Diamond grinding material sequential arraying system and method

A diamond and abrasive technology, applied in the field of diamond abrasive orderly arrangement system, can solve the problems of high cutting resistance, expensive equipment, difficult promotion, etc., and achieve the effect of high degree of automation, low equipment cost and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

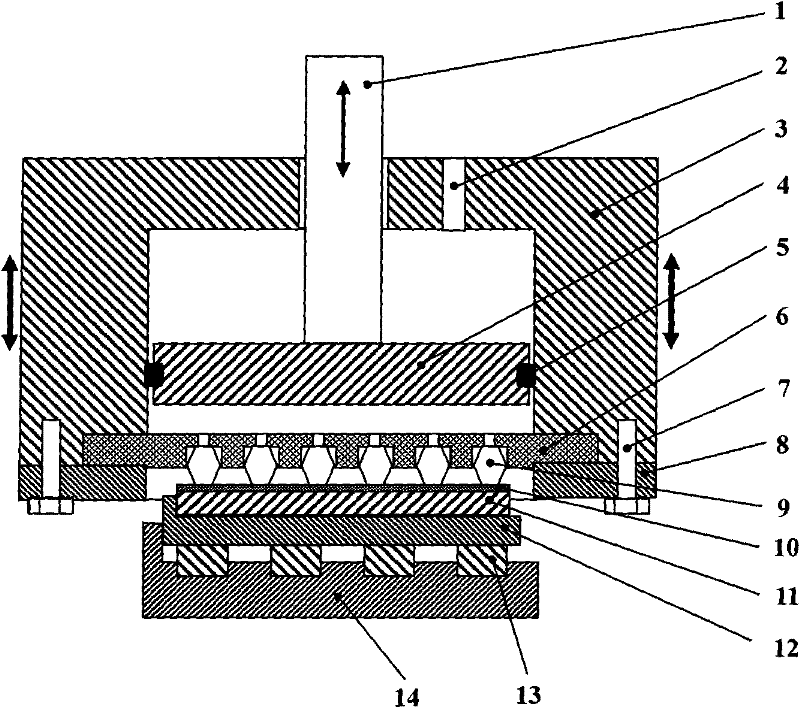

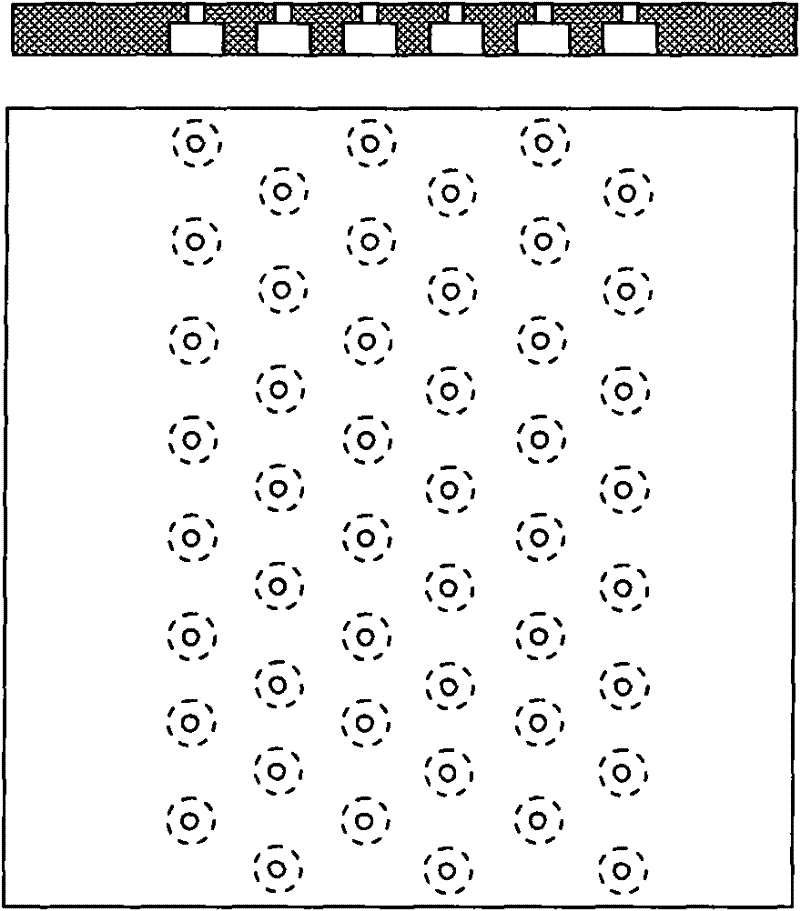

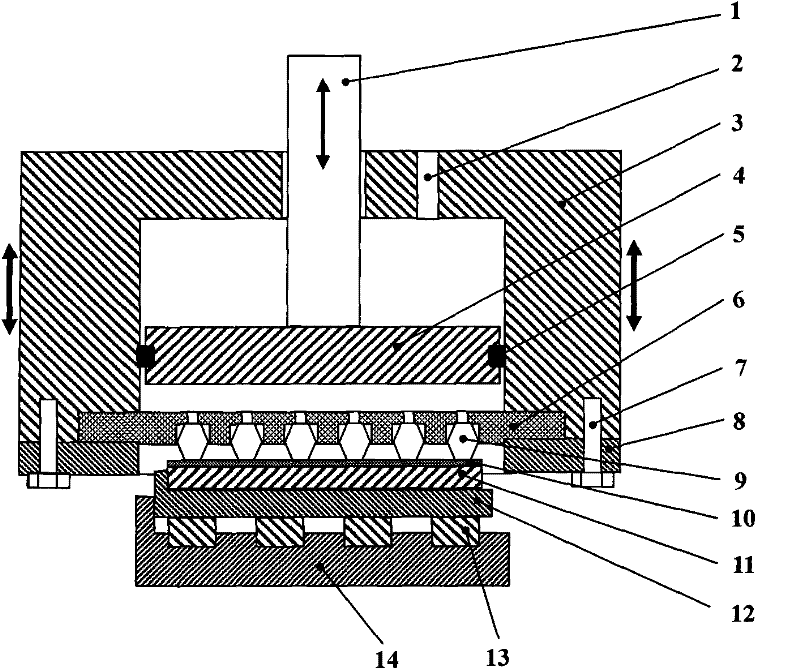

[0023] A system for orderly arranging diamond saw blades with abrasive materials, the operation steps are as follows:

[0024] ① The embryo is placed on the upper surface of the support plate;

[0025] ② Use the magnet block under the support plate to adsorb and fix the embryo;

[0026] ③Apply pressure-sensitive adhesive evenly on the upper surface of the embryo;

[0027] ④Move the diamond abrasive adsorption device to the vicinity of the diamond abrasive supply area, move the piston upward, and the airflow passes through the stepped hole in the elastic plate to adsorb and fix the diamond abrasive in the stepped hole;

[0028] ⑤ Move the diamond abrasive adsorption device to the top of the cold-pressed thin billet support platform of the cutter head, move the cylinder liner down, and the diamond abrasive is in contact with the glue on the surface of the embryo;

[0029] ⑥When the piston moves down, the airflow formed is discharged from the step hole in the elastic plate, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com