Patents

Literature

1384 results about "Dry pressing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dry pressing is characterized by low residual moisture showing a tendency towards zero. Dry pressing does not require further drying which makes the method ideally suited for parts requiring high dimensional stability and large quantities. Basically, all ceramic materials can be used. A pressing tool...

Lightweight ceramic tile and production method

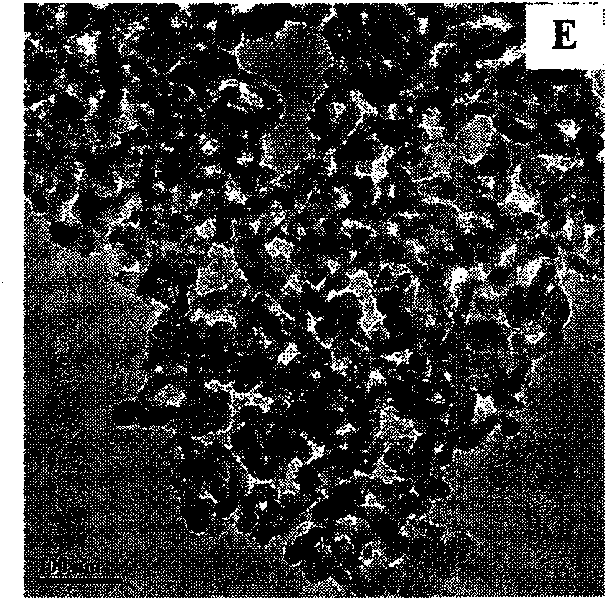

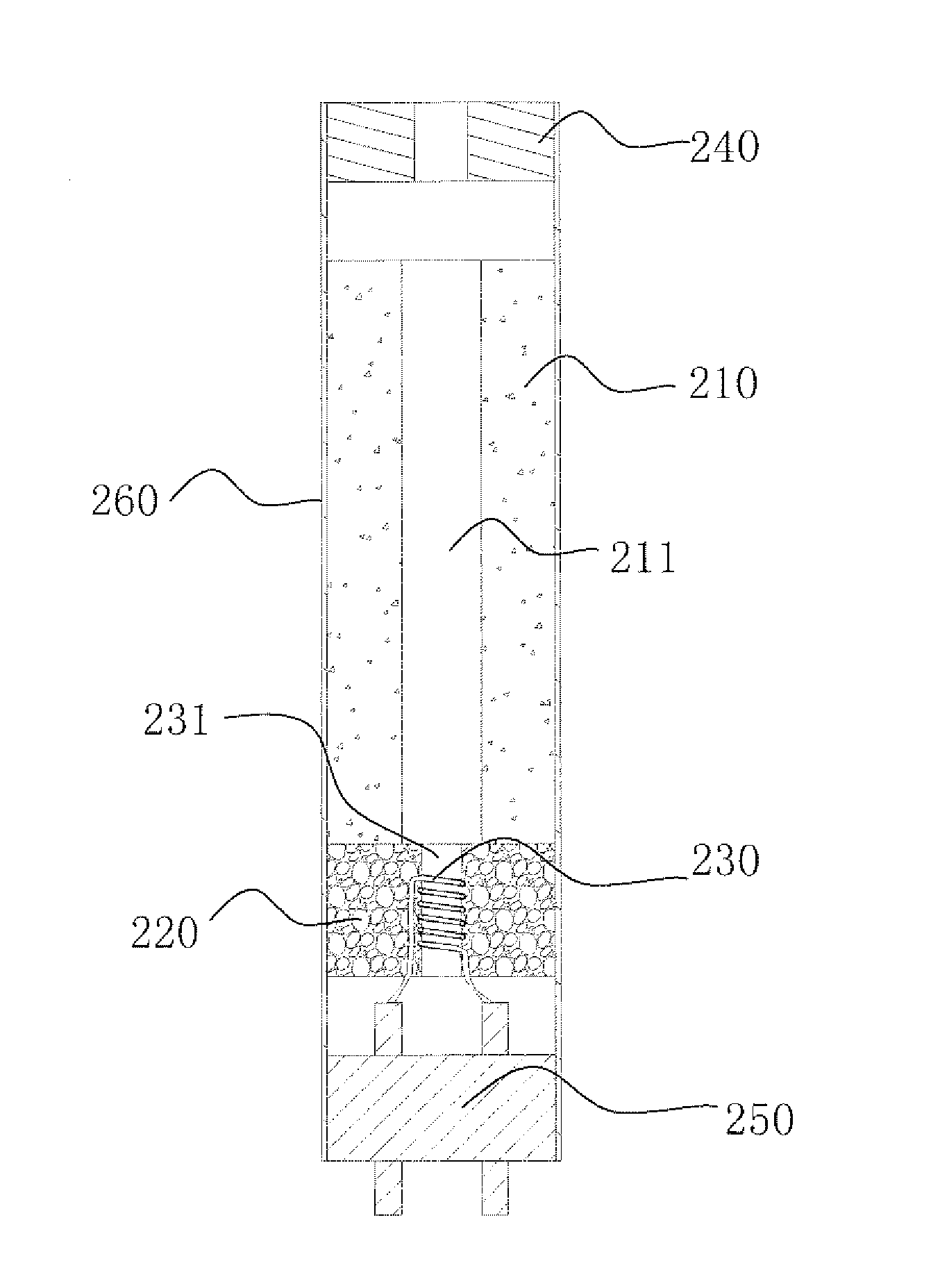

The invention discloses a light-weight ceramic brick, which is a light-weight ceramic brick fired at high temperature and has a honeycomb-like internal structure of closed pores. The invention also discloses a preparation method of the above-mentioned lightweight ceramic tiles, which is formed by dry pressing after wet ball milling, sieving, iron removal, spraying drying tower and powder spraying on the vitrified brick polishing waste produced in large quantities in the ceramic industry at present. Method forming, or kneading using wet extrusion molding, and then firing products in continuous or batch kilns. Manufacture a kind of lighter quality ceramic tiles, aiming at the insufficient use of waste materials in the past, more effectively utilize industrial waste residues in large quantities, and because of its light structure, it can be used in the decoration of high-rise building walls, It has good properties such as light weight, high strength, heat preservation, and sound absorption, and it can significantly reduce the weight of the wall structure. At the same time, it also has the characteristics of easy transportation, easy construction, and fast speed. It has great advantages in saving energy and reducing the weight of buildings. The outstanding advantage is that it is an environment-friendly building ceramic decoration material.

Owner:FOSHAN OCEANO CERAMICS

Preparation method of composite silicon carbide ceramic filter membrane material

InactiveCN102718494AAvoid enteringSimple processSemi-permeable membranesCeramicwareFiberTransition layer

The invention belongs to the technical field of porous ceramic filter membrane, and relates to a preparation method of composite silicon carbide ceramic filter membrane material. The preparation method includes: well mixing silicon carbide, ceramic binder, pore-forming agent, and cellulose sodium carboxymethyl solution, forming by dry pressing to obtain a green body of a silicon carbide porous ceramic support, spreading and coating a layer of filler powder on surface of the green body, forming by dry pressing, coating ceramic fiber mixture on the surface, forming by dry pressing, coating filter membrane mixture, forming by dry pressing, and sintering to obtain the composite silicon carbide ceramic filter membrane material. The preparation method has the advantages that process is simple, volatile filler is sintered to seal pores on the surface of the support, a ceramic fiber transition layer is introduced, entering of the filter membrane material into base material can be effectively avoided, evener and smoother composite silicon carbide ceramic filter membrane material can be prepared by single sintering, and the preparation method is high in efficiency, low in energy consumption and the like.

Owner:HAINAN UNIVERSITY

Reaction sintering silicon carbide ceramic and production method thereof

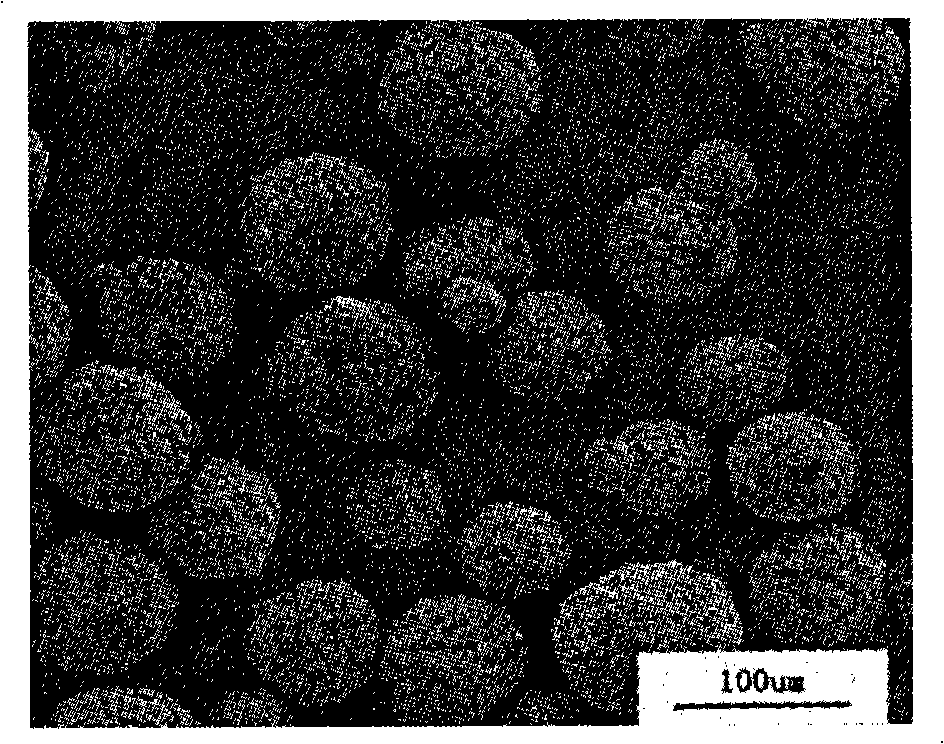

The invention relates to reactive sintering carborundum ceramics, which is characterized in that the weight percentages of the components are as following: carborundum is 80 to 95 percent, powdered carbon is 5 to 20 percent, and sintering accessory ingredient is 1 to 2 percent. The preparation method is as following: the raw materials are put into de-ionized water and caking agent, water-soluble macromolecule mixture collosol and dispersant are added; mixing by ball milling is carried out for 5 to 20 hours to form water-based carborundum sizing agent; spray dry technique is adopted to carry out spraying and drying the sizing agent, thereby obtaining carborundum compound powder amyloplastid; the amyloplastid is carried out dry pressing to obtain carborundum ceramics biscuits; the biscuits are put into a vacuum response sintering furnace for siliconizing and sintering; preparing the reactive sintering silicon carbide ceramics at the temperature of 1500 to 1800 DEG C after heat preservation for 1 to 5 hours. The reactive sintering silicon carbide ceramics of the invention has the advantages of scientific and rational raw materials and mixture ratio, safe production method and low cost. The prepared carborundum ceramics can meet requirements of mechanical seal under special working conditions.

Owner:浙江东新新材料科技有限公司

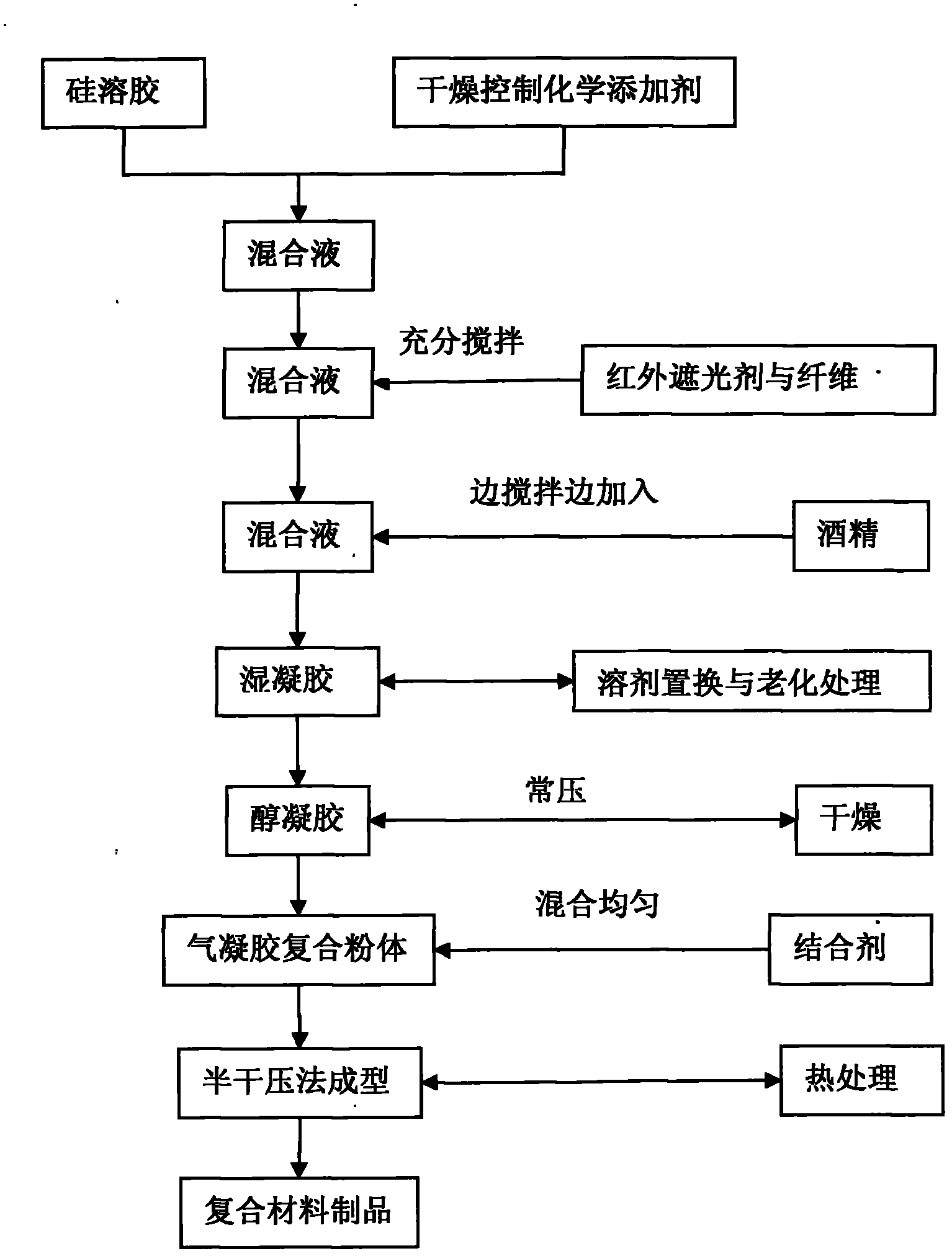

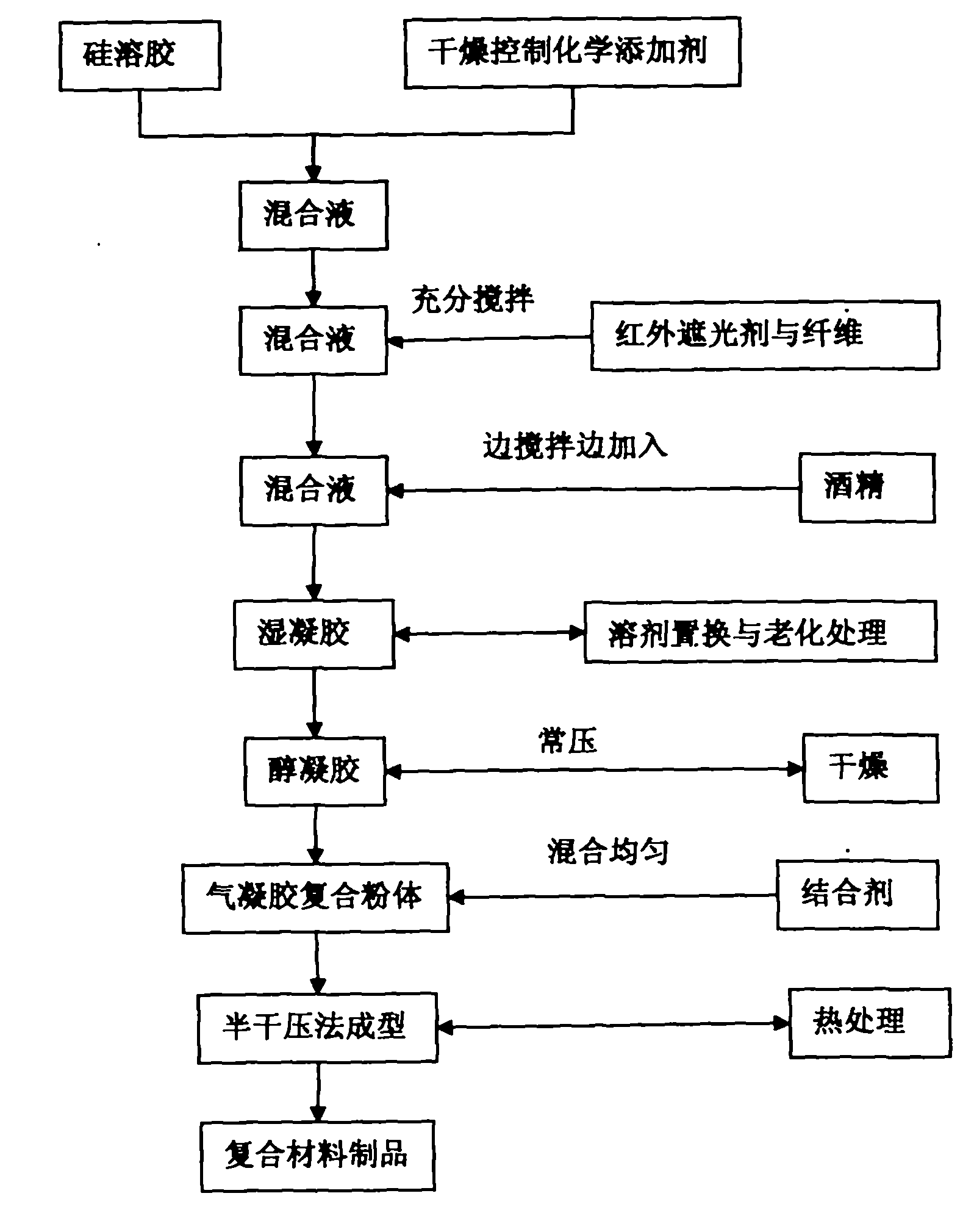

Method for preparing fiber-containing silicon dioxide aerogel composite thermal insulation material

The invention relates to a method for preparing a fiber-containing silicon dioxide aerogel composite thermal insulation material. The method is mainly characterized by comprising the following steps of: adding fiber and an infrared sunscreen agent into aerogel precursor solution to form composite gel, and treating the composite gel to obtain fiber-containing silicon dioxide aerogel composite powder; and adding a little binding agent and performing compression molding by adopting a half-dry pressing method, and performing heat treatment to obtain composite products in various shapes. By adopting a technical route for preparing the composite powder and molding by adopting the half-dry pressing method, products in complex shapes are easy to produce, supercritical drying at high cost and in danger of high pressure is avoided, and the method is easy for mass production. By taking industrial silica sol and industrial spirit as main raw materials for preparing silicon dioxide aerogel, addinga drying controlled chemical additive, the infrared sunscreen agent and the fiber in turn and finally slowly adding the industrial spirit until gelling, the fiber and the infrared sunscreen agent canbe fully and uniformly mixed with the aerogel in the composite powder, the thermal insulation of the materials is improved, and a higher-strength light thermal insulation material is prepared.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Aluminium nitride ceramics material and preparation method thereof

ActiveCN101386539ADoes not significantly affect colloidal propertiesGood dispersion propertiesAluminium acetylacetonateNano al2o3

The invention discloses an aluminium nitride ceramic material and a preparation method thereof. The method is to add nano-alumina to raw materials in the prior preparation method for preparation according to the prior preparation process. In-situ growing nano-alumina can be obtained directly through adding the nano-alumina, or indirectly through adding organic aluminum, such as aluminium secondary butylate, aluminium isopropoxide or aluminium acetylacetonate, and by means of low-temperature decomposition of the organic alumina. The method can be applied to dry pressing and tape casting shaping, can obtain slurry with good dispersing characteristic and even mixing of the aluminium nitride and the nano-alumina by the ceramic preparation process, such as normal pressure, hot pressed sintering or the like, and is favorable for the improvement of sintering activity of materials, the reduction of sintering temperature, the improvement of luster uniformity, planeness and roughness for a ceramic substrate, and the reduction of production cost. The aluminium nitride ceramic material and the preparation method thereof can be widely applied to the field of aluminium nitride ceramic production.

Owner:无锡海古德新技术有限公司

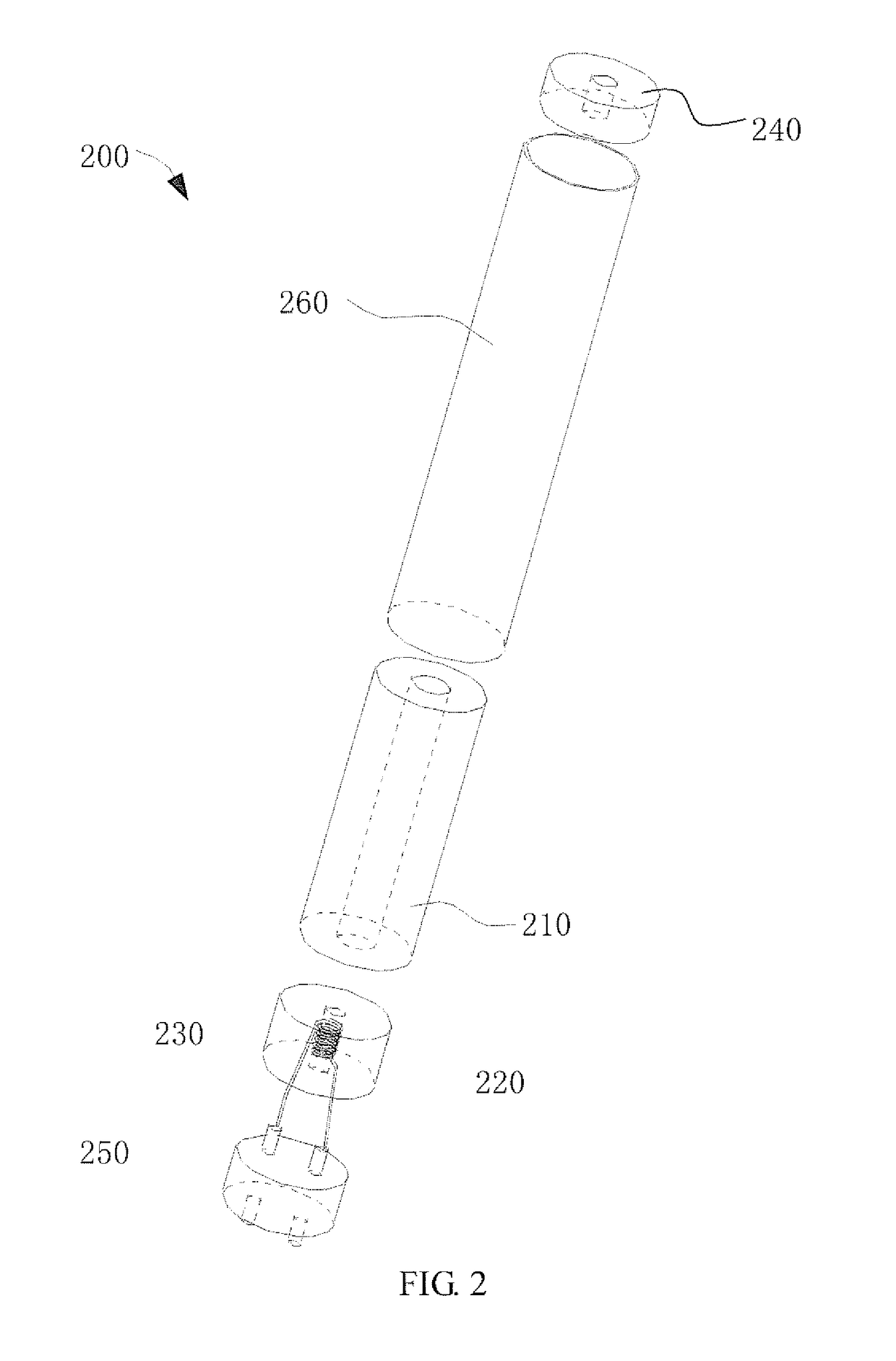

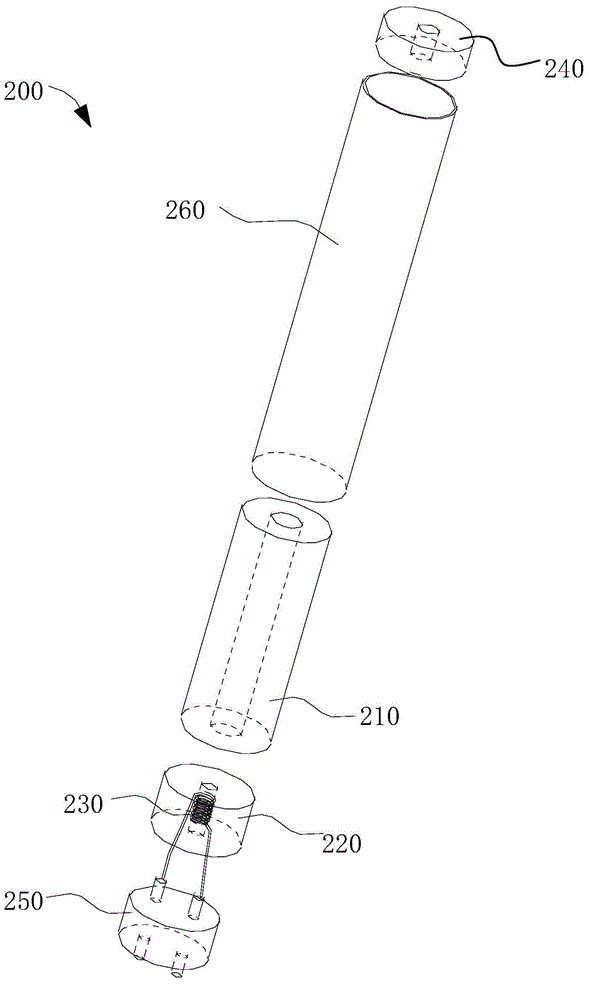

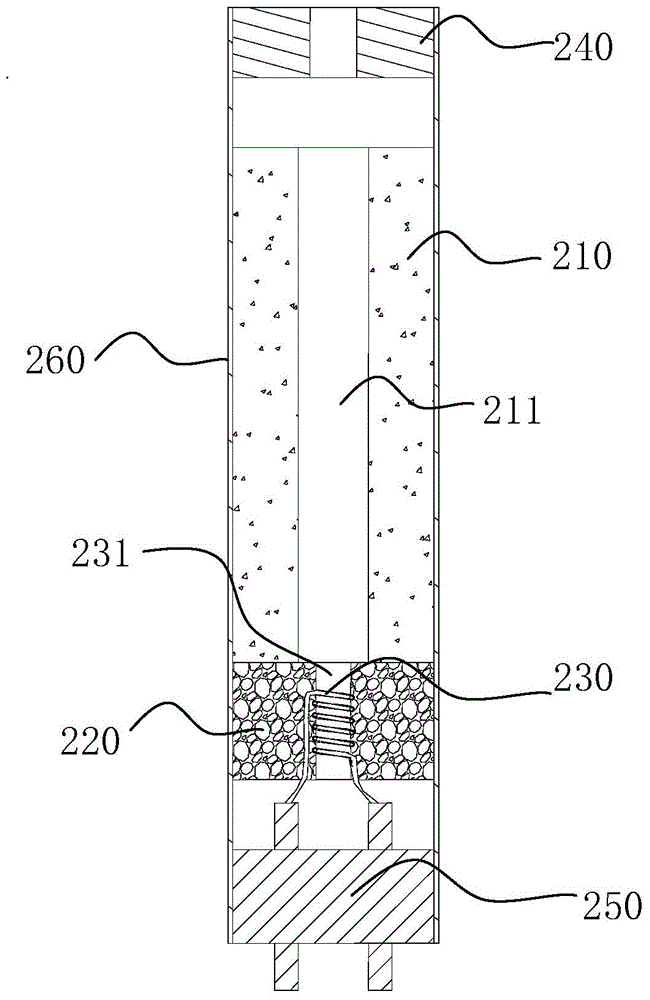

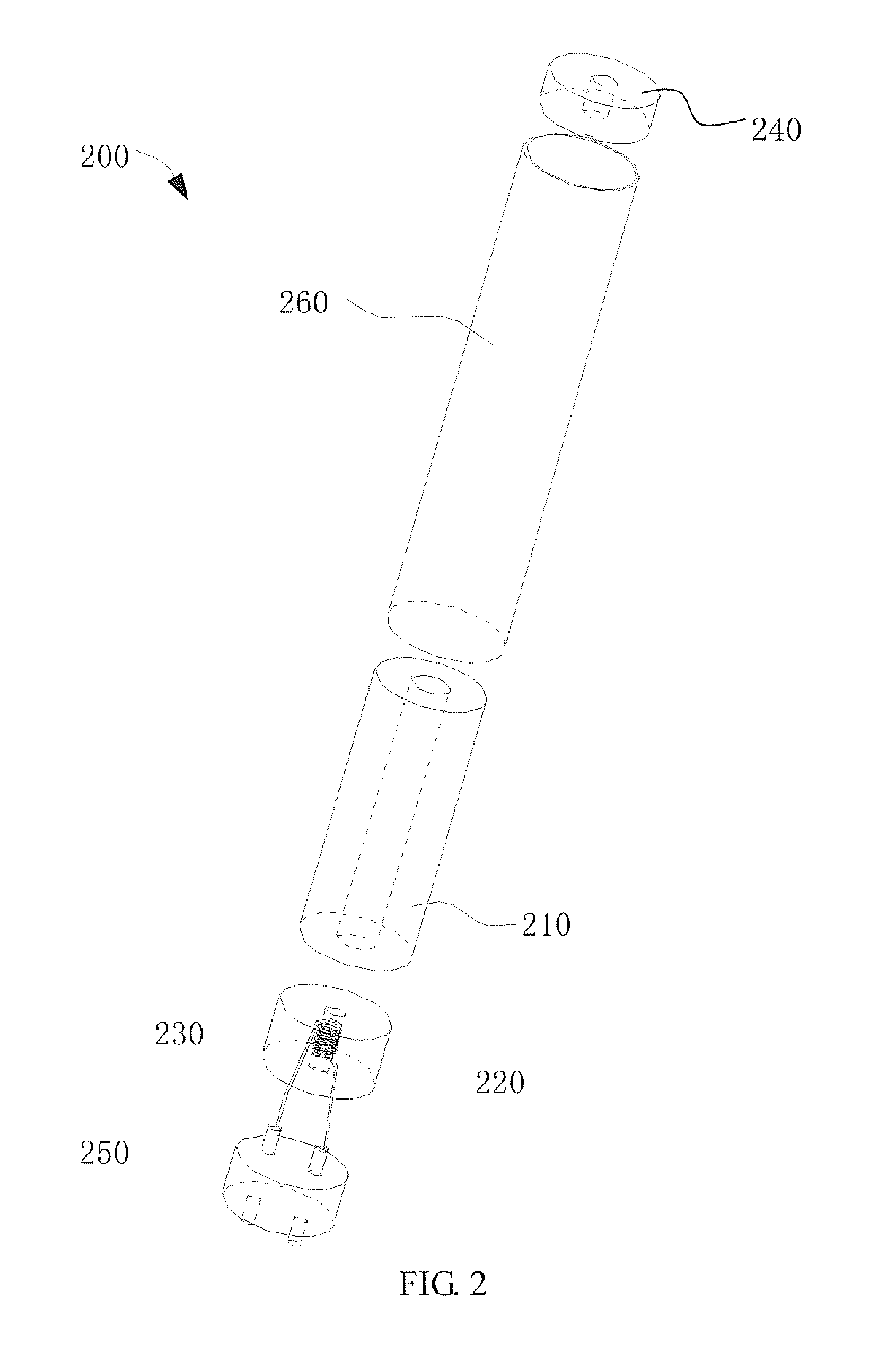

Porous ceramic material, manufacturing method and use thereof

ActiveUS9648909B2High porosityAperture controllableTobacco devicesCeramic shaping apparatusAdhesiveSpace Maintainers

Owner:SHENZHEN SMOORE TECH LTD +2

Method for producing ceramic tile by metallurgical steel slag

The invention discloses a method for producing a ceramic brick by metallurgical steel slag, which comprises the following steps: crushing waste slag after metallurgical steel-making; adding clay, talc, quartz and other materials to the waste slag according to the requirement of formulation property to mold a blank by a dry pressing method through ball milling by a wet method, and powdering by slurry spraying; drying and placing the molded blank into a roller kiln for maturing; and producing the matured product into a finished product through edging, polishing, grading and packaging. The invention can be widely applied in decoration, has the characteristics of environmental production, high strength, corrosion resistance, good decoration effect and so on. The method provided by the invention is simple and feasible, and is beneficial to industrial production.

Owner:GUANGXI OCEANO CERAMICS CO LTD

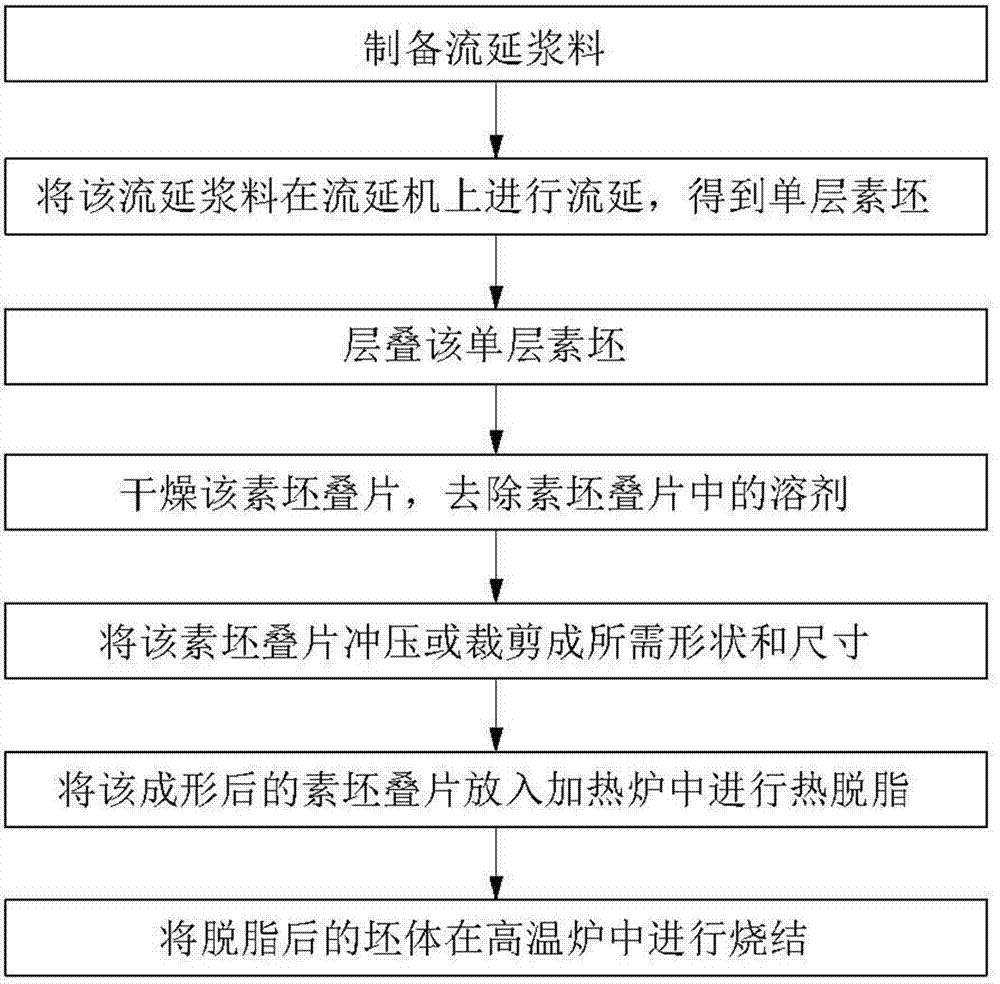

Hand-held terminal product appearance ceramic thin type member and production method thereof

A method for making a thin ceramic part involves making a casting slurry including a ceramic powder, a solvent, a binder, a plasticizer, and a dispersant. The casting slurry is tape casted to achieve a single layer green tape. At least two single layer green tapes are laminated to form a green tape lamination. The green tape lamination is dry pressed, dried, shaped, degreased, and fired to achieve the exterior component required.

Owner:TSINGHUA UNIV +1

Preparation method for uniform gradient-colour zirconium oxide porcelain blocks

ActiveCN104909745AContinuous uniform changeEasy to processImpression capsDentistry preparationsPolyethylene glycolMaterials science

The invention relates to zirconium oxide porcelain blocks for dental prosthesis, and aims at providing a preparation method for uniform gradient-colour zirconium oxide porcelain blocks. The preparation method comprises the following steps: (1) weighing the raw materials of CeO2, Fe2O3, ZrO2, Y2O3, Pr6O11 and Er2O3; (2) adding a polymer binder in the dried mixed powder, and granulating; (3) shaping the granulated material by a die by means of dry pressing to obtain porcelain block blanks; (4) carrying out isostatic cool pressing on the shaped porcelain block blanks; (5) pre-sintering the porcelain block blanks after the isostatic cool pressing; (6) flatly placing the pre-sintered porcelain block blanks in a dyeing container and dyeing, wherein the depth of soaking solution in the dyeing container is 0.1-5mm, the dyeing time is 1-3min, and the used dyeing solution comprises 1-5wt% of polyethylene glycol, 0.1-3wt% of erbium oxide, 0.5-10wt% of praseodymium oxide and the balance of ultrapure water; and (7) sintering the dyed porcelain blocks to obtain the uniform gradient-colour zirconium oxide porcelain blocks for dentistry. The porcelain blocks disclosed by the invention are stable and uniform in colouring, and continuous and uniform in colour changes.

Owner:CHENGDU BESMILE BIOTECH

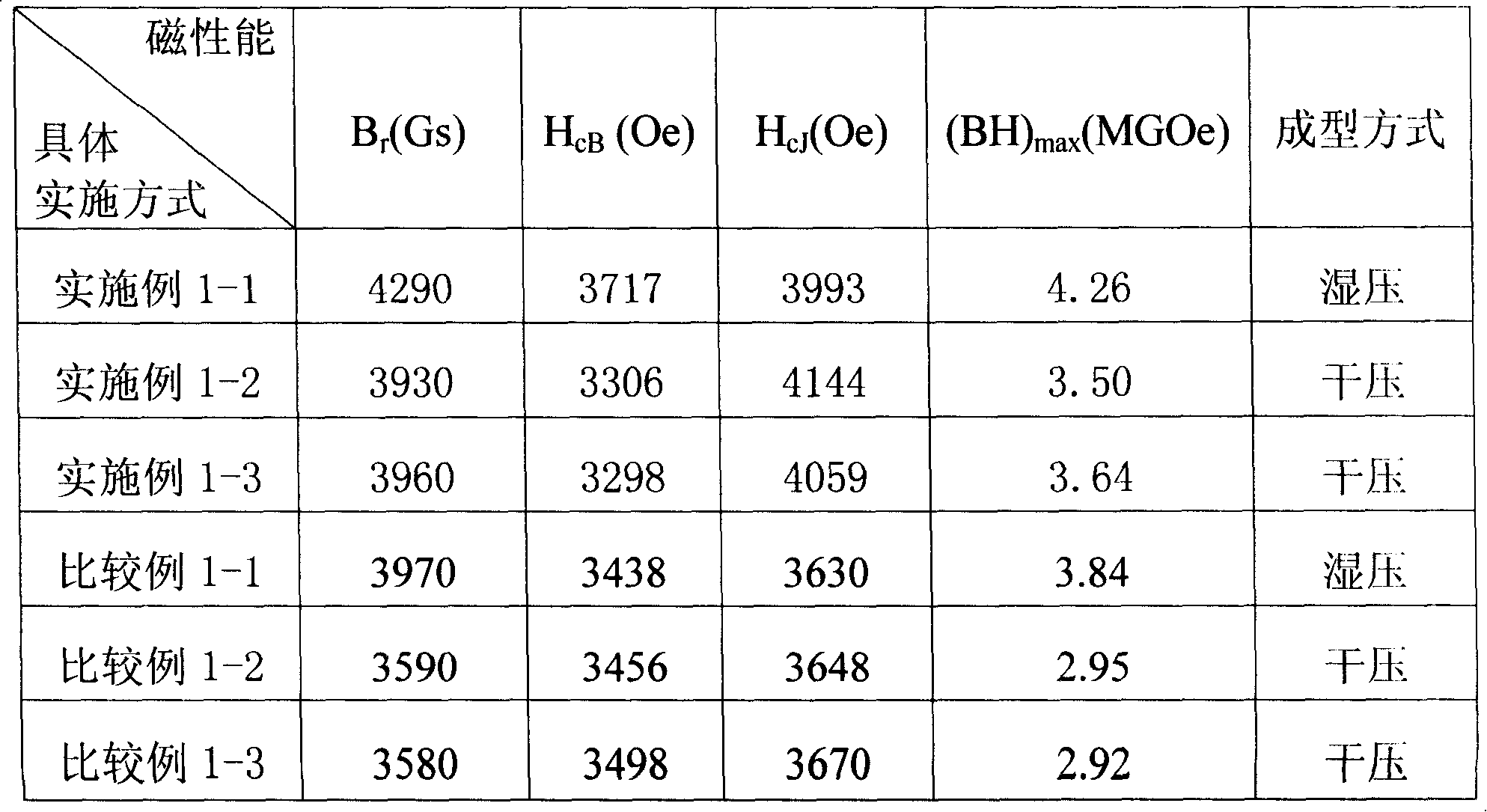

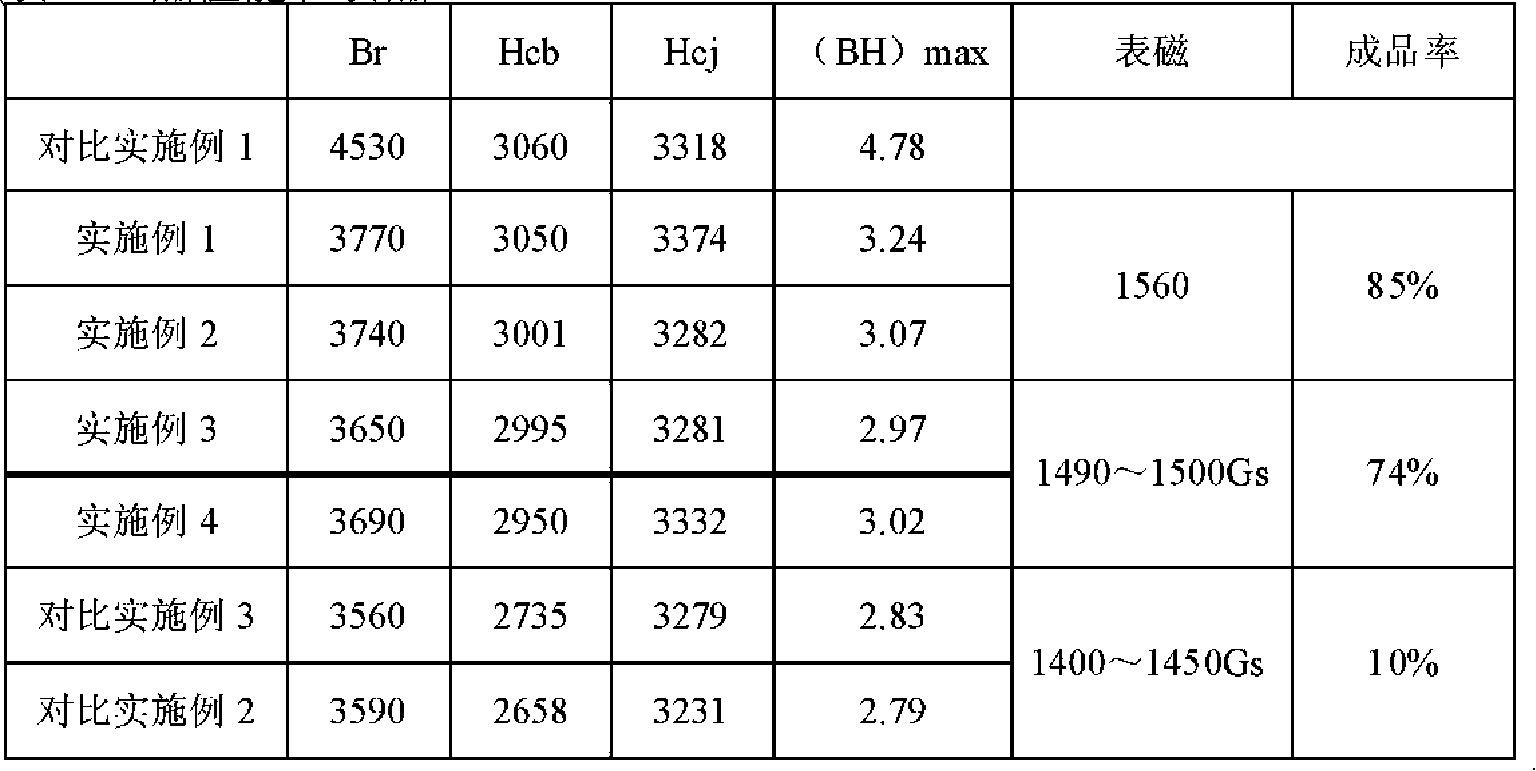

Method for manufacturing dry-pressing formed sintered permanent ferrite

InactiveCN101205137AIncrease productivityEasy to realize automatic moldingMetallurgyPolyethylene glycol

The invention relates to a manufacturing method of sintering permanent magnetism ferrite by dry-pressing molding. The method comprises following working procedures: crushing process, the preparation process of dry pressing the magnetic powder, dry pressing process and sinter process. The organic dispersant added in the crushing process is one or a plurality among polyethylene glycol, calcium stearate and calcium gluconate, and the content of the organic dispersant is 0.1wtpercent-1.5wtpercent; the bond added in the he preparation process of dry pressing the magnetic powder is one or a plurality among PVA, polyethylene glycol, camphor and stearate, and the content of the bond is 0.1wtpercent-1.5wtpercent. 1. The manufacturing method of sintering permanent magnetism ferrite by dry-pressing molding of the invention has the advantages of that the productivity effect is high, the molding mould is simple and the automation molding is easy to be realized; the surface of the molded finished product is lubricous and even, the fettling is not needed, and the workload of the post processing is decreased greatly; 2. The manufacturing method of sintering permanent magnetism ferrite by dry-pressing molding of the invention adopts the unique preparation technique of dry pressing the magnetic powder, and the orientation in the process of magnetic field press is relatively good, and the high Br and high HCJ dry-pressing sintering permanent magnetism ferrite is easy to be gained; 3. The manufacturing method of sintering permanent magnetism ferrite by dry-pressing molding of the invention adopts the pre-sintering material with a better performance of ion substitutional main prescription, and a dry-pressing anisotropic sintering permanent magnetism ferrite with a better magnetism performance can be achieved.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

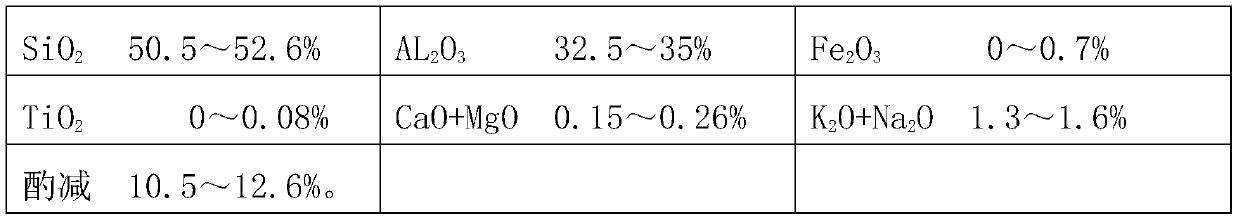

Preparation method of diatomite ceramic particles or ceramic plates

InactiveCN102093033AIncrease contentImprove adsorption capacityClaywaresExpanded clay aggregateVegetable fibers

The invention relates to a preparation method of diatomite ceramic particles or diatomite ceramic plates. The preparation method of the diatomite ceramic particles comprises the following steps: grinding diatomite, adding cosolvent, mineral powder and vegetable fiber powder to mix evenly and grind; and adding water to mix, shaking to obtain diatomite ceramic particles, and roasting to obtain the finished diatomite ceramic particles. The preparation method of the ceramic plates comprises the following steps: using evenly mixed powder to perform dry pressing with a pressure forming machine, or using mud with the water content of 15-25wt% to perform extrusion forming; and roasting to obtain the diatomite ceramic plates. The formed and dried diatomite ceramic plates or diatomite ceramic particles are soaked in slurry prepared from anatase titanium dioxide nanometer powder or metatitanic acid powder and then dried and roasted to obtain diatomite ceramic particles or diatomite ceramic plates with photochemical activity. In the invention, the low temperature sintering method is adopted to prepare the diatomite diatomite ceramic plates and ceramic particles which have high diatomite content and good adsorption property and water resistance and can be combined with various functional components on the surface. The diatomite ceramic products in the invention are convenient to use and have simple production technology and cheap and easy available raw materials.

Owner:JILIN UNIV +1

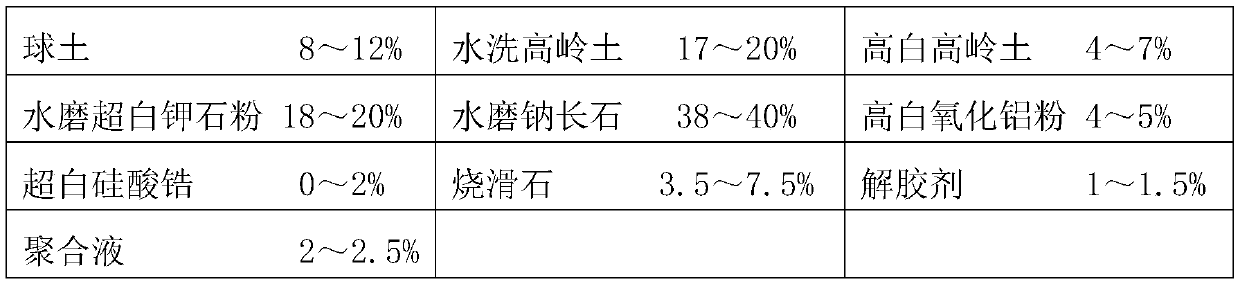

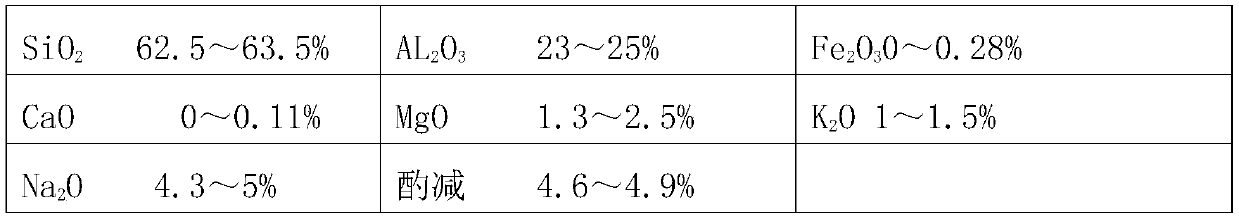

Thin ceramic rock plate and preparation method thereof

The invention relates to a preparation method of a thin ceramic rock plate. A thin ceramic rock plate blank is composed of the following components in percentage by weight: 8-12% of ball clay; 17-20%of washed kaolin; 4-7% of high-whiteness kaolin; 18-20% of water-milled ultra-white potash stone powder; 38 to 40% of water milled albite; 4-5% of high-whiteness aluminum oxide powder; 0-2% of ultra-white zirconium silicate; 3.5%-7.5% of calcined talc; 1 to 1.5% of a dispergator; and 2-2.5% of a polymerization liquid. The preparation method of the thin ceramic rock plate comprises the following steps: preparing a green body, processing a blank, spray-drying to prepare powder, dry-pressing to form, brushing the green body to remove ash, printing ground coat on a roller, decorating patterns, decorating a pattern protective layer, firing, polishing and edging.

Owner:JIANGXI HEMEI CERAMICS +3

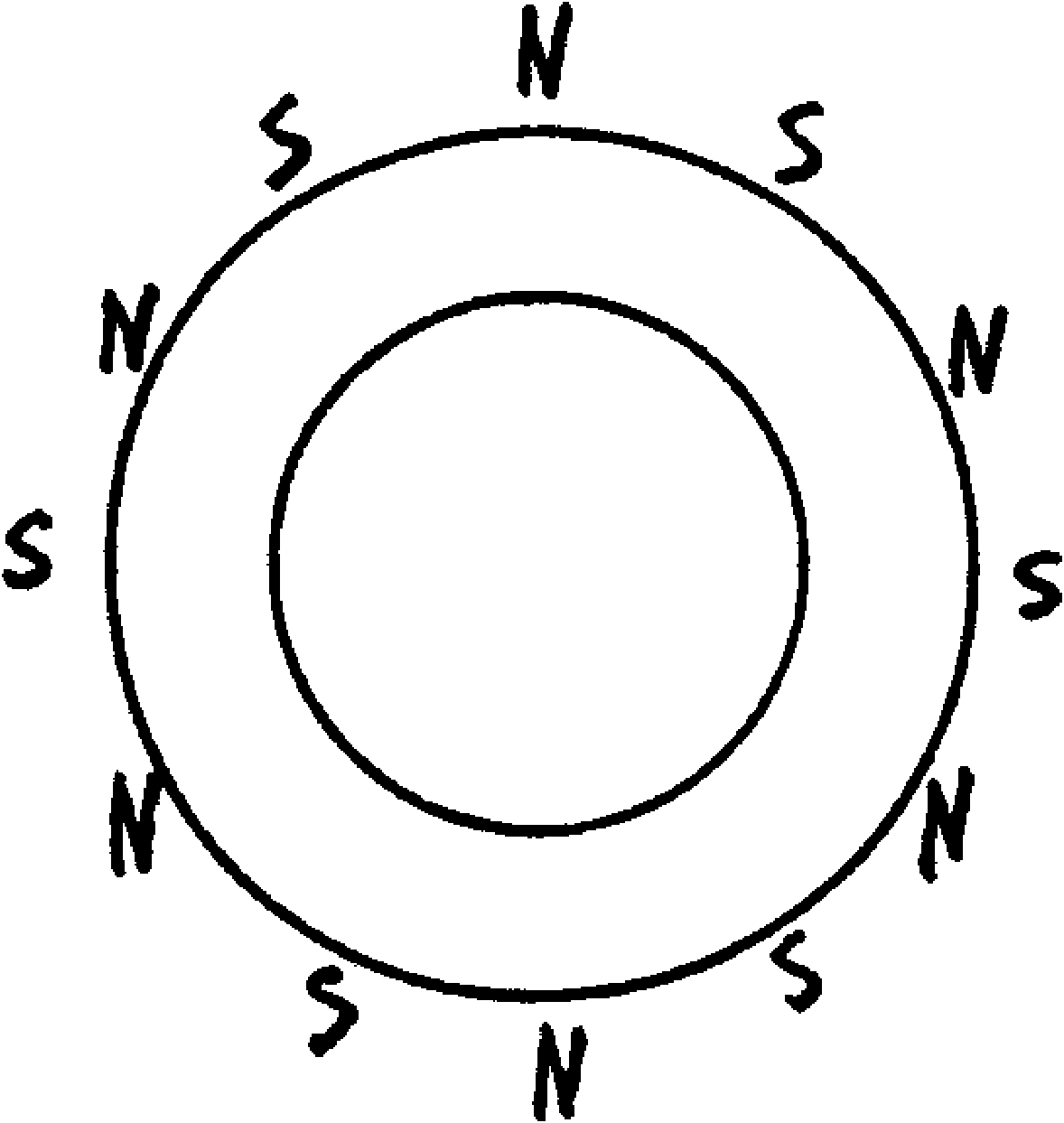

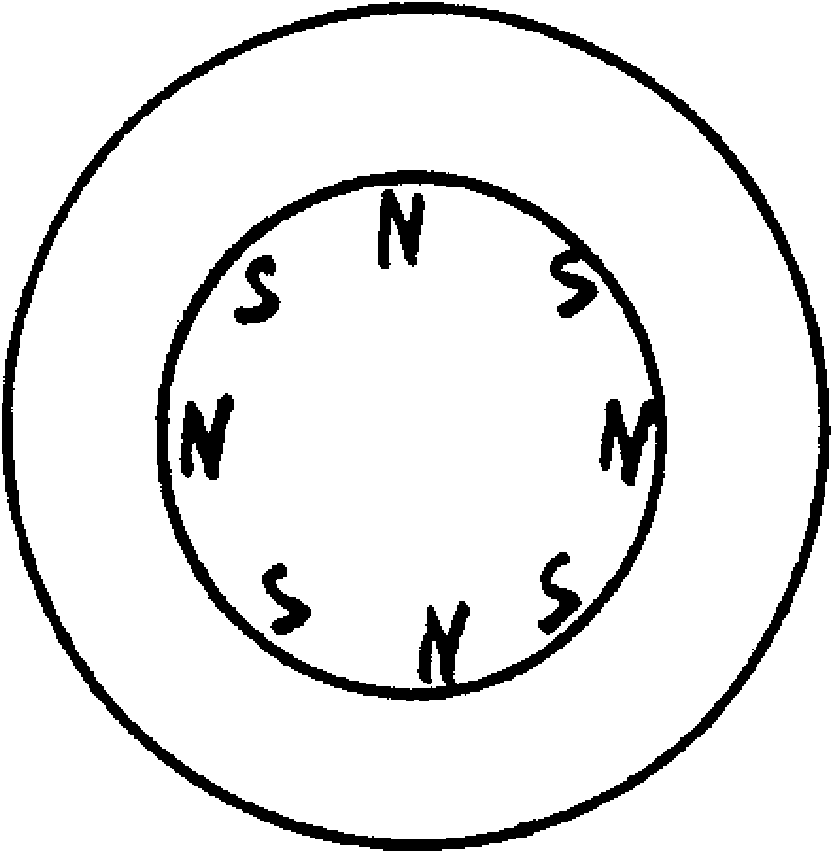

Method for manufacturing anisotropic multi-pole magnetic ring through dry-press forming

ActiveCN101599333AGood orientationWell formedCellulose derivative adhesivesWax adhesivesMetallurgyMagnetization

The invention relates to the field of magnetic materials, in particular to a method for manufacturing an anisotropic multi-pole magnetic ring through dry-press forming. Aiming at the problem that the multi-pole magnetic ring manufactured by the prior art through the dry-press forming is easy to crack, has low yield and the like, the invention provides the method for manufacturing the anisotropic multi-pole magnetic ring through the dry-press forming, and for the multi-pole magnetic ring manufactured by the method, the surface magnetism is more than 1,500 Gs, the Br is more than 3,600 Gs, and the Hcb is more than 3,000 Oe. The aim of the invention is achieved through the following technical proposal: performing wet method pulverization on magnetic powder; adding more than one binding agent and lubricating agent into the magnetic powder which is dried; then performing prepressing and pre-magnetization on the mixture, and then performing a mixing process for mixing the mixture by using a high-speed disintegrator; performing a double-sided equal pressure forming process on the powder in a radial magnetic field; and performing a sintering process for sintering the formed sample, wherein the magnetic powder contains a pre-sintering material and an additive.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Method for preparing rare earth-doped yttrium aluminum garnet transparent ceramic

ActiveCN101985397AHigh linear transmittanceImprove mechanical propertiesRare-earth elementSpray Granulation

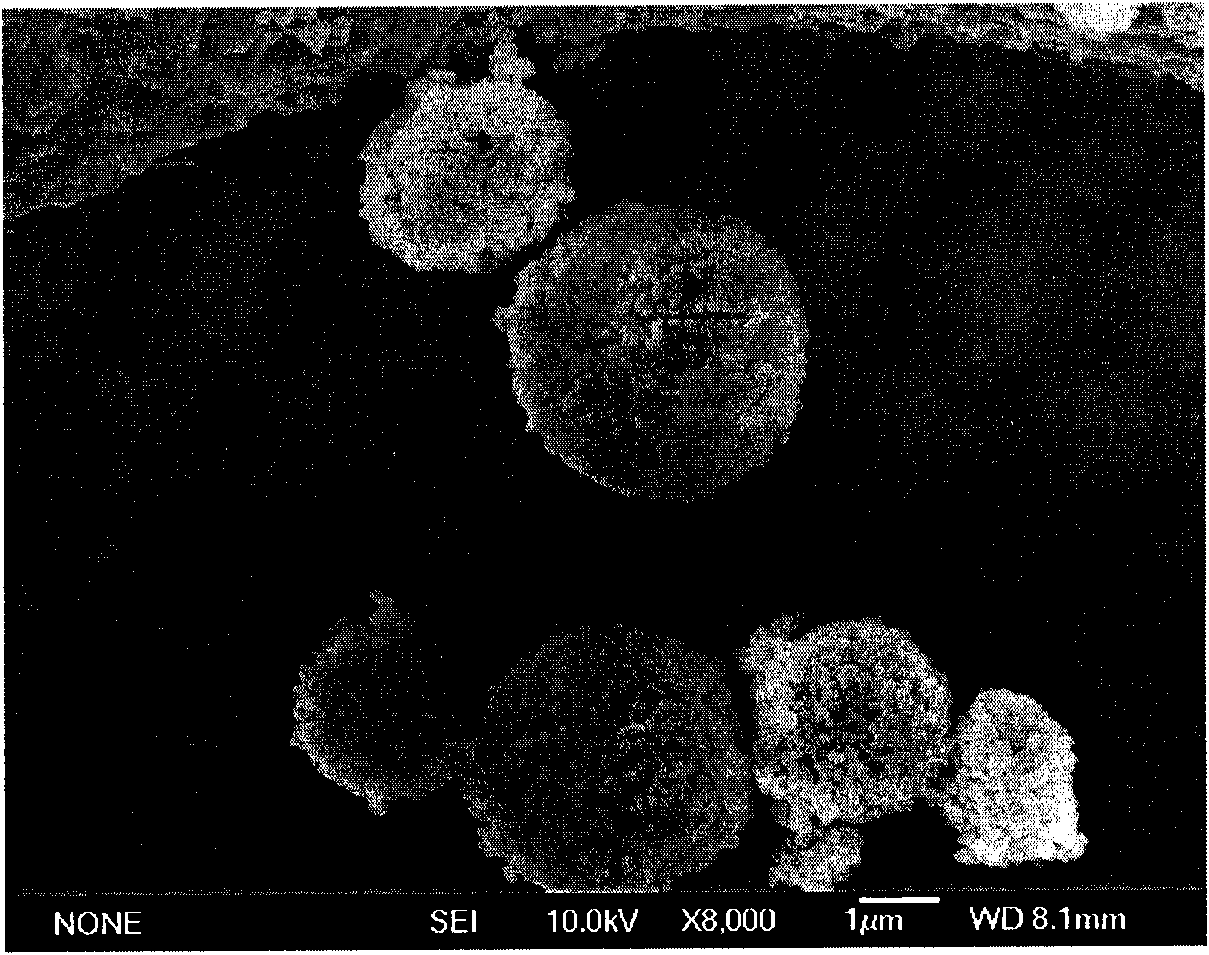

The invention relates to a method for preparing rare earth-doped yttrium aluminum garnet transparent ceramic. In the invention, high-transparency polycrystalline ceramic is prepared by using commercial powdered Y2O3, Al2O3 and Re2O3, of which the purities are over 99.9 percent, as main raw materials and by spray granulation dry pressing molding process and vacuum reaction and sintering, wherein the Re may be one or several of trivalent rare earth elements such as Nd<3+>, Yb<3+>, Cr<3+>, Er<3+>, Ce<3+>, Sm<3+> and Eu<3+>; MgO or CaO or tetraethyl orthosilicate (TEOS) or SiO2 is used as a sintering assistant; a certain amount of bonding agent, plasticizer and dispersant is added; the oxides, sintering assistant and additive are mixed and added into a liquid medium, and the mixture is ball-milled and mixed for 0.5 to 100 hours; after the powder materials are mixed uniformly, the powder is made into spherical or approximately spherical grains; blanks formed by drying pressing isostatic forming are degreased; sintering the blanks in a vacuum sintering furnace; and annealing after sintering. The transmissivity at a laser wavelength of the rare earth-doped yttrium aluminum garnet transparent ceramic prepared by the method is more than or equal to 77 percent.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

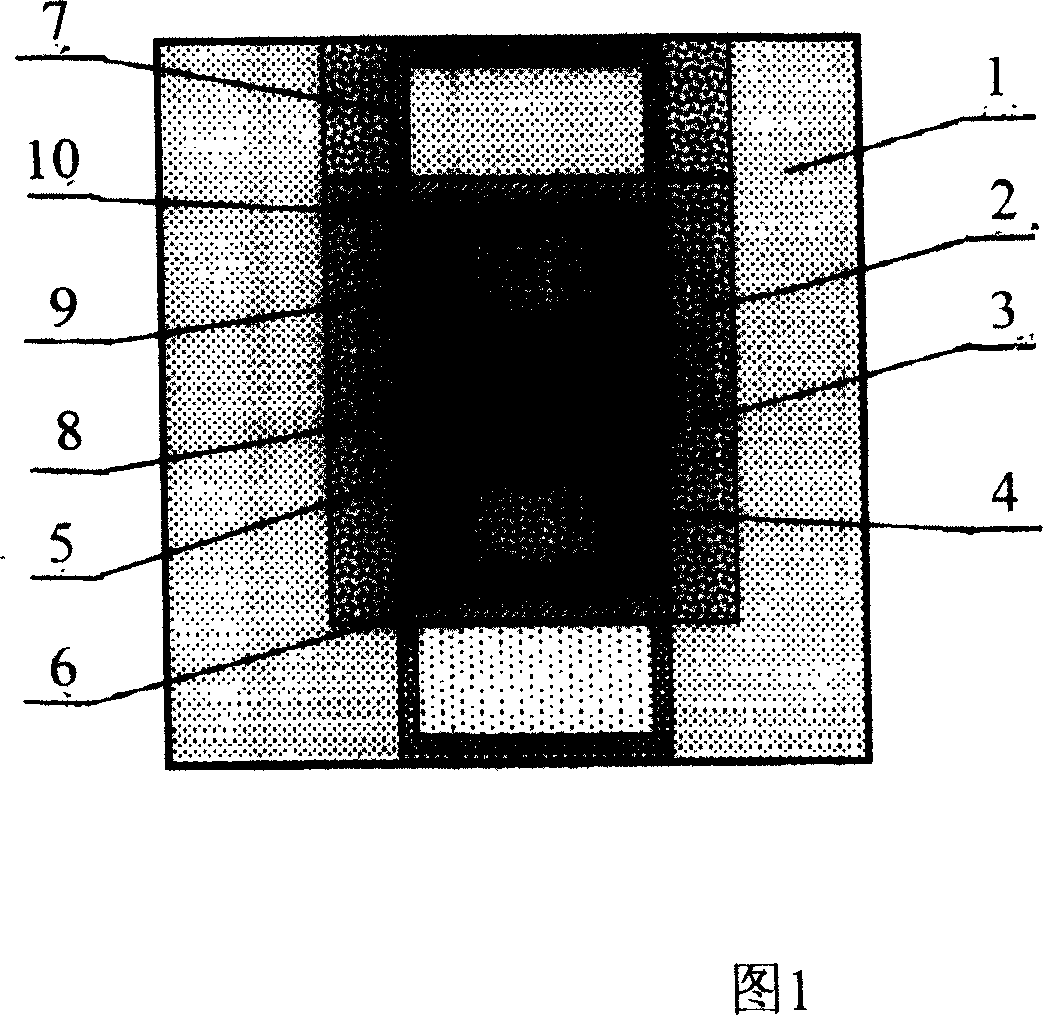

Hydroxyapatite-zirconium dioxide composite bioceramic material and its preparing method

The invention relates to a kind of hydroxyl apatite - zirconia compound biology ceramic material and its producing method, belonging to biology medical material producing technological field. The invention makes zirconia as substance central layer, on its upper and lower surfaces, respectively spread mix middle layer of zirconia and hydroxyl apatite mixed as per different proportion, on the most outside spread a surface layer of pure hydroxyl apatite, to form a kind of gradient nappe structure; in steel mould, at pressure of 10 - 30 MPa, dry press to molding, then at high temperature of 1500 - 1600 Deg. C, sinter without pressure, then can get hydroxyl apatite - zirconia compound biology ceramic material. The compound material produced by the method of the invention, its anti-bending strength is 900 - 1100 MPa, its fracture toughness (KIC) is 7 - 10 MPaíñm1 / 2, its roughness is 0.5 - 5.0 micron; the compound material has good biology compatibility, so can meet the requirement of load bearing planting body of different parts of human body.

Owner:SHANGHAI UNIV

Ceramics of containing powder body of cubic silicon nitride, and preparation method

This invention discloses a ceramic containing cubic nitride powder. The ceramic is composed of: gamma-Si3N4 5-100 wt.%, at least one of Al2O3, ZrO2, alpha- or beta-Si3N4, SiC, BN and AlN 0-95 wt.%, and at least one of Y2O3, Al2O3 and La2O (sintering aid) 0-10 wt.%. The ceramic is prepared by: preparing the raw materials, dry-cooling, grinding by isostatic cool pressing, dry-pressing, assembling the sintering chamber, and sintering under an ultrahigh pressure. The method has such advantages as simple process, easy operation, low sintering temperature, and short sintering time. The ceramic has such advantages as high compactness, uniform microstructure, and good mechanical properties, and can be used in the fields of mechanics, chemical engineering, aviation and photoelectronics.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Preparation method of low-cost high-alumina ceramic thin plate

The invention relates to a preparation method of a low-cost high-alumina ceramic thin plate. The preparation method of the low-cost high-alumina ceramic thin plate is characterized by including the steps: 1) raw material treatment; 2) raw material proportioning and mixing: weighing raw materials including, in weight percent, 10%-25% of coal series kaolinite, 10%-25% of calcined bauxite, 20%-30% ofcommon kaolinite, 15%-25% of feldspar, 0-5% of talcum and 18%-25% of quartz to obtain a blank; adding reinforcing agents equivalently accounting for 0.1%-0.25% of the total weight of the blank, performing ball milling for 12-18 hours and uniformly mixing the raw materials to obtain mixed materials; 3) pelleting and aging; 4) semi-dry pressing; 5) drying; 6) glazing; 7) sintering to obtain the low-cost high-alumina ceramic thin plate. The feldspar is formed by mixing potassium feldspar with soda feldspar, and the weight ratio of K2O to Na2O of the mixed feldspar chemical composition is 2:1. The sintering temperature of the high-alumina ceramic thin plate prepared by the method is only 1180 DEG C, so that the ceramic thin plate is low in cost and high in strength.

Owner:WUHAN UNIV OF TECH

Silicon carbide carbonized complex phase ceramic sealing material and preparation method thereof

InactiveCN101591169AImproved dry friction propertiesGood self-lubricating performanceWater basedHigh density

The invention relates to a silicon carbide carbonized complex phase ceramic sealing material, which comprises the following component in portion by weight: 100 portions of silicon carbide powder, 0.1 to 1 portion of boron carbide, 5 to 30 portions of carbon powder, 0.5 to 3 portions of binding agent PVA, and 0.5 to 1.5 portions of dispersing agent. A preparation method comprises the following steps in turn: (1) blending the raw materials in proportion and then adding the mixture into deionized water, and after ball milling and mixing, preparing the mixture into a water-based silicon carbide composite slurry of which the solid phase weight content is between 40 and 60 percent; (2) adopting a spraying granulating process to perform spray drying on the slurry to obtain silicon carbide granulated powder; (3) adopting a two-step mode of 140 MPa dry pressing pre-compaction and 200 MPa isostatic cool pressing final compaction to carry out forming on the granulated powder to obtain a high-density sealing material blank; and (4) putting the blank into a vacuum pressureless sintering furnace, raising the temperature to between 2,000 and 2,100 DEG C, keeping the temperature for 1 to 1.5 hours, and sintering the blank to obtain the silicon carbide carbonized complex phase ceramic sealing material.

Owner:东新密封有限公司

Machinable aluminium oxide ceramics and preparation method of machinable aluminium oxide ceramics

The invention discloses machinable aluminium oxide ceramics which is characterized in that the machinable aluminium oxide ceramics comprises the following components in percentage by mass: 60 percent to 68 percent of nano alumina, 30 percent to 36 percent of tabular alumina, 0.5 percent to 1.5 percent of magnesium oxide and 1 percent to 3 percent of titanium dioxide. A preparation method of the ceramics comprises the following steps of: preparing the nano alumina; after carrying out mixing and ball milling on the nano alumina, alumina, the magnesium oxide, titanium dioxide and absolute ethyl alcohol, drying the mixture, removing zirconium oxide grinding balls, and carrying out roasting, washing, filtering and drying on the obtained product to obtain composite powder; and after uniformly mixing the composite powder and a polyvinyl alcohol 1799 binder and pelleting the obtained mixture, carrying out dry-pressing forming to obtain a green body and placing the formed green body into a high temperature furnace to carry out sintering so as to obtain the ceramics. The bending strength of the ceramics reaches 526MPa. The fracture toughness of the ceramics reaches 6.4MPa.m1 / 2. The ceramicshave excellent machinable performance. The problems of complex structure and high cost and difficultly-controlled preparation process of the existing machinable ceramics are effectively solved.

Owner:SOUTHWEAT UNIV OF SCI & TECH

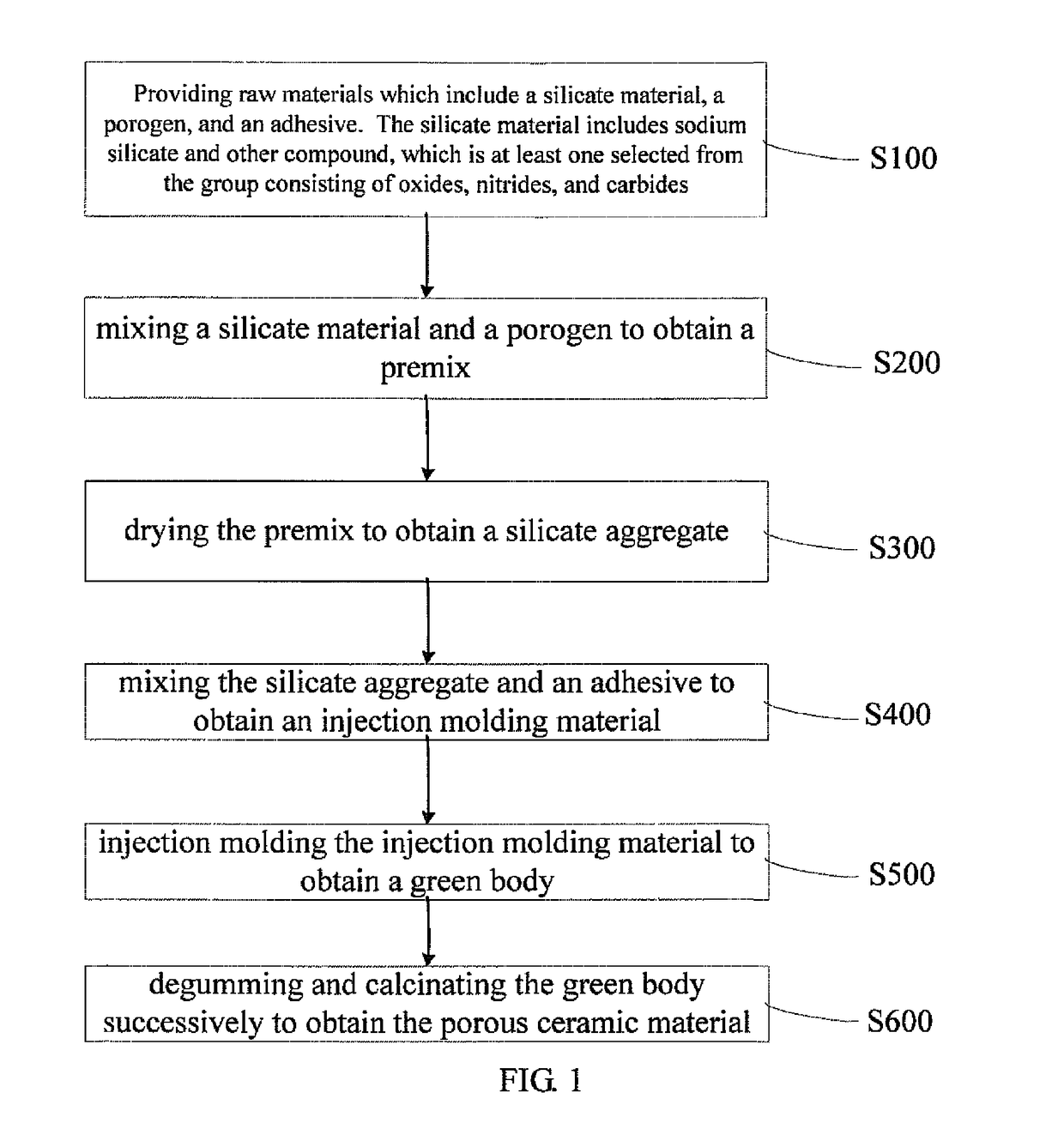

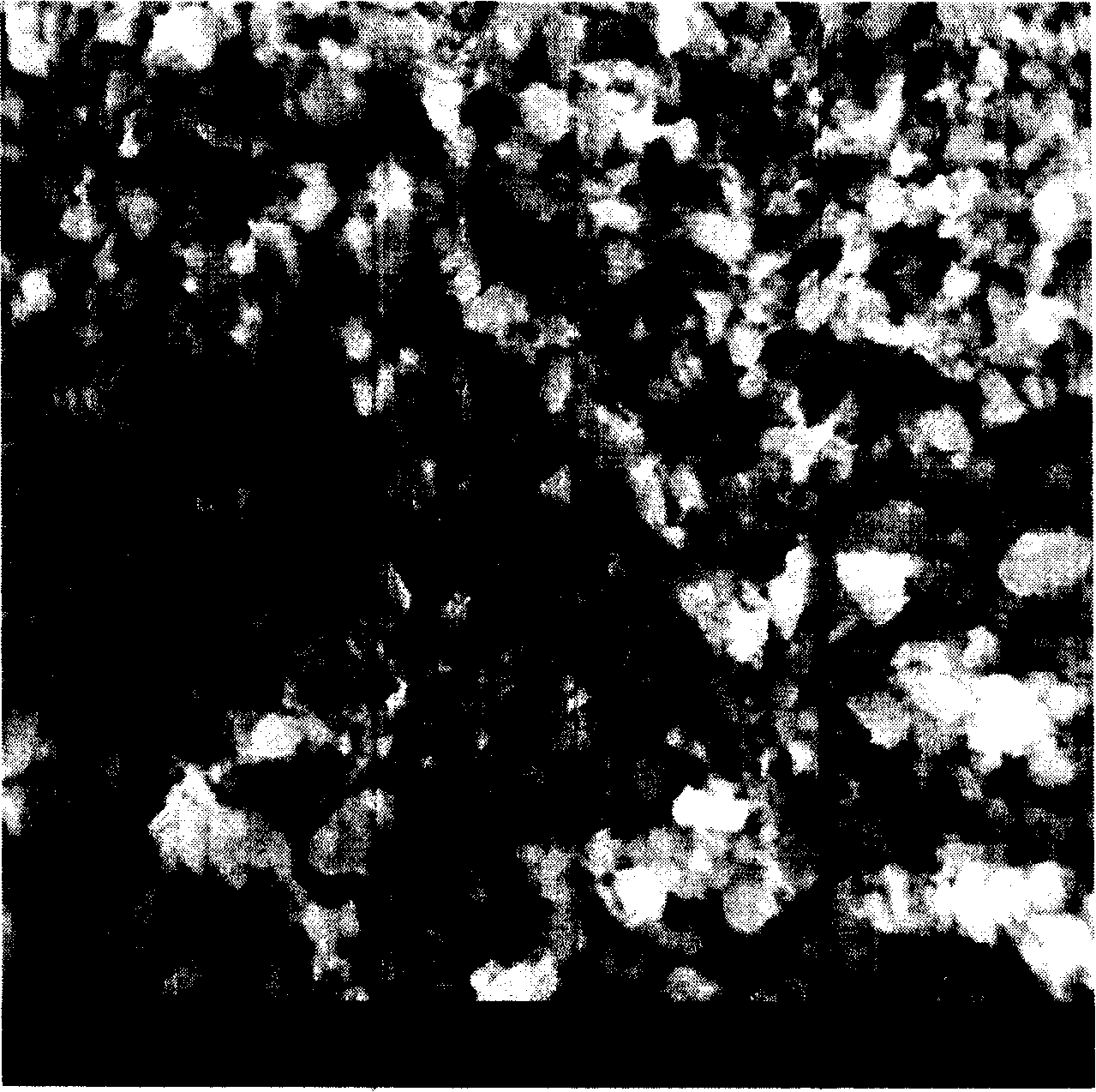

Preparation method of porous ceramic material, porous ceramic material and application of porous ceramic material

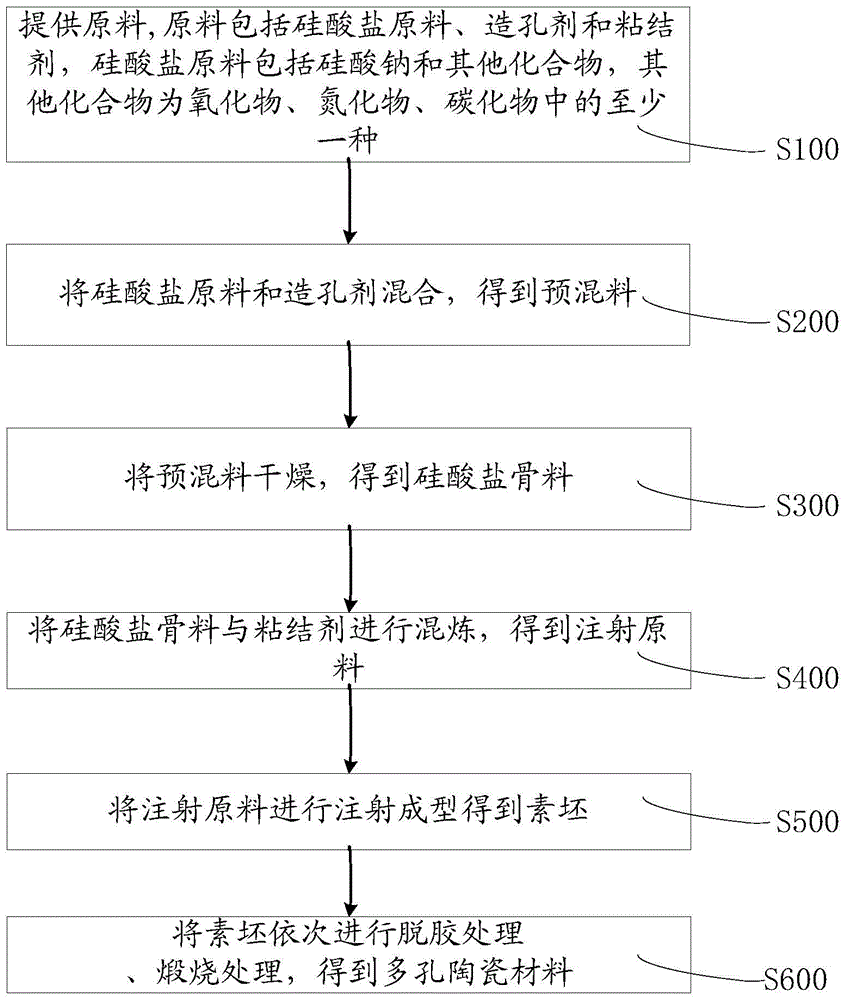

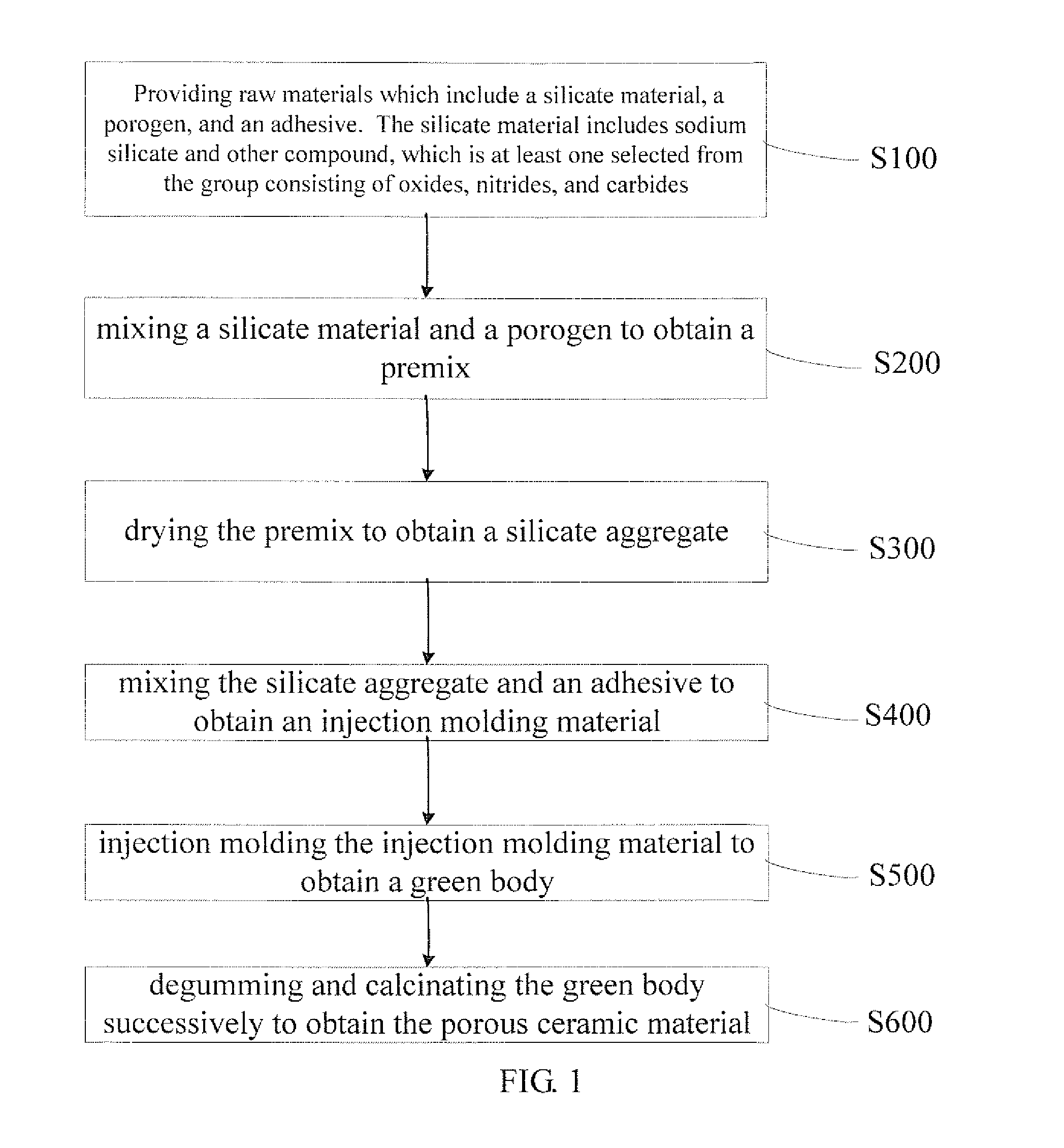

The invention relates to a preparation method of a porous ceramic material. The preparation method comprises the following steps of mixing metasilicate raw materials with a pore forming agent so as to obtain a premix, wherein the metasilicate raw materials comprise sodium silicate and other compounds, and the other compounds are at least one of oxide, nitride and carbide; drying the premix so as to obtain metasilicate aggregate; performing mixed refining on the metasilicate aggregate and a bonding agent so as to obtain injection raw materials, wherein in percentage by mass, the metasilicate aggregate is 50-60%, and the bonding agent is 40-50%; performing injection molding on the injection raw materials so as to obtain a green body; and sequentially performing degumming treatment and calcination treatment on the green body so as to obtain the porous ceramic material. According to the preparation method of the porous ceramic material, a method for adding the pore forming agent and an injection molding method are combined, and the prepared porous ceramic material is high in porosity and controllable in pore diameter and has favorable mechanical properties; and an injection molding technology is adopted, so that compared with a dry pressing shaping technology, the injection molding technology has the advantage that the production efficiency is obviously increased, and the porous ceramic material is suitable for large-scale production.

Owner:SHENZHEN SMOORE TECH LTD +2

Ceramic rock plate and preparation method thereof

ActiveCN111470848AImprove plasticityGood molding effectCeramic materials productionClaywaresGlazeSpray dried

The invention relates to a ceramic rock plate and a preparation method thereof. A ceramic rock plate blank is composed of the following components in percentage by weight: 35-46.1% of mud; 50 to 60 percent of a water abrasive; 1-7% of a green body toughening material; 0.5 to 3 percent of a reclaimed material; and 0.1-0.8% of an additive. The preparation method comprises the following steps: preparing a green body, processing the green body, performing spray drying to prepare powder, performing dry pressing to form the green body (with a plane or concave-convex effect), drying, polishing the green body, blowing ash, spraying water, spraying white ink, spraying engobe, decorating patterns, decorating isolation glaze, decorating a transparent glaze layer, firing, polishing and edging.

Owner:JIANGXI WONDERFUL CERAMICS CO LTD +3

Alumina ceramic and preparation method thereof

The invention provides alumina ceramics and a manufacturing method of the alumina ceramics. The main materials of the alumina ceramics are as follows: alumina micro mist or a superfine alumina micro mist which is formed by Gamma alumina and an Alpha alumina with an particle diameter of between zero point one to three point five micron and a purity of ninety-nine point nine percent or more than ninety-nine point nine percent according to certain proportion. One or a mixture of a small quantity of magnesia, yttria, lanthana, thulia and yttria stabilized zirconia is added into the micro mist as sinter accessory ingredient and is subject to dry pressing, grouting and isostatic cool pressing after being even mixed evenly, thus ceram green pressing is obtained. Only a little organic addition agent is needed to be added. After drying, the green pressing body does not need to be roasted and can be directly introduced to an ordinary high temperature si-mo rod resistance furnace or a continuous type si-mo rod electrothermal tunnel kiln to be sintered for one to three hours at a temperature below one thousand six hundred and seventy Celsius system. Therefore, the alumina ceramics can be obtained with high tightness, mechanical property and good dielectric property and with a nonconventional structure and a placode the size of which is zero point two to two hundred millimeter and a purity of ninety nine to ninety-nine point nine percent.

Owner:BEIJING SINOMA SYNTHETIC CRYSTALS CO LTD +1

Calcium silicate/hydroxylapatite composite biological ceramic material and preparation method and application thereof

InactiveCN101700415AGood mechanical propertiesModulate biological activityProsthesisCalcium silicateApatite

The invention relates to a calcium silicate / hydroxylapatite composite biological ceramic material and a preparation method and application thereof, belonging to the field of biological materials. Calcium silicate / hydroxylapatite nano composite powder prepared by a chemical method is used as a raw material and carried out the dry pressing and molding to obtain a material biscuit, and the biscuit is calcined at 1000-1200 DEG C for 1-10 hours to obtain a degradable calcium silicate / hydroxylapatite composite biological ceramic material which has good mechanical properties and is used for repairing the defects of hard tissues. The biological activity, the degradability and the mechanical strength of the biological ceramic material of the invention can be adjusted and controlled. The invention has simple and easy processes and convenient popularization.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Low-temperature fast-fired ceramic tile and production process thereof

ActiveCN103693942AReduce burning energy consumptionReduce energy consumptionCeramic materials productionClaywaresBrickFiltration

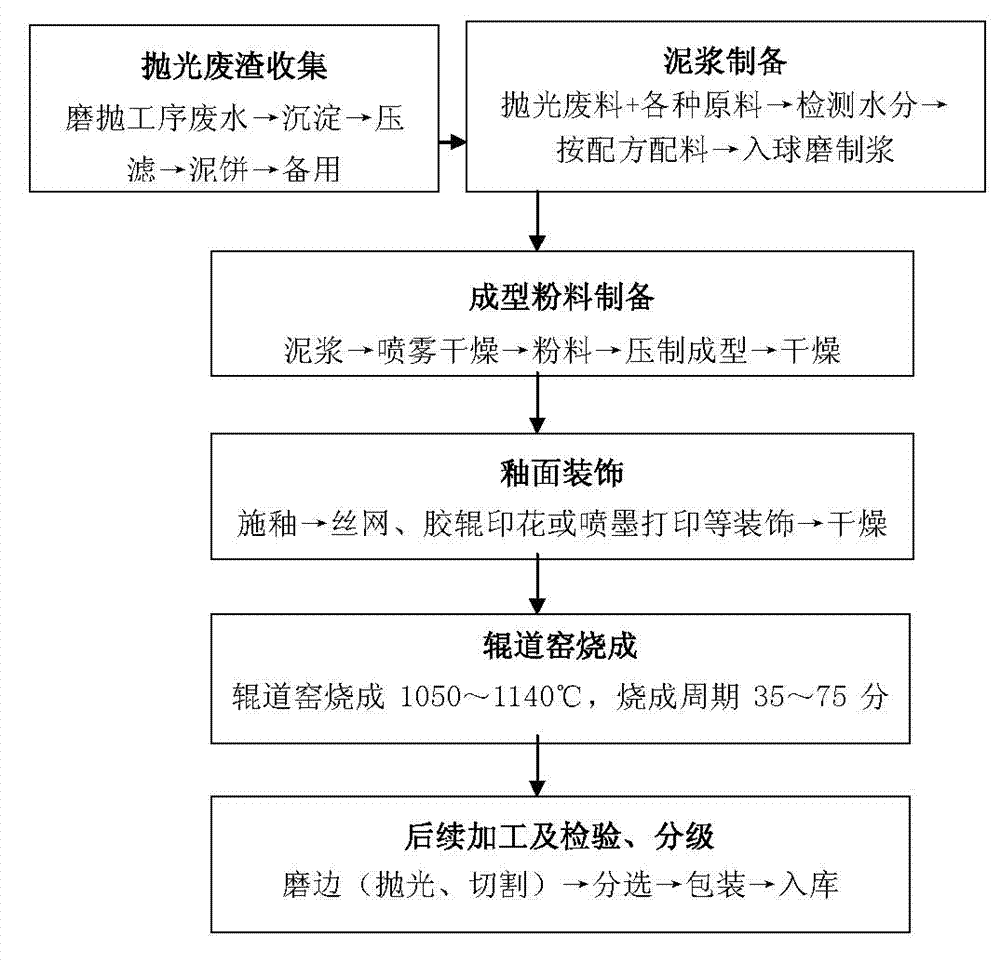

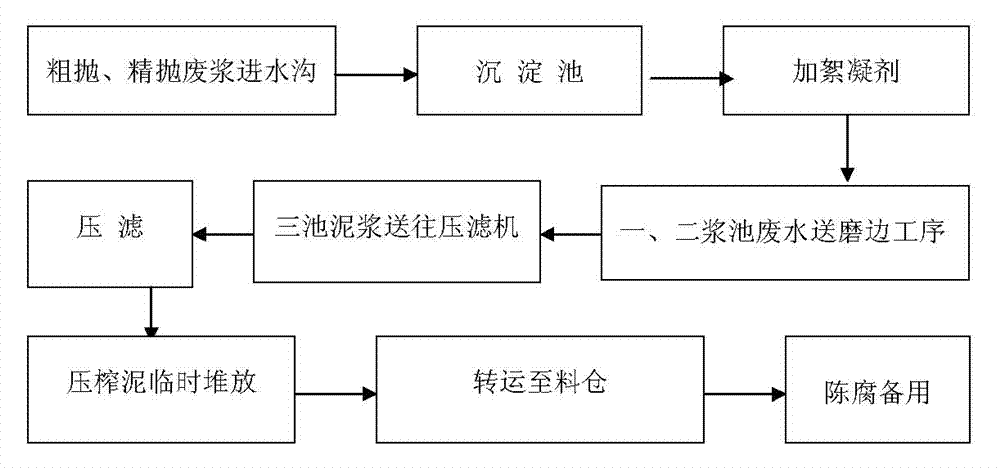

The invention relates to a low-temperature fast-fired ceramic tile and a production process thereof. The blank material of the ceramic tile comprises at least one selected from the group consisting of fine granules produced during grinding and polishing in production of polished tiles, fine granule-containing waste water collected after polishing and a waste polishing material obtained after deposition and press filtration; the blank material of the ceramic tile is composed of, by weight, 48 to 73% of the waste polishing material, 5 to 20% of porcelain sand, 20 to 27% of clay and 2 to 5% of a mineralizer. The production process comprises the following steps: (1) collecting the waste polishing material, carrying out batching according to a formula and then carrying out wet ball milling so as to obtain slurry, wherein the waste polishing material stood for subsequent usage in press filtration and other raw materials are calculated on a dry basis; (2) subjecting the slurry to spray drying so as to obtain powder and carrying out dry-pressing so as to form a ceramic adobe; (3) drying the adobe, glazing the adobe and carrying out surface decoration; and (4) putting a decorated blank into a ceramic roller kiln for firing, wherein fast firing temperature is 1050 to 1140 DEG C, a firing period is 35 to 75 min, and the ceramic tile with a water absorption rate of less than 0.5% is sintered.

Owner:GUANGDONG JIA MEI CERAMIC

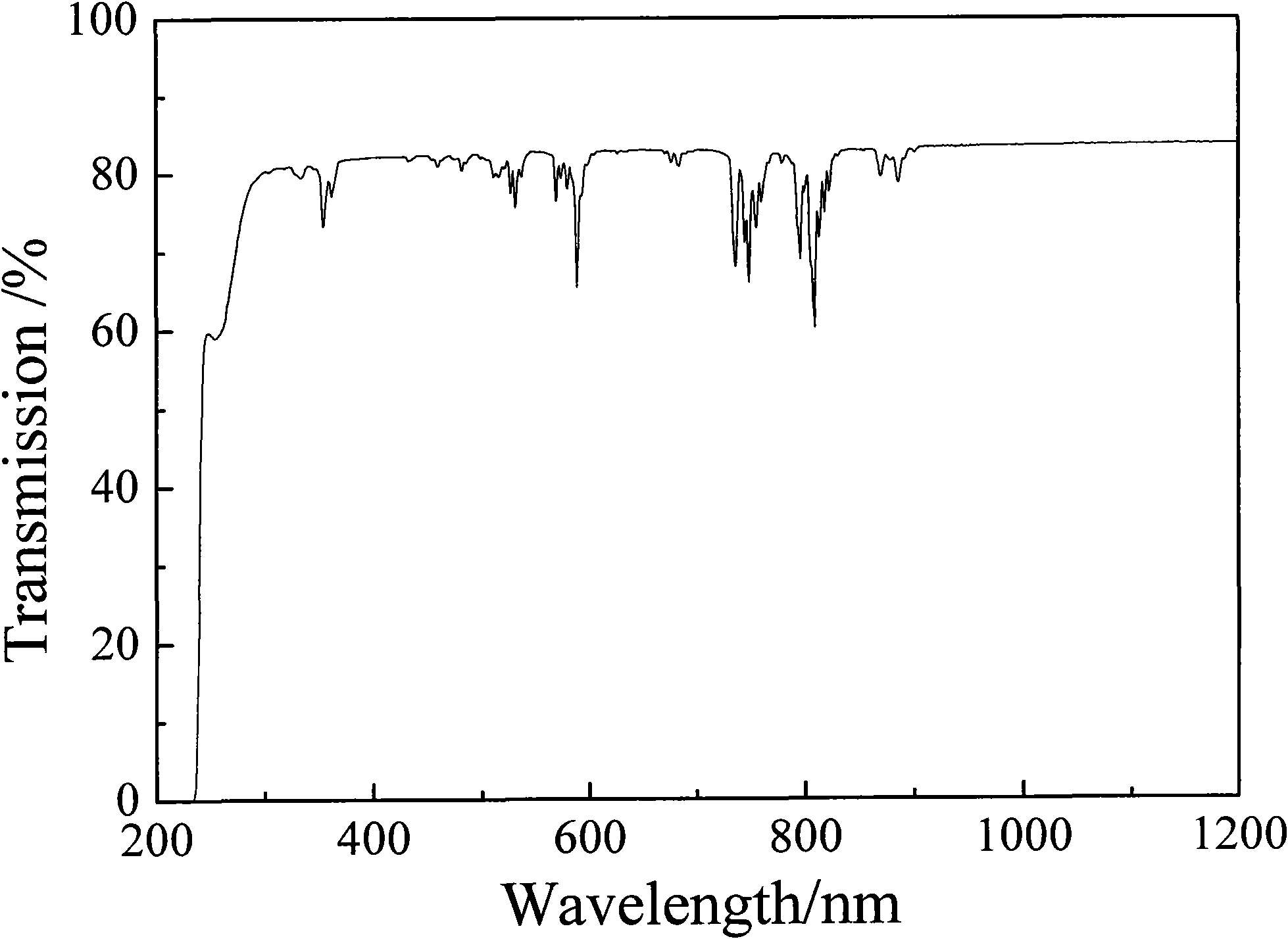

Submicron transparent crystal alumina ceramic possessing high linear transmittance

The present invention belongs to the field of transparent ceramic material technology, and is especially preparation process of submicron transparent crystal alumina ceramic possessing high linear transmittance. The transparent alumina ceramic is prepared with high purity alumina and nanometer zirconia additive, and through drying pressing and cold isostatic pressing or gel injecting to form, low temperature pre-sintering and hot isostatic pressing sintering. It has ceramic body relative density greater than 99.95 %, average crystal size not greater than 0.5 micron, Vickers hardness of 2200, bending strength of 650-800 MPa and linear transmittance at 600 nm greater than 60 %. It is suitable for use in making transparent bulletproof armoring, high temperature observation window, false teeth, etc.

Owner:韩敏芳 +1

Gradient transparent zirconium oxide dental ceramic and preparation method thereof

The invention discloses a gradient transparent zirconium oxide dental ceramic and a preparation method thereof, which belongs to the technical field of preparation of dental ceramics. The raw material is formed by mixing 2 to 5 kinds of zirconium oxide ceramic powder with different sintering transparences. The transparence of the sintered zirconium oxide ceramic from the bottom to the top is gradually increased, and the ceramic comprises 5 to 11 types of ceramic layers with different transparences. The preparation method comprises five steps, namely preparation of mixed powder, dry pressing, cold isostatic pressing, pre-sintering and blank restoration. The preparation method is simple and feasible, the transparence distribution characteristic of the prepared dental zirconium oxide full-ceramic material is similar to that of natural teeth, and the attractiveness of the zirconium oxide full-ceramic restoration is improved.

Owner:AIDITE (QINHUANGDAO) TECH CO LTD

Porous ceramic material, manufacturing method and use thereof

ActiveUS20160316819A1High porosityAperture controllableTobacco devicesCeramic shaping apparatusAdhesiveInjection molding machine

The present invention relates to a manufacturing method of a porous ceramic material, which includes the following steps: mixing a silicate material and a porogen to obtain a premix, wherein the silicate material includes sodium silicate and other compounds being at least one selected from the group consisting of oxides, nitrides, and carbides; drying the premix to obtain a silicate aggregate; mixing the silicate aggregate and an adhesive to obtain an injection molding material, wherein in a weight percentage, the silicate aggregate is in the range of from 50% to 60%, the adhesive is in the range of from 40% to 50%; injection molding the injection molding material to obtain a green body; and degumming and calcinating the green body successively to obtain the porous ceramic material. In the aforementioned manufacturing method of the porous ceramic material, the space-holder method is combined with the injection molding method, such that the obtained porous ceramic material has a high porosity, controllable pore sizes and good mechanical properties. In addition, compared with the dry pressing process, the use of the injection molding process can significantly improve the production efficiency, and is suitable for large-scale production.

Owner:SHENZHEN SMOORE TECH LTD +2

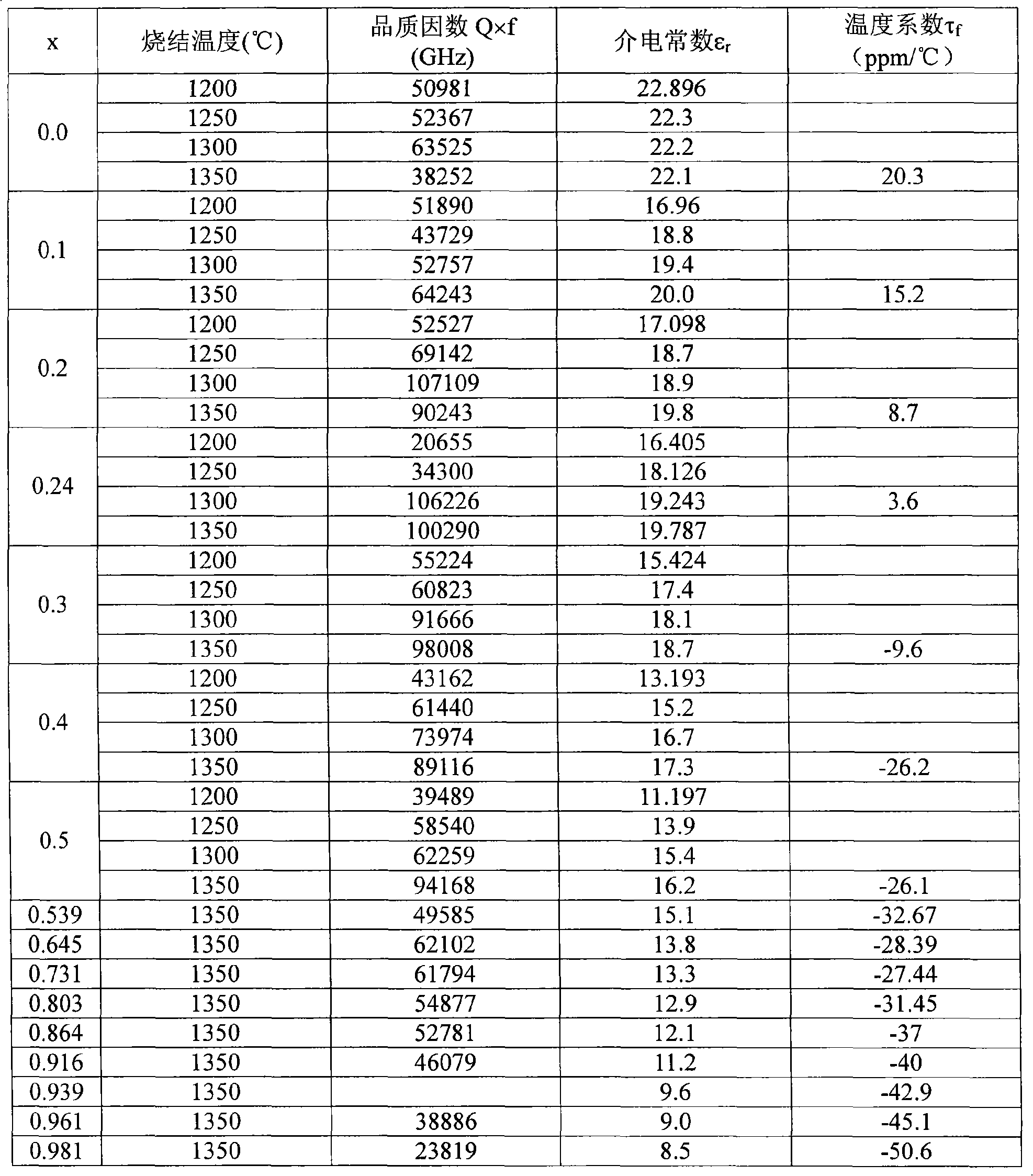

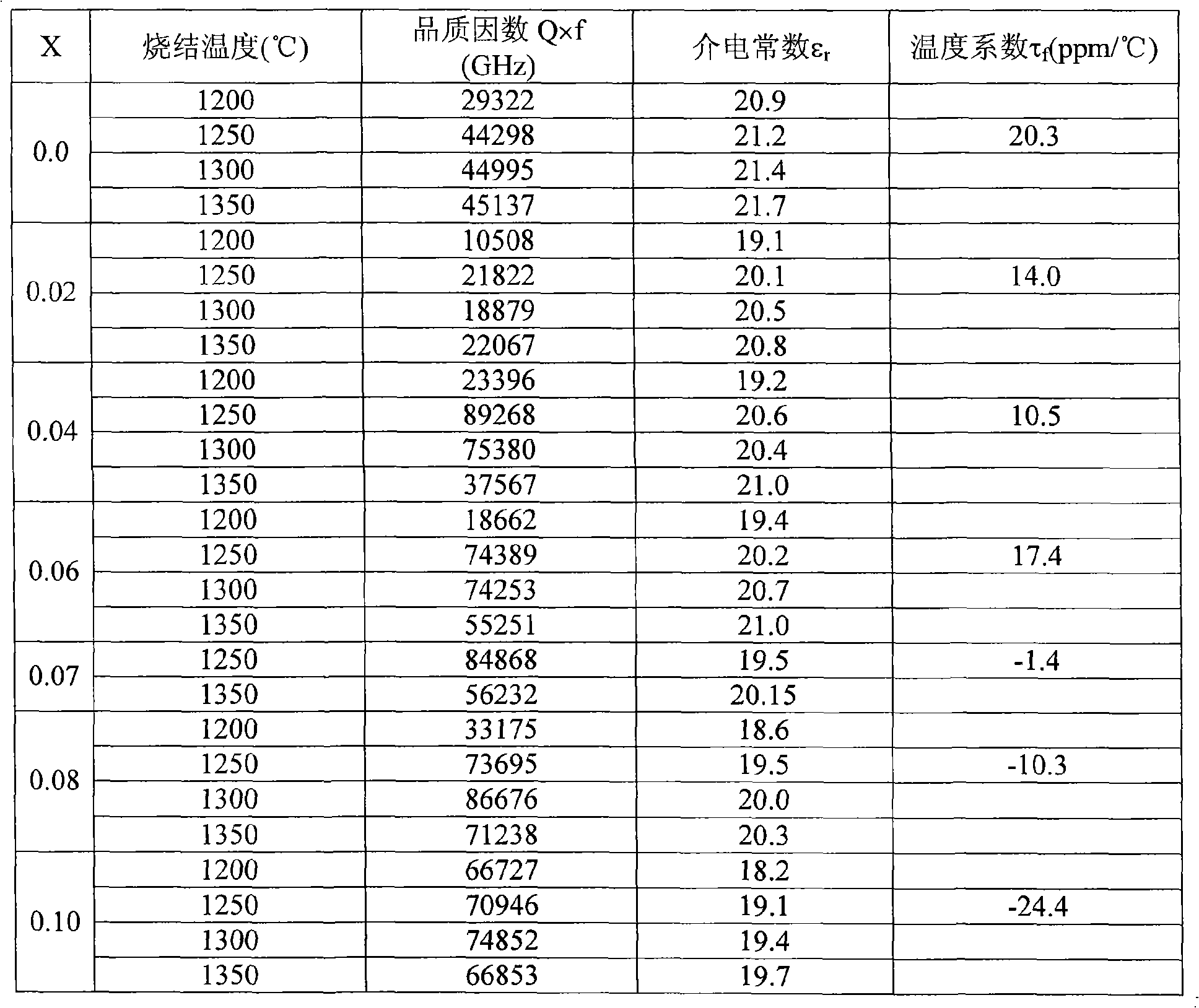

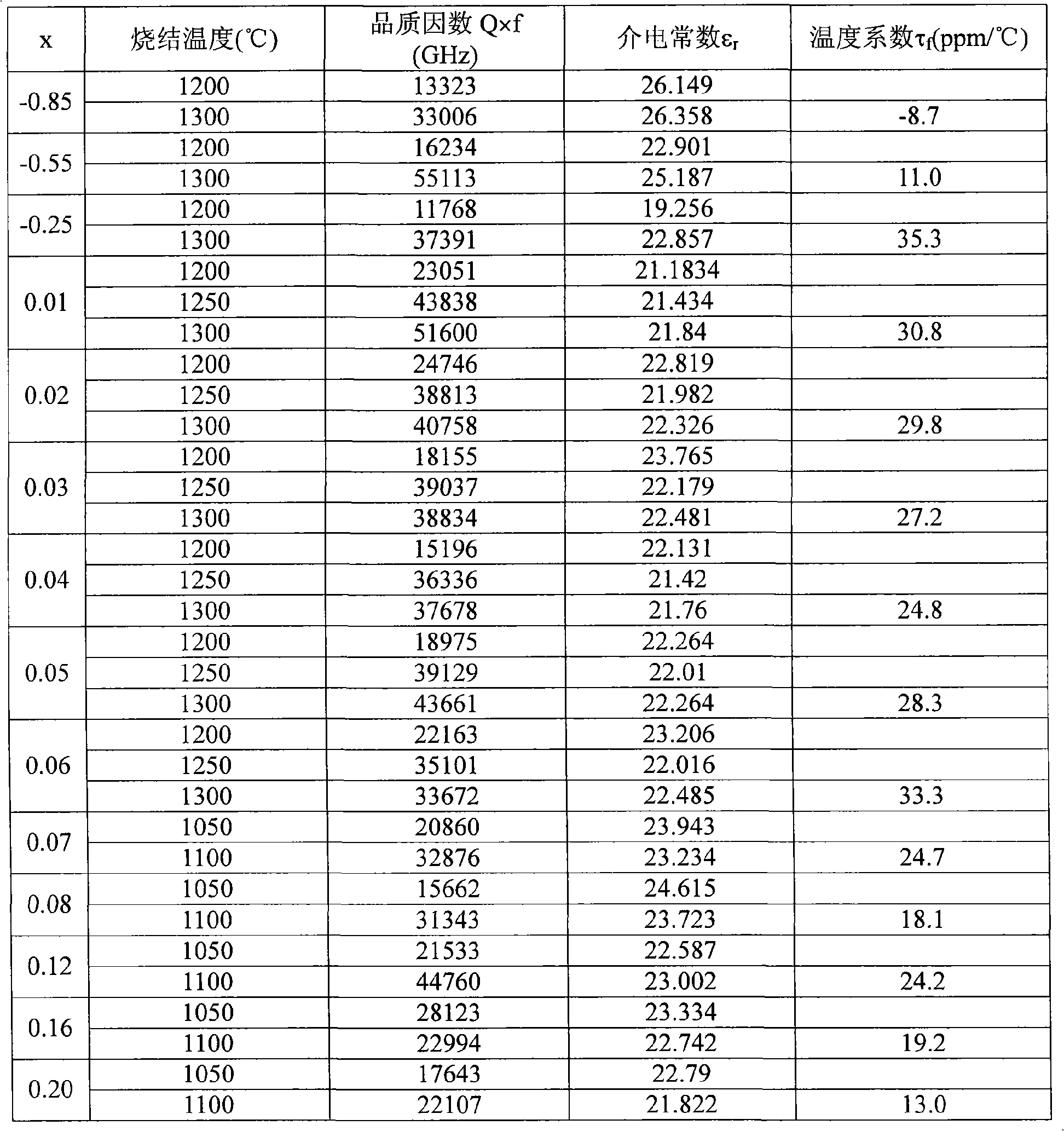

High-Q microwave dielectric ceramic material and preparing method thereof

The invention relates to a plurality of novel high-Q microwave medium ceramic materials and preparation methods thereof, belonging to the special ceramic material process technical field. The novel high-Q microwave medium ceramic materials comprise the following four chemical formulas: (1) (1-x)Li2TiO3-xMgO with x ranging between 0 and 0.981; (2) Li2+xTi1-4xNb3xO3 with x ranging from 0 and 0.1; (3) Li2+xTiO3 with x ranging between minus 0.85 and 0.20; (4) Li3Mg2NbO6. The preparation method comprises the following steps: according to the specified chemical formulas, the mass of each raw material is calculated; the raw material adopts chemical analytically pure with the purity of the raw materials including Li2CO3, TiO2, MgO and Nb2O5 more than 99 percent; the specified raw materials, zirconia grinding ball and dehydrated alcohol are packed in a resin ball milling tank according the to weight ratio of 1:2:0.75, and then are dried and screened after 24-hour ball milling; then, polyvinyl alcohol solution is added to carry out granulation and then the mixture is screened; particles are packed in a mould and are formed through dry stamp under 150 MPa pressure; and finally, blocks are calcined two hours under 1,200 DEG C to 1,350 DEG C to obtain the required high-Q microwave medium ceramic materials of rock-salt structures.

Owner:SHANGHAI UNIV

Multilayer-color composite material for dental department and preparation method of composite material

ActiveCN105362084AImprove aestheticsHigh similarityImpression capsDentistry preparationsNatural toothTooth colour

The embodiment of the invention discloses a preparation method of a multilayer-color composite material for dental department. The preparation method comprises the following steps: preparing N types of monochromatic composite material precursor powder differing in color, and dry-pressing and pre-forming the prepared precursor powder, so that a preformed green body is obtained; and then warming up and heating the preformed green body, so that the multilayer-color composite material is obtained. The multilayer-color composite material for dental department prepared by the method disclosed by the invention has a gradient multilayer color system, so that the aesthetic effect of a dental repair prepared from the composite material is effectively improved; and the composite material can simulate the characteristic of natural tooth that color gradually varies from tooth neck to biting end, so that a higher similarity to the natural tooth is achieved.

Owner:SHENZHEN UPCERA DENTAL TECH

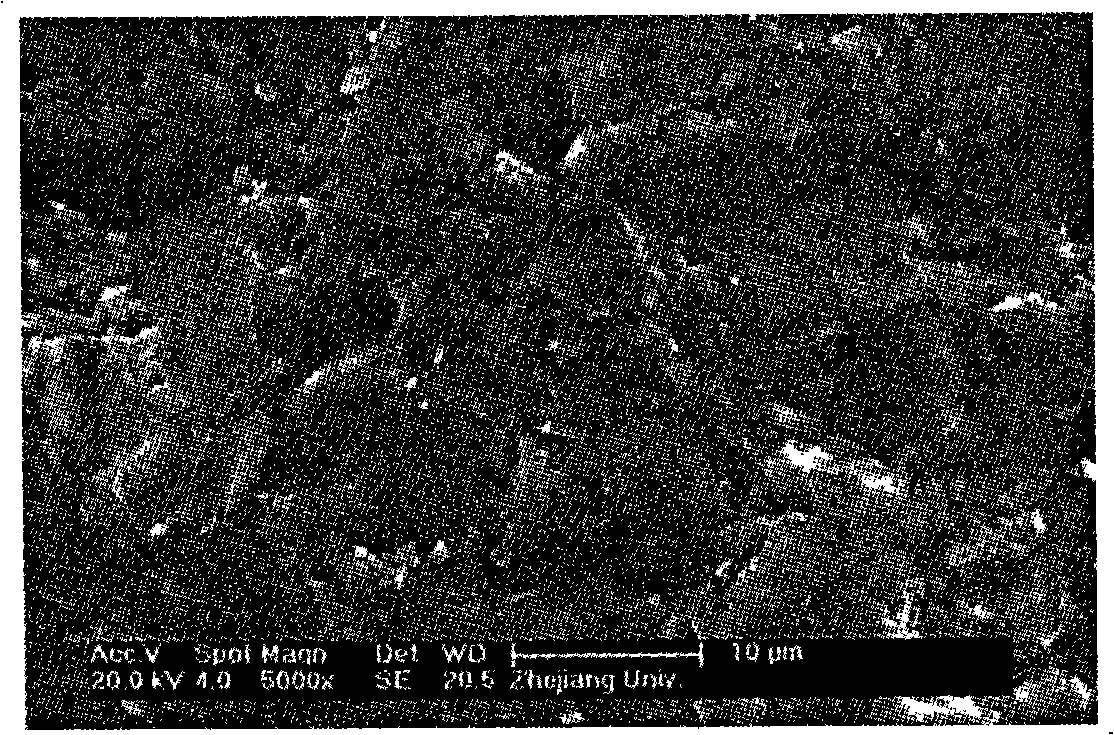

Method of preparing alumina ceramic prilling powder for sealed ring

The invention relates to a preparation method for alumina ceramic granulated powder used by a sealing ring, which is characterized in that the preparation process comprises: (1) weighting and mixing alpha alumina, silicon powder, light calcium carbonate, kaolin, burning talc magnesia and yttria, carrying out dry milling, crashing and uniformly mixing; (2) placing the uniformly mixed powder in a ball mill, diluting, adding a dispersant, a binder and a release agent and milling into slurry; (3) screening the milled slurry, removing iron, putting in a spray drying tower to carry out spray granulation; and (4) screening the spray granulated powder by a 40-mesh screen and a 200-mesh screen, taking the powder between the two screens as the finished product. The granulated powder prepared by the method of the invention has the advantages of solid granule, reasonably distributed granularity, large loose packed density, moderate strength, good fluidity and easy mold release. Moreover, the alumina sealing ring can be provided with microcrystalline structure only through the common dry pressing and sintering technology. The ceramic article has high tightness, and the surface of which has no pores found when being amplified by 20 times after abrasive polishing.

Owner:ZHENGZHOU HICER HIGH TECH CERAMICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com