Patents

Literature

5853results about How to "Less impurities" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of forming an oxide film

InactiveUS6960812B2Improve performanceReduce the temperatureSolid-state devicesVacuum evaporation coatingAlkali ionsSputtering

A method of forming an oxide film and a method of manufacturing an electronic device utilizing the oxide film is disclosed. A silicon oxide film is formed on a substrate by sputtering. Therefore, the film formation is carried out at a low temperature. The sputtering atmosphere comprises an oxidizing gas and an inert gas such as argon. In order to prevent fixed electric charges from being generated in the film and to obtain an oxide film of good properties, the proportion of argon is adjusted to 20% or less. Alternatively, a gas including halogen elements such as fluorine is added to the above sputtering atmosphere at a proportion less than 20%. Hereupon, alkali ions and dangling bonds of silicon in the oxide film are neutralized by the halogen elements, whereby a fine oxide film is obtained.

Owner:SEMICON ENERGY LAB CO LTD

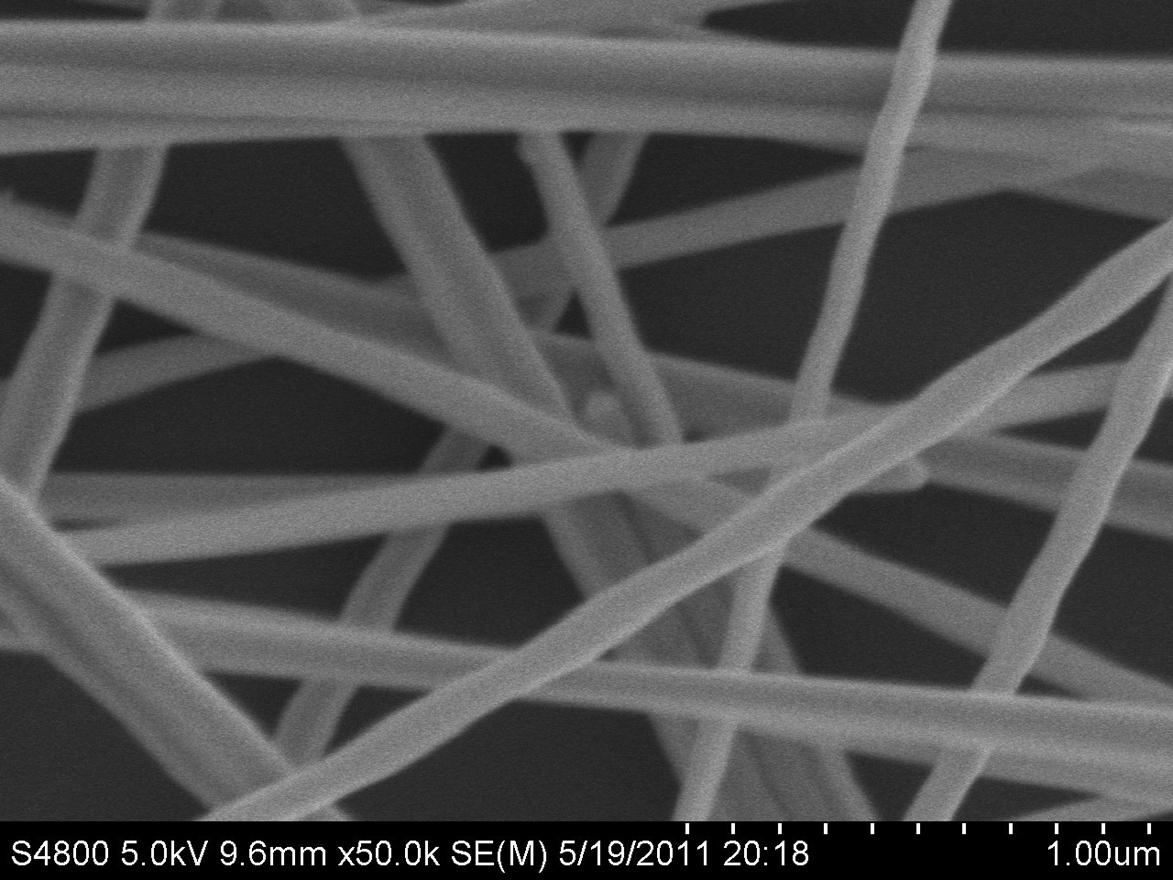

Cellulose Nonwoven Fabric

ActiveUS20070207692A1Raw materials are simpleSimple structureFats/resins/pitch/waxes removal in pulpPaper/cardboardPorosityCellulose fiber

Disclosed is a cellulose nonwoven fabric containing cellulose fibers having a maximum fiber diameter of not more than 1500 nm and a crystallinity determined by solid state NMR techniques of not less than 60%. The porosity of the cellulose nonwoven fabric is not less than 40% and not more than 99%.

Owner:ASAHI KASEI KK

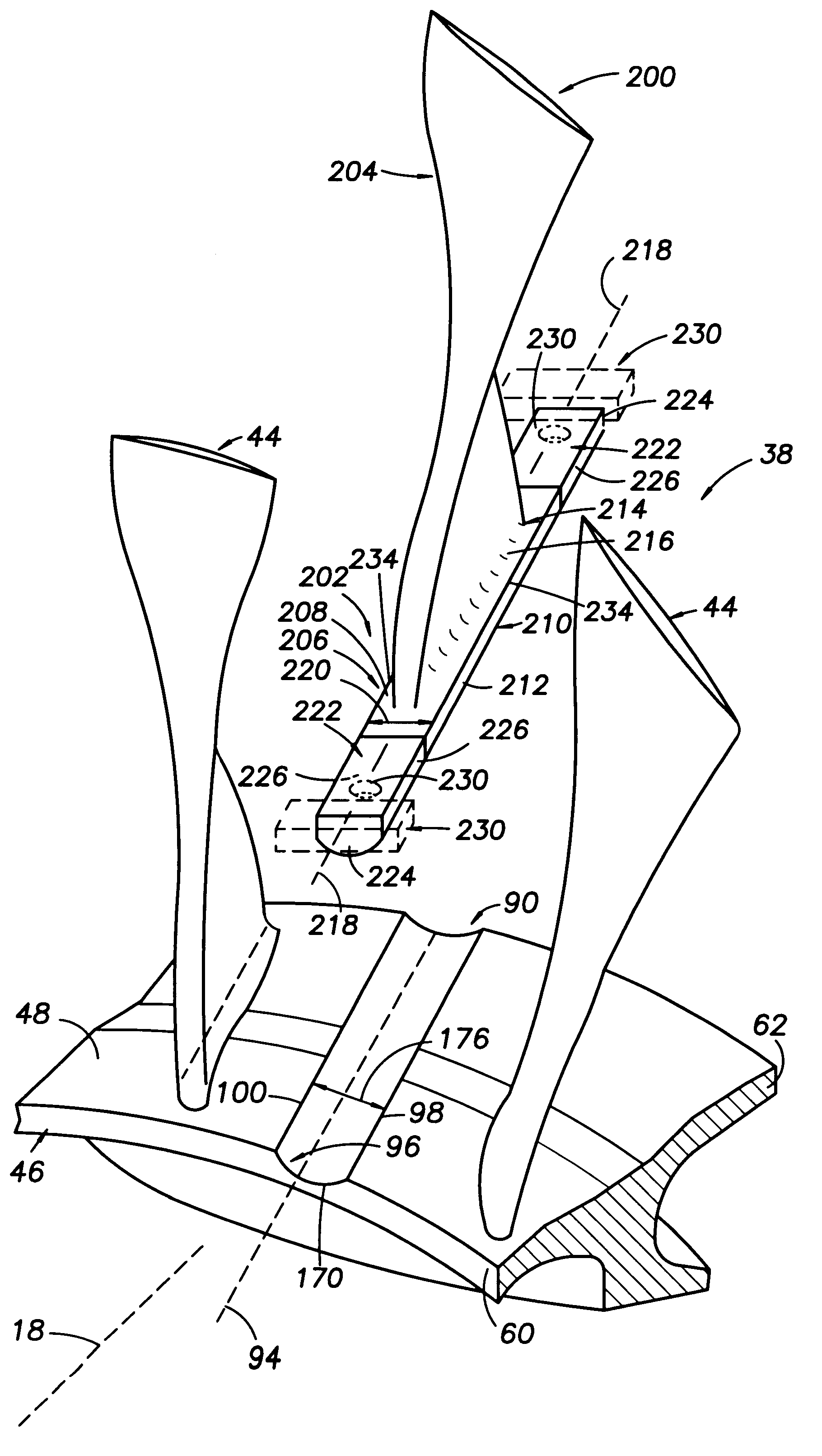

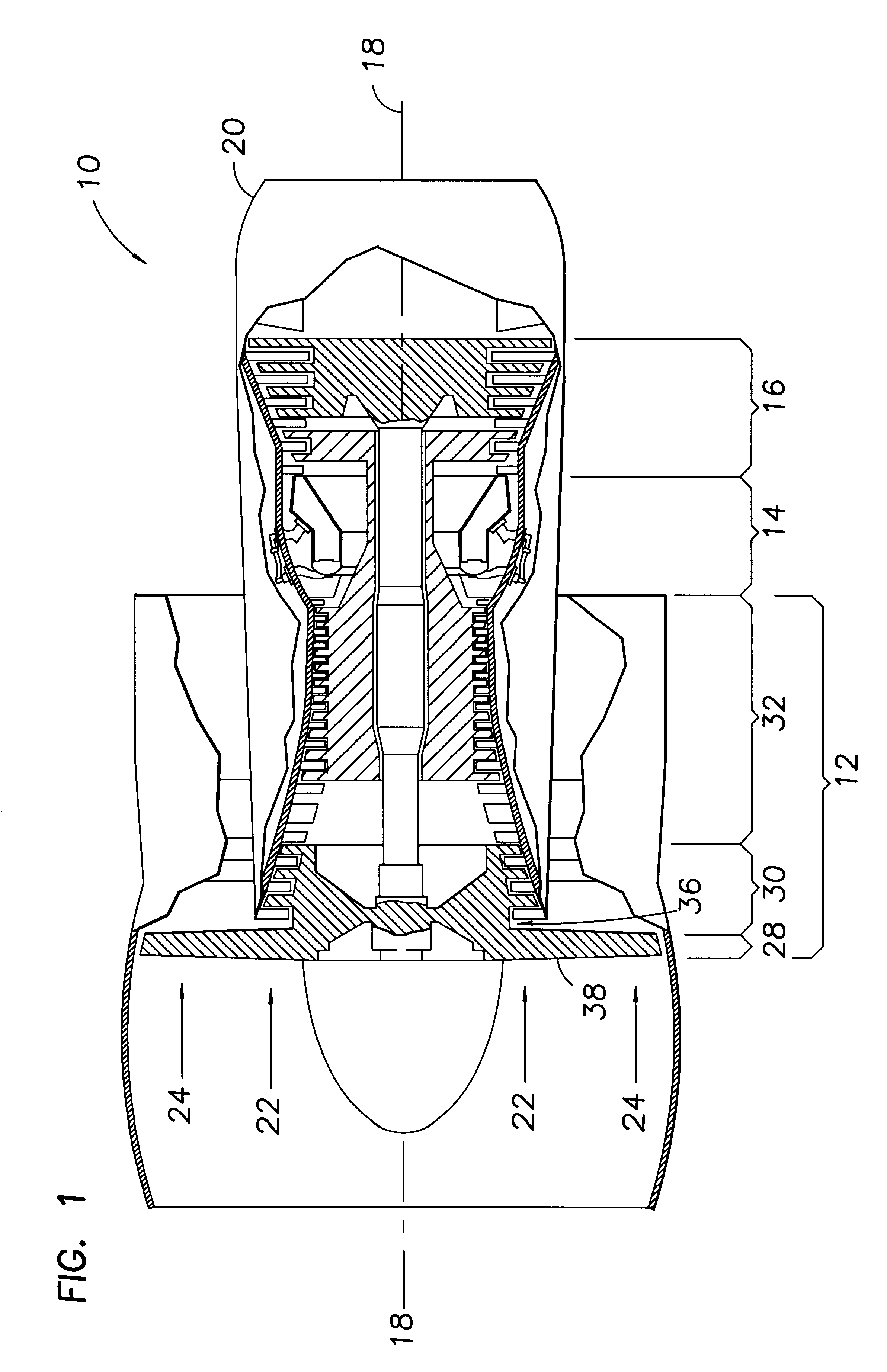

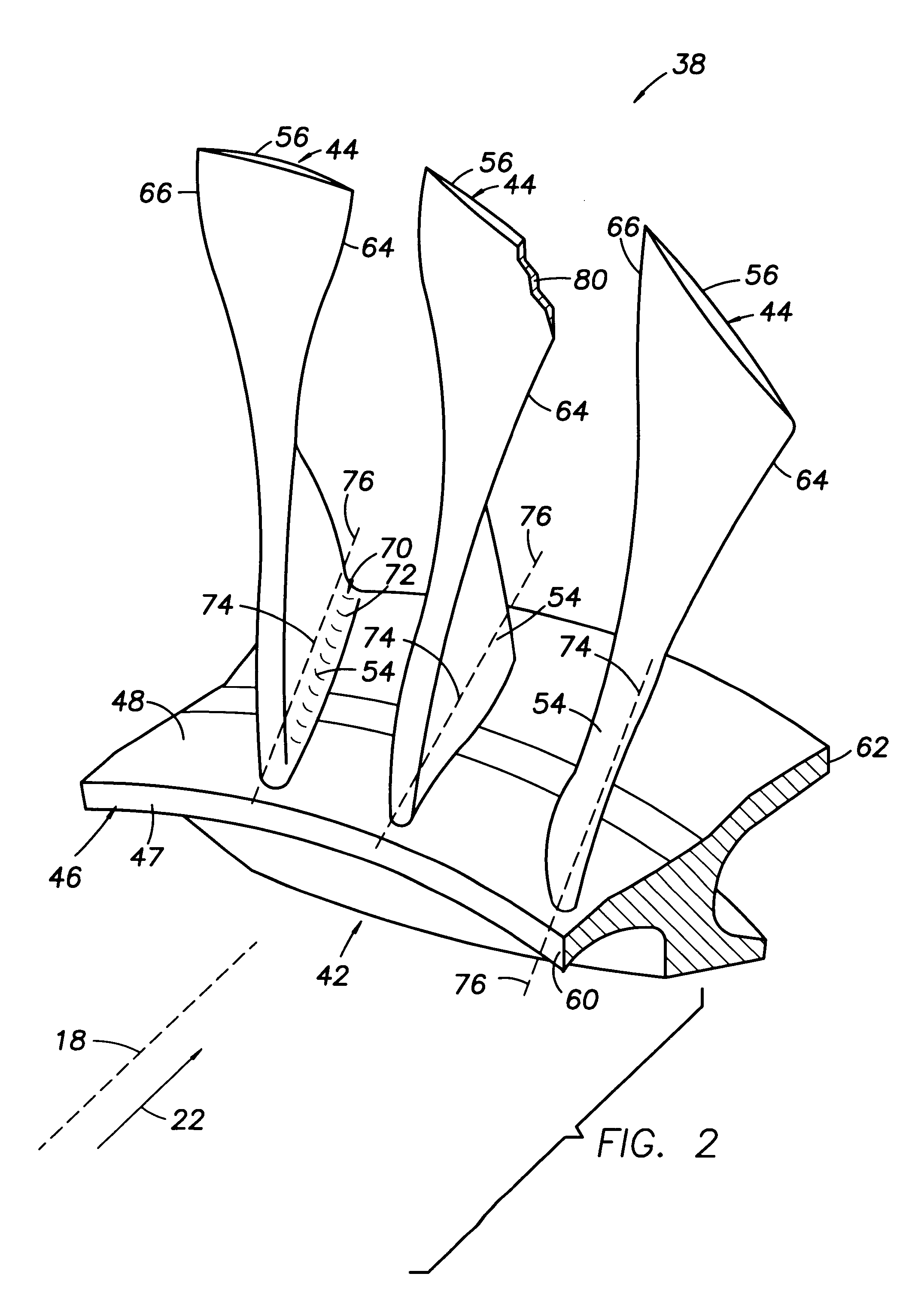

Method for linear friction welding and product made by such method

A process for joining a base for an airfoil to a disk for an integrally bladed rotor stage in a gas turbine engine includes providing a disk having a radially outer rim with a slot defined therein by a recessed surface, and further includes providing a base having a longitudinally extending root portion facing opposite a longitudinally extending support portion for supporting the airfoil. The root portion has a root surface and the support portion has an outer surface. The process further includes bringing the root surface of the root portion into contact with the recessed surface bounding the slot, applying pressure and relative movement between the base and the rim to achieve during welding, substantial contiguity between the root surface and the recessed surface over the area of the recessed surface, resulting in a substantially continuous linear friction weld between the base and the rim.

Owner:UNITED TECH CORP

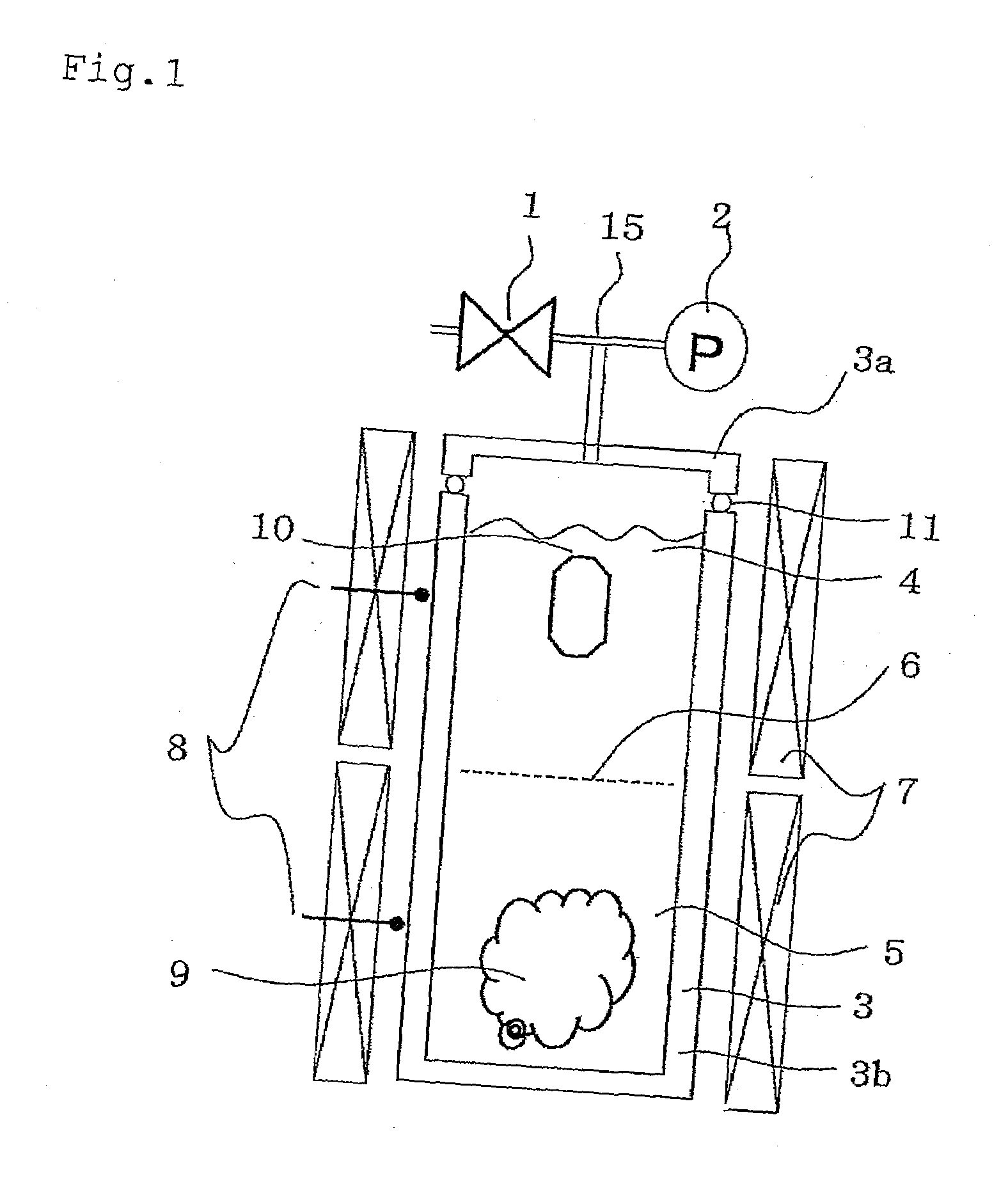

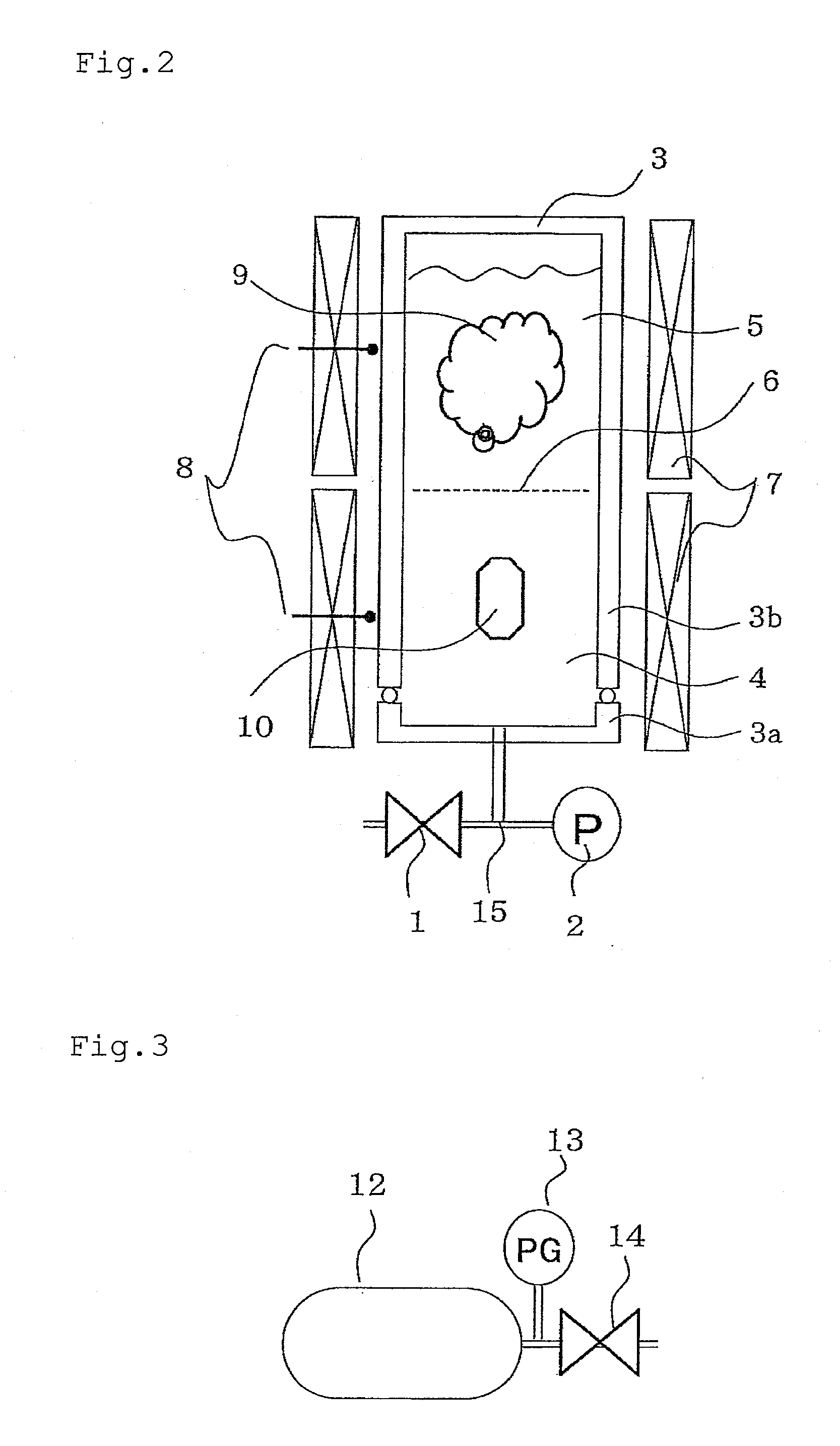

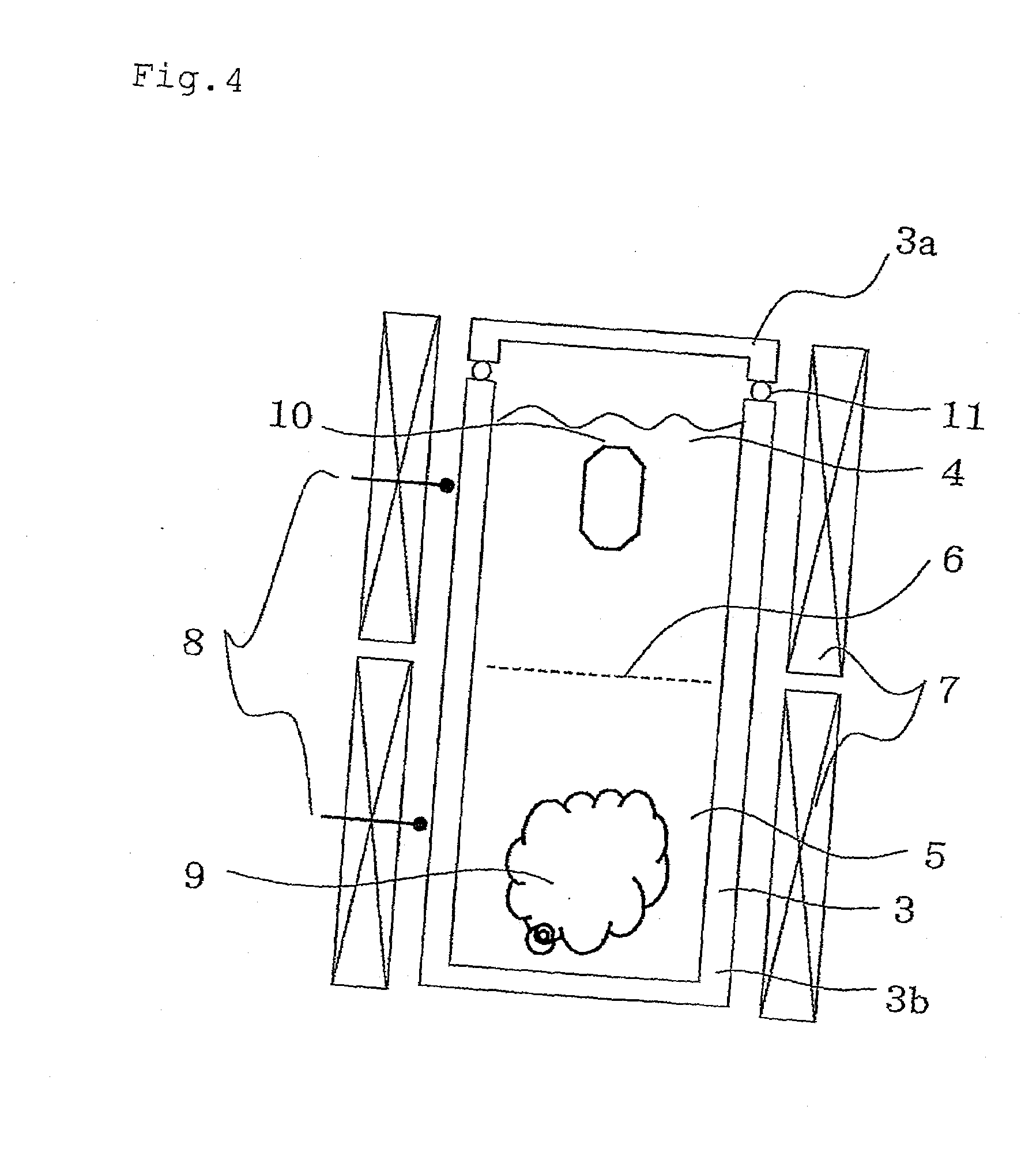

Crystal production process using supercritical solvent, crystal growth apparatus, crystal and device

InactiveUS20090092536A1Efficient productionEasy to controlPolycrystalline material growthFrom normal temperature solutionsSolventCrystal growth

To control the precipitation position of a crystal and increase the yield of the crystal by performing the crystal growth according to the solvothermal method while allowing a predetermined amount of a substance differing in the critical density from the solvent to be present in the reaction vessel; and to prevent mixing of an impurity into the crystal and improve the crystal purity.

Owner:MITSUBISHI CHEM CORP +1

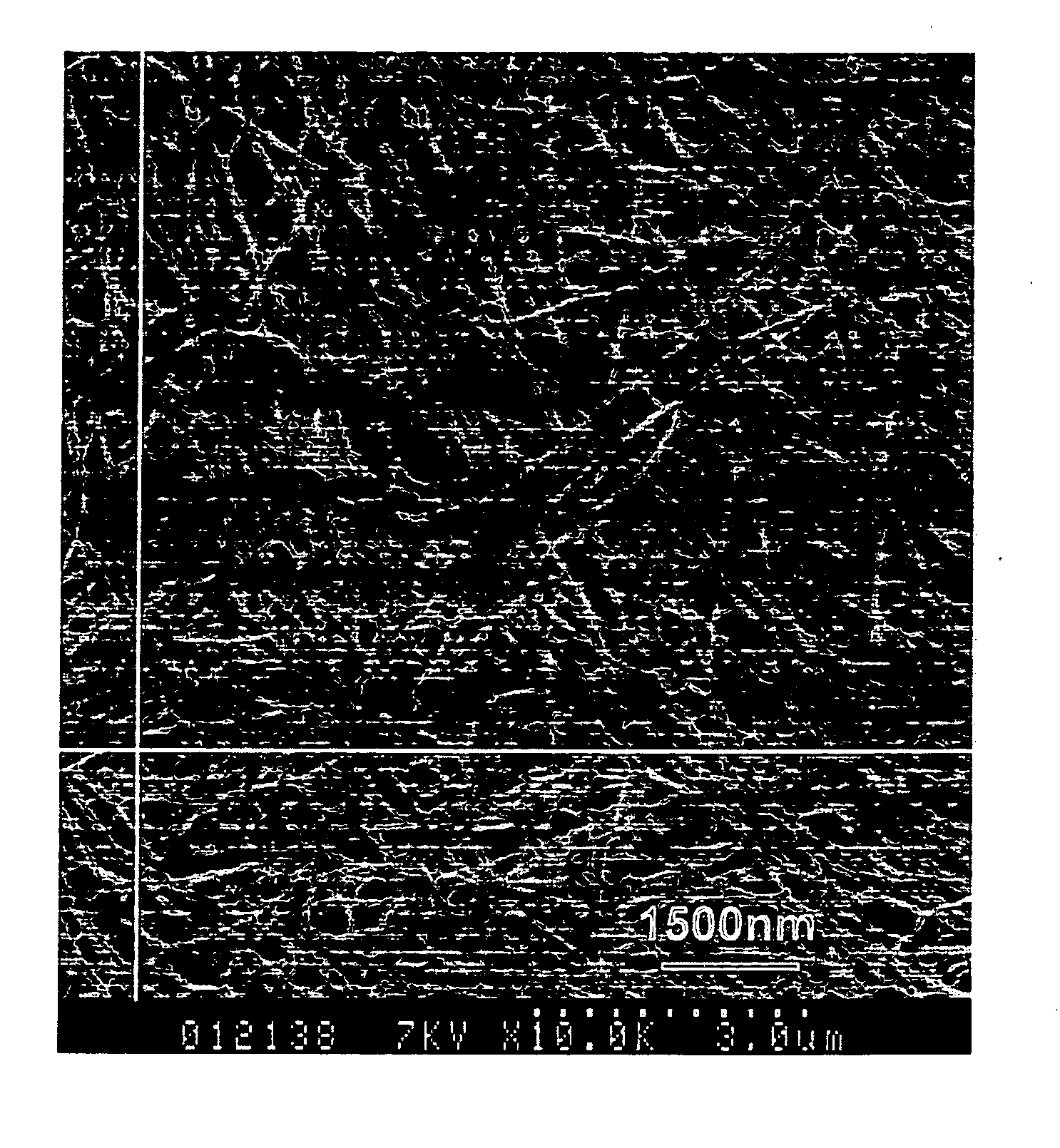

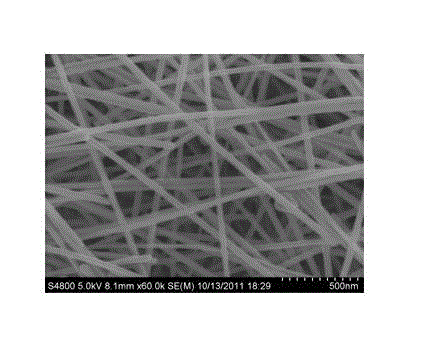

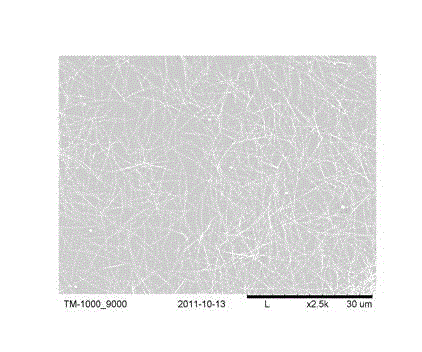

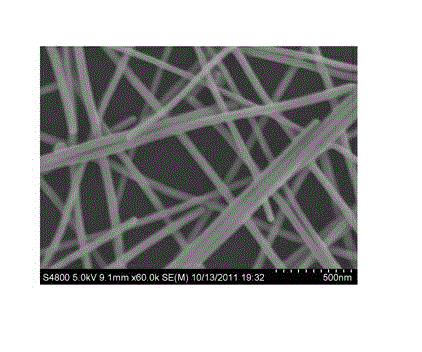

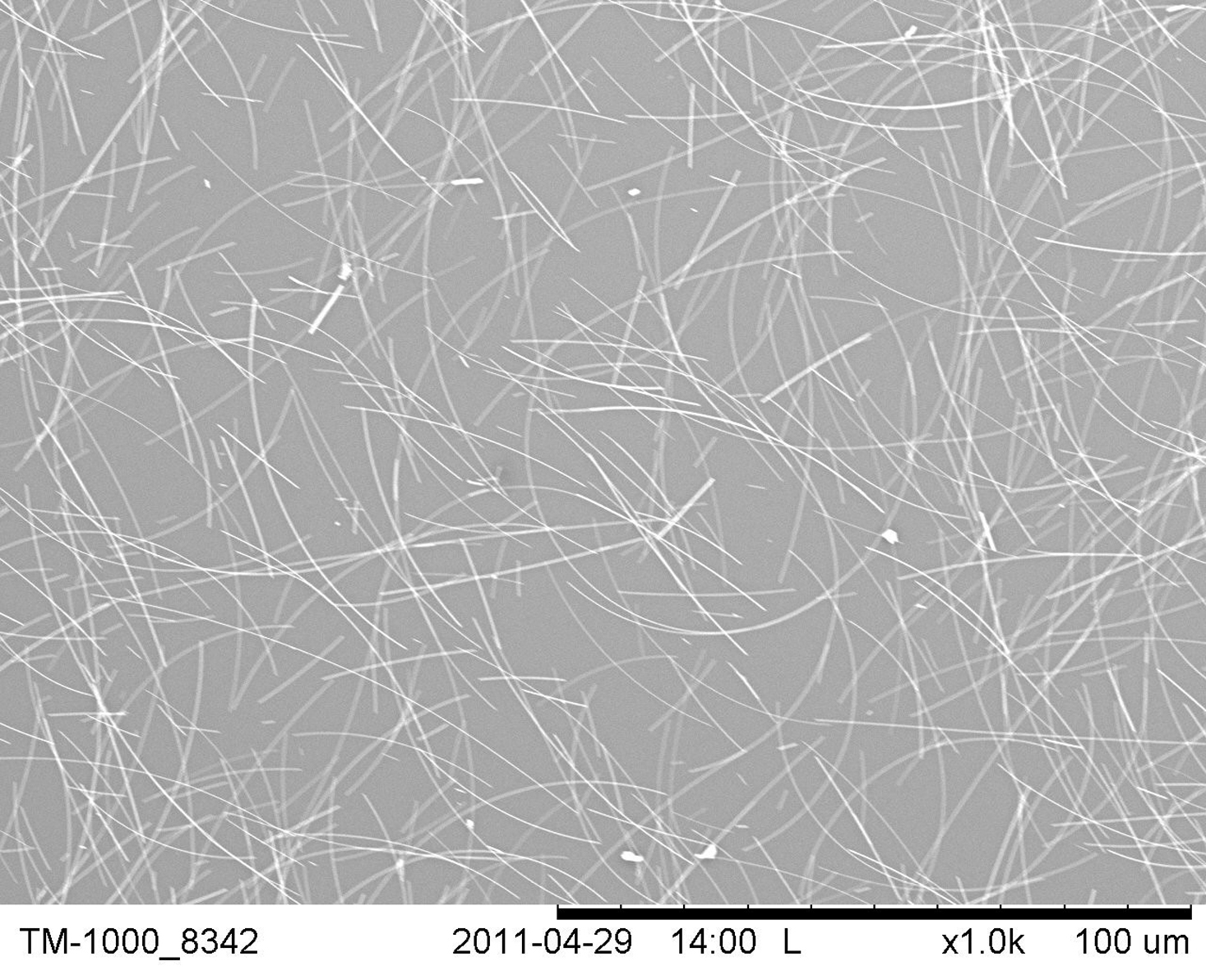

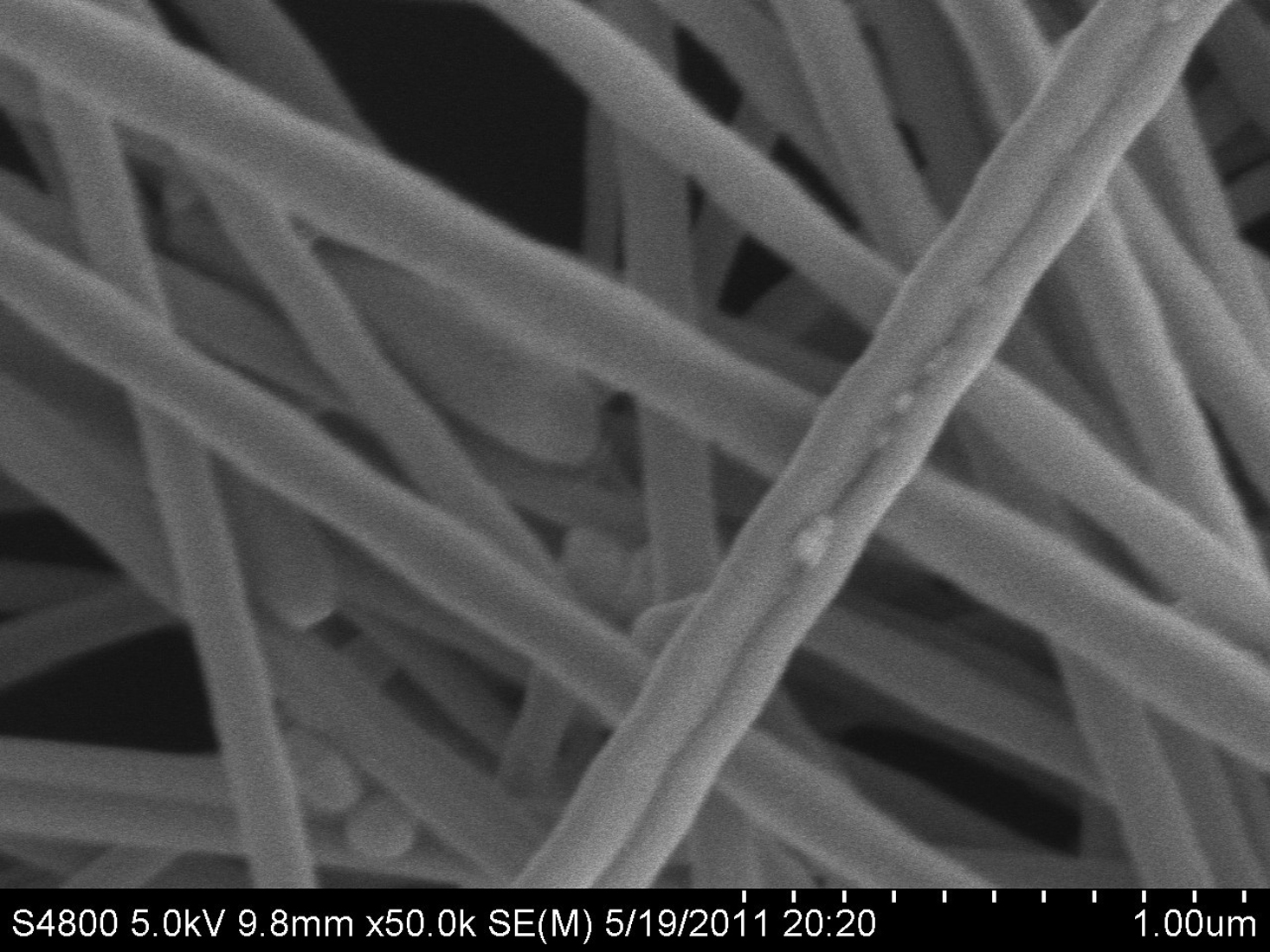

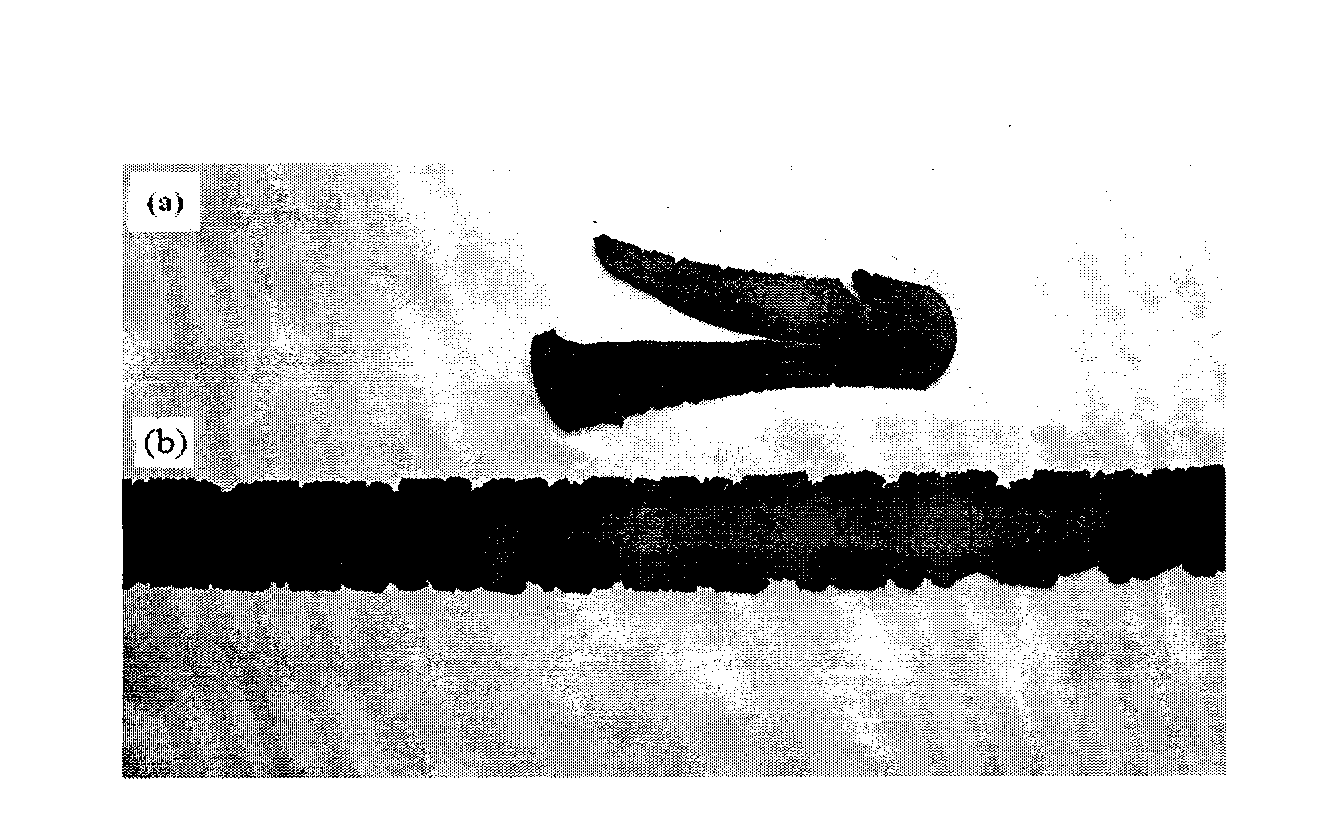

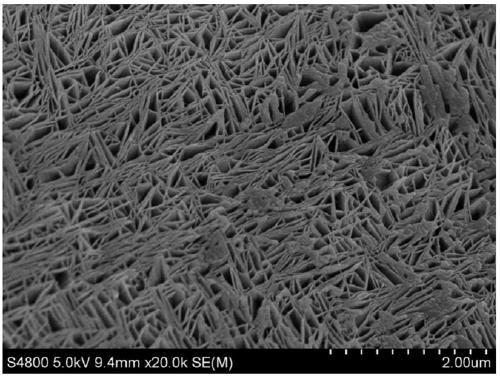

Method for preparing nano-silver wire with high length-diameter ratio

ActiveCN102744417AQuality improvementSimple preparation processPolycrystalline material growthFrom normal temperature solutionsHydrogen NitrateMicrowave method

The invention provides a method for preparing a nano-silver wire with high length-diameter ratio. At least one polyhydroxy liquid organic (1), silver nitrate (2), polyvinylpyrrolidone (PVP) with a K value equal to or larger than 30 (3), at least one hydrogen nitrate compound or one hydrogen-containing compound (4) and at least one chloride for a reaction solution, wherein the chloride can be dissolved in the polyhydroxy liquid organic and can produce chloride ions after dissolved. Reaction is perform for more than 10 minutes under the condition that the reaction temperature is lower than the boiling temperature of the polyhydroxy liquid organic or a part of ingredients is subjected to chemical reaction to form a nano-silver wire solution containing length-diameter ratio exceeding 200, and solid-liquid separation is performed to obtain the nano-silver wire or nano-silver wire dispersing liquid. The nano-silver wire prepared by means of the method is high in length-diameter ratio and yield, few in impurities and good in thickness and length uniformity, and the shortcomings including complicated preparing technology process by means of a traditional polyol method, many impurities and non-uniformity by means of a microwave method and the like are overcome.

Owner:JIANGSU NANOWELL ADVANCED MATERIALS SCI&TECH

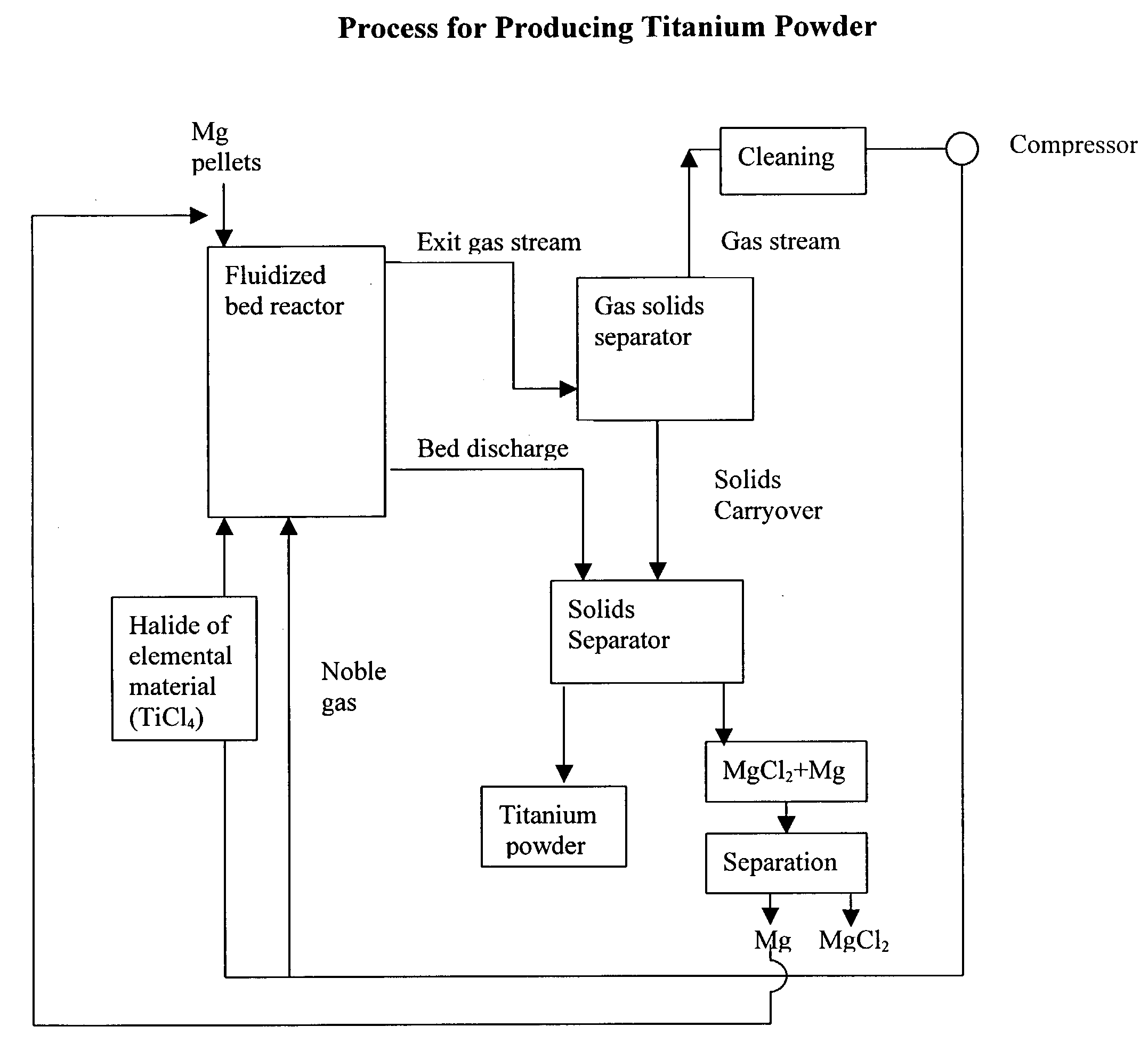

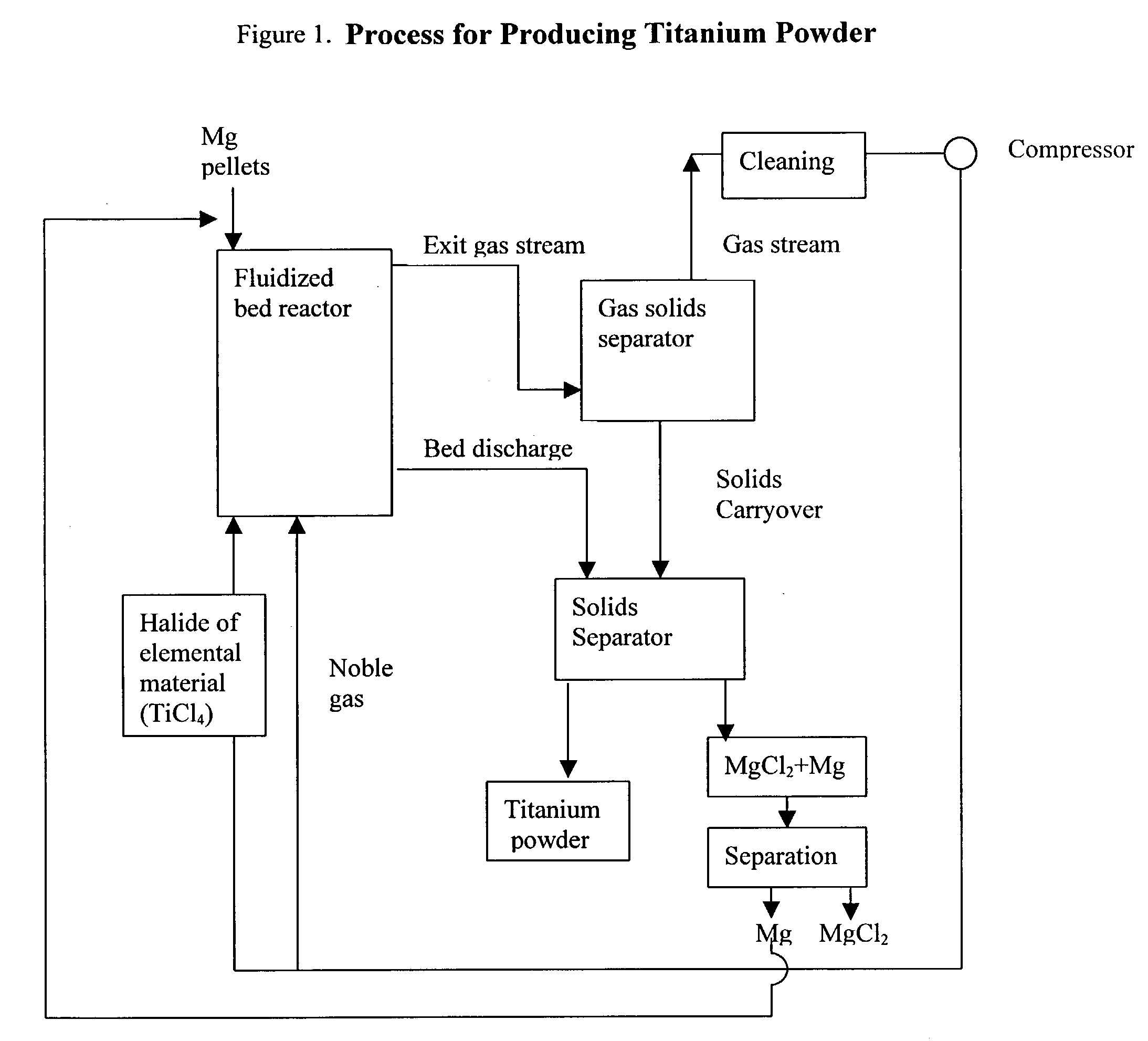

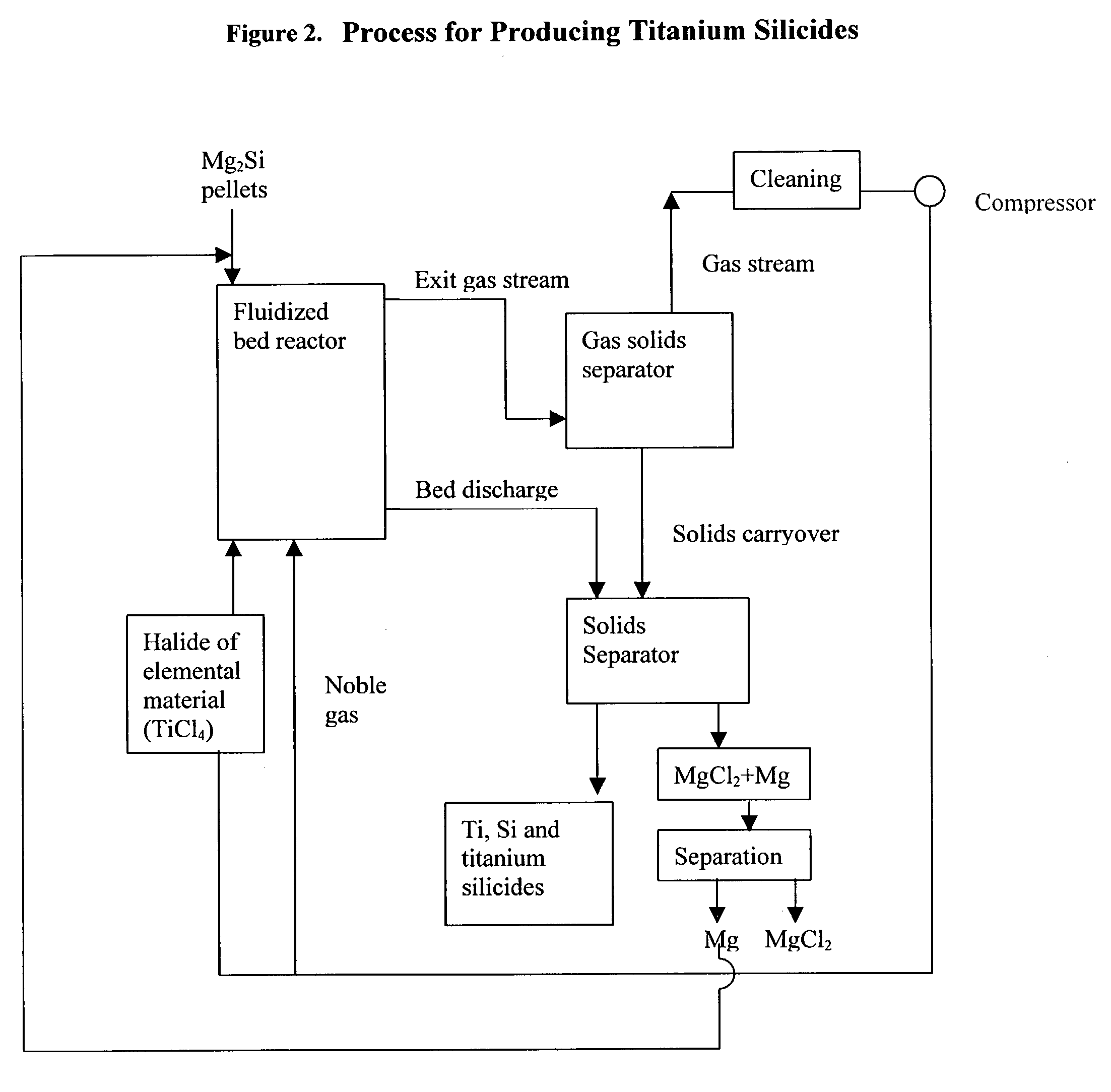

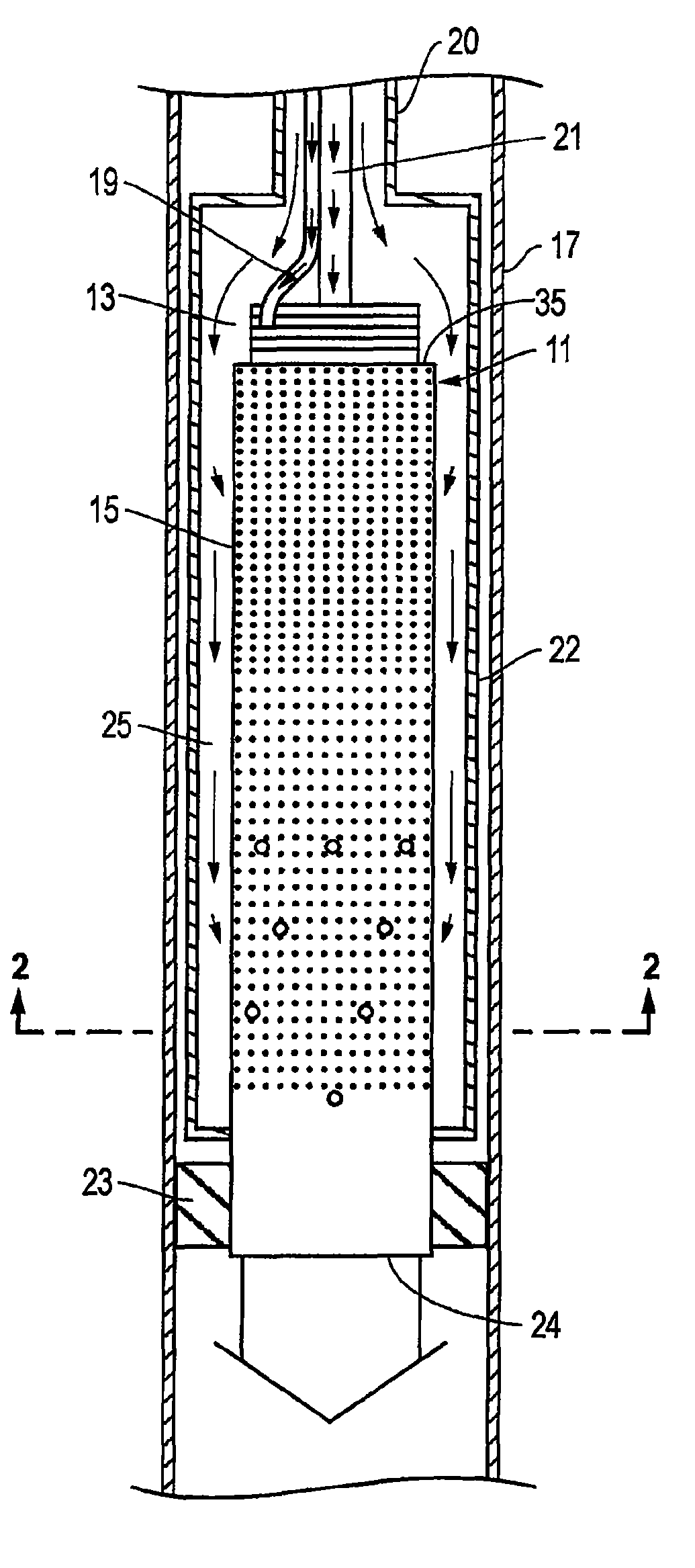

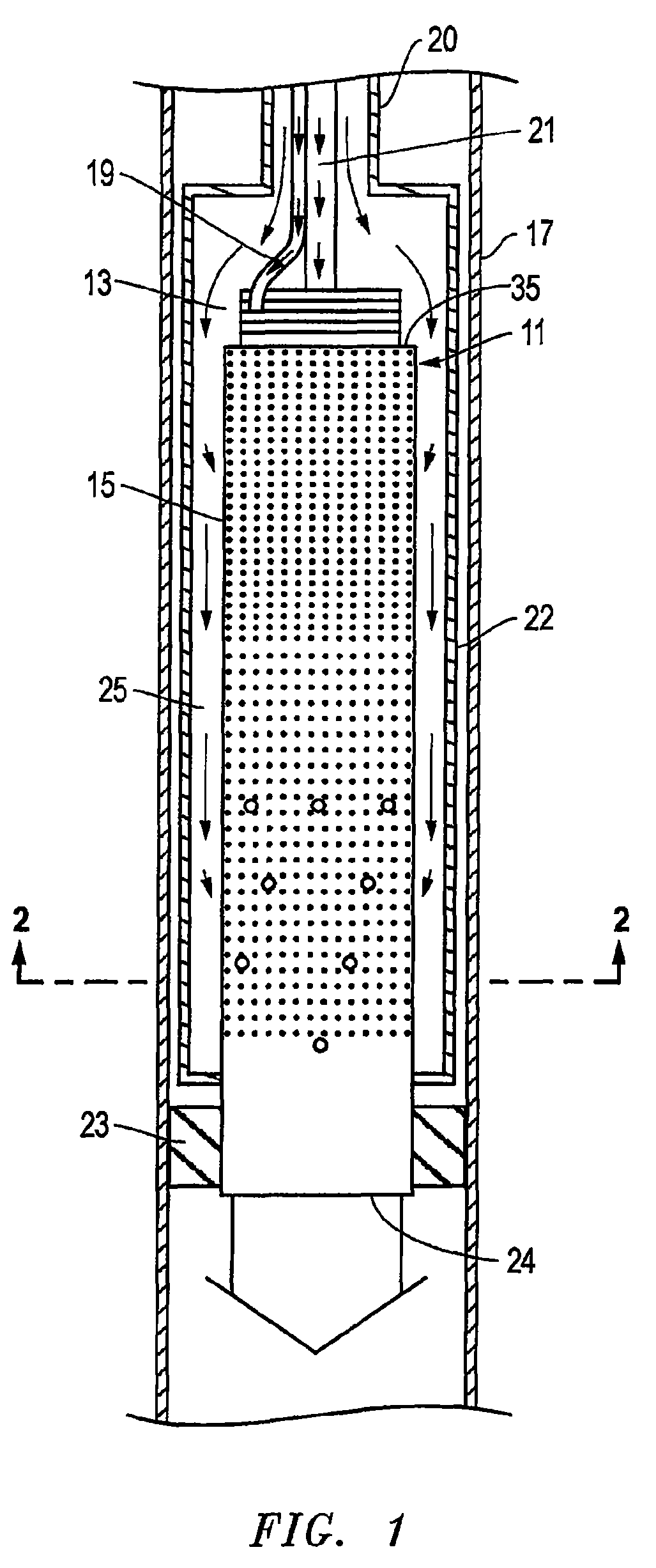

Process for the production of elemental material and alloys

The present invention relates to a process for the production of an elemental material, comprising the step of reacting a halide of the elemental material with a reducing agent in solid form in a fluidized bed reactor at a reaction temperature which is below the melting temperature of the reducing agent. In a preferred embodiment of the present invention, the elemental material is titanium and the titanium is produced in powder form. The invention also relates to the production of alloys or intermetallics of the elemental materials.

Owner:MILLENNIUM INORGANIC CHEM

Process for dispersing nanocatalysts into petroleum-bearing formations

Owner:WORLD ENERGY SYST

Water soluble humic acid multi-element solid fertilizer and production method thereof

InactiveCN101570456ADissolve fastNot easy to agglomerateAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersSoil scienceWater soluble

The invention discloses a water soluble fertilizer and a production method thereof, in particular to a water soluble humic acid multi-element solid fertilizer and a production method thereof. The water soluble humic acid multi-element solid fertilizer is made by mixing water soluble humic acid, water soluble nitrogenous fertilizer, water soluble phosphorous fertilizer, water soluble potassic fertilizer and water soluble complex trace elements. Compared with the prior art, the water soluble humic acid multi-element solid fertilizer can reduce the transporting and packing cost, can be rapidly dissolved without agglomeration when in use, is applied along with water, and has the advantages of strong points, high nutrient content, complete nutrition, good water-solubility, combination of organic and inorganic matters as well as high effect of fertilizer and utilization rate. The utilization rate of product nitrogen reaches 60%, the utilization rate of phosphorus is 30-35%, and the utilization rate of potassium is 60-70%, so that the fertilizer application utilization rate is increased by more than 10% compared with the conventional fertilizer.

Owner:新疆三赢农业科技发展有限公司

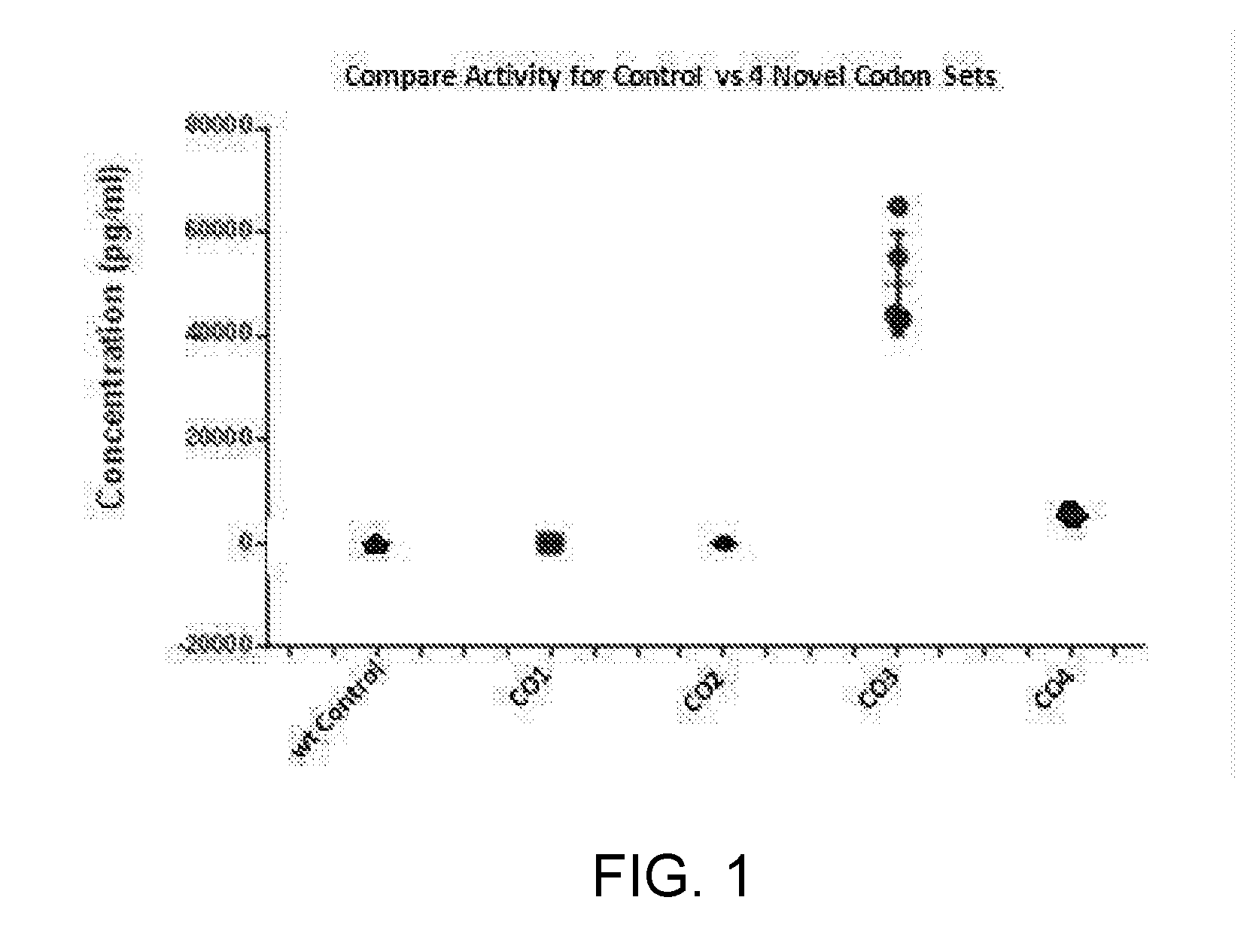

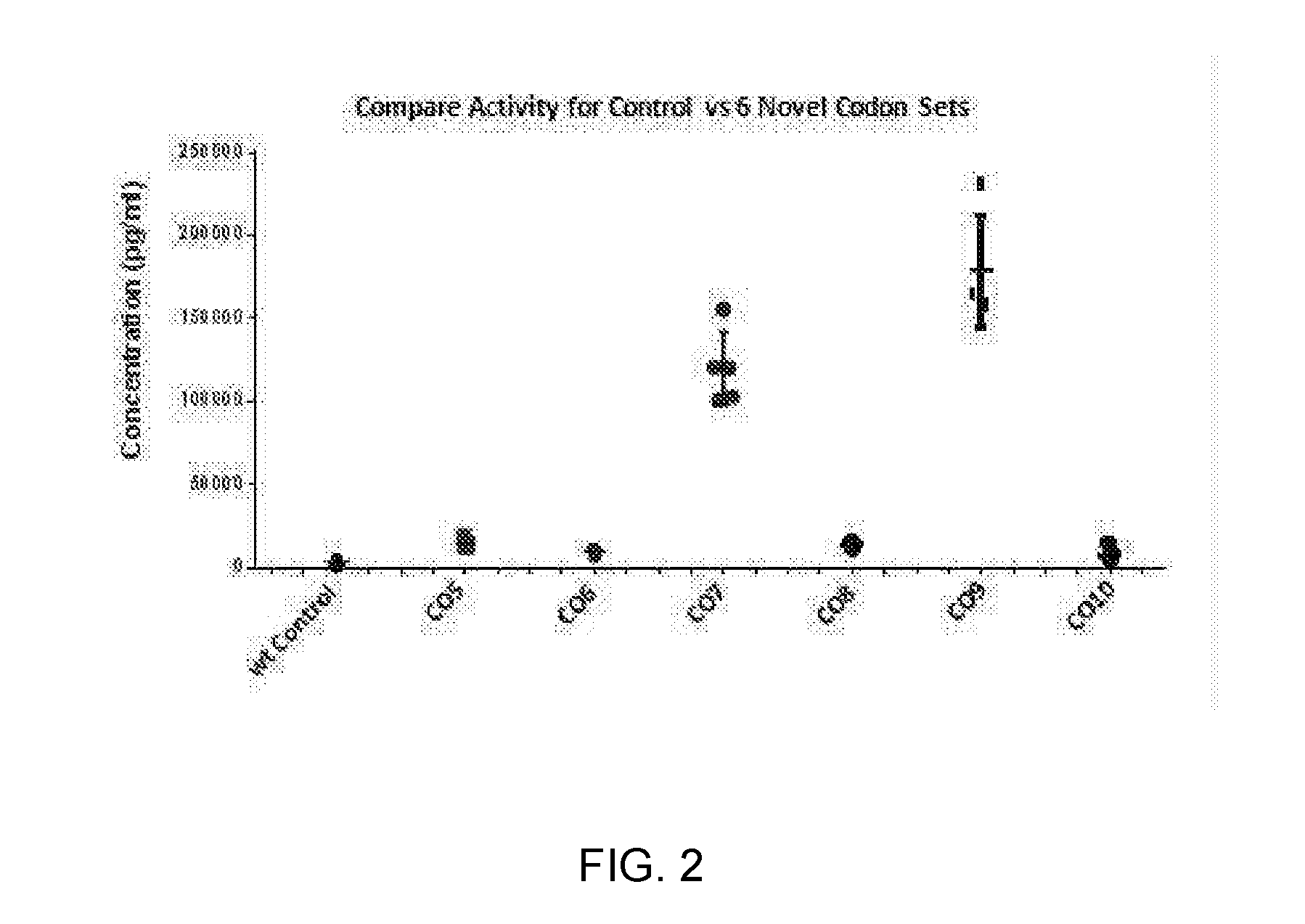

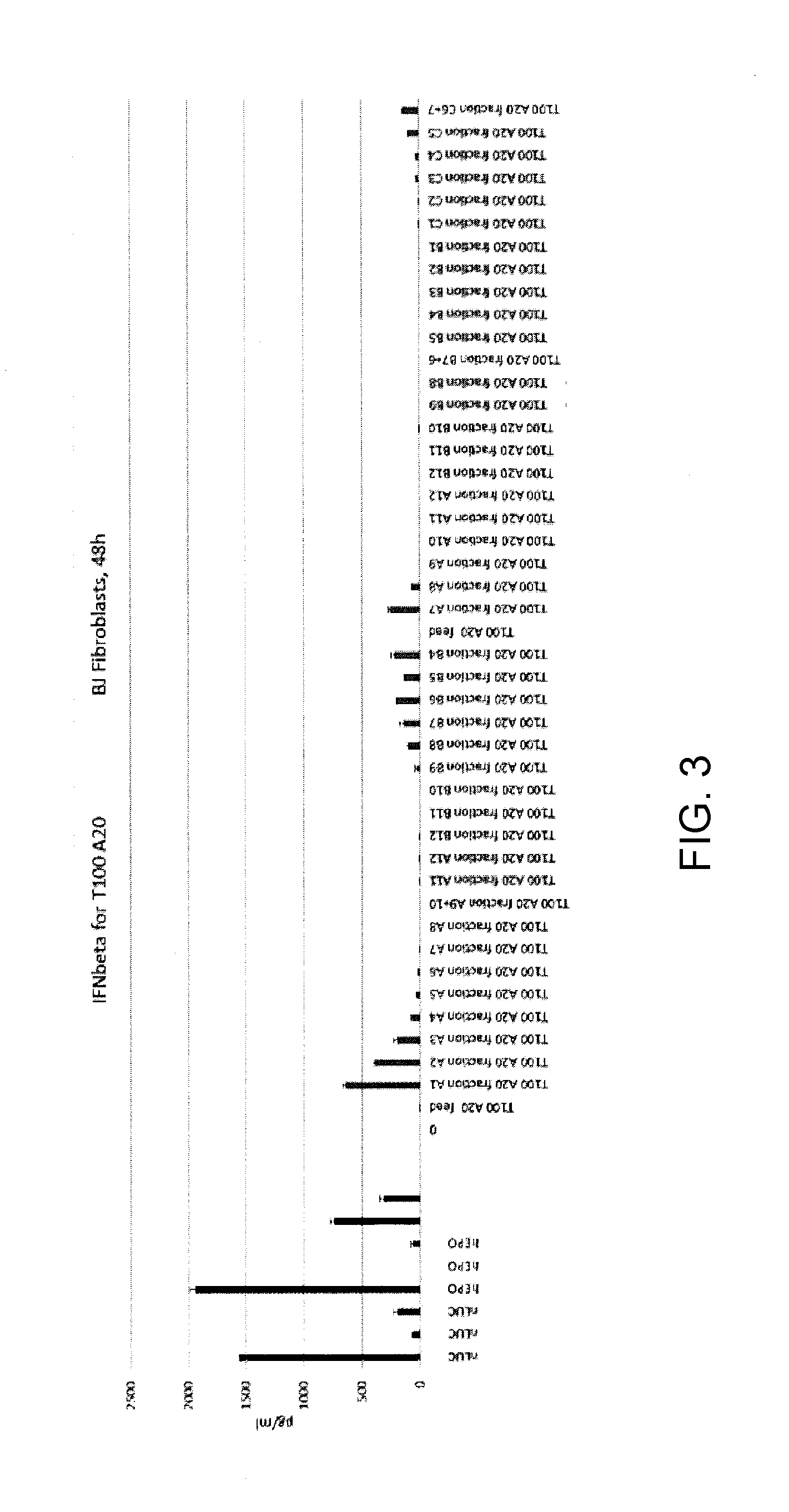

Alternative nucleic acid molecules containing reduced uracil content and uses thereof

ActiveUS20160237134A1Low immunogenicityEnhance protein expressionDepsipeptidesOxidoreductasesBiotechnologyUracil

The present disclosure provides alternative nucleosides, nucleotides, and nucleic acids, and methods of using them. In some aspects, the disclosure provides mRNA wherein the uracil content has been modified and which may be particularly effective for use in therapeutic compositions, because they may benefit from both high expression levels and limited induction of the innate immune response. In some aspects, the disclosure provides methods for the production of pharmaceutical compositions including mRNA without reverse phase chromatography.

Owner:MODERNATX INC

Method for preparing length-diameter-ratio nano-silver wire by pH-value regulation solvothermal method

The invention relates to a method for preparing a length-diameter-ratio nano-silver wire by a pH-value regulation solvothermal method. The method comprises the following steps of: preparing the following ethylene glycol solution, namely an ethylene glycol solution A of silver nitrate or silver acetate, an ethylene glycol solution B of polyvinyl pyrrolidone (PVP), an ethylene glycol solution C of water-soluble chloride and concentrated acid D; mixing the components according to a certain amount and fully stirring to form a final mixed solution; moving the final mixed solution into a reaction kettle; placing in an oven for reaction for a certain time; taking the reaction kettle out and cooling to room temperature to obtain mother liquid of the nano-silver wire; adding alcohol into the mother liquid for diluting, and removing supernatant liquor to obtain a precipitate; and repeatedly performing centrifugal separation, and thus obtaining nano-silver wire dispersion liquid uniformly dispersed in the alcohol. The method is simple, high in efficiency and low in cost, and can prepare high-quality nano-silver wires within a wider range of reaction condition; and prepared products are high in length-diameter ratio, good in length uniformity and low in impurity content.

Owner:JIANGSU NANOWELL ADVANCED MATERIALS SCI&TECH

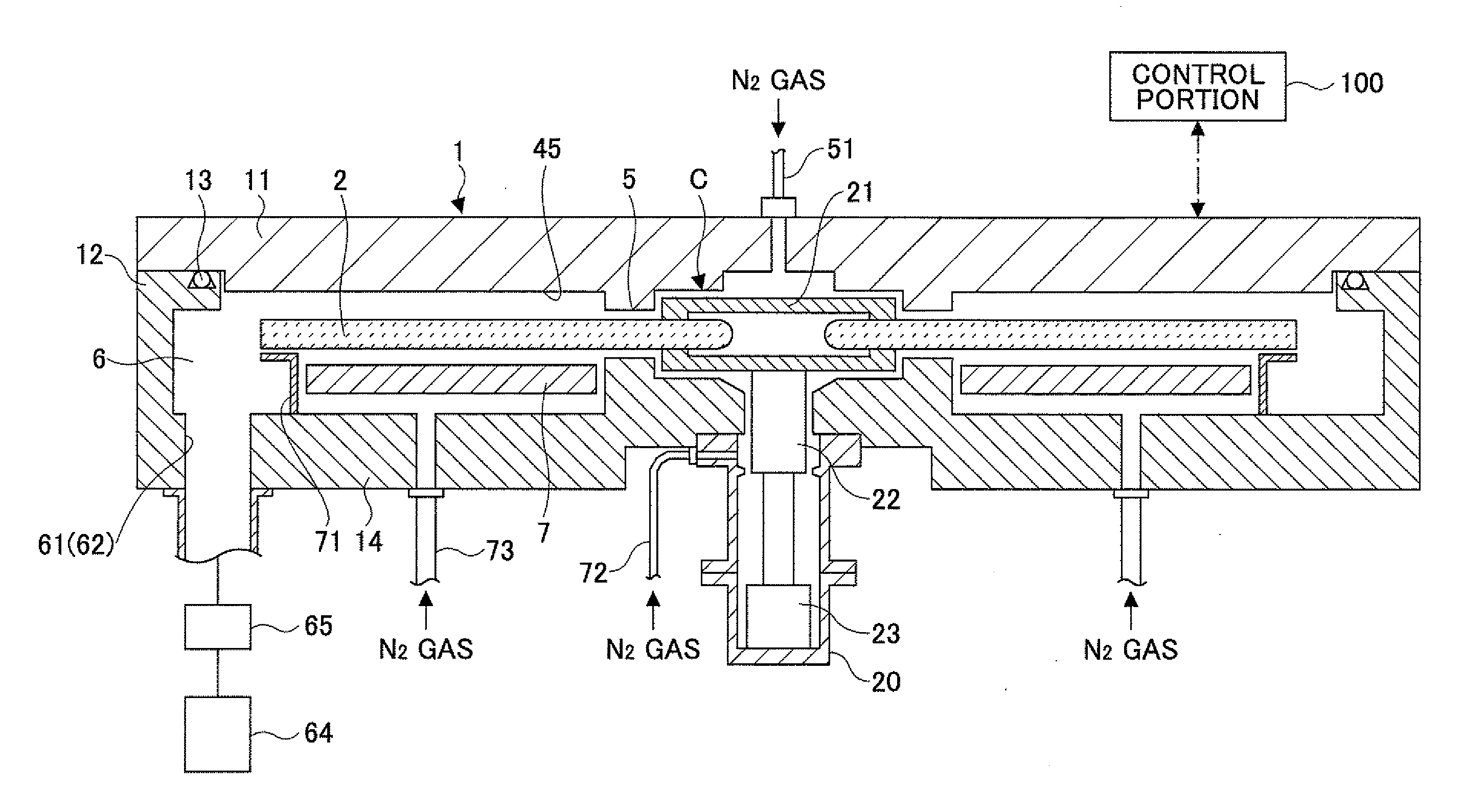

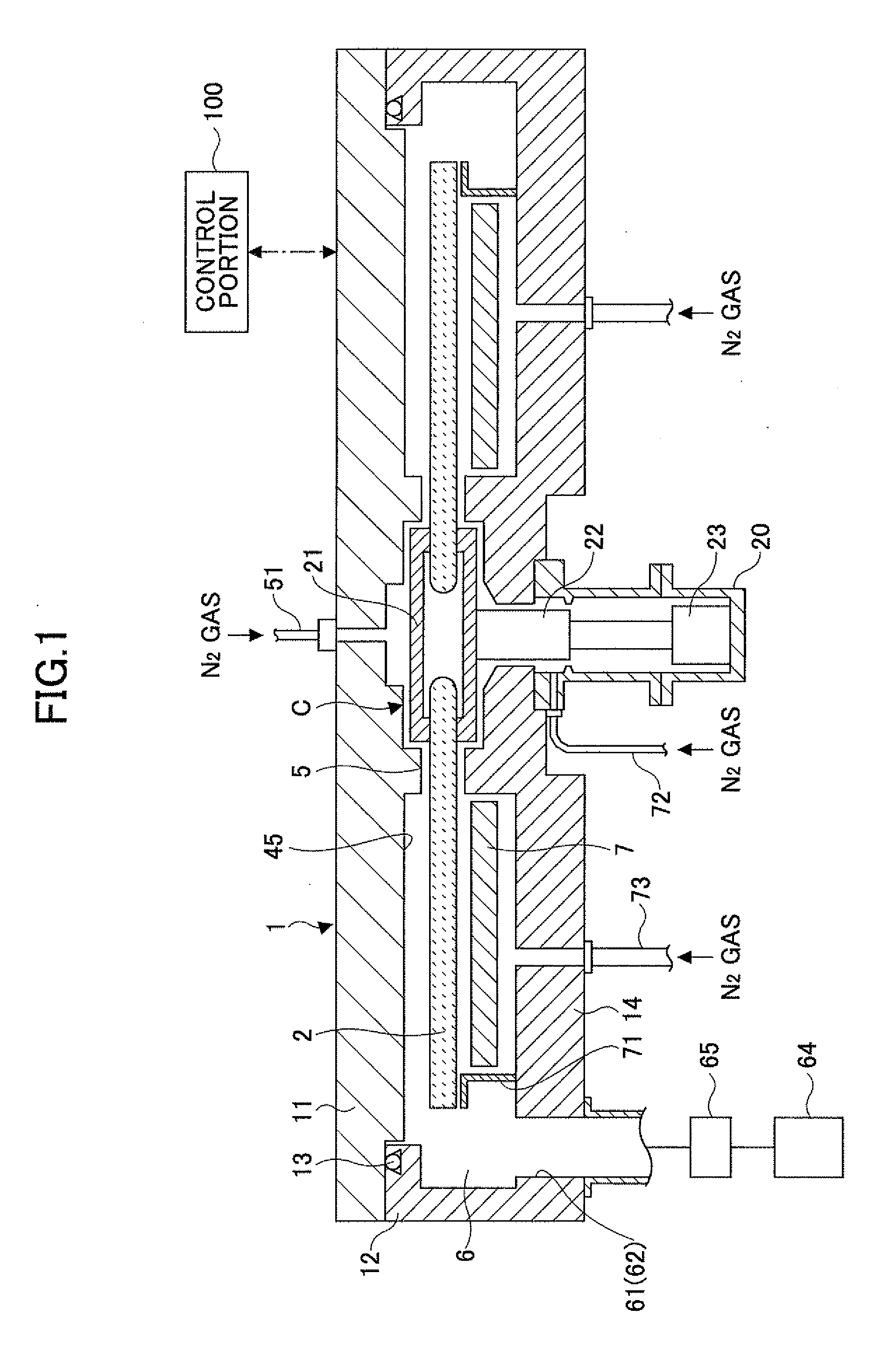

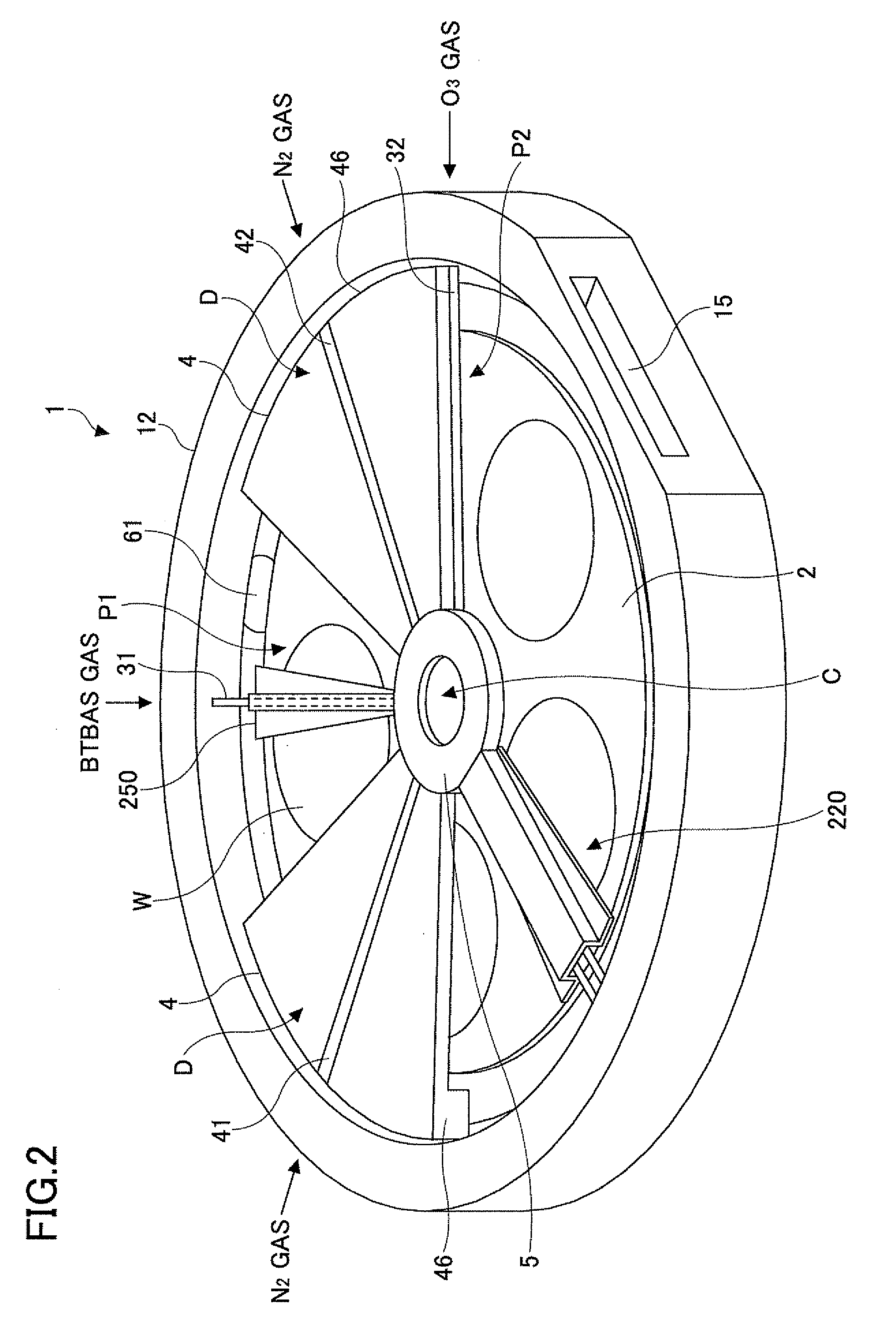

Film deposition apparatus, film deposition method, and computer readable storage medium

InactiveUS20110039026A1Uniform film thickness and film propertyLess impuritiesVacuum evaporation coatingSputtering coatingInjectorEngineering

A silicon oxide film is deposited by rotating a rotation table on which a wafer W is placed to allow BTBAS gas to be adsorbed on an upper surface of the wafer W and supply a O3 gas to the upper surface of the wafer W for allowing the BTBAS gas adsorbed on the upper surface of the wafer W to react. After depositing the silicon oxide film, a reforming process is performed every deposition cycle by supplying a plasma of Ar gas to the silicon oxide film on the wafer from an activated gas injector.

Owner:TOKYO ELECTRON LTD

Method of preparing walnut polypeptide powder

InactiveCN101228918ALess impuritiesAnti-fatigueMetabolism disorderProtein composition from vegetable seedsEnzymatic hydrolysisCentrifugation

The invention relates to a preparation method of a walnut peptide powder, which effectively embodies a plurality of biological functional properties of the walnut peptide powder, reserves a plurality of nutritional components of walnuts. The polypeptide content in the walnut peptide powder is 60-80 percent, while the walnut peptide powder is light yellow or yellow-white color and has functions of anti-fatigue and antioxidation, etc. The invention comprises the following operation steps: crushing the walnut cakes before extracting the walnut protein, then carrying out enzymatic hydrolysis and centrifugation to the crude walnut protein to acquire the supernatant, dialyzing the supernatant and removing impurities and macromolecular compounds, and then concentrating the acquired dialysate, and at last vacuum drying to prepare the walnut peptide powder and packing into finished products.

Owner:NORTHWEST A & F UNIV +1

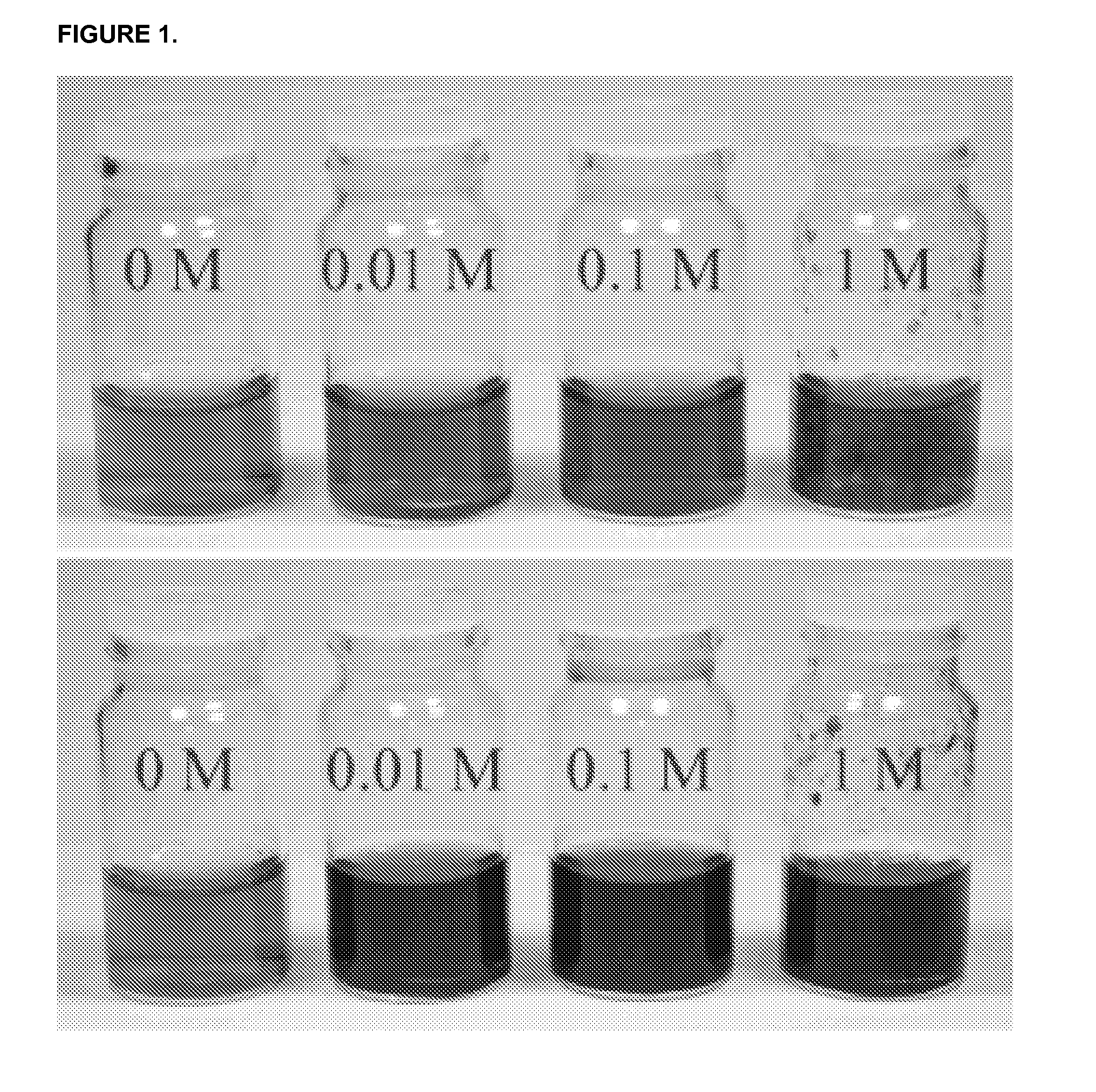

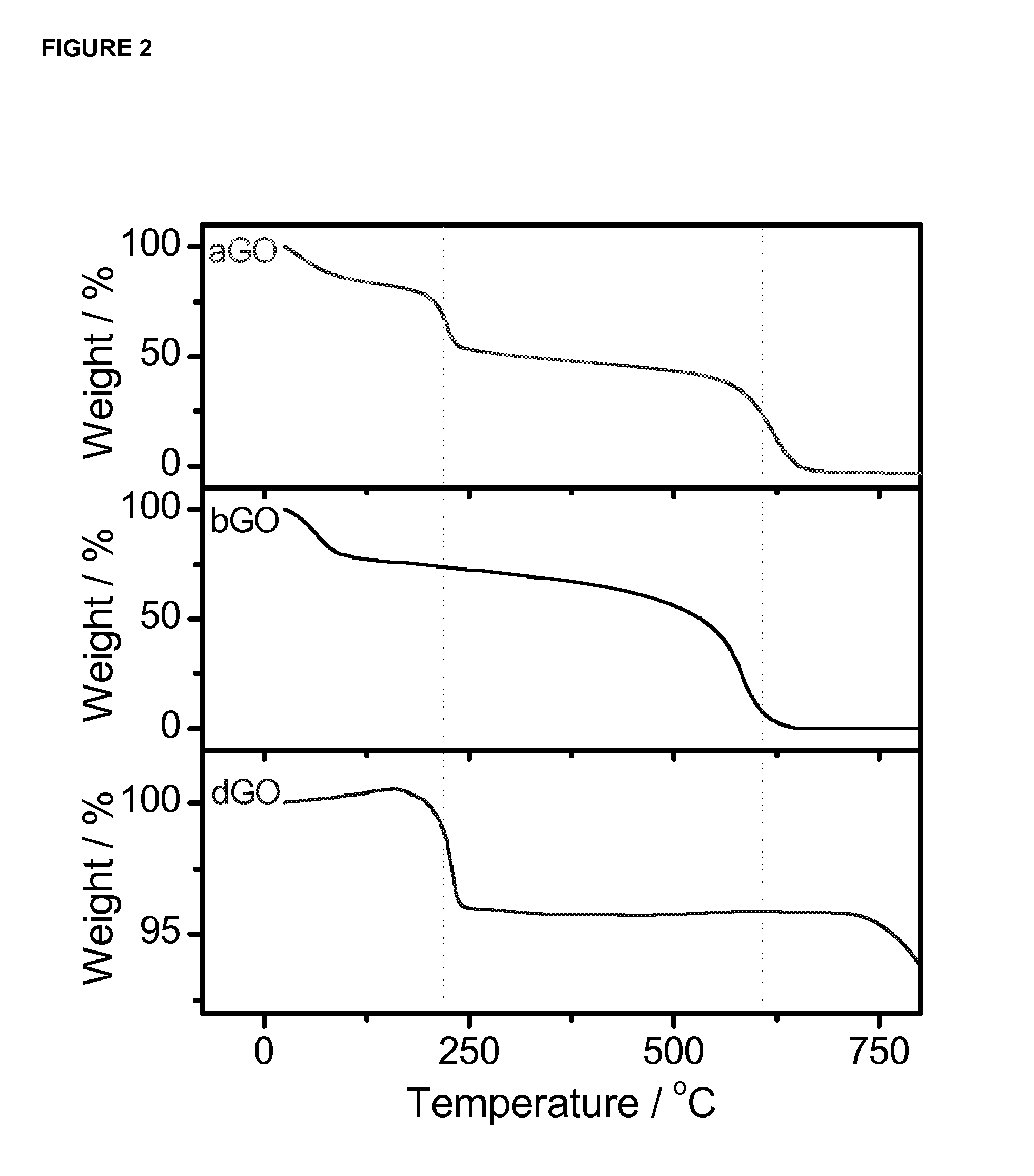

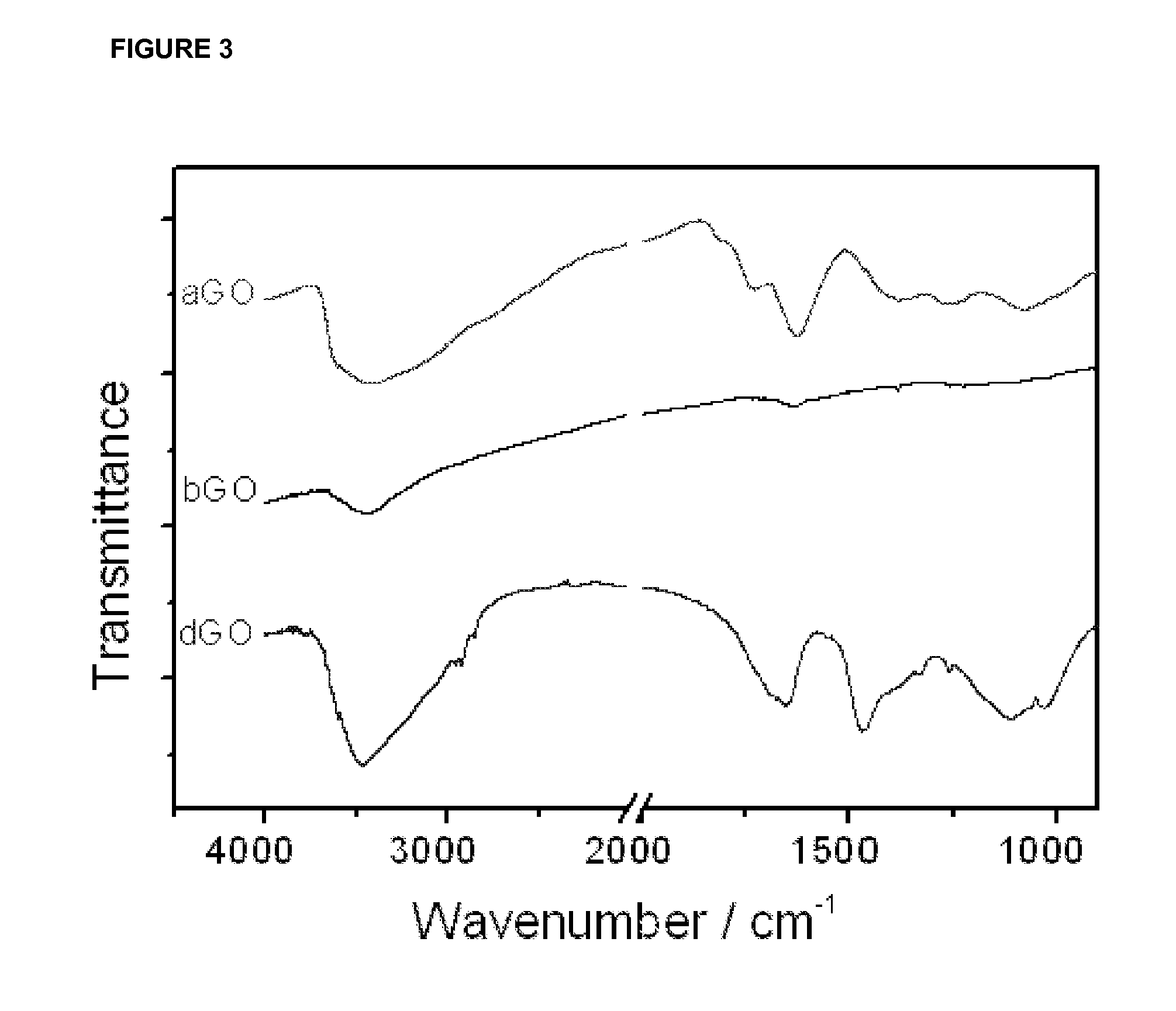

Method of producing graphene oxide and its uses

InactiveUS20130190449A1High yieldHigh purityMaterial nanotechnologyOrganic chemistryOxygenCvd graphene

This invention relates to a method for the production of graphene oxide and its use in various applications. The invention provides a method for the preparation of graphene oxide which involves treating a mixture of graphene oxide and impurities with a solution of a base. The impurities in the graphene oxide include oxygen-containing species that are associated with it i.e. bound to the graphene oxide but which are not covalently bonded to the graphene. The graphene oxide of the present invention has improved purity relative to the poorly characterised graphene oxide that is produced by existing methods.

Owner:KINLOCH IAN +3

Method for preparing and transferring graphene transparent film

ActiveCN102719803AIncrease contactNo crackGrapheneChemical vapor deposition coatingElectrochemistryCvd graphene

The invention discloses a method for preparing and transferring a graphene transparent film. The technical problem required be solved is that impurities, cracks and bumps after the graphene transparent film is transferred are required to be reduced. The preparing and transferring method disclosed by the invention comprises the steps of: carrying out chemical vapor deposition on the graphene film on a metal substrate, coating methyl methacrylate or photoresist to form a support layer; electrolyzing the graphene film and separating the metal substrate; and coating the methyl methacrylate or photoresist on the support layer, putting the support layer into acetone solution, and attaching the graphene film to an appointed substrate. Compared with the prior art, the film composed of the graphene film and the support layer is separated from the metal substrate by an electrochemical foaming method; the graphene film is transferred to an appointed substrate and then the graphene film well contacts the plane of the appointed substrate without the cracks by spin coating for second time; the metal substrate can be repeatedly used, and the cost of preparation of the graphene transparent film is reduced; the transferred graphene film is well contacted with the substrate, and the impurities are relatively few.

Owner:BTR NEW MATERIAL GRP CO LTD

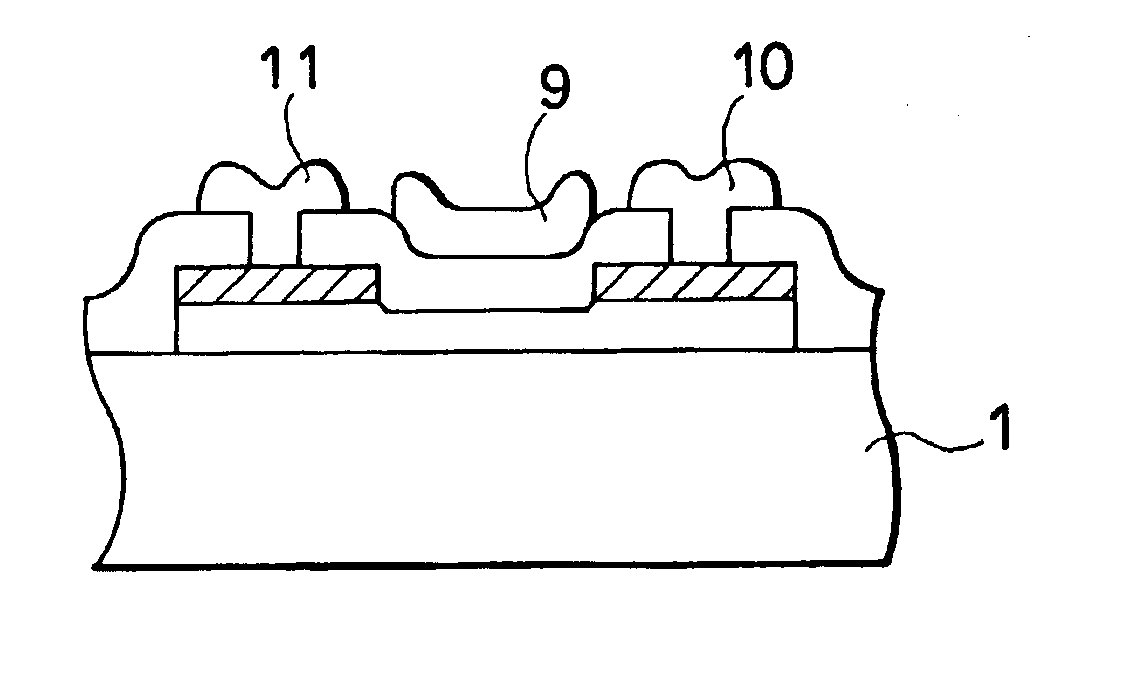

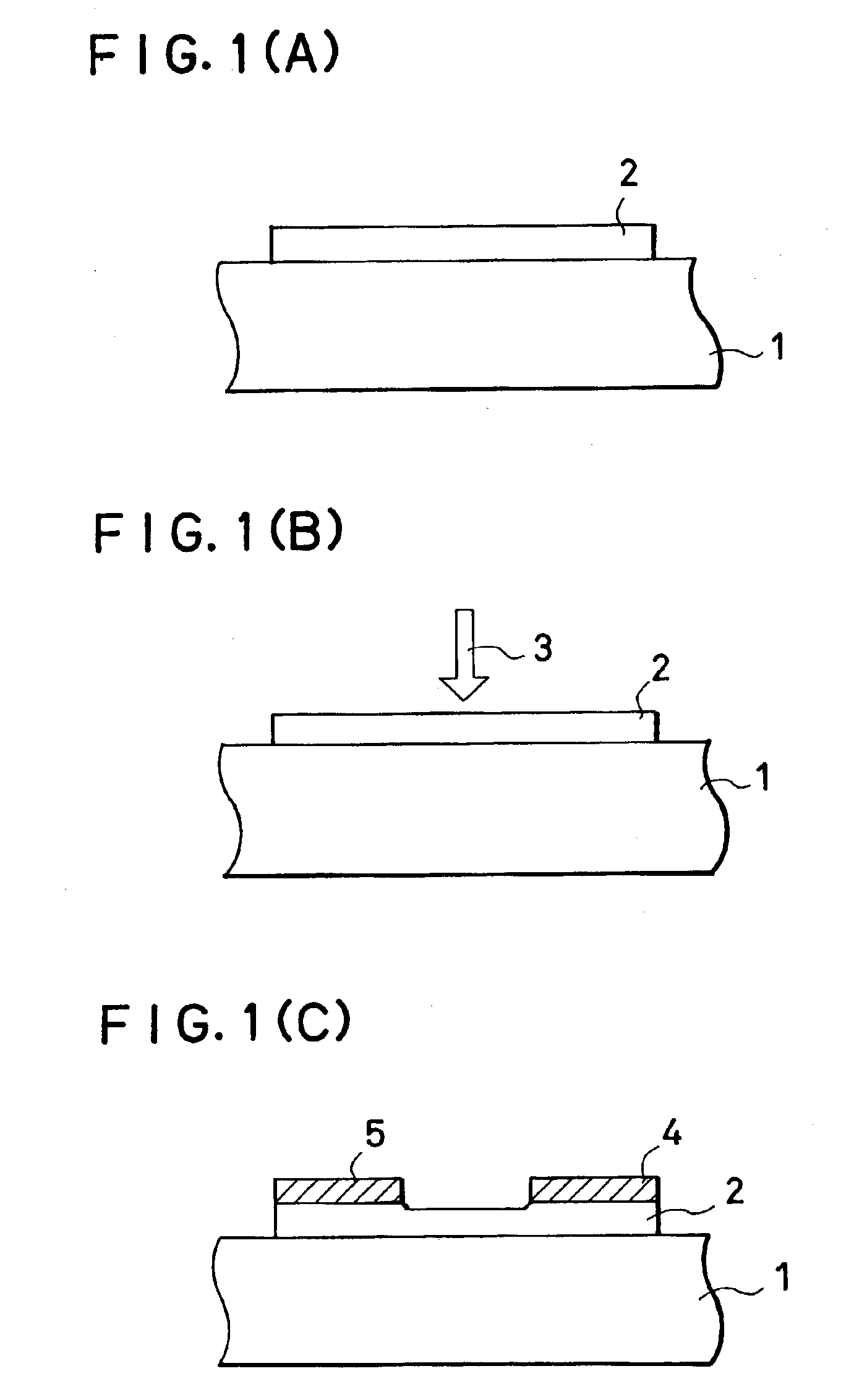

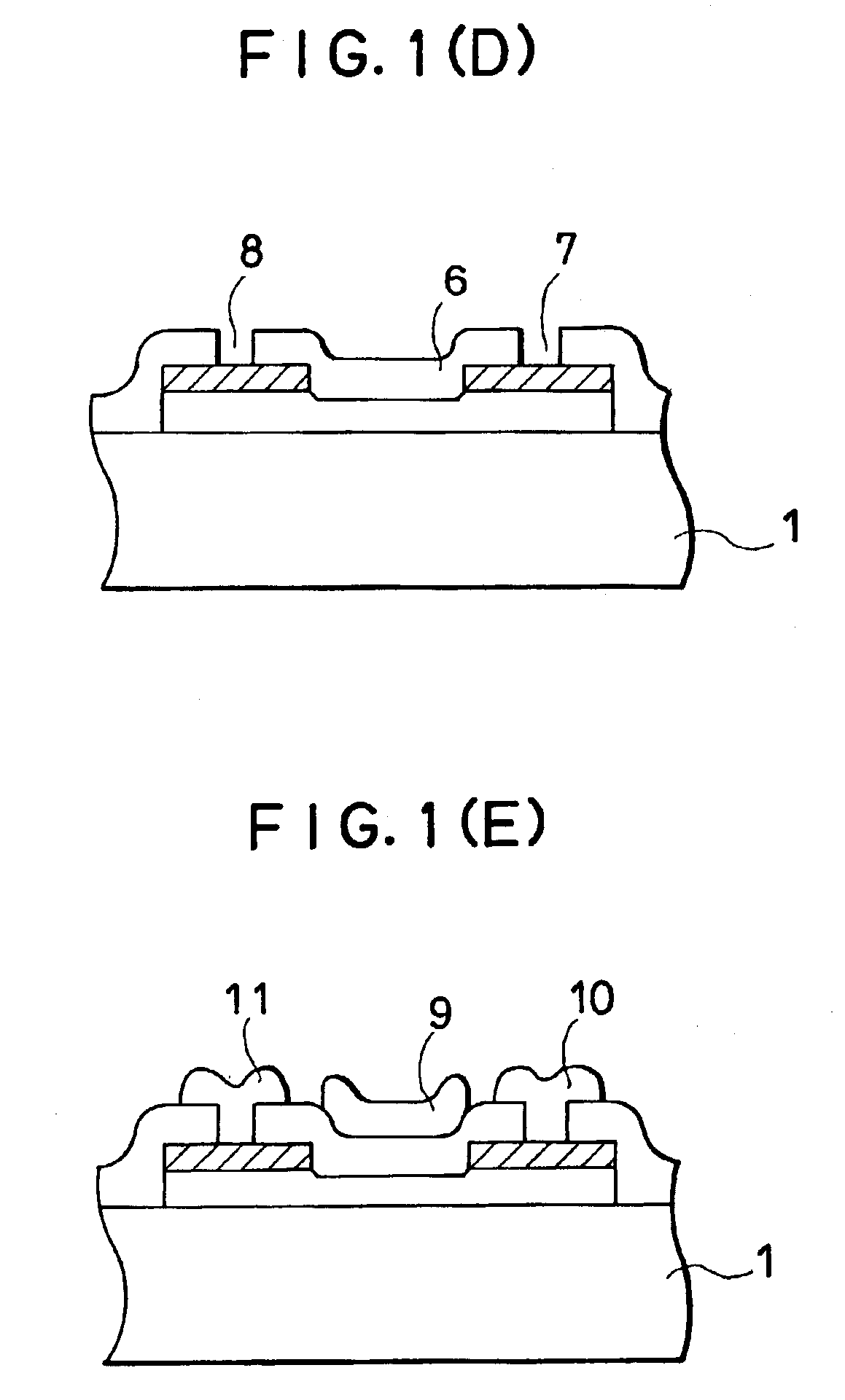

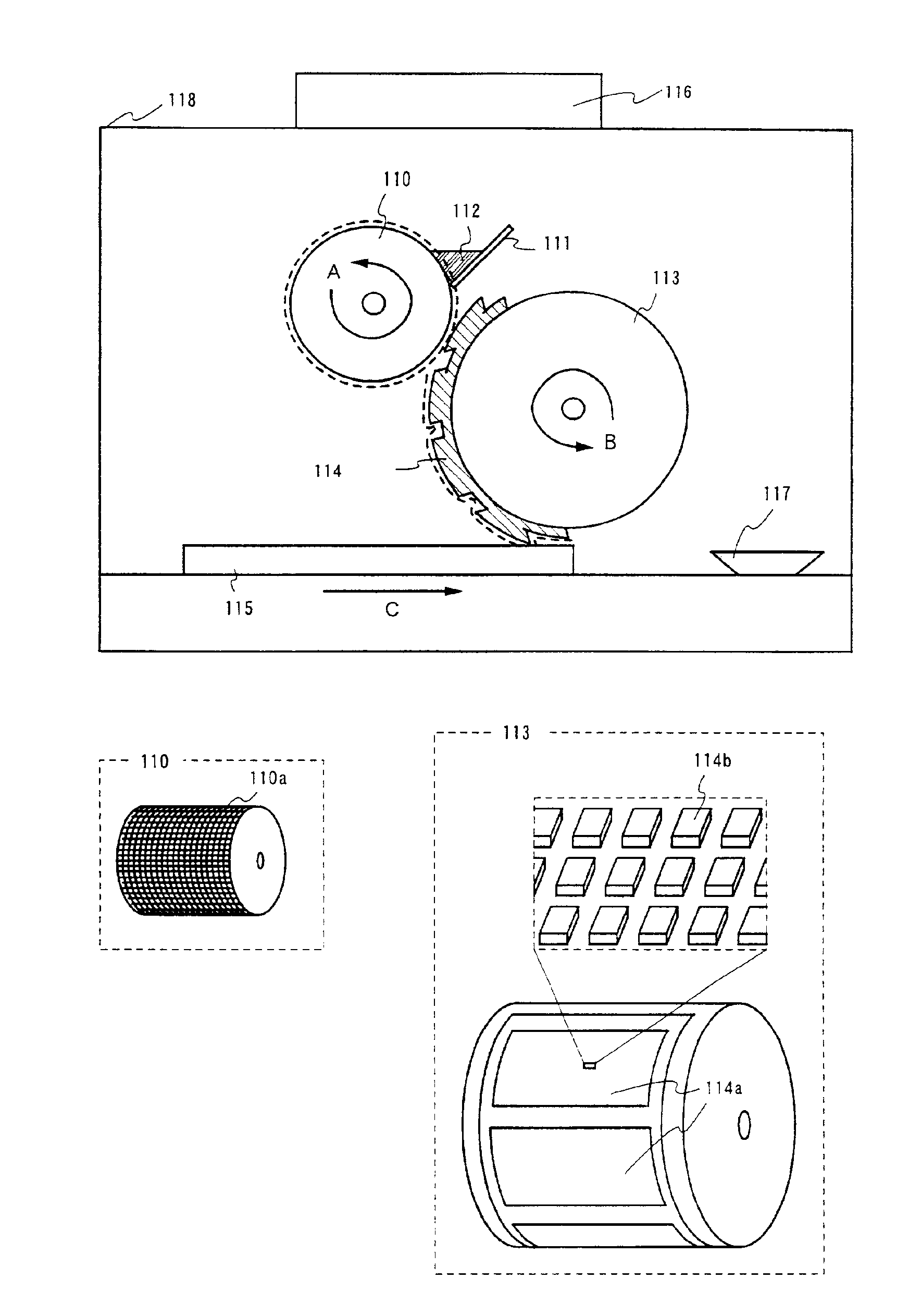

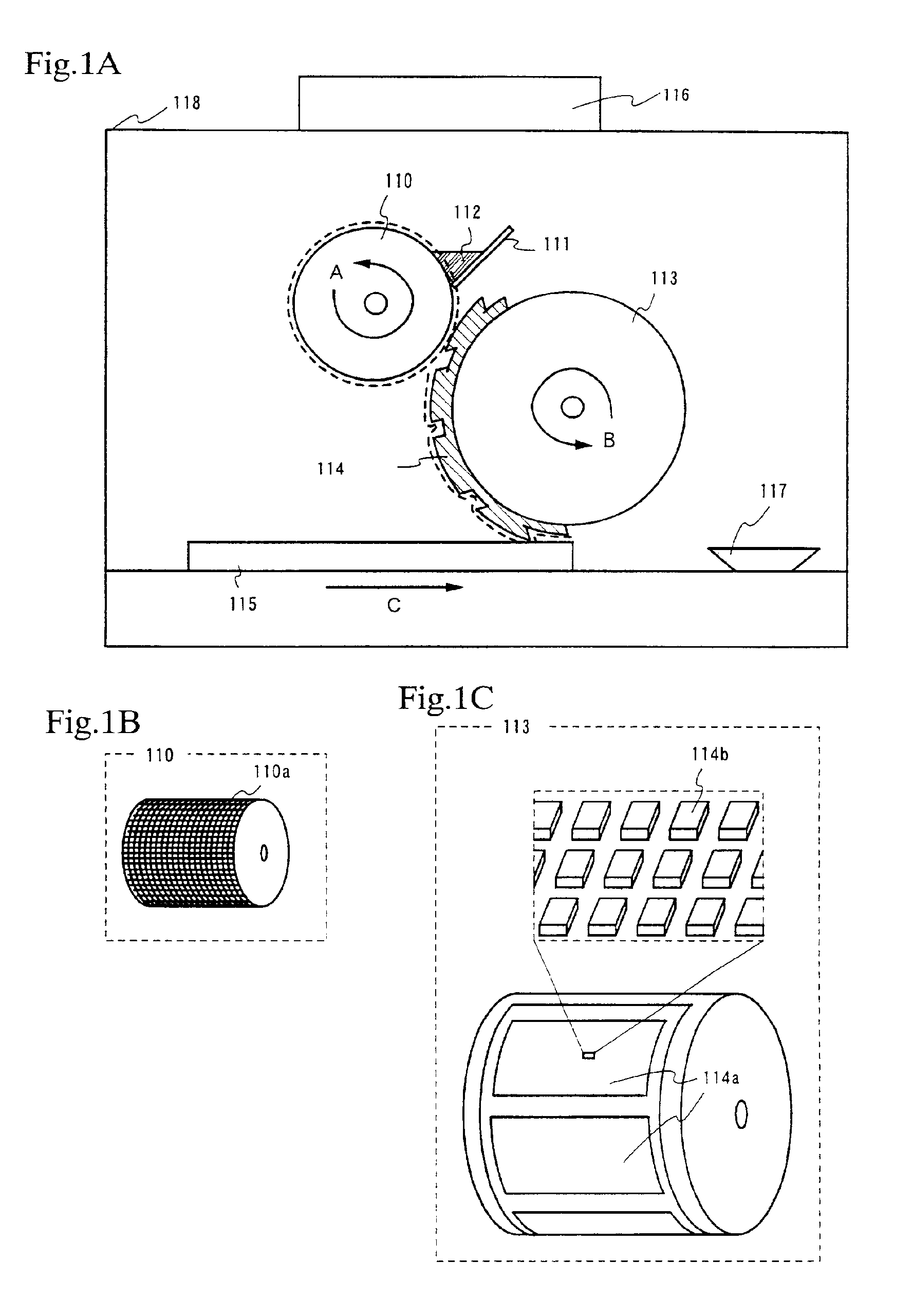

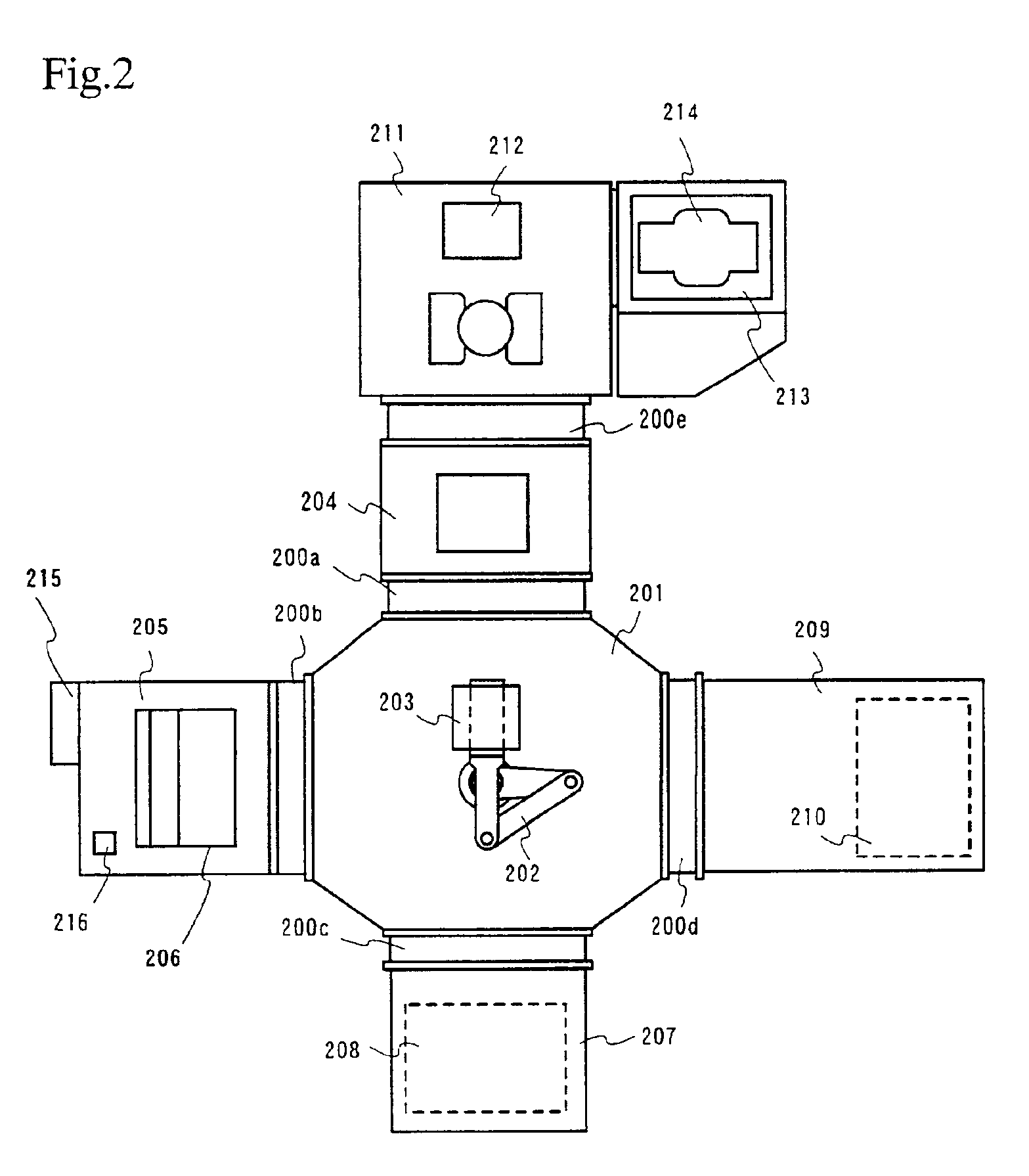

Film forming apparatus and method of manufacturing light emitting device

InactiveUS6940223B2Easy maintenanceLow light emitting efficiencyDischarge tube luminescnet screensLamp detailsSolventAtmospheric pressure

The problem regarding volatileness of a solvent in an EL forming material, which occurs in adopting printing, are solved. An EL layer is formed in a pixel portion of a light emitting device by printing. Upon formation of the EL layer, a printing chamber is pressurized to reach a pressure equal to or higher than the atmospheric pressure, and the printing chamber is filled with inert gas or set to a solvent atmosphere. Thus the difficulty in forming an EL layer by printing is eliminated.

Owner:SEMICON ENERGY LAB CO LTD

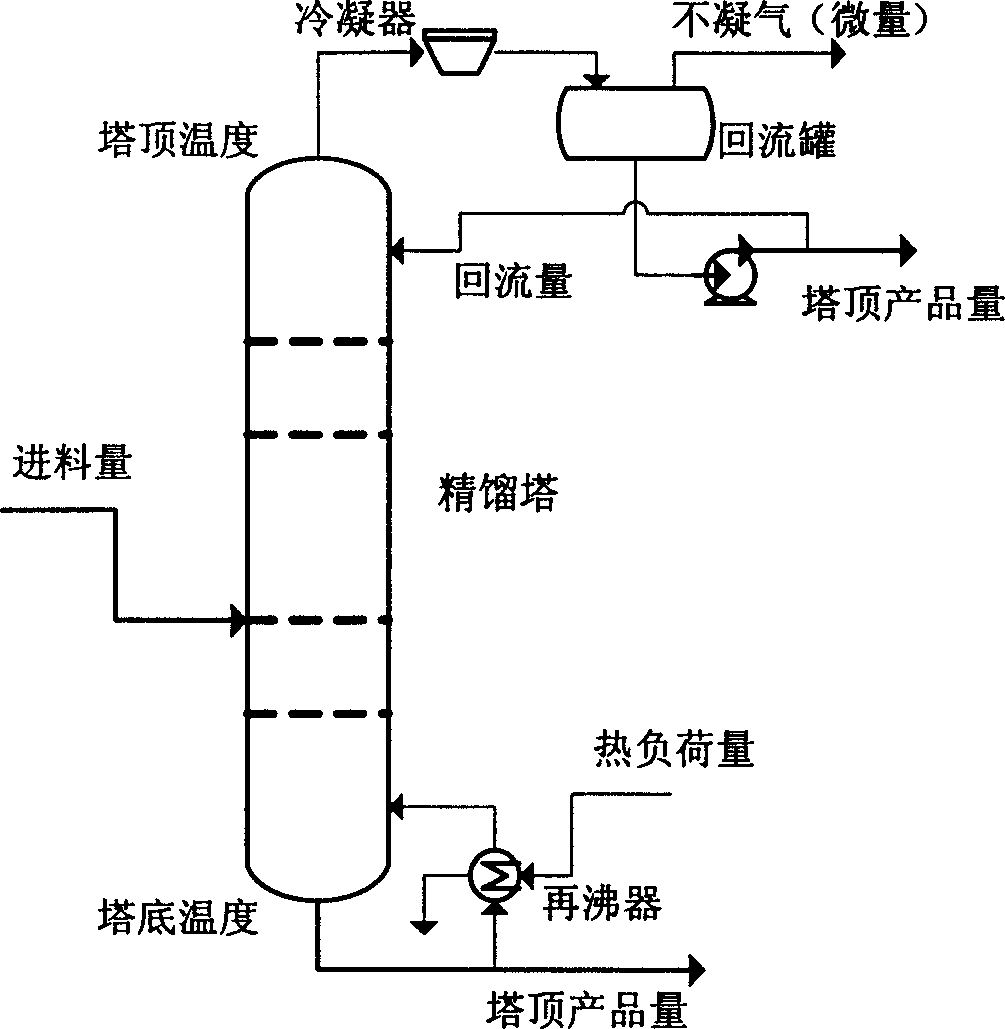

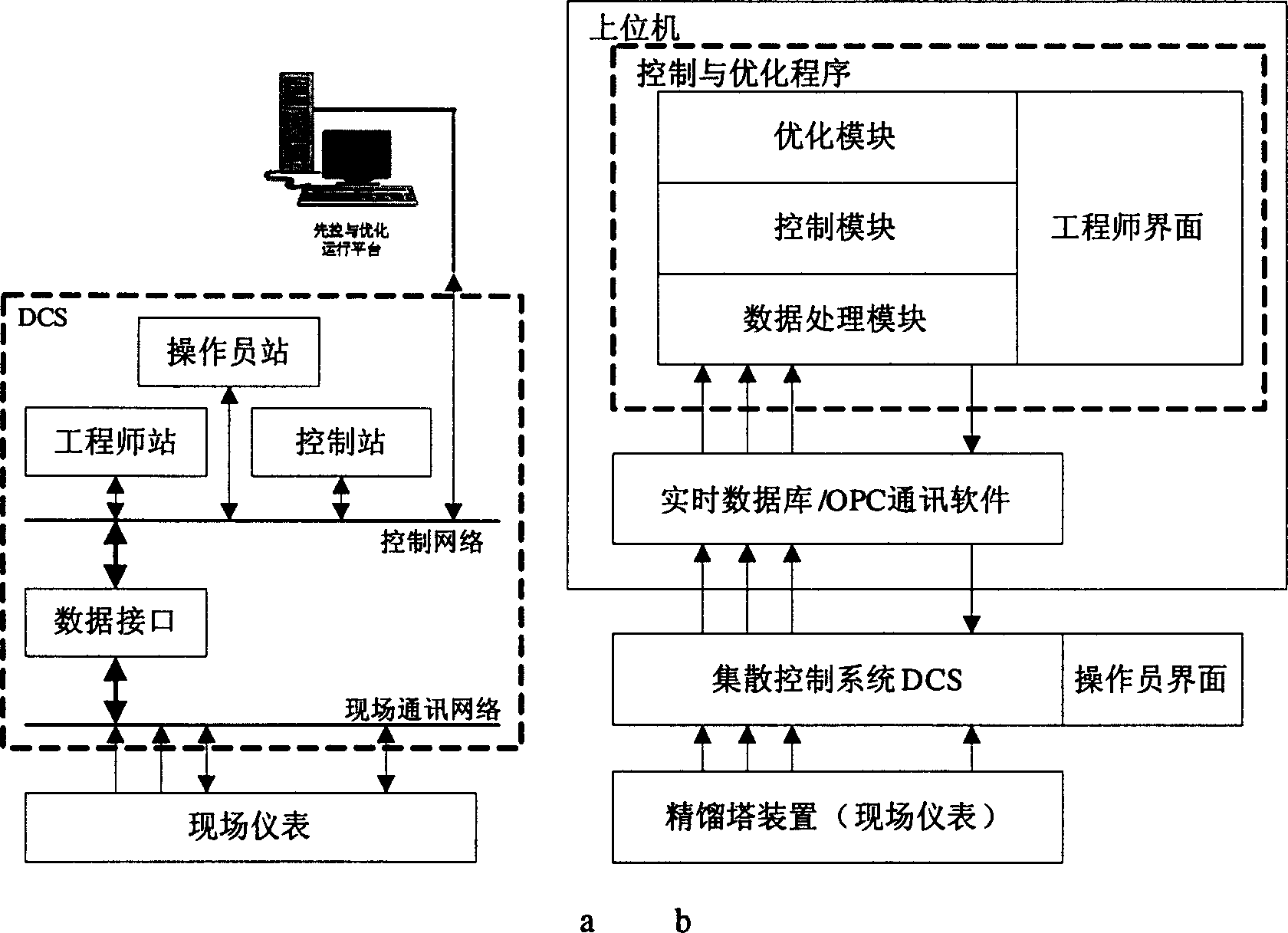

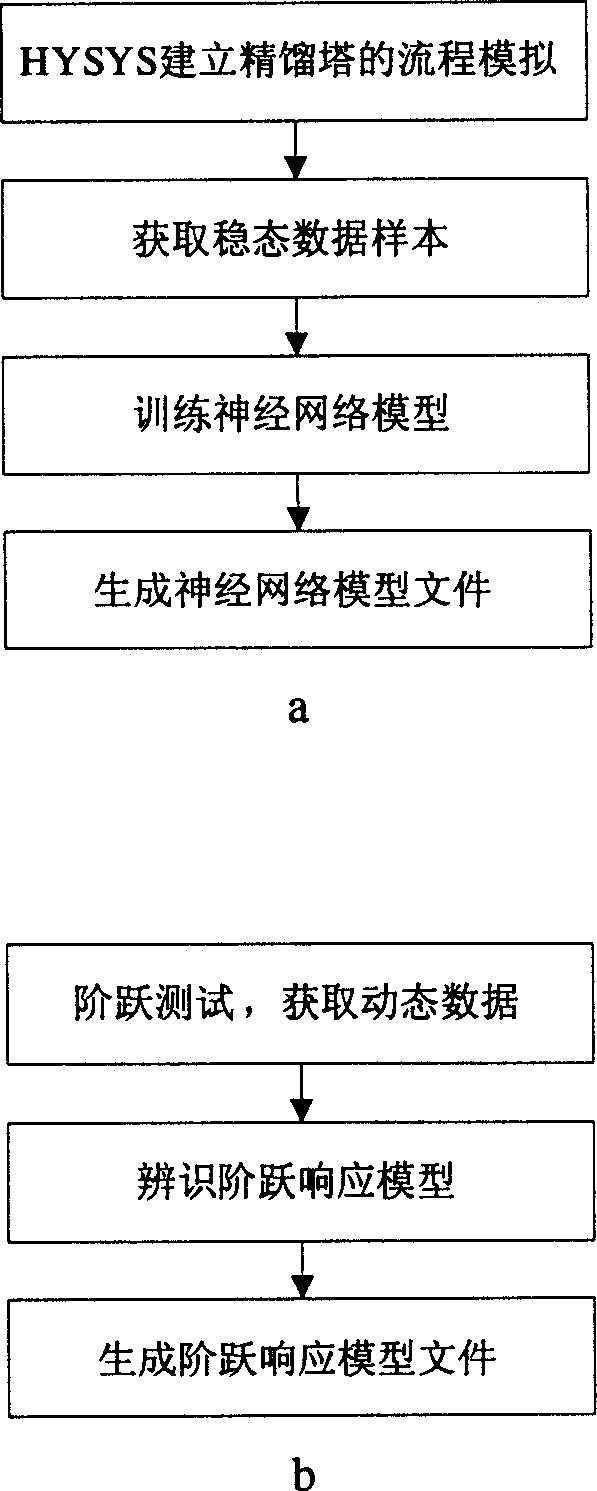

Rectification tower automatic control and optimization method

InactiveCN1762525AEasy to operateLess impuritiesDistillation regulation/controlAutomatic controlMaterial balance

The invention relates to a method for controlling and optimizing the distillation tower. It controls the distillation tower in dependence on the material balance relation and component balance relation, optimizes the distillation tower by using representative model. Employing the abstraction proportion between the light product on the top of the tower and heavy product in the bottom of the tower (in following, taking the proportion between light and heavy product for abbreviation) as main controlled variable depending on the distillation principle, the material balance and component balance in the distillation tower, controlling the proportion between the light and heavy product, temperature, reflux ratio to realize stable operation by regulating the quantity of reflux and heat load of re-boiler. Simulating the practical course through the technological process simulation software, and training the nerve net model to become the representative model for the course optimization. Optimizing the operation with the representative model by using the analytical data for the raw material and product to realize the product Ka bian optimization, increasing the productivity of product with high value on the condition of guaranteeing the product quality and realizing the device energy saving and consumption reduction.

Owner:TSINGHUA UNIV

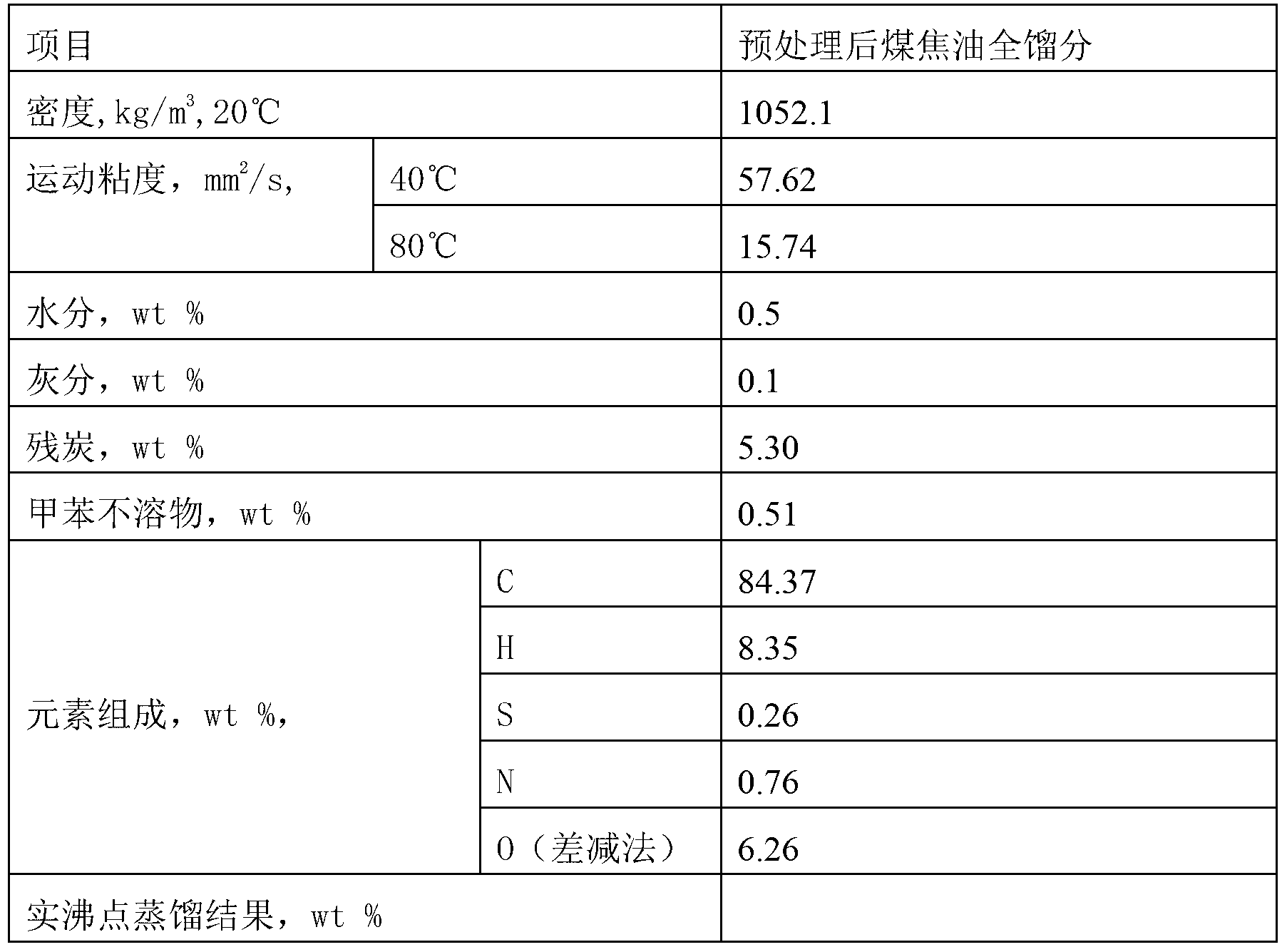

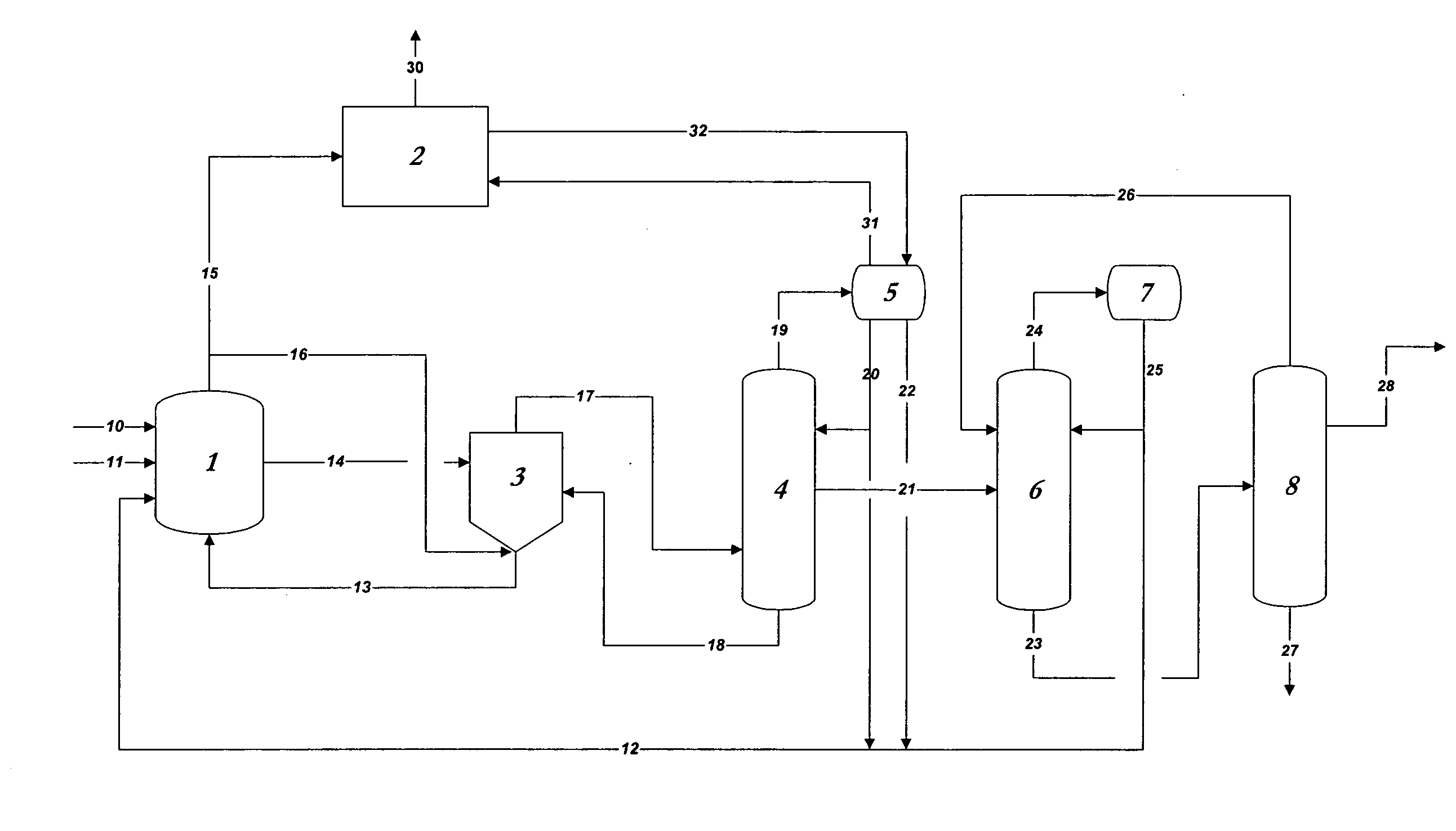

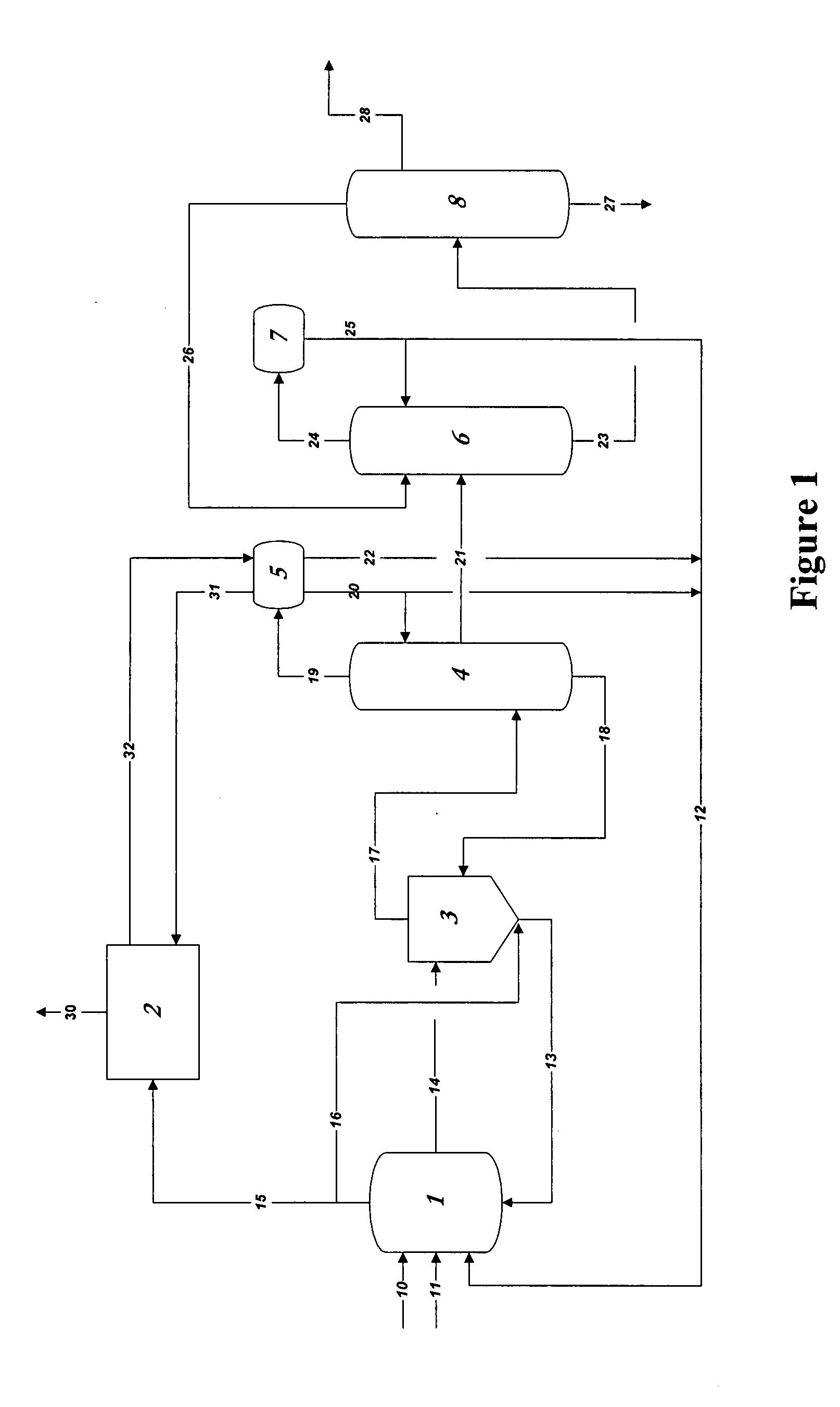

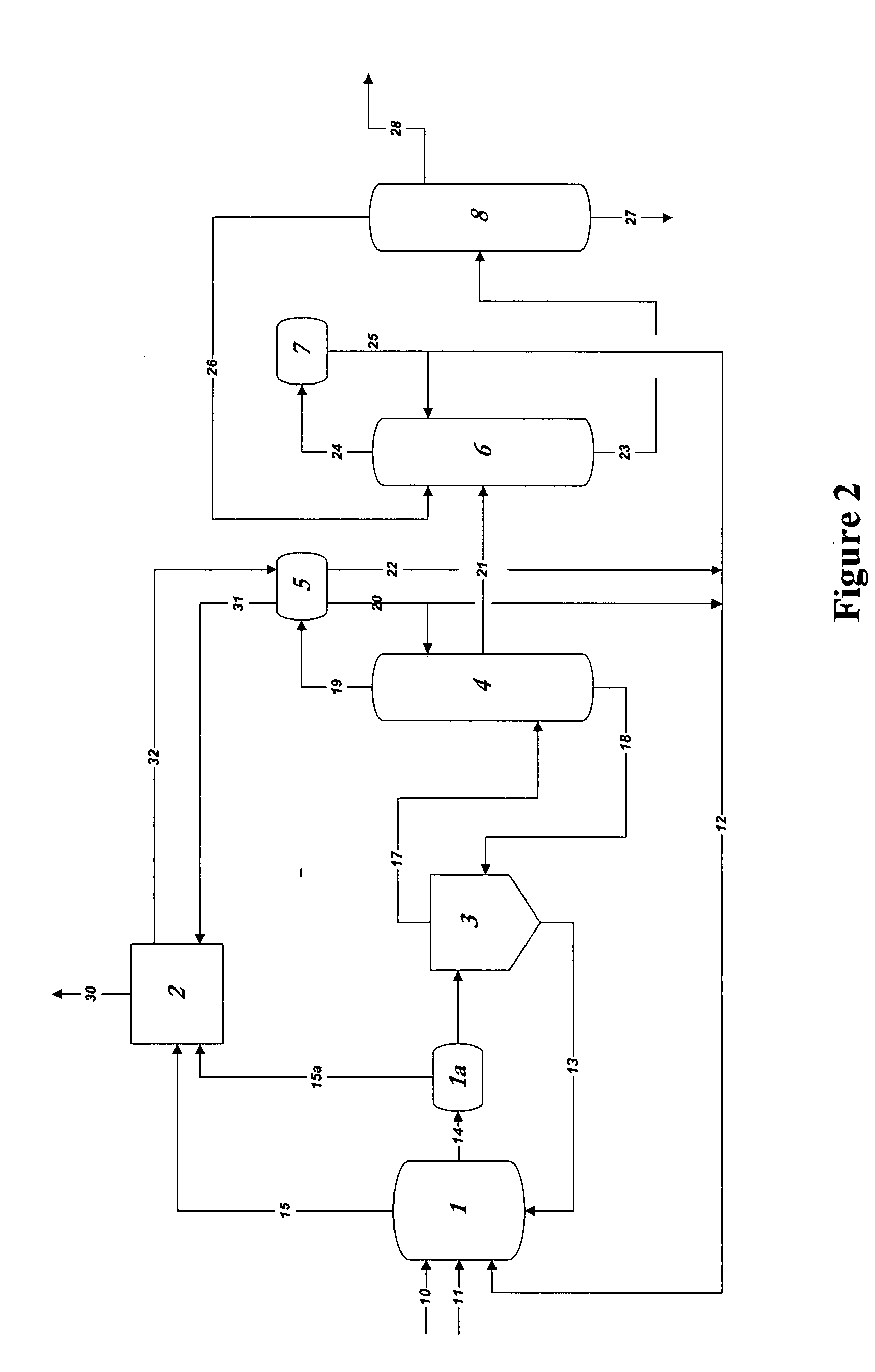

Heterogeneous coal tar suspension bed hydrogenation method

ActiveCN103265971AReduce processing stepsSolve delivery problemsLiquid hydrocarbon mixture productionHydrocarbon oil crackingSlurryFuel oil

The invention discloses a heterogeneous coal tar suspension bed hydrogenation method which comprises the following steps: mixing catalyst oil slurry with full fraction or heavy fraction oil of coal tar and catalyst-containing circulating oil, adding into a suspension bed hydrogenation reactor, and performing hydrocracking reaction, wherein the catalyst is a powdery particle coal tar suspension bed hydrogenation catalyst containing a single-metal active component or composite multi-metal active component of molybdenum, nickel, cobalt, tungsten or iron; separating out light oil from the hydrogenation reaction product, and then directly circulating a large amount of the tail oil containing the catalyst to the suspension bed reactor; and performing catalyst removal treatment on a small amount of the tail oil, recirculating to the suspension bed reactor, and performing further light fraction conversion. The heavy oil is wholly or maximally circulated to realize the maximal, convenient and flexible light oil production from the coal tar having different characteristics and the cyclic utilization of the catalyst, thus greatly improving the utilization efficiency and operating flexibility of the raw materials and the catalyst.

Owner:CCTEG CHINA COAL RES INST

Control of formic acid impurities in industrial glacial acetic acid

InactiveUS20080293967A1High purityLess impuritiesOrganic compound preparationCarboxylic preparation from carbon monoxide reactionProtein carbonylChemistry

This invention relates to carbonylation of methanol, methyl acetate, dimethyl ether or mixtures thereof to produce glacial acetic acid, and more specifically to the manufacture of glacial acetic acid by the reaction of methanol, methyl acetate dimethyl ether or mixtures thereof with carbon monoxide wherein the product glacial acetic acid contains low formic acid impurities.

Owner:SCATES MARK O +1

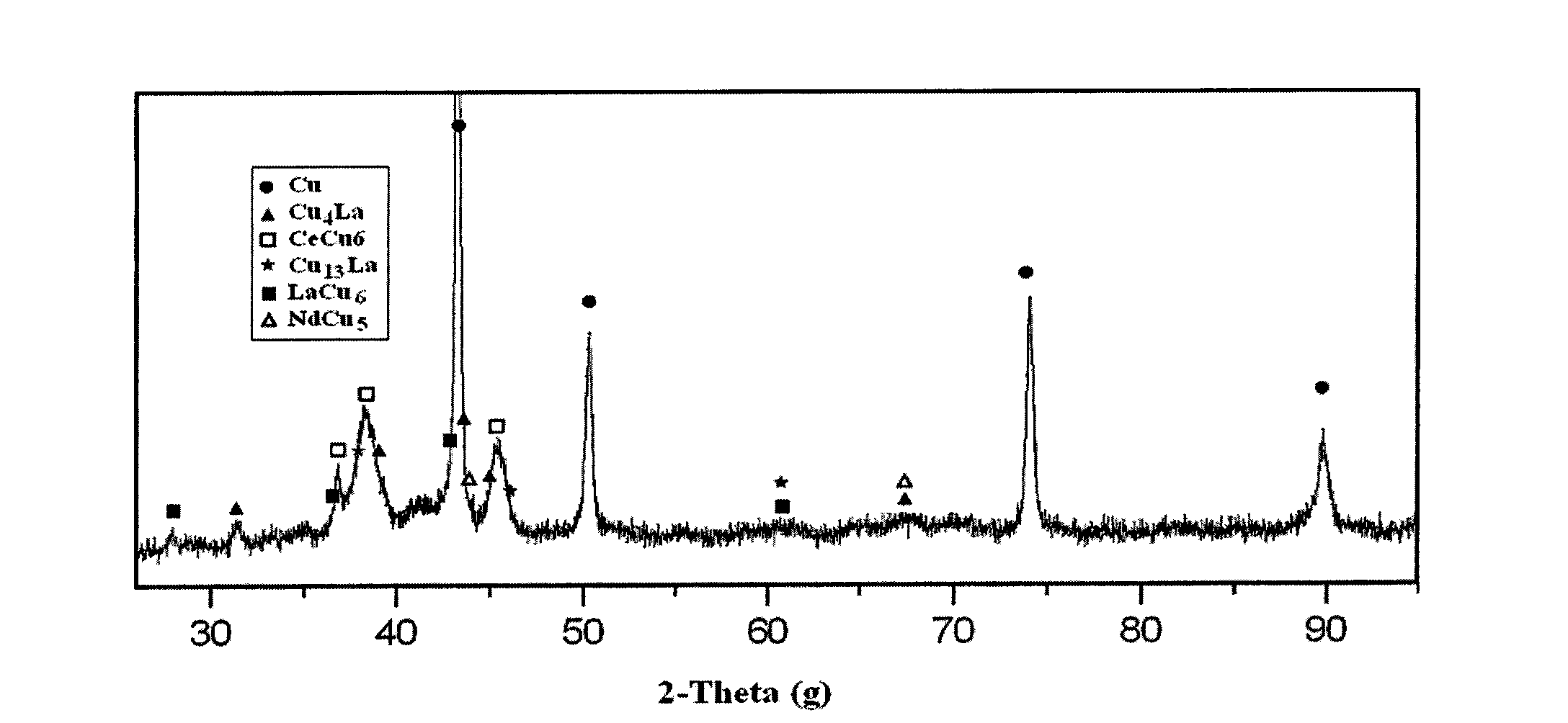

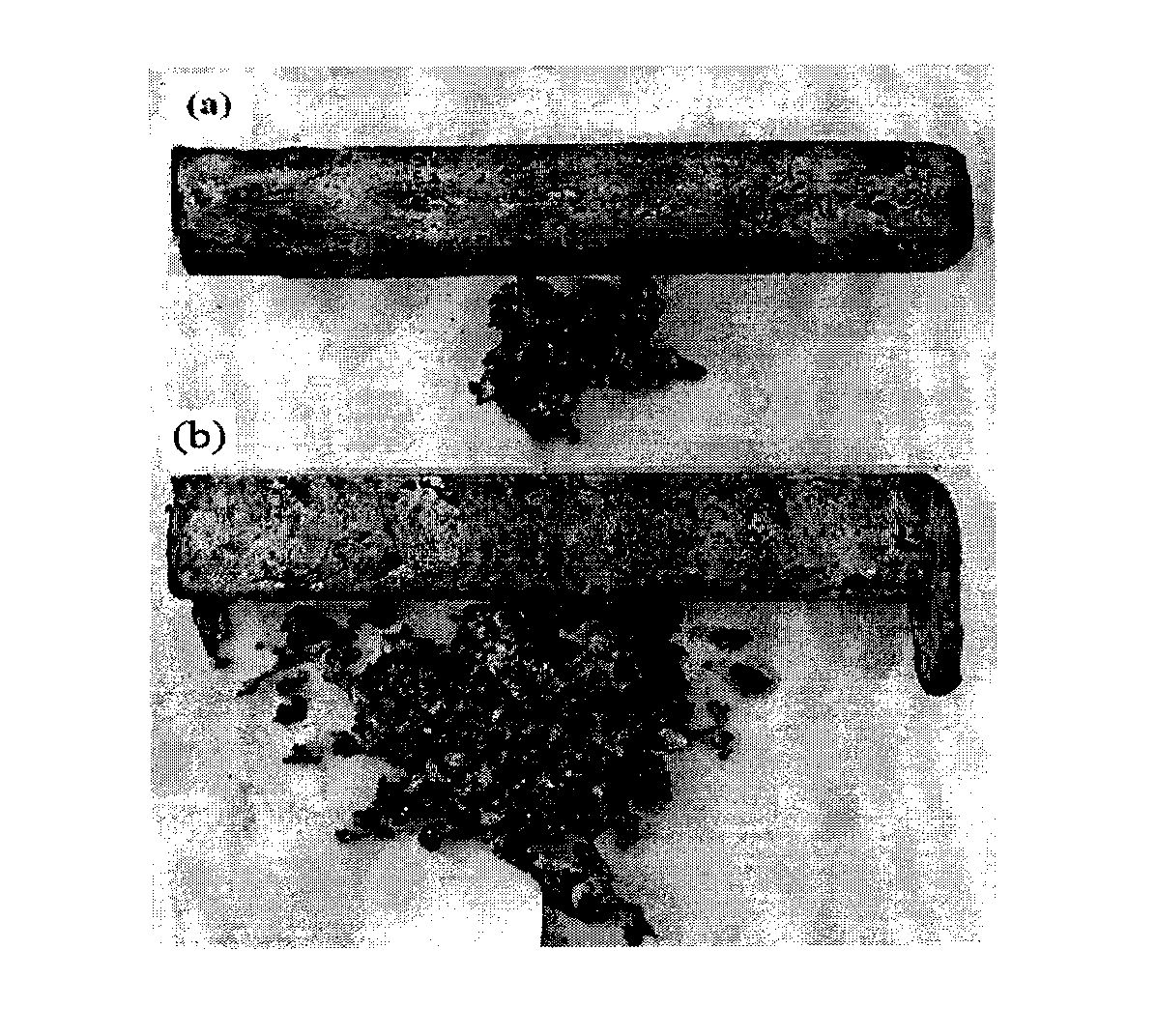

High Cu-RE interalloy refining agent for refining scrap copper and preparation and application thereof

The invention relates to a high Cu-RE refining agent which has high efficiency and low burning loss rate and can be used for copper and copper alloy, applied to mass refining of the copper and the copper alloy, especially applied to refining and modification of red impure copper and white impure copper. The Cu-RE interalloy refining agent is prepared by a vacuum melting method, wherein, rare earth content is up to 30-65%; and only 2-6g / kg refining agent is added while the Cu-RE interalloy refining agent is applied to remelting refining of scrap copper. The Cu-RE refining agent enhances slagging and deslagging of copper fused mass, reduces deleterious substances in the fused mass of the scrap copper, and improves texture and performance of the copper and the copper alloy, therefore, products prepared from the red impure copper as a raw material reach or exceed the quality of the products prepared from electrolytic copper as a raw material, and the white copper process waste can be used for directly producing high-quality products after remelting refined, thus promoting recycle and reutilization of the scrap copper, saving energy and resource, reducing environmental pollution and generating significant economic and social benefits.

Owner:CENT SOUTH UNIV

Extraction agent used for extracting proanthocyanidin from plants and extracting method

An extractant for extracting proanthocyanidin from plant is metaphosphoric acid and / or sulfite. Its extracting process includes adding water to prepare solution, regulating pH value, immersing extracting by controlling temp and time, filtering, purifying, solvent eluting, concentrating and drying. Its advantages are dosage of extractant, high extracting rate and high purity and water solubility of product.

Owner:HUAZHONG AGRI UNIV

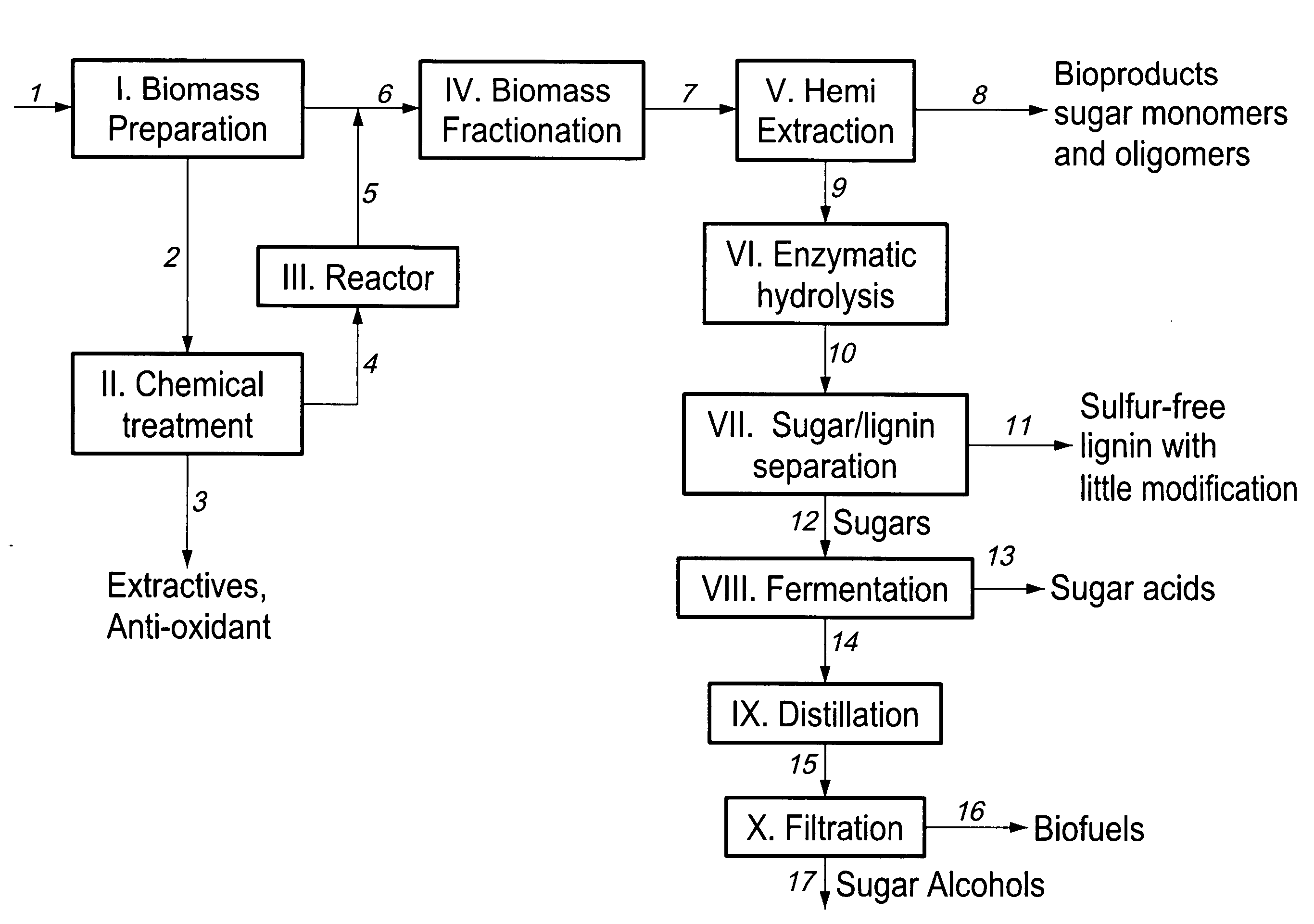

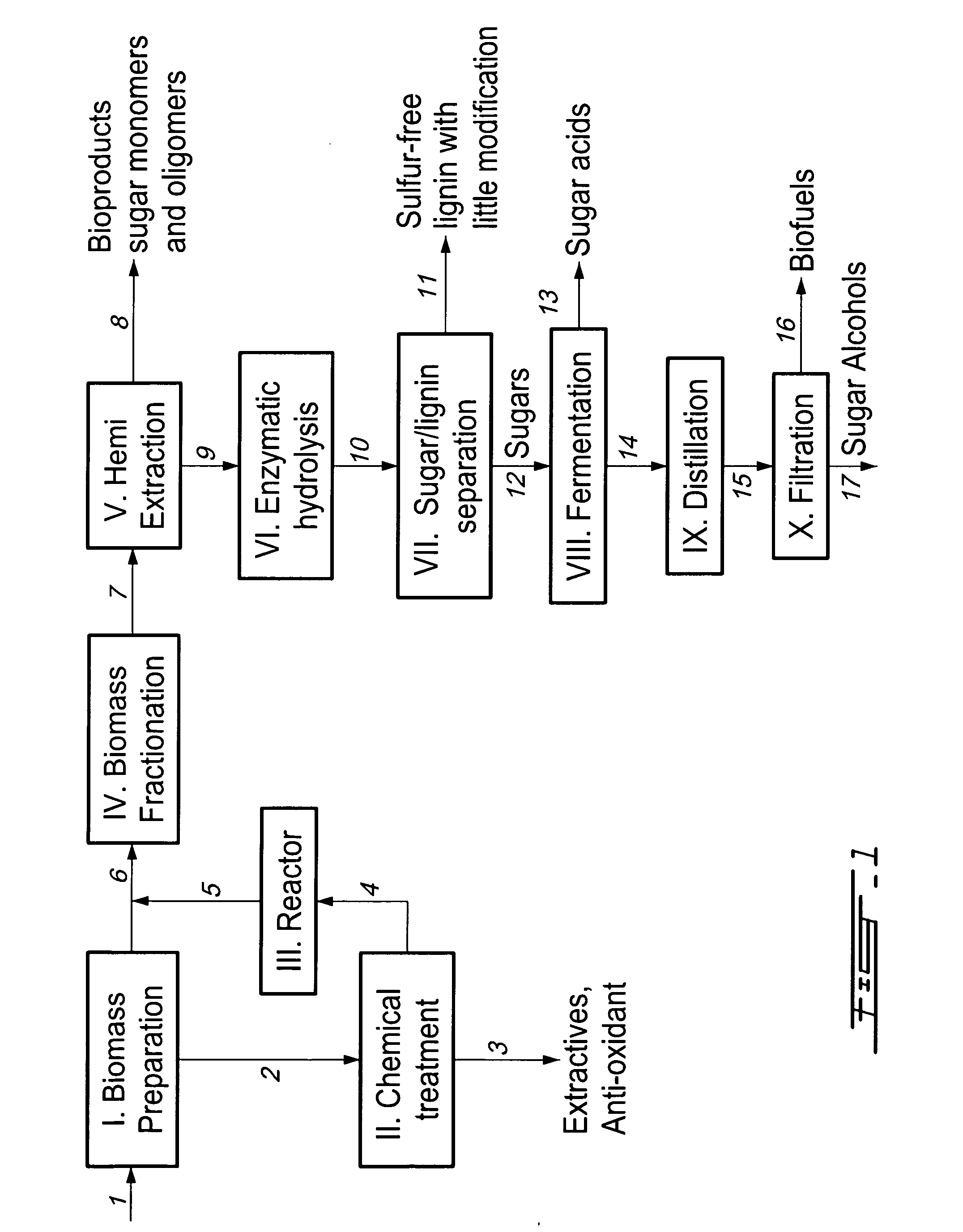

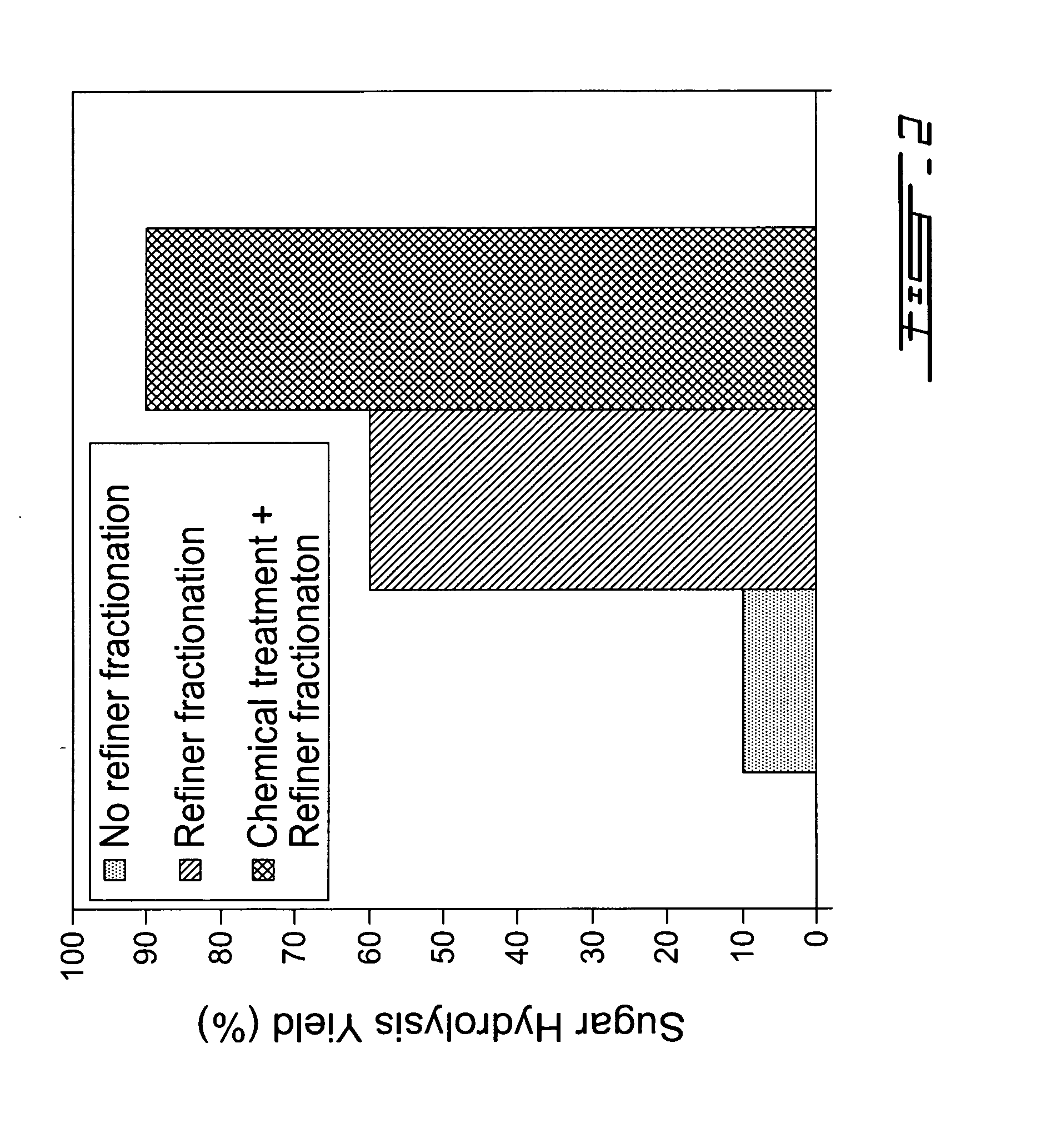

Biomass fractionation process for bioproducts

A fractionation process for producing value-added products from a lignocellulosic biomass, comprises: a) mechanically refining the lignocellulosic biomass under mild refining conditions to form a refined biomass pulp with enhanced susceptibility to separation of hemicellulose, cellulose and lignin, and enhanced digestibility of carbohydrates in hydrolysis b) separating hemicellulose and sulfur-free high-quality lignin from cellulose in the refined biomass, and, optionally c) producing various bioproducts from the above said process.

Owner:FPINNOVATIONS INC

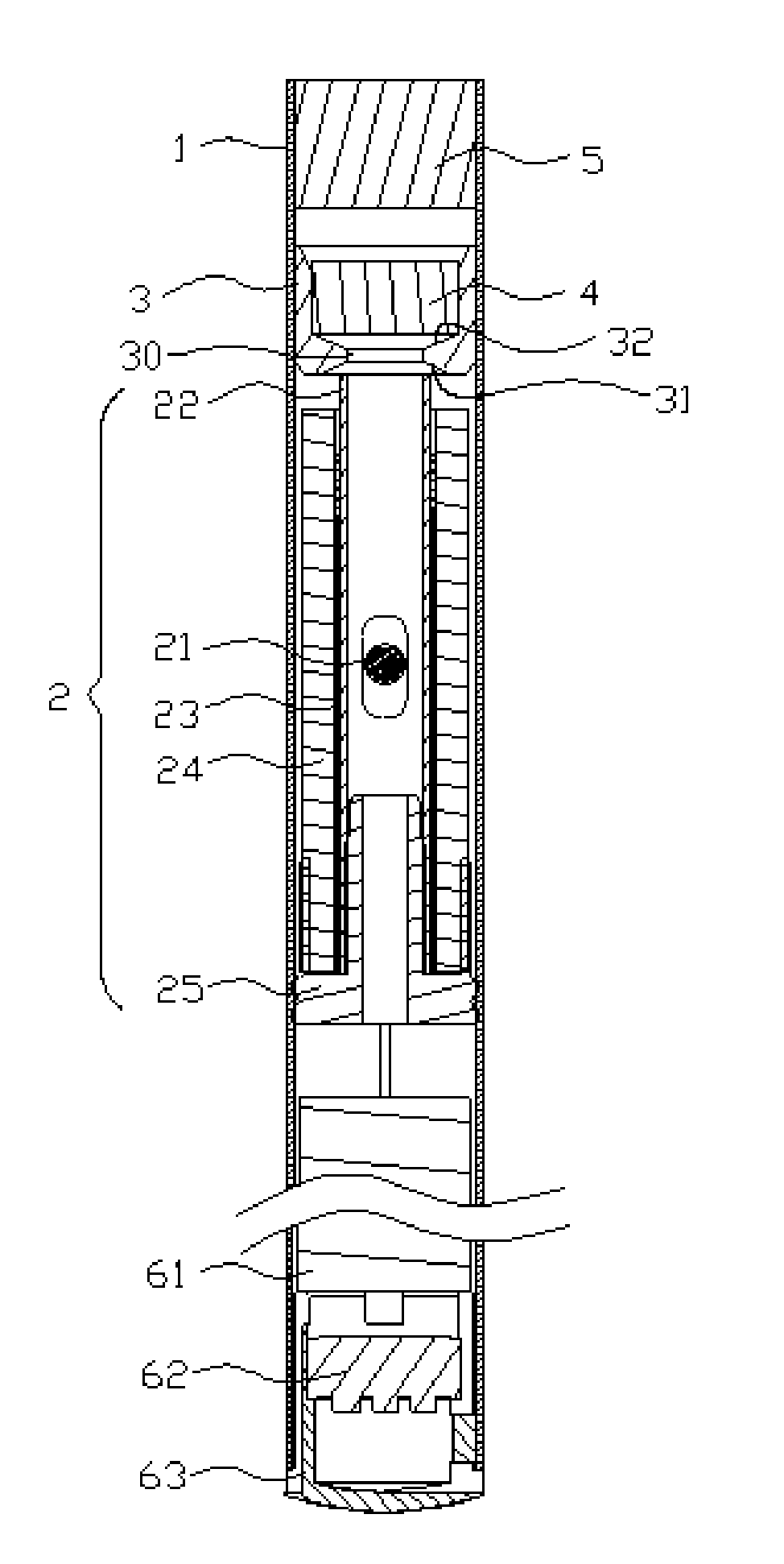

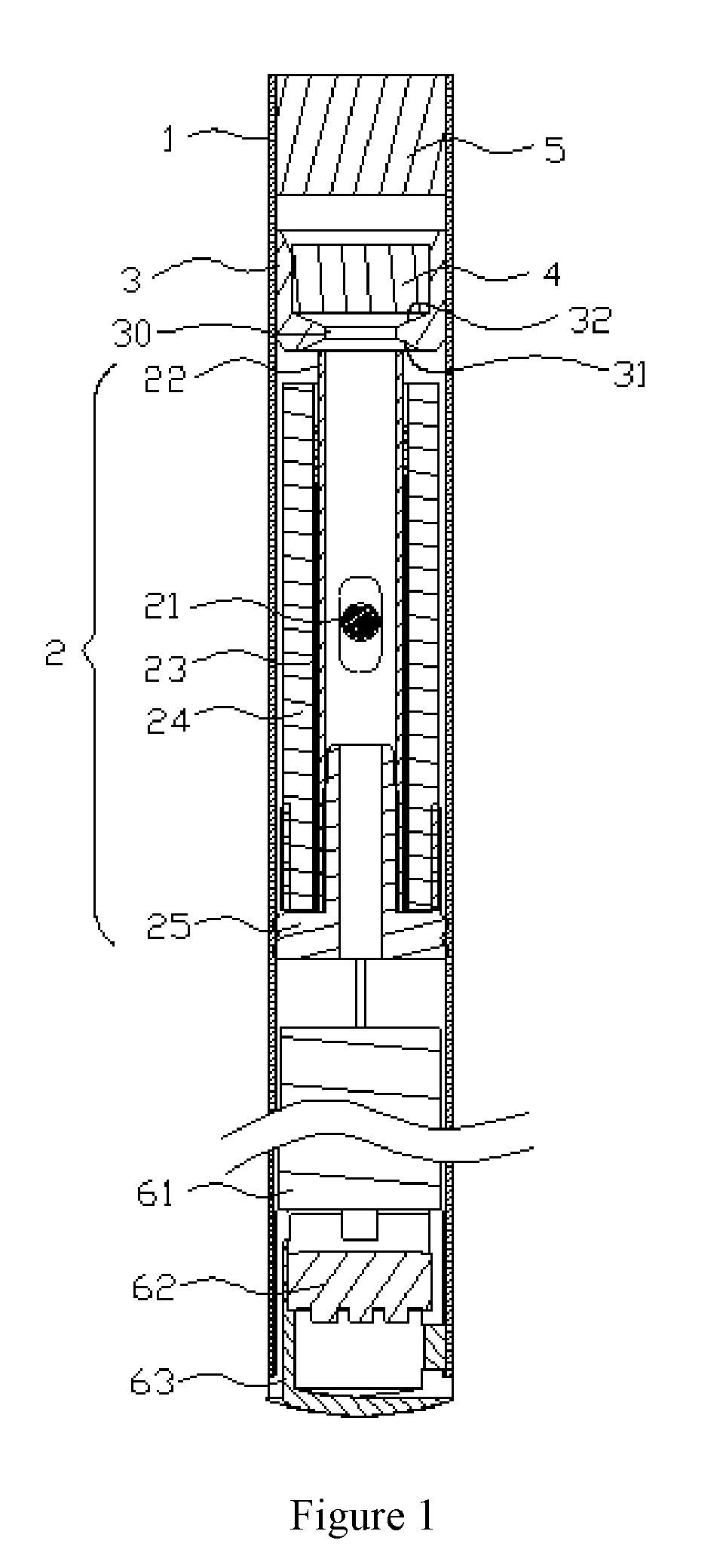

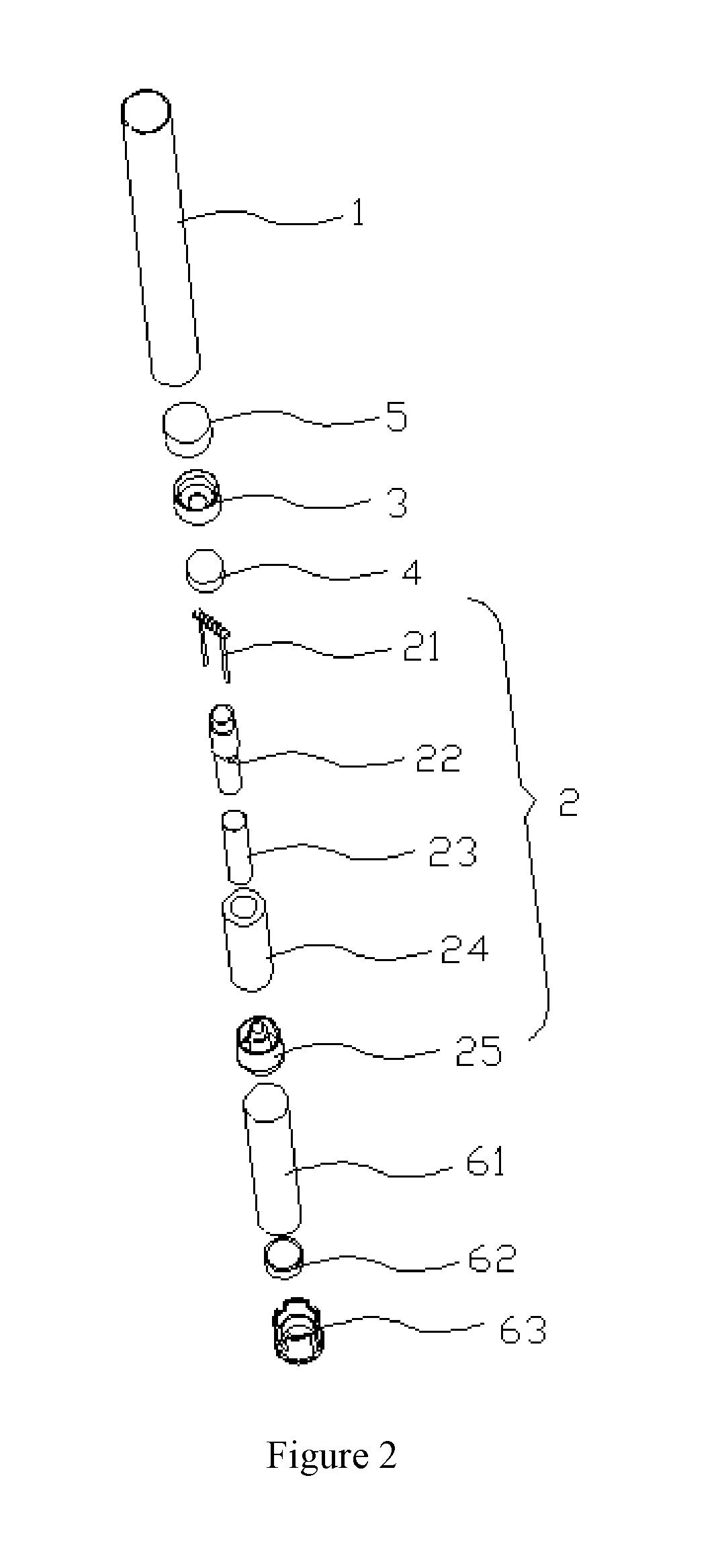

Atomizer and electronic cigarette comprising same

InactiveUS20170156402A1Easily leaks out can be avoidedLess impuritiesTobacco smoke filtersTobacco pipesTarElectronic cigarette

An atomizer and an electronic cigarette comprising the same are provided. The atomizer comprises an atomization sleeve and an atomizer assembly contained in the atomization sleeve, a first filter and a second filter separated from each other are provided successively on one end of the atomizer assembly that is close to the smoking end; the first filter is breathable and is configured to prevent tobacco tar in smoke from exhausting, and the second filter is configured to discharge the smoke filtrated by the first filter; the second filter is made from breathable porous material; and is capable of deforming elastically when subjected to an external force. The first filter filtrates the tobacco tar for the first time; the suction nozzle is replaced by the second filter which may deform elastically; besides, the second filter may not be contaminated by the tobacco tar impurity adsorbed by the first filter.

Owner:KIMREE HI TECH

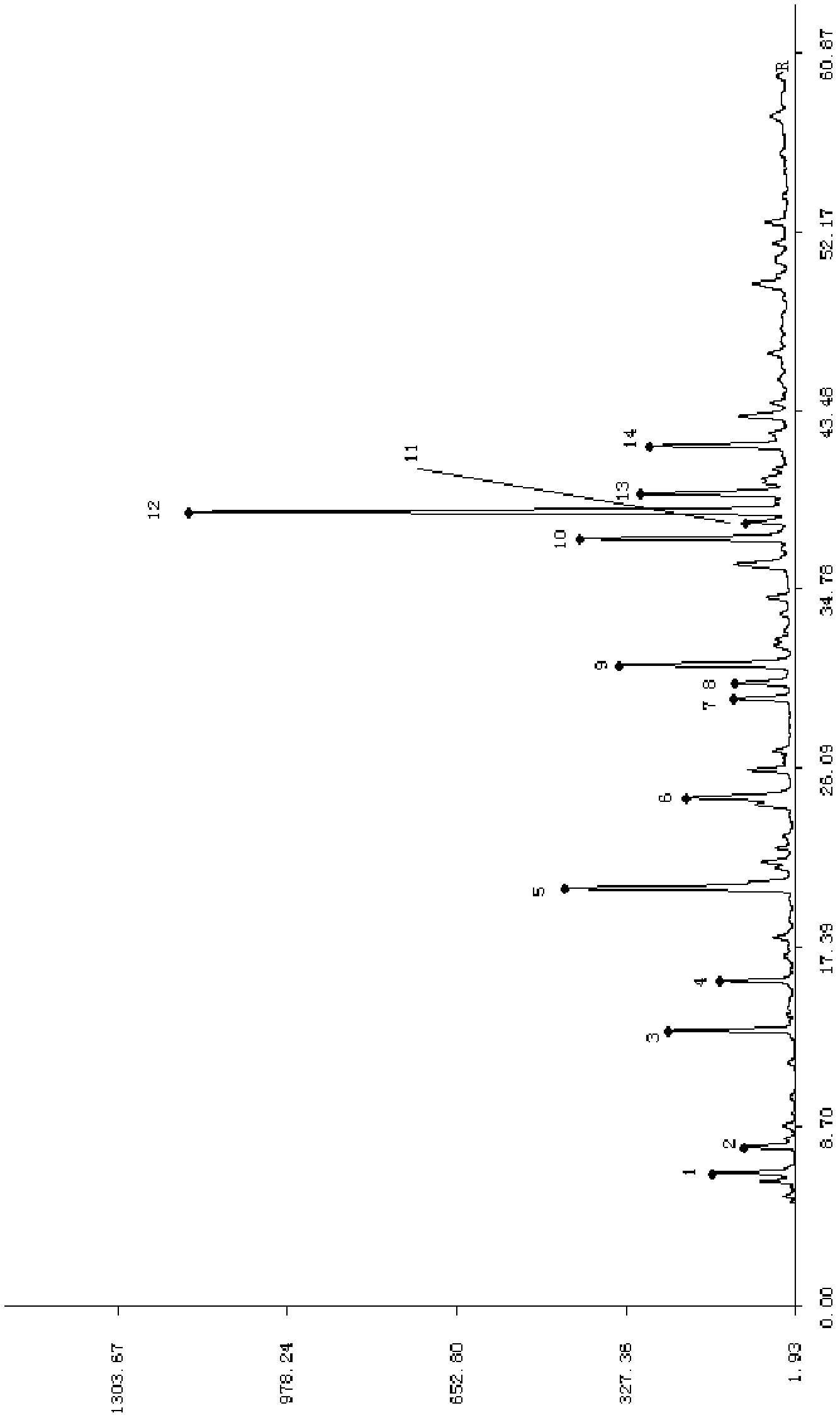

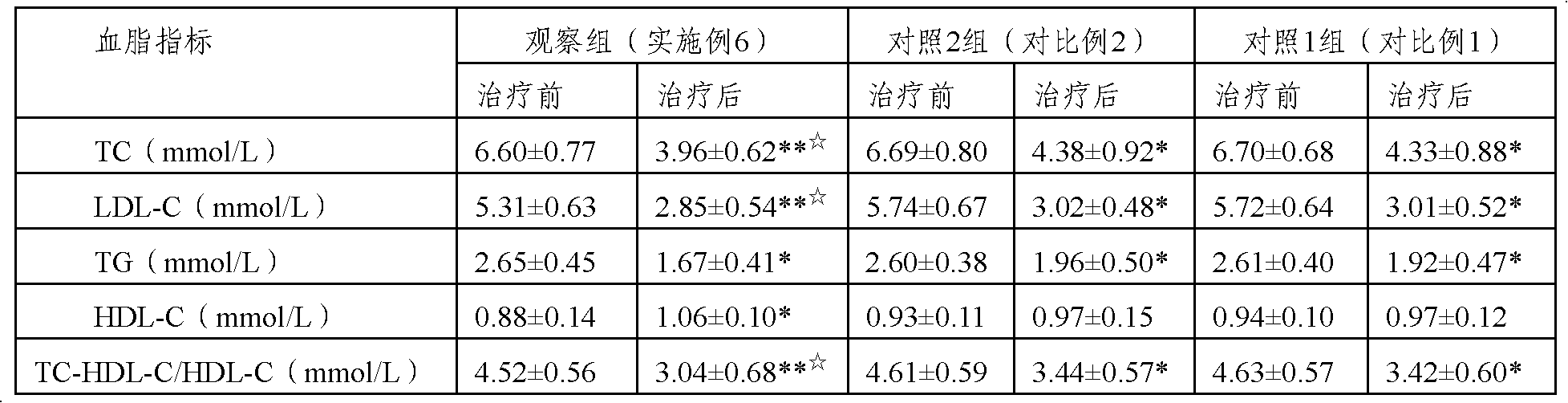

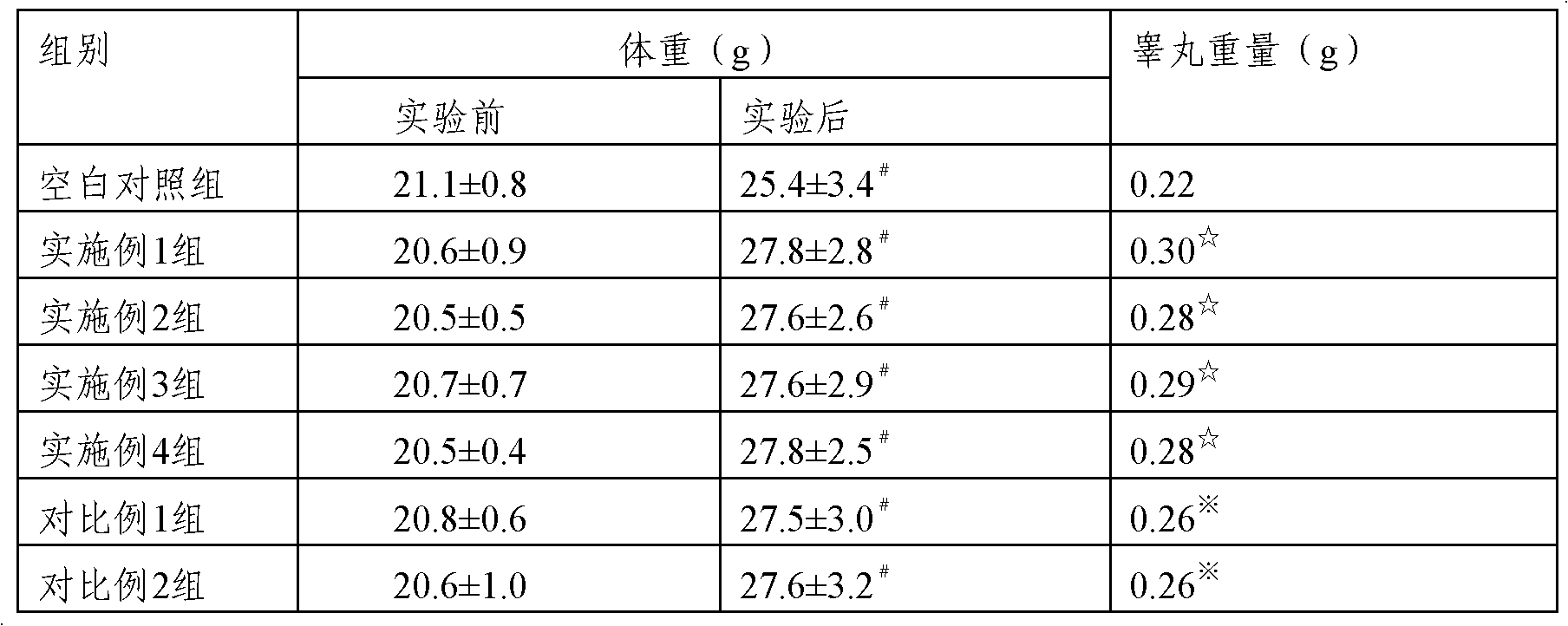

Radix acanthopanacis senticosl composition, preparation containing composition and detection method of preparation

ActiveCN102579532AHigh content of active ingredientsLight colorOrganic active ingredientsNervous disorderMedicineGram

The invention relates to a radix acanthopanacis senticosl composition, a preparation containing the composition and a content detection method of the preparation. The composition per gram contains 50-120mg of total flavones, 12.5-30mg of syringin and 4-15mg of eleutheroside E. The composition and preparation provided by the invention have effects on lowering blood sugar level, lowering blood lipid and treating male sterility and have better effects than the prior art.

Owner:HARBIN ZHENBAO PHARMA

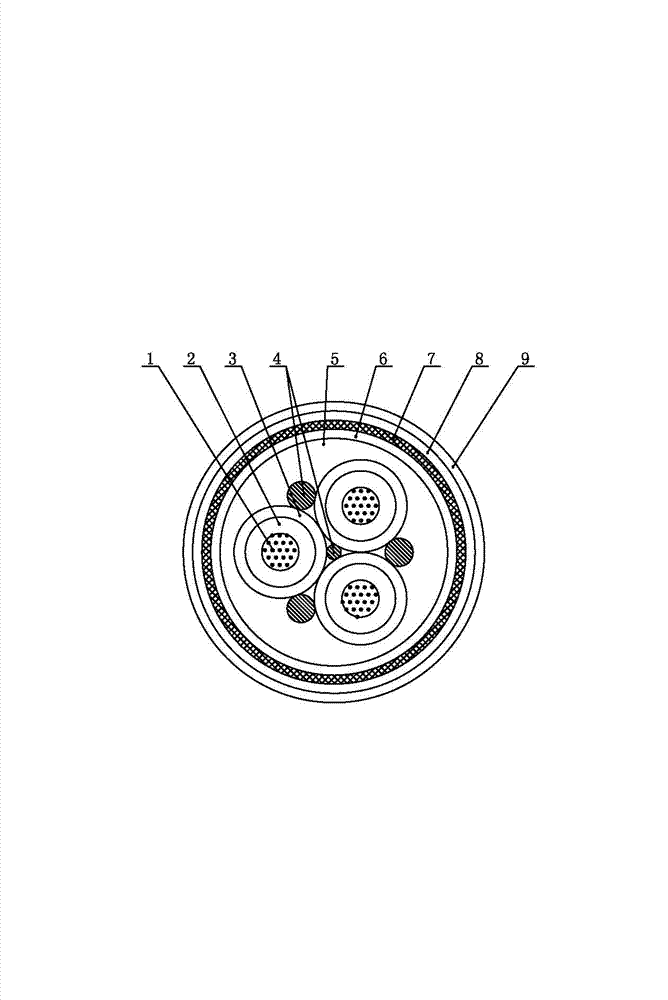

Shielding longitudinal watertight degaussing cable and production method thereof for ships

ActiveCN102855982AEnsure watertight effectImprove sealingInsulated cablesCable/conductor manufactureCopper conductorVulcanization

The invention discloses a shielding longitudinal watertight degaussing cable and a production method thereof for ships. A tinned copper wire is impregnated with a sealant and then twisted into a twisted copper conductor which is impregnated with a conductor sealant layer on the periphery, an electro-insulating rubber layer is extruded on the periphery of the conductor sealant layer to form insulation core wires, chloroprene rubber filling bars are filled into gaps between the insulation core wires, and a plurality of insulation core wires are twisted wholly into a cable core. A cable core inner sealant layer, an inner jacket rubber layer, an armor shielding layer and an outer jacket rubber layer are sequentially arranged on the periphery of the cable core. A single wire of the cable conductor is impregnated with the sealant, the twisted copper conductor is impregnated with the conductor sealant layer on the periphery, the cable core inner sealant layer is extruded on the periphery of the cable core to form multiple sealing, the chloroprene rubber filling bars swell during follow-up vulcanization and can fill in the gaps inside the cable core completely, and tangency between the insulation core wires can be avoided, so that the sealant can permeate to the inside of the cable core to guarantee the watertight effect when the cable core inner sealant layer is extruded.

Owner:嘉兴顾翔制冷设备有限公司

Cathode material of lithium-nickel-cobalt-aluminum composite oxide, a method of fabricating the same and a lithium ion battery including the same

ActiveUS20150194662A1Excellent storage and cycling performanceReduce the presence of impuritiesAluminium compoundsElectrode thermal treatmentTemperature cyclingOrganic acid

The present invention relates to a cathode material of Lithium-Nickel-Cobalt-Aluminum composite oxide, a method of fabricating the same, and a lithium ion battery including the same. The composite cathode material has a core-shell structure, wherein the core portion is made of LiNi1-x-yCoxAlyO2 which is washed with an alcohol and organic acid-mixed solution, wherein 0<x≦0.2, 0<y≦0.1; the shell is metal oxide layer. In the present invention, the composite cathode material is fabricated by a combined method, wherein the base material is washed with an alcohol and organic acid-mixed solution and the shell layer material is coated by spray drying. The composite cathode material of the present invention has low content of lithium impurities and excellent high-temperature cycling and storage performance.

Owner:BTR NEW MATERIAL GRP CO LTD

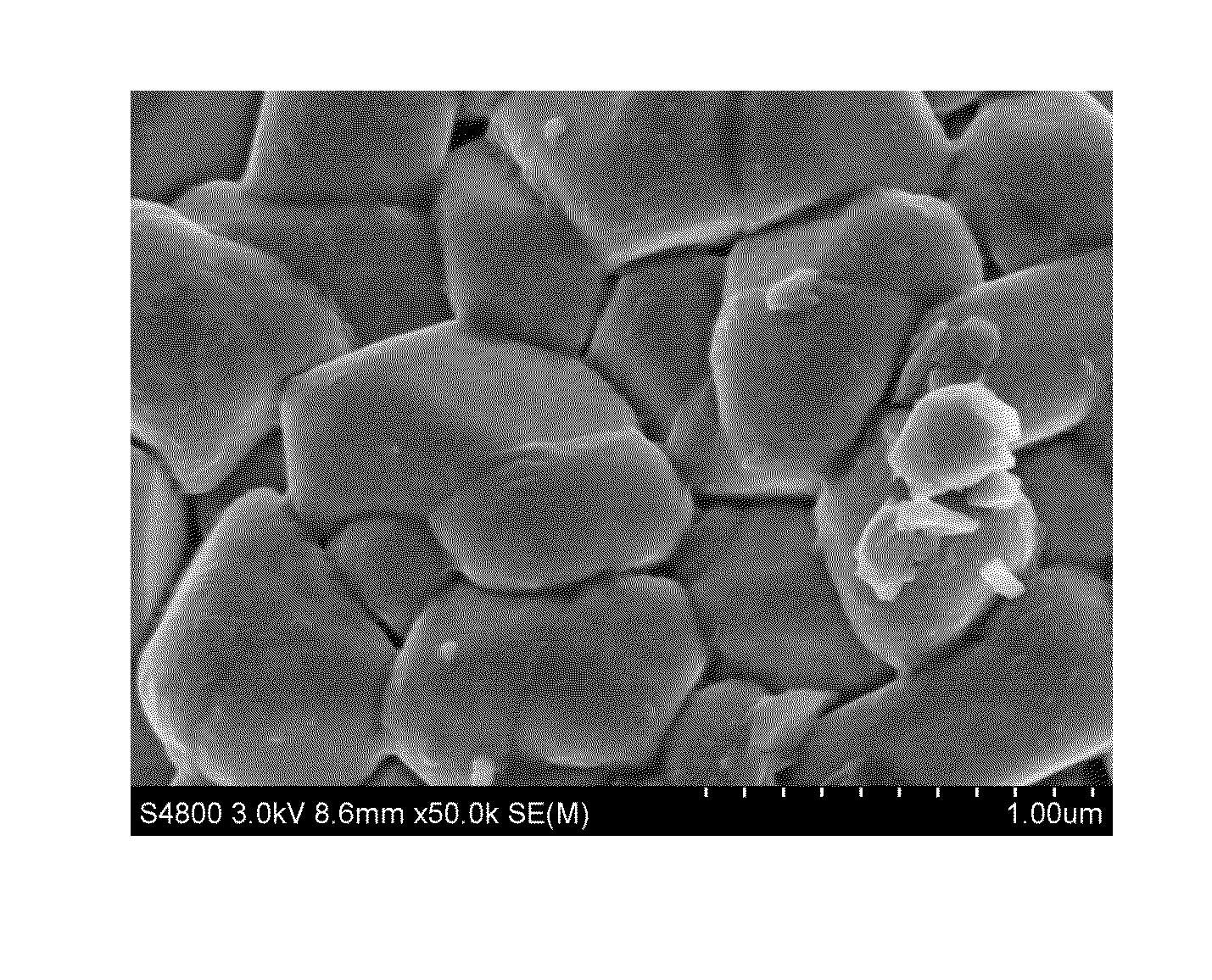

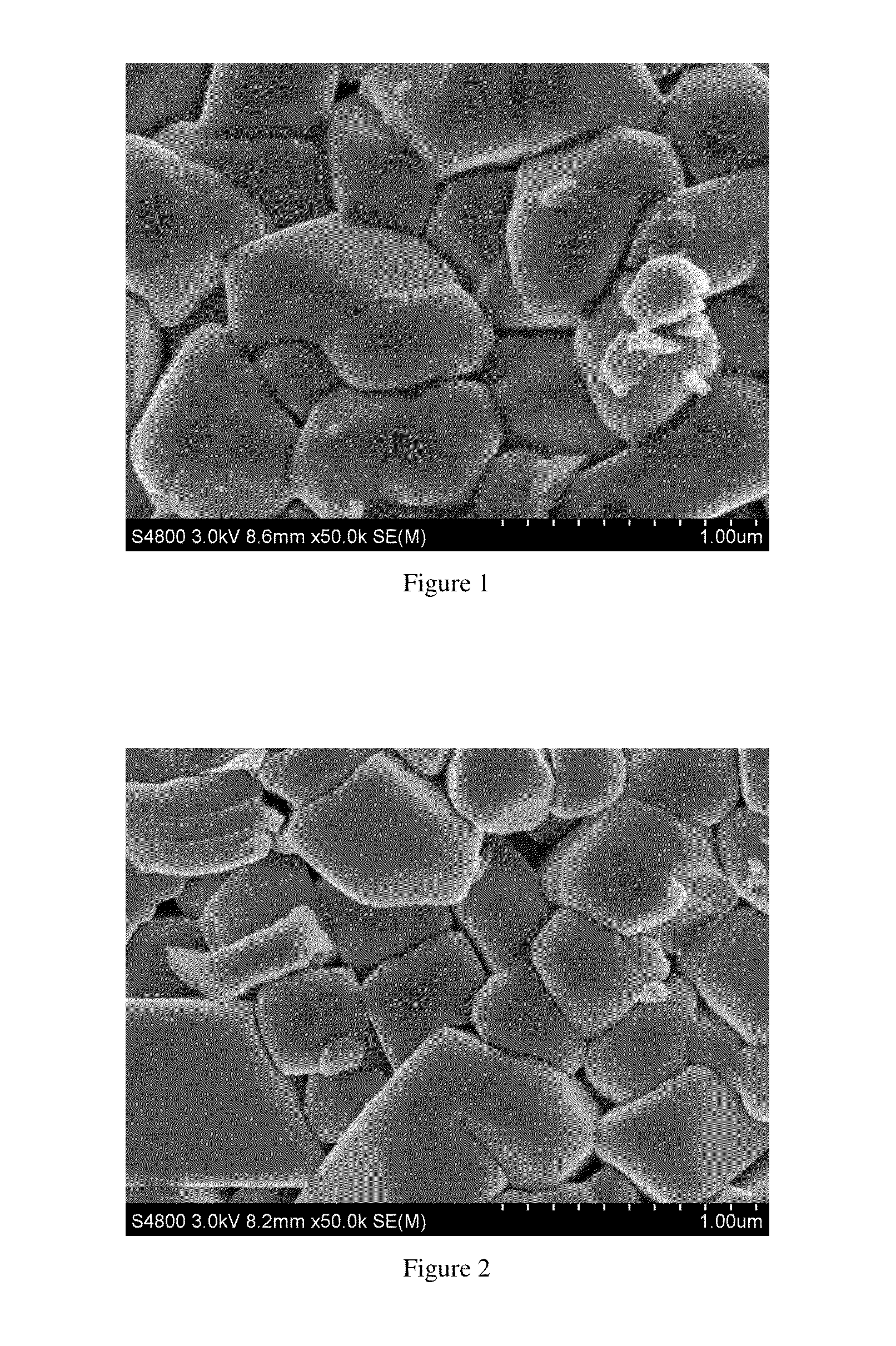

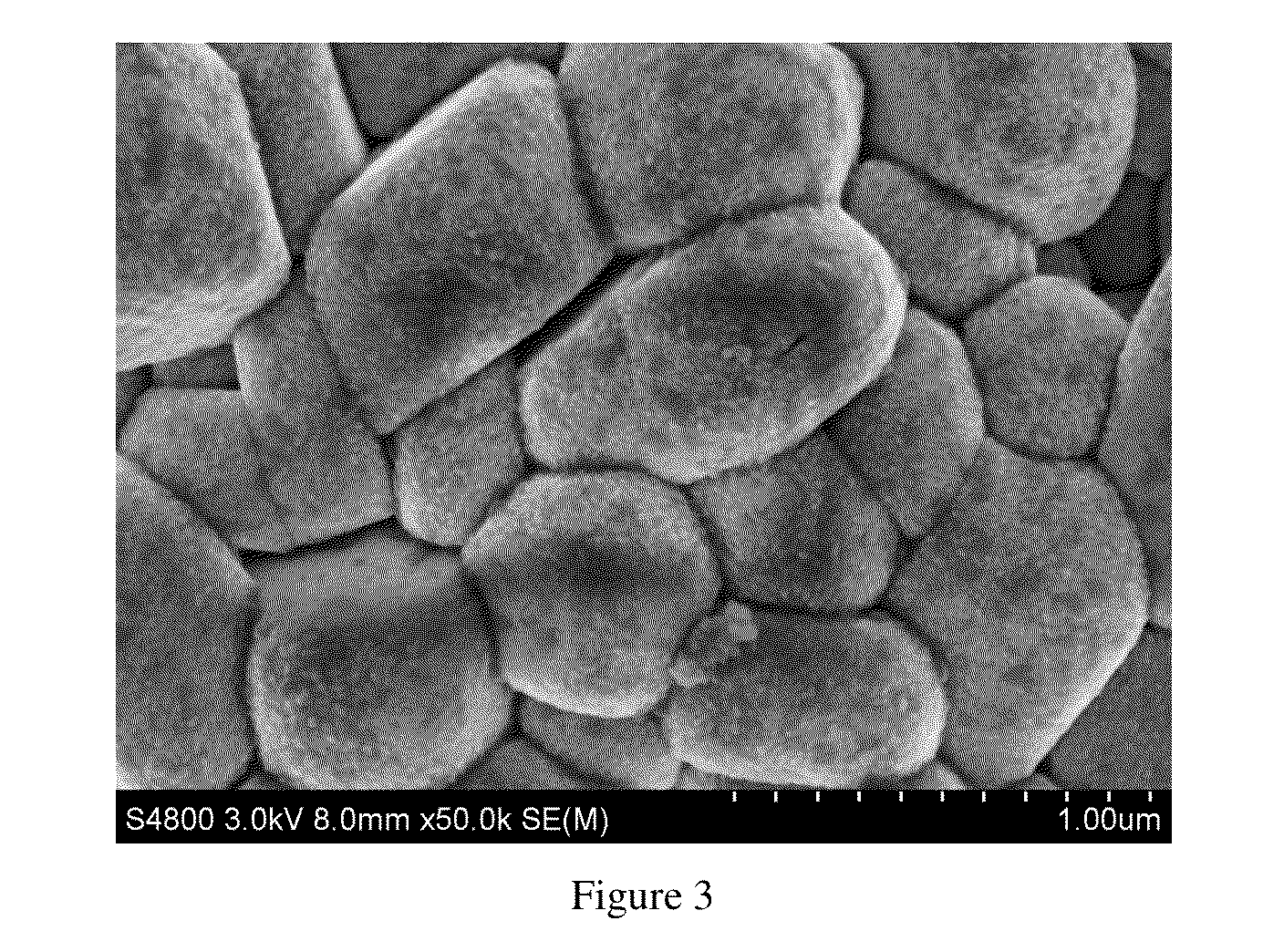

Nodular Silica Sol and Method of Producing the Same

InactiveUS20100146864A1Easy to getImprove polishing effectPigmenting treatmentOther chemical processesMaterials scienceNitrogen absorption

A novel nodular silica sol adapted to use as a polishing material for polishing, for instance, CMP.The nodular silica sol has a ratio of an average particle diameter (r) measured by the dynamic light scattering method versus a particle diameter (r′) converted to that of an equivalent sphere computed from an average specific surface area measured by means of the nitrogen absorption method (r / r′, referred to as “association ratio”) in a range from 1.2 to 10, the particle diameter (r′) in a range from 5 to 200 nm, and the specific surface area in a range from 13 to 550 m2 / g. The nodular silica particles have heterogeneous forms, and contents of Ca and Mg contained in the nodular silica particles are below 1000 ppm against SiO2 respectively.

Owner:JGC CATALYSTS & CHEM LTD

Method for extracting anthocyanin from lycium ruthenicum fruit

The invention relates to a method for extracting anthocyanin from lycium ruthenicum fruit. The method comprises the following steps of: (1) leaching raw material lycium ruthenicum fruit for 1-30h with an ethanol solution with a pH value of 1-4, and then filtering to obtain leach liquor; (2) carrying out vacuum concentration on the leach liquor obtained in the step (1) to obtain a concentrated solution of which the concentration of the solid is >= 40%; (3) adsorbing the concentrated solution obtained in the step (2) by utilizing macroporous resin, then eluting with an ethanol water solution, and beginning to collect when color of an eluant darkens to obtain a purified anthocyanin extracting solution of the lycium ruthenicum fruit; and (4) carrying out vacuum concentration on the anthocyanin extracting solution of the lycium ruthenicum fruit. Which is obtained in the step (3), to obtain a concentrated solution of which the concentration of the solid is >= 60%, and refrigerating and drying the concentrated solution to finally obtain the lycium ruthenicum fruit anthocyanin. The method for extracting the anthocyanin from the lycium ruthenicum fruit is simple in process, and the prepared anthocyanin has less impurities, excellent quality and favorable stability.

Owner:CHINA ACAD OF SCI NORTHWEST HIGHLAND BIOLOGY INST

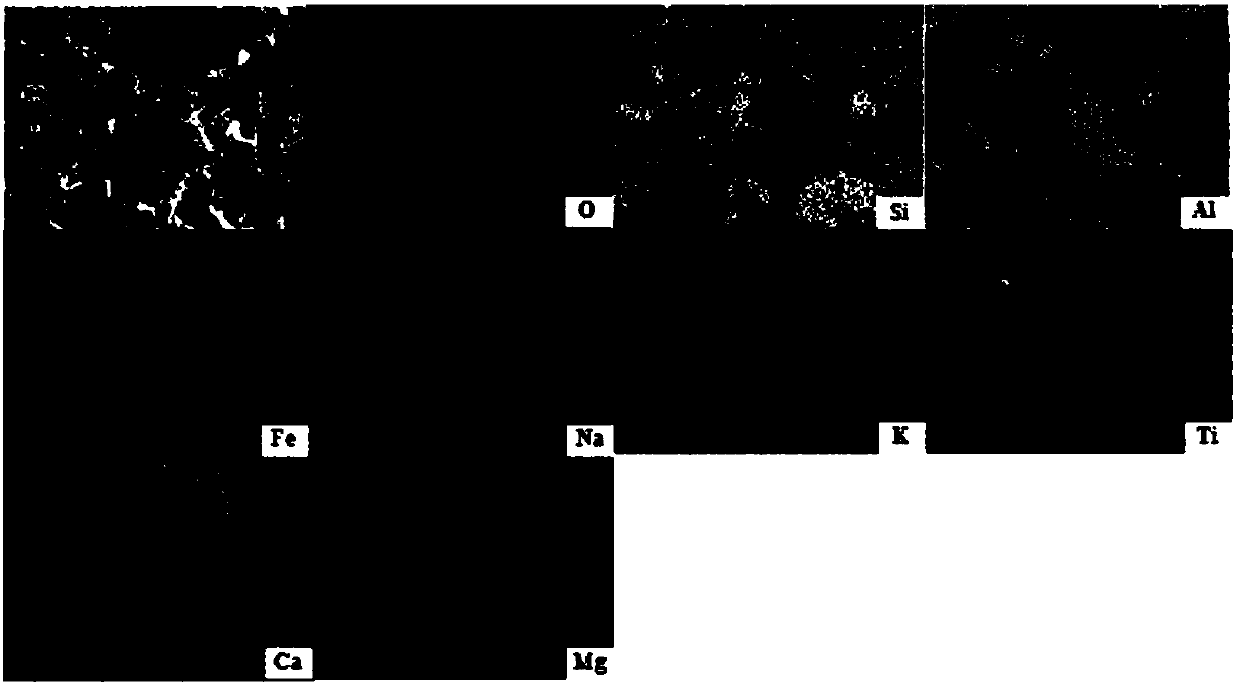

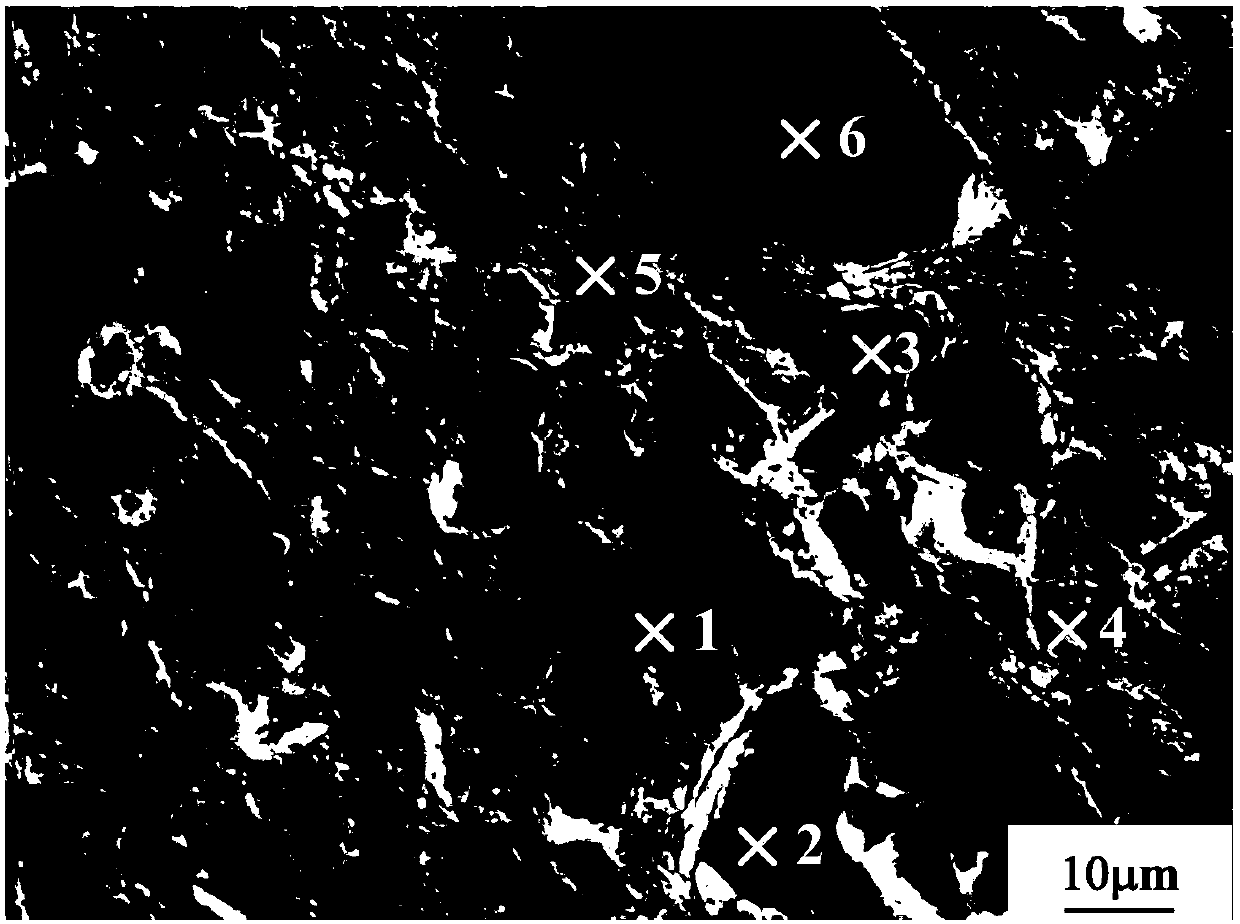

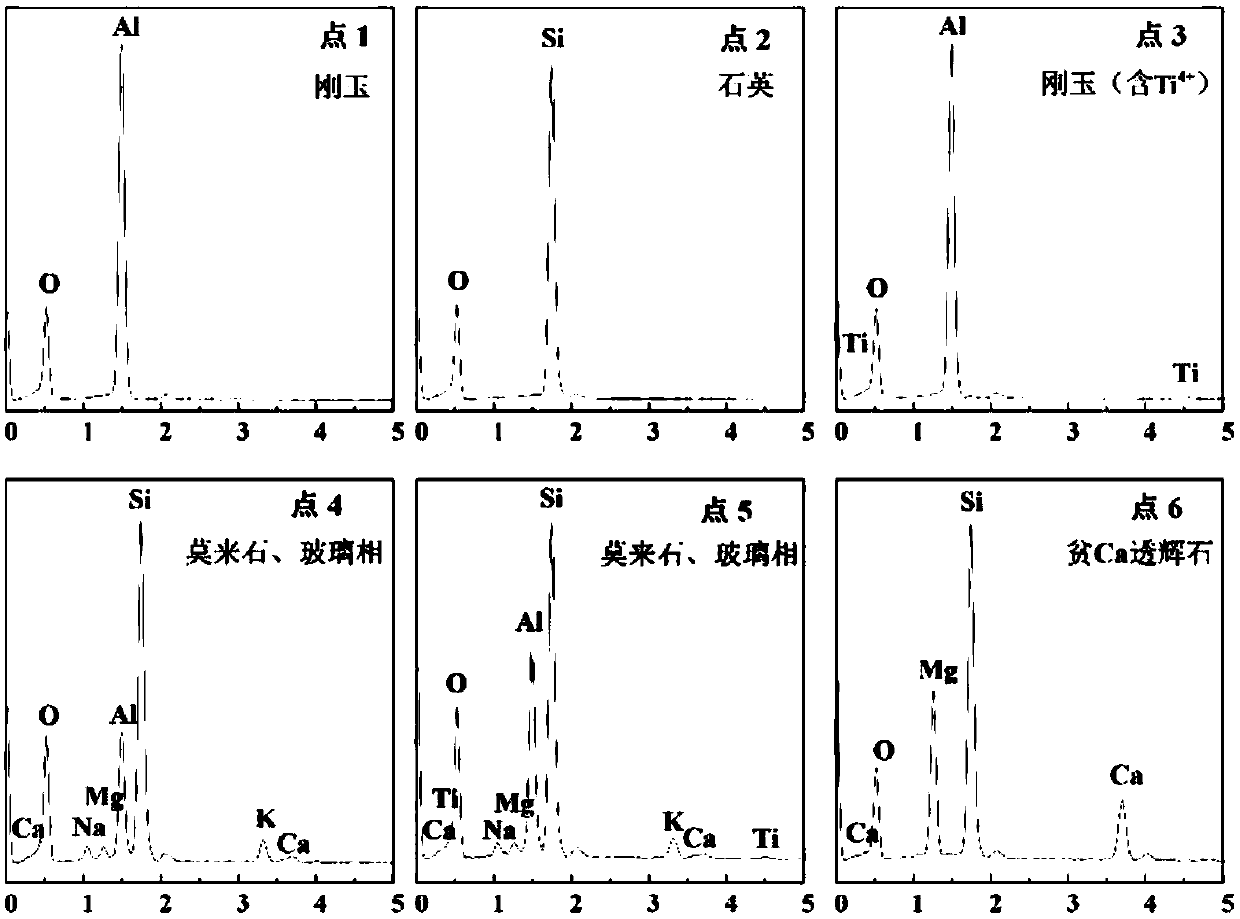

Preparation method of low-cost high-alumina ceramic thin plate

The invention relates to a preparation method of a low-cost high-alumina ceramic thin plate. The preparation method of the low-cost high-alumina ceramic thin plate is characterized by including the steps: 1) raw material treatment; 2) raw material proportioning and mixing: weighing raw materials including, in weight percent, 10%-25% of coal series kaolinite, 10%-25% of calcined bauxite, 20%-30% ofcommon kaolinite, 15%-25% of feldspar, 0-5% of talcum and 18%-25% of quartz to obtain a blank; adding reinforcing agents equivalently accounting for 0.1%-0.25% of the total weight of the blank, performing ball milling for 12-18 hours and uniformly mixing the raw materials to obtain mixed materials; 3) pelleting and aging; 4) semi-dry pressing; 5) drying; 6) glazing; 7) sintering to obtain the low-cost high-alumina ceramic thin plate. The feldspar is formed by mixing potassium feldspar with soda feldspar, and the weight ratio of K2O to Na2O of the mixed feldspar chemical composition is 2:1. The sintering temperature of the high-alumina ceramic thin plate prepared by the method is only 1180 DEG C, so that the ceramic thin plate is low in cost and high in strength.

Owner:WUHAN UNIV OF TECH

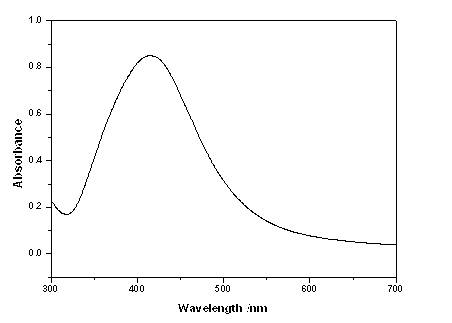

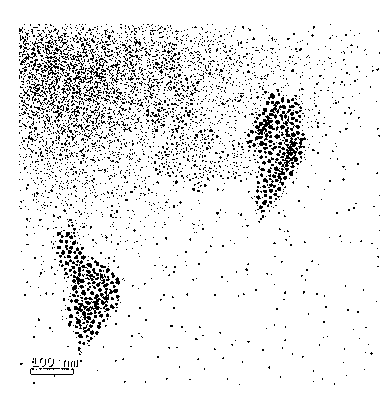

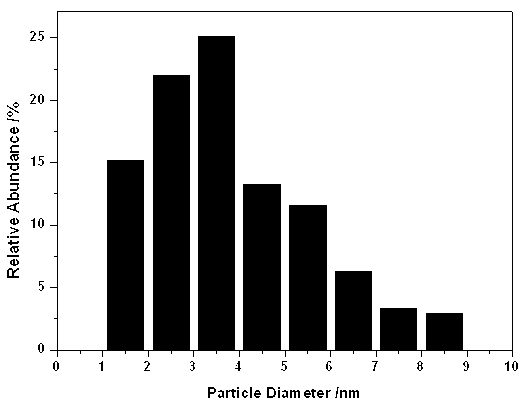

Stable nanometer silver colloidal sol and preparation method thereof

The invention relates to a stable nanometer silver colloidal sol and a preparation method thereof. The stable nanometer silver colloidal sol adopts a silver containing compound, a protective agent and a solvent, water is used as the solvent, and the silver containing compound, the protective agent and the water are mixed so as to prepare the colloidal sol; and the particle diameters of nanometer silver grains are 1nm-10nm, and the nanometer silver grains are uniformly distributed in the colloidal sol, and can be preserved for 6 months to 24 months without changing at room temperature. The preparation method provided by the invention comprises the following steps of: adopting the silver containing compound and the protective agent as raw materials, adopting the water as the solvent, mixing the silver containing compound, the protective agent and the water so as to form a mixed solution which contains 200-10000ppm of silver, 0.02%-1% of protective agent, and the balance of water according to weight percent; and dissolving and mixing the components when the stable nanometer silver colloidal sol is prepared, then uniformly stirring, conducting ultrasonic processing, using a light source containing ultraviolet rays to light 30 minutes to 24 hours to obtain the nanometer silver colloidal sol containing the nanometer silver grains. The stable nanometer silver colloidal sol and the preparation method thereof provided by the invention have the advantages that the cost is low, the process is simple, and the stable nanometer silver colloidal sol is suitable for large-scale preparation.

Owner:WUHAN KANGYIN GAOKE

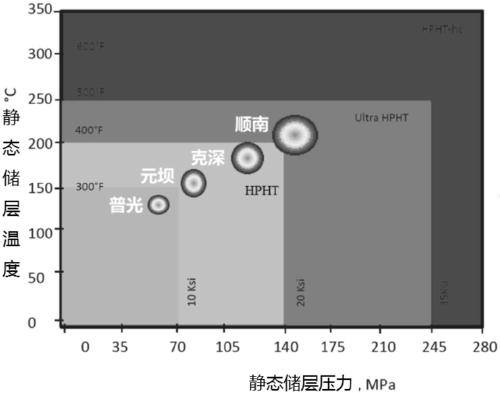

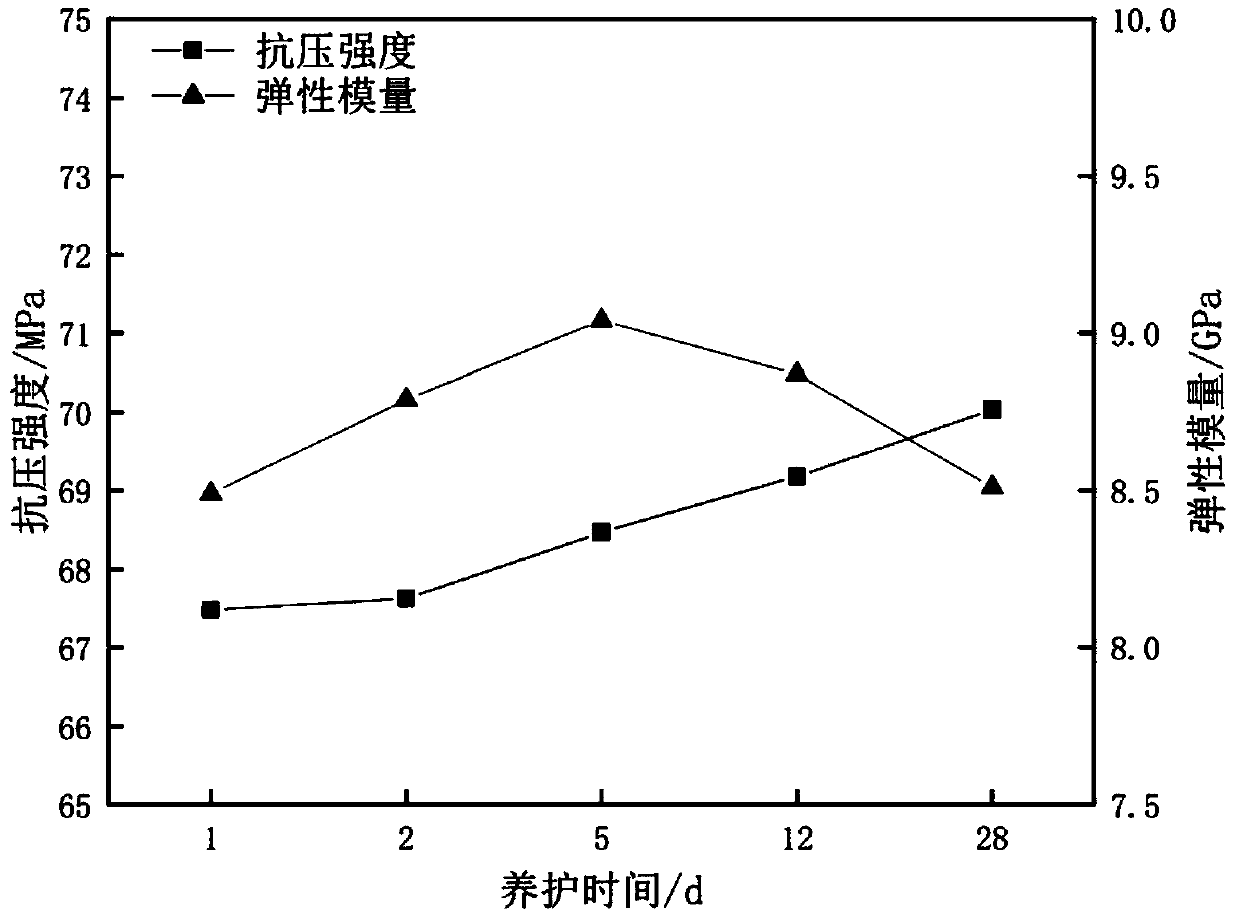

Nano-material mixed modified superhigh-temperature high-performance well cementing slurry system and preparation method thereof

The invention relates to a nano-material mixed modified superhigh-temperature high-performance well cementing slurry system and a preparation method thereof. The slurry system comprises the followingingredients in parts by weight: 100 parts of oil well cement, 15-25 parts of coarse silica sand, 15-20 parts of fine silica sand, 1-10 parts of nano-silicon dioxide, 1-10 parts of nano-calcium carbonate, 0.2-1 part of a defoaming agent, 4-10 parts of a fluid loss agent, 0-3 parts of a drag reduction agent, 0.5-4 parts of a retarder and 30-100 parts of water. In the slurry system, set cement has excellent compressive strength and toughness under superhigh temperature, and the compressive strength and the elasticity modulus cannot be obviously changed as the maintenance time is prolonged. The slurry system has good rheological property, lower water loss and proper thickening time, and the comprehensive properties of the slurry system can completely meet the related requirements of site wellcementing construction, so that the technical support is provided for well cementing under high temperature. A nano-material obtained by mixing the nano-silicon dioxide and the nano-calcium carbonateis added, and micropores of the set cement can be effectively filled, so that the system becomes denser. Therefore, the volume shrinkage of the set cement is relieved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com