Bismuth layer-structured piezoelectric ceramic material and preparation method thereof

A piezoelectric ceramic and bismuth layered technology, which is applied in the field of materials, can solve problems such as high sintering temperature and lower Curie temperature, and achieve the effect of lowering sintering temperature and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1 of the present invention provides a piezoelectric ceramic material with bismuth layered structure, whose general chemical formula is: Ca 1-x-y Li x A y B z Bi 4 Ti 4-z o 15 ;

[0029] Among them, A is one or more of the variable-valence doping elements Ce, Mn, and Sr, and B is one or more of the variable-valence doping elements Cr, Nb, and W; x, y, and z are Li, A, respectively. Mole fraction of bit element and B bit element, 0<x≤0.1, 0≤y≤0.1, 0≤z≤0.1, and the values of y and z are not zero at the same time.

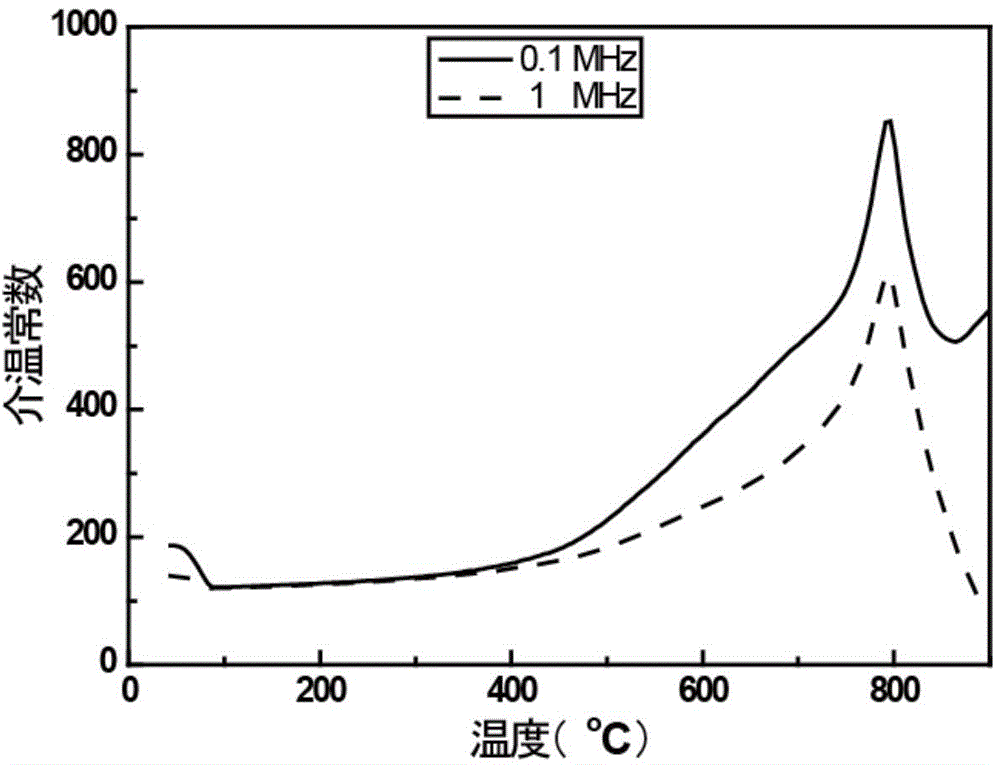

[0030] The bismuth layered piezoelectric ceramic material provided by the embodiments of the present invention has an ultra-high Curie temperature (750°C-800°C), a relatively high piezoelectric constant (15pC / N-30pC / N), and a wide range of Mechanical quality factor (100-6000) and lower dielectric loss (0.001-0.05). Compared with the preparation of existing bismuth layer structure piezoelectric ceramic materials, the sintering temperature in ...

Embodiment 2

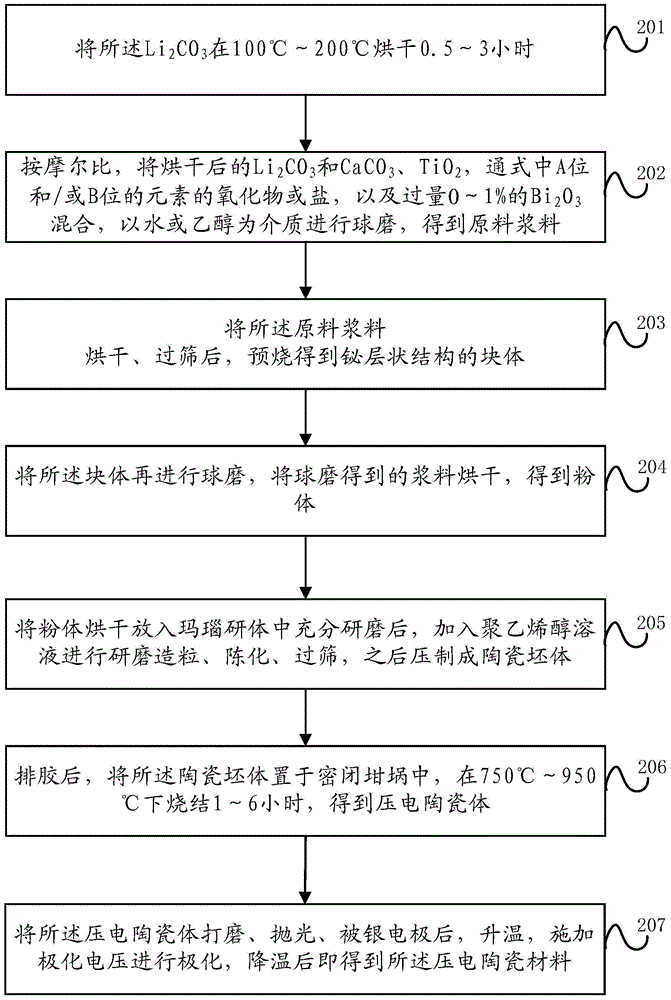

[0032] This embodiment provides the preparation method of the bismuth layered structure piezoelectric ceramic material in the above-mentioned embodiment 1, such as figure 1 shown, including:

[0033] Step 201, the Li 2 CO 3 Dry at 100°C-200°C for 0.5-3 hours;

[0034] Step 202, according to the molar ratio, the dried Li 2 CO 3 and CaCO 3 、TiO 2 , oxides or salts of elements at the A and / or B positions in the general formula, and an excess of 0-1% Bi 2 o 3 Mixing and ball milling with water or ethanol as a medium to obtain raw material slurry;

[0035] Wherein, A is one or more of the variable-valence doping elements Ce, Mn, and Sr, and B is one or more of the variable-valence doping elements Cr, Nb, and W.

[0036] Step 203, after drying and sieving the raw material slurry, pre-calcine to obtain a bismuth layered block;

[0037] Step 204, ball milling the block again, drying the slurry obtained by ball milling to obtain a powder;

Embodiment 3

[0051] Will Li 2 CO 3 After baking at 120°C for 1 hour, with Bi 2 o 3 , CaCO 3 、TiO 2 , CeO 2 and Li 2 CO 3 Press Ca 0.997 Li 0.002 Ce 0.001 Bi 4 Ti 4 o 15 Weigh the molar ratio, add an appropriate amount of ethanol to mix and ball mill, dry and sieve, pre-fire at 750°C for 2 hours, then ball mill and dry, add 5% PVA to grind and granulate, and age for 6 hours , After sieving, put it into a mold and press it into a ceramic green body with a diameter of 12mm and a thickness of about 1.2mm.

[0052] The ceramic body was placed in a closed crucible and sintered at 950°C for 1 hour. After grinding, polishing, and silver coating, the piezoelectric ceramic body was polarized in 150°C silicone oil at 5kV / mm for 30 minutes. After cooling down, the desired piezoelectric ceramic material is obtained.

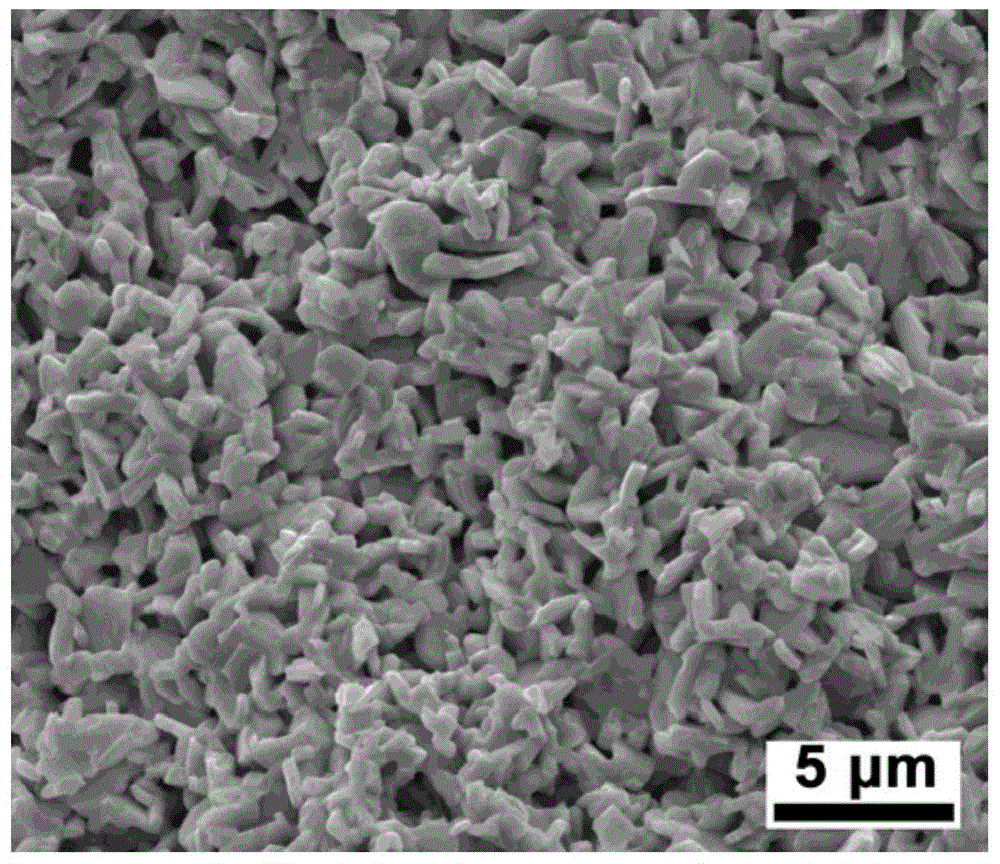

[0053] The piezoelectric ceramic material is made into a ceramic disc with a diameter of about 10mm and a thickness of about 1mm for testing. The comprehensive electrical p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie temperature | aaaaa | aaaaa |

| Piezoelectric constant | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com