Patents

Literature

131 results about "Li element" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium is the chemical element with symbol Li and atomic number 3. In the periodic table, it is located in group 1, among the alkali metals. Lithium in its pure form is a soft, silver white metal, that tarnishes and oxidizes very rapidly in air and water.

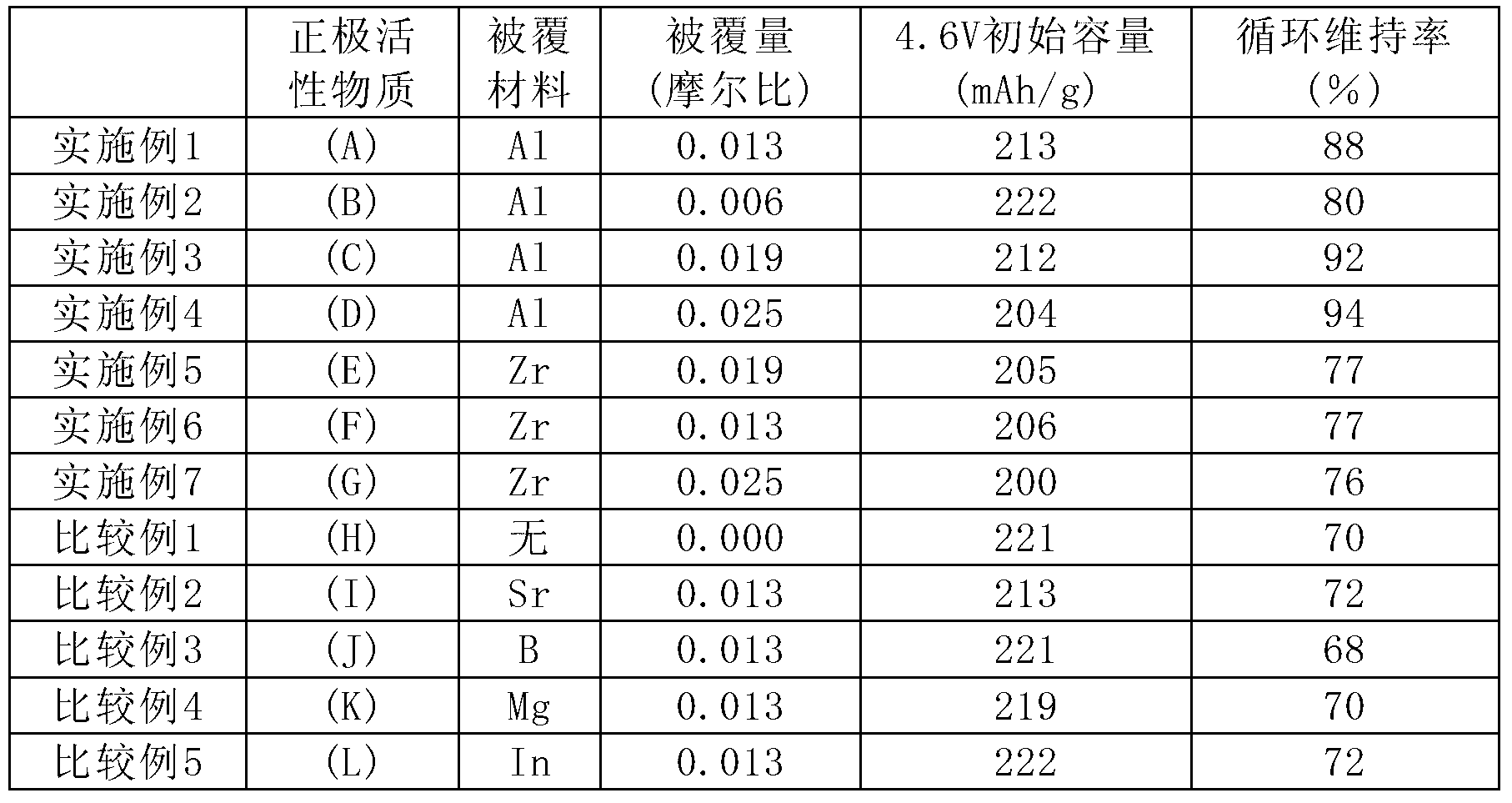

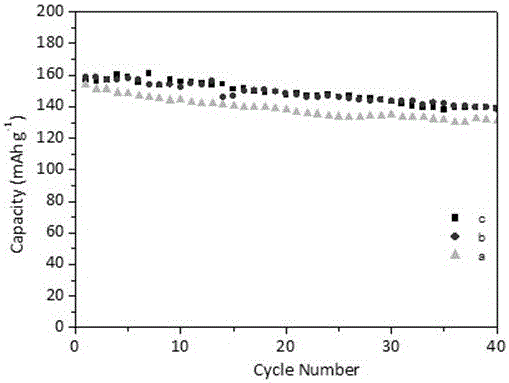

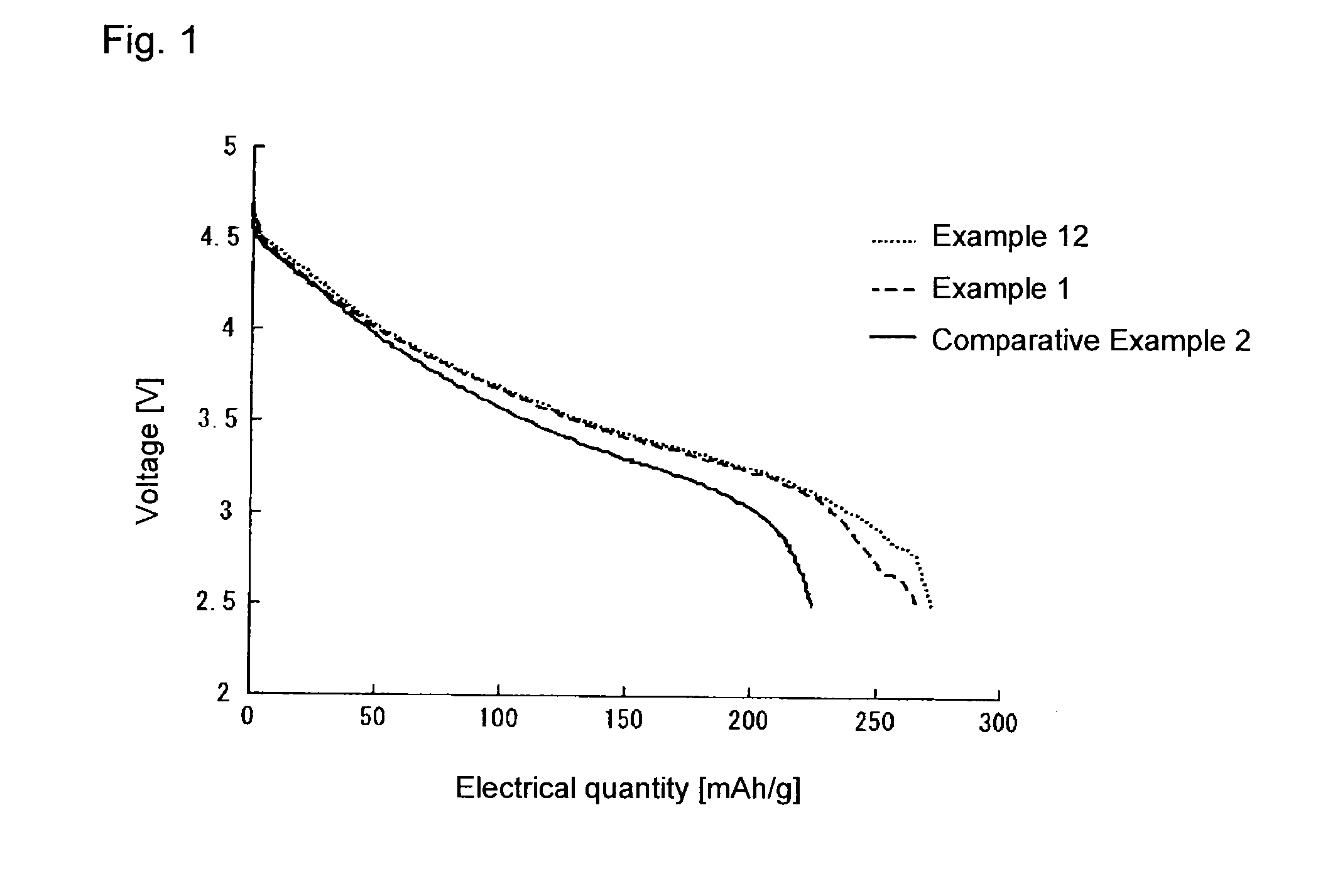

Positive electrode active material and its manufacturing method, positive electrode for lithium secondary cell using same, and lithium secondary cell

InactiveUS20060177739A1Deteriorated in battery performanceGood charge and discharge cycle performanceActive material electrodesNon-aqueous electrolyte accumulator electrodesLithiumEngineering

A positive active material is provided which can inhibit side reactions between the positive electrode and an electrolyte even at a high potential and which, when applied to a battery, can improve charge / discharge cycle performance without impairing battery performances even in storage in a charged state. Also provided are: a process for producing the active material; a positive electrode for lithium secondary batteries which employs the active material; and a lithium secondary battery which has improved charge / discharge cycle performance while retaining intact battery performances even after storage in a charged state and which can exhibit excellent charge / discharge cycle performance even when used at a high upper-limit voltage. The positive active material comprises: base particles able to dope and release lithium ions; and an element in Group 3 of the periodic table present on at least part of that part of the base particles which is able to come into contact with an electrolyte. It is produced by, e.g., a process which comprises: producing base particles containing lithium and able to dope and release lithium ions; and then imparting an element in Group 3 of the periodic table to the base particles so that the element can be present on at least part of that part of the base particles which is able to come into contact with an electrolyte.

Owner:GS YUASA INT LTD

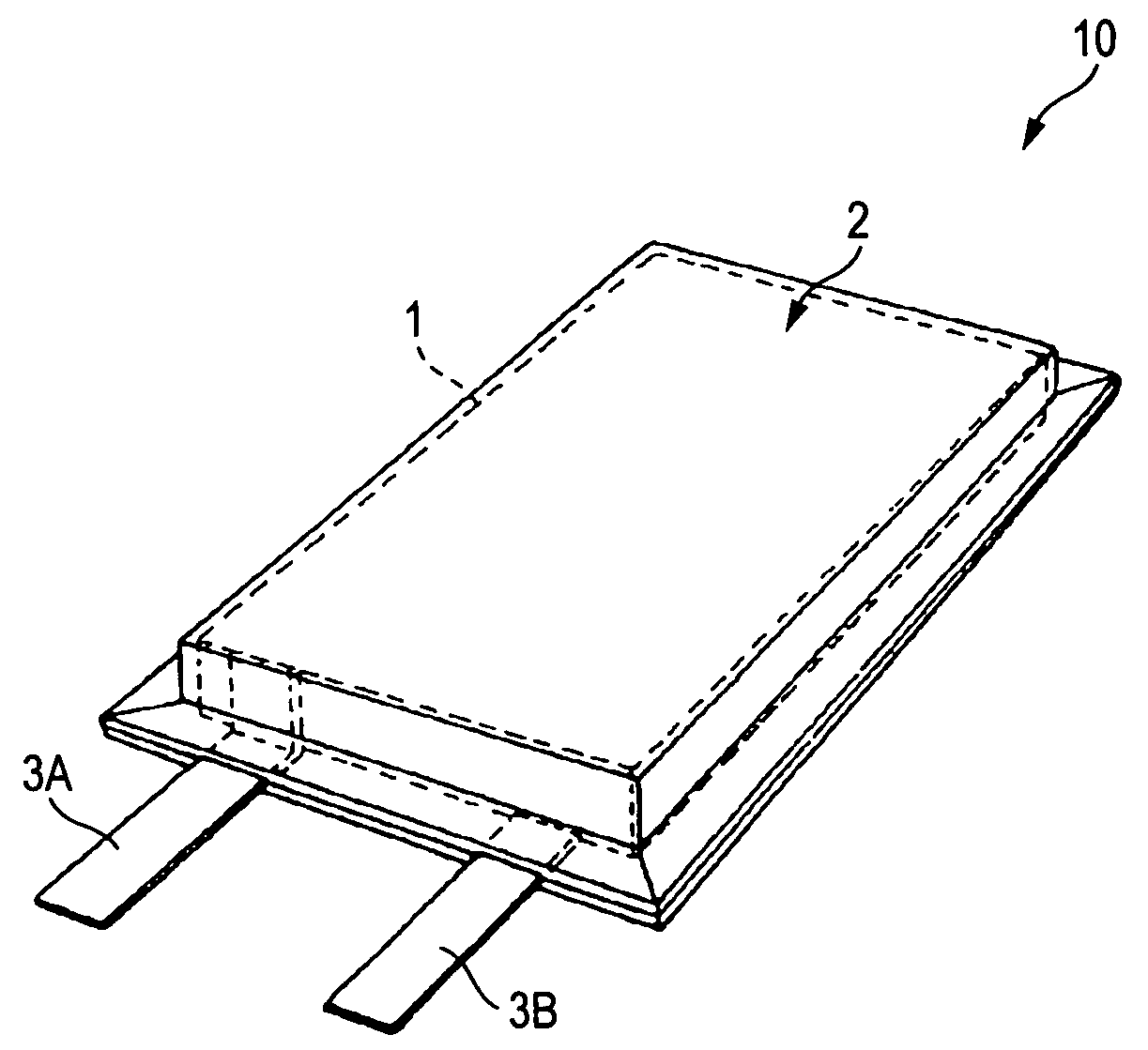

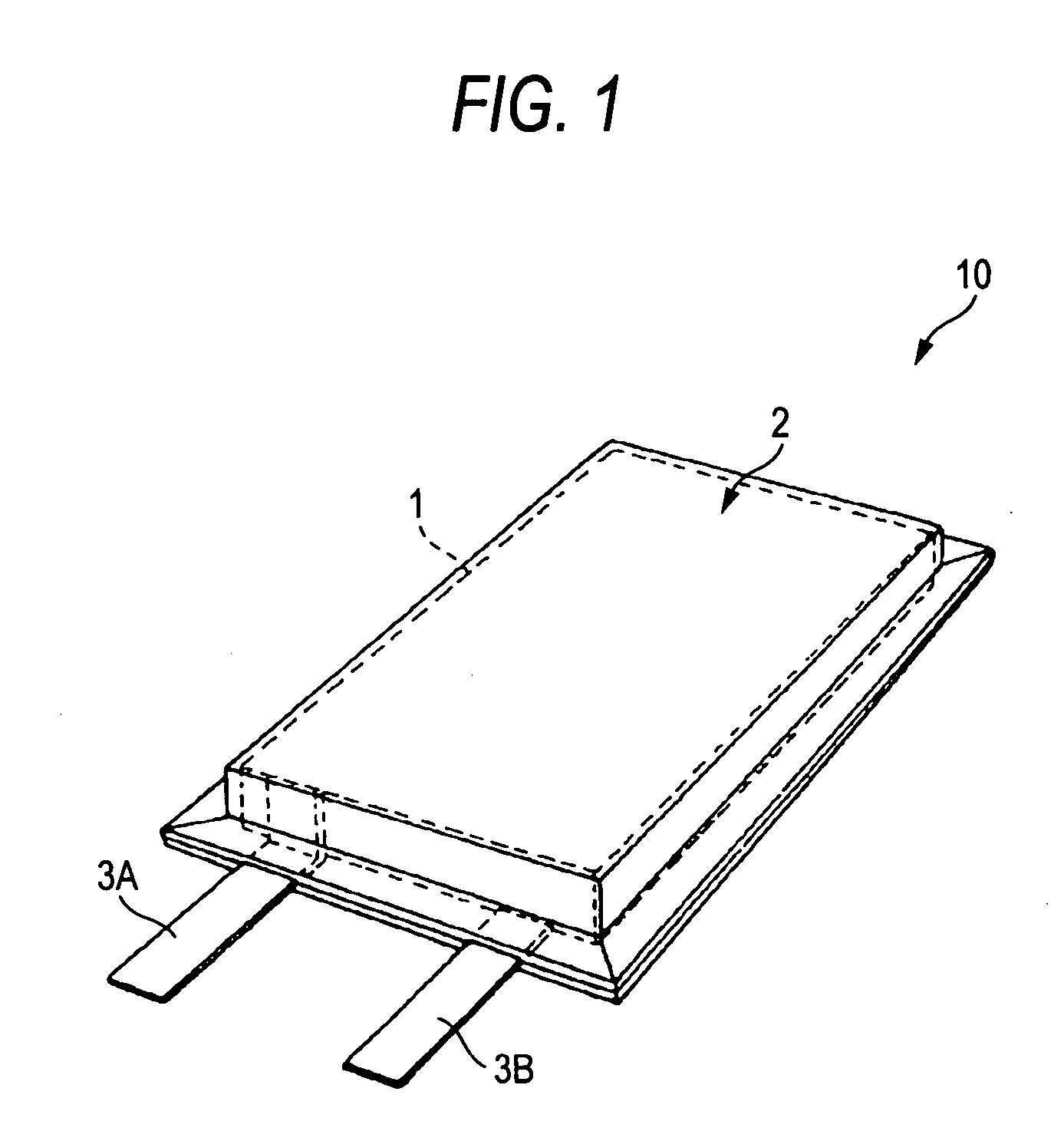

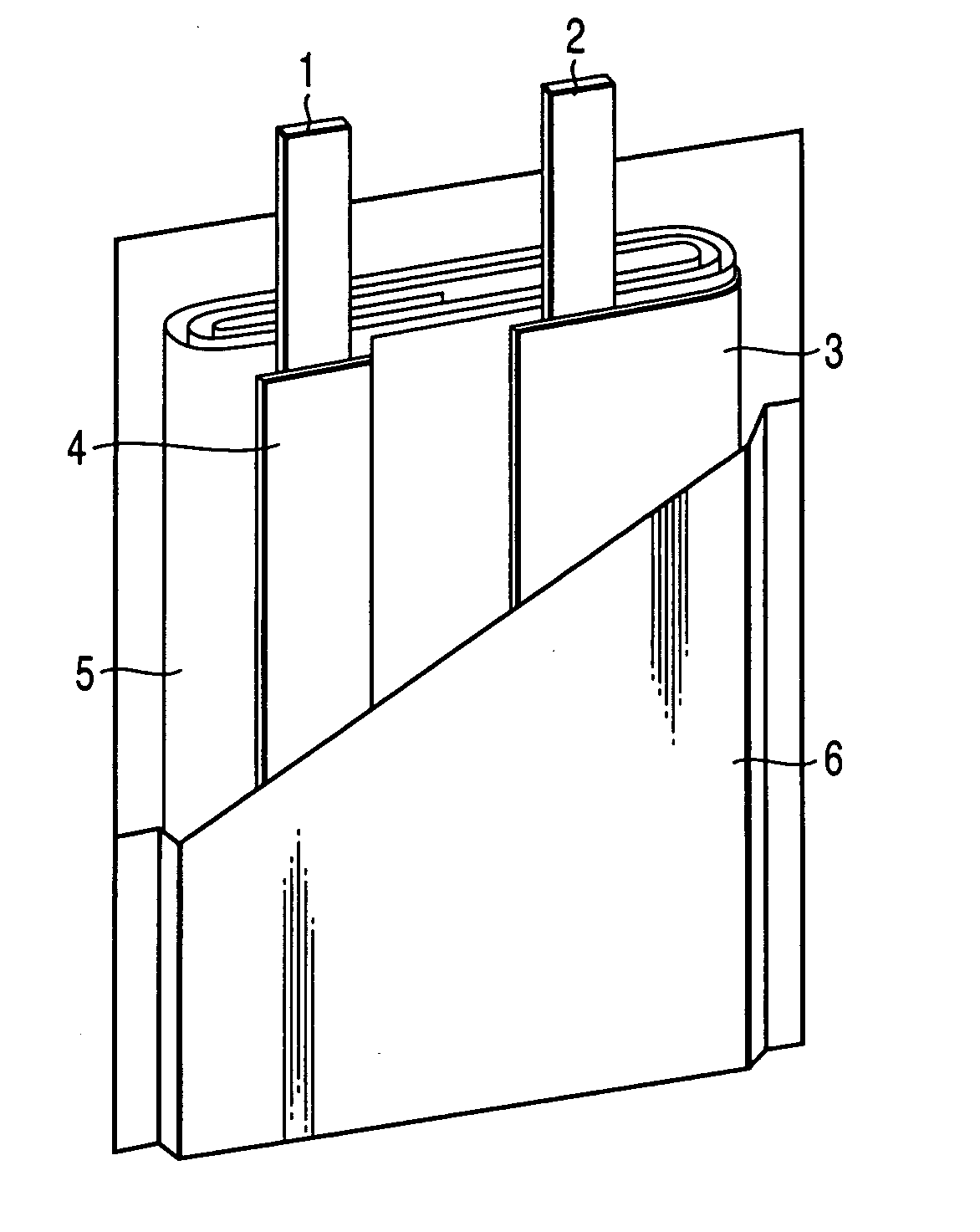

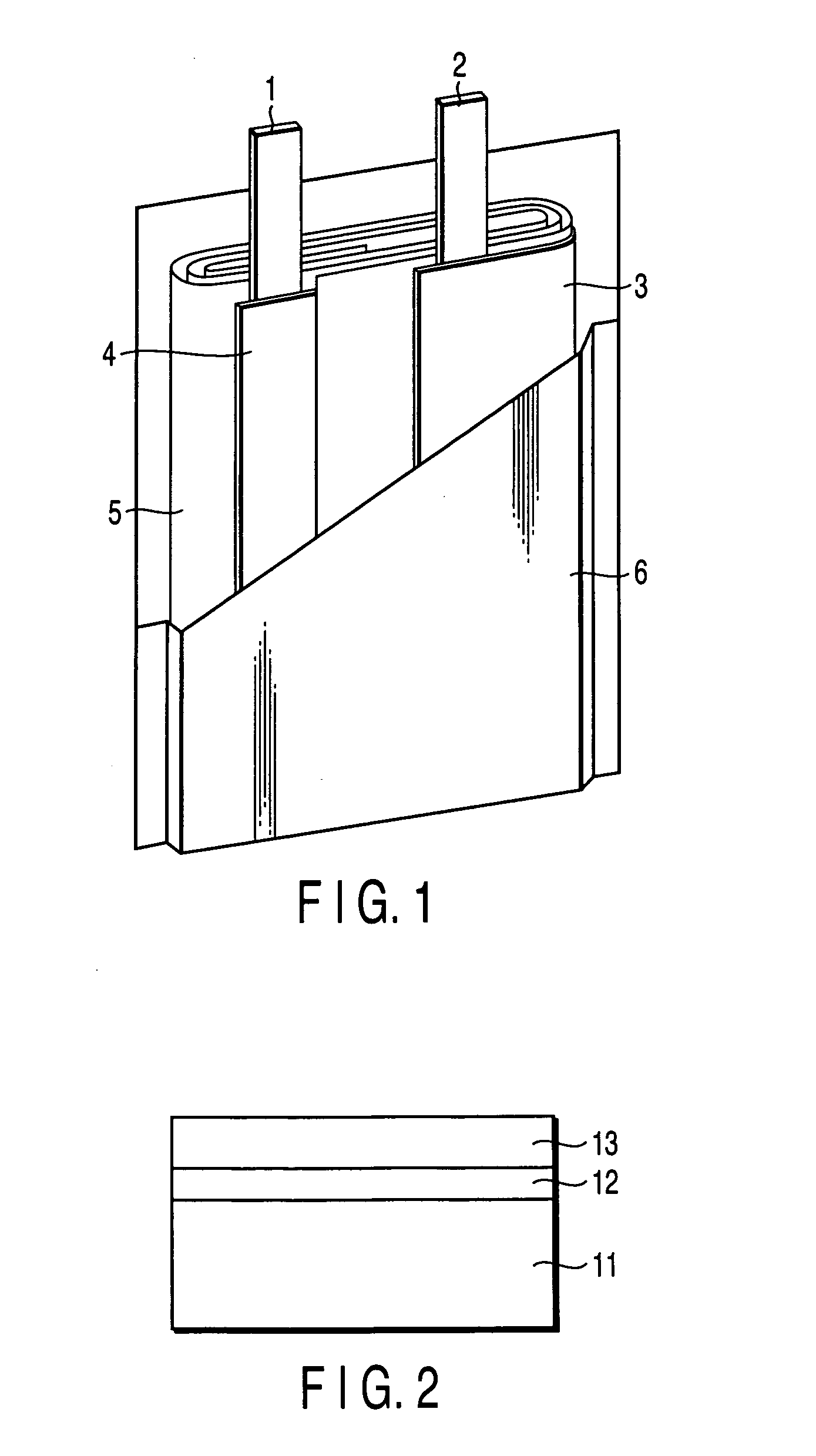

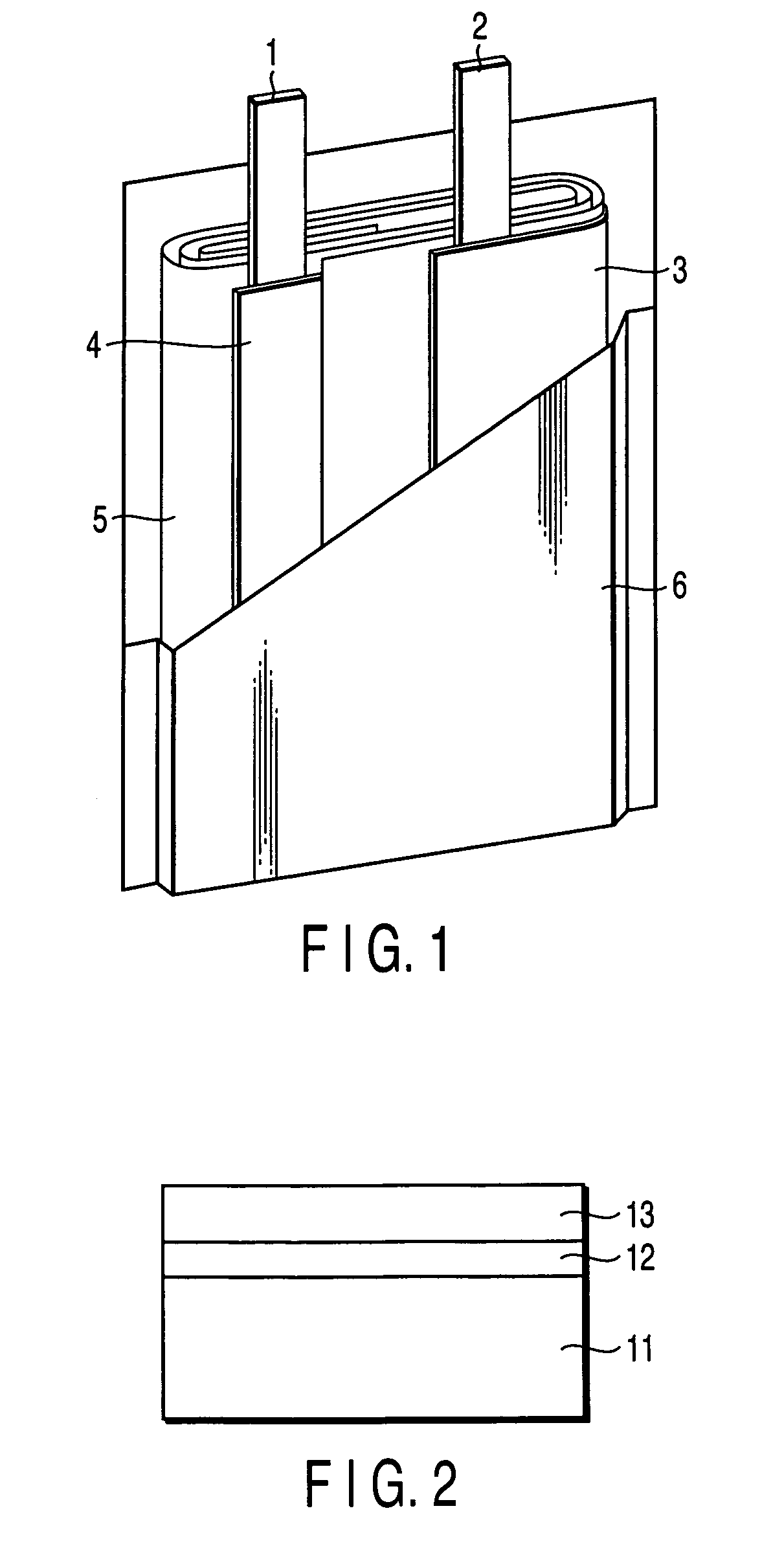

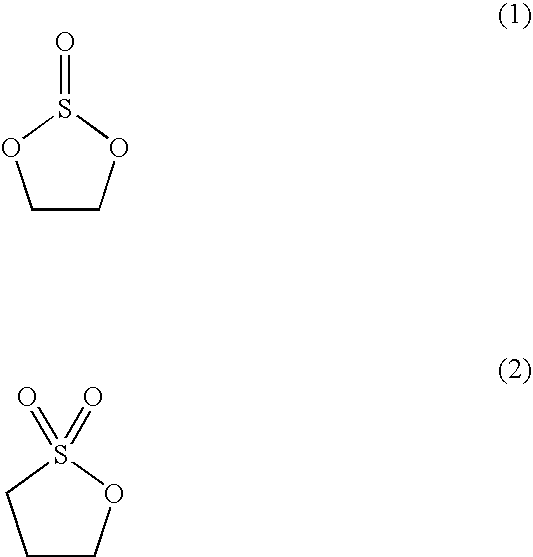

Nonaqueous electrolyte secondary battery

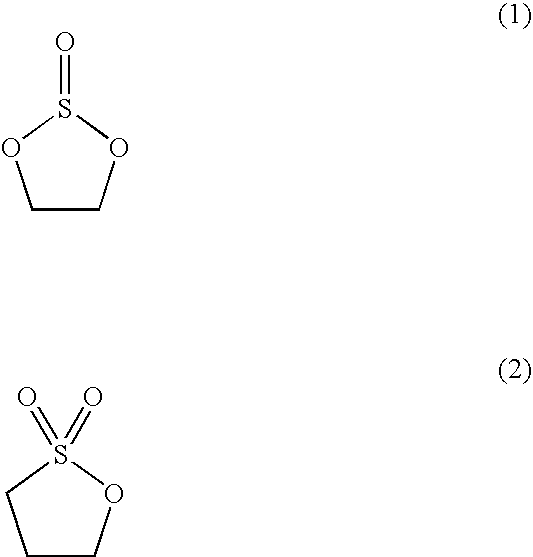

ActiveUS20050221187A1Excellent high rate characteristicsNon-aqueous electrolyte accumulatorsOrganic electrolyte cellsEngineeringLi element

A nonaqueous electrolyte secondary battery includes a case, a nonaqueous electrolyte provided in the case and containing a linear sulfite, a positive electrode provided in the case and capable of absorbing-releasing Li element or Li ions, and a negative electrode provided in the case and containing a lithium titanium oxide and a conductive agent that includes a carbonaceous material.

Owner:KK TOSHIBA

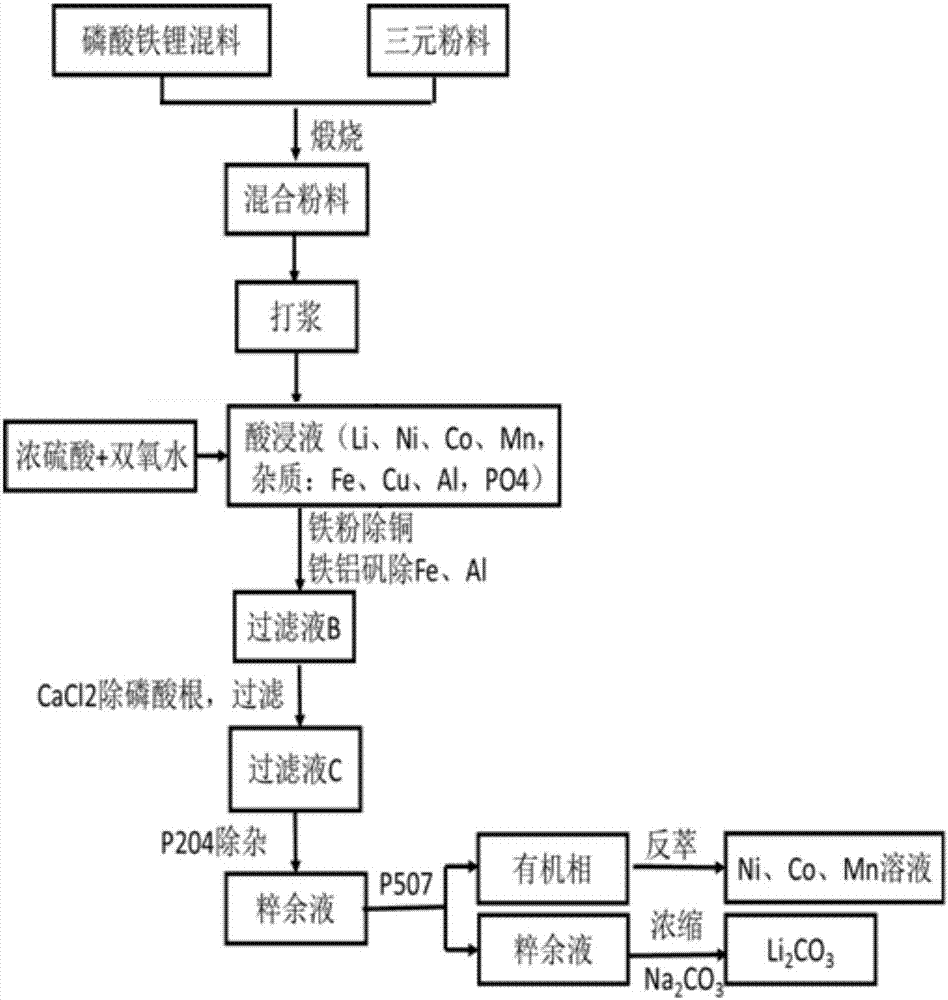

Comprehensive recycling method of lithium ion battery anode material

ActiveCN107267759AReduce sorting costsImprove recycling economicsWaste accumulators reclaimingProcess efficiency improvementSlagElectrical battery

The invention provides a comprehensive recycling method of a lithium ion battery anode material. The method comprises the steps that the anode material of lithium iron phosphate and the anode material of a ternary battery are subjected to high-temperature pretreatment; a product is added into water for pulping processing; concentrated sulfuric acid and hydrogen peroxide are added, and filtering is performed to remove undissolved substances; iron powder is added, filtering is performed to remove copper elements, and heating is performed to generate iron aluminum vanadium slag; a calcium chloride solution is added, and filtering is performed to remove phosphate radicals; series-connection countercurrent extraction is performed through an extraction agent P204 to remove Fe and Ca impurities, and series-connection countercurrent extraction is performed through an extraction agent P507 to separate Ni, Co, Mn elements from Li elements; the organic phase is subjected to reverse extraction with sulfuric acid, a Ni, Ca and Mn solution is obtained, and recycling of nickel, cobalt and manganese is achieved; and the water phase is concentrated, and then a saturated sodium carbonate solution is added to generate lithium carbonate precipitation. By means of the comprehensive recycling method, the anode material of a lithium iron phosphate battery and the anode material of the ternary battery are recycled simultaneously, the battery separation cost is lowered, and the economic benefits of lithium battery recycling are increased.

Owner:南京国轩新能源有限公司

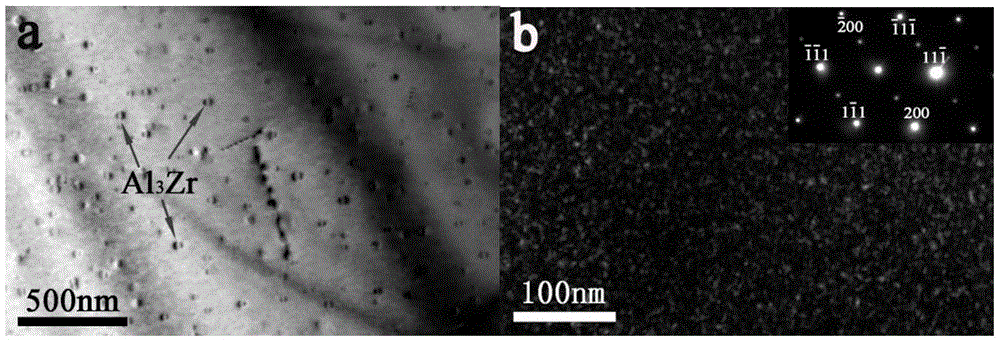

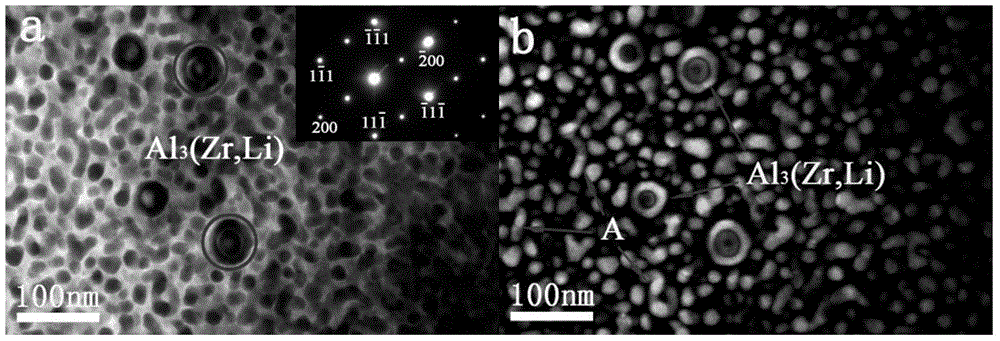

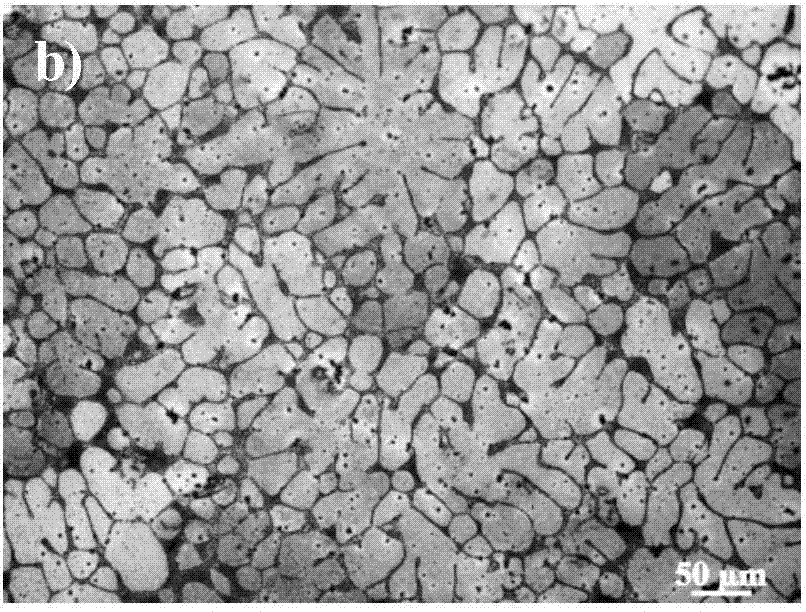

Low-density and high-rigidity cast aluminum-lithium alloy and method for preparing same

The invention discloses low-density and high-rigidity aluminum-lithium alloy and a method for preparing the same. The low-density and high-rigidity cast aluminum-lithium alloy comprises, by weight, 3-3.5% of Li, 1-2% of Cu, 0.5-2% of Mg, 0.4-0.8% of Ag, 0.14-0.2% of Zr, 0.3-0.8% of Mn, lower than 0.25% of impurity elements Si, Fe, Na and K and the balance Al. The low-density and high-rigidity cast aluminum-lithium alloy and the method have the advantages that alloy elements (the Li, the Cu, the Mg, the Ag, the Zr and the Mn) are added by the aid of the method, solid solution and aging treatment is carried out by the aid of the method, and accordingly the low-density and high-rigidity cast aluminum-lithium alloy with excellent mechanical properties can be obtained and is high in elastic modulus and low in density as compared with the traditional cast aluminum alloy; the low-density and high-rigidity cast aluminum-lithium alloy is high in Li element yield and low in cost.

Owner:SHANGHAI JIAO TONG UNIV

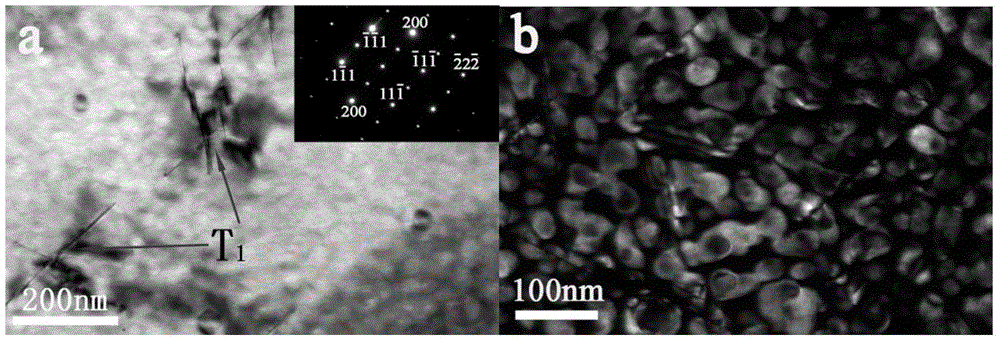

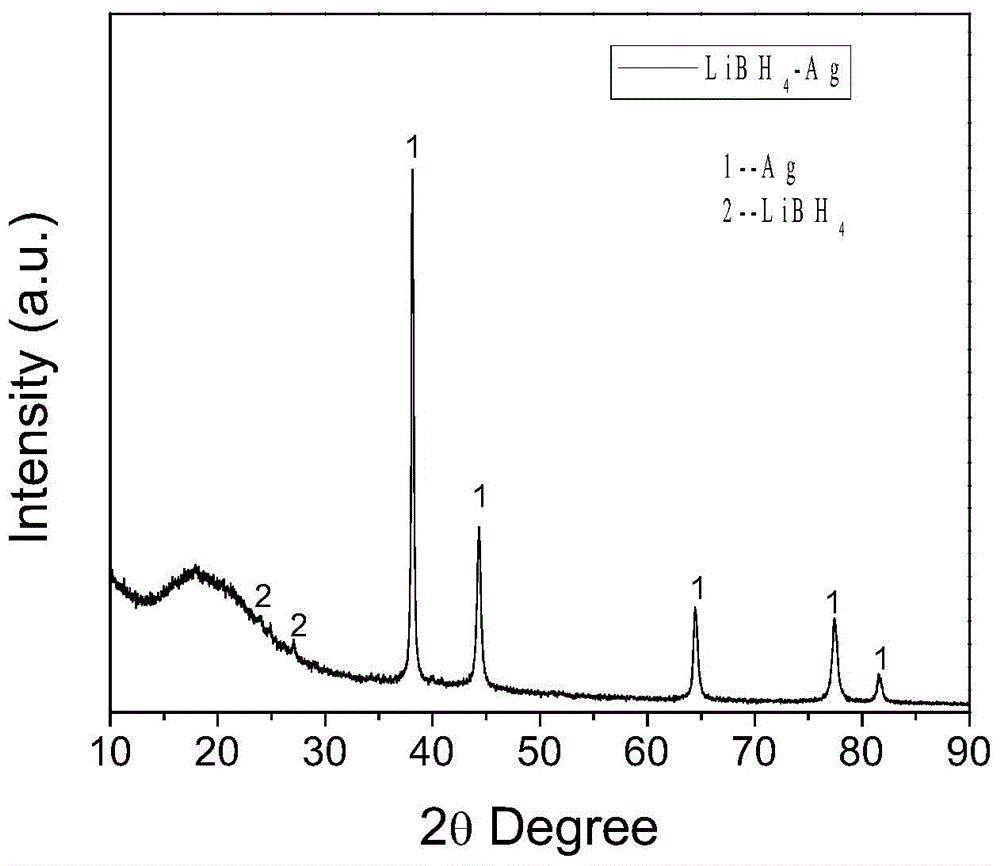

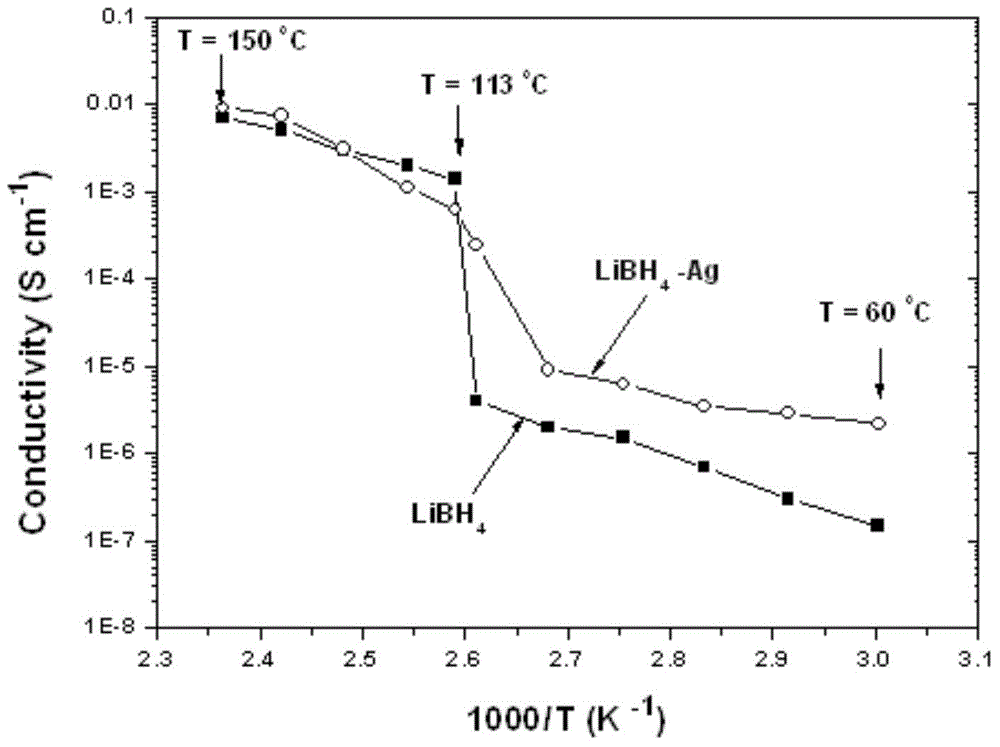

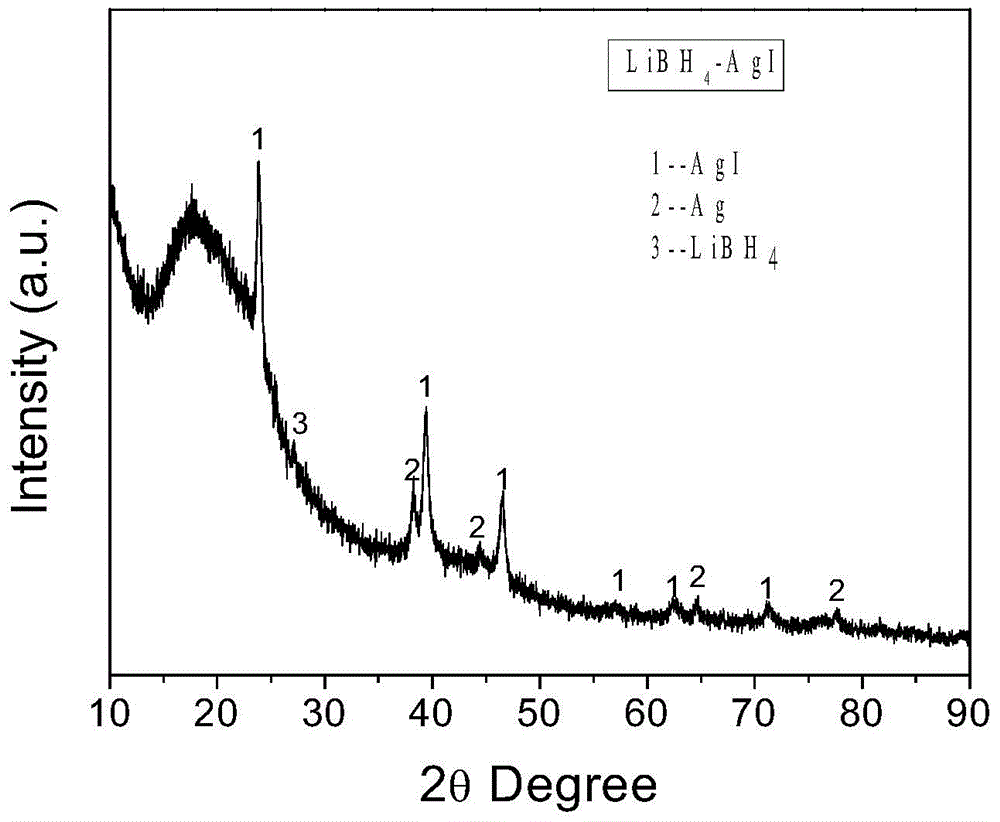

LiBH4-silver/silver halide compound fast-ion conductor and preparation method thereof

The invention provides an LiBH4-silver / silver halide compound fast-ion conductor and a preparation method thereof. The LiBH4-silver / silver halide compound fast-ion conductor is prepared from LiBH4 and silver or silver halide which are at the mole ratio of 20:1 to 4:1. The preparation method of the LiBH4-silver / silver halide compound fast-ion conductor, which is provided by the invention, is simple and low in cost, and can be used for stabilizing the high-temperature phase of LiBH4 and increasing the diffusion channel of an Li element by forming an LiBH4-Ag / AgX (X is a halogen element) compound by adding Ag and the halide of Ag to LiBH4, thus greatly enhancing the ionic conductivity compared with the ionic conductivity of LiBH4, achieving the cm-1 order of magnitude at 100 DEG C for 10-3 seconds and providing wider application prospect for solid electrolyte.

Owner:SOUTHEAST UNIV

Positive electrode mix

ActiveUS20150162614A1Improve securityIncrease discharge voltageSolid electrolytesSolid electrolyte cellsHalogenSulfur

A positive electrode mix including a solid electrolyte and a sulfur-based active material, wherein the solid electrolyte comprises a Li element or a Na element; a S element; and a halogen element selected from the group consisting of I, Br, Cl and F.

Owner:IDEMITSU KOSAN CO LTD

Spectral standard sample of Al-Li alloy and its prepn

InactiveCN1403613AAvoid burnsPrevent surface oxidationPreparing sample for investigationAnalysis by material excitationIngotLi element

The present invention is a spectral standard sample of Al-Li alloy and its preparation process. The present invention features the alloy contains the following chemical elements dispersed homogeneously in aluminum: Si 0.025-0.223 wt%, FE 0.044-0.264 wt%, Cu 0.0019-1.61 wt%, Mg 0.193-6.000 wt%, Li 0.930-2.530 wt%, Zr 0.042-0.168 wt%, Zn 0.023-0.205 wt%, Ti 0.0026-0.134 wt% and Mn 0.015-0.139 wt%. The present invention can avoid the burn loss and surface oxidation of Li element to ensure the correct ratio of Li element in the standard sample. The intermittent semi-continuous casting process prevents the cracking of the alloy ingot.

Owner:SOUTHWEST ALUMINUM GRP

Nonaqueous electrolyte secondary battery

ActiveUS7629081B2Excellent high rate characteristicsNon-aqueous electrolyte accumulatorsOrganic electrolyte cellsSulfiteEngineering

A nonaqueous electrolyte secondary battery includes a case, a nonaqueous electrolyte provided in the case and containing a linear sulfite, a positive electrode provided in the case and capable of absorbing-releasing Li element or Li ions, and a negative electrode provided in the case and containing a lithium titanium oxide and a conductive agent that includes a carbonaceous material.

Owner:KK TOSHIBA

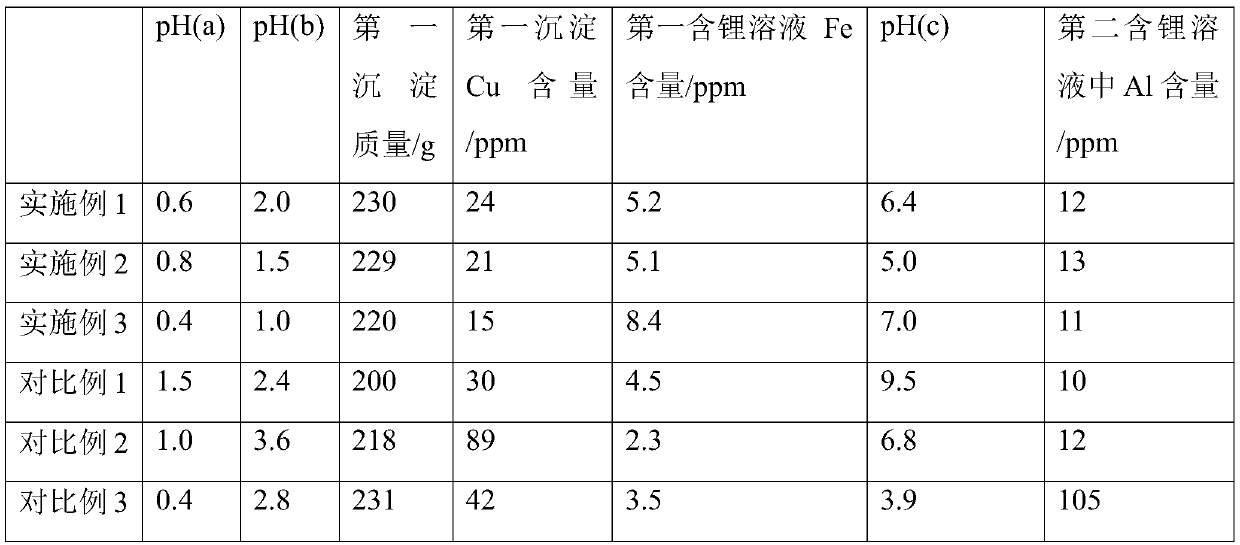

Method for recycling lithium iron phosphate positive electrode material

ActiveCN109721043AEasy to recycleImprove recycling ratesCell electrodesWaste accumulators reclaimingLithium iron phosphateSolvent

The present invention relates to the field of electrochemistry, and more particularly to a method for recycling a lithium iron phosphate positive electrode material. The method comprises the followingsteps: contacting a recycled cell material with an acid solution, and carrying out solid-liquid separation to obtain a first liquid phase and an insoluble substance; adjusting the pH value of the first liquid phase, and carrying out solid-liquid separation to obtain a first lithium-containing solution and a first precipitate; mixing the first precipitate, a second lithium-containing solution andan auxiliary agent to obtain a second liquid phase; adjusting the contents of Li element, Fe element, P element and C element in the second liquid phase to obtain a third liquid phase; removing the solvent of the third liquid phase to obtain a lithium iron phosphate precursor; and calcining the precursor in a reducing environment to obtain the lithium iron phosphate positive electrode material. The method for recycling the lithium iron phosphate positive electrode material provided by the present invention has the advantages of simple process, high recycling rate, low impurity content and thelike, and has a good industrialization prospect.

Owner:CONTEMPORARY AMPEREX TECH CO

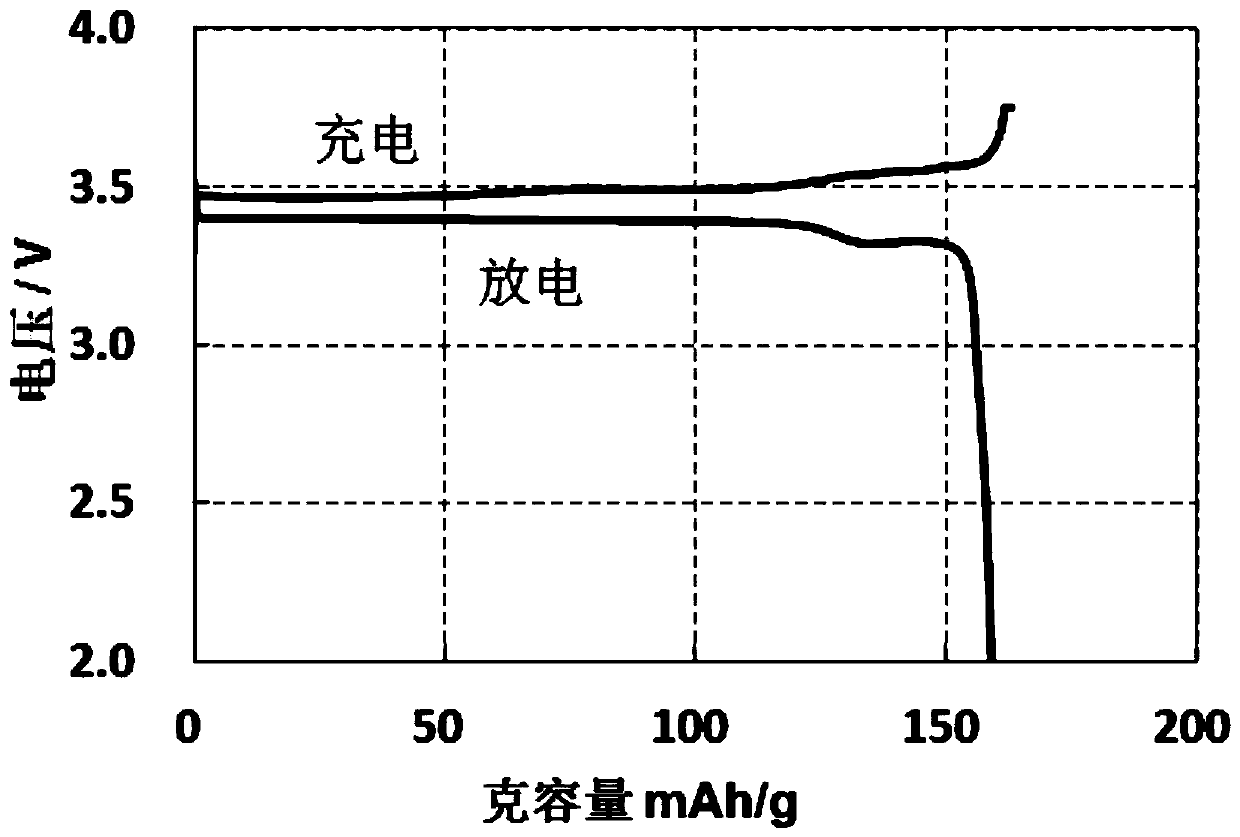

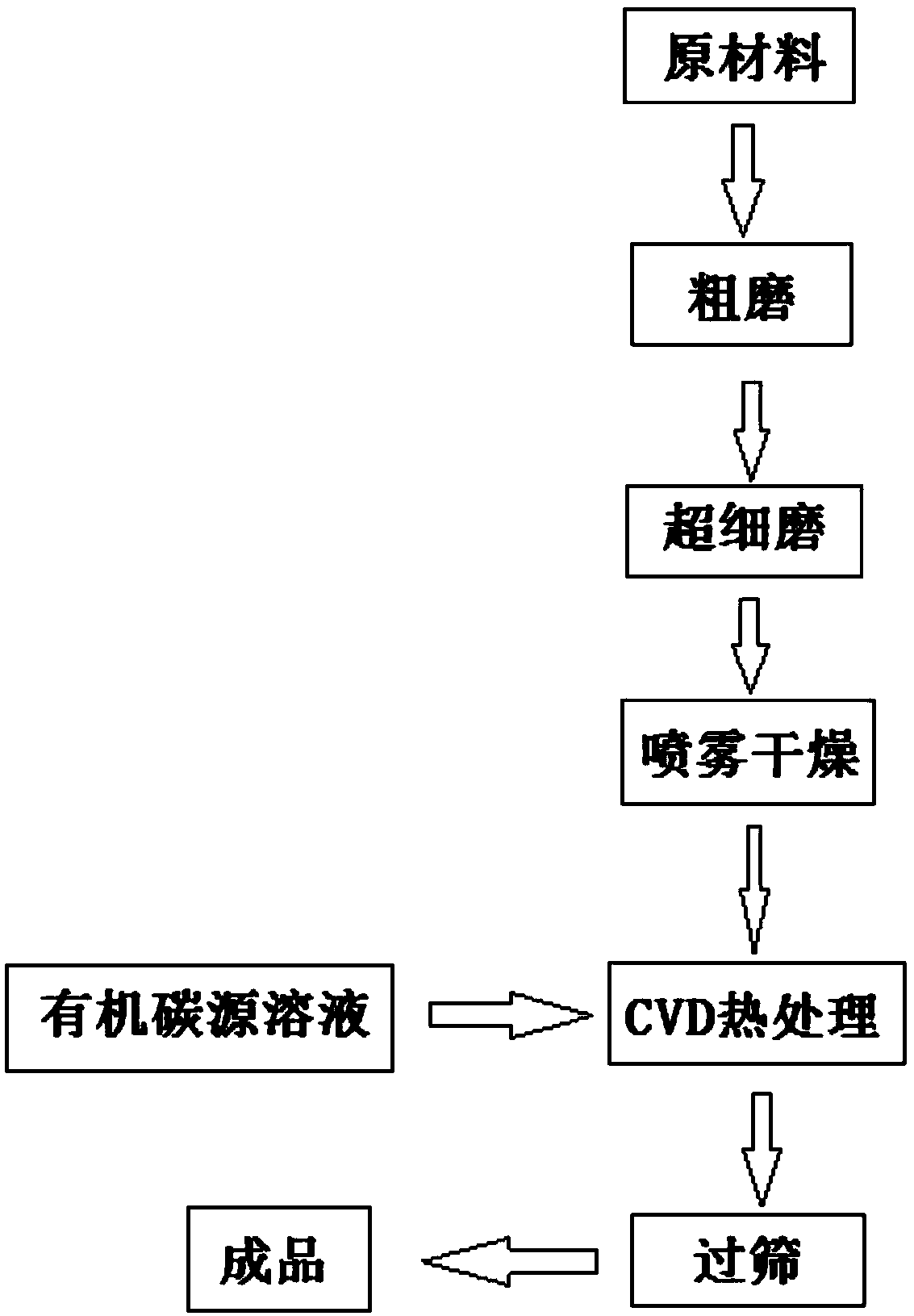

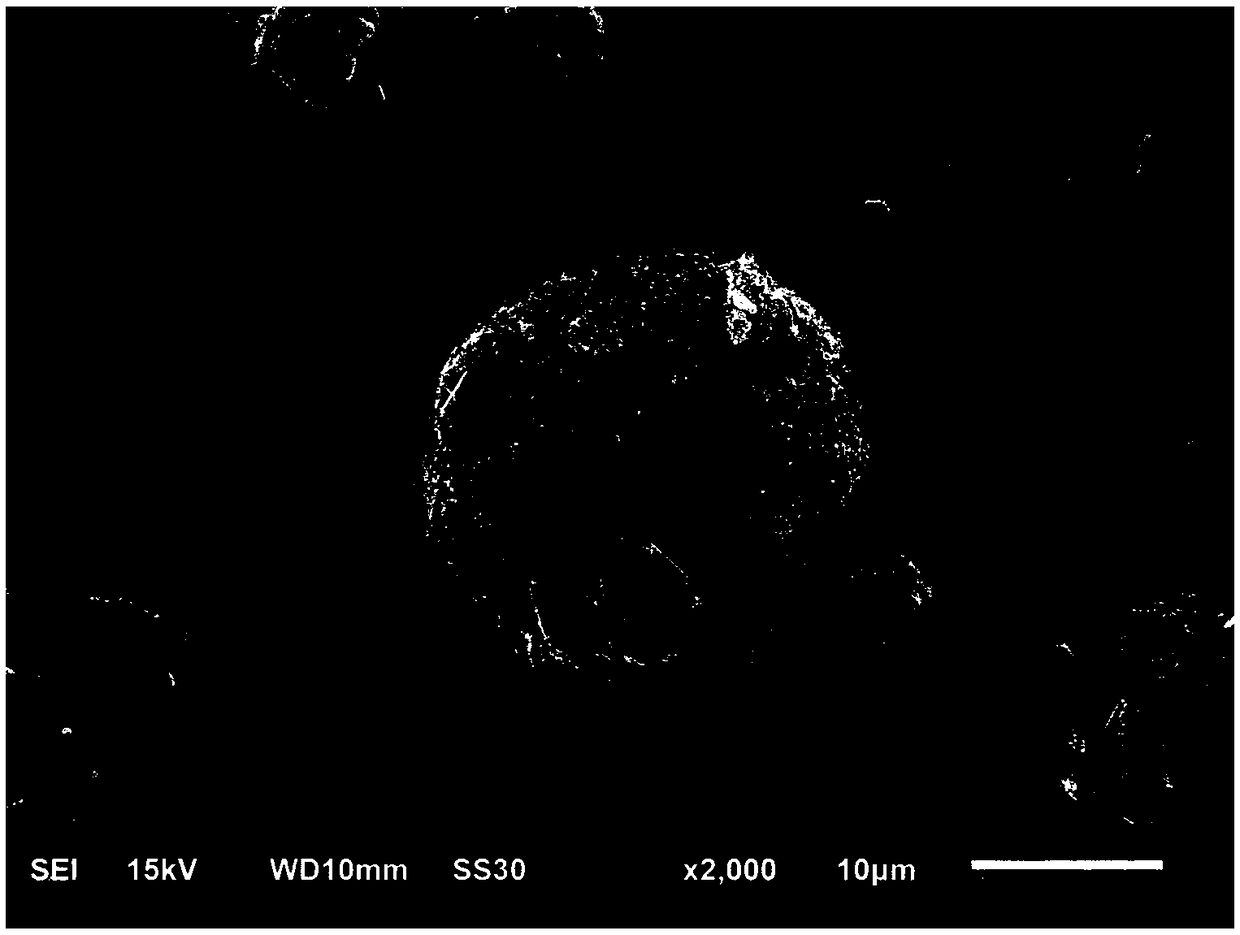

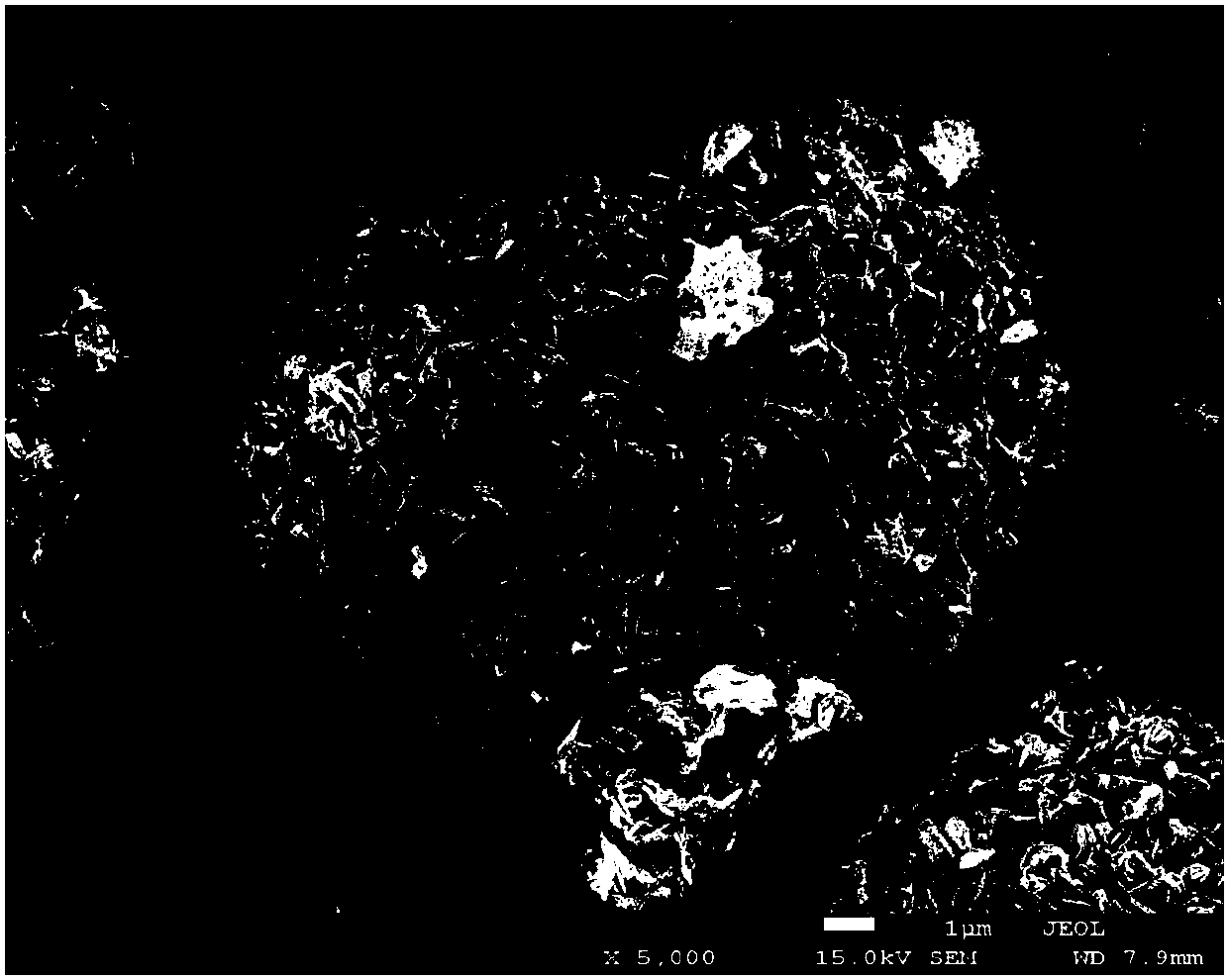

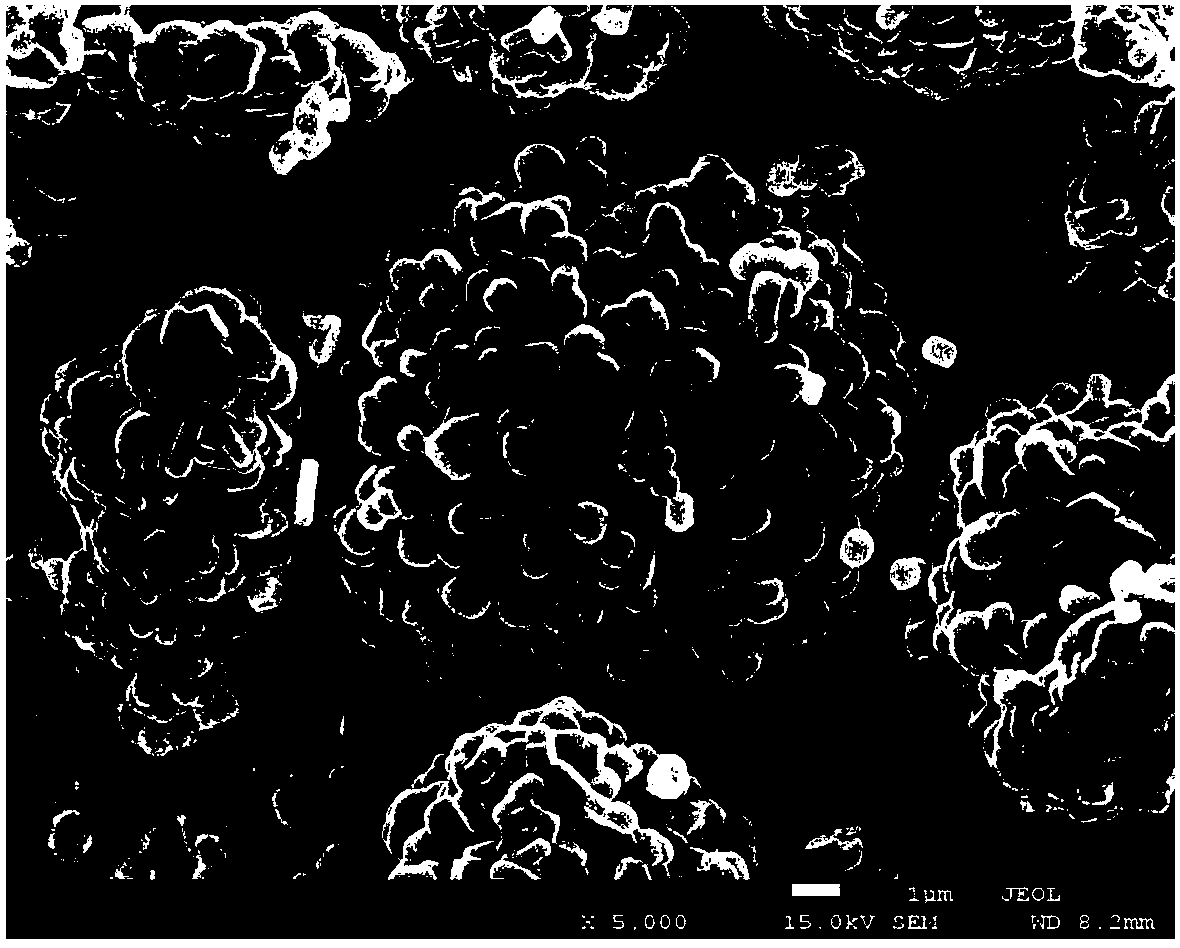

A high magnification spherical lithium iron phosphate carbon composite positive electrode material and a preparation method thereof

ActiveCN109192953AImprove qualityEfficient coatingMaterial nanotechnologyCell electrodesCarbon compositesPhosphate

A high magnification spherical lithium iron phosphate composite positive electrode material and preparation method are provided. The positive electrode material comprises the following raw material components: iron phosphate, lithium source, carbon source A, metal oxide additive, dispersant and carbon source B; among them, Li element in lithium source accounts for 6.0% -8.0% of the mass of iron phosphate; carbon source A accounts for 0.3%-12.5% of the mass of iron phosphate; the metal oxide additive accounts for 0.5%-5.0% of the mass of ferric phosphate; the dispersant accounts for 0.2%-1.5% of the mass of ferric phosphate; carbon source B accounts for 1% -15.0% of the mass of iron phosphate. The preparation method comprises the following steps: (1) grinding the ingredients; (2) spray drying and granulating; (3) heat treatment, adding carbon source A and metal oxide additive in the grinding process, adding carbon source B in the heat treatment process. The lithium iron phosphate positive electrode material prepared by the invention is spherical shape particles, the surface and the interior of the lithium iron phosphate positive electrode material are uniformly coated with metal-doped carbon, the conductivity is high, the crystallinity is good, the compaction density is 1.3 g / cm3 to 1.8 g / cm3, and the 10C discharge capacity can reach 148mAh / g.

Owner:湖南桑瑞新材料有限公司

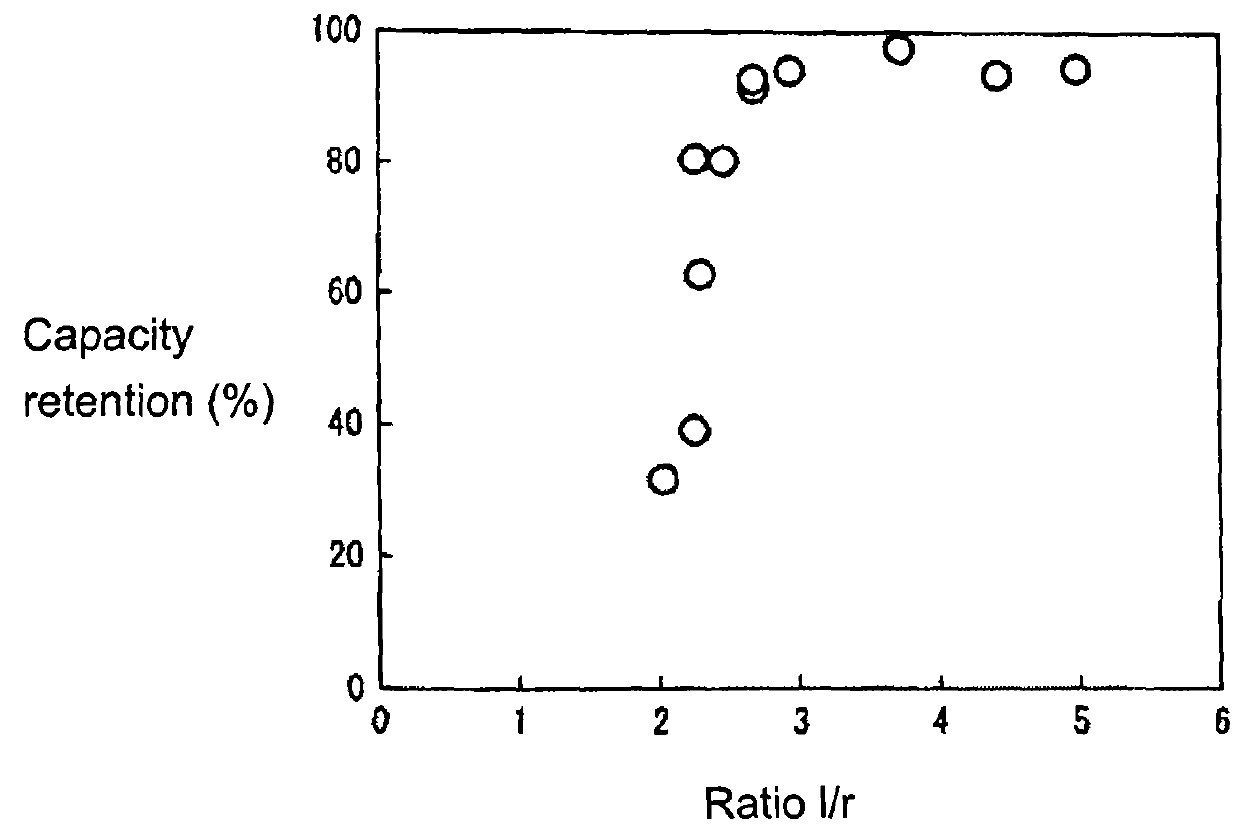

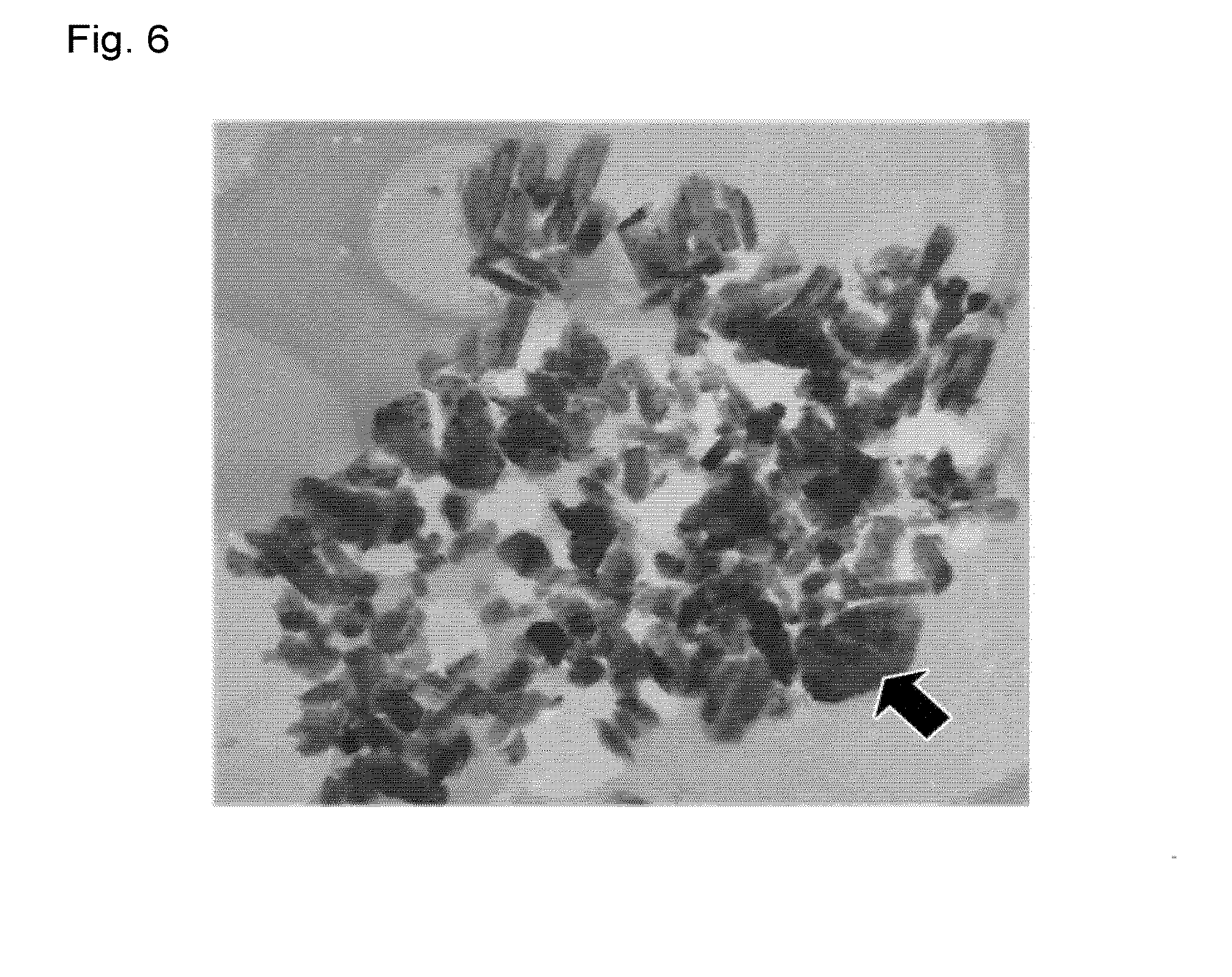

Cathode active material

InactiveUS20160056462A1Improve discharge performanceHigh cycle durabilityPositive electrodesNon-aqueous electrolyte accumulator electrodesSpace groupX-ray

To provide a cathode active material which achieves a high discharge capacity and excellent cycle durability.A cathode active material represented by LiaMOx (wherein M is an element including at least one member selected from Ni element, Co element and Mn element (other than Li element and O element), “a” is from 1.1 to 1.7, and x is the number of moles of O element required to satisfy the valences of Li element and M),wherein in an X-ray diffraction pattern, the ratio (I / r) of the crystallite size (I) of (003) plane to the crystallite size (r) of (110) plane assigned to a crystal structure with space group R-3m is at least 2.6.

Owner:SUMITOMO CHEM CO LTD

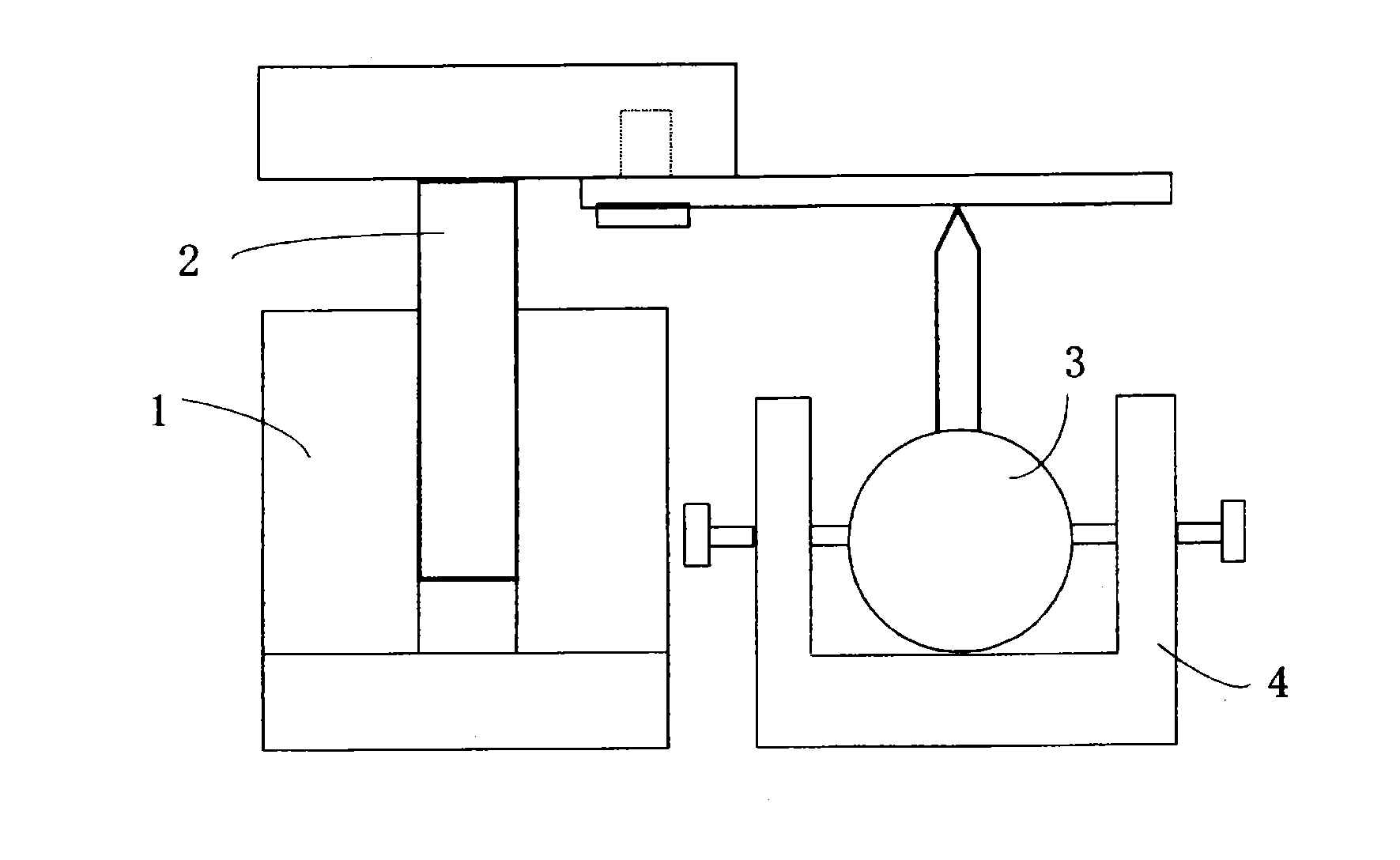

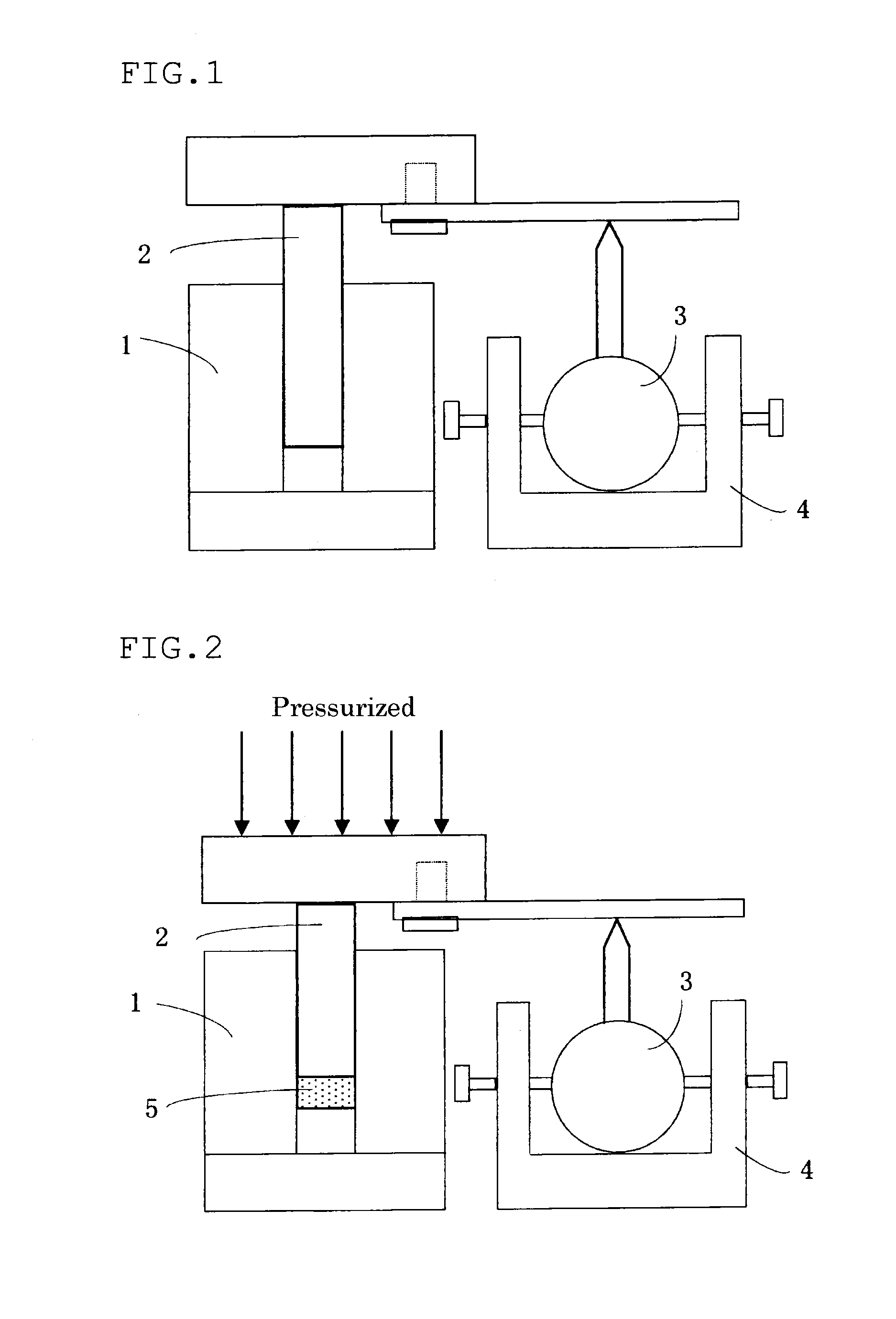

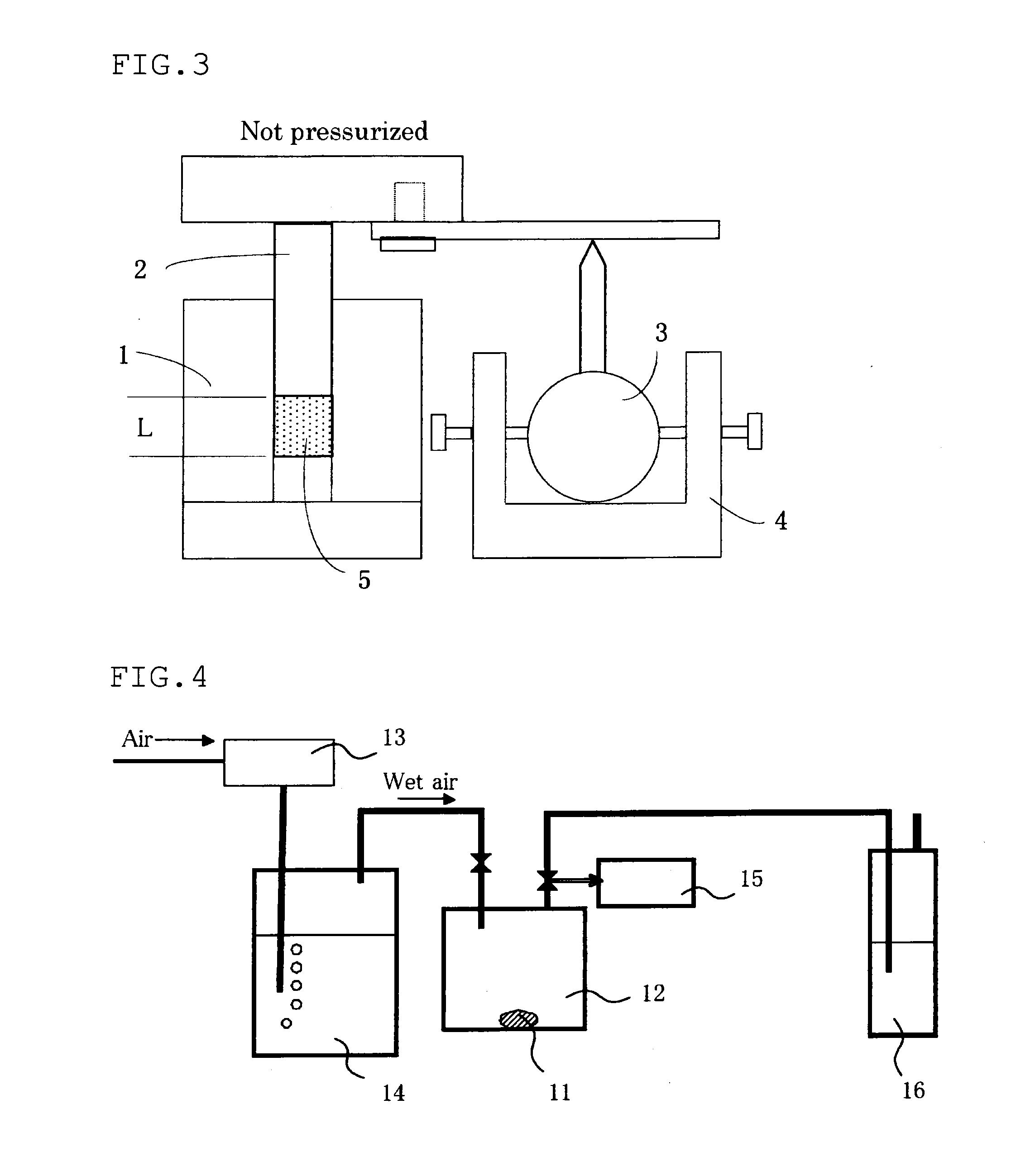

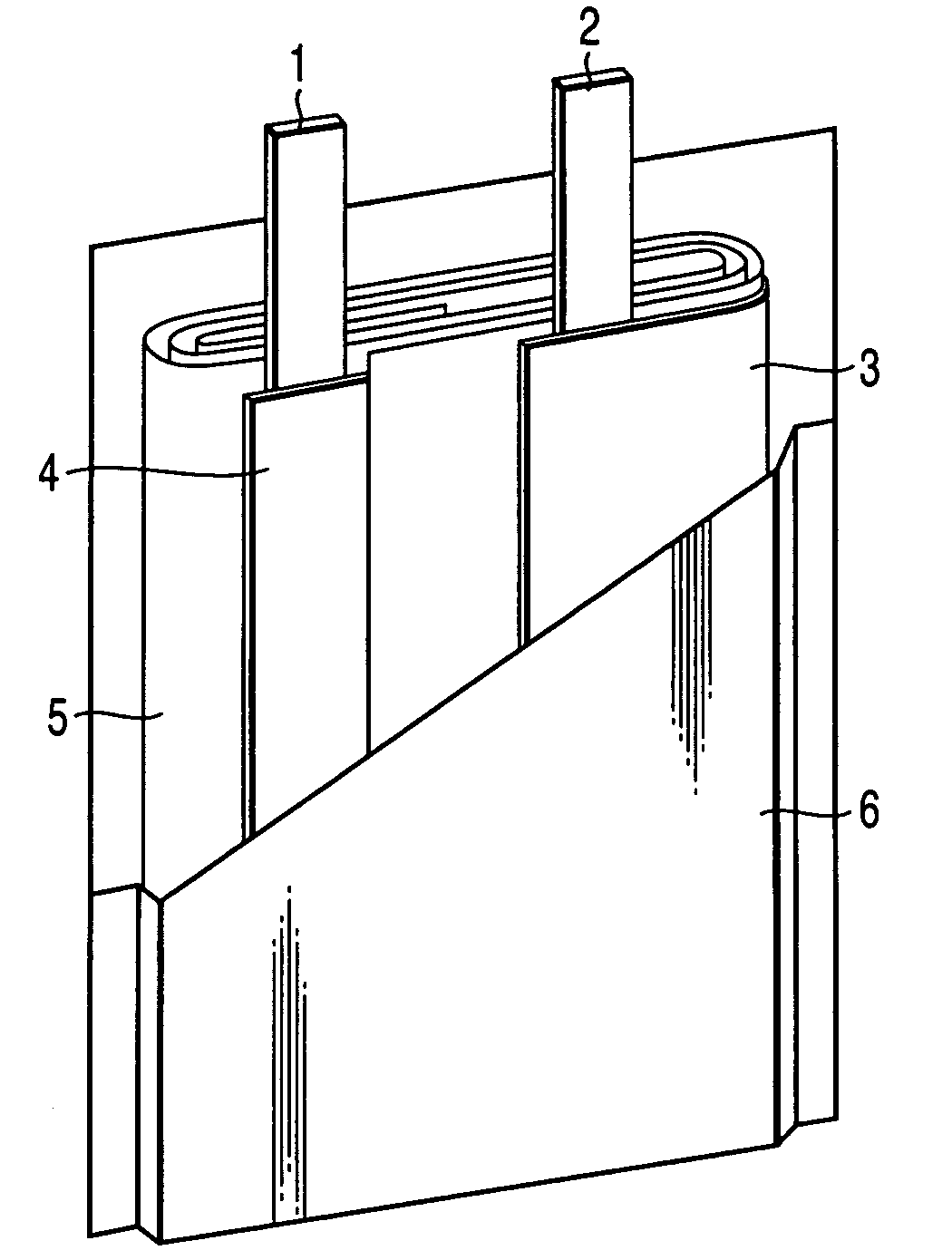

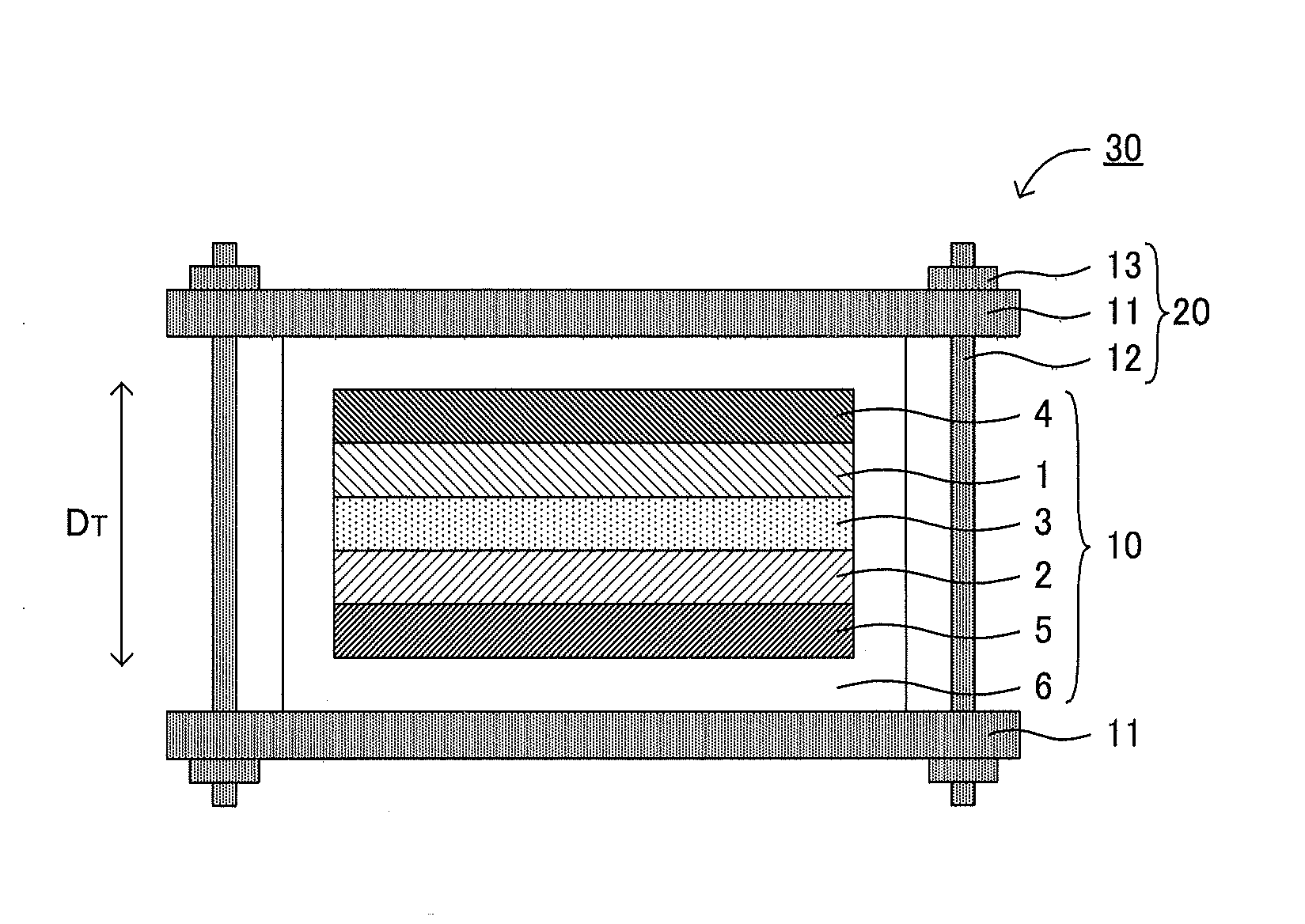

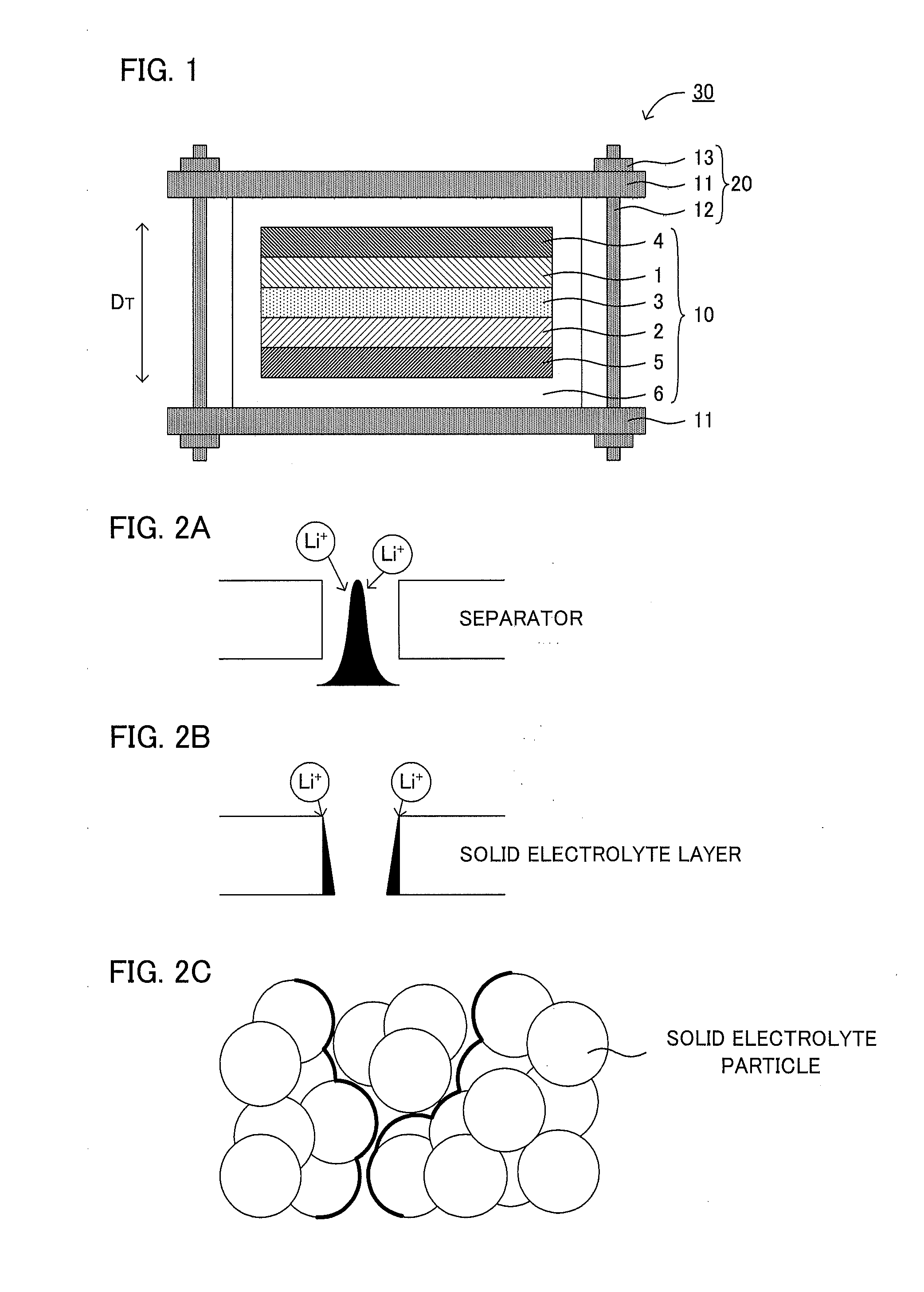

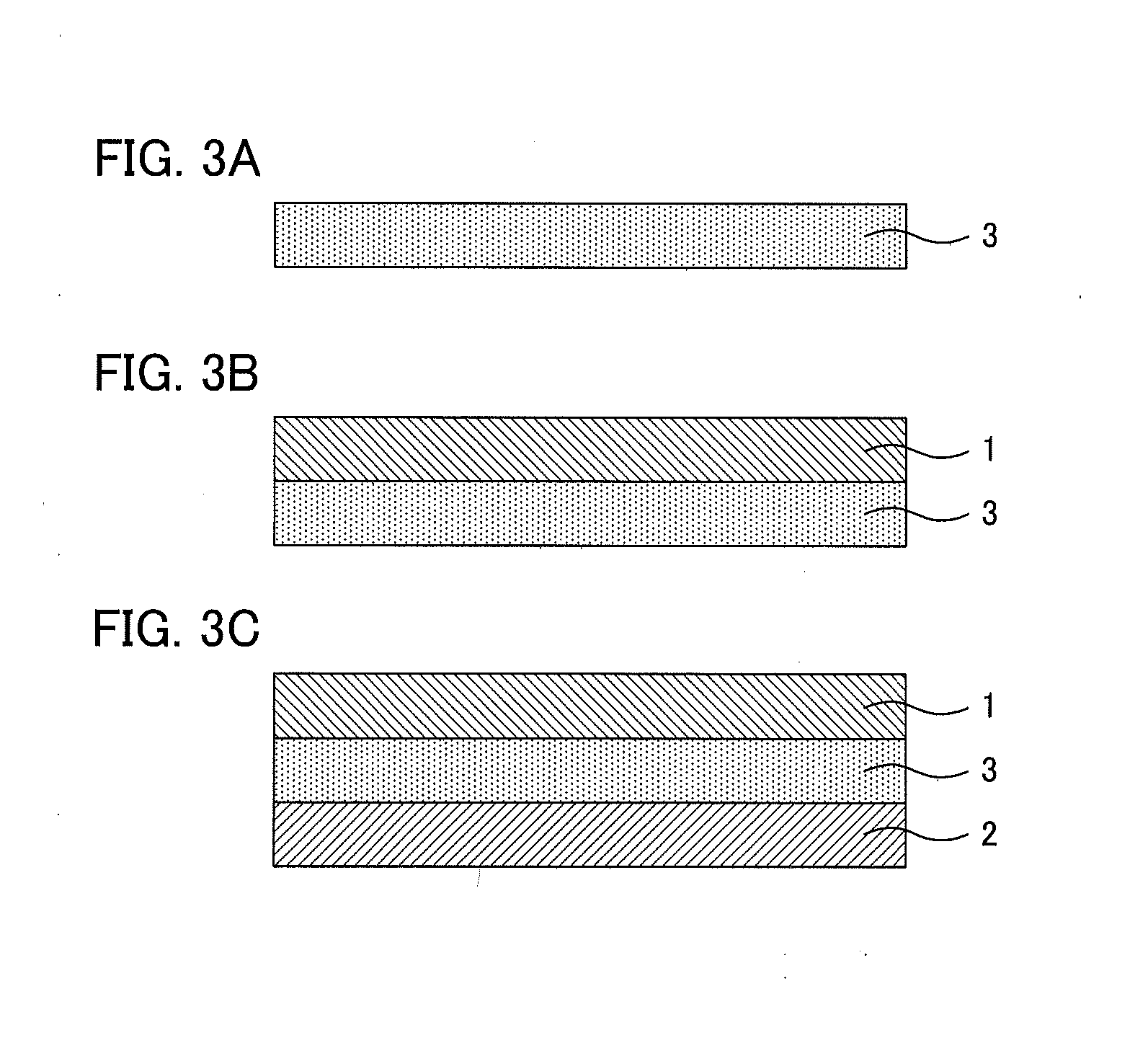

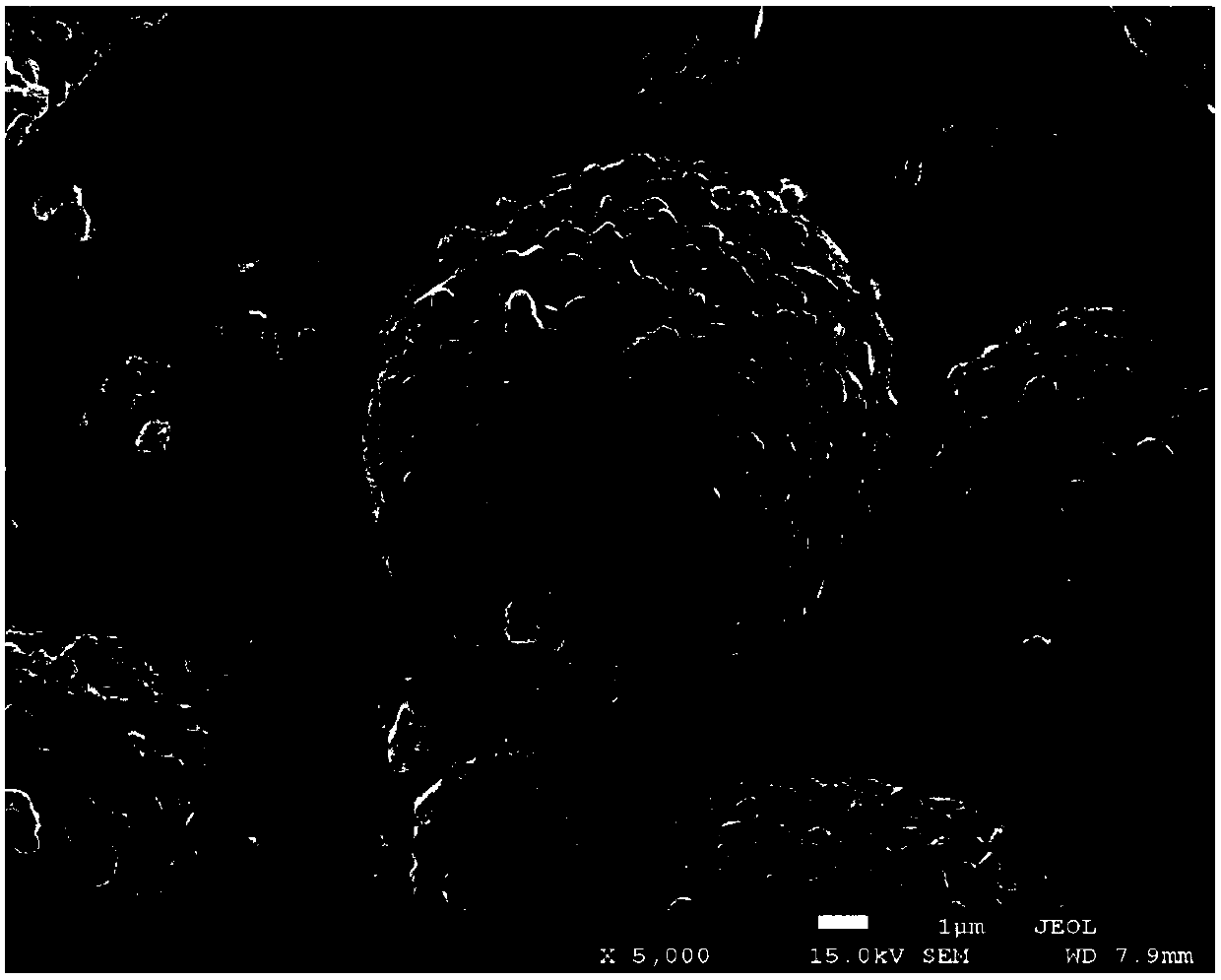

Method of producing solid state lithium battery module

The invention provides a method of producing a solid state lithium battery module in which the occurrence of short circuit caused by dendrites is suppressed. The invention solves this problem by providing a method of producing a solid state lithium battery module, including steps of: a pressing step of pressing a sulfide glass having an ion conductor containing a Li element, a P element, and a S element, and forming a solid electrolyte layer; and a restraining step of restraining a solid state lithium battery including the solid electrolyte layer, using restraining member, wherein, in the pressing step, the solid electrolyte layer is formed such that the average pore radius obtained by a mercury intrusion method is R (μm), and in the restraining step, the solid state lithium battery is restrained such that when the confining pressure is designated as P(MPa), the relationship: P≦−5900R+74 is satisfied.

Owner:TOYOTA JIDOSHA KK

Composite anode active material and preparation method thereof, anode and battery

ActiveCN109873129AEvenly distributedGood performance in lithium deintercalationNon-aqueous electrolyte accumulatorsCell electrodesDivalent metalCrystal structure

The invention relates to the field of anode materials, in particular to a composite anode active material and a preparation method thereof, an anode and a battery. The composite anode active materialhas a core-shell structure, wherein a core contains an anode active material, a shell layer contains a silicate material of a pmn2<1> crystal structure, the silicate material contains Li elements andM elements, and the M elements are divalent metal elements. According to the composite anode active material with the core-shell structure, lithium-supplementing agents are distributed on the shell layer, the anode active material is formed in the core, so that the lithium-supplementing agents are distributed more uniformly and combined more tightly, lithium disembedding performance is better, andthe composite anode active material has an excellent lithium-supplementing effect and can obtain better circulation performance.

Owner:HUIZHOU BYD BATTERY

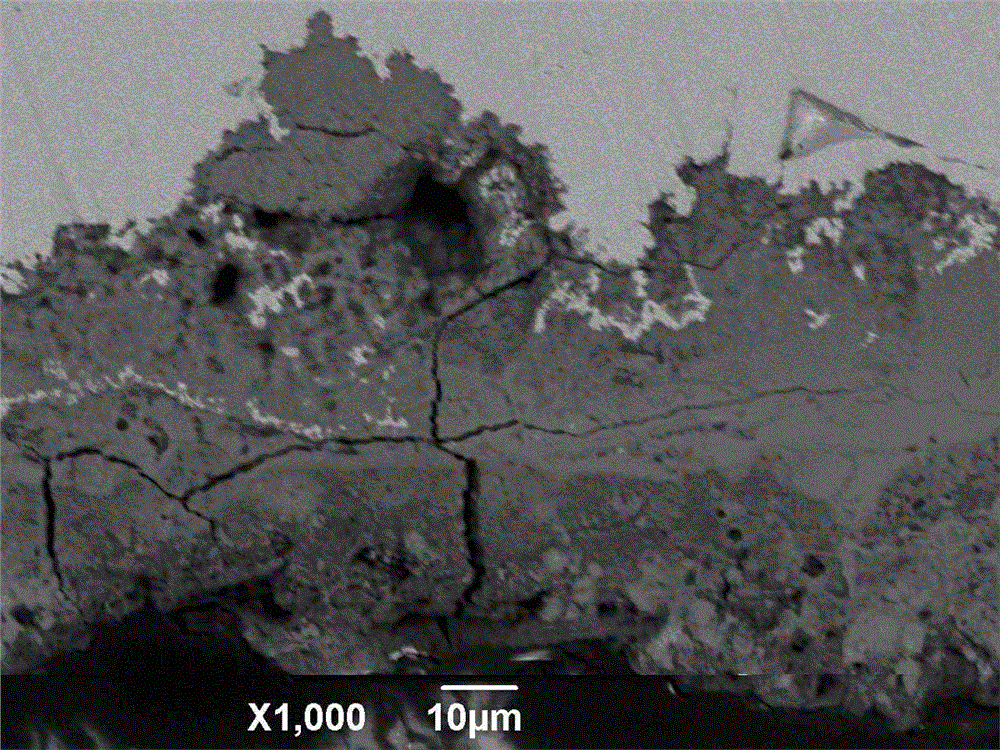

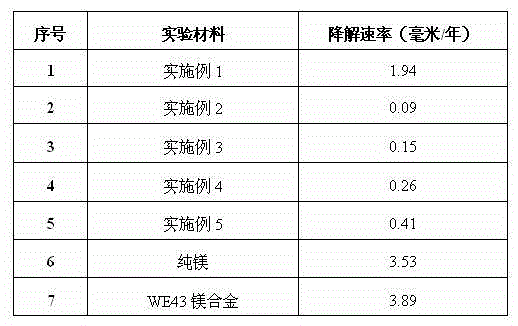

Corrosion-resistant and high-strength and toughness Zn-Fe-Li-based zinc alloy capable of being degraded in human body and application of corrosion-resistant and high-strength and toughness Zn-Fe-Li-based zinc alloy

The invention discloses a corrosion-resistant and high-strength and toughness Zn-Fe-Li-based zinc alloy capable of being degraded in a human body and an application of the corrosion-resistant and high-strength and toughness Zn-Fe-Li-based zinc alloy, relates to field of medical implantation materials, and provides the corrosion-resistant and high-strength and toughness Zn-Fe-Li-based zinc alloy which is low in cost of added materials, high in strength, good in plasticity and controllable in degradation rate, has non-expanding and non-migrating degradation products and can be simultaneously degraded in the human body against the defects in the prior art. The zinc alloy comprises Zn, Fe and Li elements, wherein the content of the Zn element in mass percentage is 80-99.997%, the content of the Fe element in mass percentage is 0.002-10%, and the content of the Li element in mass percentage is 0.001-10%. The cost of the materials added into the zinc-based alloy disclosed by the invention is low, the degradation products of various components in the prepared alloy material can be degraded in the human body by metabolism, the corrosion resistance is much higher than that of a magnesium alloy, the degradation speed is greatly reduced, the mechanical support can be provided for a longer time, and the alloy material has good strength and toughness.

Owner:XIAN ADVANCED MEDICAL TECH

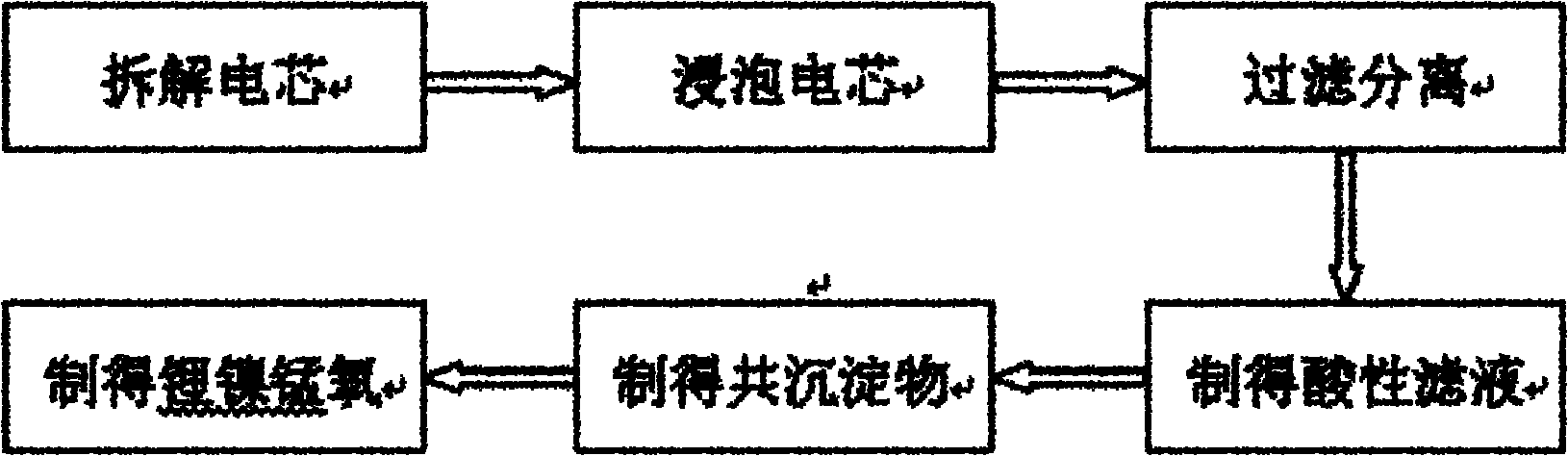

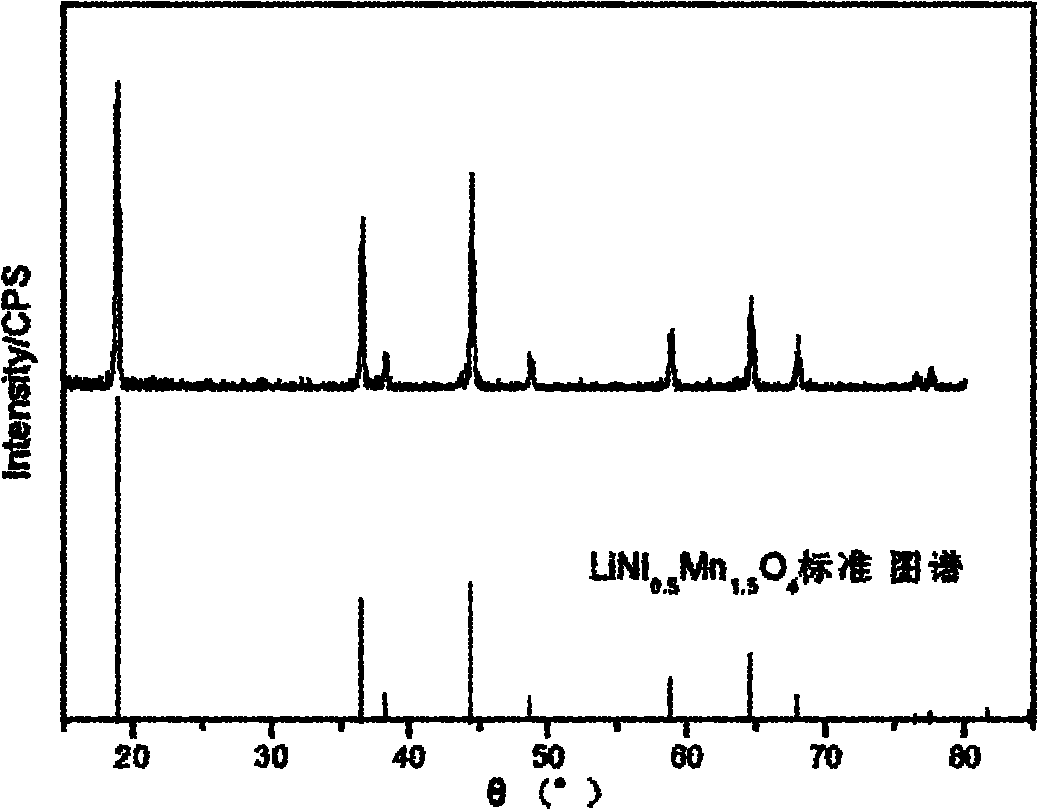

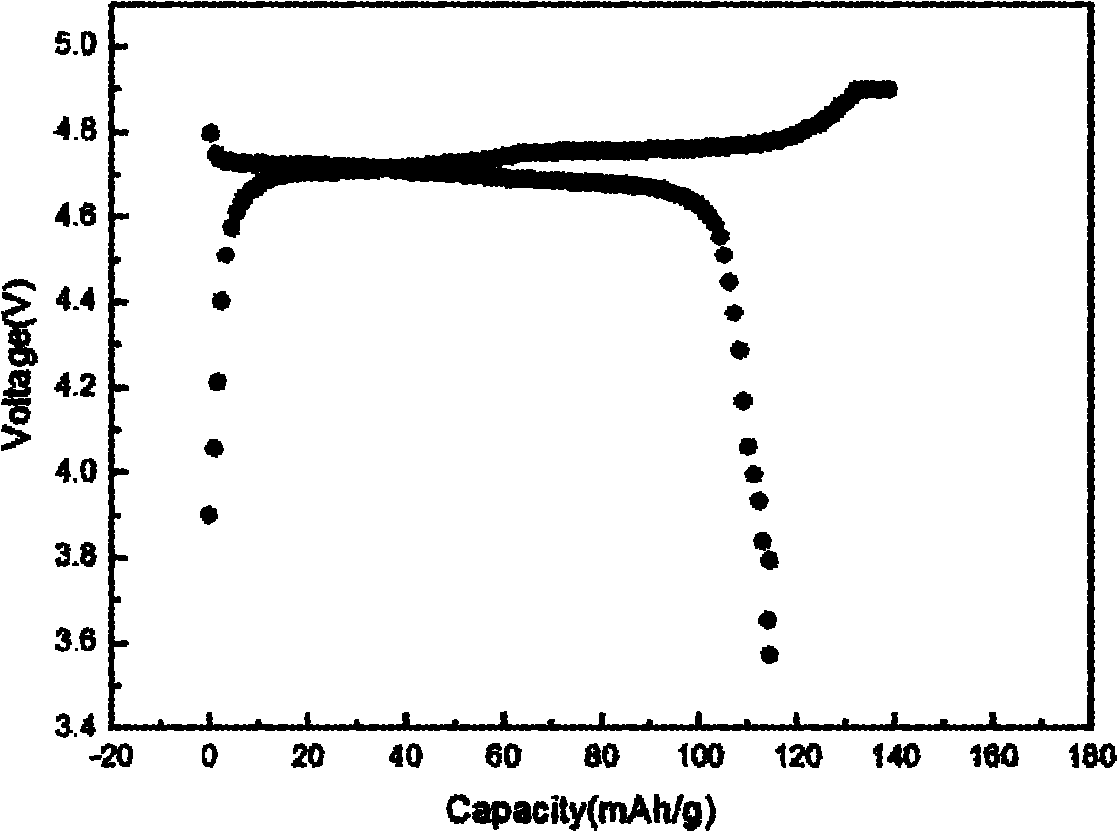

Method for preparing high-voltage cathode material lithium-nickel-manganese-oxygen battery

The invention discloses a method for preparing a high-voltage cathode material lithium-nickel-manganese-oxygen battery. The method comprises a plurality of steps of: dismantling an electric core, immersing the electric core, filtering and separating, preparing acidic filtrate, preparing coprecipiate, and preparing a lithium-nickel-manganese-oxygen battery. The method has the advantages that: 1, comprehensive recycling of Mn, Ni, Li, Al and Cu in waste and old LiMnO batteries, lithium nickel batteries and lithium nickel-manganese batteries is realized, Mn or Ni and Li elements are not needed to be separated, and the new good-performance high-voltage cathode material lithium-nickel-manganese-oxygen battery is synthesized directly; 2, the process is simple, the method is suitable for mass processing, the cost is low, the obtained battery has an impressive market prospect, and the additional value is high; and 3, the recycling rate of manganese and nickel metal in the battery is over 96 percent, and the recycling rate of lithium carbonate is 78 percent.

Owner:CHERY AUTOMOBILE CO LTD

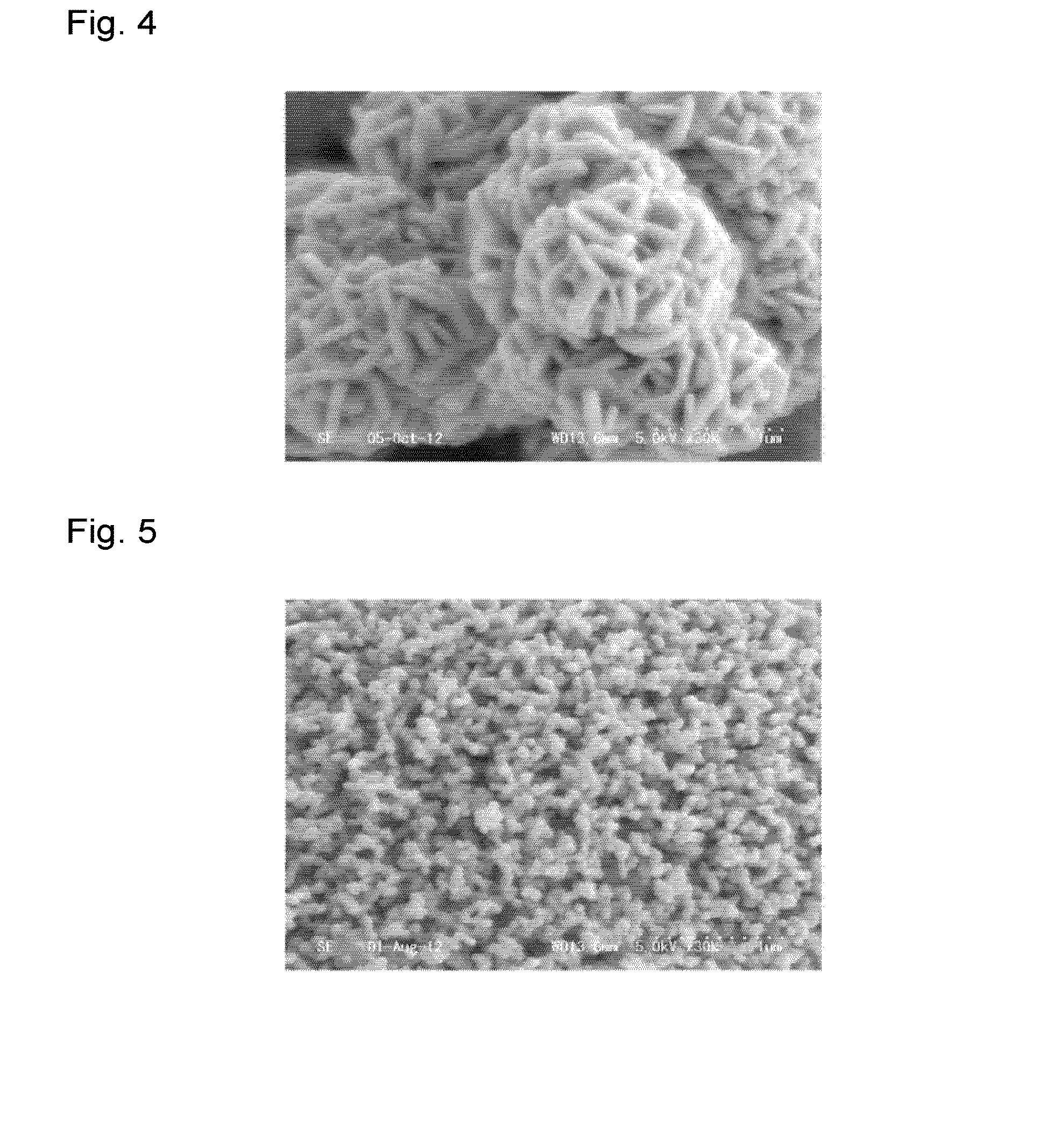

Cathode active material

InactiveUS20160043396A1Improve discharge performanceHigh cycle durabilityPositive electrodesCobalt compoundsSpace groupX-ray

To provide a cathode active material to be used for a positive electrode of a lithium ion secondary battery having a high discharge capacity and favorable cycle durability.A cathode active material, which comprises a lithium-containing composite oxide containing at least one transition metal element (X) selected from the group consisting of Ni element, Co element and Mn element, and Li element (provided that the molar ratio (Li / X) of the Li element based on the total amount of the transition metal element (X) is from 1.1 to 1.7),wherein the aspect ratio of primary particles is from 2.5 to 10, andin an X-ray diffraction pattern, the ratio (I020 / I003) of the integrated intensity (I020) of a peak of (020) plane assigned to a crystal structure with space group C2 / m to the integrated intensity (I003) of a peak of (003) plane assigned to a crystal structure with space group R-3m is from 0.02 to 0.3.

Owner:SUMITOMO CHEM CO LTD

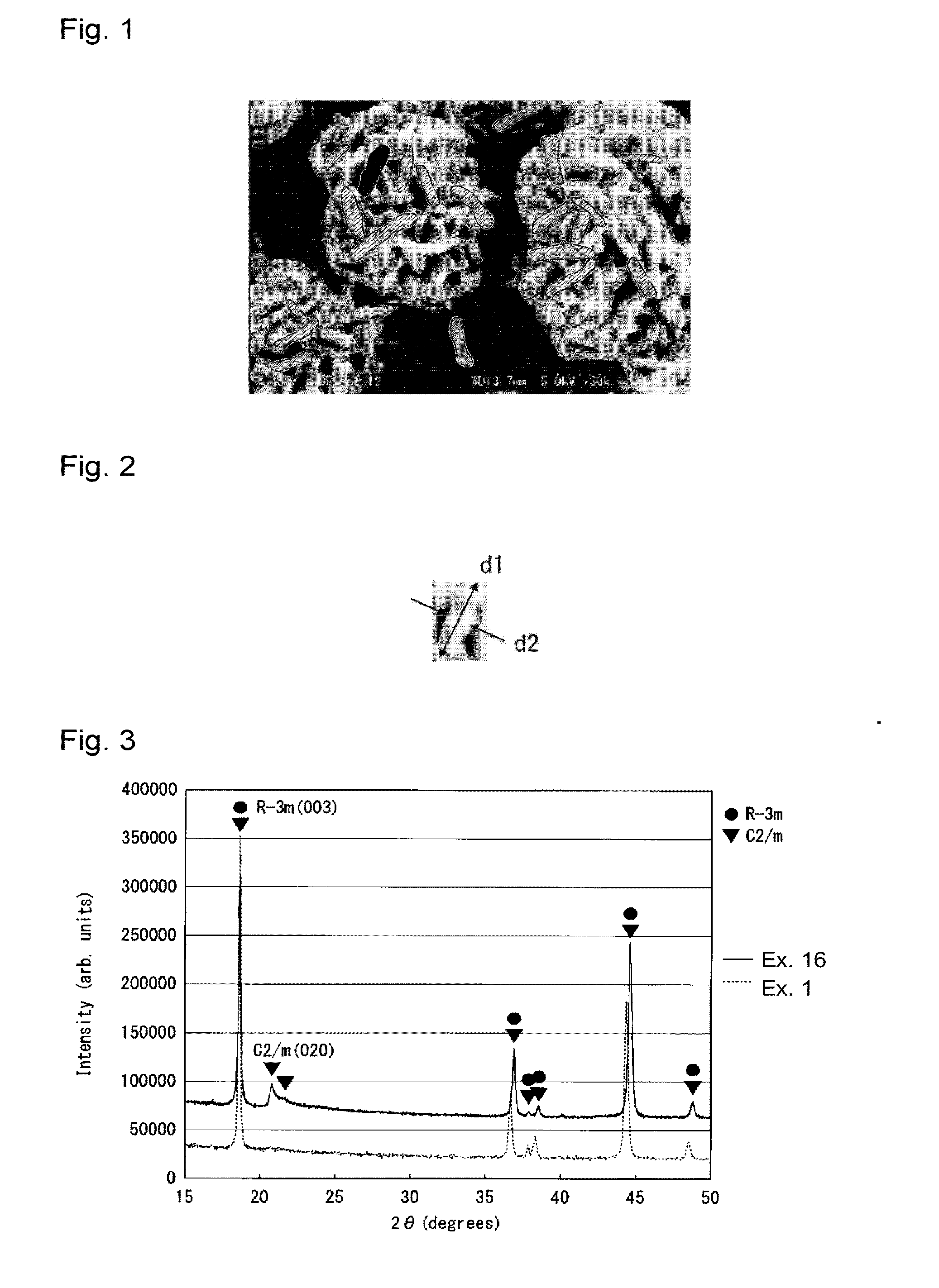

Positive electrode active material, positive electrode, battery, and production method for lithium ion secondary battery

InactiveCN103181006AExcellent cycle characteristicsGood rate characteristicsElectrode thermal treatmentPositive electrodesLi elementMetal

The present invention provides a positive electrode active material, a positive electrode, a lithium ion secondary battery, and a method for producing the positive electrode active material, for a lithium ion secondary battery which exhibits superior cycle characteristics and rate characteristics even when charged with high voltage. The invention is characterized by comprising particles (II) in which an oxide (I) of at least one type of a metal element selected from a group consisting of Zr, Ti, and AI is unevenly distributed on the surface of a lithium-containing complex oxide containing Li and at least one type of transition metal element selected from a group consisting of Ni, Co, and Mn (with the proviso that the molar quantity of the Li element is greater than 1.2 times the total molar quantity of the transition metal element or elements).

Owner:ASAHI GLASS CO LTD

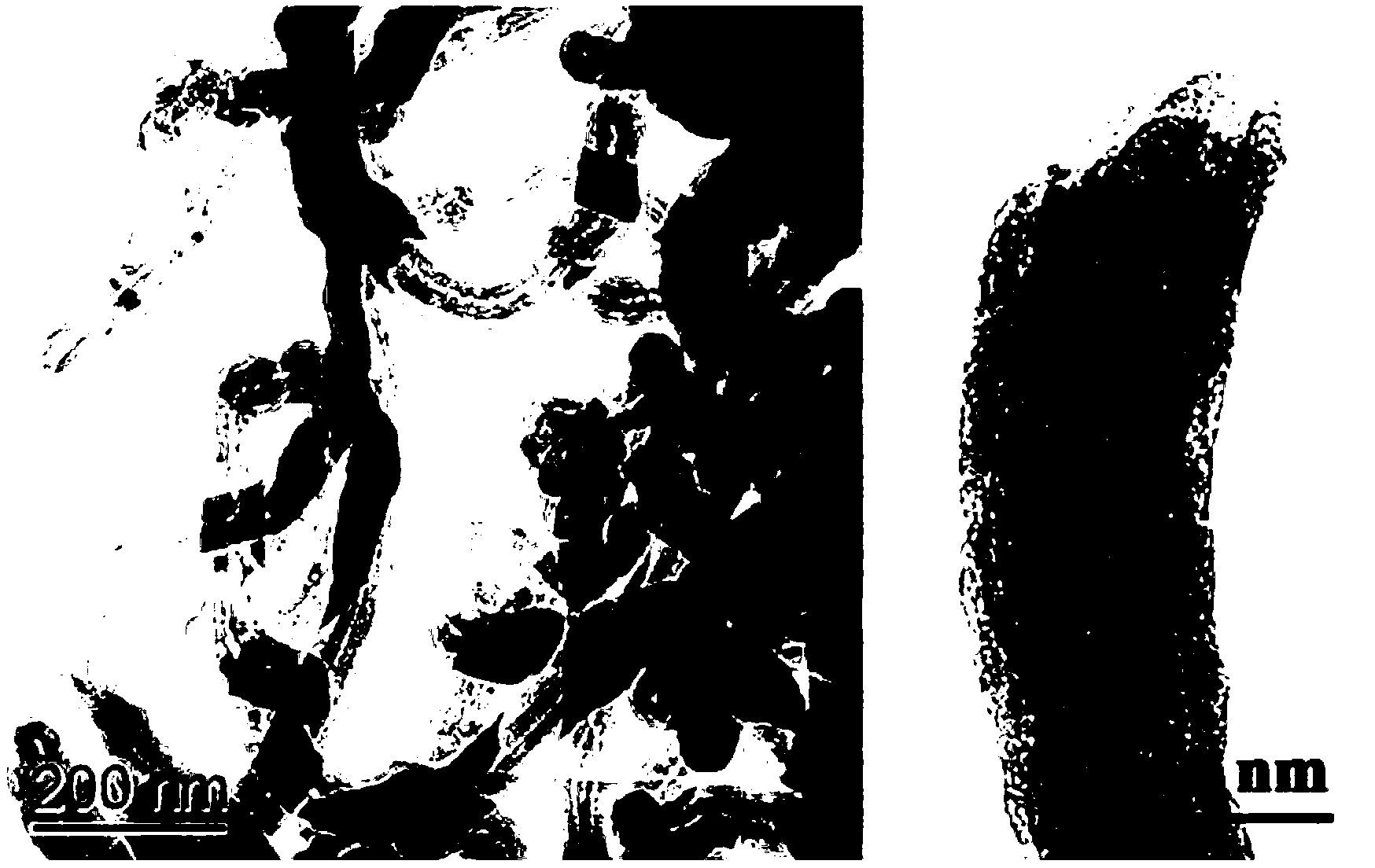

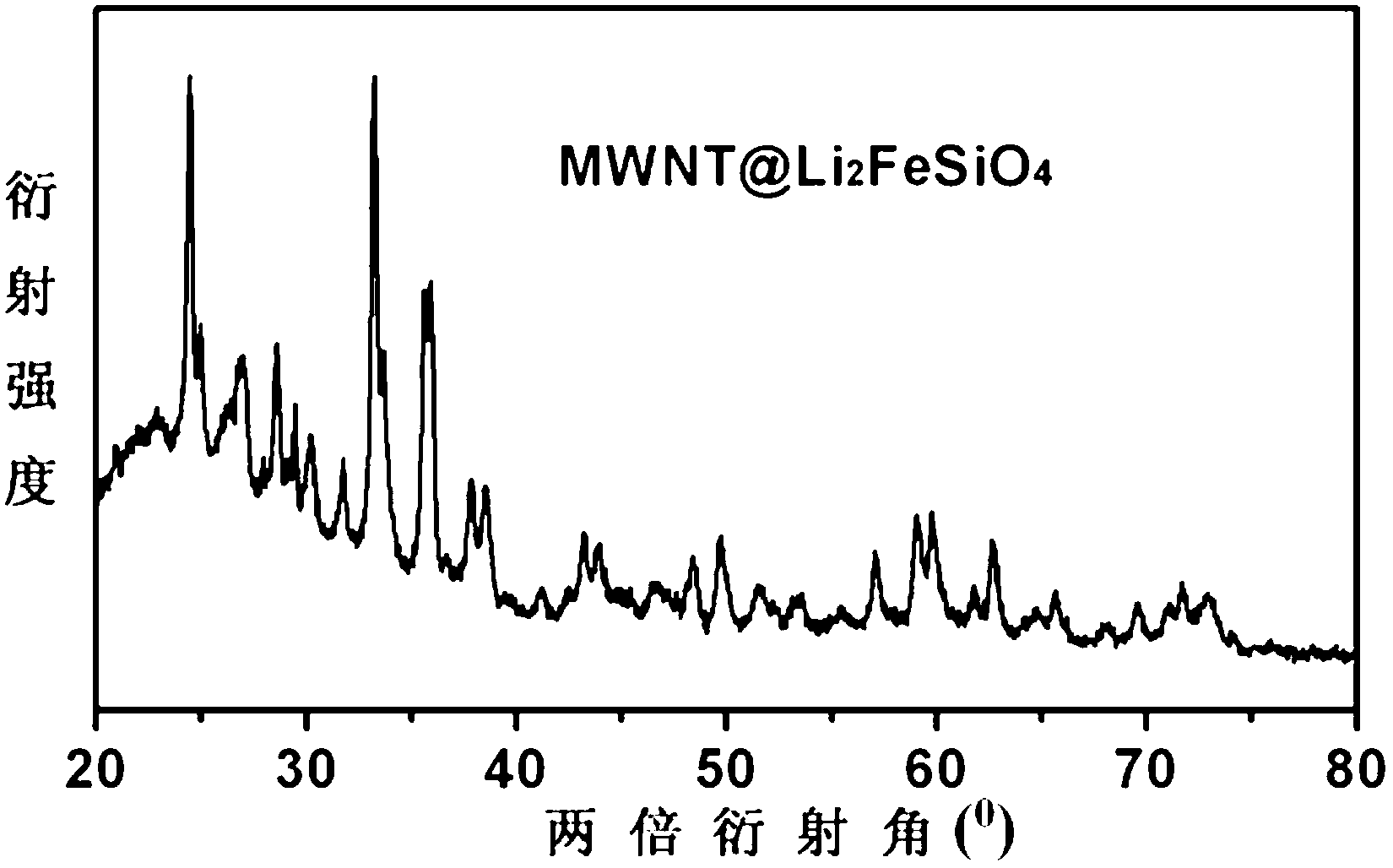

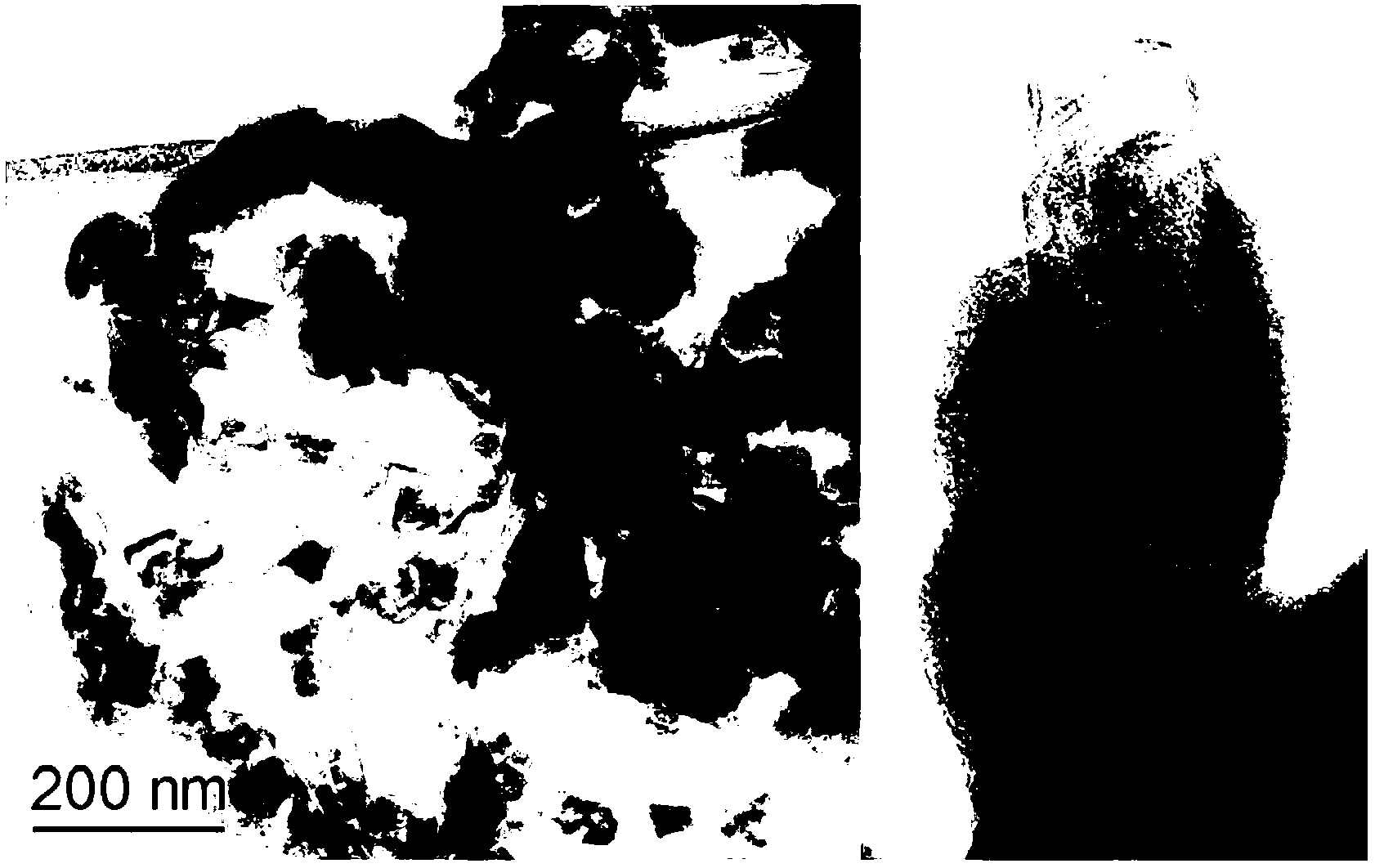

Preparation method of carbon nano-Li2FeSiO4 composite cathode material

InactiveCN102709561AImprove conductivityImprove electrochemical activityCell electrodesComposite cathodeCarbon nanomaterials

The invention provides a preparation method of a carbon nano-Li2FeSiO4 composite cathode material. The preparation method comprises the following steps of: uniformly loading different contents of silica on the surface of a carbon nanomaterial, taking a carbon nano-silica compound as a template, dissolving the carbon nano-silica compound in ethanol according to the molar ratio of Fe element to Si element to Li element of 1: 1: 2 and carrying out uniform ultrasonic mixing; stirring the mixing liquid at 60 DEG C till the ethanol is completely volatilized, uniformly grinding the obtained solid in an agate mortar, and tabletting the powder obtained after grinding; and heating the tablets in an inert atmosphere to 550-650 DEG C and calcining at constant temperature for 5-10h to obtain the carbon nano-Li2FeSiO4 composite cathode material with a core-shell structure.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

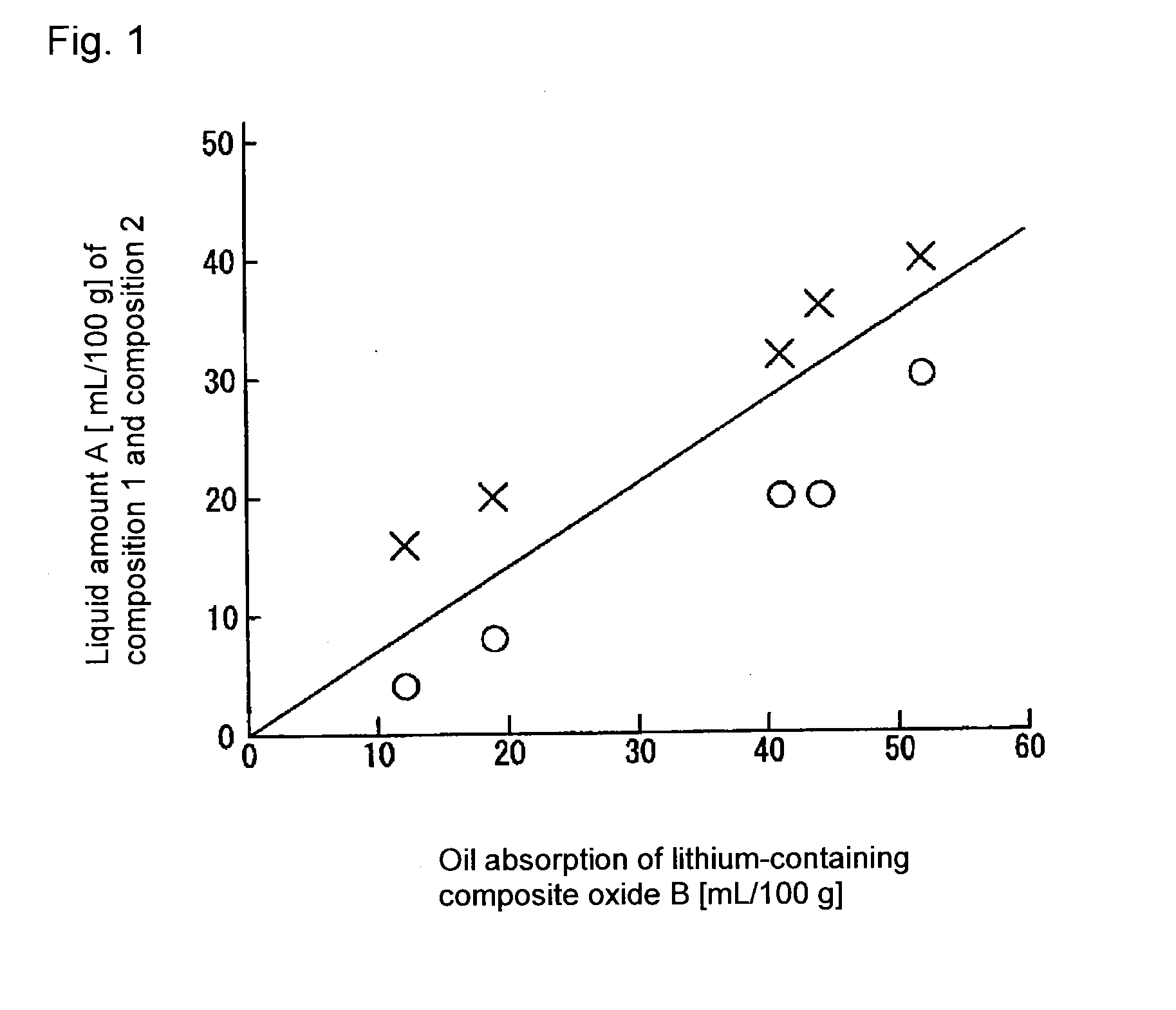

Process for producing cathode active material for lithium ion secondary battery

ActiveUS20140113193A1Excellent in cycle characteristic and rate characteristicIncrease production capacityFinal product manufactureNon-aqueous electrolyte accumulator electrodesAqueous solutionLi element

To provide a process for producing a cathode active material for a lithium ion secondary battery, a cathode for a lithium ion secondary battery, and a lithium ion secondary battery.A production process which comprises contacting a lithium-containing composite oxide containing Li element and a transition metal element with a composition (1) {an aqueous solution containing cation M having at least one metal element (m)} and a composition (2) {an aqueous solution containing anion N having at least one element (n) selected from the group consisting of S, P, F and B, forming a hardly soluble salt when reacted with the cation M}, wherein the total amount A (mL / 100 g) of the composition (1) and the composition (2) contacted per 100 g of the lithium-containing composite oxide is in a ratio of 0.1<A / B<5 based on the oil absorption B (mL / 100 g) of the lithium-containing composite oxide.

Owner:SUMITOMO CHEM CO LTD

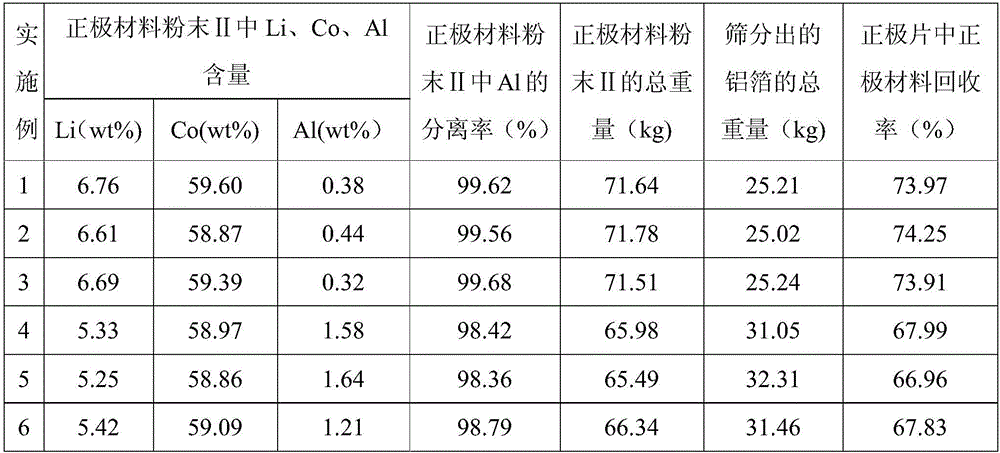

Method for reparative regeneration of lithium cobalt oxide anode material in waste batteries

InactiveCN106450555AAvoid over-sinteringAvoid chippingWaste accumulators reclaimingBattery recyclingHigh energyPole piece

The invention provides a method for reparative regeneration of a lithium cobalt oxide anode material in waste batteries. The method includes: separating the anode material from lithium cobalt oxide waste batteries; laying positive pole pieces on a mesh belt, and controlling the mesh belt to vibrate continuously while controlling gas to pass through the meshes of the mesh belt from bottom to top; under conditions of vibration of the mesh belt and gas circulation of the meshes of the mesh belt, respectively heating the positive pole pieces for 10-60min at 100-300 DEG C and 380-520 DEG C, and collecting anode material powder I; sequentially subjecting the anode material powder I to screening removal of broken aluminum foils and electromagnetic removal of iron to obtain anode material powder II, and sampling to detect contents of Li, Co and Al in the anode material powder II; replenishing Li element and Al element to the anode material powder II according to a detection result obtained at the step 4 to obtain anode material powder III, wherein a mole ratio of Li to Co to Al is 1-1.05:1-x:x, and x refers to 0.05-0.2; subjecting the anode material powder III to ball milling in a high-energy ball mill to obtain anode material powder IV; calcining the anode material powder IV in a pure oxygen atmosphere to obtain repaired regenerated lithium cobalt oxide.

Owner:JINGMEN GEM NEW MATERIAL

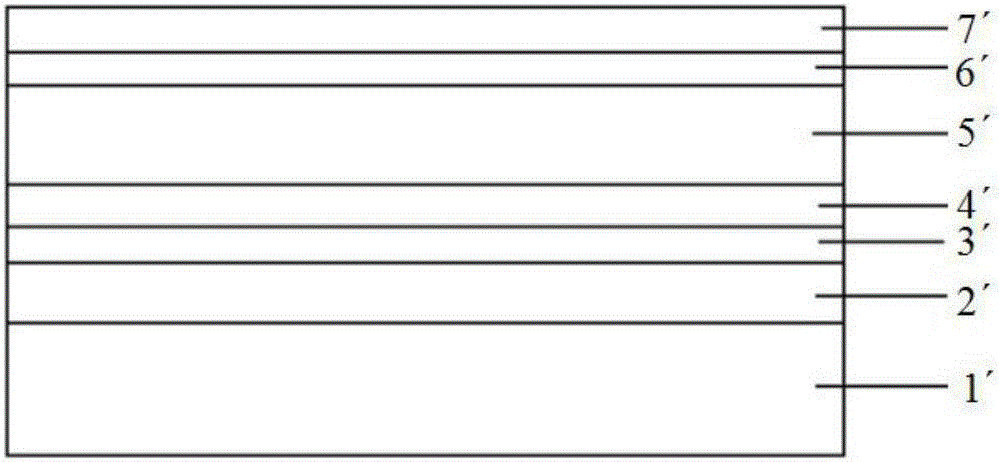

Cadmium-telluride thin-film solar battery and preparation method thereof

InactiveCN106098816AImprove adhesionImprove mechanical resistanceFinal product manufacturePhotovoltaic energy generationEngineeringContact layer

The invention, which belongs to the technical field of the solar battery, discloses a cadmium-telluride thin-film solar battery comprising a glass substrate, a lamination structure, a transparent conductive layer, a buffer layer, an n type semiconductor layer, a p type semiconductor layer, a back contact layer and a back electrode layer. The lamination structure, the transparent conductive layer, the buffer layer, the n type semiconductor layer, the p type semiconductor layer, the back contact layer and the back electrode layer are arranged on the glass substrate successively along a direction far away from the glass substrate. The lamination structure consist of an inhibition layer and a dielectric medium layer; the inhibition layer is arranged on the glass substrate; the dielectric medium layer is arranged between the inhibition layer and the transparent conductive layer; the inhibition layer contains Si and O elements as well as at least one of a Al element and a B element and at least one of a Li element and a K element; and the inhibition layer and the dielectric medium layer have light-transmitting properties. In addition, the invention also discloses a preparation method for the cadmium-telluride thin-film solar battery. The lamination layer structure is set and is used as a front contact element of the cadmium-telluride thin-film solar battery, so that the short-circuit current of the cadmium-telluride thin-film solar battery is increased.

Owner:盐城普兰特新能源有限公司

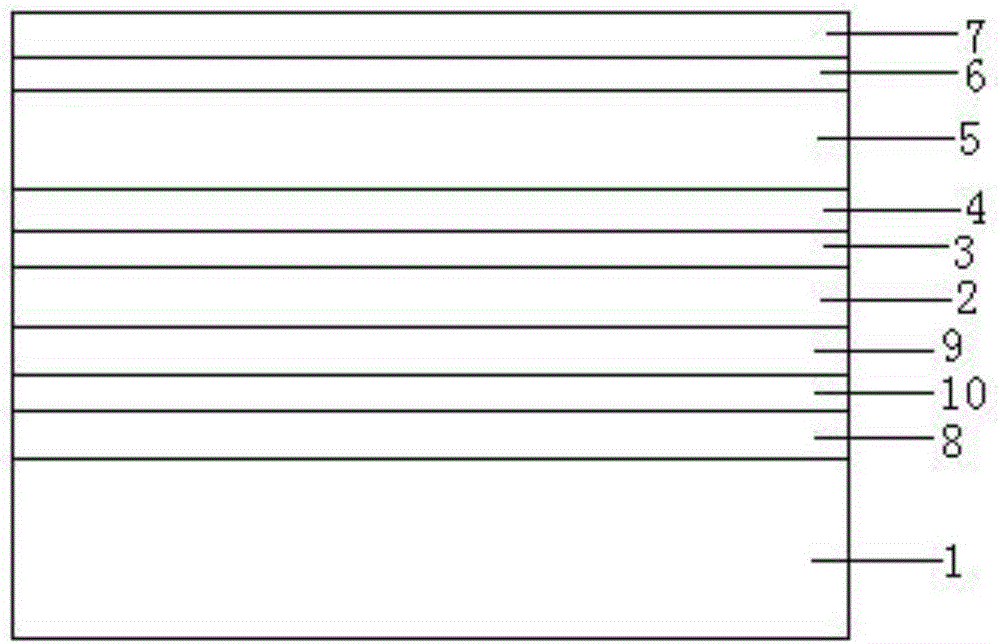

Lithium nickelate-based positive electrode active substance particles and process for producing the same, and non-aqueous electrolyte secondary battery

ActiveUS20170207455A1Excellent in repeated charge/discharge cycle characteristicEasy to useElectrode thermal treatmentPositive electrodesHigh energyLithium hydroxide

The present invention provides lithium nickelate-based positive electrode active substance particles having a high energy density which are excellent in charge / discharge cycle characteristics when highly charged, and hardly suffer from generation of gases upon storage under high-temperature conditions, and a process for producing the positive electrode active substance particles, as well as a non-aqueous electrolyte secondary battery. The present invention relates to positive electrode active substance particles each comprising a core particle X comprising a lithium nickelate composite oxide having a layer structure which is represented by the formula: Li1+aNi1-b-cCobMcO2 wherein M is at least one element selected from the group consisting of Mn, Al, B, Mg, Ti, Sn, Zn and Zr; a is a number of −0.1 to 0.2 (−0.1≦a≦0.2); b is a number of 0.05 to 0.5 (0.05≦b≦0.5); and c is a number of 0.01 to 0.4 (0.01≦c≦0.4); a coating compound Y comprising at least one element selected from the group consisting of Al, Mg, Zr, Ti and Si; and a coating compound Z comprising an Li element, in which a content of lithium hydroxide LiOH in the positive electrode active substance particles is not more than 0.40% by weight, a content of lithium carbonate Li2CO3 in the positive electrode active substance particles is not more than 0.65% by weight, and a weight ratio of the content of lithium carbonate to the content of lithium hydroxide is not less than 1.

Owner:TODA IND

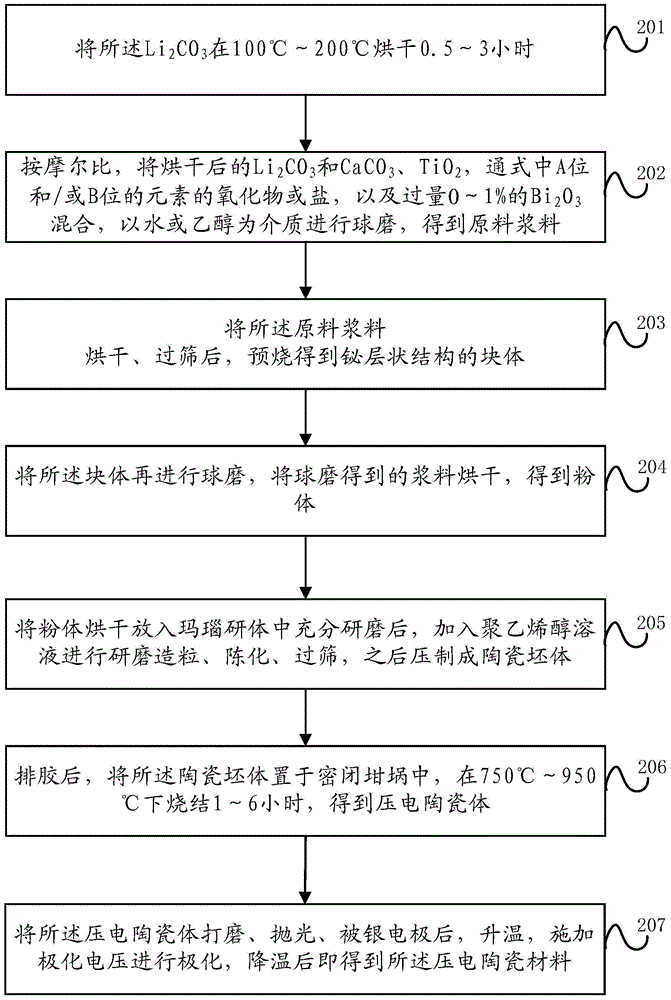

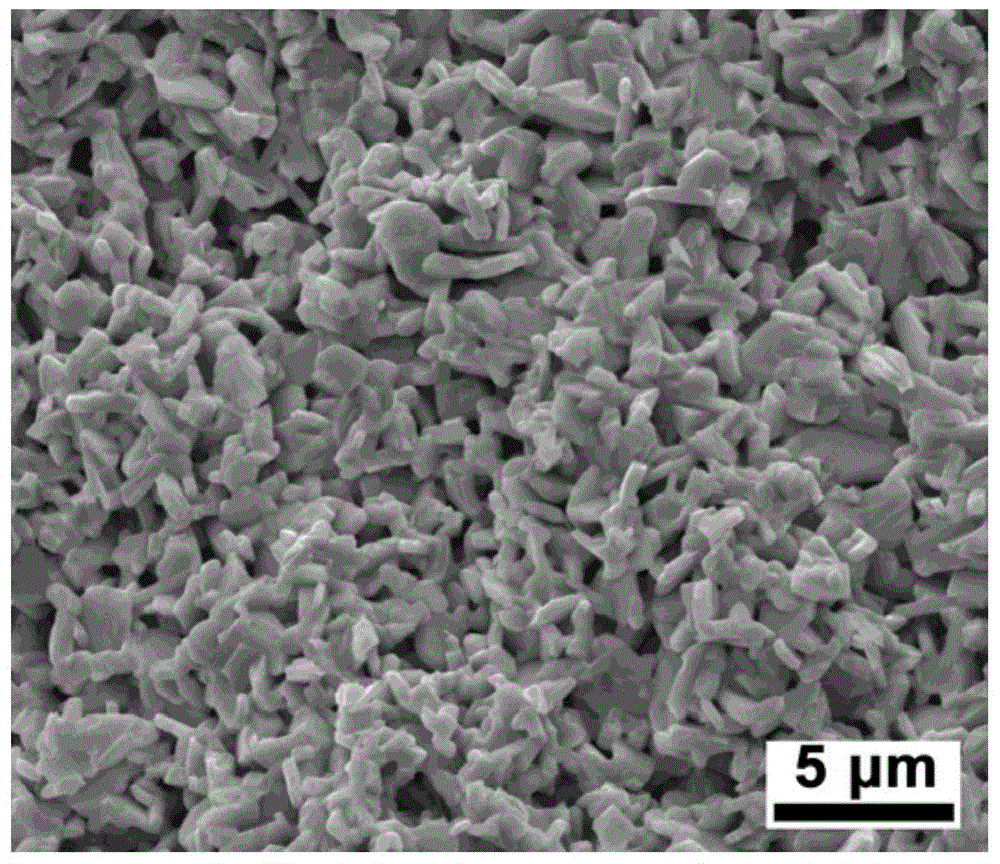

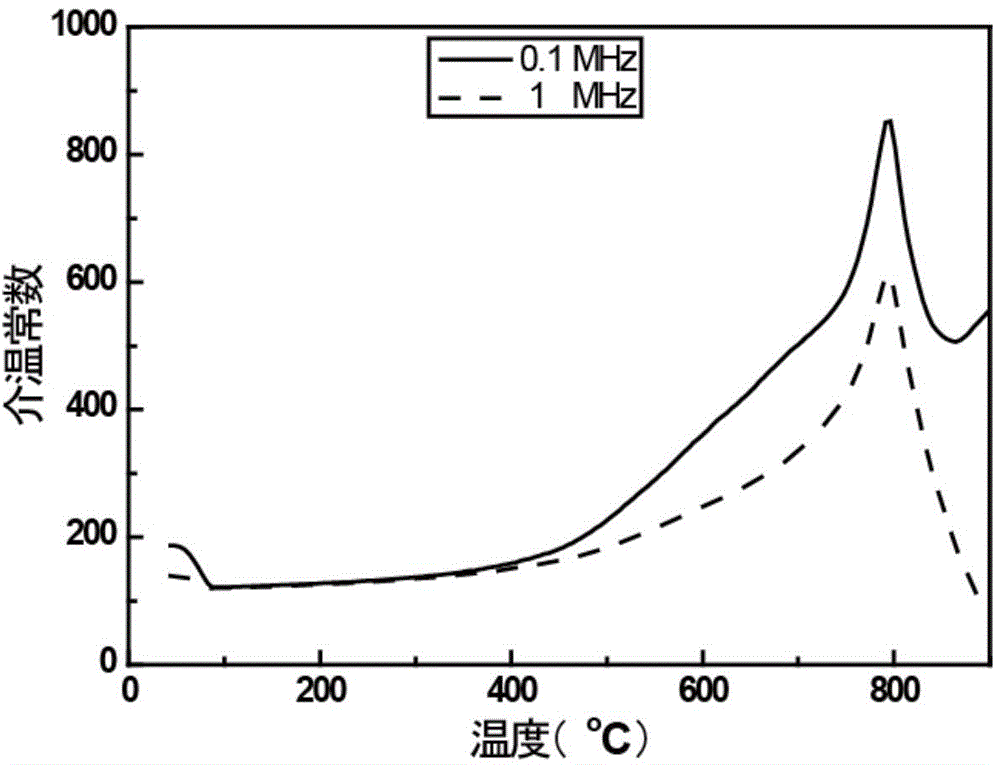

Bismuth layer-structured piezoelectric ceramic material and preparation method thereof

The invention discloses a low-temperature sintered bismuth layer-structured piezoelectric ceramic material and a preparation method thereof. A chemical general formula of the piezoelectric ceramic material is Ca1-x-yLixAyBzBi4Ti4-zO15, wherein A is one or more of valence-variable doping elements Ce, Mn and Sr; B is one or more of valence-variable doping elements Cr, Nb and W; x, y and z are respectively mole fractions of a Li element, an A-position element and a B-position element; x is smaller than or equal to 0.1 and greater than 0; y is smaller than or equal to 0.1 and greater than or equal to 0; z is smaller than or equal to 0.1 and greater than or equal to 0; and y and z are not simultaneously zero. The piezoelectric ceramic material disclosed by the invention has the advantages of relatively low sintering preparation temperature, relatively high curie temperature, and excellent piezoelectric property and overall dielectric properties, and can be applied to various high-temperature piezoelectric devices.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

Preparation method of lithium ion battery cathode material coated with carbon on surface

The invention provides a preparation method of a lithium ion battery cathode material coated with carbon on the surface, providing a low-cost line for stably producing LiFePO4 and batteries thereof. The preparation method of the material comprises the following three steps of: partially carbonizing carbohydrate, preparing NH4MPO4 in a porous carbon material and preparing YMPO in the porous carbon material, wherein the Y element is Li element or alkali metal elements of Na and K or the combination of the elements, M is a divalent transition metal element ion or a certain MxN1-x containing the combination of metal elements of other valences, x is not smaller than 0 and is smaller than 1, and N is a trivalent transition metal element ion or a doped metal ion of other valences. Compared with other process lines, the process line of the invention has lower requirements for process control conditions, the product can have evener particles and stabler performance by synthesizing the LiFePO4 in a porous channel which is formed by carbonizing the carbohydrate, and the only two byproducts in the production process of the LiFePO4 can be favorably recycled.

Owner:SOUTHEAST UNIV

Magnesium-lithium alloy used for sand mold casting and preparing method of magnesium-lithium alloy

ActiveCN106148787AImprove melt fluidityGood solid solution strengthening effectSolid solution strengtheningLi element

The invention provides a magnesium-lithium alloy used for sand mold casting and a preparing method of the magnesium-lithium alloy. The magnesium-lithium alloy comprises, by weight percent, 3%-10% of Li, 2%-7% of Al, 0.5%-3.5% of Zn, 0.5%-3% of Nd, 0.5%-3% of Ce, 0.05%-0.2% of Ti, 0.005%-0.05% of C and the balance Mg and inevitable impurities. The preparing method includes smelting and heat treatment. According to the magnesium-lithium alloy used for sand mold casting and the preparing method of the magnesium-lithium alloy, Li, Al and Zn serve as the main alloy elements and Nd, Ce, Ti and C are added, so that the solid solution strengthening effect of the magnesium-lithium alloy use for sand mold casting is improved, shrinkage porosity defects are reduced, the sand mold casting performance is improved, grain growth of the alloy in the sand mold casting process and the later solid solution process is inhibited, segregation of the Li element is reduced, and the yield of the Li element is increased. According to the magnesium-lithium alloy used for sand mold casting and the preparing method of the magnesium-lithium alloy, magnesium-lithium alloy grains are well refined on the premise that the alloy cost is not improved obviously, and the beneficial effects that the sand mold casting forming performance is good, the comprehensive mechanical performance is high, and the cost is low are achieved.

Owner:SHANGHAI JIAO TONG UNIV +1

Method for producing cathode active material for lithium ion secondary battery

InactiveUS20130318780A1Stable structureDecrease in capacity of lithium can be suppressedPrimary cellsElectrode carriers/collectorsSolventLi element

The present invention provides a method for producing a cathode active material for a lithium ion secondary battery excellent in the discharge capacity and the cycle characteristics and having high durability, and methods for producing a lithium ion secondary battery and a cathode for a lithium ion secondary battery.A lithium-containing composite oxide comprising Li element and at least one transition metal element selected from the group consisting of Ni, Co and Mn (provided that the molar amount of the Li element is more than 1.2 times the total molar amount of said transition metal element) and a composition (1) {a composition having a compound (1) containing no Li element and comprising Mn element as an essential component, dissolved or dispersed in a solvent} are contacted, followed by heating to produce a cathode active material for a lithium ion secondary battery.

Owner:ASAHI GLASS CO LTD

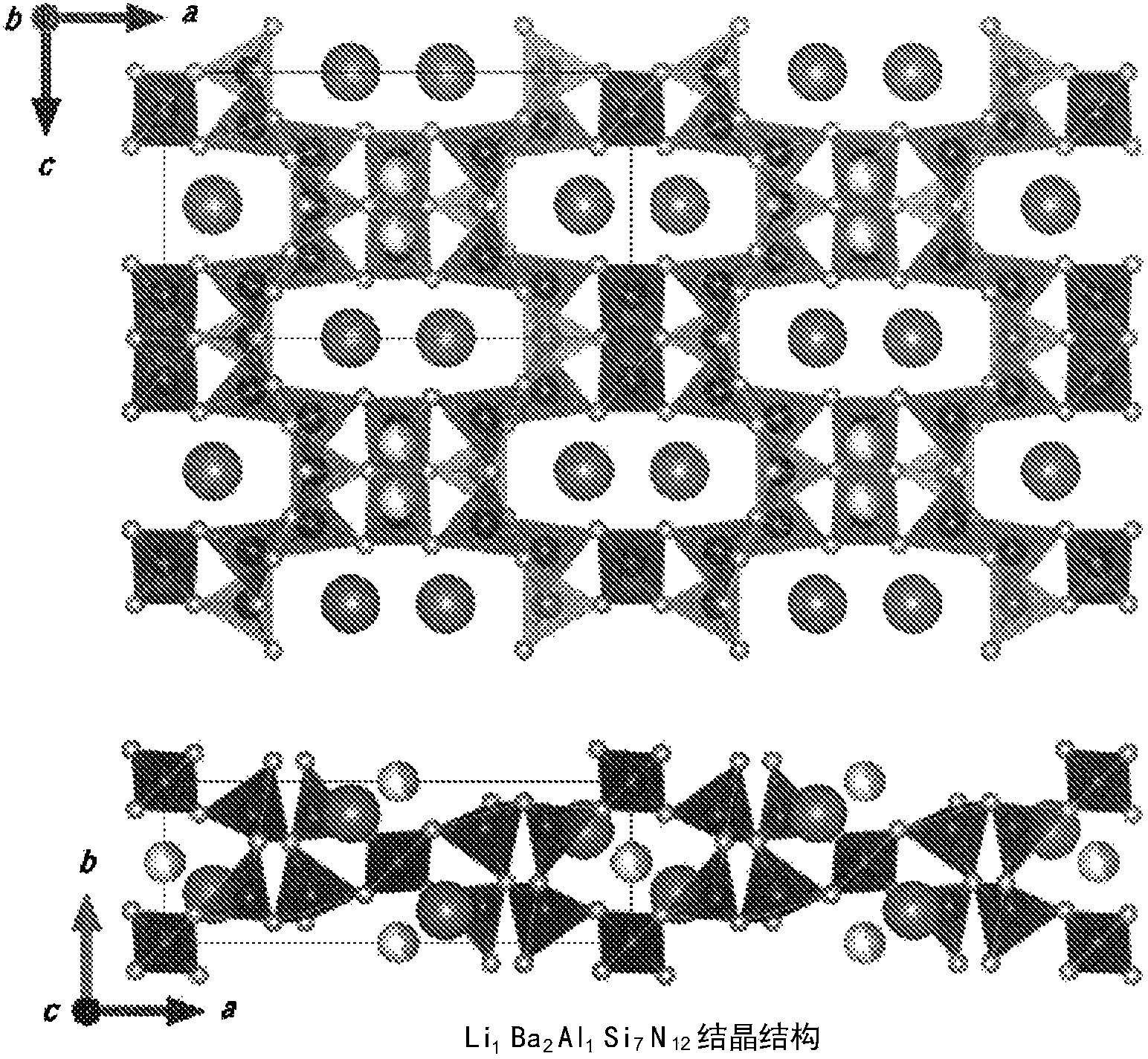

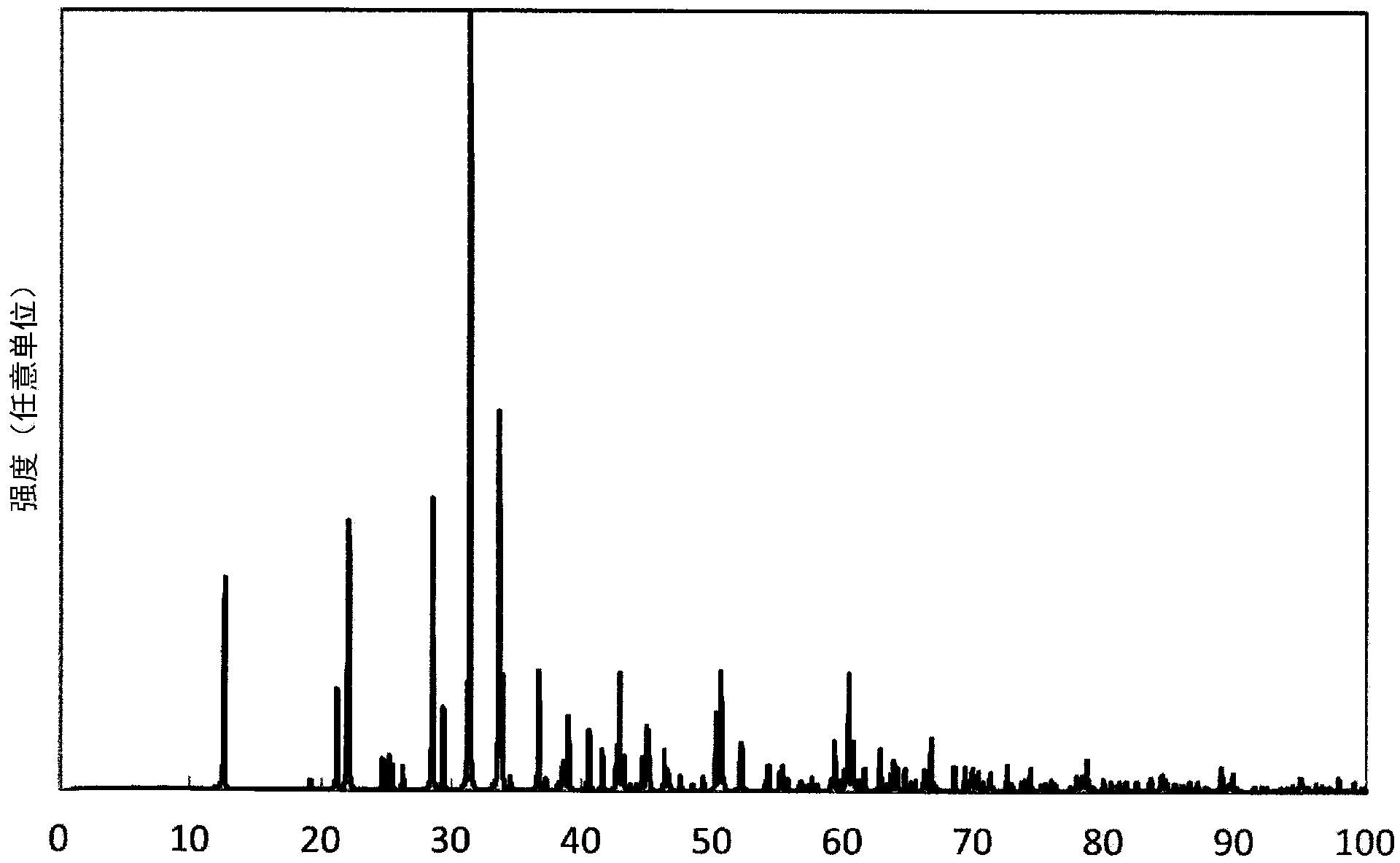

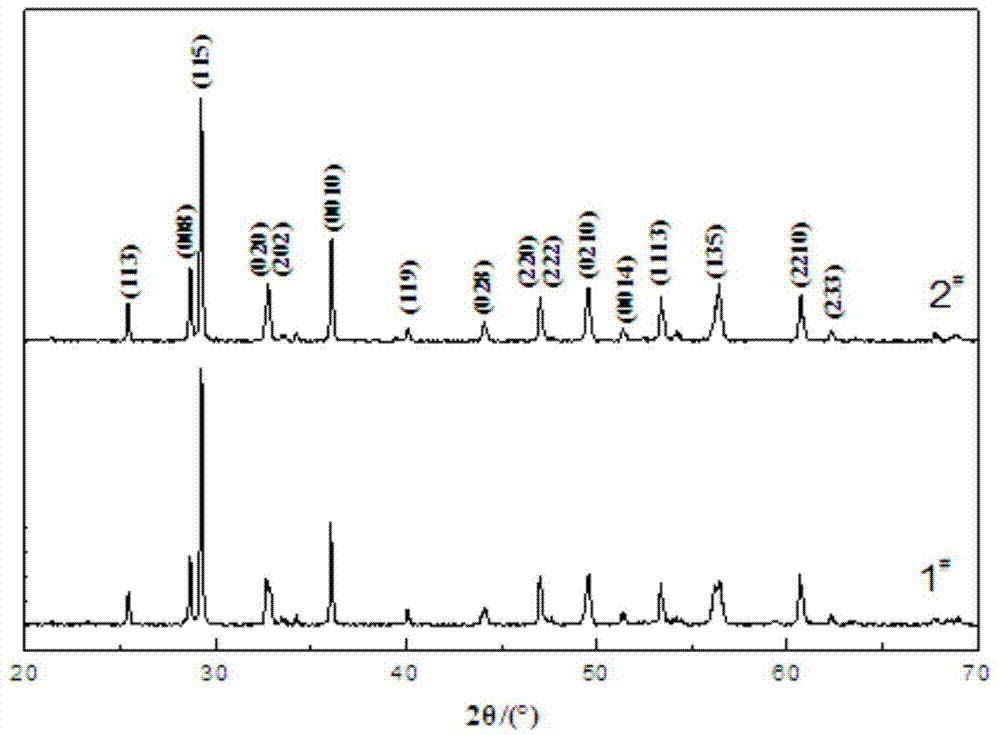

Phosphor, method for producing same, light emitting device, and image display device

ActiveCN104080886AIncrease brightnessLaser optical resonator constructionDischarge tube luminescnet screensLuminous intensityInorganic compound

The invention provides a phosphor which is chemically and thermally stable and has high luminous intensity even in cases where the phosphor is combined with an LED of 470 nm or less. A phosphor of the present invention contains: a crystal that is represented by Li1Ba2Al1Si7N12 and contains Li element, an element A, an element D, an element E and an element X (A represents at least one element selected from among Mg, Ca, Sr, Ba, Sc, Y and La; D represents at least one element selected from among Si, Ge, Sn, Ti, Zr and Hf; E represents at least one element selected from among B, Al, Ga and In; and X represents at least one element selected from among O, N and F); a crystal that is represented by (Li, A)3(D, E)8X12; an inorganic crystal that has the same crystal structure as a crystal that is represented by Li1Ba2Al1Si7N12; or an inorganic compound wherein an element M (M represents at least one element selected from among Mn, Ce, Pr, Nd, Sm, Eu, Tb, Dy and Yb) is solid-solved in one of the above-mentioned solid solution crystals.

Owner:NAT INST FOR MATERIALS SCI

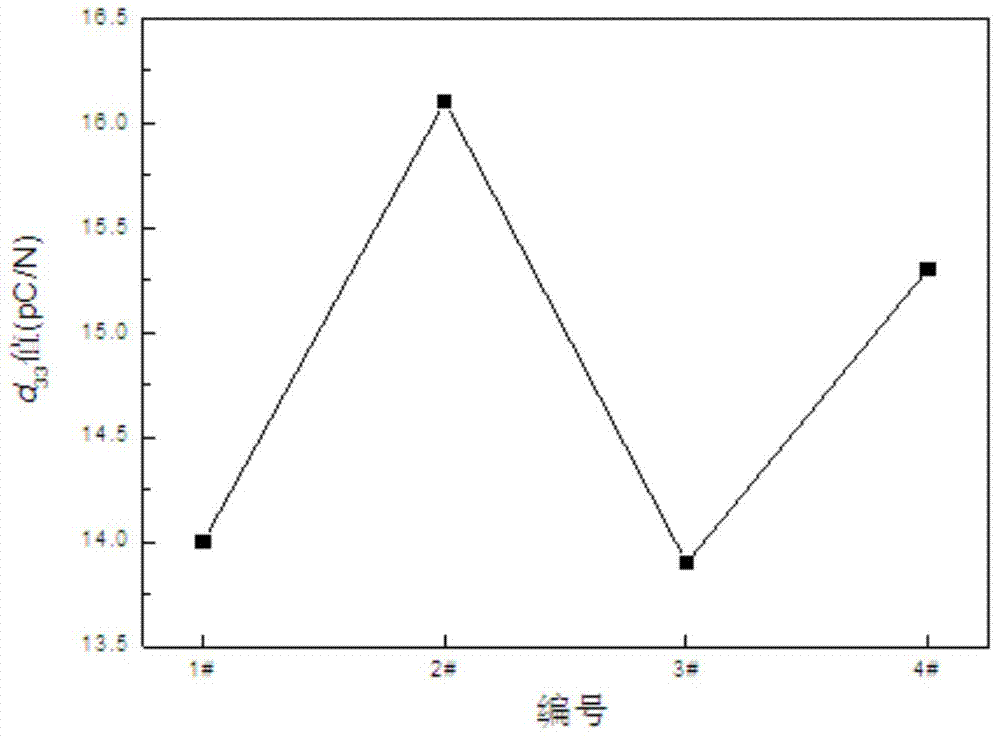

Lithium, cerium, tungsten (Li, Ce, W) co-doped bismuth calcium niobate (CBN)-based piezoelectric ceramic material and preparation method thereof

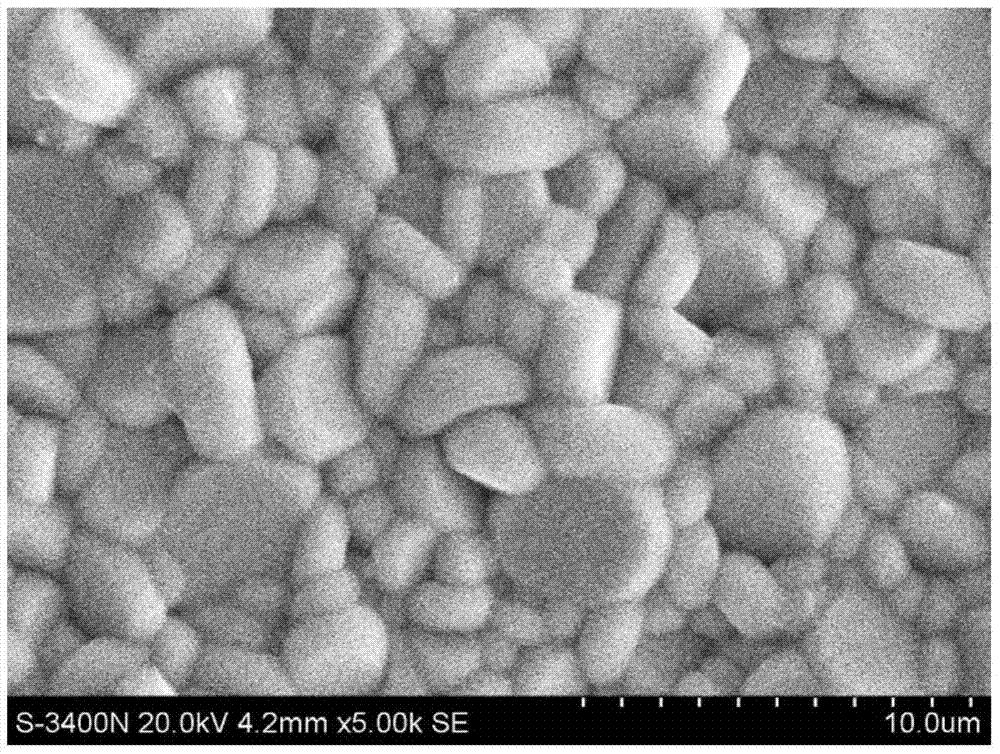

The invention discloses a lithium, cerium, tungsten (Li, Ce, W) co-doped bismuth calcium niobate (CBN)-based piezoelectric ceramic material and a preparation method thereof. The piezoelectric ceramic material is characterized by being represented by the following general formula: Ca1-x(Li, Ce)x / 2Bi2Nb2-yWyO9, wherein the x is greater than or equal to 0.02 and less than or equal to 0.15; the y is greater than or equal to 0.01 and less than or equal to 0.1; the X represents the mole fraction of an A-bit Li element and an A-bit Ce element; the Y represents the mole fraction of a B-bit W element. The preparation method comprises the following steps: preparing a CBN ceramic powder material with different doping quantities of the A-bit Li, the A-bit Ce and the B-bit W via a solid phase method; and carrying out the processes of granulation, tabletting, glue removing, sintering, silver coating and polarization so as to prepare the Li, Ce, W co-doped CBN-based piezoelectric ceramic material. The result shows that the Li, Ce, W co-doped CBN-based piezoelectric ceramic material prepared at a relatively low sintering temperature (about 1100 DEG C) has relatively compact and uniform crystalline grains, i.e., the sintering activity and the ceramic compactness are improved, so that a good sintering effect is obtained. Thus, the piezoelectric property of the piezoelectric ceramic material is greatly improved; the dielectric loss of the piezoelectric ceramic material is decreased.

Owner:SICHUAN UNIV

Red rare earth luminescent material for purple light LED conversion white light and preparation thereof

InactiveCN101348714ALow costImprove luminous efficiencyGas discharge lamp usageLuminescent compositionsRare earthStructural formula

The invention belongs to the luminescence and display technical field, in particular to a novel red rare earth luminescent material for transferring white light by a violet LED. The structural formula of the novel red rare earth luminescent material is M.N1-a-b(MoO4)2-x(SiO4)x:Ra.Rb, wherein M refers to alkali metal Li element or K element or alkali metal Li and Ba element or K and Ba element; N1-a-b refers to alkali metal Na element; and quantitive latent solvent is added. The materials of the compositions of the M.N1-a-b (MoO4) 2-x (SiO4) x: Ra.Rb are weighed by weight percent; the weighed materials are fully grinded and uniformly mixed and then added into an alumina crucible which is covered and placed into a high-temperature furnace and sintered in the air; after the mixture is cooled, the mixture is taken out and crushed and then added into the alumina crucible which is then covered and placed into the high-temperature furnace and sintered in the air; and the mixture is cooled, taken out and grinded, and then the red crystal powder which gives out red light within 365 nanometers under excitation of the violet LED is obtained.

Owner:NORTHEAST NORMAL UNIVERSITY

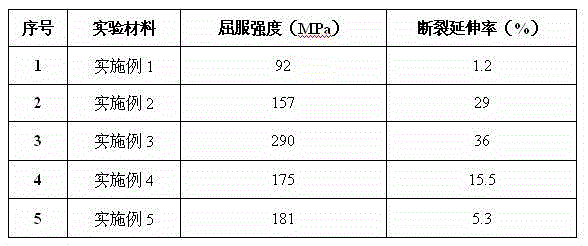

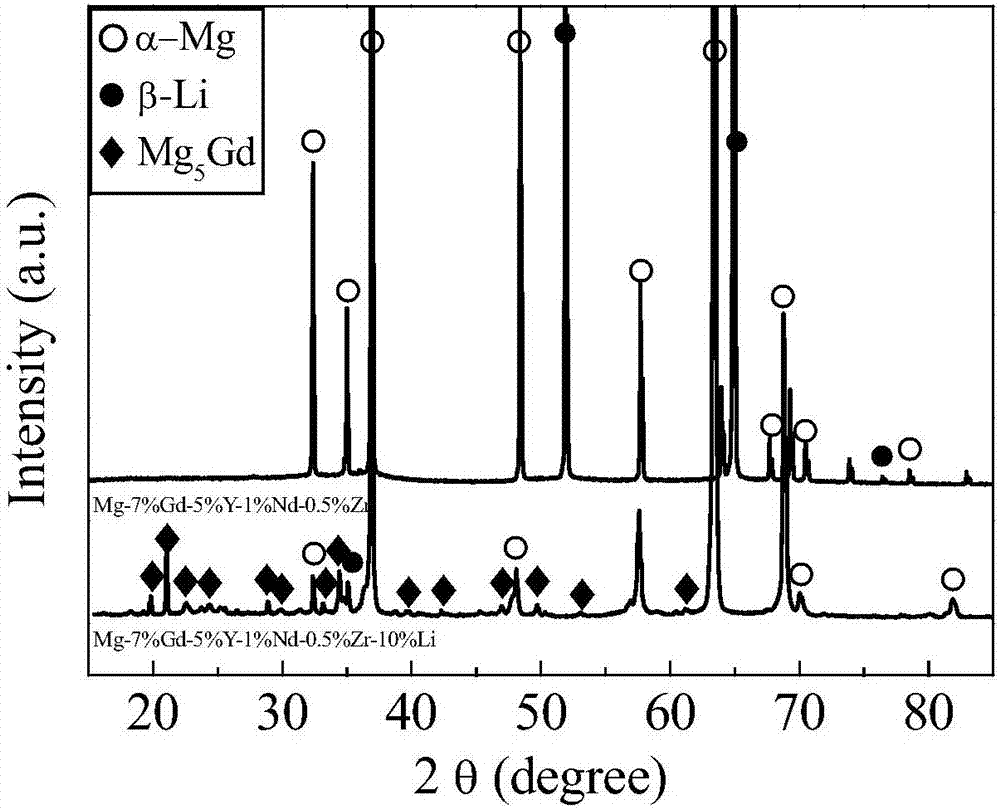

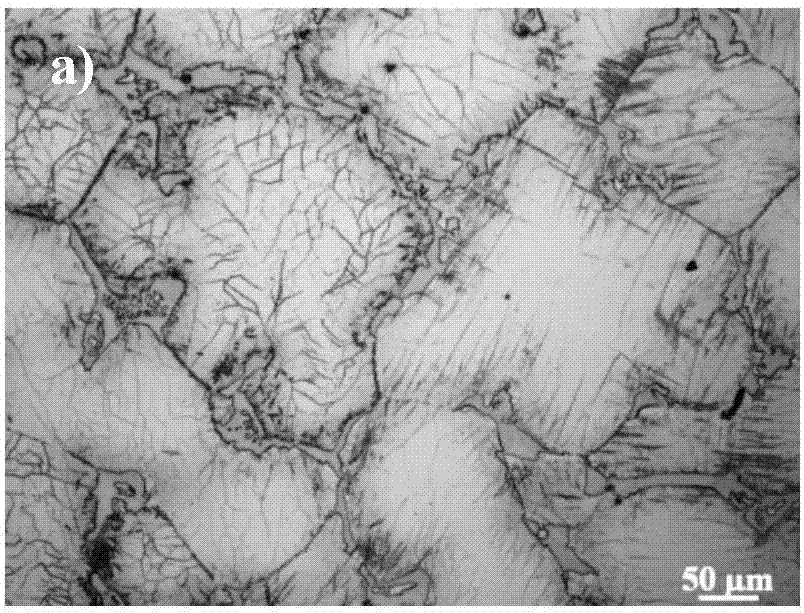

Effective method for improving plastic molding capacity of high-strength Mg-Gd-Y-Nd-Zr magnesium alloy

ActiveCN107964602AImproved coordination of plastic deformationImprove plastic processing and forming abilityPlastic moldingZr alloy

The invention relates to the field of plasticity improvement of high-strength magnesium alloys, in particular to a method for improving plastic molding cavity of a high-strength Mg-Gd-Y-Nd-Zr magnesium alloy by effectively using an element Li, and solves the problem of weaker high-strength plasticity. Under the precondition of keeping relative contents of all elements in the alloy invariable, 5-20weight% of Li element is added to form a beta-Li phase with higher plasticity deformation capacity in the alloy; the volume fraction (20-90%) of forming the beta-Li phase is controlled to prepare a lithium-contained Mg-Gd-Y-Nd-Zr alloy with high strength and better plasticity; the alloy is smelted and hot rolled subsequently to prepare a plate; and the machining process is simple and convenient to operate. The tensile strength of the material under cast-state condition is ob=120-250 MPa, the yield strength is o0.2=80-150 MPa, the ductility is delta=10-30%, and the density is 1.50-1.89 g / cm3;and the plate cannot generate the edge cracking phenomenon after deformation with 40% of rolling quantity at room temperature.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com