Patents

Literature

188 results about "Co element" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-voltage cathode material for lithium ion battery and preparation method thereof

ActiveCN104022280ADissolution controlIncrease working voltageCell electrodesSecondary cellsHigh energySodium-ion battery

The invention discloses a high-voltage cathode material for a lithium ion battery. The high-voltage cathode material is a clad material, the core material has the general formula of [LiaNibCocMdO2]; the shell material has the general formula of [LipNixCoyMnzO2]; the cathode material of the lithium ion secondary battery has the general formula of[LiaNibCocMdO2] [LipNixCoyMnzO2]; the content of the core material is 50-99.5wt%, the content of the shell material is 0.05-50wt%. The preparation method comprises the steps of preparing the core material; preparing the precursor [NixCoyMnz (OH)2] of the shell material; cladding; and carrying out sintering twice or many times. According to high-voltage cathode material disclosed by the invention, advantages of Ni and Co elements can be given a full play, the high-voltage cathode material has the advantages of high operation voltage and high energy density as well as excellent high-temperature cycle performance and the dissolution amount of Co can be controlled well.

Owner:NANTONG RESHINE NEW MATERIAL

Compound metal oxide and nitride catalyst for low-temperature selective catalytic reduction of ammonia

InactiveCN101549290AImprove oxidation activityHigh reactivityMolecular sieve catalystsDispersed particle separationMolecular sieveAlkaline earth metal

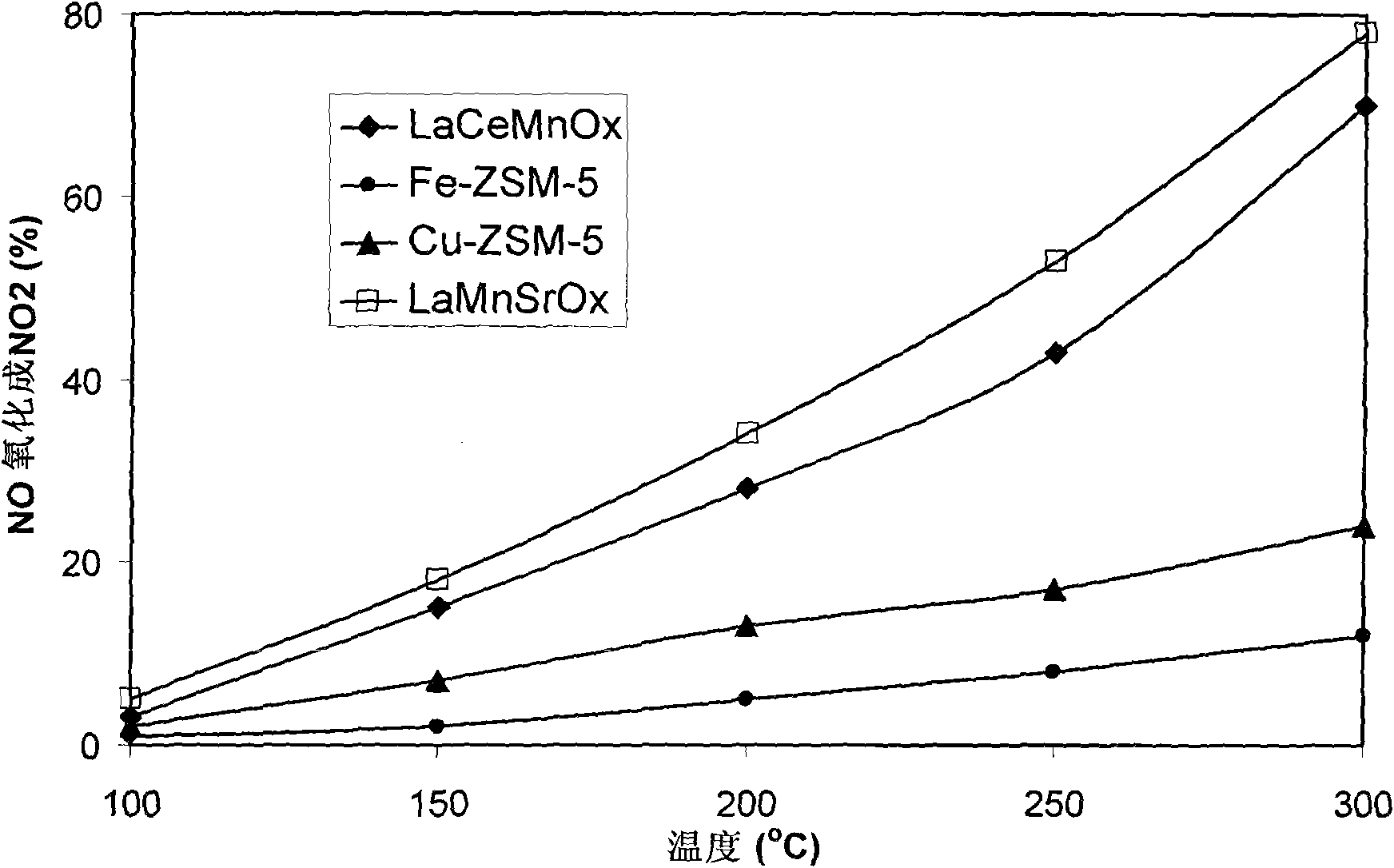

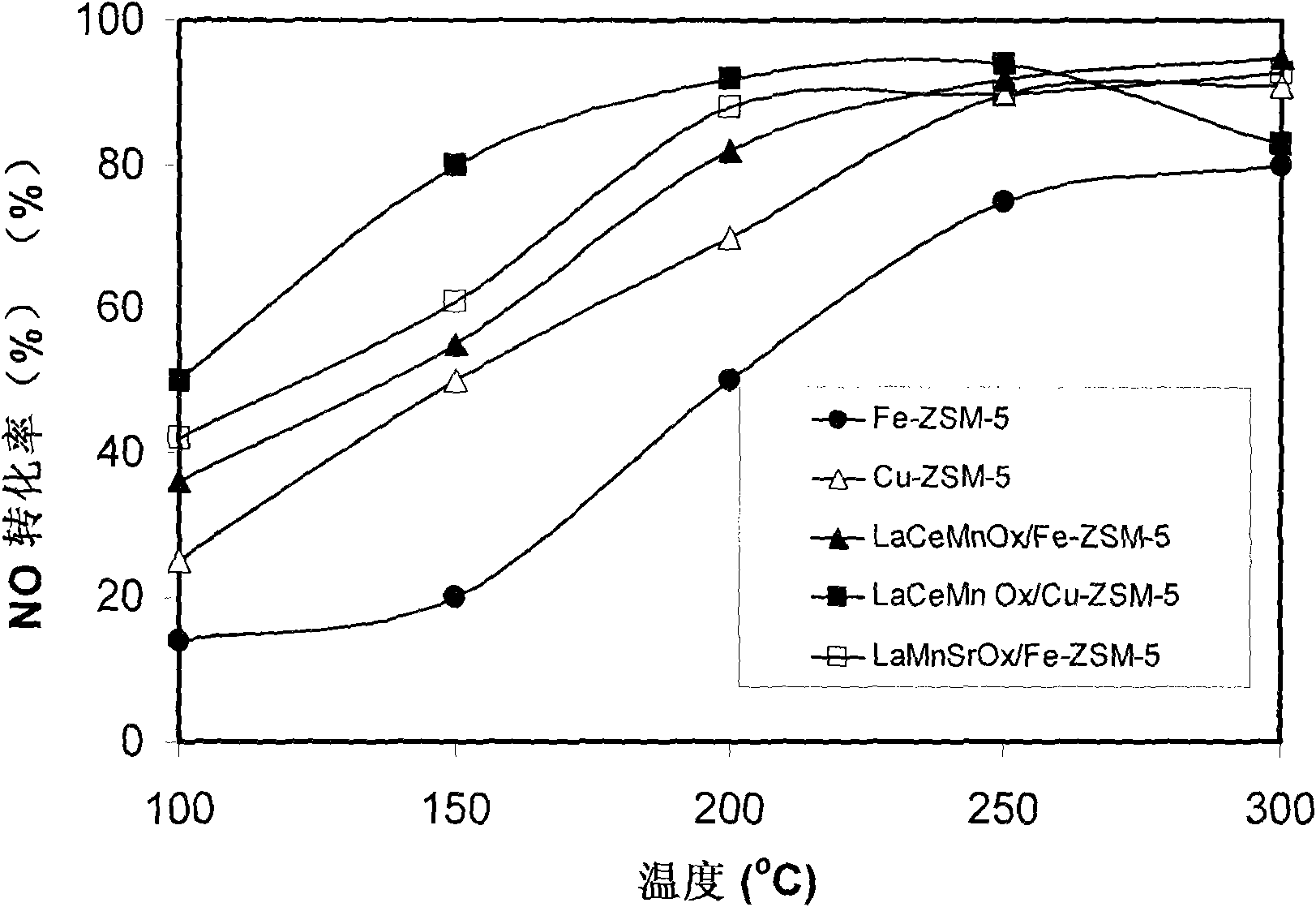

The present invention relates to 'compound metal oxide and nitride catalyst for low-temperature selective catalytic reduction of ammonia' and pertains to the field of catalysts. In A-B-C compound metal oxide, A is a or multiple kinds of lanthanide series metals, B is a or multiple kinds of transition metals, C is a or multiple kinds of alkaline or alkaline earth metals, A must contain La, and when C content is zero, B is not Co element alone. As proved by experiments, the compound metal oxide of the present invention can obviously raise the conversion rate from NO to NO2. When the oxide contains A, B and C elements, its activity will be higher than that only containing A and B elements. Meanwhile when this compound metal oxide of the present invention is used as a catalyst together with copper and iron molecular sieve, it may realize the function of low-temperature selective catalytic reduction of ammonia, particularly below 200 DEG C, it makes the industrialization of SCR technique simpler and more energy conserving.

Owner:无锡科立泰科技有限公司

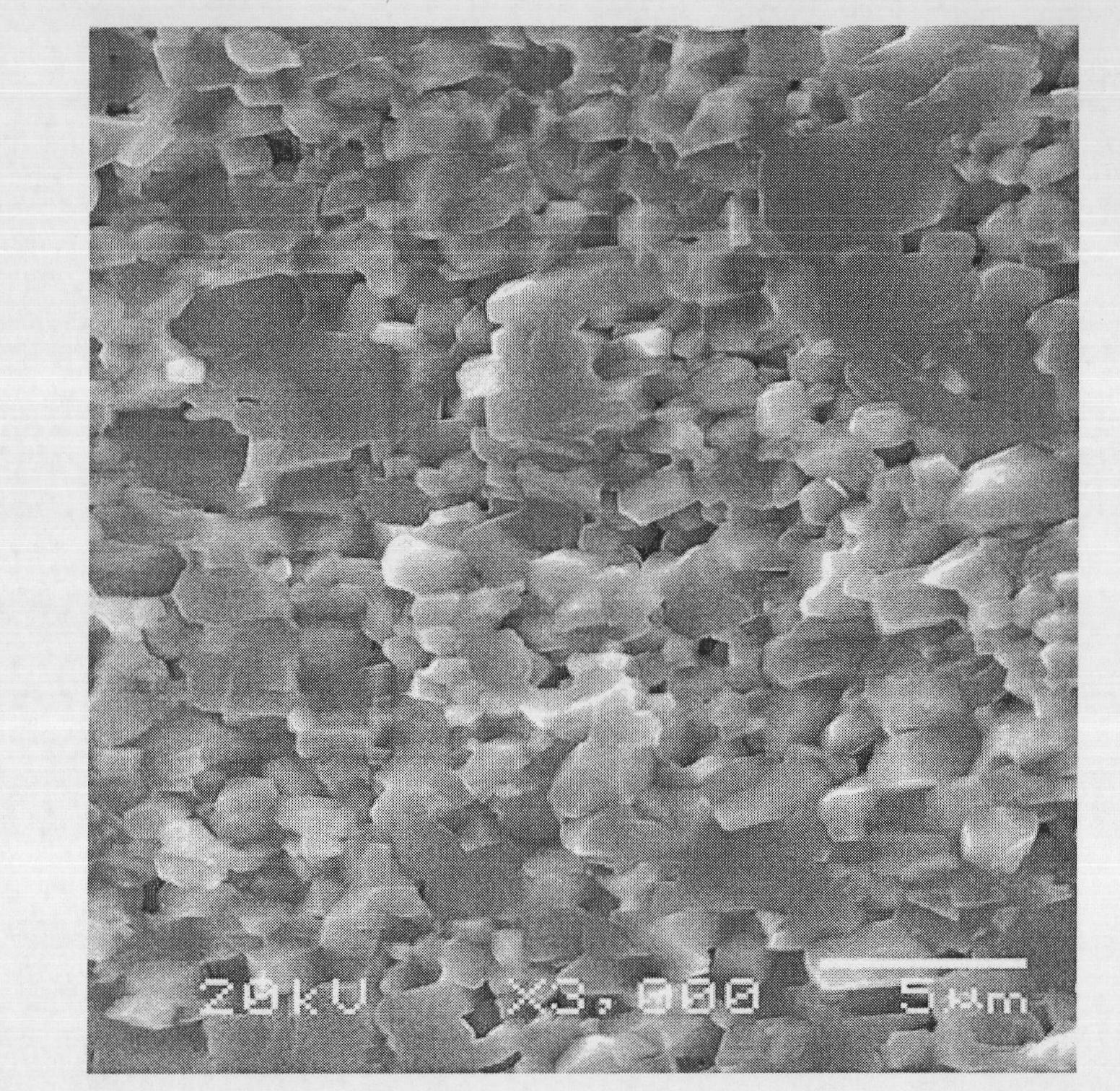

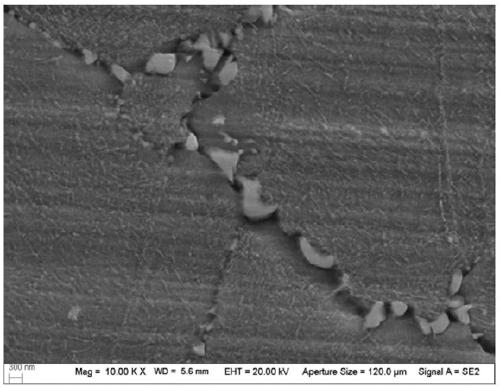

Method for improving bonding strength of hard alloy and diamond coating

ActiveCN104746030AAvoid the problem of interfacial stressHigh bonding strengthVacuum evaporation coatingSputtering coatingShielding gasGlow plasma

The invention relates to a method for improving the bonding strength of a hard alloy and a diamond coating. The method is realized by the technical scheme that by adopting a double glow plasma surface alloying technology, taking a metal carbide forming element material or a composite material of metal carbide forming elements as a target, inert gases as protecting gases, as well as carbon-containing gases as precursors, a diffusion barrier layer is prepared on the surface layer of the hard alloy, and then the diamond coating is deposited on the hard alloy surface on which the diffusion barrier layer is prepared by using a chemical vapor deposition method. By the use of the diffusion barrier layer prepared by the method disclosed by the invention, the diffusion of Co element to the surface layer of the hard alloy can be effectively stopped, the damage to a hard alloy matrix due to a surface Co removing treatment method is avoided, and the interface stress problem introduced by a transition layer applying method due to new interface addition can be avoided, so that the bonding strength between the diamond coating and the hard alloy matrix can be greatly improved.

Owner:TAIYUAN UNIV OF TECH

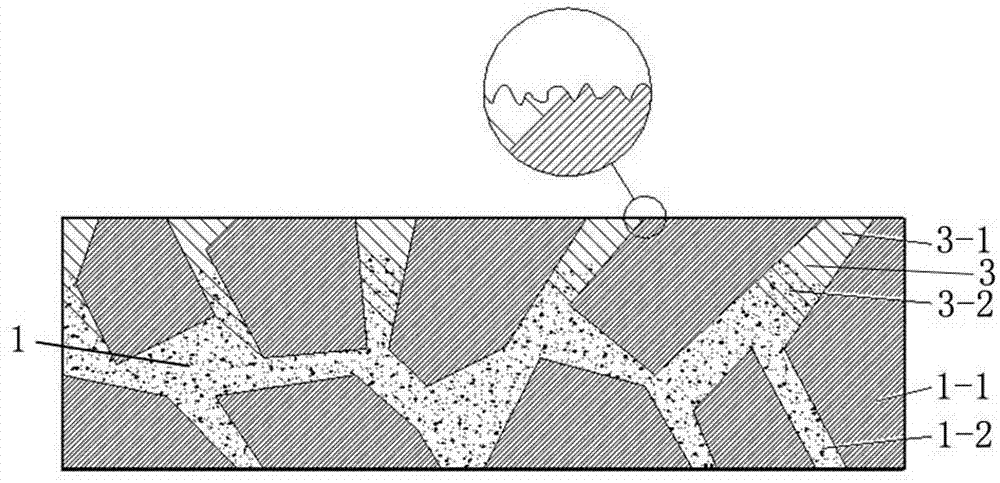

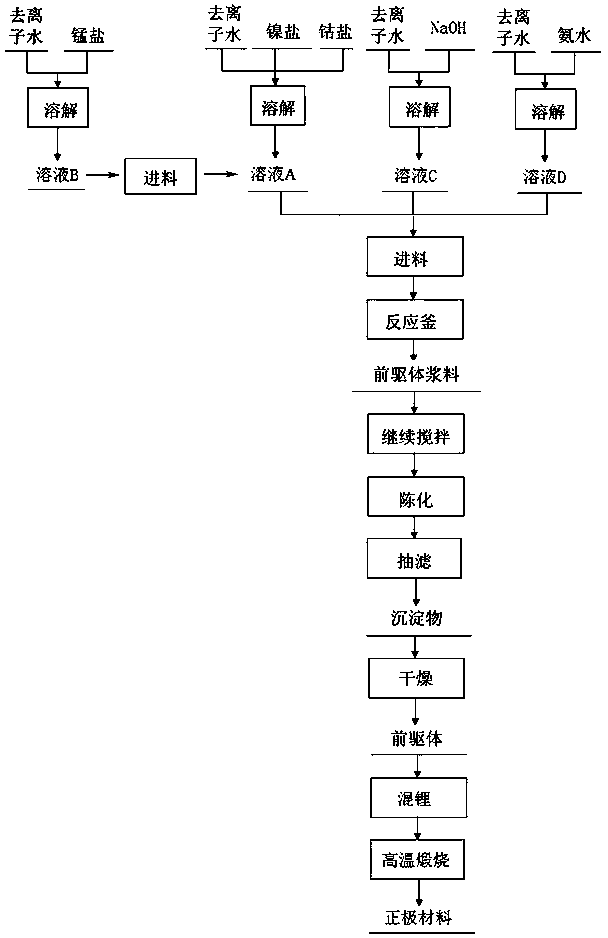

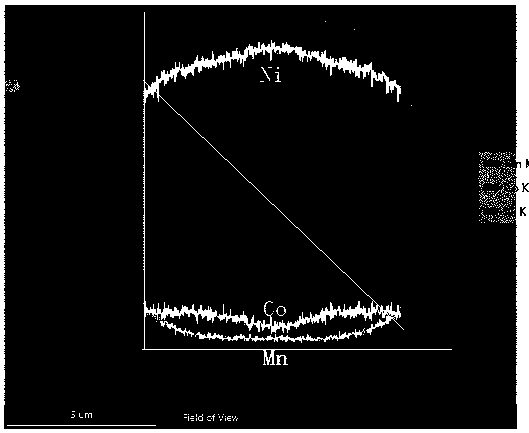

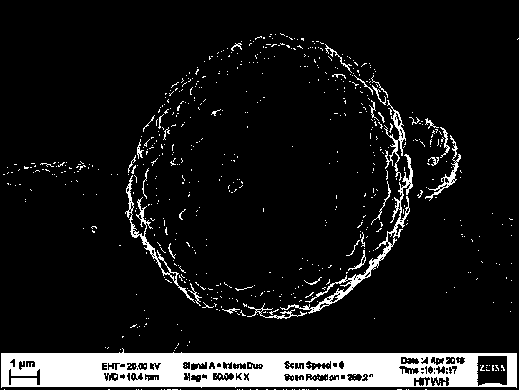

Preparation method of nickel-cobalt-manganese ternary material enabling element content in gradient distribution

InactiveCN108598466AImprove co-precipitation synthesis processImprove stabilitySecondary cellsPositive electrodesManganeseLithium-ion battery

The invention belongs to the technical field of the lithium ion battery material preparation, and specifically relates to a preparation method of a nickel-cobalt-manganese ternary material enabling element content in gradient distribution. The chemical formula of the positive material is LiNixCoyMnzO2, x is not less than 0.5 and not more than 0.9, and the sum of x, y and z is equal to 1. The preparation process disclosed by the invention is based on co-precipitation method principle, the concentration of the metal ion entering the reaction kettle is continuously changed by changing the feedingway, the Mn element concentration is gradually increased, the concentration of each of the Ni element and the Co element is gradually reduced, thereby synthesizing the nickel-enriched positive material precursor particle with gradiently increased Mn element content and gradiently reduced Ni element content from center to the surface, and finally the nickel-enriched positive material with elementsin gradient distribution is formed by calcining the nickel-enriched positive material precursor particle with the lithium source in a mixed way. The full-gradient material is obviously different fromthe material with uniformly distributed elements from inside to outside and synthesized through the common co-precipitation method, and the higher specific capacity and good circulating performance and heat stability are provided.

Owner:HARBIN INST OF TECH AT WEIHAI

Cobaltiferous aluminum alloy material and preparation thereof

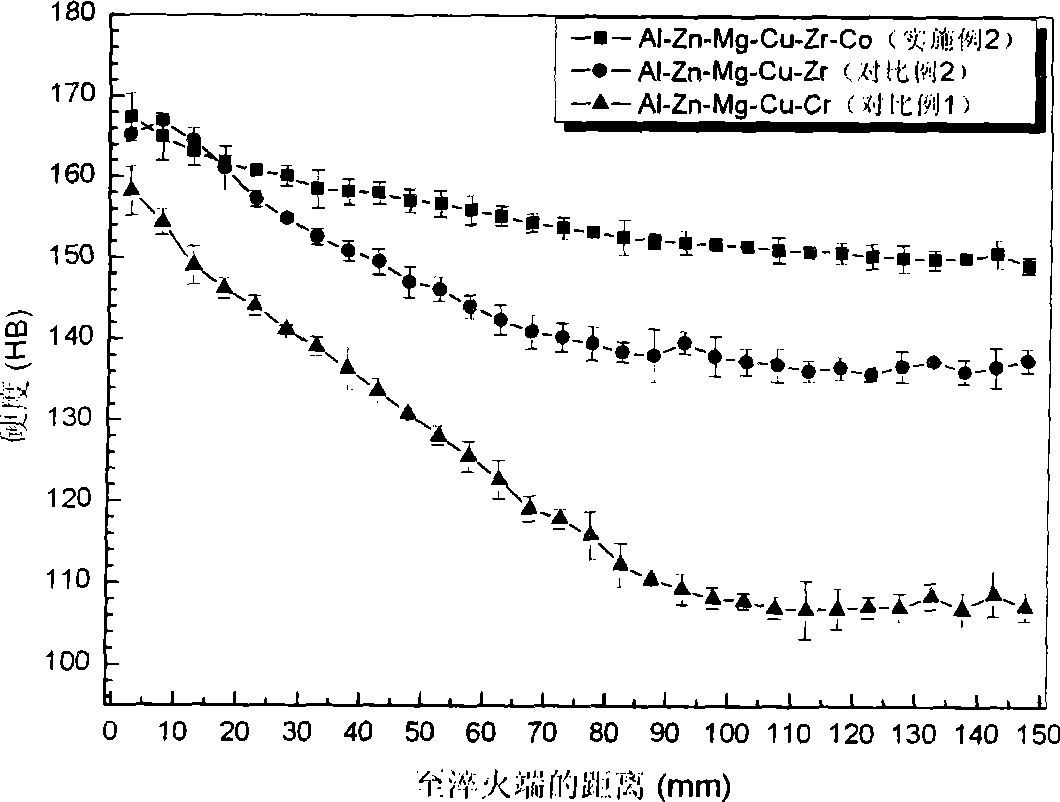

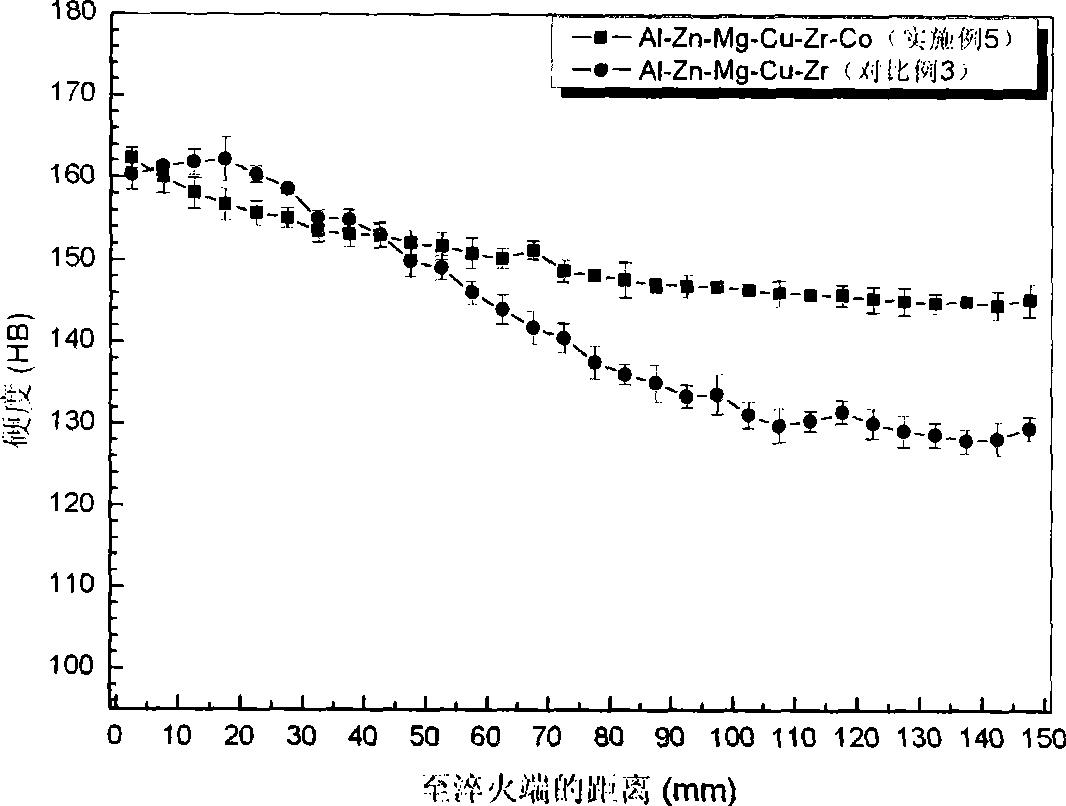

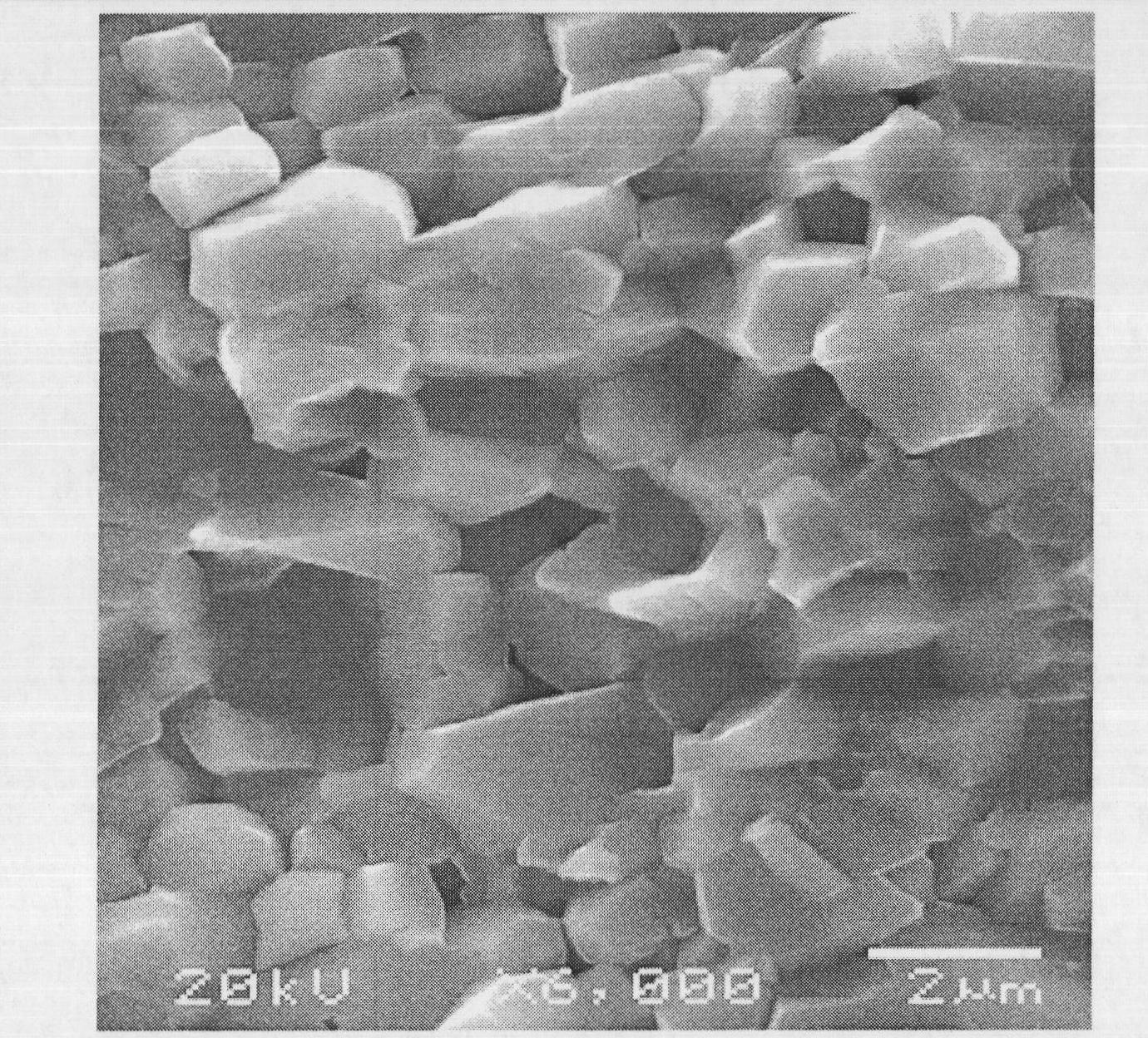

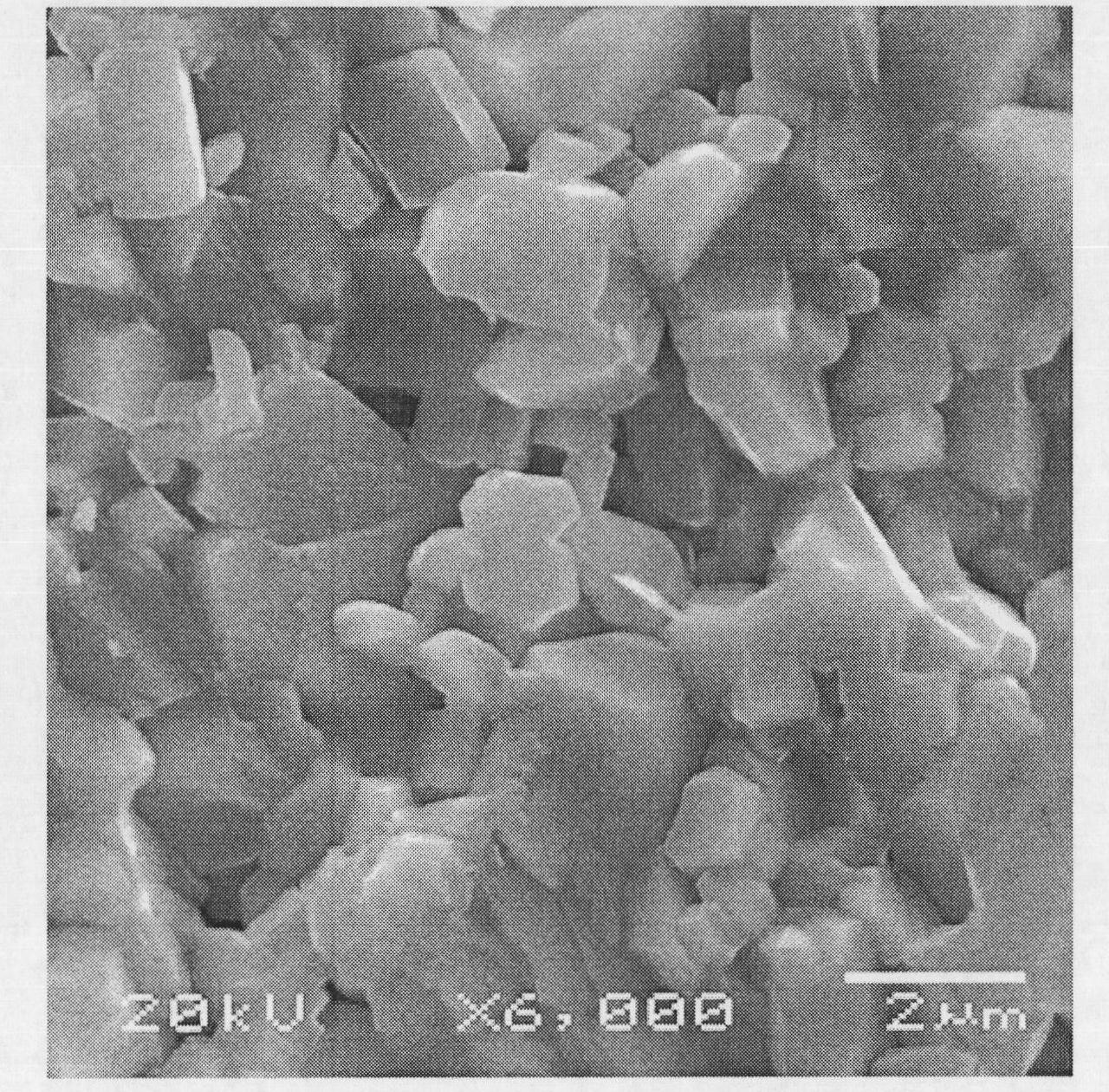

ActiveCN101413079AImprove heat treatment hardenabilityImprovement of hardenability by heat treatmentChemical compositionMetal alloy

The invention provides a Al-Zn-Mg-Cu-Zr-Co aluminum alloy, which relates to the technical field of metal alloy. The alloy is characterized by comprising the following chemical compositions in weight percentage: 6 to 8 weight percent of Zn, 1 to 3 weight percent of Mg, 1.0 to 2.6 weight percent of Cu, 0.1 to 0.25 weight percent of Zr, 0.07 to 0.5 weight percent of Co, and the balance being Al. The key point of the alloy is to add Co element with certain amount in the prior 7xxx series aluminum alloy; the method for preparing the novel aluminum alloy is to add a Al-Co intermediate alloy which is subject to vacuum melting in the Al-Zn-Mg-Cu-Zr alloy. The alloy has high strength, toughness and corrosion resistance, simultaneously has excellent thermal treatment hardenability, and can be applied to production of semi-finished products with large dimension. The material can be used in key large main load-carrying structural members in aero-space, transportation, war industry and other fields.

Owner:GRIMAT ENG INST CO LTD

Preparing method of PCD cutter long in service life

The invention discloses a preparing method of a PCD cutter long in service life. The preparing method comprises the first step of line cutting of a PCD blade, the second step of vacuum welding of the PCD blade, the third step of precise laser machining of the PCD cutter, and the fourth step of the cobalt removing treatment measure of a PCD layer. By means of the manner, the oxidation effect of a front cutter face of the PCD cutter is weakened, meanwhile, the size of a broken blade of a cutting edge is controlled within 2 microns, and distribution of the Co element and the W element at the cutting edge is even. The distribution of the Co element and the W element on a rear cutter face is even along with the increasing of the layer thickness. The welding temperature is reduced through low-temperature welding flux, the tendency of graphitization of the PCD cutter is reduced, and the service life of the cutter is prolonged.

Owner:WUXI GUOHONG MEASURING & CUTTING TOOLS

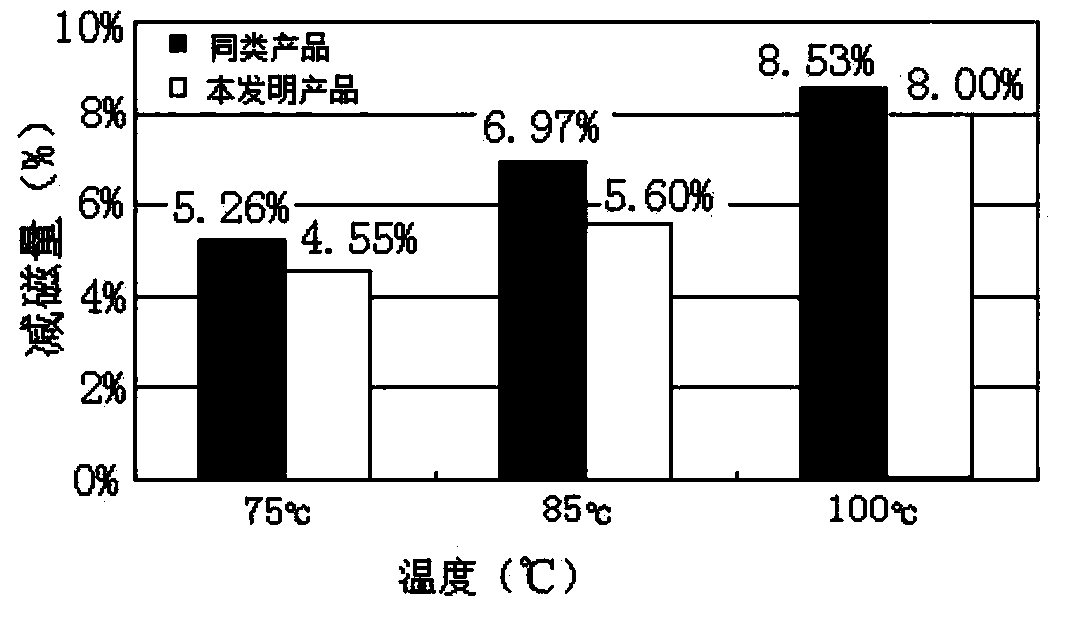

Magnetoplumbate-type permanent magnetic ferrite and manufacturing method thereof

InactiveCN101844914AImprove powder propertiesUniform powder propertiesCrystal structureProcess design

The invention relates to a magnetoplumbate-type permanent magnetic ferrite and a manufacturing method thereof, which relate to the field of the permanent magnet. Main component of the magnetoplumbate-type permanent magnetic ferrite is expressed by the following formula: (1-x-y)Ca0.xSrO.(y / 2)R2O3.(n-z / 2-m / 2)Fe2O3.zMO.MzrO2, wherein R is of at least one element of La, Nd and Pr and contains La, M is selected from at least one element of Co, Zn, Ni, Mn and Cu and contains Co, and x, y, z, m and n respectively indicating the addition ratio of each main metal element calculated at mol. By adopting optimized formula and process design and adding less Zr element, the Zr element is introduced into ferrite lattice during the pre-burning process so as to inhibit the growth of abnormal crystal particle and to reduce the pores; moreover, N(CH2CH2OH)3 dispersing agent is particularly added, the appearance of the powder particles is effectively controlled, so the obtained crystal particles are moreuniform, the arrangement of the crystal structure is more compact, and the permanent magnetic ferrite material is obtained under the condition that substitute of the Co element is not high.

Owner:杨宗维

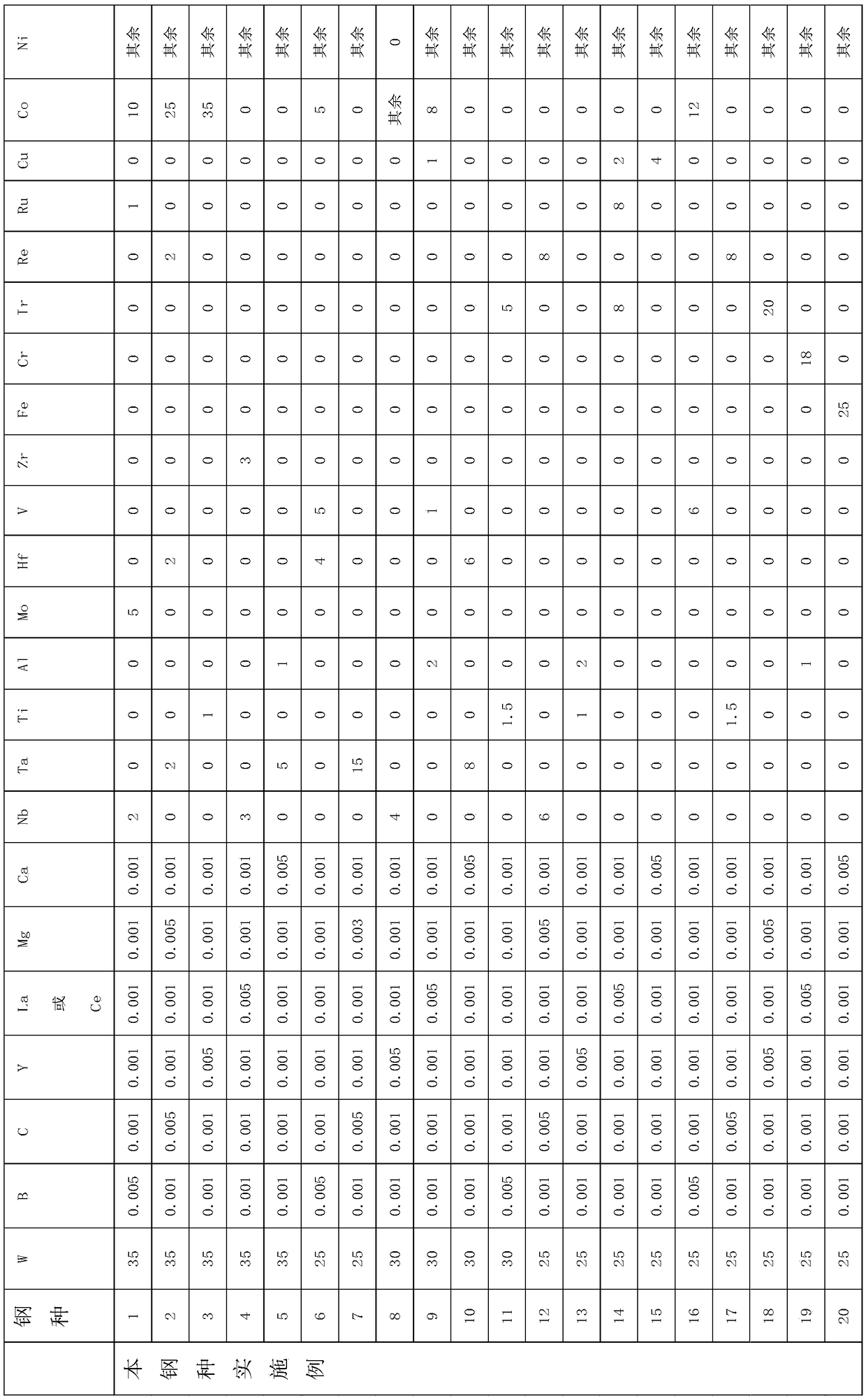

Castable and forgeable solid solution tungsten alloy and preparation method

The invention discloses castable and forgeable solid solution tungsten alloy and a preparation method, and belongs to the technical field of refractory alloy. According to the chemical components, thecastable and forgeable solid solution tungsten alloy comprises, by weight percentage, 20%-75% of W, 0%-20% of Mo, 0%-20% of Nb, 0%-20% of Ta, 0%-10% of Hf, 0%-10% of V, 0%-10% of Zr, 0%-10% of Ti, 0%-10% of Al, 0%-5% of Cu and the balance Ni or Co and inevitable impurity elements and microelements, specifically, the Ni element and the Co element can be partially replaced by one or two or more elements of 0%-50% of Ir, 0%-30% of Fe, 0%-20% of Cr, 0%-20% of Re and 0%-20% of Ru. The castable and forgeable solid solution tungsten alloy further comprises the following one or two or more grain boundary strengthening elements of 0.001%-1.0% of C, 0.001%-1.0% of B, 0.001%-1.0% of Y, 0.001%-1.0% of La or Ce or the rare earth element, 0.001%-1.0% of Mg and 0.001%-1.0% of Ca. The castable and forgeable solid solution tungsten alloy has the advantages of being high in density, ultrahigh in strength, high in toughness and high in hot-working performance. The alloy is castable and forgeable and canbe formed through 3D printing, the density ranges from 11.0g / cm<3> to 15.0g / cm<3>, the impact toughness is 80J / cm<2> or above, and the tensile strength is 1700MPa or above.

Owner:CENT IRON & STEEL RES INST

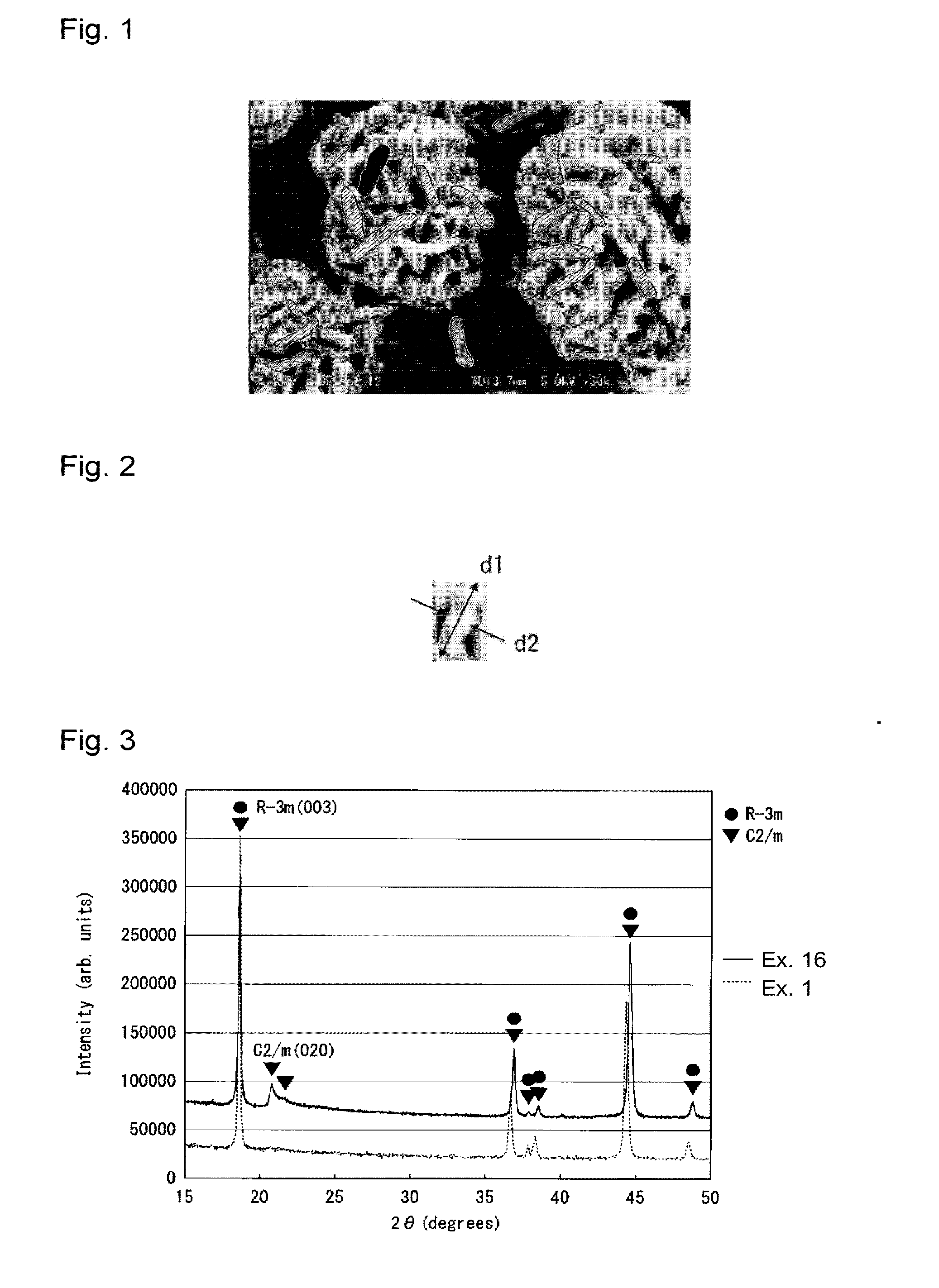

Cathode active material

InactiveUS20160056462A1Improve discharge performanceHigh cycle durabilityPositive electrodesNon-aqueous electrolyte accumulator electrodesSpace groupX-ray

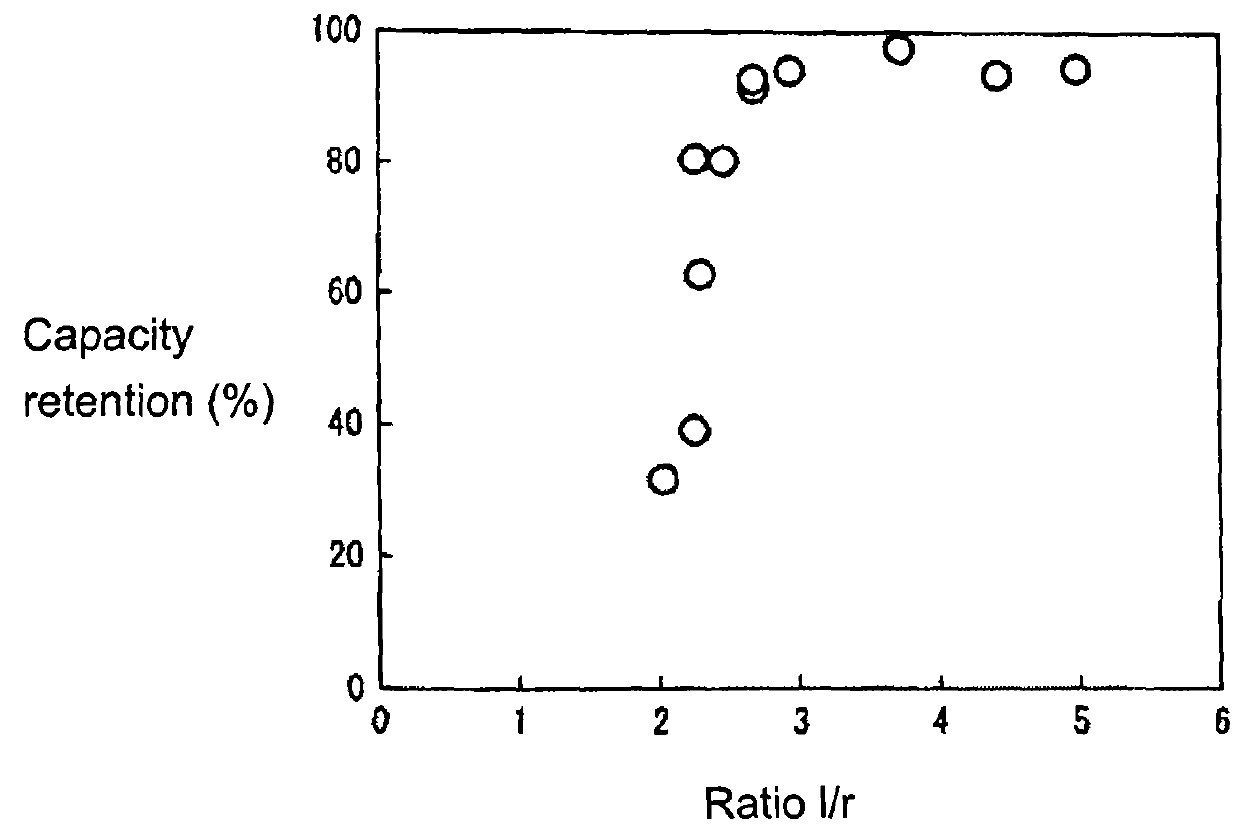

To provide a cathode active material which achieves a high discharge capacity and excellent cycle durability.A cathode active material represented by LiaMOx (wherein M is an element including at least one member selected from Ni element, Co element and Mn element (other than Li element and O element), “a” is from 1.1 to 1.7, and x is the number of moles of O element required to satisfy the valences of Li element and M),wherein in an X-ray diffraction pattern, the ratio (I / r) of the crystallite size (I) of (003) plane to the crystallite size (r) of (110) plane assigned to a crystal structure with space group R-3m is at least 2.6.

Owner:SUMITOMO CHEM CO LTD

FeSiBAlNiCo block high-entropy alloy and preparation method thereof

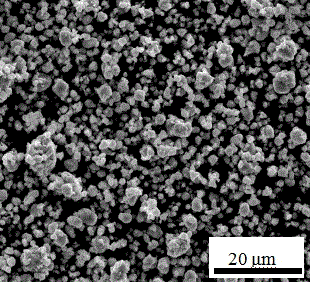

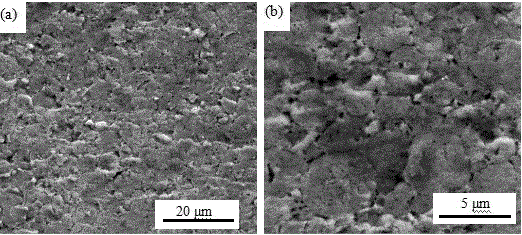

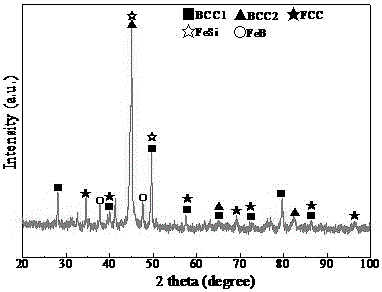

ActiveCN105861909AImprove corrosion resistanceMeet the special requirements of harsh environmentsHigh entropy alloysCrystal structure

The invention relates to FeSiBAlNiCo block high-entropy alloy and a preparation method thereof and belongs to the technical field of powder metallurgy. According to the FeSiBAlNiCo block high-entropy alloy, the molar ratio of Fe to Si to B to Al to Ni to Co is 1: 1: 1: 1: 1: (0-1); the crystal structure comprises a face-centered cubic (FCC), a body-centered cubic (BCC) and two-phase intermetallic compounds, namely FeSi and FeB. According to the FeSiBAlNiCo block high-entropy alloy and the preparation method thereof, the Co element of a medium size is added to the Fe-Si-B-Al-Ni quinary alloy, a spark plasma sintering technology is utilized, and the block high-entropy alloy with the diameter being 15 mm is prepared. The density of the high-entropy alloy reaches 96.5% or above, the hardness value reaches 1100 HV or above, prominent NaCl solution corrosion resistance is achieved, and special requirements of certain adverse environments can be met. The block high-entropy alloy is prepared through a powder metallurgic method, and the process is relatively simple; a prepared product has the advantages that few defects exist, and performance is excellent.

Owner:UNIV OF JINAN

Glass Paste, Method for Producing Display by Using Same, and Display

InactiveUS20080268382A1Increase display contrastPrevent discolorationMaterial nanotechnologyPigmenting treatmentDisplay deviceCo element

Disclosed is a glass paste containing a glass powder and an organic component, wherein a black pigment is composed of a complex oxide having a spinel structure and containing Co element and one or more metal elements other than Co element. Consequently, the glass paste is suppressed in color degradation at high temperatures, and thus enables to form a pattern having excellent color and degree of blackness after sintering.

Owner:PANASONIC CORP

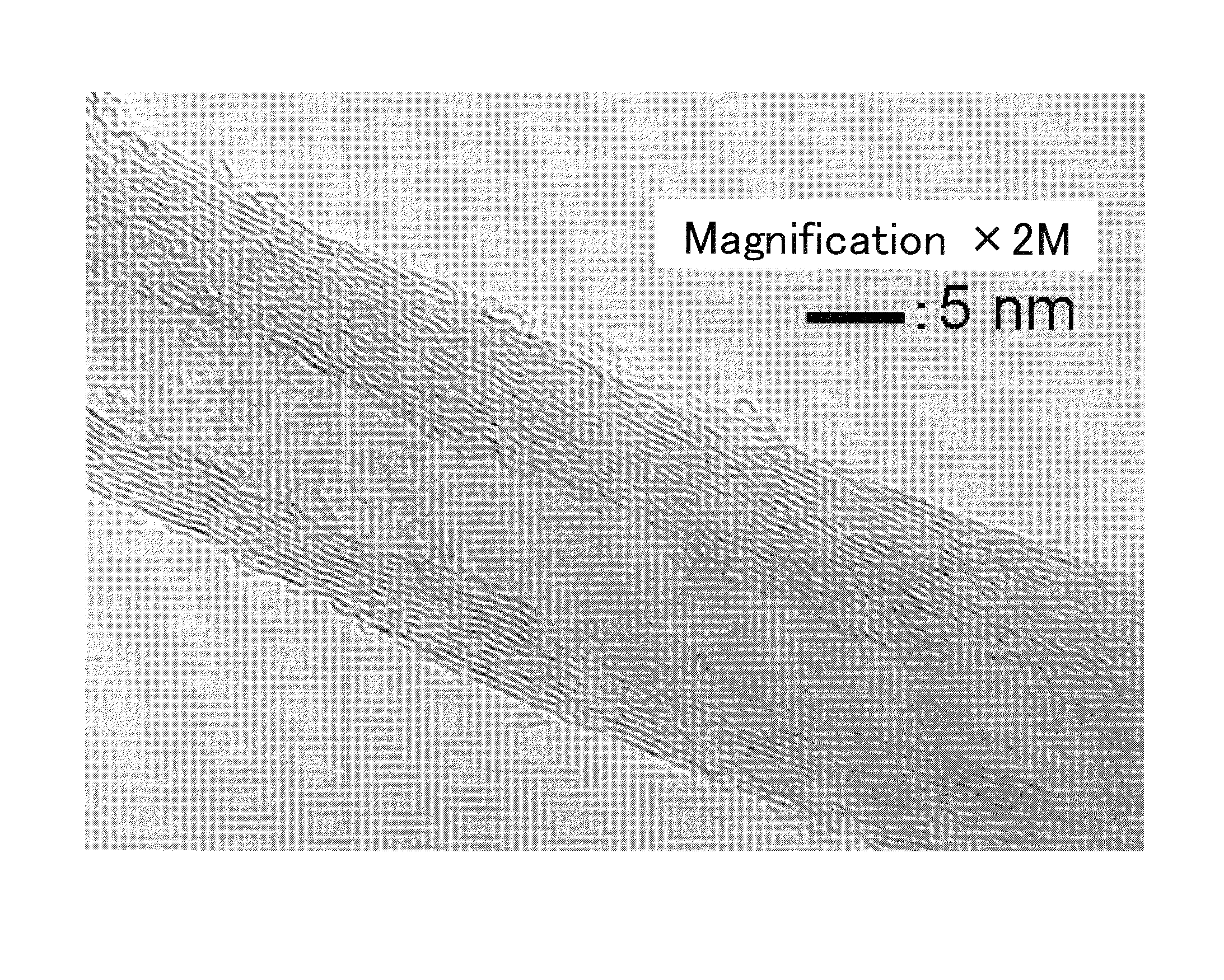

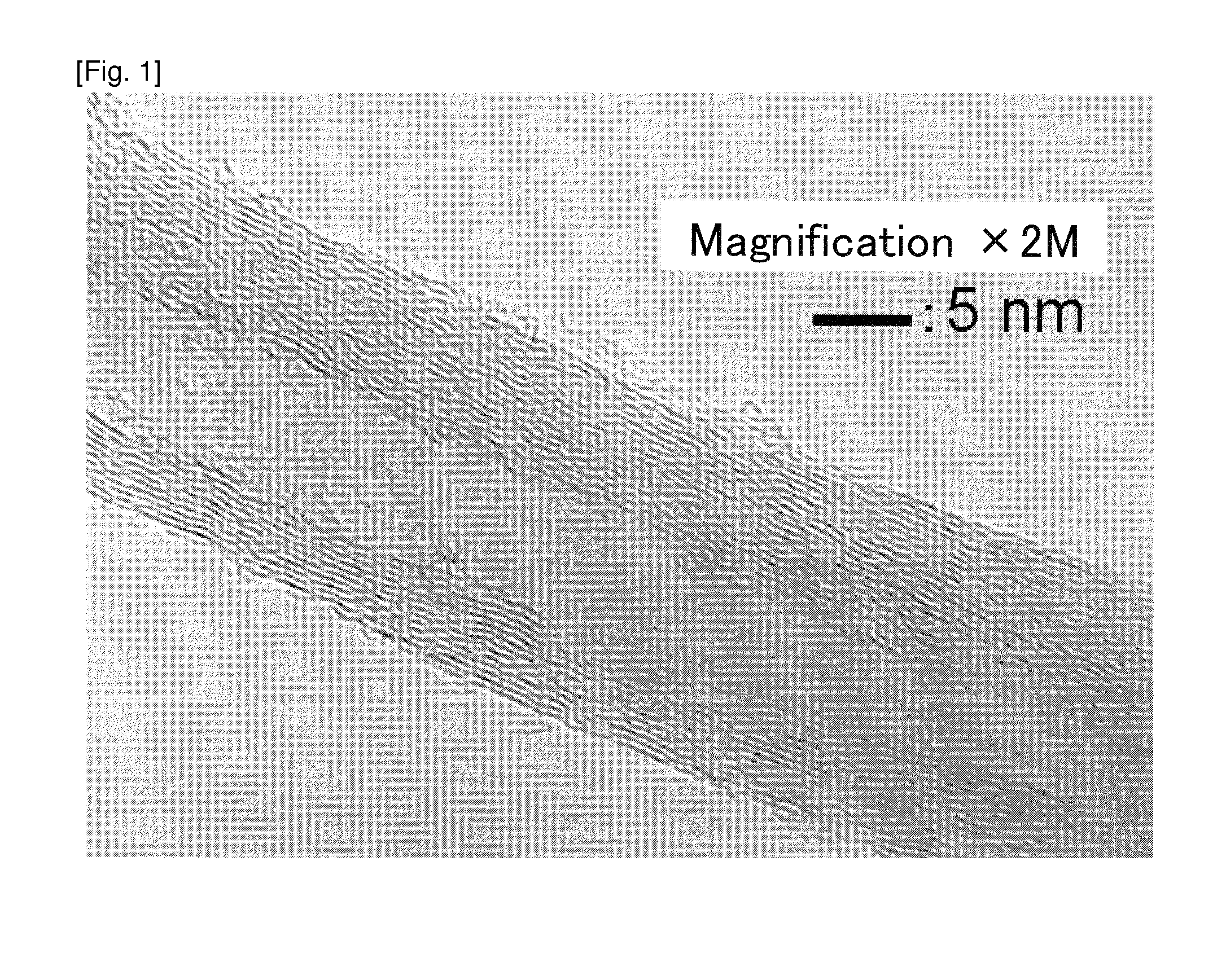

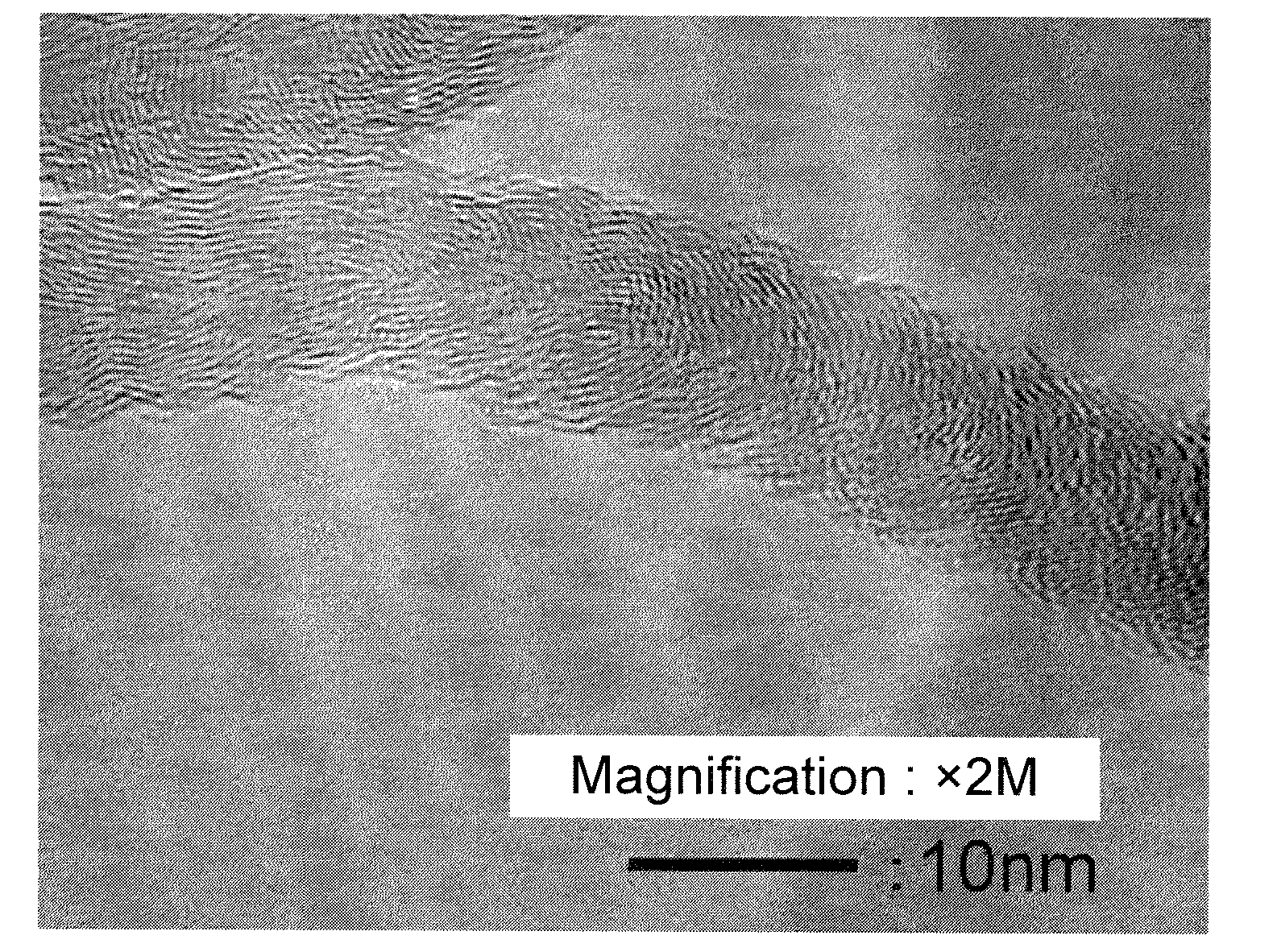

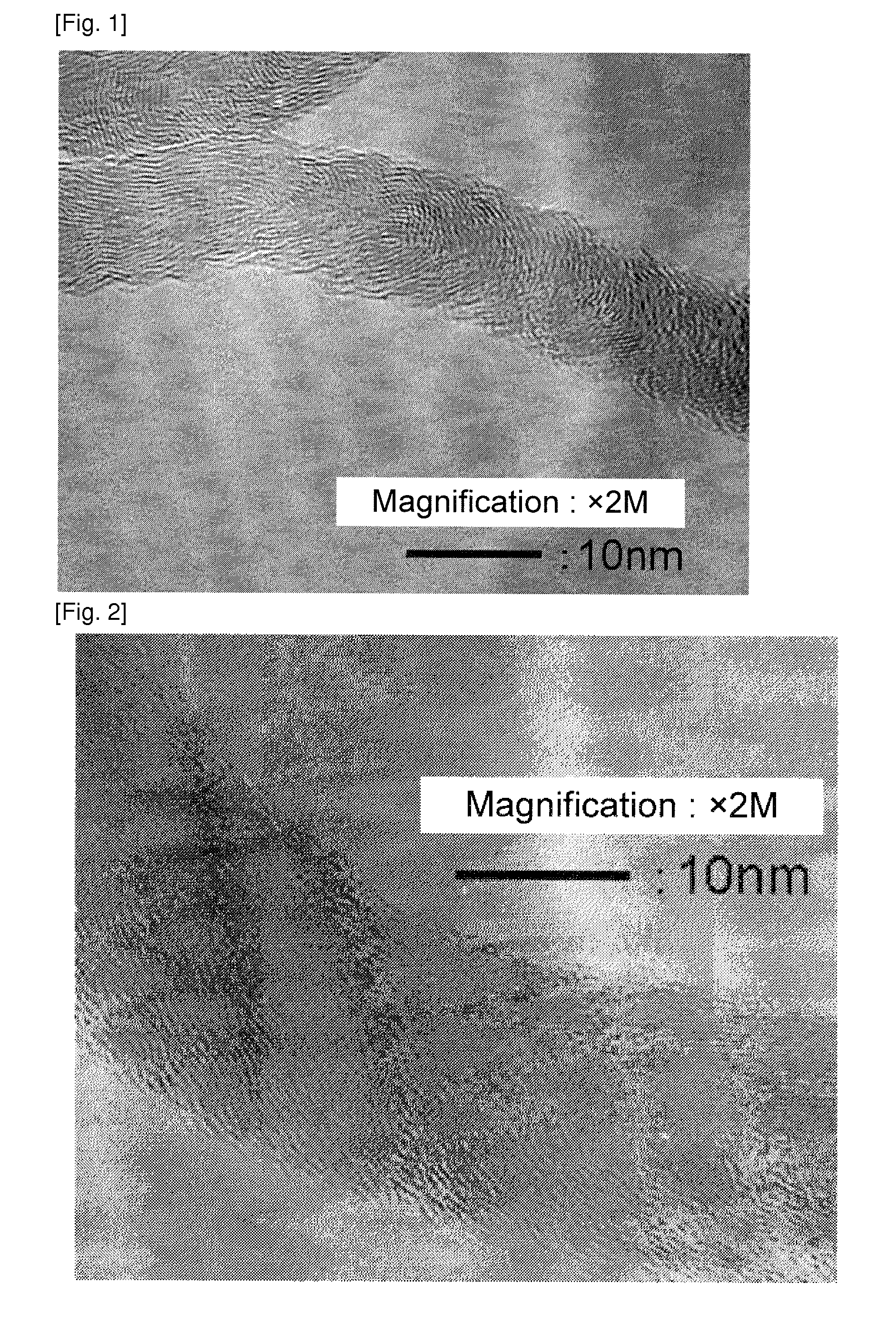

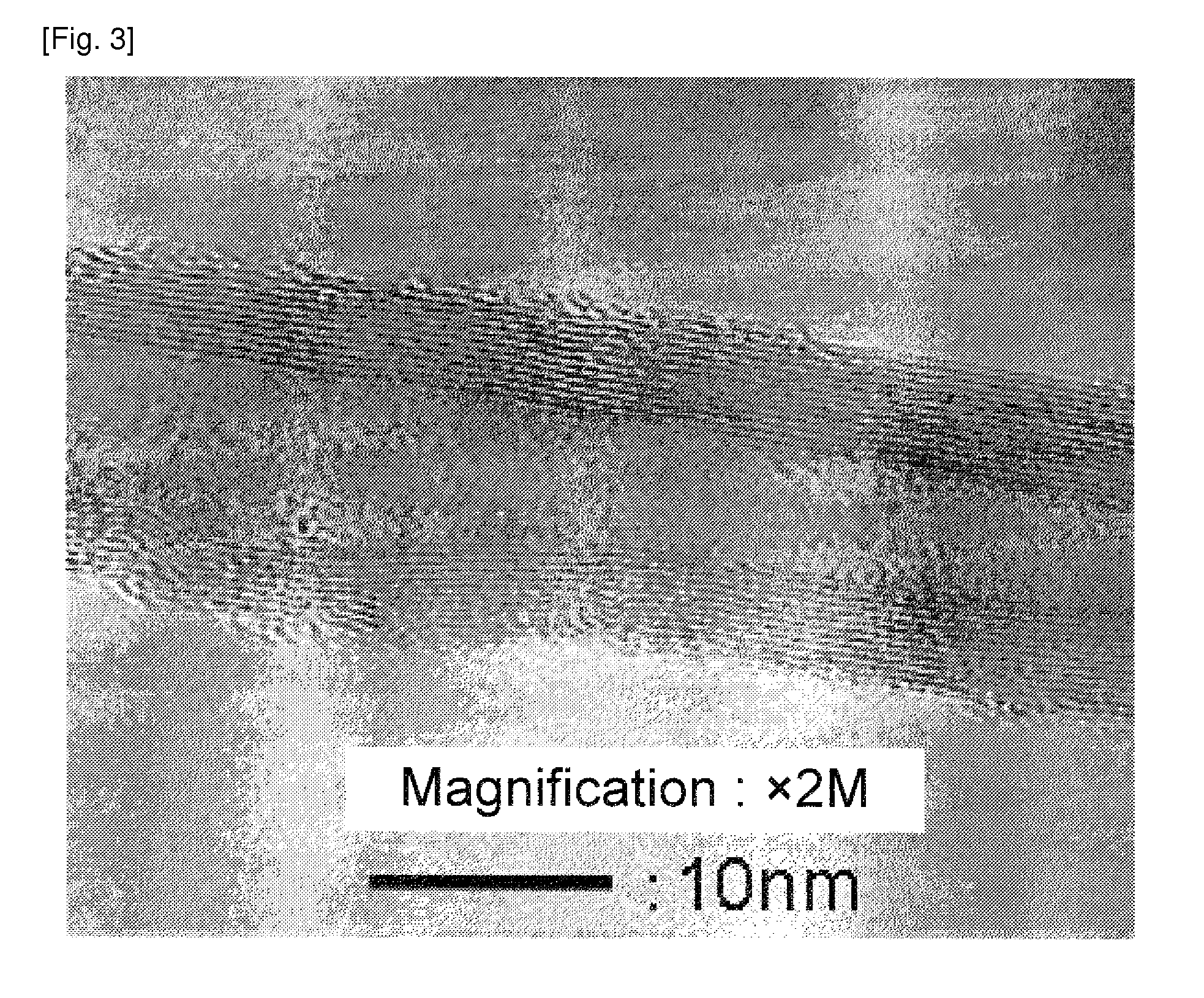

Carbon fiber and catalyst for production of carbon fiber

InactiveUS20110104490A1Simple processEffective massMaterial nanotechnologyCell electrodesFiberParticulates

A catalyst for production of a carbon fiber is obtained by dissolving or dispersing [I] a compound containing Fe element; [II] a compound containing Co element; [III] a compound containing at least one element selected from the group consisting of Ti, V, Cr, and Mn; and [IV] a compound containing at least one element selected from the group consisting of W and Mo in a solvent to obtain a solution or a fluid dispersion, and then by impregnating a particulate carrier with the solution or the fluid dispersion. By means of a step of bringing a carbon source into contact with the catalyst in a vapor phase, the carbon fiber is obtained which is tubular and in which a graphite layer is approximately parallel with the carbon fiber axis, and a shell is in a multi-walled structure.

Owner:SHOWA DENKO KK

AlCoCrFeMn high-entropy alloy with non-equal atomic ratio and preparation method of AlCoCrFeMn high-entropy alloy

ActiveCN111235454AHigh strengthGood thermal stability at high temperatureHigh entropy alloysAl element

The invention discloses an AlCoCrFeMn high-entropy alloy with a non-equal atomic ratio and a preparation method of the AlCoCrFeMn high-entropy alloy. The atomic ratio of all elements of Al to Co to Crto Fe to Mn in the high-entropy alloy is equal to (0.3-0.7): to 2 to 1 to 1 to 1. The preparation method comprises the following steps that (1) a raw material is taken in proportion, and cleaning anddrying are conducted; (2) the raw material is put into a non-consumable arc melting furnace, vacuumizing is conducted and protective gas is added; (3) Ti which is arranged in the furnace in advance is firstly smelted, then the raw material is smelted, and suction casting is conducted by using a copper mold to form an alloy ingot; (4) the alloy ingot is subjected to solid solution, water quenchingand rolling deformation; and (5) the deformed alloy ingot is annealed to obtain the AlCoCrFeMn high-entropy alloy with the unequal atomic ratio. According to the AlCoCrFeMn high-entropy alloy with the non-equal atomic ratio and the preparation method of the AlCoCrFeMn high-entropy alloy, by adding a certain amount of Co element, the strength of the high-entropy alloy is improved, the content of the Co element is increased, and the alloy has good thermal stability; and the plasticity of the high-entropy alloy is adjusted by adding a certain amount of Al element, and the prepared high-entropy alloy has good strength and plasticity.

Owner:JIANGSU UNIV OF TECH

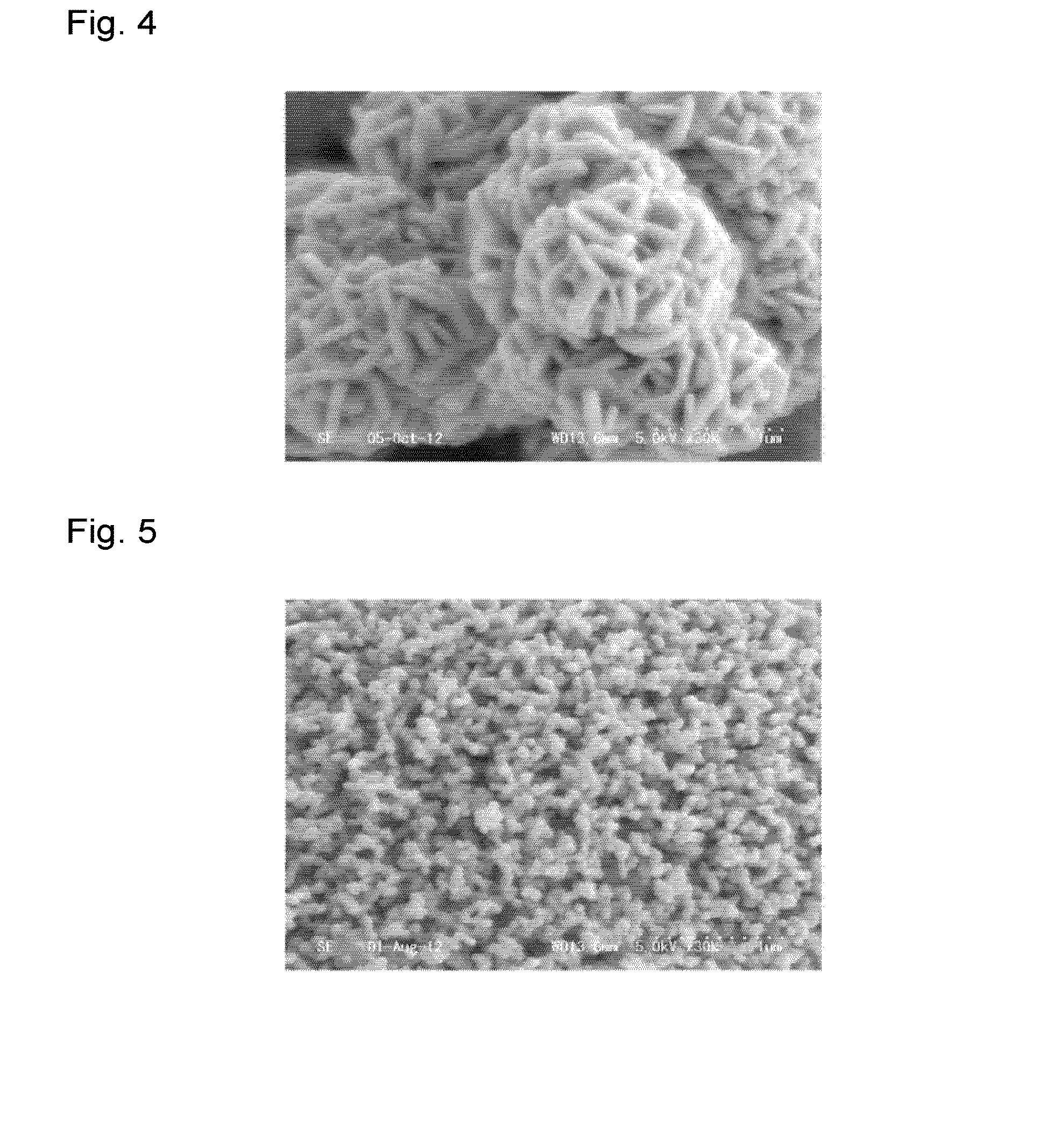

Cathode active material

InactiveUS20160043396A1Improve discharge performanceHigh cycle durabilityPositive electrodesCobalt compoundsSpace groupX-ray

To provide a cathode active material to be used for a positive electrode of a lithium ion secondary battery having a high discharge capacity and favorable cycle durability.A cathode active material, which comprises a lithium-containing composite oxide containing at least one transition metal element (X) selected from the group consisting of Ni element, Co element and Mn element, and Li element (provided that the molar ratio (Li / X) of the Li element based on the total amount of the transition metal element (X) is from 1.1 to 1.7),wherein the aspect ratio of primary particles is from 2.5 to 10, andin an X-ray diffraction pattern, the ratio (I020 / I003) of the integrated intensity (I020) of a peak of (020) plane assigned to a crystal structure with space group C2 / m to the integrated intensity (I003) of a peak of (003) plane assigned to a crystal structure with space group R-3m is from 0.02 to 0.3.

Owner:SUMITOMO CHEM CO LTD

Carbon nanofiber, producing method and use of the same

InactiveUS20110101265A1Improve surface activityImprove conductivityMaterial nanotechnologyCarbon compoundsParticulatesFiber

A catalyst for producing a carbon nanofiber is obtained by dissolving or dispersing [I] a compound containing Fe element; [II] a compound containing Co element; [III] a compound containing at least one element selected from the group consisting of Ti, V, Cr, and Mn; and [IV] a compound containing at least one element selected from the group consisting of W and Mo in a solvent to obtain a solution or the fluid dispersion, and then impregnating a particulate carrier with the solution or the fluid dispersion. A carbon nanofiber is obtained by bringing a carbon element-containing compound into contact with the catalyst in a vapor phase at a temperature of 300 degrees C. to 500 degrees C.

Owner:SHOWA DENKO KK

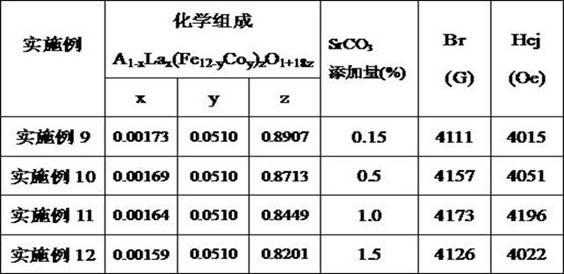

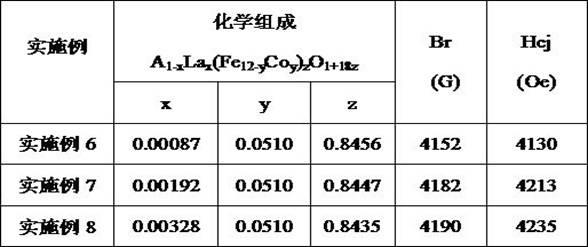

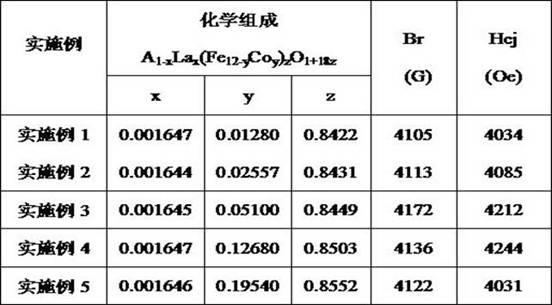

Ferrite magnetic material and manufacturing method thereof

ActiveCN102436899AIncrease solid solutionImprove magnetismMagnetsInorganic material magnetismStrontium carbonateMetallurgy

The invention discloses a ferrite magnetic material and a manufacturing method thereof. In the ferrite magnetic material, a composition shown by a combined formula of A1-xLax(Fe12-yCoy)zO1+18Z is used as a main component; in the formula, A is at least one element selected from Sr, Ba and Ca; x is 0.001-0.039; y is 0.01-0.2; and z is 0.80-0.89. According to the invention, by adding strontium carbonate and trace La element into a ball milling process, solid solubility of Co element in the ferrite can be improved, the magnetic performance of the ferrite can be greatly improved, and the production cost is low; and through the material and the method, permanent magnetic ferrite with Br greater than or equal to 4,100 G and Hcj greater than or equal to 4,000 Oe can be obtained.

Owner:HUNAN AEROSPACE MAGNET & MAGNETO

Novel high-speed steel material and preparation process thereof

The invention provides a novel high-speed steel material and a preparation process thereof. The novel high-speed steel material has cost and service life advantages in the industries of cylindrical die rolls and nut punching dies, thereby being capable of replacing M42. The novel high-speed steel material comprises the following materials in percentage by mass: 0.85-0.92% of C, 0.70-1.10% of Si, 0.20-0.50% of Mn, 0-0.030% of P, 0-0.030% of S, 1.20-2.20% of W, 4.50-6.75% of Mo, 3.80-4.50% of Cr, 1.20-2.20% of V, 0-0.55% of Ni and 0-0.55% of Cu, namely, less than or equal to 0.25% of Ni and less than or equal to 0.35% of Cu. The performance of the novel high-speed steel material is equivalent to that of the M42 steel material, the novel high-speed steel material does not contain the Co element, has a relatively low cost and is beneficial for protection of national precious metal resources.

Owner:昆山双儒模具科技有限公司

Nanometer rare earth permanent magnetic material with high-temperature stability and preparation method thereof

InactiveCN103559971AImprove microstructureInhibition of nucleation growthInorganic material magnetismRare-earth elementNiobium

A nanometer rare earth permanent magnetic material with the high-temperature stability is characterized in that a basic expression is RxFe100-x-z-y BzNy, wherein R is one or a plurality of lanthanide series rare earth elements of neodymium, praseodymium and the like, Fe is an iron element, B is an boron element, N is one of elements of niobium, zirconium and the like, x is a number ranging from 15 to 36, z is a number ranging from 2 to 10, and y is a number ranging from 4 to 10. Preferentially, x is a number ranging from 18 to 32, z is a number ranging from 2.6 to 8.5, and y is a number ranging from 4.8 to 9. The invention further provides a preparation method of the rare earth permanent magnetic material. A Co element is not added, and the material has the advantages of being low in cost and high in working temperature and intrinsic coercivity.

Owner:江西江钨稀有金属新材料股份有限公司

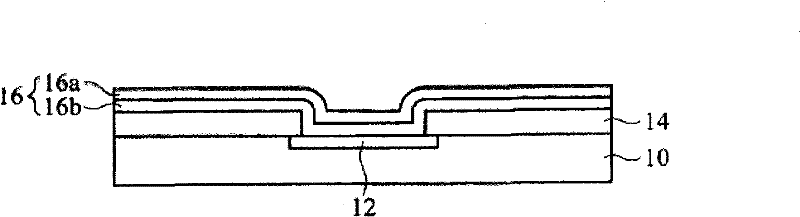

Copper pillar bump with cobalt-containing sidewall protection

An integrated circuit device includes a Cu pillar and a solder layer overlying the Cu pillar. A Co-containing metallization layer is formed to cover the Cu pillar and the solder layer, and then a thermally reflow process is performed to form a solder bump and drive the Co element into the solder bump. Next, an oxidation process is performed to form a cobalt oxide layer on the sidewall surface of the Cu pillar.

Owner:TAIWAN SEMICON MFG CO LTD

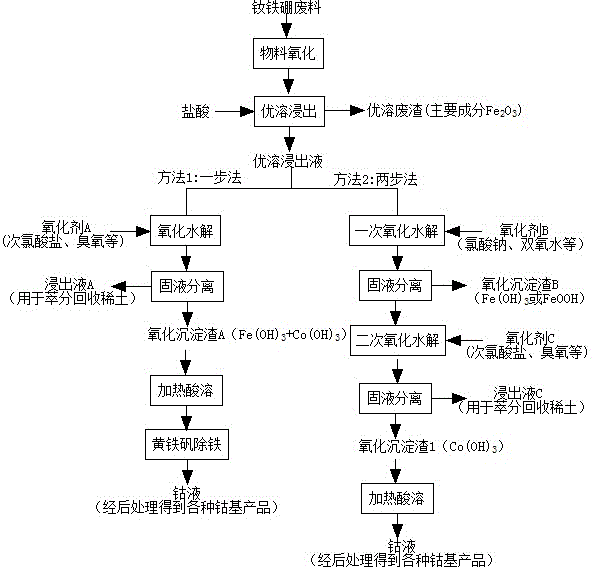

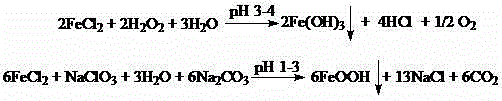

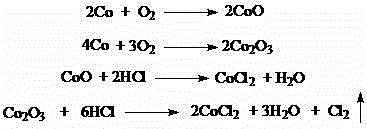

Simple and convenientindustrial method for recovering Co element from NdFeBmagnetwaste materials

ActiveCN104480316AEfficient retentionEfficient recyclingProcess efficiency improvementPregnant leach solutionDissolution

The invention discloses a simple and convenientindustrial method for recovering the Co element from NdFeBmagnetwaste materials. The simple and convenientindustrial method comprises the steps as follows: material oxidation, preferential dissolution leaching, oxidation hydrolysis, Co element recovery, compound preparation and the like. According to the technical route design, the variable valence characteristic of the Co element and stability difference of bivalent Co and trivalent Co are combined skillfully. According to the method, flow matching and technology integration between the Co recovery process link and the conventional rare earth recovery assembly line in the domestic NdFeBwaste material recovery industry can be realized; in the aspect of technical target, the same principle is followed, the Co element is effectively entrapped and recovered at the front end of the whole flow based on the process steps includingmaterial oxidation, preferential dissolution leaching and oxidation hydrolysis, meanwhile, interference of a leachatesystemby Fe and Co elements in the follow-up procedure is avoided, and a rare earth extraction separation process is realized.

Owner:LIANYUNGANG ZHAOYU NEW MATERIAL IND

NiAl-Cr(Mo) biphase eutectic crystal intermetallic compound modified by Co

InactiveCN101148726AHigh temperature strengthImprove toughnessRoom temperatureSolid solution strengthening

The present invention discloses one kind of Co modified two-phase eutectic intermetallic NiAl-Cr(Mo) compound comprising Ni in 33 at.%, Cr in 30 at.%, Mo in 4 at.%, Co in 1-16 at.% and Al for the rest. By means of lowering Al content in the two-phase eutectic intermetallic NiAl-Cr(Mo) alloy, and adding Co element with solid solution reinforcing effect to modify and introduce one third plastic phase, the Co modified two-phase eutectic intermetallic NiAl-Cr(Mo) compound has further raised high temperature strength and room temperature toughness and plasticity. The Co modified two-phase eutectic intermetallic NiAl-Cr(Mo) compound has yield strength at 1150 deg.c of 110-130 MPa and density of 6.02-7.06 g / cu cm.

Owner:BEIHANG UNIV

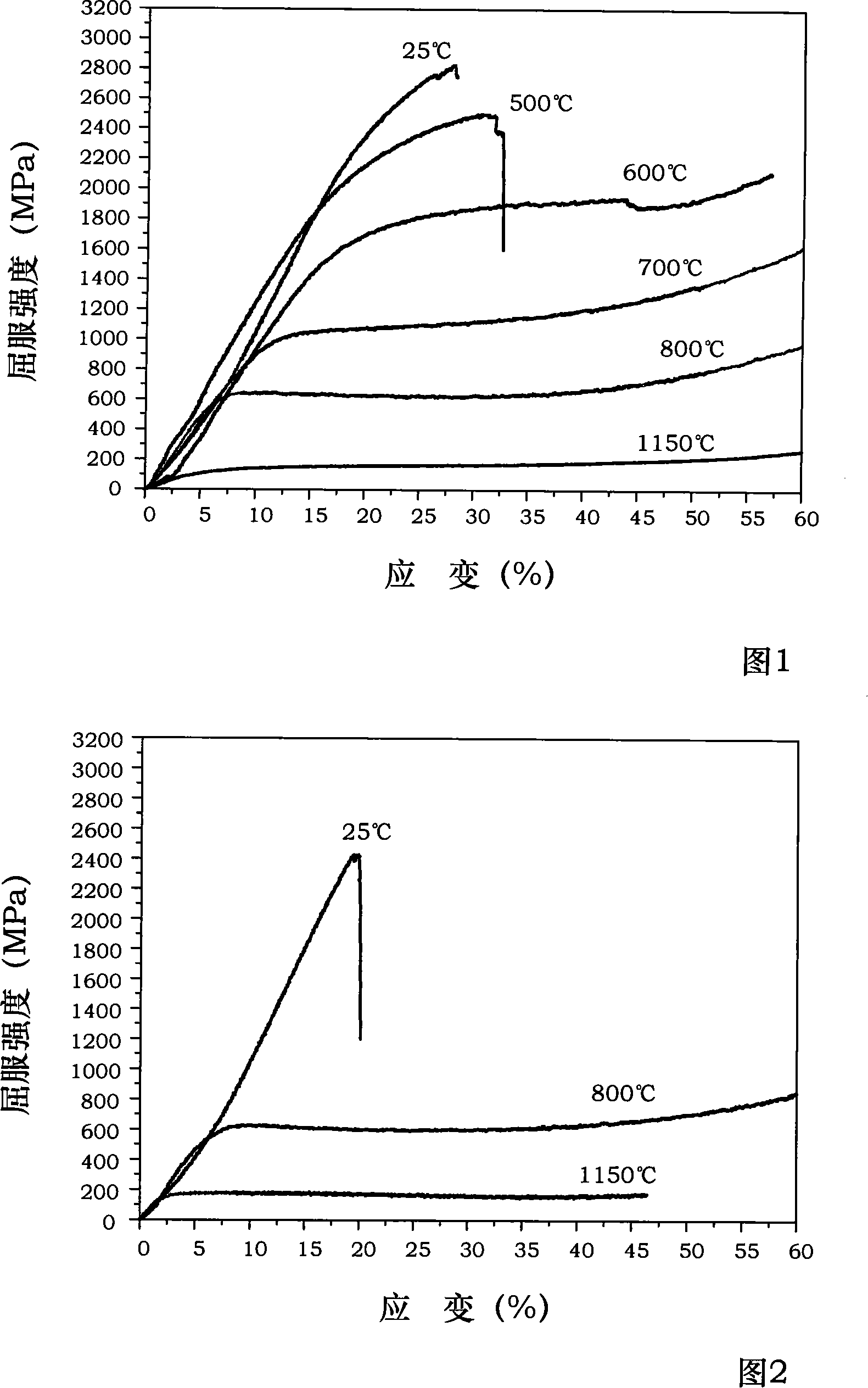

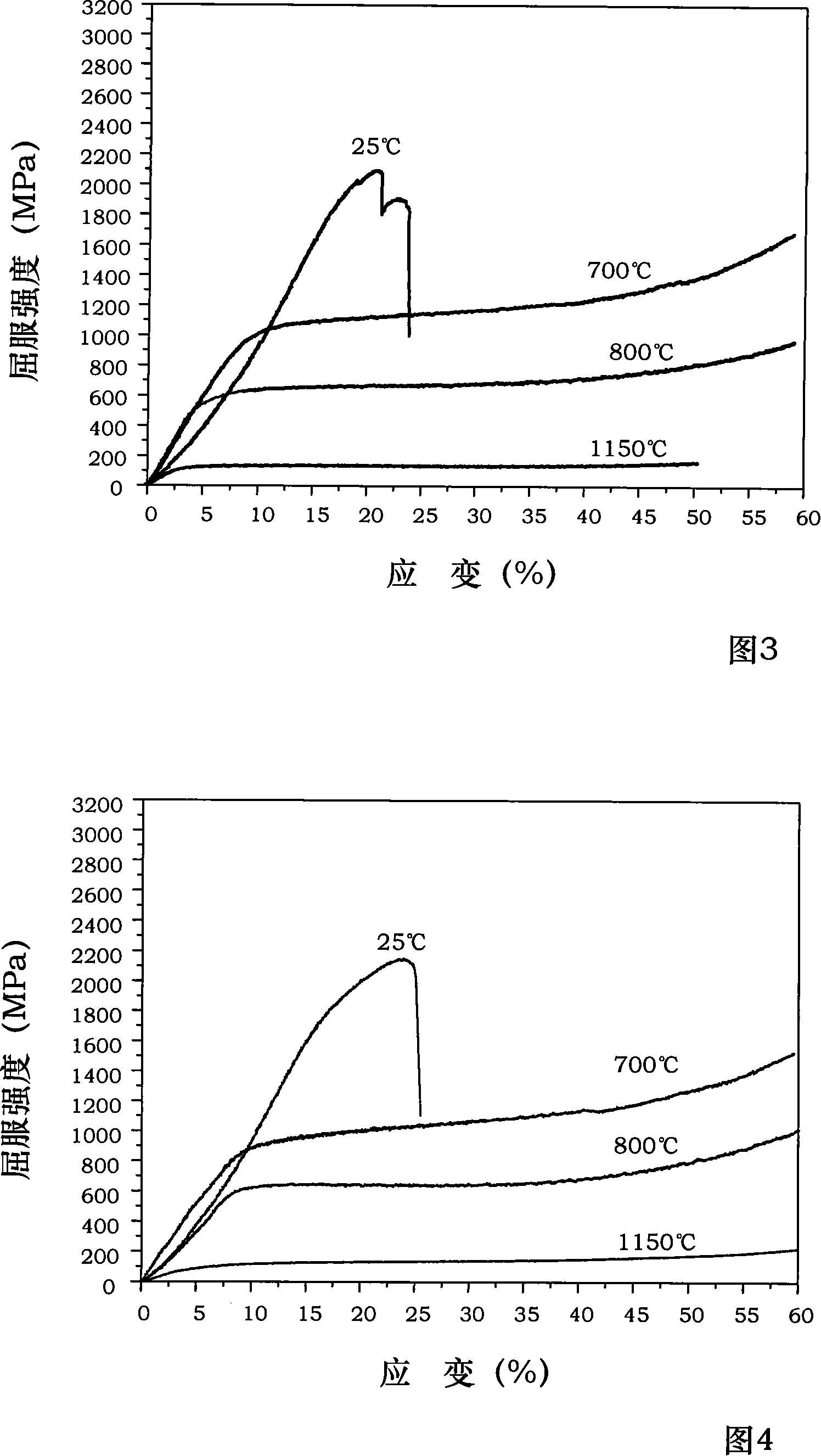

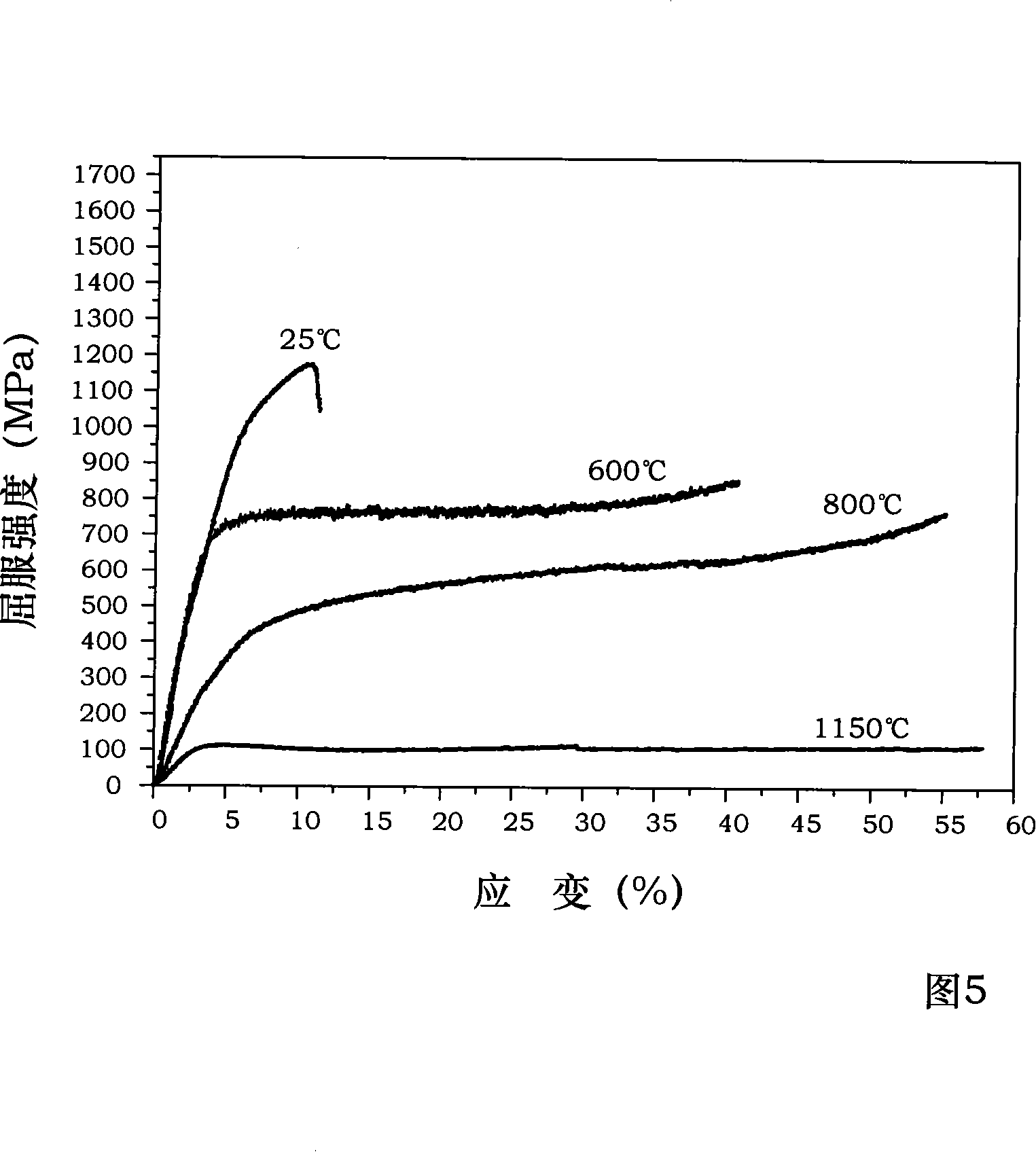

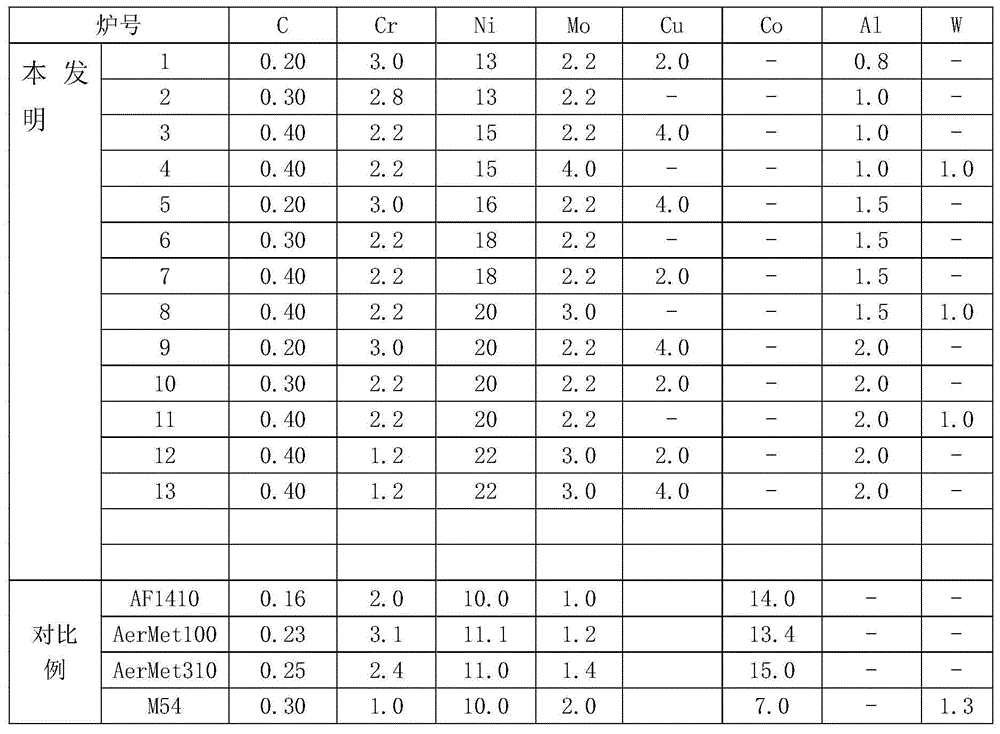

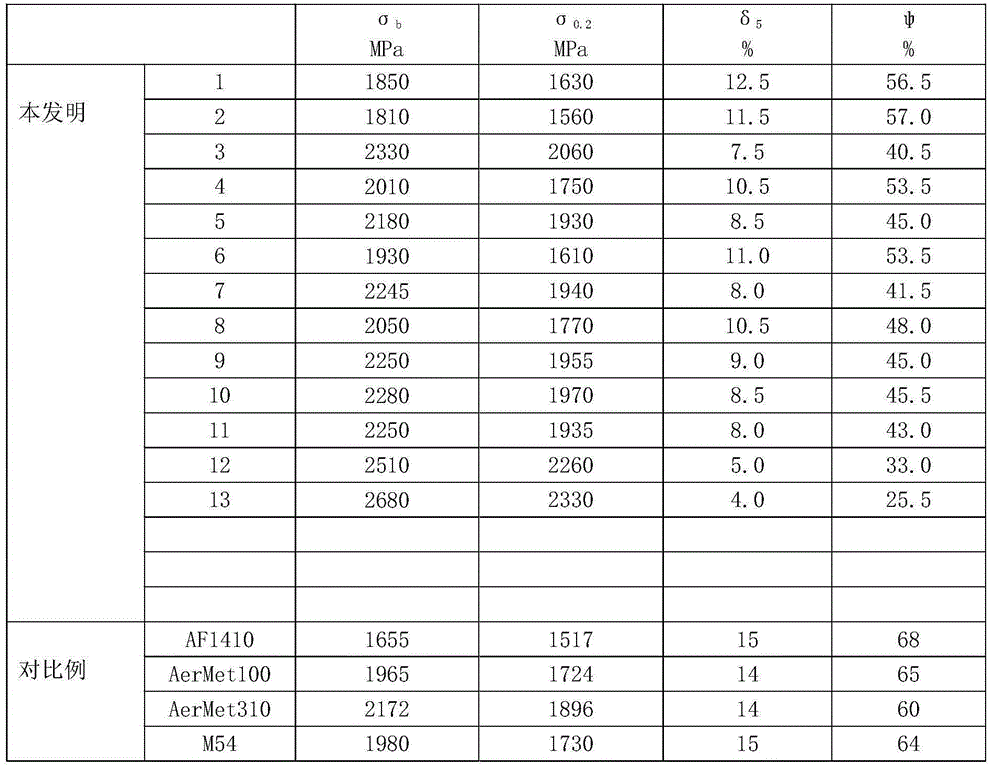

Cu-reinforced Co-free secondary-hardening ultrahigh-strength steel and preparation method thereof

ActiveCN104911499ASave Co element contentImprove performanceChemical compositionUltimate tensile strength

The invention discloses Cu-reinforced Co-free secondary-hardening ultrahigh-strength steel and a preparation method, belonging to the technical field of alloy steel. The steel comprises the following chemical components in percentage by weight: 0.20-0.50% of C, 1.0-5.0% of Cr, 8.0-30.0% of Ni, 1.0-5.0% of Mo, 1.0-5.0% of Cu, 0-3.0% of Al, 0-2.0% of W, less than or equal to 0.30% of V, less than or equal to 0.20% of Nb and the balance of Fe and unavoidable impurities. According to the preparation method, the vacuum induction and vacuum consumable remelting technology or the vacuum induction and electroslag remelting technology can be adopted. Compared with the prior art, the Cu-reinforced Co-free secondary-hardening ultrahigh-strength steel has the advantages of good comprehensive performance, higher strength, good plasticity and toughness, good heat treatment process performance and higher tempering resistance and overaging resistance; the content of strategic resource Co element is saved and the economical efficiency is remarkably improved.

Owner:CENT IRON & STEEL RES INST

Nickel-base high-temperature alloy material for guide roller and heat treatment process thereof

InactiveCN101033526AHigh hardnessExtended service lifeFurnace typesHeat treatment furnacesLife timeApplication areas

This invention relates to a new Ni base high temperature alloyed material used in rolls and its hot process technology, which takes K403 alloy as the base and adjusts composition of the alloy to eliminate Co element and adds W, Nb and Fe suitably to melt it in vacuum, then carries out different hot processes to get the nickel base alloy, which replaces traditional roll materials and has the performance of anti-high temperature and oxidation, anti-hot impact and high temperature intensity to prolong its life time.

Owner:TSINGHUA UNIV

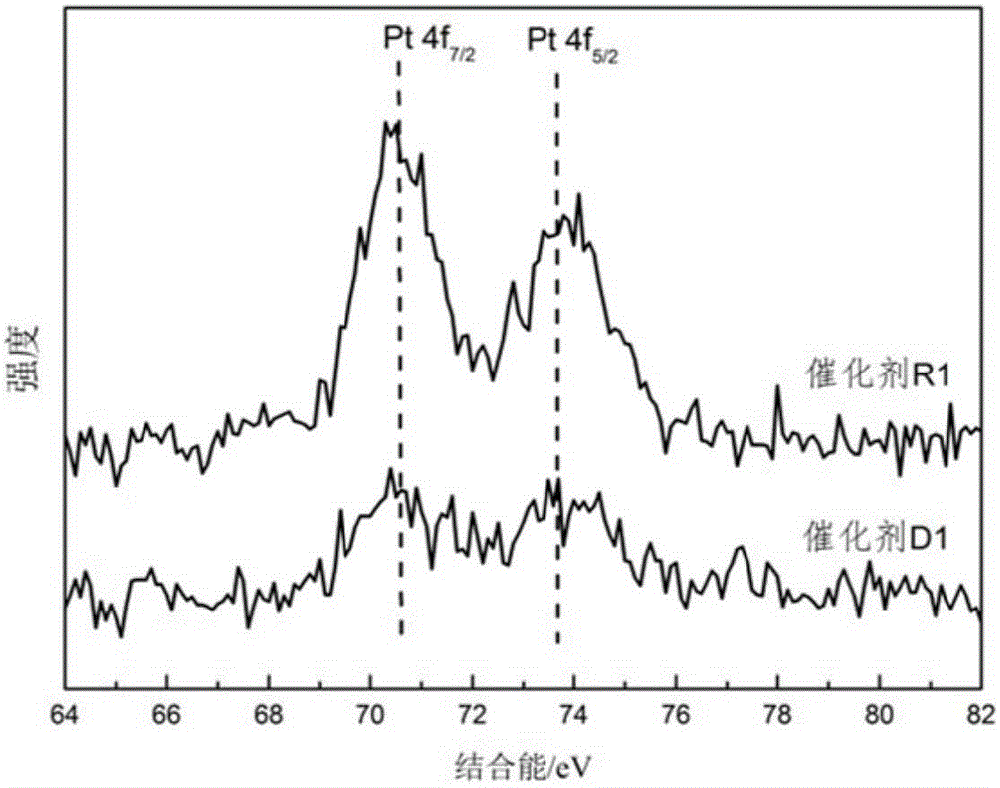

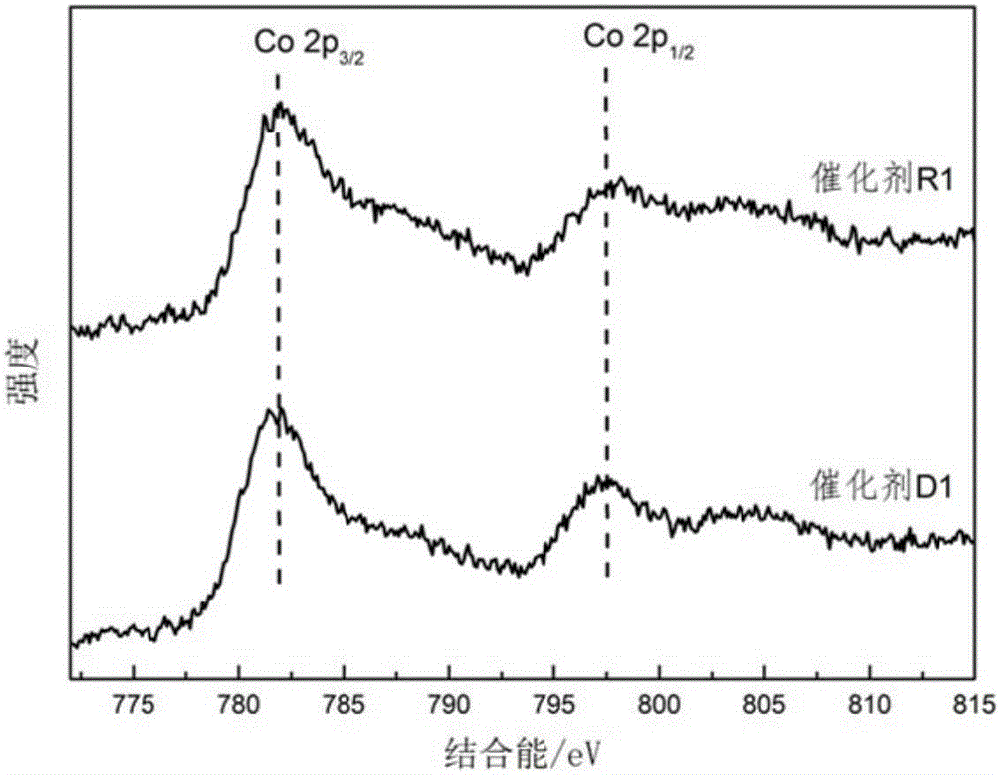

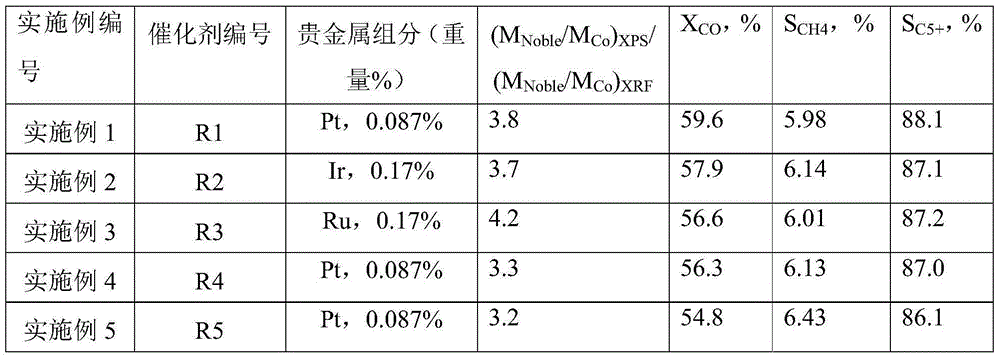

Supported type catalyst, preparation method thereof, application thereof and Fischer-Tropsch synthesis method thereof

ActiveCN106552645AHigh conversion rate of COHigh selectivityLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsSynthesis methodsActive ingredient

The invention discloses a supported type catalyst which comprises a carrier as well as an active ingredient Co element, a noble metal MNoble element and a non-noble metal auxiliary element supported on the carrier. The supported type catalyst is characterized in that a weight ratio of Co to the noble metal (in terms of a metal element) meets a relationship (MNoble / MCo)XPS / (MNoble / MCo)XRF=2.0-20.0, wherein MNoble / MCo)XPS is a weight ratio of a catalyst noble metal component represented by X-ray photoelectron spectroscopy to Co in terms of metal elements; and (MNoble / MCo)XRF is a weight ratio of the catalyst noble metal component represented by X-ray fluorescence spectrum to Co in terms of metal elements. The noble metal component is at least one of Pt, Pd, Ru, Rh and Ir. The invention also provides a preparation method for the catalyst and the Fischer-Tropsch synthesis method for the catalyst. Compared with a catalyst with the same metal content prepared in the prior art, the supported type catalyst has the advantages that a Fischer-Tropsch synthesis catalyst containing noble metal has relatively high C<5+> selectivity and relatively low methane selectivity while relatively high reaction activity is kept.

Owner:CHINA PETROLEUM & CHEM CORP +1

Olefin hydroformylation heterogeneous Co-based catalyst and preparation method thereof

ActiveCN109821567AMaintain catalytic activityValence stableMolecular sieve catalystsPreparation by carbon monoxide reactionBULK ACTIVE INGREDIENTActive ingredient

The invention relates to an olefin hydroformylation heterogeneous Co-based catalyst and a preparation method thereof. The technology problem of homogenous phase catalyst separation is solved, and theproblem that an existing heterogenous catalyst is low in target product yield is solved. A Co element is loaded on a carrier with the high specific surface area, modification is performed, a Co-basedload type heterogenous catalyst with M1xM2yCoAx being the active ingredient is formed, the Co atom electron state is changed, active loci can be evenly dispersed, the activity can be improved, and thehigh stability in air is achieved. The preparation method of the catalyst is simple and easy to store, and the obtained target product aldehyde yield is high.

Owner:NINGXIA UNIVERSITY

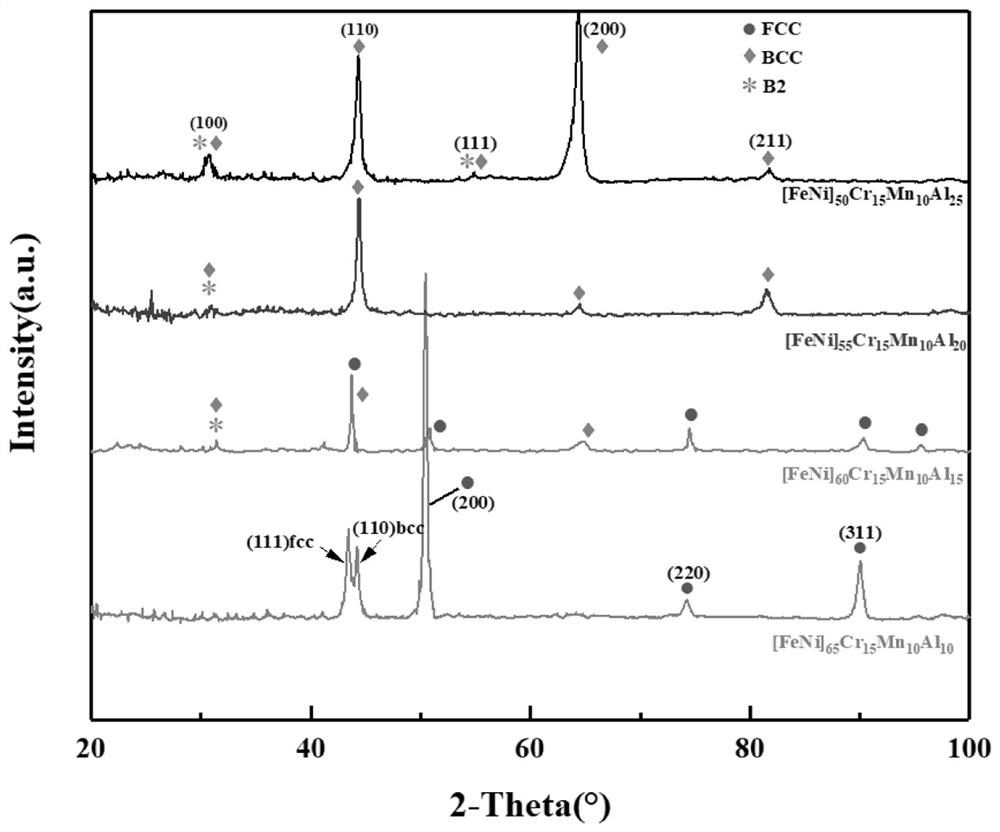

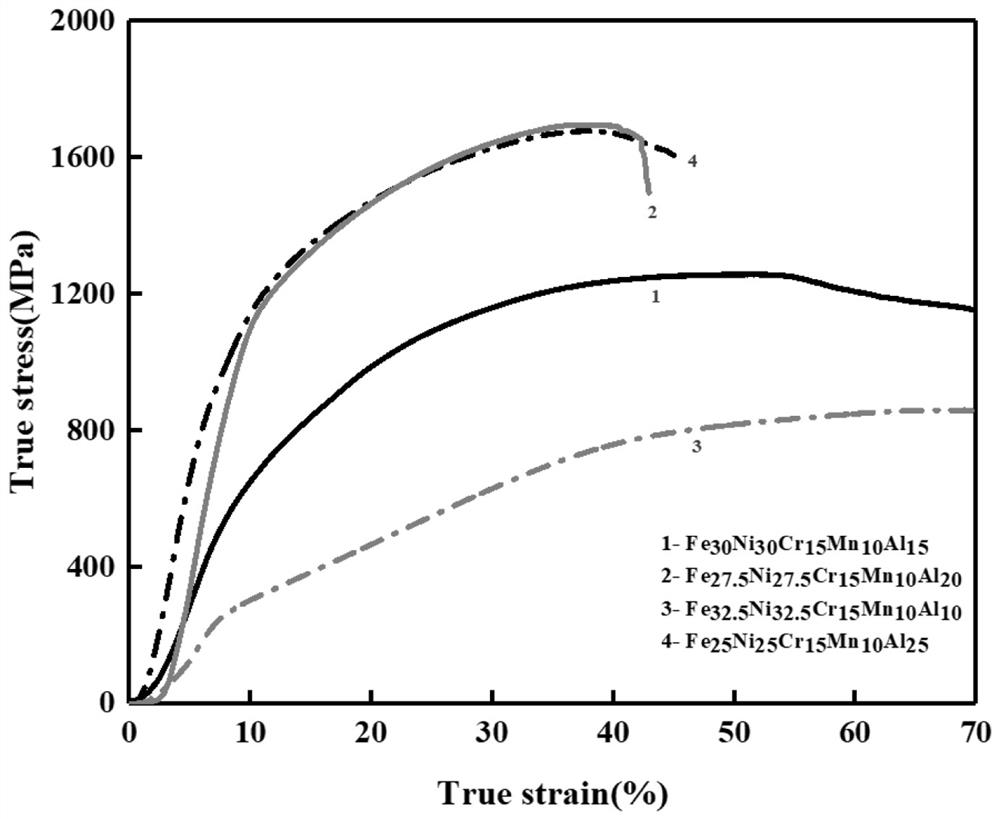

High-strength, high-toughness and anti-corrosion cobalt-free high-entropy alloy and preparation method thereof

The invention discloses high-strength, high-toughness and anti-corrosion cobalt-free high-entropy alloy and a preparation method thereof. In the high-strength, high-toughness and anti-corrosion cobalt-free high-entropy alloy, the atomic percent of Fe: Ni: Cr: Mn: Al is 30-27.5% : 30-27.5% : 15% : 10% : 15-20%. A preparation technology of the high-strength, high-toughness and anti-corrosion cobalt-free high-entropy alloy comprises the following steps: selecting the five elements including Fe, Ni, Cr, Mn and Al with the purity of each being 99.9wt% as the raw material for batching, and utilizinga non self-consuming electric arc furnace to prepare the high-entropy alloy through smelting. The high-entropy alloy is uniform in texture, shows excellent comprehensive mechanical property, does notcontain the expensive Co element and is low in price. The yield strength of the high-entropy alloy is equal to or greater than 770MPa, the breaking strain is equal to or greater than 45%, the corrosion resistance of the high-entropy alloy to 3.5wt.% NaCl is better than the corrosion resistance of stainless steel SUS 304 to 3.5wt.% NaCl, and the application prospect is broad.

Owner:CHINA THREE GORGES UNIV

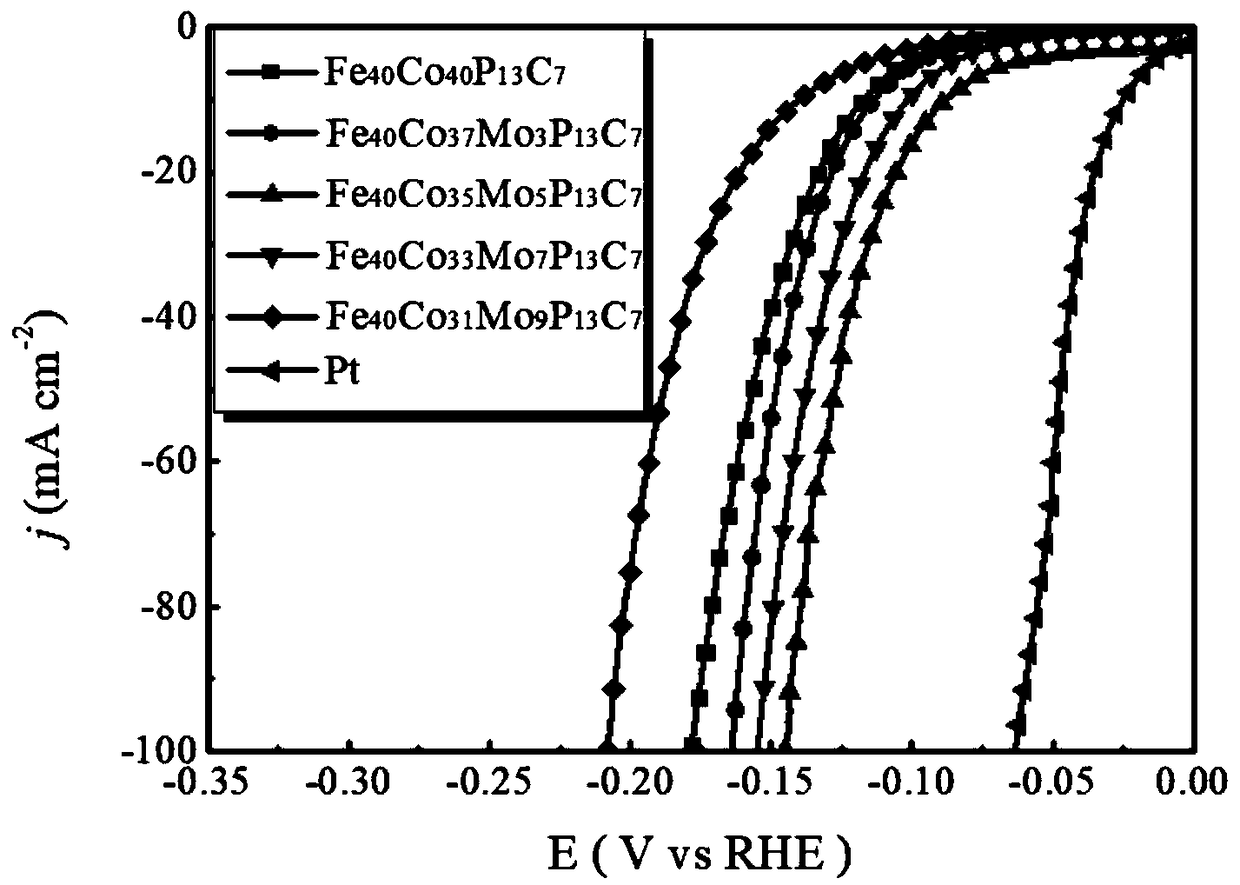

Fe-Co-Mo-P-C series amorphous alloy electrocatalyst as well as preparation method and application thereof

ActiveCN108914156AExcellent vitrification abilityImprove electrocatalytic activityElectrodesVitrificationHydrogen

The invention discloses a Fe-Co-Mo-P-C series amorphous alloy electrocatalyst as well as a preparation method and application thereof. The ingredient of the Fe-Co-Mo-P-C series amorphous alloy electrocatalyst is FexCoyMo<80-x-y>P<20-z>Cz, wherein x, y and z are the atomic percentages of the Fe element, the Co element and the C element, x is no less than 10 and no greater than 40, y is no less than10 and no greater than 40, and z x is no less than 0 and no greater than 15. The Fe-Co-Mo-P-C series amorphous alloy electrocatalyst is prepared through the melt rotary quenching method, has high vitrification forming ability and electrocatalytic activity within the wider ingredient range, is an excellent hydrogen evolution reaction electrocatalyst and has wide commercialization application prospect.

Owner:HEFEI UNIV OF TECH

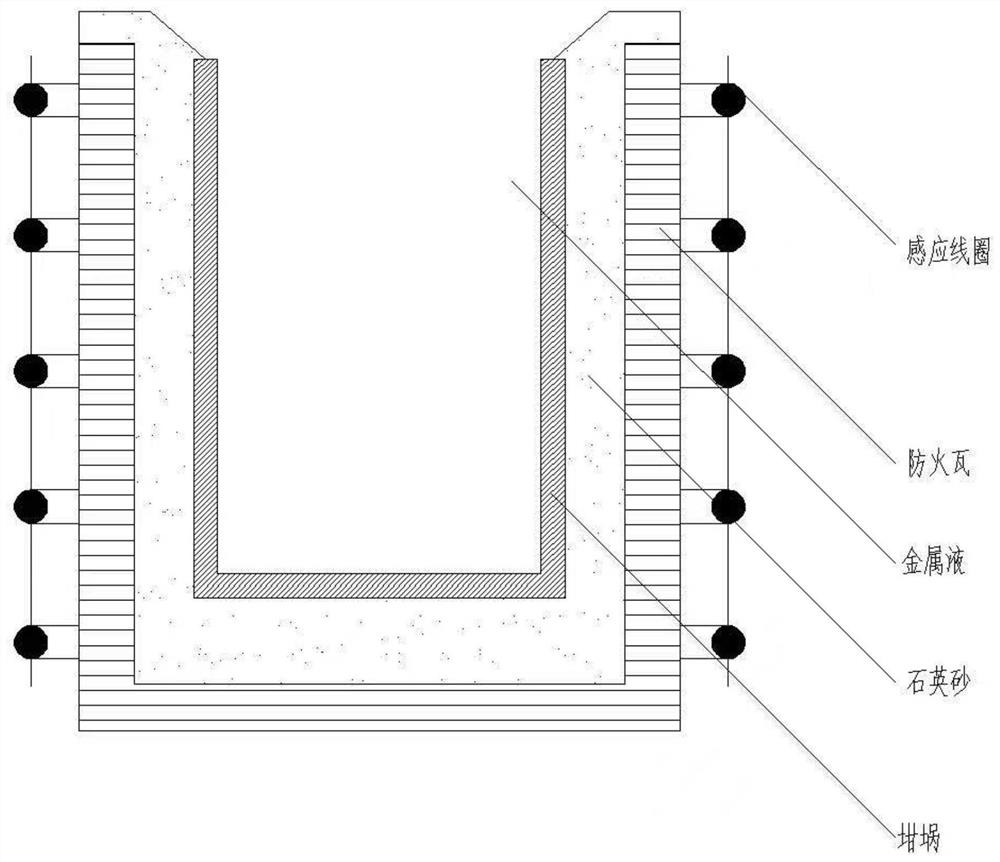

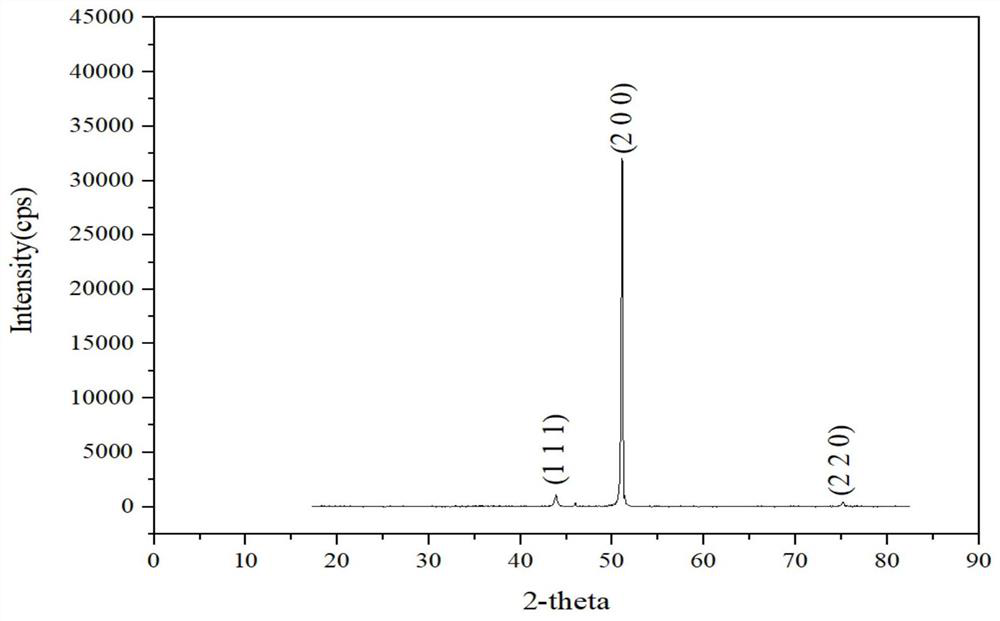

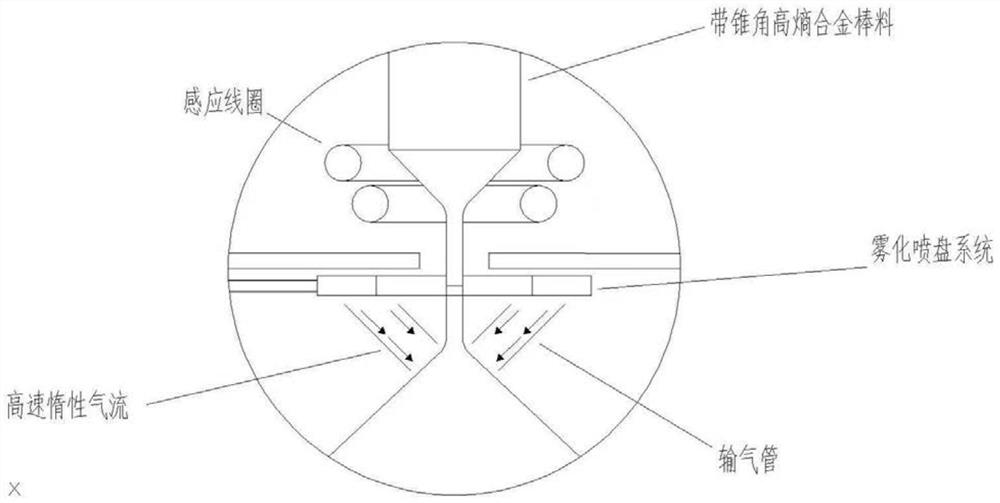

CoCrNi medium-entropy alloy and technology for preparing CoCrNi medium-entropy alloy through atomization powder preparation method

The invention discloses a CoCrNi medium-entropy alloy and a technology for preparing the CoCrNi medium-entropy alloy through an atomization powder preparation method. The technology comprises the steps that a Co element simple substance block, a Cr element simple substance block and a Ni element simple substance block are smelted according to a specified proportion to prepare a CoCrNi alloy bar; the CoCrNi medium-entropy alloy is prepared from the CoCrNi alloy bar used as a raw material through an electrode induction melting gas atomization method. The prepared CoCrNi medium-entropy alloy is in a standard FCC phase, free of microscopic segregation, round in overall shape and small and uniform in particle size. According to the technology, smelting by a medium-frequency smelting furnace and the EIGA technology are combined, the defects that an existing CoCrNi medium-entropy alloy is uneven in mixing, has microscopic segregation and is large in particle size are overcome, and the technology is simple, suitable for large-scale production, low in cost and good in application prospect.

Owner:SHANGHAI UNIV OF ENG SCI

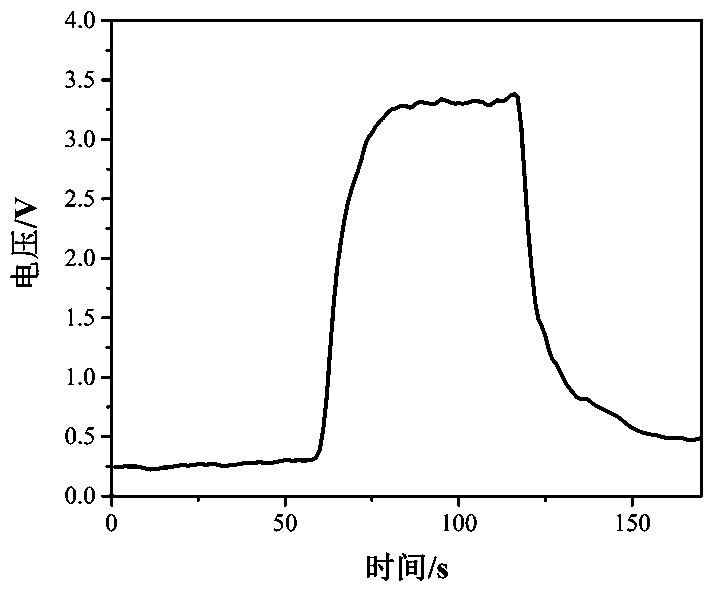

Preparation method for MOF-based Co-doped tin dioxide gas-sensitive nano material as well as product and application

ActiveCN109231261AEvenly distributedHigh purityMaterial analysisTin oxidesTin dioxideMetal-organic framework

The invention discloses a preparation method for an MOF-based Co-doped tin dioxide gas-sensitive nano material as well as a product and application. MOF (a metal organic framework structure) of Co andSn is utilized, and the Co-doped SnO2 gas-sensitive nano material is prepared by regulating conditions such as concentration, proportion, reaction time and a reaction temperature of a precursor. Thepreparation method is characterized in that Co doping amount is controllable, and Co element is uniformly distributed. The Co-doped gas-sensitive nano material prepared by the preparation method is high in purity, is uniform in dimension, is greatly improved in gas-sensitive response in comparison with a pure SnO2 gas-sensitive material, and is quick in response recovery speed.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Ni-Fe-Ga-Co high-temperature magnetic-drive memory alloy

The invention relates to a Ni-Fe-Ga-Co high-temperature magnetic-drive memory alloy which belongs to a memory alloy. The invention solves the problem that the traditional magnetic-drive shape memory material can not meet the relational expression that Ms is less than Tc and is more than 100 DEG C. The molecular formula of the Ni-Fe-Ga-Co high-temperature magnetic-drive memory alloy is Ni56Fe17Ga27-xCox, wherein x is 2-6. A Co element is added in the Ni-Fe-Ga-Co high-temperature magnetic-drive memory alloy to obtain a Ni-Fe-Ga-Co alloy meeting the relational expression that Ms is less than Tc and is more than 100 DEG C. The Ni-Fe-Ga-Co high-temperature magnetic-drive memory alloy can be used at high temperature, especially, Ms and Tc of a Ni56Fe17Ga21Co6 alloy are respectively 177 DEG C and 201 DEG C, thereby guaranteeing the application of the high-temperature magnetic-drive memory alloy under high temperature environment.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com