Stiffened flexible mould

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

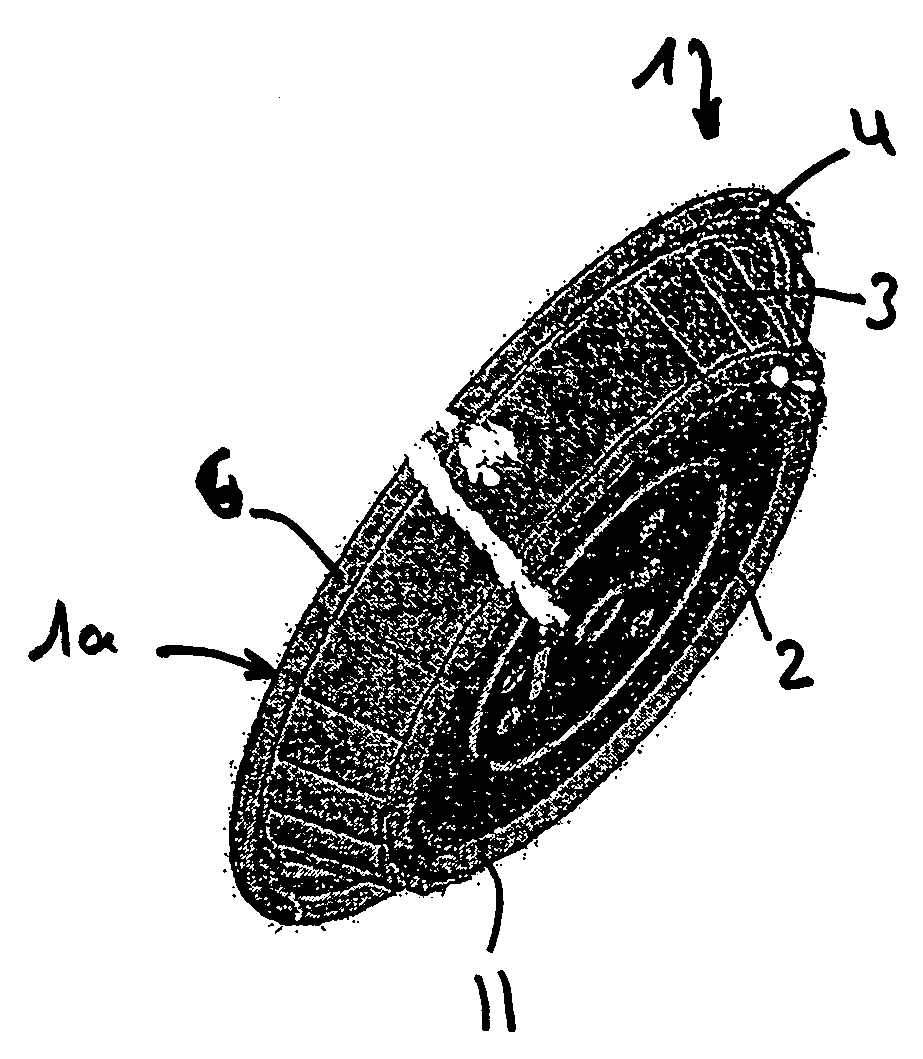

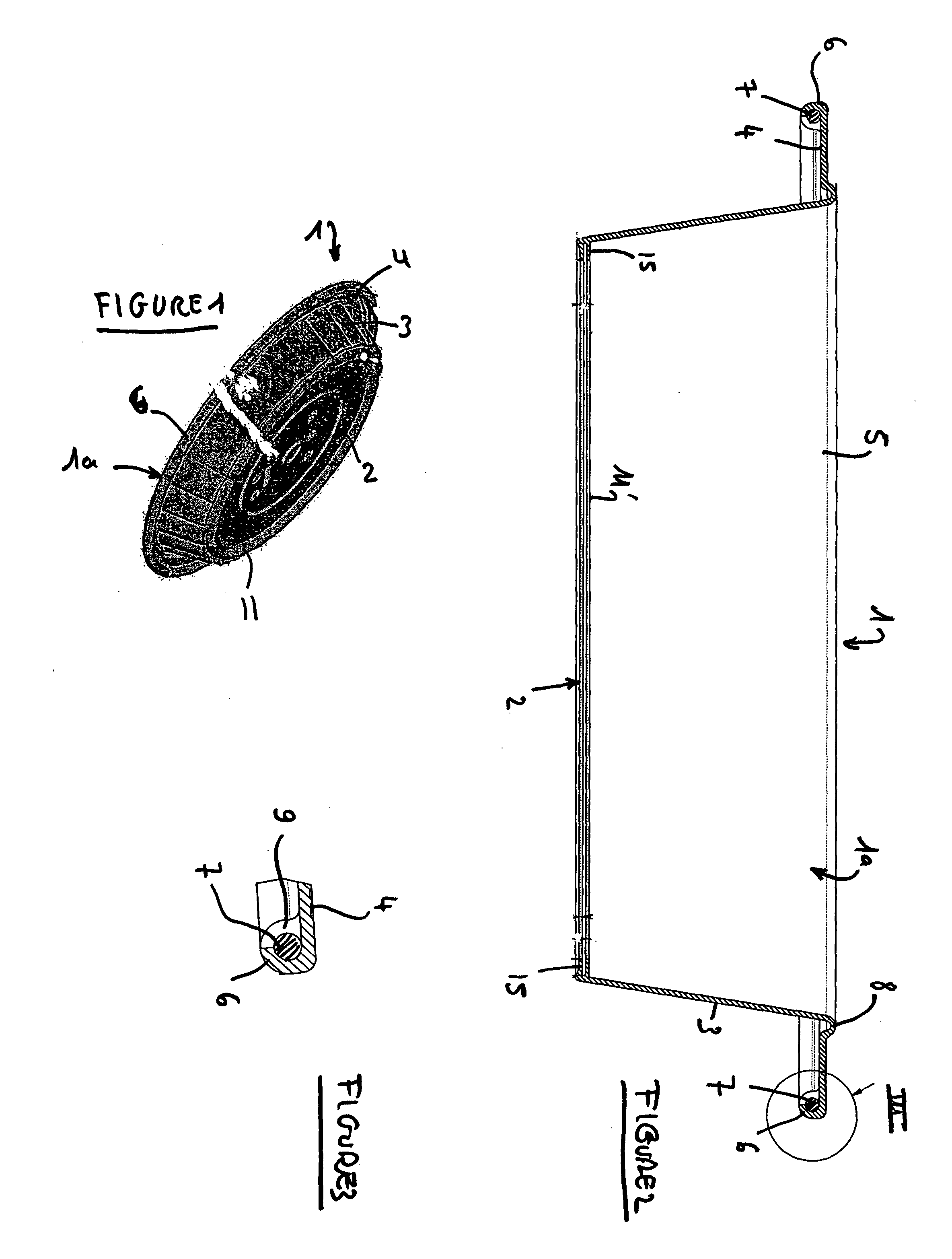

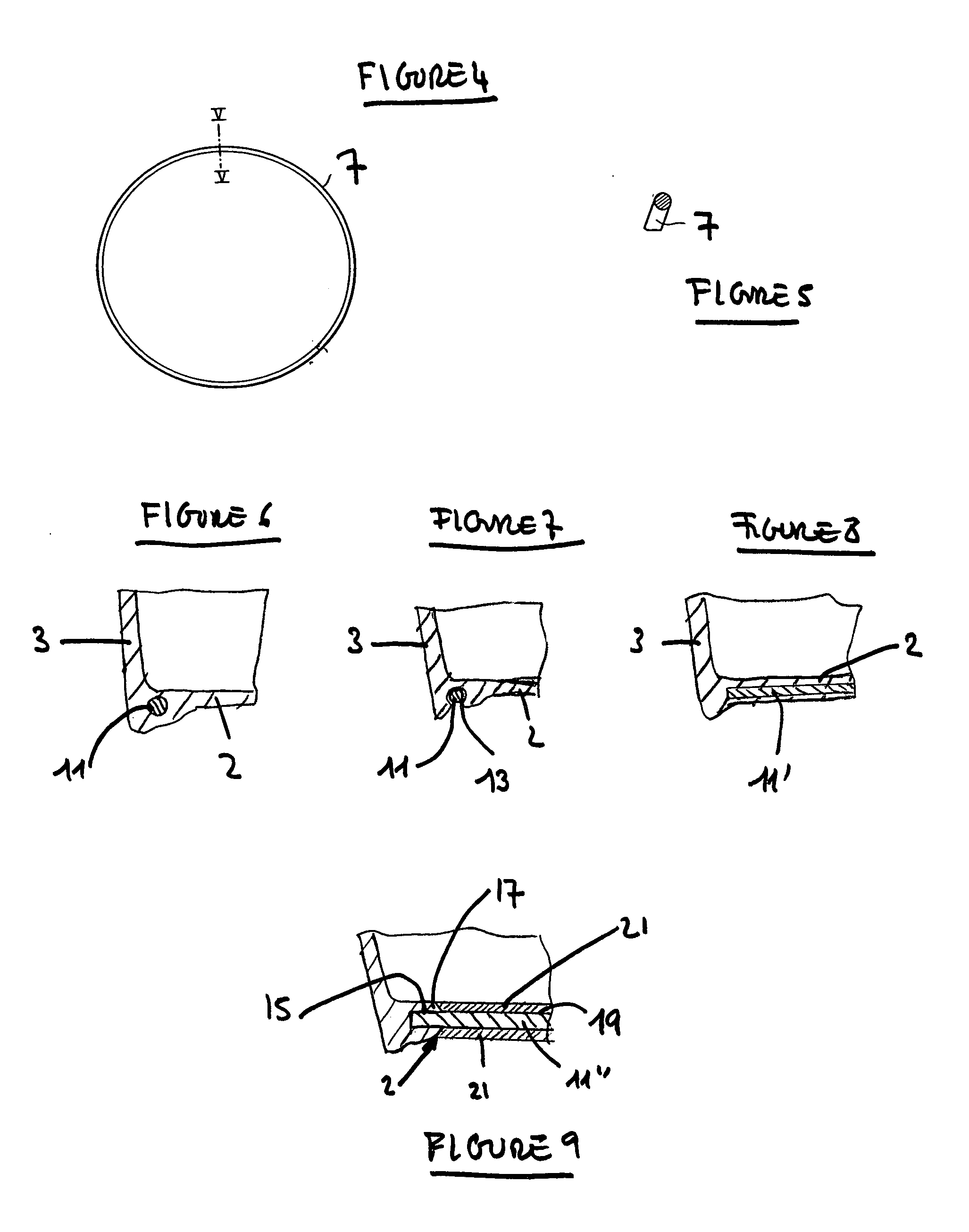

[0052] As can be seen particularly in FIGS. 1 and 2, the culinary preparation mould 1 according to this invention is in the form of a hollow tray la made of a flexible (easily deformable), elastomer material (therefore with elastic characteristics) for example made of silicone. This hollow tray forms the receptacle inside which the preparation may be placed. It includes a bottom wall 2, a side wall 3 that stands up from the bottom and a top ring (or wing) 4 defining an outer stiffening and gripping rim that extends radially from the top part of the side wall 3 around the opening 5.

[0053] The mould 1 may have different shapes, for example round, rectangular, elliptical.

[0054] The thickness of the side wall(s) is preferably essentially uniform (a few millimeters everywhere), and said side wall is free of any undercut for receiving the article to be heated or for improving local bending of the tray. The bottom wall has advantageously the same features.

[0055] If it is round as shown...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Flexibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com