Preparation method of nickel-cobalt-manganese ternary material enabling element content in gradient distribution

A technology of gradient distribution and element content, applied in electrical components, active material electrodes, electrochemical generators, etc., can solve the problems of poor material stability, poor safety, and affecting material performance, and achieve excellent electrochemical performance and enhanced stability Effects on safety, good cycle performance and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

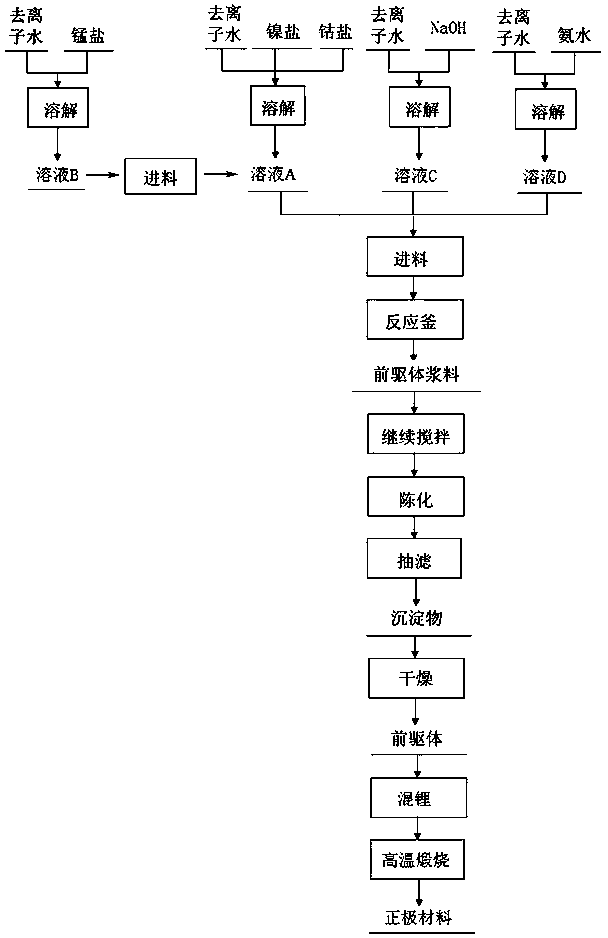

Method used

Image

Examples

Embodiment 1

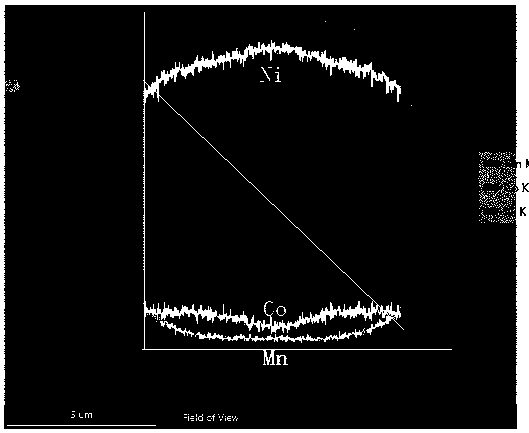

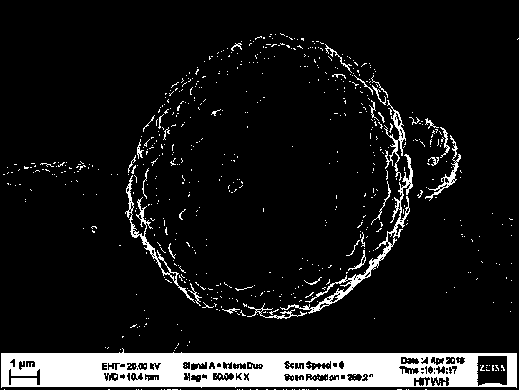

[0024] In this example, the nickel-rich cathode material LiNi with gradient distribution of element content is prepared. 0.8 co 0.1 mn 0.1 o 2 .

[0025] In this example x=0.8, y=0.1, z=0.1.

[0026] Weigh NiSO respectively according to the molar ratio of 8:1:1 4 ·6H 2 O. CoSO 4 ·H 2 O and MnSO 4 ·H 2 O, NiSO 4 ·6H 2 O and CoSO 4 ·H 2 O was dissolved in deionized water and prepared to 2mol L -1 of salt solution A, the MnSO 4 ·H 2 O was dissolved in deionized water and prepared to 2mol L -1 salt solution B, and prepare 4mol·L at the same time -1 Sodium hydroxide solution C and 4mol·L -1 Ammonia solution D. Add deionized water bottom liquid into the reaction kettle, pump three solutions A, C, and D into the reaction kettle at the same time, at the same time, pump solution B into solution A, and keep the feed rate ratio of solution A and solution B as 10:1. Precisely control the pH=11.60 by adjusting the flow rate of the C solution, control the reaction tempe...

Embodiment 2

[0030] In this example, the positive electrode material LiNi with gradient distribution of element content was prepared. 0.6 co 0.2 mn 0.2 o 2 .

[0031] In this example x=0.6, y=0.2, z=0.2.

[0032] Weigh NiSO respectively according to the molar ratio of 6:2:2 4 ·6H 2 O. CoSO 4 ·H 2 O and MnSO 4 ·H 2 O, NiSO 4 ·6H 2 O and CoSO 4 ·H 2 O was dissolved in deionized water and prepared as 2.5mol L -1 of salt solution A, the MnSO 4 ·H 2 O was dissolved in deionized water and prepared as 2.5mol L -1 salt solution B, and prepare 5mol·L at the same time -1 Sodium hydroxide solution C and 5mol·L -1 Ammonia solution D. Add deionized water bottom liquid into the reaction kettle, pump the three solutions of A, C and D into the reaction kettle at the same time, at the same time, pump the B solution into the A solution, and keep the feed rate ratio of the A solution and the B solution as 5:1. Precisely control the pH=11.40 by adjusting the flow rate of the C solution, c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com