Brazed diamond flexible abrasive disc and manufacturing method thereof

A manufacturing method and diamond technology, applied in the manufacture of tools, abrasives, metal processing equipment, etc., can solve the problems of not achieving the soft effect of resin soft abrasive sheets, complex manufacturing process, easy crushing of the abrasive layer, etc. Improve the service life and not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

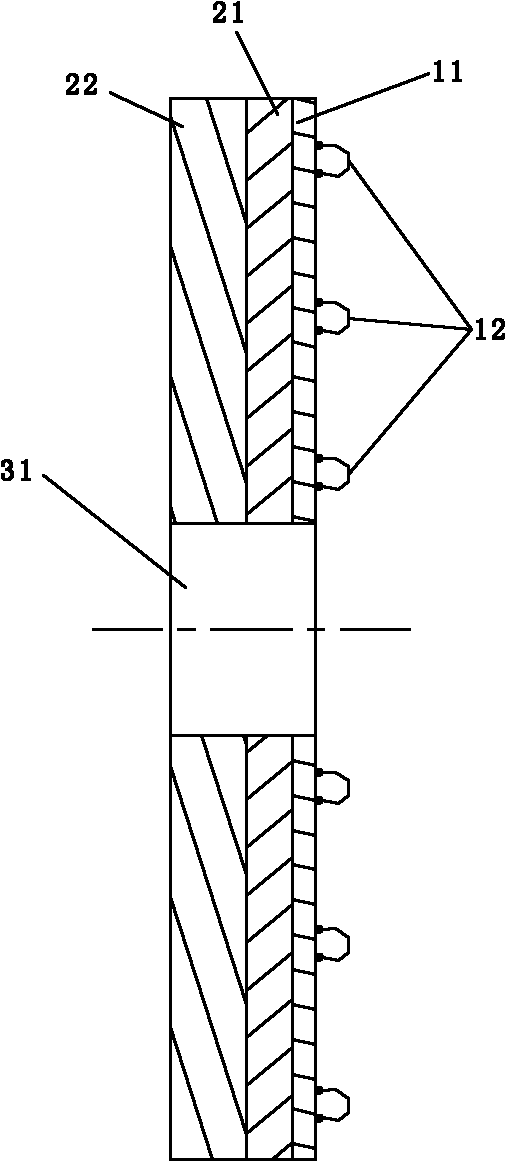

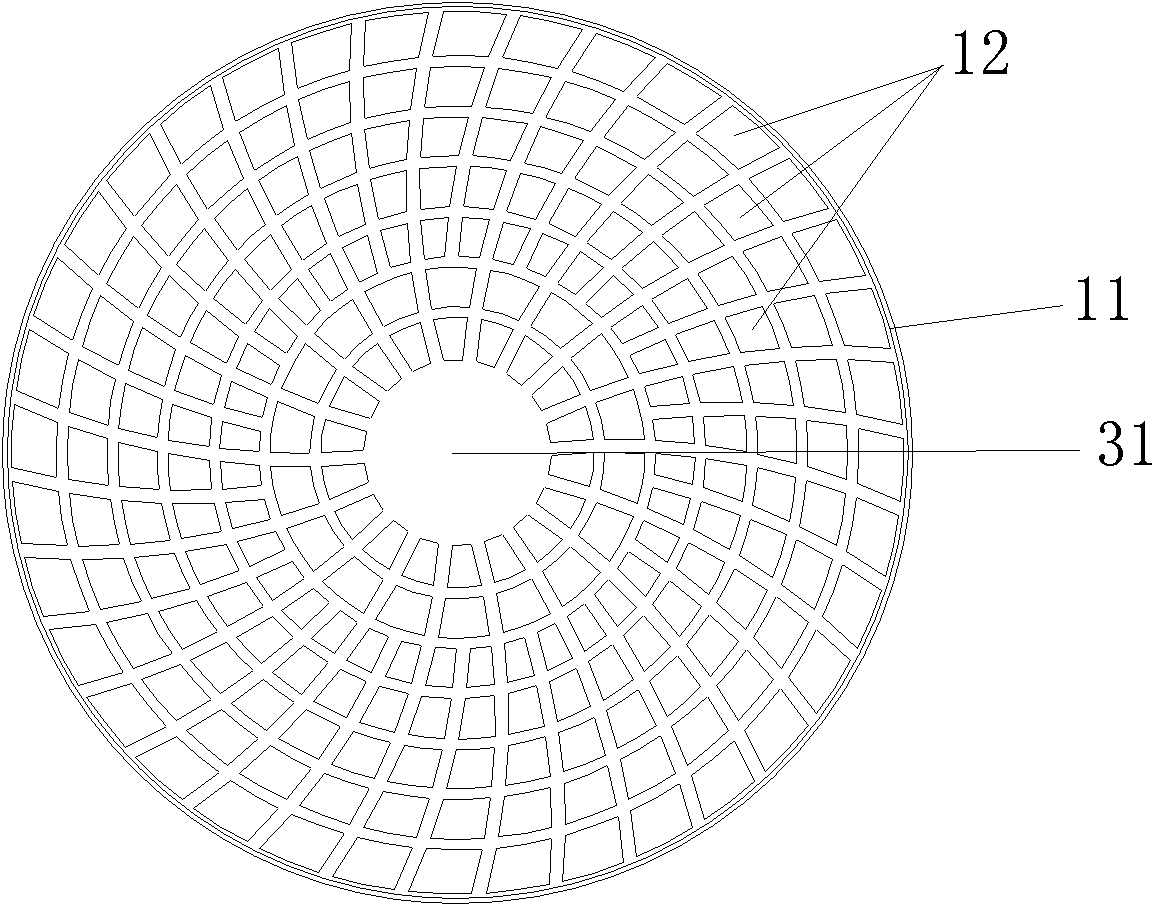

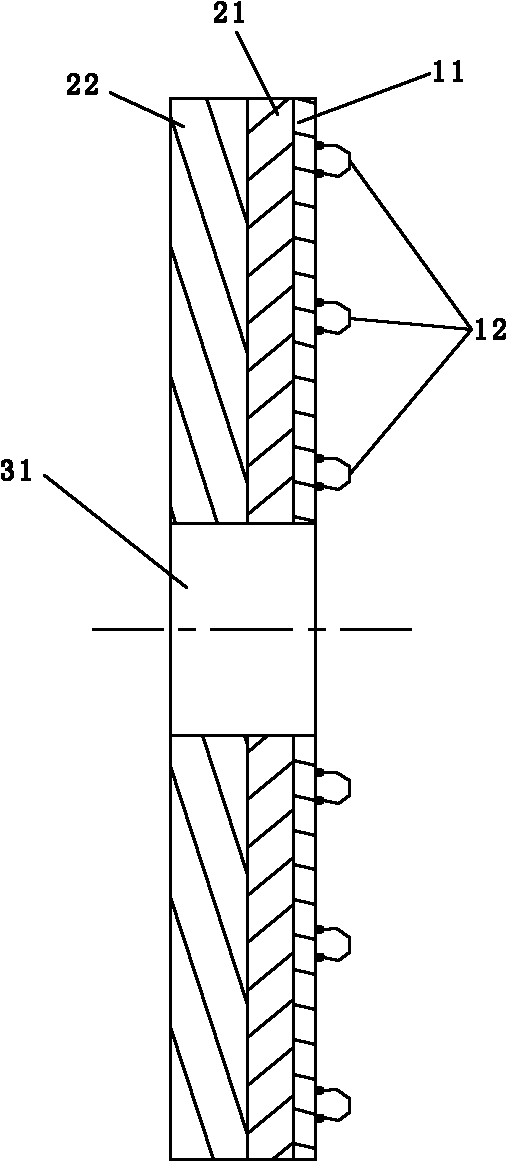

[0031] see figure 1 and 2 , Brazed diamond soft grinding disc is equipped with diamond grinding layer and connecting parts. The diamond grinding layer is provided with a substrate 11 (soft thin steel sheet) and many diamond particles 12, each diamond particle 12 is fixed on the upper surface of the substrate 11 by brazing, and gaps are left between adjacent diamond particles 12 to facilitate slag removal. The diamond particles 12 expose 2 / 3 of the height of the brazing material, so that the sharpness of the diamond particles 12 during grinding can be maintained. The connector is provided with an elastic layer 21 (the elastic layer 21 is a rubber sheet, which can also be a resin fiber sheet or a foam plastic sheet) and a velcro layer 22, the elastic layer 21 is bonded to the velcro layer 22, and the elastic layer 21 is connected to the substrate 11 The lower surface is bonded. Mark 31 is the central hole of the brazing diamond soft grinding disc. The thickness of the thin s...

Embodiment 2

[0036] Similar to Example 1, the difference is that the substrate (soft thin steel sheet) adopts a mesh-shaped soft thin steel sheet.

[0037] The preparation method of embodiment 2 comprises the following steps:

[0038] 1) After the surface treatment of the mesh-shaped thin steel sheet, first coat the high-temperature-resistant inorganic adhesive on one side of the mesh-shaped soft thin steel sheet, and after drying, apply brazing on the other side of the mesh-shaped soft thin steel sheet Arrange the diamond particles (coated according to the designed appearance pattern model), and send the rough diamond grinding layer into the vacuum furnace to heat up to 900°C (the temperature of different brazing materials is different), keep it warm for 5-15min, and stop Heating, cooling to below 150°C, and making a whole piece of brazed diamond grinding layer. The mesh-shaped thin steel sheet has a thickness of 0.15 mm to 0.60 mm.

[0039] 2) Remove the inorganic adhesive that is coat...

Embodiment 3

[0041] Similar to Embodiment 1, the difference is that the connecting piece is only provided with a Velcro layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com