Film processing device

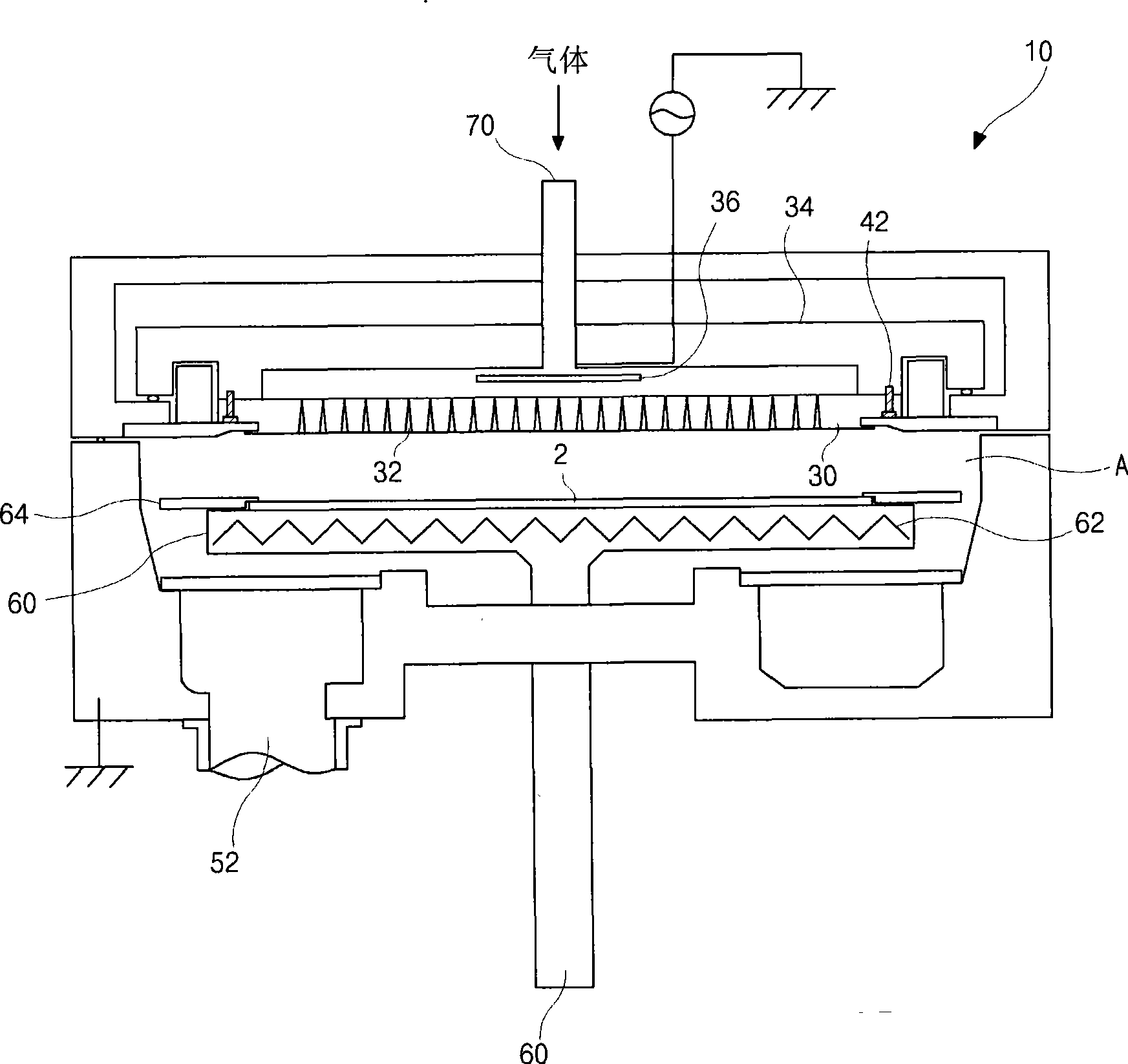

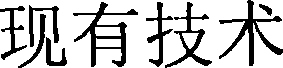

A thin film processing and equipment technology, applied in the field of thin film processing equipment, can solve the problems of uneven deposition and etching films, degradation of film uniformity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Reference will now be made in detail to the illustrated embodiments of the invention, which are illustrated in the accompanying drawings.

[0039] image 3 is a cross-sectional view illustrating a thin film processing apparatus according to a first embodiment of the present invention, and Figure 4 is to zoom in image 3 A view of area B.

[0040] see image 3 and 4 , the thin film processing apparatus according to the first embodiment includes a chamber 110 .

[0041] The reaction space A is in the processing chamber 110 and is a sealed space for performing a thin film processing process. The reaction space A is between the upper electrode 134 and the lower electrode 160 . The upper electrode 134 may be supplied with an RF high voltage, and the lower electrode 160 may be supplied with a bias voltage. The lower electrode 160 may serve as a chuck or a substrate replacement portion on which the substrate 102 is placed, and moves up and down.

[0042]Gas distributi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com