A device and method for double-sided alignment of an inner layer board

A technology of alignment device and inner layer board, which is applied to the exposure device of photoengraving process, the removal of conductive materials by chemical/electrolytic methods, and the photoengraving process of pattern surface, etc. holes, etc., to simplify the production process, the method is simple, and the alignment accuracy is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

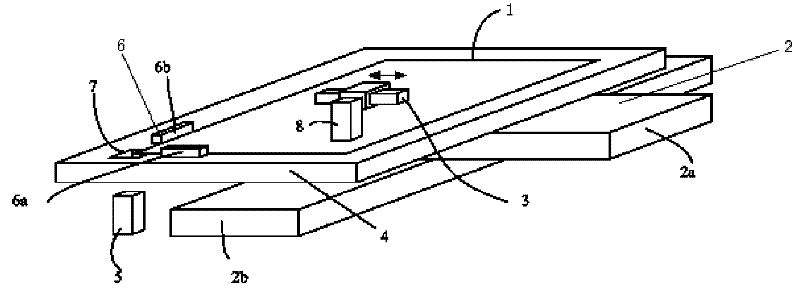

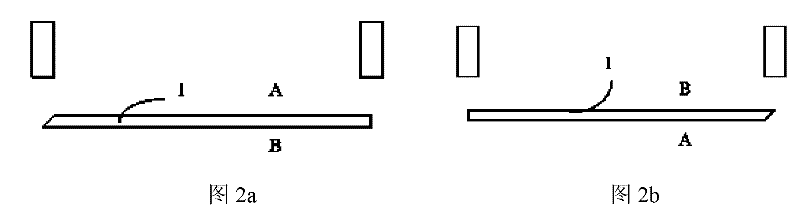

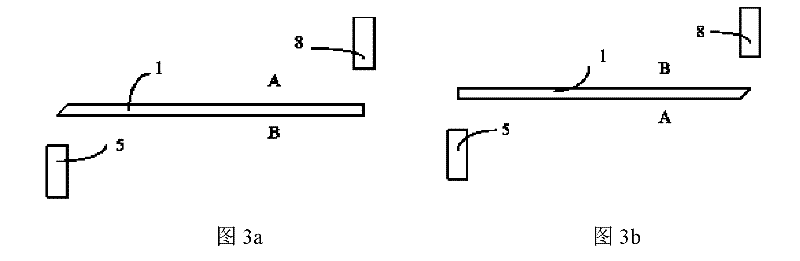

[0029] Such as figure 1 As shown, the alignment device for both sides of the inner plate of the present invention includes: a stage 4, a coarse positioning device 6 composed of a left positioning bar 6a and a lower side positioning bar 6b, and a kinematic pair 2a in the X direction and a Y direction The precision X-Y mobile platform 2 that the motion pair 2b constitutes, the lower image acquisition device 5, the upper image acquisition device 8, the one-dimensional mobile platform 3, the detection through hole 7, the control processing unit ( figure 1 not shown).

[0030] The stage 4 is used to place the circuit board 1 to be exposed, and the circuit board 1 is tightly attached to the stage 4 by vacuum adsorption.

[0031] The positioning bars 6a, 6b are perpendicular to each other and are on the same plane, and are installed on the stage 4 for positioning the circuit board 1 .

[0032] The precision X-Y moving platform 2 is used to move the circuit board 1 to a designated p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com