Patents

Literature

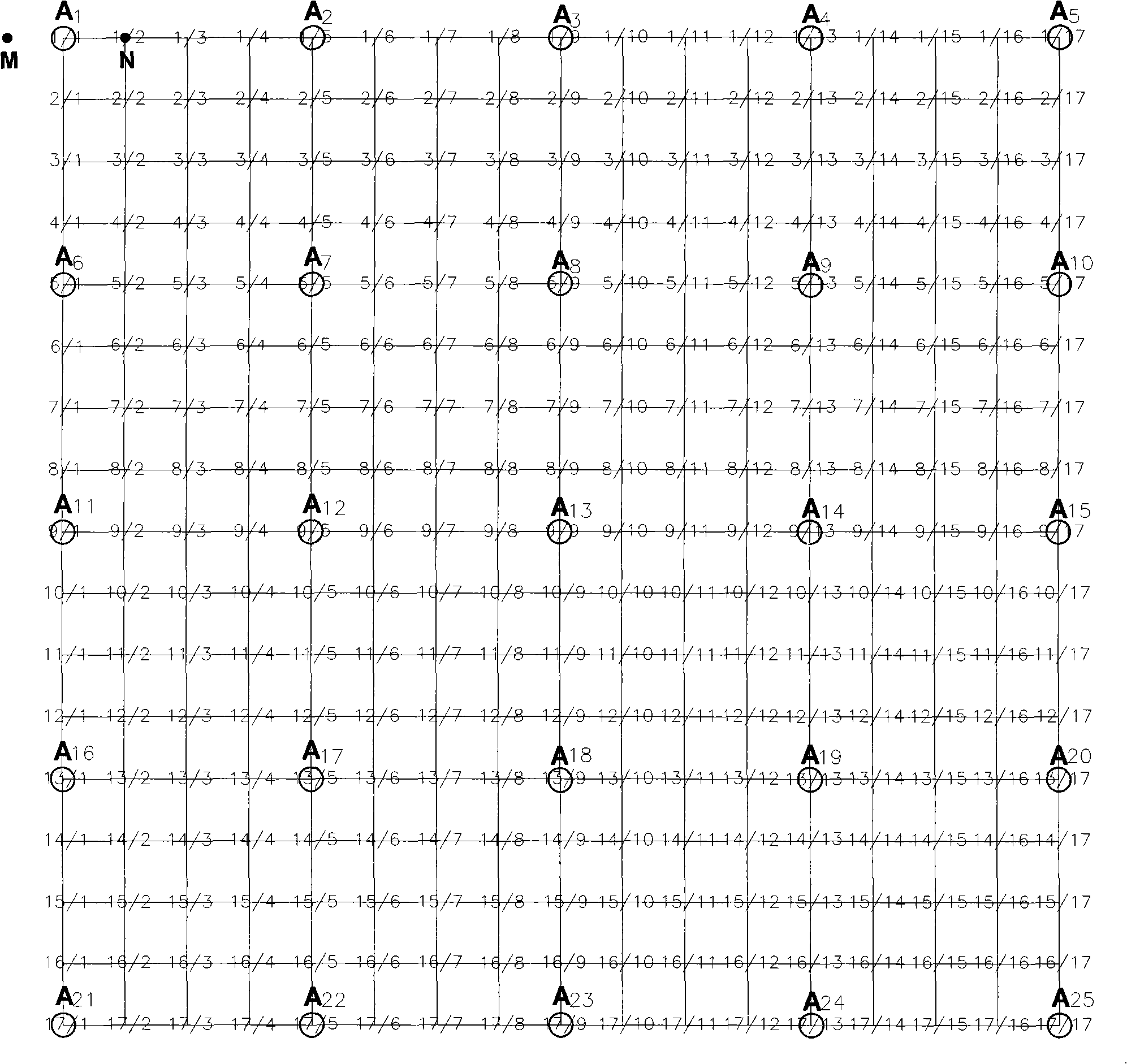

315 results about "Direct imaging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

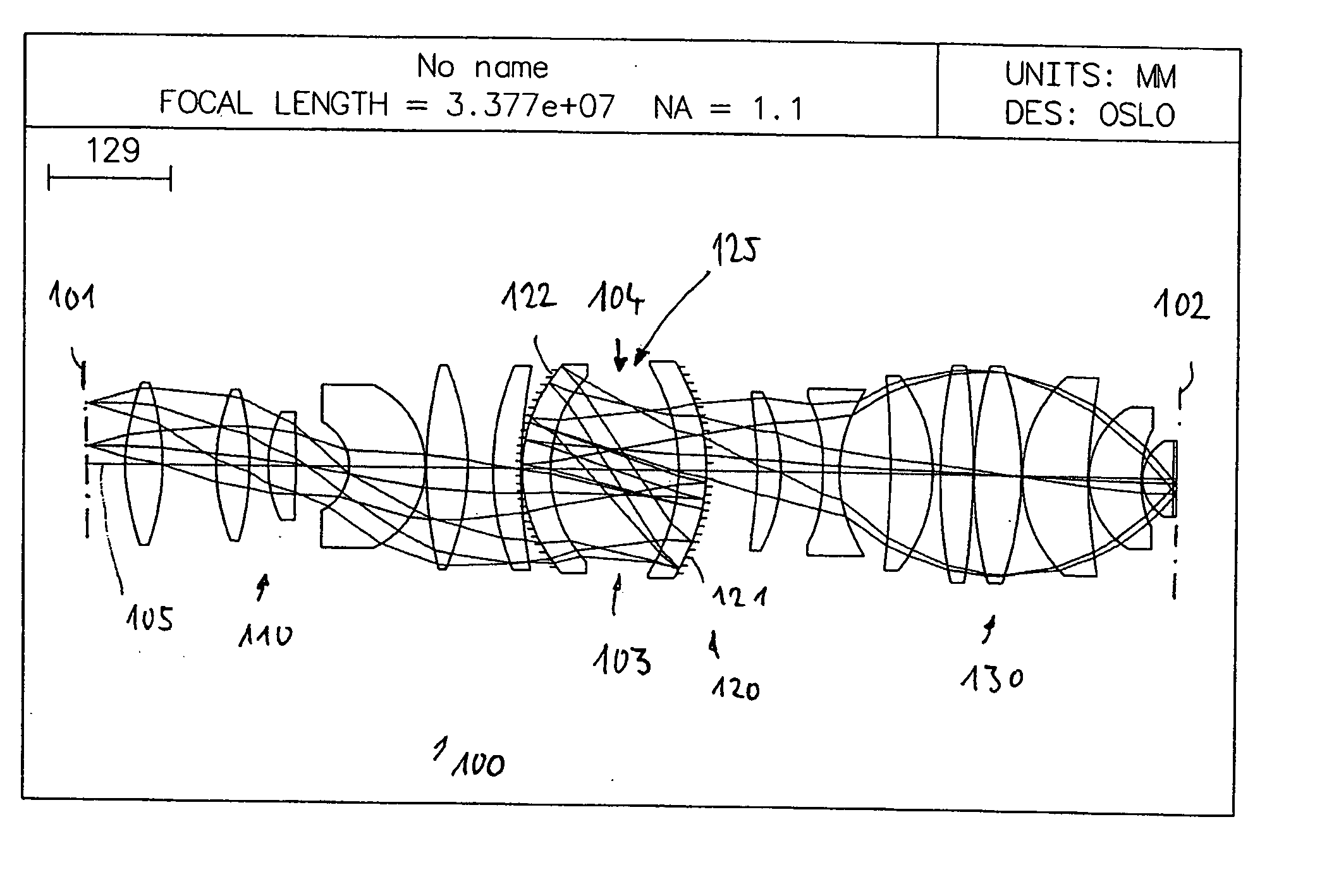

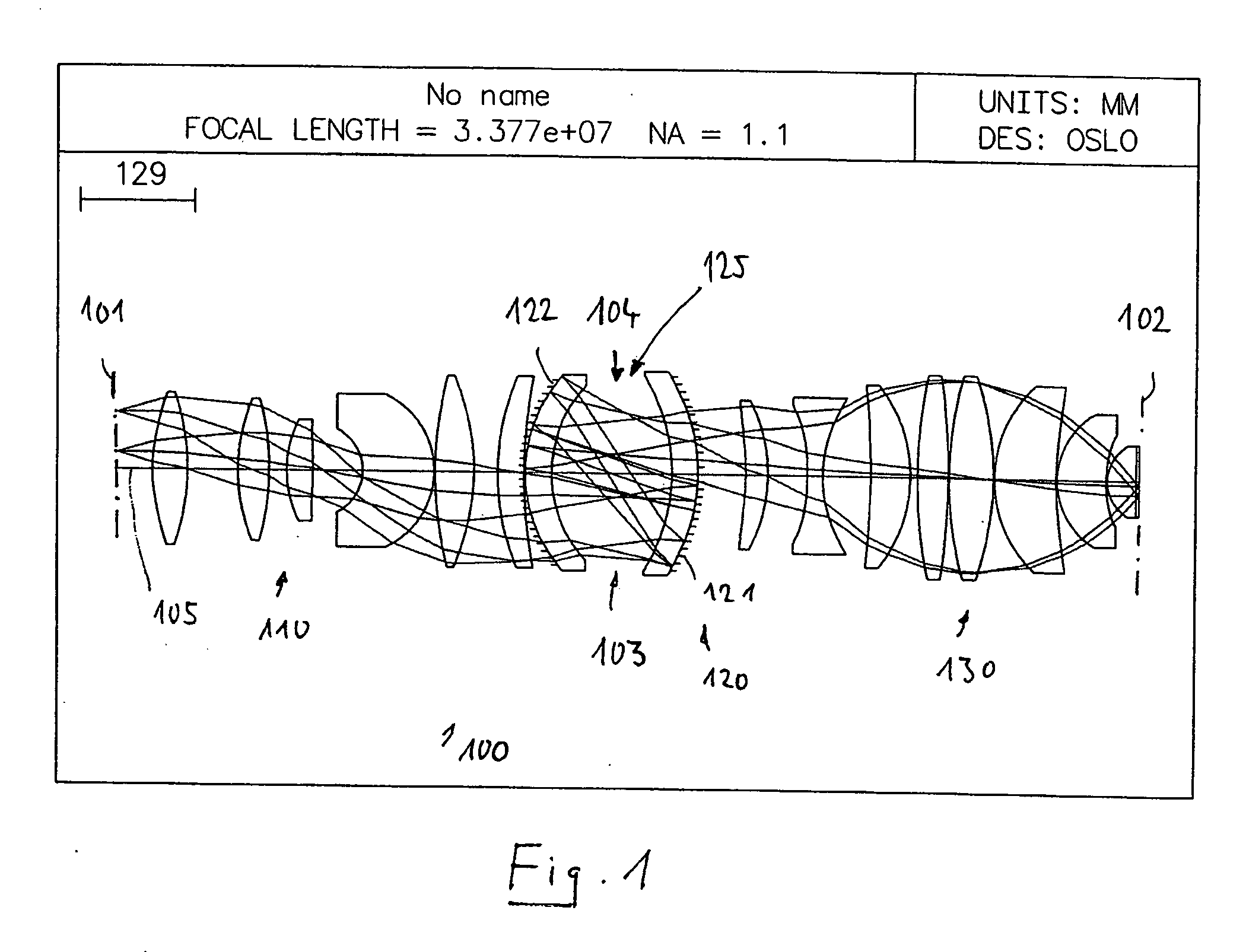

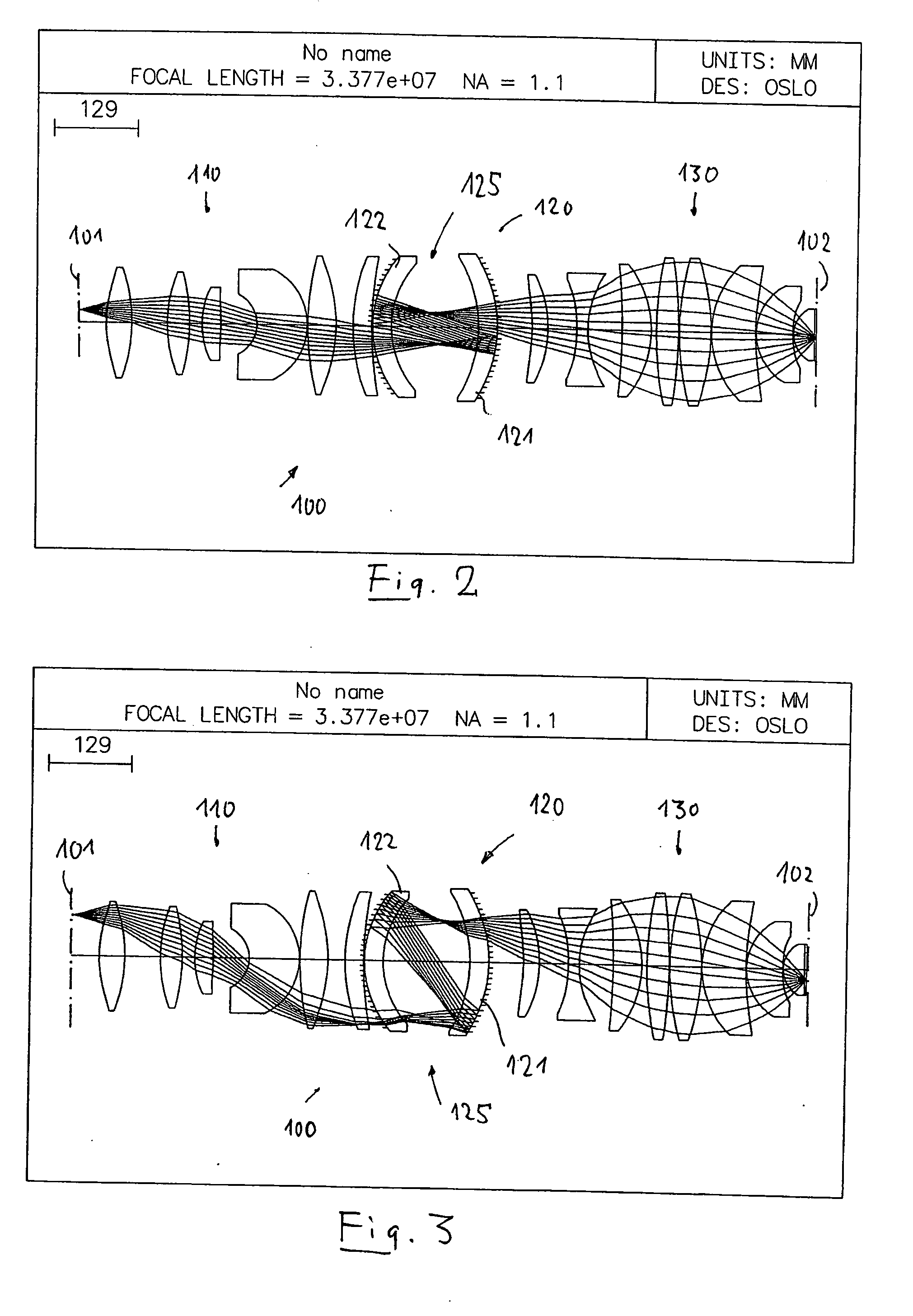

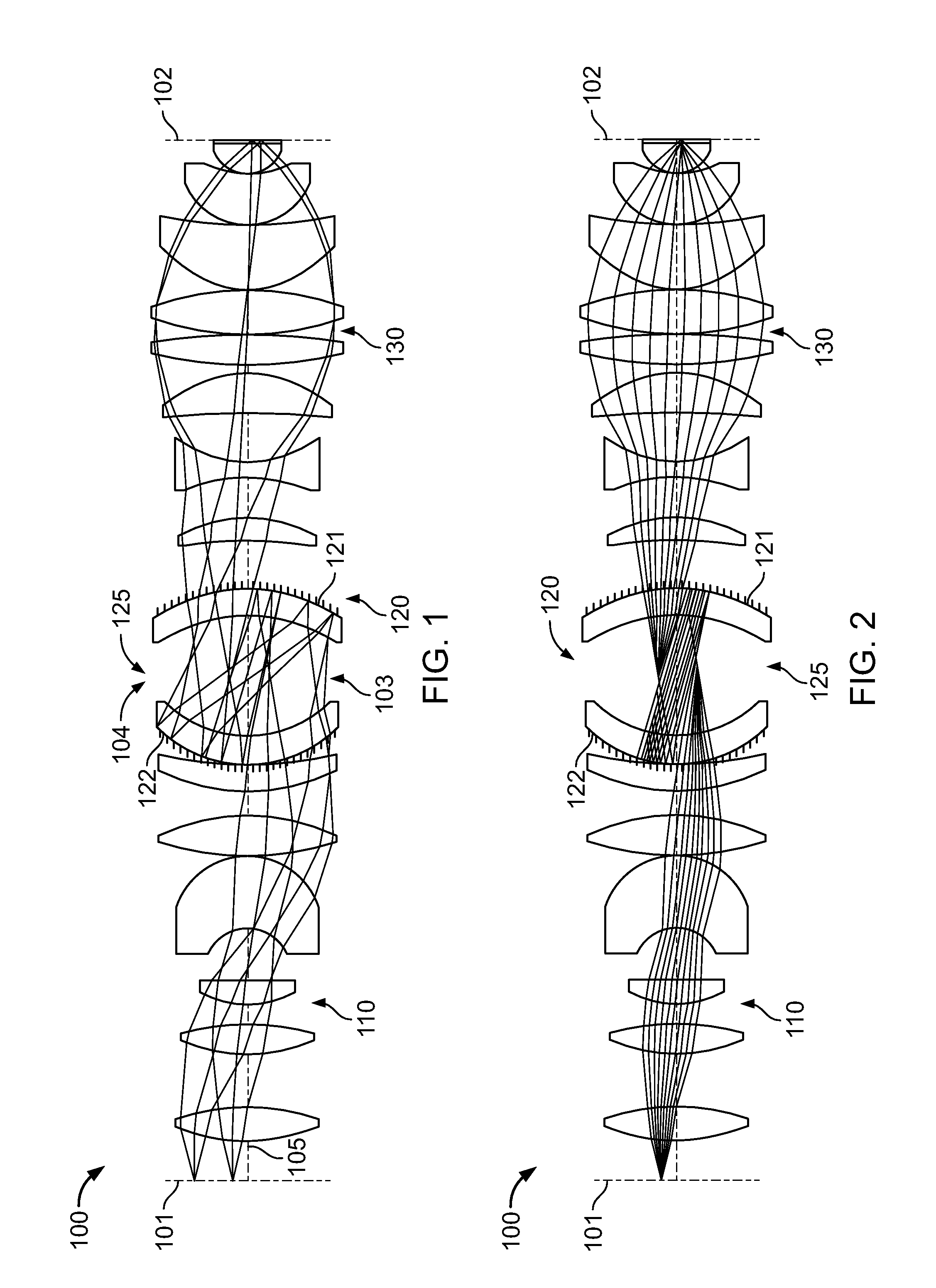

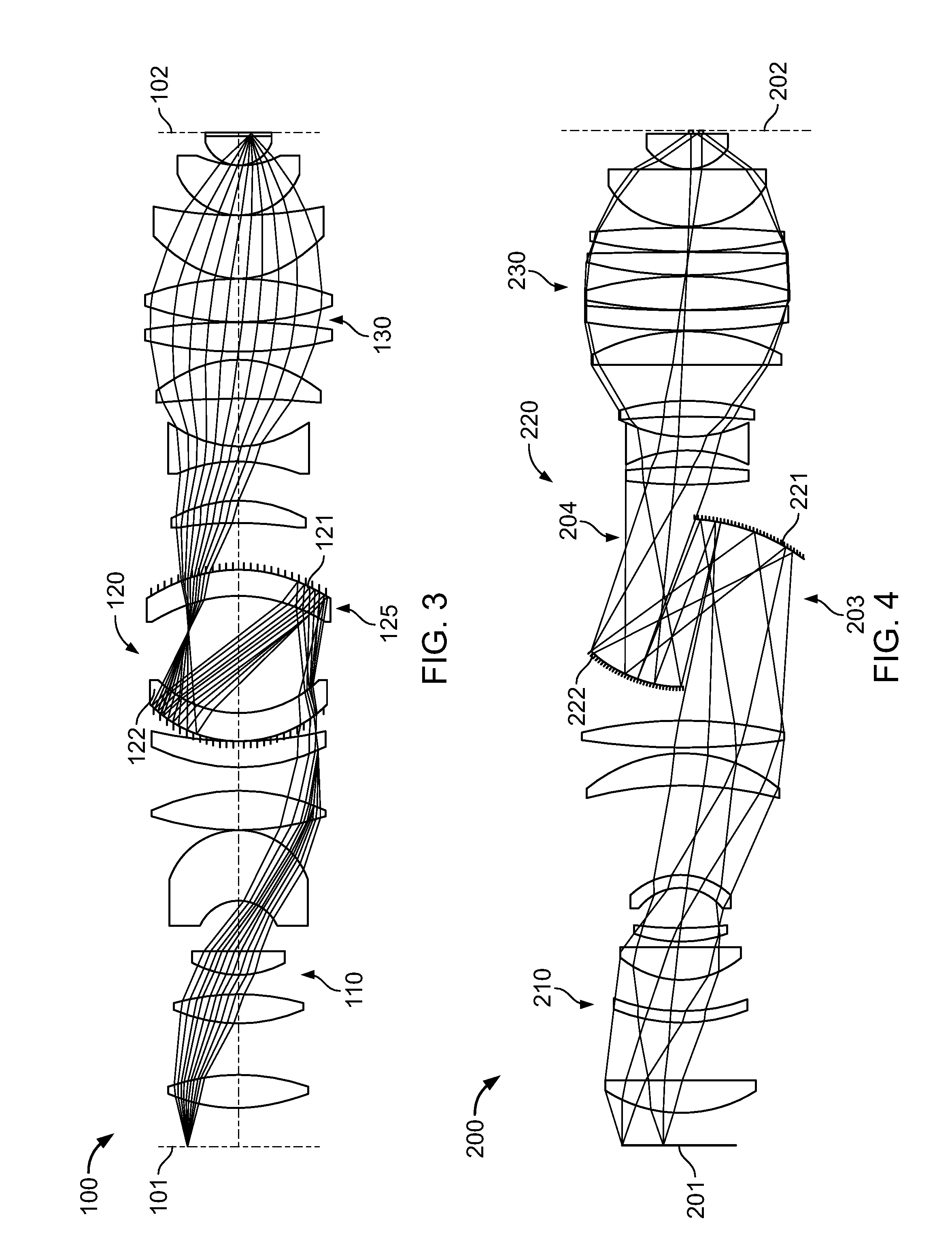

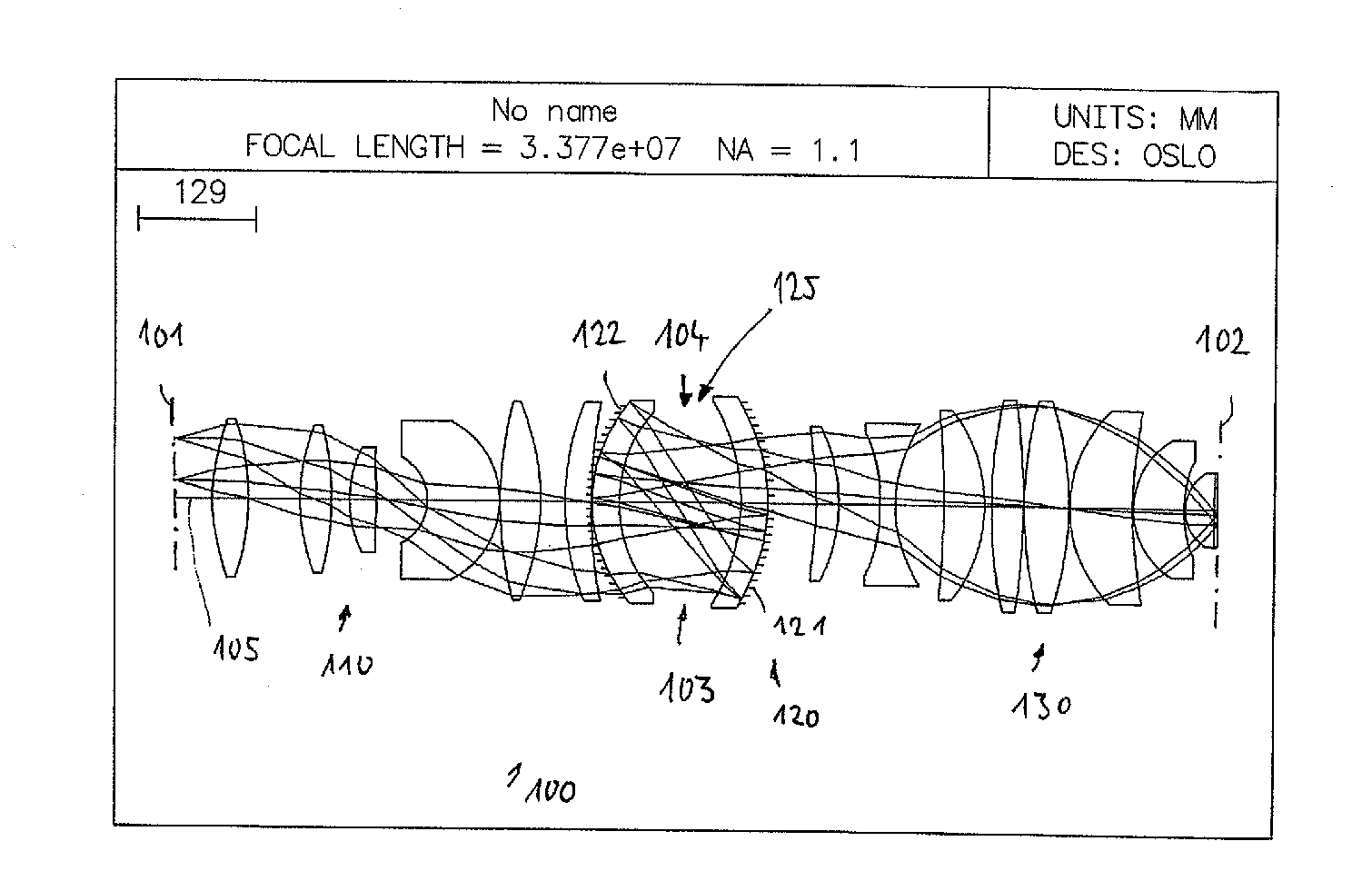

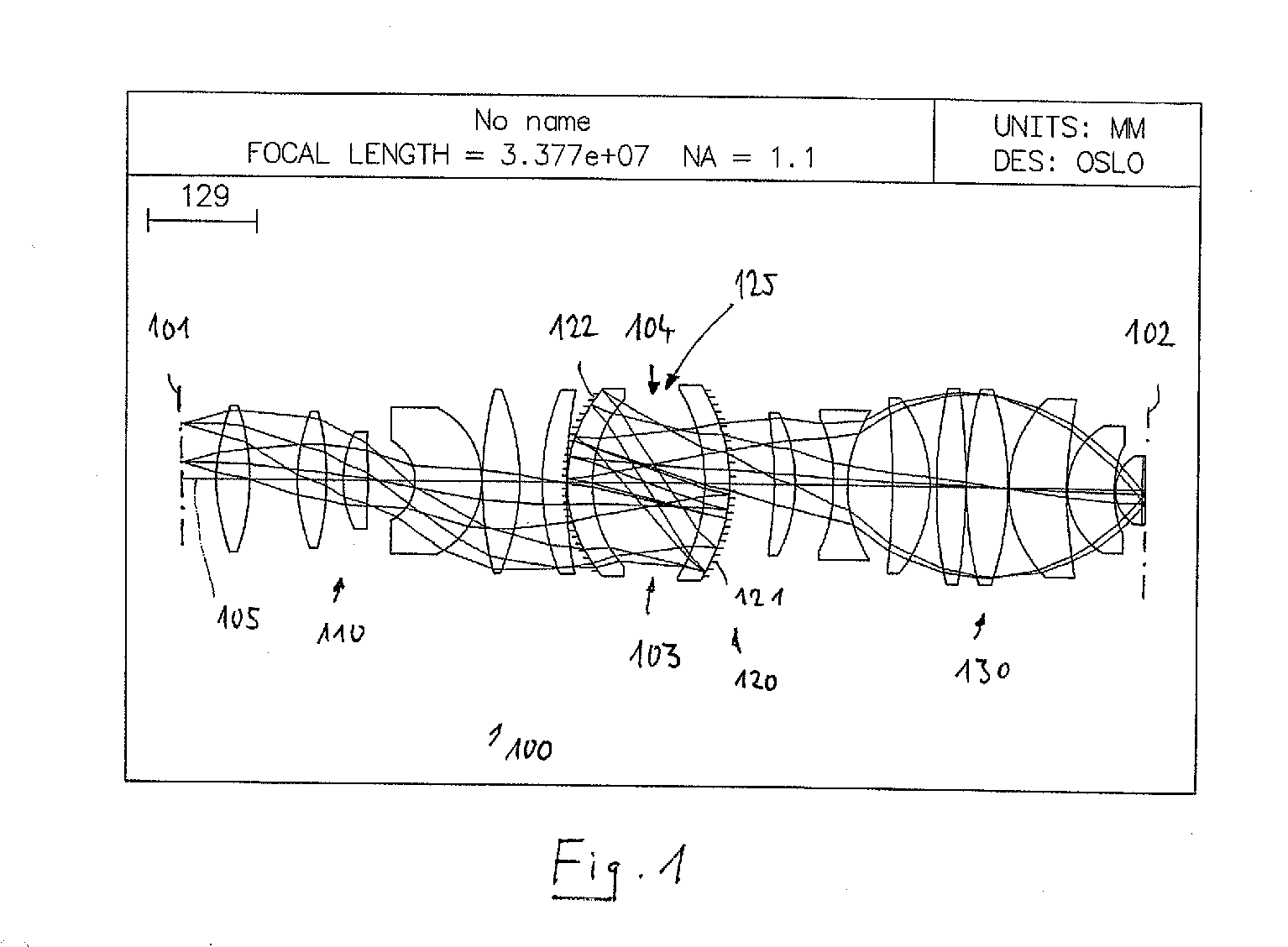

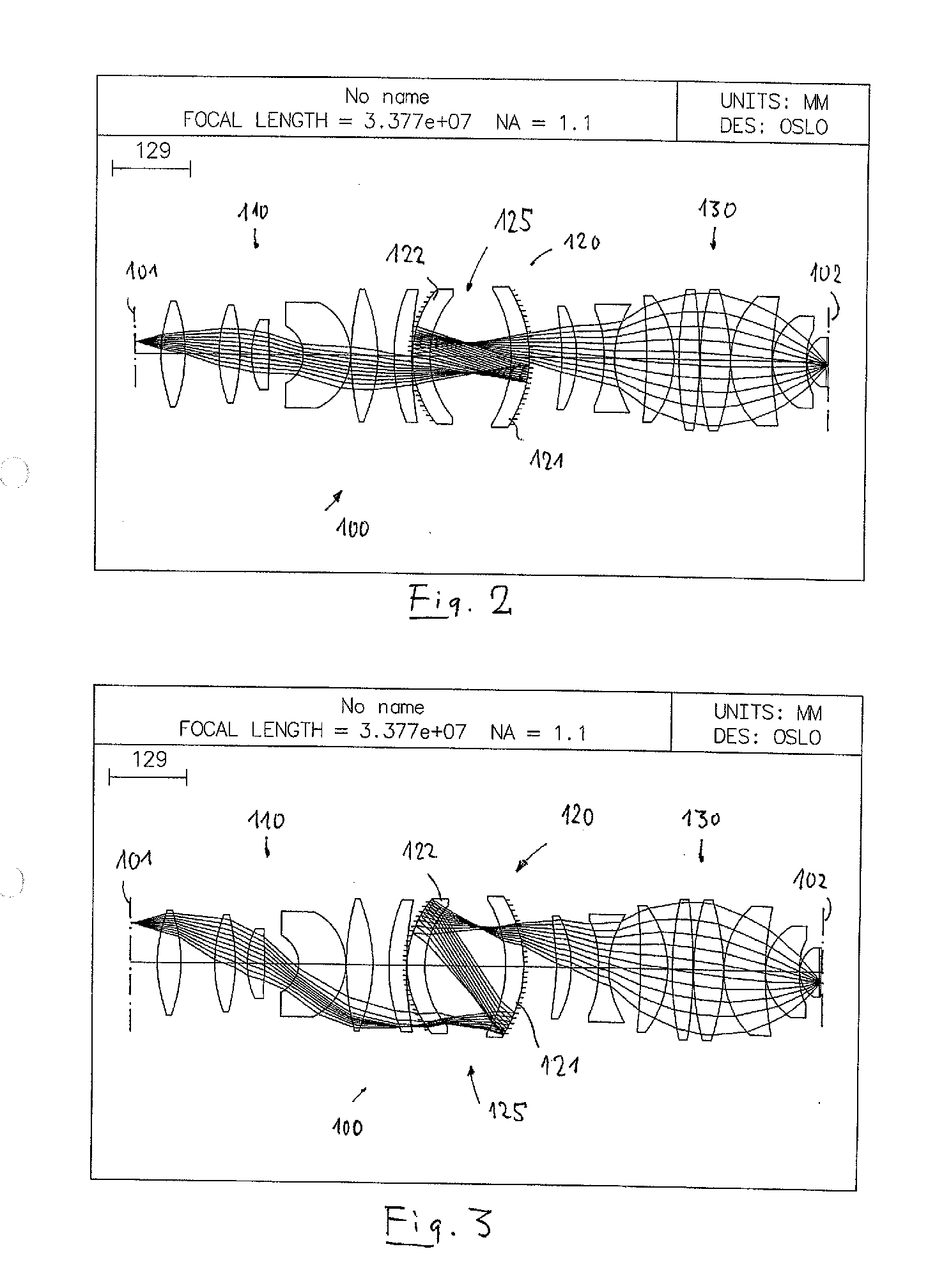

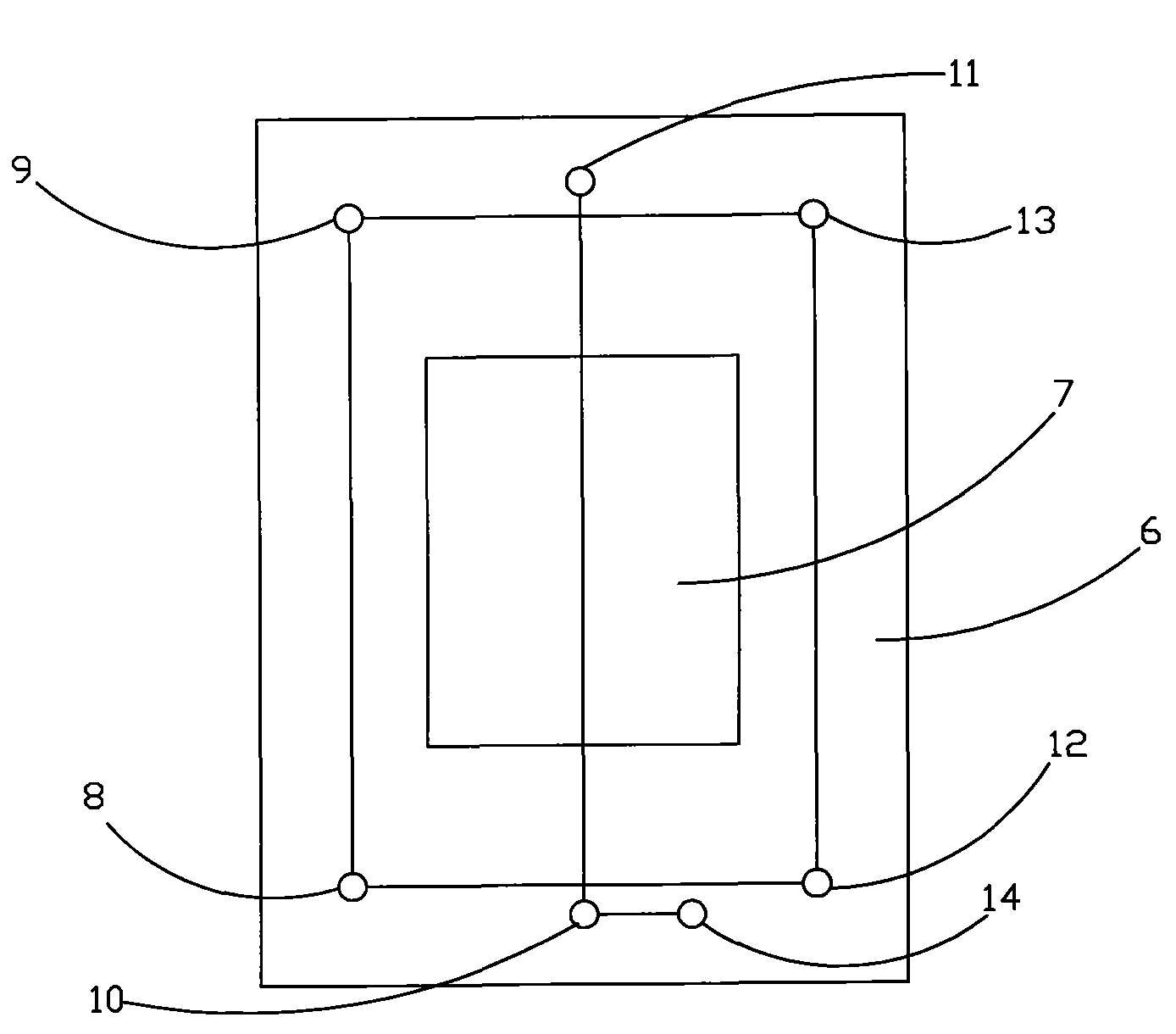

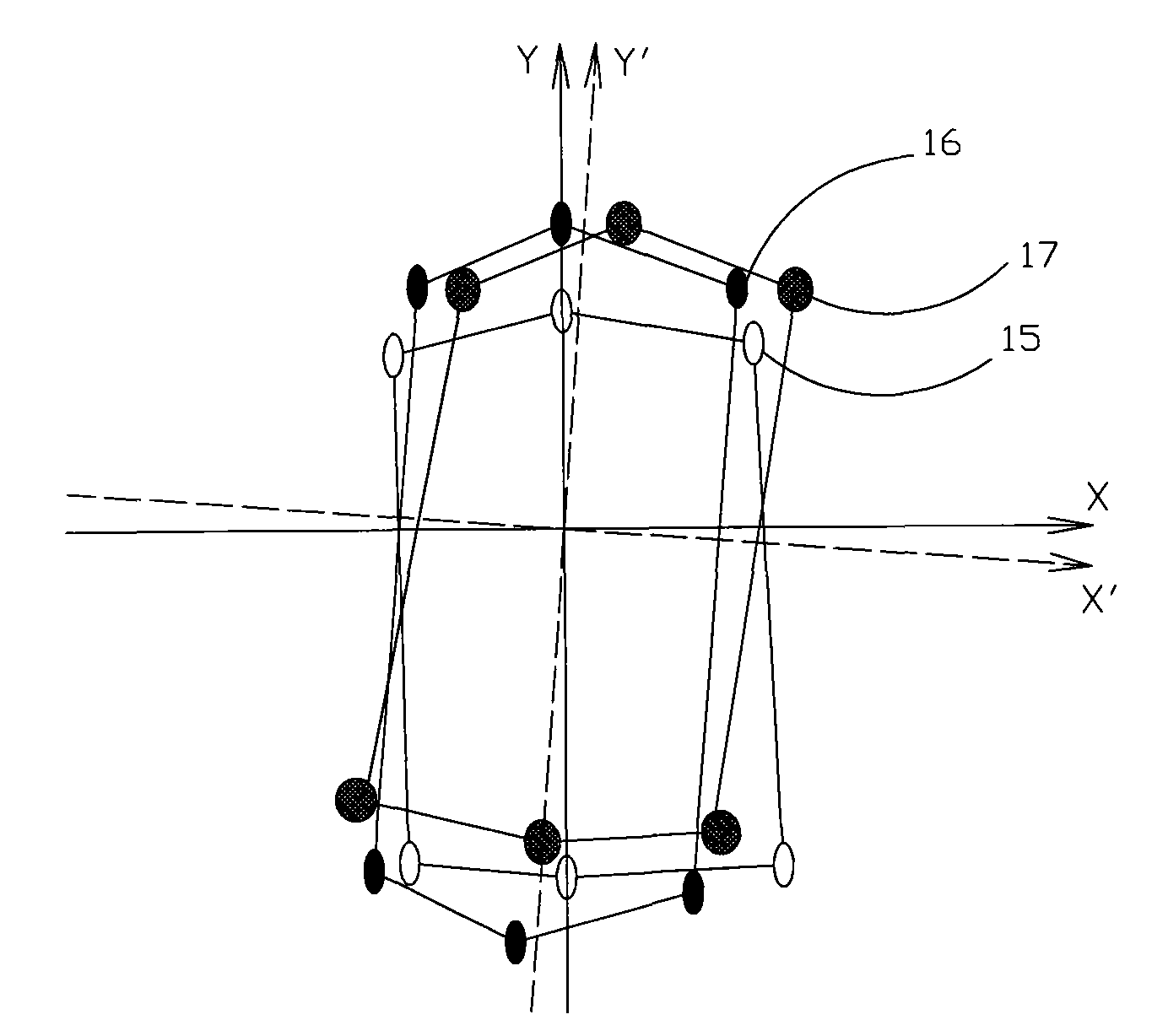

Catadioptric projection objective

ActiveUS20050190435A1High image side numerical apertureSmall amountSemiconductor/solid-state device manufacturingMicroscopesIntermediate imageHigh numerical aperture

A catadioptric projection objective for imaging a pattern provided in an object plane of the projection objective onto an image plane of the projection objective comprises: a first objective part for imaging the pattern provided in the object plane into a first intermediate image; a second objective part for imaging the first intermediate imaging into a second intermediate image; a third objective part for imaging the second intermediate imaging directly onto the image plane; wherein a first concave mirror having a first continuous mirror surface and at least one second concave mirror having a second continuous mirror surface are arranged upstream of the second intermediate image; pupil surfaces are formed between the object plane and the first intermediate image, between the first and the second intermediate image and between the second intermediate image and the image plane; and all concave mirrors are arranged optically remote from a pupil surface. The system has potential for very high numerical apertures at moderate lens material mass consumption.

Owner:CARL ZEISS SMT GMBH

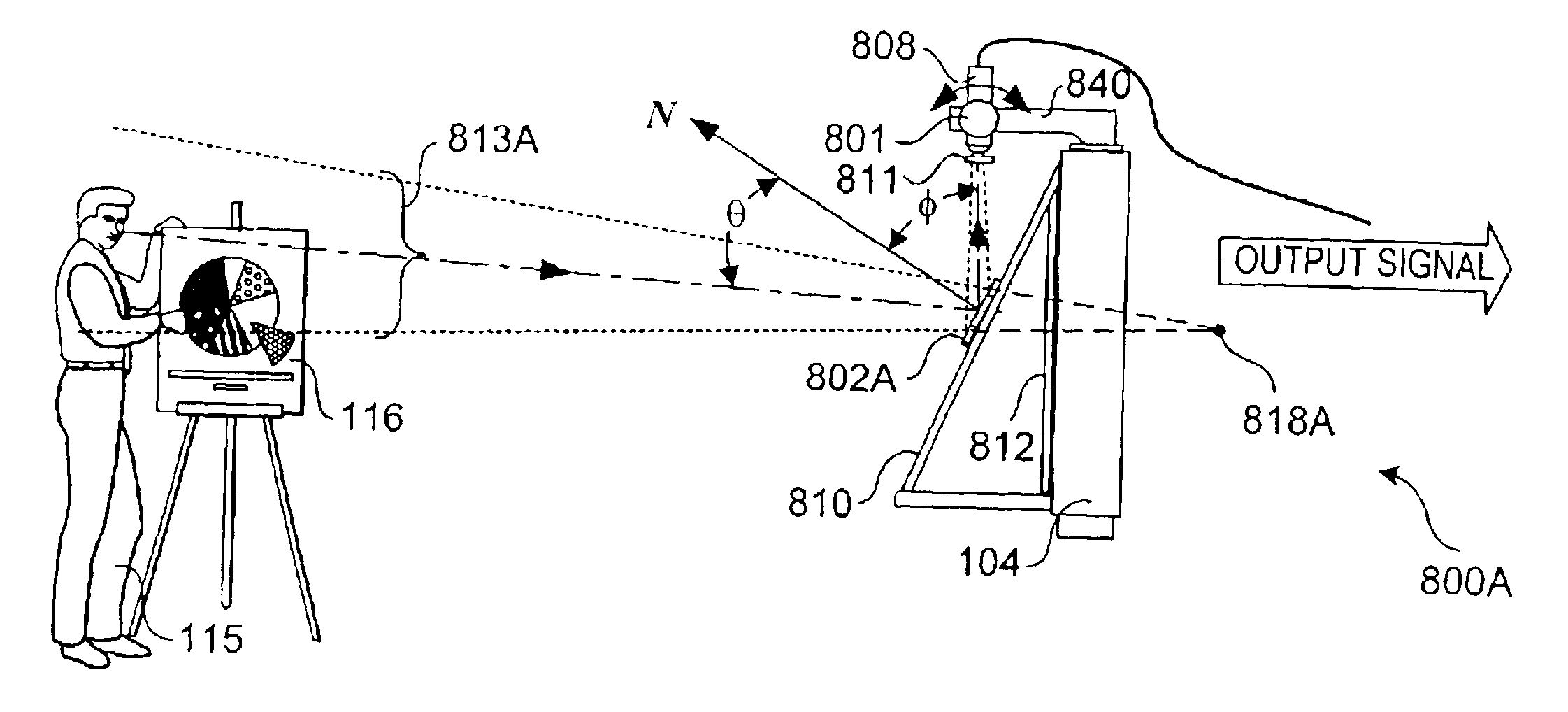

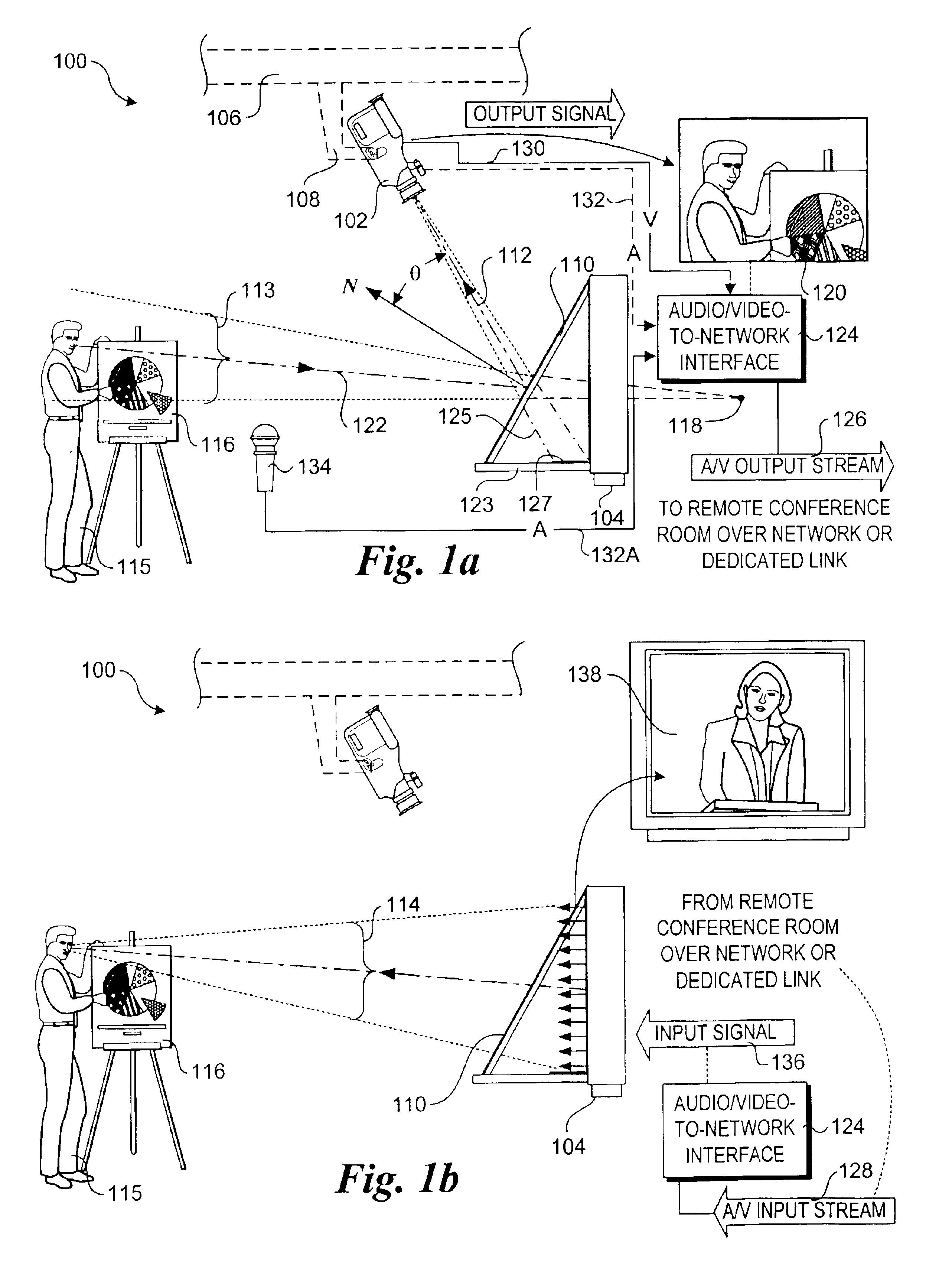

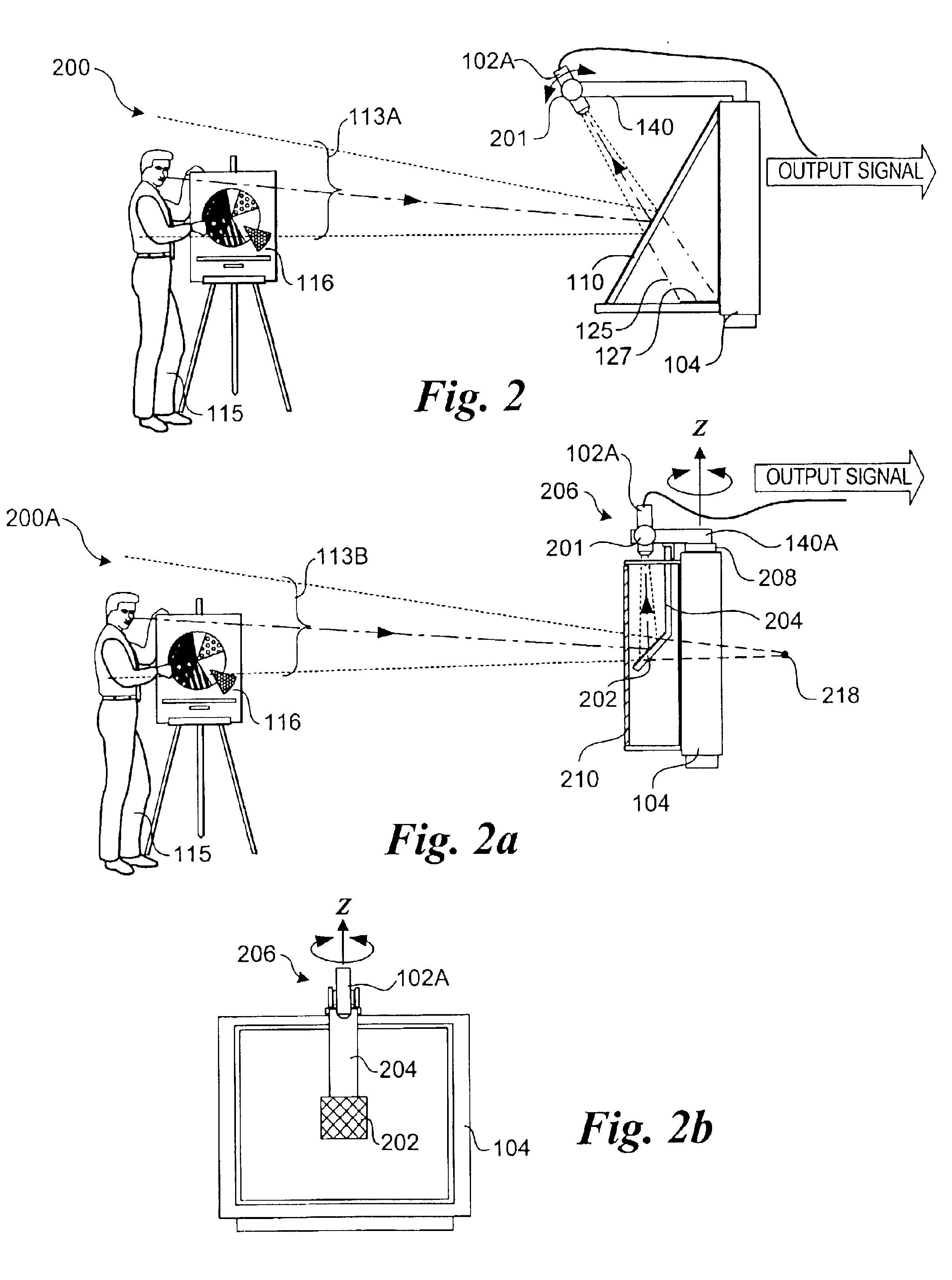

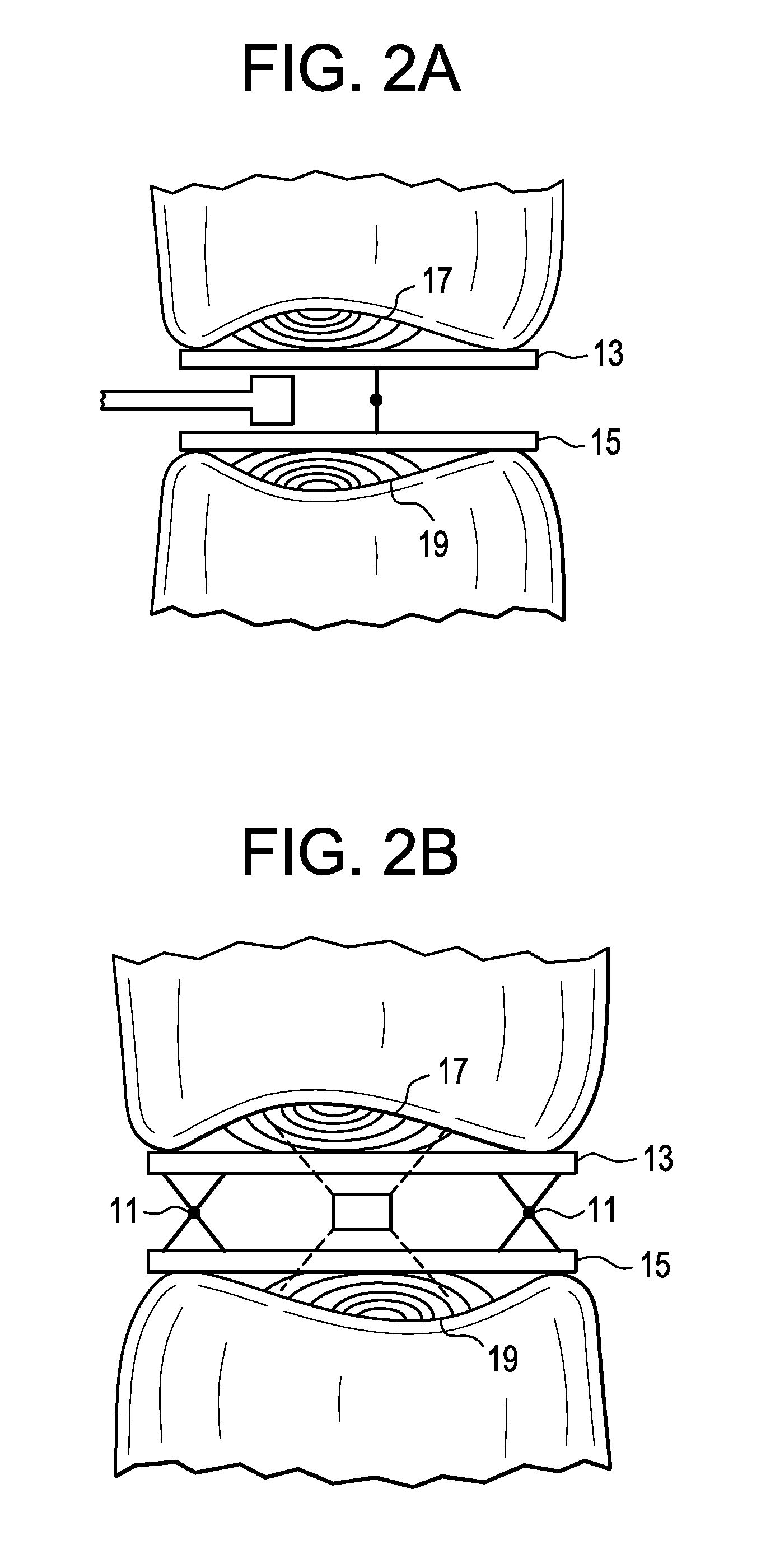

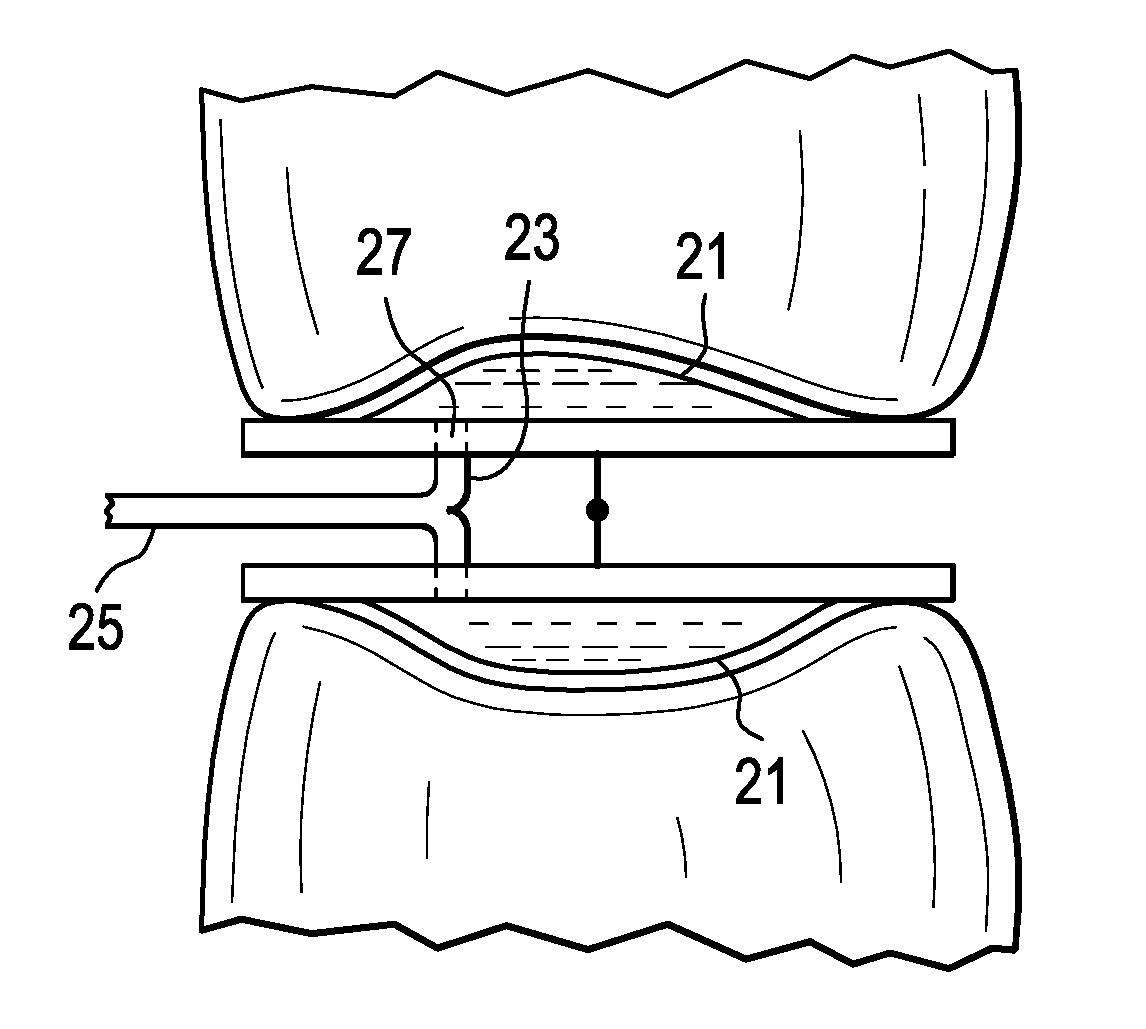

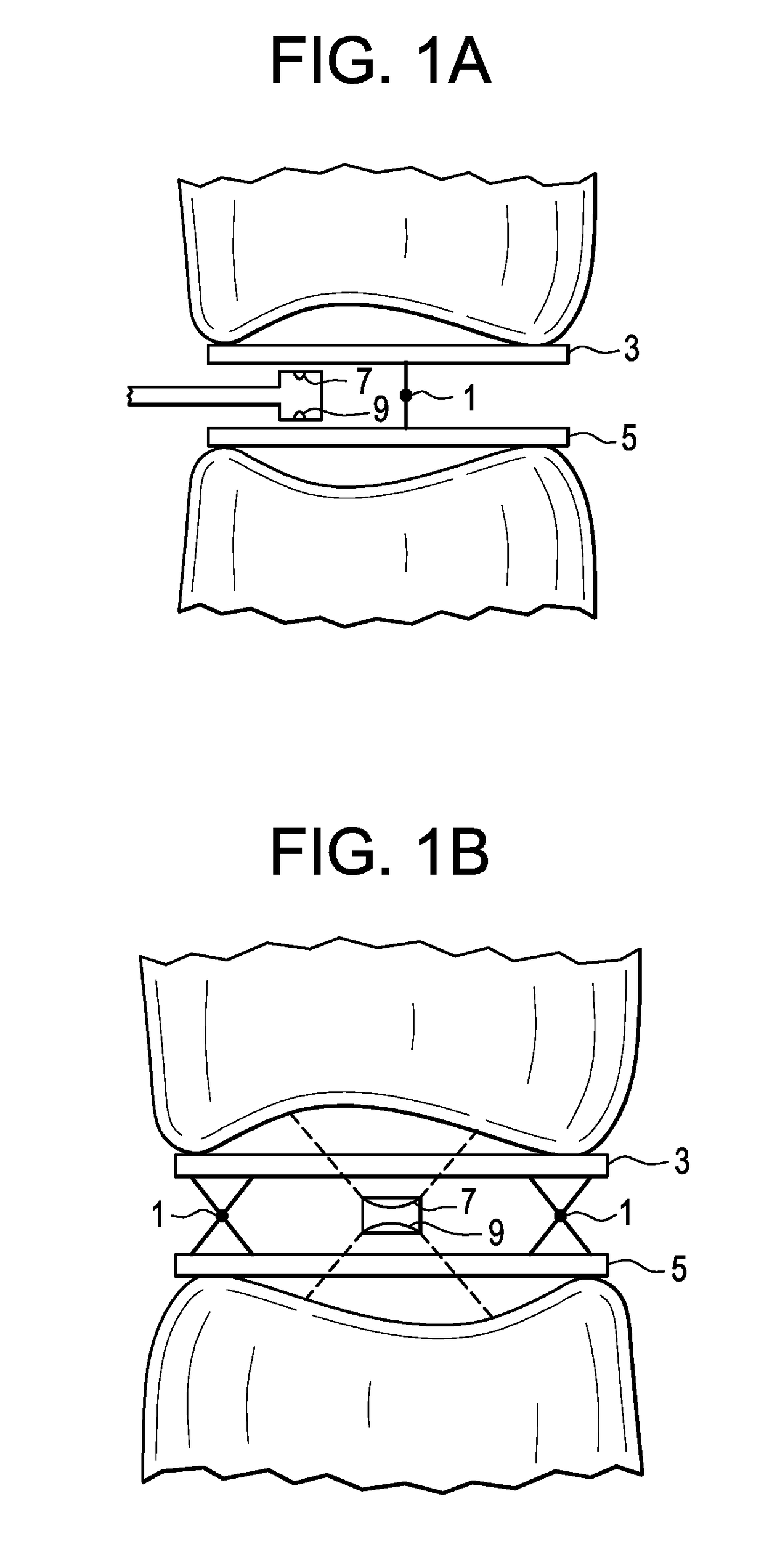

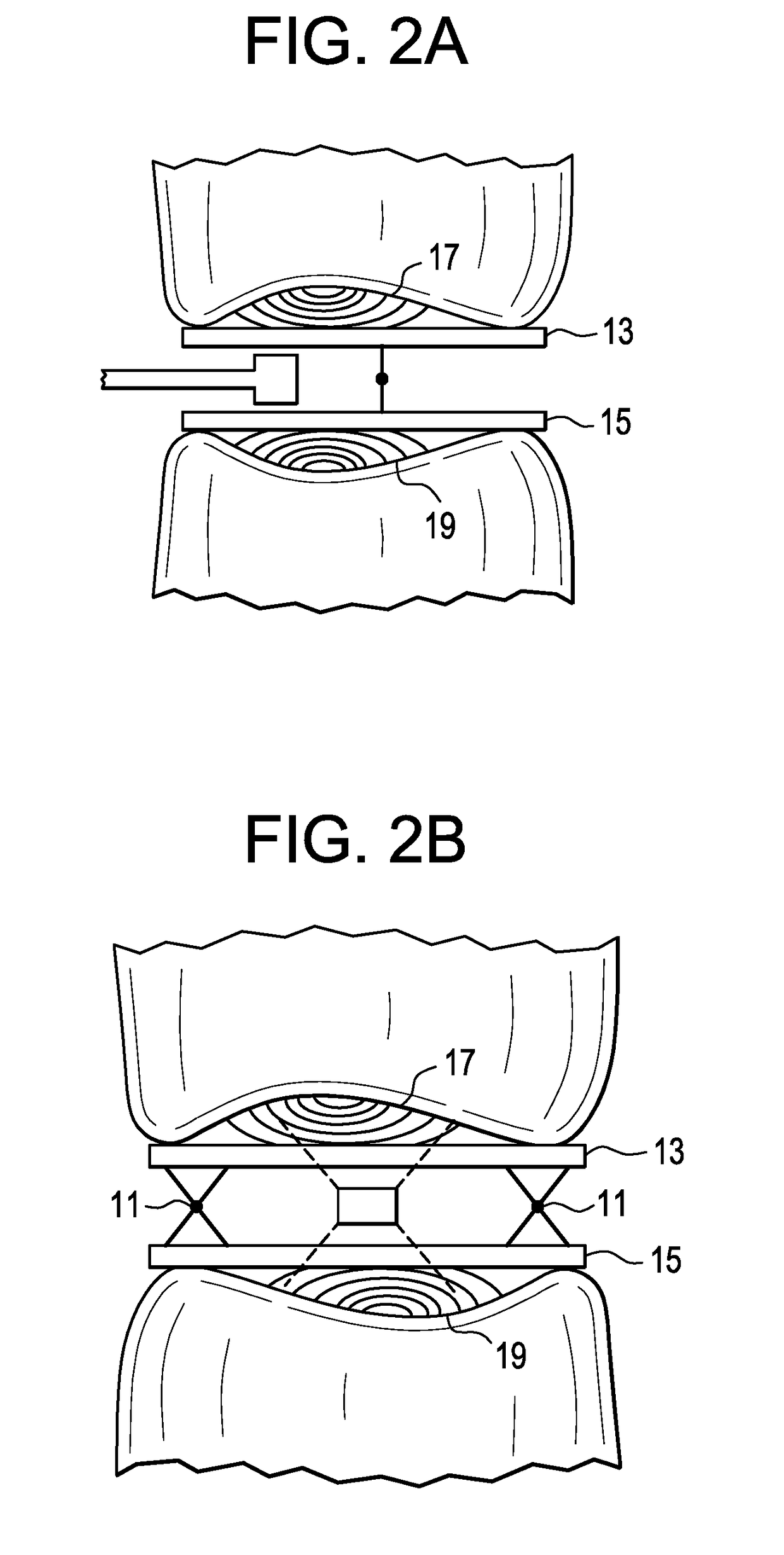

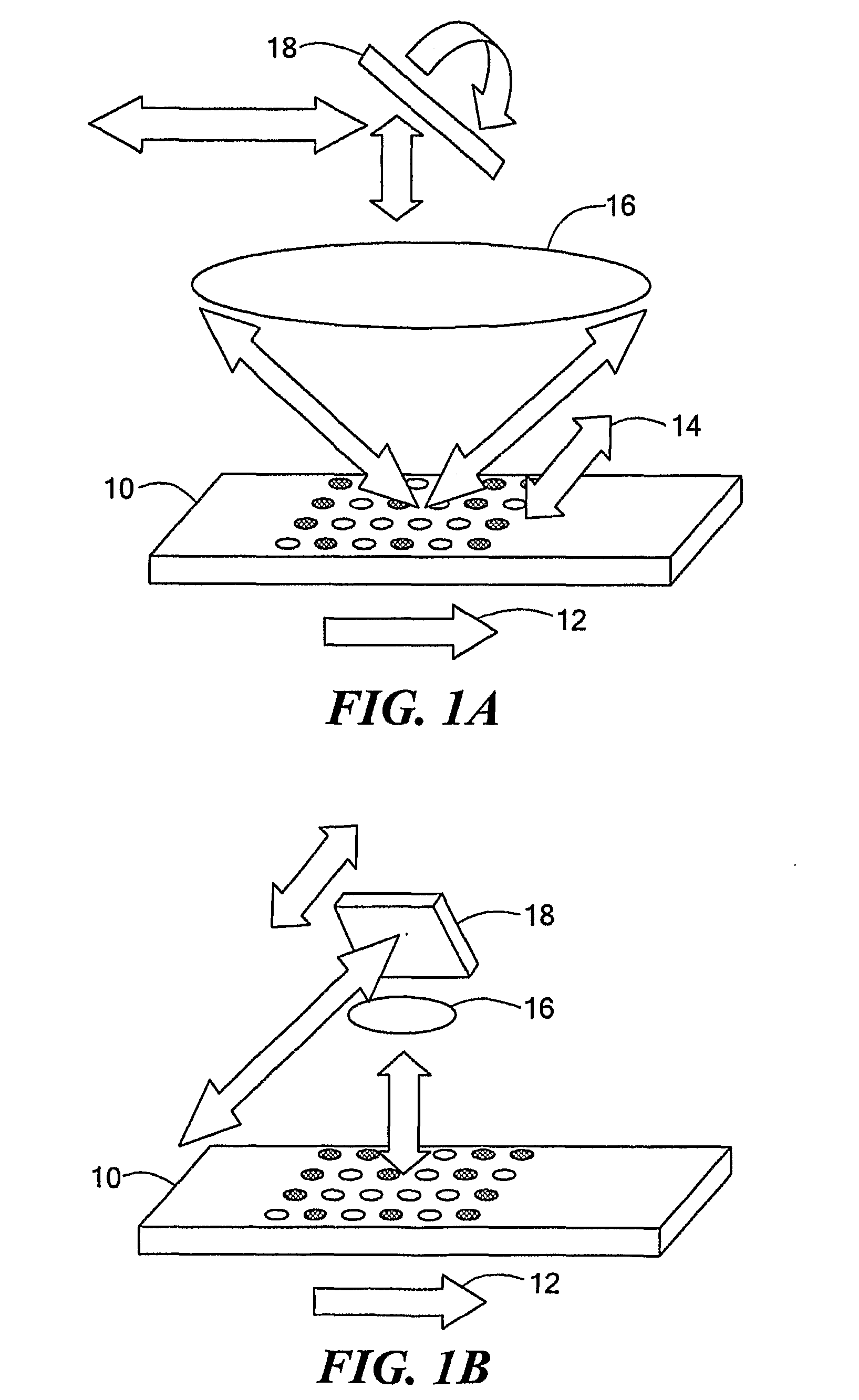

Apparatus, system and method for enabling eye-to-eye contact in video conferences

Apparatus, system, and method for enabling eye-to-eye contact in video conferences. In general, the system and apparatus employ means for generating video images corresponding to real images that would be produced if a video camera were disposed at or behind a video display having a field of view directed toward a target object such as a participant. An image (either real, reflected, or holographic) is formed based on light reflected off of the target object, and object light corresponding to the image is received by the video camera, which produces a video signal containing the image. Typically, the means for generating the video images employs direct imaging, reflective imaging, or holographic imaging. The means for generating the video images are also configured in such a manner as to be substantially transparent to video conference participants viewing the display images on the video display. A similar configuration is deployed at two or more conference rooms, thereby enabling participants to communicate with one another using eye-to-eye contact.

Owner:GOOGLE LLC

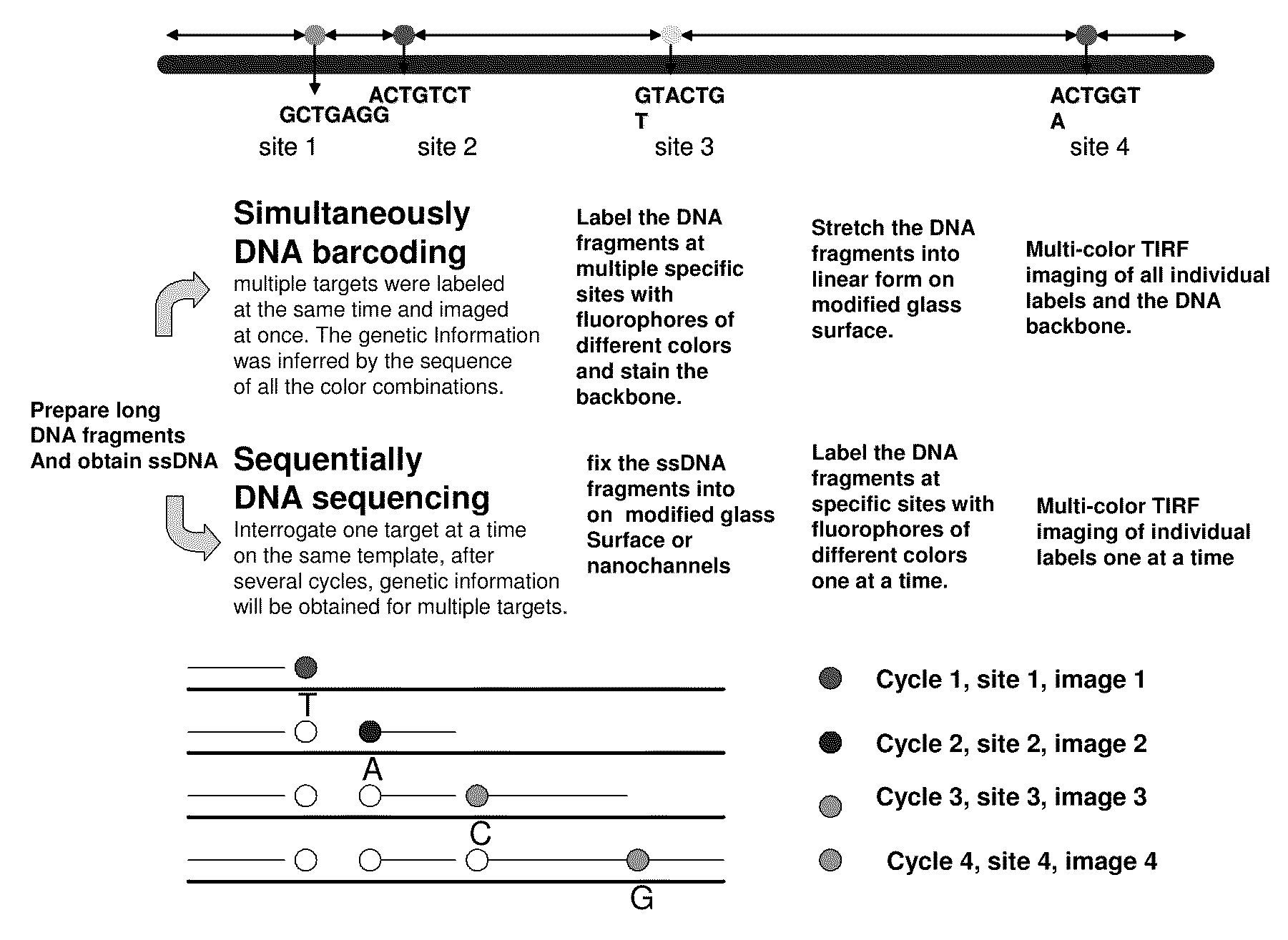

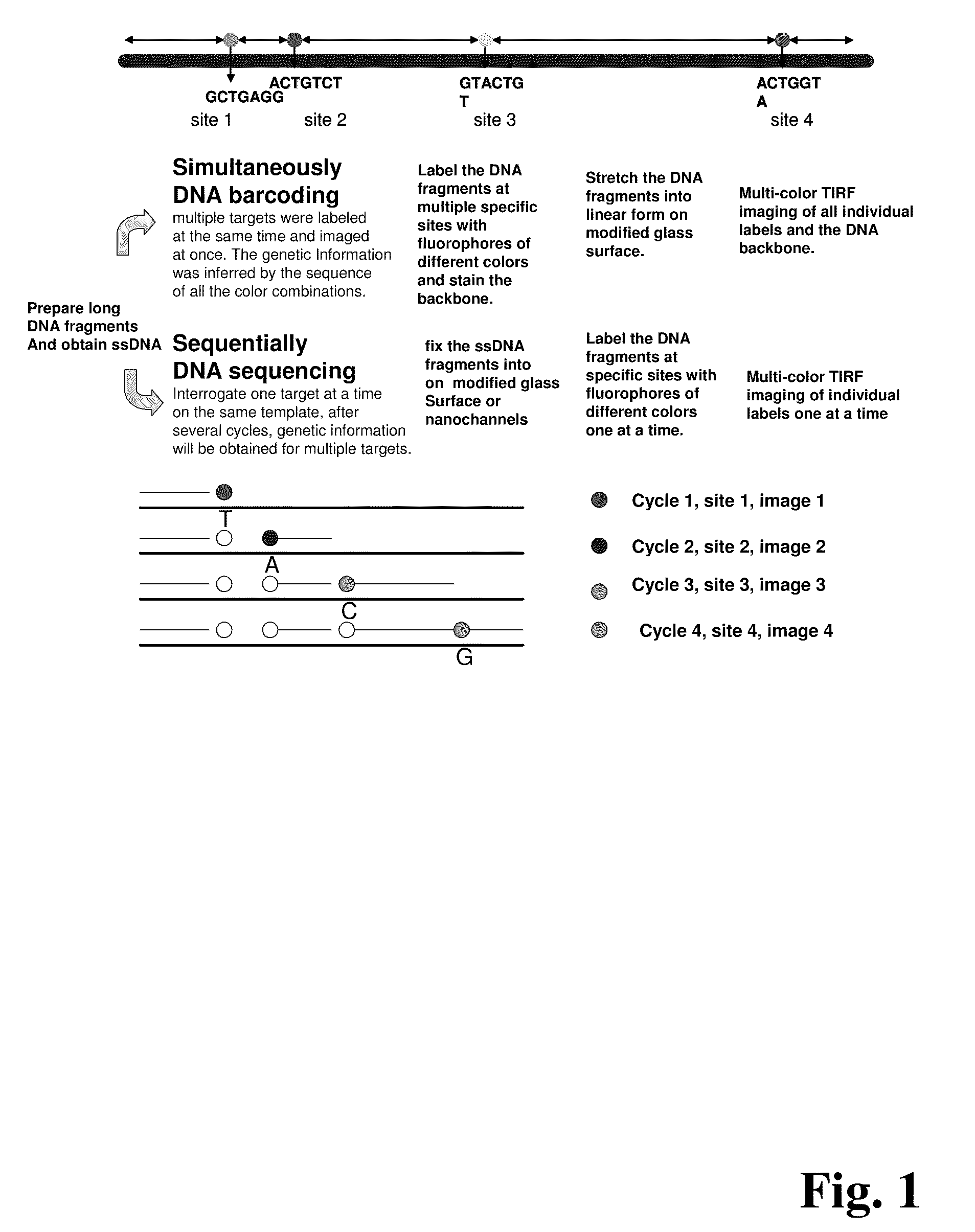

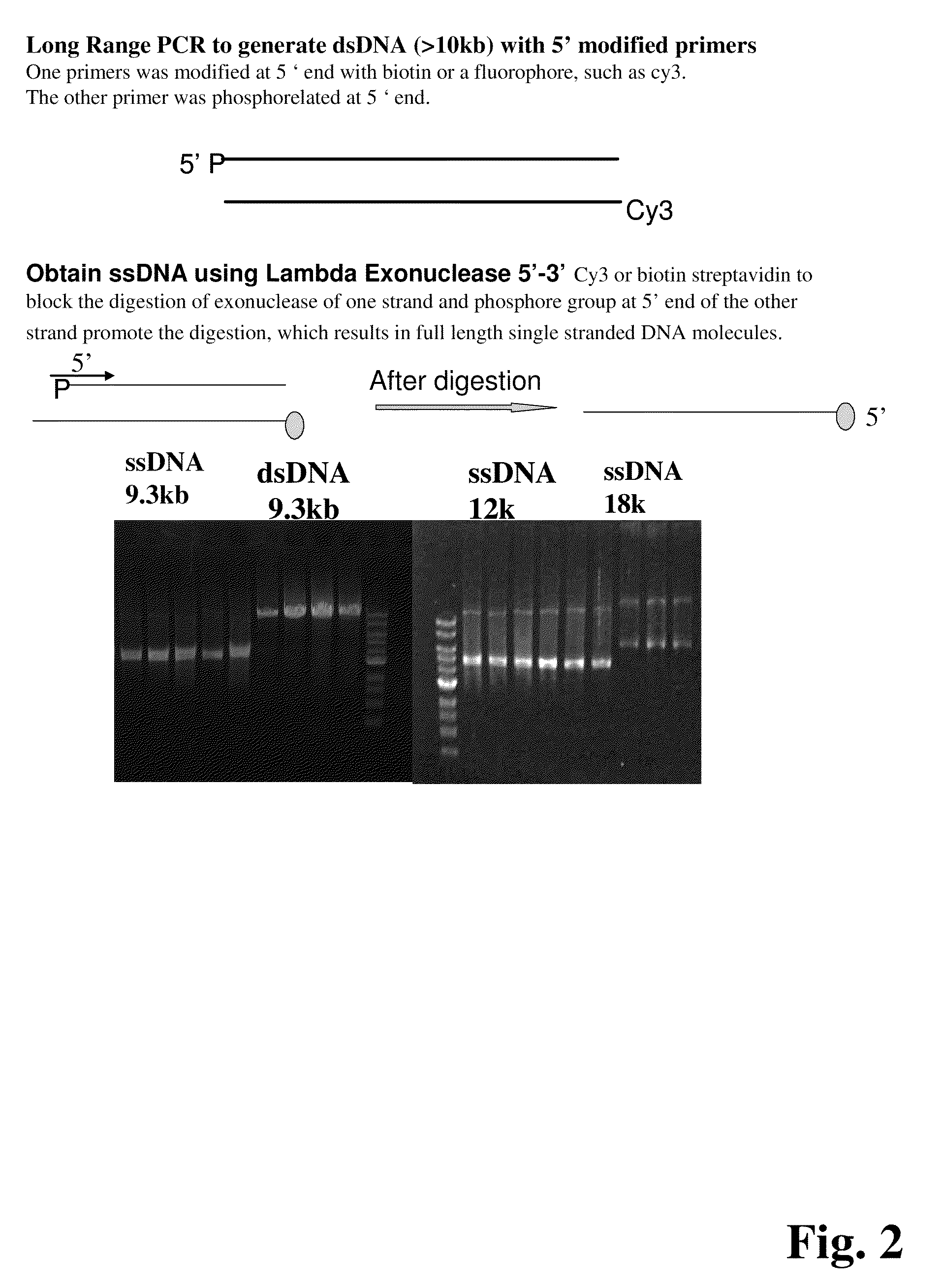

Methods for determining genetic haplotypes and DNA mapping

ActiveUS20090155780A1Improve labeling efficiencyStable labelingMicrobiological testing/measurementFermentationDirect imagingDNA barcoding

Improved methods of genetic haplotyping and DNA sequencing and mapping, including methods for making amplified ssDNA, methods for allele determination, and a DNA barcoding strategy based on direct imaging of individual DNA molecules and localization of multiple sequence motifs or polymorphic sites on a single DNA molecule.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS +1

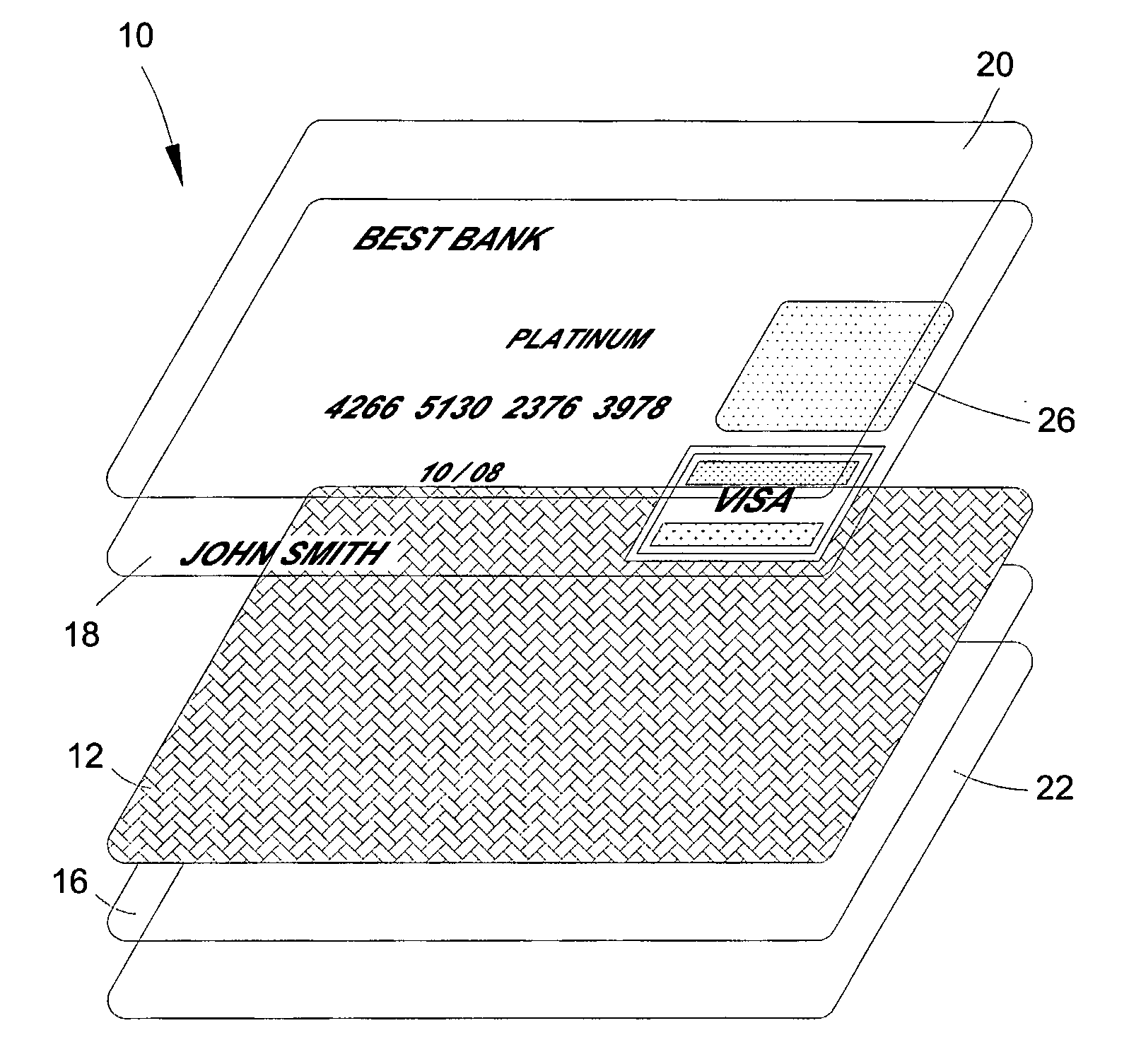

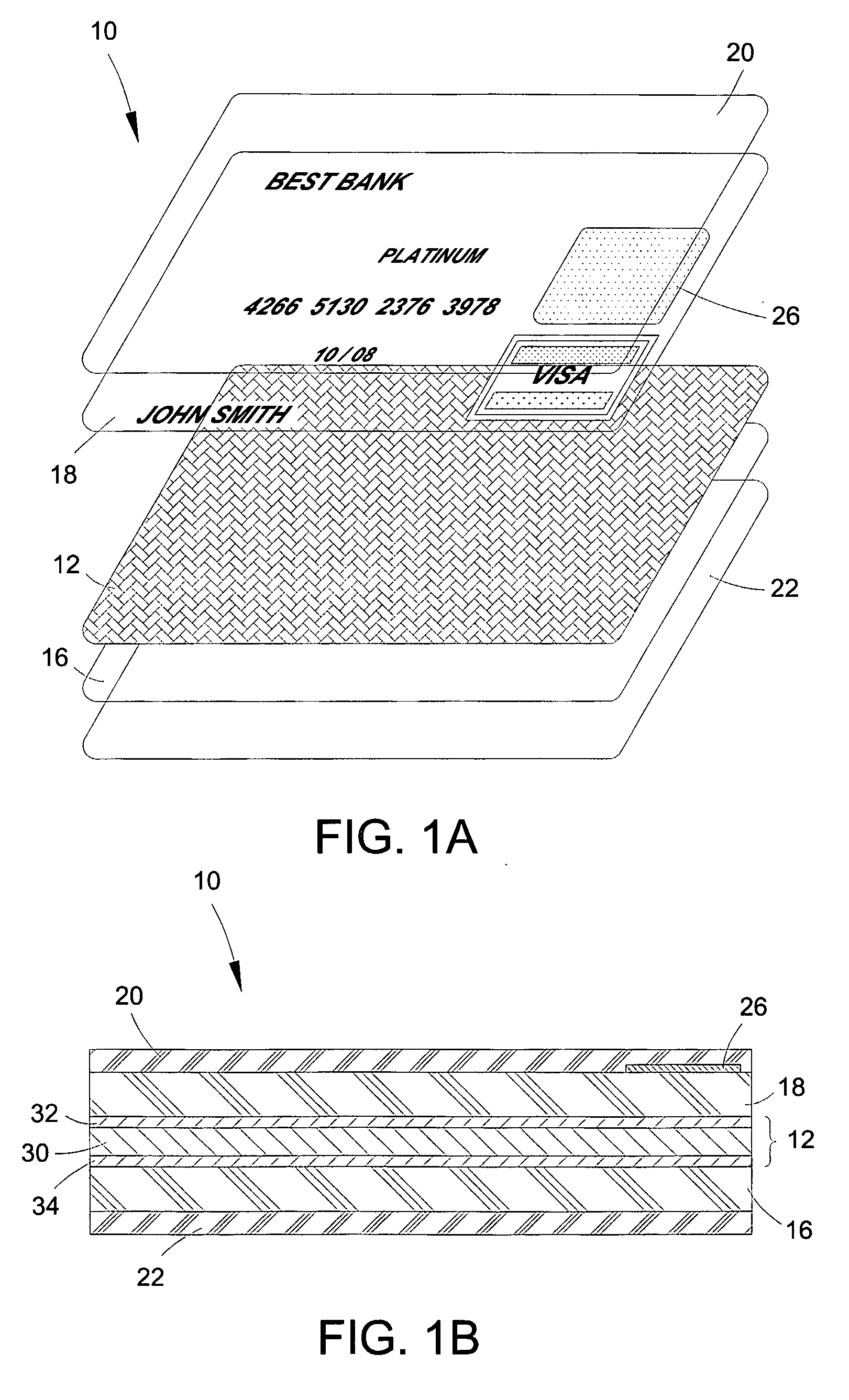

Multi-Layer Cards with Aesthetic Features and Related Methods of Manufacturing

ActiveUS20080245865A1Minimize the numberEasy to mergeOther printing matterRecord carriers used with machinesDirect imagingEngineering

Multi-layer cards with aesthetic and / or functional features, e.g. banking, access, or identification cards, having a bearing layer that includes an effects layer disposed directly between two core layers are disclosed herein. Among other potential benefits, the layered structure of the bearing layer reduces overall manufacturing costs, as compared to methods known in the art, by facilitating a balanced card construction while minimizing the number of layers formed from relatively expensive materials, avoiding direct imaging of the effects layer and minimizing waste associated therewith, as well as providing for reliable incorporation of the effects layer into the multi-layered structure with minimal expenditure of resources and reduced possibility of waste.

Owner:IDEMIA FRANCE

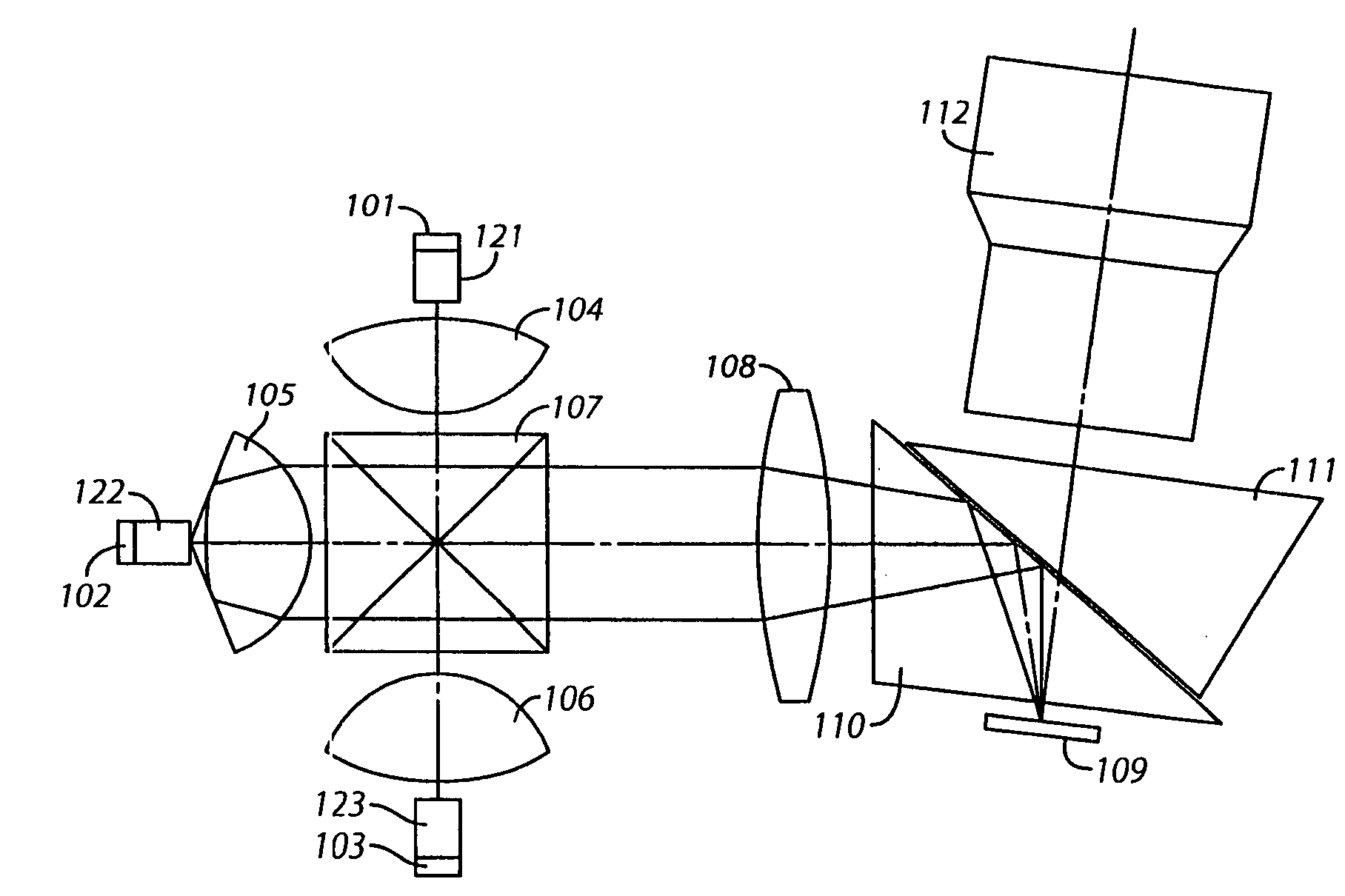

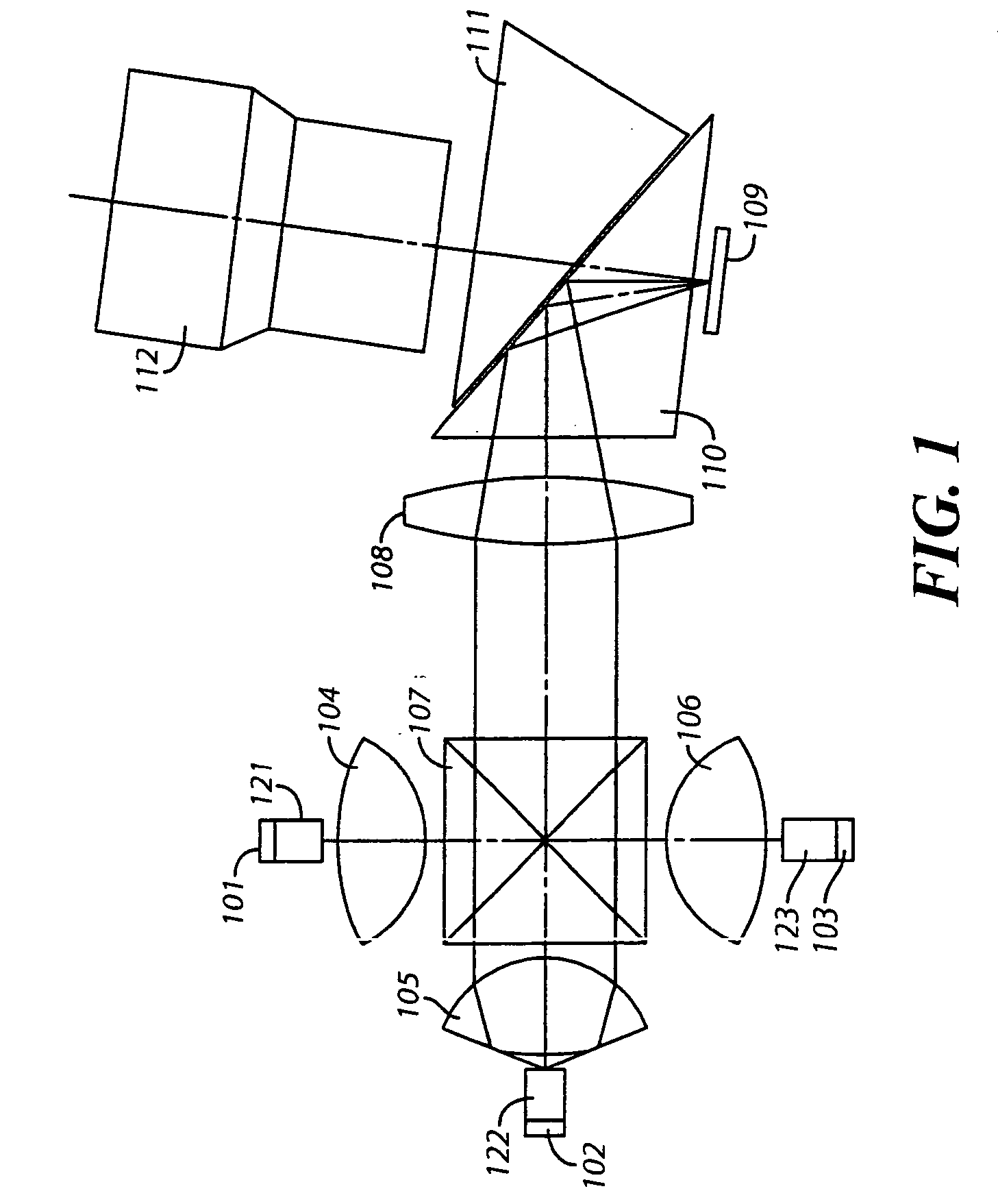

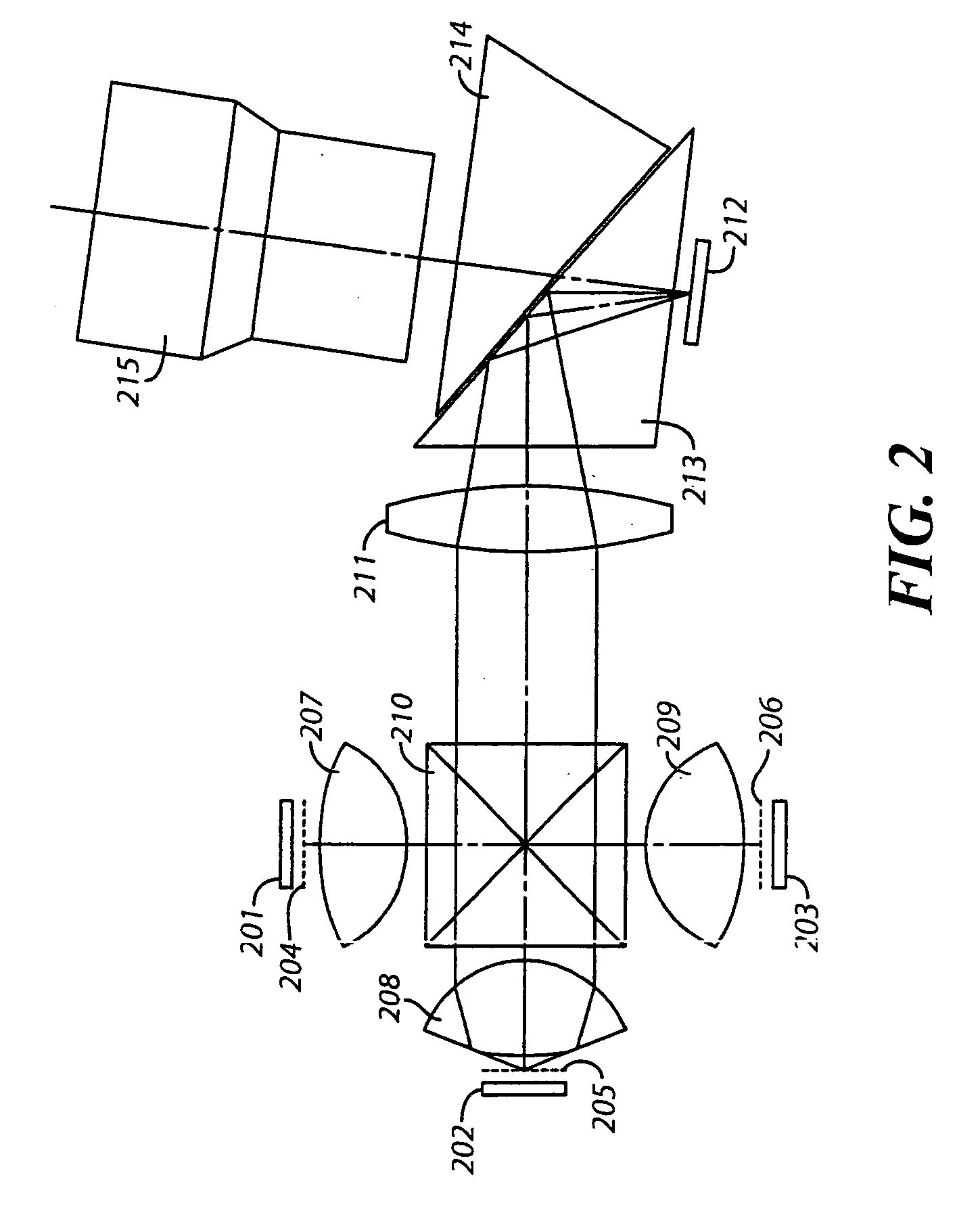

High efficiency LED optical engine for a digital light processing (DLP) projector and method of forming same

An optical light engine (100) includes one or more light-emitting diode (LED) panels (101, 102, 103) that are combined into a common path and directly imaged onto panel device to provide a source of light to a microdisplay panel (109). Preferably, the LED panel (101, 102, 103) is shaped such that the aspect ratio of light propagating the LED panel is substantially equal to the light received at the microdisplay panel (109). An aspect ratio of 4:3 or 16:9 is typically selected in view of the sizes of the LED panels used in the light engine.

Owner:JABIL CIRCUIT INC

Catadioptric projection objective

ActiveUS7385756B2High image side numerical apertureSmall amountSemiconductor/solid-state device manufacturingMicroscopesIntermediate imageDirect imaging

A catadioptric projection objective for imaging a pattern provided in an object plane of the projection objective onto an image plane of the projection objective comprises: a first objective part for imaging the pattern provided in the object plane into a first intermediate image; a second objective part for imaging the first intermediate imaging into a second intermediate image; a third objective part for imaging the second intermediate imaging directly onto the image plane; wherein a first concave mirror having a first continuous mirror surface and at least one second concave mirror having a second continuous mirror surface are arranged upstream of the second intermediate image; pupil surfaces are formed between the object plane and the first intermediate image, between the first and the second intermediate image and between the second intermediate image and the image plane; and all concave mirrors are arranged optically remote from a pupil surface. The system has potential for very high numerical apertures at moderate lens material mass consumption.

Owner:CARL ZEISS SMT GMBH

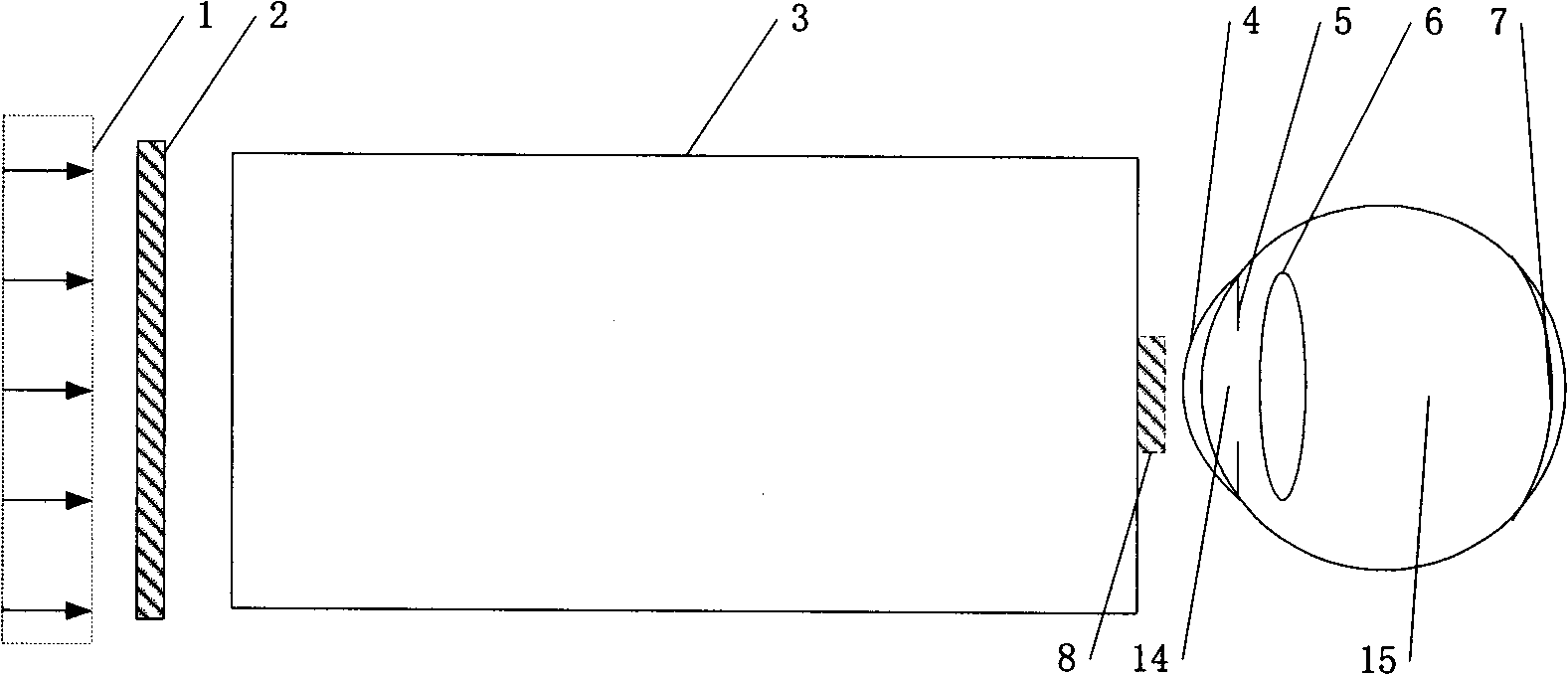

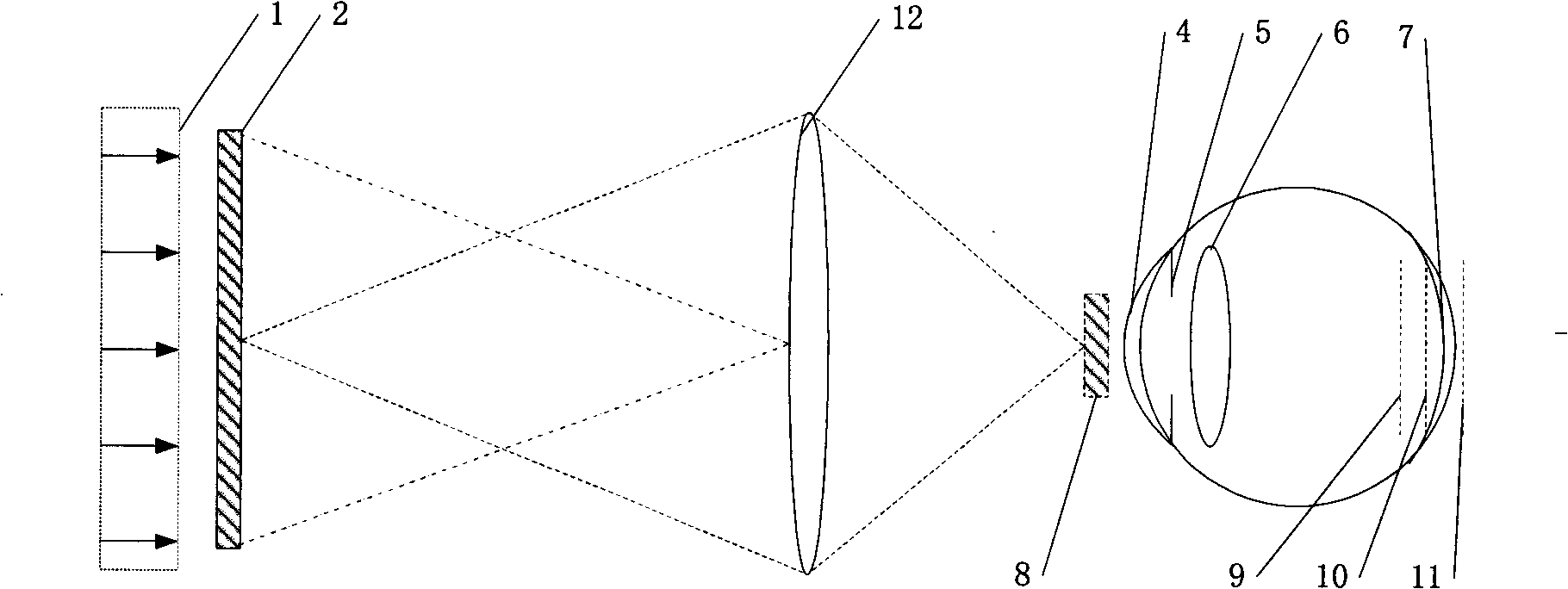

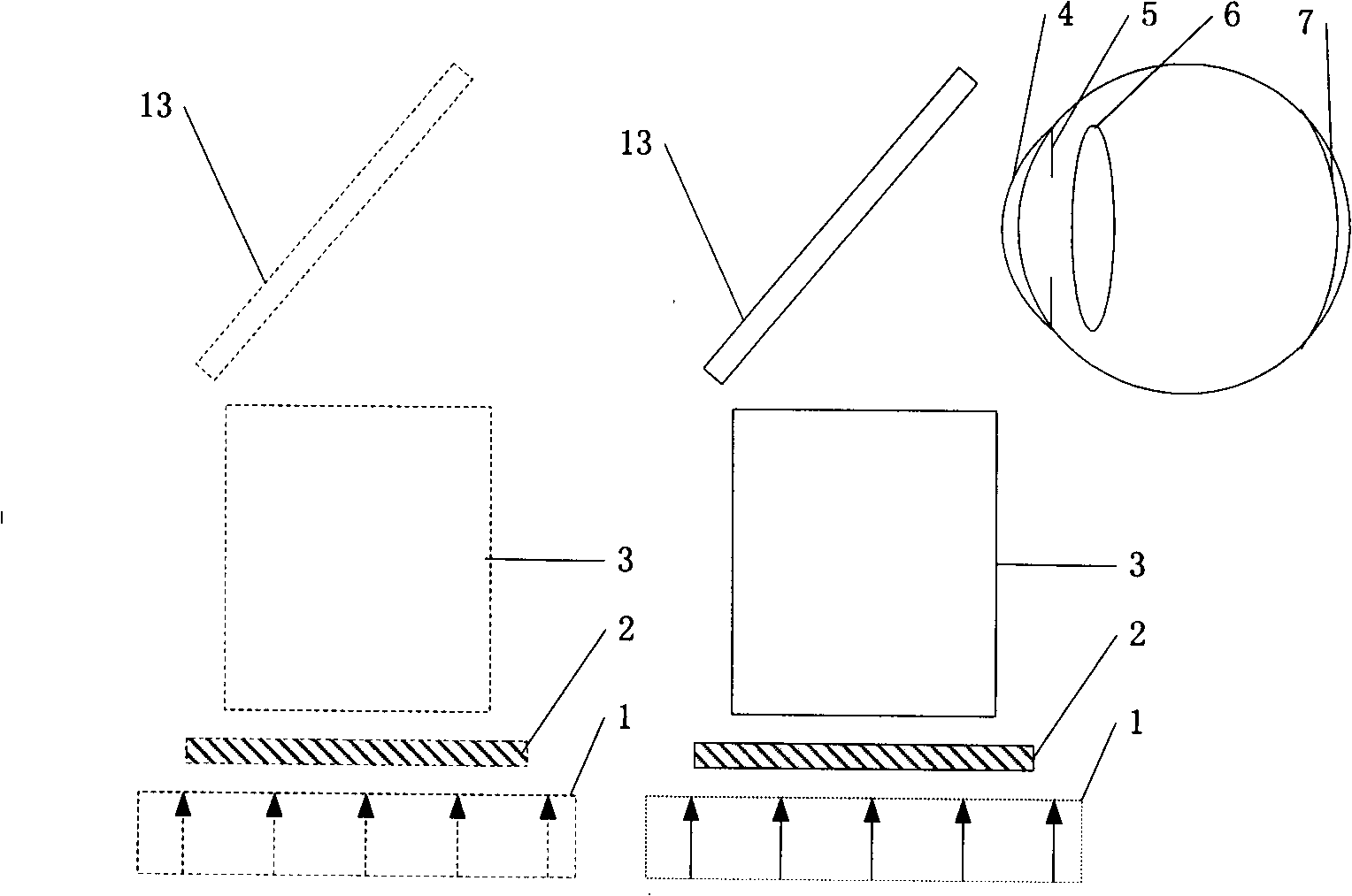

Imaging device of coherent light

ActiveCN101359098AEnhanced medical diagnosisSimple structureEye diagnosticsOptical elementsSpatial light modulatorPupil

A coherent light imaging device adopts a coherent light source 1 to irradiate an all-phase spatial light modulator 2; the coherent light transmitted by the all-phase spatial light modulator 2 is propagated through an optical system 3; the optical system transmits an optical pupil 8 in front of a cornea 4; the coherent light goes through the cornea 4, an iris 5, a lens 6, and finally reaches a retina 7; the amplitude distribution pf the coherent optical fields on a plurality of imaging planes before and behind the retina 7 is modulated by the all-phase spatial light modulator 2. The coherent light imaging device enables two-dimensional or three-dimensional images to be directly imaged the retina and has a simple structure, which can be applied to virtual reality display, augmented reality display and fundus medical diagnosis.

Owner:东莞市芯萌慧显电子科技有限公司

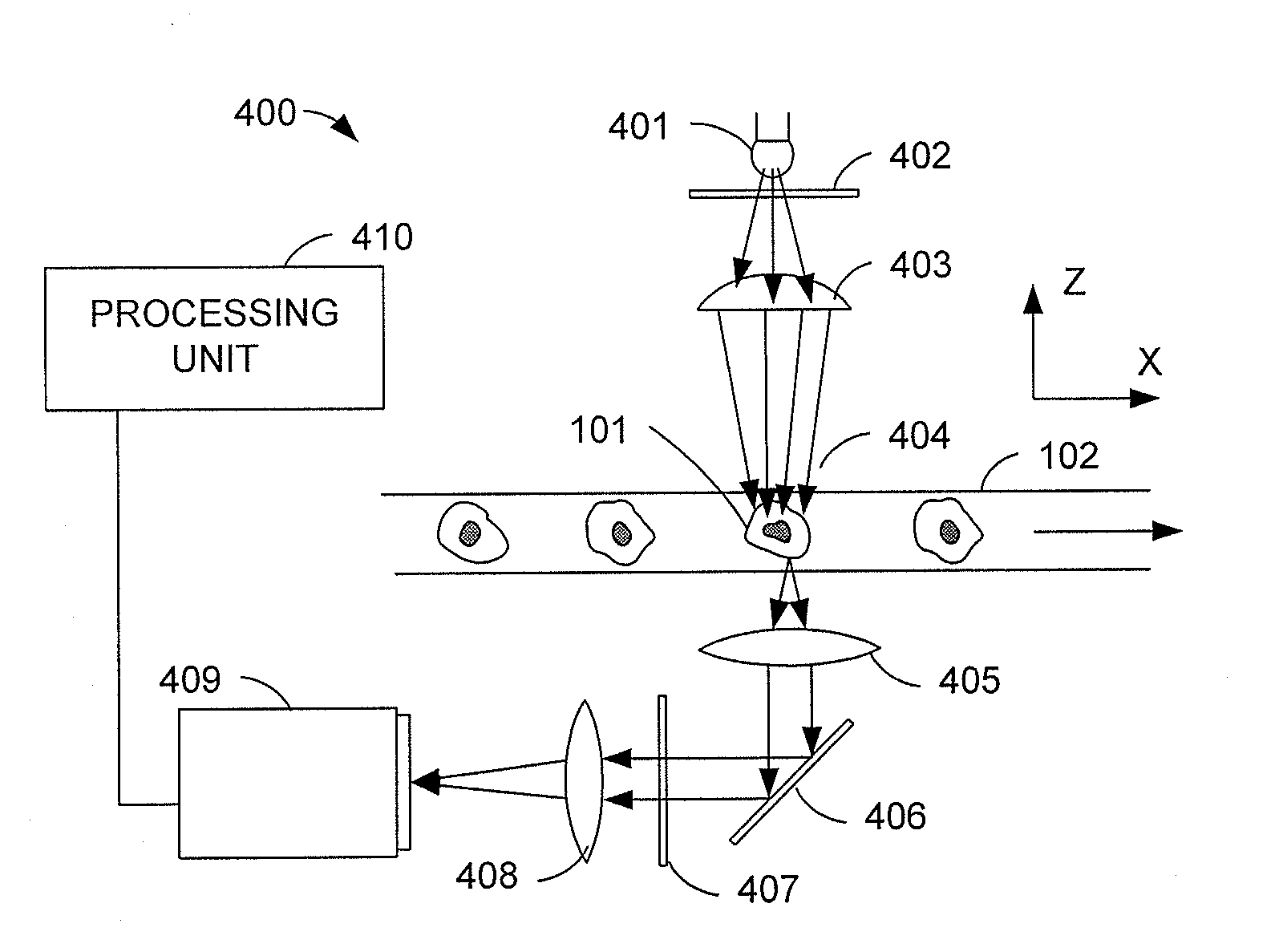

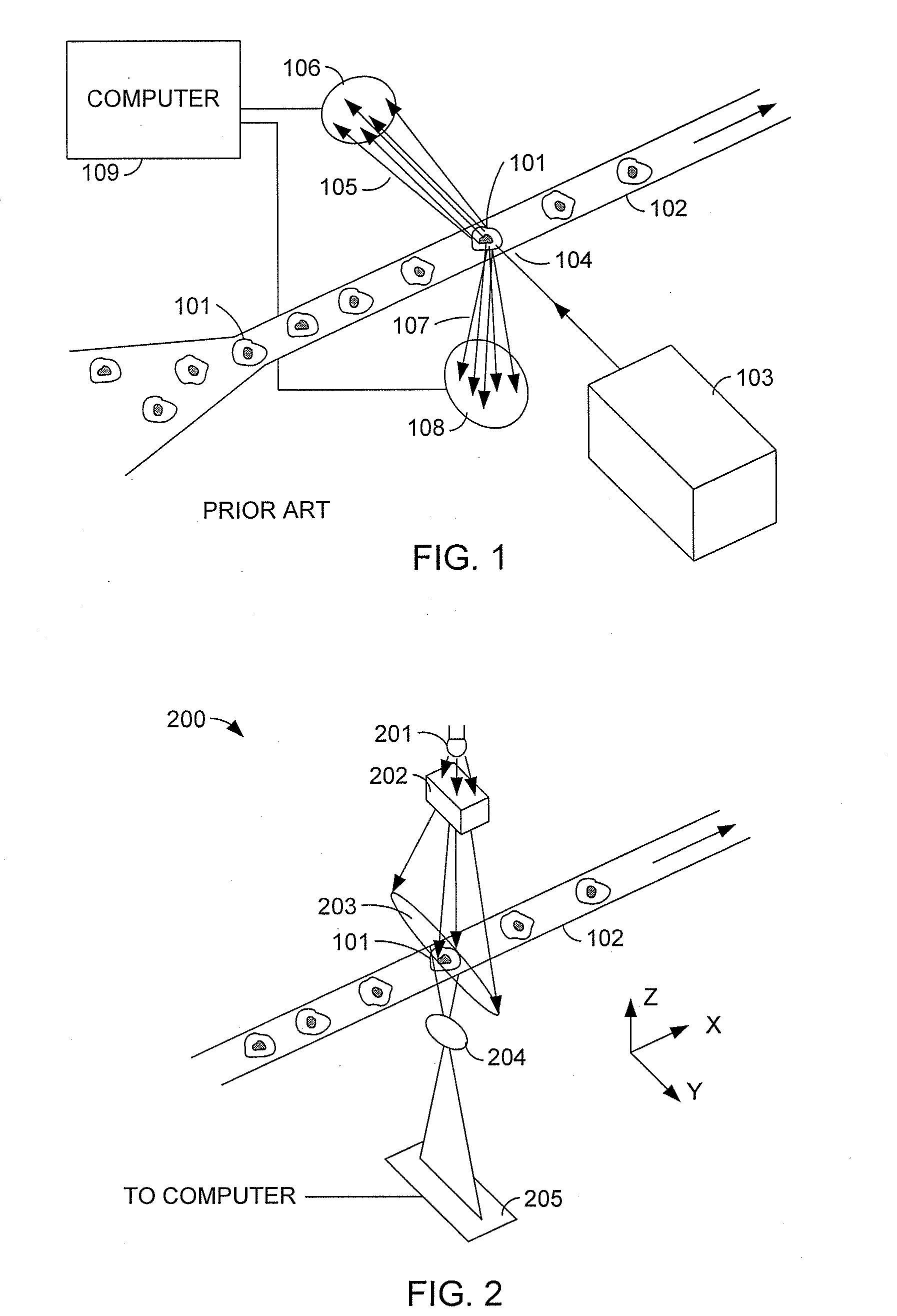

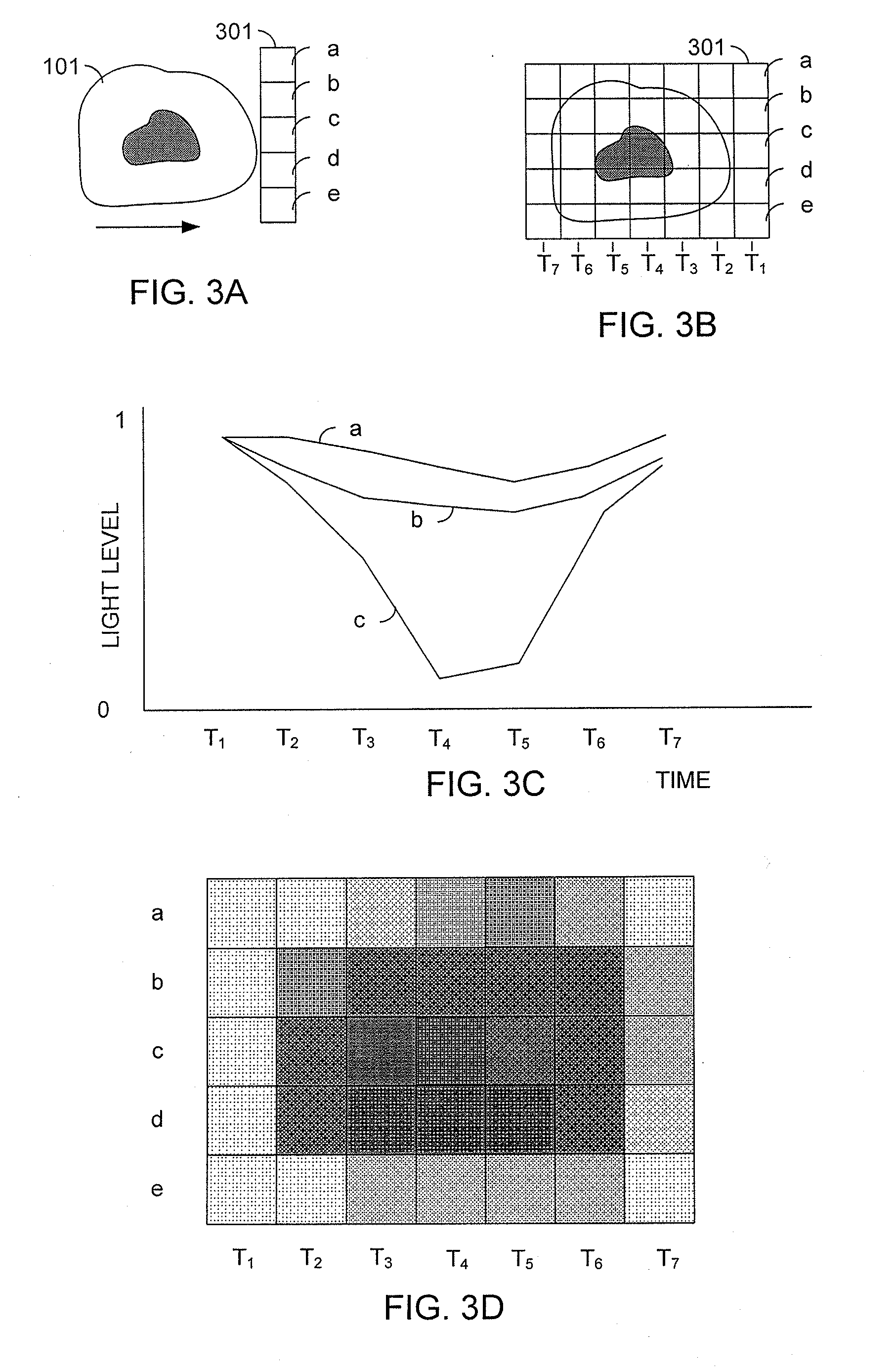

Serial-line-scan-encoded multi-color fluorescence microscopy and imaging flow cytometry

InactiveUS20100238442A1Improved signal-to-noise ratioRaman/scattering spectroscopyPhotometryHigh resolution imagingSerial line

A system for performing high-speed, high-resolution imaging cytometry utilizes a line-scan sensor. A cell to be characterized is transported past a scan region. An optical system focuses an image of a portion of the scan region onto at least one linear light sensor, and repeated readings of light falling on the sensor are taken while a cell is transported though the scan region. The system may image cells directly, or may excite fluorescence in the cells and image the resulting light emitted from the cell by fluorescence. The system may provide a narrow band of illumination at the scan region. The system may include various filters and imaging optics that enable simultaneous multicolor fluorescence imaging cytometry. Multiple linear sensors may be provided, and images gathered by the individual sensors may be combined to construct an image having improved signal-to-noise characteristics.

Owner:BIO RAD LAB INC

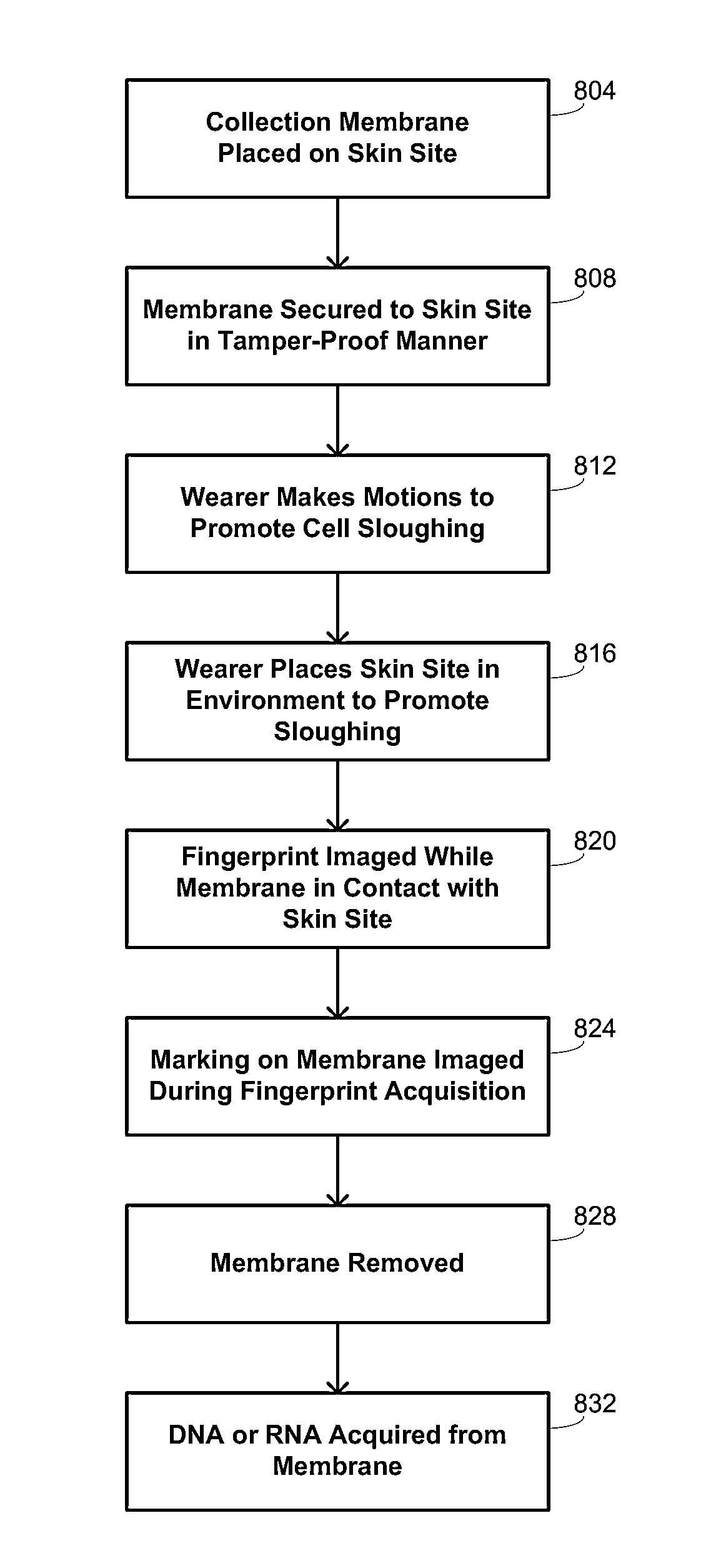

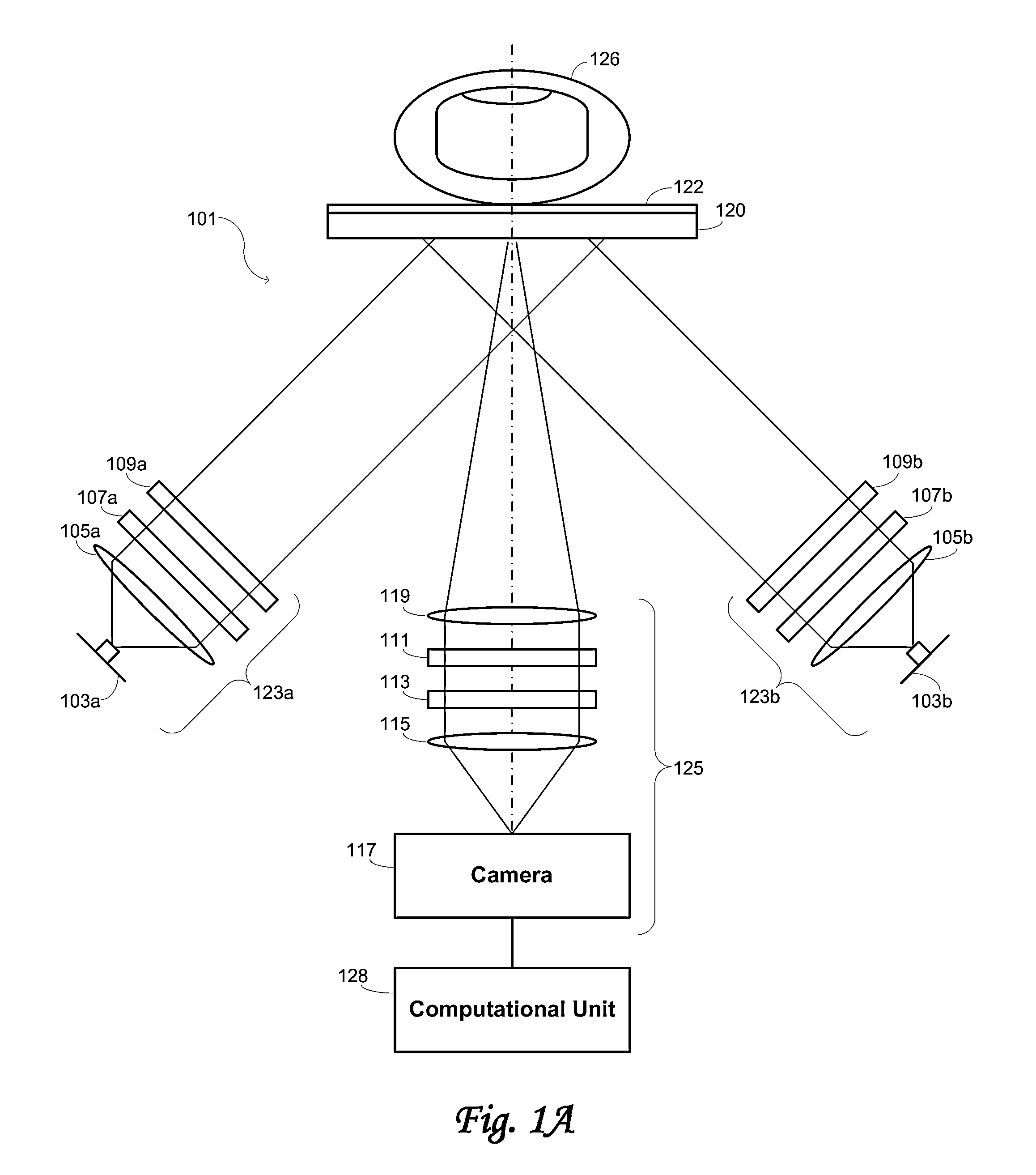

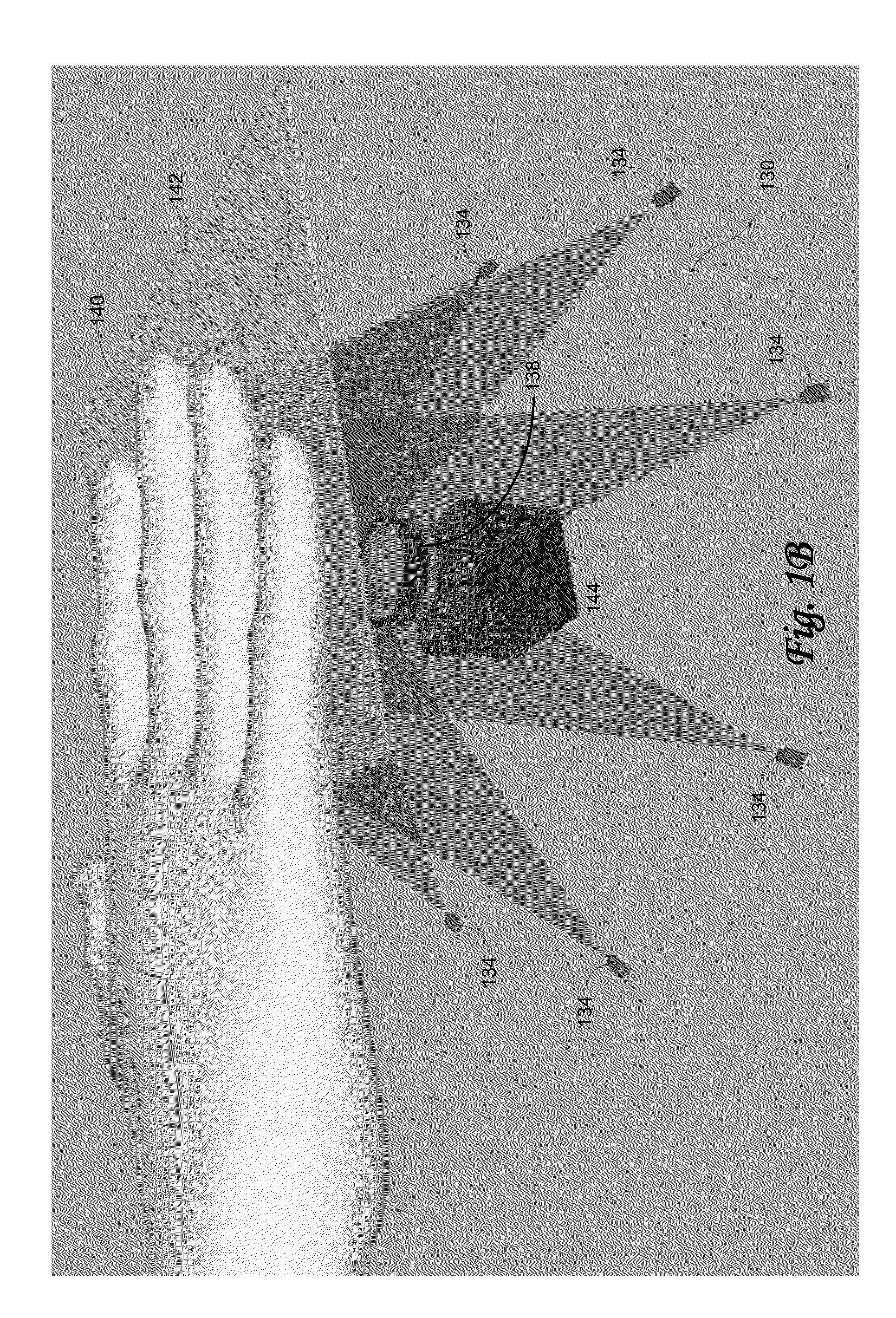

Methods and systems for estimating genetic characteristics from biometric measurements

Methods and devices are disclosed for collecting fingerprint and genetic information from an individual during a single collection session. A skin site is illuminated by direct imaging of the skin site using light reflected from the illuminated skin site. A cell of the individual, such as a skin cell, is retrieved from the collection surface.

Owner:HID GLOBAL CORP

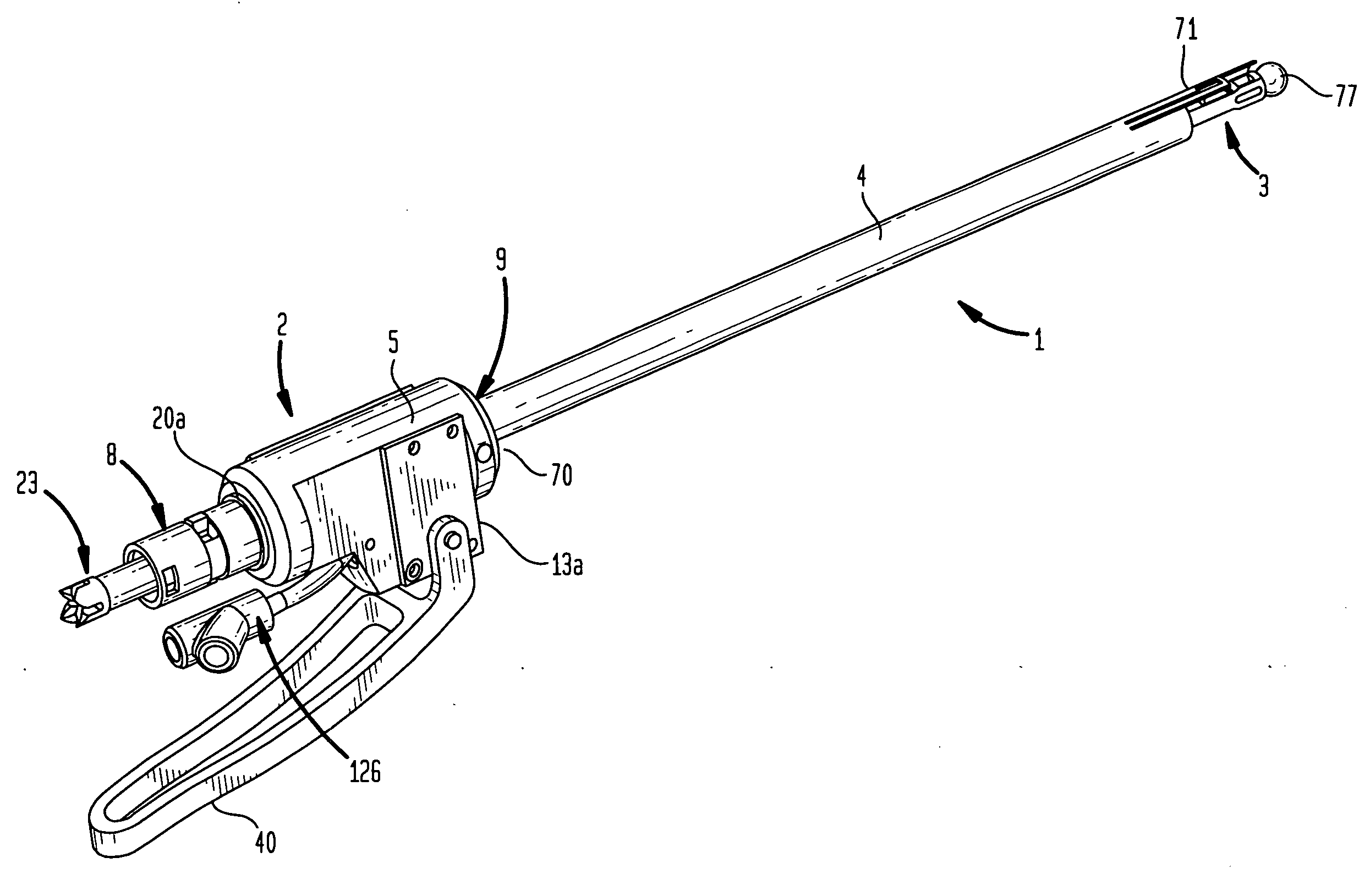

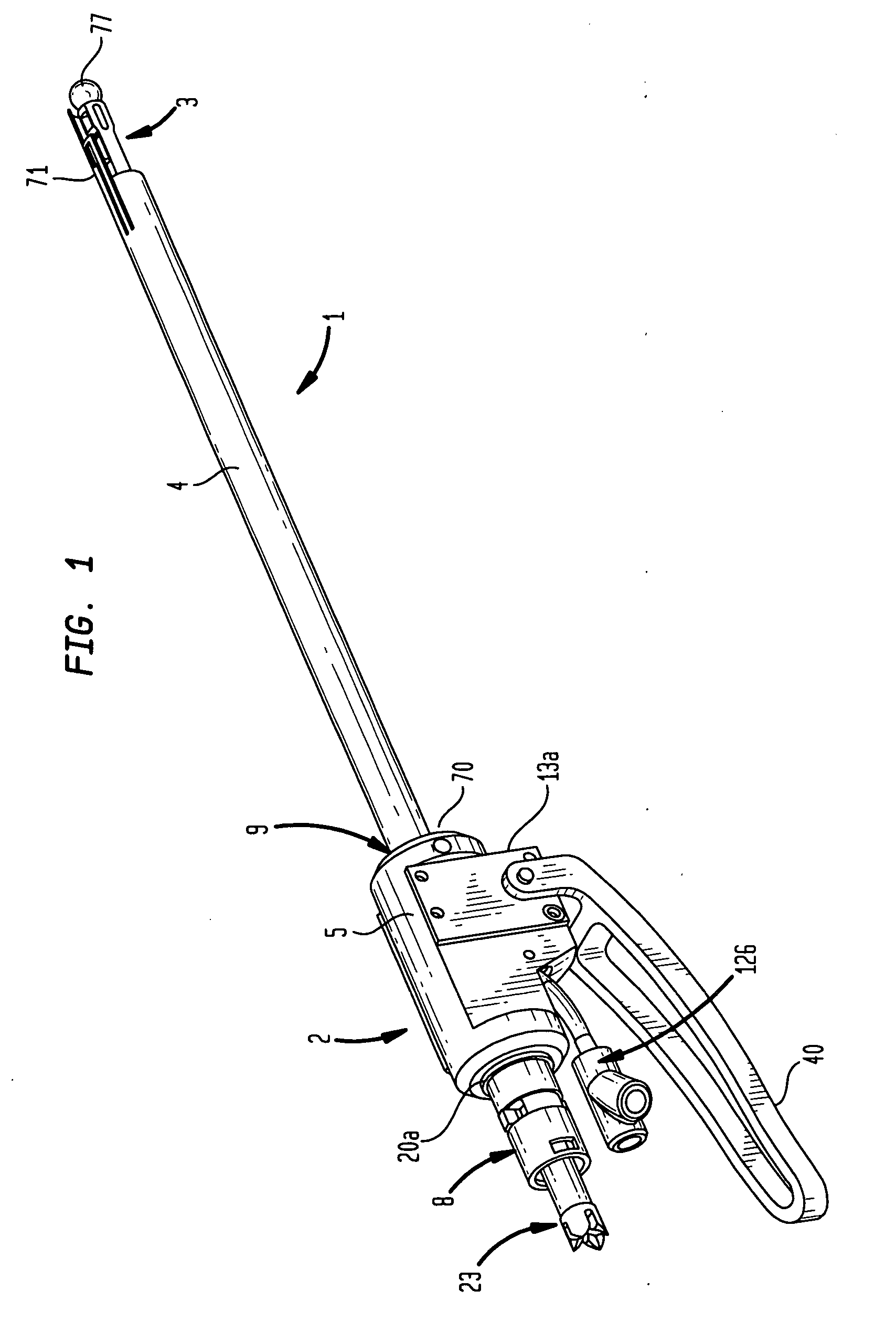

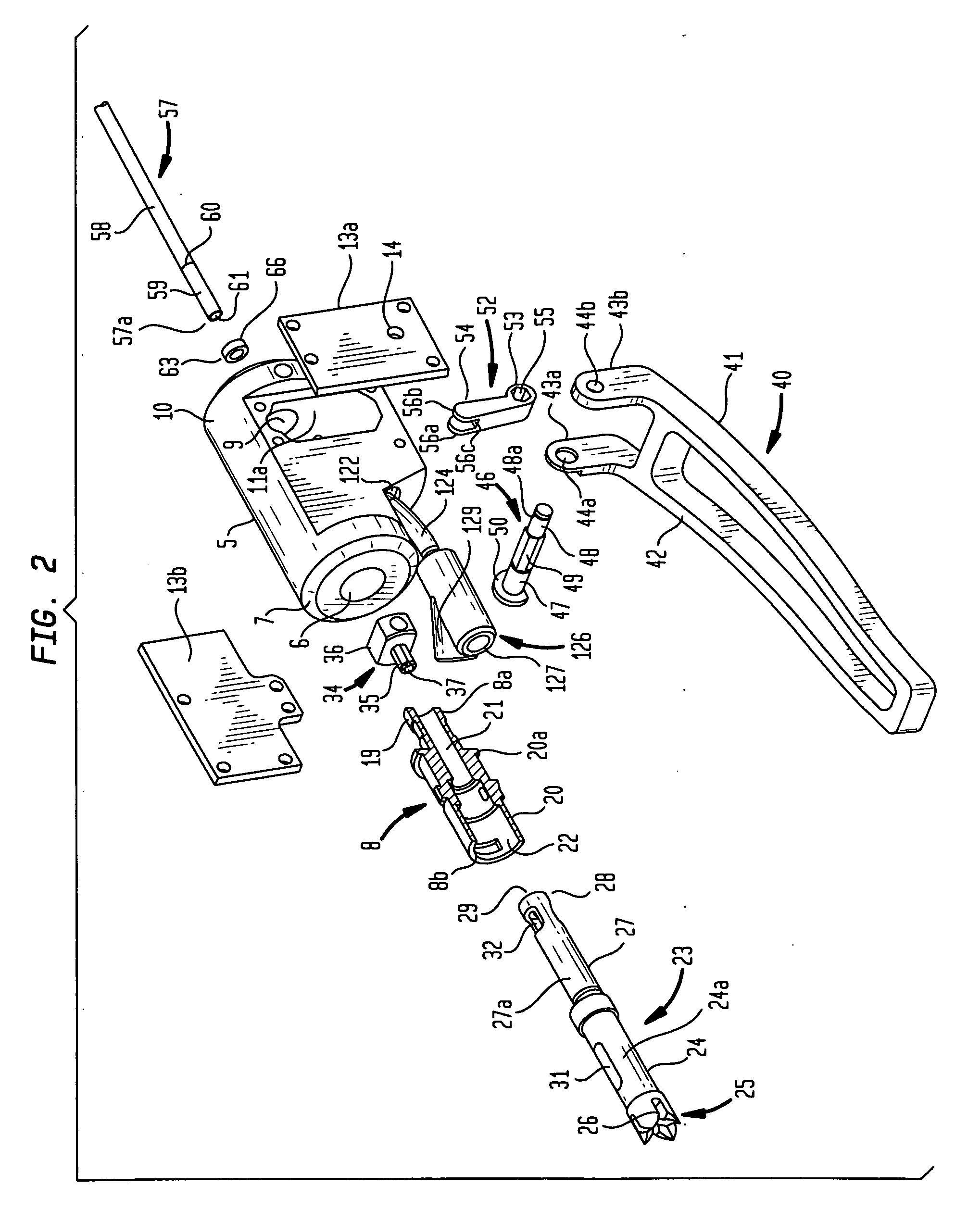

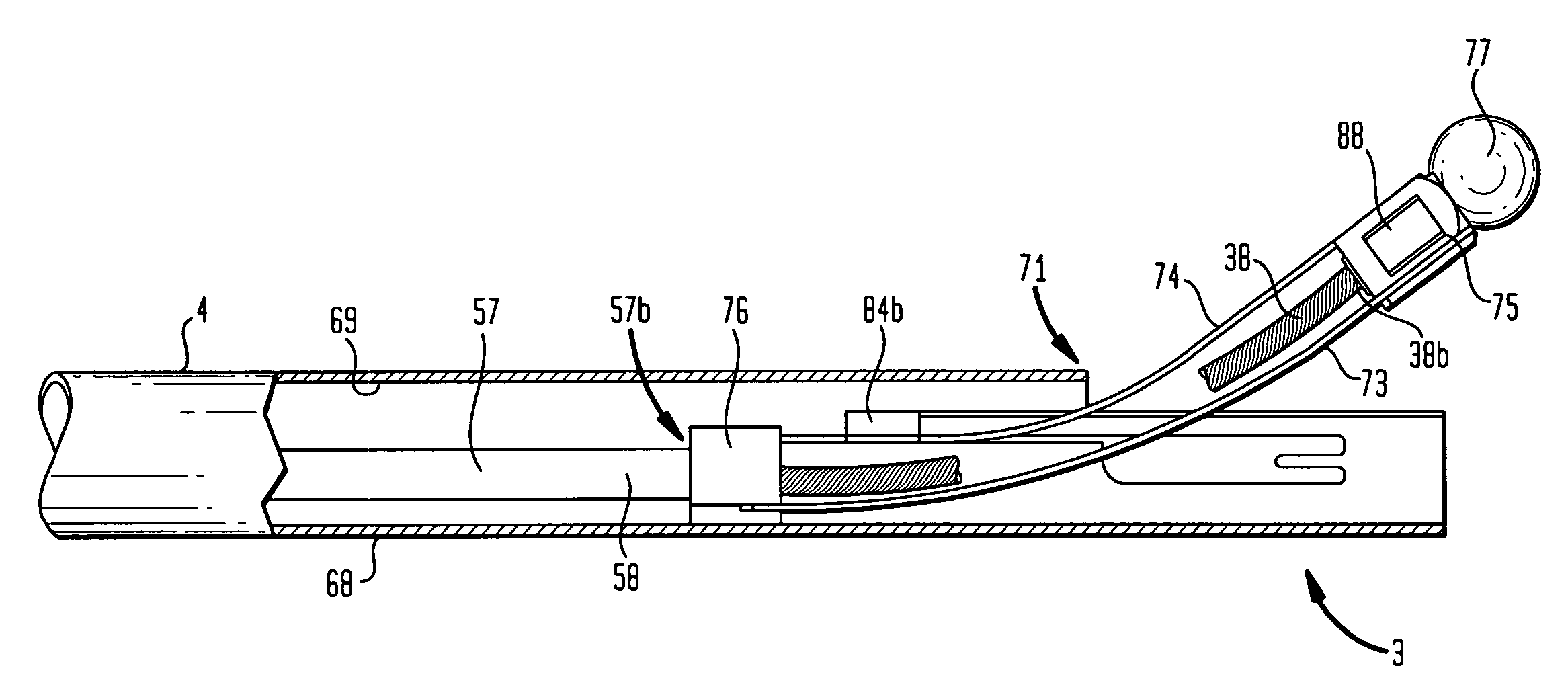

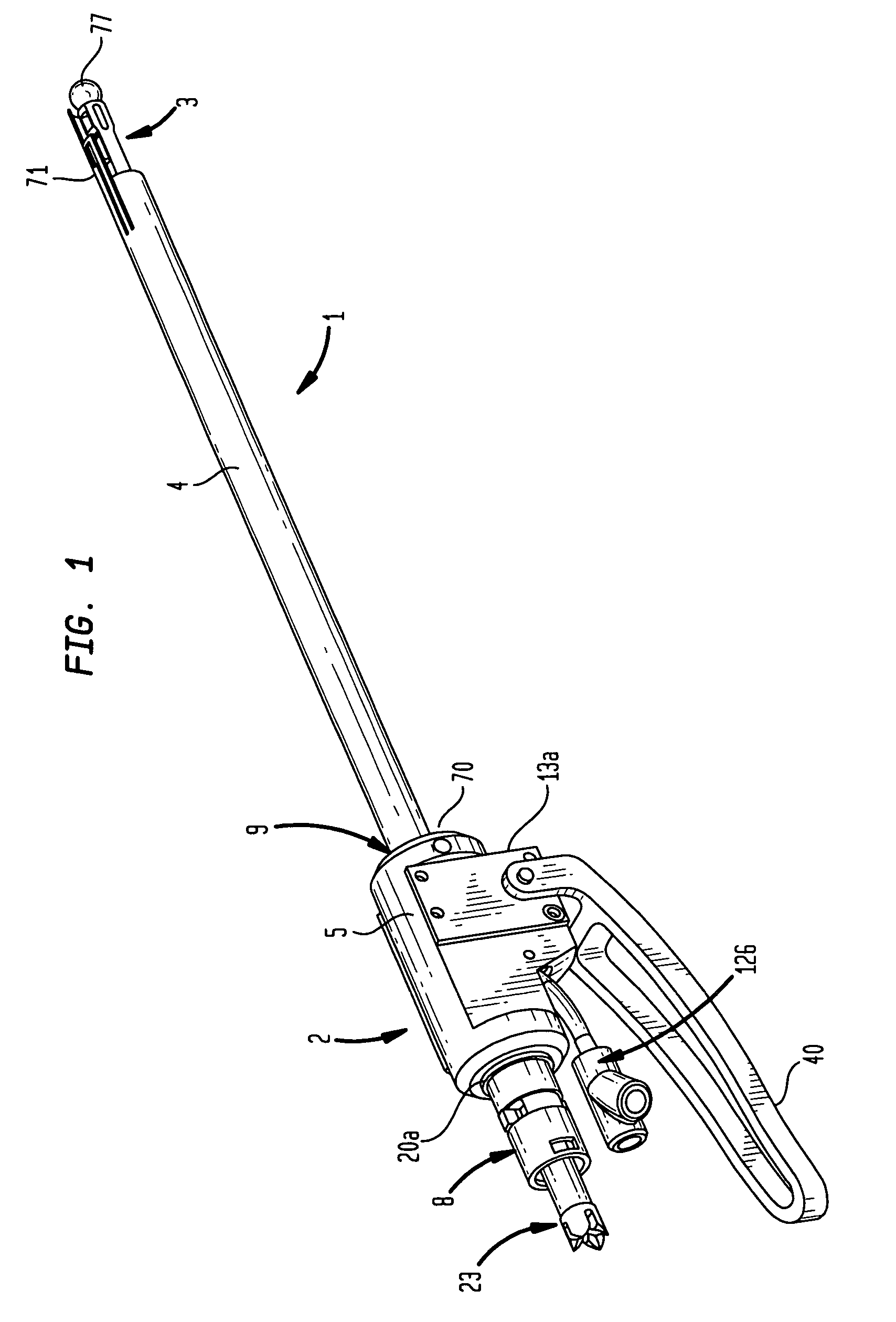

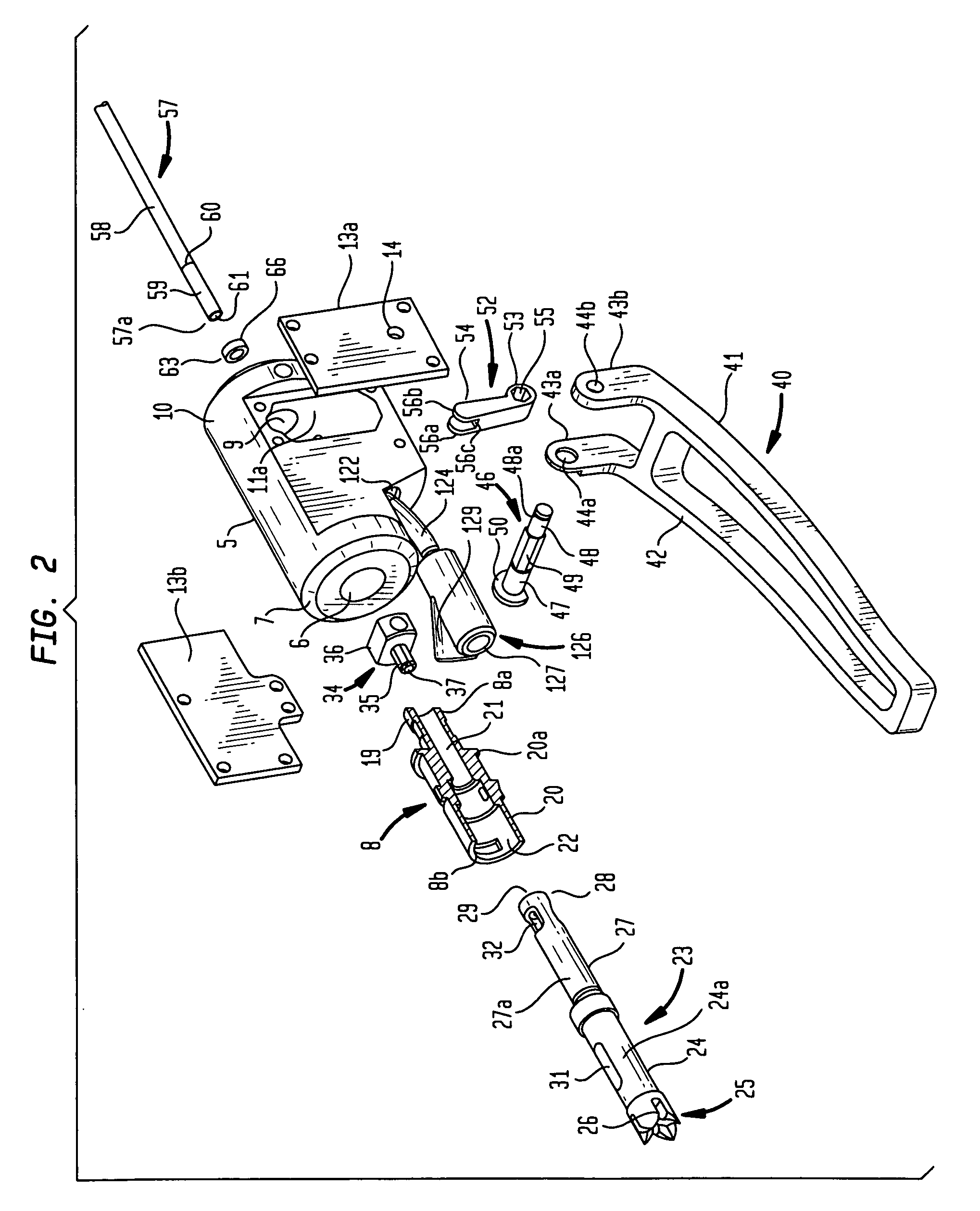

Method and apparatus for removal of tissue

A surgical instrument includes a deflectable cutting element extending from the distal end of the instrument. The deflection of the cutting element is controllable based on a user operating a moveable member of the instrument. The deflectable cutting element is normally disposed within a circumferential region defined by the distal end of the instrument. The moveable member can be moved in relation to the instrument to deflect the deflectable cutting element, such that the cutting element is at least partially outside of the circumferential region. The extent that the cutting element is outside of the circumferential region is a function of the position to which the moveable member is moved in relation to the instrument. The instrument further includes direct imaging of the distal end, such that the deflection of the cutting element for selective removal of bone tissue at the distal end of the instrument can be controlled in real-time.

Owner:HOWMEDICA OSTEONICS CORP

Development enhancement of radiation-sensitive elements

InactiveUS20050003296A1High sensitivityEasy to operateDuplicating/marking methodsPhotomechanical apparatusDirect imagingComputer to plate

A positive-working radiation-sensitive composition for use with a radiation source comprises one or more polivinyl acetal polymers capable of being dissolved in an alkaline aqueous solution and a development-enhancing compound. The sensitivity of a radiation-sensitive coating based on the composition of this invention is increased without compromising the handling characteristics. Radiation-sensitive elements based on the composition of the invention have good development latitude. A positive-working lithographic printing precursor is based on the radiation-sensitive composition coated on a hydrophilic surface. The precursor is developable using an alkaline aqueous solution, and may be used with a radiation source in lithographic applications, such as conventional imaging systems, computer-to-plate systems or other direct imaging applications. The precursor is stable in its state before exposure and has an excellent handling property.

Owner:KODAK GRAPHIC COMM CANADA CO

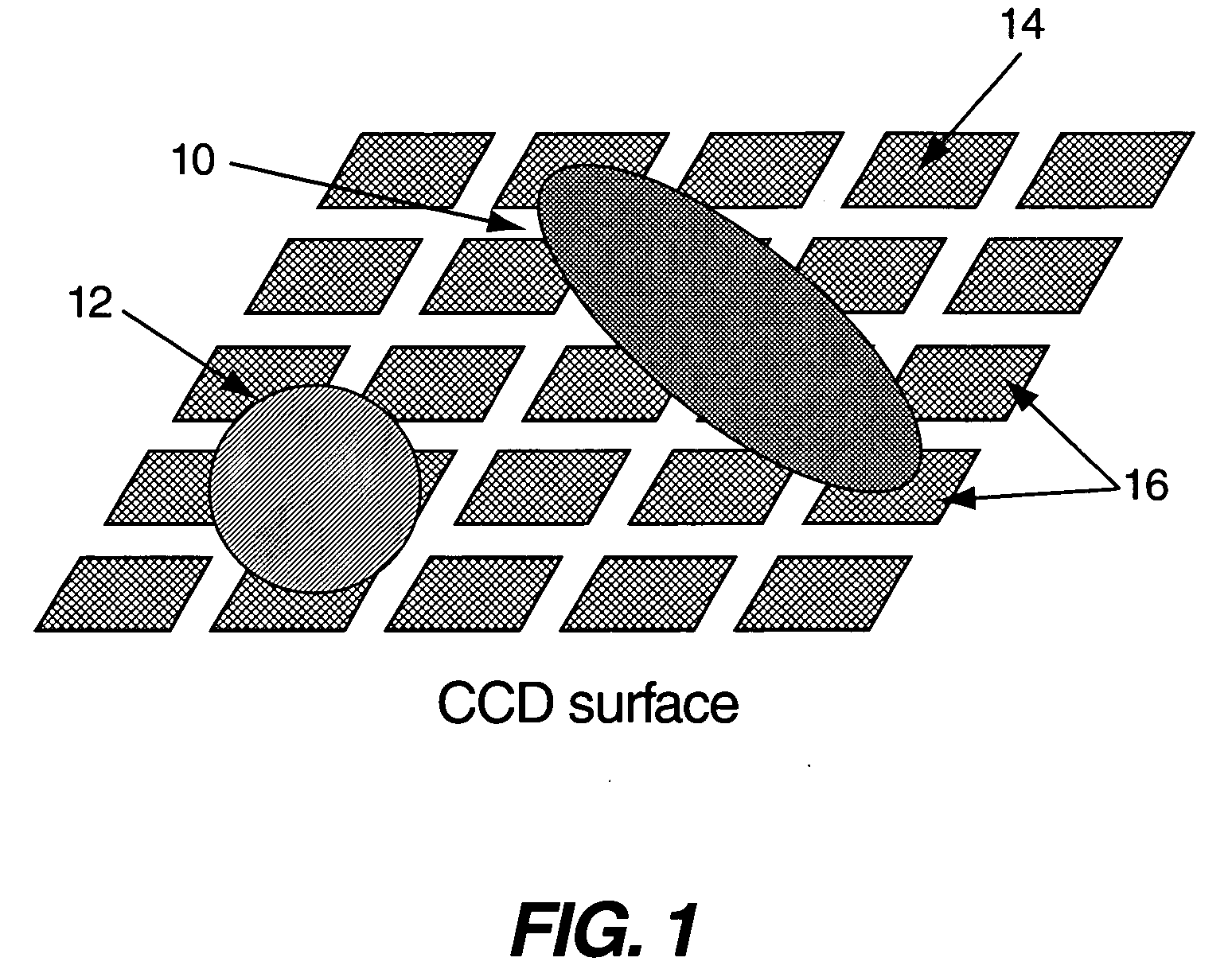

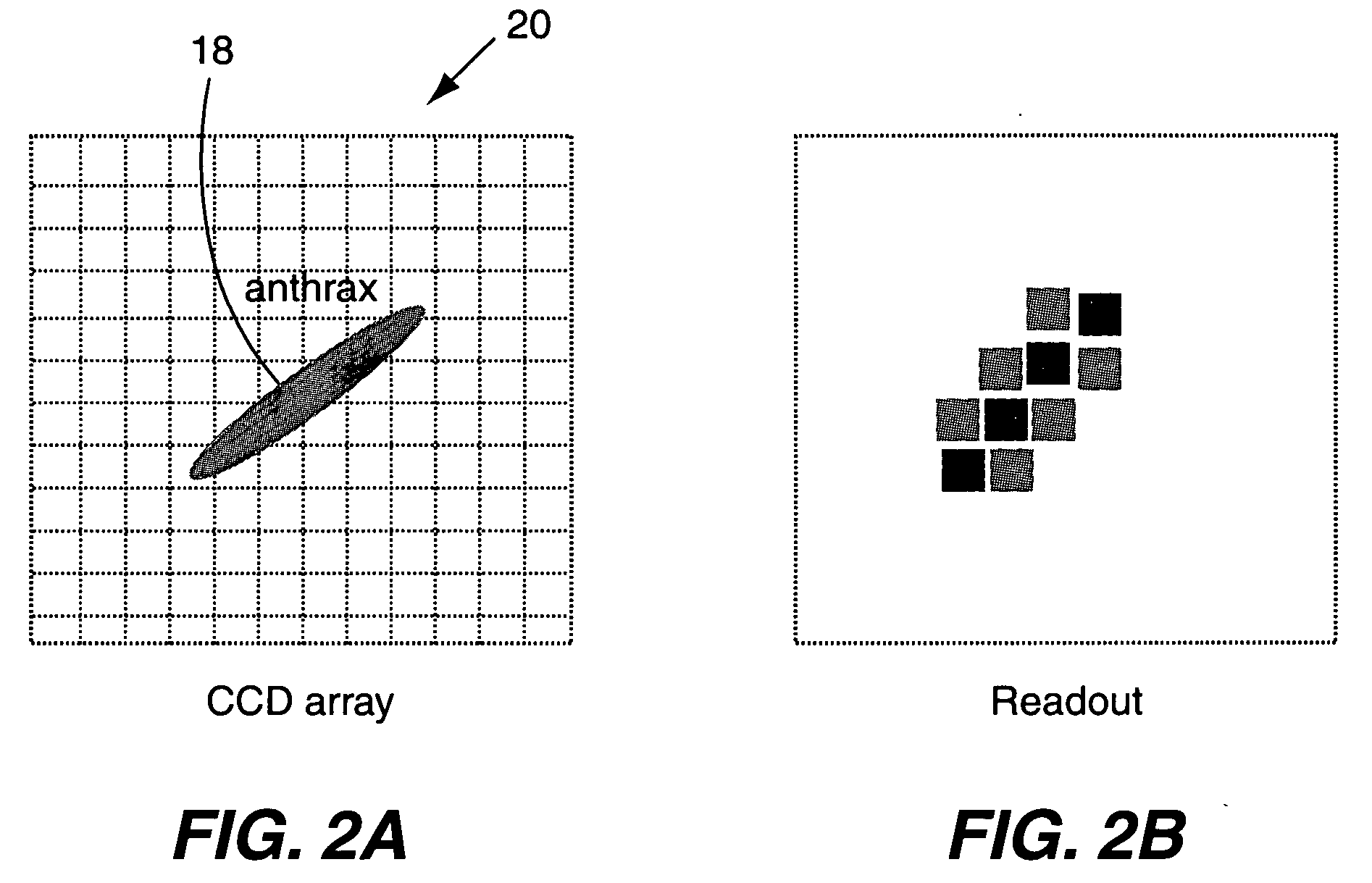

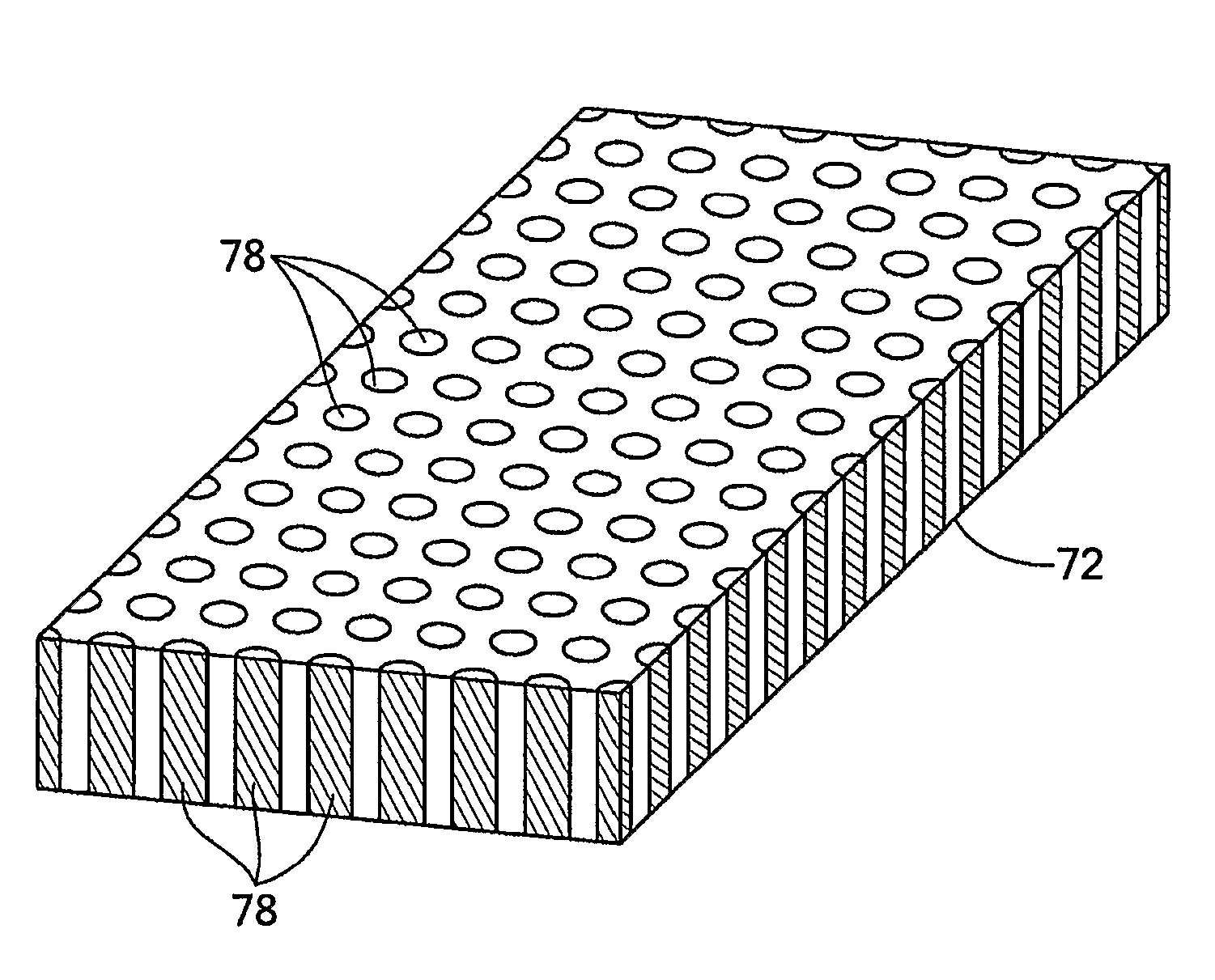

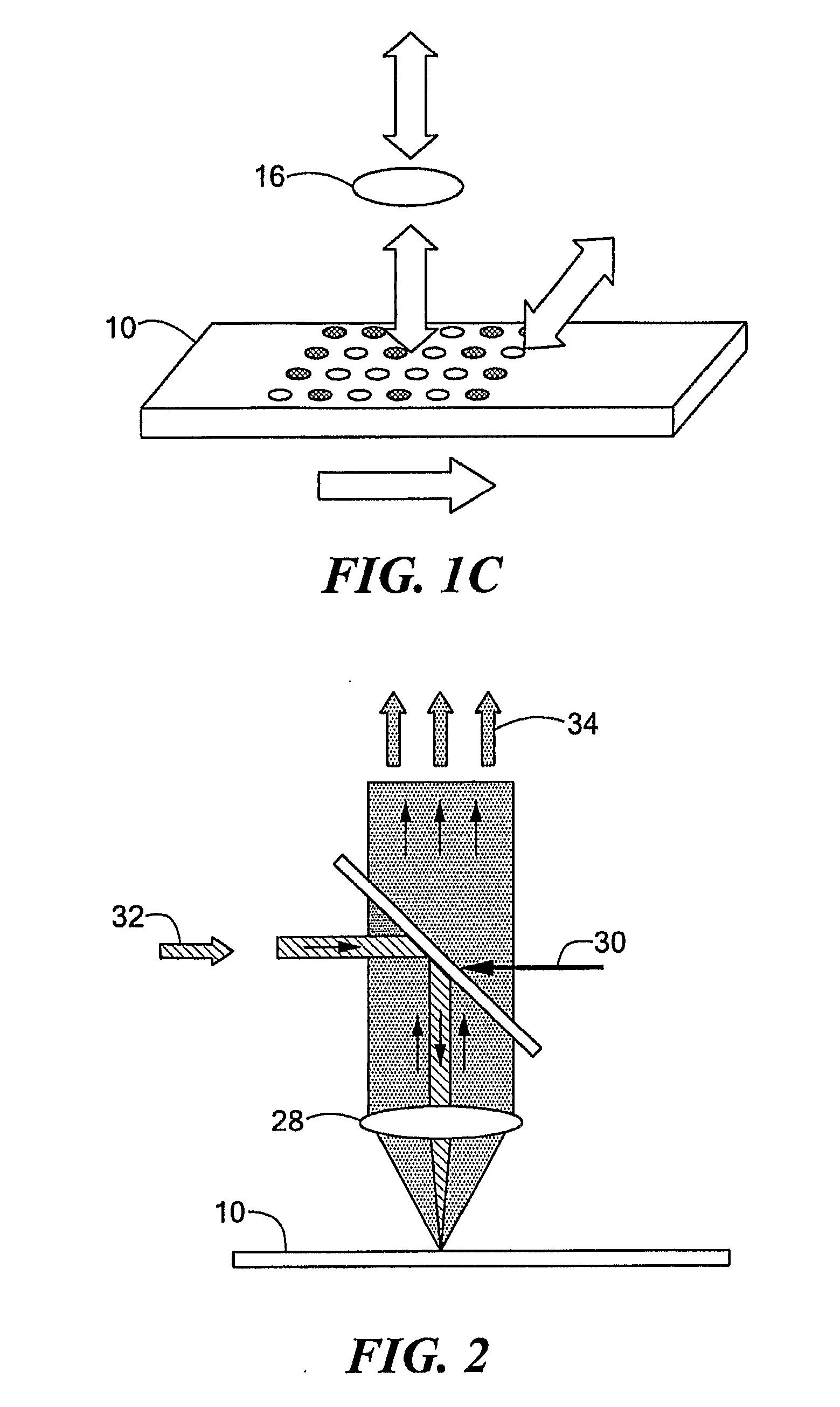

Integrated array sensor for real time measurements of biological samples

An integrated array of light sensitive pixels has a surface configured to receive the small particles within a distance effective for the particles to affect the pixel readout amplitude and where the pixels have an area on the order of the area of the small particles to be directly imaged. A collimated light source is provided for illuminating the integrated array. A video display receives an output from the pixels to provide an image of the small particles directly contacting the surface of the array.

Owner:LOS ALAMOS NATIONAL SECURITY

Direct drawing type waterless planographic original form plate

InactiveUS6096476AHigh nitrogen contentHigh degreePhotosensitive materialsSemiconductor/solid-state device manufacturingEngineeringHeat sensitive

PCT No. PCT / JP96 / 03296 Sec. 371 Date Oct. 27, 1997 Sec. 102(e) Date Oct. 27, 1997 PCT Filed Nov. 8, 1996 PCT Pub. No. WO97 / 17208 PCT Pub. Date May 15, 1997A directly imageable raw plate for waterless planographic printing plate, in which a heat insulating layer, heat sensitive layer and ink repellent layer are formed in this order on a substrate, comprising physical properties of 5 to 100 kgf / mm2 in initial elastic modulus and 0.05 to 5 kgf / mm2 in 5% stress as tensile properties of the heat sensitive layer or the heat insulating layer or the laminate consisting of both the layers. It can be suitably used also for large printing presses and web offset printing presses requiring high printing durability, and makes it possible to obtain an economically advantageous printing plate.

Owner:TORAY IND INC

Dual-wavelength positive-working radiation-sensitive elements

InactiveUS7279263B2High sensitivityEasy to operateSemiconductor/solid-state device manufacturingDiazo compound compositionsRadiation sensitivityUltraviolet

A positive-working radiation-sensitive composition for use with a radiation source comprises one or more polymers capable of being eluted in an alkaline aqueous solution and a development-enhancing compound. The invention provides a positive-working photosensitive composition of good sensitivity for use with one or both of ultra-violet radiation and an infrared laser radiation source. The composition is stable in its state before exposure and has an excellent handling property. The sensitivity of a radiation-sensitive coating based on the composition of this invention is increased without compromising the handling characteristics. Radiation-sensitive elements based on the composition of the invention have good development latitude. A positive-working lithographic printing precursor is based on the radiation-sensitive composition coated on a hydrophilic surface. The precursor is developable using an alkaline aqueous solution, and may be used with a radiation source in lithographic applications, such as conventional imaging systems, computer-to-plate systems or other direct imaging applications. The precursor is stable in its state before exposure and has an excellent handling property.

Owner:KODAK GRAPHIC COMM CANADA CO

Manufacturing process for step circuit of PCB (Printed Circuit Board)

InactiveCN102651946AReduce copper thickness dropEliminate poor quality defectsConductive material chemical/electrolytical removalProduction scheduleEngineering

The invention discloses a manufacturing process for a step circuit of a PCB (Printed Circuit Board). According to the manufacturing process, different film patterns are adopted twice for manufacturing the circuit, during the primary film pattern circuit manufacture, a positive film circuit pattern is adopted, compensation is carried out a film substrate circuit at different positions according to copper thickness so as to manufacture a special circuit, and sunk copper plate electrification is carried out on the special circuit, so that the copper thickness meets the requirement; then board grinding is carried out by a twice board grinding mode so as to reduce the copper thickness difference of step positions; a dry film is enabled to be fully combined with the step positions by virtue of a film attaching and air compressing mode; and finally, normal circuit pattern manufacturing is carried out by utilizing a high-precision LDI (Laser Direct Imaging) exposure machine. Compared with the prior art, the manufacturing process for the step circuit can be used for eliminating the defects of open circuit at the position of the step circuit, notches, large deckle edges, serious lateral erosion, halfway etching and poor quality of thin lines and the like existing in the step circuit manufacturing process, improving the production efficiency and the production quality, quickening the production schedule and lowering the production cost.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

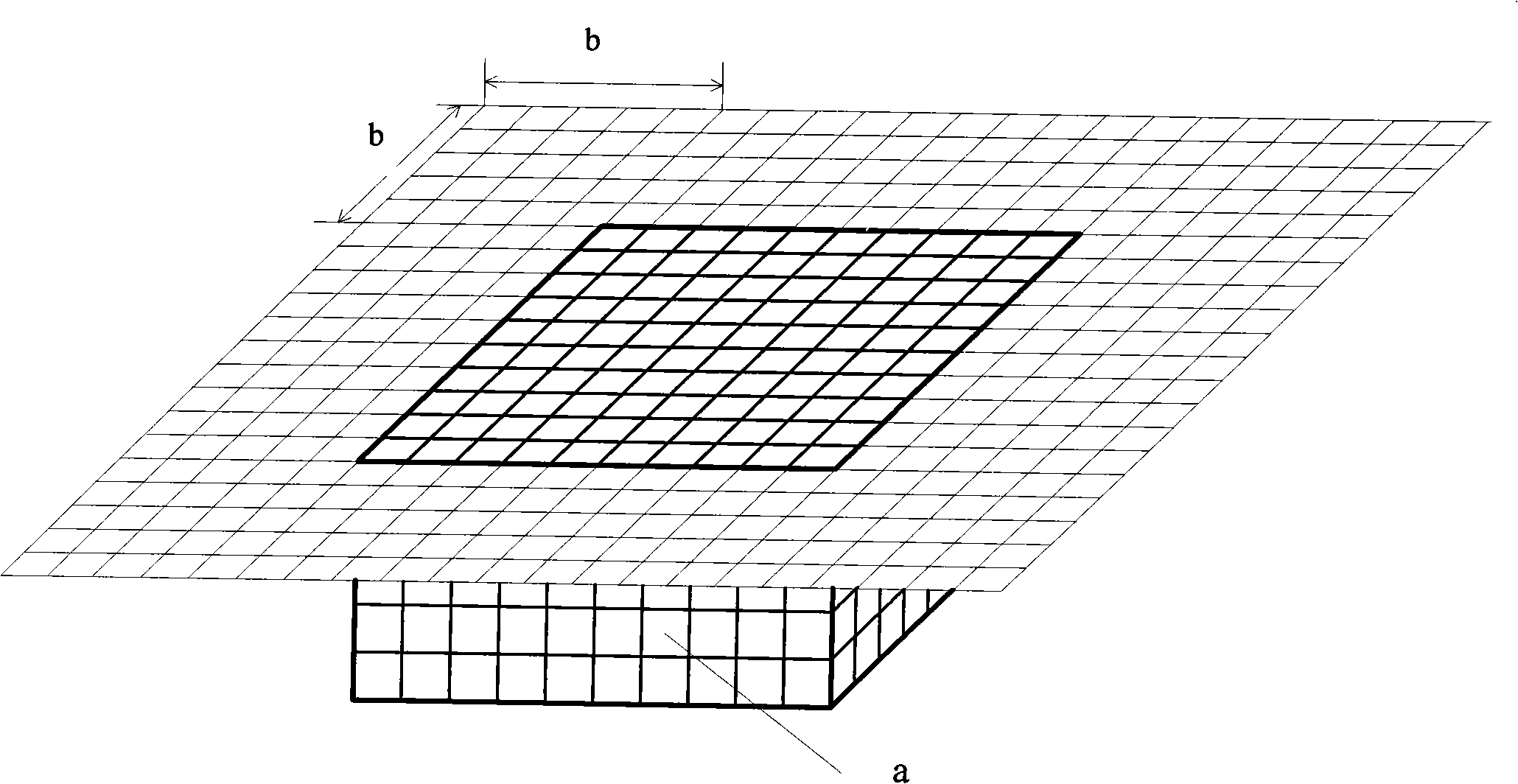

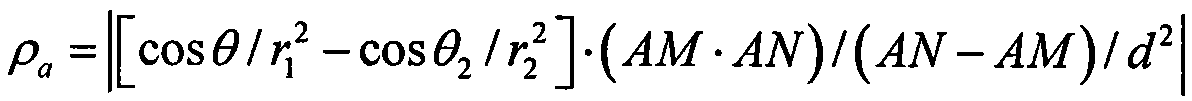

Three-dimensional high definition electric resistivity exploration and direct imaging method

InactiveCN101334484AAchieve multiple coverage measurementsImprove detection accuracyElectric/magnetic detectionAcoustic wave reradiationHigh densityInterference resistance

The invention discloses a three-dimensional high-resolution resistivity prospecting and direct imaging method, the main content is to use a unipolar-dipole device for forming a mutually crossed orthogonal observation system in a total test area; the application of the three-dimensional high-resolution resistivity prospecting and direct imaging method can overcome the problems that the existing two-dimensional high-resolution resistivity prospecting method has inaccurate tunnel positioning and undetermined tunnel shape caused by the side effects. Compared with the general three-dimensional high-density resistivity prospecting method, the three-dimensional high-resolution resistivity prospecting and direct imaging method has high sensitivity to underground tunnels, thereby truly realizing the multiple coverage measurements of underground analysis and distinguishing units, having stronger anti-interference and static offset removing capabilities and easily realizing the rolling measurement and the seamless connection of the test area. The three-dimensional direct imaging method is fast and effective, and has no problem of difficult convergence. The method can obtain more precise information of the positions, the sizes and the shapes of the underground tunnels, thereby having great significance for the study of the shallow fine geological structure.

Owner:JIANGSU UNIV

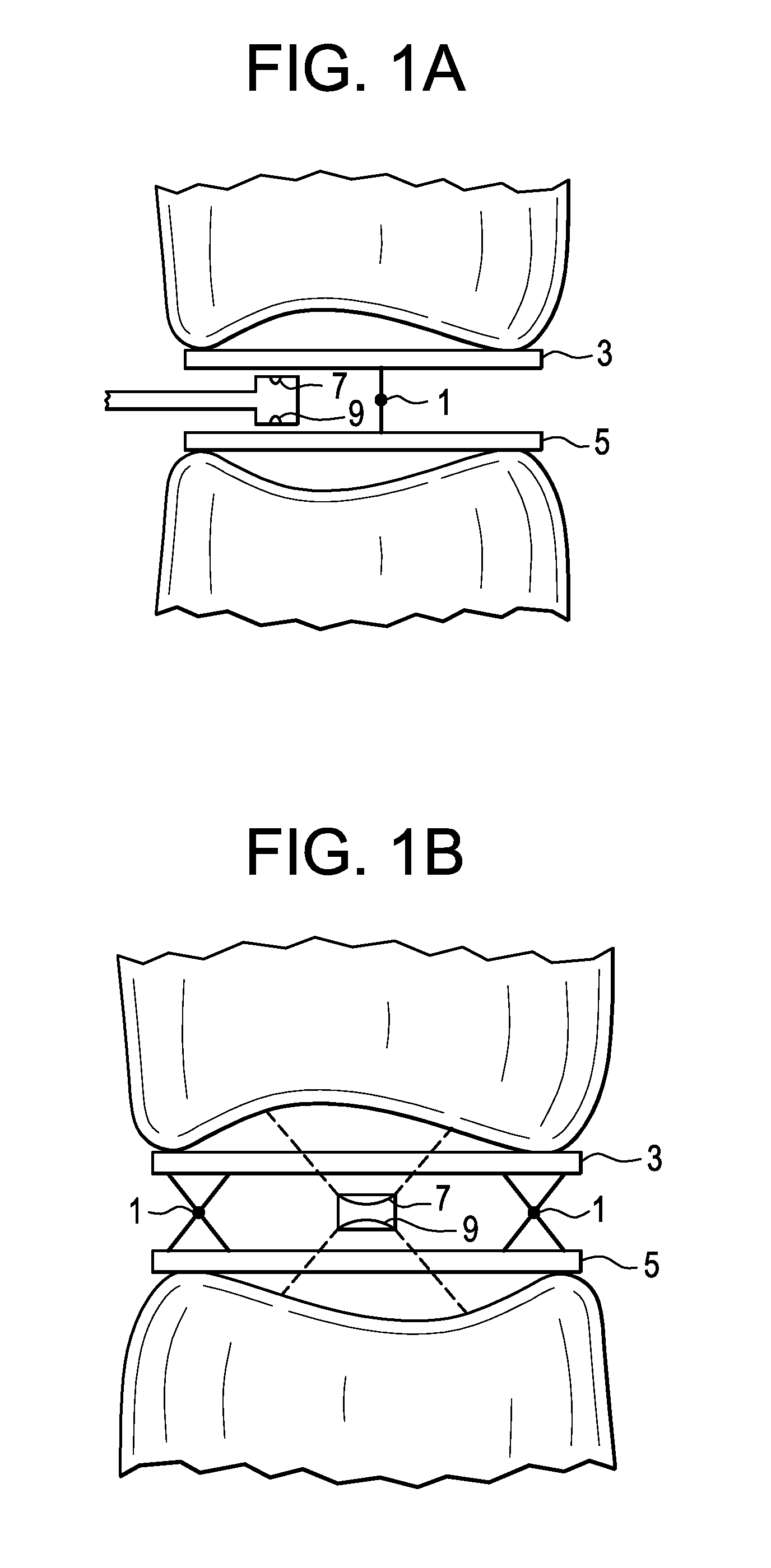

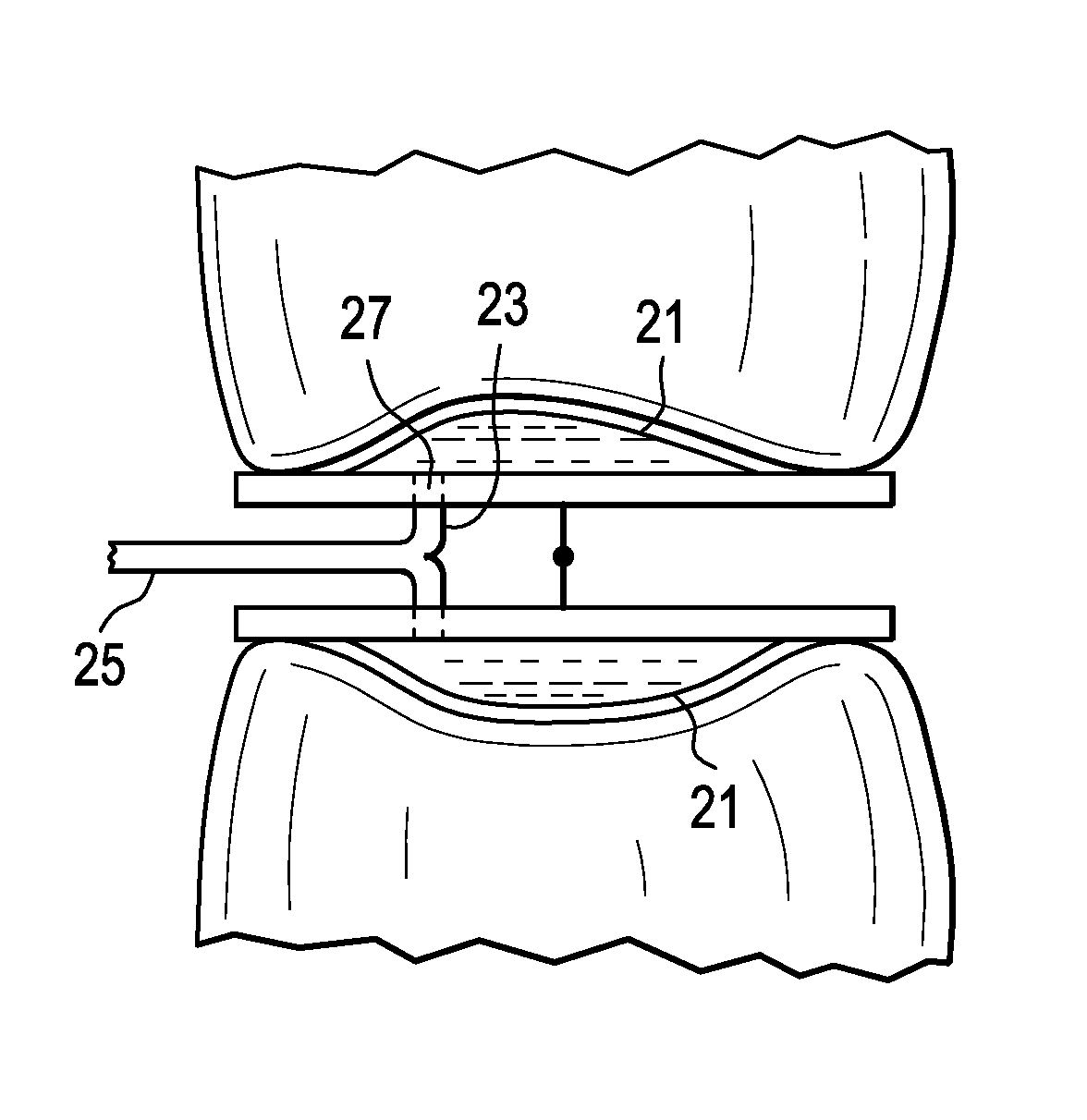

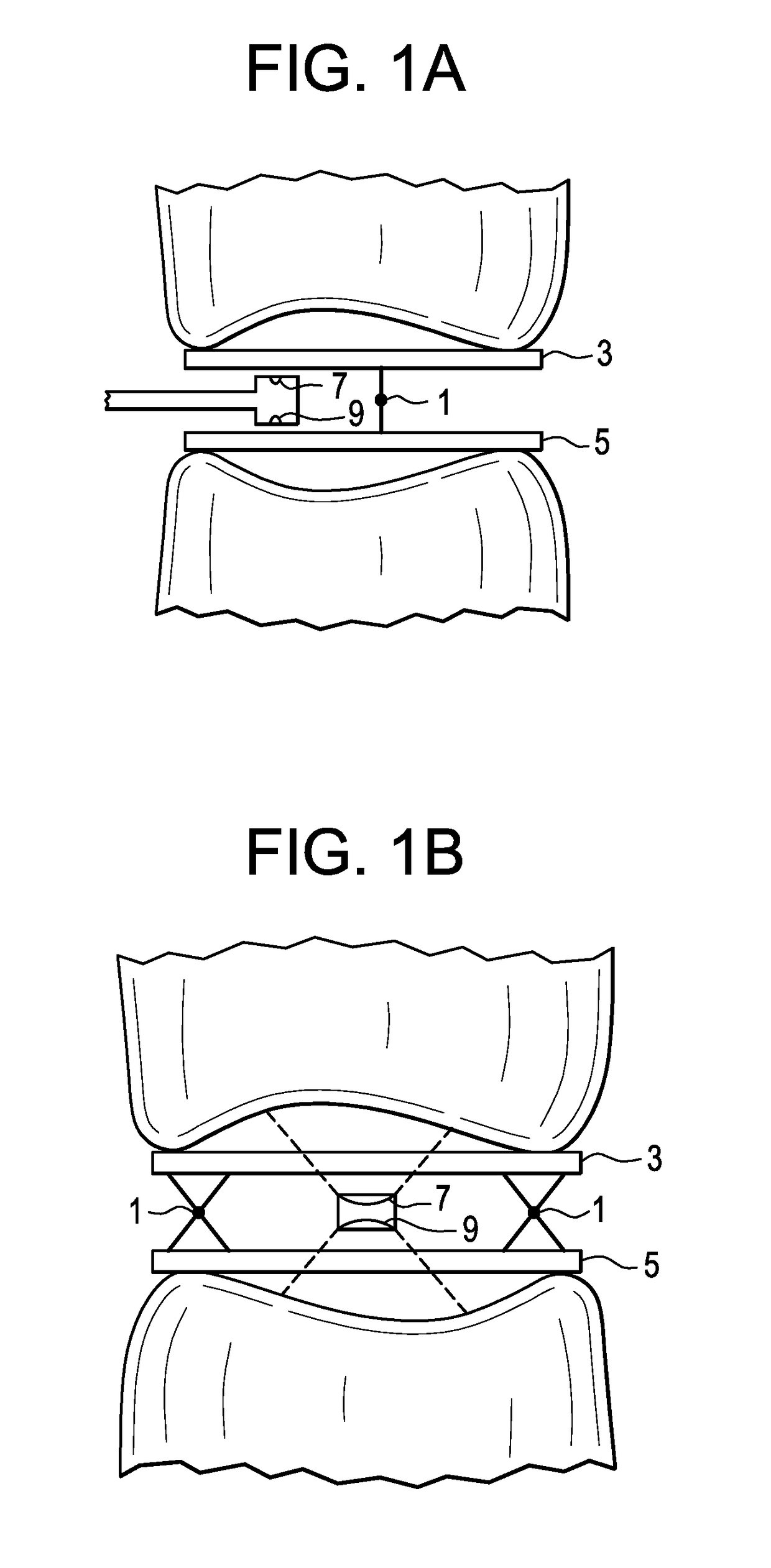

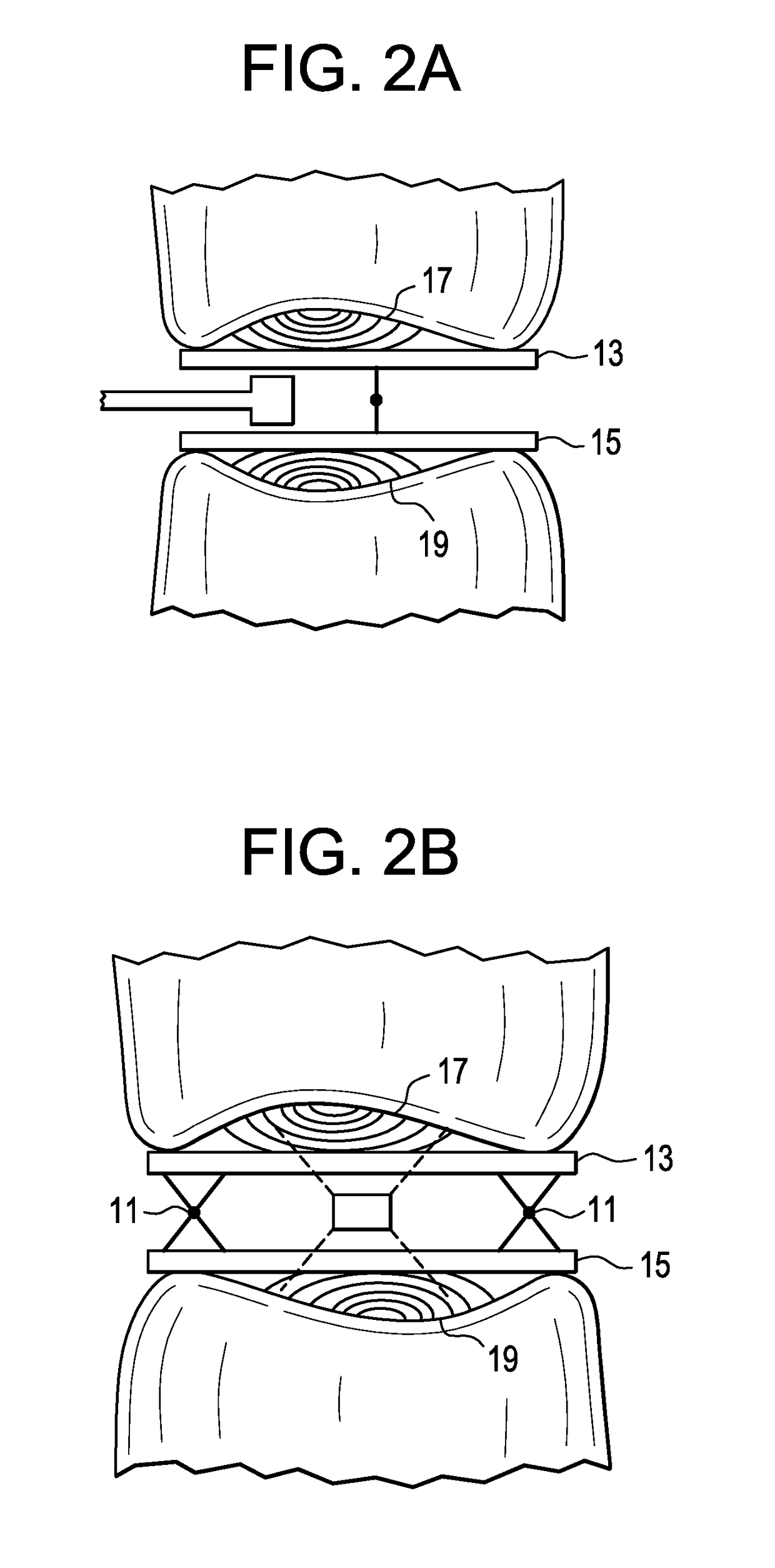

Patient-Specific Spinal Fusion Cage and Methods of Making Same

ActiveUS20150305878A1Maximize contact areaReduce subsidenceMusculoskeletal system evaluationCatheterSpinal columnFluoroscopic imaging

A method of determining disc space geometry with the use of an expandable trial having endplate-mapping capabilities. An expandable trial is inserted into the disc space and its height is adjusted to obtain the desired decompression and spinal alignment (which is typically confirmed with the use of CT or Fluoroscopic imaging). The endplate dome / geometry dome is then determined by one of the following three methods:a) direct imaging through the trial,b) balloon moldings filled with flowable in-situ fluid (for example, silicon, polyurethane, or PMMA) from superior / inferior endplates orc) light-based imaging through superior & inferior balloons.

Owner:DEPUY SYNTHES PROD INC

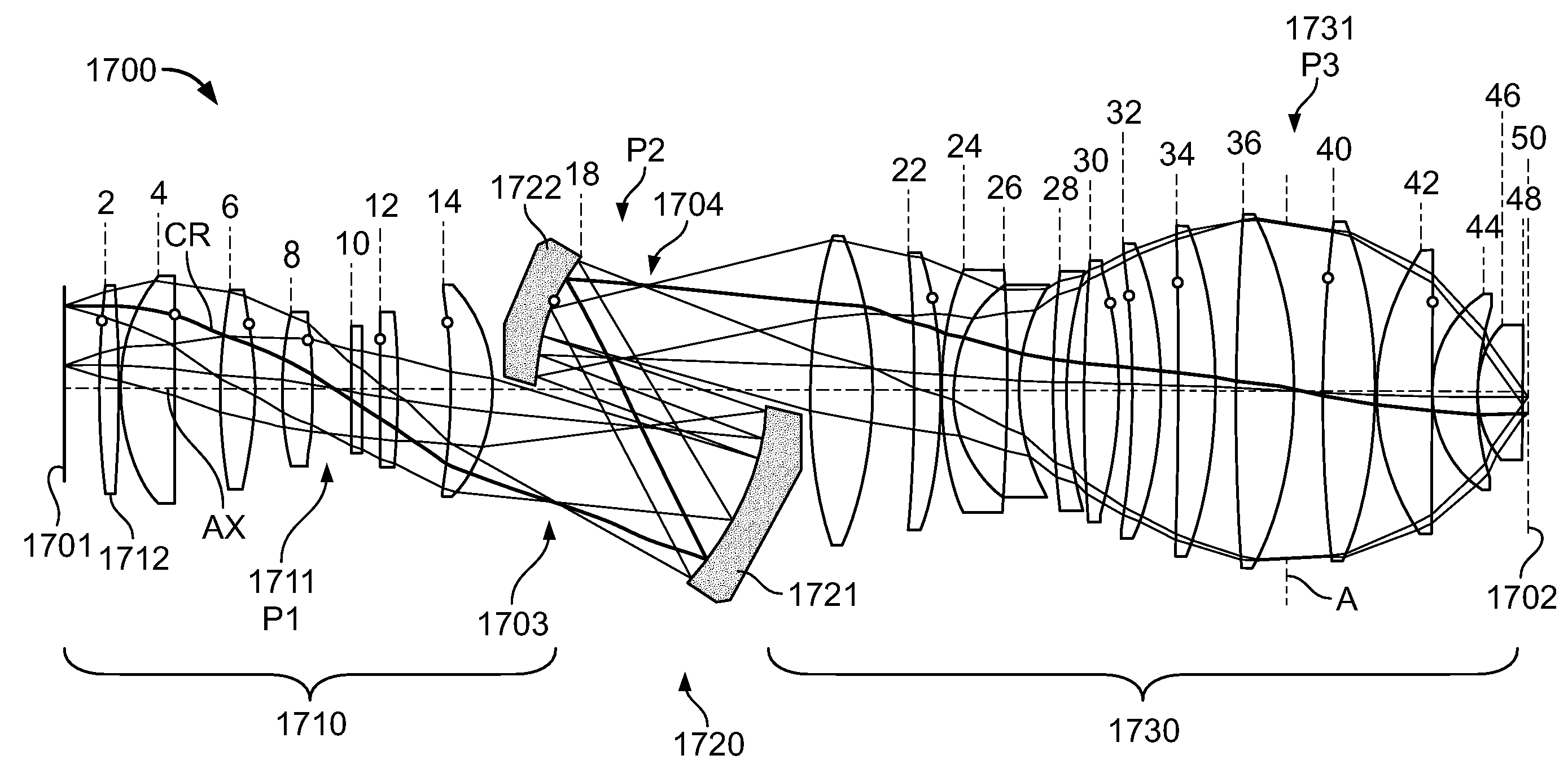

Catadioptric projection objective

InactiveUS20080151365A1High image side numerical apertureSmall amountPhotomechanical apparatusMicroscopesIntermediate imageHigh numerical aperture

A catadioptric projection objective for imaging a pattern provided in an object plane of the projection objective onto an image plane of the projection objective comprises: a first objective part for imaging the pattern provided in the object plane into a first intermediate image; a second objective part for imaging the first intermediate imaging into a second intermediate image; a third objective part for imaging the second intermediate imaging directly onto the image plane;wherein a first concave mirror having a first continuous mirror surface and at least one second concave mirror having a second continuous mirror surface are arranged upstream of the second intermediate image;pupil surfaces are formed between the object plane and the first intermediate image, between the first and the second intermediate image and between the second intermediate image and the image plane; andall concave mirrors are arranged optically remote from a pupil surface. The system has potential for very high numerical apertures at moderate lens material mass consumption.

Owner:CARL ZEISS SMT GMBH

Patient-Specific Spinal Fusion Cage and Methods of Making Same

ActiveUS20170354510A1Maximize contact areaReduces expulsionMusculoskeletal system evaluationSurgeryFluoroscopic imagingDirect imaging

A method of determining disc space geometry with the use of an expandable trial having endplate-mapping capabilities. An expandable trial is inserted into the disc space and its height is adjusted to obtain the desired decompression and spinal alignment (which is typically confirmed with the use of CT or Fluoroscopic imaging). The endplate dome / geometry dome is then determined by one of the following three methods:a) direct imaging through the trial,b) balloon moldings filled with flowable in-situ fluid (for example, silicon, polyurethane, or PMMA) from superior / inferior endplates orc) light-based imaging through superior & inferior balloons.

Owner:DEPUY SYNTHES PROD INC

Respiratory referenced imaging

InactiveUS20050187464A1Accurate measurementUltrasonic/sonic/infrasonic diagnosticsMagnetic measurementsRespiratory gatingSonification

Methods, systems and devices are presented that provide improved medical diagnostic and intervention procedures such as magnetic resonance imaging, cardiac imaging, cardiac nuclear scintigraphy, computed tomography, echocardiography, imaging to direct laser ablation, imaging to direct radio frequency radiation ablation, imaging to direct gamma knife radiation therapy, and imaging to direct radiation therapy by respiratory gating. In a preferred embodiment, one or more balloon pressure probes within a catheter are placed into the esophagus and detect pressure within the esophagus to infer respiratory air-flow. Other probes such as those based on fiber optics and other useful materials are described. Many of these devices interact poorly or not at all with magnetic and electromagnetic fields, and are particularly useful for use in respiratory gating of MRI.

Owner:THE HENRY M JACKSON FOUND FOR THE ADVANCEMENT OF MILITARY MEDICINE INC

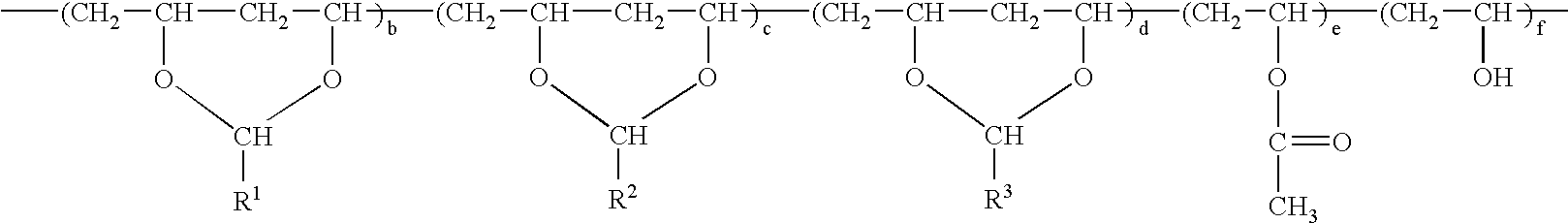

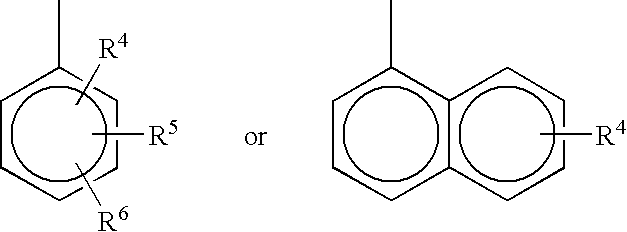

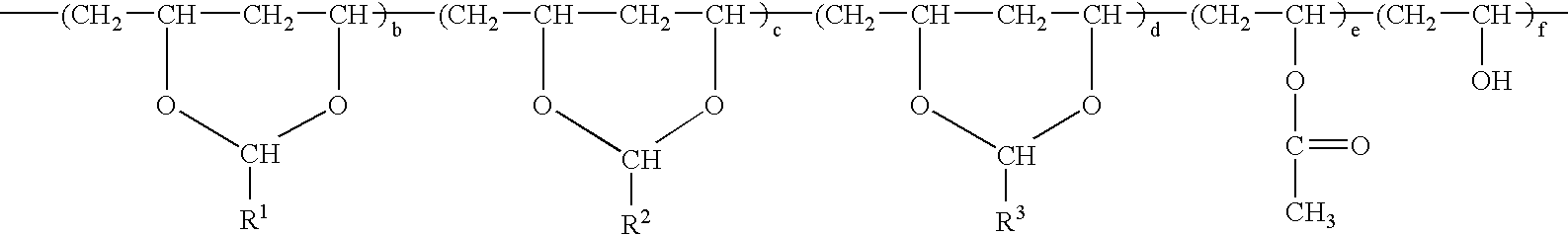

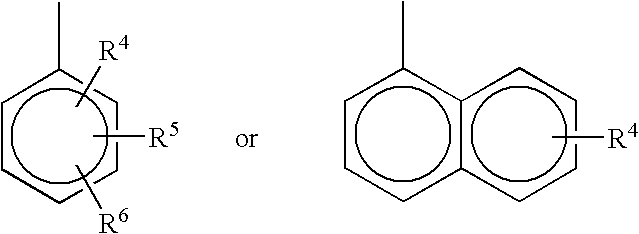

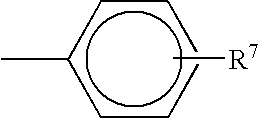

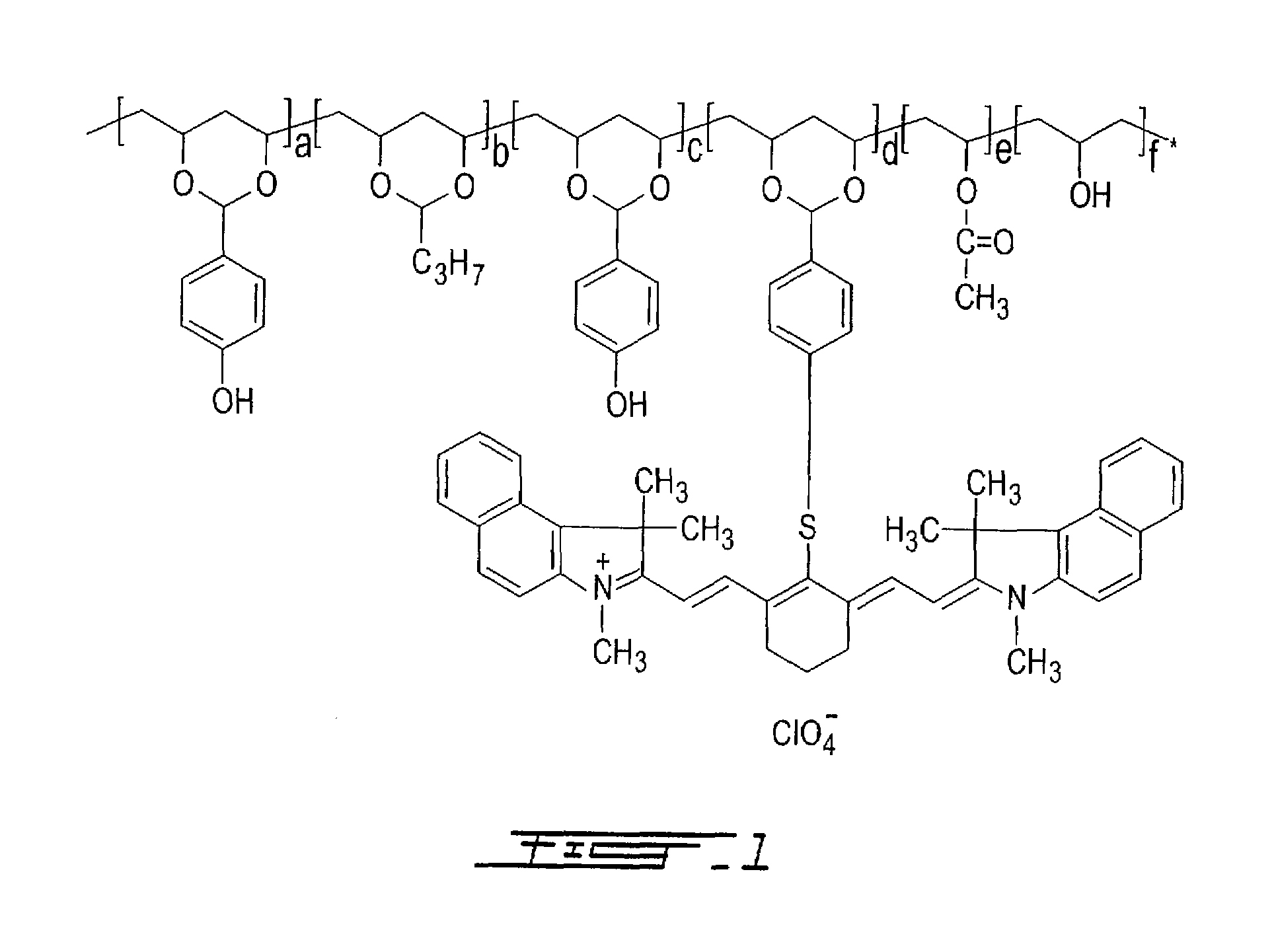

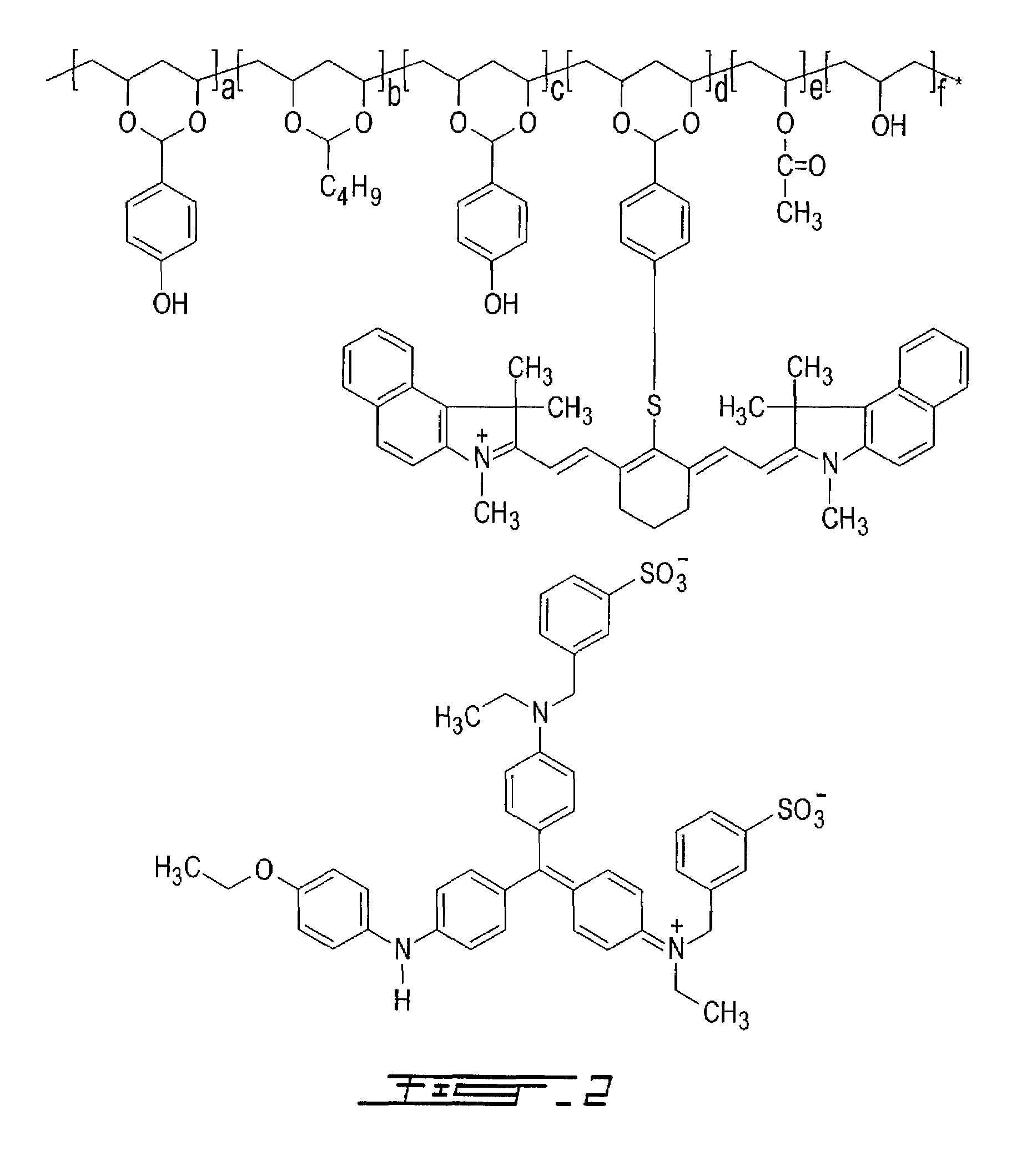

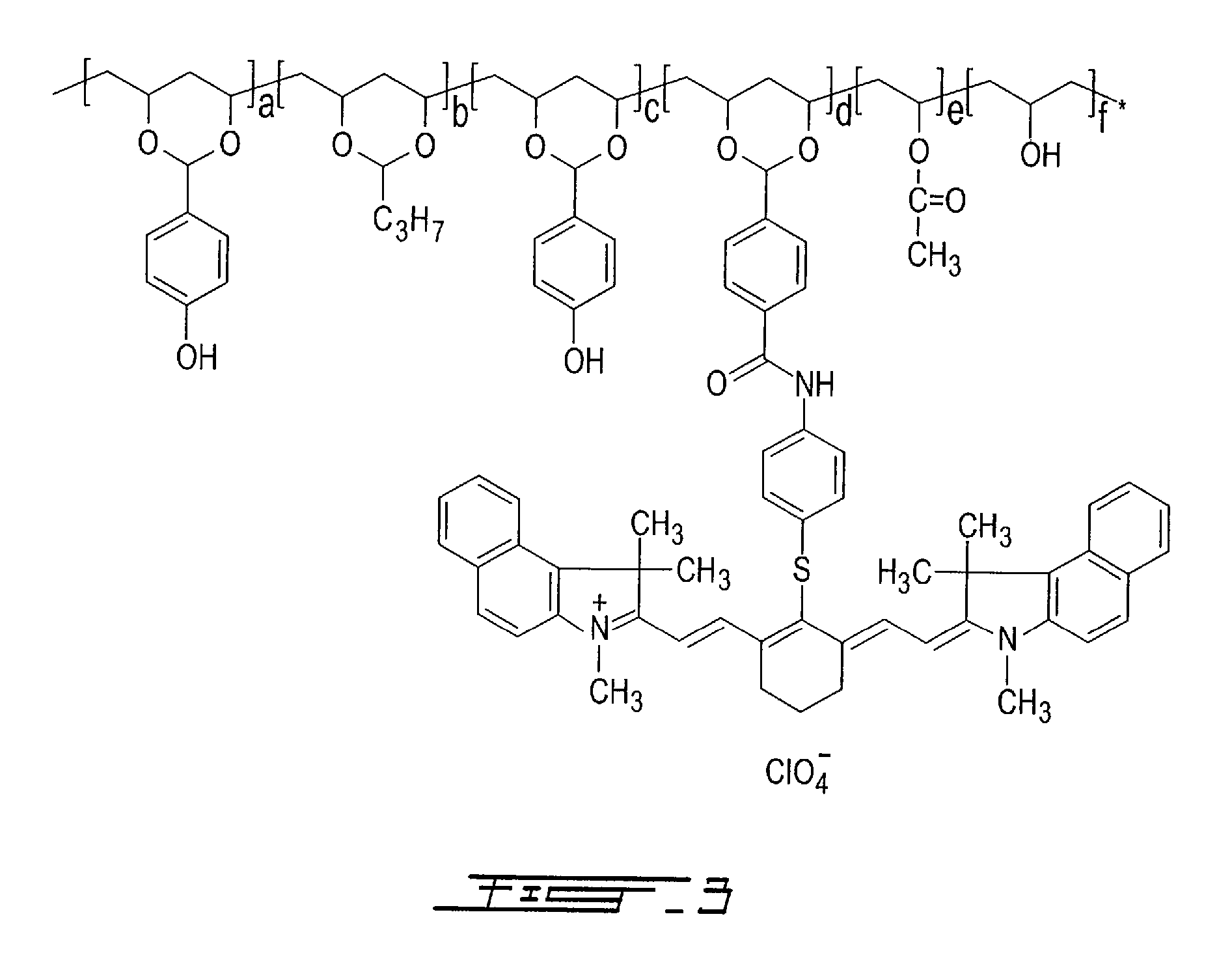

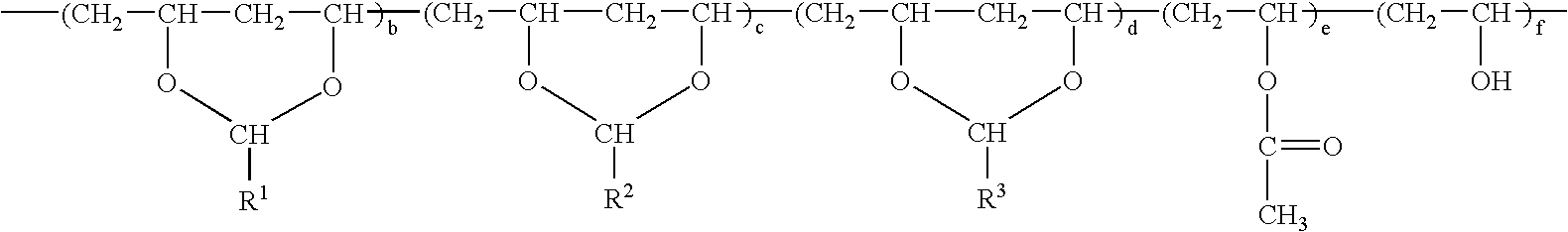

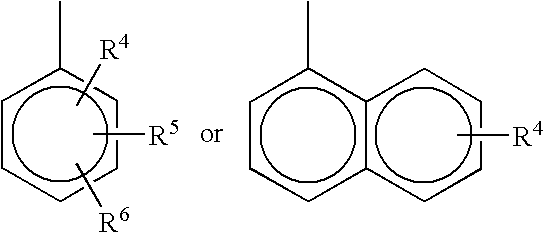

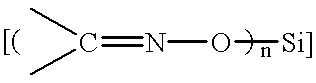

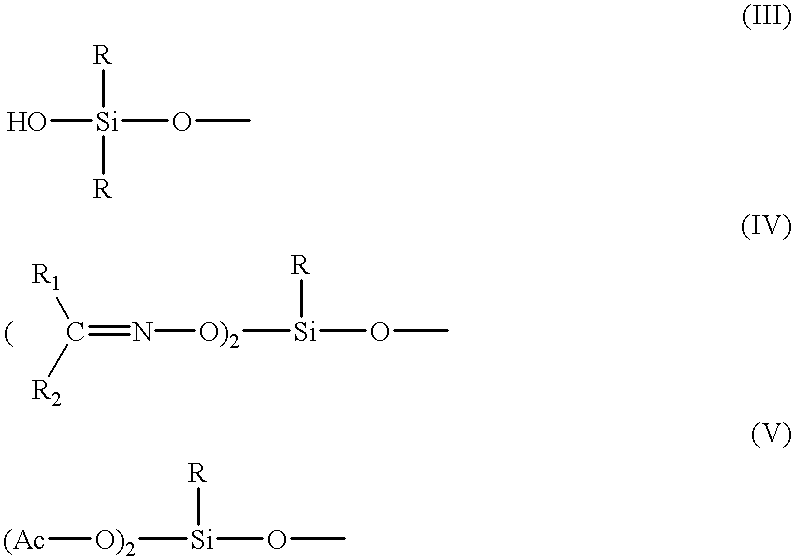

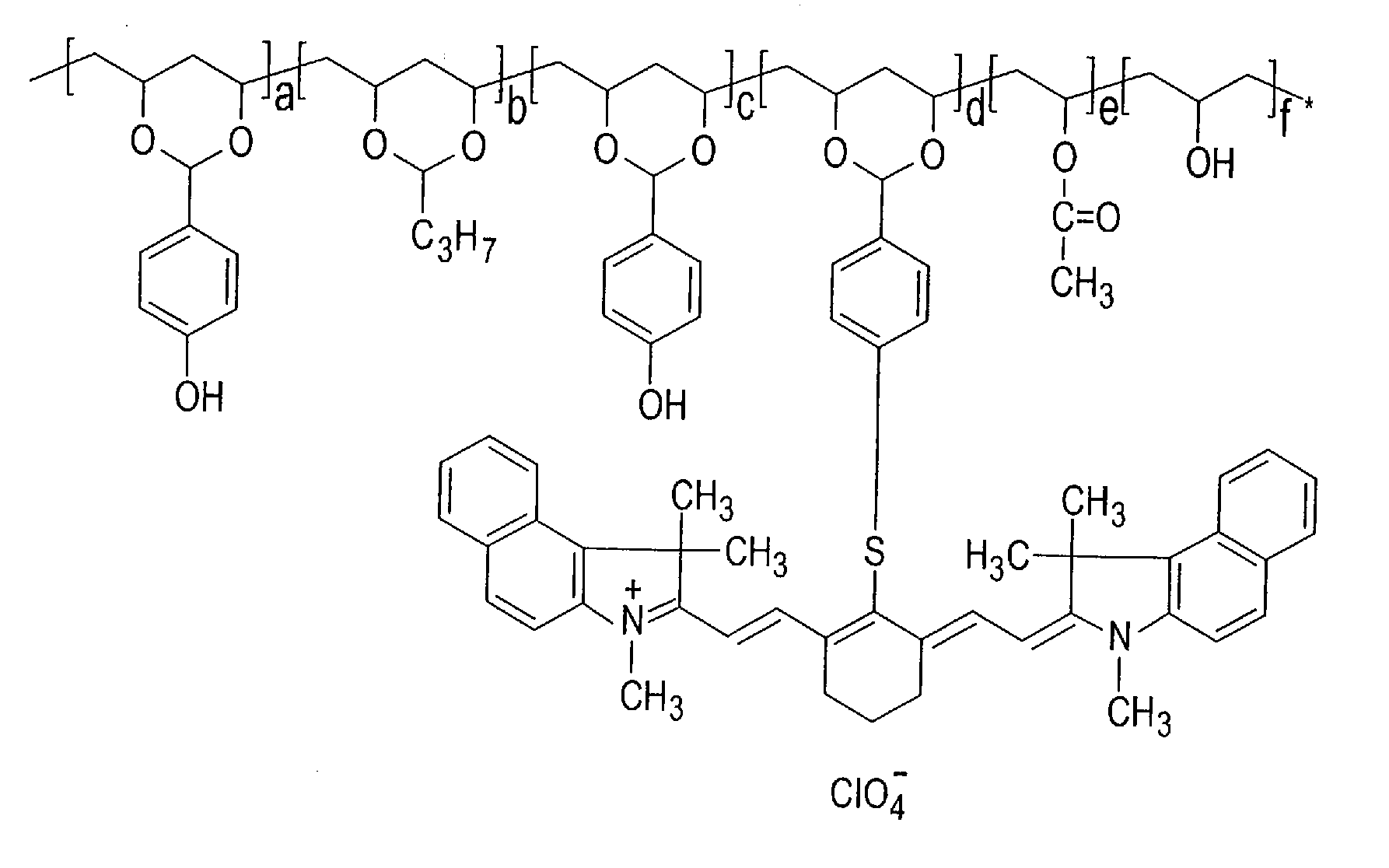

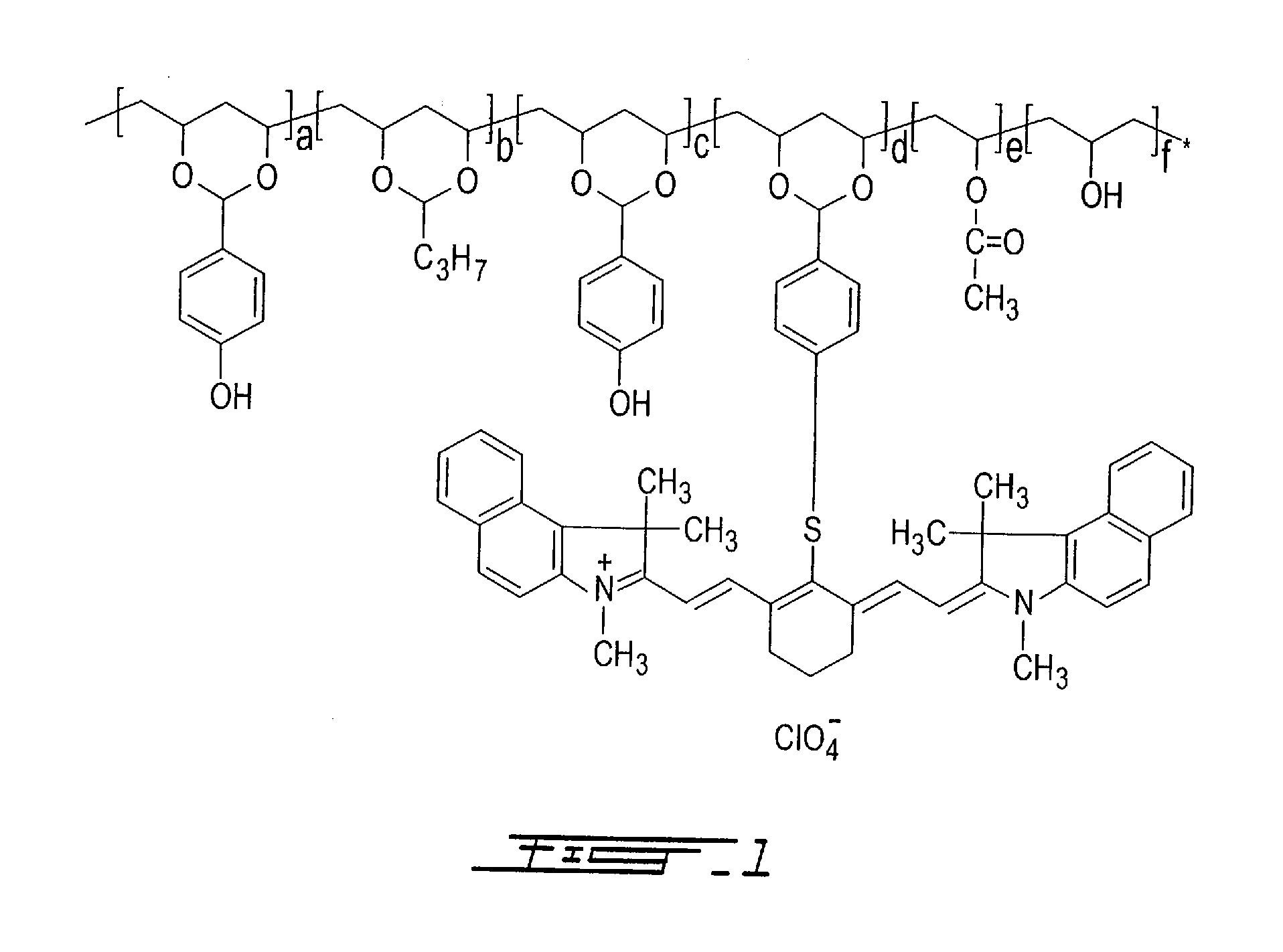

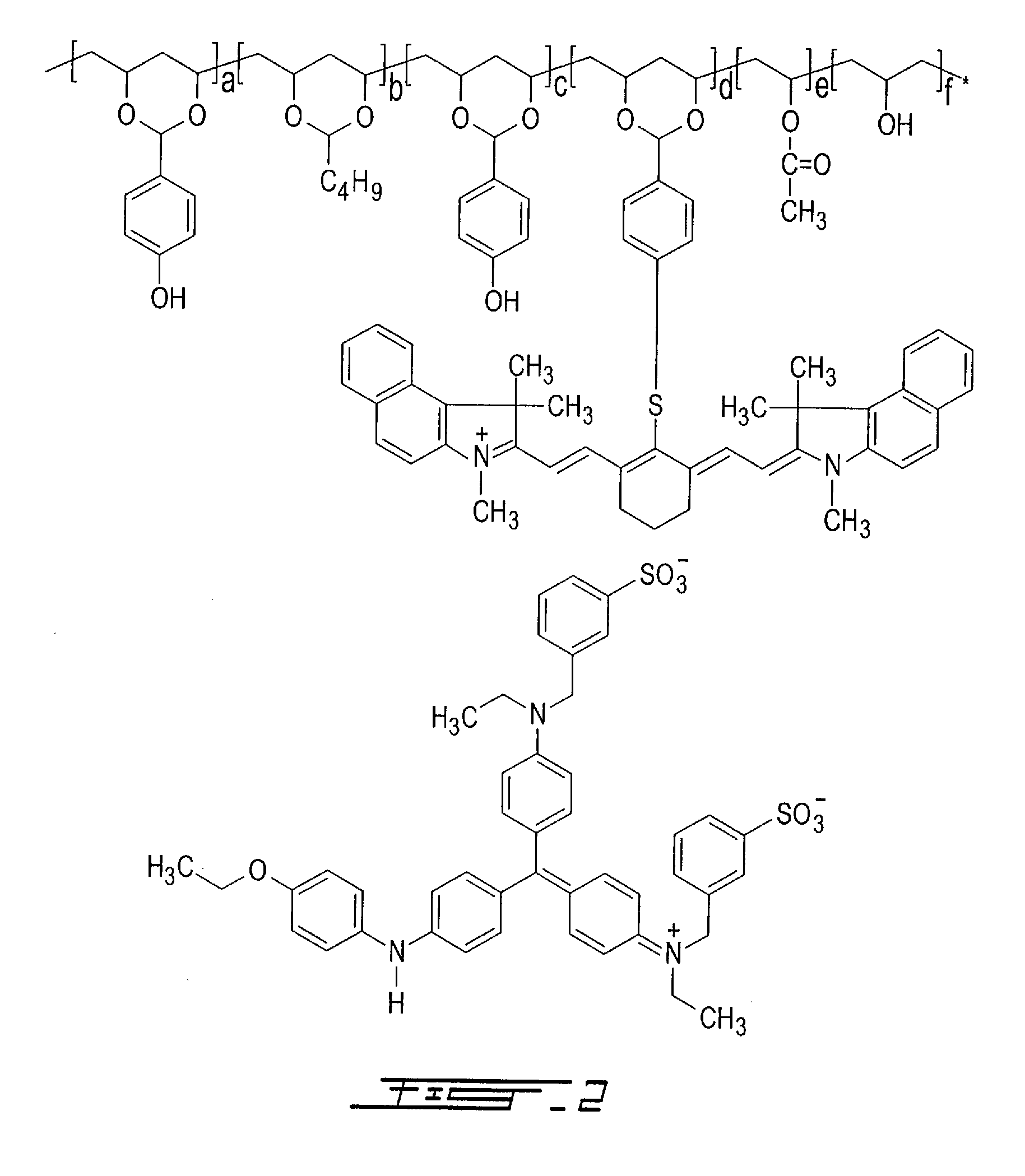

Thermally reactive near-infrared absorbing acetal copolymers, methods of preparation and methods of use

InactiveUS7473515B2Photosensitive materialsSemiconductor/solid-state device manufacturingGum printingAcetal copolymer

Described herein are novel thermally reactive near-infrared absorbing acetal copolymers that undergo chemical and physical changes upon exposure to near-infrared radiation. Also described are the methods of preparation of the novel acetal copolymers starting either with vinyl-alcohol polymers or with acetal copolymers. Also described are the methods of use of the new near-infrared absorbing acetal copolymers in coatings used in lithographic offset printing plates that can be directly imaged with near-infrared laser imaging devices in computer-to-plate and digital offset printing technologies. The novel acetal copolymers are also useful in photoresist applications, rapid prototyping of printed circuit boards and chemical sensor development.

Owner:AMERICAN DYE SOURCE

Development of radiation-sensitive elements

InactiveUS20060154187A1Easily rinse awayModerates aggressivenessPhotomechanical apparatusOriginals for photomechanical treatmentSodium metasilicatePolyvinyl alcohol

An aqueous alkaline developer for use with an imaged lithographic printing precursor comprises an aqueous alkaline medium, sodium metasilicate, a steric or electrosteric stabilizer, and a rinse aid or a phase stabilizer. It is suited for developing a lithographic printing precursor comprising, on a substrate, a coated and dried layer of a radiation-sensitive composition comprising one or more acetal resins. The developer may further contain a moderator, a dispersing agent capable of solvating a hydrophobic image colorant, and a wetting agent. The acetal resin of the precursor may be derived from polyvinyl alcohol by condensation with aldehydes. The imageable element is imageable by radiation, preferably infrared radiation, and provides good sensitivity for use in lithographic applications, such as conventional imaging systems, computer-to-plate systems or other direct imaging elements and applications when treated with the developer. The invention also provides a positive-working lithographic printing master comprising a precursor as aforesaid, imaged and developed with the developer. The invention further provides a method for cleaning the processor equipment in which the imaged lithographic printing precursor has been developed, comprising treating the deposit with an acid to yield liberated image colorant and treating the liberated image colorant with a cleaning composition.

Owner:KODAK GRAPHIC COMM CANADA CO

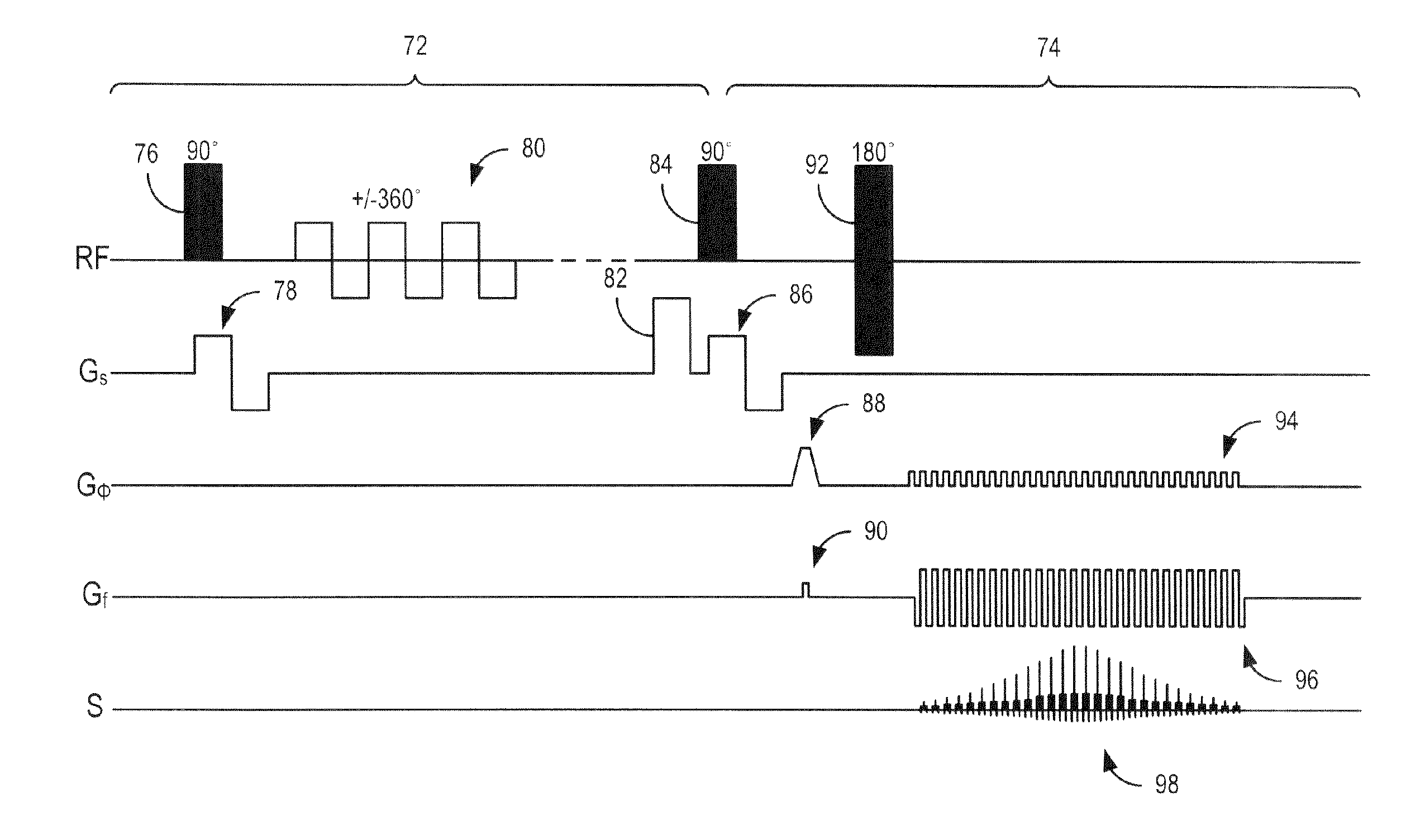

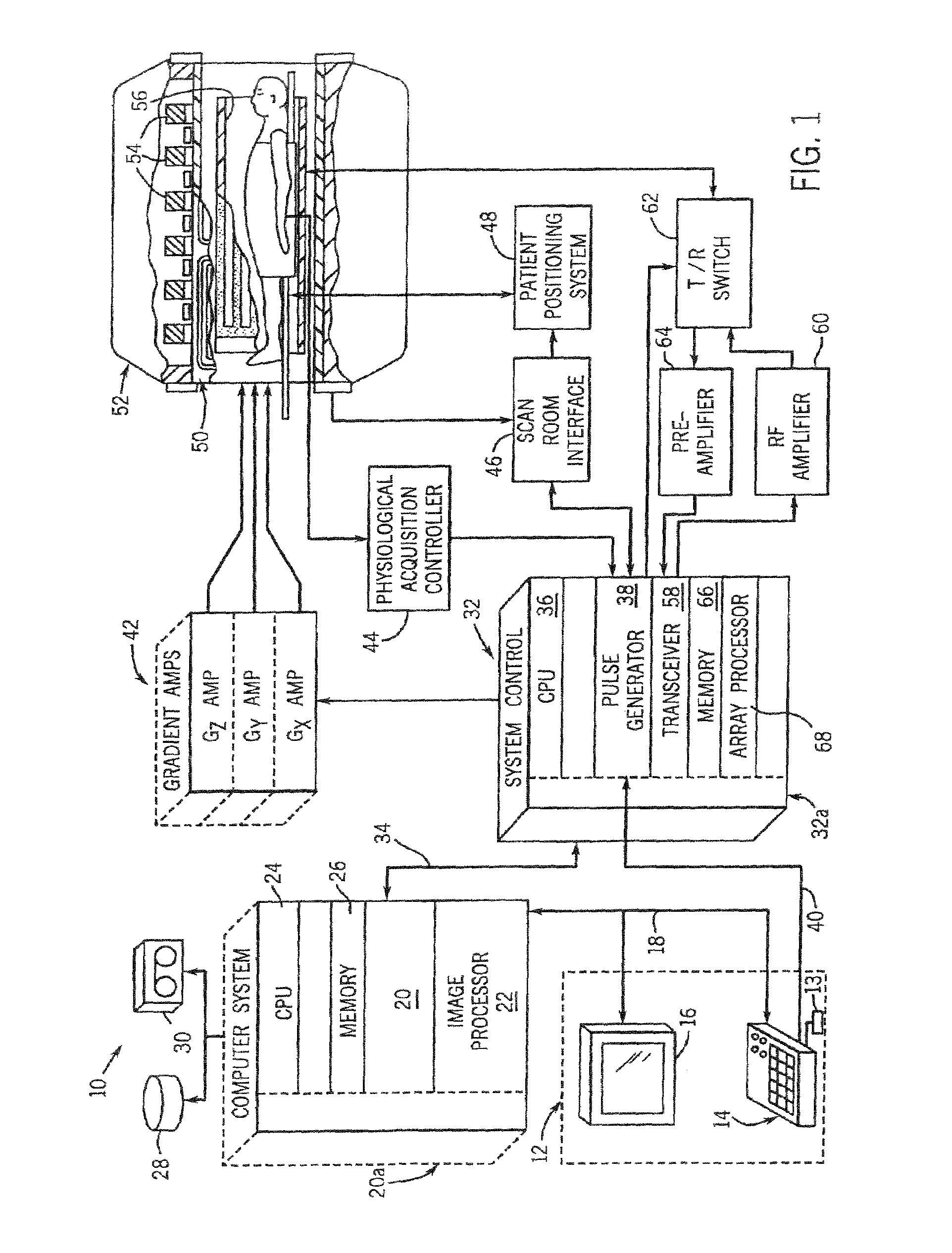

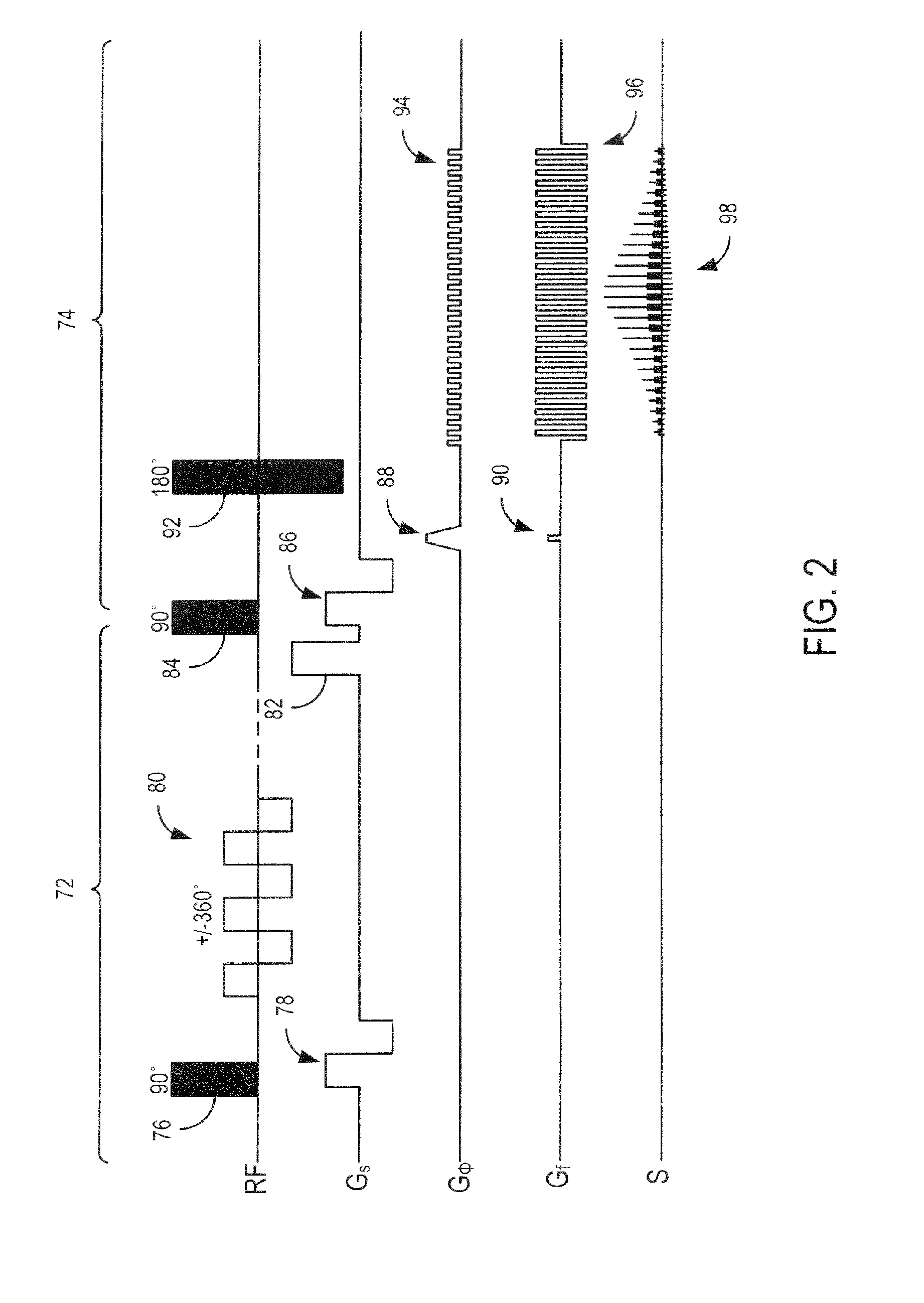

Method and apparatus of background suppression in MR imaging using spin locking

ActiveUS7064545B2Efficient magnetizationLongitudinal magnetization regrowth is minimizedMagnetic measurementsElectric/magnetic detectionBlood flowTransverse magnetization

The present invention is directed to a method and system of tissue or background suppression for the acquisition of image data from blood flow or tissue perfusion. Background suppression with minimal effects upon inflowing spins is achieved through a series of spin locking low level RF pulses that cause adiabatic demagnetization of tissue with a relaxation time T1-rho that is intermediate between T1 and T2 relaxation times. In this regard, the effective transverse magnetization of static tissue resulting from the application of a series of low level RF pulses is reduced and, with the spin locking, longitudinal magnetization regrowth is minimized. As such, inflowing spins to an imaging volume may be directly imaged with significant background tissue suppression. The present invention is particularly applicable to time-of-flight MRA and MR perfusion imaging.

Owner:RGT UNIV OF CALIFORNIA +2

Patient-specific spinal fusion cage and methods of making same

ActiveUS9757245B2Maximize contact areaReduces expulsionMusculoskeletal system evaluationInternal osteosythesisSpinal columnFluoroscopic imaging

A method of determining disc space geometry with the use of an expandable trial having endplate-mapping capabilities. An expandable trial is inserted into the disc space and its height is adjusted to obtain the desired decompression and spinal alignment (which is typically confirmed with the use of CT or Fluoroscopic imaging). The endplate dome / geometry dome is then determined by one of the following three methods:a) direct imaging through the trial,b) balloon moldings filled with flowable in-situ fluid (for example, silicon, polyurethane, or PMMA) from superior / inferior endplates orc) light-based imaging through superior & inferior balloons.

Owner:DEPUY SYNTHES PROD INC

Directly imageable waterless planographic printing plate

InactiveUS6194122B1High sensitivityReduce sensitivityPhotomechanical apparatusPhotosensitive material auxillary/base layersDirect imagingEngineering

A directly imageable waterless planographic printing plate precursor is a laminate of, in turn, at least a heat sensitive layer and a silicon rubber layer on a substrate. The heat sensitive layer includes (A) a light-to-heat converting material and (B) a compound which contains N-N bonds.

Owner:TORAY IND INC

Thermally reactive near-infrared absorbing acetal copolymers, methods of preparation and methods of use

InactiveUS20060275698A1Photosensitive materialsSemiconductor/solid-state device manufacturingAcetal copolymerNear infrared radiation

Described herein are novel thermally reactive near-infrared absorbing acetal copolymers that undergo chemical and physical changes upon exposure to near-infrared radiation. Also described are the methods of preparation of the novel acetal copolymers starting either with vinyl-alcohol polymers or with acetal copolymers. Also described are the methods of use of the new near-infrared absorbing acetal copolymers in coatings used in lithographic offset printing plates that can be directly imaged with near-infrared laser imaging devices in computer-to-plate and digital offset printing technologies. The novel acetal copolymers are also useful in photoresist applications, rapid prototyping of printed circuit boards and chemical sensor development.

Owner:AMERICAN DYE SOURCE

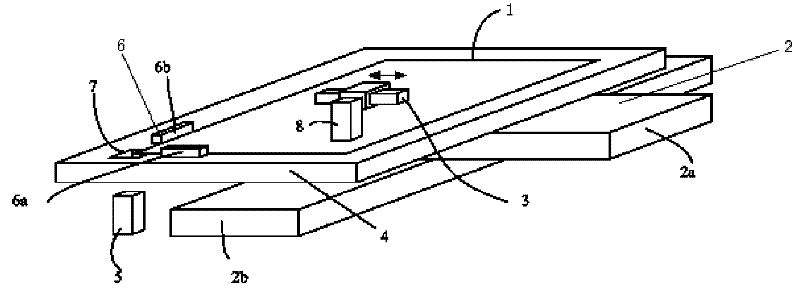

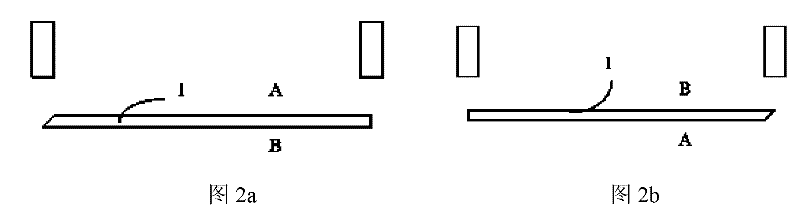

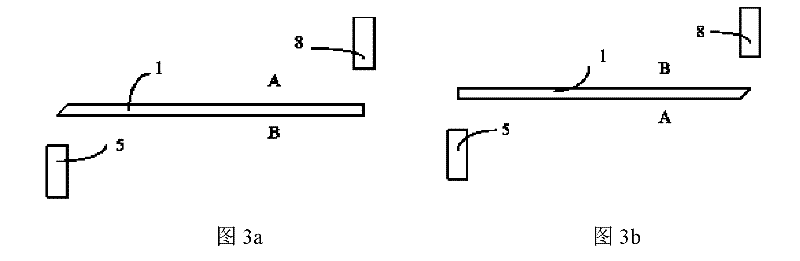

A device and method for double-sided alignment of an inner layer board

InactiveCN102262358ASimple production processImprove alignment accuracyPhotomechanical exposure apparatusMicrolithography exposure apparatusImaging processingDirect imaging

The invention discloses a double-side aligning device and method for an inner plate, which is suitable for a laser direct imaging system (LDI). In order to reduce the time required for alignment, at least two sets of image acquisition devices are used to simultaneously measure the alignment marks, one of which is installed above the stage, and the other image acquisition device is installed below the stage. In order to meet the requirements of fast alignment of inner boards of different sizes, one image acquisition device is fixed, and the other image acquisition device is installed on a single-axis moving mobile platform. Using the method of image processing, the feature points at the corners of the inner board are extracted for double-sided alignment.

Owner:HEFEI ADVANTOOLS SEMICON

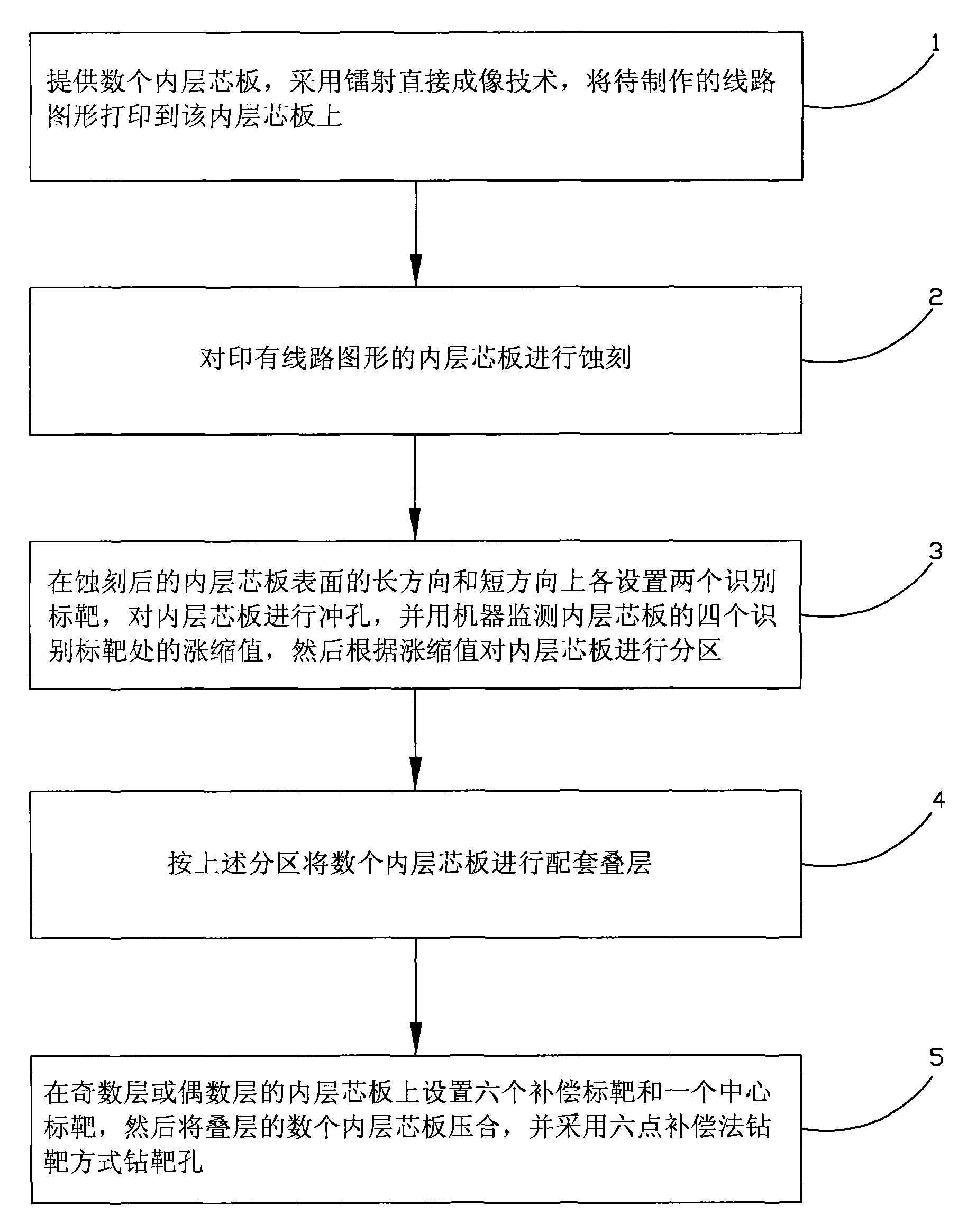

Method for making high alignment printed circuit board

ActiveCN101668389AHigh control precisionEasy alignmentConductive material chemical/electrolytical removalMultilayer circuit manufactureDirect imagingEngineering

The invention relates to a method for making a high collimation printed circuit board, comprising the following steps: step 1. providing a plurality of internal layer core plates, and printing circuitpatterns to be made onto the internal layer core plates by adopting a laser direct imaging technique; step 2. etching the internal layer core plates printed with the circuit patterns; step 3. respectively arranging two identifying targets for punching holes on the internal layer core plates in the long direction and short direction of the surfaces of the etched internal layer core plates, monitoring the expansion and shrinkage values of four identifying targets of the internal layer core plates by using a machine, and then partitioning the internal layer core plates according to the expansionand shrinkage values; step 4. matching and overlaying the plurality of internal layer core plates according to the partitions; and step 5. arranging six compensation targets and a central target on the internal layer core plates of odd layers or even layers, then pressing the plurality of overlaid internal layer core plates and drilling target holes by adopting a target drilling mode of six-pointcompensation method. With the method, the quality of the printed circuit board products can be effectively monitored, so that the invention is propitious to the improvement of the alignment of the printed circuit boards.

Owner:DONGGUAN MEADVILLE CIRCUITS

Fiber Optic Interrogated Microslide, Microslide Kits and Uses Thereof

InactiveUS20090161100A1Eliminate the problemEliminates adverse optical effectBioreactor/fermenter combinationsBiological substance pretreatmentsMicroscope slideFiber

The present invention provides a substrate that overcomes the performance limitations of conventional microscope slides, microarrays, or microtiter plates when optically interrogated through the thickness of the substrate. With conventional microscope slides, image quality and resolution are degraded as a result of distortions introduced by imaging through the thickness of the glass. Fiber Optic Interrogated Microslides (FOI) consist of many fiber optics that have been fused together. When sliced and polished to form microscope slides, the fibers effectively transfer optical images from one surface of the microslide to the other. The finished microslide is the optical equivalent of a zero thickness window. The image of an object on the top surface is transferred to the bottom surface allowing it to be viewed without focusing through the thickness of the slide. In addition to providing improved image quality, FOI microslides allow objects to be directly imaged without complex and expensive focusing optics.

Owner:INCOM INC

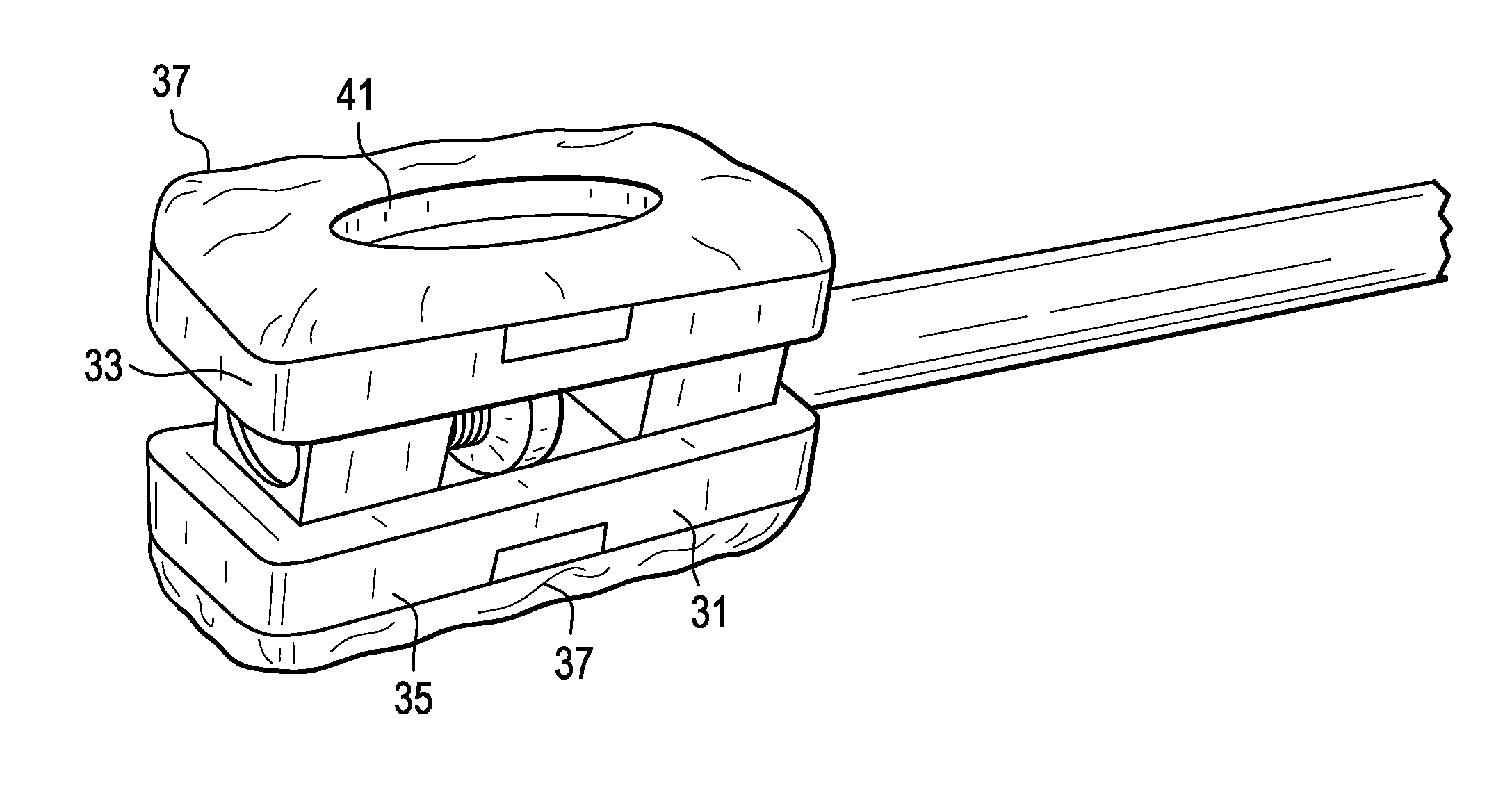

Method and apparatus for removal of tissue

A surgical instrument includes a deflectable cutting element extending from the distal end of the instrument. The deflection of the cutting element is controllable based on a user operating a moveable member of the instrument. The deflectable cutting element is normally disposed within a circumferential region defined by the distal end of the instrument. The moveable member can be moved in relation to the instrument to deflect the deflectable cutting element, such that the cutting element is at least partially outside of the circumferential region. The extent that the cutting element is outside of the circumferential region is a function of the position to which the moveable member is moved in relation to the instrument. The instrument further includes direct imaging of the distal end, such that the deflection of the cutting element for selective removal of bone tissue at the distal end of the instrument can be controlled in real-time.

Owner:HOWMEDICA OSTEONICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com