Nickel-cobalt-manganese multi-doped lithium ion battery cathode material and preparation method thereof

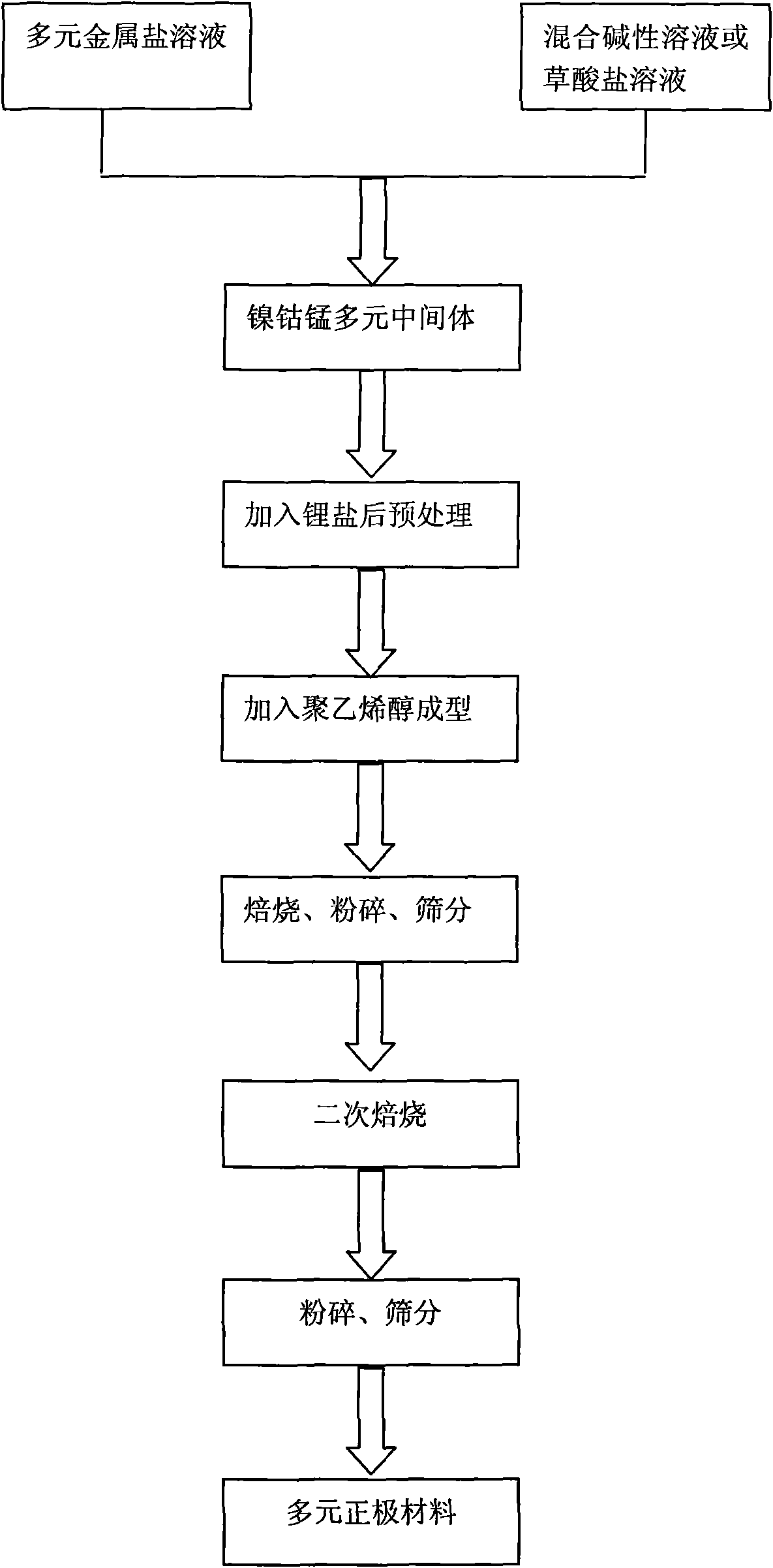

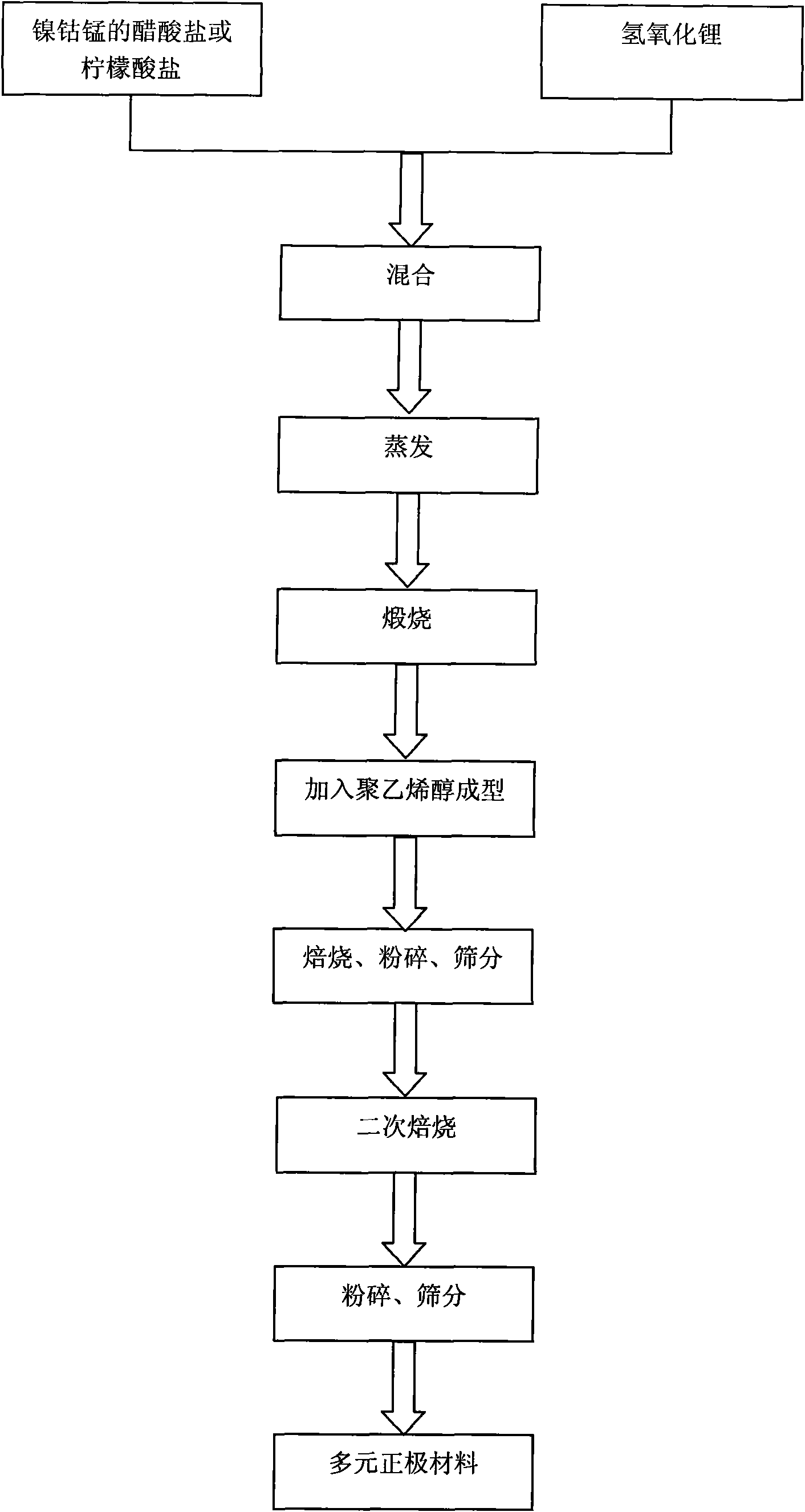

一种锂离子电池、正极材料的技术,应用在镍钴锰多元掺杂锂离子电池正极材料及其制备领域,能够解决影响产品使用性能、产品稳定性差、粒径难以均一等问题,达到挤压稳定性好、低吸湿性、操作控制容易的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033]311g of nickel sulfate (the weight percentage of the Ni element is 21.2%), 158g of cobalt sulfate (the weight percentage of the Co element is 20.56%), 62.7g of manganese sulfate (the weight percentage of the Mn element is 32.2%) In 2.2L of pure water, stir to dissolve, filter, and then add europium nitrate (containing 0.03g of Eu element), dysprosium nitrate (containing 0.07g of Dy element), potassium tantalate (containing 0.07g of Ta element), molybdenum nitrate to the above filtrate Ammonium acid (containing M 0 Element 0.05g), stirring and dissolving, being mixed with the multi-element metal salt solution (2.5L) that total metal molar concentration is 0.82mol / L, the mol ratio of nickel-cobalt-manganese in this solution is Ni: Co: Mn=3.06: 1.50: 1 The content of dysprosium, europium, tantalum and molybdenum is 0.185% of the total mass of nickel, cobalt and manganese elements.

[0034] Raise the temperature of the above multi-element metal salt solution to about 70°C, ...

Embodiment 2

[0039] Dissolve nickel nitrate containing 52.2g of Ni element, cobalt nitrate containing 42.9g of Co element, and manganese nitrate containing 25g of Mn element in 1.7L pure water to prepare a solution with a volume of 2.11 l, and then add 0.04 g of Lanthanum nitrate of lanthanum g, europium nitrate containing 0.06g europium, dysprosium nitrate containing 0.10g dysprosium, and potassium tantalate containing 0.08g tantalum were stirred and dissolved to prepare a multi-element metal salt solution with a total metal molar concentration of 0.99mol / L (2.1 liters), the mol ratio of nickel-cobalt-manganese in this solution is Ni:Co:Mn=1.95:1.59:1, and the content of lanthanum, dysprosium, tantalum, europium is 0.23% of nickel-cobalt-manganese element mass total amount.

[0040] The temperature of the above solution was raised to about 60°C, and 1 L of multi-metal salt solution was added to 1.64 liters of alkaline solution containing 1.1 g of polyethylene glycol 6000 at a rate of 7 to ...

Embodiment 3

[0044] Dissolve 219.3g of nickel sulfate (the weight percentage of Ni element is 21.2%), 250.6g of cobalt sulfate (the weight percentage of Co element is 20.56%), and 71.2g of manganese sulfate (the weight percentage of Mn element is 32.2%) In 1.3 liters of pure water, stir to dissolve, filter, and then add dysprosium nitrate (containing 0.1g of Dy element), neodymium nitrate (containing 0.11g of Nd element), sodium molybdate (containing 0.07g of Mo element), and tantalum nitrate to the above filtrate Potassium acid potassium (containing Ta element 0.07g), stirring and dissolving, is mixed with the multi-element metal salt solution 1.8L that total metal molar concentration is 1.16mol / L, the mol ratio of nickel-cobalt-manganese in this solution is Ni: Co: Mn=1.9: 2.1:1, the content of dysprosium, neodymium, molybdenum, and tantalum is 0.29% of the total mass of nickel, cobalt, and manganese elements.

[0045] Raise the temperature of the above solution to 45°C, and add it into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| actual density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| actual density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com