Patents

Literature

251results about How to "Maximize contact area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

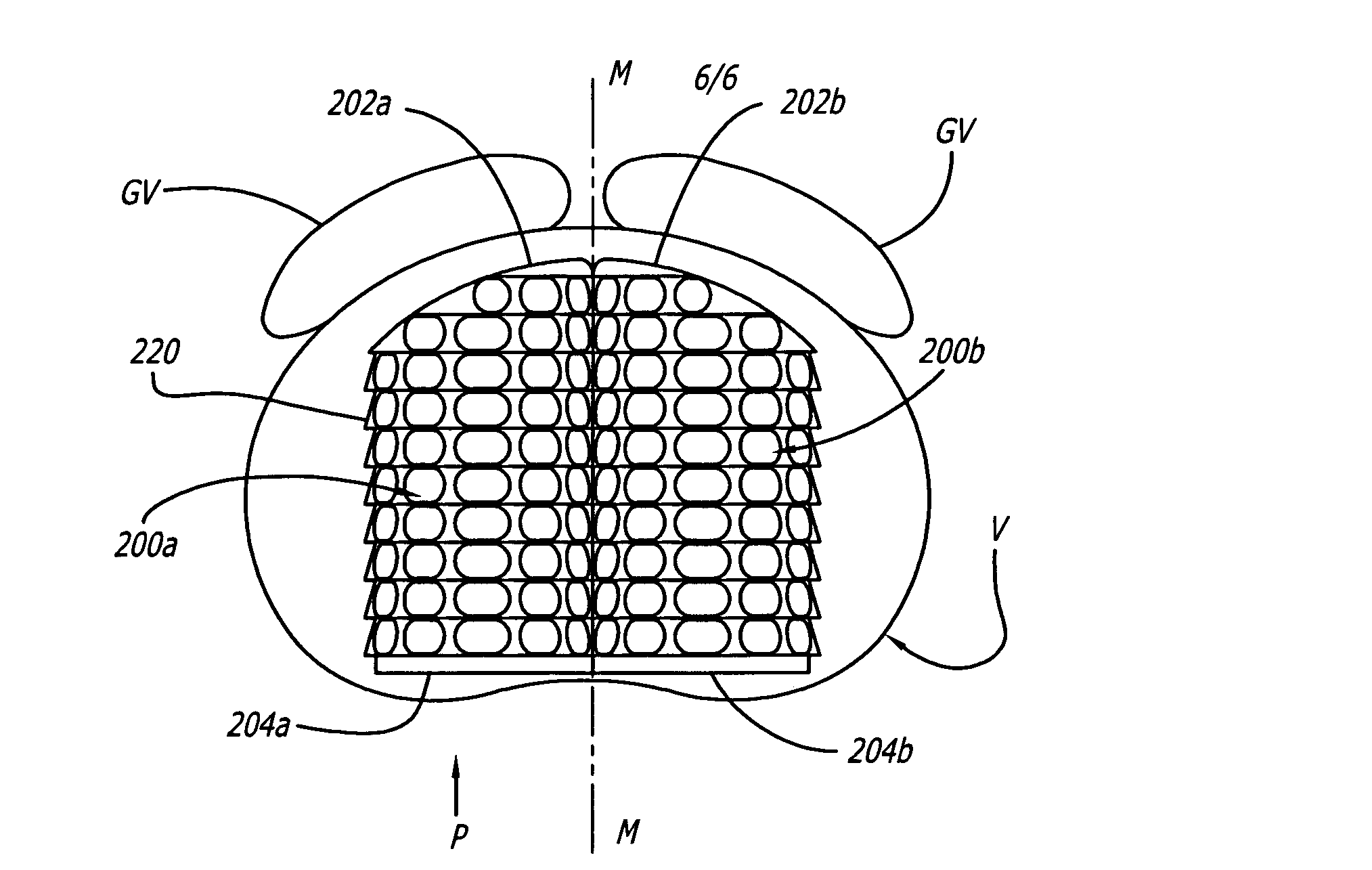

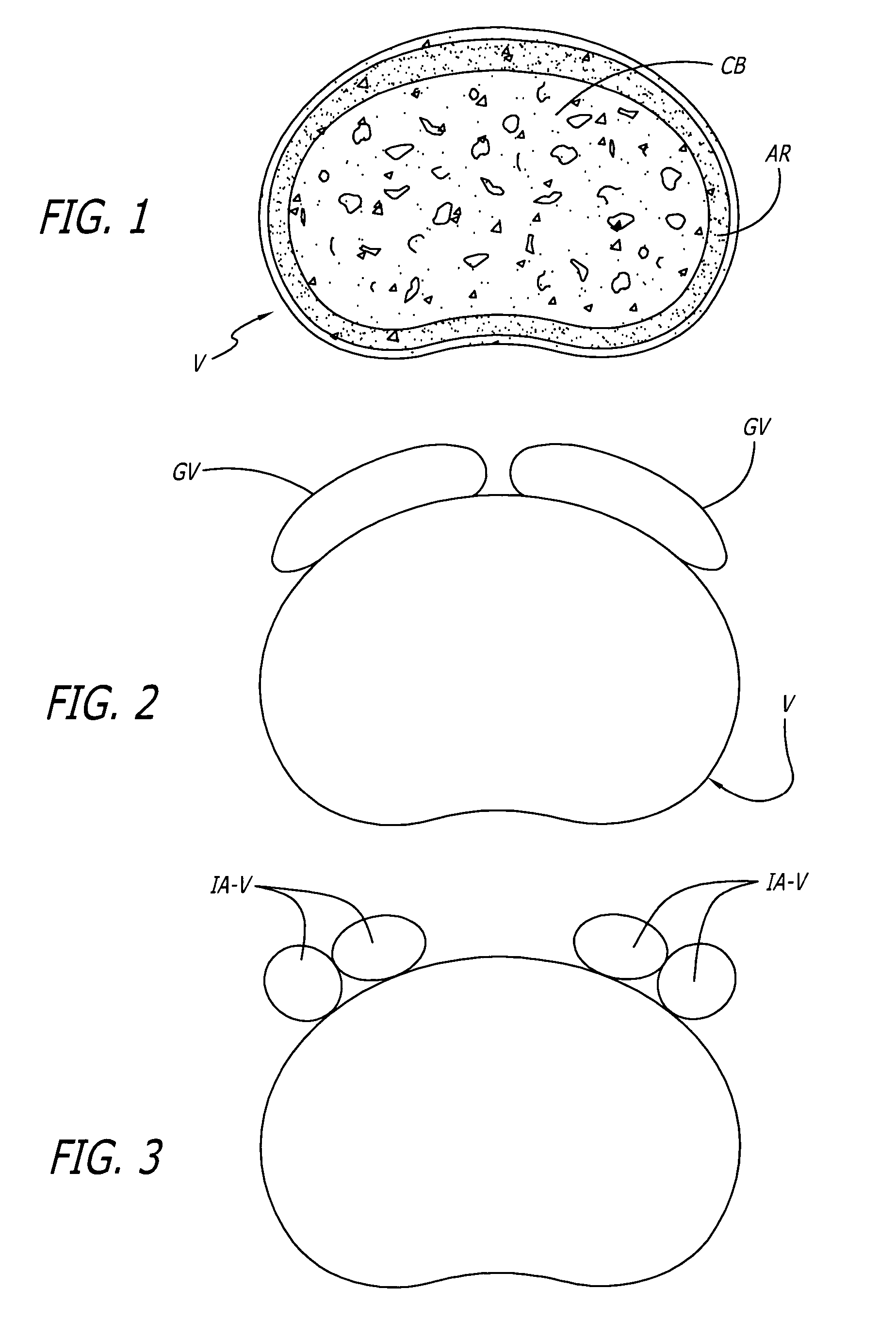

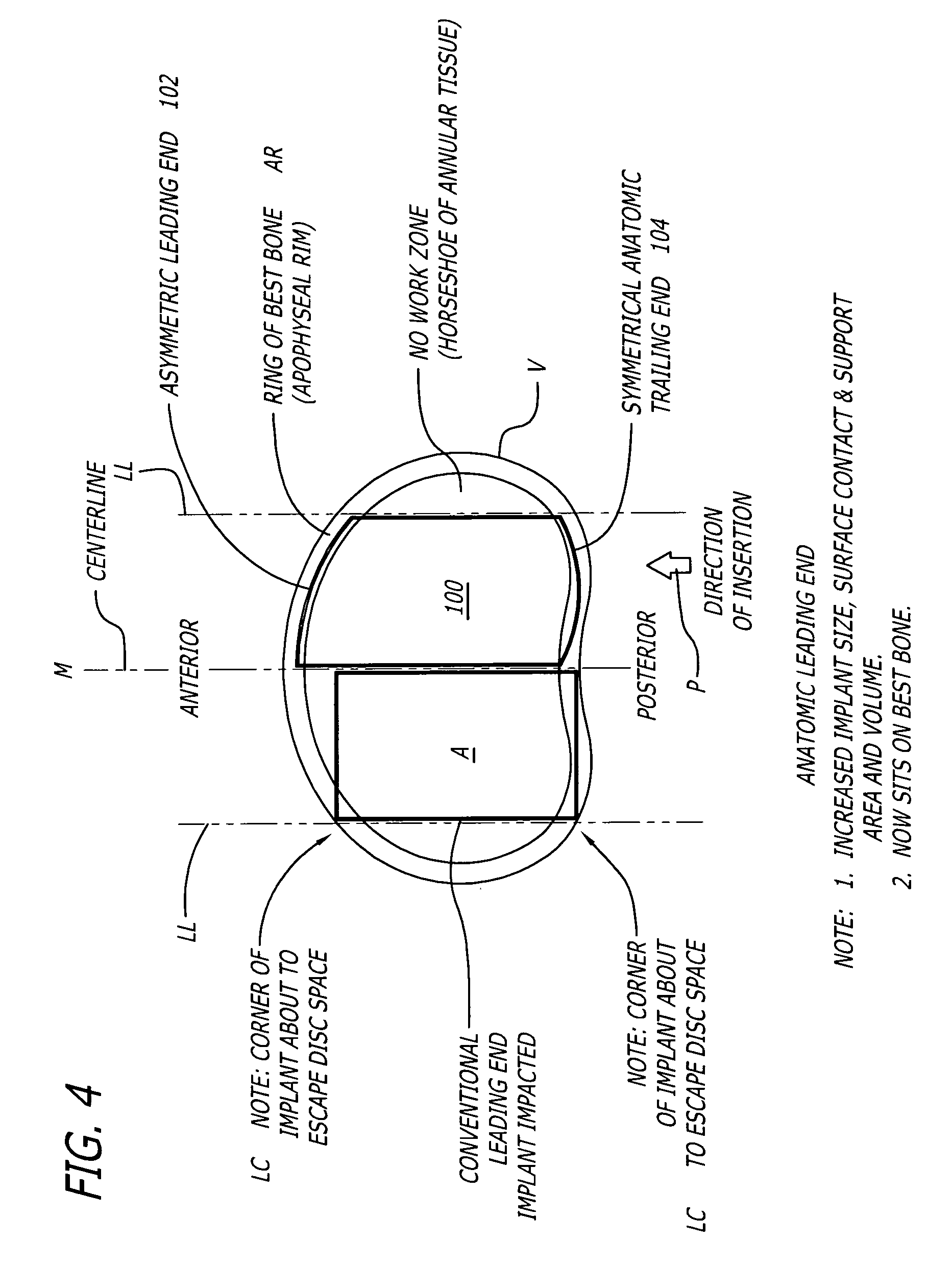

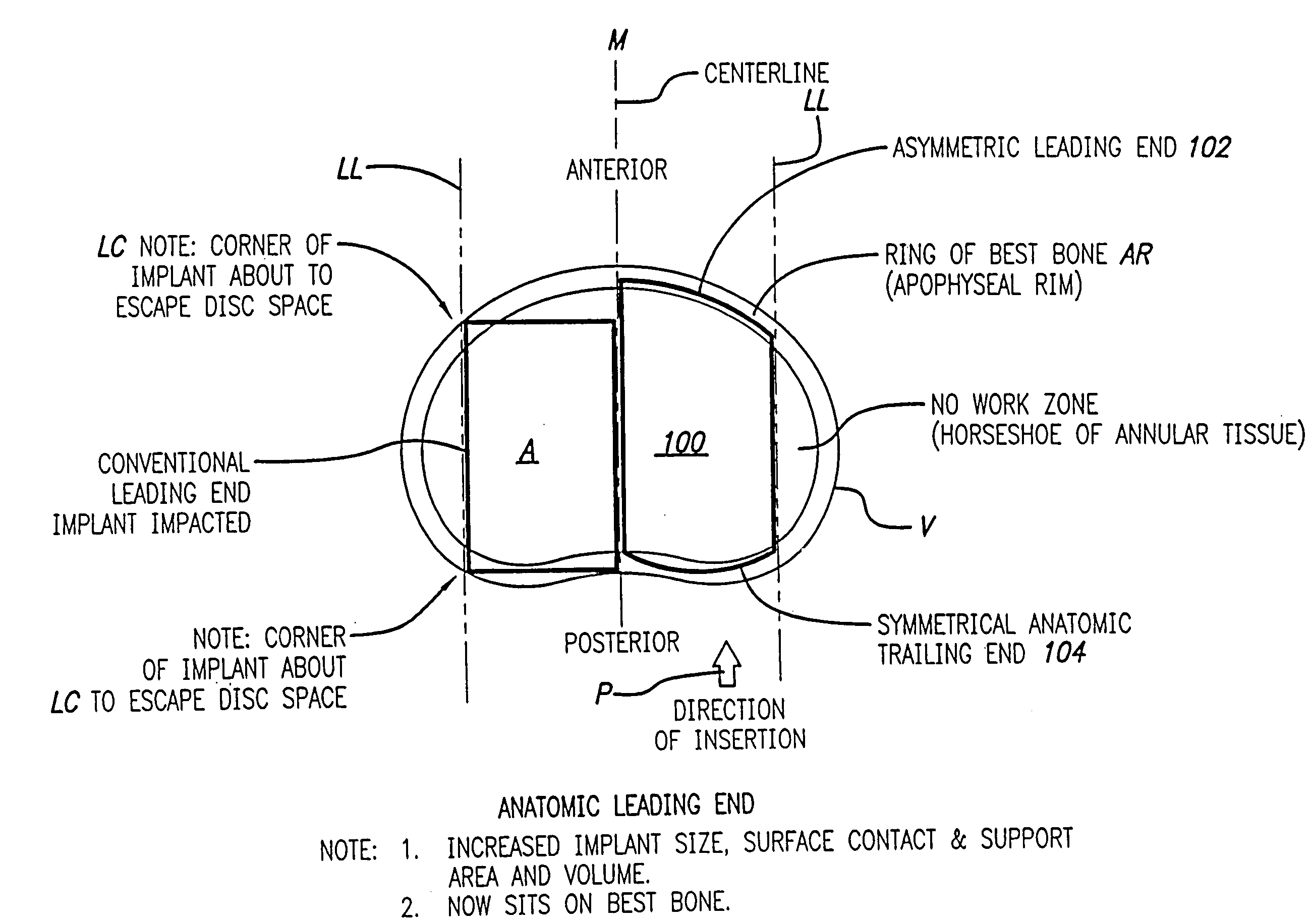

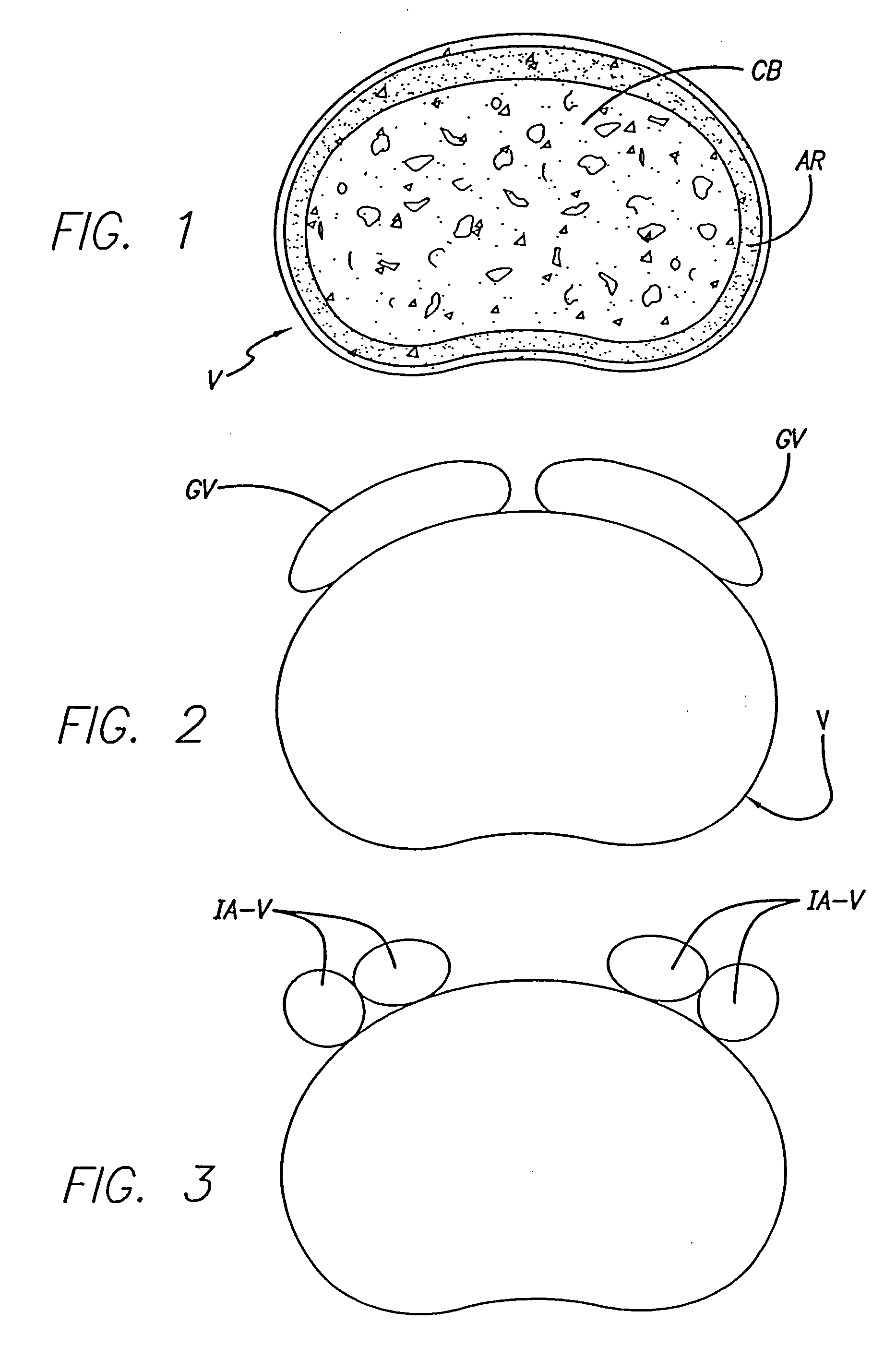

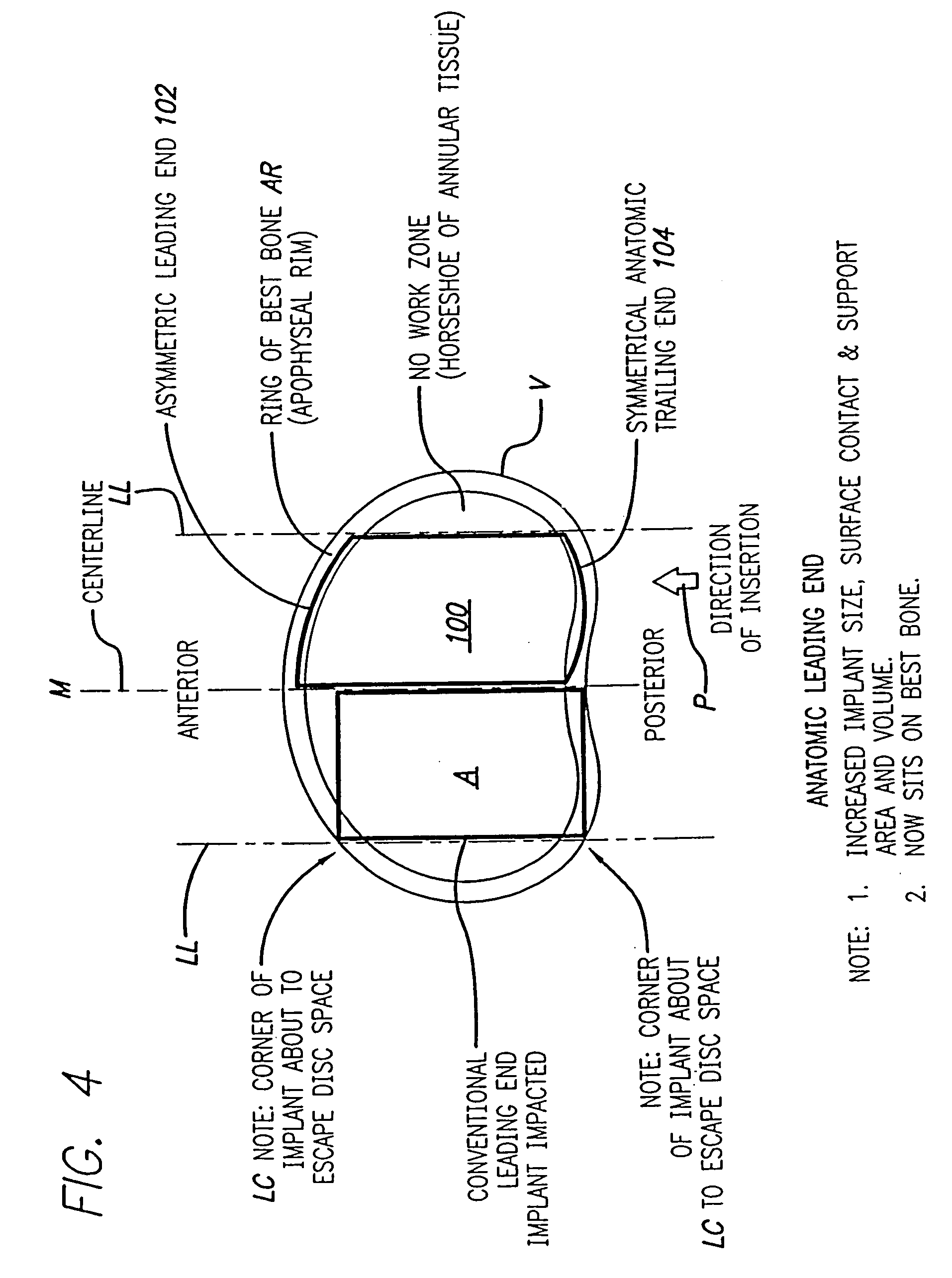

Method for installation of artificial hemi-lumbar interbody spinal fusion implant having an asymmetrical leading end

InactiveUS7387643B2Maximize contact areaIncrease the lengthBone implantJoint implantsSpinal columnIntervertebral space

An artificial interbody spinal implant adapted for placement across an intervertebral space formed across the height of a disc space between two adjacent vertebral bodies is disclosed. The implant has an asymmetrical leading end adapted to sit upon the more peripheral areas, such as the apophyseal rim and the apophyseal rim area, of the vertebral end plate region of the vertebral bodies without protruding therefrom. The asymmetrical leading end allows for the safe use of an implant of maximum length for the implantation space into which it is installed. The implant can also include an asymmetric trailing end adapted to sit upon the more peripheral areas of the vertebral end plate region of the vertebral bodies.

Owner:WARSAW ORTHOPEDIC INC

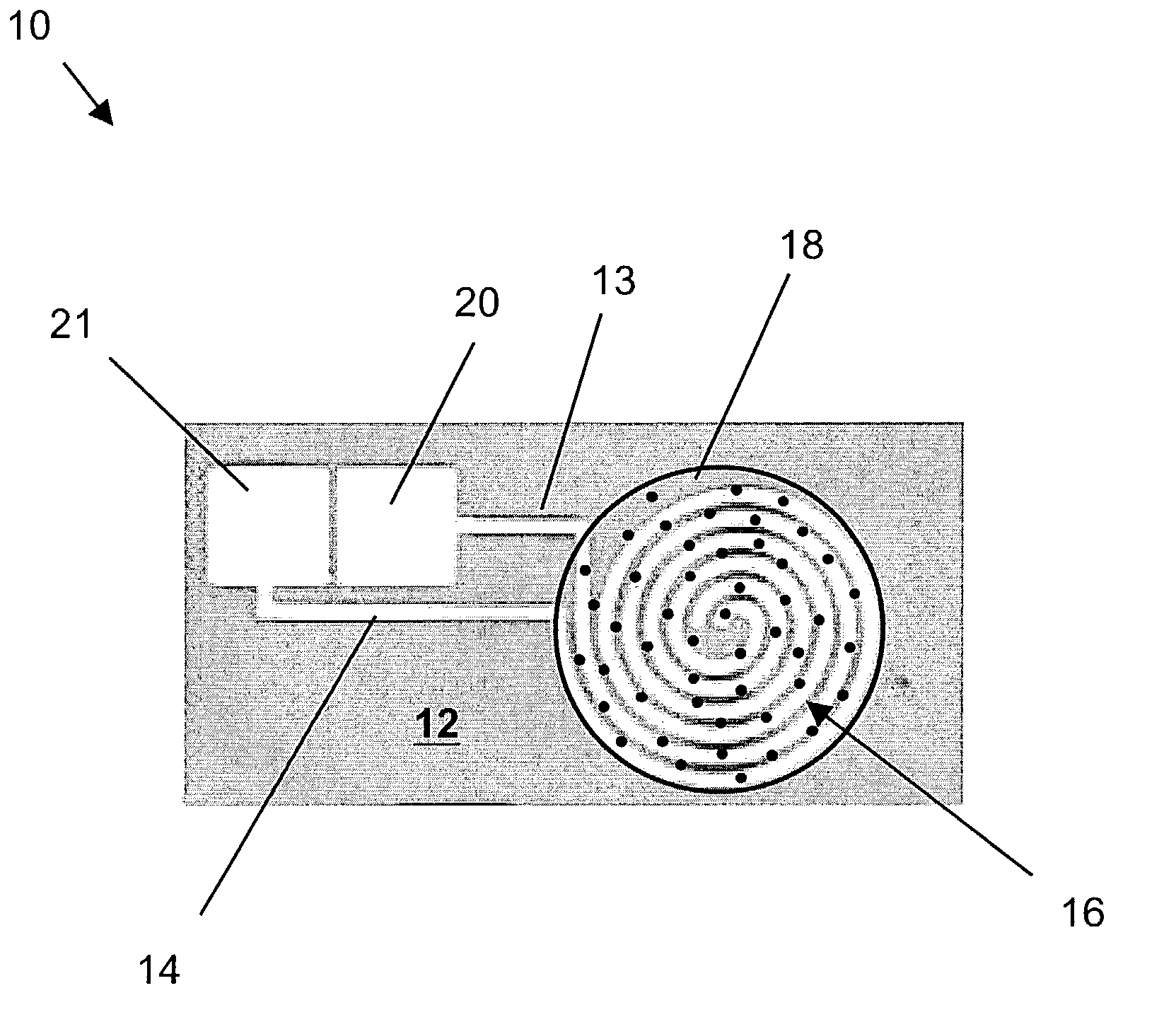

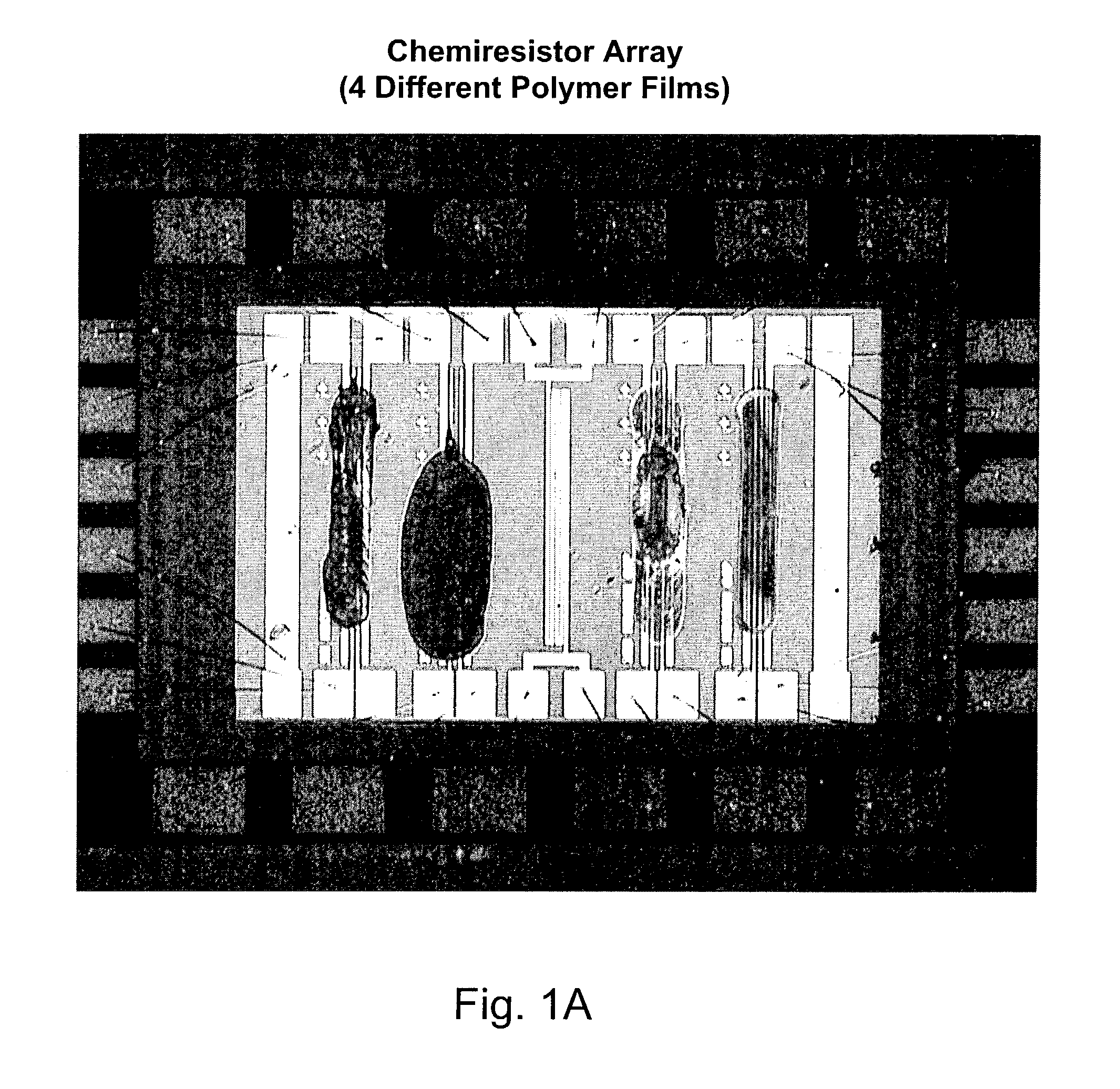

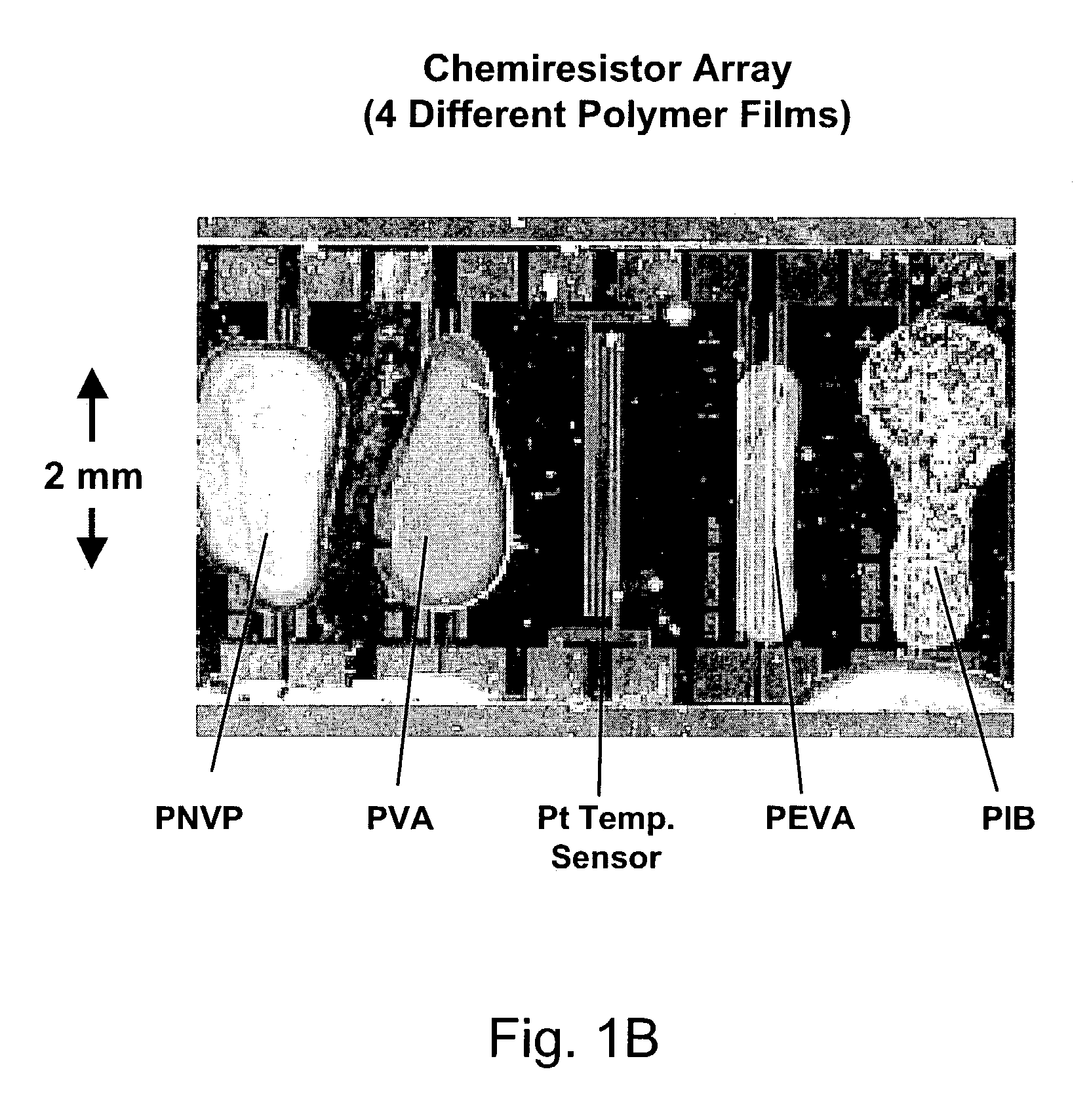

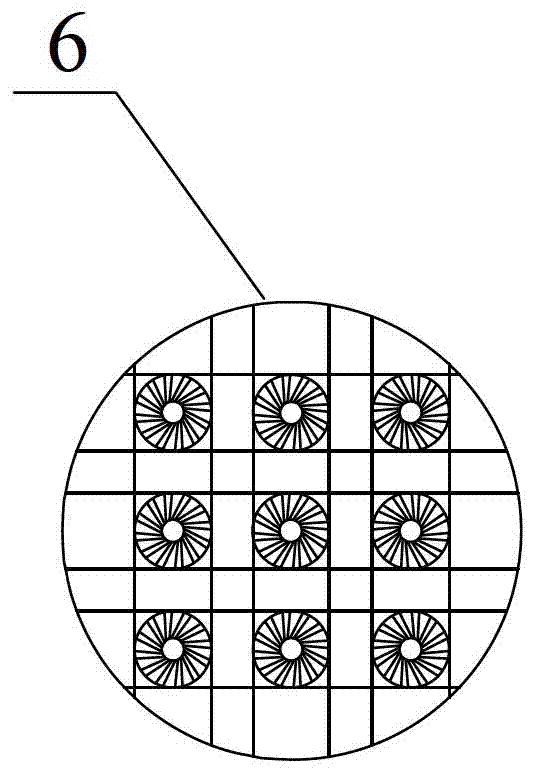

Circular chemiresistors for microchemical sensors

InactiveUS7189360B1Minimize batch-to-batch variationMaximize contact areaAnalysing fluids using sonic/ultrasonic/infrasonic wavesWave amplification devicesElectrical resistance and conductanceElectricity

A circular chemiresistor for use in microchemical sensors. A pair of electrodes is fabricated on an electrically insulating substrate. The pattern of electrodes is arranged in a circle-filling geometry, such as a concentric, dual-track spiral design, or a circular interdigitated design. A drop of a chemically sensitive polymer (i.e., chemiresistive ink) is deposited on the insulating substrate on the electrodes, which spreads out into a thin, circular disk contacting the pair of electrodes. This circularly-shaped electrode geometry maximizes the contact area between the pair of electrodes and the polymer deposit, which provides a lower and more stable baseline resistance than with linear-trace designs. The circularly-shaped electrode pattern also serves to minimize batch-to-batch variations in the baseline resistance due to non-uniform distributions of conductive particles in the chemiresistive polymer film.

Owner:SANDIA NAT LAB

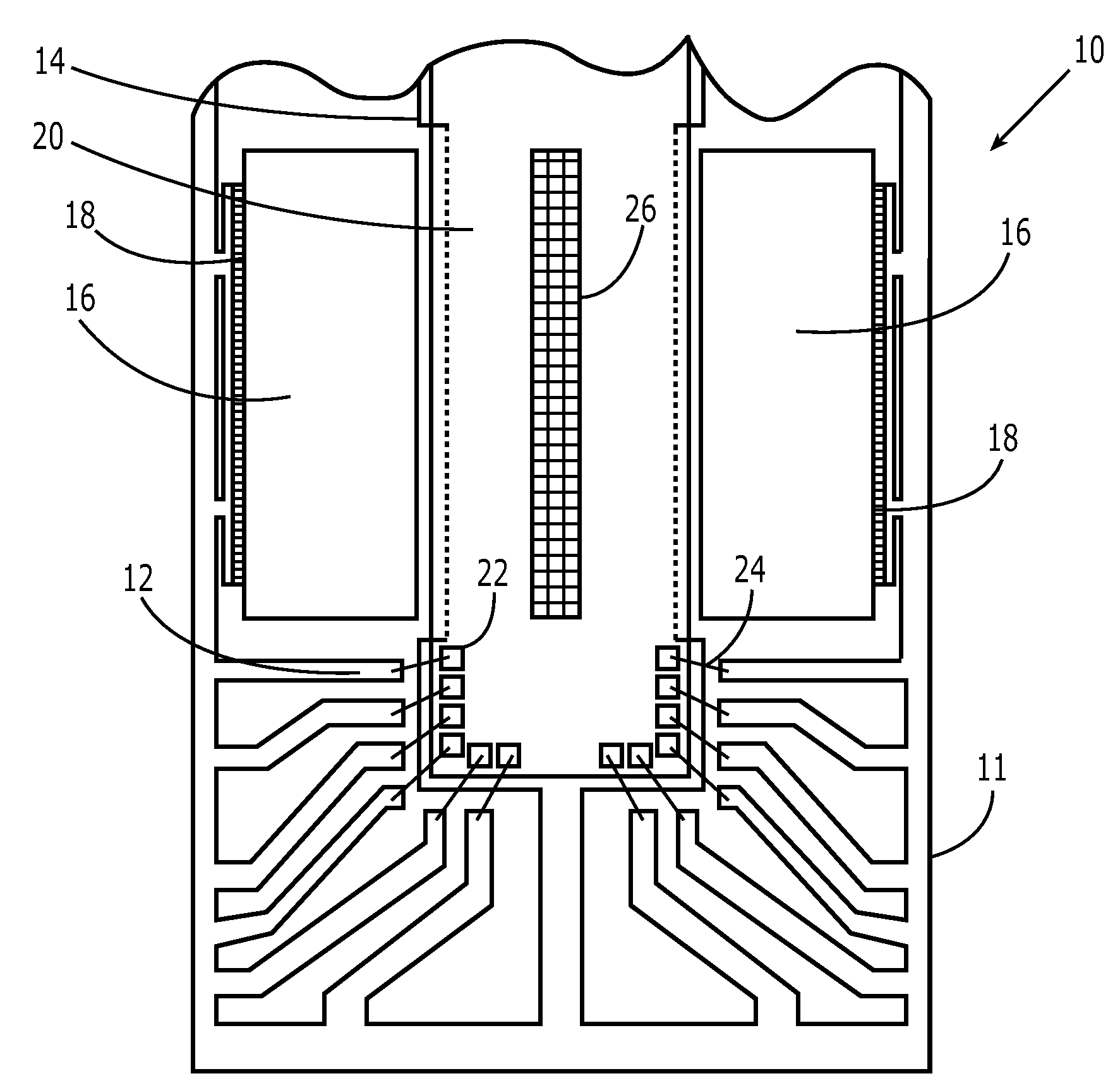

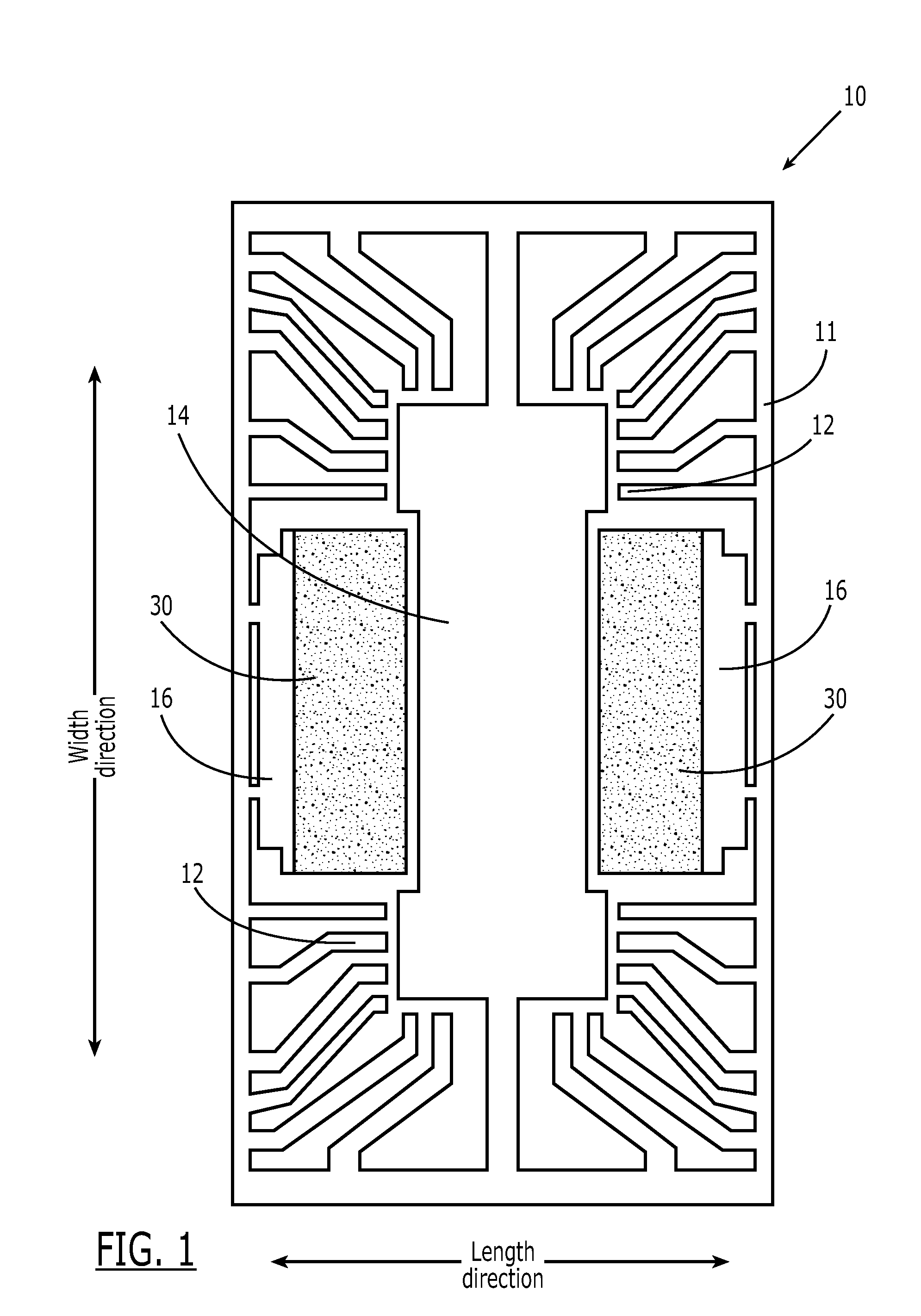

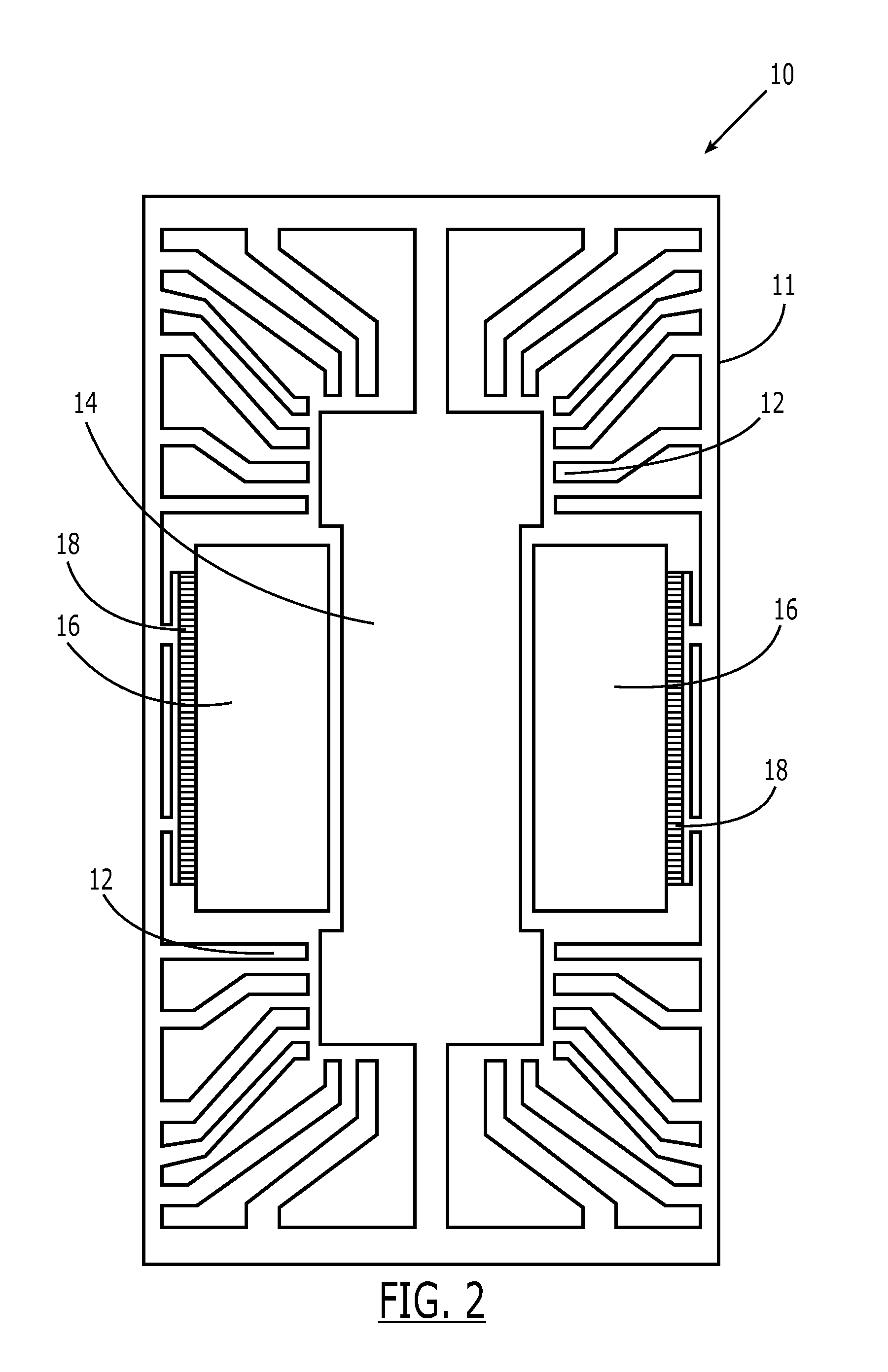

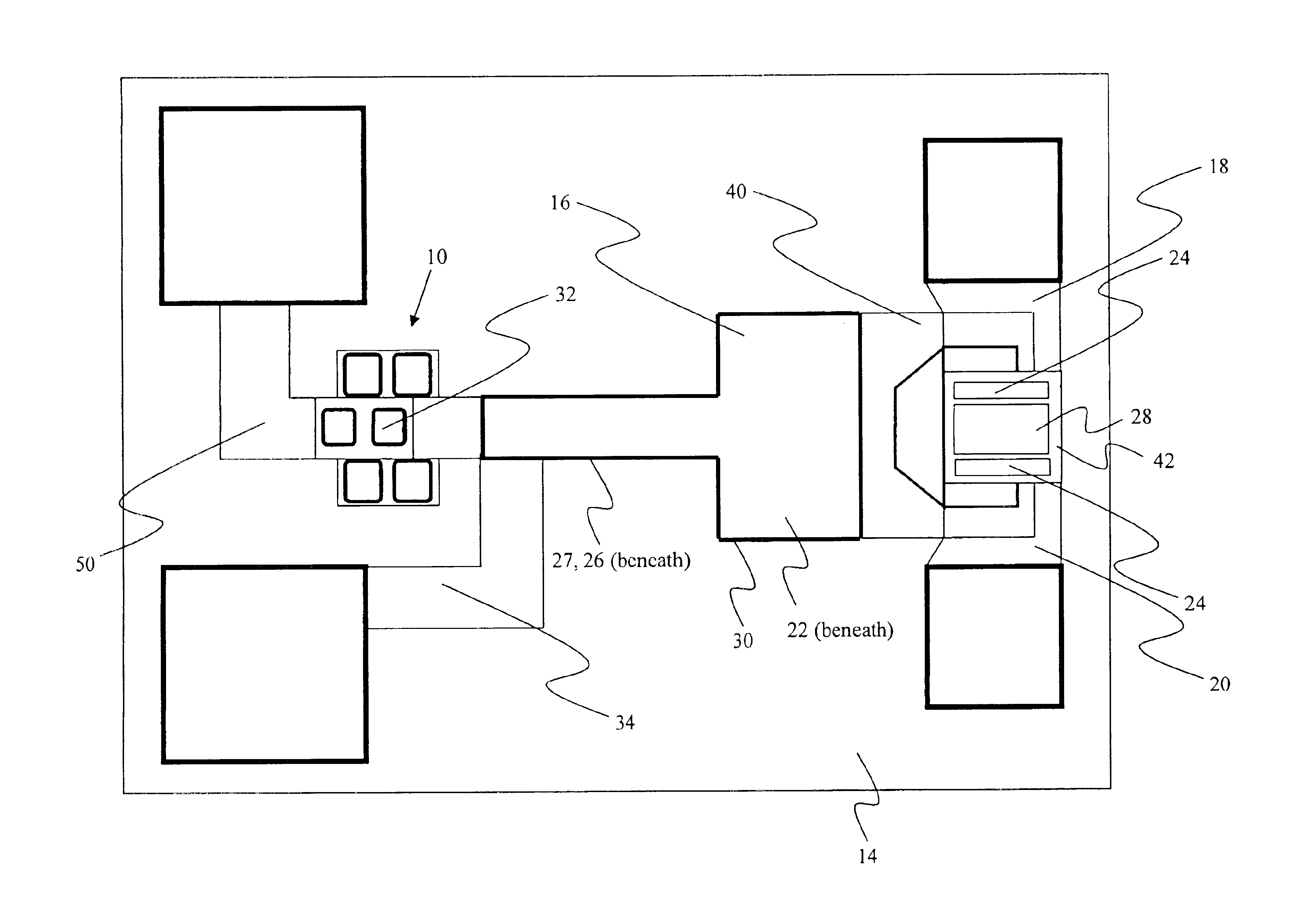

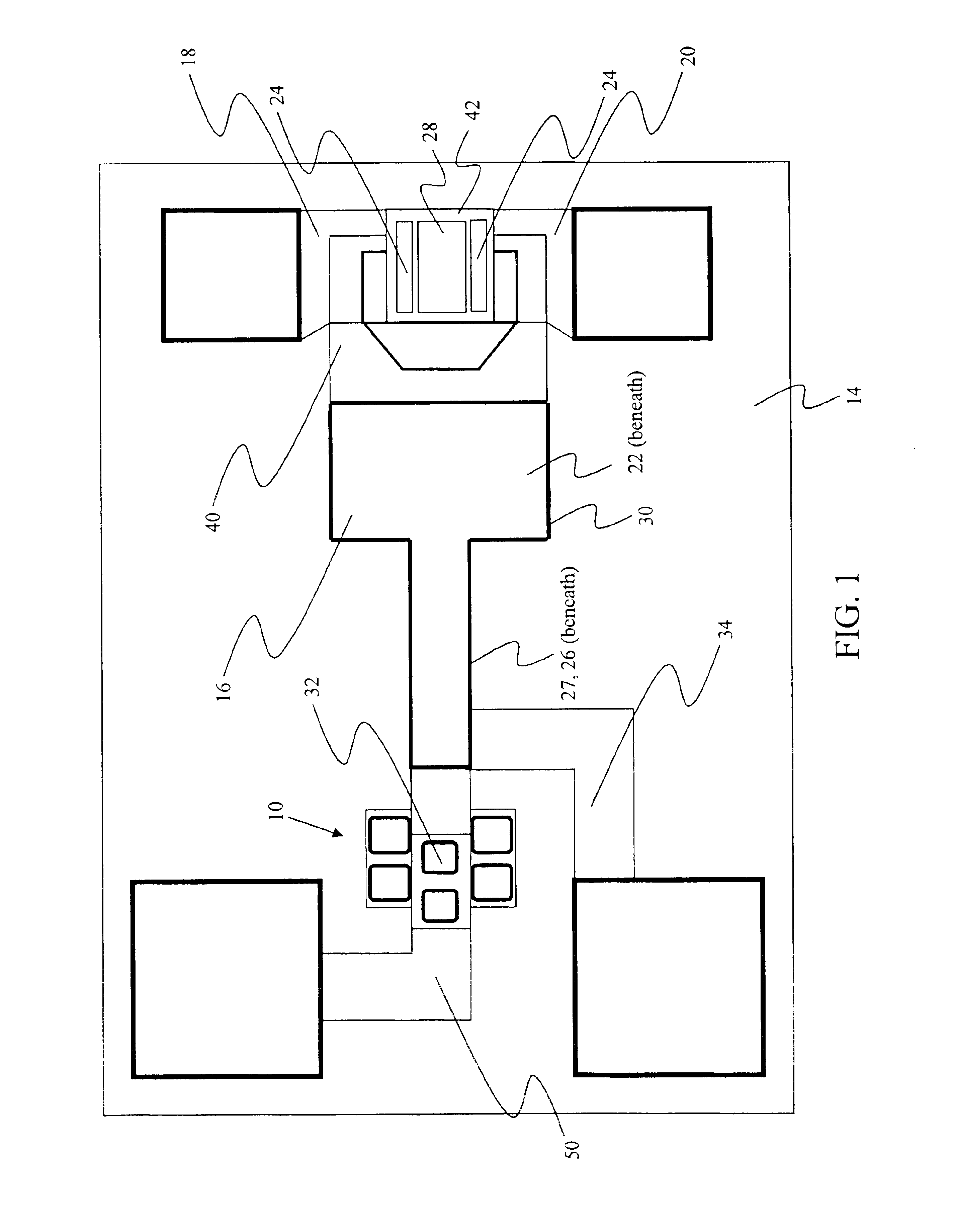

Integrated Leadframe And Bezel Structure And Device Formed From Same

InactiveUS20100127366A1Fast preparationMaximize contact areaSemiconductor/solid-state device detailsSolid-state devicesContact padDevice form

An integrated leadframe and bezel structure includes a planar carrier frame, a plurality of bonding leads, a die pad region, and a bezel structure. The bezel structure includes a bending portion shaped and disposed to facilitate a portion of said bezel structure being bent out of the plane of said carrier frame. A sensor IC may be secured to the die pad region, and wire bonds made to permit external connection to the sensor IC. The bezel structure includes portions which are bent such that their upper extent is in or above a sensing surface. The assembly is encapsulated, exposing on the top surface part of the bezel portions and the upper surface of the sensor IC, and on the bottom surface the contact pads. Two or more bezel portions may be provided, one or more on each side of the sensor IC.

Owner:APPLE INC

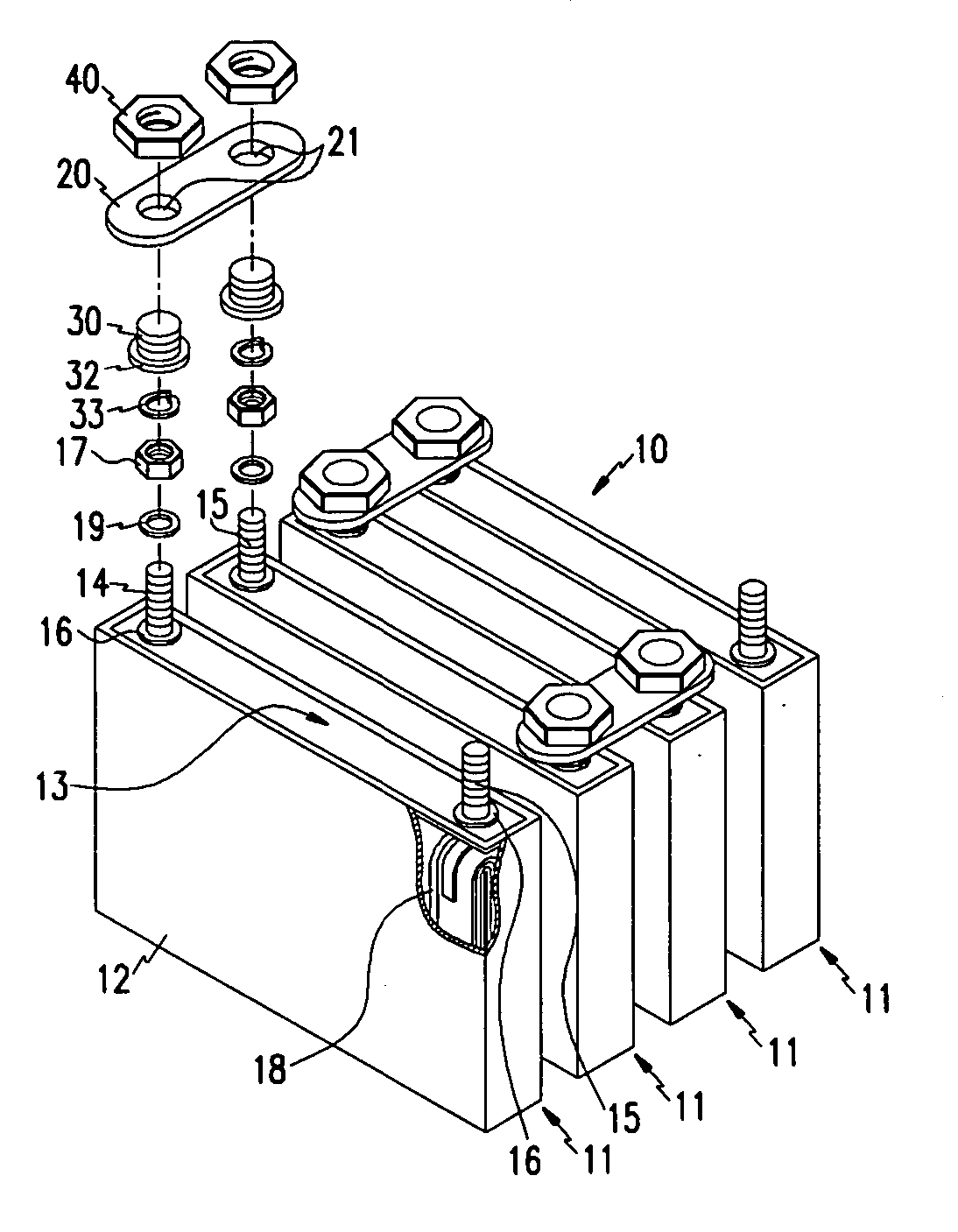

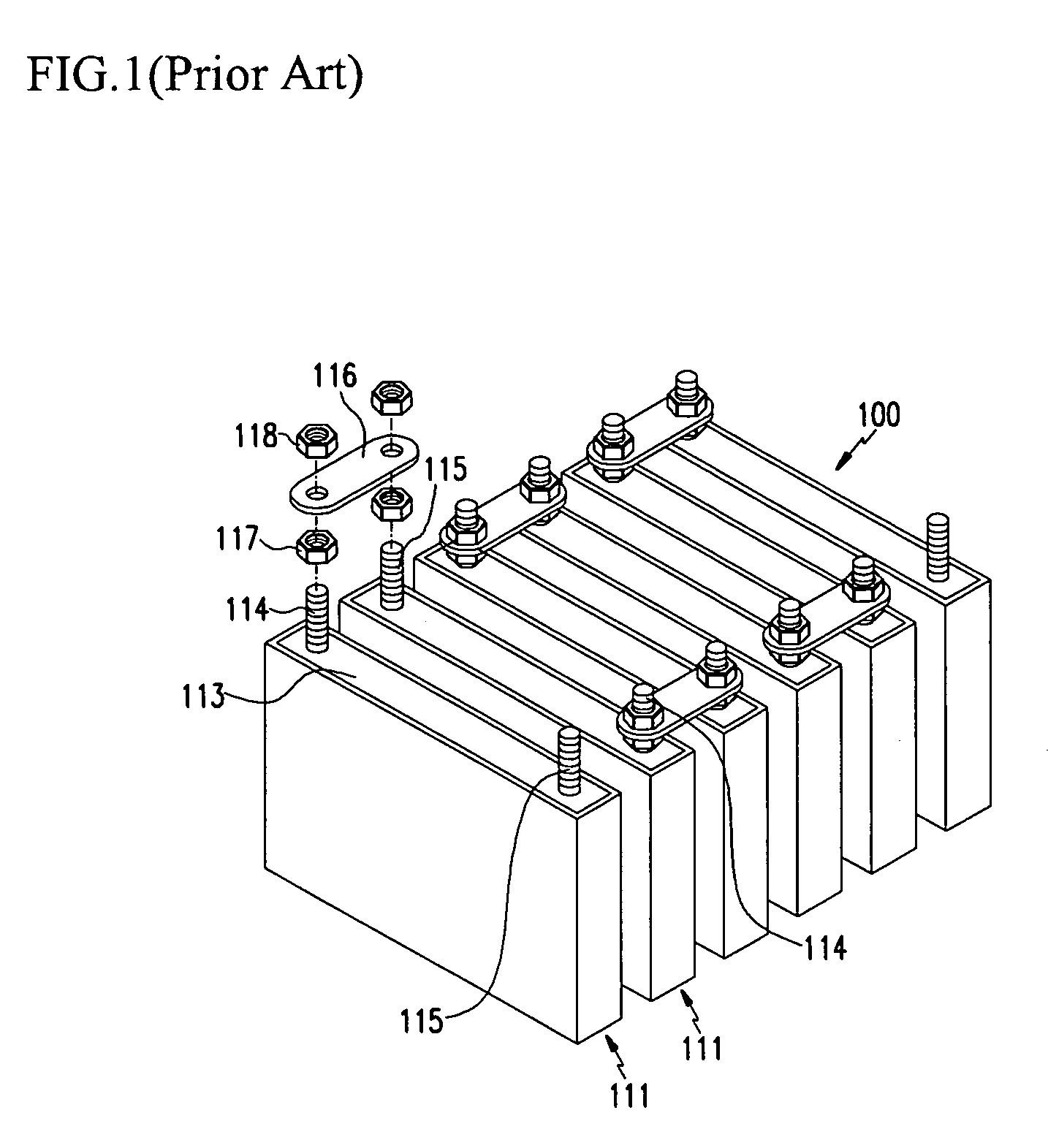

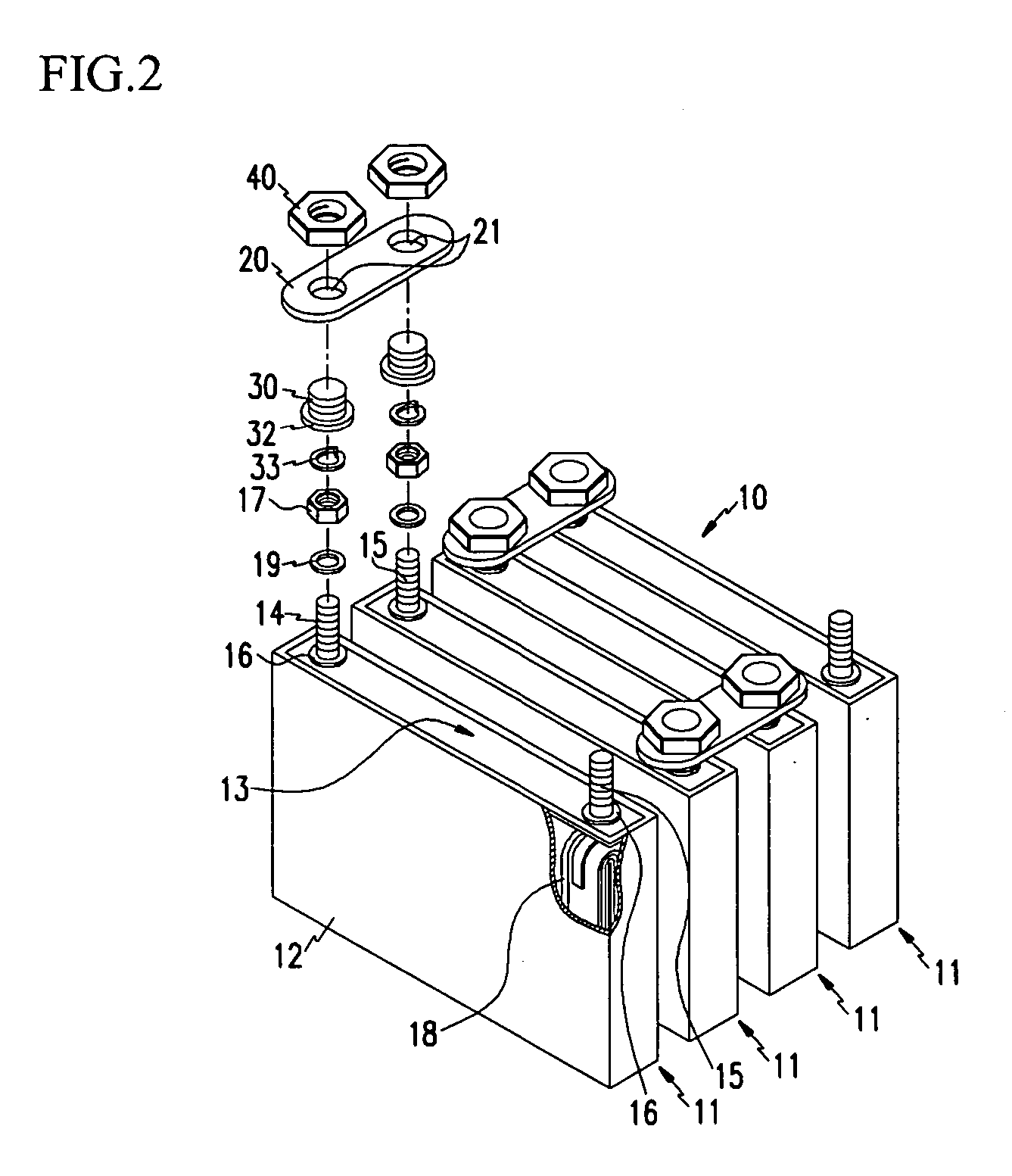

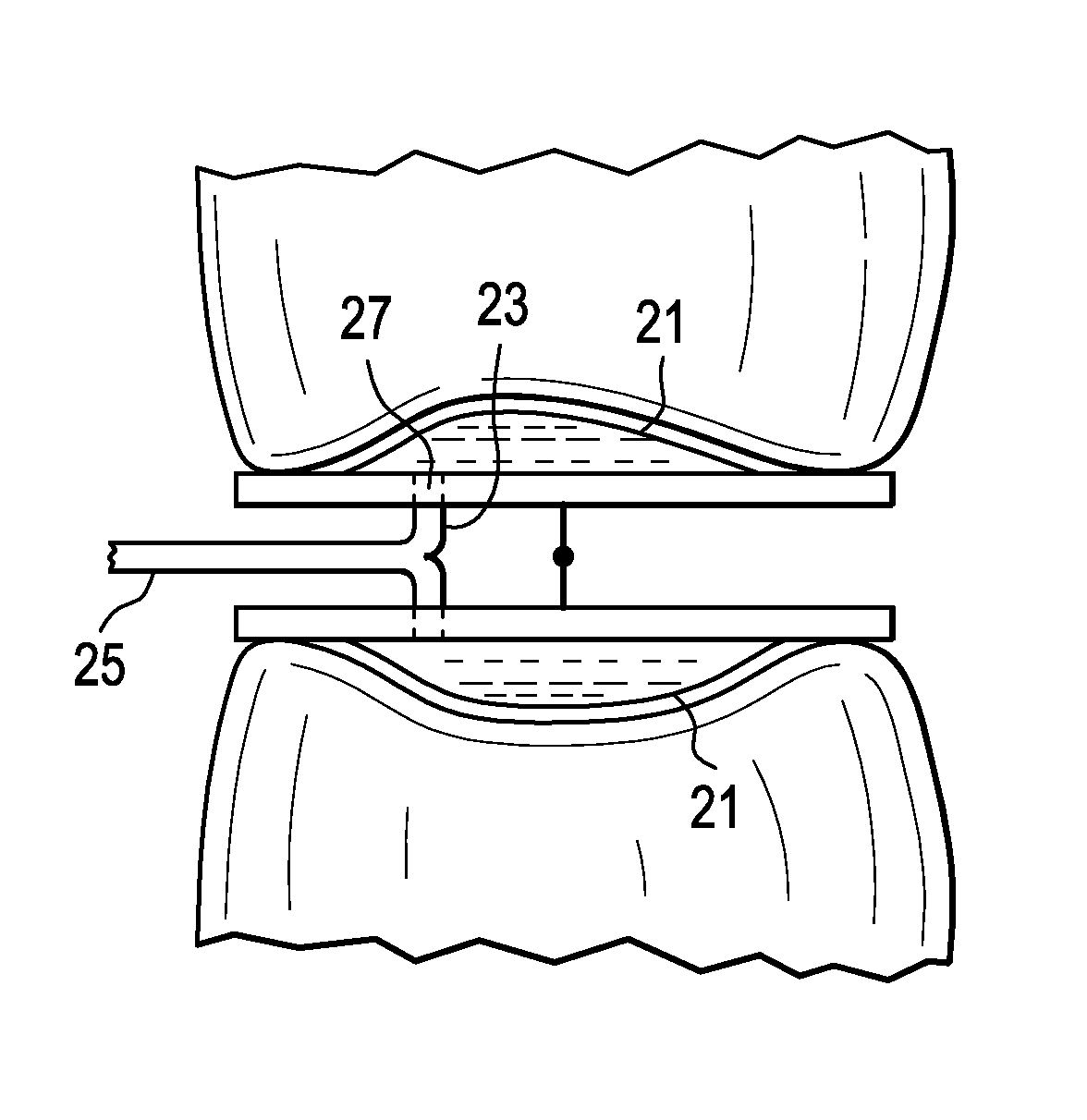

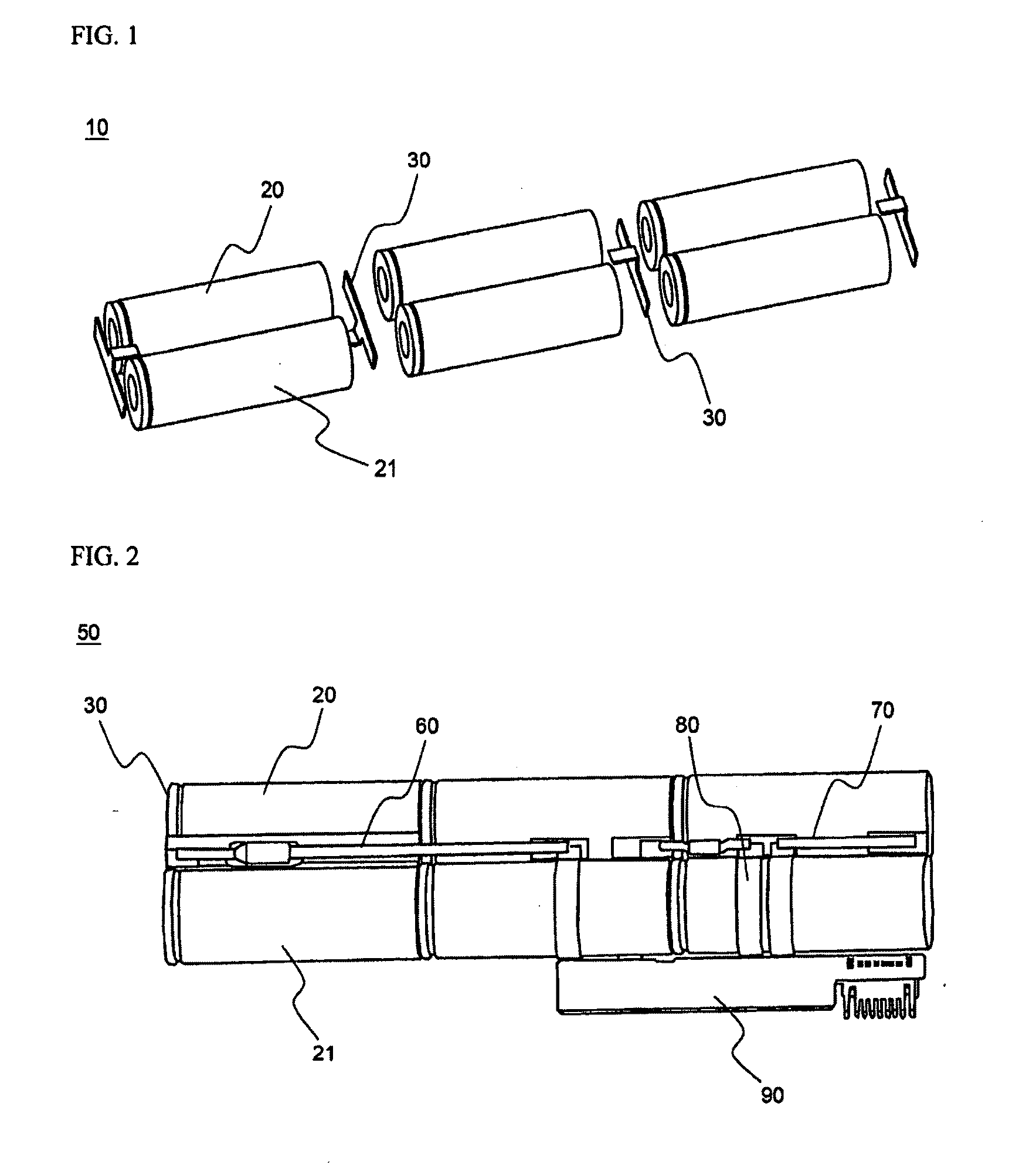

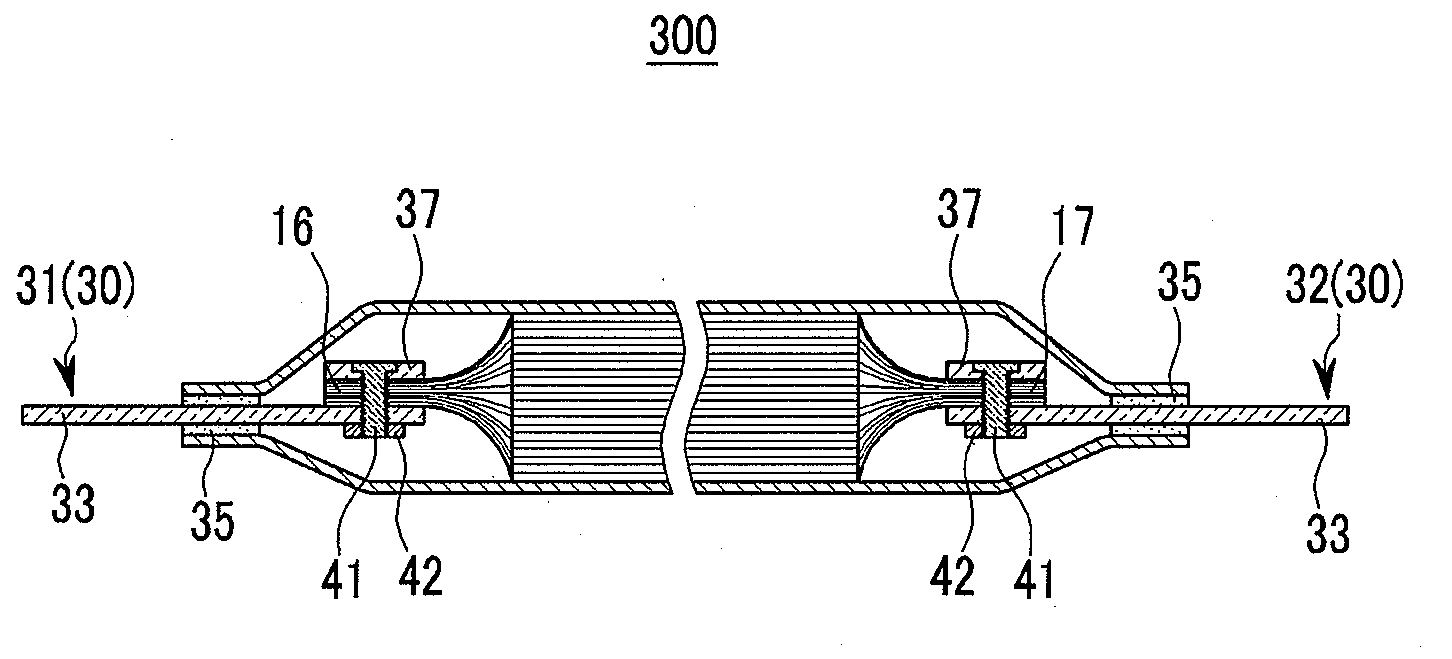

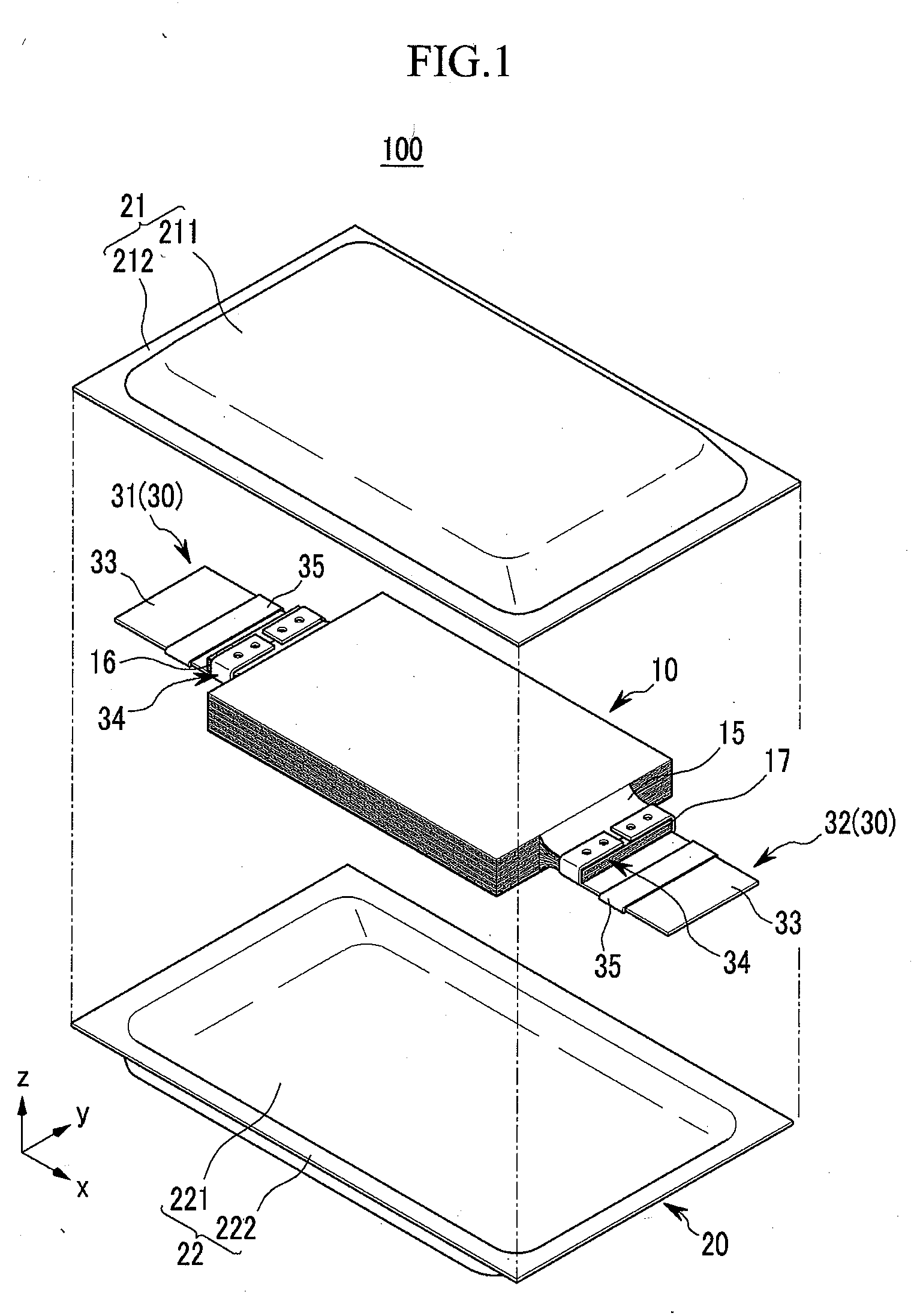

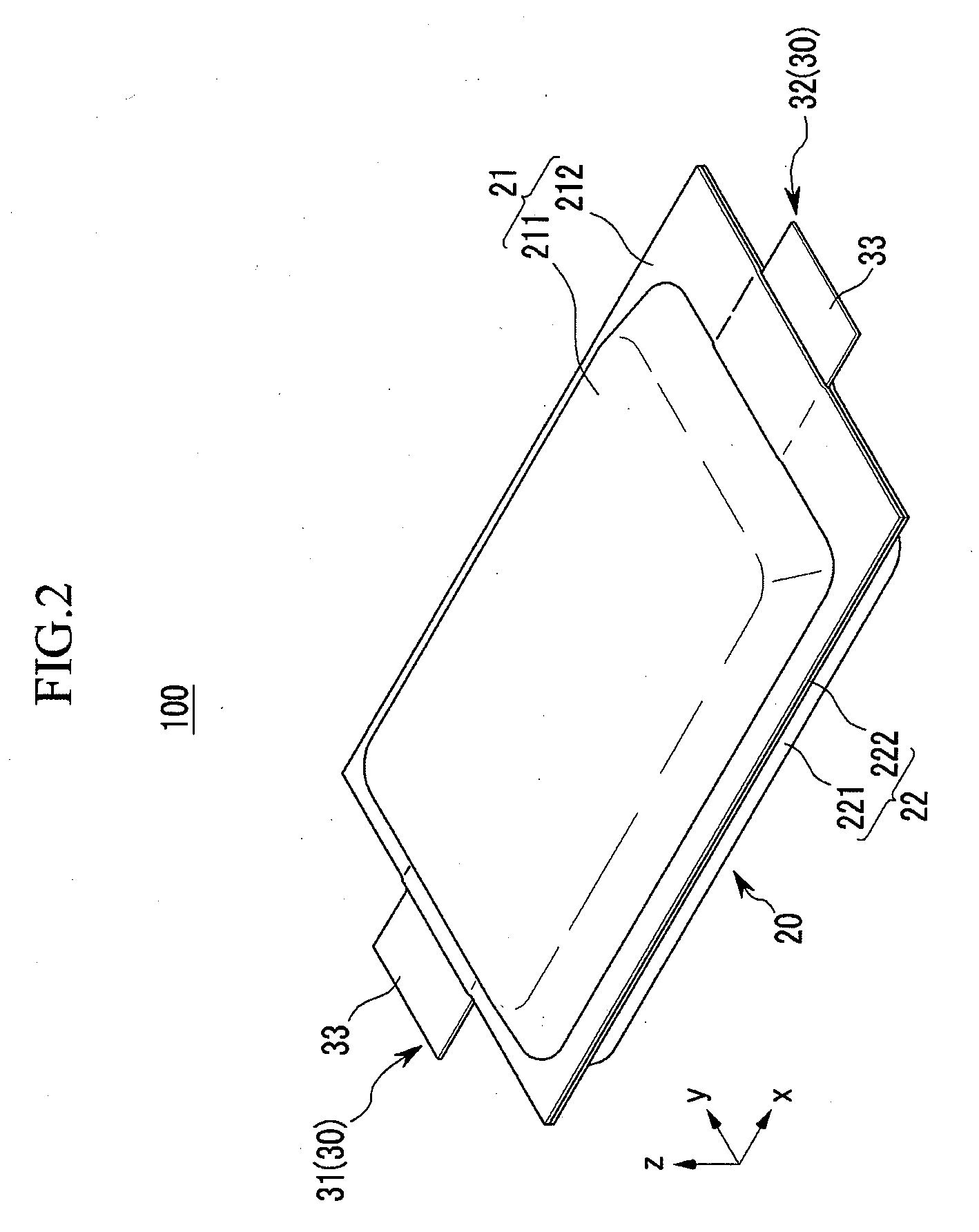

Secondary battery and a secondary battery module using the same

InactiveUS20060094289A1Electric conductivity and current collecting efficiencyMaximize contact areaLarge-sized flat cells/batteriesCurrent conducting connectionsEngineeringFlange

A secondary battery module includes a connector, which electrically connects a first unit battery to an adjacent unit battery. The connector is connected to the first battery through a connecting member, which is connected to a terminal of the first battery. The connecting member has external threads and a flange on which the connector is positioned. The connector is also fitted to the connecting member and fixed thereto through a nut, which is joined with the external threads of the connecting member.

Owner:SAMSUNG SDI CO LTD

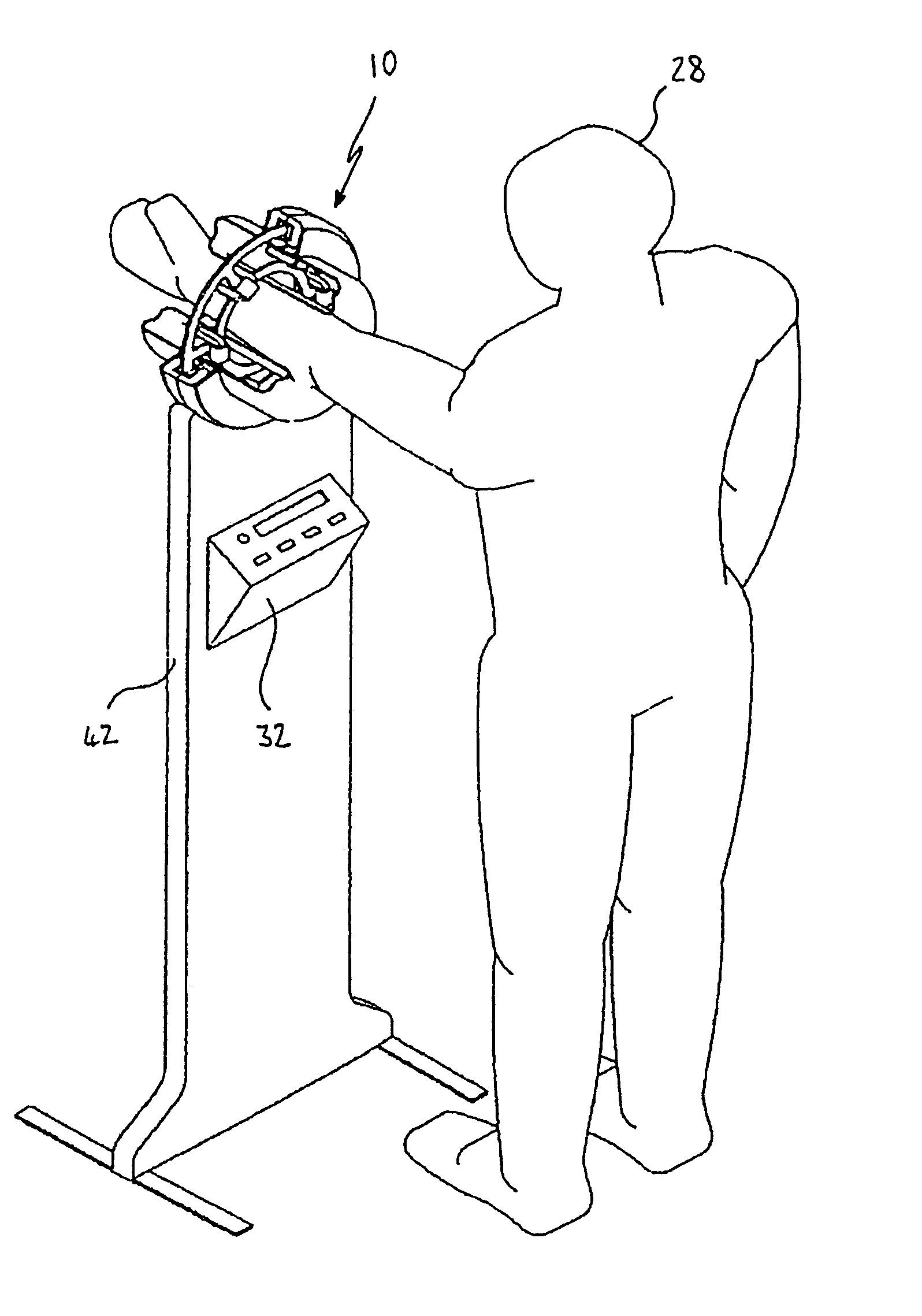

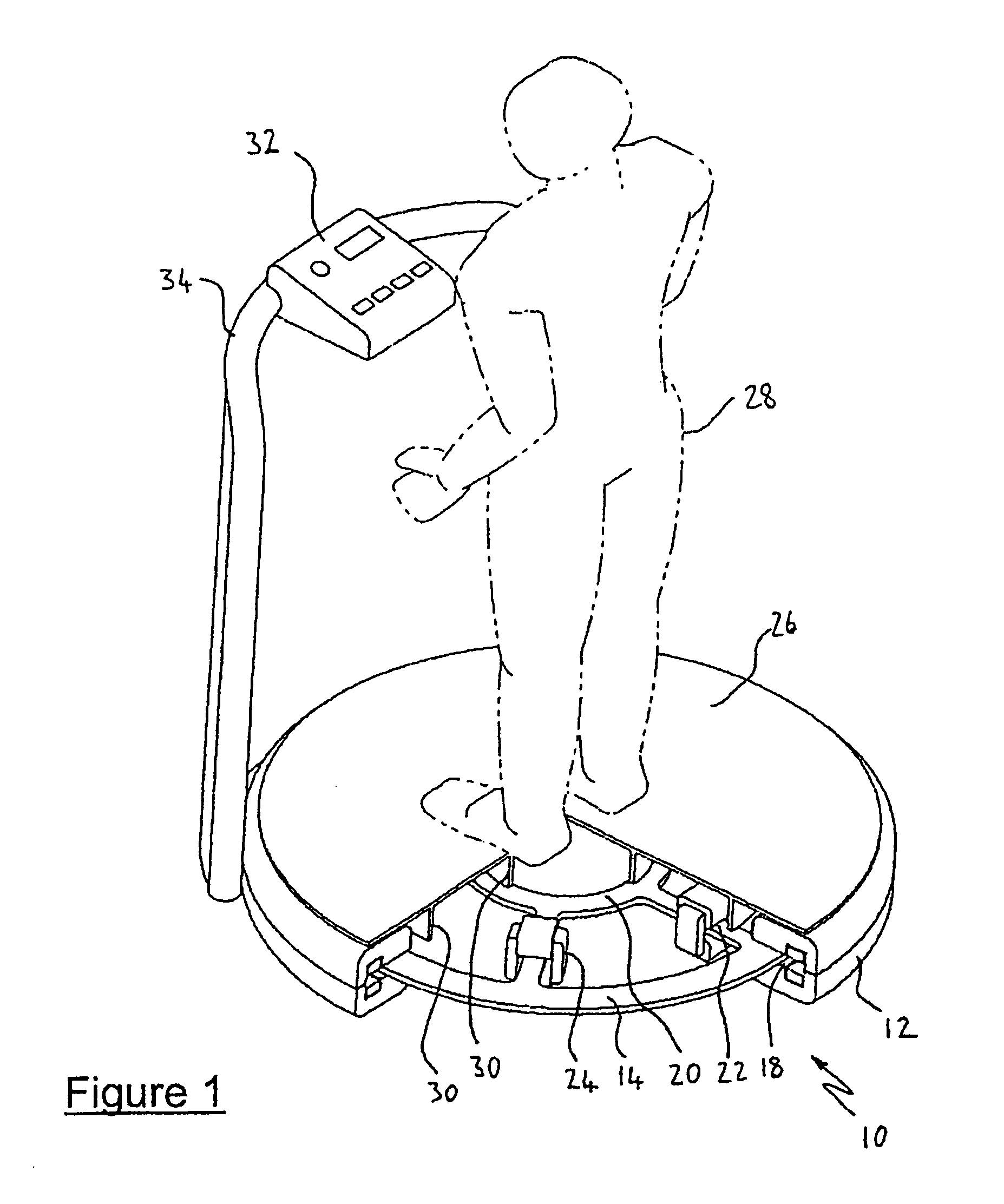

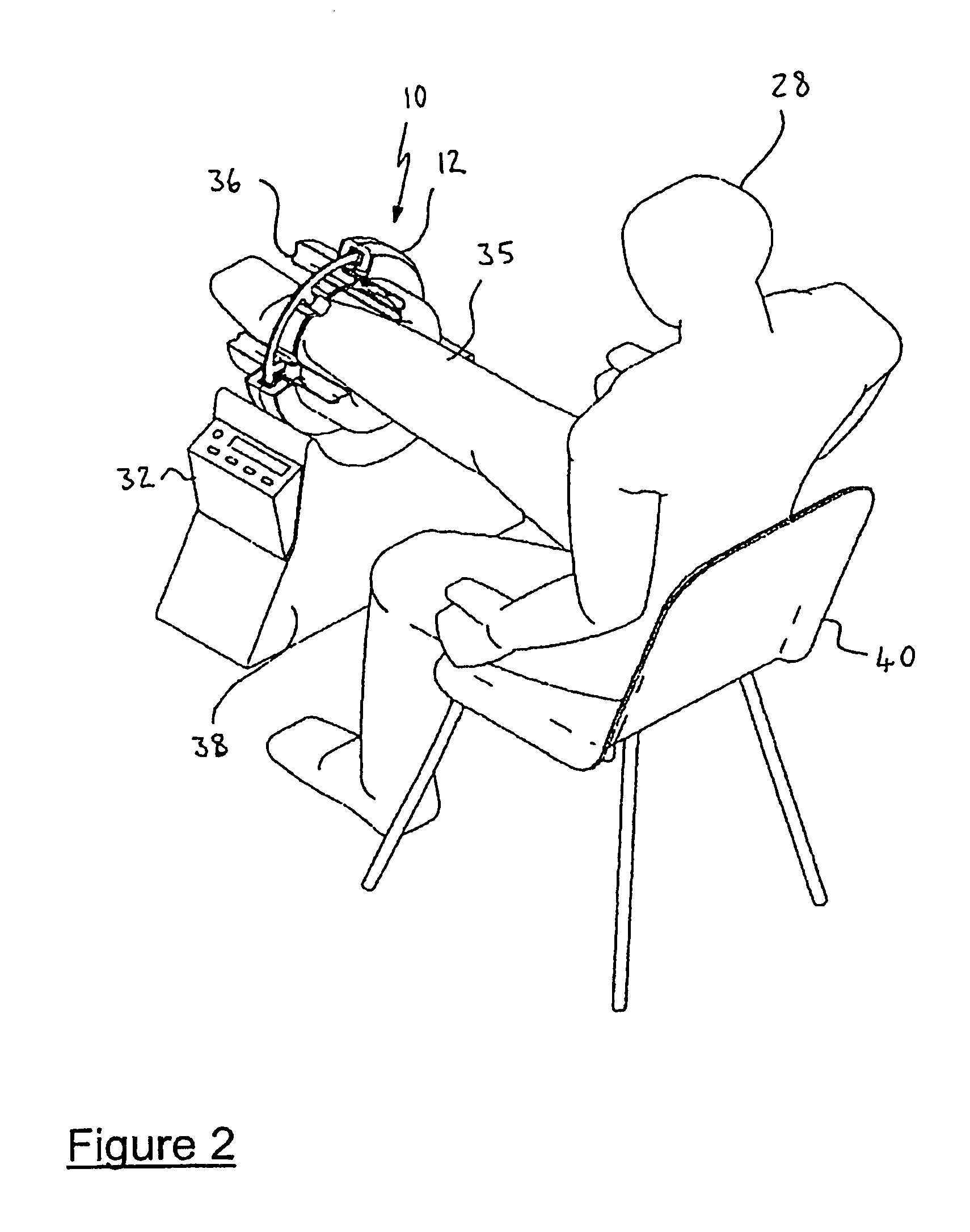

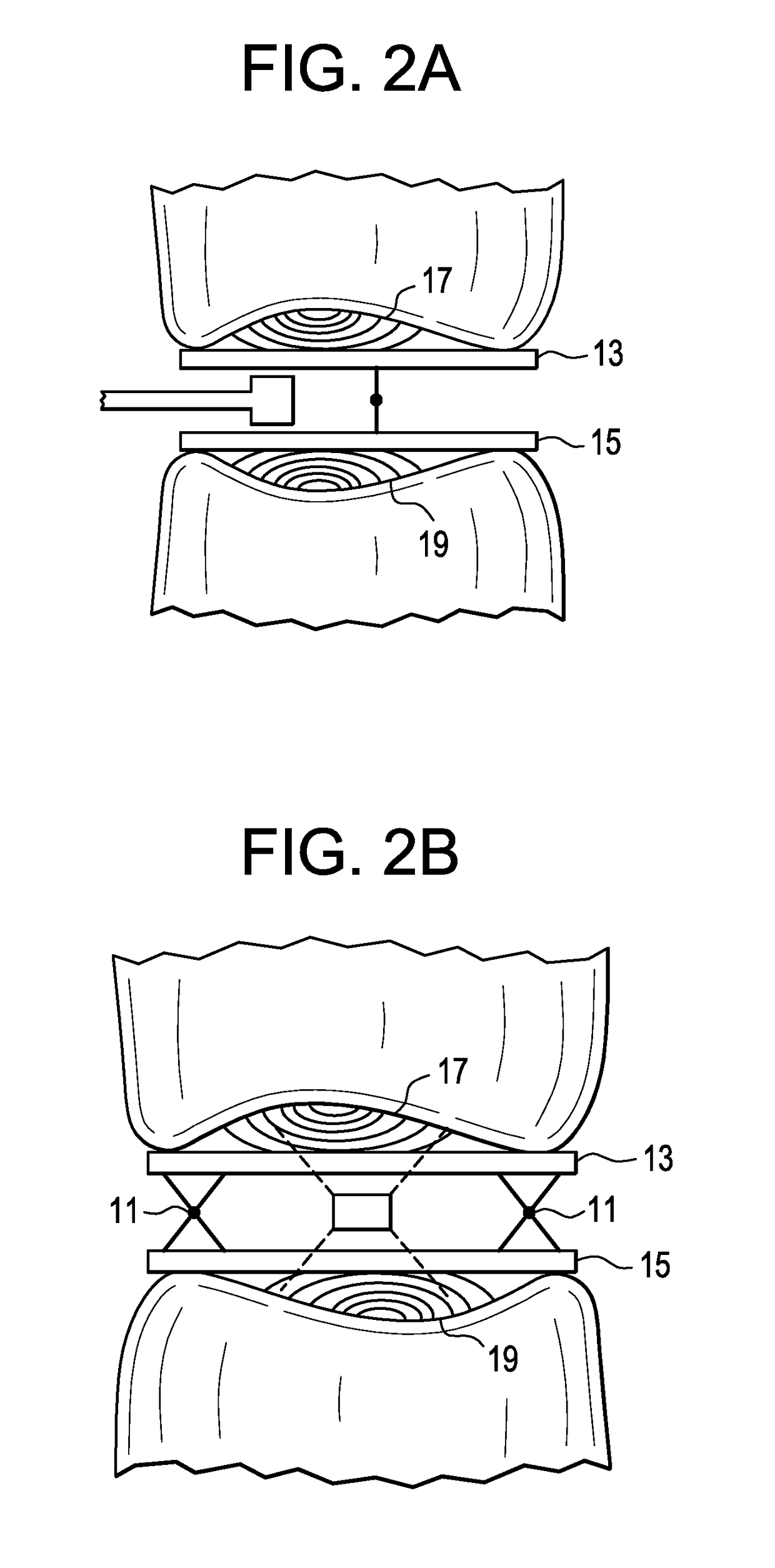

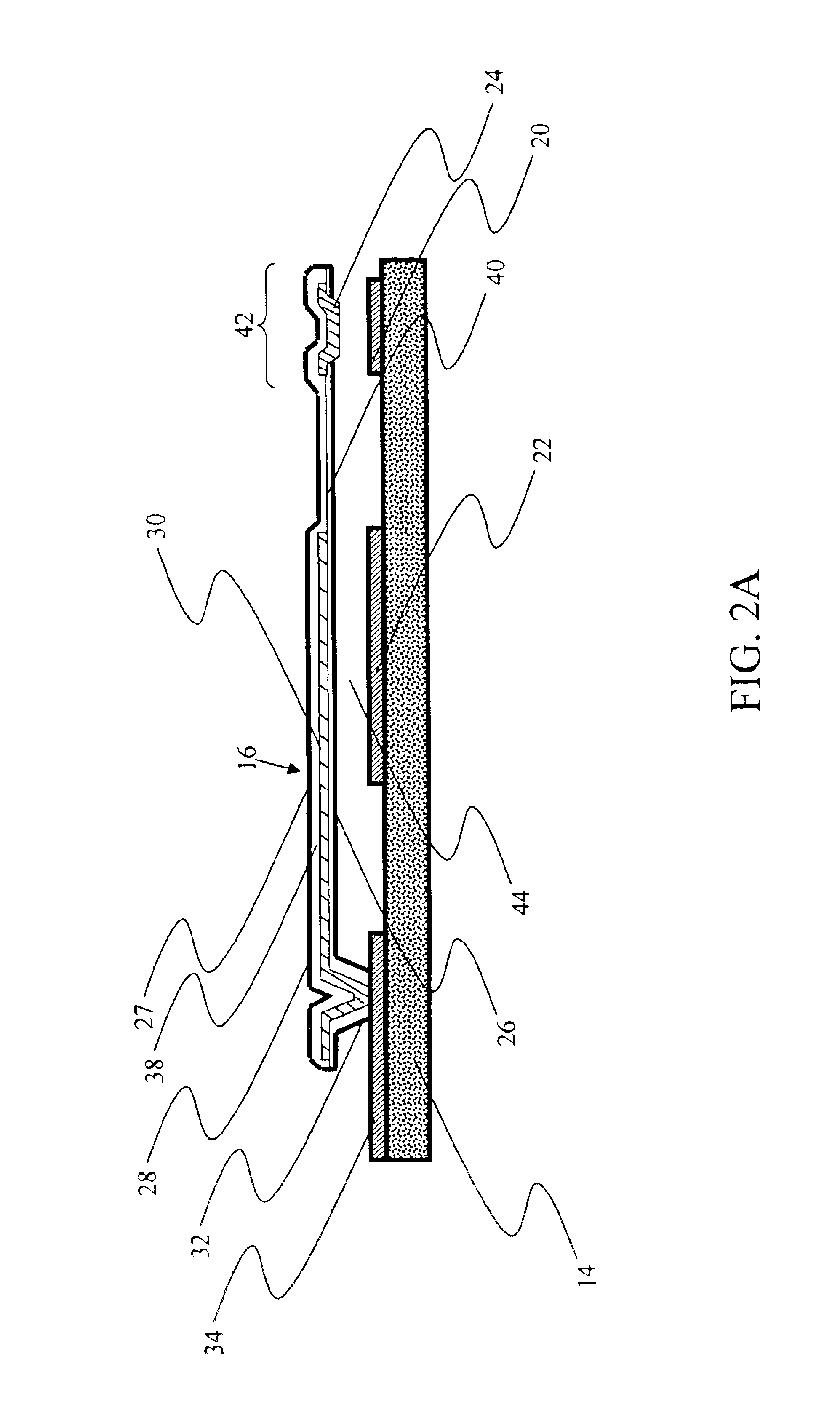

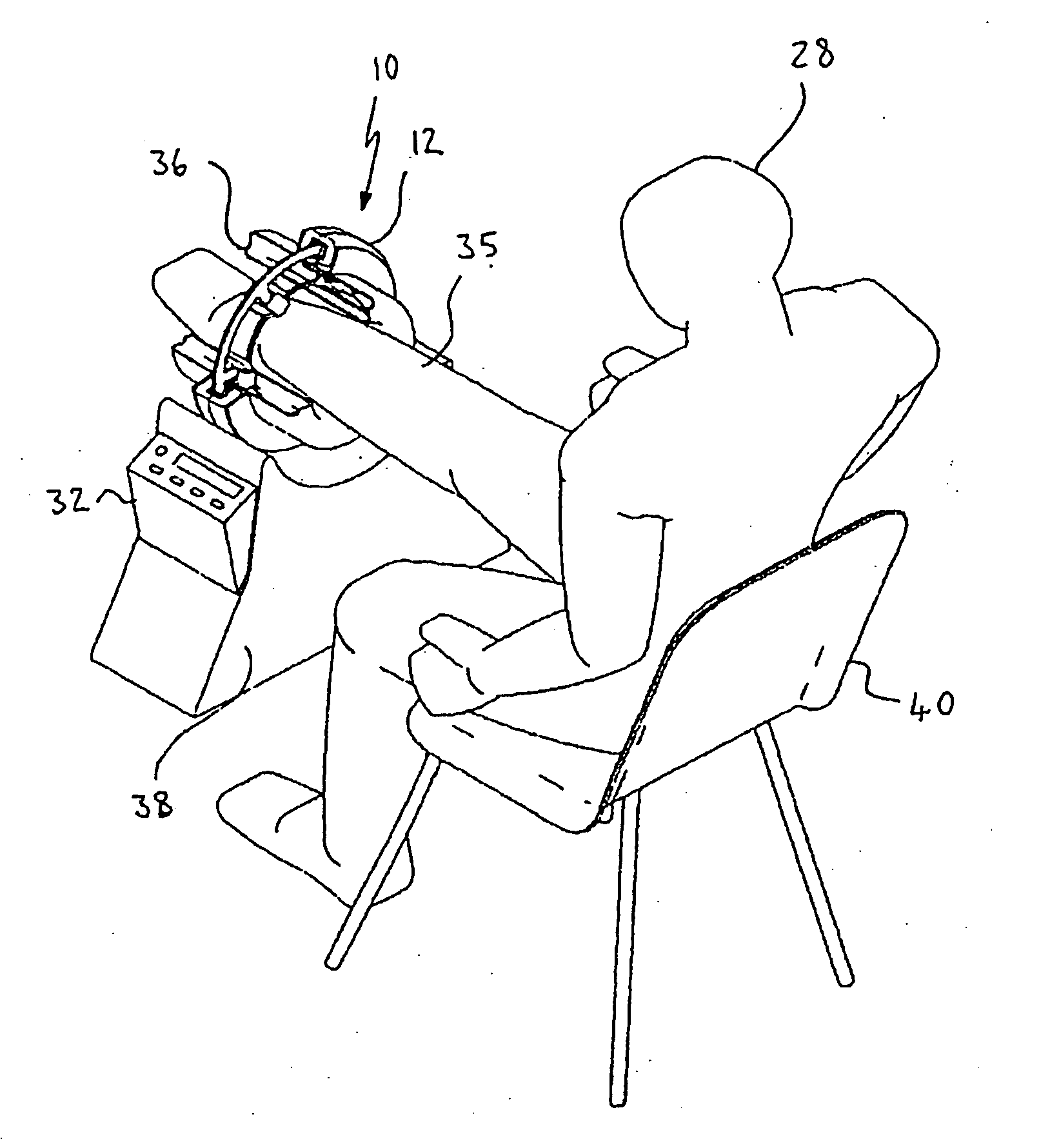

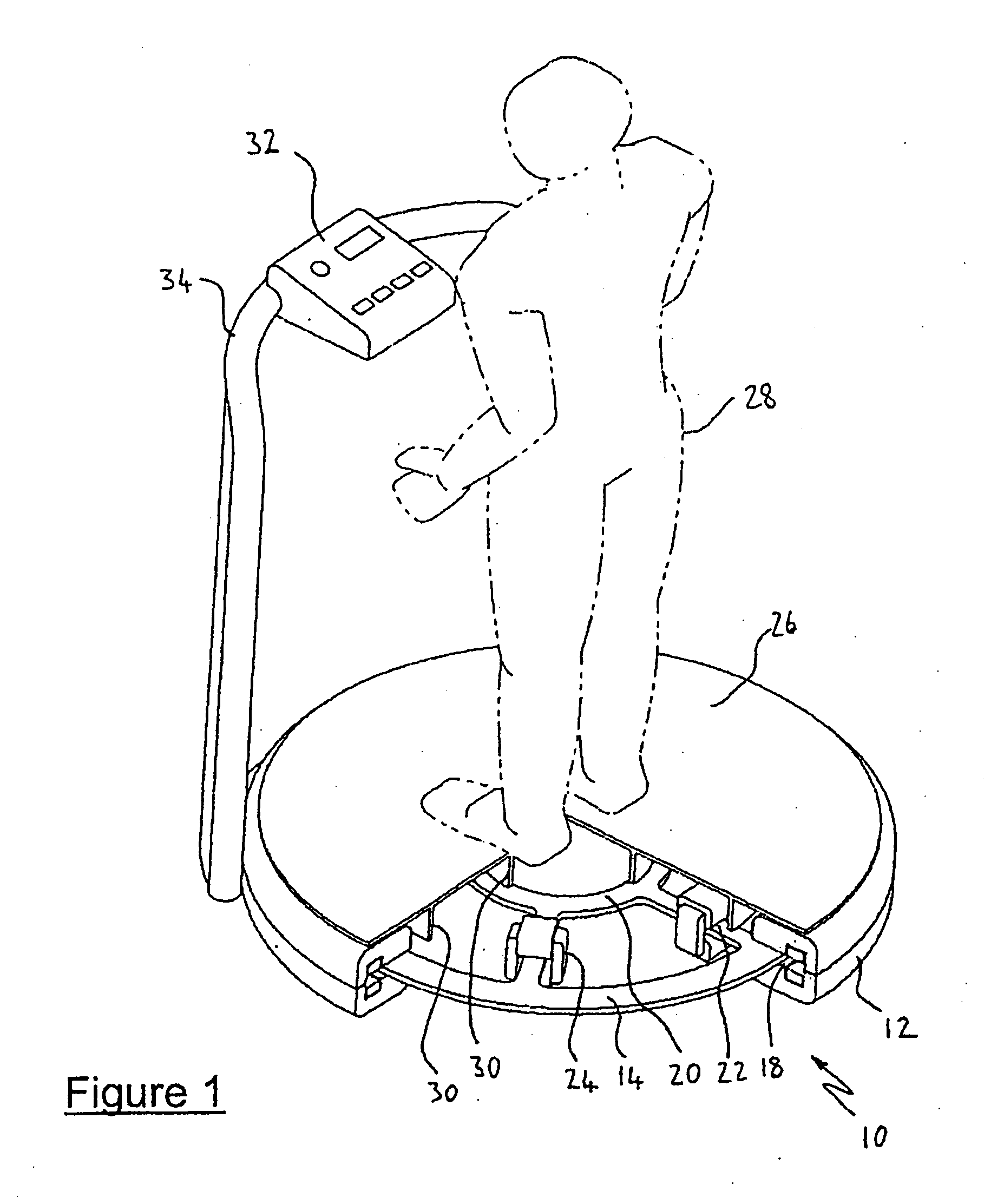

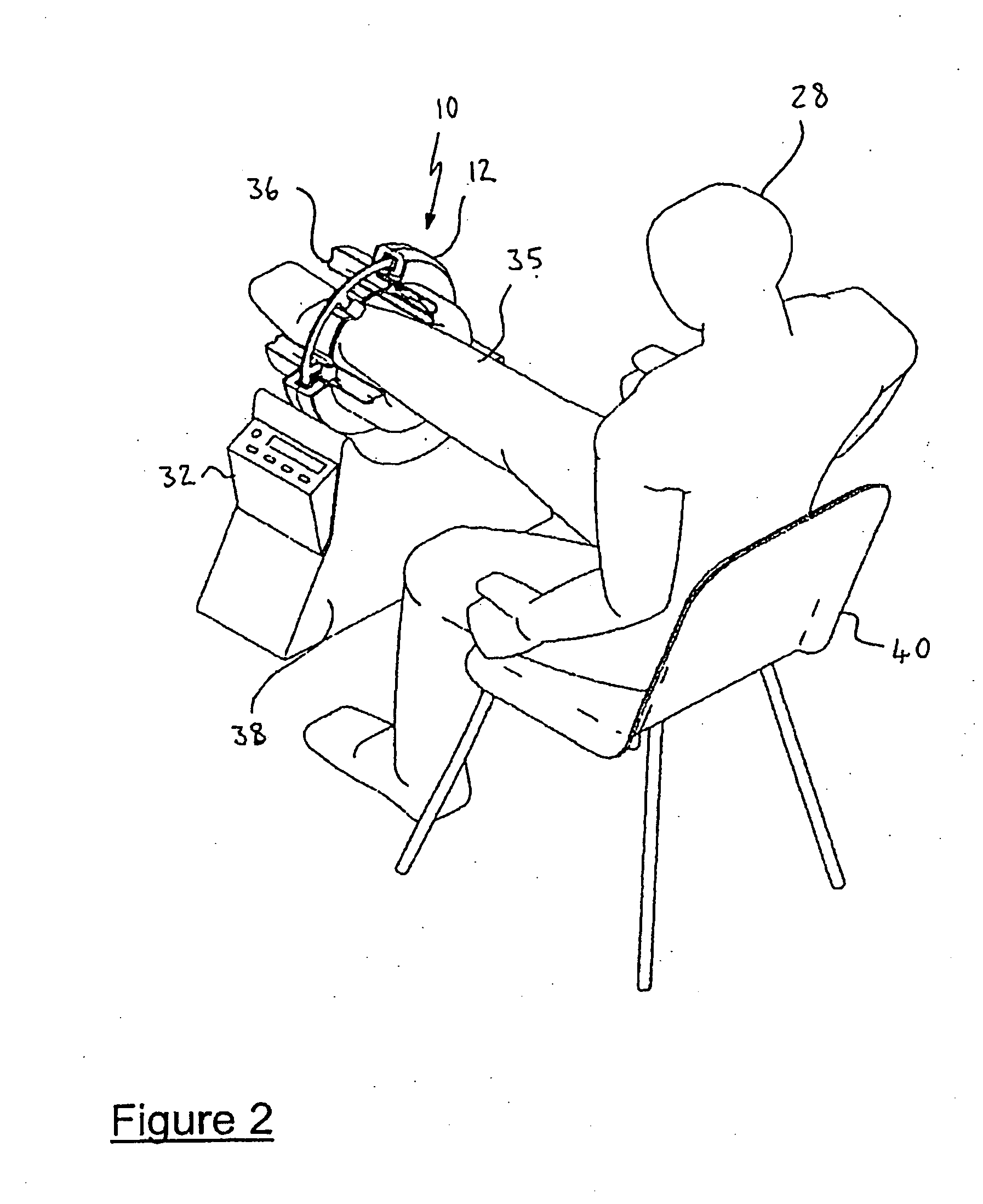

Medical apparatus, use and methods

InactiveUS7648471B2Maximize contact areaMove quicklyElectrotherapyChiropractic devicesTransducerBiomedical engineering

In accordance with one embodiment, a vibratory transducer has an armature suspended in a magnetic field. The armature has a plurality of electrical conductive paths to provide electrical current flow in said armature to react with said magnetic field and cause movement in the armature controlled by variation in the electrical current flow. A contact surface is secured to the armature, with a surface area for frictionally coupling to a corresponding surface area of a patient for example. Movement of the vibratory transducer induces movement in the patient, and the transducer can produce movement in the contact surface in at least two dimensions simultaneously. In one embodiment the contact surface is flat, while in alternative embodiments the contact surface is incorporated in a toroidal structure so as to surround part of the patient. Medical application can include treatment of bone fractures, oedema, and in elastography, amongst other applications.

Owner:MERLEX CORP PTY LTD

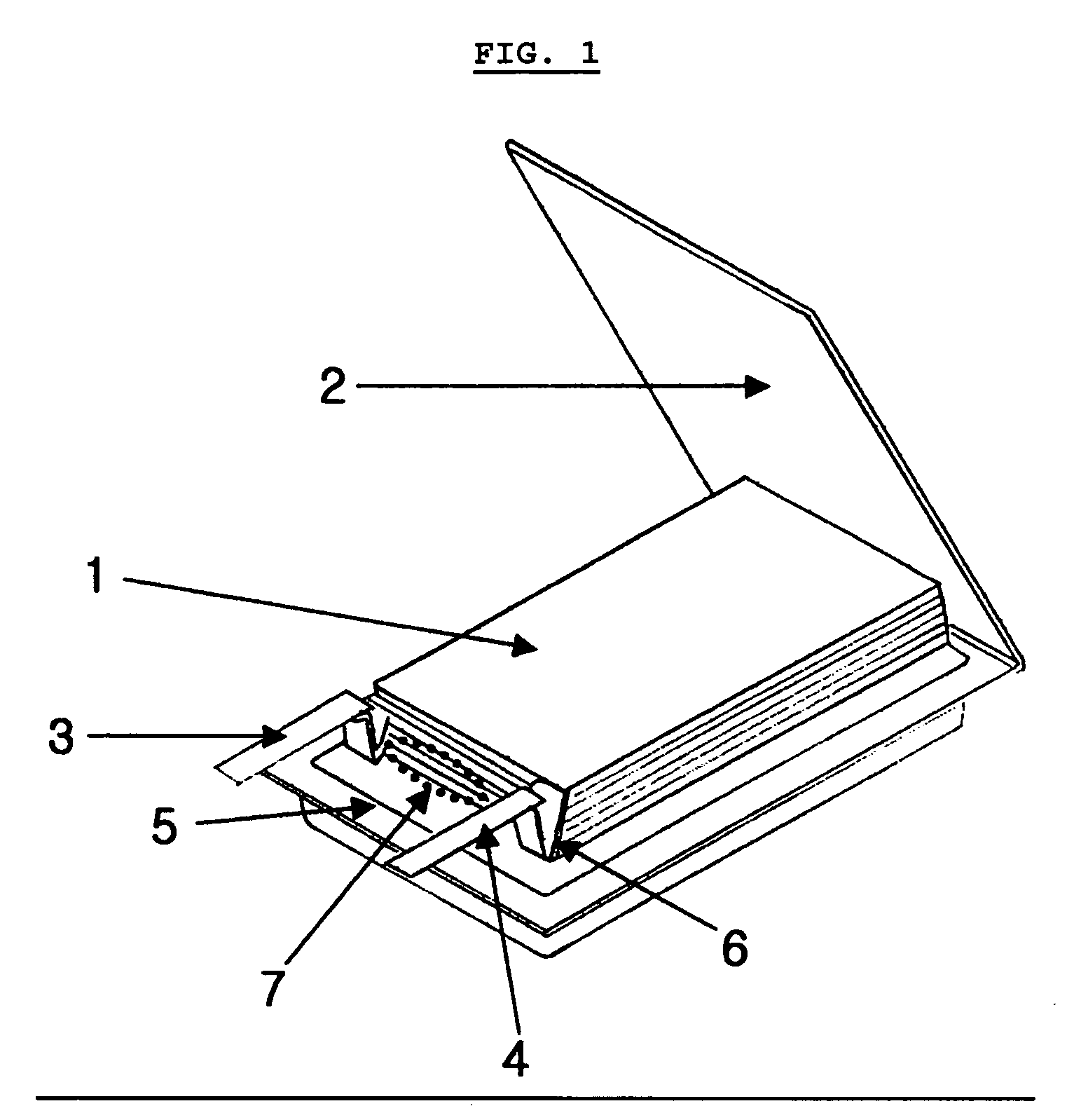

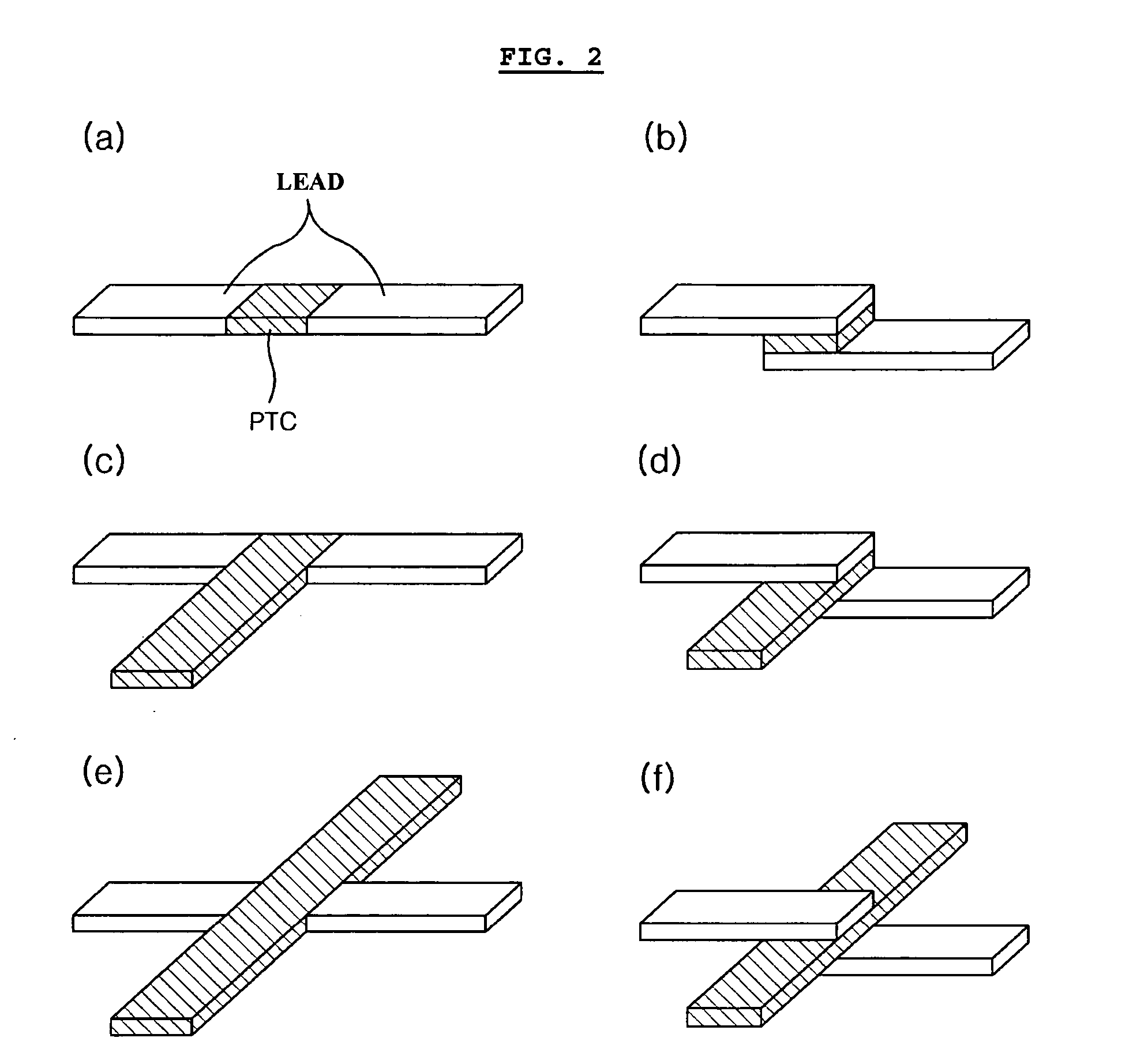

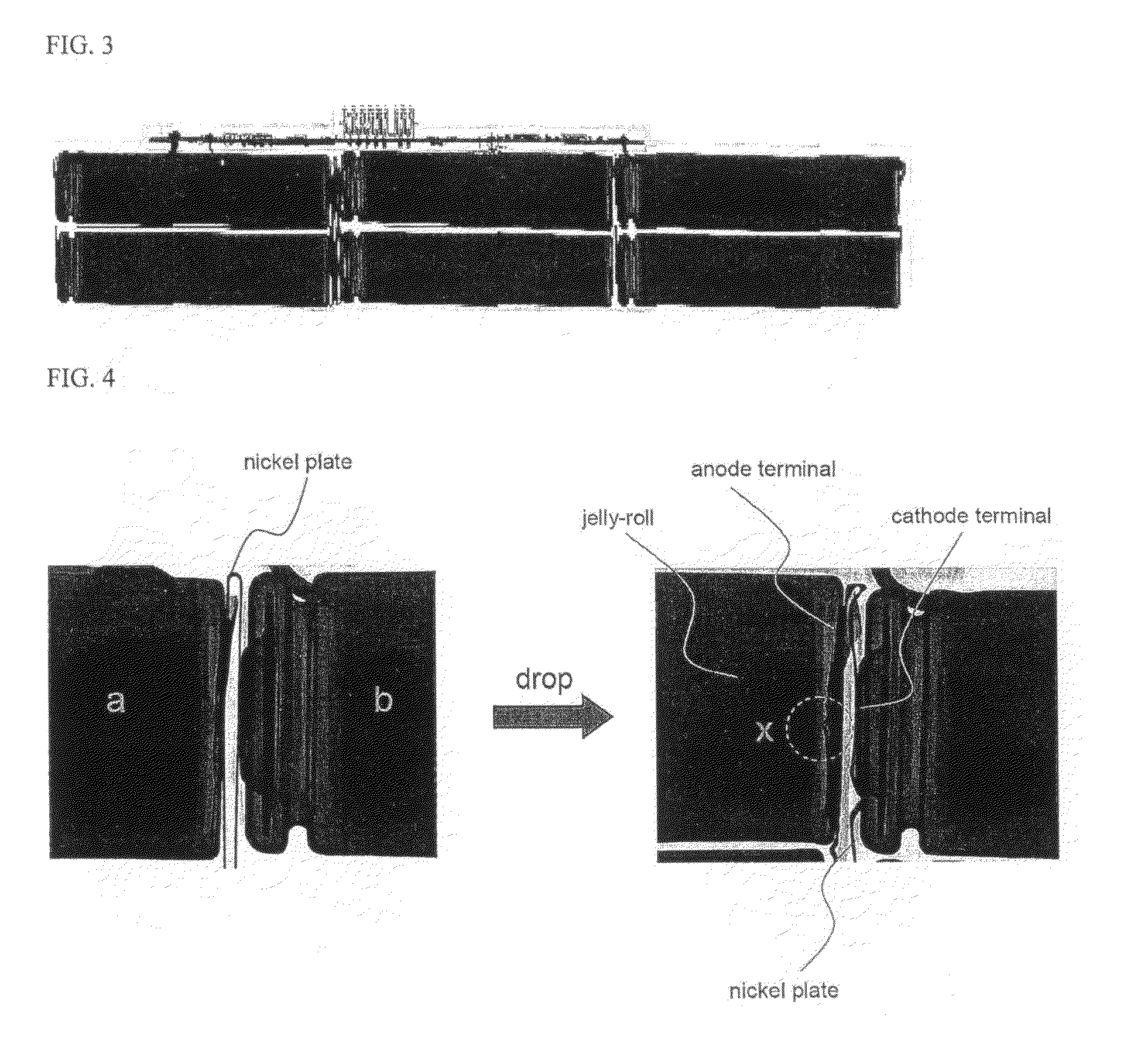

Electrochemical device comprising electrode lead having protection device

ActiveUS20060008698A1Minimized dropImprove the immunityPrimary cell maintainance/servicingNon-aqueous electrolyte accumulatorsEngineeringElectrochemistry

Disclosed is an electrochemical device including an electrode assembly having a cathode, anode and an electrolyte, and a casing surrounding the electrode assembly. The device further includes a protection device to which either or both of a cathode lead for connecting a cathode with an outer terminal and an anode lead for connecting an anode with an outer terminal are connected electrically, wherein the protection device is disposed in the inner space of the casing and the electrode lead equipped with the protection device is folded at both sides of the protection device so that the largest surface of the protection device is layered on a lateral surface of the casing where the electrode lead is present.

Owner:LG ENERGY SOLUTION LTD

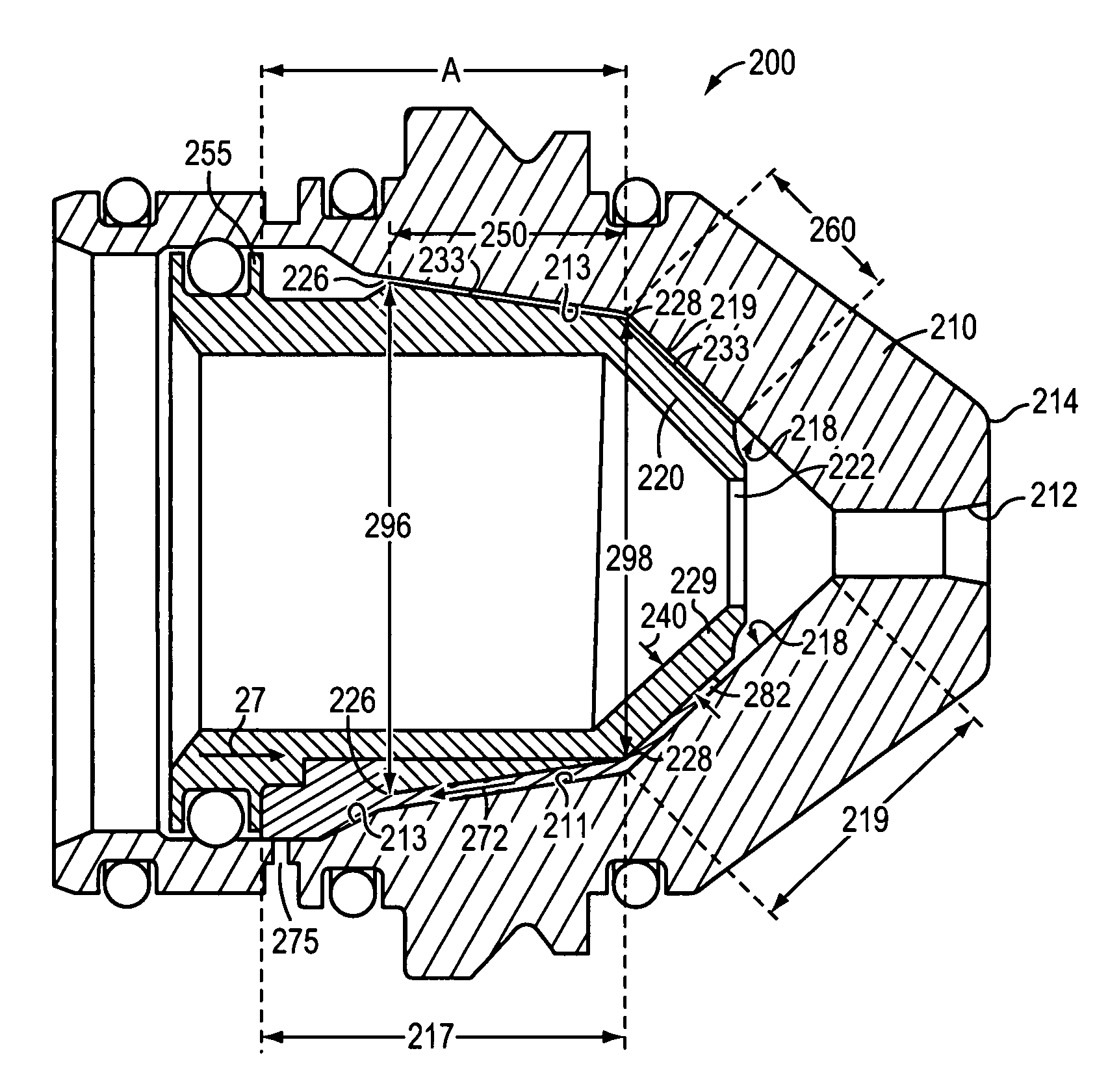

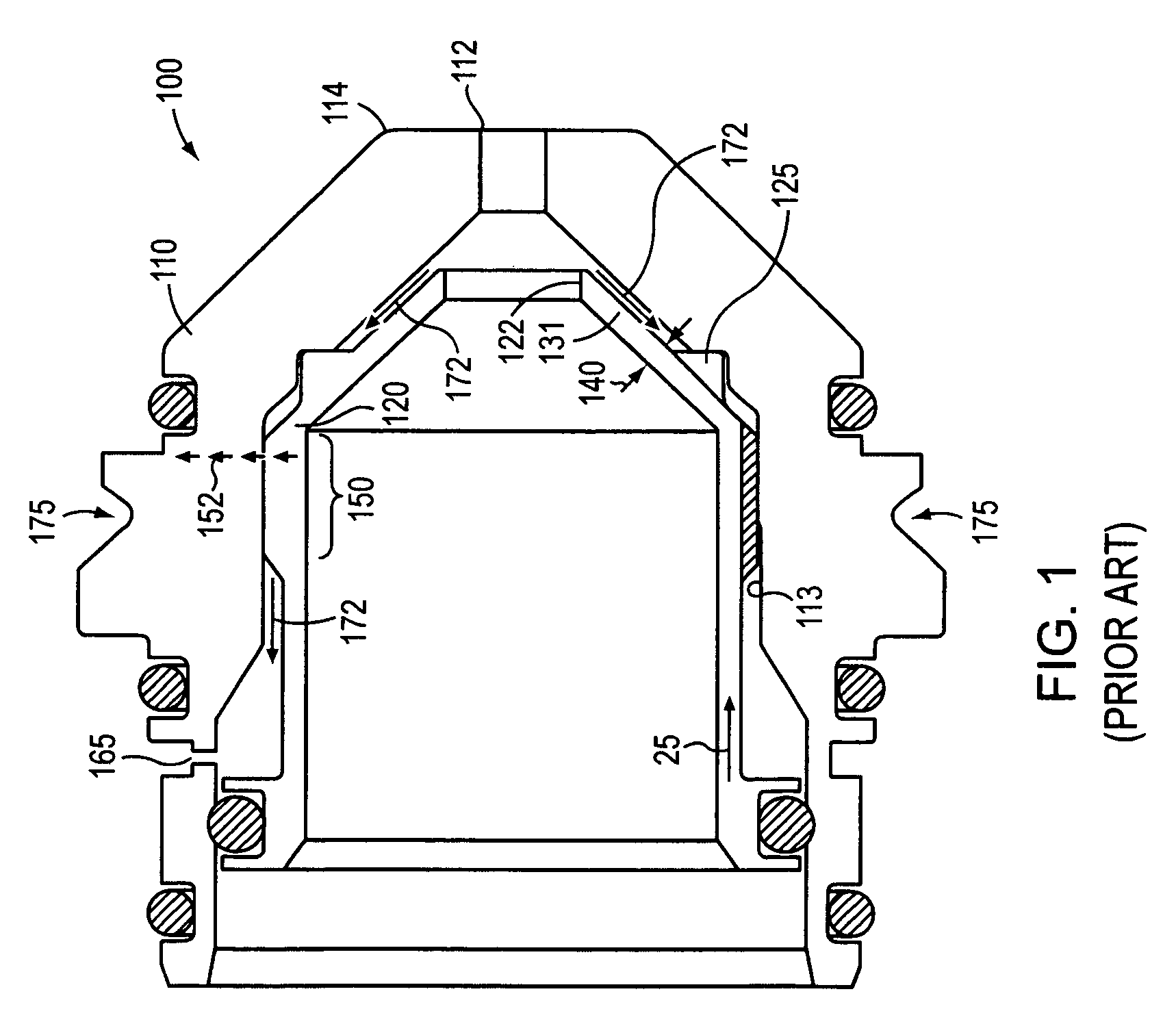

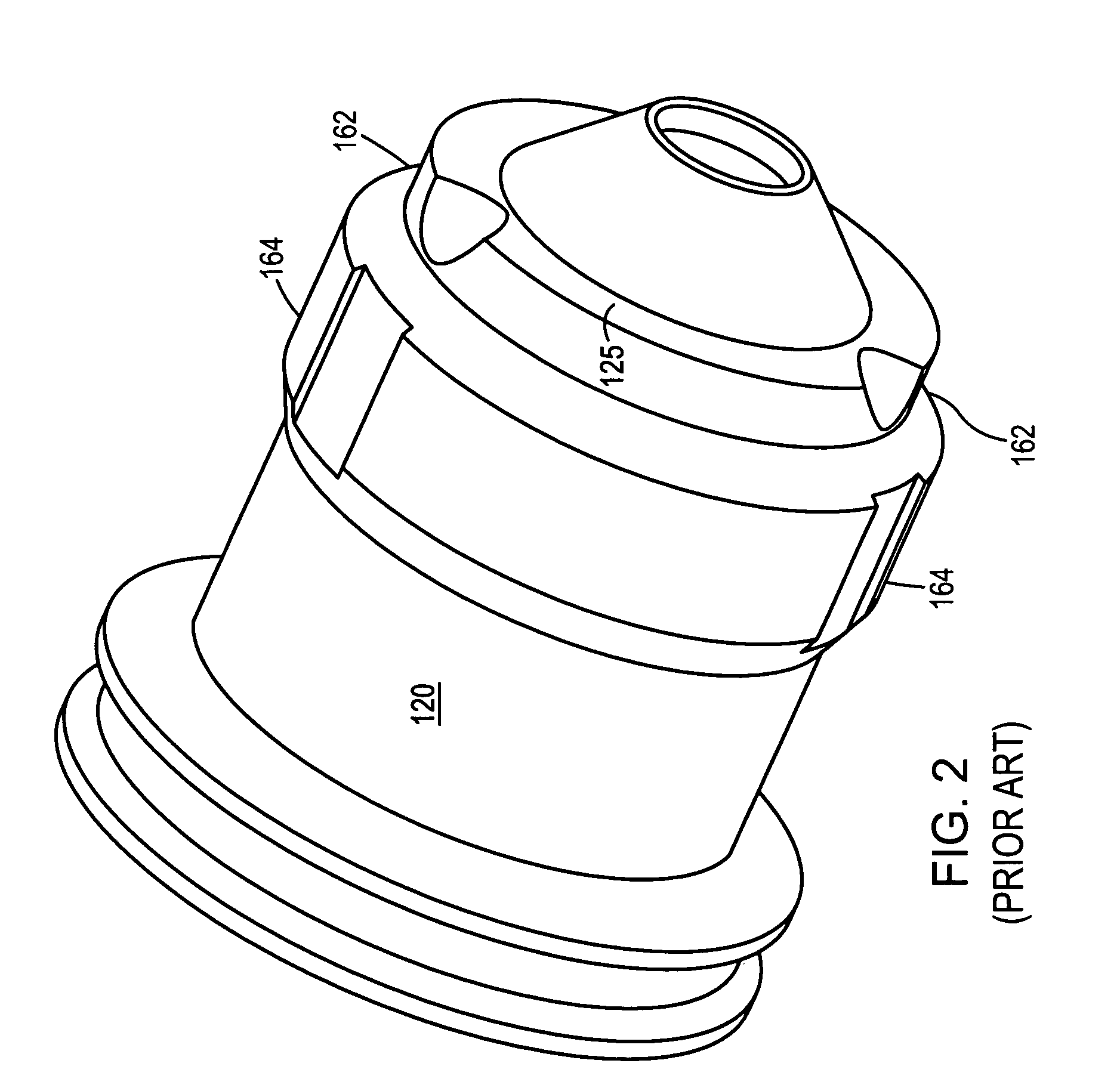

Apparatus for cooling plasma arc torch nozzles

ActiveUS7605340B2Maximize contact areaOvercome limitationsElectric heatingWelding/cutting media/materialsTorchThermal contact

The invention relates to a nozzle for a plasma arc torch and methods of manufacturing the nozzle. The nozzle includes a nozzle body and a nozzle liner. The nozzle body has a cylindrical portion and the nozzle liner has a cylindrical section in close thermal contact with a majority of an interior surface of a cylindrical portion of the nozzle body.

Owner:HYPERTHERM INC

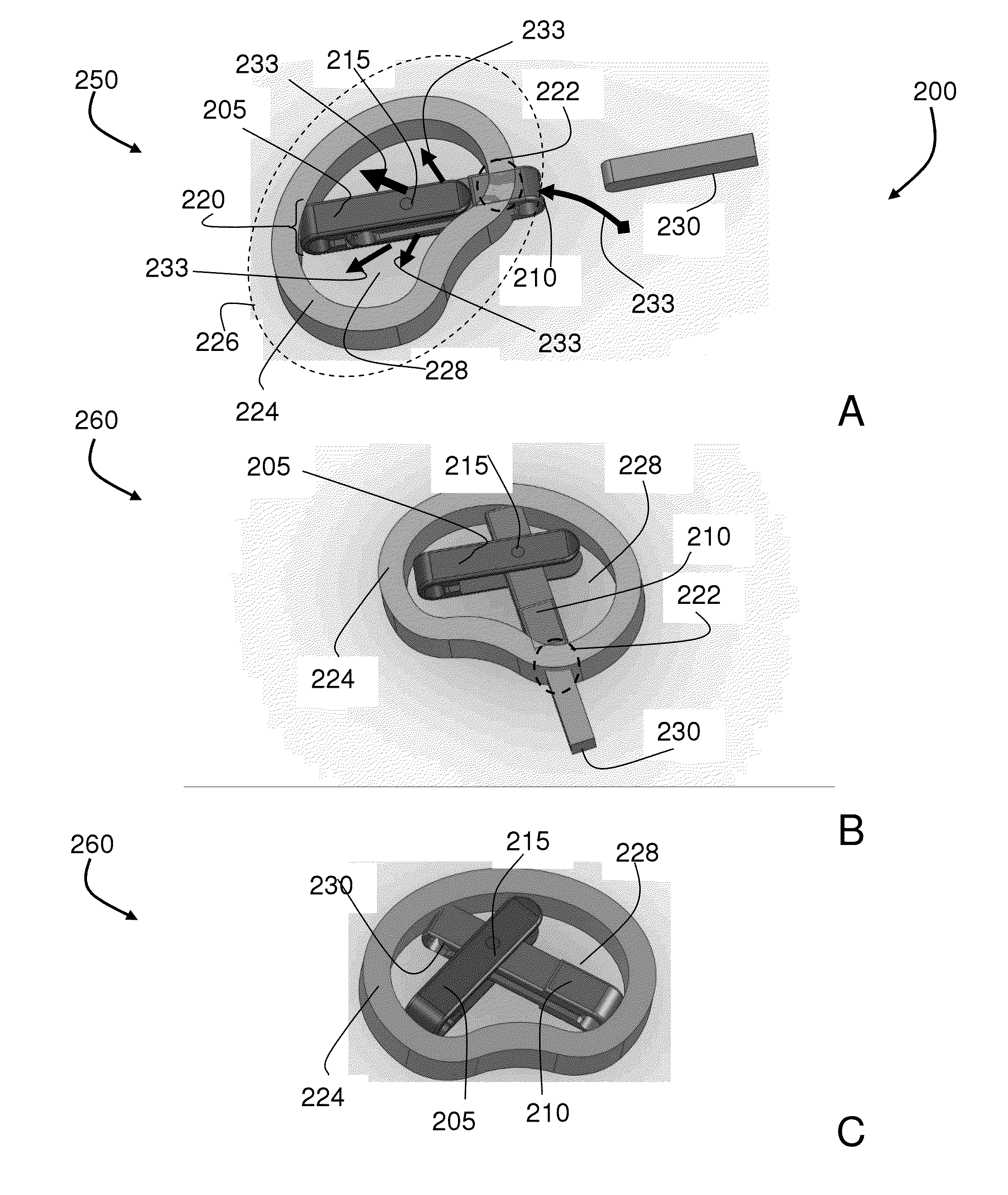

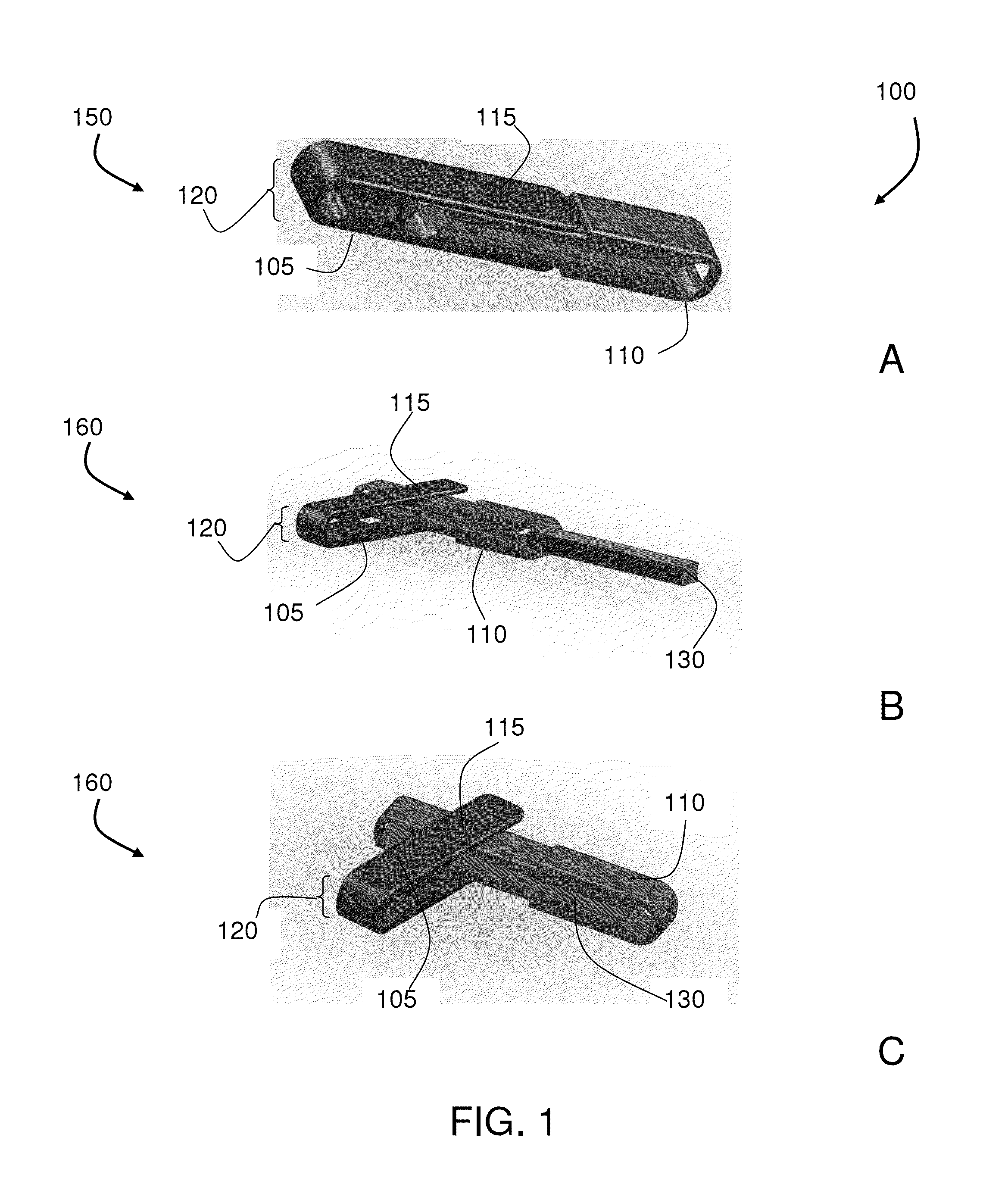

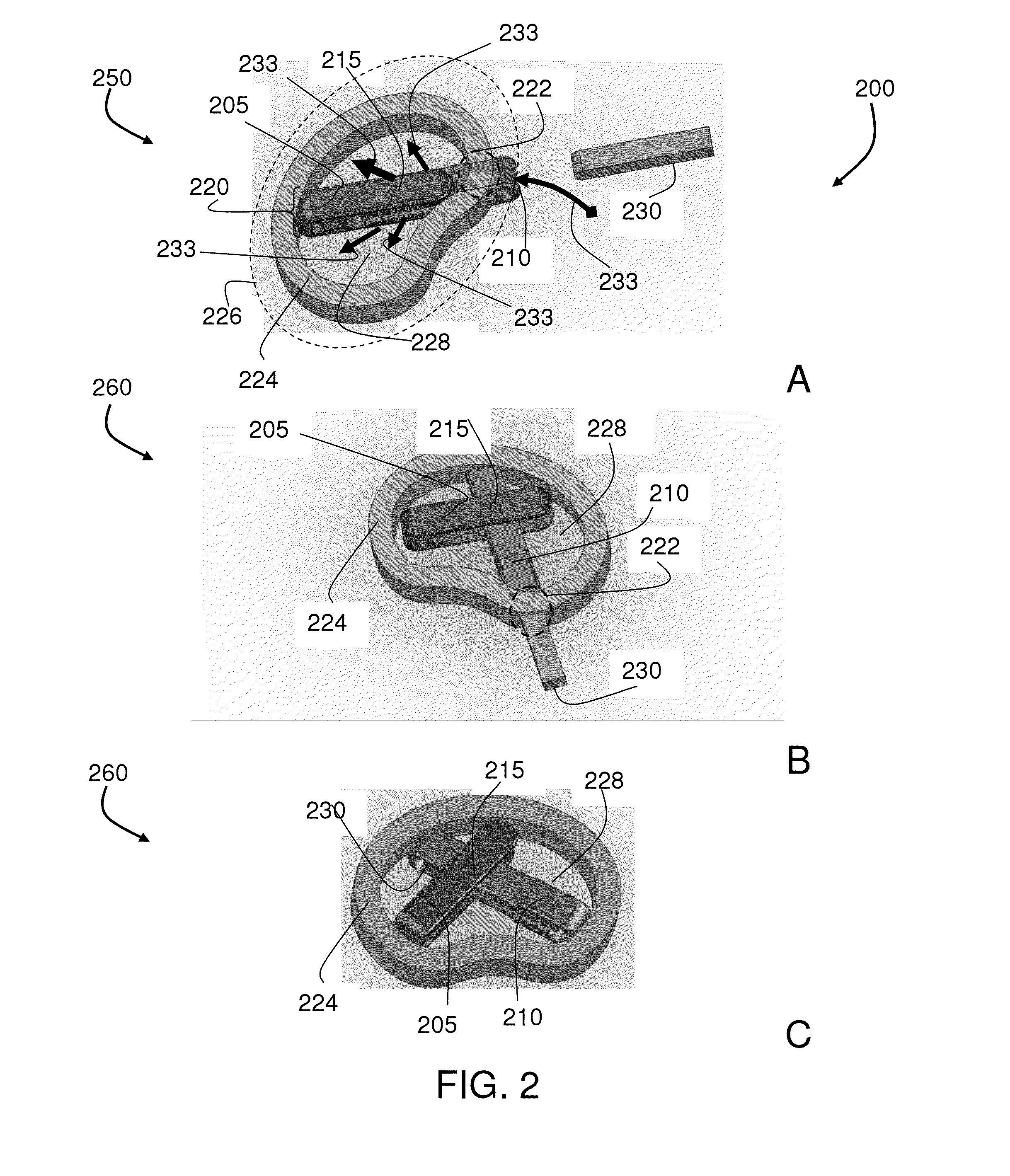

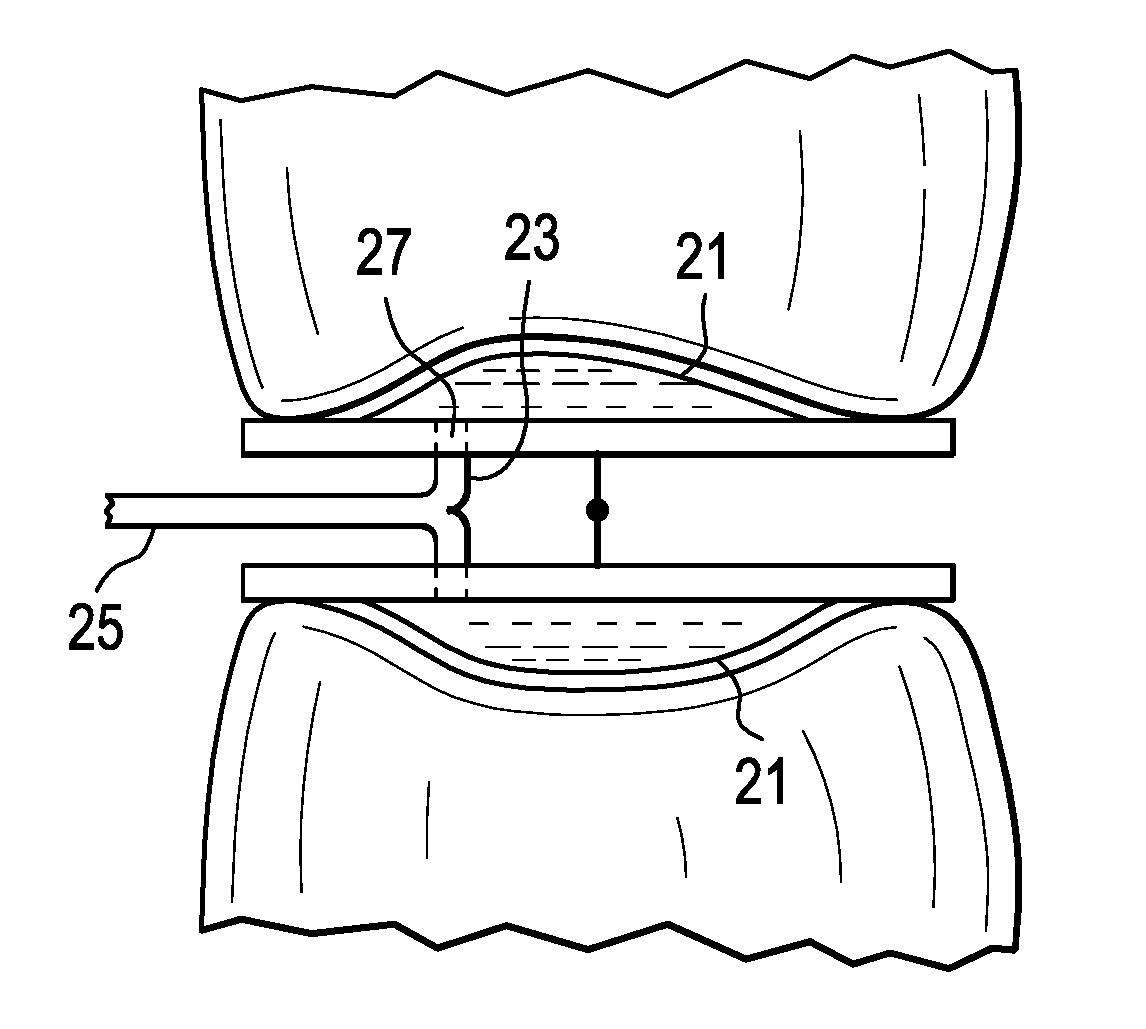

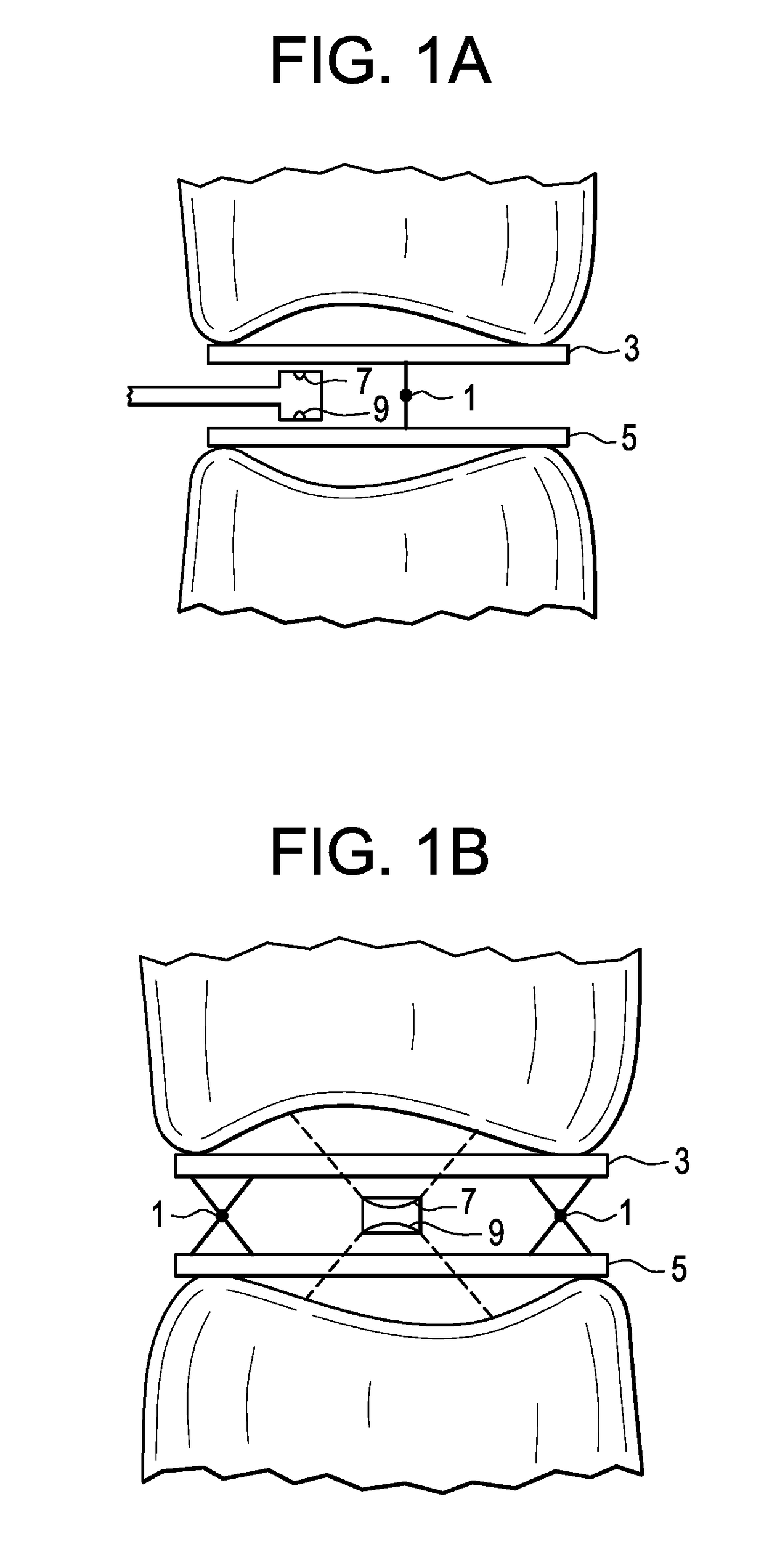

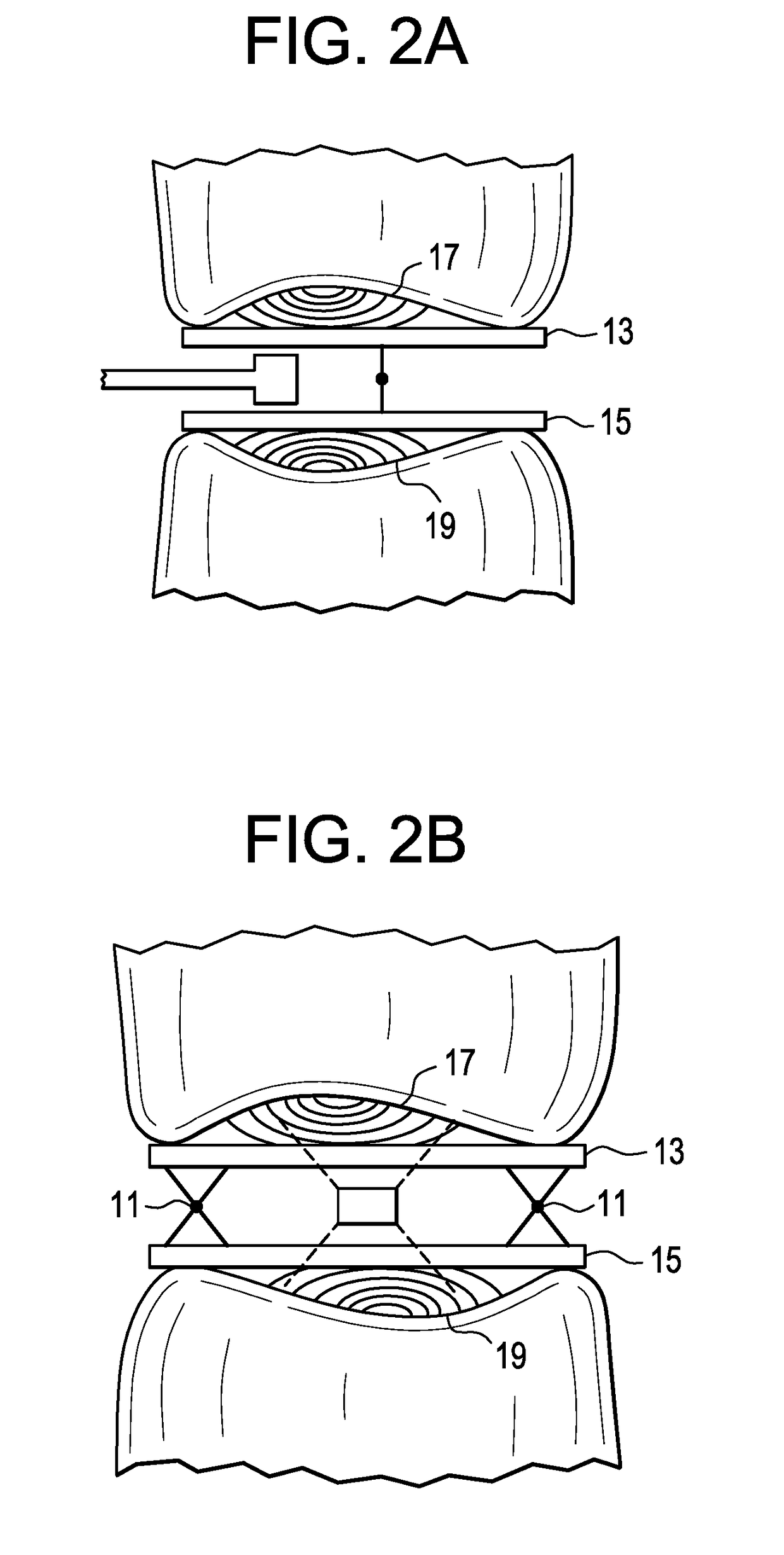

A minimally-invasive, laterovertically expanding, intervertebral disc scaffolding

InactiveUS20140039625A1Firm supportSimple materialBone implantJoint implantsDistractionMini invasive surgery

A laterovertically expandable scaffolding is provided for supporting an intervertebral disc space using a minimally invasive procedure. The scaffolding can be configured to provide a low-profile entry in a collapsed configuration through the single point of entry through the annulus. The expanding including laterally expanding at least a portion of a first support and at least a portion of a second support away from each other; and, vertically expanding at least a portion of the first support or at least a portion of the second support for a distraction of the intervertebral space. The lateral movement can include a rotation at a point of intersection between the first support and the second support, the intersection being biased anteriorly in the intevertebral space to facilitate the adding of the grafting material.

Owner:SPIDER TEK

Patient-Specific Spinal Fusion Cage and Methods of Making Same

ActiveUS20170354510A1Maximize contact areaReduces expulsionMusculoskeletal system evaluationSurgeryFluoroscopic imagingDirect imaging

A method of determining disc space geometry with the use of an expandable trial having endplate-mapping capabilities. An expandable trial is inserted into the disc space and its height is adjusted to obtain the desired decompression and spinal alignment (which is typically confirmed with the use of CT or Fluoroscopic imaging). The endplate dome / geometry dome is then determined by one of the following three methods:a) direct imaging through the trial,b) balloon moldings filled with flowable in-situ fluid (for example, silicon, polyurethane, or PMMA) from superior / inferior endplates orc) light-based imaging through superior & inferior balloons.

Owner:DEPUY SYNTHES PROD INC

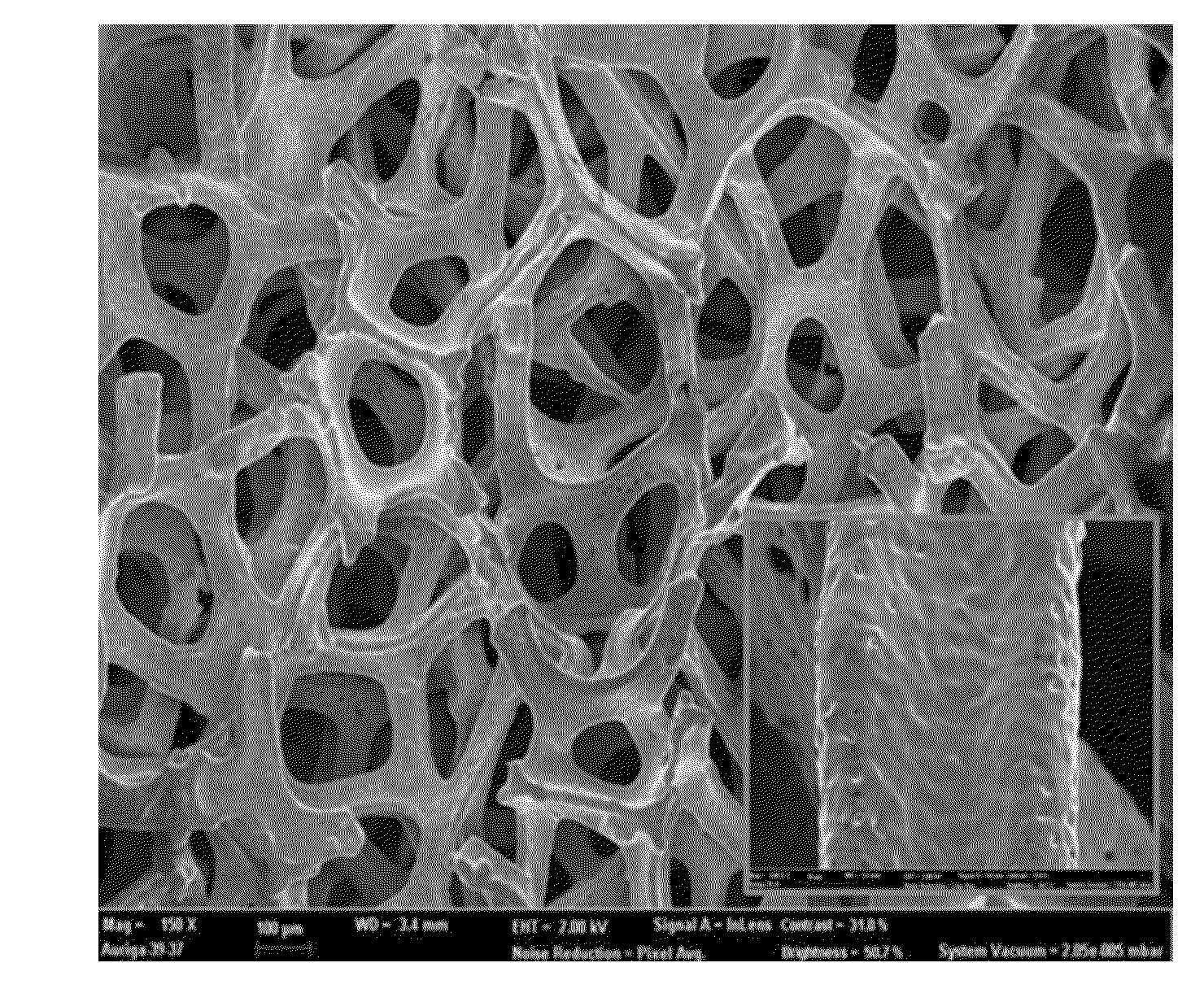

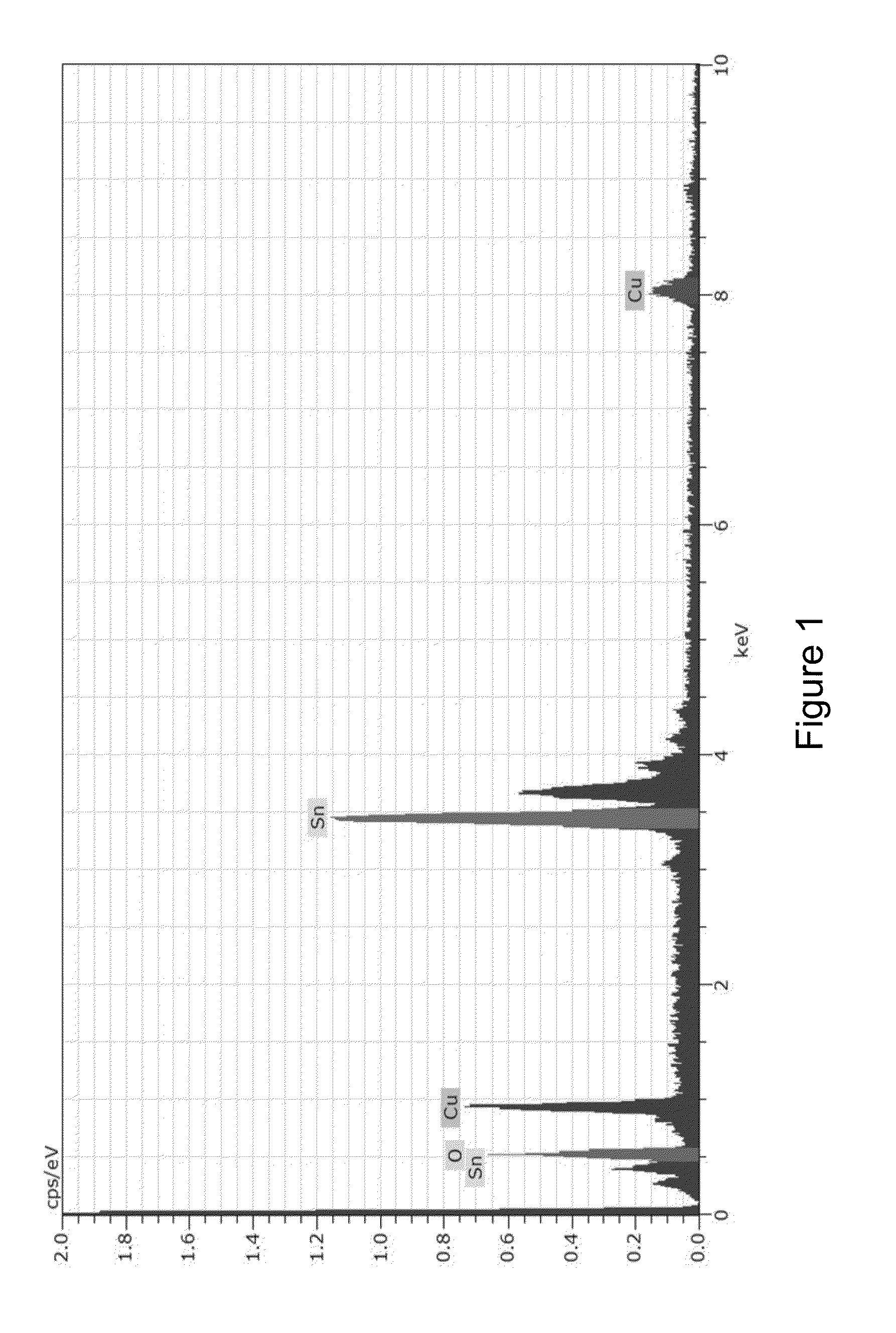

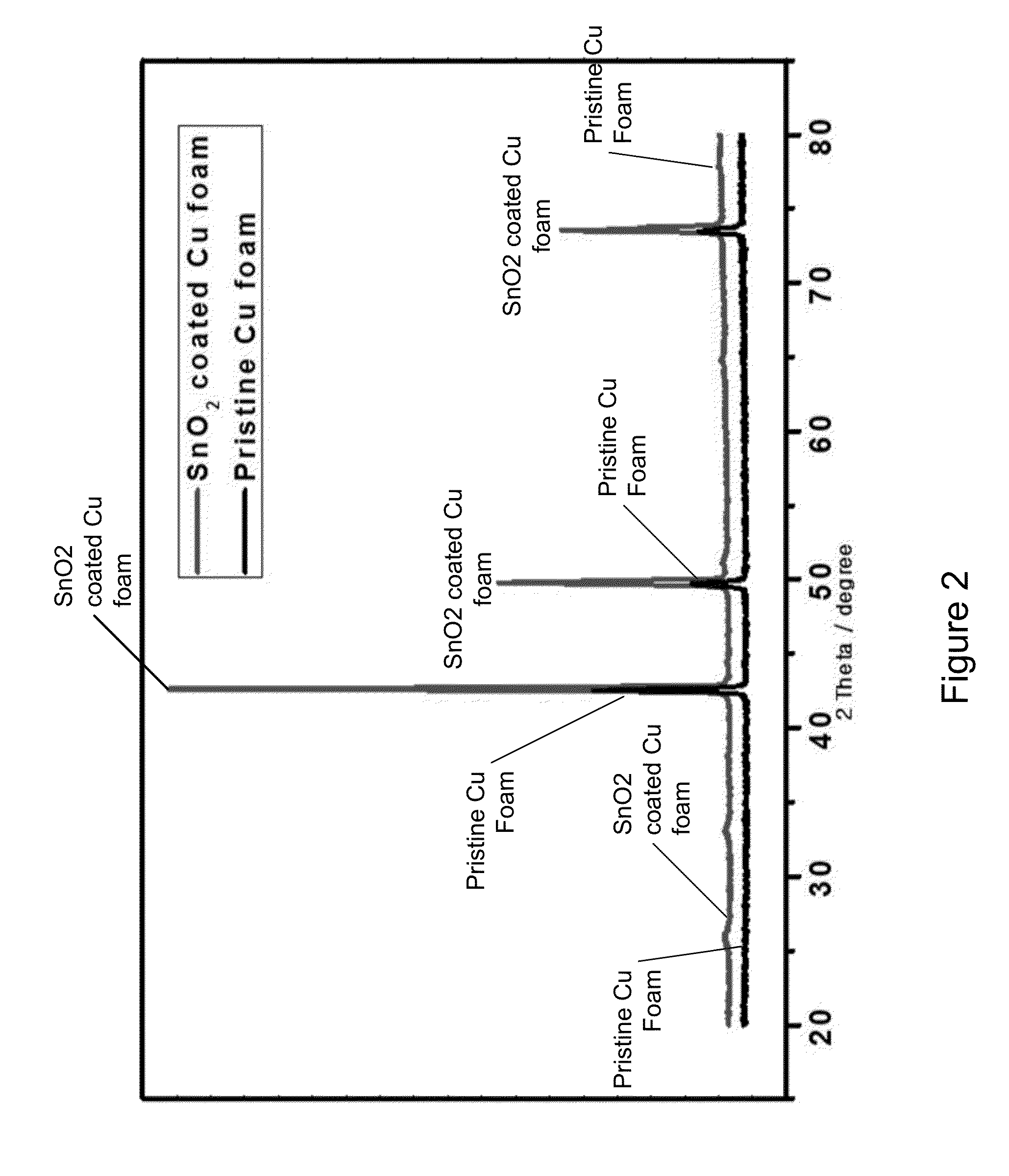

Metal Foam for Electrode of Secondary Lithium Battery, Preparing Method Thereof, and Secondary Lithium Battery Including the Metal Foam

ActiveUS20150072236A1Improve abilitiesImprove featuresSilver accumulatorsElectrode thermal treatmentMetal foamMaterials science

Using metal foams for the electrode of secondary lithium battery, preparing method thereof, and secondary lithium battery including the metal foam. A metal foam is used in an electrode of secondary lithium battery where the surface and the inner pore walls are coated with the active materials, a method of manufacturing such metal foam, and secondary lithium battery including the metal foam.

Owner:CELLMO MATERIALS INNOVATION INC

Patient-specific spinal fusion cage and methods of making same

ActiveUS9757245B2Maximize contact areaReduces expulsionMusculoskeletal system evaluationInternal osteosythesisSpinal columnFluoroscopic imaging

A method of determining disc space geometry with the use of an expandable trial having endplate-mapping capabilities. An expandable trial is inserted into the disc space and its height is adjusted to obtain the desired decompression and spinal alignment (which is typically confirmed with the use of CT or Fluoroscopic imaging). The endplate dome / geometry dome is then determined by one of the following three methods:a) direct imaging through the trial,b) balloon moldings filled with flowable in-situ fluid (for example, silicon, polyurethane, or PMMA) from superior / inferior endplates orc) light-based imaging through superior & inferior balloons.

Owner:DEPUY SYNTHES PROD INC

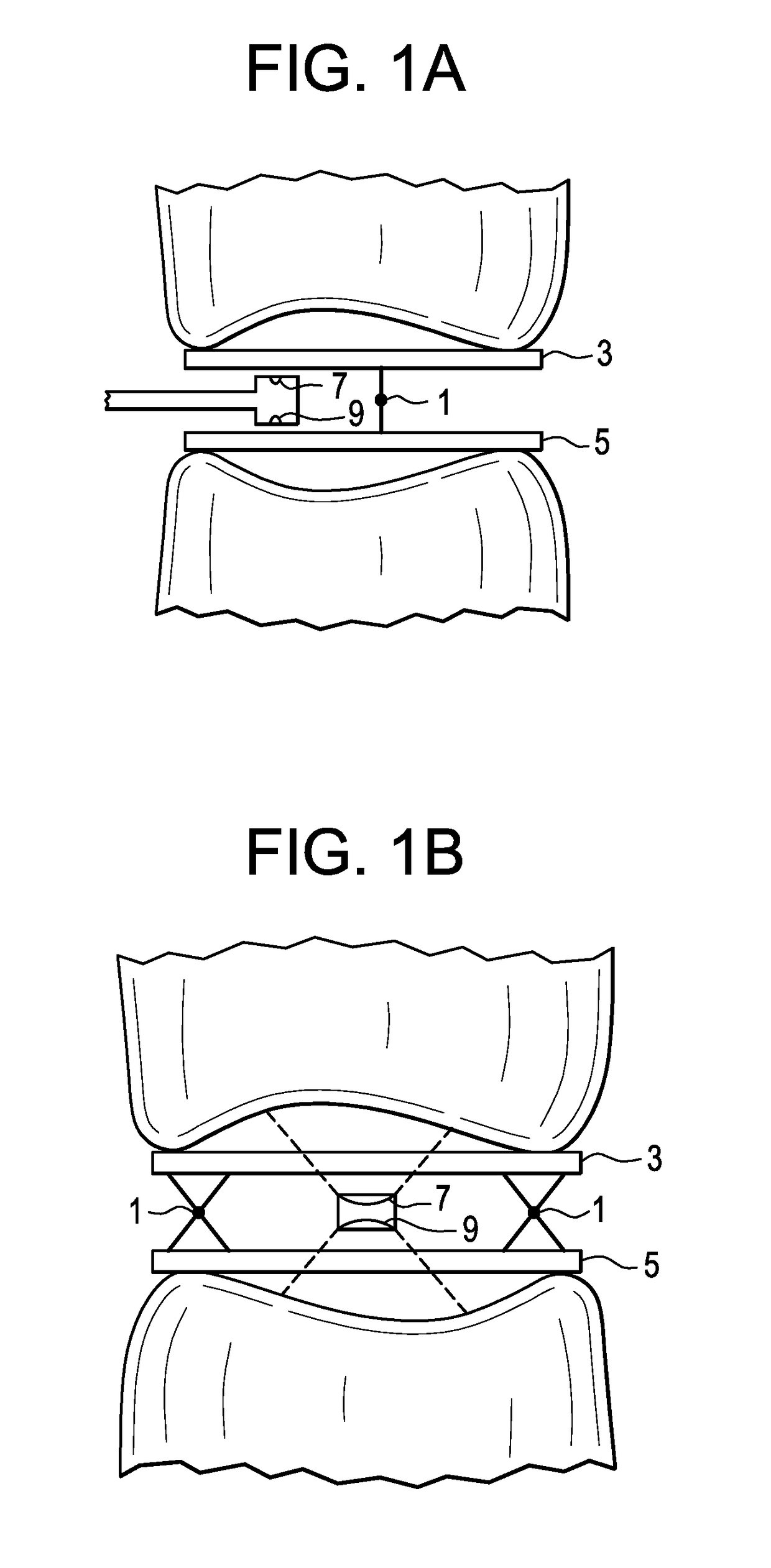

Electrical connecting member for secondary battery

ActiveUS20110104958A1Easy to manufactureContact areaCoupling device detailsCell component detailsElectricityElectrical connection

Disclosed herein is a connection member for secondary batteries to achieve the electrical connection in a battery pack including two or more cylindrical secondary batteries in a physical contact manner, the connection member including an outer circumferential contact part contacting an electrode terminal of a lower battery cell along the outer circumferential region of the electrode terminal of the lower battery cell, such that the outer circumferential contact part can be electrically connected to the electrode terminal of the lower battery cell in a surface contact manner, for minimizing the change of resistance at the contact region against an external force and restraining a possibility that the electrode terminal of the lower battery cell is depressed, and a central contact part contacting an electrode terminal of an upper battery cell or the central region of a sidewall of the battery pack for providing an elastic contact force to the entire connection member mounted between the electrode terminals of the respective battery cells or between the electrode terminals of the battery cells and the sidewall of the battery pack.

Owner:LG ENERGY SOLUTION LTD

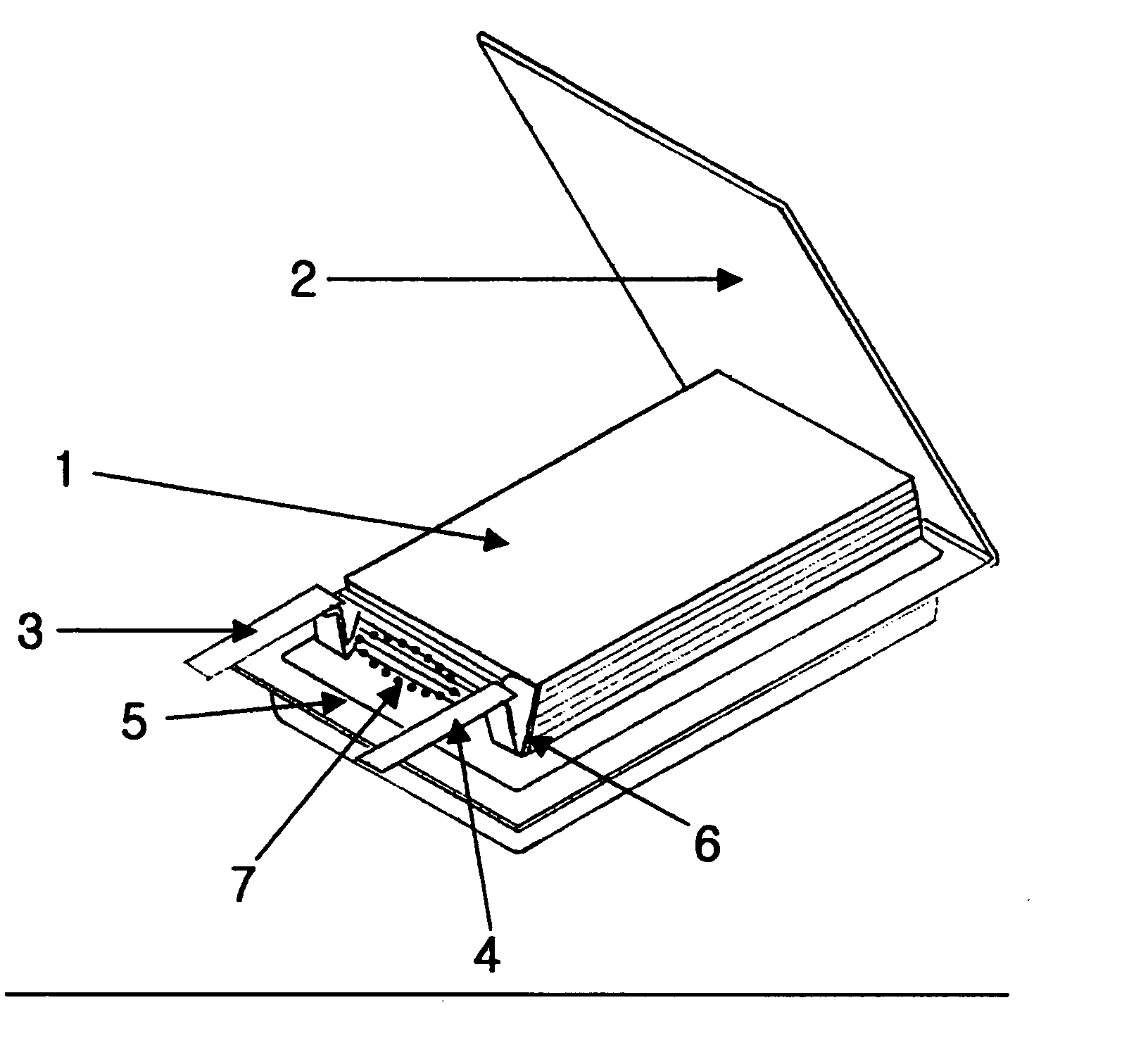

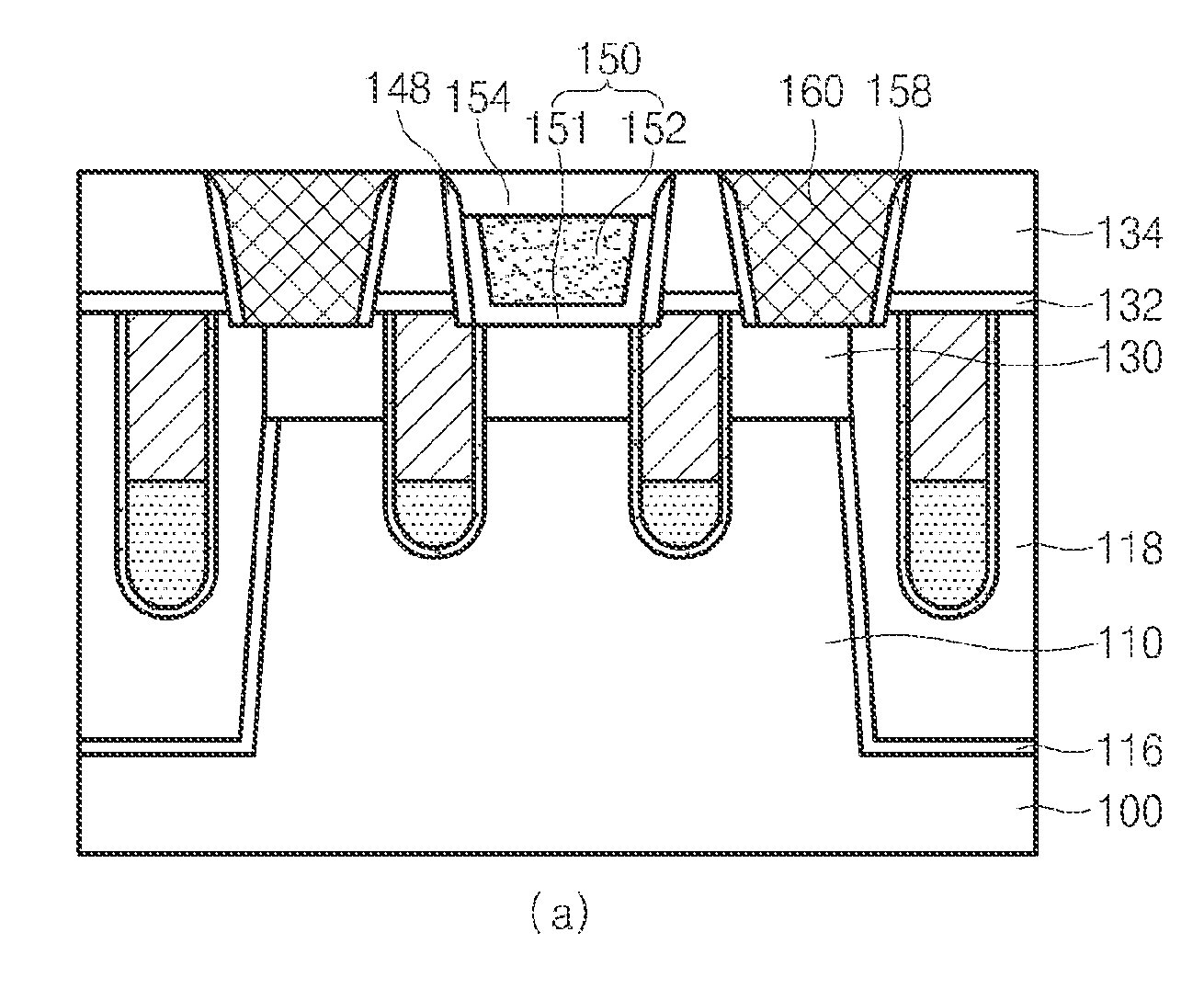

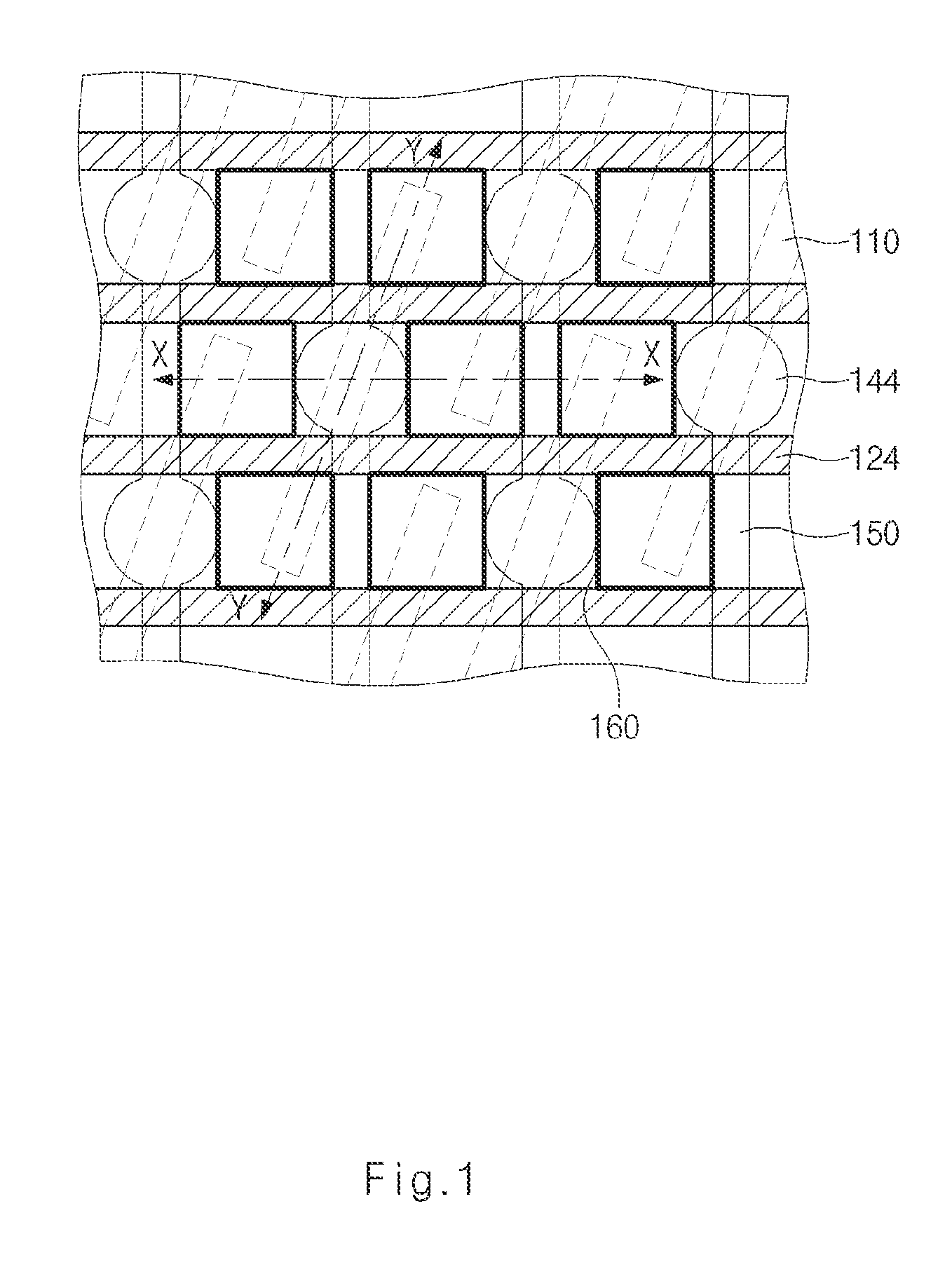

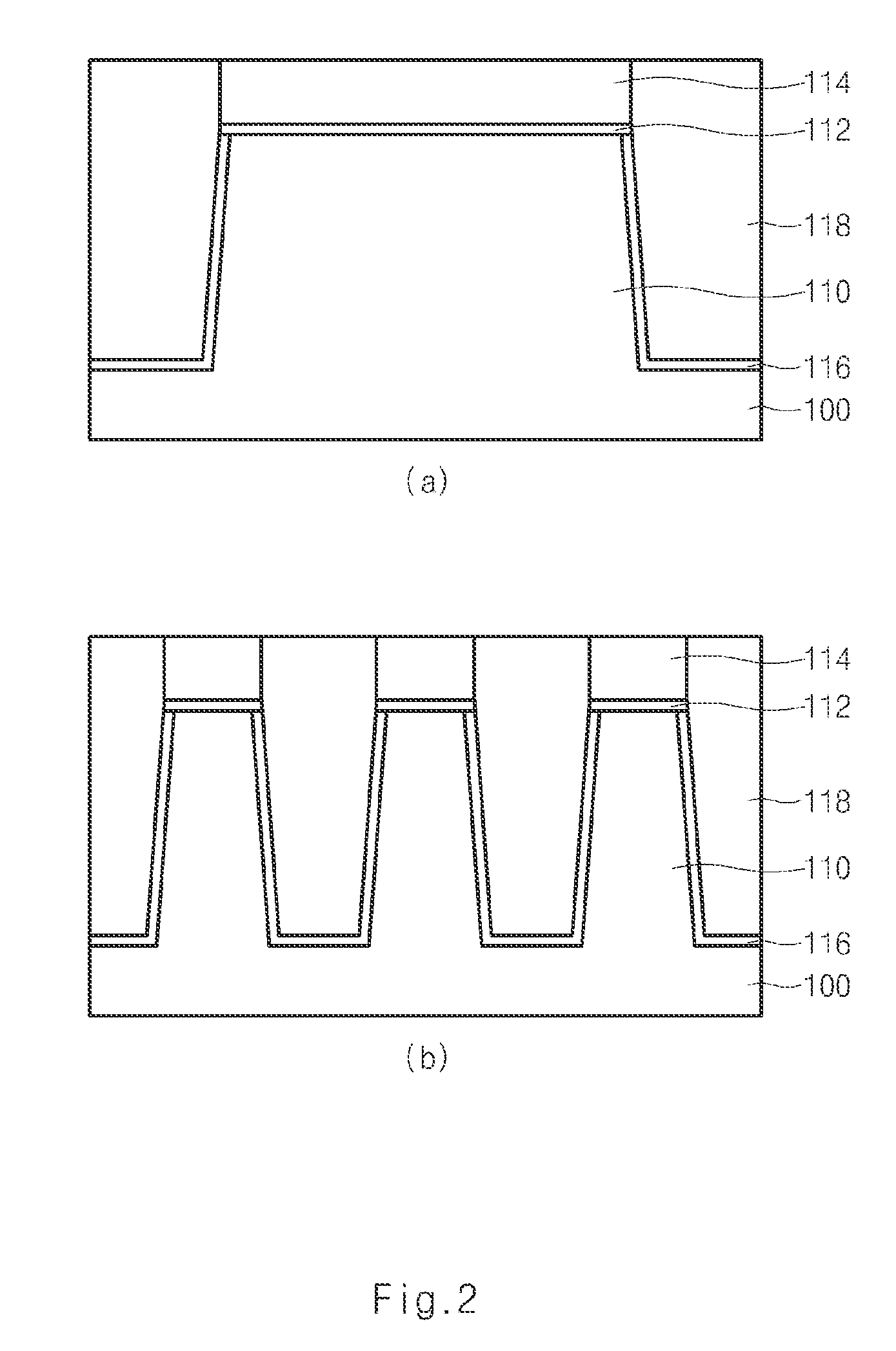

Manufacturing method of capacitor in semiconductor device

ActiveUS20110070716A1Exquisite patternIncrease contact areaTransistorSolid-state devicesBit lineContact resistance

Example embodiment is provided to a method for manufacturing a semiconductor device, including forming a hard mask layer on a buried bit line and forming a storage node contact hole by using the selectivity between an interlayer insulating layer and the hard mask layer, thereby forming a contact hole using a mask of a line pattern instead of a hole pattern. Accordingly, a mask for the contact hole can be easily fabricated and the contact area can be maximized, thereby reducing the contact resistance.

Owner:SK HYNIX INC

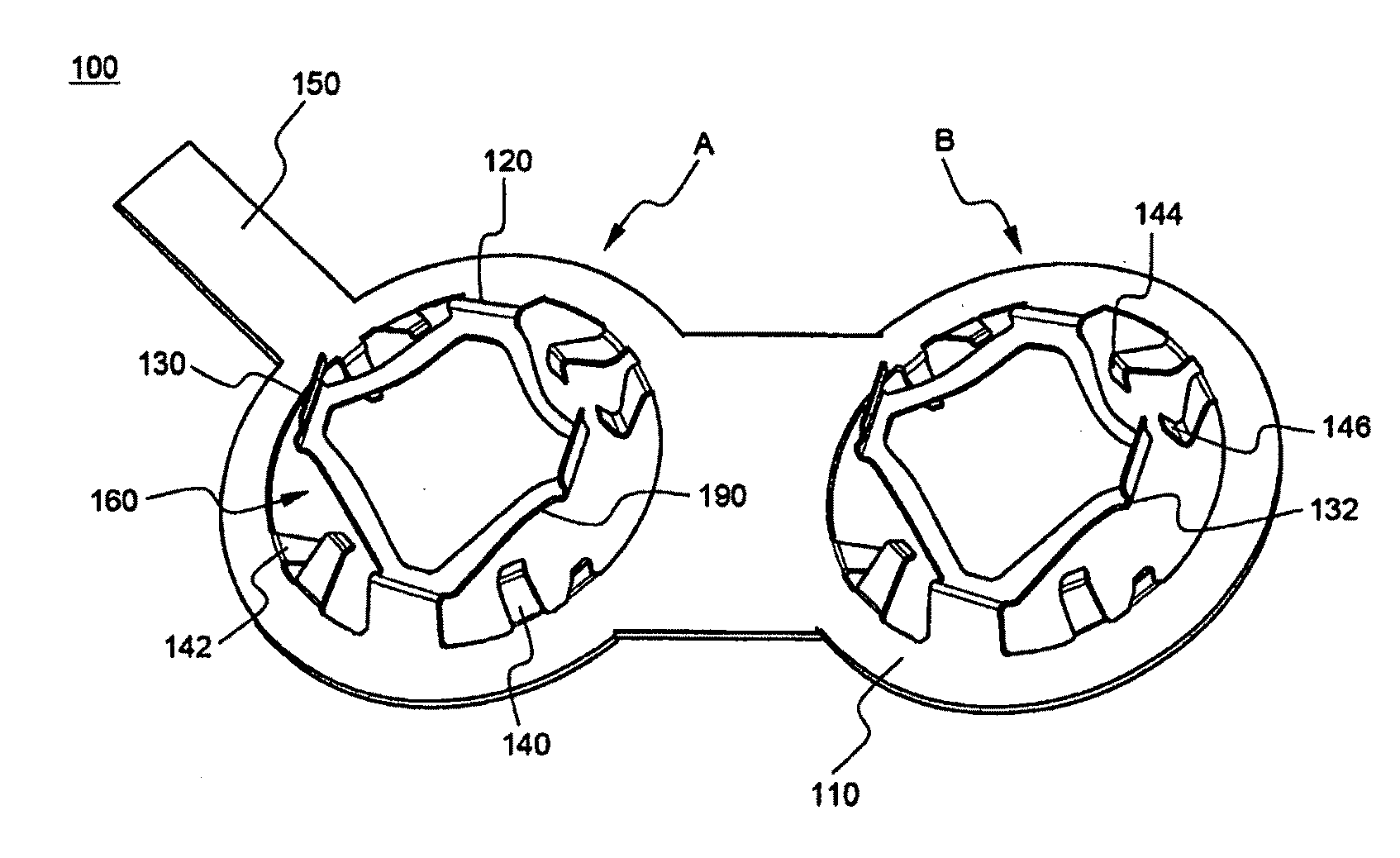

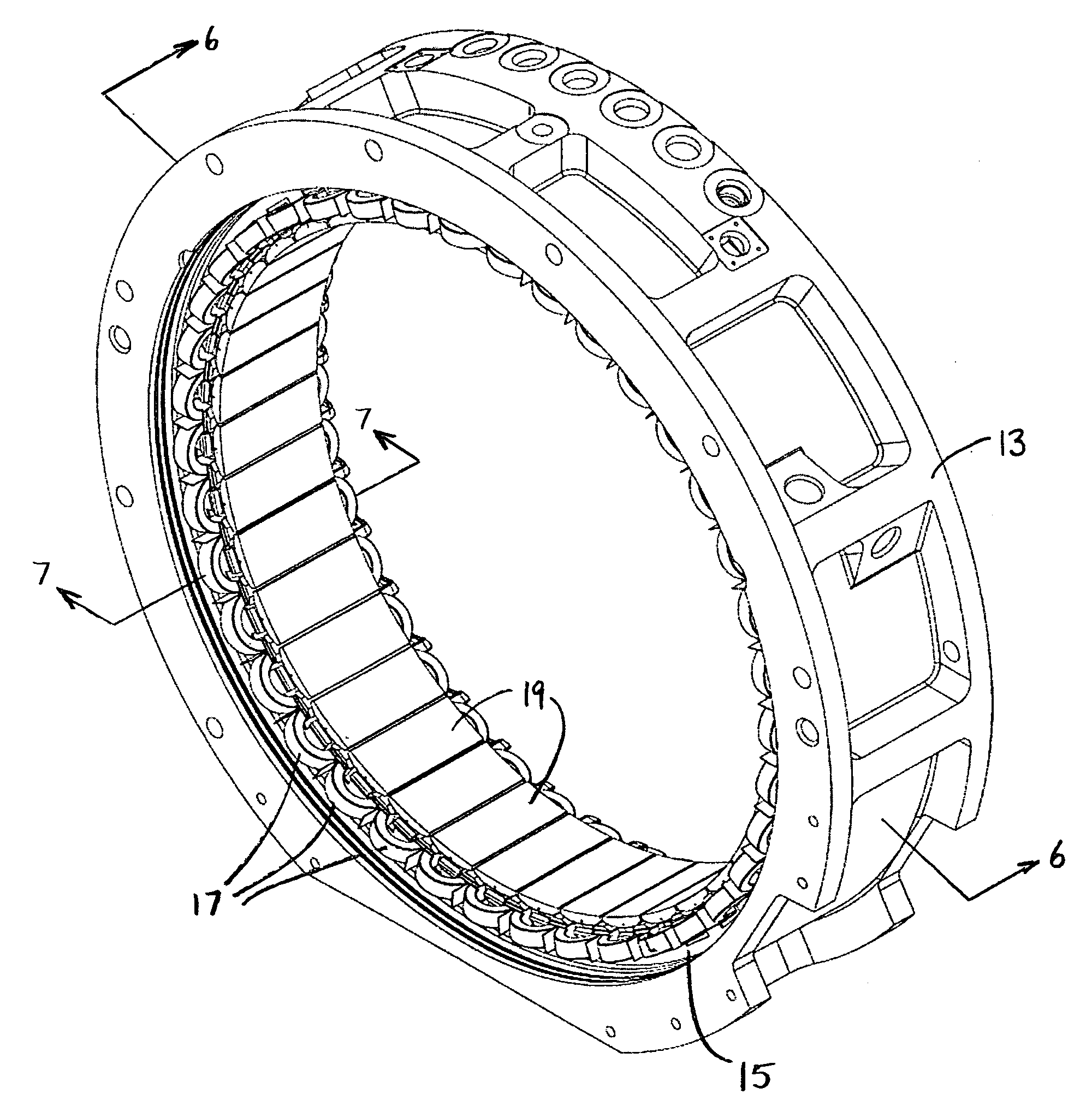

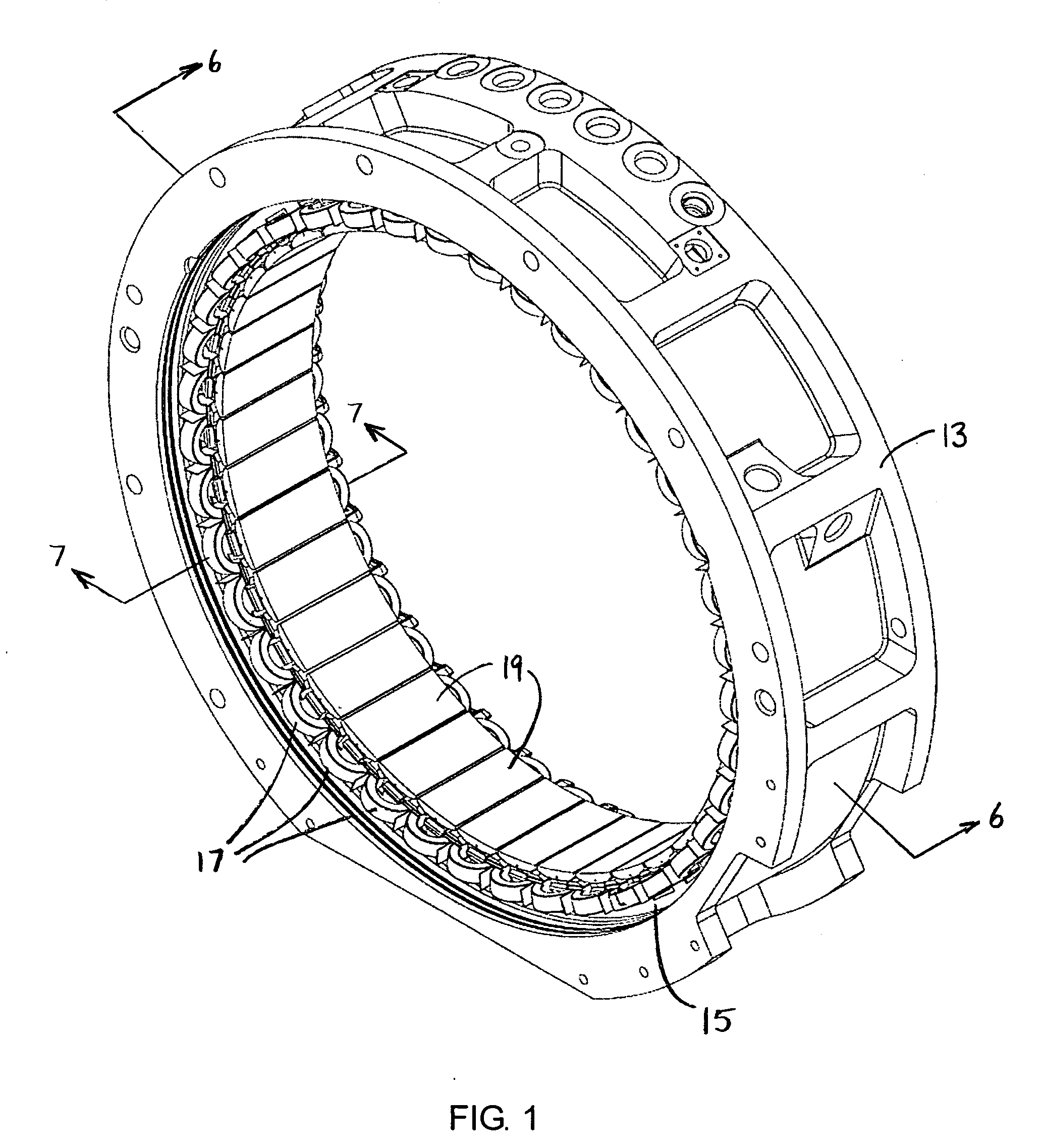

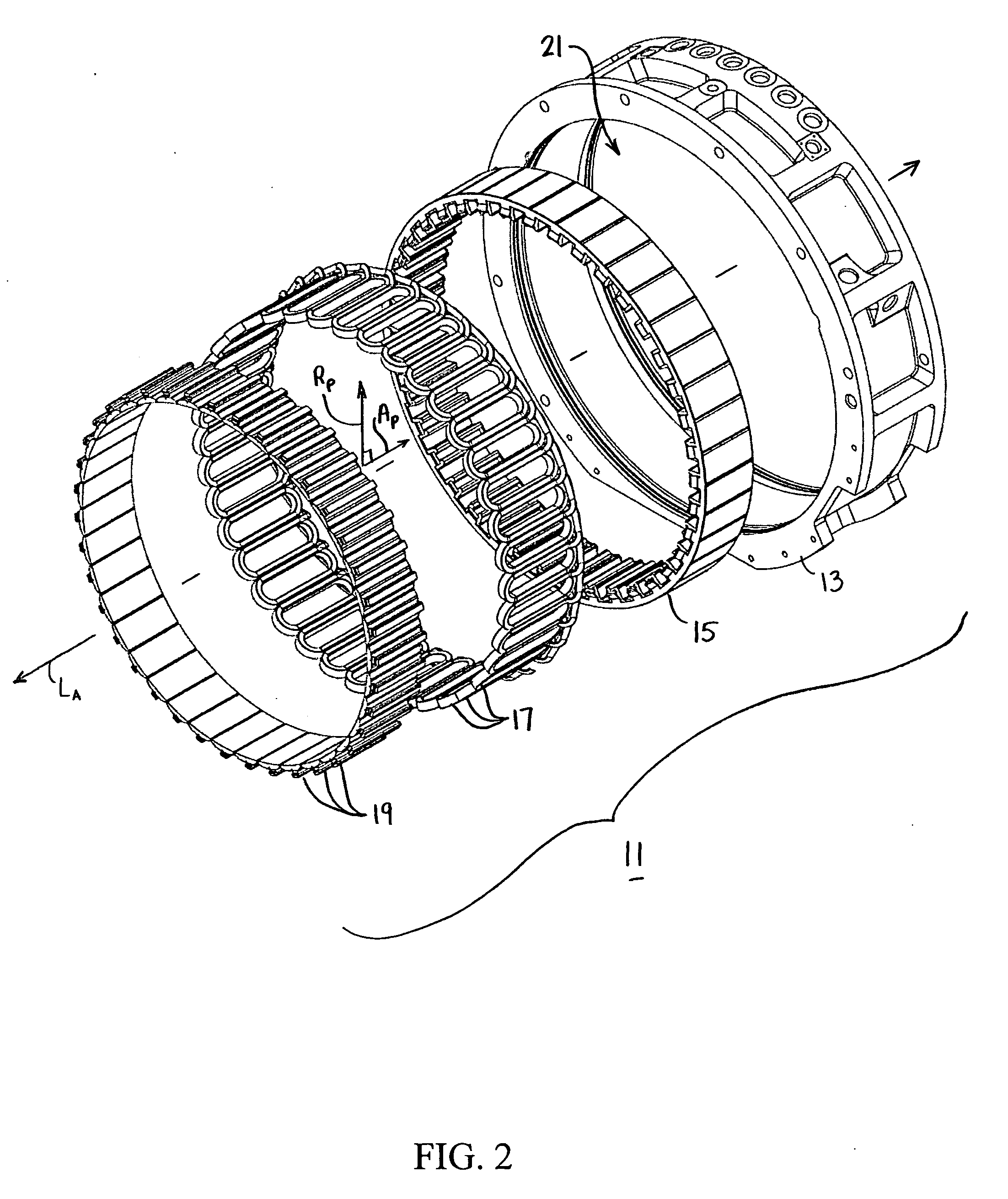

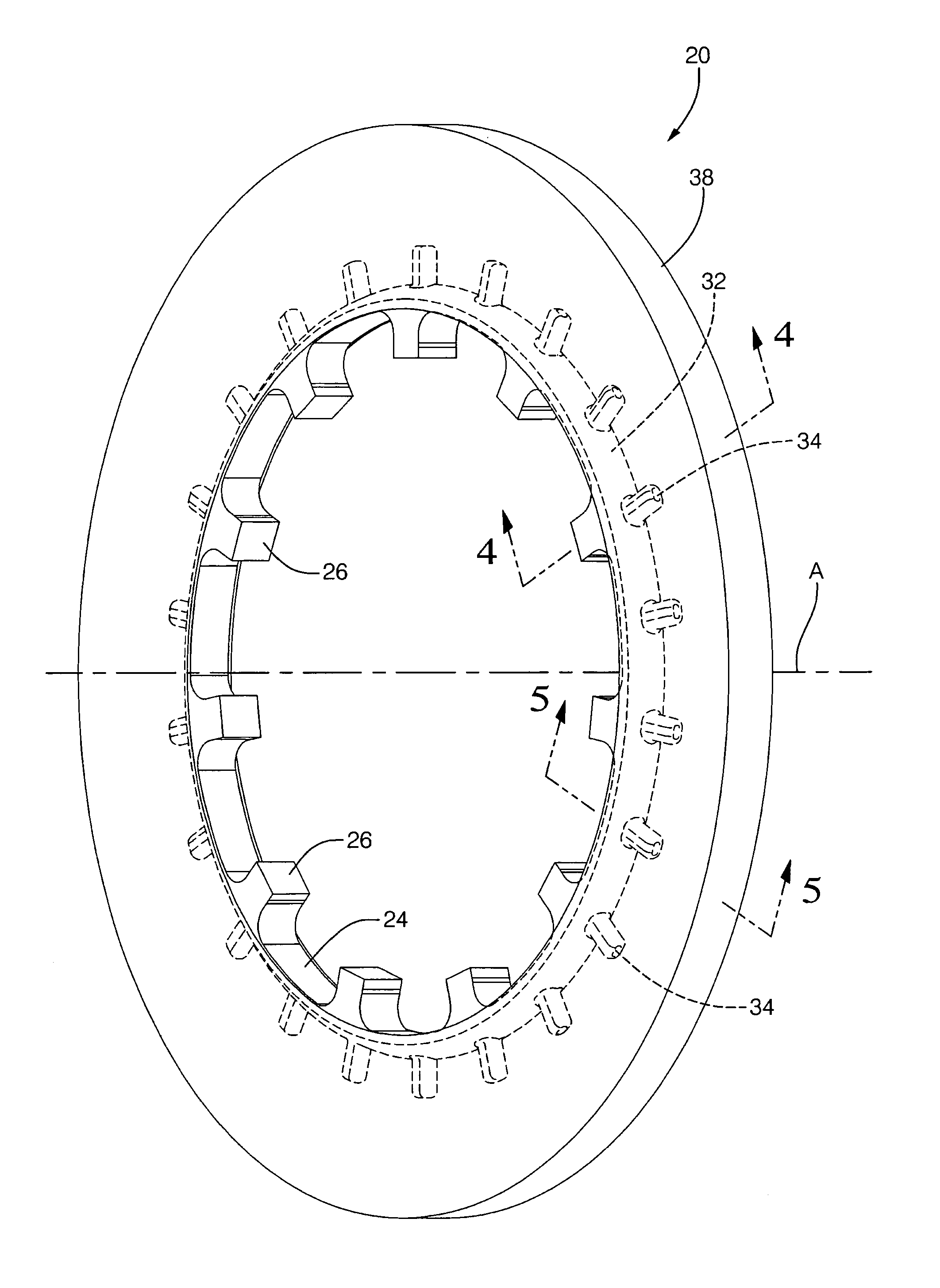

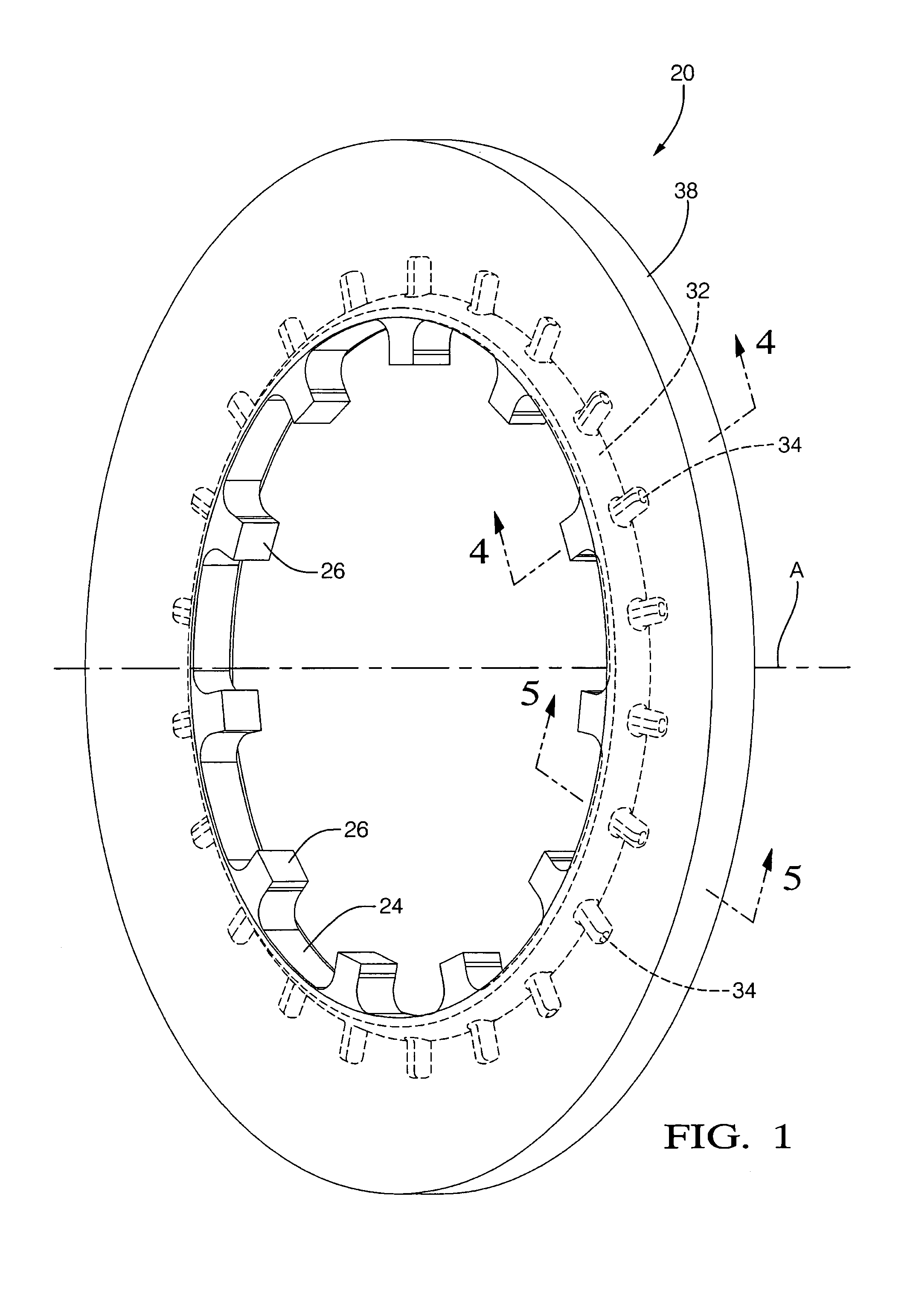

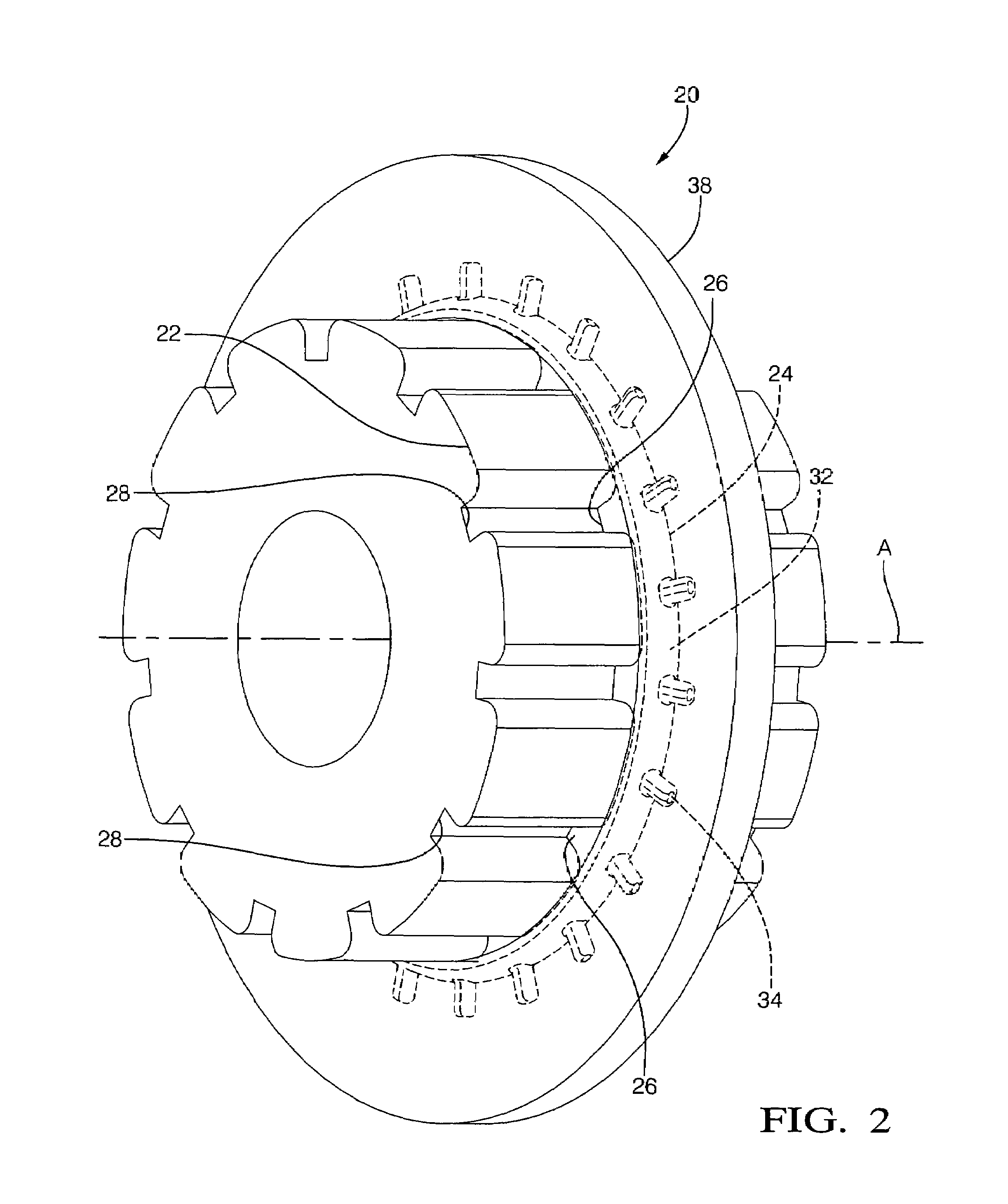

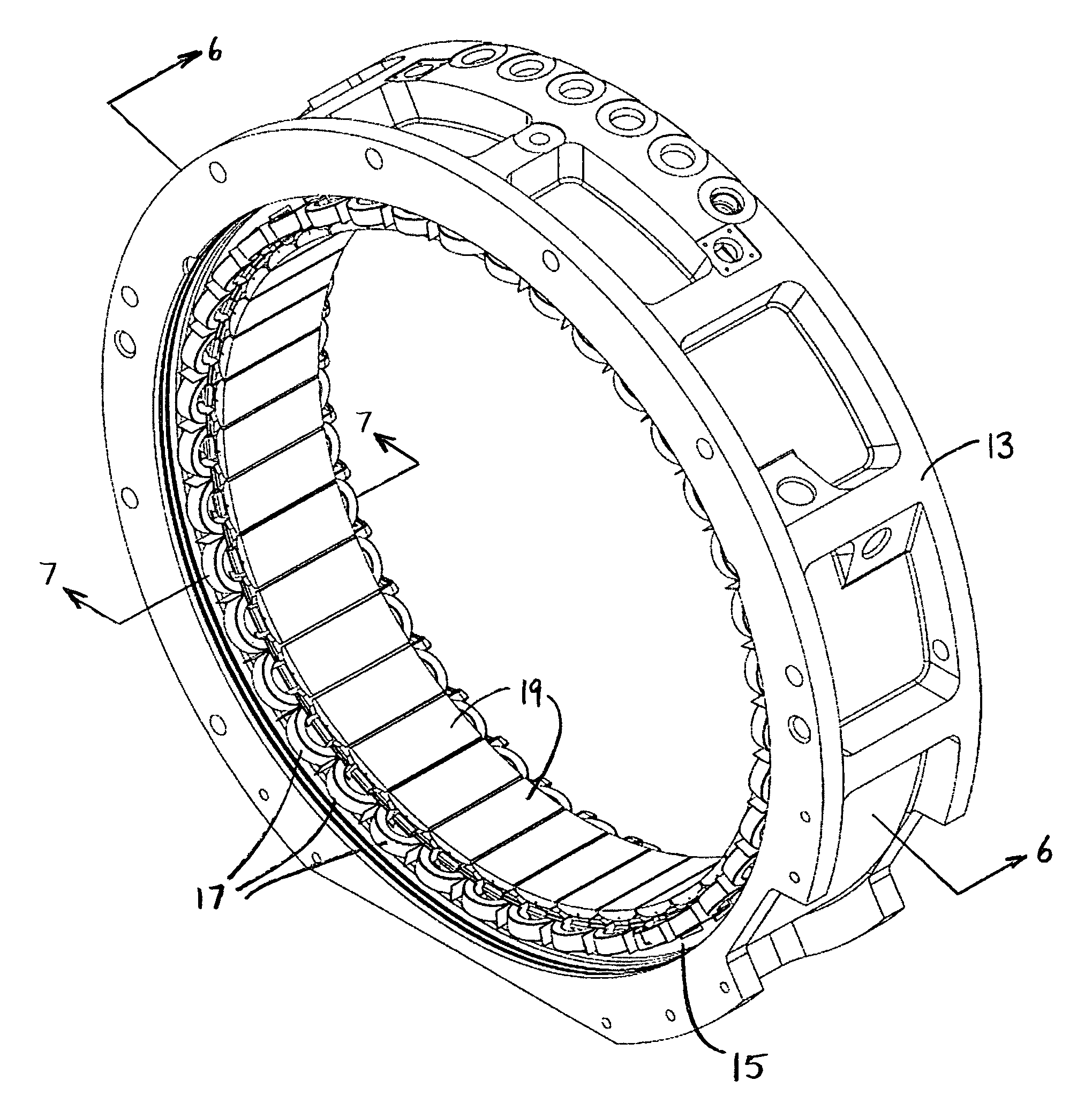

Attachment for a magnetic structure

InactiveUS20090026875A1Reduce mechanical stressMaximize contact areaWindingsMagnetic circuit stationary partsProtruding shouldersElectric machine

Attachments are removably coupled to the magnetic core of a rotating electric machine, the magnetic core being shaped to include a plurality of coil-receiving slots that are separated by radial teeth. Each attachment is constructed as a unitary member and includes a base and a stem, the stem being dimensioned for fitted insertion within a recess formed in the distal end of a corresponding tooth. The base includes a convex bottom wall, a flattened top wall and a pair of non-planar sidewalls. The stem is integrally formed on the top wall of the base and includes a front end, a rear end, a flattened top wall and a pair of opposing sidewalls. A longitudinal groove is formed into each of the pair of opposing sidewalls of the stem. An outwardly protruding shoulder designed for engagement by a retention plate is formed into the front and rear ends of the stem.

Owner:VESTAS WIND SYST AS

Brake rotor assembly

A brake rotor assembly for a dual brake disc braking system includes an annular ring having a plurality of teeth. The teeth are disposed radially about a central axis of the annular ring, and extend inward toward the central axis. The teeth are for slideably engaging a hub (wheel end) having a plurality of channels. The annular ring includes a plurality of pins extending outwardly from the annular ring. A friction disc is disposed radially about the annular ring, and is in interlocking engagement with the plurality of pins. The annular ring and the plurality of teeth are integrally cast from a high strength corrosion resistant material having a tensile strength greater than 260 megapascals to resist fracture during high stress braking conditions and high thermal loads. The friction disc is cast around the annular ring from a grey cast iron.

Owner:BWI CO LTD SA

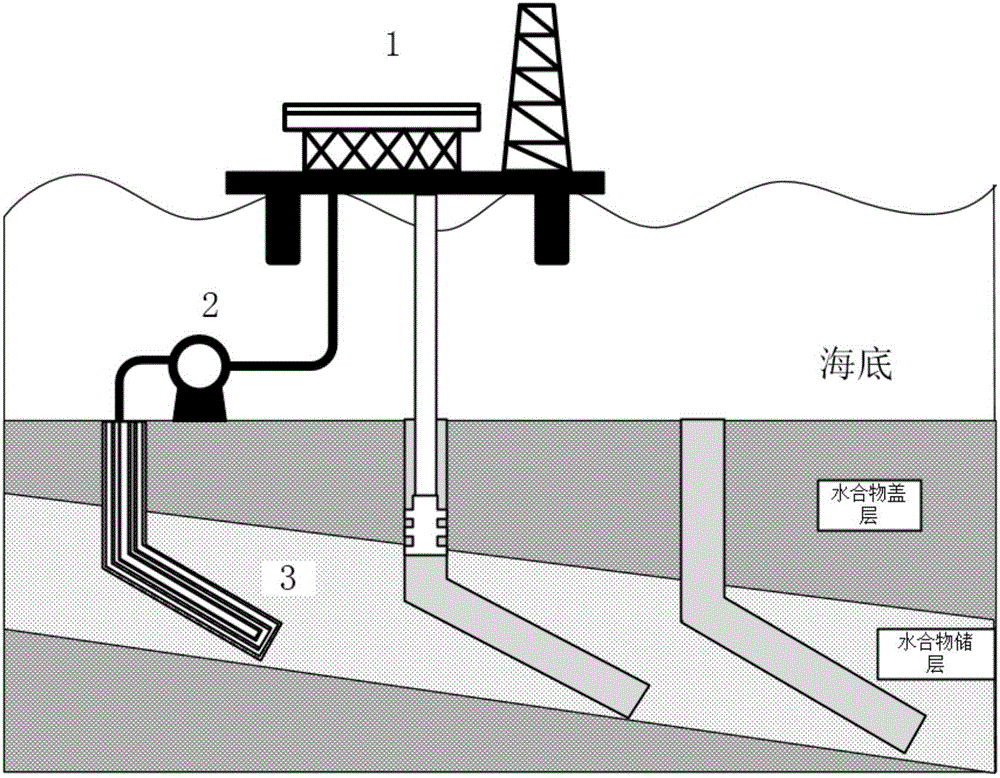

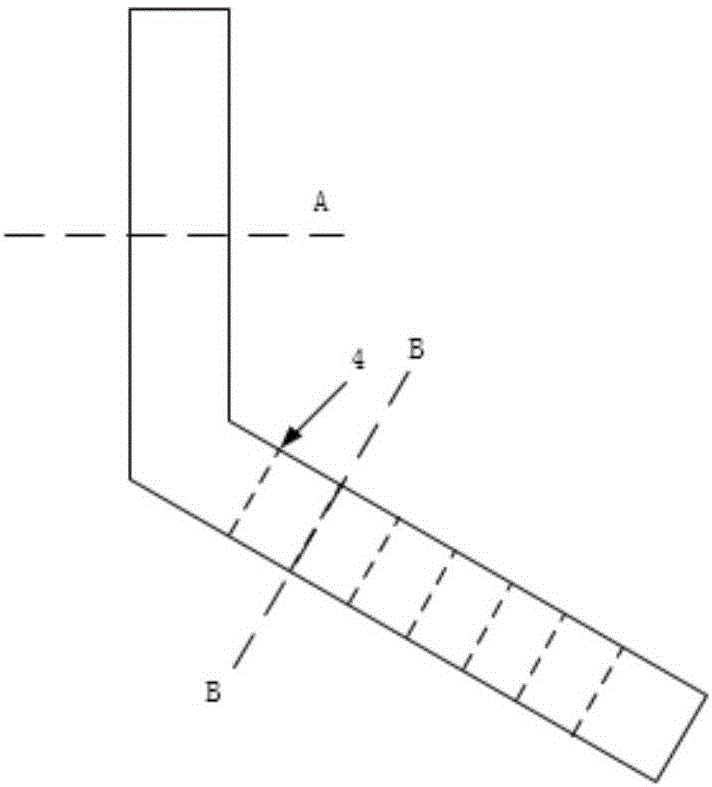

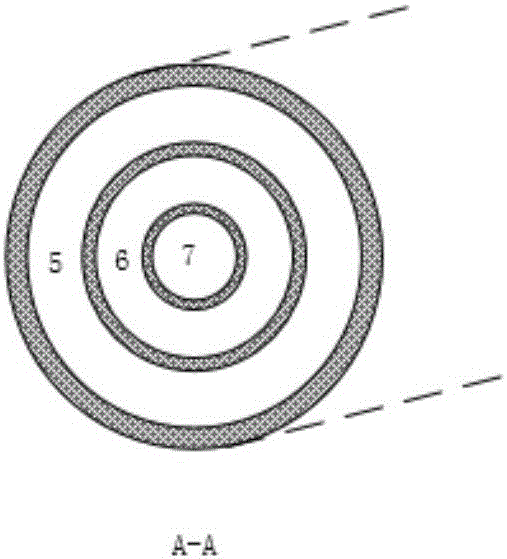

Slant well marine gas hydrate extracting method

ActiveCN106703780AMaximize contact areaImprove development efficiencyDrilling rodsConstructionsSaline waterDecomposition

The invention belongs to the technical field of marine gas hydrate extraction and provides a slant well marine gas hydrate extracting method. The method comprises, after a drilling location is determined, performing well drilling through a semi-submersible drilling platform to construct a hydrate extracting well; running waterproof casing pipes, which are provided with three layers of pipe walls, inside the hydrate extracting well; cementing the front ends of the waterproof casing pipes inside a vertical well and a slant well for fixation; performing gas hydrate extraction in a depressurizing and heat injection combined manner, and injecting hot brine through a heat injection pipe to break phase equilibrium of gas hydrate to decompose the gas hydrate; extracting cooled liquid through a reflux pipe for recycling; through a gas-liquid mixed flow pump, extracting free gas and water, which are generated by decomposing the gas hydrate, from an extracting pipe, and performing further depressurized decomposition on the gas hydrate; performing gas-liquid separation on gas-liquid mixtures conveyed to the ground, and then storing separated natural gas inside high-pressure gas tanks.

Owner:DALIAN UNIV OF TECH

Torsion spring for electro-mechanical switches and a cantilever-type RF micro-electromechanical switch incorporating the torsion spring

InactiveUS6842097B2Increased durabilityGood electrical contactContact surface shape/structureElectrostatic/electro-adhesion relaysConformal connectionEngineering

A torsion spring for an electro-mechanical switch is presented. The torsion spring comprises a set of tines including at least one tine extending from the free end of the armature of a switch. A terminus portion is rotatably suspended between the tines, and includes a conducting transmission line, at least a portion of which is exposed for electrical contact. The conducting transmission line has a length selected such that the exposed portion of the transmission line forms a circuit between the input and output of the micro-electro-mechanical switch when the micro-electro-mechanical switch is urged into a closed position, with the terminus portion rotating via the tines to form a conformal connection between the exposed portion of the conducting transmission line and the input and output of the switch, thus optimizing the electrical flow therebetween. The switch is also applied to MEMS devices.

Owner:HRL LAB

Medical apparatus, use and methods

InactiveUS20060106313A1Move quicklyNot so rapidElectrotherapyChiropractic devicesTransducerBiomedical engineering

In accordance with one embodiment, a vibratory transducer has an armature suspended in a magnetic field. The armature has a plurality of electrical conductive paths to provide electrical current flow in said armature to react with said magnetic field and cause movement in the armature controlled by variation in the electrical current flow. A contact surface is secured to the armature, with a surface area for frictionally coupling to a corresponding surface area of a patient for example. Movement of the vibratory transducer induces movement in the patient, and the transducer can produce movement in the contact surface in at least two dimensions simultaneously. In one embodiment the contact surface is flat, while in alternative embodiments the contact surface is incorporated in a toroidal structure so as to surround part of the patient. Medical application can include treatment of bone fractures, oedema, and in elastography, amongst other applications.

Owner:MERLEX CORP PTY LTD

Bone hemi-lumbar arcuate interbody spinal fusion implant having an asymmetrical leading end

InactiveUS20060235519A1Maximize contact areaIncrease the lengthBone implantJoint implantsSpinal columnIntervertebral space

An interbody spinal implant is formed of cortical bone adapted for placement across an intervertebral space formed across the height of a disc space between two adjacent vertebral bodies. An asymmetrical leading end on the implant is adapted to sit upon the peripheral areas, such as the apophyseal rim and the apophyseal rim area, of the vertebral end plate region of the vertebral bodies without protruding therefrom. The asymmetrical leading end allows for the safe use of an implant of maximum length for the implantation space into which it is installed. The implant can also include an asymmetric trailing end adapted to sit upon the more peripheral areas of the vertebral end plate region of the vertebral bodies.

Owner:WARSAW ORTHOPEDIC INC

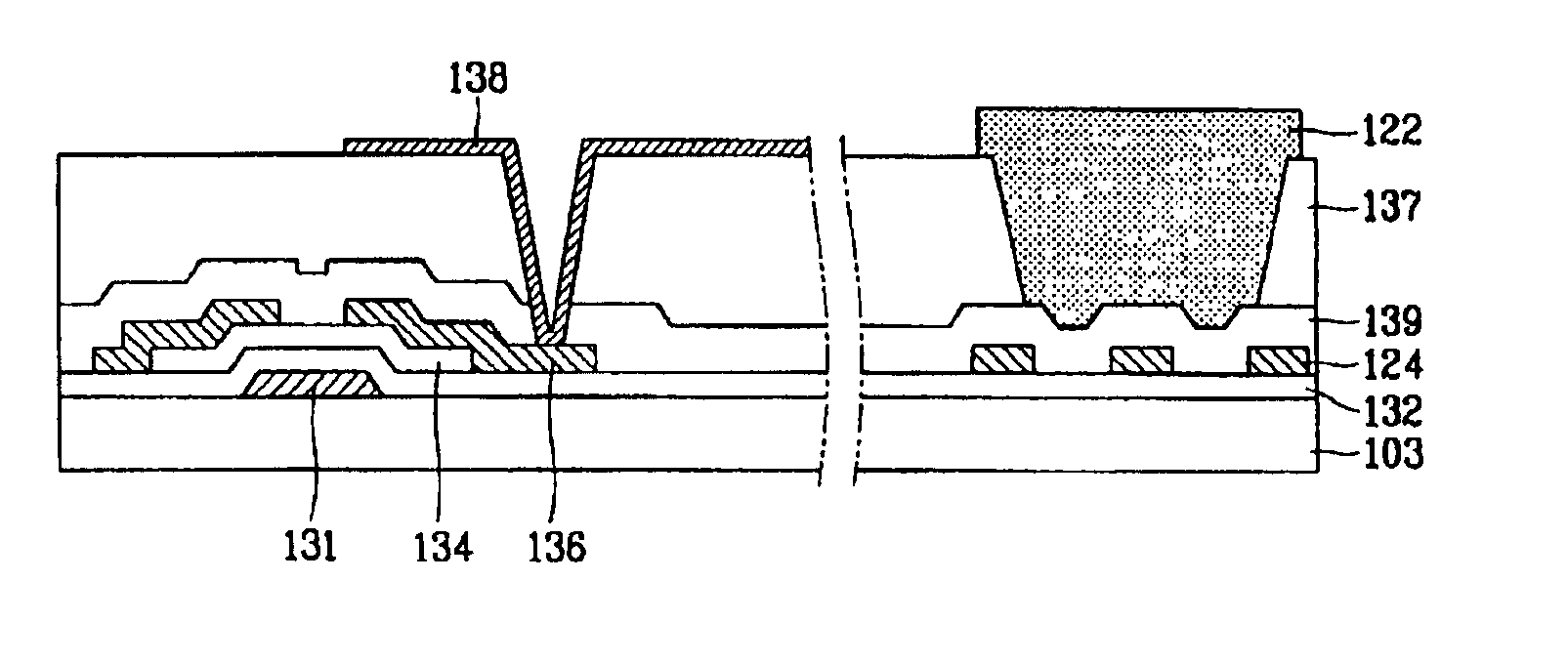

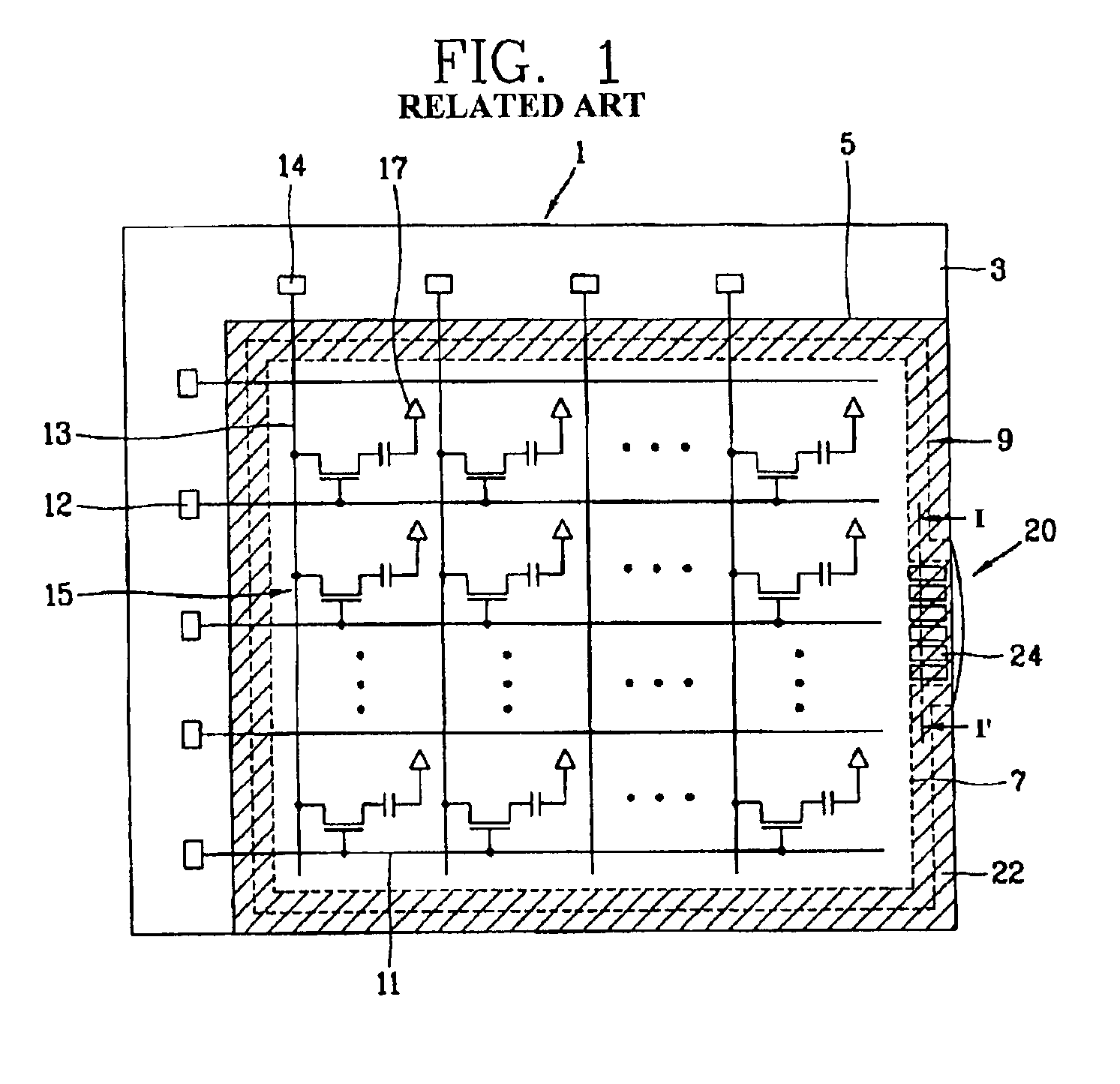

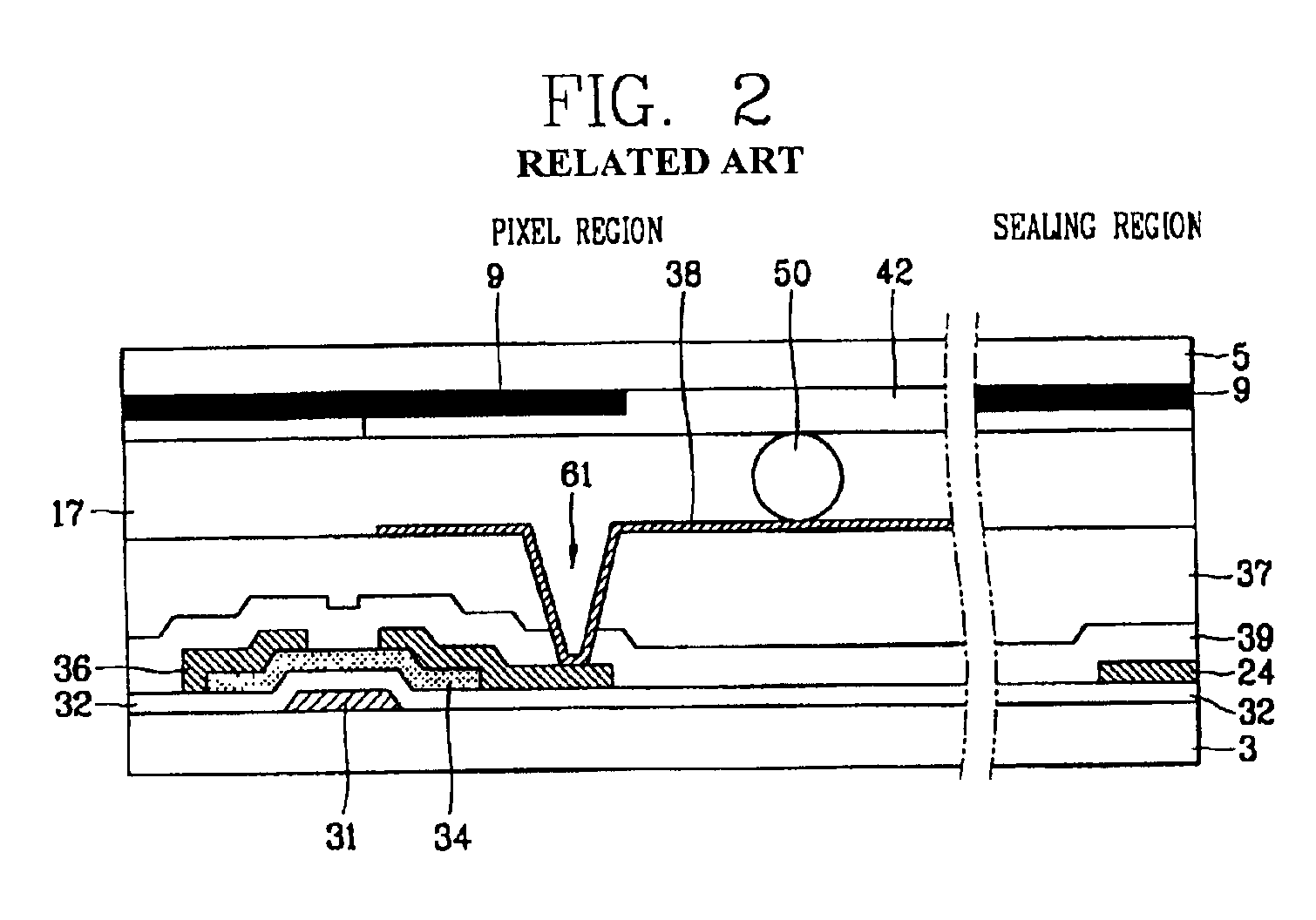

Liquid crystal display device and method for fabricating the same

InactiveUS6859254B2Improve adhesionMinimized contact areaNon-linear opticsLiquid-crystal displayLiquid crystal

A liquid crystal display device includes a first substrate having a plurality of thin film transistors and a plurality of metal lines, a first insulation material layer formed on the metal lines, a second insulation material layer formed on the first insulation material layer on the metal lines, a first hole formed in the second insulation material layer over at least two of the metal lines, a second contact hole formed in the first and second insulation layers exposing a drain electrode of the thin film transistors, a pixel electrode connected to the drain electrode through the second contact hole, a sealing material formed within the first hole, a second substrate bonded to the first substrate via the sealing material, and a liquid crystal material disposed between the first and second substrates.

Owner:LG DISPLAY CO LTD

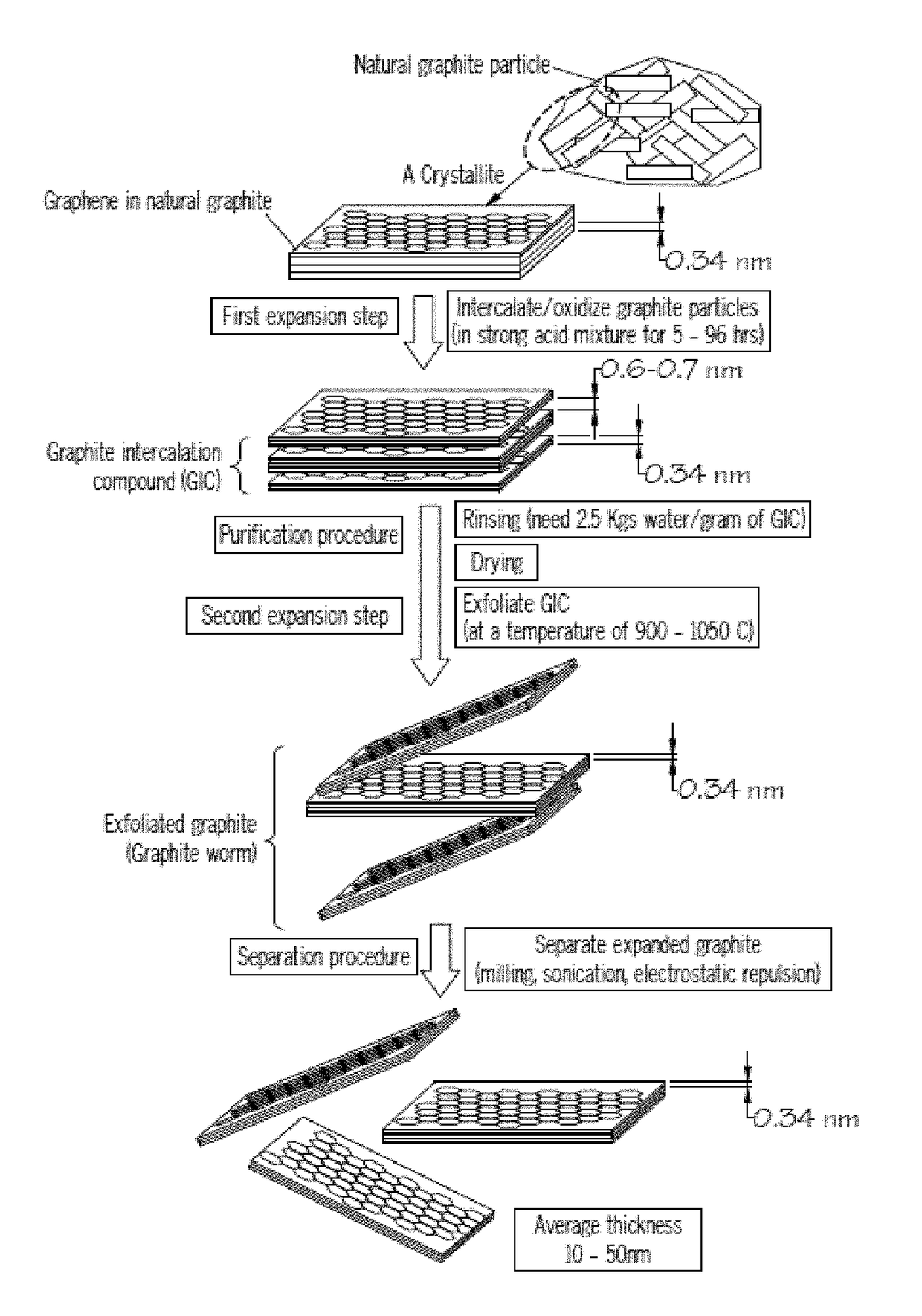

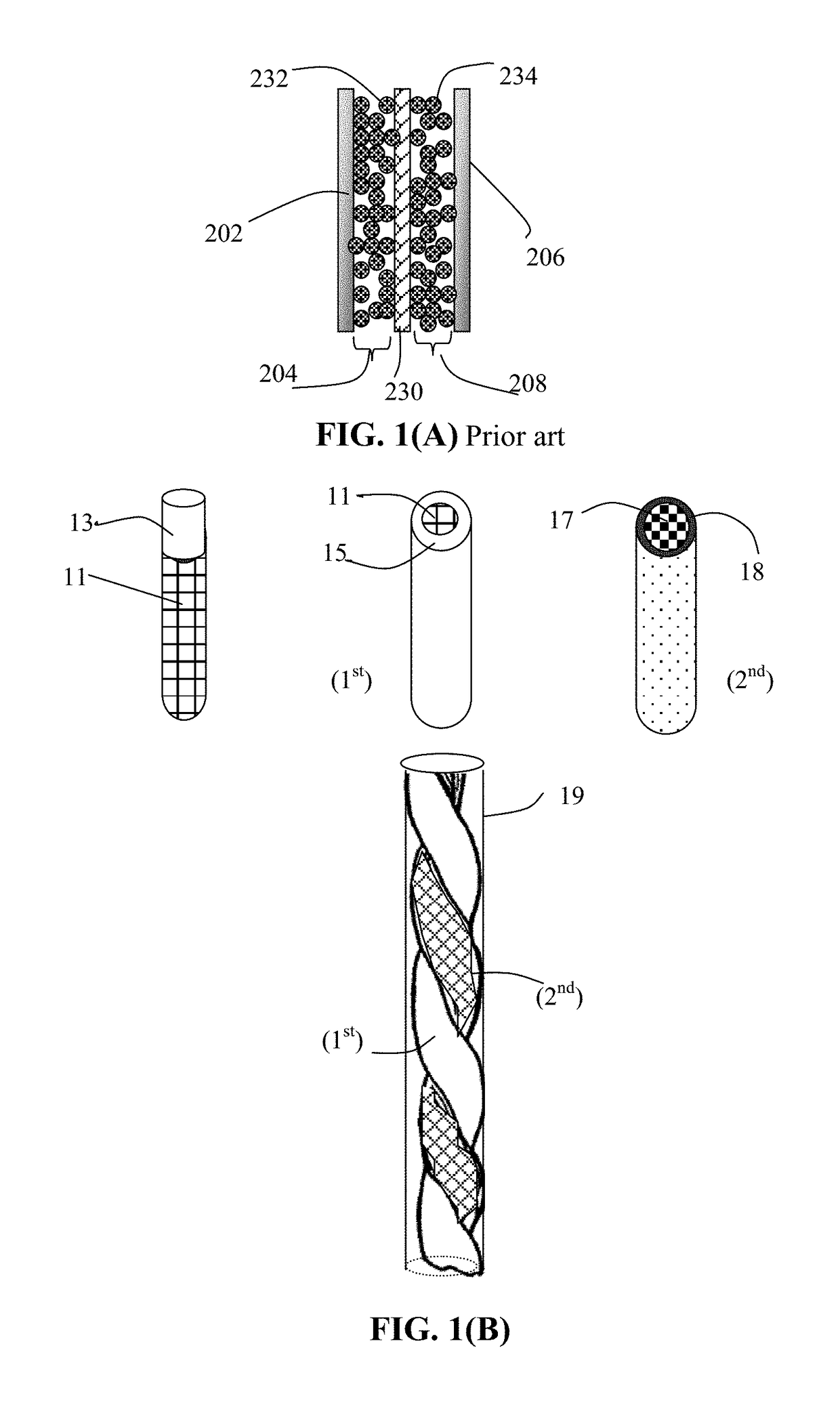

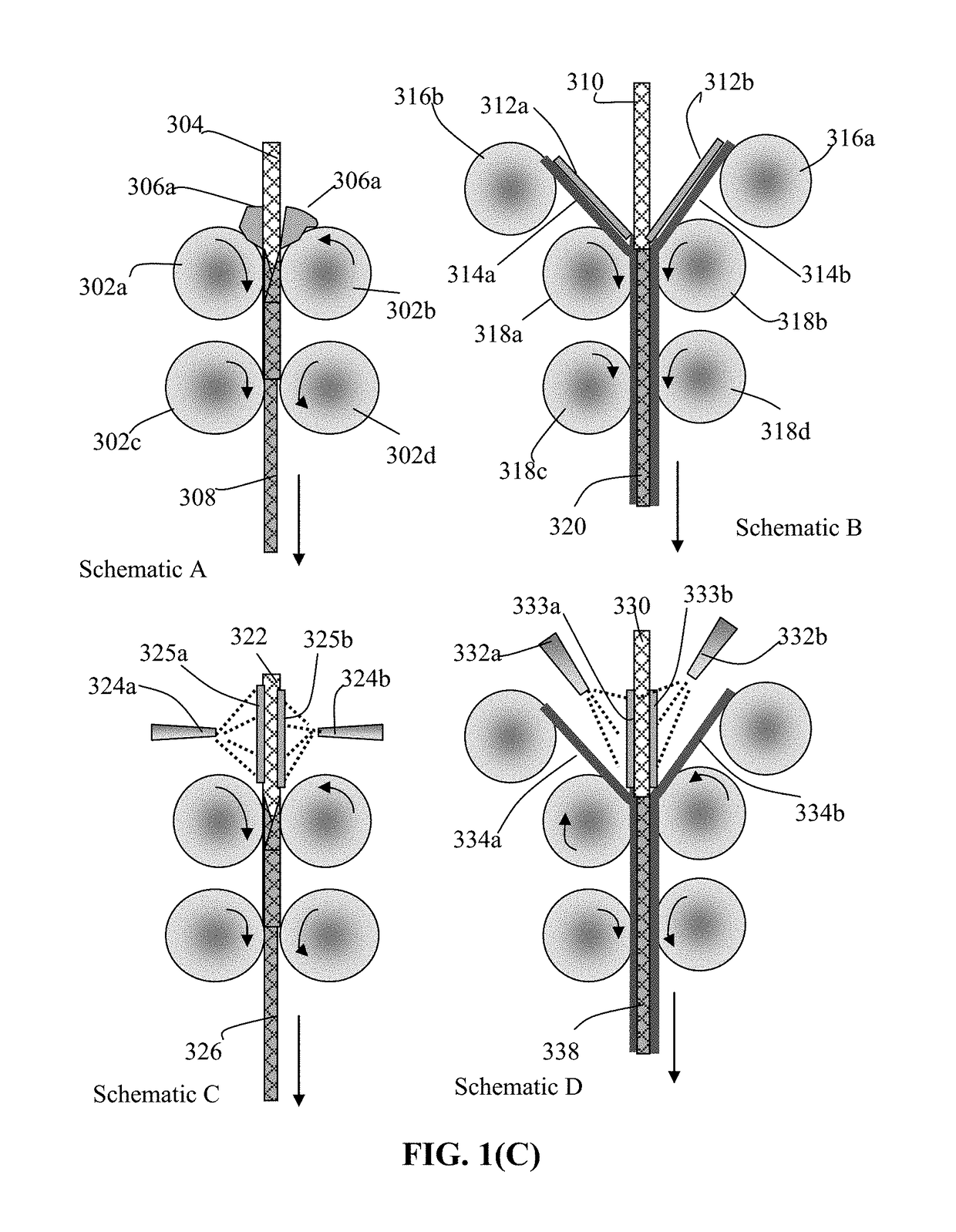

Process for Flexible and Shape-Conformal Rope-Shape Supercapacitors

ActiveUS20180233297A1Maximize contact areaMaximize interfacial areaHybrid capacitor separatorsHybrid capacitor electrolytesYarnActivated carbon

Provided is a process for producing a rope-shaped supercapacitor comprising: (a) impregnating a first mixture of a first electrode active material (e.g. activated carbon or isolated graphene sheets) and a first electrolyte into pores of a first porous rod to form a first electrode; (b) encasing a porous separator around the first electrode to form a separator-protected first electrode; (c) impregnating a second mixture of a second electrode active material and a second electrolyte into pores of a second conductive porous rod to form a second electrode; (d) combining the separator-protected first electrode and second electrode form a braid or twist yarn; and (e) wrapping or encasing a protective sheath around the braid or yarn to form the supercapacitor.

Owner:NANOTEK INSTR GRP LLC

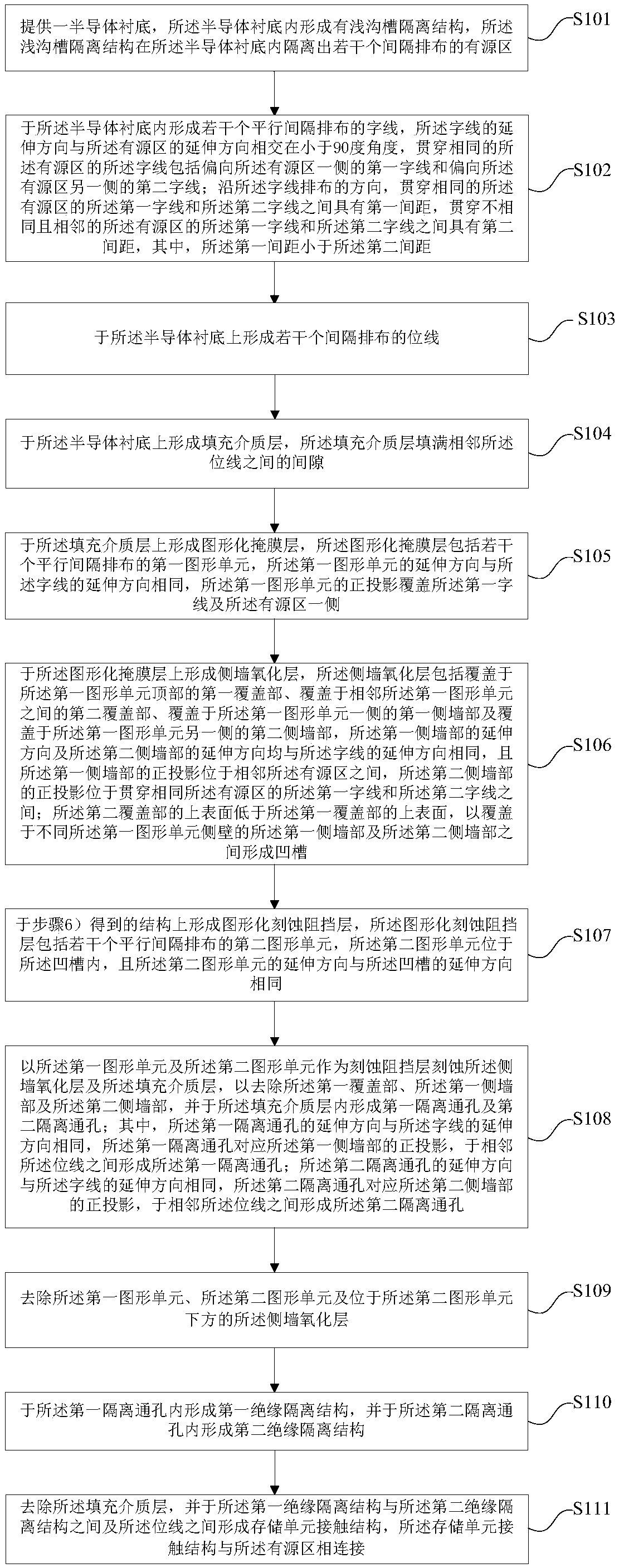

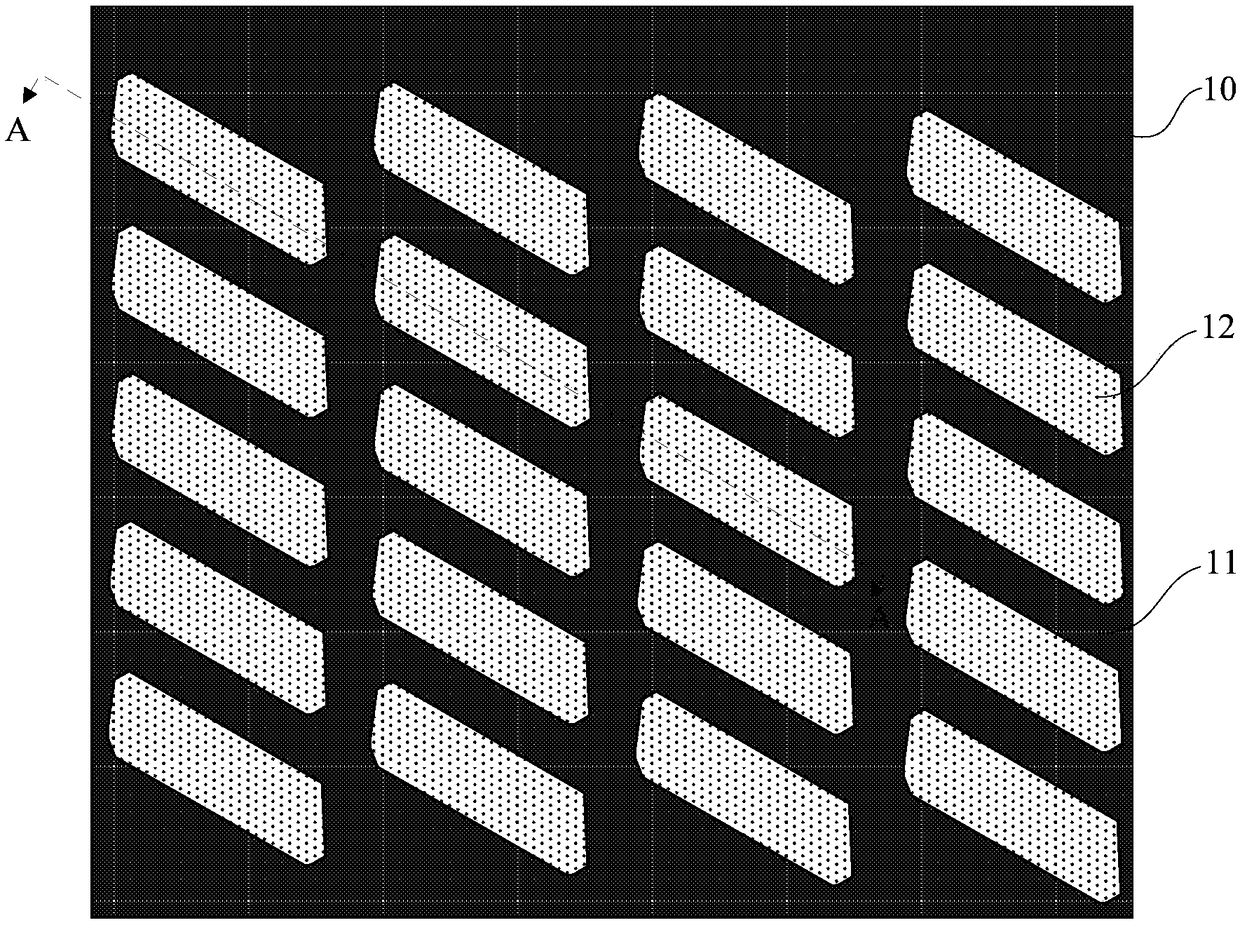

Semiconductor structure, memory structure and manufacturing method thereof

ActiveCN108933136AReduce contact resistanceMaximize contact areaTransistorSemiconductor/solid-state device manufacturingElectrical conductorSemiconductor structure

The invention provides a semiconductor structure, a memory structure and a manufacturing method thereof. The method comprises the following steps: 1) a semiconductor substrate is provided; 2) a word line is formed in the semiconductor substrate; 3) a bit line is formed on the semiconductor substrate; 4) a filling dielectric layer is formed on the semiconductor substrate; 5) a graphical mask layeris formed on the filling dielectric layer; 6) a side wall oxide layer is formed on the graphical mask layer; 7) a graphical etching barrier layer is formed on the structure obtained in the step 6); 8)a first isolation through hole and a second isolation through hole are formed in the filling dielectric layer; 9) a first graphical unit, a second graphical unit and a side wall oxide layer below thesecond graphical unit are removed; 10) a first insulation isolation structure is formed in the first isolation through hole, and a second insulation isolation structure is formed in the second isolation through hole; and 11) the filling dielectric layer is removed, and a conductive plug is formed. The conductive plug can realize reduction of contact resistance between the conductive plug and an active region.

Owner:CHANGXIN MEMORY TECH INC

Method of tooth whitening including wrapping the teeth

InactiveUS20070122769A1Shorten the timeStabilize whitening resultCosmetic preparationsGum massageOxygenLength wave

In the inventive method, a tooth whitener having a concentration of hydrogen peroxide significantly lower than the concentration typically used in in-office applications is applied to the teeth in gel form. Next, thin transparent film is placed over the teeth to seal the tooth whitener onto the teeth. The film creates a closed system that precludes oxygen from migrating away from the teeth into the atmosphere. A white light in the range of 380-660 nm wavelength is then activated to assist in exciting oxygen in the path of the light and the oxygen molecules bombard the tooth surfaces. The oxygen molecules may not easily escape from the tooth surfaces into the atmosphere due to the wrap and, thus, their whitening “power” is enhanced and lengthened. Then, the patient may stabilize the whitening results over a 7 to 10 day regime using a lower concentration tooth whitener.

Owner:GOSMILE

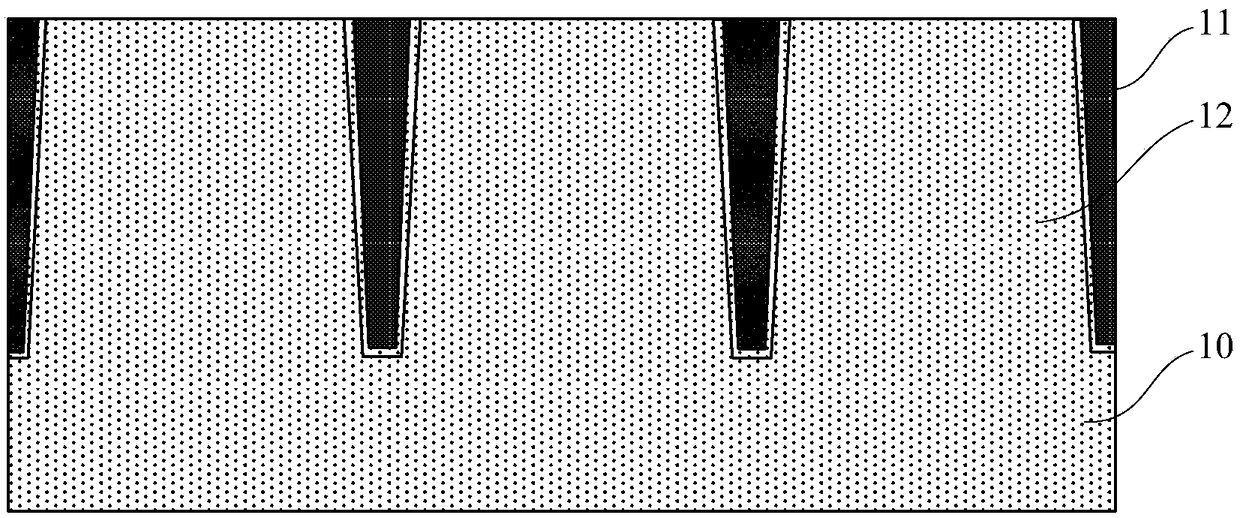

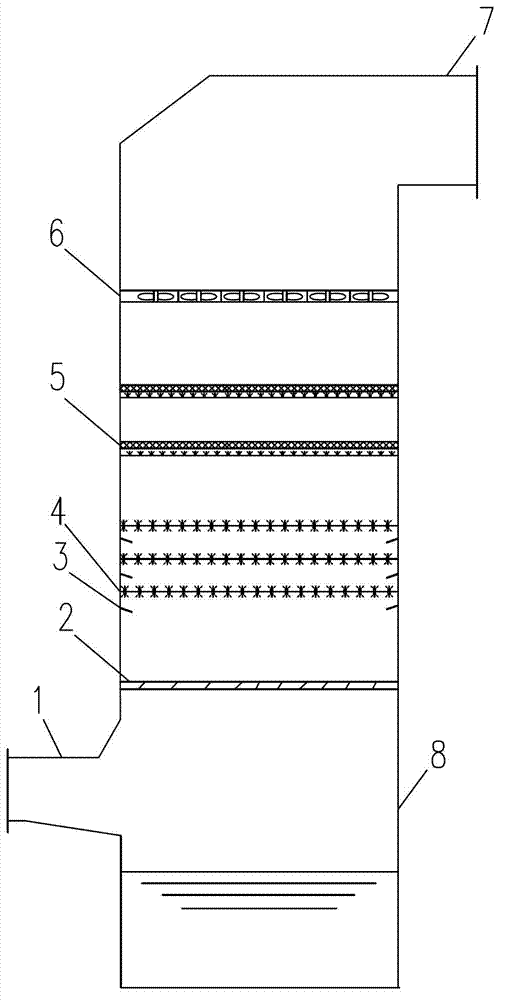

High-quality spray absorber for wet flue gas desulfurization

ActiveCN102764582AOvercomes easy crystallization and scalingNot easy to blockDispersed particle separationGypsumSulfur dioxide

The invention discloses a high-quality spray absorber for wet flue gas desulfurization. The absorber comprises an absorber cylinder body which is provided with a flue gas inlet channel and a flue gas outlet channel. A perforated screen plate, flue gas redistribution rings, slurry spray devices, a demister and a rotating-stream plate device are arranged horizontally from bottom to top between the flue gas inlet channel and the flue gas outlet channel. Inner side edges of the flue gas redistribution rings are in an undulate or serrated shape, and the rotating-stream plate device is composed of a plurality of evenly-distributed independent rotating-stream plate separators. According to the high-quality spray absorber for wet flue gas desulfurization, the problem of no flue gas flowing above the absorber close to the flue gas inlet section is solved, the phenomenon of the easy crystallization and scaling of the area is overcome, gas-liquid contact area is maximized, absorption reaction is effective, and the absorber is applicable to desulfurization of flue gas with high sulfur dioxide content. 'fog-drop particles' carried in the flue gas are eliminated to the maximum extent, chimney 'rain' phenomena are reduced greatly, and the content of fog-drop particles can achieve 60 milligrams / nanometer3. The absorber is wide in applicable range, and can be used for wet flue gas desulfurization in a double-alkali way, an acetylene sludge way, a lime-gypsum way and the like.

Owner:武汉华德环保工程技术有限公司

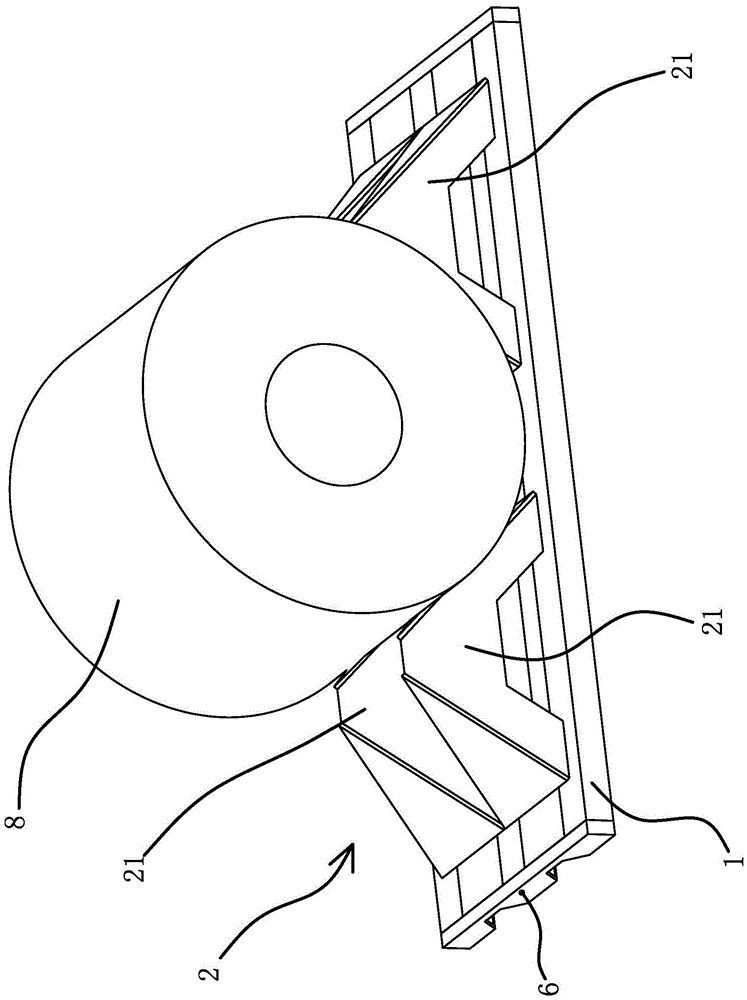

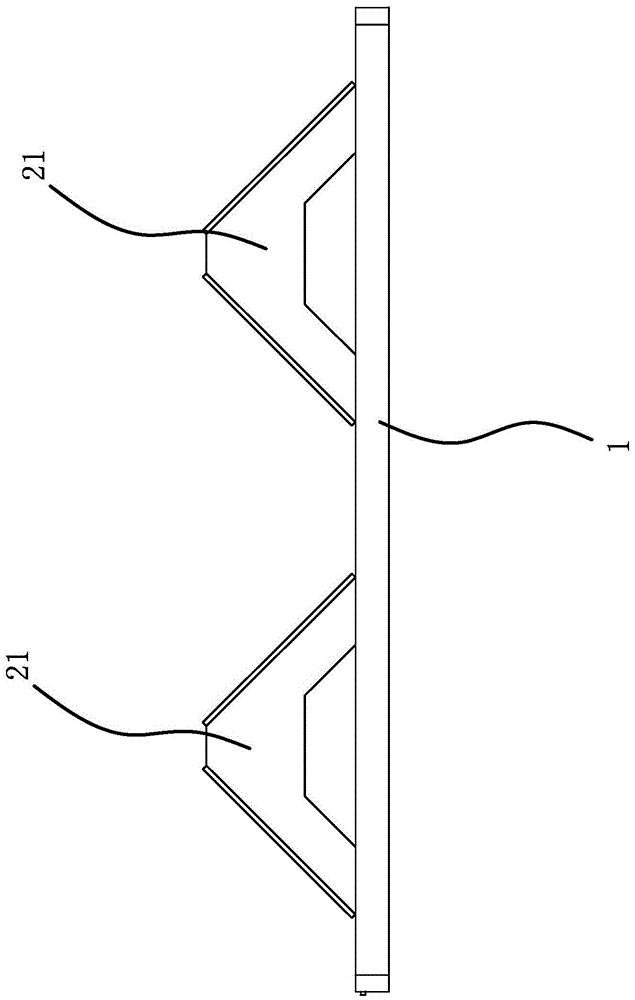

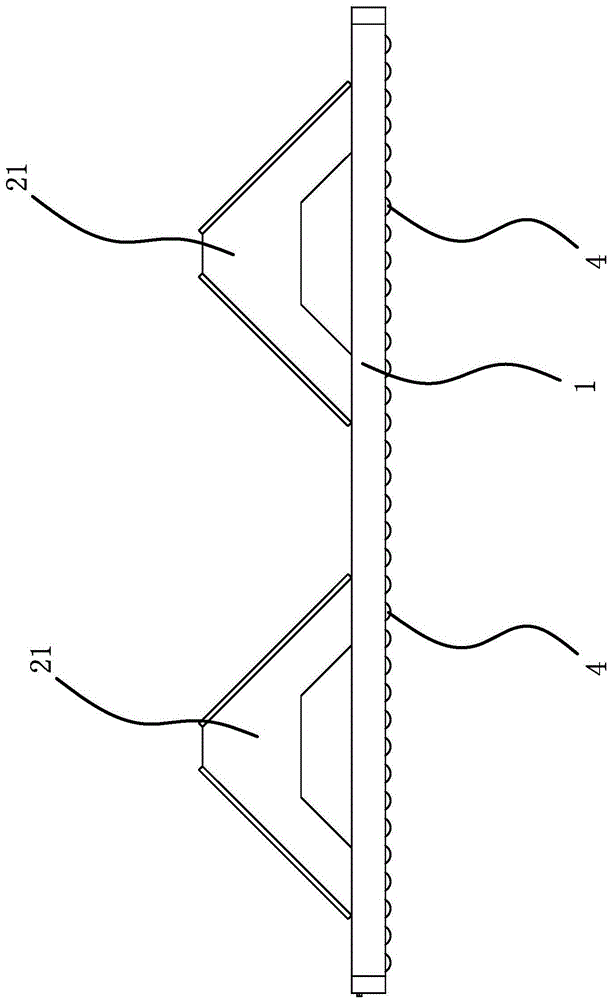

Tray used for steel coil transportation

ActiveCN105600134AEasy to transfer and transportEasy to transportExternal framesRigid containersEngineeringMechanical engineering

The invention provides a tray used for steel coil transportation, and belongs to the technical field of transportation. The tray solves the technical problem that an existing movable tray is not suitable for bearing steel coils. The tray comprises a tray frame and a limiting frame arranged on the tray frame and used for positioning a steel coil. At least two long-strip-shaped installation grooves are formed in the bottom of the tray frame. Long-strip-shaped rolling wheel frames are arranged in the installation grooves. A plurality of rolling wheels are connected to the rolling wheel frames in the length direction of the rolling wheel frame. Guide structures capable of guiding the rolling wheel frames to move up and down relative to the tray frame and limiting structures capable of preventing the rolling wheel frames from being disengaged from the installation grooves are arranged on the portions, located in the installation grooves, on the tray frame. Gas bags are arranged in the installation grooves and located above the rolling wheel frames. The whole rolling wheels can be located in the installation grooves when the gas bags are not inflated. The gas bags can act on the rolling wheel frames to make the rolling wheels stretch out of the installation grooves when the gas bags are inflated and expanded. The tray has the advantage that the steel coil can be stably transported.

Owner:ZHEJIANG TOPSUN LOGISTIC CONTROL CO LTD

Rechargeable battery

ActiveUS20110123855A1Increased rigidity and durabilityImprove binding structureLarge-sized flat cells/batteriesFinal product manufactureRechargeable cellEngineering

A rechargeable battery comprises an electrode assembly comprising an anode, a cathode, and a separator, a case for receiving the electrode assembly, and an electrode terminal electrically connected to the electrode assembly and drawn outside the case. The anode and the cathode each comprises an electrode uncoated region exposed past the separator and including a current collector at an edge. The electrode terminal comprises a terminal plate having a first terminal portion adhered to a bottom surface of the current collector and a second terminal portion drawn outside the case, and a combiner installed on the terminal plate to surround and adhere to a side surface and a top surface of the current collector.

Owner:SAMSUNG SDI CO LTD

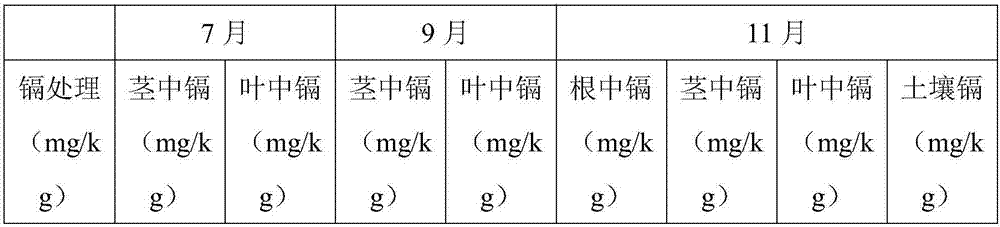

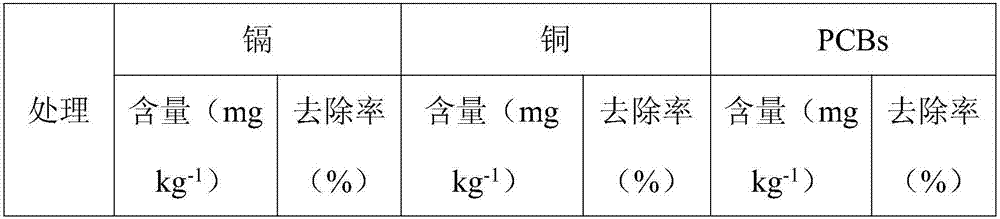

Method for efficiently repairing composite polluted soil by artificial ecological system

ActiveCN106964646AMaximize the root-soil interface areaHigh DensityContaminated soil reclamationShrubArtificial ecosystem

The invention discloses a method for efficiently repairing composite polluted soil by an artificial ecological system. Scientific allocation is conducted according to different latitudes and longitudes, different temperature and humidity and different coastal pollution types. The ecological system of trees, shrubs, vines, herbaceous plants and benthonic animals is artificially constructed, and a unique sediment microbial community is naturally formed, so that heavy metal and organic pollutants in the polluted soil are quickly and effectively adsorbed and transformed by microorganism and are adsorbed and extracted by plants, and the effect of efficient purifying of the soil is achieved by artificially harvesting aboveground vegetation. According to the method for efficiently repairing the composite polluted soil by the artificial ecological system, the ecological system suitable for any soil pollution repairing can be derived in the case of scientific species configuration and the method has good ecological benefits and economic value. The maximization of the ecological benefits and repairing efficiency is ensured, meanwhile, repairing cost is reduced, and certain economic benefits can be produced.

Owner:杜道林

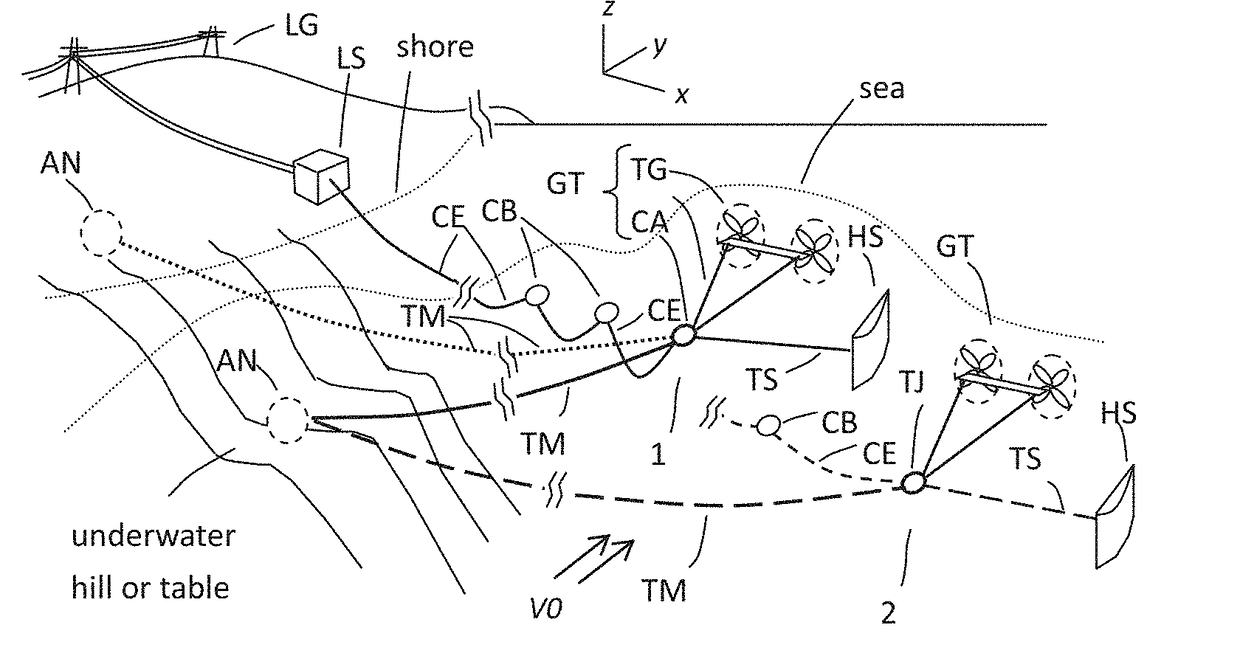

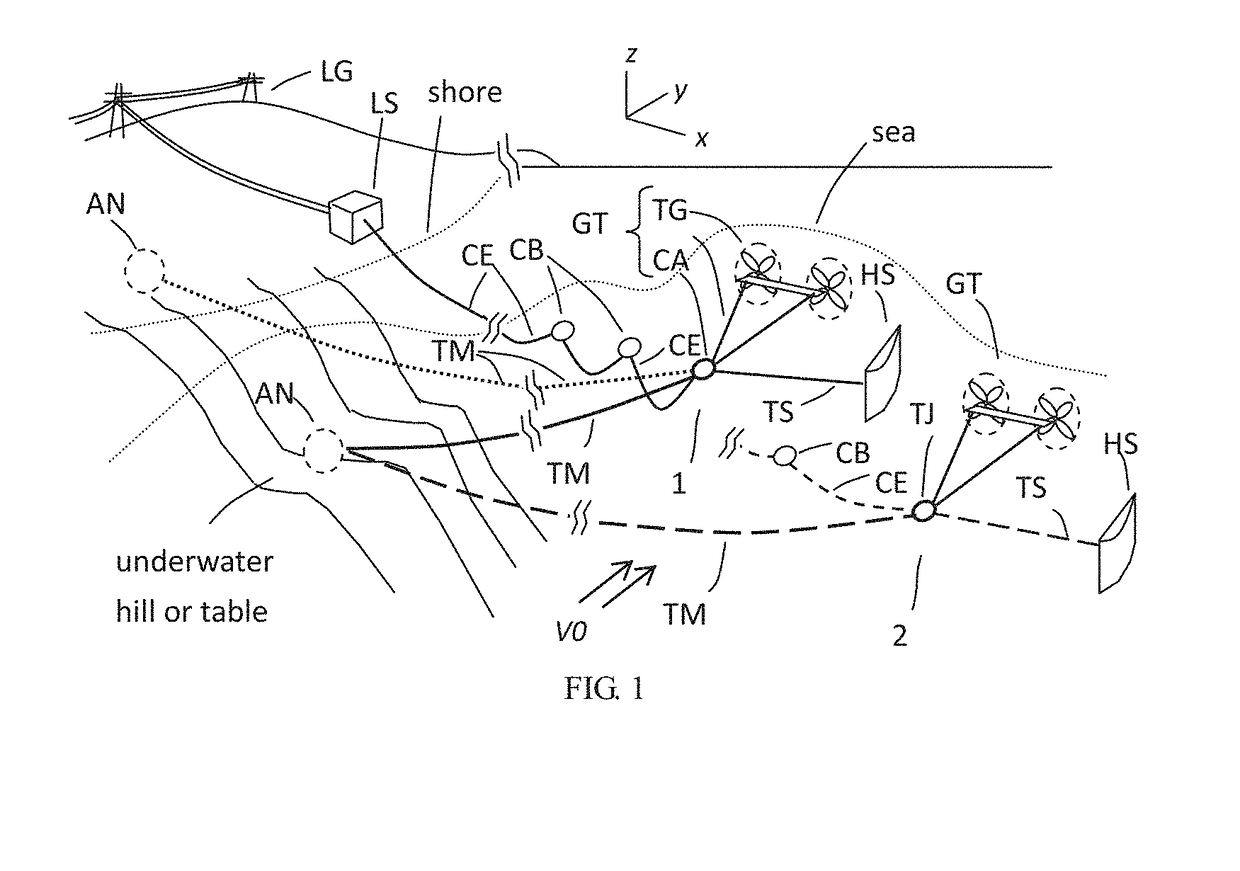

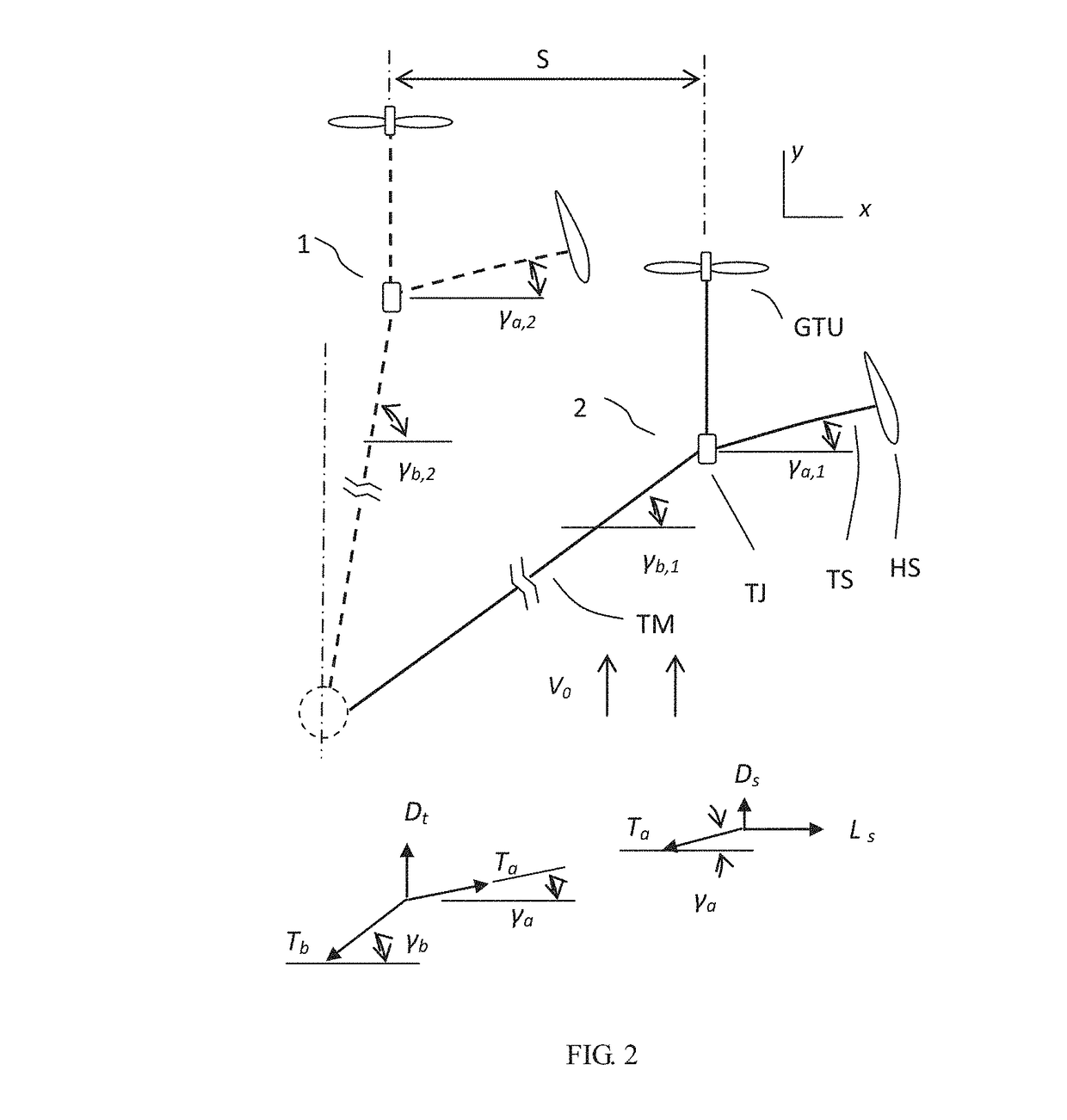

Mooring System and Method

ActiveUS20180111665A1Easing depth issueExtended lateral displacement capacityHydro energy generationMachines/enginesMooring systemMarine engineering

A mooring system for deploying a payload in a fluid moving relative to the payload and placing the payload to a position across moving path of the fluid from an anchoring point, the mooring system comprises: a main tether; an anchor means attached to a first end of the main tether and fixed to the anchoring point; and a main sail means attached to a second end of the main tether and immersed in the fluid; wherein the payload is attached to the second end of the main tether; and the fluid moving relative to the main sail means creates a fluid dynamic lift force on the main sail means and pulls the payload in a lateral direction with respect to the moving path of the fluid.

Owner:NATIONAL TSING HUA UNIVERSITY

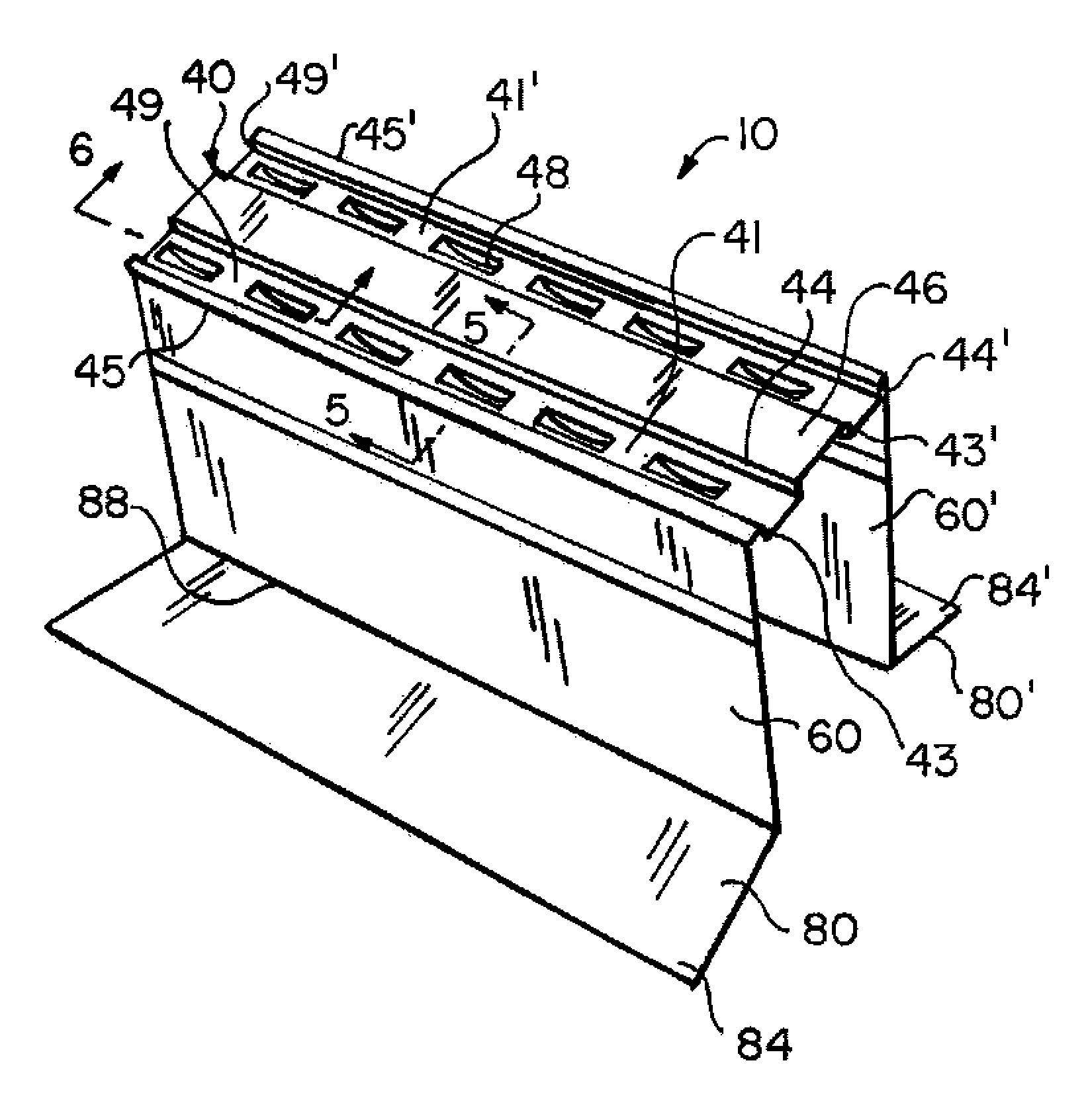

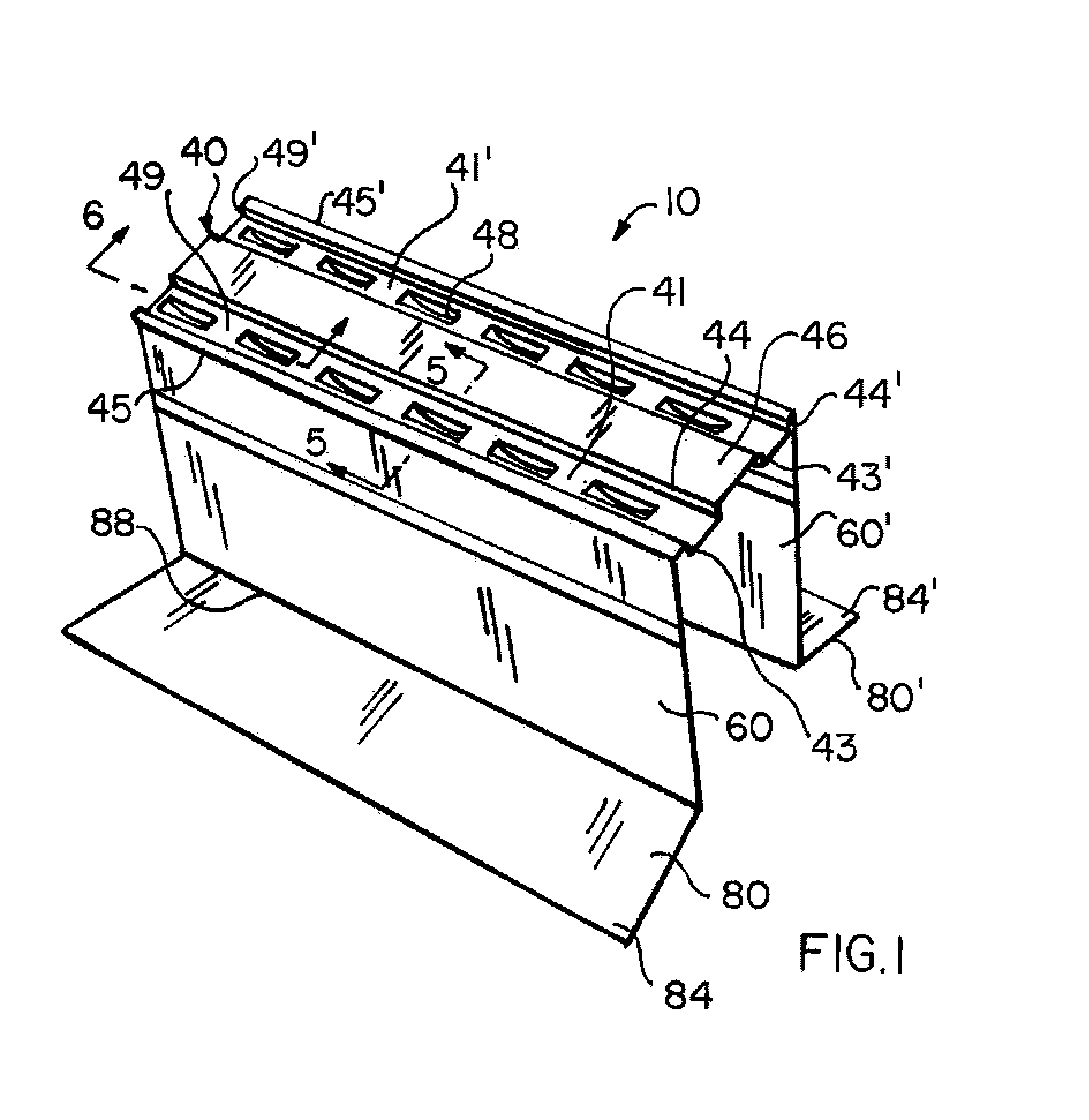

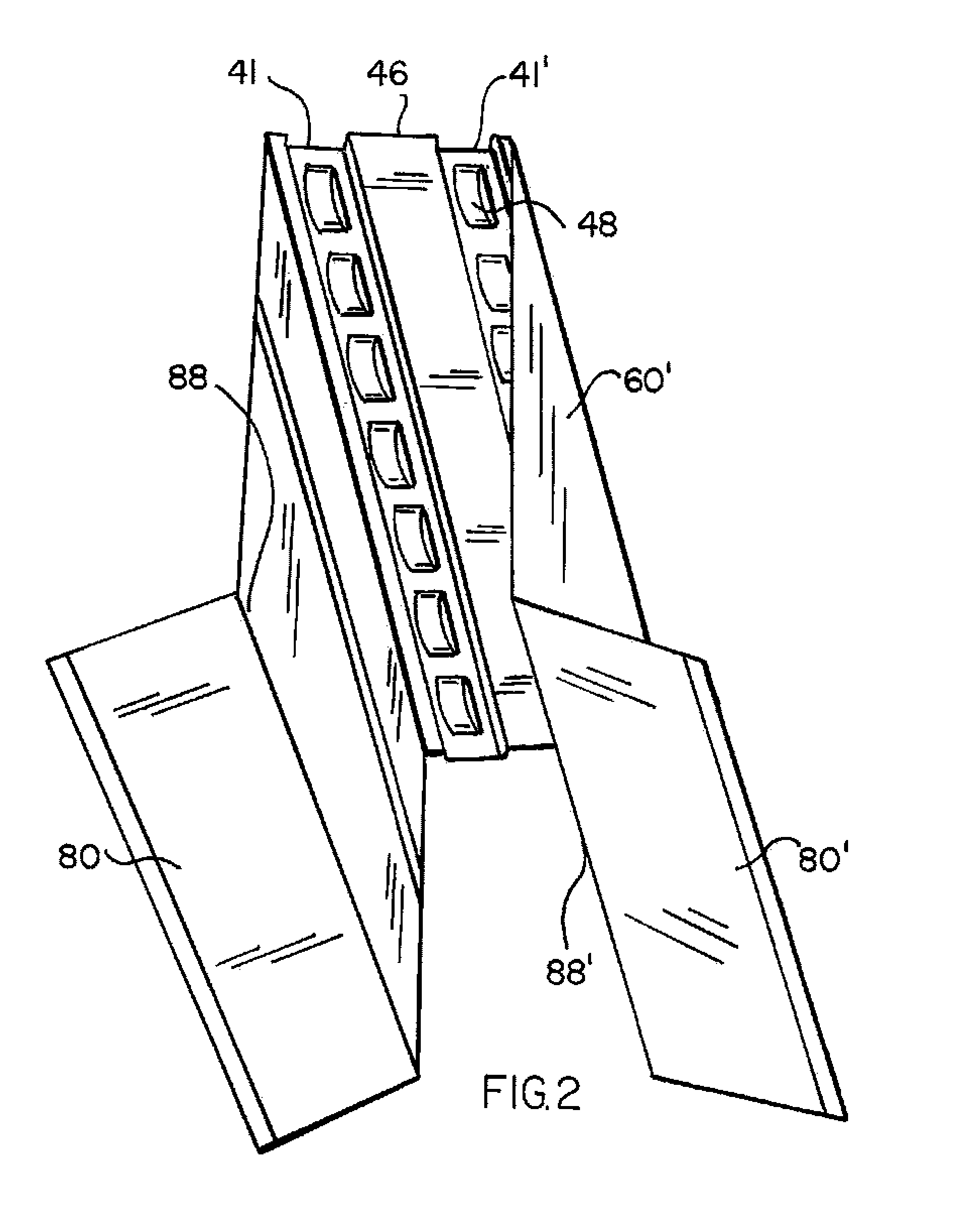

Roof hip and ridge anchor device (CIP)

ActiveUS7774990B1Manufacturing process compatibleMaximize contact areaRailway roofsBuilding roofsAdhesiveEngineering

A device for roof structures having a ridge or hip defined by the planes of two roof decks, disposed at an angle with respect to each other defining a longitudinal joint. A longitudinally extending cover with at least one coextensive channel defined by a bottom, two spacer walls and two lateral walls are mounted over the ridge or hip. The channel(s) increases the effective contact area to enhance the gripping action of the adhesive compound. From the longitudinal bends of the cover wall extend two perpendicularly extending walls with distal ends that continue with longitudinally coextensive flanges. The longitudinal flanges extend at an angle to be cooperatively and rigidly mounted over the roof decks with mechanical fasteners. An adhesive compound is positioned in the channel and over the cover. The adhesive is pressed so that part of it passes through and is lodged within the connected depressed slots positioned along the bottom, spacer and / or lateral walls that define the channel thereby creating a mechanical anchorage with the device. Tile accessories are placed over the cover and in contact with the adhesive compound to secure them to the device.

Owner:EAST COAST METALS

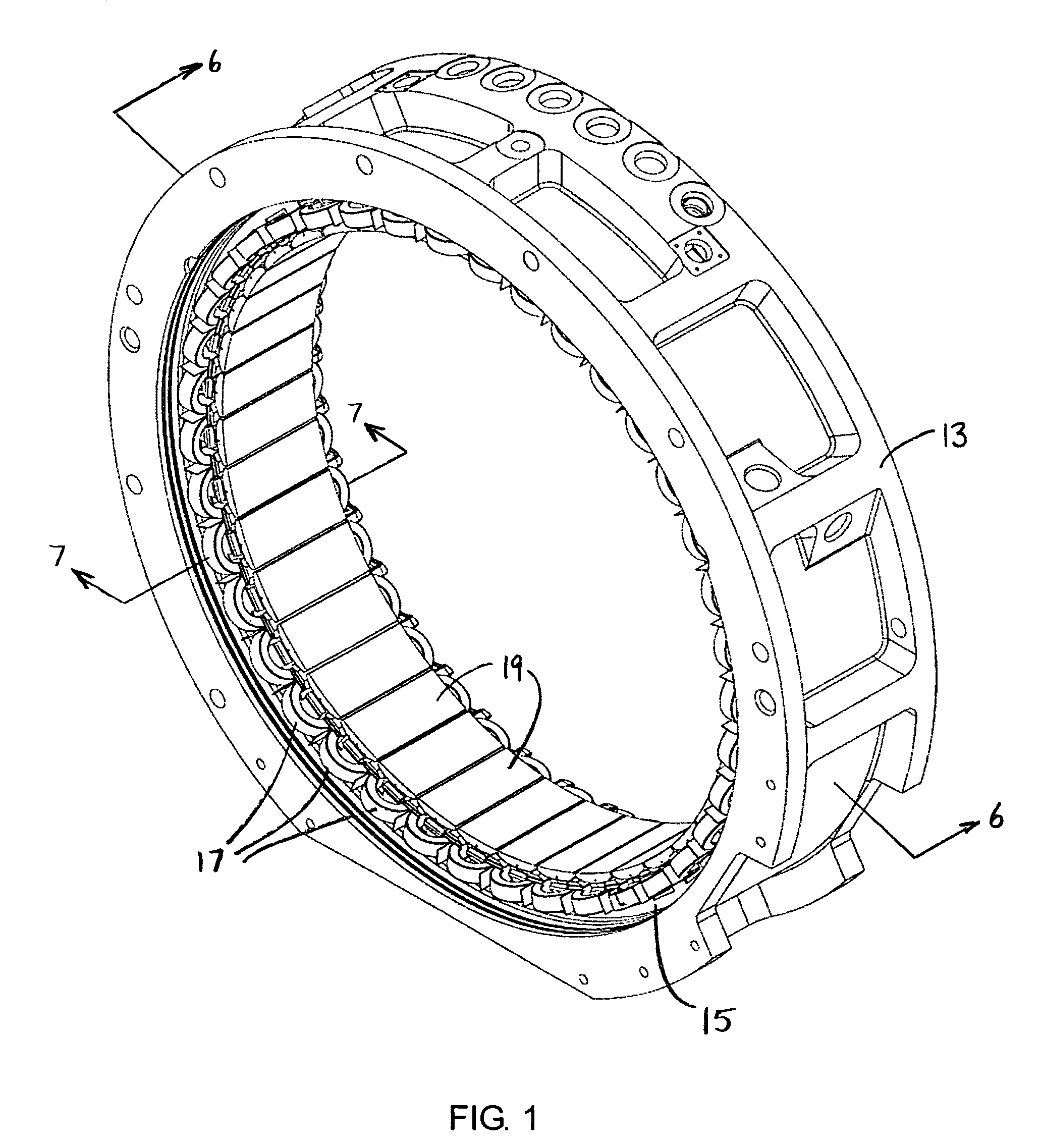

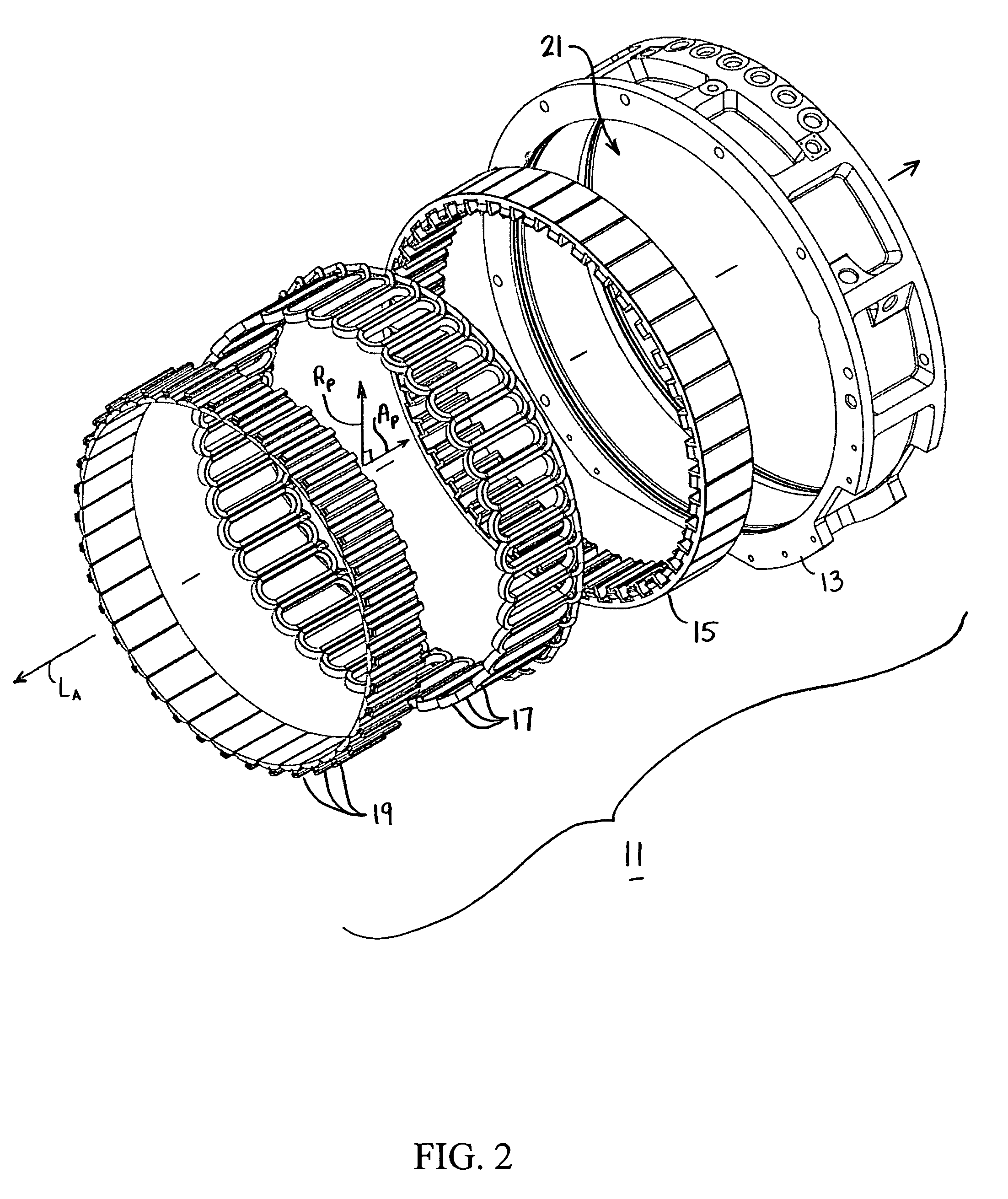

Pole tip attachment for a magnetic structure

InactiveUS7990015B2Reduce gapReduce mechanical stressWindingsMagnetic circuit stationary partsProtruding shouldersElectric machine

Attachments are removably coupled to the magnetic core of a rotating electric machine, the magnetic core being shaped to include a plurality of coil-receiving slots that are separated by radial teeth. Each attachment is constructed as a unitary member and includes a base and a stem, the stem being dimensioned for fitted insertion within a recess formed in the distal end of a corresponding tooth. The base includes a convex bottom wall, a flattened top wall and a pair of non-planar sidewalls. The stem is integrally formed on the top wall of the base and includes a front end, a rear end, a flattened top wall and a pair of opposing sidewalls. A longitudinal groove is formed into each of the pair of opposing sidewalls of the stem. An outwardly protruding shoulder designed for engagement by a retention plate is formed into the front and rear ends of the stem.

Owner:VESTAS WIND SYST AS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com