Patents

Literature

1537results about How to "Low hygroscopicity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pharmaceutical co-crystal compositions

InactiveUS20070026078A1Improve solubilityLow hygroscopicityBiocidePowder deliveryThioketoneHydroxamic acid

A pharmaceutical composition comprising a co-crystal of an API and a co-crystal former; wherein the API has at least one functional group selected from ether, thioether, alcohol, thiol, aldehyde, ketone, thioketone, nitrate ester, phosphate ester, thiophosphate ester, ester, thioester, sulfate ester, carboxylic acid, phosphonic acid, phosphinic acid, sulfonic acid, amide, primary amine, secondary amine, ammonia, tertiary amine, sp2 amine, thiocyanate, cyanamide, oxime, nitrile diazo, organohalide, nitro, s-heterocyclic ring, thiophene, n-heterocyclic ring, pyrrole, o-heterocyclic ring, furan, epoxide, peroxide, hydroxamic acid, imidazole, pyridine and the co-crystal former has at least one functional group selected from amine, amide, pyridine, imidazole, indole, pyrrolidine, carbonyl, carboxyl, hydroxyl, phenol, sulfone, sulfonyl, mercapto and methyl thio, such that the API and co-crystal former are capable of co-crystallizing from a solution phase under crystallization conditions.

Owner:JOHNSON & JOHNSON CONSUMER COPANIES +2

Propanoic acid polyhexamethylene guanide and preparation method thereof

InactiveCN101037503AOvercome strong hygroscopicityImprove the bactericidal effectBiocideFungicidesPolyhexamethylene guanidinePropynoic acid

The invention discloses polyhexamethylene guanidine propionic acid and preparing method thereof. The preparing method employs stepwise synthesis, which includes steps of: sufficiently mixing dicyandiamide and alanine under high temperature to synthesize aminoguanidine propionic acid, mixing the aminoguanidine propionic acid, triethylidenepropyldiamine and initiator under high temperature to synthesize the polyhexamethylene guanidine propionic acid. Advantages of the invention are: sterilization effect is excellent, toxity is actually nontoxic level, effect of sterilization is better than existent technique, due to overcoming strong hygroscopicity in existence, the polyhexamethylene guanidine propionic acid can be produced to stable powder, thereby being widely used in fields such as weave, plastic, daily chemicals and water treatment.

Owner:SHANGHAI HIPOLY IND

Pharmaceutical propylene glycol solvate compositions

InactiveUS20070015841A1Less hygroscopicMore solubleBiocideOrganic chemistryIsopropylene glycolChemistry

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

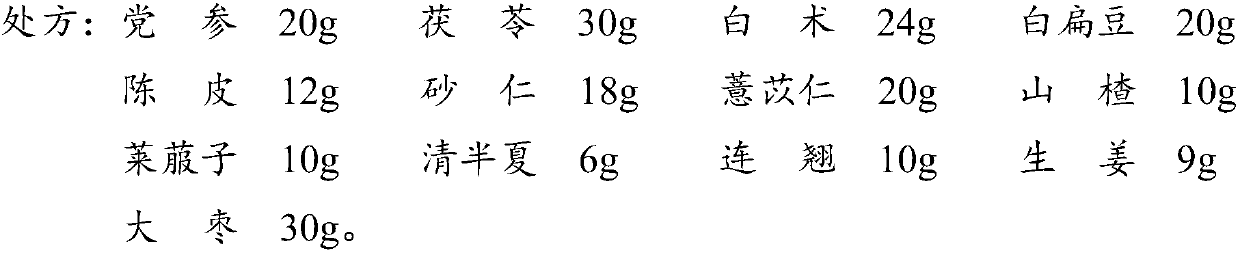

Preparation method of pellet-type formula granules

InactiveCN107744510ASimple preparation processImprove compliancePharmaceutical product form changeCoatingsMedicineMoisture absorption

The invention discloses a preparation method of pellet-type formula granules. The method comprises the following steps: (1) selecting at least one of the traditional Chinese medicinal materials; (2) respectively extracting the medicinal materials selected in step (1) for obtaining extracts, or respectively grinding the medicinal materials, or respectively carrying out partial extraction and partial grinding, thus obtaining pretreated materials; and (3) preparing the pretreated materials obtained in step (2) into pellets, thus obtaining the pellet-type formula granules. According to the preparation method provided by the invention, on the basis of the prior art, the preparation process of the formula granules is innovated, the formula granules are innovated into pellets, the fluidity and moisture absorption resistance are good, the friability is small, the shape is round and uniform as well as regular, the content uniformity is small, and the divided dose is accurate.

Owner:GUANGDONG LUOFUSHAN SINOPHARM

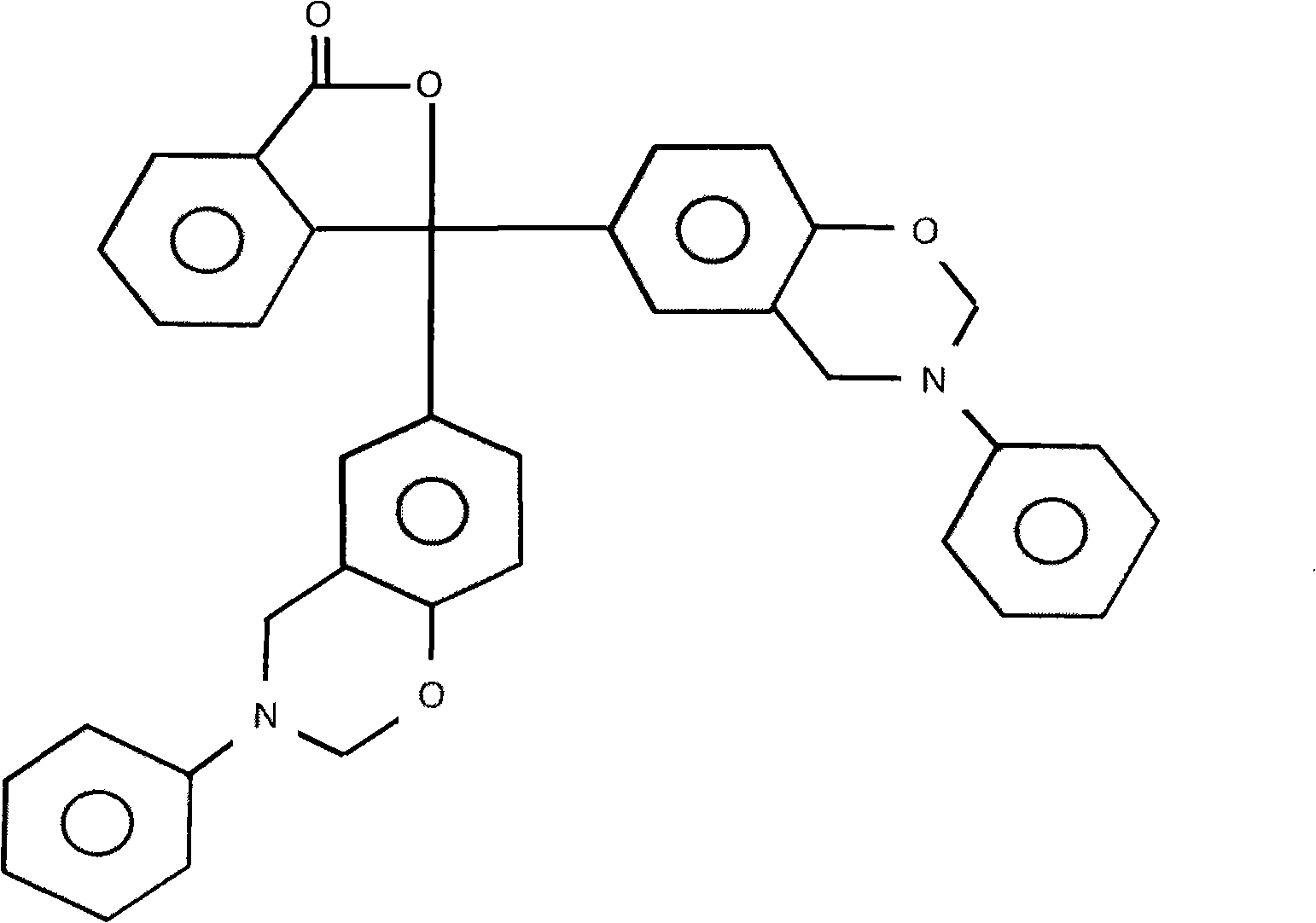

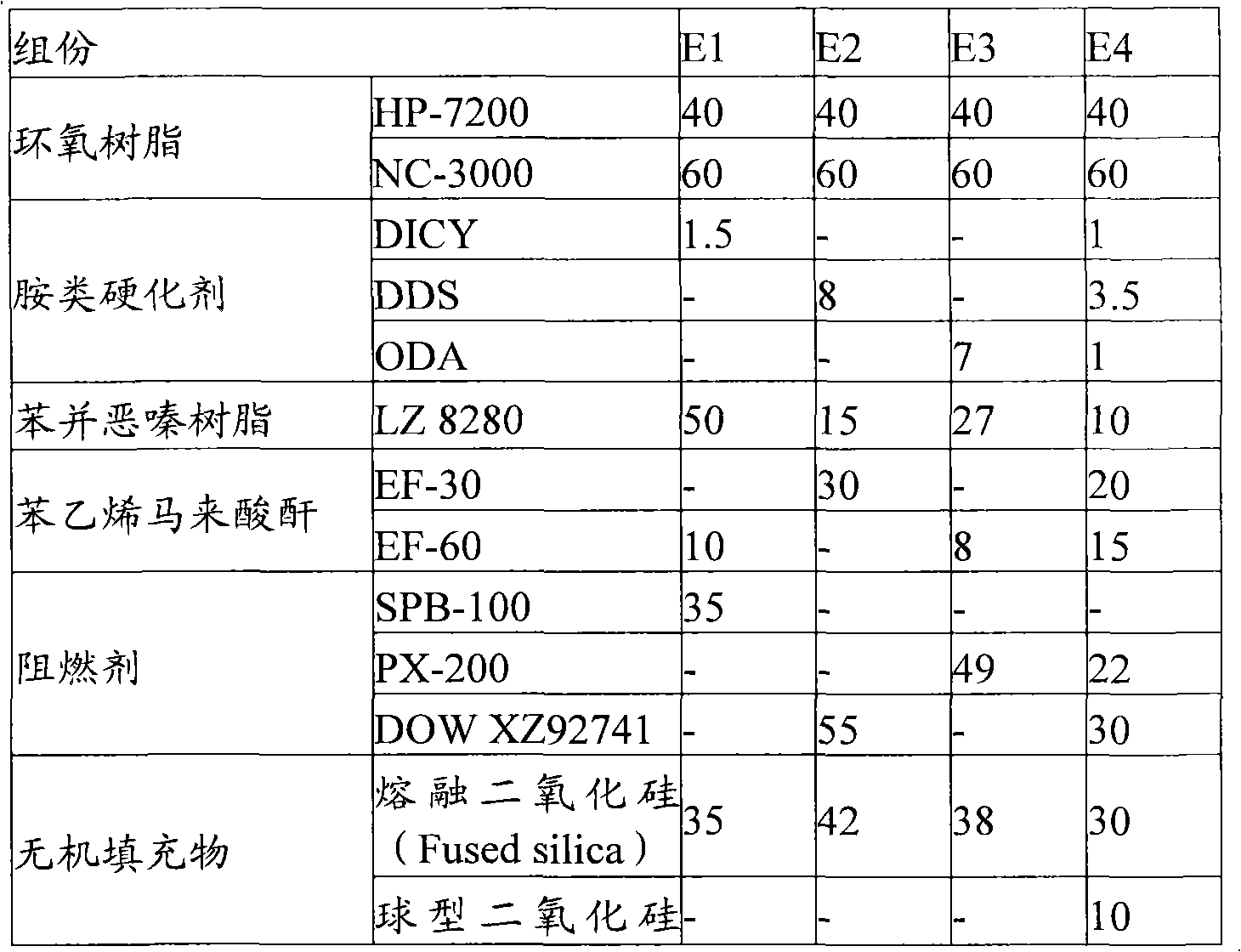

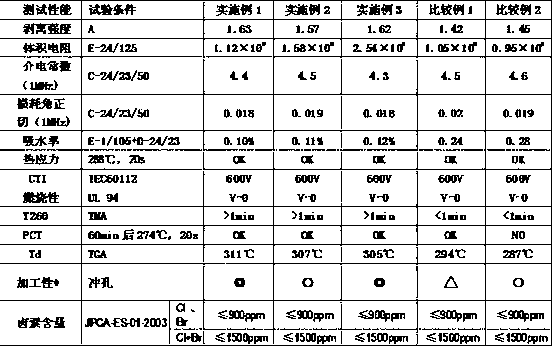

Halogen-free resin composition and copper clad laminate and printed circuit board applying the same

ActiveCN103131131ALow dielectric propertiesLow heat resistanceCircuit susbtrate materialsEpoxySheet film

The invention provides halogen-free resin composition, and a copper clad laminate and a printed circuit board applying the halogen-free resin composition. The halogen-free resin composition comprises, by weight, (A) 100 parts of epoxy resin, (B) 1 part -100 parts of benzoxazine resin, (C) 1part -100 parts of styrene maleic anhydride, (D) 0.5 part -30 parts of amine curing agents, and (E) 5-150 parts of halogen-free flame retardants. By means of the specified constituents and ration, the halogen-free resin composition achieves the purposes of low dielectric constant, low dielectric loss, high heat resistance, and high flame resistance, can be manufactured into semi-solidified rubber pieces or resin films, and then achieves the purposes of being applied to the copper clad laminate and the printed circuit board.

Owner:ELITE MATERIAL

Pharmaceutical co-crystal compositions of drugs such as carbamazepine, celecoxib, olanzapine, itraconazole, topiramate, modafinil, 5-fluorouracil, hydrochlorothiazide, acetaminophen, aspirin, flurbiprofen, phenytoin and ibuprofen

A pharmaceutical composition comprising a co-crystal of an API and a co-crystal former; wherein the API has at least one functional group selected from ether, thioether, alcohol, thiol, aldehyde, ketone, thioketone, nitrate ester, phosphate ester, thiophosphate ester, ester, thioester, sulfate ester, carboxylic acid, phosphinic acid, phosphonic acid, sulfonic acid, amide, primary amine, secondary amine, ammonia, tertiary amine, imine, thiocyanate, cyanamide, oxime, nitrile diazo, organohalide, nitro, S-heterocyclic ring, thiophene, N-heterocyclic ring, pyrrole, 0-heterocyclic ring, furan, epoxide, peroxide, hydroxamic acid, imidazole, pyridine and the co-crystal former has at least one functional group selected from amine, amide, pyridine, imidazole, indole, pyrrolidine, carbonyl, carboxyl, hydroxyl, phenol, sulfone, sulfonyl, mercapto and methyl thio, such that the API and co-crystal former are capable of co-crystallizing from a solution phase under crystallization conditions.

Owner:UNIV OF SOUTH FLORIDA +3

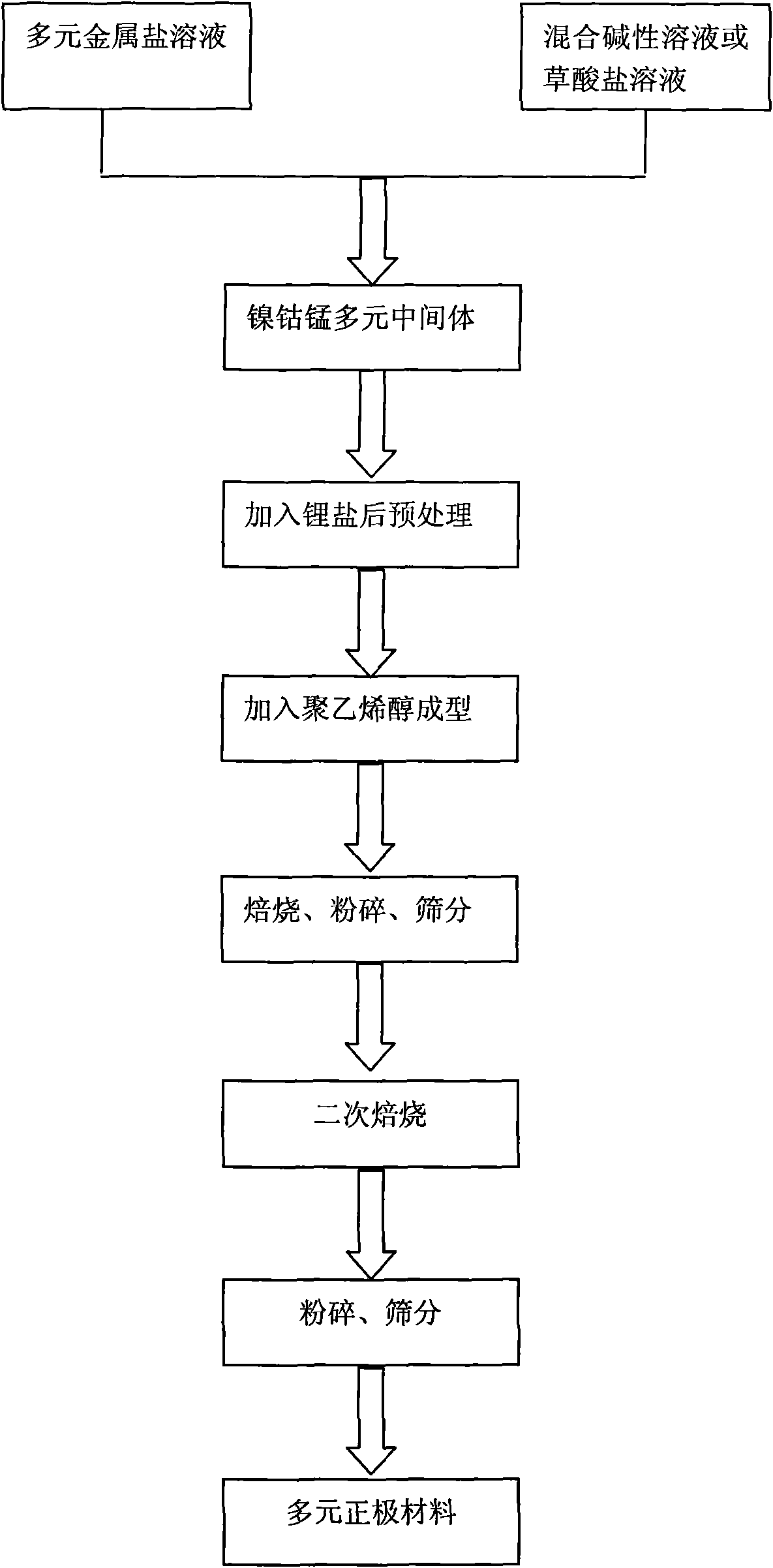

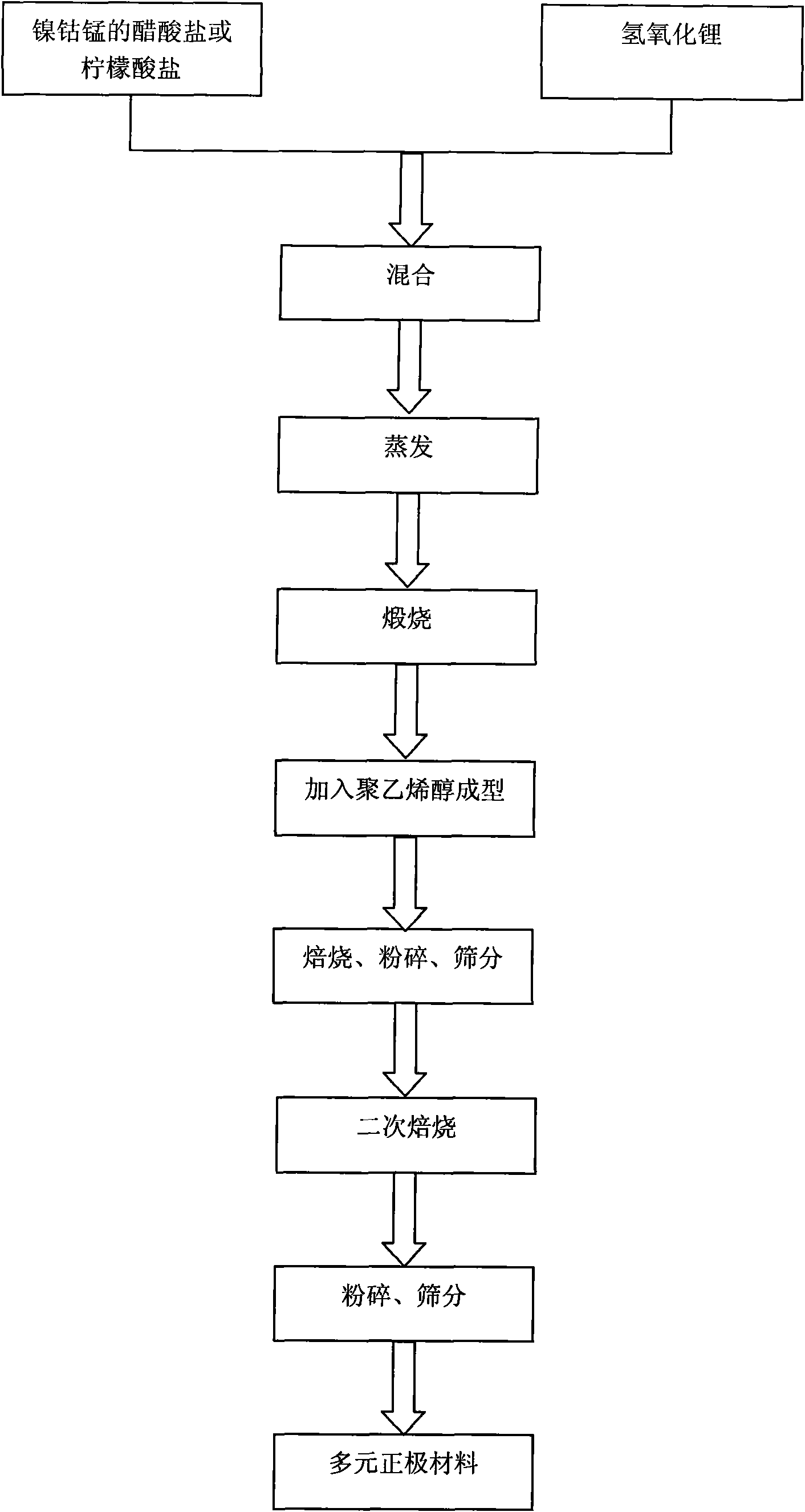

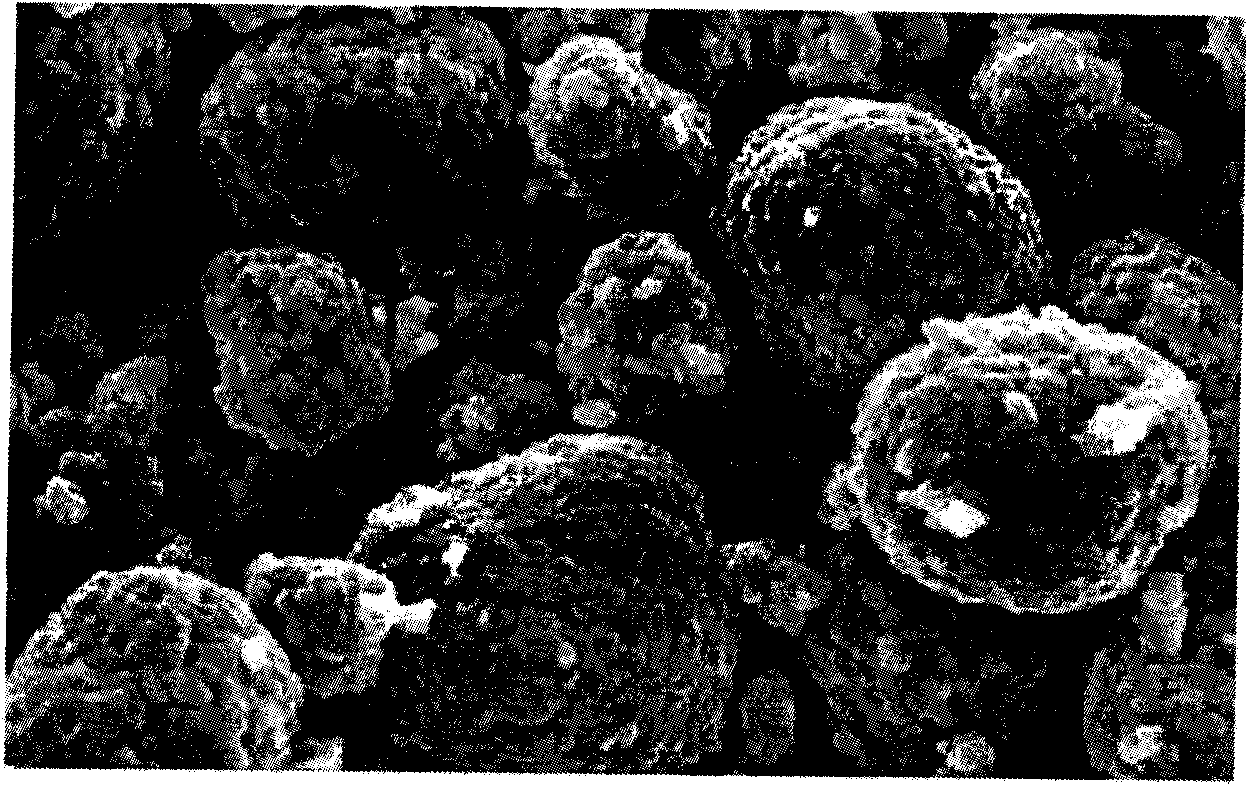

Nickel-cobalt-manganese multi-doped lithium ion battery cathode material and preparation method thereof

InactiveCN101621125AIncrease compaction densityLow hygroscopicityElectrode manufacturing processesSecondary cellsChemical synthesisPolyvinyl alcohol

The invention discloses a nickel-cobalt-manganese multi-doped lithium ion battery cathode material with high compacted density and a preparation method thereof, belonging to the technical field of energy materials. The preparation method of the battery cathode material comprises the following steps: preparing a nickel-cobalt-manganese multi-doped intermediate by a coprecipitation method or a chemical synthesis method; mixing the multi-doped intermediate with lithium salts; after pretreatment, adding polyvinyl alcohol to the obtained mixture; uniformly mixing the polyvinyl alcohol and the mixture and then pressing the mixture into a cake; roasting the cake at 800-950 DEG C; taking the roasted cake out and carrying out cooling, pulverization and 400 meshes of sieving on the cake; then roasting obtained powder at 700-800 DEG C, taking the powder out and carrying out cooling, pulverization and sieving on the powder to obtain the battery cathode material. Granules of the battery cathode material are non-agglomerated single-crystal grains with a grain diameter of 0.6-30 microns, a chemical formula of LiNixCoyMnzM[(1-x-y-z)]O2, a degree of compaction of 3.5-3.7g / cm<3> and a primary discharge capacity of 150-165mAh / g, thus the battery cathode material has good cycle performance and higher safety performance.

Owner:CHENGDU JINGYUAN NEW MATERIALS TECH

Production method for non-oil instant edible fungus chips

The invention discloses a production method for non-oil instant edible fungus chips and belongs to the technical field of agricultural product deep processing. The production method for the edible fungus chips comprises the following steps: selecting, cleaning, precisely cutting, ironing, bleaching, deactivating enzyme and cooling the edible fungus raw materials, and then performing ultrasonic auxiliary dipping, leachating, quick-freezing, vacuum freeze drying, vacuum microwave puffing drying, seasoning and packaging on the pretreated edible fungus raw materials. In the production method, a new process of ultrasonic auxiliary dipping, vacuum freeze drying and follow-up vacuum microwave staged combination drying is adopted, thereby reserving the thermal sensitivity nutritive components andbiological activity functional components of the edible fungus to the largest extent, obviously shortening the drying time and saving the production cost. The product has the characteristics of non-frying property, high puffing rate, attractive color, crisp mouthfeel, and the like, and is natural and environmentally-friendly as well as healthy. Compared with the vacuum freeze drying, the process has the advantages that the production period of the finished product can be greatly shortened, the production cost is saved, the puffing effect of the product is good, the mouthfeel of the product iscrisp and the drying quality of the product is improved. A new practical and feasible way for deep processing of the edible fungus is provided.

Owner:NANJING UNIV OF FINANCE & ECONOMICS +1

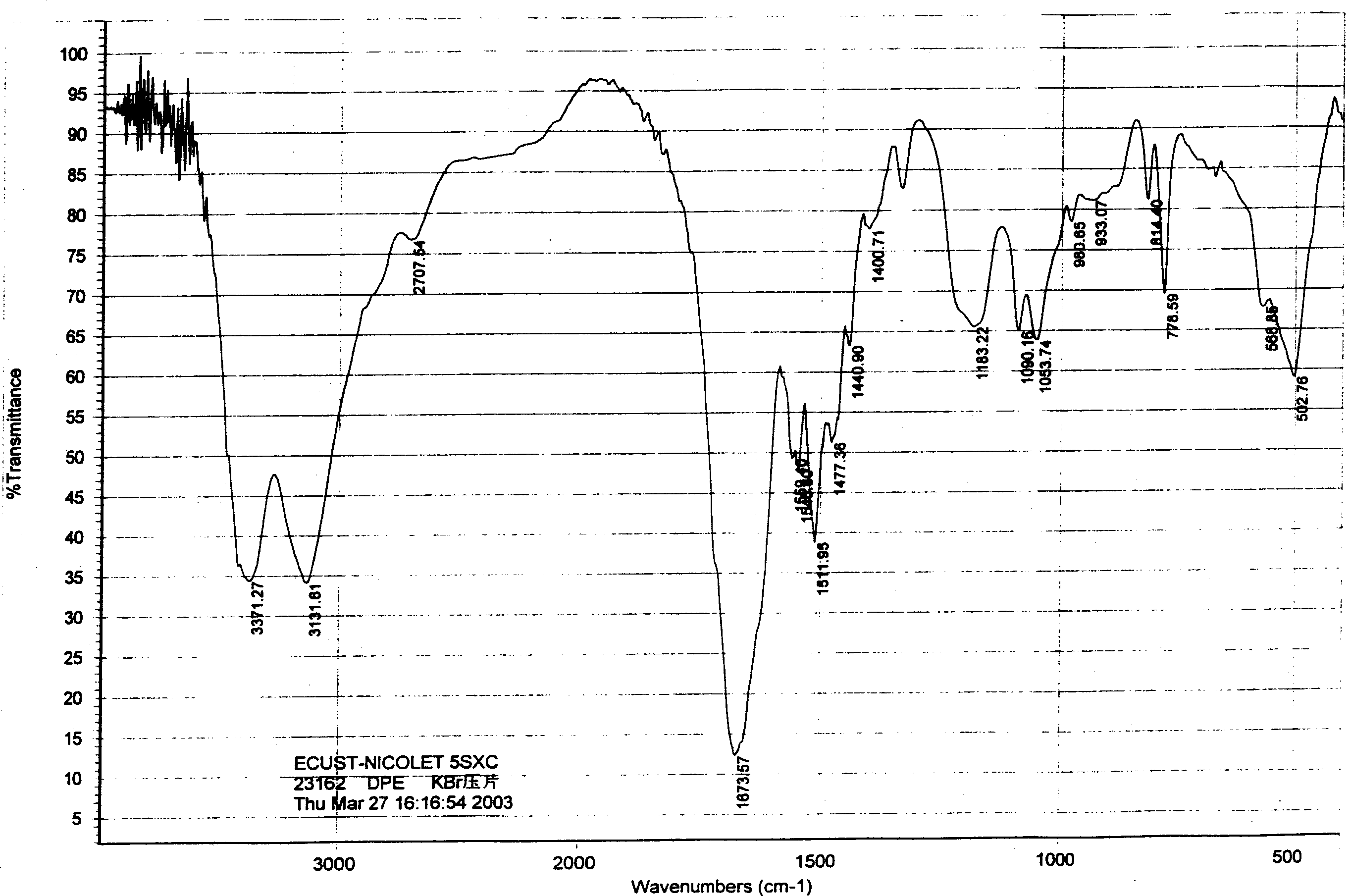

Expansion type fire retardant material

An expansion-type flame-retarding material is prepared through reaction between polyol and phosphorus compound containing hydroxy, adding melamine, reaction and modifying surface by high-molecular substance. Its advantages are high compatibility to polyethene and polypropyene, less consumption, high mechanical performance and flame-retarding effect, no poison and corrosion, and environment friendly.

Owner:EAST CHINA UNIV OF SCI & TECH

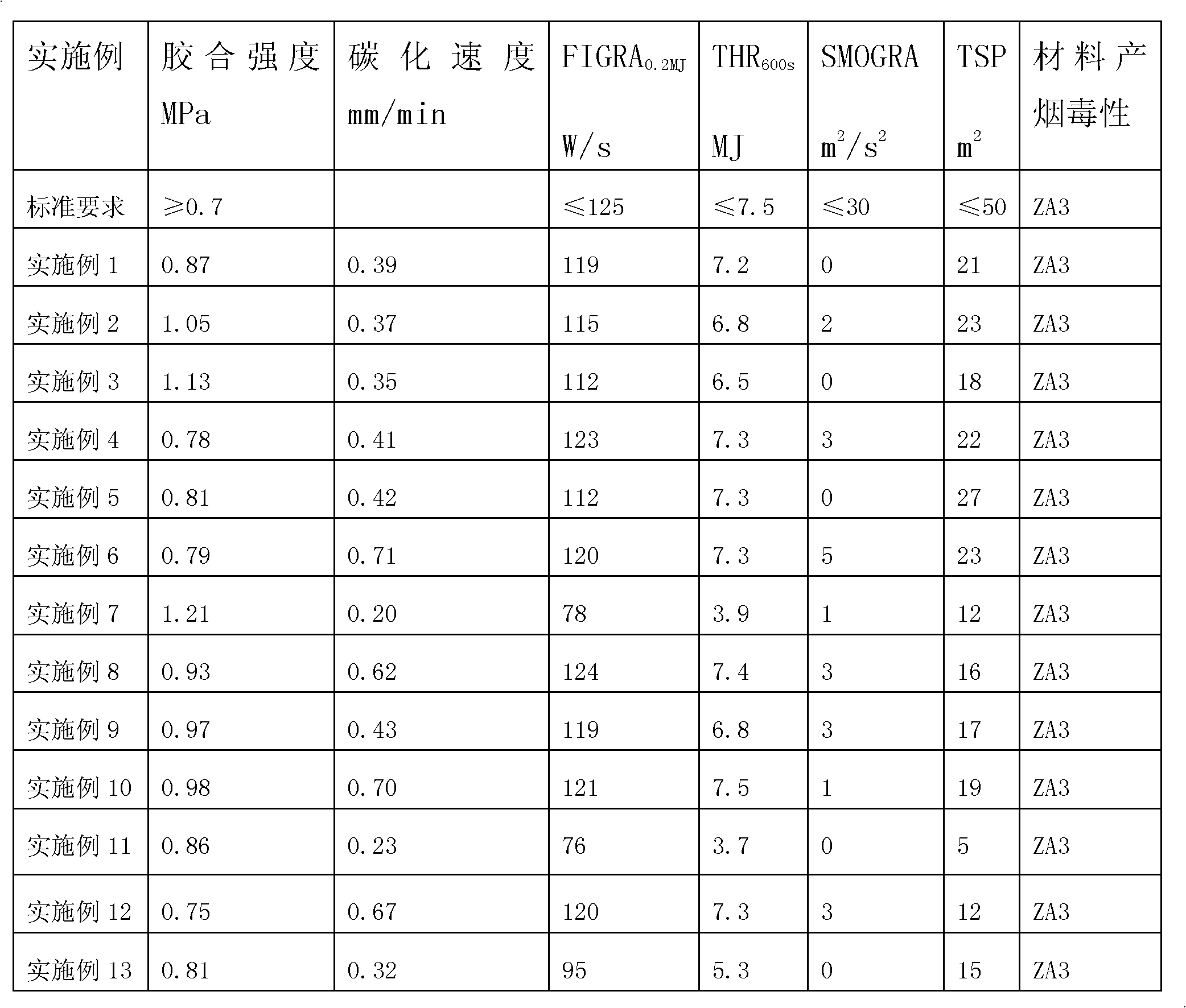

Antiflaming plywood or veneer lamination and manufacturing method thereof

ActiveCN102114650ASlow down the rate of carbonizationReduce burnWood veneer joiningWood impregnation detailsAdhesiveCarbonization

The invention discloses an antiflaming plywood or a veneer lamination, which comprises a wood veneer, a phosphorus-nitrogen fire retardant, a boron fire retardant, oxide or hydroxide of magnesium, aluminum, calcium, zinc, titanium and barium, and an adhesive, which have over dry weight percentage ratio being 100:2-50:0.2-30:4-40. The antiflaming plywood or the veneer lamination has the characteristics of low carbonization speed, accordance with related standards on physical mechanics property, flame retardant property and smoke toxicity, low formaldehyde emission values, and the like; the invention further discloses a manufacturing method for the antiflaming plywood or the veneer lamination, which comprises the following steps: impregnating the phosphorus-nitrogen fire retardant, the boron fire retardant, the oxide or hydroxide of magnesium, aluminum, calcium, zinc, titanium and barium on the wood veneer, coating the adhesive, and conducting processing of assembling, prepressing, hot pressing, sand polishing and the like.

Owner:固安盛辉阻燃材料有限公司

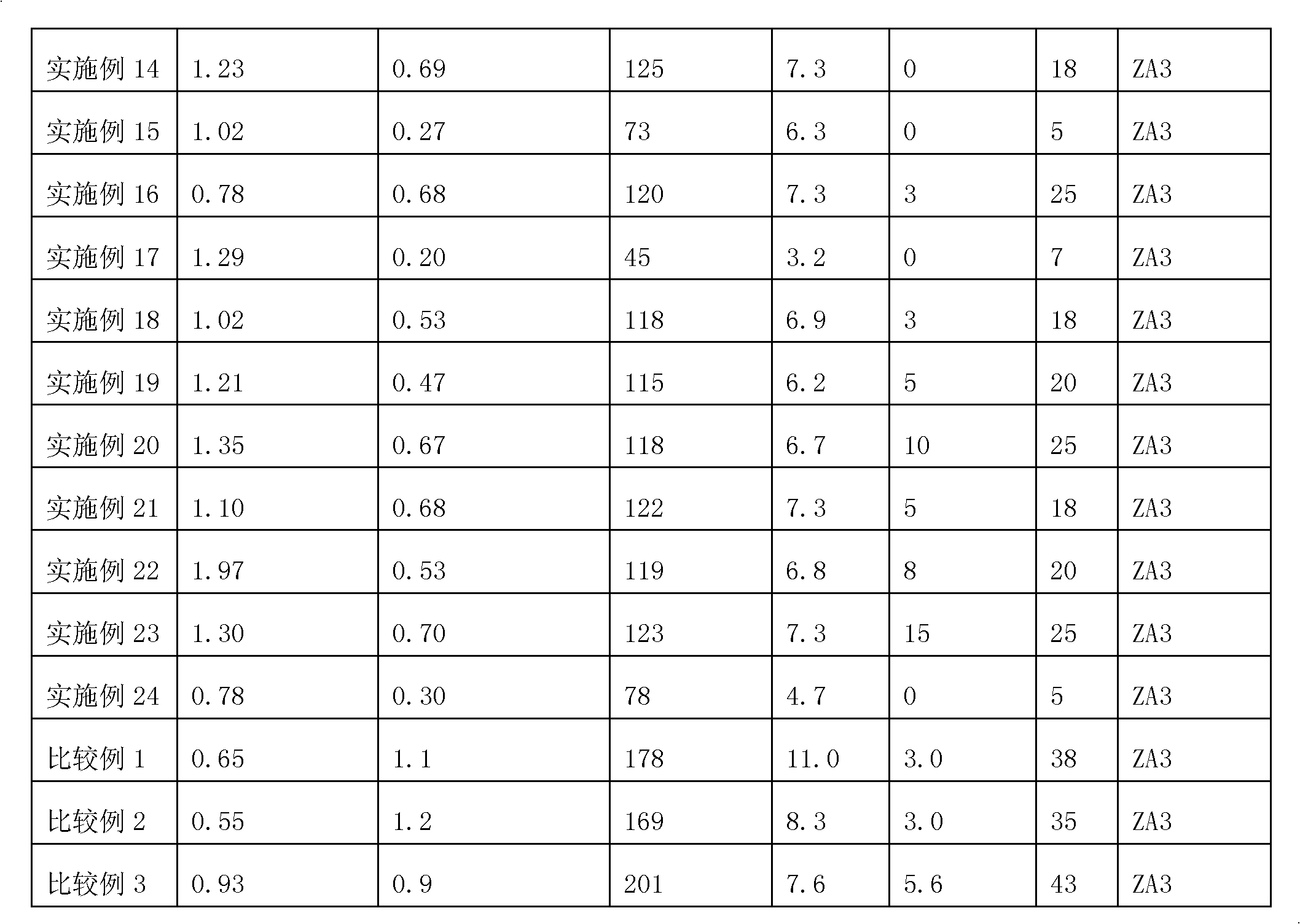

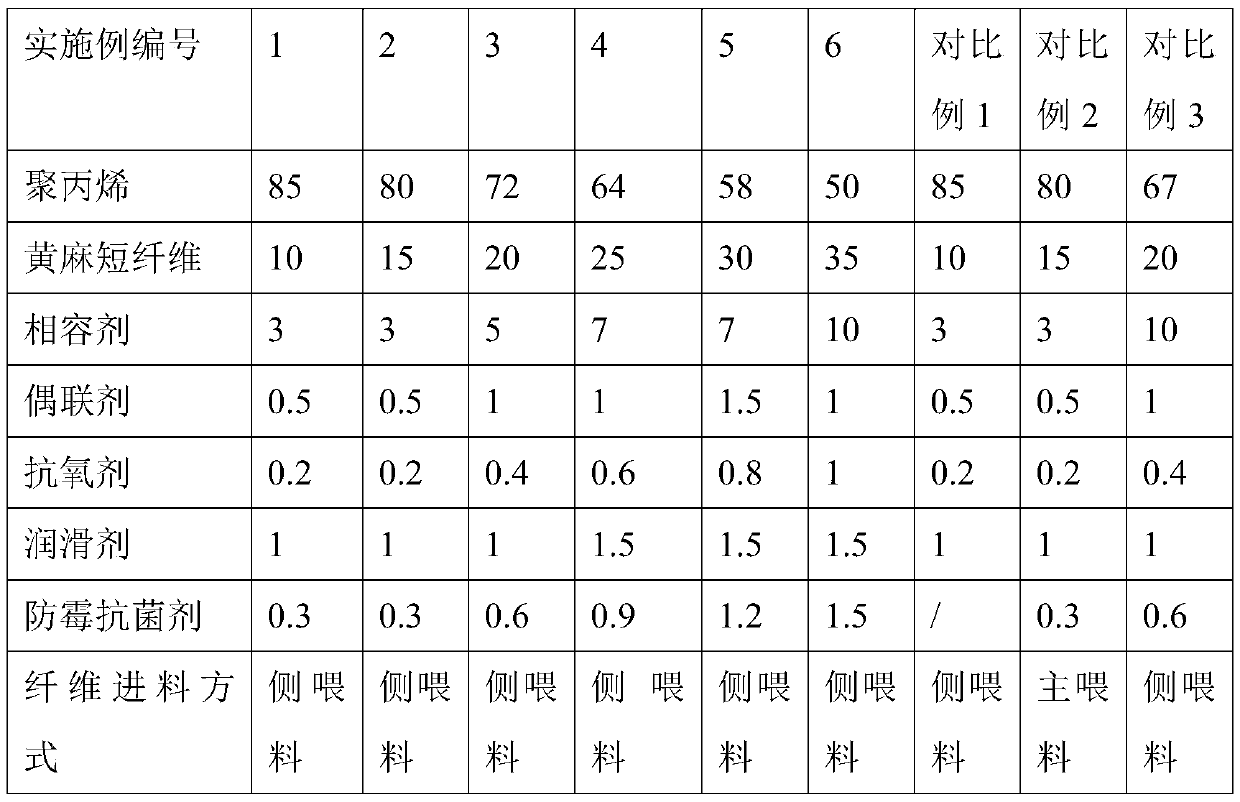

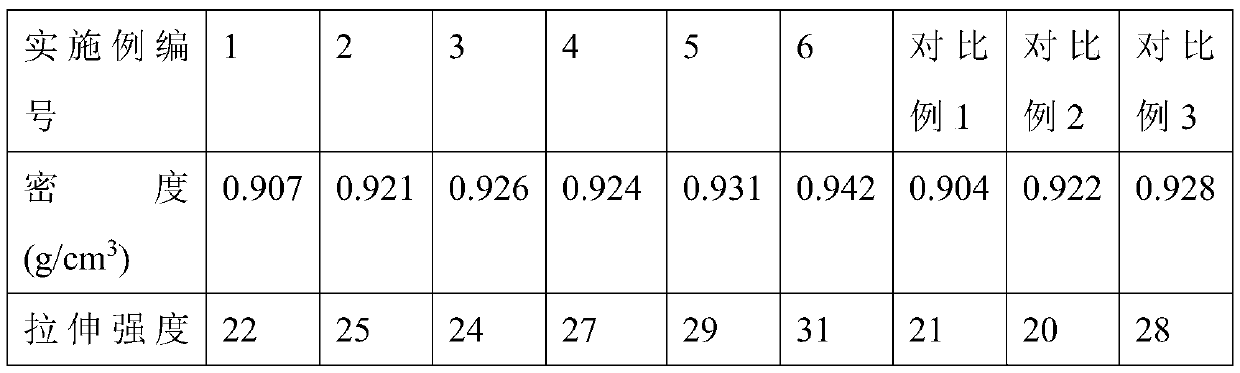

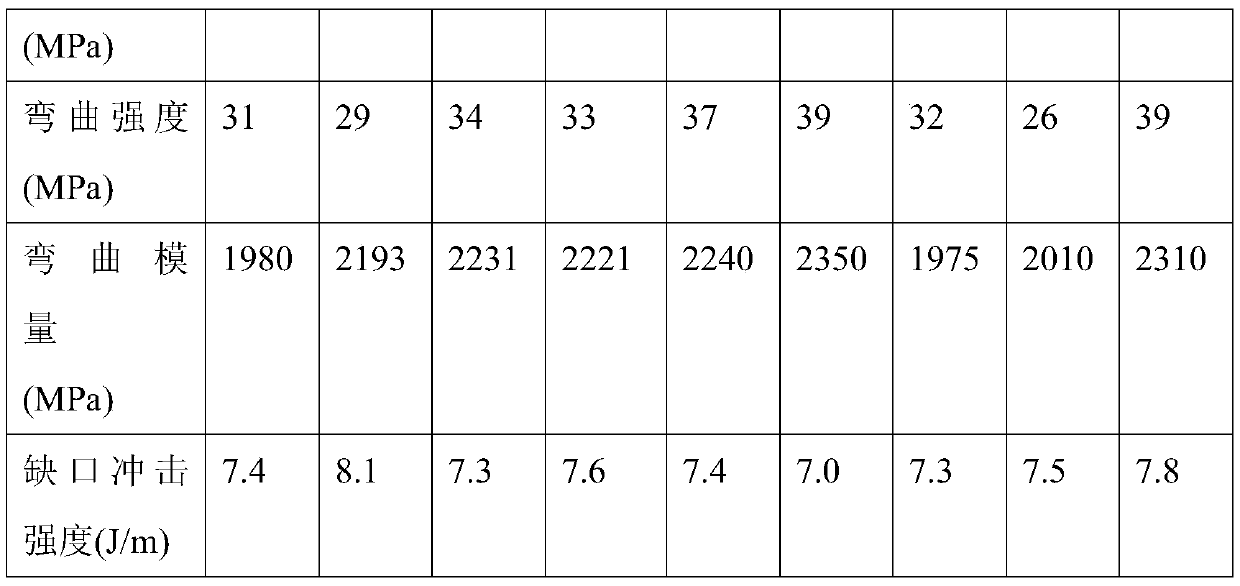

Natural-fiber-reinforced polypropylene composite material with mildewproof and antimicrobial properties and preparation method thereof

InactiveCN105504501ALow hygroscopicityImprove anti-mold and anti-bacterial propertiesNatural fiberAntibacterial action

The invention discloses a natural-fiber-reinforced polypropylene composite material with mildewproof and antimicrobial properties and a preparation method thereof. The natural-fiber-reinforced polypropylene composite material with mildewproof and antimicrobial properties comprises the following raw materials in parts by weight: 10-35 parts of natural fiber, 50-85 parts of polypropylene, 1-10 parts of compatilizer, 0.5-2 parts of coupling agent, 0.1-1 part of antioxidant, 0.5-2 parts of lubricant and 0.2-2 parts of mildewproof and antimicrobial agent. By using the natural fiber, which has the advantages of low price, abundant resources, high specific modulus and low density, to prepare the reinforced polypropylene composite material for vehicles, the production cost can be lowered. By using the combination of the alkali solution, coupling agent and compatilizer to treat the natural fiber, the hydroscopic property of the fiber is lowered. By adding the mildewproof and antimicrobial agent, the mildewproof and antimicrobial properties of the natural-fiber-reinforced polypropylene composite material with mildewproof and antibacterial functions can be greatly improved, so that the composite material is beneficial to human health in application, and has longer service life.

Owner:SHANGHAI PRET COMPOSITES

Pharmaceutical propylene glycol solvate compositions

InactiveUS7790905B2More stableLow hygroscopicityBiocideOrganic active ingredientsPropylene glycolPharmacology

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

Preparation technology of copper-clad laminate based on halogen-free flame-retardant resin compositions

ActiveCN103182831ALow resistance to moisture absorptionLow hygroscopicityLaminationLamination apparatusPulp (paper)Copper foil

A preparation technology of a copper-clad laminate based on halogen-free flame-retardant resin compositions comprises the following steps: a fabric glue solution, a glue solution A and a glue solution B are sequentially manufactured; the fabric glue solution is impregnated by 7628 or 2116 glass fabric; solvent is removed in a drying oven to prepare a fabric prepreg; the glue solution A and the glue solution B are sequentially impregnated by wood pulp paper; baking is carried out in the drying oven to prepare a core material prepreg; and finally, two fabric prepregs are respectively pasted on both sides of each of 1-12 core material prepregs, an electrodeposited copper foil is pasted on one side or two sides of each core material prepreg, and the core material prepregs are overlapped and subjected to hot-forming. The copper-clad laminate prepared by adopting the preparation technology has the advantages of low hygroscopicity, high heat resistance, high reliability, high CTI (Comparative Tracking Index), halogen-free and flame-retardant performance, and excellent machinability, and meets the lead-free demand.

Owner:SHAANXI SHENGYI TECH

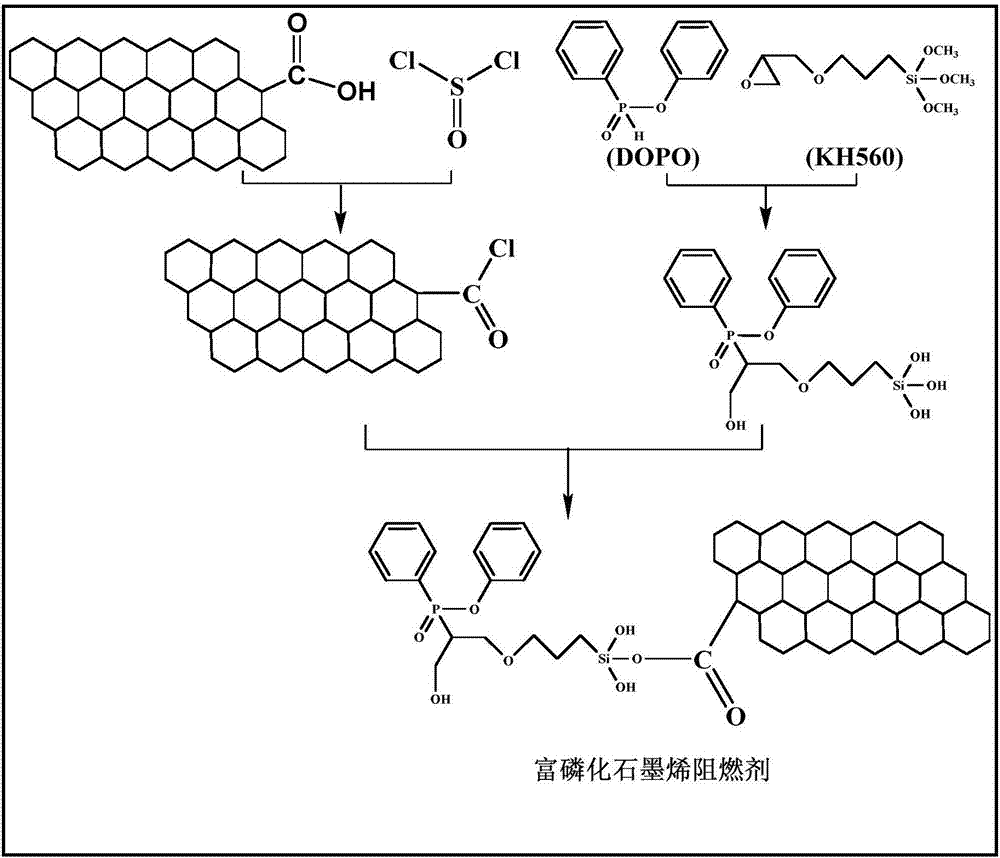

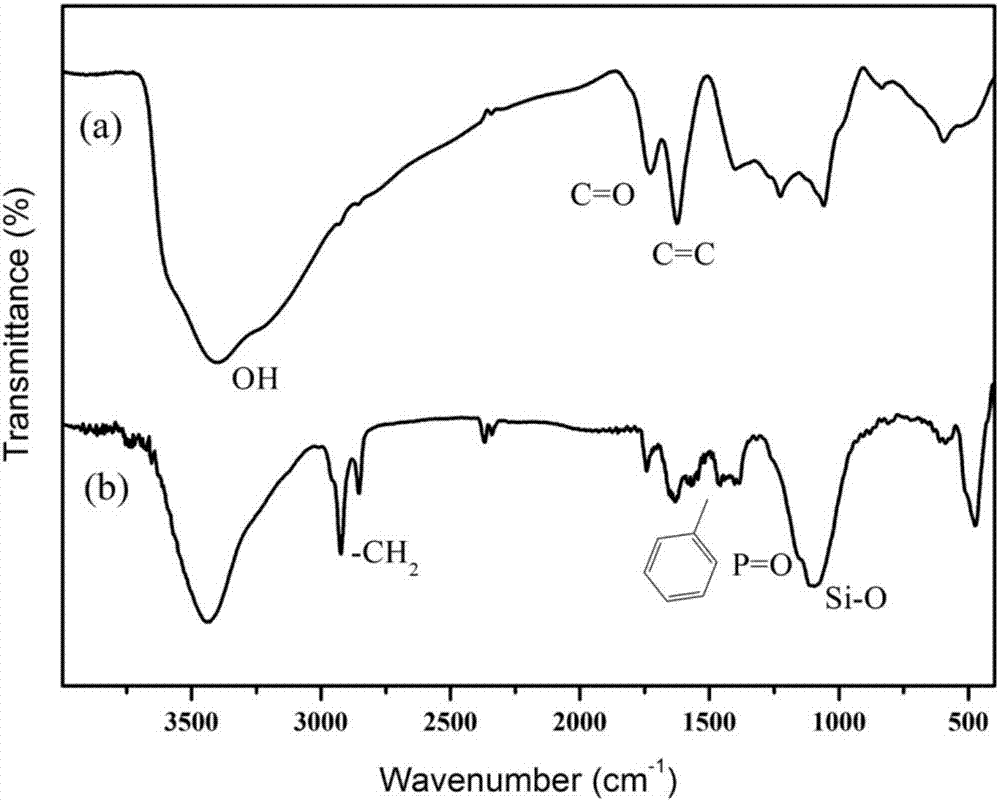

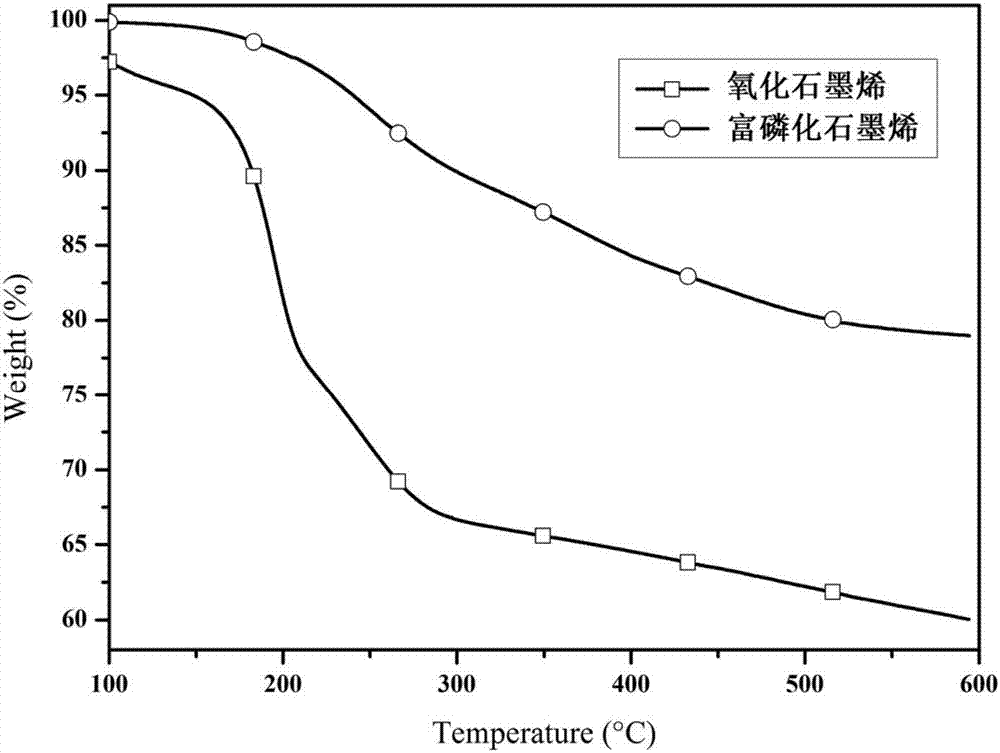

Phosphor-rich graphene flame-retardant agent and preparation method thereof

ActiveCN106883450AHigh flame retardant efficiencyConducive to synergistic flame retardantFireproof paintsPolyurea/polyurethane coatingsCarbon layerSilanes

The invention provides a phosphor-rich graphene flame-retardant agent with a structural formula shown in the description. The invention also provides a preparation method of the phosphor-rich graphene flame-retardant agent. The preparation method is characterized in that graphene oxide is used as a basic raw material, reactive groups at both ends of a silane coupler containing a silicon carbon layer improving agent are fully utilized, one end of the silane coupler is connected with acid source components, such as CEPPA (carboxyethyl phenyl phosphinic acid), DOPO or derivatives, and the other end of the silane coupler is connected with the graphene oxide, so as to obtain a macromolecular flame retardant integrating a physical carbon layer, an acid source and the carbon layer improving agent. The phosphor-rich graphene flame-retardant agent has the advantages that the flame-retardant efficiency is high, the polarity is low, the moisture absorbing property is little, and the mechanical property of the material can be well maintained; by not containing halogen, the flame-retardant agent is friendly to the human body and environment, and meets the green development direction of future flame-retardant agents.

Owner:宿迁聚萃功能复合材料研究所有限公司 +1

Disodium hexahydrophthalate salt compositions and nucleated polymers comprising such compositions

InactiveUS6562890B2Improve compatibilityExcellent high peak crystallization temperatureChemical/physical processesScavengerPolyolefin

Compositions comprising specific disodium hexahydrophthalate(HHPA) salts in combination with acid scavengers (such as organic calcium salts or dihydrotalcite complexes) that provide highly desirable and effective nucleating properties within polymer articles (such as polyolefins) are provided. Surprisingly, such a combination of HHPA salt and acid scavenger provides high crystallization temperatures, low haze, and / or high flexural modulus to the finished polymer product. Other sodium salt polymer nucleators (such as sodium benzoate) deleteriously react with calcium organic salt acid scavengers such that characteristically high crystallization temperatures are drastically reduced when in combination with calcium salts (such as calcium stearate). Also, sodium benzoate when combined with dihydrotalcite acid scavengers produce extremely high haze levels in the finished target polymer article, whereas the inventive compositions surprisingly reduce haze. The finished polymer articles comprising such an inventive composition are also contemplated within this invention.

Owner:MILLIKEN & CO

Hydrogenated block copolymer having alkoxysilyl group and use therefor

InactiveUS20130244367A1High glass transition temperatureImprove heat resistanceNon-fibrous pulp additionAluminium compoundsHigh humidityPolymer science

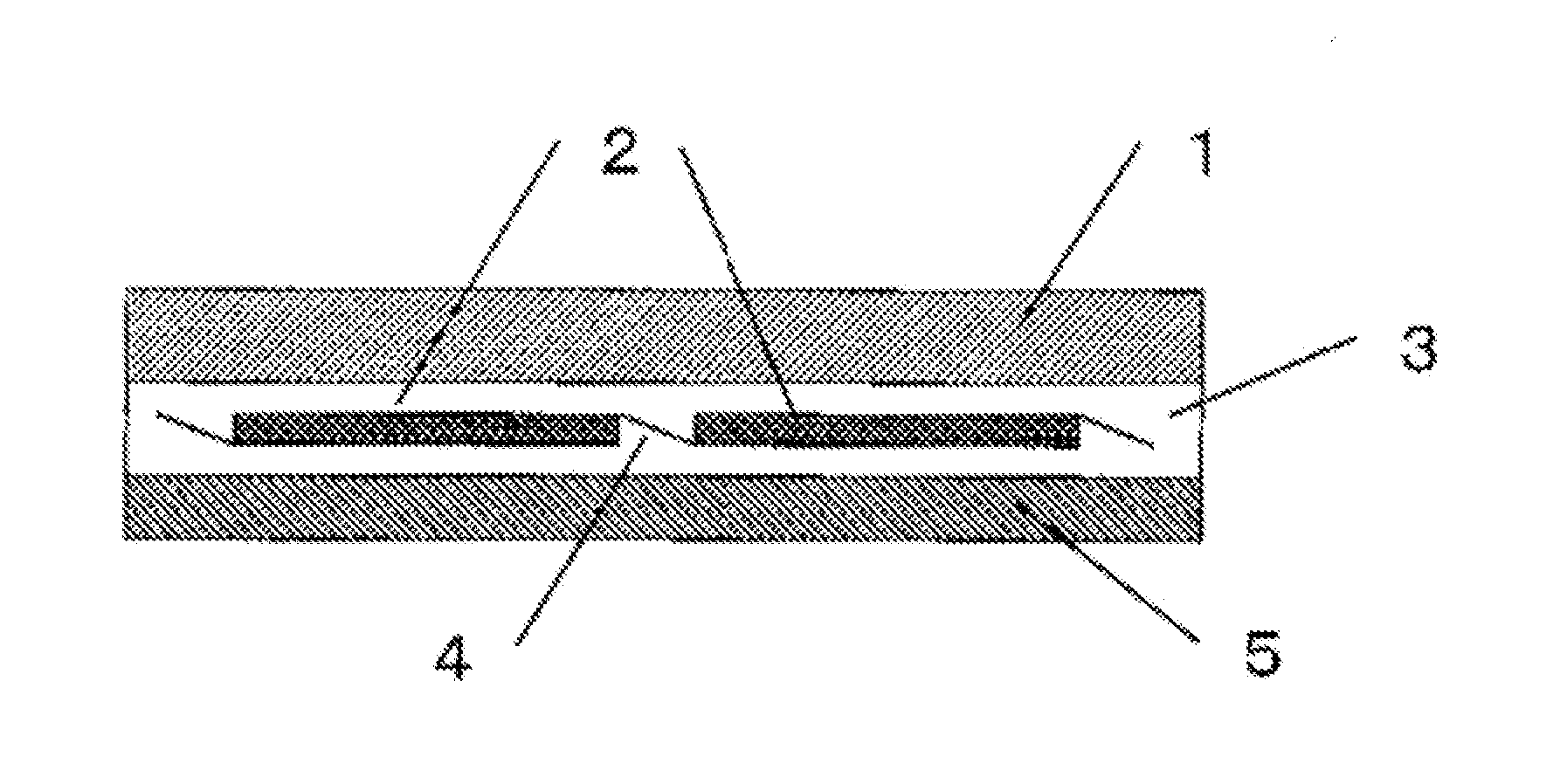

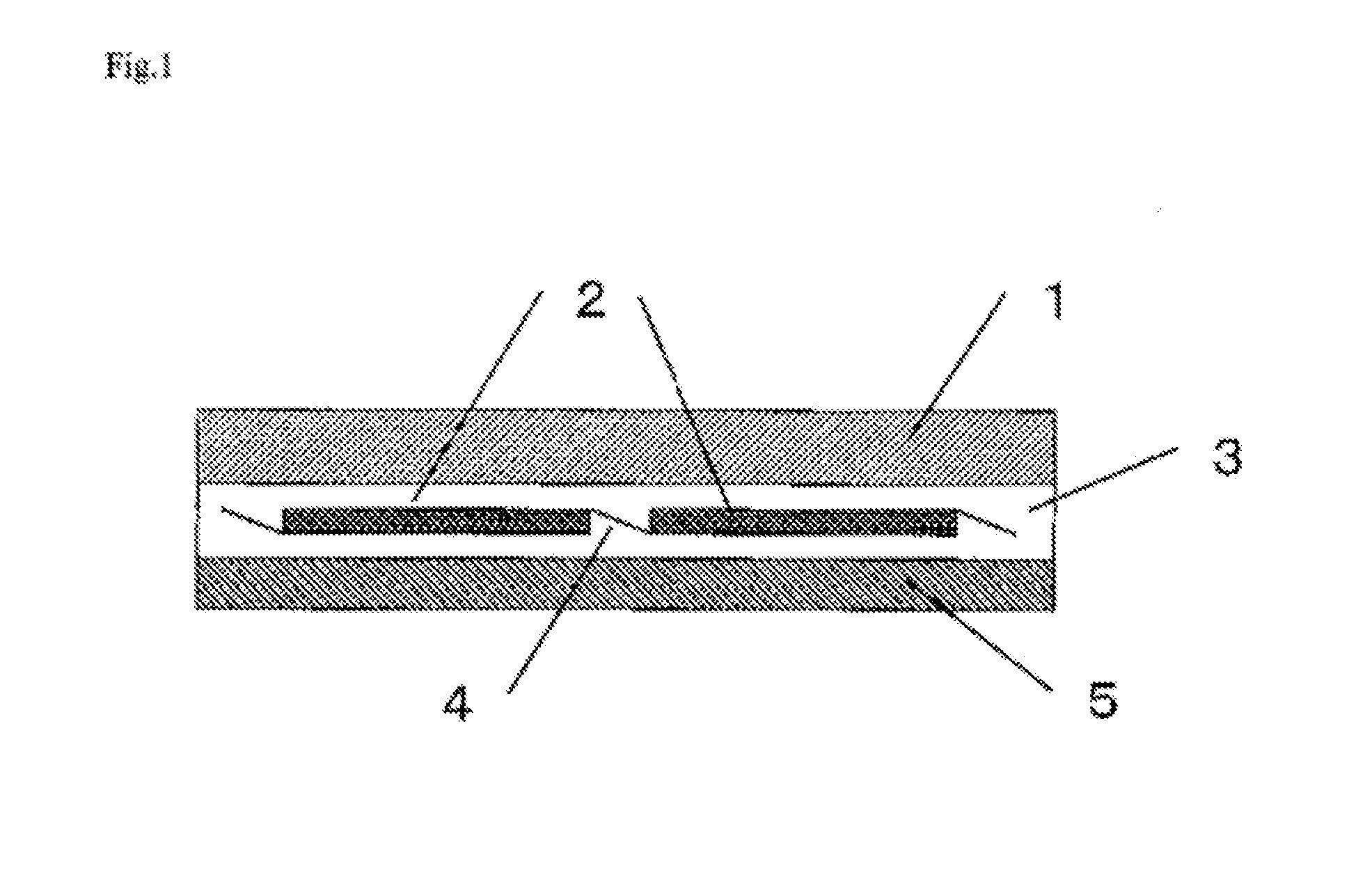

Provided are: an alkoysilyl group-containing hydrogenated block copolymer produced by introducing an alkoxysilyl group into a hydrogenated block copolymer that is obtained by hydrogenating 90% or more of unsaturated bonds of a block copolymer that includes at least two polymer blocks [A] and at least one polymer block [B], the polymer block [A] including a repeating unit derived from an aromatic vinyl compound as a main component, the polymer block [B] including a repeating unit derived from a linear conjugated diene compound as a main component, and a ratio (wA:wB) of a weight fraction wA of the polymer block [A] in the block copolymer to a weight fraction wB of the polymer block [B] in the block copolymer being 20:80 to 60:40; a method for producing the same; a solar cell element encapsulating material; a sheet, a laminated sheet; a multilayer sheet; and a method for encapsulating a solar cell element. The alkoxysilyl group-containing hydrogenated block copolymer exhibits low hygroscopicity, a low water vapor permeability, transparency, weatherability, and flexibility, maintains excellent adhesion to glass even when exposed to a high-temperature / high-humidity environment for a long time, and can encapsulate a solar cell element without applying a special waterproof treatment.

Owner:ZEON CORP

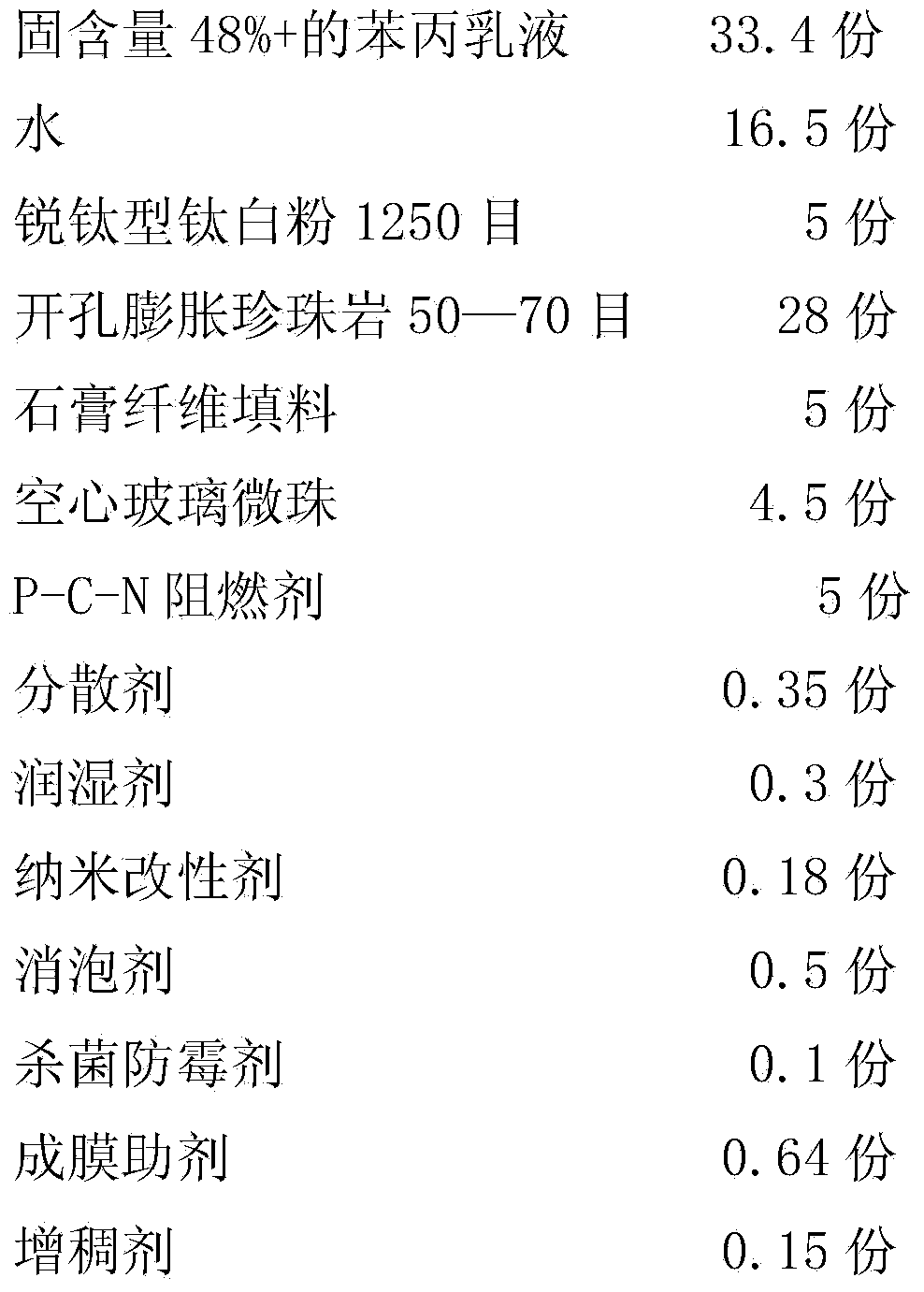

Nano modified water-base multifunctional sound-absorbing paint and preparation method thereof

InactiveCN103980771ABasic mechanicsBasic sound-absorbing functionCoatingsWater basedThermal insulation

The invention discloses a nano modified water-base multifunctional sound-absorbing paint and a preparation method thereof. The paint is composed of the following components in parts by weight: 28-38 parts of emulsion, 2-10 parts of pigment, 30-45 parts of filler, 15-25 parts of water, 4-8 parts of flame retardant and 2.25-5.43 parts of assistant. By optimizing the paint system structure, the polymer and filler are selected, modified and proportioned to ensure the basic mechanical properties and sound-absorbing function, and the paint has high-value service properties, such as thermal insulation, moisture resistance, fire resistance, aging resistance, fouling resistance, sterilization, air purification and the like, and is especially suitable for rooms and other occasions with higher environmental requirements.

Owner:南京创宁空间新材料科技有限公司

Processes for making dense, spherical active materials for lithium-ion cells

ActiveUS20060239883A1Easy to handleHigh stabilityElectrode manufacturing processesTantalum compoundsSodium phosphatesLithium-ion battery

Processes are provided for making dense, spherical mixed-metal carbonate or phosphate precursors that are particularly well suited for the production of active materials for electrochemical devices such as lithium ion secondary batteries. Exemplified methods include precipitating dense, spherical particles of metal carbonates or metal phosphates from a combined aqueous solution using a precipitating agent such as ammonium hydrogen carbonate, sodium hydrogen carbonate, or a mixture that includes sodium hydrogen carbonate. Other exemplified methods include precipitating dense, spherical particles of metal phosphates using a precipitating agent such as ammonium hydrogen phosphate, ammonium dihydrogen phosphate, sodium phosphate, sodium hydrogen phosphate, sodium dihydrogen phosphate, or a mixture of any two or more thereof. Further provided are compositions of and methods of making dense, spherical metal oxides and metal phosphates using the dense, spherical metal precursors. Still further provided are electrodes and batteries using the same.

Owner:UCHICAGO ARGONNE LLC

Halon-free intumescent fire-retardant epoxy resin compound

A halogen-free expansion flame-retardant epoxy resin combination mainly includes the following components (in terms of weight portion) 45 to 85 portions of epoxy resin, 4 to 40 portions of ammonium polyphosphate, 2 to 30 portions of melamine or the derivatives, 1 to 20 portions of phosphonate ester, 1 to 13 portions of solidified agent, 0.1 to 8 portions of diluting agent and 0.1 to 4 portions of filling agent. The combination with no halogen, strong moisture resistance and good flame retardance can reach V-0 standard in UL-94; therefore, the combination is used as the substrate of manufacturing spare parts and fittings in the electronic and electric field.

Owner:SHANGHAI RES INST OF CHEM IND

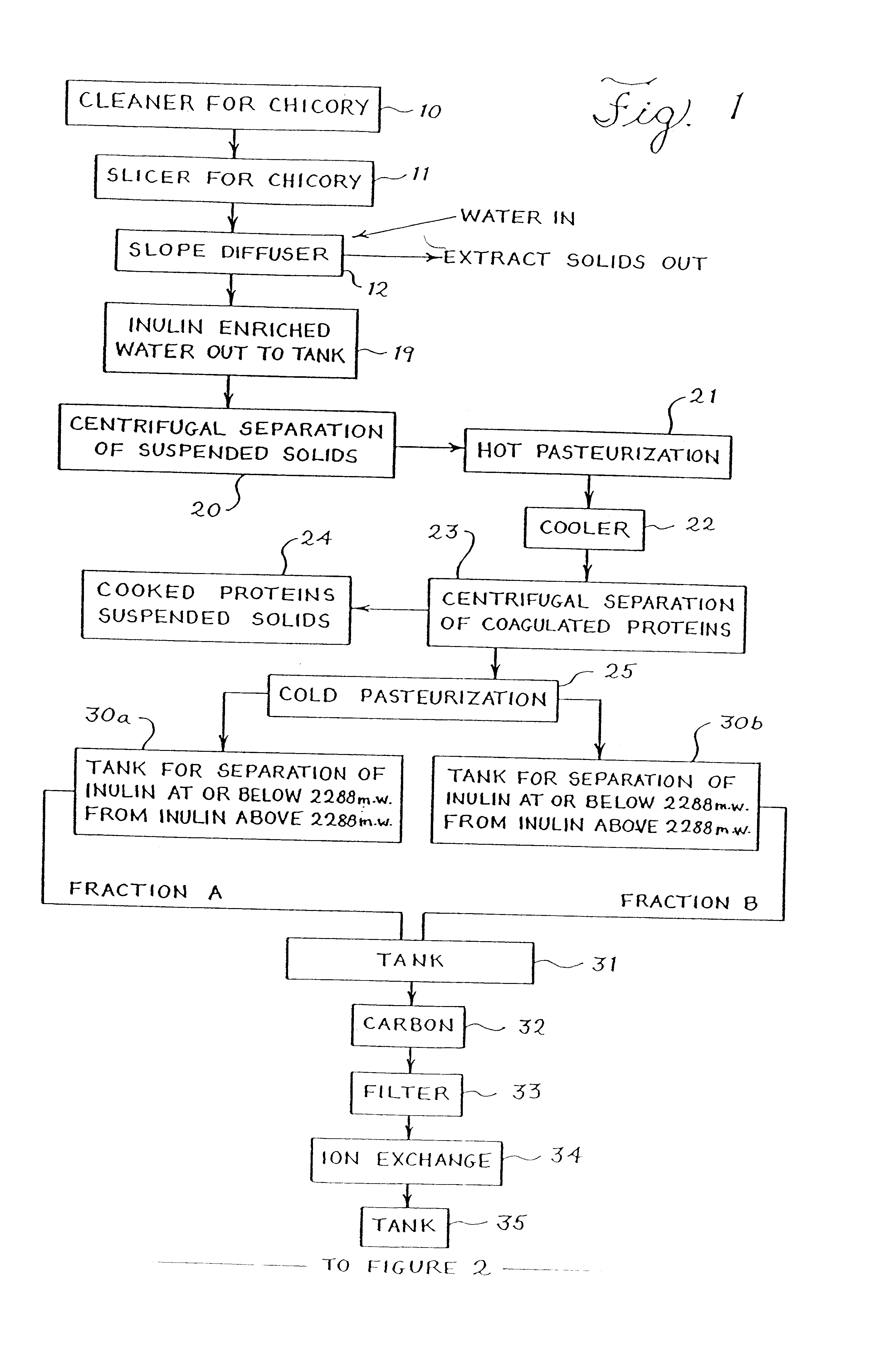

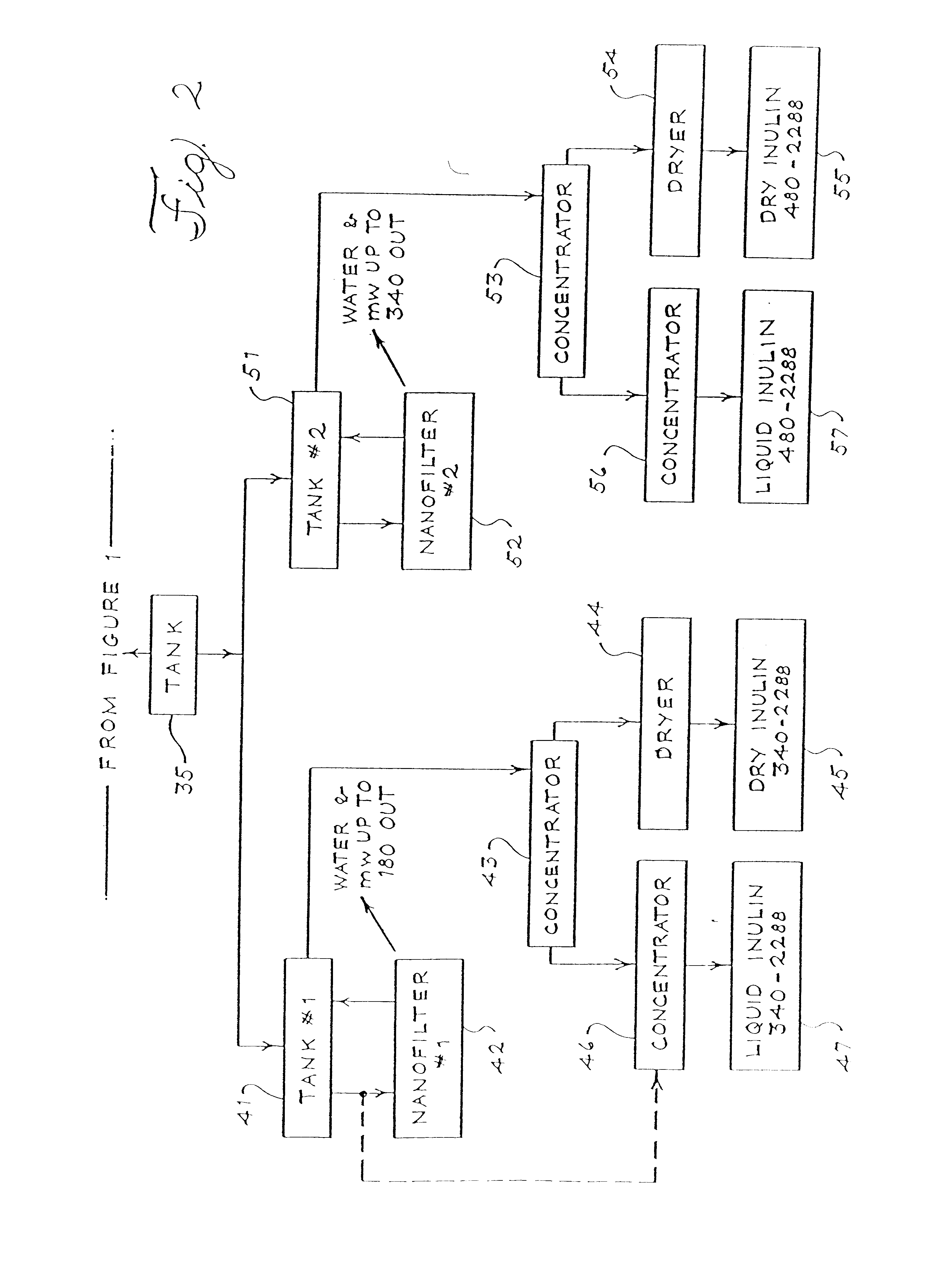

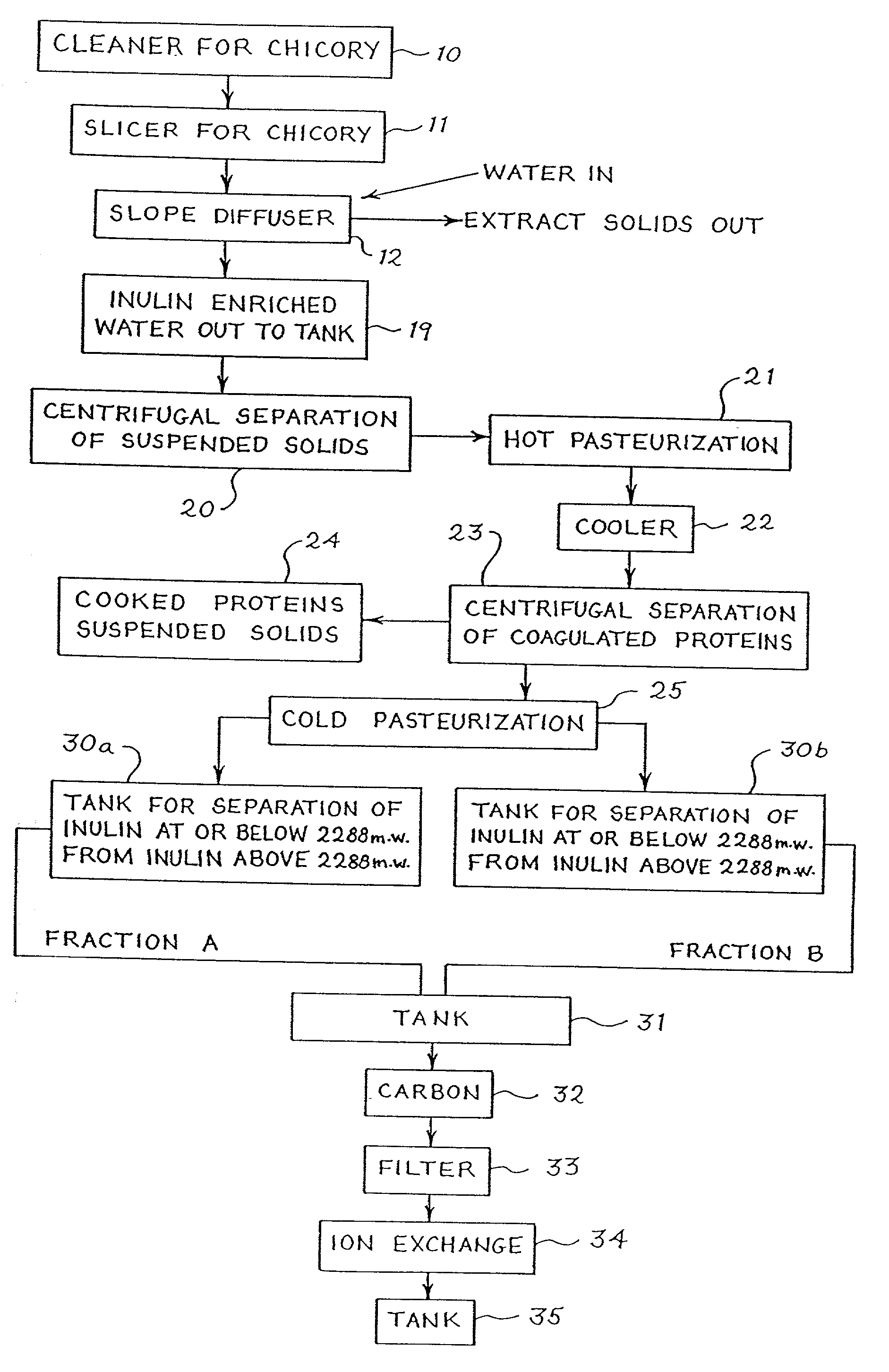

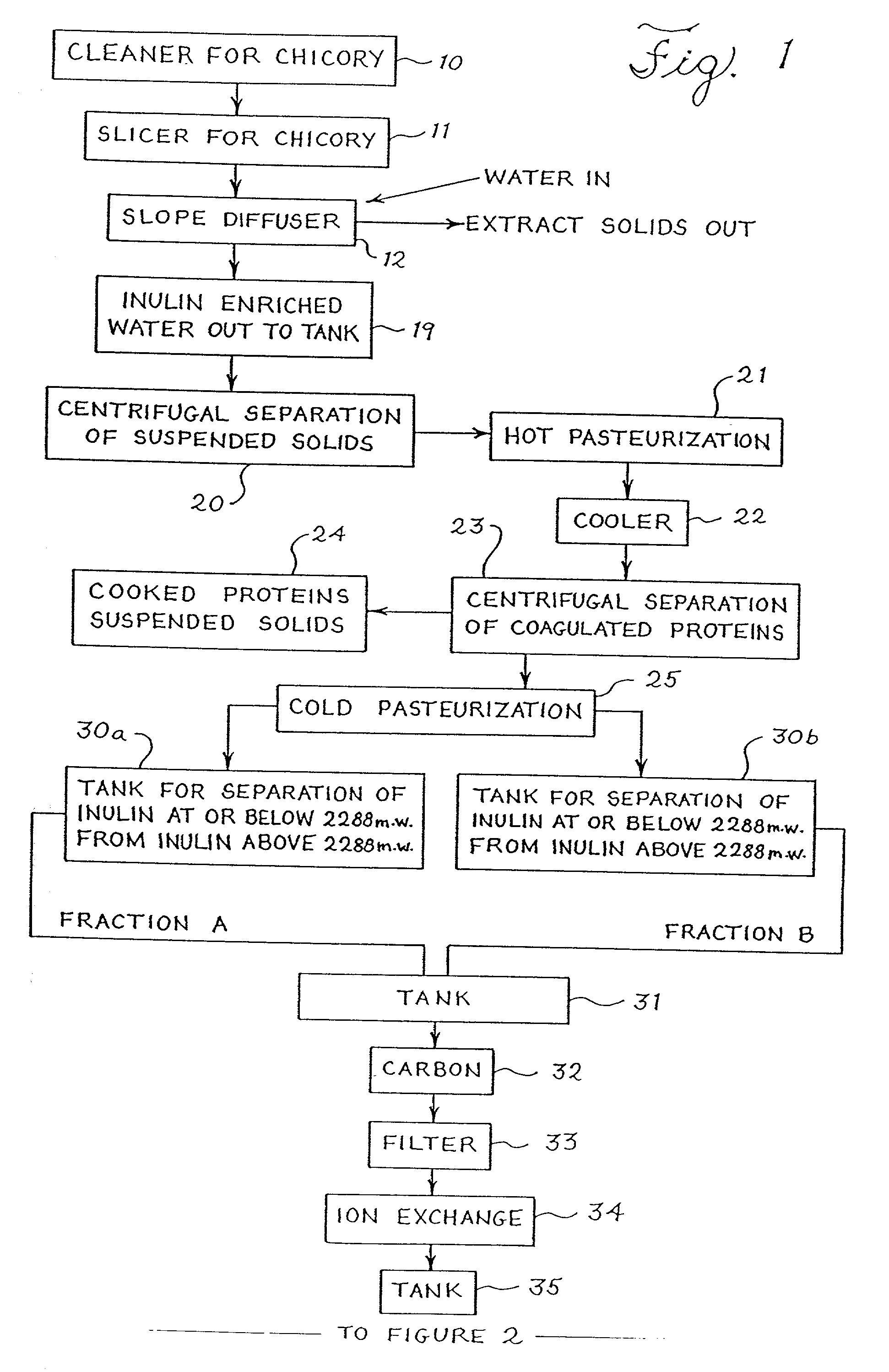

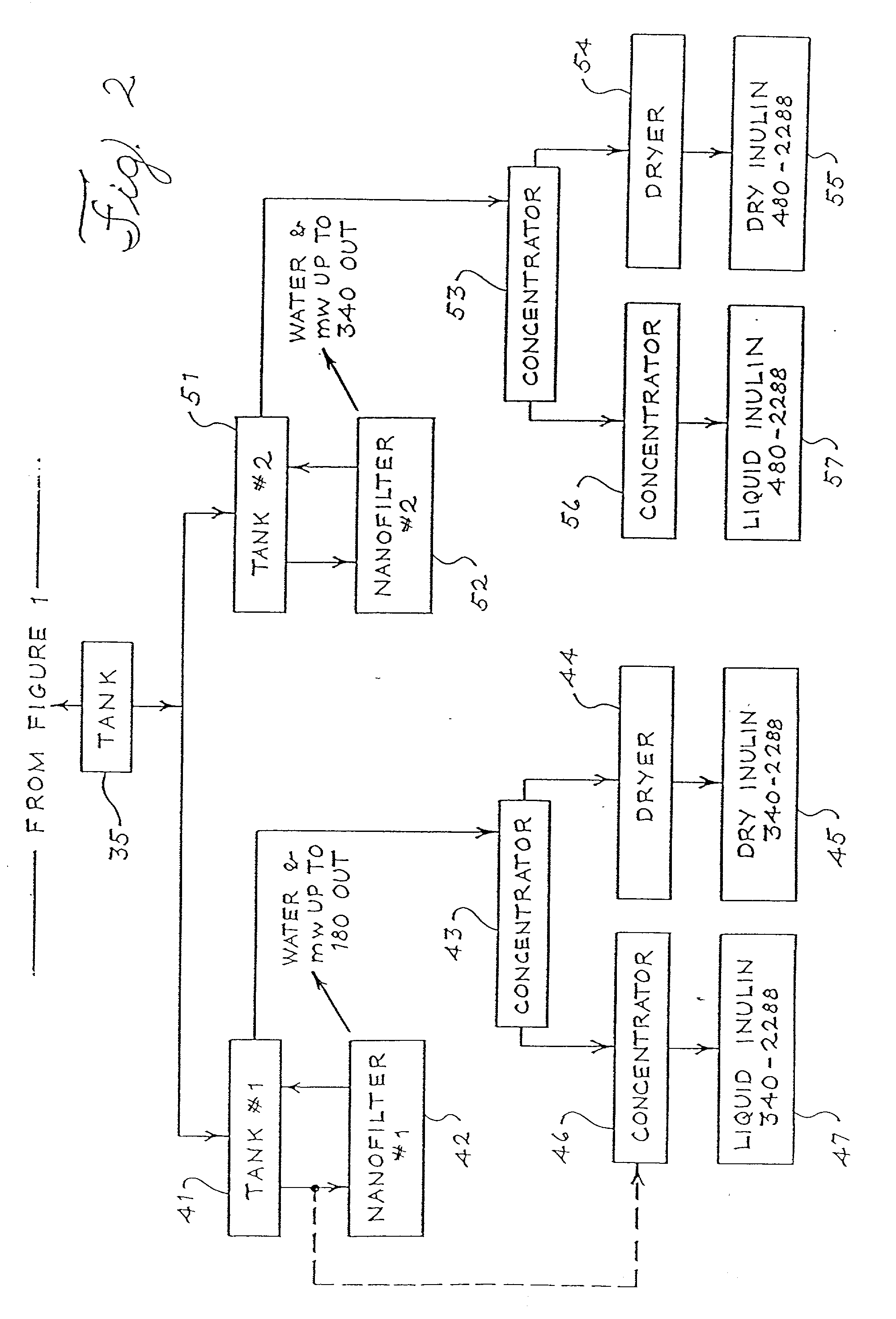

Processes for making novel inulin products

InactiveUS6569488B2Improve propertiesImprove solubilityMilk preparationSugar food ingredientsInulinWater soluble

The process for preparing the novel inulin products includes extracting inulin with water from subdivided plant materials, holding the inulin rich extraction water in a settling tank while maintaining the temperature from about 0° C. to 7° C. which causes higher molecular weight polysaccharides to separate from water soluble lower molecular weight polysaccharides, and separating the higher molecular weight inulin fructose fractions from the more water soluble lower molecular weight inulin fractions.

Owner:SILVER BARNARD STEWART

Heat-conductive insulated adhesive tape for large-power light-emitting diode (LED) and preparation method thereof

InactiveCN102161871AImprove thermal conductivityHigh bonding strengthLiquid surface applicatorsFilm/foil adhesivesFirming agentMoisture absorption

The invention discloses a heat-conductive insulated adhesive tape for a large-power light-emitting diode (LED) and a preparation method thereof. The preparation process comprises the following steps: mixing 5-10 parts by weight of mixture consisting of epoxy resin and toughening resin at a weight ratio of 1:1, 5-10 parts by weight of curing agent, 0-3 parts by weight of flexibilizer, 0.5 part by weight of accelerator and 0.5-1.5 parts of coupling agent; dissolving the obtained mixture in a solvent, wherein the weight ratio of the solvent to the mixture is 1:5; stirring for 1 hour, then adding 75-89 parts by weight of heat conductive filling material, and evenly mixing; and coating the obtained mixture on a substrate and carrying out graded curing, wherein the first-stage curing temperature is 80 DEG C, the first-stage curing time is 0.5 hour, the second-stage curing temperature is 120 DEG C, and the second-stage curing time is 1 hour, so that a semi-cured adhesive film is obtained. The heat-conductive insulated adhesive tape has the advantages of high heat conductive coefficient, high bonding strength, low moisture absorption, good room-low temperature storage and the like.

Owner:YANTAI DARBOND TECH

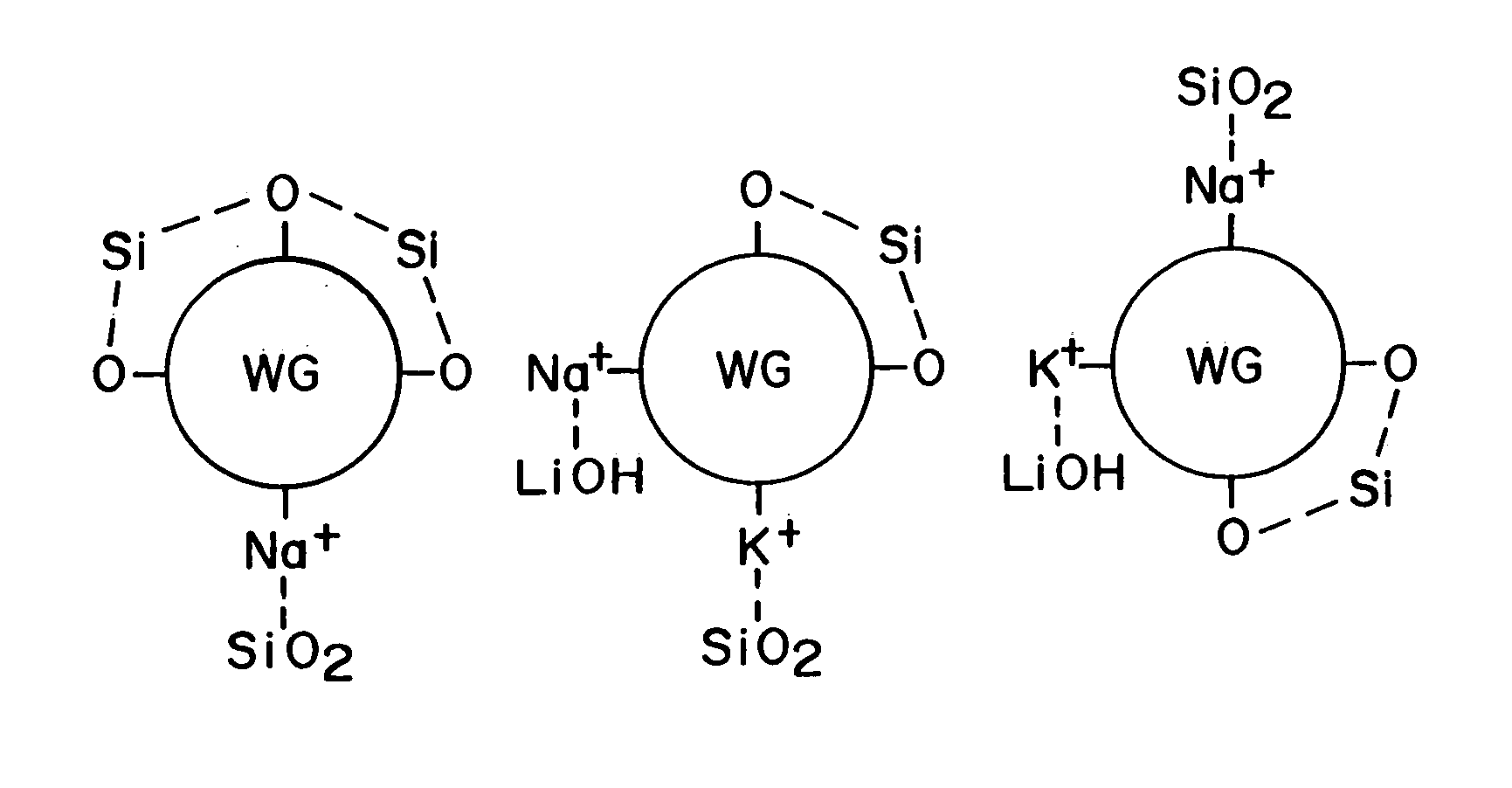

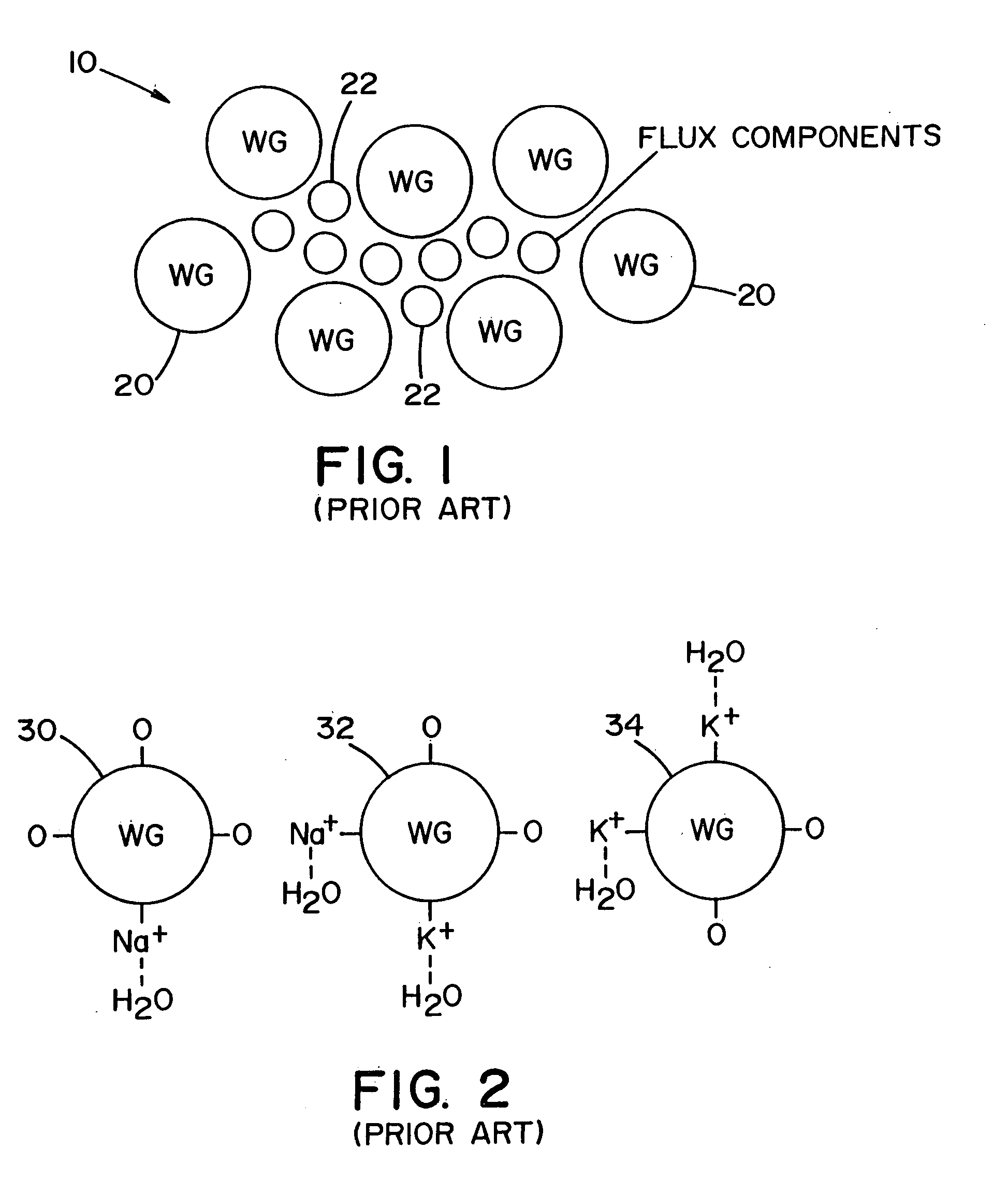

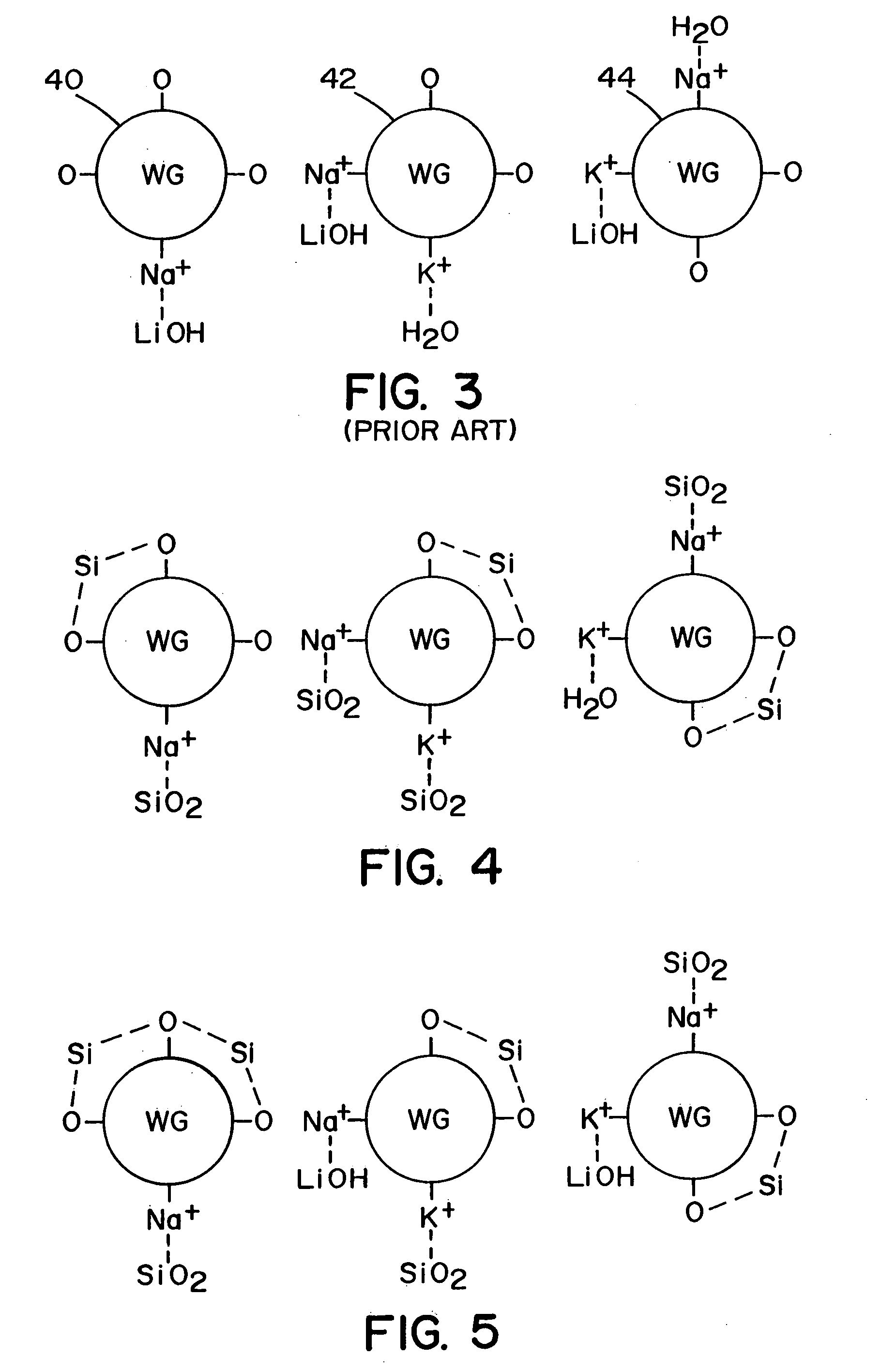

Colloidal silica binder system

InactiveUS20050121110A1Hygroscopic property is decreasedReduce dryingWelding/cutting media/materialsSoldering mediaColloidal silicaHydrogen

A welding flux that includes a flux agent, water glass and colloidal compound formed from small particles of silicon dioxide. The welding flux has a very low hygroscopicity, thus is well suited from low hydrogen electrodes.

Owner:LINCOLN GLOBAL INC

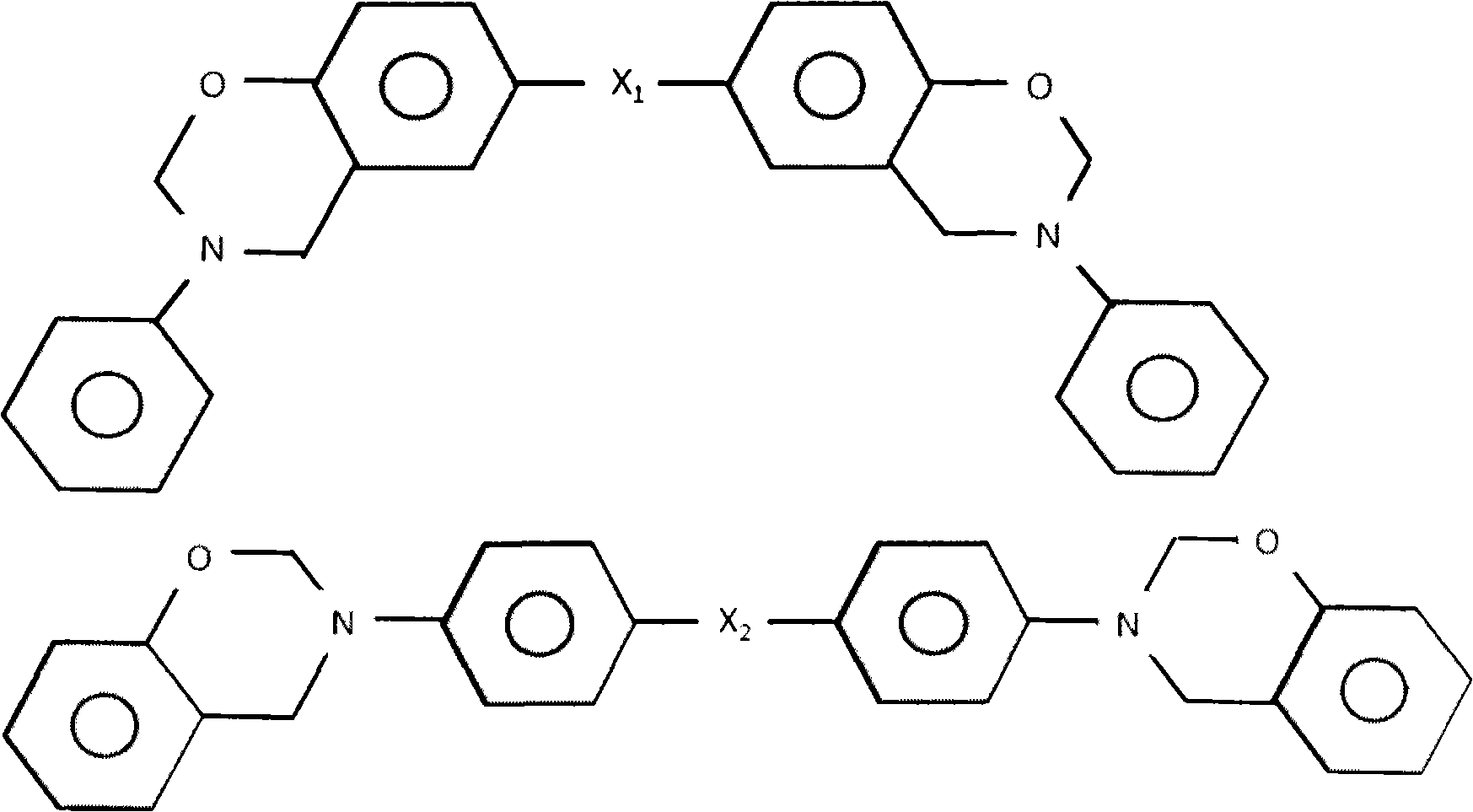

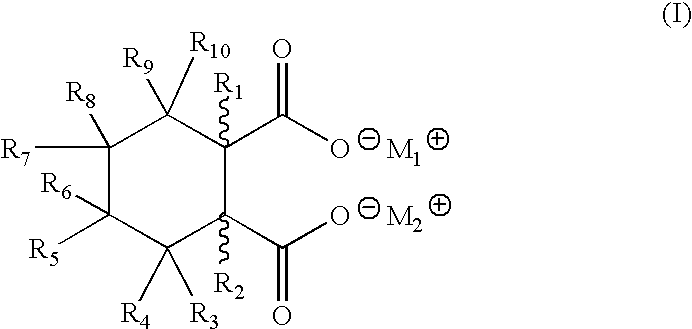

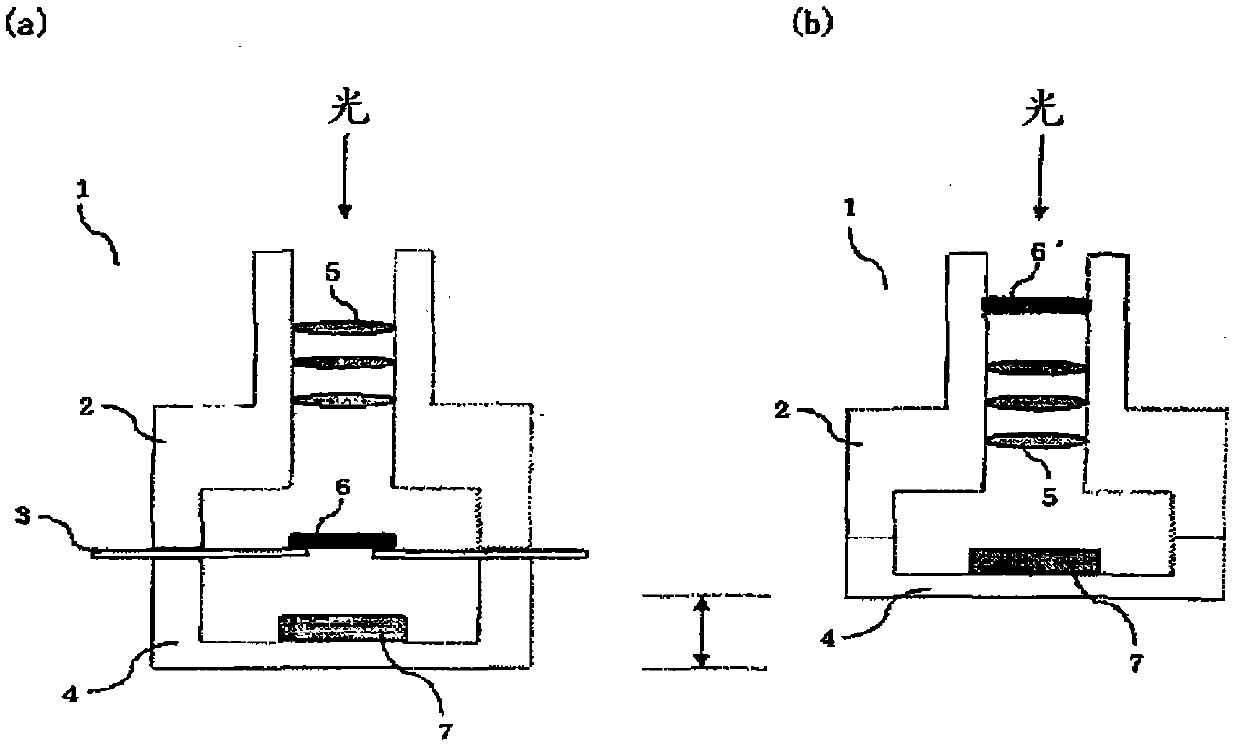

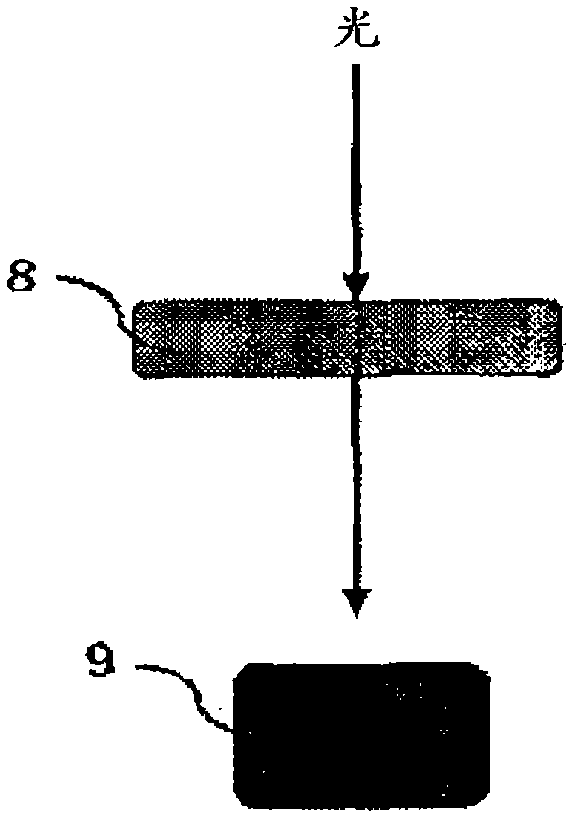

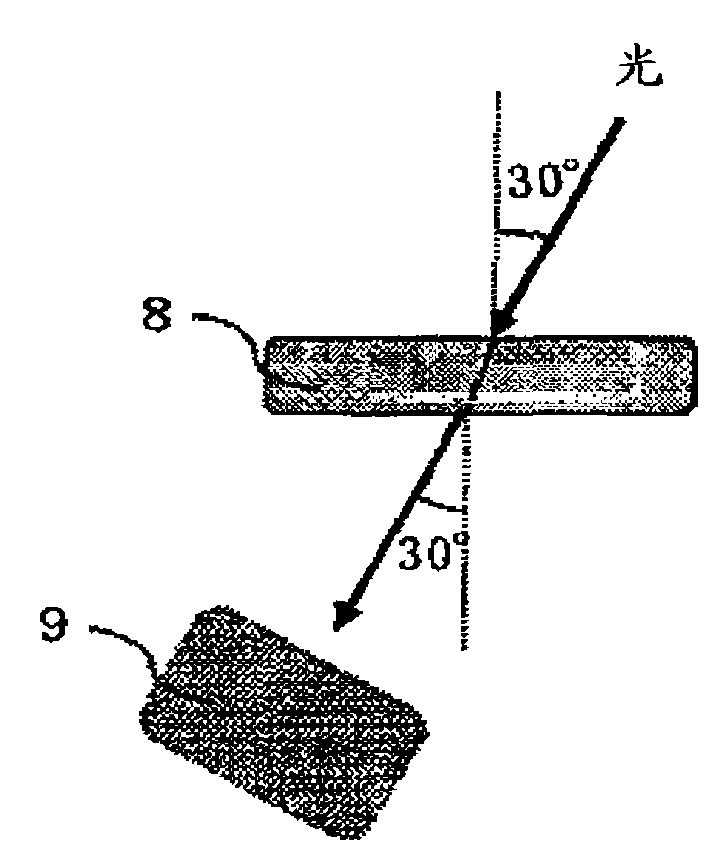

Near-infrared cut filter and device using near-infrared cut filter

ActiveCN102262254AGood cutoffLow hygroscopicityCamera body detailsOptical elementsForeign matterInfrared cut-off filter

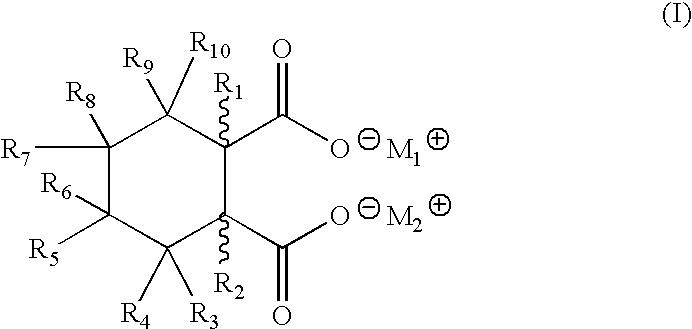

PROBLEM TO BE SOLVED: To obtain a near-infrared ray cut filter which has a wide viewing angle, is superior in near-infrared ray cutting capability, has a low hygroscopicity, and is free from foreign matters and warpage.SOLUTION: The near-infrared ray cut filter includes a resin substrate (I) containing a compound (I) which has a structure derived from a compound expressed by a formula (I).

Owner:JSR CORPORATIOON

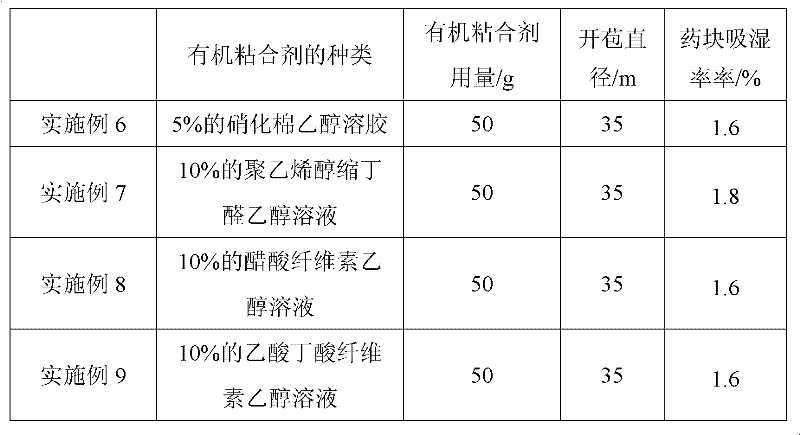

Modular smokeless firework ammunition capable of improving dampproof performance and preparation method for modular smokeless firework ammunition

InactiveCN102584505ALow hygroscopicityNo pollution in the processNitrated explosive compositionsAdhesiveEngineering

The invention discloses a modular smokeless firework ammunition capable of improving the dampproof performance. The modular smokeless firework ammunition comprises nitrocotton which has a large number of tiny holes, a block-type appearance and dampproof performance. The preparation method for the modular smokeless firework ammunition capable of improving the dampproof performance comprises the following steps of: preparing granular micro-hole firework ammunitions; mixing an organic adhesive with the dampproof characteristic, an ignition performance enhancer and the granular micro-hole firework ammunitions; preparing an ammunition block with a specific shape by the mixed materials; then attaching a layer of adhesive thin film with the dampproof performance to the surface of the ammunition block by an immersing or coating method, wherein the adhesive coated on the surface is the same as that of the adhesive for forming the modular ammunition; and finally drying. By adopting the waterproof adhesive and the preparation method, the dampproof performance of the modular smokeless firework ammunition can be improved greatly, and the problem that the firing effect of a firework product prepared by the smokeless firework ammunition is unstable is solved.

Owner:NANJING UNIV OF SCI & TECH

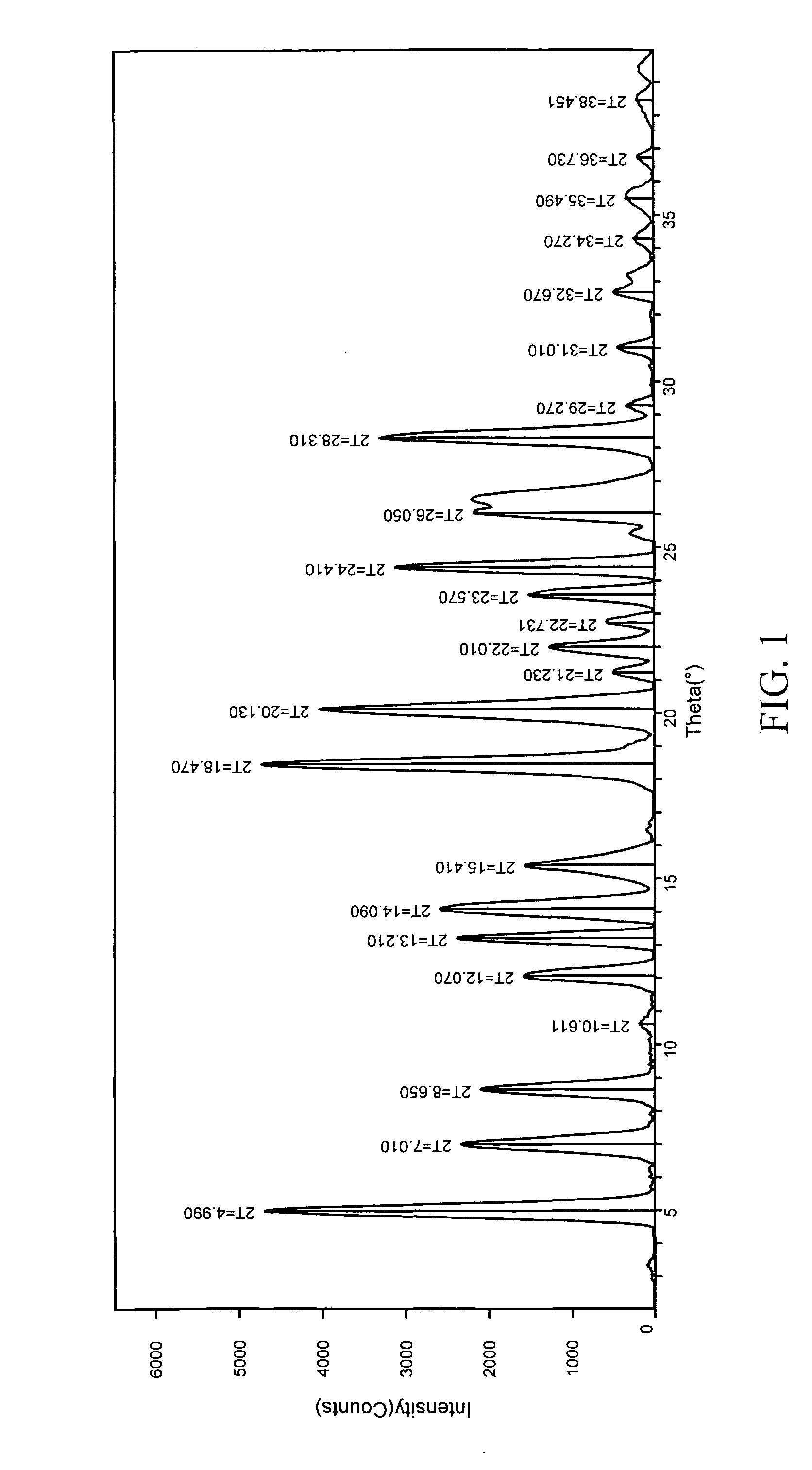

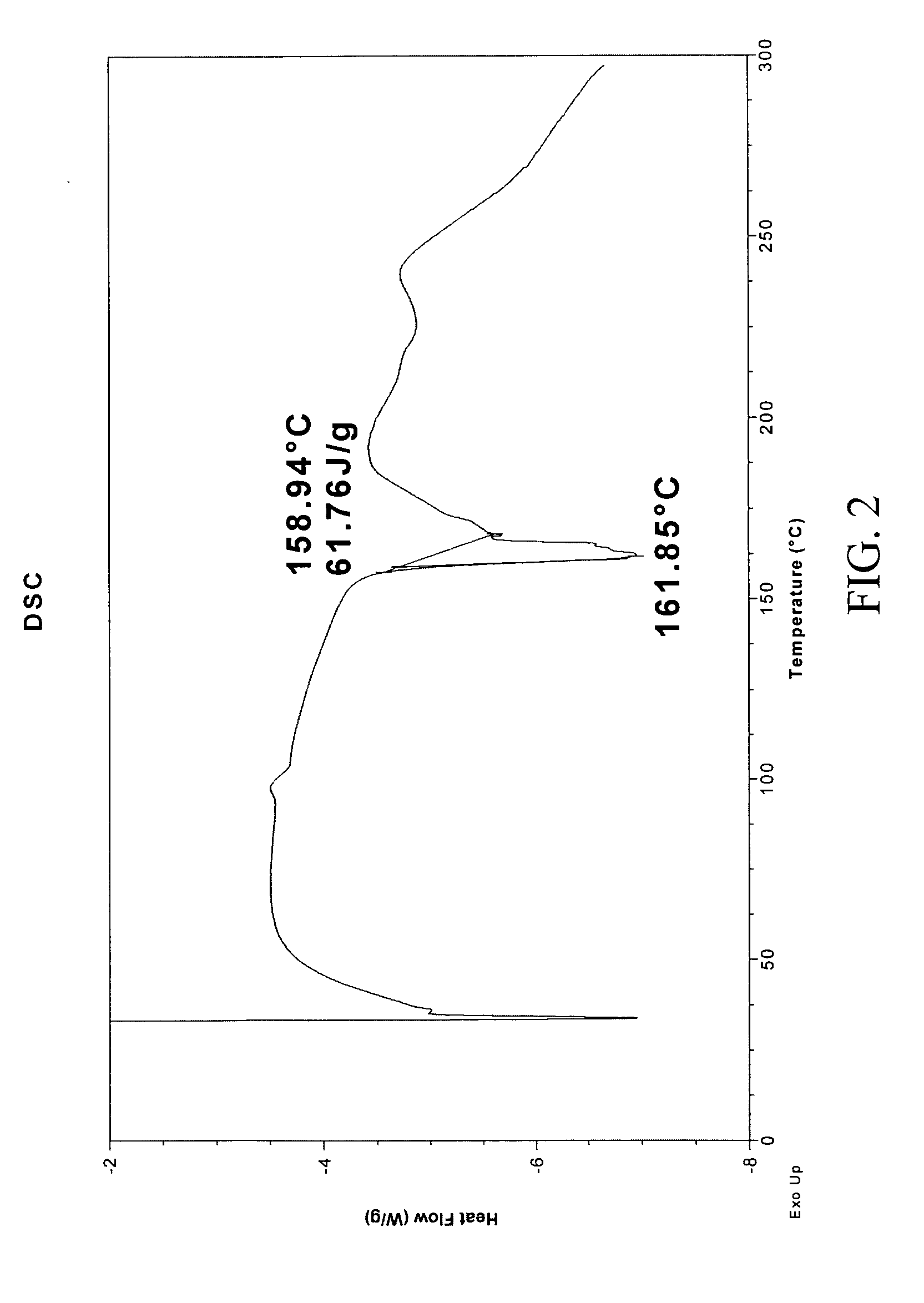

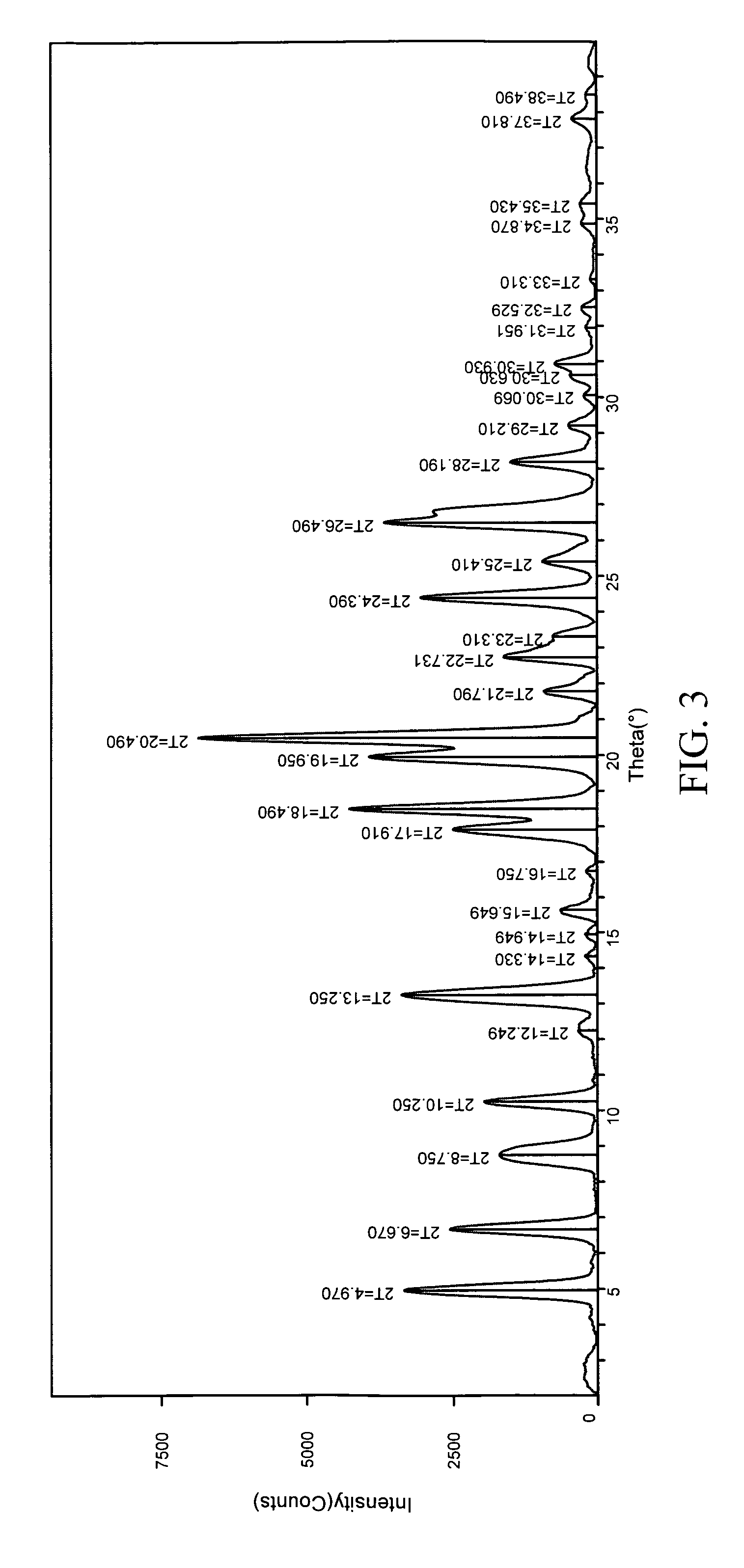

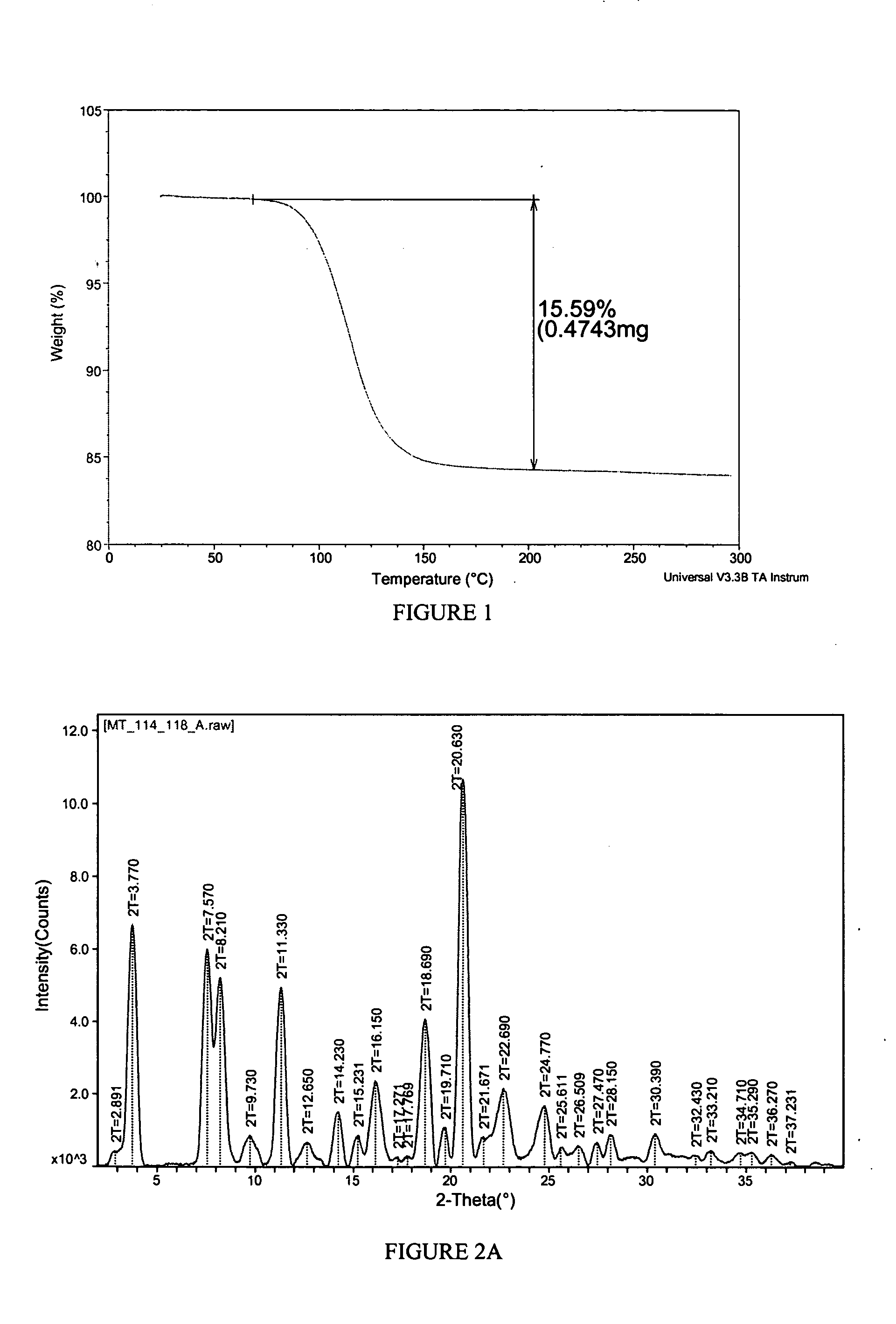

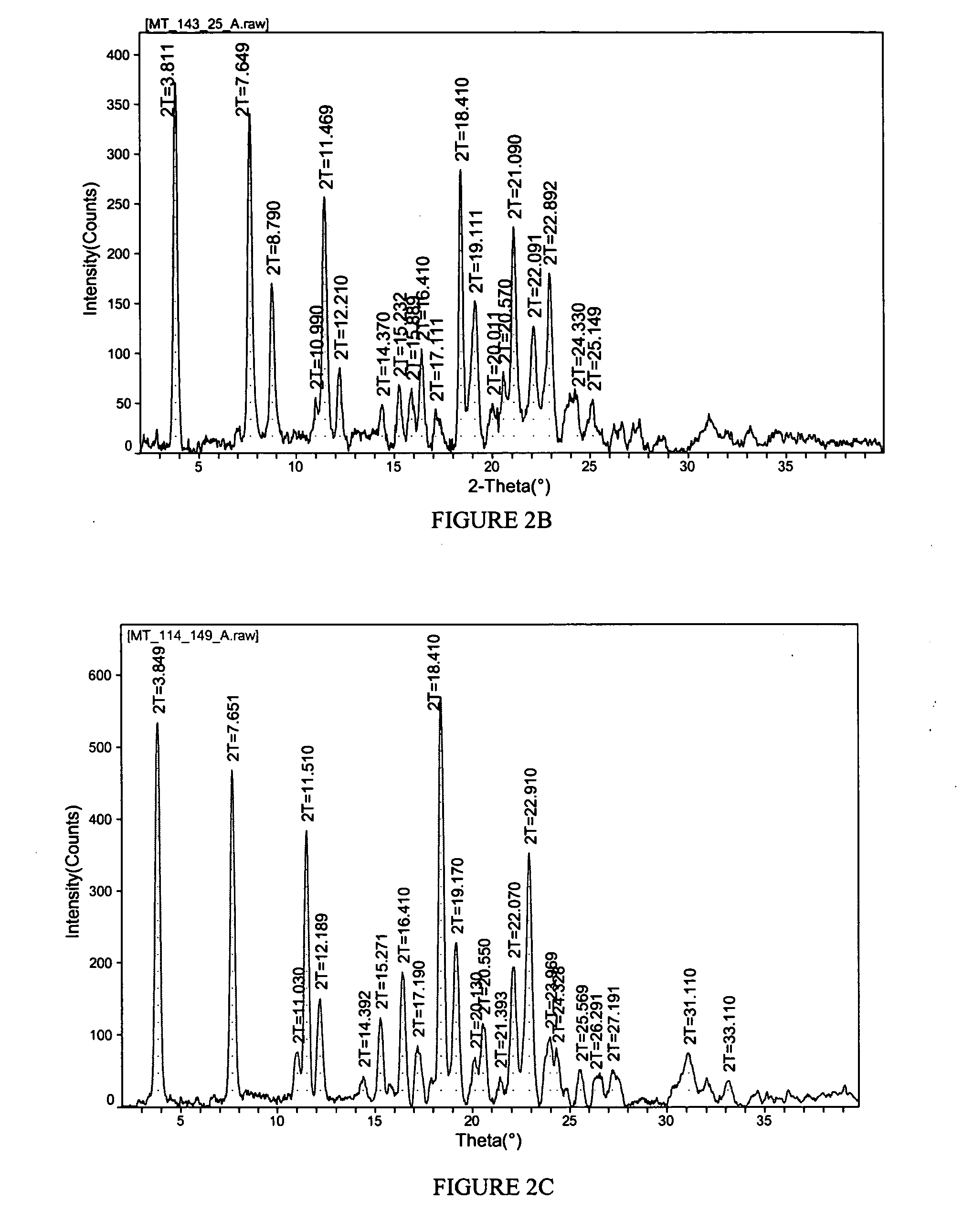

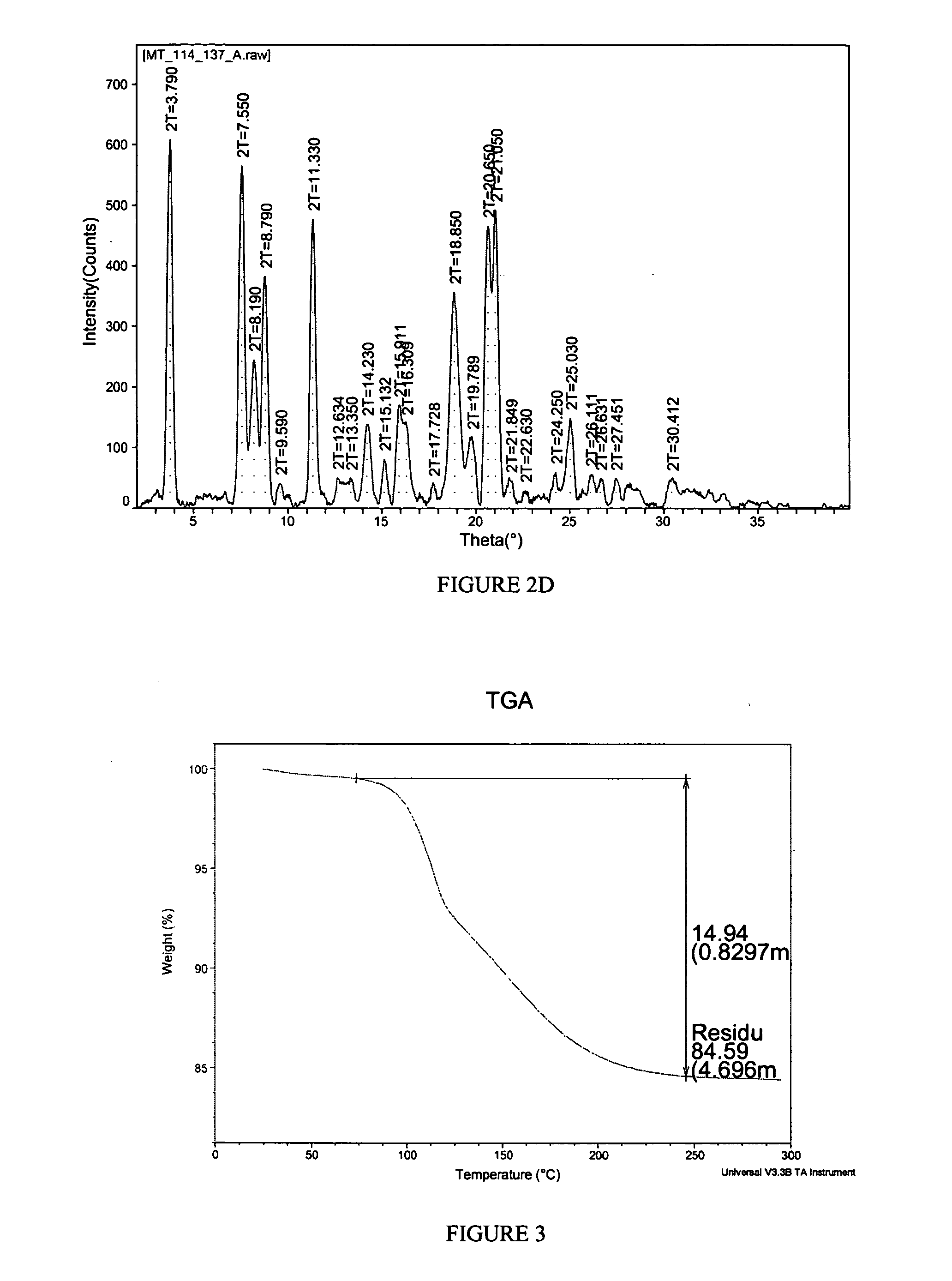

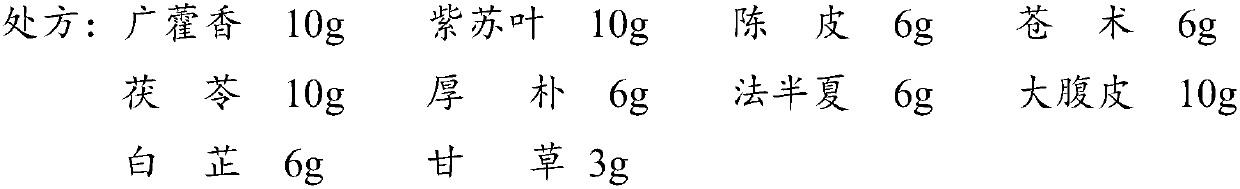

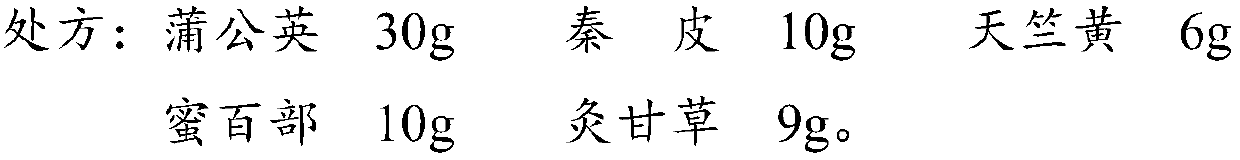

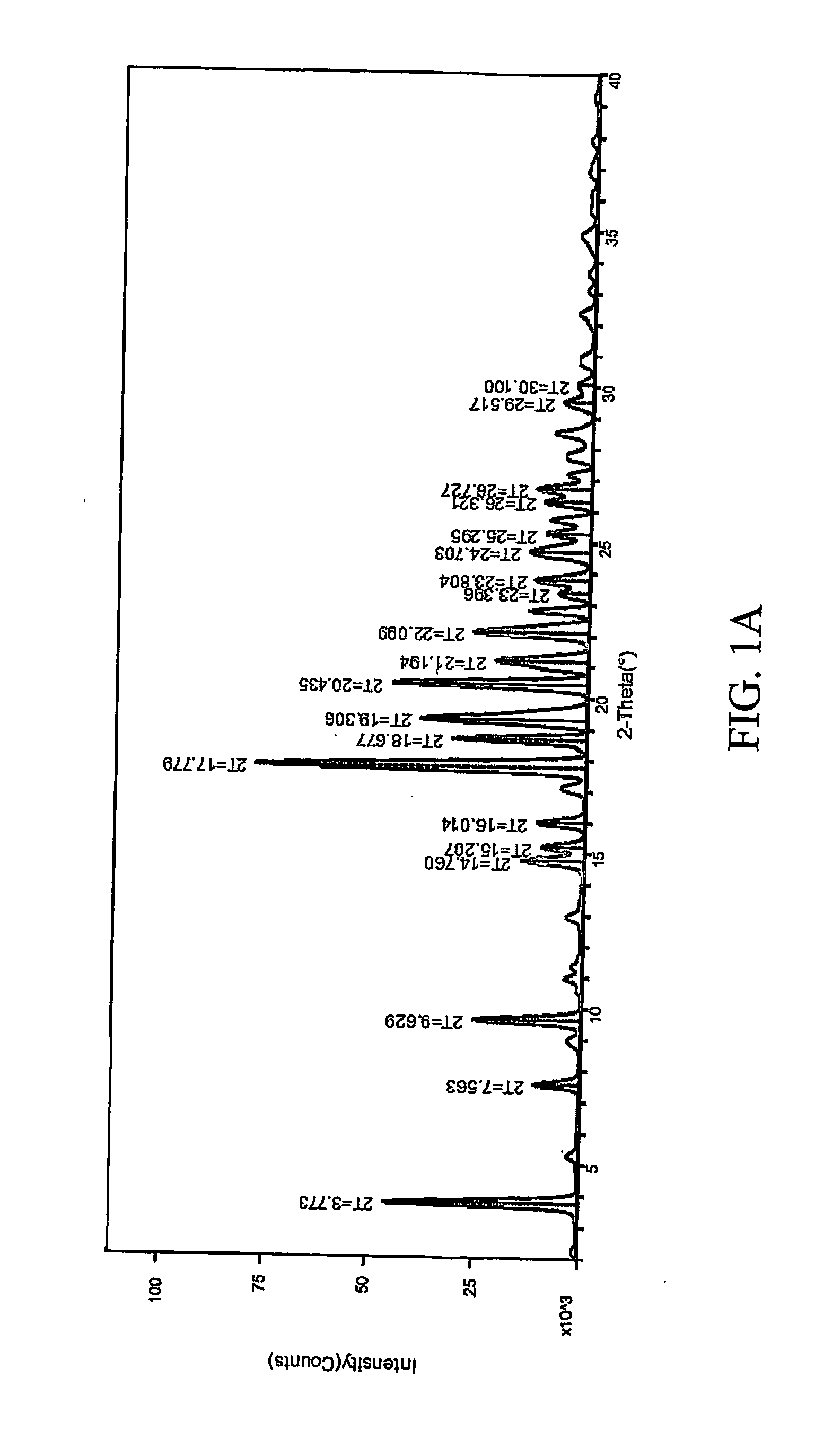

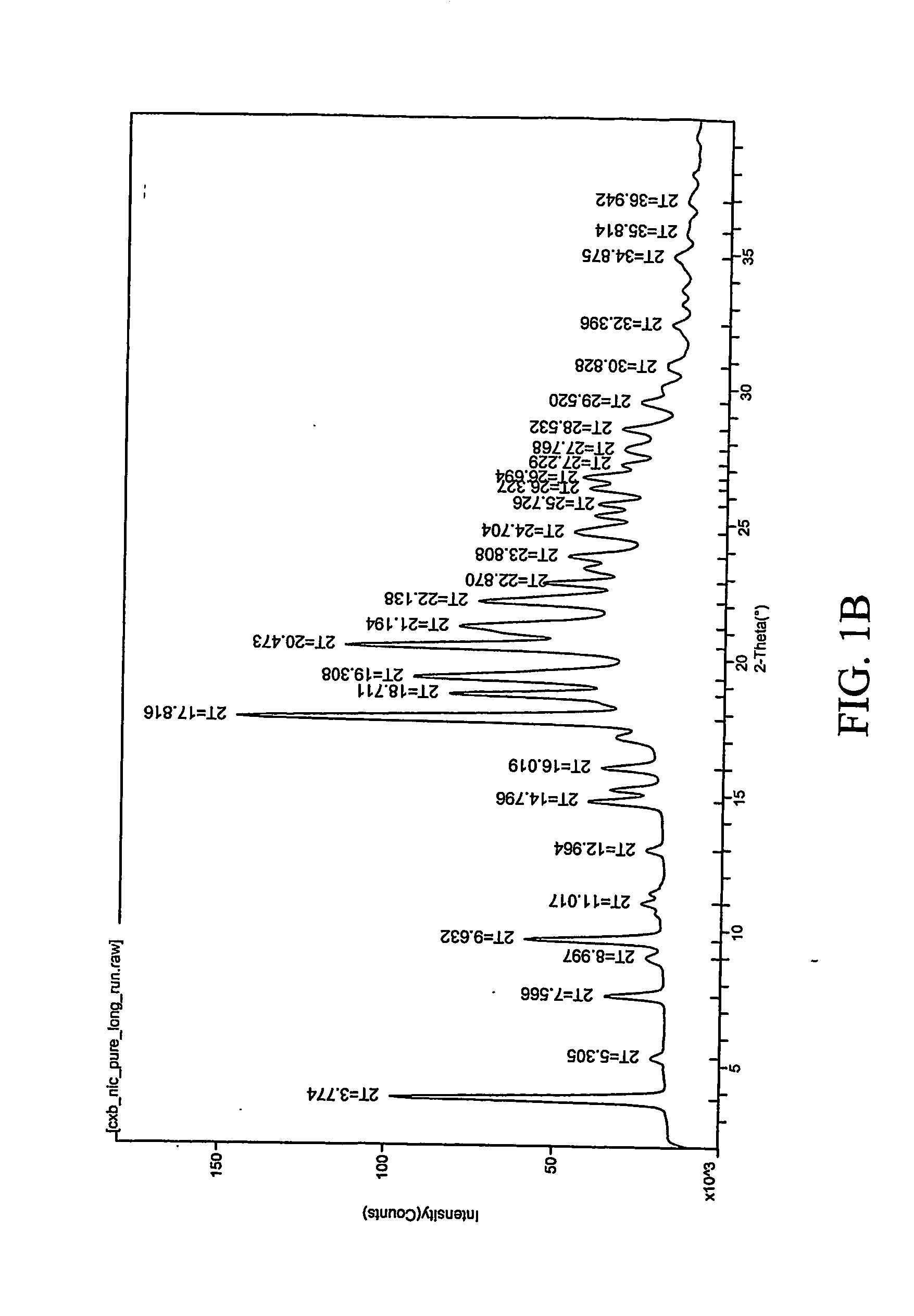

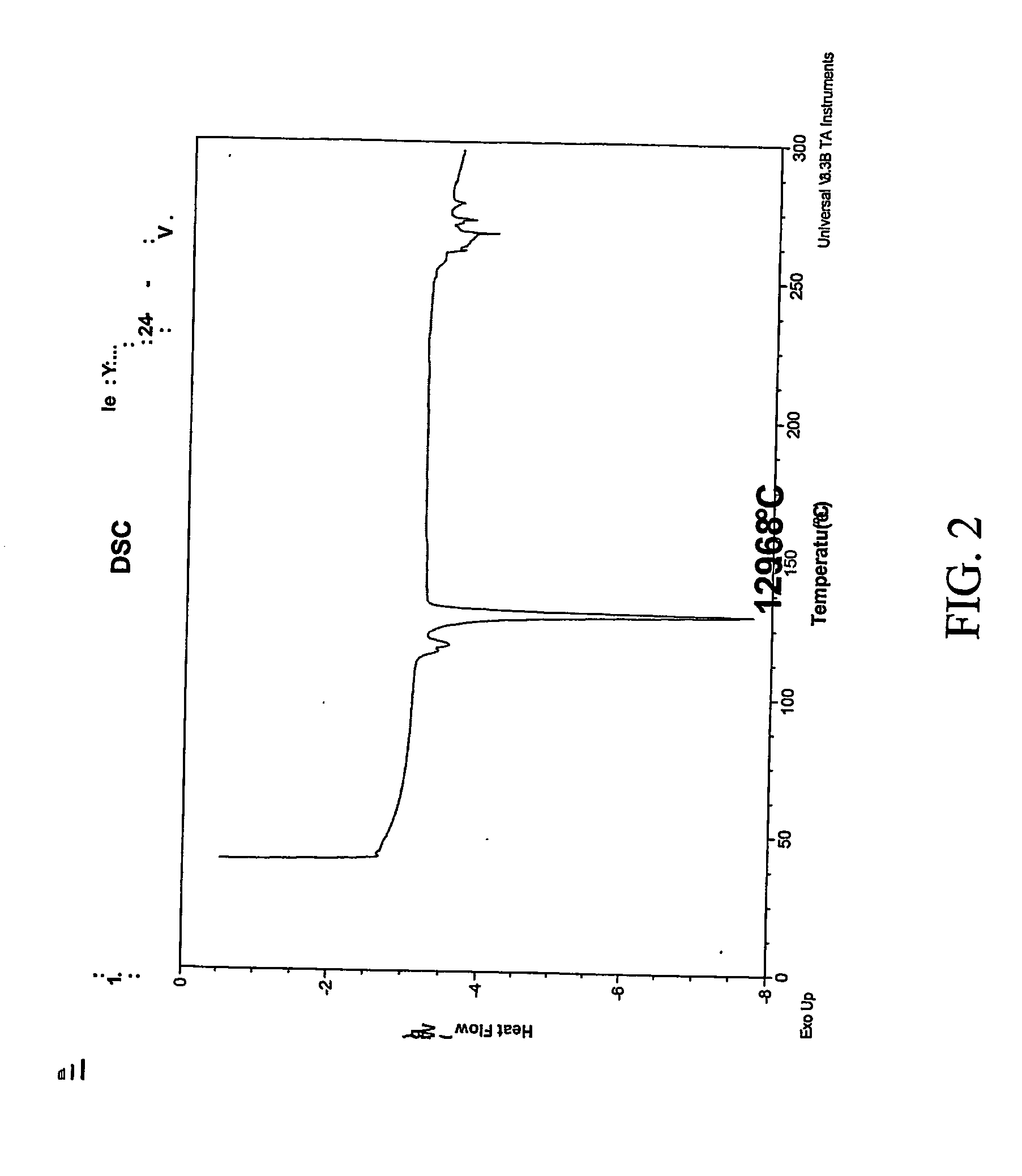

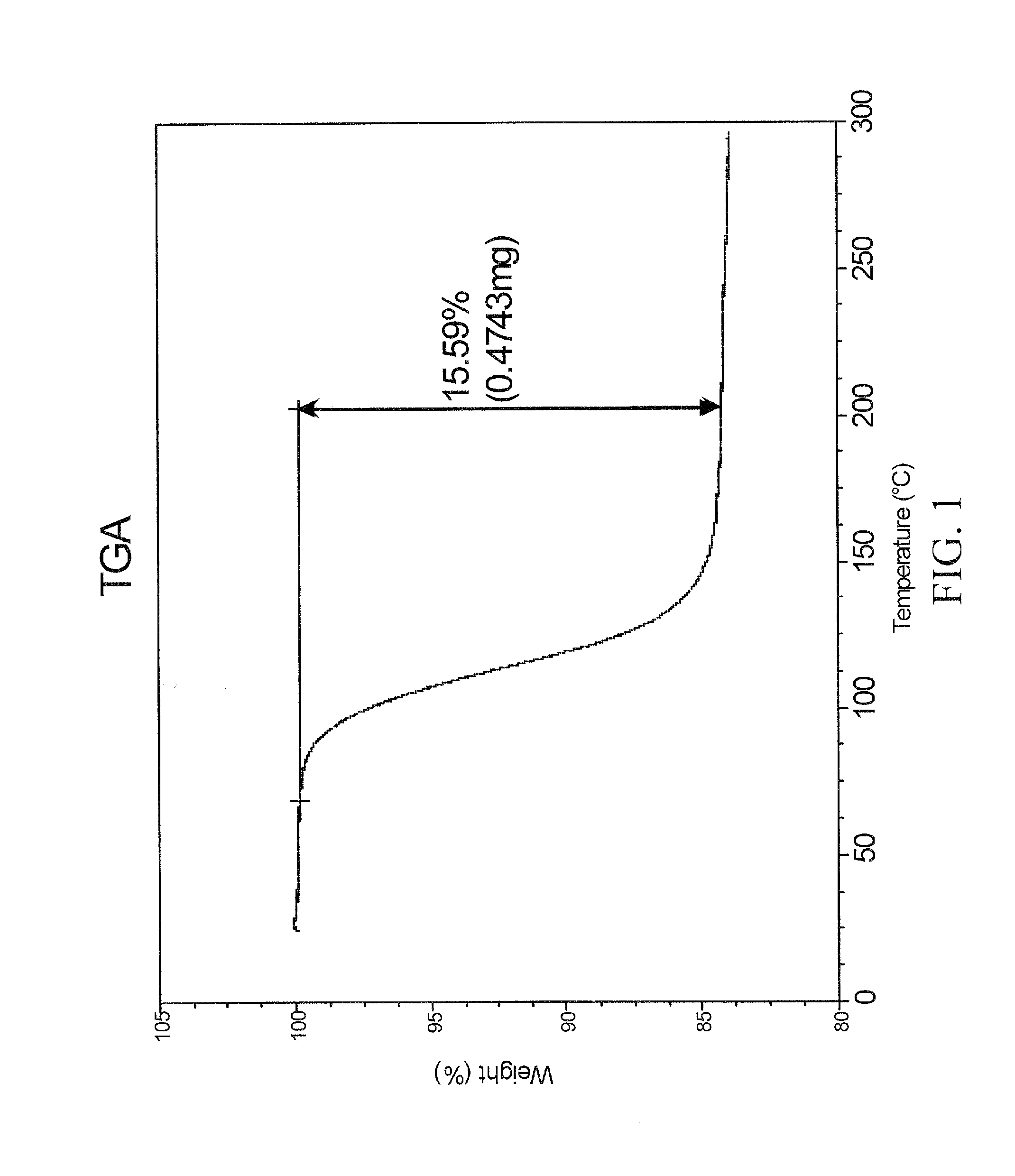

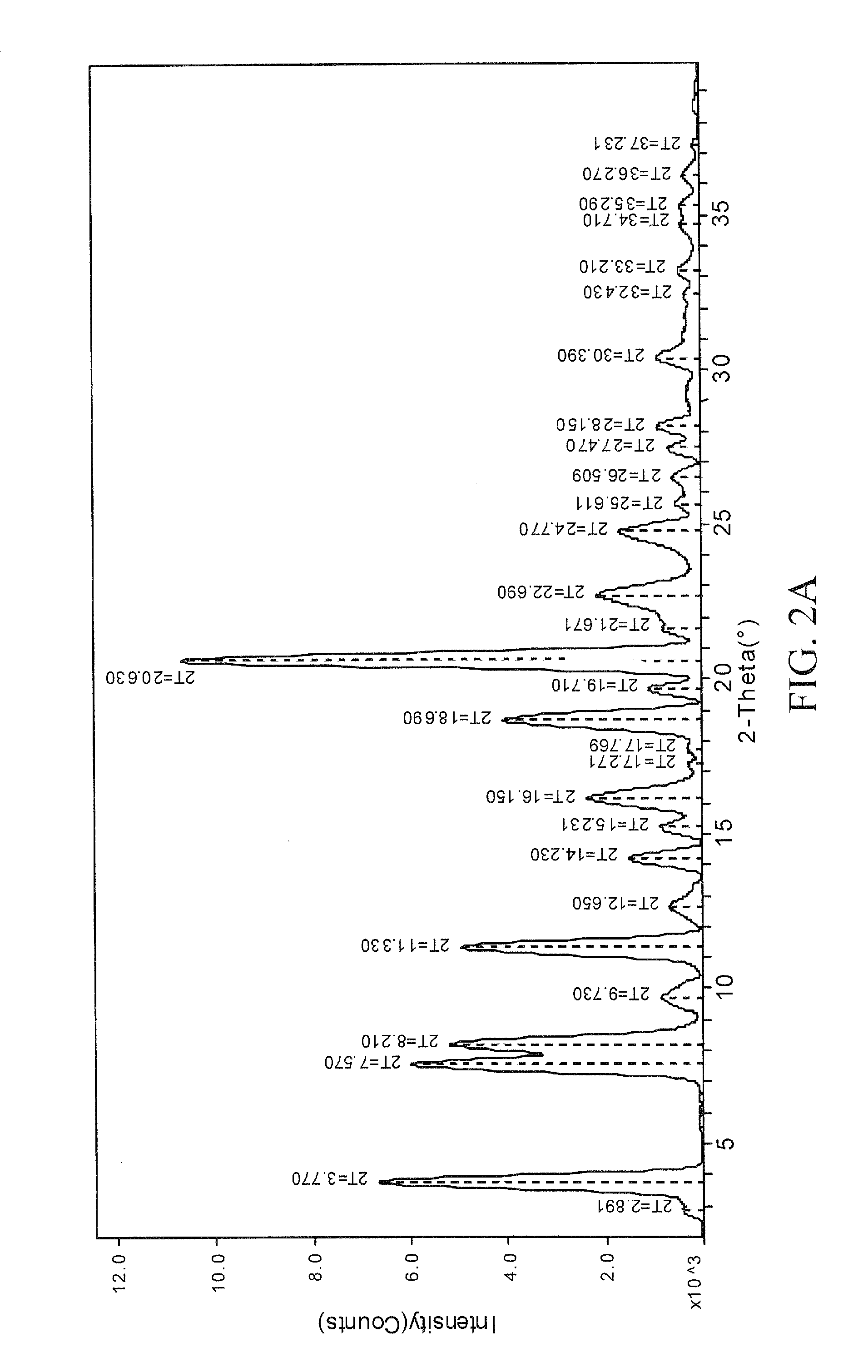

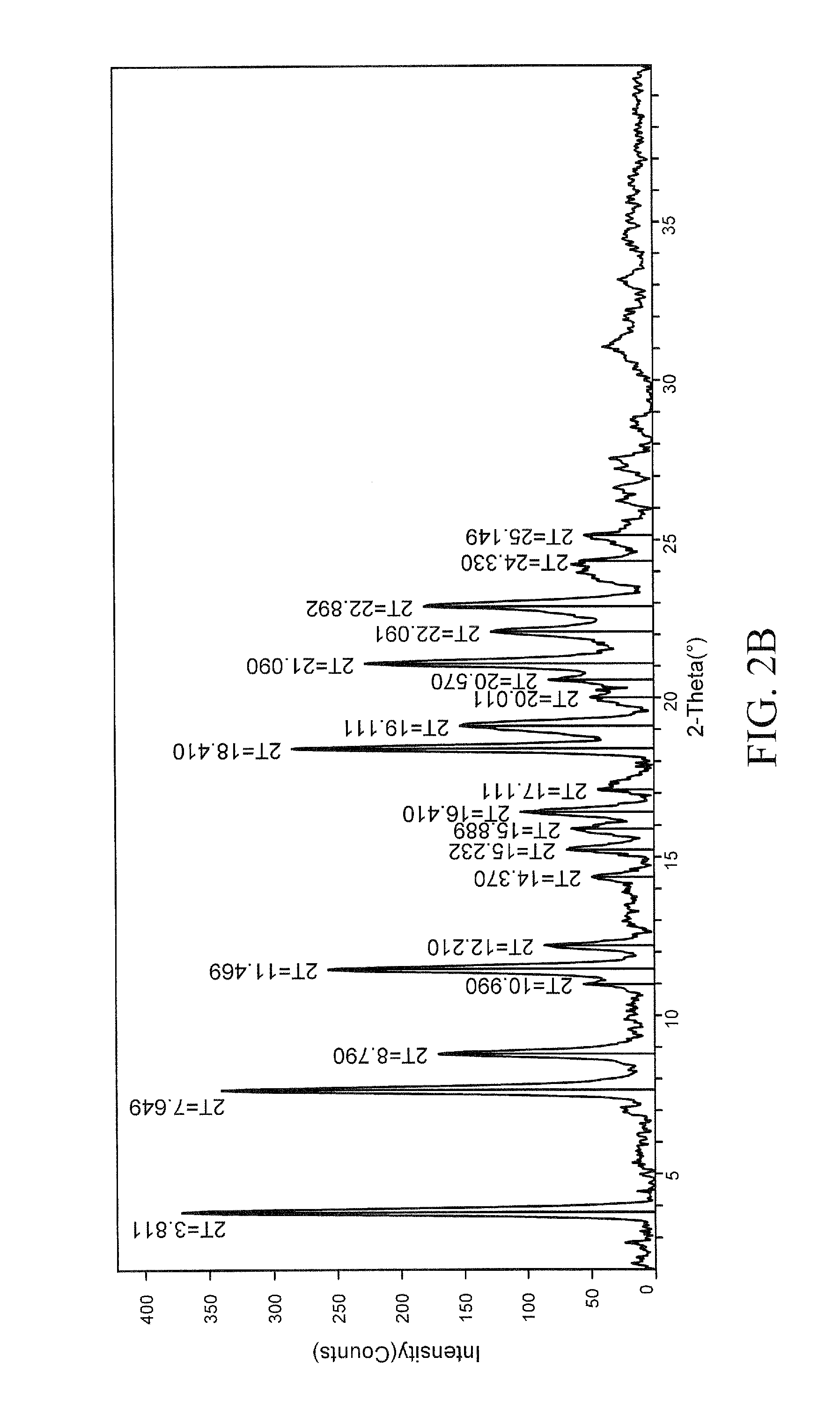

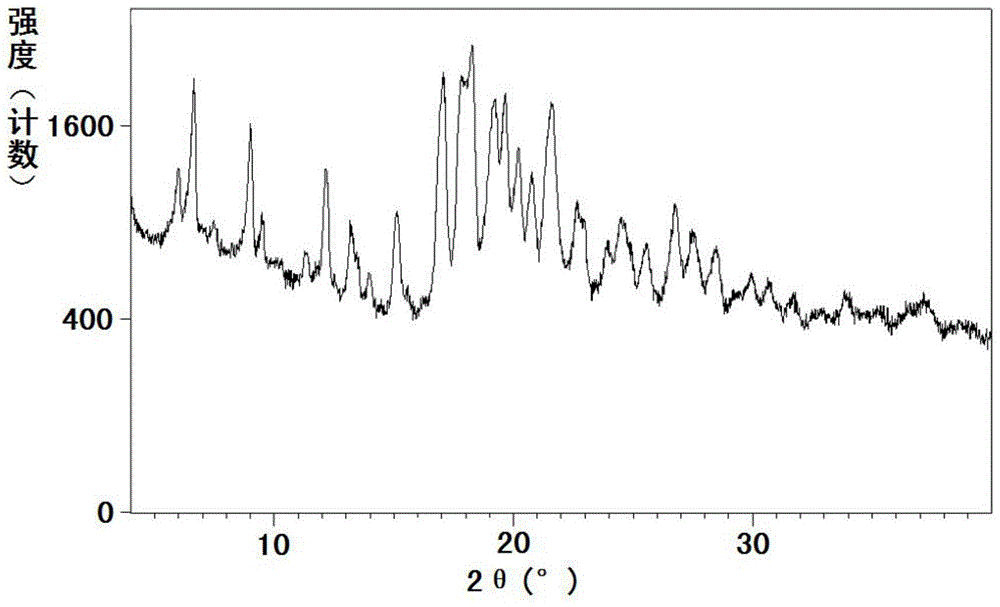

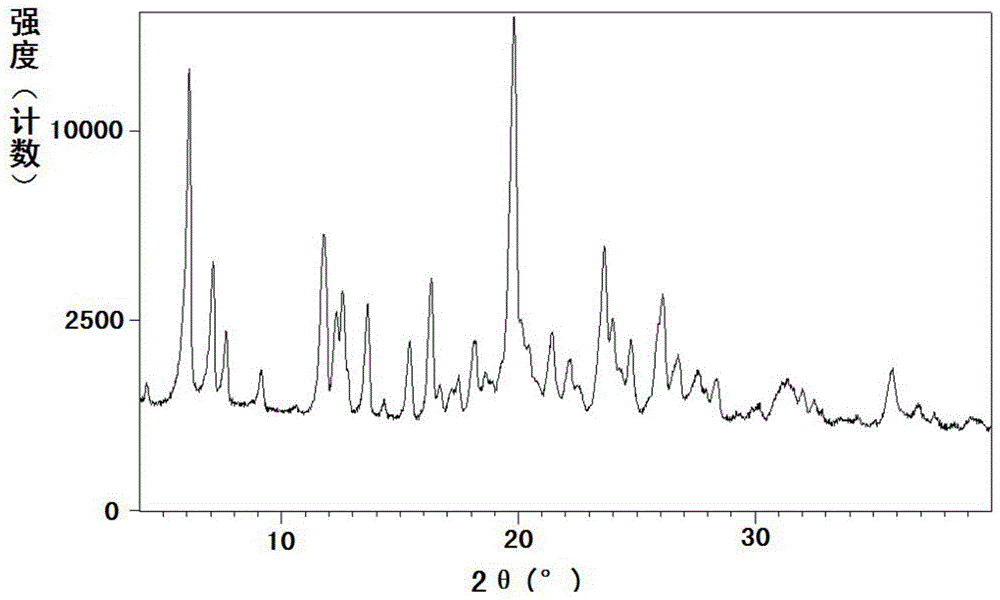

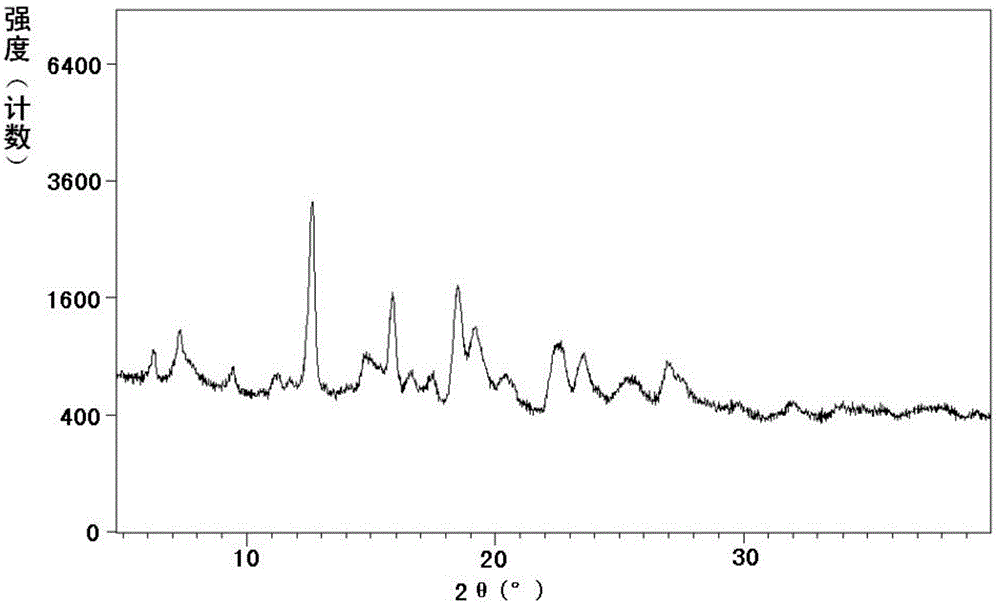

Sacubitril sodium crystal forms, preparation method and application thereof

InactiveCN105837464ALow hygroscopicityEasy to prepareOrganic active ingredientsOrganic compound preparationWater contentDrug

The invention relates to sacubitril sodium being lower than 15% in water content, and a crystal form A, a crystal form B, a crystal form C, a crystal form D and amorphous form [alpha] of the sacubitril sodium. These crystal forms are easy to prepare, have good stability and solubility and are suitable for various preparations. The invention also relates to a preparation of the sacubitril sodium crystal forms, a medicine composition comprising the same and a preparation method thereof, and applications of the sacubitril sodium crystal forms in preparation of medicines for preventing and / or treating cardiac failure and hypertension.

Owner:SICHUAN HAISCO PHARMA CO LTD

Processes for making novel inulin fractions

InactiveUS20020098272A1Improve propertiesImprove solubilitySugar food ingredientsSugar productsInulinWater soluble

The process for preparing the novel inulin products includes extracting inulin with water from subdivided plant materials, holding the inulin rich extraction water in a settling tank while maintaining the temperature from about 0° C. to 7° C. which causes higher molecular weight polysaccharides to separate from water soluble lower molecular weight polysaccharides, and separating the higher molecular weight inulin fructose fractions from the more water soluble lower molecular weight inulin fractions.

Owner:SILVER BARNARD STEWART

Propellant for fireworks and crackers

InactiveCN103396276AThe production process is simpleLow hygroscopicityInorganic oxygen-halogen salt explosive compositionsGunpowderSolvent

The invention relates to a propellant for fireworks and crackers. The propellant is prepared from the following four raw materials: potassium perchlorate, potassium hydrogen terephthalate, charcoal powder and an adhesive, wherein the adhesive is glutinous rice flour or phenolic resin. The propellant is prepared by the following steps: mixing: by mass percentage, the four raw materials are put into a gunpowder machine and are uniformly mixed to obtain mixed chemical powder; and prilling: the well mixed chemical powder is added into a solvent and is kneaded into powder balls, and the powder balls are made into small spherical particles by a sugarcoating machine or rubbed into small particles by a screen mesh, and then the propellant for the fireworks and crackers is obtained by drying in the sun. A finished product of the propellant for the fireworks and crackers is prepared from the four raw materials and by the two processes of mixing and prilling, the production technology is simple, ball milling, tabletting, crushing and other processes in which exploding is easy to occur can be omitted, and the safety performance of the propellant is greatly improved. The propellant has the advantages of low hygroscopicity, stable performance, long shelf life, small shot noises, high shot height, small lateral force, low production cost and less use amount, and has obvious price advantage.

Owner:LILING HENGDA FIREWORKS

Film-forming agent composition and starchiness vegetable adhesive containing the composition

InactiveCN101245157APromote digestion and absorptionReduce breakage rateMicroballoon preparationMicrocapsule preparationMicrobial pollutionAdhesive

The invention provides a film forming compound with modified starch as the main component, a film forming material containing the compound, and more particularly a hard-shell natural capsule made from the compound. The compound contains no or very little animal protein such as gelatin, etc. The compound can partially or completely replace the gelatin from animals for producing natural hard-shell capsules. The prepared natural capsule shell product has the advantages of excellent film forming property, high strength, good flexibility, high transparency, decomposability and microbial pollution resistance. The main component of the compound, modified starch, has stable quality and highly controllable performance.

Owner:长春大成特用玉米变性淀粉开发有限公司

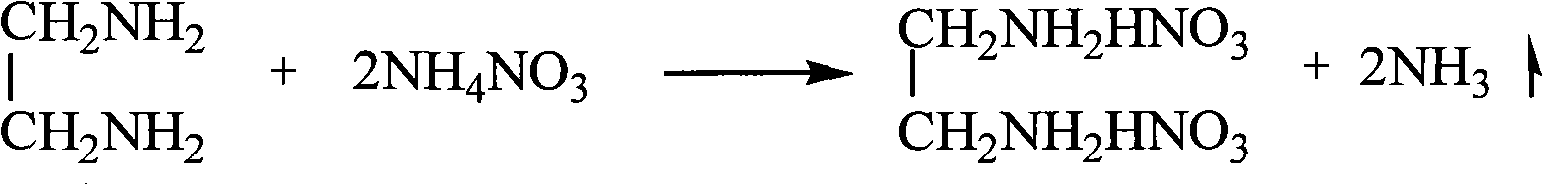

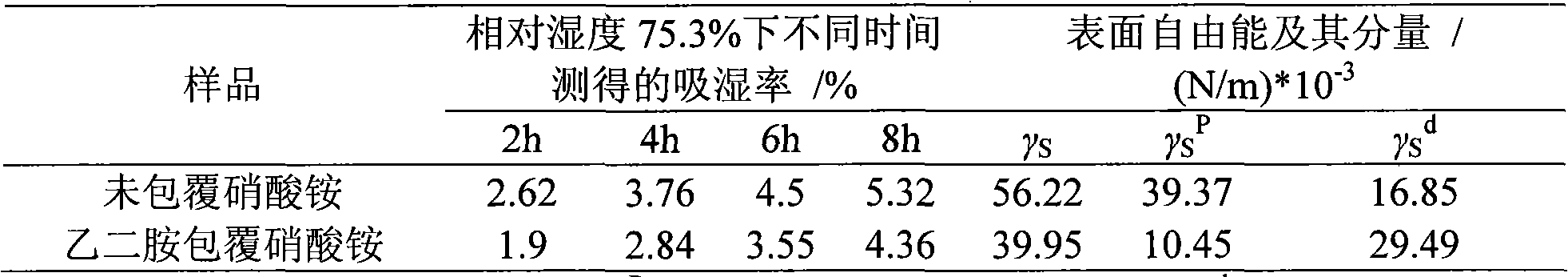

Ammonium nitrate cladding method

InactiveCN101774870ALow hygroscopicityReduce surface polarityExplosivesPressure gas generationChemical reactionOxidizing agent

The invention relates to an ammonium nitrate cladding method, which belongs to the technical field of ammonium nitrate surface modification and the technical field of propelling agents, in particular to a method for cladding ammonium nitrate through the chemical reaction with the surface of the ammonium nitrate and application effect of the clad ammonium nitrate to the propelling agents. The method comprises the following steps: dripping cladding agents dissolved in a polar solvent into a mixed system of ammonium nitrate particles and a non-polar solvent so that the cladding agents are attached to the surface of the ammonium nitrate and take the chemical reaction with the surface of the ammonium nitrate; then, removing the solvent and drying the materials to obtain the chemical reaction type clad ammonium nitrate; uniformly mixing the cladd ammonium nitrate and other ingredients of a propelling agent recipe in a container to obtain propelling agent medicine slurry; then, casting the propelling agent medicine slurry into a mold in vacuum; and heating and solidifying the propelling agent medicine slurry to obtain a composite propelling agent medicine block. The invention has the advantages that consumption of the cladding agents is little, the combining force with the surface of clad oxidizers is strong, the hydroscopic property of the clad ammonium nitrate is reduced, the surface polarity is reduced, and the mechanical property of the propelling agents is obviously improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Active packaging film for chilled meat and preparation method of the active packaging film

ActiveCN102604292AConsistent thicknessDelicate feelFlexible coversMeat/fish preservationChemistryPolylactic acid

The invention relates to an active packaging film for chilled meat and a preparation method of the active packaging film. The active packaging film employs polyvinyl acetate (PVA) and polylactic acid (PLA) as film-forming materials and sustained-release microcapsules as an active antimicrobial agent. The natural antimicrobial agent is slowly released from the microcapsules, migrates in the film and finally reaches the surface of the chilled meat to achieve antimicrobial and fresh-keeping effects. Meanwhile, as PVA has a good gas barrier property, good chilled meat packaging atmosphere conditions can be kept. PLA has a good water vapor barrier property, and can effectively reduce the moisture loss of the chilled meat during storage. The active packaging film for the chilled meat provided by the invention is a colorless transparent film with a smooth and uniform surface without visible air bubbles, and mechanical properties of the film can meet the mechanical requirements of chilled meat packaging.

Owner:HUNAN NEW WELLFUL CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com