Preparation method for silicon nano material and application

A silicon nanotechnology, reaction technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of high energy consumption and high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The invention provides a preparation method of silicon nanometer material, comprising: mixing silicon source, reducing agent and molten salt, heating and reacting under airtight conditions to obtain silicon nanometer material; the reducing agent is metal.

[0038] Among them, the present invention has no special limitation on the raw materials for the reaction, which can be commercially available.

[0039] The silicon source can be a silicon-containing material well known to those skilled in the art without any special limitation. In the present invention, it is preferably one or more of silicon-oxygen compounds, silicates, silicon-containing minerals, and biomass; The silicon oxide compound is preferably one or more of silicon dioxide, white carbon black and silicon monoxide; the silicate is preferably a molecular sieve; the silicon-containing mineral is preferably diatomaceous earth, potassium feldspar, One or more of albite, quartz sand and sepiolite; the biomass is ...

Embodiment 1

[0051] Mix 0.6g of silicon dioxide, 0.6g of magnesium powder and 5.0g of anhydrous aluminum trichloride evenly, put it into a 20ml stainless steel autoclave, seal it and place it in a resistance crucible furnace, heat it to 200°C for 10h, and then cool it naturally to room temperature; after opening the kettle, the obtained product was washed with water, washed with 1mol / L dilute hydrochloric acid and centrifuged, and the obtained solid was soaked in hydrofluoric acid for a short period of time for 60 seconds, and then further washed with water and centrifuged to dry to obtain silicon nanomaterials with a yield of 60%.

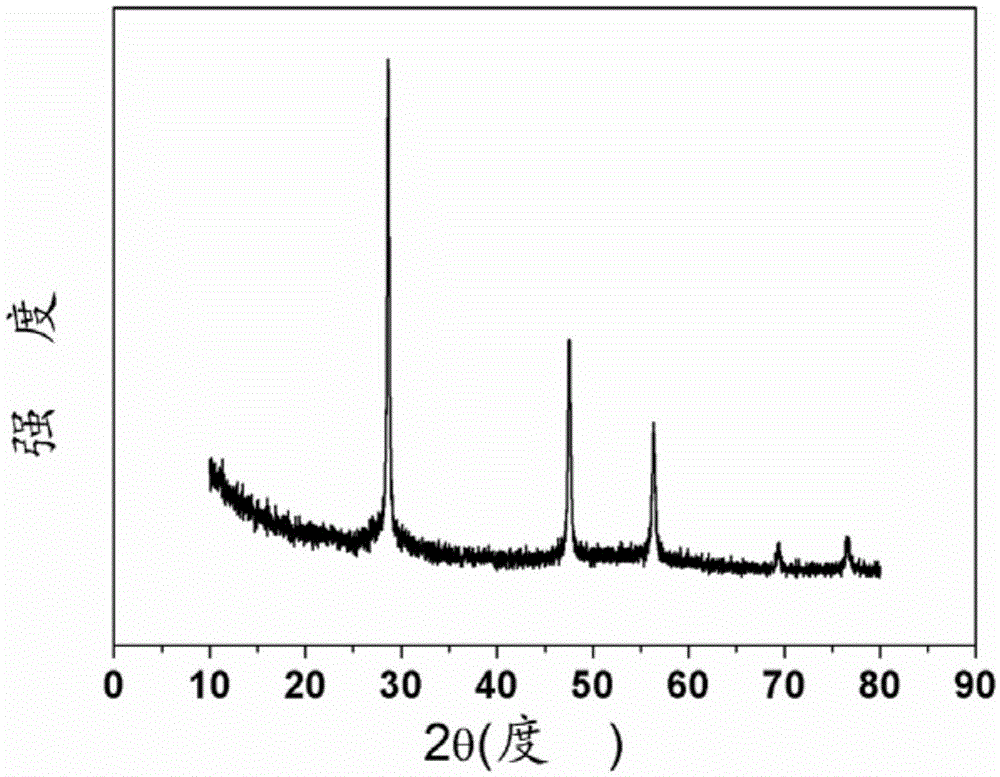

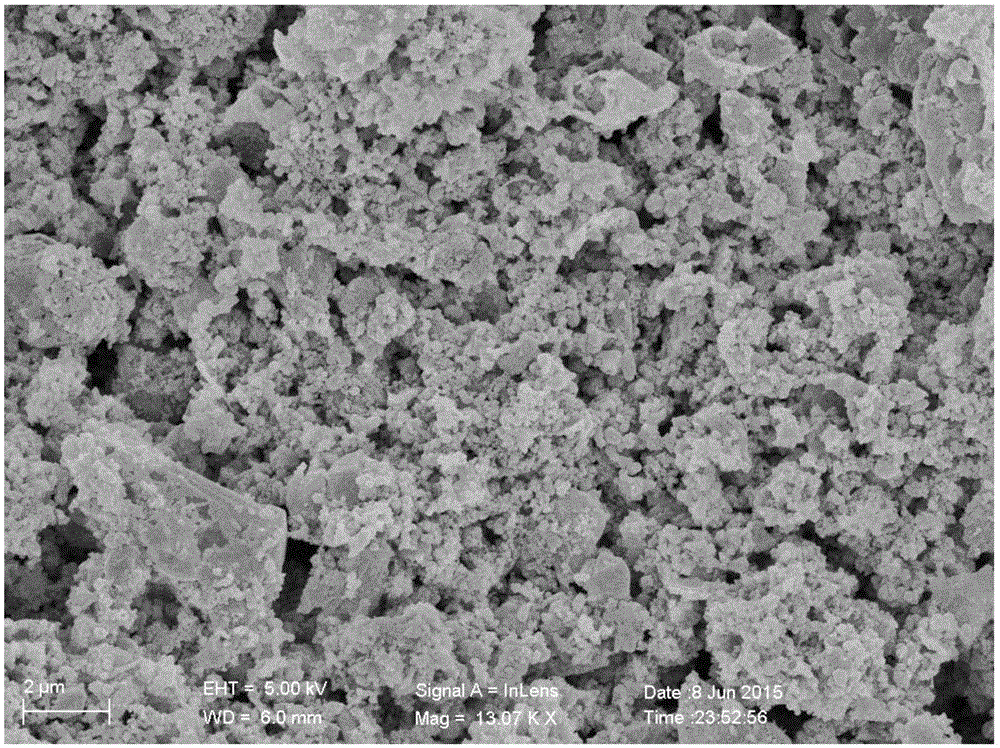

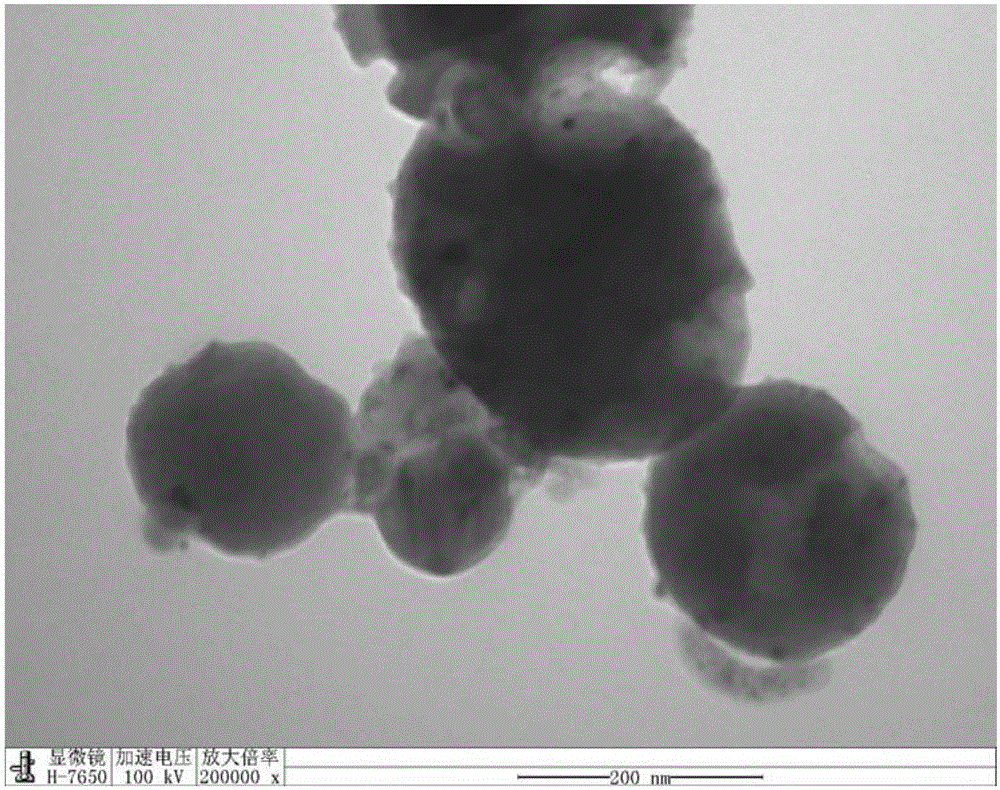

[0052] Utilize X-ray powder diffractometer to carry out X-ray diffraction analysis to the silicon nanomaterial obtained in embodiment 1, obtain its X-ray diffraction spectrum figure such as figure 1 shown. Depend on figure 1 It can be seen that in the X-ray diffraction spectrum, 2θ has clearly visible diffraction peaks in the range of 10° to 80°, and all diff...

Embodiment 2

[0057] Mix 0.6g of silicon dioxide (a by-product of the optical fiber preform of Jiangsu Zhongtian Technology Co., Ltd., with a purity of 99.999%), 0.6g of magnesium powder and 5.0g of anhydrous aluminum trichloride evenly and put them into 20ml of stainless steel high-pressure Kettle, sealed and placed in a resistance crucible furnace, heated to 500 ° C for 10 hours, and then naturally cooled to room temperature; after the kettle was opened, the product obtained was washed with water, washed with 1mol / L dilute hydrochloric acid and centrifuged, and the obtained solid was treated with hydrofluoric acid. Soak for 60 seconds for a short time, then further wash with water and centrifuge and dry to obtain silicon nanomaterials with a yield of 80%.

[0058] Utilize X-ray powder diffractometer to carry out X-ray diffraction analysis to the silicon nanomaterial obtained in embodiment 2, obtain its X-ray diffraction spectrum figure such as Figure 4 shown. Depend on Figure 4 It can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com