Patents

Literature

184 results about "Magnetocrystalline anisotropy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In physics, a ferromagnetic material is said to have magnetocrystalline anisotropy if it takes more energy to magnetize it in certain directions than in others. These directions are usually related to the principal axes of its crystal lattice. It is a special case of magnetic anisotropy.

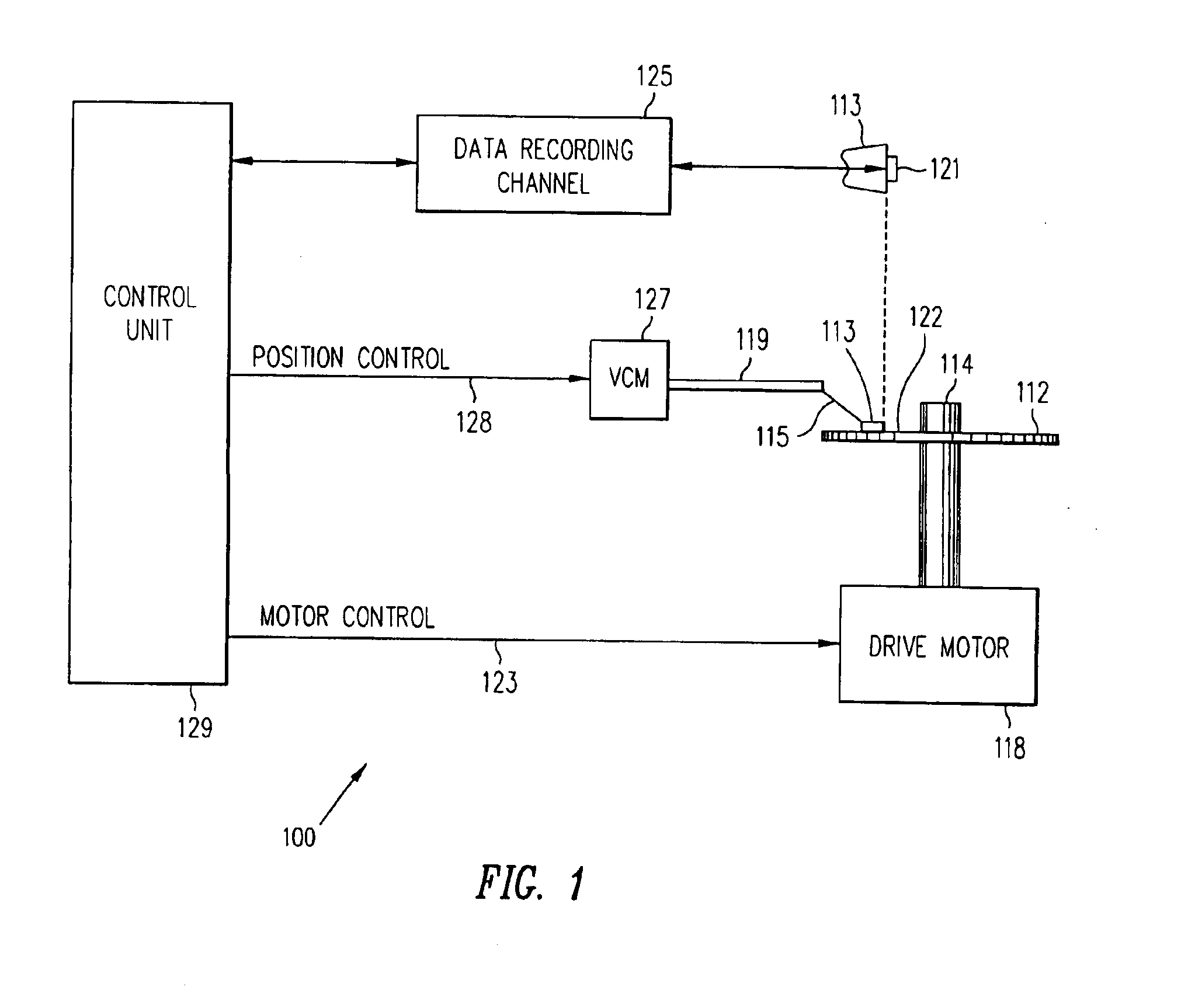

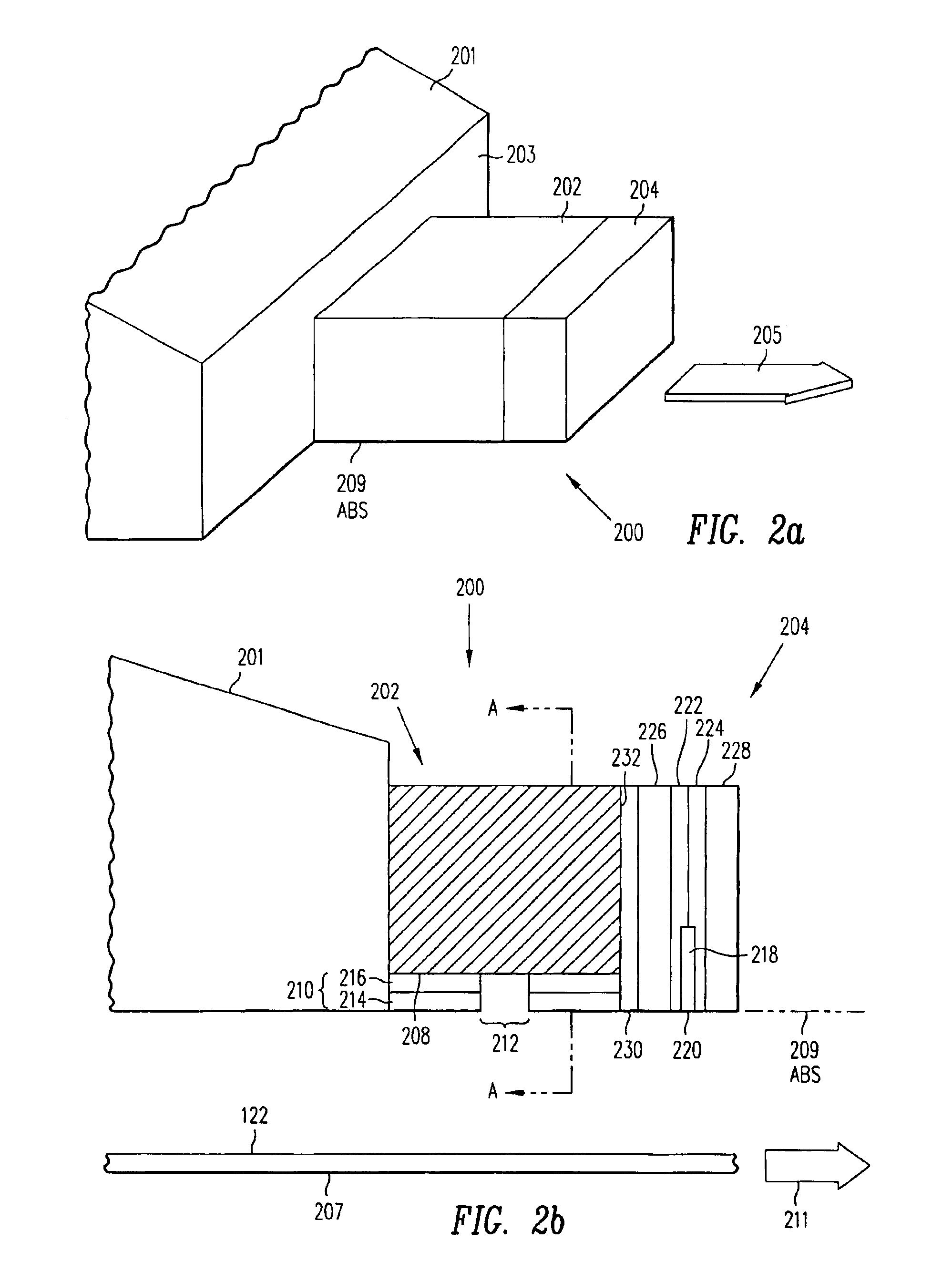

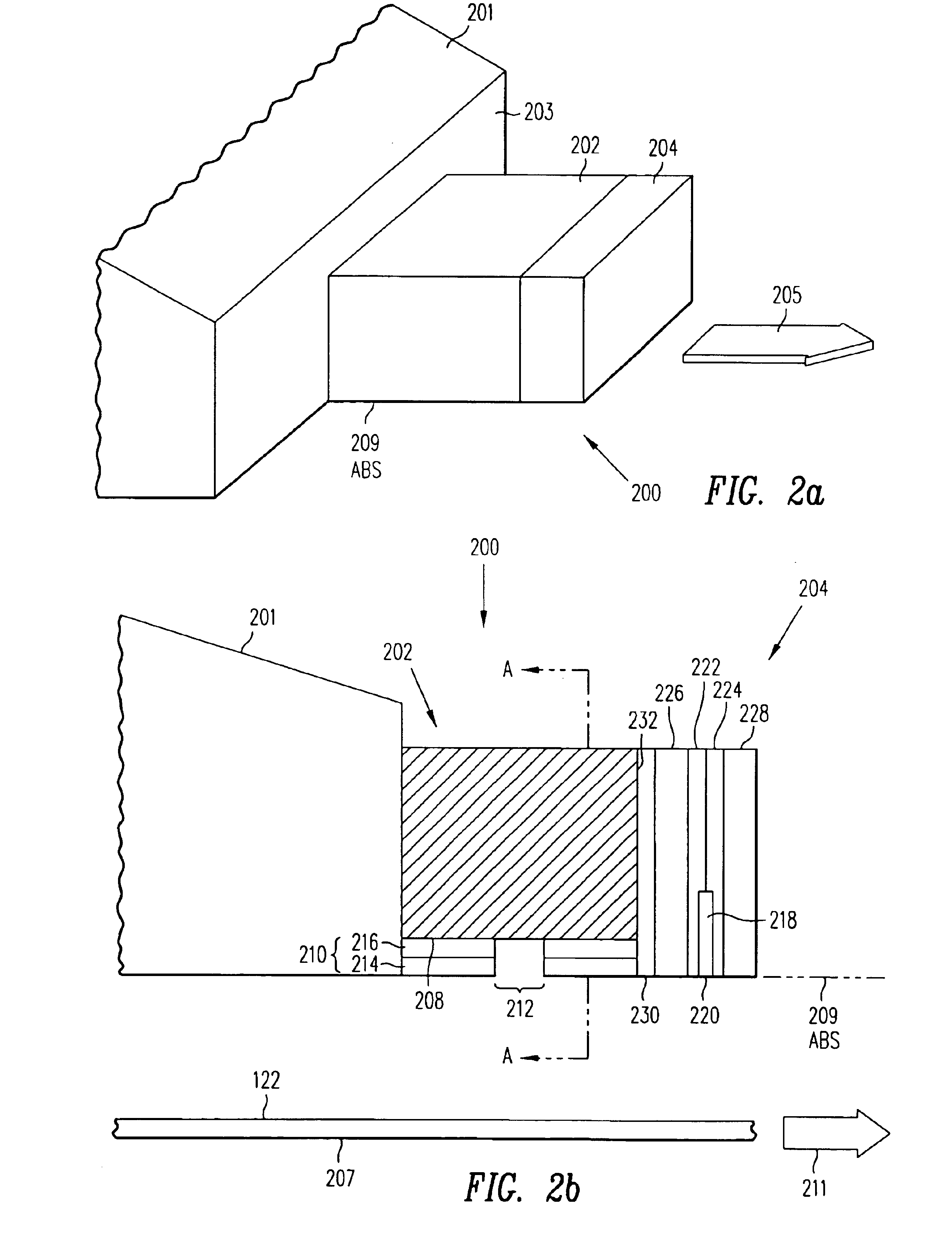

Horizontal magnetic recording media having grains of chemically-ordered FEPT of COPT

InactiveUS6086974ABase layers for recording layersRecord information storageAlloyMagnetocrystalline anisotropy

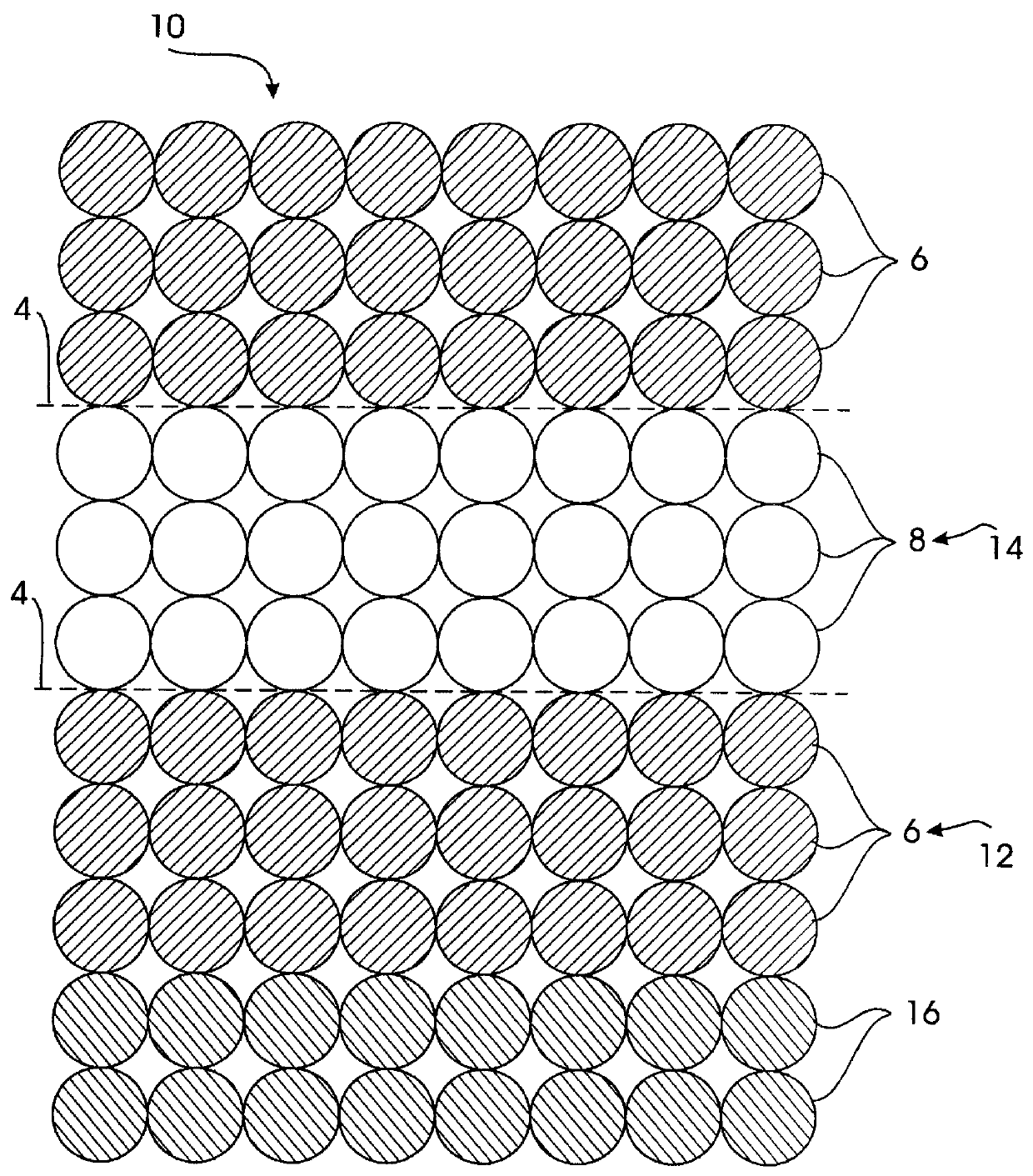

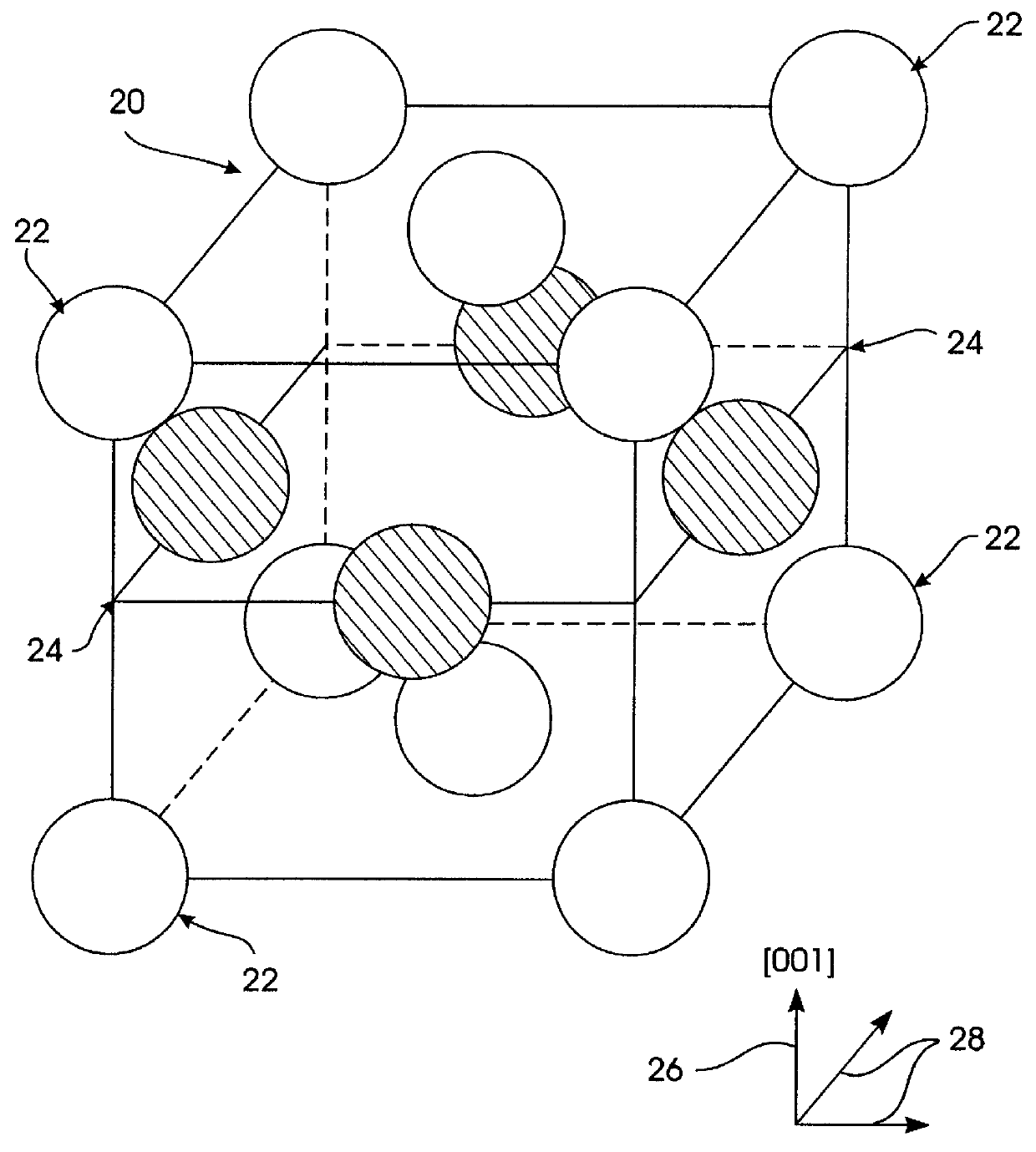

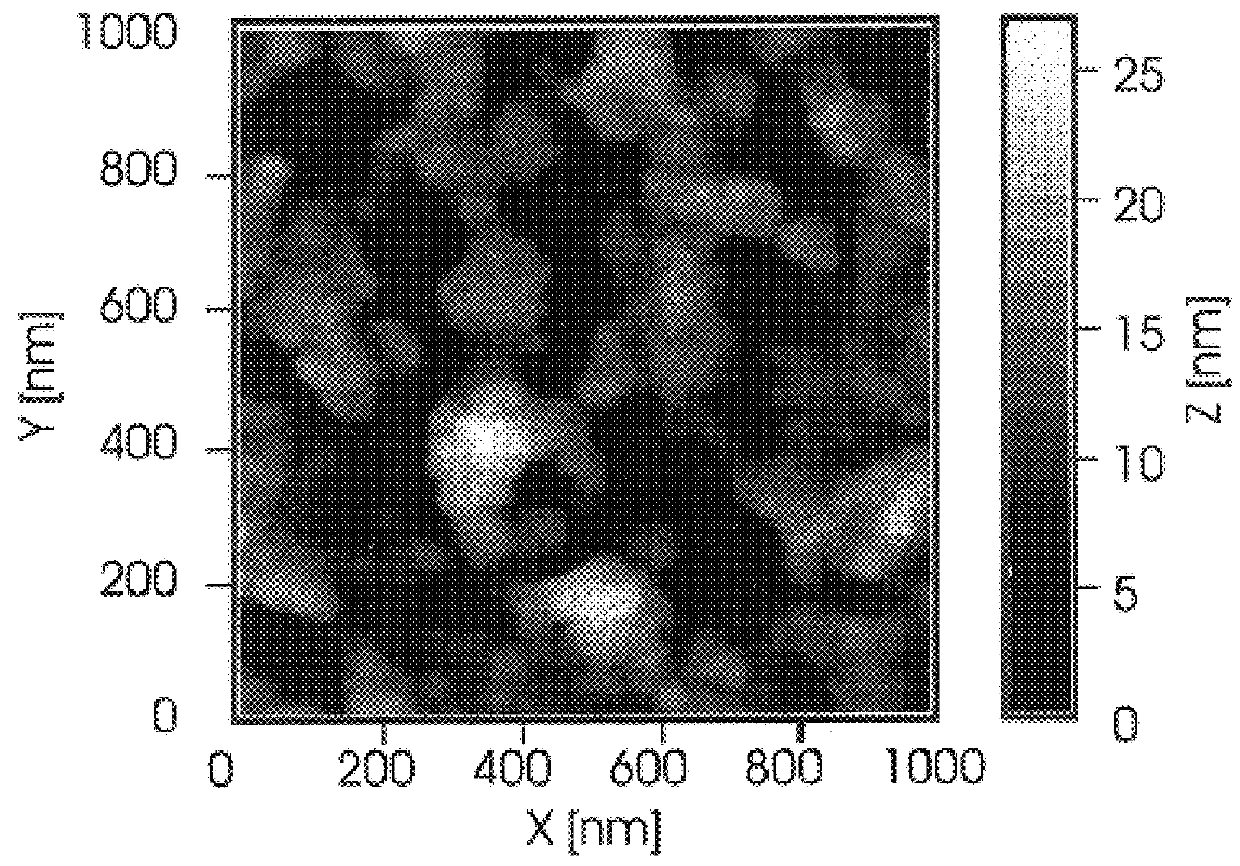

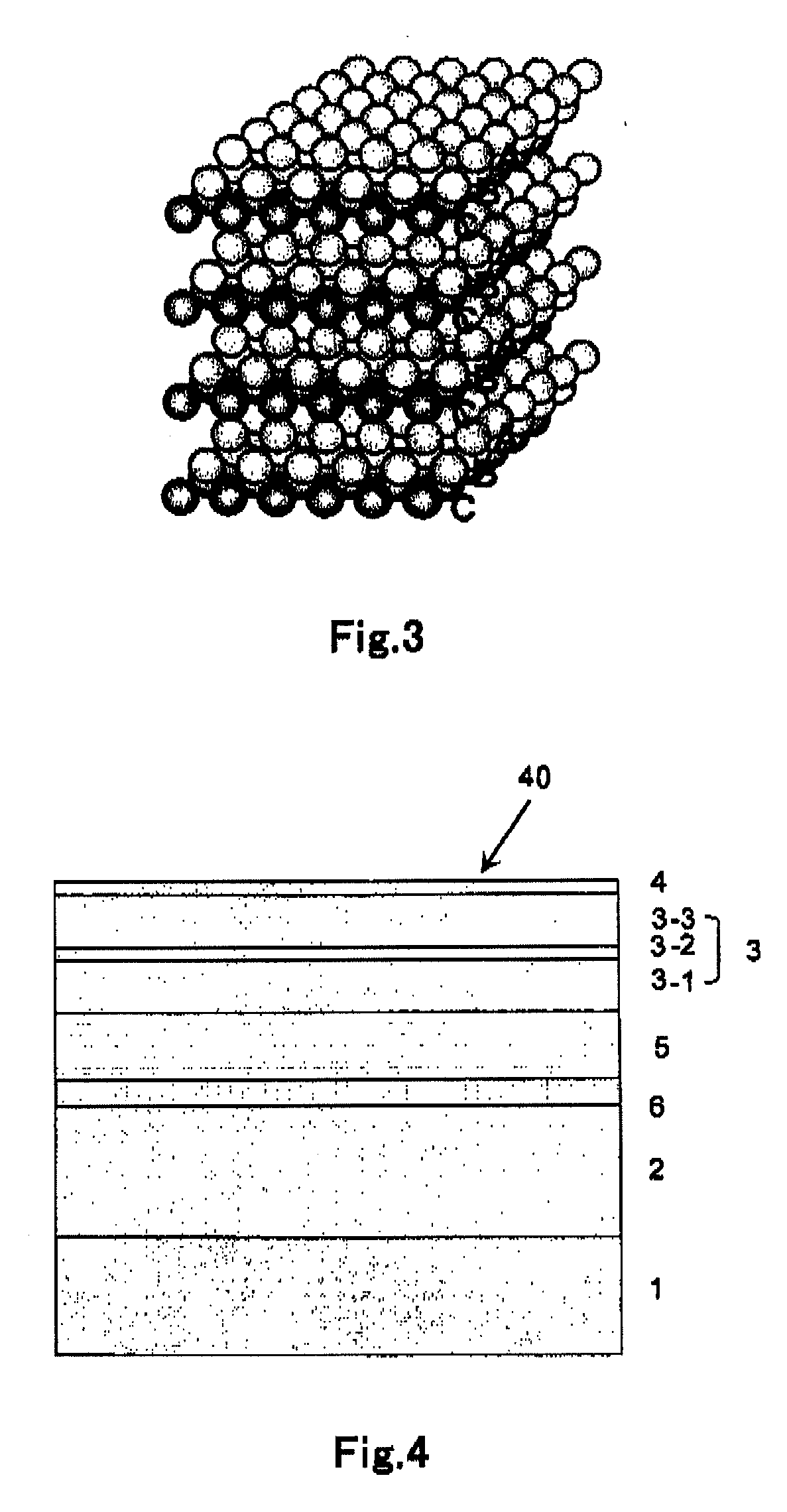

A horizontal magnetic recording medium that has as its magnetic film a granular film with grains of a chemically-ordered FePt or FePtX (or CoPt or CoPtX) alloy in the tetragonal L10 structure uses an etched seed layer beneath the granular film. The granular magnetic film reveals a very high magnetocrystalline anisotropy within the individual grains. The film is produced by sputtering from a single alloy target or cosputtering from several targets. The granular structure and the chemical ordering are controlled by means of sputter parameters, e.g., temperature and deposition rate, and by the use of the etched seed layer that provides a structure for the subsequently sputter-deposited granular magnetic film. The structure of the seed layer is obtained by sputter etching, plasma etching, ion irradiation, or laser irradiation. The magnetic properties, i.e., Hc and areal moment density Mrt, are controlled by the granularity (grain size and grain distribution), the degree of chemical ordering, and the addition of one or more nonmagnetic materials, such as Cr, Ag, Cu, Ta, or B. The resulting granular magnetic film has magnetic properties suitable for application in high-density, horizontal magnetic recording media.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

‘Thermal spring’ magnetic recording media for writing using magnetic and thermal gradients

InactiveUS6881497B2Avoid thermal instabilityRapid coolingSoldering apparatusRecord information storageMagnetic gradientMagnetic media

A thermal spring magnetic medium is provided having first and second stacks providing two exchange coupled ferromagnetic layers having different Curie temperatures. The first stack has a high magneto-crystalline anisotropy, a relatively low saturation magnetization and a low Curie temperature. The second stack has a relatively low magneto-crystalline anisotropy, a high saturation magnetization and a high Curie temperature. Preferably the first stack includes an alloy of Fe—Pt or Co—Pt, and the second stack includes an allow of Co—Pt or Co—Pd. A disk drive system having the novel medium is also provided.

Owner:WESTERN DIGITAL TECH INC

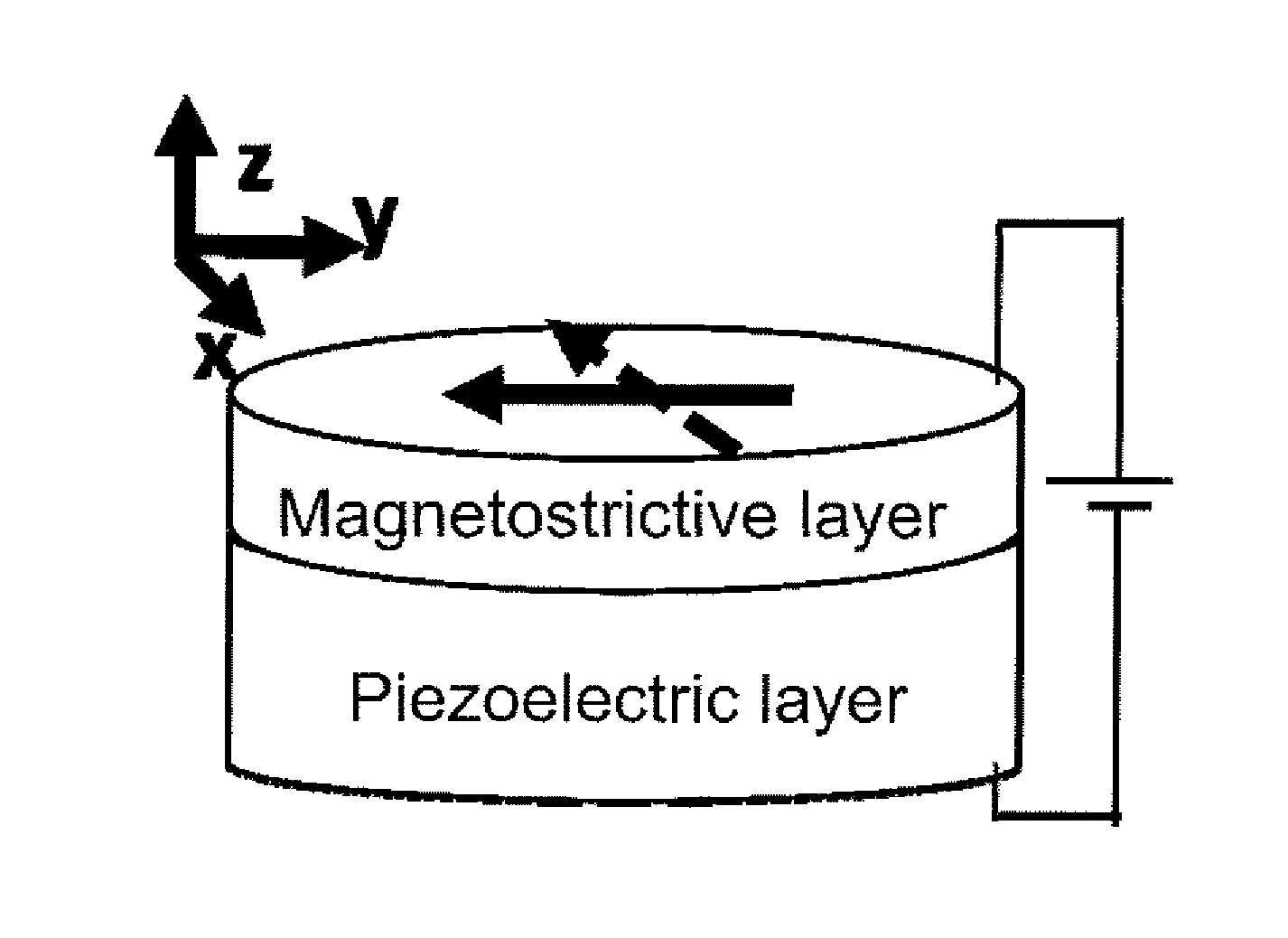

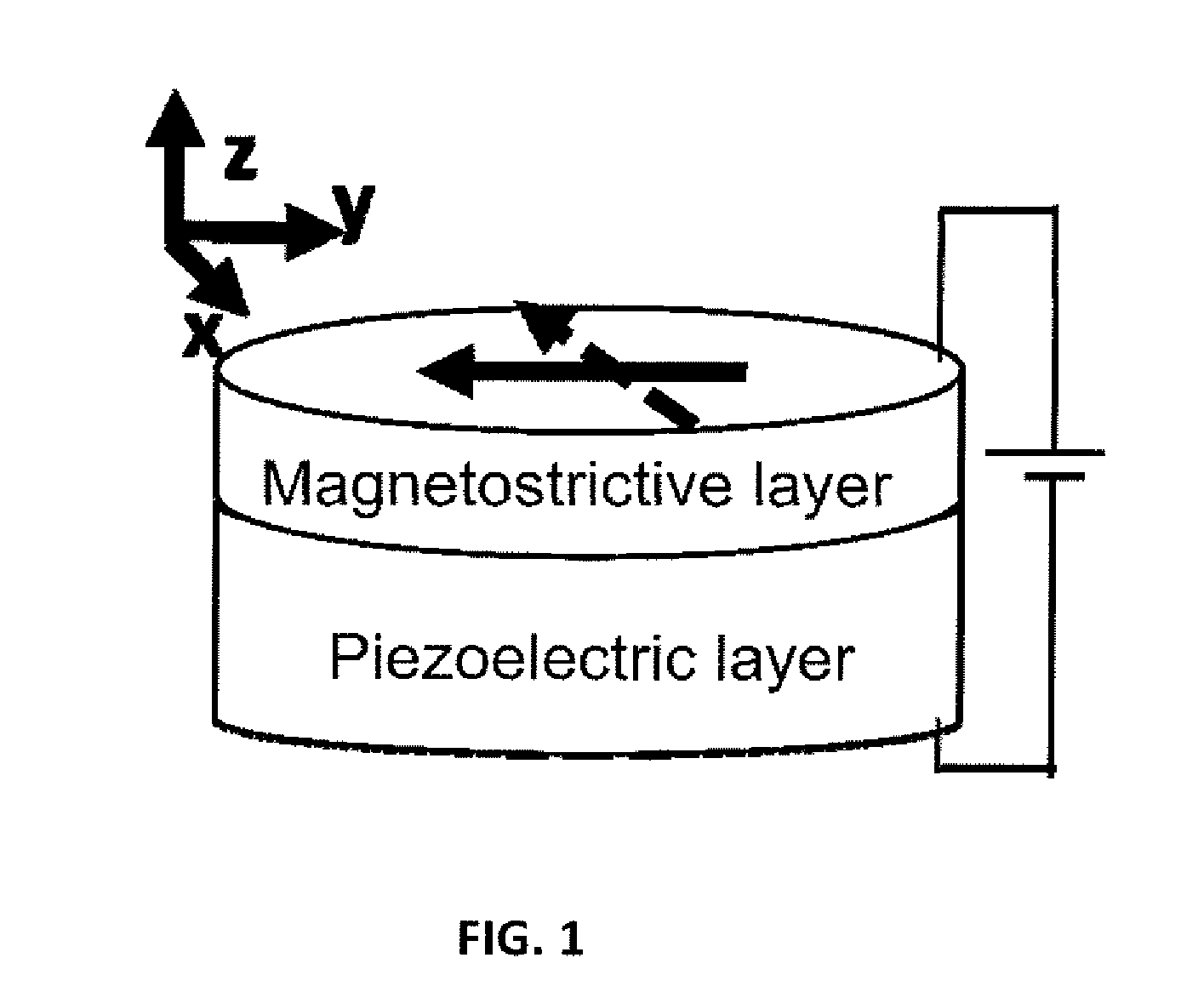

Planar Multiferroic/Magnetostrictive Nanostructures as Memory Elements, Two-Stage Logic Gates and Four-State Logic Elements for Information Processing

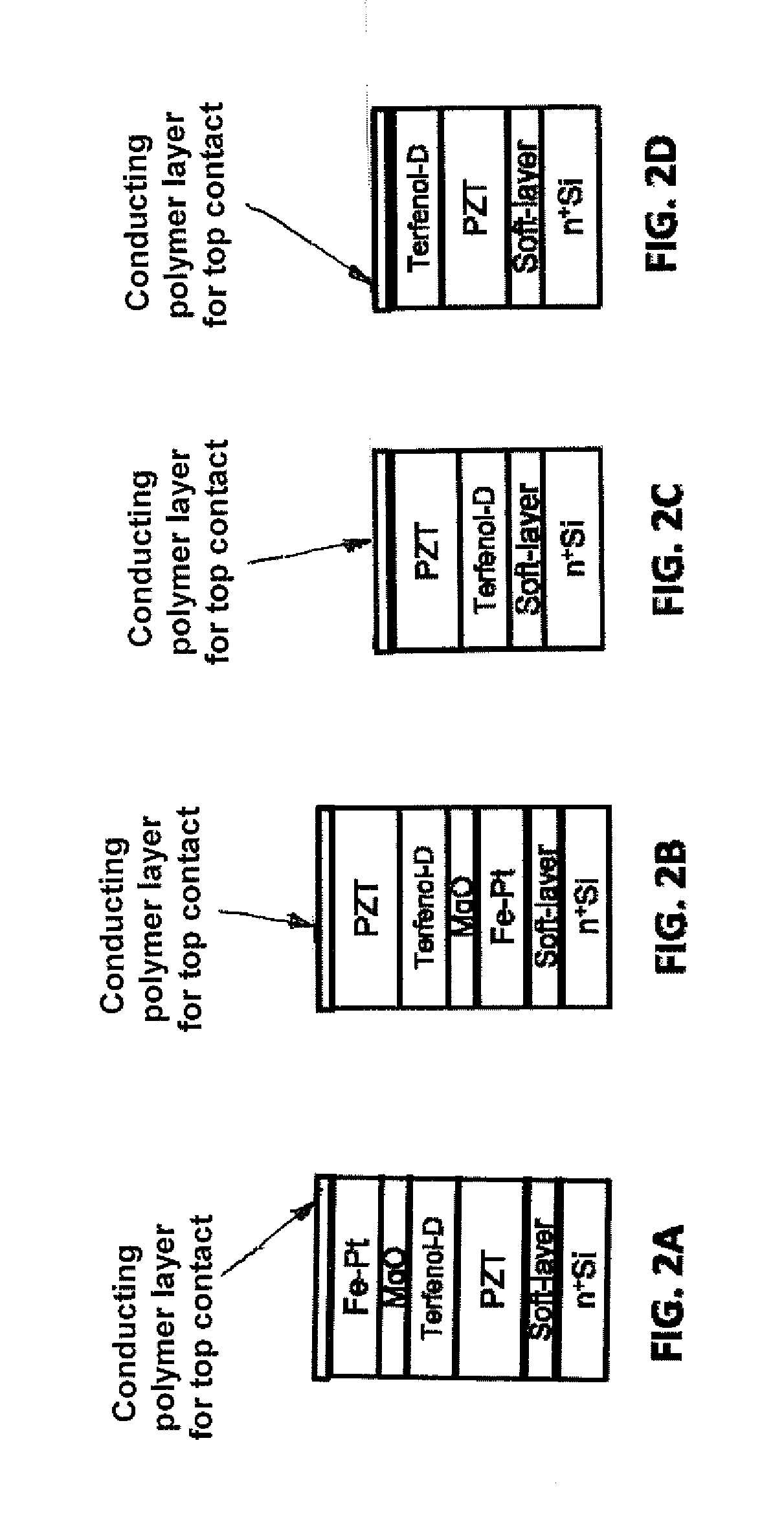

InactiveUS20120267735A1Energy efficiencyMinimize dipole momentSolid-state devicesSemiconductor/solid-state device manufacturingInformation processingNanomagnet

A magnetostrictive-piezoelectric multiferroic single- or multi-domain nanomagnet whose magnetization can be rotated through application of an electric field across the piezoelectric layer has a structure that can include either a shape-anisotropic mangnetostrictive nanomagnet with no magnetocrystalline anisotropy or a circular nanomagnet with biaxial magnetocrystalline anisotropy with dimensions of nominal diameter and thickness. This structure can be used to write and store binary bits encoded in the magnetization orientation, thereby functioning as a memory element, or perform both Boolean and non-Boolean computation, or be integrated with existing magnetic tunneling junction (MTJ) technology to perform a read operation by adding a barrier layer for the MTJ having a high coercivity to serve as the hard magnetic layer of the MTJ, and electrical contact layers of a soft material with small Young's modulus. Equivalently, mangnetostrictive nanomagnetic elements whose magnetization is rotated by strain transferred from the substrate that has acoustic waves propagating on the substrate can be used.

Owner:VIRGINIA COMMONWEALTH UNIV

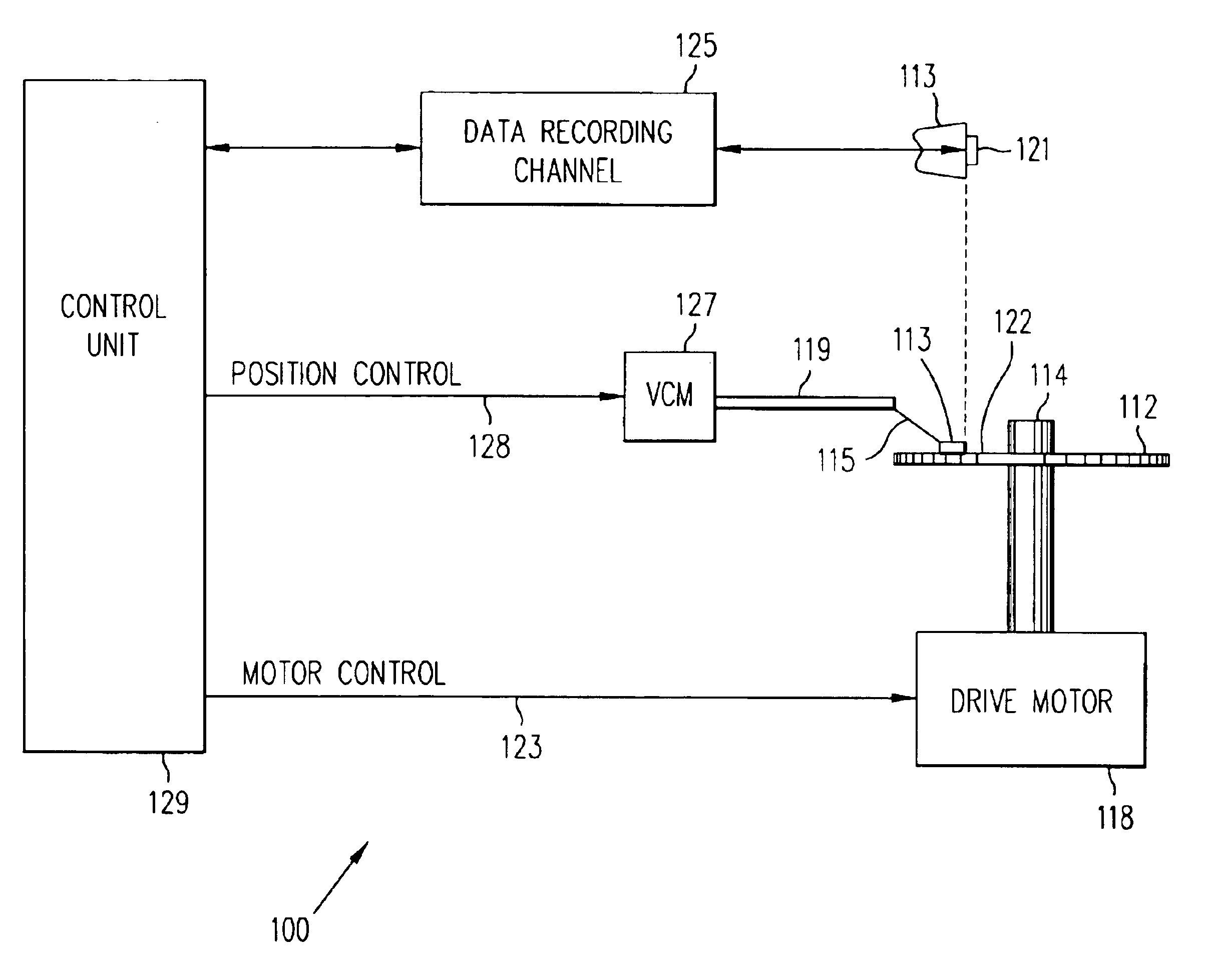

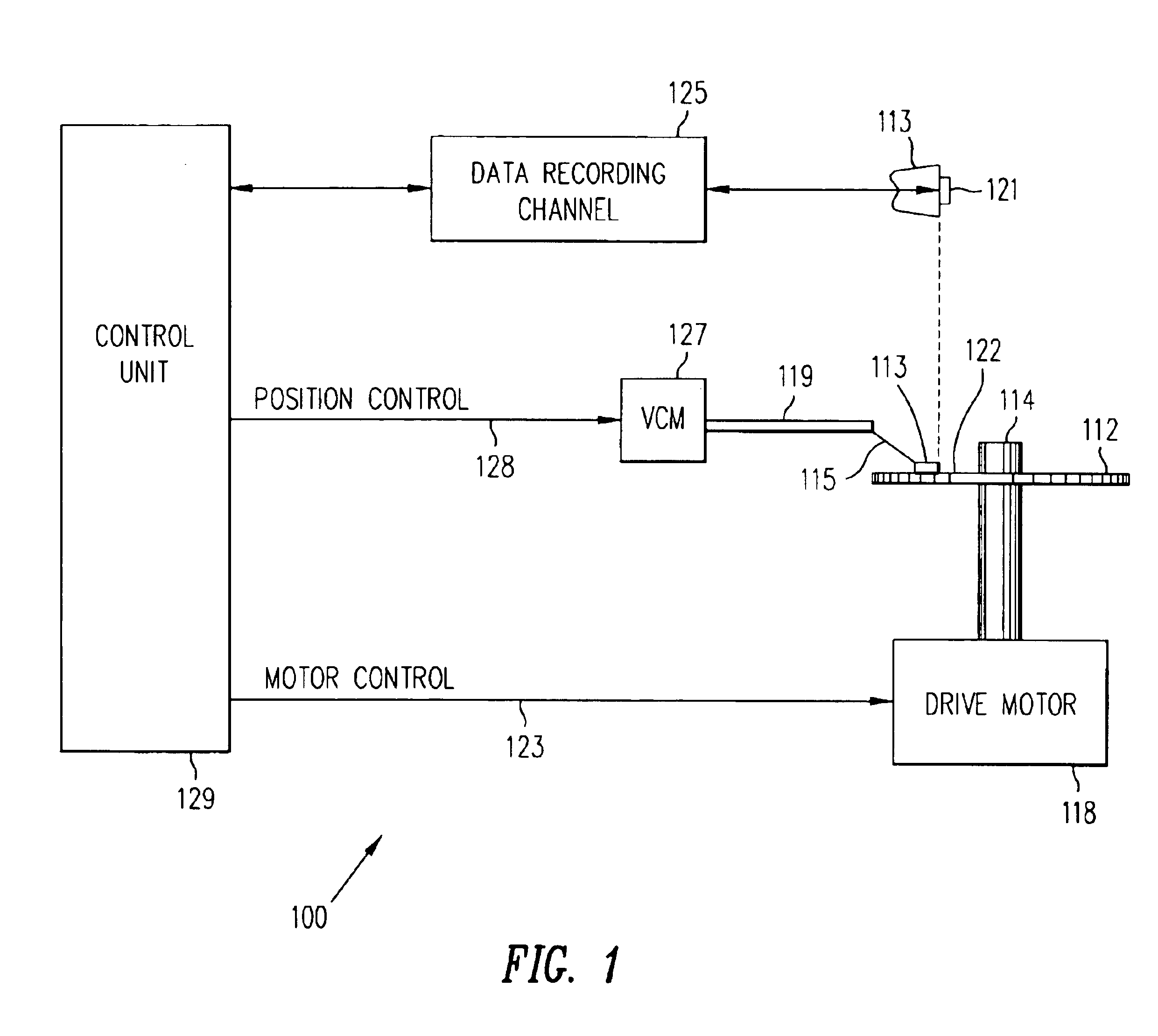

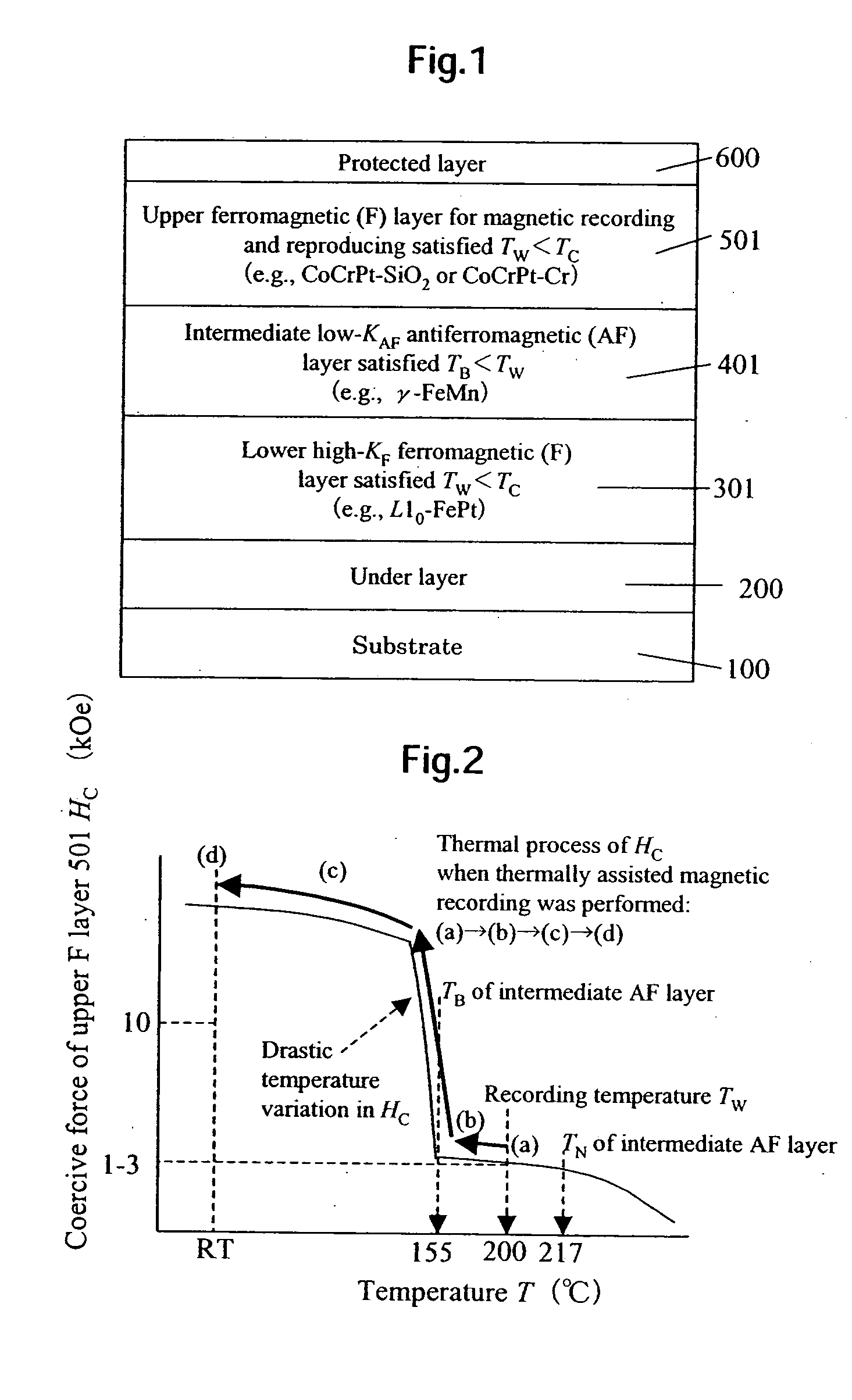

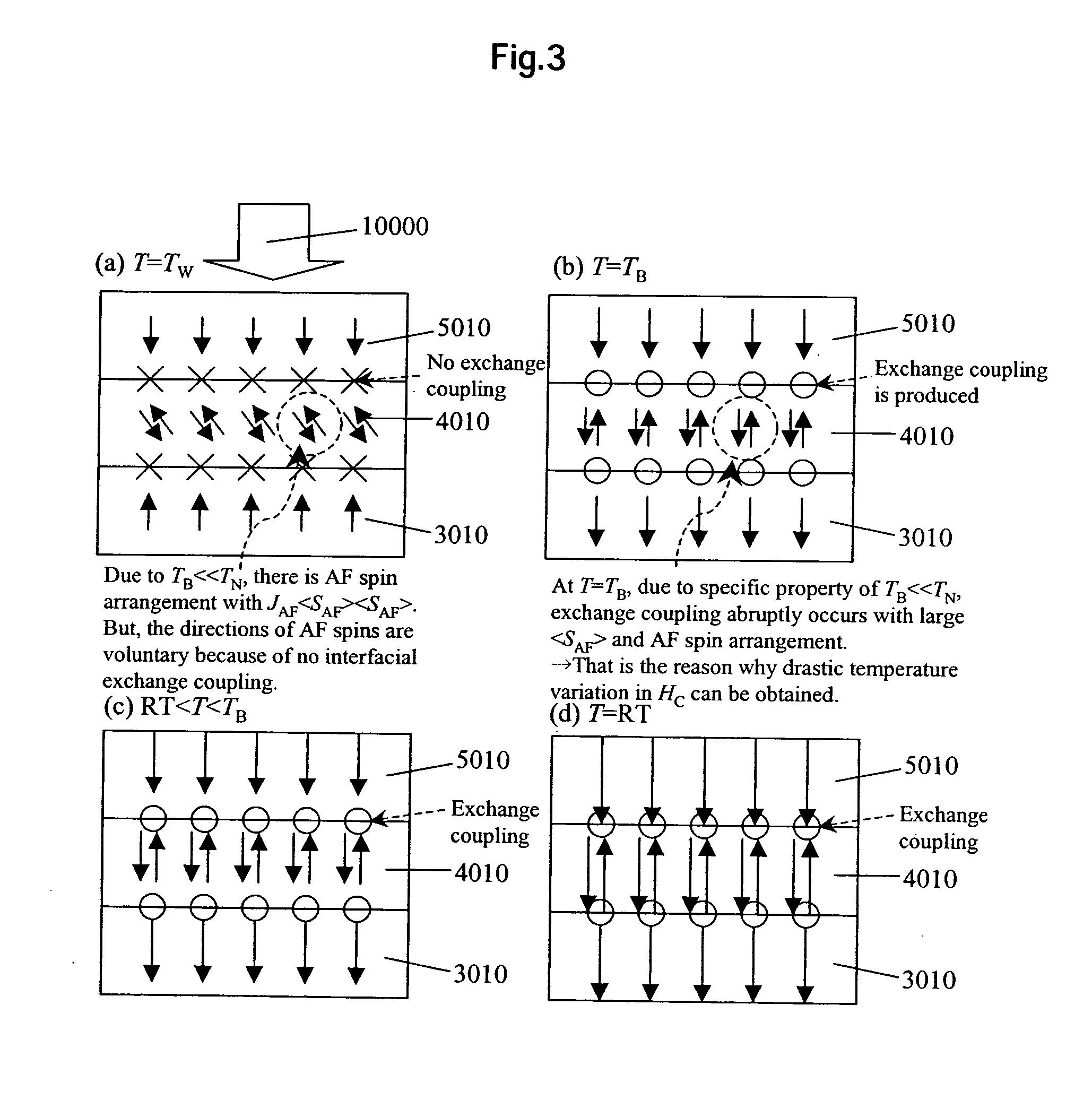

Thermally assisted magnetic recording system and method of writing using magnetic and thermal gradients

InactiveUS6950260B2Avoid thermal instabilityRapid coolingCombination recordingRecord information storageMagnetic field gradientMagnetic media

A magnetic recording system is provided having a write head employing a combination of magnetic write field gradient and thermal gradient to write data on a ‘thermal spring’ magnetic recording media. The write head comprises a magnetic element using a write current to induce a magnetic write field at the magnetic media and a thermal element using a very small aperture laser to heat a portion of the media. The thermal spring magnetic media comprises [comprises] first and second stacks providing two exchange coupled ferromagnetic layers having different Curie temperatures [The first stack has a high magneto-crystalline anisotropy, a relatively low saturation magnetization and a low Curie temperature.] [The second stack has a relatively low magneto-crystalline anisotropy, a high saturation magnetization and a high Curie temperature.] The magnetic field gradient and the thermal gradient are arranged to substantially overlap at the trailing edge of the heated portion of the magnetic media allowing data at high density with high thermal stability to be recorded on the rapidly cooling thermal spring magnetic recording media.

Owner:WESTERN DIGITAL TECH INC

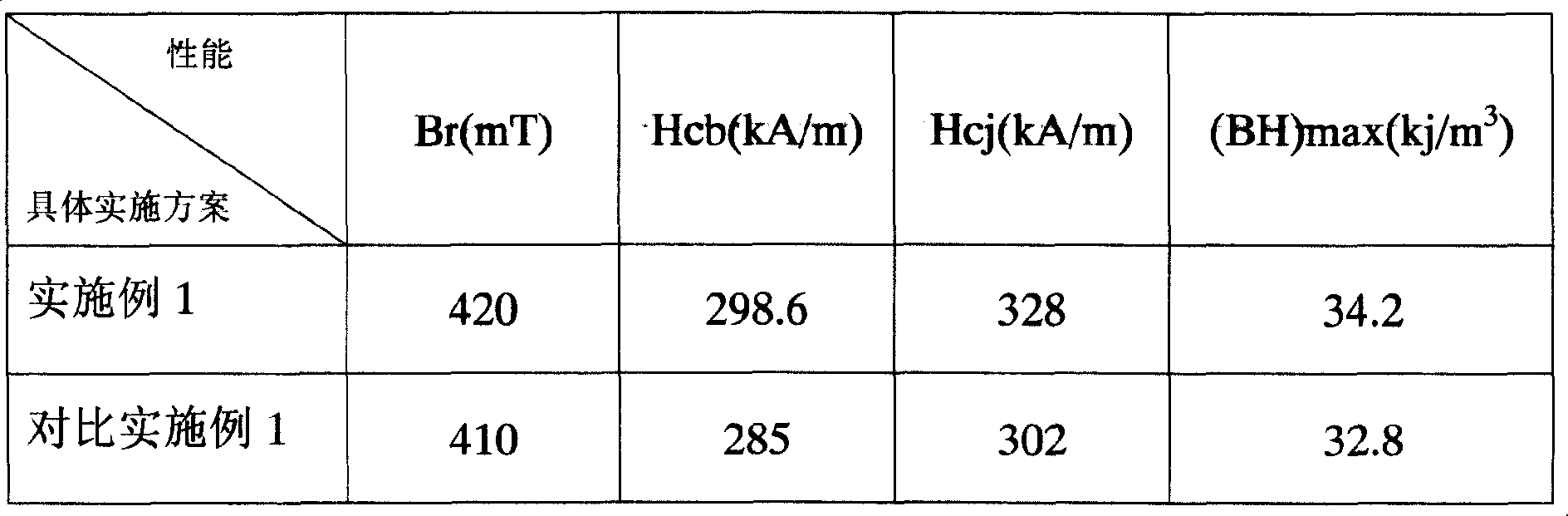

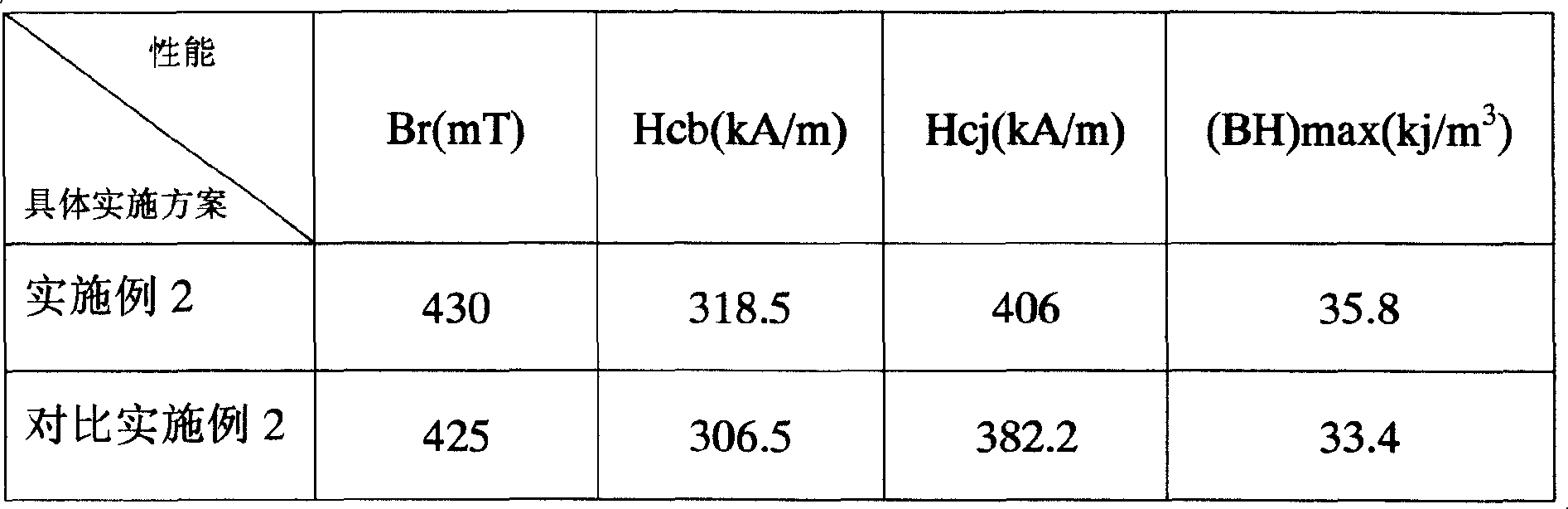

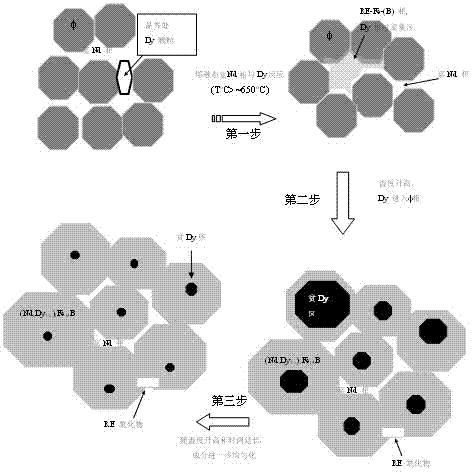

Ultrahigh-coercivity sintered neodymium-iron-boron magnet and preparation method thereof

ActiveCN103794322AImprove coercive forceAchieve magnetic hardeningPermanent magnetsInductances/transformers/magnets manufactureRare-earth elementHigh volume manufacturing

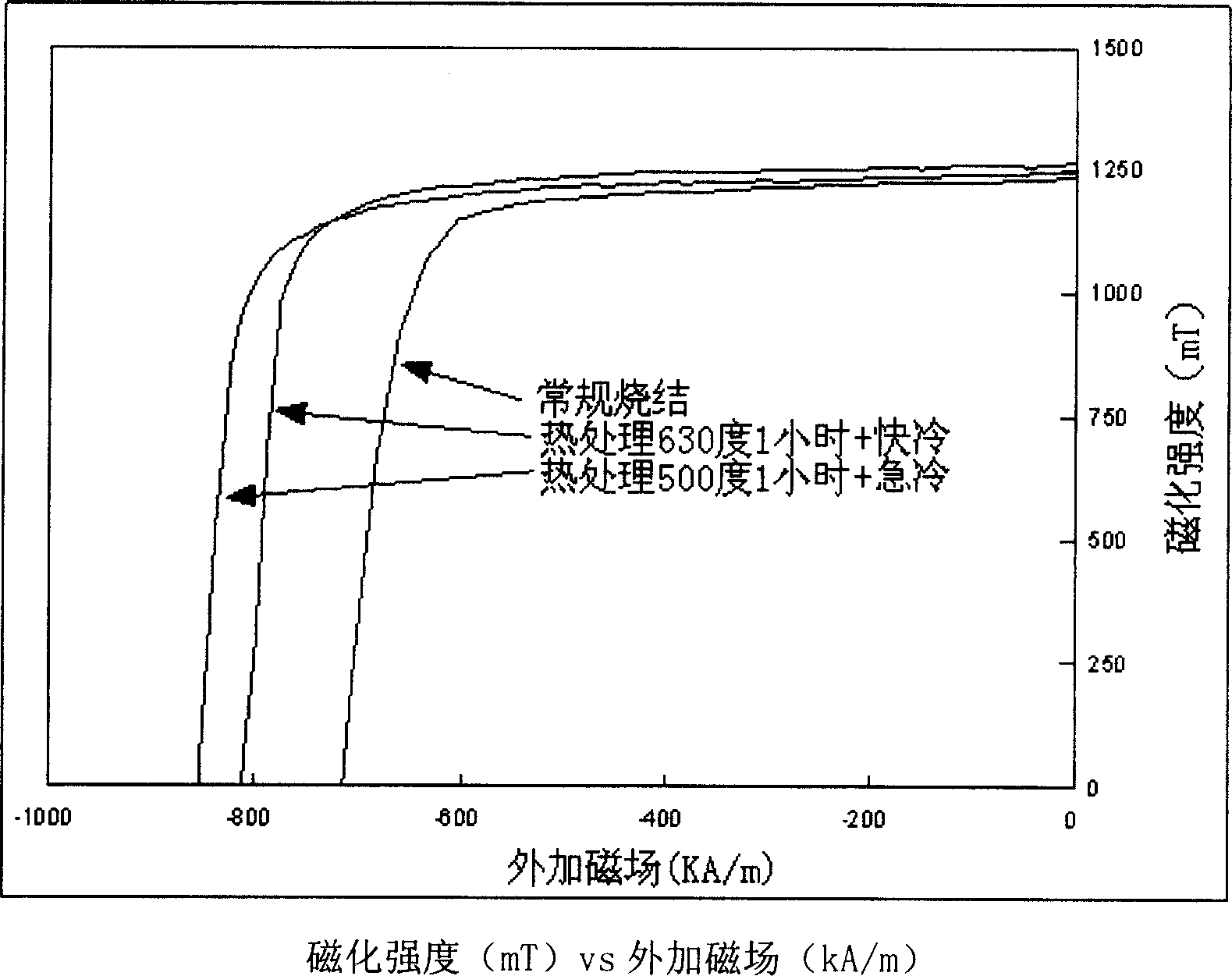

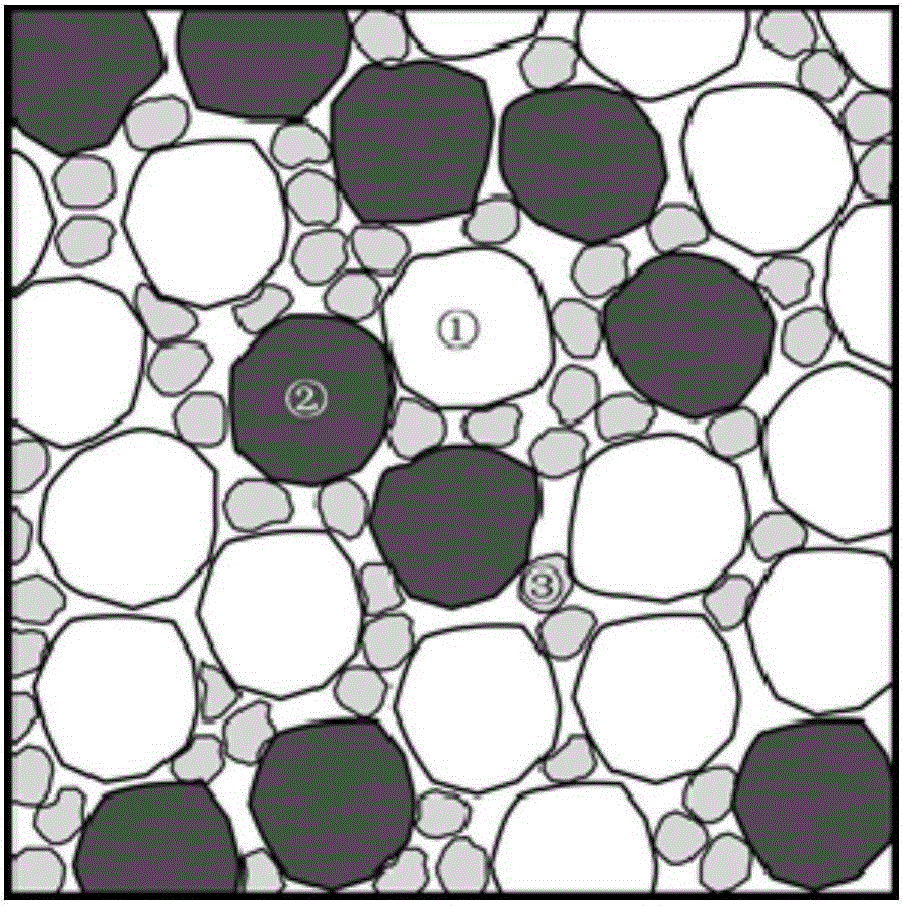

The invention discloses an ultrahigh-coercivity sintered neodymium-iron-boron magnet and a preparation method thereof. The ultrahigh-coercivity sintered neodymium-iron-boron magnet comprises a main phase and a crystal boundary adding phase. The main phase comprises low-HA main alloy and high-HA main alloy. The high magnetocrystalline anisotropy field HA main alloy and the low-HA main alloy are used as the main phase, so that the heavy rare earth element diffuses from the high-HA phase to the low-HA phase in the sintering and heat treatment process to initially improve the coercivity; in addition, alloy components and the preparation technology can be controlled at the same time, the content of Nd2Fe14B in the magnet is improved, and it is ensured that the magnet has the high magnetic energy product. The crystal boundary adding phase can further achieve crystalline grain surface magnetic hardening and improve the coercivity, the microscopic structure is optimized, and the coercivity is further improved. The preparation method of the ultrahigh-coercivity sintered neodymium-iron-boron magnet has the advantages of both a traditional dual alloy method and a single alloy crystal boundary adding method, and is easy to operate and suitable for mass production of ultrahigh-coercivity high-residual-magnetism sintered neodymium-iron-boron magnets.

Owner:ZHEJIANG UNIV +1

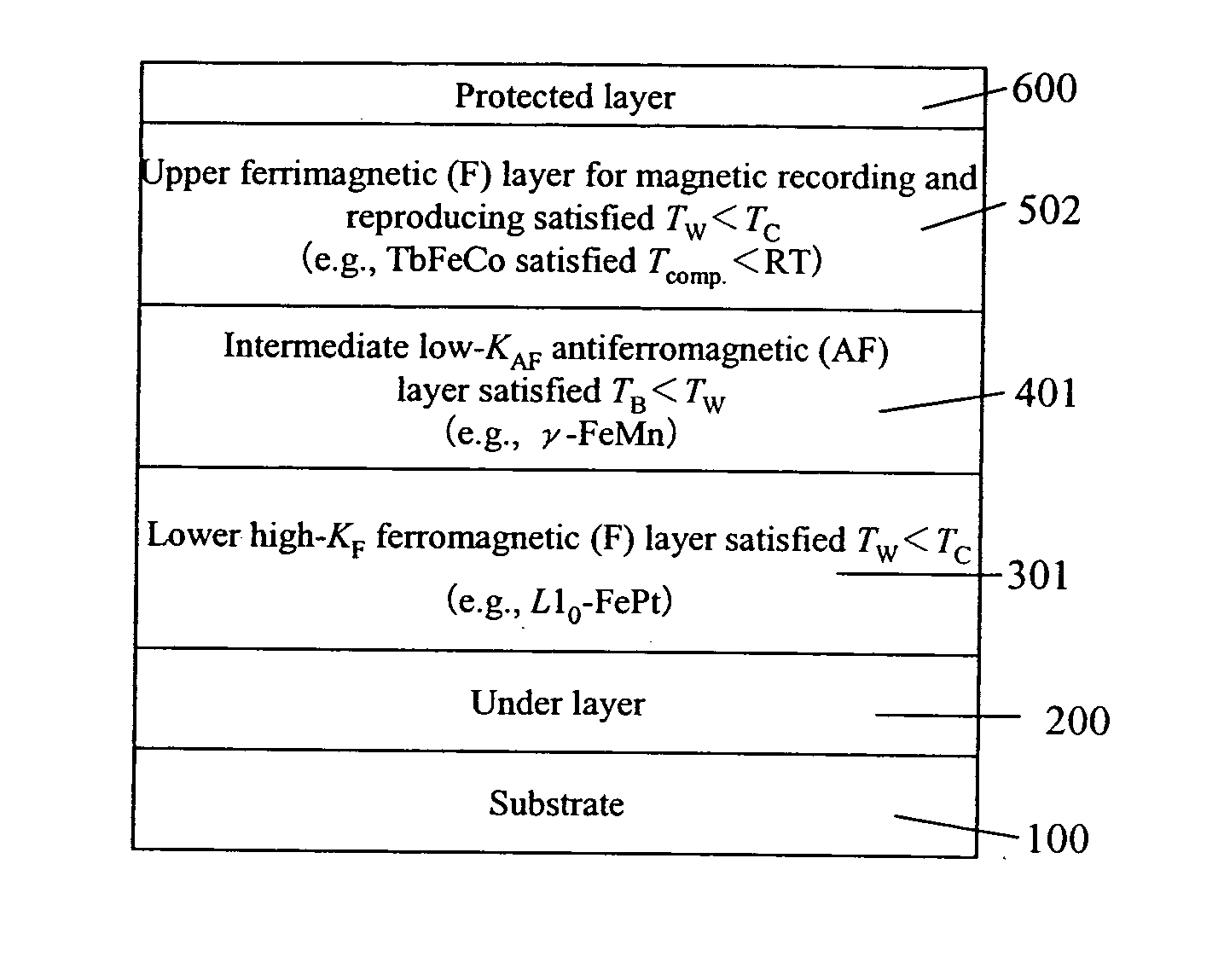

Thermally assisted magnetic recording media and magnetic recording and reproducing apparatus

InactiveUS20070048552A1Overcome resistance against thermal fluctuationImprove coercive forceCombination recordingDifferent record carrier formsHeat-assisted magnetic recordingMagnetocrystalline anisotropy

Owner:WESTERN DIGITAL TECH INC

Method for manufacturing neodymium iron boron permanent magnetic material with high performance

InactiveCN101877265AIncrease molecular anisotropy fieldImprove performanceInorganic material magnetismInductances/transformers/magnets manufactureRare-earth elementMetallurgy

The invention discloses a method for manufacturing a neodymium iron boron permanent magnetic material with high performance. The method improves the coercive force of a magnet by adding a heavy rare earth element Tb instead of Dy into the raw material and reduces the production cost by substituting a small amount of Pr for Nd. The neodymium iron boron permanent magnetic material containing Pr and Tb consists of (Nd, Pr)xFebalanceByDyzTbuCovAlw, wherein the atom percent of each element in the invention is as follows: x is not less than 7% and not greater than 15%, y is not less than 5.5% and not greater than 8.0%, z is not less than 0.05% and not greater than 6%, u is not less than 0 and not greater than 2%, v is not less than 0 and not greater than 3% and w is not less than 0 and not greater than 1.5%; and the balance is Fe and impurities introduced by the raw material. The materials are mixed according to the atom percents, melted, made into powder, formed and sintered. Due to the addition of Tb, the anisotropy field of the magnet molecules is improved and the coercive force of the magnet is obviously improved. Moreover, as the magnetocrystalline anisotropy field of Pr2Fe14B is slightly higher than that of Nd2Fe14B, the coercive force of the magnet is improved a little by adding a small amount of Pr.

Owner:TIANHE ADVANCED TECH MAGNET

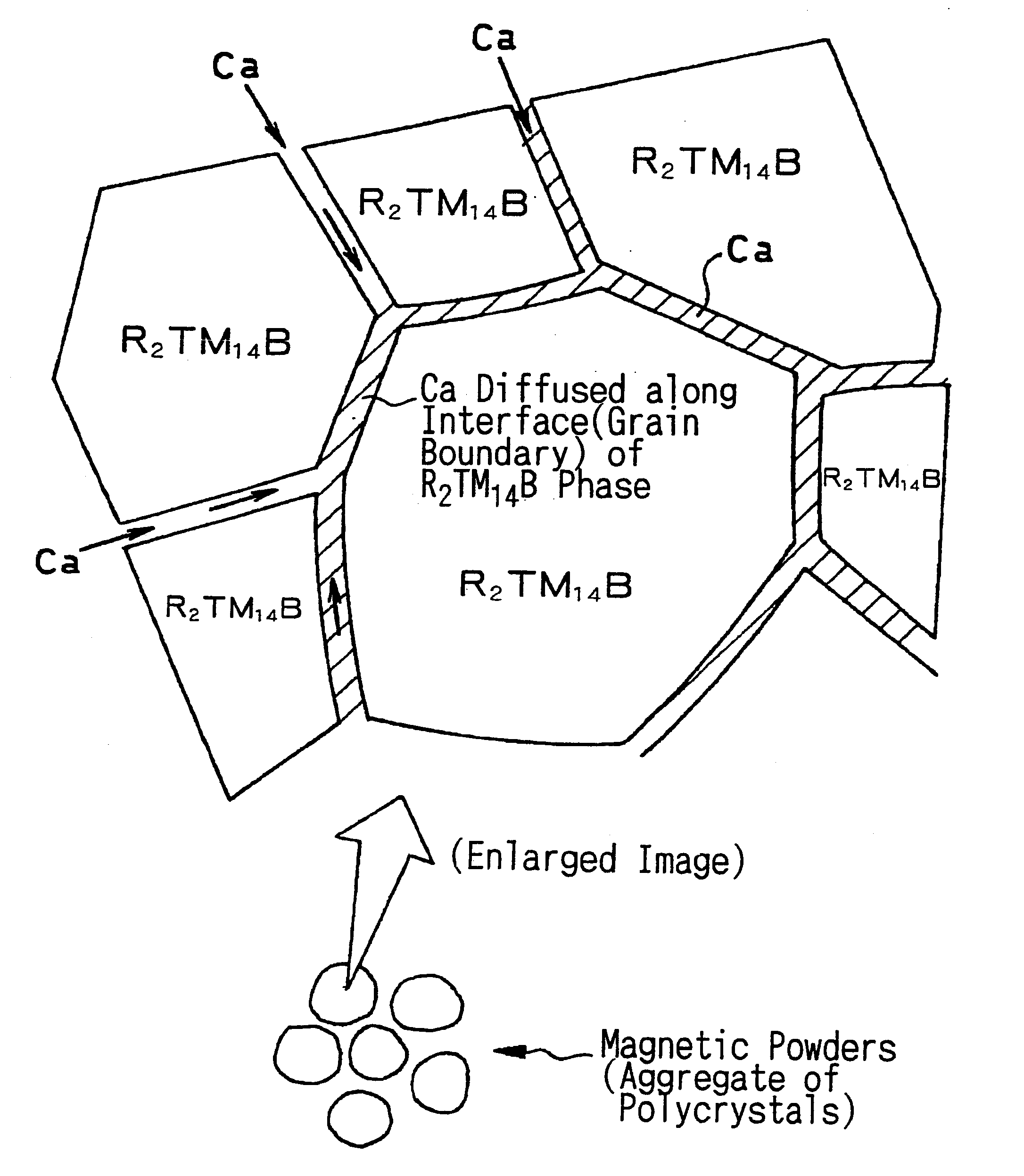

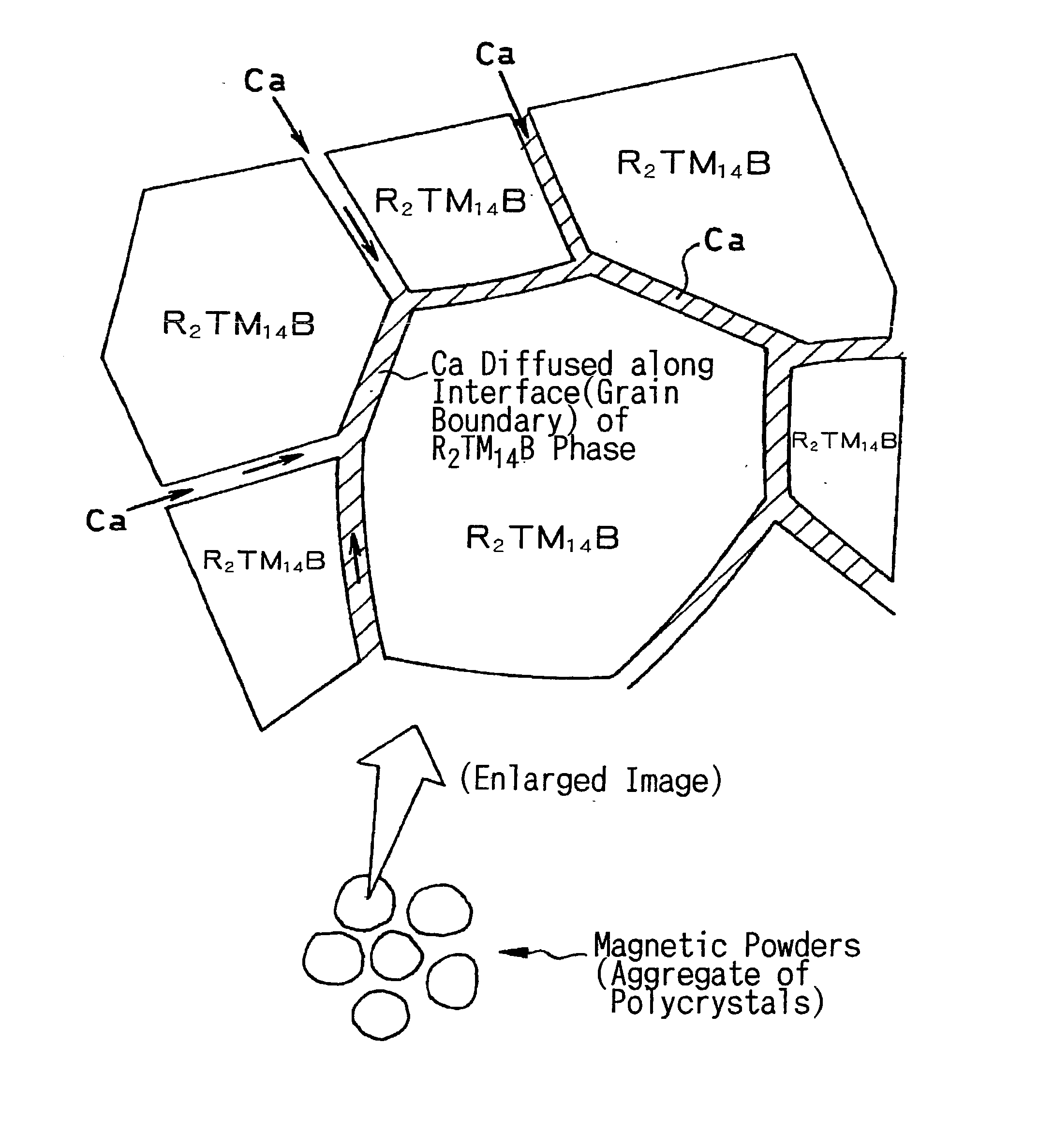

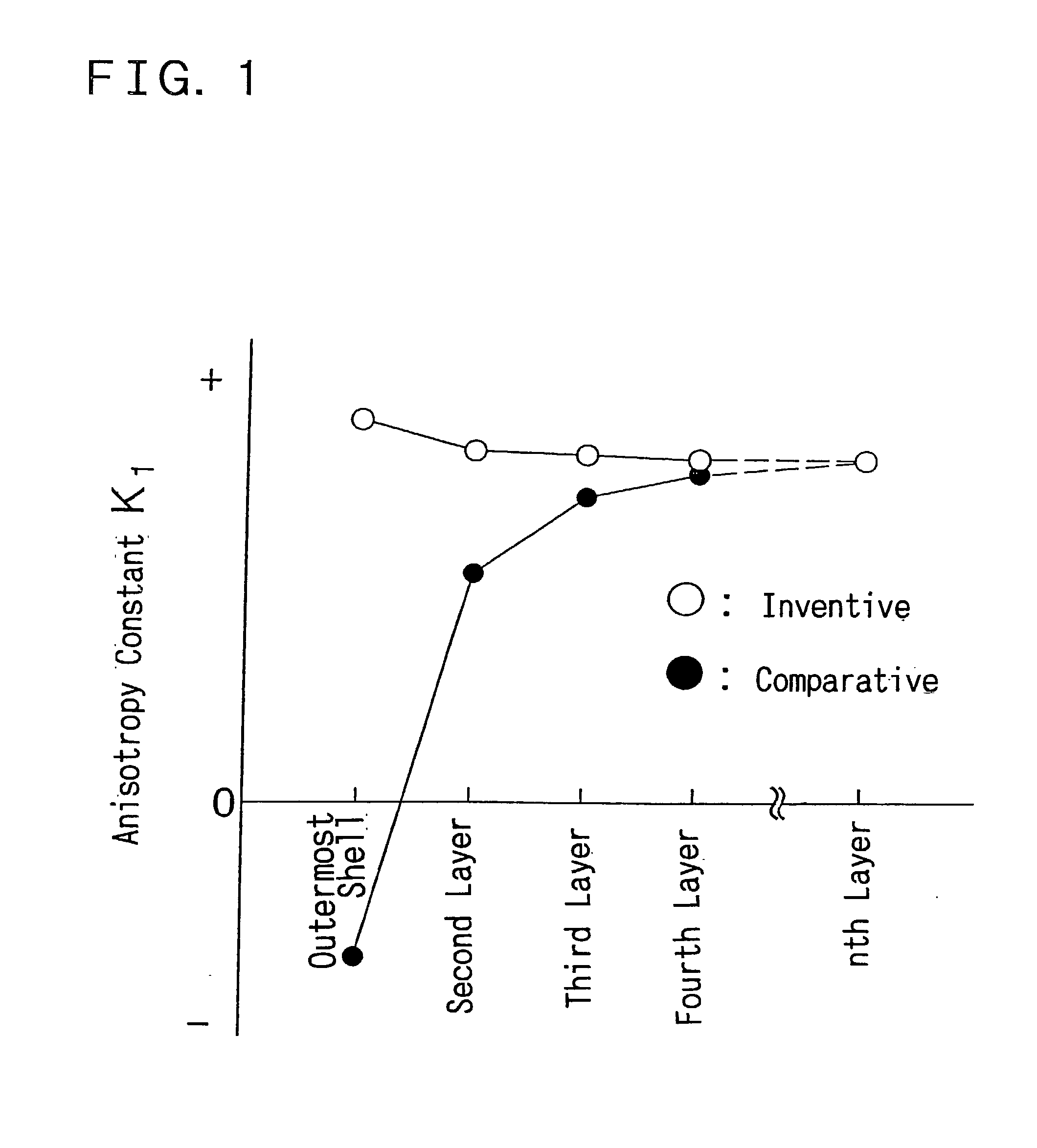

Permanent magnets and R-TM-B based permanent magnets

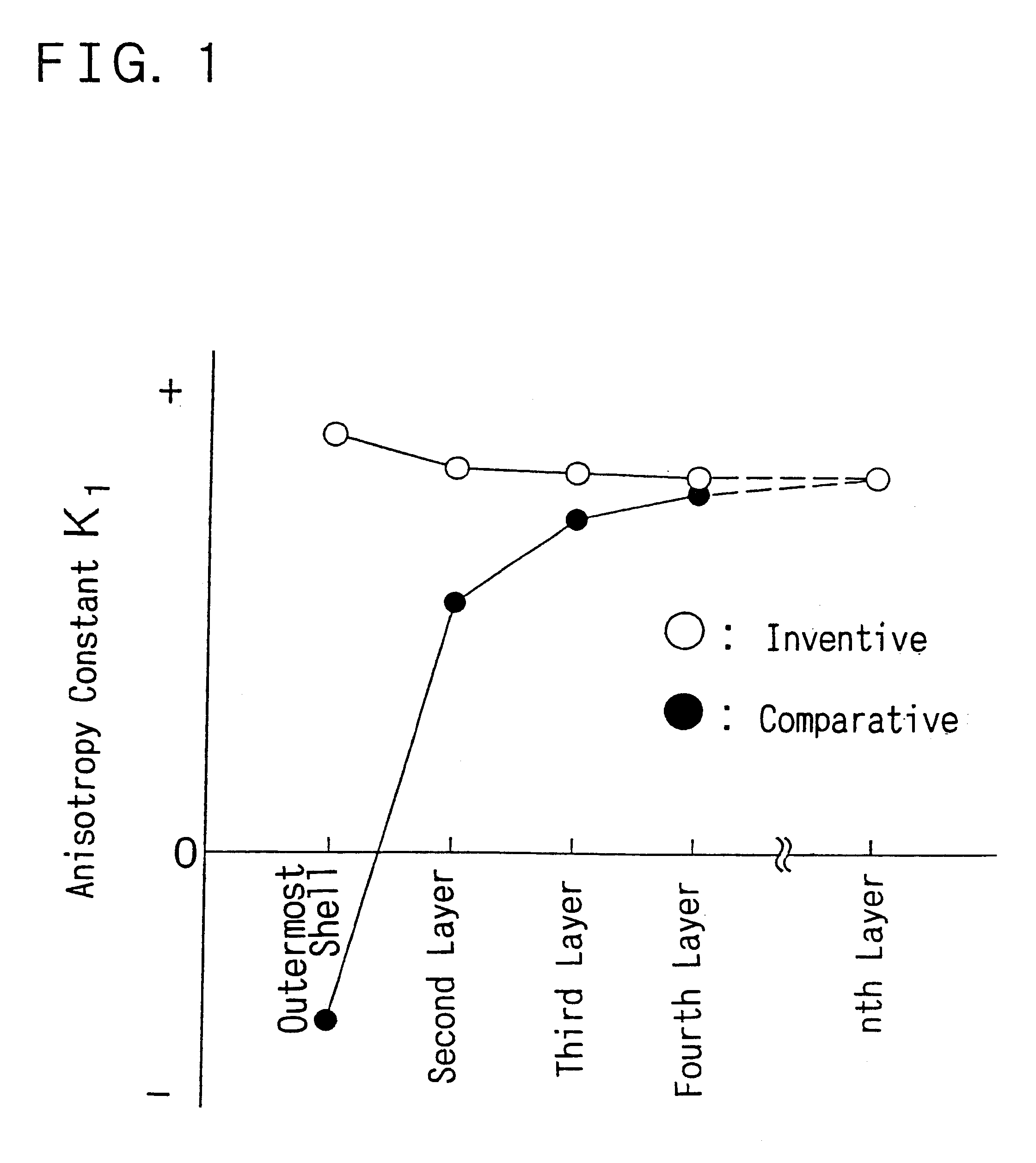

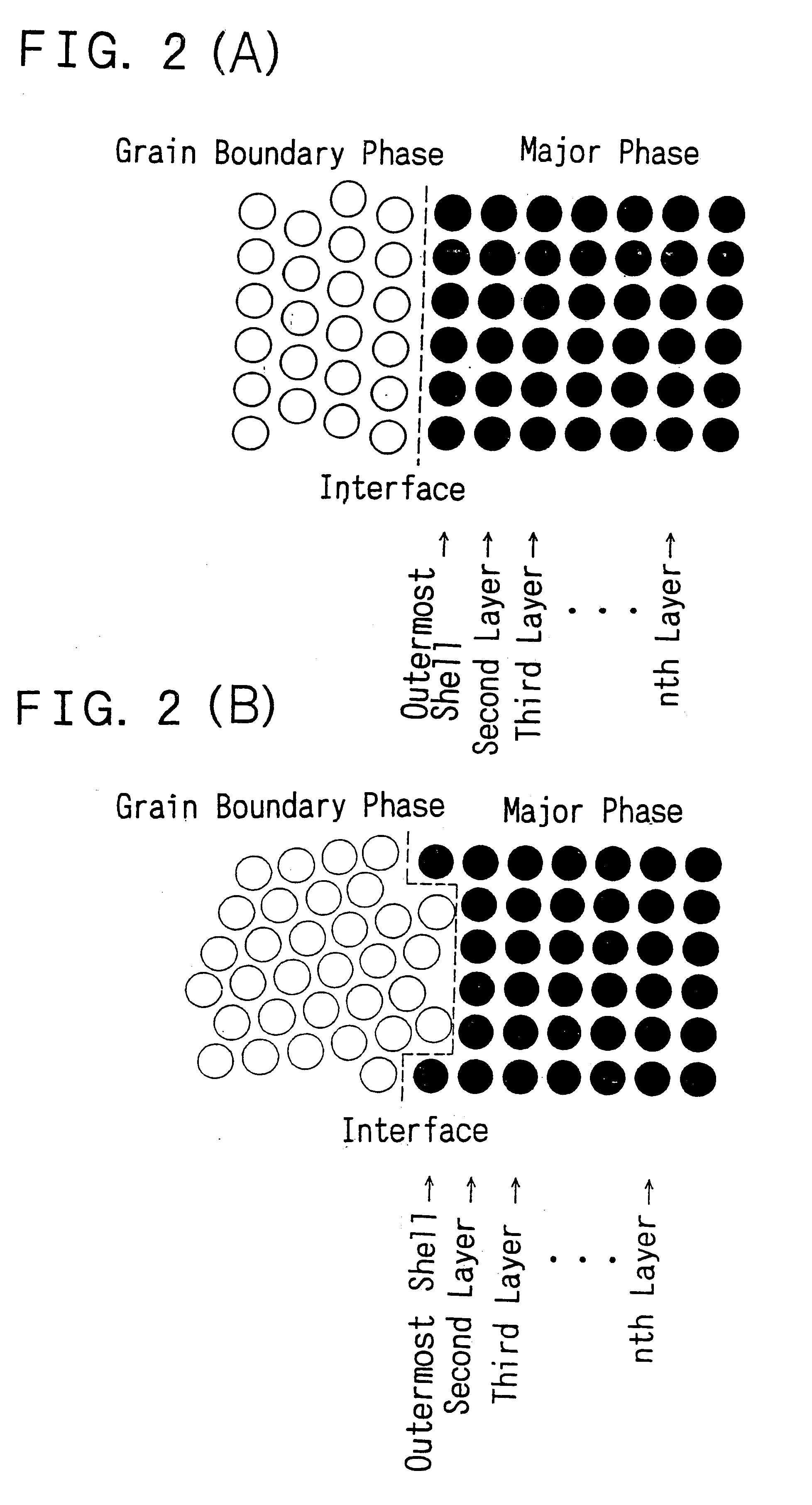

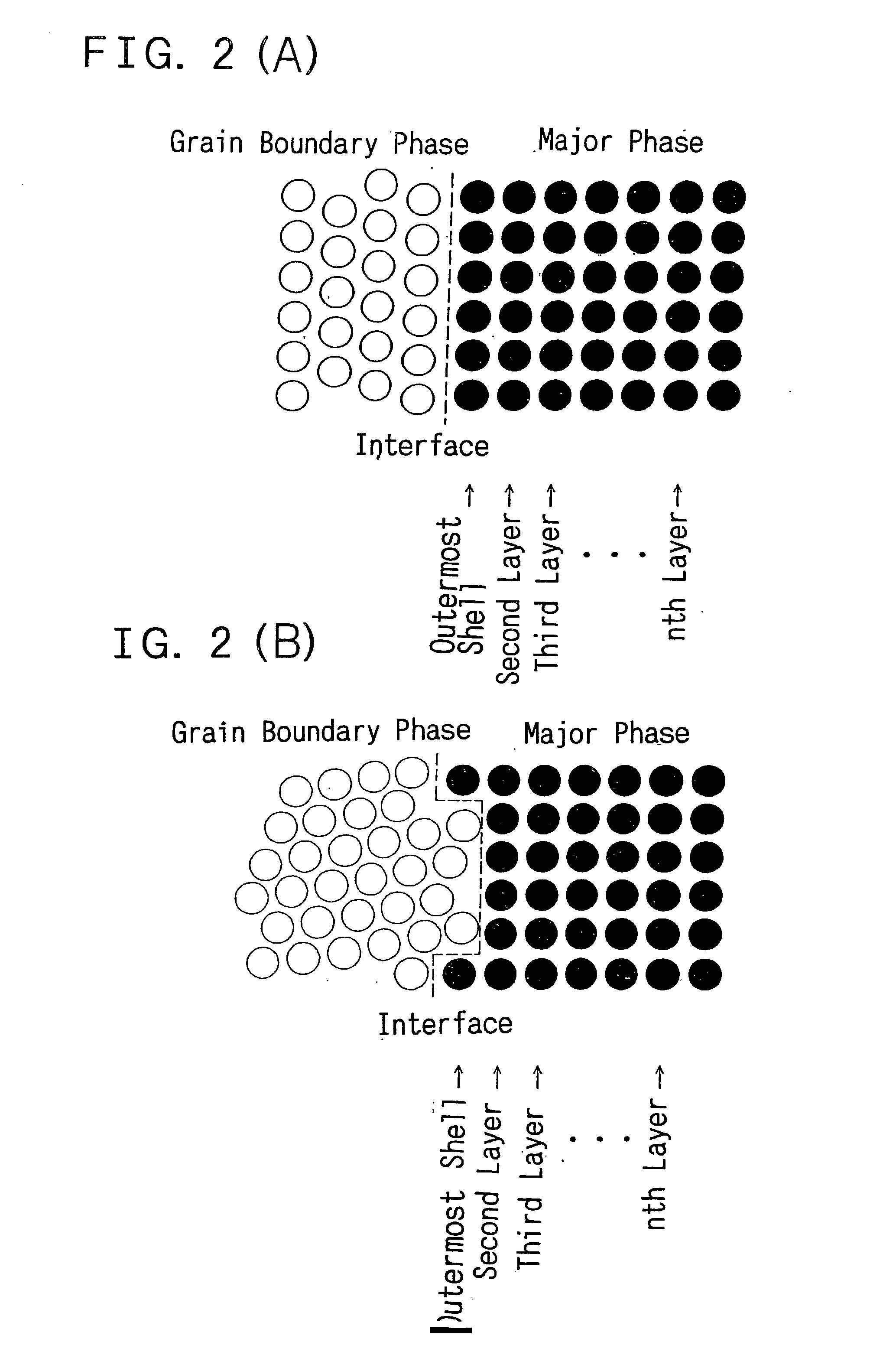

InactiveUS6511552B1Improve magnetic propertiesSure easyInductances/transformers/magnets manufactureMagnetic materialsNucleationMagnetocrystalline anisotropy

Permanent magnets in which the ferromagnetic phase is matched with the grain boundary phase, and permanent magnets in which magnetocrystalline anisotropy in the vicinity of the outermost shell of the major phase is equivalent in intensity to that in the inside to suppress nucleation of the inverse magnetic domain. Guideline for designing permanent magnets having high magnetic performance is provided.

Owner:HITACHI METALS LTD

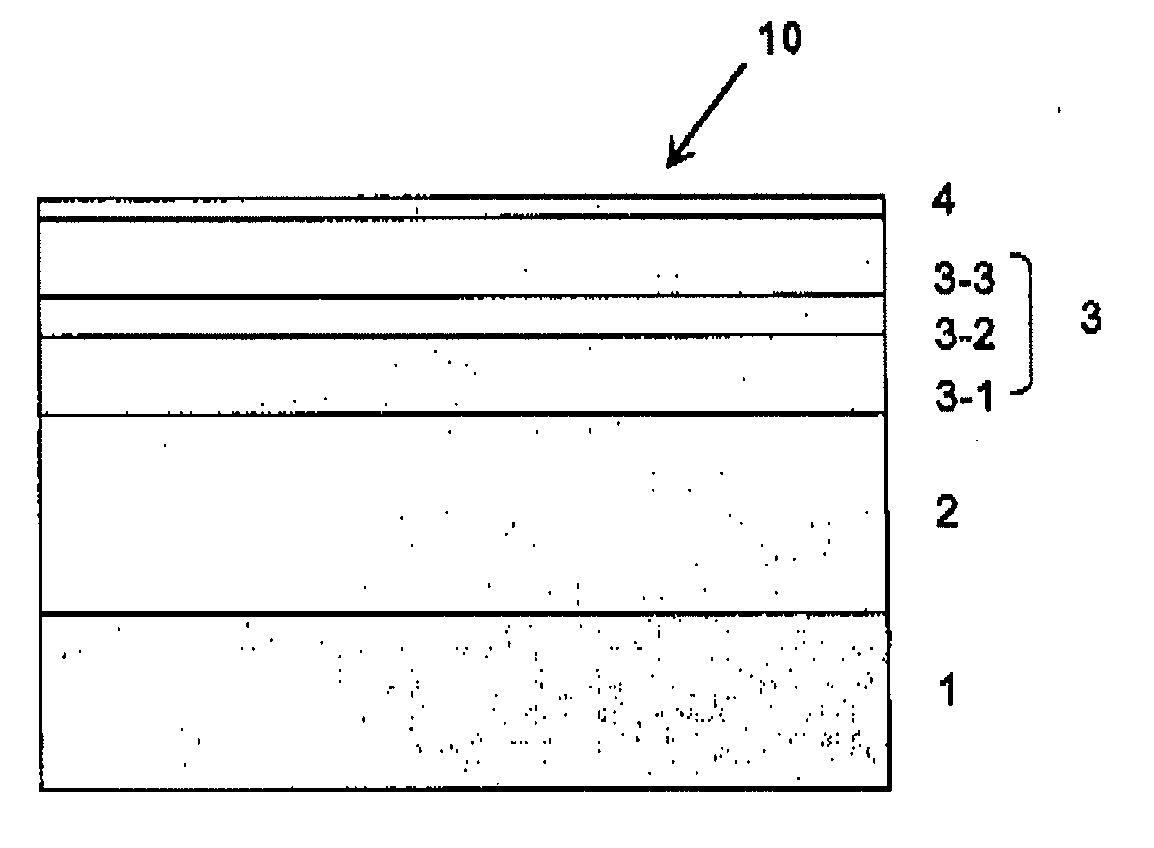

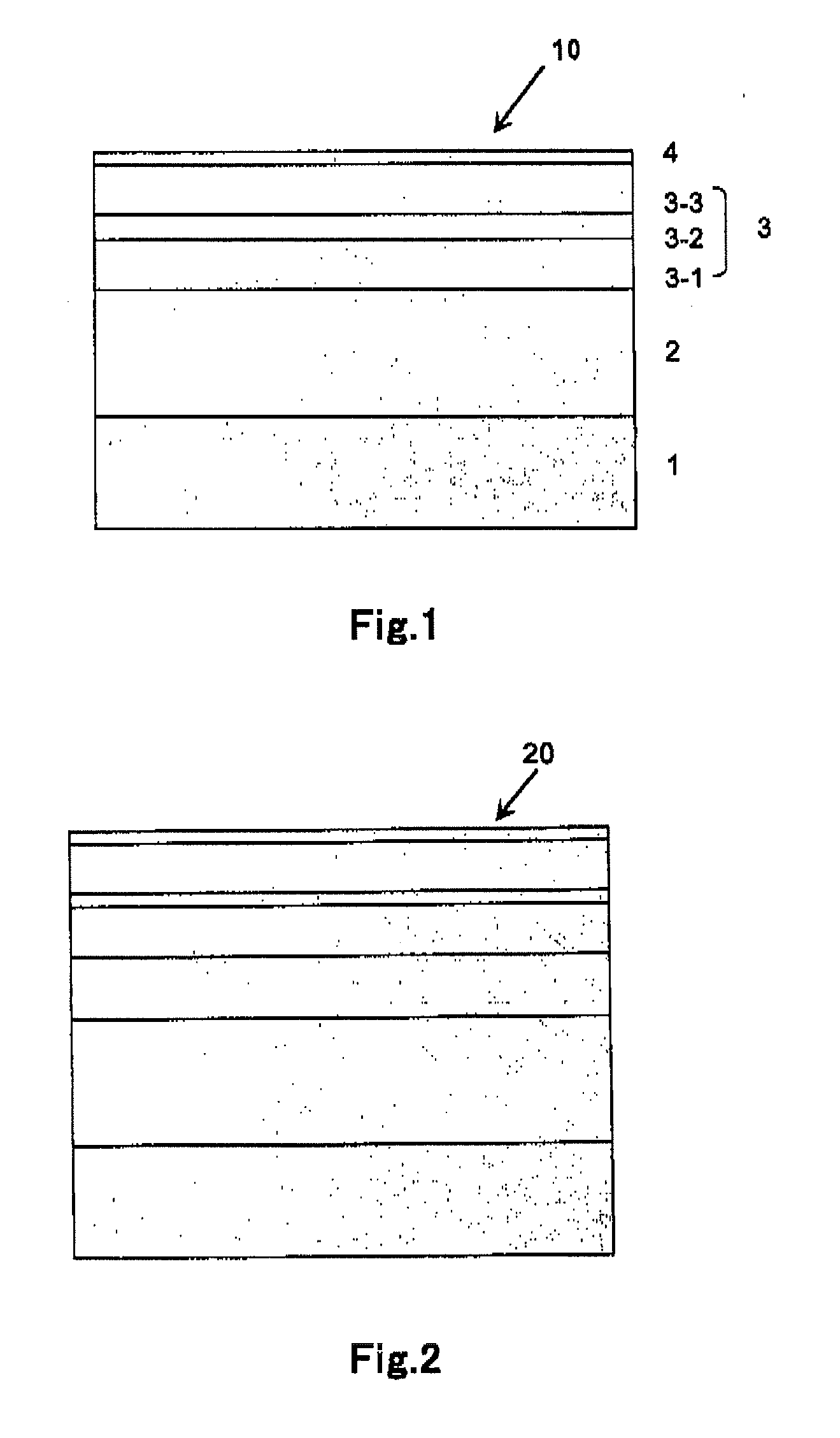

Vertical magnetic recording medium and magnetic recording reproducing apparatus

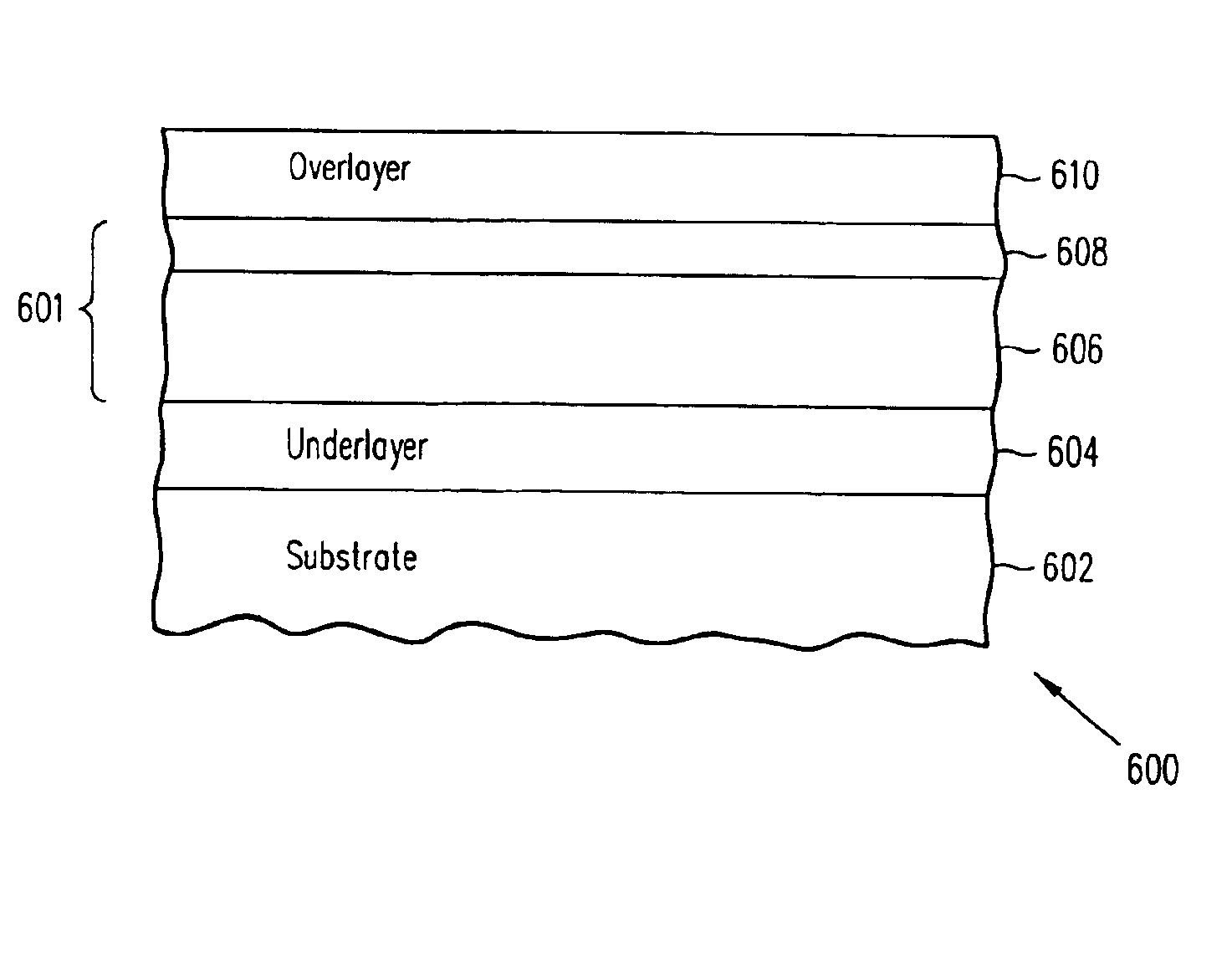

InactiveUS20100165510A1Good overwrite (OW) characteristicEnhanced resistance to heat fluctuationRecord information storageDisk carriersAlloyRecording density

A magnetic recording medium comprising a substrate, at least one soft magnetic underlayer formed on the substrate, a perpendicular magnetic recording layer formed on the soft magnetic underlayer, and a protective layer formed on the perpendicular magnetic recording layer, is provided wherein the perpendicular magnetic recording layer is comprised of a primary recording layer, a non-magnetic intermediate layer and an auxiliary layer; the primary recording layer comprises magnetic crystal grains and grain boundary portions surrounding the magnetic crystal grains, and has a perpendicular magnetic anisotropy; the auxiliary layer has a negative magneto crystalline anisotropy; and the non-magnetic intermediate layer is formed between the primary recording layer and the auxiliary layer and comprises at least one metal selected from Ru, Rh and Ir, or at least one alloy thereof. This magnetic recording medium exhibits high heat resistance and good recording / reproducing characteristics, and enables a high recording density.

Owner:TOHOKU UNIV +2

Magnetic field orientation three-dimensional printing anisotropic bonded permanent magnet and preparation method thereof

ActiveCN104269265AAchieve regulationElimination of magnetic interaction forcesInductances/transformers/magnets manufactureRare earthNitrogen

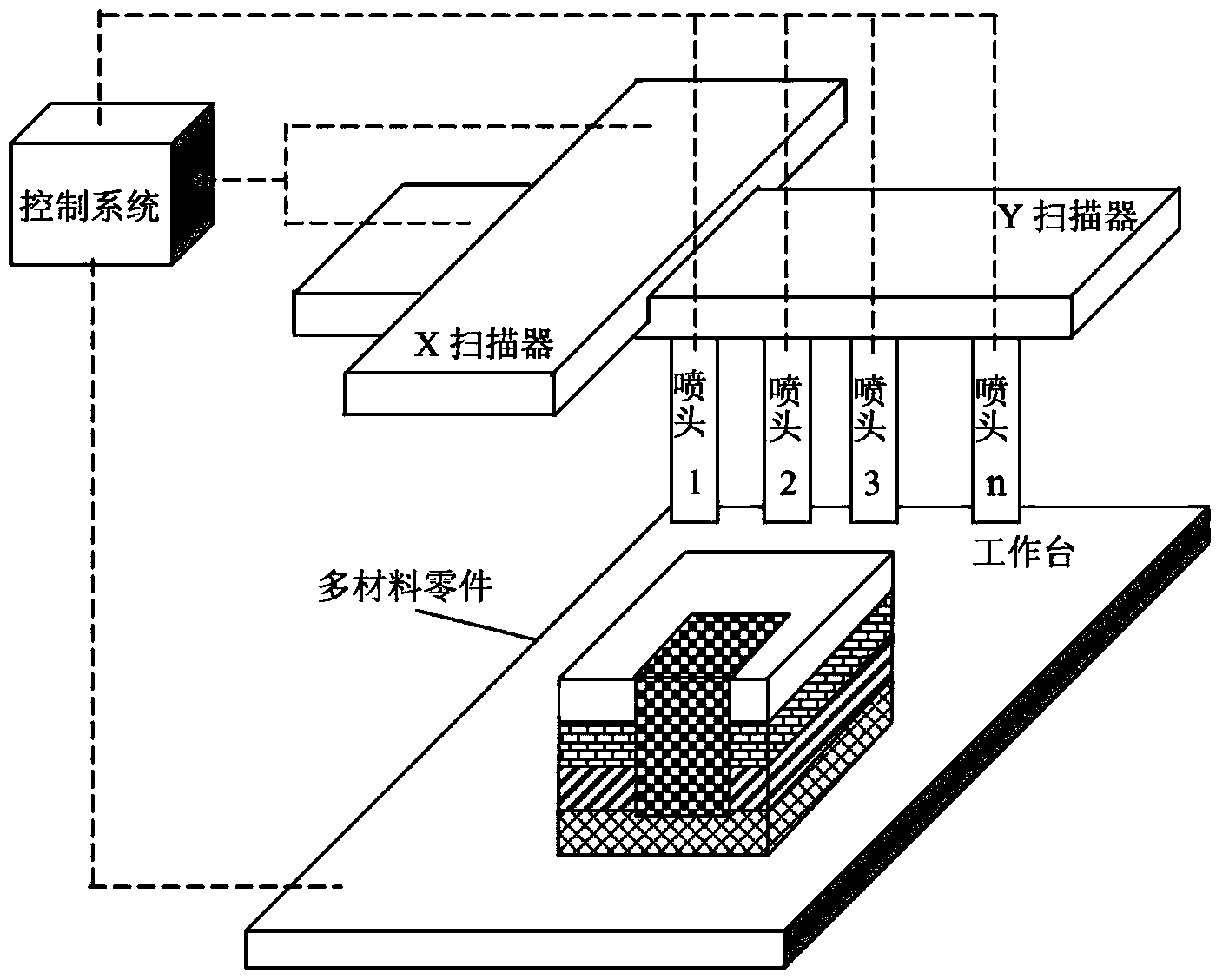

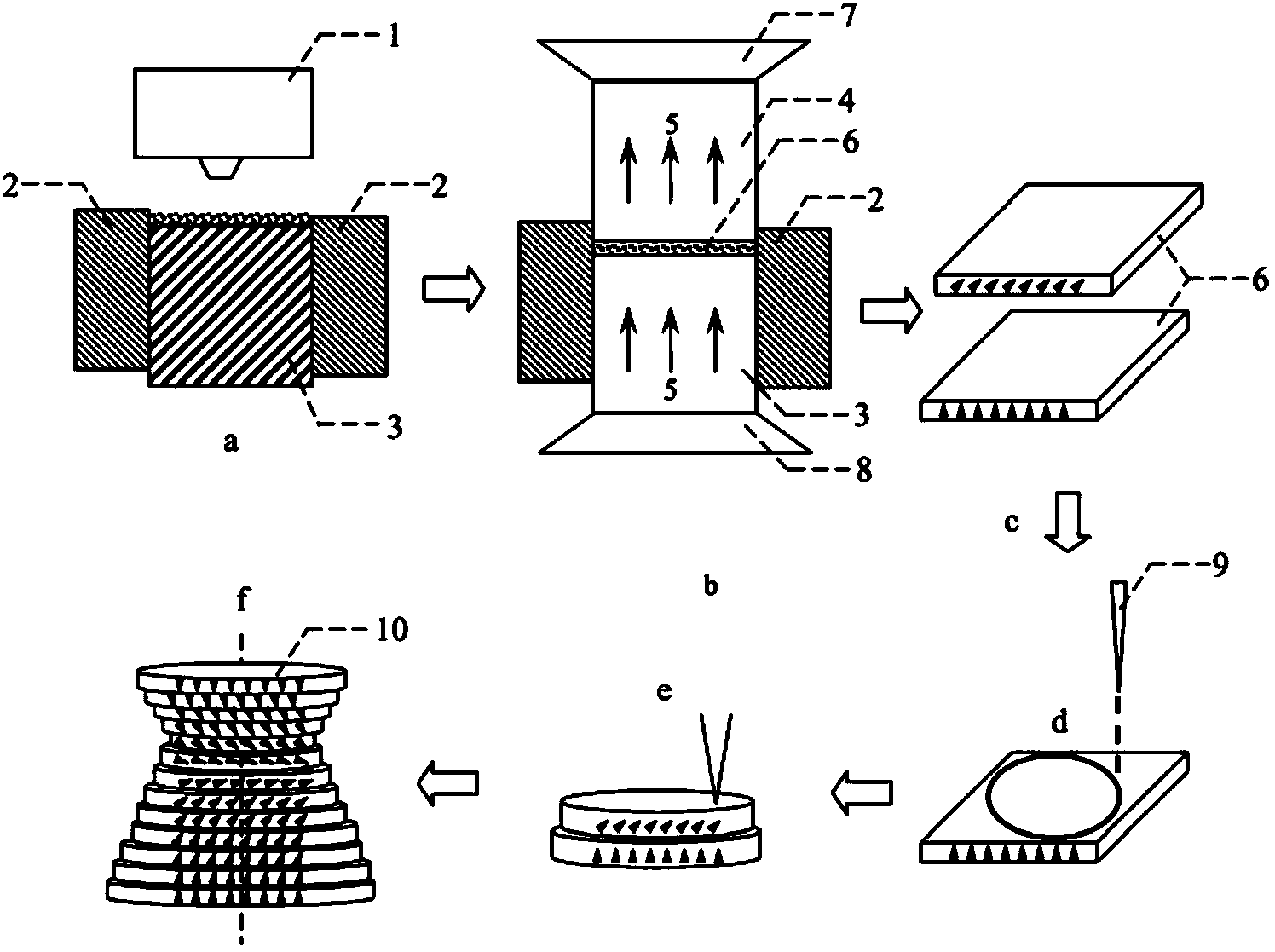

The invention relates to the technical field of rare earth permanent magnetic materials, in particular to a magnetic field orientation three-dimensional printing anisotropic bonded permanent magnet and a preparation method thereof. The magnetic field orientation three-dimensional printing anisotropic bonded permanent magnet, adopts magnet powder having magnetocrystalline anisotropy, comprises one or a plurality of anisotropic neodymium iron boron magnetic powder, samarium cobalt magnetic powder and samarium iron nitrogen powder and is a semi-continuous or continuous orientation changed anisotropic bonded permanent magnet. The magnetic field orientation three-dimensional printing anisotropic bonded permanent magnet is prepared by the following steps of powder filling, orienting and forming into sheet layers, thermal demagnetizing, cutting the sheet layers into required-shaped unit sheet layers, stacking and solidifying the unit sheet layers layer by layer and magnetizing. According to the magnetic field orientation three-dimensional printing anisotropic bonded permanent magnet and the preparation method thereof, preparation of the three-dimensional printing anisotropic bonded permanent magnet is achieved, adjustment of the orientation and the order degree of powder in the sheet layers are achieved by adjusting the magnetic field direction and or the magnetic field strength, the defect that orientation of the traditional bonded permanent magnet cannot be changed is overcame, and continuous or semi-continuous change of magnetic orientation in the same three-dimensional entity is achieved.

Owner:CENT IRON & STEEL RES INST

Process for preparing magnetic powder and sintered magnet and product produced thereby

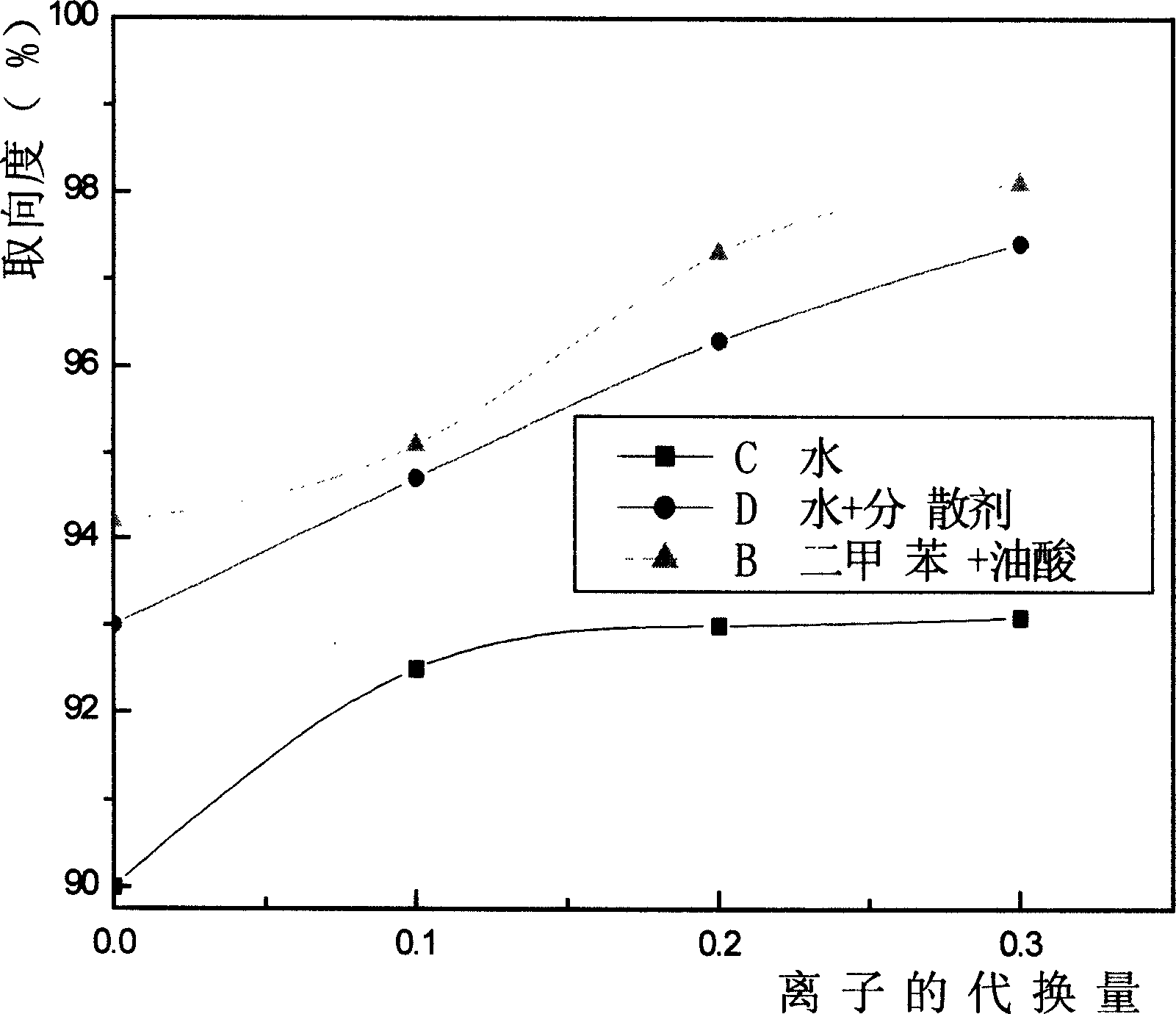

ActiveCN1655295AIncrease the anisotropy constantImprove intrinsic coercive forceInorganic material magnetismInductances/transformers/magnets manufactureMetallurgyFerrite powder

This invention relates to magnetic material field and especially to a process method improvement and its formula to hexagonal magnetic lead ferrite powder and sinter magnetism, wherein the said magnetism or magnetic powder has one-Curie temperature with A,R, B and Fe hexagonal ferrite main phase and the following molecular formula: A1-XRx[(Fe3+aFe2+b)12-yBy]zO19, through adding positive three Co and optimizing the formula and improving the magnetism crystal aeolotropism constant K1.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Optimization process method for preparing high-coercivity permanent magnet by adding heavy rare earth hydroxide into neodymium iron boron

ActiveCN102368439ASimple processSimple process conditionsPermanent magnetsInductances/transformers/magnets manufactureRare-earth elementMagneto

The invention relates to an optimization process method for preparing a high-coercivity permanent magnet by adding heavy rare earth hydroxide into neodymium iron boron. The optimization process method comprises the following steps of: 1, putting heavy rare earth R into a hydrogen environment and heating the heavy rare earth R to 350-450 DEG C to obtain hydroxide of the heavy rare earth R; 2, carrying out ball milling or jet milling in a protective atmosphere of nitrogen or inert gas to obtain micro-powder of the heavy rare earth hydroxide; 3, carrying out hydrogen decrepitation treatment and ball milling or jet milling on an Nd-Fe-B alloy to obtain Nd-Fe-B hydrogen decrepitation micro-power; 4, uniformly mixing two kinds of the micro-power, magnetizing by using a small-frequency alternative and reverse magnetic field pulse, and then isostatically pressing to obtain a press blank; and 5, placing the press blank into a vacuum furnace to sinter and carry out a heat treatment to obtain a high-coercivity sintered magnet. The optimization process method is convenient, simple and reasonable in technology, saves cost and achieves the purpose of improving the coercivity by controlling a microstructure distribution of the magnet, so that the industrial application to preparing the high-temperature high-coercivity rare earth permanent magnet by using trace quantities of heavy rare earth elements with high magneto-crystalline anisotropy becomes possible.

Owner:严高林

Permanent magnets and R-TM-B based permanent magnets

InactiveUS20030136469A1Increase in coercivityInorganic material magnetismInductances/transformers/magnets manufactureNucleationMagnetocrystalline anisotropy

Permanent magnets in which the ferromagnetic phase is matched with the grain boundary phase, and permanent magnets in which magnetocrystalline anisotropy in the vicinity of the outermost shell of the major phase is equivalent in intensity to that in the inside to suppress nucleation of the reverse magnetic domain, more specifically having a magnetocrystalline anisotropy not less than one-half the magnetocrystalline anisotropy of the interiors of the ferromagnetic grains, are disclosed.

Owner:HITACHI METALS LTD

Method for preparing rolling anisotropic magnetic powder and magnet

ActiveCN1937111AHigh residual magnetic inductionImprove coercive forceInorganic material magnetismInductances/transformers/magnets manufactureExtensibilitySingle crystal

Using specific technique of rapid hardening slice produces alloy based on neodymium (or praseodymium) iron. Then, through reaction of gas-solid phase, crumbling procedure produces RxFe100-x-y-zMyIz magnetic powder. The magnetic powder is single crystal grain in sheet form with average grain size as 1-3 micro. The magnetic powder produced by the disclosed technique possesses anisotropy of magnetocrystalline under action of external magnetic field as well as rolling anisotropy and stress anisotropy. Based on three kinds of anisotropy, the invention discloses method for preparing high performance flexible rubber magnet with rolling anisotropy. The prepared flexible magnet possesses excellent magnetism, flat surface, good cohesiveness, and feasible mechanical properties including tensile strength, extensibility, and rigidity as well as characteristics of temperature resisting, moisture resistance, oil proof and anticorrosion.

Owner:NINGXIA MAGVALLEY NOVEL MATERIALS TECH CO LTD

Anisotropic rare-earth permanent magnet material and its magnetic powder and magnet mfg. method

ActiveCN1937110AInhibitionUniphasic goodTransportation and packagingMetal-working apparatusRare-earth elementMetallurgy

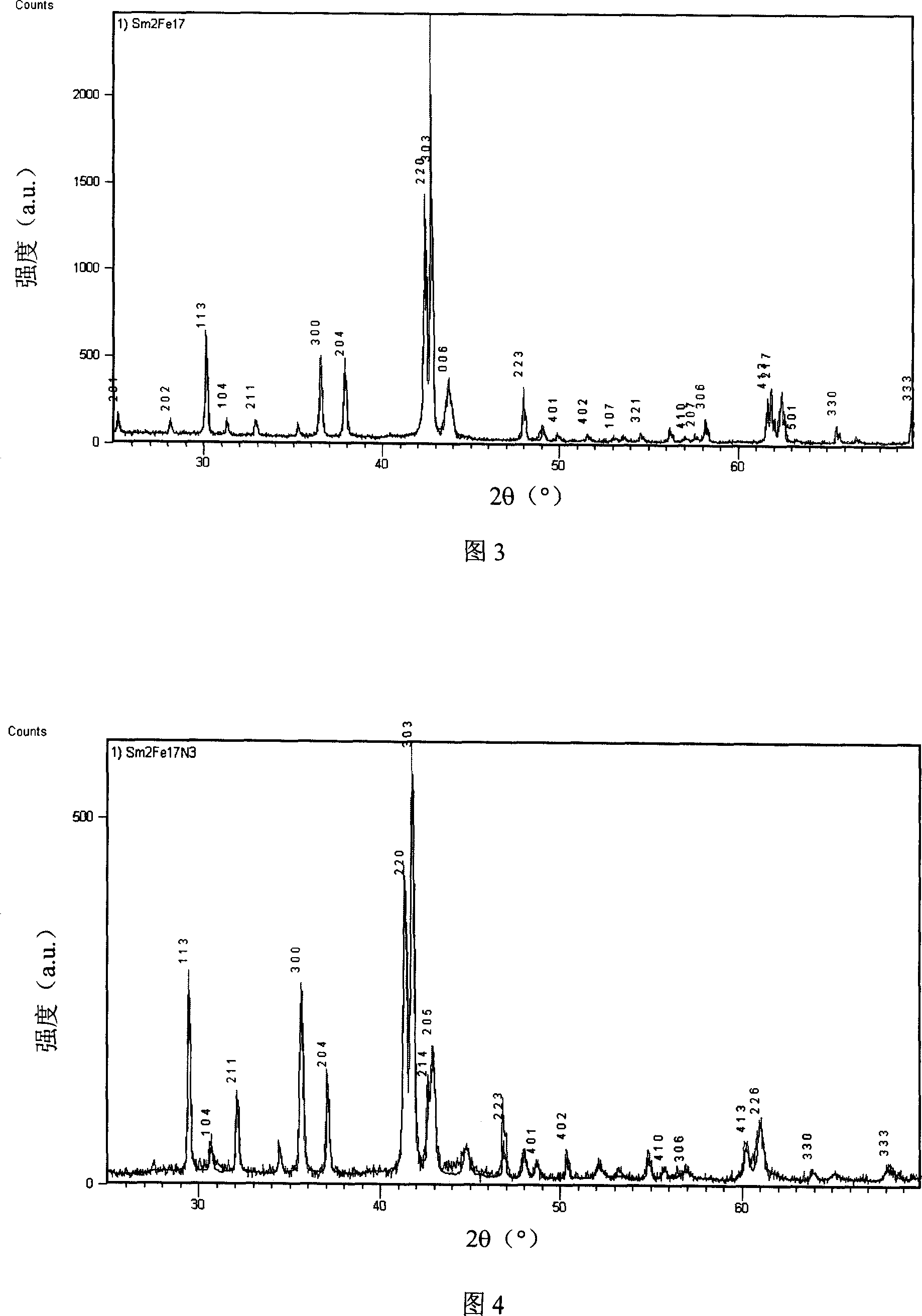

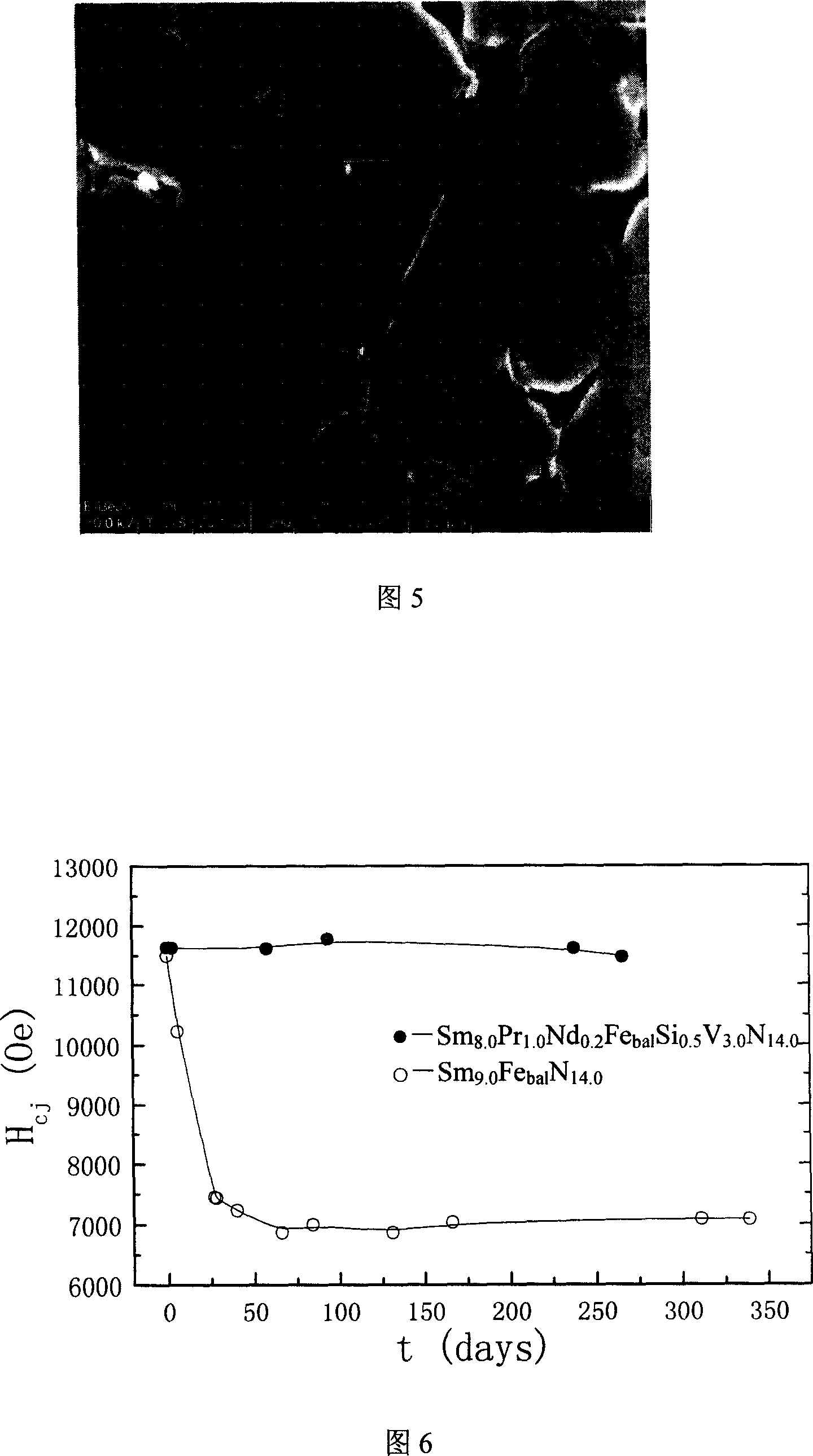

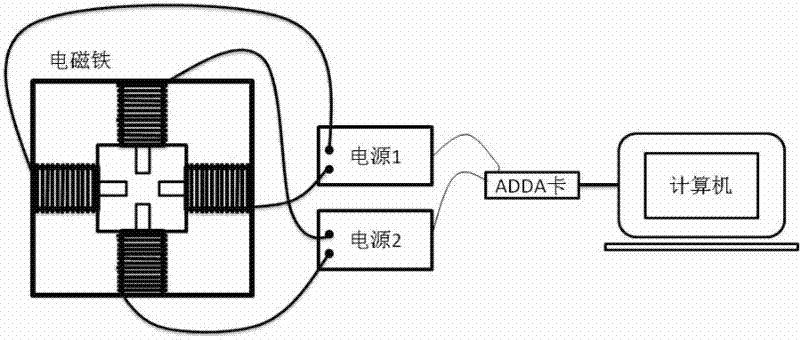

Possessing Th2Zn17 type crystal structure, the disclosed material of anisotropic rare earth permanent magnet with its components can be expressed as (Sm1-alphaRalpha)xFe100-x-y-zMyIz, where R as Pr or combination between Pr or other rare earth elements, 0.01<= alpha <=0.30, M selected from Si, Ti, V, Cr, Mn, Co, Ni, Cu, Zn, Nb, Mo, Al, and Zr, I as N only or combination between N and C, 7<=x<=12,0.01<=y<=8.0,6<=z<=14.4. Using the specific technique produces magnetic powder of single crystal grain in sheet form with average grain size as 1-3 micro. The magnetic powder possesses anisotropy of magnetocrystalline under action of external magnetic field as well as rolling anisotropy and stress anisotropy. Based on three kinds of anisotropy, the invention discloses method for preparing high performance flexible rubber magnet with rolling anisotropy.

Owner:NINGXIA MAGVALLEY NOVEL MATERIALS TECH CO LTD

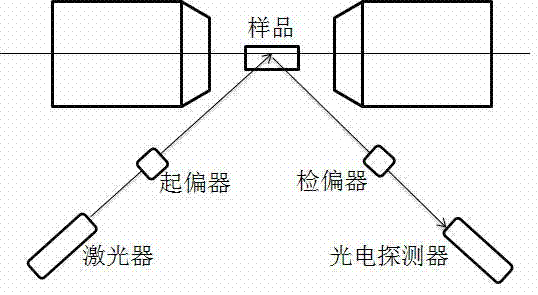

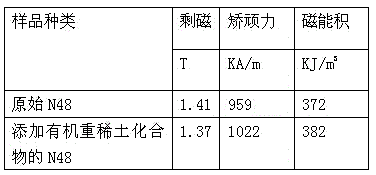

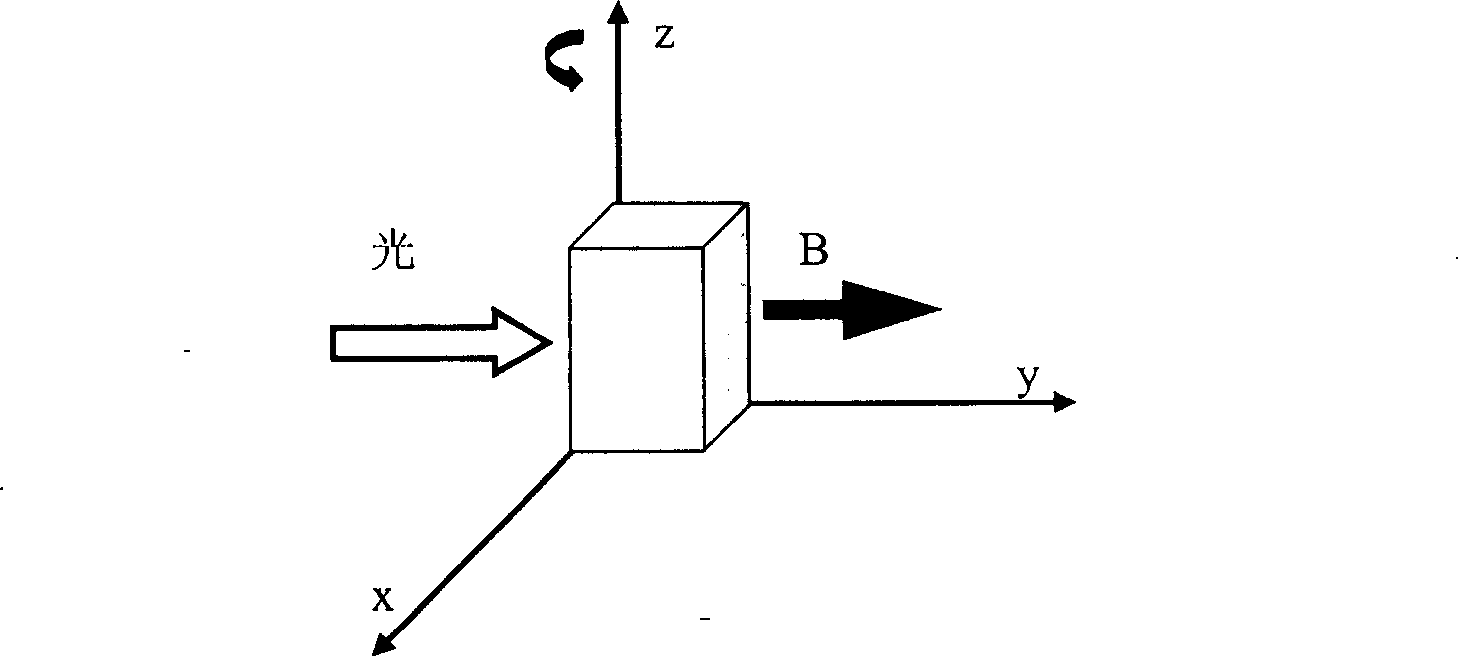

Magneto-optic Kerr effect and magnetocrystalline anisotropy field measurement system and measurement method

InactiveCN102252969AEfficient measurementGet efficientlyPolarisation-affecting propertiesMagnetic property measurementsPower flowPhotovoltaic detectors

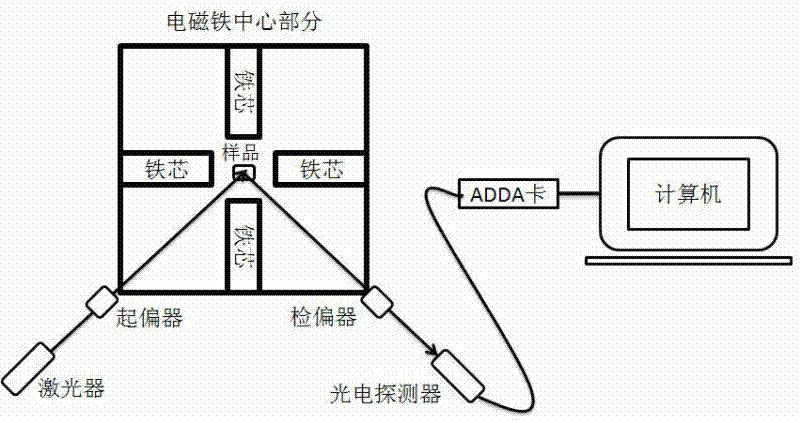

The invention belongs to the technical field of physical measurement, and in particular relates to a magneto-optic Kerr effect and magnetocrystalline anisotropy field measurement system and a measurement method. The measurement system comprises a magnet control part and a laser detection part. The magnet control part mainly comprises a magnet bracket, power supplies, an ADDA (analog-digital and digital-analog) card and a computer, wherein the computer respectively controls the size and the direction of output current of the two power supplies through the ADDA card, and respectively controls the size and the direction of magnetic fields so as to obtain a required resultant magnetic field; and the laser detection part is composed of a laser device, a polarizer, a polarization analyzer, a photoelectric detector, an ADDA card and a computer, wherein laser emitted by the laser device is projected to the photoelectric detector after being filtered by the polarizer and the polarization analyzer, signals are transmitted to the computer after being converted by the ADDA card, and then Kerr signals of a detection point are obtained. According to the measurement system and the measurement method, the mechanical vibration can be eliminated, the noise in the measurement can be reduced, the accuracy of the measurement can be increased, and magnetic signals and the magnetocrystalline anisotropy field of a sample can be accurately and efficiently obtained.

Owner:FUDAN UNIV

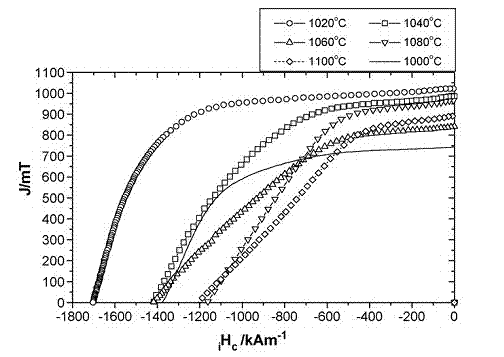

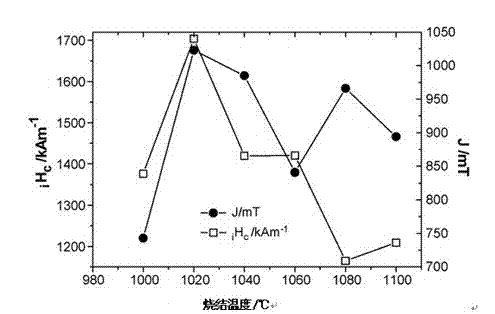

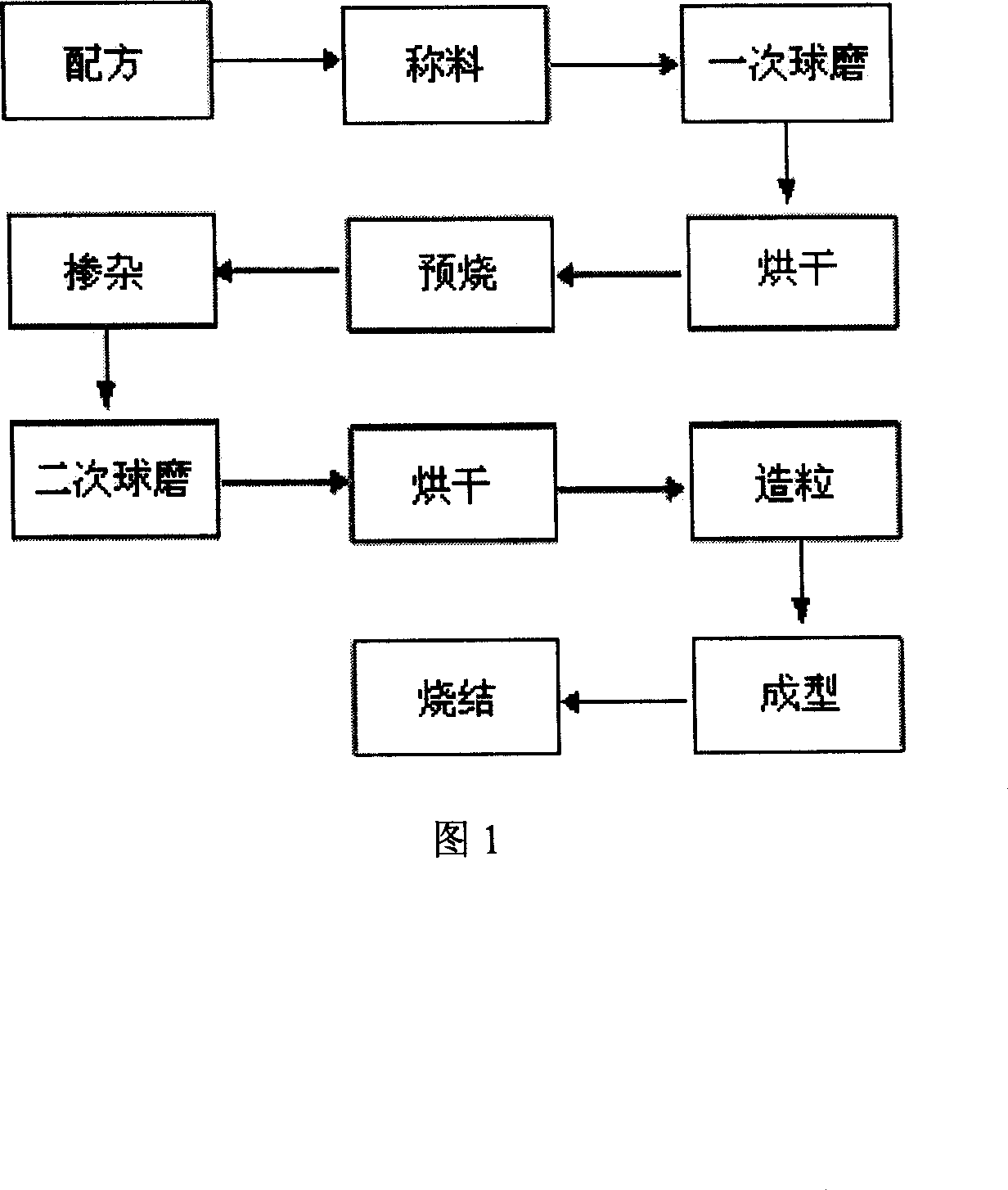

NiZn soft magnetic ferrite material with high magnetic conductivity and high Curie temperature and its preparing method

InactiveCN1929048AHigh curie temperatureRaise the burn-in temperatureInorganic material magnetismCurie temperatureMagnetocrystalline anisotropy

This invention relates to regular high magnetic rate NiZn iron oxidation formula and provides one NIZn iron oxidation materials and its process method, which adopts metal oxidation as materials by use of oxidation wet method, which comprises Fe2O3,NiO,ZnO,CuO and WO3 with each content as: Fe2O3 for 50.5-51mol %; NiO for 13.5-14mol%; ZnO for 31.5-32mol%; CuO for 3.5-4.5mol%; WO3 for 0.1-0.3mol%.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

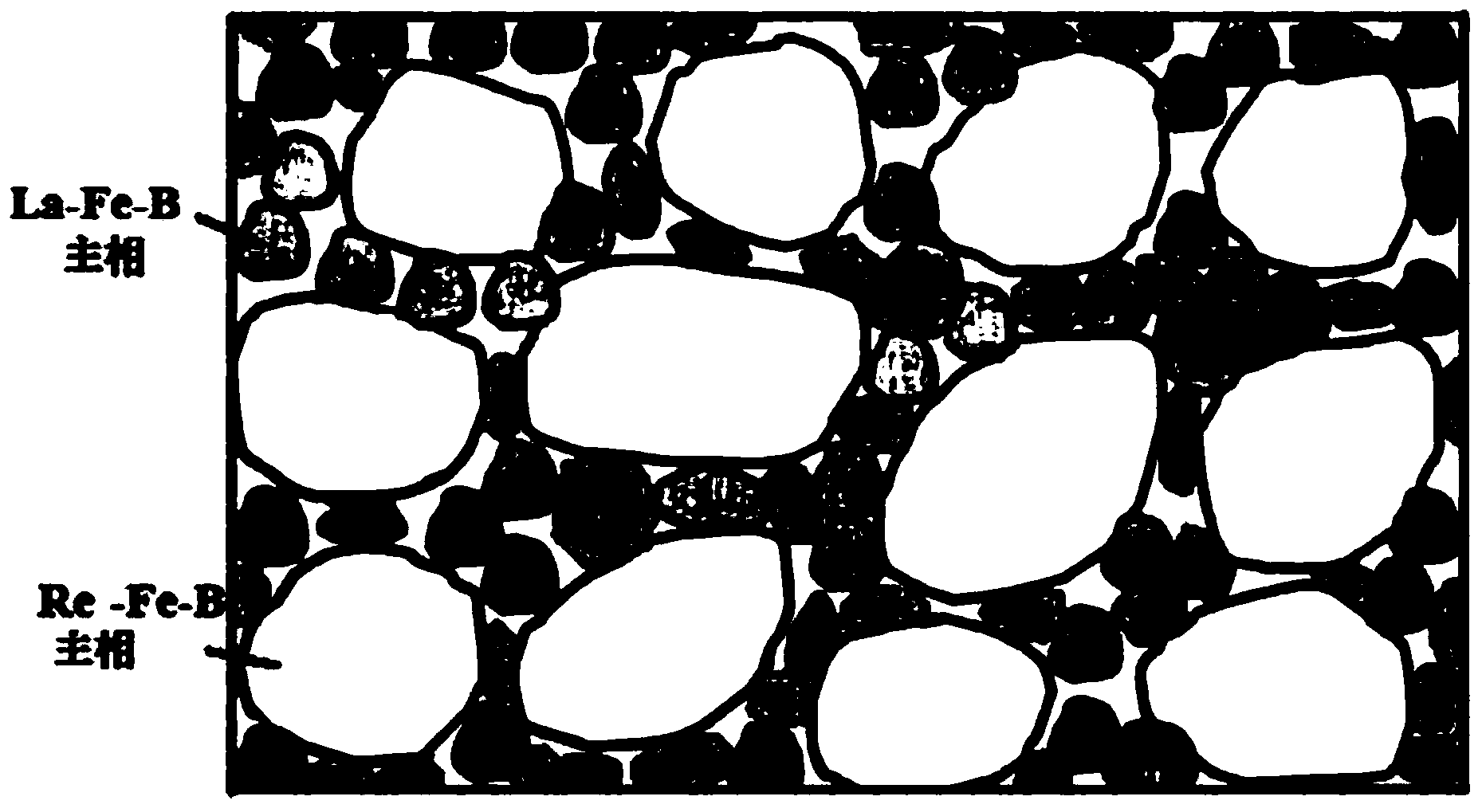

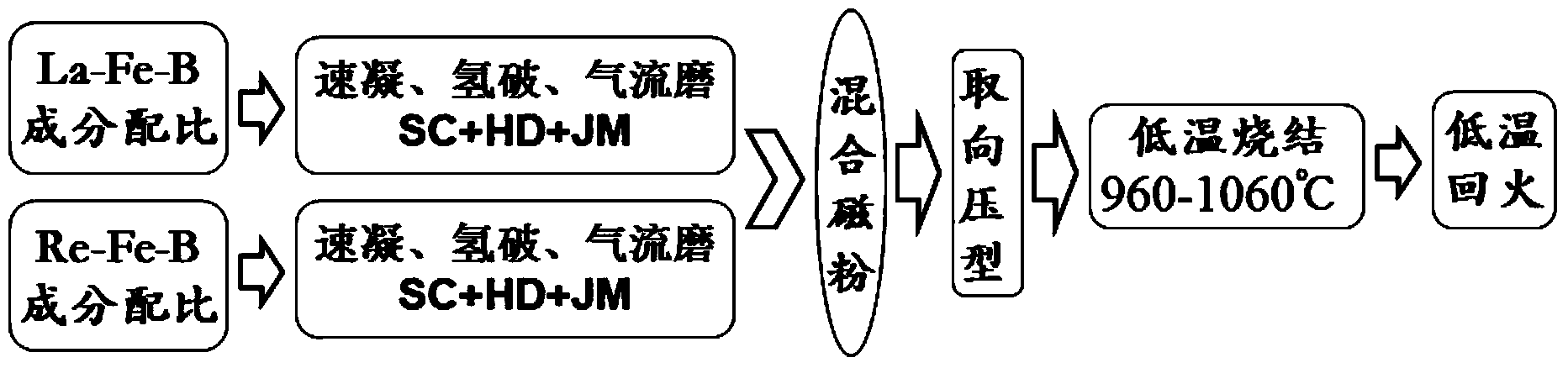

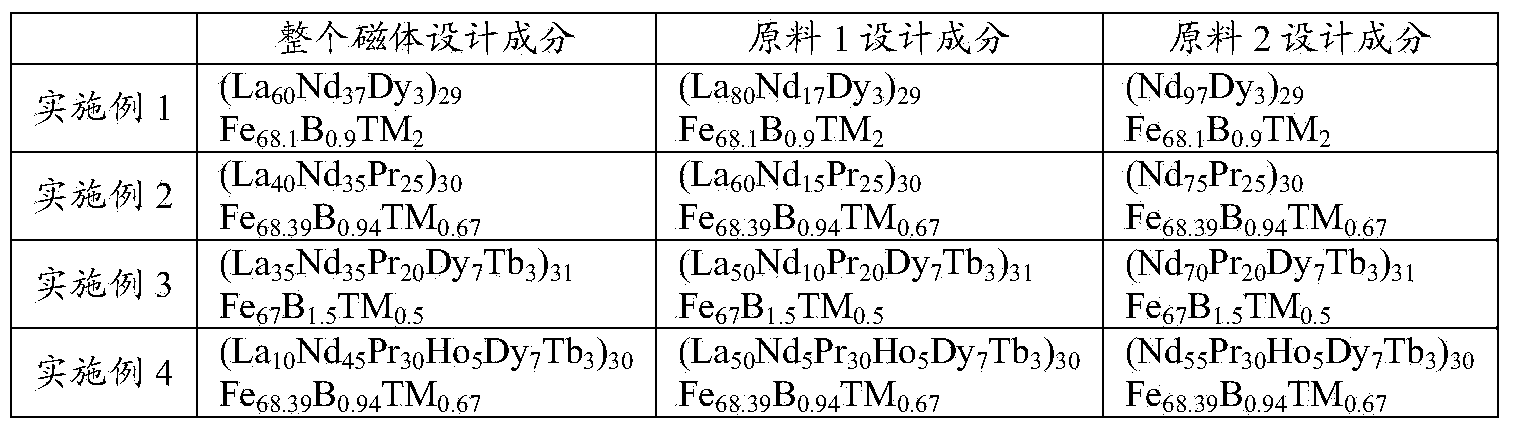

La-Fe-based magnet with double hard-magnetic main phases and preparation method for same

ActiveCN103714939AReduce consumptionReduce manufacturing costPermanent magnetsInductances/transformers/magnets manufactureRare-earth elementAlloy

Owner:CENT IRON & STEEL RES INST

Preparation method of rare earth doped high-coercivity manganese-bismuth alloy magnetic powder

InactiveCN105689726AIncreased magnetocrystalline anisotropySpread evenlyTransportation and packagingMetal-working apparatusRare-earth elementHigh energy

The invention relates to a preparation method of rare earth doped high-coercivity manganese-bismuth alloy magnetic powder. The preparation method comprises the following steps: dissolving a rare earth complex into anhydrous ethanol, then uniformly soaking manganese-bismuth alloy microparticles into the anhydrous ethanol containing the rare earth complex, then ensuring rare earth elements to diffuse into and enter crystal lattices of manganese-bismuth molecules in an atom form through high-energy ball milling, and ensuring doped elements to be uniformly dispersed into main alloy so as to dramatically improve the magnetocrystalline anisotropy of the magnetic powder. The finally prepared rare earth doped manganese bismuth magnetic powder has the coercivity which is dramatically higher than that of cobalt-manganese-bismuth magnetic powder without containing the rare earth. According to the method, MnBi coarse particles are soaked into mixed liquid of the rare earth complex and the anhydrous ethanol, the rare earth complex uniformly wraps powder particles, the rare earth elements can be uniformly dispersed into the crystal lattices of the manganese-bismuth molecules in the ball milling process, the magnetocrystalline anisotropy of MnBi is improved, and thus the intrinsic coercivity of the MnBi alloy is imroved; and in addition, the process is simple, the operation is easy, and the production cost of high-performance magnetic powder is lowered.

Owner:CHINA JILIANG UNIV

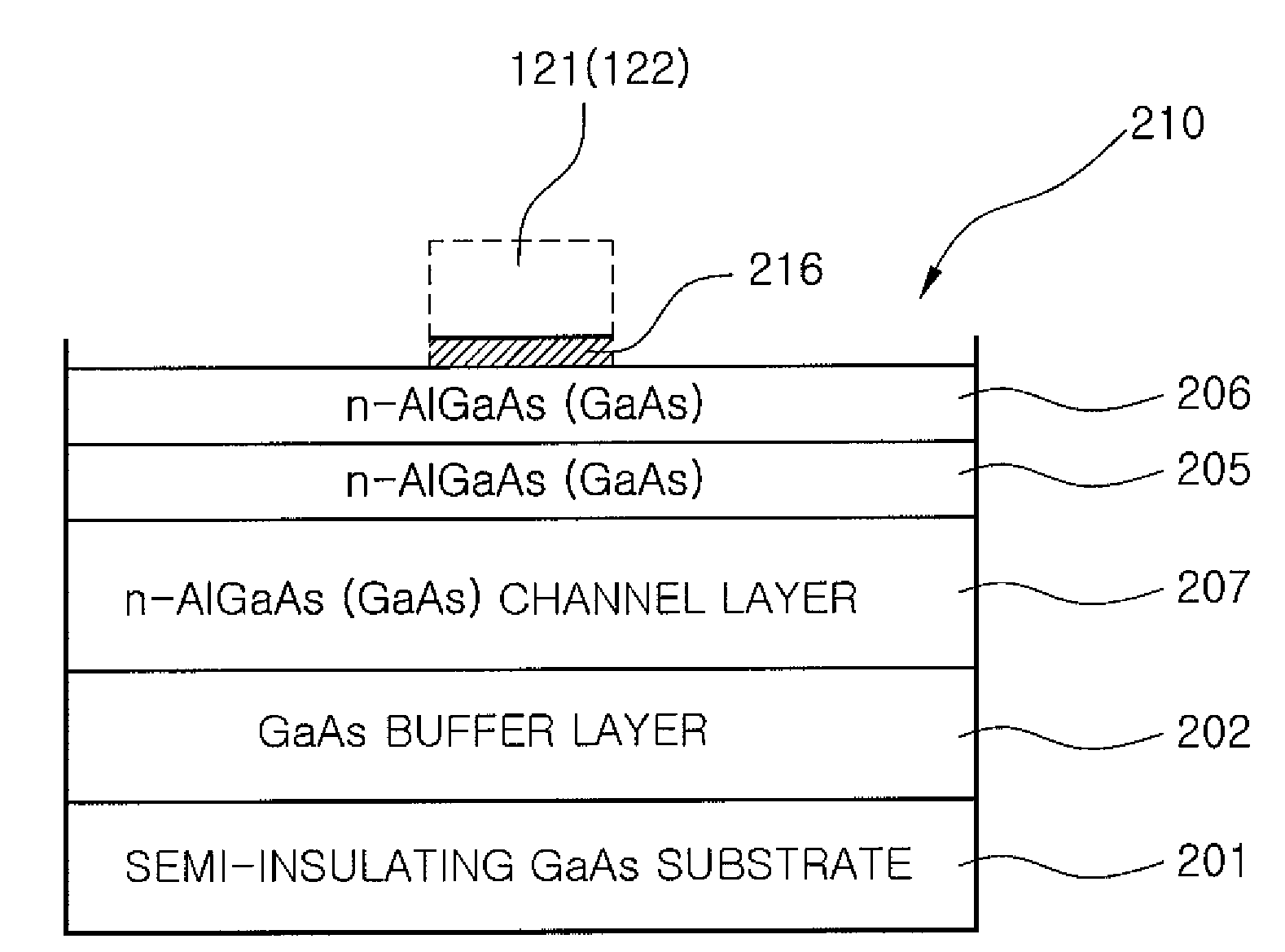

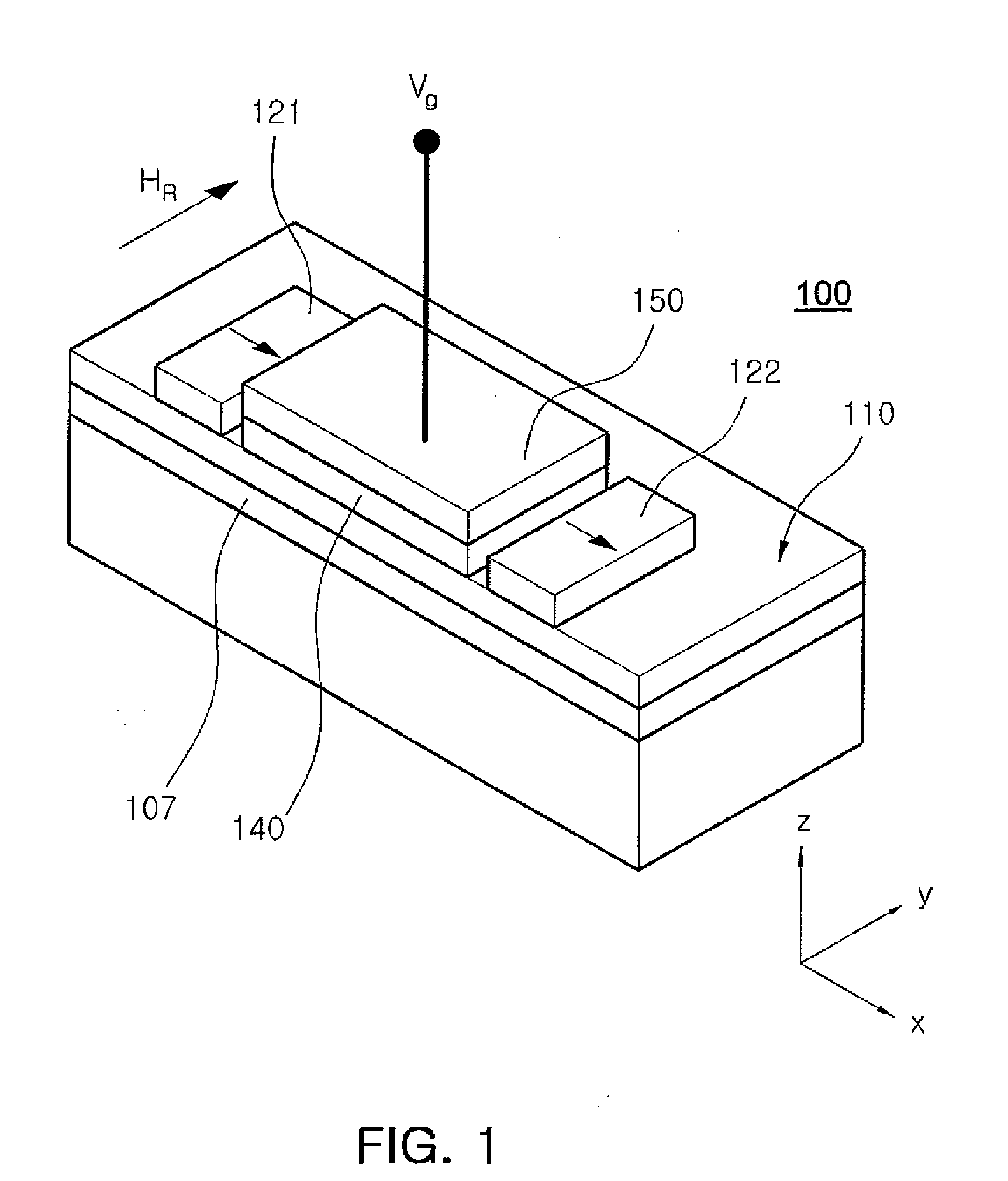

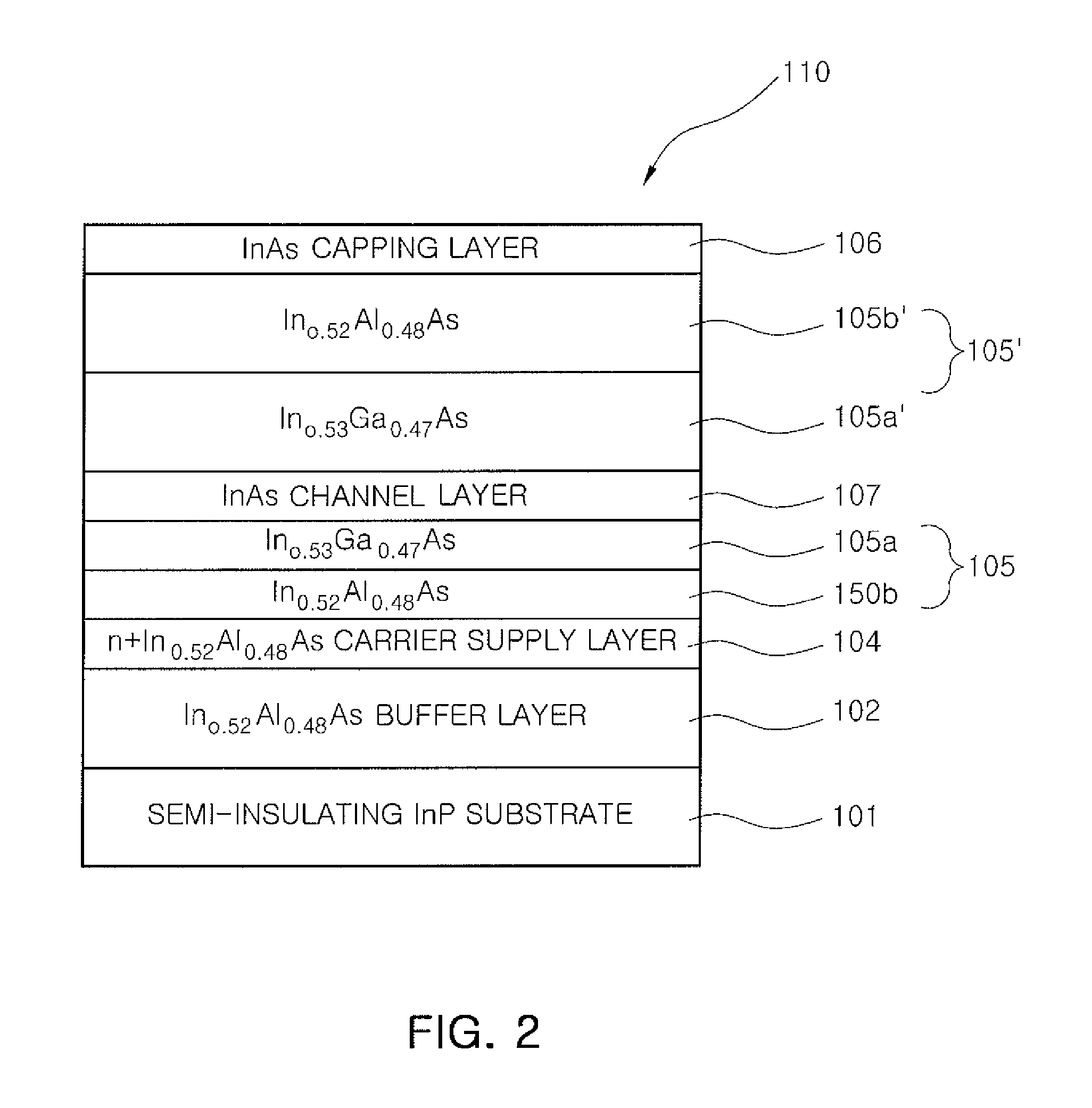

Spin Transistor Using Epitaxial Ferromagnet-Semiconductor Junction

InactiveUS20090152606A1MiniaturizationConducive to large scale integrationNanoinformaticsSolid-state devicesMiniaturizationMagnetization

A spin transistor conducive to the miniaturization and large scale integration of devices, because a magnetization direction of a source and a drain is determined by a direction of the epitaxial growth of a ferromagnet. The spin transistor includes a semiconductor substrate having a channel layer formed thereinside; ferromagnetic source and drain epitaxially grown on the semiconductor substrate and magnetized in a longitudinal direction of the channel layer due to magnetocrystalline anisotropy—the source and drain being disposed spaced apart from each other in a channel direction and magnetized in the same direction—; and a gate disposed between the source and the drain to be insulated with the semiconductor substrate and formed on the semiconductor substrate to control the spin of electrons that are passed through the channel layer.

Owner:KOREA INST OF SCI & TECH

Method for regenerating high-performance permanent magnet by degenerated rare earth permanent magnet material

The invention discloses a permanent magnet regenerating method of degenerated rare earth permanent magnet material, which comprises the following steps: grinding mechanically; removing impurity; dewetting in the vacuum; proceeding hydrogen disposal or hydrogen disproportionating reaction; adding high-magnetocrystalline anisotropic element and auxiliary texture forming element or alloy; moulding through sintering or adhering to produce anisotropic regenerated permanent magnet. The technology is reasonable with little oxide reaction, which can explore new path for degenerated rare earth permanent magnet.

Owner:严高林

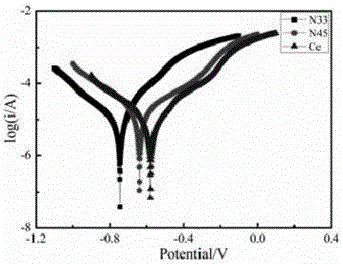

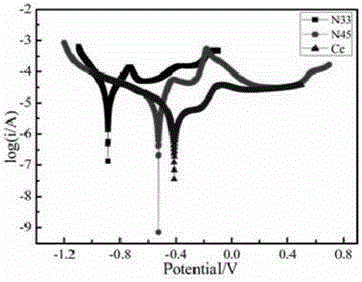

High-corrosion-resistance multi-hard-magnetic-principal-phase Ce permanent magnet and preparation method thereof

ActiveCN105225781AReduce defectsReduce porosityInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementDehydrogenation

The invention belongs to the technical field of rare earth permanent magnet materials, and relates to a high-corrosion-resistance multi-hard-magnetic-principal-phase Ce permanent magnet and a preparation method thereof. The permanent magnet is prepared through a process that hydrogen absorption and oxygen control are achieved through powder and dehydrogenation is achieved through pre-sintering. The rare earth element with the maximum mass percentage content in the final magnet is Ce. The chemical formula of the permanent magnet is shown, according to the mass percentage, as (Ce,Re)aFe100-a-b-cBbTMc. The permanent magnet is prepared from multiple hard magnetic principle phases including (Pr,La,Ce,Nd)-Fe-B, (Nd,Pr)-Fe-B and (Dy,Ho,Gd,Er)-Fe-B which are different in particle size and magnetocrystalline anisotropy constant k. The chemical formulas of the principle phase are (RL1-x,Cex)a1Fe100-a1-b1-c1Bb1TMc1, (NdyPr1-y)a2Fe100-a2-b2-c2Bb2TMc2 and [RHz, (Nd,Pr)1-z]a3FE100-a3-b3-c3Bb3TMc3 respectively, wherein x is larger than 0.25 and smaller than or equal to 1.0, y is larger than or equal to 1 and smaller than or equal to 1.0, z is larger than 1 and smaller than or equal to 1.0, a is larger than or equal to 27 and smaller than or equal to 31, b is larger than or equal to 0.8 and smaller than or equal to 1.5, c is larger than or equal to 0.5 and smaller than or equal to 2, the value range of a is the same as those of a1, a2 and a3, the value range of b is the same as those of b1, b2 and b3, and the value range of c is the same as those of c1, c2 and c3. Re is selected from rare earth elements. RL contains light rare earth elements. RH contains heavy rare earth elements. TM is one or more of Ga, Co, Cu, Nb and Al. The permanent magnet has the advantages of being high in corrosion resistance and small in weight-loss ratio, and the preparation technology is suitable for engineering large-scale production.

Owner:CENT IRON & STEEL RES INST

Manufacture of high-performance neodymium iron boron permanent magnet material

InactiveUS20130039797A1High energyIncrease forceInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementMagnetocrystalline anisotropy

The invention relates to a method of manufacturing high-performance neodymium iron boron permanent magnet material, which improves the coercive force of a magnet by replacing Dy with heavy rare earth element Tb, and simultaneously reduces the production cost by replacing Nd with a small amount of Pr. The neodymium iron boron permanent magnet material containing Pr and Tb comprises (Nd,Pr)x, Feresidual, By, Dyz, Tbu, Coy, and Alw; the atomic percents of the elements are respectively 7≦x≦15, 5.5≦y≦8, 0.05≦z≦6, 0≦u≦2, 0≦v≦3, 0≦w≦1.5 and Fe and inducted impurity from raw material for the residual. The compounding, smelting, dusting, moulding and sintering processes are performed according to the atomic percents. The added Tb improves the anisotropy field of the molecule of the magnet, therefore, the coercive force of the magnet is obviously improved. Simultaneously, as the anisotropy field of the magnetocrystalline of Pr2Fe14B is slightly higher than that of Nd2Fe14B, and the small amount of added Pr also slightly improves the coercive force of the magnet.

Owner:YUAN WEN JIE

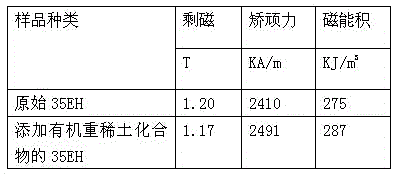

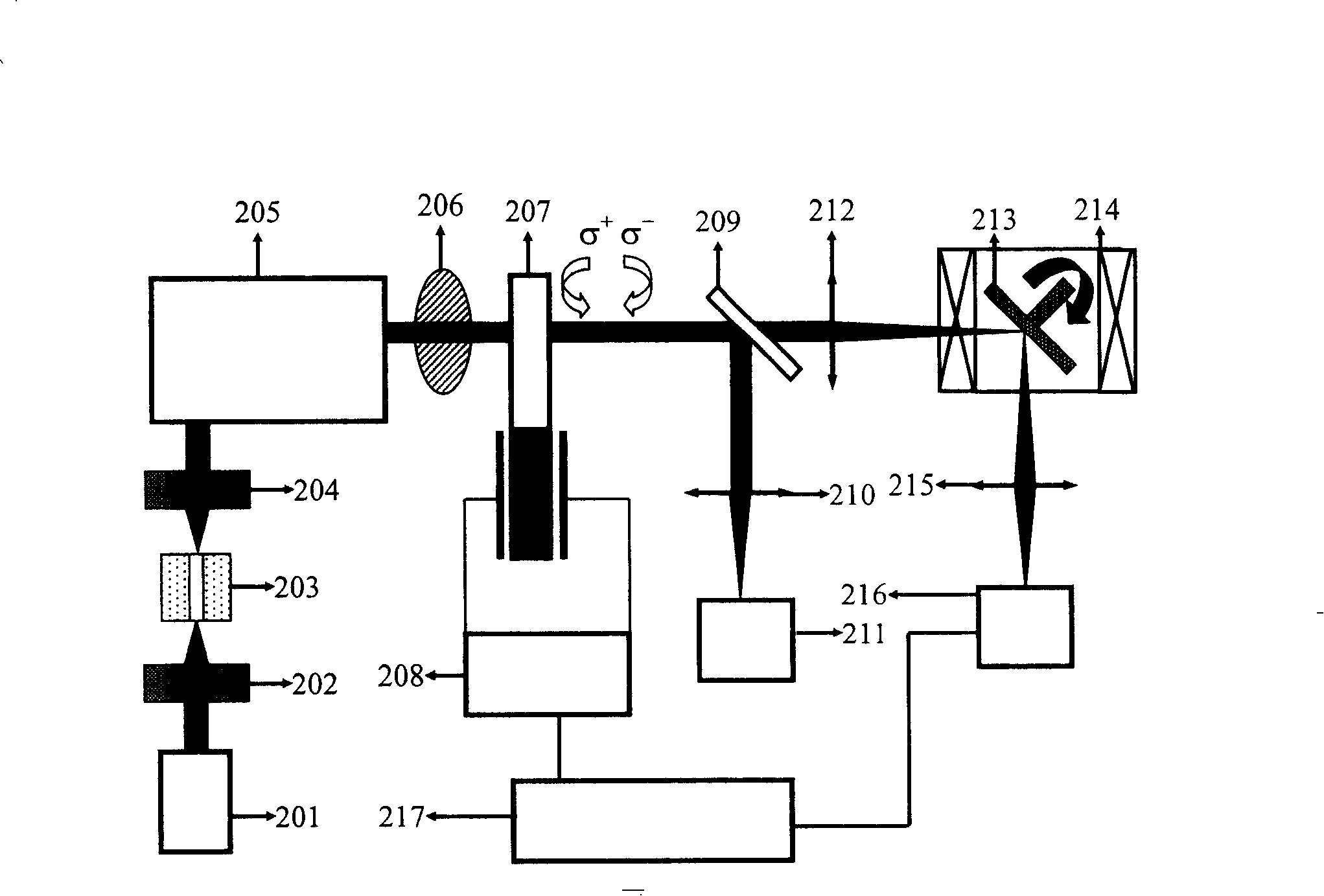

Preparation method for improving NdFeB (neodymium iron boron) coercivity by organic heavy rare earth complex

ActiveCN105427995AAvoid contactReduced oxygen uptakeTransportation and packagingMetal-working apparatusAntioxidantAlloy

The invention discloses a preparation method for improving NdFeB (neodymium iron boron) coercivity by organic heavy rare earth complex. The preparation method comprises the following steps: preparing NdFeB alloy particles and smashing the NdFeB particles into powder, and injecting an antioxidant at the same time; injecting mixed liquid of the organic heavy rare earth complex and ethyl ether into the NdFeB alloy powder in a spraying manner; and pressing the mixed material into a blank magnet in a magnetic orientation manner, and sintering the blank magnet. According to the preparation method, the mixture of the rare earth complex and the ethyl ether is added in the spraying manner, so that the contact between the particles and oxygen can be effectively prevented, the oxygen content of the magnetic particles is reduced, and the distribution uniformity of the organic heavy rare earth complex among sintered magnet crystal boundaries is improved; the added organic heavy rare earth complex is degraded along with the rise of the sintering temperature, the residual heavy rare earth ions are uniformly distributed on the surfaces of the NdFeB magnetic particles, and the residual heavy rare earth ions are permeating to the NdFeB particles under a high temperature so as to improve the magnetocrystalline anisotropy and the coercivity of the magnetic main phase; and in addition, the preparation method is simple in process, easy to operate, and suitable for mass production.

Owner:浙江凯文磁业有限公司

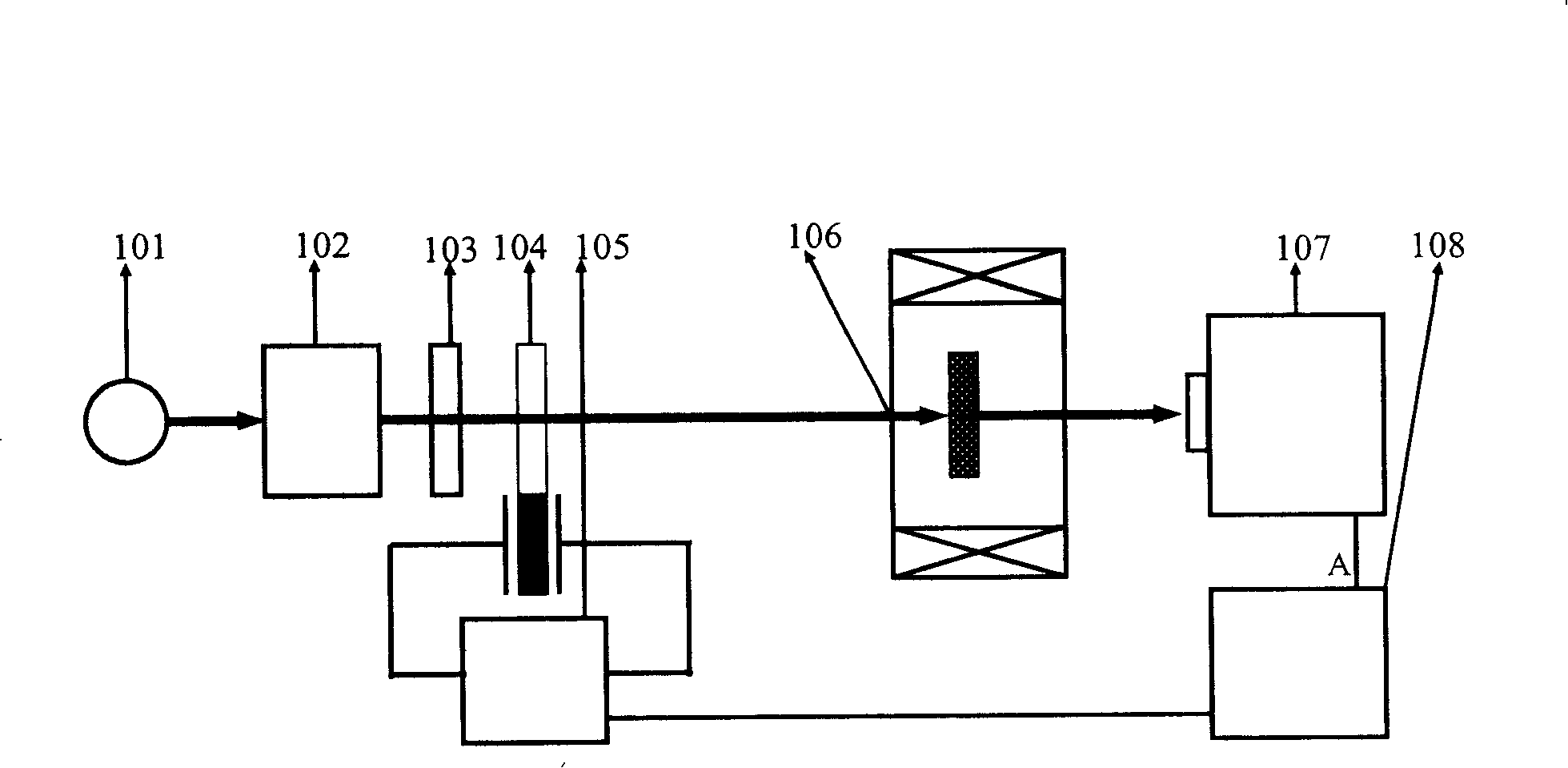

Magneto-optic circular polarization dichroism measuring system capable of adjusting measuring geometry

InactiveCN101196559AGood collimationNo lossMagnetic property measurementsTesting optical propertiesFrequency spectrumLantern

A measuring system for measuring the dichroism of the magneto-optical circular polarization with adjustable measuring geometry is provided, whose structure is that: a femtosecond laser excites the white light of the ultra-continuous spectrum, and divides the light by a monochrometer, which forms a monochromatic light whose wavelength can be adjustable. The monochromatic light can polarize through a purified Glan-Taylor prism with the extinction coefficient of 10 <5>; a lantern fly modulator, whose optical axis is 45degree angled with the optical axis of the Glan-Taylor prism to make the light become the circularly polarized light with the alternative variation of the sinistrality and the dextrorotation; a sample, which is put on the center of the cryogenic magnet; The circularly polarized light focuses on the sample, and the reflex reflected from the sample is focuses on the first LED detector; a phase-locking amplifier, whose reference signal is provided by the lantern fly modulator used for testing the difference of light intensity between the sinistrality and the dextrorotation of the circularly polarized light. The invention can not only test the frequency spectrum of the dichroism of the magneto-optical circular polarization of the materials, magnetic density and temperature dependence, but also can test the magnetocrystalline anisotropy of the magnetic semiconductor.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

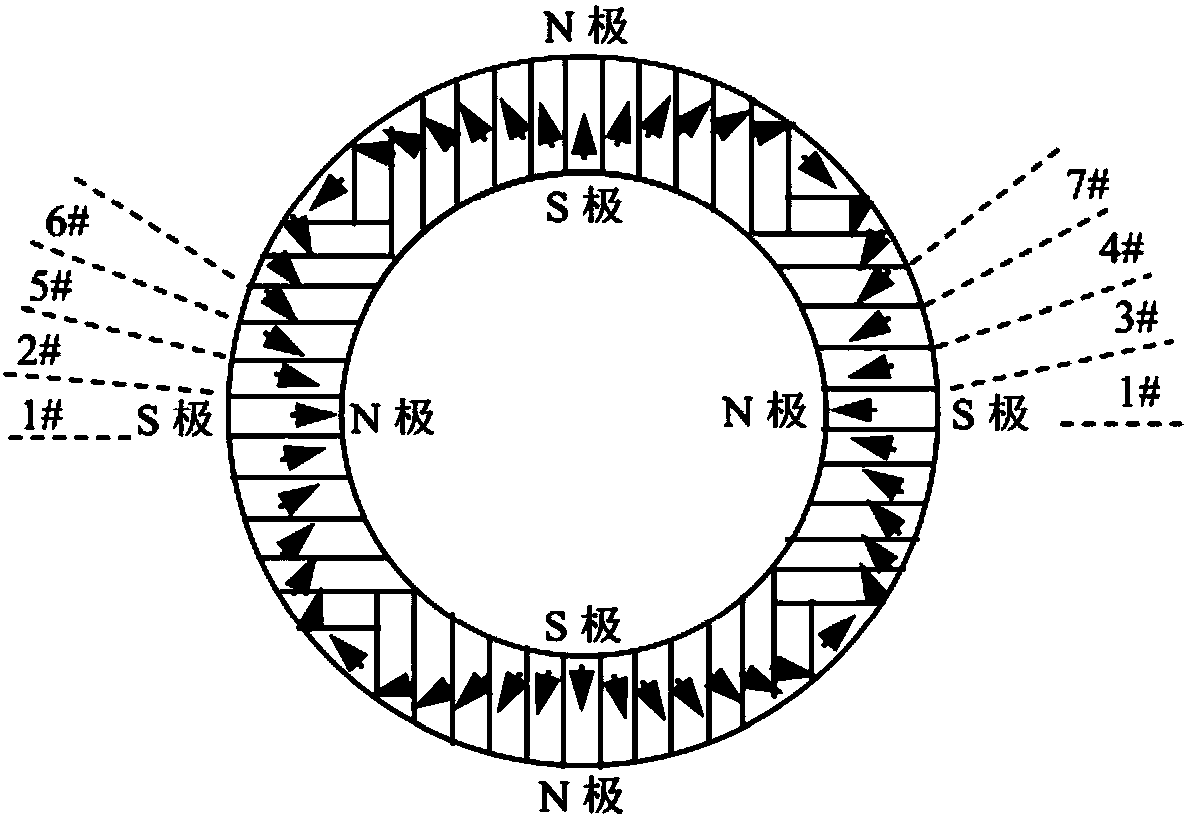

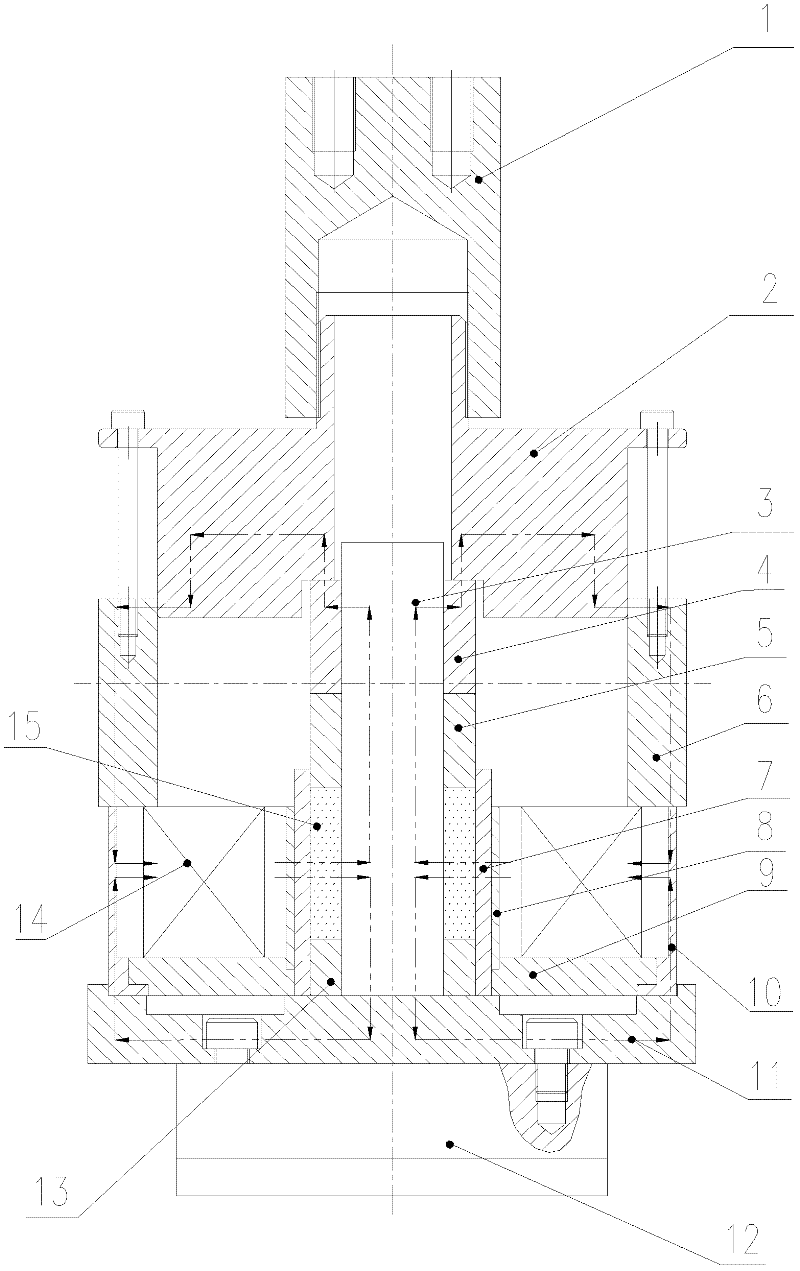

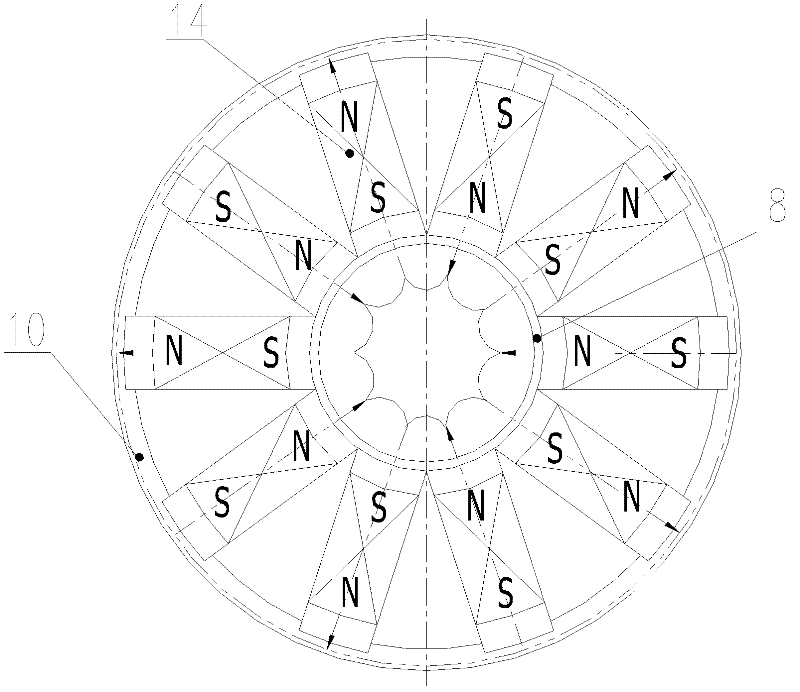

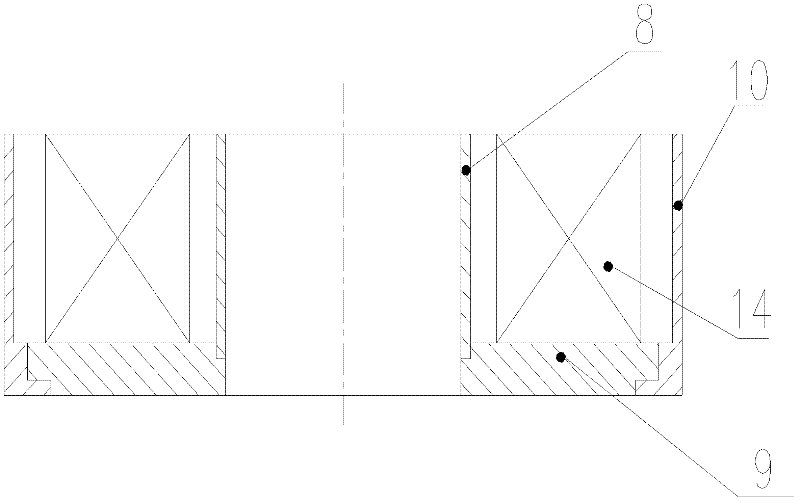

Pressing mold for manufacturing amplitude/multi-polar oriented whole permanent magnetic ring

InactiveCN102416471AUniform densityImprove consistencyInductances/transformers/magnets manufactureEngineeringVolumetric Mass Density

The invention relates to a pressing mold for manufacturing an amplitude / multi-polar oriented whole permanent magnetic ring. The pressing mold comprises a core rod arranged on a lower bearing plate, and a lower mold, a non magnetic conducting upper mold and a magnetic conducting upper mold which are sleeved on the core rod from bottom to top in turn, wherein a pressing upper pressure head for making the magnetic conducting upper mold slide along the core rod is arranged on the top of the magnetic conducting upper mold; a female mold is sleeved outside the lower mold and the non magnetic conducting upper mold; a pressing cavity for accommodating magnetic powder is formed among the female mold, the lower mold, the non magnetic conducting upper mold and the core rod; and an electromagnetic iron ring for providing a magnetic field is sleeved outside the female mold. Permanent magnetic powder with magnetocrystalline anisotropy is put into a forming mold and is formed under the action of an amplitude / multi-polar oriented magnetic field and a pressure field, and the whole permanent magnetic ring with amplitude / multi-polar oriented texture characteristics is obtained. The amplitude / multi-polar oriented magnetic ring is produced by the same set of mold, and the manufactured whole permanent magnetic ring has the characteristics of uniform density and orientation degree, high consistency, uniform surface magnetic field and high magnetic property.

Owner:湖南航天有限责任公司

Anisotropic Z-type hexagonal ferrite and antenna using same

InactiveCN101800107ARaise the cutoff frequencyHigh dielectric constantInorganic material magnetismAntennasDielectricMagnetocrystalline anisotropy

The invention discloses an anisotropic Z-type hexagonal ferrite which is suitable for high and ultrahigh frequency band antennas and has the components: Ba3Me2Fe24O41, wherein Me is one of Co, Zn, Ni, Mg and Cu. The sintering temperature of the anisotropic Z-type hexagonal ferrite is controlled to be from 1150 DEG C to 1300 DEG C; trace oxides are added for regulating a dielectric constant, permeability and the sintering temperature; therefore, a real part epsilon' of the dielectric constant is from 1 to 20; a real part mu' of complex permeability is from 1 to 10; and the dielectric constant or the permeability is basically unchanged as certain values within a certain frequency band of 100 MHz to 3 GHz. The hexagonal ferrite has high cut-off frequency, high dielectric constant and high permeability due to higher magnetic anisotropy field, and can be applied to miniaturization of the sizes of the high and ultrahigh frequency band antennas.

Owner:SOUTHWEST JIAOTONG UNIV

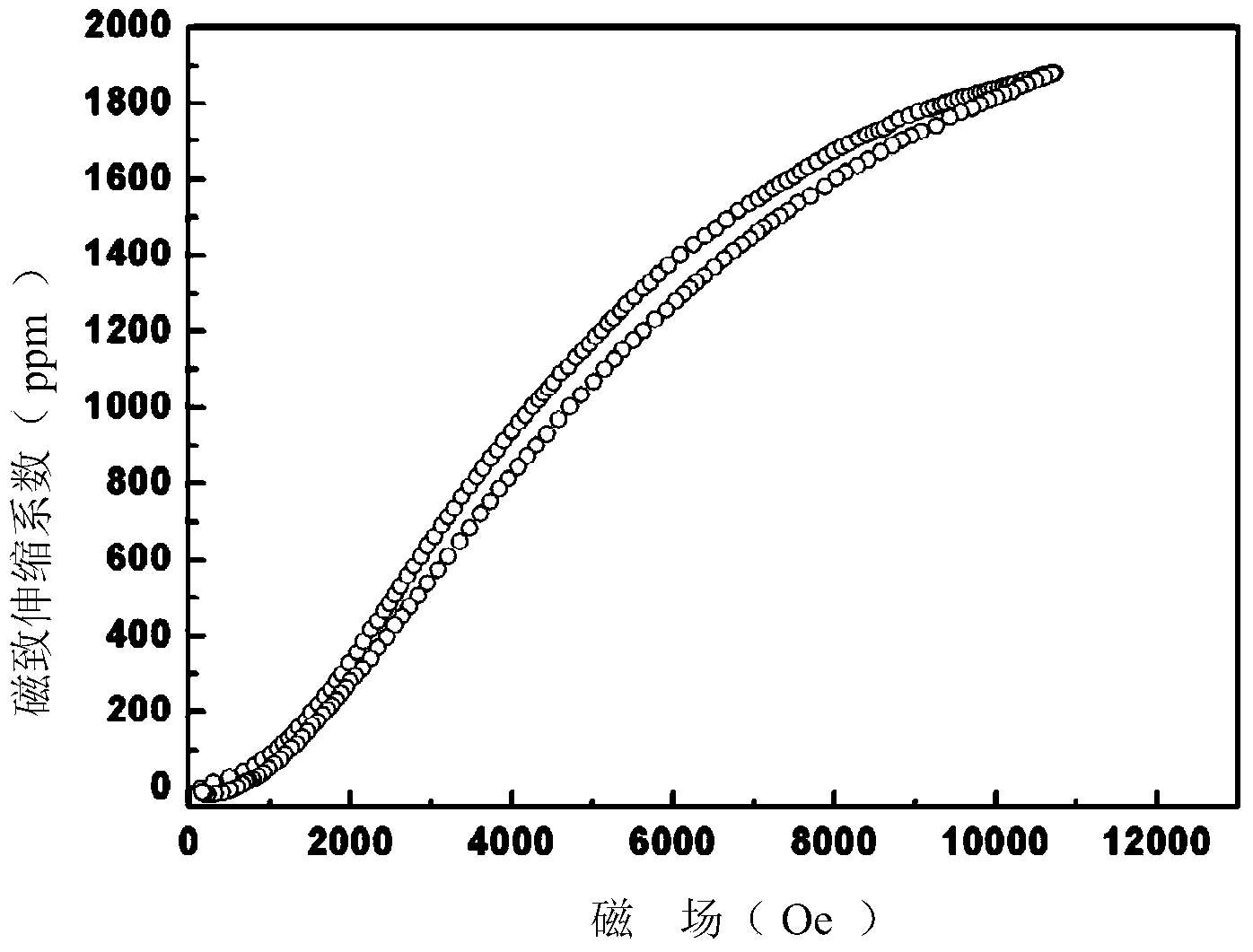

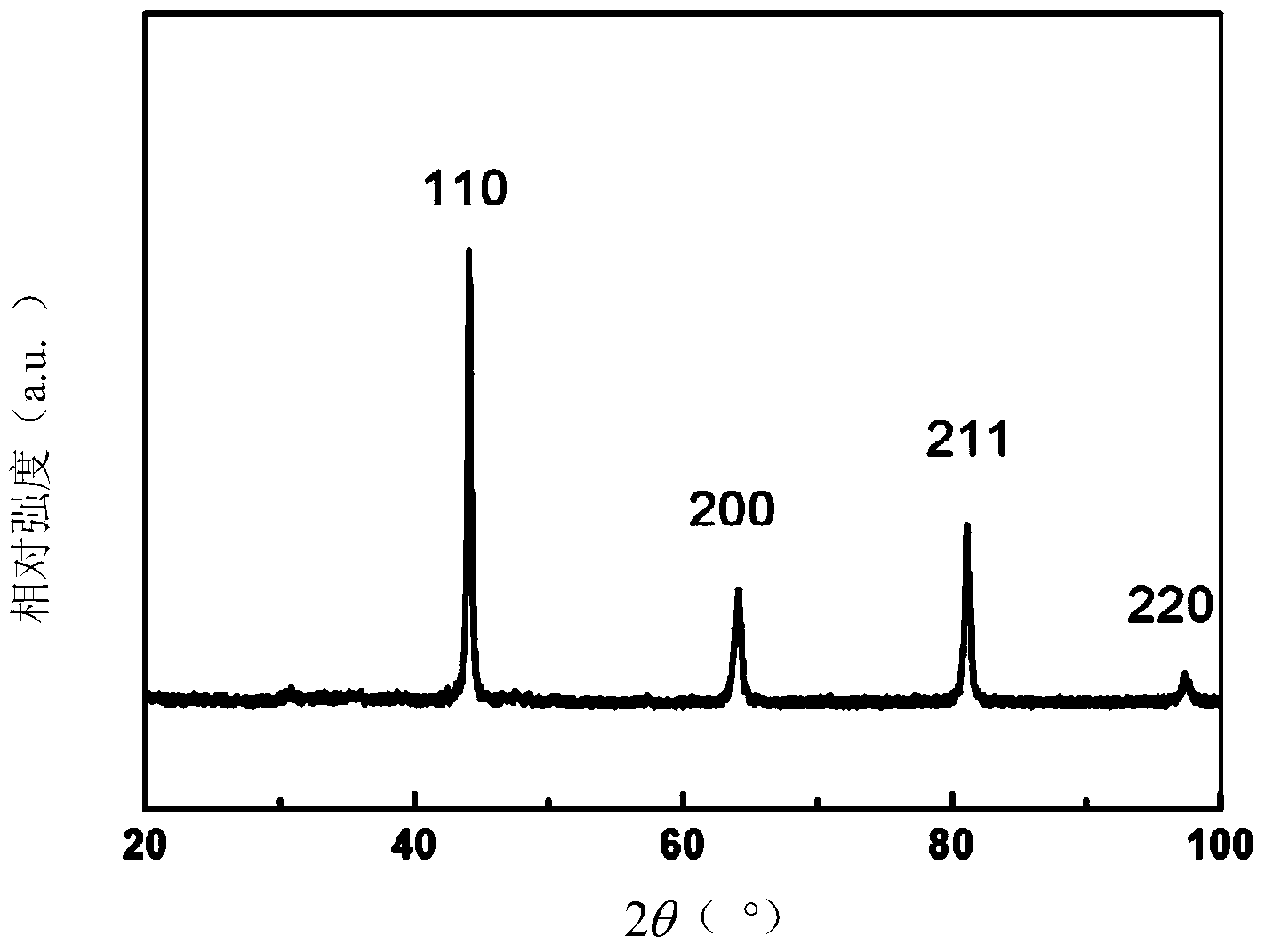

Novel magnetostrictive material designed according to FeGa-RFe2 magnetocrystalline anisotropy compensation principle and preparation method thereof

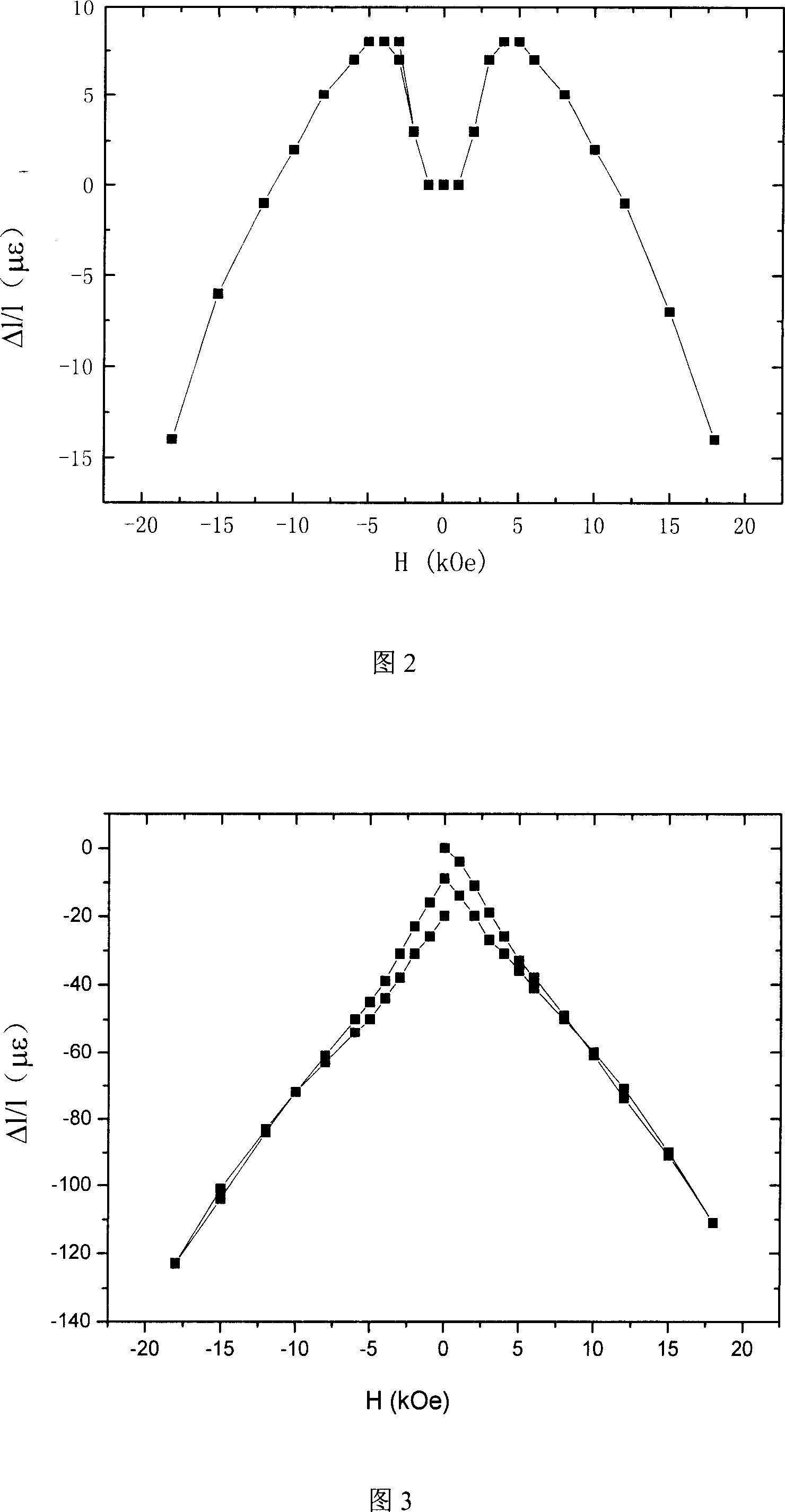

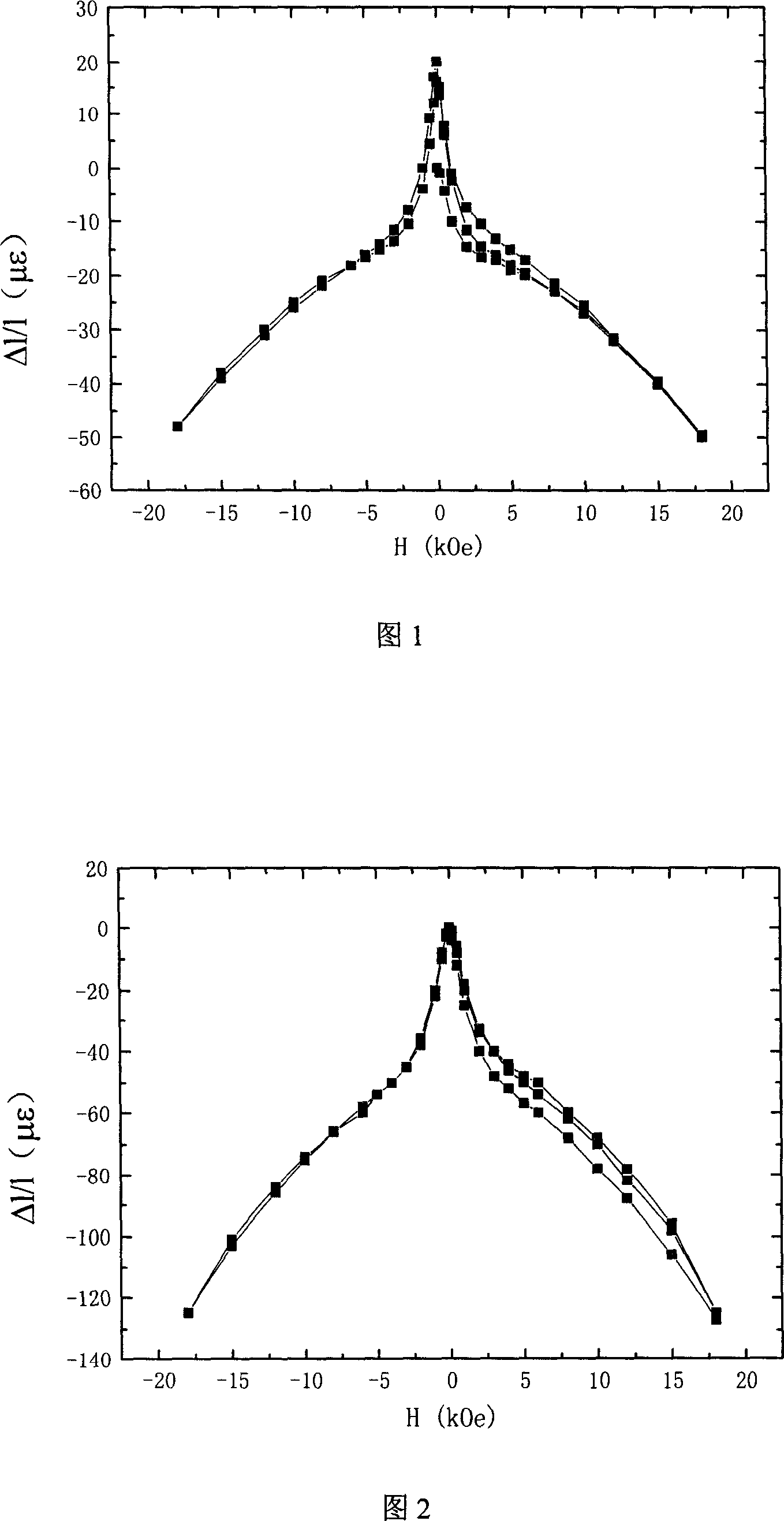

ActiveCN103556045ALow coercivityHigh magnetostrictive performanceMagnetostrictive material selectionMaterial DesignRare earth

The invention discloses a novel magnetostrictive material designed according to a FeGa-RFe2 magnetocrystalline anisotropy compensation principle and a preparation method thereof. The composition of the magnetostrictive material is (Fe100-XGaX)Y(RFe2)Z, wherein X is more than or equal to 10 and less than or equal to 40, the compensation compositions ratio of Y:Z in a Y-Z regulating pseudo-binary system is 1-20, RFe2 is one or more than one of TbFe2, SmFe2, DyFe2, HoFe2, ErFe2 and TmFe2, and X, Y, and Z are mole percentage contents. In the novel magnetostrictive material designed according to a FeGa-RFe2 magnetocrystalline anisotropy compensation principle, since a trace of rare-earth RFe2 component with large magneto-strain property is added into non-rare-earth FeGa based magnetostrictive alloy compositions, and magnetocrystalline anisotropy compensation is carried out on FeGa compositions, thus obtaining the novel magnetostrictive material with advantageous properties such as large magneto-strain, low drive field, high mechanical property, low cost, and the like.

Owner:BEIHANG UNIV

Sintered Nd-Fe-B permanent magnet producing method

ActiveCN104966607ALow cost of industrializationImprove utilizationInorganic material magnetismInductances/transformers/magnets manufactureRare-earth elementAlloy

The invention relates to a sintered Nd-Fe-B permanent magnet producing method and belongs to the field of magnetic materials. The sintered Nd-Fe-B permanent magnet preparing method comprises the following steps of smelting, crushing, powder making, pressing for forming, sintering and aging treatment. According to the technical scheme, a certain proportion of abundant rare earth elements including La, Ce and Gd are utilized to partially replace elements Pr, Nd, Dy, Tb and the like, comprehensive utilization of rare earth resources is promoted by means of a produced sintered Nd-Fe-B permanent magnet, and the industrial cost of the sintered Nd-Fe-B permanent magnet is reduced. In the magnet producing process, liquid-phase alloy rich in Pr-Nd phases and liquid-phase alloy rich in La-Ce phases are respectively smelt, the wettability of a main phase and magneto-crystalline anisotropy field of a boundary phase are improved by means of the two rich rare earth phases, and crystal boundary is strengthened by doping Cu-Co nano alloy powder. Compared with a traditional single-alloy method process and a double-alloy method process, intrinsic coercive force and magnetic energy product in the magnet are improved, and the advantages are remarkable.

Owner:EARTH PANDA ADVANCE MAGNETIC MATERIAL

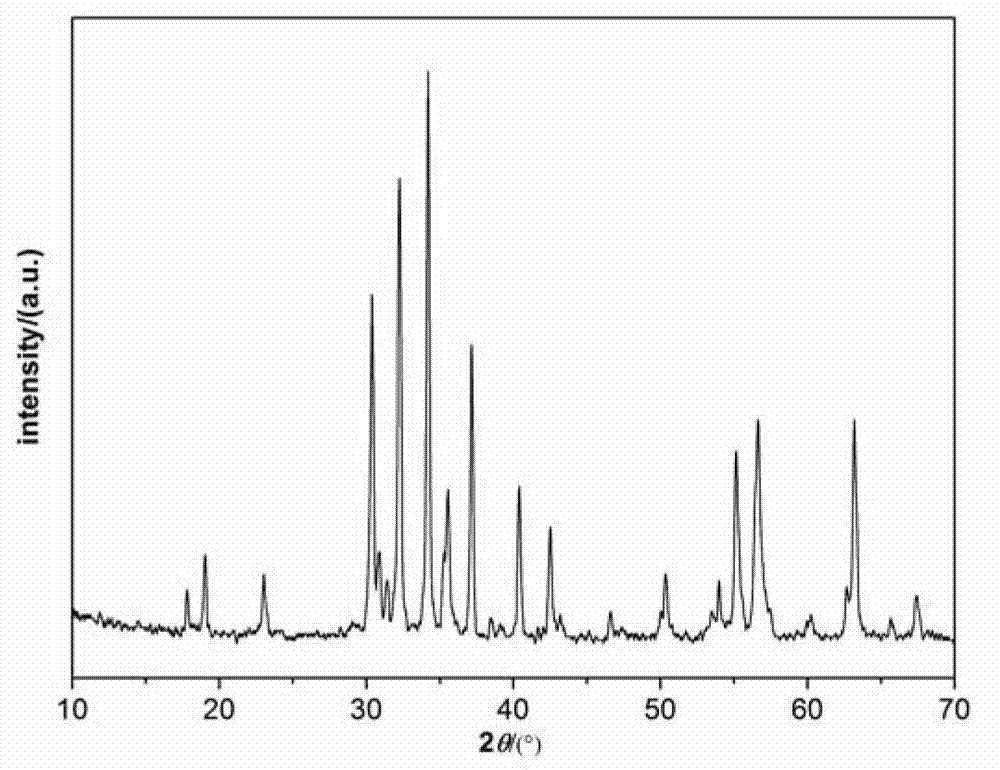

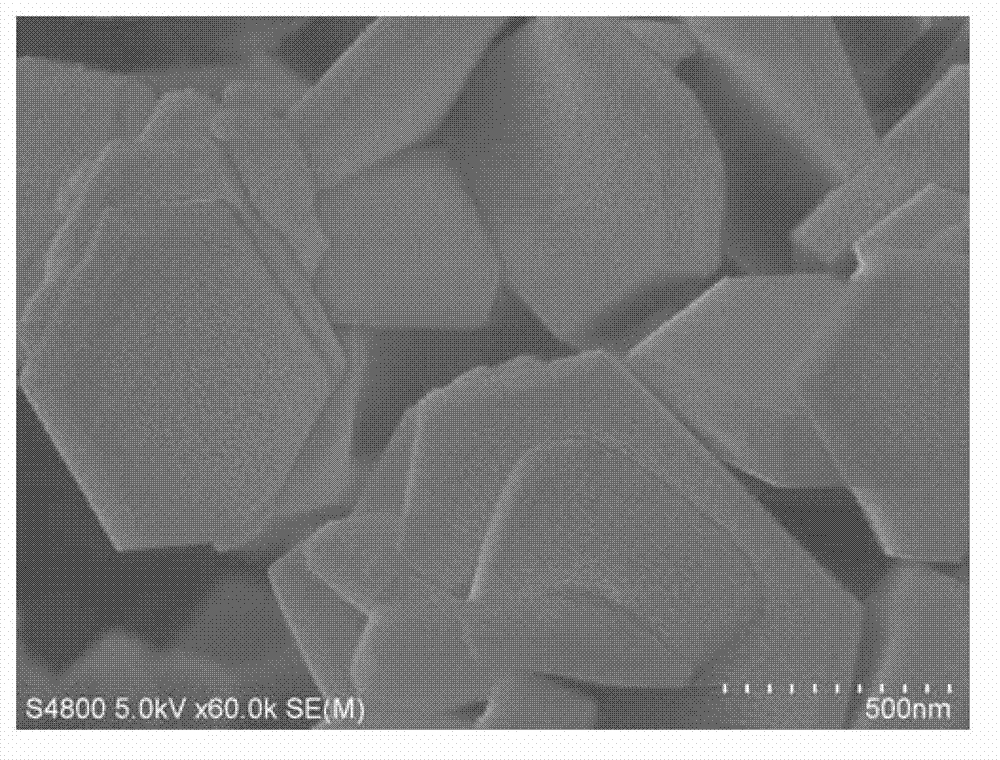

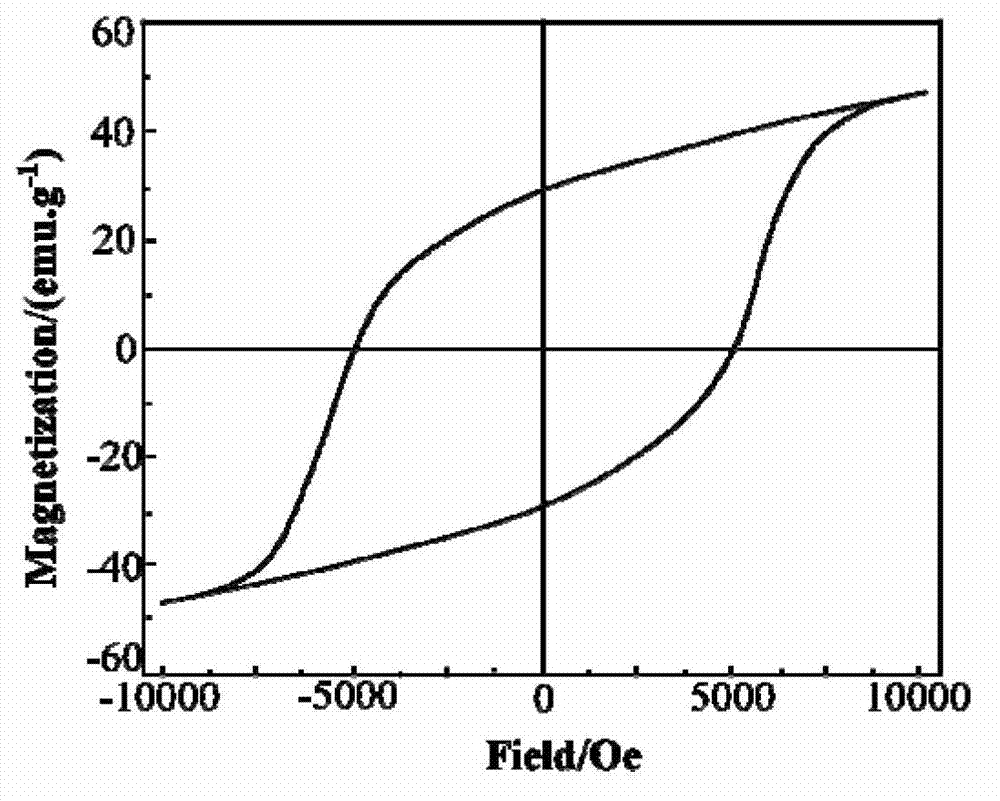

Preparation method for Zr-Mn-Co multi-doped barium ferrite wave-absorbing material

The invention provides a preparation method for a Zr-Mn-Co multi-doped barium ferrite wave-absorbing material. The preparation method comprises the following steps of: preparing a mixed solution A containing Zr, Mn and Co; adjusting the total molar concentration of the metal ions in the mixed solution A to be 0.01mol / L-0.1mol / L; adding ethylenediamine tetraacetic acid to the mixed solution A to form a solution B; adding a barium source and an iron source to the solution B to form a solution C; adjusting the pH value of the solution C to 8-9 to form uniform and stable transparent sol; preparing the sol into dry sol; carrying out hydrothermal reaction on the dry sol in a water-heating kettle; centrifugally washing the product; and sintering the centrifugally washed materials in a muffle furnace. According to the preparation method provided by the invention, an inorganic salt is used as a precursor, and EDTA (Ethylene Diamine Tetraacetic Acid) is used as a complexing agent to prepare the Zr-Mn-Co multi-doped barium ferrite, so that the crystal morphology and dimension of the barium ferrite are adjusted, thereby providing a novel way for researching the novel water-absorbing agent in stealth materials.

Owner:SHAANXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com