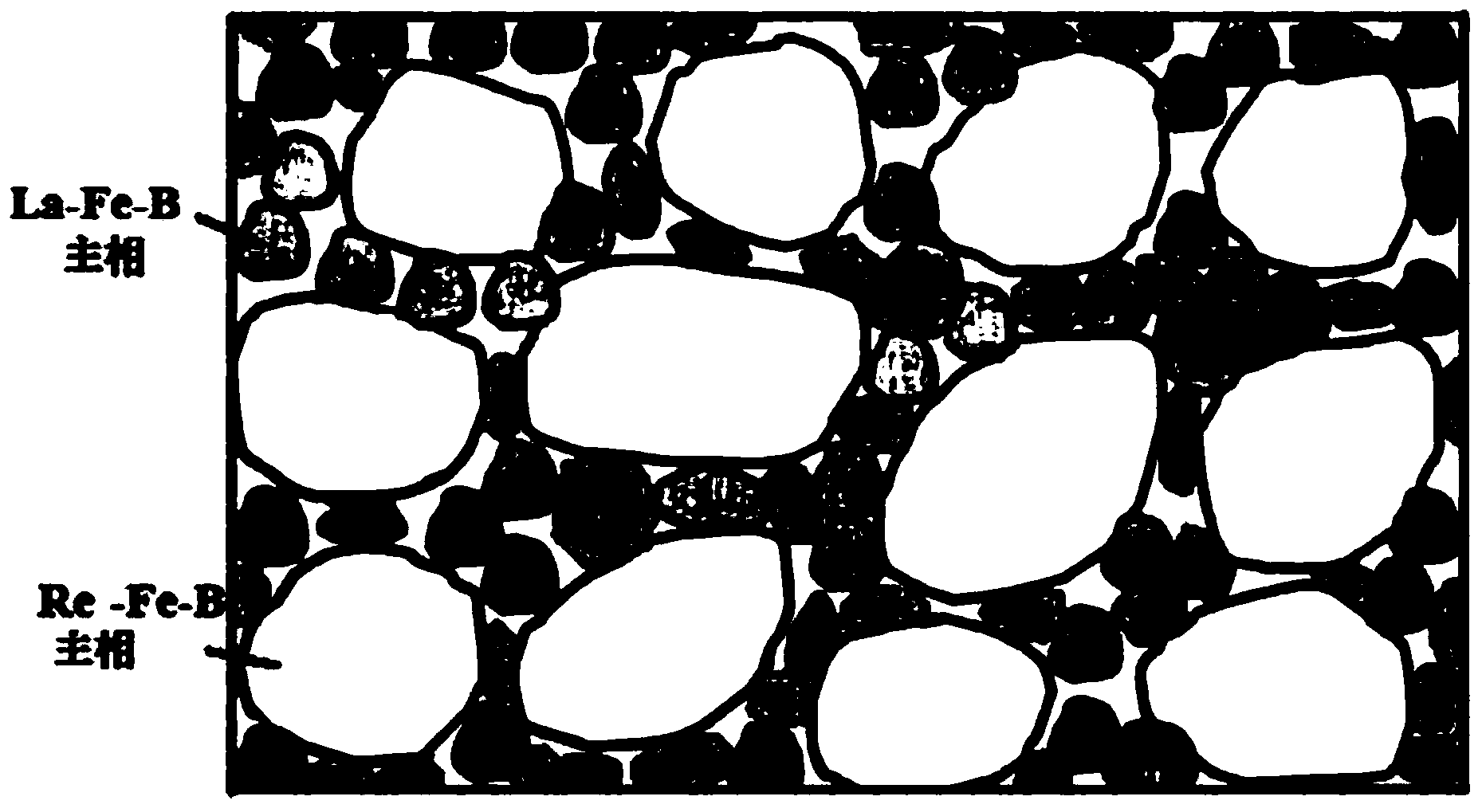

La-Fe-based magnet with double hard-magnetic main phases and preparation method for same

A dual hard magnetic main phase, double main phase technology, applied in the direction of magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc., can solve the problems of deteriorating magnet performance, achieve cost-effective, good magnetic performance, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

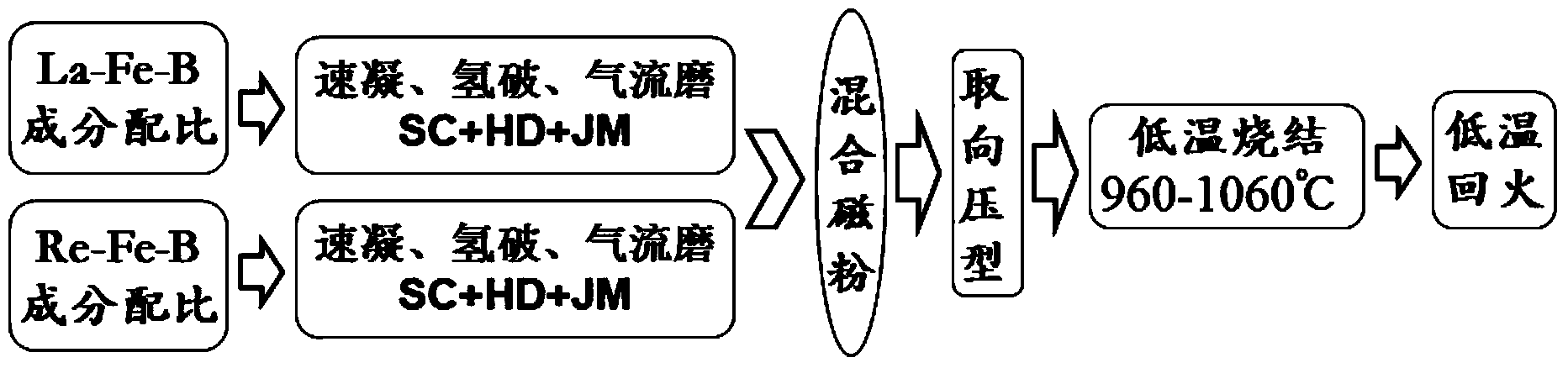

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

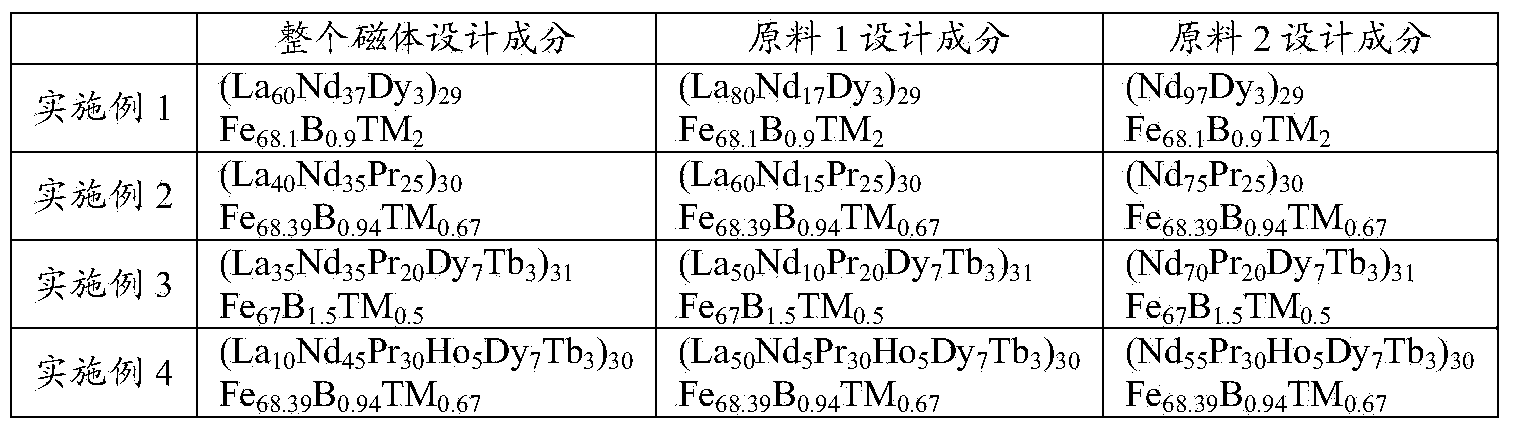

[0034] The composition chemical formula of the whole magnet design is (La x Re 100-x ) a Fe 100-a-b-c B b tm c , where x, a, b and c represent the mass percentage of the corresponding elements, Re is one or more of Nd, Pr, Dy, Tb, Ho elements, TM is Ga, Co, Cu, Nb, Al elements One or more of them (as shown in Table 1).

[0035] Step 1: prepare two kinds of raw materials respectively according to the composition chemical formula of mass percent as shown in table 1: (La x1 Re 100-x1 ) a Fe 100-a-b-c B b tm c (wt.%) and Re a Fe 100-a-b-c B b tm c (wt.%), where x, a, b and c respectively represent the mass percentage of the corresponding element, 50%≤x1≤80%, 29%≤a≤31%, 0.9%≤b≤1.5%, 0.5%≤c ≤2%, TM is one or more of Ga, Co, Cu, Nb, Al elements;

[0036] Table 1 Alloy composition chemical formul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com