Double scanning thin film processing system

A double-scanning, deposition system technology, applied in vacuum evaporation plating, coating, sputtering plating, etc., can solve problems such as target distance limitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

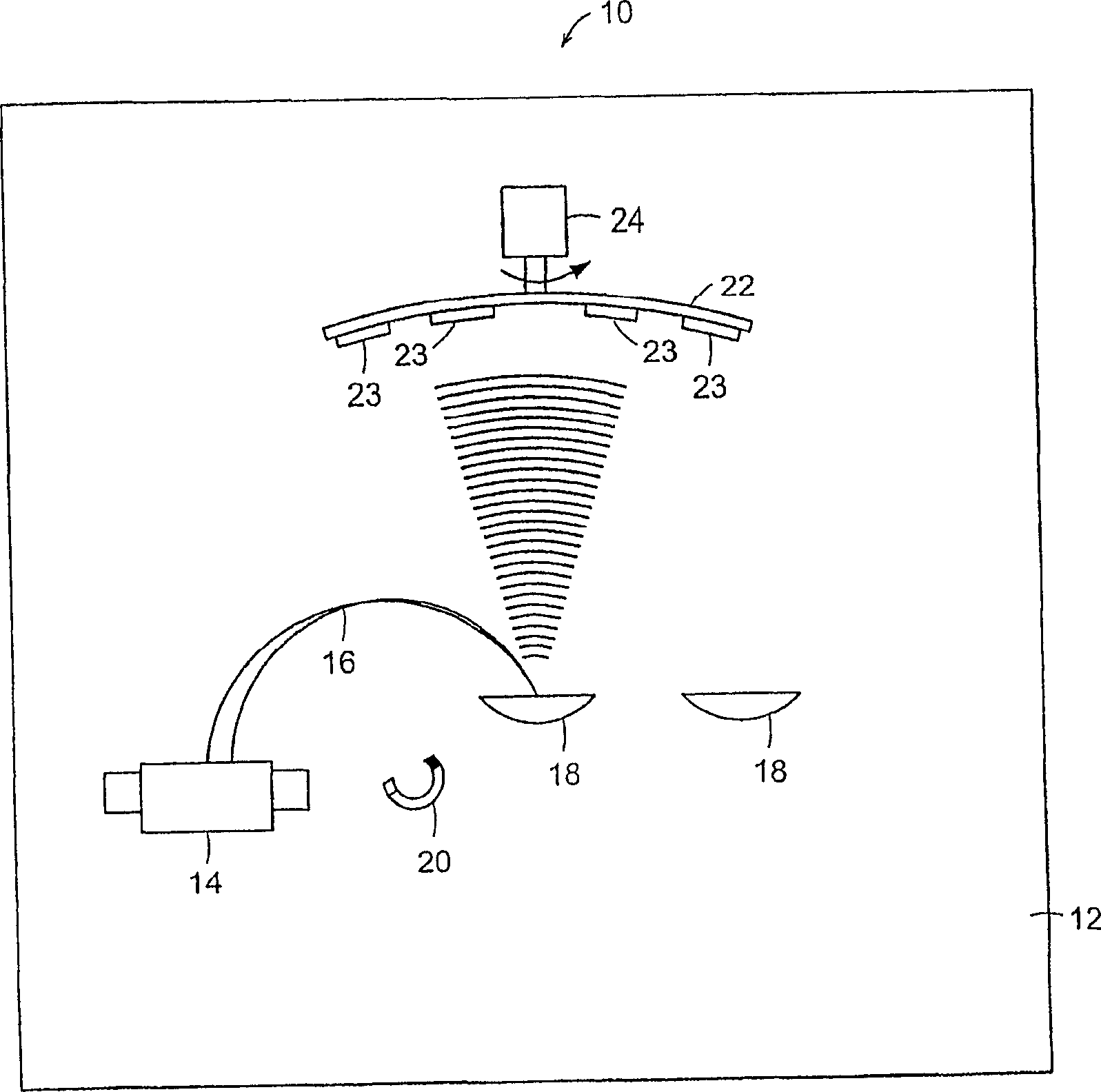

[0030] There are many devices that require highly uniform optical film coatings. For example, optical filters used in fiber optic communication system applications may require multiple layers of highly uniform thin films, where each layer has a precise thickness. Optical fiber communication systems are now widely used. Recently, new communication services such as the Internet, high-speed data links, video services, and wireless services have led to a rapid demand for broadband. Currently, data traffic is increasing at a rate of 80% per year, and voice traffic is increasing at a rate of 10% per year.

[0031]One way to increase bandwidth in fiber optic communication systems is to increase the wavelength of light propagating in the fiber. Wavelength Division Multiplexing (WDM) is an optical technique that propagates multiple wavelengths in the same fiber, thus effectively increasing the total bandwidth of each fiber to the sum of the bit rates of each wavelength. A bandwidth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com