Patents

Literature

210results about How to "Guaranteed sharpness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Peripheral edge grinding wheel for machining PCBN (polycrystalline cubic boron nitride) blades

InactiveCN103753413AEvenly distributedUniform pore sizeBonded abrasive wheelsGrinding devicesLithium hydroxideBoron nitride

The invention discloses a peripheral edge grinding wheel for machining PCBN (polycrystalline cubic boron nitride) blades. The peripheral edge grinding wheel comprises a grinding wheel matrix and a grinding material layer. The grinding material layer is positioned on the grinding wheel matrix and is made of raw materials including, by weight, 44-65% of diamond, 22.5-40.5% of ceramic bonding agents, 0.5-10% of pore forming agents and 5-10% of phenolic resin liquid; the ceramic bonding agents are made of raw materials including, by weight, 40-60.5% of silicon dioxide, 5.5-17% of alumina, 25-35% of boric acid, 2-7% of sodium carbonate, 8-11% of lithium hydroxide and 2-6% of calcium oxide; pore forming agents are alumina hollow balls. The peripheral edge grinding wheel has the advantages of good sharpness, high grinding quality and long service life.

Owner:江苏赛扬精工科技有限责任公司

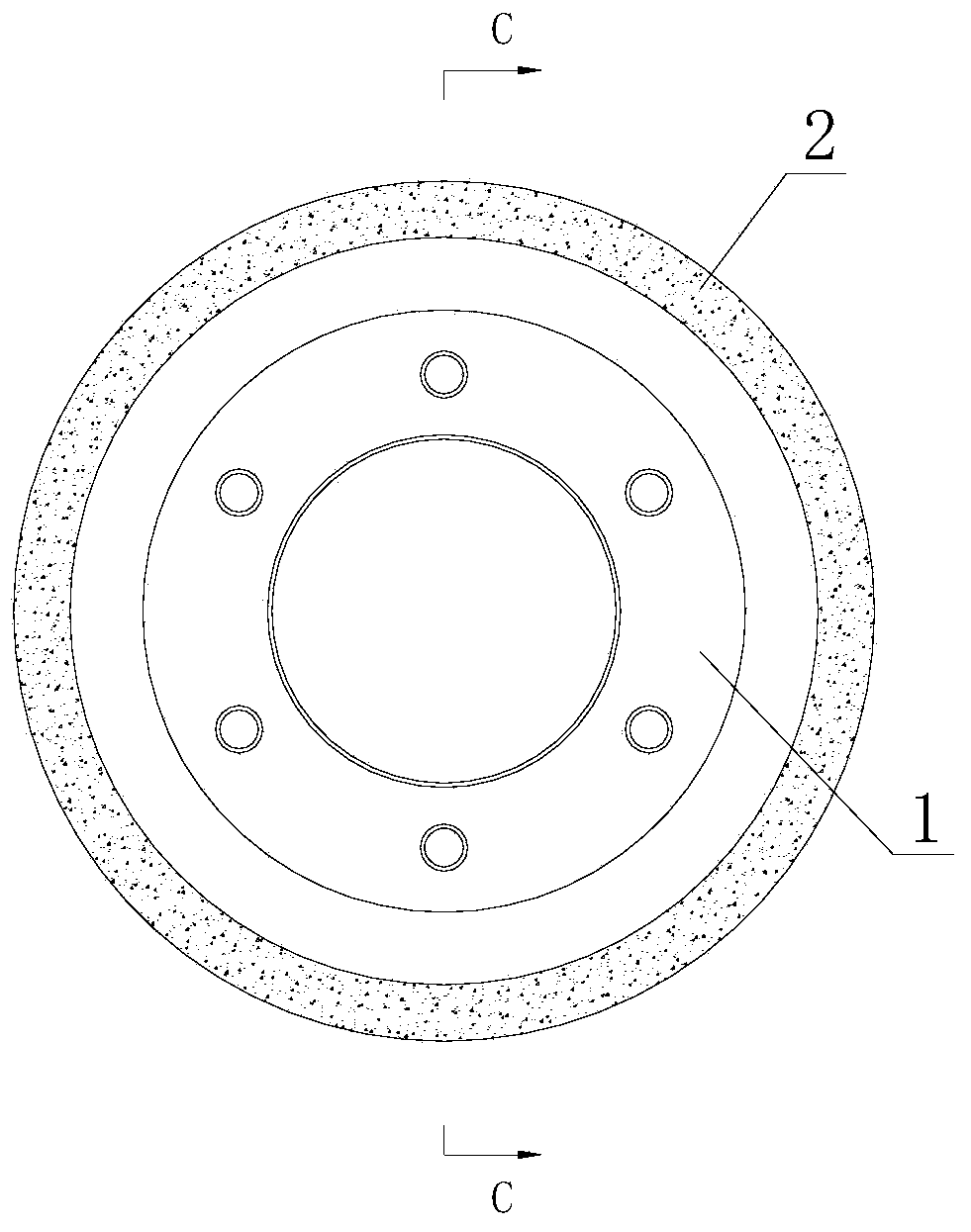

Resin cement cubic boron nitride grinding wheel and preparation method thereof

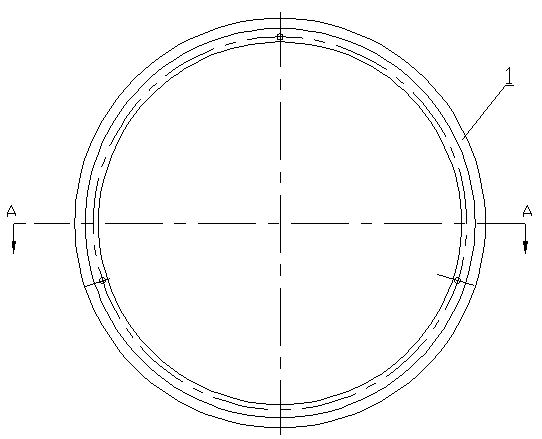

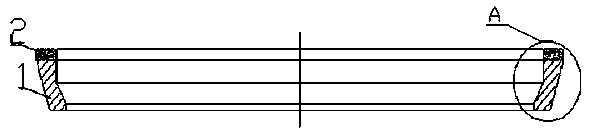

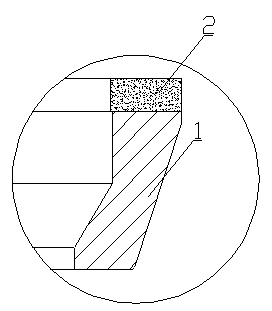

ActiveCN101332587AExtend your lifeIncrease grinding ratioBonded abrasive wheelsMetal working apparatusPass rateBoron nitride

The invention relates to a resinoid wedding agent cubic boron nitride grinding wheel and a manufacturing method thereof, the resinoid wedding agent cubic boron nitride grinding wheel comprises a grinding wheel matrix and a grinding layer, the grinding layer is arranged on the external wall of the grinding wheel matrix and peripheries of an upper end face and a lower end face; the grinding layer includes 12-40% of cubic boron nitride (nickel plating), 25-50% of Dialok939p resin, 1-10% of villaumite grinding aid, 1-10% of a solid lubricant filler, 10-30% of a powder filler with high thermal conductivity and 1-15% of oxide filler by volume percentage of the grinding layer. A specially designed hot pressing dies and separately batch feeding method are adopted, which causes the pressed products to have homogeneous structure and consistent density; the formula of the grinding wheel is simple, and the designed die has the advantages of simple and reasonable structure, easy die filling and die release, the product obtained has high once-pass rate, homogeneous structure and consistent density; the grinding wheel has good grinding performance and long service life, can perform peripheral grinding and end face grinding, and is equivalent to three grinding wheels with the same specification, the matrix and making cost are saved, production cost is reduced, the product value is improved.

Owner:广东奔朗新材料股份有限公司

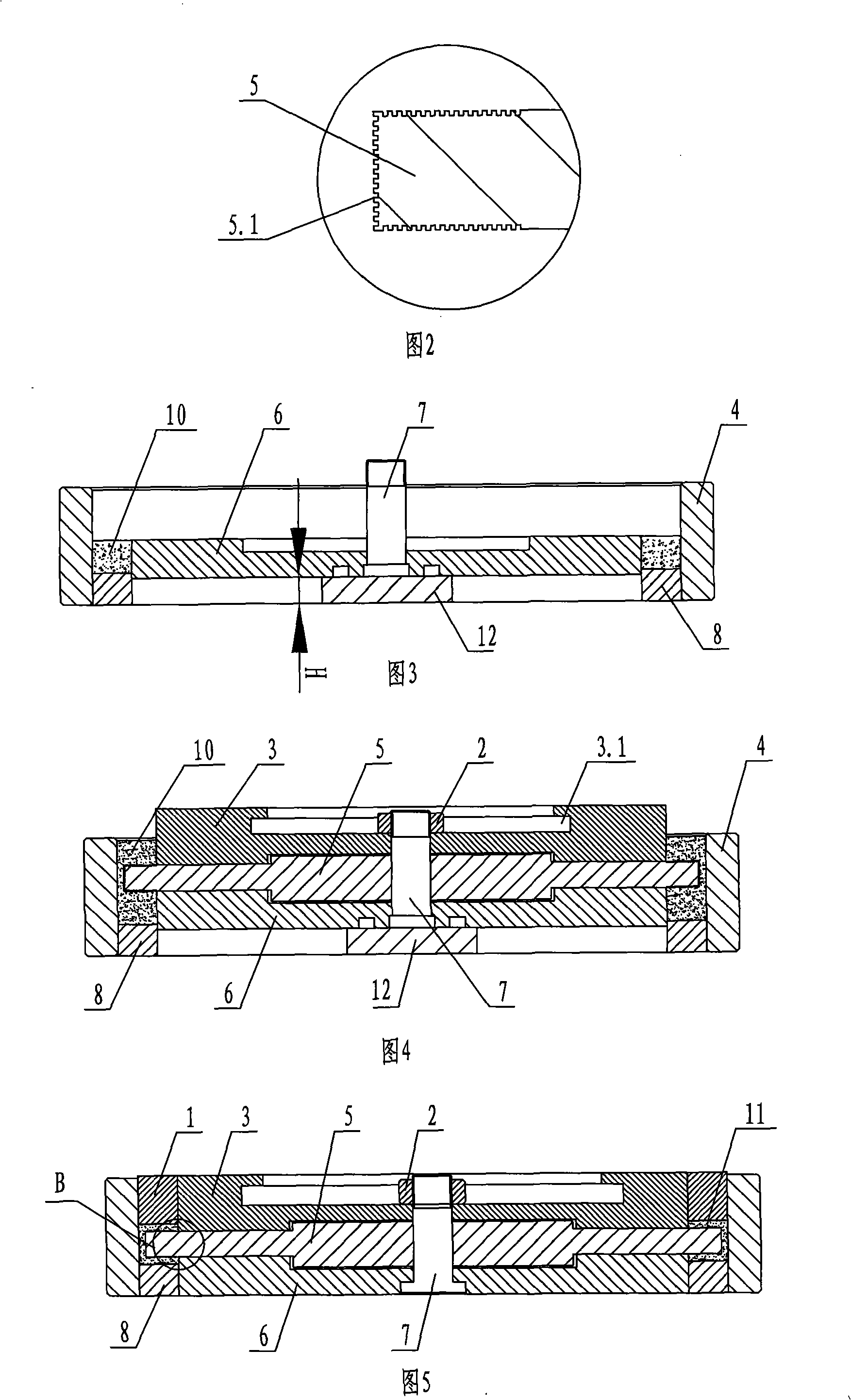

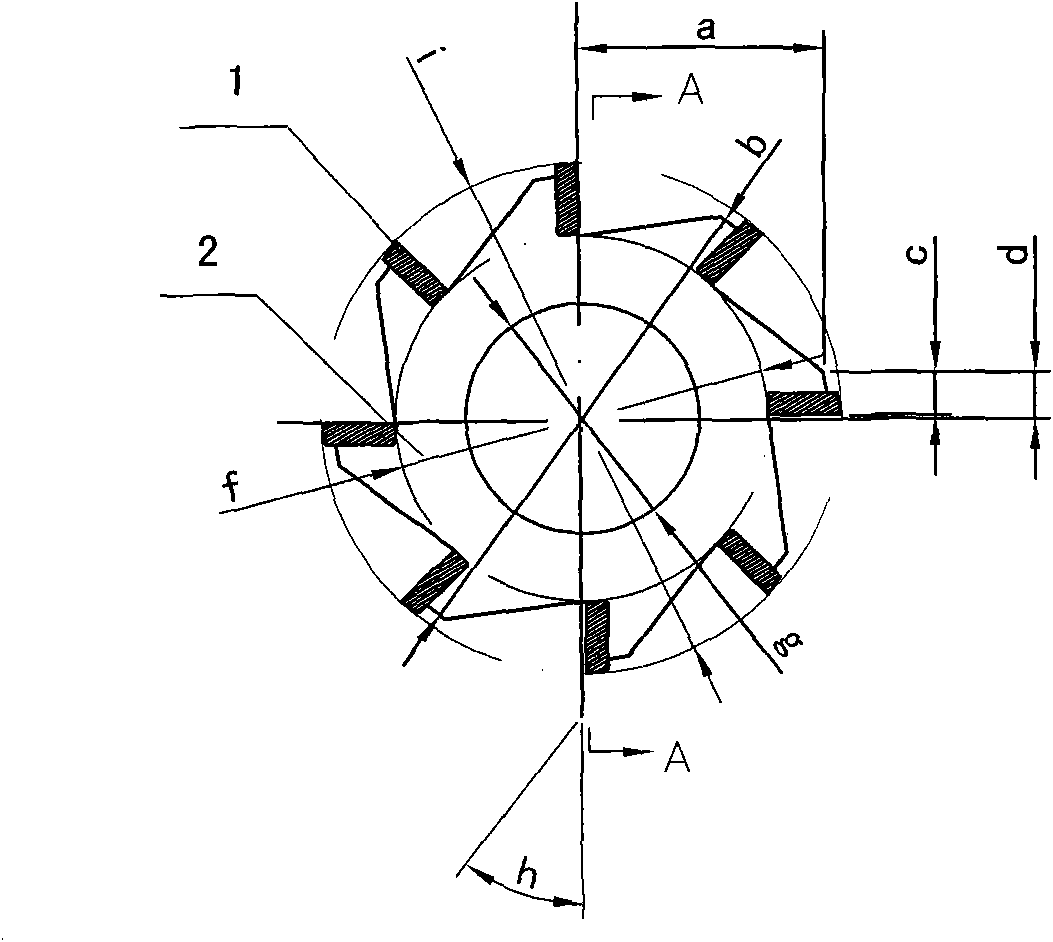

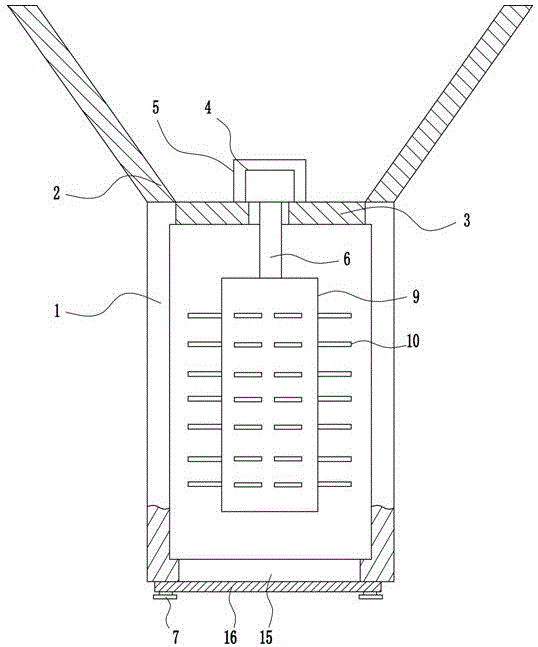

Production process of diamond saw blade formed by compressing granular powders

Disclosed is a production process of a diamond saw blade formed by compressing granular powders. The production process includes steps of using a copper powder, an iron powder, a tin powder, a nickel powder and a cobalt powder as raw materials, adding liquid paraffin for mixing and stirring, and then performing procedure steps of compressing, sintering and post-treating. The production process is characterized in that an agglomerating procedure is performed before a compressing procedure, and the powder raw materials are agglomerated to be granular and then compressed. According to experiments, the production process is obvious in effects, no defect is produced after the compression, and the yield of the finished diamond saw blade can reach above 97%.

Owner:SHIJIAZHUANG XINDA DIAMOND TOOLS CO LTD

Oil groove milling cutter of hard alloy cold-working mould pressing blank

InactiveCN101637829ASolve the discharge problemDischarge in timeMilling cuttersMilling equipment detailsMilling cutterMachined surface

The invention discloses an oil groove milling cutter of a hard alloy cold-working mould pressing blank, which comprises a steel basal body (2) and a PCD blade (1), wherein the steel basal body (2) isprovided with 6-12 saw teeth, the number of PCD blade (1) is the same with the number of saw teeth, the back of the saw teeth of the steel basal body (2) is designed into an inclined flat bottom shape, and the PCD blade (1) is welded on the saw teeth of the steel basal body (2). Aiming at the difficult problems of low integrated intensity, hard grains and easy machined surface collapse in the processing process of a hard alloy pressing blank, the invention concretely limits multiple items of geometric parameters of the milling cutter, particularly a geometric angle. When the milling cutter isused for processing an oil groove of the hard alloy cold-working mould pressing blank, the edge of the oil groove can be kept integrated, and the machined surface roughness is kept to be not more thanRa 0.8, solving the difficult problem that the quality of the machined surface can not be ensured when the existing milling cutter is used for processing the hard alloy pressing blank.

Owner:FUJIAN JINXIN TUNGSTEN

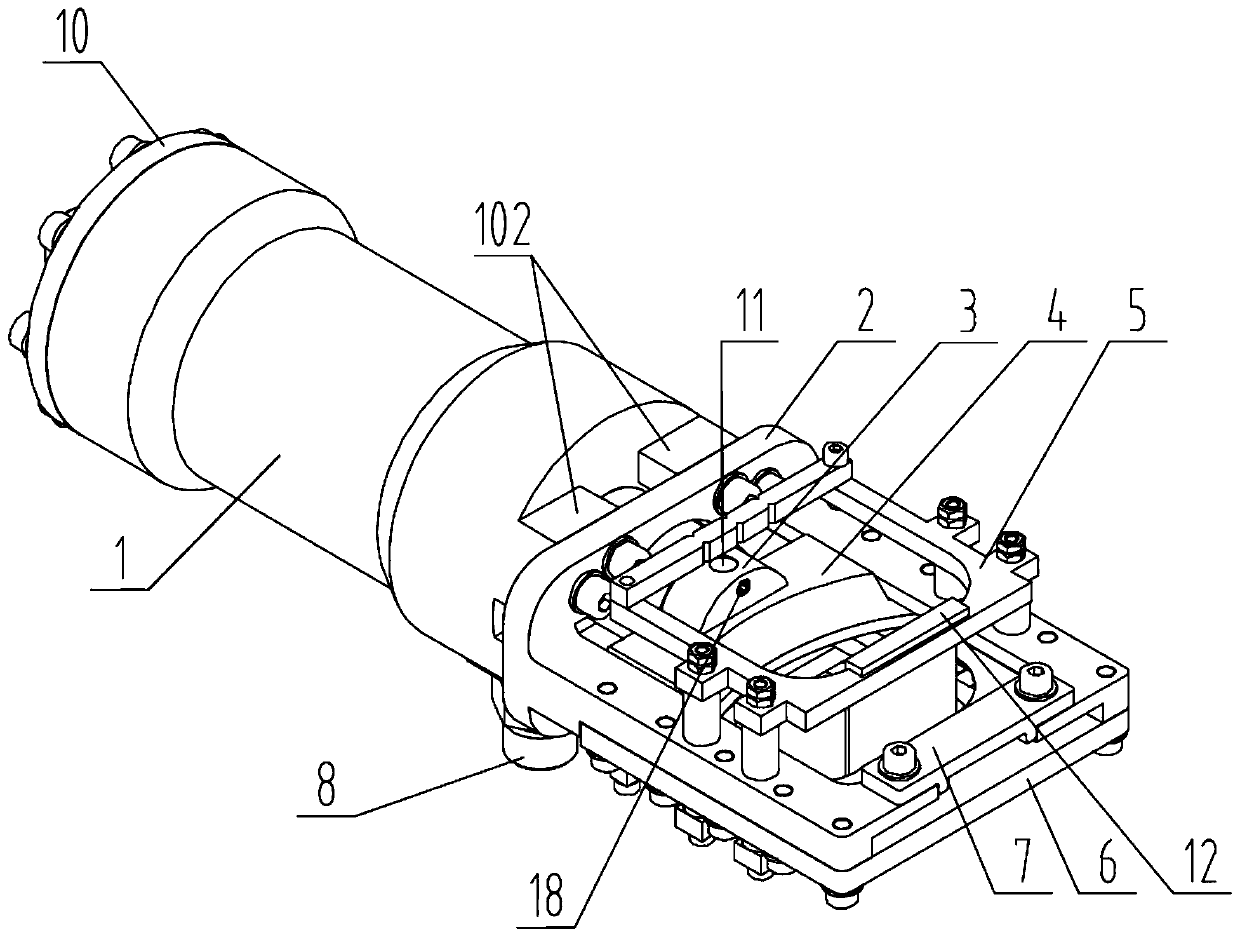

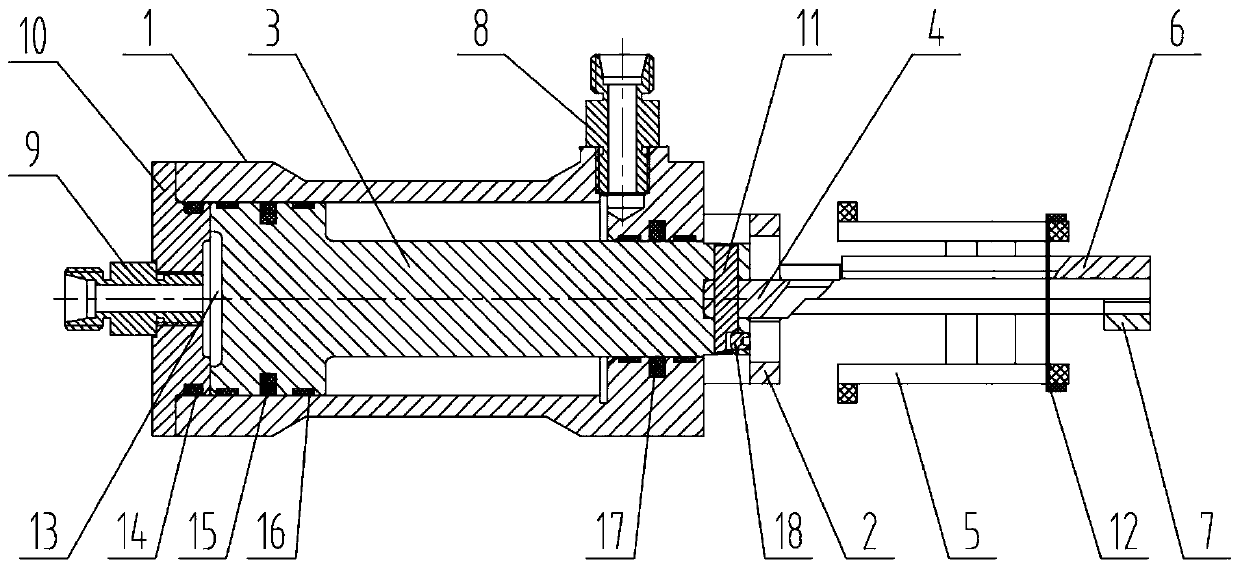

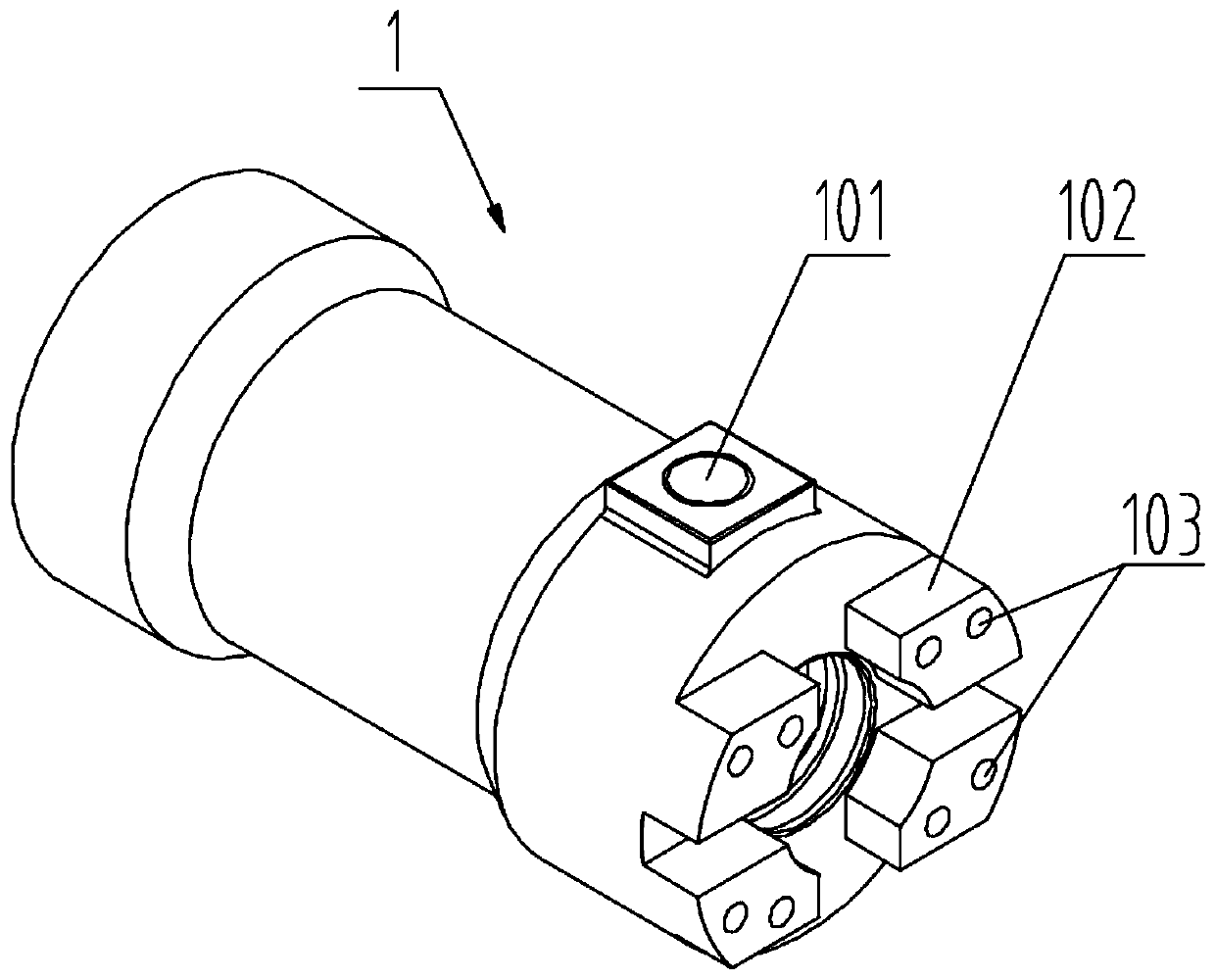

Small underwater cable cutting device

The invention relates to a small underwater cable cutting device which comprises an oil cylinder barrel, wherein a piston rod is mounted inside the oil cylinder barrel; a movable cutting knife is connected with one end part of the piston rod through a shaft pin and a set screw; a guiding frame is connected with one end of the oil cylinder barrel; after extending out of the guiding frame, the movable cutting knife is matched with a fixed cutting knife to cut off a cable; the fixed cutting knife is mounted on the bottom surface of the guiding frame; two limiting frames are correspondingly mounted on the upper surface of the guiding frame and the lower surface of the fixed cutting knife; one end of the upper limiting frame and that of the lower limiting frame are simultaneously connected witha vertically-mounted gasket; the movable cutting knife and the fixed cutting knife are positioned between the two limiting frame; and the gasket is positioned between the movable cutting knife and the fixed cutting knife. By the adoption of the small underwater cable cutting device provided by the invention, the technical problem that a conventional underwater cutting device is complex in structure, large in weight and occupied space, high in operating difficulty and low in autonomous operability can be solved; the space can be greatly saved; and the underwater cutting efficiency can be improved.

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

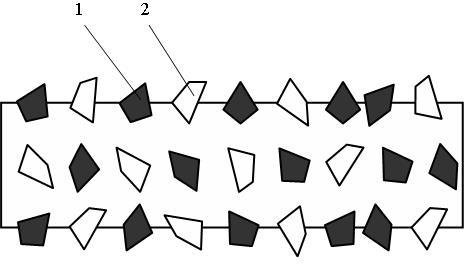

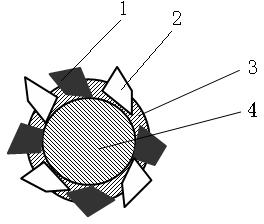

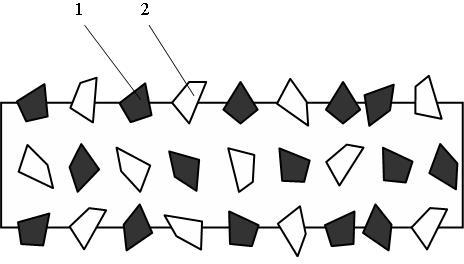

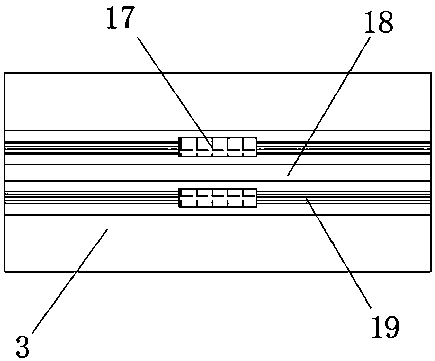

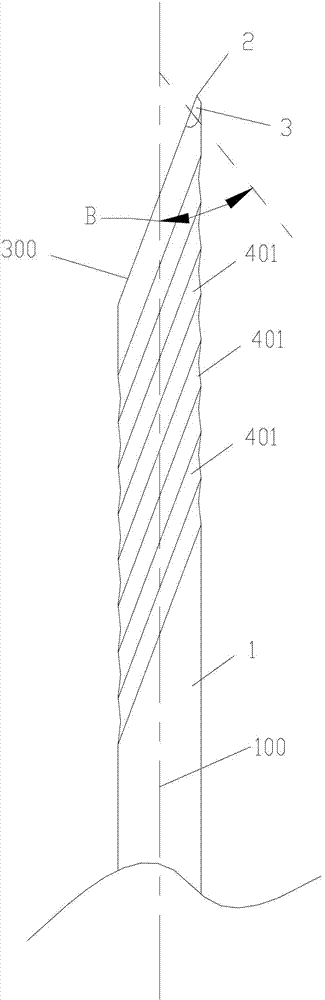

Cutting line solidified with mixed grinding materials of diamond and cubic boron nitride and method for manufacturing cutting line

InactiveCN102555088AImprove sharpnessGuaranteed sharpnessElectrolytic coatingsFine working devicesBoron nitrideSilicon

The invention provides a cutting line solidified with mixed grinding materials of diamond and cubic boron nitride and a method for manufacturing the cutting line. The cutting line comprises a metal steel wire solidified with grinding materials. The cutting line is characterized in that the grinding materials are the mixed grinding materials of diamond and cubic boron nitride, the mixed grinding materials of diamond and cubic boron nitride are solidified onto the metal steel line by means of electronickelling, the particle diameter of the grinding materials ranges from 5mum to 75mum, and the diameter of the diamond is not larger than 1.5mm. The method for manufacturing the cutting line includes removing oil and rust of the metal steel wire; solidifying the mixed grinding materials of diamond and cubic boron nitride onto the metal steel line by means of electronickelling; and forming the cutting line. A diamond grinding material is combined with a cubic boron nitride grinding material, the diamond and the cubic boron nitride are used for cutting alternately when the cutting line is used for cutting hard and brittle materials, and cutting capacity and cutting efficiency of the cutting line are improved. In addition, the cutting line can be more effectively applied to cutting off crystal silicon, slicing the crystal silicon and slicing sapphire by means of regulating the proportion of the diamond and the cubic boron nitride.

Owner:QINGDAO GAOCE TECH CO LTD

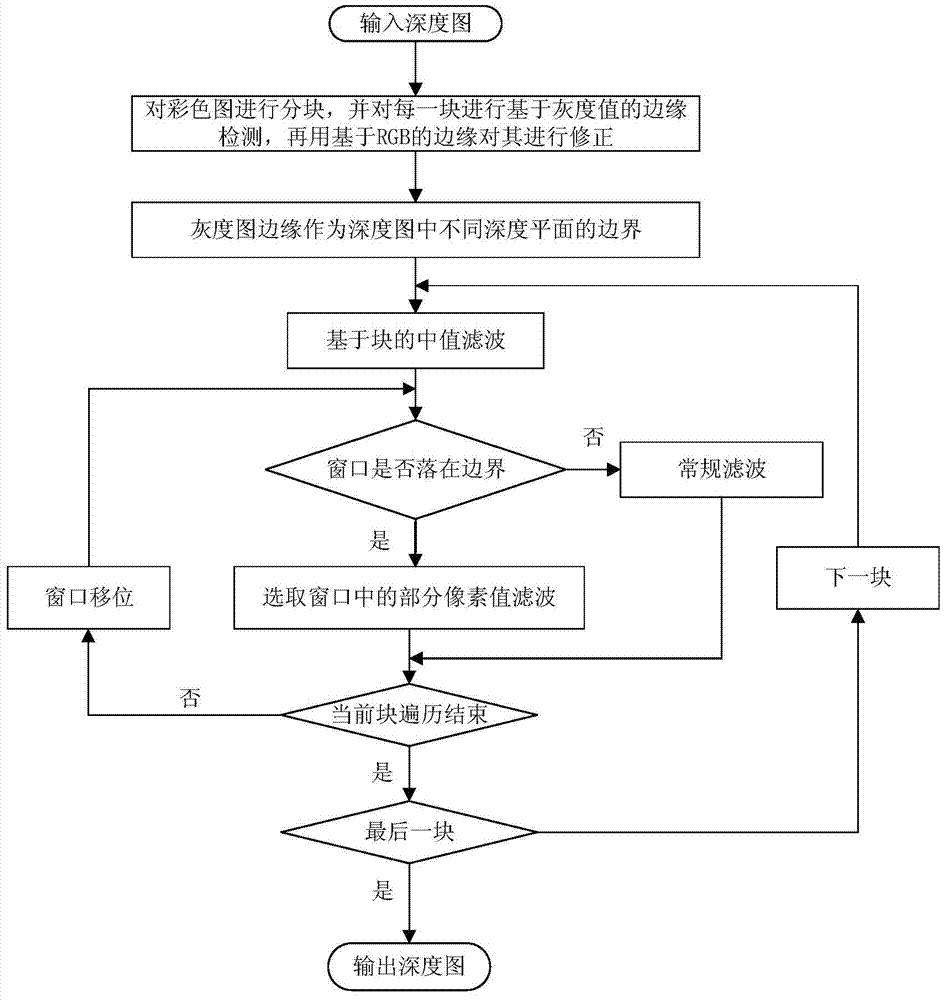

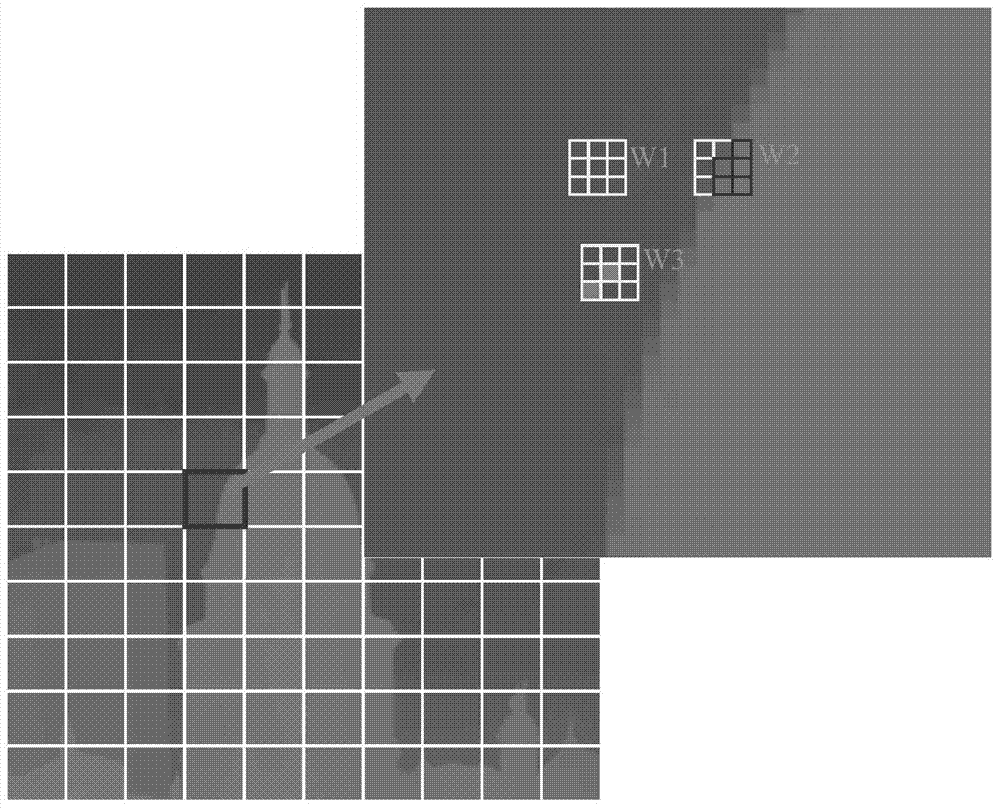

Post-processing filtering method for depth map

ActiveCN103942756AQuality improvementGuaranteed sharpnessImage enhancementImage analysisPattern recognitionTime domain

The invention relates to a post-processing filtering method for a depth map. The post-processing filtering method for the depth map comprises the following steps that (A1) the depth map and a color map on the same scene are input; (A2) the color map is partitioned into blocks, edge detection based on a grey-scale map is carried out on each block, a boundary based on a chrominance component is used for correcting a grey-scale edge on the scene, and the obtained boundary serves as the boundary of different depth planes in the depth map; (A3) the depth map is divided into blocks as large as those in the step (A2) and is segmented based on the blocks, and denoising filtering is carried on the depth map with each block as a unit; (A4) the steps from (A1) to (A3) are carried out repeatedly until all maps are processed; (A5) an obtained depth map sequence is output. According to the post-processing filtering method for the depth map, the smoothness features of pixel points in a space domain and a time domain are extracted, and calculation on the depth map is carried out in the reading and scanning processes, so that the depth map with the defects of time domain vibration, space domain instability, low scene reducibility and the like is improved.

Owner:HUAZHONG UNIV OF SCI & TECH +1

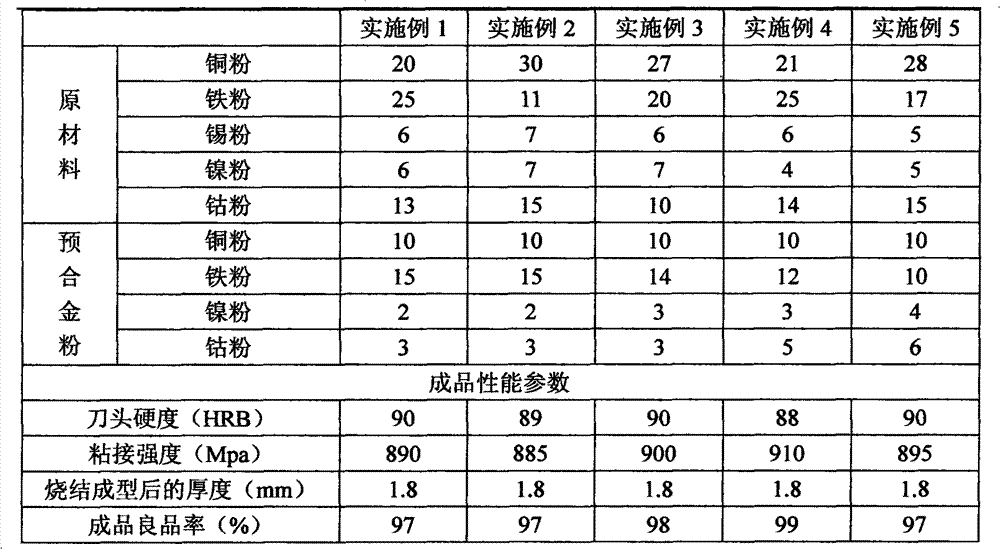

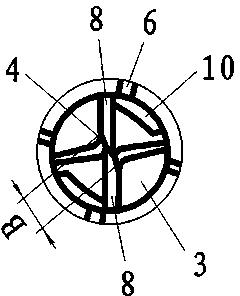

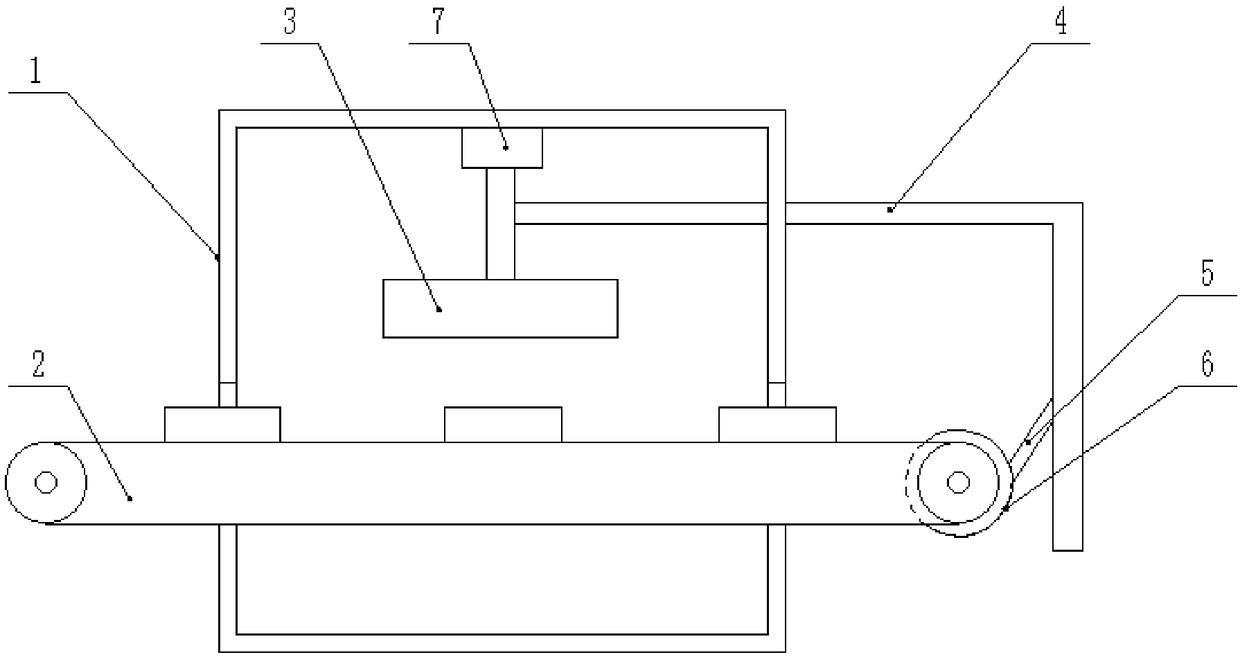

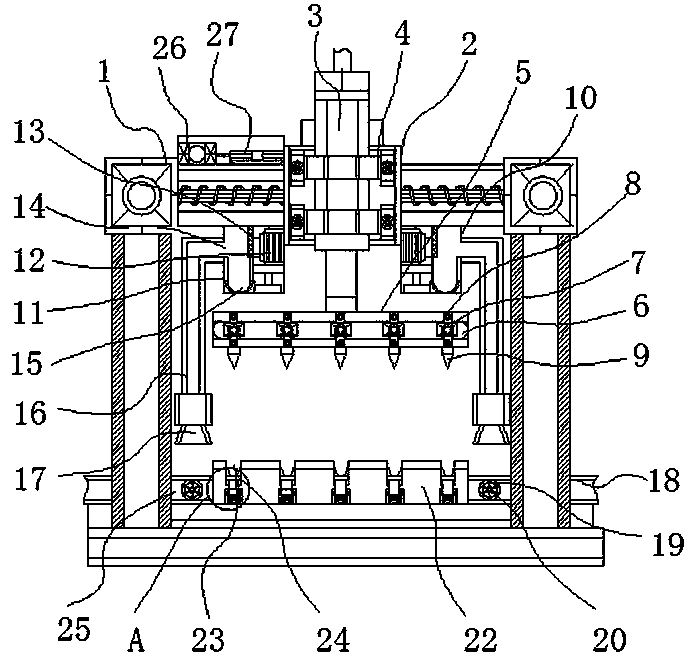

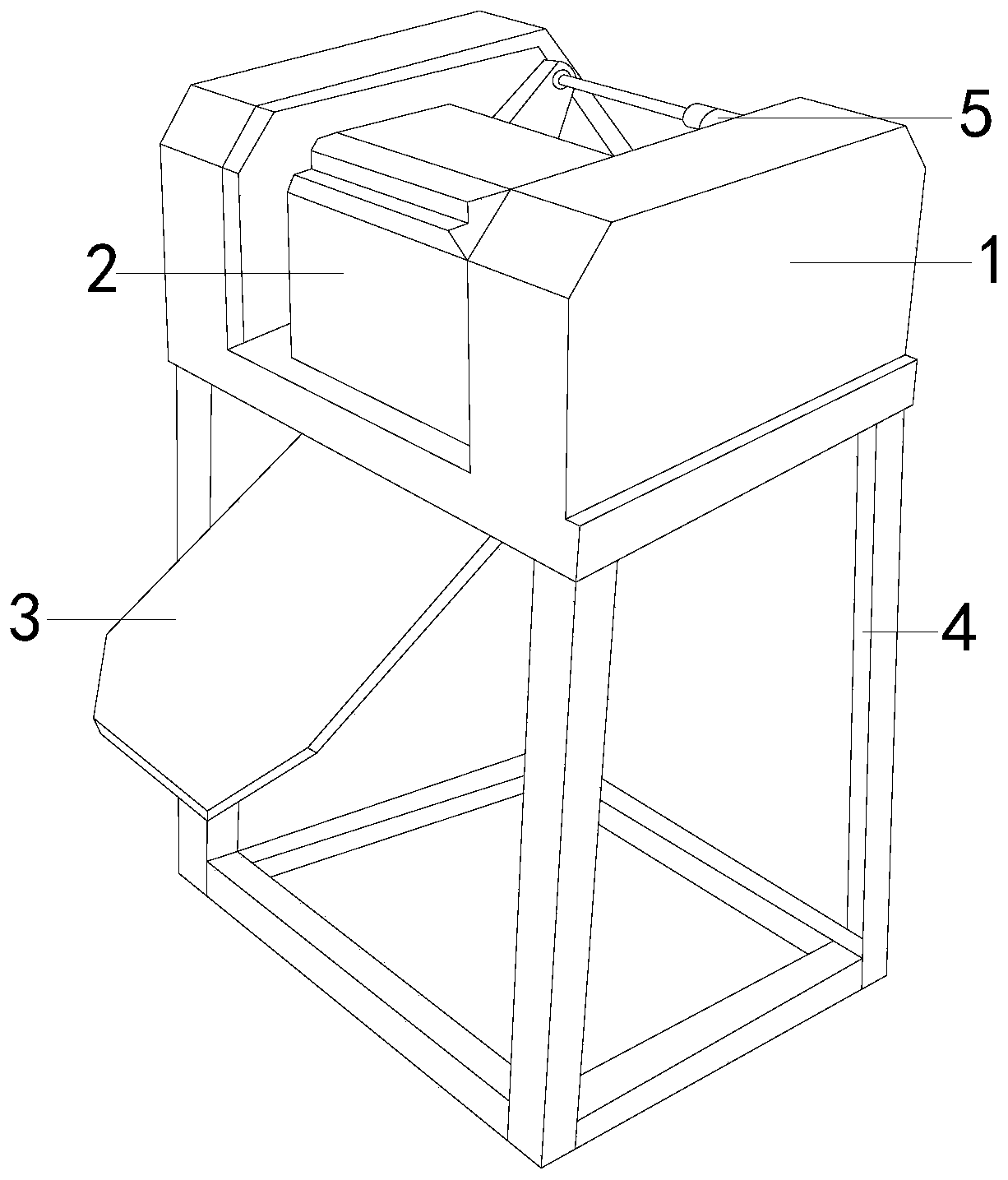

Novel composite material drilling bit and manufacturing method thereof

InactiveCN105458354AAvoid centralized distributionReduced axial cutting forceTwist drillsMechanical engineeringDrill bit

The invention discloses a novel composite material drilling bit and a manufacturing method thereof. The novel composite material drilling bit comprises a cutter handle (1) and a cutting part (2). The end of the cutting part (2) is provided with a step (9). The cutting part (2) is divided into a first cutting part and a second cutting part which is connected with the cutter handle (1) through the step (9), and the diameter of the first cutting part is smaller than that of the second cutting part. First main cutting blades (8) and first auxiliary cutting blades (7) are symmetrically arranged on the first cutting part along the axis. Transverse blades (4) are arranged between the first main cutting blades (8). Second main cutting blades (6) and second auxiliary cutting blades (5) are symmetrically arranged on the second cutting part along the axis. The step (9) is connected with the first auxiliary cutting blades (7) and the second main cutting blades (6). When the drilling bit is used for machining a composite material, the service life of the drilling bit is long, and the precision and roughness of a machined hole are high.

Owner:XINAN TOOLS GUIZHOU PROV

Brazed diamond flexible abrasive disc and manufacturing method thereof

ActiveCN102172897AGood flexibilityOvercome the shortcomingsAbrasion apparatusTemperature resistanceDiamond grinding

The invention discloses a brazed diamond flexible abrasive disc and a manufacturing method thereof, and relates to a diamond abrasive disc. The invention provides the brazed diamond flexible abrasive disc which is mainly used for coarse grinding processing of hard and brittle materials such as stone, glass, ceramic, concrete and the like, has good sharpness during grinding, is easy to grind special-shaped faces such as planes, edges, angles, arcs and the like, has good high temperature resistance and long service life and does not produce discoloration after long-time dry grinding, and the manufacturing method thereof. The flexible abrasive disc is provided with a diamond grinding layer and a connector; and the diamond grinding layer is provided with a matrix and diamond granules, the matrix is a flexible thin steel sheet, the diamond granules are brazed on the upper surface of the matrix, and the connector is connected with the lower surface of the matrix. The method comprises the steps of manufacturing the diamond grinding layer and manufacturing a finished product of the diamond flexible abrasive disc.

Owner:XIAMEN ZL DIAMOND TECH CO LTD

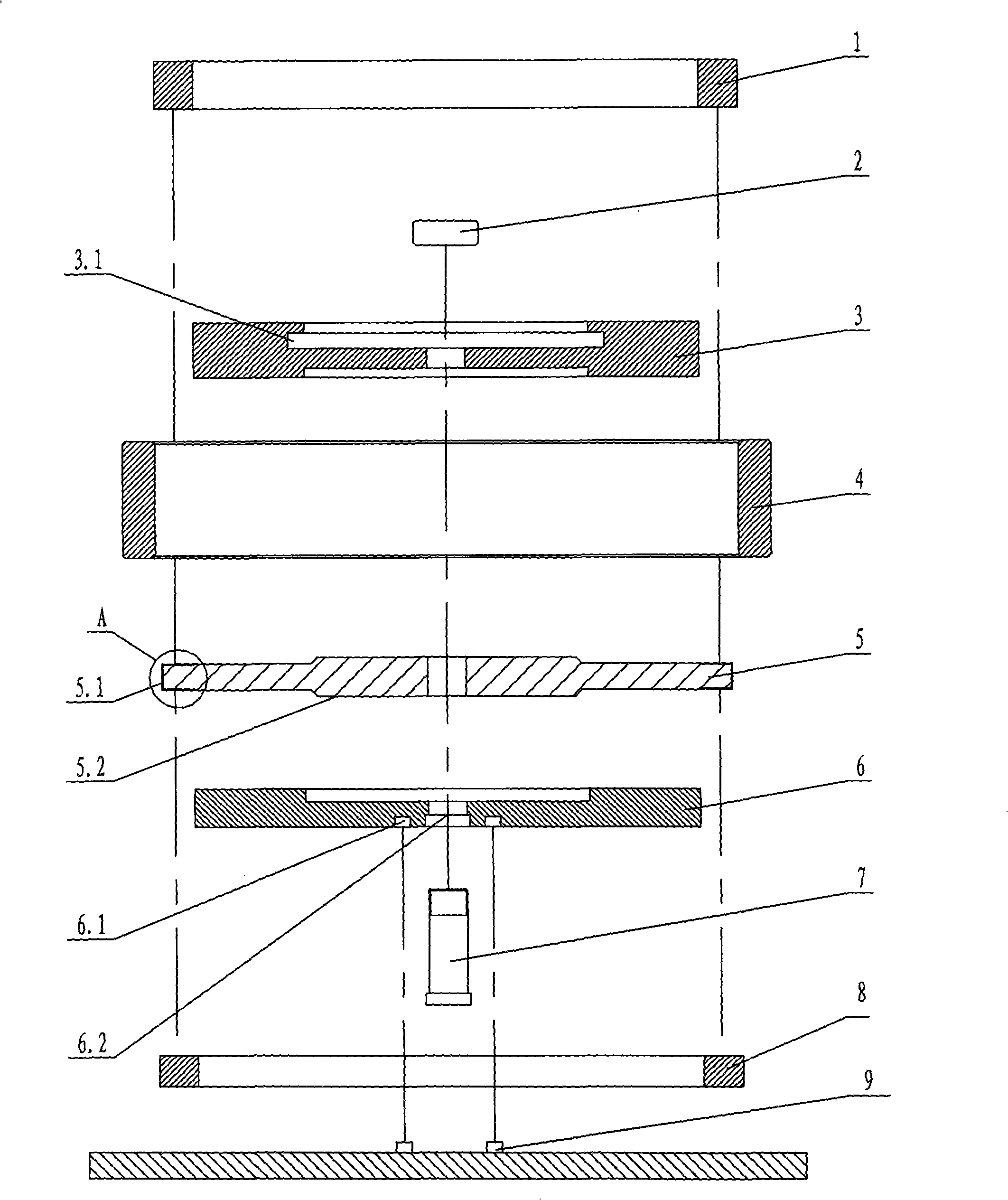

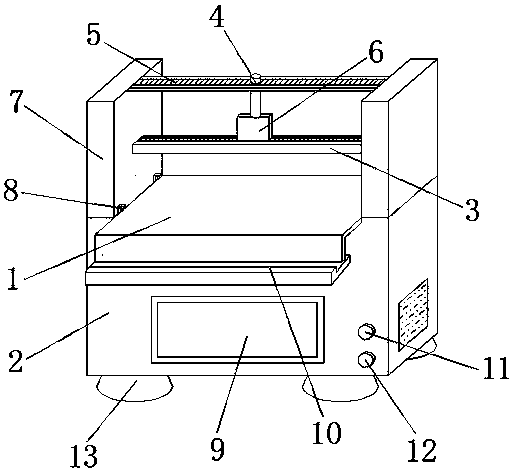

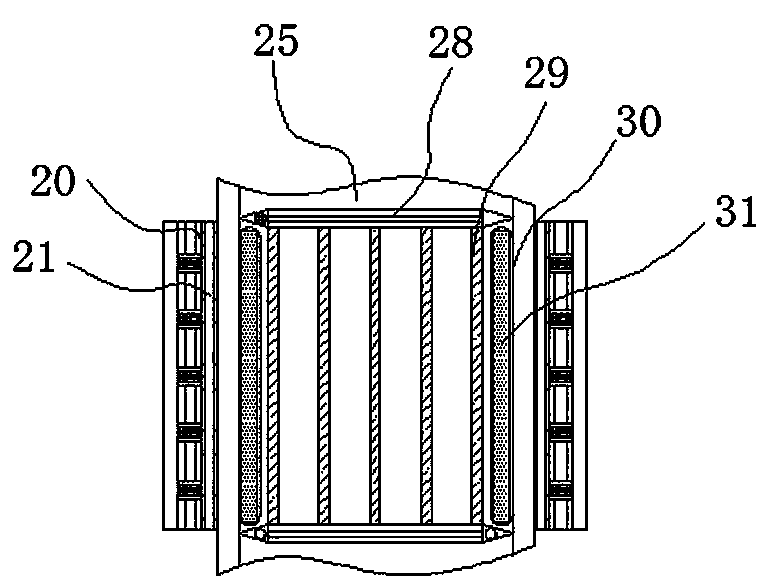

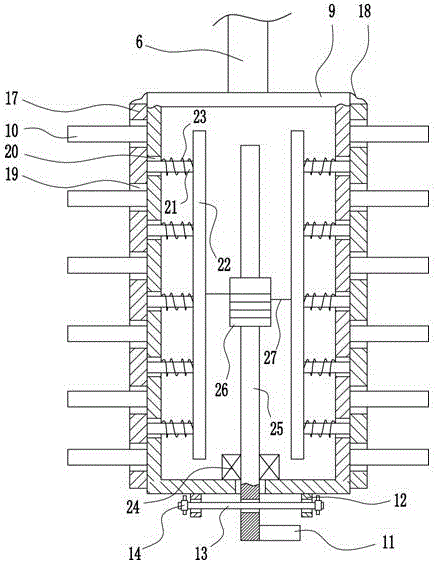

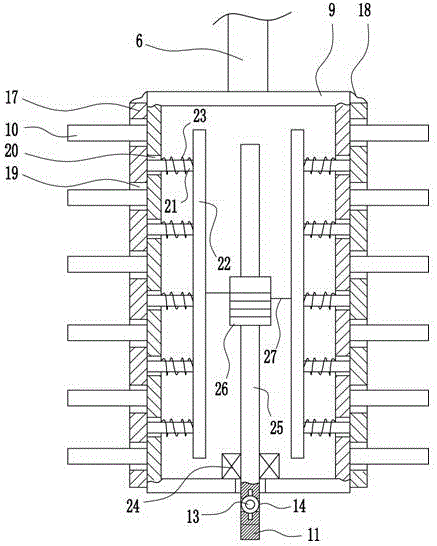

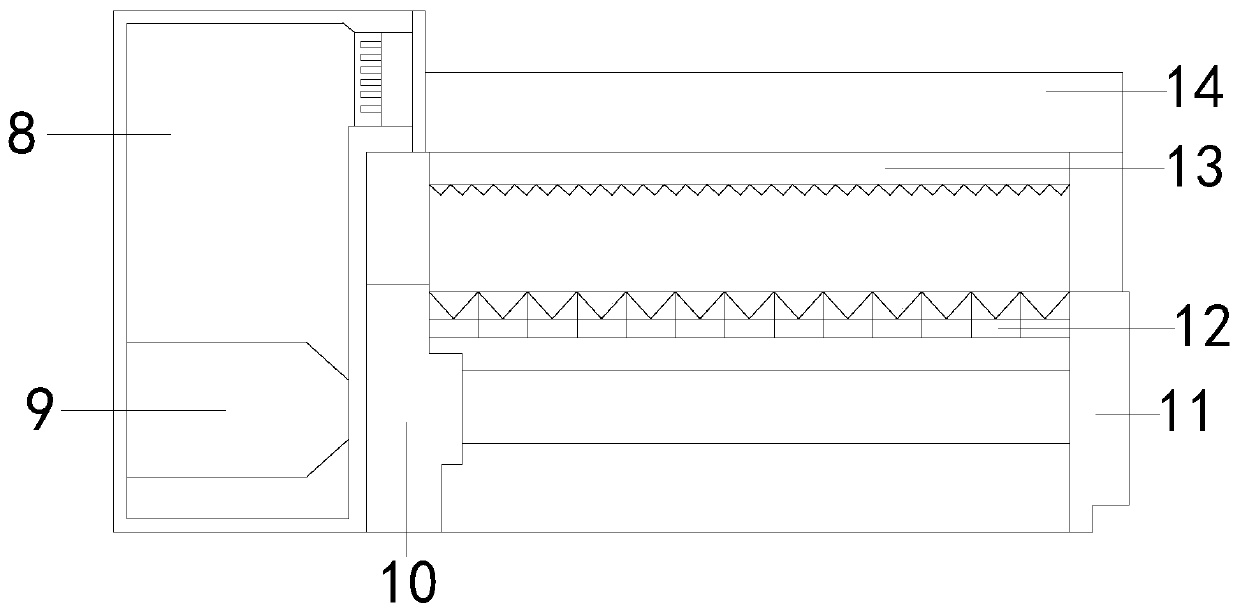

Method for machining rotor of screw compressor through formation CBN grinding wheel

The invention discloses a method for machining a rotor of a screw compressor through a formation CBN grinding wheel. The method includes the steps of preparation of a grinding wheel matrix, semi-finishing of the grinding wheel matrix, finish machining of the grinding wheel matrix, electroplating of CBN grinding materials and the like. The outline of the outer circle of the grinding wheel matrix is machined through a high-precision numerically controlled lathe, the outlines of different profiles can be converted conveniently and efficiently, production cost is greatly lowered, production cycle is shortened, non-milling deep grinding can be really achieved through the formation CBN grinding wheel, namely tooth profiles are machined by directly grinding an entity without carrying out preprocessing according to a traditional lathing method or a traditional milling method or other methods, a large amount of time and high expenses for manufacturing milling cutters are saved, and research, development and production of novel rotor profiles are accelerated.

Owner:郑州众邦超硬工具有限公司

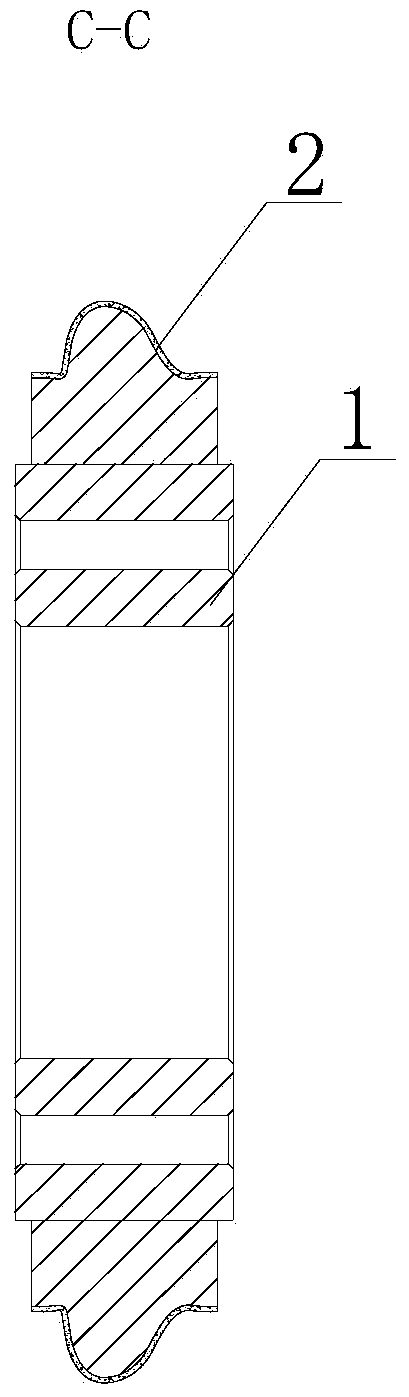

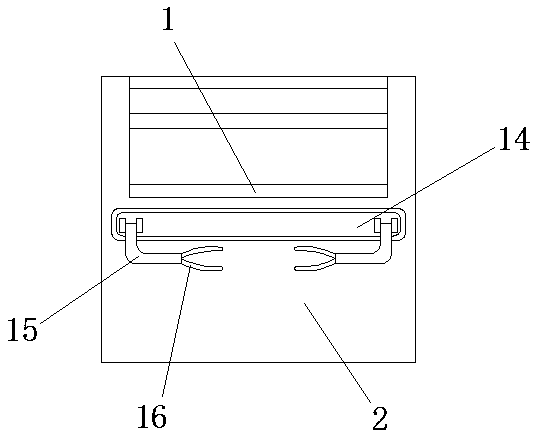

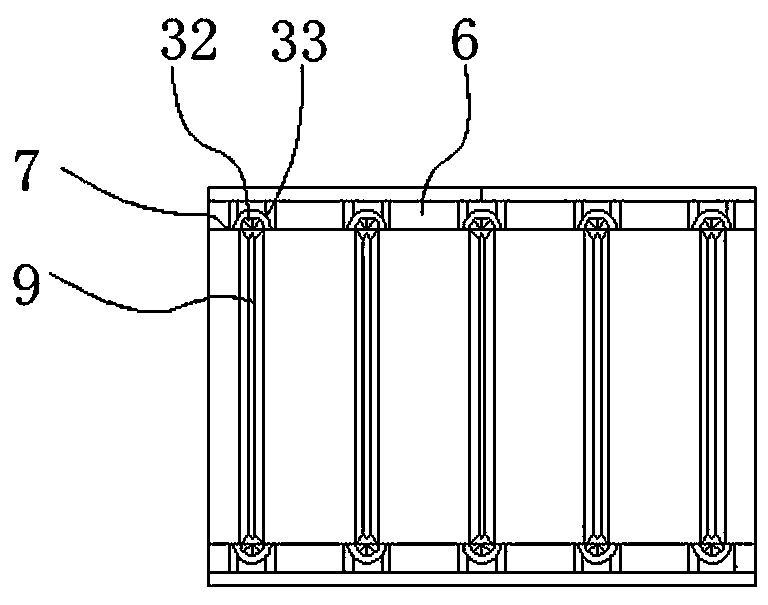

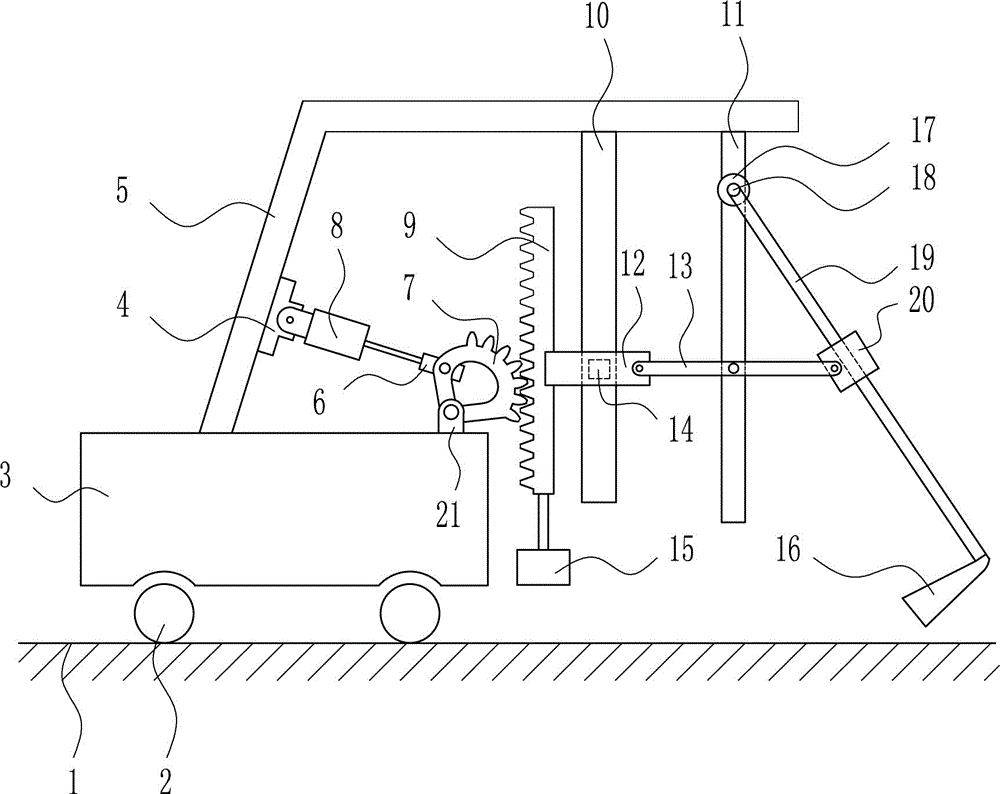

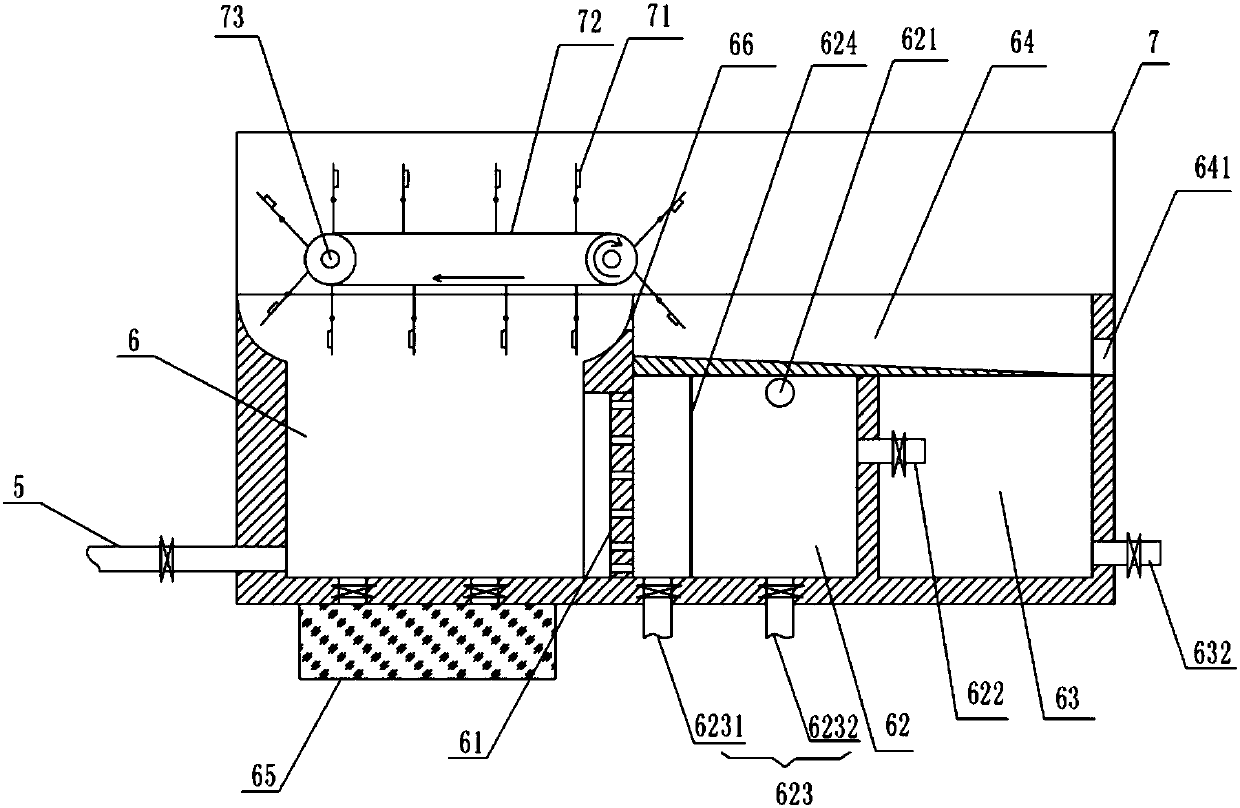

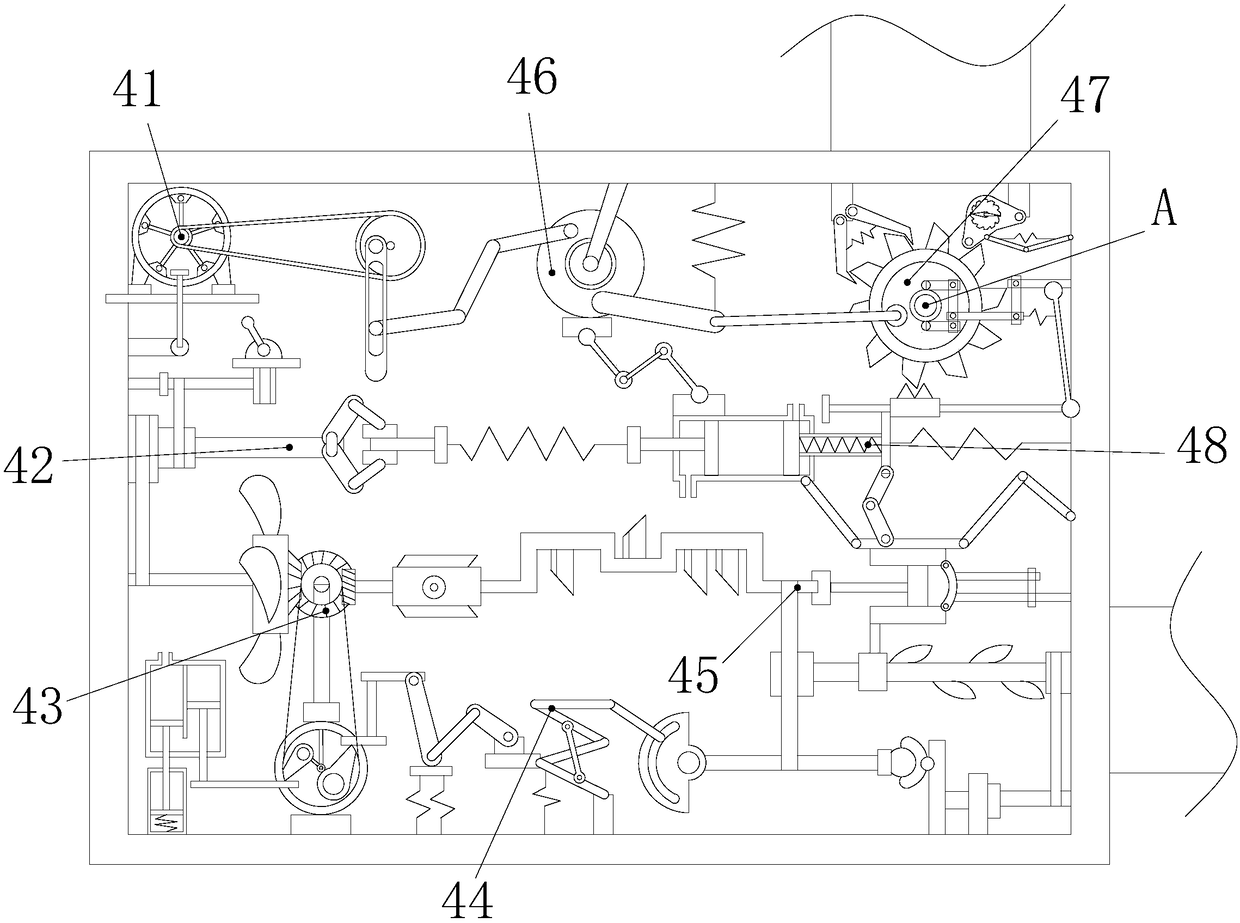

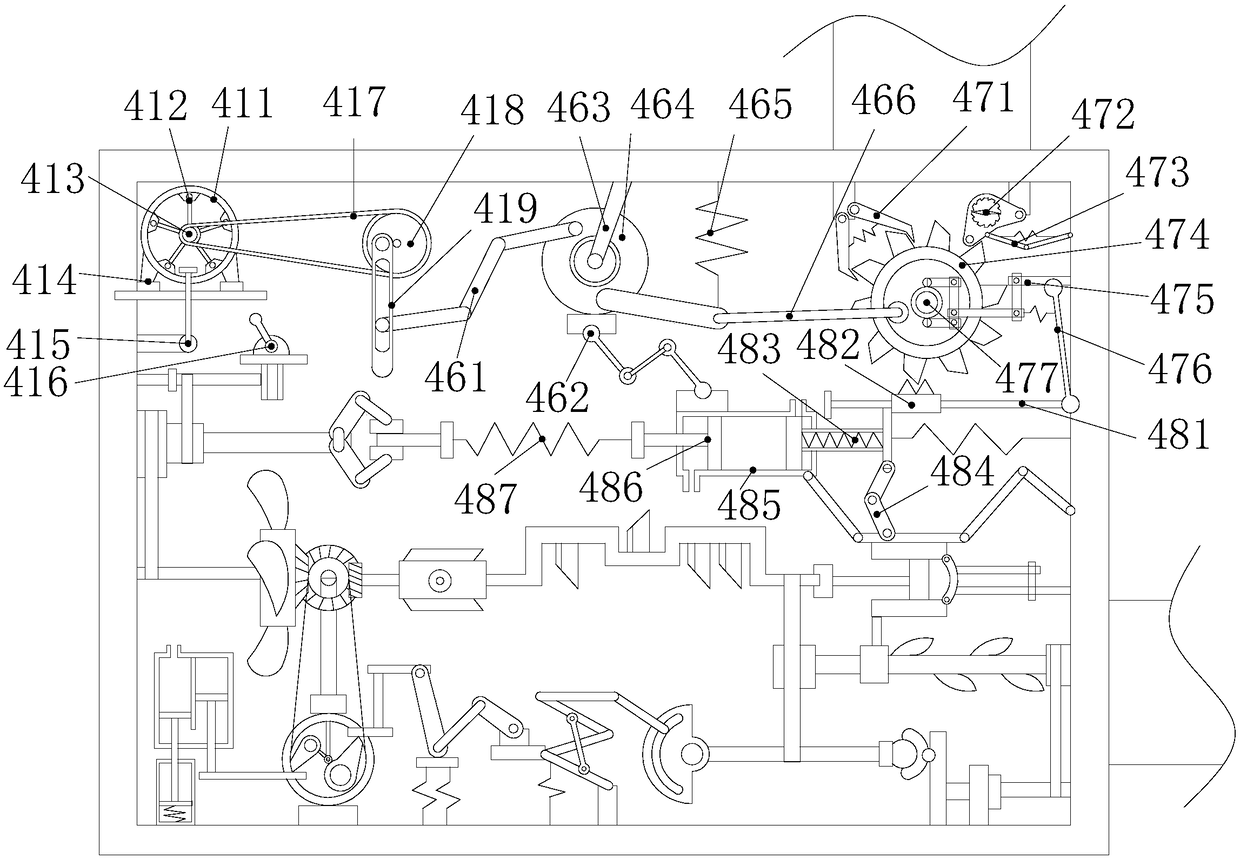

Book edge-cutting device

ActiveCN108356869ARealize automatic trimmingRealize transportationMetal working apparatusMechanical engineering

The invention relates to the technical field of paper cutting, and discloses a book edge-cutting device. The book edge-cutting device comprises a machine frame, the machine frame is rotatably connected with a belt transport mechanism, the machine frame is slidably connected with a cutter and a first connecting rod, and the cutter is located above the belt transport mechanism. The first connectingrod is fixedly provided with a first ratchet claw, the belt transport mechanism is coaxially connected with a first ratchet wheel which meshes with the first ratchet claw, and the machine frame is provided with a fixing mechanism used for fixing a book. The book edge-cutting device can automatically fix the book with the edge to be cut while cutting the edge, the book is prevented from deviation,and the efficiency of cutting edge and the qualified rate of the product are improved.

Owner:普天印务(重庆)股份有限公司

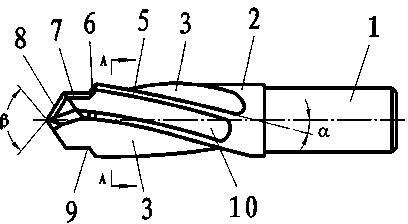

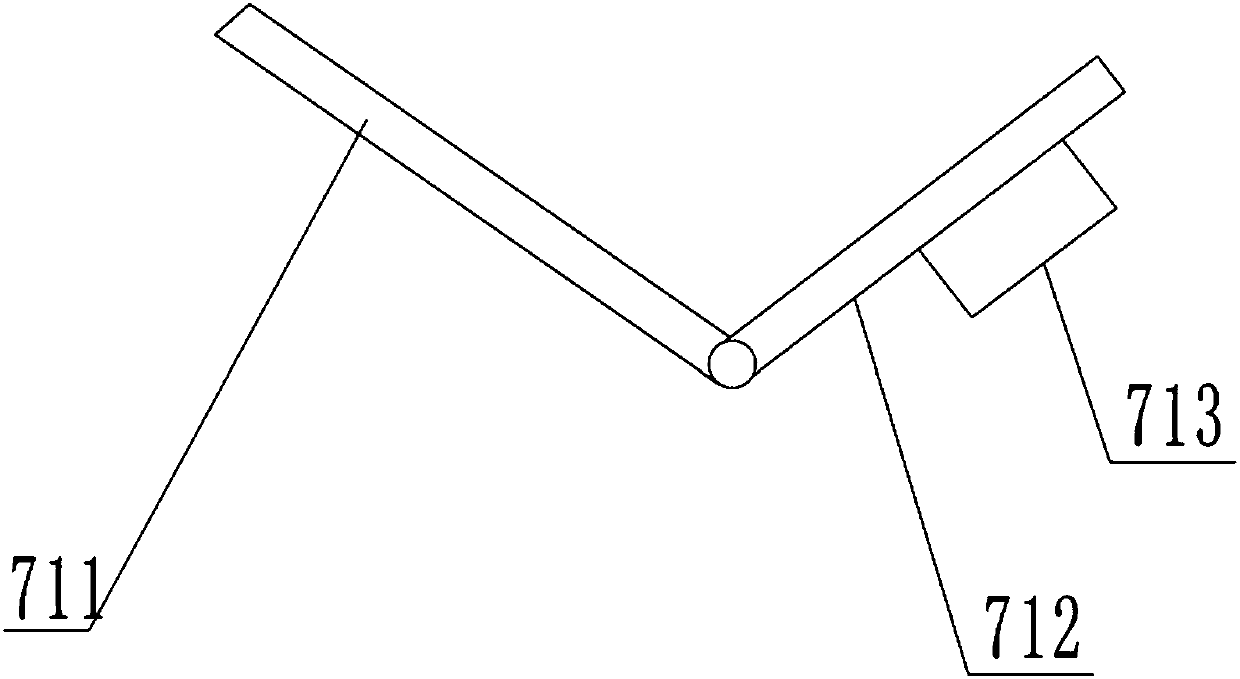

Nano-diamond coating cutting tool and application thereof to mouth rehabilitation ceramic machining

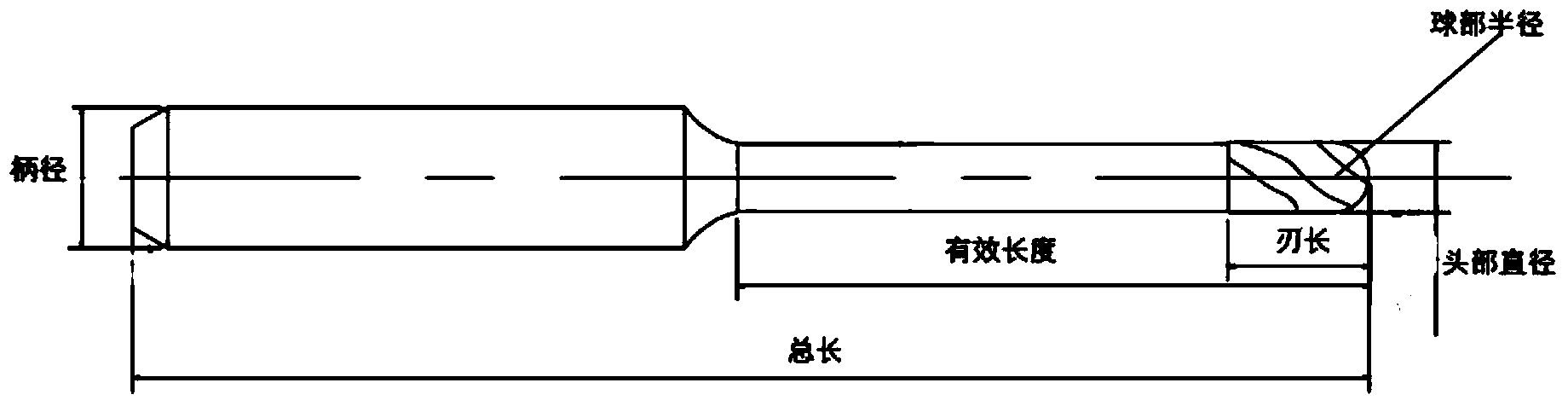

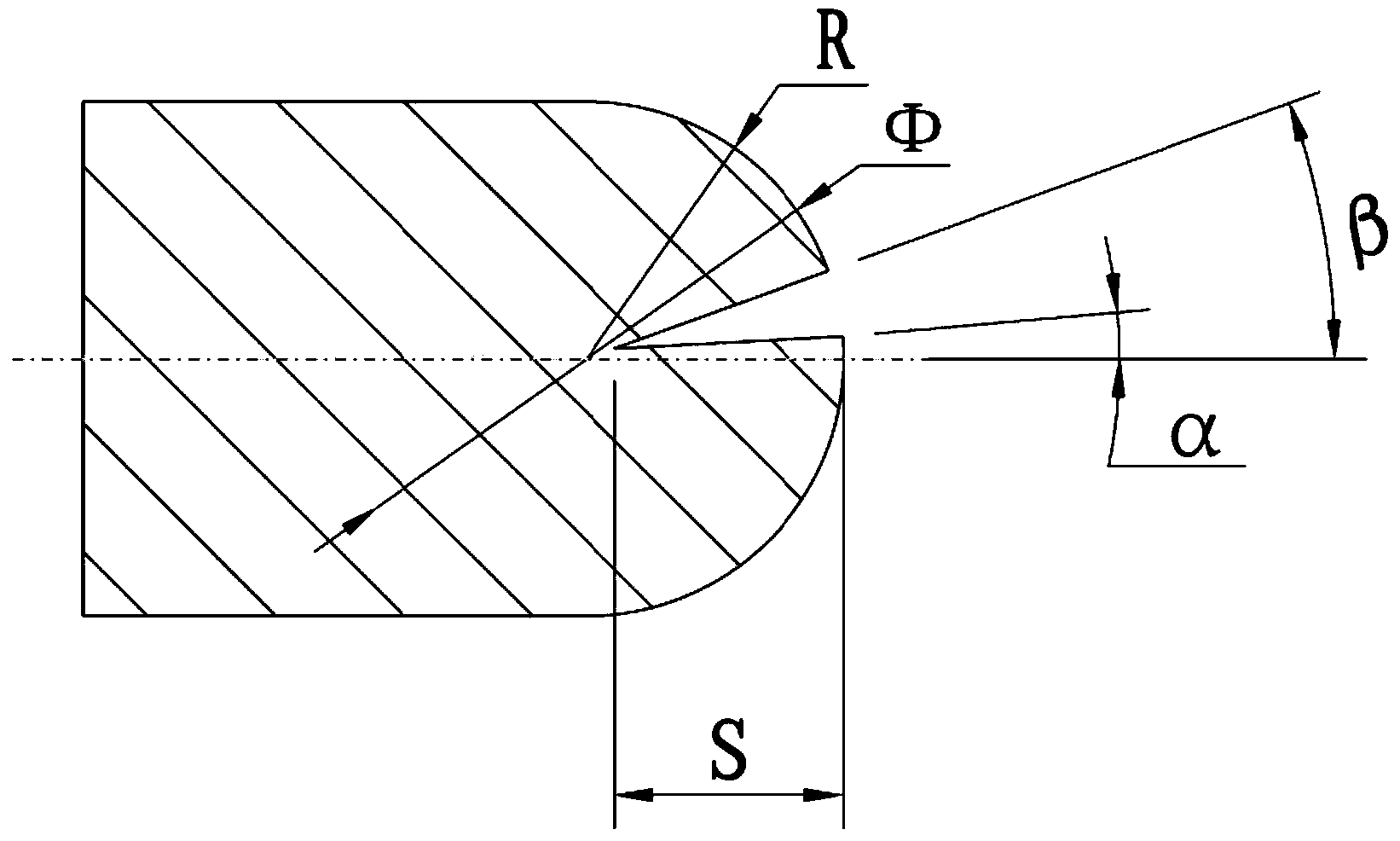

InactiveCN103770223AExtended service lifeImprove machinabilityMilling cuttersChemical vapor deposition coatingTO-18Milling cutter

The invention relates to a nano-diamond coating cutting tool and the application thereof to mouth rehabilitation ceramic machining. The nano-diamond coating cutting tool is characterized in that (1) the cutting tool is a ball milling cutter, a spiral angle of a spiral groove in a cutting edge of the cutting tool is 30 degrees, and the length of the cutting edge is 2mm; (2) a V-shaped groove is formed in the top of the cutting edge of the cutting tool, a vertical included angle alpha between the V-shaped groove and the center of the cutting tool is equal to 1-5 degrees, an included angle beta is equal to 18-25 degrees, the depth of the V-shaped groove is changed along with the diameter change of the cutting tool, and the depth S value of the V-shaped groove is 10-18 percent of the diameter Phi value of the cutting tool; (3) the cutting edge of the cutting tool is a nano-diamond coating, the diameter of nano-diamond particles is 20-50nm, and the diameter of the head is 2-10mm. When the diameter of the head is less than or equal to 4mm, the diameter of a tool handle is less than or equal to 4mm, and the diameter of a handle part is 4mm; when the diameter of a ball is more than 4mm, the diameter of the handle part is equal to the diameter of the head. When the provided nano-diamond coated cutting tool is applied to pre-sintering ceramic machining for mouth rehabilitation, the feed is 1,400mm / min, and the speed of a main shaft is 25,000rpm. Powder formed by cutting is effectively discharged, the phenomenon of tool breakage is reduced, and the service life is prolonged by 25-30 percent.

Owner:SHANGHAI XIANGREN NEW MATERIALS

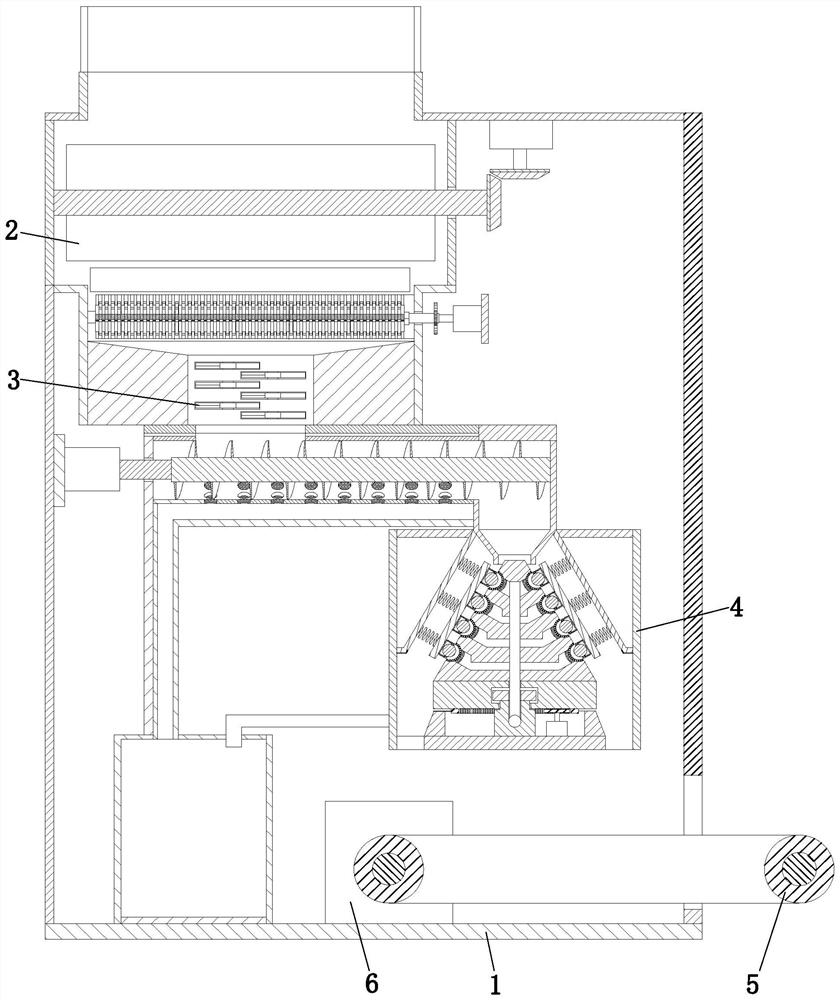

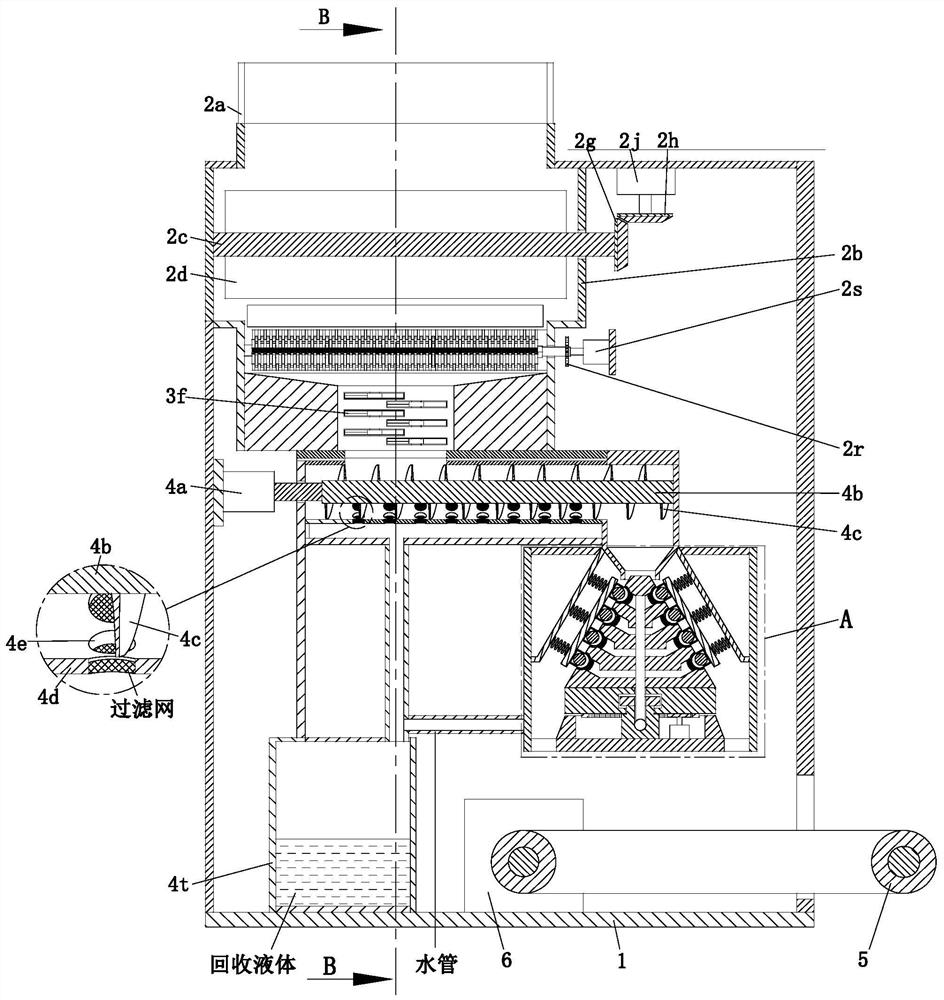

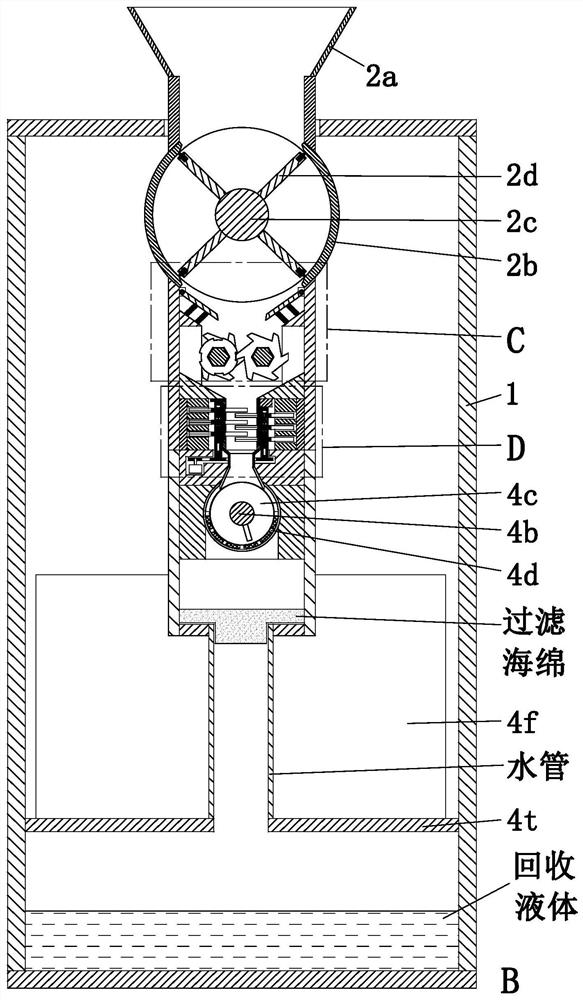

Single-face automatic feeding four-column cutting machine

The invention discloses a single-face automatic feeding four-column cutting machine. The single-face automatic feeding four-column cutting machine comprises a workbench, a lifting rod and a container.Fixing supports are arranged on the two sides of a cutting mechanism, and fixing buckles are arranged below the cutting mechanism. A motor is arranged on the inner surface of the base, and a carryingtable is arranged on one side of the base. Rotation rods are arranged on the outer surface of the container, and mechanical arms are arranged at one ends of the rotation rods. Sharpening blocks are arranged in the cutting mechanism. According to the single-face automatic feeding four-column cutting machine, the fixing buckles, the carrying table, the mechanical arms and the sharpening blocks arearranged, to-be-cut materials on the workbench can be fixed, it is guaranteed that the materials are flatly placed on the workbench, cutting is convenient, the cut materials can be received, automaticfeeding can be conducted, and the work efficiency is improved; and a cutting blade can be ground, the sharpness of the cutting blade is guaranteed, the cutting effect is ensured, the single-face automatic feeding four-column cutting machine is applicable to different work conditions, and better using prospects are brought.

Owner:江苏华驰机械有限公司

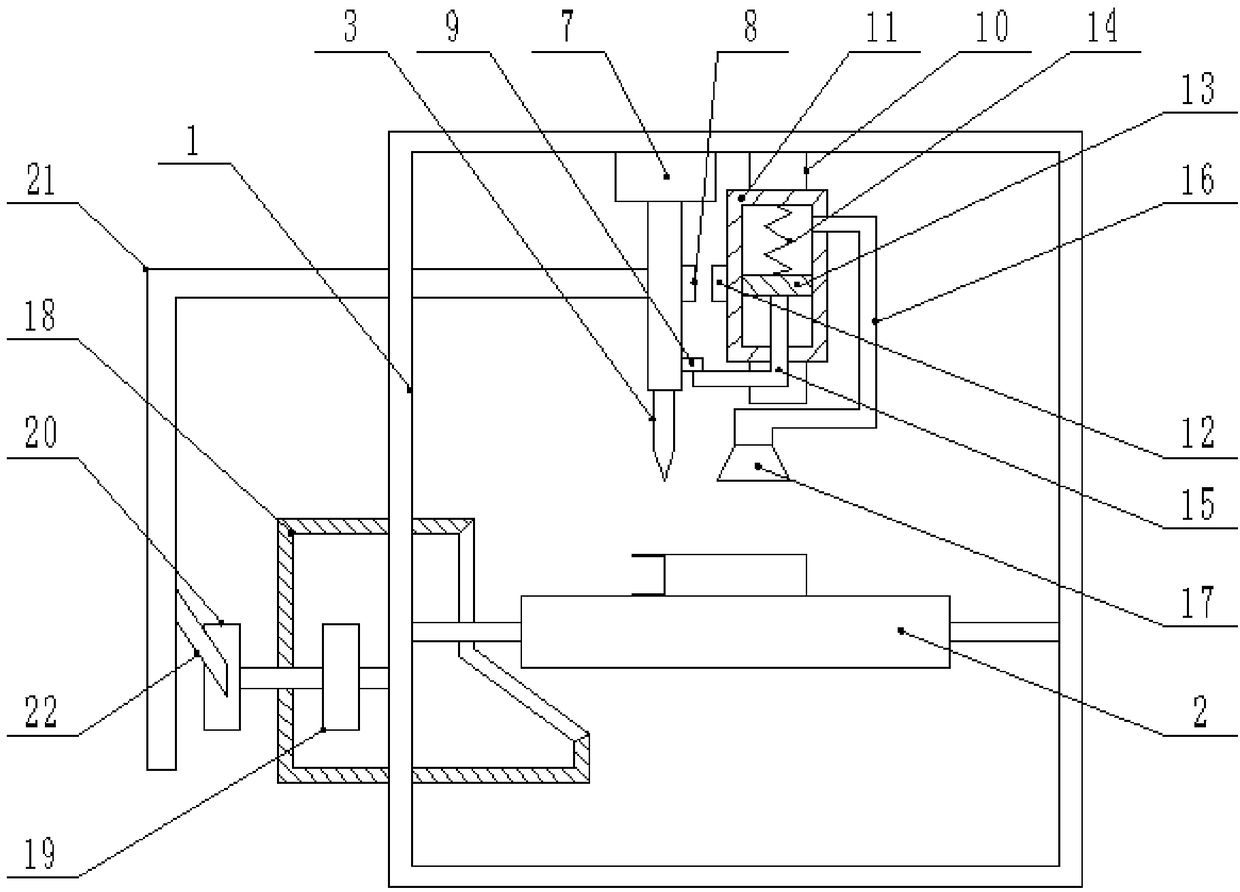

Rapid beef slitting device

ActiveCN109676657AEasy to processImprove cleanupMetal working apparatusMeat shaping/cuttingEngineeringMachining

The invention discloses a rapid beef slitting device, and relates to the technical field of food processing. The device comprises a supporting mechanism and a conveying mechanism, a driving mechanismis arranged in the middle end of the top of the supporting mechanism, the conveying mechanism is arranged at the bottom of the supporting mechanism, the supporting mechanism is fixedly connected withthe driving mechanism through a screw, and the front face of the driving mechanism is provided with a hydraulic air cylinder. The device has the beneficial effects that according to the rapid beef slitting device, through slitting blades and a mounting sliding block, a worker refers to numerical value on a graduation ruler in advance and marks the needed slitting interval numerical value on the front face of the slitting mechanism through a corresponding marking tool, through the manual control sliding method, each slitting blade is sequentially drawn to be adjusted to the corresponding slitting interval segment point through the mounting sliding block, and through changing of the interval numerical value of each slitting blade in the sliding adjusting process, the device can convenientlyachieve cutting machining of beef needing different slitting intervals.

Owner:济南高投能源发展有限公司

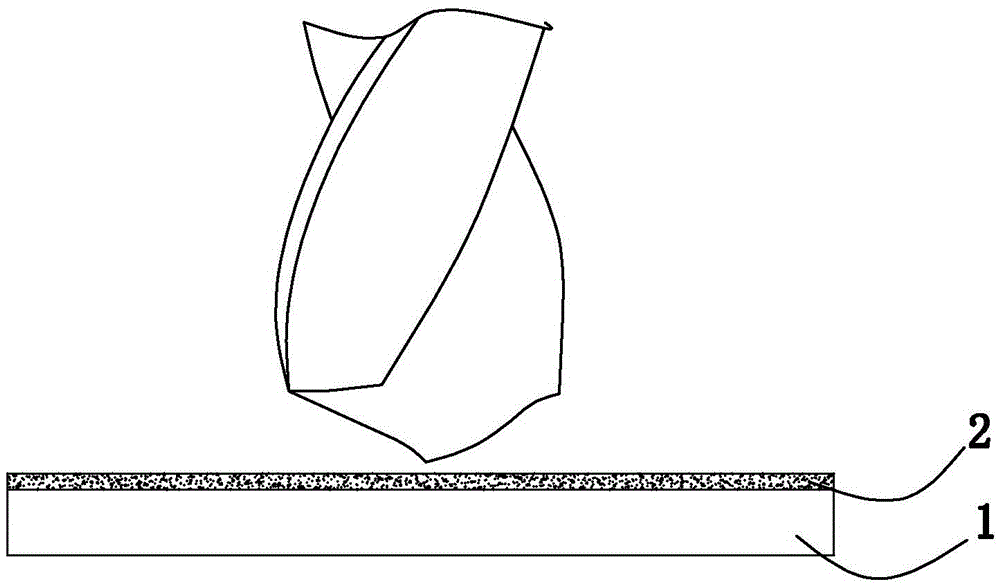

Coating aluminum sheet and technological process for manufacturing same

InactiveCN105537090AEasy curingStrong adhesionPretreated surfacesSpecial surfacesEpoxyManufacturing technology

The invention discloses a coating aluminum sheet which comprises a substrate body and a plate body layer. The plate body layer comprises main materials and auxiliary materials, the main materials comprise coating pigment and diluent, the auxiliary materials comprise calcium powder, color powder, a defoaming agent, a complex compound and a flatting agent, and the plate body layer is mainly composed of epoxy resin materials. When drilling is conducted, the plate body layer can stick to and fix the position of the head of a drill bit, the positioning effect on the dill bit in the downward drilling process is achieved, and the hole position positioning precision in the drilling process is improved. Due to the fact that the surface hardness of the plate body layer is lower than that that of the substrate body, the drill bit can drill through the surface of the plate body layer more easily, tool face abrasion of the drill bit is reduced, the sharpness of the tool face of the drill bit can be well guaranteed, the situation that the drill bit is broken in the drilling process due to the fact that the surface is too hard is reduced, and debris produced in the drilling process can be discharged to the outside in time, so that the hole wall surface inside a hole drilled by the drill bit is smoother, and the effect of improving the hole wall quality of the drilled hole is achieved. A manufacturing technology of the coating aluminum sheet is easy and convenient to operate and convenient to process.

Owner:SHENZHEN HONGYUHUI TECH CO LTD

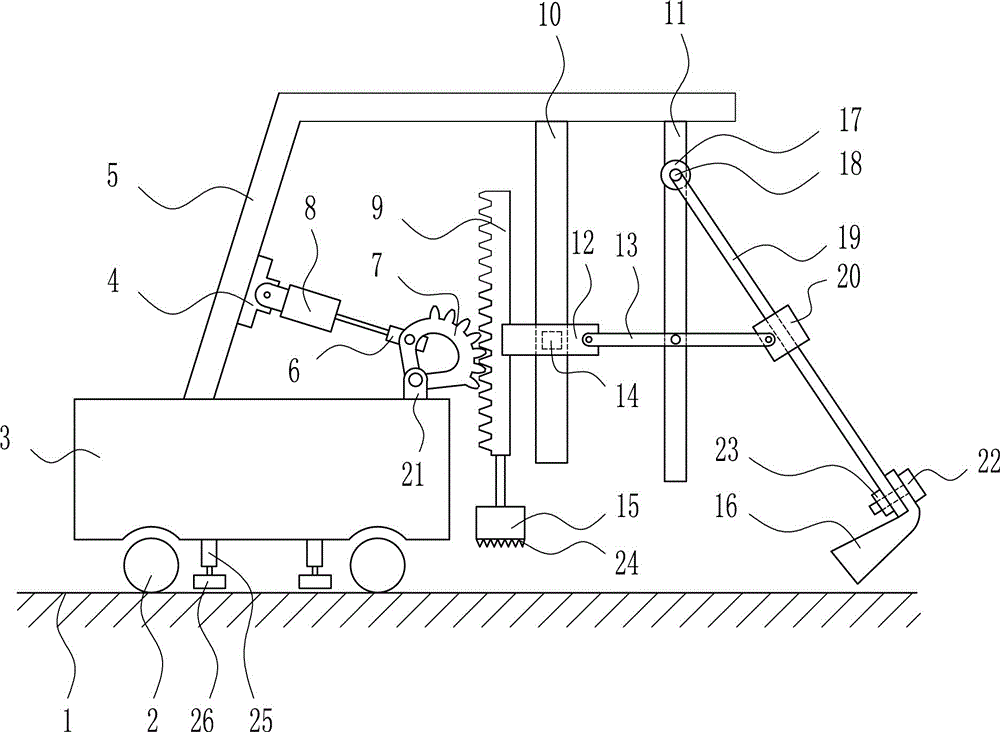

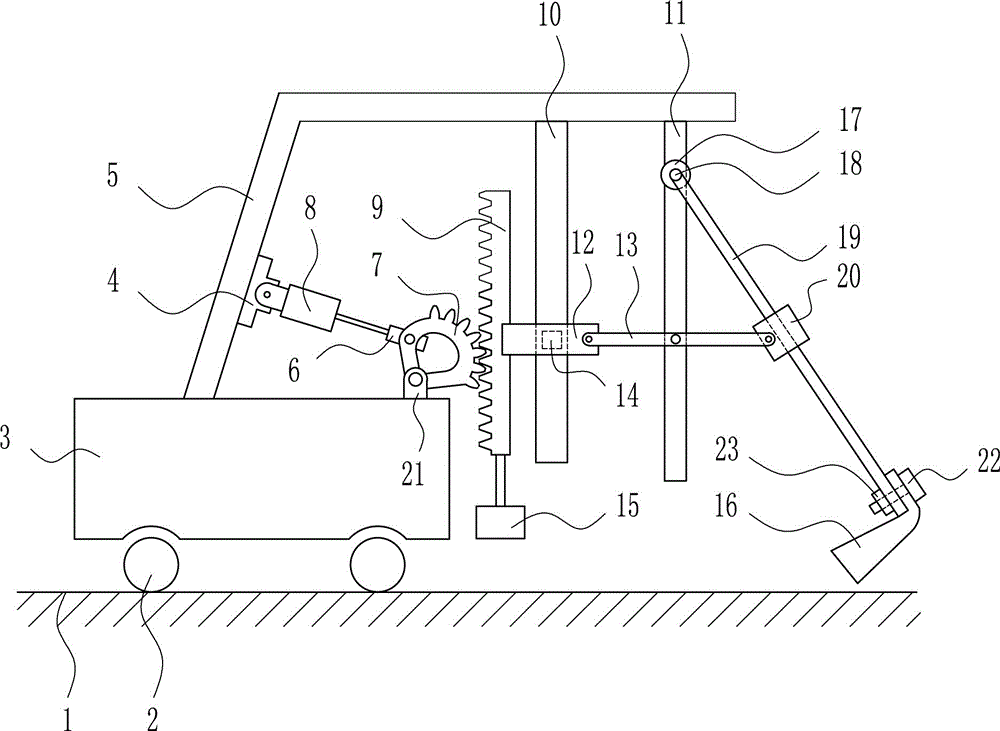

Efficient excavating device for mineral mining

ActiveCN106545043AGuaranteed sharpnessImprove crushing effectSoil-shifting machines/dredgersEngineering

Owner:安康市翔泽油田材料有限公司

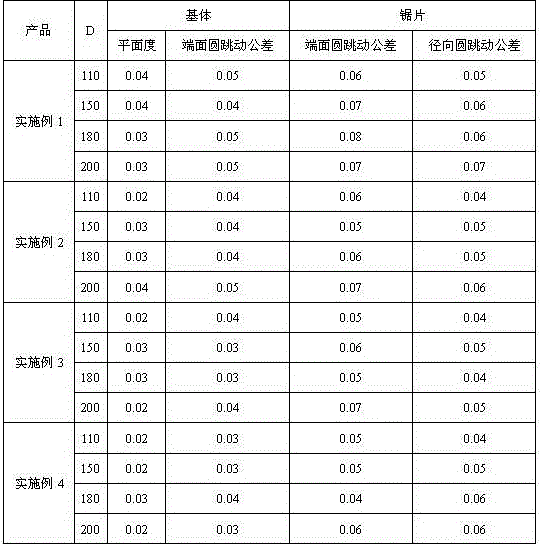

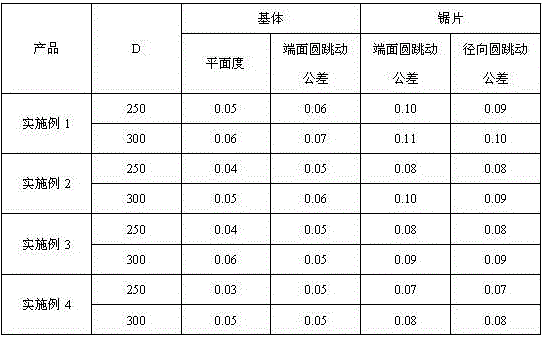

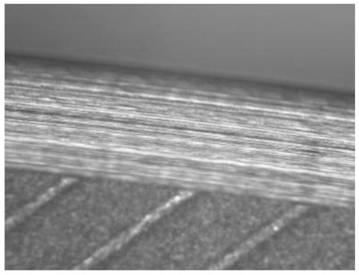

Machining method for hard alloy saw web

InactiveCN105750653AGuaranteed sharpnessReduce collisionMetal sawing tool makingMachining processCarbide saw

The invention relates to a machining method for a hard alloy saw web.The machining method includes the following steps of leveling of a base body of the hard alloy saw web, gear rolling, tool bit welding, sand blasting, gear grinding, polishing, antirust treatment and finished product storage.Gear spacing welding is adopted for the tool bit welding step.An abrasive belt in the polishing step is 180 mesh or 240 mesh, and the relative speed of the base body of the hard alloy saw web and the abrasive belt is 4,000-4,500 r / min.Heating deformation of the base body in the machining process can be effectively controlled, the surface smooth degree is high, and the anti-corrosion effect is good.

Owner:HEBEI JIMEIDA TOOLS CO LTD

Diamond grinding wheel for precise grinding of semiconductor substrate chamfering

ActiveCN111267010AGood self-sharpeningGuaranteed wear resistanceAbrasion apparatusGrinding devicesIron powderSilicon chip

The invention relates to the technical field relevant to grinding wheels and particularly provides a diamond grinding wheel for precise grinding of semiconductor substrate chamfering. On the first aspect, the diamond grinding wheel for precise grinding comprises, by weight, 230-380 parts of adhesion agent and 50-80 parts of diamond, wherein the adhesion agent is one or the combination of multipleones selected from cobalt powder, iron powder, silver powder, tin powder, nickel powder and copper powder. According to the diamond grinding wheel for precise grinding, the adhesion agent of a specific particle size is adopted to be combined with the diamond, so that the holding force on the diamond by the adhesion agent is improved, the self-sharpening performance is good, and the wear resistanceand sharpness of the grinding wheel are guaranteed; meanwhile, the surface of an obtained silicon wafer is good in roughness and smooth beneficially, and the grinding wheel can guarantee the dimension and precision of arc grooves of the grinding wheel under the conditions of repeated machining; and besides, the grinding wheel is good in machining performance, and it can be achieved that the wearresistance and sharpness of each arc groove in the grinding wheel are kept consistent.

Owner:上海橄榄精密工具有限公司

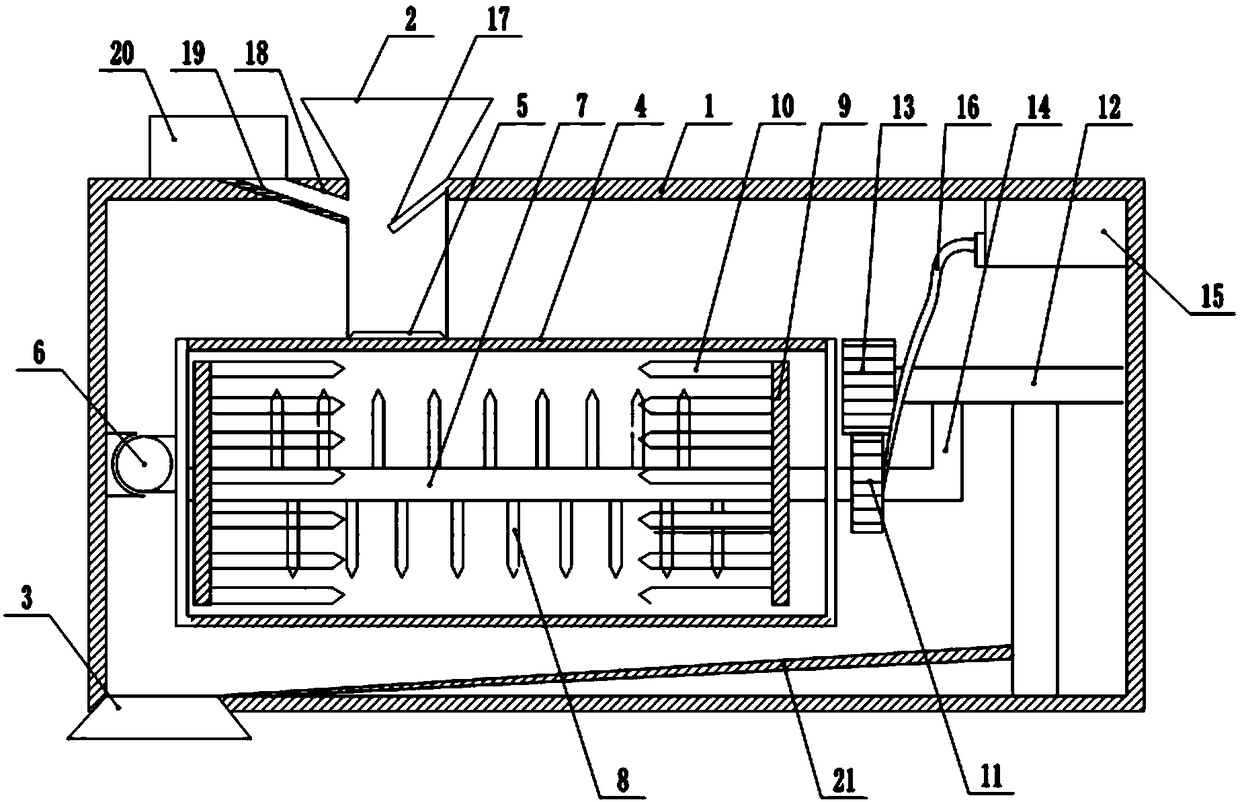

Efficient smashing equipment of foamed plastic

ActiveCN106493880AEfficient DryingReduce in quantityPlastic recyclingGrain treatmentsSmall holeElectrical and Electronics engineering

The invention relates to smashing equipment of foamed plastic, in particular to efficient smashing equipment of the foamed plastic. According to the efficient smashing equipment of the foamed plastic, blades can be conveniently cleaned. The efficient smashing equipment of the foamed plastic comprises a smashing box, a feed hopper, a stop rod, a rotating motor, a first protective cover, a first rotating rod and the like, wherein the top of the smashing box is connected to the feed hopper through bolts, the stop rod is connected to the upper part in the smashing box through bolts, a small hole is formed in the middle of the stop rod, the middle of the top of the stop rod is connected to the first protective cover through bolts, and the rotating motor is connected inside the first protective cover through bolts. According to the efficient smashing equipment of the foamed plastic, a moving plate capable of moving is arranged, and therefore the foamed plastic left on the blades can be conveniently and quickly cleared.

Owner:徐州大塑人机械有限公司

Application method of sewage treatment device

ActiveCN107827284APrevent waterloggingEasy dischargeSewerage structuresSpecific water treatment objectivesSewageSewage treatment

The invention relates to the technical field of treatment of domestic sewage, in particular to an application method of a sewage treatment device. The method includes the steps of firstly, dischargingsewage and performing anti-blocking treatment; secondly, purifying the sewage; thirdly, discharging impurities. By the method, reutilization of the sewage can be achieved.

Owner:宁波江北峰尚环保设备有限公司

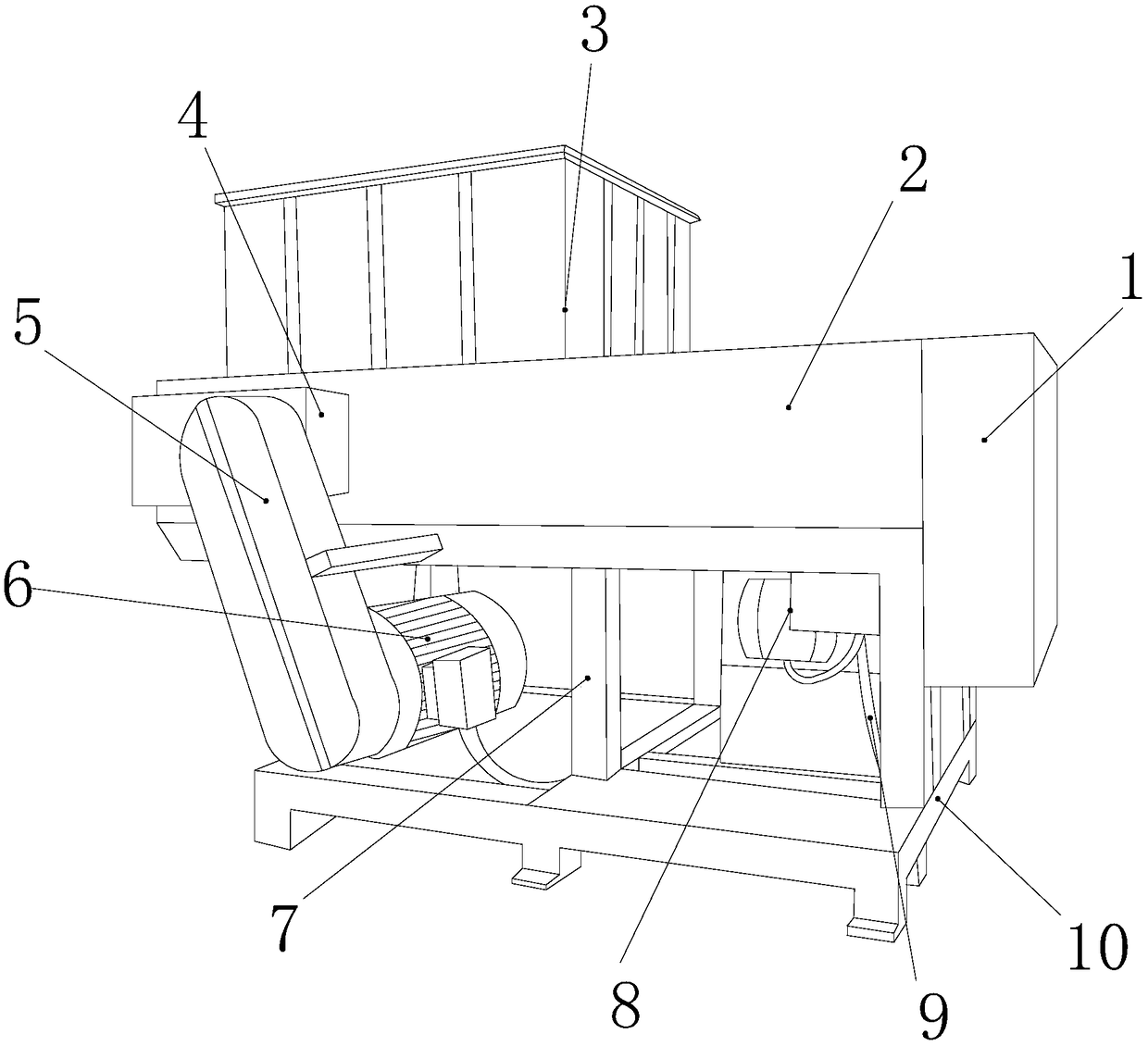

Intelligent crushing treatment equipment for household garbage

InactiveCN112024573AReduce lossAvoid causing uneven crushingTransportation and packagingSolid waste disposalElectric machinerySewage

The invention provides intelligent crushing treatment equipment for household garbage. The intelligent crushing treatment equipment comprises a crushing box, a material conveying mechanism, a crushingmechanism, a sewage collecting mechanism, a material returning conveying belt and a material returning motor, wherein the material conveying mechanism is installed at the upper end of the crushing box, and the crushing mechanism is installed below the material conveying mechanism in a running fit mode; the sewage collecting mechanism is installed below the crushing mechanism, the material returning conveying belt is installed inside the portion, located below the sewage collecting mechanism, of the crushing box in a running fit mode, the material returning motor is installed inside the crushing box through a motor base, and an output shaft of the material returning motor is connected with the material returning conveying belt. The material conveying mechanism can achieve quantitative conveying of kitchen garbage, and preliminarily breaks broken bone type hard garbage in the kitchen garbage, crushing blades are installed at the crushing mechanism in a clamped mode, and can be detachedand replaced in time during damage, and the sewage collecting mechanism can collect water contained in the kitchen garbage, and reduces odor and garbage leachate.

Owner:蔡焕年

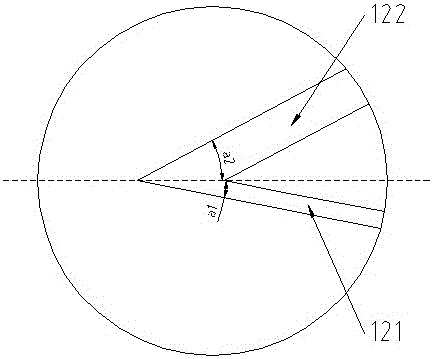

Scalpel

InactiveCN106236196AAccurately grasp the insertion depthPrevent looseningIncision instrumentsInsertion depthEngineering

The invention relates to a scalpel which comprises a blade, a scalpel handle and a scalpel rest. The blade and the scalpel handle are integrally formed. The blade comprises a body part and cutting edge parts, the cutting edge parts comprise the first cutting edge part and the second cutting edge part, the first cutting edge part is longer than the second cutting edge part, and the included angle a1 between the first cutting edge part and the medial axis of the blade is smaller than the included angle a2 between the second cutting edge part and the medial axis of the blade. The scalpel handle comprises a holding part and a connection part, the holding part is arranged at the front end of the scalpel handle and has a radian, the connection part is arranged at the rear end of the scalpel handle and provided with threads, a cylinder structure with built-in threads is arranged at the front end of the scalpel rest, and the rear end of the scalpel rest is arranged to be of a regular hexahedron structure. The scalpel is simple in structure, insertion depth of the scalpel can be accurately controlled, mechanical strength and sharpness of a cutting edge can be ensured, and operation quality is improved.

Owner:王少峰

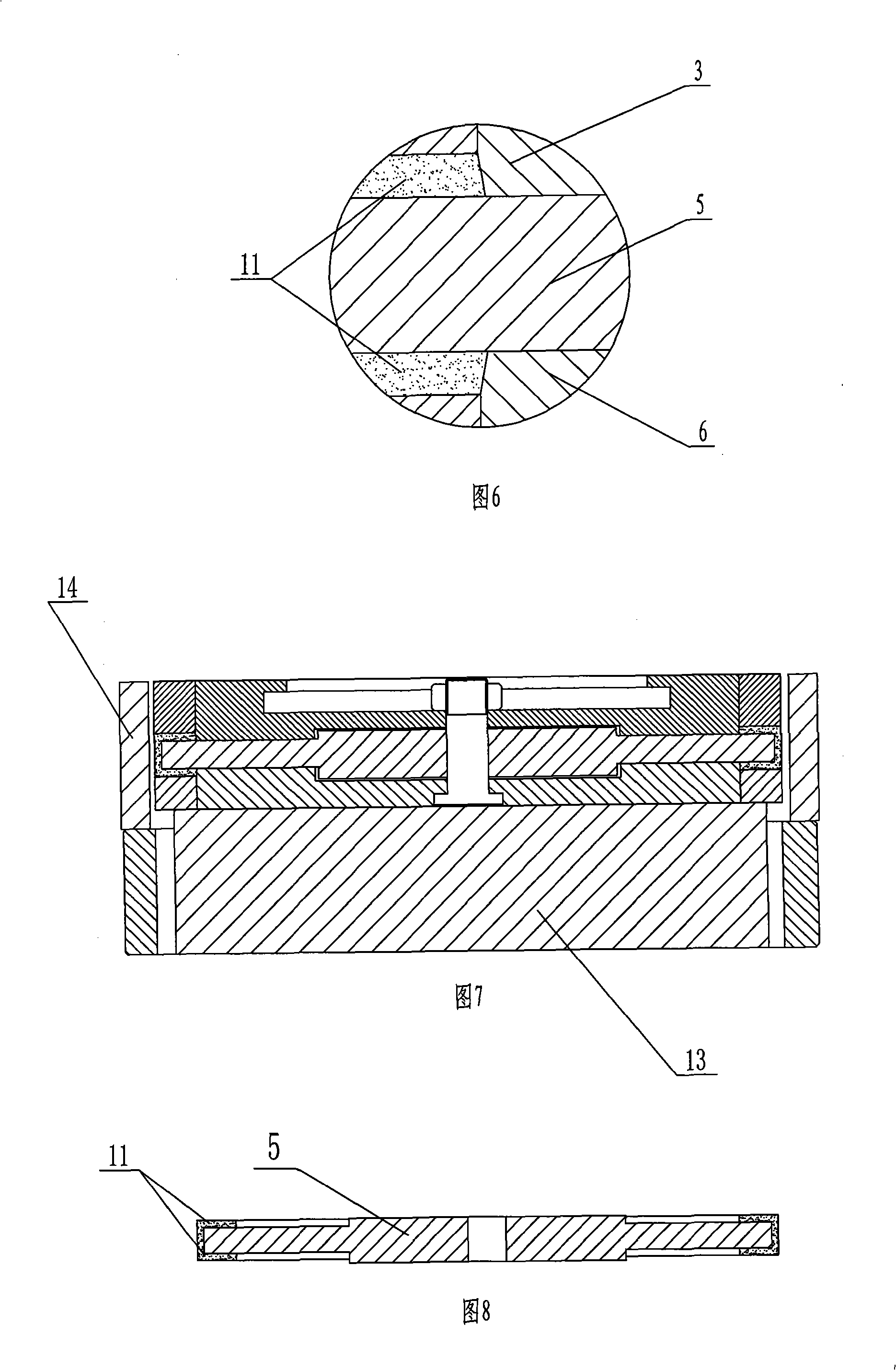

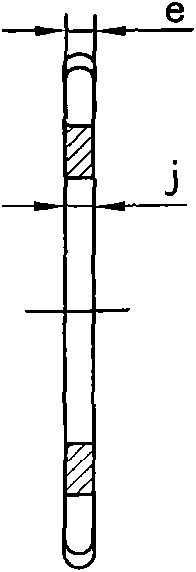

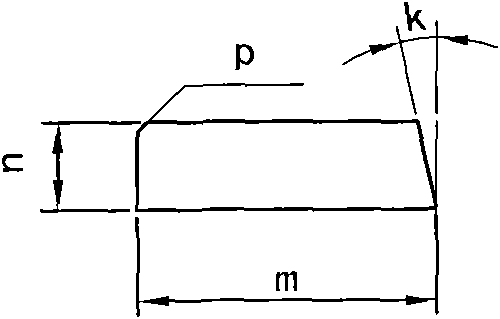

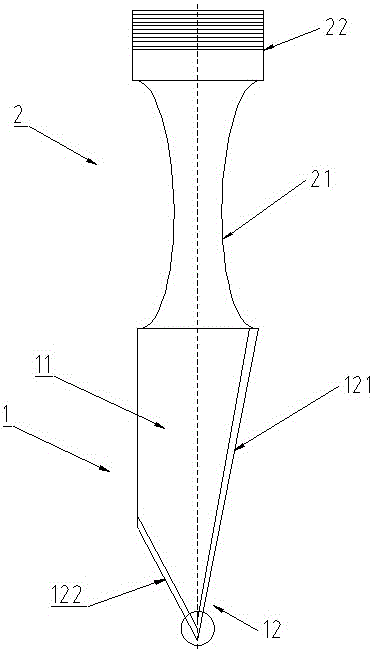

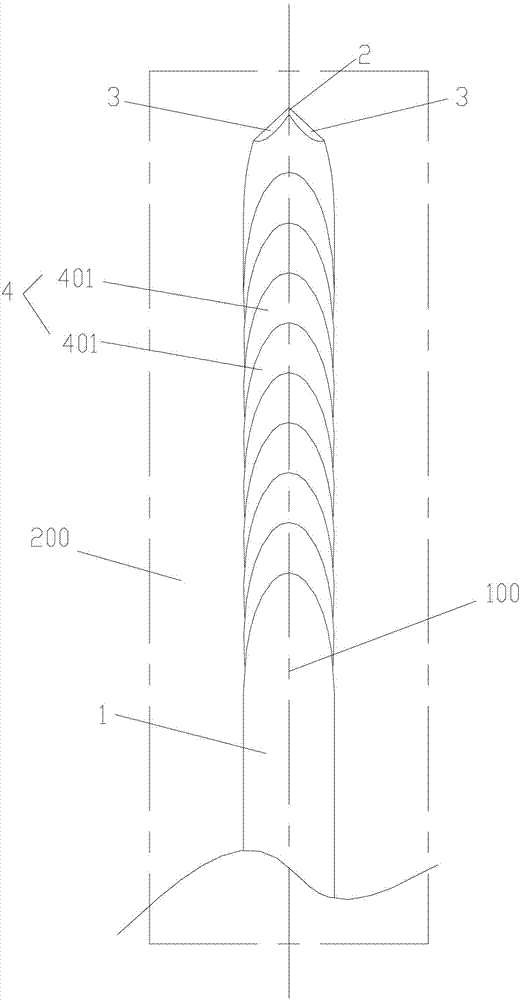

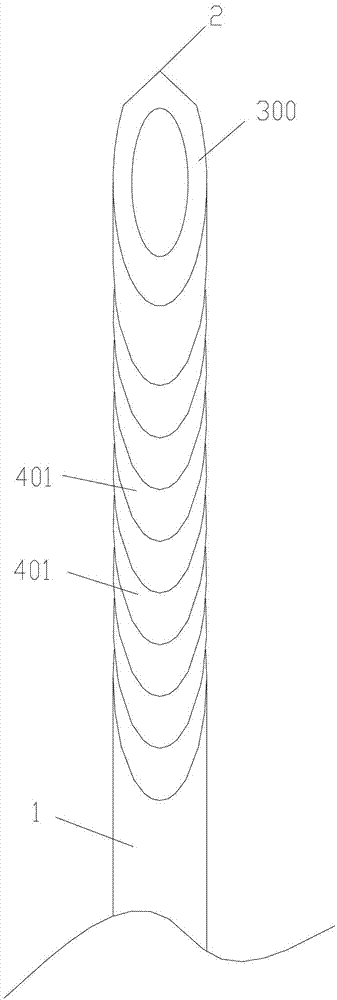

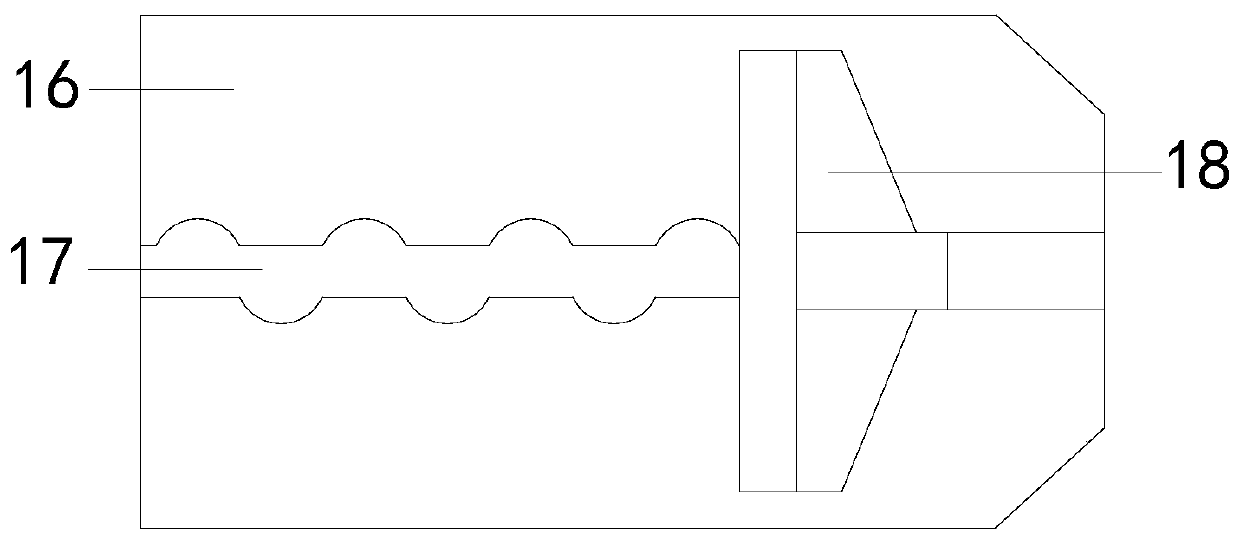

Puncture needle of oocyte collector

ActiveCN102860859AGuaranteed sharpnessReduce resistanceSurgical needlesMedical devicesTissue traumaBiomedical engineering

The invention relates to a puncture needle of an oocyte collector, which comprises a needle tube, wherein a needle point is formed on the front end face of the needle tube, an ultrasonic identification grain is formed on the outer wall of the front end of the needle tube and comprises a plurality of annular grooves which are sequentially arranged along the axle wire of the needle tube and are mutually in parallel; and a chamfer is formed between the outer wall of the front end of the needle tube and the front end face of the needle tube and is positioned on two sides of the needle point. By adopting the ultrasonic identification grain and the needle point provided in the invention, the sharpness of the needle point when the follicular wall is repeatedly punctured for picking up ovums is maximally ensured, and the problems of failure, deformation or barbs cannot be caused; and meanwhile, the resistance of the needle point when the follicular wall is repeatedly punctured for picking up ovums is maximally reduced, the tissue trauma is maximally reduced, the pain of a patient is decreased, and even the problems of haemorrhage and the like on a punctured part can be well avoided.

Owner:GUANGZHOU PINZHI MEDICAL DEVICE CO LTD

Rubber and plastic granulator

InactiveCN110877362AResolve issues where shape is affectedTroubleshoot issues where particle shape is affectedMetal working apparatusBlade plateStructural engineering

The invention discloses a rubber and plastic granulator. The granulator structure comprises a driving case, a granulating mechanism, a conveying plate and a rack, the side edge of the driving case isconnected to the granulating mechanism, a conveying plate is arranged at the bottom of the granulating mechanism and communicates with the granulating mechanism, and the rack is arranged on the bottomend surface of the driving case. The granulator has the beneficial effects that: a knife groove of a unique folding knife holder can accommodate a knife edge on a knife board, so that the knife boardcan descend for a certain distance again after the rubber plastic strip is cut and is prevented from being in contact with a pressure-bearing seat, the phenomenon that nicks are generated due to impact and collision between the knife edge and the pressure-bearing base is effectively eradicated, the granulator guarantees that the knife edge can have a sharp cutting state in the operation process,a unique knife sharpening shaft structure is beneficial for keeping the sharpness degree of the knife edge, and therefore it is guaranteed that the cut rubber plastic particles are standard in shape and flat in fracture.

Owner:陈牡蓉

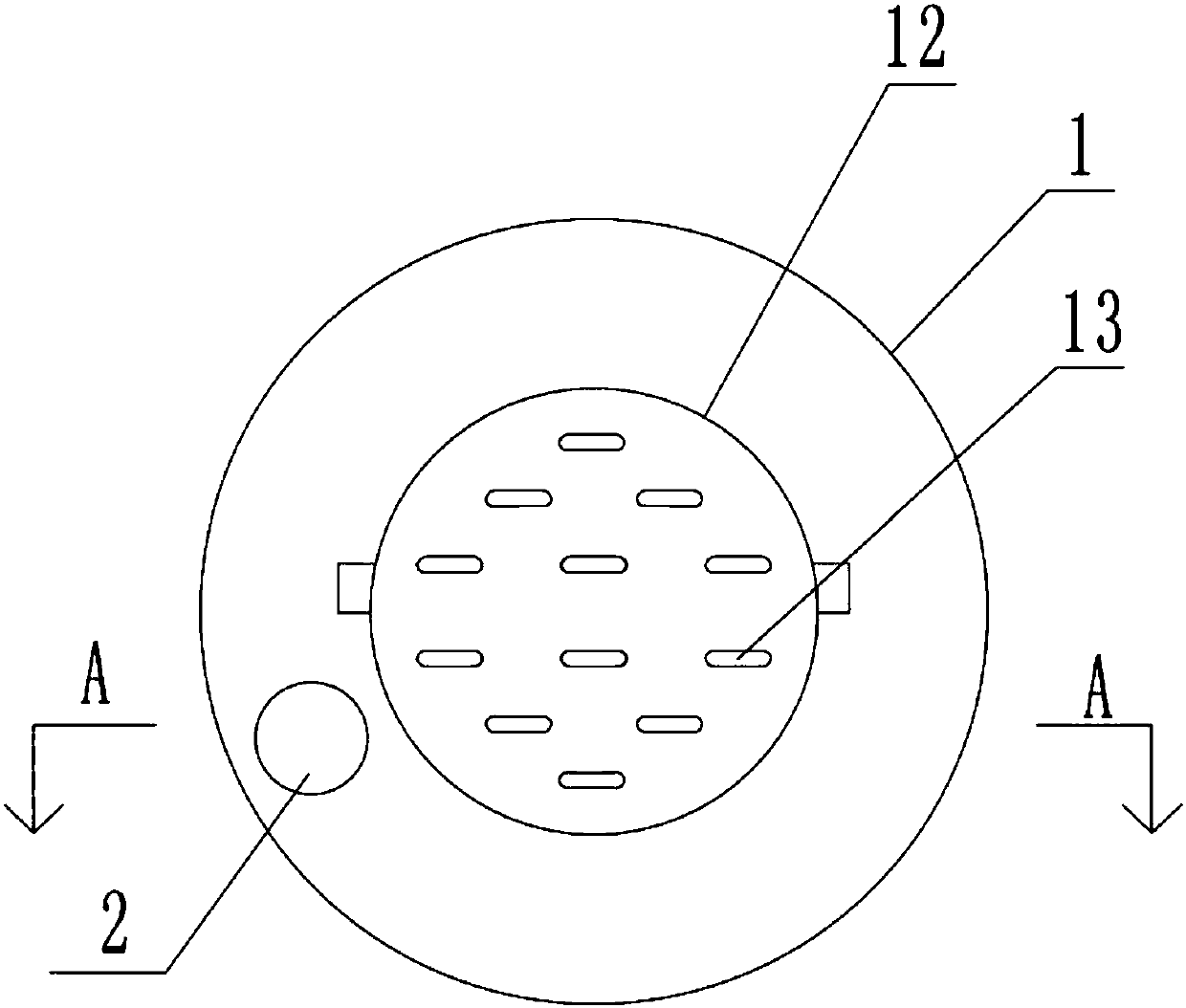

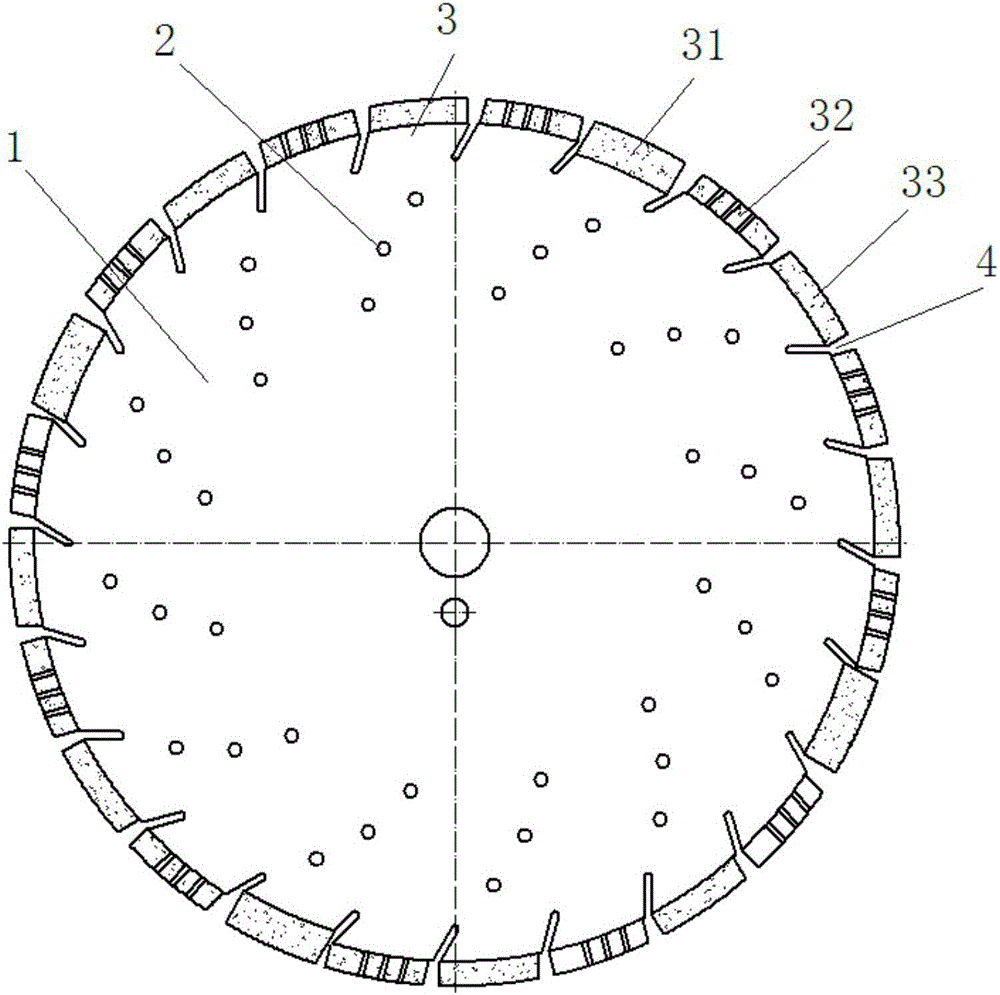

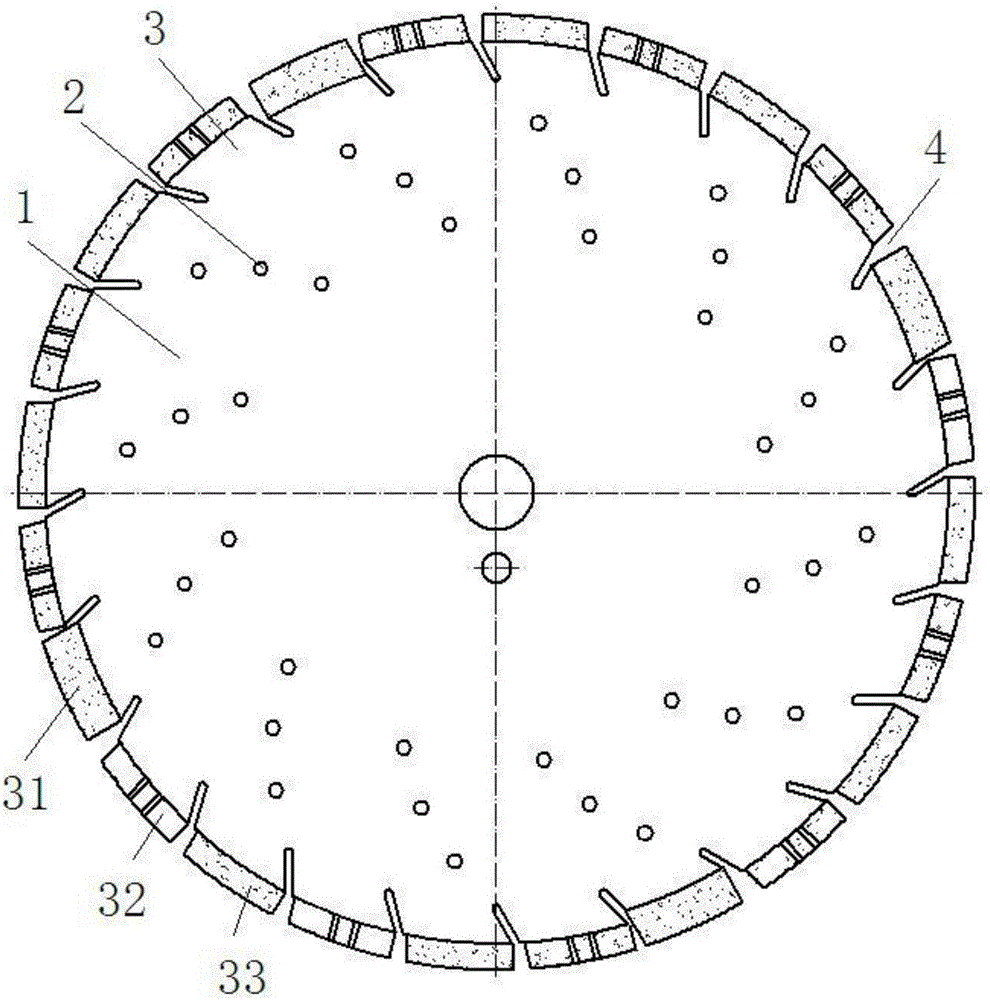

Three-system porous laser welding diamond circular saw blade

InactiveCN106493430AGuaranteed cutting lifeReduce weightMetal sawing toolsRadiationMaterials science

The invention discloses a three-system porous laser welding diamond circular saw blade, and relates to the field of diamond circular saw blades. The three-system porous laser welding diamond circular saw blade comprises a base body, chip grooves, chip removal cooling holes and cutter bits, and is characterized in that the chip removal cooling holes arranged centrifugally and orderly in the cutting direction of the cutter bits are formed in the base body; the cutter bits are evenly distributed on the edge of the base body; the chip grooves are formed between the adjacent cutter bits and arranged obliquely; and the cutter bits comprise the conventional common cutter bits, the corrugated toothed water groove cutter bits and the heightened toothed protection cutter bits, the heightened toothed protection cutter bits are evenly arranged on the edge of the base body, and the conventional common cutter bits and the corrugated toothed water groove cutter bits are evenly arranged at the positions, between the adjacent heightened toothed protection cutter bits, of the edge of the base body in a staggered manner. According to the three-system porous laser welding diamond circular saw blade, the sharpness of the saw blade is guaranteed, and the service cutting life of the saw blade is guaranteed; meanwhile, the saw blade is protected against tooth losing during continuous cutting through added high teeth, and the saw blade is used more safely; and meanwhile, the mass is low, and heat radiation performance is good.

Owner:河北小蜜蜂工具集团有限公司

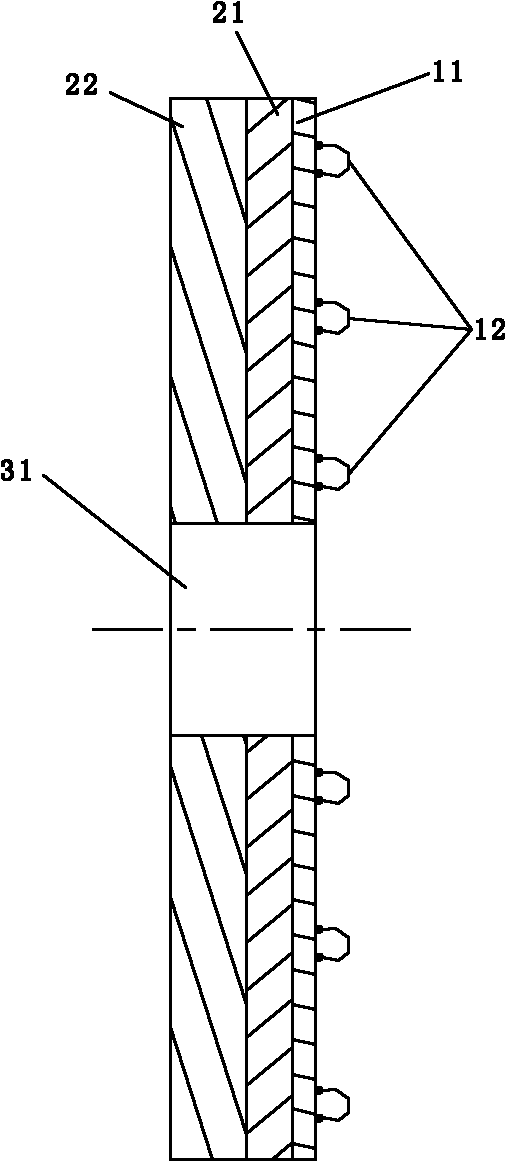

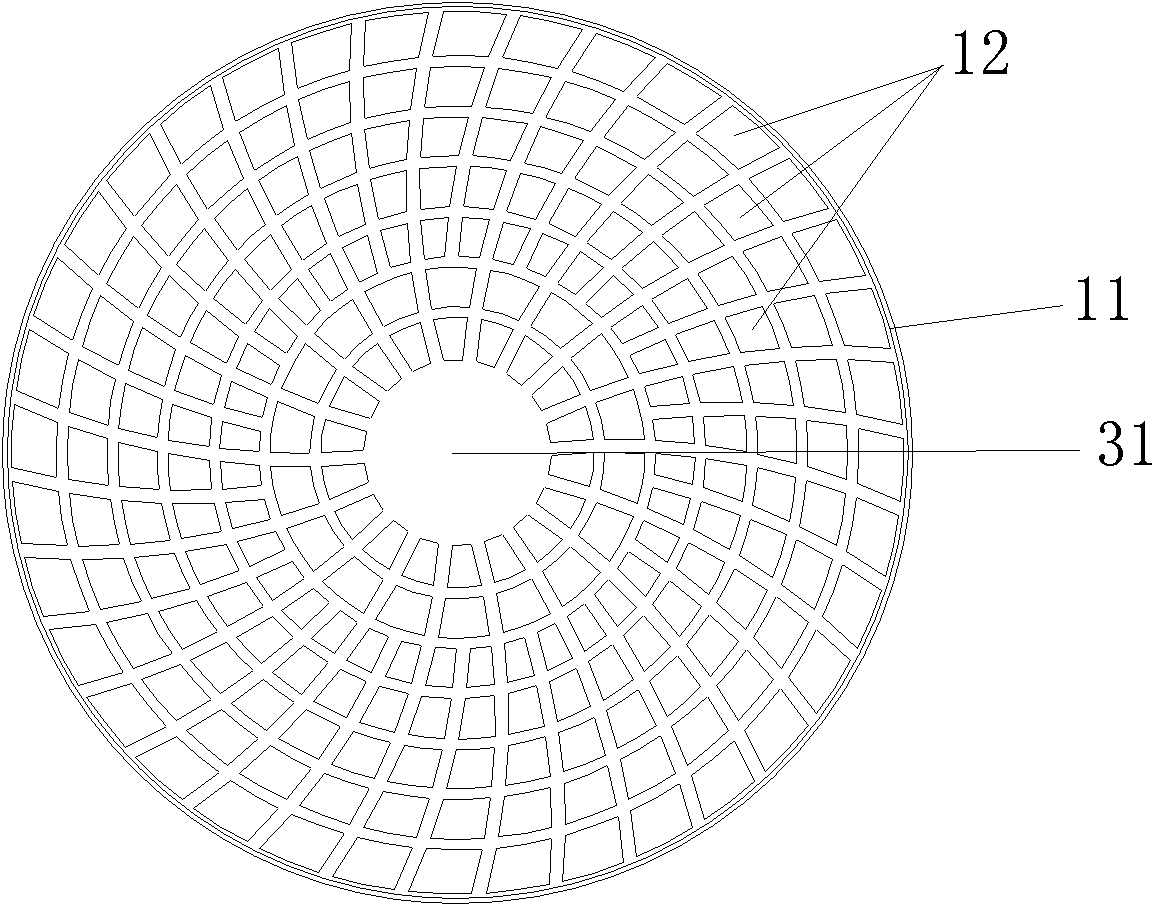

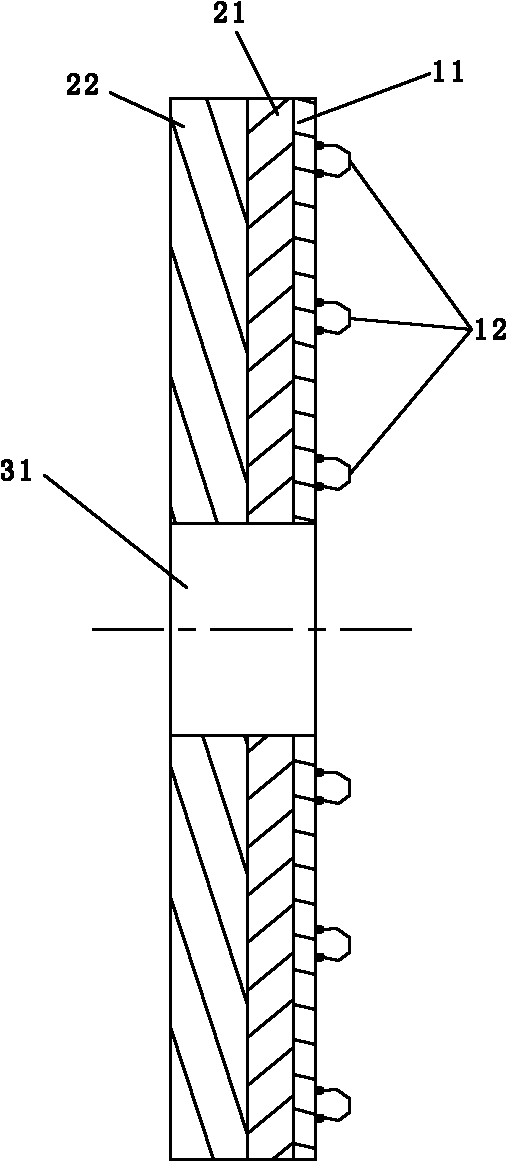

Nano ceramic bond cubic boron nitride (cBN) grinding wheel for cardan joint ball groove grinding as well as preparation method of grinding wheel

ActiveCN107042475AHigh strengthGood shape retentionAbrasion apparatusGrinding devicesBoron nitrideHardness

The invention provides a nano ceramic bond cubic boron nitride (cBN) grinding wheel for cardan joint ball groove grinding as well as a preparation method of the grinding wheel. A nano ceramic bond is prepared from SiO2, V2O5, Na2O, Al2O3 and K2O, and 5%-8% of nano ZrO2 is added. According to the nano ceramic bond grinding wheel, the adopted bond is different from common ceramic bonds in that common B2O3 is replaced with rare metal oxide V2O5, meanwhile, nano ZrO2 is added, the strength and the hardness of the grinding wheel are improved by the aid of the effect that the rare metal oxide can improve the wetting ability of the bond, and the grinding wheel has the better shape retention while the relatively high sharpness is guaranteed, so that the grinding speed and the trimming interval are increased, the grinding efficiency is greatly improved, and the service life of the grinding wheel is greatly prolonged.

Owner:江苏赛扬精工科技有限责任公司

Cattle feed processing device

ActiveCN108816417ACrushed fullyEven contactFeeding-stuffDrying gas arrangementsDrive shaftEngineering

The invention relates to a cattle feed processing device. The cattle feed processing device comprises a shell and a crushing cylinder located in the shell, a feeding hopper and a discharging hopper are arranged at the top and the bottom of the shell respectively, a screening net is arranged on the cylinder wall of the crushing cylinder, a feeding opening is formed in the crushing cylinder, a silodoor is arranged in the feeding opening, one end of the crushing cylinder is hinged to the inner wall of the shell through a universal ball, a crushing shaft is rotatably connected within the crushingcylinder, the crushing shaft is hollow, a plurality of vertical crushing cutters are arranged on the crushing shaft in the axial direction, and the two ends of the crushing shaft are fixedly connected with fixing plates; and a plurality of transverse crushing cutters are arranged on each fixing plate, the ends, away from the fixing plates, of the transverse crushing cutters face the center of thecrushing cylinder, the end, away from the universal ball, of the crushing shaft penetrates through the side wall of the crushing cylinder and is fixedly connected with a crushing gear coaxially, a driving shaft is fixedly connected within the shell, the driving shaft is fixedly connected with a driving gear coaxially, the driving gear is engaged with the crushing gear, and a driving rod is connected between the crushing shaft and the driving shaft. The cattle feed processing device is simple in operation and low in manual input.

Owner:肖艳梅

Waste tire crusher for rubber plastics

ActiveCN109435108ARealize the effect of water injection pressurizationIncrease squeezePlastic recyclingCleaning using liquidsWater flowDrive motor

The invention disclose a waste tire crusher for rubber plastics, the structure comprises a discharging chute, a transmission groove, a feeding square tube, a hydraulic crushing box, a transmission chain belt, a shaft driven motor, an iron column chassis, a power distribution box, a cable and a substrate plate; the left face of the discharging chute is adhered to the right side of the transmissiongroove and interpenetrates; the feeding square tube is inserted into the upper left corner of the transmission groove; the hydraulic crushing box provided by the invention is provided with an opticalaxes motor, a fan wheel device, a pushing mechanism, a connecting rod device, a shaft rod mechanism, a traction device, a crusher mechanism and a piston device, so that the effect of water injection and pressurization of the crushing action of the tire crusher is realized; the extrusion force and the impact force are increased by fitting with crushing; moreover, the dope of a crushing cutter and aroller is cleaned for a long time so as to keep sharp degree; the parts of the equipment are maintained effectively so as to improve the crushing performance and prolong the service life of the equipment; the crushed material is scoured, cleaned and crushed; and the work of the equipment is assisted by combing with steam pressurization in multi-direction.

Owner:KARAMAY BODA ECOLOGICAL ENVIRONMENTAL PROTECTION SCI & TECH

Composite binder grinding wheel for silicon carbide crystal thinning, preparation method and application

ActiveCN111331525ARealize thinning processingImprove surface qualityAbrasion apparatusGrinding devicesCarbide siliconAlloy

The invention provides a composite binder grinding wheel for silicon carbide crystal thinning, a preparation method and an application. The composite binder grinding wheel is prepared from the following raw materials of, by weight, 15%-45% of diamond abrasive, 15%-60% of pre-alloyed powder, 20%-45% of polytetrafluoroethylene, 3%-15% of cerium oxide and 0.5%-6% of a wetting agent. According to thecomposite binder grinding wheel for silicon carbide crystal thinning, the preparation method and the application, an alloy system used is Ga-Cu-Sn, the low-melting-point element of gallium is added into the alloy system, so that the forming temperature of the alloy powder is low, and the problem of heterogeneous forming of a resin metal binding agent is solved. Gallium metal is added to generate eutectic reaction to generate phases beta and delta with high gallium content and high brittleness, so that the conversion of a traditional alloy system from hard toughness to high brittleness is realized, and the self-sharpening property of a binding agent system is improved. The composite binding agent has the advantages of the metal binding agent and the advantages of a resin bonding agent, themetal binding agent forms a framework to improve strength and hardness, the resin powder increases elasticity of a grinding tool, impact resistance in the grinding process is reduced, and the surfacequality of a silicon carbide sheet is improved.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

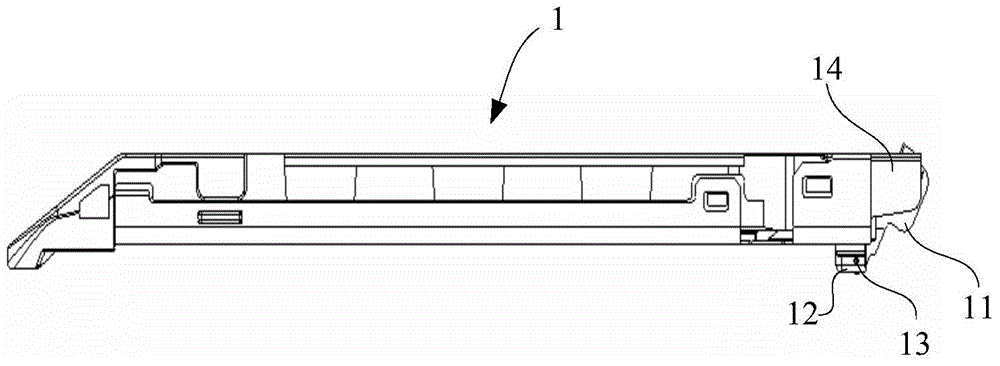

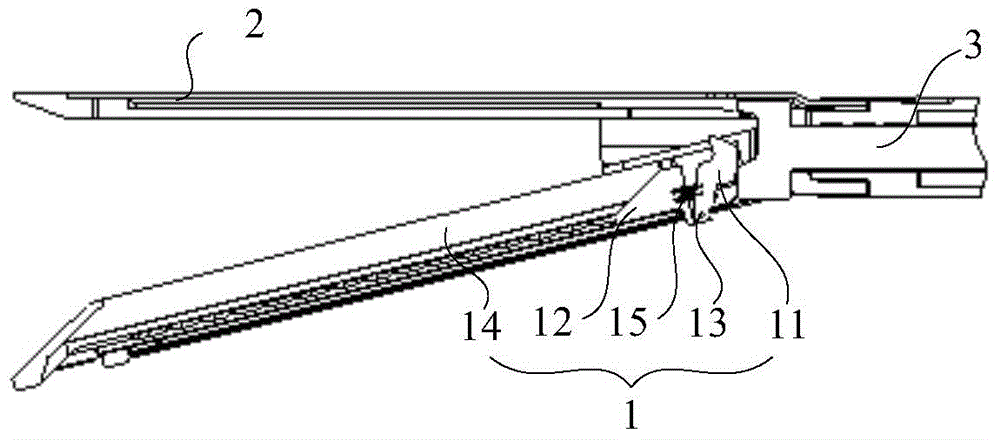

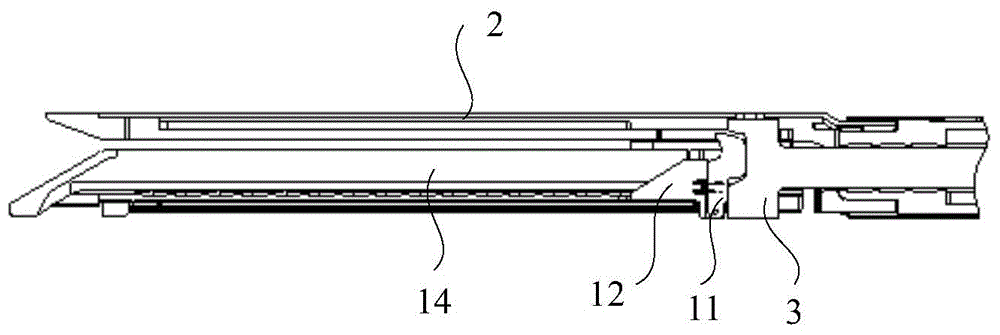

End executor, nail box assembly thereof and surgical operating instrument

ActiveCN105395229AGuaranteed sharpnessIncrease profitIncision instrumentsSurgical staplesEngineeringActuator

The invention relates to the technical field of medical apparatuses and instruments, and discloses an end executor, a nail box assembly thereof and a surgical operating instrument. The nail box assembly comprises a nail bin, a nail push slide block and a cutter. The nail push slide block is arranged on the nail bin in a slidable mode. The cutter is located in a cutter groove formed in the nail bin. The end, away from the nail outlet face of the nail bin, of the cutter is connected to the nail push slide block in a pivoted mode through a pin shaft, the axis of the pin shaft is perpendicular to the cutter groove, and the end face, facing the near side, of the cutter is a push face abutting against a cutter push rod of the surgical operating instrument. An elastic reset piece is arranged between the cutter and the nail push slide block. The blade part of the cutter is contained in the cutter groove of the nail bin under the acting force of the elastic reset piece when the cutter does not bear thrust of the cutter push rod. The cutter can rotate to the cutting state around the pin shaft when bearing thrust of the cutter push rod. The cutter of the nail box assembly is used only once, the sharpness of the blade part of the cutter is ensured when an operation is performed through the surgical operating instrument, and therefore operation quality is improved, and medical risks are lowered.

Owner:REACH SURGICAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com