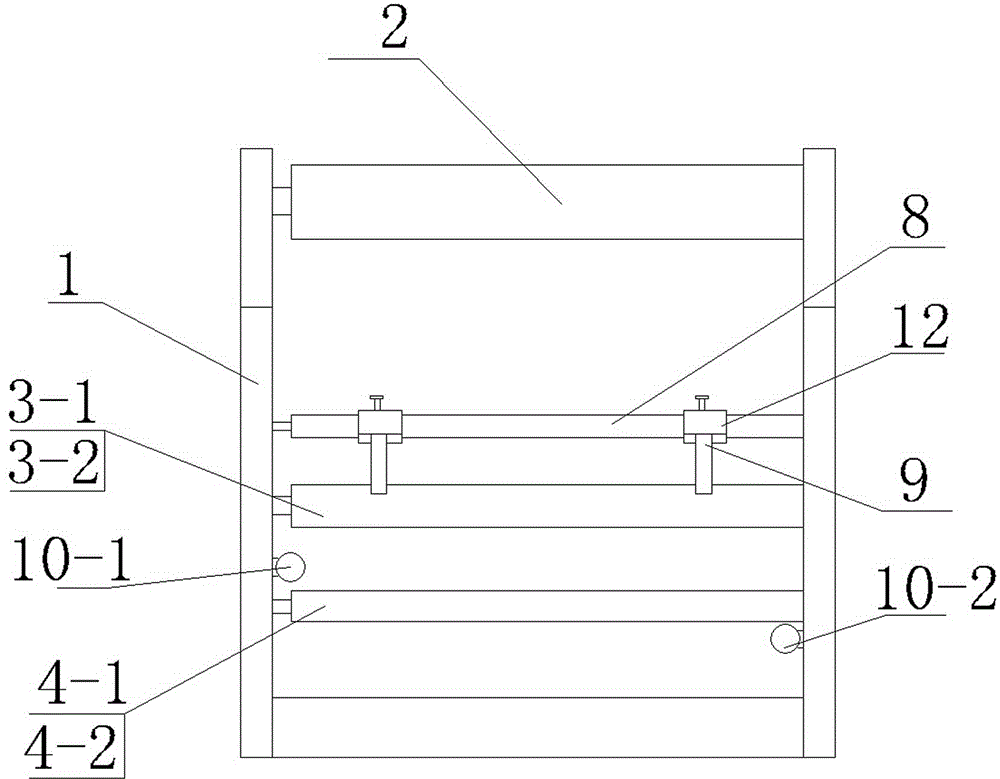

Double scanning thin film processing system

The present invention describes a deposition system. The deposition system includes a deposition source that generates a deposition flux containing neutral atoms and molecules. A shield defining an aperture is located in the path of the deposition flow. The shield passes the deposition flux through the aperture and virtually blocks the deposition flux from propagating anywhere else behind the shield. There is an underlying support near the shield. A dual scanning system utilizes first and second motions to scan the underlying support associated with the well.

Owner:尤纳克西斯美国公司

Flattening device for PVC film processing

ActiveCN108247998AImprove ironing effectQuality improvementFlat articlesEngineeringMachining process

The invention discloses a flattening device for PVC film processing. The flattening device comprises an upper rack, a lower rack, a first material spreading component and a second material spreading component, wherein the first material spreading component and the second material spreading component are arranged between the upper rack and the lower rack in a rotatable manner, wherein a first material conveying component which conveys materials through the cooperation of the first material spreading component and a second material conveying component which conveys materials through the cooperation of the second material spreading component are arranged on the upper rack, and the lower part of the first material spreading component is provided with an electric corona device used for producing electric corona so as to flatten materials. In the flattening device provided by the invention, by arranging the electric corona device which can send out electric corona or electric arcs when beingelectrified, ironing treatment on a PVC film is carried out, the good flatness of the PVC film is ensured, the condition that the PVC film has creases in the processing process is effectively solved,the uneven places of the PVC film also can be fully ironed flatly in a material forming period, the flatness of the PVC film is improved to an utmost degree, and the performance of the PVC film during later use period is better.

Owner:黄山市鑫丰瑞新材料科技有限公司

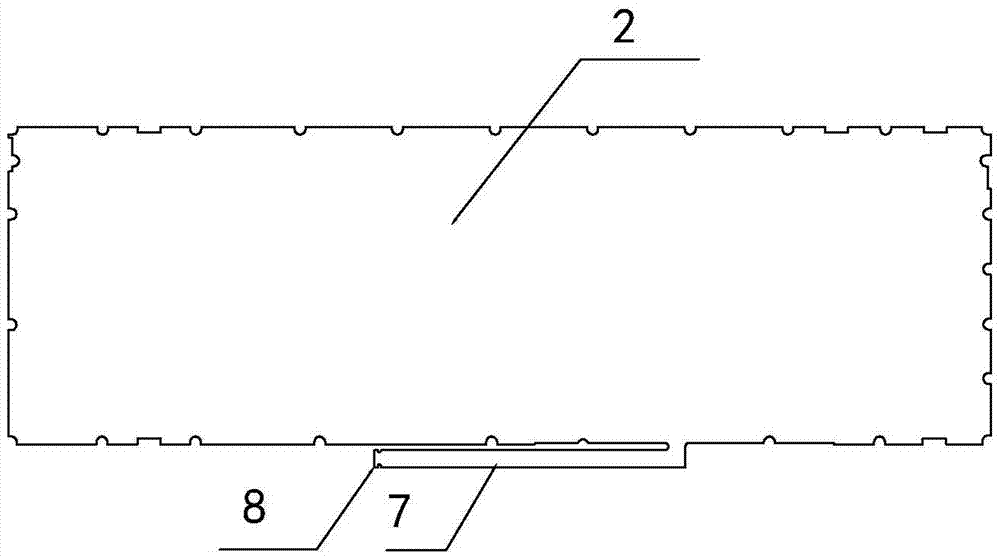

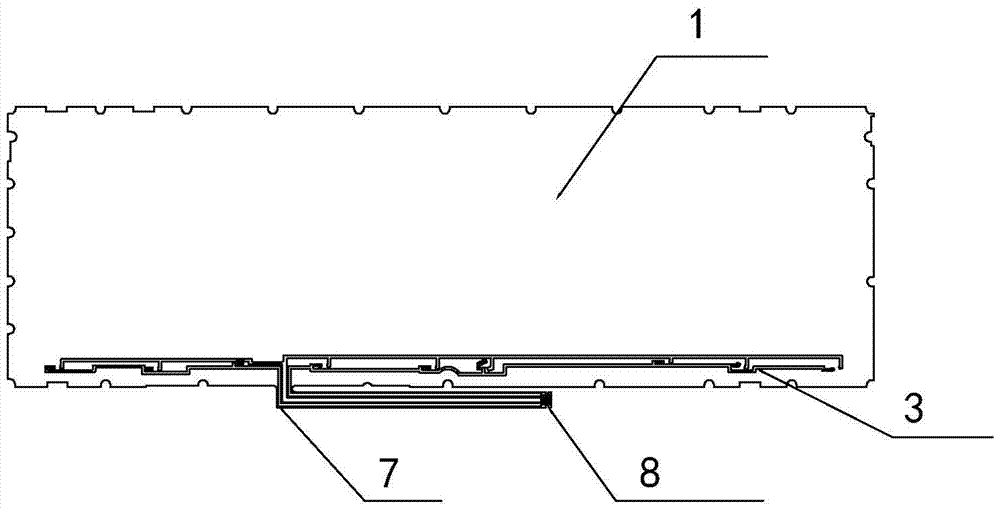

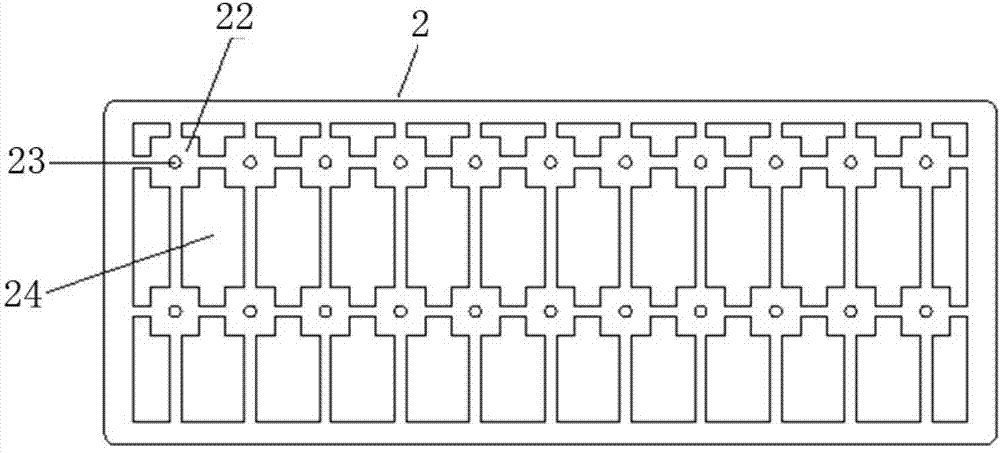

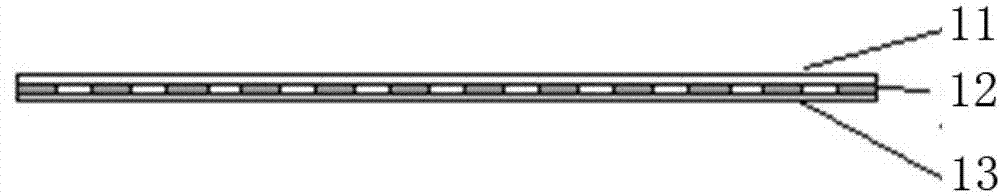

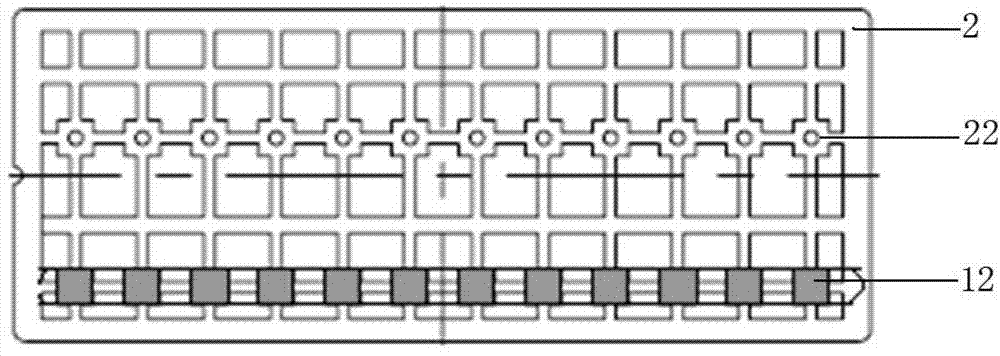

Integrated light guide module bottom film, light guide module and bottom film processing method

PendingCN107132608ALow costSave the step of attaching the FPC light barOptical light guidesSilver pasteLight guide

The invention discloses an integrated light guide module bottom film, a light guide module and a bottom film processing method. The bottom film comprises a substrate and a connection bar, wherein the connection bar and the substrate are arranged integrally; a conductive silver paste layer is arranged on the front surface of the substrate and the connection bar; the conductive silver paste layer is arranged corresponding to the line of a lighting circuit; the end position of the connection bar is provided with a connector; the front surface of the substrate is provided with a reflective ink layer; the pad position of the line formed by the conductive silver paste layer is not provided with the reflective ink layer; the pad position of the line formed by the conductive silver paste layer is provided with an LED; and a water adhesive layer is arranged above the reflective ink layer. Through directly arranging the line and the LED on the bottom film, a step of gluing an FPC lamp strip can be saved, mechanical production is facilitated, the material cost can be reduced, the manual cost can also be reduced, the production efficiency is improved, and the product quality can also be improved.

Owner:SHENZHEN HUICHUANGDA TECH

Film processing device

A film processing device including a chamber that includes a reaction space; an upper electrode which is in the chamber and includes plural through holes around the central part of the upper electrode; an air distribution plate, which is below the upper electrode and includes plural receiving holes corresponding to the plural through holes each; a coupling device, which passes through the throughholes and is inserted in the receiving holes to couple the upper electrode and the air distribution plate; a lower electrode, on which a substrate is arranged, and faces the air distribution plate, where the reaction space is between the lower electrode and the air distribution plate; a hermetic portion, which is on the surface of the top of the upper electrode around the through holes, where thehermetic portion is a O-shaped ring; and at least one refrigeration portion, which includes a refrigeration path so as to refrigerate the hermetic portion.

Owner:JUSUNG ENG

Processing method of IPE blown film

The invention relates to the technical field of film processing, and discloses a processing method of an IPE blown film. The processing method comprises the following steps (1) carrying out heating and mixing on raw materials, a filler and an assistant to prepare a mixture; (2) adding the mixture into an extruder, and after the mixture is completely molten and plasticized, extruding to form a tubular film bubble by the extruder; (3) carrying out cooling sizing on the tubular film bubble by using a cooling mechanism, then clamping the tubular film bubble flat by utilizing a herringbone board soas to enable the tubular film bubble to become a planar film; (4) pulling the film to a receiving roll by utilizing a pull roll and a guide wheel; (5) when the film rolled on the receiving roll reaches a regulated weight, cutting off the film between the receiving roll and a guide roll by a cutting mechanism, and then taking down and replacing the receiving roll; (6) repeating the steps (1) to (5) so as to obtain multiple rolls of film finished products with equal weights. The processing method can solve the problems of poor cooling effect and fussy component process in the production processof a blown film in the prior art.

Owner:CHONGQING RUITING PLASTIC

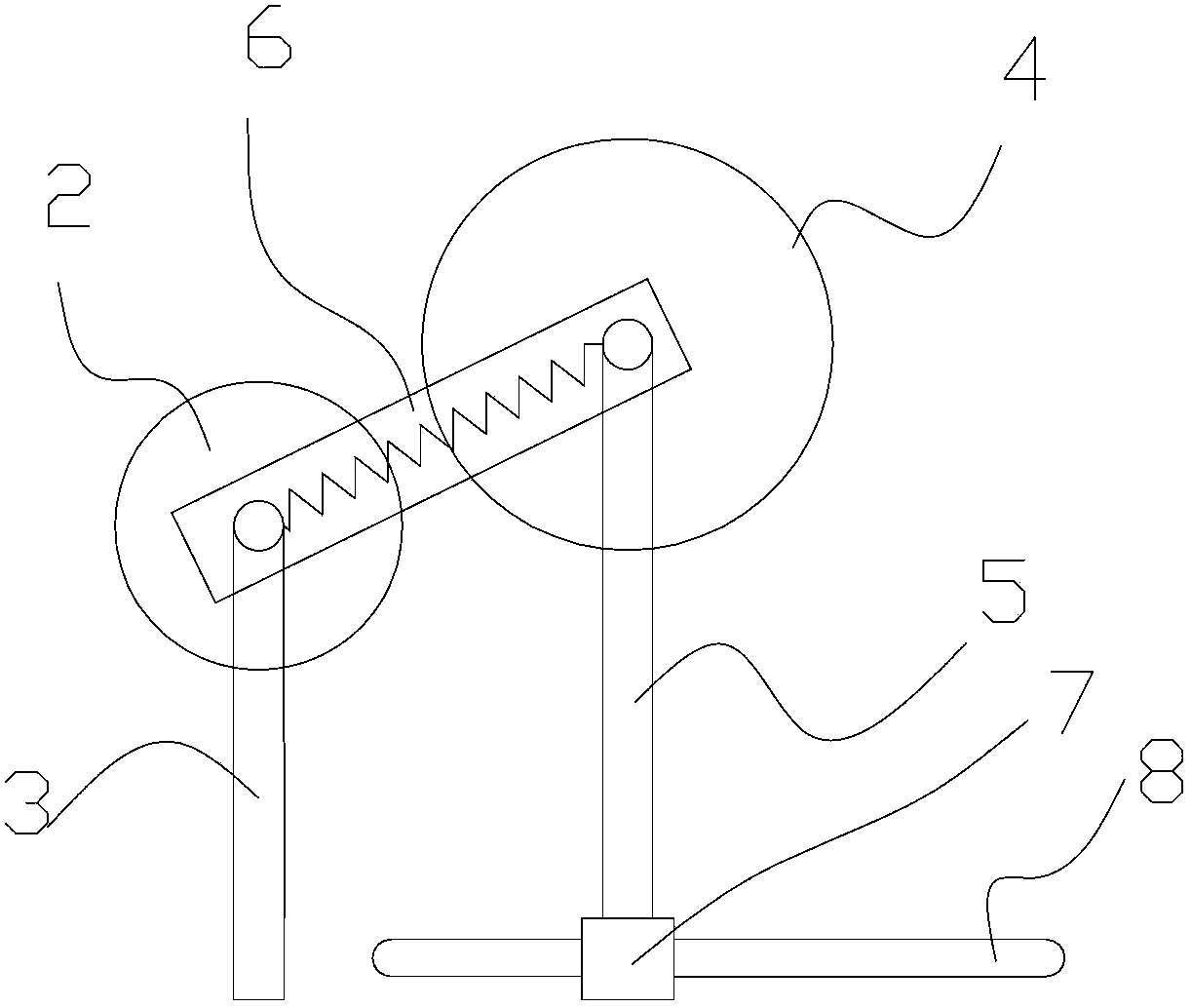

Thin film cutting auxiliary mechanism

InactiveCN109205373ASimple structureWorking principle is clearArticle deliveryPlastic filmConveyor belt

The invention discloses a thin film cutting auxiliary mechanism, and belongs to the technical field of thin film processing. The thin film cutting auxiliary mechanism comprises a machine frame and a working table surface. A friction wheel is arranged on one side of the working table surface, a conveyor belt is arranged on the friction wheel, and the conveyor belt is flush with the working table surface. A rack press tool is arranged above the working table surface, an upper cutting cutter is arranged in the rack press tool, an upper cylinder is connected to the upper cutting cutter, a gear isarranged on one side of the rack press tool, a lower guide rail is arranged below the working table surface, a lower cutting-off tool is arranged in the lower guide rail, and a lower cylinder is arranged under the lower cutting-off tool. A thin film to be processed is moved between the upper cutting cutter and the lower cutting-off tool by the conveyor belt, the cutting-off of the plastic thin film to be processed is completed by the combined action of an upper cylinder and the lower cylinder. The thin film cutting auxiliary mechanism has a simple and reasonable structure and a clear working principle, compared with a traditional plastic thin film cutting device, the rapid cutting of the plastic thin film is realized, the cutting efficiency of the plastic thin film is improved, and the requirements of the line production of the plastic thin film are satisfied.

Owner:苗洪敏

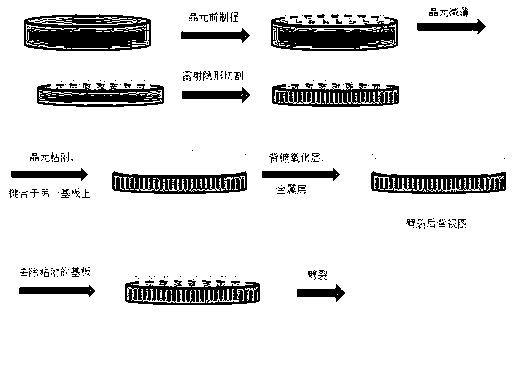

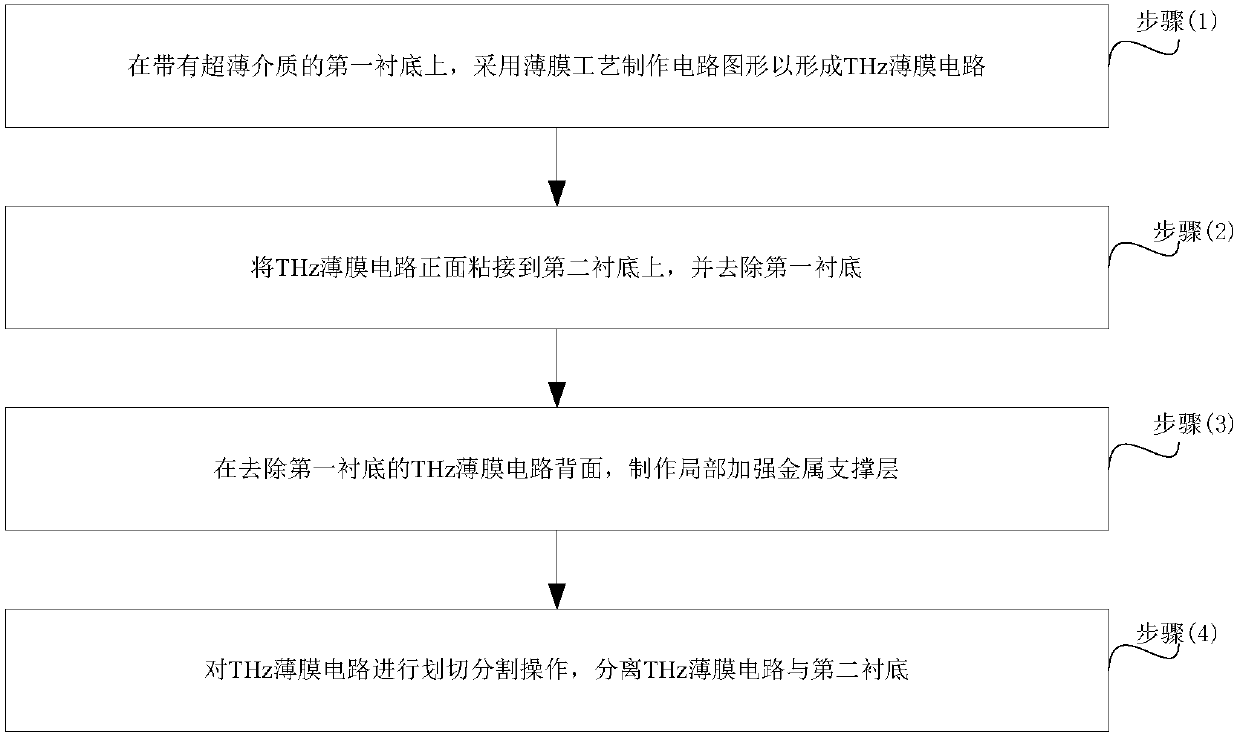

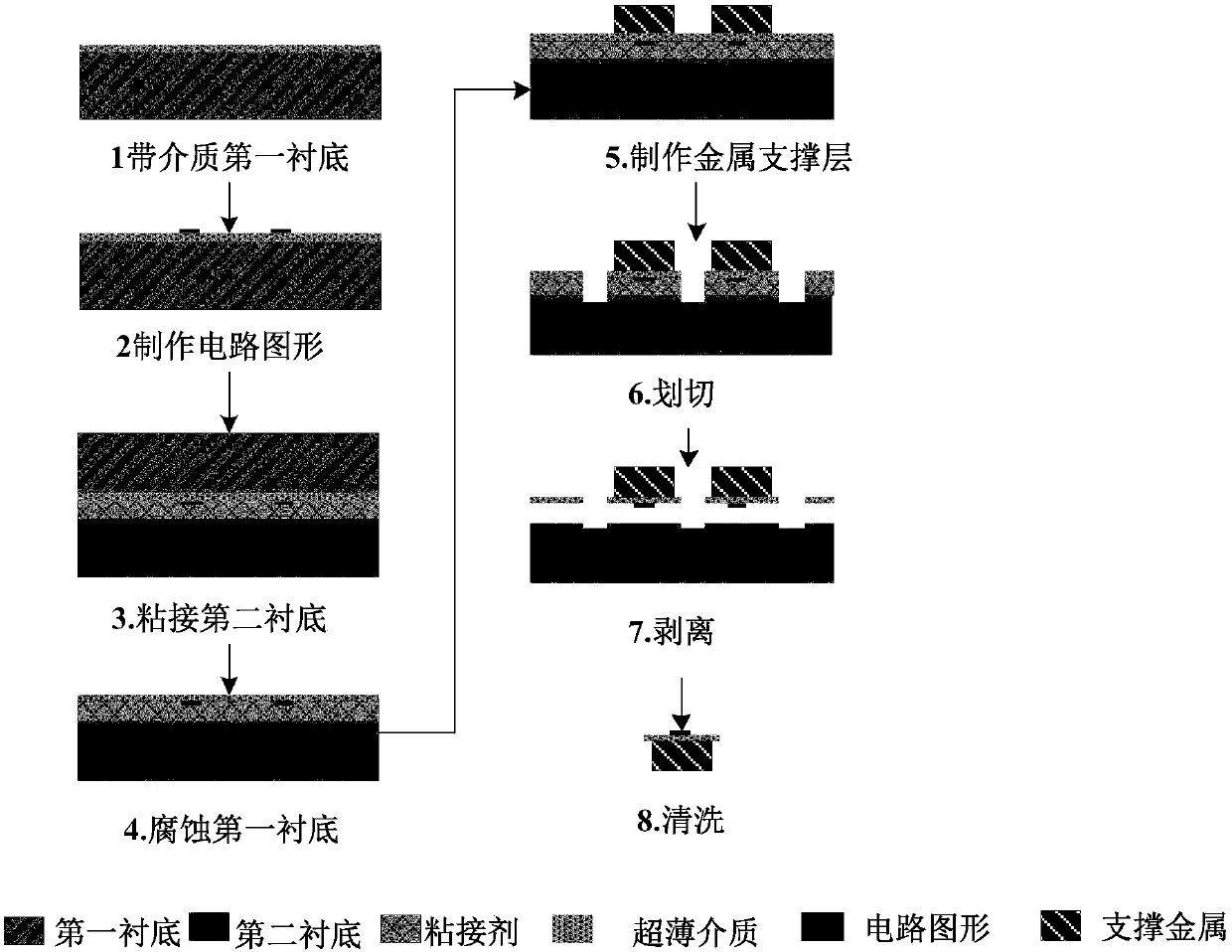

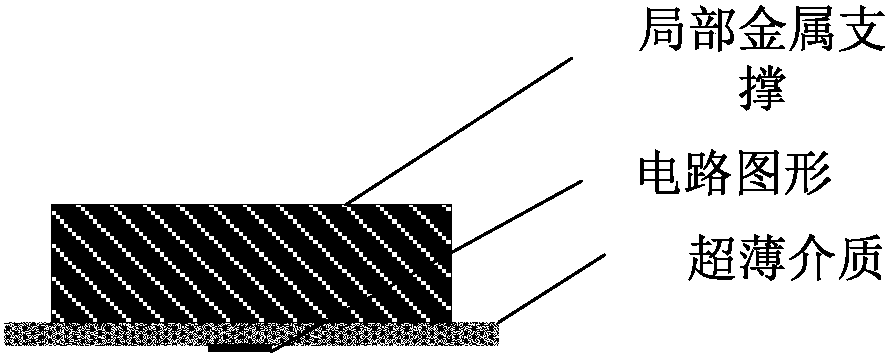

Ultrathin THz thin film circuit processing method with local metal support and thin film circuit

ActiveCN107863317AHigh mechanical strengthMeet performance needsSolid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsUltimate tensile strength

The invention discloses an ultrathin THz thin film circuit processing method with local metal support and a thin film circuit. The ultrathin THz thin film circuit processing method with local metal support comprises the steps of (1) fabricating a circuit pattern on a first substrate with an ultrathin medium by employing a thin film process so as to form a THz thin film circuit; (2) pasting a frontsurface of the THz thin film circuit onto a second substrate, and removing the first substrate; (3) removing a back surface of the THz thin film circuit on the first substrate, and fabricating a local reinforcement metal support layer; and (4) performing dividing and cutting operation on the THz thin film circuit, and separating the THz thin film circuit from the second substrate. By the ultrathin THz thin film circuit processing method, the mechanical strength of the ultrathin THz thin film circuit is improved, and the precision assembly operation demand is satisfied.

Owner:THE 41ST INST OF CHINA ELECTRONICS TECH GRP

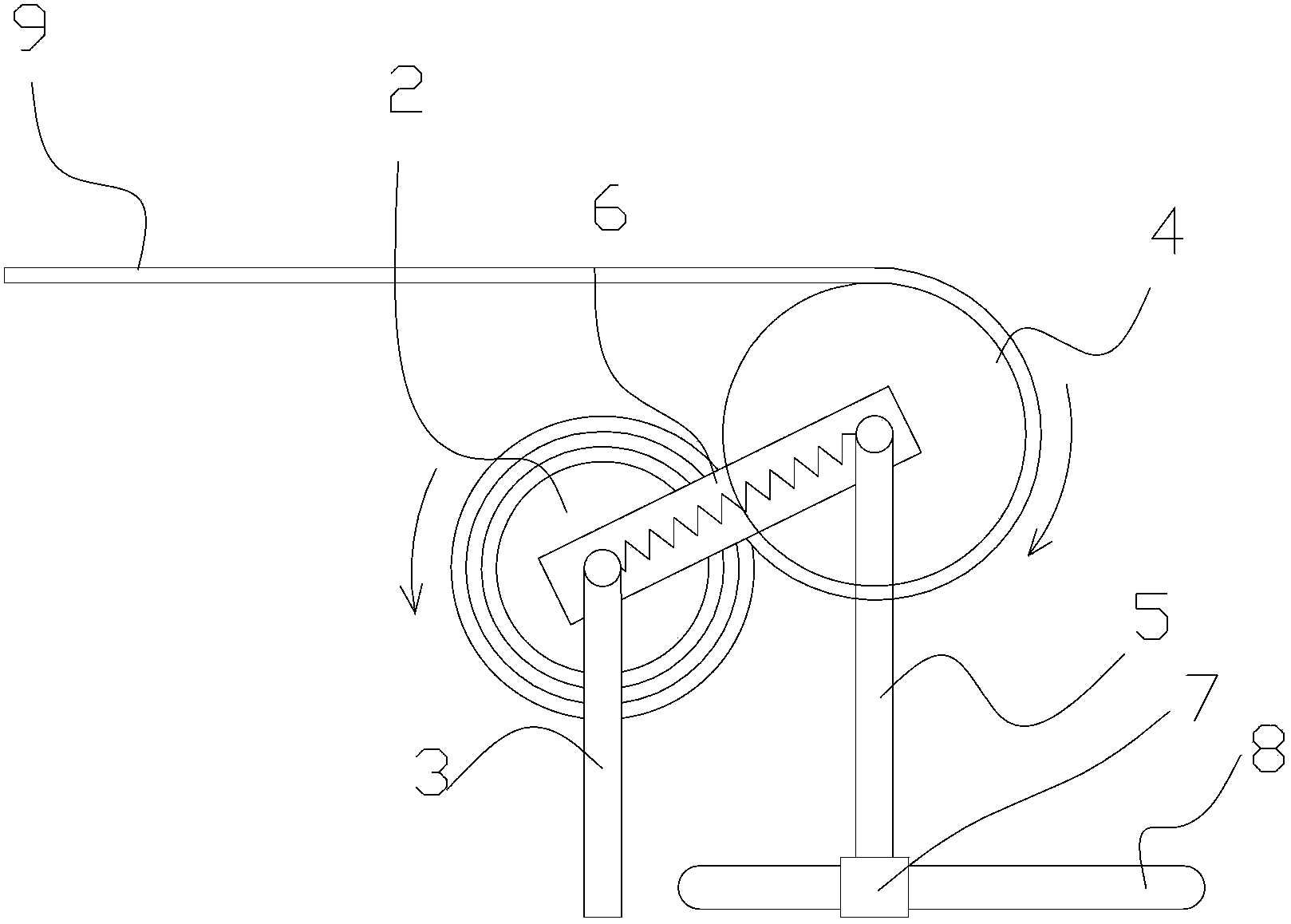

Thin film processing device

The invention provides a thin film processing device, which is simple in structure and processing technique. According to the thin film processing device, the labor intensity is greatly alleviated, the automatic production of the thin film is realized and the work efficiency is improved. The thin film processing device comprises a bracket and is characterized in that a first winding roller is arranged at the upper end of the bracket; a middle roller, a press roller and a second winding roller are separately arranged at two sides of the bracket, corresponding to the first winding roller; the press roller is connected with a driving device; a cutter shaft and a transition roller are arranged at the upper and lower ends of a middle roller at one side of the bracket; cutters are arranged at two ends of the cutter shaft; scrap winding transition rollers are arranged at the lower ends of the bracket, corresponding to the two ends of the cutter shaft; the scrap winding transition rollers are arranged in an up and down crossed manner; a scrap winding device is arranged at one side of the bracket.

Owner:WUXI JIATAI TECH

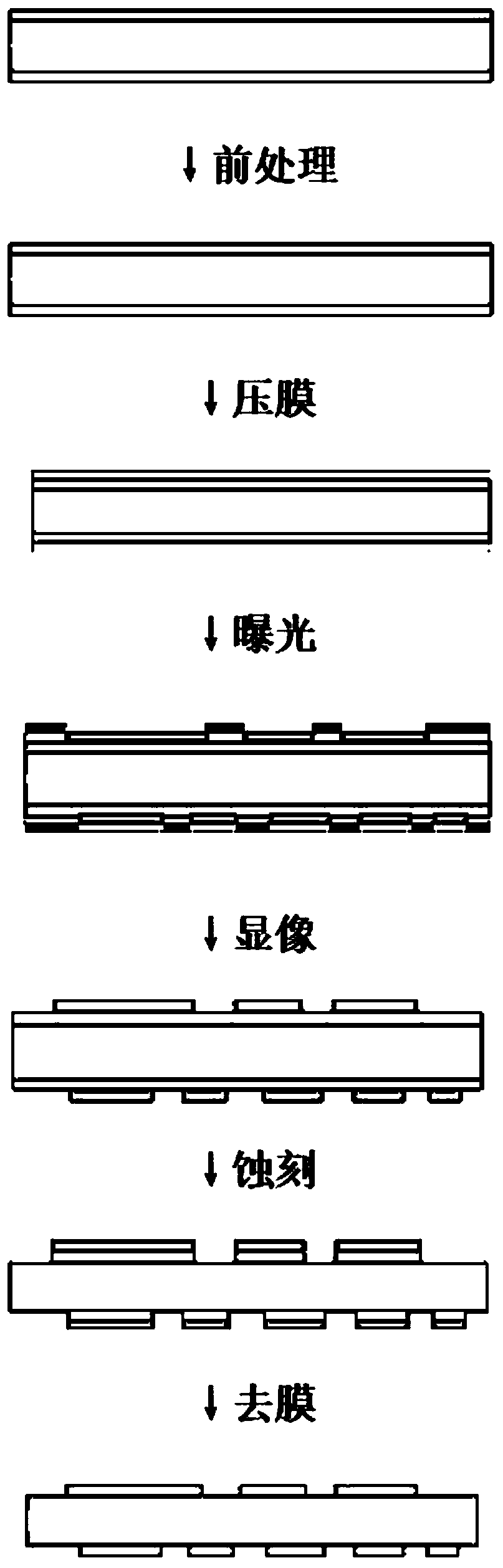

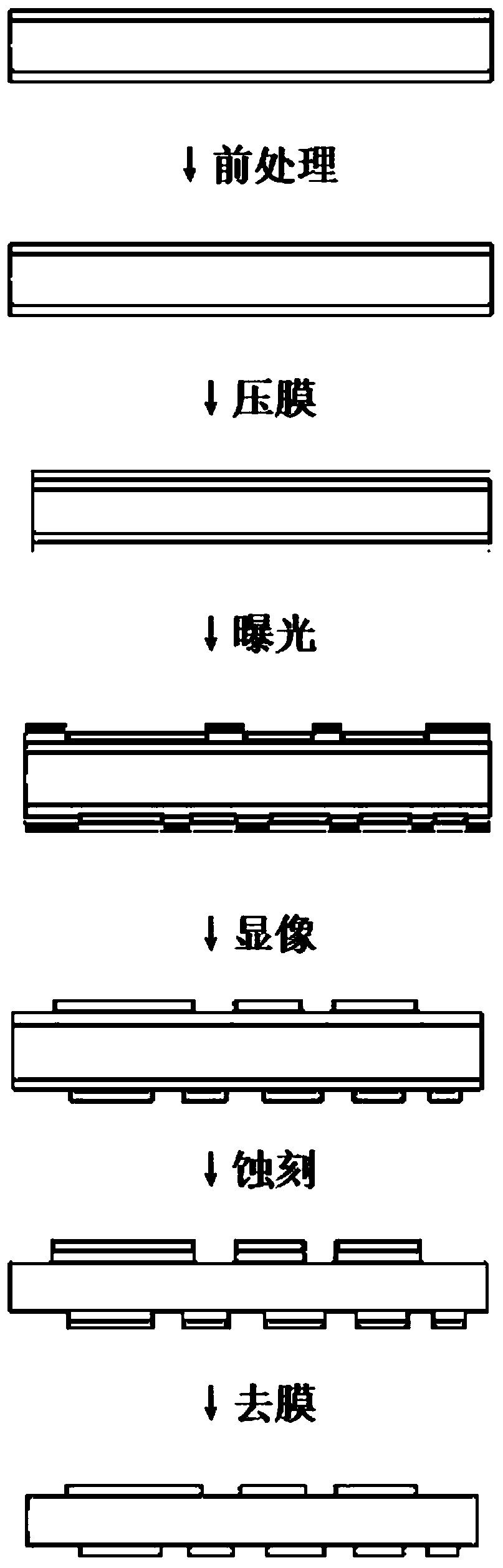

Inner-layer dry film production method

InactiveCN110035619AReduce dry film resolving power reductionExposure costs dropTransfer patterningConductive material chemical/electrolytical removalFine lineDirect imaging

The invention discloses an inner-layer dry film production method in the technical field of printed circuit boards. The method comprises the steps of 1, pre-treatment; 2, film pressing; 3, exposure; 4, development; 5, etching; and 6, film removal. According to the method, direct imaging is carried out in combination with a DI laser exposure machine by adopting a dry film process, and a negative film does not need to be used, so that the exposure cost is greatly reduced, and meanwhile, the dry film analysis capability reduction caused by negative film variation is reduced; after pre-treatment,film pressing, exposure and development parameters are optimized, the dry film analysis capability can reach 40 microns, and 2 / 2mil lines can be massively produced; and the method is an ideal production process of fine lines in current PCB production.

Owner:JIANDING (HUBEI) ELECTRONICS CO LTD

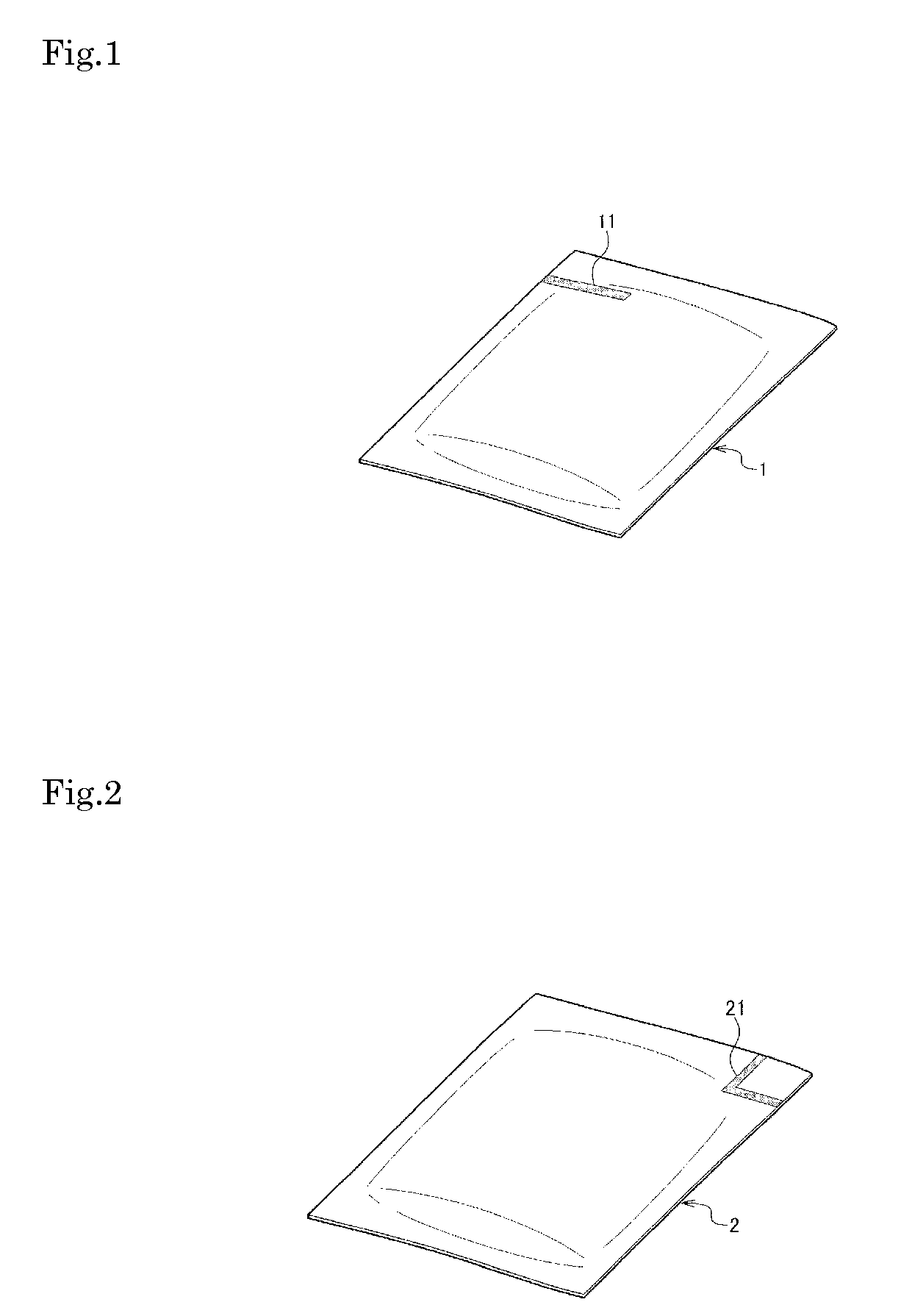

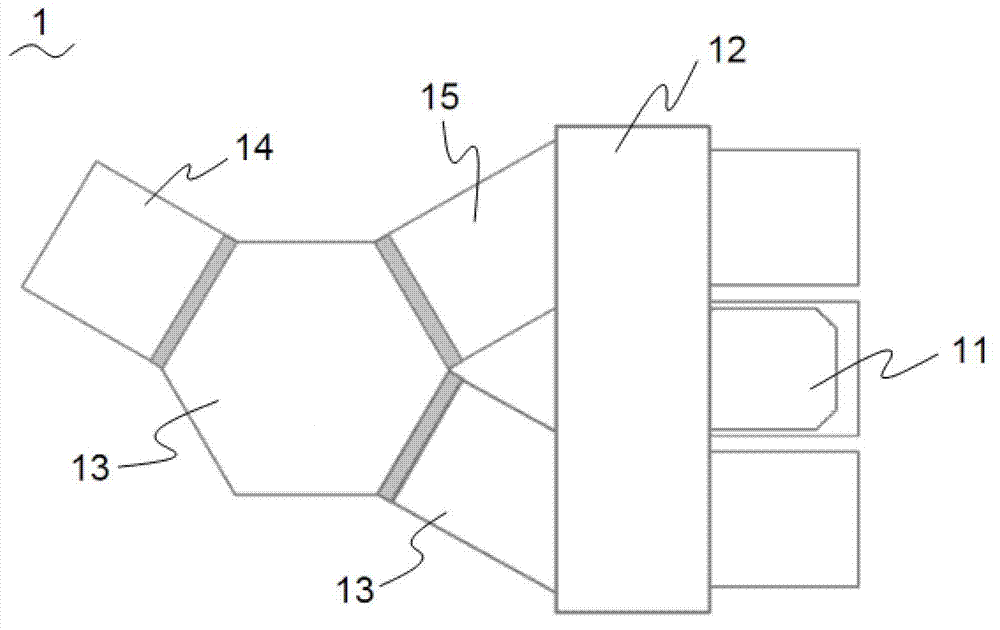

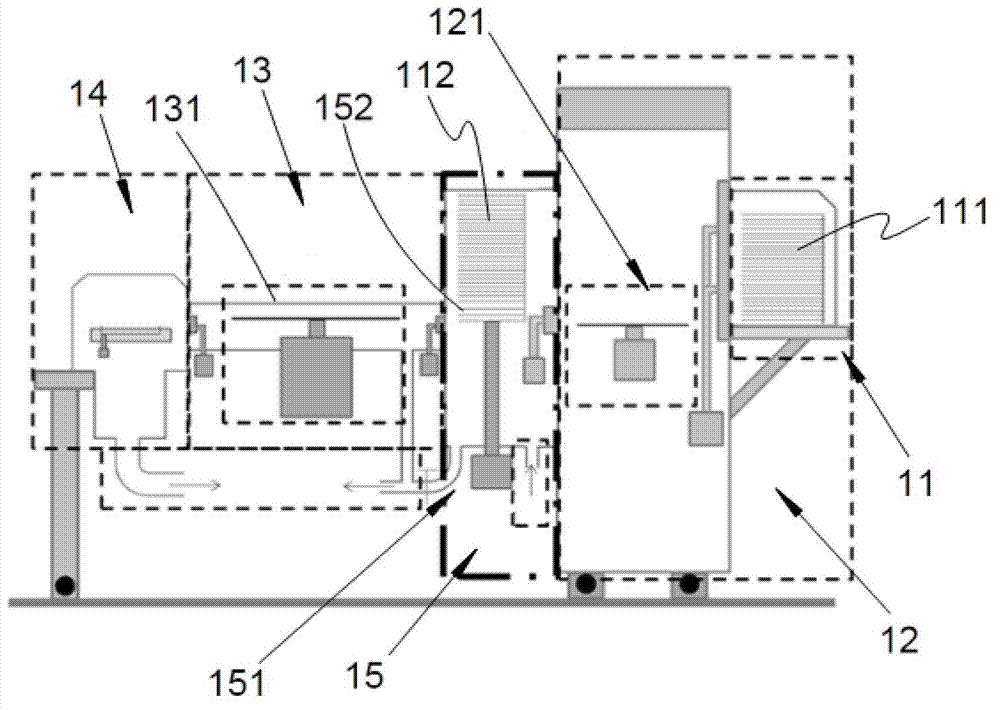

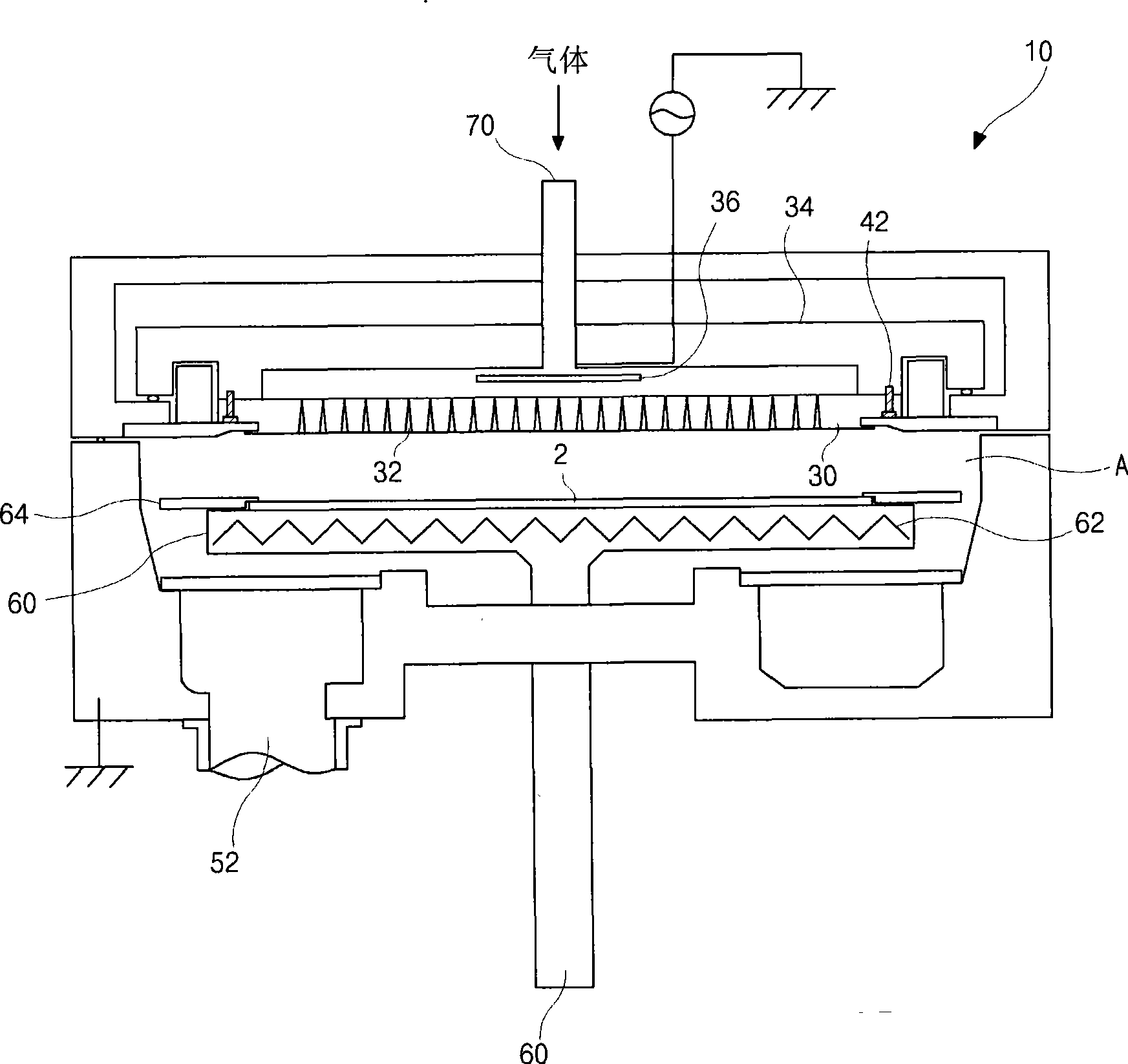

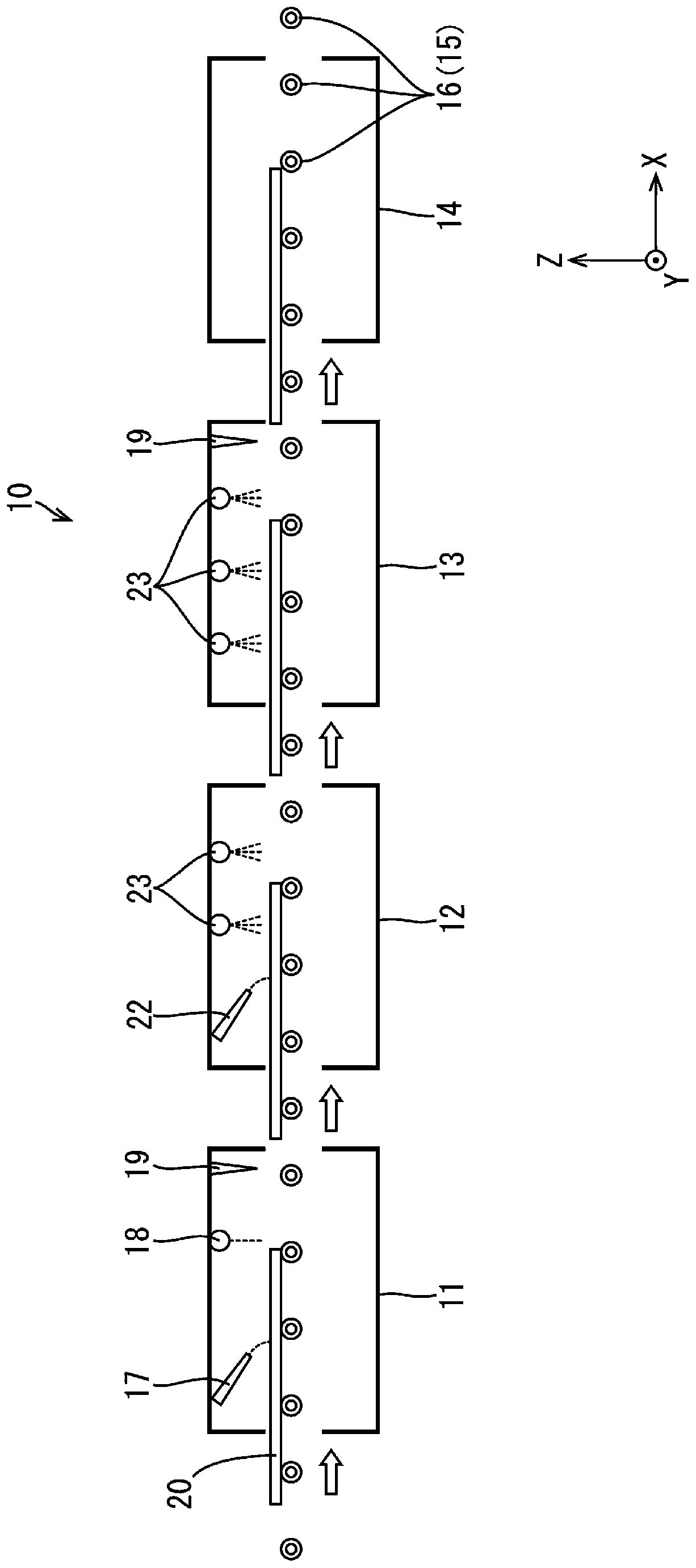

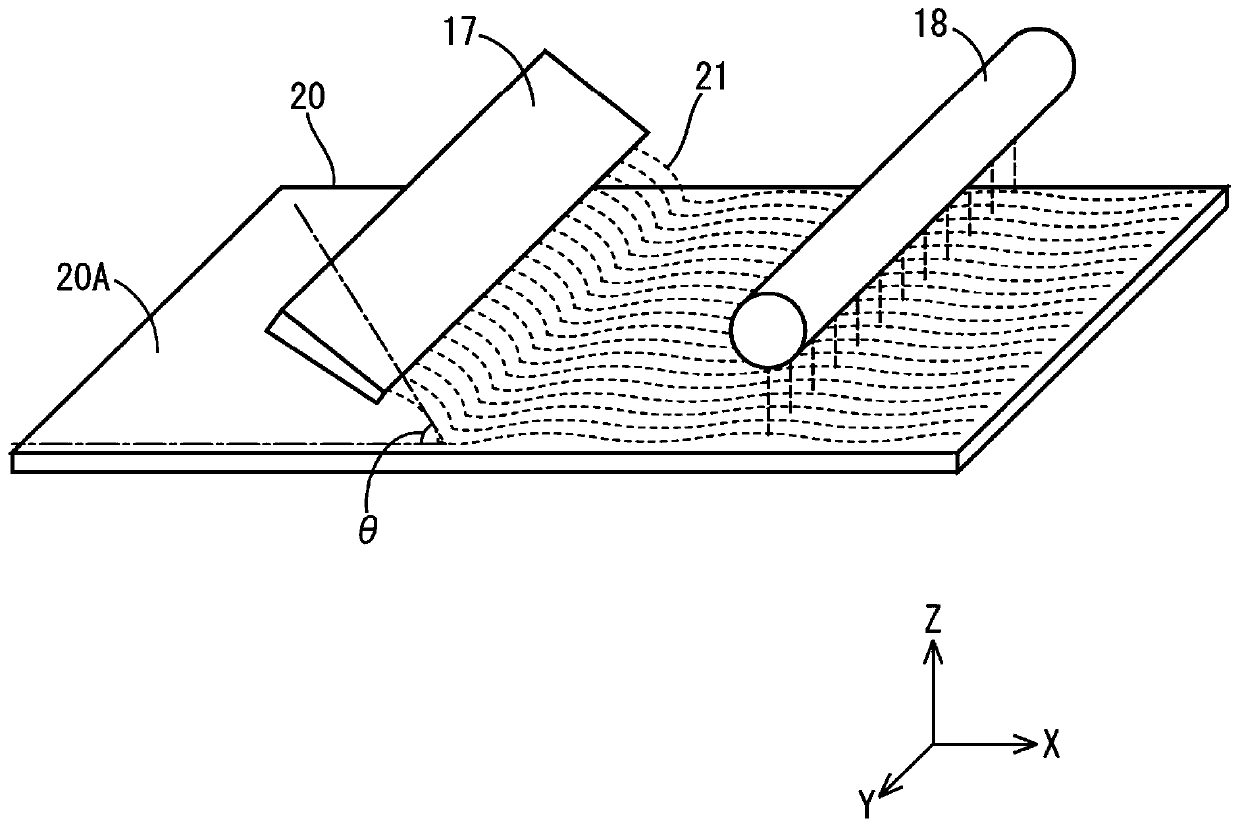

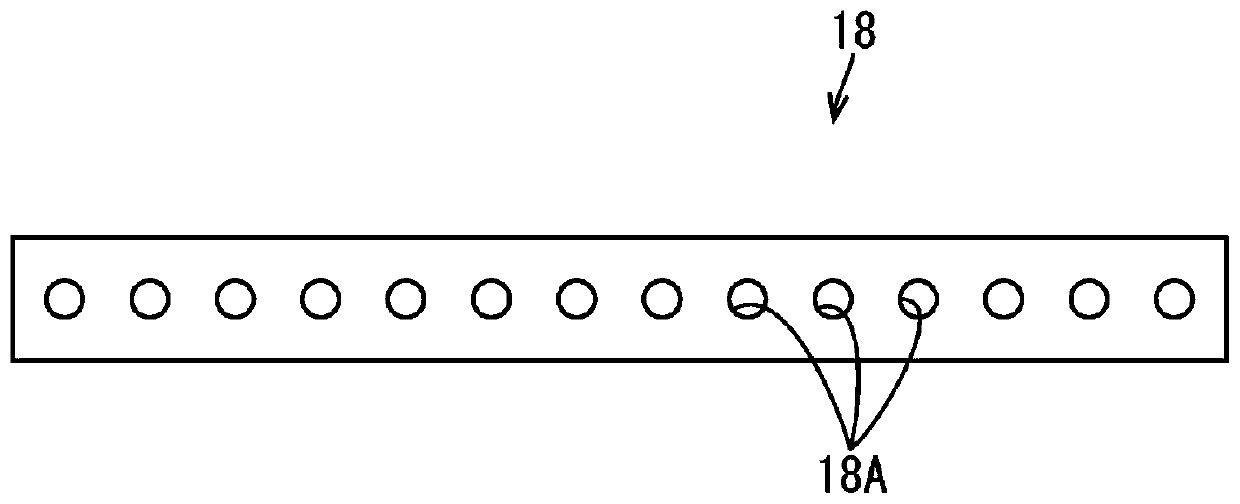

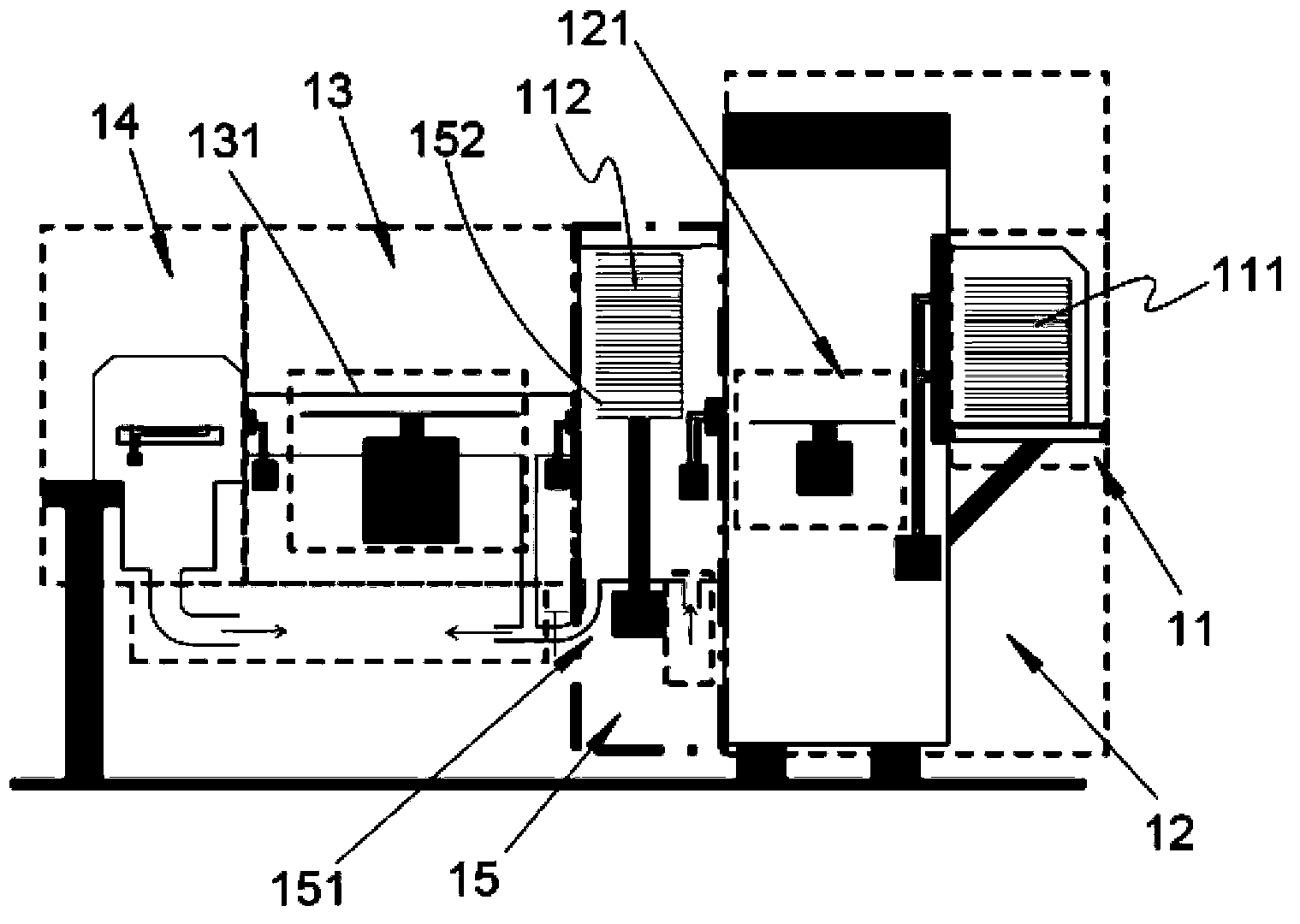

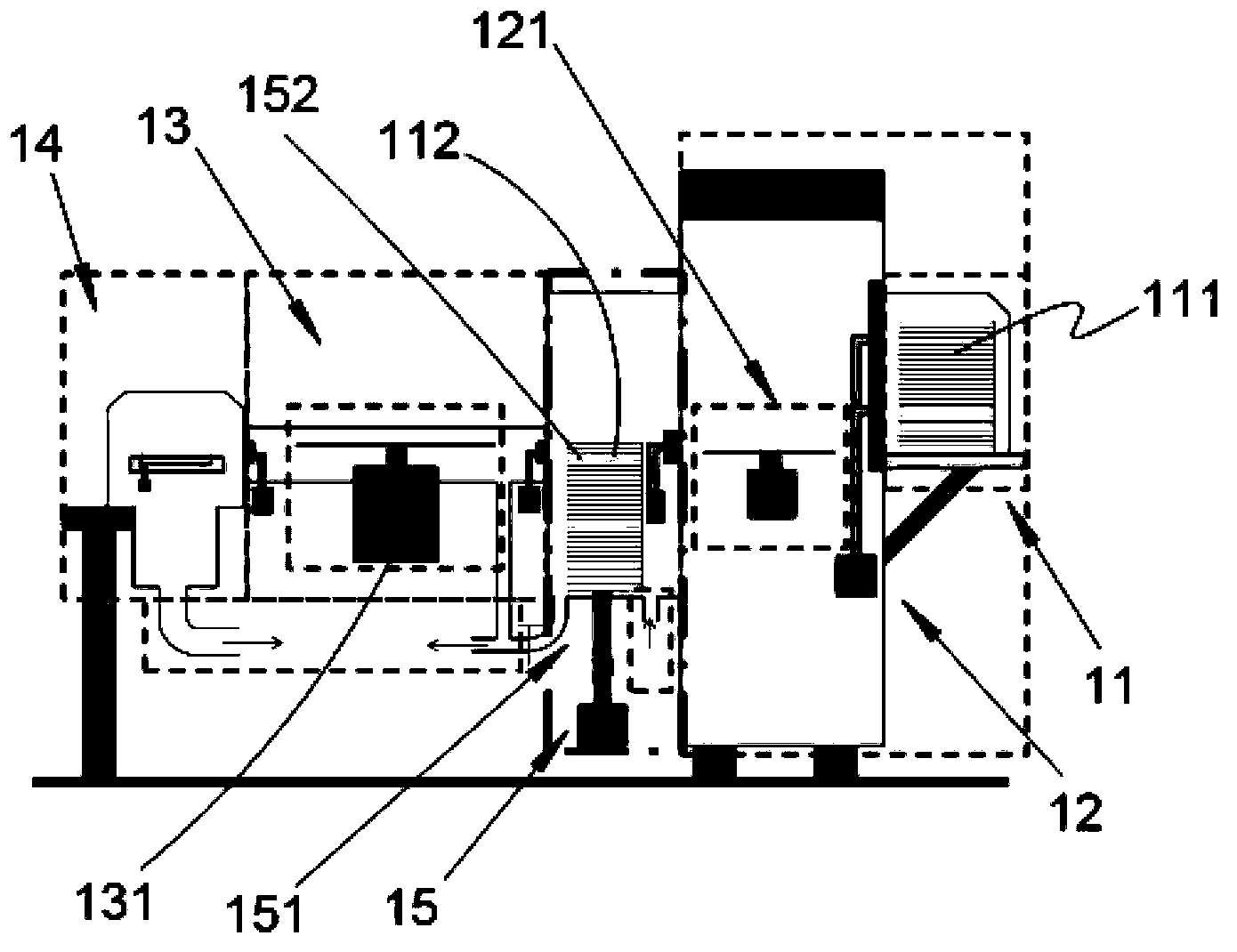

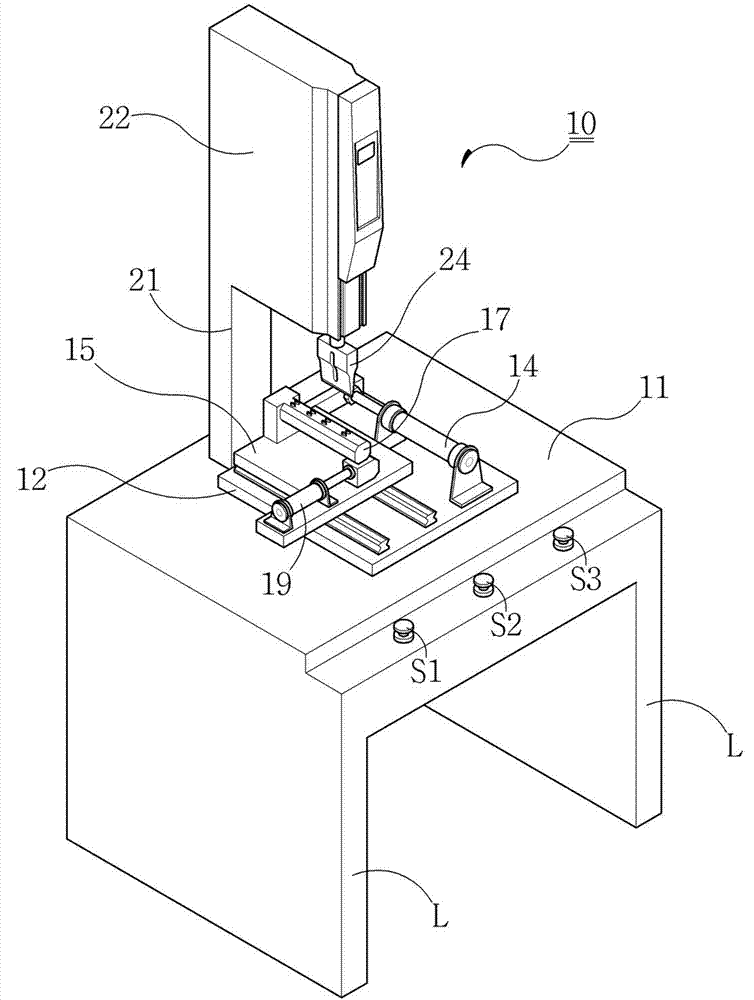

Substrate processing device

InactiveCN110007491ASemiconductor/solid-state device manufacturingNon-linear opticsEngineeringPre treatment

The invention provides a substrate processing device in which a liquid crystal substrate that has been subjected to an alignment treatment is transferred from a film forming tank to a subsequent tankwhile the liquid crystal substrate being entirely covered with a thin film of pretreatment material. In the substrate processing device (10) for performing cleaning processing on the liquid crystal substrate (20) after alignment treatment, a film processing tank (11) has a first supply unit (17) which supplies a pretreatment material (21) to an alignment treatment surface (20A) of the liquid crystal substrate (20) that is conveyed by a conveying device (15). The first supply unit (17) supplies the pretreatment material (21) to the alignment treatment surface of the substrate so as to spread ina curtain form in a direction along the alignment treatment surface (20A) and perpendicular to the transferring direction and supply the pretreatment material obliquely toward a downstream side in the transferring direction. A second supply unit is arranged at the downstream side in the conveying direction of the first supply unit (17) in the film processing tank (11) supplies the pretreatment material to at least a section of the alignment treatment surface.

Owner:SHARP KK

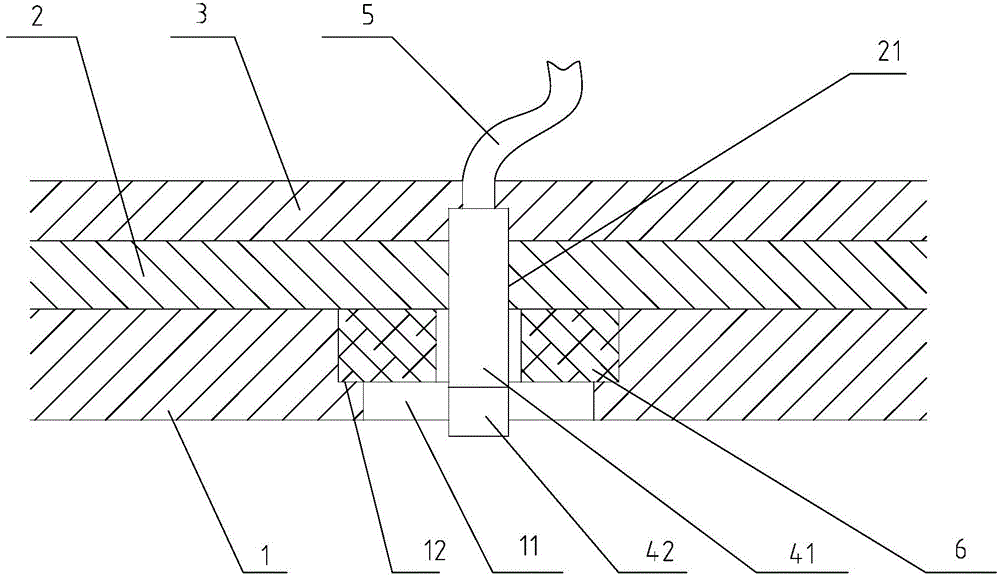

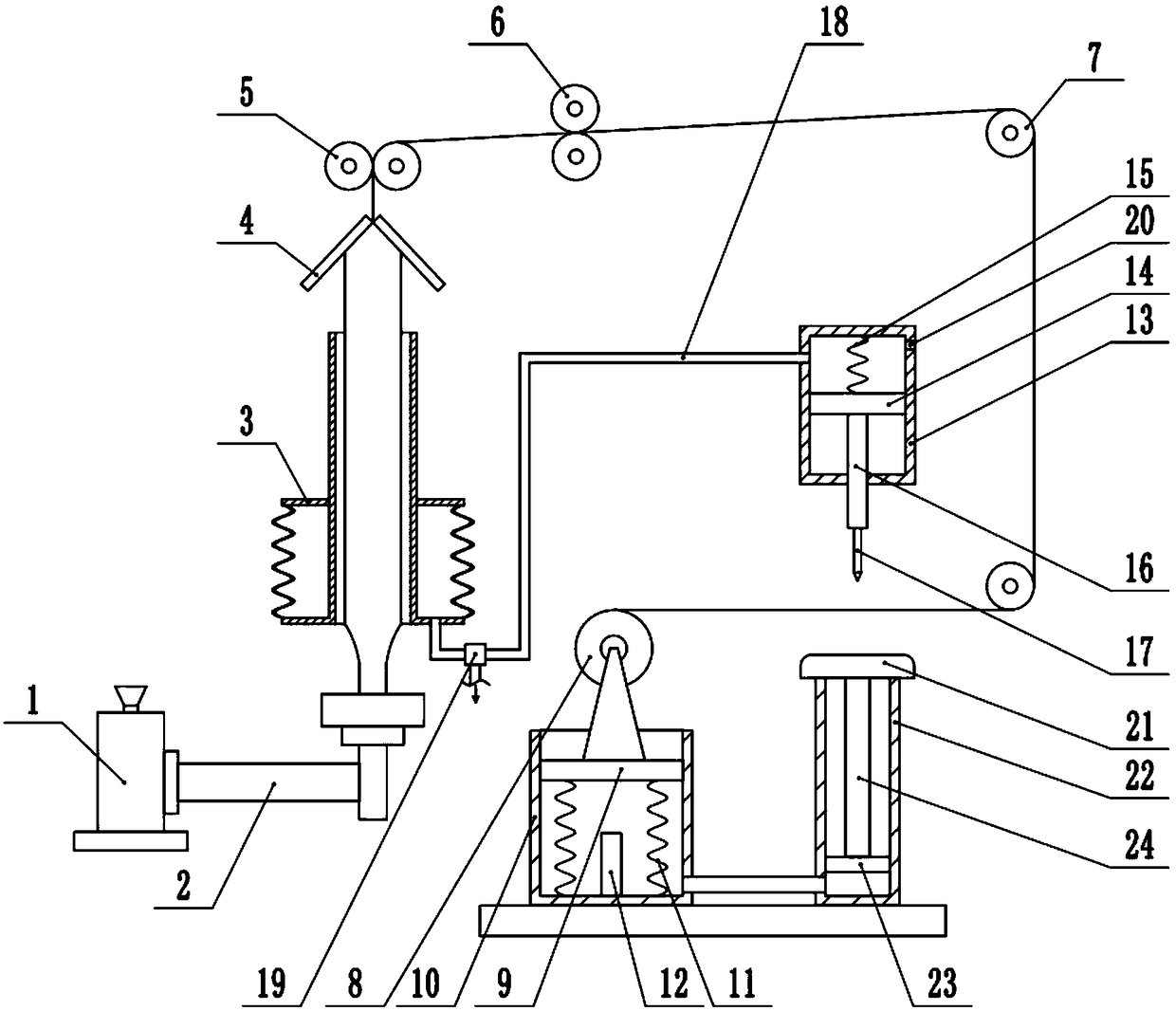

A kind of spraying masking film processing method

InactiveCN104441920BEasy to operateImprove processing efficiencyLamination ancillary operationsLaminationEngineeringPlastic film

The invention discloses a coated masking film processing method. The coated masking film processing method is characterized in that an adhesive tape is pulled out from an adhesive tape coil, a plastic film is pulled out from a plastic film winding drum, the pulled-out adhesive tape and the pulled-out plastic film pass through three third wheels arranged in a high-low staggered manner to enable the adhesive tape to be bonded at the side edge position of the plastic film, and then the bonded masking film is wound on a masking film winding drum. According to the coated masking film processing method, the coated making film can be processed, and the method has the advantages of simplicity in operation, high processing efficiency, high automation degree and the like.

Owner:CHONGQING XIESHI ADHESIVE PROD

Film rolling device

InactiveCN103625964ASolve the problem of prone to wrinklesReach smoothWebs handlingWrinkle skinProduction line

The invention relates to an improvement to a film rolling mode on the film processing tail section of PVC production line equipment, and provides a film rolling device which can prevent a film from being corrugated in a film rolling process. According to the technical scheme, the film rolling device is arranged on the film processing tail section of a PVC production line and comprises a motor, a film rolling roller and a film rolling roller support, wherein the motor is fixedly connected to the film rolling roller, and the film rolling roller is connected to the film rolling roller support in a rolling mode; the film rolling device further comprises a film guide roller, a film guide roller support, an elastic tightening device and a sliding guide device, wherein the sliding guide device comprises a sliding block and a guide rod; the sliding block is provided with a through hole, and the guide rod is arranged in the through hole of the sliding block; the film guide roller support is fixed connected to the position above the sliding block; the film guide roller is connected to the film guide roller support in a rolling mode; the initial end of the elastic tightening device is fixedly connected to a shaft head of the film guide roller, the tail end of the elastic tightening device is fixedly connected to a shaft head of the film rolling roller, and therefore the film guide roller and the film rolling roller are kept tightened. The film rolling device effectively solves the problem of wrinkles, and avoids a distortion phenomenon.

Owner:YANGZHOU HAICHUANG PLASTIC PROD

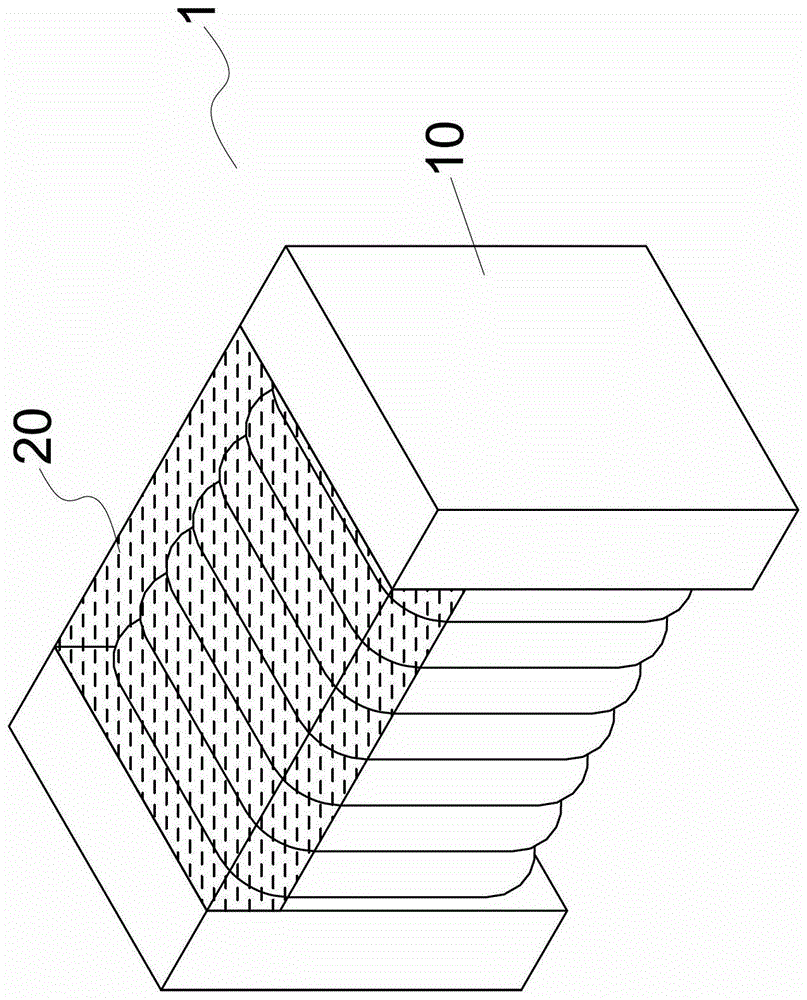

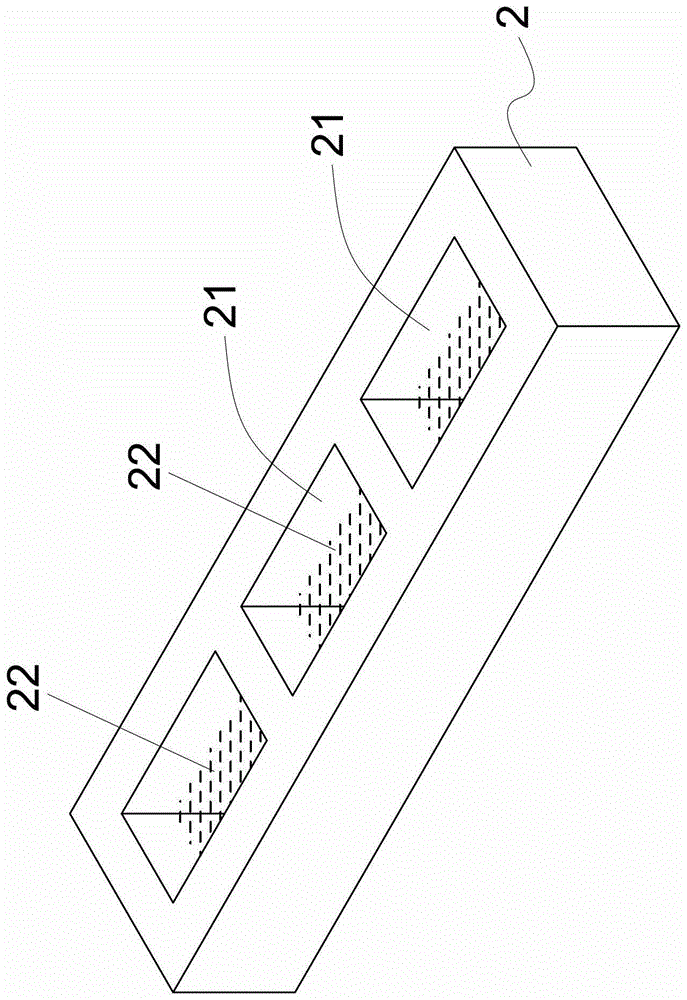

A method that can increase the yield of inductive back film processing

ActiveCN104240931BIncrease production capacityInductances/transformers/magnets manufactureScreen printingAdhesive

Owner:TAI TECH ADVANCED ELECTRONICS CO LTD

Thin-film process system with wafer storage groove and wafer accessing method thereof

ActiveCN102820245BReduce waiting timeAvoid interactionSemiconductor/solid-state device manufacturingConveyor partsProcess systemsAir atmosphere

The invention relates to a thin-film process system with a wafer storage groove. The system comprises a wafer storage unit, a wafer transfer cavity, a vacuum wafer conveying cavity, a process cavity and a vacuum wafer storage cavity arranged between the wafer conveying cavity and the vacuum conveying cavity connected in sequence successively. The vacuum wafer storage cavity further comprises a pumping unit communicated with the vacuum wafer storage cavity. The pumping unit is used to provide a vacuum atmosphere or an air atmosphere for the vacuum wafer storage cavity. The wafer storage groove is moveably arranged in the vacuum wafer storage cavity. According to the thin-film process system with the wafer storage groove provided by the invention, the vacuum wafer storage cavity with the moveably arranged wafer storage groove is additionally arranged so that not only the waiting time of risk of processed wafers is effectively reduced, but also mutual influence between wafers after thin-film process and wafers to be processed is avoided, and potential risks are avoided and the performance and quality of products are improved.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

Non-film jig and application of non-film process in manufacturing process of chip on board (COP)

ActiveCN102915931BAvoid stickingImprove cleaning yieldSemiconductor/solid-state device manufacturingBlack spotOn board

The invention provides application of non-film process in the manufacturing process of chip on board (COP), which comprises the following steps: 1) tearing down a release film on one side of a double-sided adhesive tape and adhering the release film to a non-film jig, wherein the bearing surface of the non-film jig is correspondingly adhered to the double-sided adhesive tape; the double-sided adhesive tape comprises a first release film, an adhesive tape and a second release film; the adhesive tape is segmentally arrayed; and the viscous force of the first release film and the adhesive tape is less than the viscous force of the second release film and the adhesive tape; 2) tearing down a release film on the other side of the double-sided adhesive tape and adhering a COB product to the position corresponding to the bearing surface of the adhesive tape; and 3) treating the COB, removing the double-sided adhesive tape after the COB production process is finished, cleaning the non-film jig and recycling. The COB product adhered to the jig can completely cover the adhesive tape, so that the phenomenon that water is directly impacted on the surface of the adhesive tape in the cleaning process of the product to lift dust to be adhered to the surface of a chip is avoided, so that the cleaning yield is increased by 5 percent and the black spot proportion is reduced by over 2 percent.

Owner:NINGBO SUNNY OPOTECH CO LTD

Thin film pasting device

ActiveCN101920606BIncrease productivityQuality improvementInking apparatusLaminationSlide plateEngineering

The invention provides a thin film pasting device with the object to process thin films on a stirring unit adopted by a powdered ink supply instrument in the printing powder supply machine as well as to process various thin films used to be pasted in a cylinder shape manner. The thin film pasting device of the invention comprises a sliding plate capable of being slidingly connected to a guide rail in a fixed plate and capable making the sliding plate slide through the combination with the movable cylinder on the fixed plate. The fixed station of the movable plate is provided with plural fixedly protruding pasting rods which mutually correspond to each other; the piston rod arranged on a support cylinder at one side of the movable plate is provided with a support block used to support the front side part at the bottom of the support rod; the bottom of a lifting rod is provided with an ultrasonic wave and high frequency pasting instrument which can be lifted up or down in accordance to the lifting instrument arranged inside the lifting outer cover. With the thin film pasting device of the invention, processing time devoted to pasting can be shortened at the maximum; productivity is increased; production costs are reduced; quality of thin film processing is increased so as to prevent low quality products to the maximum.

Owner:威海奥尔特电子有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com