Patents

Literature

883 results about "Zinc compounds" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Zinc is mainly used as a protective coating for iron and steel (galvanising). It is further used for the production of zinc alloys (e.g. brass), rolled zinc, zinc dust (a pigment and a reducing agent), and zinc compounds (e.g. zinc oxide). Zinc oxide is the industrially most important zinc compound.

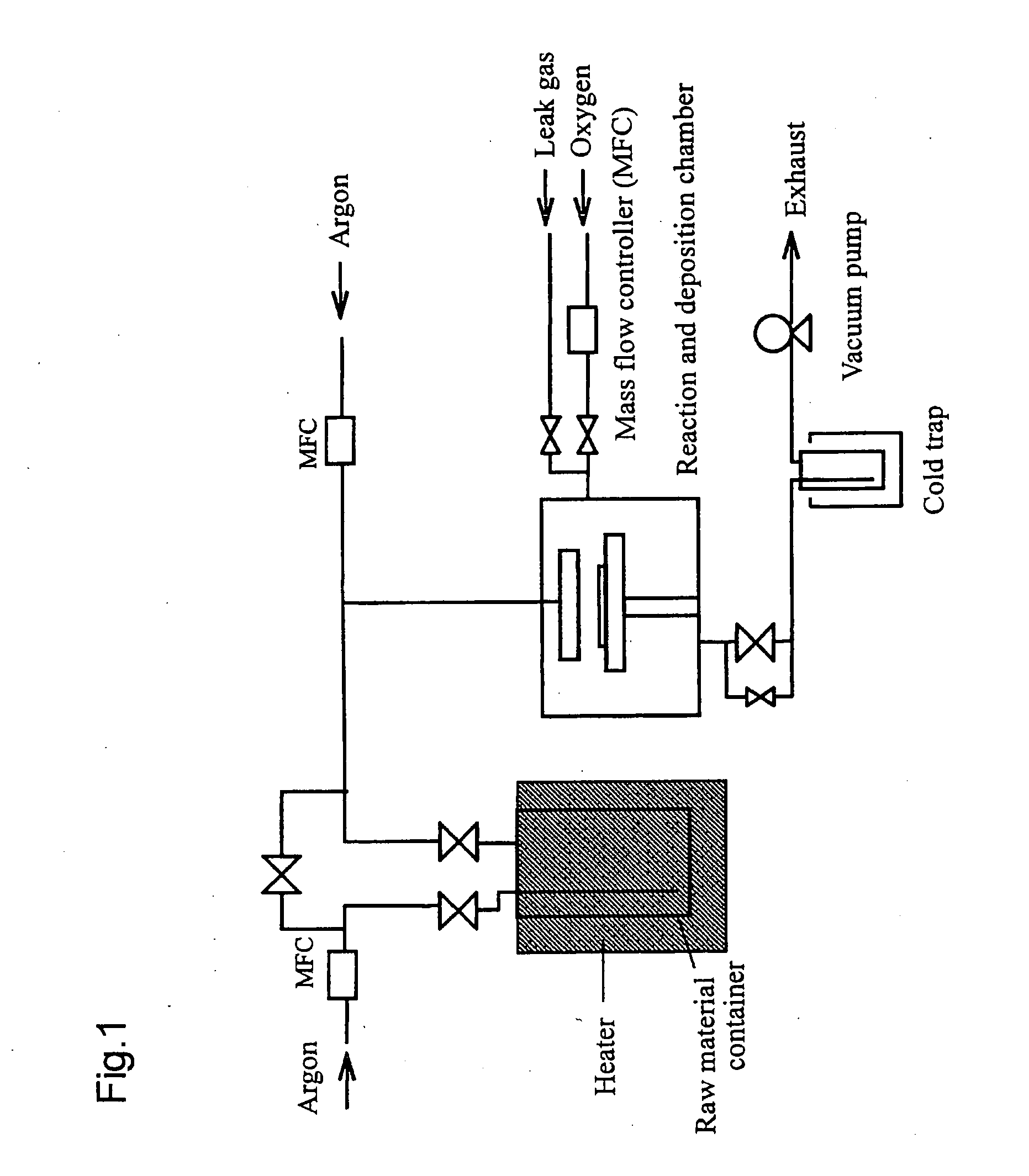

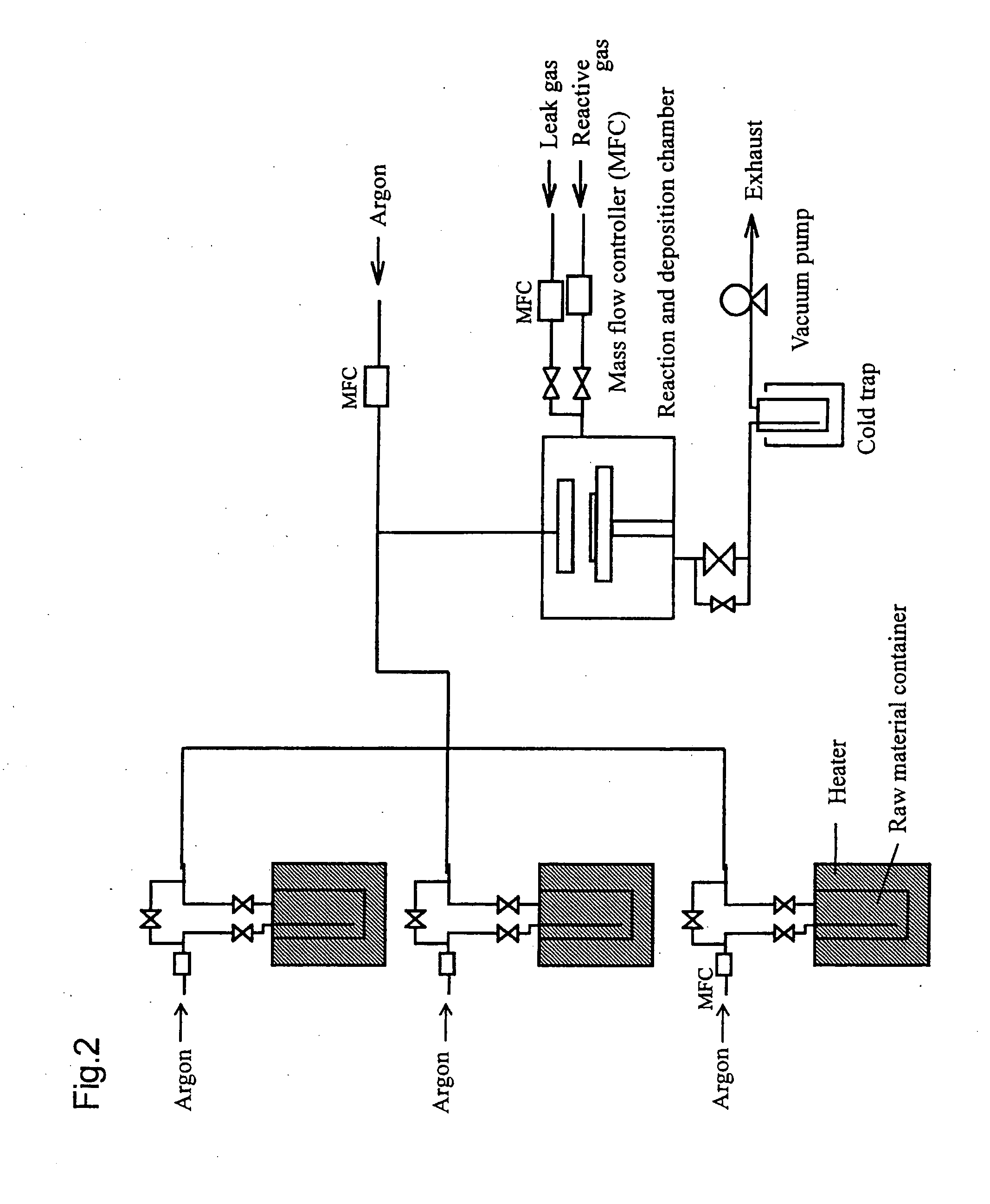

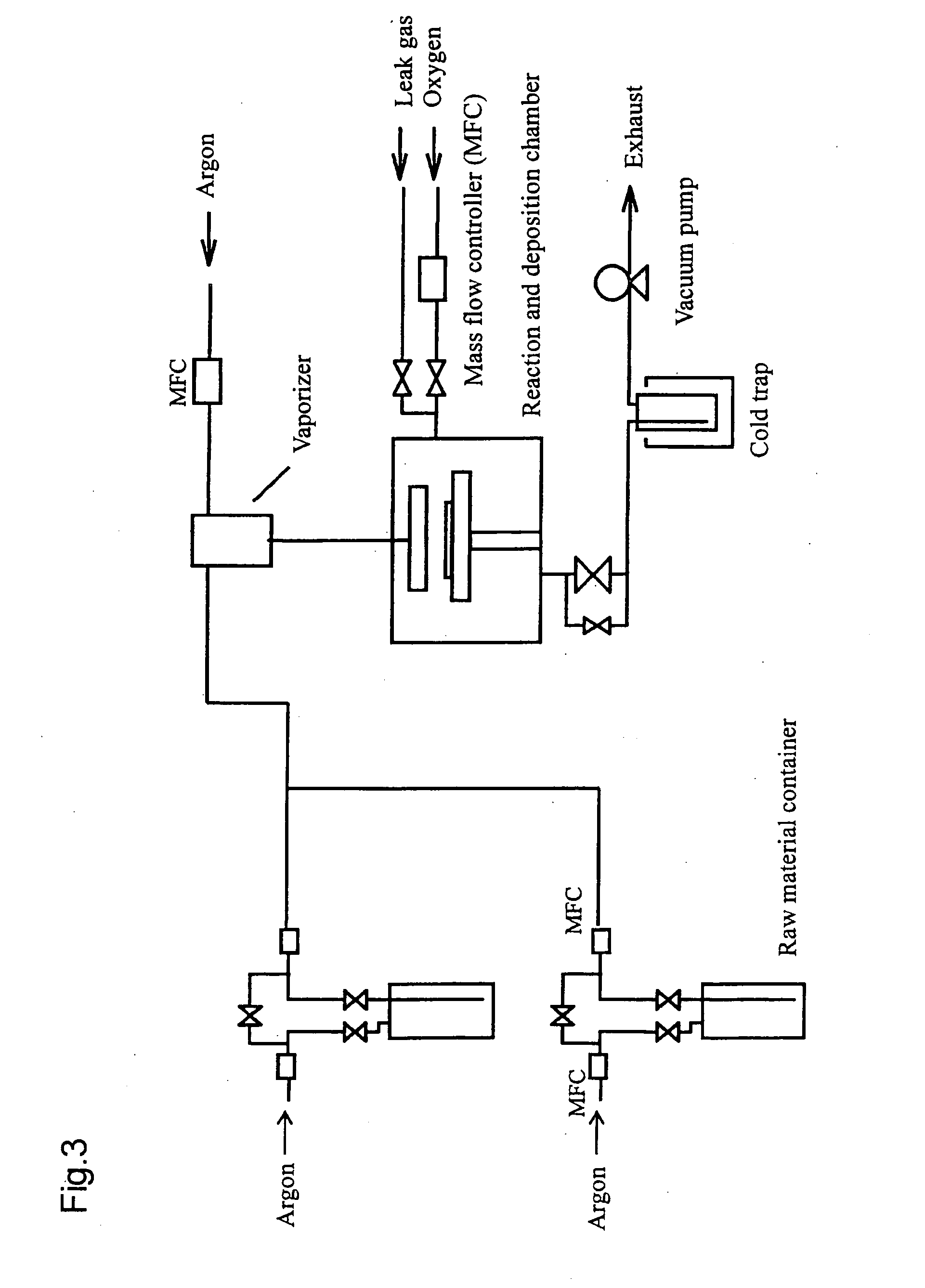

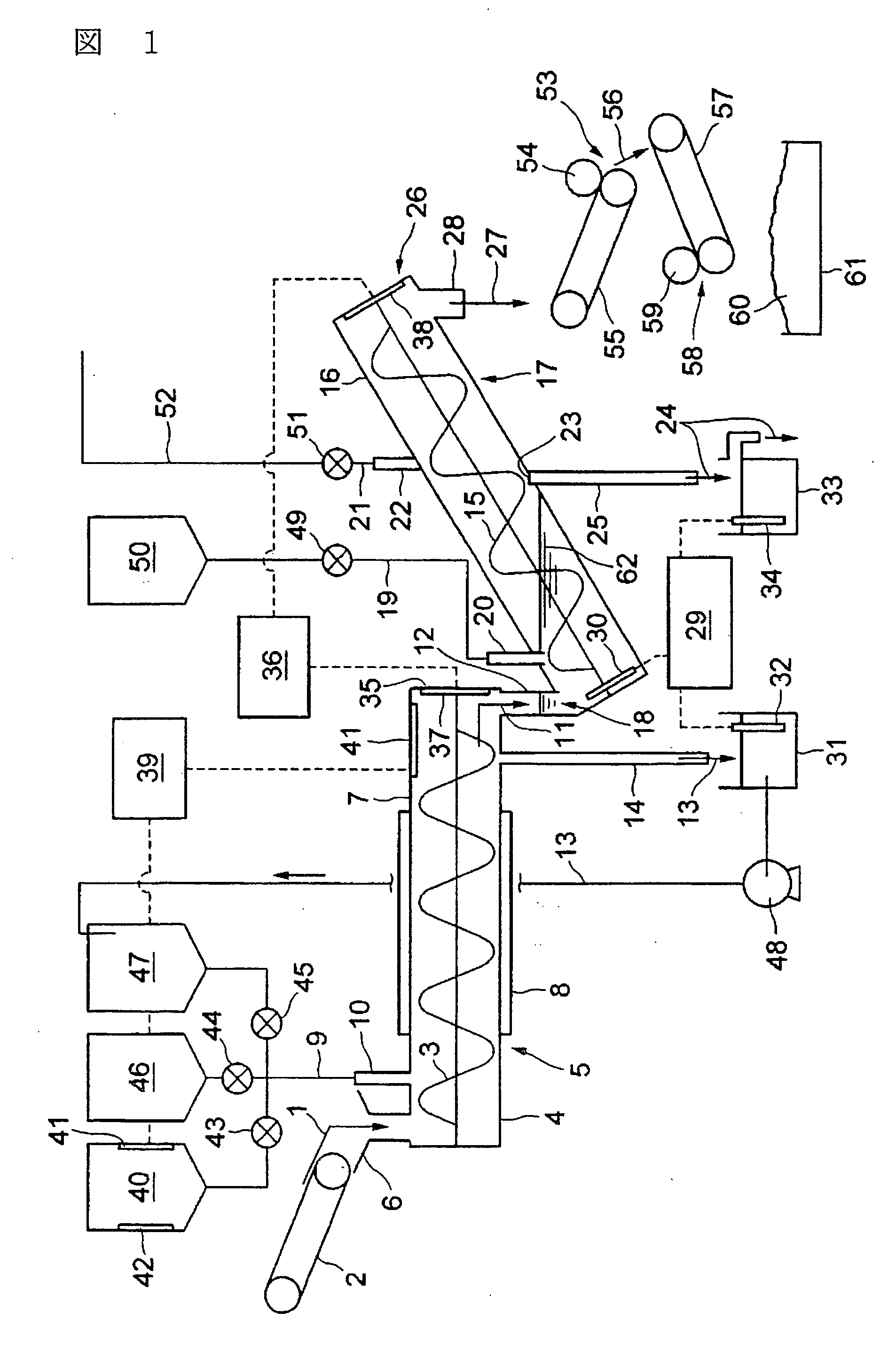

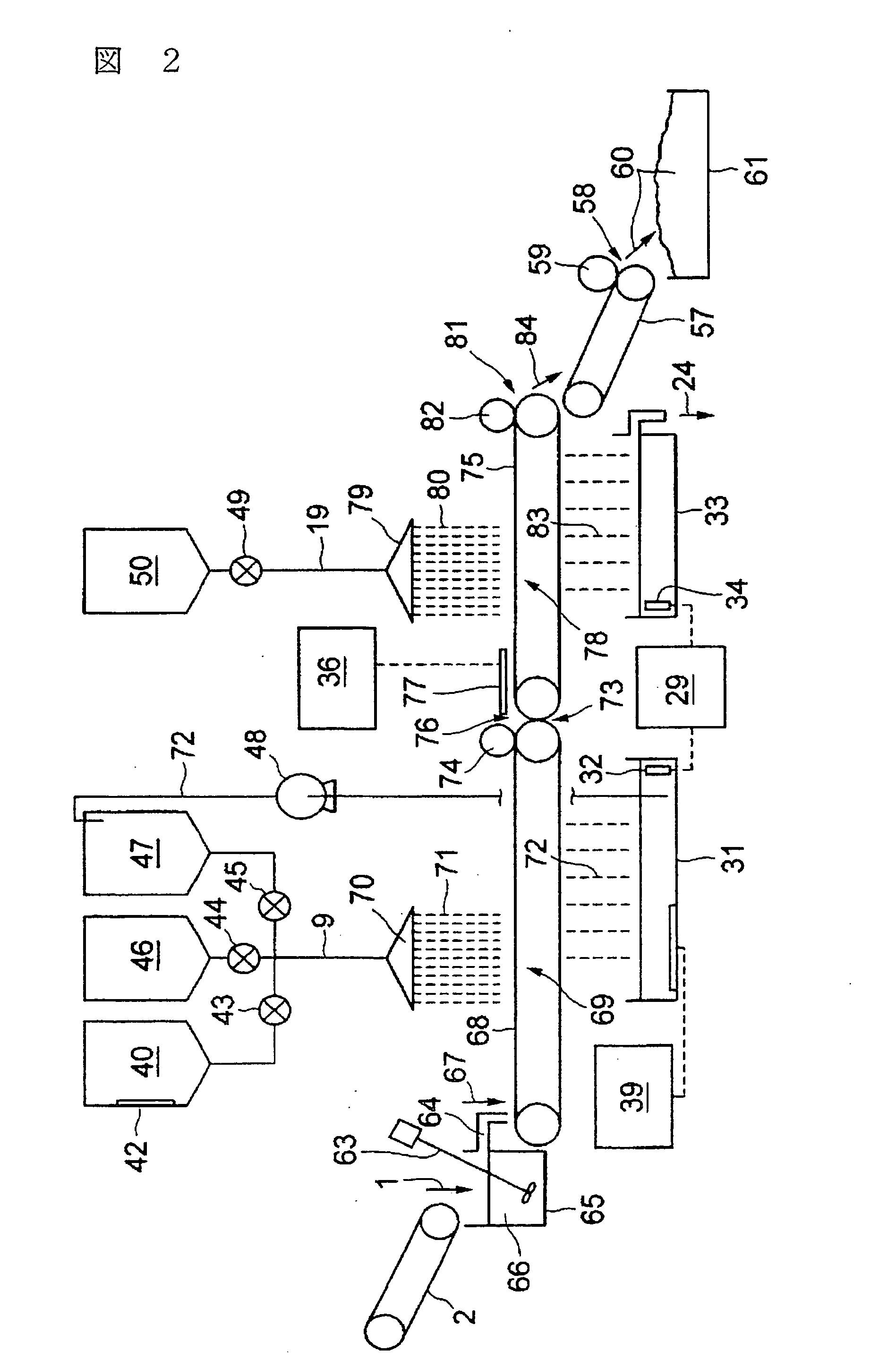

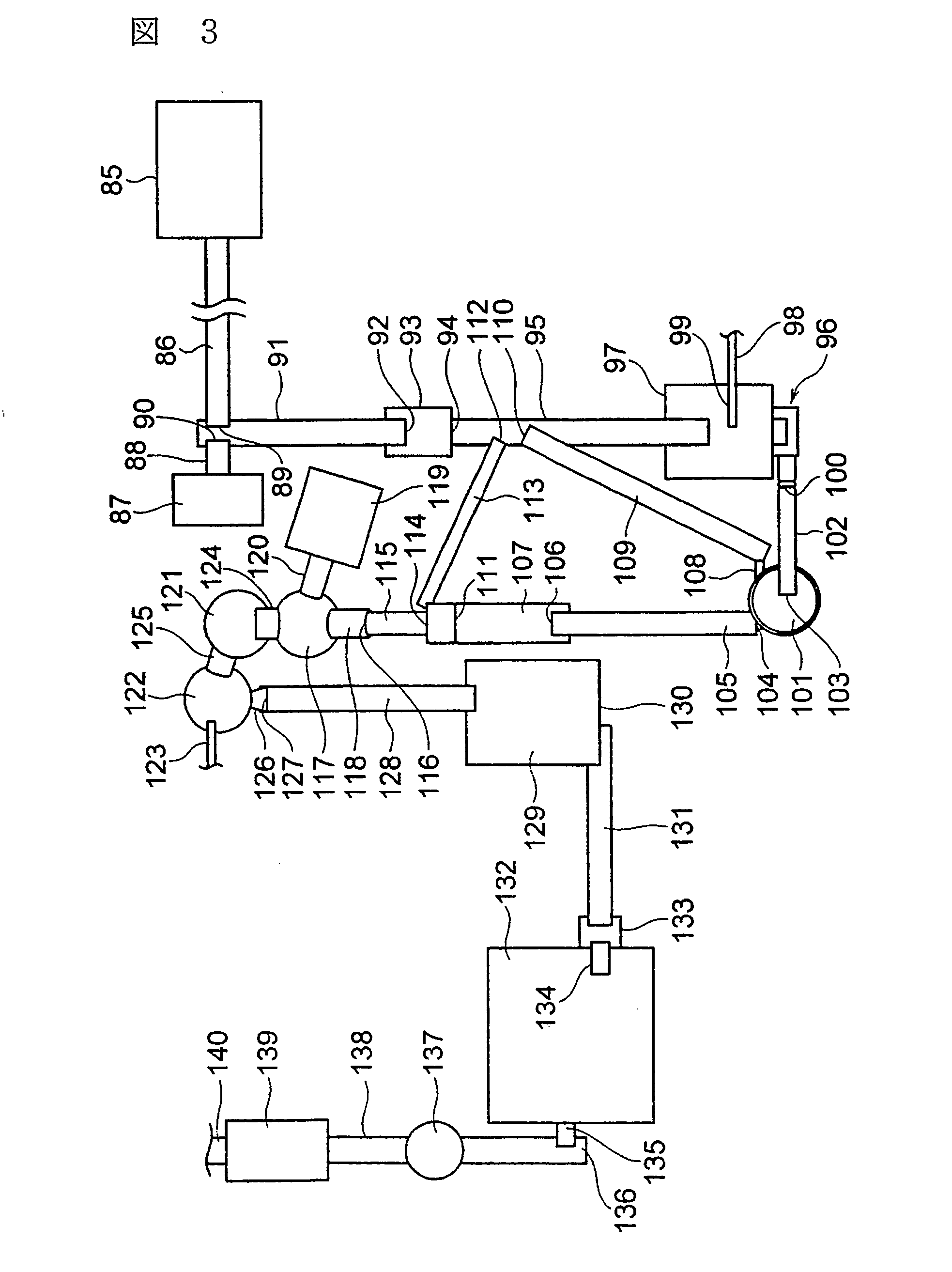

Thin film-forming material and method for producing thin film

InactiveUS20070178235A1Chemical vapor deposition coatingZinc organic compoundsZinc compoundsMaterials science

The thin film-forming material of the present invention comprises a bis(β-diketonato)zinc compound that is liquid at 25° C. and is suitable for forming a zinc-containing thin film. By using the thin film-forming material, a thin film can be produced with stable film-forming rate or stable film composition control without suffering from problems of raw material gas suppliability and in-line raw material transport. Preferred (β-diketonato)zinc compounds include, for example, bis(octane-2,4-dionato)zinc and bis(2,2-dimethyl-6-ethyldecane-3,5-dionato)zinc.

Owner:ADEKA CORP

Compositions and polymer composites prepared from the same

ActiveUS20160005932A1Good storage stabilityOther chemical processesSolid ballsZinc compoundsPolymer composites

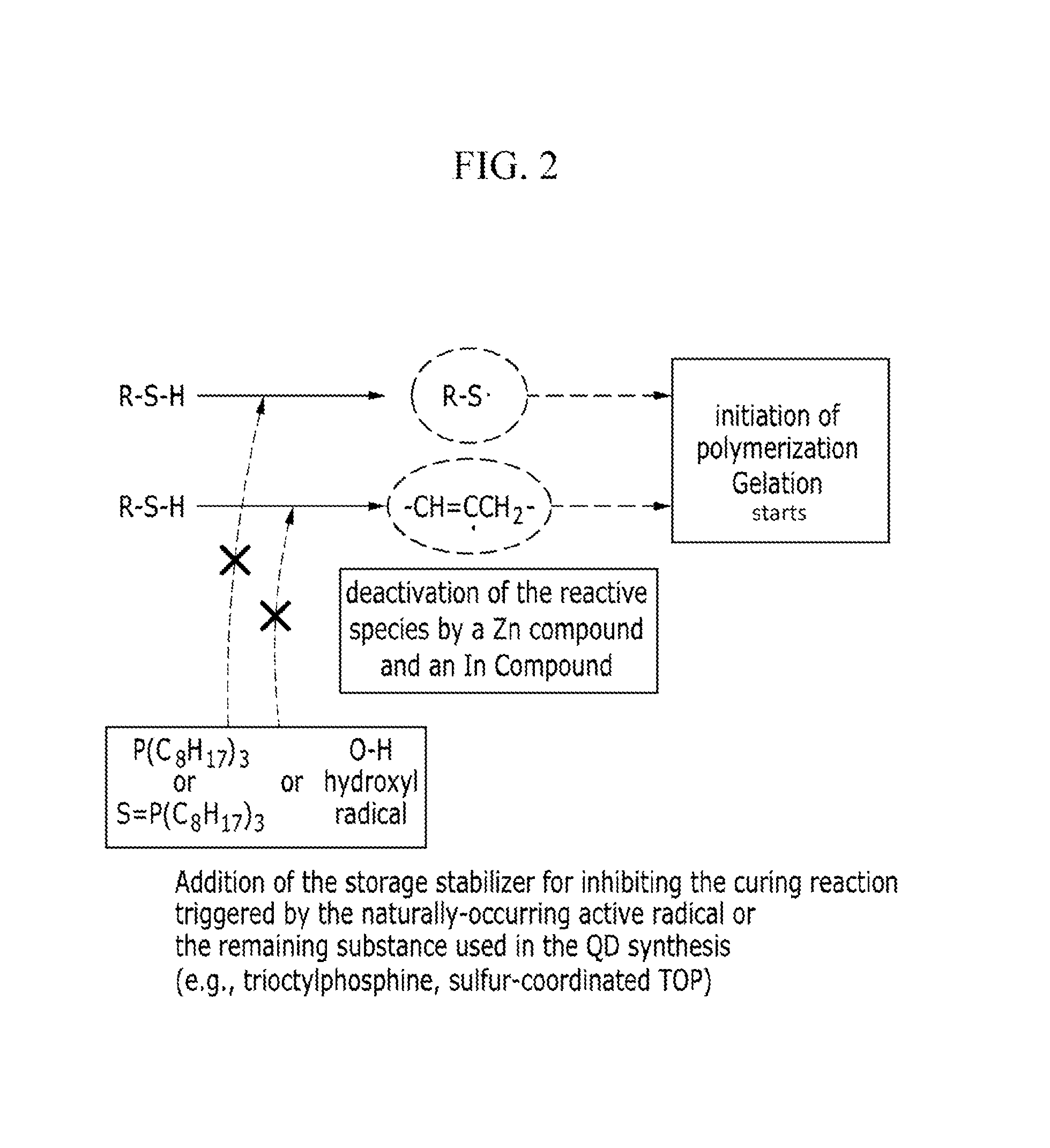

A composition including: a monomer mixture including a first monomer having at least two thiol groups at its terminal end and a second monomer having at least two carbon-carbon unsaturated bond-containing groups at its terminal end; and at least one additive selected from a zinc compound, an indium compound, ascorbic acid or a salt thereof, citric acid or a salt thereof, a tocopherol, and a tocotrienol.

Owner:SAMSUNG ELECTRONICS CO LTD

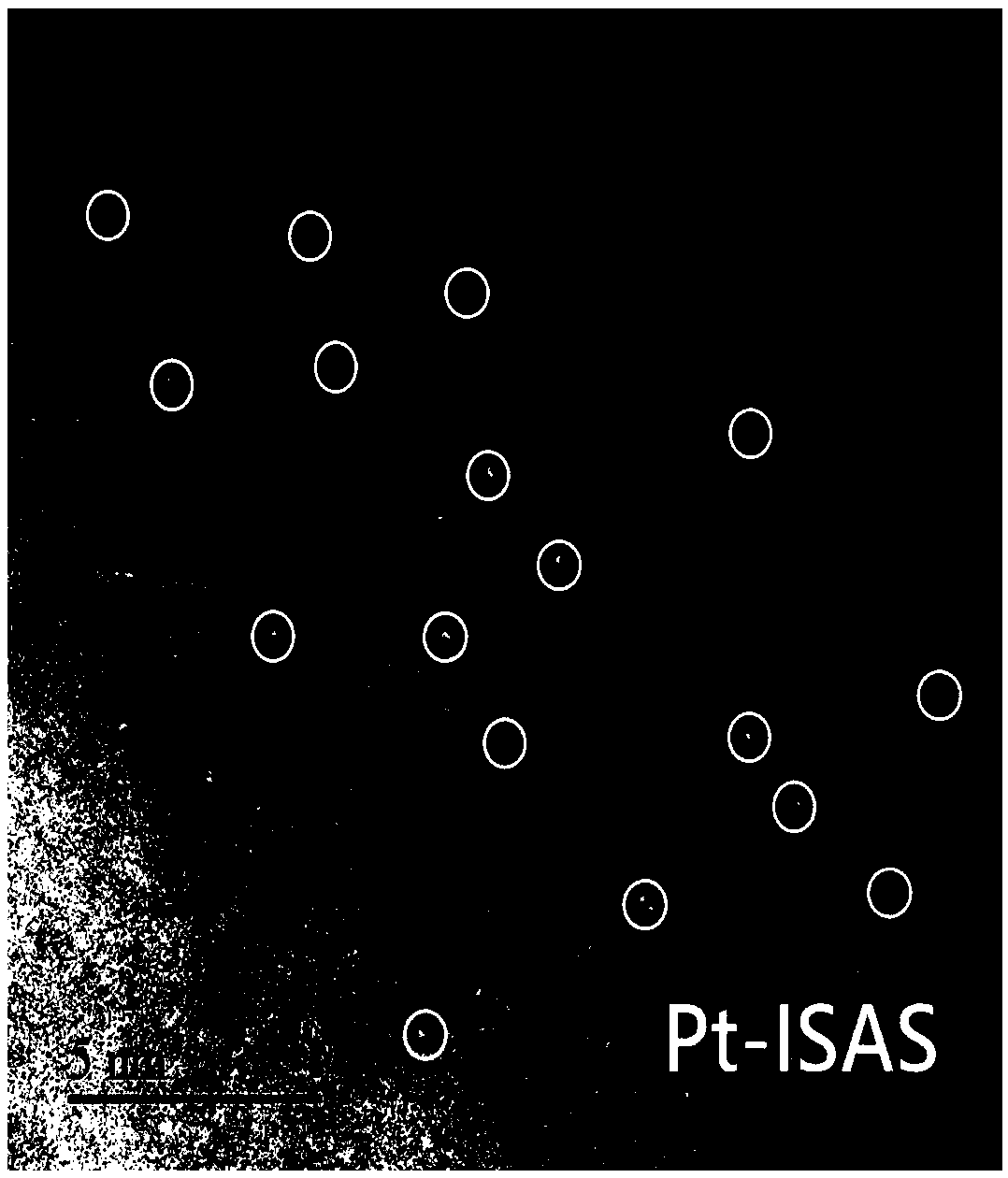

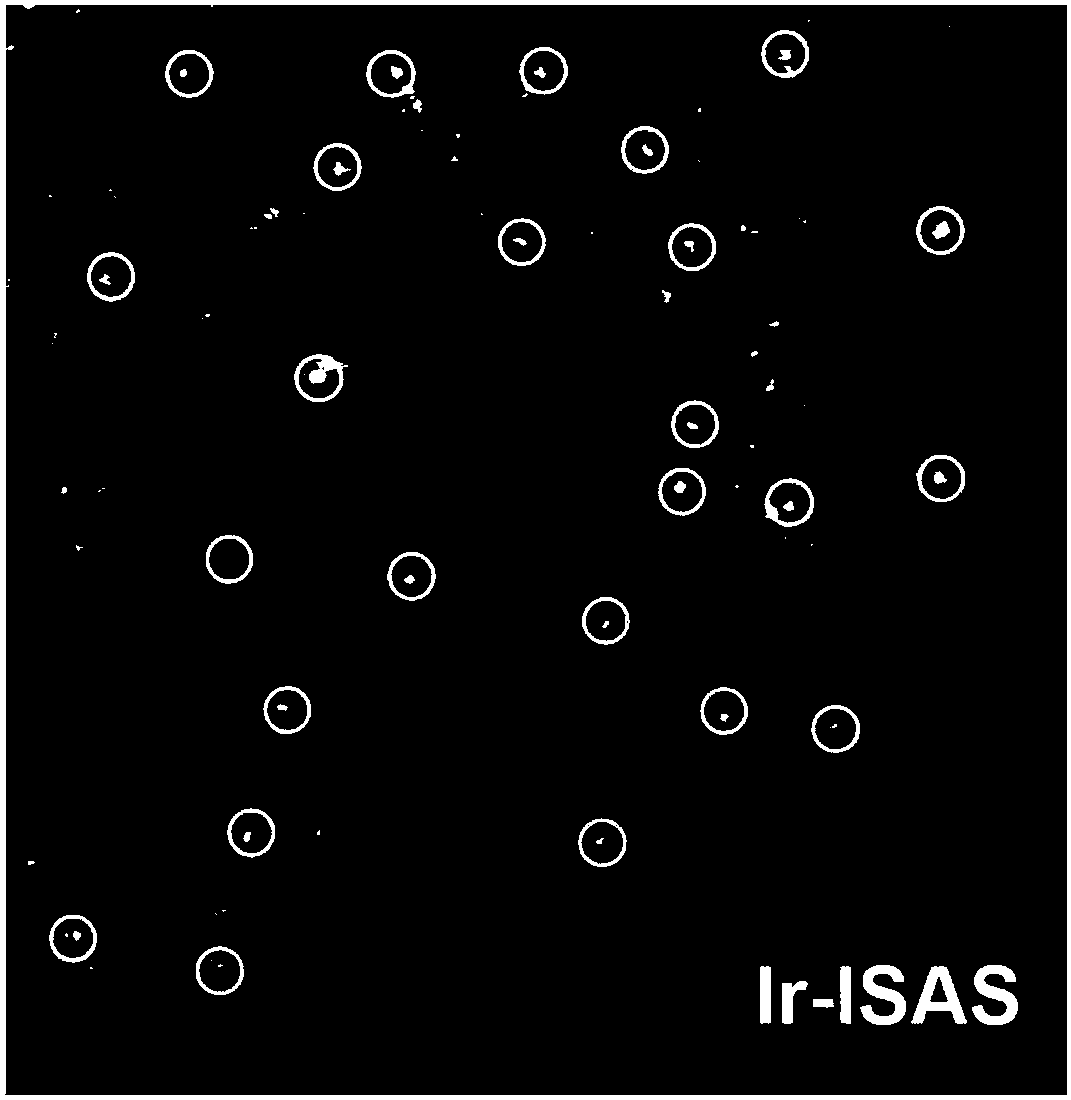

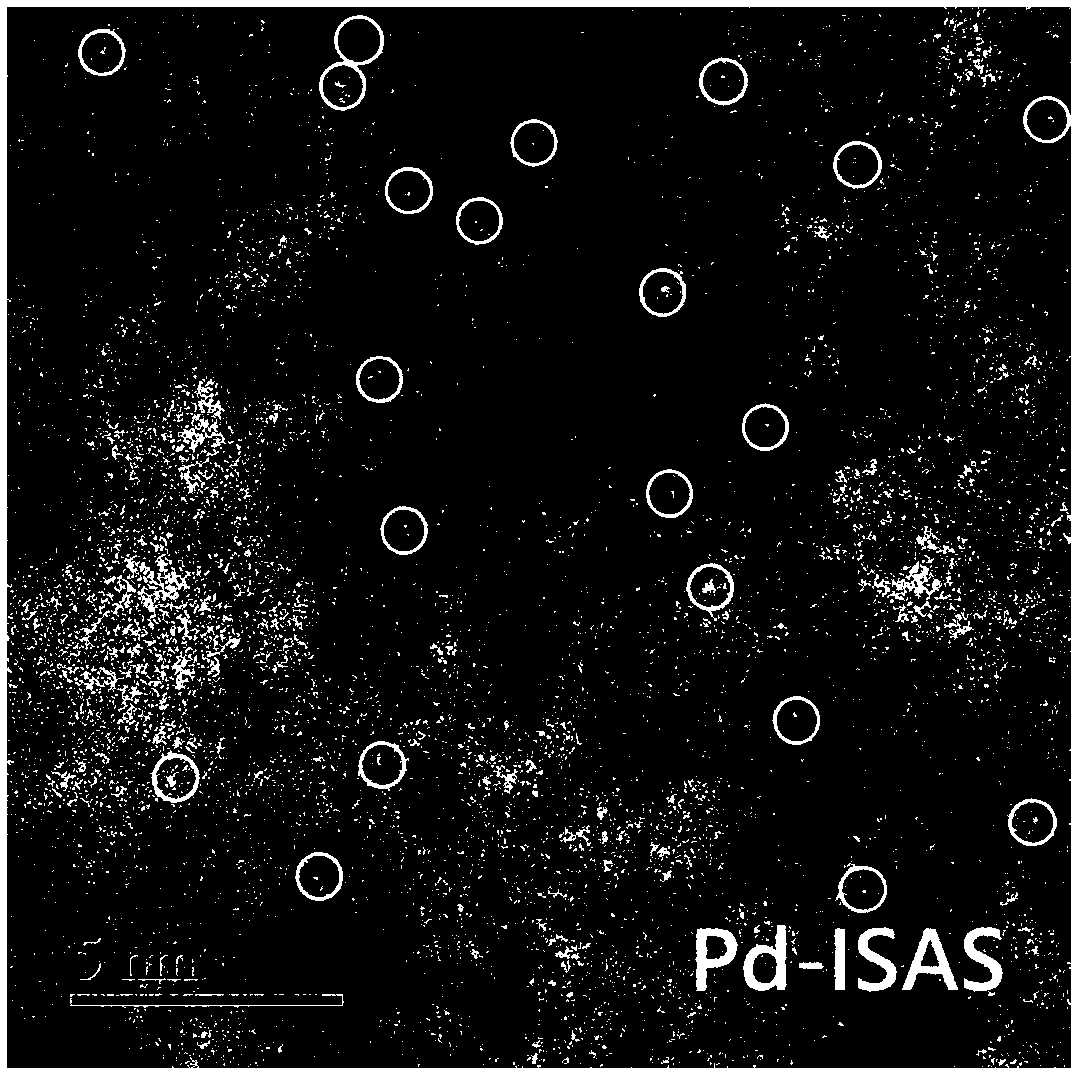

Preparation method of metal monatomic site catalyst

ActiveCN107626294ASmall particlesUniform particle size distributionCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsZinc compoundsPorous carbon

The invention provides a preparation method of a metal monatomic site catalyst. According to the synthetic strategy, a porous complex composite material coated with an acetylacetone metal salt is formed from a zinc compound and an imidazole organic ligand through coordination in a methanol solution of the acetylacetone metal salt, and then a porous carbon support doped with nonmetal heteroatomic nitrogen is formed from the imidazole organic ligand through a high-temperature pyrolytic reaction in an inert gas atmosphere, wherein metal atoms interact with surrounding nonmetal heteroatomic nitrogen and exist in the form of single atoms. The method is simple, safe, low in cost and applicable to synthesis of various noble metal and non-noble metal monatomic site catalysts, and the obtained metal monatomic site catalyst is high in metal concentration and good in heat stability, can be applied to the fields of energy, catalysis, medicine, biology and the like and has quite broad market prospect.

Owner:TSINGHUA UNIV

Topical zinc compositions and methods of use

InactiveUS6558710B1Increase the effective concentrationMinimize skin irritationBiocidePeptide/protein ingredientsZinc compoundsSkin treatments

Compositions including zinc compounds and select amino acids in a carrier base, and methods of skin treatment with such compositions, are described. The compositions are useful for healing skin and minimizing the irritation incurred from contact with the zinc compound without loss of zinc availability during absorption into the integument.

Owner:GODFREY HELEN REBECCA

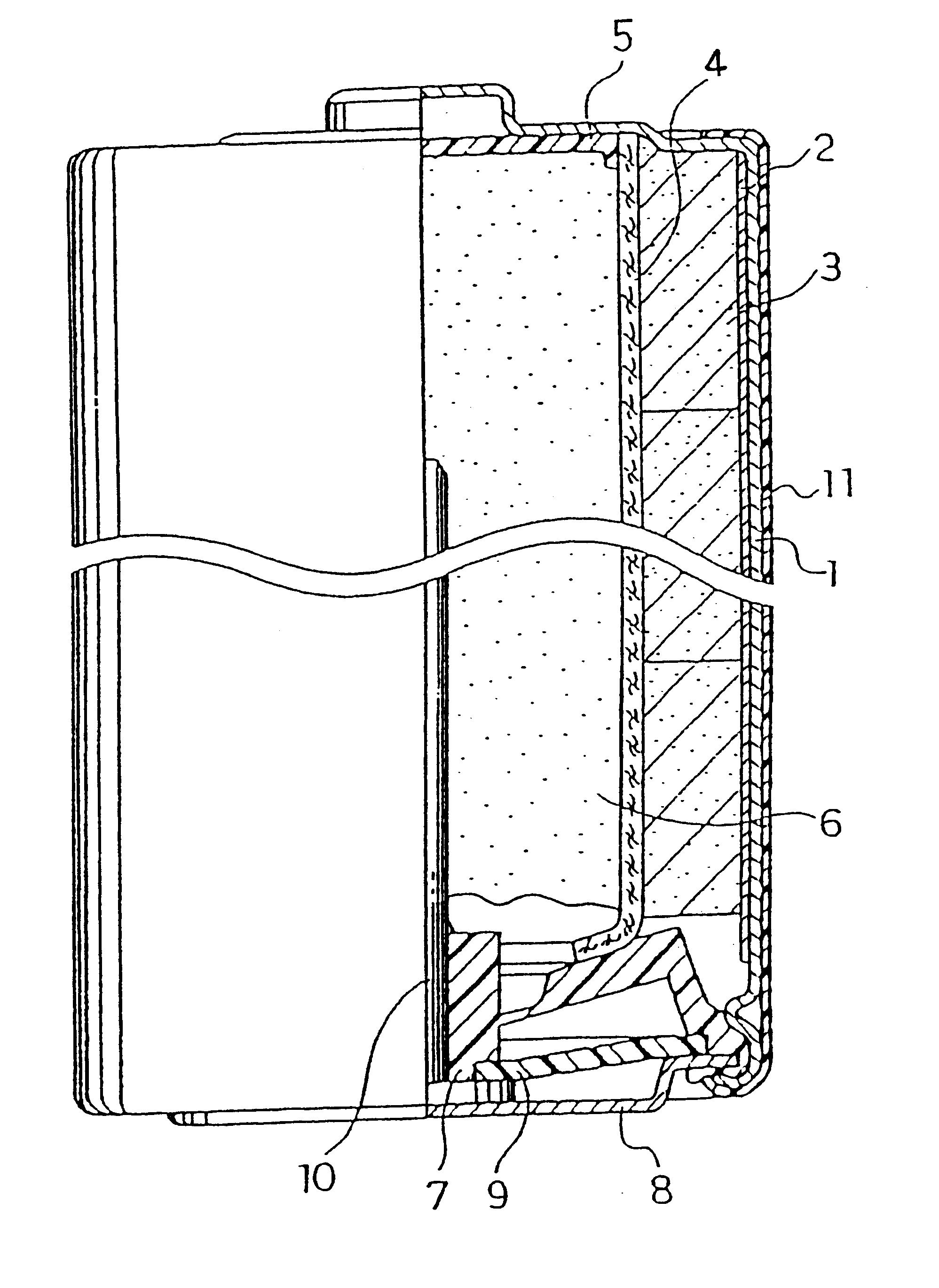

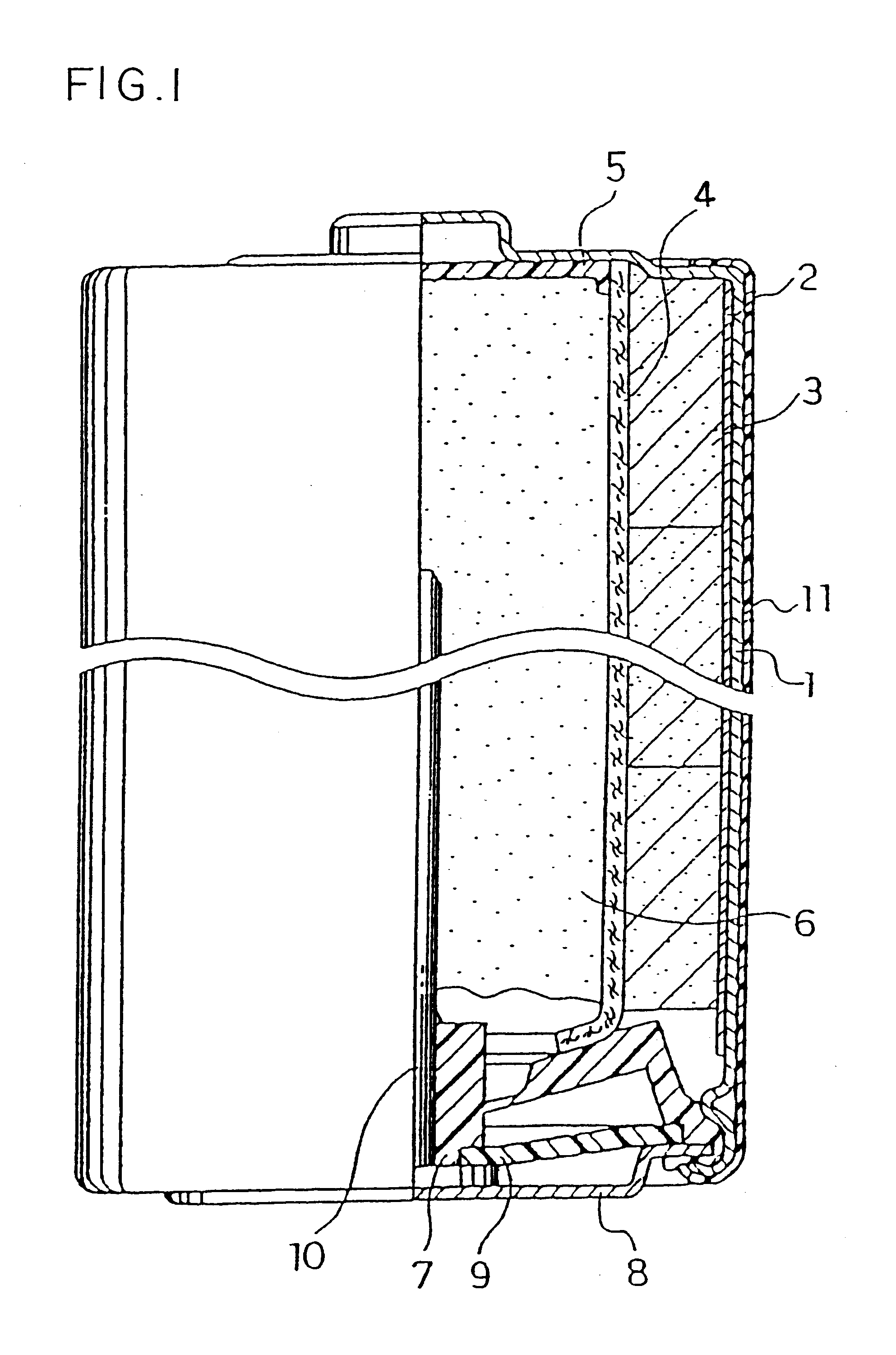

Alkaline battery

InactiveUS6566009B1Good heavy-loading discharge characteristicImprove discharge characteristicsGel electrodesAlkaline accumulator electrodesZinc compoundsTitanium

The present invention provides an alkaline battery having good heavy-loading discharge characteristics even after long-term storage at high temperatures. The alkaline battery of the present invention comprises a positive electrode containing manganese dioxide and nickel oxyhydroxide as an active material, a negative electrode containing zinc as an active material, and an alkaline electrolyte. The positive electrode further contains at least one compound selected from the group consisting of an oxygen-containing zinc compound, an oxygen-containing calcium compound, an oxygen-containing yttrium compound, and an oxygen-containing titanium compound.

Owner:PANASONIC CORP

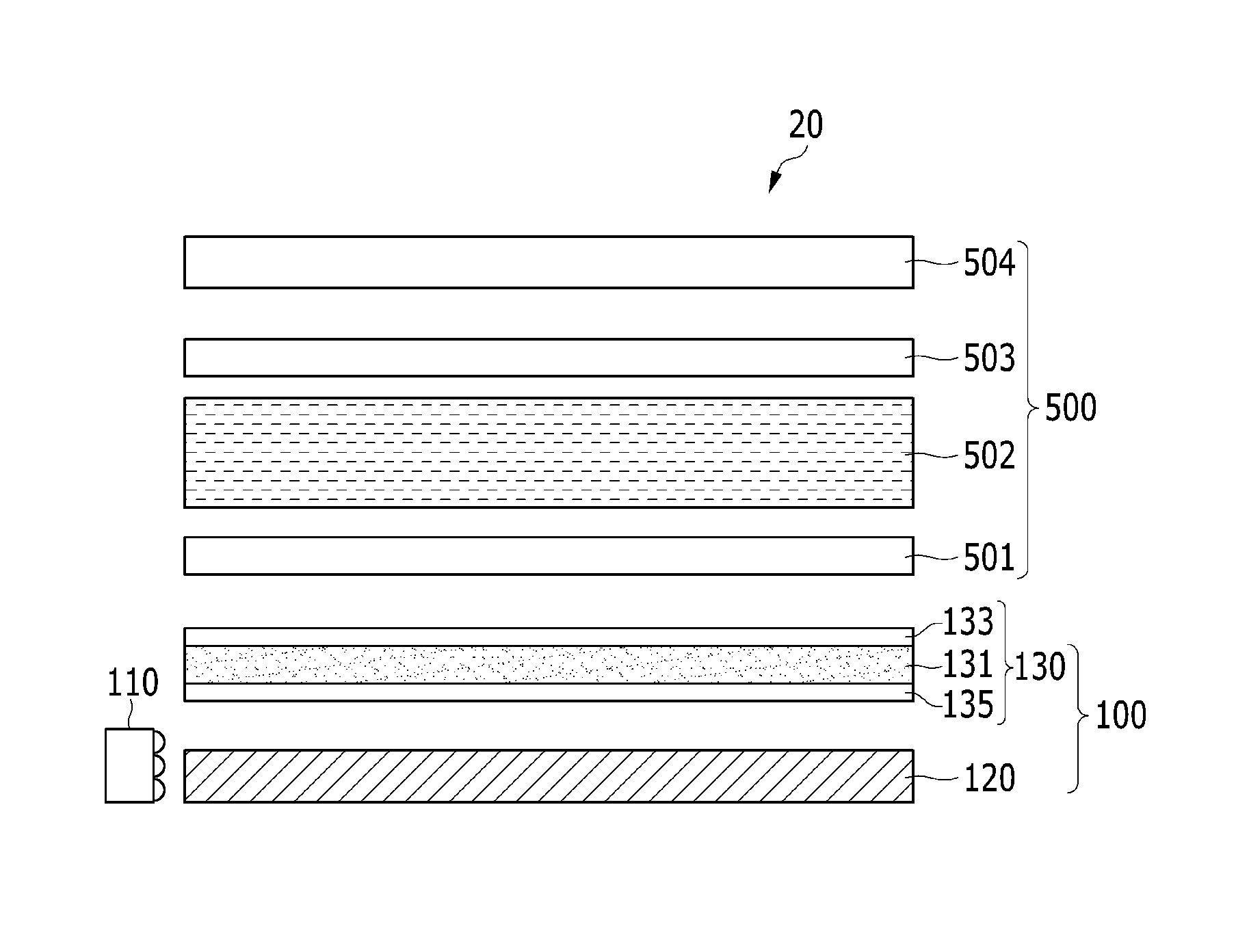

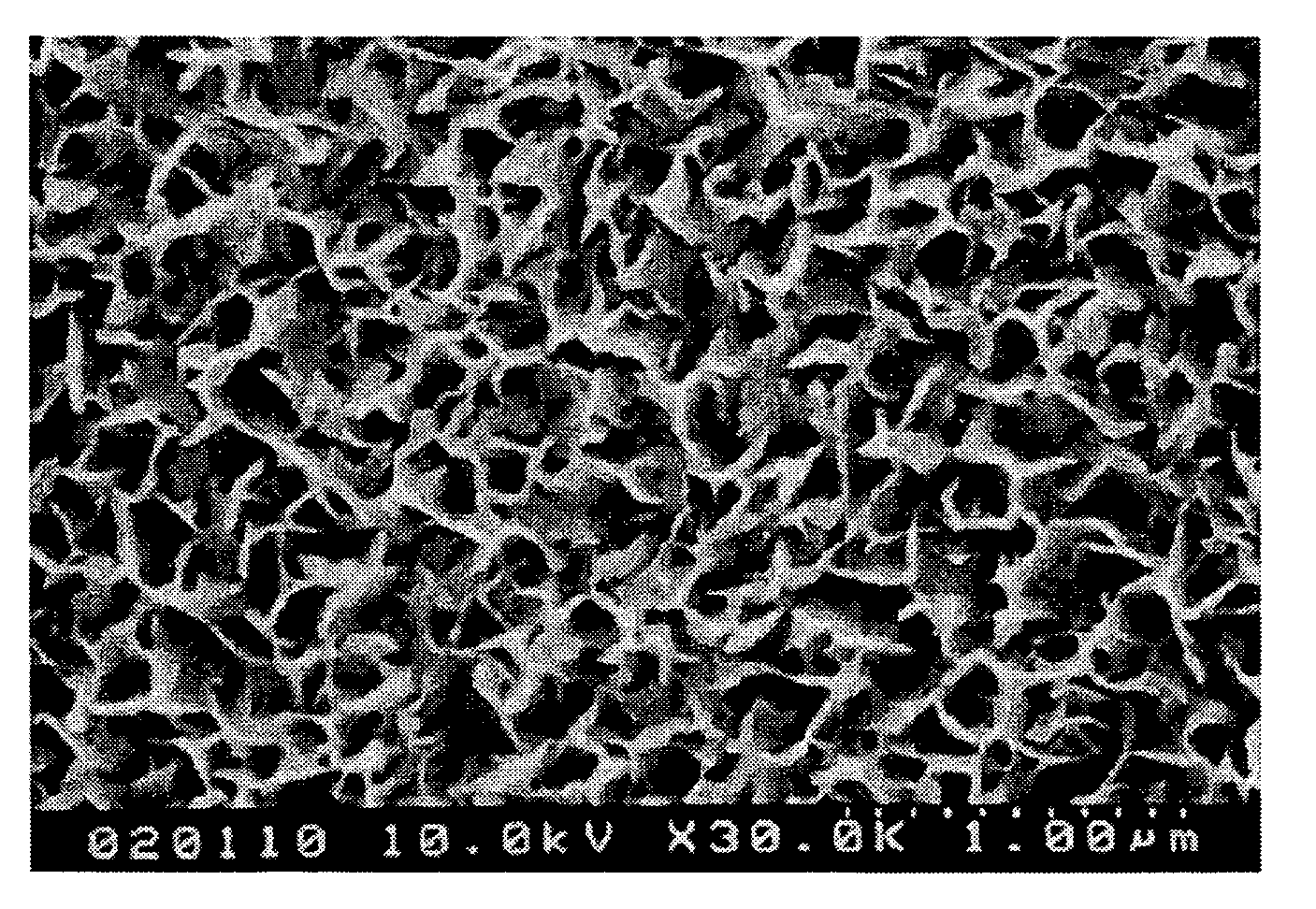

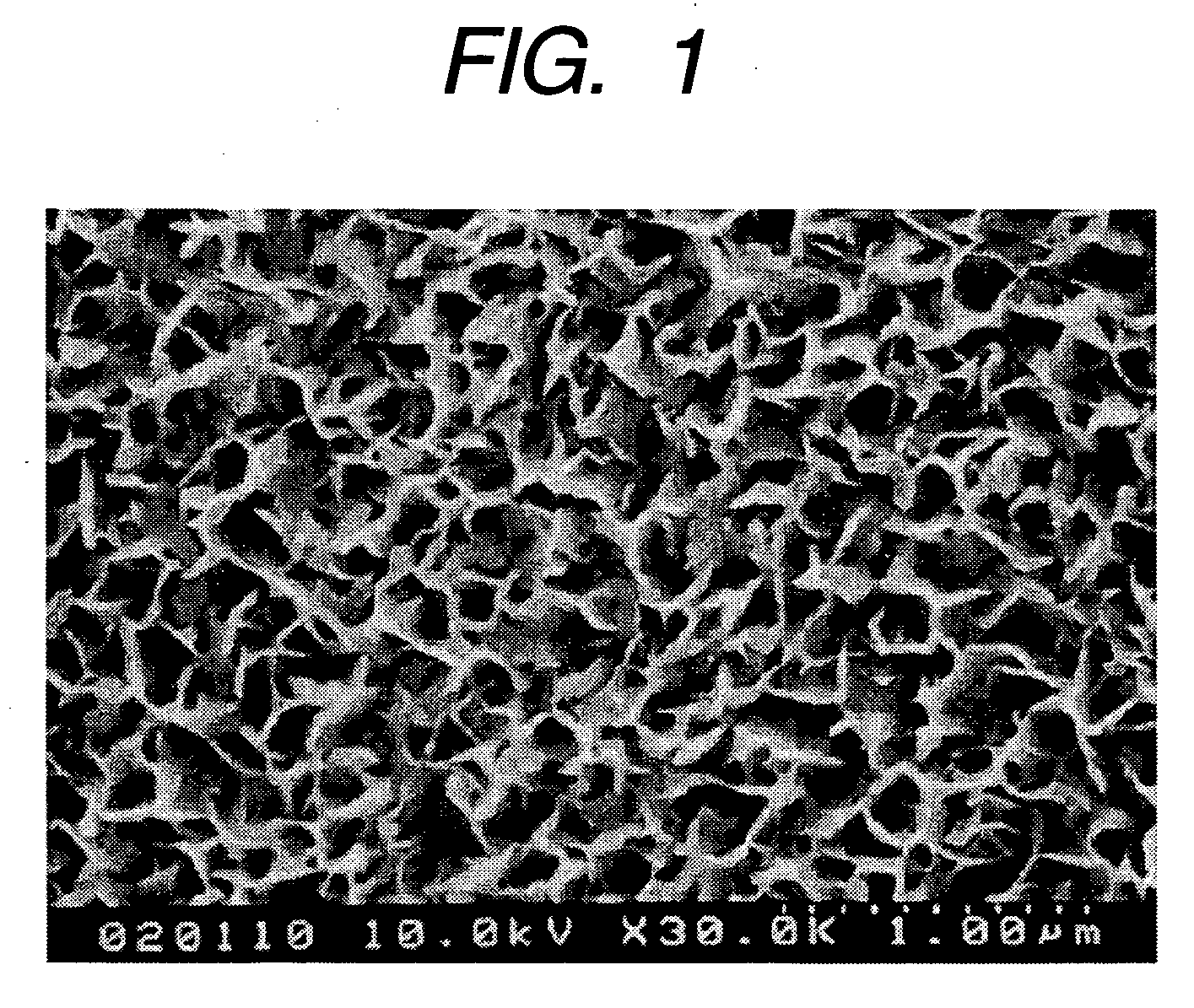

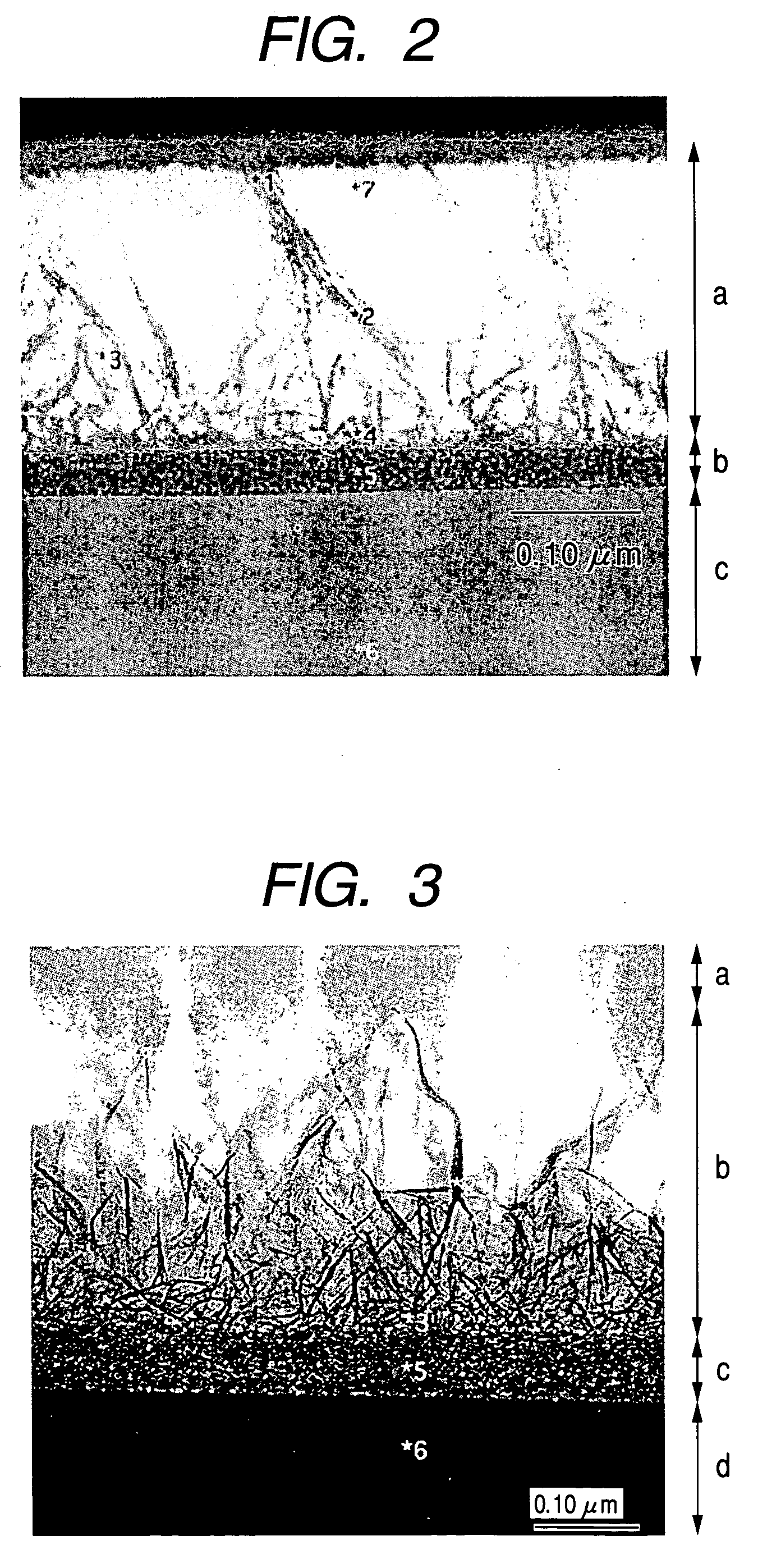

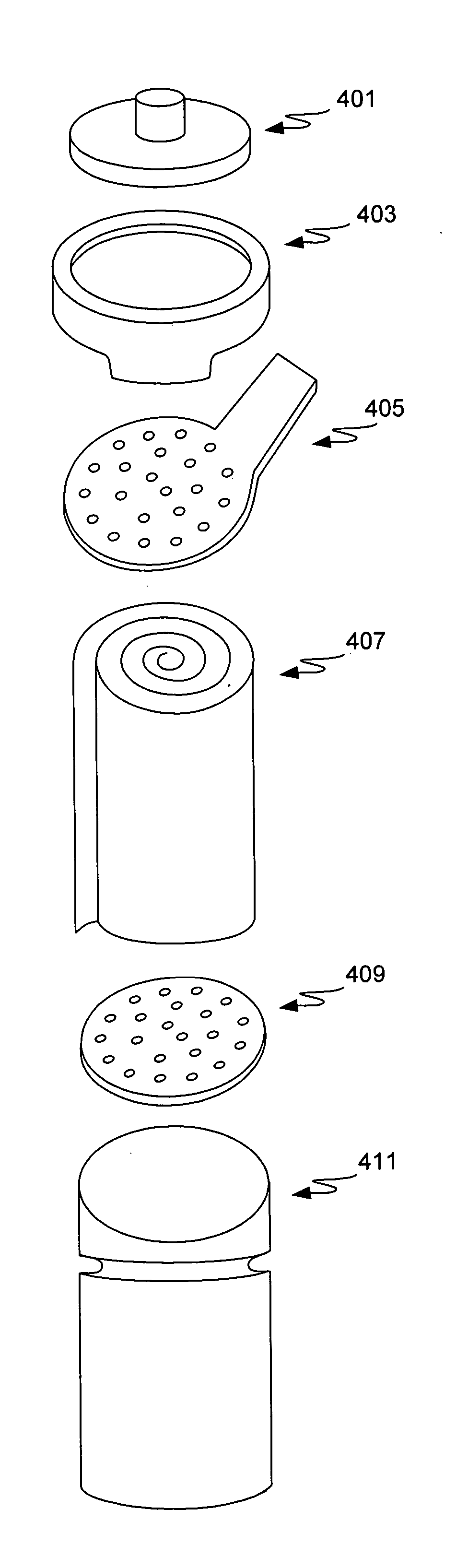

Film and antireflection film having fine irregularities on surface, production method for the same, and optical member using the same

InactiveUS20050233113A1Improve anti-reflection effectReduce reflectionDiffusing elementsLayered productsZirconia silicaZinc compounds

A transparent antireflection film, including fine irregularities mainly composed of alumina, and a transparent thin film layer supporting the fine irregularities, in which the transparent thin film layer contains at least one selected from the group consisting of zirconia, silica, titania, and zinc oxide. A production method for the aforementioned transparent antireflection film, including: forming a multicomponent film using an application liquid containing at least one compound selected from the group consisting of a zirconium compound, a silicon compound, a titanium compound, and a zinc compound, and at least an aluminum compound; and subjecting the multicomponent film to warm water treatment.

Owner:PUBLIC UNIVERSITY CORPORATION OSAKA CITY UNIVERSITY +1

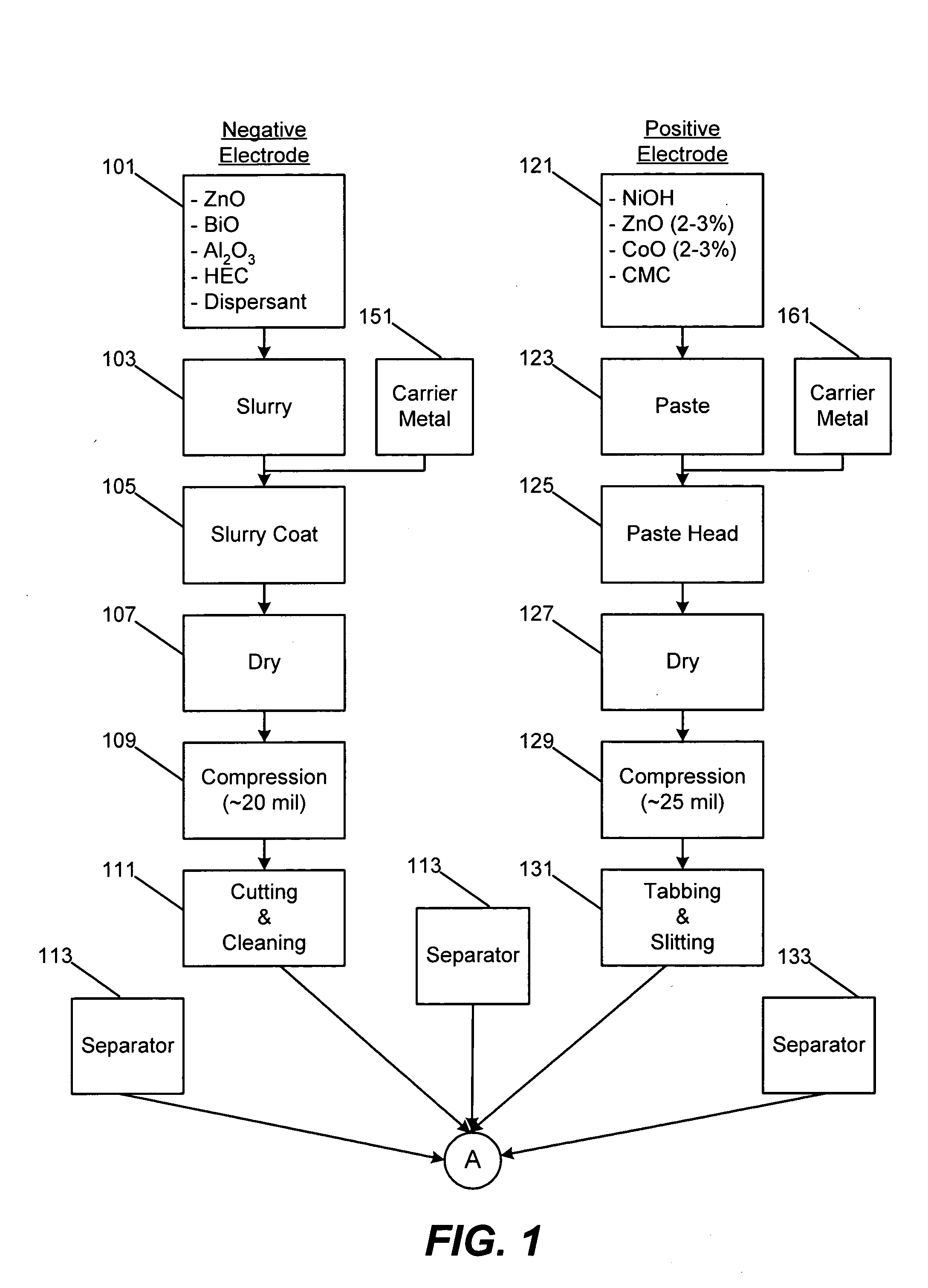

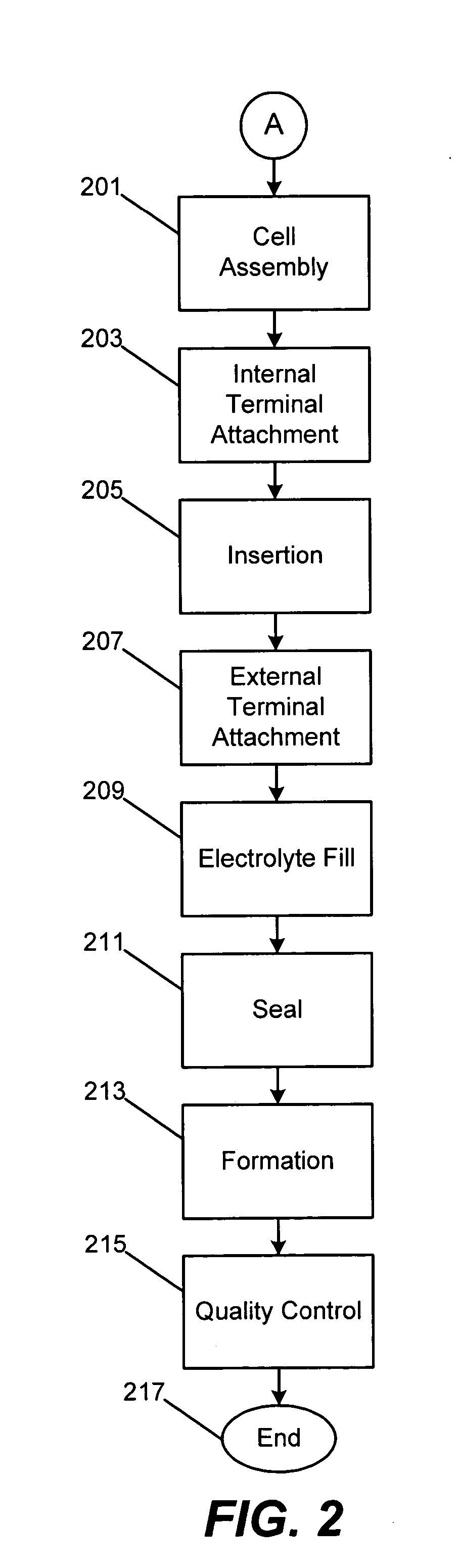

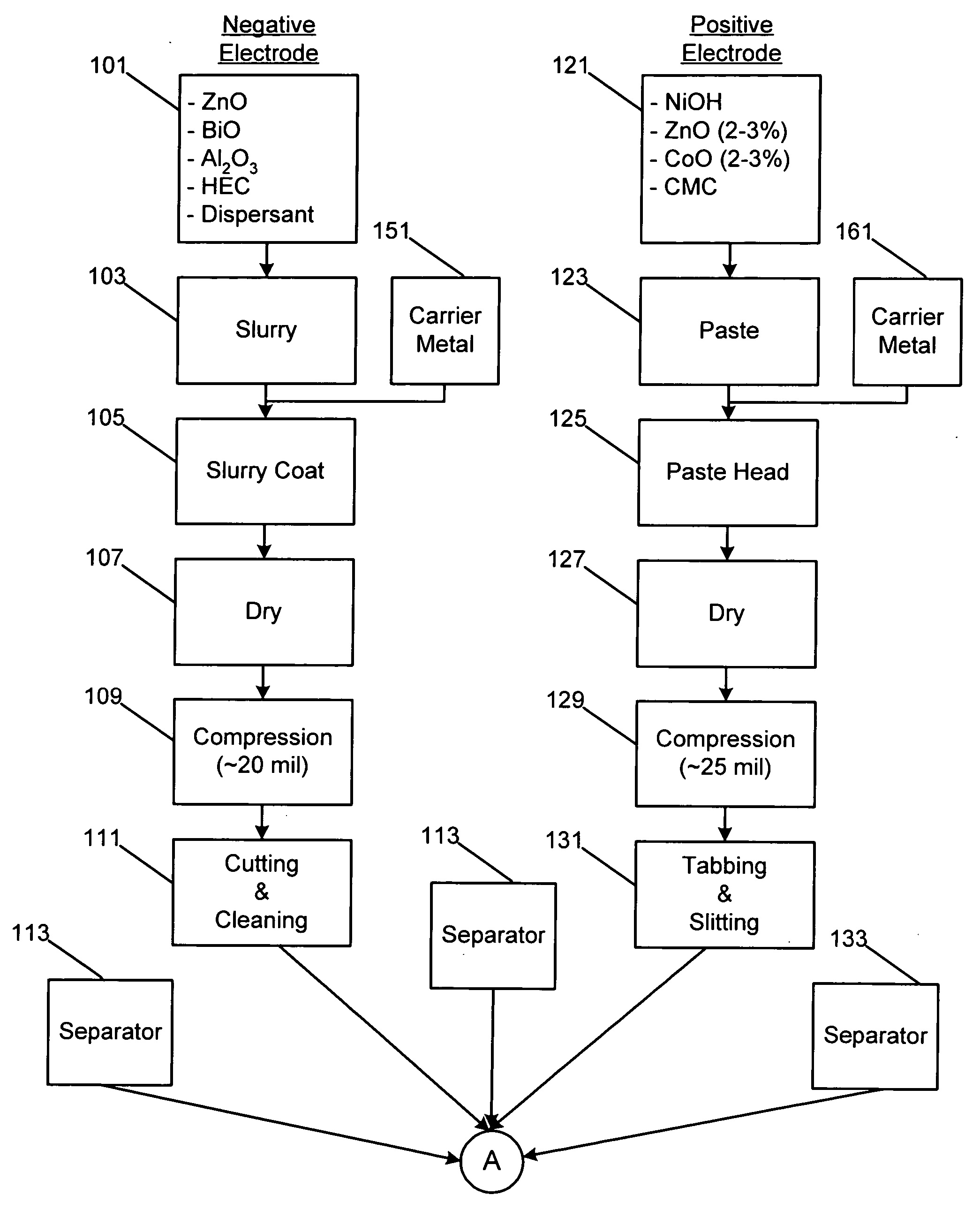

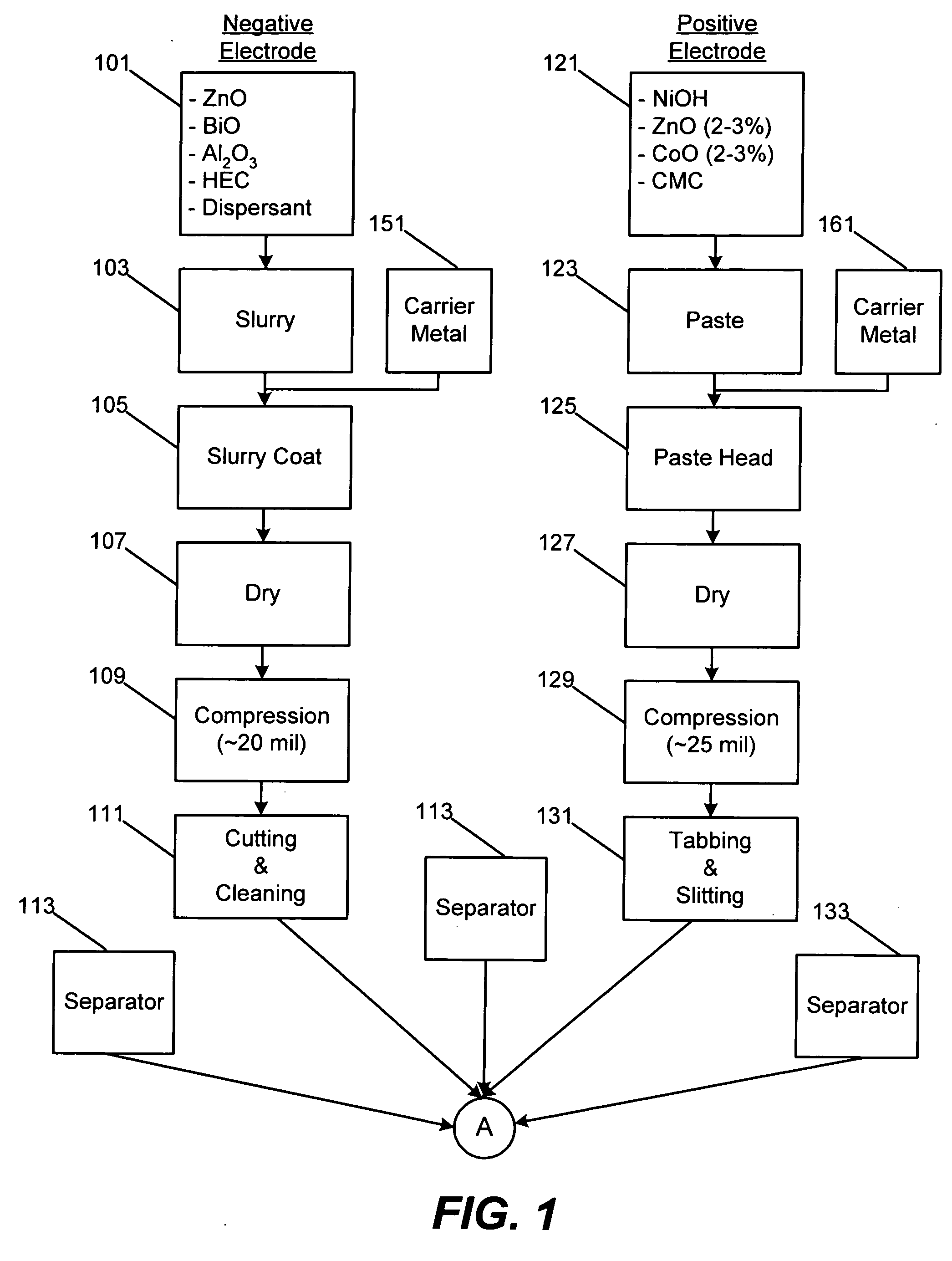

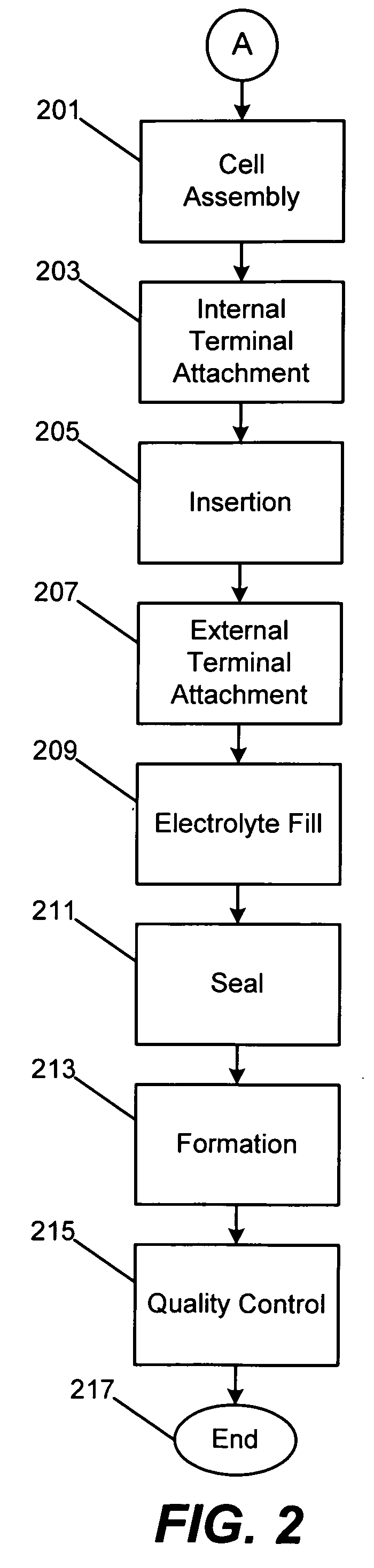

Method of manufacturing nickel zinc batteries

ActiveUS20050064292A1Improve efficiencyFinal product manufactureElectrode carriers/collectorsZinc compoundsSlurry

Methods of manufacturing a rechargeable power cell are described. Methods include providing a slurry or paste of negative electrode materials having low toxicity and including dispersants to prevent the agglomeration of particles that may adversely affect the performance of power cells. The methods utilize semi-permeable sheets to separate the electrodes and minimize formation of dendrites; and further provide electrode specific electrolyte to achieve efficient electrochemistry and to further discourage dendritic growth in the cell. The negative electrode materials may be comprised of zinc and zinc compounds. Zinc and zinc compounds are notably less toxic than the cadmium used in NiCad batteries. The described methods may utilize some production techniques employed in existing NiCad production lines. Thus, the methods described will find particular use in an already well-defined and mature manufacturing base.

Owner:ZINCFIVE POWER INC

Material having deodorizing function and process for production thereof

InactiveUS20070065397A1Inexpensive deodorizing functionInexpensive sterilizing and deodorizing functionsSolid waste disposalBathsZinc compoundsWater insoluble

A material having a deodorizing function, characterized in that it comprises a paper powder containing a copper or zinc compound or copper and zinc compounds retained therein. A method for producing a material having a deodorizing function, characterized in that it comprises mixing an aqueous solution of a copper or zinc compound or copper and zinc compounds into a paper powder; mixing the resulting mixture into an aqueous solution of a pH adjuster to form a water-insoluble basic compound or hydroxide of copper or zinc or copper and zinc; and retaining the formed water-insoluble basic compound or hydroxide in the paper powder. It is possible to form a material having a deodorizing function by effectively utilizing a waste such a paper powder and to provide an inexpensive material having a deodorizing function and a method for producing the same. A granular excrement treating article comprising a granular core portion and a coating layer portion covering the granular core portion, both of which are formed utilizing the material having a deodorizing function. During and after use of the excrement treating article, an obnoxious odor generated by excrement can be deodorized by the copper or zinc compound having the deodorizing function.

Owner:DAIKI CO LTD

Flavor blend for masking unpleasant taste of zinc compounds

A synergistic flavoring combination of at least two flavoring oils and lauryl alcohol for use in an orally administered formulation which contains an ionizable zinc compound having an undesirable taste, the flavoring combination is unexpectedly effective in masking the unpleasant taste or aftertaste of zinc.

Owner:BLOCK DRUG CO INC

Pretreatment for aluminum and aluminum alloys

InactiveUS6669764B1Reduce electrical contact resistanceImprove adhesionPretreated surfacesSolid state diffusion coatingChromium CompoundsZinc compounds

Pretreated aluminum and aluminum alloys and the process and composition for pretreating said aluminum and its alloys to provide a coating with color recognition for identification purposes and to improved the corrosion-resistance, electrical conductivity, and adhesion properties which comprises pretreating said aluminum and its alloys with an effective amount of an acidic aqueous solution having a pH ranging from about 2.5 to 5.5 comprising water soluble trivalent chromium compounds, alkali metal hexafluorozirconates, divalent zinc compounds, alkali metal fluoro-compounds, and effective amounts of water soluble thickeners, surfactants or wetting agents.

Owner:CHIEF OF NAVAL RES

Zinc composition and their use in anti-microbial applications

The invention relates generally to antimicrobial compositions that are non-toxic to mammals and plants, and are highly effective against a broad spectrum of detrimental pathogenic microorganisms. The antimicrobial compositions contain at least one zinc compound that is microbicidal to at least one microorganism. The antimicrobial compositions of the invention can be diluted in suitable proportions into suitable solvents to produce the desired dosages for each individual application. The antimicrobial compositions can be applied by conventional methods, e.g., spraying, soaking, fogging, impregnation, and the like. The compositions can also be used as preservatives. The antimicrobial compositions can also be made as gels or solids in different forms by using techniques available to those skilled in the art.

Owner:SWISS AMERICAN CDMO LLC

Oligomerisation of olefinic compounds with reduced polymer formation

ActiveUS20120316303A1Promote recoveryPromote activationOrganic-compounds/hydrides/coordination-complexes catalystsCatalystsZinc compoundsHydrogen

The invention relaters to a process for producing an oligomeric product by oligomerisation of at least one olefinic compound, the process including a) providing an activated oligomerisation catalyst by combining, in any order, i) a source of chromium, ii) a ligating compound of the formula I (R1)mX1(Y) X2 (R2)n. . . . I wherein X1 and X2 are independently an atom selected from the group consisting of nitrogen, phosphorus, arsenic, antimony, bismuth, oxygen, sulphur and selenium or said atom oxidized by S, Se, N or O where the valence of X1 and / or X2 allows for such oxidation, Y is a linking group between X1 and X2, m and n are independently 0, 1 or a larger integer, and R1 and R2 are independently hydrogen, a hydrocarbyl group, an organoheteryl group or a heterohydrocarbyl group, and R1 being the same or different when m>1, and R2 being the same or different when n>1, iii) a catalyst activator or combination of catalyst activators, b) providing a zinc compound, and c) contacting the at least one olefinic compound with a composition containing the activated oligomerisation catalyst and the zinc compound, the zinc compound being present in a sufficient quantity such that the ratio of the molar amount of zinc in the zinc compound to the molar amount of chromium in the source of chromium is between 1 and 10000 The invention also provides for a process for activating an oligomerisation catalyst to be used to produce an oligomeric product from at least one olefinic compound, as described above

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD

Post-treatment for metal coated substrates

InactiveUS6663700B1Metal-working apparatusSolid state diffusion coatingChromium CompoundsZinc compounds

Aqueous compositions for post-treating metal coated substrates such as cadmium-plated steel, and zinc-nickel coated substrates and the process for using said compositions to provide a color recognizable coating and to improve the corrosion-resistance, abrasion, electrical, and adhesion properties of the coating. The post-treatment composition comprises an acidic aqueous solution having a pH ranging from about 2.5 to 5.5 and contains effective amounts of trivalent chromium compounds, alkali metal hexafluorozirconates, at least one divalent zinc compound, alkali metal fluoro-compounds, and effective amounts of water soluble thickeners, wetting agents or surfactants.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

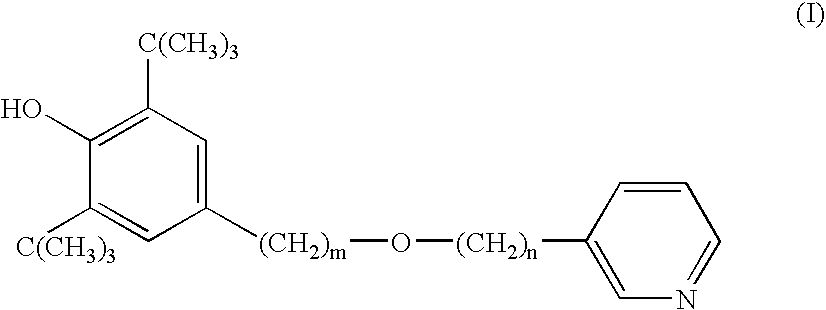

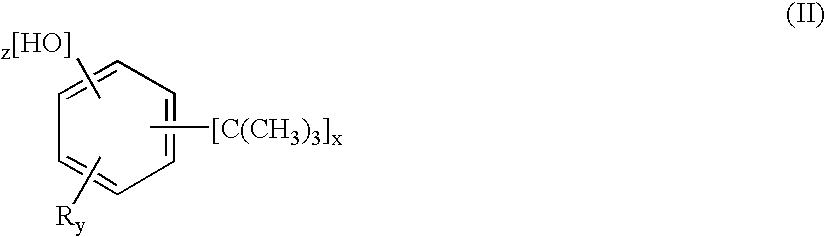

Anti-viral compositions and methods of making and using the anti-viral compositions

Disclosed are anti-viral compositions containing at least one zinc compound and at least one phenolic antioxidant (and optionally other ingredients), and a pharmaceutical carrier. Also disclosed are methods of treating lesionous symptoms of a viral infection involving applying an effective amount of the anti-viral composition to the lesions.

Owner:SMITH JEFFREY B

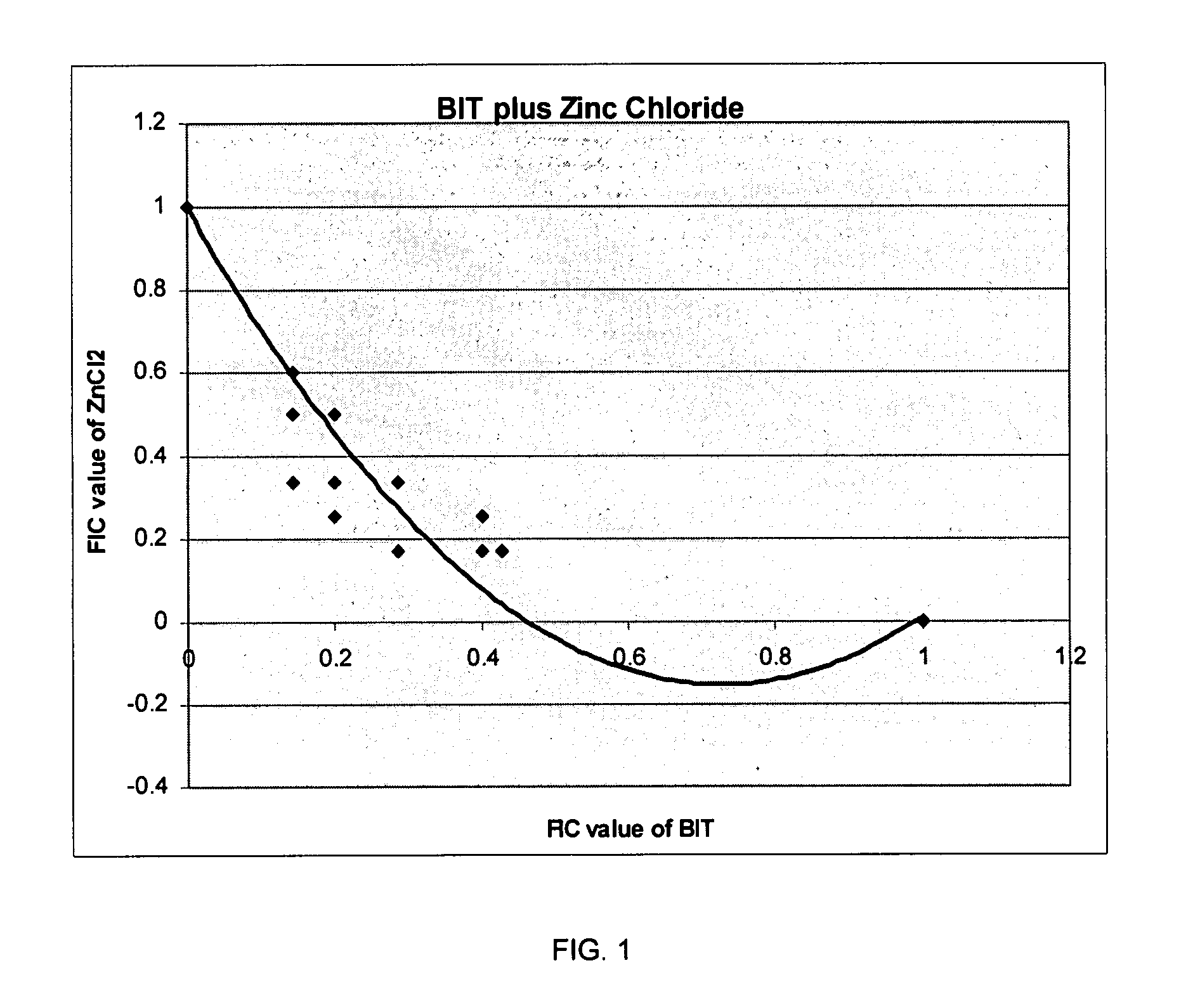

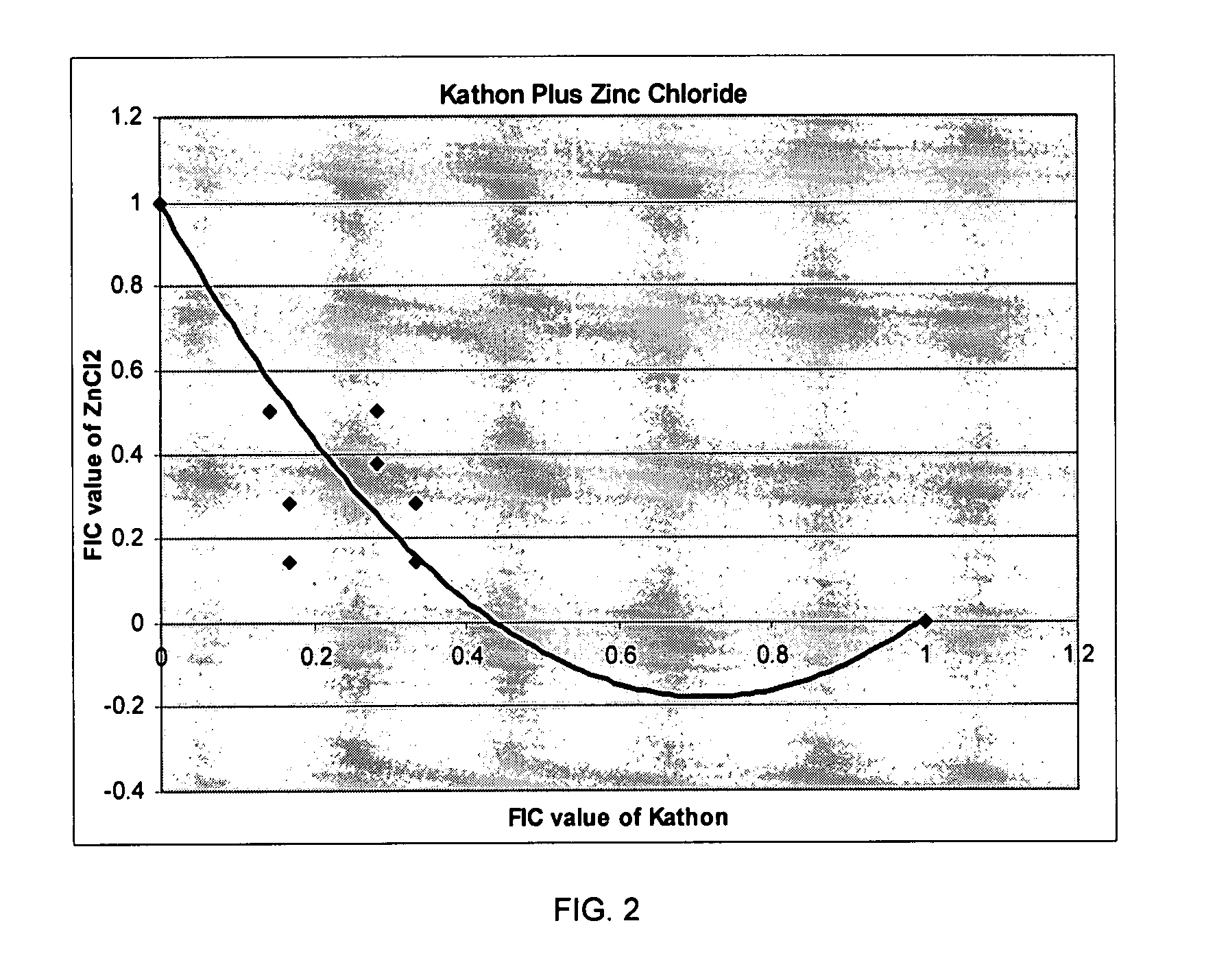

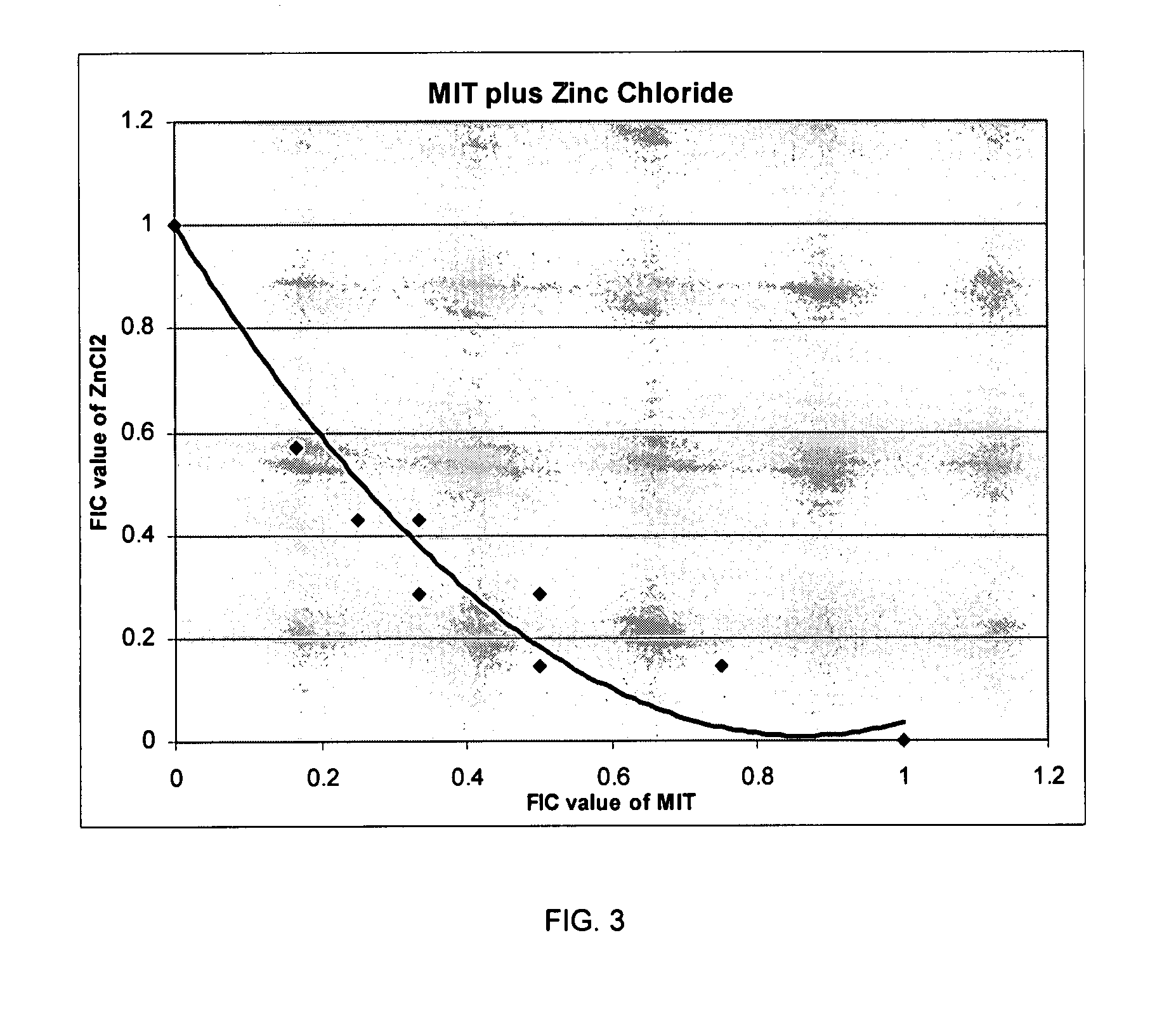

Isothiazolinone biocides enhanced by zinc ions

The present invention relates to an antimicrobial composition comprising an isothiazolinone, such as 1,2-benzisothiazolin-3-one, and a zinc compound selected from zinc salts, zinc oxides, zinc hydroxides or combinations thereof. Useful zinc salts include for example, oxides, sulfates, chlorides, and combinations thereof. In use, the zinc from the zinc compound enhances the antimicrobial activity to the isothiazolin-containing composition. This enhancement permits achieving the desired antimicrobial activity at a lower usage rate than is achieved using the isothiazolinone in the absence of the zinc compound. The antimicrobial composition can also contain co-biocides, such as pyrithiones, including zinc pyrithione or copper pyrithione.

Owner:ARCH CHEM INC

Method of manufacturing nickel zinc batteries

InactiveUS20060207084A1Reduce reunionImprove efficiencyFinal product manufacturePrimary cellsZinc compoundsNickel cadmium

Methods of manufacturing a rechargeable power cell are described. Methods include providing a slurry, paste, or dry mixture of negative electrode materials having low toxicity and including dispersants to prevent the agglomeration of particles that may adversely affect the performance of power cells. The methods utilize semi-permeable sheets to separate the electrodes and minimize formation of dendrites; and further provide electrode specific electrolyte to achieve efficient electrochemistry and to further discourage dendritic growth in the cell. The negative electrode materials may be comprised of zinc and zinc compounds. Zinc and zinc compounds are notably less toxic than the cadmium used in nickel cadmium batteries. The described methods may utilize some production techniques employed in existing NiCad production lines. Thus, the methods described will find particular use in an already well-defined and mature manufacturing base.

Owner:POWERGENIX SYST

Oxide sintered body, manufacturing method therefor, manufacturing method for transparent conductive film using the same, and resultant transparent conductive film

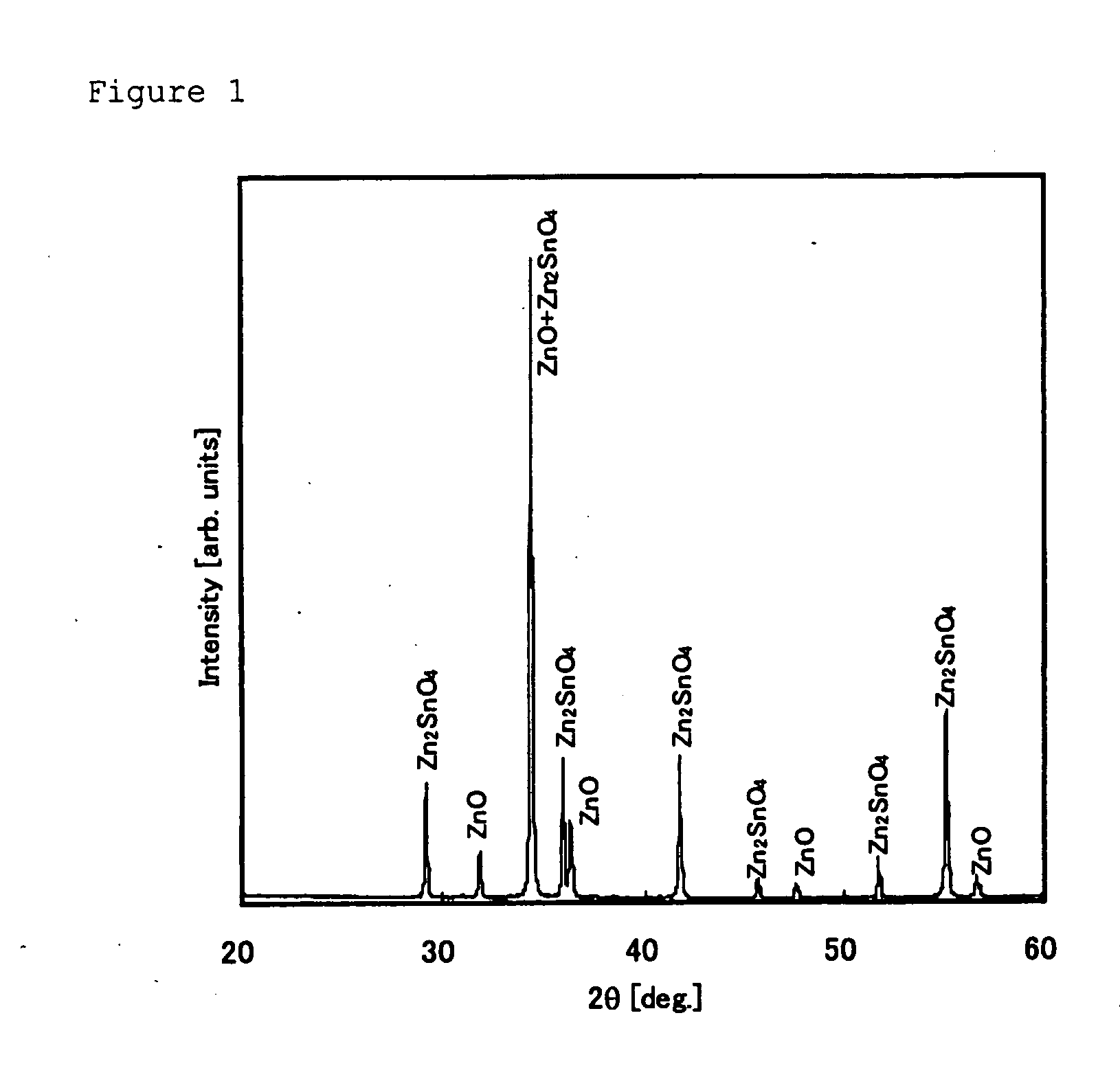

The present invention relates to the oxide sintered body substantially containing zinc, tin and oxygen, useful as a target, which can be sputtered under charging of high DC power, without generation of arcing or crack, and a manufacturing method for an oxide transparent conductive film formable in high-speed, and the oxide transparent conductive film excellent in chemical resistance. The oxide sintered body substantially containing zinc, tin and oxygen; containing tin at an atomic number ratio, Sn / (Zn+Sn), of 0.23 to 0.50, and being composed mainly of a zinc oxide phase and at least one kind of zinc stannate compound phase, or being composed of at least one kind of zinc stannate compound phase; provided by a method for manufacturing the oxide sintered body by formulating an aqueous solvent to raw material powder containing powder of a zinc stannate compound, or mixed powder of tin oxide powder and zinc oxide powder, and after mixing the resulting slurry for equal to longer than 15 hours, by subjecting the slurry to solid-liquid separation, drying and granulation, and subsequently compacting by charging the granule into a mold, followed by sintering the resultant compact under sintering atmosphere at 1300 to 1500° C. for equal to or longer than 15 hours.

Owner:SUMITOMO METAL MINING CO LTD

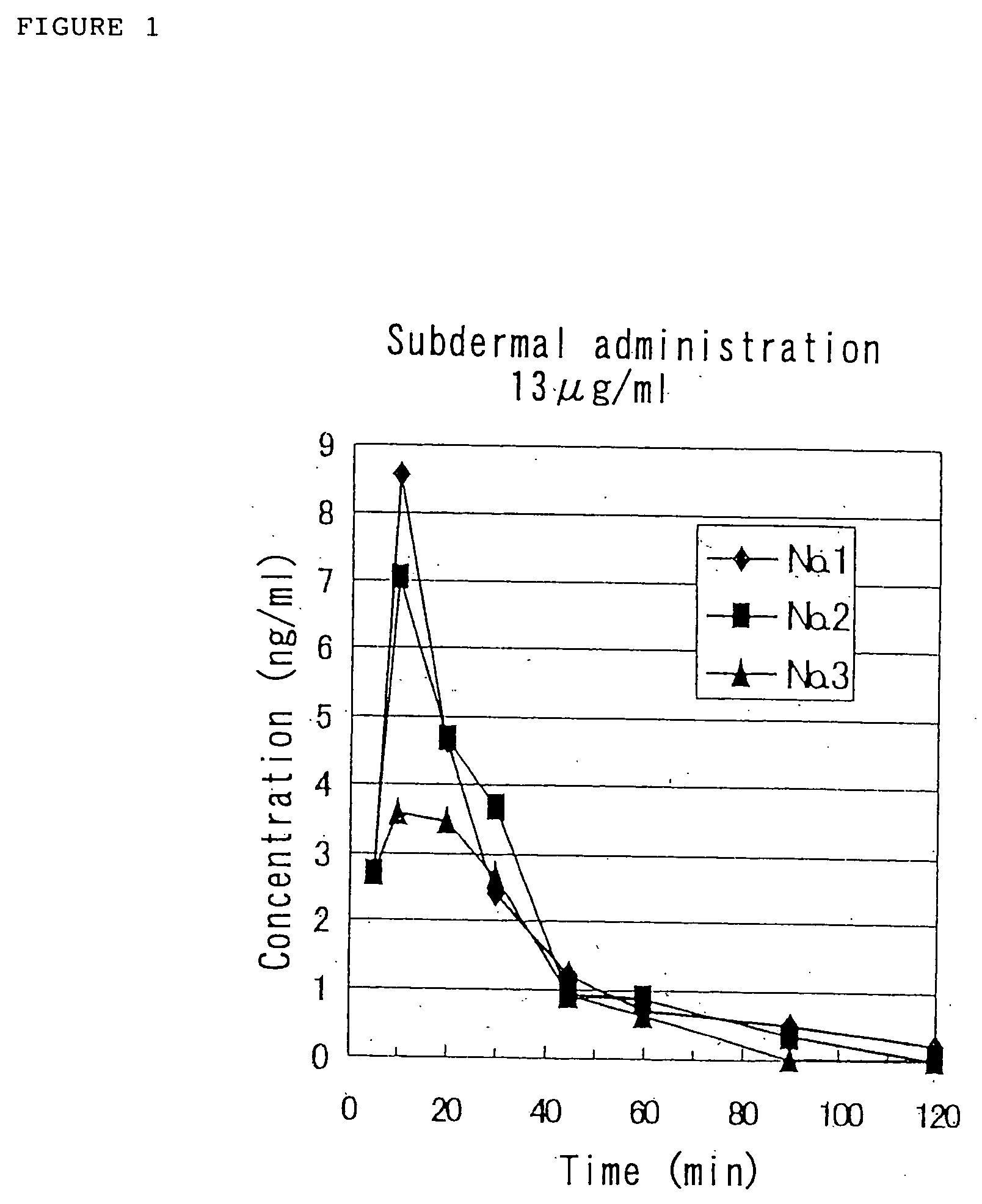

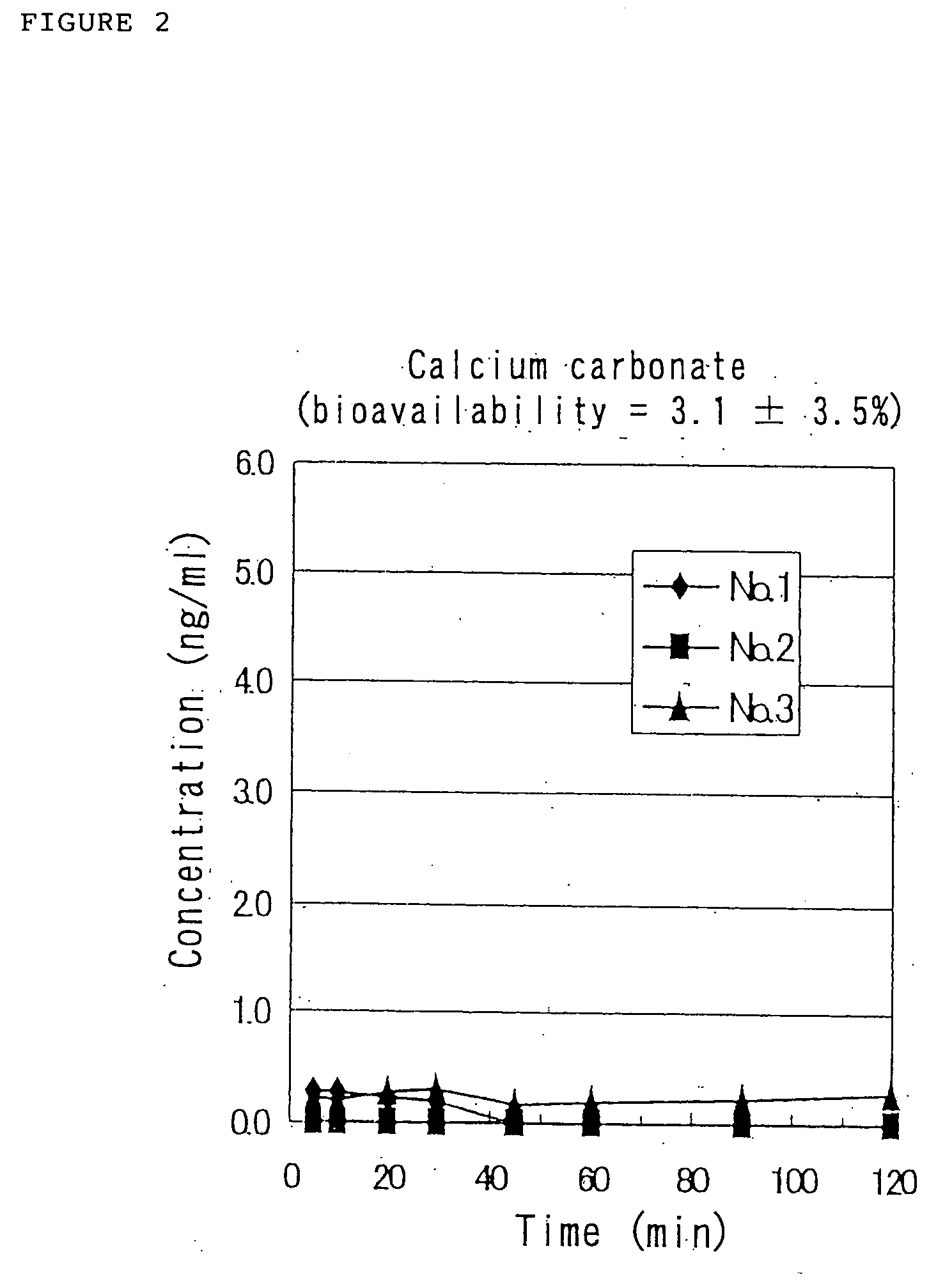

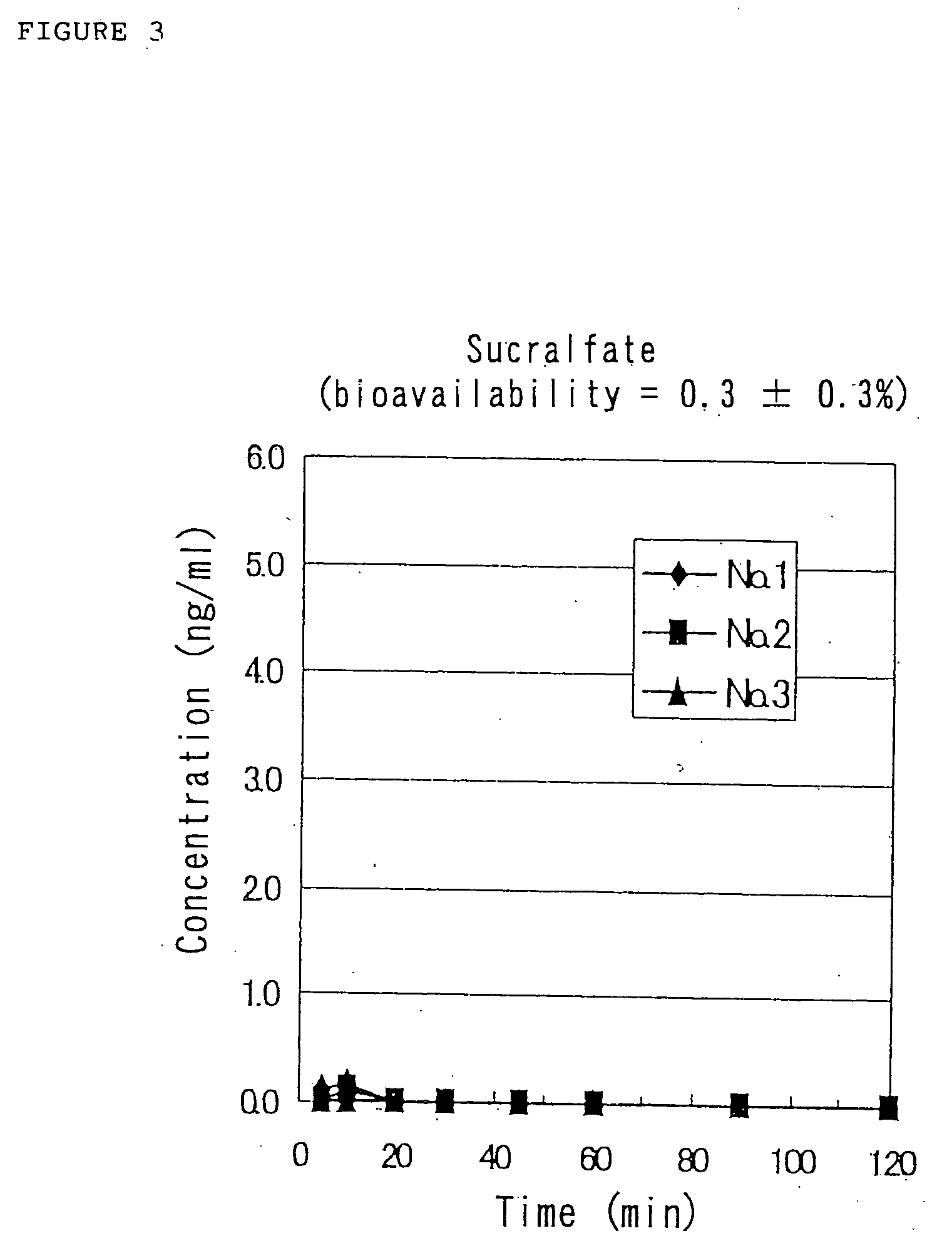

Medicinal compositions for nasal absorption

InactiveUS20050014681A1Evenly dispersedPowder deliveryPeptide/protein ingredientsZinc compoundsBULK ACTIVE INGREDIENT

A pharmaceutical composition for nasal administration exhibits an improved bioavailability of a biologically active polypeptide, the active ingredient of the pharmaceutical composition. Specifically, the composition is prepared by uniformly dispersing and embedding a biologically active acidic polypeptide having an isoelectric point of 7 or lower on the surfaces of a polyvalent metal compound carrier with the help of an additive capable of dispersing and embedding the polypeptide on the surfaces of the carrier. The polyvalent metal compound carrier is a metal compound with a valent of 2 or higher that is either insoluble or little soluble in water, examples being aluminum compounds, calcium compounds, magnesium compounds, silicone compounds, iron compounds, and zinc compounds.

Owner:ASUBIO PHARMA

Antisepticize and mildew preventive of bamboo wood material

InactiveCN101229645AStrong loss resistanceLow hygroscopicityBiocideAnimal repellantsSolubilityZinc compounds

The invention provides an anti-septic and anti-mildew agent for bamboo and wood, which is obtained by adding zinc compounds, copper compounds and cationic surfactant to substrates. The invention adopts bamboo vinegar, wood vinegar and grass vinegar as main ingredients and is composed by water-insoluble inorganic compounds to prepare biological (of a chemical type) wood preservative and can also be added with ammonia, ammonium salt or nitrogen compounds of the ammonia to increase the solubility. The invention has the advantages of strong resistance of leachability (wastage rate is less than 2 percent), low moisture absorption, no frosting, low toxicity and good effect of anti-sepsis and anti-mildew, and can also be applied to discoloration of timber or bamboo.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Topical zinc compositions and methods of use

InactiveUS20030077332A1High zinc ion availabilityMinimal skin irritanceBiocideOrganic active ingredientsSkin treatmentsZinc compounds

Compositions including zinc compounds and select amino acids in a carrier base, and methods of skin treatment with such compositions, are described. The compositions are useful for healing skin and minimizing the irritation incurred from contact with the zinc compound without loss of zinc availability during absorption into the integument.

Owner:ALLTERRA

Disinfectant composition and disinfecting method

InactiveUS20120164236A1Effectively eliminating gram negative bacteriaImprove disinfection effectInorganic/elemental detergent compounding agentsBiocideZinc compoundsPeroxy acid

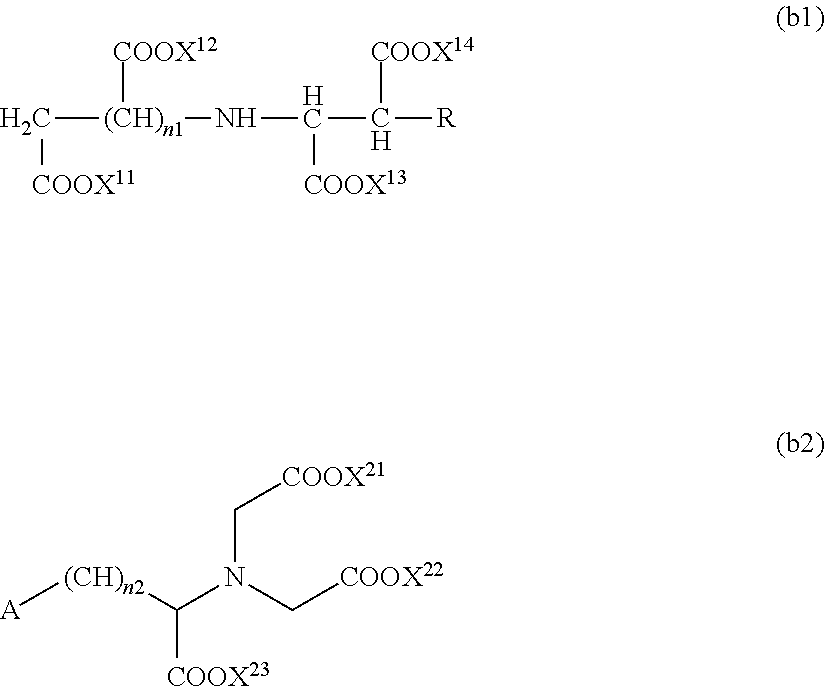

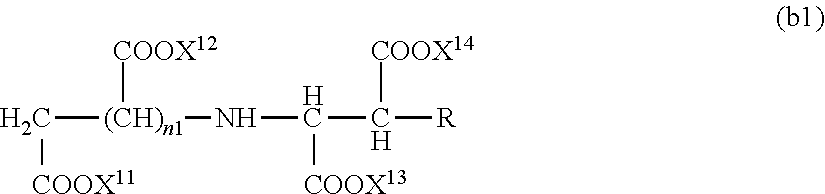

The present invention relates to a disinfectant composition containing the following components (A) to (D): component (A): a zinc compound, component (B): a chelate compound represented by the following general formula (b1) or (b2), component (C): hydrogen peroxide or a peroxide that releases hydrogen peroxide in water, and component (D): an organic peroxy acid precursor that generates an organic peroxy acid by reacting with the component (C). According to the present invention, a disinfectant composition and a disinfecting method can be provided that enable the effective elimination of gram negative bacteria adhered to textile products, and particularly cotton products.

Owner:LION CORP

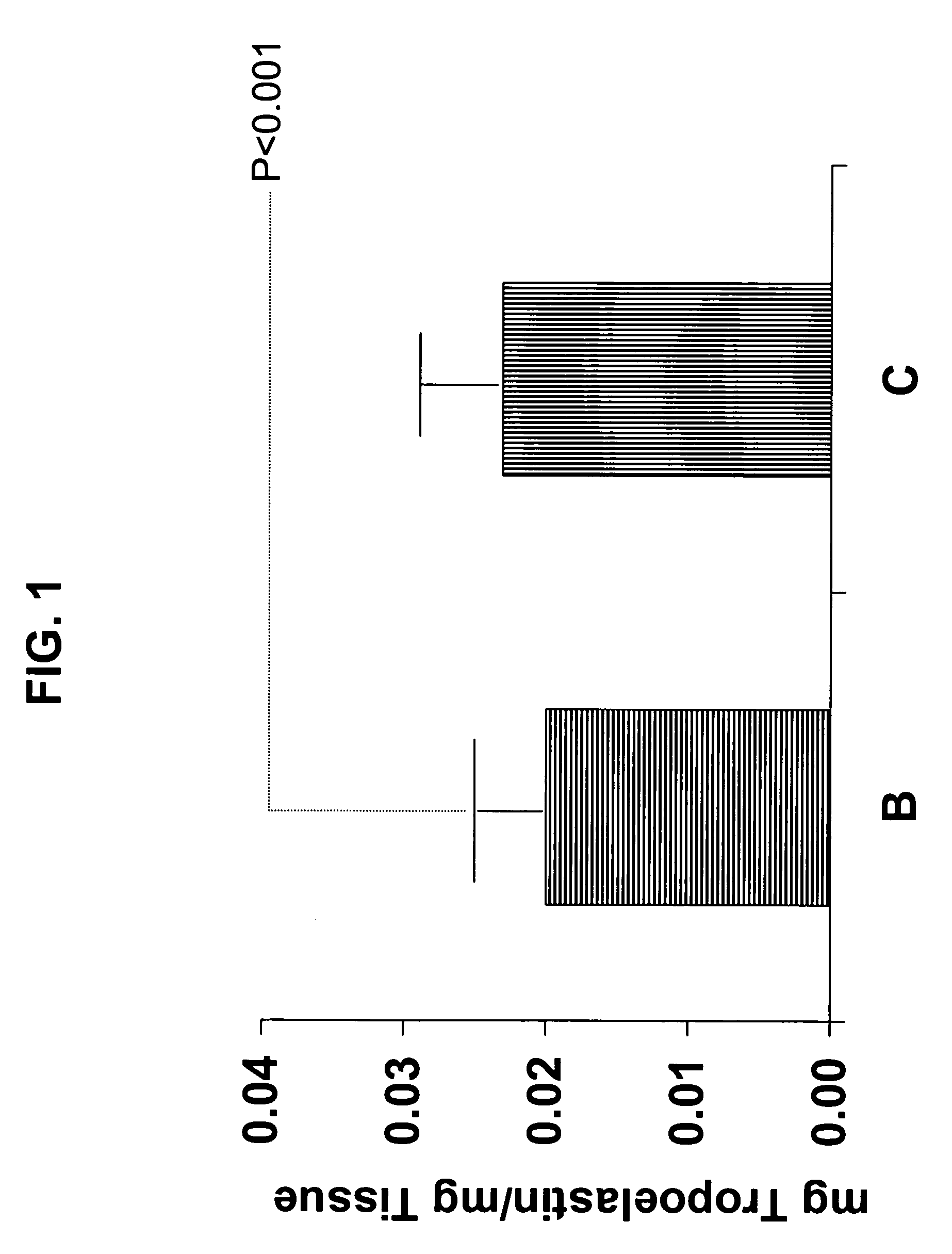

Anti-aging treatment using copper and zinc compositions

ActiveUS20070184017A1Improve biological activityReduce or eliminate undesirable age related skin conditionsBiocideHeavy metal active ingredientsZinc compoundsCopper

Composition and methods for alleviating or eliminating age related skin conditions by providing an effective amount of one or more copper, zinc and copper-zinc compositions are disclosed. Treatment is accomplished through the use of topical compositions containing one or more copper or zinc salts and / or copper-zinc compounds or complexes, particularly copper-zinc malonate active ingredient.

Owner:OBAGI COSMECEUTICALS LLC

Ultra-permeable PVC (polyvinyl chloride) film and preparation method thereof

The invention discloses an ultra-permeable PVC (polyvinyl chloride) film which comprises the following raw materials by weight percentage: 60%-80% of PVC sizing material, 5%-10% of zinc powder, 1.5%-2% of oil, 10%-30% of plasticizer DOP (dioctyl-phthalate) and 2%-4% of cadmium barium zinc compound stabilizer. A preparation method of the ultra-permeable PVC film comprises the following steps of: burdening, banburying, refining in an open way, filtering, extruding, calendaring by six rollers, introducing purified water, drying, shaping, refrigerating, coiling and packing. The PVC film obtained by the invention is small in thickness which can be less than 1.2mm, nontoxic, high in photo-permeability, impact-resistant, tear-resistant, free from combustion, and free from moisture absorption, thereby being particularly suitable for the requirement of various high-speed automatic packaging machinery. Therefore, the film disclosed by the invention can be widely used for the package for the printing industry, the furniture, the drug, the articles of everyday use and the like, and plays a part in moisture resistance and dust resistance.

Owner:FOSHAN WEIMING PLASTICS

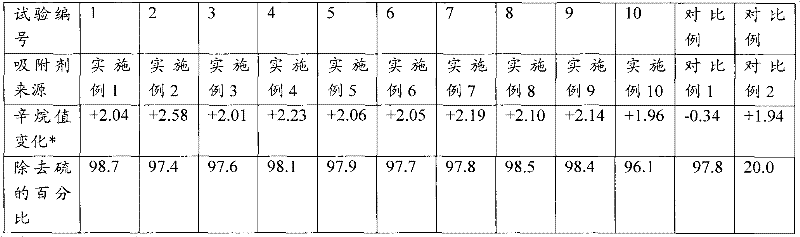

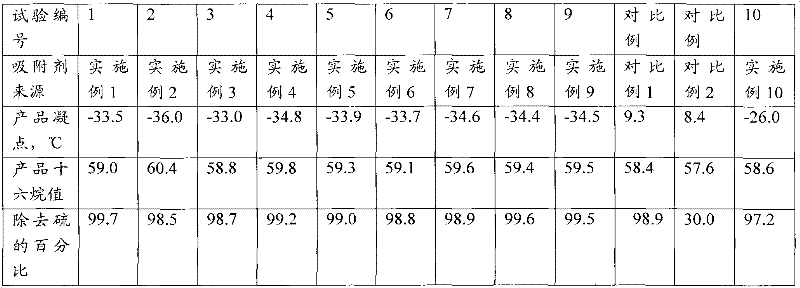

Adsorbent for adsorptive desulfurization of fuel oil

ActiveCN102463098ABoost octaneLowering the freezing pointOther chemical processesAluminium silicatesMolecular sieveZinc compounds

The invention relates to adsorbent for adsorptive desulfurization of fuel oil. An adsorbent composition contains a metal promoting agent, zinc oxide, an AEL-type structured phosphoaluminate molecular sieve and an oxide carrier. At least a part of promoting agent metal exists in a reduction state. A method for preparing the adsorbent composition comprises the steps of forming, roasting and reducing a mixture containing a zinc compound, a promoting agent metal compound, an oxide carrier component and the AEL-type structured phosphoaluminate molecular sieve. The adsorbent composition is applied to adsorptive desulfurization of hydrocarbon oil and has a better desulfurization effect; furthermore, the octane value of cracked gasoline can be increased; and the low-temperature flowing property of diesel can be improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

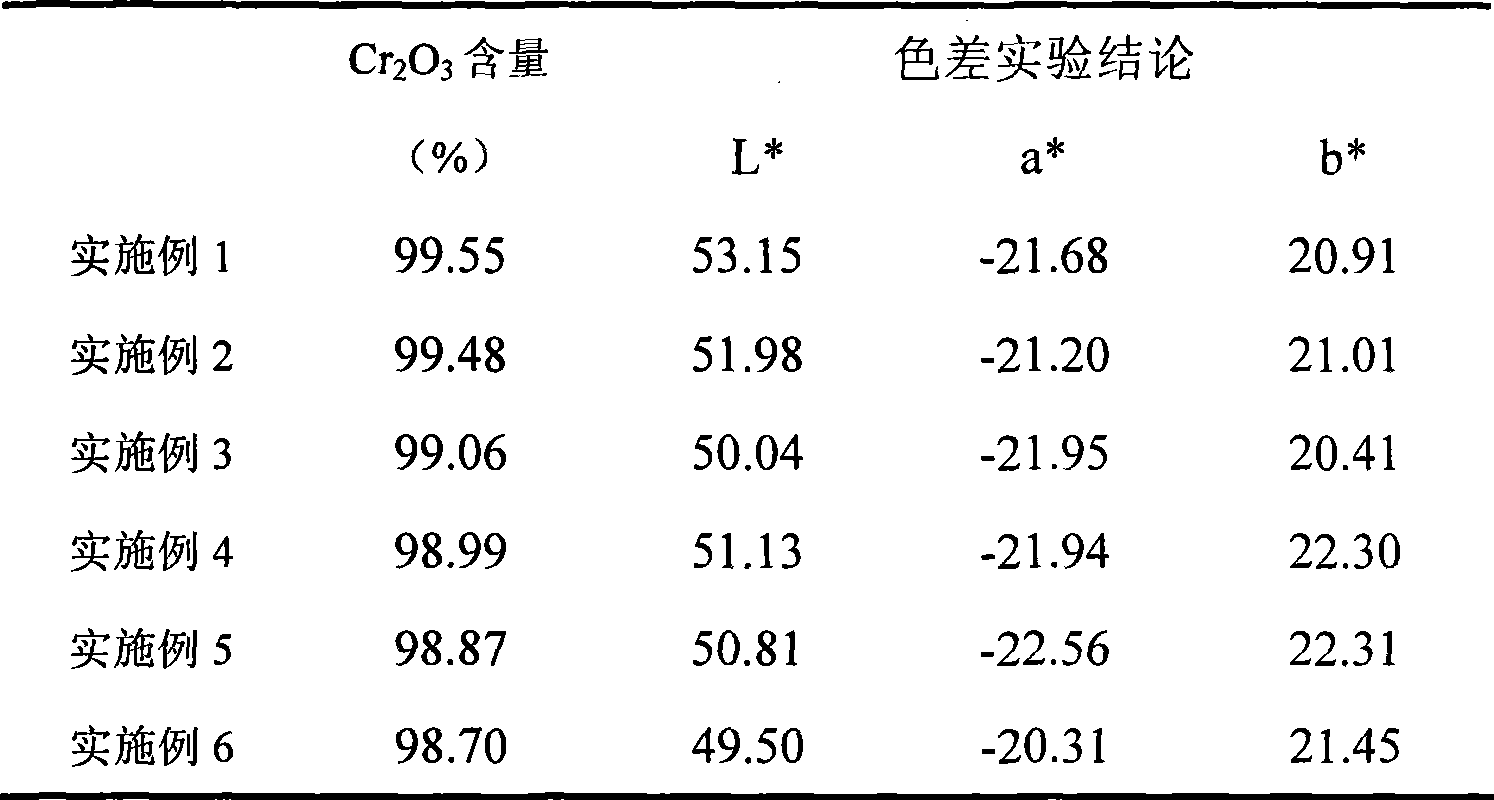

Method for preparing pigment grade chromium hemitrioxide green by using gaseous reducing agent low temperature reduction chromate salt

The invention discloses a method for preparing pigment-grade chromium oxide green. The method comprises the steps of taking reducing gas as a reducing agent, allowing chromic salt to react with the reducing gas for 0.5 to 3 hours at a temperature between 300 and 800 DEG C, cooling, using water to wash and hydrolyzing a reaction mixture, mixing the reaction mixture with additives at a temperature between 700 and 1,300 DEG C, activating and sintering the reaction mixture and the additives for 0.5 to 3 hours, washing, drying and grading the sintered material to obtain the pigment-grade chromium oxide green, wherein the chromic salt is chromate or bichromate; the reducing gas is hydrogen, natural gas, ammonia gas, coal gas or a mixture thereof; and the additives are silicon compounds, titanium compounds, boron compounds, phosphorus compounds, aluminum compounds, barium compounds, zinc compounds and other compounds, such as SiO2, K2SiO3, Na2SiO3, TiO2, K2TiO3, B2O3, H2BO3, H3PO4, P2O3, Al2O3, Al(OH)3, Al2(SO4)3, AlCl3, Al(NO3)3, BaO, Ba(OH)2, BaSO4, BaCl2, Ba(NO3)2, ZnO, ZnCl2, ZnSO4, Zn(NO)3, Sb2O3 and other substances.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Preparation method of chitin/zinc compound bactericide

A composite chitosan / Zn antibacterial agent with broad spectrum is prepared from chitosan and Zn ions through ionic coordination, depositing in the mixture of acetone and alcohol, washing and drying.

Owner:WUHAN UNIV

Pollution-resistant polyamide composite membrane and preparation method thereof

InactiveCN103480284AExtended service lifeIncrease water fluxSemi-permeable membranesZinc compoundsNanoparticle

The invention discloses a pollution-resistant polyamide composite membrane which comprises a nonwoven fabric layer, a porous support layer, a polyamide layer and a pollution-resistant layer which are stacked sequentially, wherein the pollution-resistant layer comprises a polymer compounding inorganic nano particles; the inorganic nano particles are modified or unmodified inorganic nano particles, and preferably are at least one kind of the nano particles of silver, silver compound, modified silver, modified silver compound, copper, copper compound, modified copper, modified copper compound, zinc, zinc compound, modified zinc, modified zinc compound, titanium, titanium compound, modified titanium and modified titanium compound. The invention also provides a preparation method of the pollution-resistant polyamide composite membrane and an application of the pollution-resistant polyamide composite membrane in the field of liquid separation.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

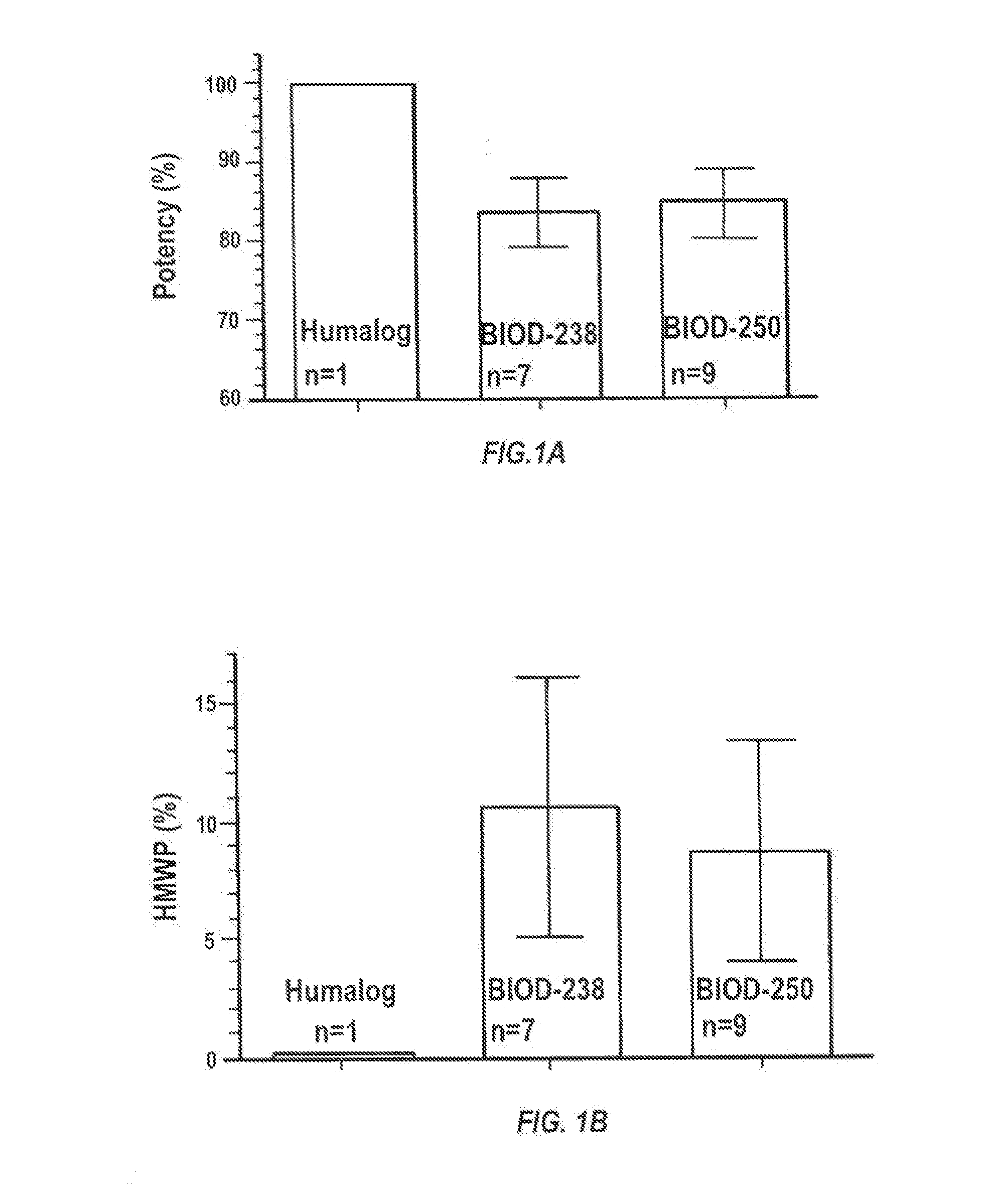

Stabilized ultra-rapid-acting insulin formulations

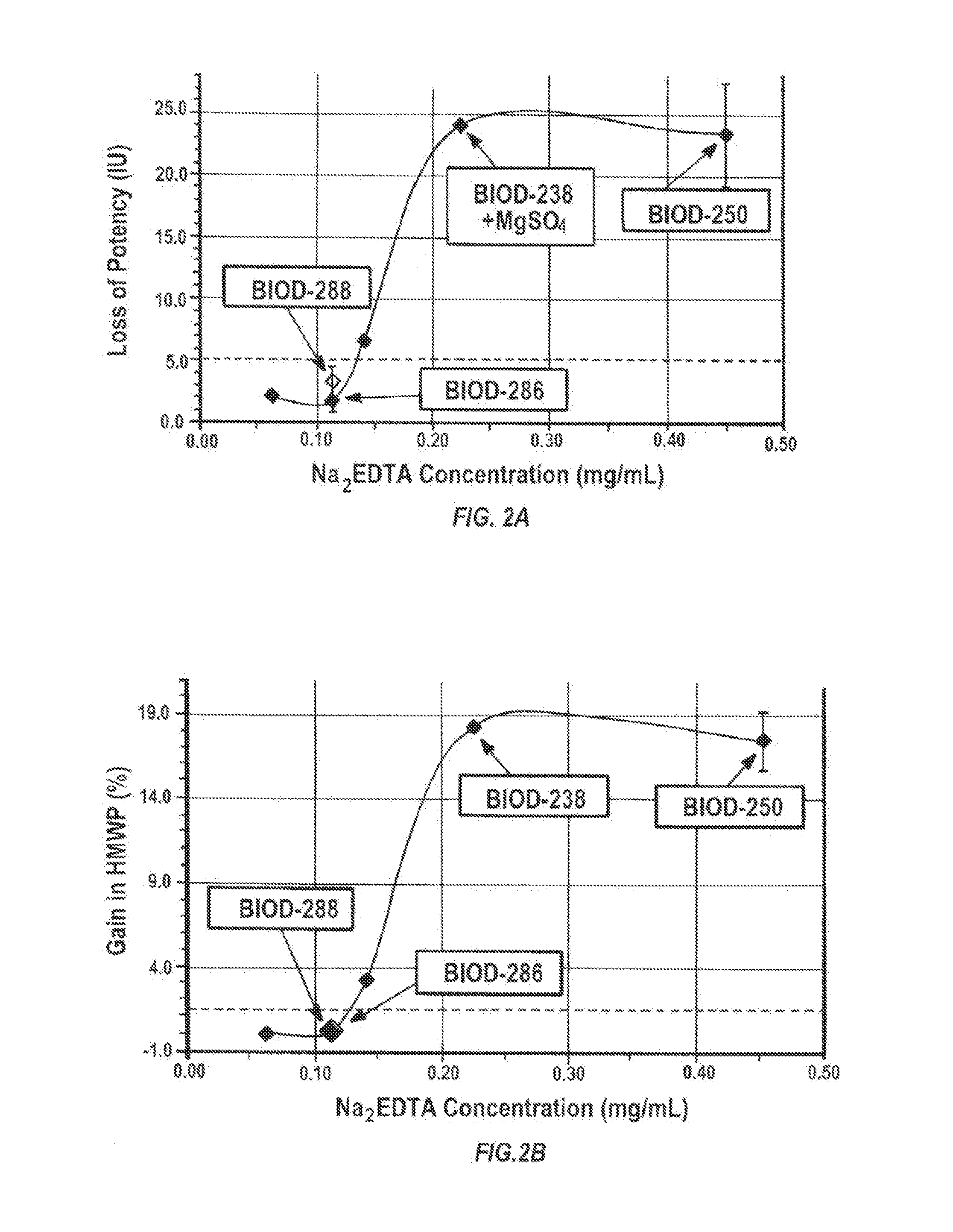

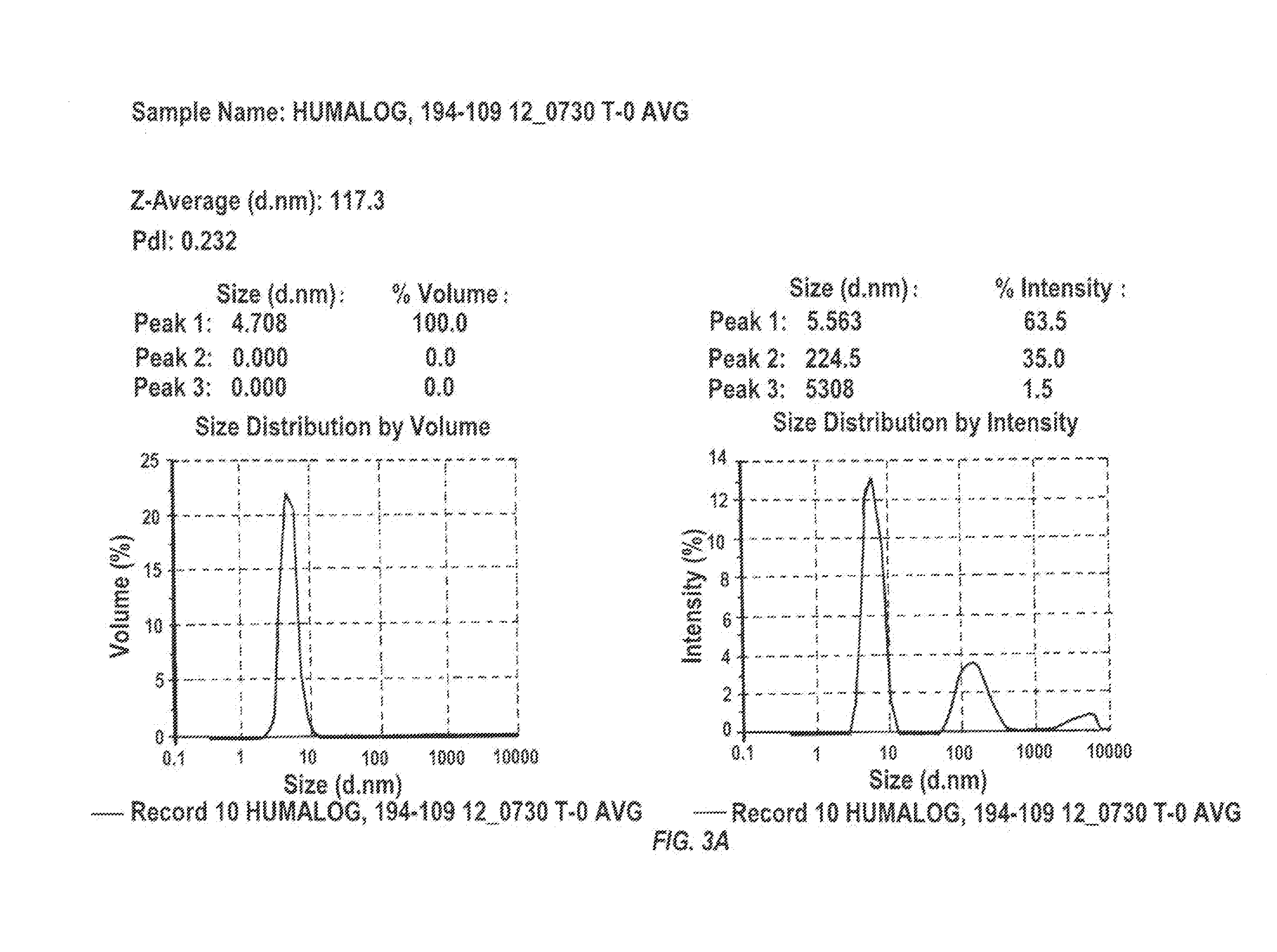

InactiveUS20150273022A1Quick effectPromote absorptionBiocidePeptide/protein ingredientsZinc compoundsMagnesium salt

Compositions and methods for enhancing the stability of rapid acting injectable insulin formulations have been developed for subcutaneous injection. The formulations contain insulin in combination with a zinc chelator such as ethylenediaminetetraacetic acid (“EDTA”), a dissolution / stabilization agent such as citric acid, a magnesium salt, a zinc compound and, optionally, additional excipients. New presentations include rapid acting concentrated insulin formulations and a way to enhance the absorption of commercially available rapid acting analog formulations while maintaining insulin stability.

Owner:ALBIREO PHARMA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com