Patents

Literature

1261 results about "Diamond grinding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Diamond grinding is a grinding process that can be applied to a variety of surfaces including floors, stones and engineering ceramics. It takes advantage of the fact that diamond has the highest hardness of any bulk material.

Oily diamond grinding liquid and preparation method thereof

InactiveCN103013345AImprove polishing efficiencyImprove matchPolishing compositions with abrasivesStable stateEnvironmental resistance

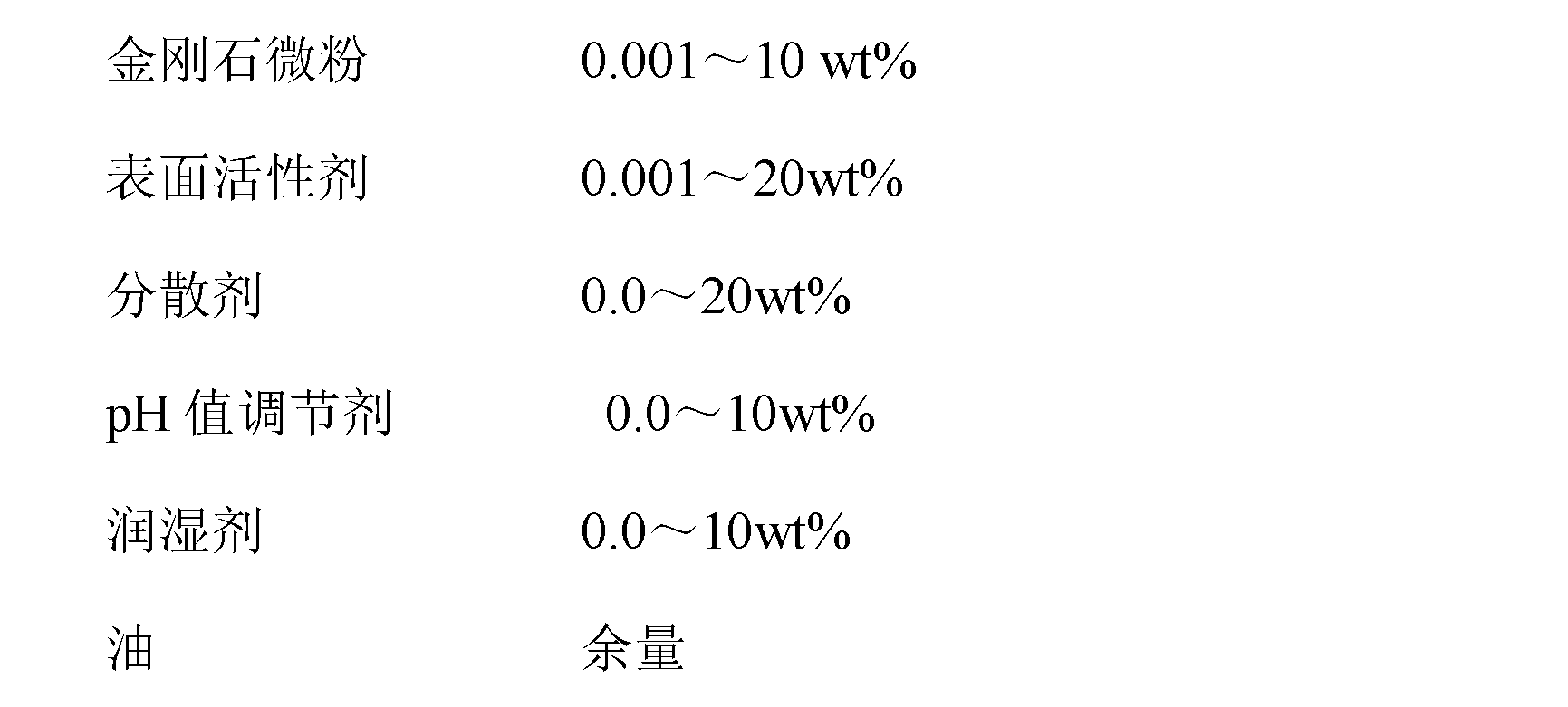

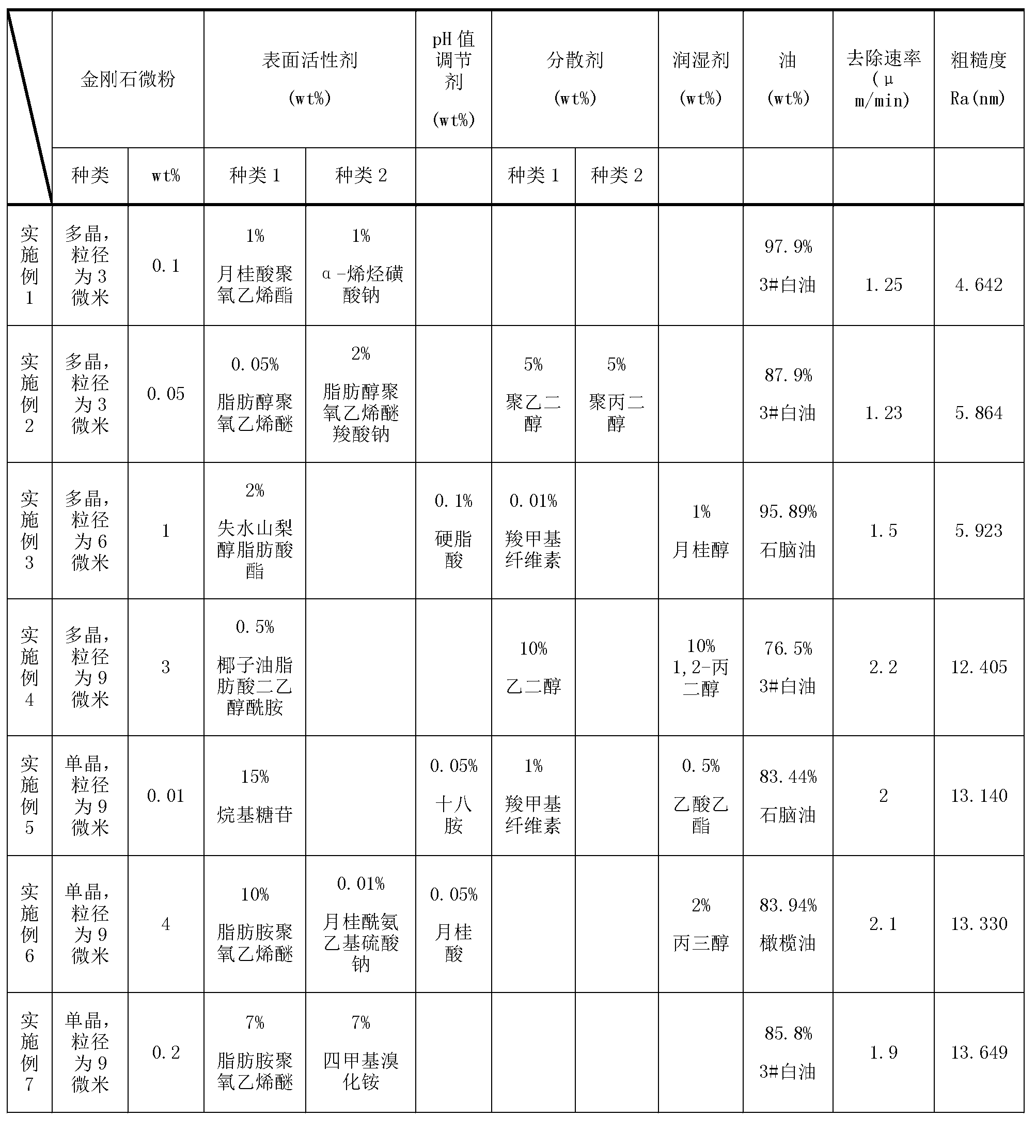

The invention discloses an oily diamond grinding liquid and a preparation method thereof, and belongs to the technical field of surface superfine grinding. The grinding liquid comprises the following components by weight percent: 0.001%-10% of diamond micro powder, 0.001%-20% of surface active agent, 0-20% of dispersant, 0-10% of pH value regulator, 0-10% of wetting agent and oil in balancing amount. The oily diamond grinding liquid is mainly applied to surface grinding and polishing of silicon carbide wafers, LED sapphire substrate slices, ceramic, optical fiber, dies, semi-conductor compound wafers and the like. By the use of the oily diamond grinding liquid provided by the invention, the polishing efficiency can be greatly improved; the dispersing performance is good; a uniform and stable state can be kept for a long time; the degree of finish of products polished with the oily diamond grinding liquid is high; the polishing effect is good; no ingredient harmful to human body is contained; the cleaning is easy; and the environmental protection is facilitated.

Owner:TSINGHUA UNIV +2

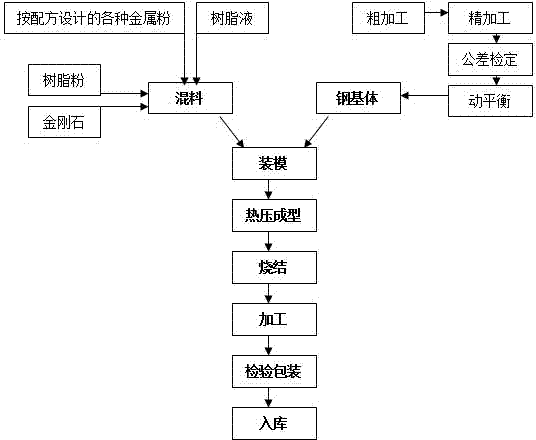

Resin anchoring agent diamond grinding wheel and production method thereof

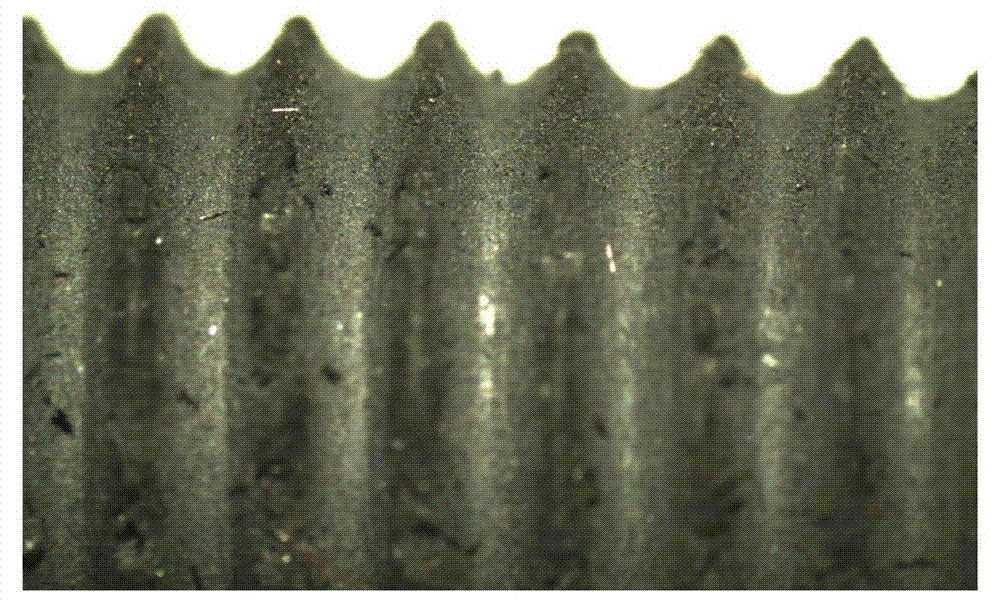

ActiveCN101386154AIncreased durabilityImprove adhesionAbrasion apparatusGrinding devicesBoron carbideZirconia alumina

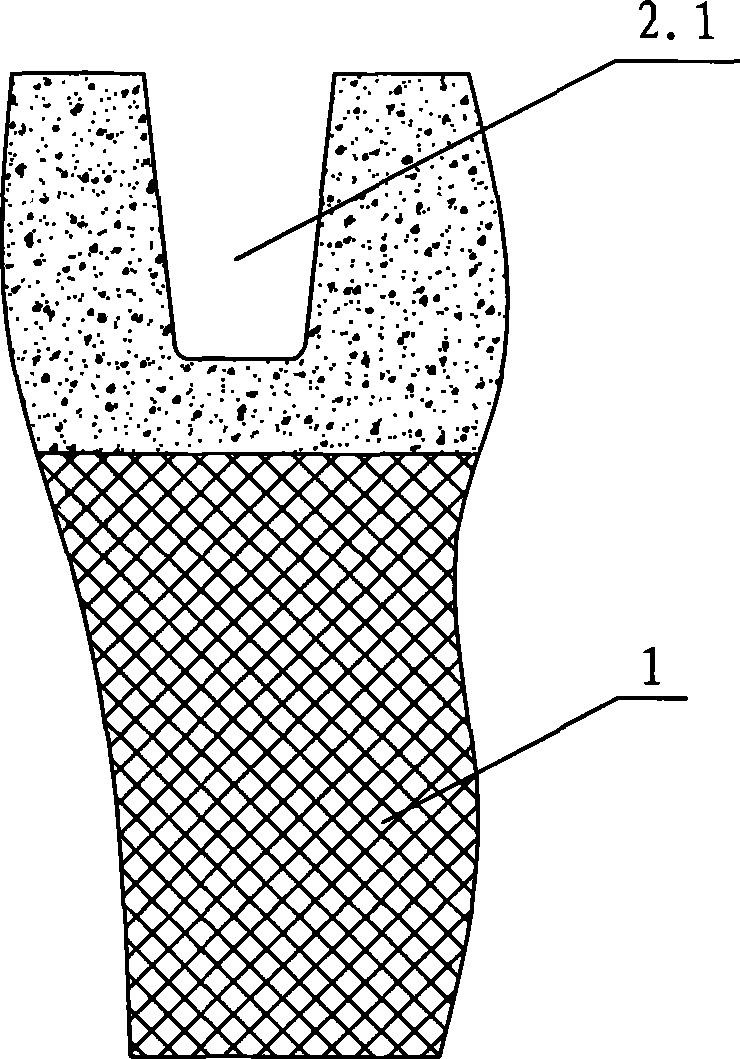

The invention relates to a resin bonding agent diamond grinding wheel and a manufacturing method thereof, and the grinding wheel comprises a grinding medium layer and a base body, wherein, the grinding medium layer is arranged on the base body and comprises diamond grinding medium, resin bonding agent, filling reinforcement which is a copper cladded iron powder and auxiliary abrasives which can be one or the combination of carborundum, boron carbide, white alundum, single alundum and fused zirconia alumina. The grinding medium layer comprises 5-15% of diamond grinding medium, 10-25% of auxiliary abrasive, 25-50% of thermosetting polyimide resin, 3-10% of copper cladded iron powder, 15-40% of silicon carbide powder and 0-8% of filling of metallic oxide in terms of volume percent. The diamond grinding wheel is characterized by low production cost, strong adhesive force, good sharpness and self-sharpness, long service life and good abrasion cutting effect.

Owner:广东奔朗新材料股份有限公司

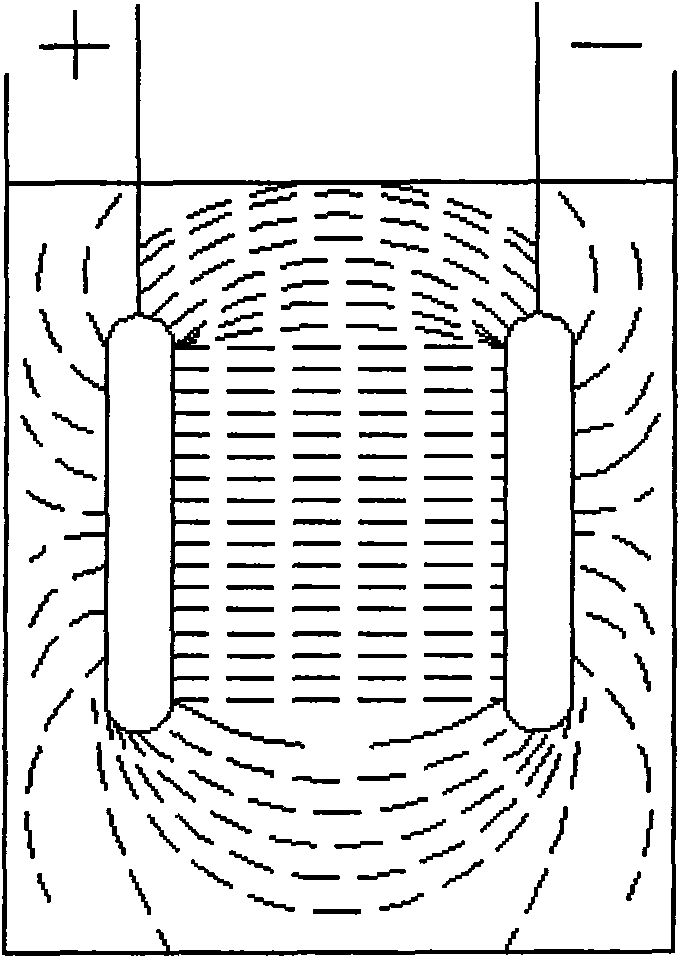

Diamond wire saw production method of surface modified diamond

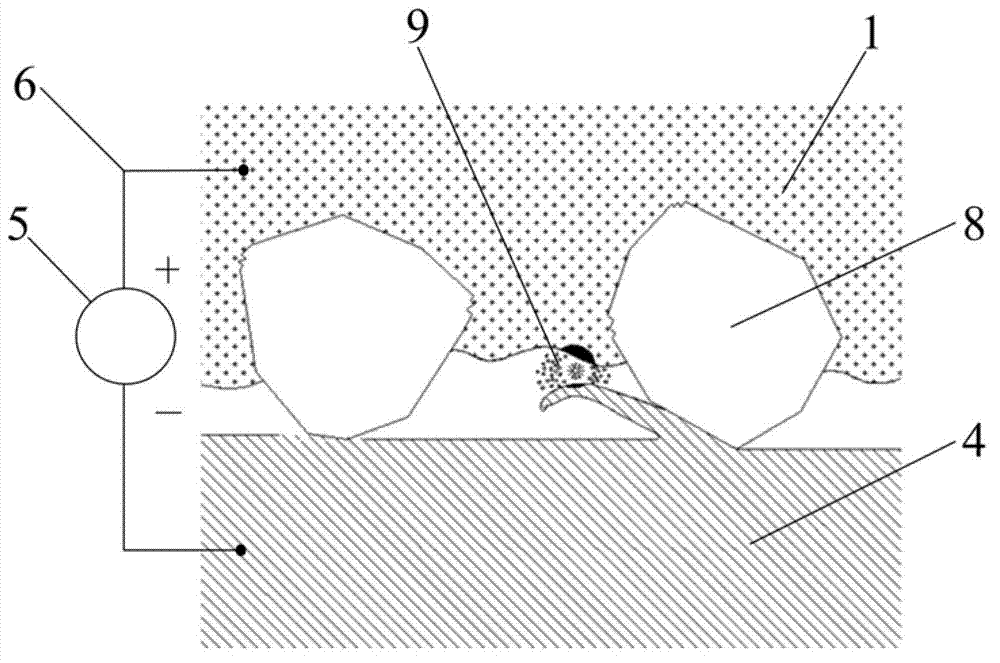

InactiveCN101812710AAchieve electroplating depositionEasy to operateElectrophoretic coatingsElectrophoresisDiamond wire saw

The invention relates to a diamond wire saw production method of a surface modified diamond, which comprises the following steps: 1. removing surface grease and surface metal oxides on the surface of the diamond; 2. placing diamond micropowder into a cationic surfactant solution, applying positive potential and forming a layer of positive charge film on the surface of the diamond under the electrophoretic action by action of a cationic surfactant; and 3. carrying out composite electroplating of a diamond wire saw. In the invention, conductive processing is carried out on the diamond, so that diamond grains can orderly move in a plating solution under the action of an electric field to realize the electroplating deposition on the surface of a metal wire without the influence of the size of the diamond grains; the surfactant is adsorbed on the surface of the diamond, so that a plating layer and the diamond present an infiltrative type interface, and a Ni plating layer has strong holding capability on the diamond; and the diamond micropowder has high utilization ratio. The invention has simple process method and convenient operation, the diamond grains have rapid deposition speed, good deposition uniformity and high deposition density on the metal wire, an electroplating layer has high holding force on the diamond grains, and the diamond micropowder has high utilization ratio. The invention can realize industrialized production and provides a method for efficiently and rapidly producing the diamond wire saw.

Owner:CHANGSHA DIAT NEW MATERIAL SCI & TECH

A method for manufacturing electroplating diamond wire saw

InactiveCN101531035AIncrease the concentration of nickel ionsIncrease current densityFine working devicesStone-like material working toolsDiamond wire sawElectroplating

The invention relates to a method for manufacturing electroplating diamond wire saw. The invention has main features as follows: firstly, winding the metal lines on a string releasing wheel, continuous operating the metal lines, completing the fore treatment, pre-plating, sanding and thickening procedures, and finally winding the metal lines on a string receiving wheel to complete the electroplating process, wherein, the pre-plating, sanding and thickening procedures are completed in a same electroplating bath; sanding is completed by annular feather belt subsequent rotated in the electroplating bath; the diamond grinding medium in the plating solution is suspended in the plating solution under the mixing function, and naturally depositing on the annular feather belt; and the linear velocity passing through the annular feather belt and the metal lines of the annular feather belt are identical, so the diamond grinding medium on the metal lines and the annular feather belt has a definite relative still time, to ensure sanding time. The invention uses annular feather belt to perform sanding, improves sanding efficiency, improves the manufacturing efficiency of electroplating diamond wire saw and reduces the manufacturing costs.

Owner:QINGDAO UNIV OF SCI & TECH

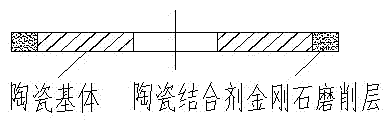

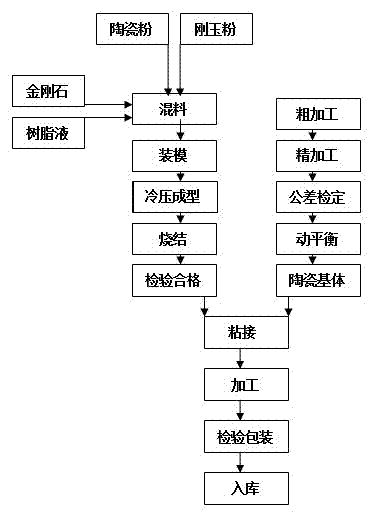

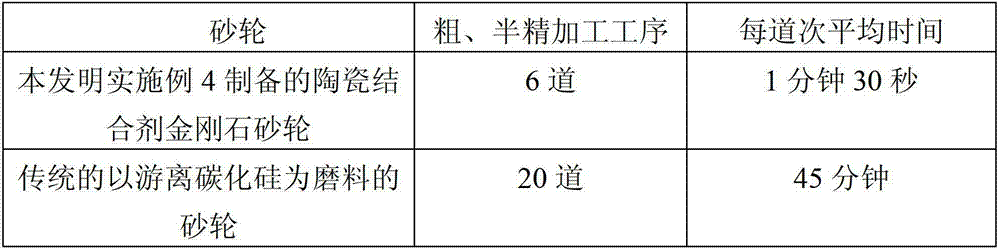

Special ceramic bond diamond grinding wheel for grinding diamond

InactiveCN102229122AHigh strengthSmall expansion coefficientAbrasion apparatusGrinding devicesDiamond grindingCeramic

The invention belongs to the field of diamond grinding wheels, and particularly relates to a ceramic bond and a method for manufacturing a ceramic bond diamond grinding wheel for grinding a diamond by adopting the ceramic bond. The ceramic bond is prepared from the following raw materials in percentage by weight: silicon dioxide, borax, lithium hydroxide, zinc oxide, calcium oxide and aluminum oxide; and the ceramic bond is obtained through the steps of: mixing the raw materials, then smelting at the high temperature of 1300+ / -5 DEG C, cooling, then performing ball milling to prepare ceramic powder, and sieving through a standard sieve of 180 meshes. The ceramic bond provided by the invention has high intensity and a low coefficient of expansion, so that the ceramic bond can be perfectly matched with the adopted ceramic grinding wheel basal body. The diamond grinding wheel manufactured by adopting the ceramic bond has good heat conductivity and heat resistance; and compared with the traditional resin bond diamond grinding wheel, the ceramic bond diamond grinding wheel not only ensures that the diamond is excellently sintered at the temperature of not being carbonized, but also ensures that grinding grains are always at an excellent holding state without falling off when grinding is carried out. The special ceramic bond diamond grinding wheel has the grinding efficiency and service life far higher / longer than that of the traditional grinding wheel, and has a comprehensive benefit which is increased by over 50%.

Owner:SUZHOU SAILI PRECISION TOOLS

Resin metal composite bonding agent and composite bonding agent diamond grinding wheel

InactiveCN102350667AImprove temperature resistanceGood self-sharpeningAbrasion apparatusGrinding devicesNumerical controlHeavy load

The invention belongs to the field of diamond grinding wheels, and in particular relates to a resin metal composite bonding agent and a composite bonding agent diamond grinding wheel prepared by adopting the resin metal composite bonding agent. The resin metal composite bonding agent consists of the following raw materials in percentage by weight: polyimide resin powder, copper powder, tin powder, zinc powder, phosphorus powder and lead powder; and the composite bonding agent diamond grinding wheel consists of the following raw materials: 65 to 85 volume percent of composite bonding agent, 15to 35 volume percent of diamond abrasive, and 0.5 to 1 volume percent of resin liquid. When the diamond grinding wheel prepared by adopting the resin metal composite bonding agent is used on a numerical control grinder, the diamond grinding wheel has the original characteristics of high grinding efficiency and good self-sharpening property of a resin bonding agent diamond grinding wheel and also has the advantages of high rigidity, high heat resistance and good profile retaining property of a metal bonding agent diamond grinding wheel, one-way cutting depth of heavy-load powerful grinding canreach 6 millimeters, and the comprehensive economic benefit can be improved by over 100 percent.

Owner:SUZHOU SAILI PRECISION TOOLS

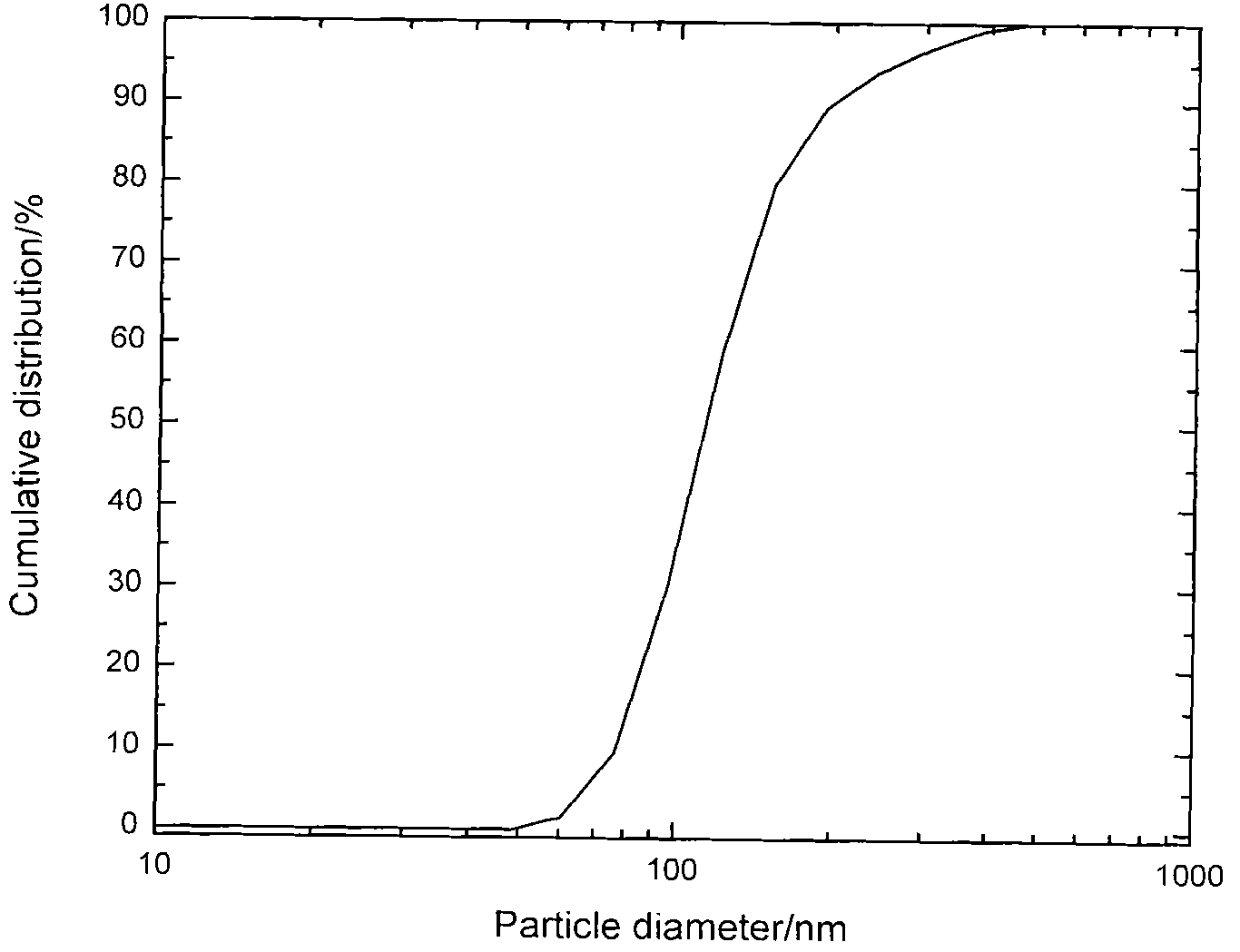

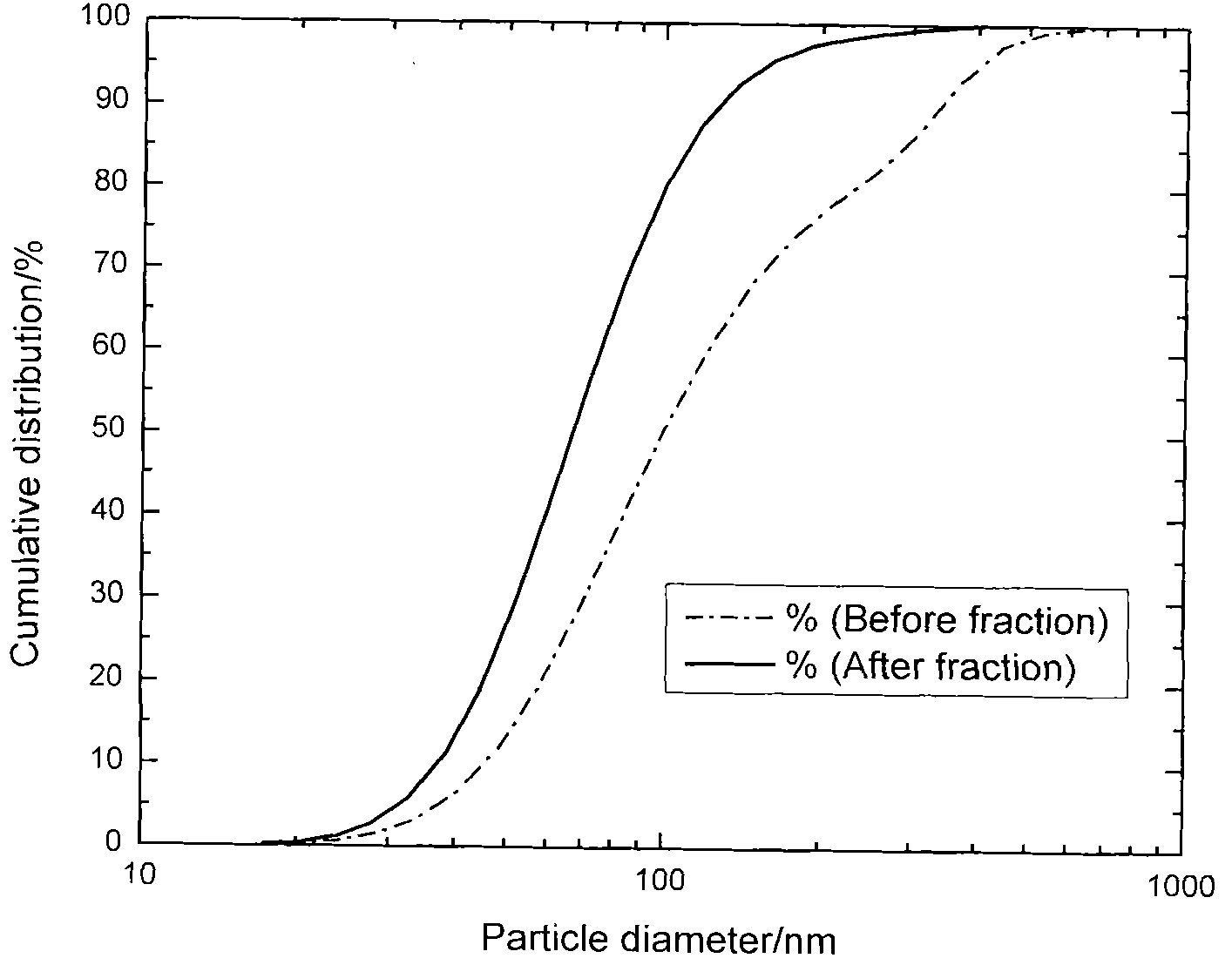

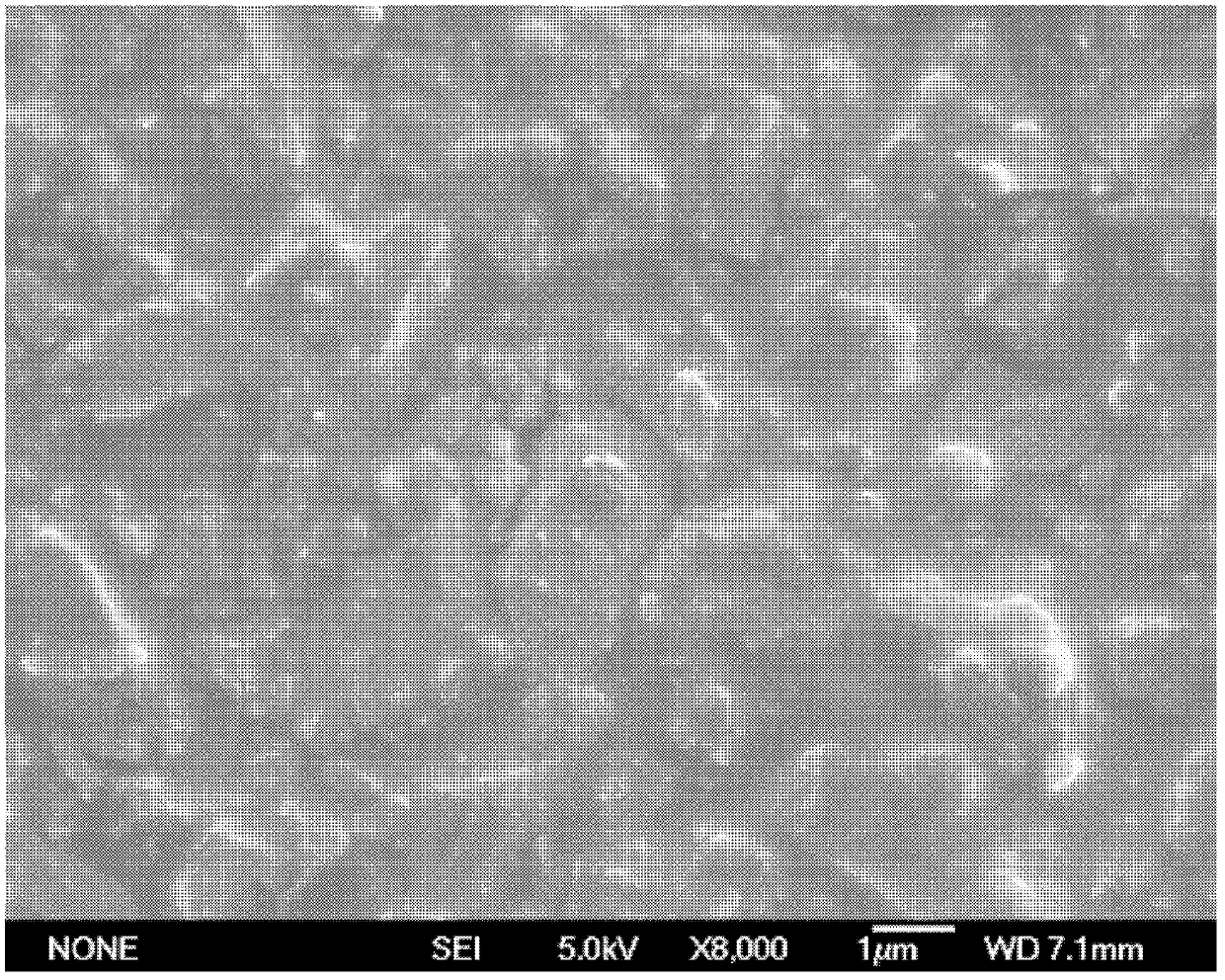

High-precision non-water-based nano-diamond grinding fluid and preparation method and application thereof

InactiveCN101831243AStrict control of particle size distributionTight control of particle morphologyPolishing compositions with abrasivesWater basedAlloy

The invention provides a high-precision non-water-based nano-diamond grinding fluid and a preparation method and application thereof. The high-precision non-water-based nano-diamond grinding fluid comprises main components of nano-diamond particles, a dispersion stabilizing agent, a suspension agent, a pH value regulator, an antistatic agent, an antioxidant, a dispersion medium and the like. In the invention, the particle size distribution is 130nm or smaller D50 particle size; the ratio of D10 to D50 is 50 percent or more; and the ratio of D90 to D50 is 200 percent or less. The preparation method comprises the following steps of: thinning diamond raw materials; carrying out modifying processing; deeply purifying; separating particle size; and finally mixing components according to a certain ratio. The invention has the advantages of completely eliminating deliquesce, hydrolization, chemical corrosion and electrochemical corrosion during the premise polishing and improving the polishing efficiency and the polishing quality to be maximum extent. The products have wide application to hard alloys, disk moulds, computer magnetic heads, computer disks, solar batteries and the like.

Owner:CHINA JILIANG UNIV

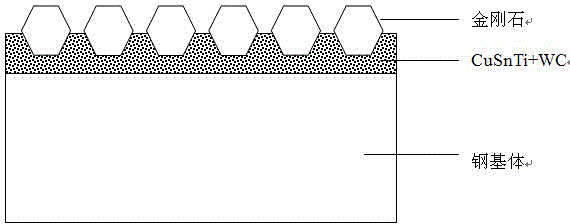

Manufacturing method of single-layer brazing diamond grinding wheel

InactiveCN103817610ALow costImprove wear resistanceAbrasion apparatusGrinding devicesChemical reactionFiller metal

The invention discloses a manufacturing method of a single-layer brazing diamond grinding wheel. The manufacturing method includes steps of preparing a base body of the diamond grinding wheel by a machining method, deoiling and descaling; utilizing mixture of Cu powder, Sn powder, TiH2 powder and WC (wolfram carbide) powder as brazing filler metal of the diamond grinding wheel, and mechanically blending uniformly; sequentially arranging the base body, the brazing filler metal and diamond grains of the diamond grinding wheel to manufacture a tool forming blank; placing the tool forming blank into a vacuum furnace, subjecting the brazing filler metal and the diamond grains to chemical reaction by means of brazing process, cooling to the room temperature along with the furnace, and discharging. Cost for raw materials can be reduced to some extent and oxidation pollution can be avoided by utilizing TiH2 as a Ti source, wear resistance and heat resistance of the brazing filler metal can be improved by adding the superfine WC powder into the Cu powder, the Sn powder and the TiH2 powder, graphitization of diamond can be reduced, thereby heat damage of the diamond can be reduced, and the diamond grinding tool can sufficiently give into play.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Method for preparing ultra-fine diamond grinding wheel of vitrified bond

InactiveCN101870091AReduce surface roughness valueReduce depthAbrasion apparatusGrinding devicesPotassiumUltra fine

Owner:DALIAN UNIV OF TECH

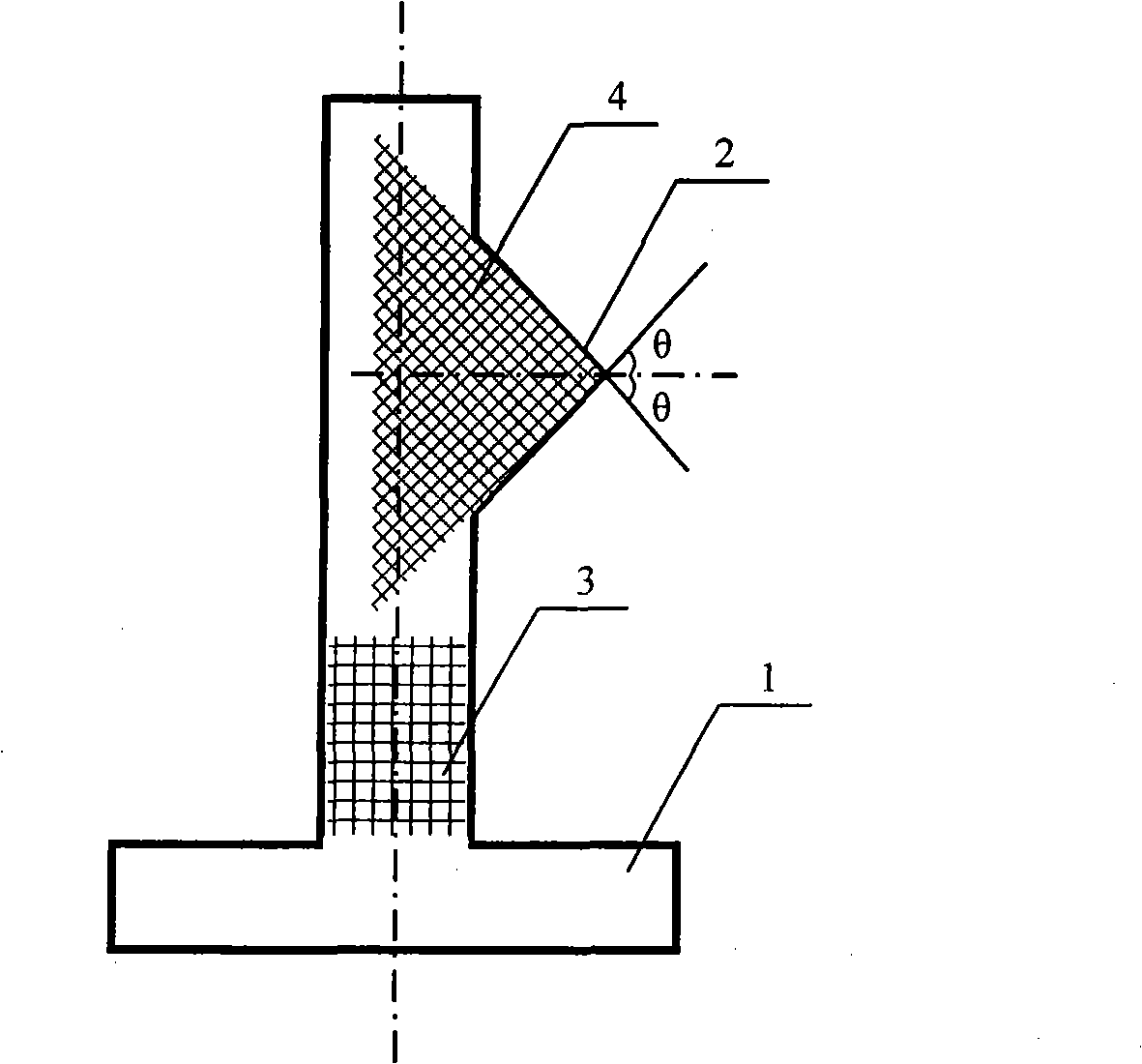

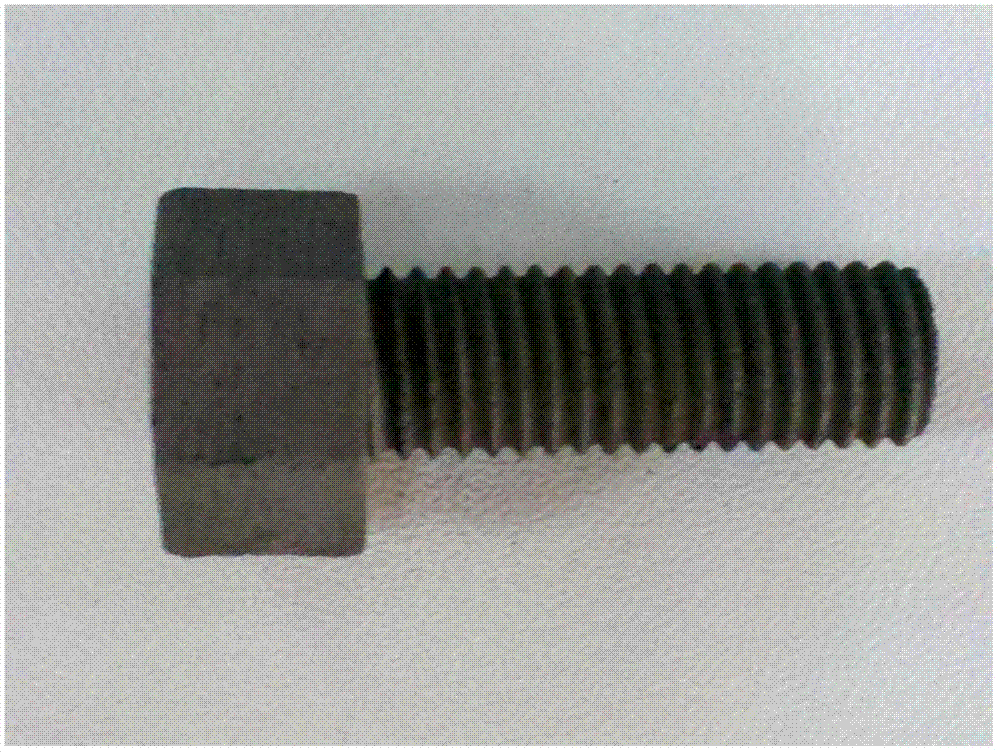

Ceramic base compound material bolt preparation method

The invention discloses a preparation method for a ceramic matrix composite bolt, which is characterized in that the method comprises the following steps: producing a fiber prefabricated product by shaping with a graphite plate after alternatively laminating a 1K carbon fiber 0 / 90 degree positive ply and a plus / minus Theta inclined ply; depositing a pyrolysis carbon interface layer on the prefabricated product and then depositing a silicon carbide matrix on the two-dimensional sheet with a deposited pyrolysis carbon interface layer to produce a semi-finished product of ceramic matrix composite sheet which is cut to form a bolt blank; grinding wheel and tapping the bolt blank; lastly obtaining the product of C / SiC composite bolt after many times of infiltration pyrolysis of polycarbosilane and continuing CVI depositing of SiC anti-oxidation coating. By the method, the bolt is processed and tapped on the semi-finished ceramic matrix composite prefabricated product which is not fully deposited and dense, so that the diamond grinding wheel wear is slow and the production cost is reduced. The technology of CVI combining with PIP process enables the elongation breaking strength of composite bolts to improve from 180 to 190MPa in prior art to 210 to 230MPa.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Diamond grinding wheel and preparation method thereof

ActiveCN102922436AImprove processing efficiencyLow costAbrasion apparatusGrinding devicesProcess systemsProcess efficiency

The invention belongs to the field of grinding tools, and discloses a diamond grinding wheel and a preparation method thereof. The diamond grinding wheel comprises a base body and an abrasion block, and a raw material of the abrasion block contains a ceramic binding agent made of the follow raw materials: SiO2 of 40-46wt%, Al2O3 of 8-13%, B2O3 of 18-22%, Na2O of 8-10%, CaF2 of 11-15 wt%, Li2O of 4-6wt% and TiO2 of 1-2wt%. The diamond grinding wheel can effectively improve processing efficiency of gorilla glass, reduce processing cost, reduce pollution to environment, and meets the requirements for grinding and processing the gorilla glass. In addition, according to the diamond grinding wheel, firing temperature of a binding agent is low, holding force on an abrasion material is strong, damage on diamond is greatly reduced under a process system, and the grinding wheel does not need to be repaired in the grinding process.

Owner:BEIJING GANG YAN DIAMOND PROD CO +1

Method for producing plated diamond grinding wheel

The invention relates to and discloses a method for producing a plated diamond grinding wheel, which comprises the steps of grinding wheel substrate preparation, before-plating processing, vacuum plating, sanding, thickening and finishing, wherein in a thickening process, a shielding strip is used for shielding the two sides and middle of the grinding wheel respectively. The method for producing the plated diamond grinding wheel of the invention improves the sanding mode, avoids uneven sand plating circumference, saves the remanufacture of a profiling anode and reduces cost by arranging the shielding strip on the grinding wheel, and reduces the wear of diamond and improves the life of the diamond grinding wheel due to specific finishing.

Owner:SHENZHEN CHANGXING TECH

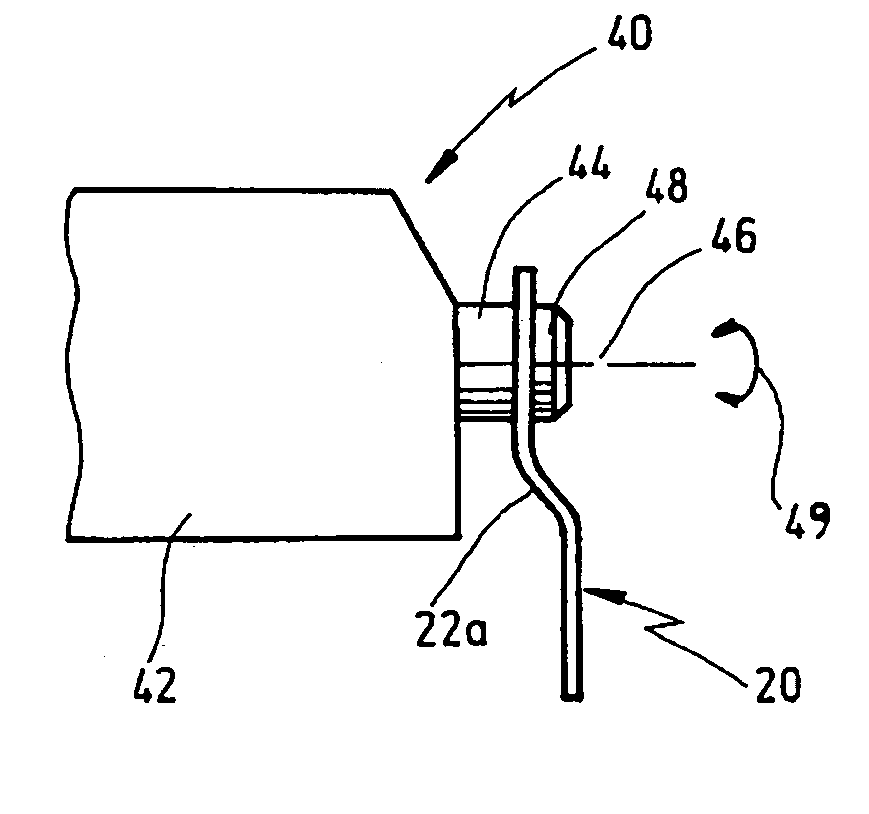

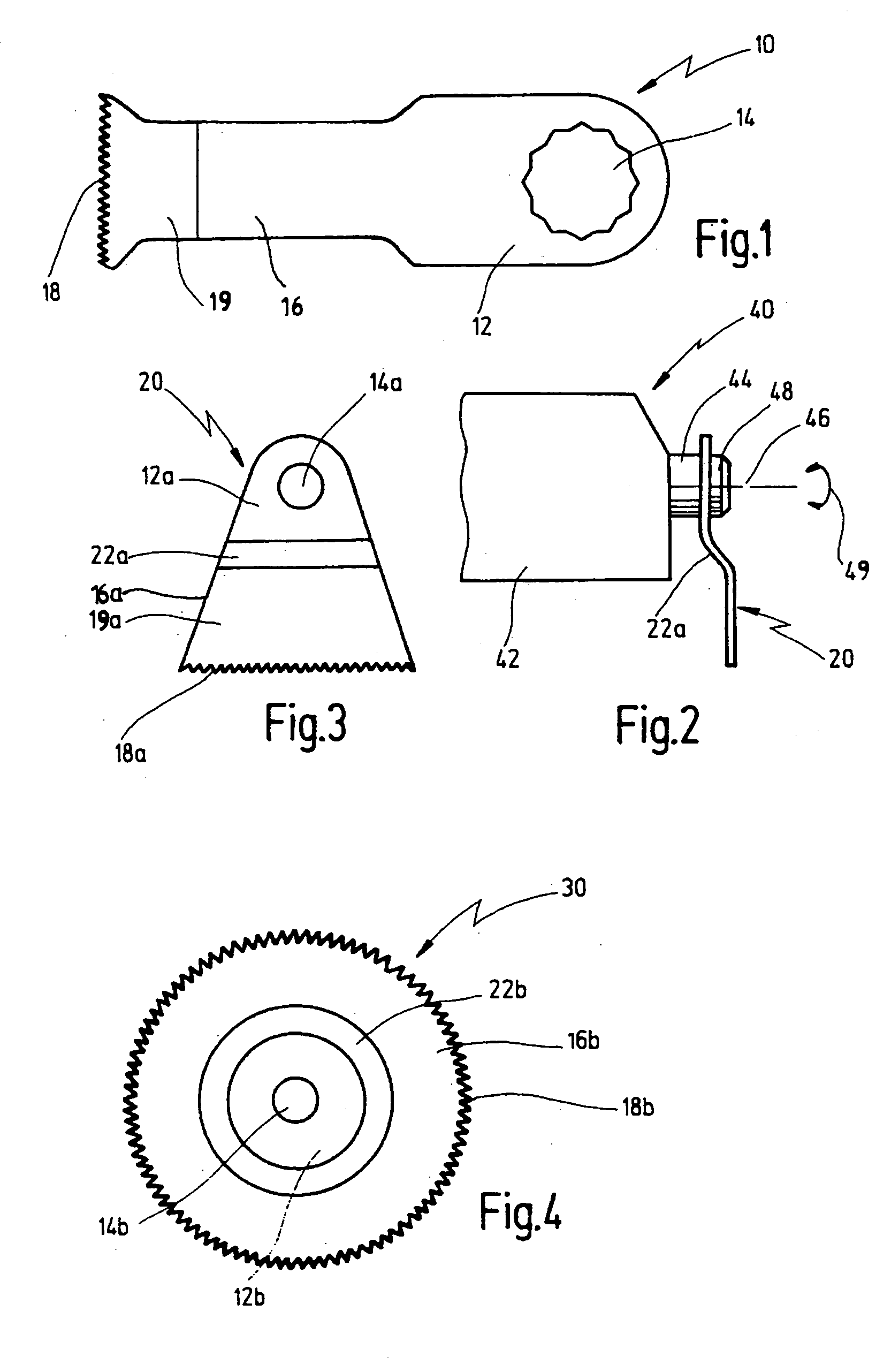

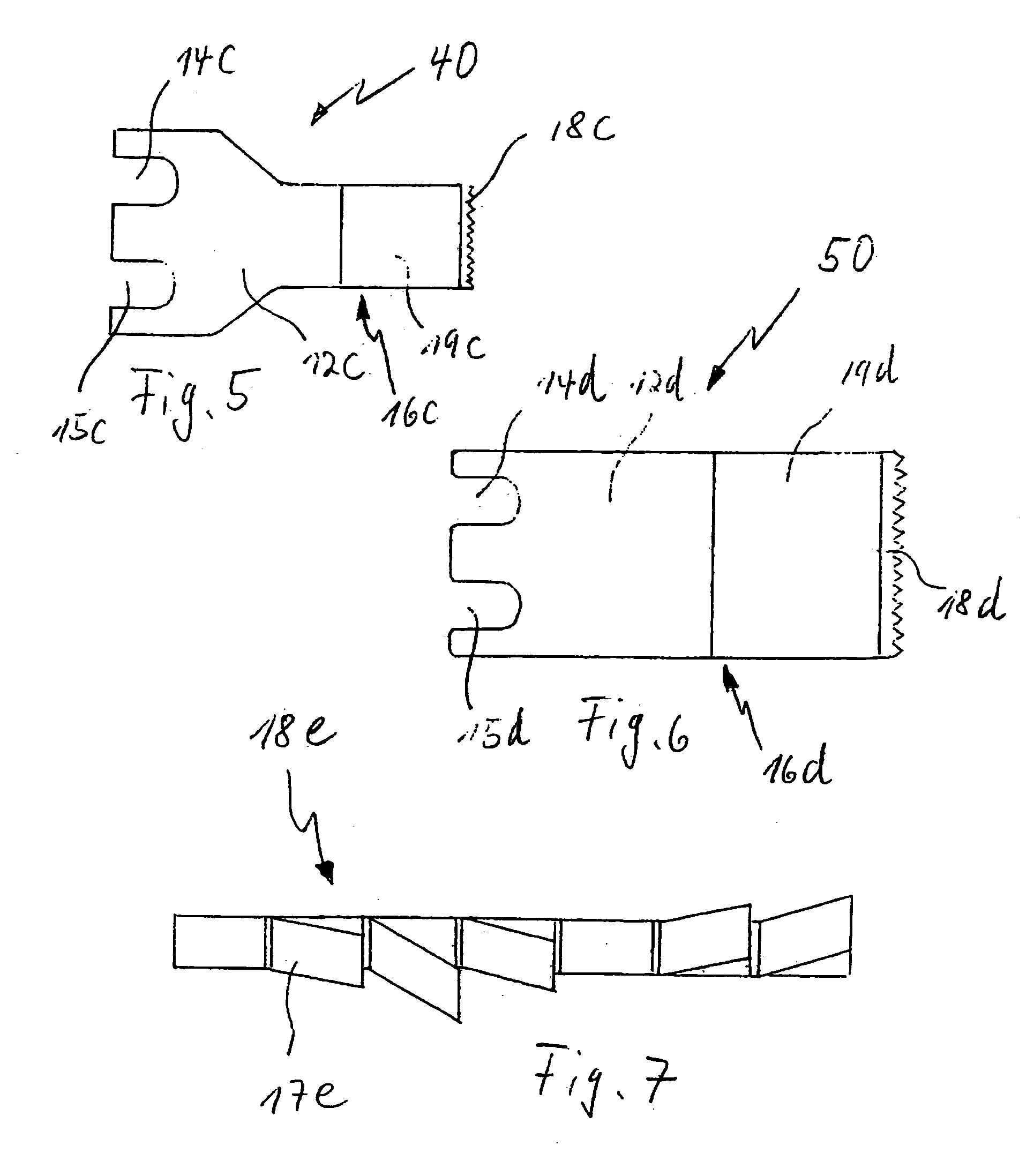

Saw blade and saw having an oscillatory drive

InactiveUS20050178261A1Wide applicationLong lastingPower driven reciprocating sawsMetal working apparatusDrive shaftEngineering

A saw comprising an oscillatory drive for oscillatingly driving a drive shaft about its longitudinal axis is disclosed. The saw comprises a saw blade being driven oscillatingly by the drive shaft and further comprises a mounting section comprising a mounting opening for engaging the drive shaft of the oscillatory drive positively or non-positively. The working section has a cutting edge comprising a series of cutting teeth, wherein at least the cutting edge is made of bimetal. Also preferably there is provided on both sides of the saw blade adjoining the cutting edge a coating comprising diamond grinding particles.

Owner:C & E FEIN

Monocrystalline silicon high-efficient composite cutting method and cutting system thereof

InactiveCN101138869AImprove cutting effectSave the texture processFine working devicesMetalElectric spark

An efficiently composite cutting method of monocrystalline silicon is characterized in that a monocrystalline silicon rod for cutting is installed and nipped at an electric spark linear cutting machine; metallic thread which is concreted with diamond grinding material is used as cutting wire to make the electric spark linear cutting; the advantages that the processing speed of the electric spark linear cutting is high and the cutting effect of the diamond grinding material at the metallic thread of the concreted grinding material is good are completely exerted; the purpose to realize the quickly and efficiently cutting towards the monocrystalline silicon rod is achieved; at the same time the surface of the cut monocrystalline silicon naturally forms a fleece-faced texture which has the effect of anti-reflection. The present invention has a series of advantages of simple method, high efficiency of processing, good quality etc.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

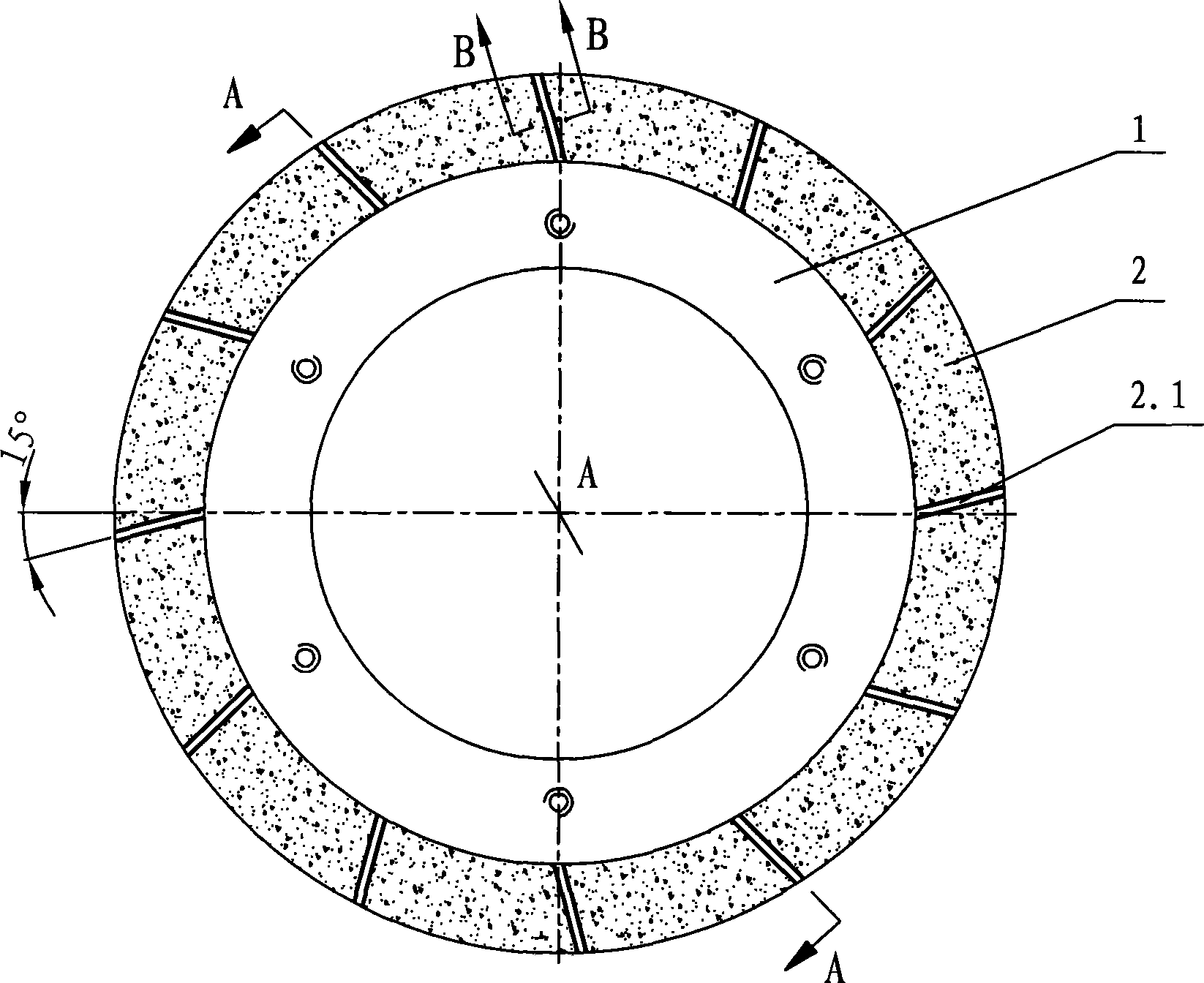

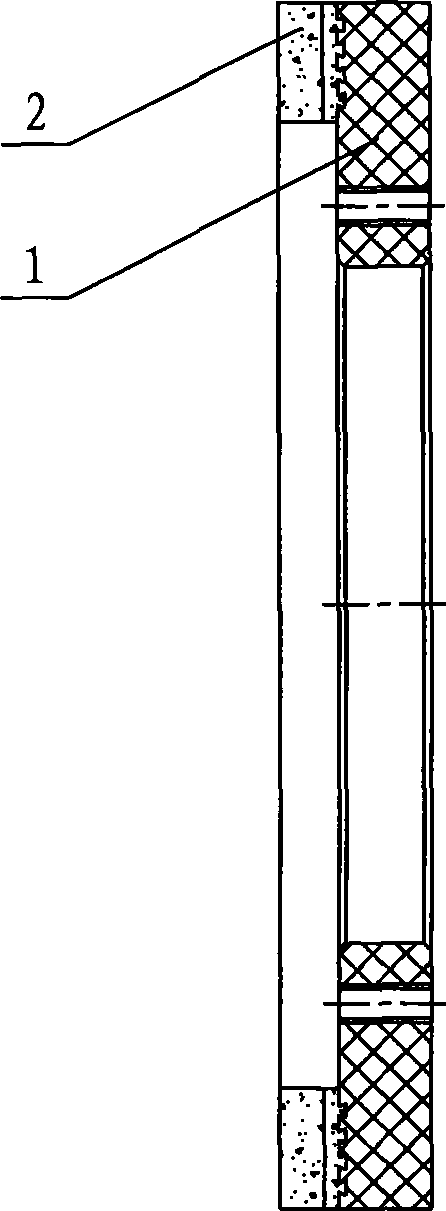

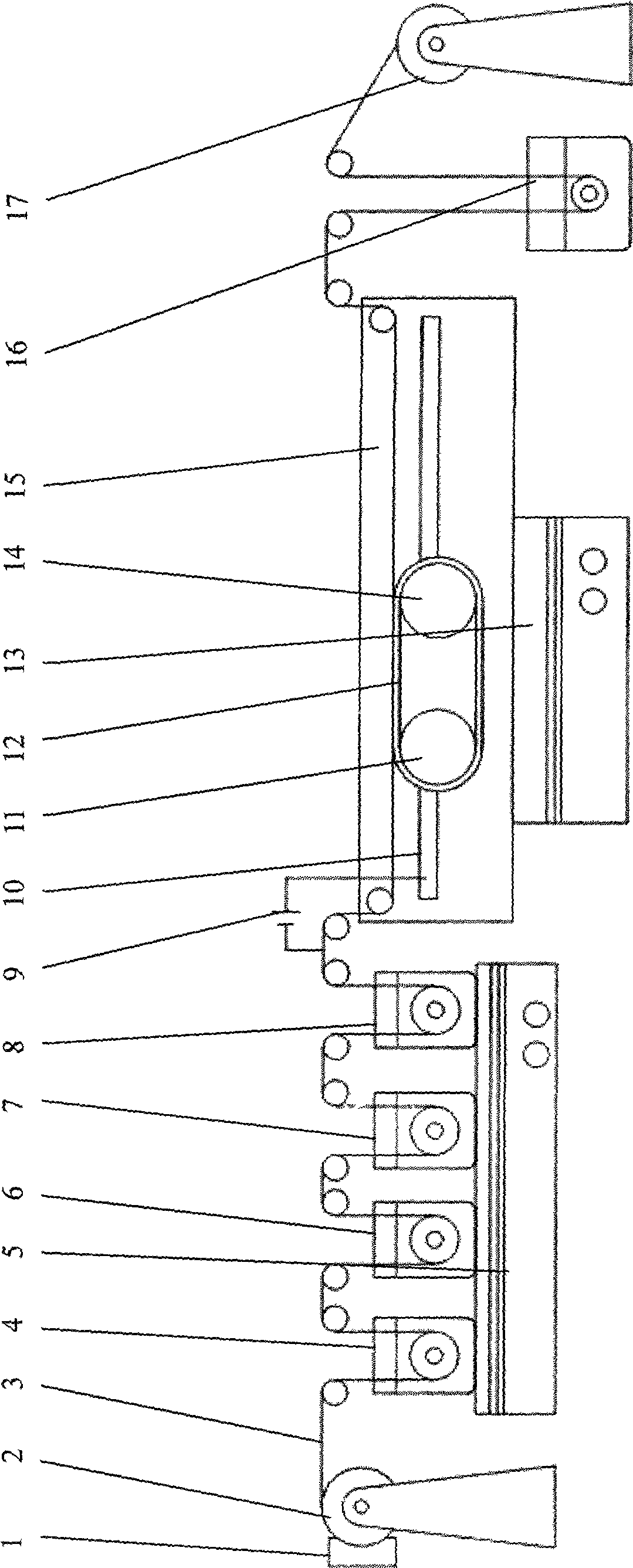

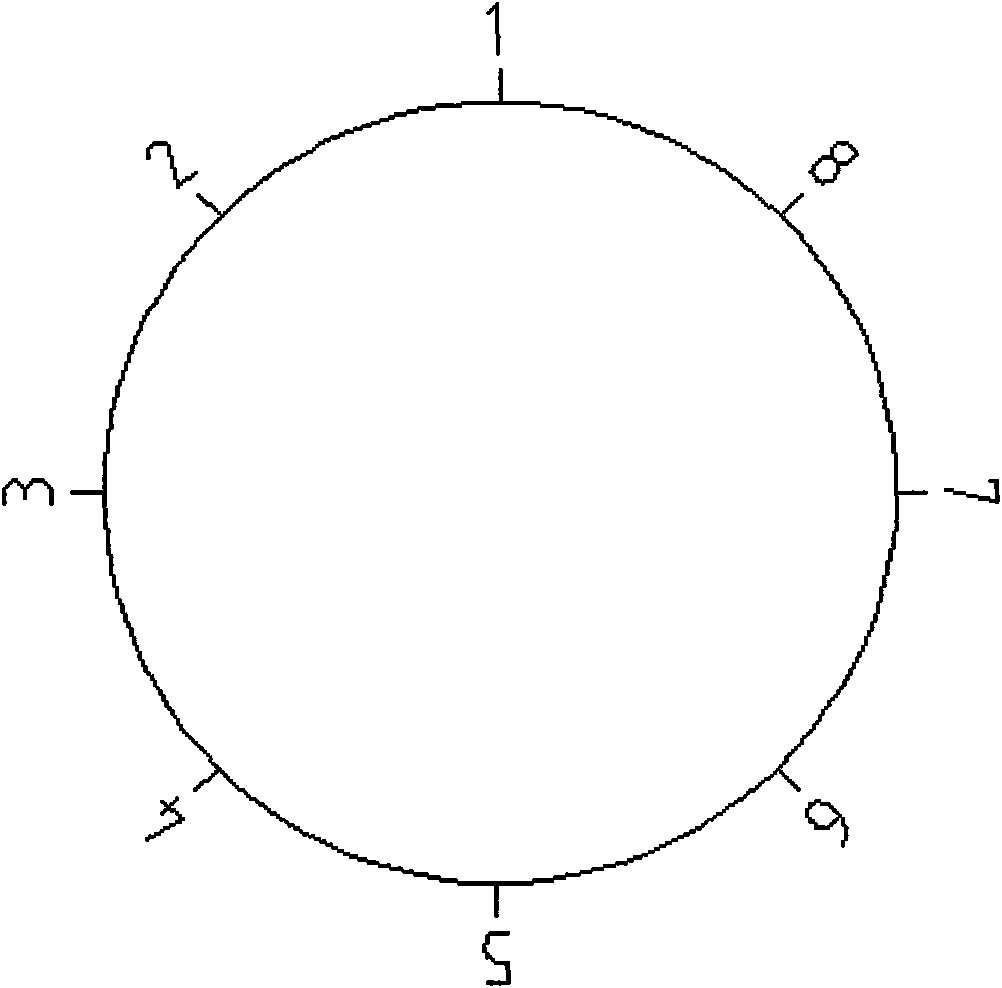

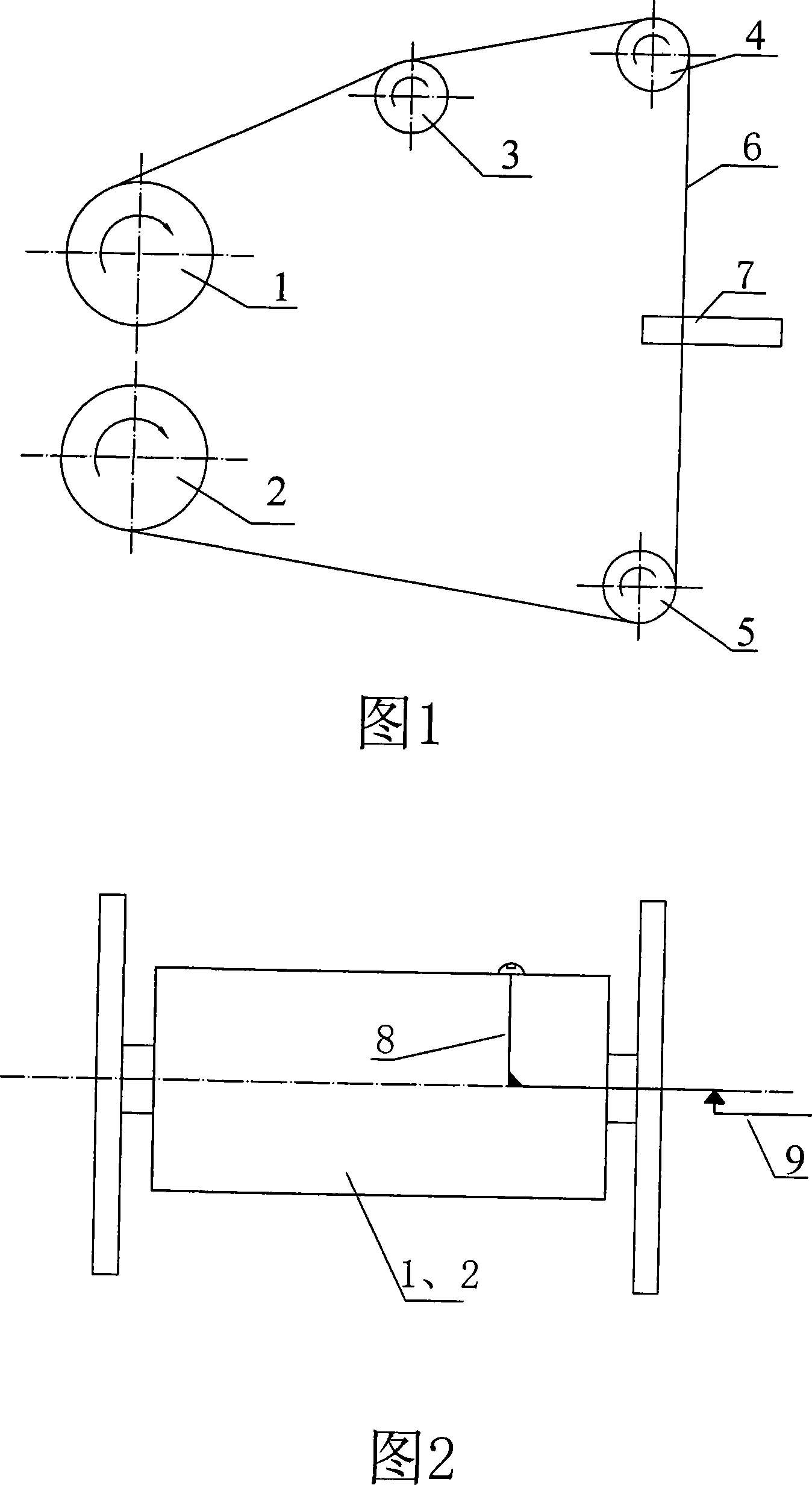

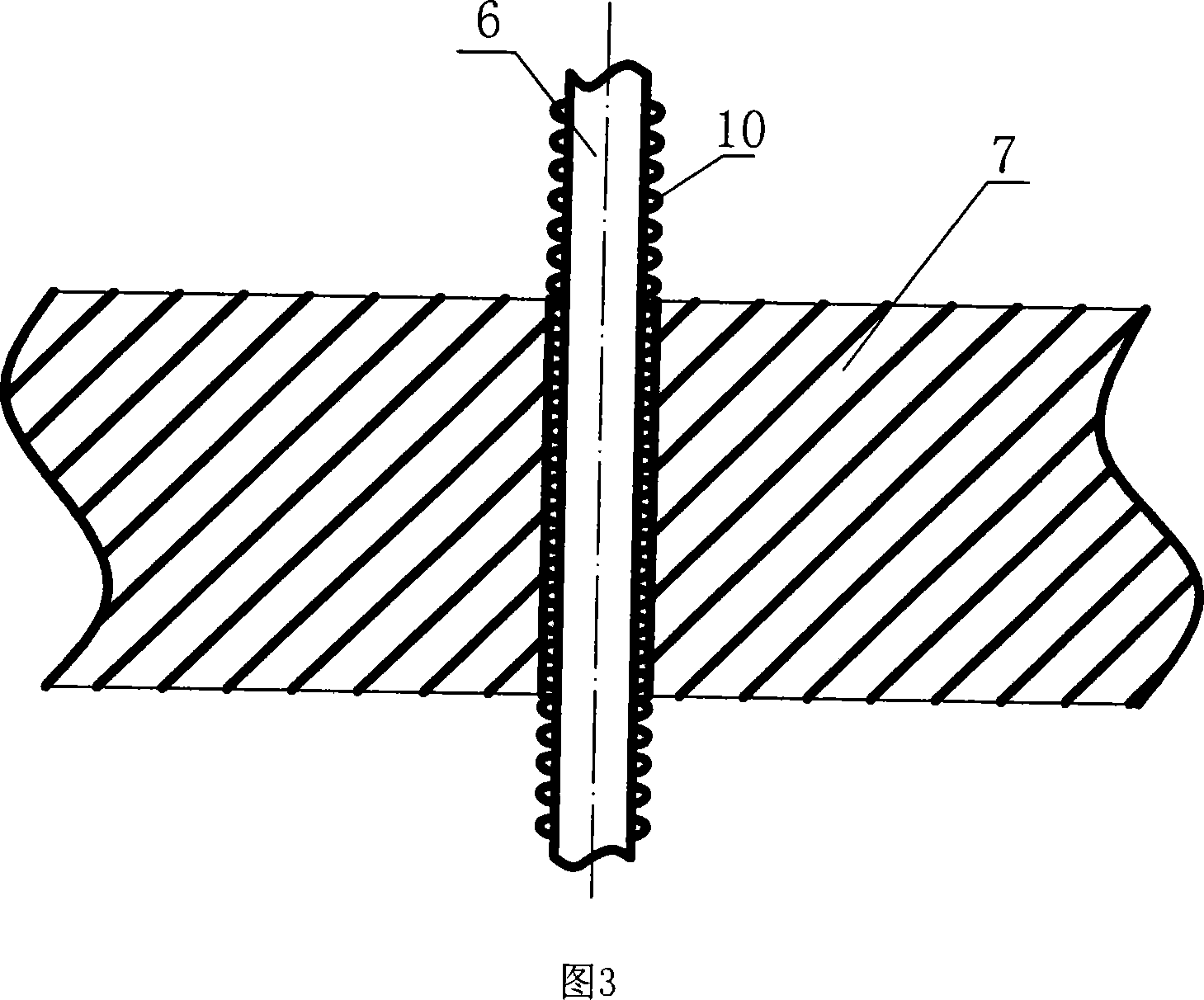

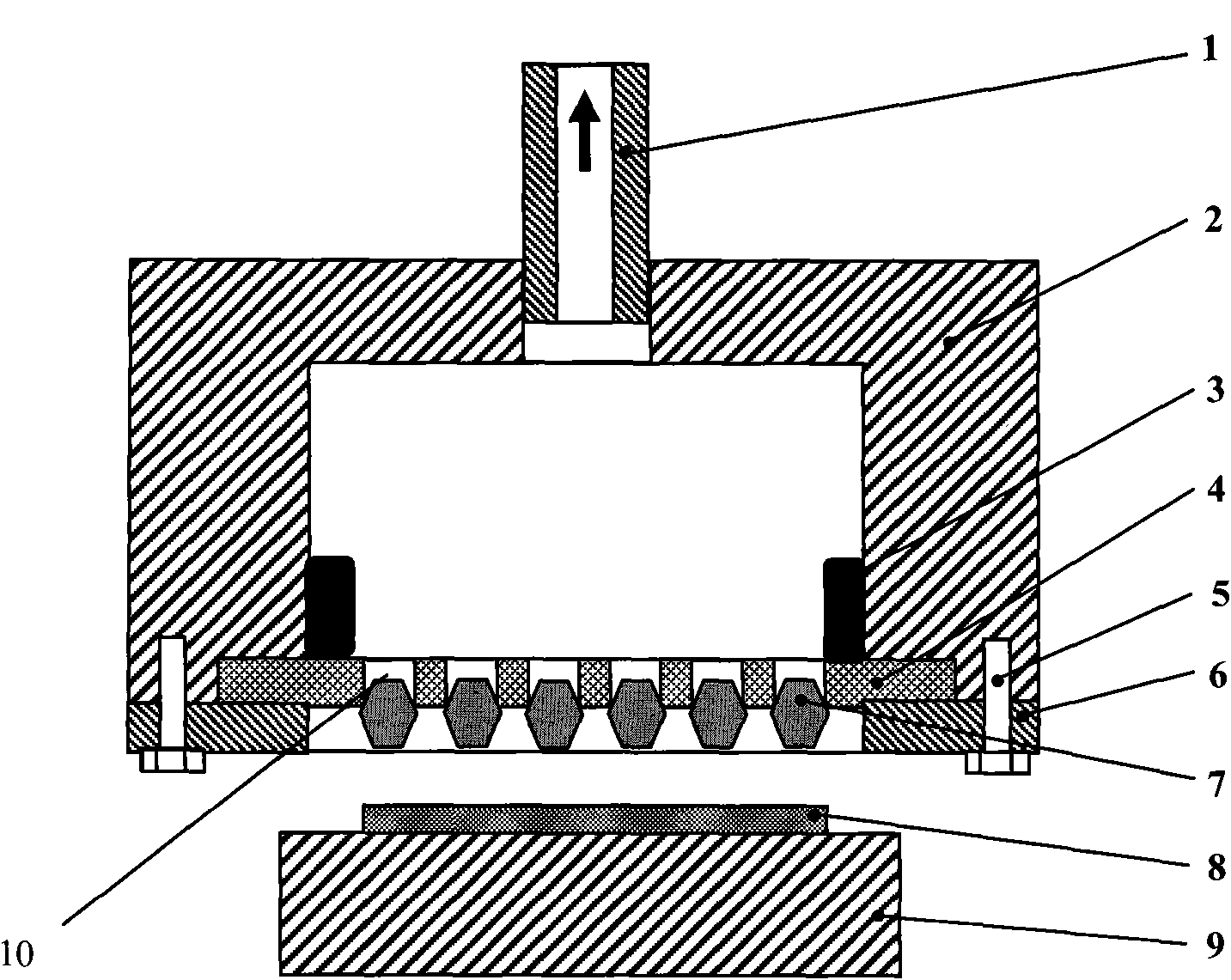

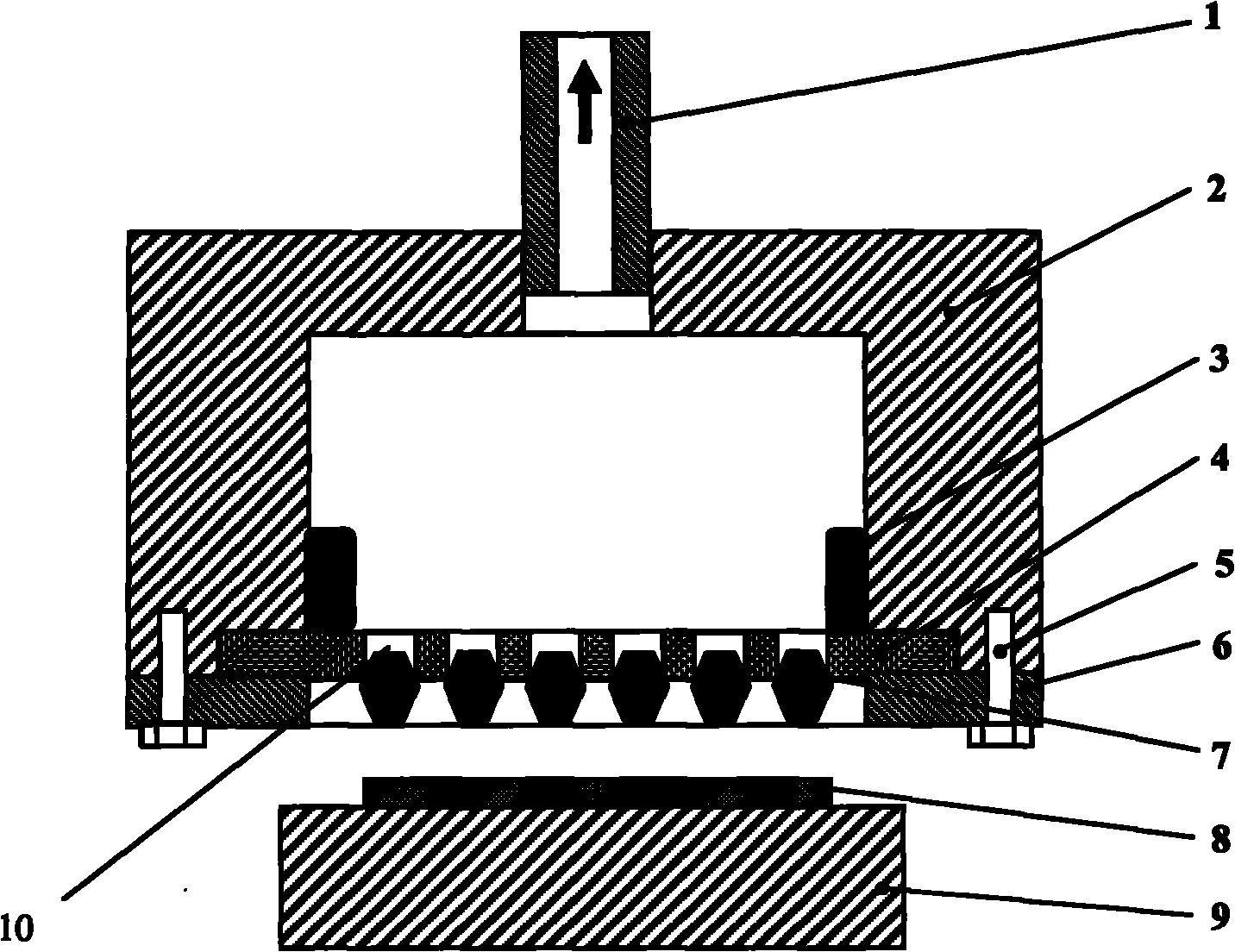

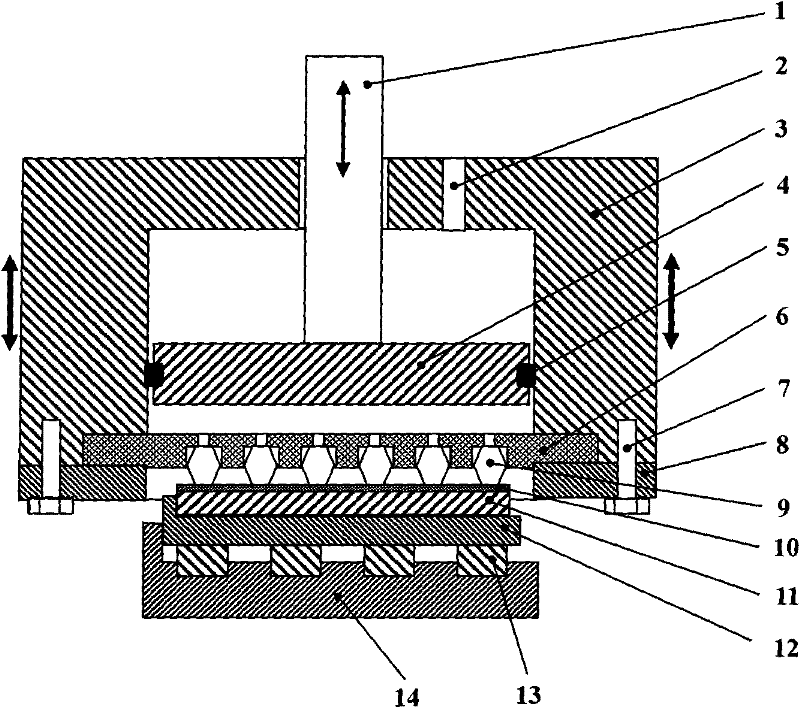

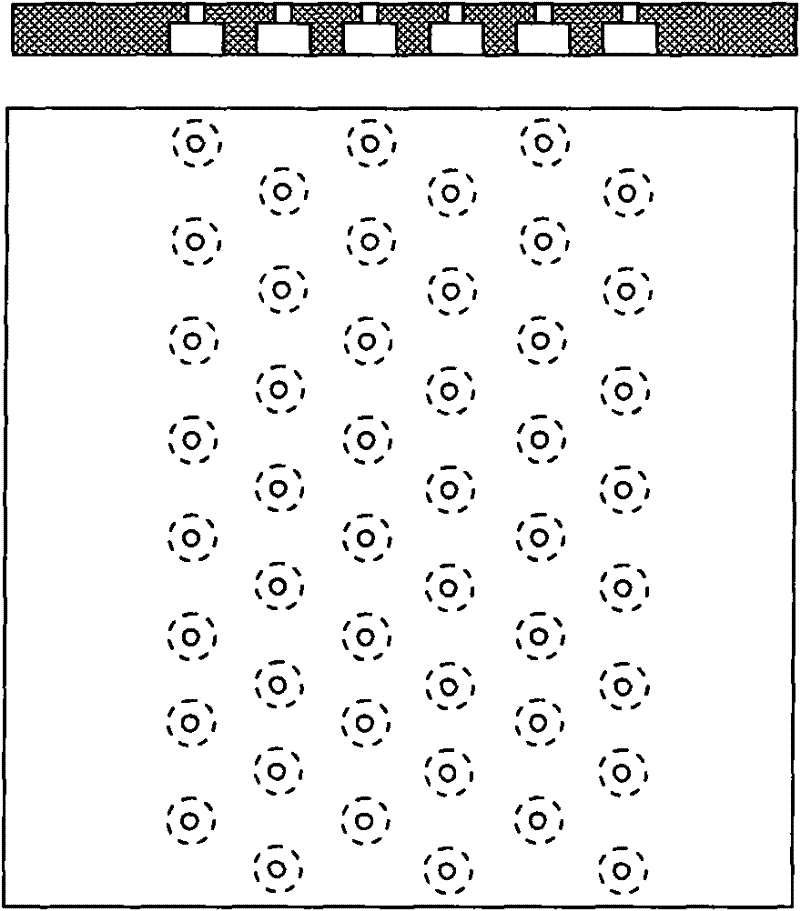

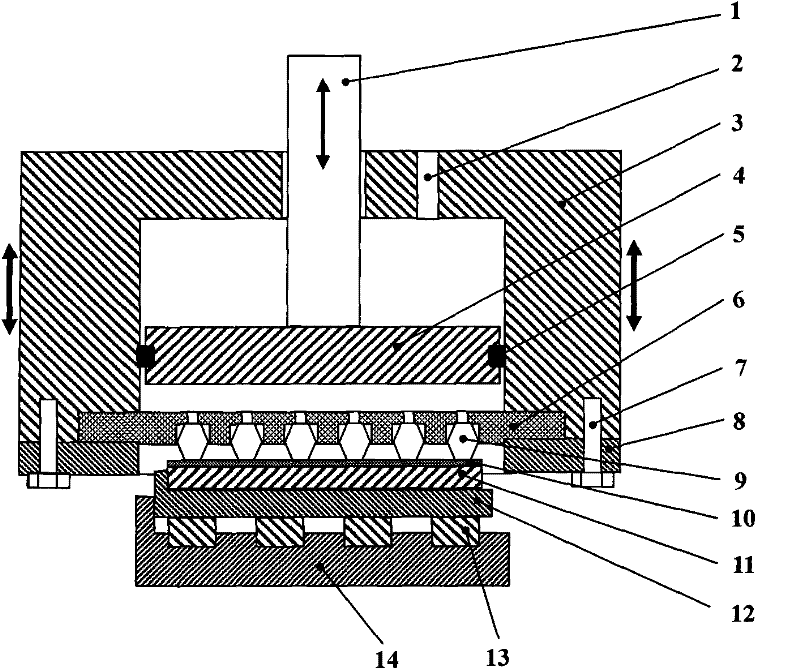

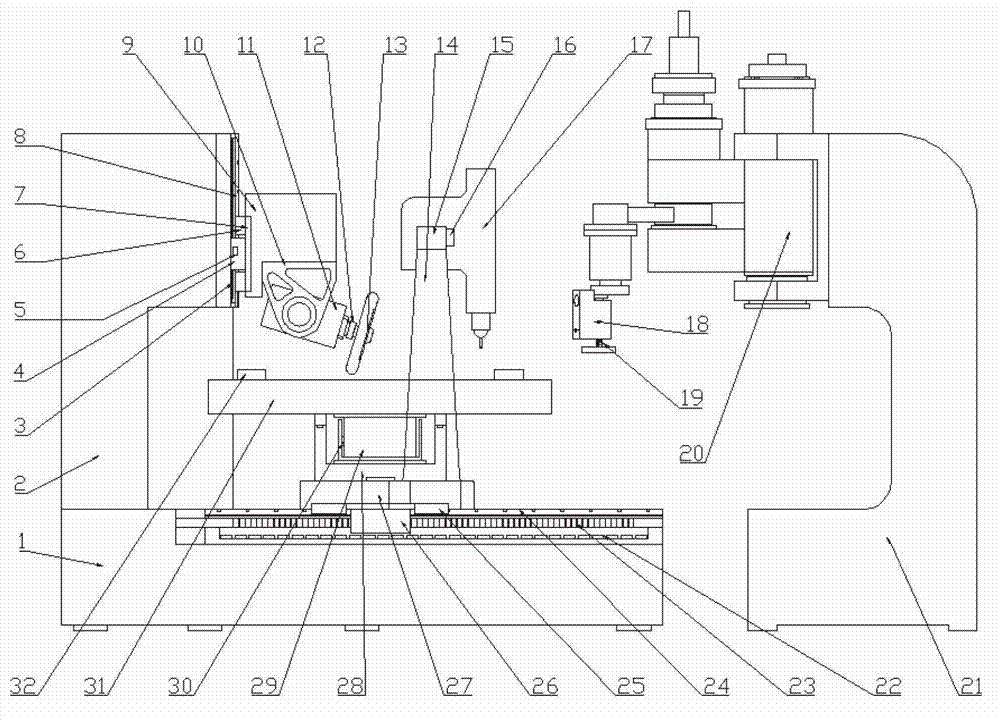

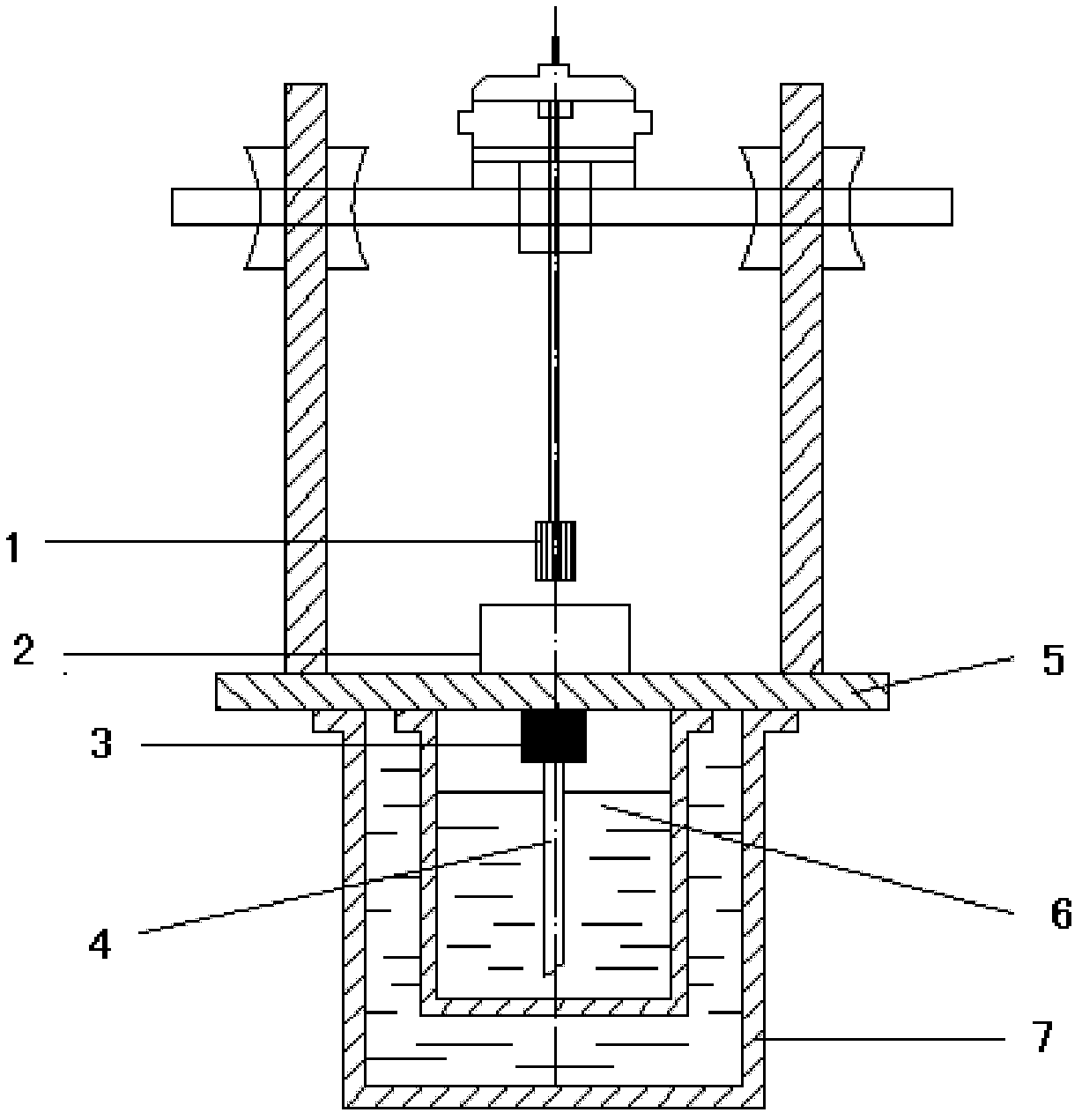

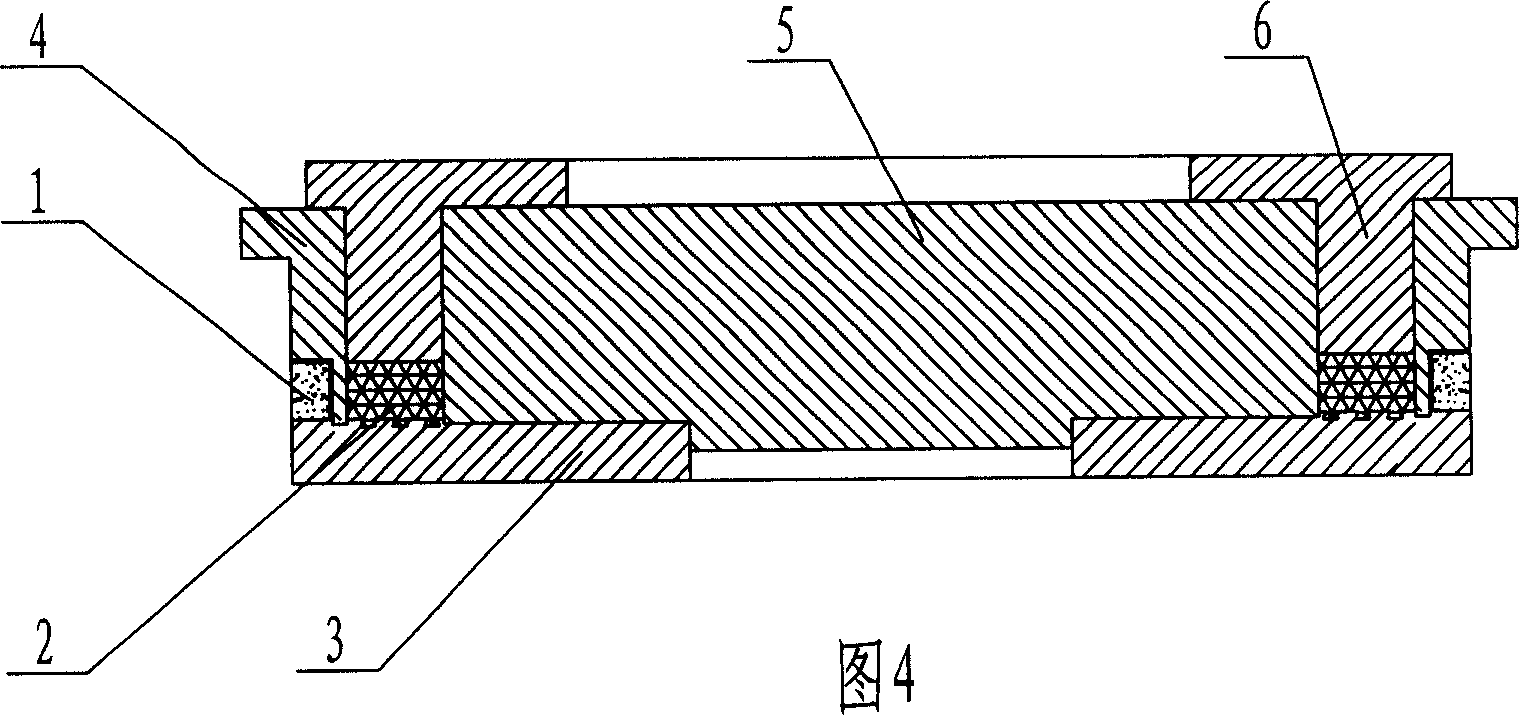

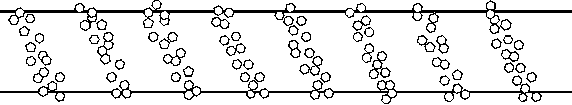

Diamond grinding material sequential distributing system and process

InactiveCN101797725AIncrease productivityImprove efficiencyGrinding devicesVacuum pumpingMaterial distribution

The invention relates to the field of manufacture of diamond grinding material grinding tools, in particular to diamond grinding material sequential distributing system and process for producing a saw bit cutter head and a thin wall-drilling drill. The diamond grinding material sequential distributing system comprises a vacuum pumping pipe (1) and a vacuum chamber cylinder sleeve (2), wherein a grinding material distributing plate (4) is fixed to the lower end of the vacuum chamber cylinder sleeve (2); a plurality of holes (10) which can adsorb and fix a diamond grinding material (7) are sequentially distributed in the grinding material distributing plate (4); and a magnetic working platform (9) which can adsorb and fix a cold press thin blank (8) is arranged under the grinding material distributing plate (4). The invention provides the diamond grinding material distributing system with highest production efficiency at present and has high automation degree, and the key action of grinding material distribution is completely linked and finished by equipment; and the system has simple structure and low cost and is easy for popularization.

Owner:HANGZHOU BODA DIAMOND

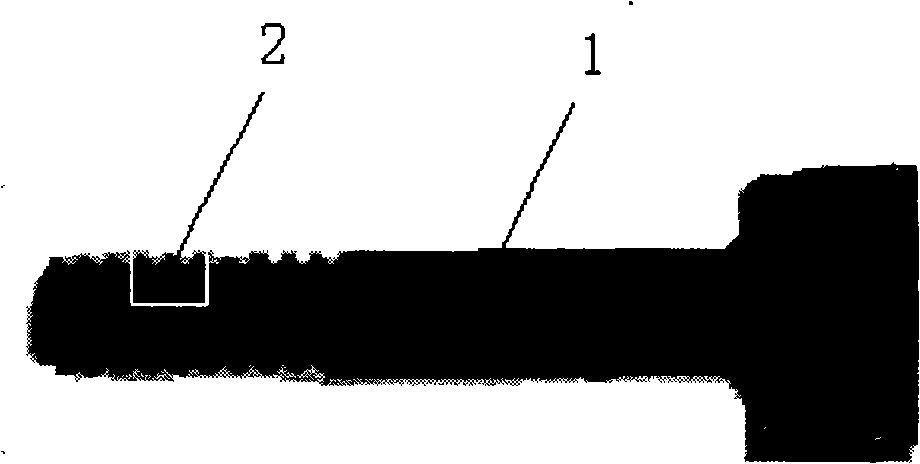

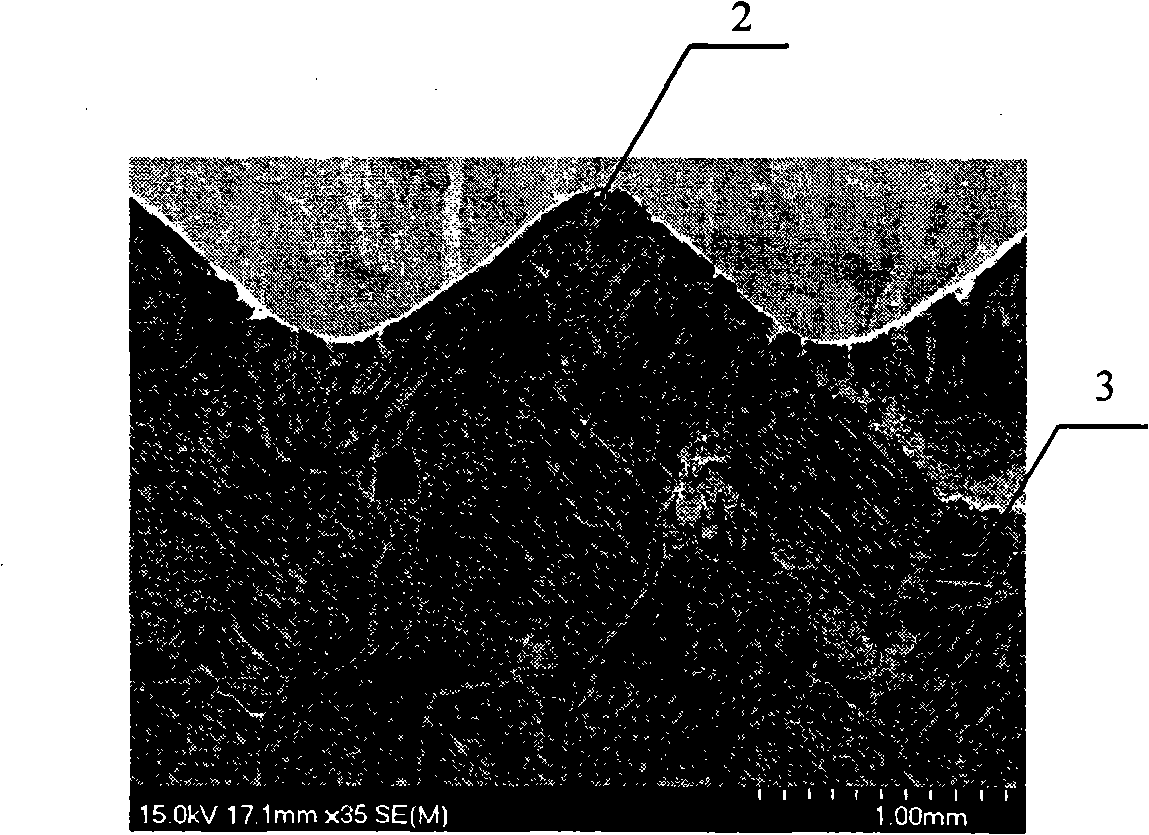

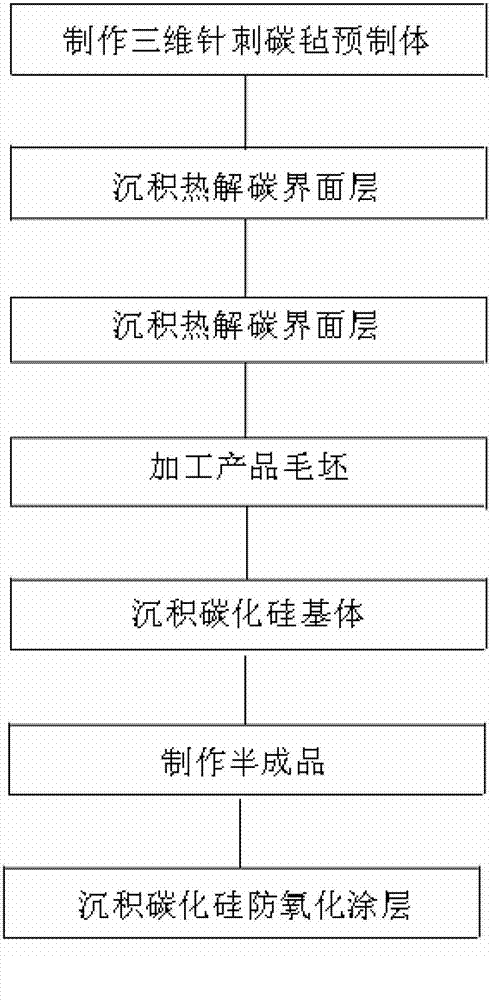

Preparation method of three-dimensional needling carbon/carborundum composite material bolt

ActiveCN102775176AIncreased shear strengthReduce wearScrewsChemical vapor infiltrationMaterials science

A preparation method of a three-dimensional needling carbon / carborundum composite material bolt adopts a three-dimensional needling fiber prefabrication body to prepare the composite material bolt. Pyrolytic carbon is deposited on the prefabrication body, carborundum substrates are deposited through chemical vapor infiltration (CVI), and a bolt bar blank and a bolt cap blank are obtained. The carborundum substrates of the bolt bar blank and the bolt cap blank which are obtained through machining are deposited through the CVI, a carborundum anti-oxidation coating is deposited through the CVI, and a three-dimensional needling C / SiC composite material bolt end product with the shear strength being 80-100MP is obtained. Compared with the prior art, the preparation method has the advantages that the number of times for getting into a furnace is reduced by 6-10, the densifying period is shorter, and the production cost is reduced. By means of a test of a CK6180-3000 numerically controlled lathe, the preparation method is small in diamond grinding wheel abrasion, hour norm for machining 30 bolt threads is reduced by about 10 hours, and as the abrasion of a grinding wheel is less, the working accuracy is improved, and industrialized batch production is achieved.

Owner:XIAN XINGUI CERAMIC COMPOSITE MATERIAL CO LTD

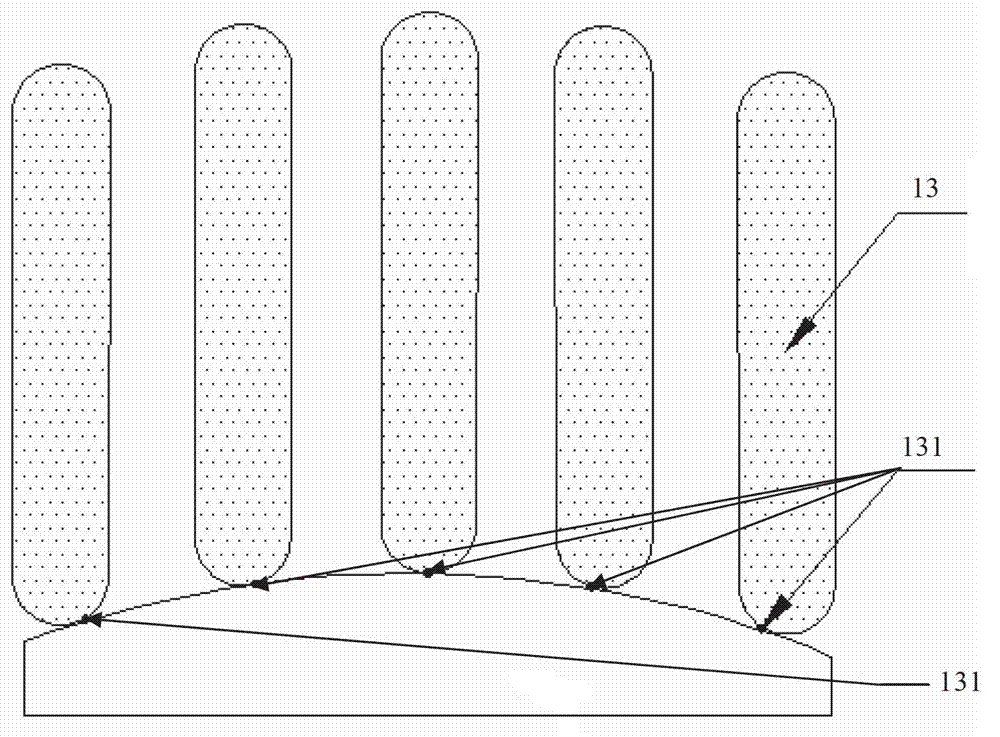

Diamond grinding material sequential arraying system and method

The invention relates to a diamond grinding material sequential arraying system and a method, belonging to the field of grinding material and tool manufacturing. The system comprises a cylinder sleeve (3) and a piston (4). The piston (4) which can move up and down is arranged in the cylinder sleeve by a piston rod (1), the cylinder sleeve is sealed with the piston by a sealing ring (5), an elastic plate (6) is fixed at the lower end face of the cylinder sleeve by a screw (7) and a pressing plate (8), and stepped holes are sequentially arrayed in the elastic plate. The system further comprises a worktable (14) and a supporting plate (12) arranged on the worktable (14) by a magnet block (13). With low cost and easy popularization, the system and the method can effectively, accurately and sequentially array and distribute diamond grinding materials.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

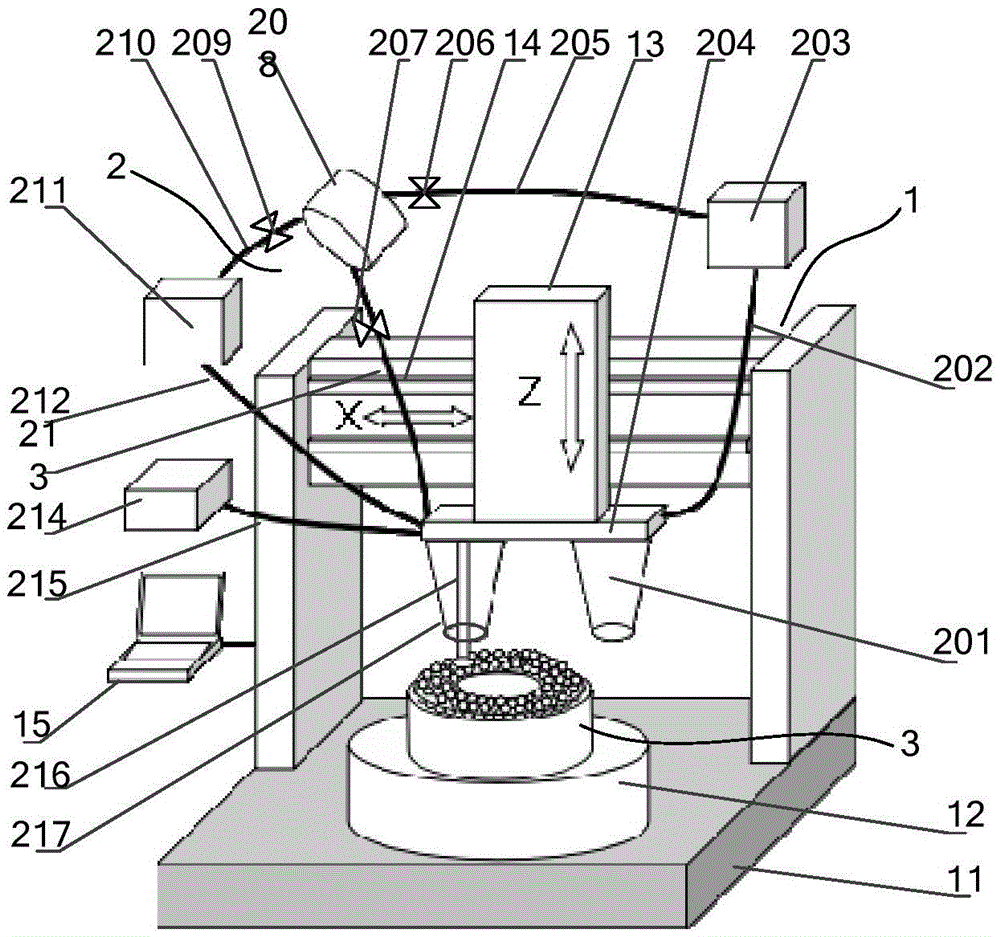

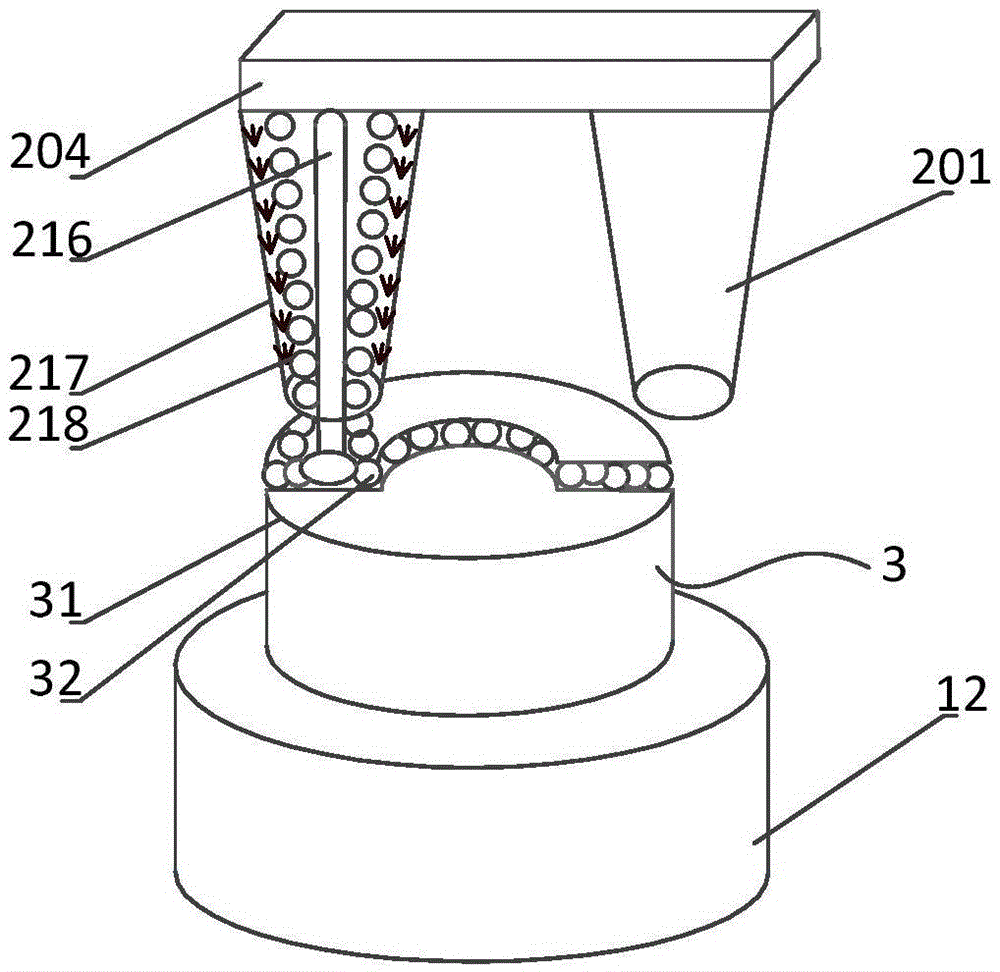

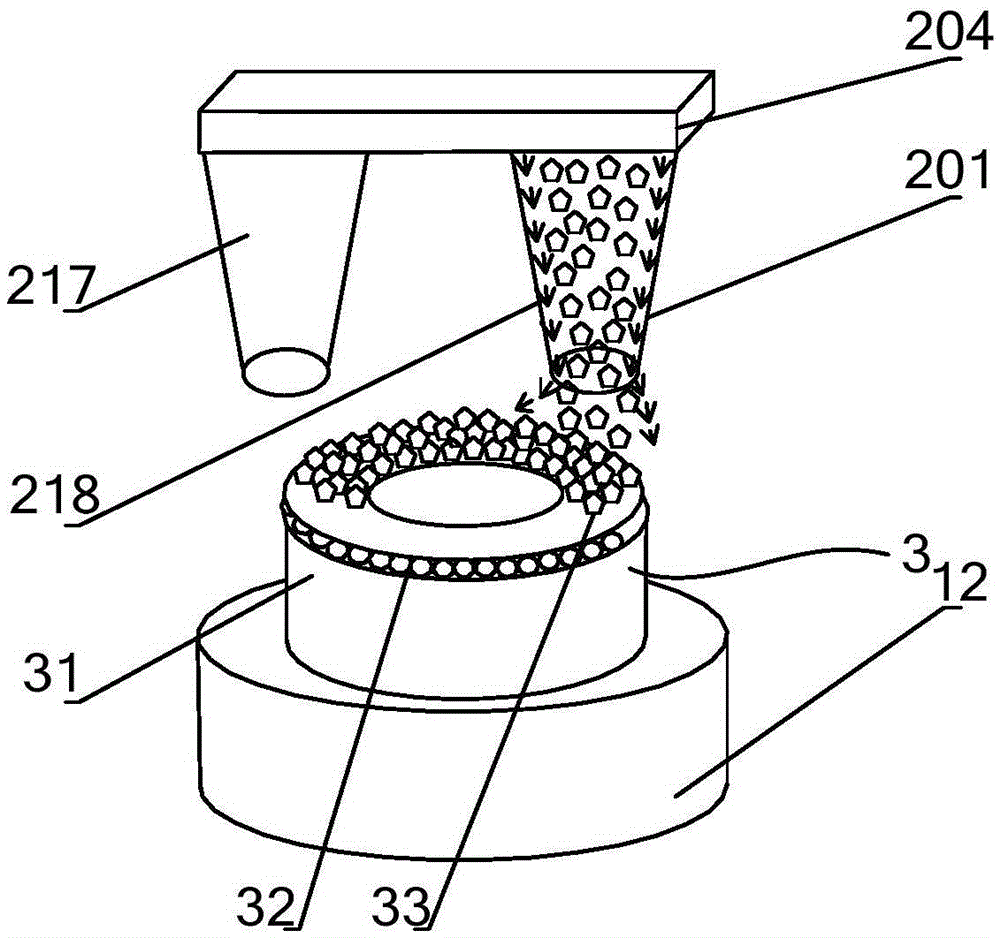

Manufacturing method for 3D printing diamond grinding wheel with abrasive particles arranged regularly

ActiveCN105415216AImprove grinding efficiencyUniform grinding forceGrinding devicesManufacturing technologyMachined surface

The invention belongs to the technical field of grinding machining and 3D printing and relates to a manufacturing method for a diamond grinding wheel with abrasive particles arranged regularly. Related devices mainly comprise a movement control platform, a grinding wheel printing system and a 3D printing grinding wheel. The movement control platform comprises a base, a rotation movement table, a lifting platform, a horizontal-moving platform, a movement control device and a supporting frame. The grinding wheel printing system comprises a diamond abrasive particle nozzle, a conveying pipe I, a diamond abrasive particle box, a nozzle supporting plate, an air pipe I, an air valve I, an air valve III, an air source, an air valve II, an air pipe II, a metal bonding agent powder box, a conveying pipe II, an air pipe III, a laser source, a laser optical path, a laser beam, a bonding agent nozzle and airflow. The 3D printing grinding wheel comprises a grinding wheel base body, a metal bonding agent and the diamond abrasive particles. The abrasive particles can be regularly arranged in the grinding wheel, when the grinding wheel of this kind is ground, the machined surface is high in quality, grinding efficiency is high, grinding force is even, and the service life of the grinding wheel is prolonged. Thus, the manufacturing technology of the special-shaped grinding wheel is simplified, platform constructing is convenient, and operation is easy and convenient.

Owner:HUNAN UNIV

Diamond grinding tool of ceramic-metallic bond and preparation method of grinding tool

ActiveCN102152248AImprove toughnessHigh strengthAbrasion apparatusGrinding devicesDiamond grindingAluminium

Owner:长沙百通新材料科技有限公司

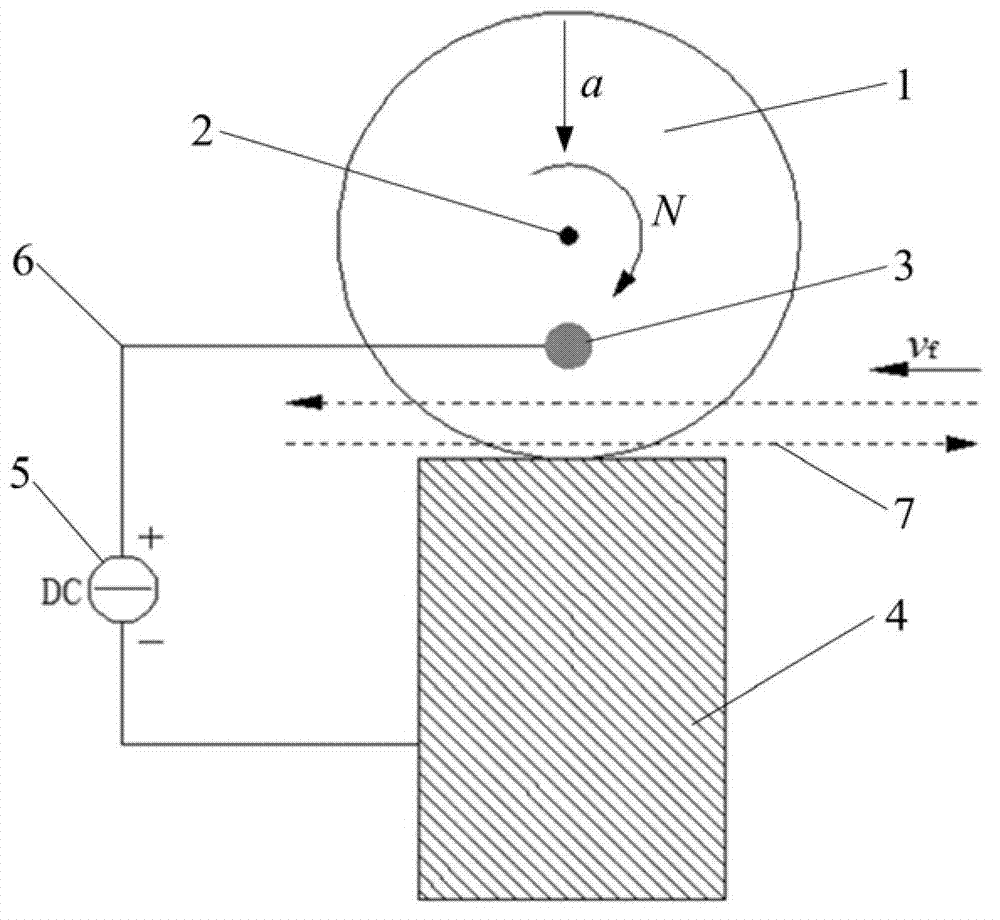

In-gas discharge dressing and truing method for large-particle diamond grinding wheel

ActiveCN103395002AWon't burnAvoid arcingAbrasive surface conditioning devicesWear particleCopper electrode

The invention discloses an in-gas discharge dressing and truing method for a large-particle diamond grinding wheel. The method includes: fixing the diamond grinding wheel on a grinding wheel shaft, and fixing a conducting electrode on the horizontal plane; connecting the diamond grinding wheel, the electrode, a graphite brush, a power source and a wire to form a discharge circuit; connecting a positive pole of the power source to the grinding wheel, and connecting a negative pole of the power source to the electrode. When rotating, the diamond grinding wheel linearly reciprocates on the surface of the electrode; metal bond is removed by pulse sparks generated between the electrode and the metal bond of the grinding wheel, so that diamond abrasive particles are edged from the surface of the grinding wheel; spark discharge occurs between the metal bond and whirling conducting chips generated when the edged diamond abrasive particles cut the copper electrode, generated instant high temperature is transmitted to cutting edges of the diamond abrasive particles in contact cutting through the chips, the tips of the cutting edges are pneumatically dressed, and accordingly micro edging, dressing and truing of the grinding wheel are achieved, more effective abrasive particles are generated and efficient grinding of smooth mirrors is achieved.

Owner:SOUTH CHINA UNIV OF TECH

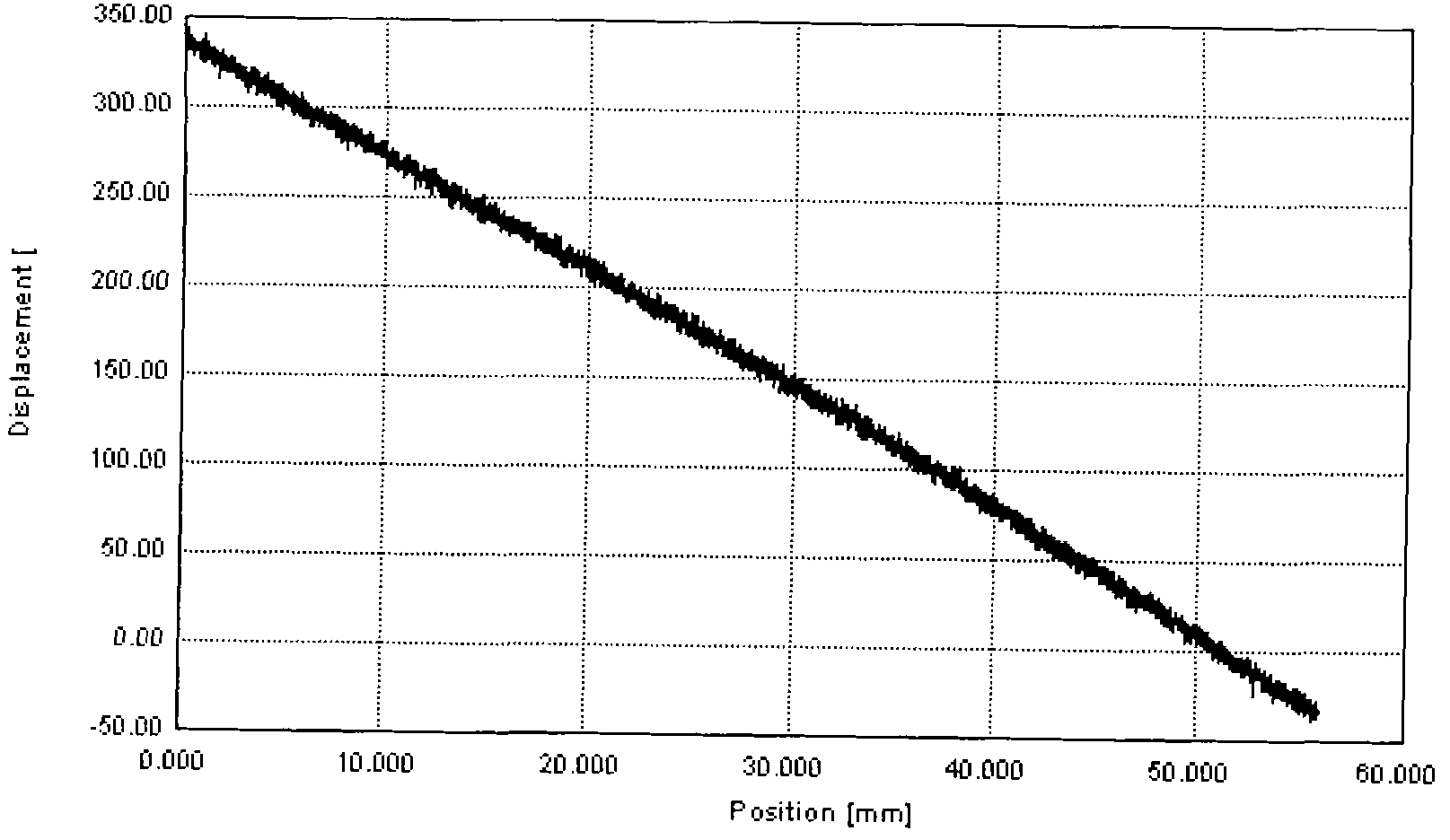

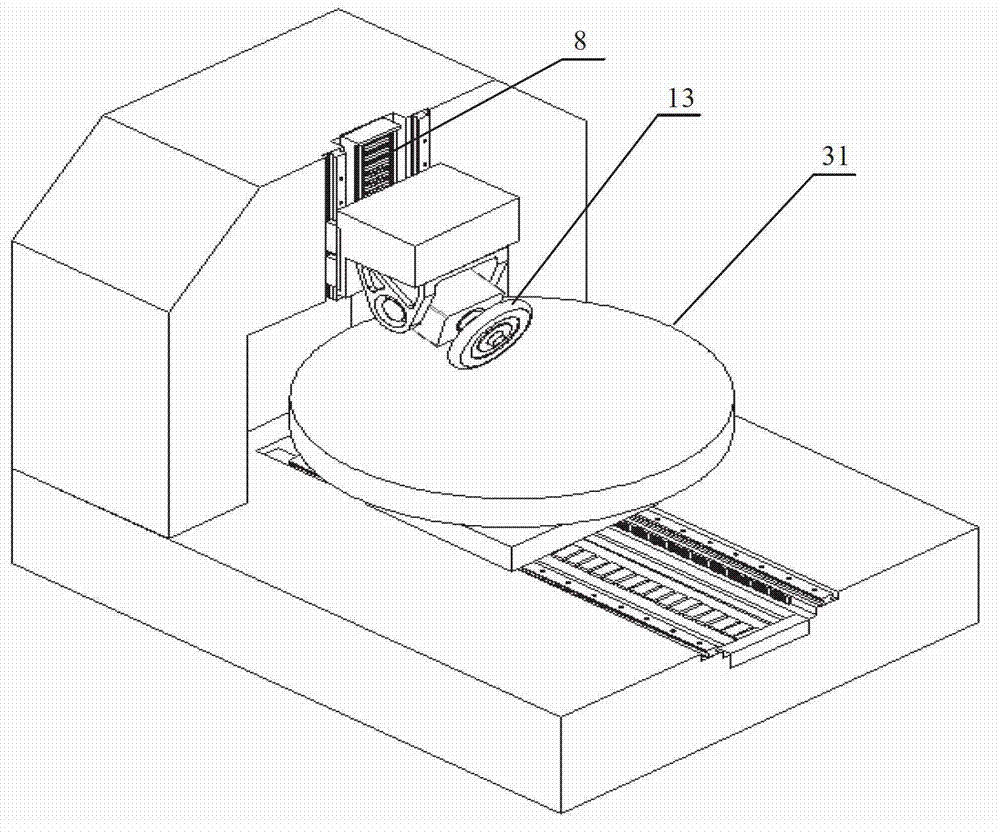

Ultra-precise processing integrated platform for large caliber optical mirror surface

ActiveCN102756316AEasy to moveAchieve multi-axis ultra-precision grindingOptical surface grinding machinesOptical processingSurface grinding

An ultra-precise processing integrated platform for a large caliber optical mirror surface solves the problem that processing and detection are not integrated while processing the large caliber optical mirror surface in the conventional optical processing technical field. The platform integrates grinding, detection and milling for processing the large caliber optical mirror surface, and comprises a base, a horizontal moving device, a rotation device, an ultra-precise grinding device, a mirror surface detection device and a milling device, wherein the horizontal moving device drives the rotation device to move to a workpiece mounting position, a grinding position, a surface shape detection position and a milling position in a horizontal direction; a vertical moving device drives a spindle system and a diamond grinding wheel to move up and down in a vertical direction; the spindle system can adjust the inclined angle of the diamond grinding wheel; the diamond grinding wheel has a cambered surface; when in the workpiece mounting position, the rotation device can conduct cambered surface grinding on a workpiece; when in the surface shape detection position, the rotation device can conduct surface shape detection on the workpiece; when in the surface shape detection position, the rotation device can mill the workpiece.

Owner:SHANGHAI JIAO TONG UNIV

Diamond resin grinding wheel and preparation method thereof

ActiveCN102814759ANot easy to fall offImprove heat resistanceAbrasion apparatusGrinding devicesIron powderHeat resistance

The invention discloses a diamond resin grinding wheel and a preparation method of the diamond resin grinding wheel. The diamond corundum resin grinding wheel is prepared from the following components by weight, 50-60 parts of diamond grinding material, 10-20 parts of silicon carbide powder, 5-15 parts of phenolic resin powder, 2-6 parts of phenolic resin liquid, 1-2 parts of dibutyl phthalate, 5-10 parts of nano fluorite powder, 5-10 parts of fungacetin, 2-5 parts of black manganese ore and 2-5 parts of scrap iron powder. According to the diamond resin grinding wheel, as the ceramic material is added into padding, the adhesive property is good, the grinding materials hardly fall off, the heat resistance and hardness of the resin grinding wheel are improved, cracks formed by rigid grinding are reduced, and the use efficiency and service life of the resin grinding wheel are improved further; in addition, as the iron power is added, fast heat dissipation effect is achieved, a great deal of heat generated in the cutting process of the grinding wheel can be dissipated quickly, and the effect of lowering cutting temperature is lowered.

Owner:安徽威铭耐磨材料有限公司

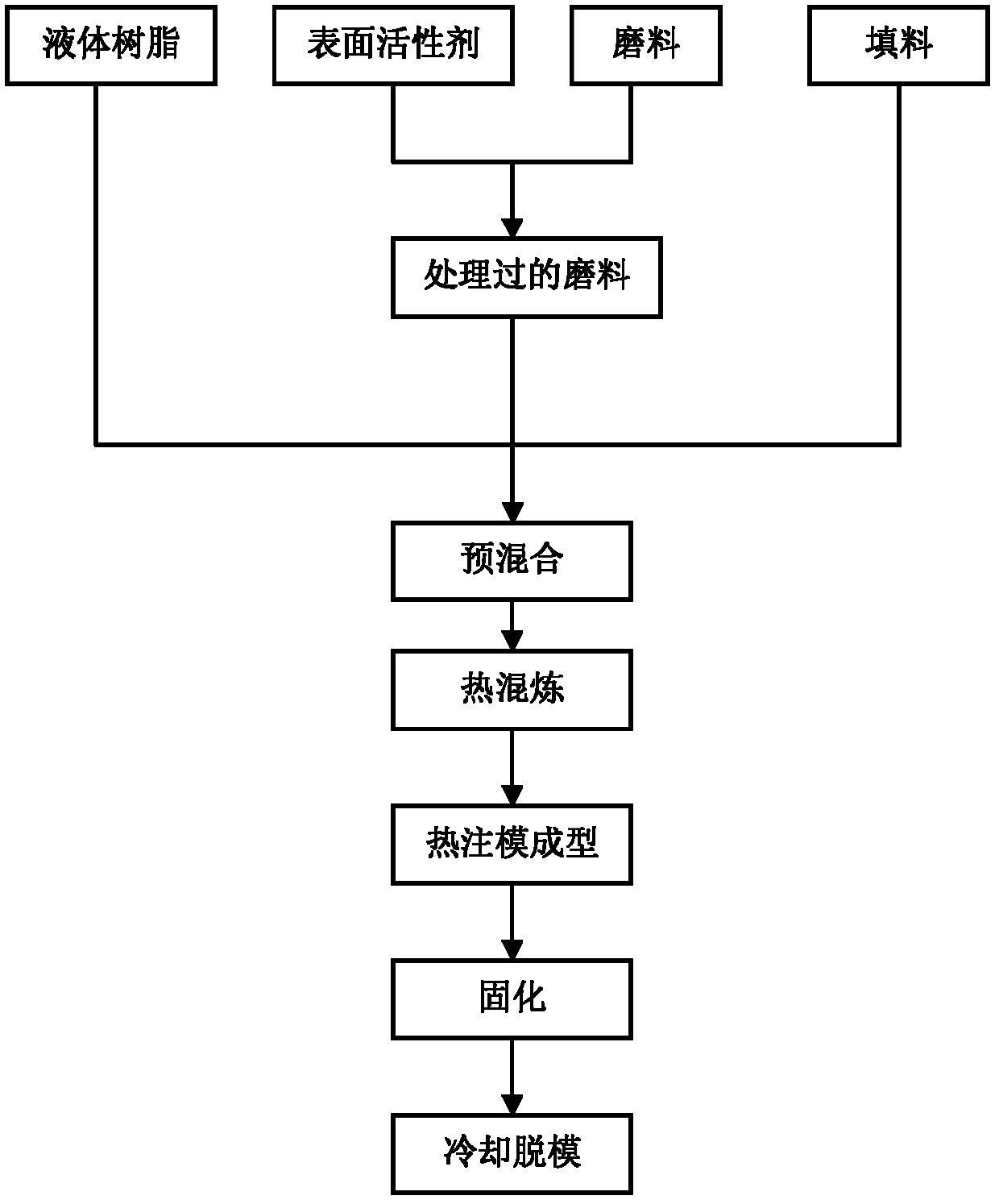

Preparation method of resin binder diamond abrasive product used for accurate grinding

ActiveCN102601745AImprove plasticityUniform tissueAbrasion apparatusGrinding devicesTemperature controlGranularity

The invention discloses a preparation method of a resin binder diamond abrasive product used for accurate grinding. The preparation method comprises the following steps: firstly, surface treatment is carried out on diamond abrasive material by a surfactant, the diamond abrasive material is pre-mixed with liquid resin, filler and the like, then the mixture is added into a material mixing device with accurate temperature control, and thermal mixing is carried out on the mixture at a certain temperature, so that uniform forming material with better plasticity is formed, finally, the forming material is poured into a grinding wheel forming die at a certain temperature and under a certain pressure and then is solidified under a certain condition, so that the resin binder diamond abrasive product is prepared. The resin binder diamond abrasive product prepared in the invention has the advantages that the tissues are uniform, the internal defects are less, the reliability is high, and the like, and therefore, the preparation method is particularly suitable for preparing diamond grinding wheels with fine granularity and super fine granularity in complex shapes.

Owner:HUNAN UNIV

Diamond resin grinder

The invention relates to a diamond resin grinding tool in the field of grinding tool technology. The working layer is formed by diamond grinding material, catalyst, and filler; the diamond grinding material adopts self-sharpening diamond grinding material which has working layer volume rate 12.5-31.25úÑ.The working layer also comprises: hardening carbonizable substance with volume rate 5-15úÑ and admixture formed by carbite 0-3úÑ.The hardening carbonizable substance comprises: one or two combines of silicon carbide, boron carbide, titanium carbide, and tungsten carbide; the hardening oxide substance comprises: aluminum oxide or / and silicon oxide. The catalyst chooses phenol resin or polyimide resin which has working layer volume rate 40-50úÑ; the filler chooses copper, chromic oxide, zinc oxide and iron oxide which have working layer volume rate 8-15úÑ, 5-15úÑ, 0-8úÑ, 0-8úÑ.

Owner:ZHENGZHOU ARTIFICIAL DIAMOND & PROD ENG TECH RES CENT

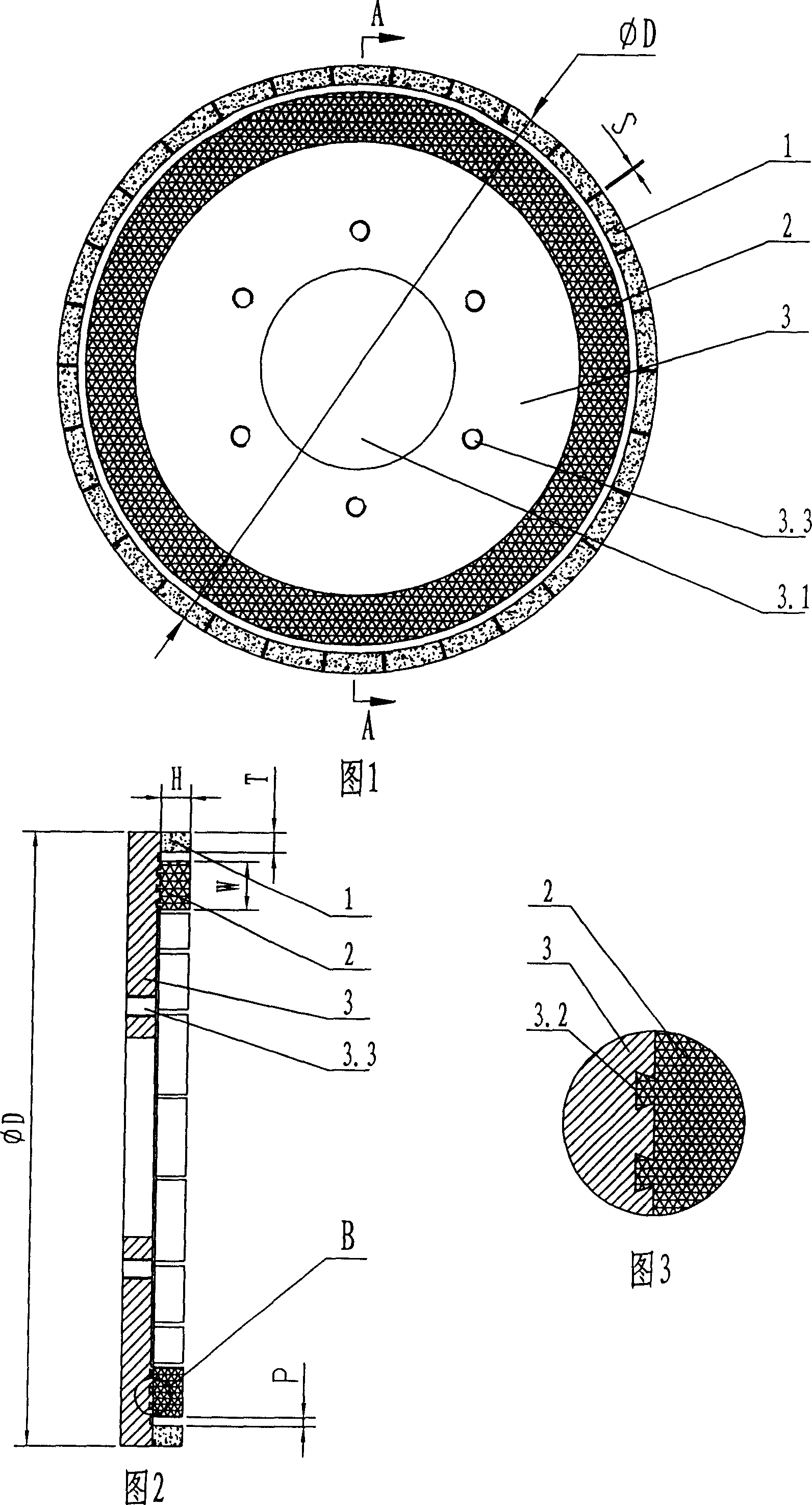

Edging wheel and method for making it

ActiveCN1919537AReduce work energy consumptionStable amount of grindingEdge grinding machinesBonded abrasive wheelsSurface displayFlute

The invention discloses a grinding wheel on the assembling base, which contains two layers or more grinding wheel with inner-layer grinding wheel and outer-layer grinding wheel distributed concentrically, wherein the inner-layer grinding wheel displays ring-shaped continuous layout and outer-layer grinding wheel displays ring-shaped continuous or even-interrupted layout, the assembling base lies in the ring-shaped assembling flute of inner layer grinding wheel, the assembling flute is set continually or intervally, whose cross surface displays dovetail or inversed-T shaped structure. the invention punches one coil of resin adhesive diamond working layer on the inner layer of diamond grinding wheel, which repairs and grinds edge on the assembling base.

Owner:广东奔朗新材料股份有限公司

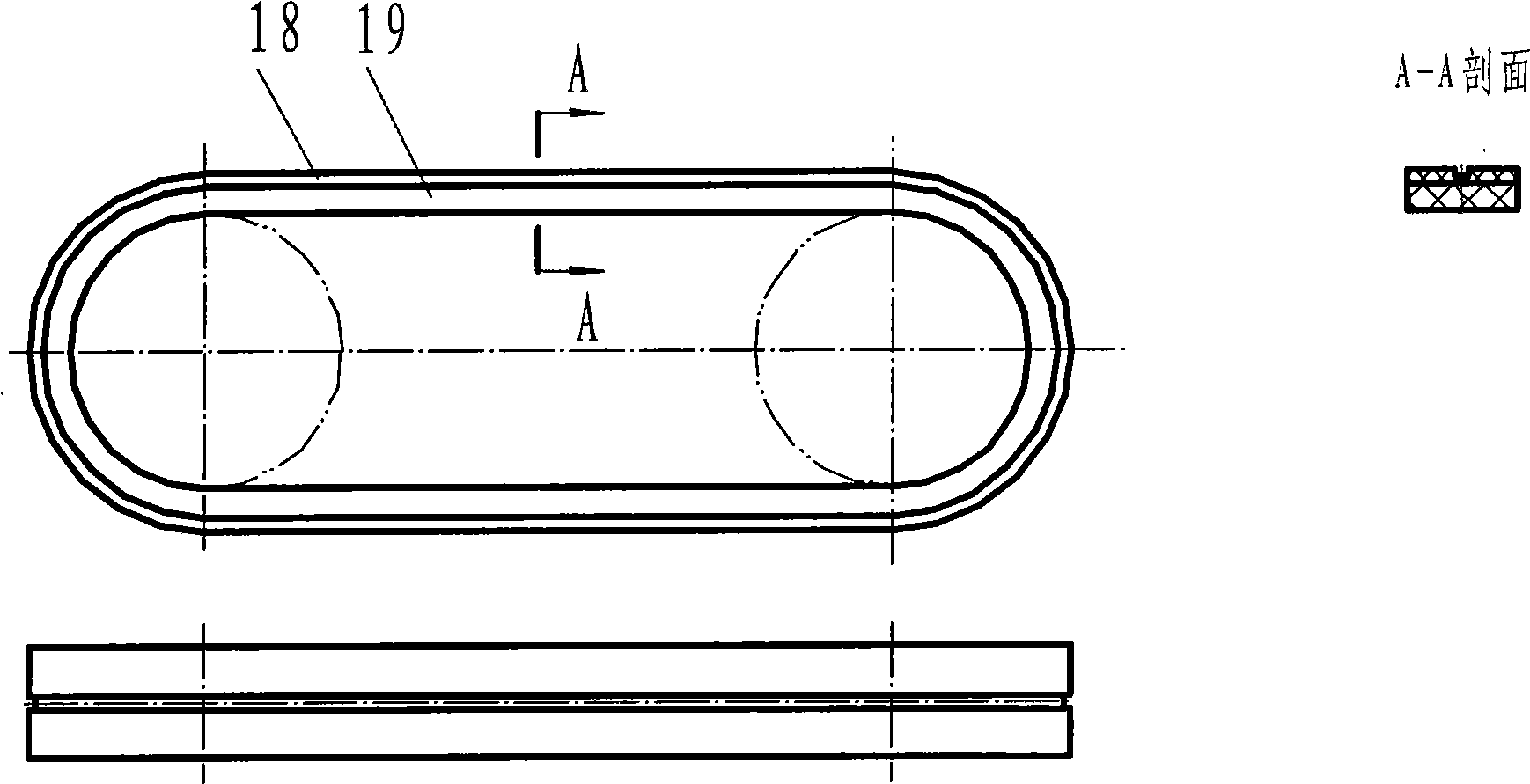

Electroplating diamond fretsaw with grinding materials controllably distributed and preparation method

ActiveCN103100987AReduce usageIncrease profitMetal sawing toolsGrinding devicesRegion selectionDiamond wire saw

The invention discloses an electroplating diamond fretsaw with grinding materials controllably distributed and a preparation method. The electroplating diamond fretsaw is composed of a steel wire base body and diamond grinding materials, and is characterized in that the diamond grinding materials on the fretsaw are electrically deposited on a surface of the steel wire base body according to a pre-arranged shape, and a chip removal groove is formed on a none-deposited-diamond surface of the grinding materials. The preparation method comprises the following critical steps: region selection and coating processing are conducted on the surface of the steel wire base body, and a reserved none-grinding-material surface of the steel wire base body is coated with a pre-arranged shape; sand-feeding process is conducted on surfaces of the steel wire base body, the steel wire base body enters an electroplating groove, and the diamond grinding materials are electrically deposited on an uncoated region of the base body; and coating removal processing is conducted on the surface of the steel wire base body, the steel wire base body enters a coating removal groove to remove the coating, and manufacturing of the diamond fretsaw is finished. The electroplating diamond fretsaw with the grinding materials controllably distributed and the preparation method have the advantages of being high in cutting efficiency, long in service life and the like.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

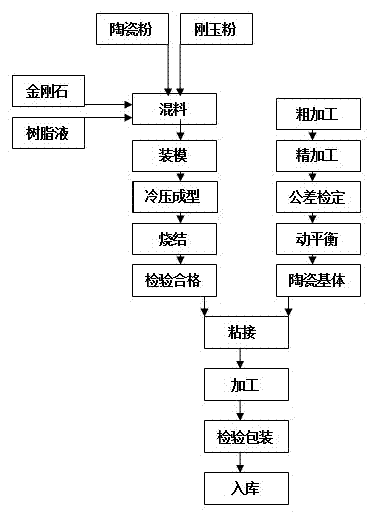

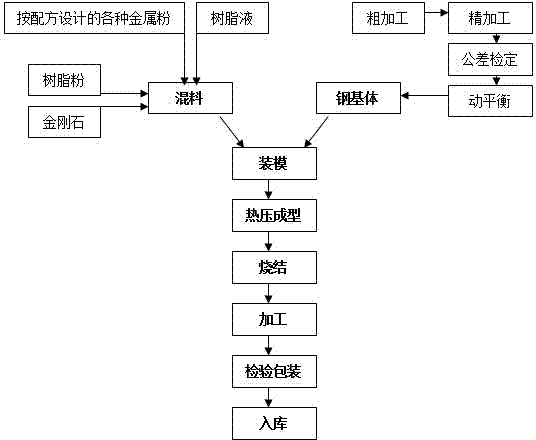

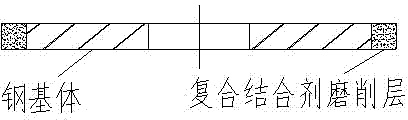

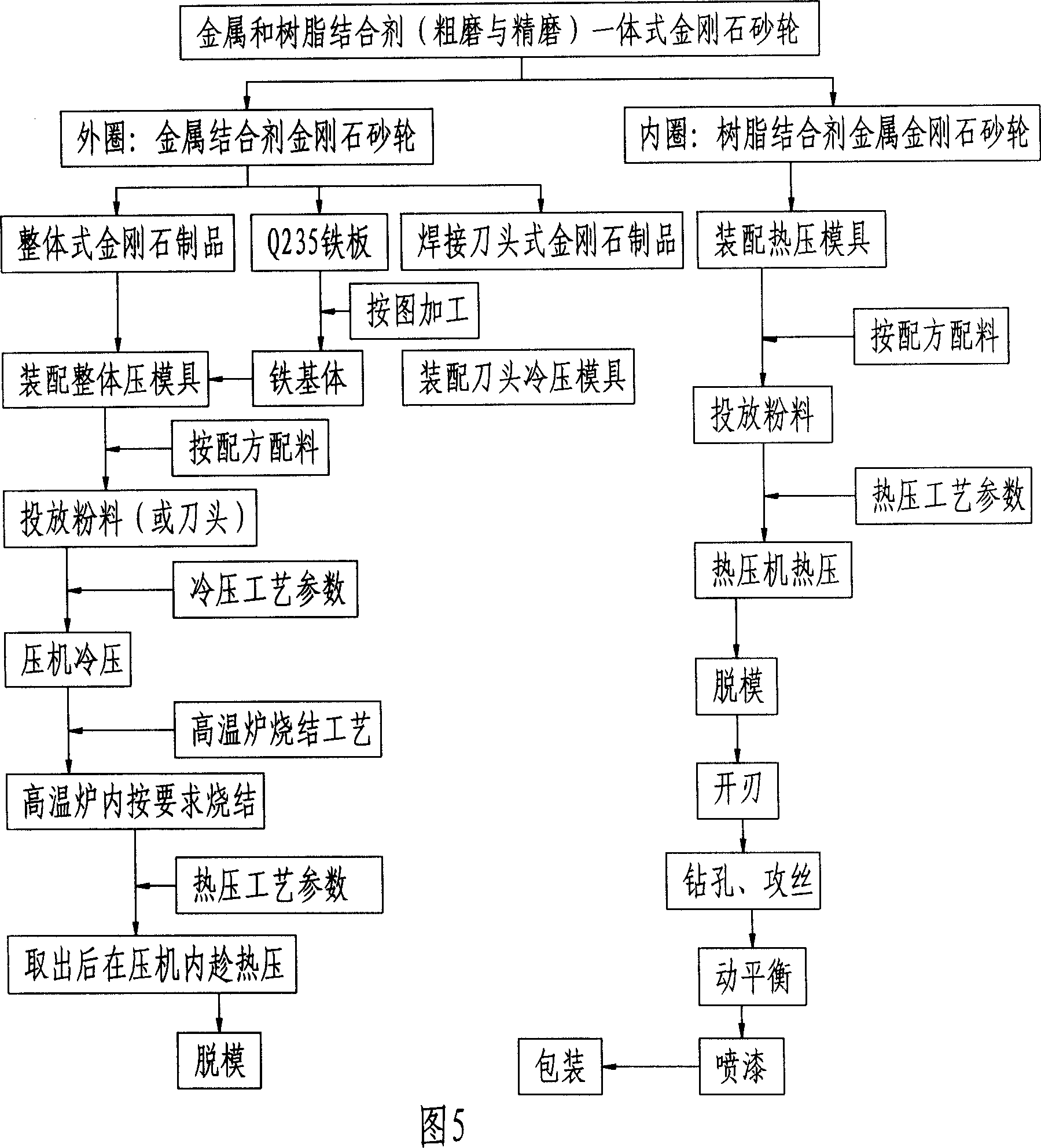

Metal-ceramic bond diamond grinding wheel and production method thereof

ActiveCN103692371AGood self-sharpeningImprove gripAbrasion apparatusGrinding devicesPowder mixtureCopper plating

The invention discloses a novel metal-ceramic bond diamond grinding wheel having the high strength and form-holding property in metal bond grinding wheels and the high self-sharpening property in ceramic bond grinding wheels, and a production method thereof. The metal-ceramic bond diamond grinding wheel is produced by: 1, preparing powder mixture out of 60-70% of copper-plated diamond powder, 15-20% of (W, Ti)C powder, 5-10% of tin powder, and 5-15% of iron group powders; mixing according to the above components and ratio to obtain the powder mixture; 2, forming, namely pressing the powder mixture into blanks by pressure forming; 3, sintering, namely subjecting the blanks to inert atmosphere low-pressure sintering, heating the blanks to 850-1050DEG C during sintering, and holding the temperature for 10-30 minutes. The copper-plated diamond powder is composed of particles with average particle size of 5-80 micrometers, and the particles are composed of diamond cores and copper coatings covering the diamond cores. Inert atmosphere during sintering is 5-10Mpa.

Owner:长沙市萨普新材料有限公司

Polyimide resin diamond grinding wheel and preparation method thereof

ActiveCN102814763AHigh mechanical strengthImprove heat resistanceAbrasion apparatusGrinding devicesCorundumPolyimide

The invention discloses a polyimide resin diamond grinding wheel and a preparation method of the polyimide resin diamond grinding wheel. The polyimide resin diamond grinding wheel is prepared from the following components in parts by weight: 50-60 parts of diamond grinding material, 5-10 parts of white corundum grinding material, 5-10 parts of garnet sand, 5-15 parts of polyimide resin powder, 2-6 parts of furfuryl alcohol, 1-2 parts of trioctyl trimellitate, 5-10 parts of cryolite, 5-10 parts of gypsum powder, 2-5 parts of nano siliceous shale powder and 2-5 parts of copper powder. According to the polyimide resin diamond grinding wheel and the preparation method of the polyimide resin diamond grinding wheel, as polyimide resin serving as a binding agent has higher mechanical strength and excellent heat resistance, the durability of the prepared resin grinding wheel is improved greatly; as ceramic material is added into padding, the adhesive property is good, the grinding materials hardly fall off, the heat resistance and hardness of the resin grinding wheel are improved, and cracks formed by rigid grinding are reduced, thereby the use efficiency and service life of the resin grinding wheel are improved further; and in addition, since copper power is added, fast heat dissipation effect is achieved, a great deal of heat generated in a cutting process of the grinding wheel can be dissipated quickly, and the effect of lowering cutting temperature is achieved.

Owner:安徽威铭耐磨材料有限公司

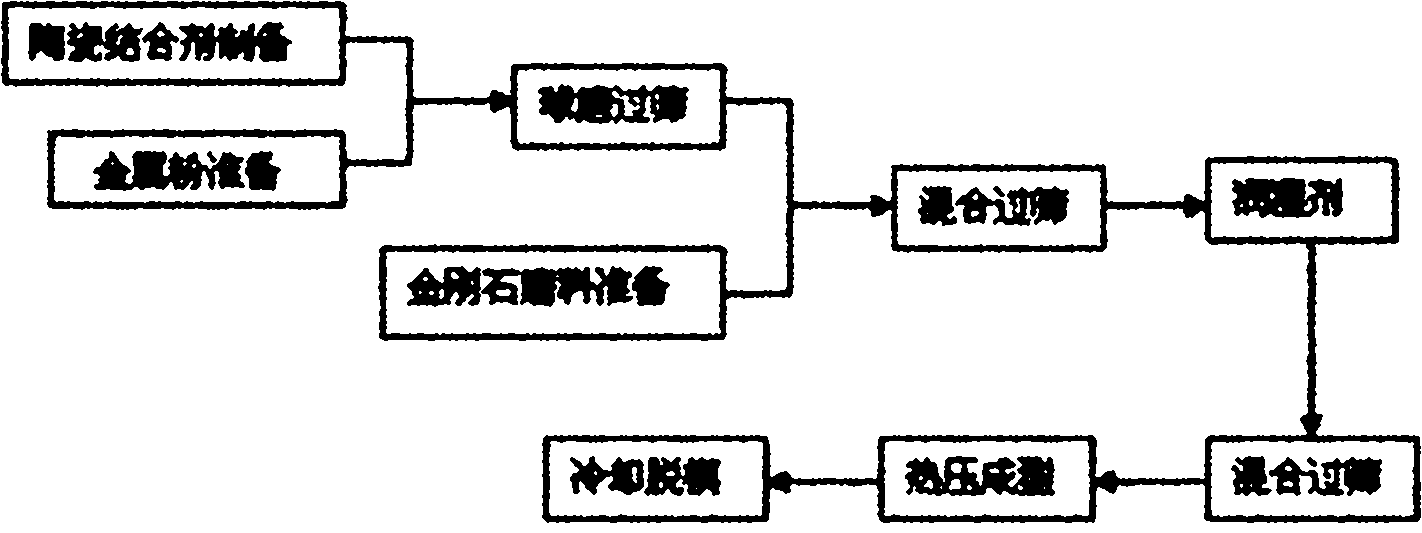

Preparation method of composite binding agent diamond grinding wheel

ActiveCN103600308AImprove grinding efficiencyGood self-sharpeningAbrasion apparatusGrinding devicesMaterials scienceTin

The invention discloses a preparation method of a composite binding agent diamond grinding wheel. The method includes the steps of firstly, mixing, by weight, 1-2 parts of phosphorus powder, 10-15 parts of polyimide resin powder, 8-10 parts of tin powder, 35-40 parts of copper powder, 9-11 parts of lead powder and 2-4 parts of zinc powder, and then sieving with a 325-mesh standard sieve to obtain composite binding agent; secondly, mixing, by weight, 10-14 parts of diamond grinding material and 25-45 parts of composite binding agent in a mixing machine, adding, by weight, 1.5-2 parts of acrylic emulsion to continue mixing, and sieving with a 70-mesh standard sieve to obtain grinding wheel mixture; thirdly, placing a steel substrate in a die, filing the grinding wheel mixture in the die, and hot pressing in a hydraulic machine to obtain grinding wheel blank; fourthly, sintering the grinding wheel blank in a sintering furnace; fifthly, machining the sintered grinding wheel blank on a lathe and a grinding machine to obtain the fished composite binding agent diamond grinding wheel. The diamond grinding wheel prepared by the method is high in grinding efficiency, good in self-sharpness, high in rigidity, high in heat resistance, and good in profile maintaining.

Owner:CHANGSHU JULI GRINDING WHEEL

Preparation method of porous metal binding agent braze welding diamond grinding wheel

The invention provides a preparation method of a porous metal binding agent braze welding diamond grinding wheel, comprising the following steps of preparing a grinding wheel segment block and connecting the grinding wheel segment block with a grinding wheel base body. The prepared porous metal binding agent braze welding diamond grinding wheel has 45-70 percent of porosity, and the bending strength of three points of the grinding wheel segment block is 75-200 MPa. Because of the introduction of a pore structure, the trimming and sharpening ability, the grinding material exposure ability and a chips-containing space of the novel grinding wheel are greatly improved compared with the compact metal binding agent grinding wheel, the grinding wheel has favorable self-sharpening property, favorable durability and high processing efficiency, and can bear heavier load when crisp and hard materials are grinded; meanwhile, the grinding wheel segment block has high strength, the metal binding agent has favorable holding force on the grinding material, and the grinding material does not fall off easily and prematurely.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com