Patents

Literature

5308 results about "Flue-gas desulfurization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flue-gas desulfurization (FGD) is a set of technologies used to remove sulfur dioxide (SO₂) from exhaust flue gases of fossil-fuel power plants, and from the emissions of other sulfur oxide emitting processes (e.g trash incineration).

Enhanced mercury control in coal-fired power plants

InactiveUS6808692B2Easy to captureEliminate dischargeChloride preparationUsing liquid separation agentPulverized fuel ashElemental mercury

A method of treating a coal combustion flue gas, which includes injecting a molecular halogen or thermolabile molecular halogen precursor, such as calcium hypochlorite, able to decompose to form molecular halogen at flue gas temperature. The molecular halogen converts elemental mercury to mercuric halide, which is adsorbable by alkaline solids such as subbituminous or lignite coal ash, alkali fused bituminous coal ash, and dry flue gas desulphurization solids, capturable in whole or part by electrostatic precipitators (ESPs), baghouses (BHs), and fabric filters (FFs), with or without subsequent adsorption by a liquid such as a flue gas desulphurization scrubbing liquor.

Owner:HAZELMERE RES

Enhanced mercury control in coal-fired power plants

InactiveUS20030161771A1Enhanced capture of mercuryEliminating undesirable dischargeUsing liquid separation agentHalide preparation methodsPulverized fuel ashElemental mercury

A method of treating a coal combustion flue gas, which includes injecting a molecular halogen or thermolabile molecular halogen precursor able to decompose to form molecular halogen at flue gas temperature. The molecular halogen coverts elemental mercury to mercuric halide adsorbable by alkaline solids such as subbituminous or lignite coal ash, alkali fused bituminous coal ash capturable in whole or part by electrostatic precipitators (ESPs), baghouses (BHs), fabric filters (FFs), dry flue gas desulphurization solids, with or without subsequent adsorption by a liquid such as a flue gas desulphurization scrubbing liquor.

Owner:HAZELMERE RES

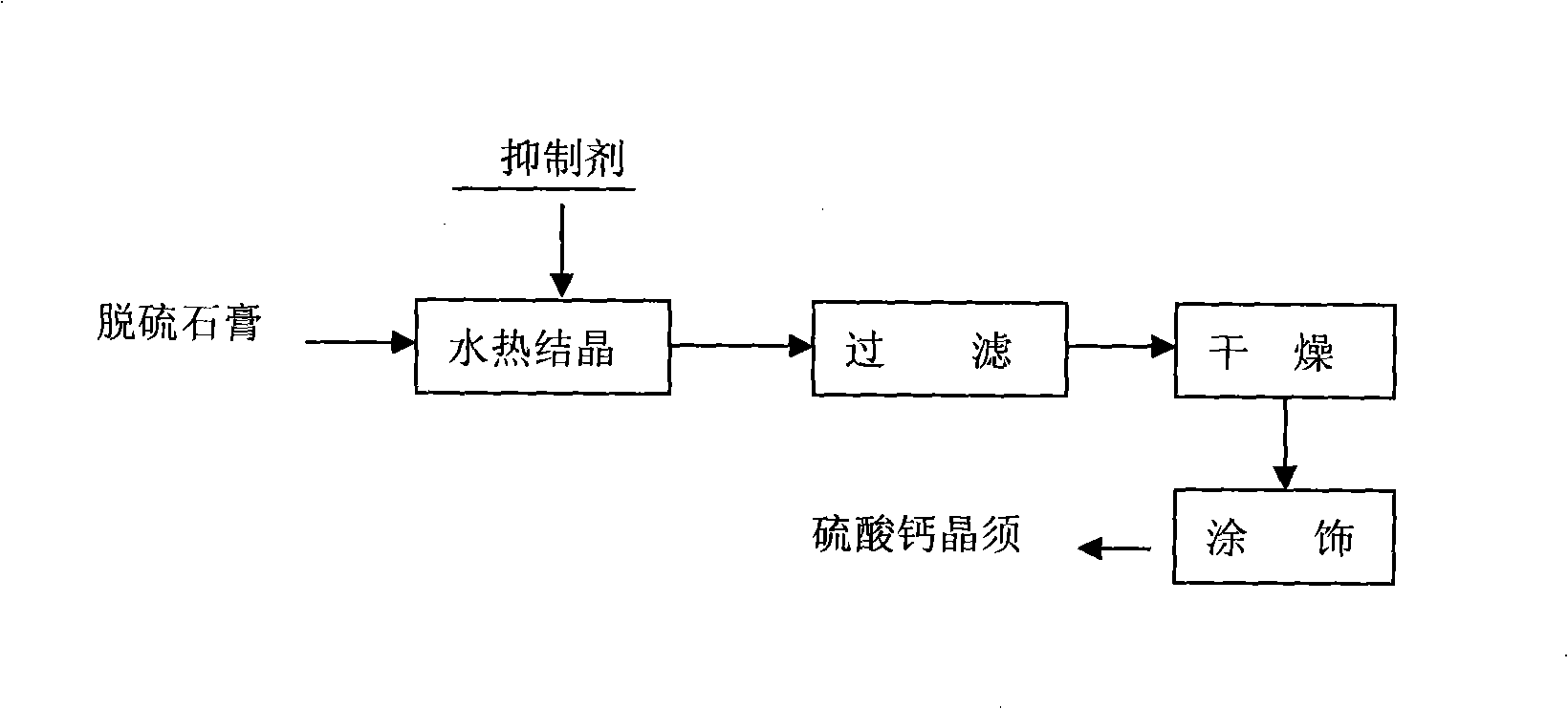

Process for preparing calcium sulphate whiskers by using flue gas desulfurization gypsum

InactiveCN101311337AReduce environmental problemsMitigation resourcesPolycrystalline material growthFrom normal temperature solutionsGlass fiberSulfate

The invention discloses a method for using flue gas desulfurization gypsum to prepare calcium sulfate whisker, comprising process steps of size mixing, high-temperature crystallization, drying and coating, etc. The method utilizes the flue gas desulfurization gypsum as the raw material, which has low production cost, short technological process and saves natural gypsum mine and effectively relieves the environmental pollution problem of the flue gas desulfurization gypsum. The product purity can be up to more than 98 percent, which can be used as filler with medium intensity or as friction material, building material or insulating material, and the like, instead of asbestos. The product can also partly replace organic macromolecular compounds such as glass fiber, resin, rubber and plastic, and the like, and has good describability.

Owner:NORTHEASTERN UNIV

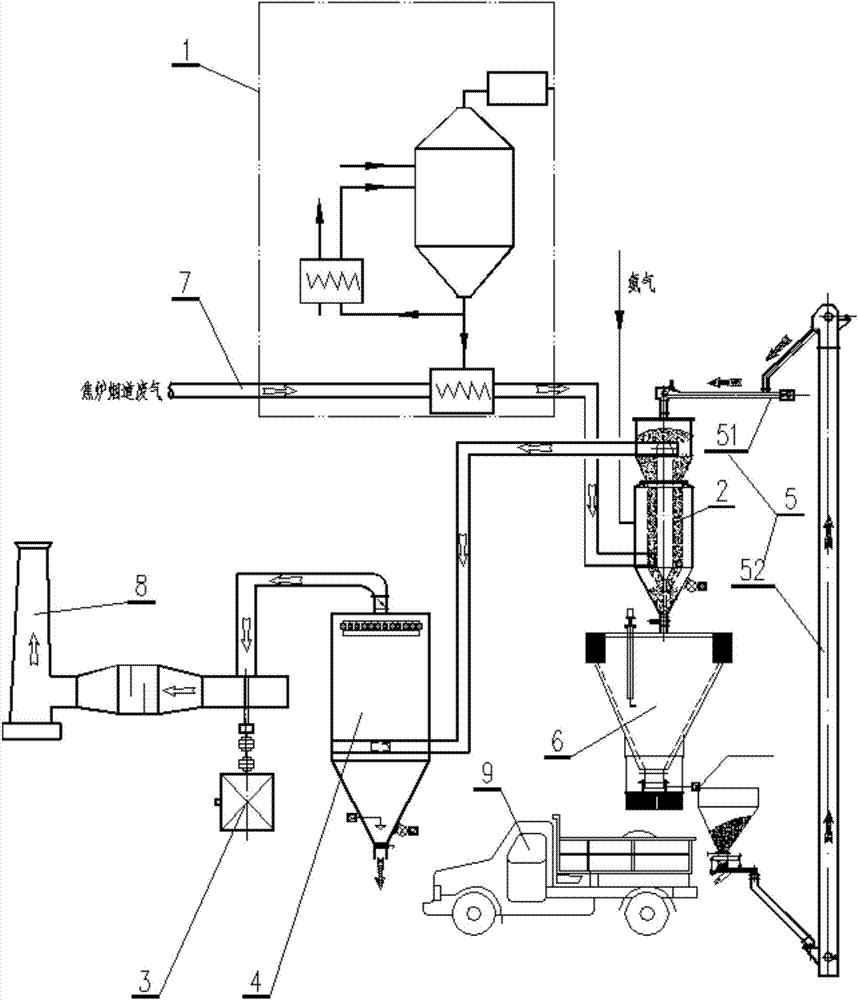

Coke oven flue gas waste heat utilization and purification method

ActiveCN103877856AReduce consumptionEfficient governanceDispersed particle separationPurification methodsCoking plant

The invention relates to the technical field of coke oven flue gas integrated utilization and pollution treatment and in particular relates to a coke oven flue gas waste heat utilization and purification method. The method is characterized in that flue gas waste heat is recovered by utilizing a flue gas waste heat recovery device, the temperature of the flue waste gas is reduced, and integrated desulfurization and denitration of the flue waste gas is realized by utilizing the activated adsorption capacity and low-temperature denitration catalytic capability of the coke. Compared with an existing process, the method has the beneficial effects that the flue waste gas desulfurization and denitration is performed under low-temperature working conditions, an additional heating system is not needed, and the energy consumption is reduced. In order to realize the desulfurization and denitration under low-temperature working conditions, the flue waste gas is cooled through the waste heat recovery device, so that the waste heat of the flue waste gas is fully utilized. The coke serves as a main catalyst for desulfurization and denitration and comes from a coking plant, the source is sufficient, and waste loss is avoided. The method disclosed by the invention can be widely applied to pollution treatment and integrated utilization of coke oven heated flue waste gas in coking production enterprises.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

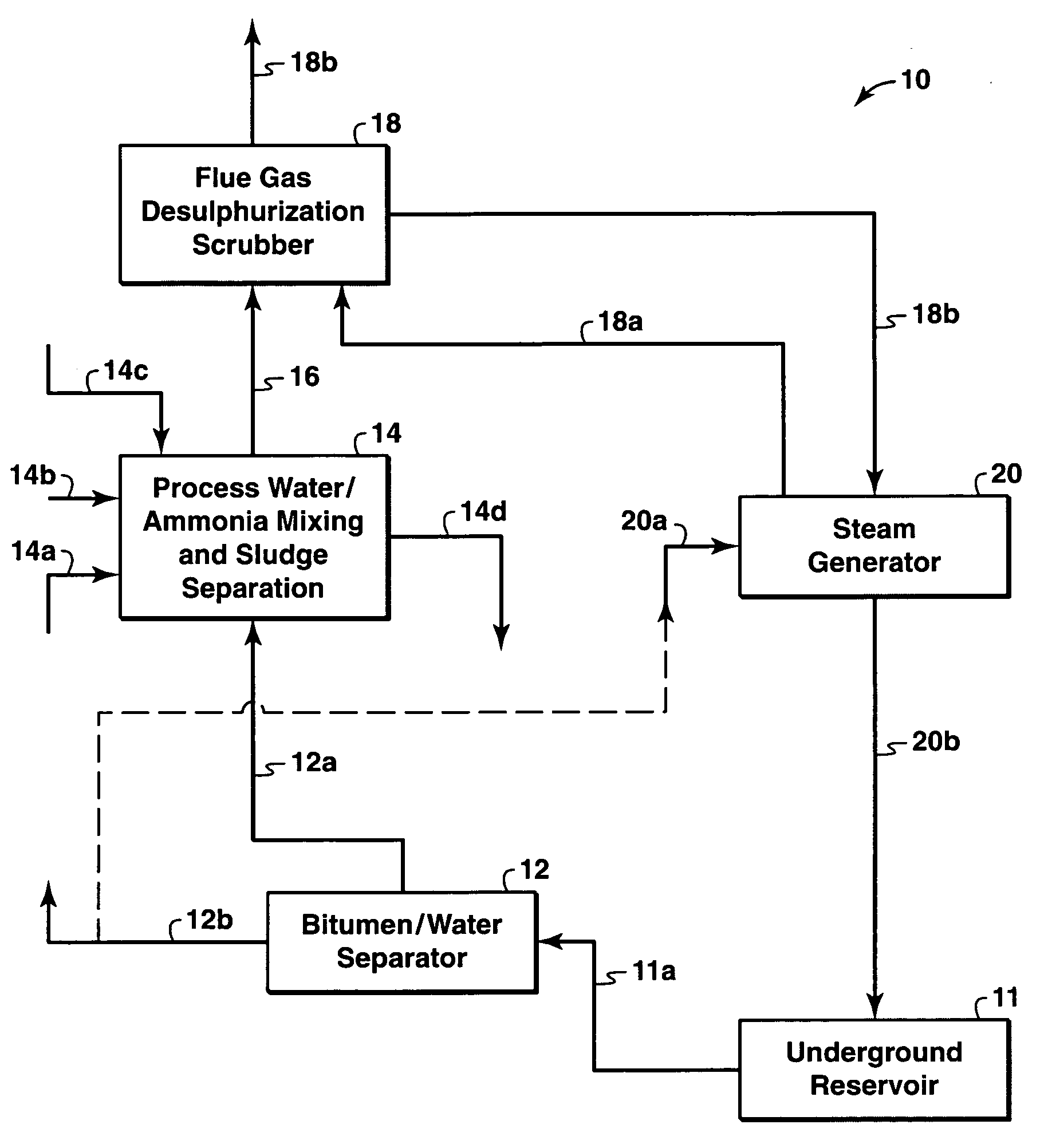

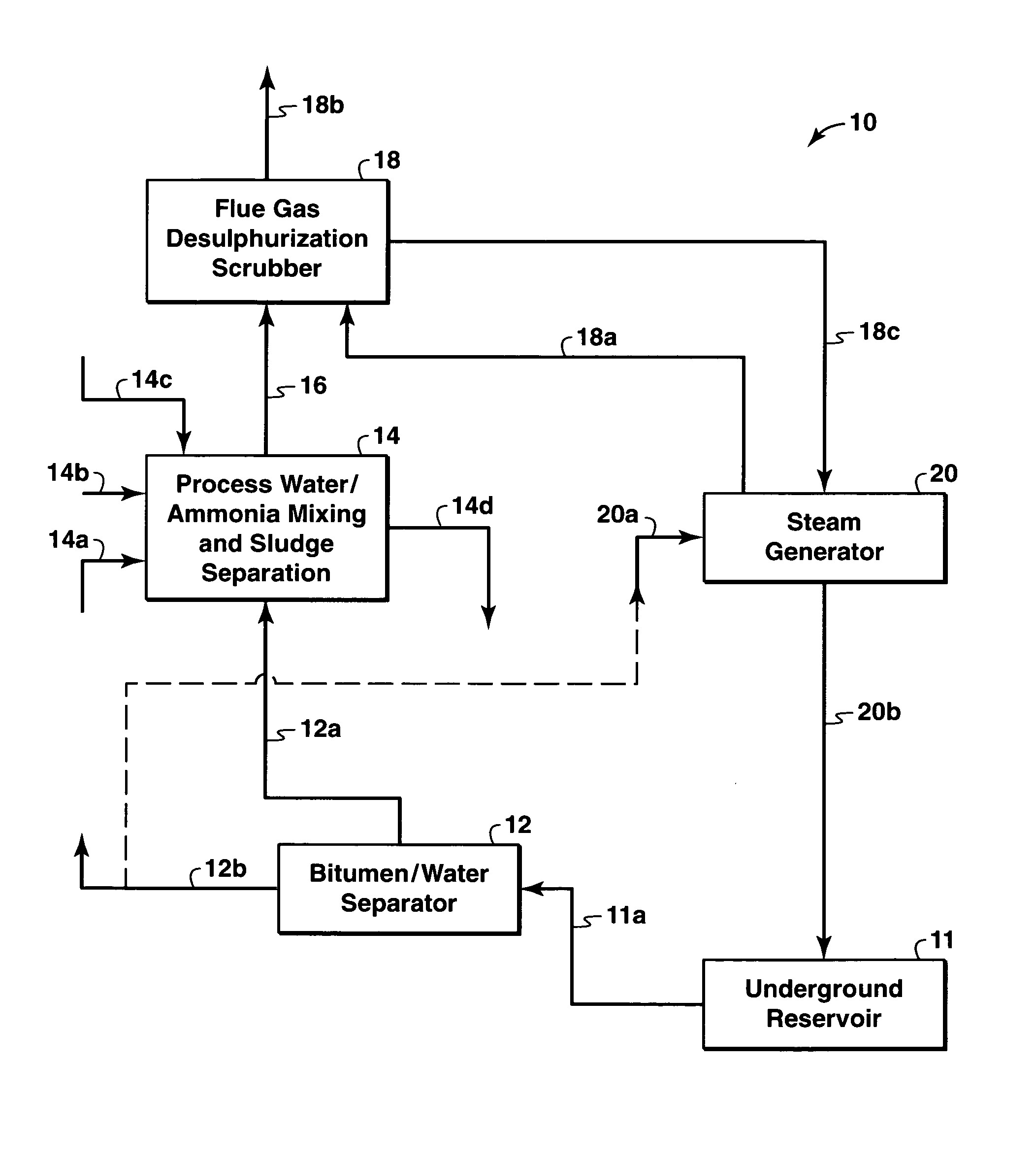

Integrated water treatment and flue gas desulfurization process

A water stream containing hardness minerals is subjected to a water treatment process using an alkali agent to precipitate the hardness minerals and to produce a softened water stream is used to create an integrated water treatment and flue gas desulfurization process. Thereafter, the softened, alkaline water stream is utilized in a scrubber to scrub a flue gas containing sulfur dioxide to produce a sulfur-lean flue gas. The invention may be applied to a steam-based bitumen recovery operation where bitumen, sour produced gas or other sulfur containing fuels are burned for producing steam for bitumen recovery. More specifically, the associated produced water from the bitumen recovery process may be softened for re-use and for utilization as a scrubbing agent for high-sulfur containing flue gas arising from the steam generators. The process provides an economically favorable process while minimizing waste disposal requirements.

Owner:EXXONMOBIL UPSTREAM RES CO

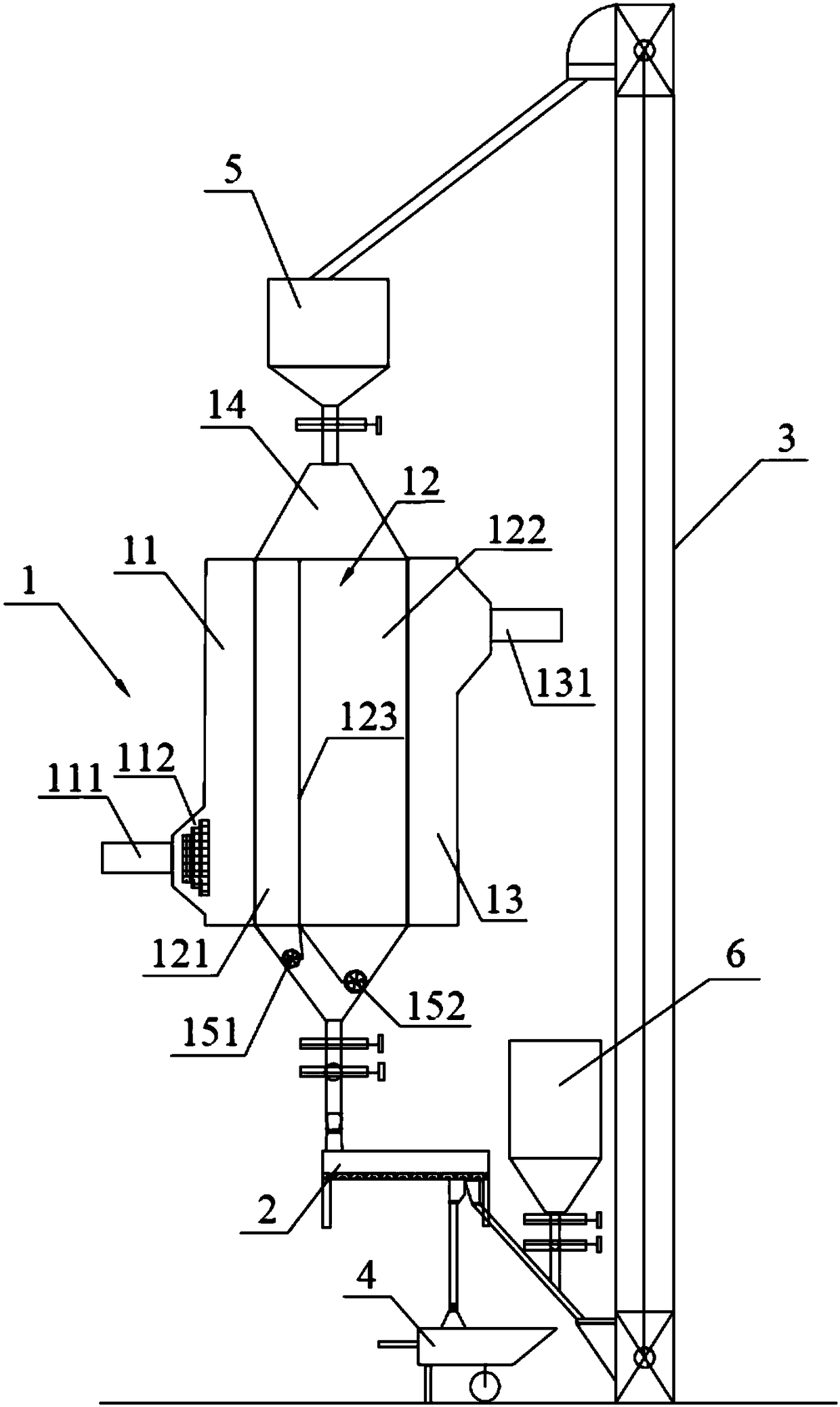

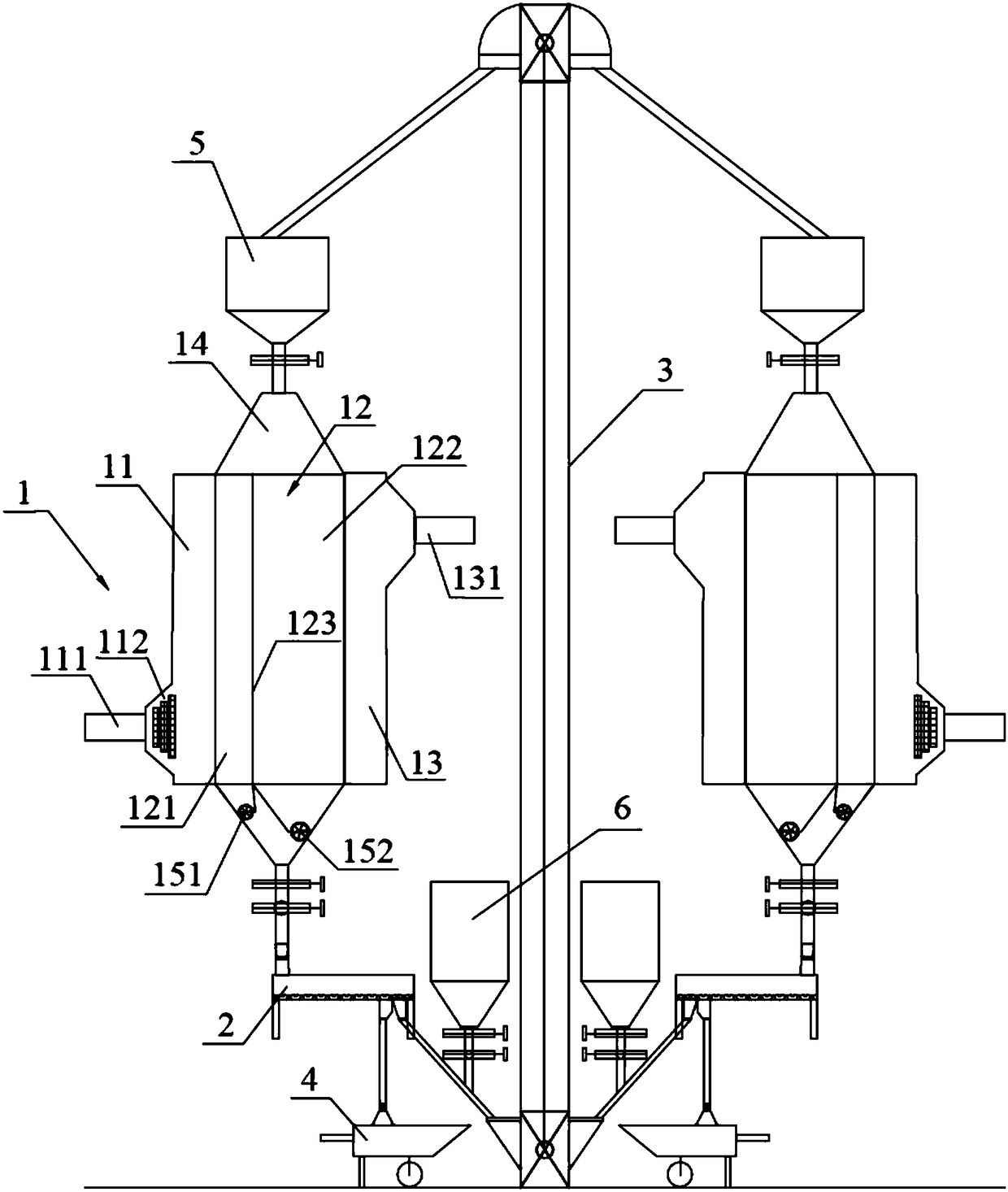

Low-sulfur flue gas desulfurization and denitrification apparatus

ActiveCN108525466AImprove controllabilitySimple processGas treatmentDispersed particle separationActivated carbonFlue gas

The invention belongs to the technical field of flue gas purification equipment and discloses a low-sulfur flue gas desulfurization and denitrification apparatus, comprising an adsorbing column and avibrating screen; the adsorbing column is provided with a first region, a second region and a third region sequentially along a flow gas circulation direction; the first region is provided with a fluegas incoming port and an ammonia spray grille arranged at the flue gas inlet; the third region is provided with a flue gas outlet; the second region is provided with a mobile activated carbon layer inside; the activated carbon layer flows in from a top inlet of the adsorbing column and flows out of a bottom outlet; the vibrating screen is connected with the bottom outlet of the adsorbing column and is connected with the top inlet of the adsorbing column through a delivery mechanism. The low-sulfur flue gas desulfurization and denitrification apparatus has the main advantages that an activatedcarbon resolution device is provided, the adsorbing column structure is selectively designed according to the characteristics of flue gas, activated carbon suitable for direct reuse is screened and separated in conjunction with the vibrating screen, efficient deep denitrification is provided for the flue gas with relatively low content of sulfur, no dependence on resolution procedures occurs, theprocess is simple, the controllability is high, and great convenience and high efficiency are achieved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +2

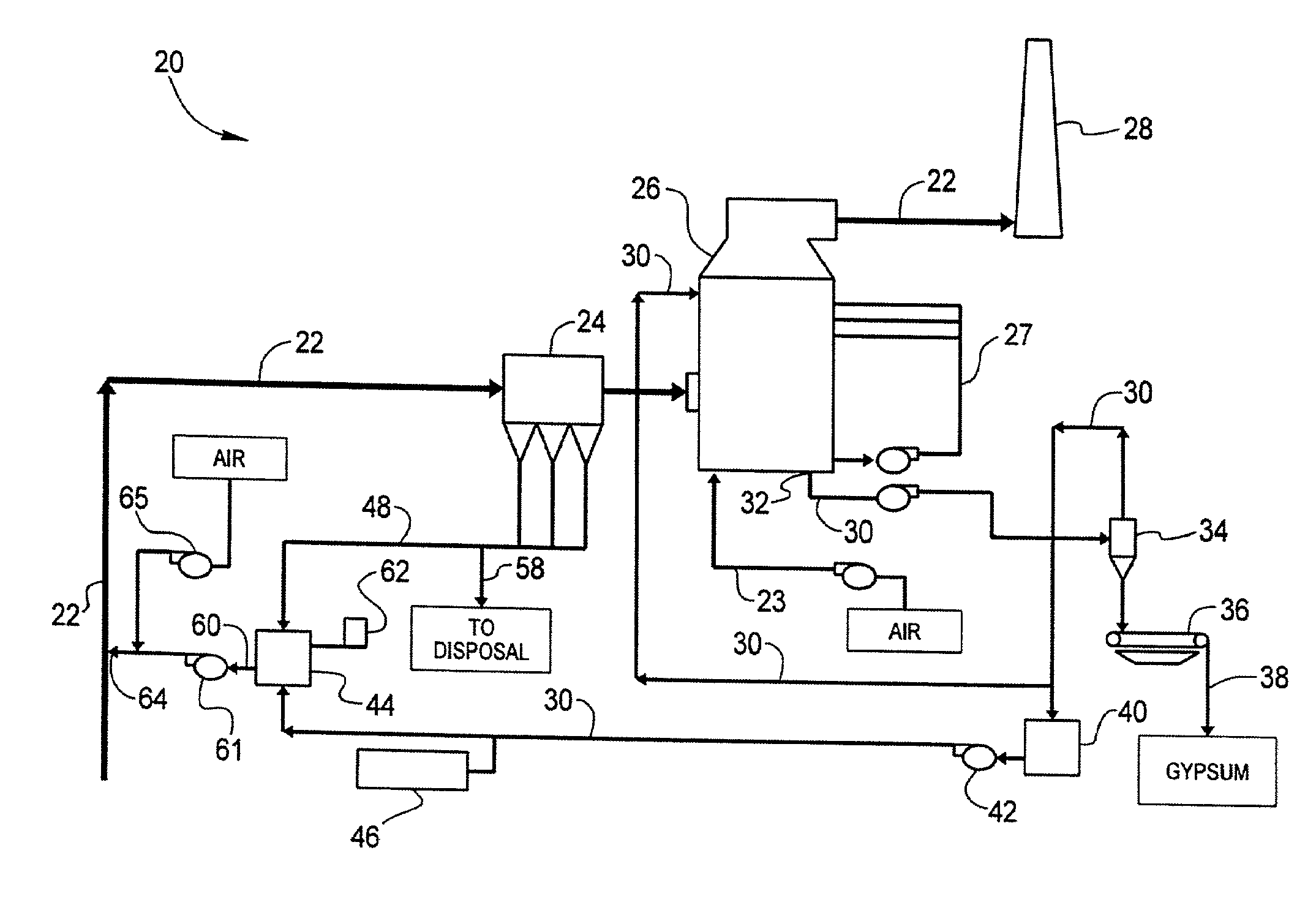

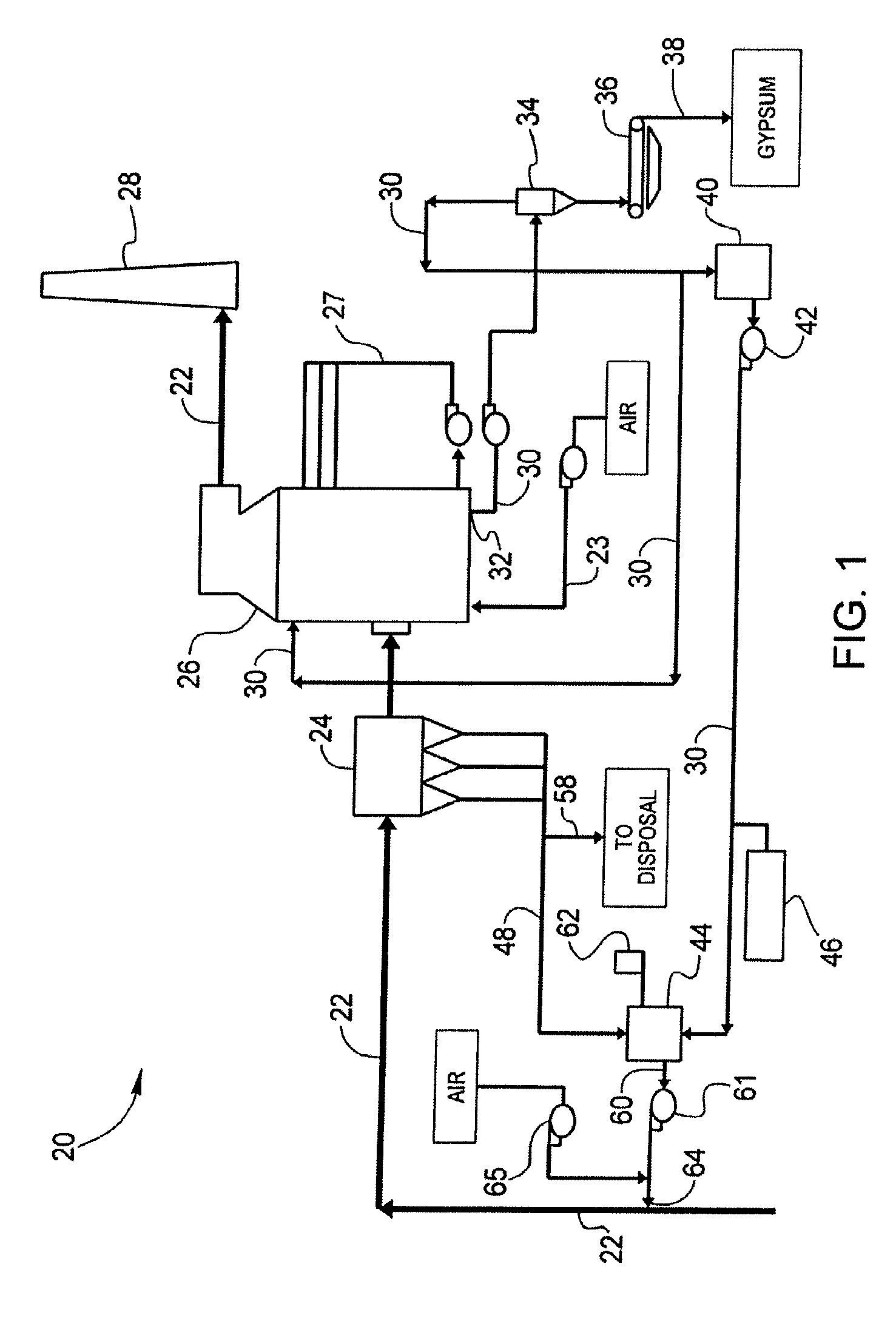

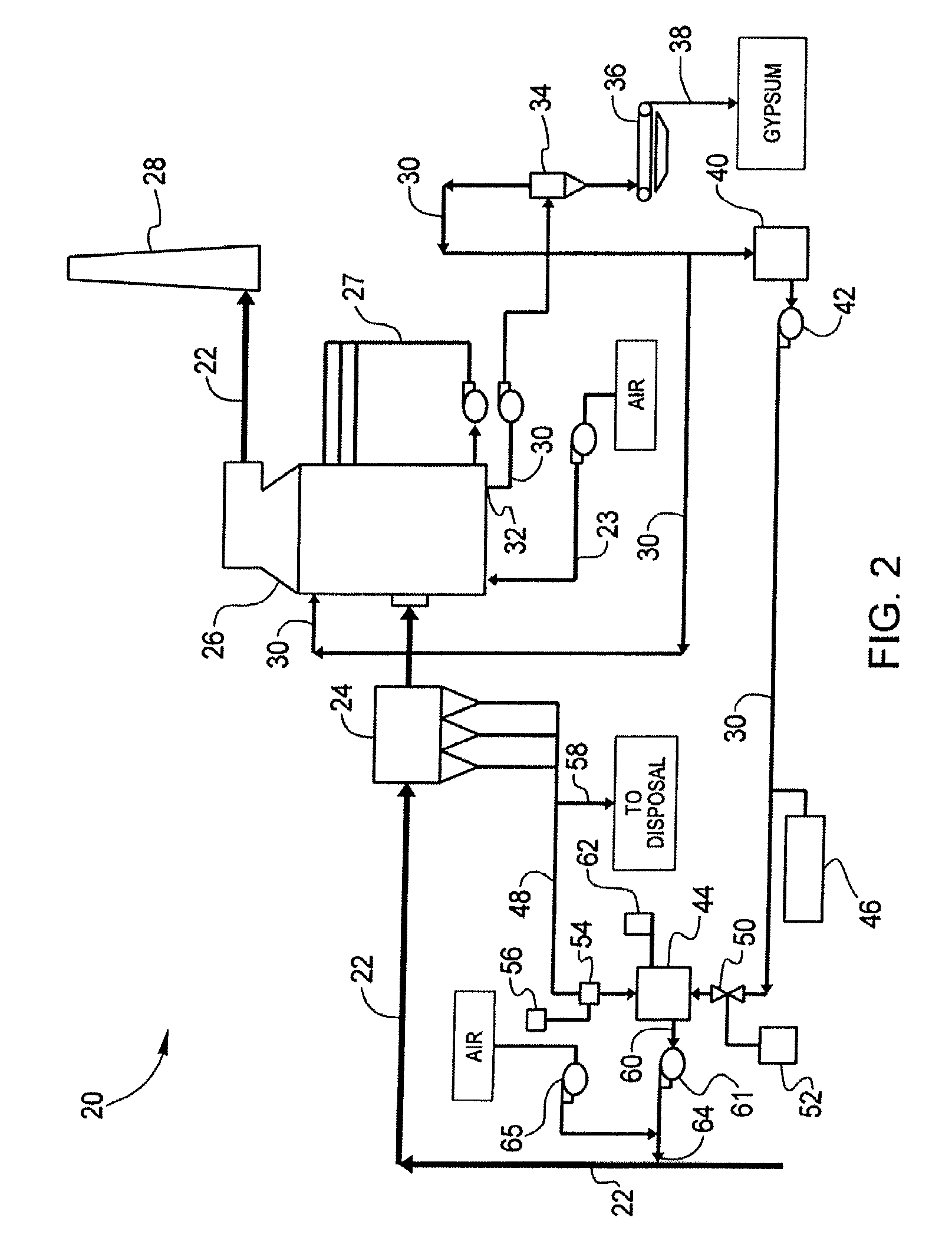

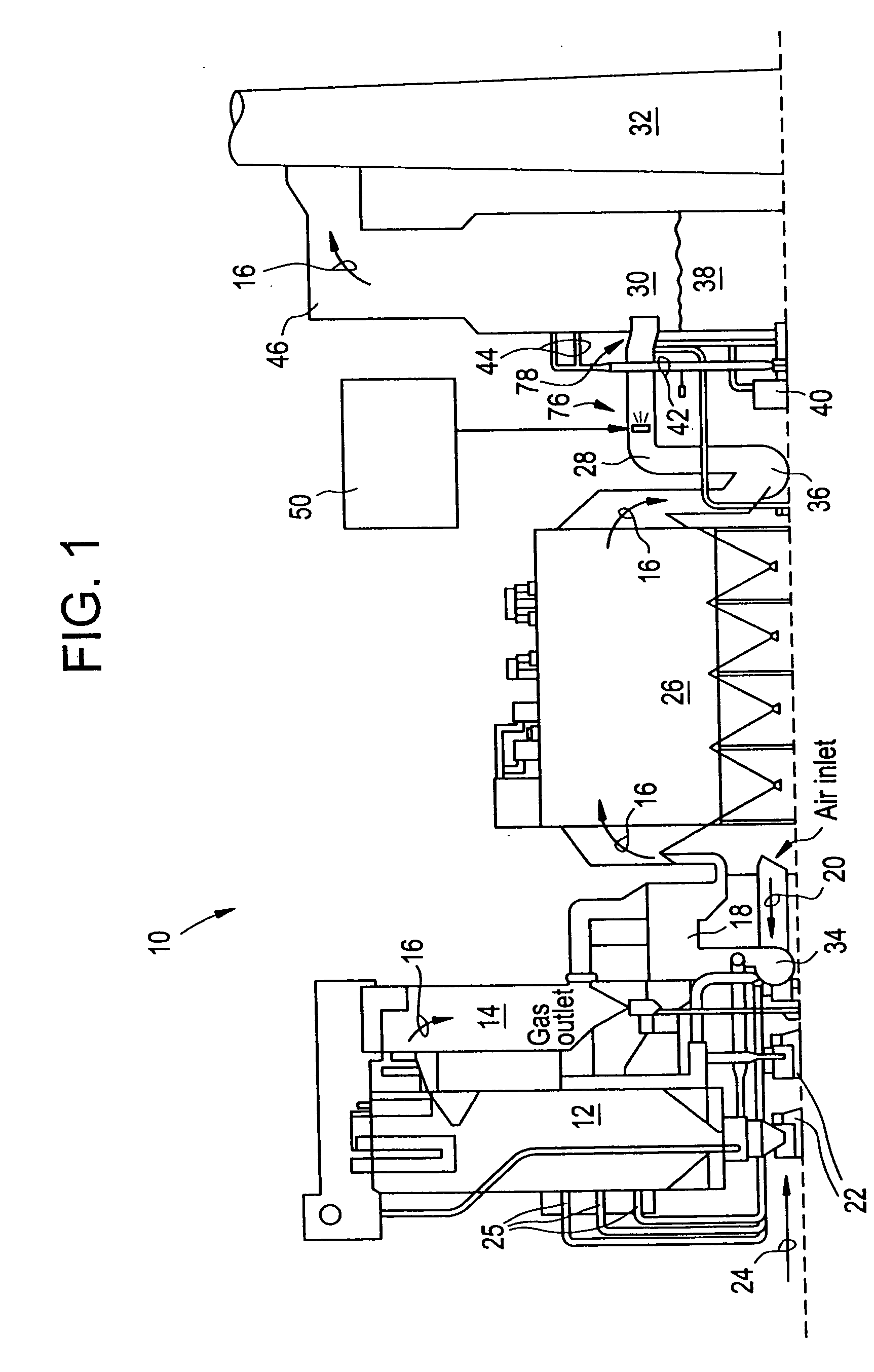

Reduced liquid discharge in wet flue gas desulfurization

One aspect of the invention relates to a method for removing contaminants from a flue gas stream (22). The method includes: removing fly ash from a flue gas stream (22) utilizing a particle collector (24); contacting the flue gas stream with an alkaline reagent in a wet scrubber (26); discharging a purge liquid (30) from the wet scrubber (26); and, combining at least a portion of the purge liquid with at least a portion of fly ash circulating within a dry circulating fluid bed scrubber (48) to form moistened fly ash (60).

Owner:GENERAL ELECTRIC TECH GMBH

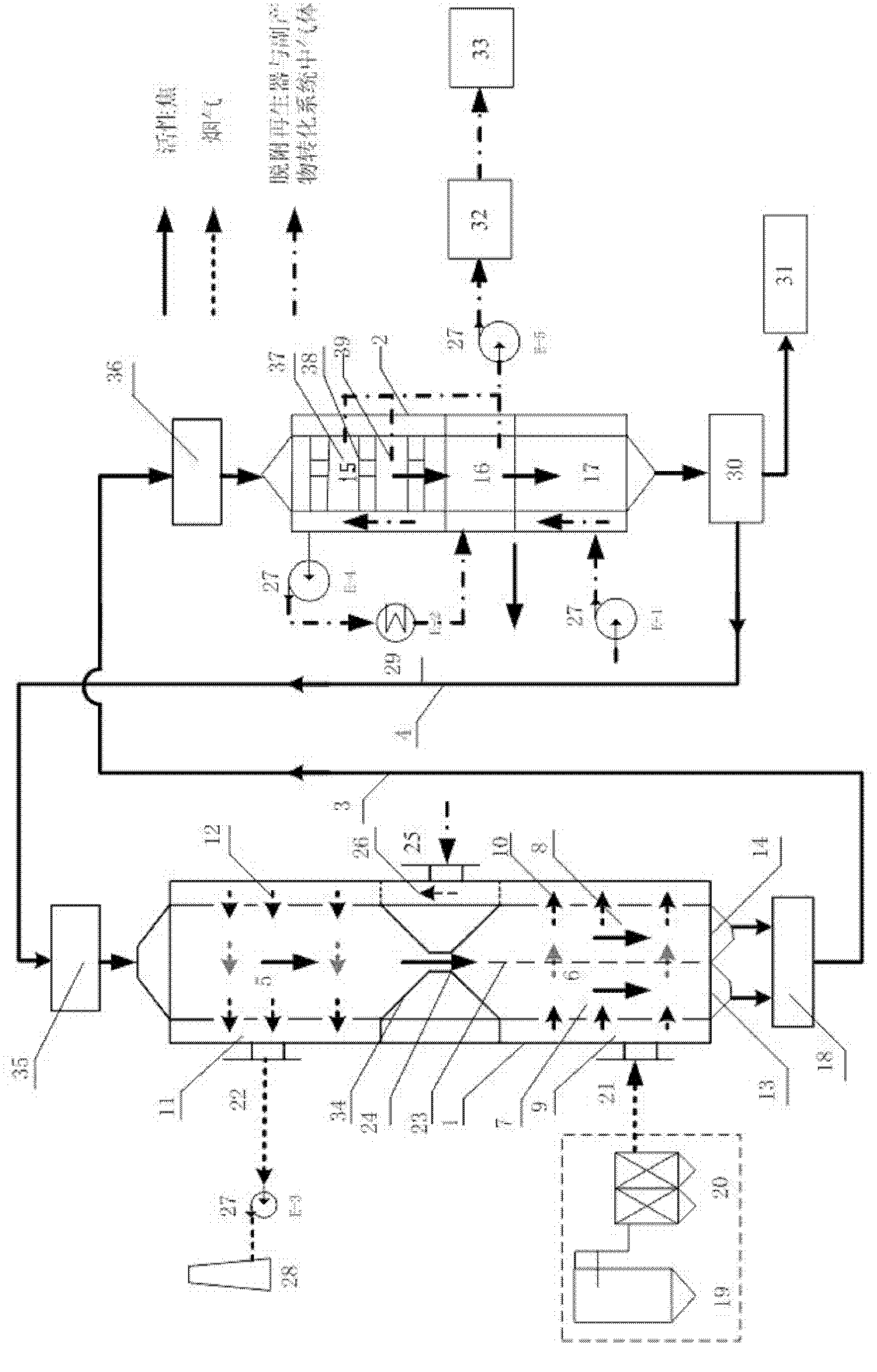

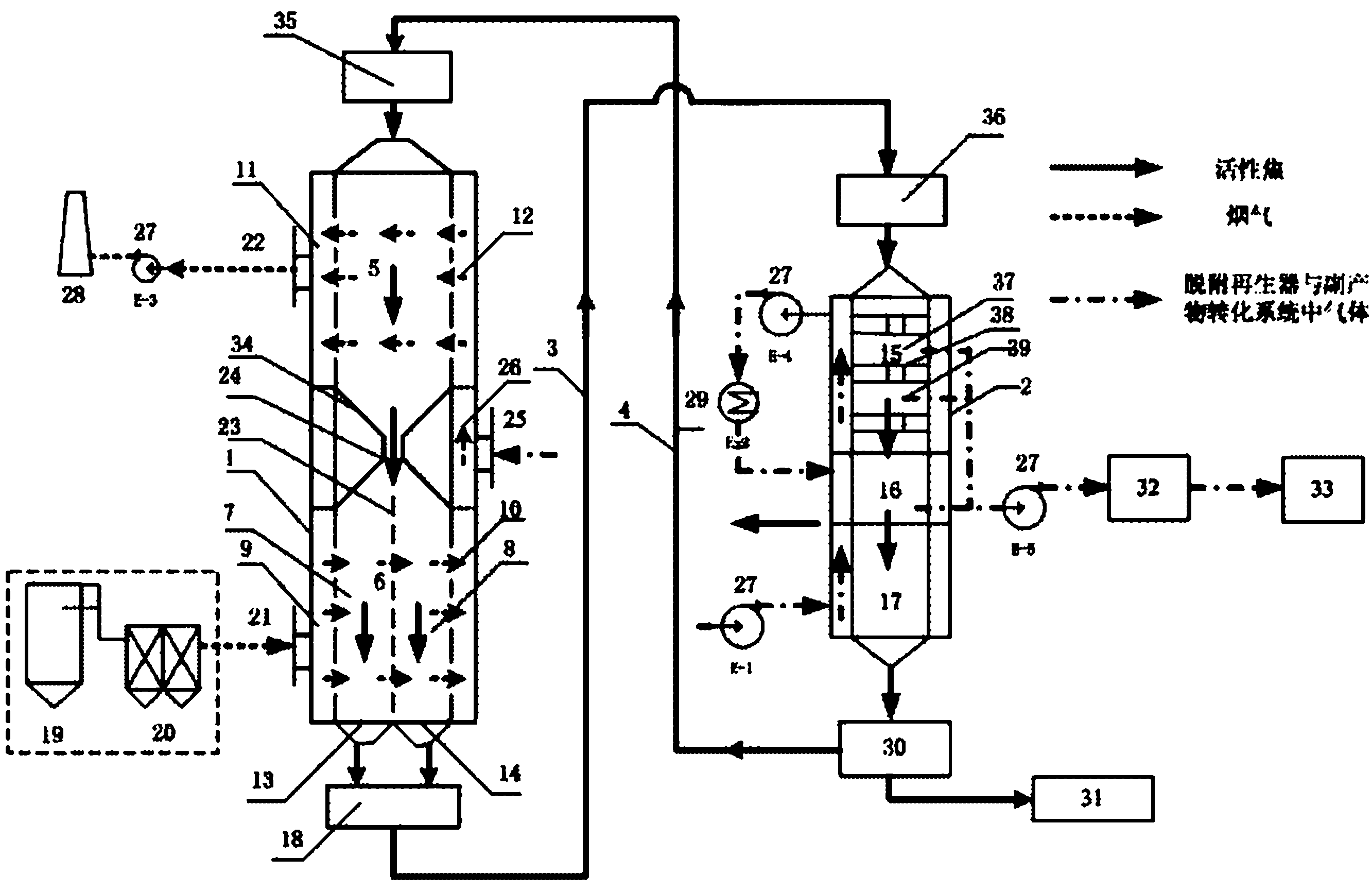

System for desulfurizing and denitrating active coke flue gas, and process method

ActiveCN102430318AIntegrated purification effect is obviousImprove utilization efficiencyDispersed particle separationSulfurDesorption

The invention discloses a system for desulfurizing and denitrating active coke flue gas, and a process method. The system comprises an adsorption reactor, a desorption regenerator, a material conveying device and a byproduct conversion device, wherein the devices are connected by specific pipelines and functions of the devices are realized by using a specific process method; the adsorption reactor is a composite layer double-section cross flow moving bed and consists of a denitration section and a desulfurization section, so that SO2, NOx, dioxin, mercury and smoke dust in flue gas are purified in an integrated mode; the desorption regenerator is divided into a preheating area, a regeneration area and a cooling area, so that active coke on which the mercury, and the dioxin are enriched are extracted, and subsequent harmless treatment of the active coke is realized; the desorption regenerator performs heat exchange by a heater and circulates heat energy for recovering, and the byproduct conversion device is used for performing sulphur recycling on desorption regenerated gas generated in the regeneration process; and by the process method, the integrated purification of the flue gas and the harmless treatment of the active coke can be realized.

Owner:SHANGHAI CLEAR ENVIRONMENTAL PROTECTION SCI & TECH

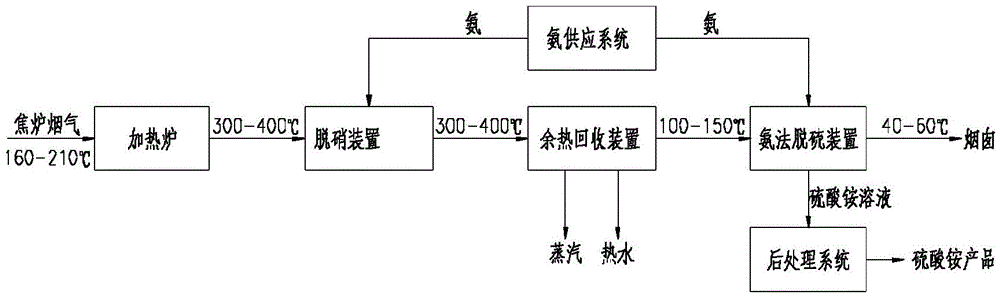

Coke oven flue gas desulfurization, denitration and waste heat recovery integrated method

InactiveCN104923046ASimple processWork lessDispersed particle separationEnergy inputFlue gasReaction temperature

The invention relates to a coke oven flue gas desulfurization, denitration and waste heat recovery integrated method. Flue gas from a coke oven firstly enters a heating furnace to be heated to 300 to 400 DEG C, and then the flue gas enters a denitration device for removing nitrogen oxide in the flue gas through a denitration reducer and a denitration catalyst, wherein the denitration reducer is ammonia; and the flue gas discharged from the denitration device is subjected to heat recovery through a waste heat recovery device and cooled to 100 to 150 DEG C, and then the flue gas enters an ammonia desulfurization device for removing sulfur dioxide in the flue gas. Both a desulfurization absorbent and the denitration reducer in the method are ammonia, and public ammonia is supplied to a system, so that operation and maintenance work is reduced. The heating furnace for heating and the waste heat recovery device are arranged, so that the flue gas temperature reaches the optimal denitration and desulfurization reaction temperatures respectively, relatively high denitration and desulfurization efficiency can be achieved, and flue gas waste heat can be recycled for greatly reducing the operation cost of coke oven flue gas treatment.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

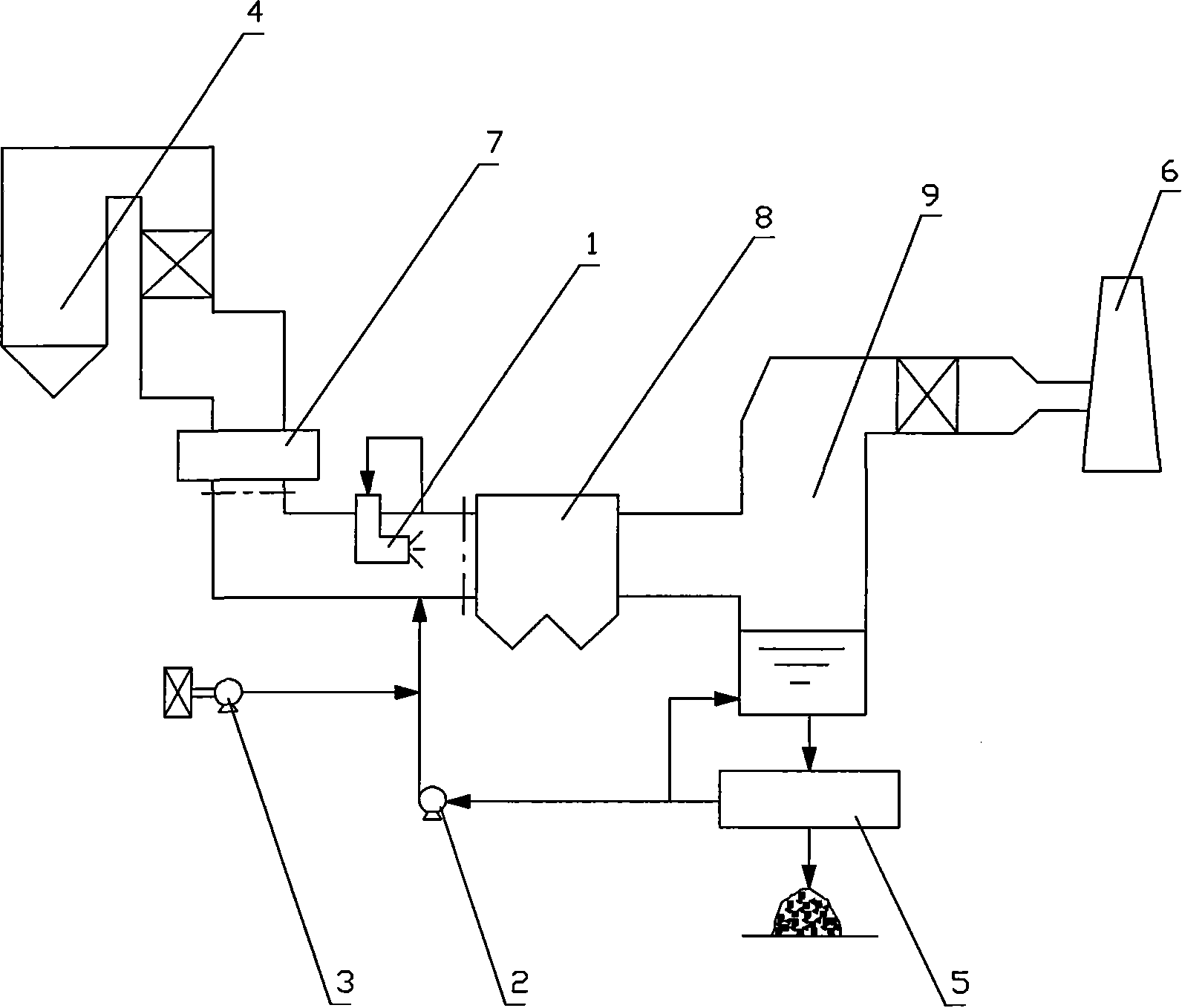

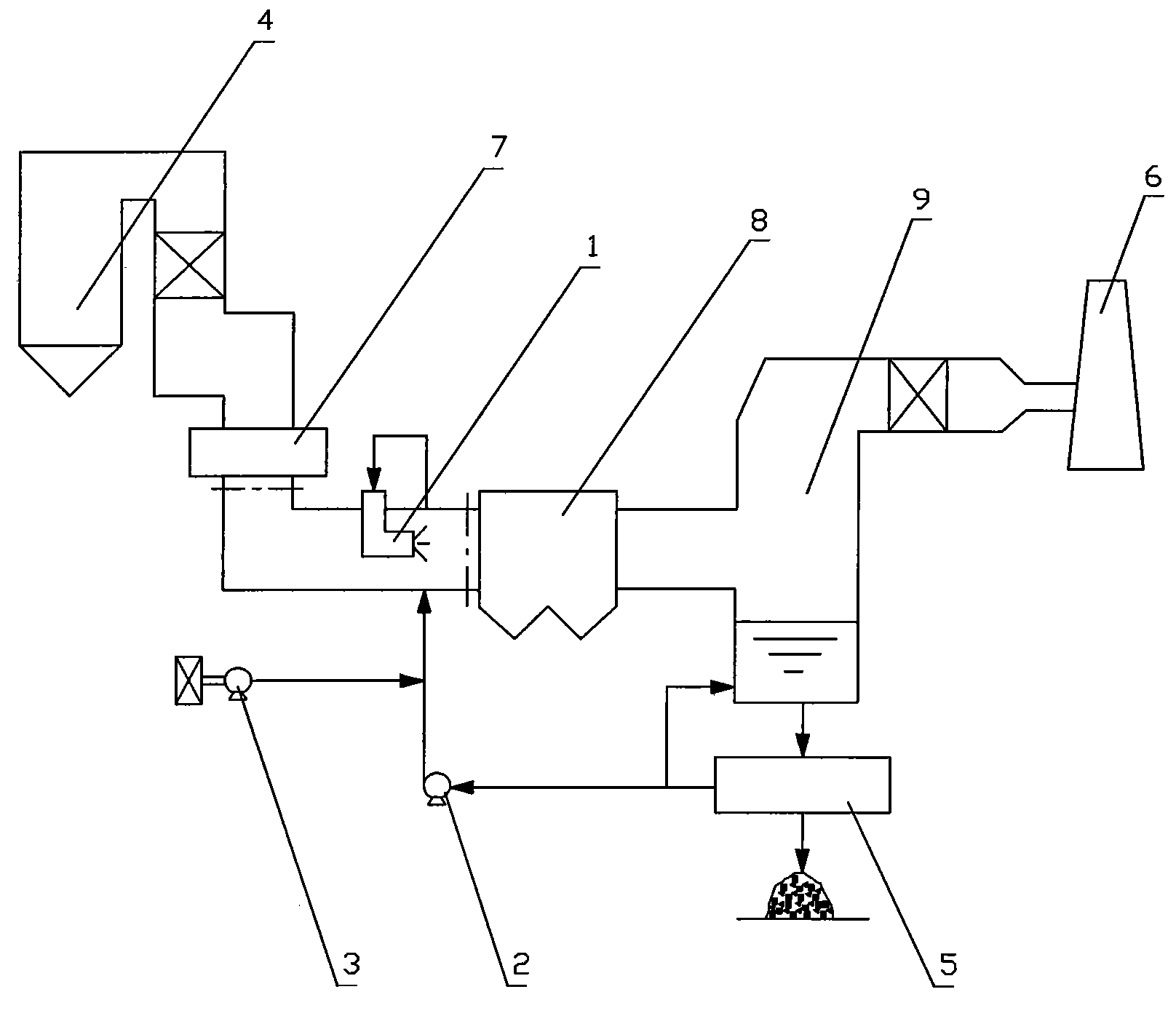

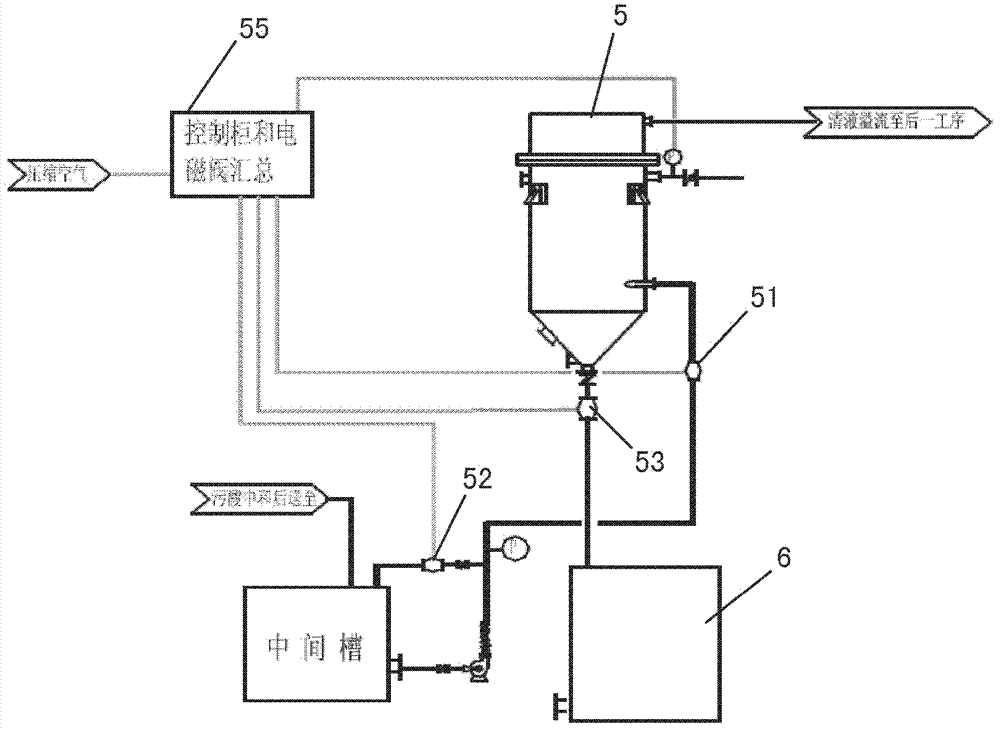

Spray evaporation treatment method of wet method flue gas desulfurization wastewater in thermal power station

ActiveCN101844819AOvercoming multiple configuration devicesSmall investmentDispersed particle separationWater/sewage treatmentEvaporationTreatment system

The invention discloses a spray evaporation treatment method of the wet method flue gas desulfurization wastewater in a thermal power station. In the method, an atomizing nozzle is arranged in the region with the temperature at 413-470 K and the flue gas speed of 5-11 m / s in a flue of the boiler tail part; desulfurization wastewater is pumped by utilizing a water pump, air is compressed by a compressor, and the pressure ratio of the compressed air to the desulfurization wastewater entering into the atomizing nozzle is 0.25-0.6; the speed of liquid droplets atomized by the atomizing nozzle is 50-80 m / s, and particle diameters of the liquid droplets are less than 50 mu m; and the liquid droplets are evaporated and then exhausted out of a chimney together with the flue gas. The invention can save chemical drugs utilized in the conventional wastewater treatment method; overcome the defects of many apparatuses, large investment, high running cost and heavy apparatus repair and maintenance load of a wastewater treatment system in the prior art, overcome the great corrosion influence of chlorine ions in water meta-acidity environment, reduce the specific resistance of ashes in a dust collector and improve the dust collector efficiency through increasing the flue gas humidity and properly lowering the flue gas temperature.

Owner:WUHAN TIANHE TECH

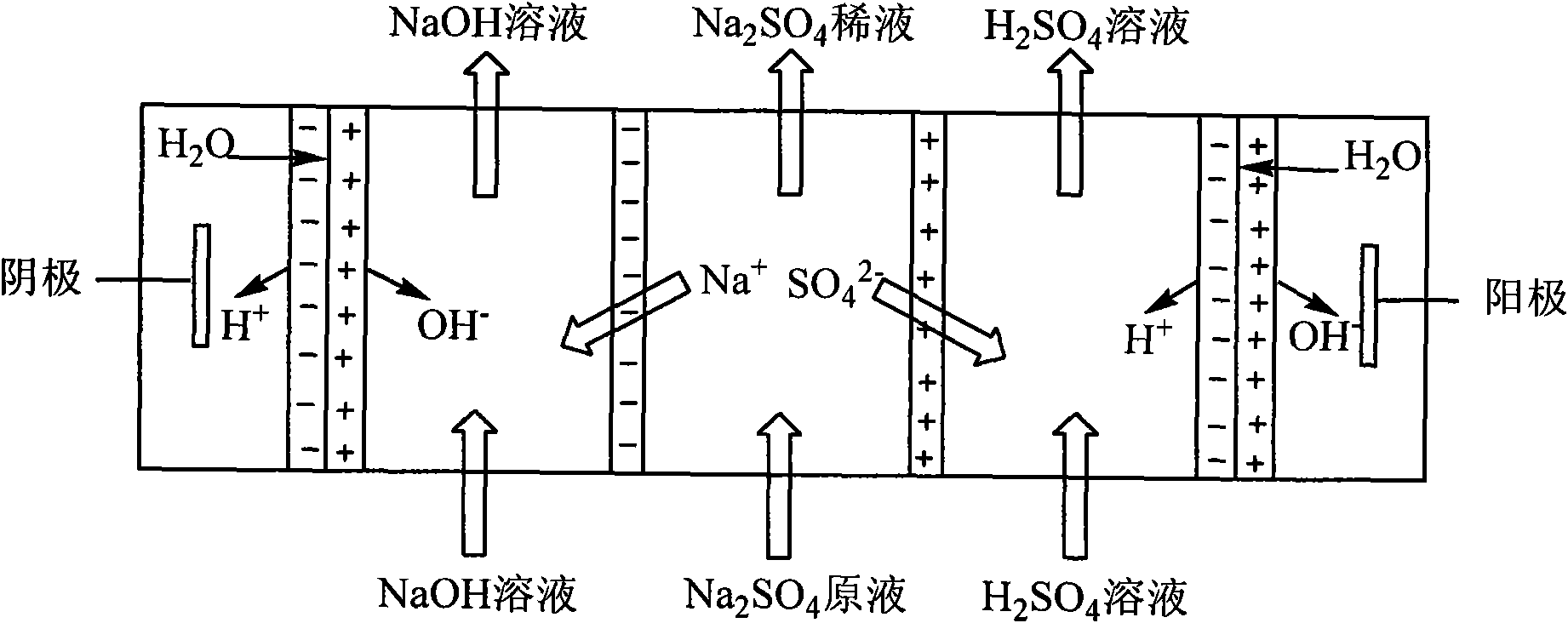

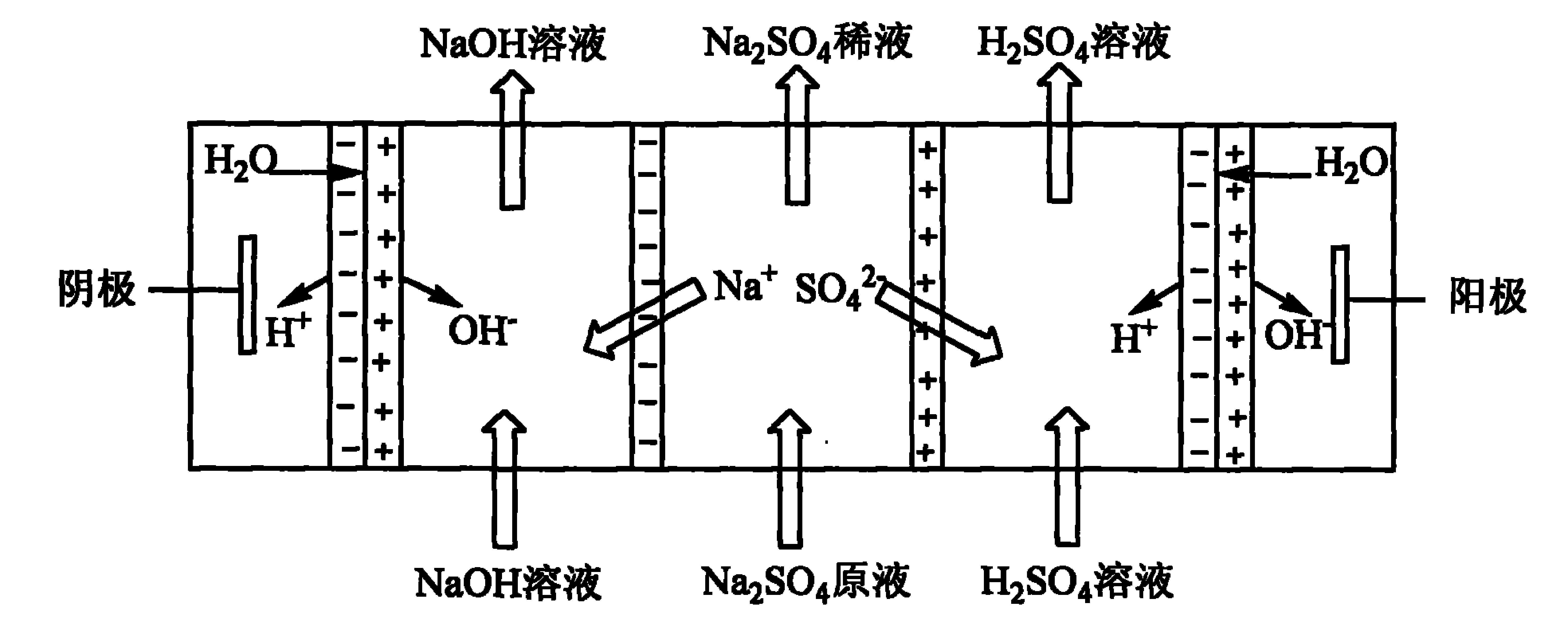

Process for producing sodium bicarbonate for flue gas desulphurization

InactiveUS20100290967A1Electrolysis componentsVolume/mass flow measurementSodium bicarbonateFlue gas

Process for producing sodium bicarbonate for purifying flue gases, according to which an aqueous solution containing sodium sulfate is subjected to electrodialysis to produce a sodium hydroxide solution and a sodium bisulfate solution, the sodium hydroxide solution being carbonated in order to obtain sodium bicarbonate.

Owner:SOLVAY SA

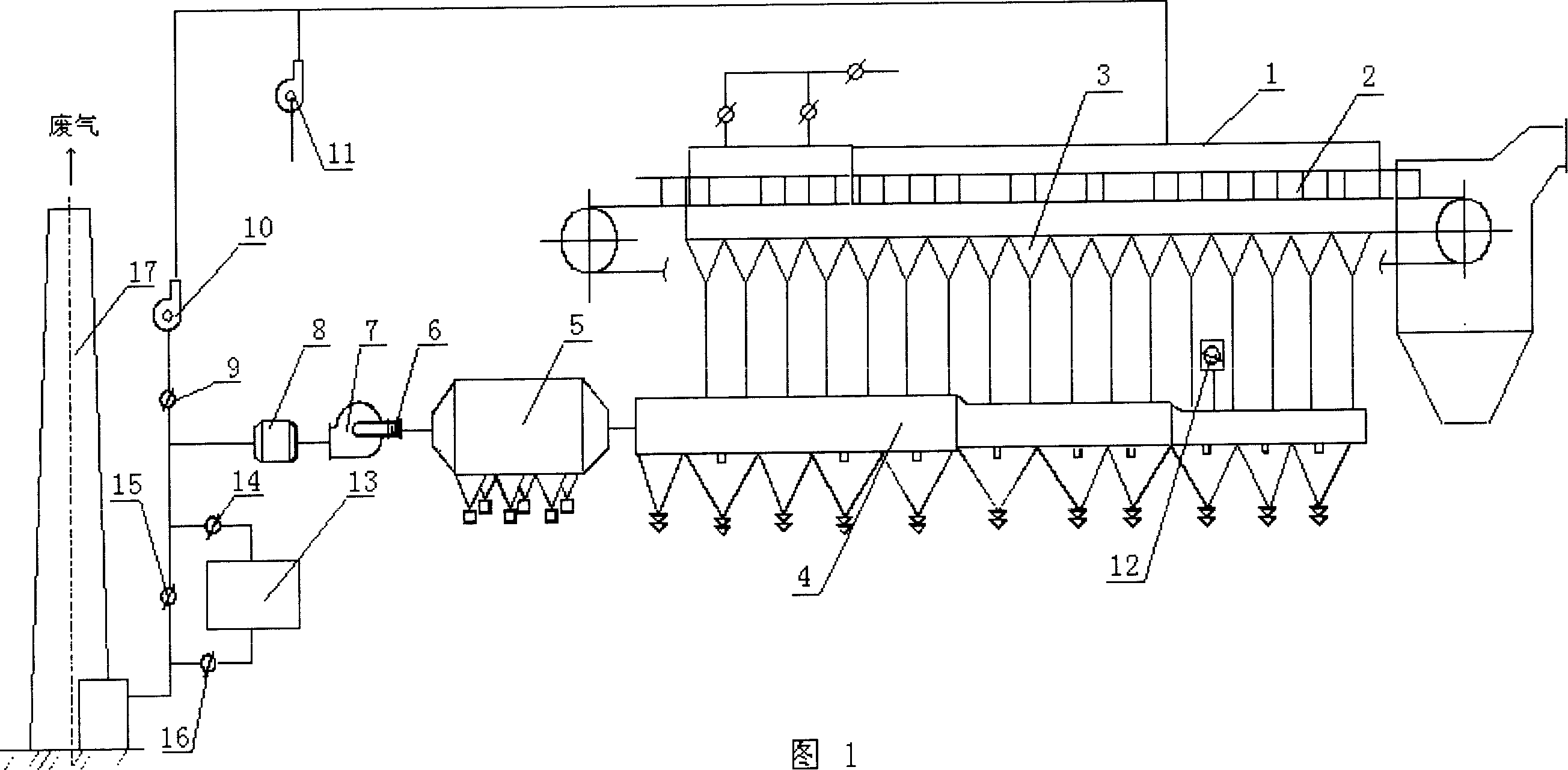

Sinter-smoke circulation collected desulfurizing method and apparatus

InactiveCN101024143AEmission reductionReduce effluxDispersed particle separationFurnace typesFlue gasEnrichment methods

The invention discloses a sintering flue gas desulfurization cycle enrichment methods and device, the described method from the sintering machine take part gas return to the top of sintering machine sealed enclosures within cycle, while complementing sintering machine burning need oxygen, the remaining part of the flue gas discharge after desulfurization. In devices, including dedusting device of flue gases between the chimney and flue, in the road before the desulfurization setup a branch pipeline to connect sintering machine sealed enclosures, in the branches of pipe setup cycle fan and supplement device. This invention due to sintered exhaust gas partly return to the seal trolley of sintering machine to reduce the displacement of gas, thereby reducing the total of dust and exhaust gas, while the SO2 of the sintering process play a enrichment role, to increase desulfurization efficiency, and reduce release total of burning exhaust gas, reducing the processing load of desulfurization device.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Supported type active carbon and its preparation method

The invention relates to a loading activated carbon and ití»s preparing method. The invention uses activated carbon as carrier and the additive components are loaded on the activated carrier via immersion method, while the additive components is distributed over most surfaces of pore passages of said activated carbon, and the additive components is 0.01-50% of absorbent. The invention is prepared via the immersion method which is processed in the temperature higher than room temperature. The invention can overcome the defect of present technique by which additive components can not be distributed over most pore passages; therefore, it can improve the availability ratio of activated carbon and the application property. In addition, according to the difference of said additive components and their contents, the invention can apply the processes of gas desulfurization, flue gas desulfurization, and exhaust gas purification.

Owner:CHINA PETROLEUM & CHEM CORP +1

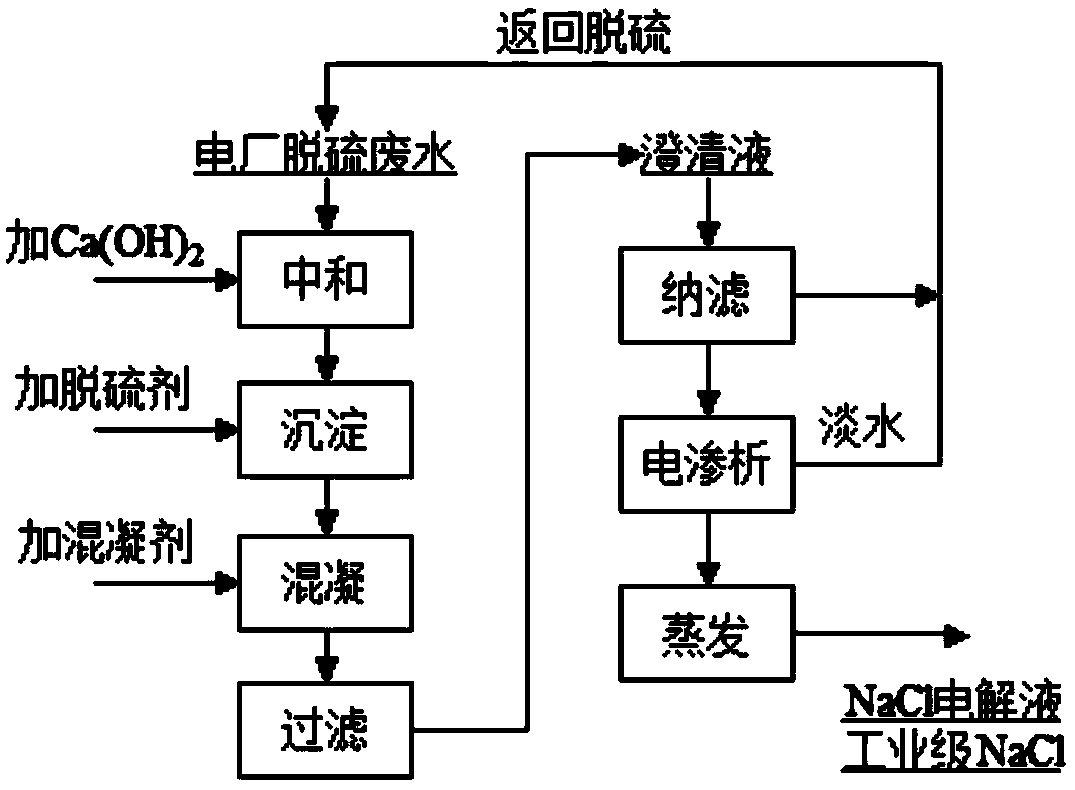

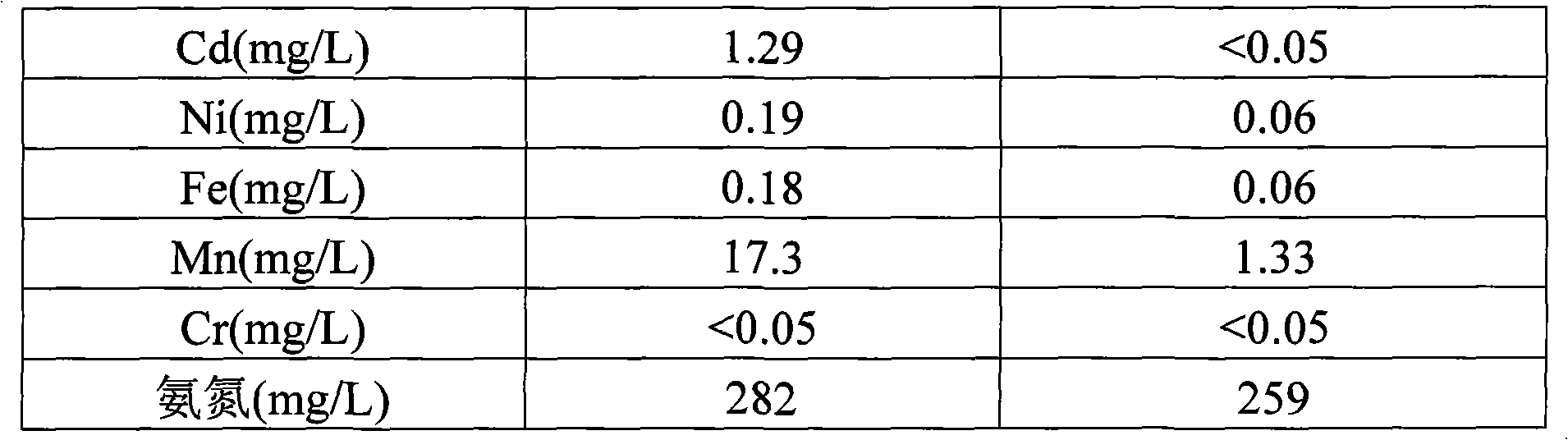

Method for carrying out desalination and zero-discharge processing of power plant desulphurization wastewater by adopting electrodialysis technology

ActiveCN104355473AMeet water requirementsImprove running stabilityGeneral water supply conservationDispersed particle separationChemical oxygen demandResource utilization

The invention relates to a method for carrying out desalination and zero-discharge processing of power plant desulphurization wastewater by adopting an electrodialysis technology. The method comprises the following steps: neutralizing, precipitating, coagulating and filtering the power plant desulphurization wastewater and removing CODs (Chemical Oxygen Demands), heavy metals, F-ions, gypsum, silicon dioxide, hydroxide of iron and aluminum and other insoluble particles in waste water; separating C1-ions and other monovalent ions in clear liquid from SO3<2->, SO4<2-> and other divalent ions through nanofiltration; desalinating and concentrating water produced by the nanofiltration by adopting a multistage countercurrent reverse electrodialysis method. The method has the advantages that the concentration of the Cl-ions in nanofiltration concentrated water and electrodialysis freshwater generated by the method is lower, and the nanofiltration concentrated water and the electrodialysis freshwater can be returned for flue gas desulfurization; the content of NaCl in a small amount of electrodialysis concentrated water produced reaches above 12 percent, the bivalent ions and other impurities are removed by nanofiltration, and the electrodialysis concentrated water is further evaporated and concentrated, so that chlorine-alkali industry electrolytes and NaCl salt can be obtained. Through the method, the zero-discharge treatment and the resource utilization of the desulfurization wastewater can be realized.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

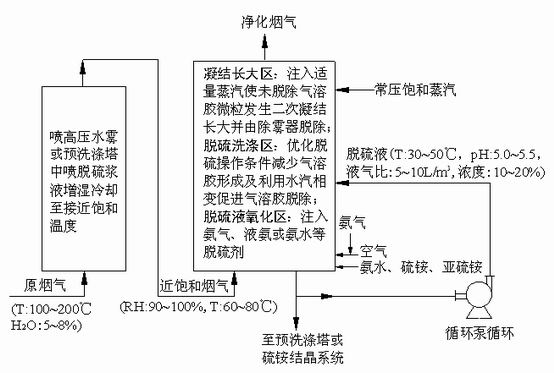

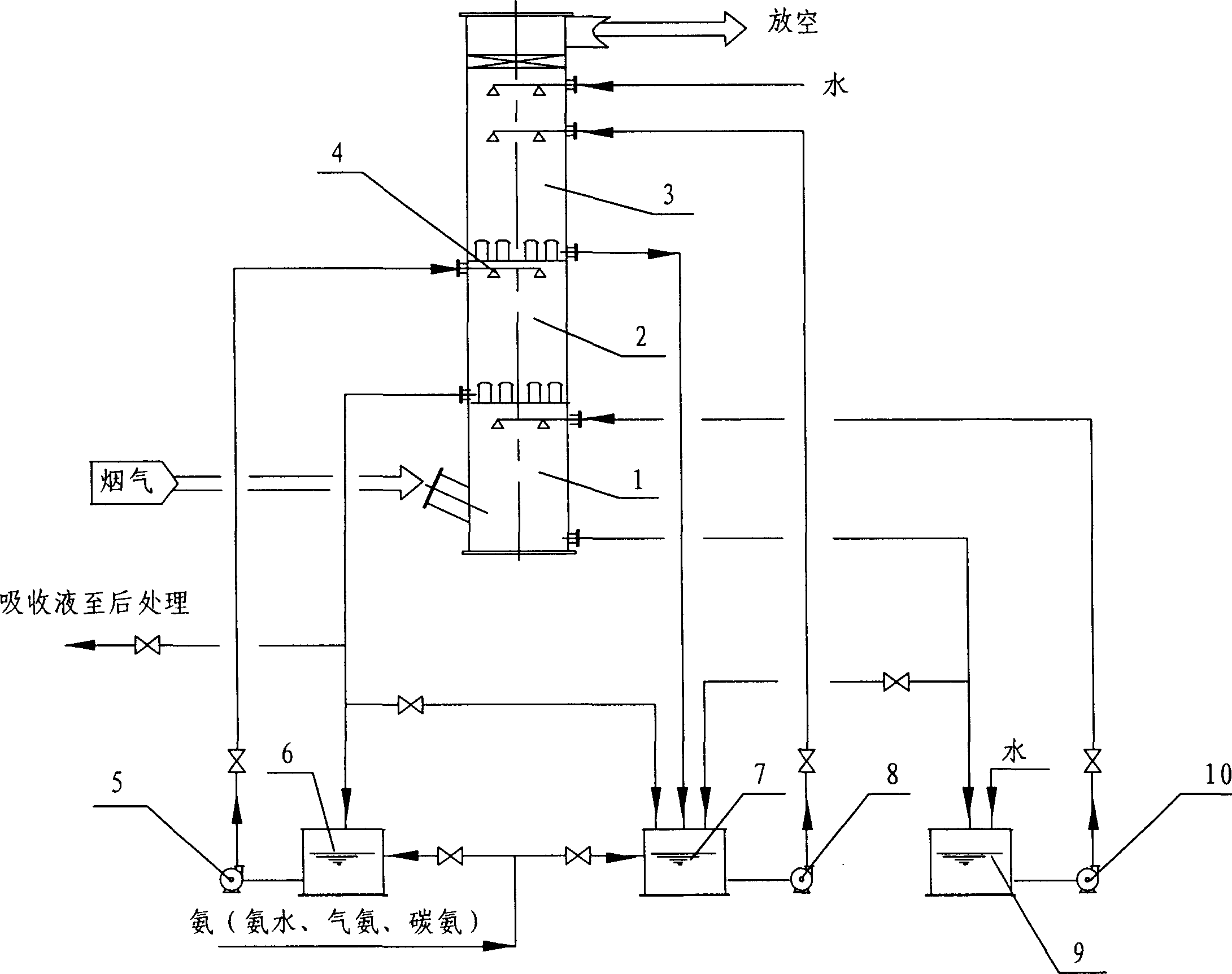

Control method for aerosol in flue gas desulfurization by utilizing ammonia method and master desulfurizing tower

InactiveCN102000490ASolve the emission problemSimple processDispersed particle separationThermodynamicsWater vapor

The invention discloses a control method for aerosol in flue gas desulfurization by utilizing an ammonia method and a master desulfurizing tower, and the control method is characterized in that flue gas enters the master desulfurizing tower after being cooled to the relative humidity of 90 to 100% and the temperature of 60 to 80 DEG C through high-pressure waster mist or prewashing temperature reduction; the generation of the aerosol particles in the desulfurization by utilizing the ammonia method is reduced by optimizing desulfurization operating conditions, and the formed aerosol particles are condensed to grow big and are partially washed to be eliminated through a desulfurizing solution; an appropriate amount of steam is injected into the saturated flue gas through desulfurizing and eliminating the partial aerosol particles; the oversaturated water vapor environment required by the secondary condensation and the growth of the aerosol particles is established on the top of the master desulfurizing tower; and the condensed and the grown aerosol particles are eliminated through a high-efficiency demister. The invention combines the formation mechanism of the aerosol in the flue gas desulfurization by utilizing the ammonia method; and the formation of the aerosol is reduced by optimizing the process conditions of the desulfurization operation and the elimination of the formed aerosol is promoted by utilizing a steam phase change principle at the same time so that the exhaust problem of the aerosol in the flue gas desulfurization by utilizing the ammonia method can be effectively solved.

Owner:SOUTHEAST UNIV

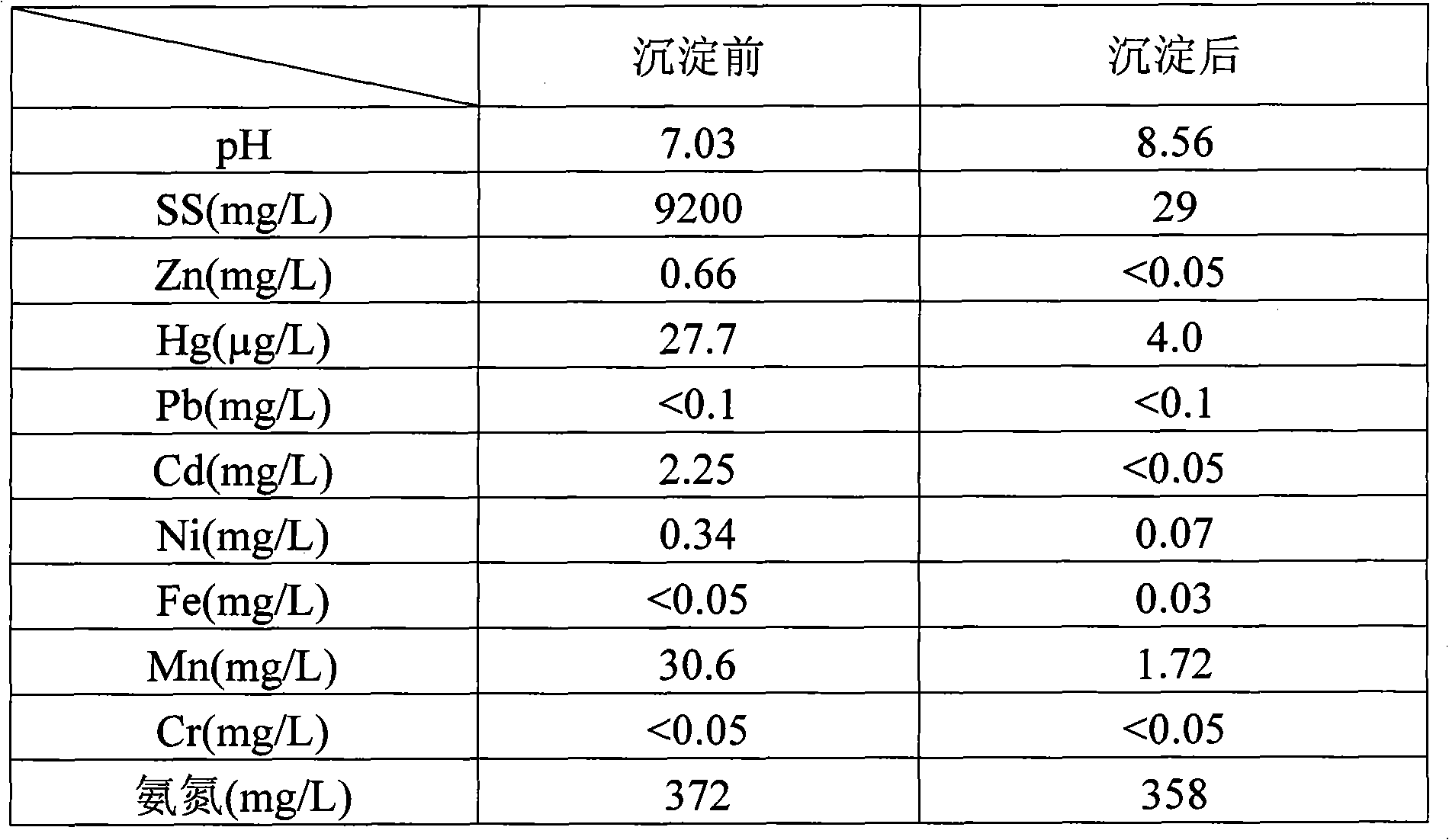

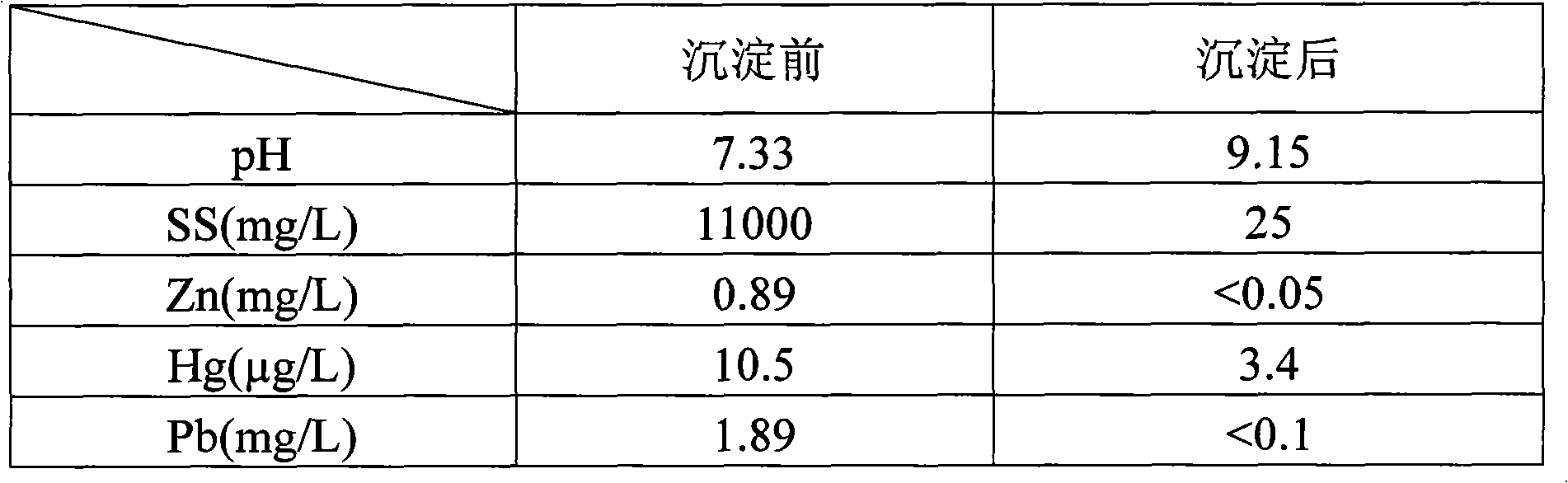

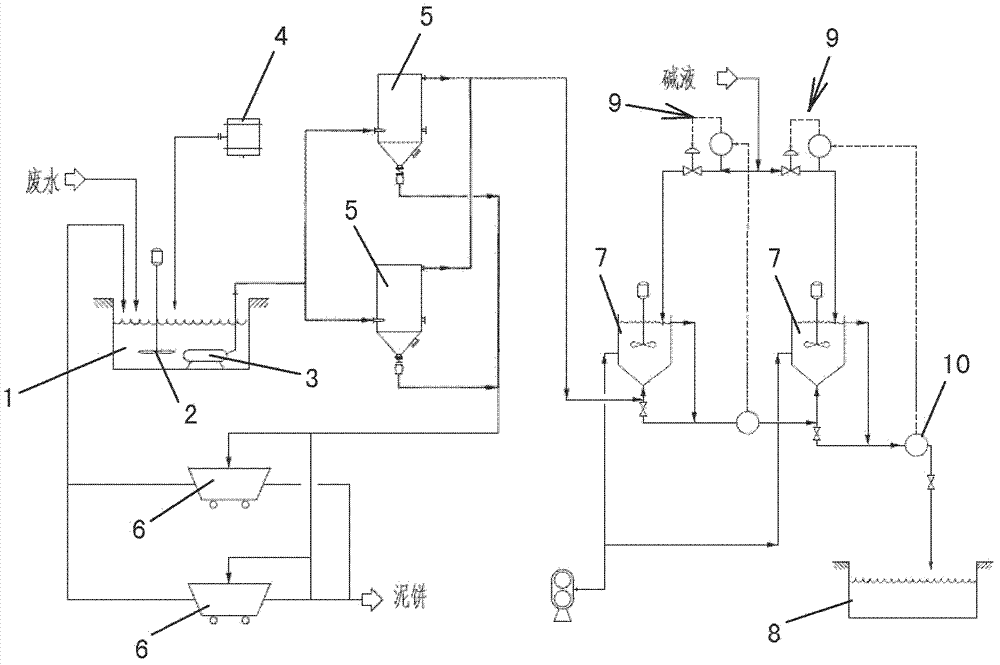

Treatment method of sintering flue gas desulphurization wastewater

ActiveCN101993169AReduce processing costsReduce the amount of waterTreatment with aerobic and anaerobic processesWater/sewage treatment bu osmosis/dialysisFlocculationFlue gas

The invention discloses a treatment method of sintering flue gas desulphurization wastewater, which completes the treatment on the sintering flue gas desulphurization wastewater through the following five steps of: 1. neutralization and coagulation: regulating the pH value of the sintering flue gas desulphurization wastewater to 8.5 to 9.5 by lye, and adding 0 to 200ppm of coagulating agents; 2. flocculation: adding 0 to 10ppm of coagulant aids for forming flocs; 3. precipitation and filter liquor separation; 4. biochemical treatment on filter liquor; and 5. deep treatment. The treatment method can be used for reducing the treatment cost of the desulphurization wastewater without generating influence on other treatment systems, thereby having good application and popularization prospects.

Owner:BAOSHAN IRON & STEEL CO LTD

Process for producing fuel

InactiveUS20060027488A1Low costHigh thermal efficiencyWorking-up pitch/asphalt/bitumen by selective extractionSolid fuelsAlkaneSorbent

A fuel is produced from bitumen by precipitating a substantial portion of asphaltenes from bitumen by contacting the bitumen with a lower alkane solvent. Suitable burners include a fluidized bed boiler, a circulating fluidized bed boiler and a pitch boiler which utilize either pre-combustion sulfur sorbents or post-combustion flue gas desulfurization. The sulfur in emissions can be used to produce sulfuric acid. The process uses a low cost fuel, generates steam, power and sulfuric acid and meets all emission requirements for SO2, NOx and PM.

Owner:GAUTHIER RICHARD

Reproduction method for sodium-base flue gas desulfurization liquid

InactiveCN102335553ALow costElectrolysis componentsDispersed particle separationElectrolysisResource utilization

The invention relates to a reproduction method for sodium-base flue gas desulfurization liquid, which is characterized in that the flue gas desulfurization liquid containing sodium sulphite and sodium bisulfite is oxidized to a solution containing sodium sulfate, the solution containing sodium sulfate is electrolyzed to a sodium hydroxide solution and a sulfuric acid solution by using bipolar membrane electrodialysis. According to the invention, the electrolytic conversion rate of sodium sulfate can reach more than 90%, the obtained sodium hydroxide solution can be used as absorption liquid for a flue gas desulfurization tower, the sulfuric acid by-product is produced simultaneously. By-product sulfuric acid can be used as sulfuric acid for treating high hardness and high alkalinity. The reproduction method for sodium-base flue gas desulfurization liquid is capable of achieving the purposes of strong brine zero-draining, comprehensive resource utilization and cost reduction.

Owner:CHINA PETROLEUM & CHEM CORP

Fertilizer for saline-alkali soil and preparation method of fertilizer

InactiveCN104262046AHigh in nutrientsLow bulk densitySuperphosphatesCalcareous fertilisersAlkali soilSoil organic matter

The invention relates to a fertilizer for saline-alkali soil. The fertilizer is prepared from the following raw materials in parts by weight: 5-20 parts of humic acid, 0.3-1 part of microorganisms, 6-16 parts of farmyard manure, 15-40 parts of straws, totally 5-10 parts of calcium superphosphate, ferrous sulfate, coal ash, furfural residues and flue gas desulfurization gypsum, 6-14 parts of a nitrogen fertilizer, 2-4 parts of a phosphatic fertilizer and 2-3 parts of a potassic fertilizer. The invention further relates to a preparation method of the fertilizer for saline-alkali soil. The fertilizer for saline-alkali soil, which is provided by the invention, has the beneficial effects that the fertilizer for saline-alkali soil has the characteristics of being low in cost and simple in preparation method, can be used for effectively improving the condition of saline-alkali soil, reducing the content of salt of soil and the pH value and increasing the content of organic matters in soil, and is particularly suitable for being applied to the saline-alkali soil.

Owner:瑞昊(北京)环境工程集团有限公司

Fuel coal smoke low oxidation rate desulfur method

InactiveCN1283346CGuaranteed desulfurization effectGuaranteed total desulfurization efficiencyDispersed particle separationFlue gasTower

The invention belongs to the environmental protection technology, and relates to a method for recycling sulfur dioxide in flue gas of a coal-fired boiler, in particular to a method for desulfurization of coal-fired flue gas with a low oxidation rate. Its treatment process and parameters in the desulfurization tower are: a. Cool down and remove dust, spray and wash the flue gas entering the tower with water first, so that the temperature of the flue gas will drop to 40-50°C within 2-3 seconds; b. For the first level of absorption, use the ammonium salt absorption solution with a concentration of 500-650g / l and a pH value of 5.2-6.2 for spray absorption; c. For the second-level absorption, use a concentration of 300-500g / l and a pH value of 5.4 ~6.5% ammonium salt absorption liquid is sprayed and absorbed; d. Washing and defogging the flue gas after absorption treatment, eluting the absorption liquid entrained in the flue gas and emptying it. The invention can reduce the oxidation rate in the ammonia desulfurization process and improve the utilization value of by-products.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

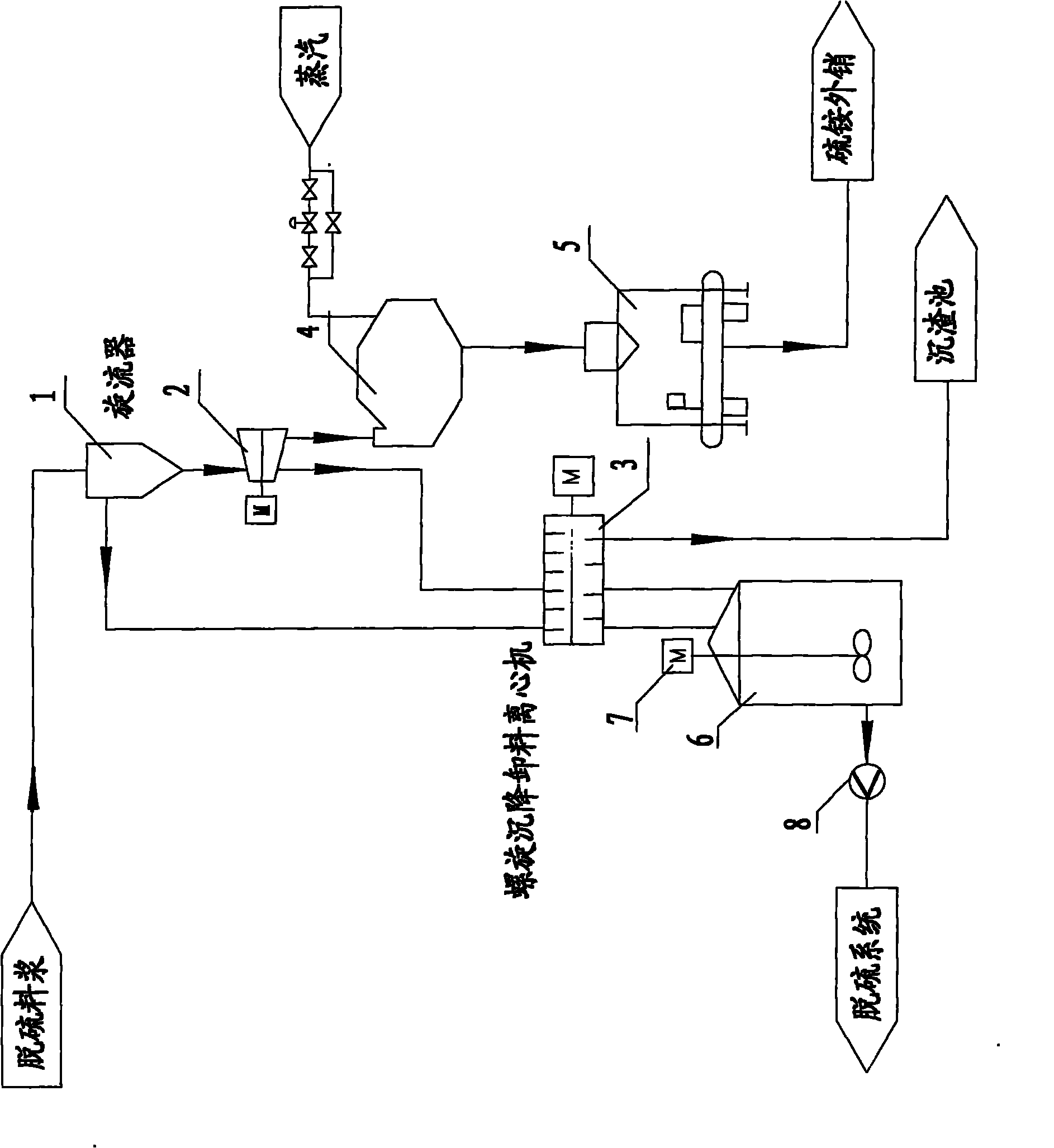

Catalytic cracking fume desulfuration wastewater treatment process

ActiveCN102815808AImprove effluent qualityEasy to operateMultistage water/sewage treatmentParticulatesChemical oxygen demand

A catalytic cracking fume desulfuration wastewater treatment process is characterized in that wastewater is discharged to a slurry pool and is mixed with a flocculating agent, a stirrer is used for stirring the wastewater and the flocculating agent, the wastewater and the flocculating agent are mixed evenly, the wastewater after being mixed is discharged to an expansion tube type filter and is subjected to the coagulation reaction at the lower end of the expansion tube type filter, small particulate matters in the wastewater are flocculated, large flocculating bodies are formed, the solid-liquid separation is achieved through the filtration of a filtering film, thick slag and supernatant fluid are obtained, the supernatant fluid is discharged to an oxidation tank further, the thick slag is subjected to back washing and enters a subsequent filtering box, the thick slag is concentrated and dewatered in the filtering box, mud cakes which are concentrated are transported outwards, the water of dehydration returns to the slurry pool again, is mixed with the wastewater and is processed again, the false chemical oxygen demand (COD) which contains sulfite and bisulfite is oxidized and removed by the supernatant fluid in the oxidation tank, and the sewage which meets standards is discharged. Compared with the prior art, the process has the advantages that the area occupied by devices is small, the operation cost is low, the solid and the liquid can be separated completely, the working environment of workers is good, device parameters can be set in accordance with parameters of different materials, and the application is wide.

Owner:CHINA PETROLEUM & CHEM CORP +3

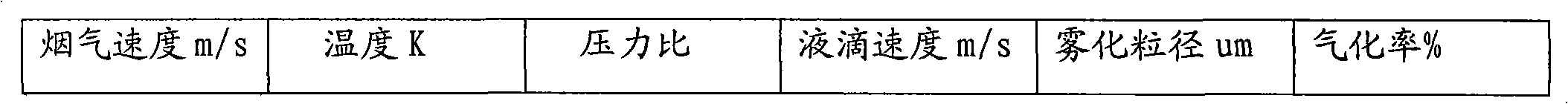

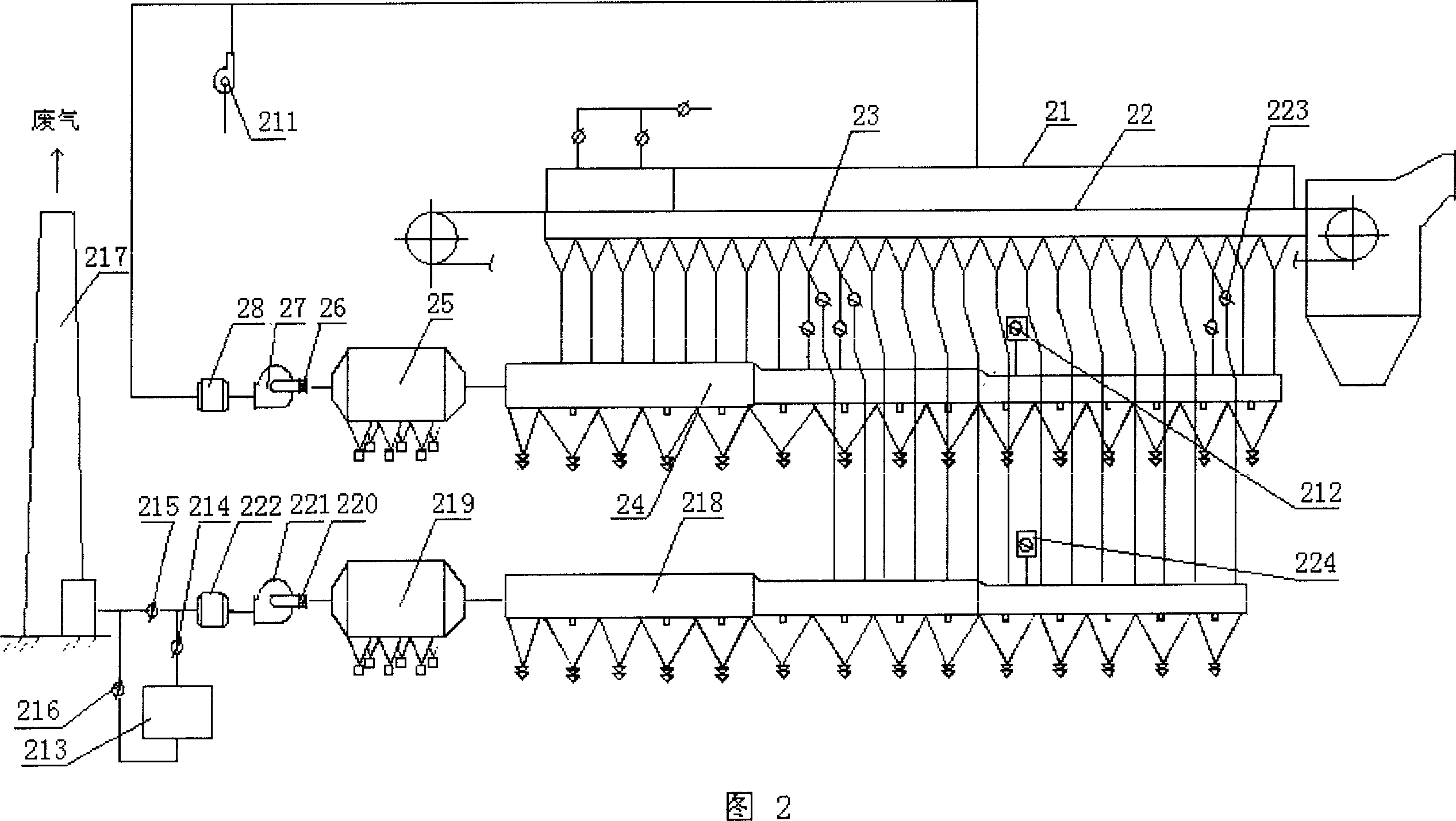

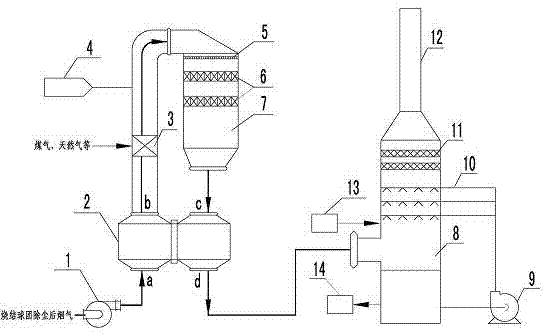

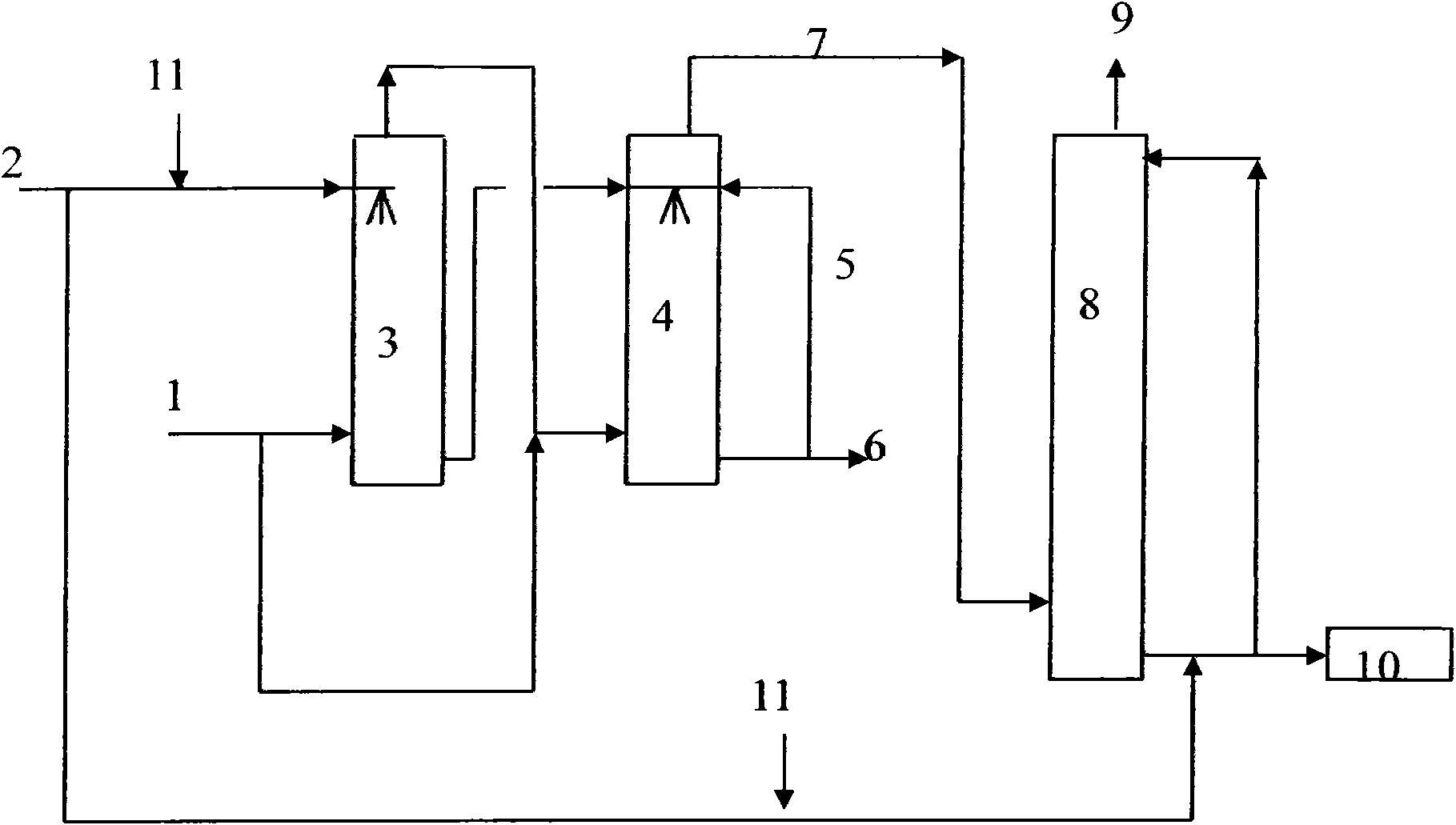

Sintering and pelletizing flue gas desulfurization and denitrification coordinating management system and process

InactiveCN103785290AGuaranteed uptimeLess investmentDispersed particle separationMetallurgical industryOperating cost

The invention relates to a coordinating management system and process for sulfur dioxide, oxynitride, heavy metal, dioxin and other pollutants in flue gas emitted in the sintering and pelletizing processes in the metallurgical industry. The system comprises a booster fan 1, a flue gas heat exchanger 2, a combustor 3, a denitrification reactor 7 and a desulfurization tower 8. The flue gas heat exchanger 2 is a rotary type or tubular heat exchanger. Sintering and pelletizing flue gas after dust removal enters the booster fan 1. The booster fan 1 is connected with an inlet a of the flue gas heat exchanger 2 through a flue. An outlet b of the flue gas heat exchanger 2 is connected with the combustor 3. An outlet of the combustor 3 is connected with the denitrification reactor 7 through a flue. A denitrification reductive agent injector 4 is arranged on the flue through which the combustor 3 is connected with the denitrification reactor 7. An outlet of the denitrification reactor 7 is connected with an inlet c of the flue gas heat exchanger 2. An outlet d of the flue gas heat exchanger 2 is connected with the desulfurization tower 8. The sintering and pelletizing flue gas desulfurization and denitrification coordinating management system and process have the advantages that operation is stable and reliable, investment is lowered, operating cost is low, and by-products can be comprehensively utilized, thereby being a sintering and pelletizing flue gas desulfurization and denitrification coordinating management technology suitable for national conditions of China.

Owner:中钢集团天澄环保科技股份有限公司

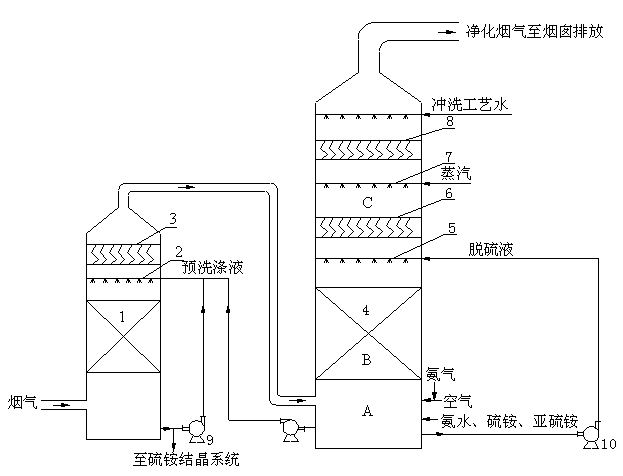

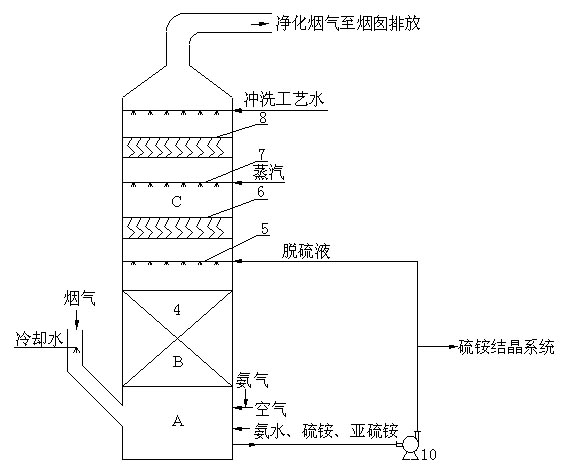

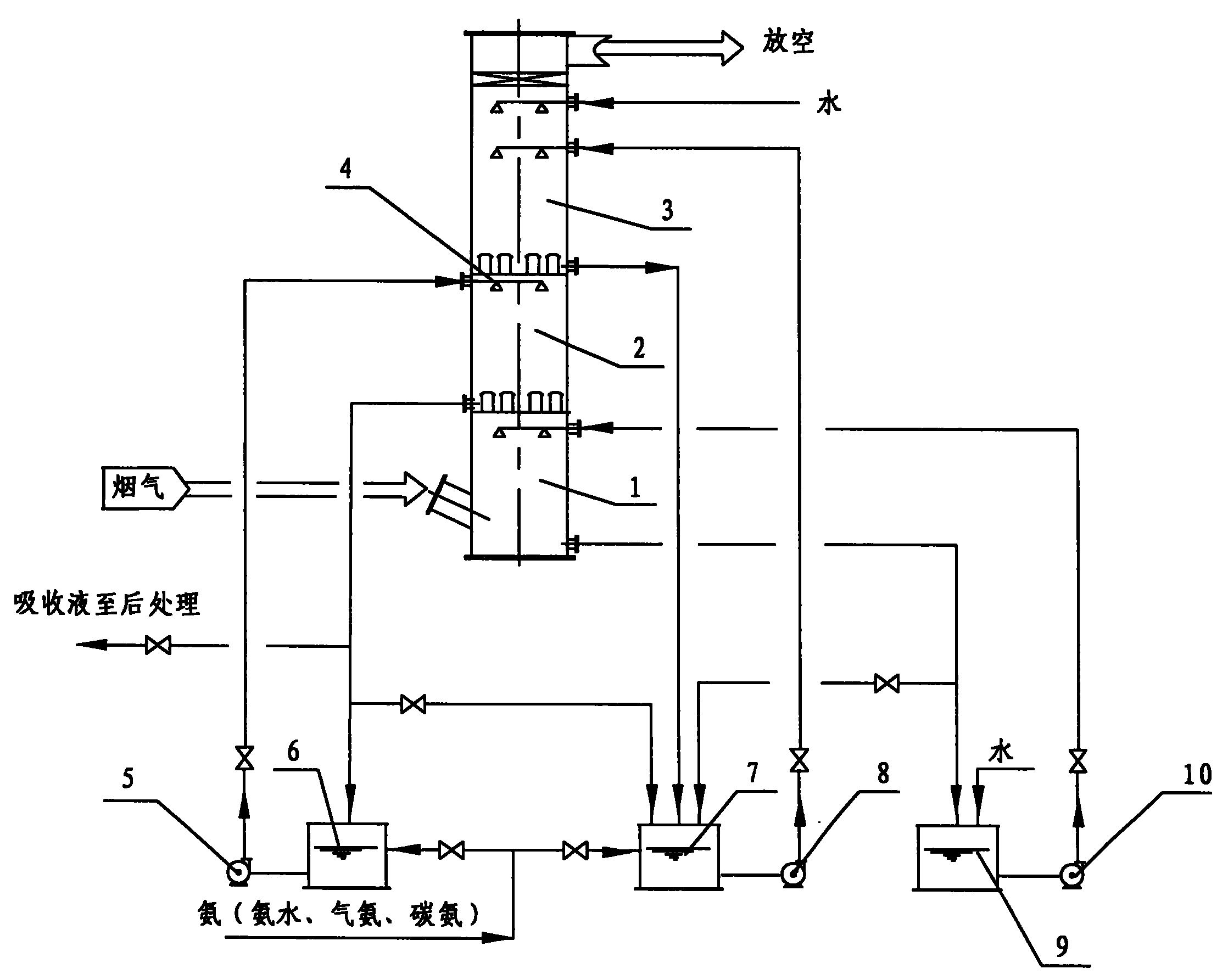

Process for removing smoke dust by wet ammonia flue gas desulphurization and device thereof

ActiveCN101972592AEfficient removalReduce processingDispersed particle separationAmmonia compoundsSulfateFlue gas

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

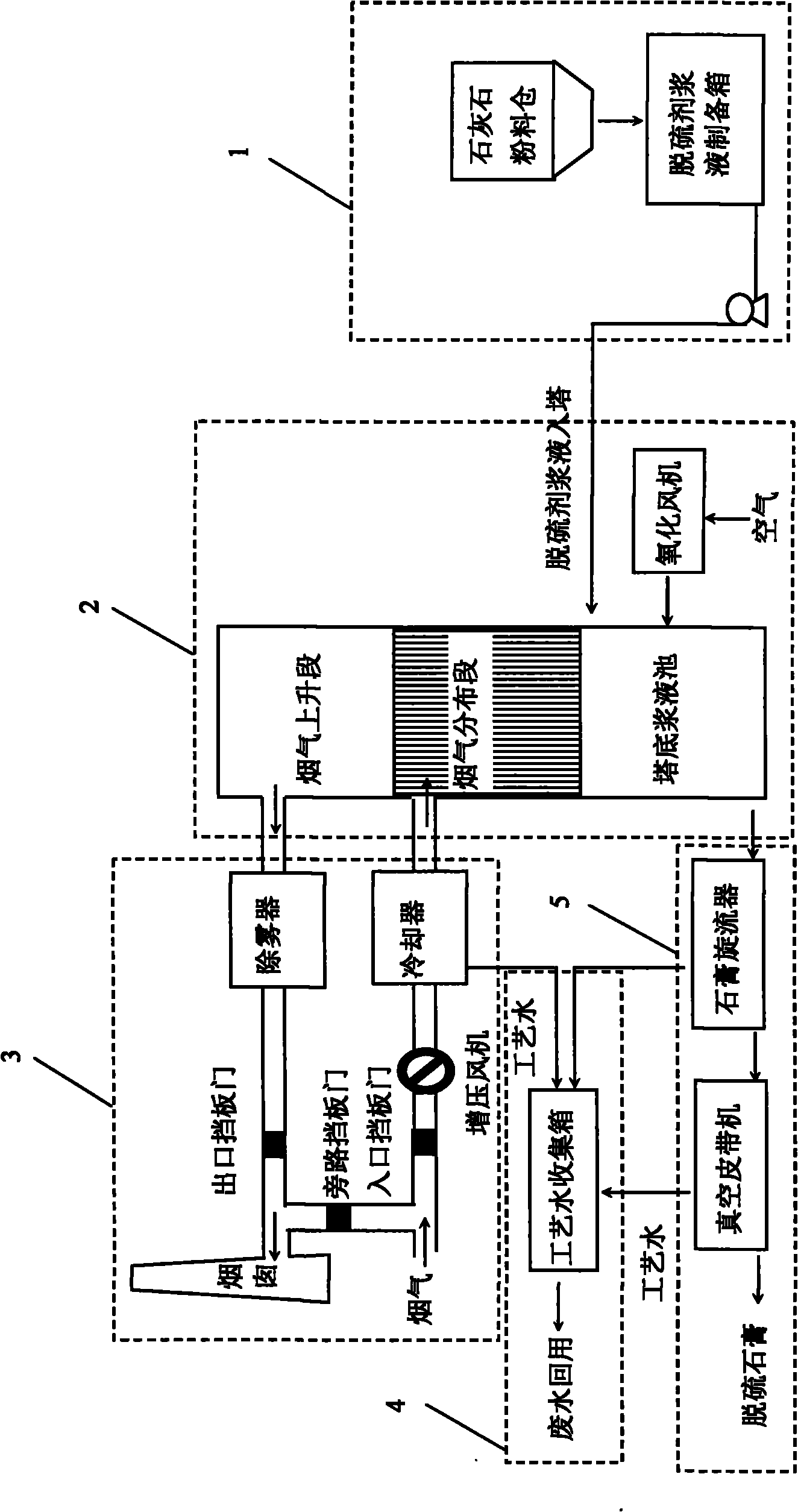

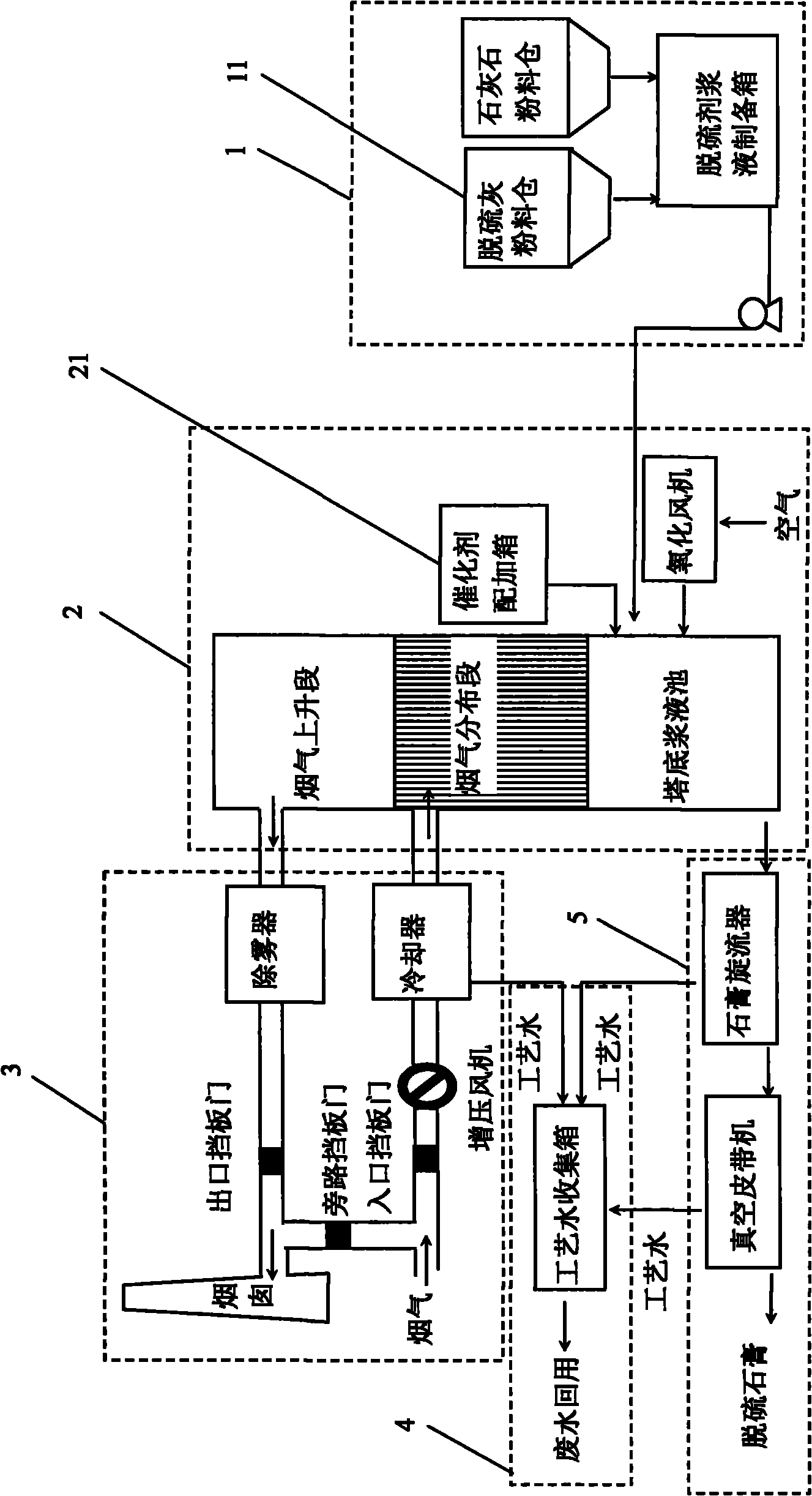

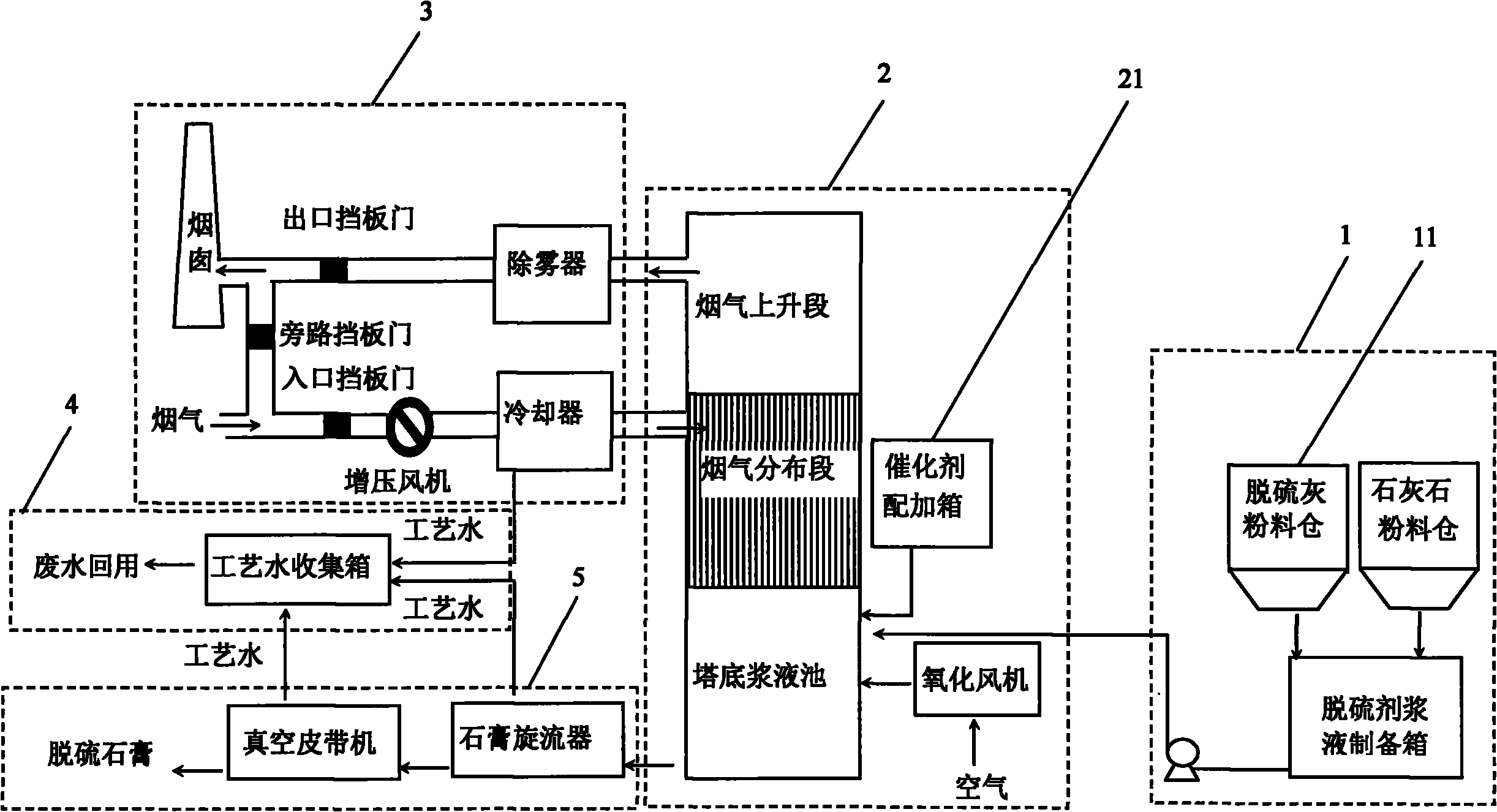

Method for treating desulfurization ash

ActiveCN102000481AEliminate hidden dangersEfficient use ofDispersed particle separationRetention timeProper treatment

The invention discloses a method for treating desulfurization ash. The method comprises the following steps of: mixing the desulfurization ash generated by a dry / semidry desulphurization process and limestone powder, which serve as raw materials of a desulfurizer in a wet flue gas desulfurization process, according to a proportion; uniformly stirring the desulfurizer and pumping the desulfurizer into a slurry pond of an absorption tower; adding a catalyst into the slurry pond; introducing oxidation air into the slurry pond; introducing flue gas into the slurry pond through a flue; reacting the desulfurizer with SO2 in the flue gas under the action of the oxidation air and the catalyst; controlling the pH value of the slurry in the absorption tower, the slurry temperature, the content of solid matters contained in the slurry and the retention time of the desulfurizer in the slurry pond; after the reaction is completed, performing vortex concentration and vacuum filtration to obtain a gypsum by-product; and adding wastewater produced in the process into a process water collection box for recycling. The method is simple, is easy to realize, has remarkable effect, provides a safe and proper treatment way for the dry / semidry desulfurization ash and has good economic and social benefits.

Owner:BAOSHAN IRON & STEEL CO LTD

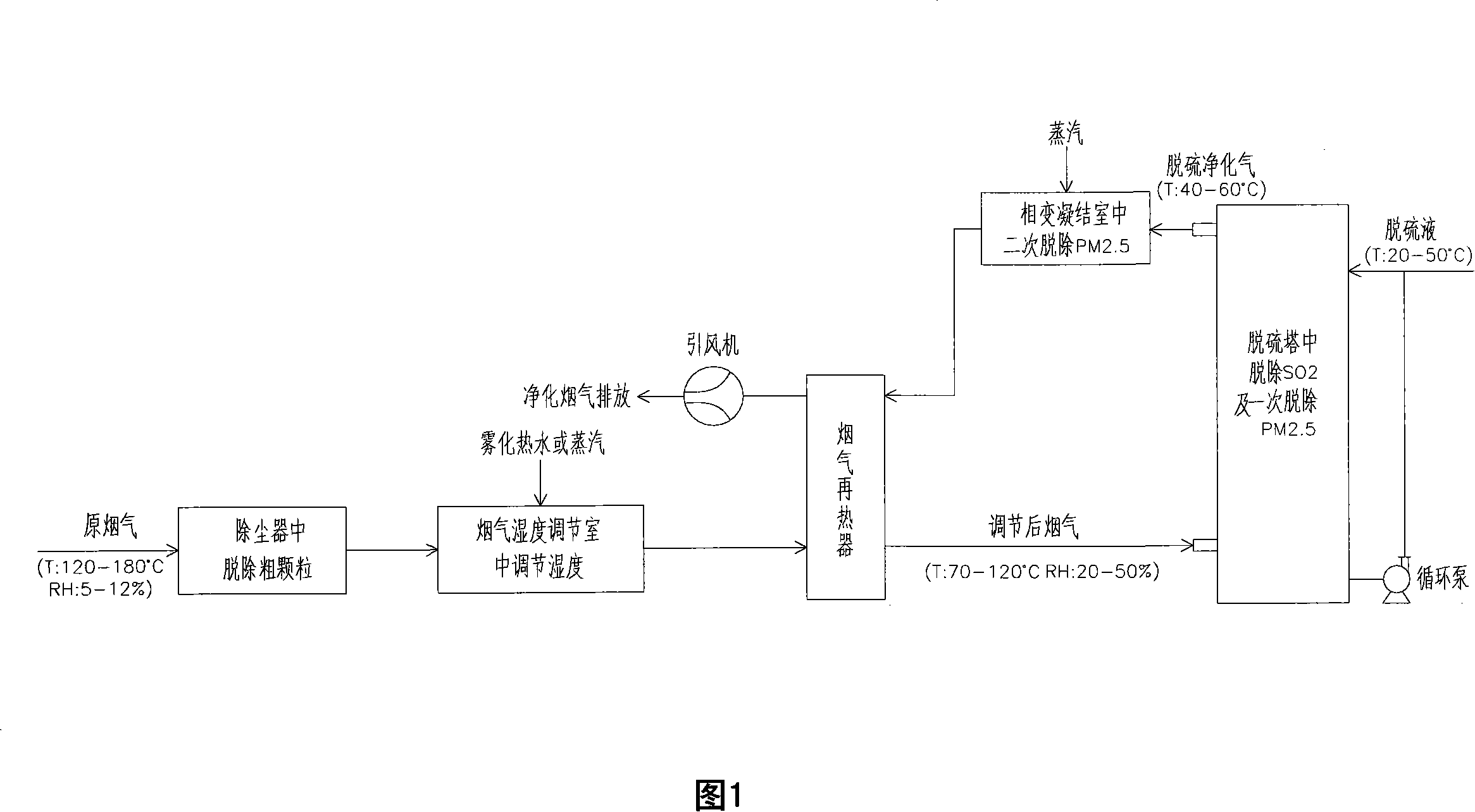

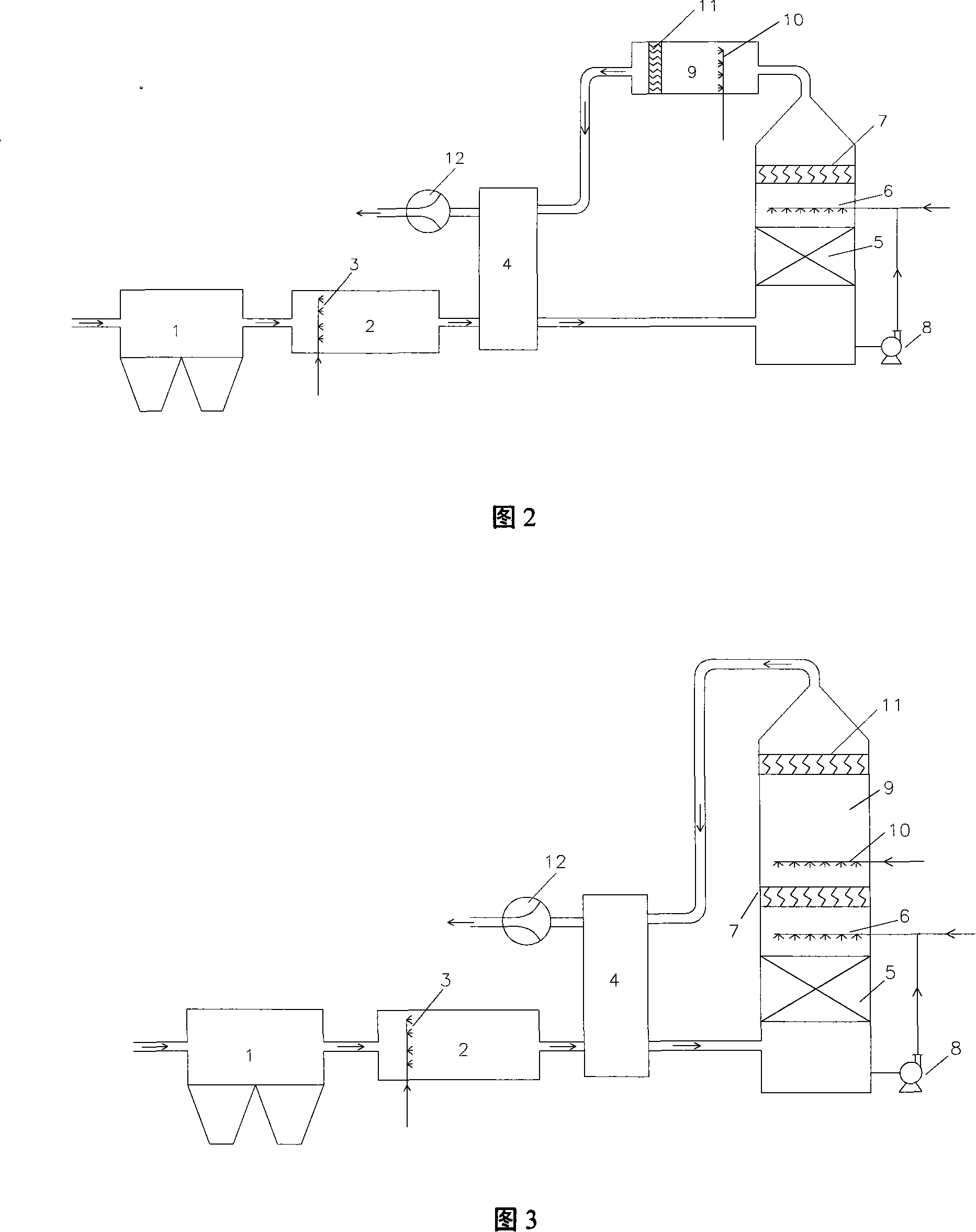

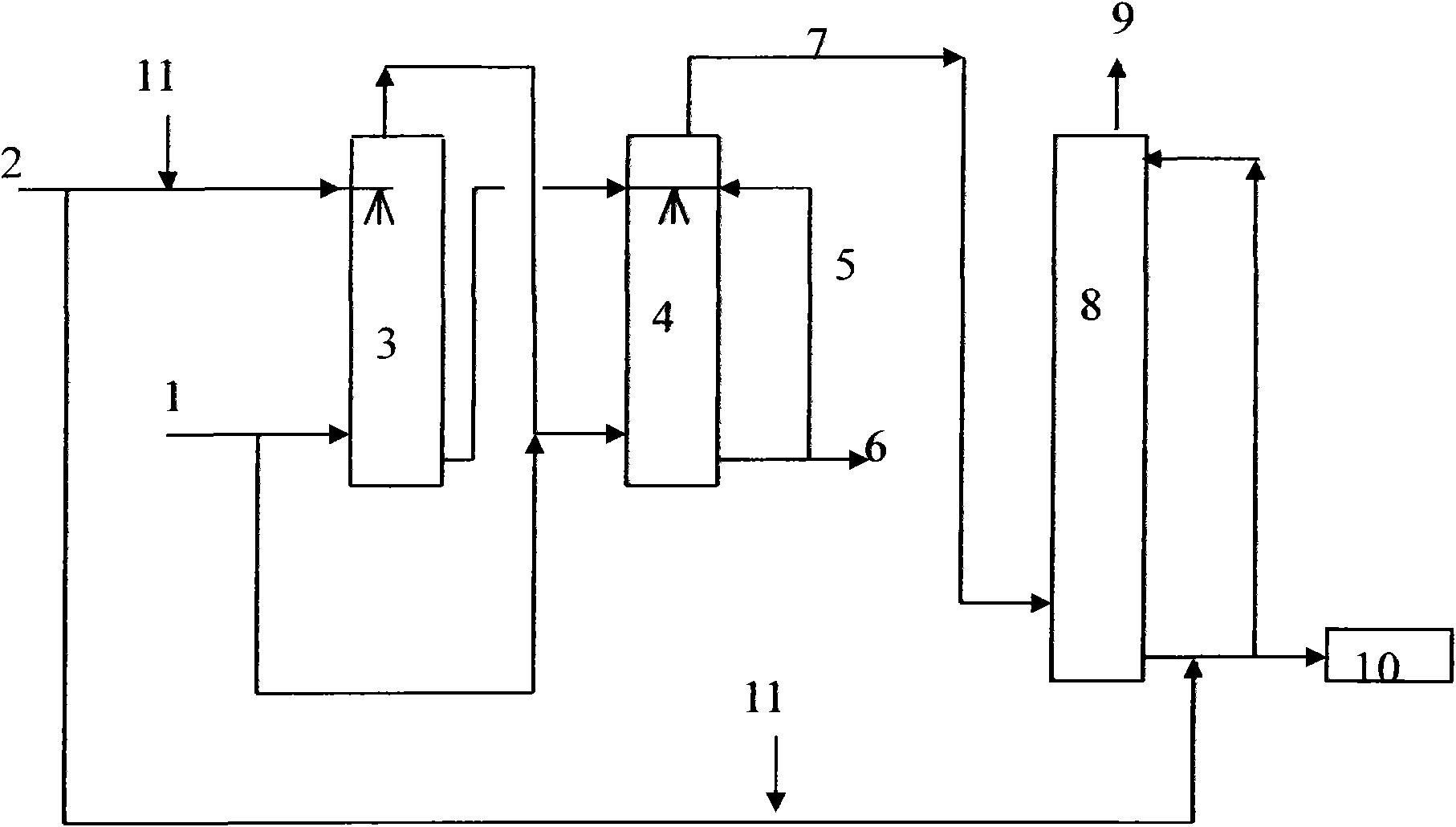

Method and device for cooperation-removal of PM2,5 in flue gas wet desulphurization

InactiveCN101219333AReduce the nucleation critical supersaturationReduce surface tensionDispersed particle separationHigh humidityFlue gas

The invention provides a method that fully utilizes the characteristics of relatively high humidity content of flue gas in the existing wet desulfurization technology and employs vapor phase change theory to effectively remove SO2 through WFGD so as to cause PM2.5 to be condensed and enlarged as well as be removed effectively and a device thereof. The invention has simple technique, and arranging a moisture regulation chamber for the flue gas and a phase change condensing chamber in the existing flue gas wet desulfurization devices can cause the wet desulfurization device to have the effect of enlarging and removing PM2.5 granules. The invention is widely used in the existing wet desulfurization devices for the flue gas generated by power plants.

Owner:SOUTHEAST UNIV

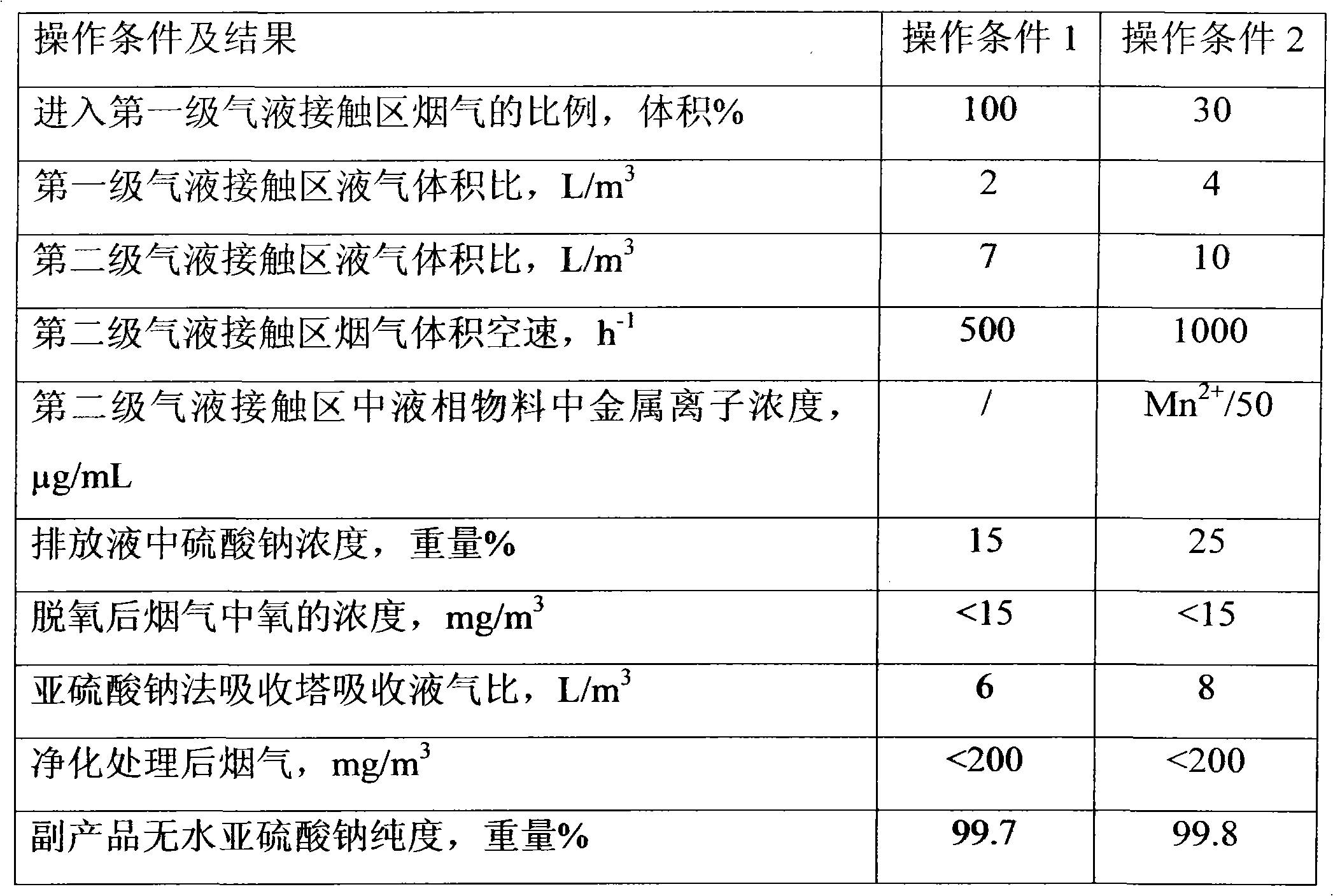

Method for desulfurizing high-concentration flue gas

ActiveCN102049186AIncrease valueLow recovery rateDispersed particle separationHigh concentrationSulfite salt

The invention discloses a method for desulfurizing high-concentration flue gas. The high-concentration flue gas is desulfurized through a sodium sulfite method, and meanwhile, the sodium sulfite is recovered as a by-product, wherein the flue gas needs to be deoxidized before being desulfurized through the sodium sulfite method. In the method for desulfurizing high-concentration flue gas disclosedby the invention, by deoxidizing the flue gas through an appropriate pretreatment process, the purity of the by-product sodium sulfite produced by the subsequent flue gas desulfurization process of the sodium sulfite method can be obviously improved, and the value of the by-product is improved, thereby obviously improving the comprehensive economic benefits. The pretreatment process of the flue gas is performed by using the sulfite and / or the hydrosulfite produced by the reaction of SO2 contained in the flue gas and alkali to react with oxygen without using any other deoxidizer. The method disclosed by the invention has simple production process and is easy to operate.

Owner:CHINA PETROLEUM & CHEM CORP +1

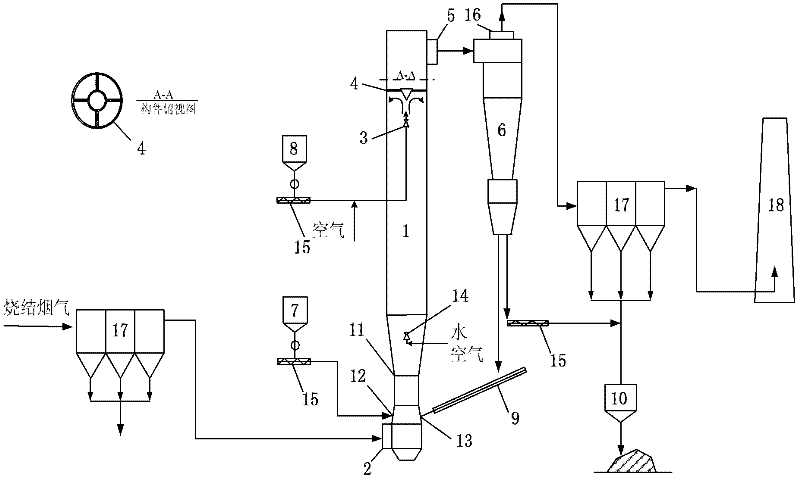

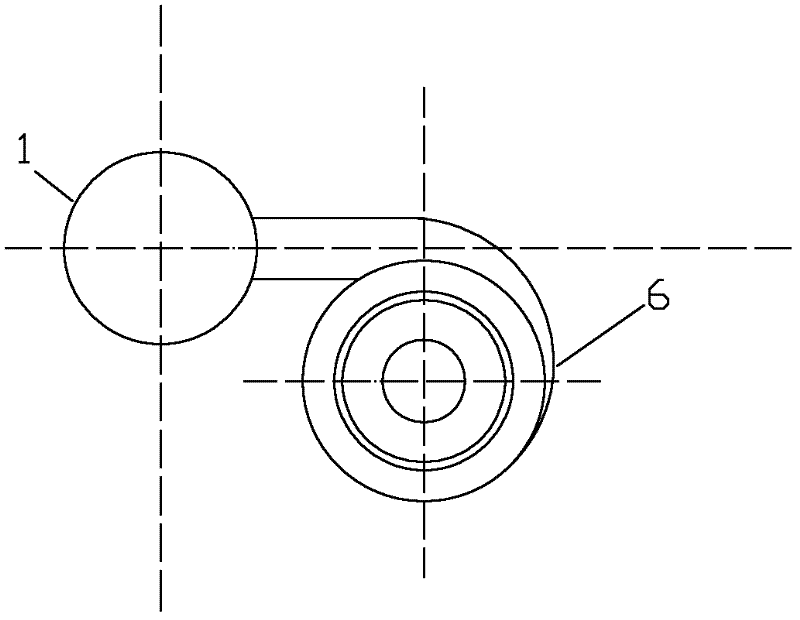

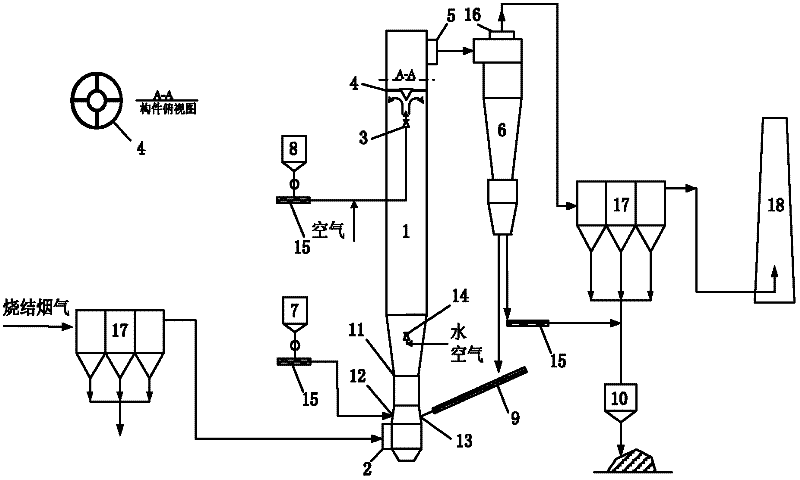

Device and method for removing sulfur dioxide and dioxin from sintering flue gas

The invention relates to a device and a method for removing sulfur dioxide and dioxin from sintering flue gas. The lower part of an absorption tower of the device has a Venturi structure; a Venturi shrinkage section is provided with a desulfurizing agent inlet and a circulating ash inlet; a Venturi expansion section is provided with a water spray nozzle; the upper middle part of the absorption tower is provided with an active carbon / coke nozzle and a conical component is arranged opposite to the nozzle; the upper part; the upper part of the absorption tower is provided with a flue gas outlet which is connected with a radially arranged cyclone separator; a hoper at the lower end of the cyclone separator is provided with two outlets, one outlet is connected with an ash bin, and the other outlet is connected with a circulating ash inlet through a spiral return device; a gas outlet on the top of the cyclone separator is communicated with an inlet of a deduster; and a gas outlet of the deduster is connected with a chimney. The sintering flue gas containing SO2 and dioxin enters the absorption tower through the Venturi, and is mixed with slaked lime Ca(OH)2, atomized water and active carbon / coke, which are sprayed in the absorption tower, the Ca(OH)2 absorbs the SO2 under the action of the atomized water and the active carbon / coke absorbs the dioxin to cooperatively remove the two pollutants.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

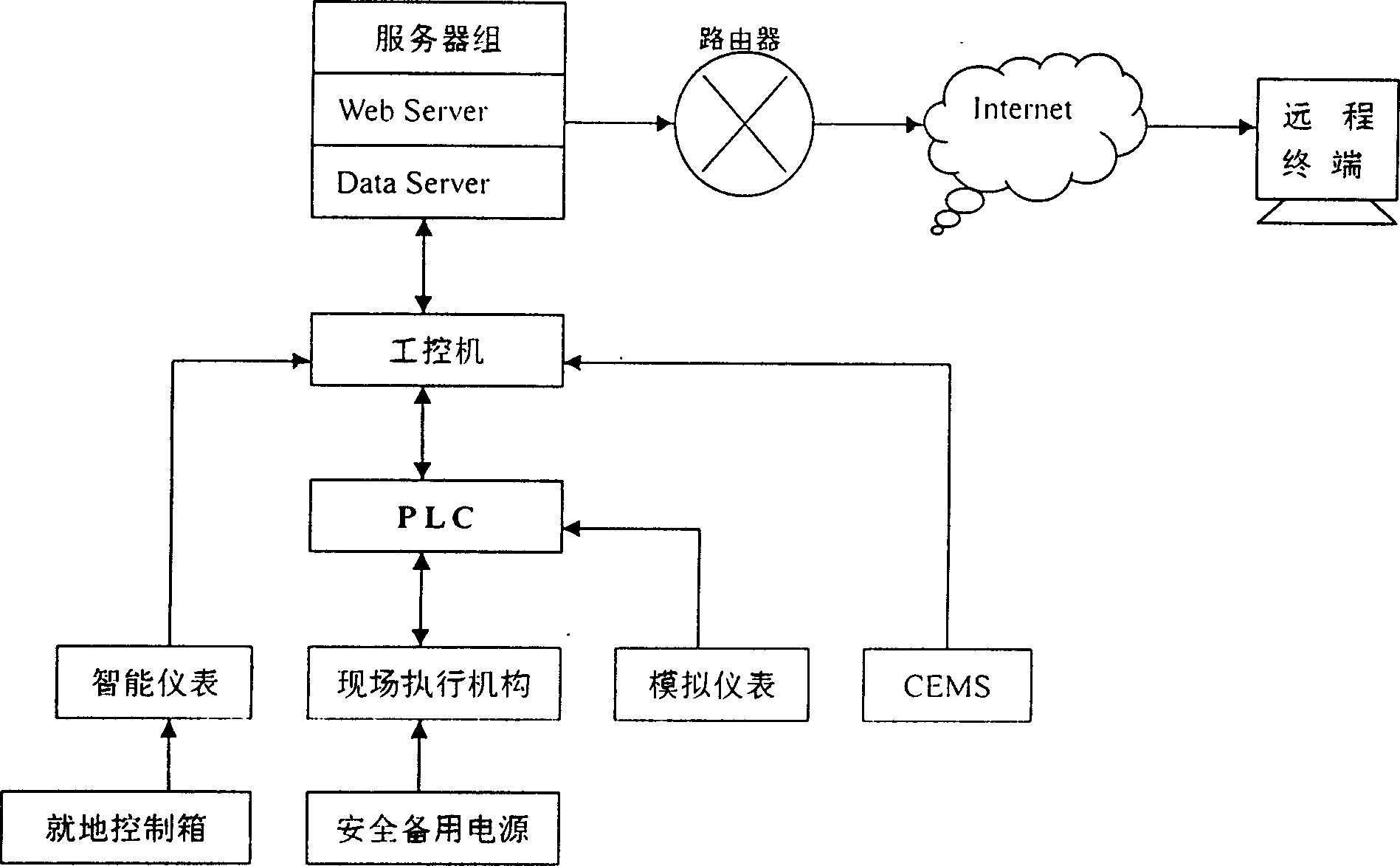

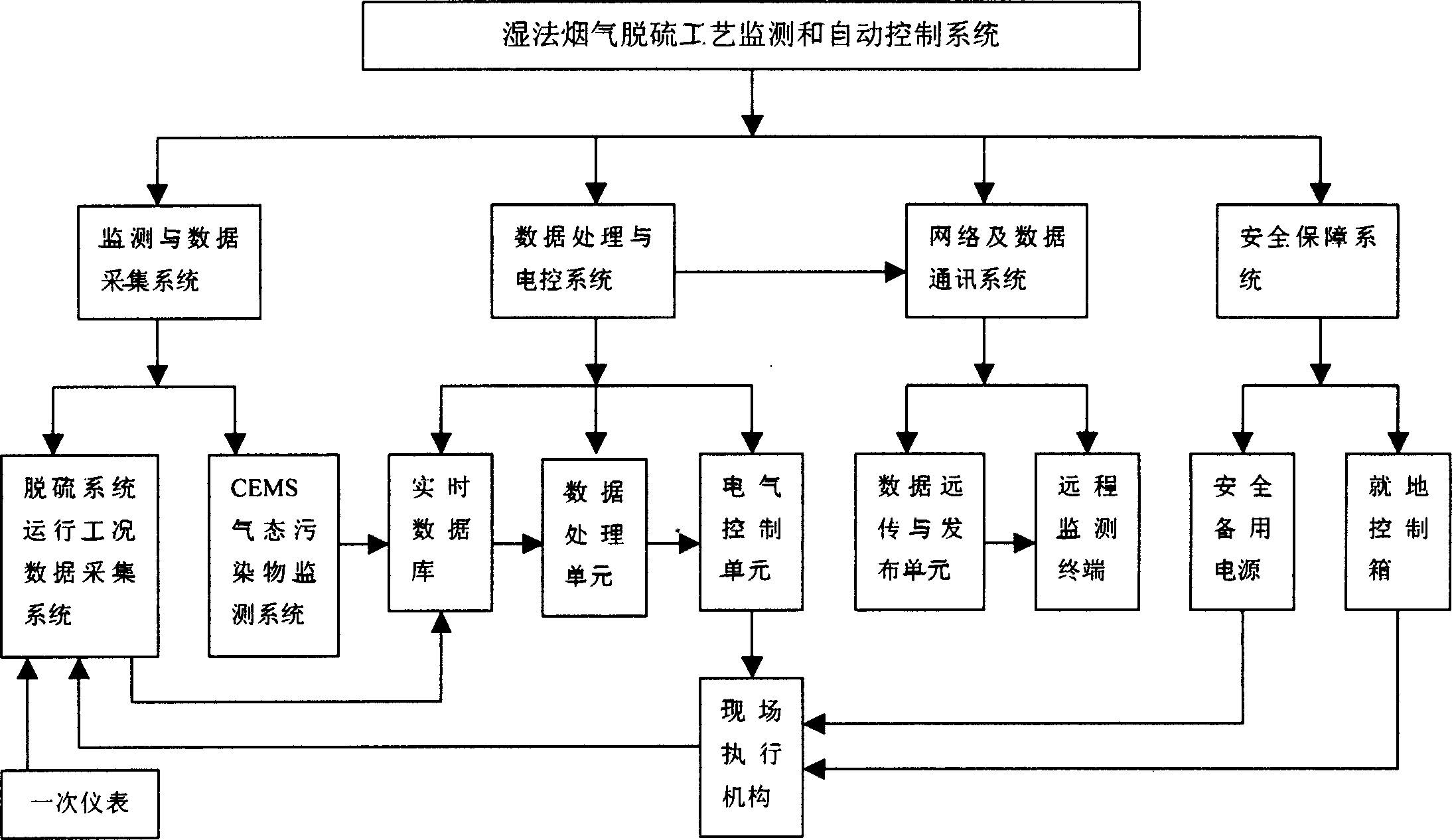

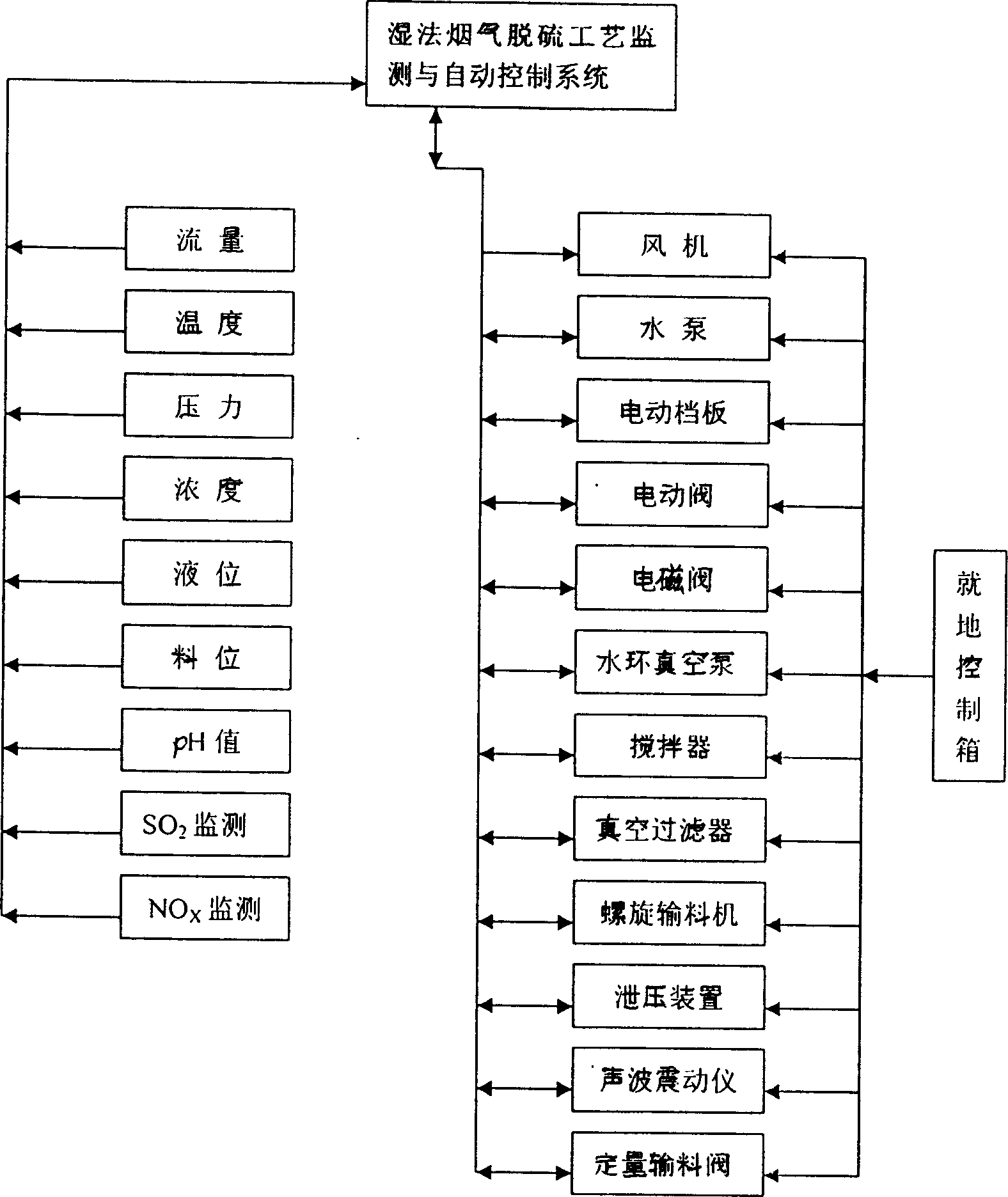

Monitoring and automatic control system for wet method flue gas desulfurization technology

InactiveCN1593726AGuaranteed uptimeEconomical and energy efficient operationDispersed particle separationAutomatic controlThe Internet

The invention relates to a kind of wet-form stack-gas desulfurizing industrial art monitoring and auto-control system, which can be used in desulfurizing industrial art by spraying lime powder or size mixture of lime to stack gases in order to forming high purity gypsum. The hardware of the invention contains industrial cybertron, PLC, group of server, router, Internet system and remote terminal. And the feature of it is that it contains the subsystems as follows: the monitoring and data acquisition subsystem, which includes the intelligence instrument; the simulated instrument and the observation system of the air pollutant that is CEMS; the data processing and electrical control system, which controls the on-the-spot actuating mechanism by PLC; the network and data communication subsystem and the safety control subsystem, which include the safety emergency power supply and the control cabinet on the spot of the subject equipment. The industrial cybertron works for data processing and central control, which uses PLC to control spot actuating mechanism, and it can manifest the data of equipment state at the right moment and can type all kinds of report form, in order to realize auto-control and remote control at the right moment.

Owner:樊金鑫

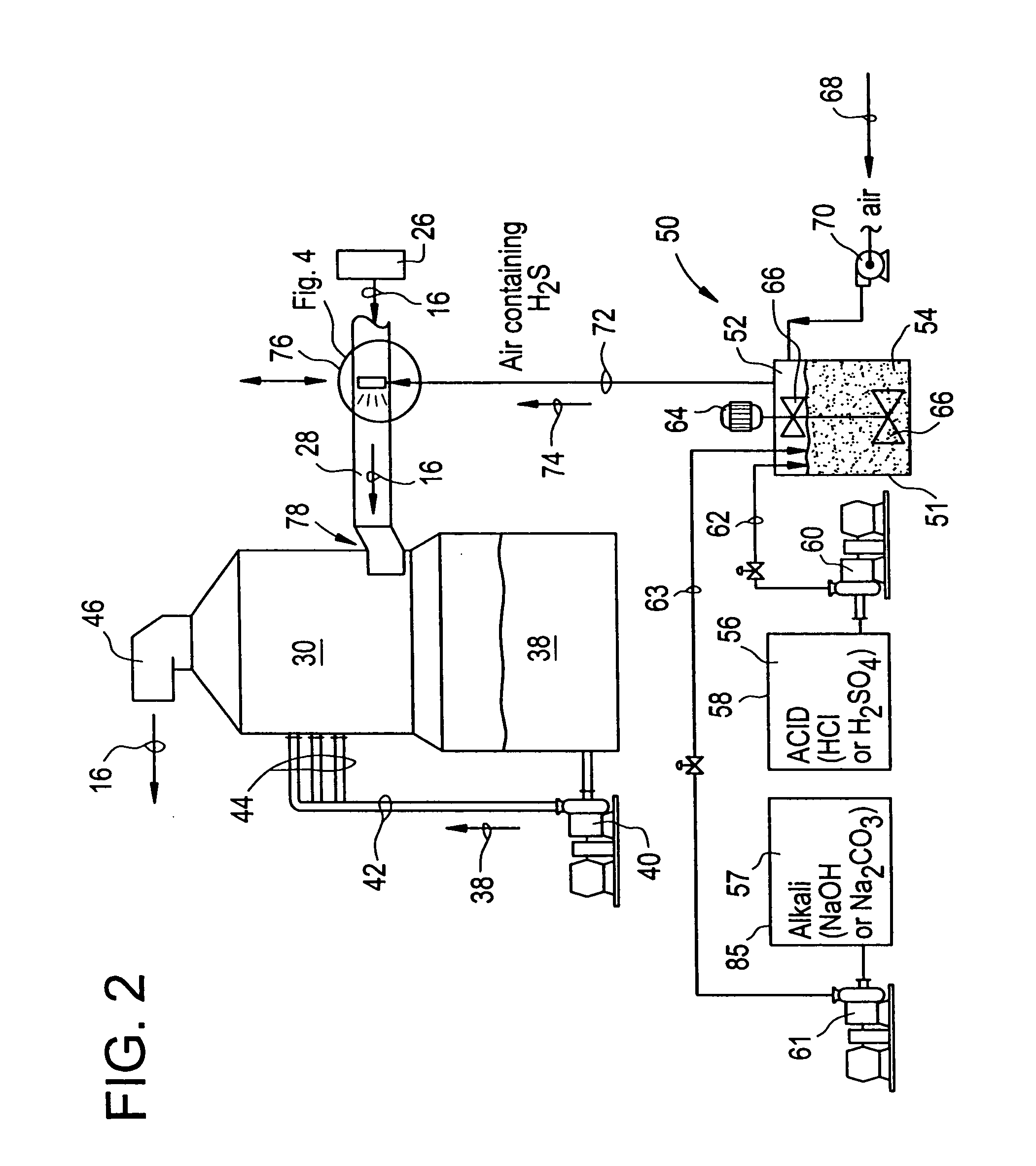

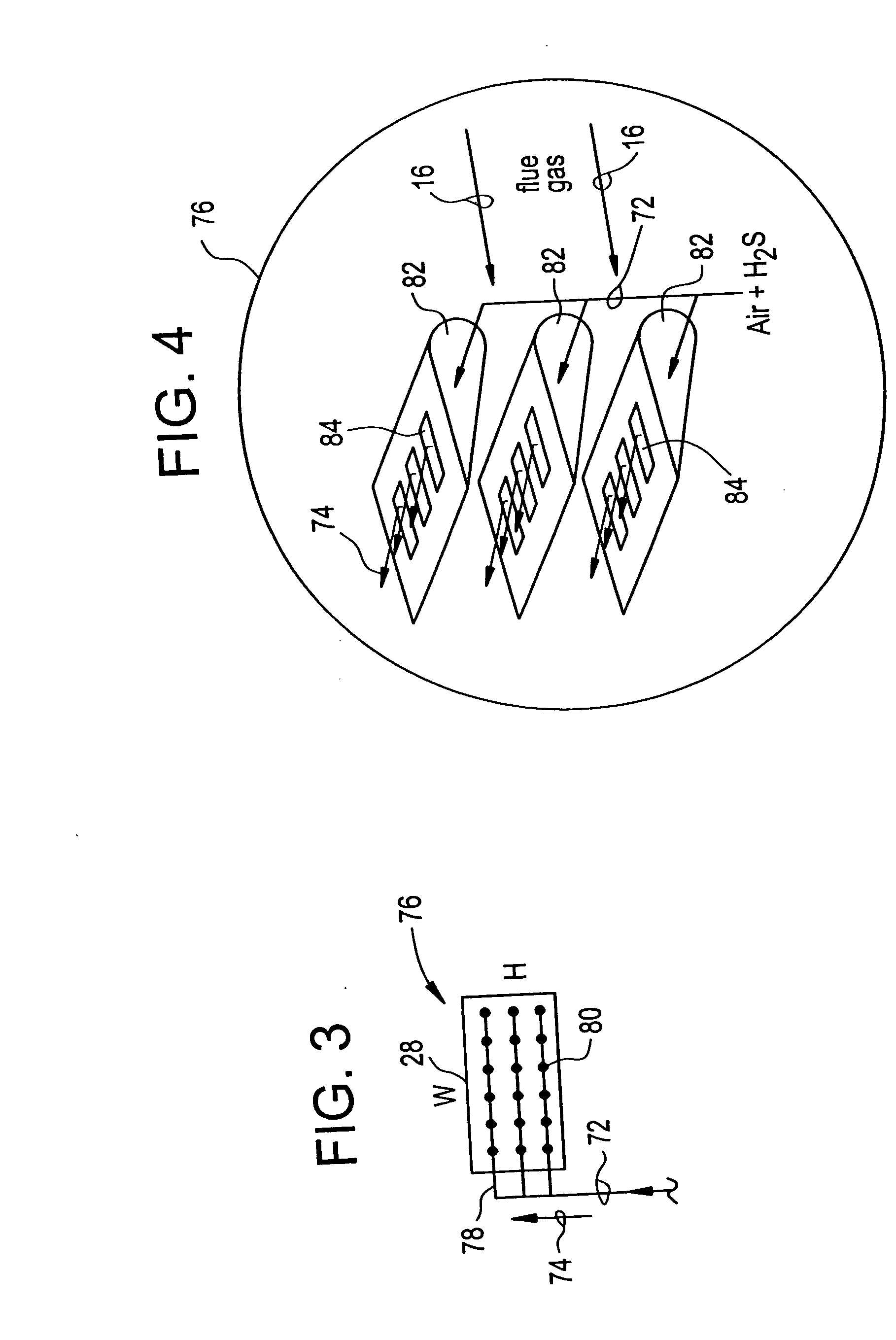

Method for control of mercury

InactiveUS20050169824A1Inherent safety advantageEfficient removalUsing liquid separation agentEmission preventionCoalWet scrubber

A method and apparatus for reducing mercury in industrial gases such as the flue gas produced by the combustion of fossil fuels such as coal adds hydrogen sulfide to the flue gas in or just before a scrubber of the industrial process which contains the wet scrubber. The method and apparatus of the present invention is applicable to installations employing either wet or dry scrubber flue gas desulfurization systems. The present invention uses kraft green liquor as a source for hydrogen sulfide and / or the injection of mineral acids into the green liquor to release vaporous hydrogen sulfide in order to form mercury sulfide solids.

Owner:DOWNS WILLIAM +1

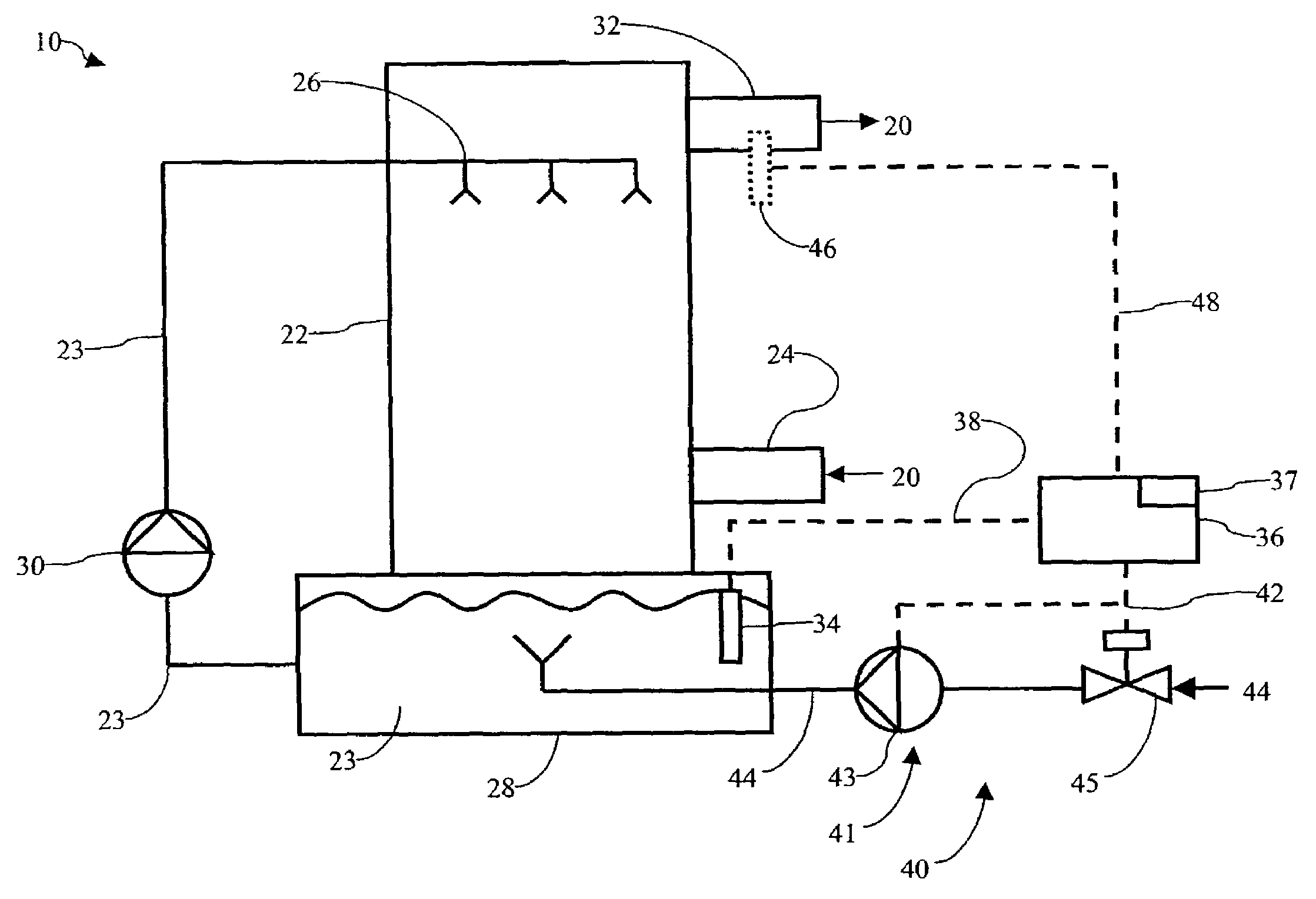

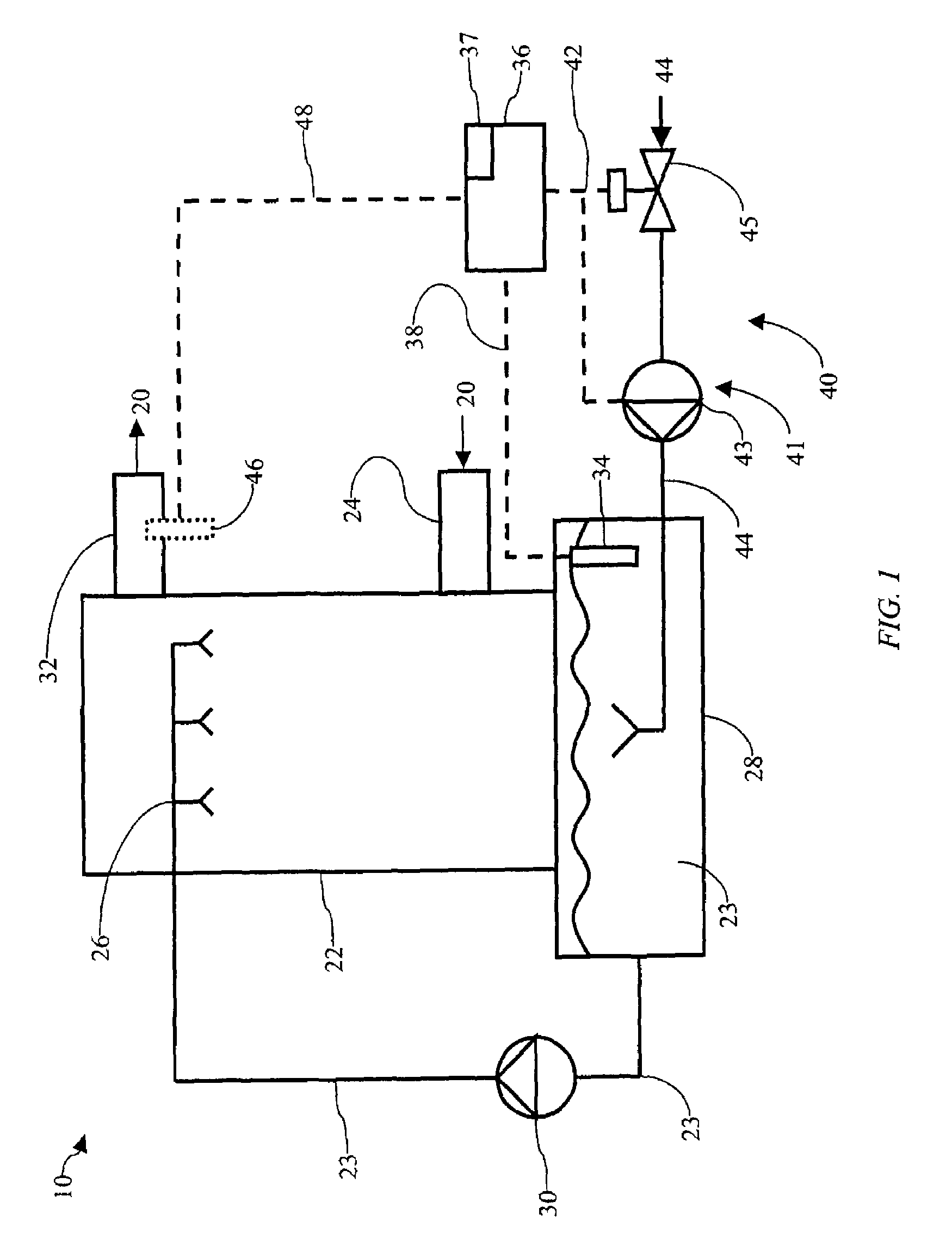

Method of mercury removal in a wet flue gas desulfurization system

Controlling the reductive capacity of an aqueous alkaline slurry (23) in a wet scrubber makes it possible to accurately control the mercury emission from the scrubber to a desired value. One method of controlling the reductive capacity of the slurry is to measure the reduction-oxidation potential (“redox potential”) of the aqueous alkaline slurry (23) and to add or remove substances that affect the redox potential and thus the reductive capacity of the slurry. In wet scrubbers in which limestone is used for absorption of acid gases and where a gypsum slurry is circulated, it has been found to be an attractive solution to control the amount of oxidation air blown into the scrubber in order to control the redox potential and thereby the mercury emissions.

Owner:GENERAL ELECTRIC TECH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com