A method that can increase the yield of inductive back film processing

A technology of inductance and back film, which is applied in the direction of inductance/transformer/magnet manufacturing, circuits, electrical components, etc., and can solve problems such as increased processing or manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

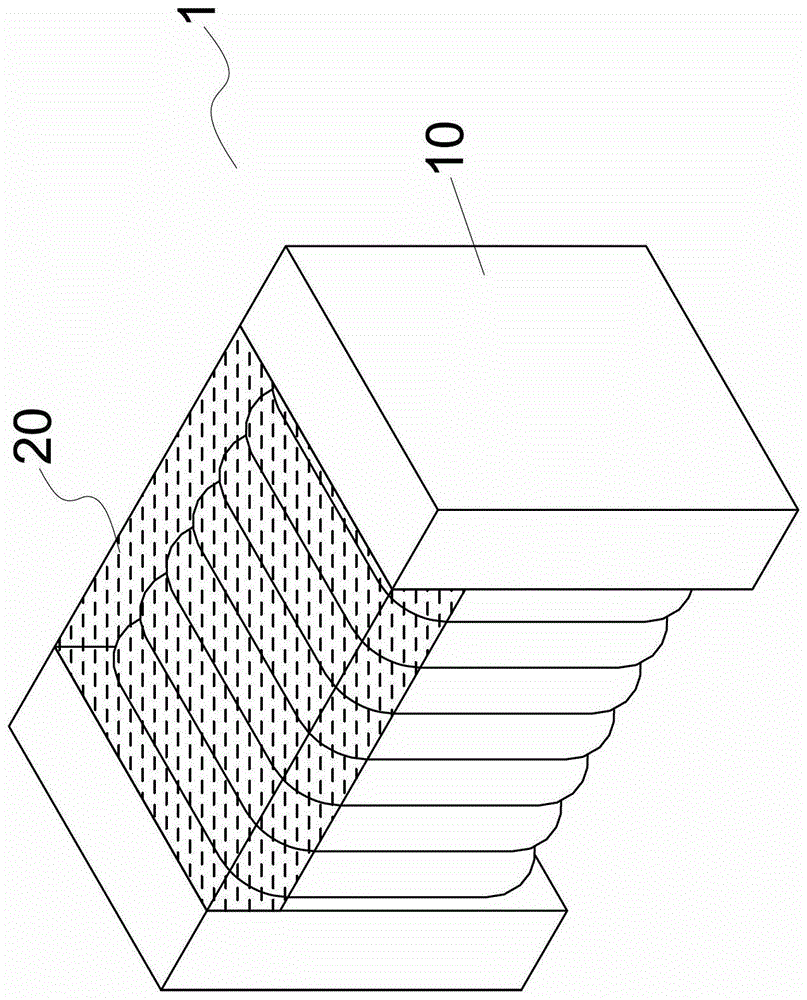

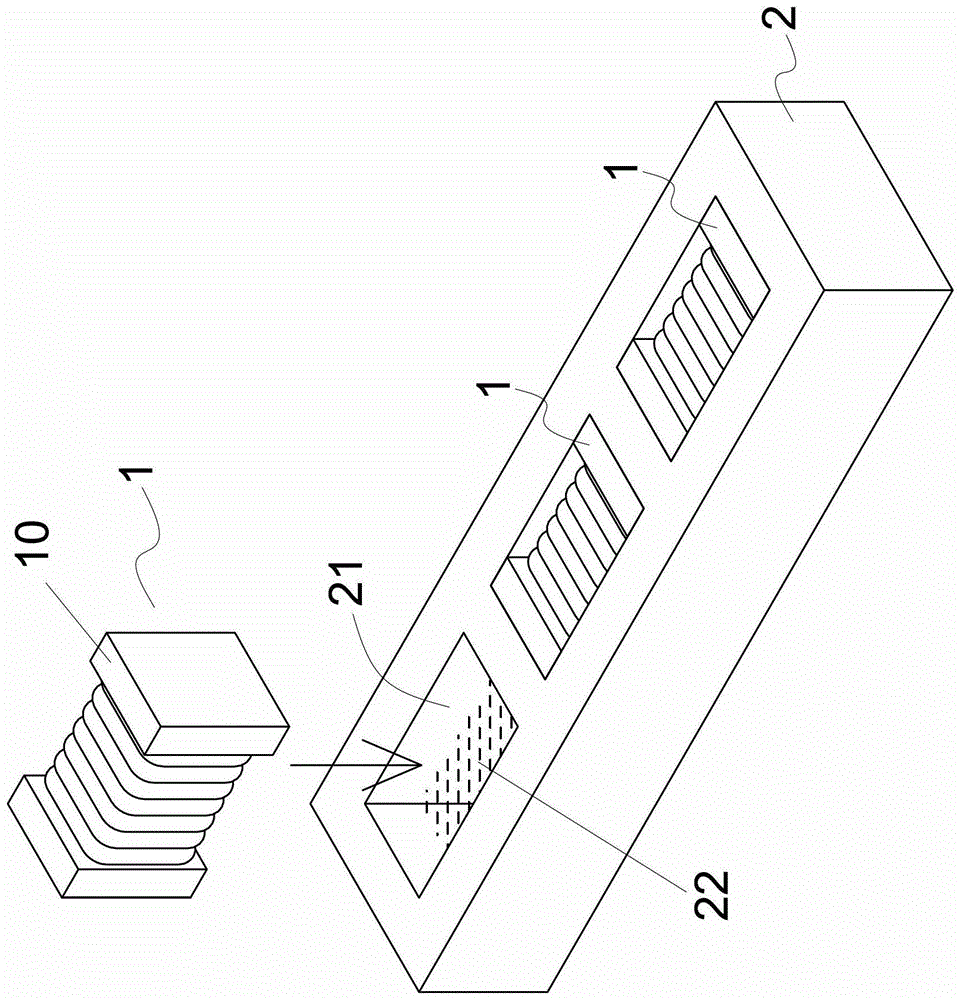

[0045] see Figure 4 As shown, the present invention provides a kind of method that can improve the processing yield of inductive back film, and its step comprises:

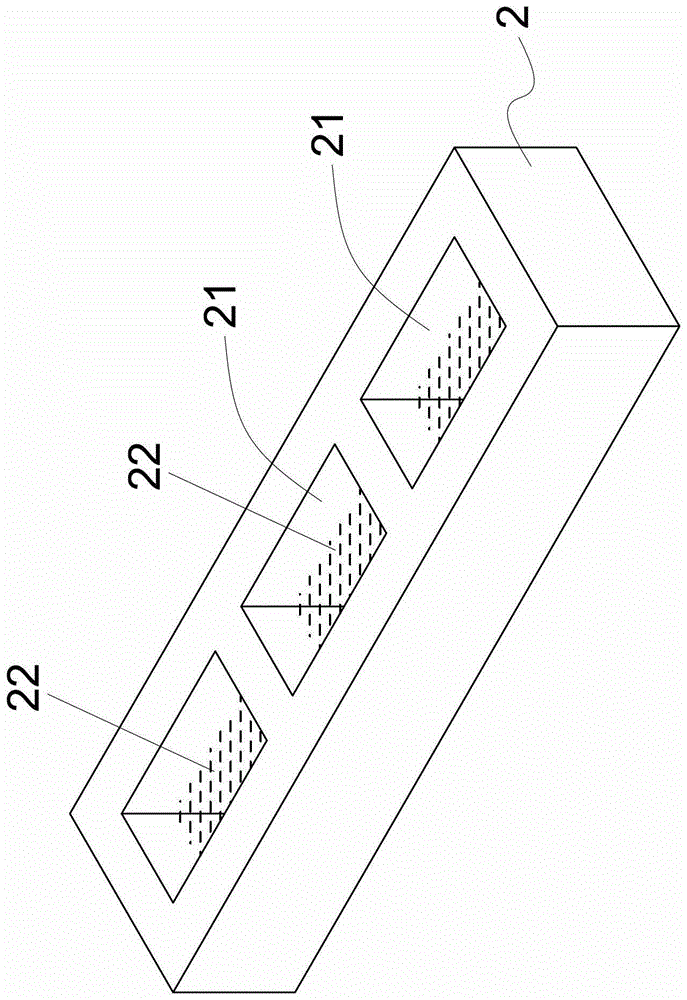

[0046] Material preparation step 3, please refer to Figure 5 As shown, the material preparation step 3 is to prepare a first material plate 31 and the inductor 8 to be processed, wherein the first material plate 31 is provided with a plurality of first holes 311 corresponding to the size of each inductor 8, the first material plate 31 A material plate 31 can be further provided with at least one first positioning hole 312, and a peelable first transparent adhesive film 32 is attached to the bottom of the first material plate 31, please refer to Figure 6 As shown, and the first transparent adhesive film 32 can be provided with at least one second positioning hole 321 corresponding to the position and size of the first positioning hole 312, in addition, in this embodiment, the first material plate 31 is more Sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com