Electromagnetic interference resistant Mn-Zn ferrite magnet material and preparation method thereof

An anti-electromagnetic interference, zinc ferrite technology, applied to the magnetic direction of inorganic materials, can solve problems such as poor DC superposition characteristics, harmonic distortion affecting signal transmission speed, device working environment restrictions, etc., to reduce the magnetic crystal anisotropy Anisotropy constant and hysteresis loss, good anti-electromagnetic and anti-interference performance, and the effect of accelerating the grain growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

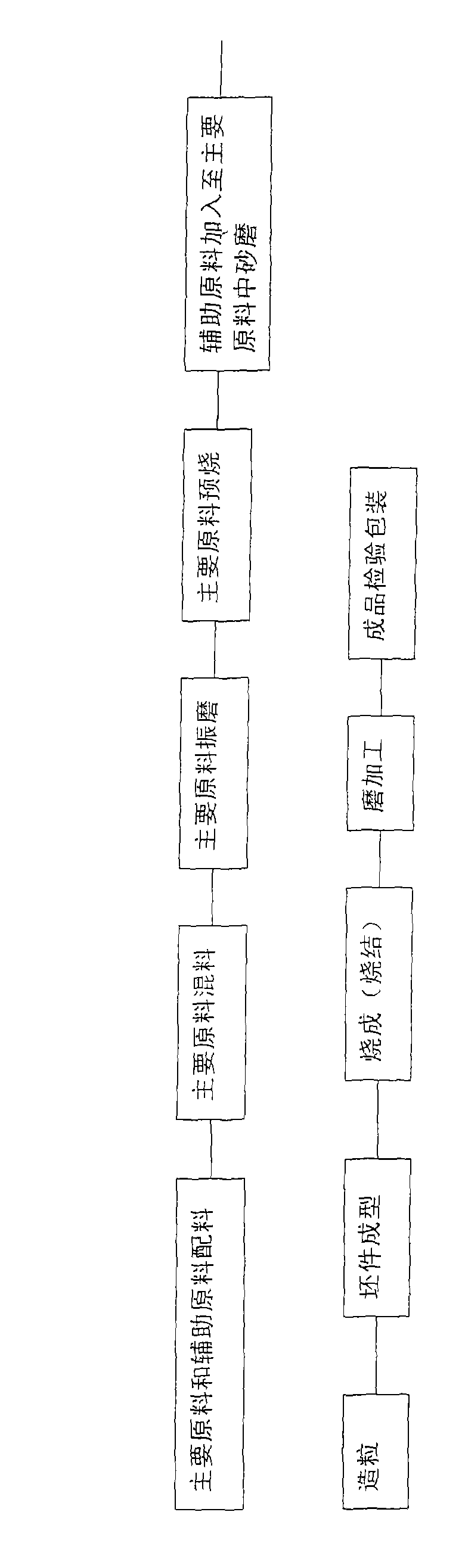

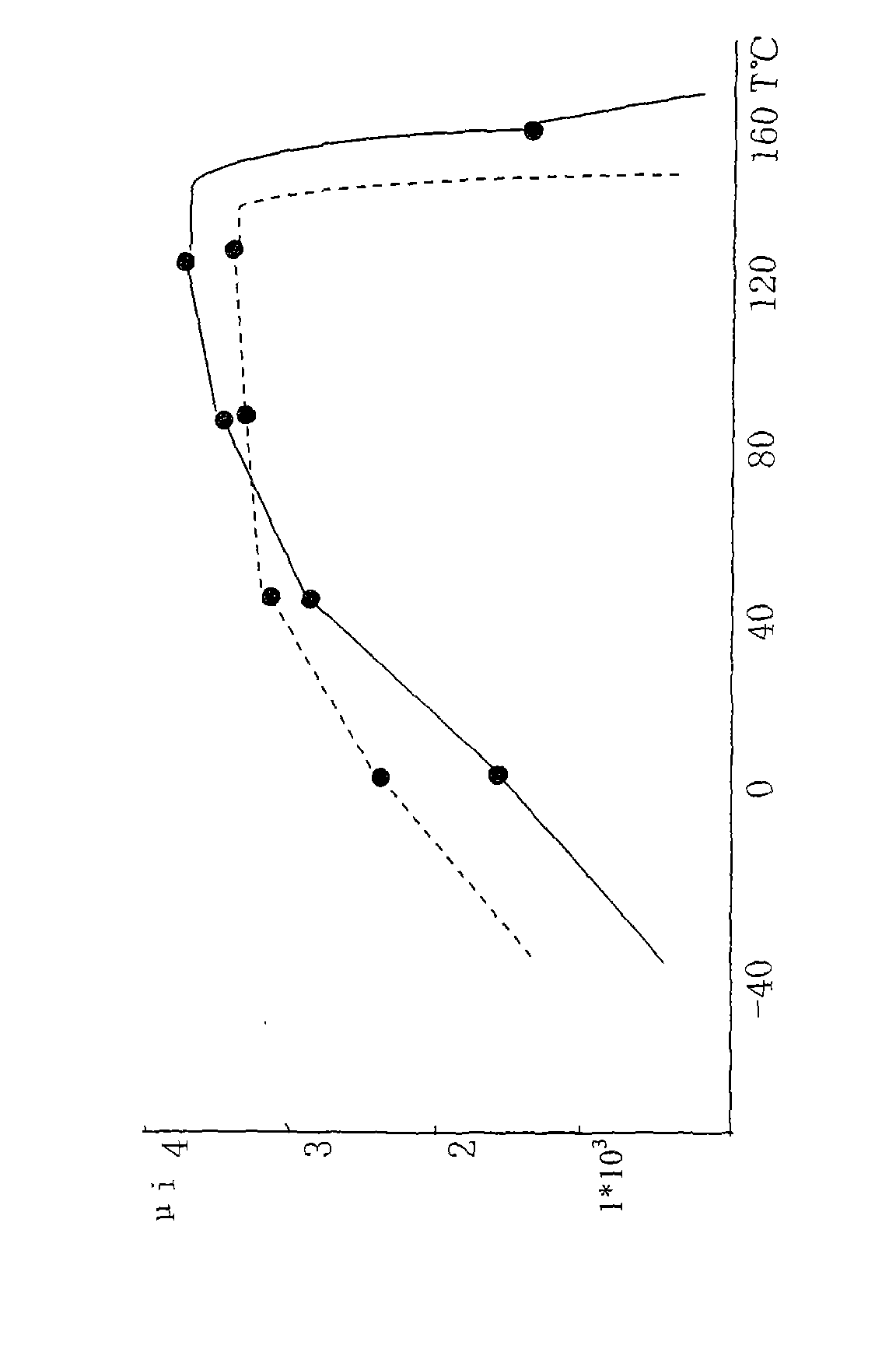

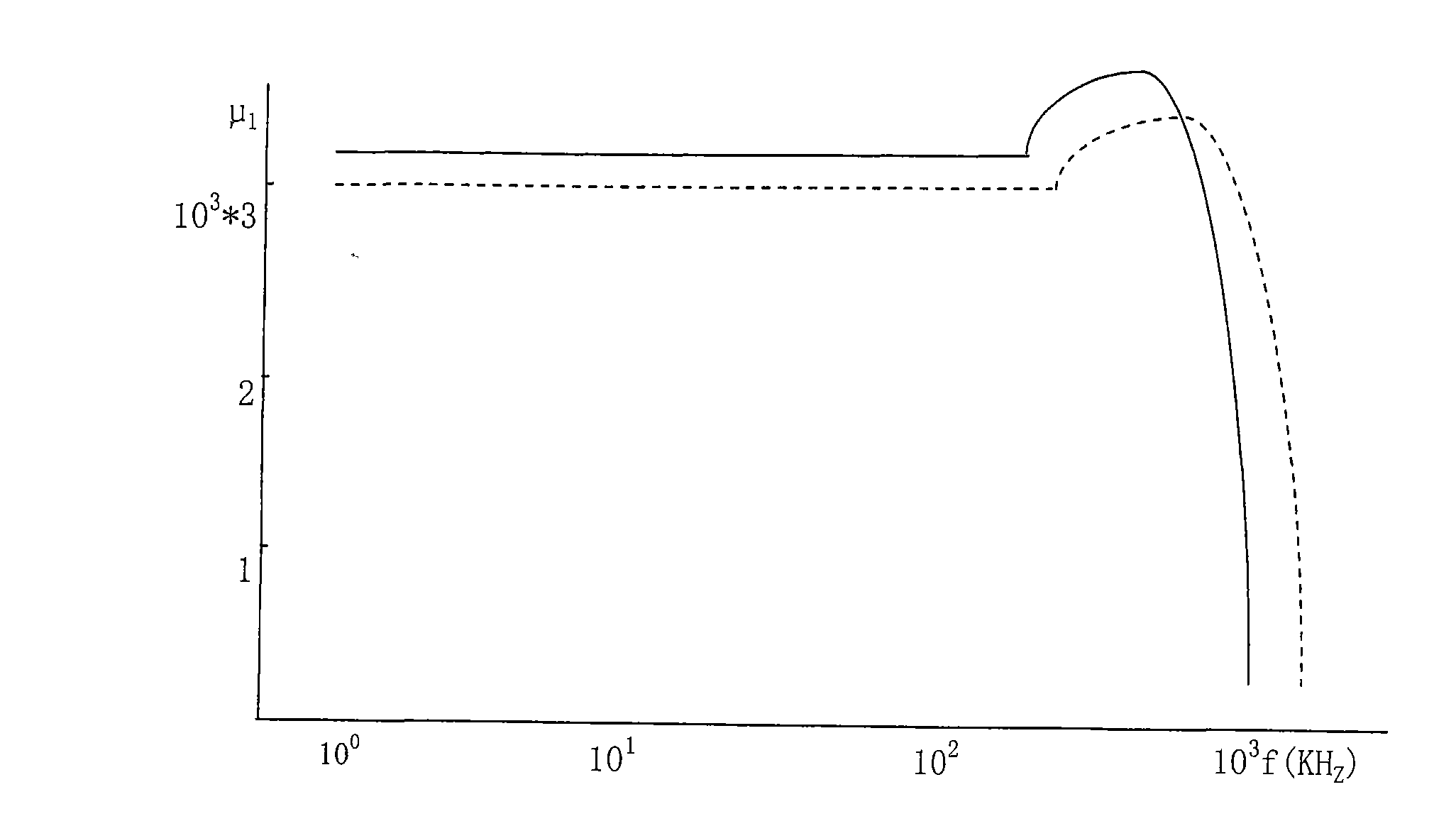

[0030] please see figure 1 ,according to figure 1 In the process flow shown, 52.8 mol% of iron oxide, 24.0 mol% of manganese oxide and 23.2 mol% of zinc oxide are converted into weight percentages and weighed as the main raw materials, which are put into the dry intensive mixer and mixed with each other for 60 minutes. The main raw materials are sent to the vibrating ball mill for 40 minutes to obtain fine powder, which is then sent to the electric rotary kiln for pre-calcination. Add 0.06wt% of titanium oxide, 0.08wt% of calcium oxide and 0.04wt% of molybdenum oxide which are selected and weighed as auxiliary raw materials, before adding the weighed auxiliary raw materials to the main raw materials First use a sand mill to grind the auxiliary raw materials for 110min. During the sand grinding process, the weight-to-volume ratio of control material (auxiliary raw materials): sanding balls: water is 1: 1: 0.6 (i.e. auxiliary raw materials and sanding balls and The proportion ...

Embodiment 2

[0036] Only iron oxide, manganese oxide and zinc oxide constituting the main raw material components were changed to Fe 2 o 3 52.5mol%, MnO23.5mol% and ZnO24.3mol%; the auxiliary raw material components titanium oxide, calcium oxide and molybdenum oxide were changed to TiO 2 0.065wt%, CaO0.085wt% and MoO 3 0.045wt%; change the mixing time of the main raw materials to 50min, and the vibration grinding time to 32min; change the pre-calcination temperature and time of the main raw materials to 975°C and 110min respectively; change the sanding time of the auxiliary raw materials to 120min; In the sintering of the blank, the heating rate from room temperature to 600°C was changed to 62°C / h, the heating rate was changed to 195°C / h from 600°C to 1360°C, and the holding time was changed to 3.9h. The cooling time from 1150°C to 1000°C was changed to 38min and the Image 6 air cooling shown. All the other are the same as the description to embodiment 1. The physical properties of t...

Embodiment 3

[0038] Change the iron oxide, manganese oxide and zinc oxide that constitute the main raw material components to Fe 2 o 3 53.4mol%, MnO23.9mol% and ZnO22mol%; the auxiliary raw material components titanium oxide, calcium oxide and molybdenum oxide were changed to TiO 2 0.07wt%, CaO0.08wt% and MoO 3 0.055wt%; change the mixing time and vibration grinding time of the main raw materials to 55min and 36min respectively; change the pre-calcination temperature and time of the main raw materials to 960°C and 120min respectively; In the sintering of the blank, the heating rate from room temperature to 600°C was changed to 58°C / h, and the heating rate was changed to 203°C / h when the temperature was above 600°C to 1345°C, and the holding time was changed to 4.2h. The cooling time from 1150°C to 1000°C was changed to 36 minutes and the Figure 5 Water cooling shown. All the other are the same as the description to embodiment 1. The physical properties of the obtained anti-electromag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com