Methods to enhance the activity of lignocellulose-degrading enzymes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

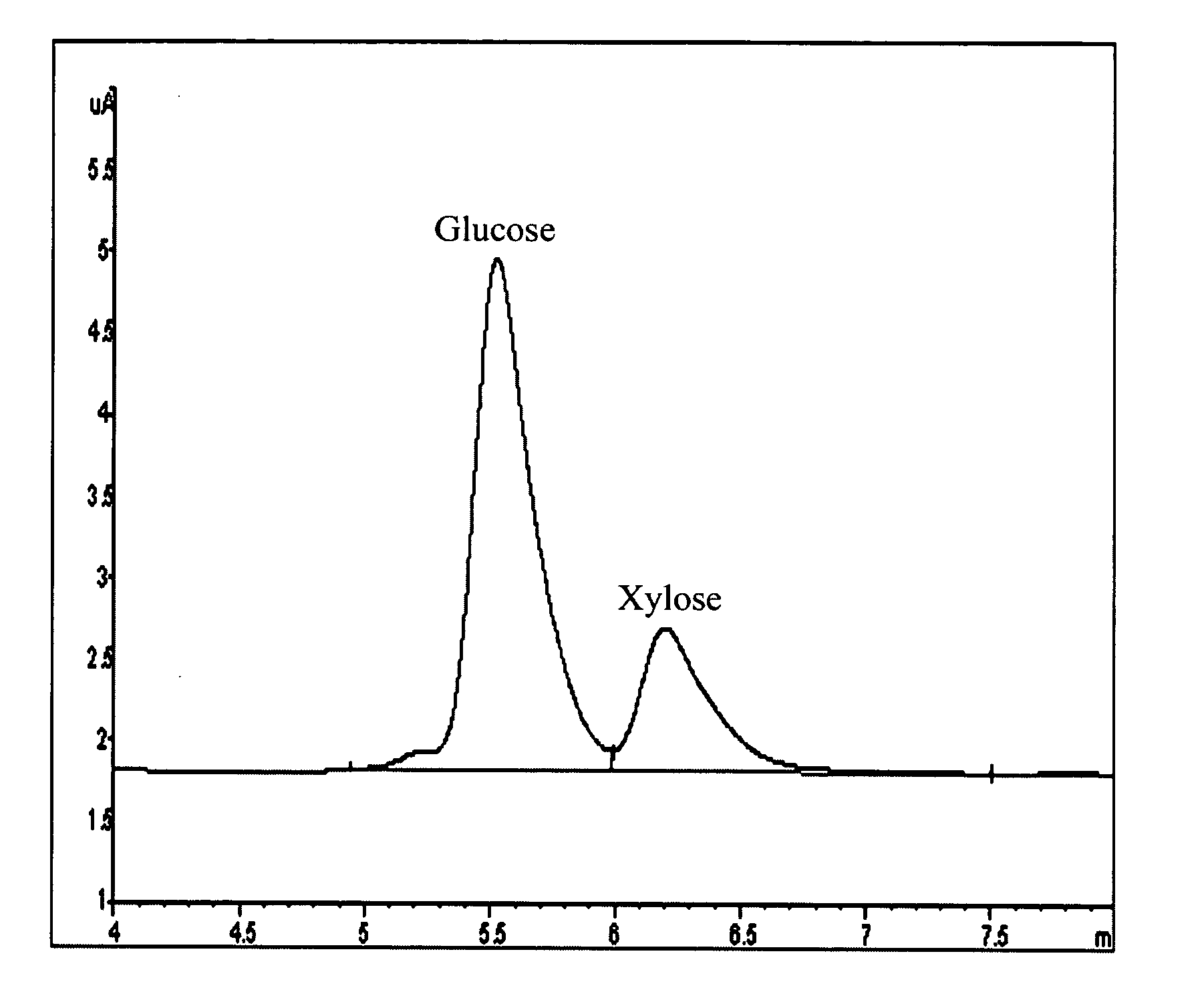

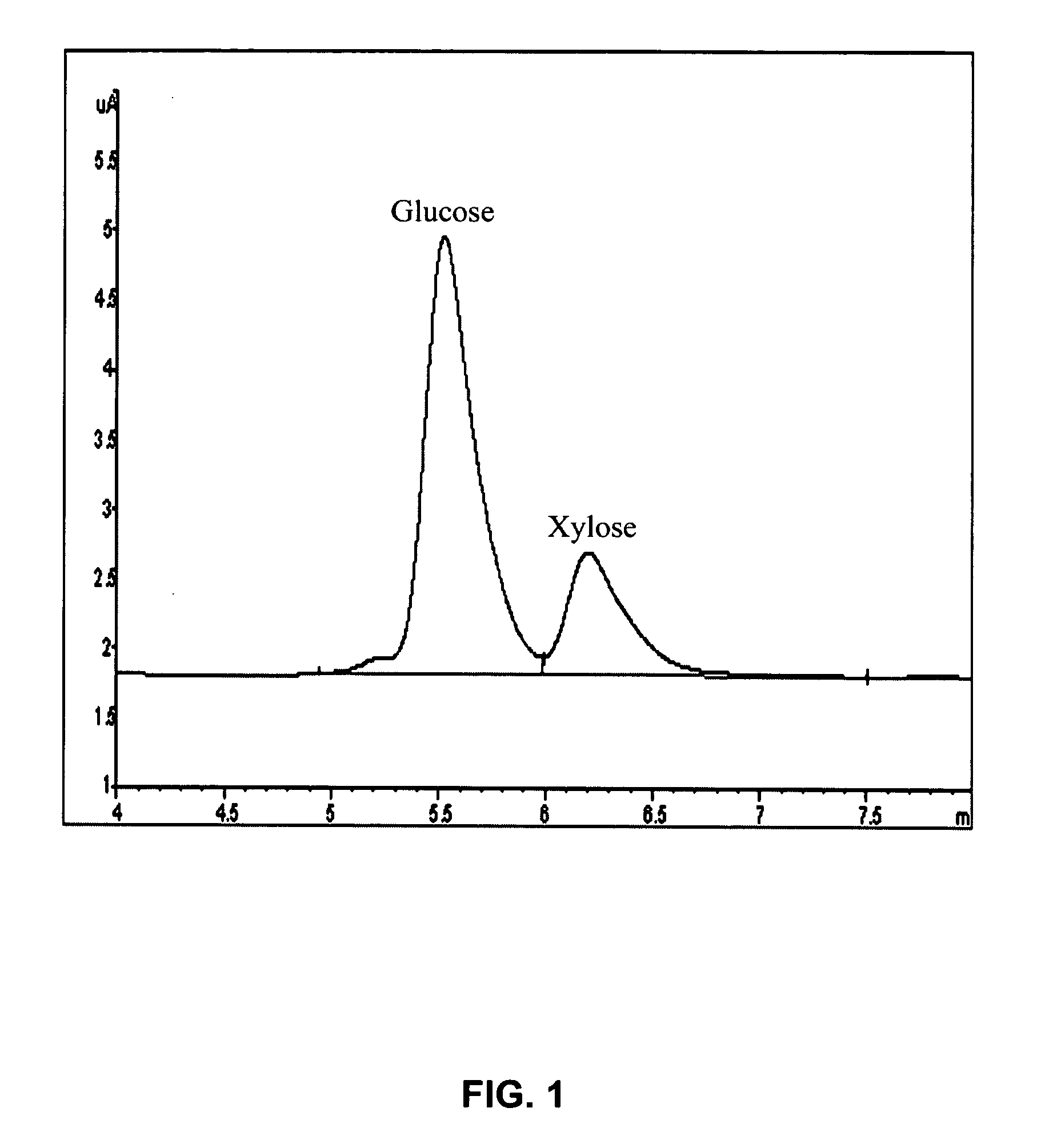

[0110] Glucose and Xylose Standard Curves

[0111] Standards for glucose, xylose, arabinose, galactose and mannose were prepared at concentrations ranging from 0%-0.12%. A modified dinitrosalicylic acid (DNS) method produced absorbance changes detected at 540 nm. A linear curve fit analysis for each sugar standard verifies that the DNS quantitation method is a precise detection method for each monomeric sugar (data not shown).

example 2

[0112] Hydrogen Peroxide Treatment Followed by Cellulase Treatment Liberates Monomeric Sugars

[0113] Hydrogen peroxide (200 mM) was reacted with 2.0 g of stover in 10 mL water (adjusted to pH 5.0). A control stover sample was untreated. After 24 hours of incubation at 80.degree. C., the reducing sugar content of each sample was determined by DNS assay (Example 1). Cellulase from T. longibrachiatum (25 mg) was then added to both samples and incubation was carried out for 24 hours at 65.degree. C. The reducing sugars were determined by DNS assay. The results are shown in Table 8. Treatment with hydrogen peroxide resulted in greater sugar release after enzyme treatment than with enzyme alone.

15TABLE 8 Reducing sugars solubilized from corn stover Sugar Release following Treatment Stover only 3.1% Stover + H.sub.2O.sub.2 4.0% Stover + Cellulase 38.6% Stover + H.sub.2O.sub.2 + Cellulase 47.0%

[0114] For further analysis by high performance liquid chromatography (HPLC), aliquots were removed...

example 3

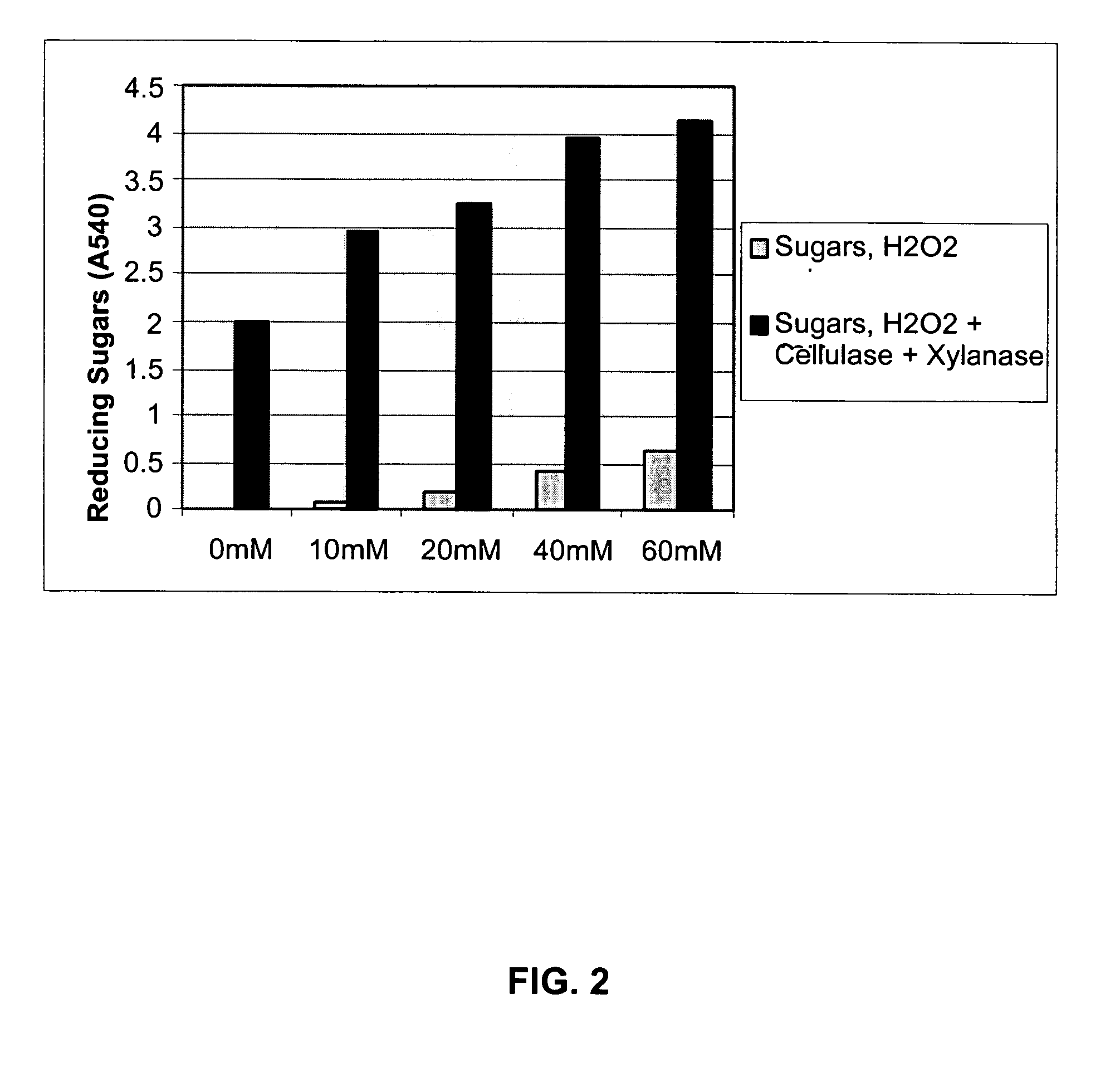

[0115] Hydrogen Peroxide Treatment Increases Enzymatic Hydrolysis of Corn Stover

[0116] Hydrogen peroxide (0-60 mM final concentration) was reacted with 0.2 g stover in sodium acetate buffer (125 mM, pH 5.0) and incubated at 50.degree. C. with shaking. After 24 hours, the reducing sugar content was determined by DNS assay. 10 units of cellulase from Trichoderma reesei and 10 units of xylanase from Trichoderma viride were then added and incubation was continued for 24 hours at 50.degree. C. Additional aliquots were removed from each sample and reducing sugars quantified. The reducing sugar content following hydrogen peroxide treatment and enzymatic treatment is shown in FIG. 2. The amount of reducing sugars released was greater with increased concentration of hydrogen peroxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com