Cubic phase cerium and zirconium based composite oxide with high specific surface area and preparation method thereof

A composite oxide and high specific surface area technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, separation methods, etc., can solve problems such as complex process and low specific surface area of catalyst products, and achieve The reaction process is simple, the drying equipment requirements are low, and the effect of high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

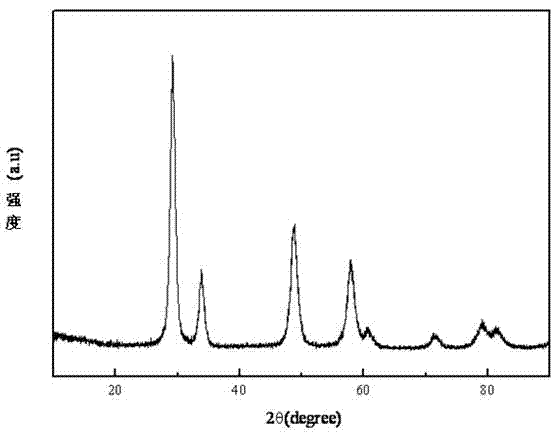

[0038] According to the molar ratio of Ce, Zr, Pr, and Nd as 1:2:0.23:0.25, dissolve the nitrates of Ce, Zr, Pr, and Nd in deionized water, and stir well to obtain a salt solution with a concentration of 0.2 mol / L . Add ammonia water dropwise to the mixed solution until the pH is 9~10, filter and wash with deionized water until pH = 7 to obtain a filter cake; transfer the filter cake to a beaker, and then pour absolute ethanol, the liquid level of the beaker must be higher than Filter cake, stirred and left to stand, and then suction filtered to obtain the precipitate exchanged with anhydrous ethanol, which was supercritically dried under supercritical conditions of 50°C and pressure of 10MPa; kept under supercritical conditions for 5 hours, and released slowly at constant temperature gas to obtain the Ce-Zr-Pr-Nd composite oxide precursor; treat the Ce-Zr-Pr-Nd composite oxide precursor in the air atmosphere at 1000°C for 12 hours to obtain the Ce-Zr-Pr-Nd composite oxide ma...

Embodiment 2

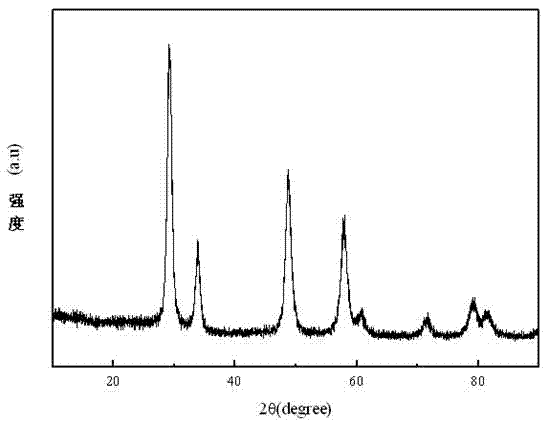

[0040] According to the molar ratio of Ce, Zr, Pr, Nd is 1:1.8:0.32:0.32, dissolve the nitrates of Ce, Zr, Pr, Nd in deionized water, after stirring evenly, add ammonia water dropwise to the mixed solution to pH 9~10, centrifugal washing to pH=7, centrifugal spray drying, inlet temperature 130~250°C, outlet temperature 100~120°C, to obtain Ce-Zr-Pr-Nd composite oxide precursor; Ce -Zr-Pr-Nd composite oxide precursor was treated in air atmosphere at 1000°C for 12 hours to obtain Ce-Zr-Pr-Nd composite oxide with a specific surface area of 38.2 m 2 / g. The Ce-Zr-Pr-Nd composite oxide precursor in N 2 Treat at 1000°C for 12 hours in the atmosphere to obtain Ce-Zr-Pr-Nd composite oxide with a specific surface area of 41.5 m 2 / g.

Embodiment 3

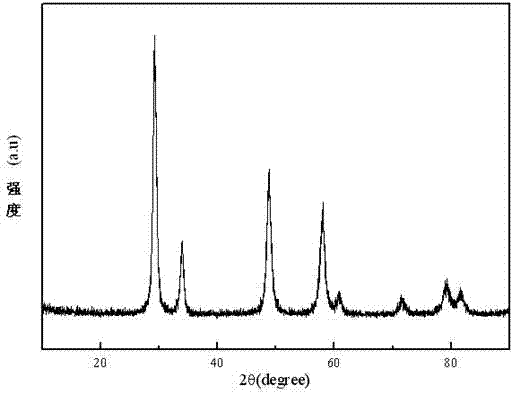

[0042] According to the molar ratio of Ce, Zr, Pr, Nd, La is 1:2:0.2:0.21:0.16, dissolve the nitrates of Ce, Zr, Pr, Nd, La in deionized water, stir well, add to the mixed solution Add ammonia water dropwise to pH 9~10, filter and wash with deionized water until pH = 7; exchange the water in the precipitate with absolute ethanol. Carry out supercritical drying, supercritical condition is 50 ℃, pressure 15MPa; Keep 5 hours under supercritical condition, release gas slowly at constant temperature, obtain Ce-Zr-Pr-Nd-La composite oxide precursor; Ce-Zr - The Pr-Nd-La composite oxide precursor was calcined at 550 °C for 2 hours in an air atmosphere, and its specific surface area was 174.5 m 2 / g. .Treat in air atmosphere at 1000℃ for 12 hours to get Ce-Zr-Pr-Nd-La composite oxide with a specific surface area of 54.3 m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com