Patents

Literature

55413 results about "Piston rod" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In a piston engine, a piston rod joins a piston to the crosshead and thus to the connecting rod that drives the crankshaft or (for steam locomotives) the driving wheels. Internal combustion engines, and in particular all current automobile engines, do not generally have piston rods. Instead they use trunk pistons, where the piston and crosshead are combined and so do not need a rod between them. The term piston rod has been used as a synonym for 'connecting rod' in the context of these engines.

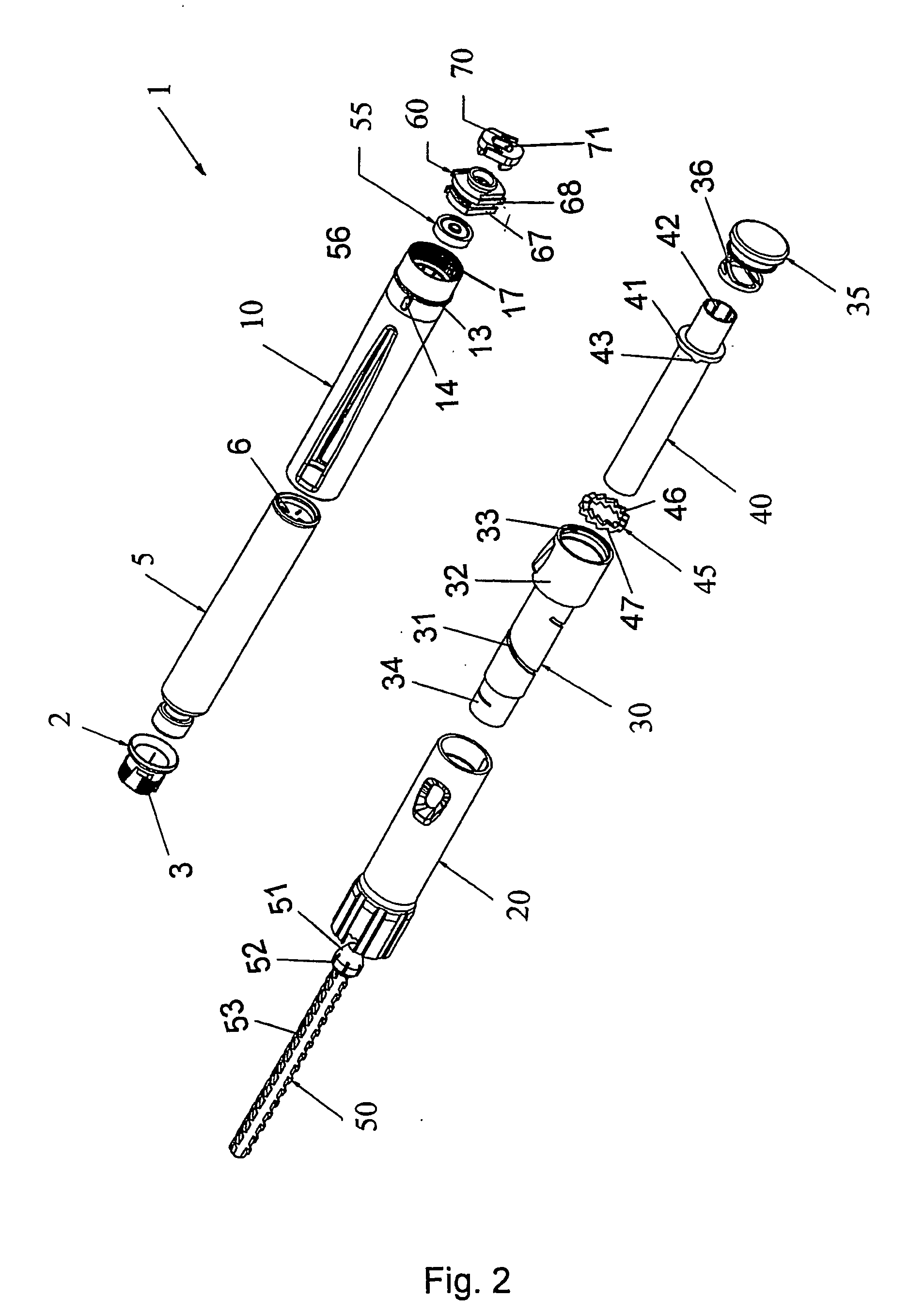

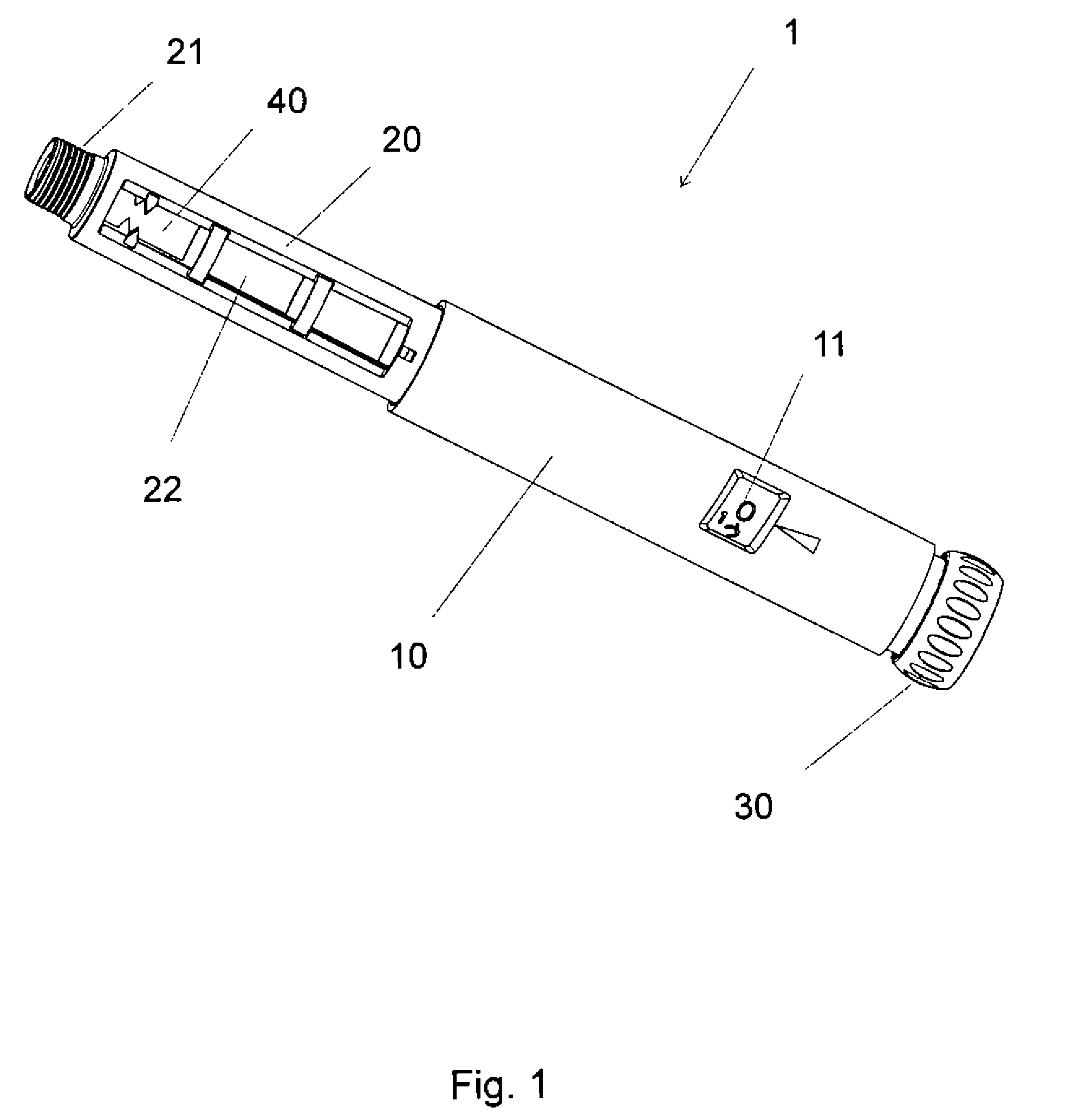

Medication delivery device with bended piston rod

InactiveUS6537251B2Improve accuracyImprove stabilityLiquid surface applicatorsAutomatic syringesDrive wheelSelf-treatment

Owner:NOVO NORDISK AS

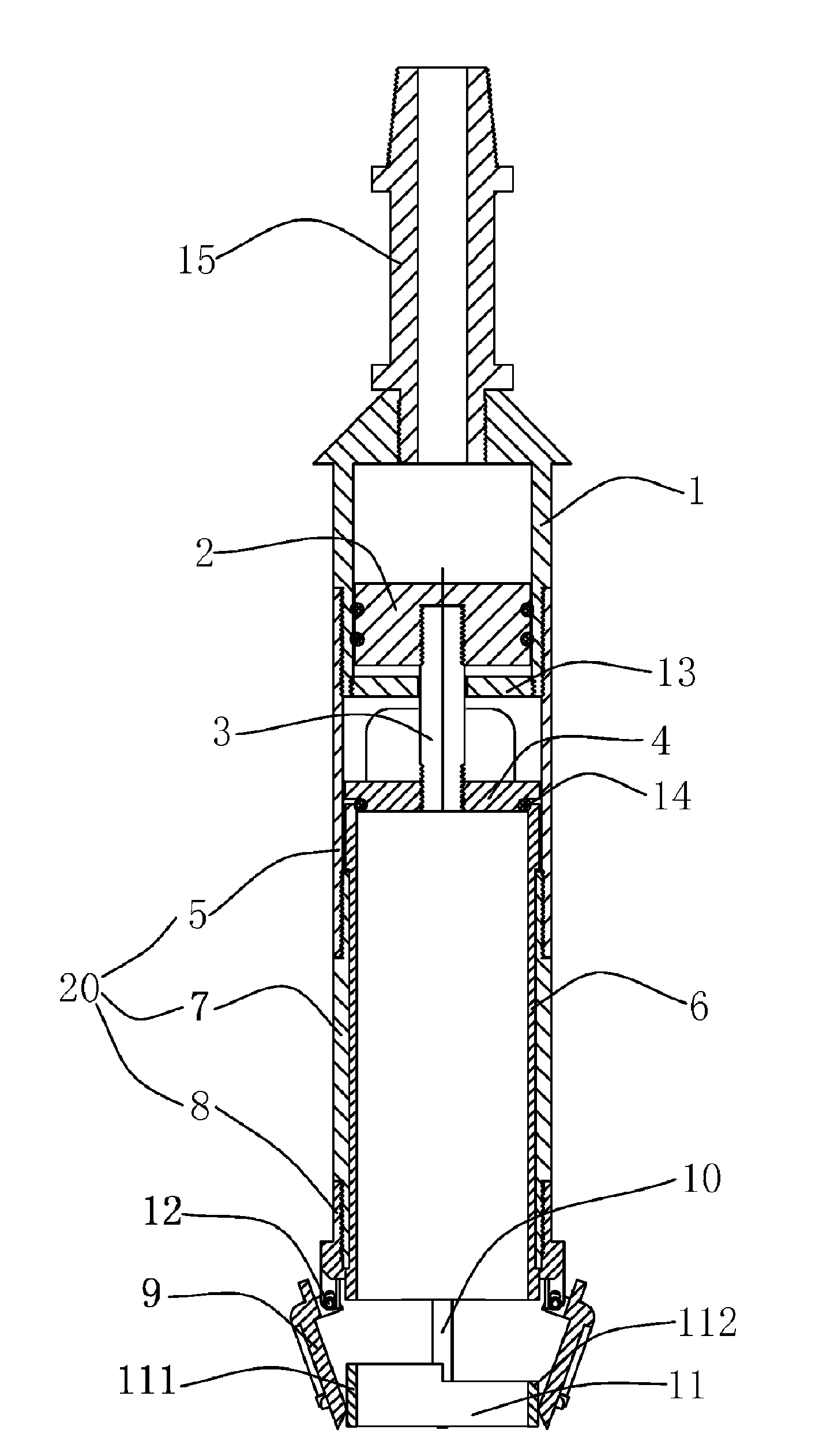

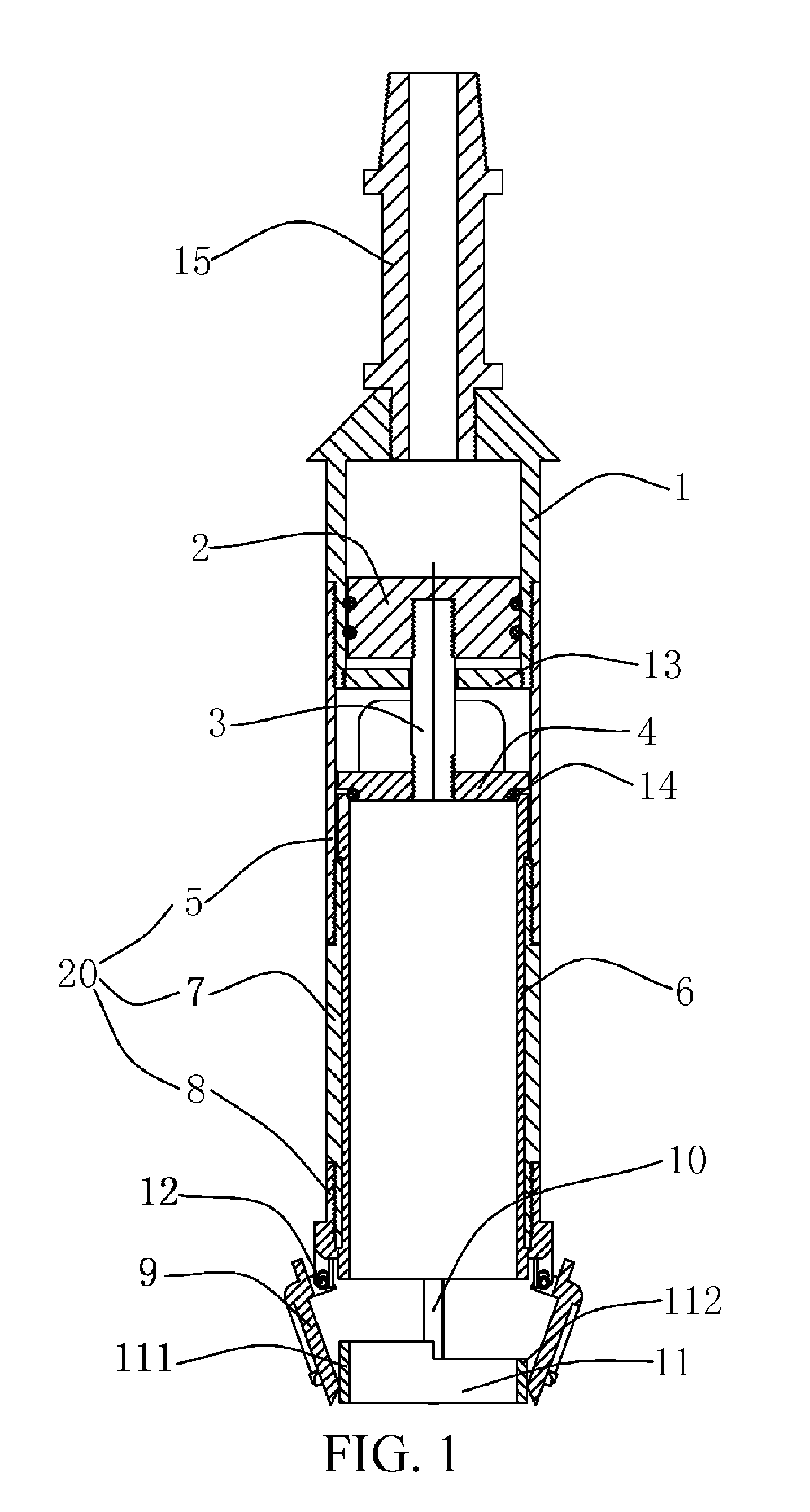

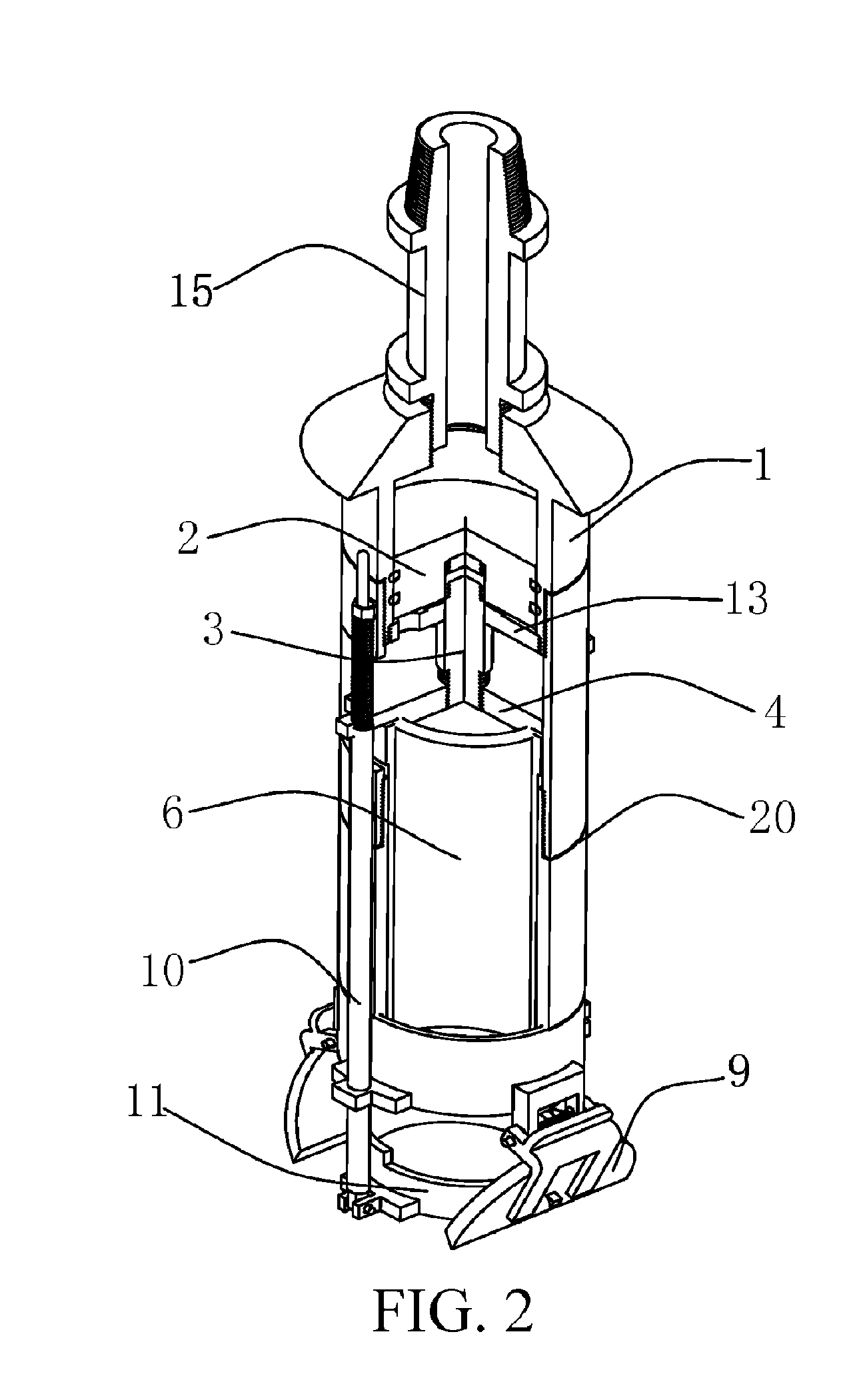

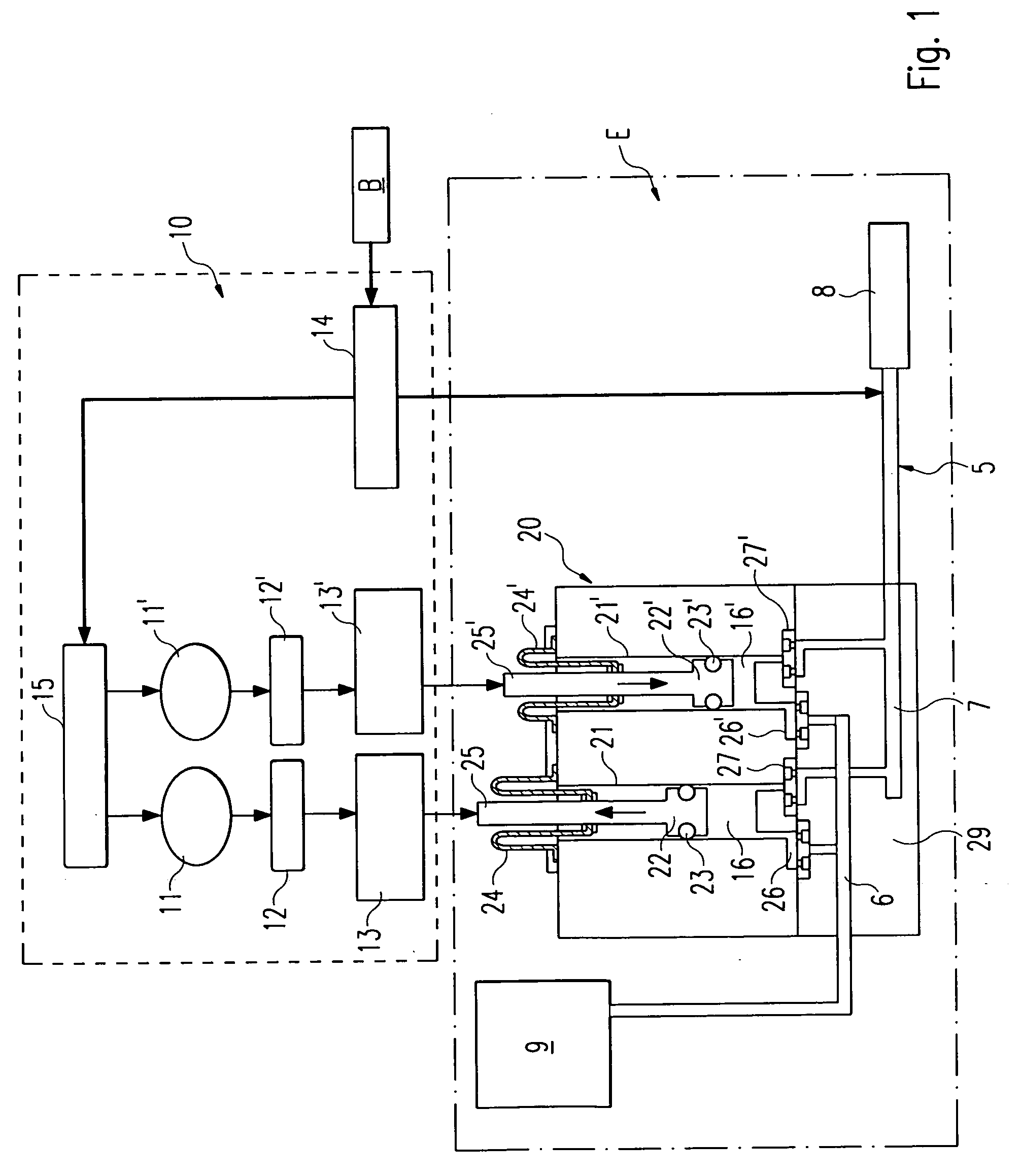

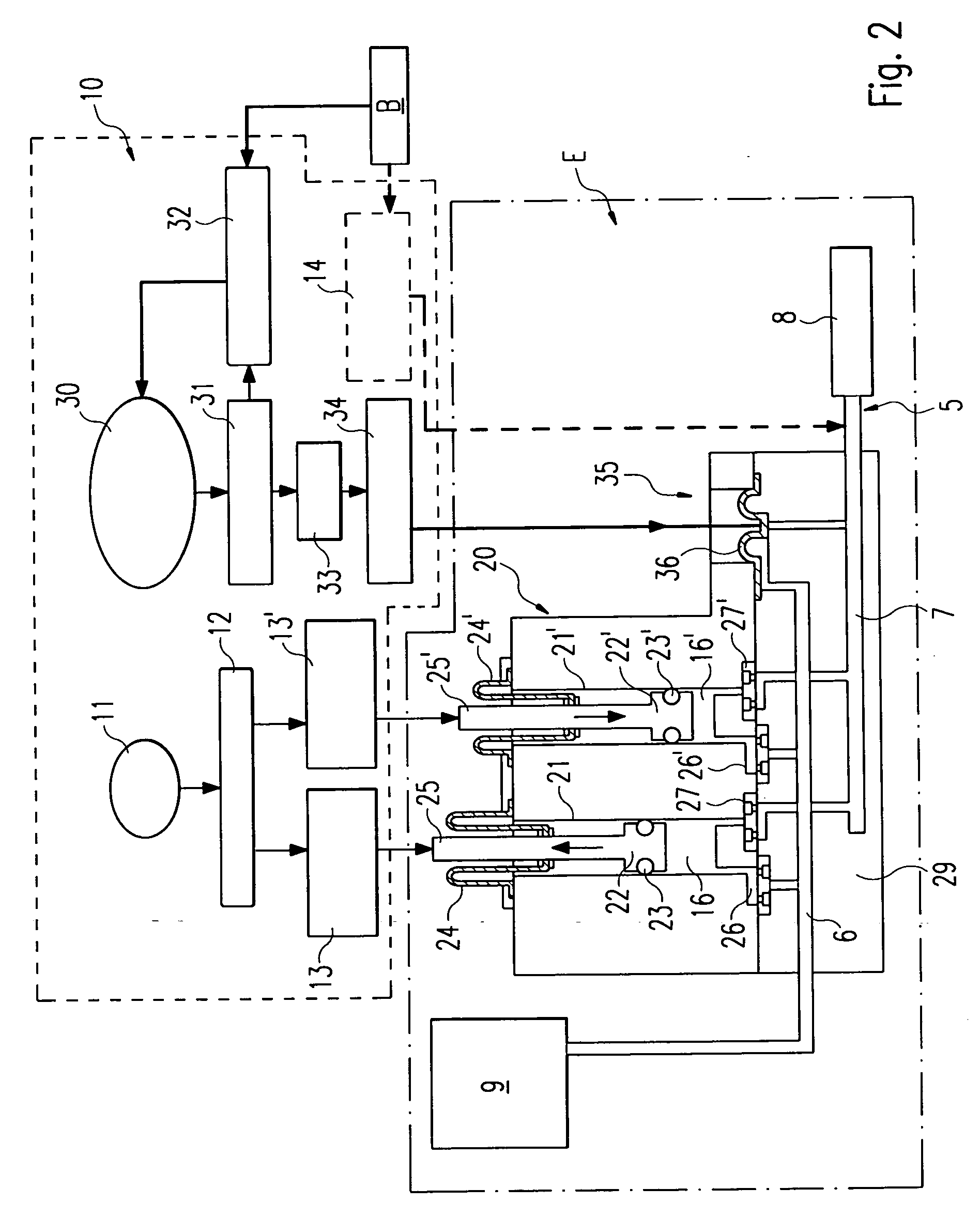

Medication delivery device with bended piston rod

InactiveUS20020091358A1Improve axial stiffnessImprove gripLiquid surface applicatorsAutomatic syringesDrive wheelSelf-treatment

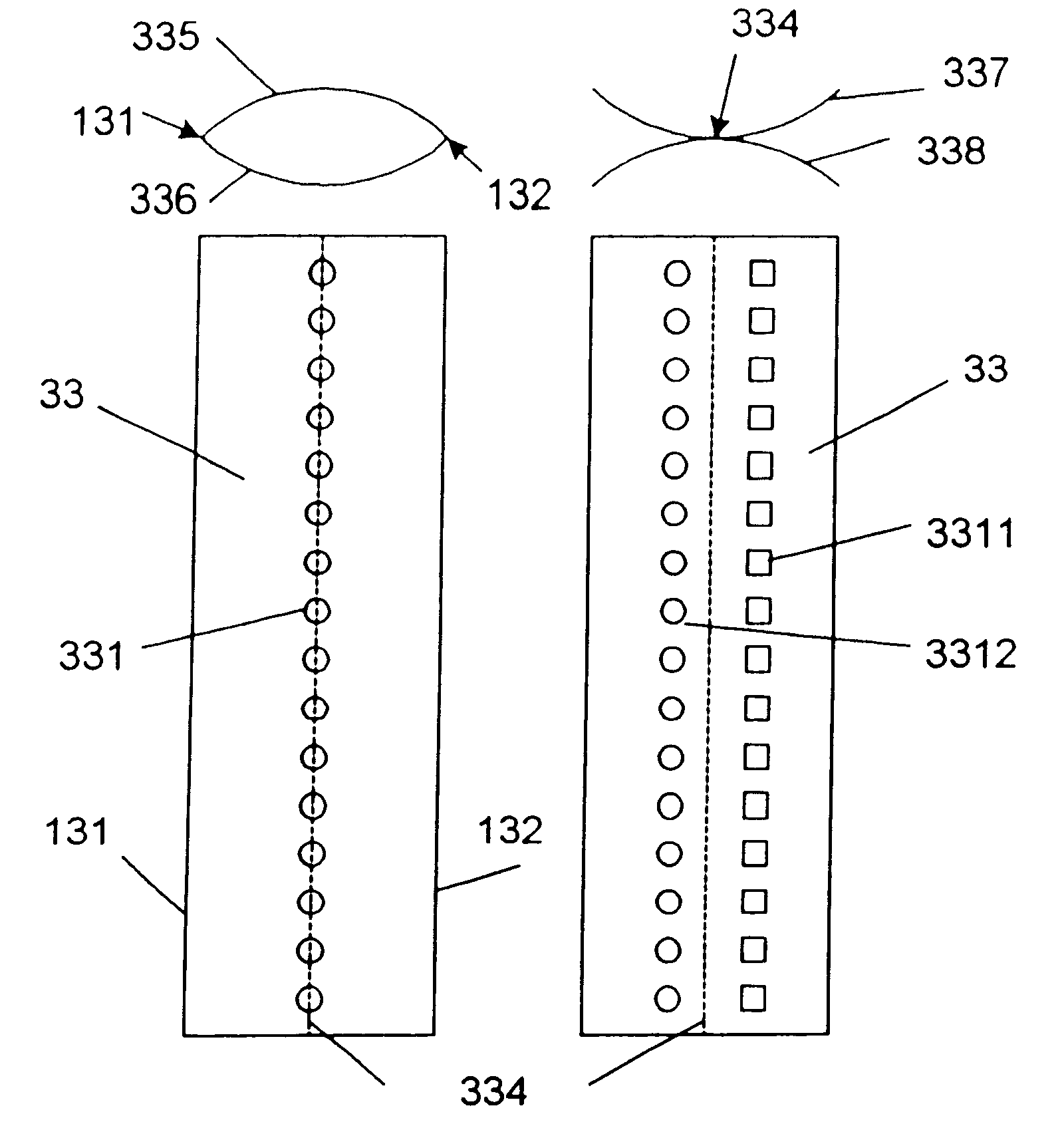

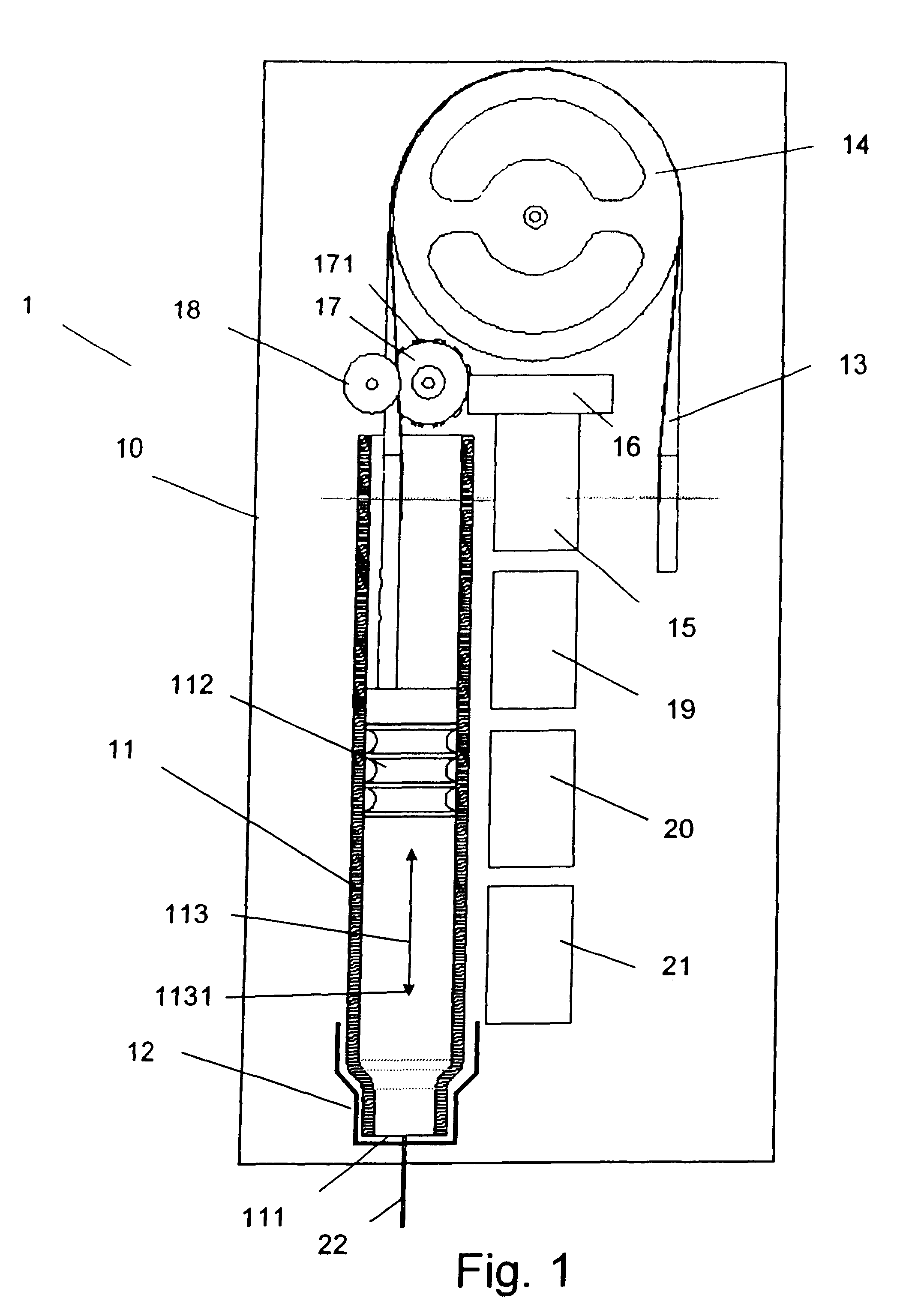

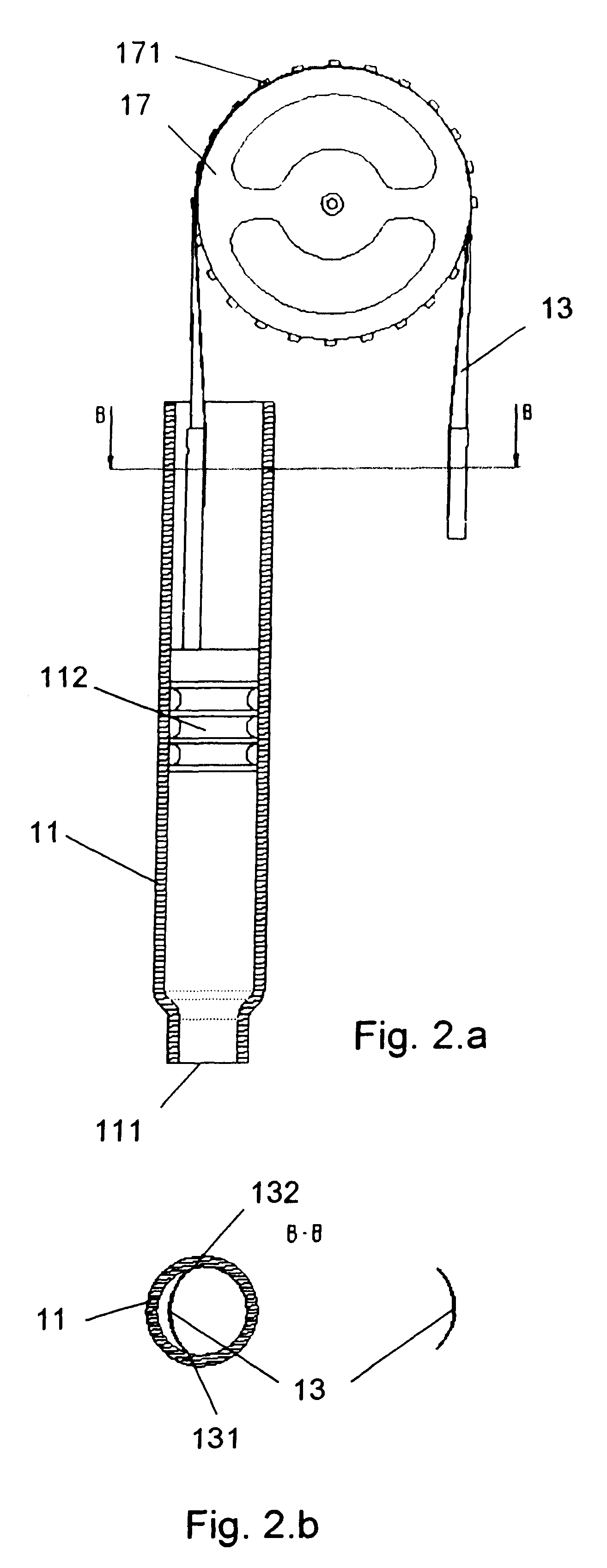

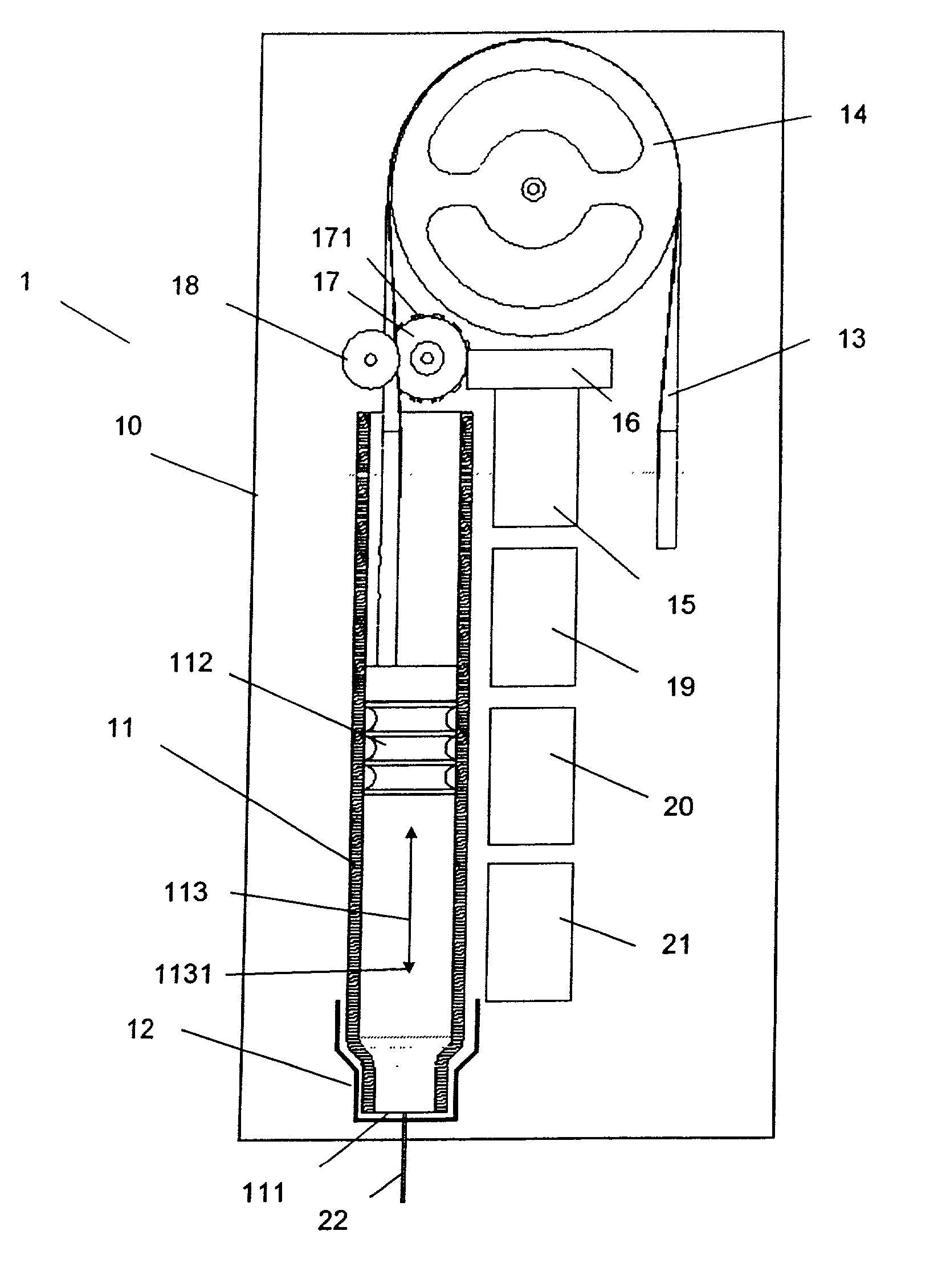

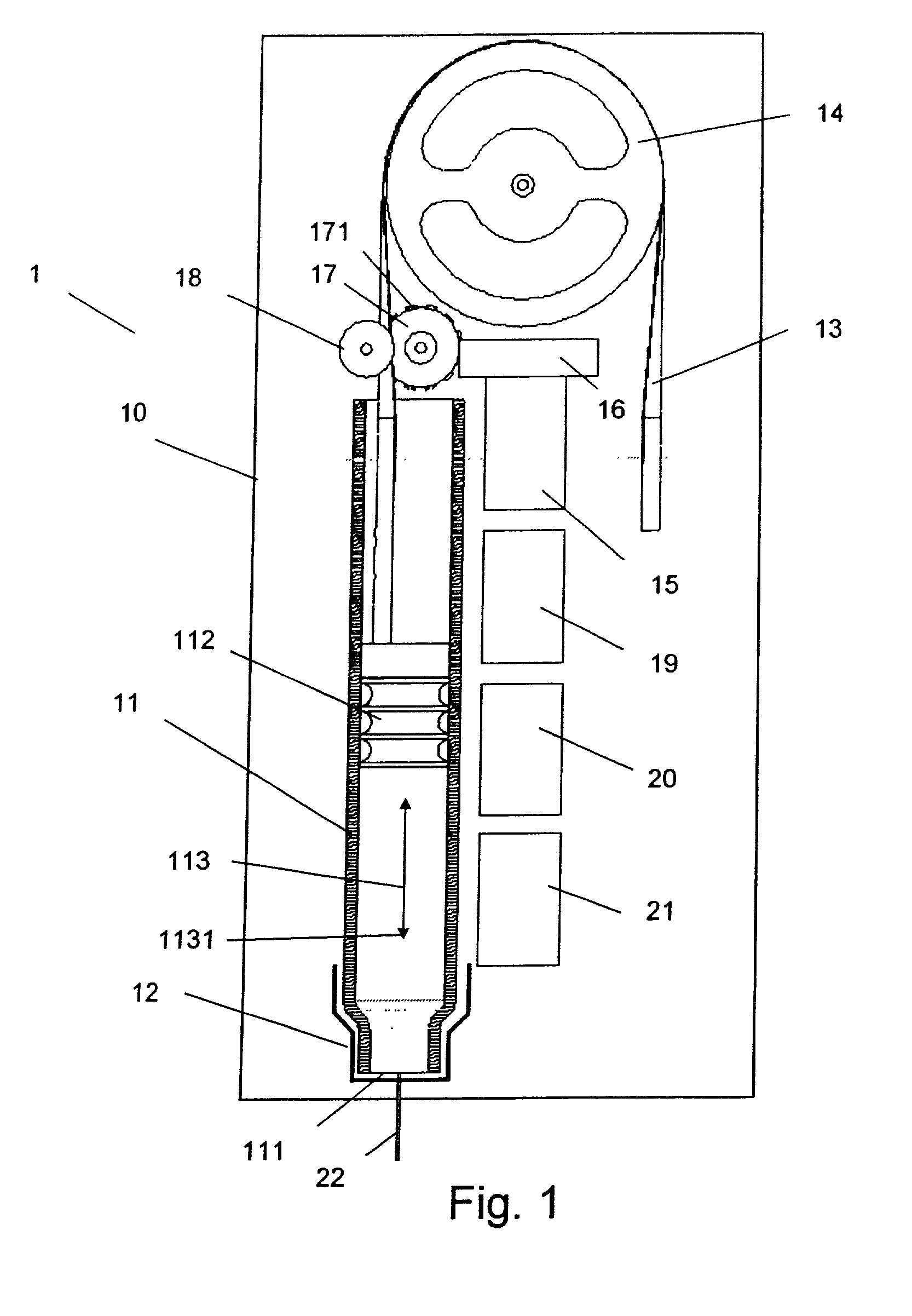

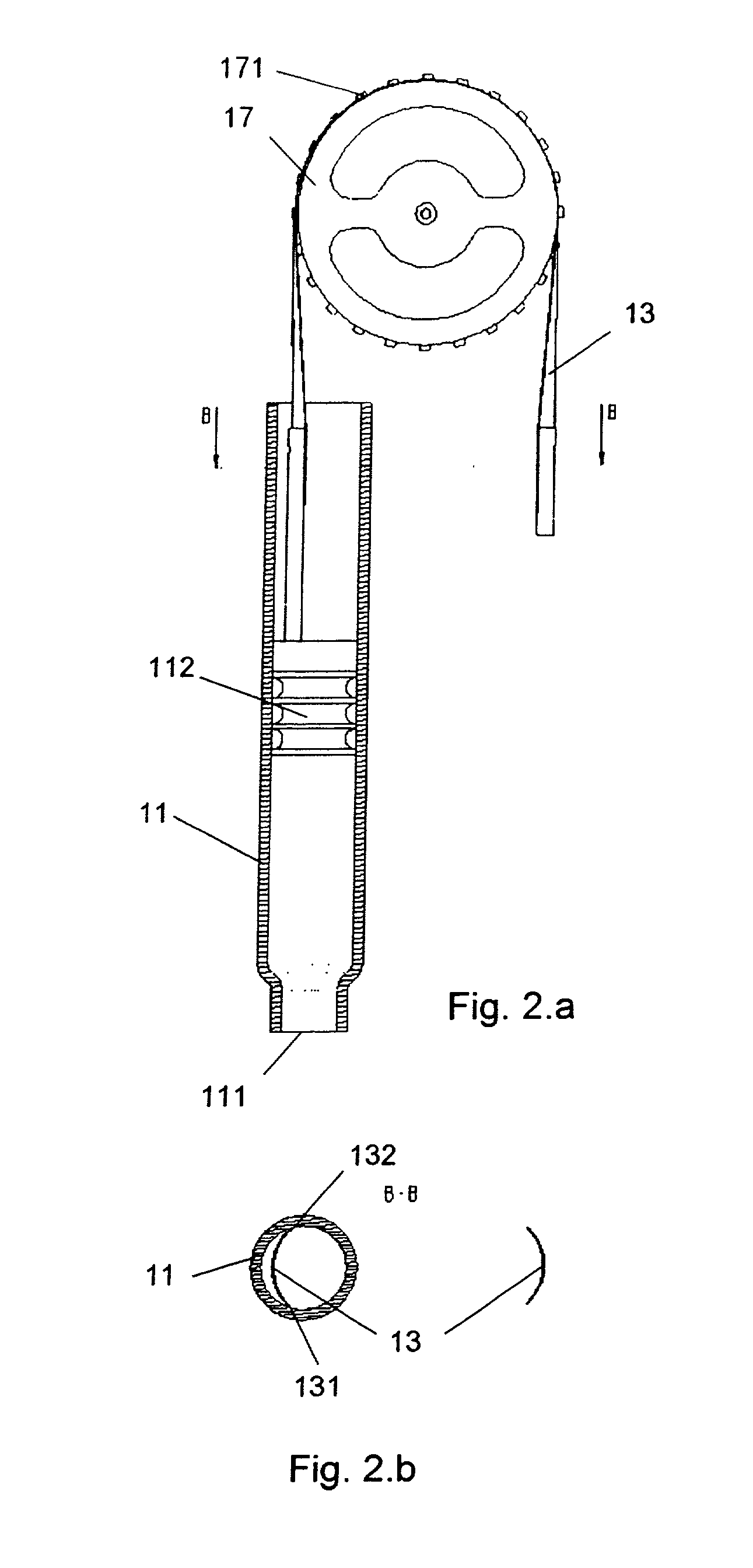

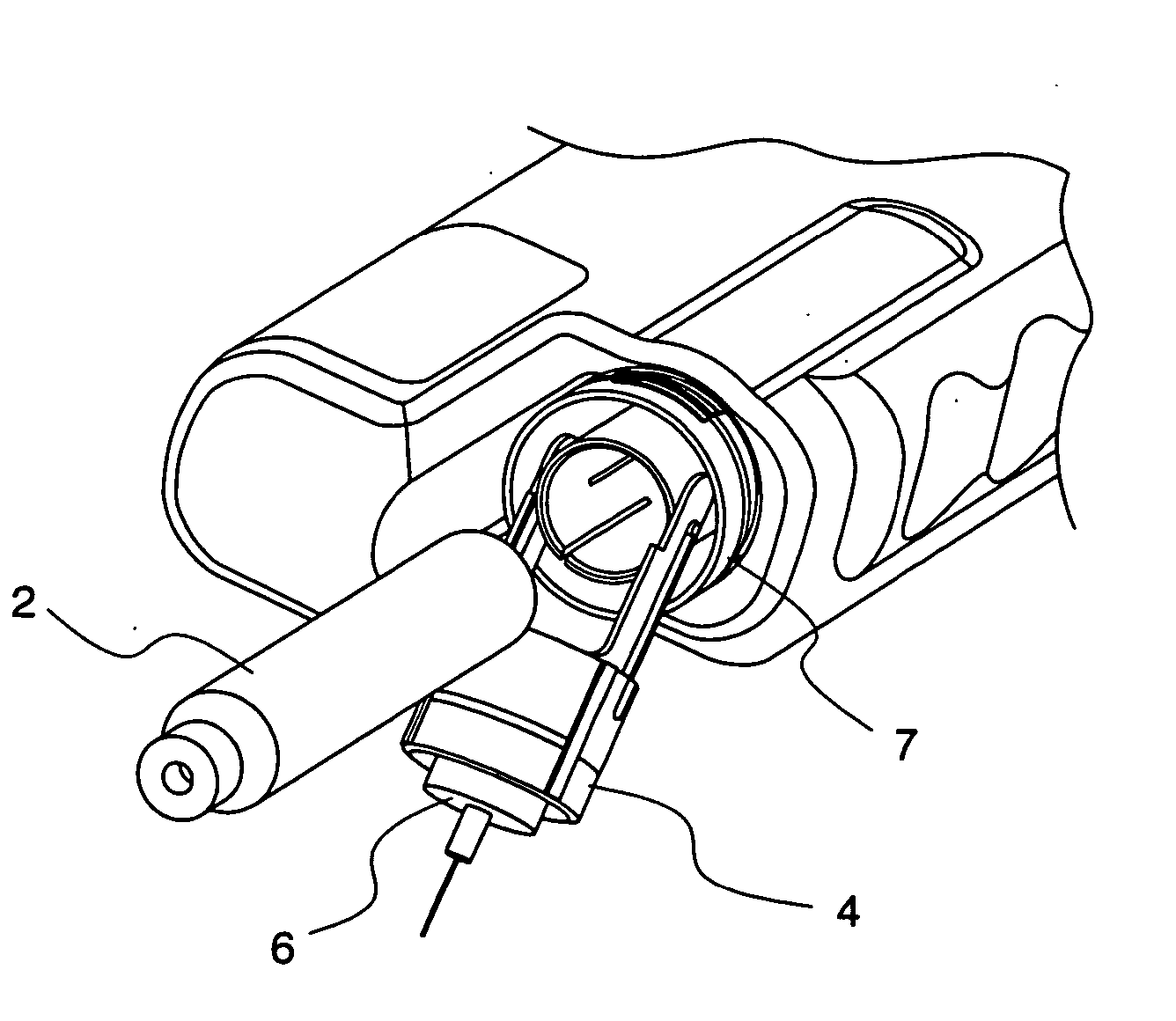

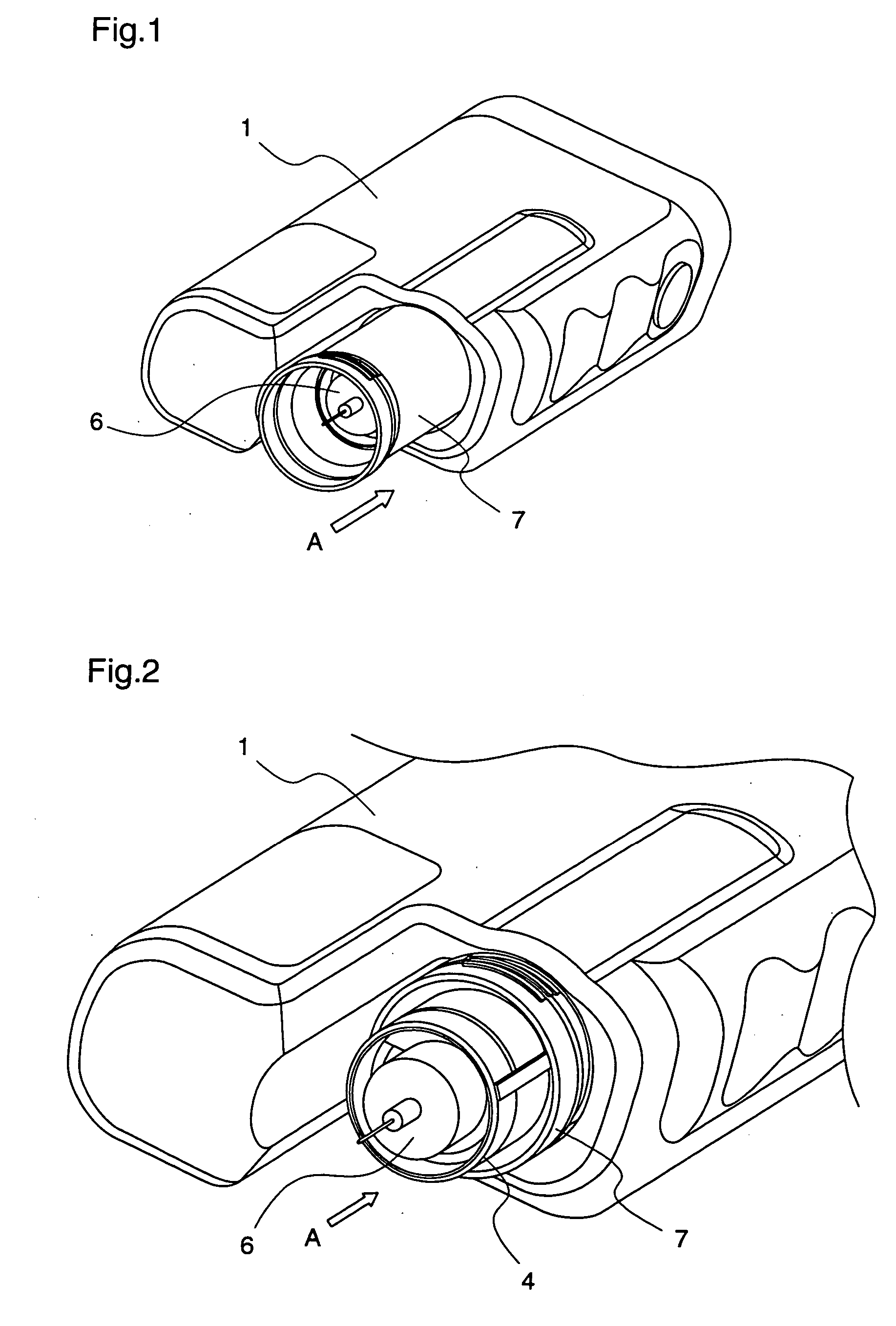

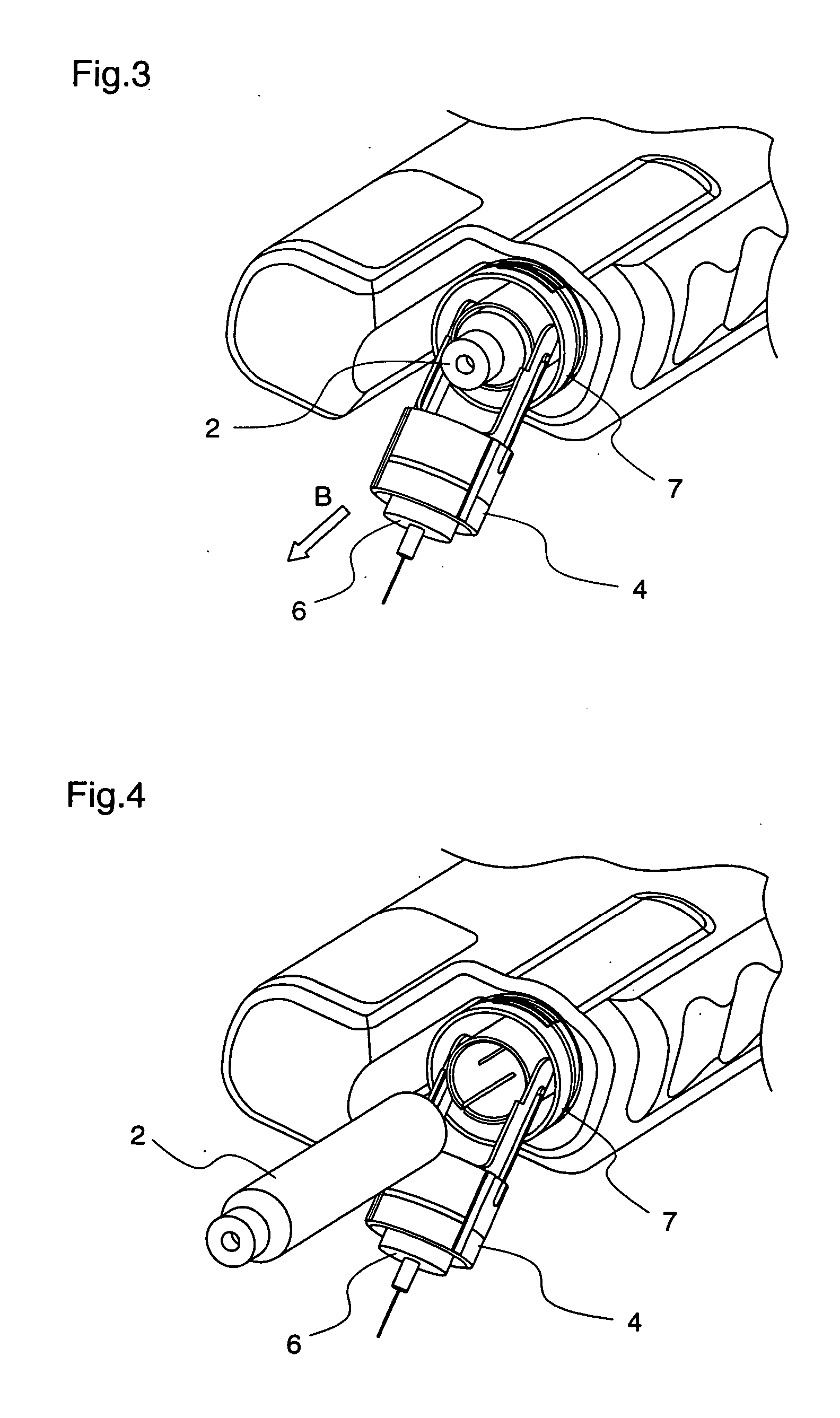

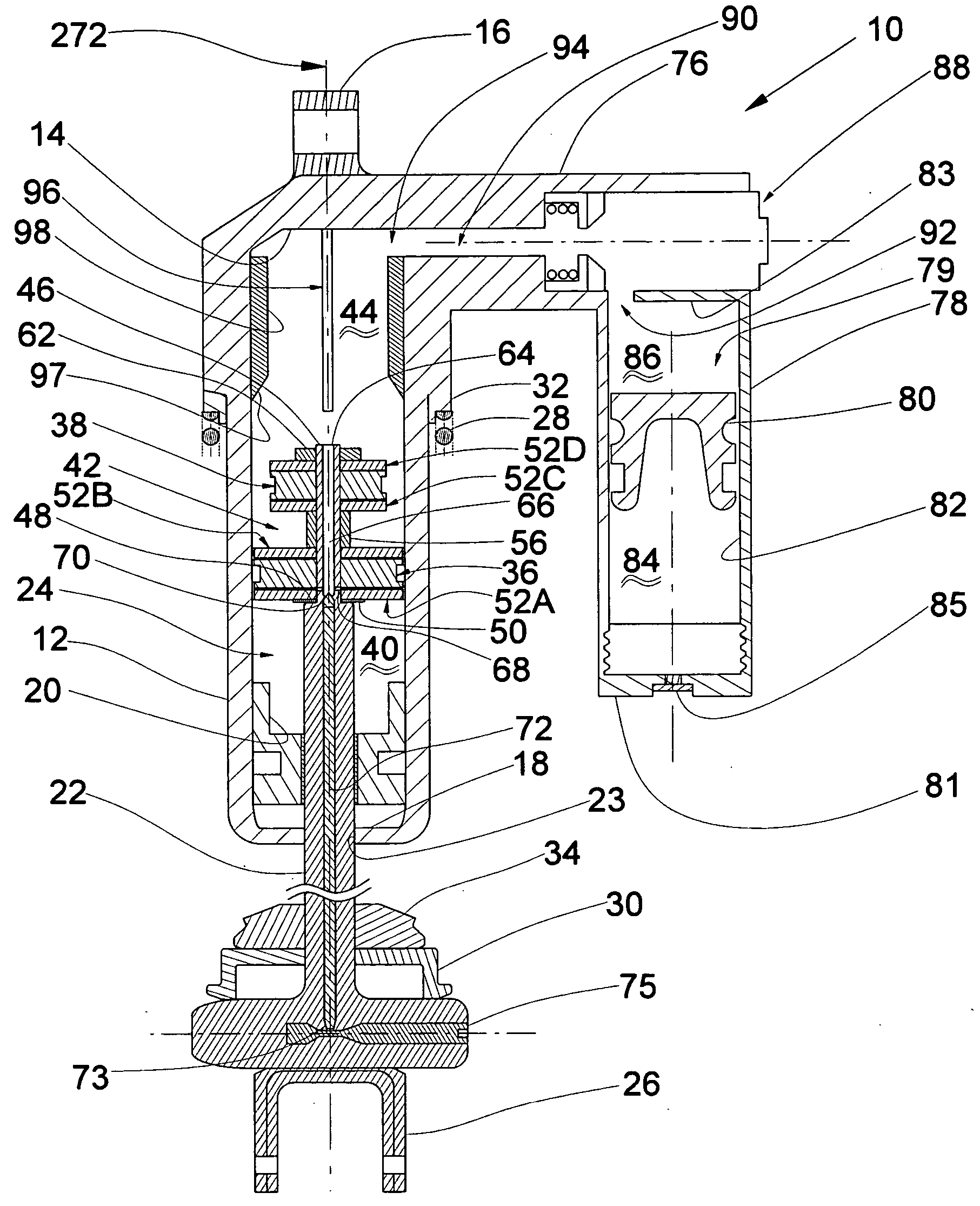

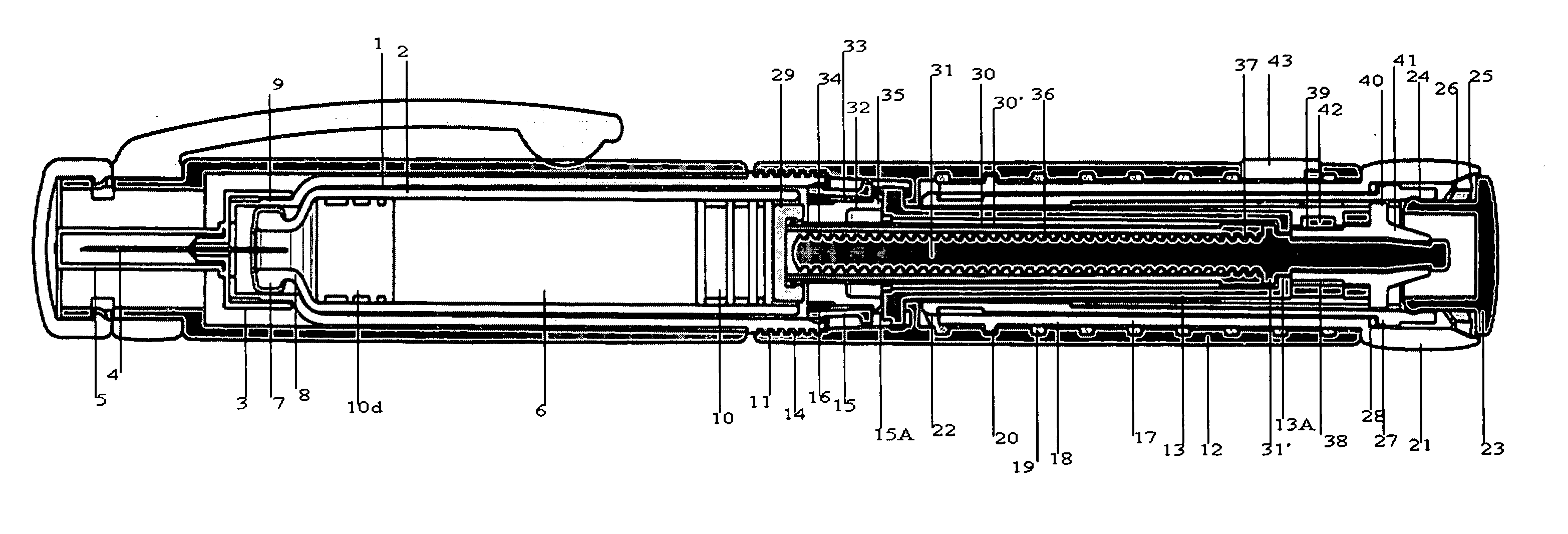

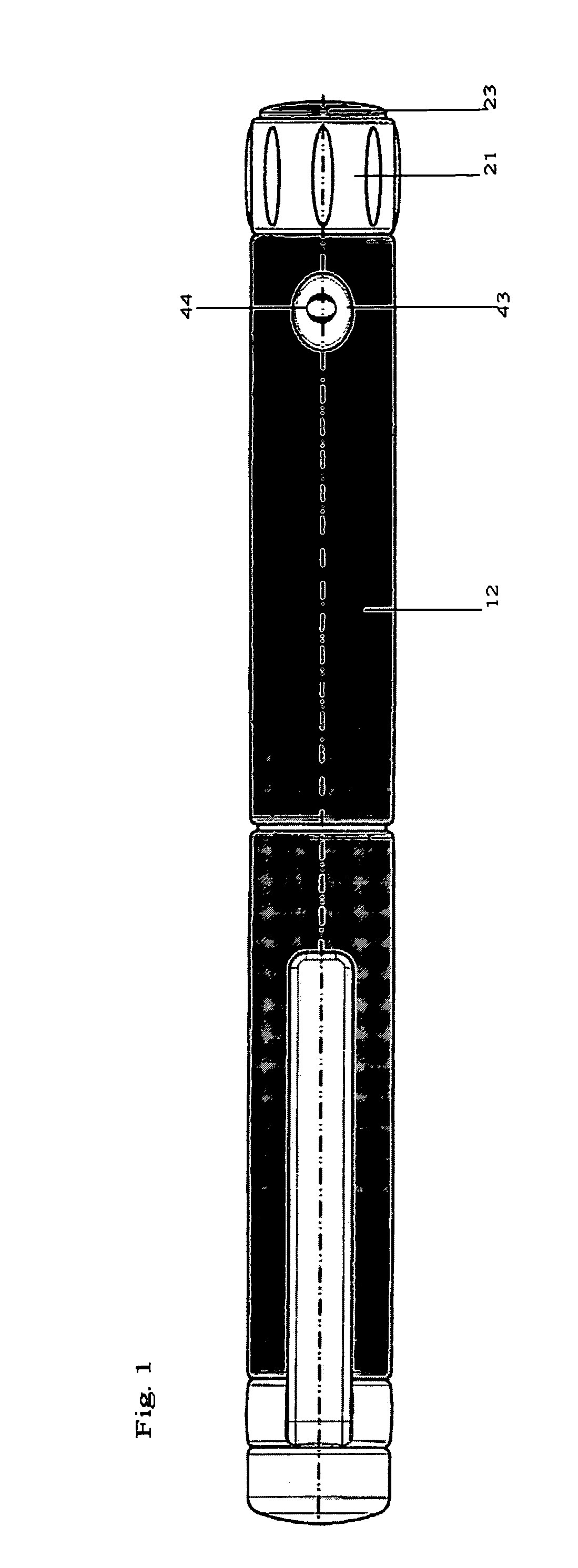

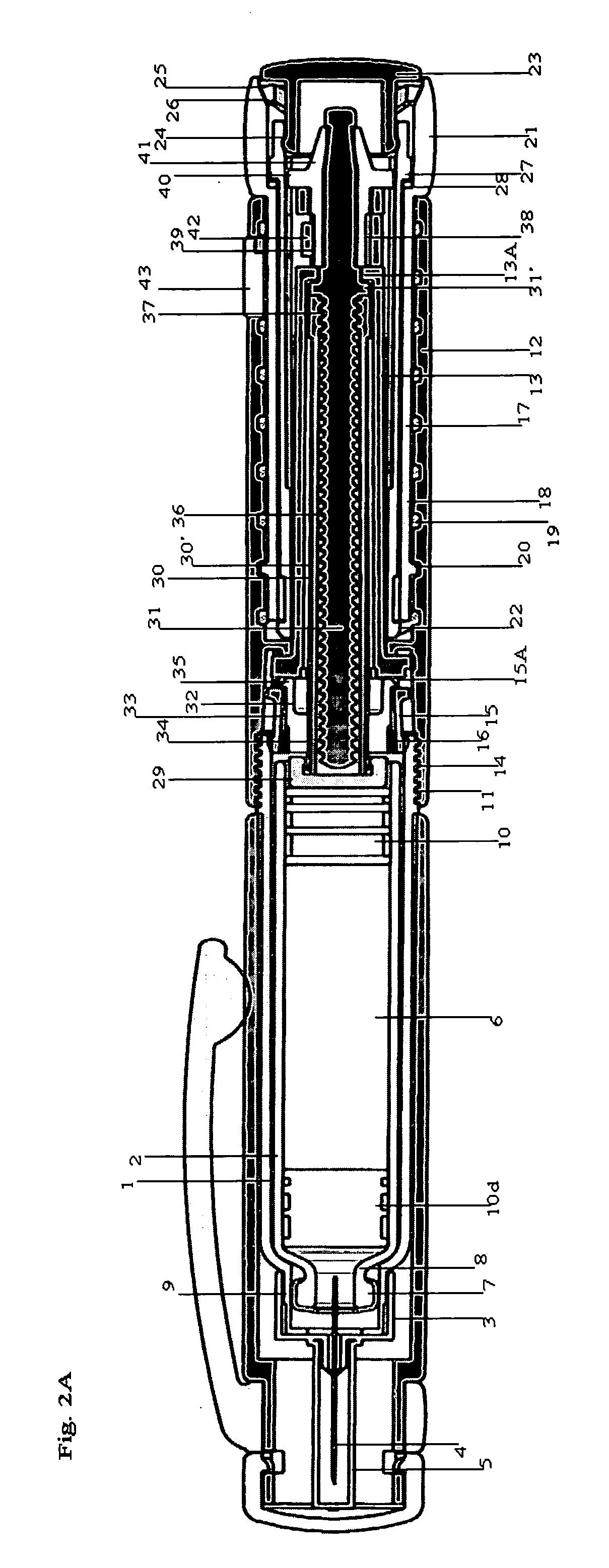

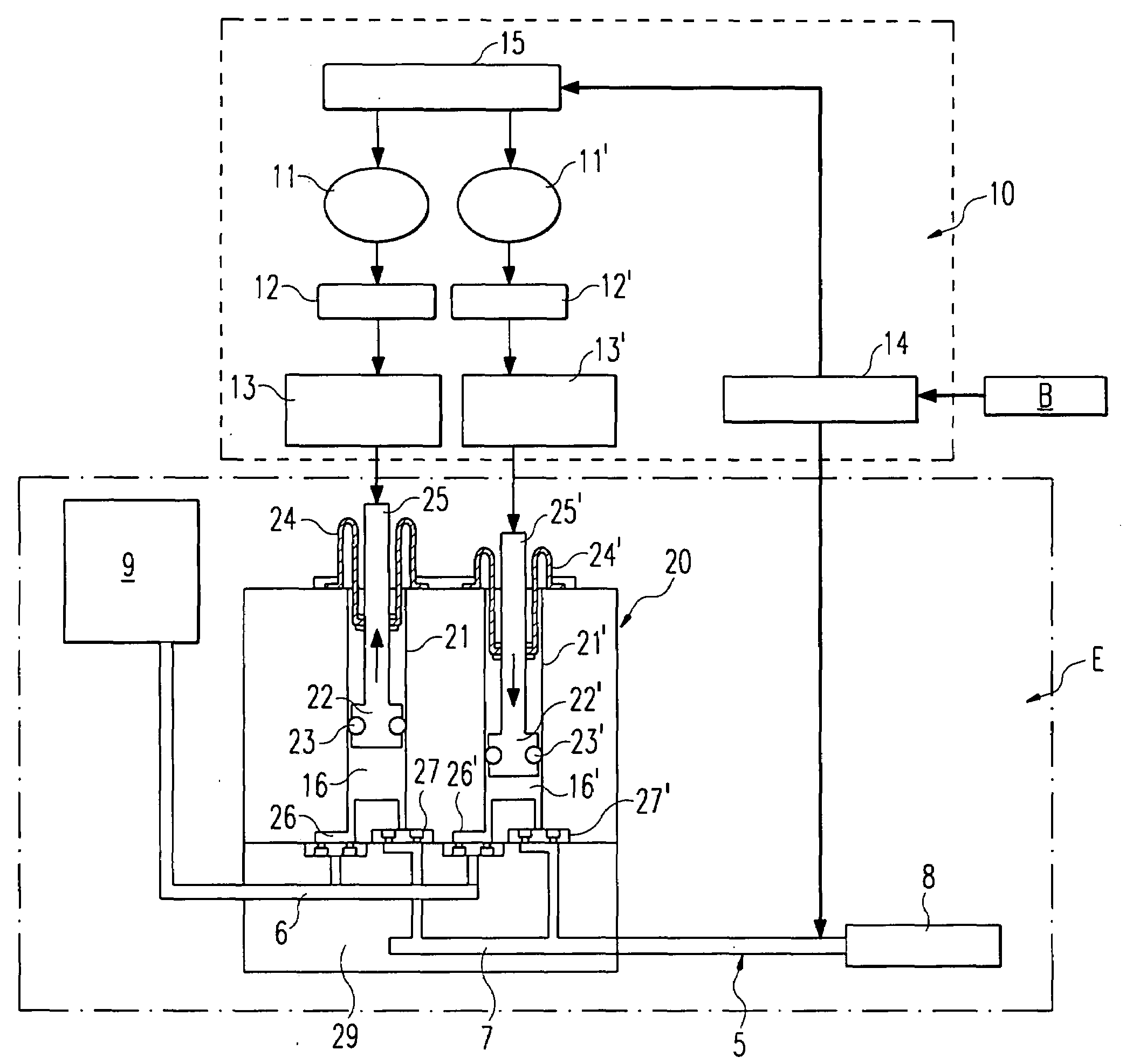

The invention relates to: A portable medication delivery device (1) comprising a medication cartridge (11) having an outlet (111) and a movable piston (112), and a housing (12) for holding said cartridge, and a flexible piston rod (13) being operable to engage and displace said piston along an axis (113) of said cartridge, and guiding means (14) for bending said piston rod away from said axis, and actuating means (15), and driving means (16, 17) for transferring movement from said actuating means to said piston rod, said driving means including a driving wheel (17) for displacing the piston rod (13), said flexible piston rod comprising regularly spaced first members (330; 331; 332) adapted to mechanically cooperate with corresponding second members (171) on said driving wheel. The object of the present invention is to provide a medication delivery system that combines compactness with an improved accuracy. The problem is solved in that said flexible piston rod (13) exhibits a linear or approximately linear path between said driving wheel (17) and said piston (112). This has the advantage of yielding a compact, low-weight device with an improved dose accuracy. The invention may e.g. be used in injection or infusion devices for a person's self-treatment of a disease such as diabetes.

Owner:NOVO NORDISK AS

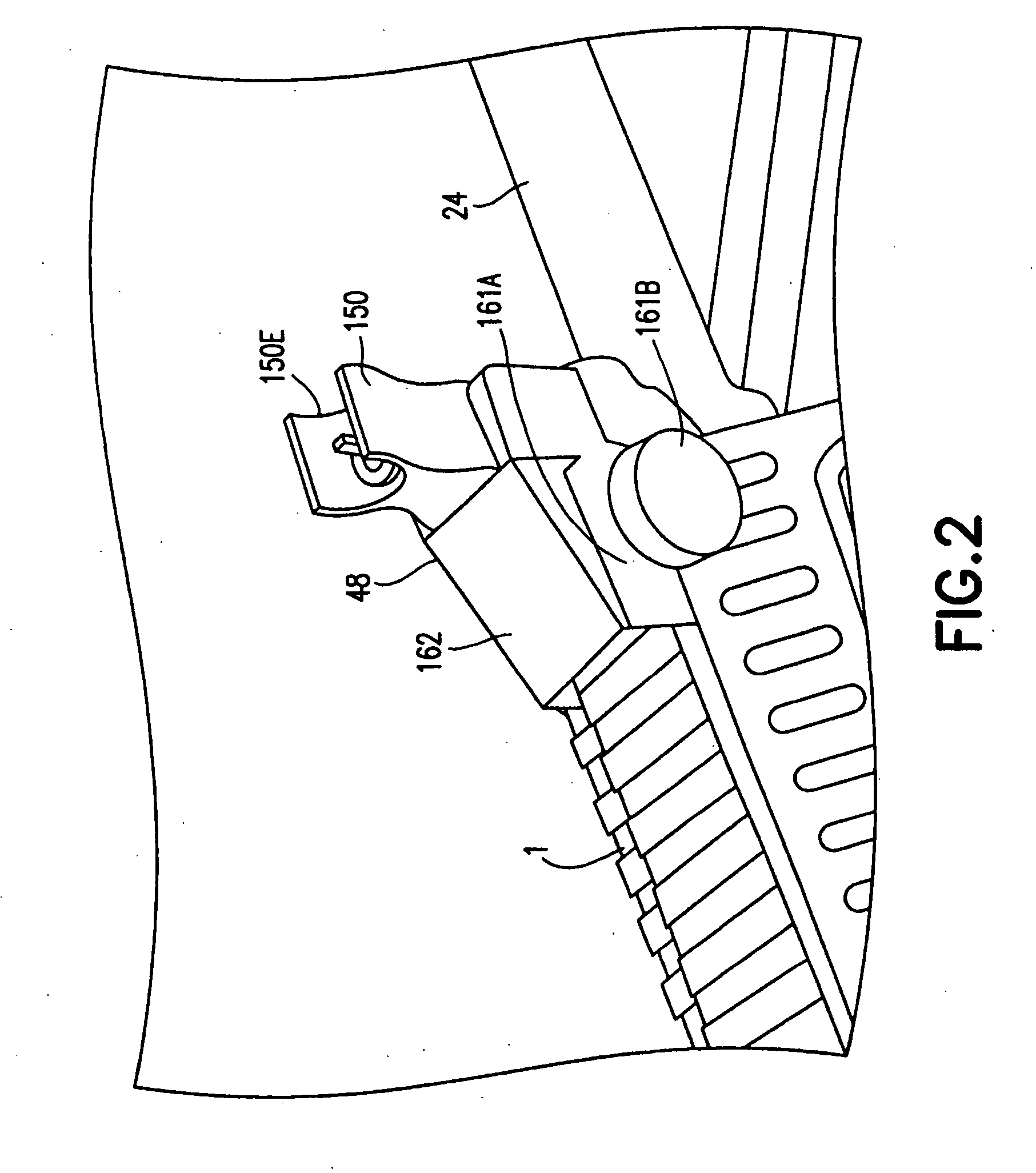

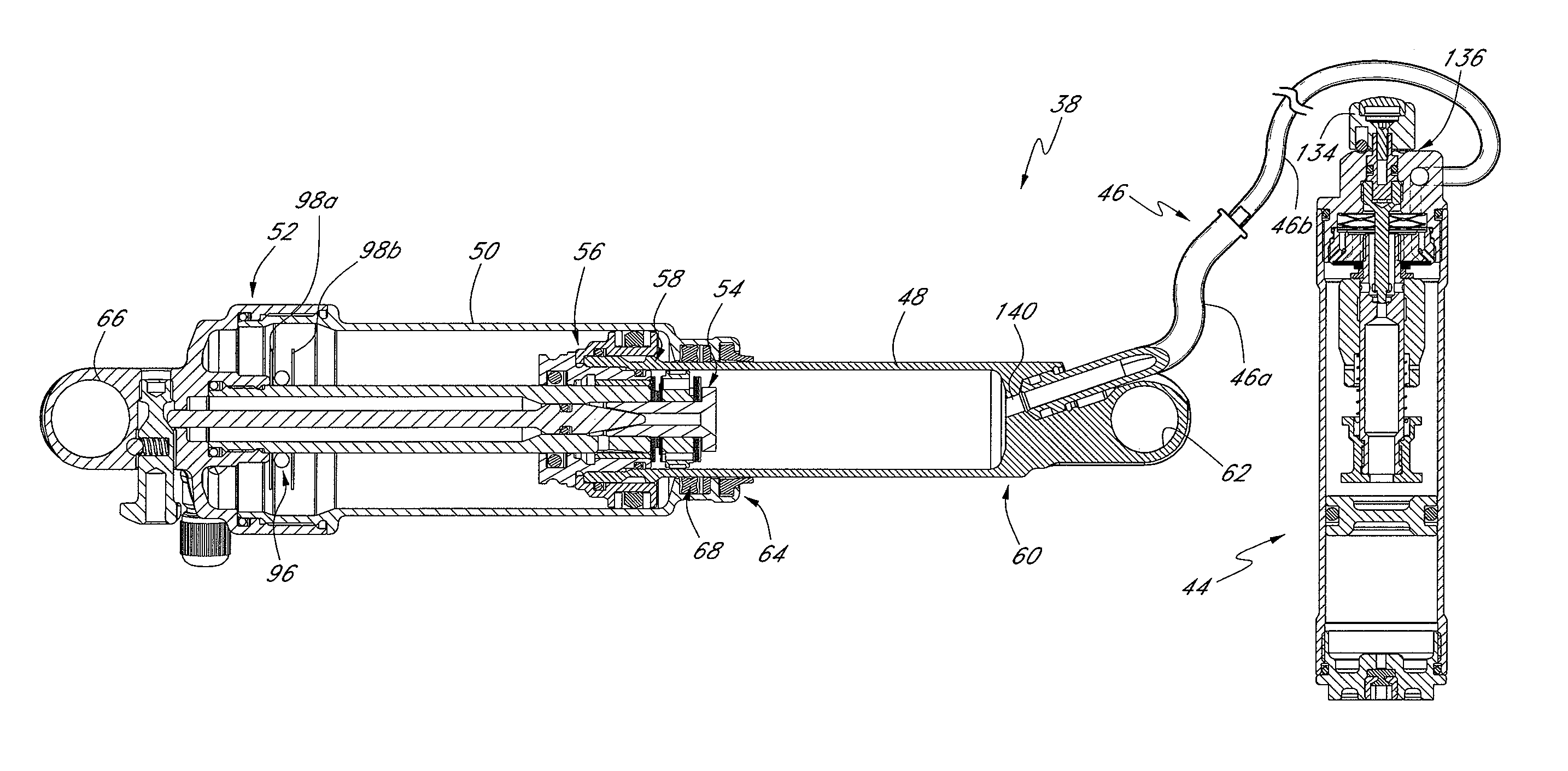

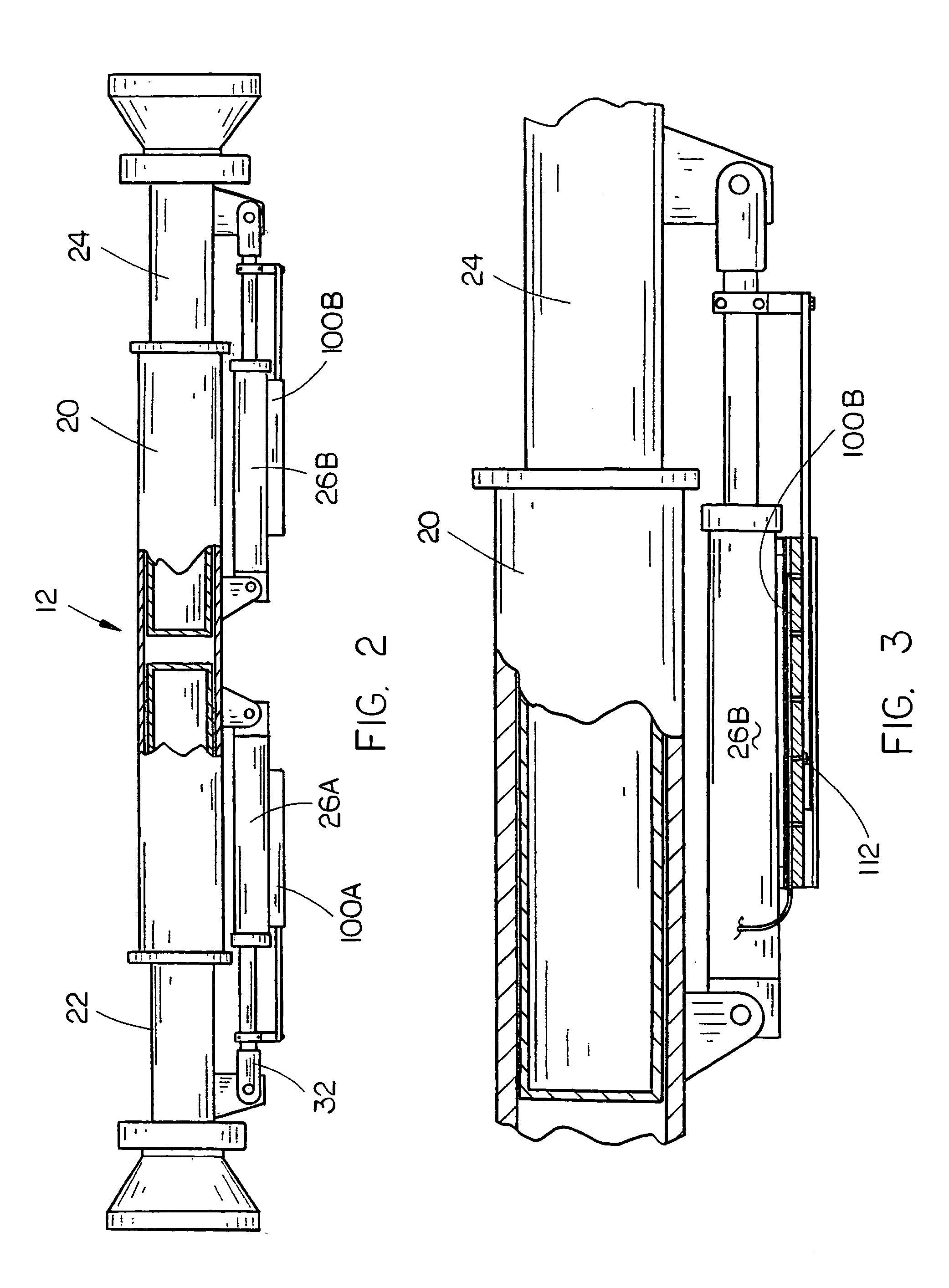

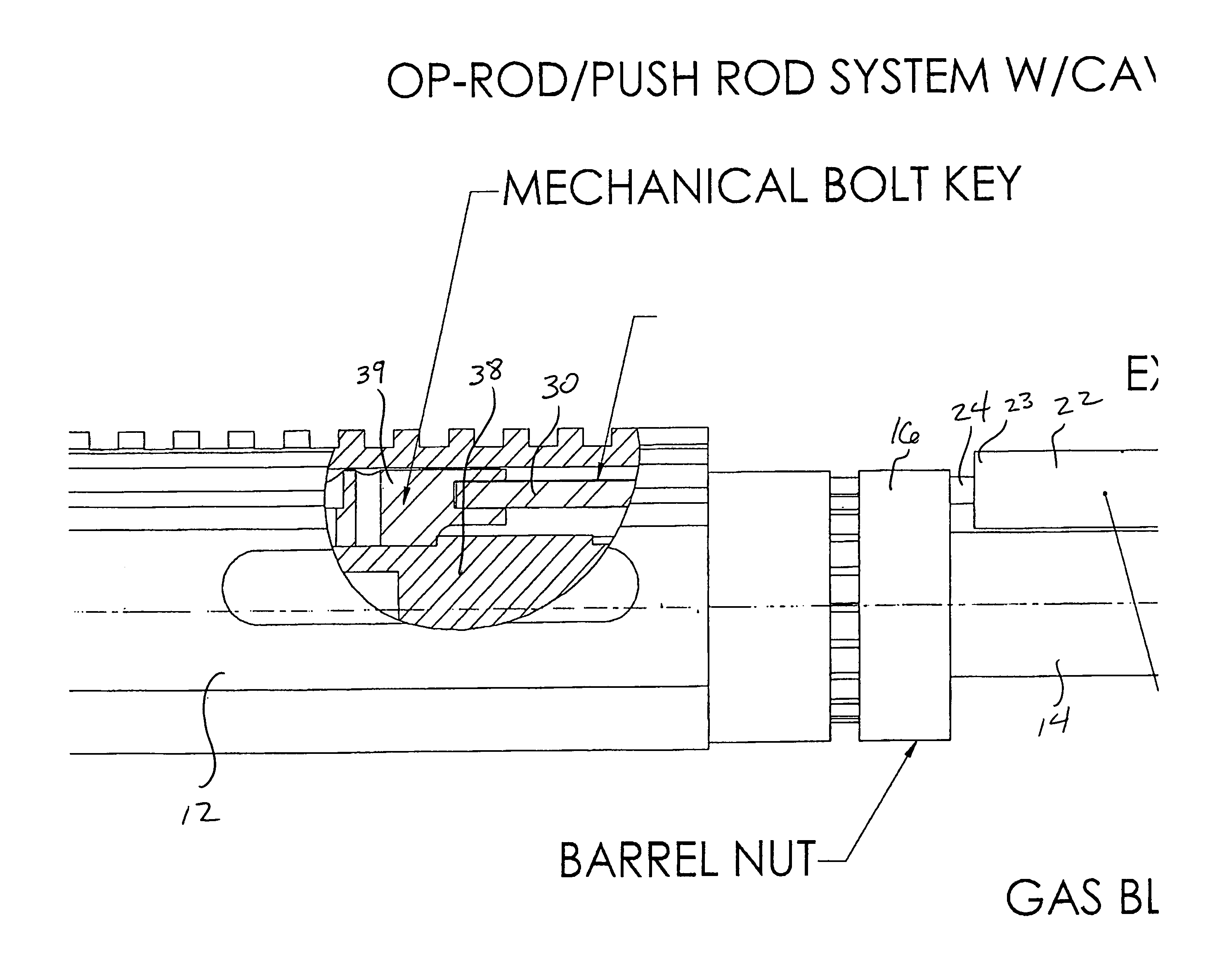

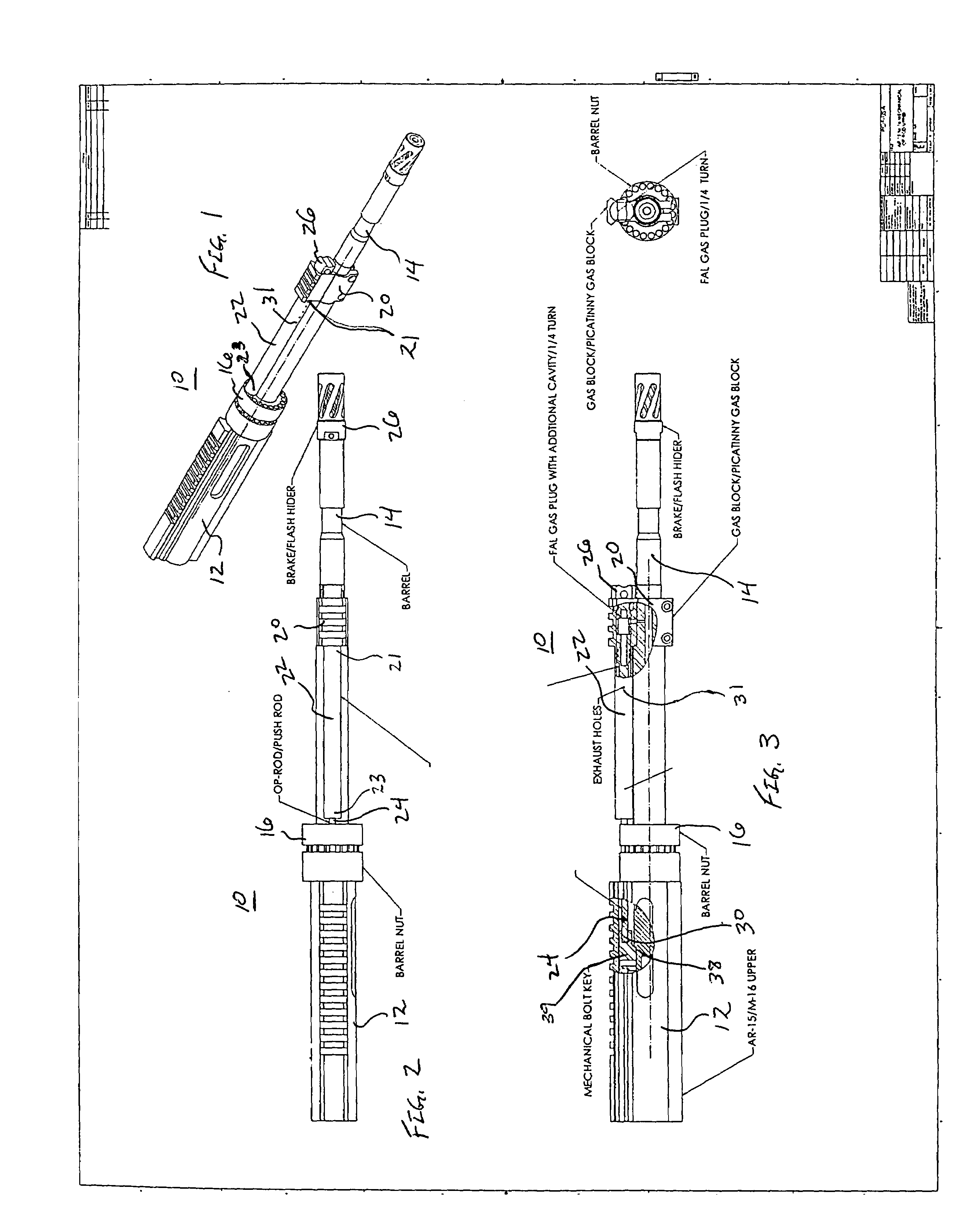

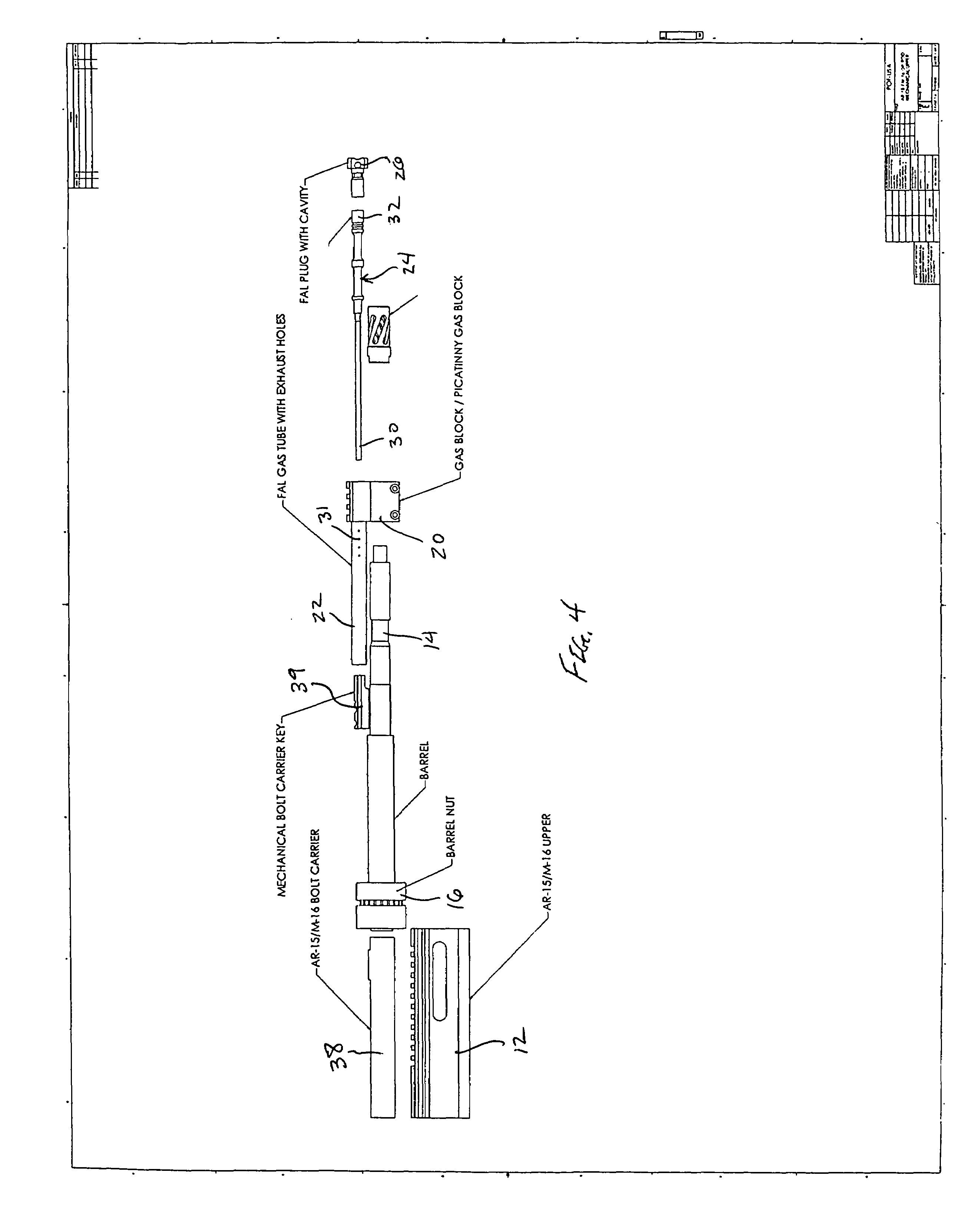

Firearm having an indirect gas operating system

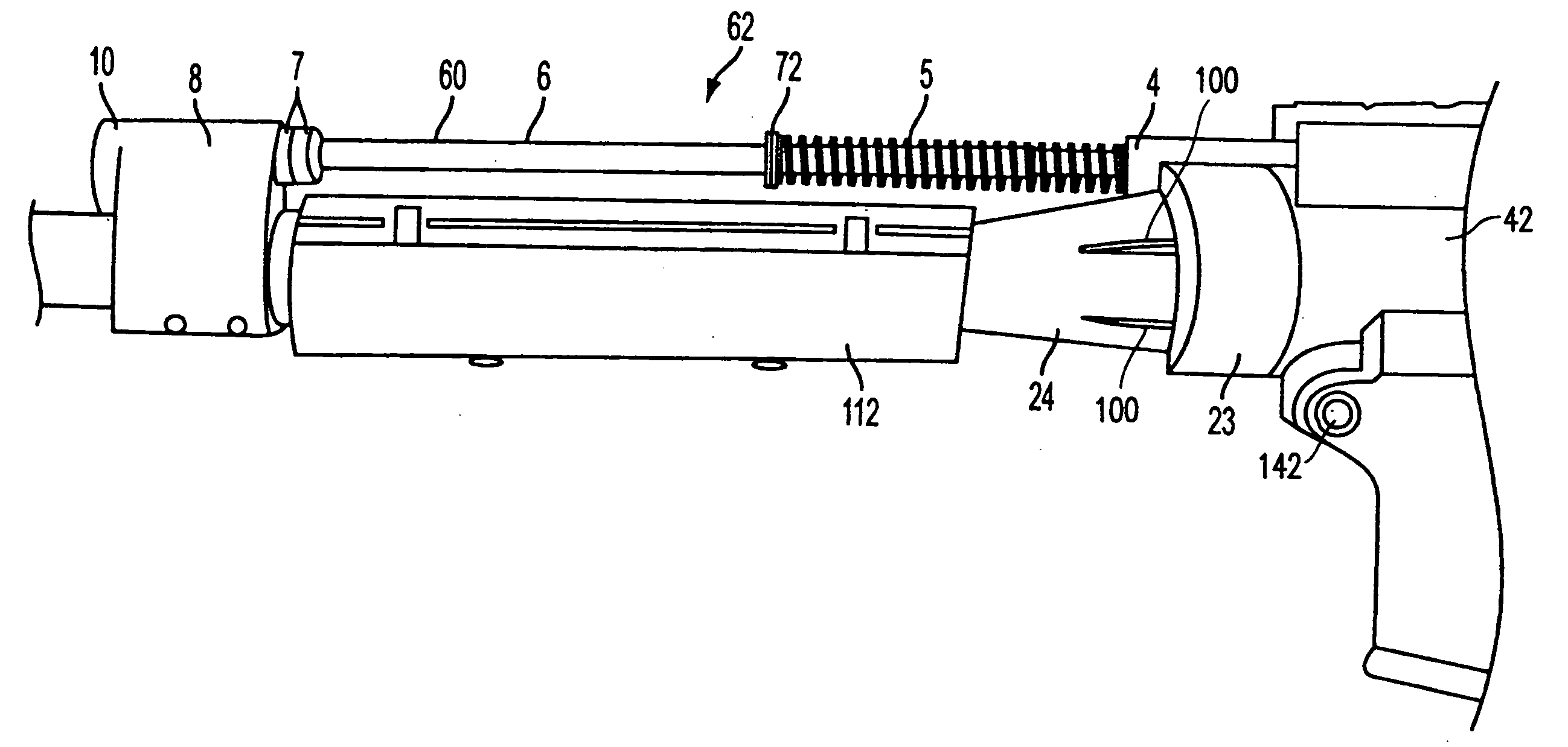

An M4 type automatic or semi-automatic firearm having an indirect gas operating system. A bolt assembly has a striking surface. The bolt assembly is enclosed within an M4 type receiver assembly. A barrel assembly having a bore is coupled to the receiver assembly. A gas block having a cylinder is fitted to the barrel assembly with the cylinder in communication with the bore. A piston and rod assembly has a piston and a striking rod, with the piston fitted to the cylinder. Gas discharged from a fired cartridge displaces the piston and causes the striking rod to strike the striking surface displacing the bolt assembly.

Owner:COLTS MFG IP HLDG COMPANY

Administration apparatus for medical use

InactiveUS20050197650A1Easy to replaceMinimized in sizeAmpoule syringesAutomatic syringesEngineeringMechanical engineering

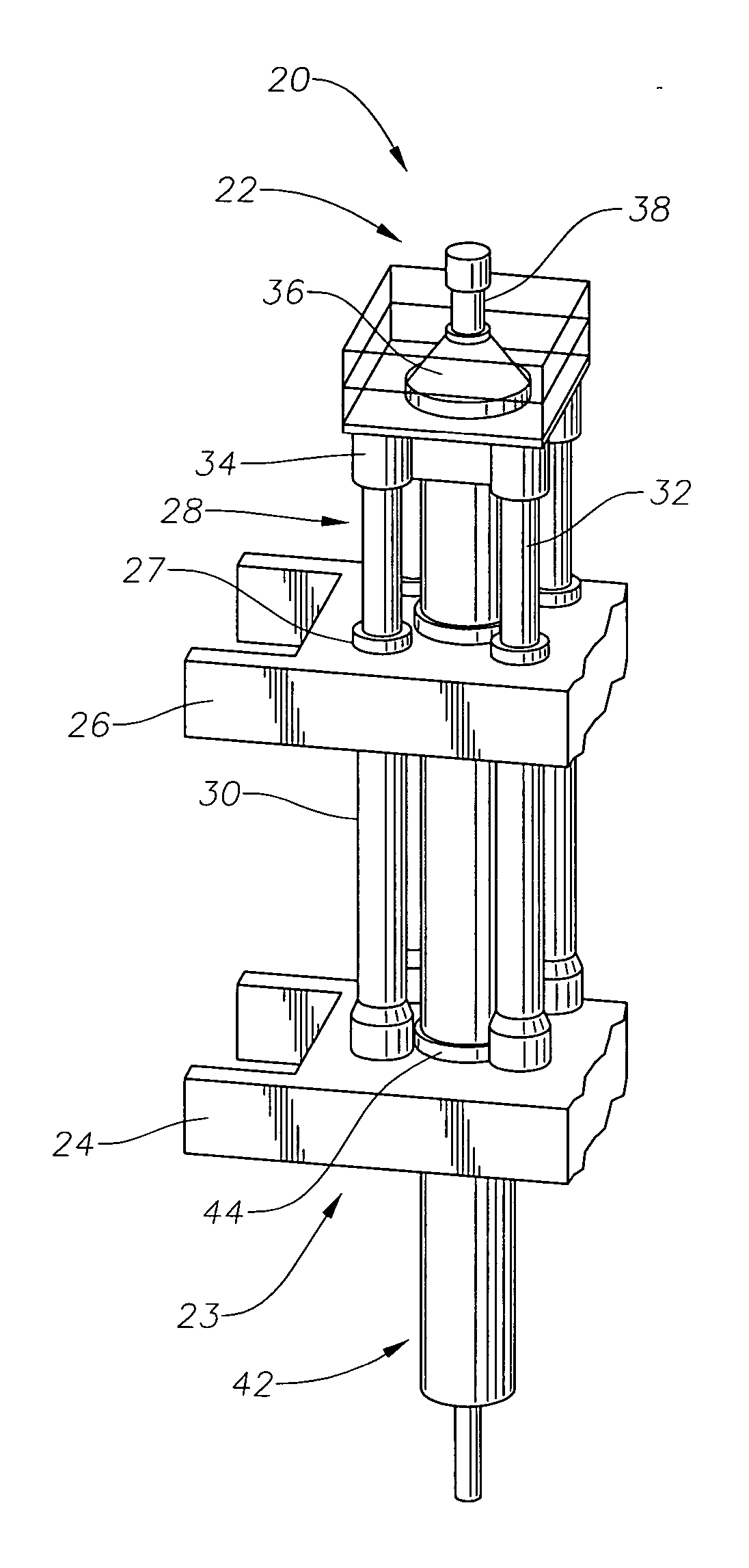

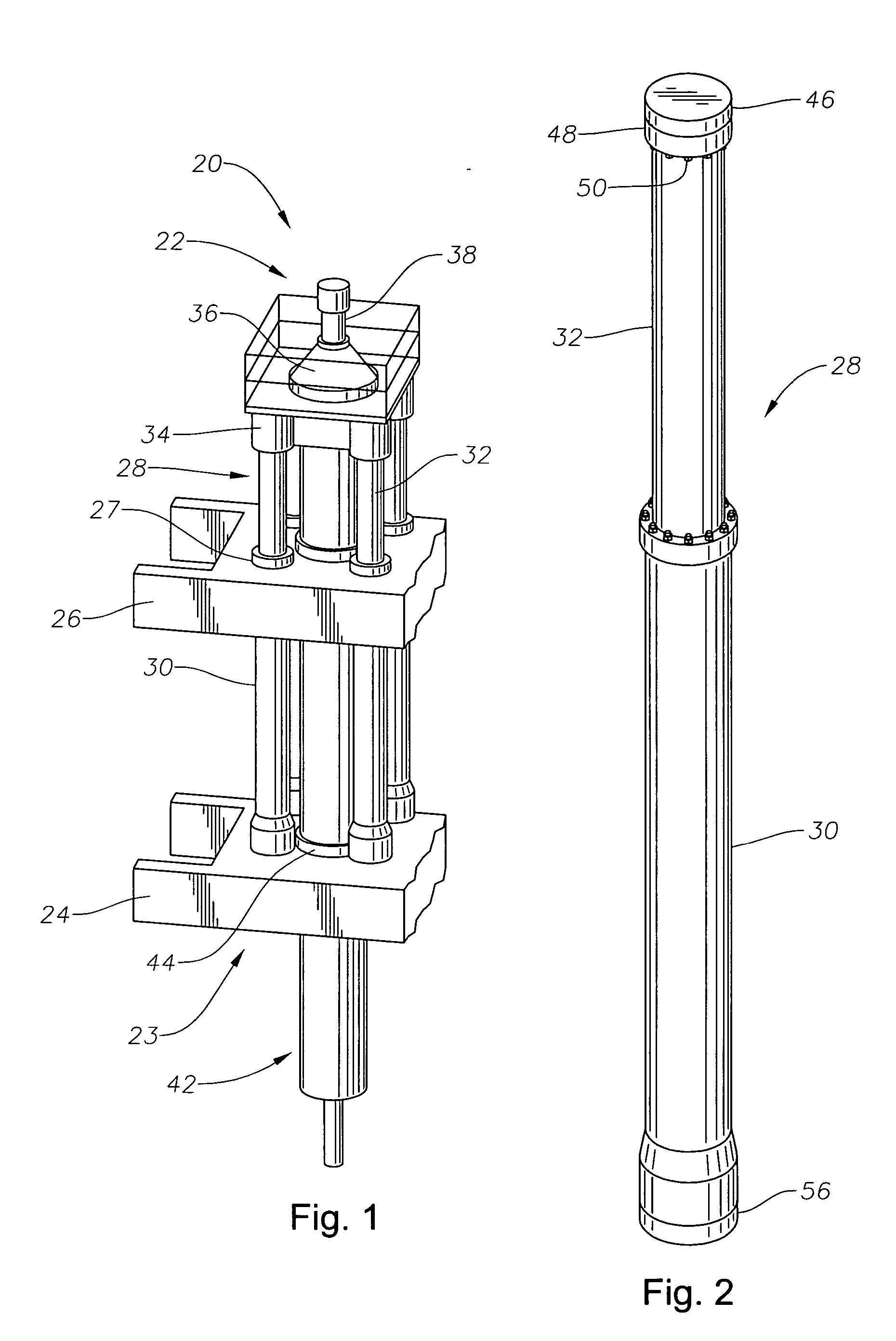

An expansion / compression mechanism of a piston rod assembly is composed of a bush shaft, a first cylindrical piston rod that is screwed with the bush shaft, a second cylindrical piston rod that is screwed with the first piston rod, and a piston rod holding member for housing the bush shaft and the piston rods. Therefore, the piston rods move linearly in multiple stages, whereby the size of the whole apparatus is reduced.

Owner:PANASONIC CORP

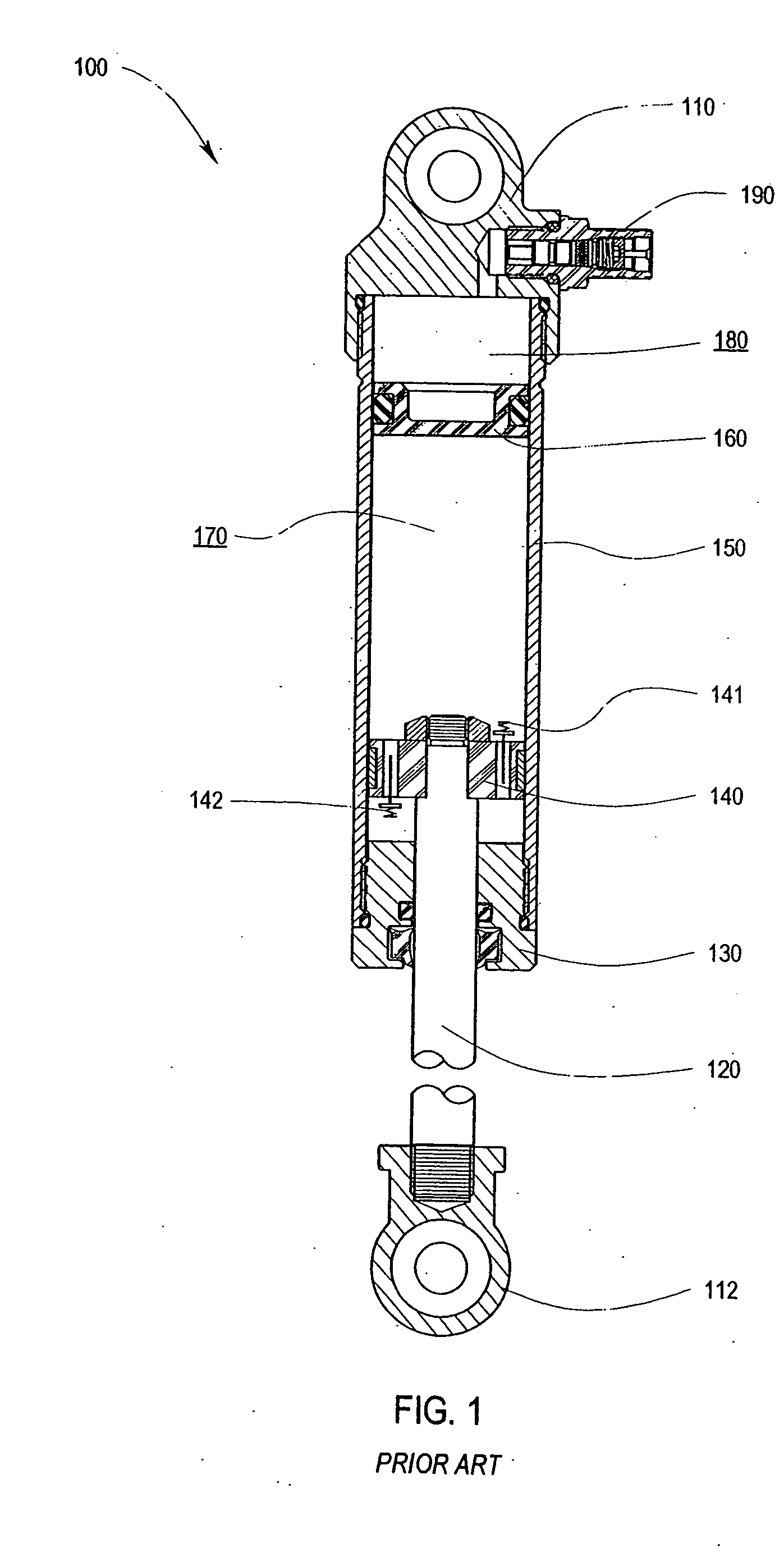

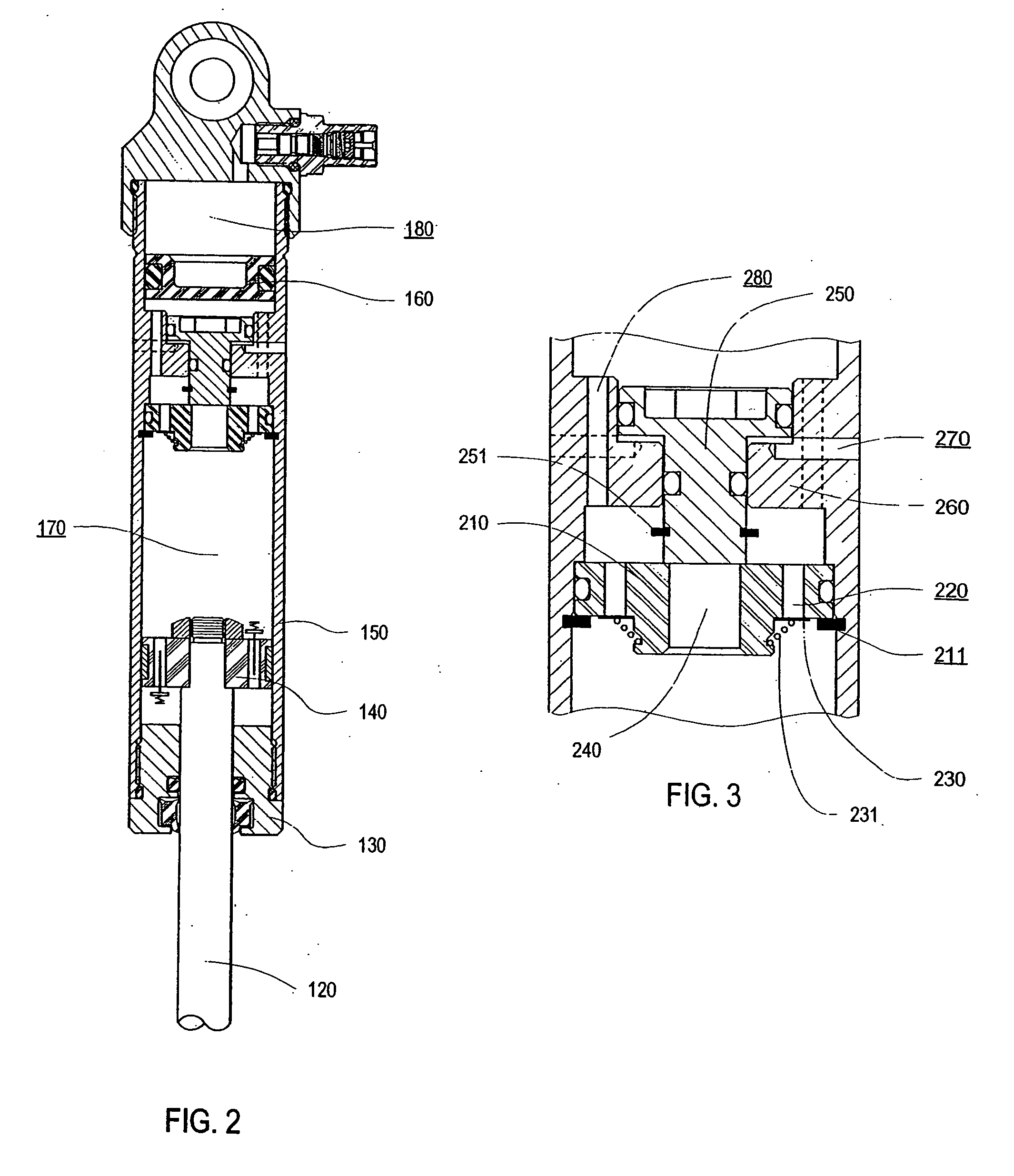

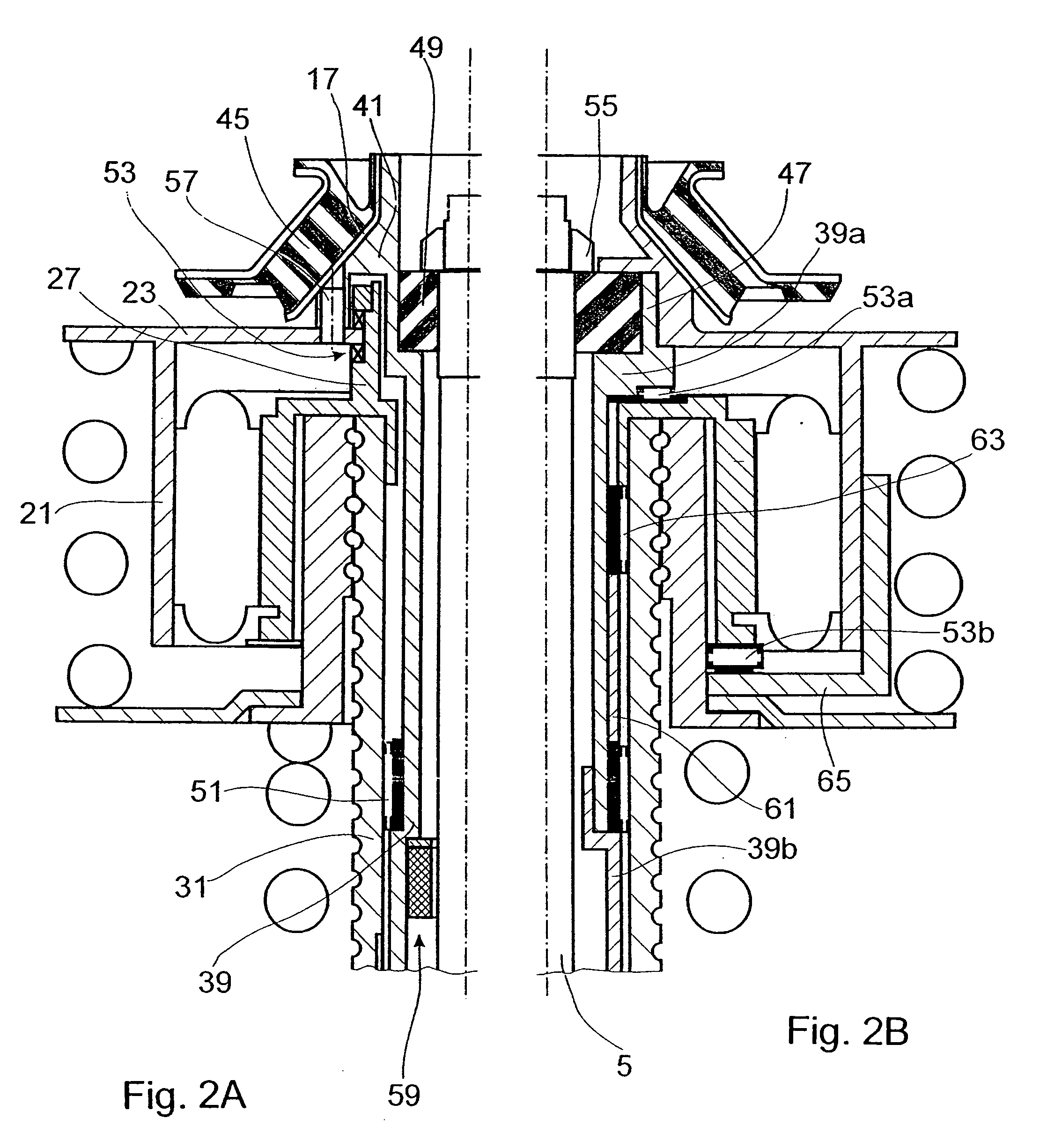

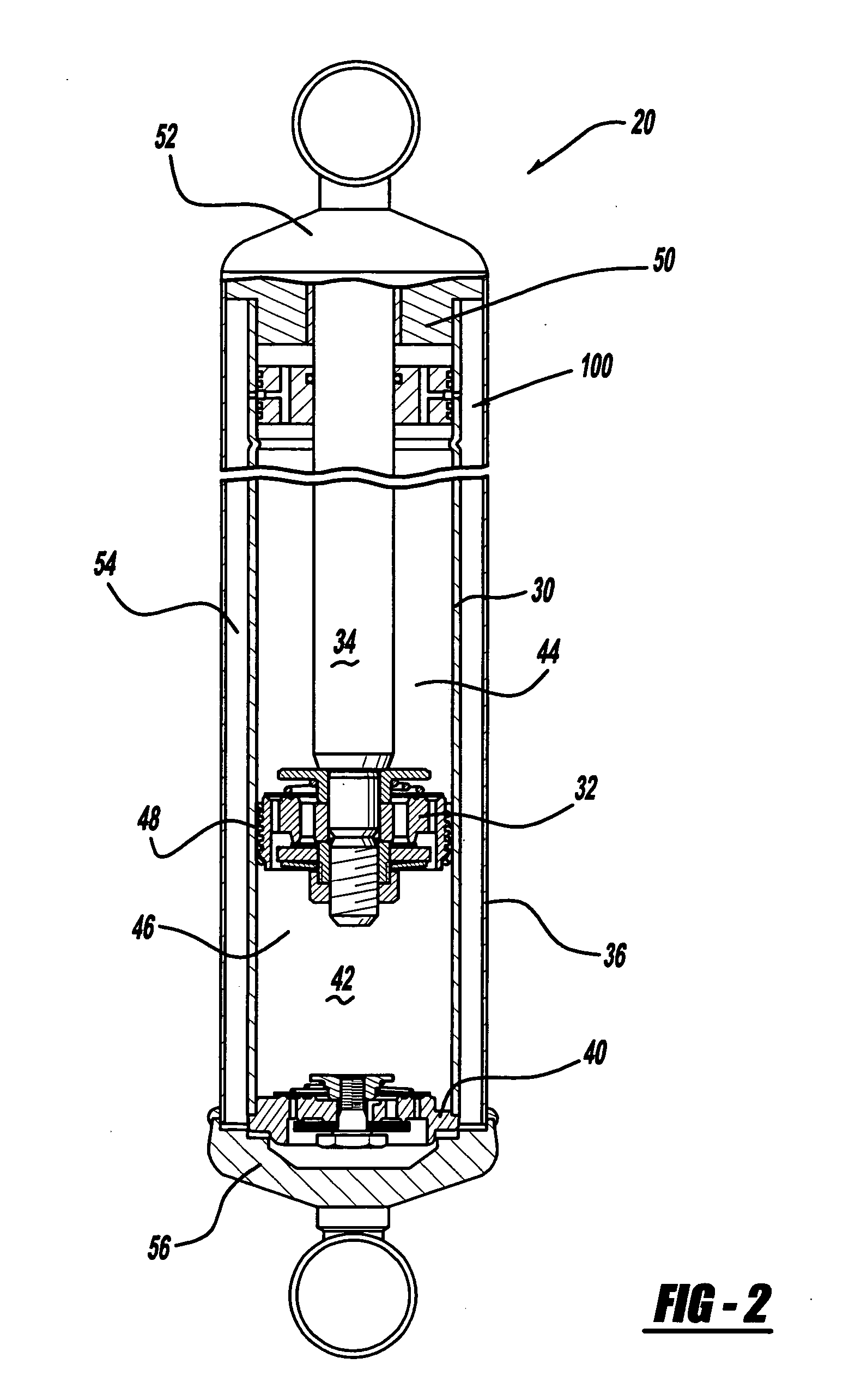

Damper with pressure-sensitive compression damping

InactiveUS20060289258A1Quickly and easily tunedQuickly and easily and adjustedSpringsShock absorbersElectrical resistance and conductanceSpring force

A damper includes a piston rod, a damping piston, at least one cylinder containing a damping liquid, a fixed partition member for partitioning the interior of the damper into two liquid chambers, a pressure source, and a valve in communication with the pressure source which reacts as a function of the pressure. The valve can also be in communication with additional forces, such as mechanical spring forces, which can be adjustable. The valve can include a pressure intensifier. The valve generates fluid flow resistance during flow of liquid in a first direction through the partition member. The fluid flow resistance in the first direction varies according to the amount of force communicated to the valve by the pressure source and any additional forces. The partition member can include means for providing low-resistance return flow of liquid in a second direction.

Owner:FOX FACTORY

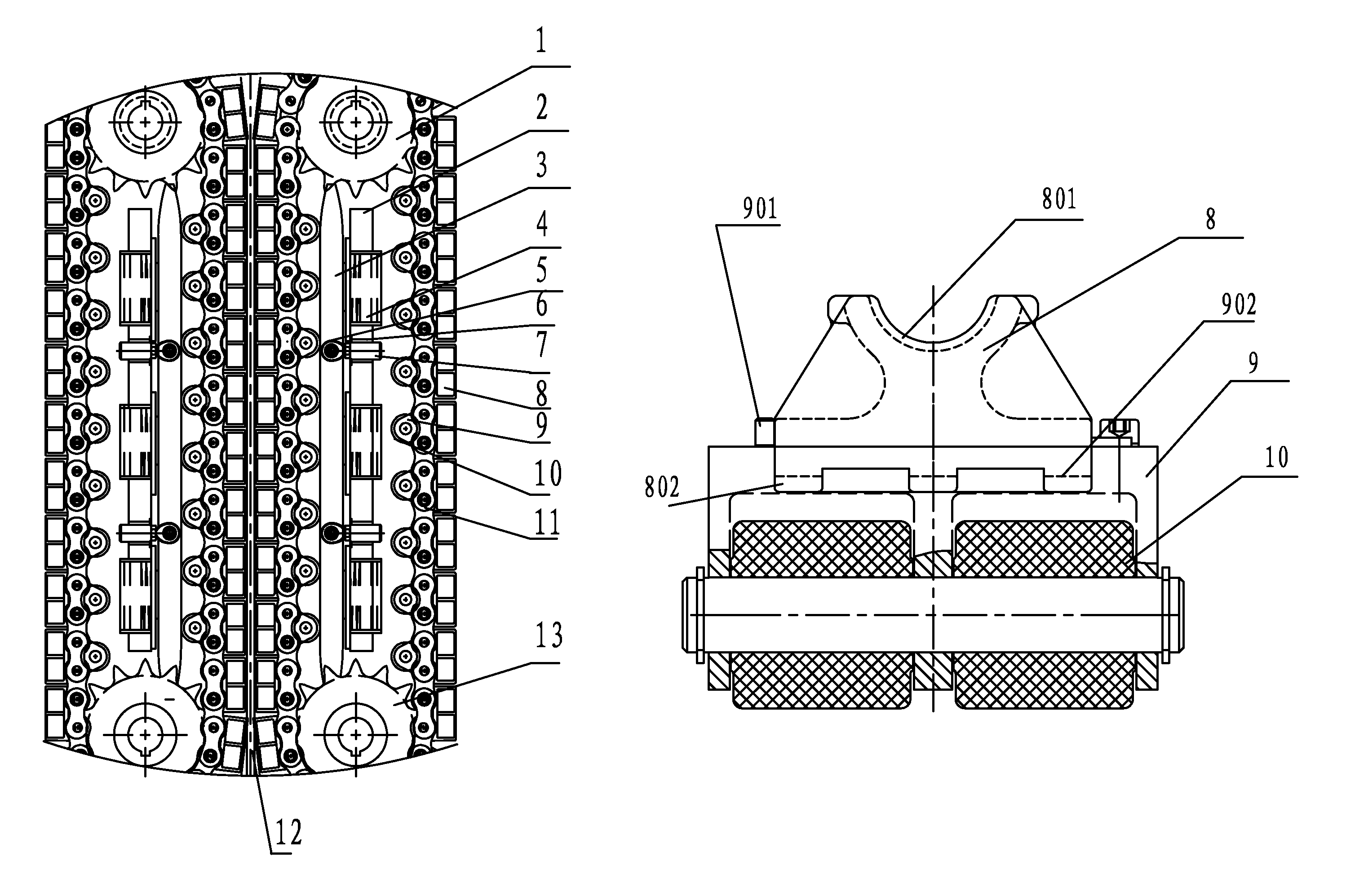

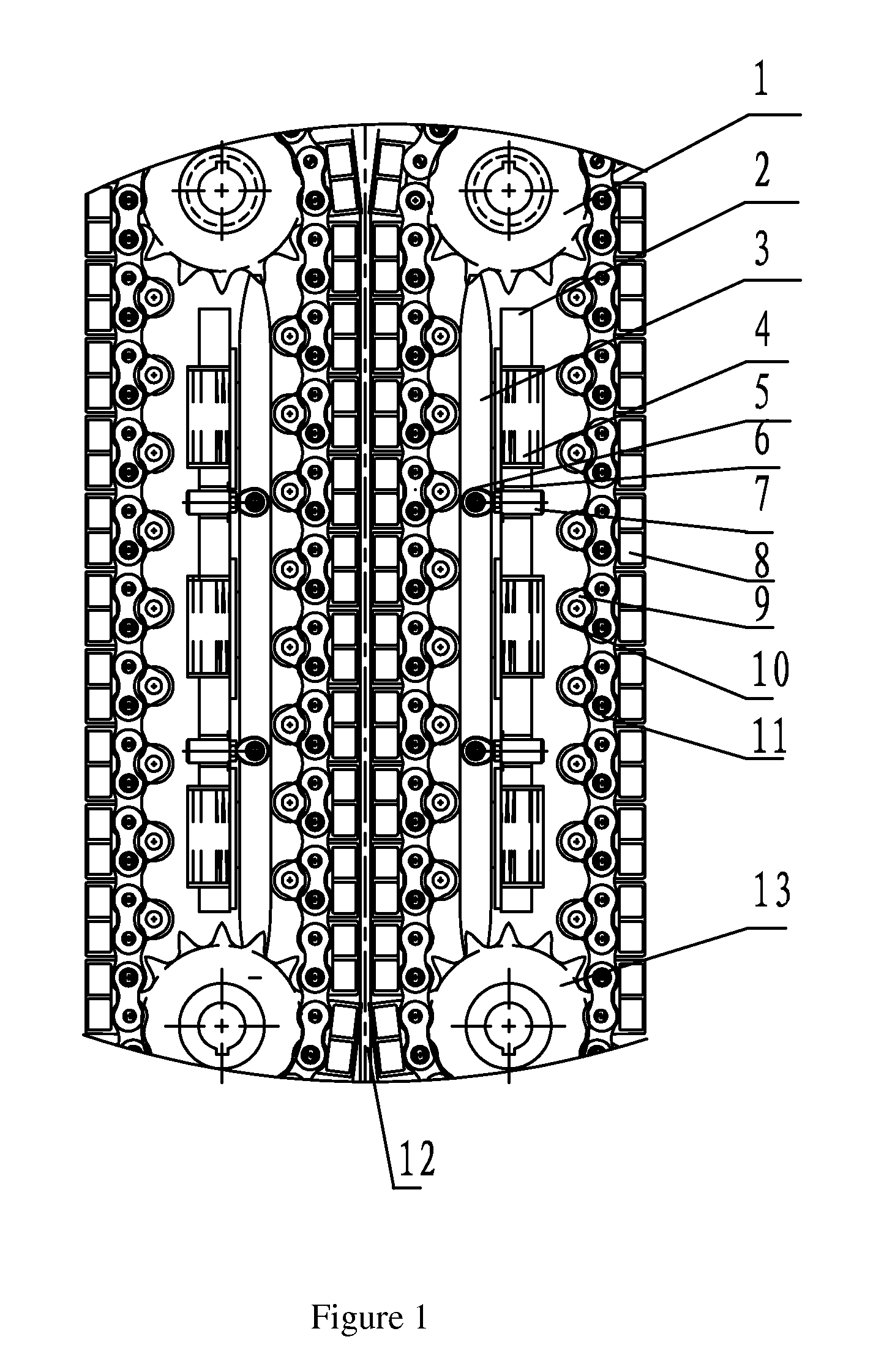

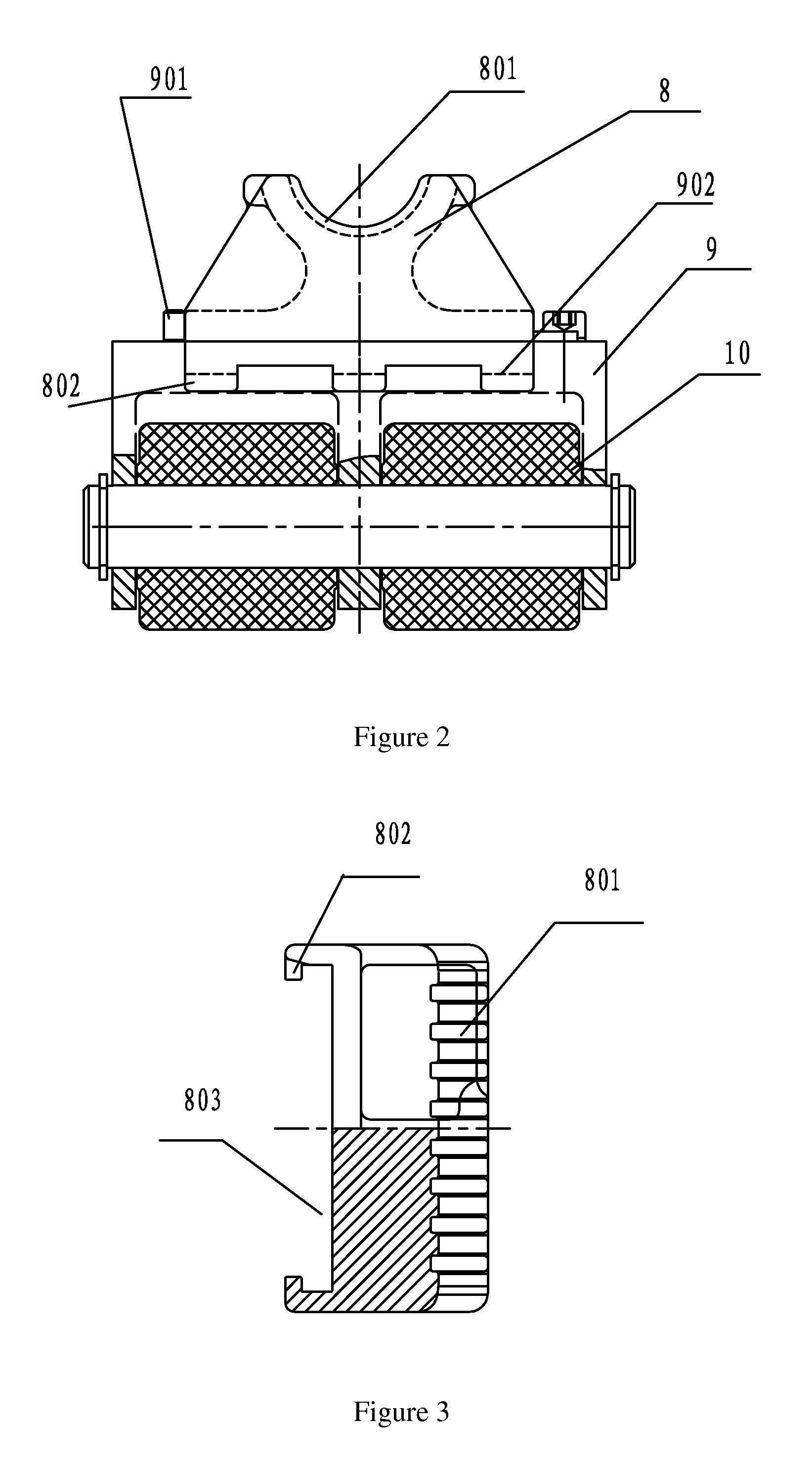

Floating clamping device for injection head of continuous oil pipe

ActiveUS9493997B2Easy to serviceEasy to operateDrilling rodsDrilling casingsCoiled tubingEngineering

A floating clamping device for an injection head of a continuous oil pipe, including a drive sprocket, a transmission chain, a supporting plate, a pushing plate, clamping oil cylinders and a clamping assembly. At least two clamping oil cylinders are installed on the supporting plate fixedly. The pushing plate is fixed on the supporting plate through a pin shaft. The clamping assembly includes a saddle-shaped clamping block, a clamping block seat and rollers which are mounted on the clamping block seat. The clamping assembly is mounted on the transmission chain. A piston rod of the clamping oil cylinder is pressed on one face of the pushing plate, while the other face of the pushing plate is pressed on the rollers. The pushing plate has a simple structure and is convenient for maintenance; the clamping device has a compact structure and a reduced volume.

Owner:YANTAI JEREH OILFIELD SERVICES GROUP +1

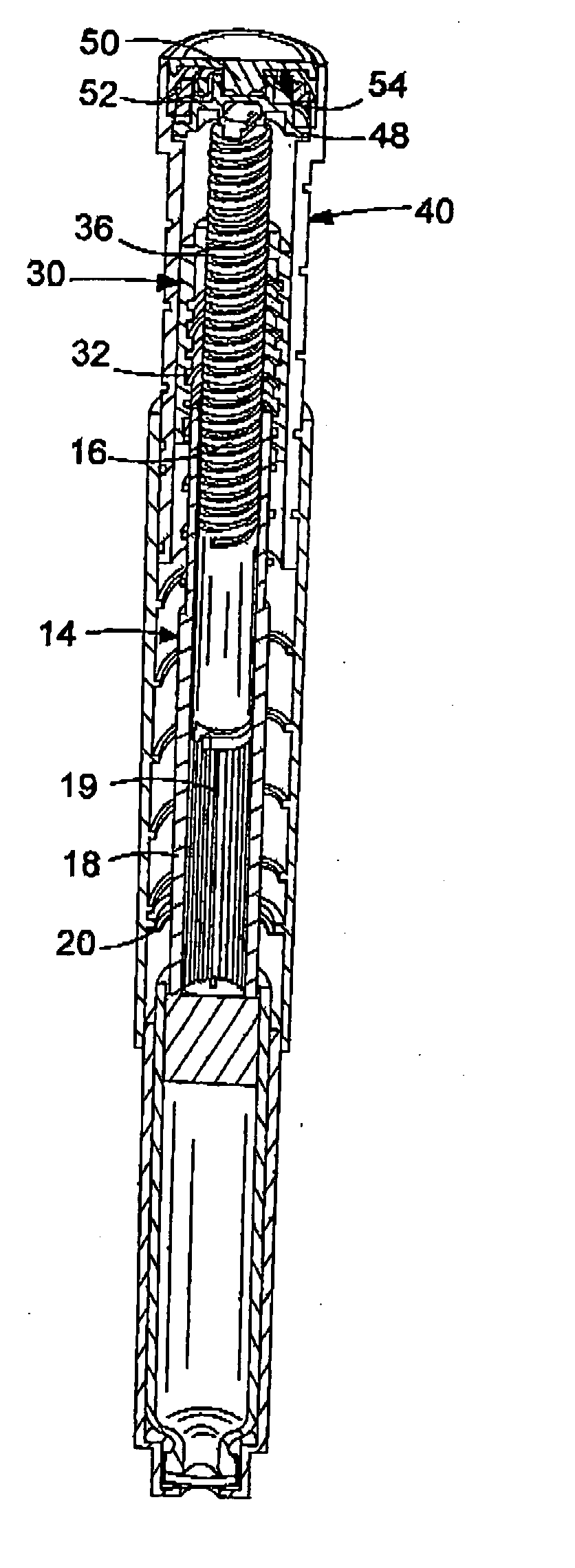

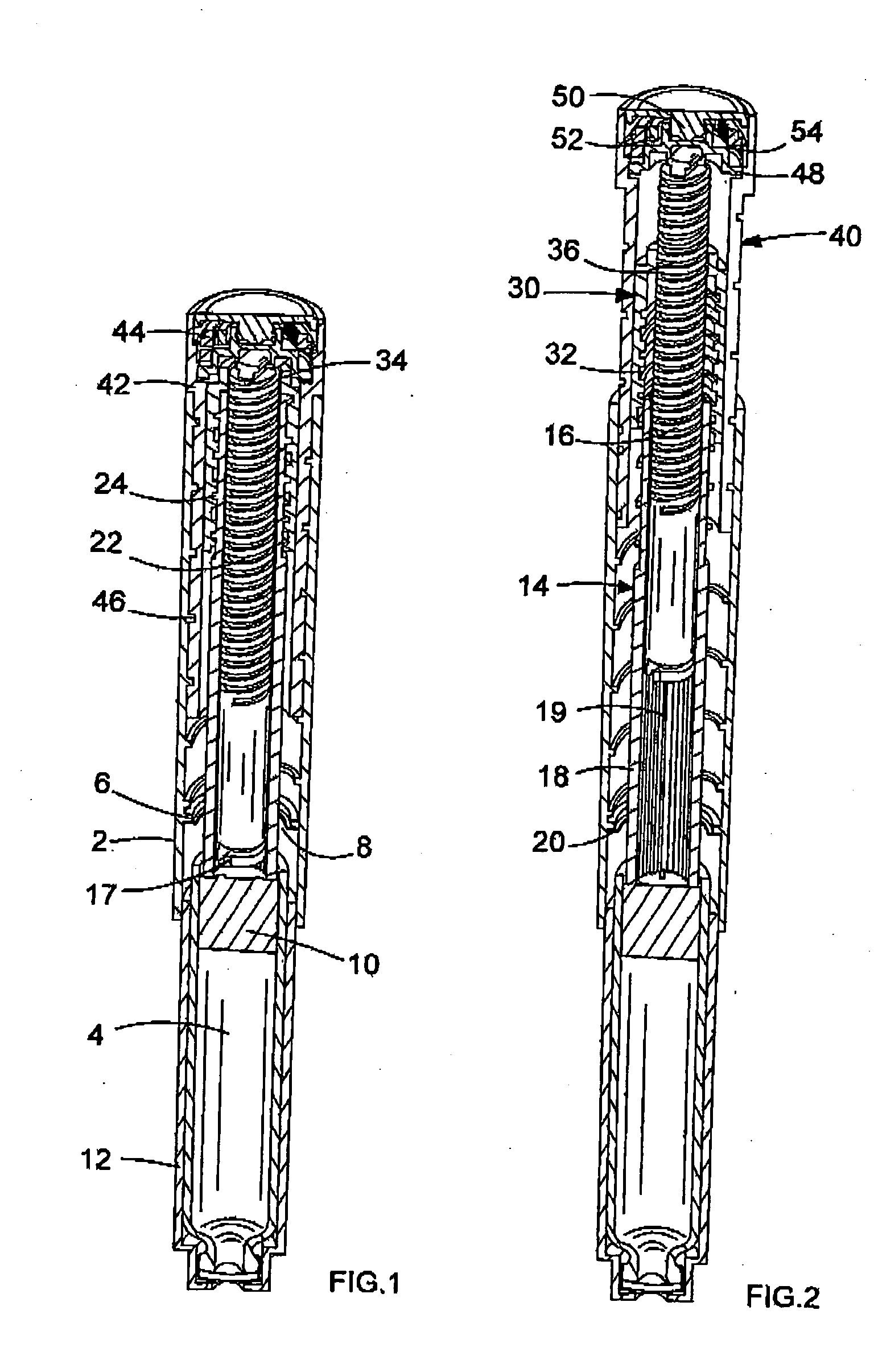

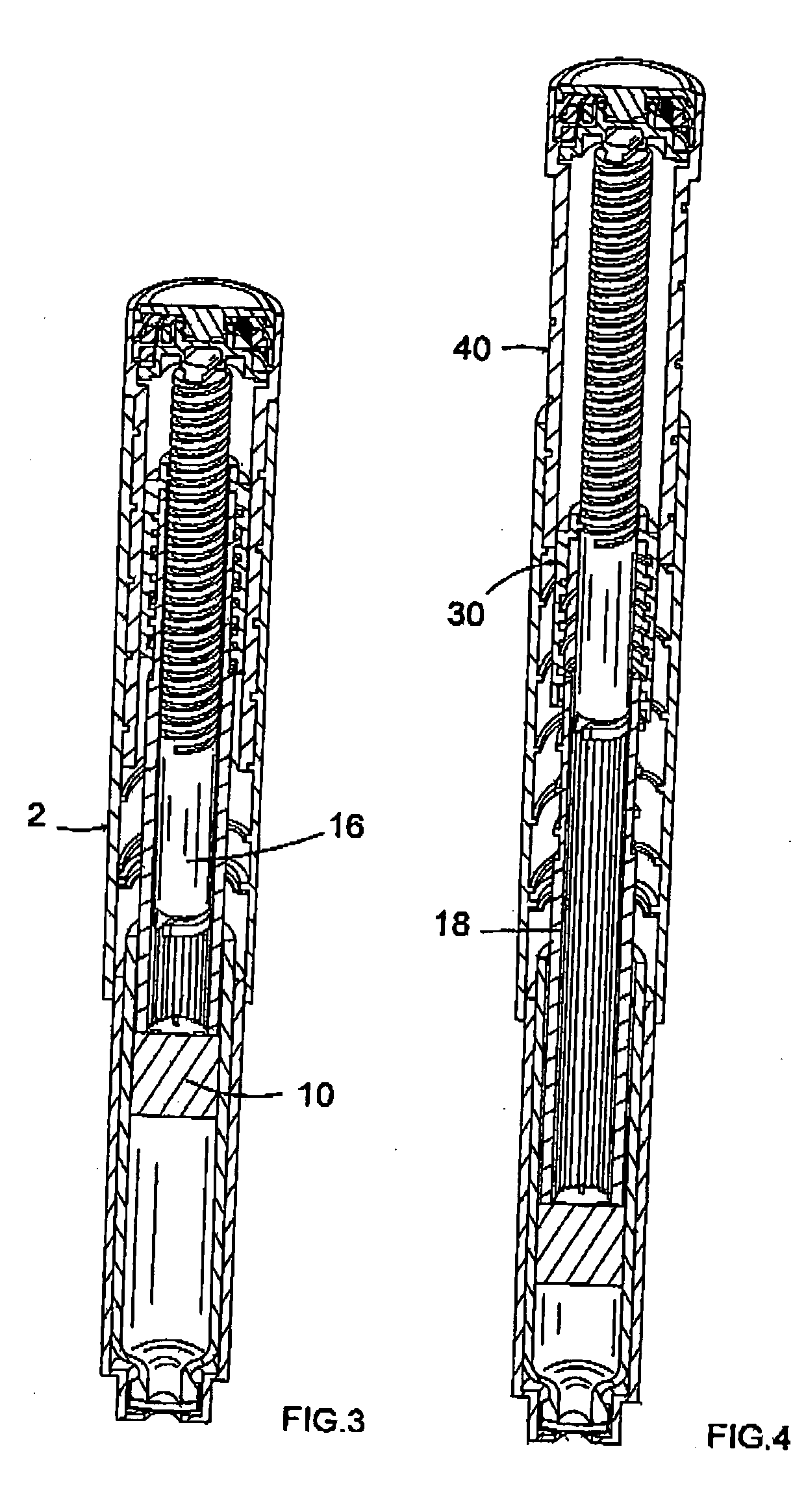

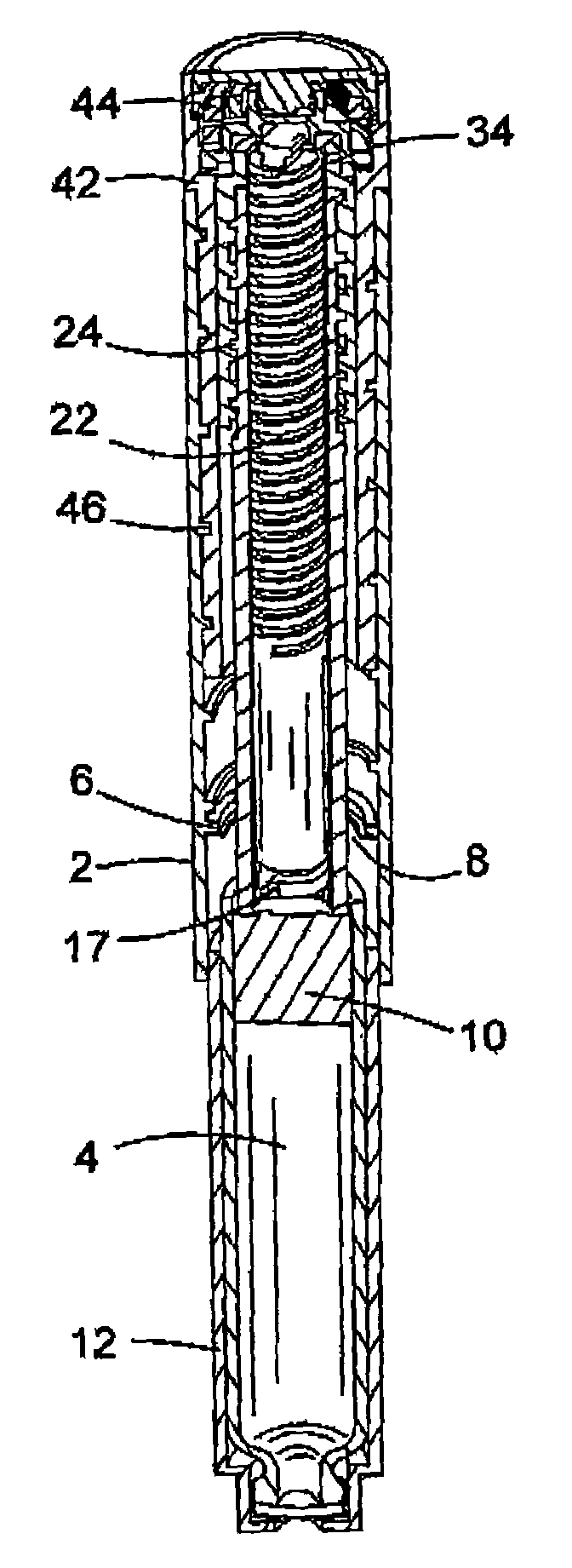

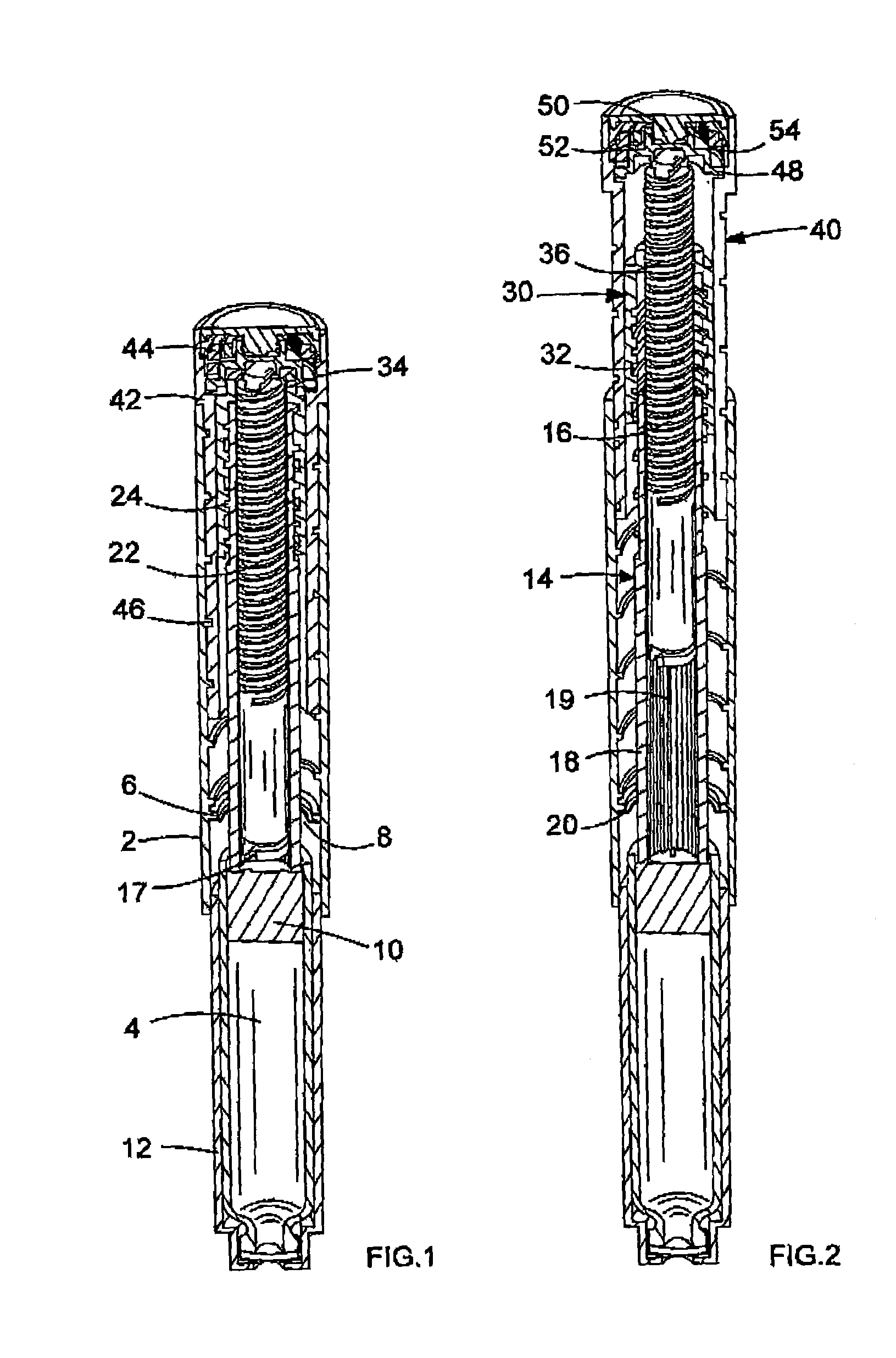

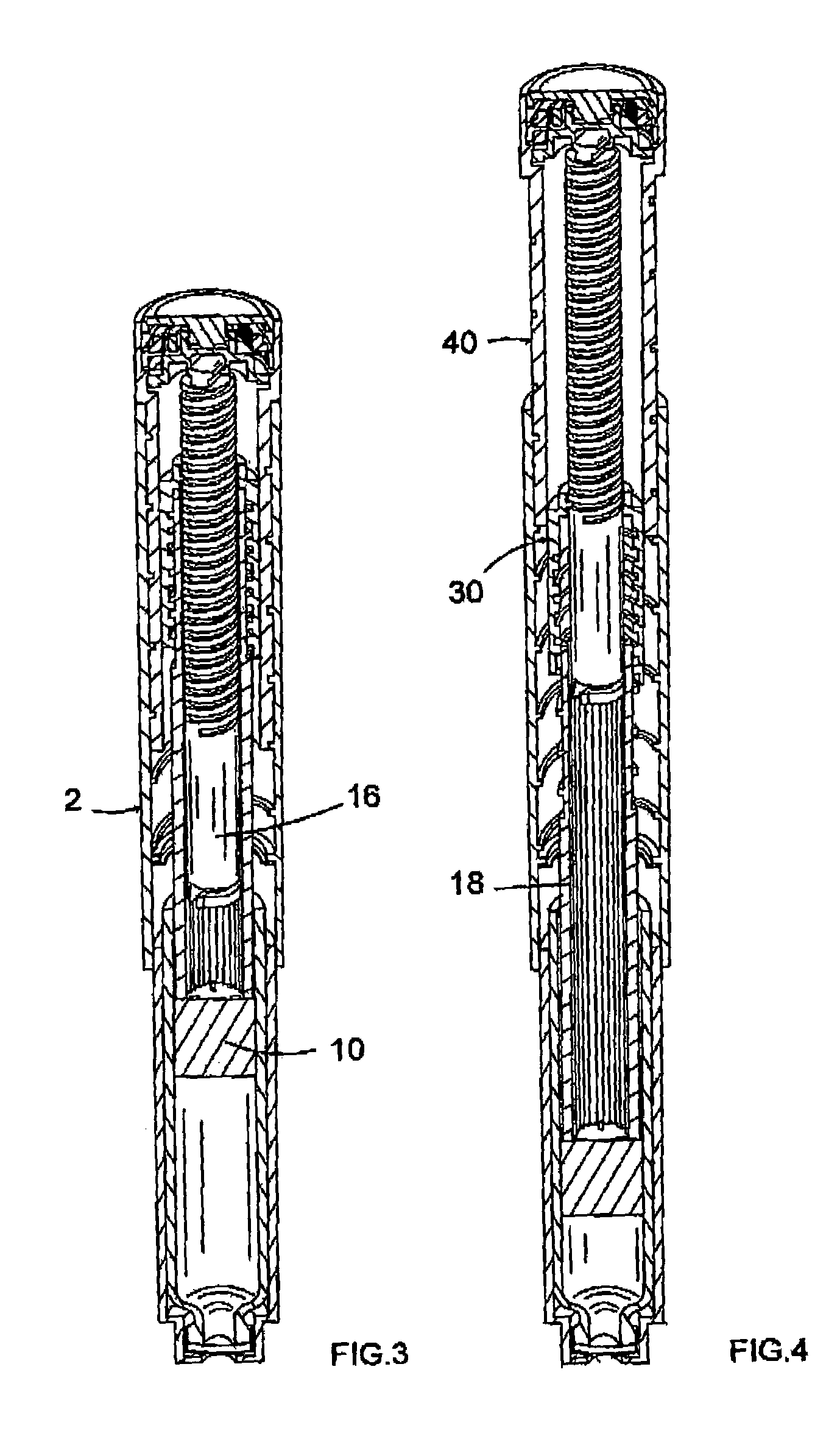

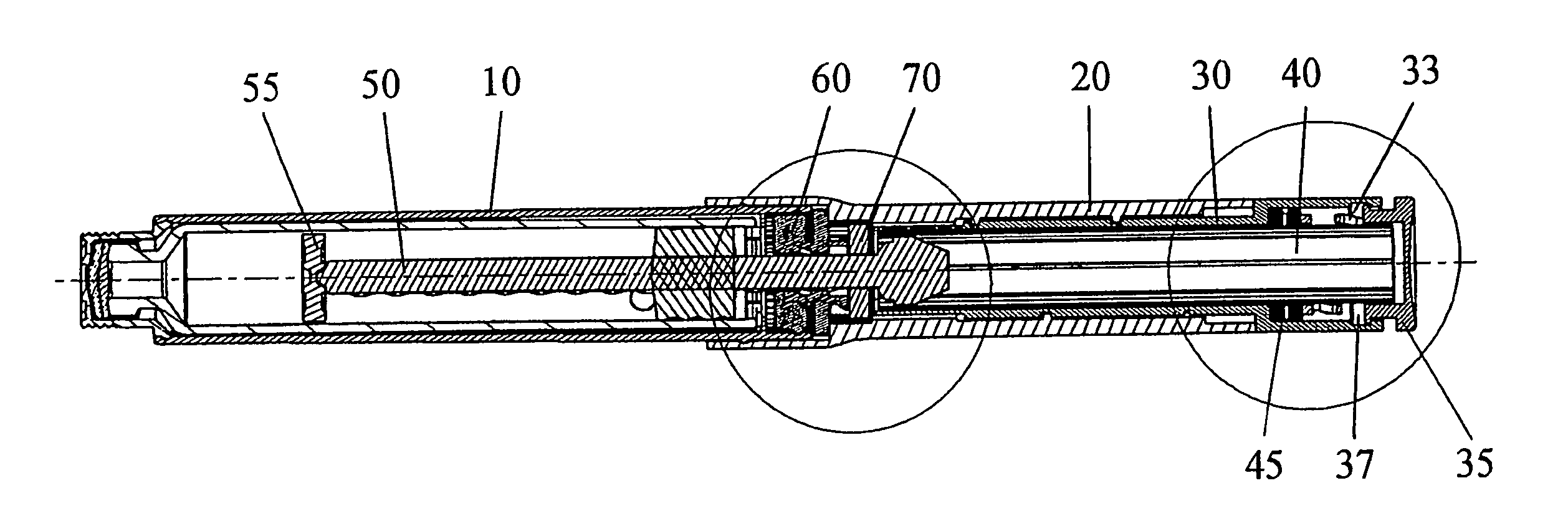

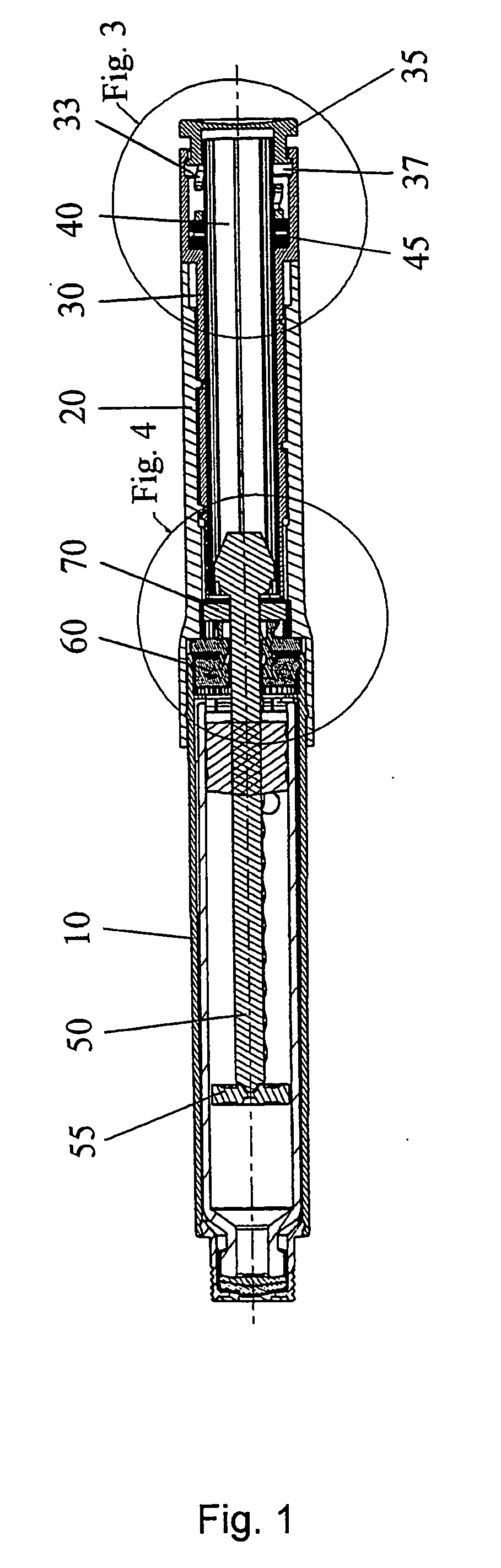

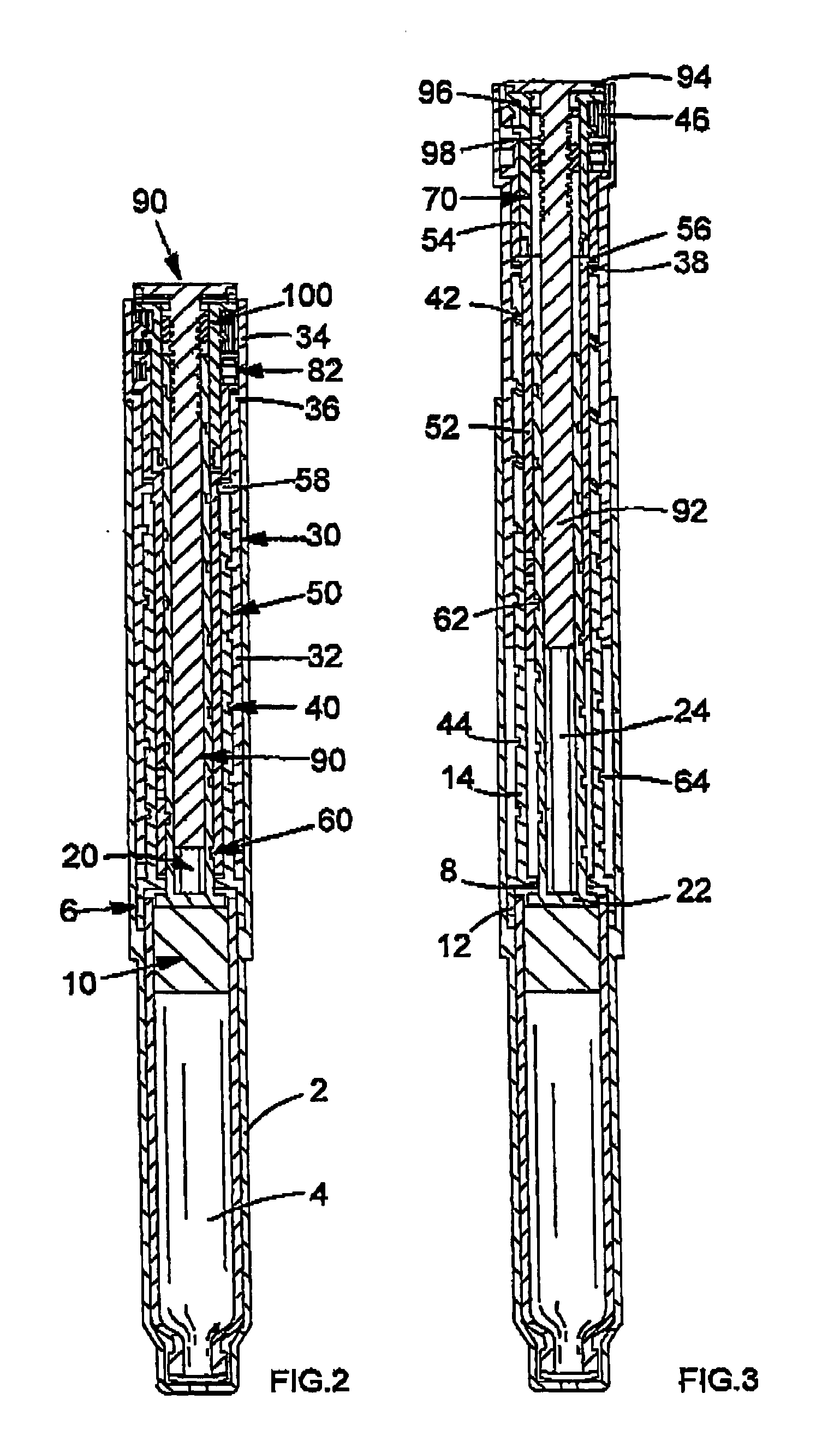

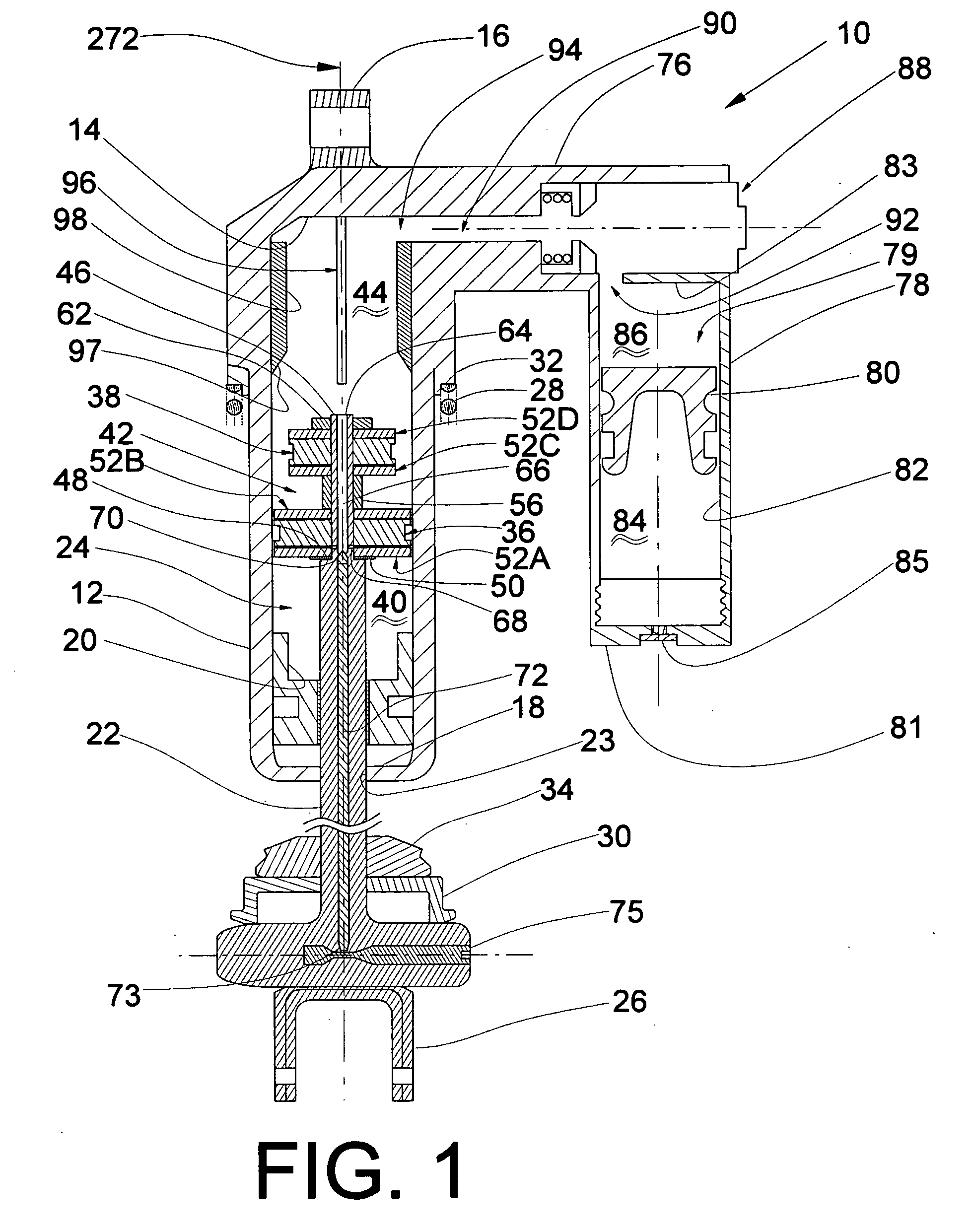

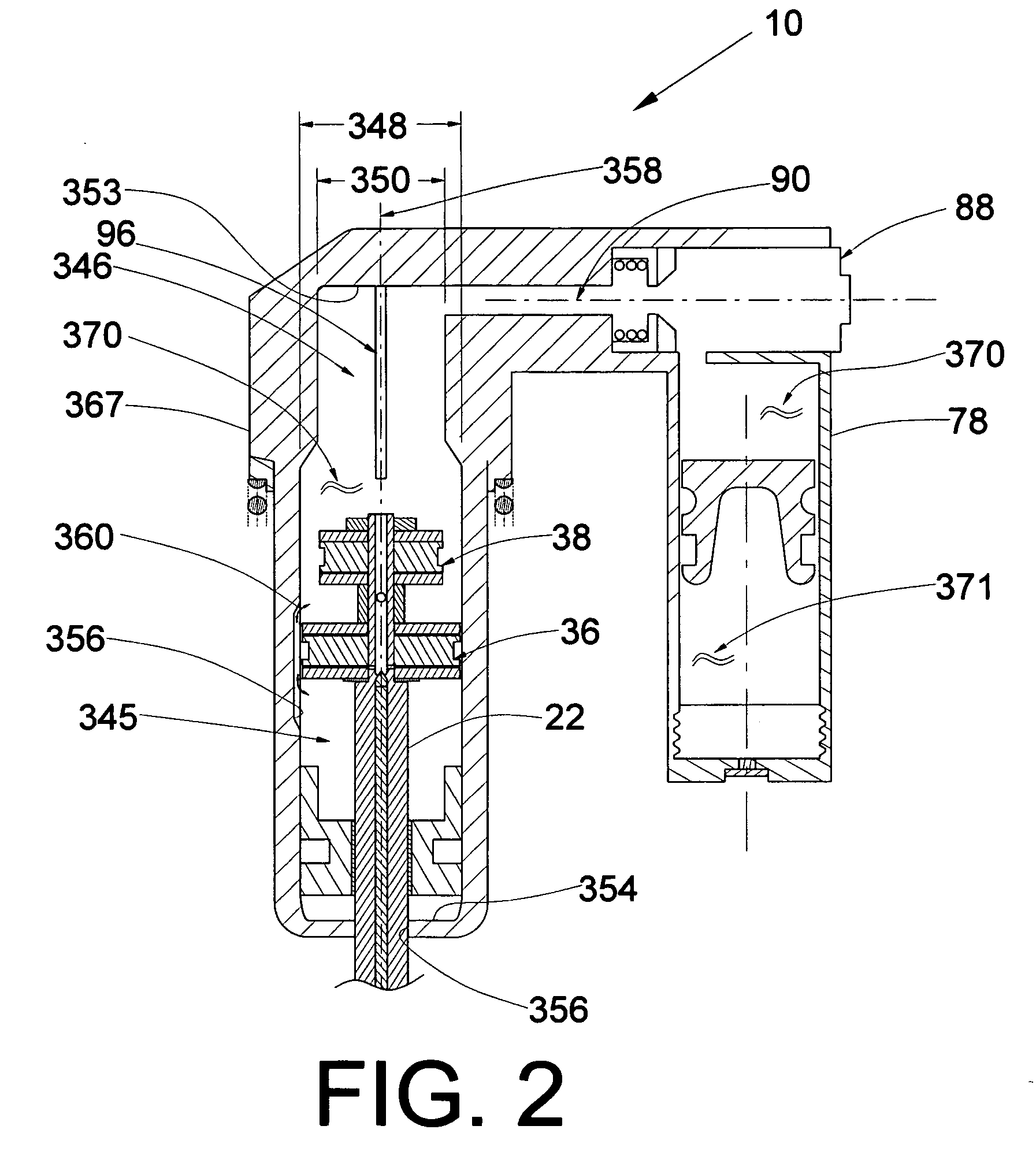

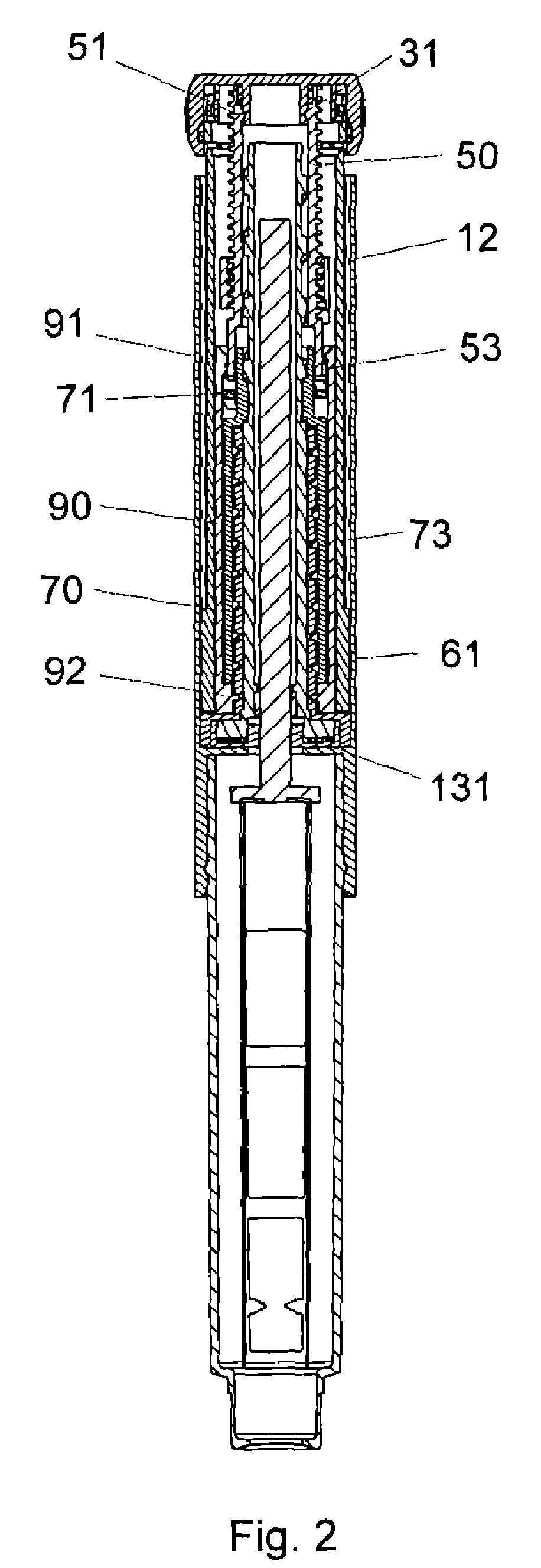

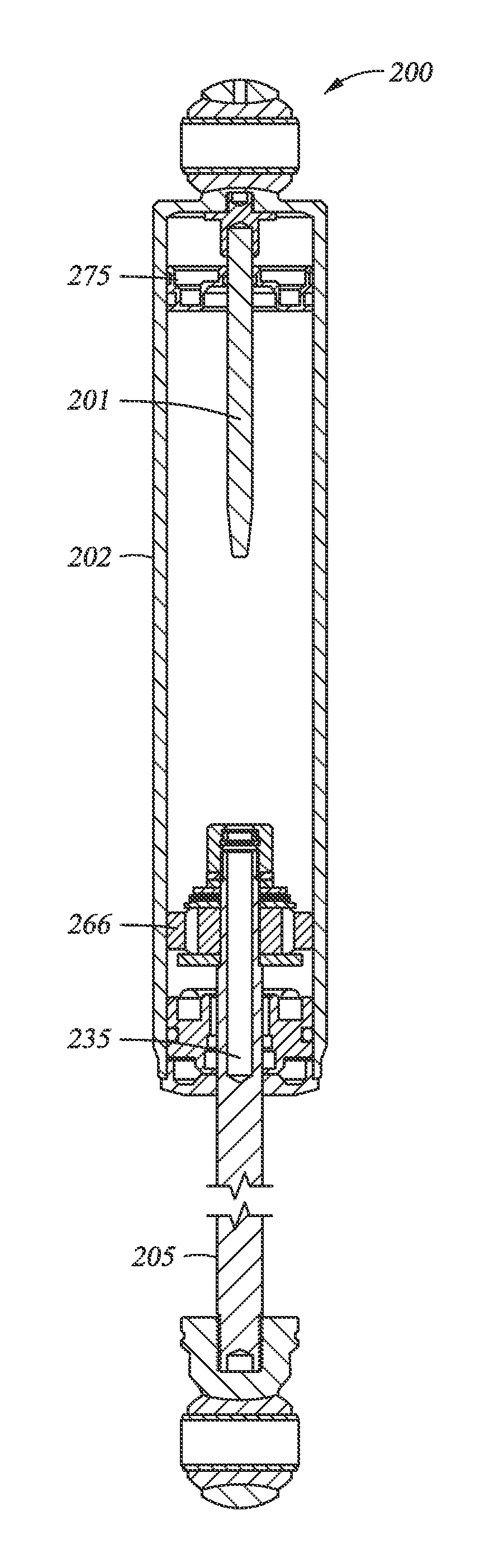

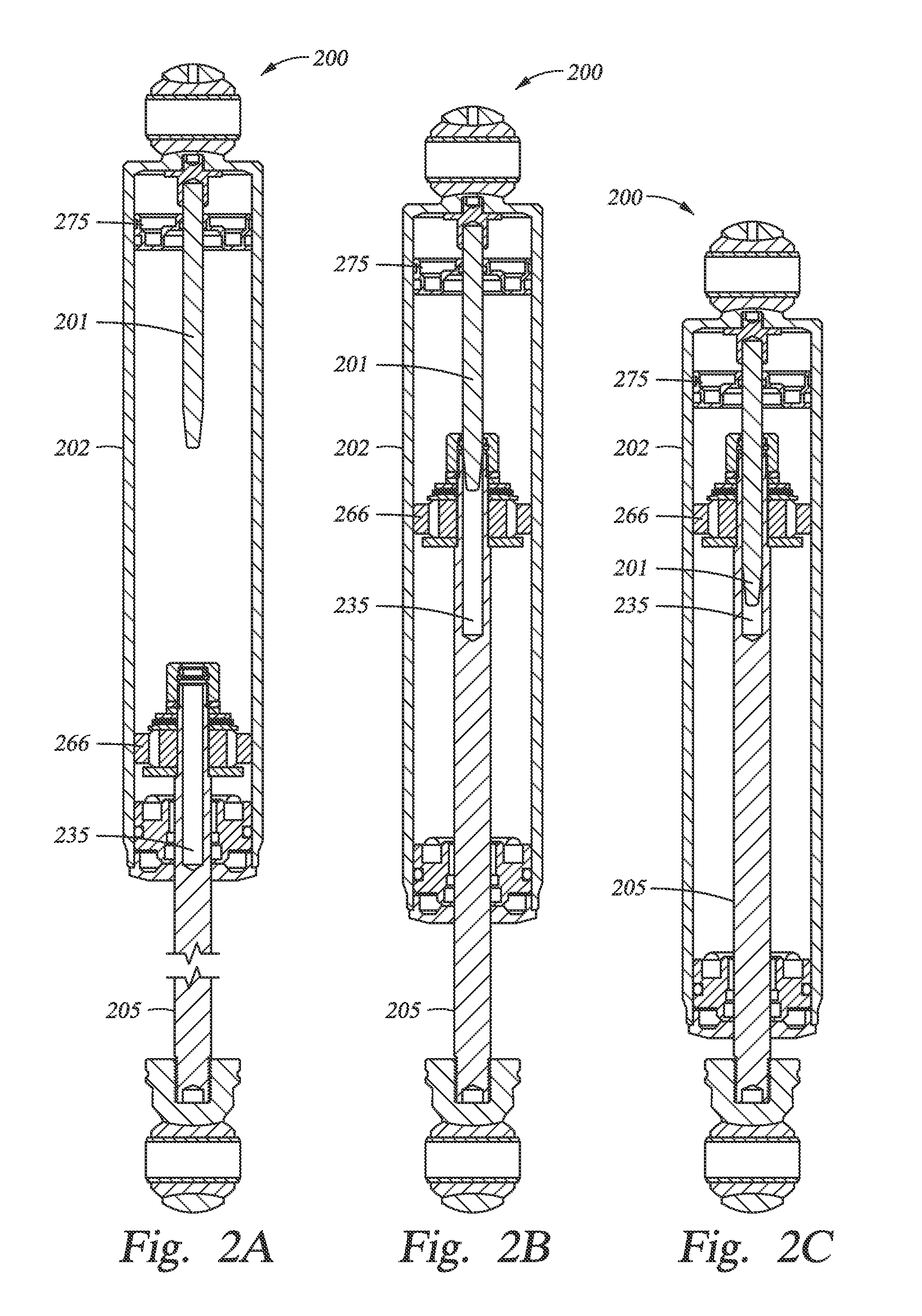

Drive mechanisms suitable for use in drug delivery devices

ActiveUS20040260247A1Prevent rotationInfusion syringesMedical devicesScrew threadBiomedical engineering

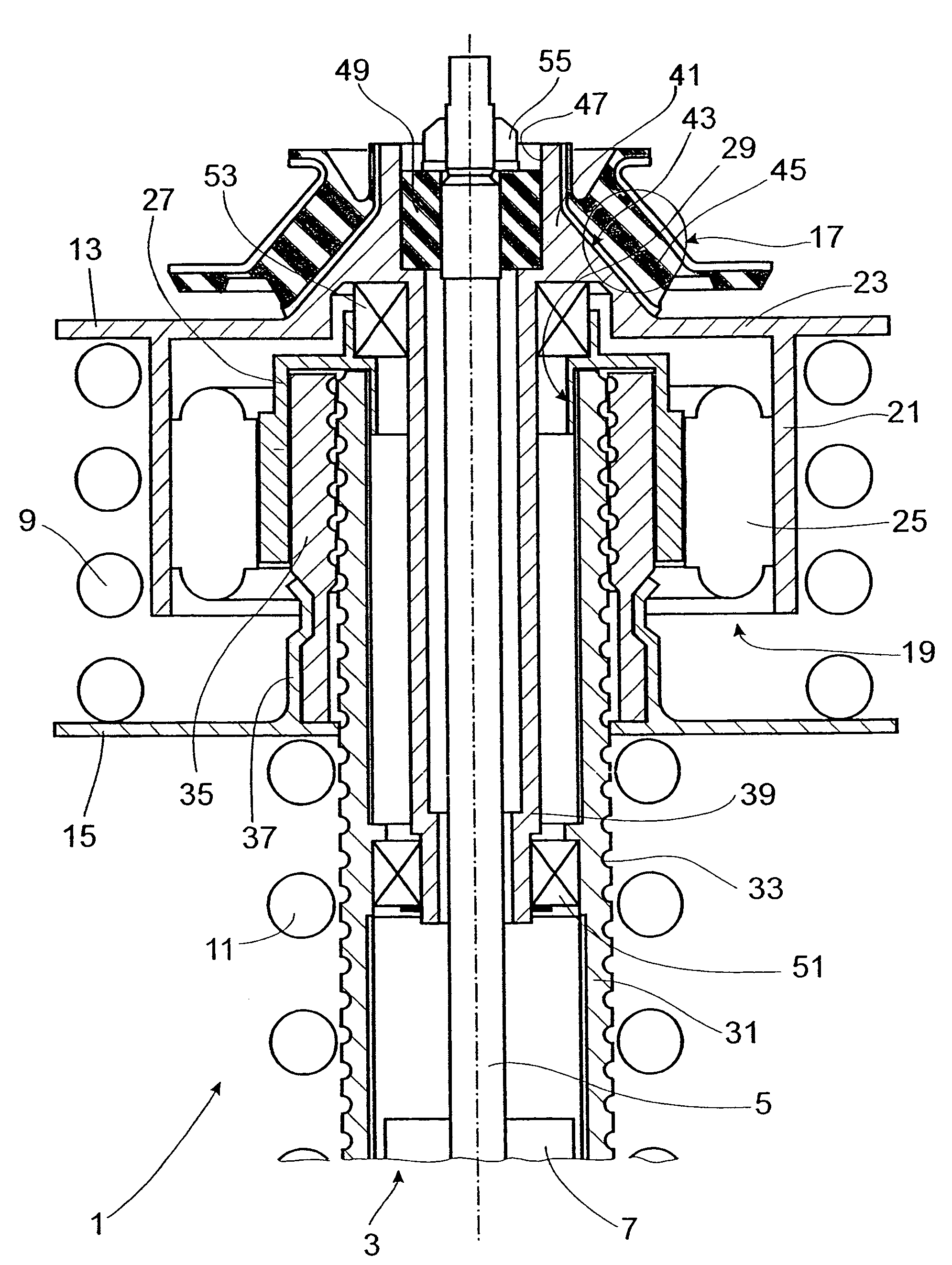

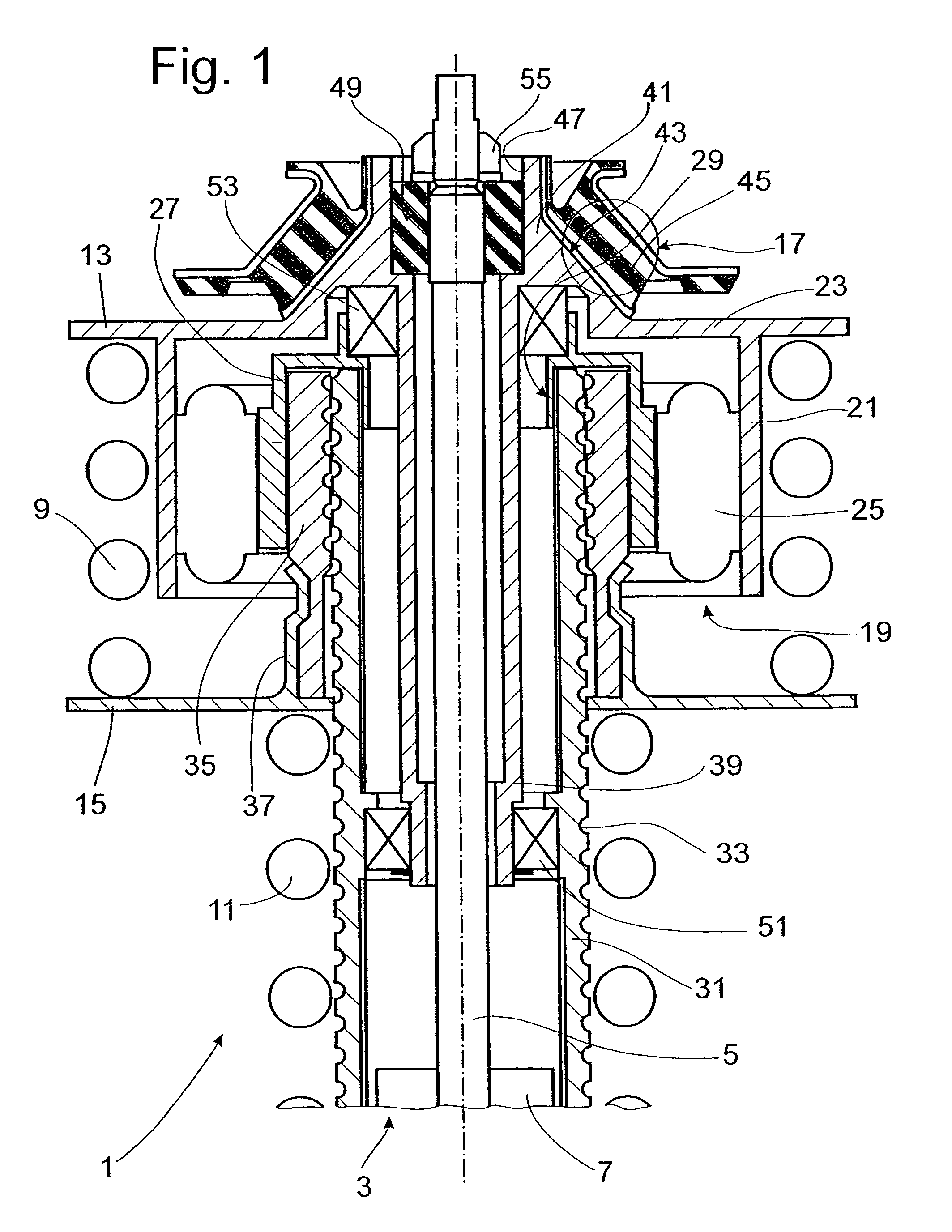

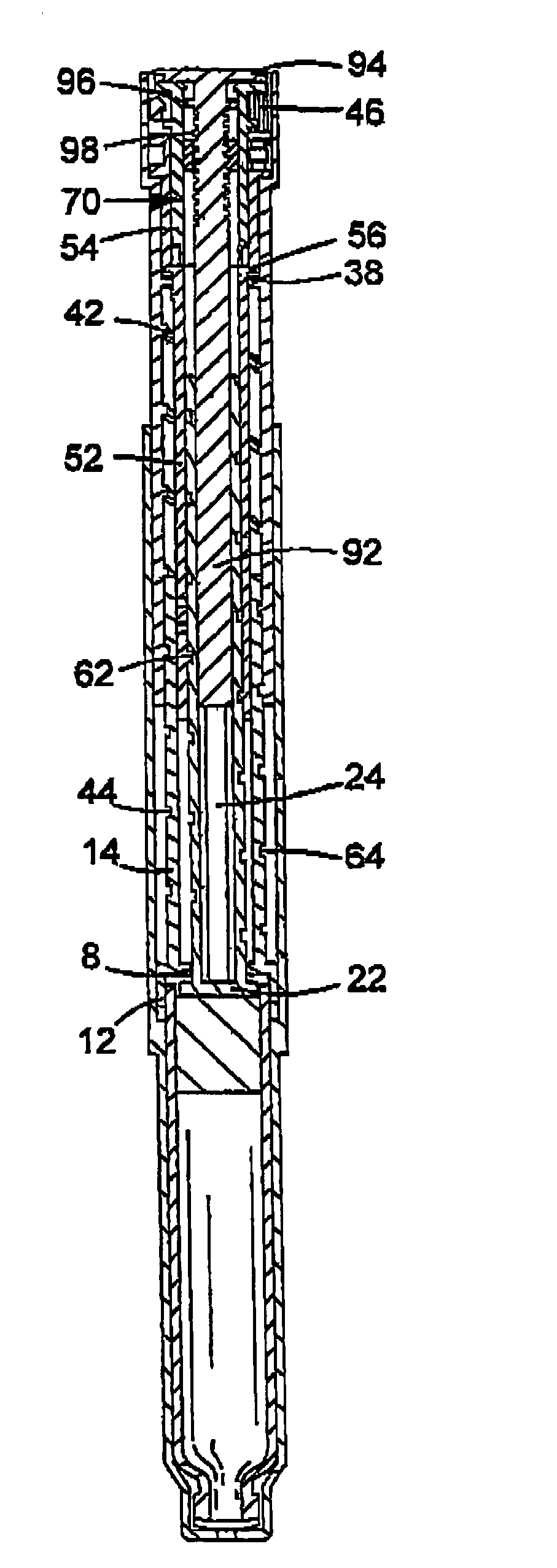

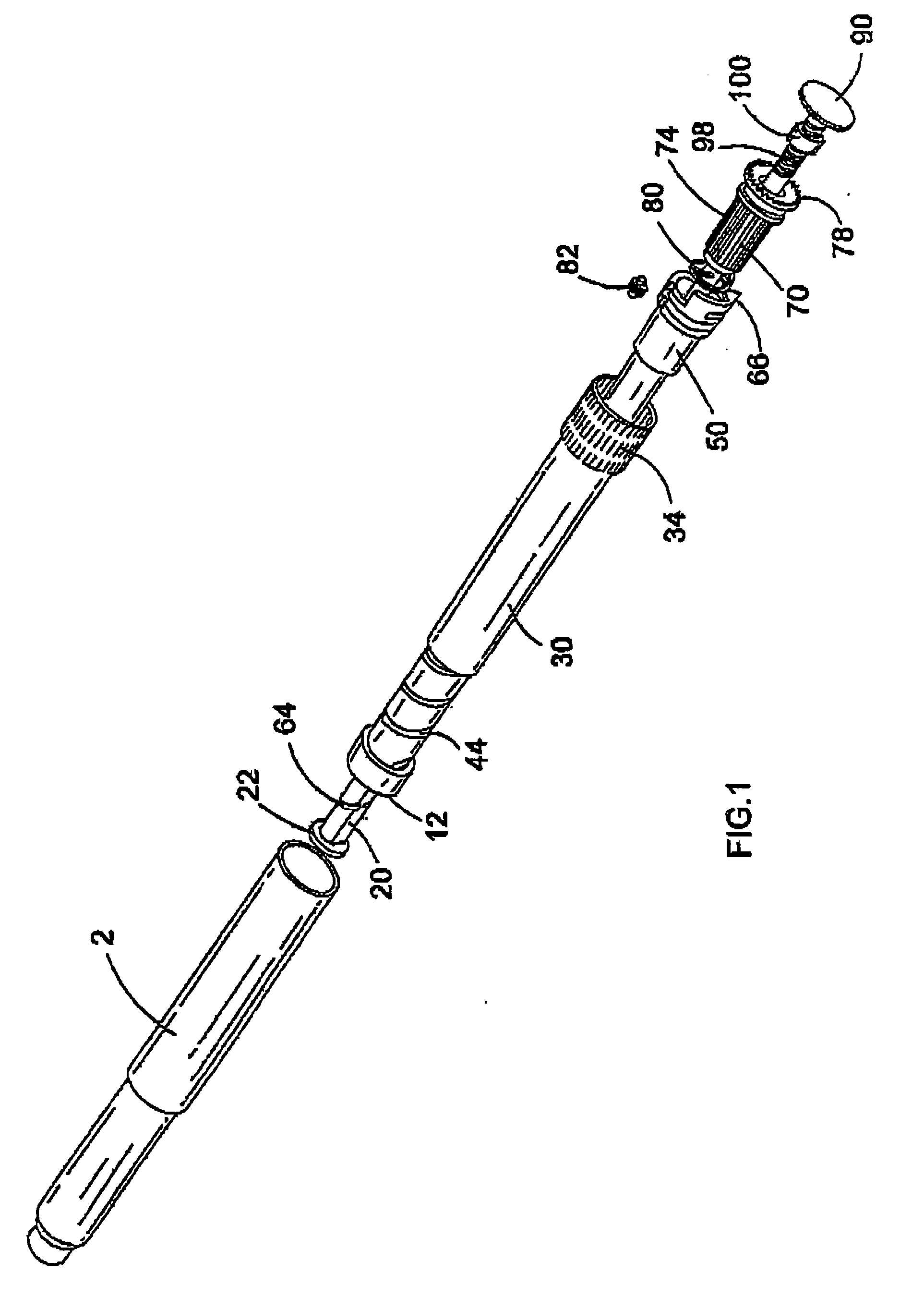

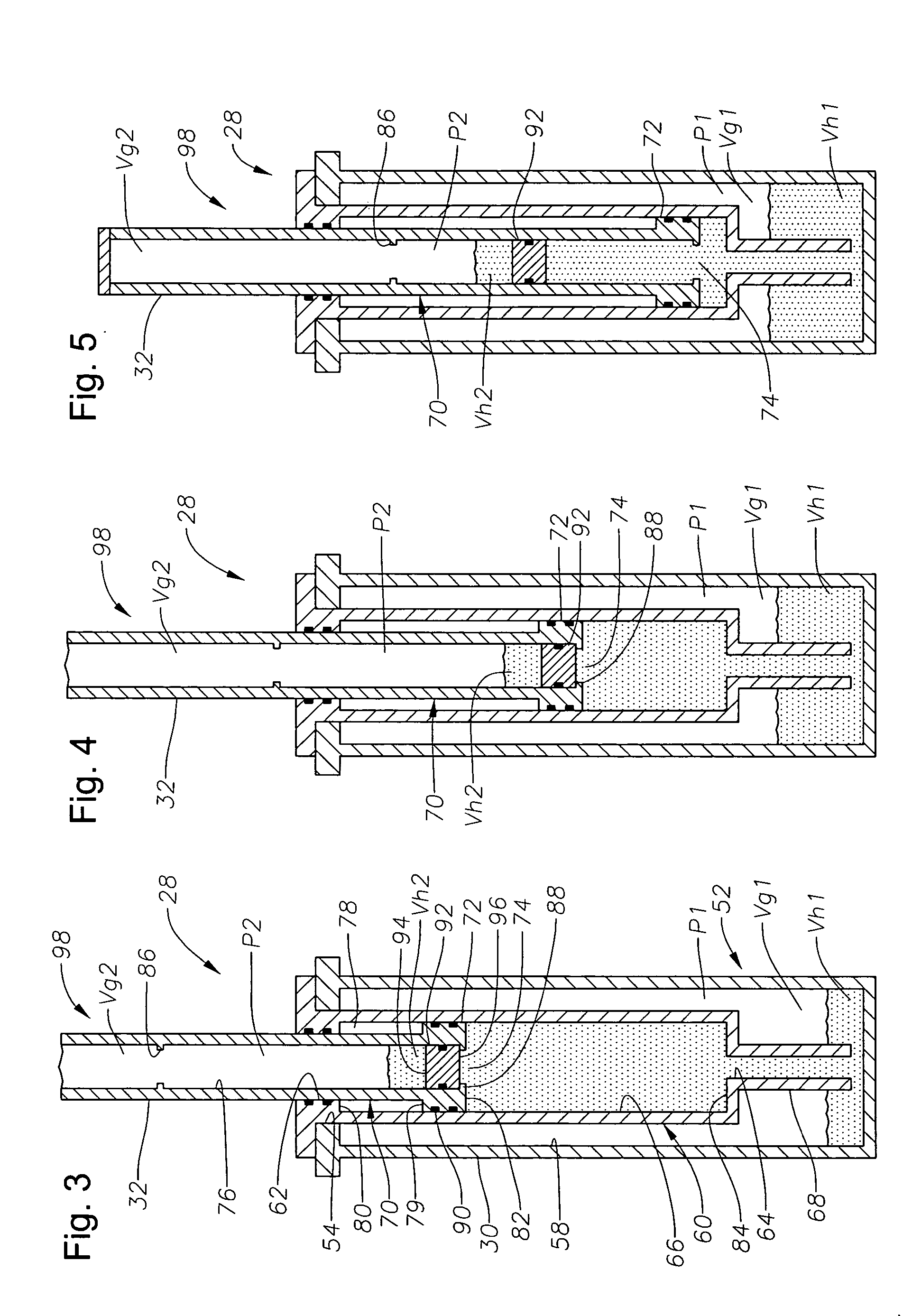

A drive mechanism suitable for use in drug delivery devices is disclosed. The drive mechanism may be used with injector-type drug delivery devices, such as those permitting a user to set the delivery dose. The drive mechanism may include a housing, a dose dial sleeve having a helical thread of a first lead, and a two-part piston rod. The two-part piston rod may include an outer part having a helical thread of a second lead and an inner part having a helical thread of a third lead. In such an embodiment, the first lead of the thread of the dose dial sleeve may be equal to the sum of the second lead of the thread of the outer part of the piston rod and the third lead of the thread of the inner part of the piston rod.

Owner:SANOFI AVENTIS DEUT GMBH

Drive mechanisms suitable for use in drug delivery devices

ActiveUS7094221B2Safe and correct and comfortable handlingExposure was also limitedInfusion syringesMedical devicesScrew threadPiston rod

A drive mechanism suitable for use in drug delivery devices is disclosed. The drive mechanism may be used with injector-type drug delivery devices, such as those permitting a user to set the delivery dose. The drive mechanism may include a housing, a dose dial sleeve having a helical thread of a first lead, and a two-part piston rod. The two-part piston rod may include an outer part having a helical thread of a second lead and an inner part having a helical thread of a third lead. In such an embodiment, the first lead of the thread of the dose dial sleeve may be equal to the sum of the second lead of the thread of the outer part of the piston rod and the third lead of the thread of the inner part of the piston rod.

Owner:SANOFI AVENTIS DEUT GMBH

Pneumatic nail gun

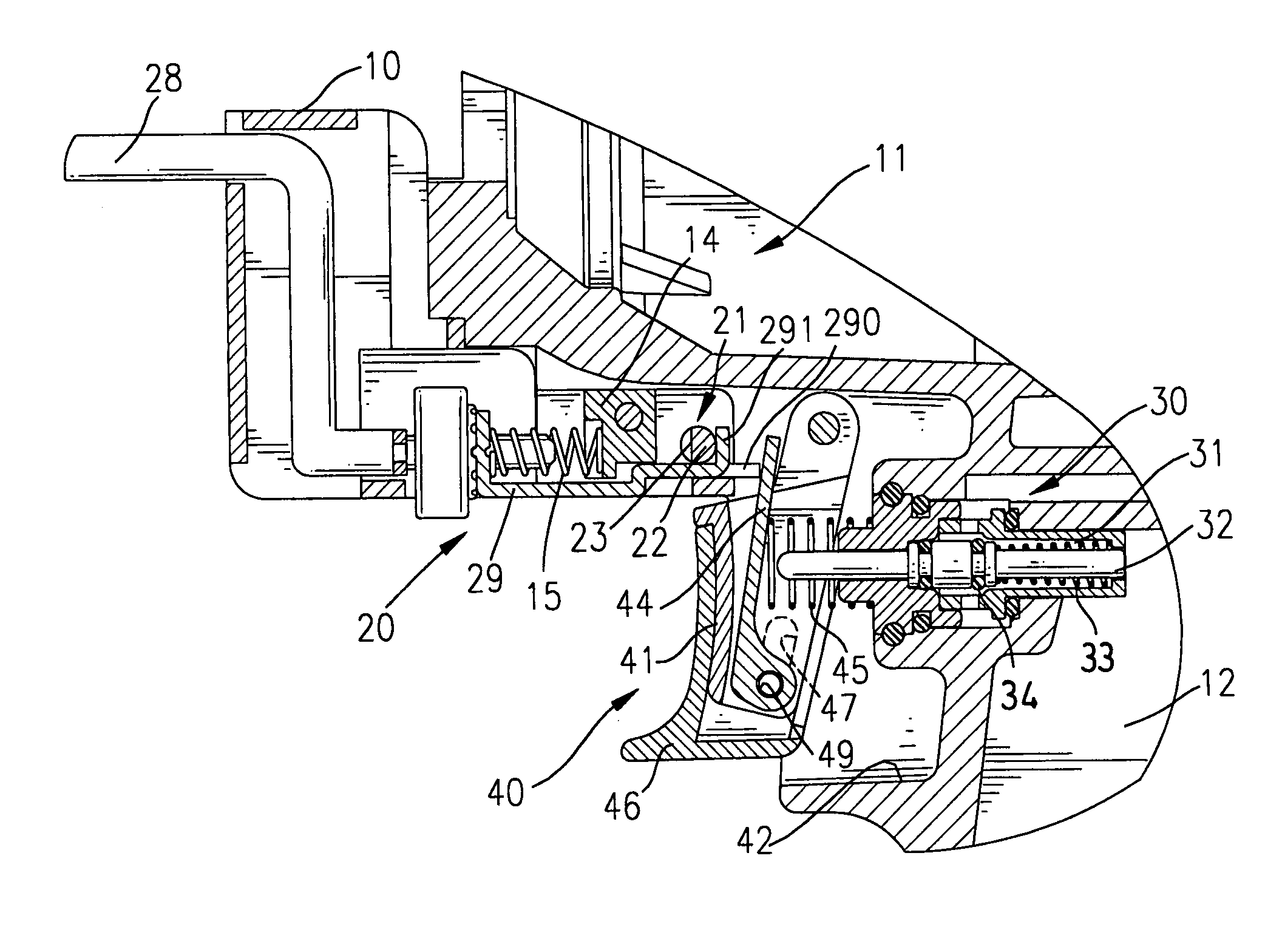

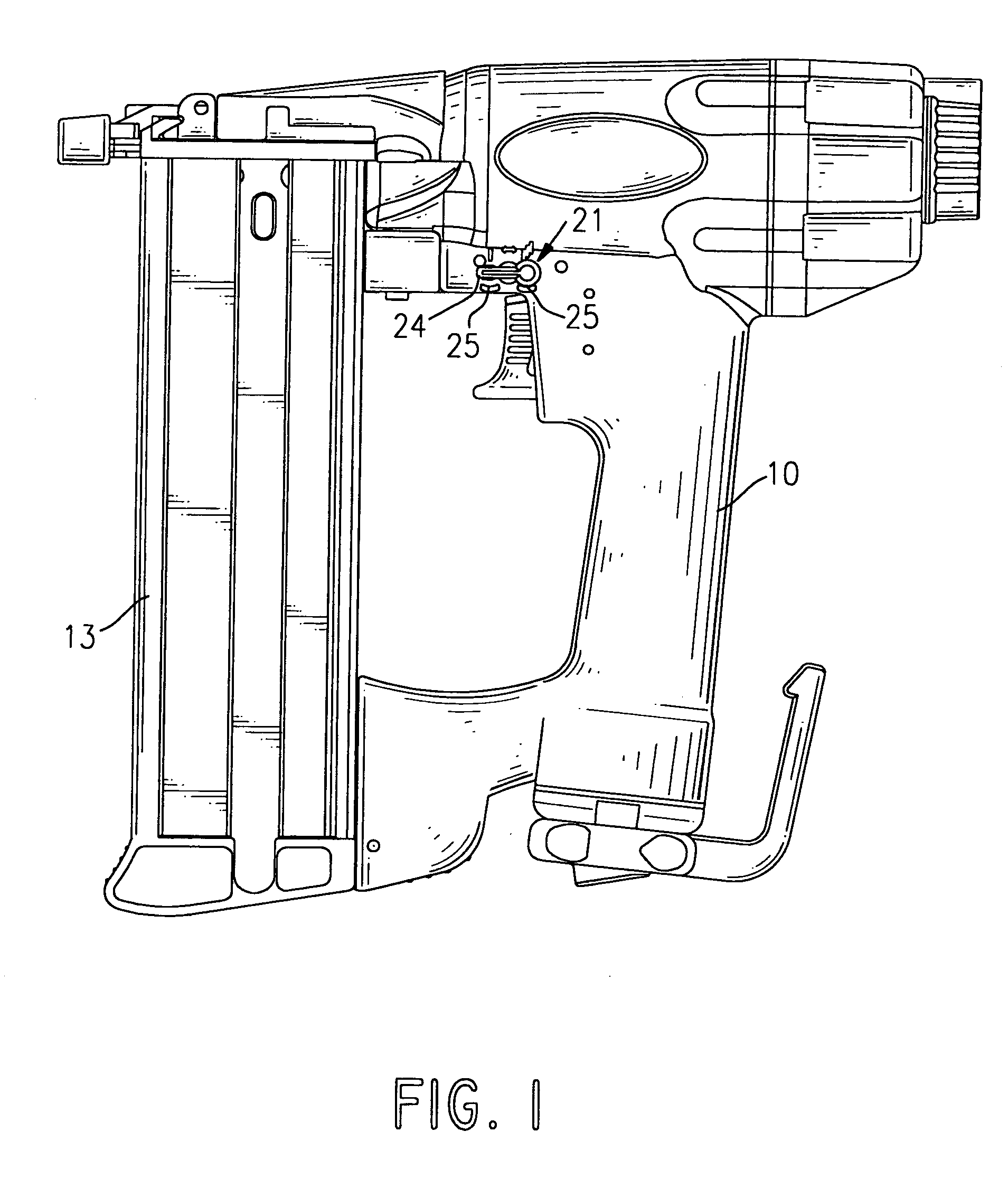

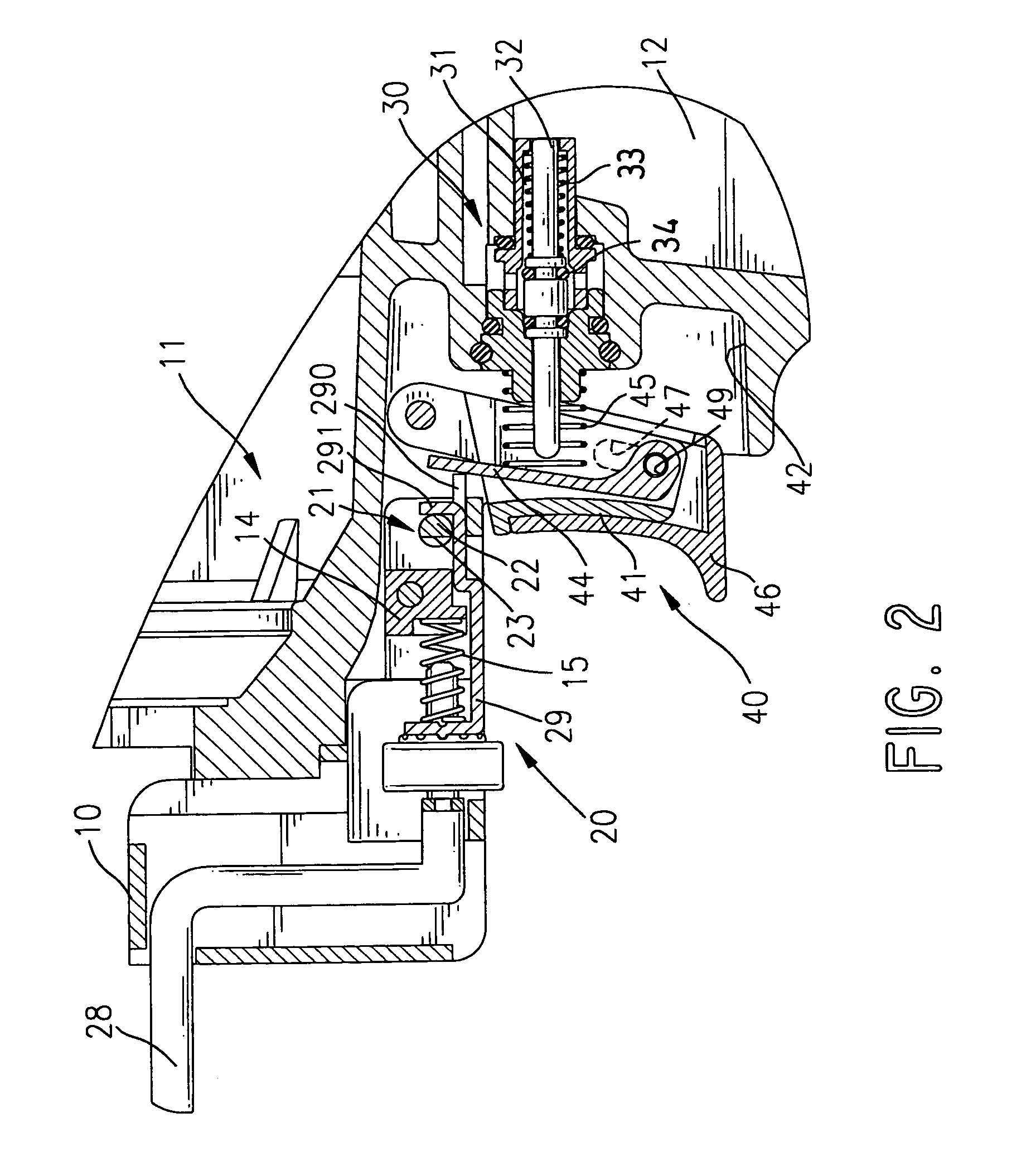

A pneumatic nail gun has a body, a nail magazine, an actuating device, a trigger assembly and a push bar assembly. The body has a housing, a handle and a nail firing device. The actuating device is mounted between the housing and the handle. The actuating device has a channel, a piston rod, an O-ring and a first spring to provide a restitute force to the piston rod. The trigger assembly is attached to the body and has an inner cap pivotally attached to the body, an outer cap slidably attached outside the inner cap, an actuating lever pivotally attached inside the inner cap and a second spring. Accordingly, the outer cap can be moved to a lock position to keep the nails from being fired unintentionally, and the pneumatic nail gun is safe in use.

Owner:REXON IND CORP LTD

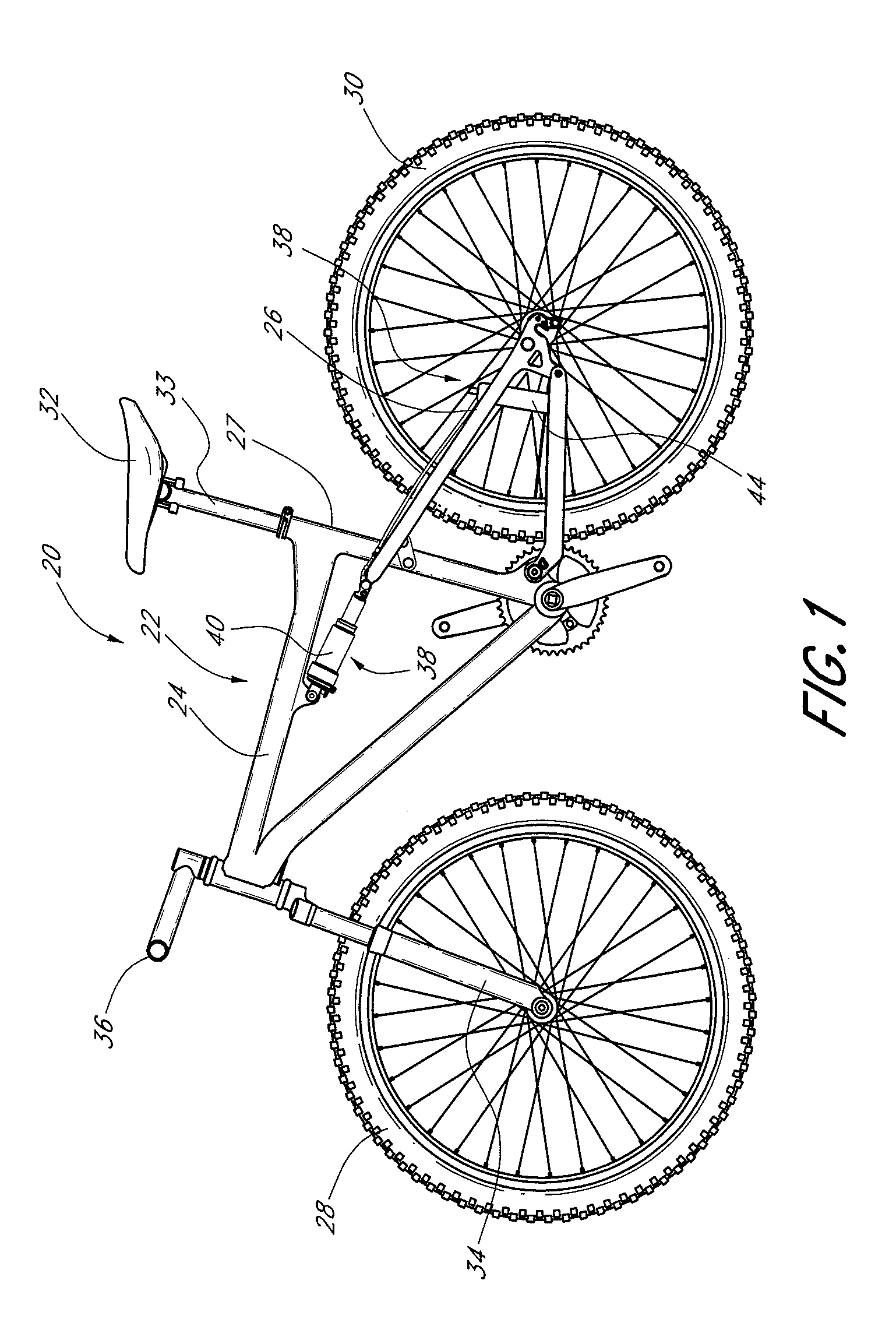

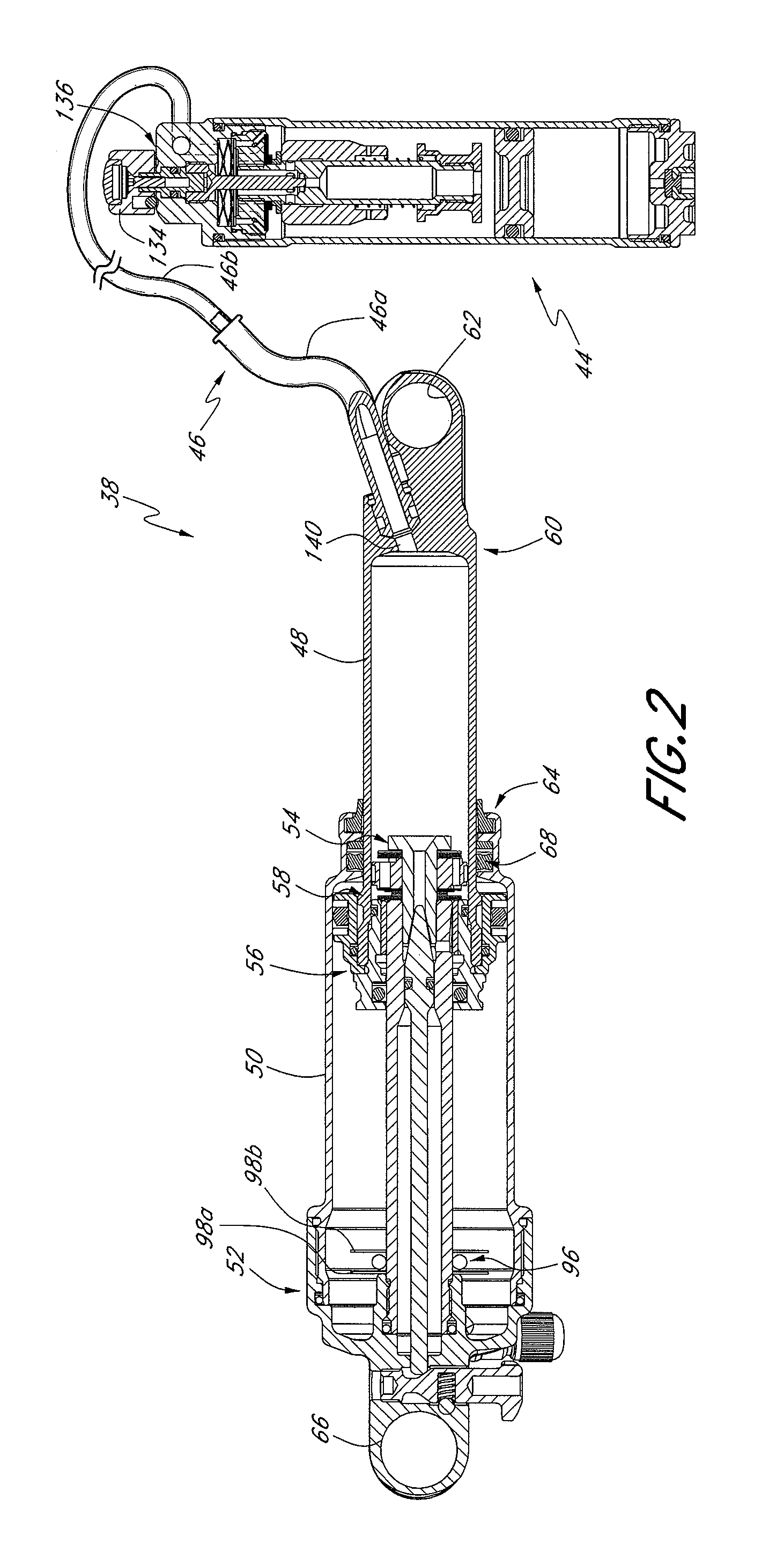

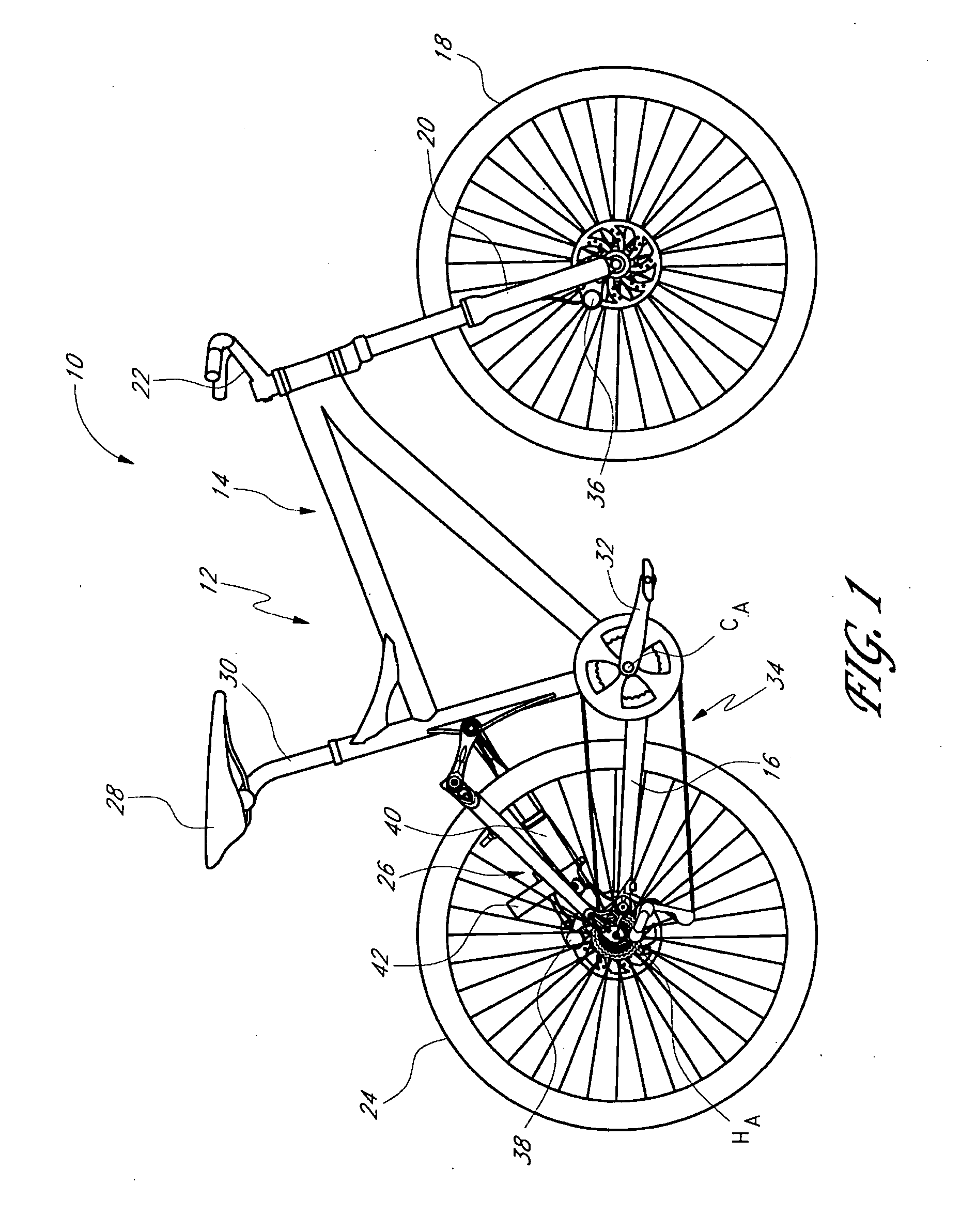

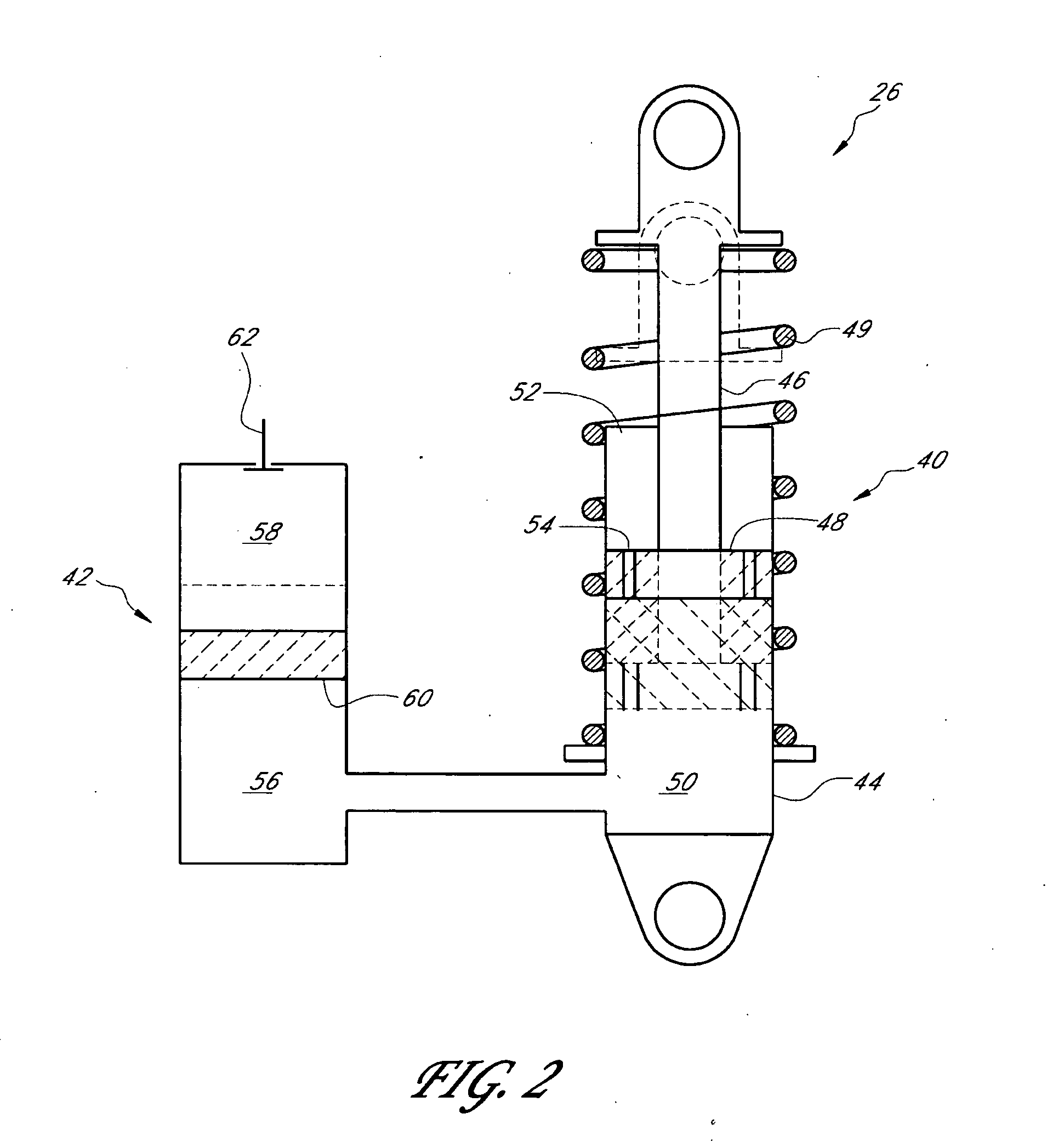

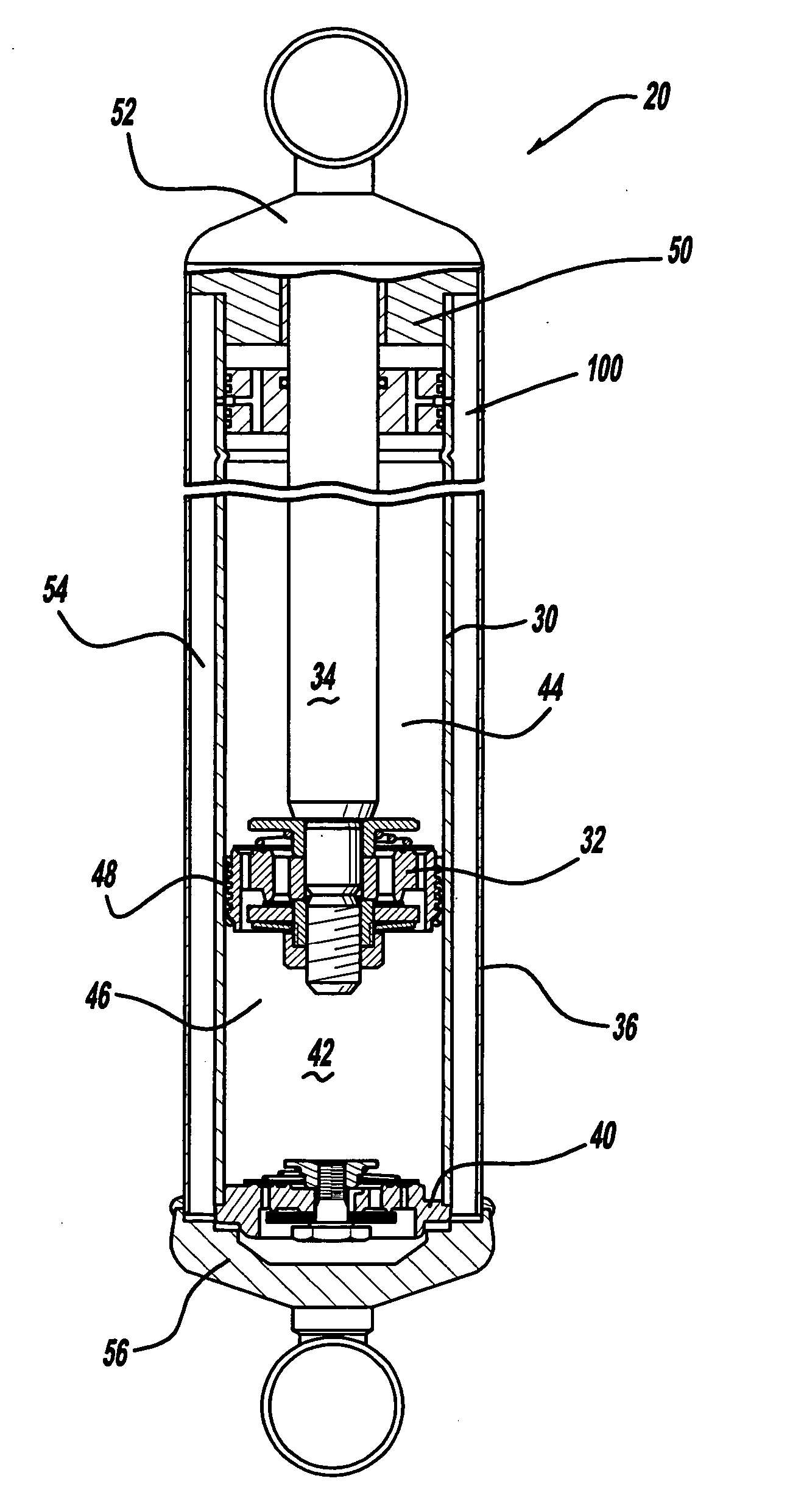

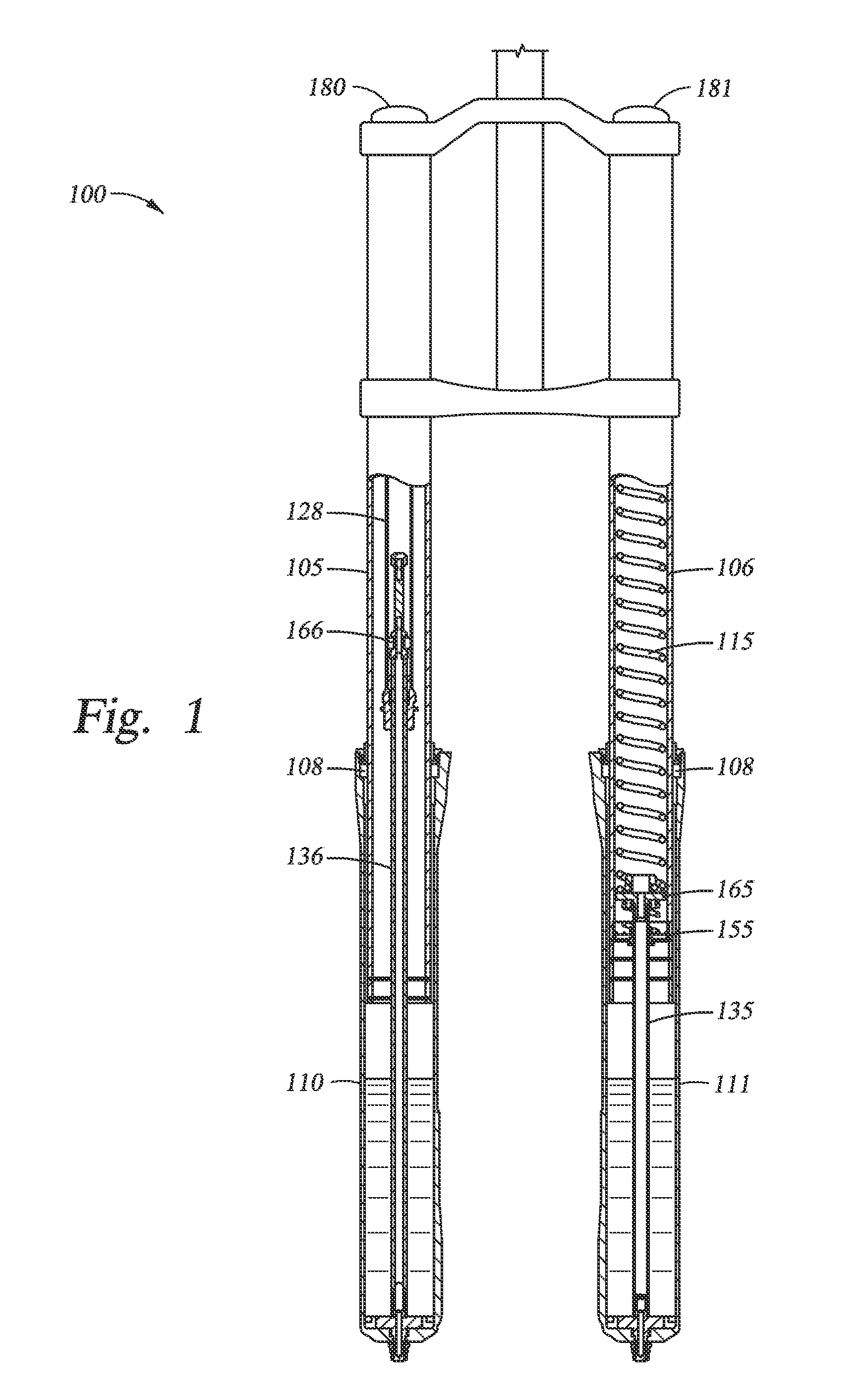

Bicycle damper

A damper for a bicycle having a primary unit and a remote unit that, in some arrangements, is substantially entirely outside of the primary unit. The primary unit includes a damper tube, a spring chamber, and a piston rod that supports a main piston. The main piston is movable within the damper chamber of the primary unit. The main piston and the damper tube at least partially define a compression chamber. The remote unit comprises a remote fluid chamber and, in some arrangements, an inertial valve within the remote unit. The inertial valve is preferably responsive to terrain-induced forces and preferably not responsive to rider-induced forces when the shock absorber is assembled to the bicycle.

Owner:SPECIALIZED BICYCLE COMPONENTS INC

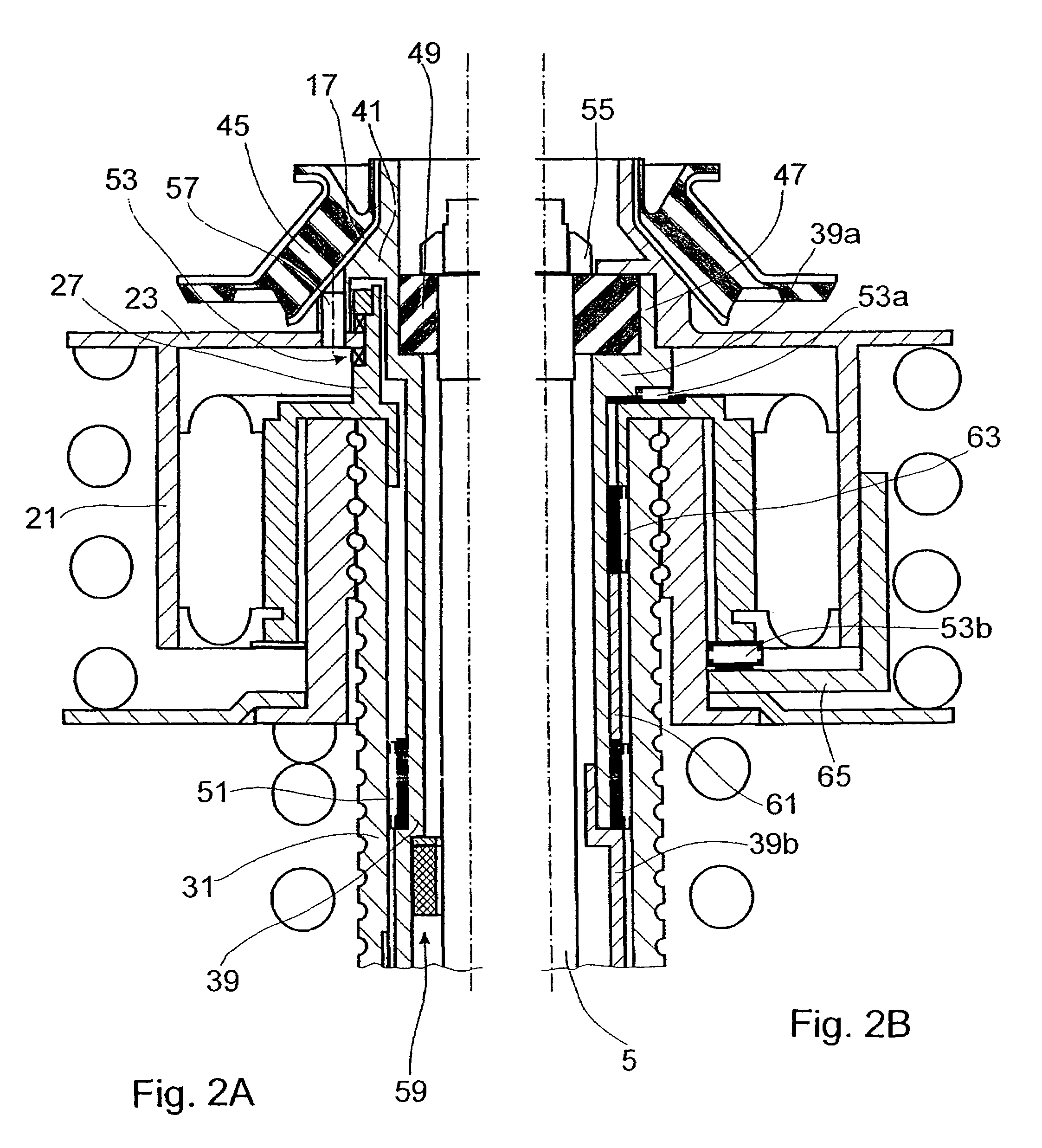

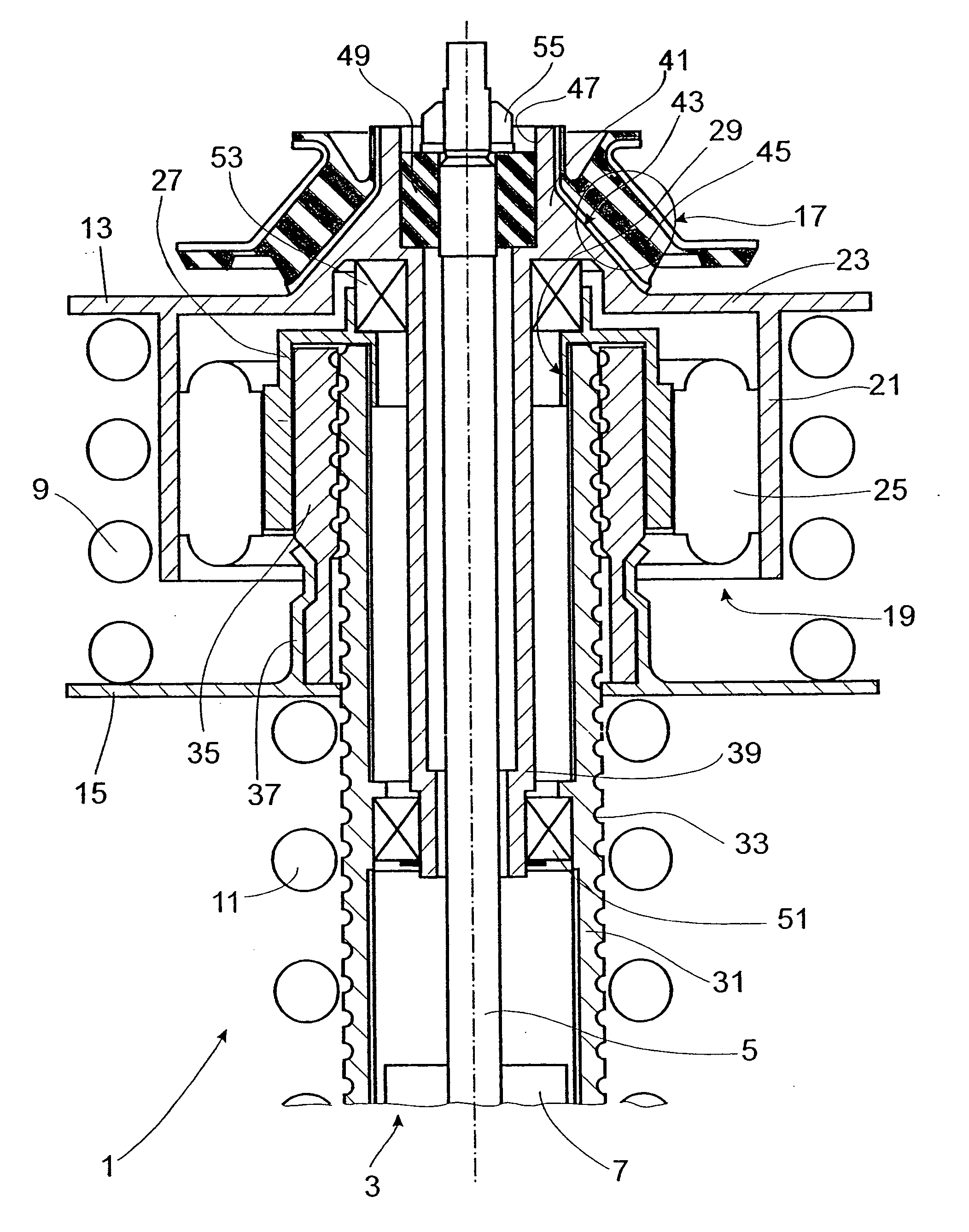

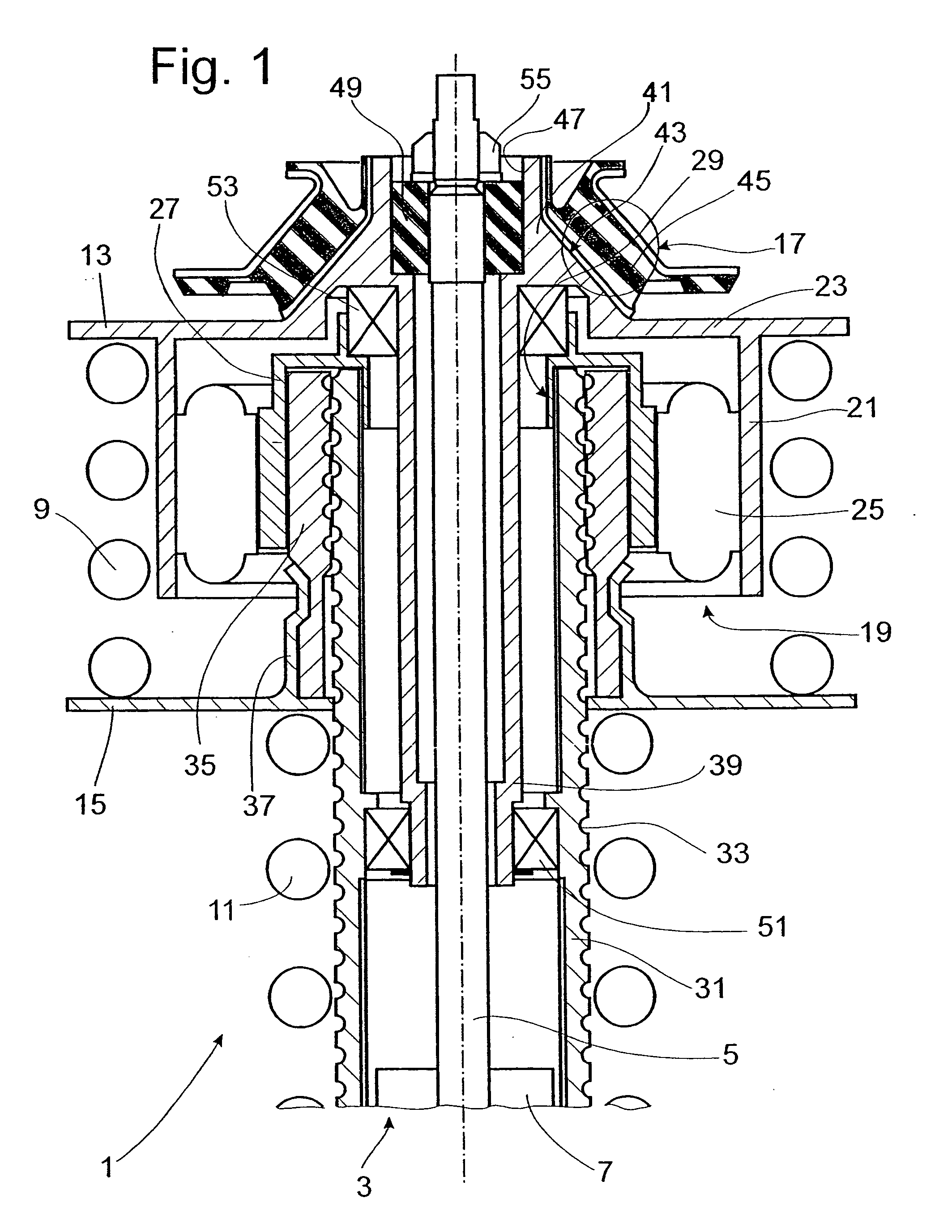

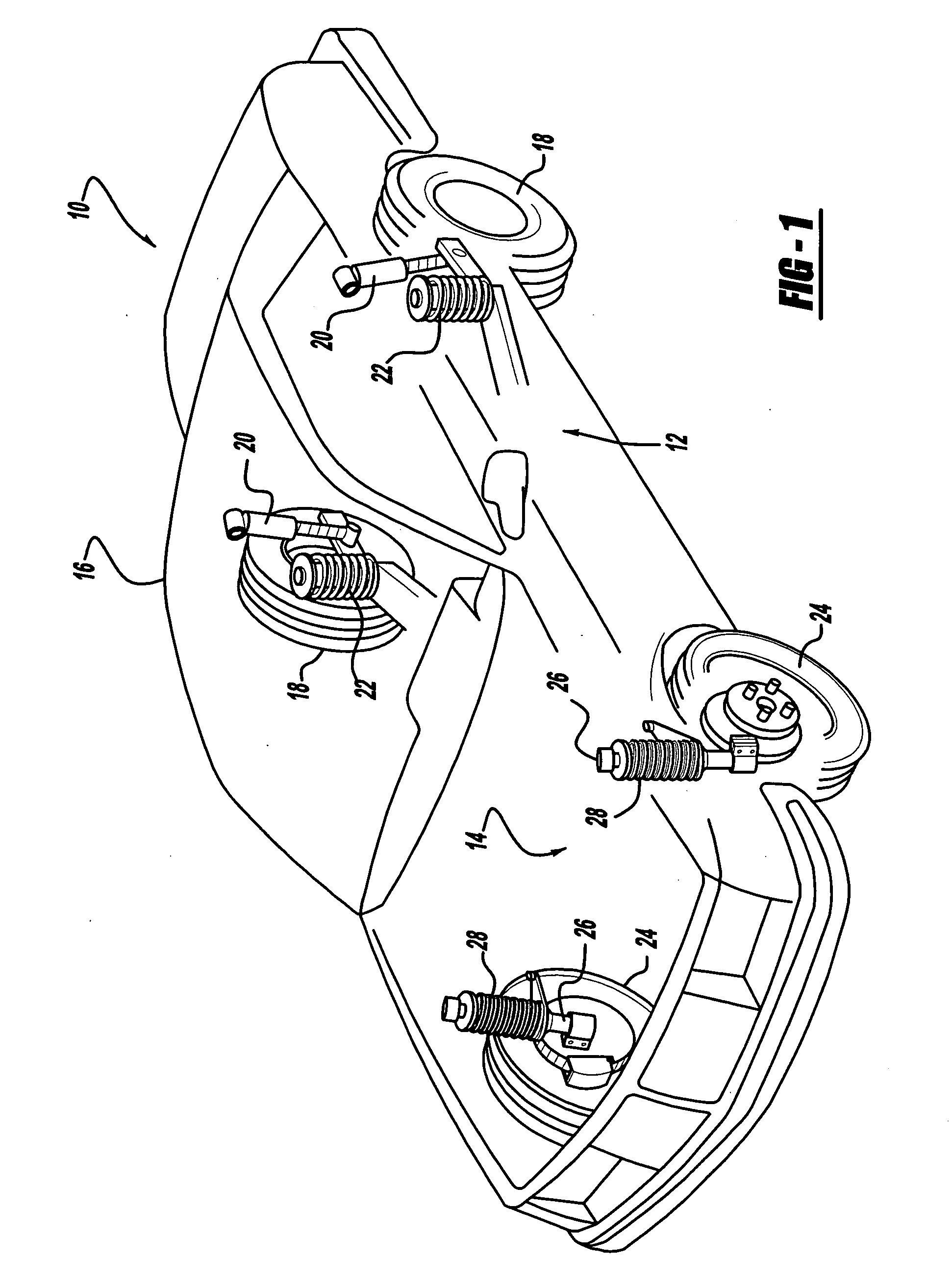

Spring carrier with adustable spring collar

InactiveUS7469910B2Easy to assembleIncrease elasticityNon-rotating vibration suppressionResilient suspensionsActuatorControl theory

A spring carrier for mounting a spring strut to a vehicle body includes a vibration damper having a cylinder and a piston rod which is axially guided in the cylinder, first and second spring collars, and a spring located between the spring collars. An actuator includes a nut and a threaded spindle surrounding the piston rod, the actuator being driven to change the relative axial position of the spring collars. A guide tube extends coaxially between the piston rod and the threaded spindle, the guide tube being fixed to the vehicle body by a first resilient mount, the piston rod being fixed to the guide tube by a second resilient mount, whereby the piston rod can move relative to the first resilient mount.

Owner:ZF FRIEDRICHSHAFEN AG

Medical delivery device having air shot means

InactiveUS20070016143A1Prevent rotationAmpoule syringesIntravenous devicesEngineeringAngular rotation

An air shot or priming mechanism for an injection pen. The injection pen comprises a cartridge-holder and a housing. The cartridge-holder interacts with a nut-member capable of driving the piston rod forward when relatively rotated. The cartridge-holder is rotational coupled to the housing such that rotation of the cartridge-holder relatively to the housing causes the nut-member and the piston rod to rotate relatively, thus the relative angular rotation between the cartridge-holder and the housing determines the size of the air shot so performed.

Owner:NOVO NORDISK AS

Spring carrier with adjustable spring collar

InactiveUS20060163787A1Easy to assembleIncrease elasticitySpringsNon-rotating vibration suppressionEngineeringActuator

A spring carrier for mounting a spring strut to a vehicle body includes a vibration damper having a cylinder and a piston rod which is axially guided in the cylinder, first and second spring collars, and a spring located between the spring collars. An actuator includes a nut and a threaded spindle surrounding the piston rod, the actuator being driven to change the relative axial position of the spring collars. A guide tube extends coaxially between the piston rod and the threaded spindle, the guide tube being fixed to the vehicle body by a first resilient mount, the piston rod being fixed to the guide tube by a second resilient mount, whereby the piston rod can move relative to the first resilient mount.

Owner:ZF FRIEDRICHSHAFEN AG

Laser fusing and coating process for wear resistant and etch-resistant coating of hydraulic support column cylinder and piston rod

ActiveCN101338427AExcellent wear resistance and corrosion resistanceImprove wear resistanceMetallic material coating processesWear resistantRoom temperature

A laser cladding process of the wear-resisting anticorrosive coating of a hydraulic pressure support pillar cylinder barrel or a piston rod cylinder barrel comprises procedures as follows: the surfaces of the standing pillar cylinder barrel and the piston rod cylinder barrel are pretreated; the surfaces of the standing pillar cylinder barrel and the piston rod cylinder barrel are decreased, de-rusted and cleaned up by alcohol under room temperature; alloying powder is chosen and an automatic powder feeder is adjusted; the iron base alloying powder with good wear-resisting anticorrosive property and sound metallurgy compatibility with a matrix is selected and the iron base alloying powder contains major constituents, including Fe, C, Cr, Ni, Mo, Si, N, Nb, Ta and B; and at last, the automatic powder feeder is adjusted. Adjusting the automatic powder feeder can lead the alloying powder from an automatic feeding end to a laser melting pool and feeding amount is adjusted so that the thickness of the alloying coating reaches 0.6mm to1.2mm. The alloying coating of the invention is even and dense and has good wear-resisting anticorrosive property. Compared with galvanization, the wear-resisting anticorrosive property and the service life of the standing pillar cylinder barrel and the piston rod manufactured by the invention are greatly improved.

Owner:CHONGQING JIANGLU LASER TECH

Position sensitive shock absorber

ActiveUS20070080515A1Effective levelingEasy to noticePassenger cyclesWheel based transmissionReciprocating motionEngineering

A shock absorber includes a tube and a piston rod carrying a piston. The piston is configured for reciprocal movement within the tube. A floating piston, or other type of accumulator, is configured to move to accommodate fluid displaced due to successive portions of the piston rod entering the tube during compression of the shock absorber. The shock absorber includes a valve mechanism that utilizes the movement of the floating piston to move the valve between a first and second position, which preferably are open and closed positions.

Owner:SPECIALIZED BICYCLE COMPONENTS INC

Drive mechanisms suitable for use in drug delivery devices

InactiveUS20050004529A1Safe and correct and comfortable handlingExposure was also limitedAmpoule syringesIntravenous devicesEngineeringScrew thread

A drive mechanism for use in a drug delivery device comprising an epicyclic gearbox. This drive mechanism includes a housing having a helical thread; a piston rod having a non-circular cross section and an external helical thread; a dose dial sleeve, which is threadedly engaged with the housing and being rotatable with respect to the housing; and a drive sleeve, located between the housing and the piston rod, which is threadedly engaged with the piston rod.

Owner:SANOFI AVENTIS DEUT GMBH

Silty floating mud collection device

ActiveUS20160153869A1Withdrawing sample devicesBorehole/well accessoriesControl engineeringPiston rod

A silty floating mud collection device, which includes a drive cylinder, an outer sleeve, a sampler barrel, an lug cover plate, a turning cover, a control ring and a control rod, where the drive cylinder includes a cylinder liner, a piston and a piston rod; the outer sleeve is fixedly connected below the cylinder liner; the sampler barrel is detachably installed inside the outer sleeve; the lug cover plate is fixedly connected to a lower end of the piston rod, and can close an upper-end opening of the sampler barrel; the turning cover is turnably installed at a lower end of the outer sleeve, and can close a lower-end opening of the sampler barrel; the control ring is located below the sampler barrel, and is used to block the turning cover which is in an open state; and an upper end of the control rod is connected to the lug cover plate, and a lower end of the control rod is connected to the control ring.

Owner:CCCC THIRD HARBOR CONSULTANTS

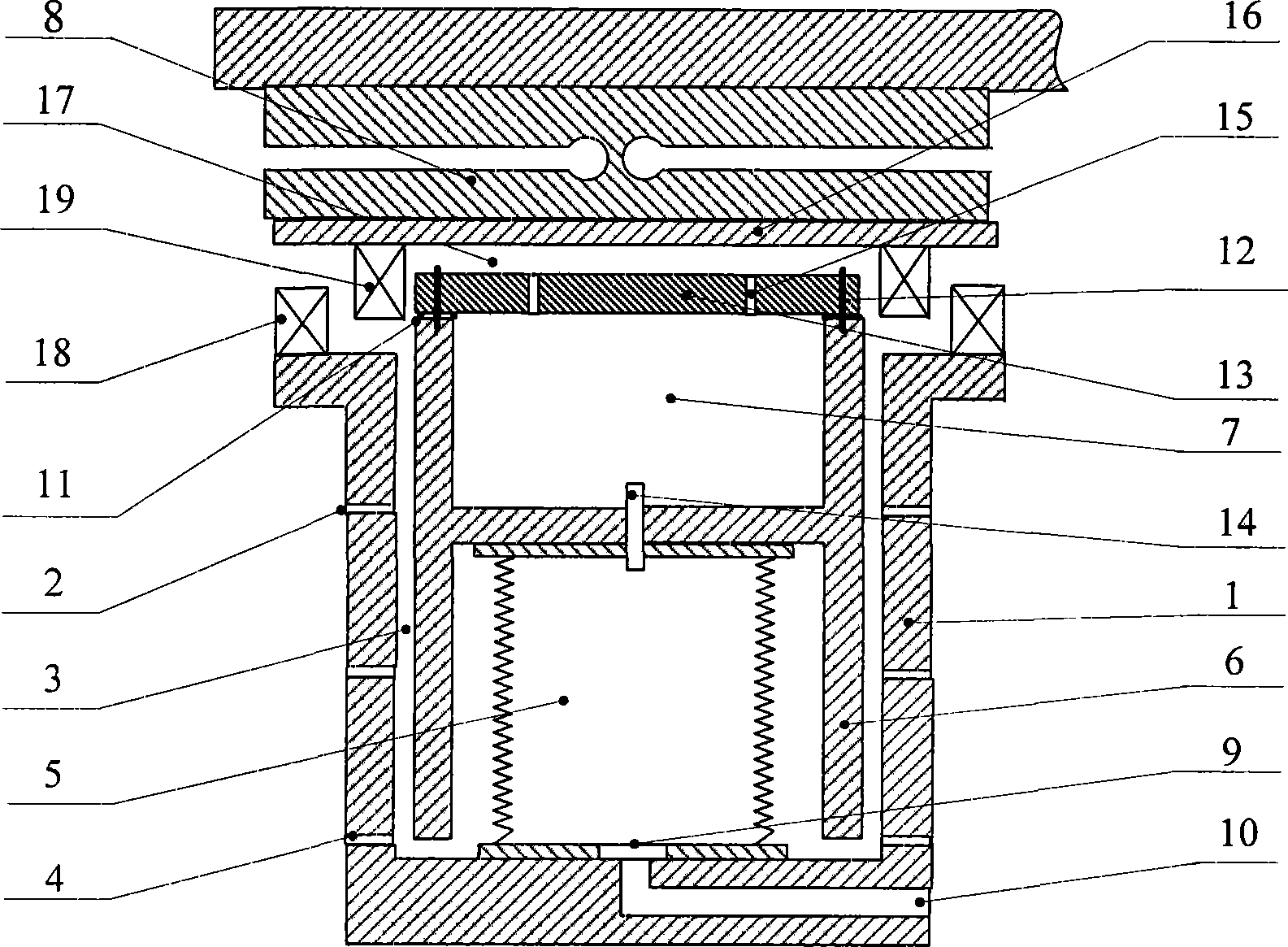

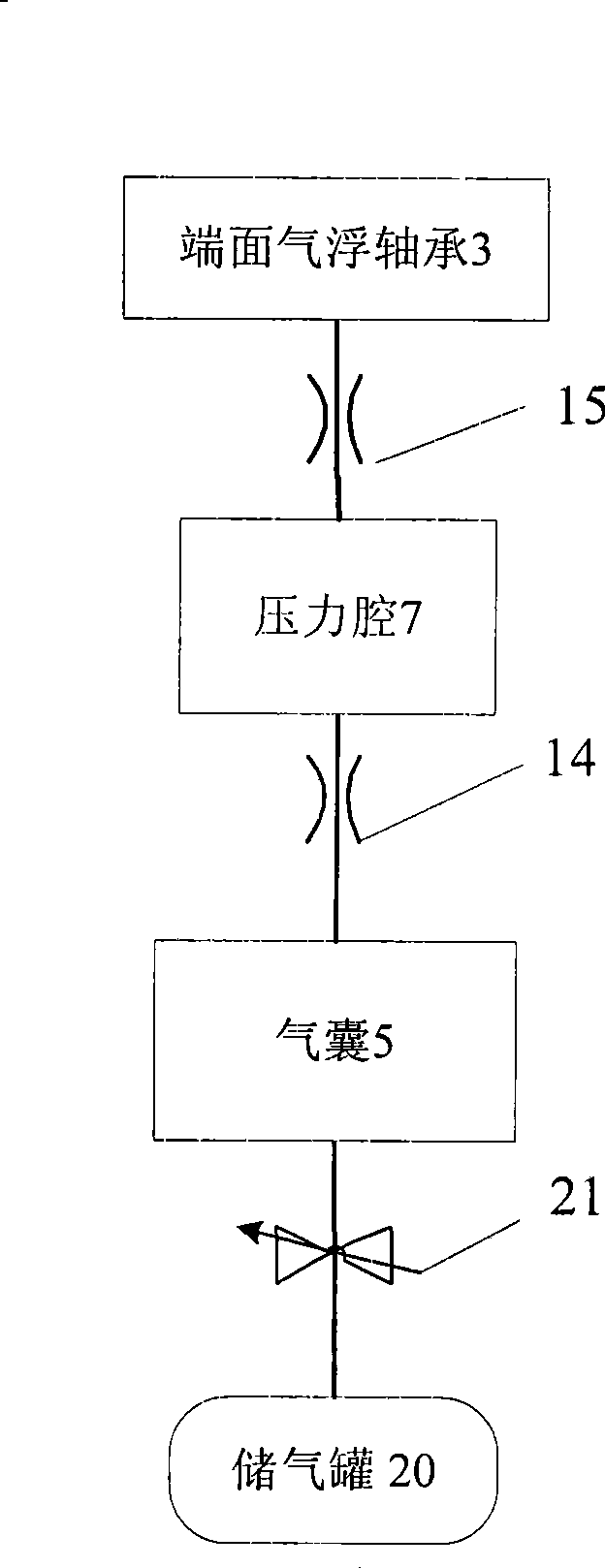

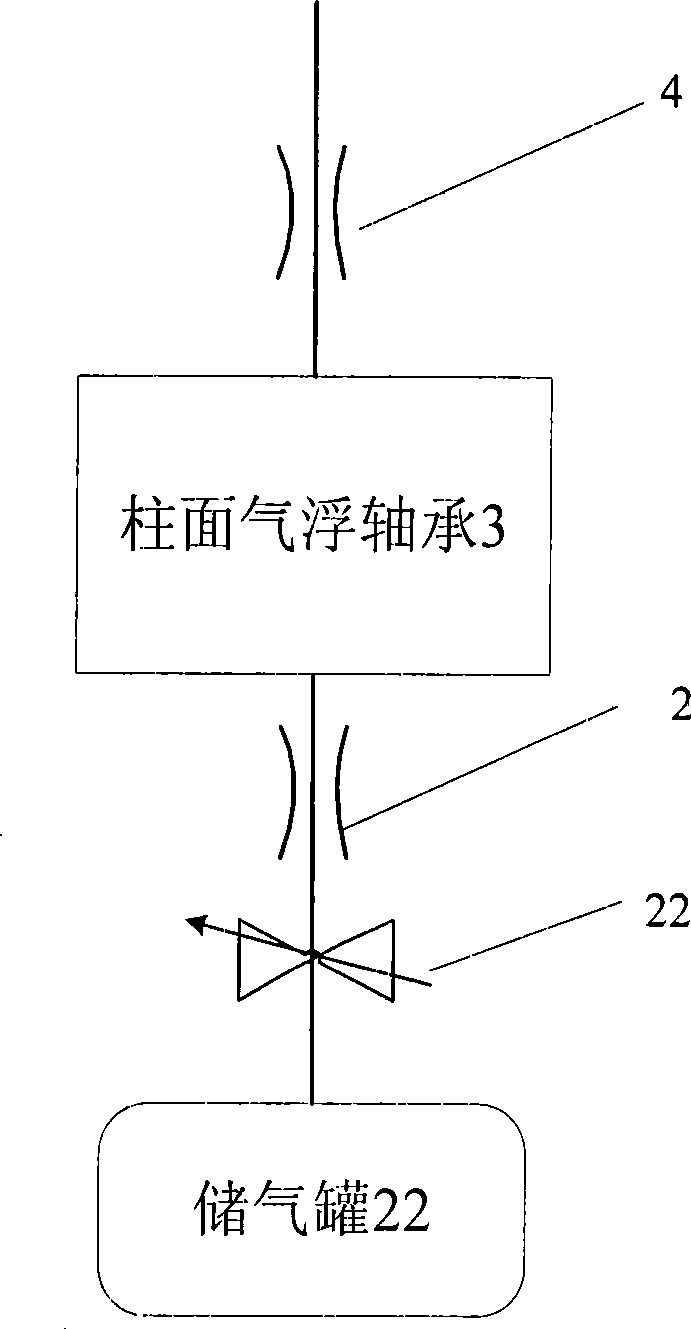

Precision vibration damping assembly and vibration damping platform composed of the assembly

InactiveCN101398636AAchieve precise positioningWith leveling and positioning functionPhotomechanical exposure apparatusMicrolithography exposure apparatusUltrasound attenuationDamping function

The invention discloses a precision damping component and a damping platform composed of the precision damping component, and the damping platform has damping function and positioning function along a Z direction. The precision damping component comprises a passive damping part, an active damping actuator and an external frame. The passive damping part is a piston rod with a structure of double cavities, an air pocket and a pressure cavity are respectively positioned in the two cavities, and the air pocket has larger longitudinal bracing power and lower rigidity, and can isolate the vibration of attenuation high frequency. The active damping actuator is a linear voice coil motor connected in parallel with the passive damping part, and applies acting force to a passive object according to the vibration condition and location information of the controlled object, so as to drive the controlled object to move to a designated position and compensate the vibration. The damping platform composed of at least three precision damping components has the functions of vibration damping with a plurality of degrees of freedom, accurately positioning along the Z direction, focusing and leveling. The precision damping component and the damping platform can be used in the apparatus with precision damping requirements such as mask aligners, ultra-precision numerically-controlled machine tools, biochip scanners and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

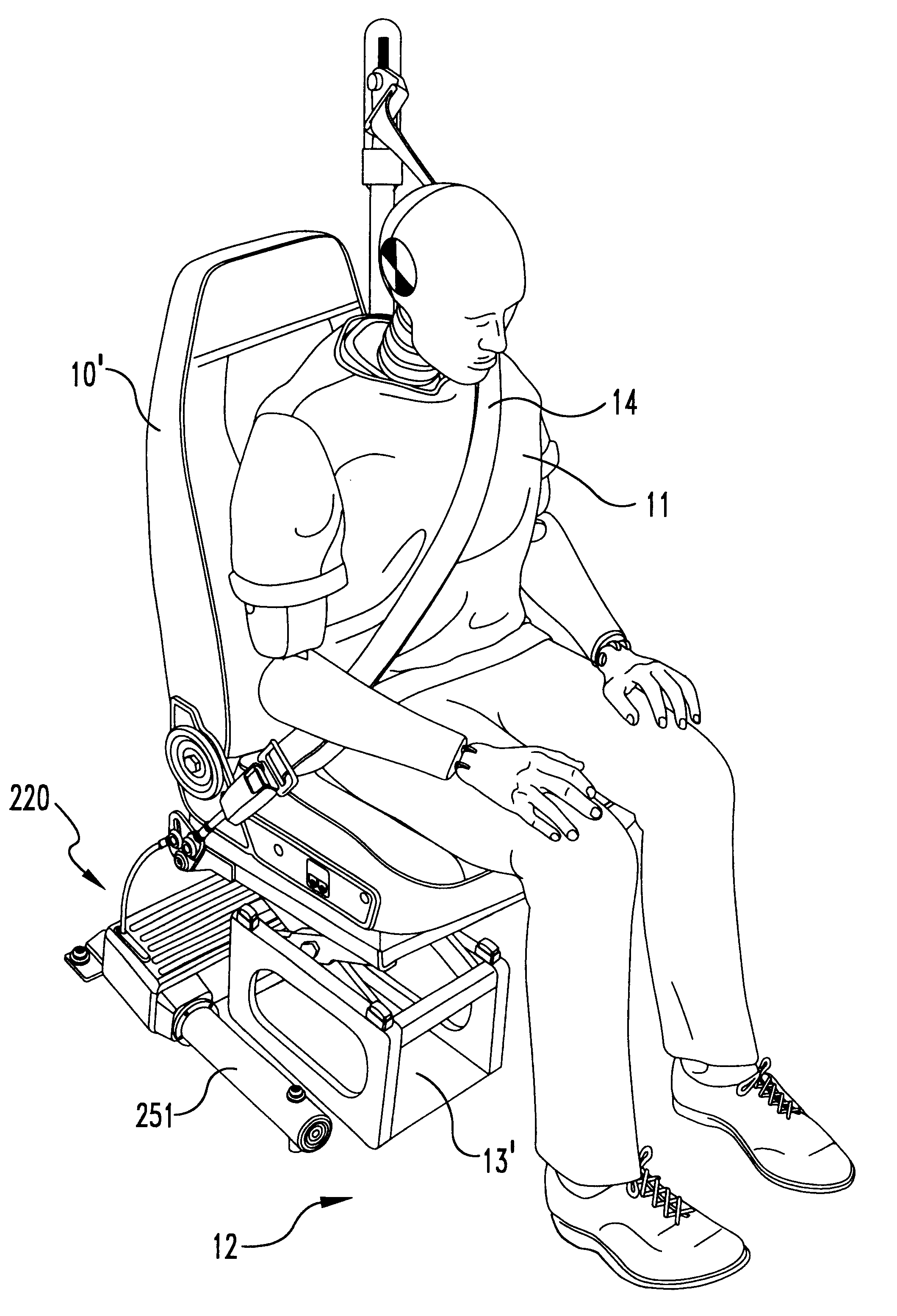

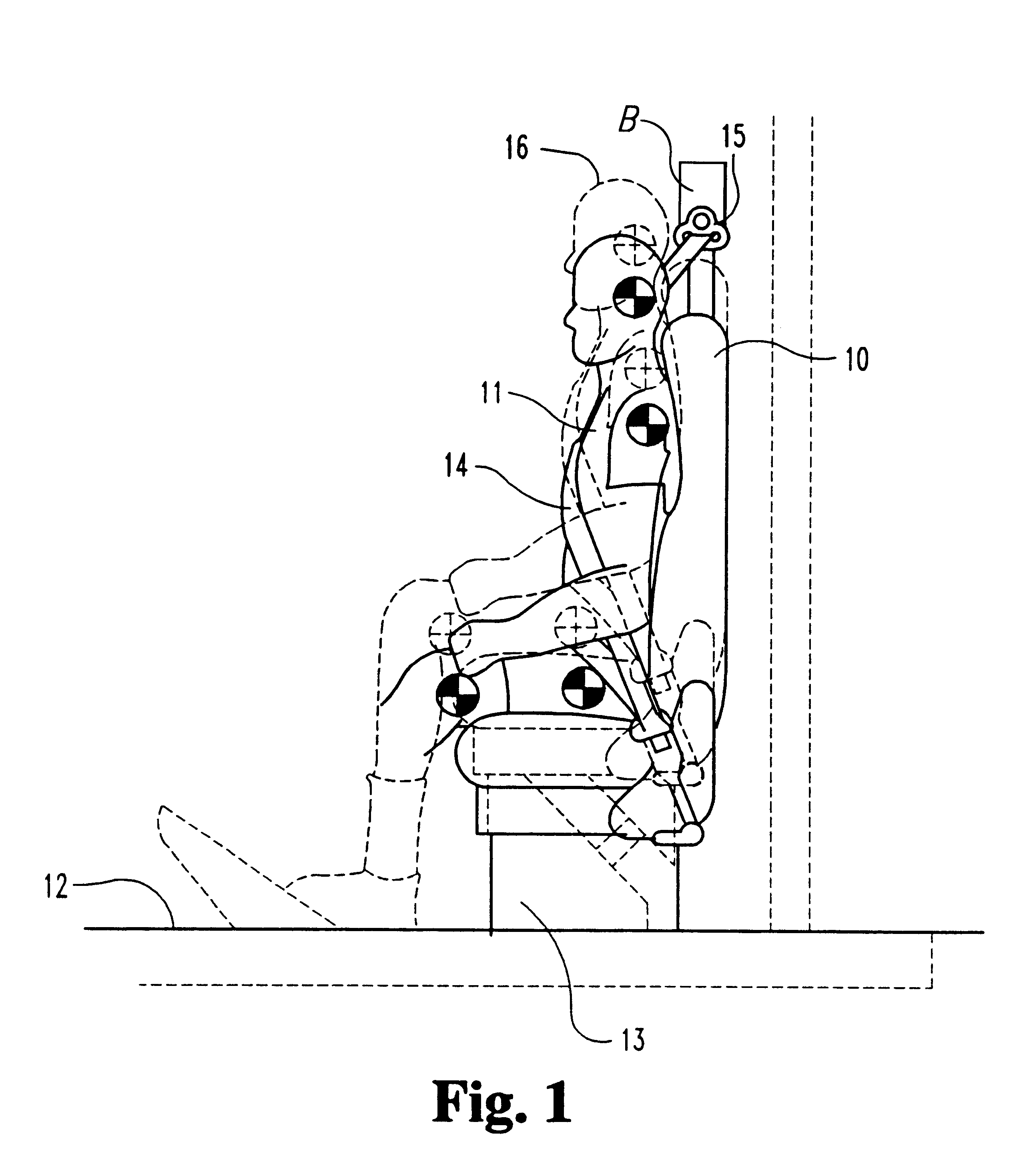

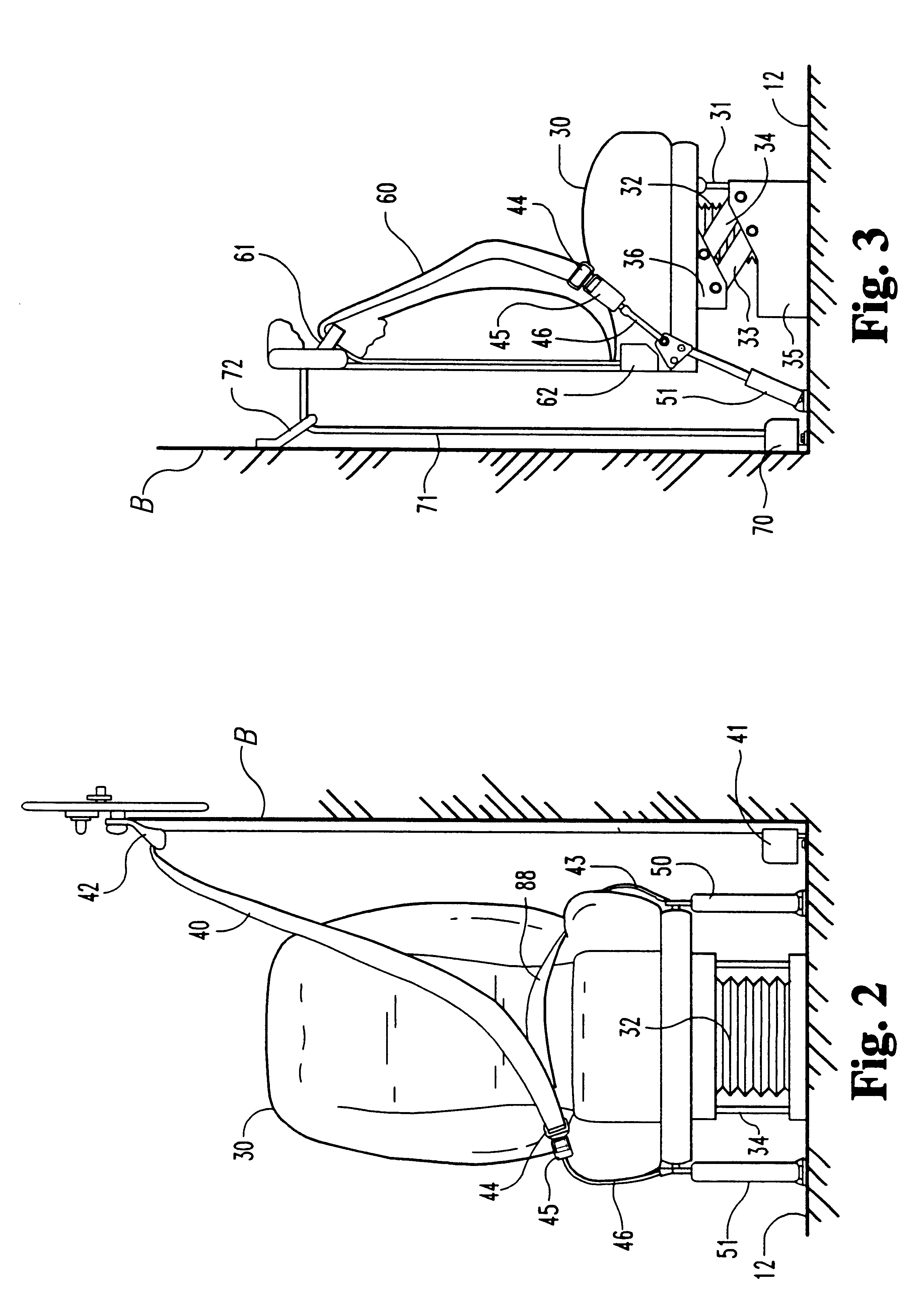

Seat and occupant restraint system

A restraint system for moving a vehicle seat and occupant toward the vehicle floor. In one embodiment a fluid cylinder pivotally mounted to the floor has an extendable piston rod connected to a linkage mounted to the vehicle seat. A three point belt assembly mounted to the seat is connected to the cylinder rod. Retraction of the cylinder rod pretensions or tightens the three point buckle assembly and subsequently moves the seat towards the vehicle floor. In an alternate embodiment a displacement member including at least a flexible portion is connected at one end to a piston within a fluid cylinder and is connected at the other end to the linkage. An angle between 0 and 180 degrees is imparted to the flexible portion of the displacement member, allowing the cylinder to be oriented in alternate directions for space efficiency. Retraction of the cylinder rod tightens the three point buckle assembly and moves the seat towards the vehicle floor.

Owner:INDIANA MILLS MFG

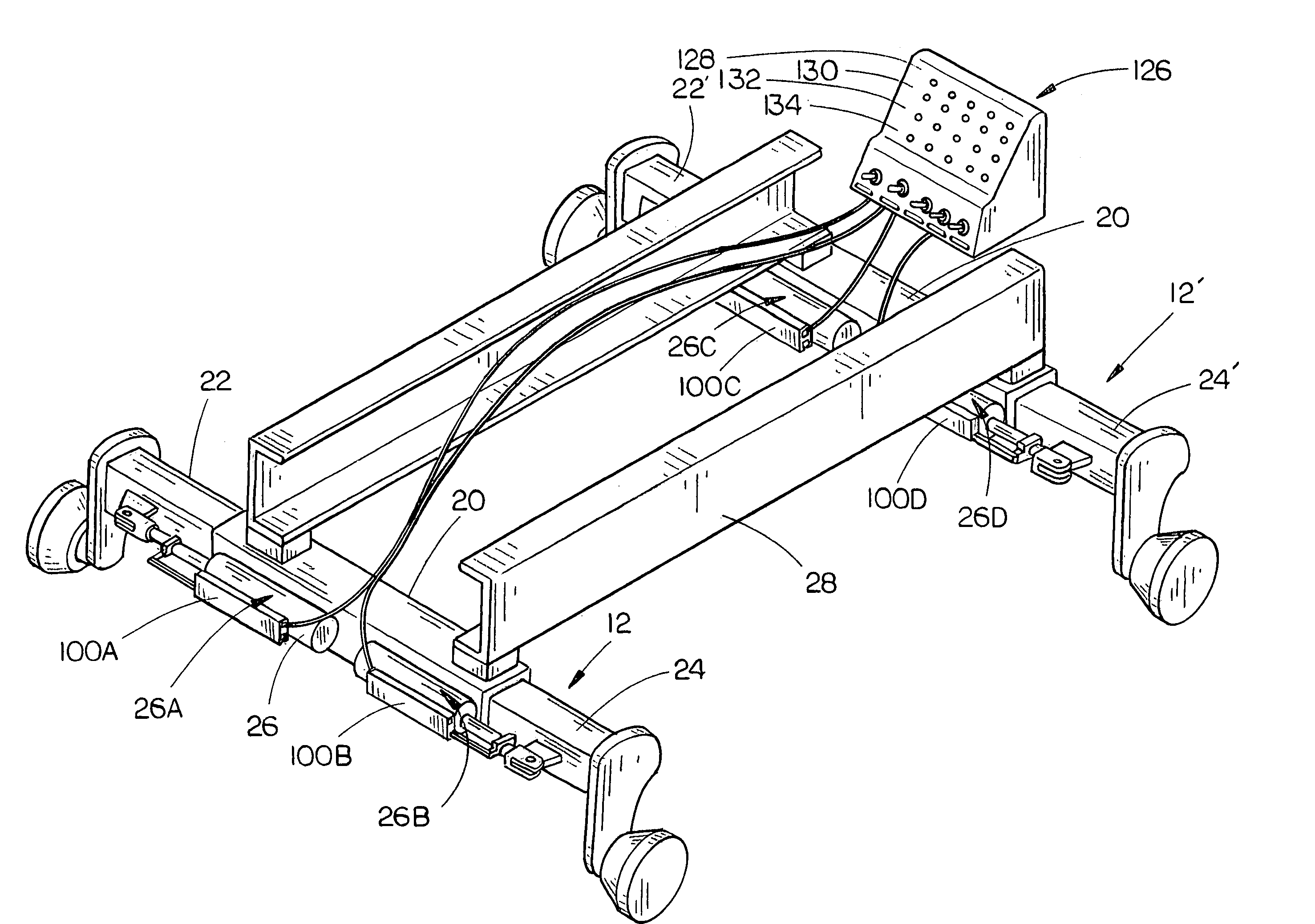

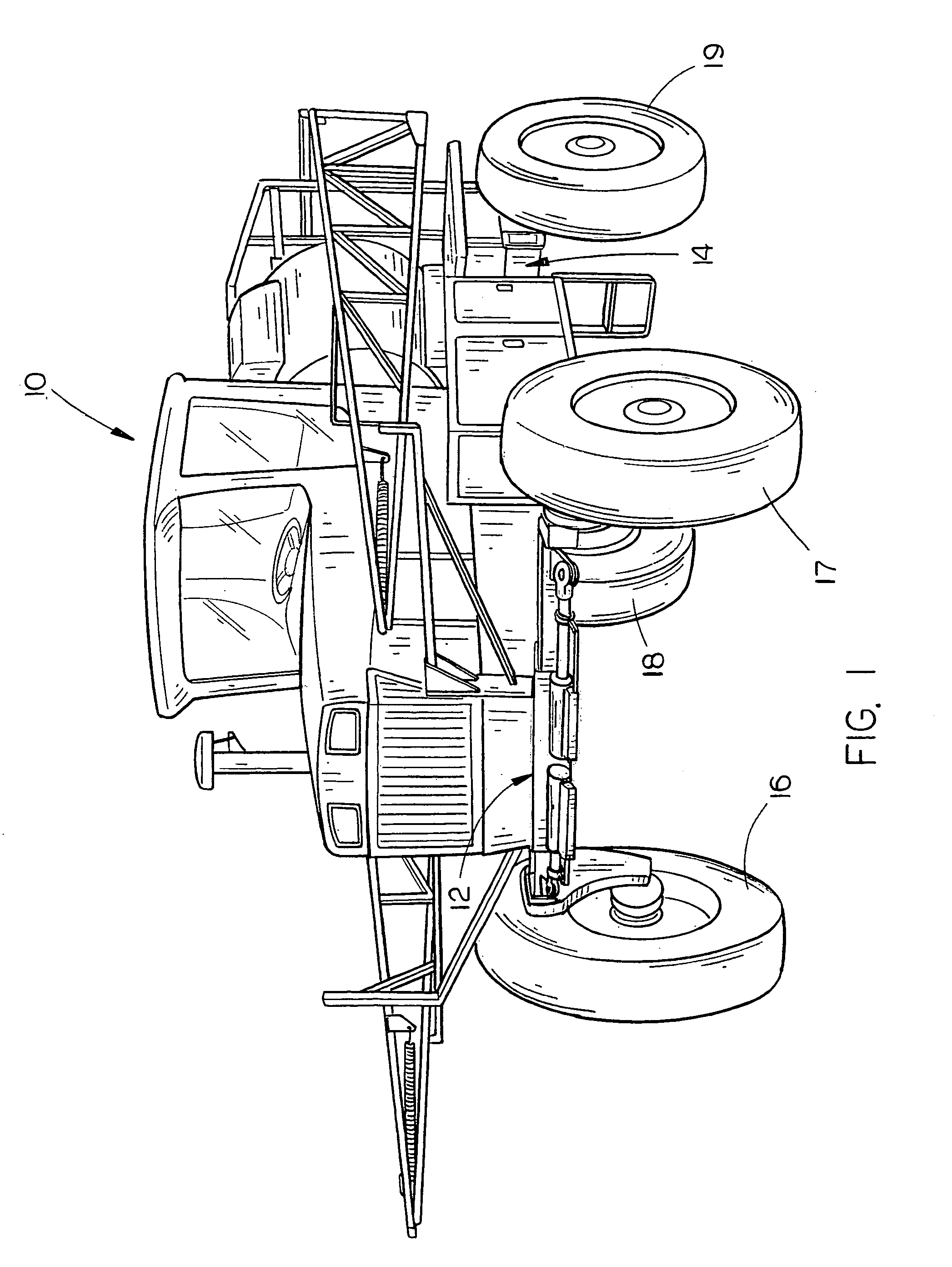

Multi-position track width sensor for self-propelled agricultural sprayers

InactiveUS7163227B1Track width can be easily and quicklyPositioning is simple and fastAgricultural vehiclesCarriage/perambulator accessoriesSprayerEngineering

A multi-position track width sensor for agricultural sprayers wherein a piston rod position sensor is connected to each of the adjustable axle members of the front and rear axle assemblies of the sprayer. A display panel is mounted in the cab of the sprayer and includes LEDs which indicate various positions of the piston rods with respect to the respective cylinder.

Owner:BURNS KERRY C

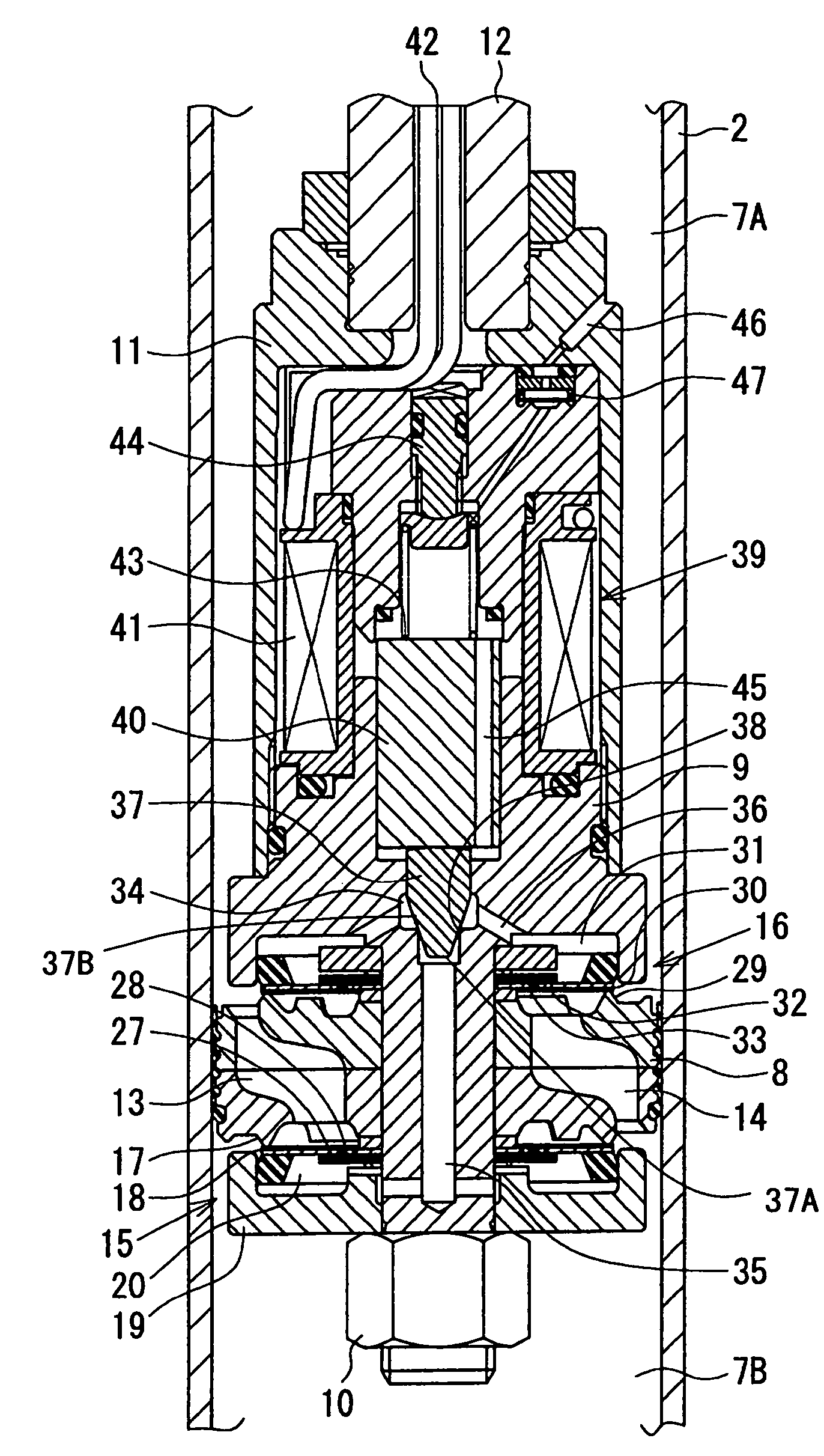

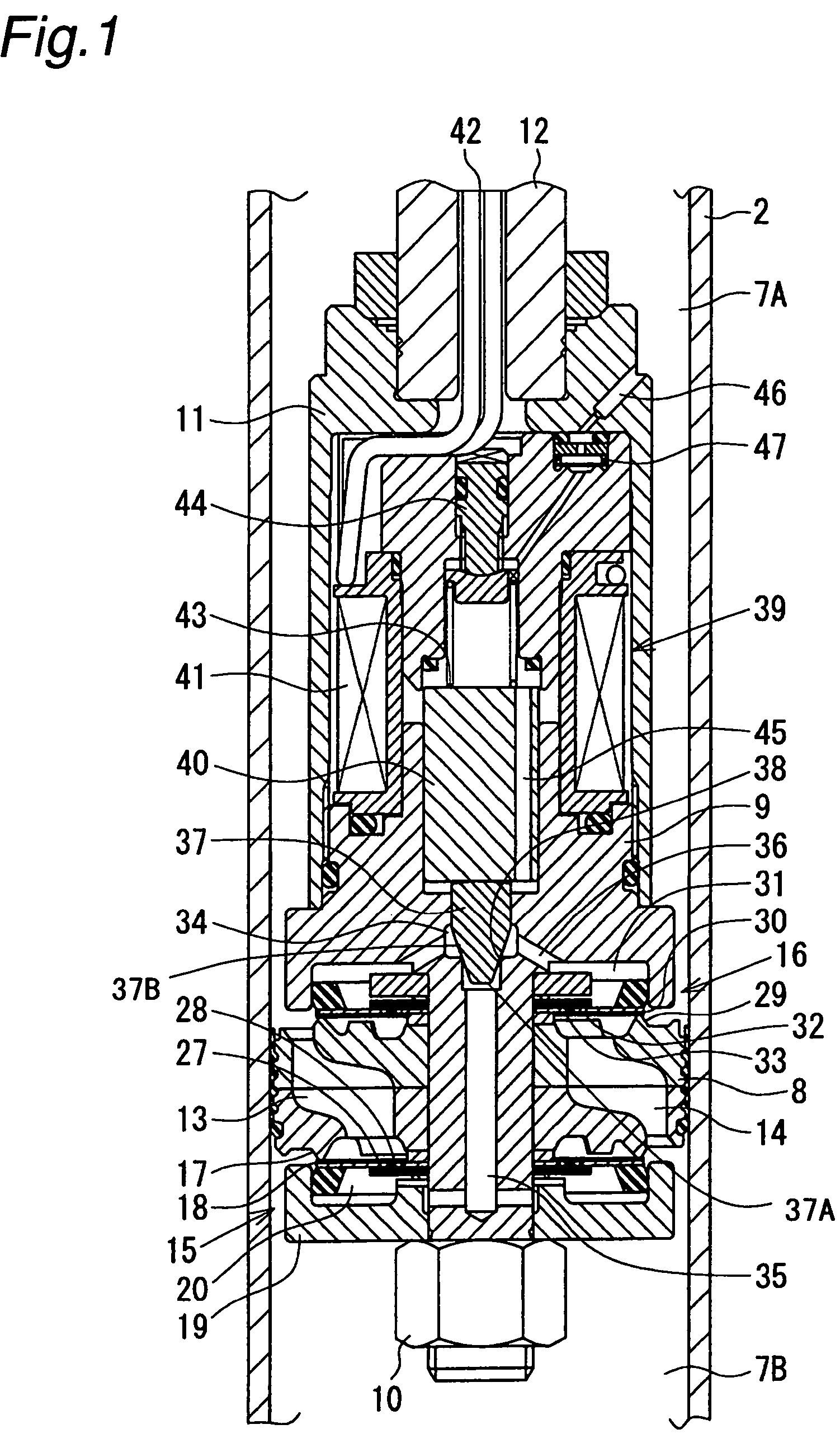

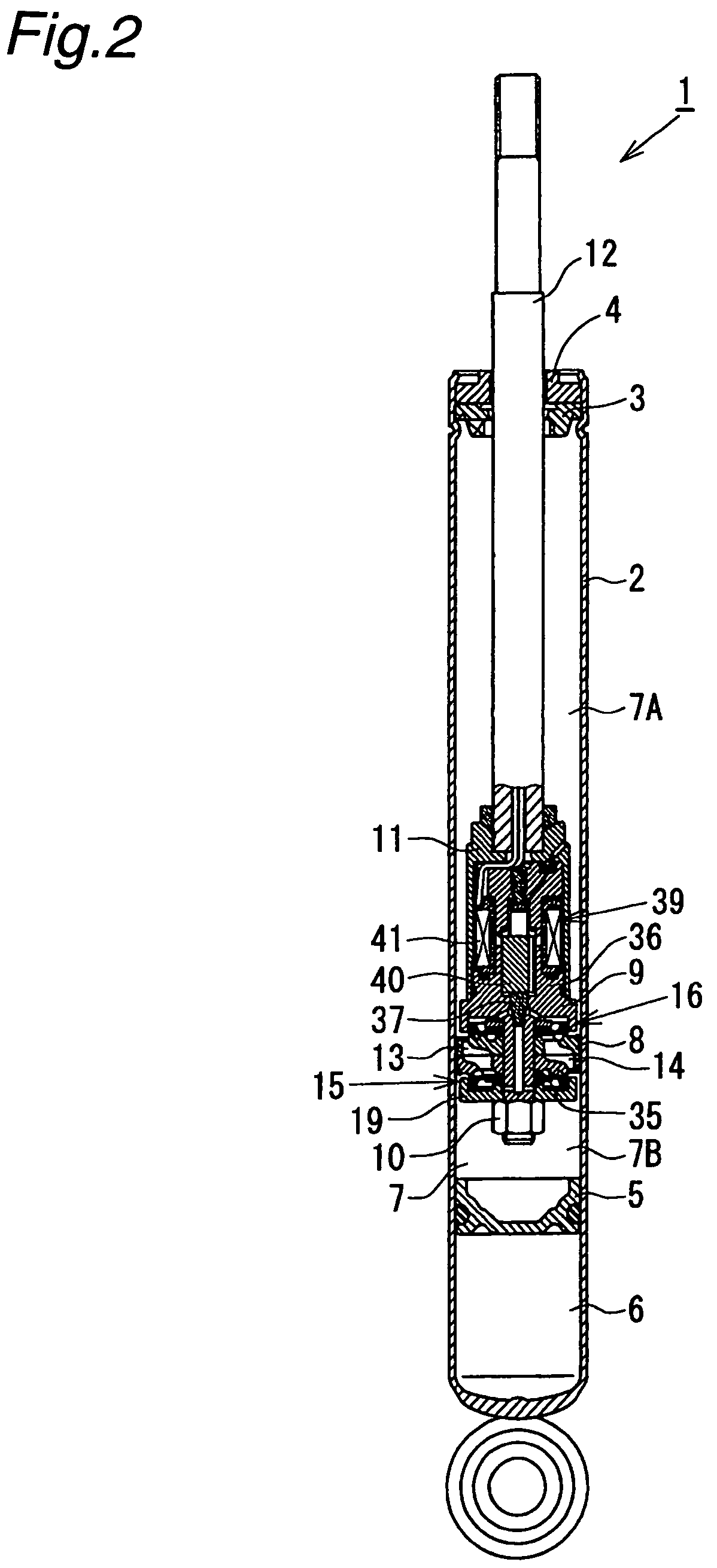

Controllable damping force hydraulic shock absorber

A controllable damping force hydraulic shock absorber including a pilot type damping valve having a back-pressure chamber for each of an extension stroke and a compression stroke. A piston connected to a piston rod is fitted into a sealed cylinder in which a hydraulic fluid is contained. During an extension stroke of the piston rod, the hydraulic fluid in an upper cylinder chamber flows to a lower cylinder chamber through an extension-side hydraulic fluid passage, an extension-side orifice hydraulic fluid passage, an extension-side back-pressure chamber, an axial hydraulic fluid passage, a radial hydraulic fluid passage, a compression-side back-pressure chamber, an extension-side check valve and a compression-side hydraulic fluid passage. During a compression stroke, the hydraulic fluid in the lower cylinder chamber flows to the upper cylinder chamber through the compression-side hydraulic fluid passage, the compression-side orifice passage, the compression-side back-pressure chamber, the radial hydraulic fluid passage, the axial hydraulic fluid passage, the extension-side back-pressure chamber, the compression-side check valve and the extension-side hydraulic passage. The hydraulic fluid passage for an extension stroke and the hydraulic fluid passage for a compression stroke have some elements in common, thus simplifying the structure of the controllable damping force hydraulic shock absorber.

Owner:HITACHI ASTEMO LTD

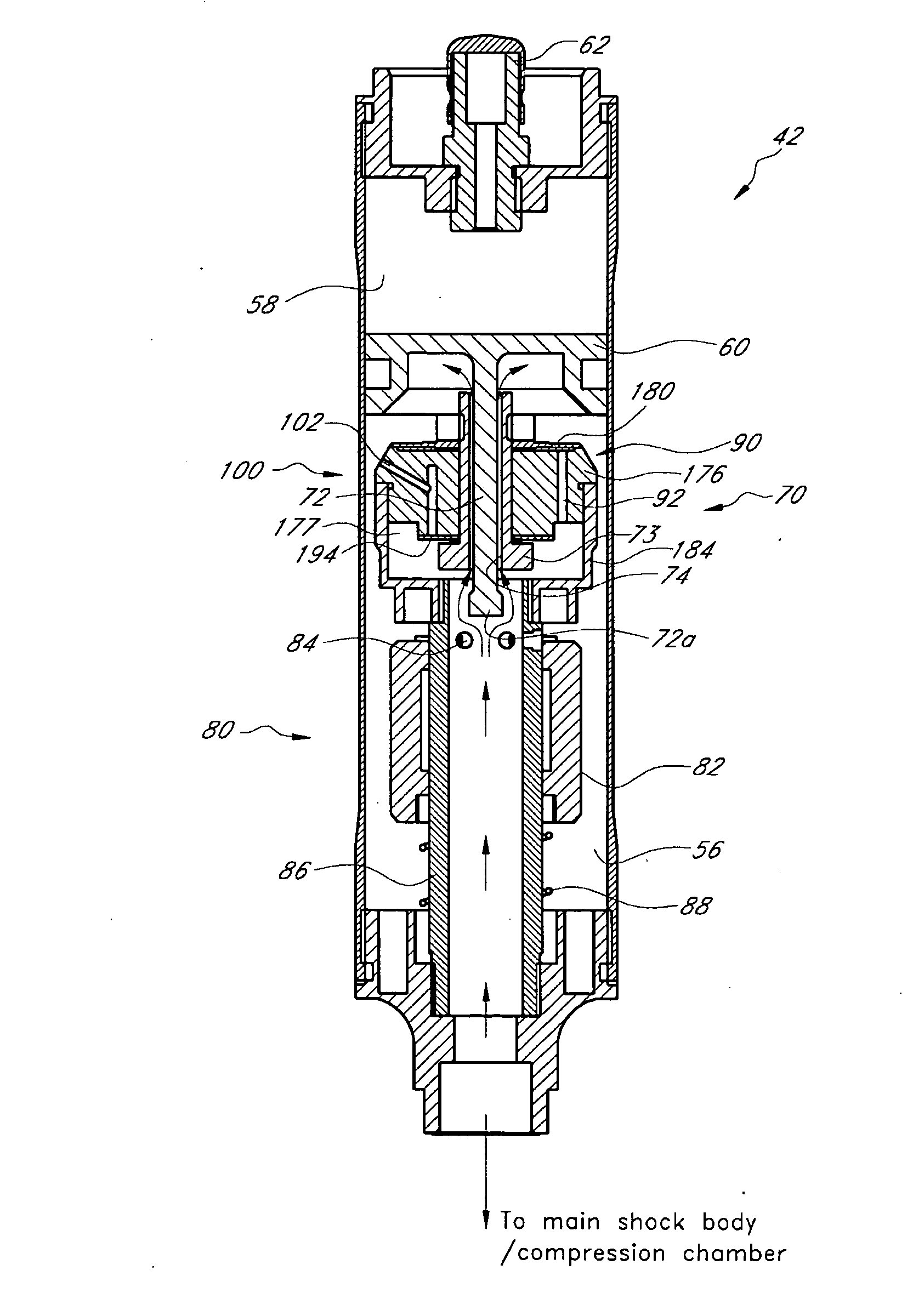

Hydro-pneumatic tensioner with stiffness altering secondary accumulator

InactiveUS20050074296A1Reduce stiffnessReduce maximum tensionDrilling rodsSpringsEngineeringPiston rod

A hydro-pneumatic tensioner includes a barrel having an inner bore and a pressurized fluid contained within to form at least part of a primary accumulator having a preset volume of gas at a preselected pressure. A piston having a piston rod extending from an aperture in the barrel is slidably carried in the bore of the barrel and is in communication with the pressurized fluid and positioned to increase the fluid pressure when the piston strokes in the direction of the pressurized fluid. A secondary accumulator also has a preset volume of gas at a preselected pressure. A fluid separator maintains functional separation of the fluid volumes of the primary and secondary accumulators when the primary accumulator pressure is less than a preselected secondary accumulator pressure. The fluid separator allows functional combining of the fluid volumes of the primary and secondary accumulators when the primary accumulator pressure equals or is greater than the preselected secondary accumulator pressure.

Owner:ABB VETCOGRAY

Shock absorber apparatus

A shock absorber apparatus includes a response adjustment mechanism connected in fluid transmission relation between a first cylinder and a second cylinder that is configured to provide three or more adjustments for tuning the response of the shock absorber system. The shock absorber may also include a damping valve assembly which may include a step washer positioned concentrically around a piston rod, and in stacking relation, and may be further positioned proximate to a piston. The damping valve assembly may also include a pressure plate positioned concentrically around the step washer in sliding relation, and a plate spring positioned concentrically around the rod so that the plate spring is borne by the step washer and a portion of the plate spring is held in tension by the pressure plate.

Owner:NOST TECH

Amplitude controlled orifice valving

A dual tube shock absorber includes a spool valve located between the upper working chamber and the reserve chamber. The spool valve moves with the piston rod to open and close a flow path between the upper working chamber and the reserve chamber. This provides a low damping characteristic for small movements of the piston rod which changes to a high damping characteristic for larger movement of the piston rod.

Owner:TENNECO AUTOMOTIVE OPERATING CO INC

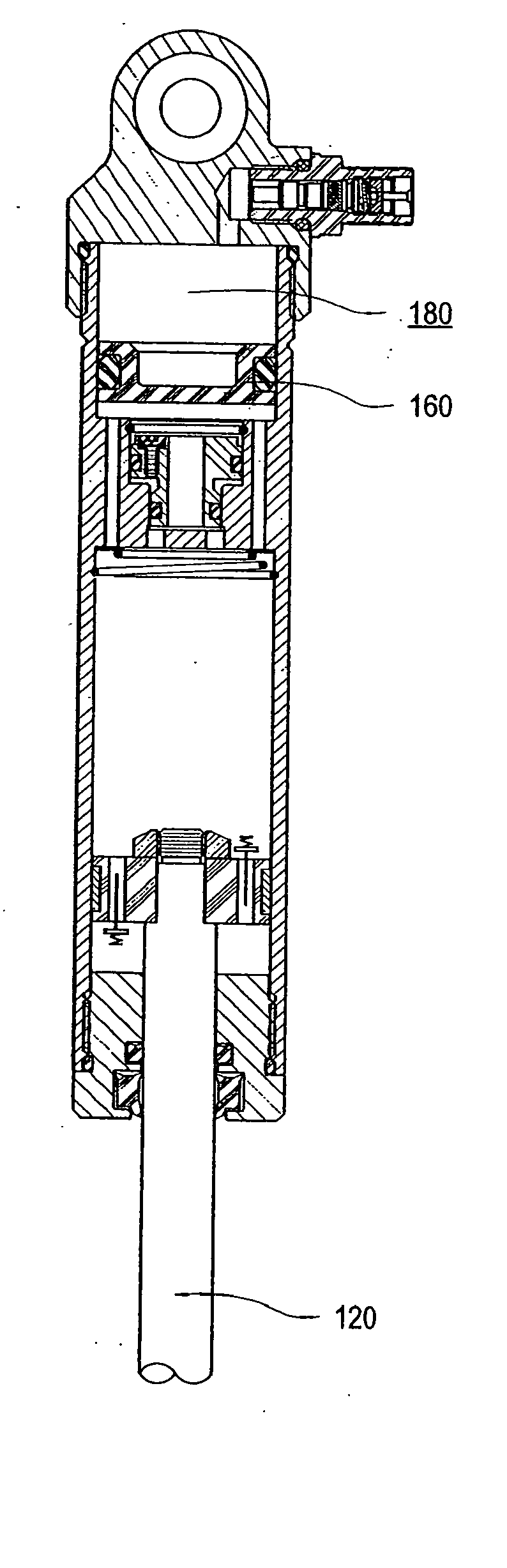

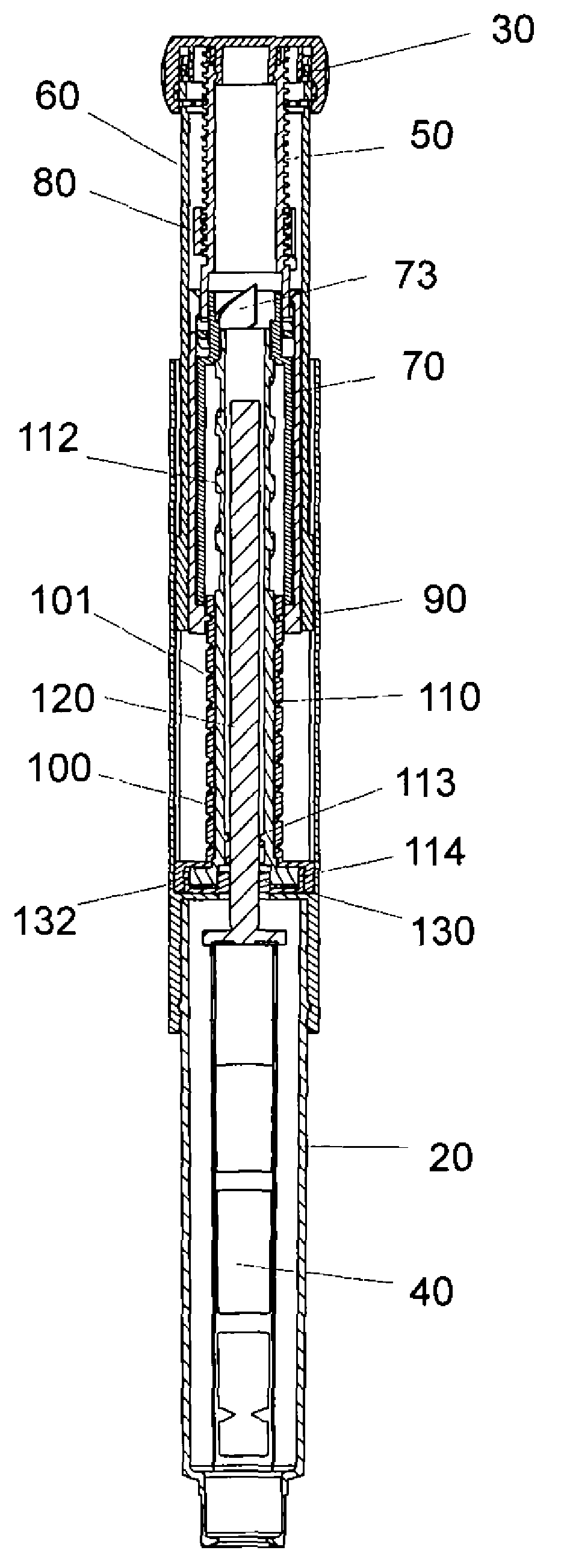

Injection Device

InactiveUS20080287883A1Reduce displacementReduce frictionAmpoule syringesIntravenous devicesTowerPiston rod

The application concerns an injection device for apportioning set doses of a drug from a reservoir (40) to a subject. The injection device comprises a housing having an interior thread (101,112) formed as an outwardly pointing thread (101,112) carried on an upstanding tower centrally located in the pen shaped device. This outwardly pointing thread (101,112) forms a first thread connection with the interior thread of the rotatable scale drum (90). The injection device further comprises a driver (70) for moving the piston rod (120) forward when moved axially. The driver (70) operates the piston rod (120) through a second thread connection having a pitch different than the first thread connection.

Owner:NOVO NORDISK AS

Pen shaped medication injection devices

The present invention provides a delivery device comprising a fluid cartridge holder, housing and a piston drive mechanism that comprises a hollow piston rod and a drive-shaft. The hollow piston rod has an internal thread that mates with the external thread of the drive-shaft, forming a thread connection and being axially restrained in the proximal direction relative to the housing. The drive mechanism is in turn connected to the housing via a one way ratchet such that the piston rod is prevented from moving in the proximal direction.

Owner:WOCKHARDT AMERICAS

Medical Pump

InactiveUS20090060764A1Easy constructionPositive displacement pump componentsFluid jet surgical cuttersCylinder headEngineering

Medical pumps for water jet surgery are known. The invention relates to a pump comprising at least two pistons provided with piston rods for displacing the pistons in cylinders and for coupling to a pump actuation device, a cylinder head for closing the cylinders, and valve means for respectively connecting a pressure chamber in the cylinder to at least one fluid inlet and at least one fluid outlet. Said fluid outlet is connected to the fluid inlet in a communicating manner by means of an adjustable pressure regulating valve, in such a way that the pressure in the fluid outlet can be limited to a predetermined maximum value so that operation of the pump can be.

Owner:ERBE ELEKTROMEDIZIN GMBH

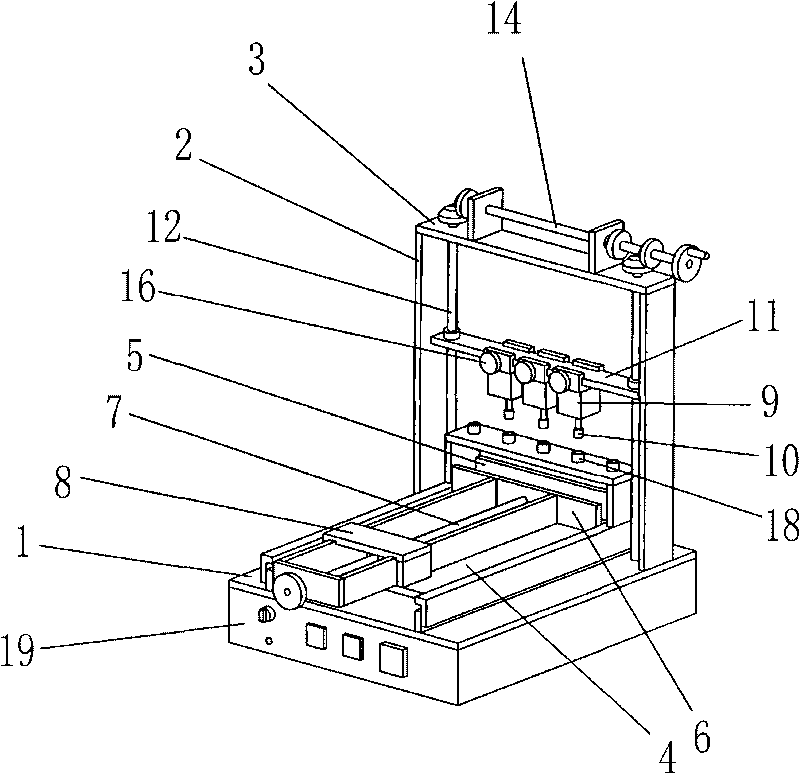

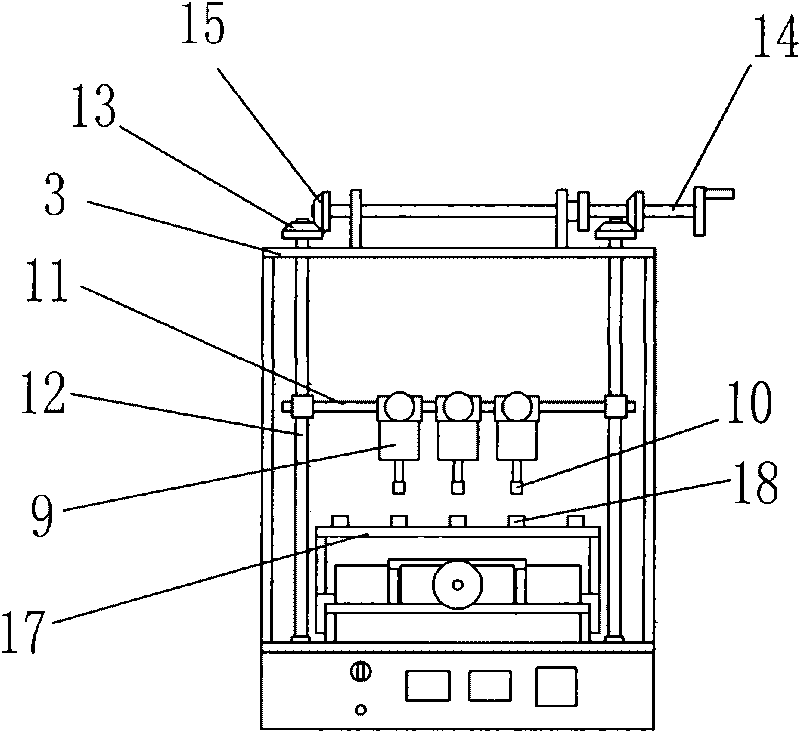

Fatigue testing device of button switch

InactiveCN101750224AIncrease productivityEasy to useStructural/machines measurementPush switchTest fixture

The invention relates to a fatigue testing device of a button switch, comprising a worktable (1) and a bracket (2) fixed on the worktable (1). A holding device for placing the button switch to be tested is arranged on the worktable (1), a cylinder (9) is arranged above the holding device, and the lower end of a piston of the cylinder (9) is connected with a pressing pole (10) for pressing the key of the button switch to be tested. The testing device also comprises a control device which is connected with the cylinder (9), used for controlling the cylinder (9) and setting testing parameters. The fatigue testing device of the button switch has the advantages that the button switch is automatically pressed by utilizing the cylinder, wherein the pressing force and the pressing frequency are kept highly consistent, and the pressing force, the pressing time interval and the pressing times all can be adjusted and set, thereby the invention has the advantages of very convenient use, good testing effect and high efficiency.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD

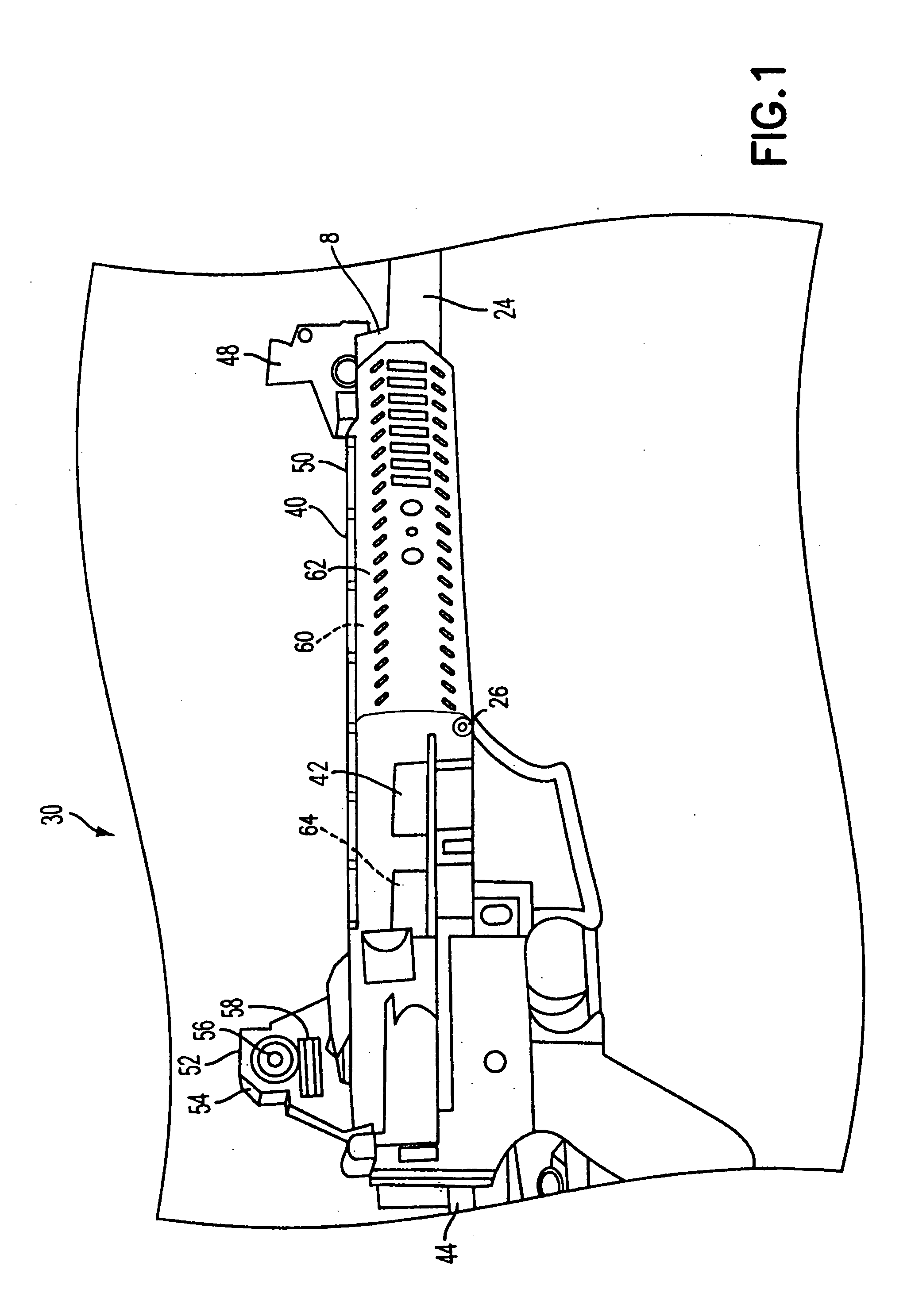

M16 modified with pushrod operating system and conversion method

A push rod operating system for an AR-15 / M-16 rifle includes an AR-15 / M-16 rifle having a barrel coupled to an upper receiver, a bolt carrier carried by the upper receiver, and a mechanical key coupled to the bolt carrier. A gas block is coupled to the barrel, the gas block having a bore therethough. A rod tube extends from the gas block in communication with the bore, toward the upper receiver. A gas plug has a gas chamber closing the bore of the gas block opposite the rod tube. A discharge gas pathway permits discharge gasses to enter the gas chamber from the barrel. A piston rod element is carried in the rod tube with a piston portion thereof reciprocally received within the bore of the gas block and movable between a first position abutting the gas plug to define an operating volume, and a second position. A push rod element is carried by the rod tube and engages the mechanical key and the piston rod element.

Owner:PATRIOT ORDNANCE FACTORY INC

Methods and apparatus for position sensitive suspension damping

An apparatus and system are disclosed that provide position sensitive suspension damping. A damping unit includes a piston mounted in a fluid-filled cylinder. A vented path in the piston may be fluidly coupled to a bore formed in one end of the piston rod, creating a flow path for fluid to flow from a first side of the piston to a second side of the piston during a compression stroke. The flow path may be blocked by a needle configured to engage the bore as the damping unit is substantially fully compressed, thereby causing the damping rate of the damping unit to increase. In one embodiment, the piston includes multiple bypass flow paths operable during the compression stroke or the rebound stroke of the damping unit. One or more of the bypass flow paths may be restricted by one or more shims mounted on the piston.

Owner:FOX FACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com