Method and device for cooperation-removal of PM2,5 in flue gas wet desulphurization

A PM2.5, wet desulfurization technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problem of low capture efficiency of PM2.5

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

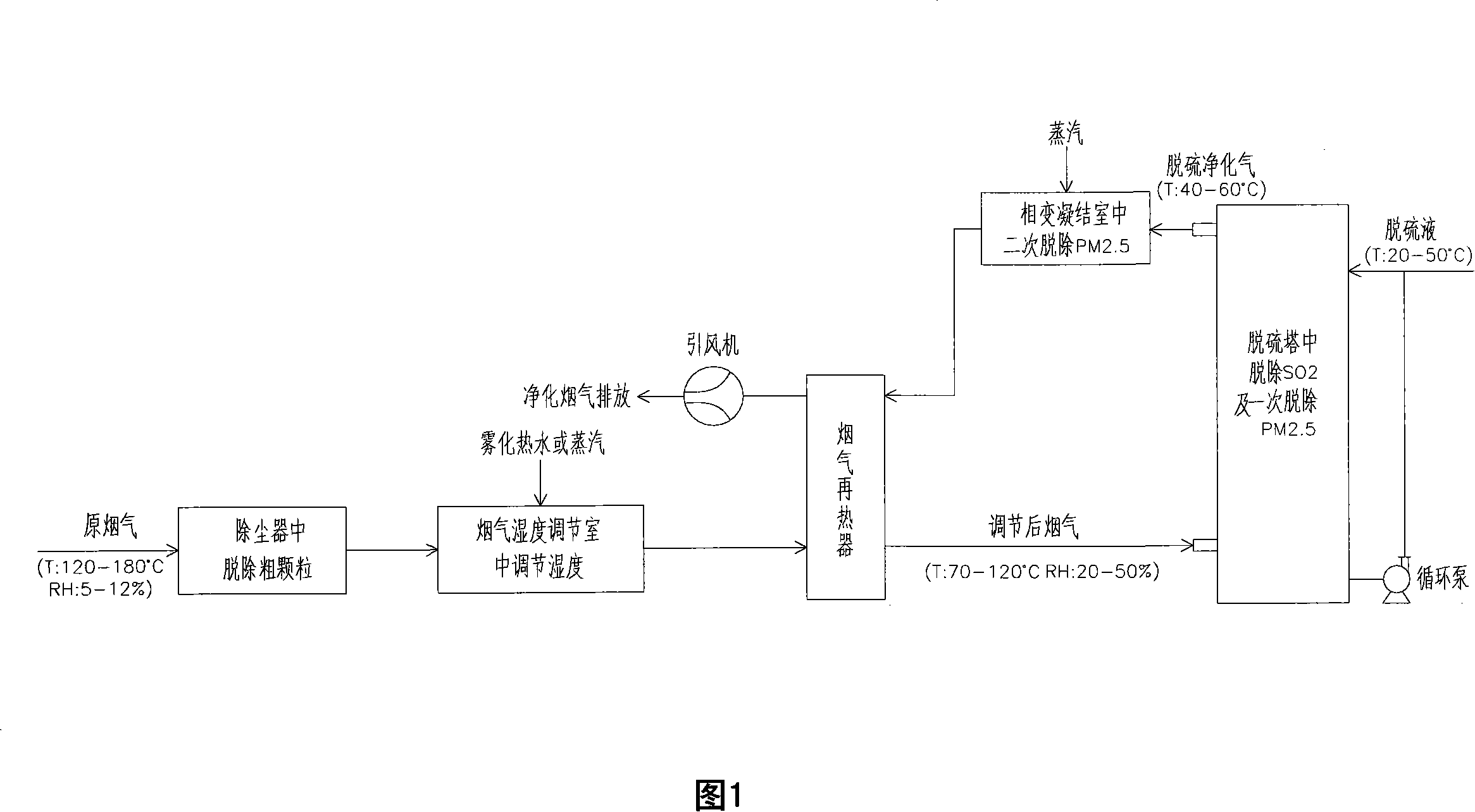

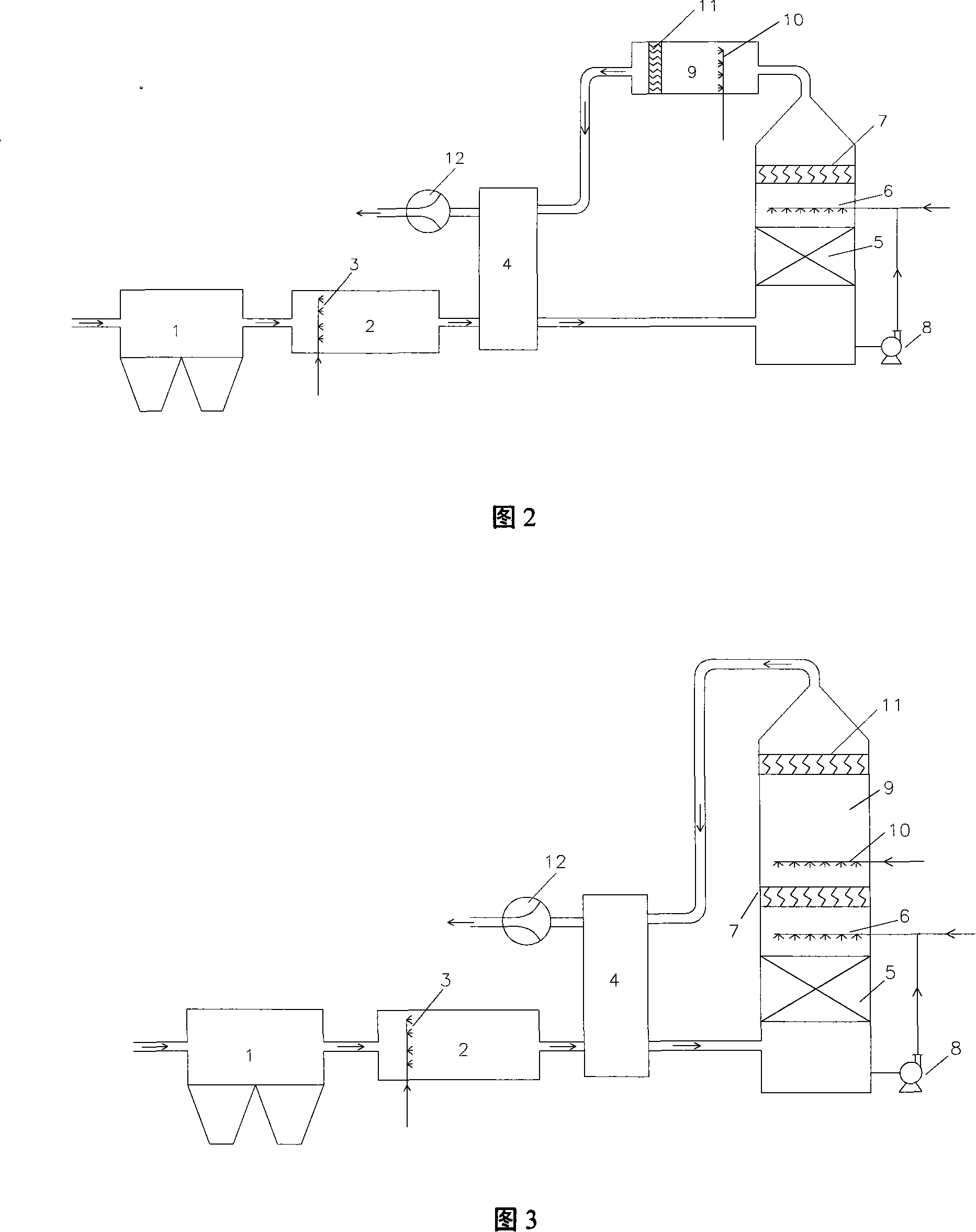

[0019] Synergistic removal of PM in flue gas wet desulfurization of the present invention 2.5 The method is shown in Figure 1: The dust-containing flue gas produced by the coal-fired boiler is removed by the dust collector (such as electrostatic precipitator) 1 after removing coarse particles with a particle size of ≥2.5 μm, and then enters the flue gas humidity control room 2 and is atomized The water nozzle 3 sprays atomized water droplets with a particle size of 20-30μm, and uses the heat of the flue gas to completely evaporate the atomized water droplets in the humidity control room 2. The amount of atomized water added is based on the flue gas's adjusted relative humidity from 5 to 12 % Increased to 20-50% to confirm. The flue gas with humidity adjustment enters the desulfurization tower 5 from the lower part of the desulfurization tower. In the desulfurization tower 5, the high-temperature wet flue gas (temperature: 70~120℃) is in countercurrent contact with the medium and l...

Embodiment 2

[0022] As shown in Figure 3, the difference from Example 1 is that the phase change condensation chamber is not specially set, but the height of the desulfurization tower is appropriately increased, and the head space of the desulfurization tower 5 (that is, the position above the demister 7 of the desulfurization tower) is used for phase change. Condensing chamber 9 is injected with an appropriate amount of steam. A high-efficiency demister 11 is installed on the top of the tower. The purified flue gas at the outlet of the tower is heated by the flue gas reheater 4 and then discharged from the chimney.

Embodiment 3

[0024] A steam nozzle is installed in the flue gas humidity control chamber 2 to directly inject an appropriate amount of steam to adjust the flue gas moisture content, and the rest is the same as in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com