Preparation method of low-cost high-alumina ceramic thin plate

A high-aluminum ceramics, low-cost technology, applied in the field of architectural ceramics, can solve the problems of high cost and limit the application of ceramic sheets, and achieve the effects of improving strength, extending crack propagation paths, and dispersing stress in the body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

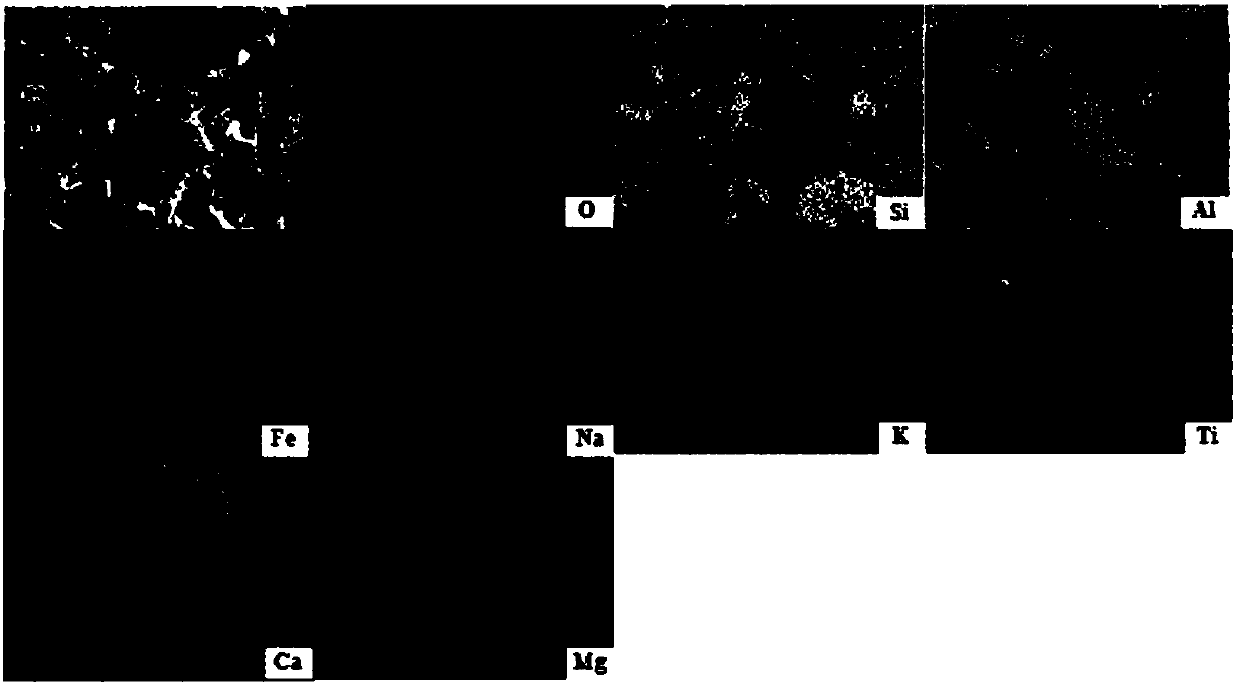

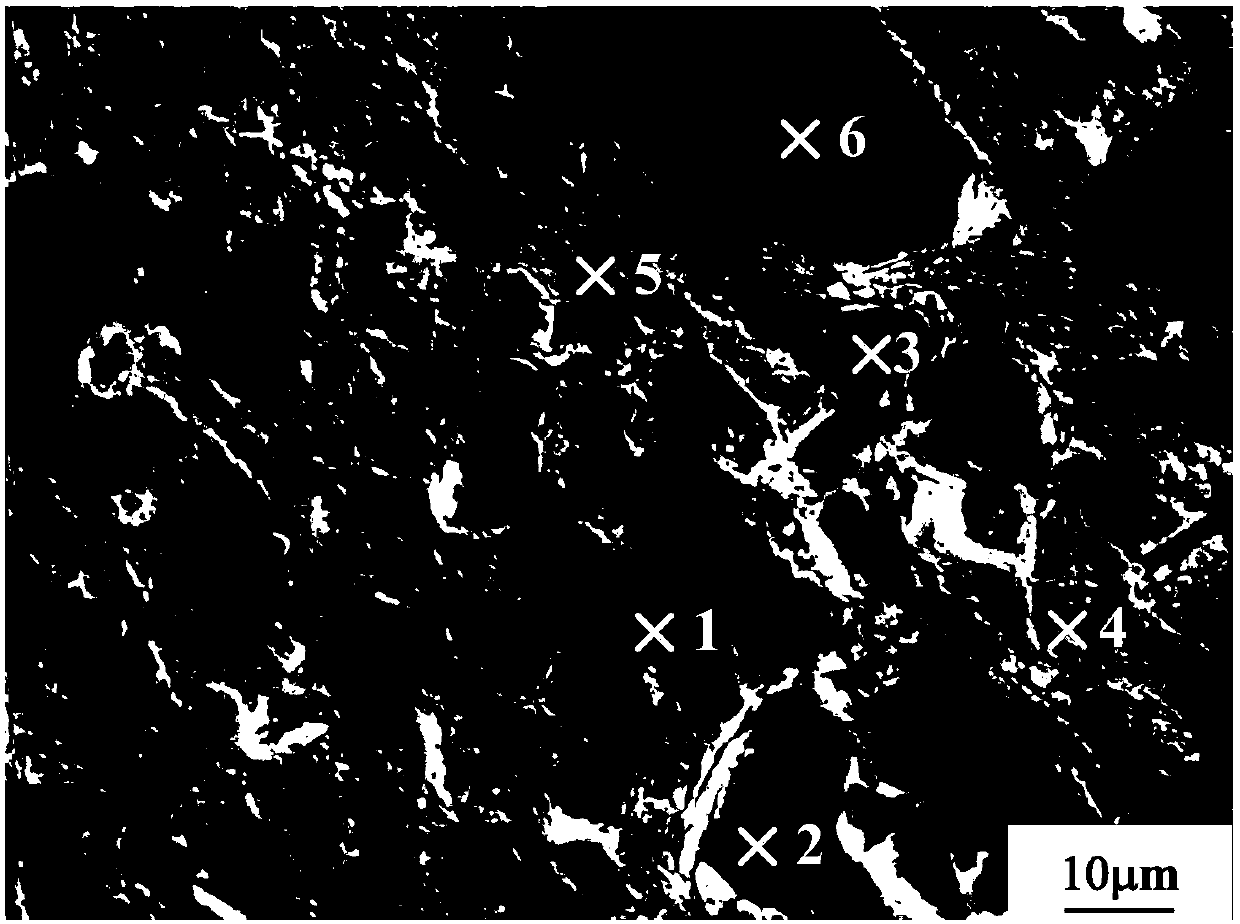

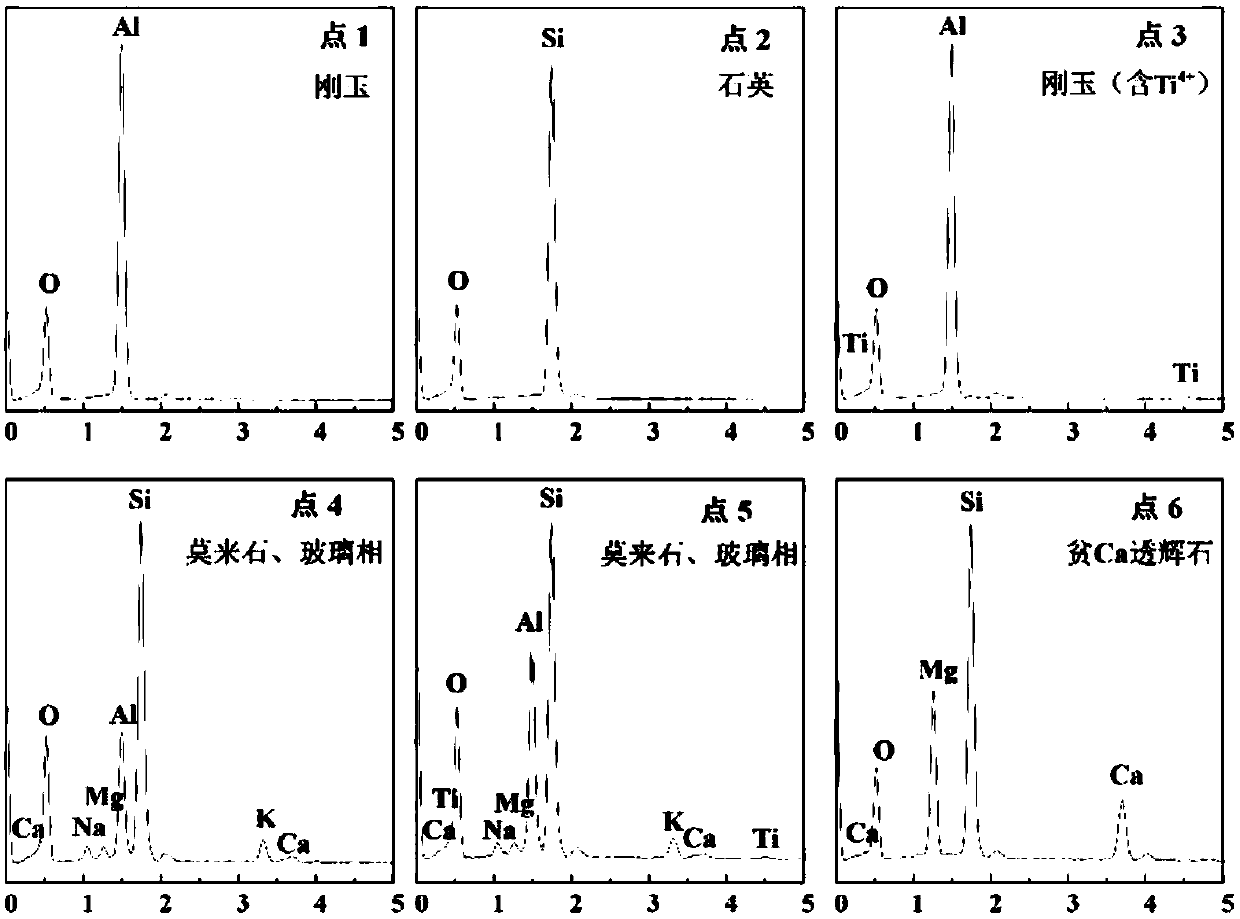

[0029] A method for preparing a low-cost high-alumina ceramic thin plate, which comprises the following steps:

[0030] 1) Raw material processing: Coal-based kaolin, calcined bauxite, ordinary kaolin, feldspar (feldspar is potassium feldspar and albite), talc, and quartz are ball-milled for 16 hours respectively, and sieved to prepare powder for later use. Calcined bauxite requires a 325-mesh sieve, and coal-series kaolin, ordinary kaolin, feldspar, talc, and quartz all pass through a 250-mesh sieve. The coal series kaolin is the coal series kaolin raw ore provided by Shanxi Gold Ocean Energy Co., Ltd. The calcined bauxite is Henan Xinmi calcined bauxite with a particle size of 325 meshes. The ordinary kaolin, feldspar, talc and quartz are from Xiangyang Gaoming Mining Co., Ltd., the green body strengthening agent is TY-2 green body strengthening agent of Jingdezhen Ceramic University;

[0031] 2) Proportion and mixing of raw materials: according to the mass percentage of ea...

Embodiment 2

[0043] A method for preparing a low-cost high-alumina ceramic thin plate, which comprises the following steps:

[0044] 1) Raw material processing: Coal-based kaolin, calcined bauxite, ordinary kaolin, feldspar (feldspar is potassium feldspar and albite), talc, and quartz are ball-milled for 18 hours with a ball mill, and sieved to prepare powder for later use. Calcined bauxite requires a 325-mesh sieve, and coal-series kaolin, ordinary kaolin, feldspar, talc, and quartz all pass through a 250-mesh sieve. The coal series kaolin is the coal series kaolin raw ore provided by Shanxi Gold Ocean Energy Co., Ltd. The calcined bauxite is Henan Xinmi calcined bauxite with a particle size of 325 meshes. The ordinary kaolin, feldspar, talc and quartz are from Xiangyang Gaoming Mining Co., Ltd., the green body strengthening agent is TY-2 green body strengthening agent of Jingdezhen Ceramic University;

[0045] 2) Proportion and mixing of raw materials: according to the mass percentage o...

Embodiment 3

[0053] A method for preparing a low-cost high-alumina ceramic thin plate, which comprises the following steps:

[0054] 1) Raw material processing: Coal-based kaolin, calcined bauxite, ordinary kaolin, feldspar (feldspar is potassium feldspar and albite), talc, and quartz are ball-milled for 20 hours respectively with a ball mill, and sieved to prepare powder for later use. Calcined bauxite requires a 325-mesh sieve, and coal-series kaolin, ordinary kaolin, feldspar, and talc all pass through a 250-mesh sieve. The coal series kaolin is the coal series kaolin raw ore provided by Shanxi Gold Ocean Energy Co., Ltd. The calcined bauxite is Henan Xinmi calcined bauxite with a particle size of 325 meshes. The ordinary kaolin, feldspar, talc and quartz are from Xiangyang Gaoming Mining Co., Ltd., the green body strengthening agent is TY-2 green body strengthening agent of Jingdezhen Ceramic University;

[0055] 2) Proportioning and mixing of raw materials: according to the mass perc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com