Patents

Literature

33 results about "Anisotropy constant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Perpendicular magnetic recording medium

ActiveUS20060177703A1Improvement in recordability of recordingHigh densityRecord information storageMagnetic recordingCouplingThermal stability

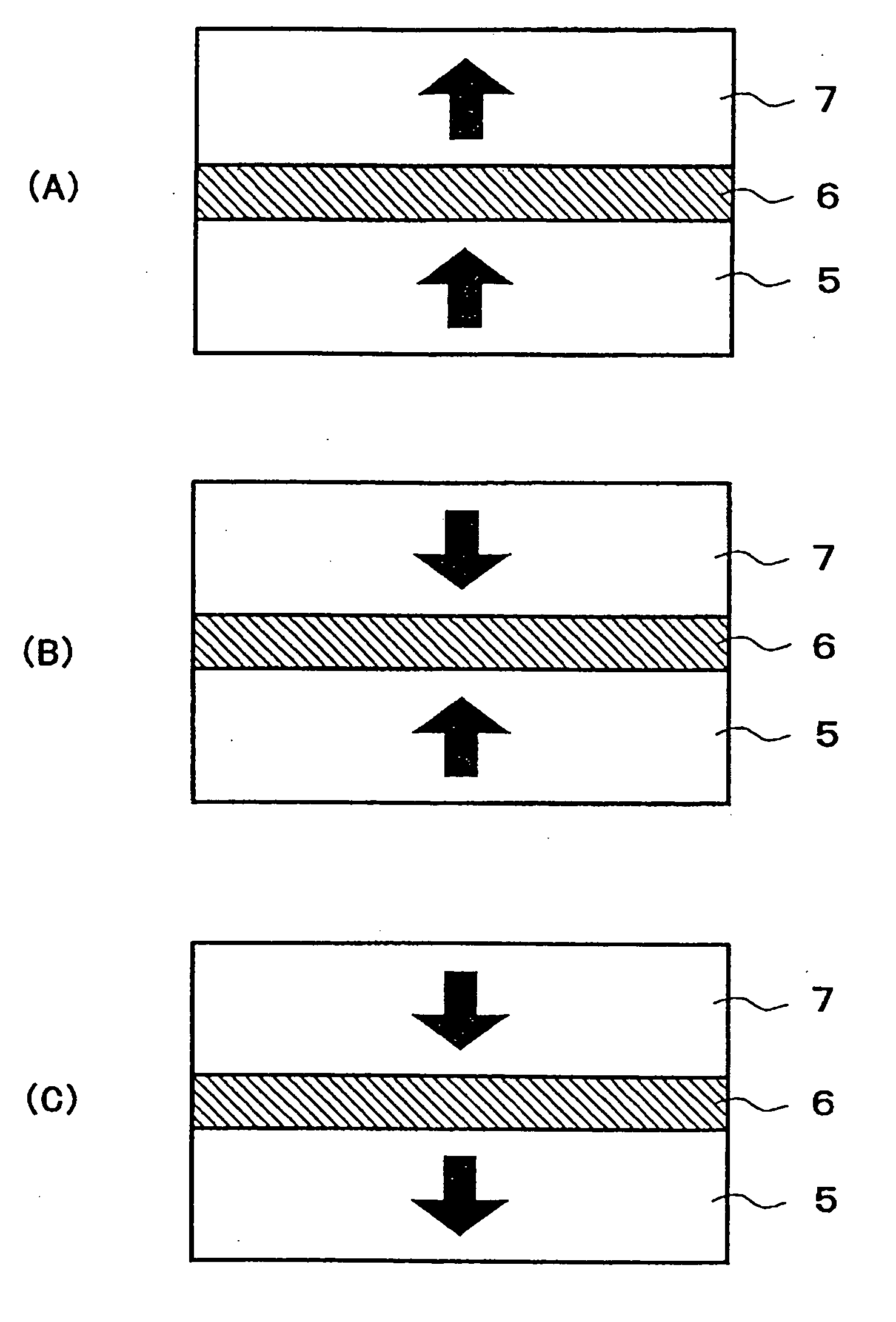

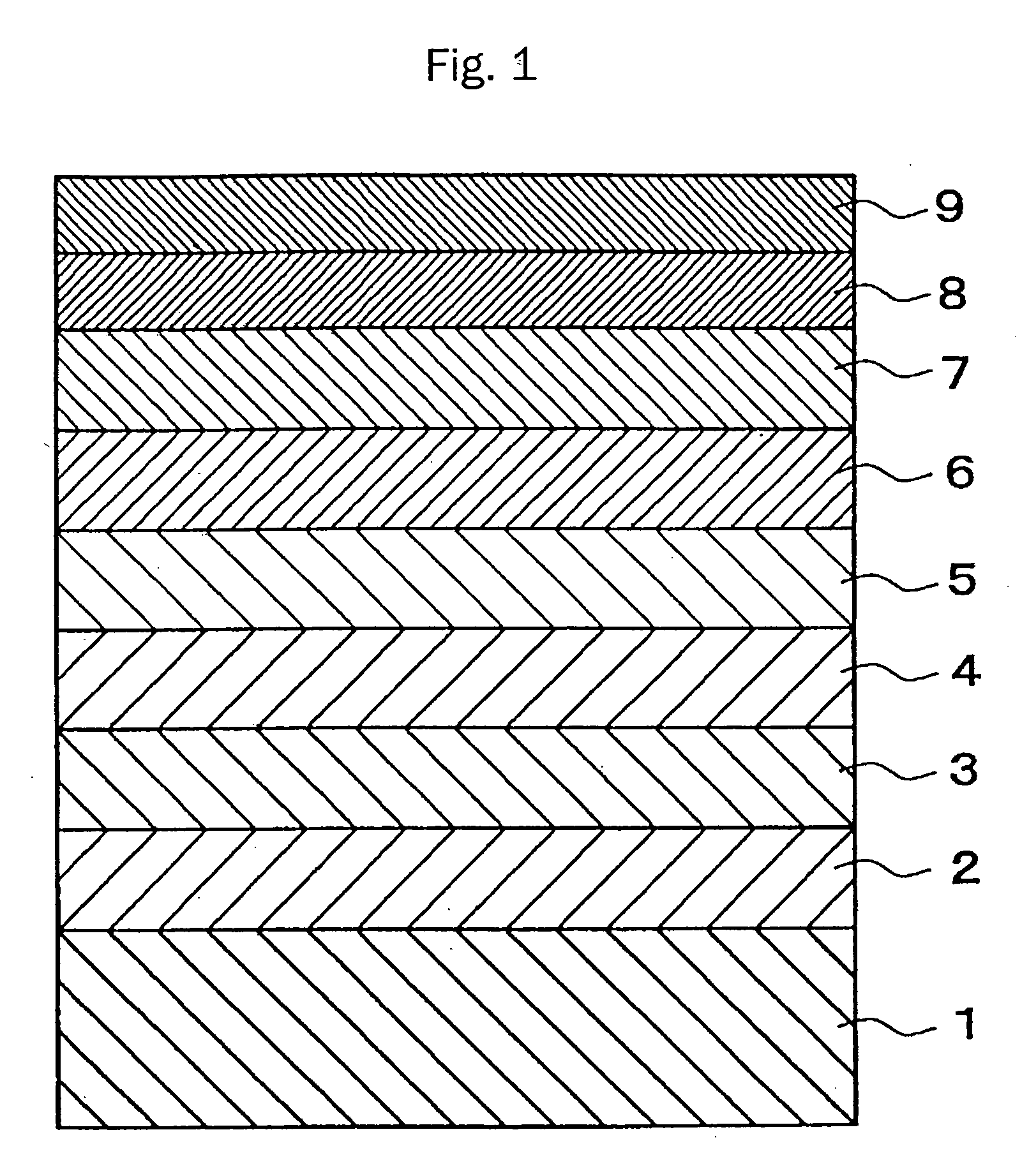

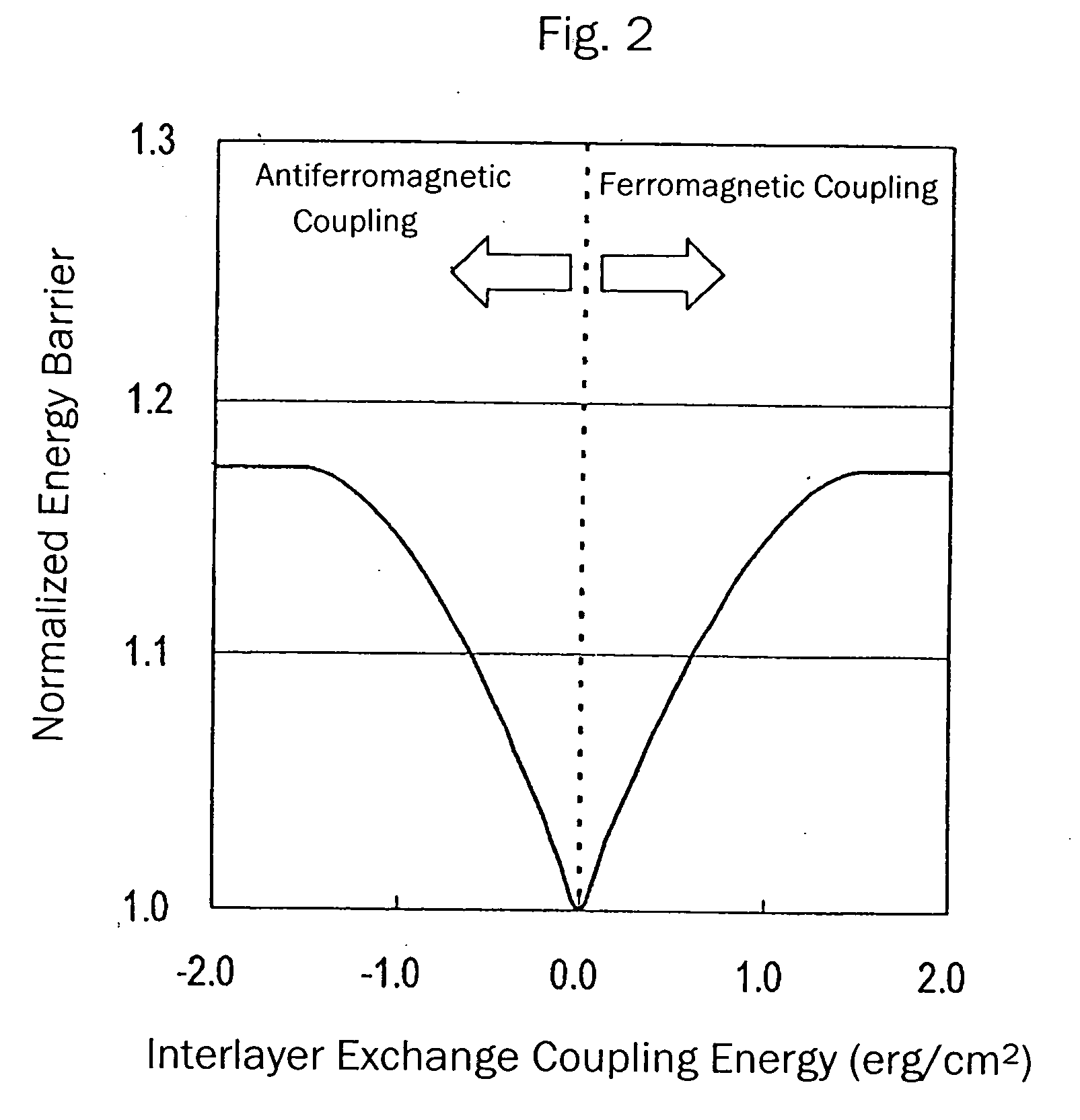

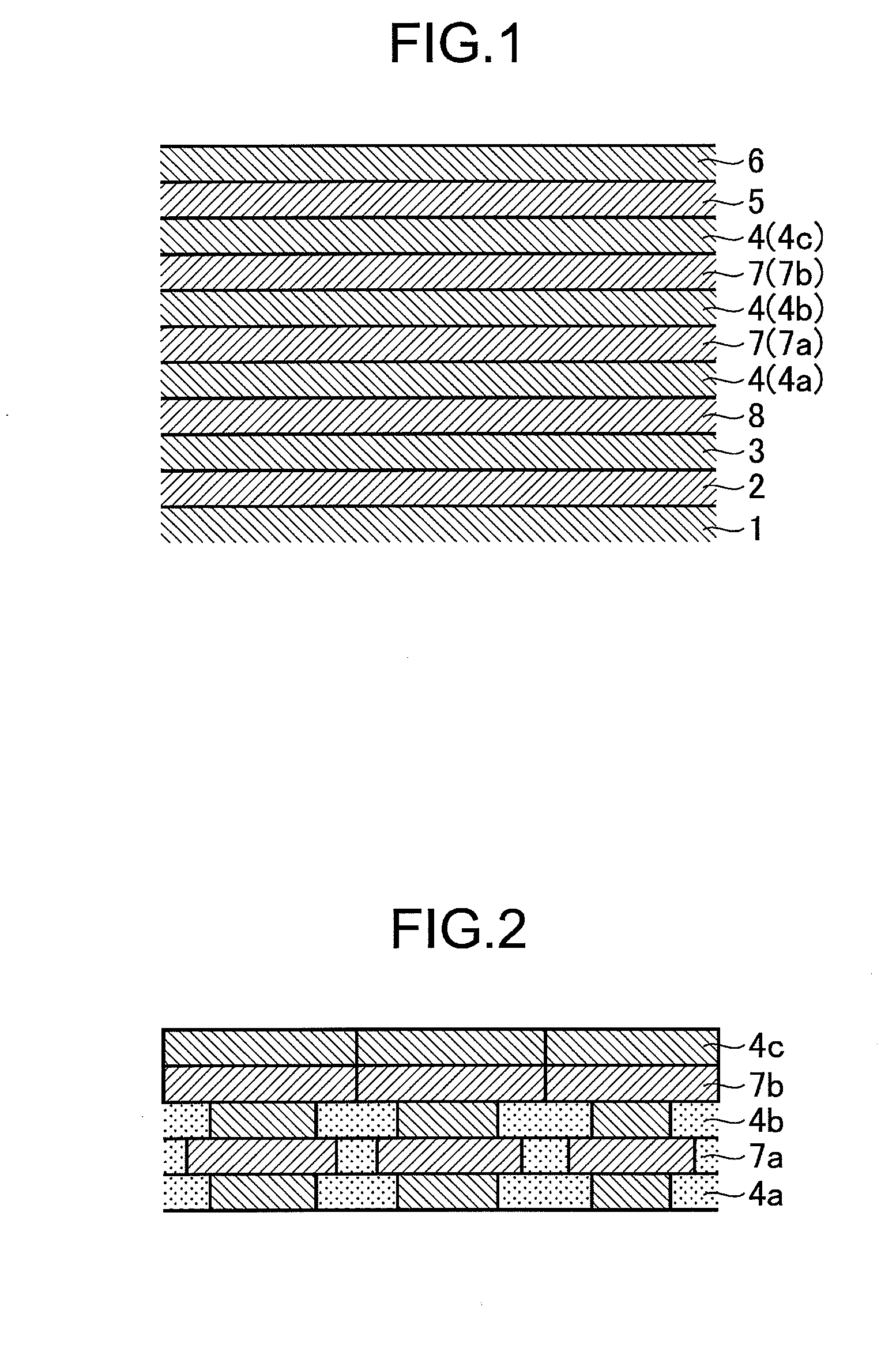

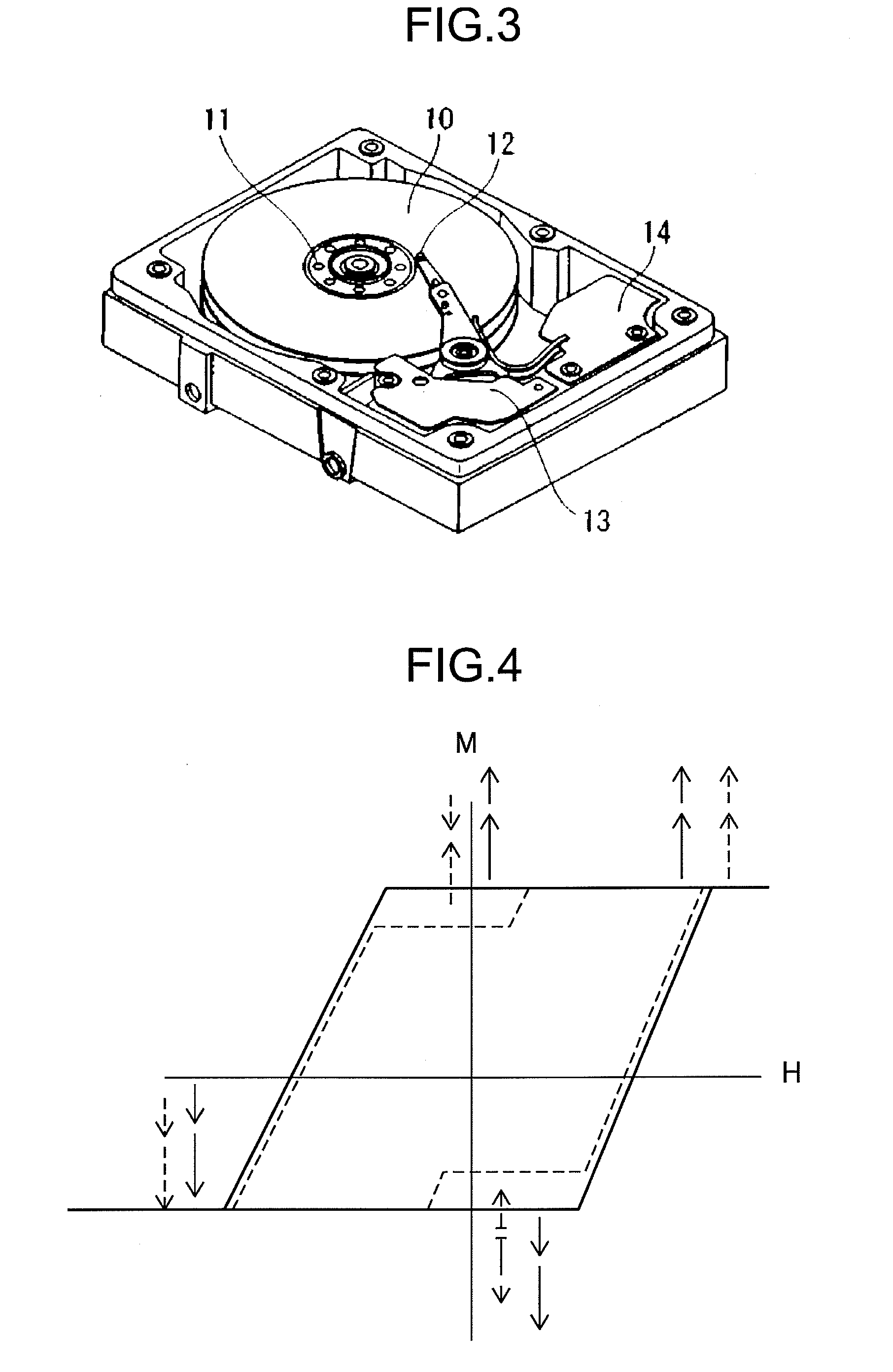

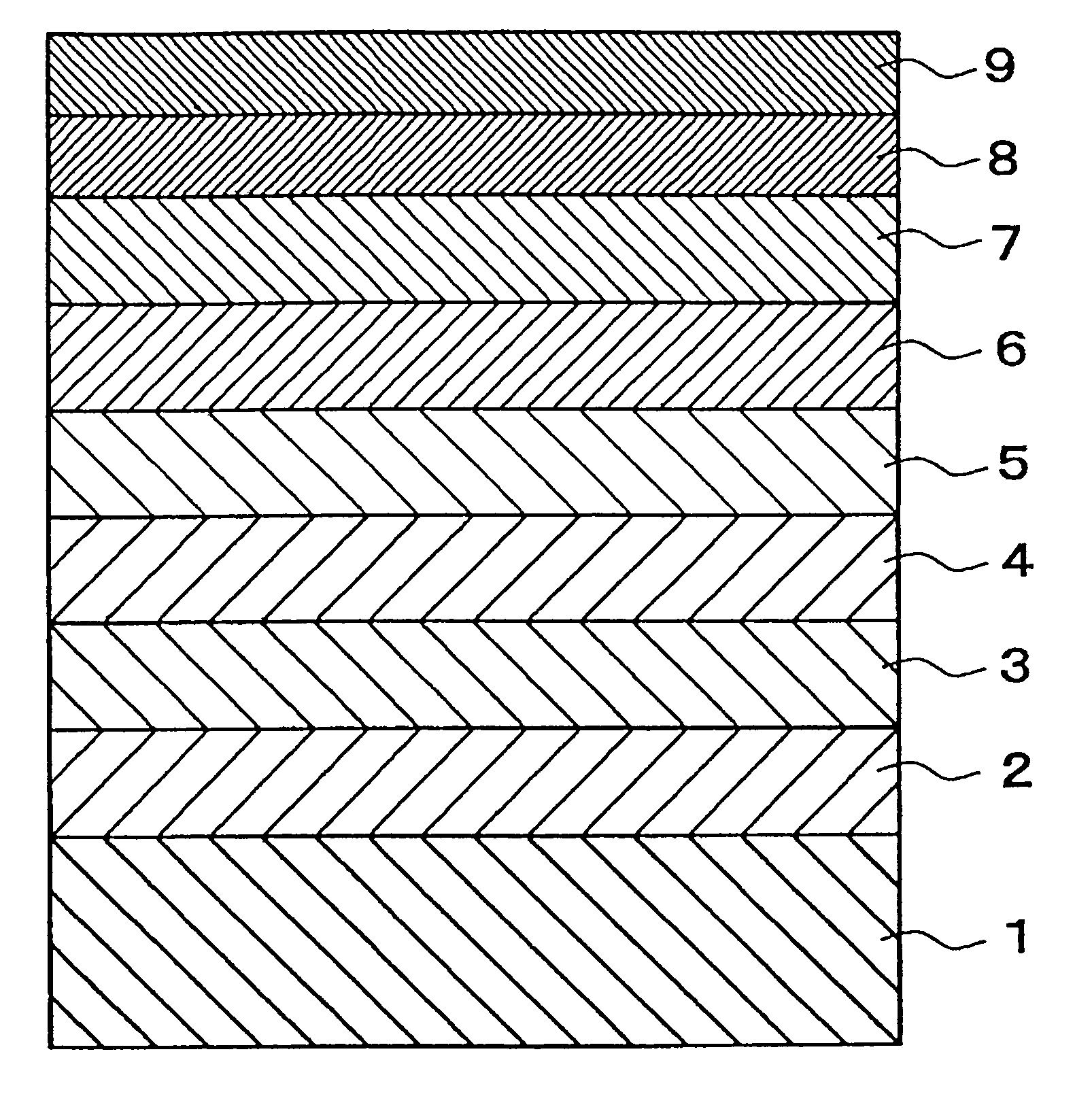

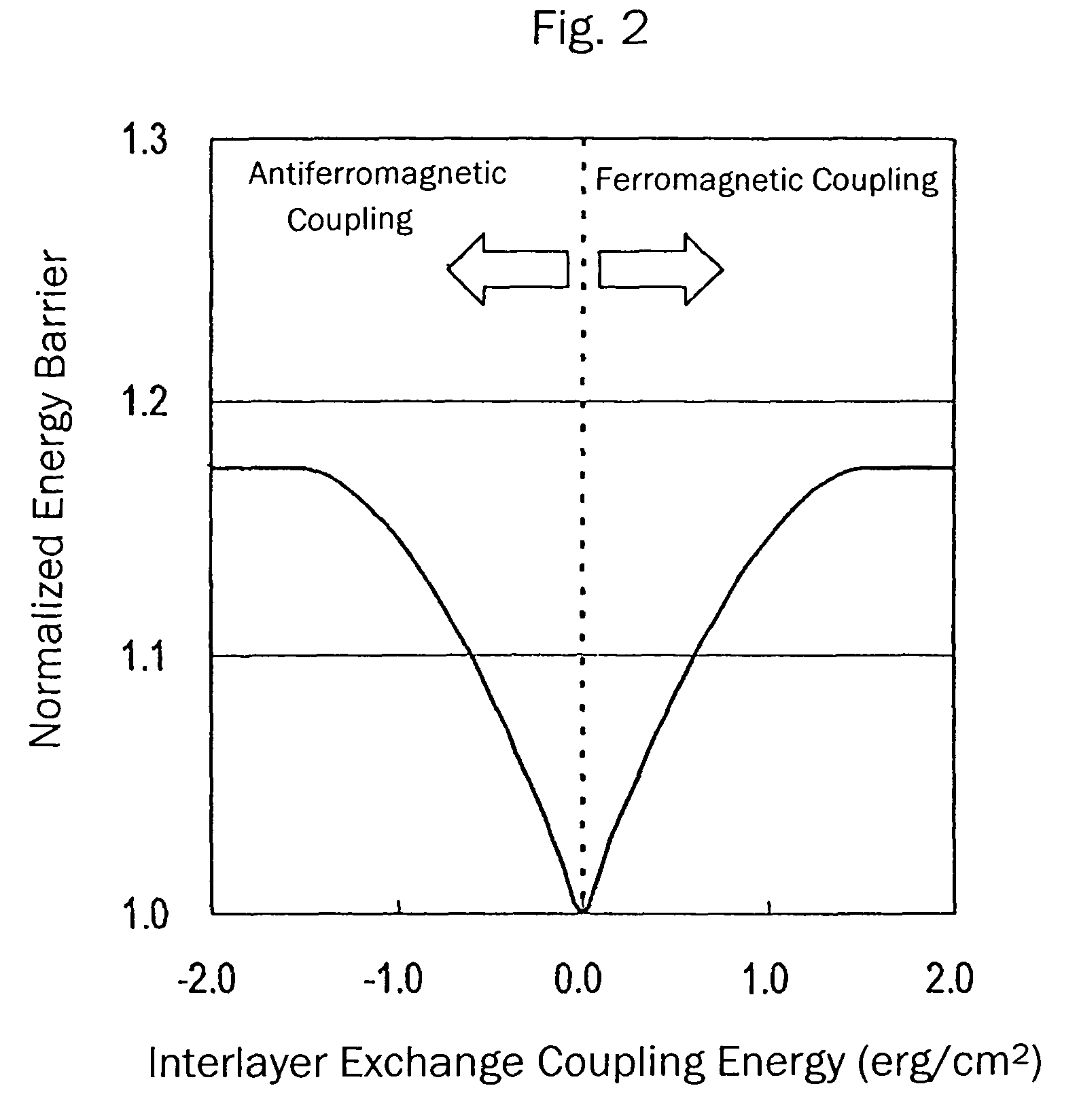

A perpendicular magnetic recording medium is disclosed that achieves improved recordability without deteriorating thermal stability by reducing the switching field. A perpendicular magnetic recording medium of the invention has a first magnetic recording layer and a second magnetic recording layer between with is interposed a coupling layer that ferromagnetically couples the two layers. The first and second magnetic recording layers satisfy an inequality Ku1T1>Ku2T2 in the case where Hk1 >Hk2 and an inequality Ku1T1<Ku2T2 in the case where Hk1<Hk2, where Hk1 and Hk2 are anisotropy magnetic fields, Ku1 and Ku2 are uniaxial anisotropy constants, and T1 and T2 are thicknesses of the first magnetic recording layer and the second recording layer, respectively. An exchange coupling energy between the magnetic recording layers is preferably at least 5×10−3 erg / cm2. Advantageously, the coupling layer is mainly composed of a material selected from V, Cr, Fe, Co, Ni, Cu, Nb, Mo, Ru, Rh, Ta, W, Re, and Ir, and has a thickness of at most 2 nm. At least one of the magnetic recording layers preferably has a granular structure.

Owner:FUJI ELECTRIC CO LTD

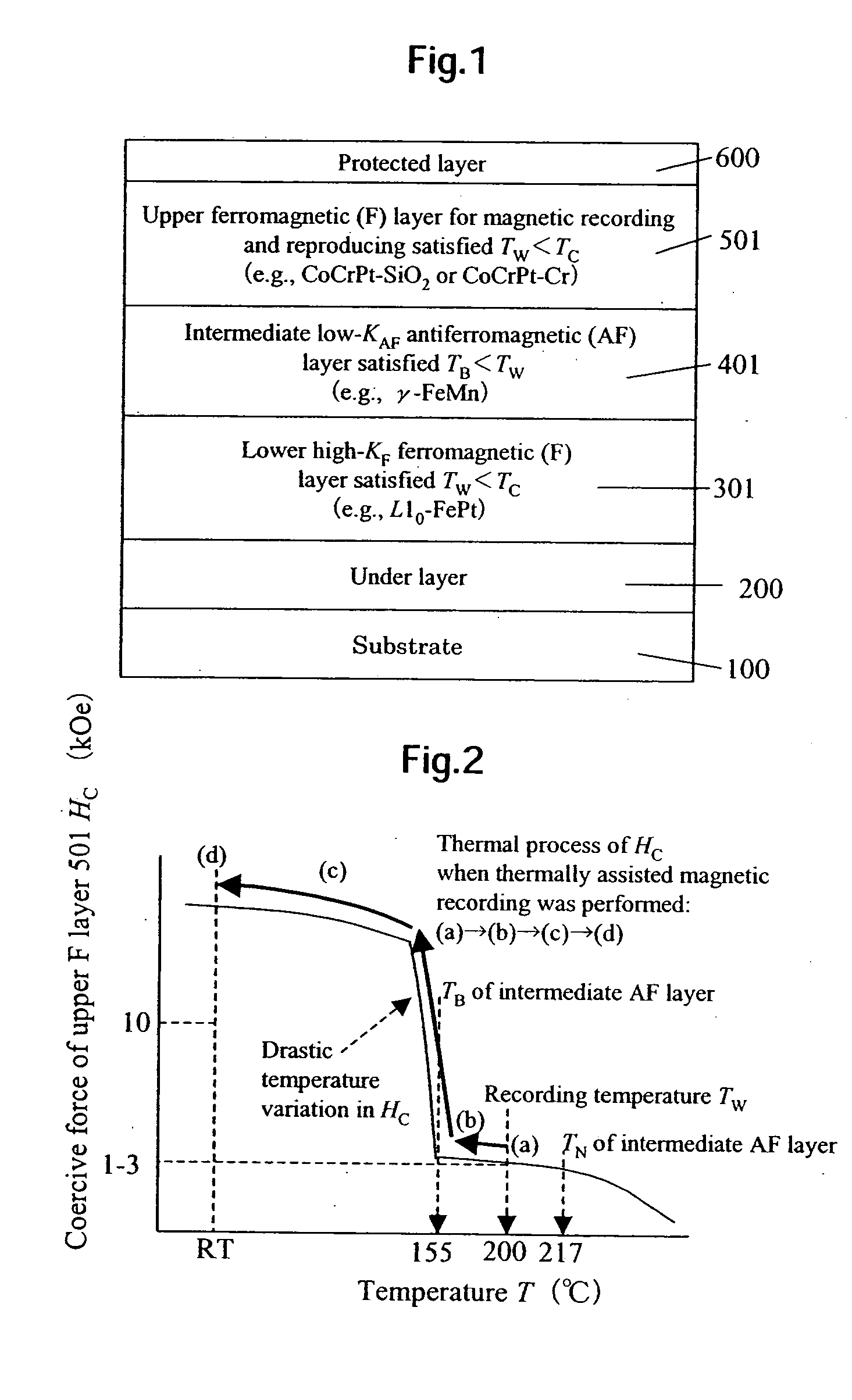

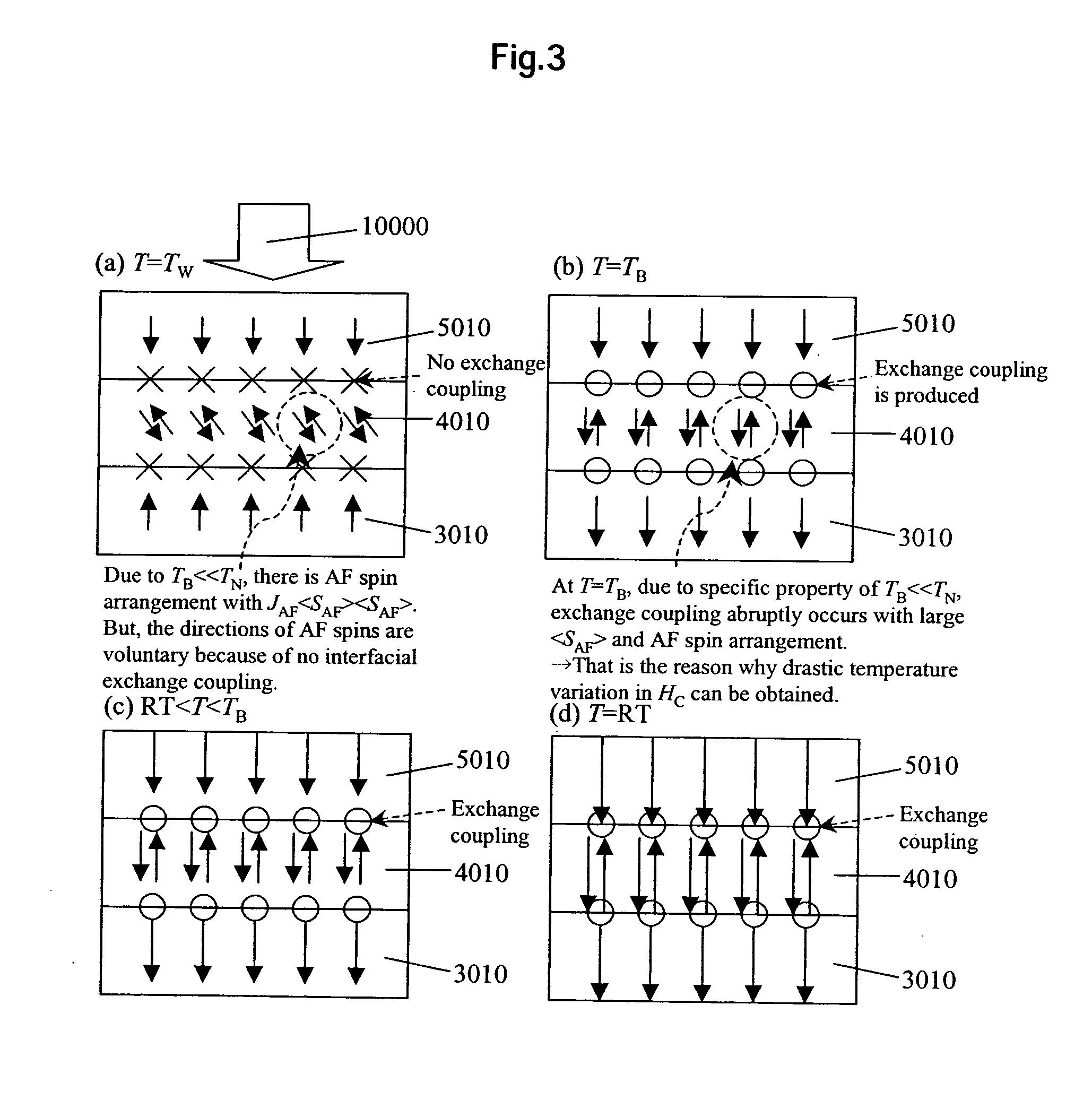

Thermally assisted magnetic recording media and magnetic recording and reproducing apparatus

InactiveUS20070048552A1Overcome resistance against thermal fluctuationImprove coercive forceCombination recordingDifferent record carrier formsHeat-assisted magnetic recordingMagnetocrystalline anisotropy

Owner:WESTERN DIGITAL TECH INC

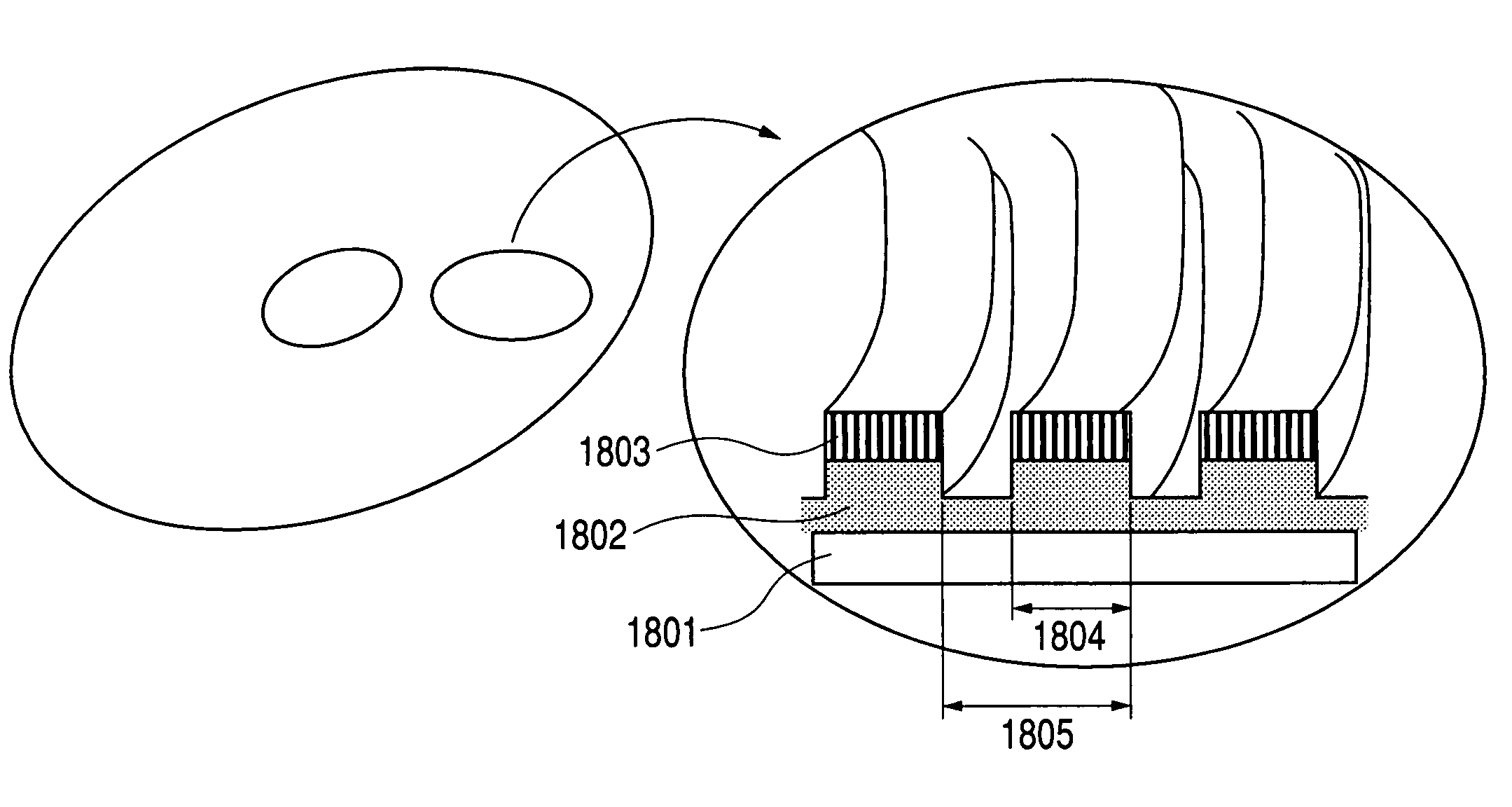

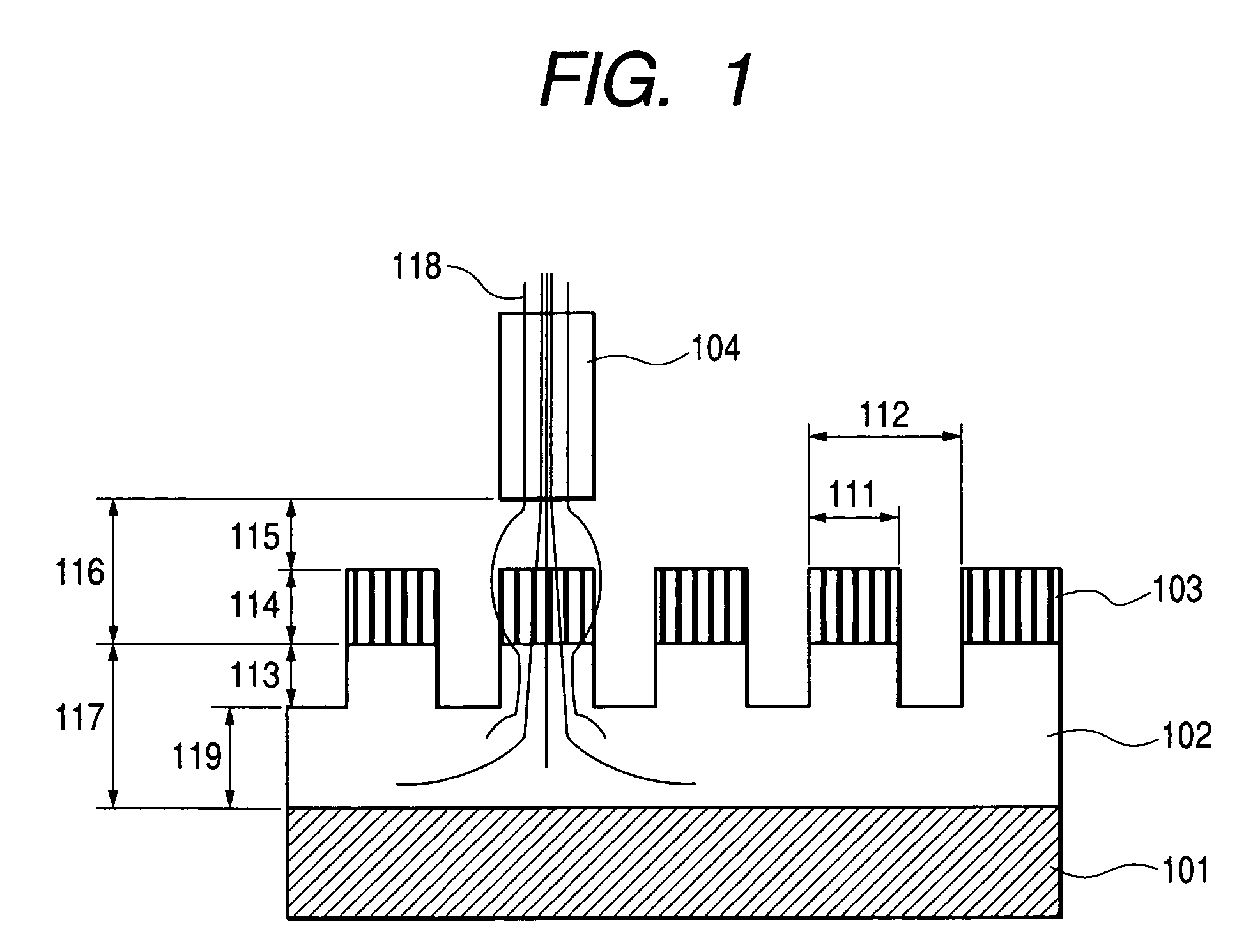

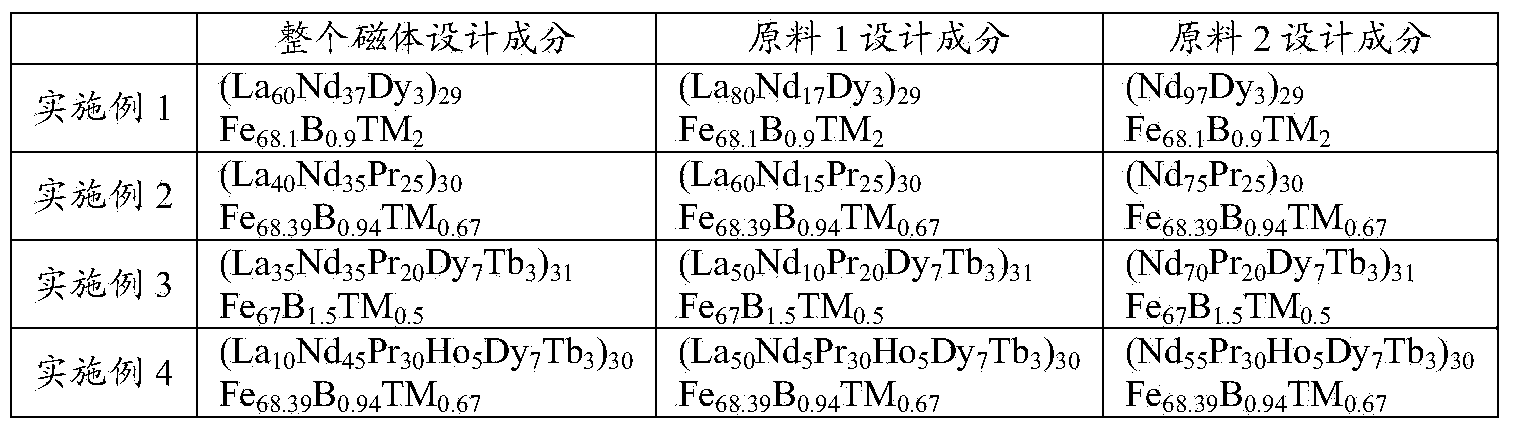

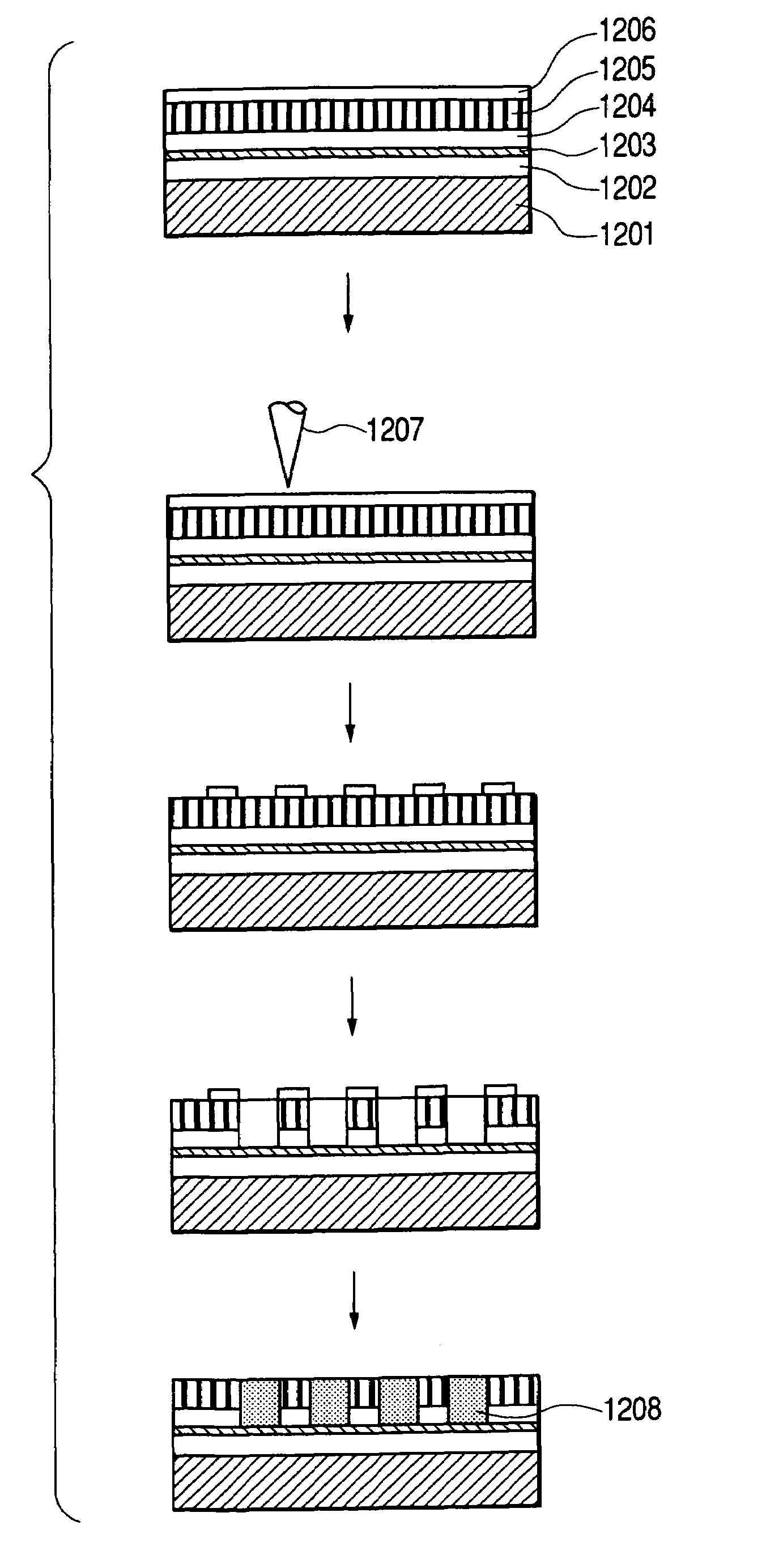

Magnetic recording media and method of forming them

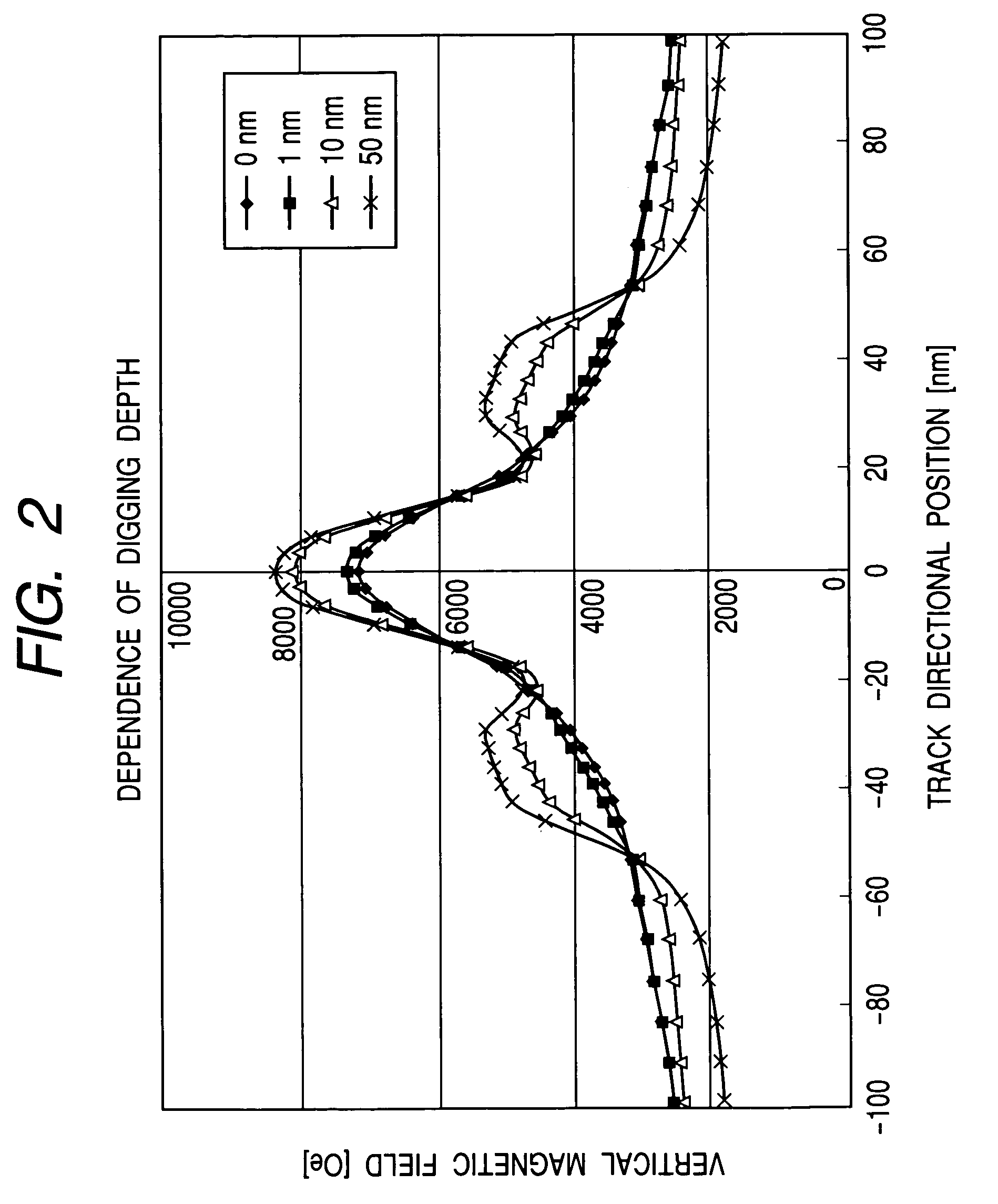

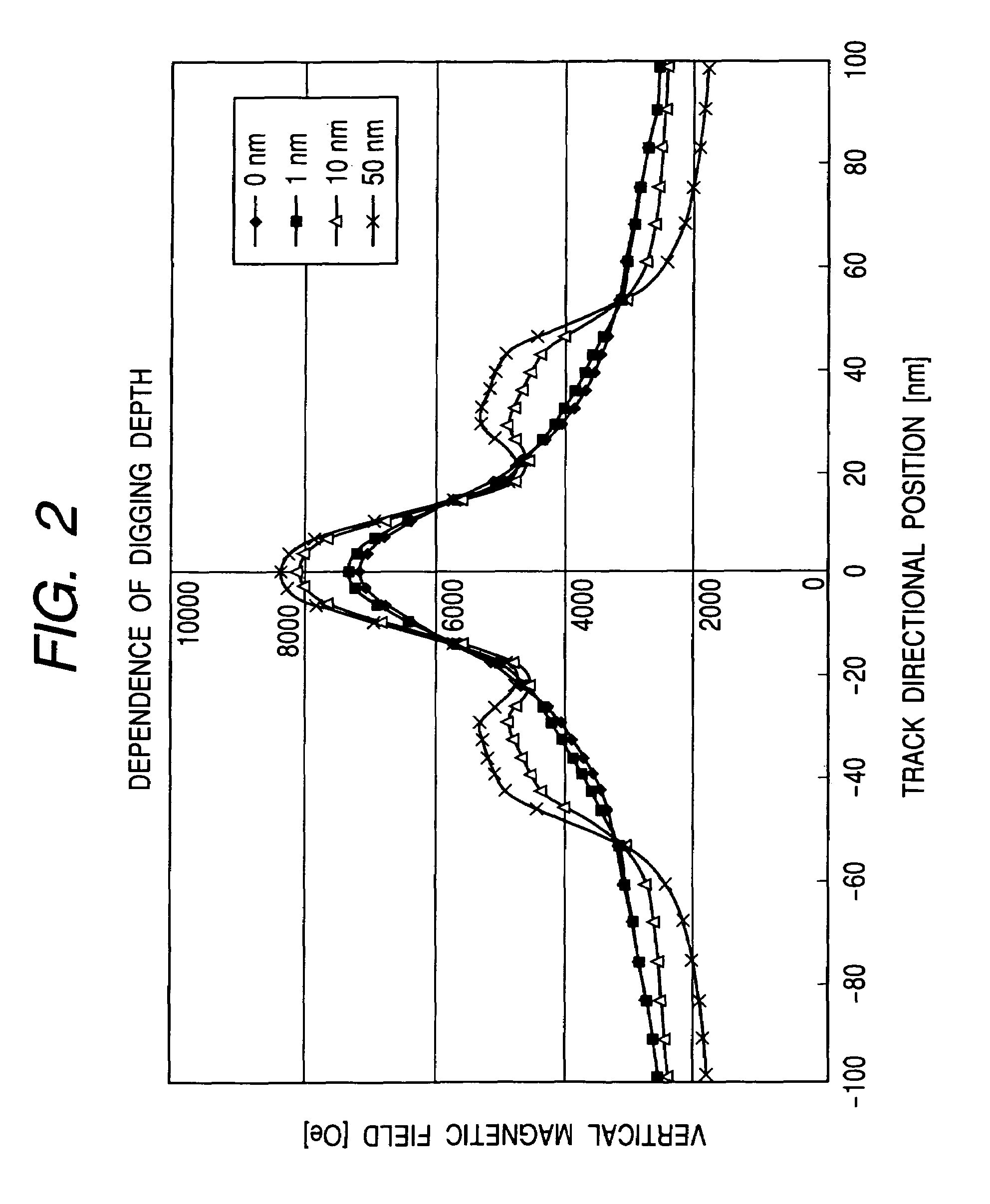

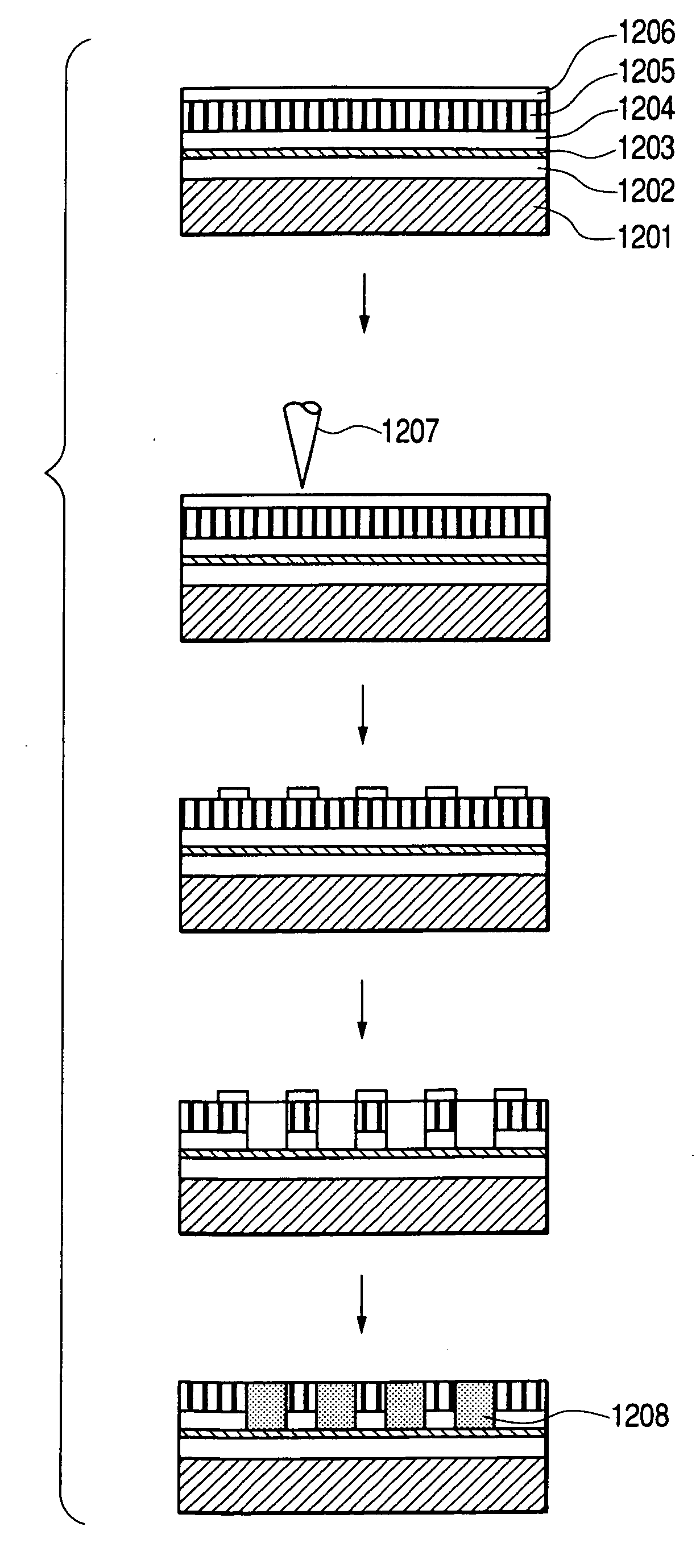

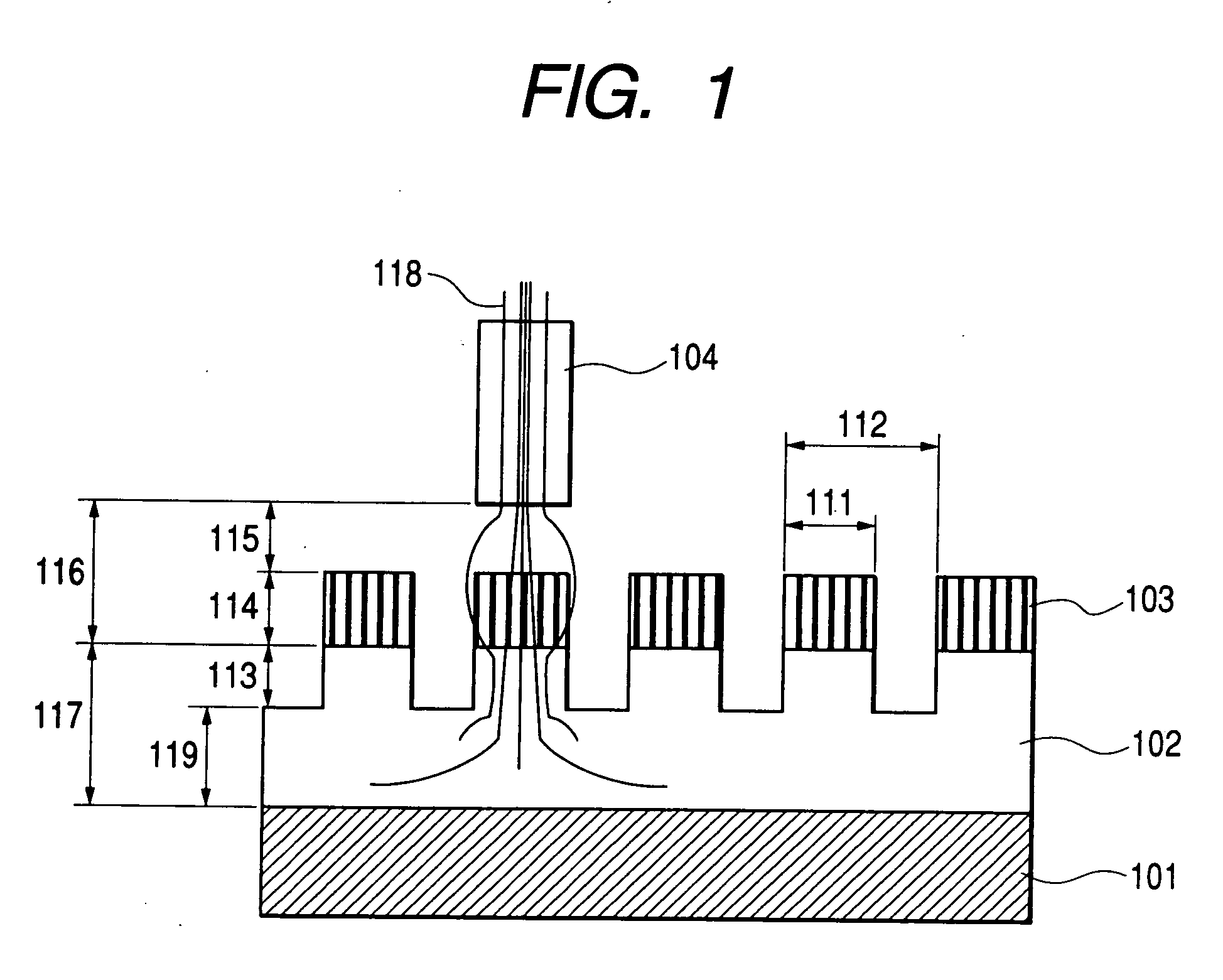

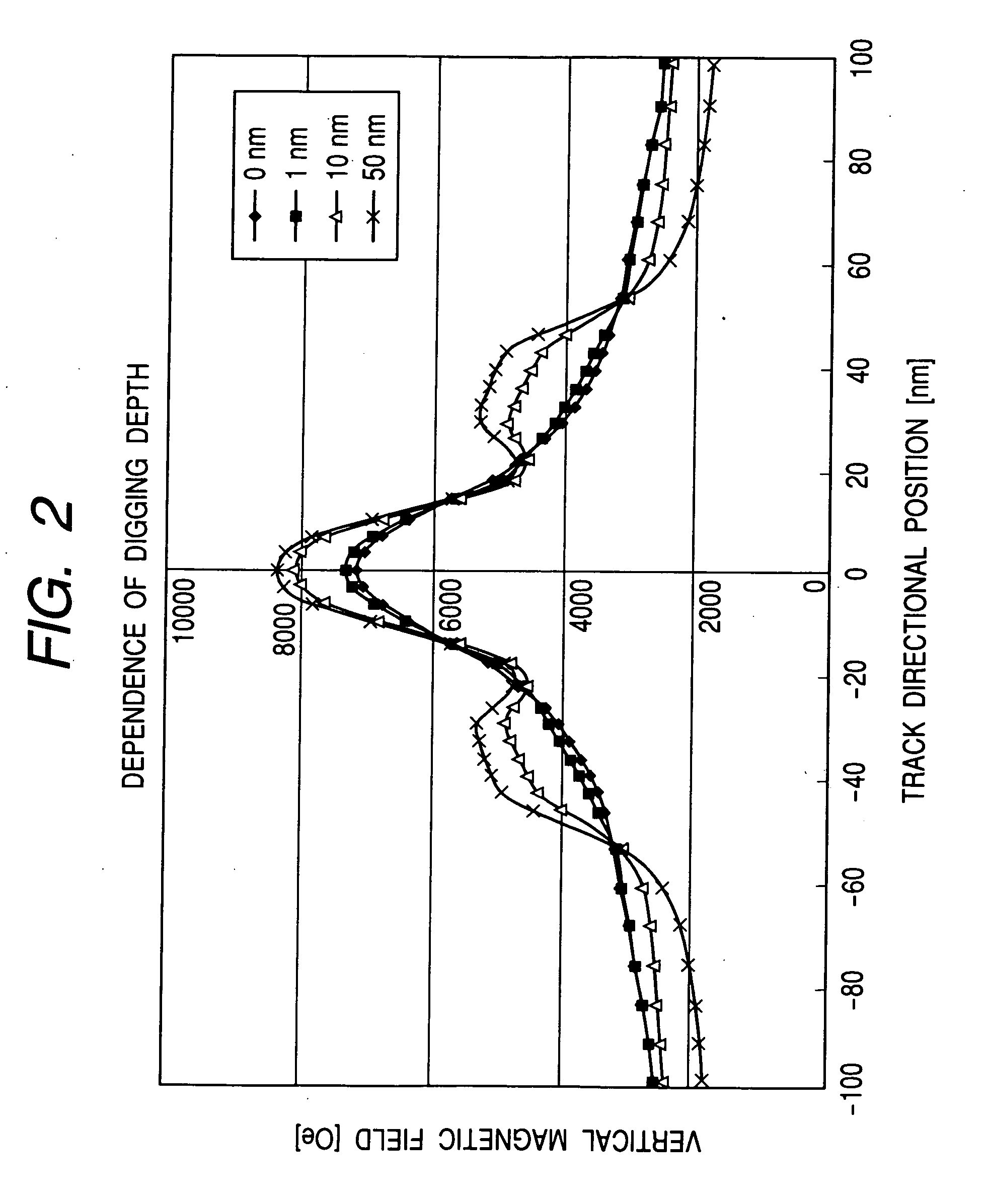

InactiveUS7097924B2Steep distribution of a recording magnetic fieldRecording magnetic field from a single magnetic polar head is increasedConstruction of head windingsBase layers for recording layersHigh densityRecording media

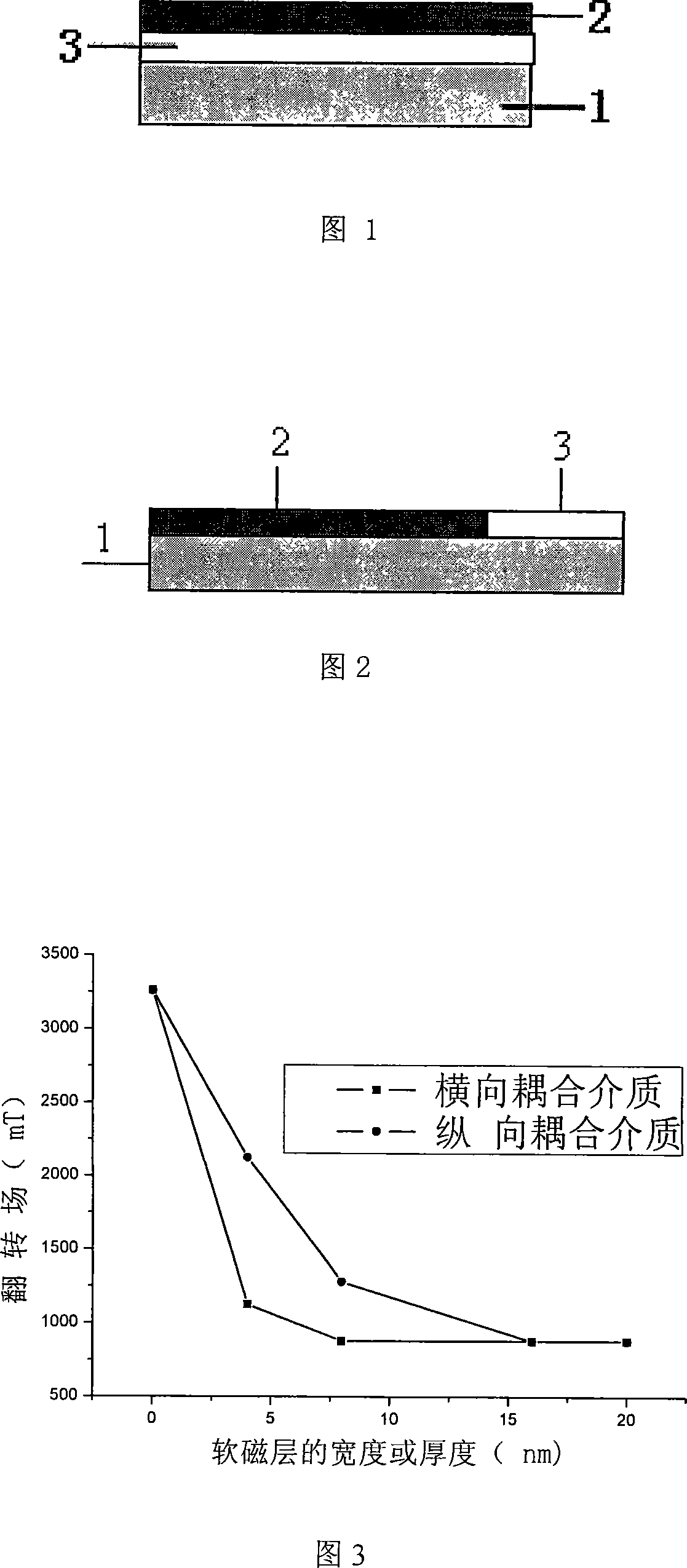

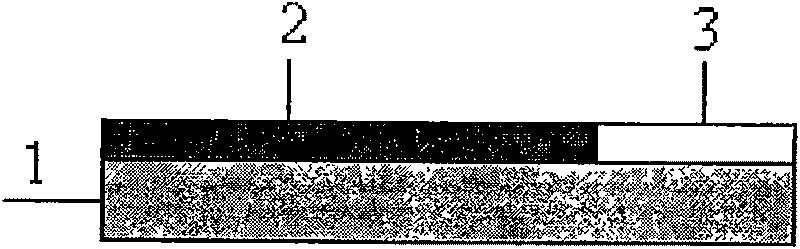

The present invention is directed to-carrying out a high density magnetic recording to a material having a large coercive force by perpendicular magnetic recording head.By giving a patterning onto a soft magnetic under layer of a perpendicular two-layer recording media in sync with a period of a recording bit, a magnetic field from a write head can be allowed to converge to a soft magnetic column. Therefore, a magnetization reversal of the magnetic recording media material having a large anisotropic constant becomes possible, and then a high density magnetic recording can be achieved.

Owner:HITACHI LTD

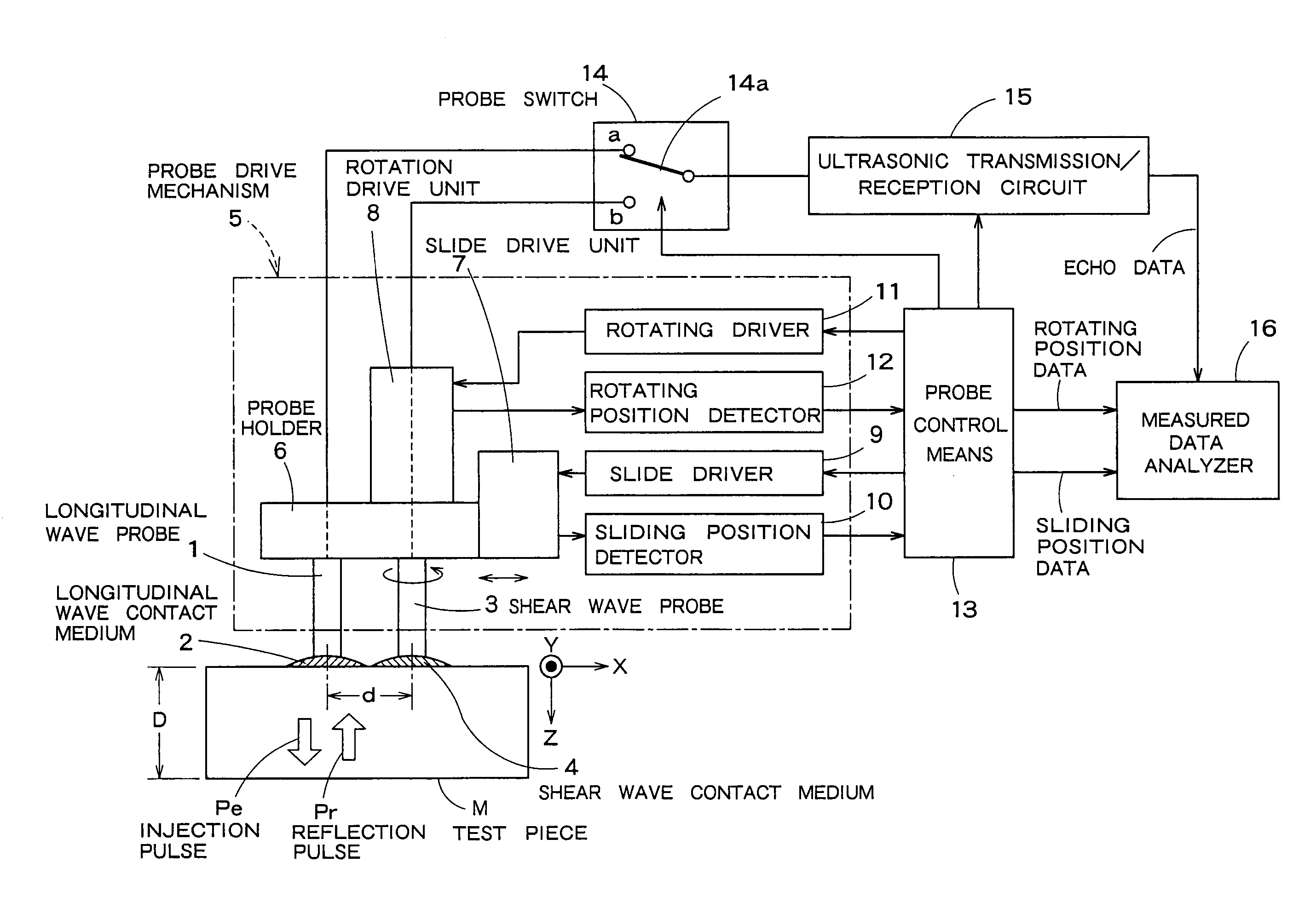

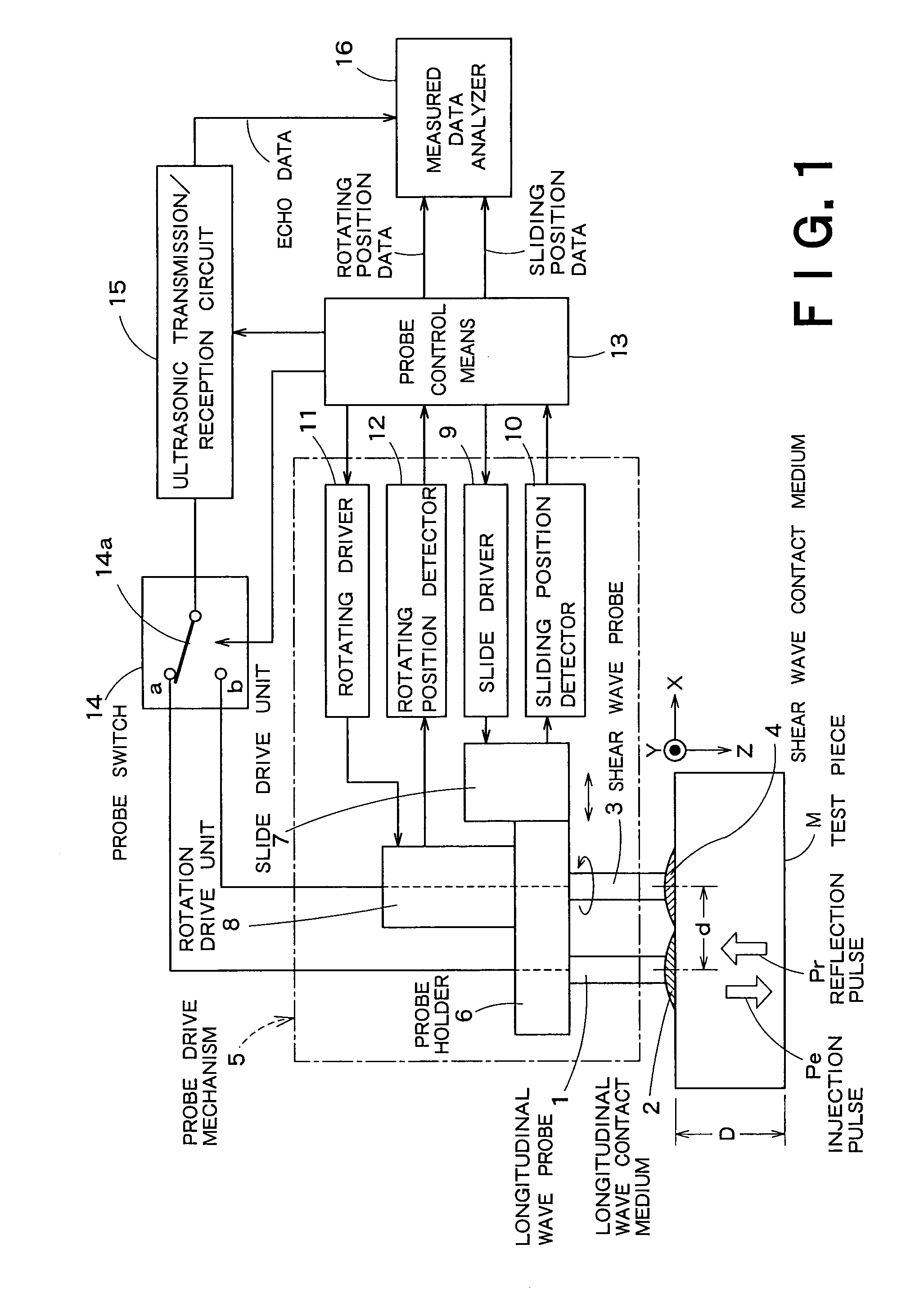

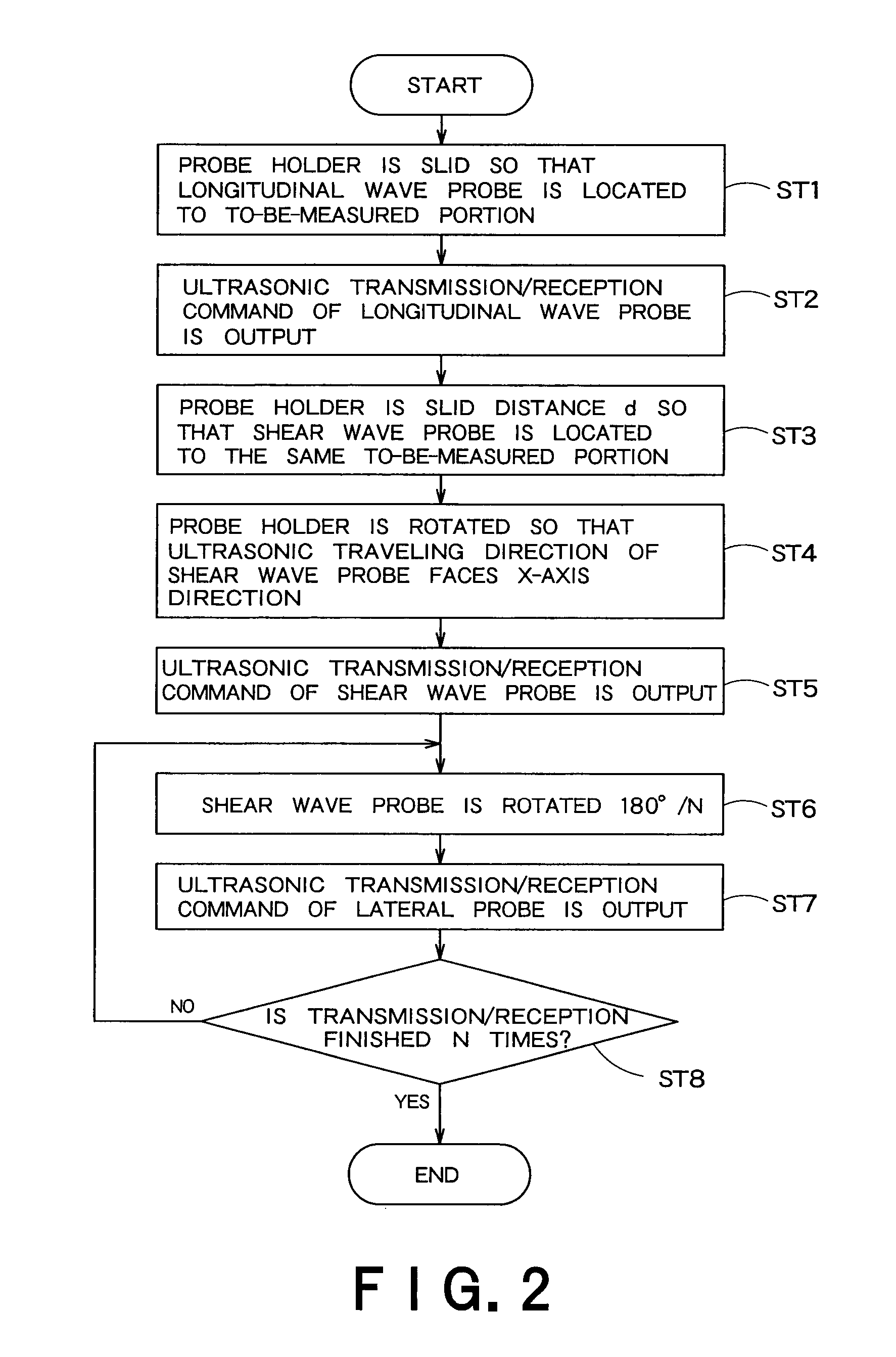

Ultrasonic stress measuring apparatus

InactiveUS20080047347A1Analysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesStress measuresMeasurement device

After a probe control means causes a longitudinal wave probe to carry out transmission and reception, it slides a shear wave probe to the same position. The probe control means rotates the shear wave probe at each predetermined angle and rotates it 180° while causing it to carry out the transmission and the reception at each rotating position. A measured data analyzer 16 calculates the constant of texture induced anisotropy in a test piece from echo data when both the probes carry out the transmission and the reception. With this arrangement, it is possible to measure the residual stress of a material, in which both texture induced anisotropy and residual stress induced anisotropy mixedly exist with pinpoint accuracy by separating only the texture induced anisotropy from the material.

Owner:KK TOSHIBA

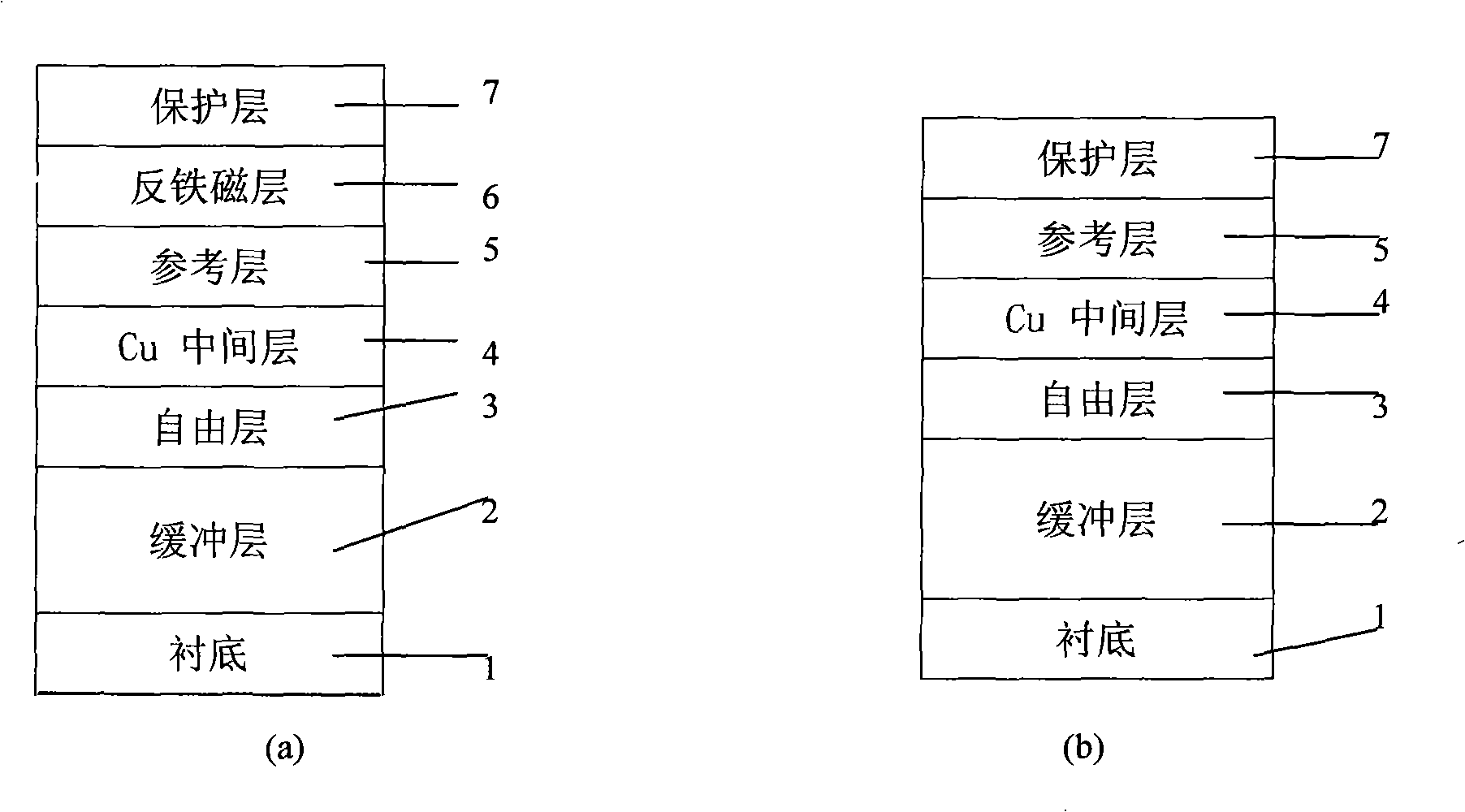

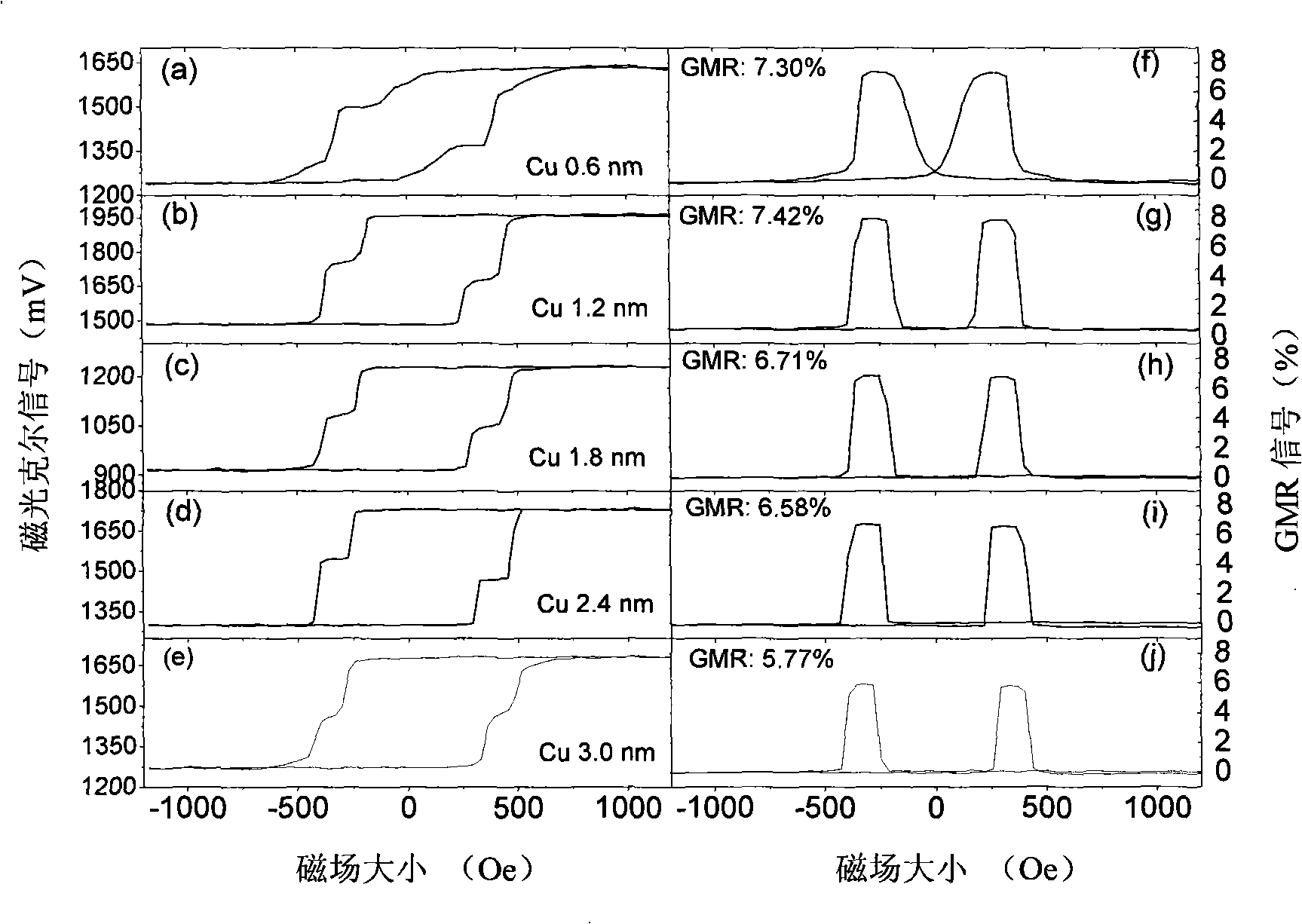

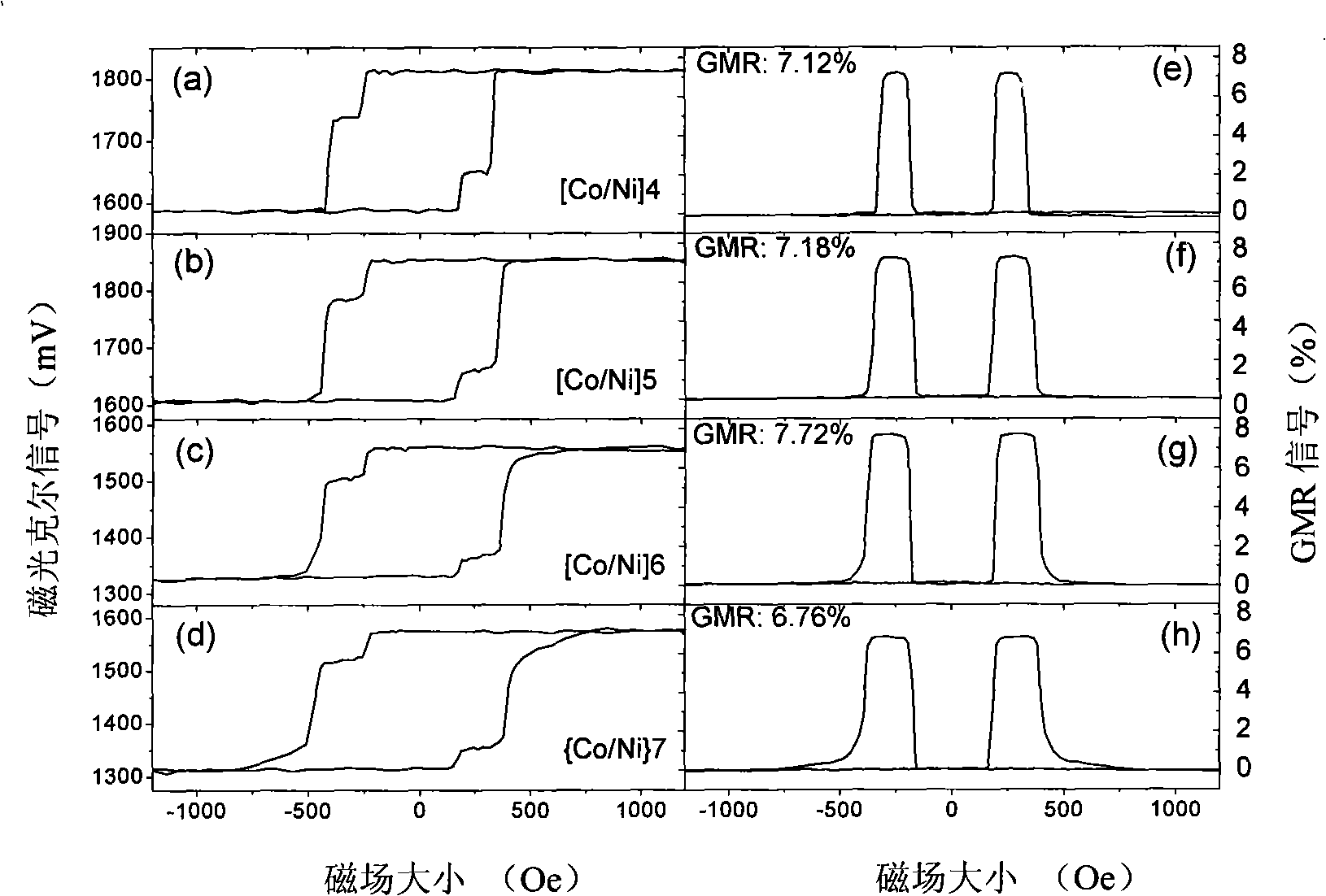

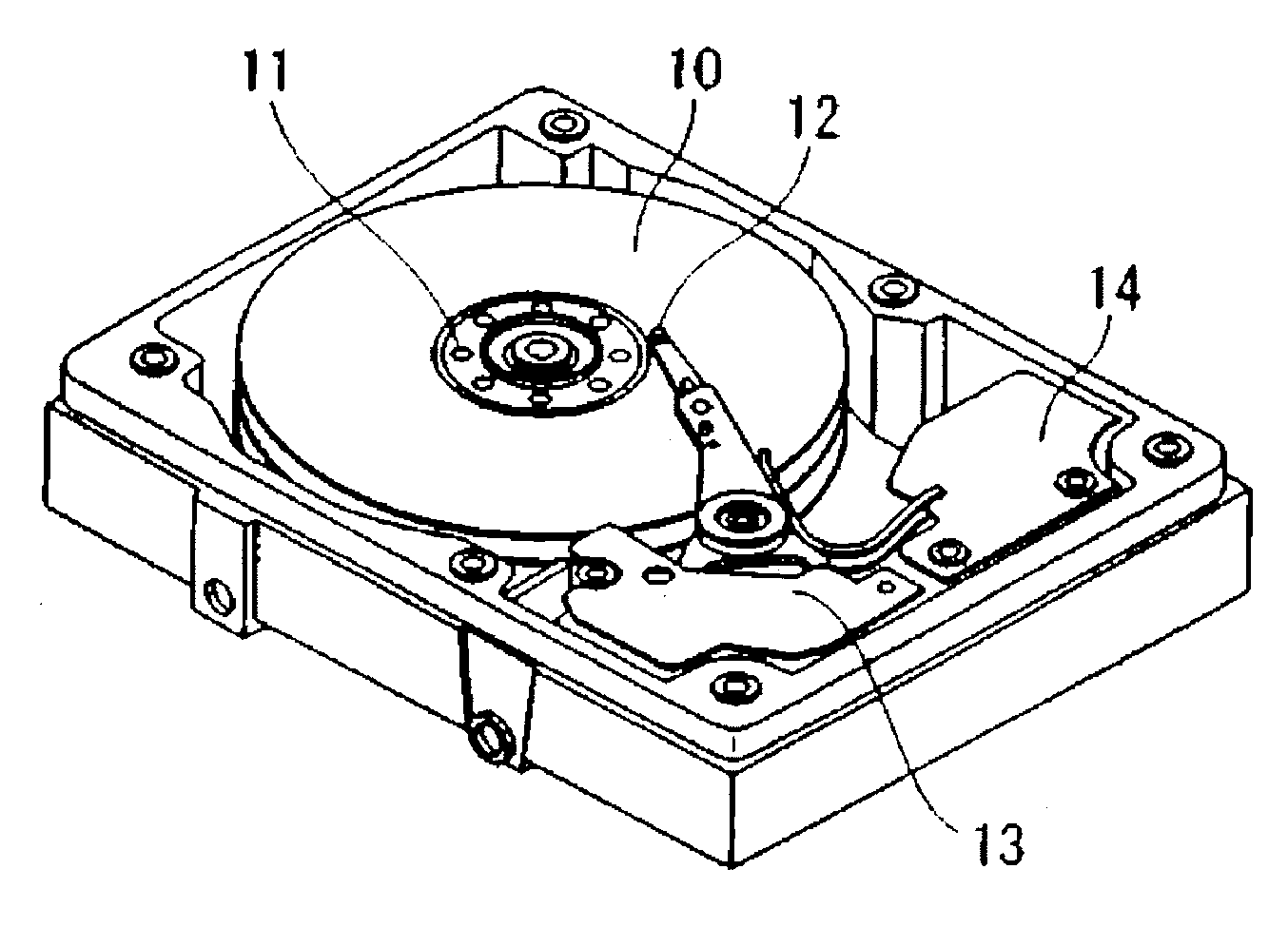

Self-rotation valve with vertical magnetic anisotropy

InactiveCN101320616AMagnetically anisotropicMeet application requirementsMagnetic-field-controlled resistorsManufacture of flux-sensitive headsPolarizabilitySpin valve

This invention belongs to the technical field of magnetic recording, specifically is a spin valve with vertical magnetic anisotropy. Ferromagnetic layers of upper, middle and lower adopt Co / Ni multi-layer film structure and are made by utilizing a method of magnetron sputtering to deposit under the normal temperature. The Co / Ni multi-layer film includes the feature of a preferred direction of magnetization vertical with a film surface because of larger surface and interface anisotropy, and the properties, such as the coefficient of the magnetic vertical anisotropy, the coercive force can be modulated through thicknesses, periodicity and buffer layer of layers of Co, Ni. In addition, Co and Ni are the magnetic materials and have bigger spin polarizability. A whole spin valve and a pseudo spin valve GMR signal can achieve 5 / 4 to 7.7%; and the exchange bias field of the whole spin valve can achieve more than 4500e, and the thermal stability can achieve 250 degrees centigrade. This invention has an important application value in the computer hard disk reading head, MRAM and the other spin electronic apparatuses.

Owner:FUDAN UNIV

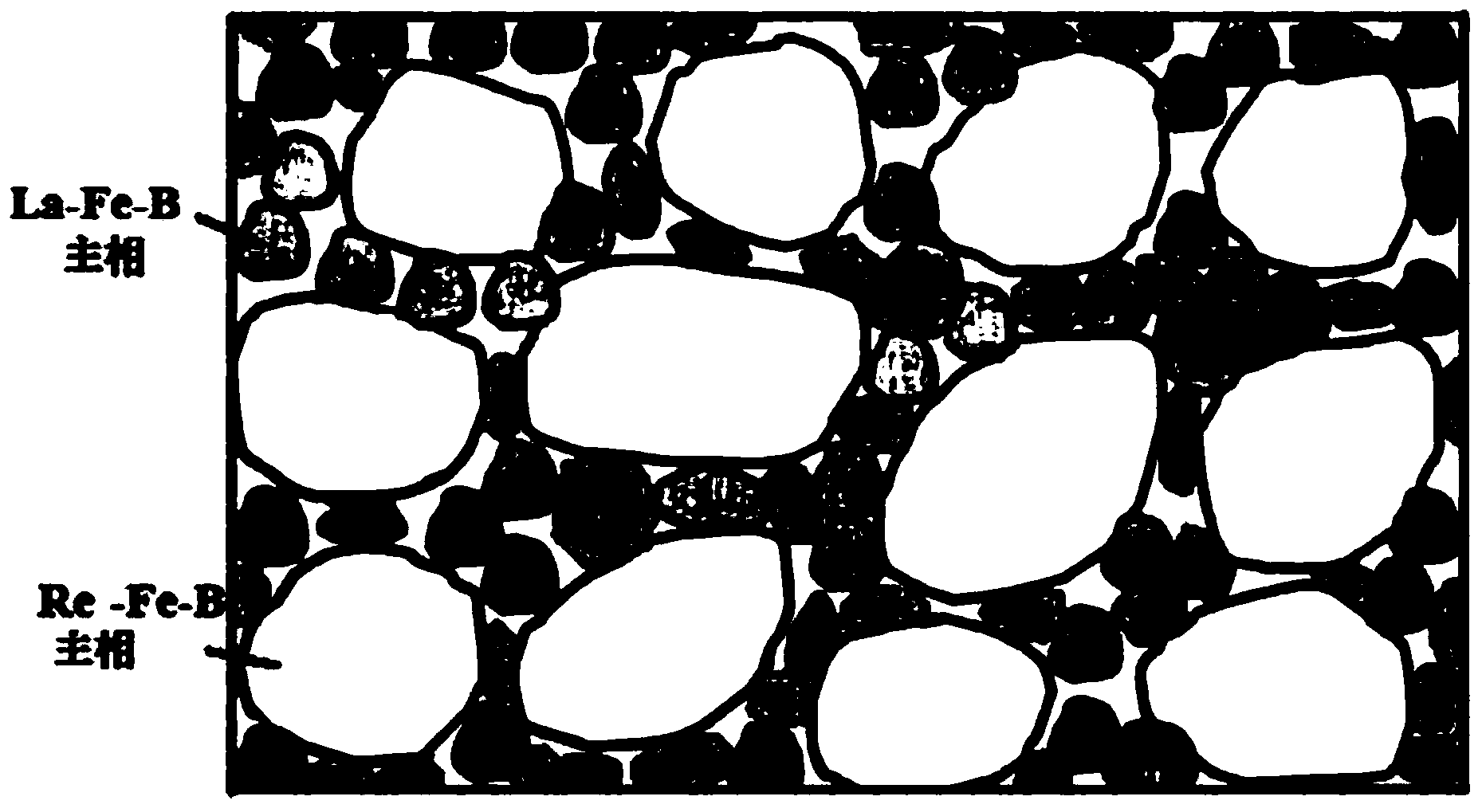

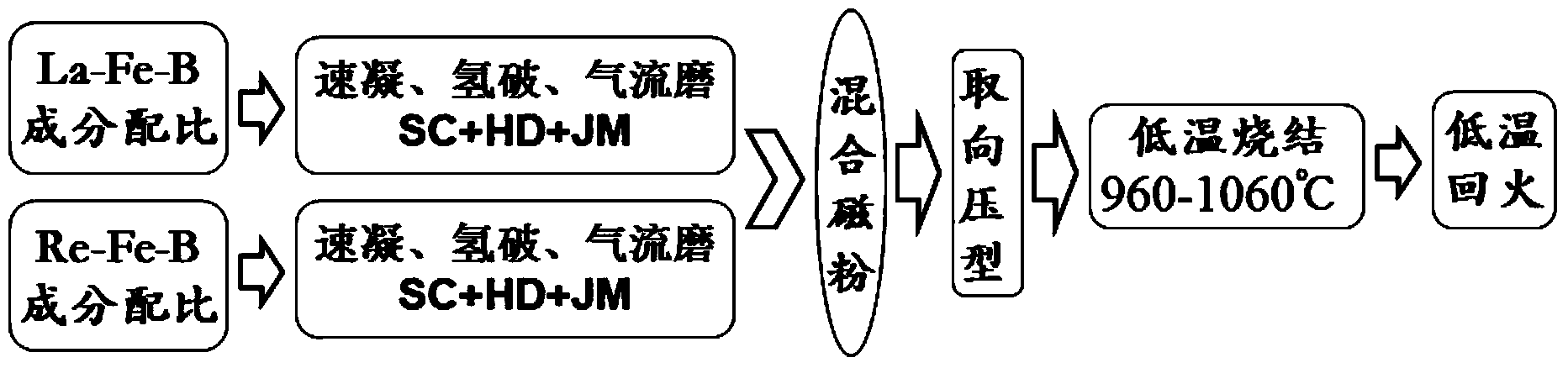

La-Fe-based magnet with double hard-magnetic main phases and preparation method for same

ActiveCN103714939AReduce consumptionReduce manufacturing costPermanent magnetsInductances/transformers/magnets manufactureRare-earth elementAlloy

Owner:CENT IRON & STEEL RES INST

Magnetic recording media and method of forming them

InactiveUS7351445B2Steep distribution of a recording magnetic fieldRecording magnetic field from a single magnetic polar head is increasedConstruction of head windingsBase layers for recording layersHigh densityRecording media

The present invention is directed to carrying out a high density magnetic recording to a material having a large coercive force by perpendicular magnetic recording head.By giving a patterning onto a soft magnetic under layer of a perpendicular two-layer recording media in sync with a period of a recording bit, a magnetic field from a write head can be allowed to converge to a soft magnetic column. Therefore, a magnetization reversal of the magnetic recording media material having a large anisotropic constant becomes possible, and then a high density magnetic recording can be achieved.

Owner:HITACHI LTD

Magnetic recording media and method of forming them

InactiveUS20060226116A1Steep distribution of a recording magnetic fieldRecording magnetic field from a single magnetic polar head is increasedBase layers for recording layersDecorative surface effectsHigh densityRecording media

The present invention is directed to carrying out a high density magnetic recording to a material having a large coercive force by perpendicular magnetic recording head. By giving a patterning onto a soft magnetic under layer of a perpendicular two-layer recording media in sync with a period of a recording bit, a magnetic field from a write head can be allowed to converge to a soft magnetic column. Therefore, a magnetization reversal of the magnetic recording media material having a large anisotropic constant becomes possible, and then a high density magnetic recording can be achieved.

Owner:HITACHI LTD

Z-type hexagonal ferrite material and preparation method thereof

InactiveCN103319165AImprove interactivityIncrease the total magnetic momentRare earth ionsMagnetization

The invention relates to ferrite magnetic materials, and specifically relates to a Z-type hexagonal ferrite material and a preparation method thereof. The Z-type hexagonal ferrite has a molecular formula of Sr3xBa3(1-x)Co2GdyFe24-yO41 or Sr3xBa3(1-x)Co2SmyFe24-yO41, wherein x is greater than 0.4 and smaller than 0.6, and y is greater than 0.05 and smaller than 0.1. According to the invention, with the introduction of rare earth ions, ion interactions can be enhanced, total magnetic moment can be increased, and saturation magnetization can be increased. Also, anisotropy constant is improved, such that higher magnetic permeability can be obtained under a high-frequency condition.

Owner:广东领益智造股份有限公司

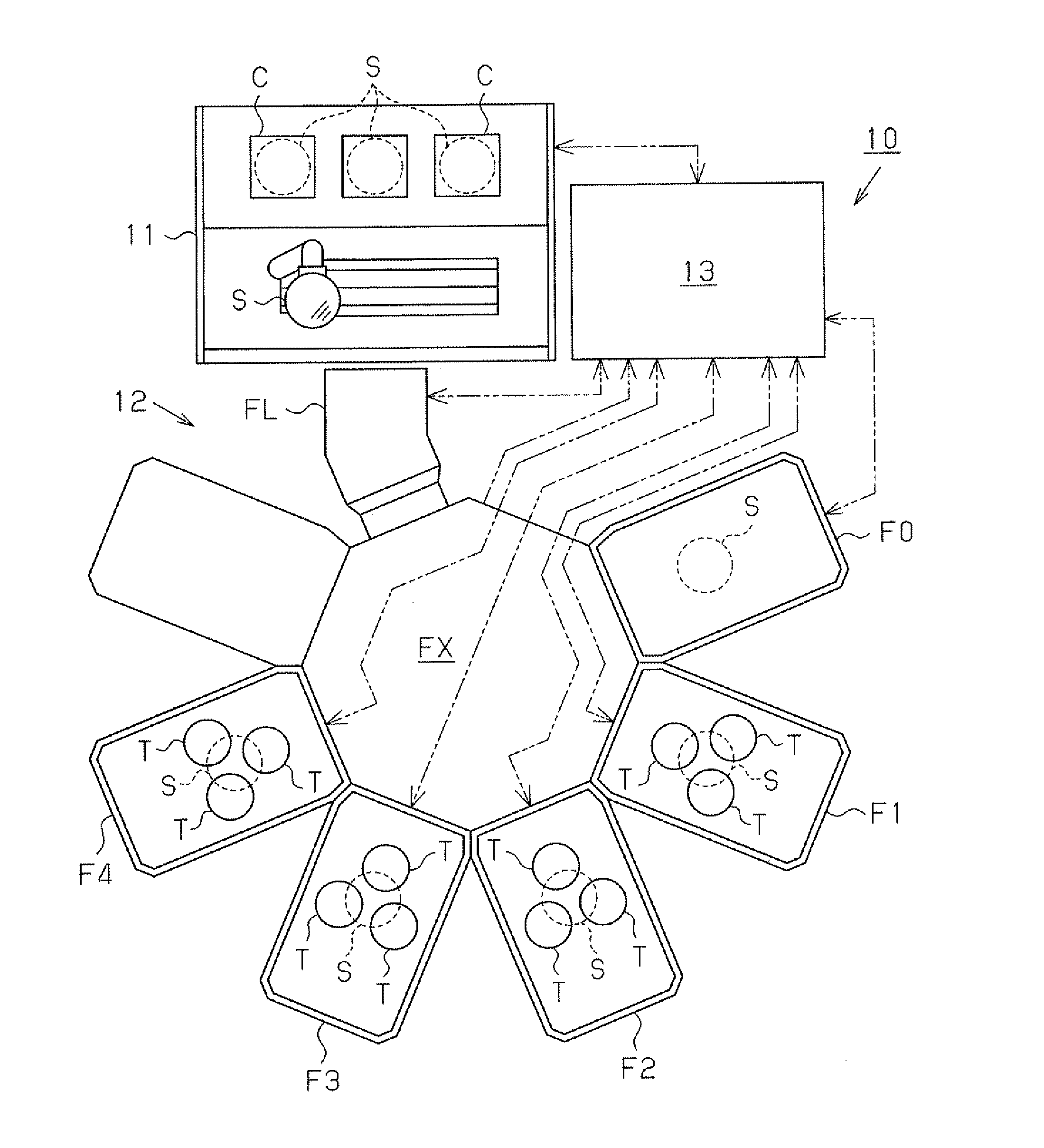

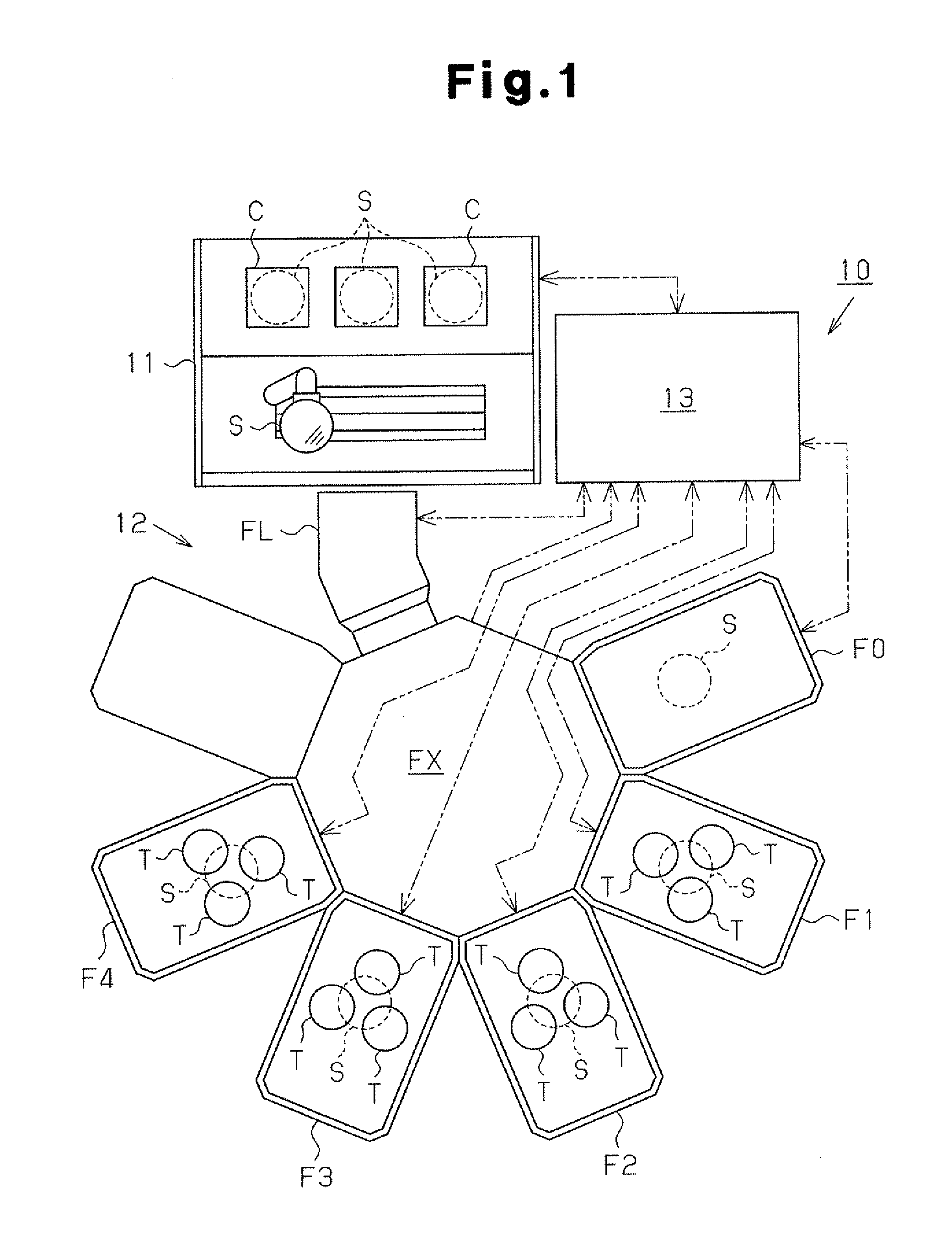

Process for producing magnetic device, apparatus for producing magnetic device, and magnetic device

A magnetic device manufacturing apparatus that increases the unidirectional anisotropy constant (JK). A substrate (S) is placed in a substrate holder (24) in a film formation area (21a), the substrate (S) is heated to a predetermined temperature, and the processing pressure is reduced to 0.1 (Pa) or lower. A target (T2) of which a main component is an element forming the antiferromagnetic layer is sputtered with at least either one of Kr and Xe to form an antiferromagnetic layer. The antiferromagnetic layer includes an L12 ordered phase expressed by compositional formula Mn100-X-MX (where M is at least one element selected from the group consisting of Ru, Rh, Ir, and Pt, and X is 20(atom %)≦X≦30(atom %)).

Owner:ULVAC INC

Magnetic recording medium and magnetic recording and reproducing device

InactiveUS20100046116A1Protective coatings for layersRecord information storageInter layerNon magnetic

The invention relates to a magnetic recording medium comprises a nonmagnetic substrate on which at least a soft magnetic under layer, an orientation adjusting layer that controls the orientation of a layer just thereon, a vertical magnetic layer with an axis of easy magnetization being mainly oriented vertically to the nonmagnetic substrate and a protective layer are disposed, the vertical magnetic layer is constituted of three or more layers including a lower layer, an intermediate layer and an upper layer from the substrate side, wherein the lower, intermediate and upper magnetic layers are constituted of magnetic particles which are columnar crystals extending continuously from the lower layer to the upper layer, the magnetic recording medium further comprises a nonmagnetic layer between the lower and intermediate magnetic layers or between the intermediate and upper magnetic layers, wherein the upper layer has a magnetic anisotropic constant (Ku) ranging from 0.8×106 to 4×106 (erg / cc), the intermediate layer has a magnetic anisotropic constant (Ku) ranging from 2×106 to 7×106 (erg / cc) and the lower layer has a magnetic anisotropic constant (Ku) ranging from 1×106 to 4×106 (erg / cc), and the lower, intermediate and upper magnetic layers are bound by ferro-coupling.

Owner:SHOWA DENKO KK

Transverse exchange-coupled magnetic information storage medium material and preparation method thereof

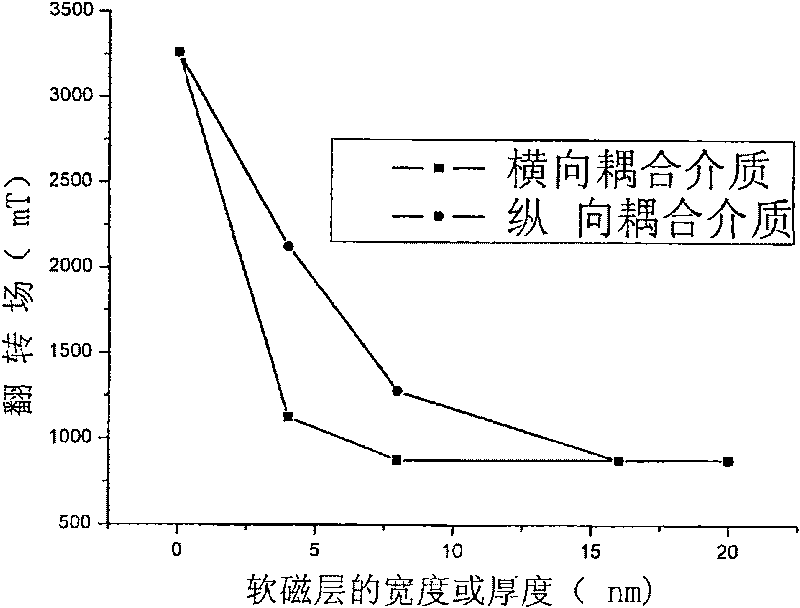

InactiveCN101202145ASolve write problemsStable record bitMagnetic materials for record carriersMagnetic layersElectronIon implantation

The invention relates to a super-high density magnetic information memorizing technique, belonging to the electronic material technique field. A magnetic information memorizing unit of the invention is formed by a horizontal exchanging and coupling of high / low anisotropy constants magnetic films. When in preparation, the high anisotropy constants magnetic film is firstly prepared and then is partially modified through an ion implantation or ion diffusion process after anneal treatment to decrease the anisotropy and coercive forces of the modified part so as to form the low anisotropy constants magnetic film. Finally, the high / low anisotropy constants magnetic films are coupled along the horizontal direction to form the magnetic information memorizing medium material of the horizontal exchange coupling. The invention overcomes the defects of a vertical exchange coupling compound magnetic information memorizing medium that an enlarged distribution of the information memorizing unit switch field and a decrease of the information recording stability are caused by interface diffusion and deterioration of memorizing layer in a high temperature treatment process. The invention can further decrease the switch field of the information memorizing unit, therefore, the information recording can be more stable, so as to satisfy the requirement of the super-high density magnetic information memorizing.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

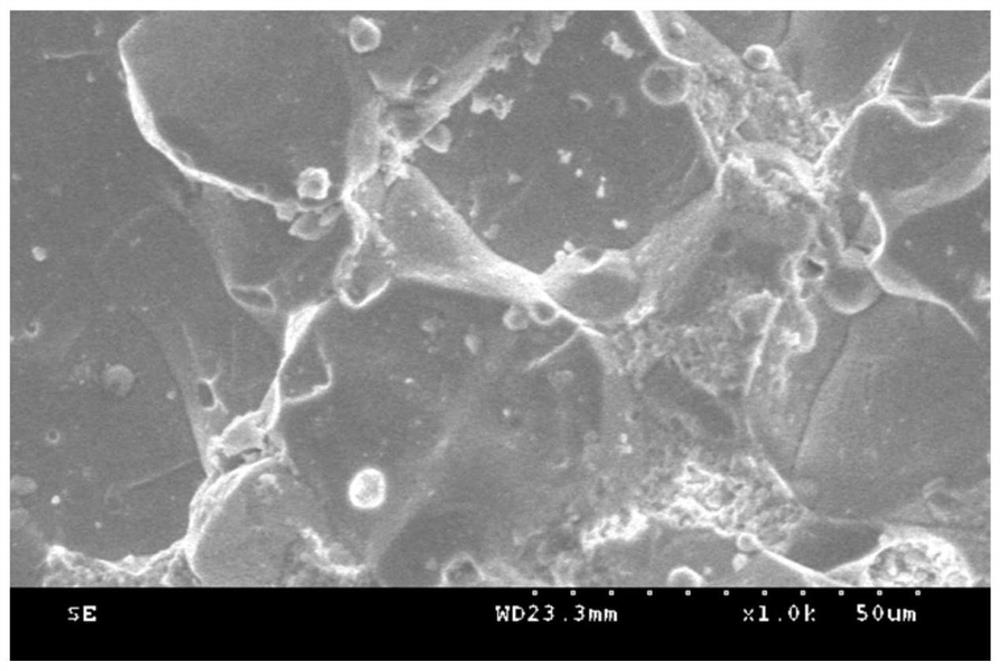

Electromagnetic interference resistant Mn-Zn ferrite magnet material and preparation method thereof

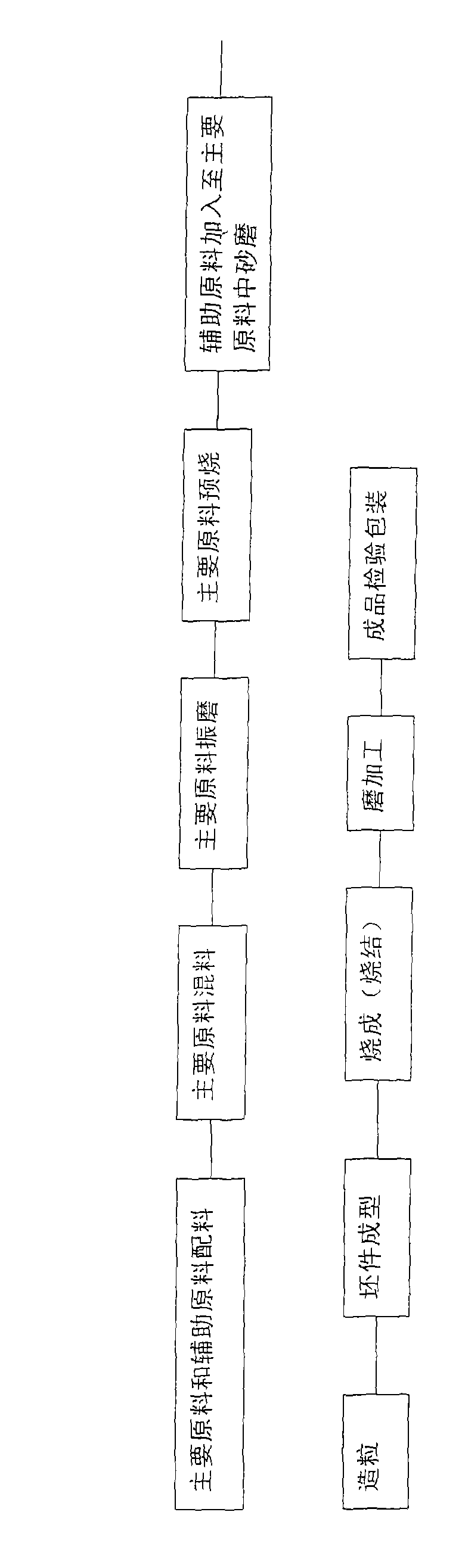

InactiveCN101651001AReasonable choiceReasonable ratioInorganic material magnetismHysteresisHigh resistivity

The invention relates to an electromagnetic interference resistant Mn-Zn ferrite magnet material which belongs to the technical field of magnetic materials and processing thereof. The Mn-Zn ferrite magnet material contains main raw materials, including 52.5-53.6 mol percent of ferric oxide, 22.8-24.0 mol percent of manganese oxide and 21.5-24.3 mol percent of zinc oxide, and also contains auxiliary raw materials, including 500-1,200 ppm of titanium oxide, 700-1,000 ppm of calcium oxide and 200-800 ppm of molybdenum oxide which are added into the main raw materials. The invention can save energy, improve resistivity, reduce eddy-current loss, a magnetocrystallite anisotropy constant and hysteresis loss, and improve magnetic conductivity temperature, frequency characteristics and high-frequency performance. A good firing process curve is selected from a firing working procedure, and the Mn-Zn ferrite magnet material has favorable electromagnetic interference resistance.

Owner:SUZHOU GUANDA MAGNET

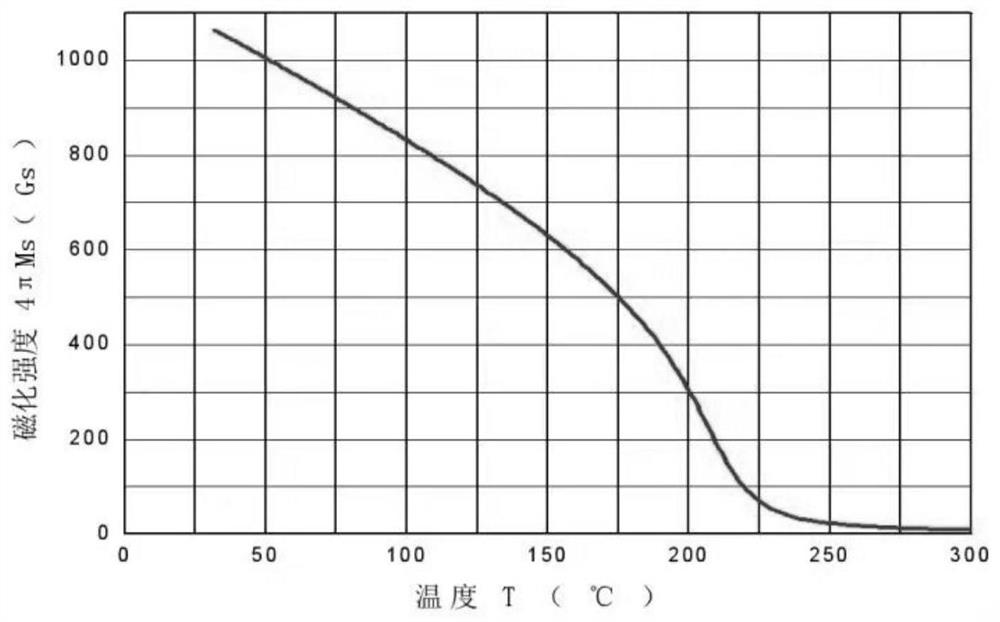

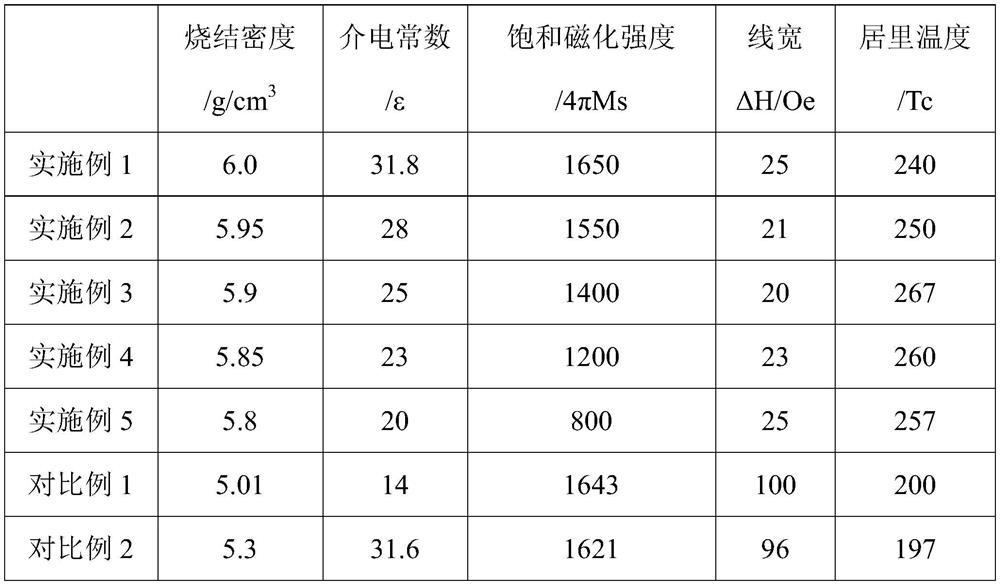

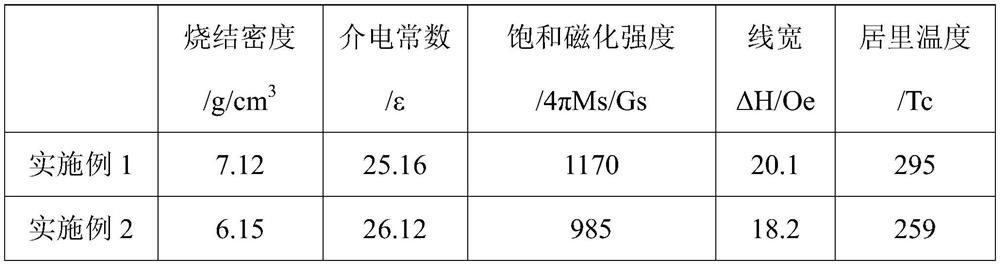

Low-saturation narrow-linewidth gyromagnetic material and preparation method thereof

InactiveCN112390638AIncrease line widthHigh dielectric constantInorganic material magnetismInductances/transformers/magnets manufactureOctahedronLine width

The invention relates to a low-saturation narrow-linewidth gyromagnetic material and a preparation method thereof. The gyromagnetic material comprises the following elements: BiAYBGd(3A-B-2a-2c-d)Ca(2a+2c+d+f)Fe(5-a-b-c-d-e-f)VaAlbNbbZrcIndSneMnfO12, wherein 0.8<=A<=1.4, 1.6<=B<=2.2, 0<=a<=0.8, 0.001<=b<=0.28, 0<=c<=0.75, 0<=d<=0.7, 0<=e<=0.7, 0<=f<=0.7, and 0<=g<=0.7. According to the microwave iron oxide provided by the invention, through reasonable design of components, the gyromagnetic material has the properties of low saturation, low loss, narrow linewidth, high Curie temperature and high dielectric constant by adjusting the content of each element, and the maximum substitution amount of Bi <3+> is controlled to be 1.4 mol. Zr <4+> is doped to replace octahedral Fe <3+>, the anisotropy constant K1 is reduced, so that the line width is reduced, Nb <5+> replaces Fe <3+> to inhibit the generation of other phases, V <5+> replaces Fe <3+> to reduce 4pi Ms, and meanwhile, the Curie temperature is not deteriorated.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Perpendicular magnetic recording medium

ActiveUS8329321B2High densityHigh recordabilityRecord information storageMagnetic recordingCouplingRecording layer

A perpendicular magnetic recording medium is disclosed that achieves improved recordability without deteriorating thermal stability by reducing the switching field. A perpendicular magnetic recording medium of the invention has a first magnetic recording layer and a second magnetic recording layer between with is interposed a coupling layer that ferromagnetically couples the two layers. The first and second magnetic recording layers satisfy an inequality Ku1T1>Ku2T2 in the case where Hk1 >Hk2 and an inequality Ku1T1<Ku2T2 in the case where Hk1<Hk2, where Hk1 and Hk2 are anisotropy magnetic fields, Ku1 and Ku2 are uniaxial anisotropy constants, and T1 and T2 are thicknesses of the first magnetic recording layer and the second recording layer, respectively. An exchange coupling energy between the magnetic recording layers is preferably at least 5×10−3 erg / cm2. Advantageously, the coupling layer is mainly composed of a material selected from V, Cr, Fe, Co, Ni, Cu, Nb, Mo, Ru, Rh, Ta, W, Re, and Ir, and has a thickness of at most 2 nm. At least one of the magnetic recording layers preferably has a granular structure.

Owner:FUJI ELECTRIC CO LTD

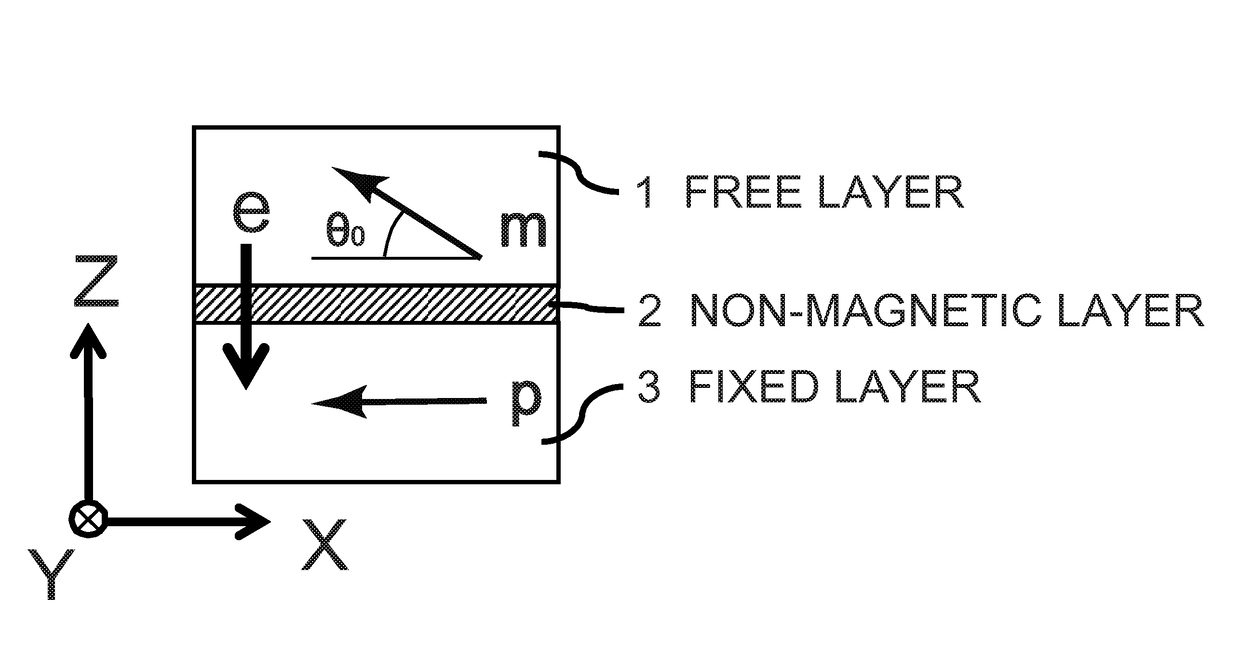

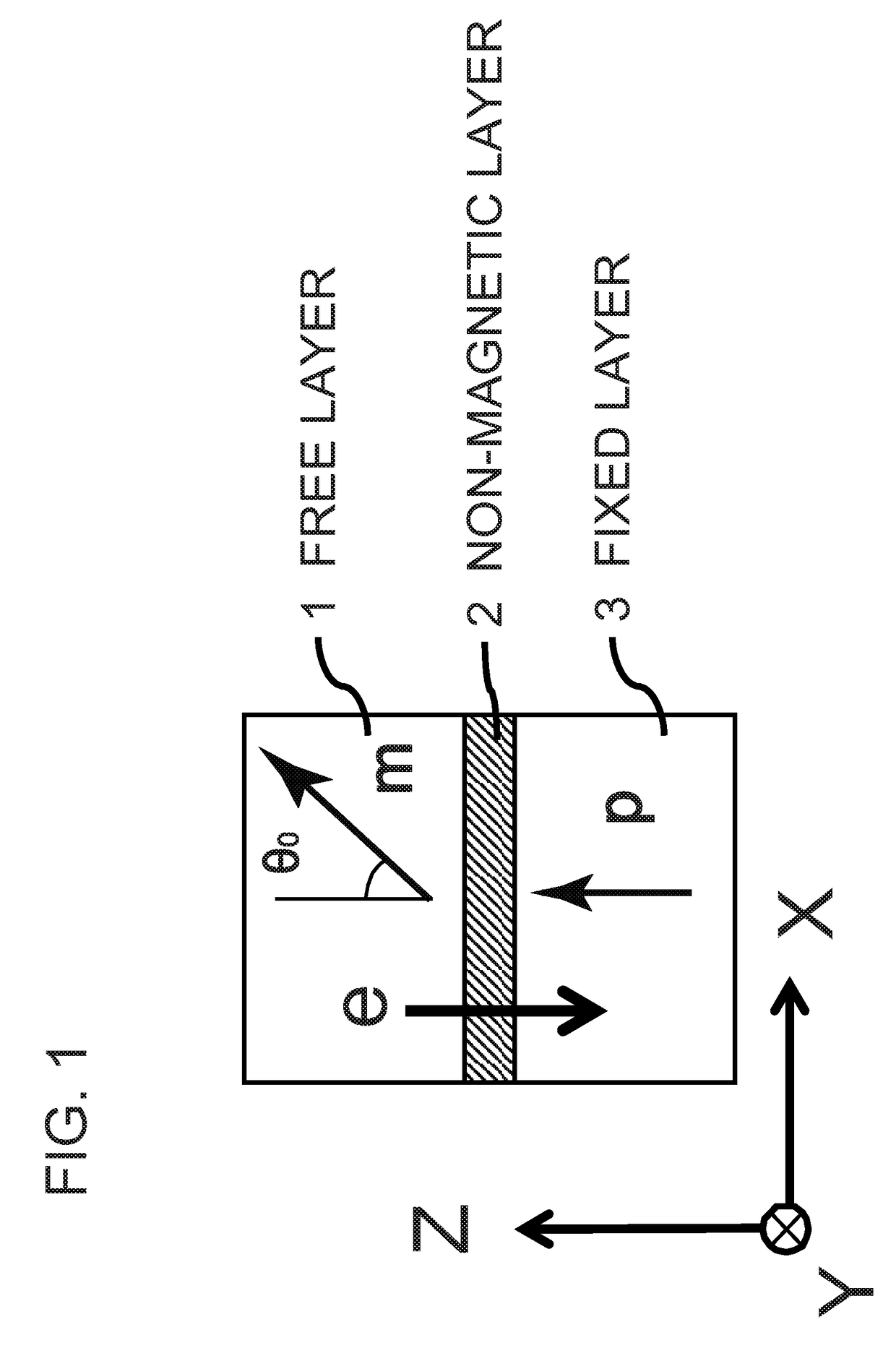

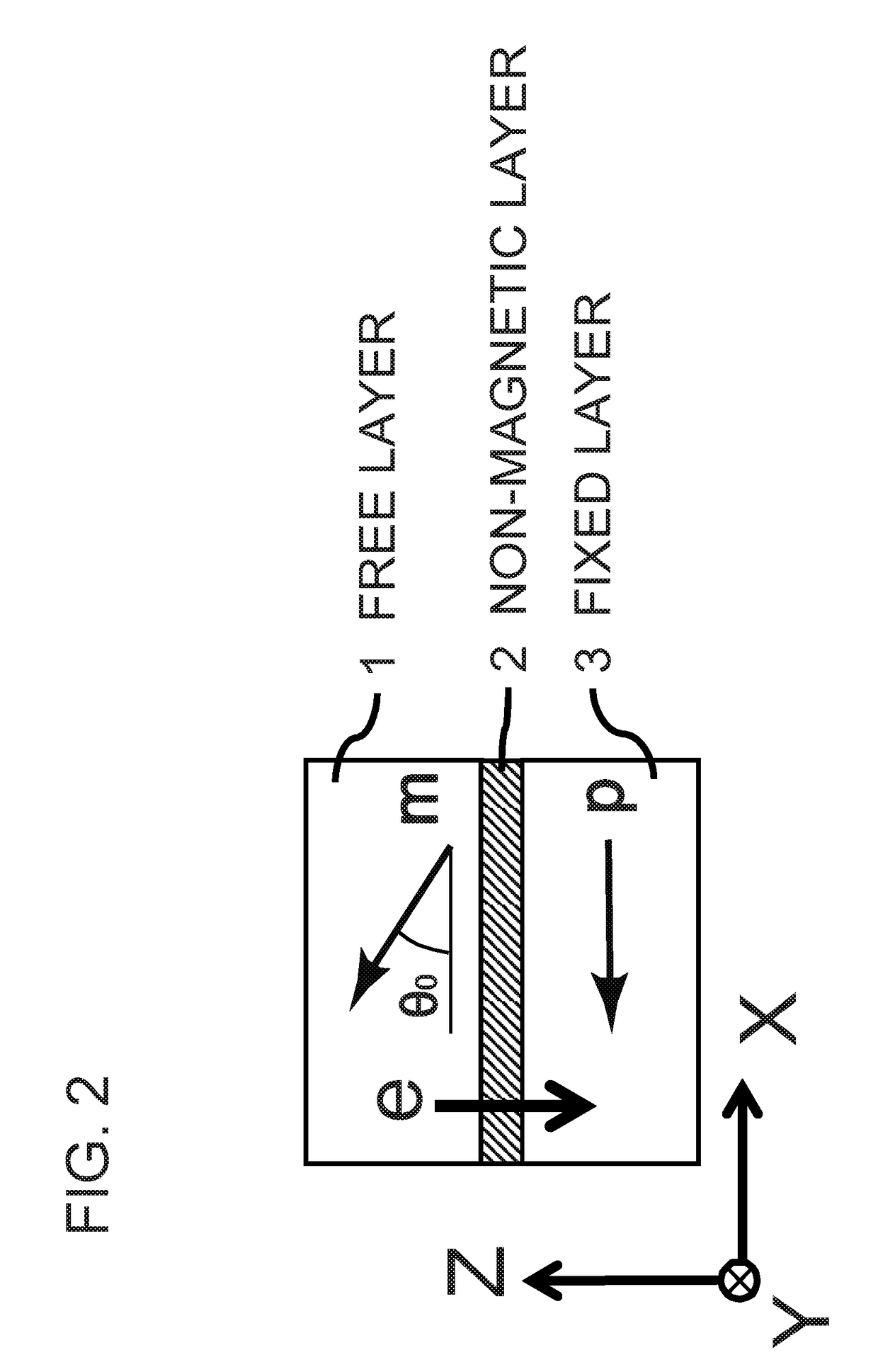

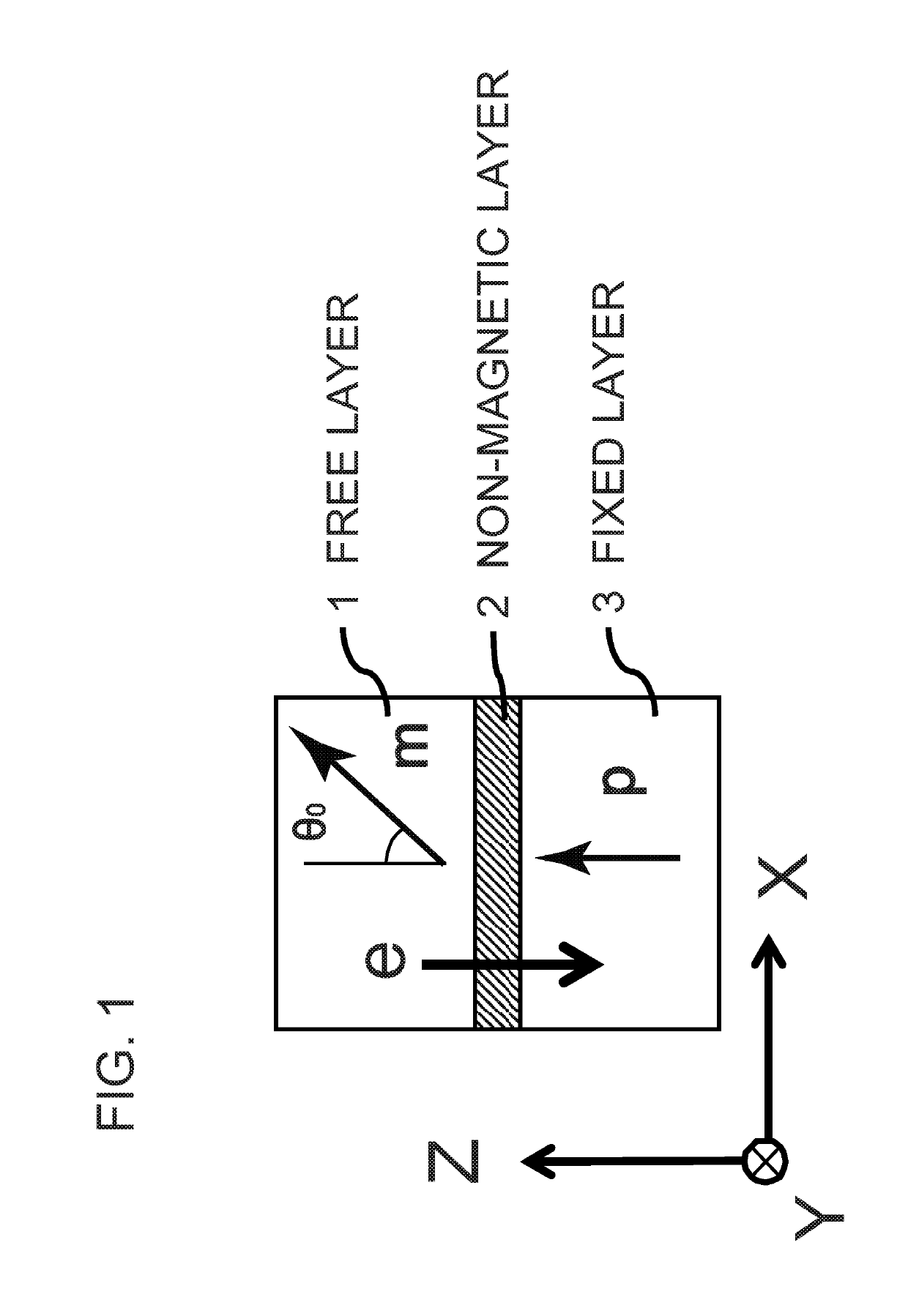

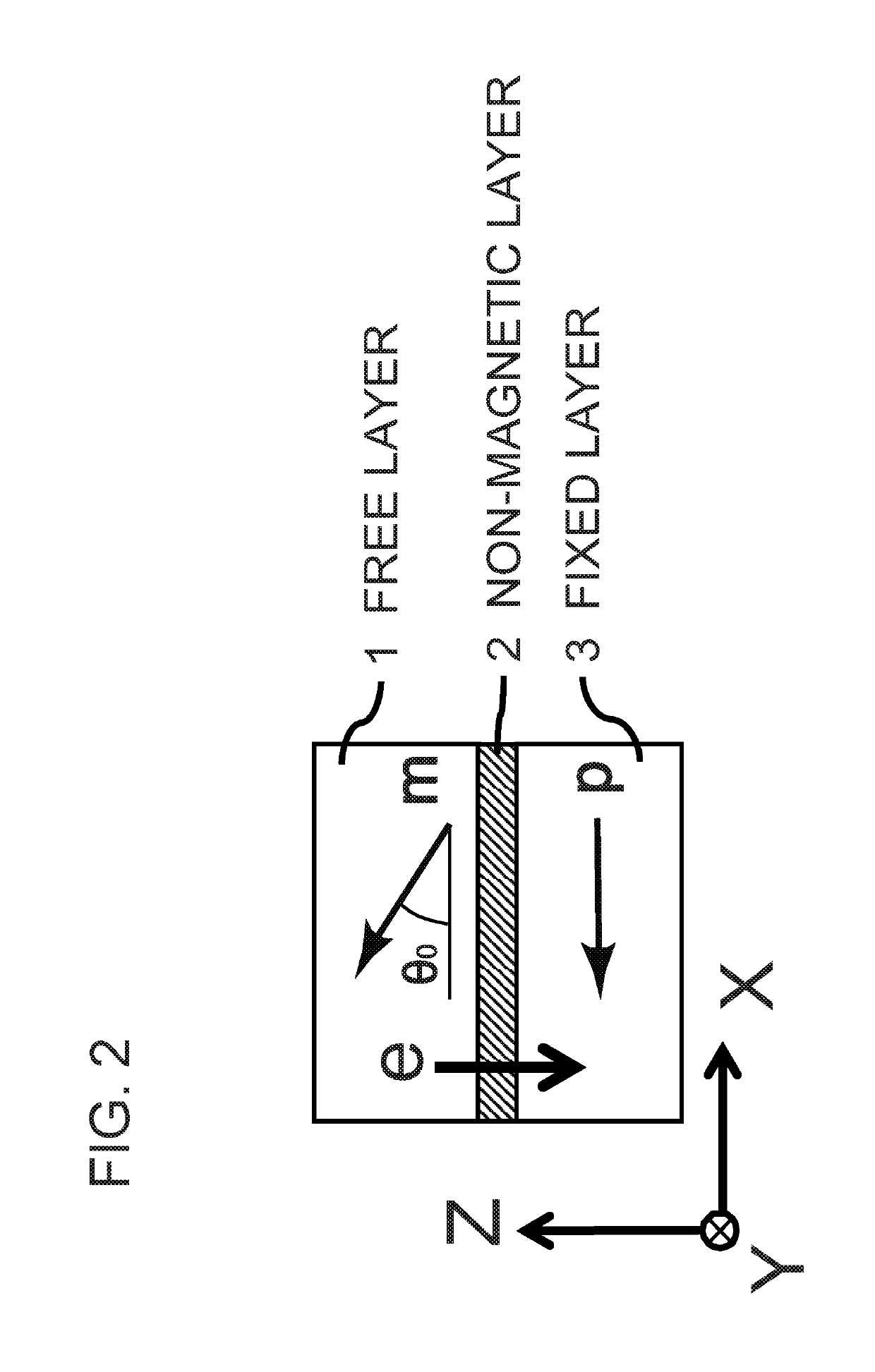

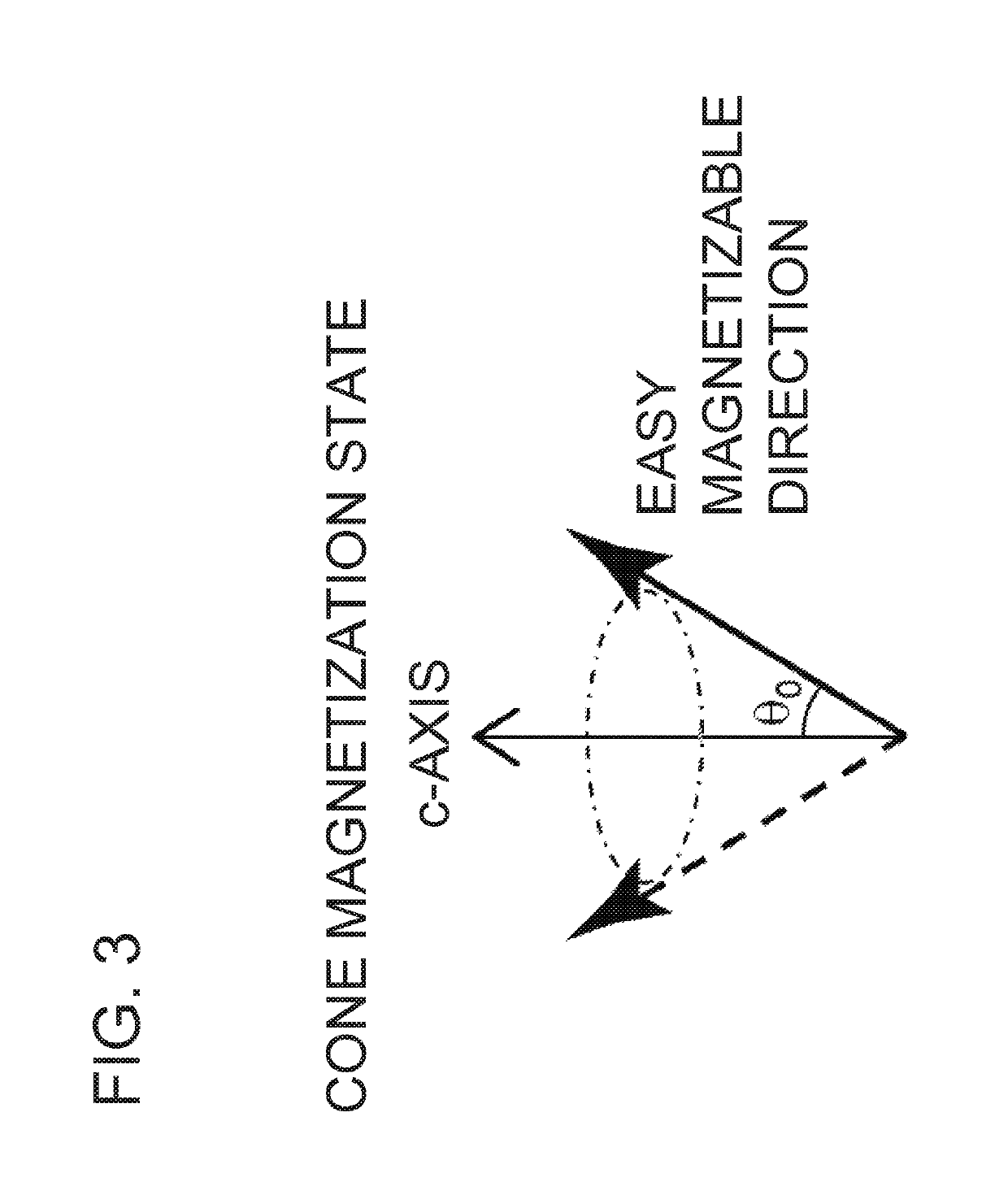

Non-collinear magnetoresistive device

ActiveUS20180151214A1Direction easyMagnetic-field-controlled resistorsGalvano-magnetic material selectionMagnetizationNon magnetic

A non-collinear magnetoresistive device, includes: a free layer; a fixed layer; and a non-magnetic layer disposed between the free layer and the fixed layer, wherein the fixed layer has an easy magnetization direction in an in-plane direction or in a perpendicular direction, the free layer satisfies at room temperature expressions (1) and (2) below:ERT≥1.66×10−19 J (1)V≤5×104 nm3 (2)where ERT=(Ku1,eff+Ku2+Ku1,eff2 / 4Ku2)×V, Ku1,eff: an effective first-order anisotropy constant, Ku2: a second-order anisotropy constant, and V: a volume, and wherein the free layer is in a cone magnetization state.

Owner:NAT INST OF ADVANCED IND SCI & TECH

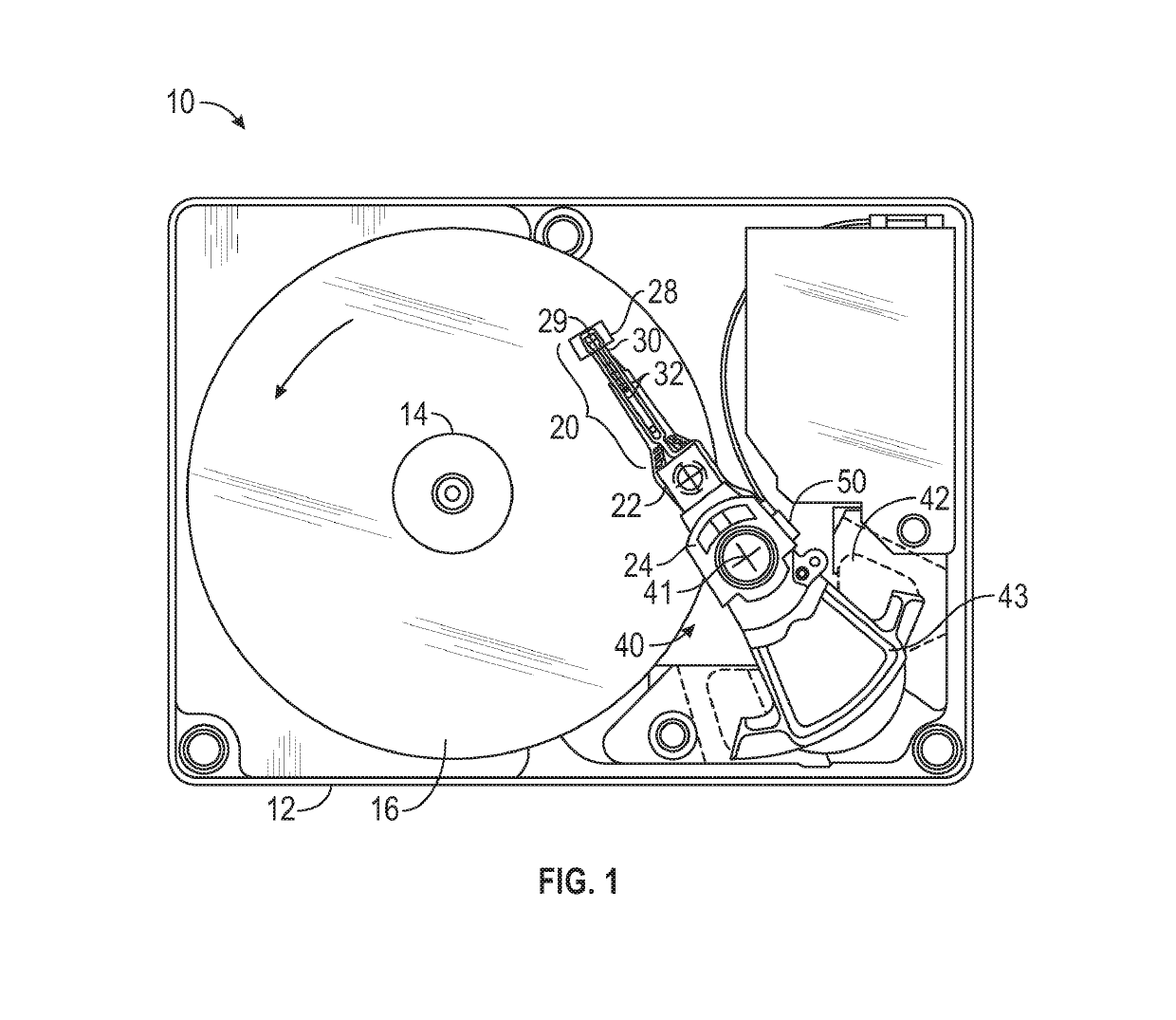

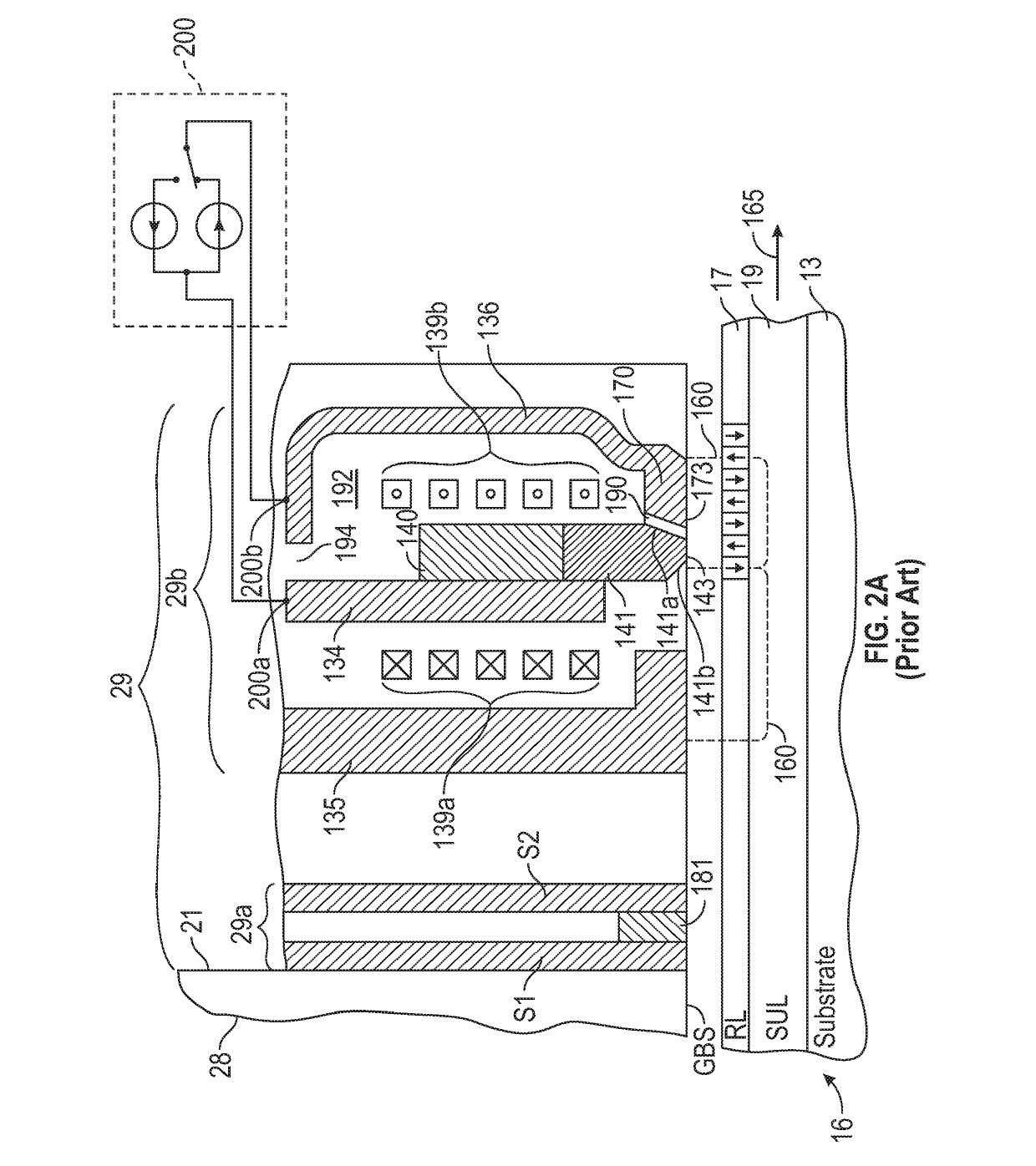

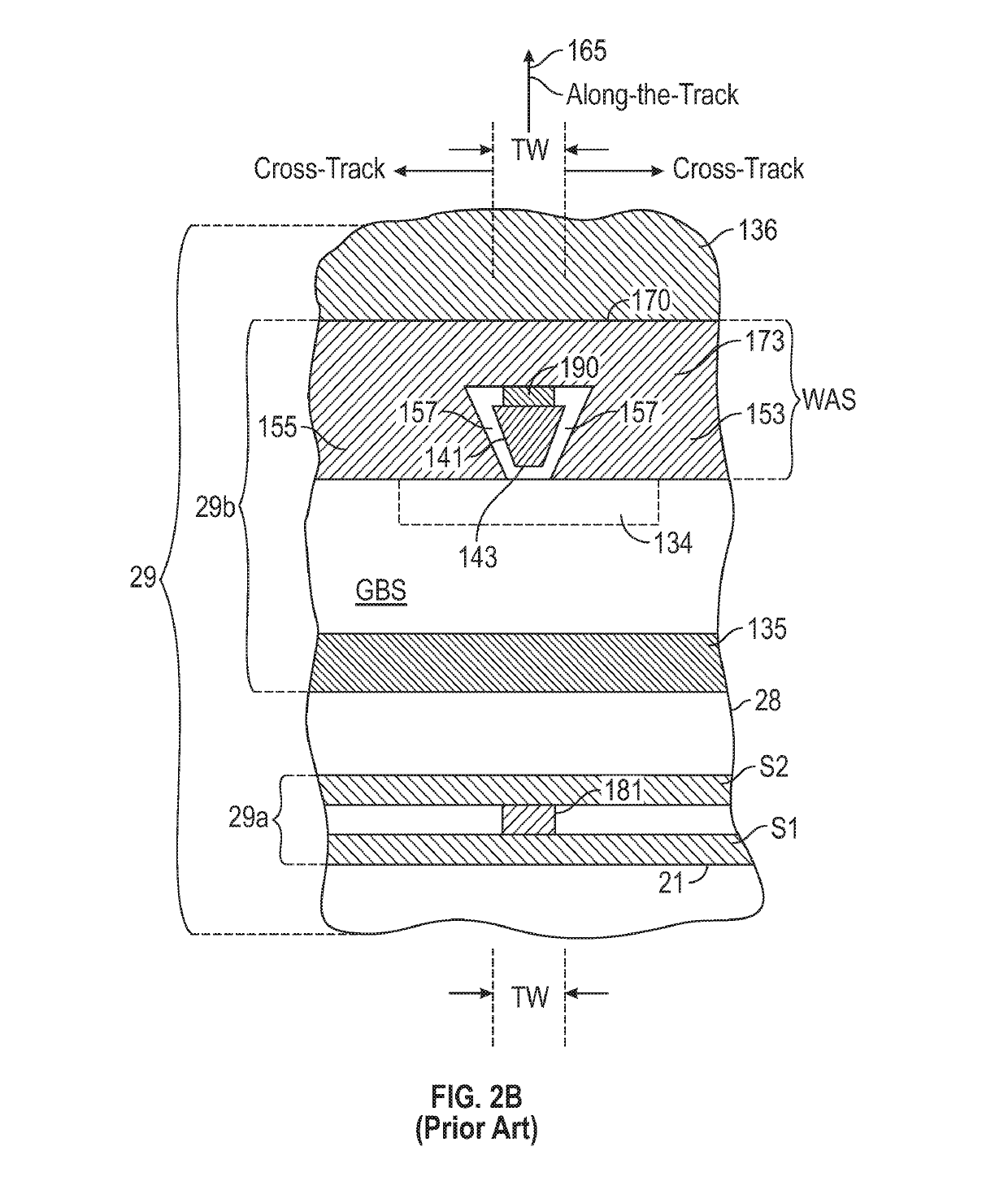

Magnetic recording write head with write pole having a tapered trailing end section with negative magnetic anisotropy

ActiveUS10762919B1Degrade writabilityReduction in fluxHeads using thin filmsRecord information storageRecording layerLayer thickness

A perpendicular magnetic recording write head includes a main portion formed of conventional high-moment magnetic materials, and a beveled or tapered trailing portion formed of a Co / Fe multilayer with negative magnetic anisotropy (negative anisotropy constant or —Ku). The Co / Fe multilayer tapered trailing portion has a high saturation magnetization (Ms) and thus functions as part of the write pole to direct the flux perpendicularly to the recording layer. Also, the —Ku Co / Fe multilayer tapered trailing portion has its hard axis oriented substantially orthogonal to the layer thickness and thus substantially prevents flux leakage into the write gap. The —Ku Co / Fe multilayer may also be formed on the sides of the write pole in the cross-track direction to prevent flux leakage into the side gaps.

Owner:WESTERN DIGITAL TECH INC

Non-collinear magnetoresistive device

ActiveUS10388347B2Magnetic-field-controlled resistorsGalvano-magnetic material selectionSoftware engineeringMagnetization

Some embodiments are directed to a non-collinear magnetoresistive device, including a free layer; a fixed layer; and a non-magnetic layer disposed between the free layer and the fixed layer, wherein the fixed layer has an easy magnetization direction in an in-plane direction or in a perpendicular direction, the free layer satisfies at room temperature expressions (1) and (2) below:ERT≥1.66×10−19 J (1)V≤5×104 nm3 (2)where ERT=(Ku1,eff+Ku2+Ku1,eff2 / 4Ku2)×V, Ku1,eff: an effective first-order anisotropy constant, Ku2: a second-order anisotropy constant, and V: a volume, and wherein the free layer is in a cone magnetization state.

Owner:NAT INST OF ADVANCED IND SCI & TECH

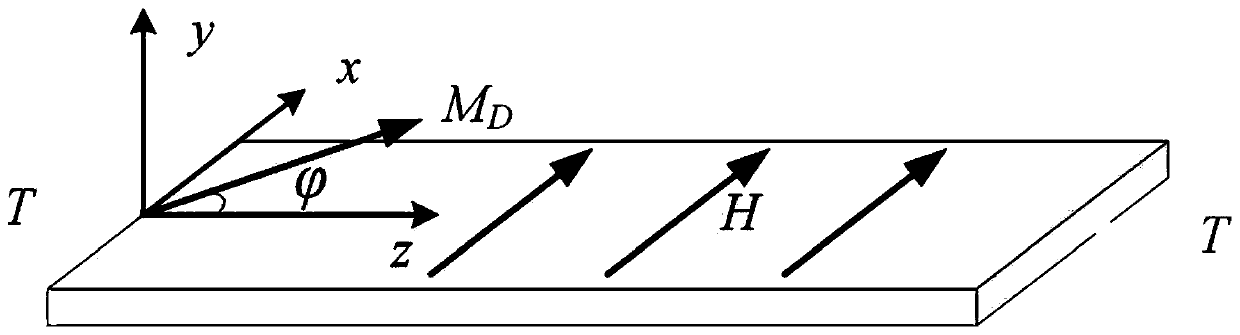

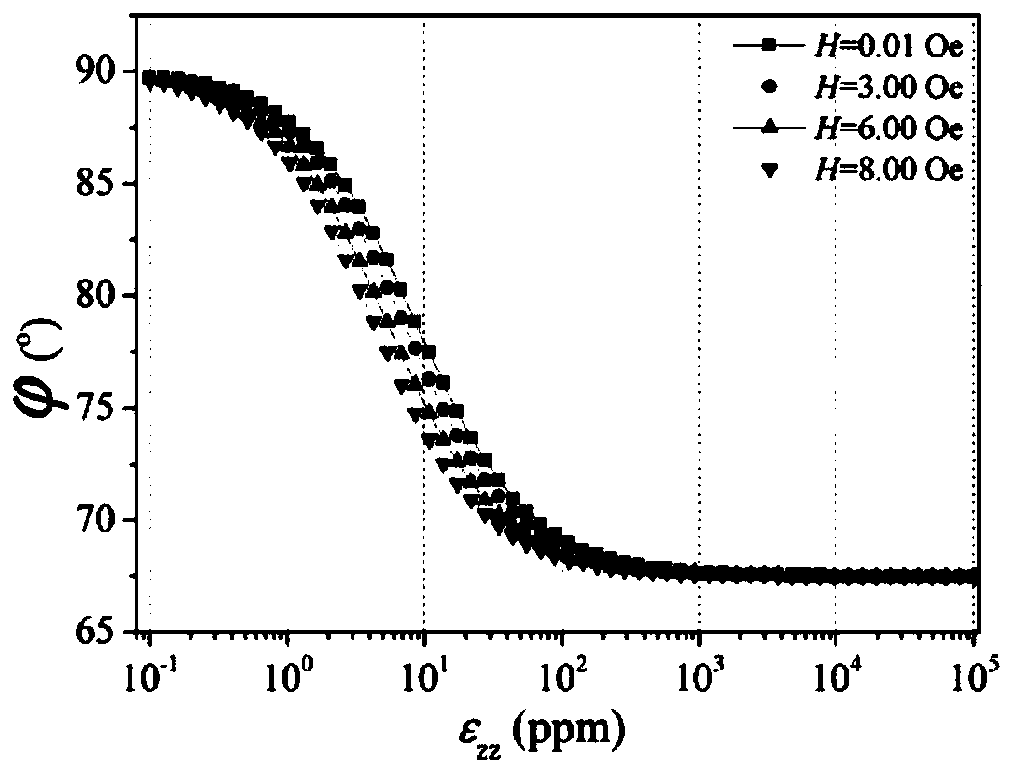

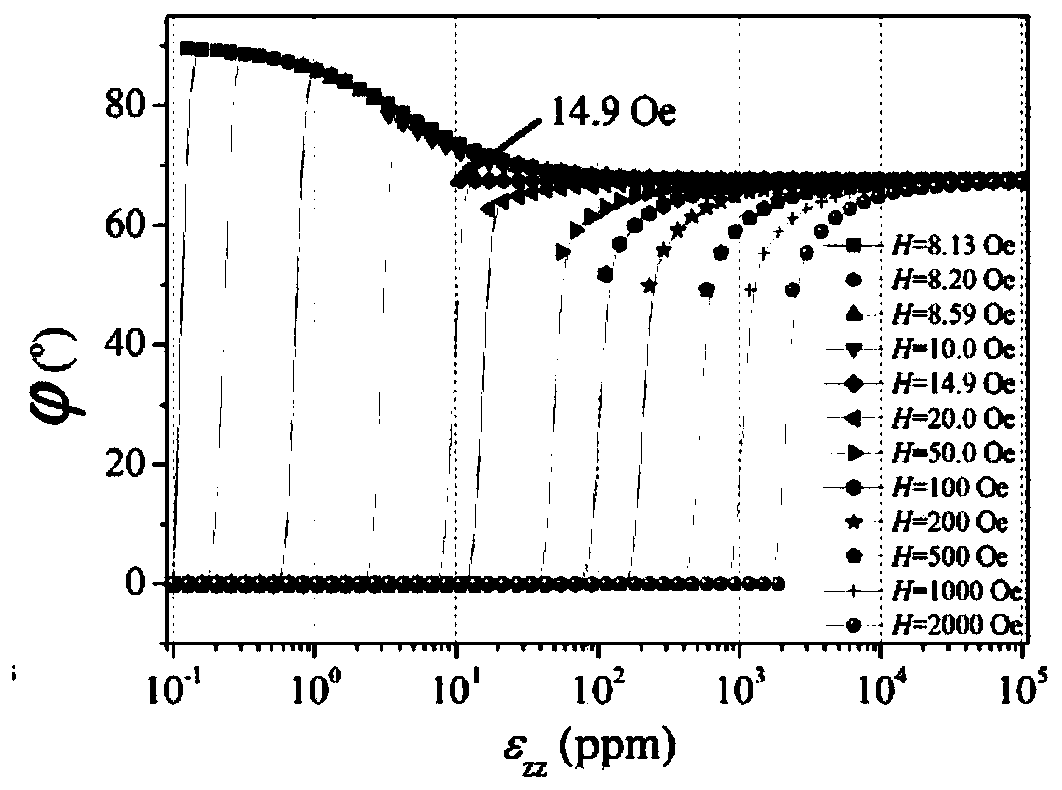

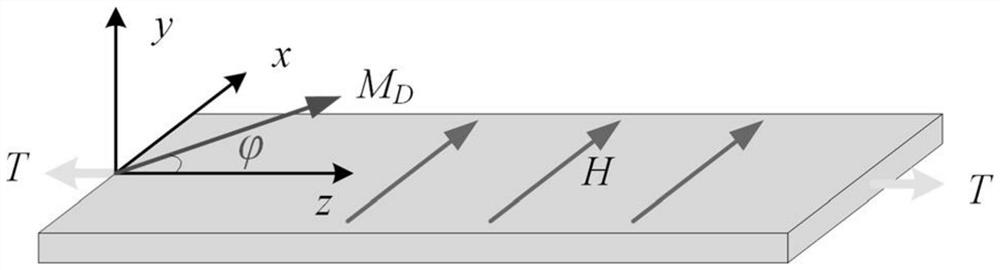

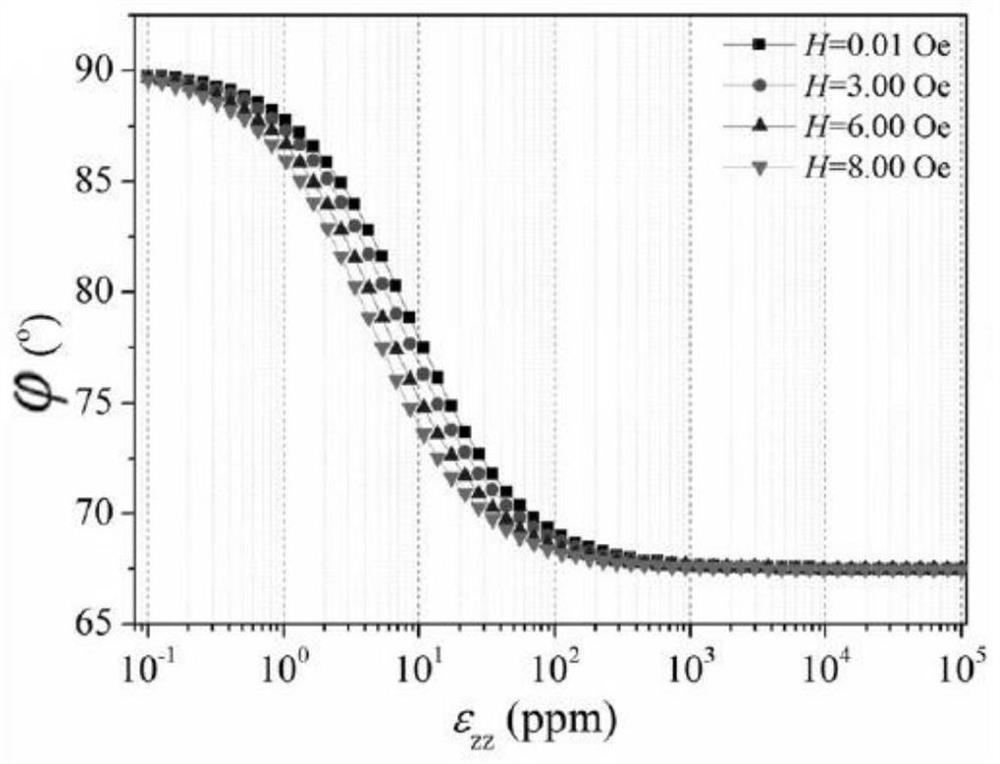

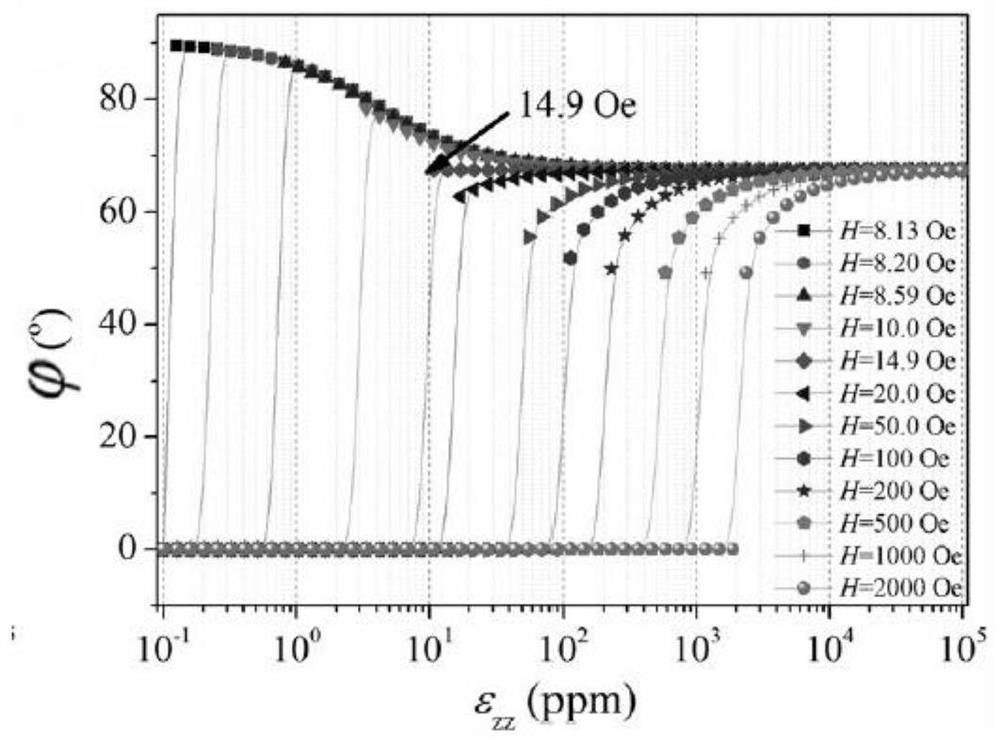

Determination method of optimal DC bias magnetic field value based on DC bias magnetic field

A determination method of an optimal DC bias magnetic field value based on a DC bias magnetic field comprises the following steps in sequence: determining the magnetization of a material in a steady state in the DC bias magnetic field by using a principle of minimum energy, establishing a single domain physical model, using a numerical calculation method to determine the steady state of the material under the DC bias magnetic field, and determining the magnitude of the DC bias magnetic field when the sensitivity of a device reaches optimal. The determination method has the beneficial effect that for different types of materials, anisotropy constants K and MD of the materials also can affect the selection of the optimal DC bias magnetic field, and analysis can be performed by the same method.

Owner:TSINGHUA UNIV

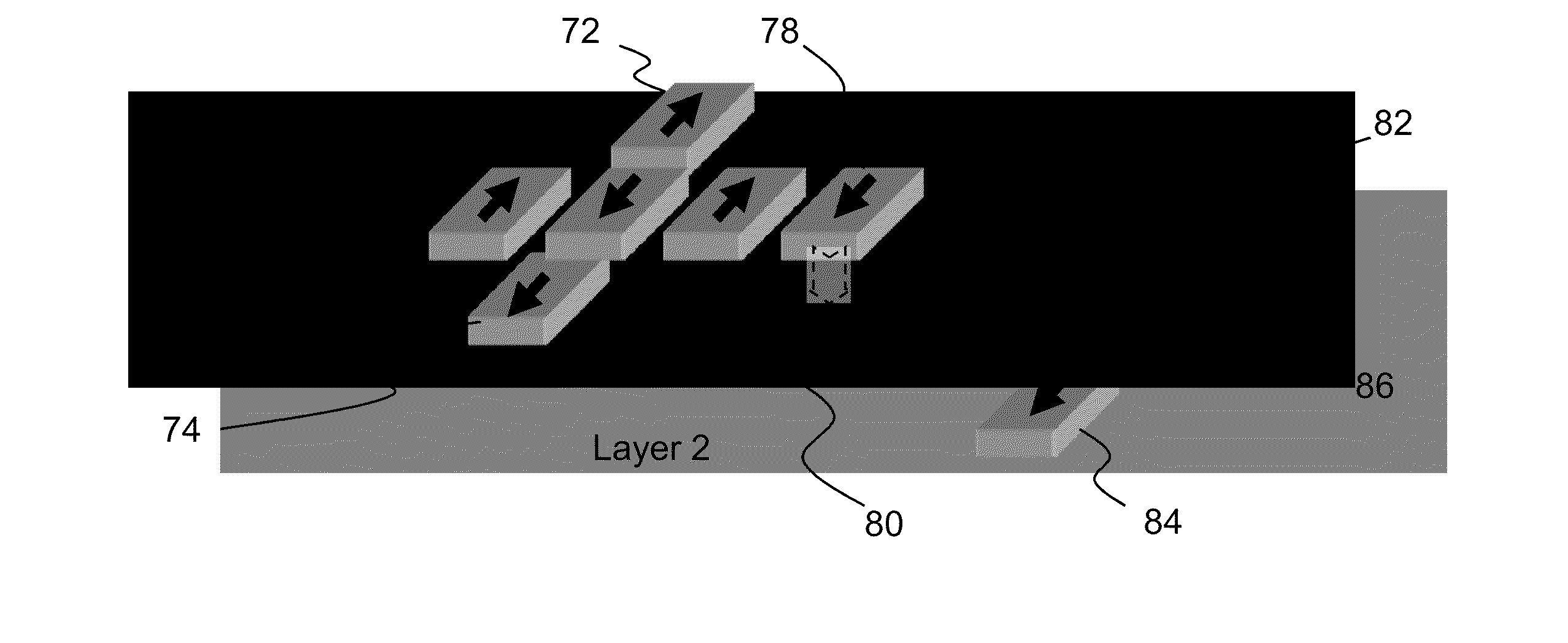

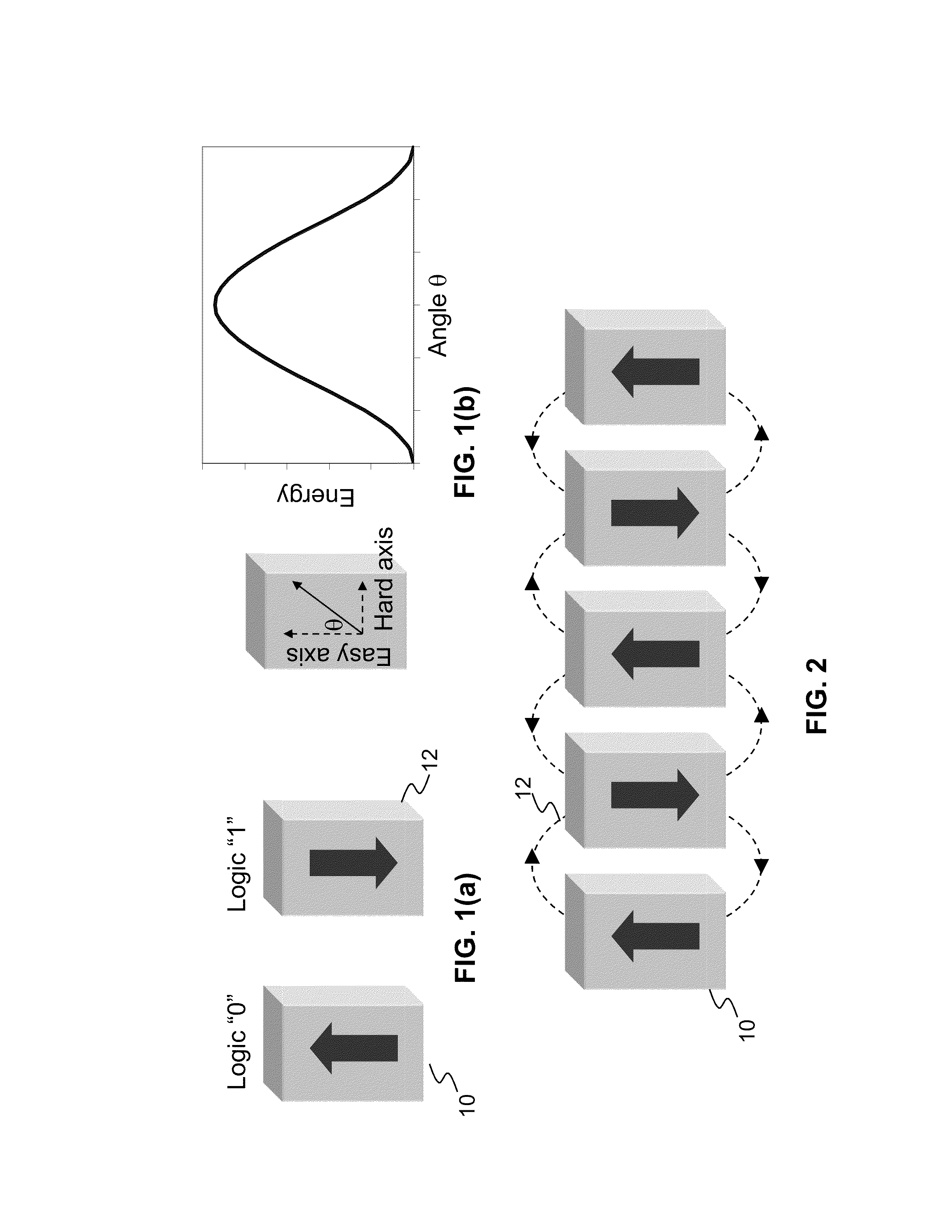

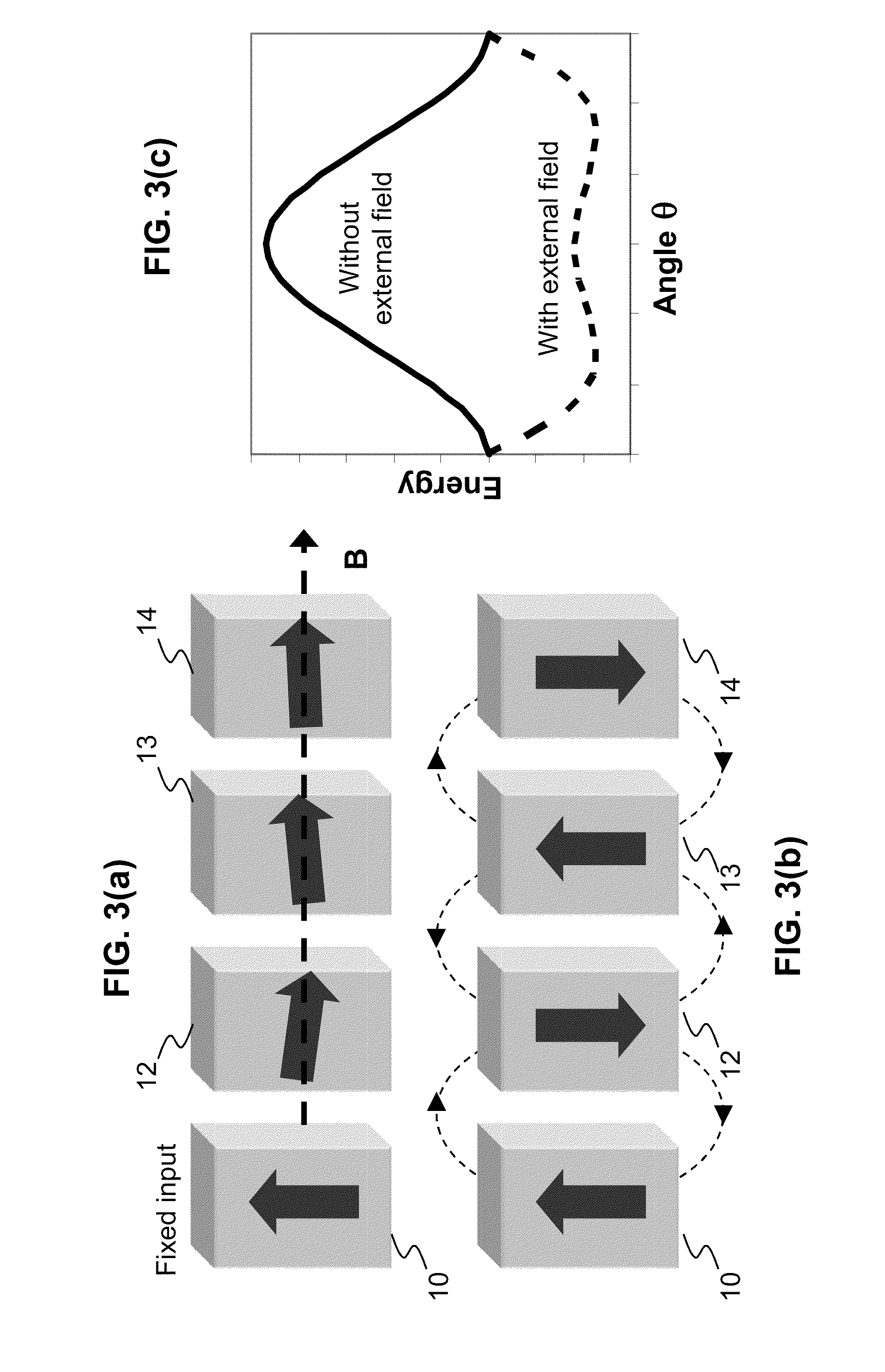

Signal control elements in ferromagnetic logic

A chain of field coupled nanomagnets includes at least one elements having substantially different anisotropy energy from that of the other nanomagnets. A signal can propagate from a first input nanomagnet having a relatively high anisotropy energy through the chain to an output nanomagnet. The output nanomagnet may have a relatively lower anisotropy energy than the other nanomagnets. Signal flow direction thus can be controlled. The higher anisotropy energy nanomagnet may be attained by use of a ferromagnet material having a higher anisotropy constant and / or configured with a larger volume than the other elements. The lower anisotropy energy magnet may be attained by use of a ferromagnet material having a lower anisotropy constant and / or configured with a smaller volume than the other elements. Logic signal flow control can also be attained making use of three dimensional geometries of nanomagnets with two different orientations.

Owner:GLOBALFOUNDRIES INC

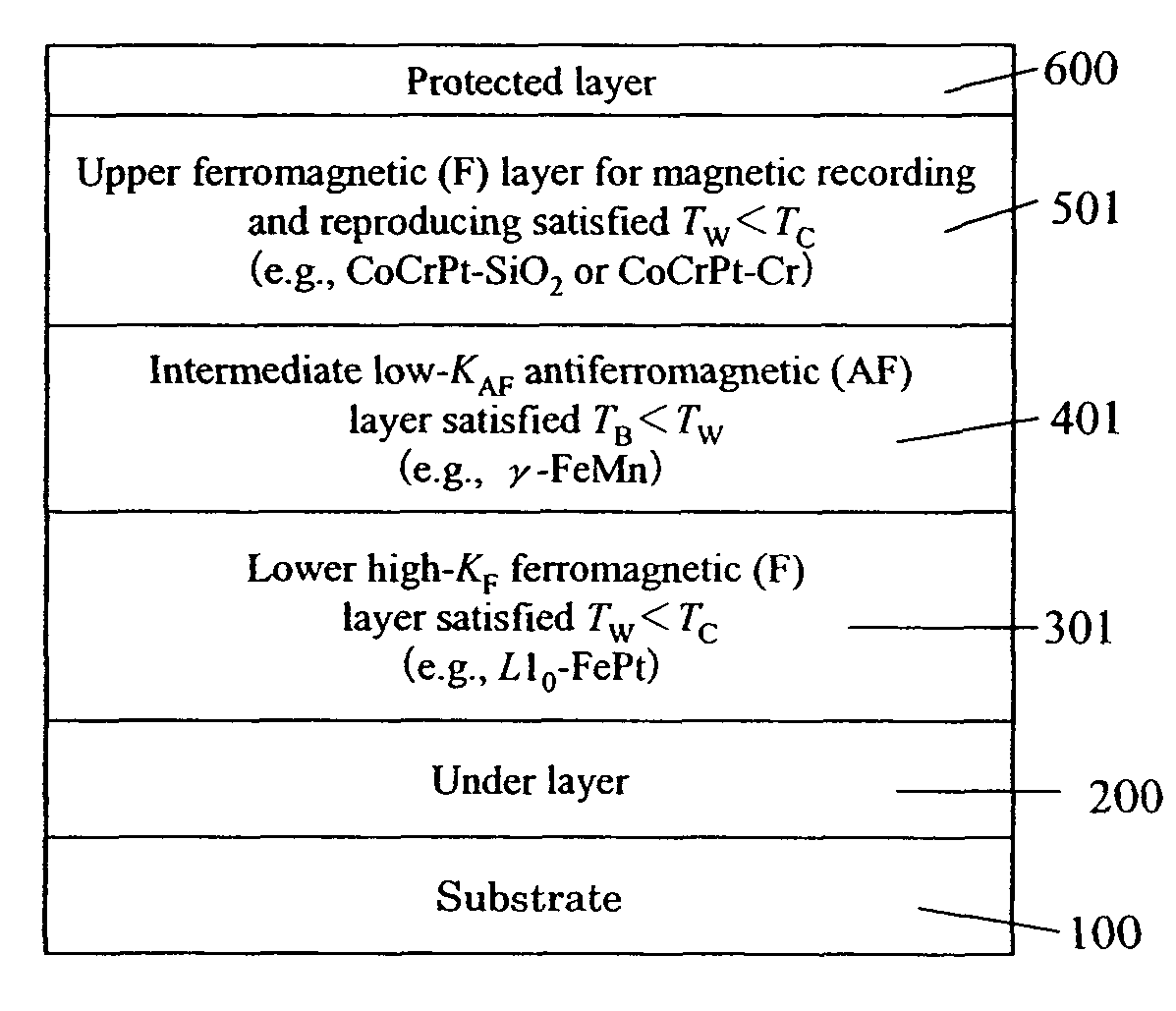

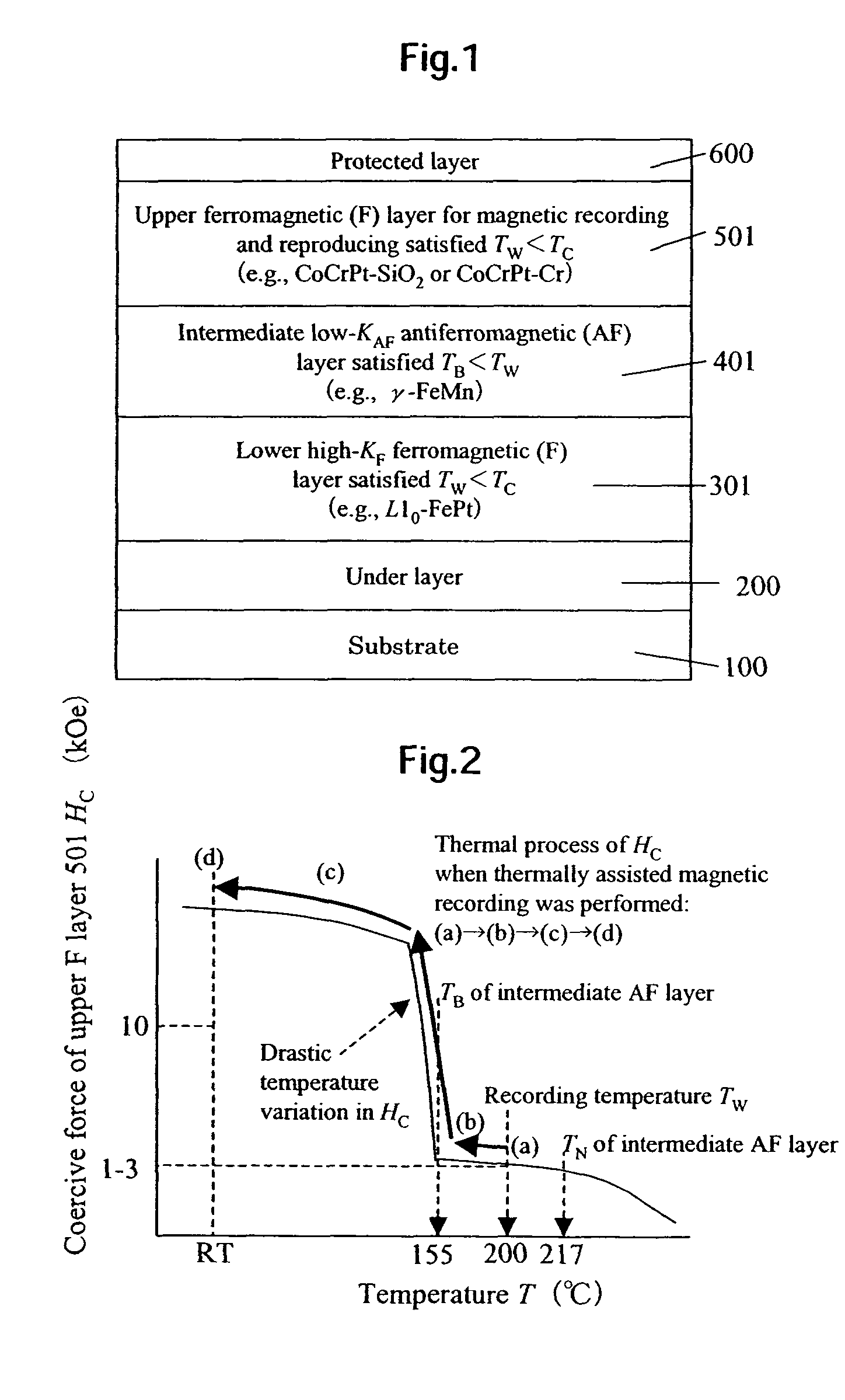

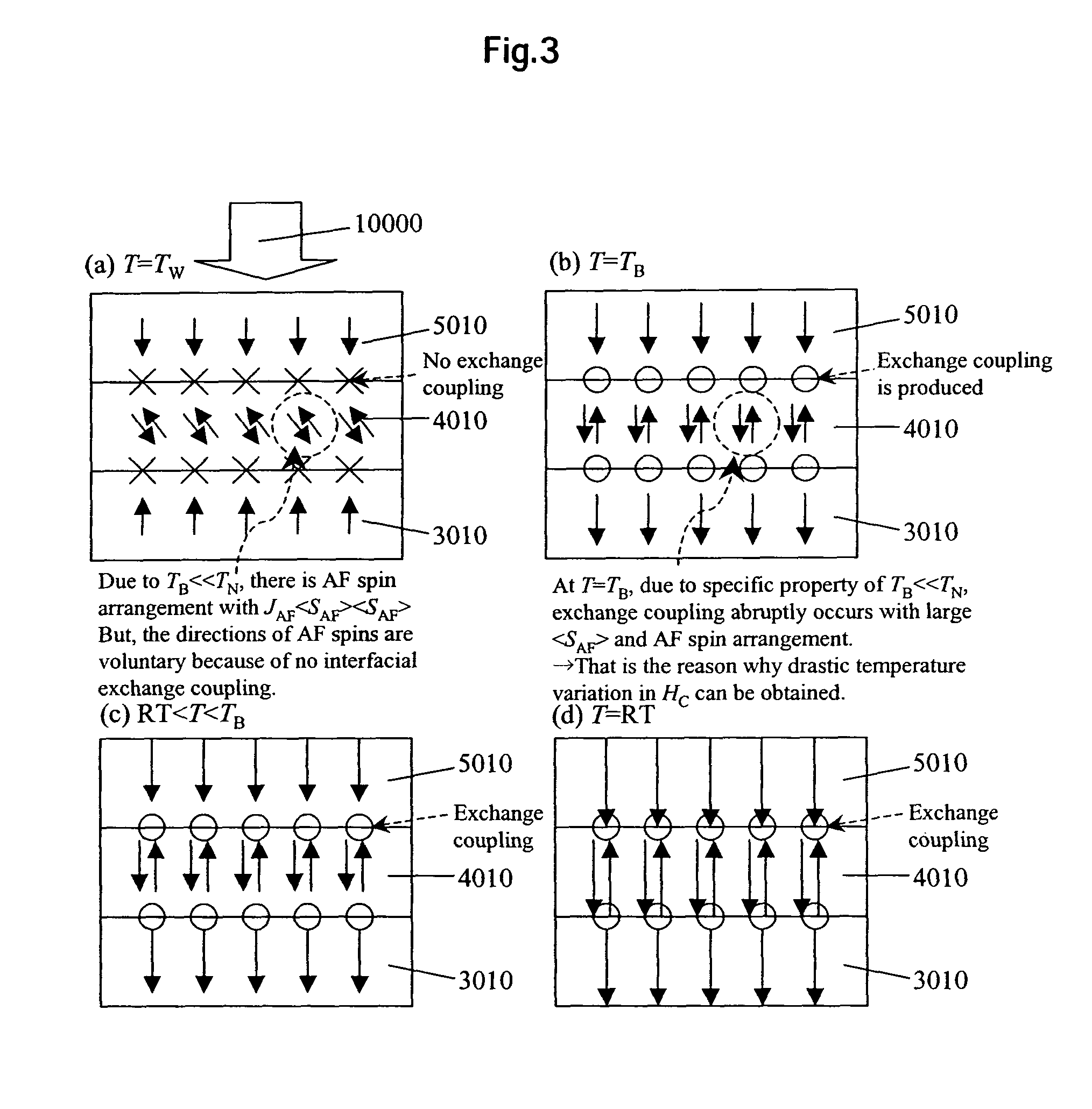

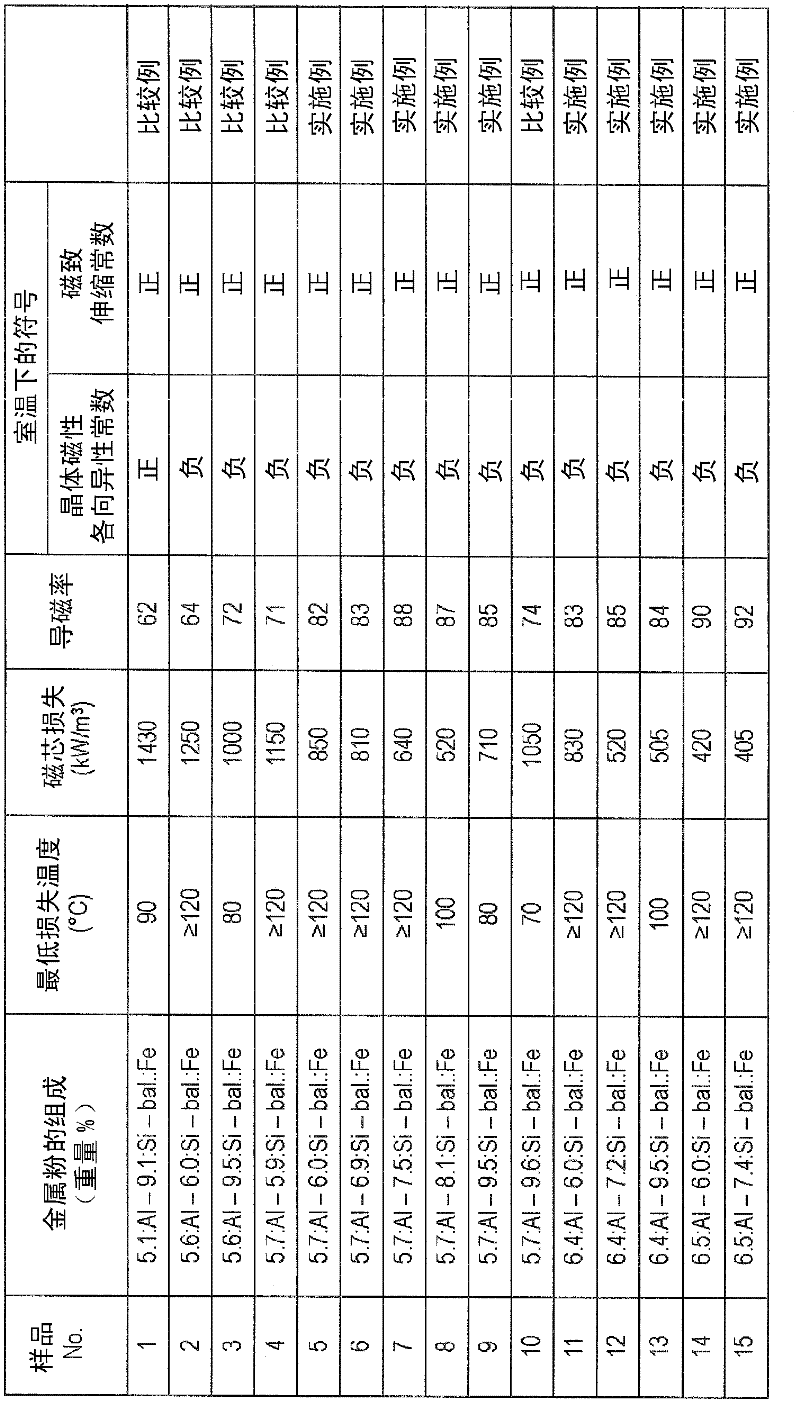

Thermally assisted magnetic recording media and magnetic recording and reproducing apparatus

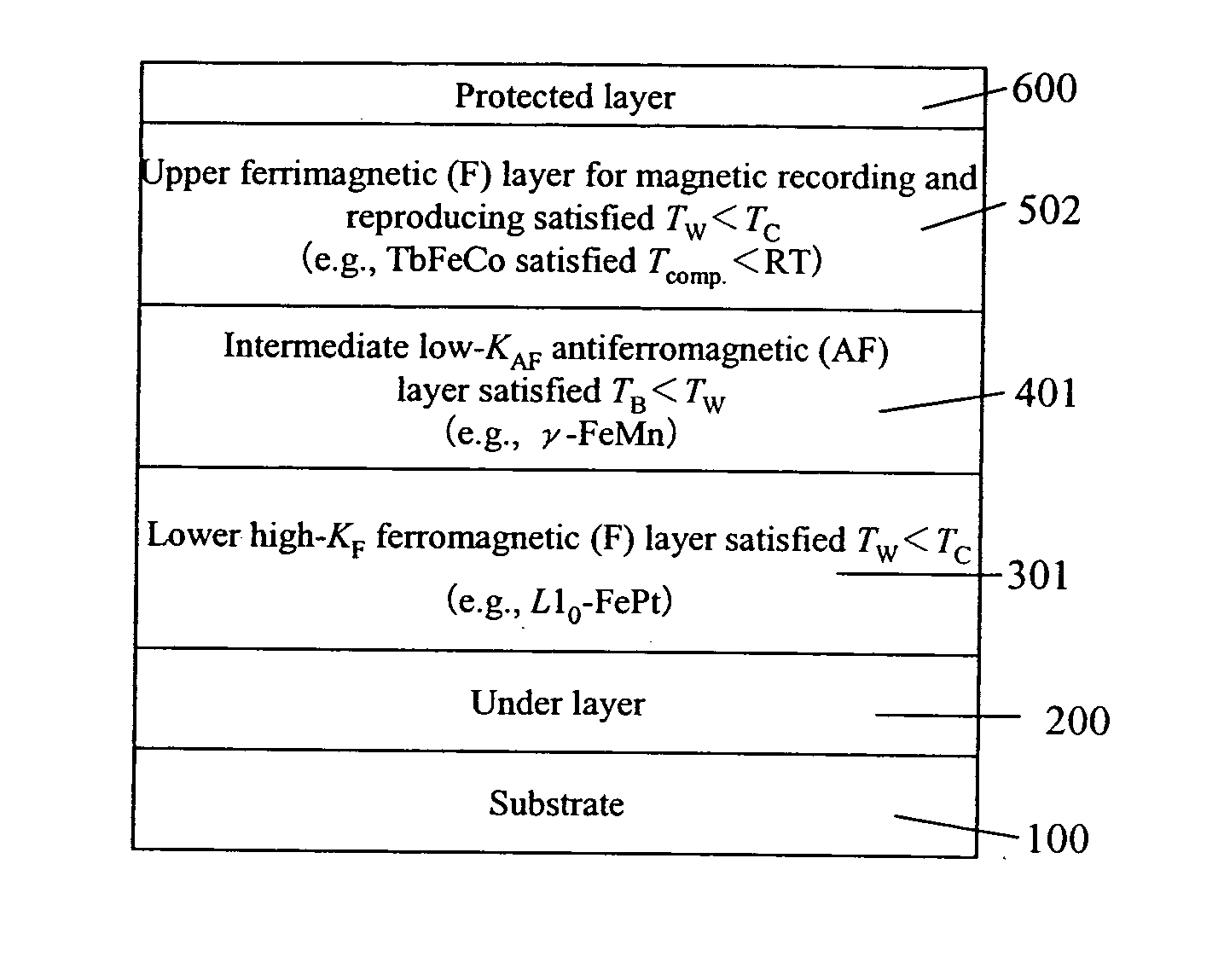

InactiveUS8084149B2Overcome resistance thermal fluctuationGreat resistance against thermal fluctuationDifferent record carrier formsCombination recordingHeat-assisted magnetic recordingMagnetocrystalline anisotropy

Embodiments of the invention provide a thermally assisted magnetic recording medium, which can overcome resistance against thermal fluctuation at RT and write capability, obtain a drastic temperature variation in coercive force at right below the recording temperature, and be formed at low temperature. In one embodiment, the medium has a layered structure formed of a lower high-KF ferromagnetic (F) layer formed on a substrate, satisfying TW<TC, an intermediate low-KAF antiferromagnetic (AF) layer satisfying TB<TW, and an upper ferromagnetic (F) layer for recording and reproducing, satisfying TW<TC, where TW is a recording temperature, TC is a Curie point, TN is a Neel point, TB is a blocking temperature, KF is a ferromagnetic magnetocrystalline anisotropy constant, and KAF is an antiferromagnetic magnetocrystalline anisotropy constant.

Owner:WESTERN DIGITAL TECH INC

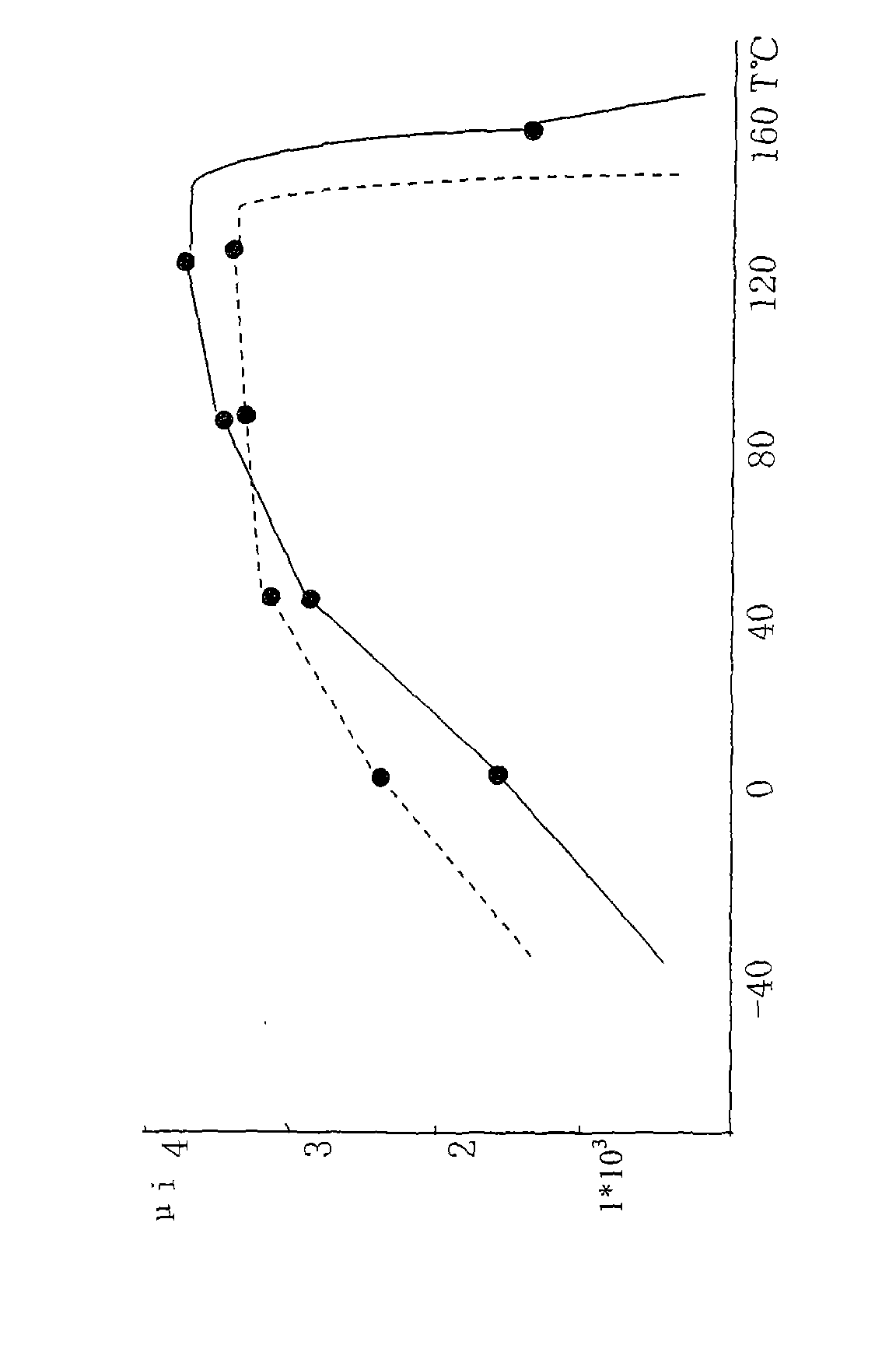

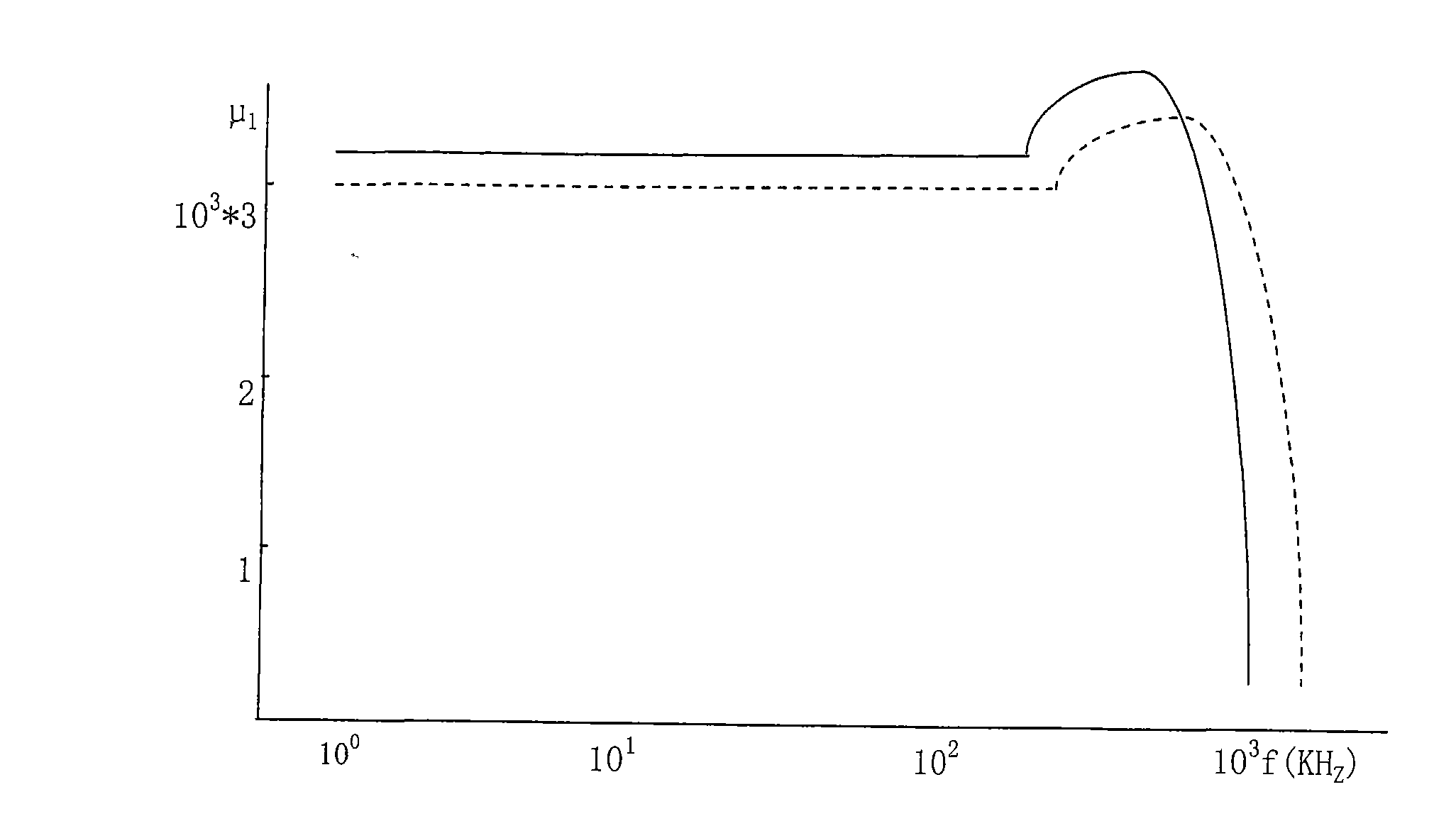

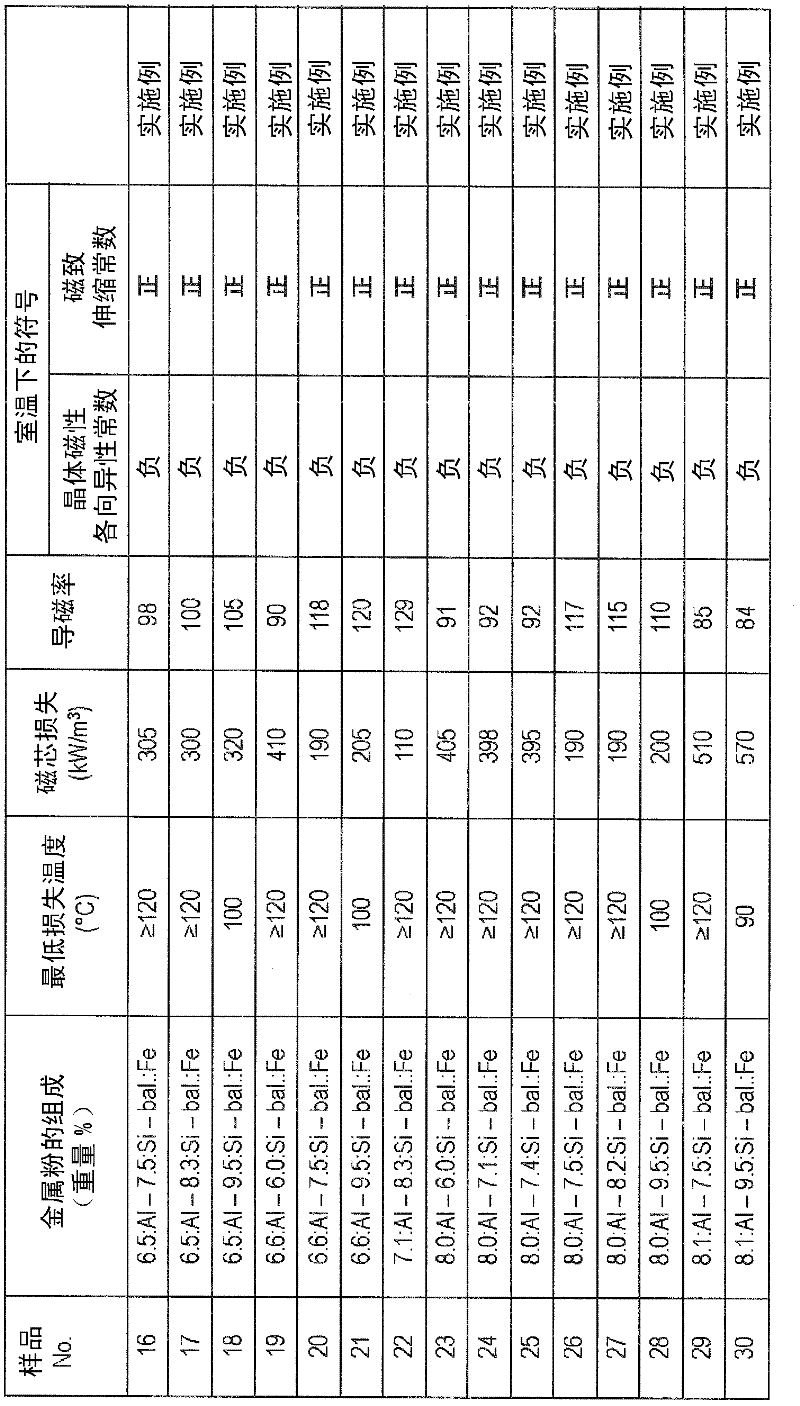

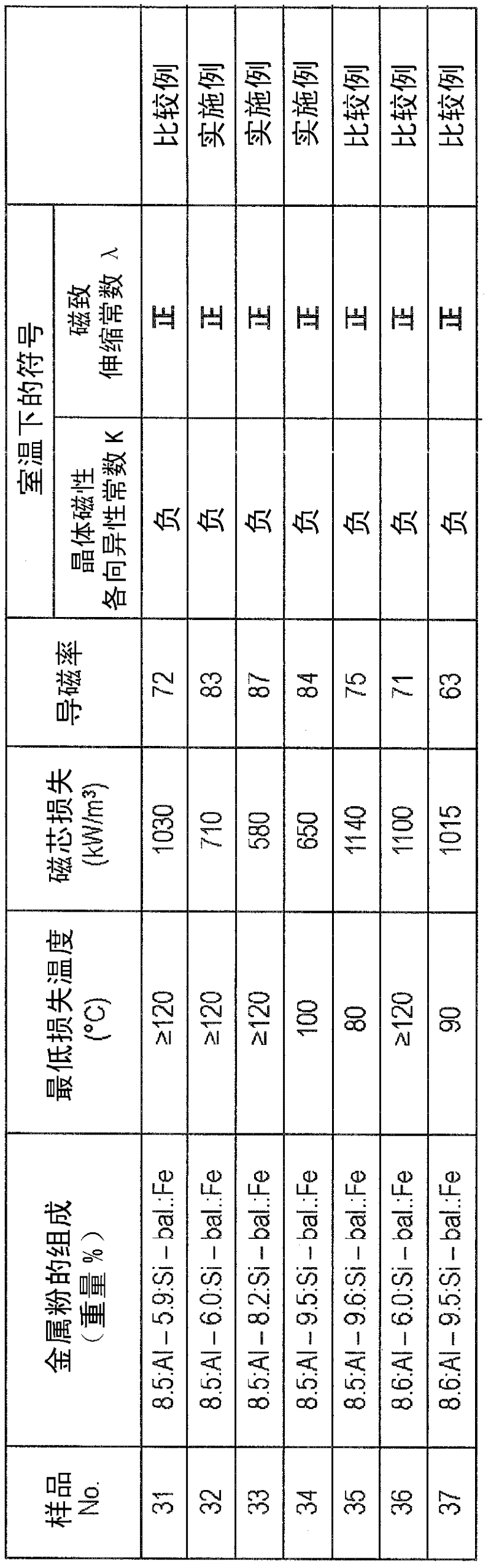

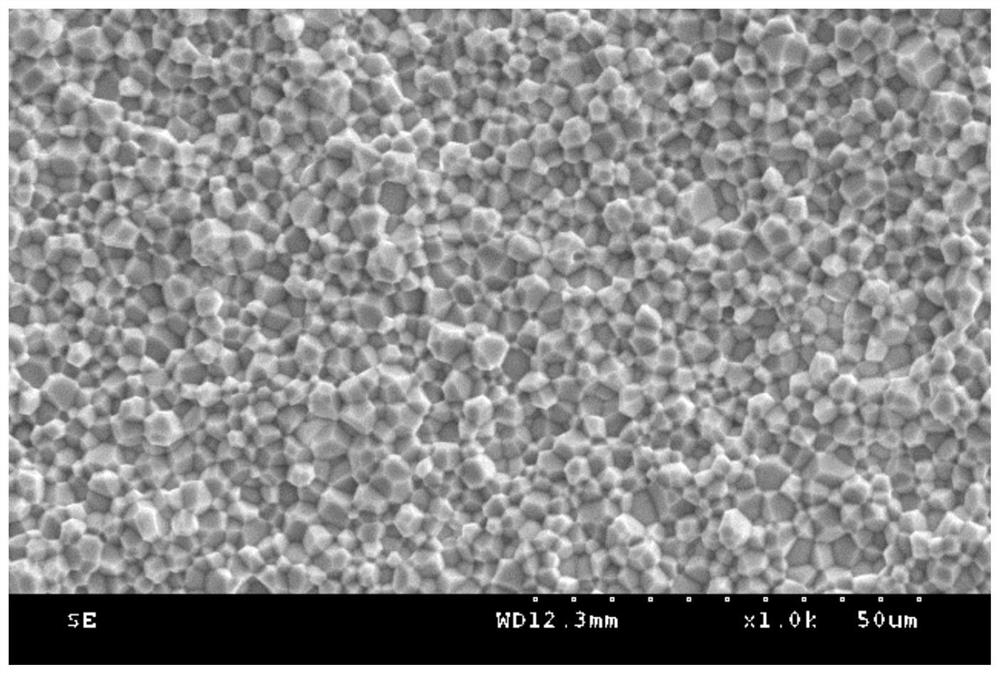

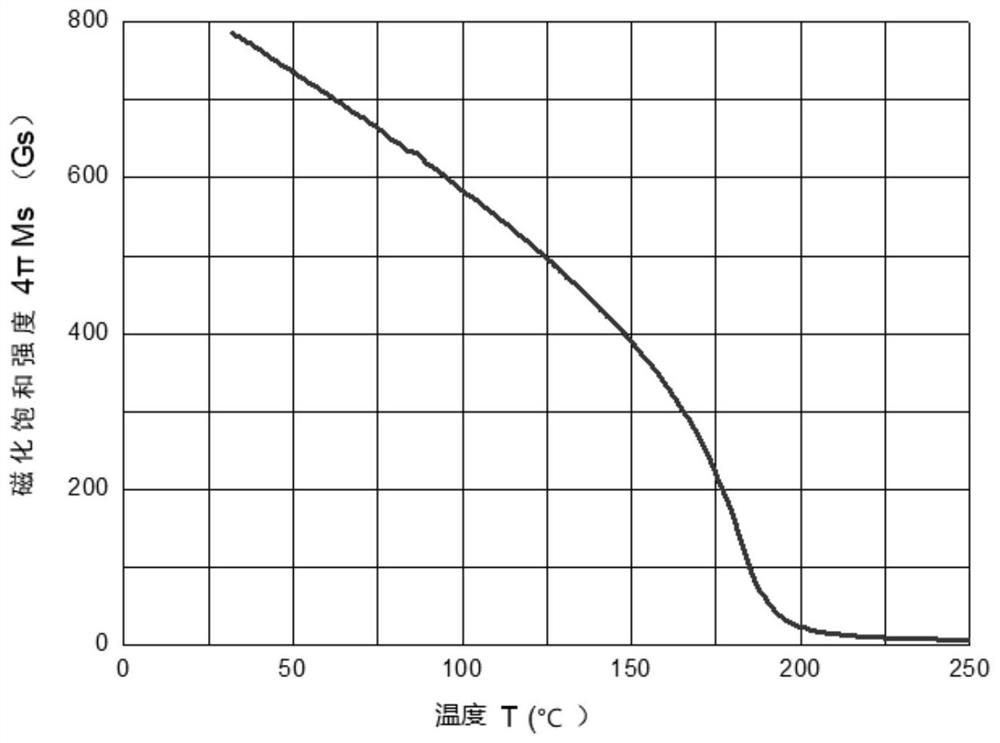

Composite magnetic body and method for producing the same

InactiveCN102473501ATransportation and packagingMetal-working apparatusRoom temperatureTemperature coefficient

A composite magnetic body is obtained by mixing Fe-Al-Si metal magnetic powders composed of 5.7 wt%=Al=8.5 wt%, 6.0 wt%=Si=9.5 wt%, and reminder Fe and an insulating binder, pressure-molding the mixed powders, and heat-treating the molding at a temperature of 600 DEG C or more and 900 DEG C or less. The sign of a crystal magnetic anisotropic constant of a metal magnetic powder in the composite magnetic body is negative at room temperature, and the sign of a magnetostriction constant is positive at room temperature. The temperature coefficient of a core loss at room temperature is negative. The composite magnetic body improves the temperature property of core loss, and has an excellent soft magnetic property with low loss and high magnetic permeability.

Owner:PANASONIC CORP

Low-saturation narrow-linewidth gyromagnetic material and preparation method thereof

ActiveCN113896521AImprove performanceInorganic material magnetismInductances/transformers/magnets manufactureOctahedronMicrowave

The invention relates to a low-saturation narrow-linewidth gyromagnetic material and a preparation method thereof. The gyromagnetic material comprises the following elements: BiAYBGd(3-A-B-2a-2c-d)Ca(2a+2c+d+f)Fe(5-a-b-c-d-e-f)VaAlbNbbZrcIndSneMnfO12, wherein 0.8<=A<=1.4, 1.6<=B<=2.2, 0<=a<=0.8, 0.001<=b<=0.28, 0<=c<=0.75, 0<=d<=0.7, 0<=e<=0.7, and 0<=f<=0.7. According to the microwave iron oxide provided by the invention, the components are reasonably designed, and the content of each element is adjusted, so that the gyromagnetic material has the properties of low saturation, low loss, narrow linewidth, high Curie temperature and high dielectric constant, and the maximum substitution amount of Bi<3+> is controlled to be 1.4 mol. Zr<4+> is doped to replace octahedral Fe<3+>, the anisotropic constant K1 is reduced, so that the line width is reduced, Nb<5+> replaces Fe<3+> to inhibit generation of other phases, V<5+> replaces Fe<3+> to reduce 4pi Ms, and meanwhile, the Curie temperature is not deteriorated.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

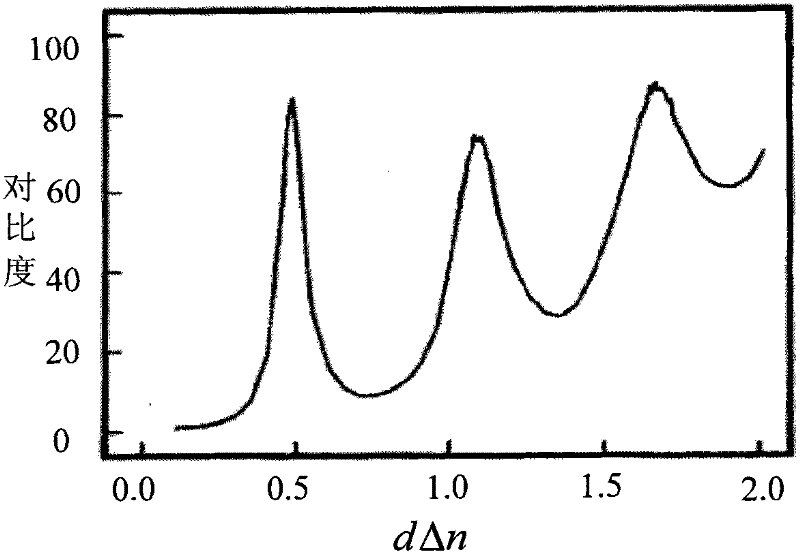

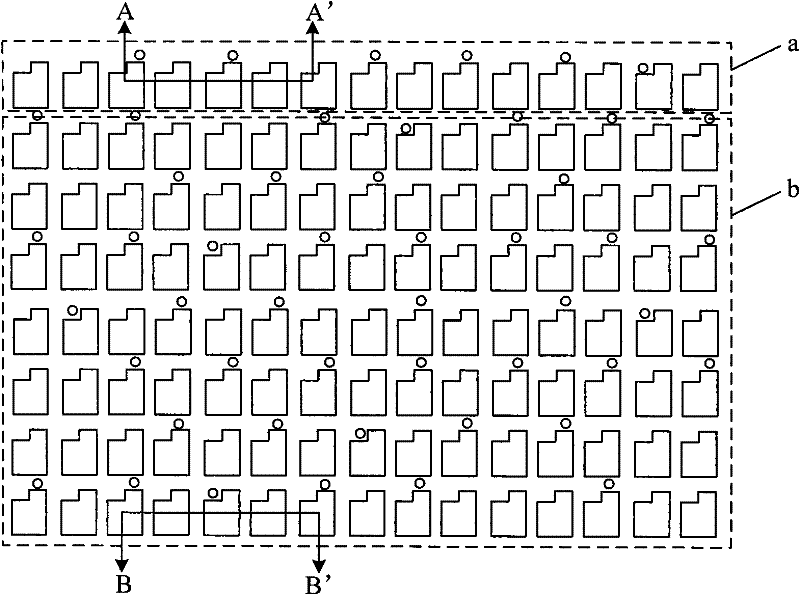

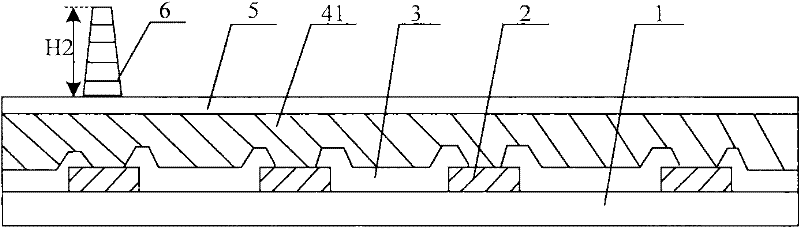

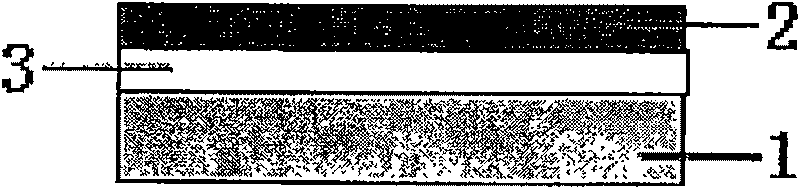

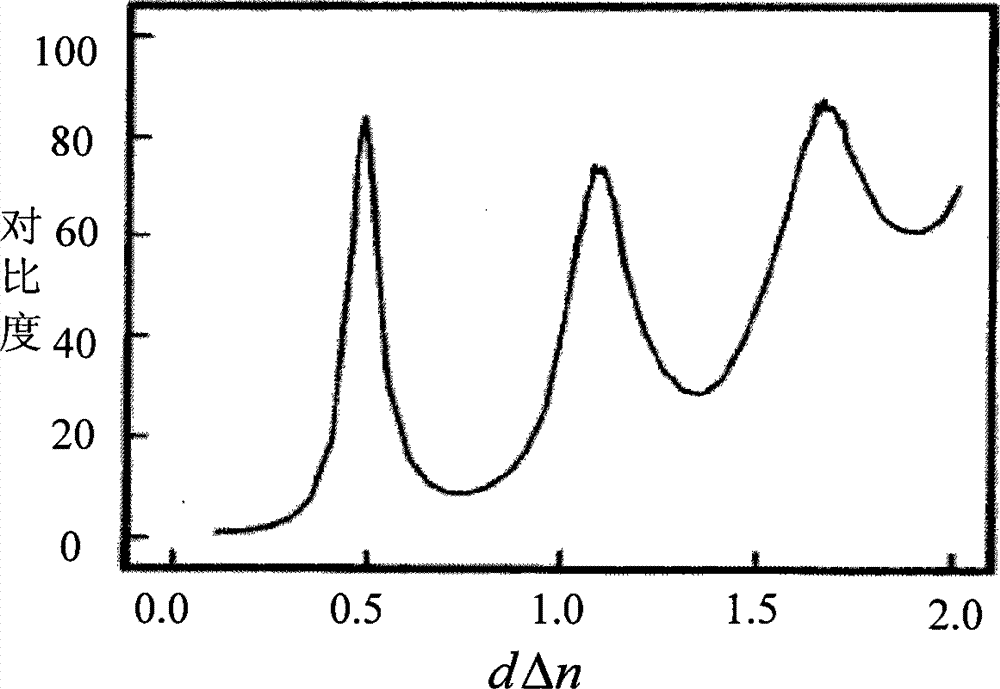

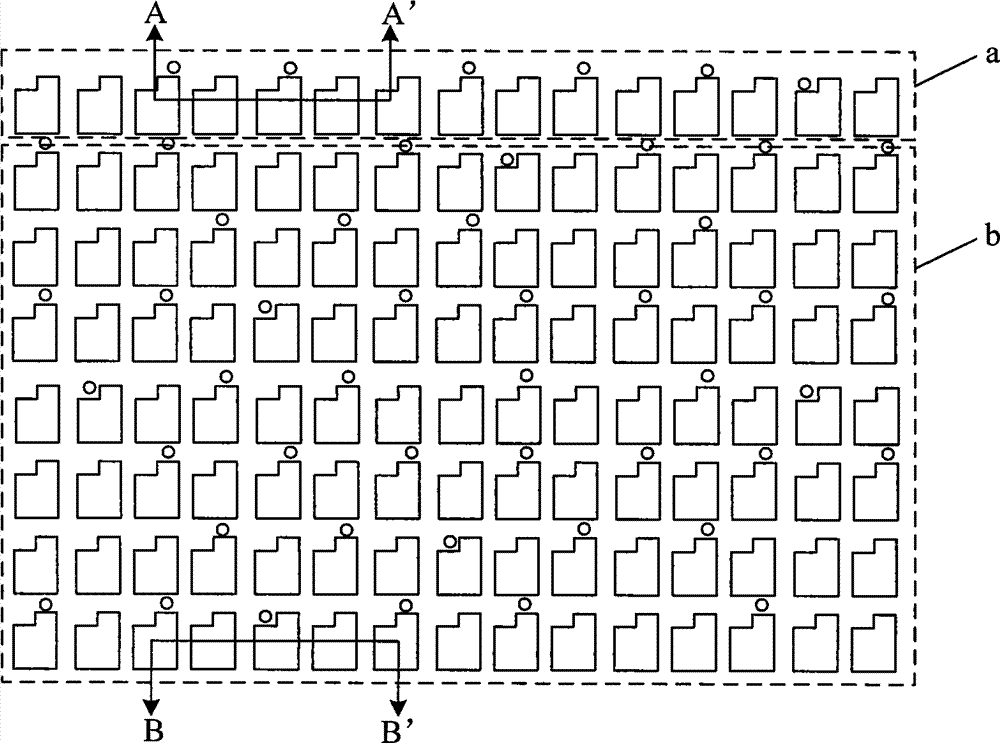

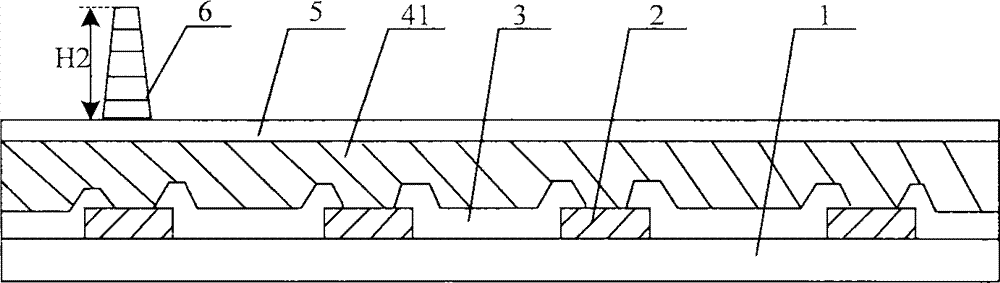

Liquid crystal panel, manufacturing method thereof and liquid crystal displayer

ActiveCN102243395AWork around the contrast reduction defectIncrease contrastNon-linear opticsLiquid-crystal displayChemistry

The invention discloses a liquid crystal panel, a manufacturing method thereof and a liquid crystal displayer. The liquid crystal panel comprises a first liquid crystal display substrate, a second liquid crystal display substrate and a liquid crystal filled between the first liquid crystal display substrate and the second liquid crystal display substrate, wherein a protecting layer is disposed onthe first liquid crystal display substrate or the second liquid crystal display substrate corresponding to the non-high-temperature area of the liquid crystal panel; a spacing article is disposed in the first liquid crystal display substrate or the second liquid crystal display substrate so that the product of the optical anisotropy constant of the liquid crystal corresponding to the non-high-temperature area of the liquid crystal panel and a box thickness keeps identical with the product of the optical anisotropy constant of the liquid crystal corresponding to the high-temperature area thereof and the box thickness. In the invention, the protecting layer and the spacing article are disposed on the substrate corresponding to the non-high-temperature area of the liquid crystal panel so that the products of the optical anisotropy constants of the liquid crystals corresponding to the non-high-temperature area and the high-temperature area of the liquid crystal panel and the box thicknesskeep identical, which realizes to design different box thicknesses according to the temperatures of the different areas of the liquid crystal panel.

Owner:BOE TECH GRP CO LTD +1

Transverse exchange-coupled magnetic information storage medium material and preparation method thereof

InactiveCN101202145BSolve write problemsStable record bitMagnetic materials for record carriersMagnetic layersElectronIon implantation

The invention relates to a super-high density magnetic information memorizing technique, belonging to the electronic material technique field. A magnetic information memorizing unit of the invention is formed by a horizontal exchanging and coupling of high / low anisotropy constants magnetic films. When in preparation, the high anisotropy constants magnetic film is firstly prepared and then is partially modified through an ion implantation or ion diffusion process after anneal treatment to decrease the anisotropy and coercive forces of the modified part so as to form the low anisotropy constants magnetic film. Finally, the high / low anisotropy constants magnetic films are coupled along the horizontal direction to form the magnetic information memorizing medium material of the horizontal exchange coupling. The invention overcomes the defects of a vertical exchange coupling compound magnetic information memorizing medium that an enlarged distribution of the information memorizing unit switch field and a decrease of the information recording stability are caused by interface diffusion and deterioration of memorizing layer in a high temperature treatment process. The invention can further decrease the switch field of the information memorizing unit, therefore, the information recording can be more stable, so as to satisfy the requirement of the super-high density magnetic information memorizing.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

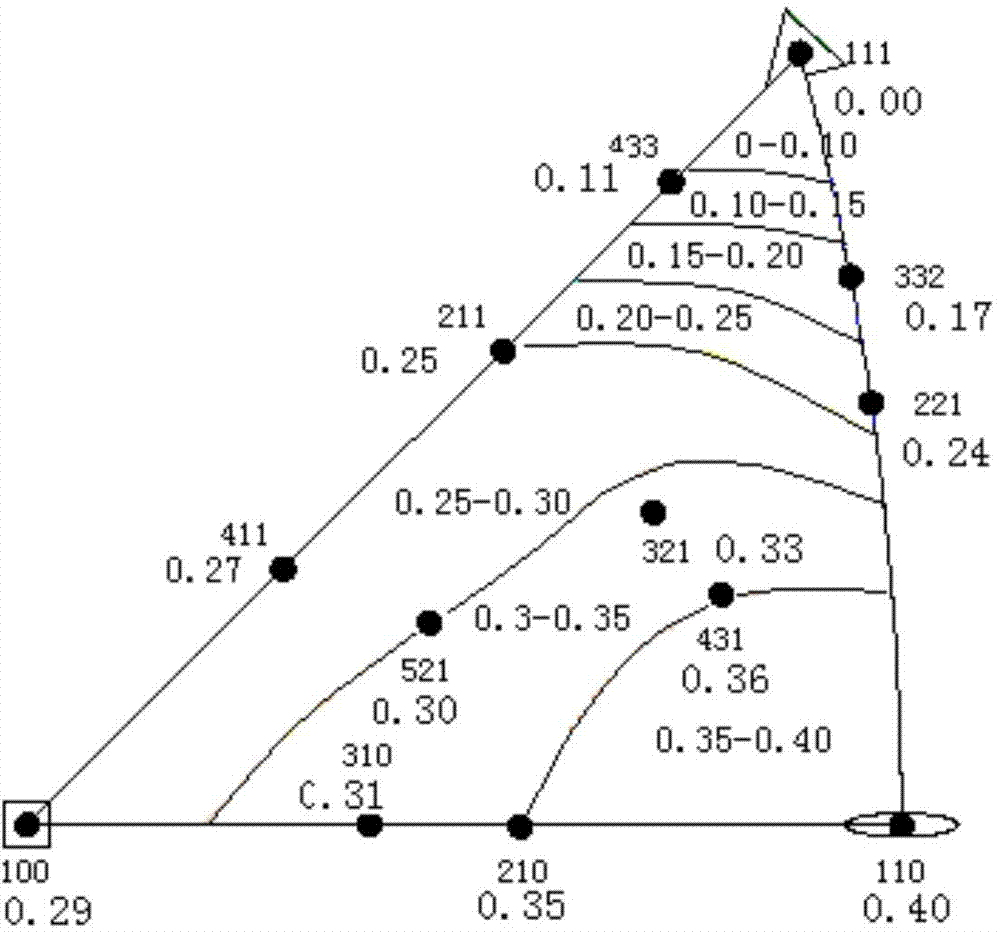

Evaluation method for auto sheet texture

InactiveCN103926262AImprove performanceSolving Texture Evaluation ProblemsMaterial analysis using radiation diffractionX-rayMetal sheet

The invention relates to an evaluation method for auto sheet texture. The method comprises the following steps: calculating the anisotropy constant m of each [uvw] in an {hkl} crystal face by adopting a formula (described in the specification), and calculating earing indexes q of different crystal faces by adopting a formula being q=[m(maximum)-m(minimum)] / m(average); measuring the texture by adopting an X-ray inverse pole figure method or a neutron-ray inverse pole figure method, and calculating the earing tendency Q of a sample by adopting a formula being Q=total summation qf; and judging the Q by comparing, and evaluating advantages and disadvantages of textures among samples. The method is simple, convenient and practical, can be used for performing quantitative evaluation on the advantages and disadvantages of the textures of metal sheets, such as auto panels, and provides a basis for improving a technique and improving the performances of the auto sheet, so that a bridge is erected between the sheet performance and the technique, and the problem of texture evaluation of the sample with the relatively small difference can be effectively solved. The method can be used in various labs as a conventional method.

Owner:武钢集团有限公司

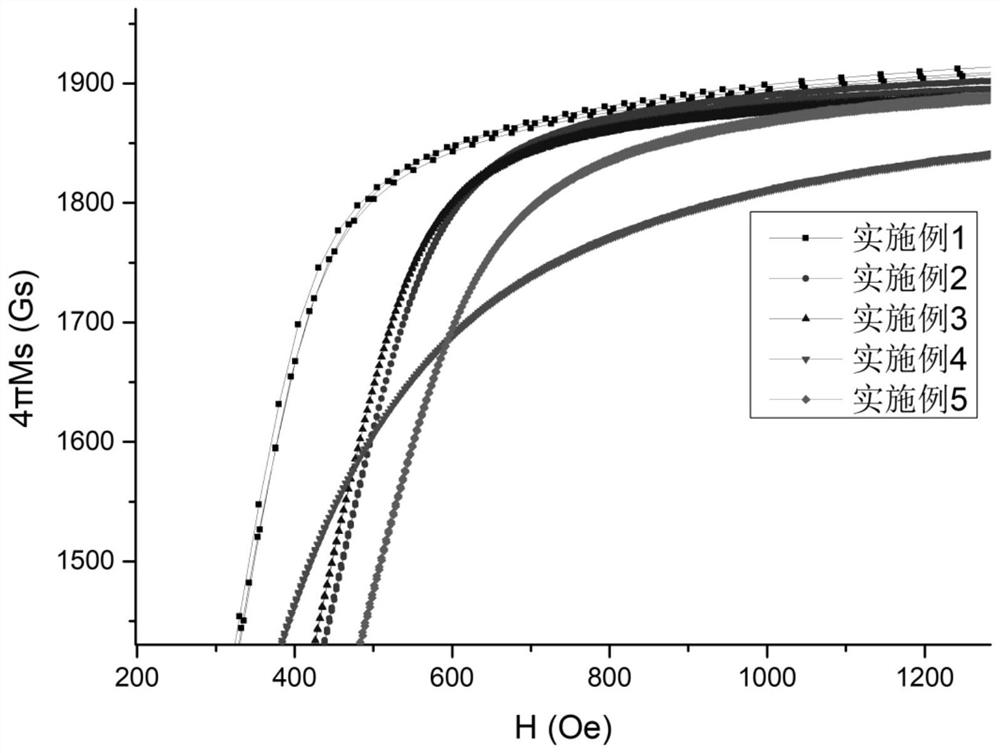

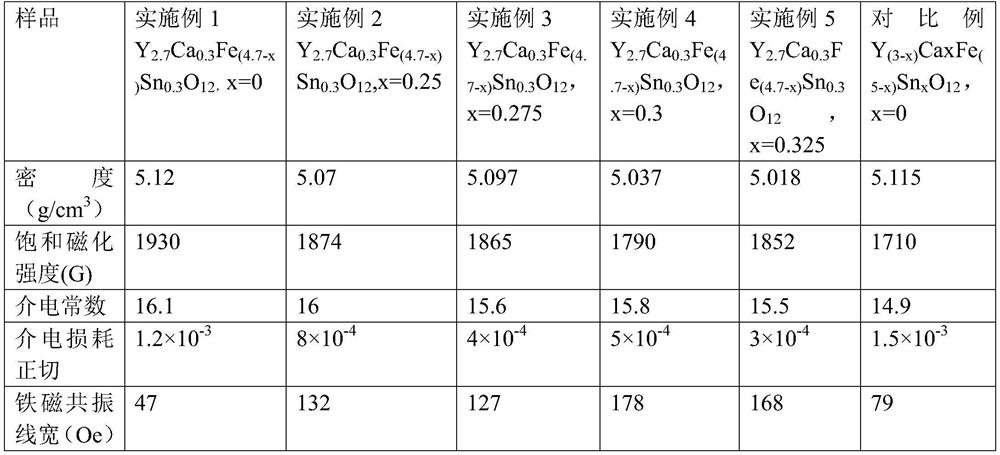

Low-loss YIG material and preparation method thereof

The invention provides a low-loss YIG material and a preparation method thereof, the structural formula of the material is Y2. 7Ca0. 3Fe (4.7-x) Sn0. 3O12, and x is greater than or equal to 0 and less than or equal to 0.325. The preparation method comprises the following steps: (1) preparation of a pre-sintered material; (2) secondary ball milling; and (3) forming and sintering: 1. Sn4 + ions are adopted to replace octahedral Fe < 3 + > so as to reduce the anisotropic constant and ferromagnetic resonance line width; meanwhile, a gradient is set for the iron deficiency amount, so that electron transfer between iron ions between an octahedron (a-site) and a tetrahedron (d-site) is reduced, and the dielectric loss of the material is reduced. The ferromagnetic resonance line width of the low-cost sample is 127Oe, the dielectric constant is 15.6, and the dielectric loss tangent is 4 * 10 <-4 >. According to the invention, octahedral Fe < 3 + > ions are replaced by Sn < 4 + > ions, the molecular magnetic moment of the ferrite material is increased, and the saturation magnetization of the obtained YIG sample is 1865Gs.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Liquid crystal panel, manufacturing method thereof and liquid crystal displayer

ActiveCN102243395BWork around the contrast reduction defectIncrease contrastNon-linear opticsLiquid-crystal displayAnisotropy constant

The invention discloses a liquid crystal panel, a manufacturing method thereof and a liquid crystal displayer. The liquid crystal panel comprises a first liquid crystal display substrate, a second liquid crystal display substrate and a liquid crystal filled between the first liquid crystal display substrate and the second liquid crystal display substrate, wherein a protecting layer is disposed onthe first liquid crystal display substrate or the second liquid crystal display substrate corresponding to the non-high-temperature area of the liquid crystal panel; a spacing article is disposed in the first liquid crystal display substrate or the second liquid crystal display substrate so that the product of the optical anisotropy constant of the liquid crystal corresponding to the non-high-temperature area of the liquid crystal panel and a box thickness keeps identical with the product of the optical anisotropy constant of the liquid crystal corresponding to the high-temperature area thereof and the box thickness. In the invention, the protecting layer and the spacing article are disposed on the substrate corresponding to the non-high-temperature area of the liquid crystal panel so that the products of the optical anisotropy constants of the liquid crystals corresponding to the non-high-temperature area and the high-temperature area of the liquid crystal panel and the box thicknesskeep identical, which realizes to design different box thicknesses according to the temperatures of the different areas of the liquid crystal panel.

Owner:BOE TECH GRP CO LTD +1

Determination Method of Optimal DC Bias Magnetic Field Value Based on DC Bias Magnetic Field

A method for determining an optimal DC bias magnetic field value based on a DC bias magnetic field, the steps of which are: using the principle of minimum energy to determine the magnetization of a material in a steady state in a DC bias magnetic field, establishing a single-domain physical model, using The numerical calculation method determines the stable state of the material under the DC bias magnetic field, and determines the optimal DC bias magnetic field size for device sensitivity. Its beneficial effect is: for different types of materials, the anisotropy constant K and M of the material D It will also affect the selection of the optimal DC bias magnetic field, which can be analyzed by the same method.

Owner:TSINGHUA UNIV

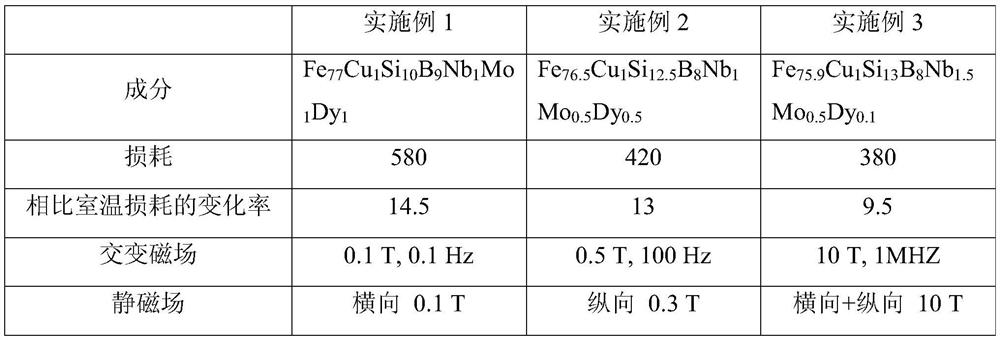

A kind of nanocrystalline alloy and preparation method thereof

ActiveCN112410531BLow high frequency lossStable performance and safe and reliableFurnace typesMagnetic materialsTransformerInductor

The invention relates to the technical field of soft magnetic alloy materials, and discloses a nanocrystalline alloy and a preparation method thereof. The temperature of FeCuSiBNbMoDy strips is slowly raised to T in an alternating magnetic field. 1 , remove the alternating magnetic field insulation t 1 ;Rapidly heat up to T 2 , insulation t 2 ; rapid cooling down to T under a constant magnetic field 3 , insulation t 3 ; slow down to T 4 , insulation t 4 Then rapidly cool down to room temperature to obtain nanocrystalline alloy. Through the synergistic effect among Fe, Cu, Nb, Si, B, Mo, and Dy elements, the precipitation of disordered phases is effectively promoted, the nucleation rate is increased, and the effective anisotropy constant is reduced. Through the regulation of the preparation process, low loss and Nanocrystalline soft magnetic alloy that is insensitive to service temperature. It can be applied to high-frequency transformers, common-mode inductors, wireless charging, filters and other devices to ensure stable, safe and reliable product performance.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com