Machinable aluminium oxide ceramics and preparation method of machinable aluminium oxide ceramics

A technology of alumina ceramics and aluminum hydroxide, which is applied in the field of machinable alumina ceramics and its preparation, can solve the problems of increased material cost, poor practicability, complicated preparation process, etc. The effect of macroscopic fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

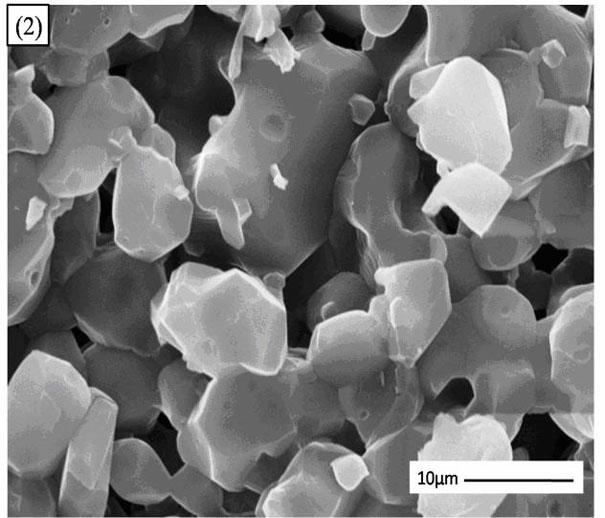

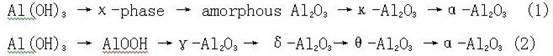

[0039] Weigh a certain amount of aluminum nitrate powder to make an aluminum nitrate aqueous solution with a concentration of 0.5mol / L; dilute the concentrated ammonia water with water 10 times to make dilute ammonia water, drop the dilute ammonia water and aluminum nitrate solution into distilled water at the same time, the distilled water The pH value of the control solution is 9, and the sol is obtained by high-speed stirring at room temperature; the obtained sol is placed in a water bath at 85°C for 24 hours, washed with deionized water and ethanol several times, and then dried in a vacuum oven at 90°C. Obtain aluminum hydroxide dry glue; put the aluminum hydroxide dry glue into an alumina crucible, and calcinate at 1200°C for 2 hours to obtain nano-alumina (α-Al 2 o 3 )pink. Weigh α-Al 2 o 3 (particle size 80nm~100nm) 50g, analytical reagent aluminum hydroxide (purity ≥ 99.5%) 23g, potassium chloride (purity ≥ 99.5%) 34g, sodium chloride (purity ≥ 99.5%) 34g, MgO (puri...

Embodiment 2

[0041] A kind of machinable alumina ceramics, the composition of mass percentage includes: 68% of nano-alumina, 30% of flake alumina, 1% of magnesium oxide (MgO) and titanium dioxide (TiO 2 )1%.

Embodiment 3—9

[0043] A kind of machinable alumina ceramics, its mass percentage composition is shown in the following table:

[0044]

[0045] In embodiment 2-9, the particle size of the nano-alumina powder is 80-100nm;

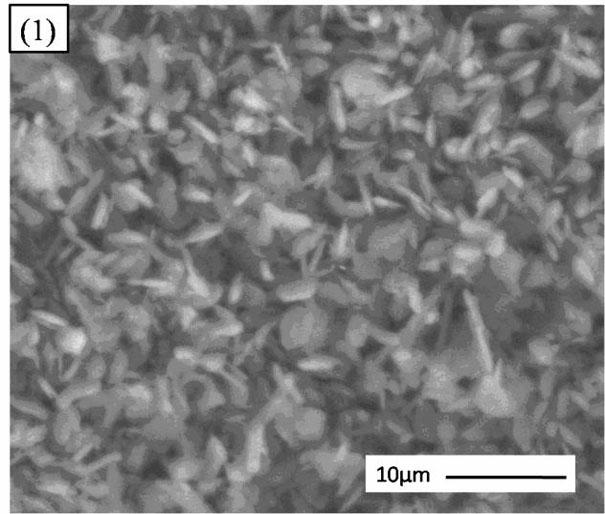

[0046] In Example 2-9, the particle size of the flaky alumina is 3-5 μm, and the thickness is 0.2-0.4 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com