Patents

Literature

1795 results about "Spool valve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

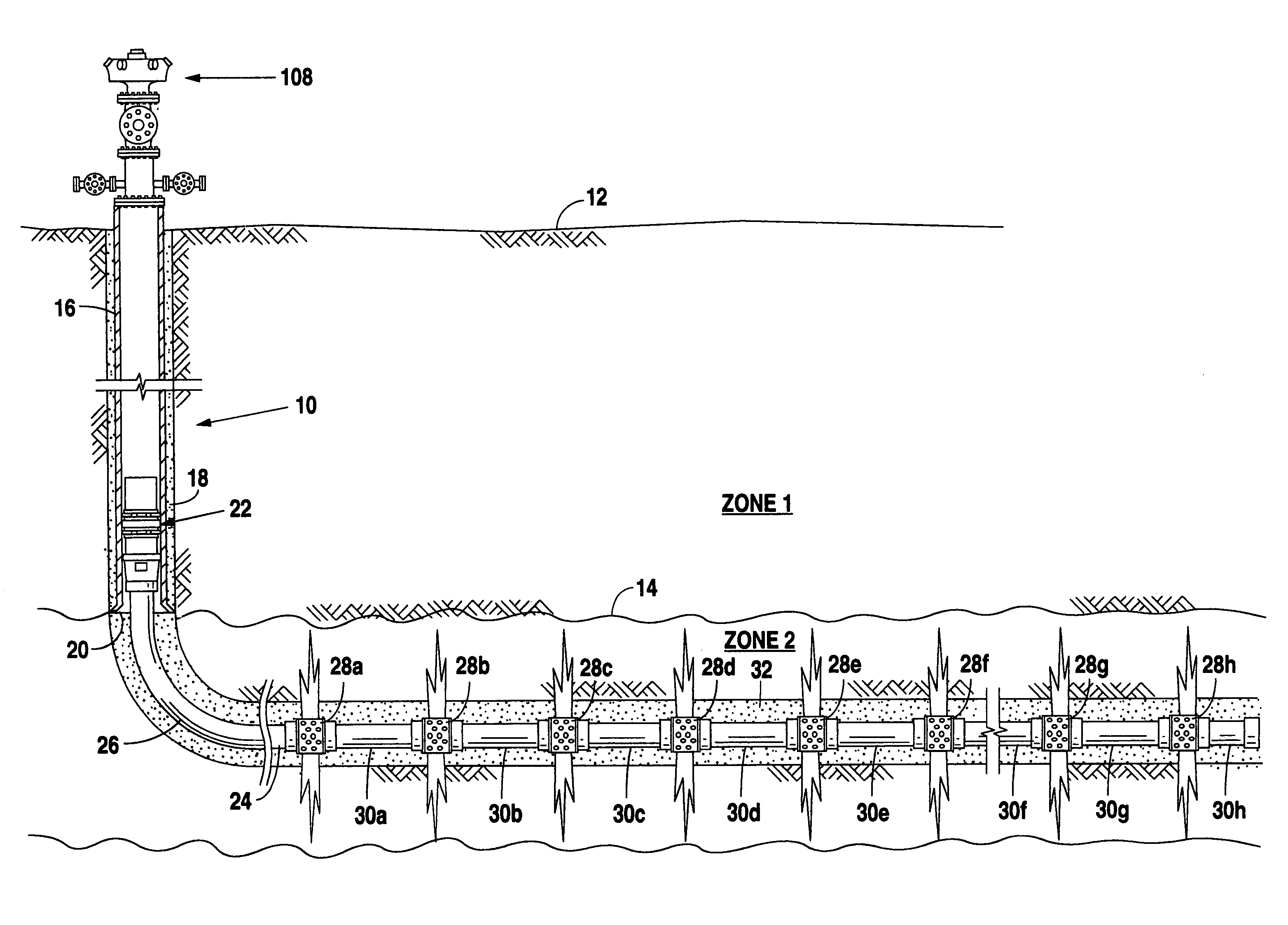

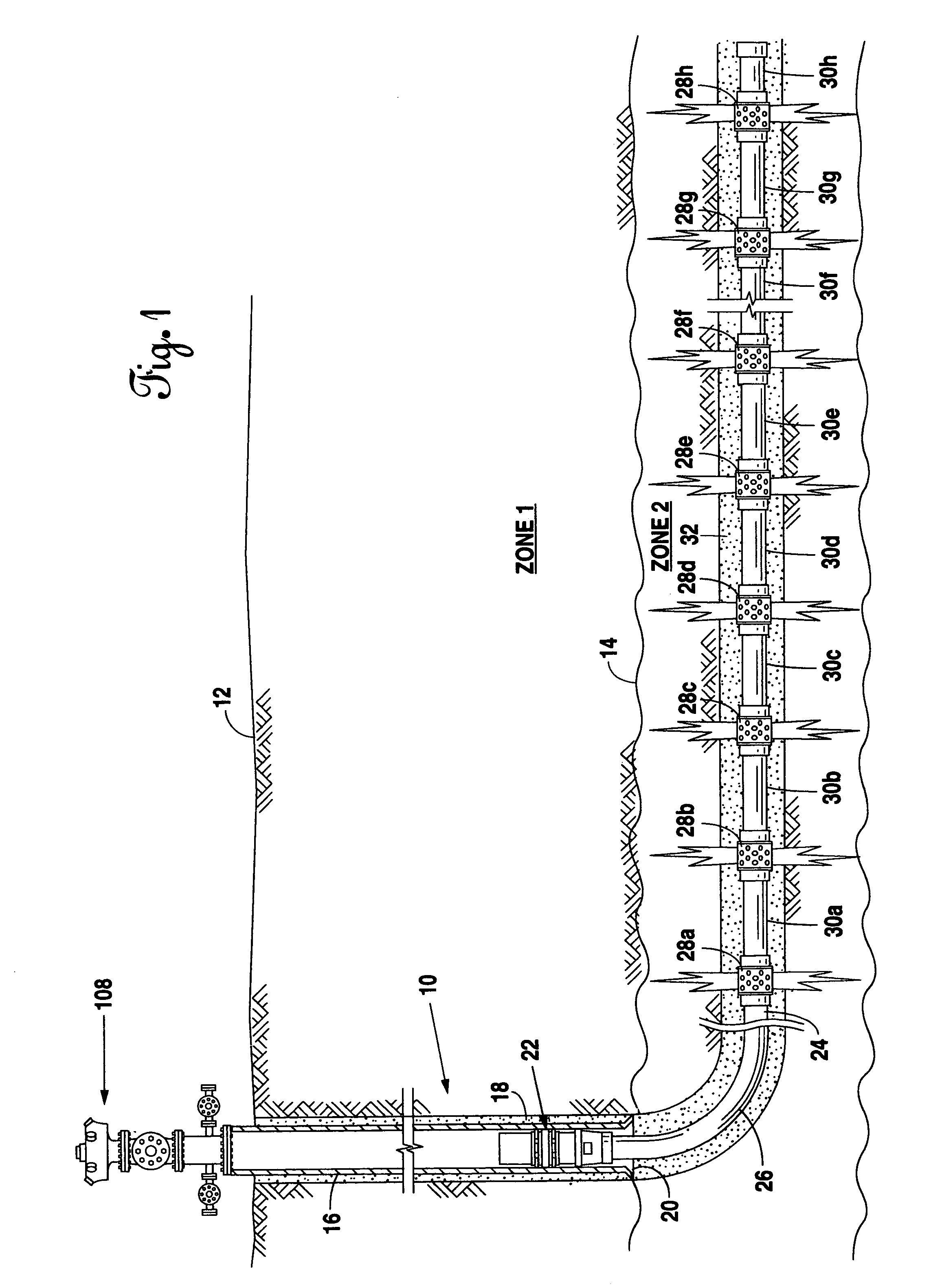

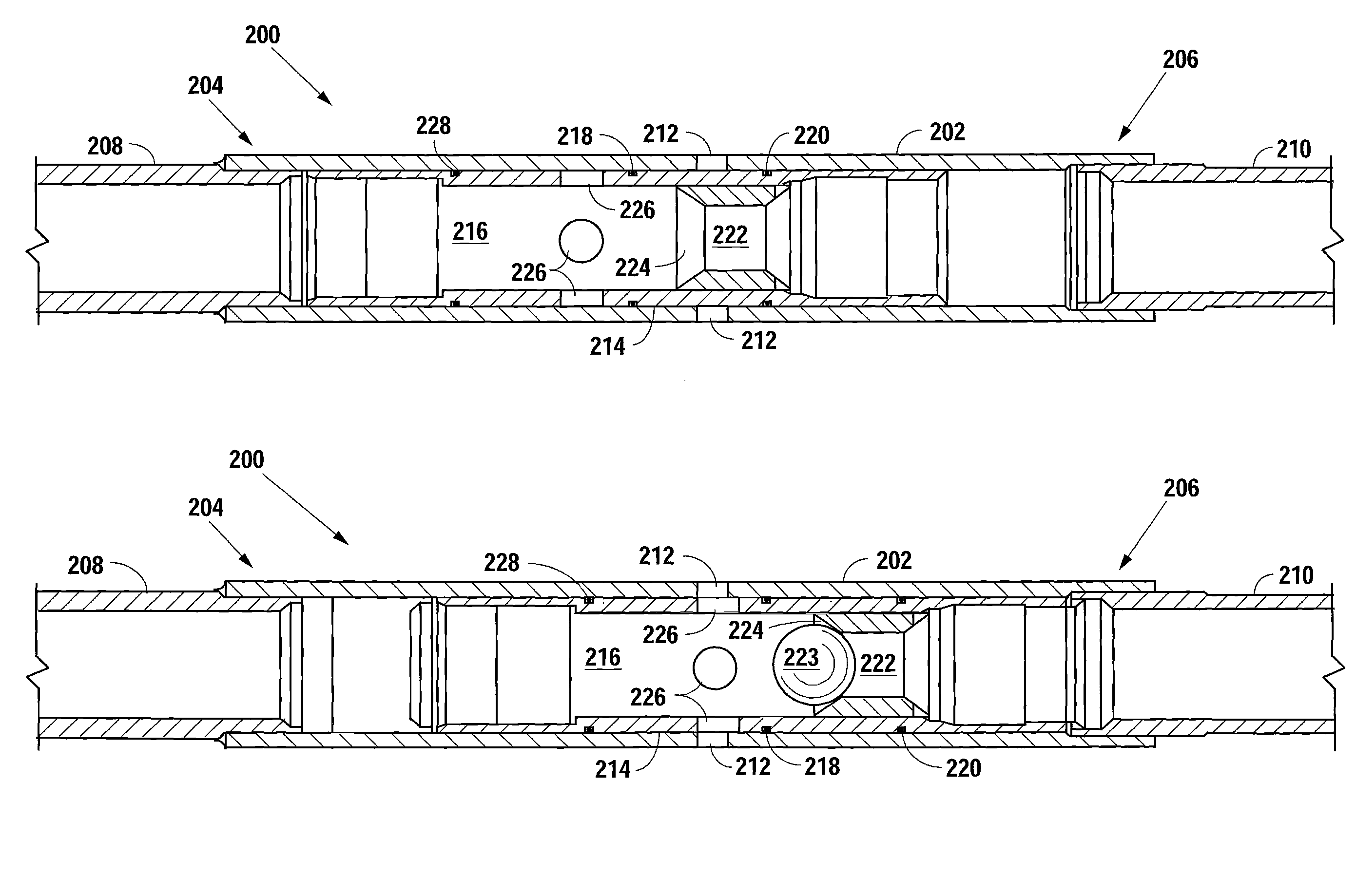

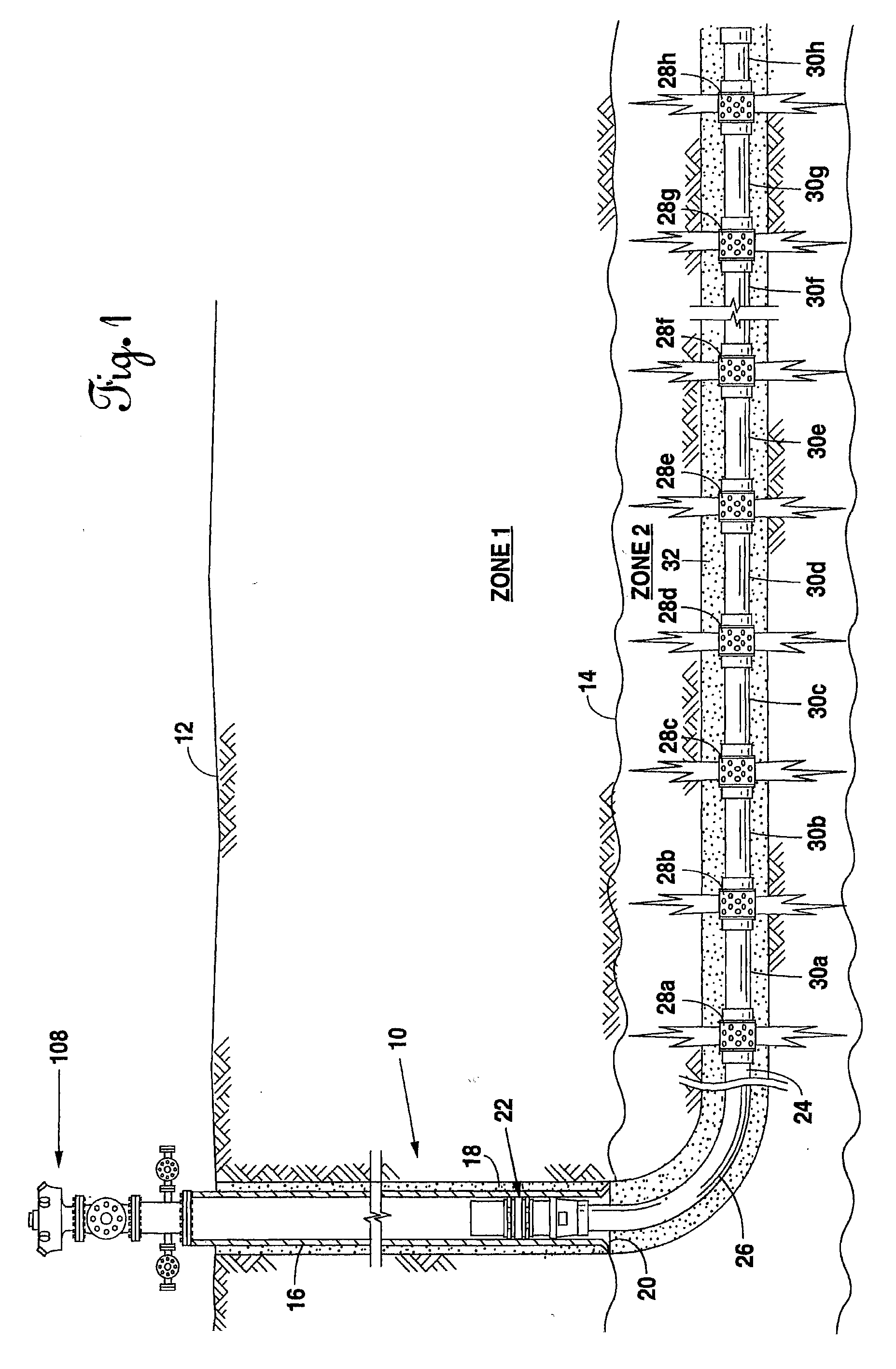

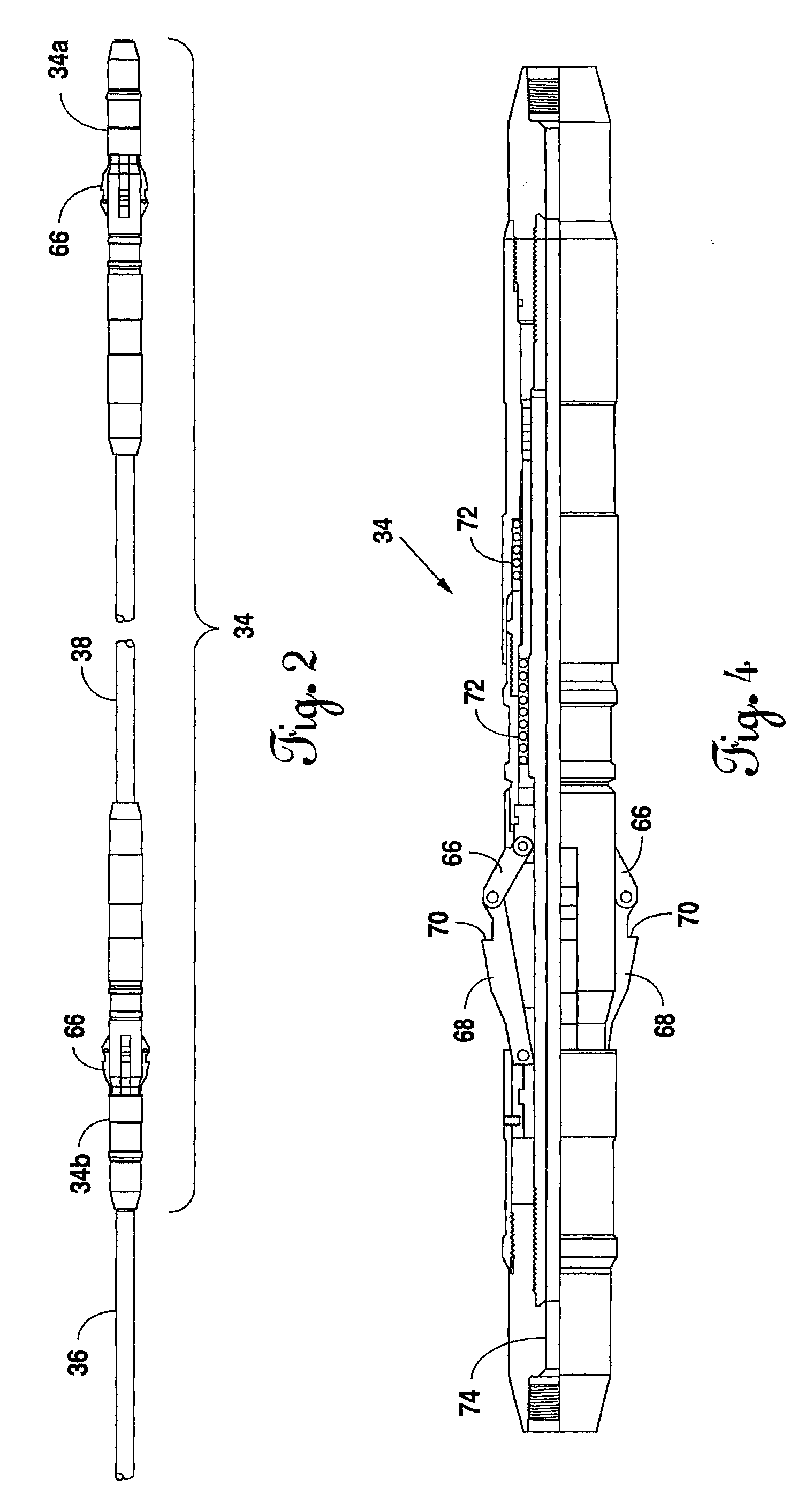

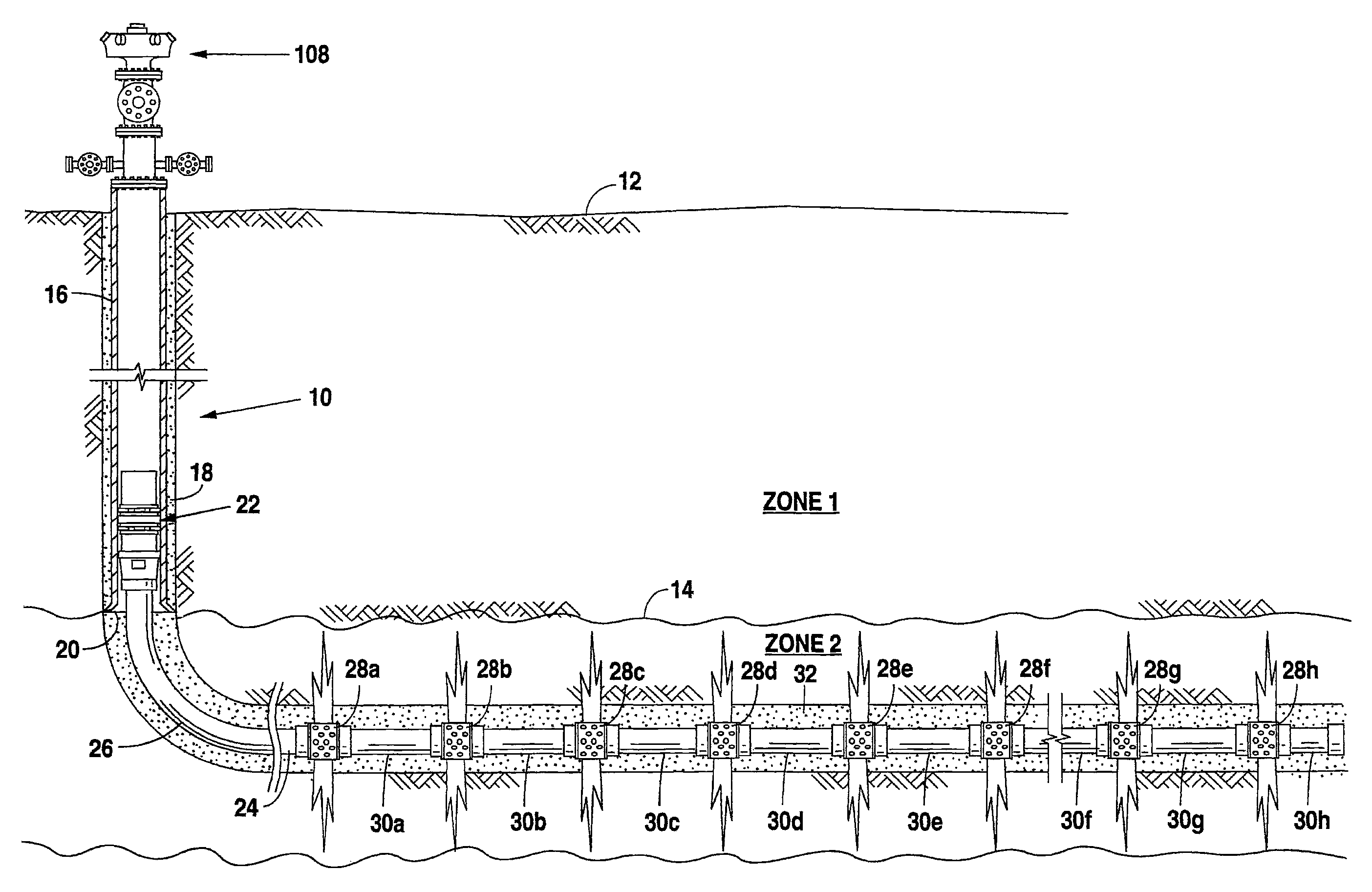

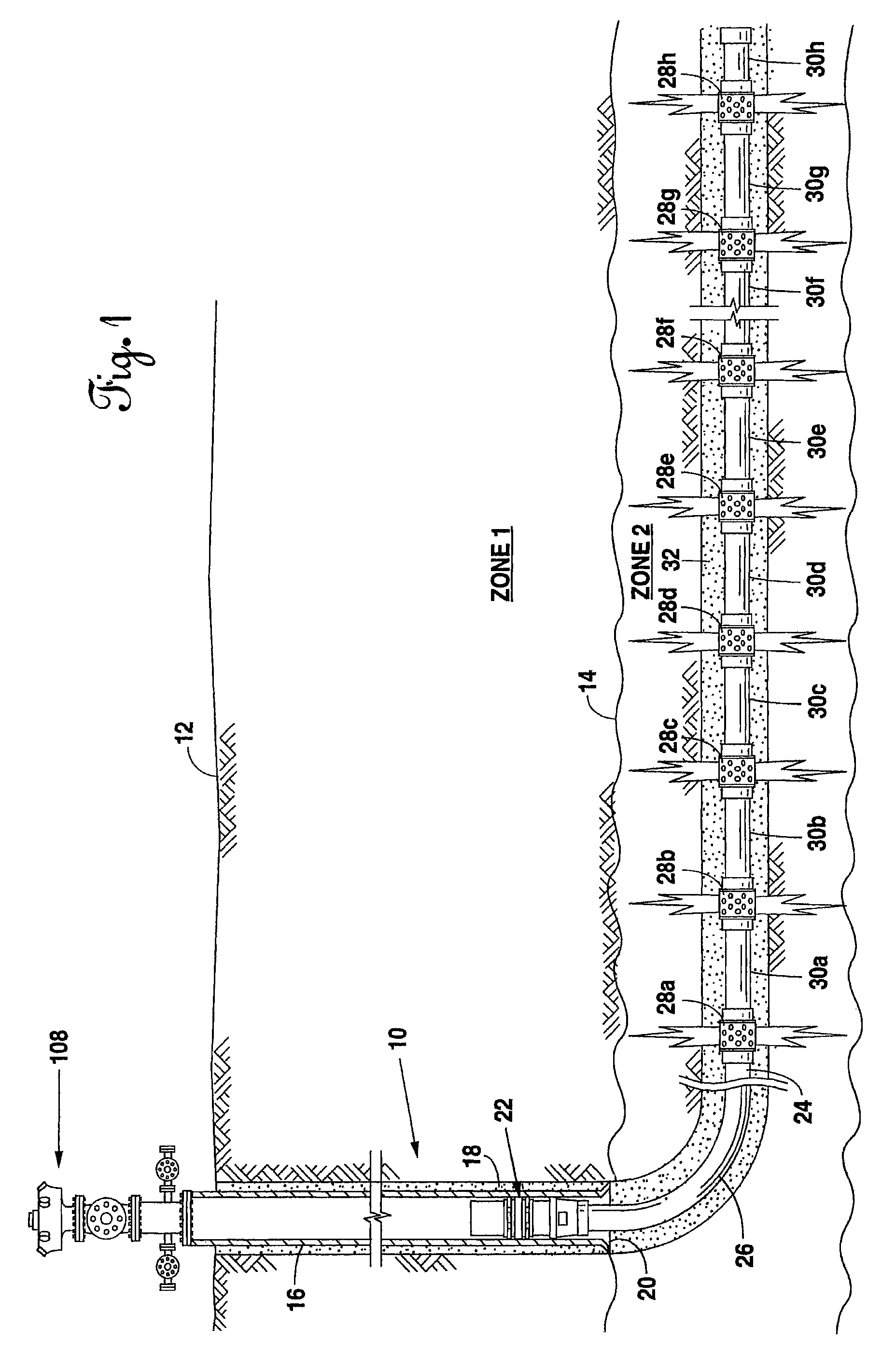

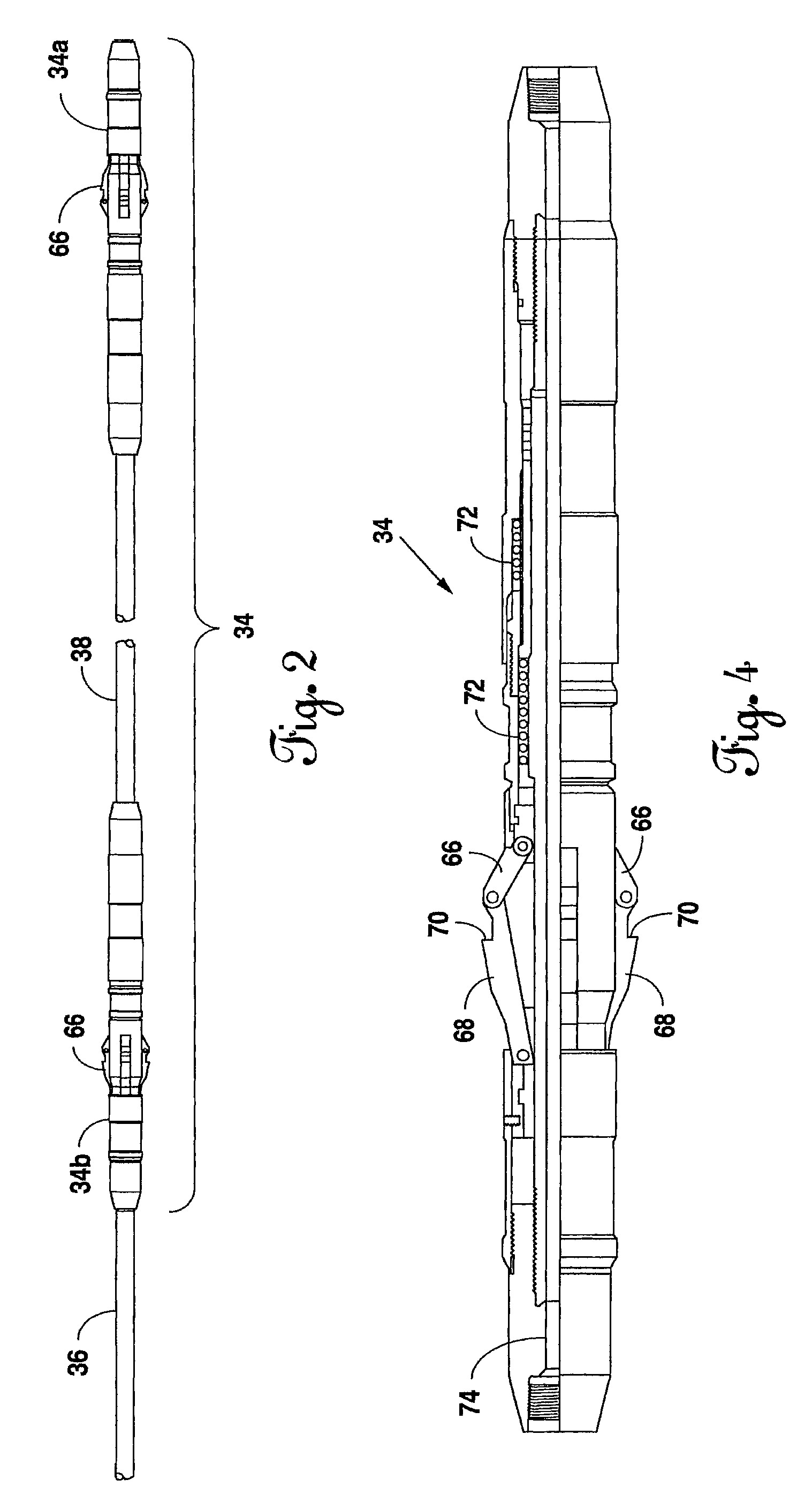

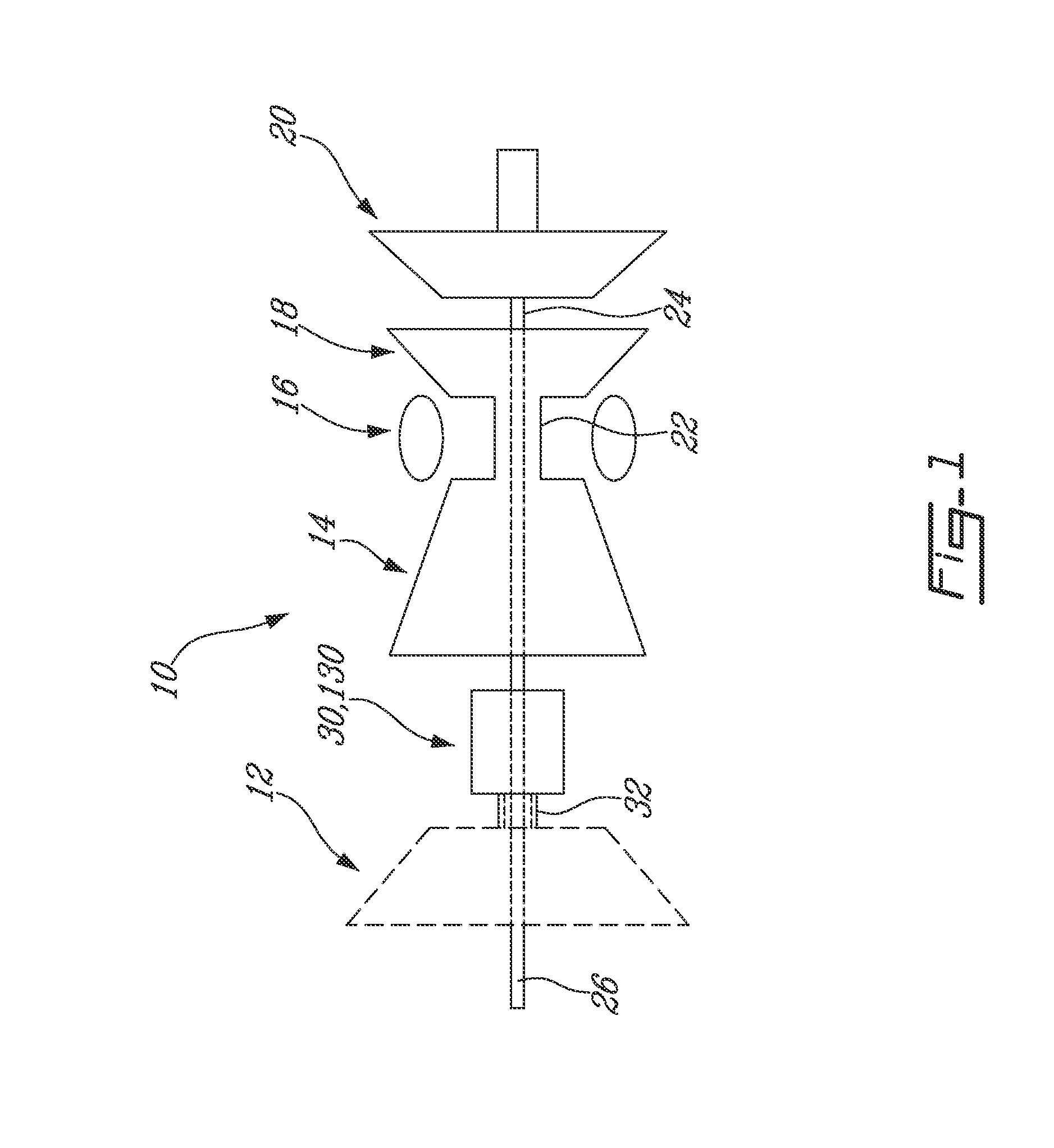

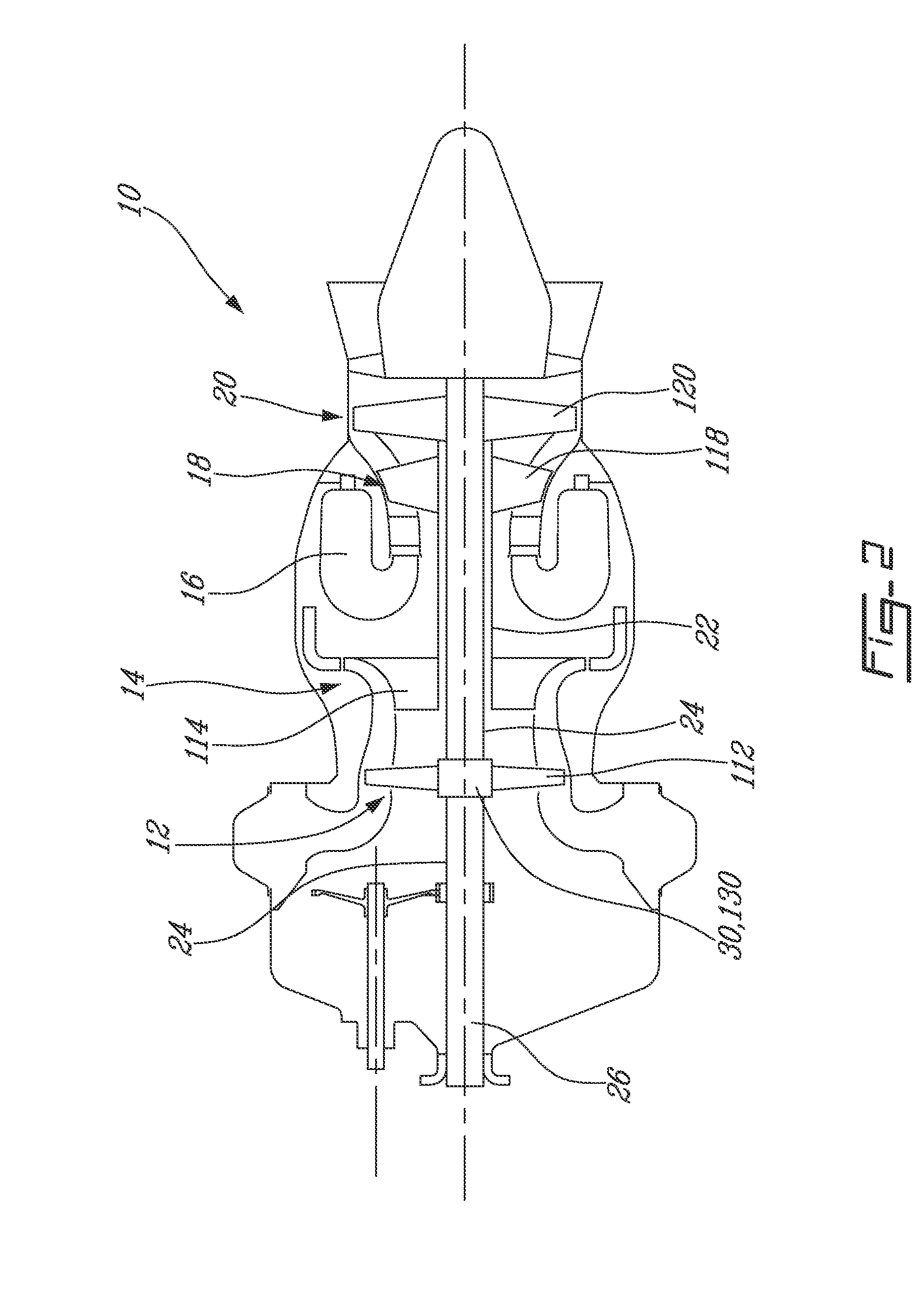

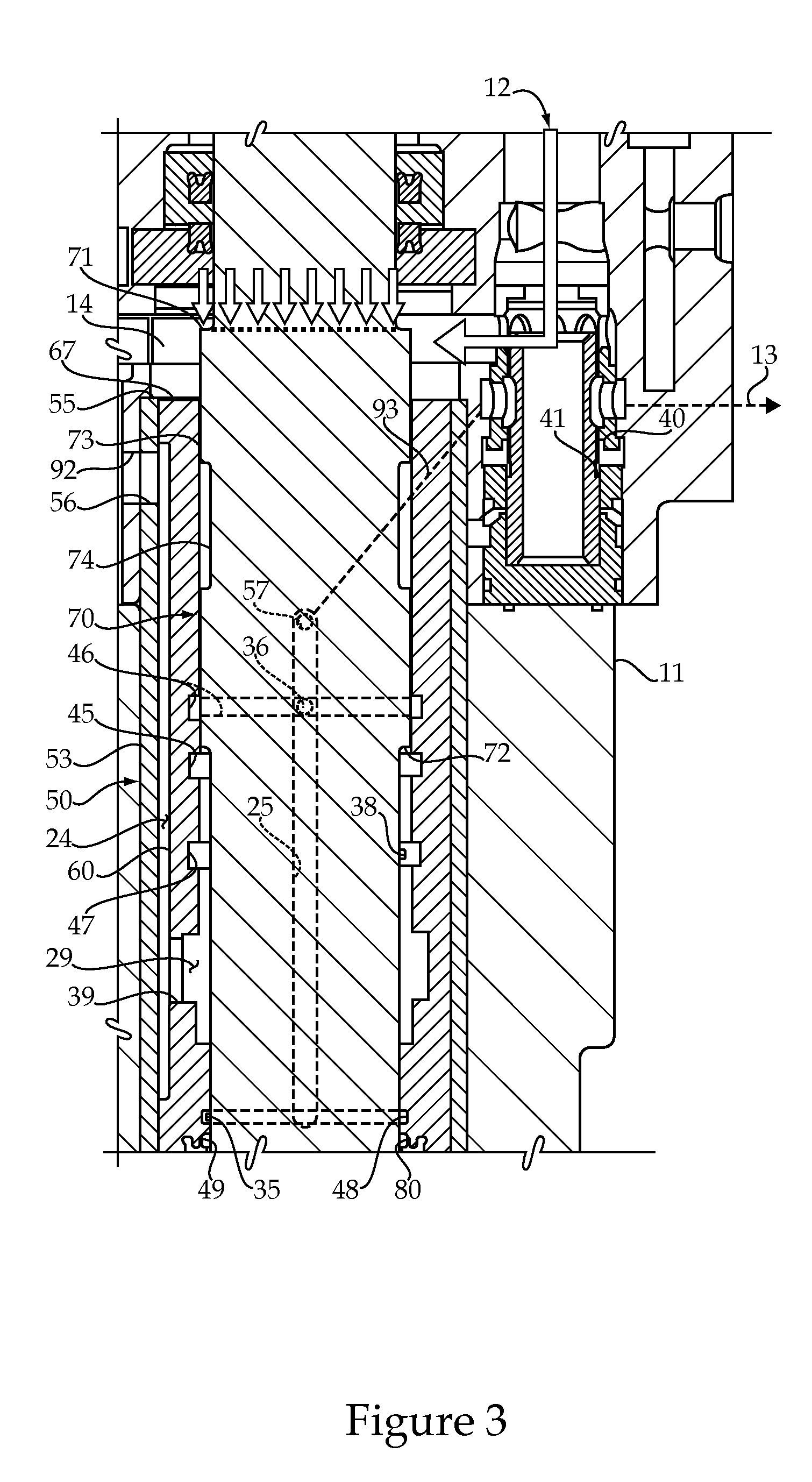

Cemented open hole selective fracing system

A cemented open hole selective fracing system is shown. In the producing zone, an open hole is drilled therein and a production tubing is cemented in place. At preselected locations along the production tubing, the production tubing will have sliding valves located there along. The sliding valves may be selectively opened by a shifting tool, and the cement around the sliding valve dissolved. Thereafter, the formation may be fraced immediately adjacent the opened sliding valve. By selectively opening different combinations of sliding valves, fracing can occur in stages with more fracing pressure and more fracing fluid being delivered deeper into the formation. Just as the sliding valves can be selectively opened with a switching tool, the sliding valves can also be selectively closed to protect the production of the well.

Owner:PEAK COMPLETIONS TECH INC

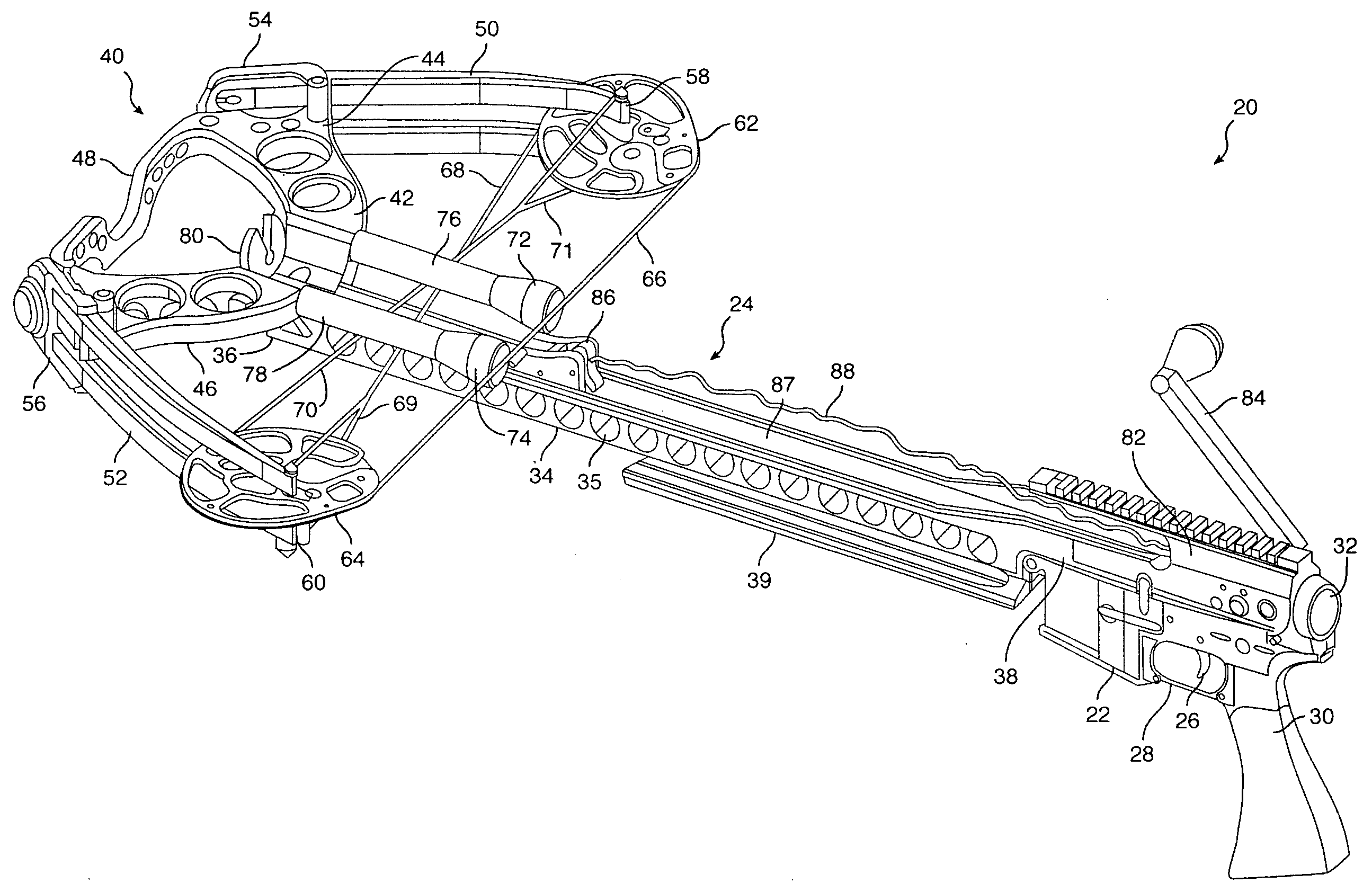

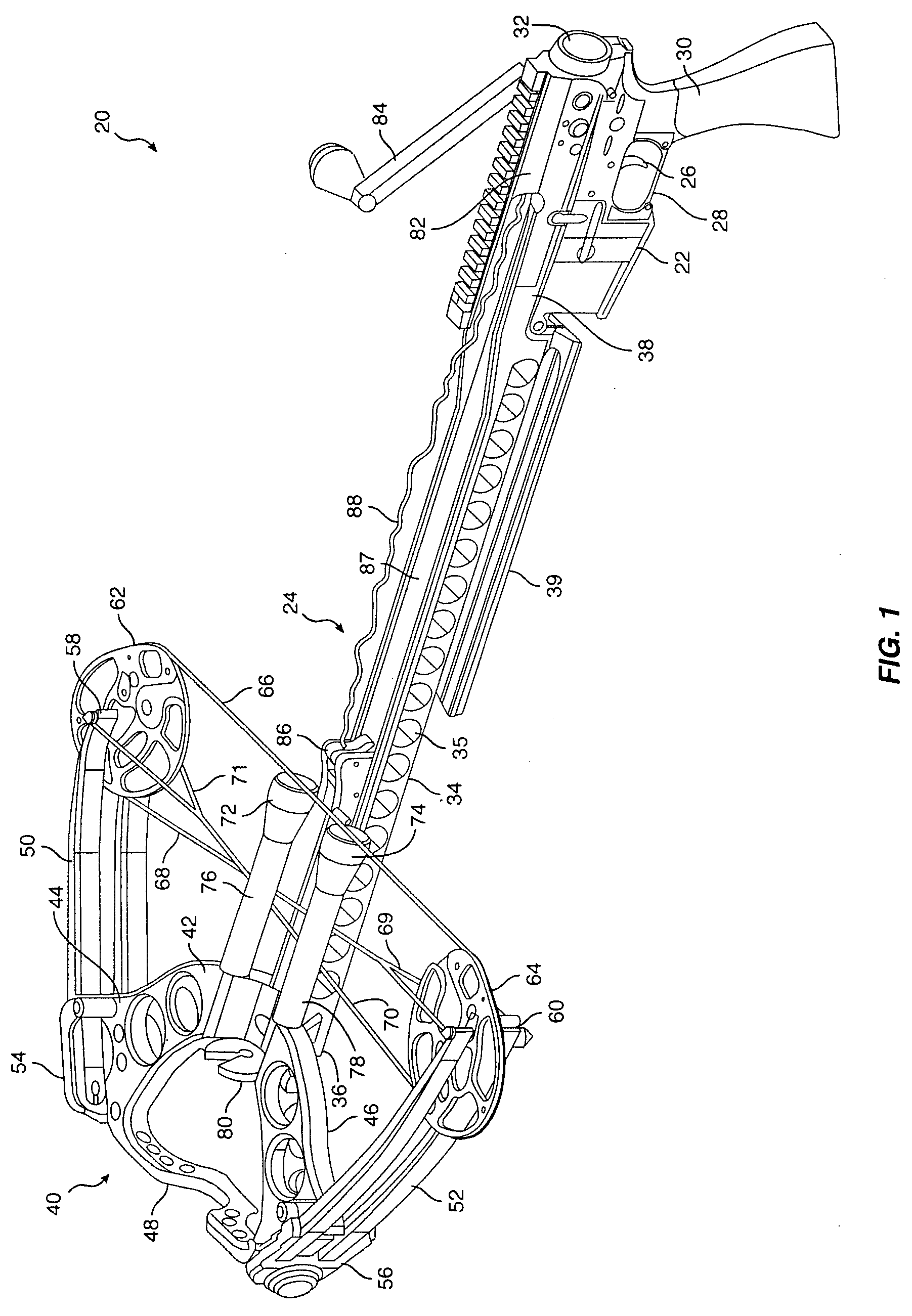

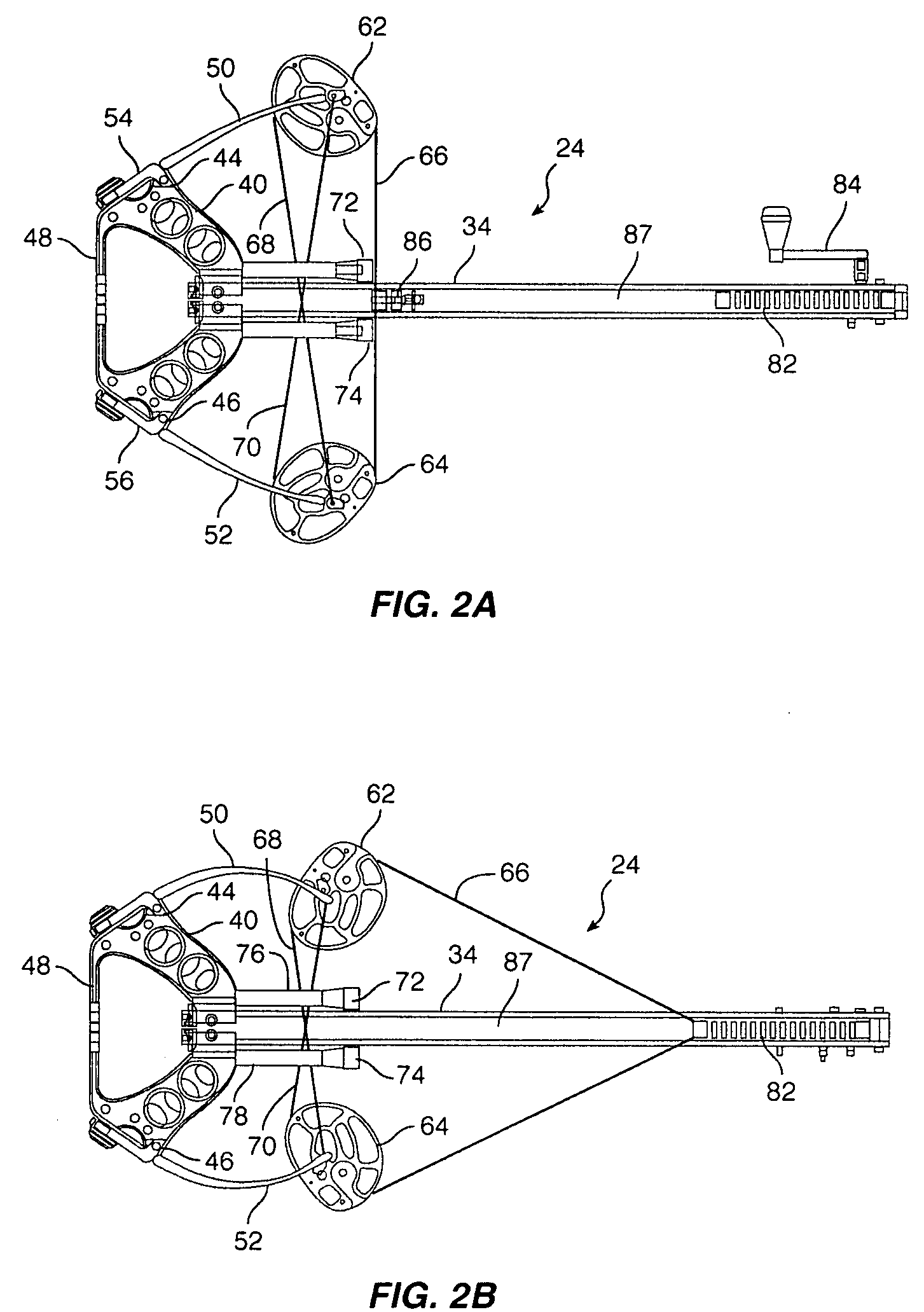

Compact Winding Mechanism for Crossbow

InactiveUS20100170488A1Enhance force/draw characteristicPermit rotationWeapon assembly/disassemblyFiring/trigger mechanismsSpool valveEngineering

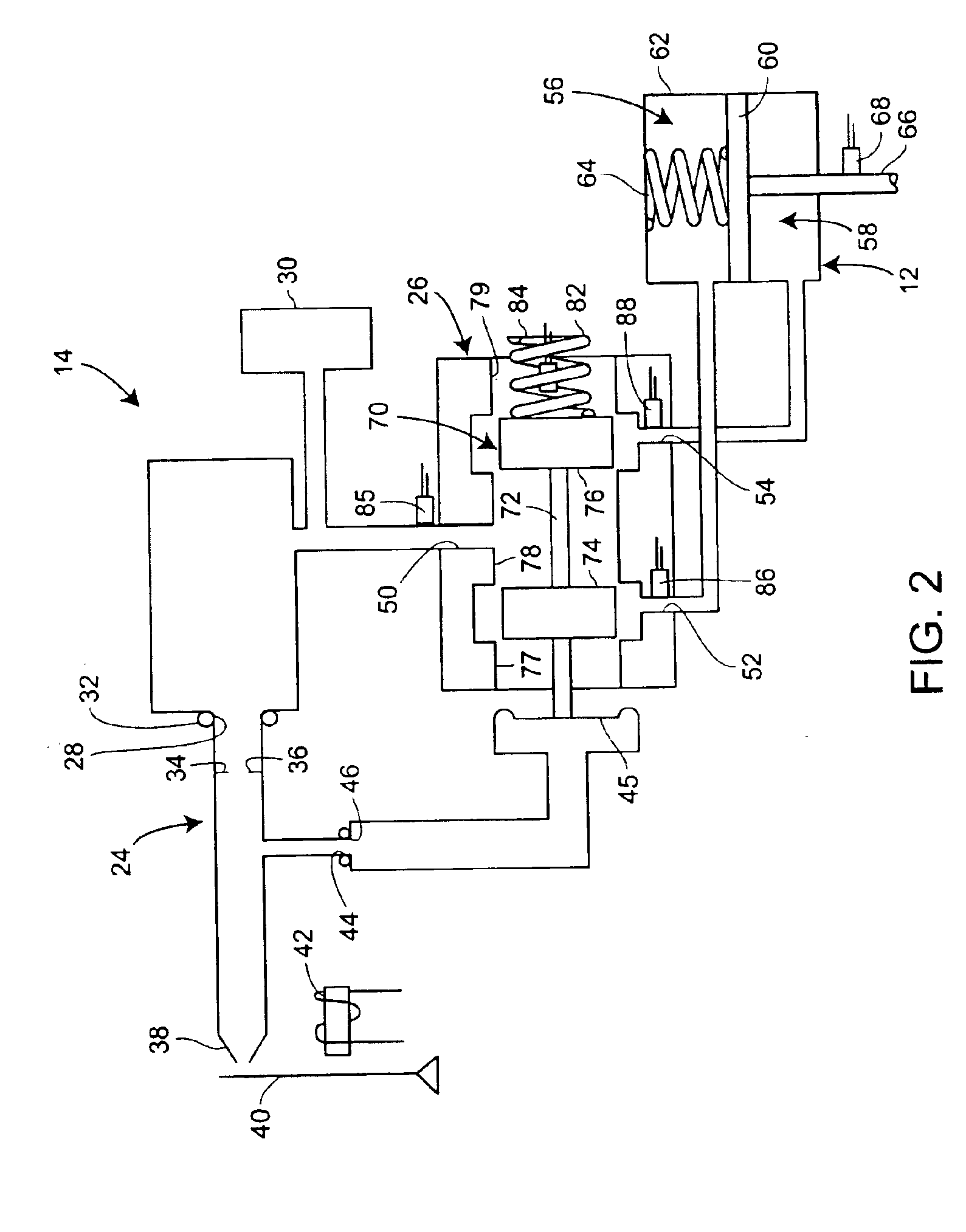

A crossbow includes an elongated frame coupled to a riser at a first end thereof and attached to an upper housing at its second end generally above the trigger region. The riser supports a pair of flexible limbs, and a bowstring extends between such limbs. A bowstring retractor is provided within the upper housing and includes a rope spool used to wind a retractor rope for retracting the bowstring. First and second spool gears surround the rope spool for rotation therewith. A spur gear mounted on a drive axle engages one of the spool gears, and a crank can be engaged with the drive axle. A pawl engages the other spool gear to prevent unintentional unwinding of the retractor rope from the rope spool. A pawl release member disengages the pawl from its associated spool gear. Drawing the bowstring beyond its full draw position also disengages the pawl.

Owner:PRECISION SHOOTING EQUIP

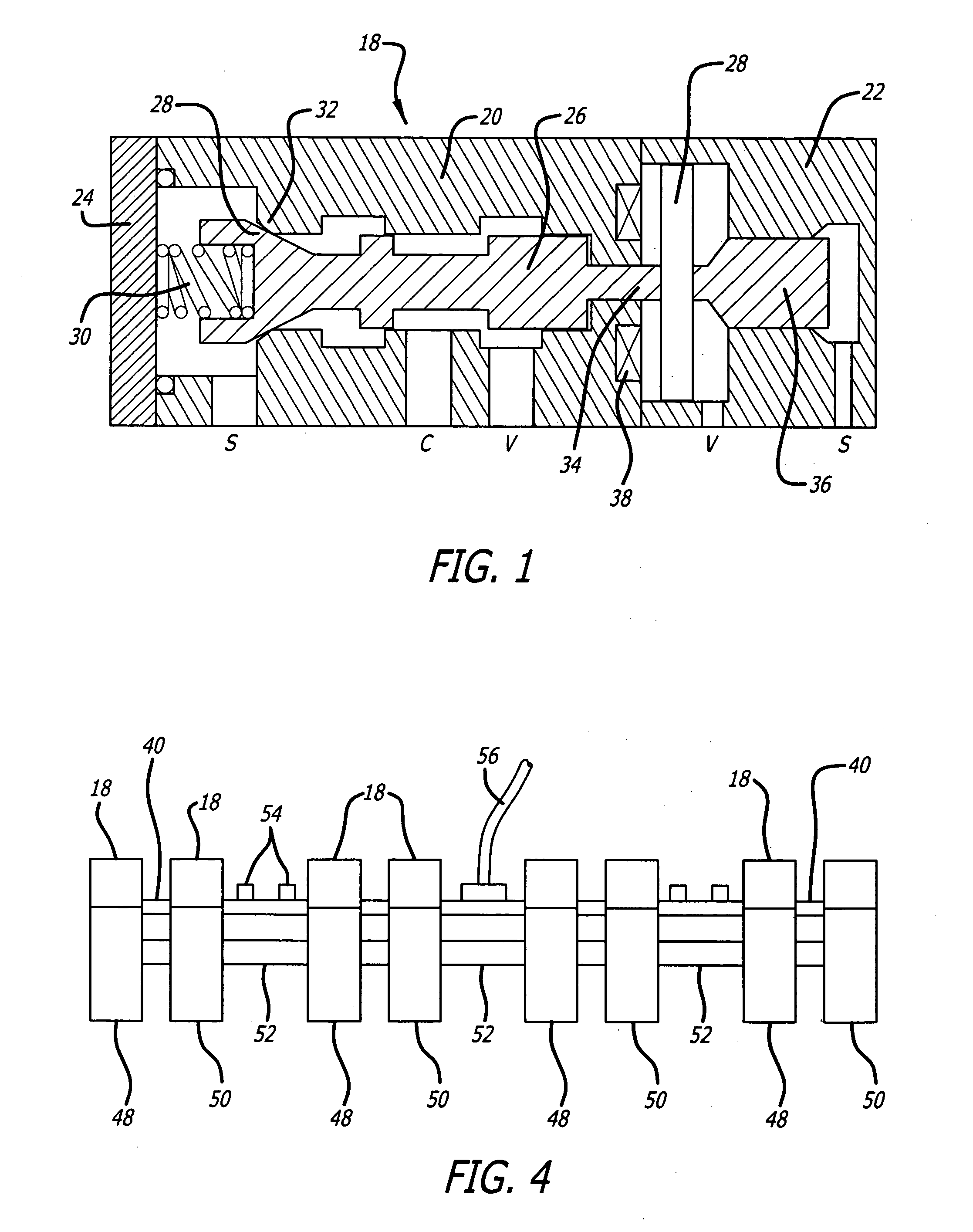

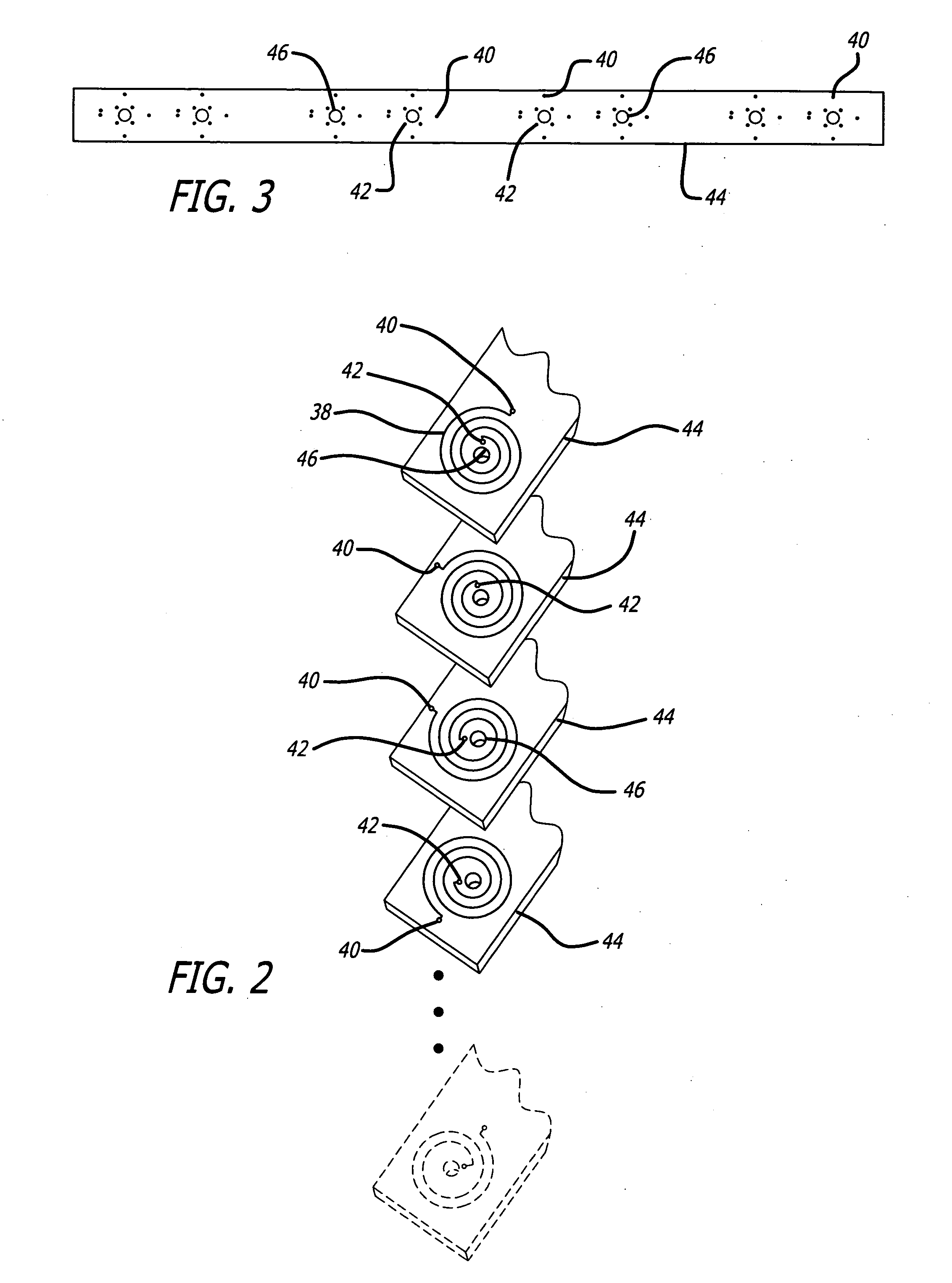

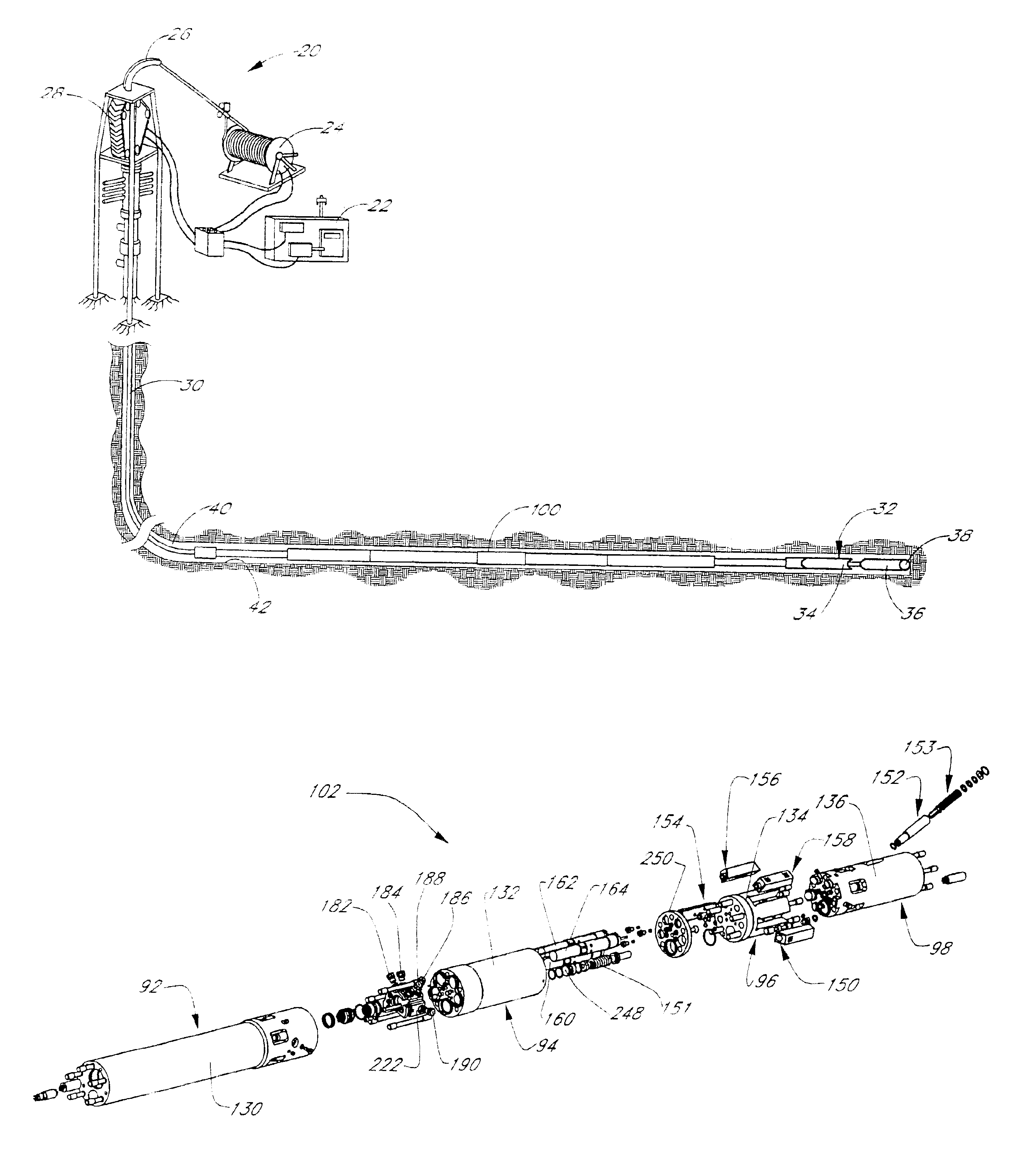

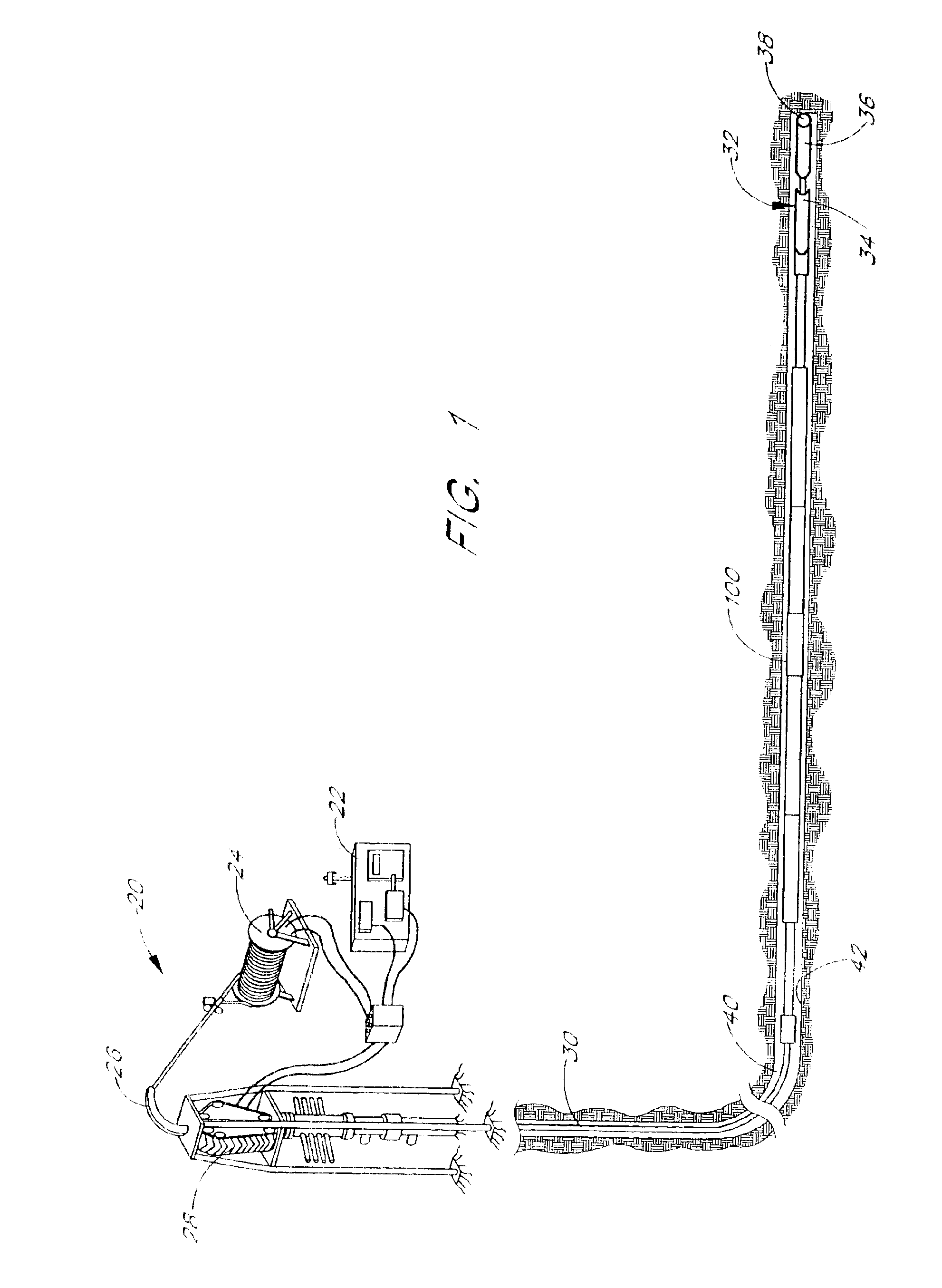

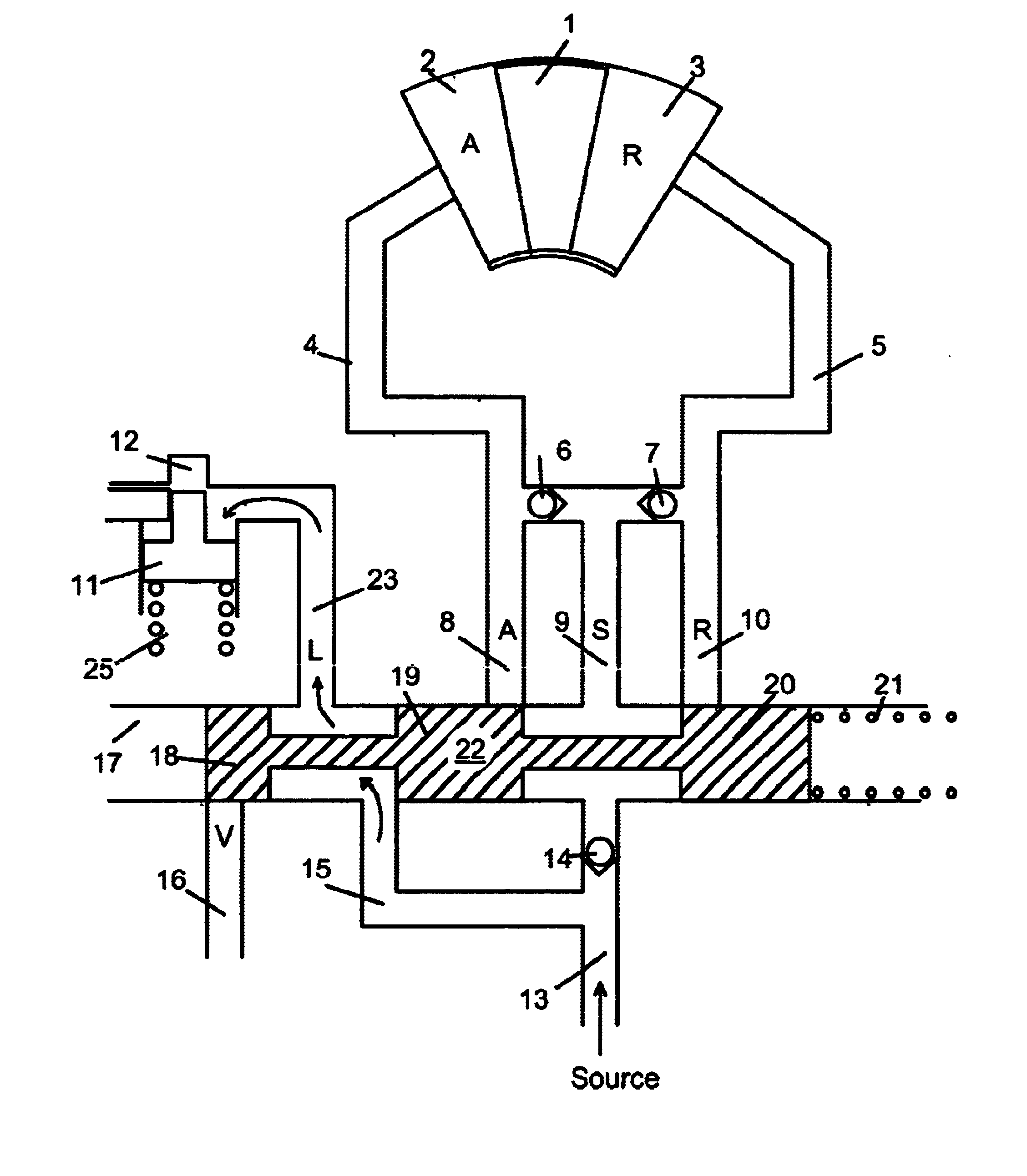

Cemented Open Hole Selective Fracing System

A cemented open hole selective fracing system and method are shown. In the producing zone, an open hole is drilled therein and a production tubing is cemented in place. At preselected locations along the production tubing, the production tubing will have sliding valves located there along. The sliding valves may be selectively opened, and the cement around the sliding valve dissolved. Thereafter, the formation may be fraced immediately adjacent the opened sliding valve. By selectively opening different combinations of sliding valves, fracing can occur in stages with more fracing pressure and more fracing fluid being delivered deeper into the formation. Just as the sliding valves can be selectively opened, the sliding valves can also be selectively closed to protect the production of the well.

Owner:PEAK COMPLETION TECH

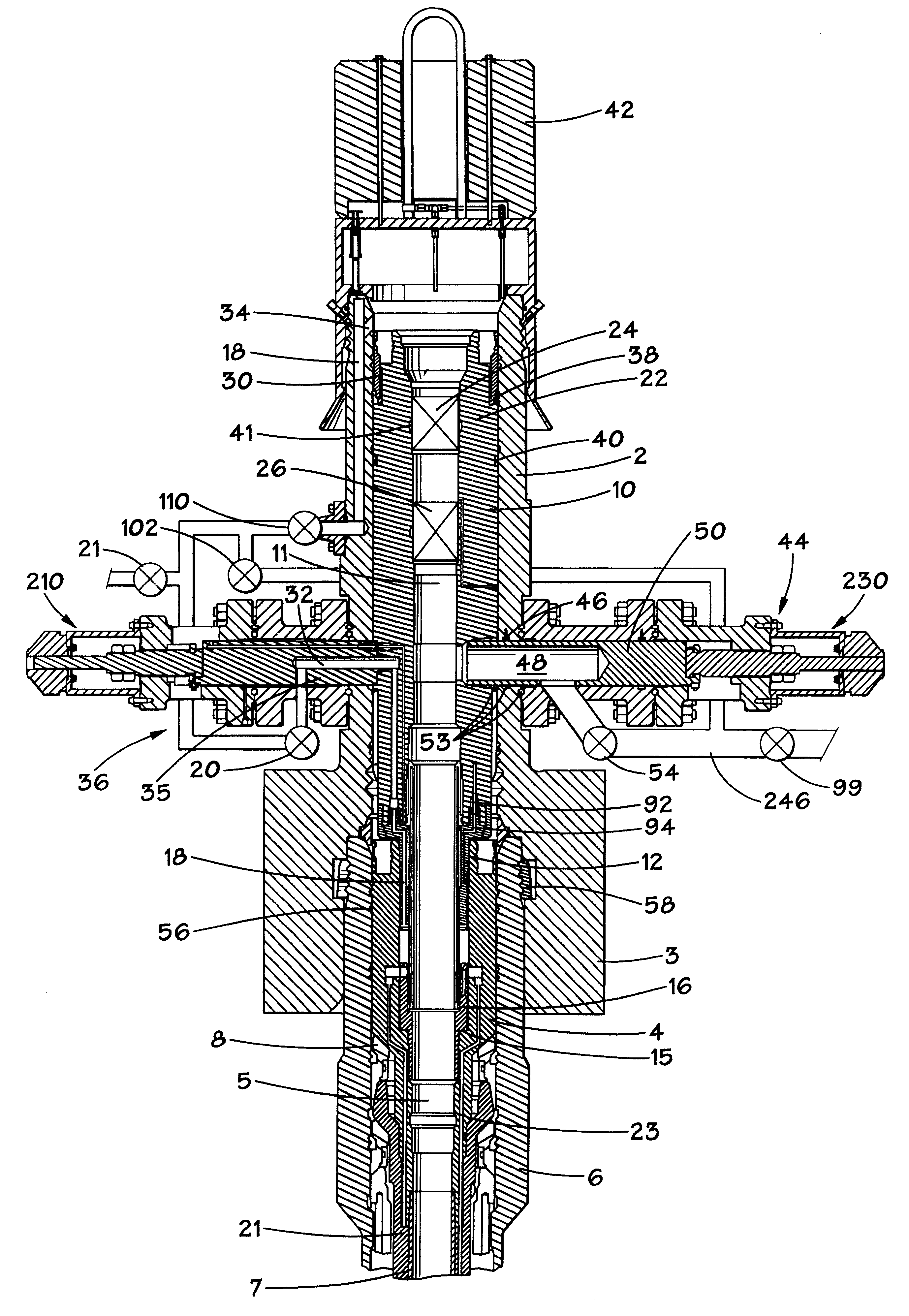

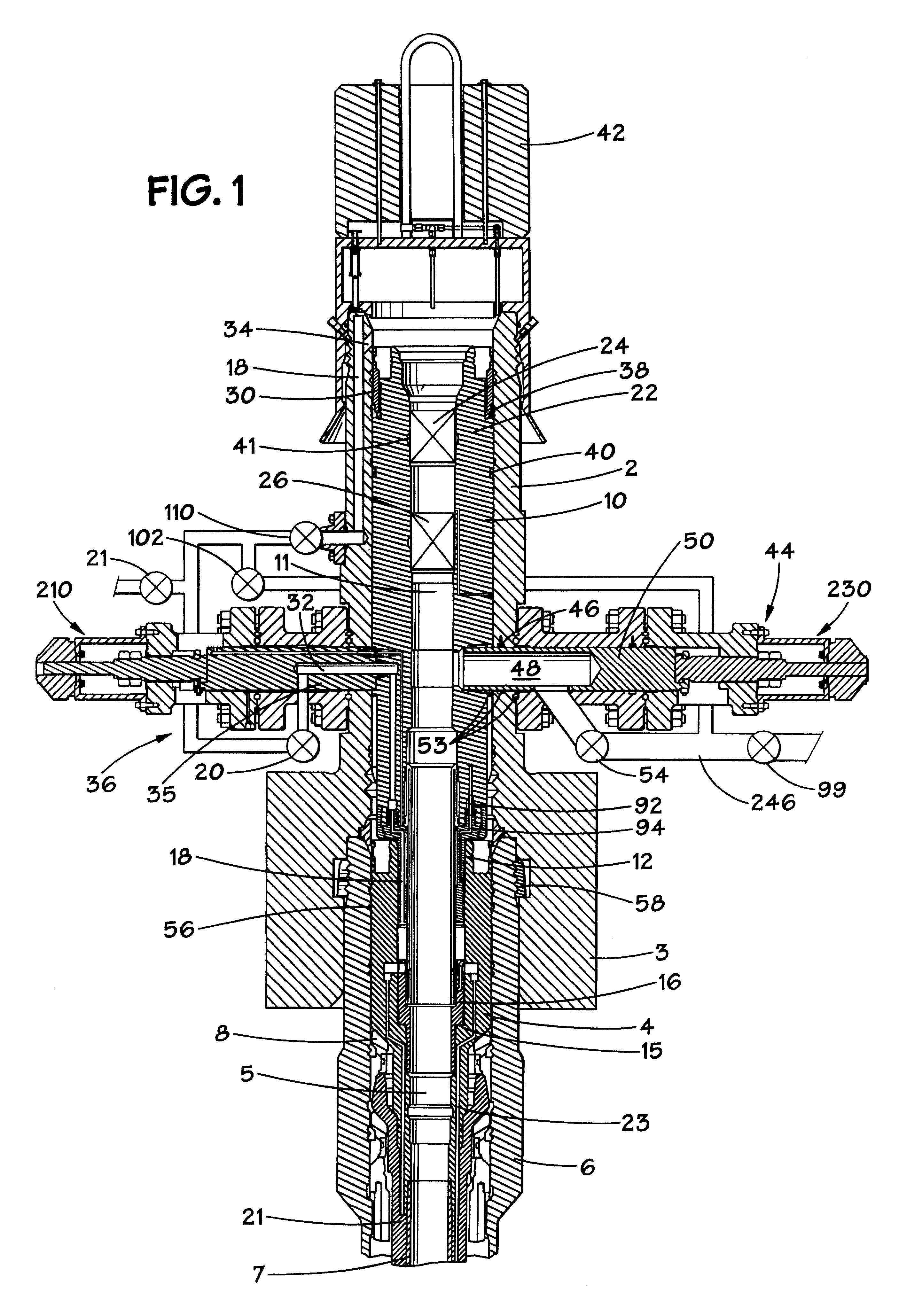

Crossover tree system

A subterranean oil or gas well apparatus is provided. The apparatus includes a single-bore production tubing hanger arranged concentric with a wellhead. The tubing hanger includes a plurality of ports and channels arranged about the tubing hanger to give operators access to the production tubing annulus and provide chemical injection capability. The ports are closable by a sliding valve. The apparatus also includes annulus and production radial-bore stab assemblies between a christmas tree and an internal crossover assembly. The stab assemblies are extendable and retractable between the chirstmas tree and the crossover assembly to allow the retrieval and installation of each independently.

Owner:AKER SOLUTIONS AS

Amplitude controlled orifice valving

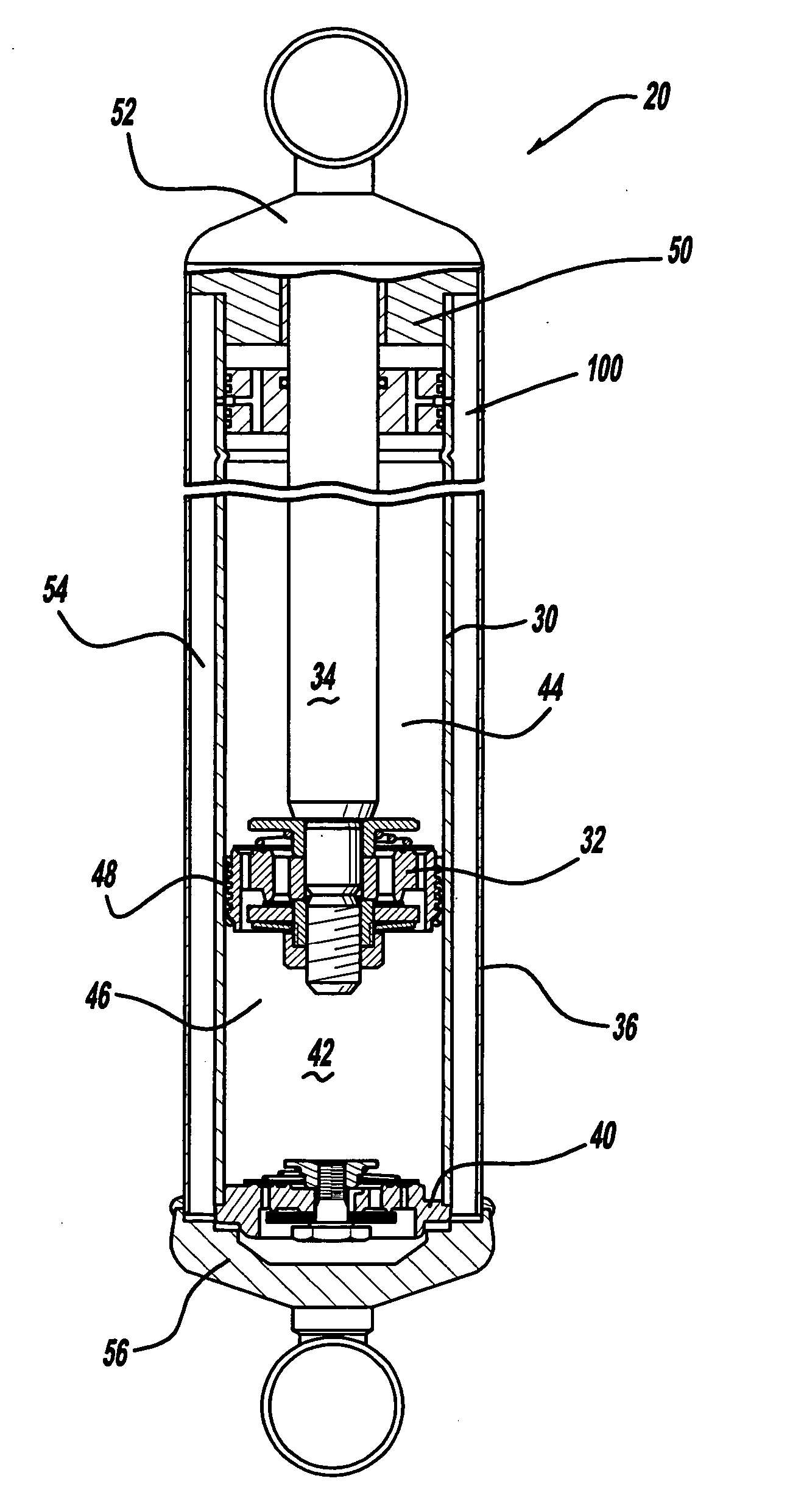

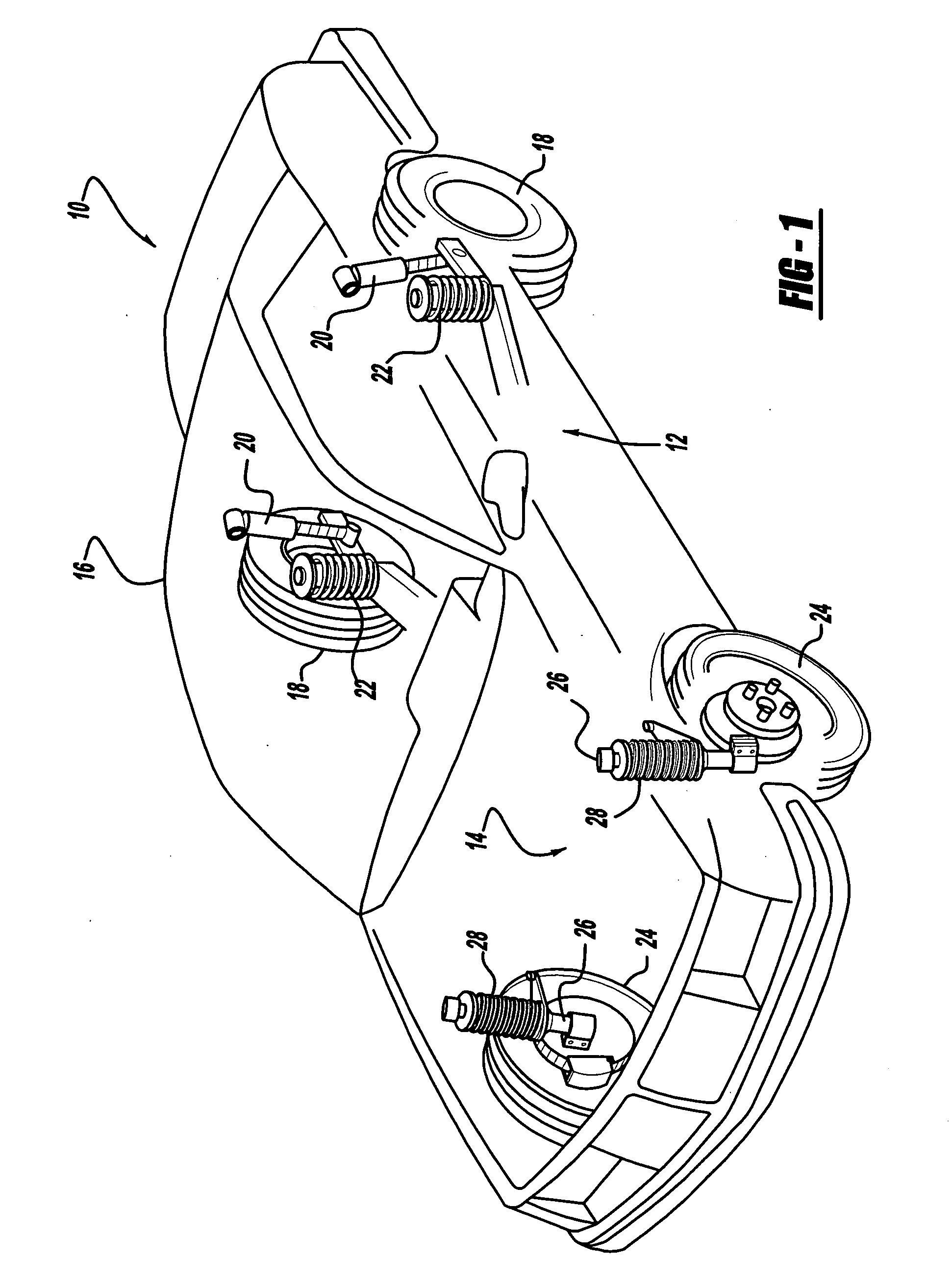

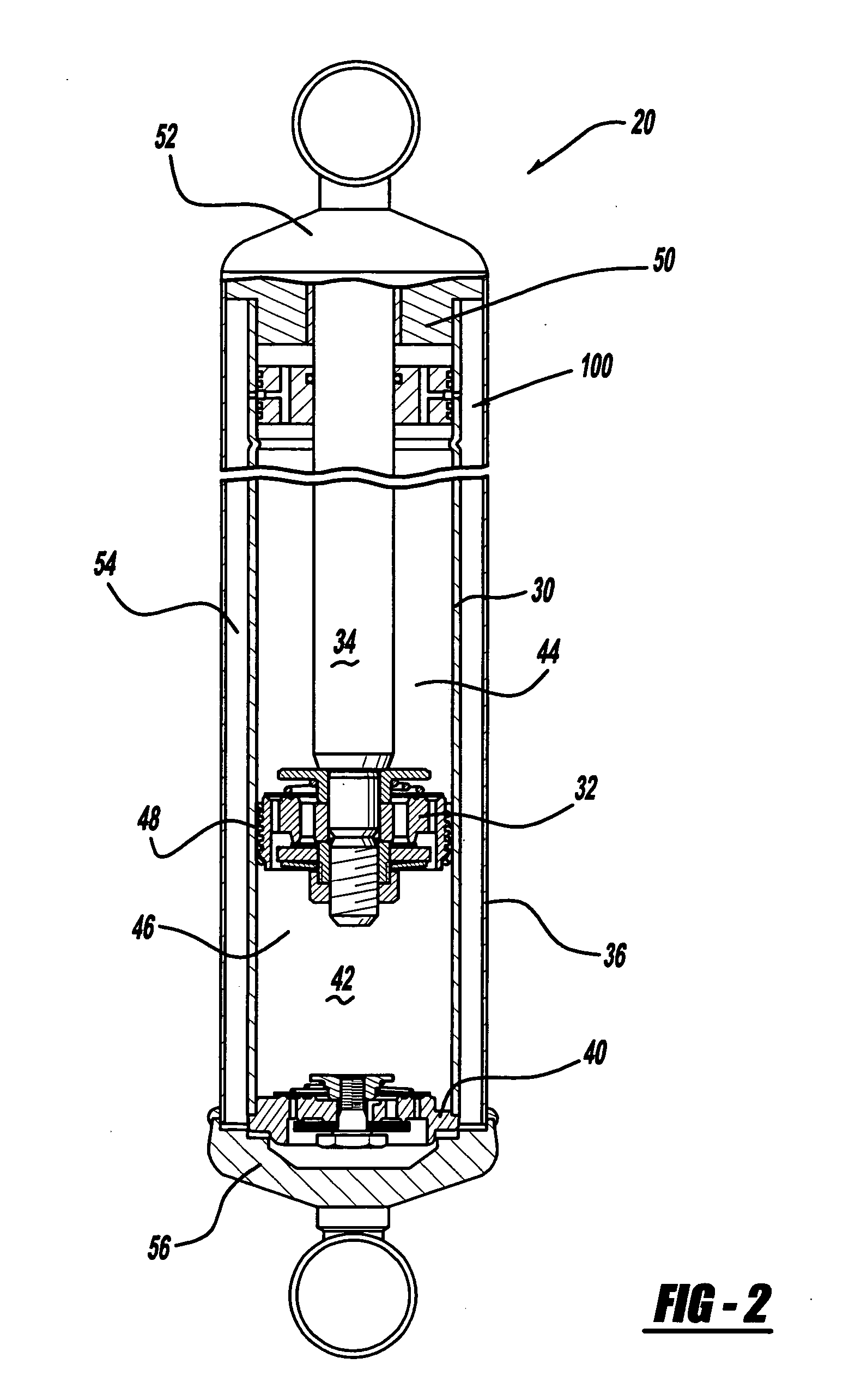

A dual tube shock absorber includes a spool valve located between the upper working chamber and the reserve chamber. The spool valve moves with the piston rod to open and close a flow path between the upper working chamber and the reserve chamber. This provides a low damping characteristic for small movements of the piston rod which changes to a high damping characteristic for larger movement of the piston rod.

Owner:TENNECO AUTOMOTIVE OPERATING CO INC

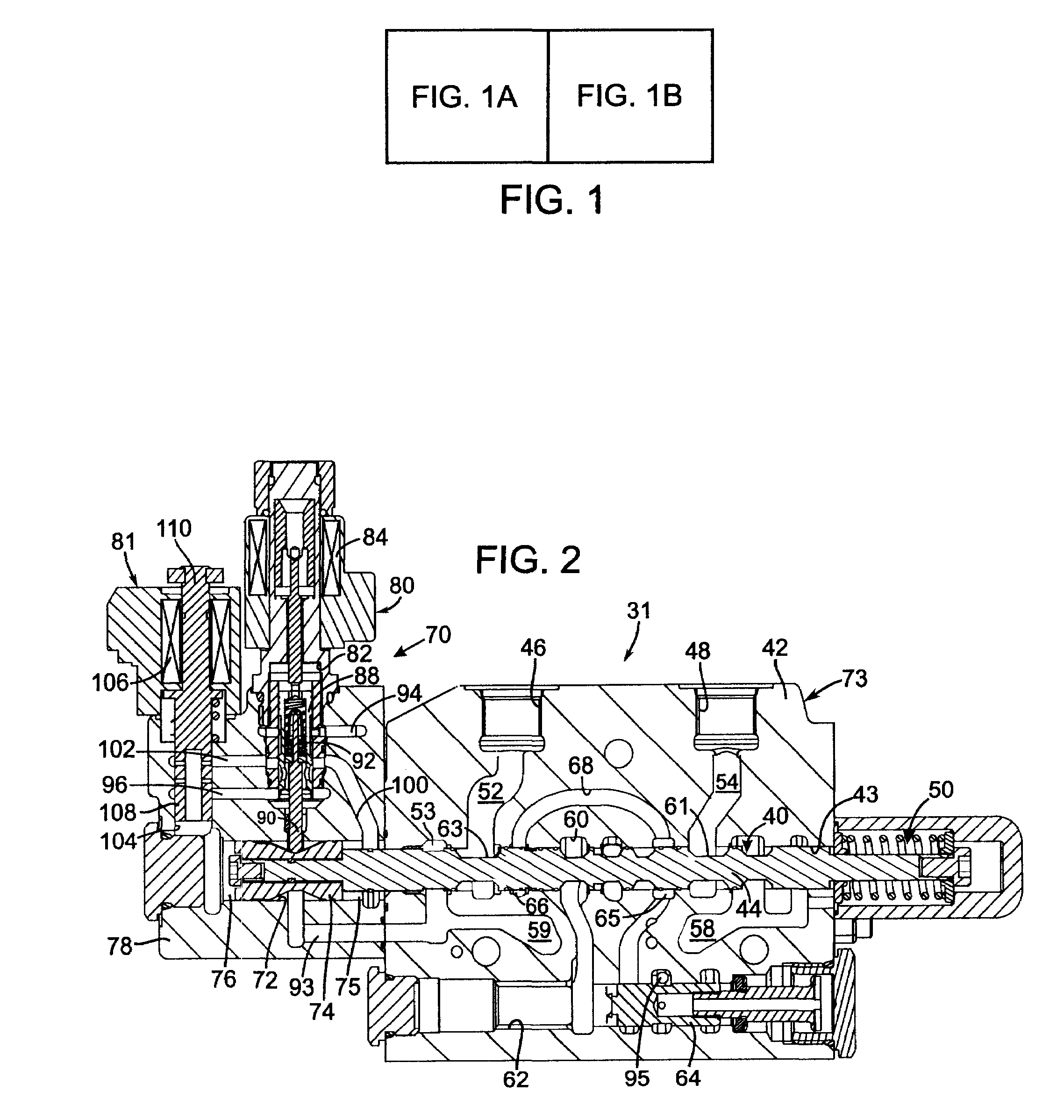

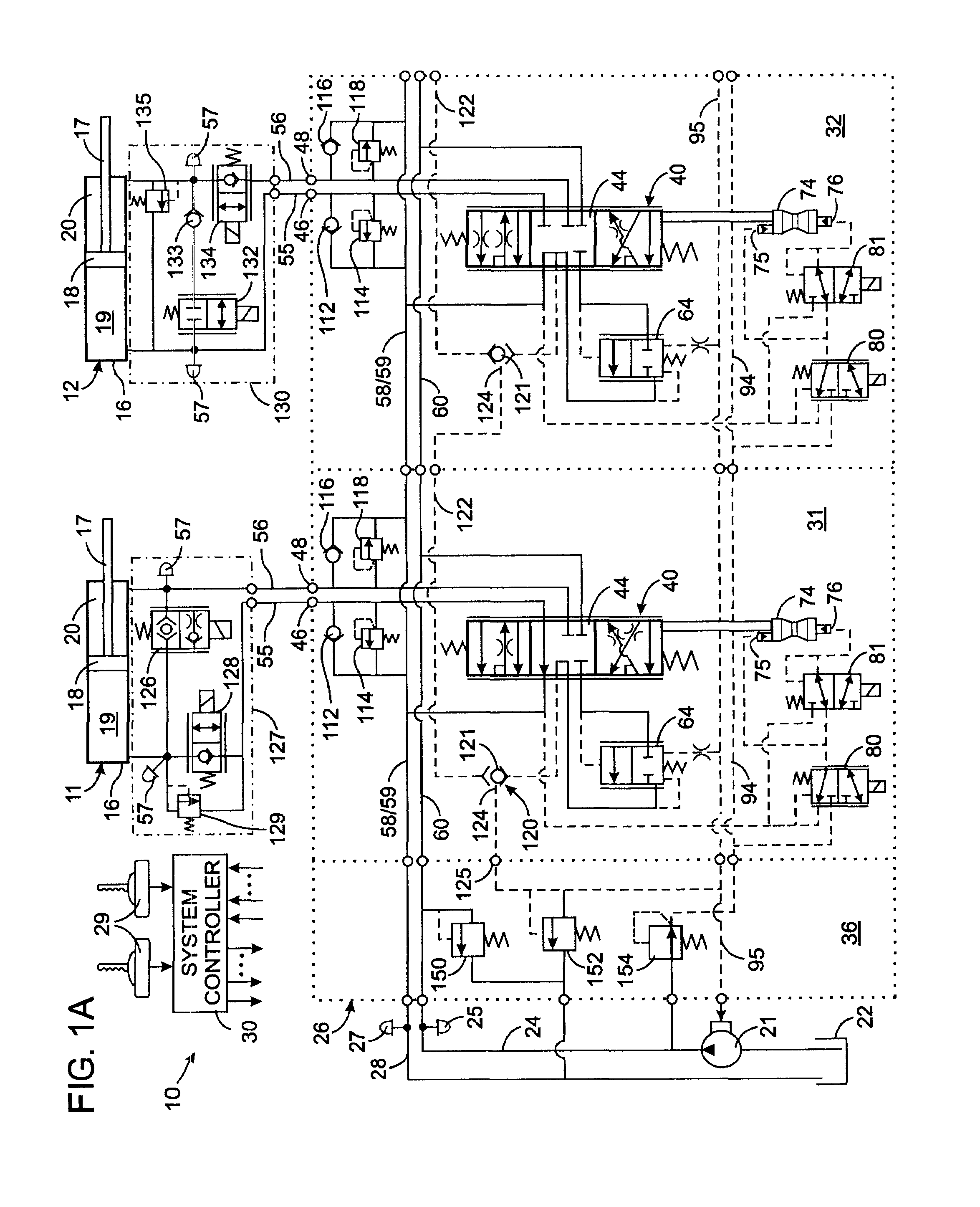

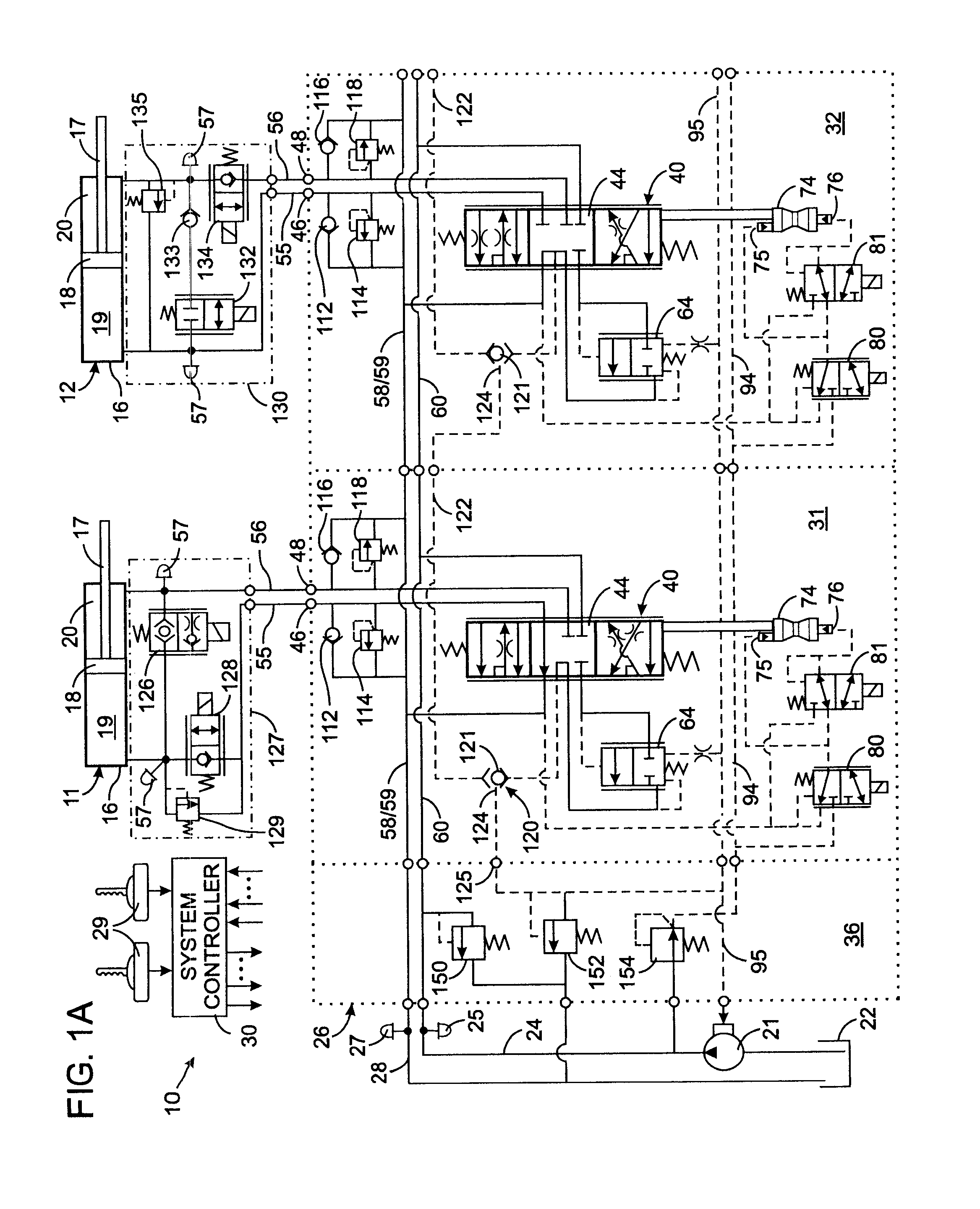

Hydraulic valve assembly with a pressure compensated directional spool valve and a regeneration shunt valve

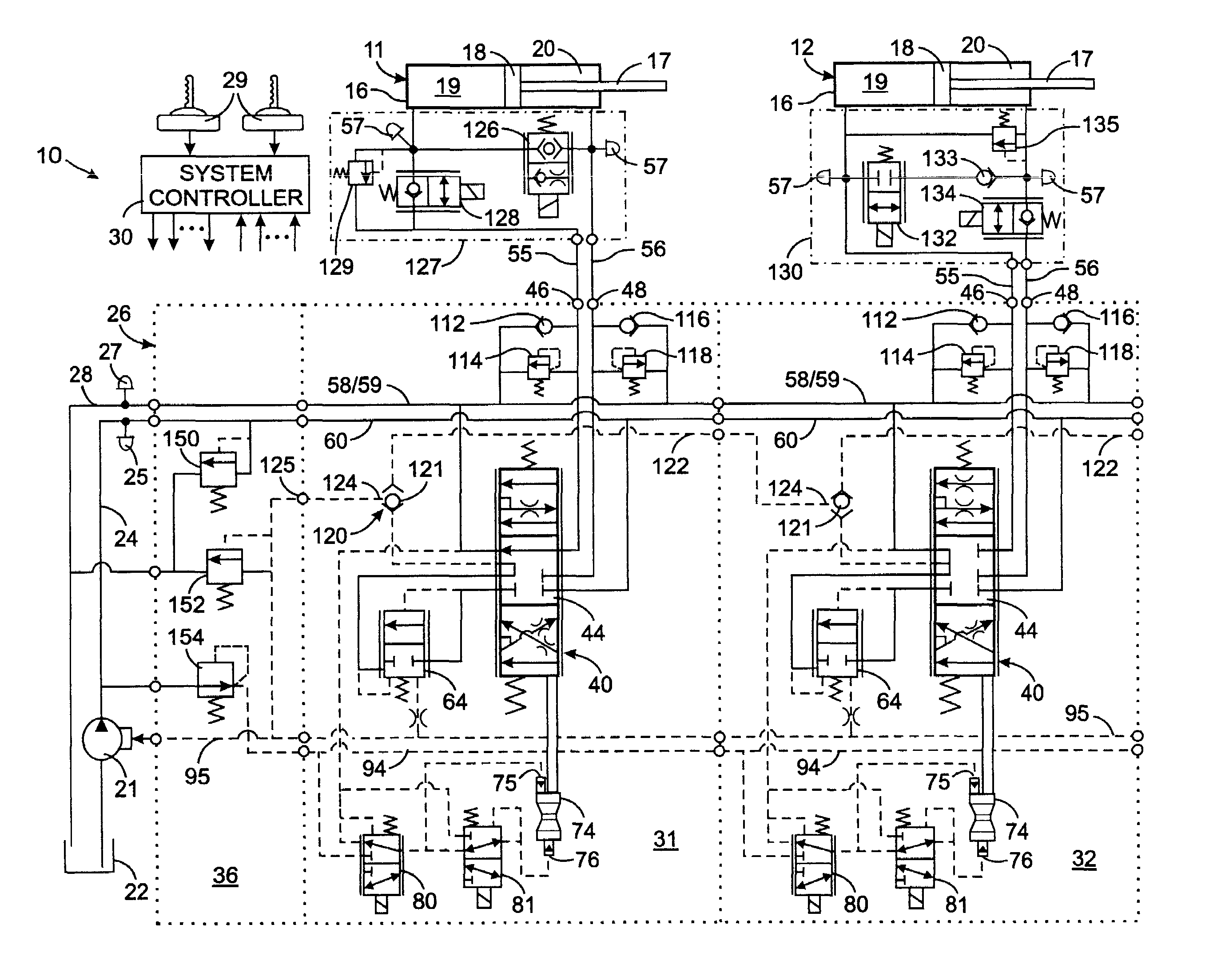

A hydraulic circuit controls flow of fluid between first and second ports of a hydraulic actuator, such as a cylinder / piston arrangement and each of a supply conduit and a tank return conduit. The hydraulic circuit operates in standard powered operating modes as well as powered and unpowered regeneration modes. In a powered operating mode, a conventional pressure compensated spool valve determines the velocity of the hydraulic actuator. A workport blocking valve connects one workport of the spool valve to the first port and the other workport is connected to the second port. A regeneration shunt valve is directly connected between the first and second ports of the hydraulic actuator. In a regeneration operating mode or a mix of powered and regeneration modes, a combination of the spool valve, the workport blocking valve, and the regeneration shunt valve determines the velocity of the hydraulic actuator.

Owner:HUSCO INT INC

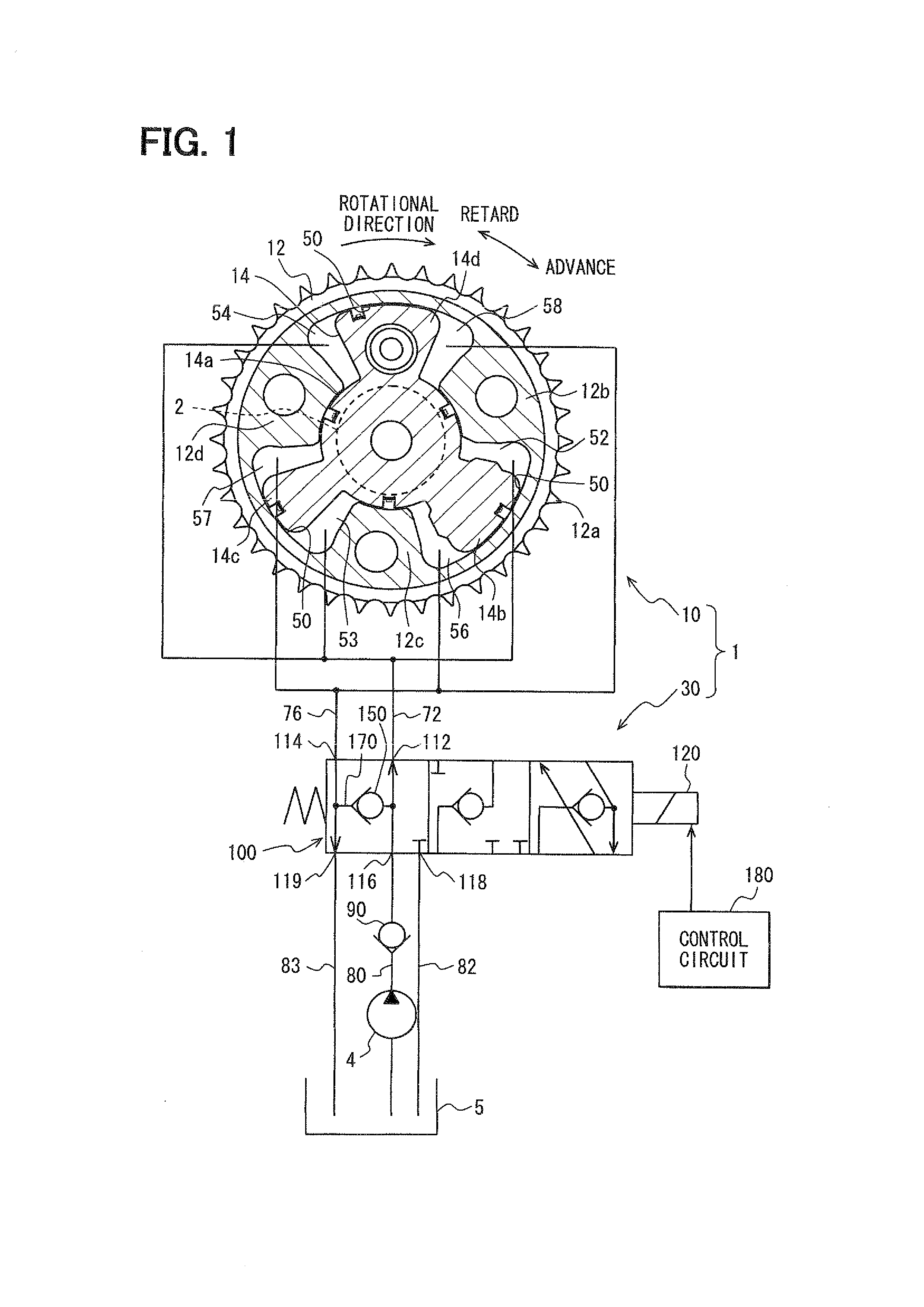

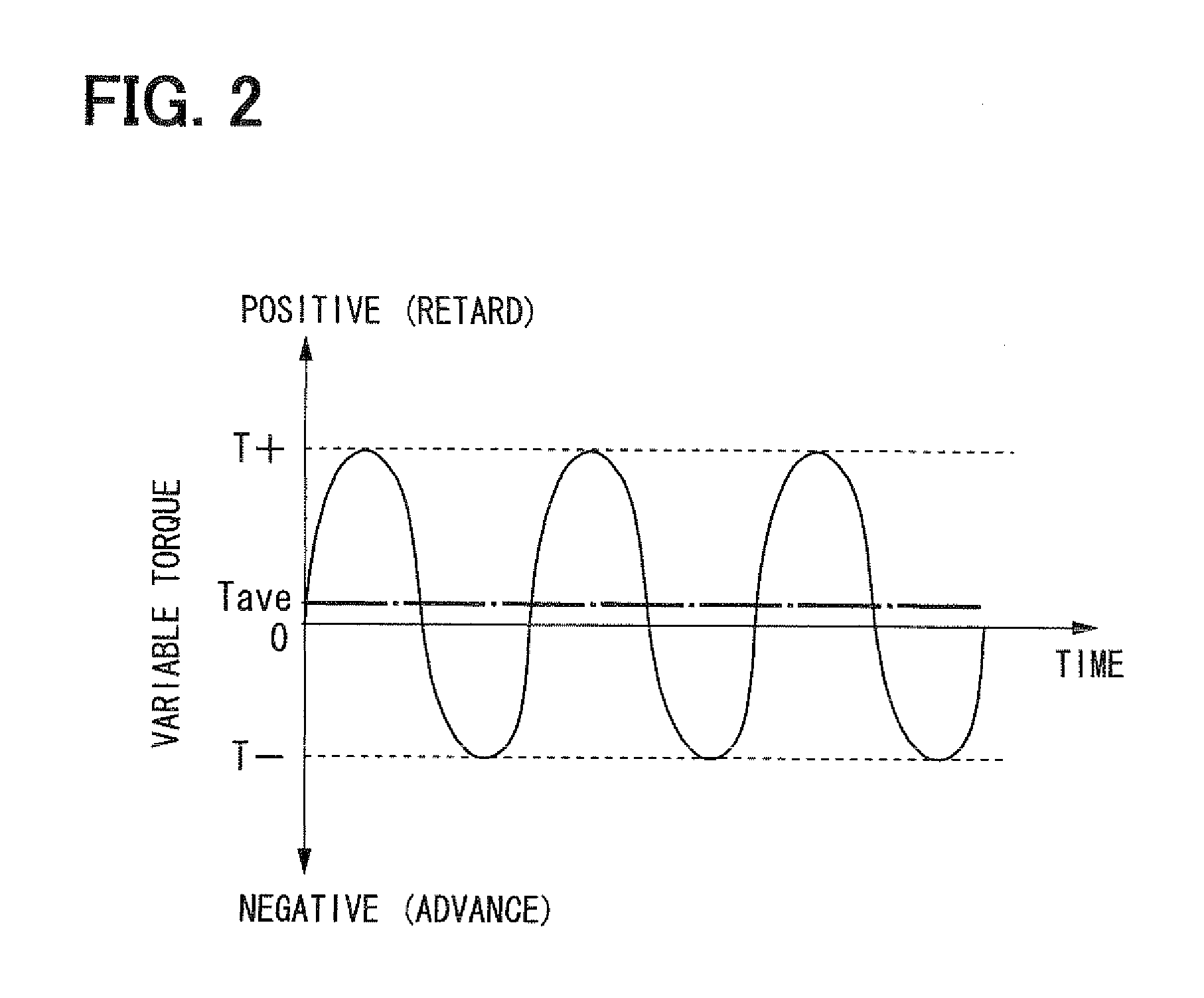

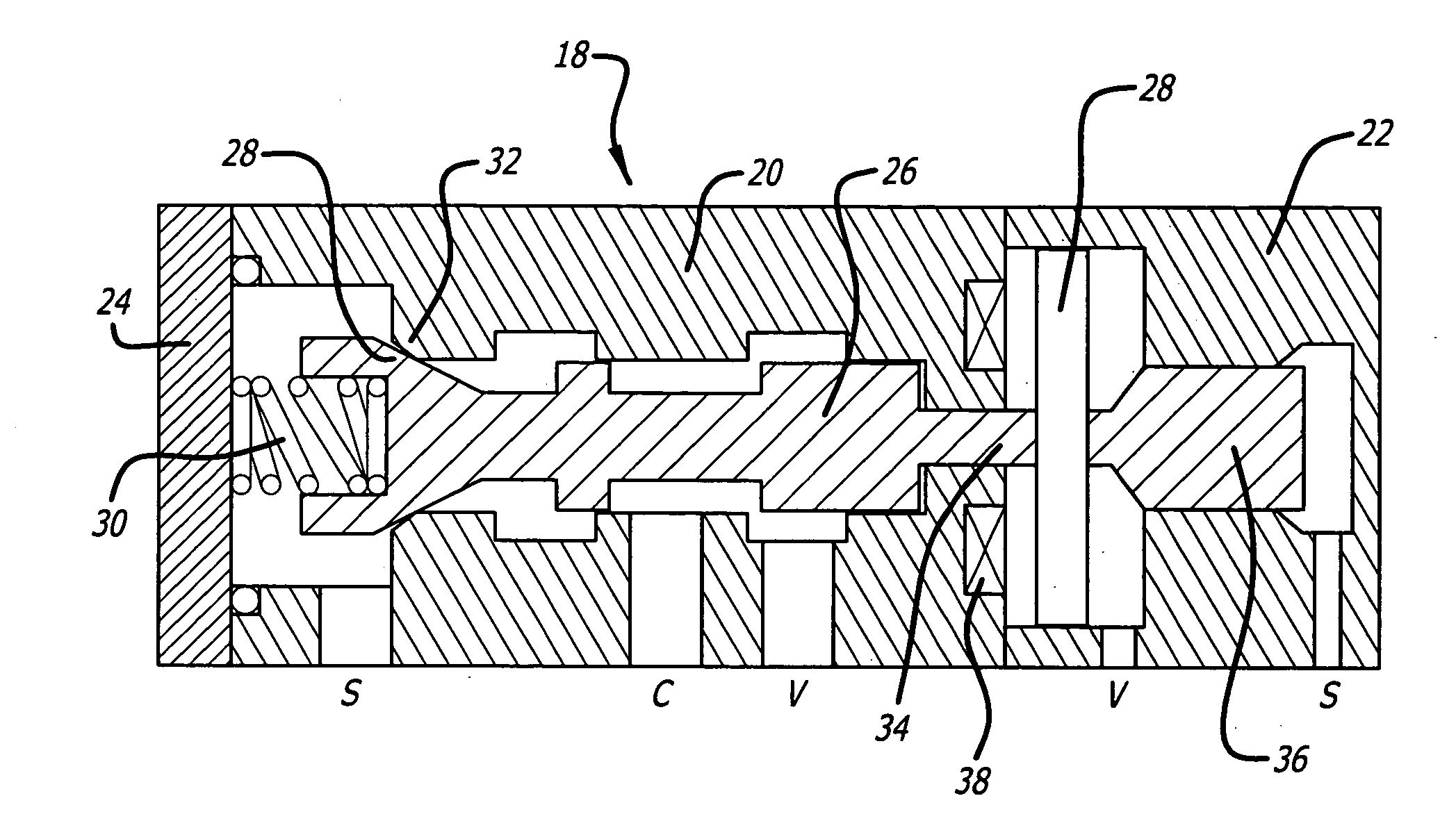

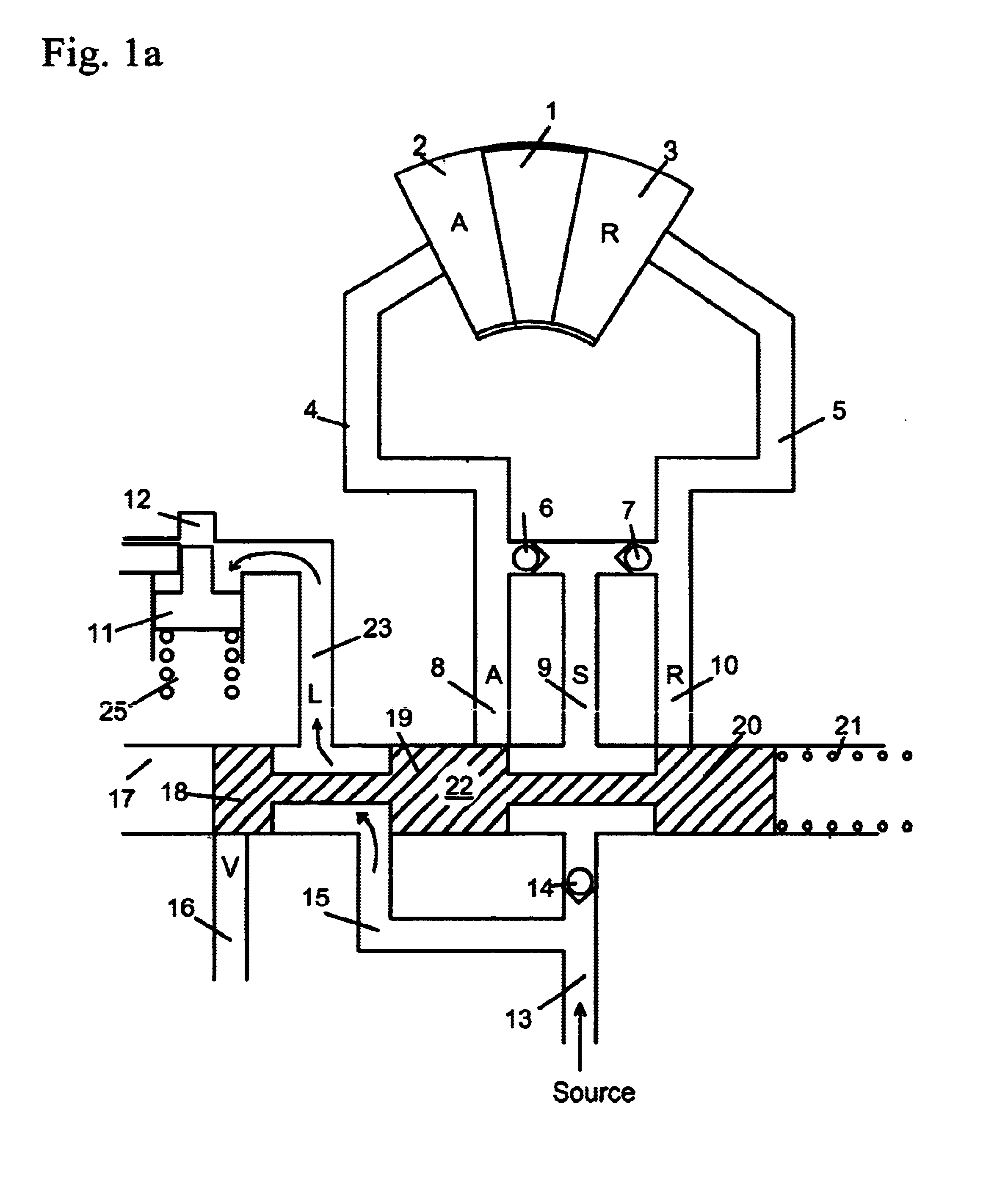

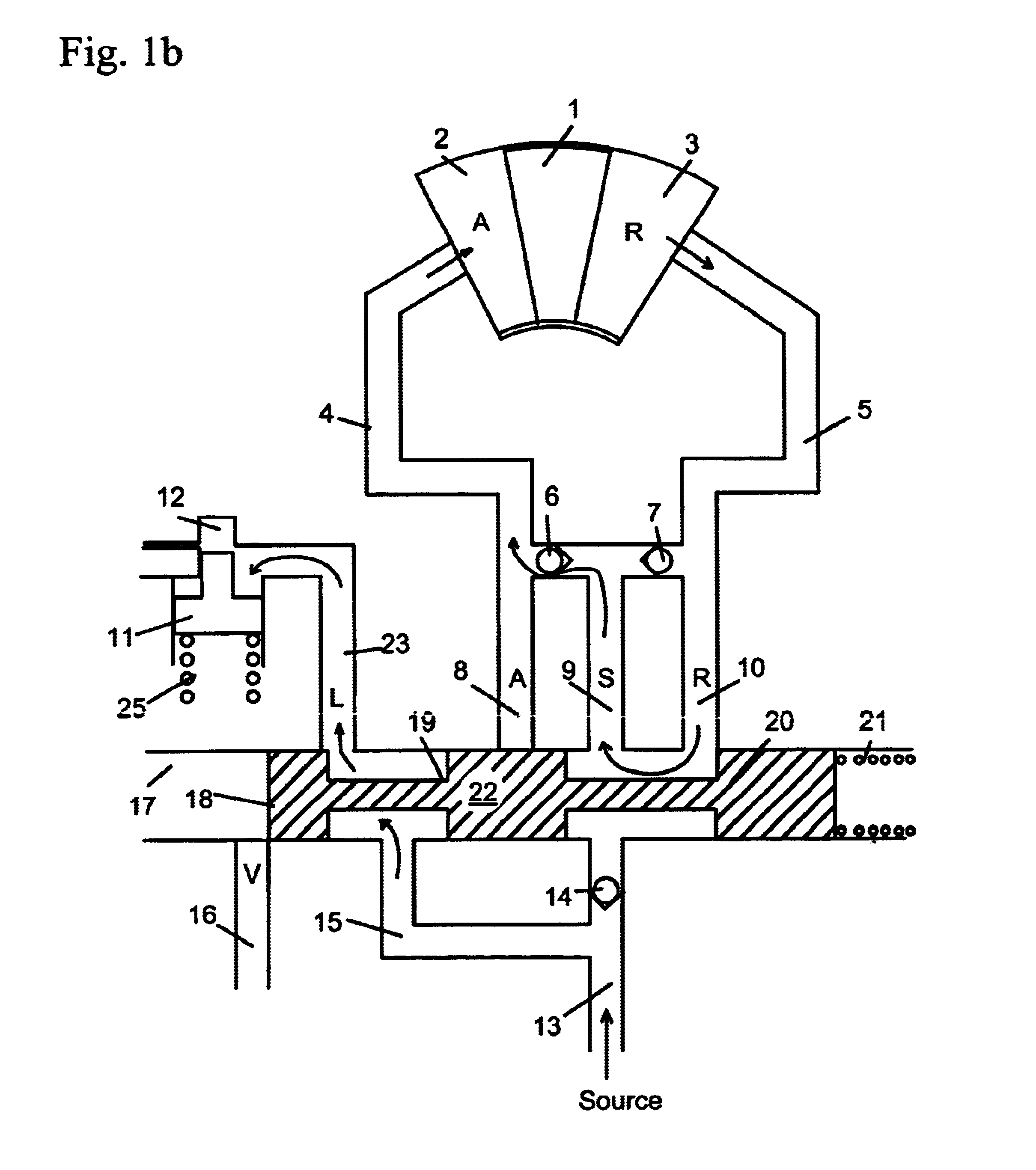

Valve timing control apparatus

A valve timing control apparatus for controlling valve timing includes a first rotor, a second rotor, and a controller. The second rotor and the first rotor defines therebetween an advance chamber and a retard chamber. The controller includes a supply passage, at least one drain passage, a spool valve, at least one connection passage, and at least one check valve. The at least one connection passage connects the supply passage to the at least one drain passage when a spool of the spool valve is moved to one of the advance and retard positions. The at least one check valve is respectively provided in the at least one connection passage. The check valve allows working fluid to flow in a direction from the at least one drain passage toward the supply passage and limits working fluid from flowing in an opposite direction.

Owner:DENSO CORP

Cemented open hole selective fracing system

A cemented open hole selective fracing system and method are shown. In the producing zone, an open hole is drilled therein and a production tubing is cemented in place. At preselected locations along the production tubing, the production tubing will have sliding valves located there along. The sliding valves may be selectively opened, and the cement around the sliding valve dissolved. Thereafter, the formation may be fraced immediately adjacent the opened sliding valve. By selectively opening different combinations of sliding valves, fracing can occur in stages with more fracing pressure and more fracing fluid being delivered deeper into the formation. Just as the sliding valves can be selectively opened, the sliding valves can also be selectively closed to protect the production of the well.

Owner:PEAK COMPLETION TECH

Magnetically sequenced pneumatic motor

A pneumatic motor having a piston and a magnetically actuated valve. The magnetically actuated valve may be adjacent the piston and, in some embodiments, include a spool valve.

Owner:CARLISLE FLUID TECH INC

Gas turbine engine with transmission

A multi spool gas turbine engine with a differential having a selectively rotatable member which rotational speed determines a variable ratio between rotational speeds of driven and driving members of the differential. The driven member is engaged to the first spool and a rotatable shaft independent of the other spools (e.g. connected to a compressor rotor) is engaged to the driving member. First and second power transfer devices are engaged to the first spool and the selectively rotatable member, respectively. A circuit interconnects the power transfer devices and allows a power transfer therebetween, and a control unit controls the power being transferred between the power transfer devices. Power can thus be transferred between the first spool and the selectively rotatable member to change the speed ratio between the first spool and the rotatable shaft.

Owner:PRATT & WHITNEY CANADA CORP

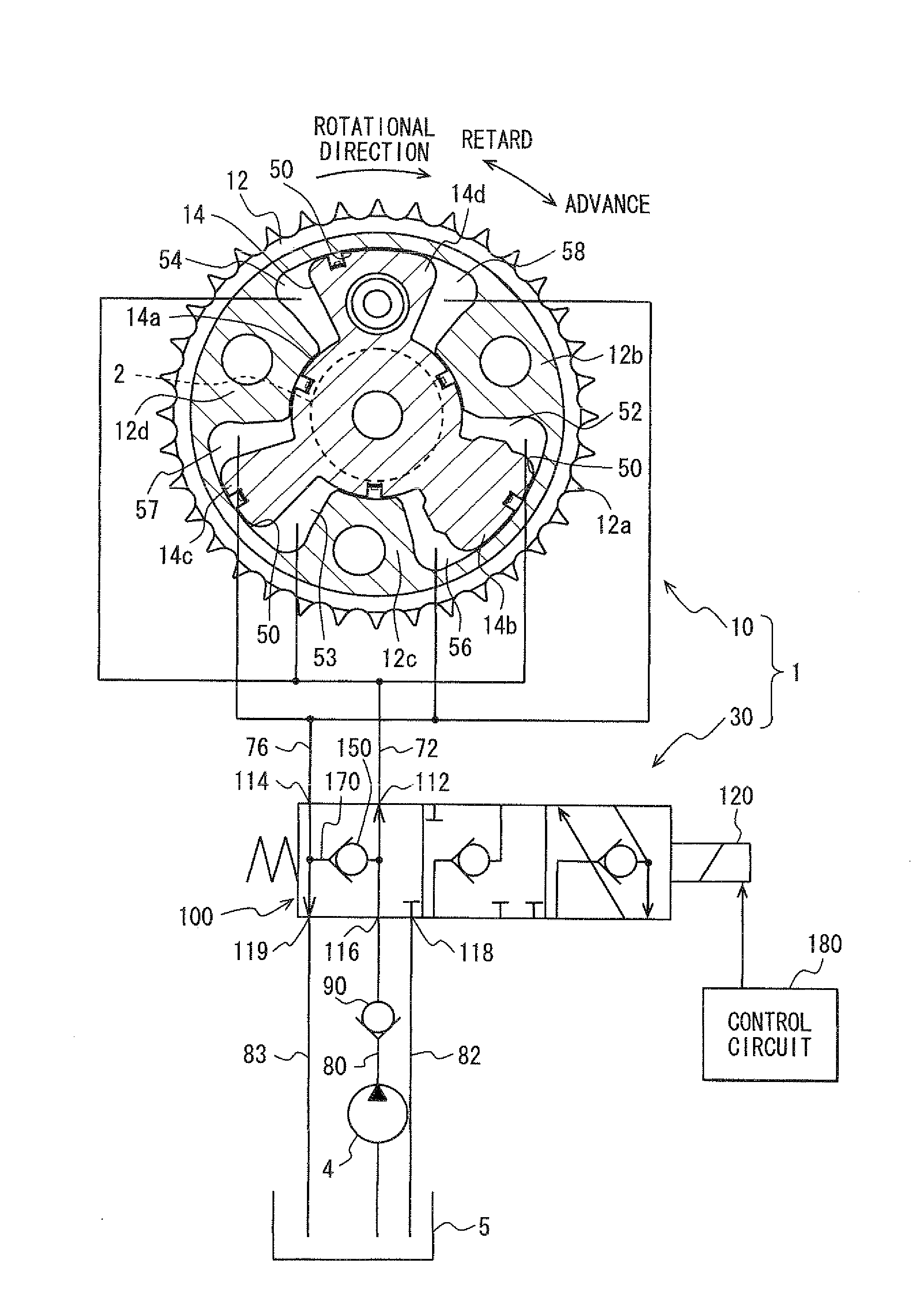

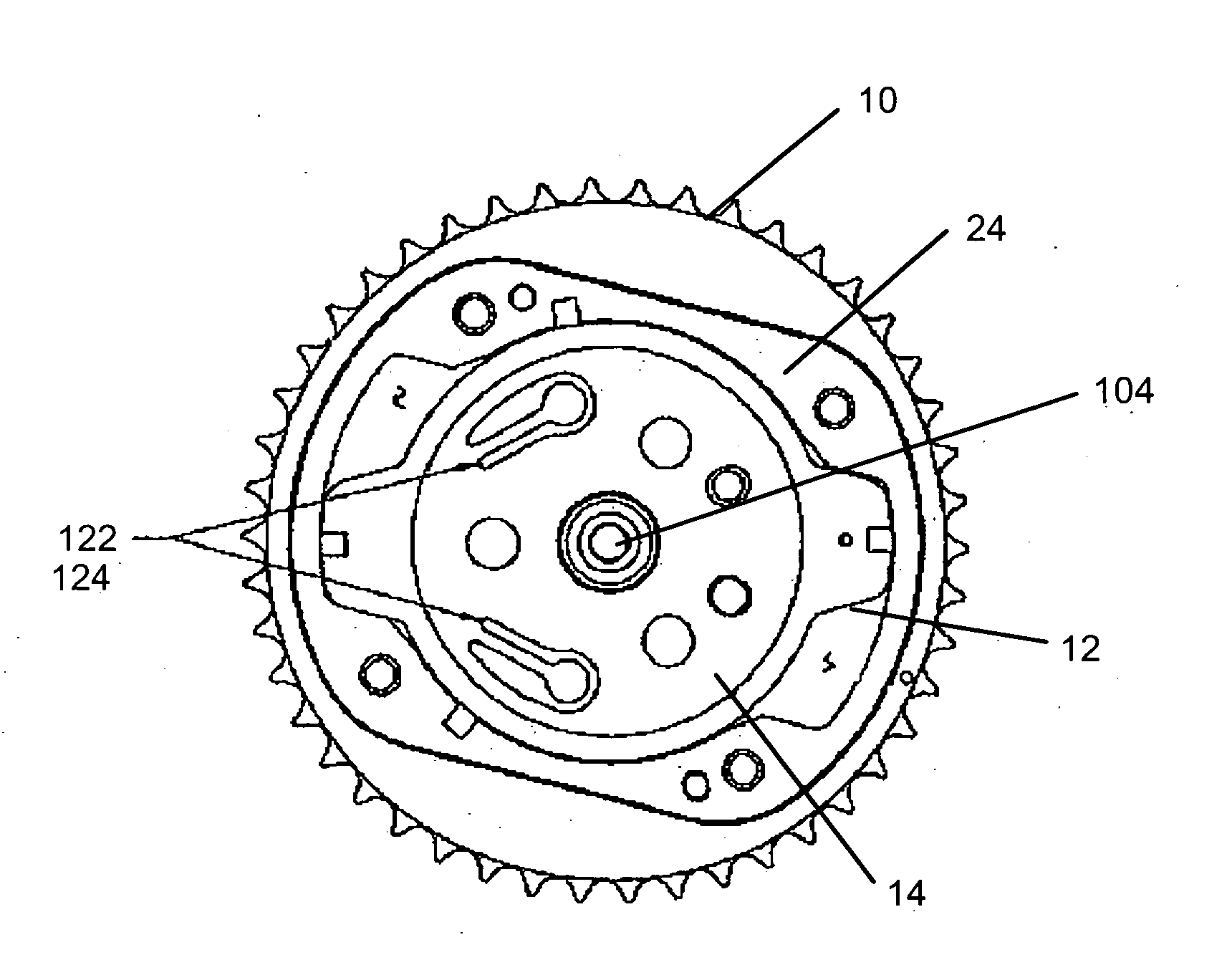

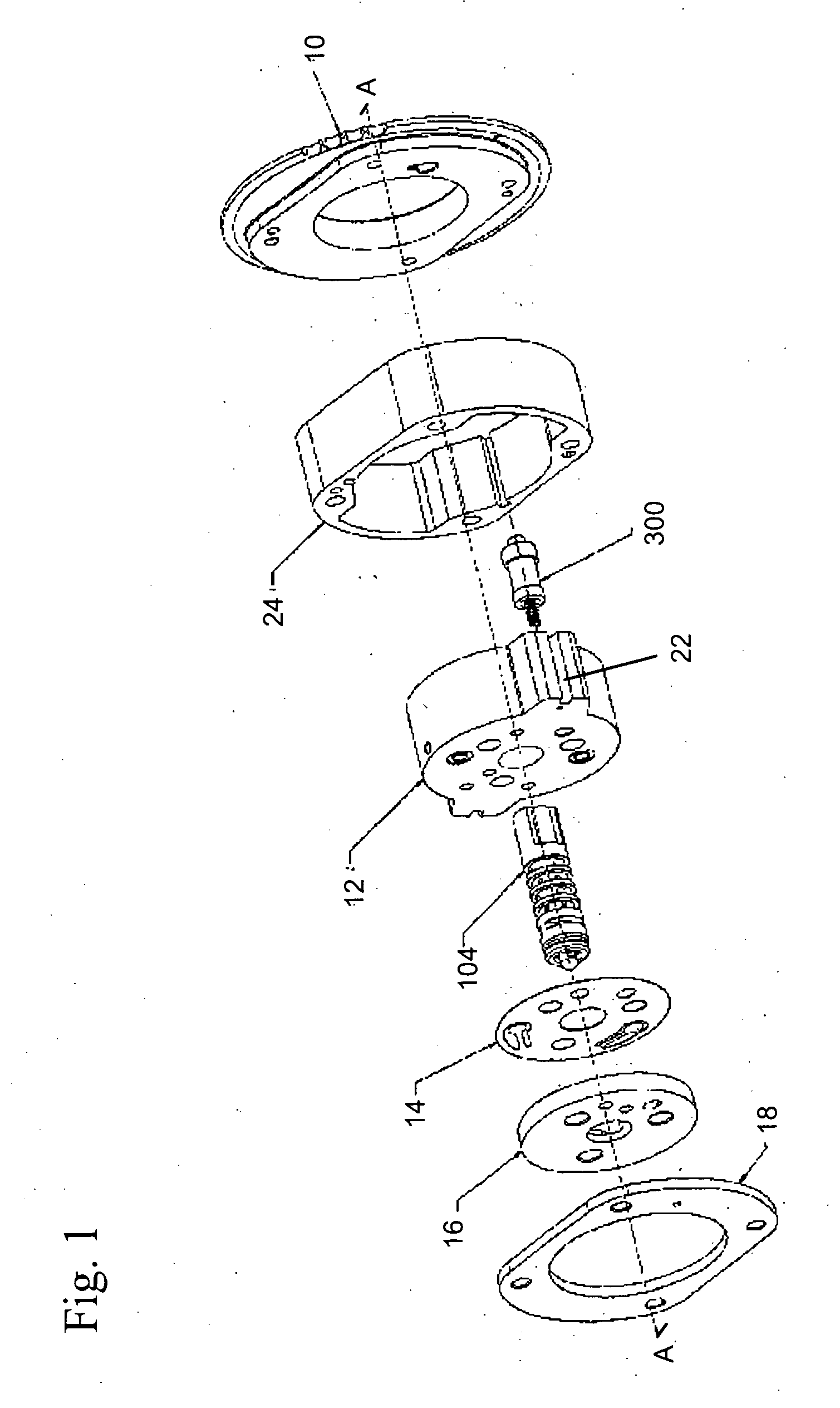

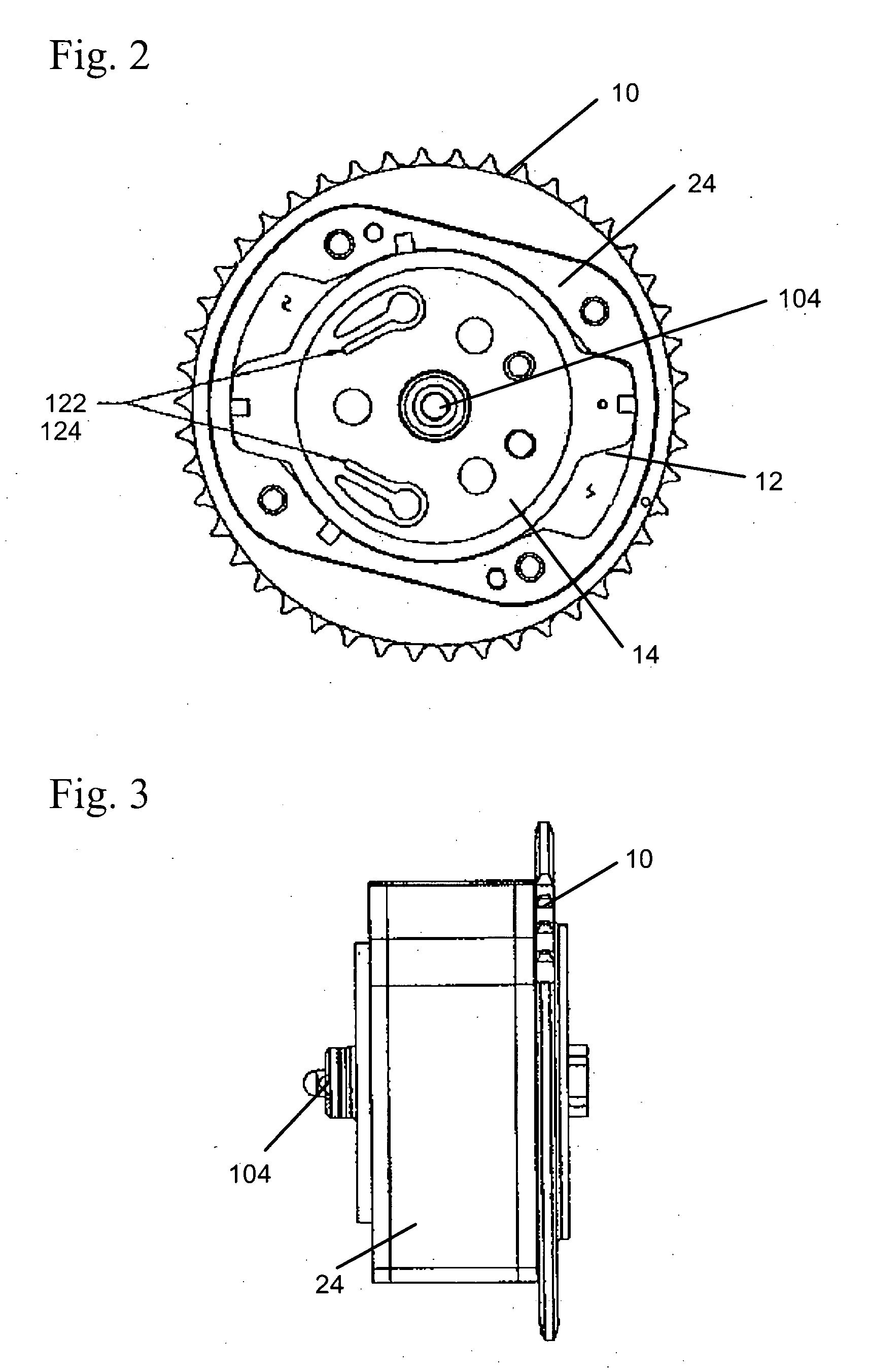

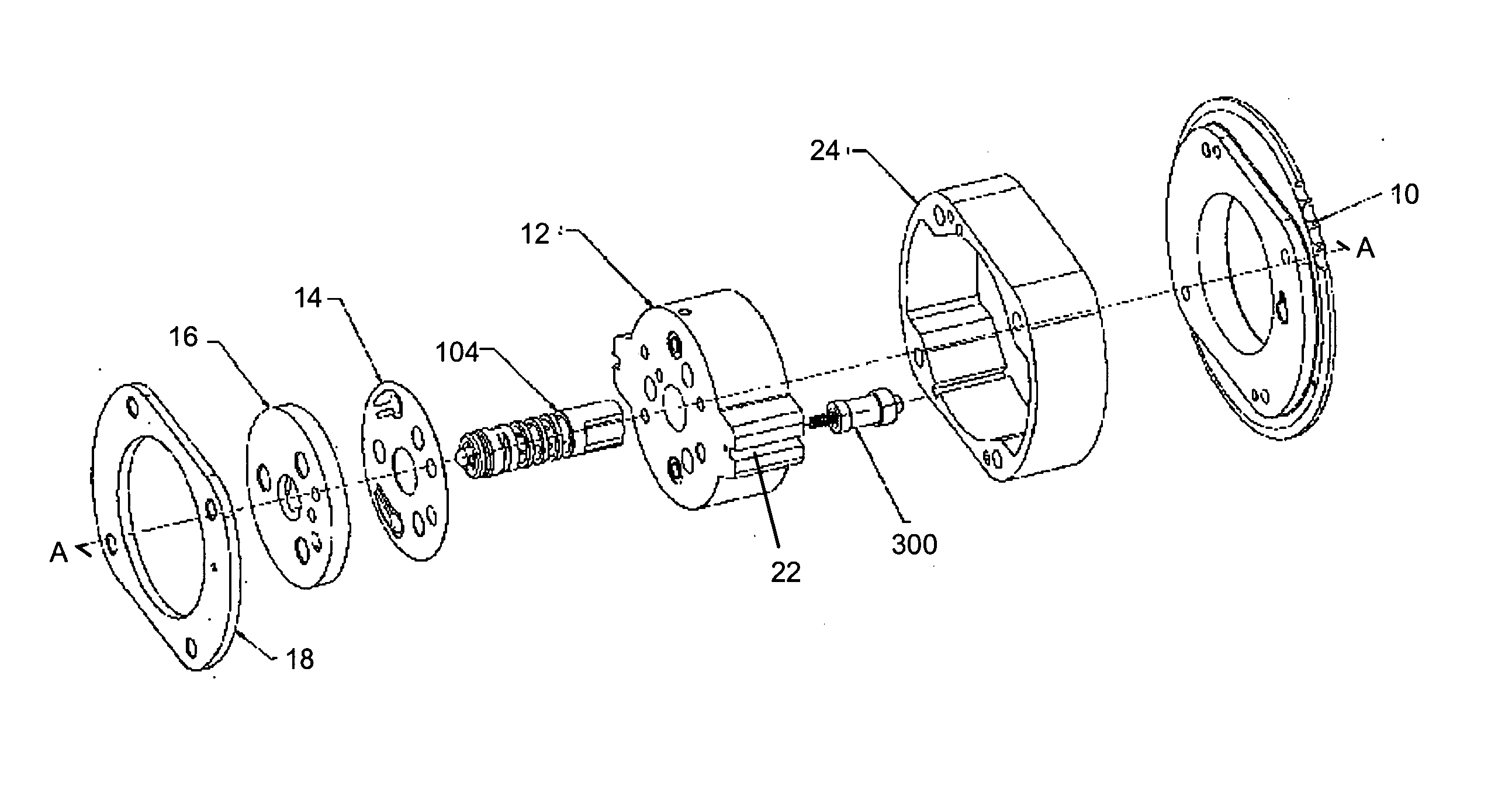

CTA phaser with proportional oil pressure for actuation at engine condition with low cam torsionals

A variable camshaft timing phaser for an internal combustion engine having at least one camshaft comprising a plurality of vanes in chambers defined by a housing and a spool valve. The vanes define an advance and a retard chamber. At least one of the vanes is cam torque actuated (CTA) and at least one of the other vanes is oil pressure actuated (OPA). The spool valve is coupled to the advance and retard chamber defined by the CTA vane and the advance chamber defined by the OPA vane. When the phaser is in the advance position, fluid is routed from the retard chamber defined by the OPA vane to the retard chamber defined the CTA vane. When the phaser is in the retard position, fluid is routed from the retard chamber defined by the CTA vane to the advance chamber defined by the CTA vane.

Owner:BORGWARNER INC

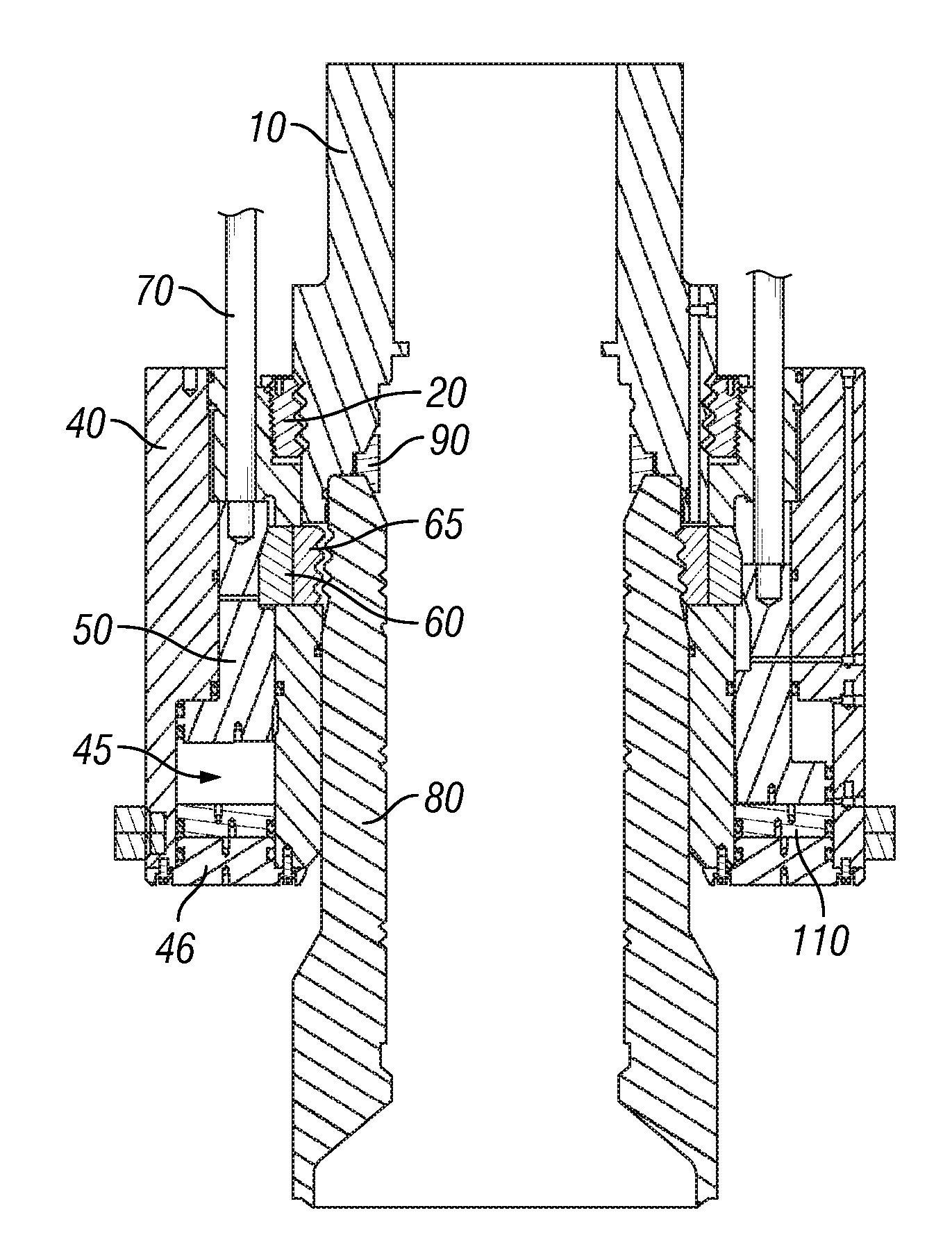

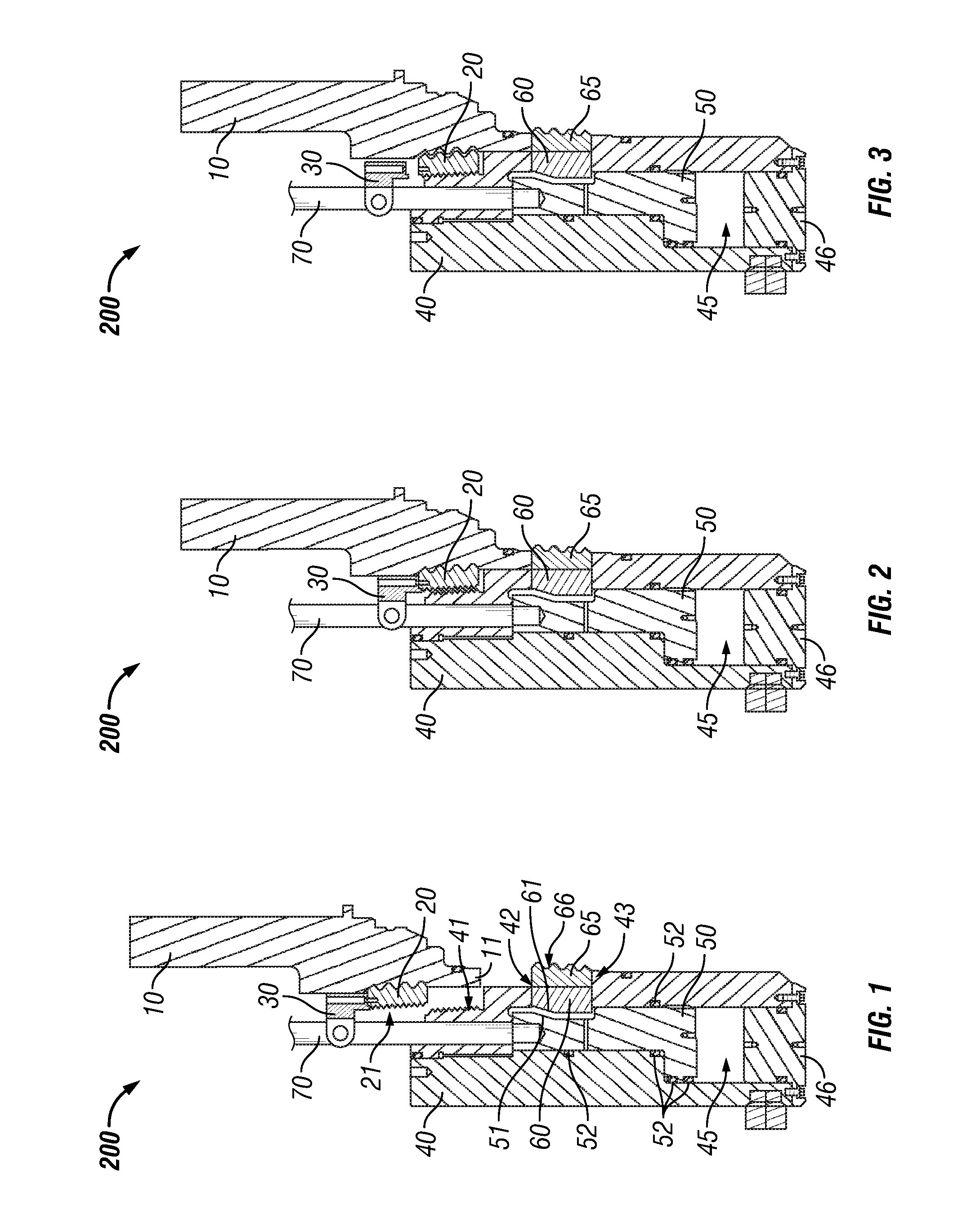

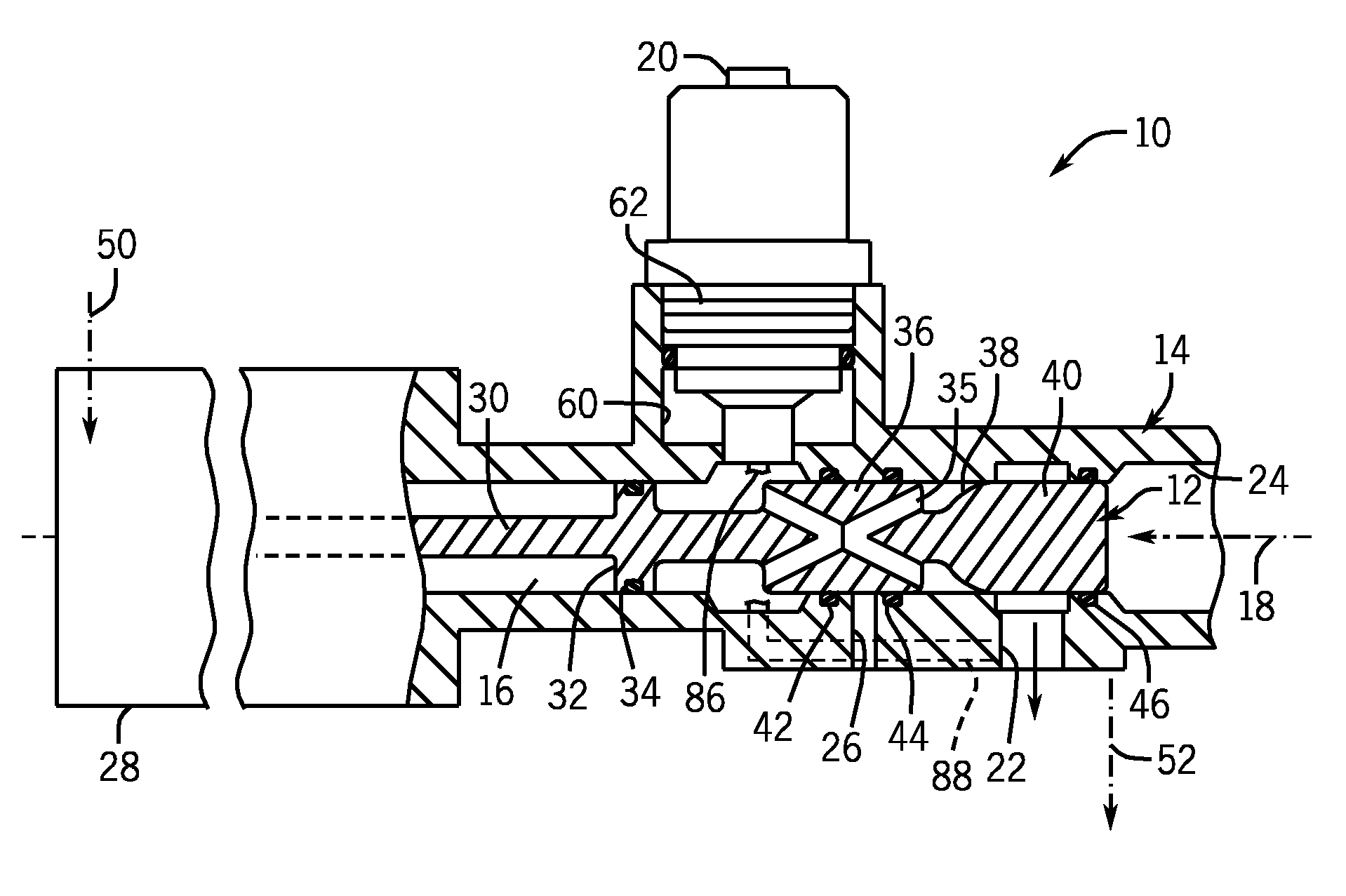

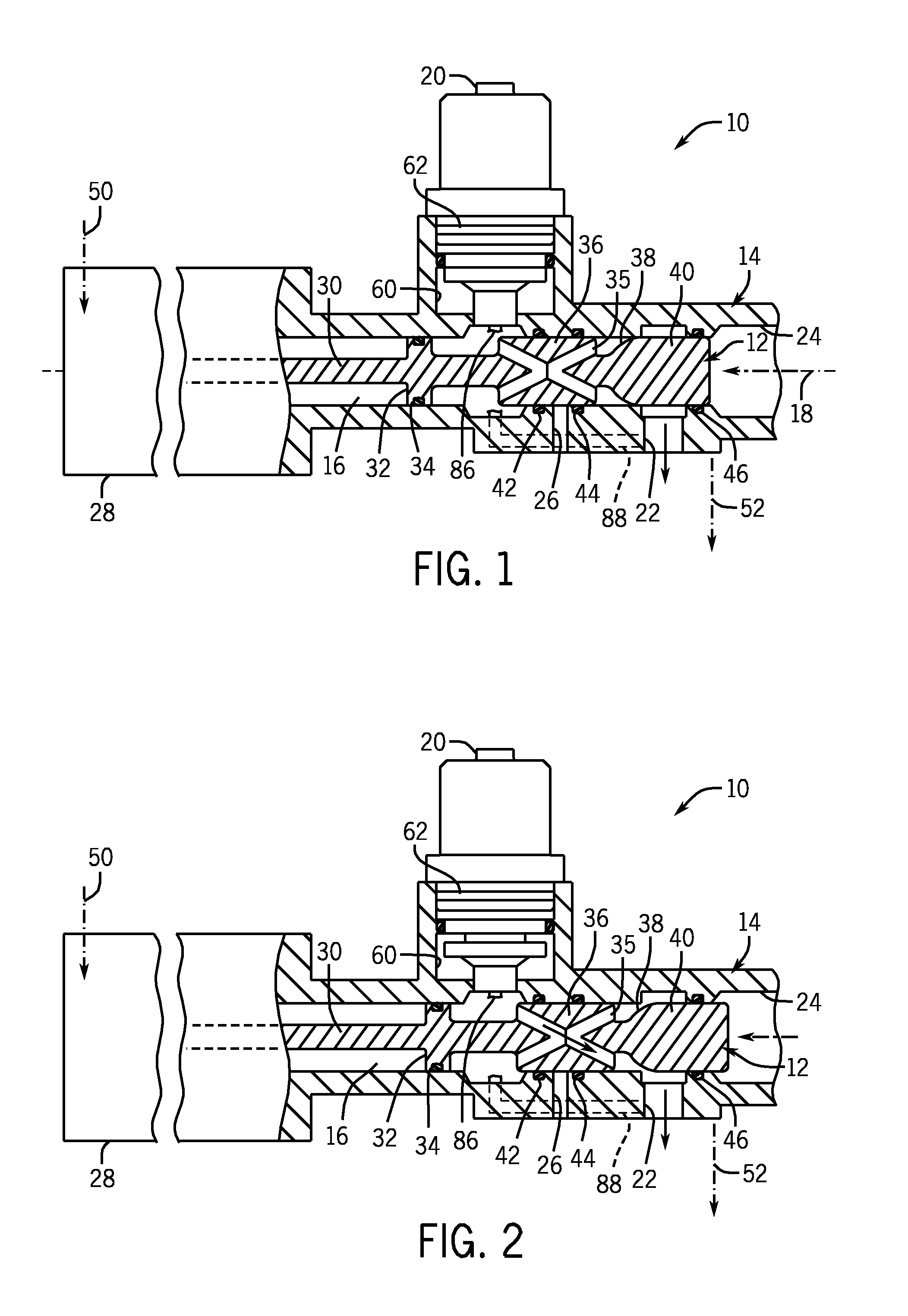

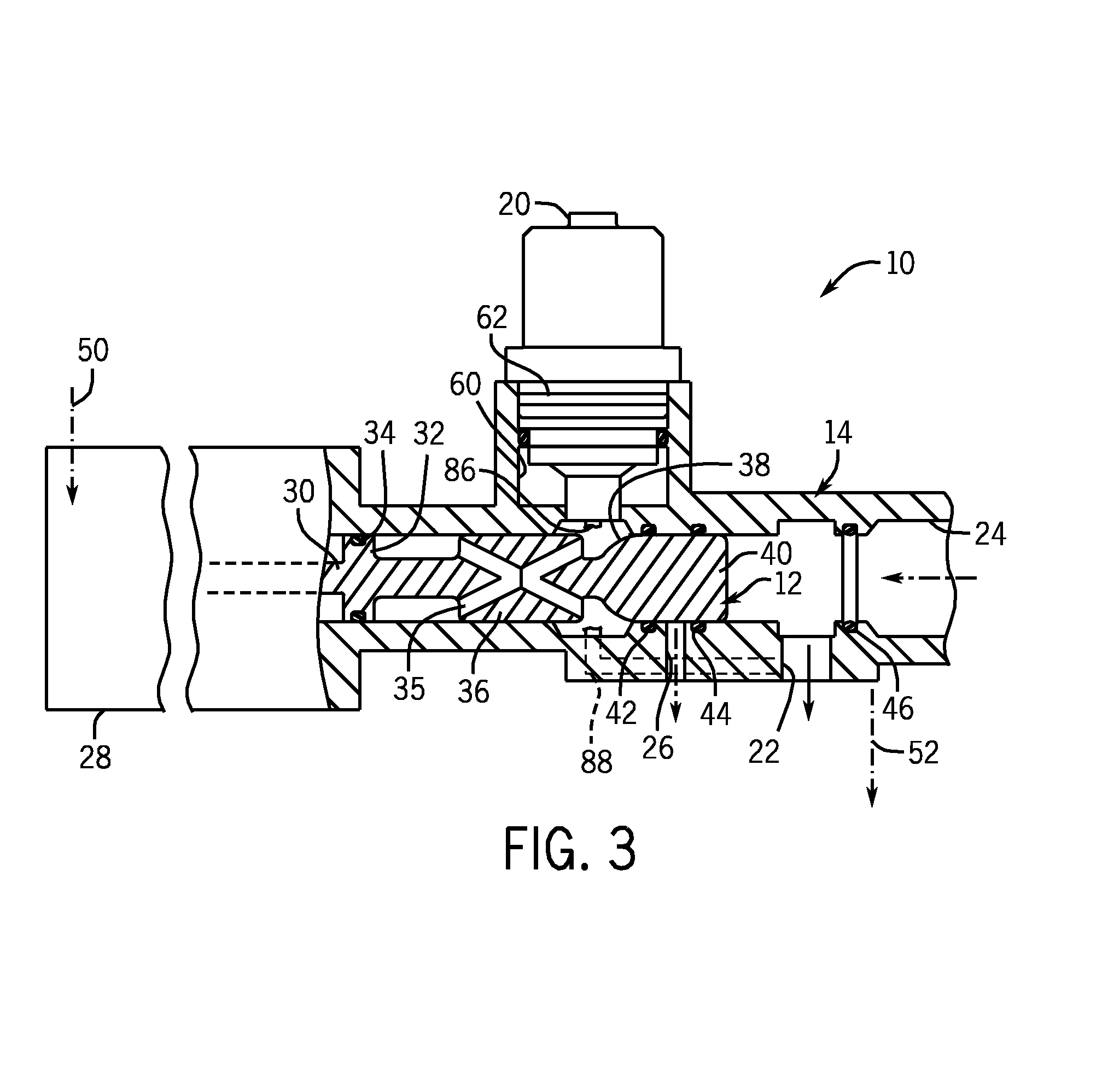

Pressure balanced spool poppet valves with printed actuator coils

InactiveUS20070113906A1Operating means/releasing devices for valvesServomotor componentsSpool valveEngineering

Pressure balanced spool poppet valves with printed actuator coils minimize valve leakage and facilitate efficient manufacturing and reliable operation. The spool poppet valves may be configured like a conventional spool valve, but further include a poppet valve at one end of the spool to proved much better sealing when the poppet valve is closed. Various features are disclosed, including pressure balancing for high pressure operation. The printed actuator coils for the spool poppet valves are formed by the interconnection of conductive coils on each of multiple layers of a multiple layer printed circuit board, which circuit board may have a hole there through for accommodation of mechanical and / or magnet requirements, and may include similar printed actuator coils for one or more additional spool poppet valves as well as electronic devices associated with the operation thereof. The spool poppet valves may be advantageously constructed without printed actuator coils, and the printed actuator coils may be advantageously used in actuators of other designs.

Owner:STURMAN DIGITAL SYST

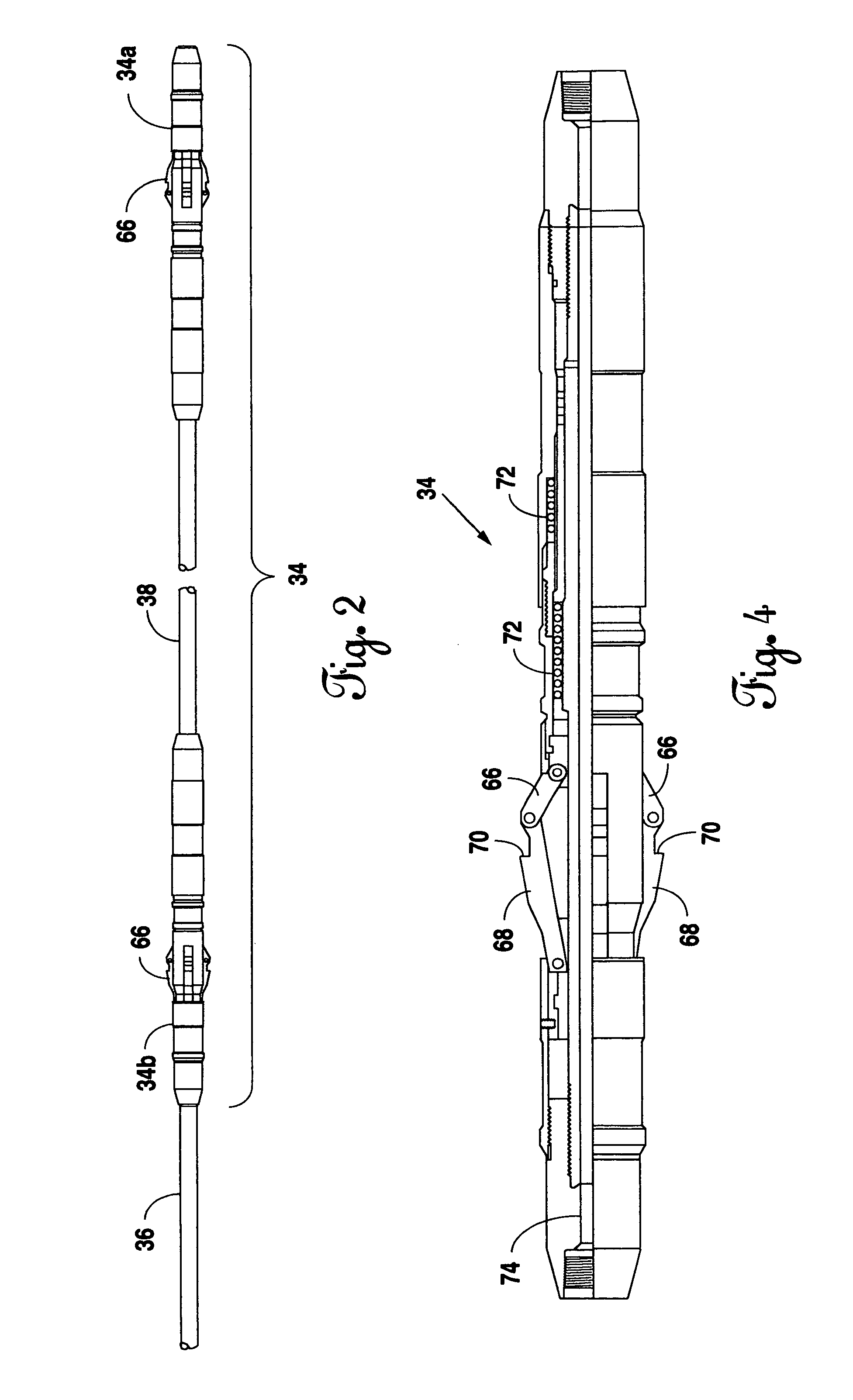

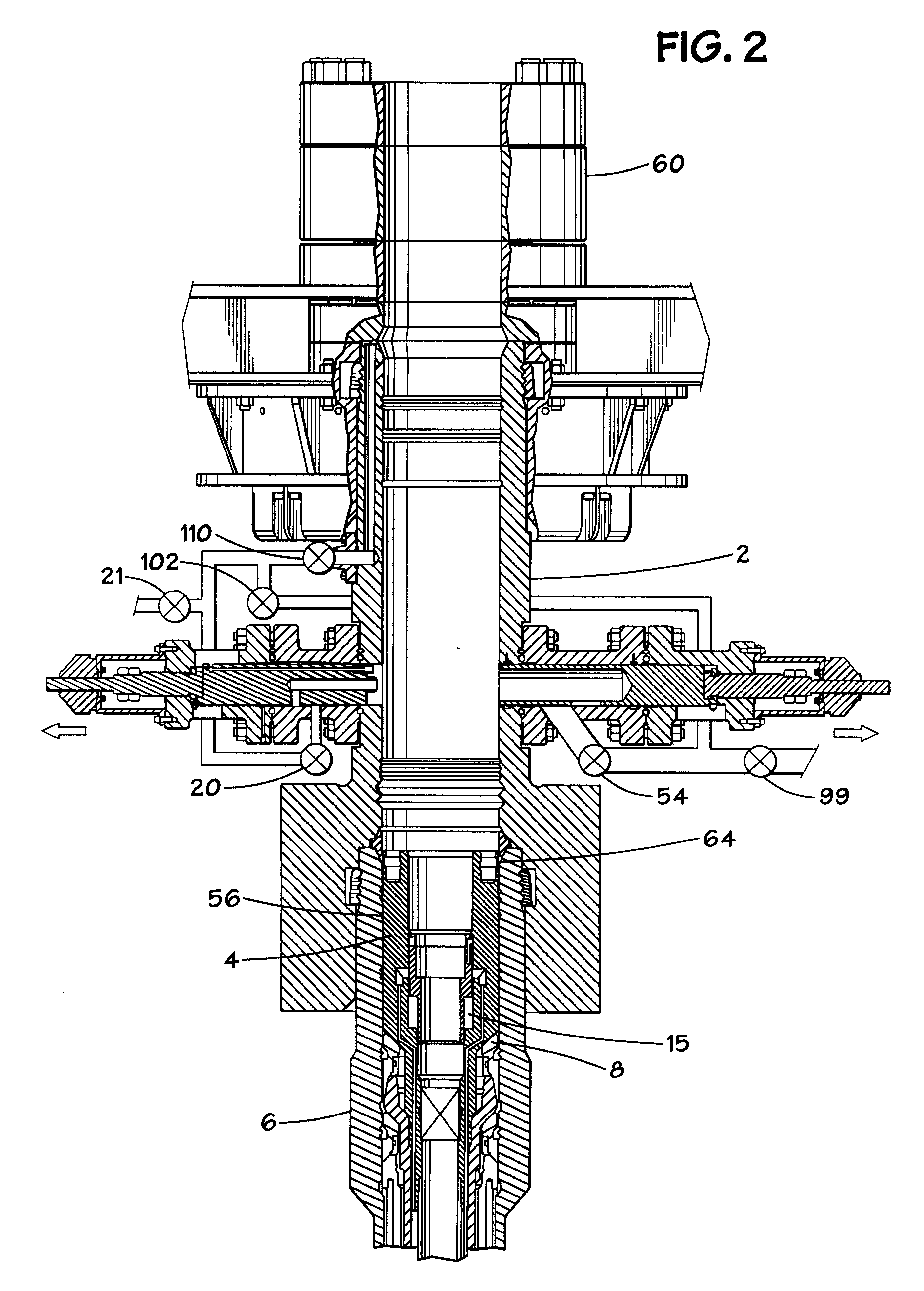

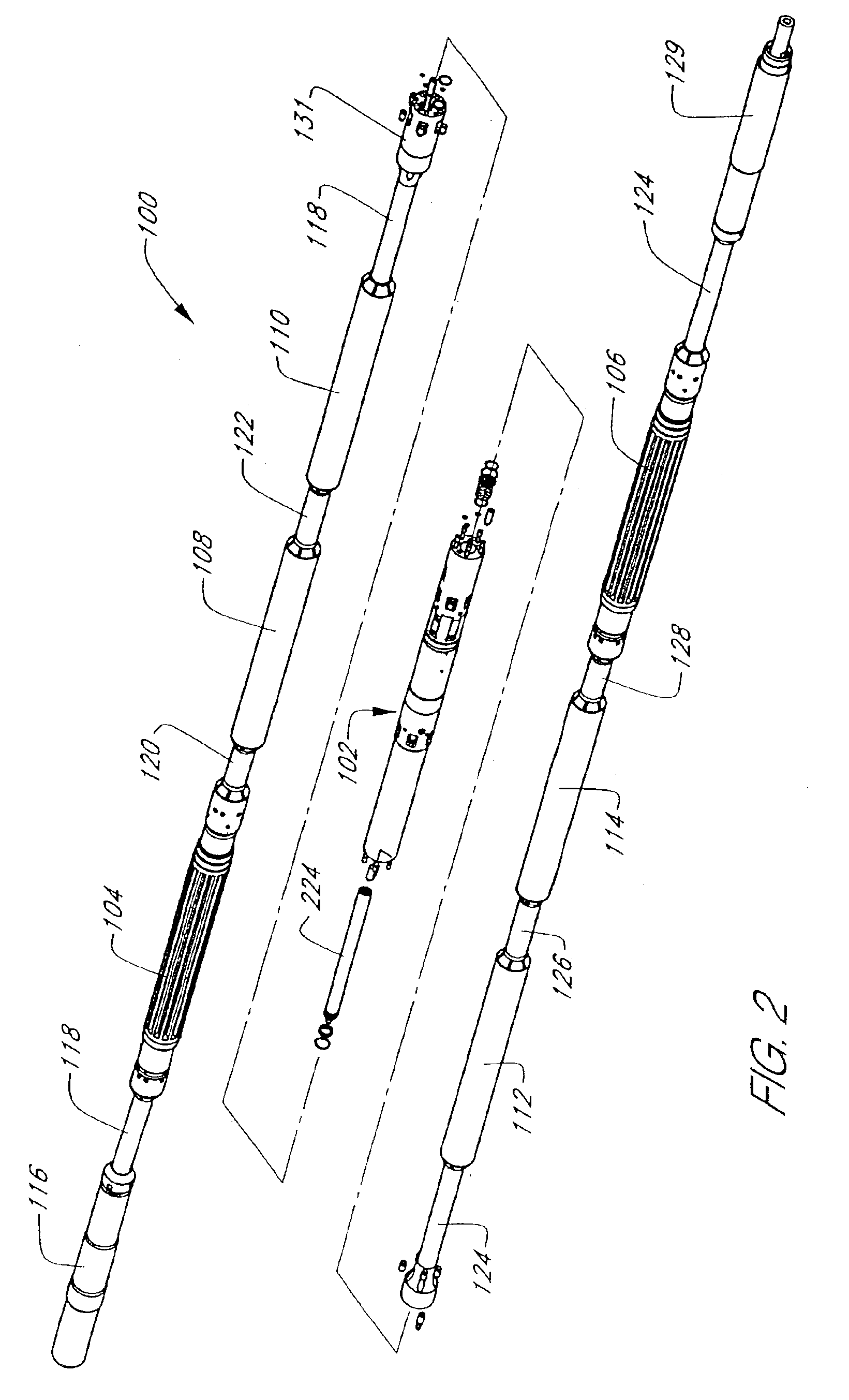

Electrically sequenced tractor

InactiveUS6938708B2Rapid responseDrilling rodsReciprocating drilling machinesSpool valveControl signal

A downhole drilling tractor for moving within a borehole comprises a tractor body, two packerfeet, two aft propulsion cylinders, and two forward propulsion cylinders. The body comprises aft and forward shafts and a central control assembly. The packerfeet and propulsion cylinders are slidably engaged with the tractor body. Drilling fluid can be delivered to the packerfeet to cause the packerfeet to grip onto the borehole wall. Drilling fluid can be delivered to the propulsion cylinders to selectively provide downhole or uphole hydraulic thrust to the tractor body. The tractor receives drilling fluid from a drill string extending to the surface. A system of spool valves in the control assembly controls the distribution of drilling fluid to the packerfeet and cylinders. The valve positions are controlled by motors. A programmable electronic logic component on the tractor receives control signals from the surface and feedback signals from various sensors on the tool. The feedback signals may include pressure, position, and load signals. The logic component also generates and transmits command signals to the motors, to electronically sequence the valves. Advantageously, the logic component operates according to a control algorithm for intelligently sequencing the valves to control the speed, thrust, and direction of the tractor.

Owner:WWT NORTH AMERICA HLDG

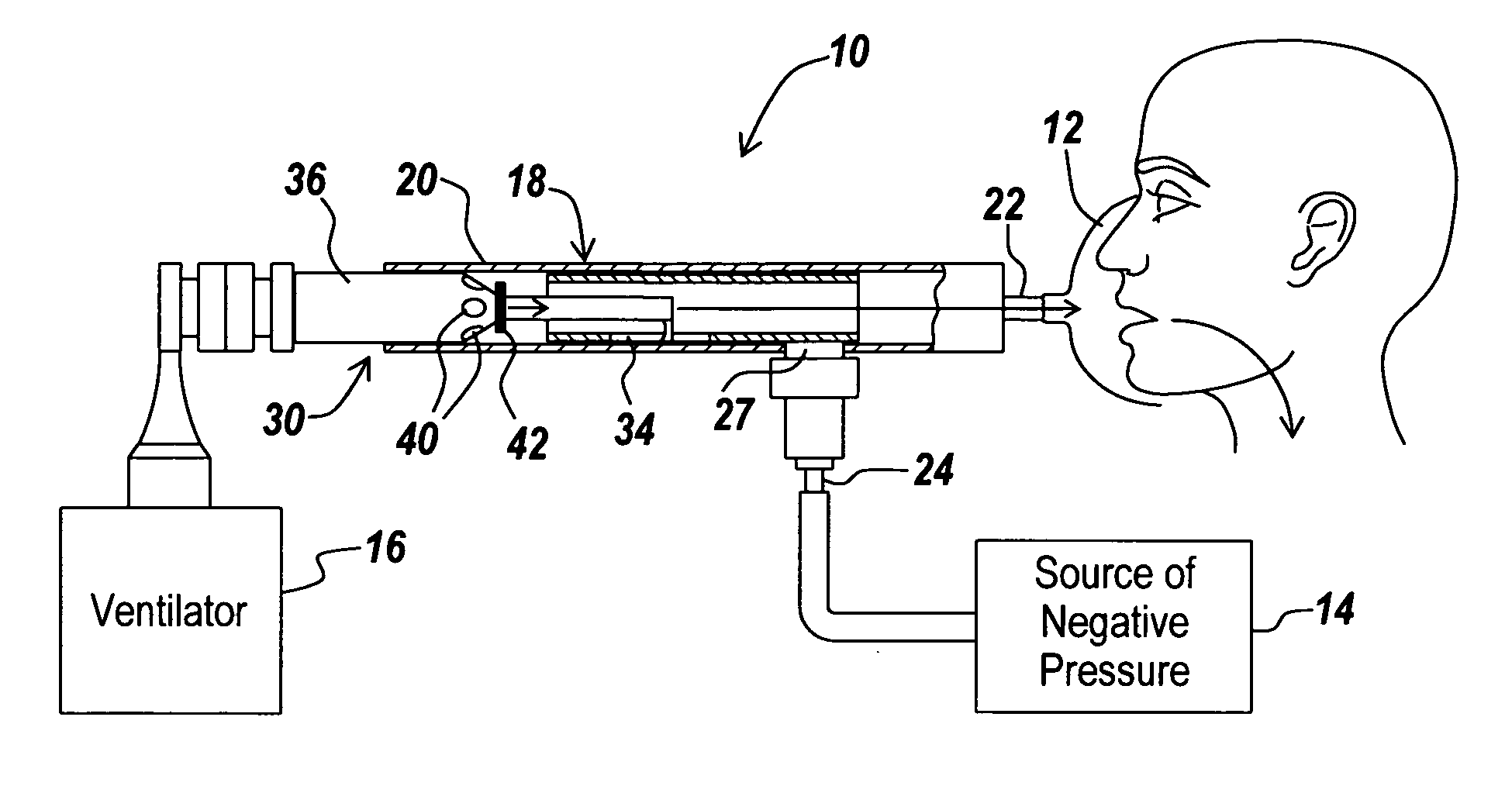

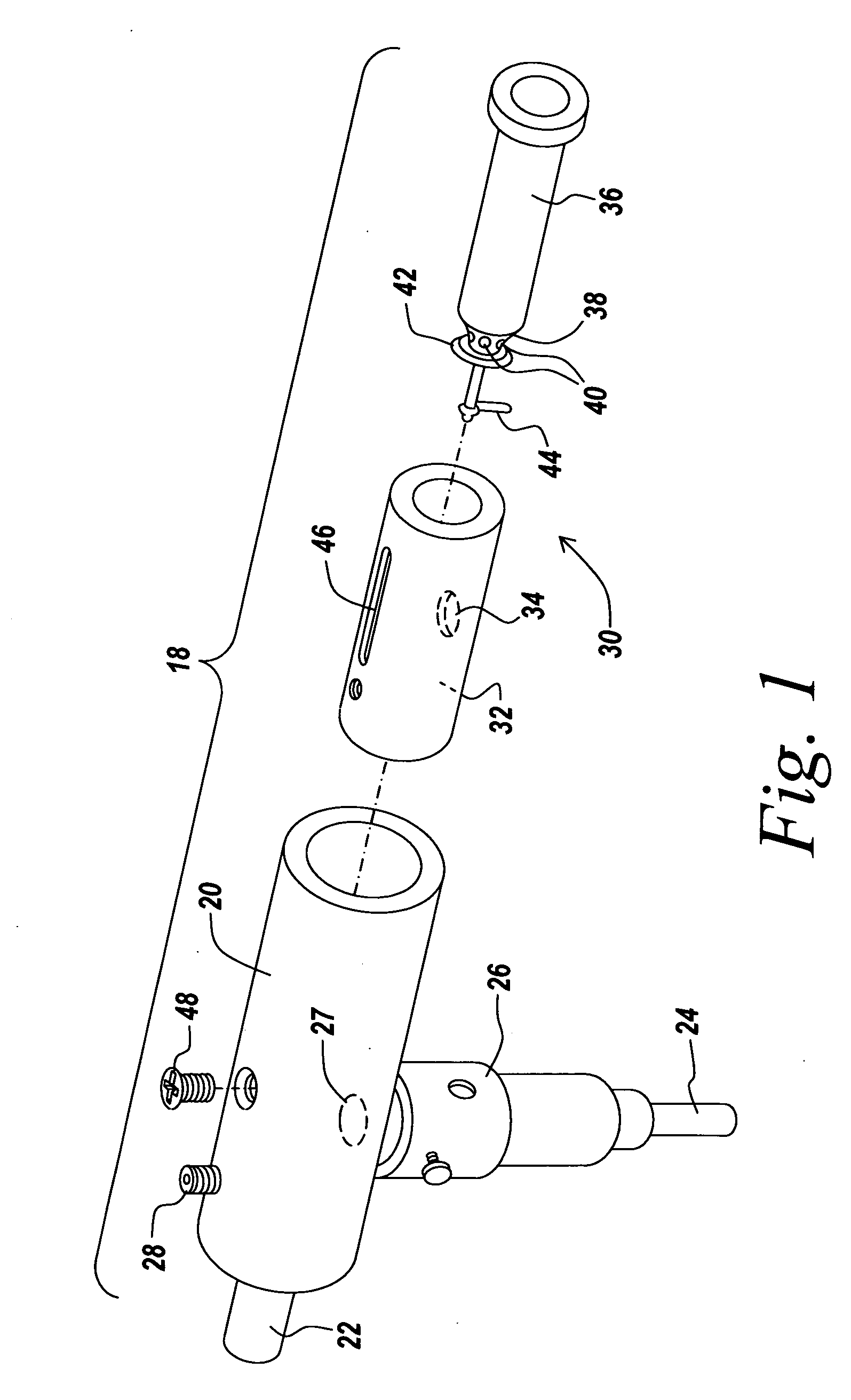

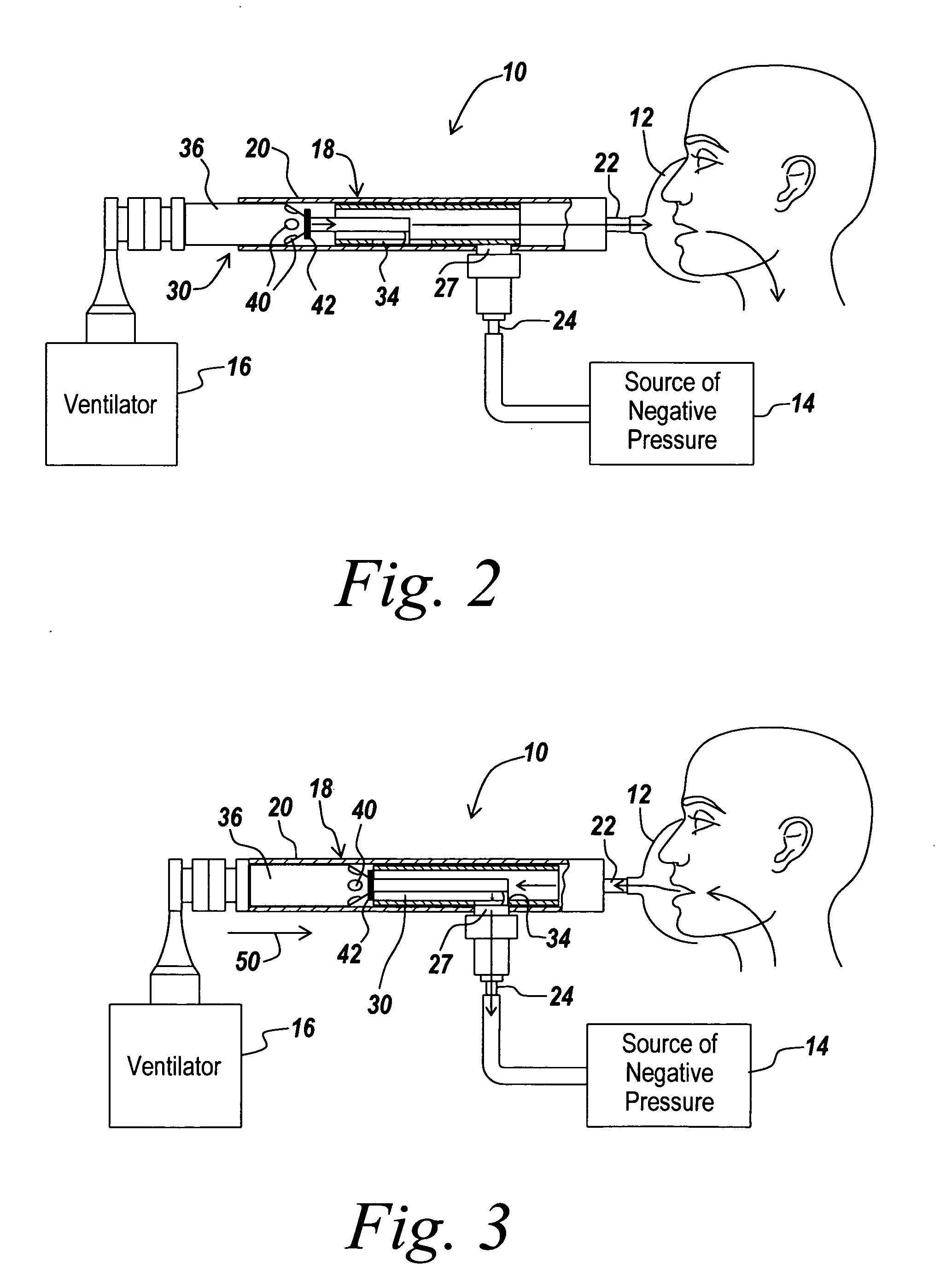

Inexsufflator

InactiveUS20070017523A1Clear secretionPreventing alveolar or airway collapseRespiratorsBuilding rescueMechanical ventilatorsSpool valve

A manual inexsufflator including a standard mechanical ventilator, a medical suction unit, and a piston-like sliding valve mechanism which connects a patient ventilation interface with either the ventilator or the suction unit. By sliding the valve mechanism in and out the user selectively connects the patient to either the ventilator, for purposes of insufflation, or the suction unit, for purposes of exsufflation. The ventilator may generate expiratory positive airway pressure between inexsufflation cycles.

Owner:ALYN WOLDENBERG FAMILY HOSPITAL

Subsea connector

ActiveUS20100288503A1Prevent further rotationIncrease forcePipe laying and repairFluid removalOcean bottomMechanical engineering

A subsea connector that includes a connector capable of selectively connecting to a spool body to form a connector assembly. The subsea connector may include an adapter ring that is capable of connecting the spool body to the connector. The connector assembly may be lowered onto a wellhead member and locked into place by a movable piston and split lock ring. While the connector assembly is in the unlocked state, the adapter ring may be rotated moving the connector up or down with respect to the spool body, which lands on the wellhead member. The movement of the connector may be used to vary the alignment of the connector locking means with respect to the locking profile of the wellhead member. This change in position may be used to modify the preload force applied to the connector when locked onto the wellhead member.

Owner:AKER SOLUTIONS AS

CTA phaser with proportional oil pressure for actuation at engine condition with low cam torsionals

ActiveUS20050103297A1Yielding couplingOscillating piston enginesSpool valveInternal combustion engine

A variable camshaft timing phaser for an internal combustion engine having at least one camshaft comprising a plurality of vanes in chambers defined by a housing and a spool valve. The vanes define an advance and retard chamber. At least one of the vanes is cam torque actuated (CTA) and at least one of the other vanes is oil pressure actuated (OPA). The spool valve is coupled to the advance and retard chamber defined by the CTA vane and the advance chamber defined by the OPA vane. When the phaser is in the advance position, fluid is routed from the retard chamber defined by the OPA vane to the retard chamber defined the CTA vane. When the phaser is in the retard position fluid is routed from the retard chamber defined by the CTA vane to the advance chamber defined by the CTA vane.

Owner:BORGWARNER INC

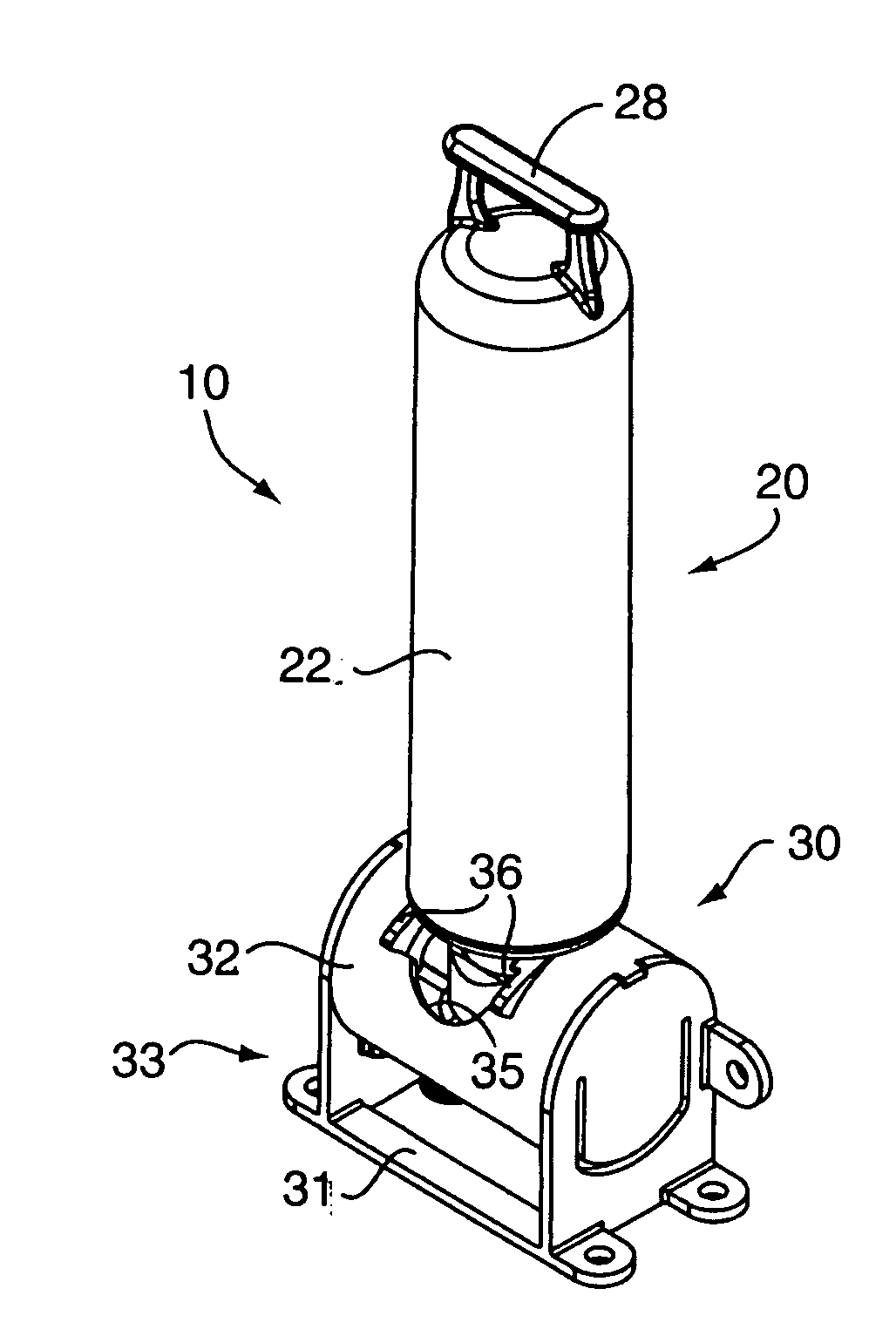

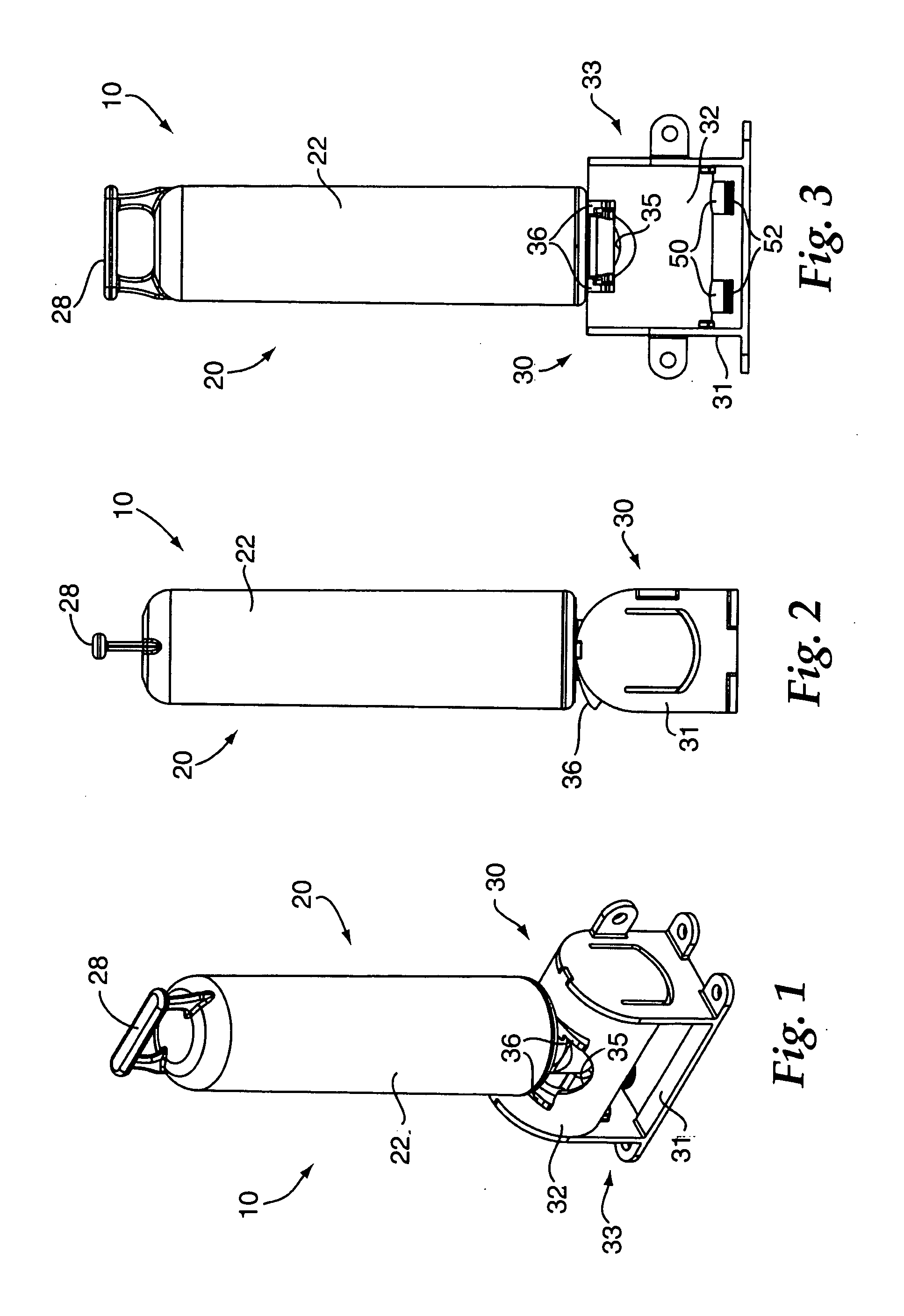

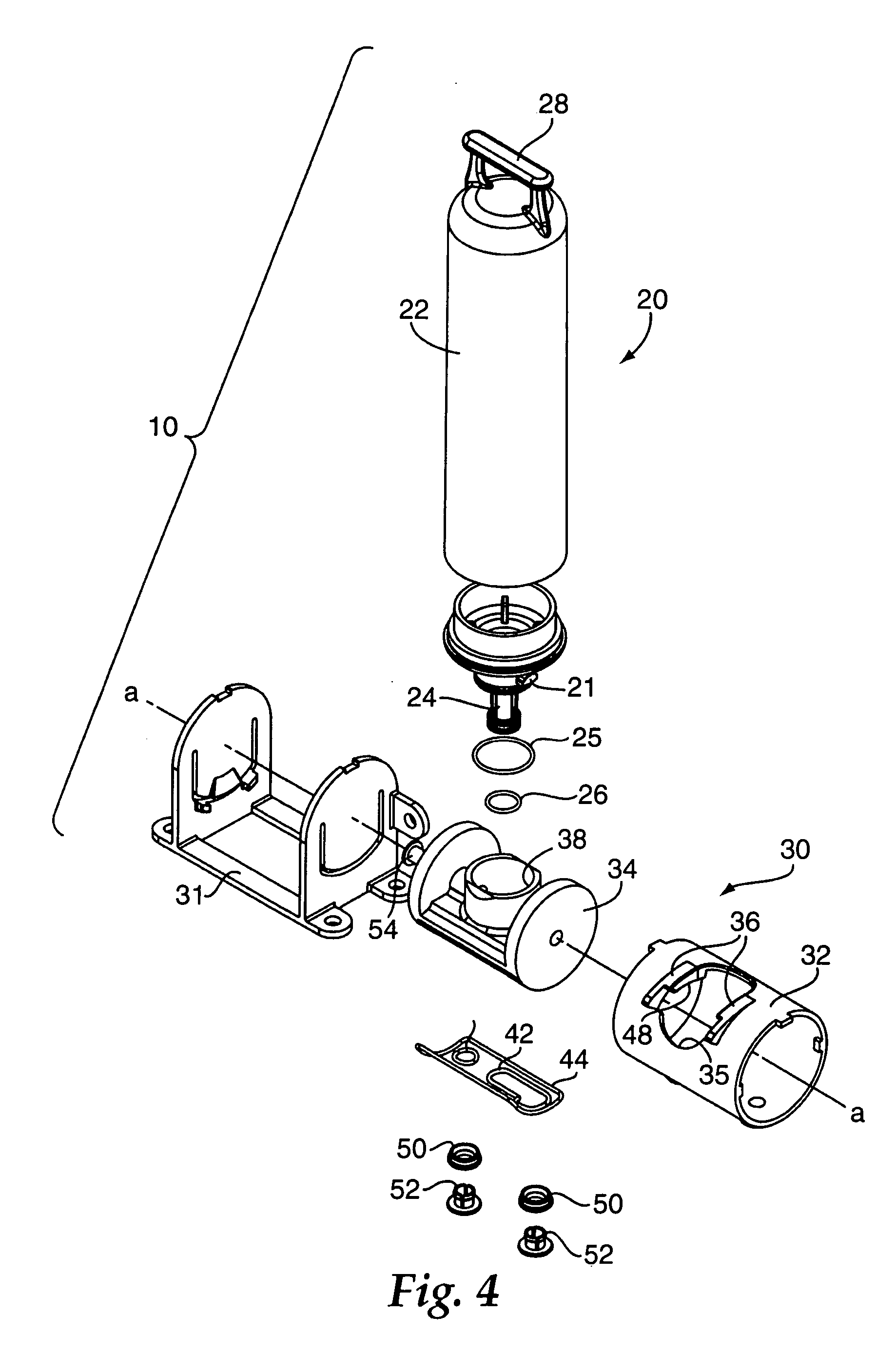

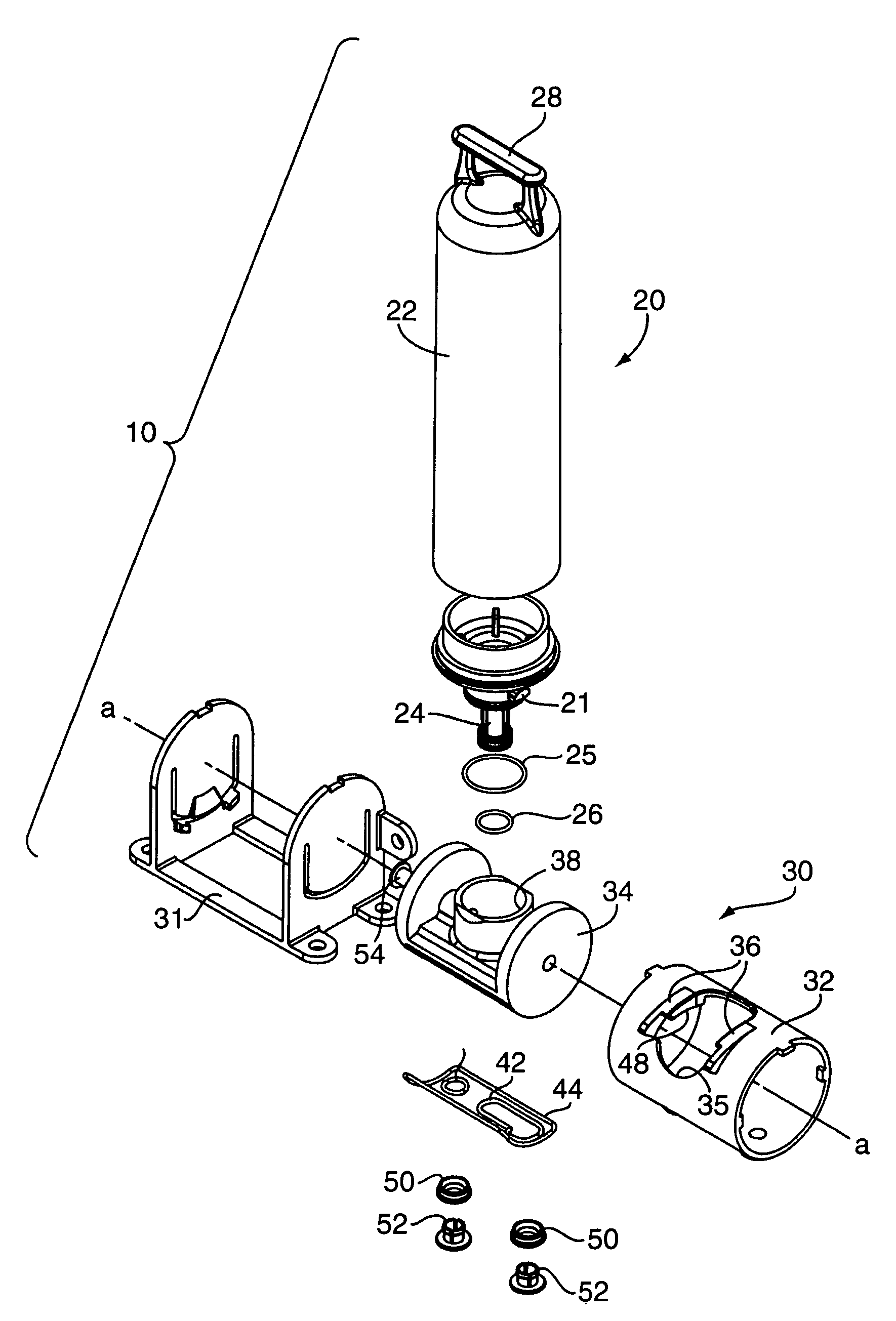

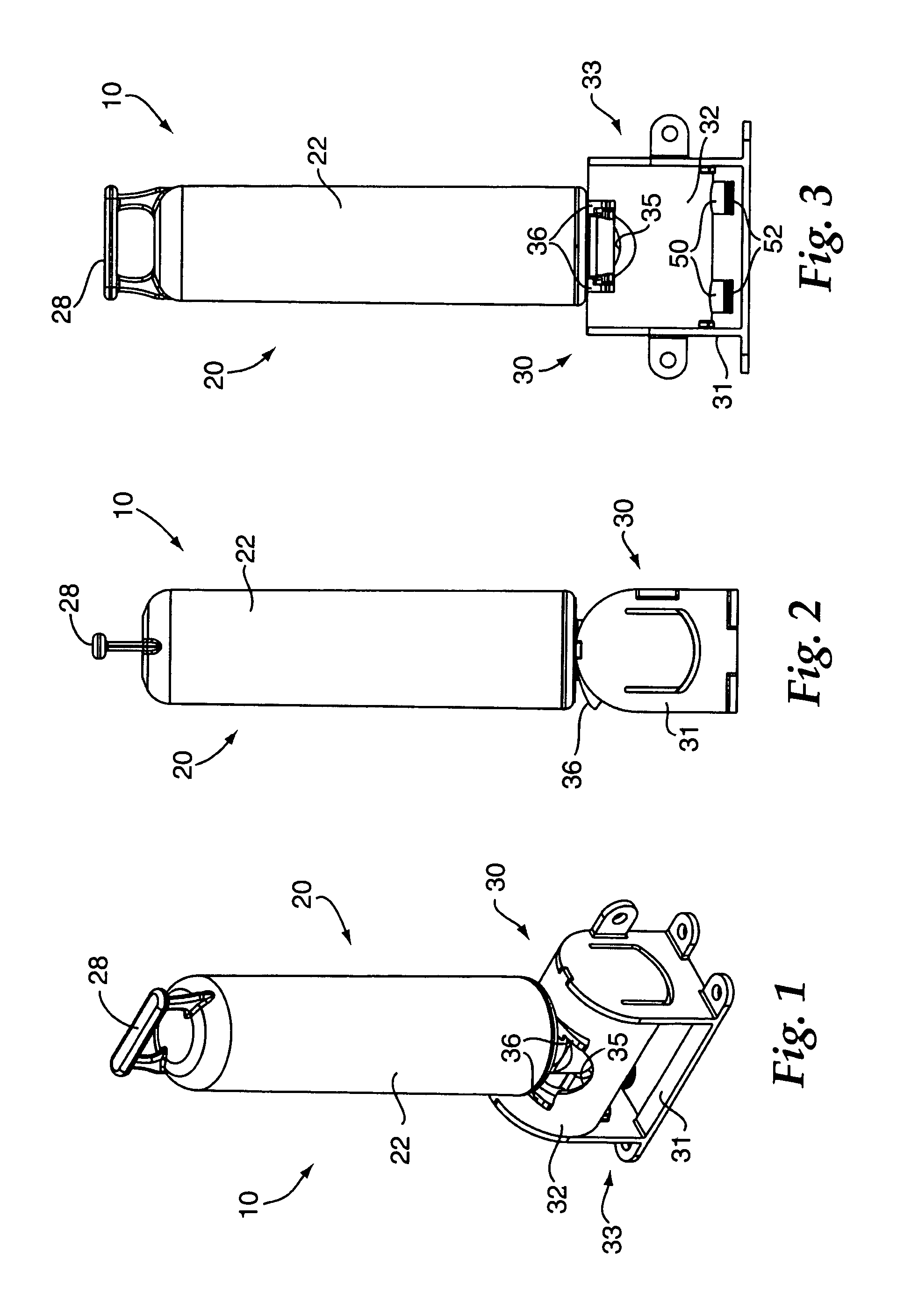

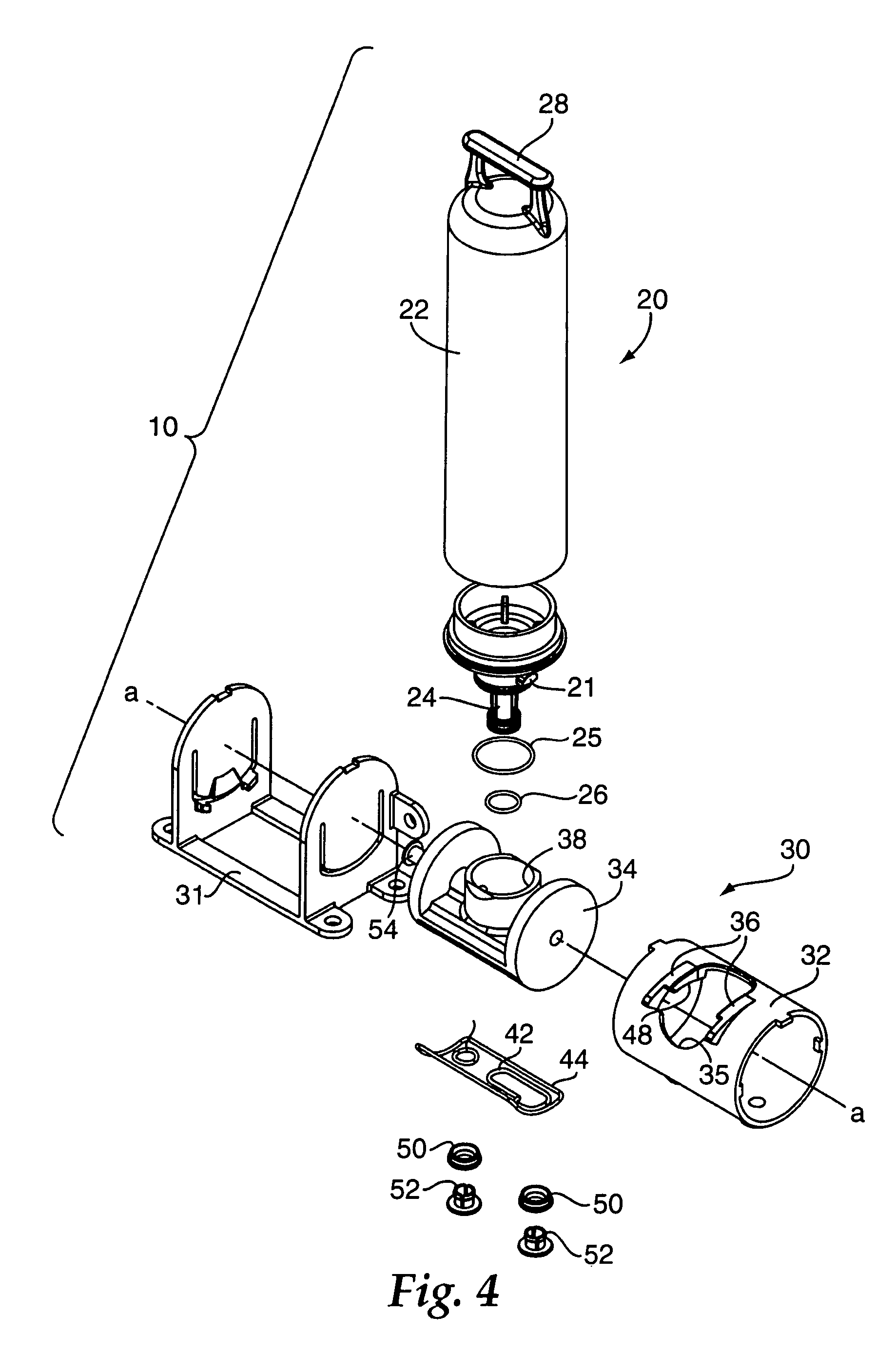

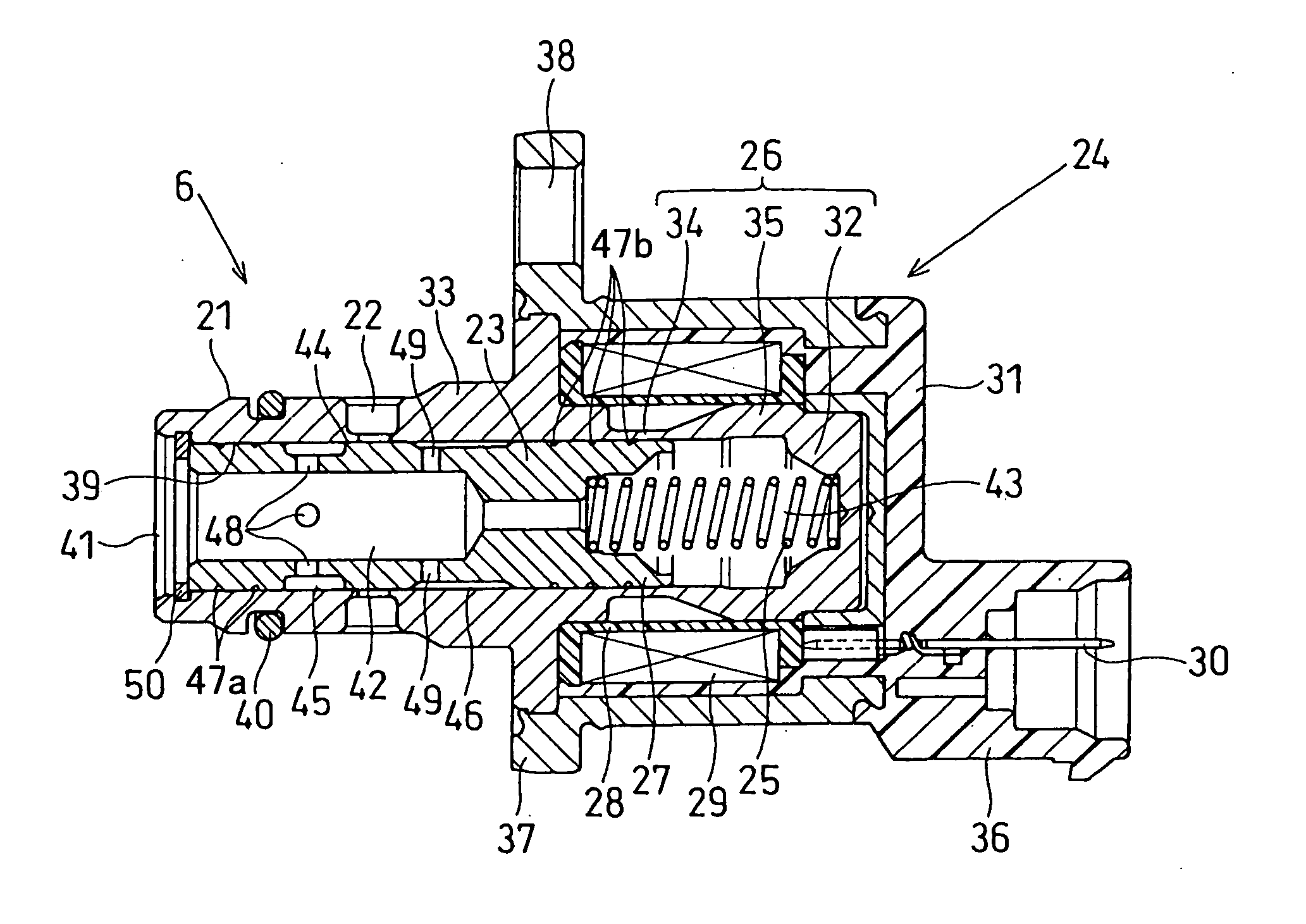

Spool valve manifold interconnect for a filter system

ActiveUS20060254971A1Prevent leakagePrevent liquid leakagePlug valvesOperating means/releasing devices for valvesSpool valveFilter system

A filter cartridge and spool valve manifold assembly includes a filter cartridge and a spool valve manifold. The filter cartridge includes a filter element and inlet / outlet portion in fluid communication with the filter element. The inlet / outlet portion has a cartridge inlet port and a cartridge outlet port. The spool valve manifold includes a housing and a body. The housing has a housing inlet port and a housing outlet port adapted for fluid communication with a fluid supply system. The body is located within the housing and configured to rotate around a first axis relative to the housing. The inlet / outlet portion of the filter cartridge is fluidly coupled to the body via insertion of the inlet / outlet portion into the body in a direction perpendicular to the first axis.

Owner:3M INNOVATIVE PROPERTIES CO

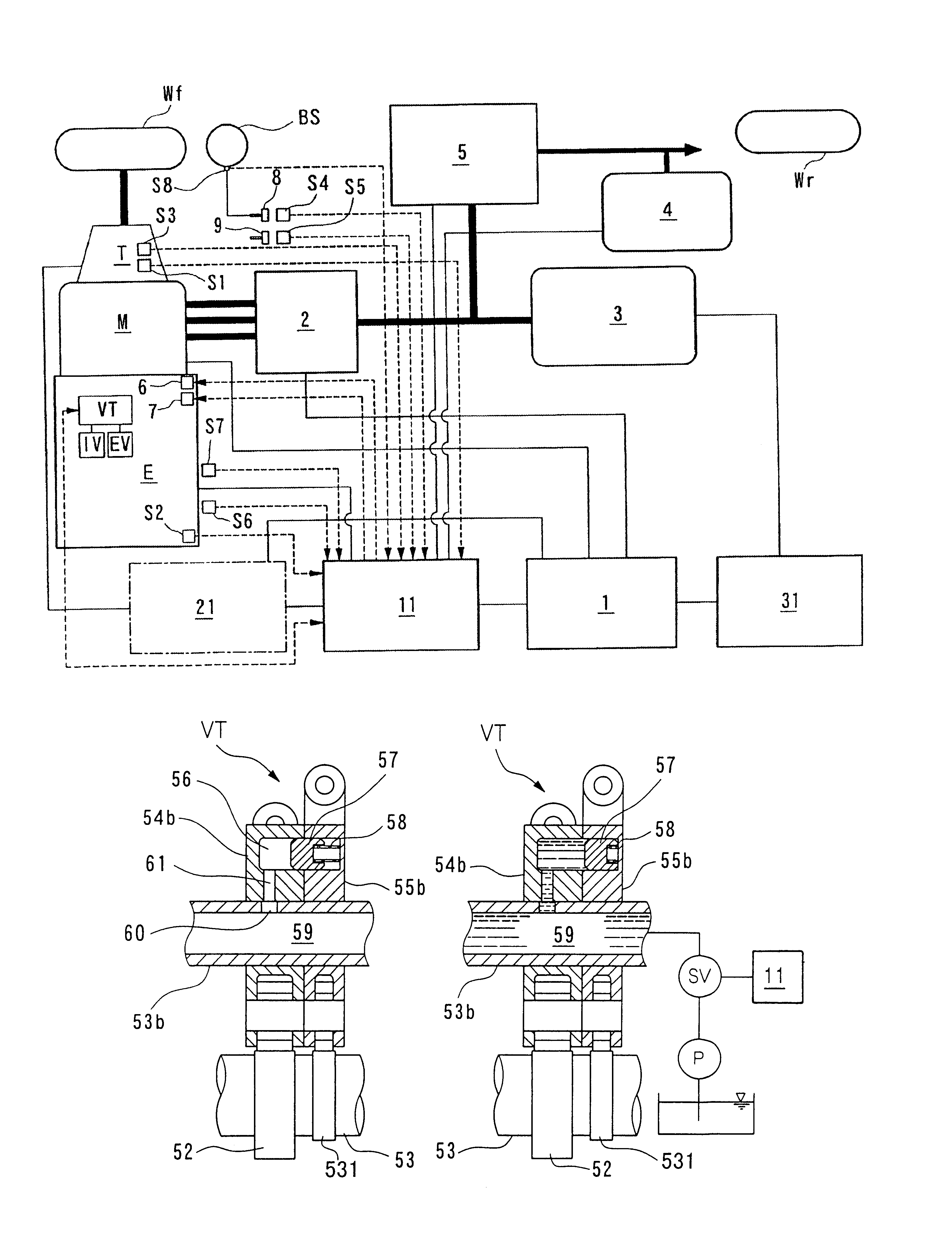

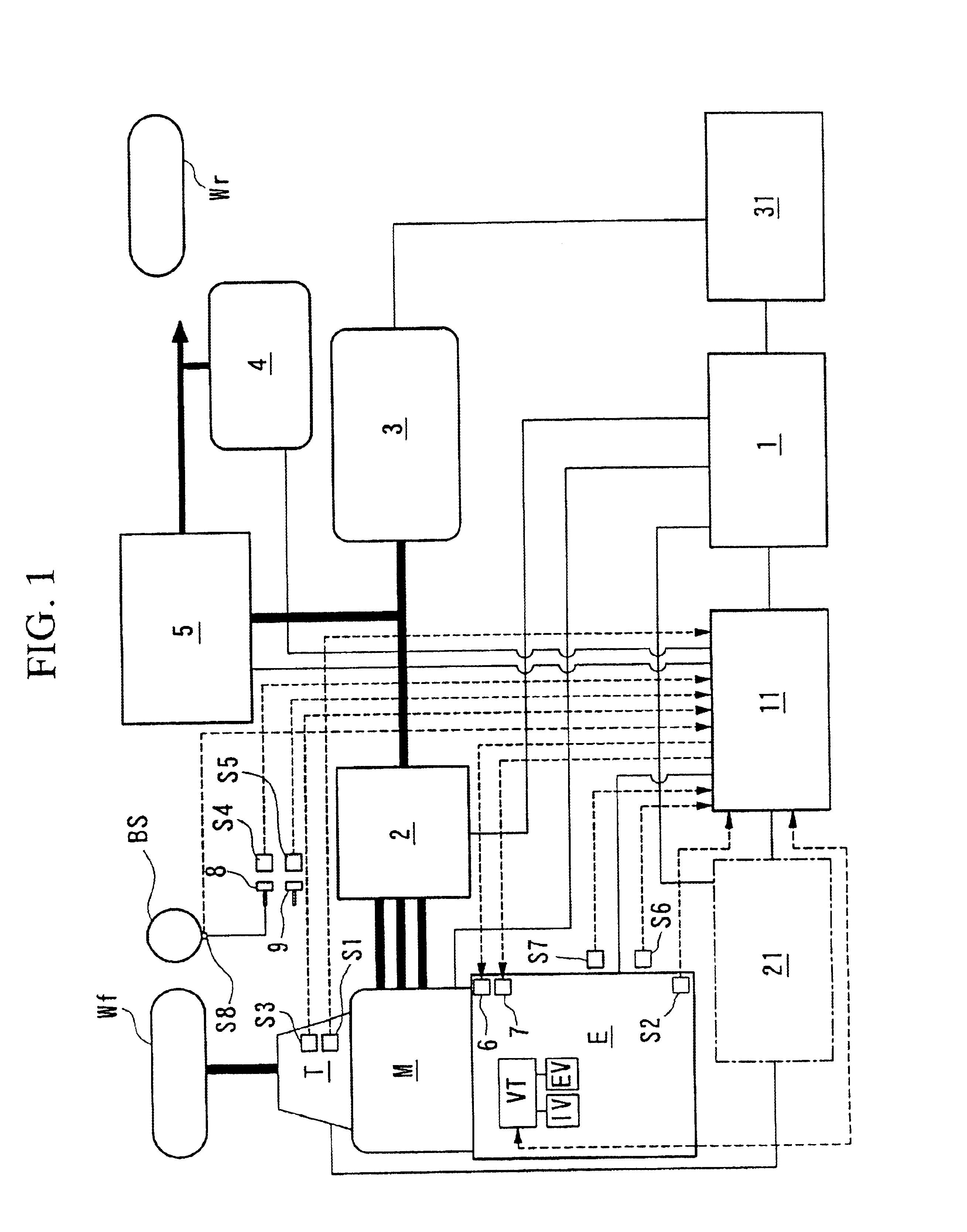

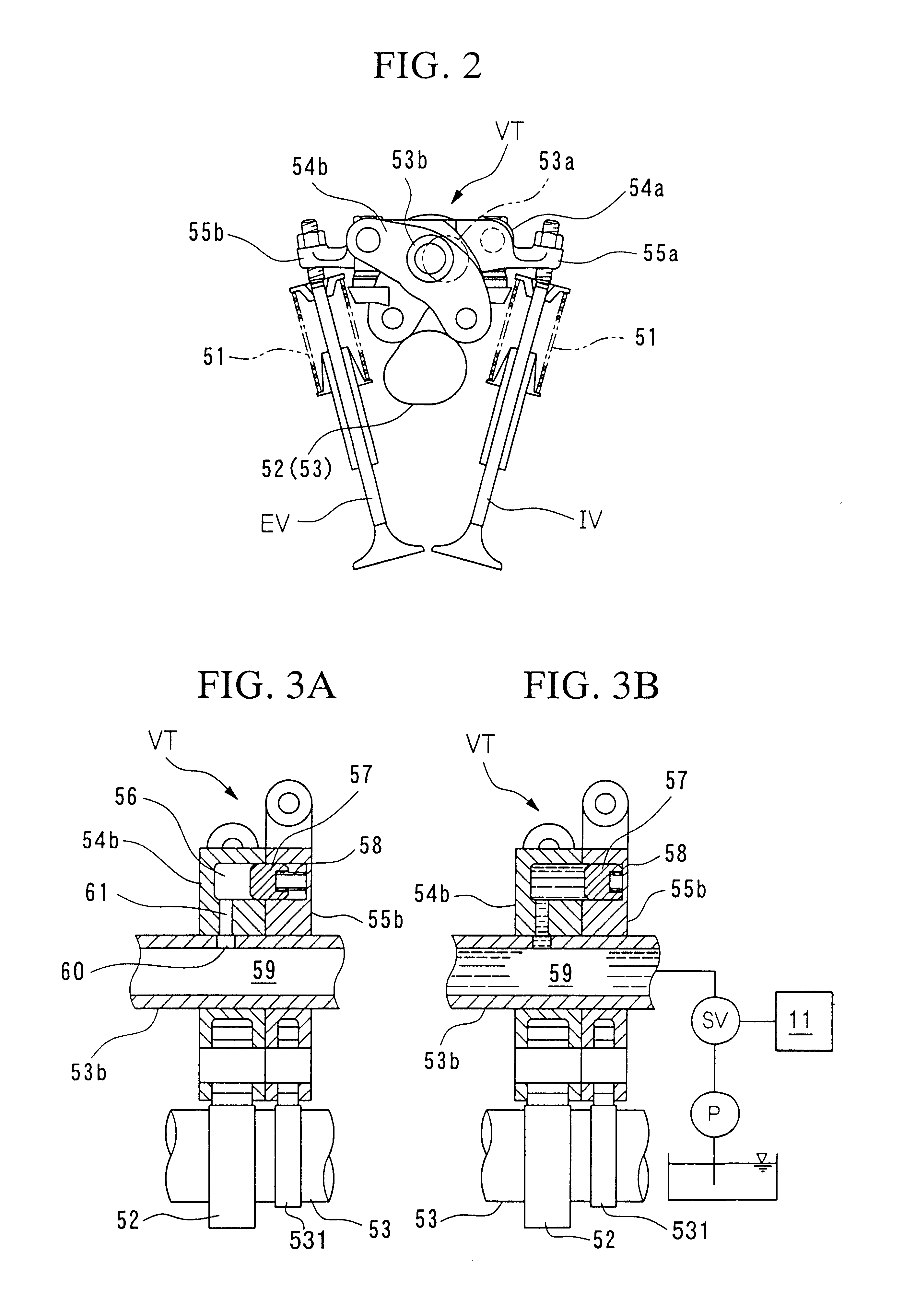

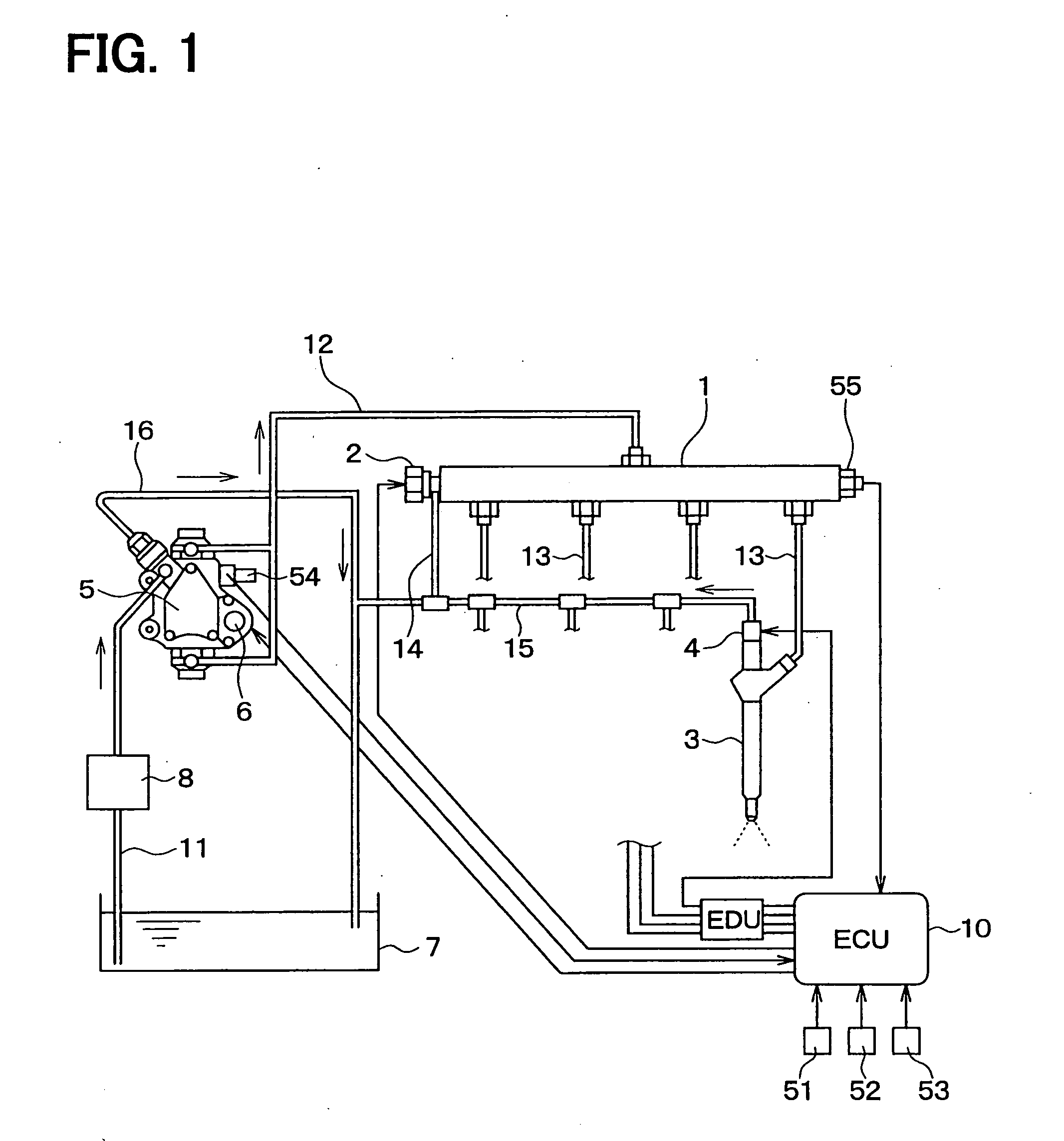

Control device for hybrid vehicles

InactiveUS6886649B2Timely maintenanceInhibition of inflowValve arrangementsElectrical controlSpool valveSolenoid valve

A control apparatus for a hybrid vehicle which includes an all cylinder deactivated operation execution flag F_ALCS for executing the all cylinders deactivated operation, when it is determined that the all cylinders deactivated operation is appropriate by the all cylinders deactivation standby flag F_ALCSSTB for determining the appropriateness of the all cylinders deactivated operation and the all cylinders deactivation release conditions realization flag F_F_ALCSSTP for determining the appropriateness of releasing the all cylinders deactivated operation, based on the all cylinders deactivation solenoid flag F_ALCSSOL for operating a spool valve, for determining an appropriateness of the operation of the solenoid valve, the all cylinder deactivation standby flag F_ALCSSTB, the all cylinder deactivation conditions realization flag F_ALCSSTP, the all cylinder deactivation solenoid flag F_ALCSSOL.

Owner:HONDA MOTOR CO LTD

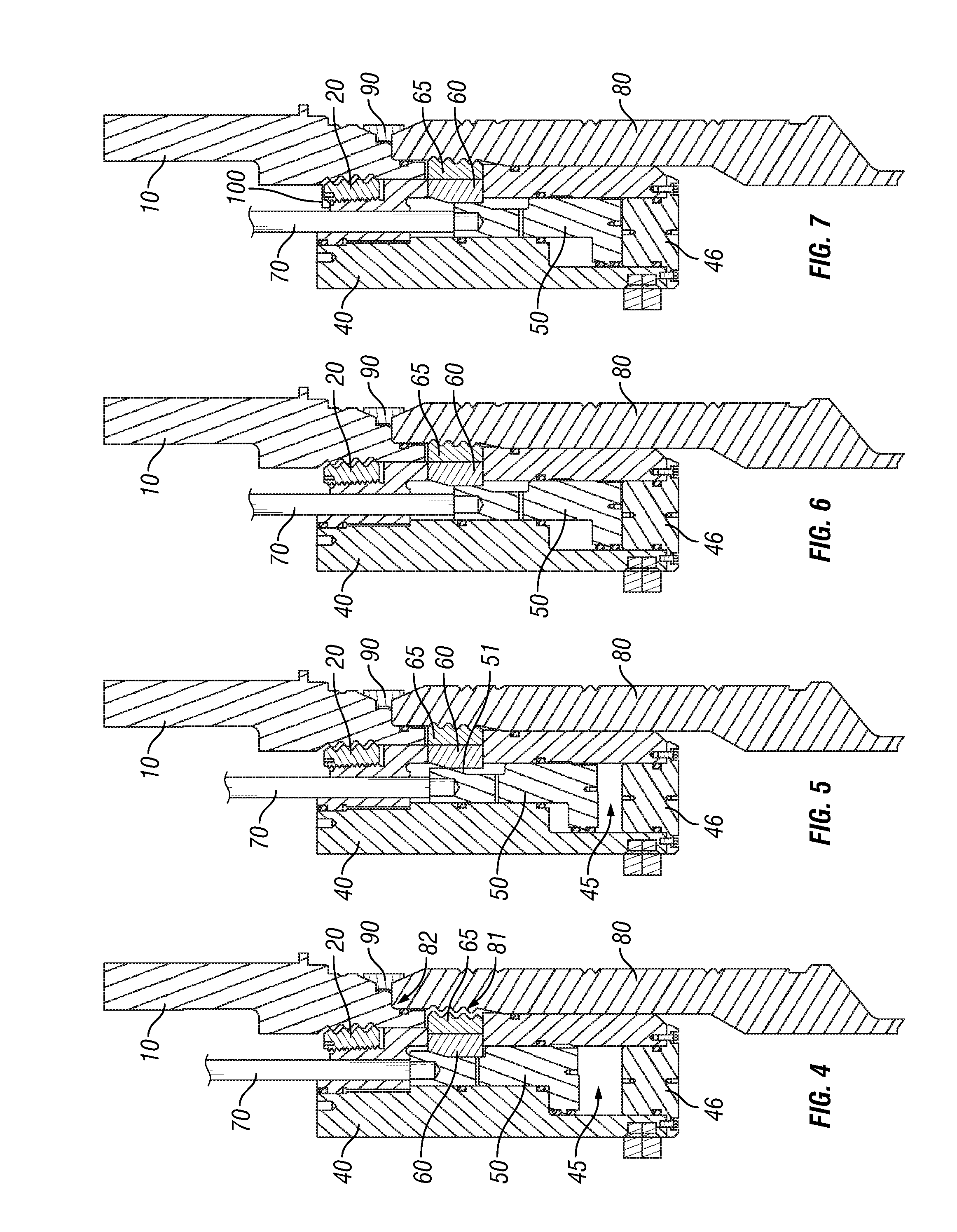

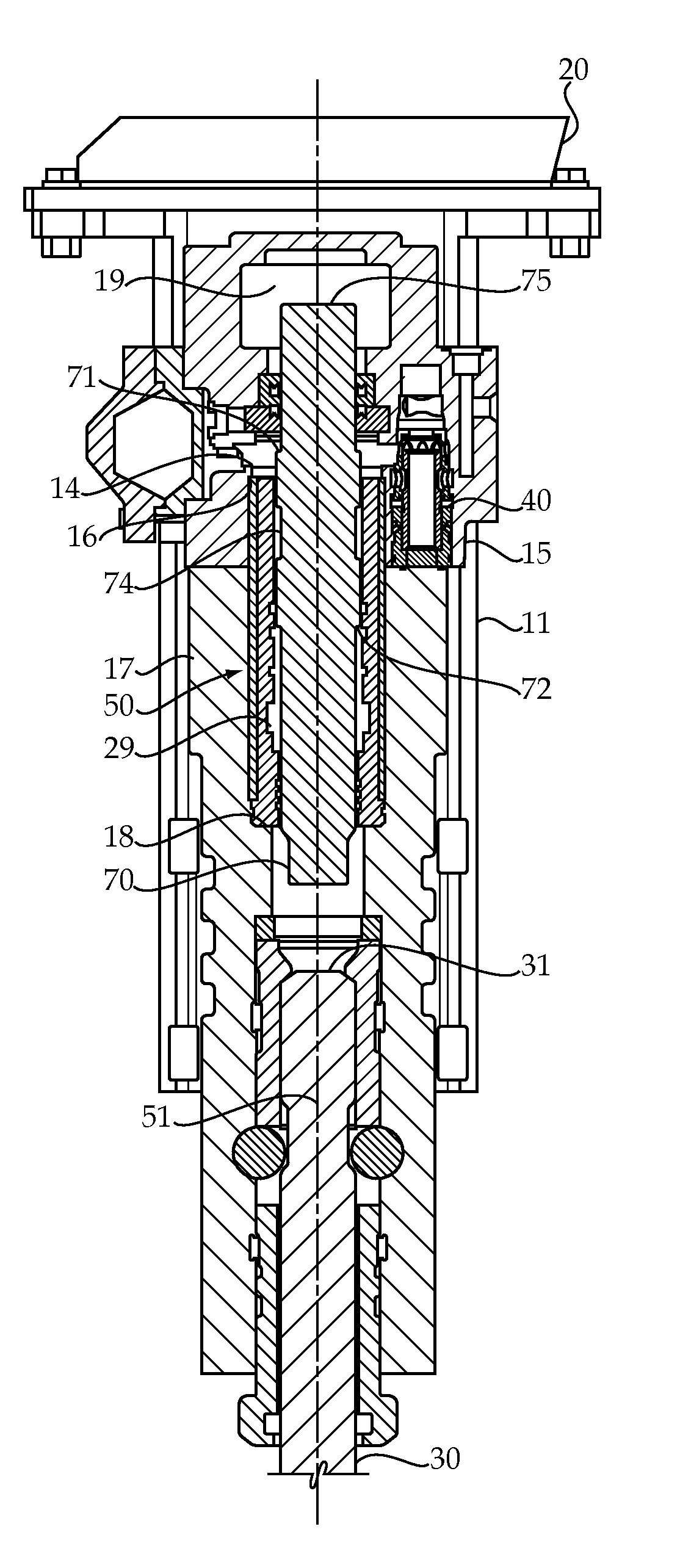

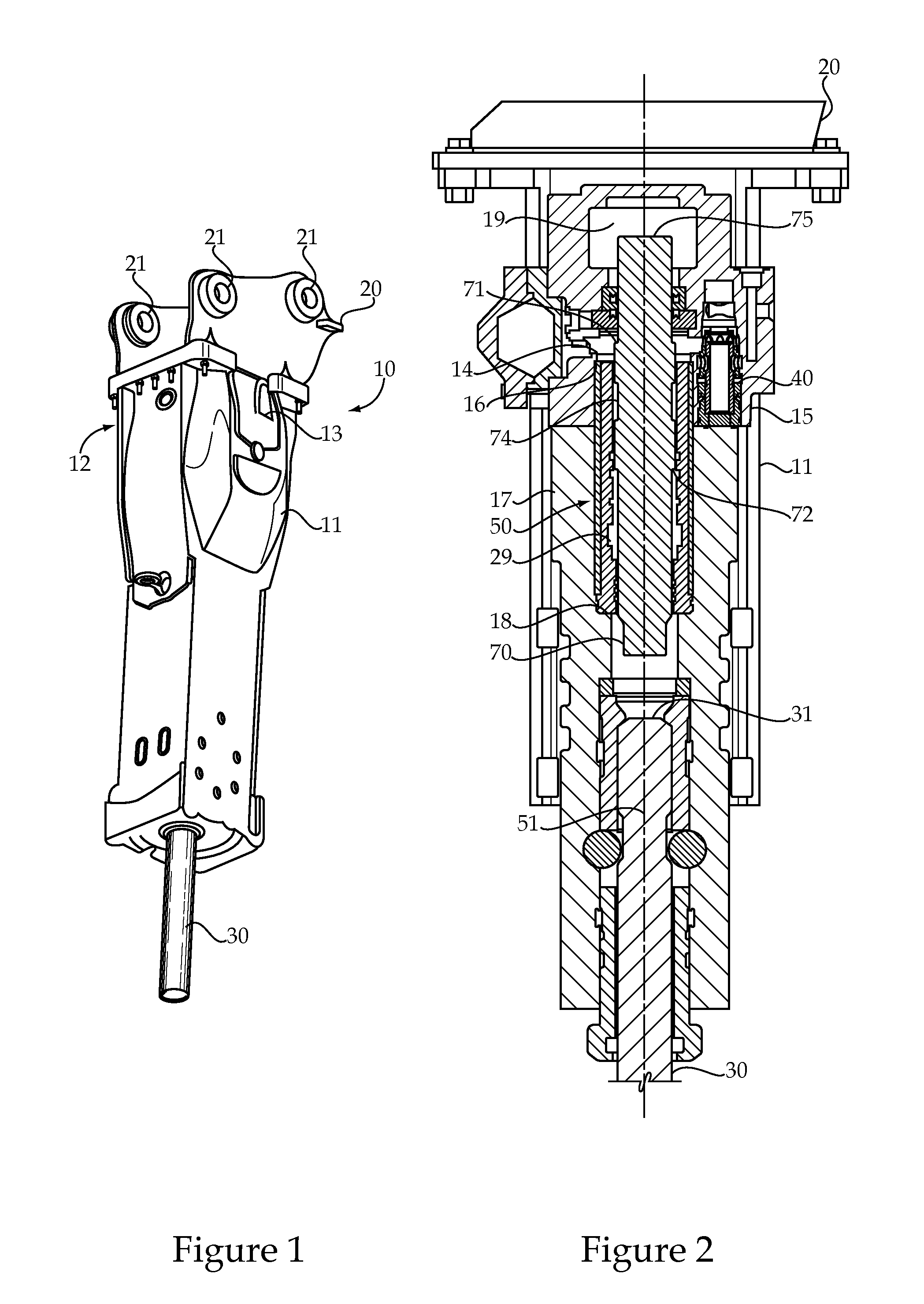

Sleeve/Liner Assembly And Hydraulic Hammer Using Same

A hydraulic hammer includes a powercell housing that defines a hydraulic inlet and a hydraulic outlet. A machine mount that defines a plurality of pin receiving bores is attached to the powercell housing. A work tool is partially received in, and movable with respect to, the powercell housing. A switching spool valve member is positioned in the powercell housing and is movable between a first position and a second position, and includes a control hydraulic surface. A sleeve / liner assembly is positioned in the powercell housing and defines a centerline. A piston with a plurality of hydraulic surfaces is positioned in the sleeve / liner assembly and is movable along the centerline between a first position in contact with the work tool and a second position out of contact with the work tool. The control hydraulic surface of the switching spool valve member is exposed to fluid pressure in a switching passage, which includes a segment defined by the sleeve / liner assembly.

Owner:CATERPILLAR INC

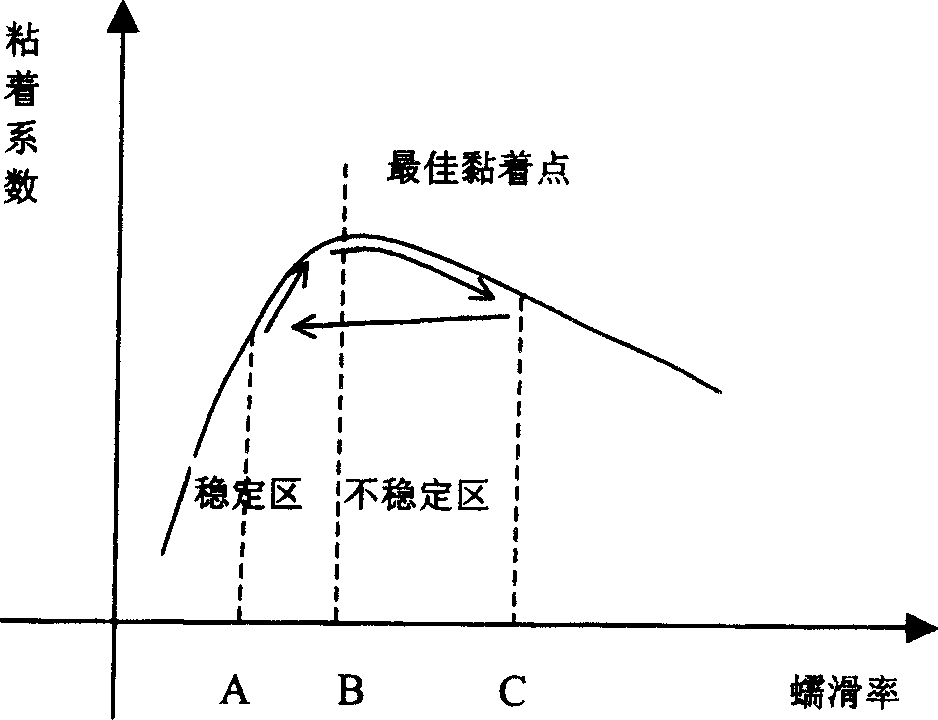

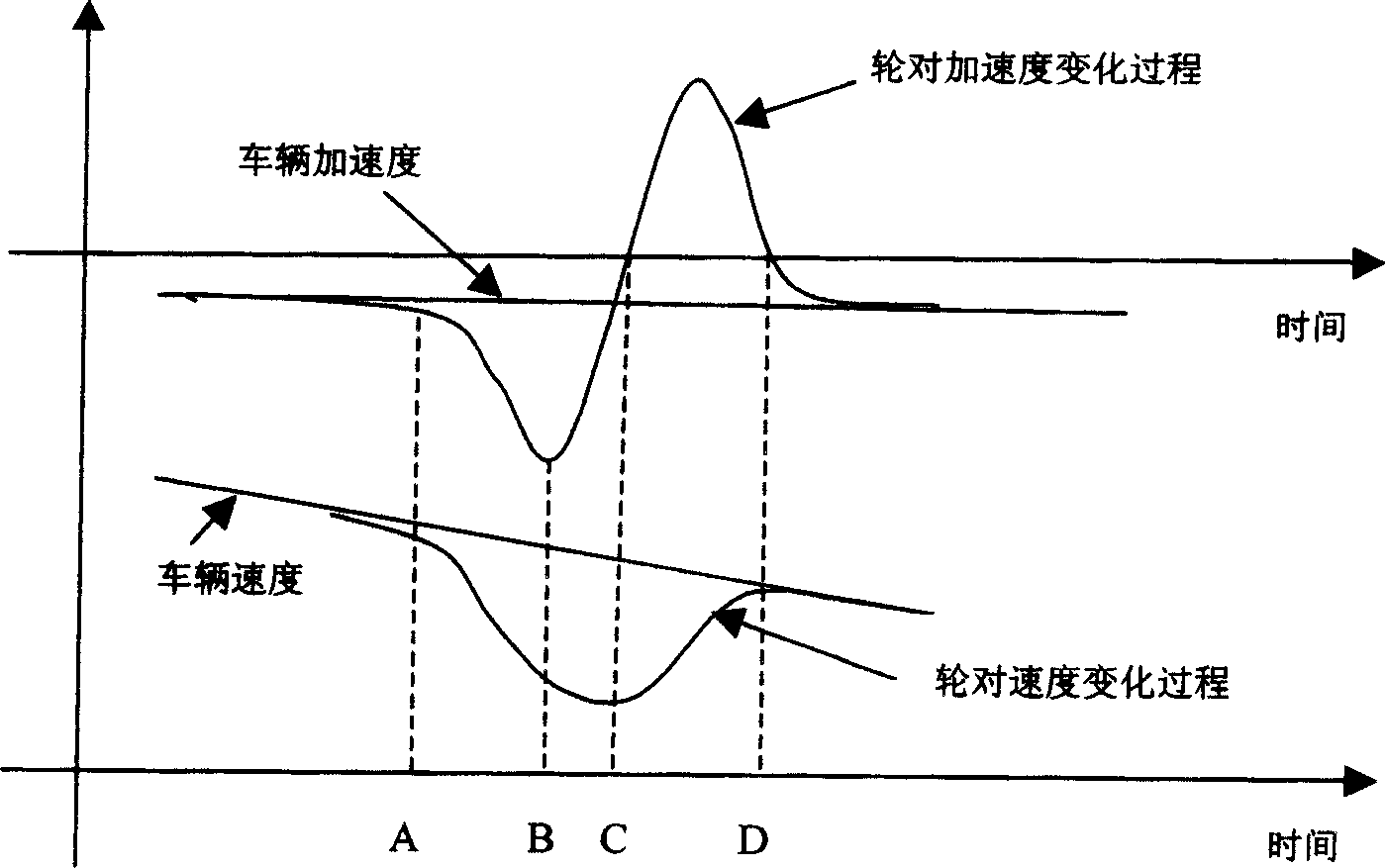

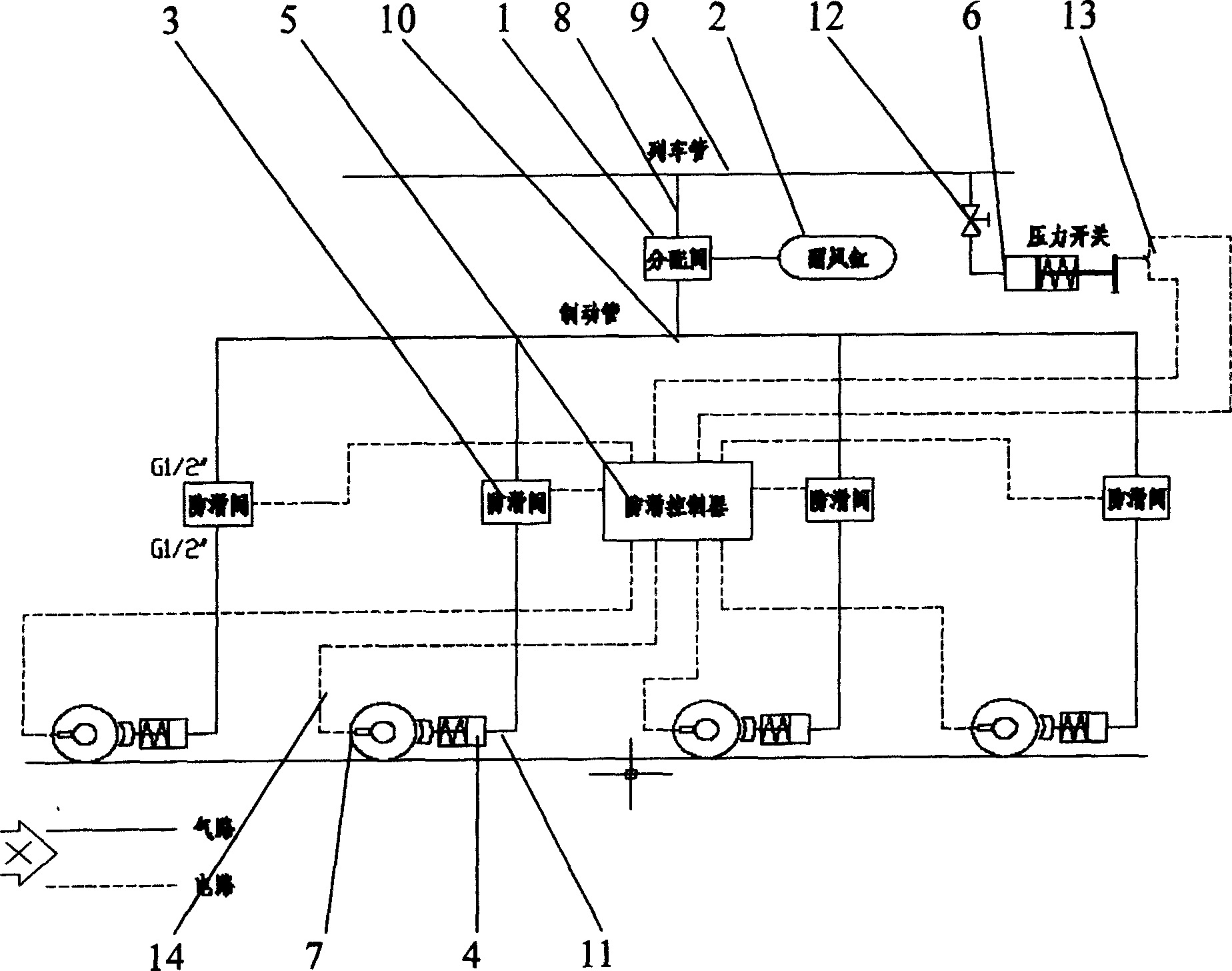

Control method and device for antislip of train

An antiskid control method for train includes such steps as setting up optimal control function according to train speed and the difference between actual speed and calculated speed, evaluating the utilization of adhesion to obtain comprehensive index value, and controlling antiskid valves to increase, decrease, or hold the pressure. Its apparatus is composed of antiskid controller. 4 antiskid valves and 4 speed sensors.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

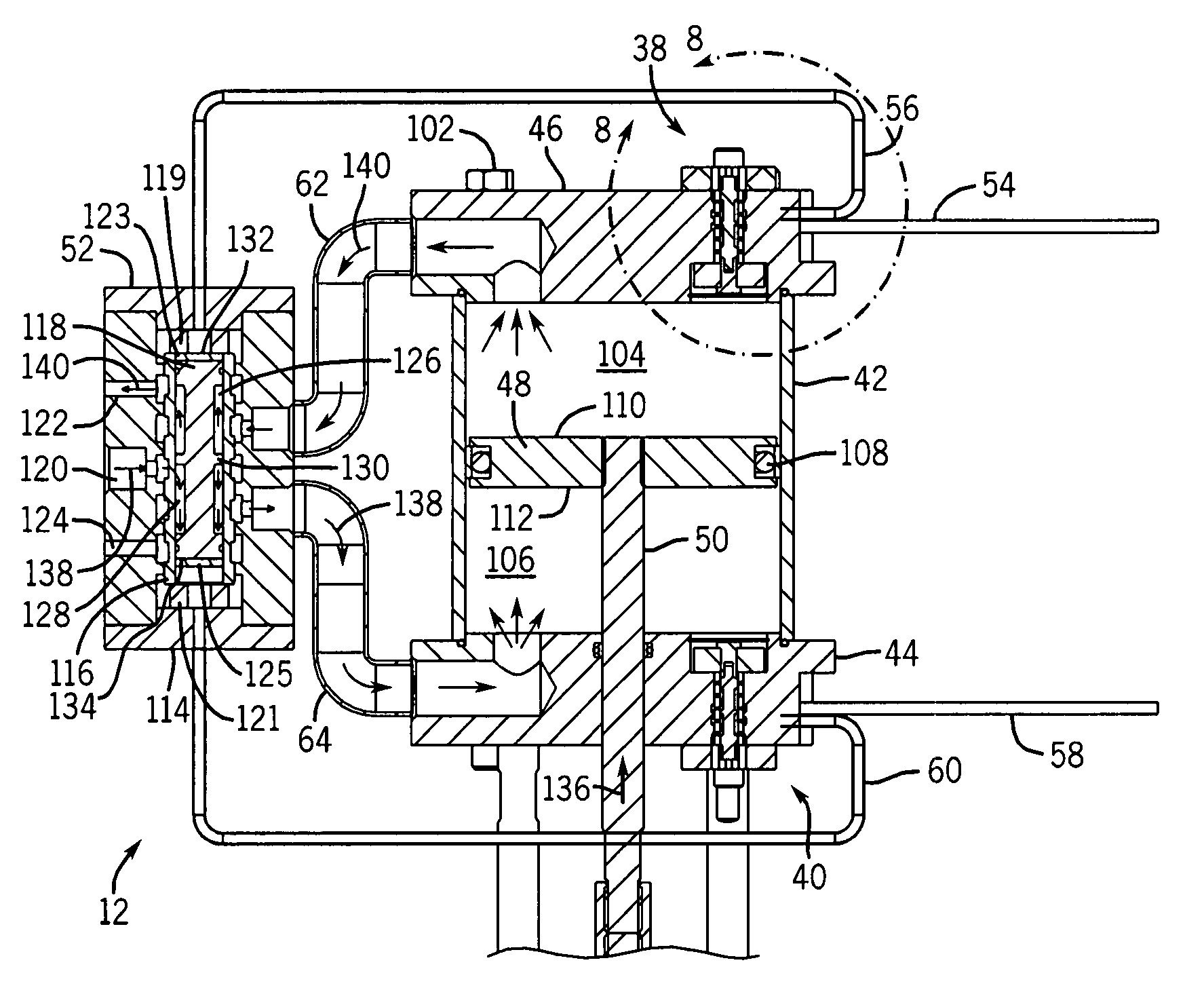

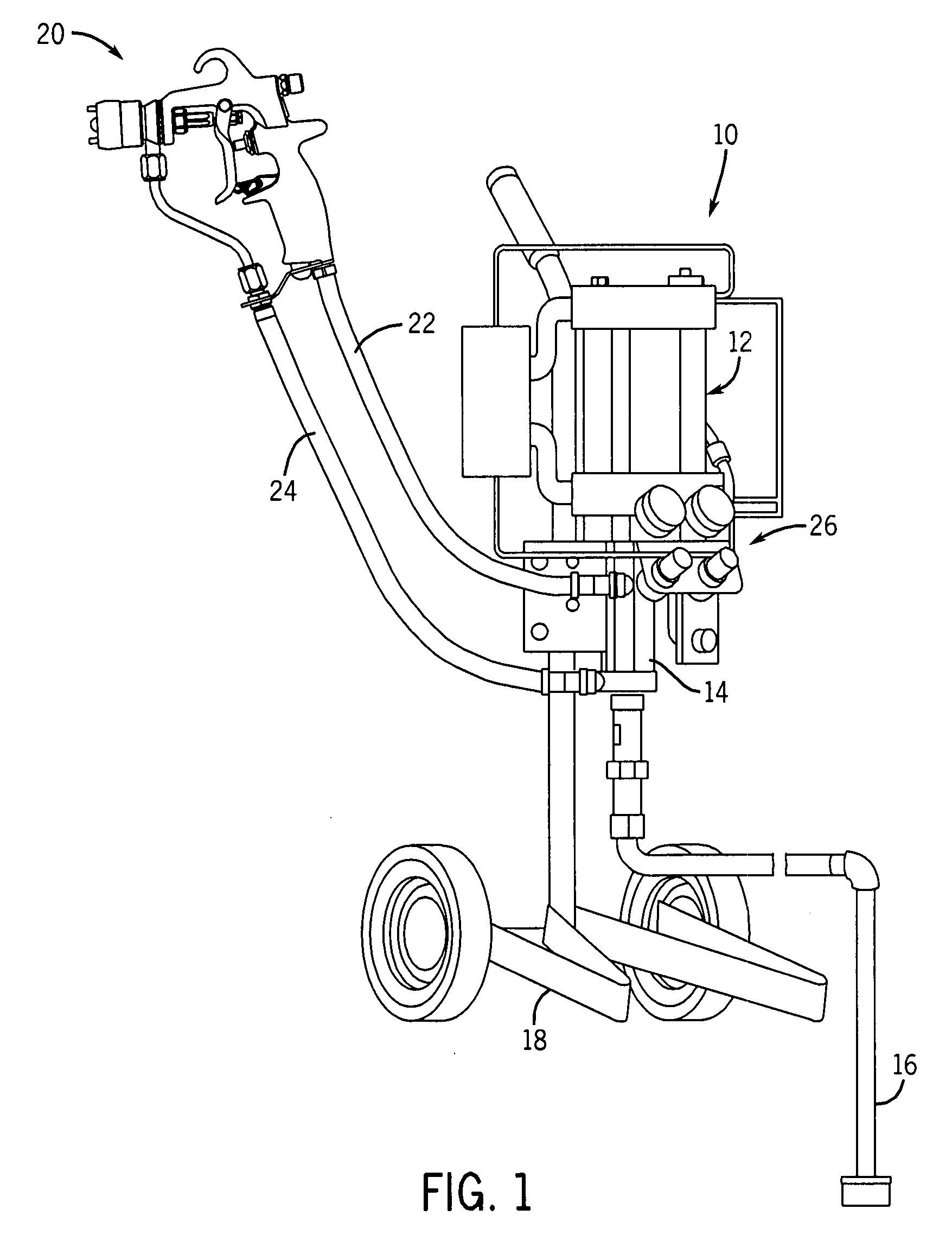

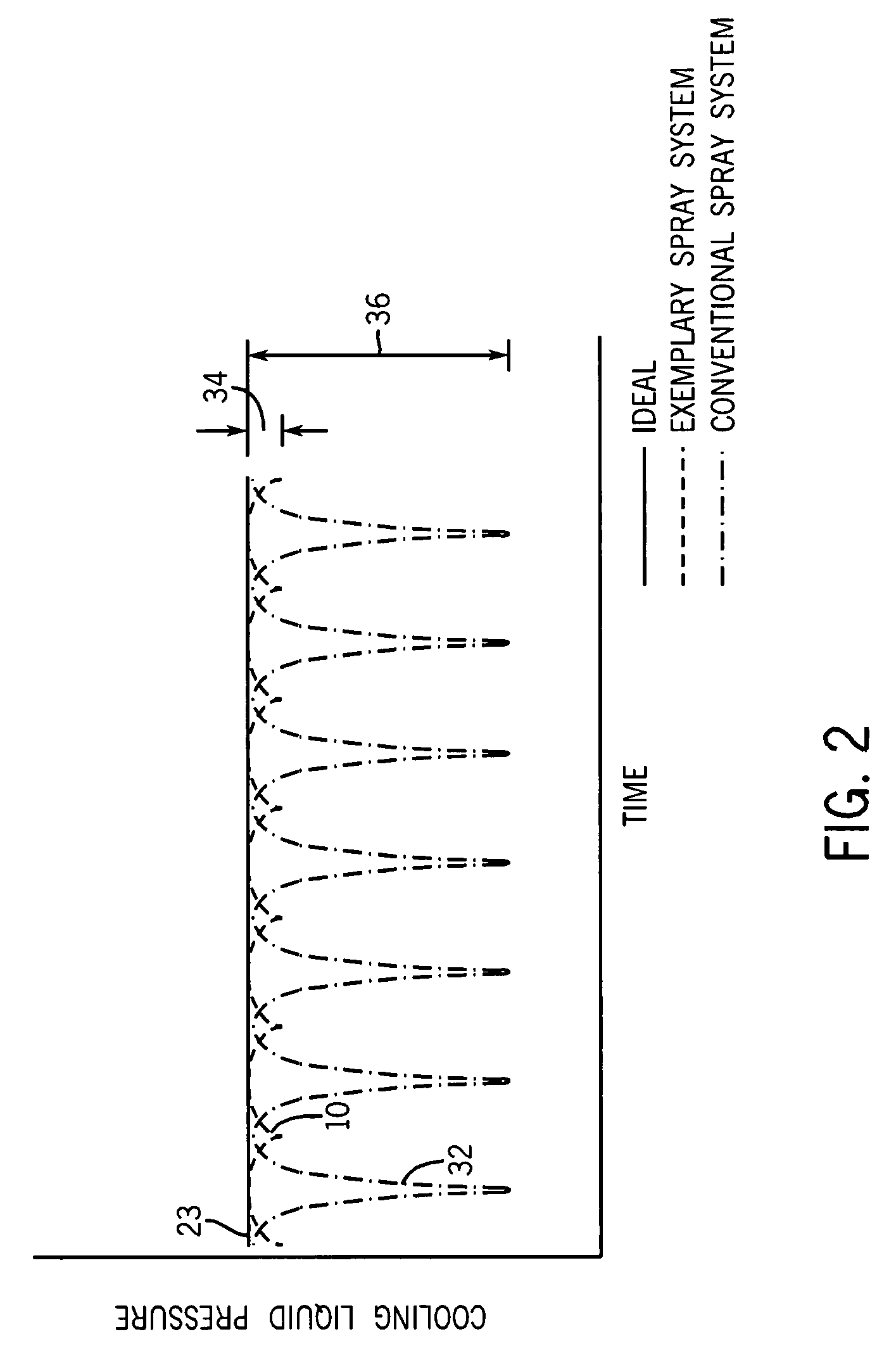

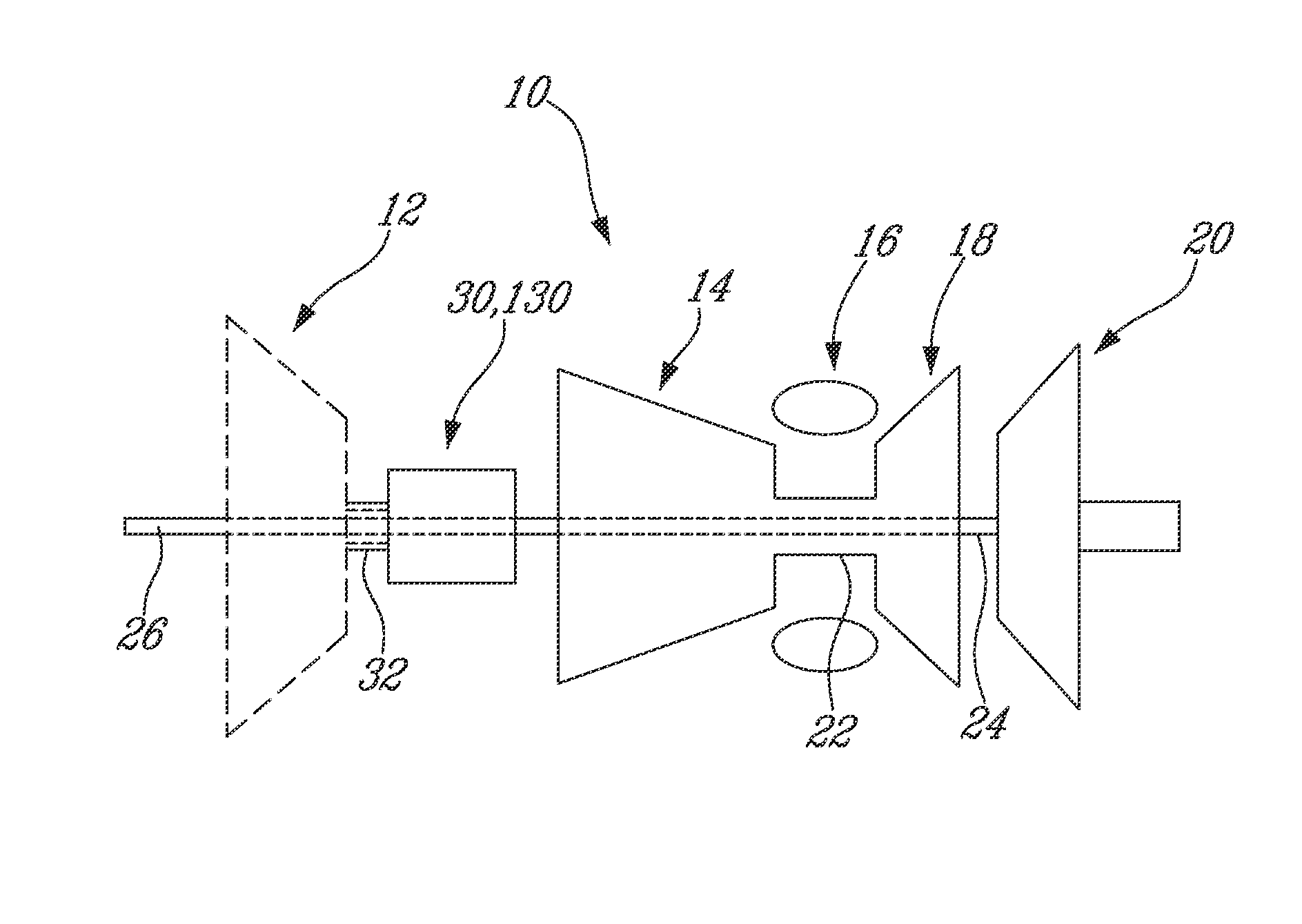

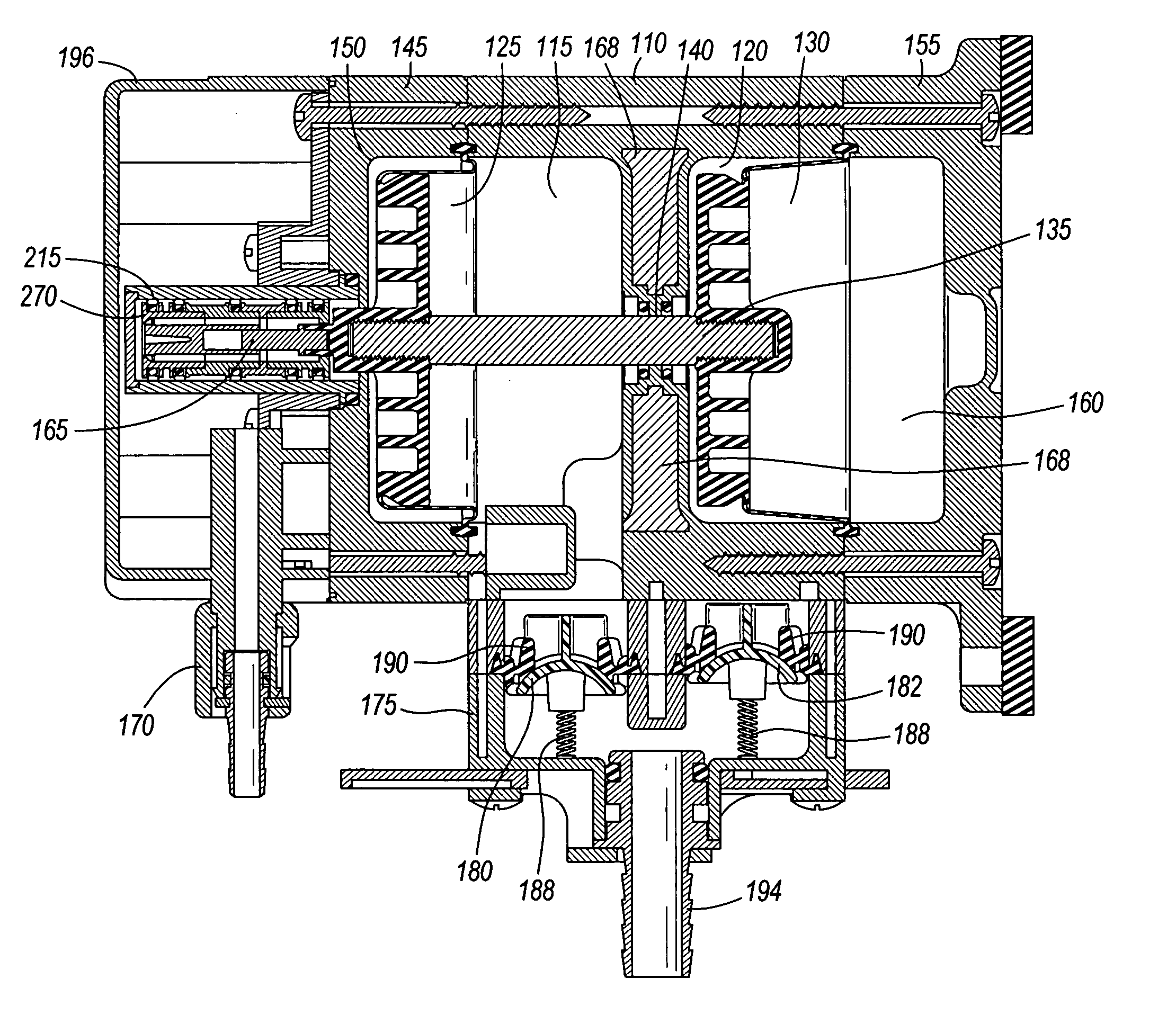

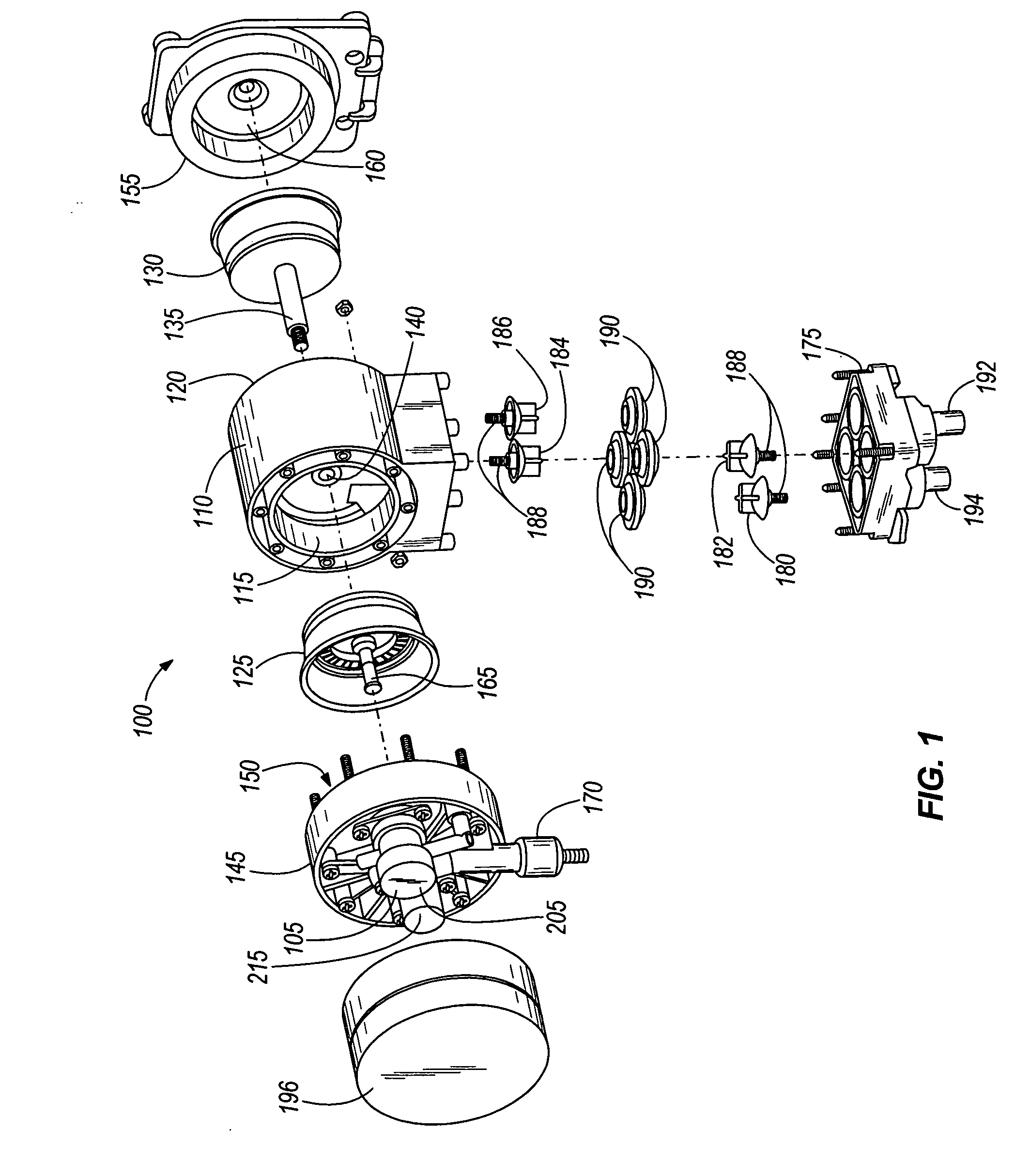

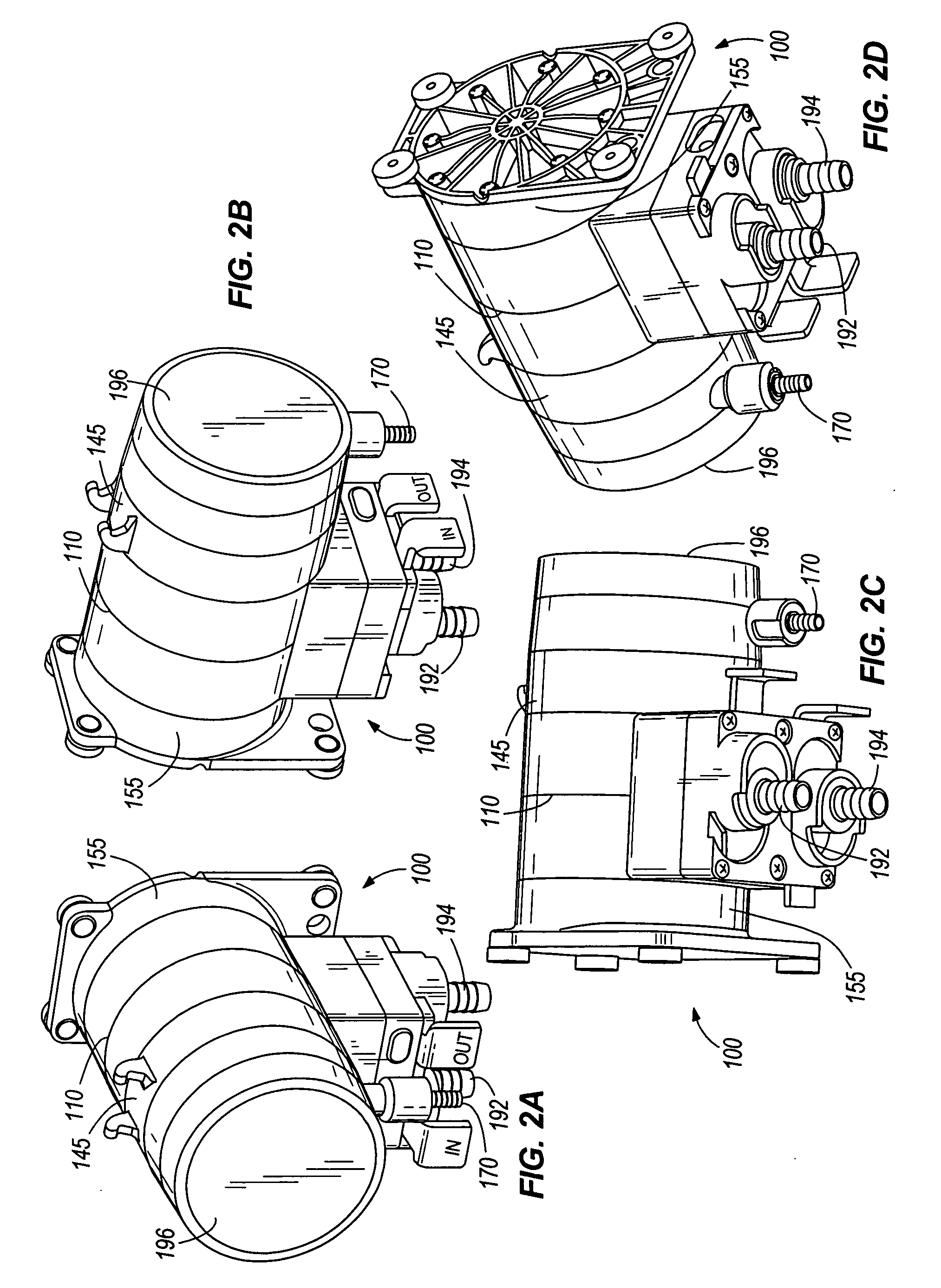

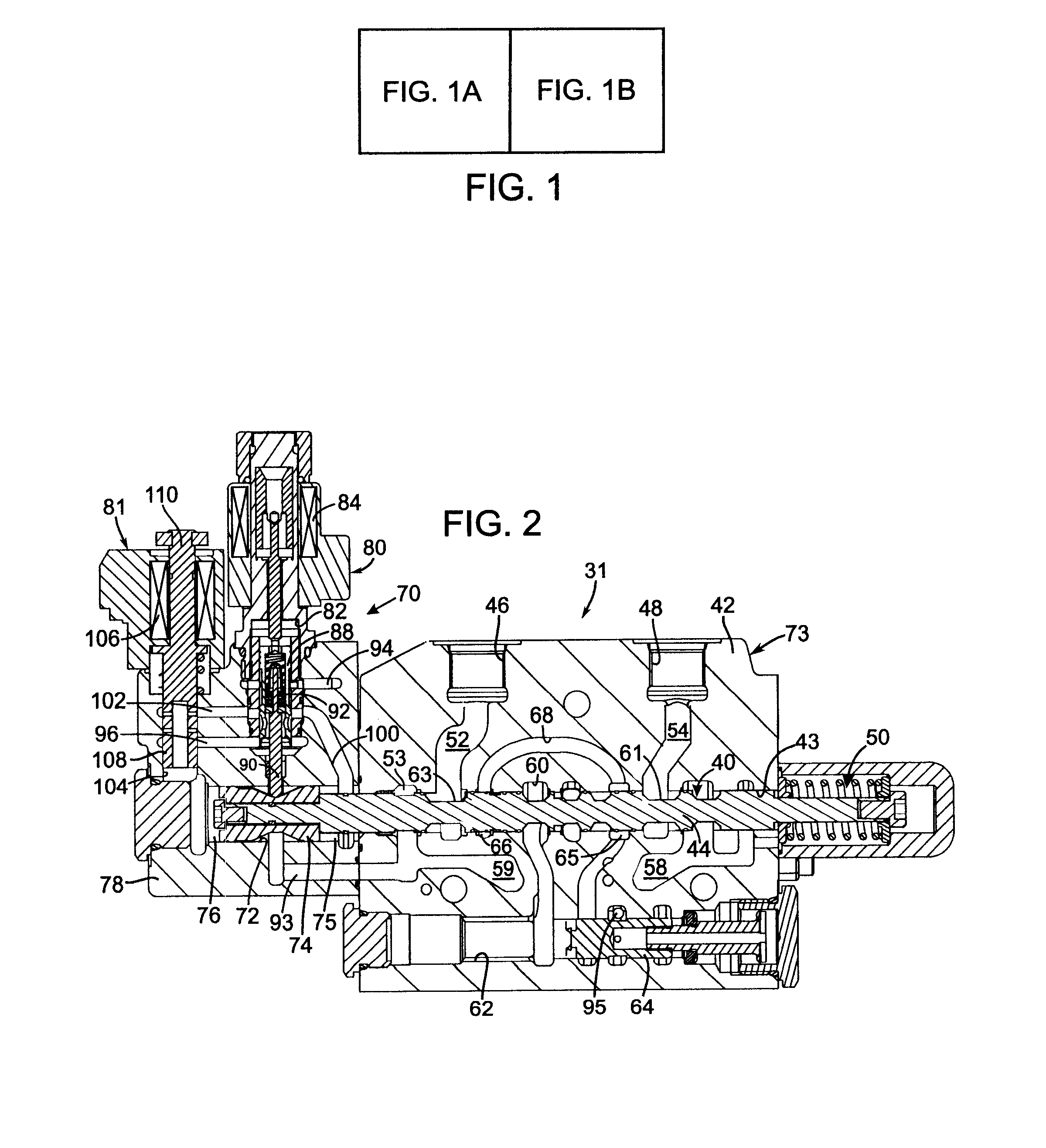

Pump and valve actuator system and method

InactiveUS20070092385A1Positive displacement pump componentsFlexible member pumpsSpool valveDiaphragm pump

A double diaphragm pump including a dual spool valve actuator. A set of piston / diaphragm assemblies can be coupled to a pilot spool valve, which can direct air flow to a main spool valve. The main spool valve can direct air flow to pump chambers. Components of the pump can be manufactured by injection molding and press-fit together. The pump can include lens-shaped ports and positive-return poppet valves.

Owner:SHURFLO

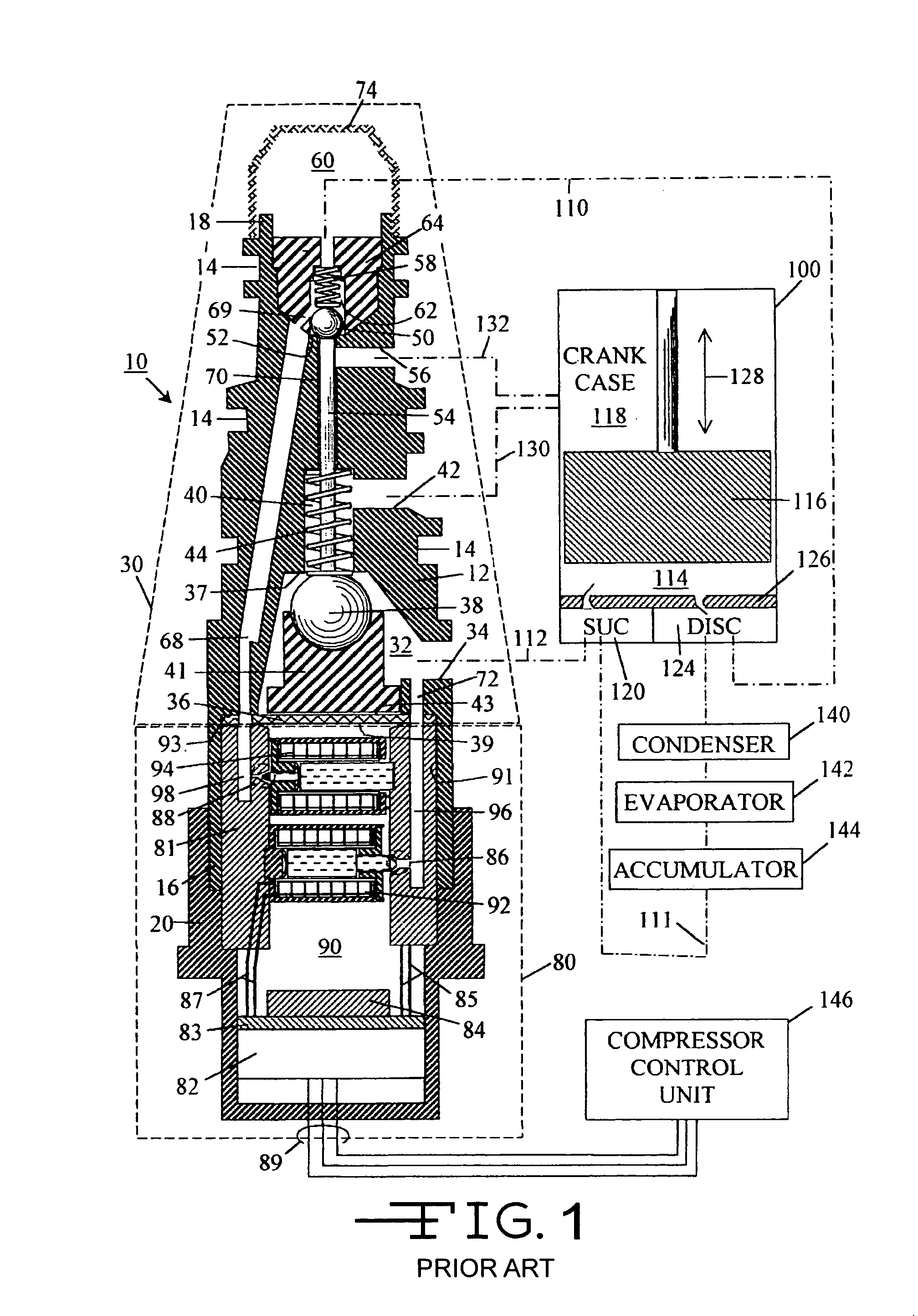

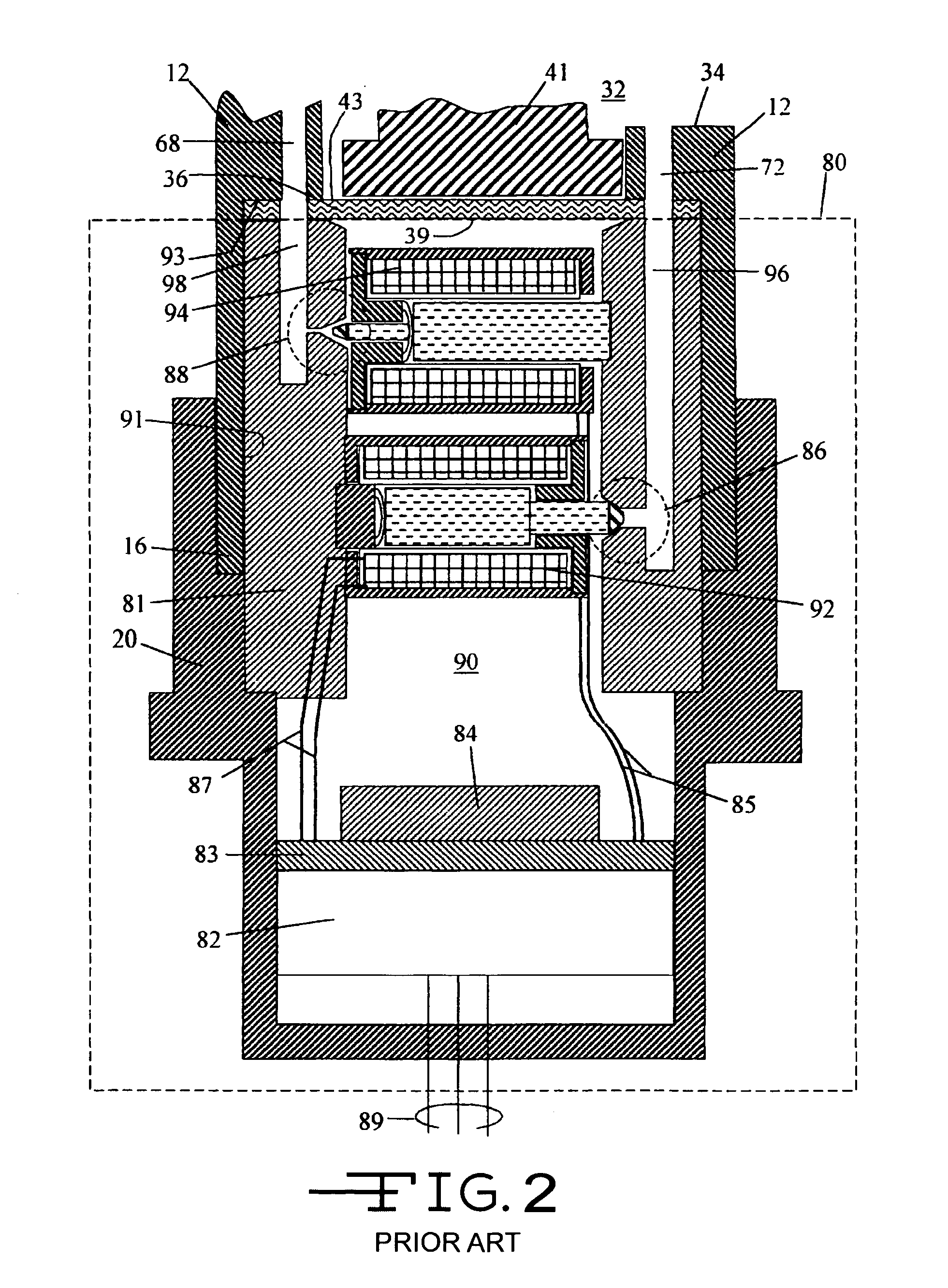

Microvalve device suitable for controlling a variable displacement compressor

ActiveUS7210502B2Fluid-pressure actuator safetyOperating means/releasing devices for valvesSpool valveEngineering

A device is disclosed for controlling a variable displacement compressor. The device comprises a microvalve operated control valve. A microvalve device for controlling fluid flow and a micro spool valve for use as a microvalve are also disclosed.

Owner:DUNAN MICROSTAQ

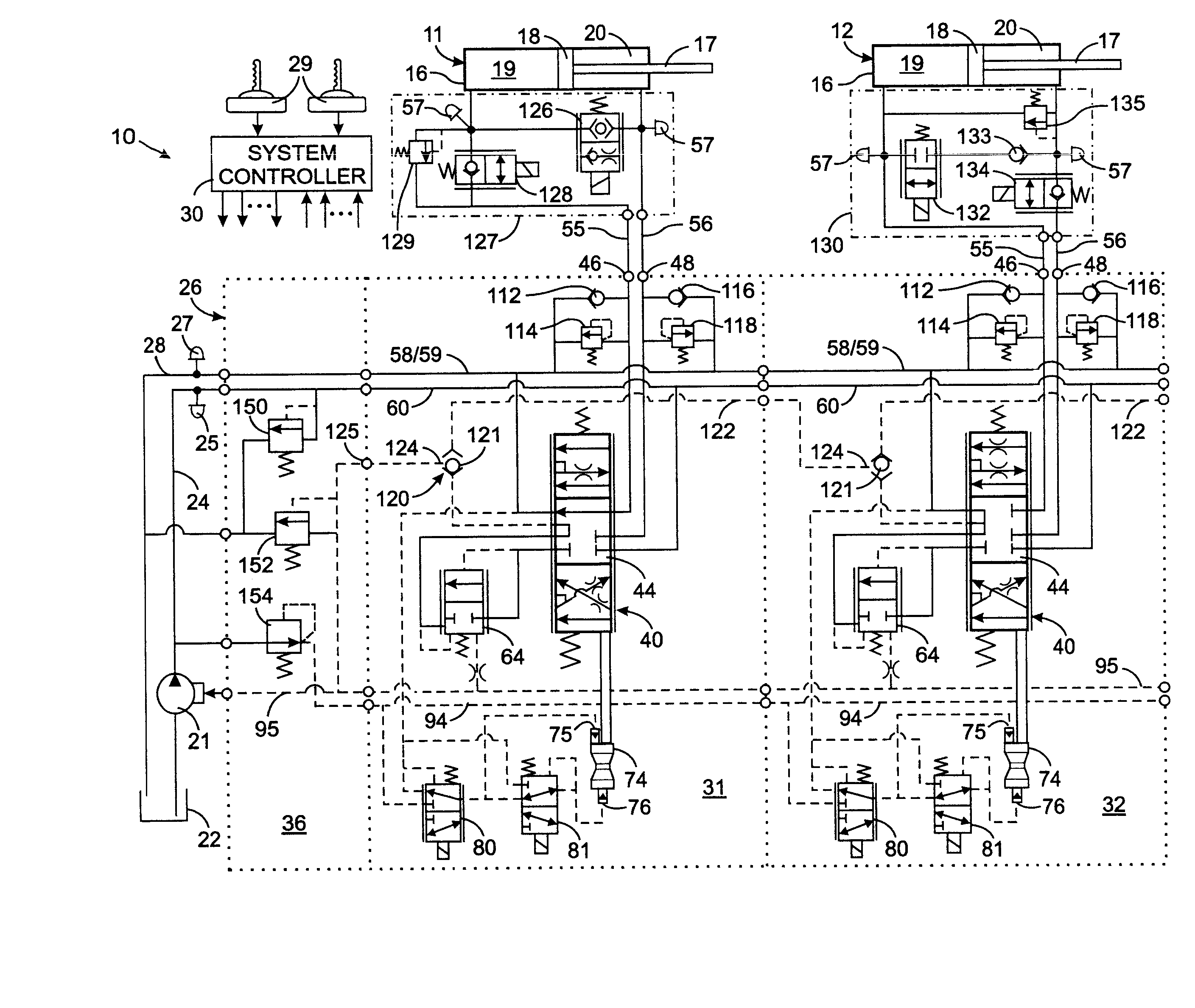

Hydraulic valve assembly with a pressure compensated directional spool valve and a regeneration shunt valve

InactiveUS20080072749A1Constant pressure dropServomotor componentsServomotorsSpool valveHydraulic circuit

A hydraulic circuit controls flow of fluid between first and second ports of a hydraulic actuator, such as a cylinder / piston arrangement and each of a supply conduit and a tank return conduit. The hydraulic circuit operates in standard powered operating modes as well as powered and unpowered regeneration modes. In a powered operating mode, a conventional pressure compensated spool valve determines the velocity of the hydraulic actuator. A workport blocking valve connects one workport of the spool valve to the first port and the other workport is connected to the second port. A regeneration shunt valve is directly connected between the first and second ports of the hydraulic actuator. In a regeneration operating mode or a mix of powered and regeneration modes, a combination of the spool valve, the workport blocking valve, and the regeneration shunt valve determines the velocity of the hydraulic actuator.

Owner:HUSCO INT INC

Fuel control system with metering purge valve for dual fuel turbine

ActiveUS8104258B1Reduce sensitivityPlug valvesLiquid fuel feeder/distributionCrossbar switchSpool valve

The fuel system of a dual fuel turbine includes a flow control valve having a metering purge valve that in one state directly meters fuel to injectors of the turbine, in another state closes of fuel flow and passes purge air to the injectors and in another state positively closes of flow of both fuel and purge air. The metering purge valve is a pressure compensated spool valve that has a unique cross-ported interchange that passes fuel from the inlet through the spool to the metering edge. The direct metering of the valve to the injectors eliminates the need for additional shut off valves, and if used with a combining valve having an integral distributor section metering fuel to multiple injectors, the need for a separate flow divider is also eliminated. The valve can be actively cooled by dedicated coolant lines or lines shared with other flow control components such as additional metering valves for either the primary or secondary fuel.

Owner:JANSENS AIRCRAFT SYST CONTROLS

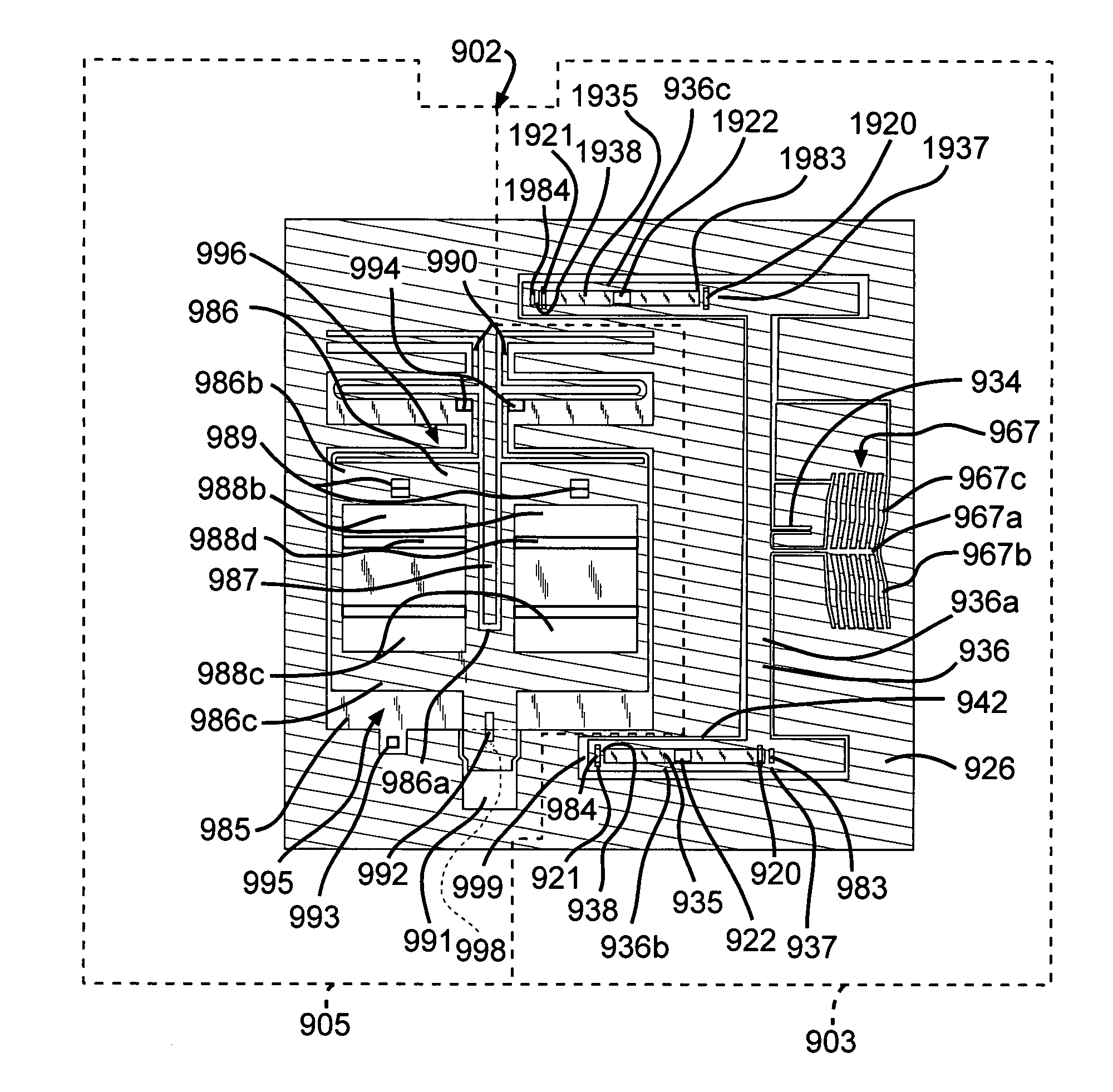

Spool valve manifold interconnect for a filter system

ActiveUS8097158B2Prevent leakagePrevent liquid leakagePlug valvesOperating means/releasing devices for valvesSpool valveFilter system

A filter cartridge and spool valve manifold assembly includes a filter cartridge and a spool valve manifold. The filter cartridge includes a filter element and inlet / outlet portion in fluid communication with the filter element. The inlet / outlet portion has a cartridge inlet port and a cartridge outlet port. The spool valve manifold includes a housing and a body. The housing has a housing inlet port and a housing outlet port adapted for fluid communication with a fluid supply system. The body is located within the housing and configured to rotate around a first axis relative to the housing. The inlet / outlet portion of the filter cartridge is fluidly coupled to the body via insertion of the inlet / outlet portion into the body in a direction perpendicular to the first axis.

Owner:3M INNOVATIVE PROPERTIES CO

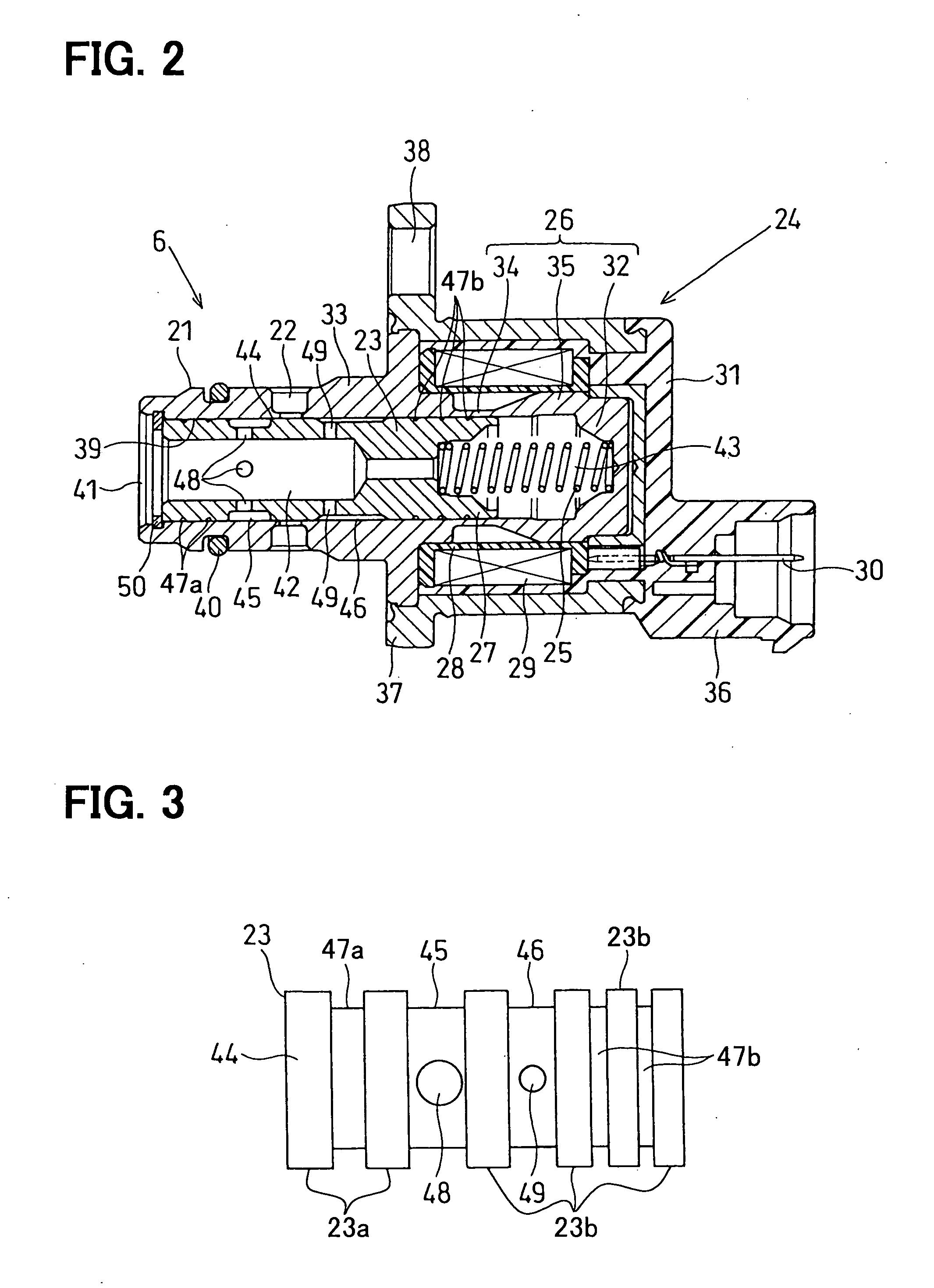

Flow control valve

InactiveUS20060065870A1Increased durabilityImprove reliabilityOperating means/releasing devices for valvesMachines/enginesSpool valveControl valves

A spool valve is movably provided in a valve sliding space of a valve casing. The spool valve has a through-hole formed in the inside thereof, and a communication port formed in the spool valve is operatively communicated with a fluid port for controlling an opening area of the fluid port by moving within the valve sliding space. Multiple circular oil grooves are formed at an outer peripheral surface of the spool valve, into which high pressure fluid is supplied so that the spool valve can be smoothly moved in the valve sliding space.

Owner:DENSO CORP

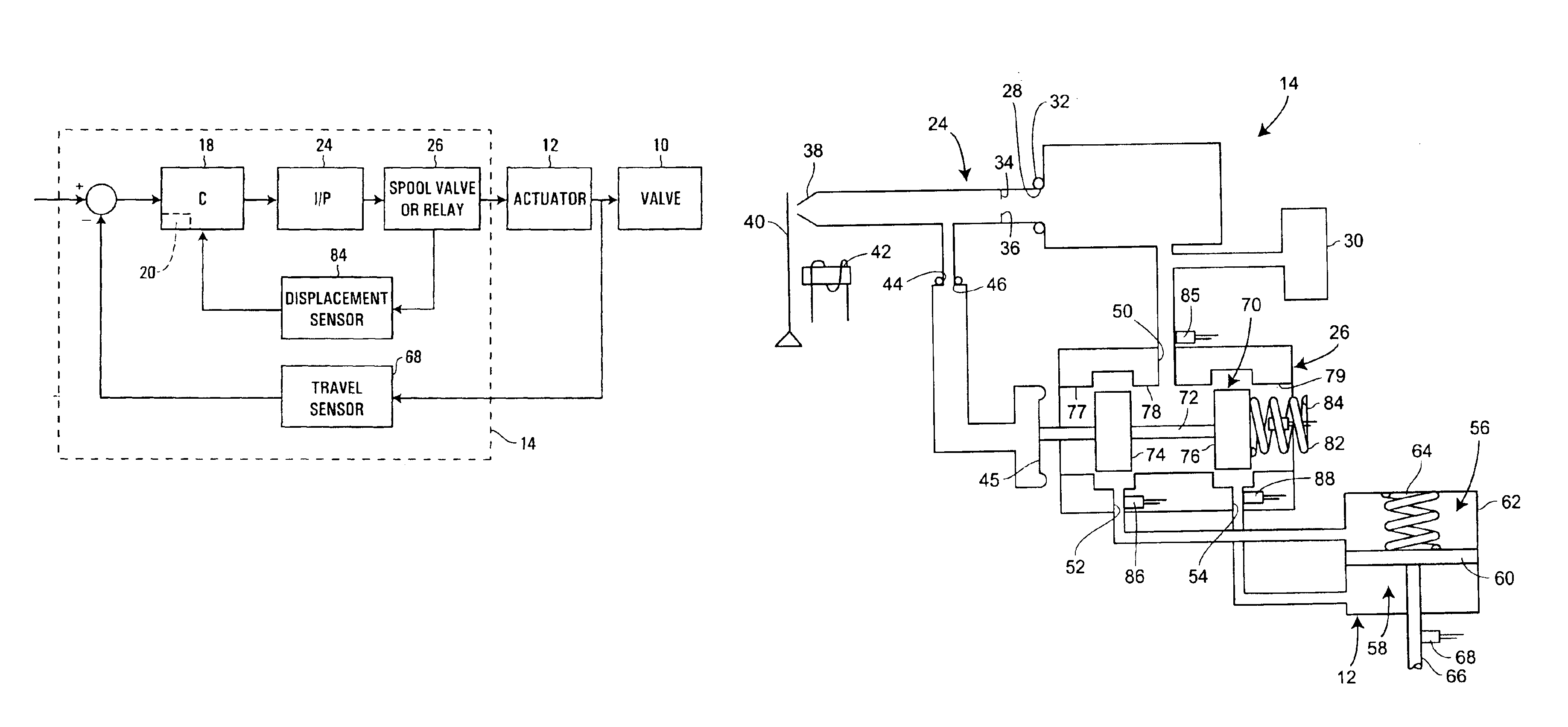

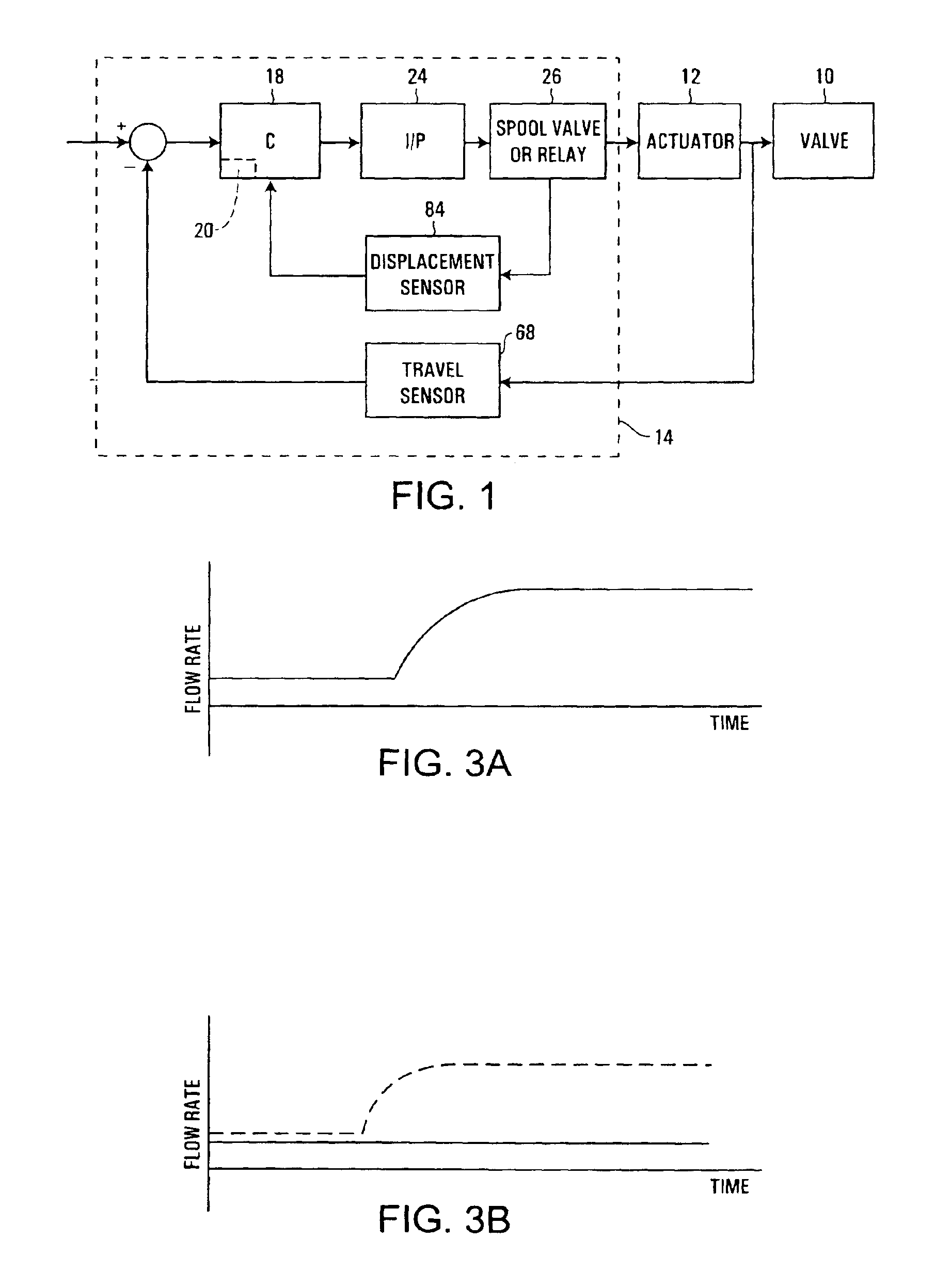

Method and apparatus for performing diagnostics in a control loop of a control valve

Method and apparatus for performing diagnostics in a pneumatic control loop for a control valve. Pressure and displacement sensors normally provided with a positioner are used to detect operating parameters of the control loop. A processor is programmed to receive feedback from the sensors and generate fault signals according to a logic sub-routine. The logic sub-routine may include calculating mass flow of control fluid through spool valve outlet ports and comparing other operating parameters of the control fluid to detect leaks and blockages in the control loop. Once a fault is detected, the location of the root cause of the fault may be identified by characterizing operating parameters of the control loop at the time of the fault.

Owner:FISHER CONTROLS INT LLC

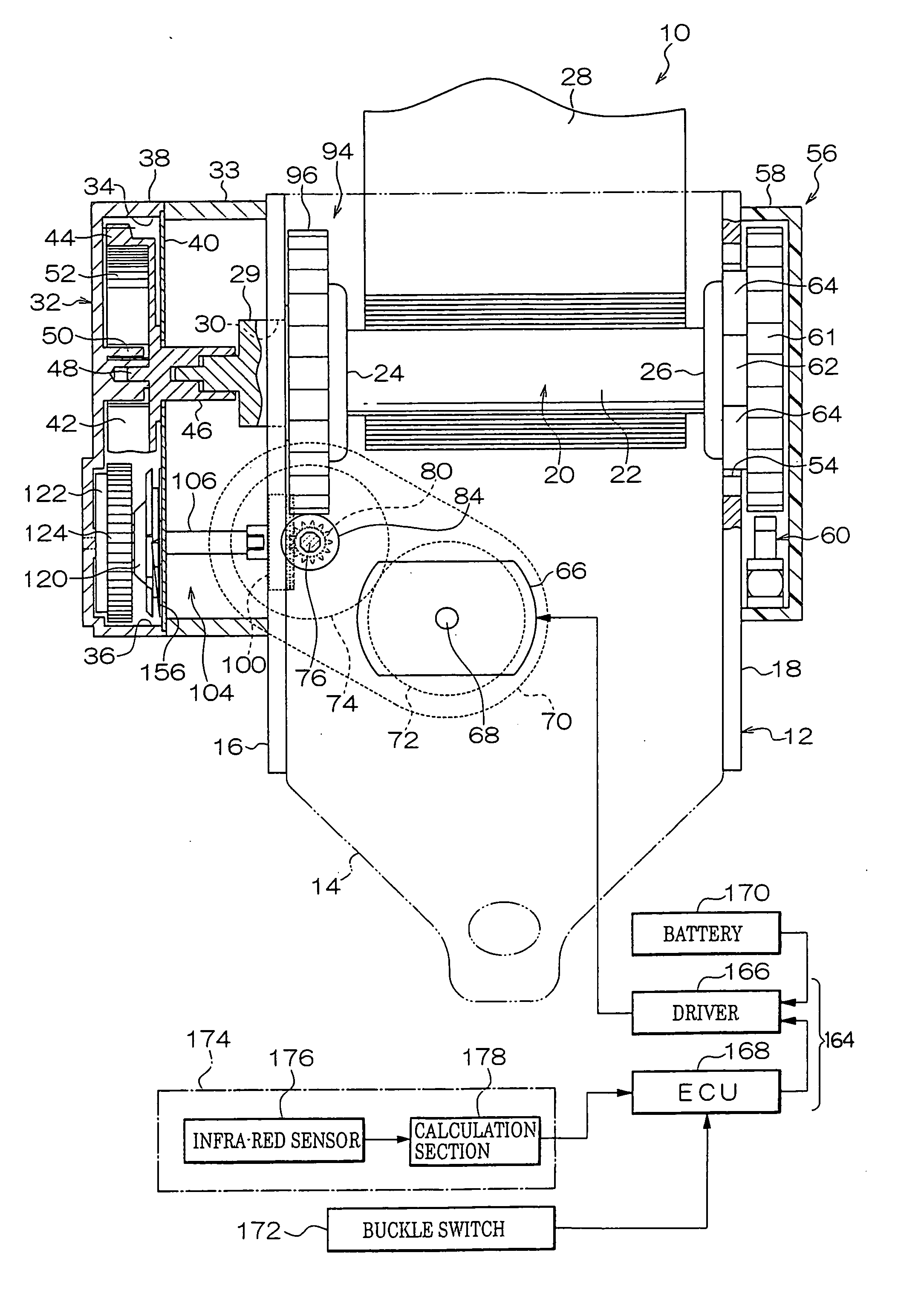

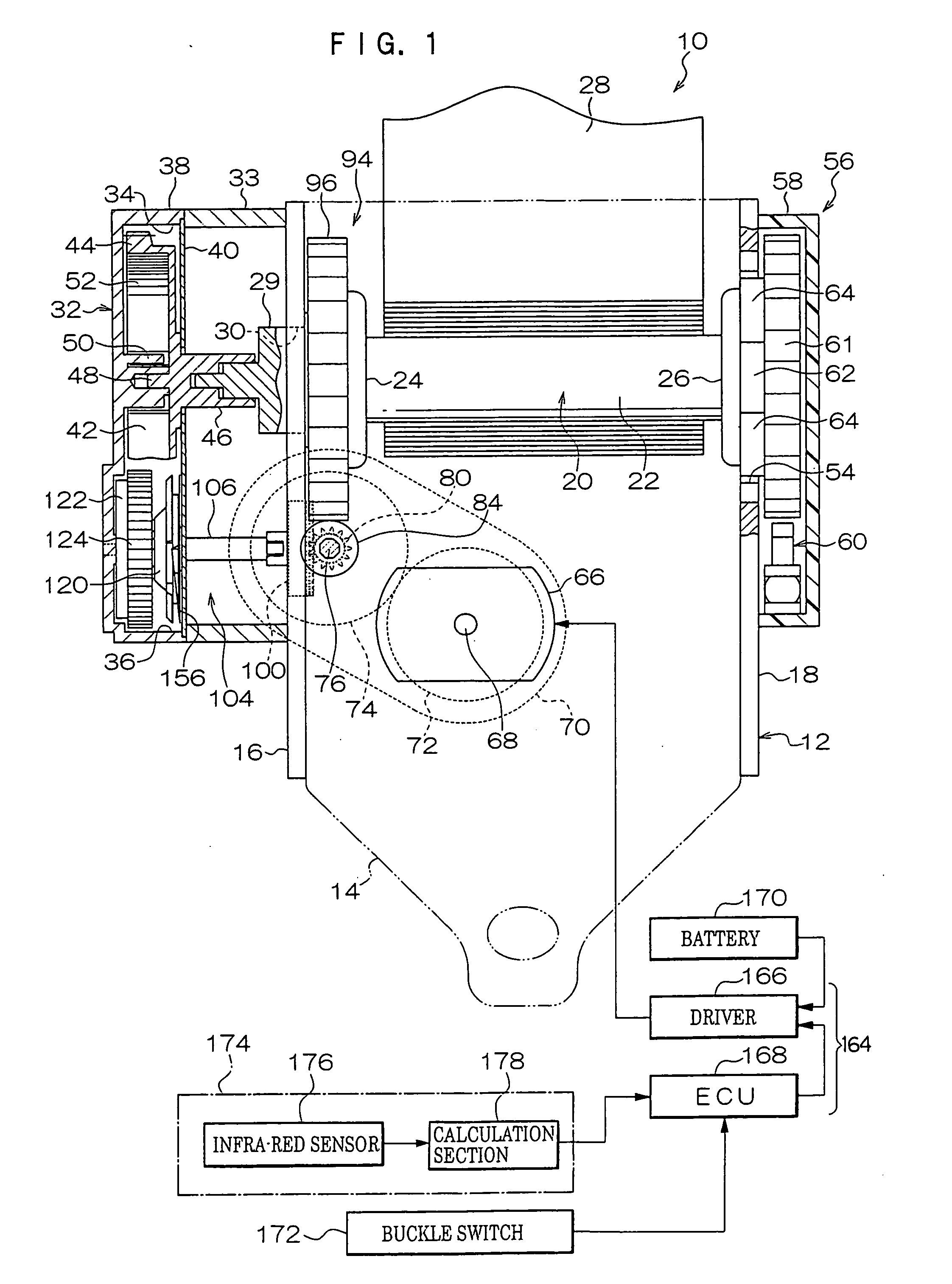

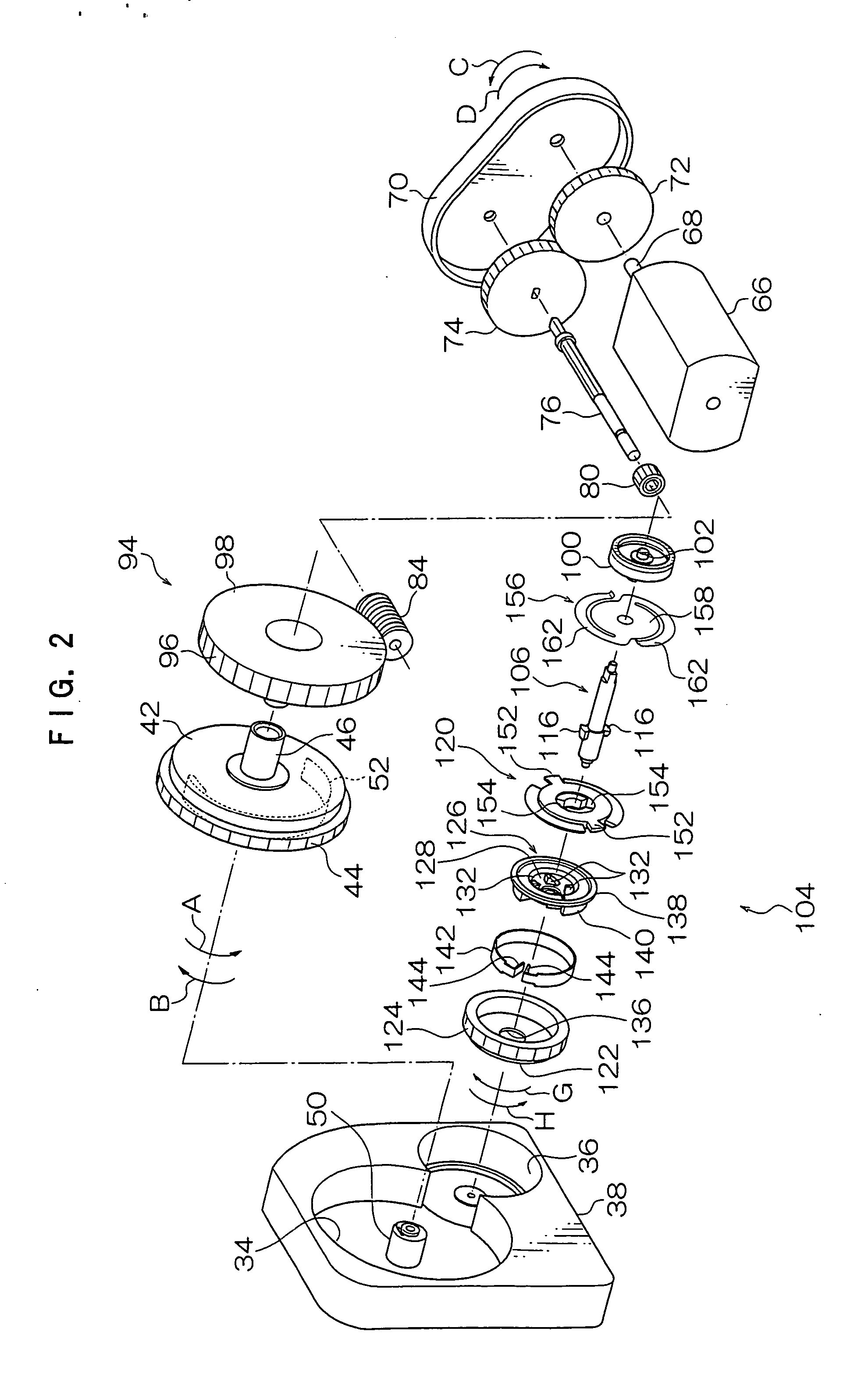

Motorized retractor

ActiveUS20050224621A1Increase torqueAvoid using forceBelt retractorsBelt control systemsSpool valveReduction ratio

A motorized retractor which includes a spool with a webbing wound therearound, a reversible motor, a forward and a reverse driving force transmission mechanisms. The forward and the reverse driving force transmission mechanisms are provided between the spool and an output shaft of the motor, respectively. The forward driving force transmission mechanism reduces forward rotation of the output shaft by a predetermined reduction ratio and transmits this rotation to the spool for rotating the spool in a winding direction. The reverse driving force transmission mechanism reduces reverse direction rotation of the output shaft by a reduction ratio which is lower than the predetermined reduction ratio of the forward driving force transmission mechanism, and transmits this rotation to the spool for rotating the spool in the winding direction. The forward and the reverse driving force transmission mechanisms both block transmission to the output shaft of rotations generated at the spool side.

Owner:KK TOKAI RIKA DENKI SEISAKUSHO

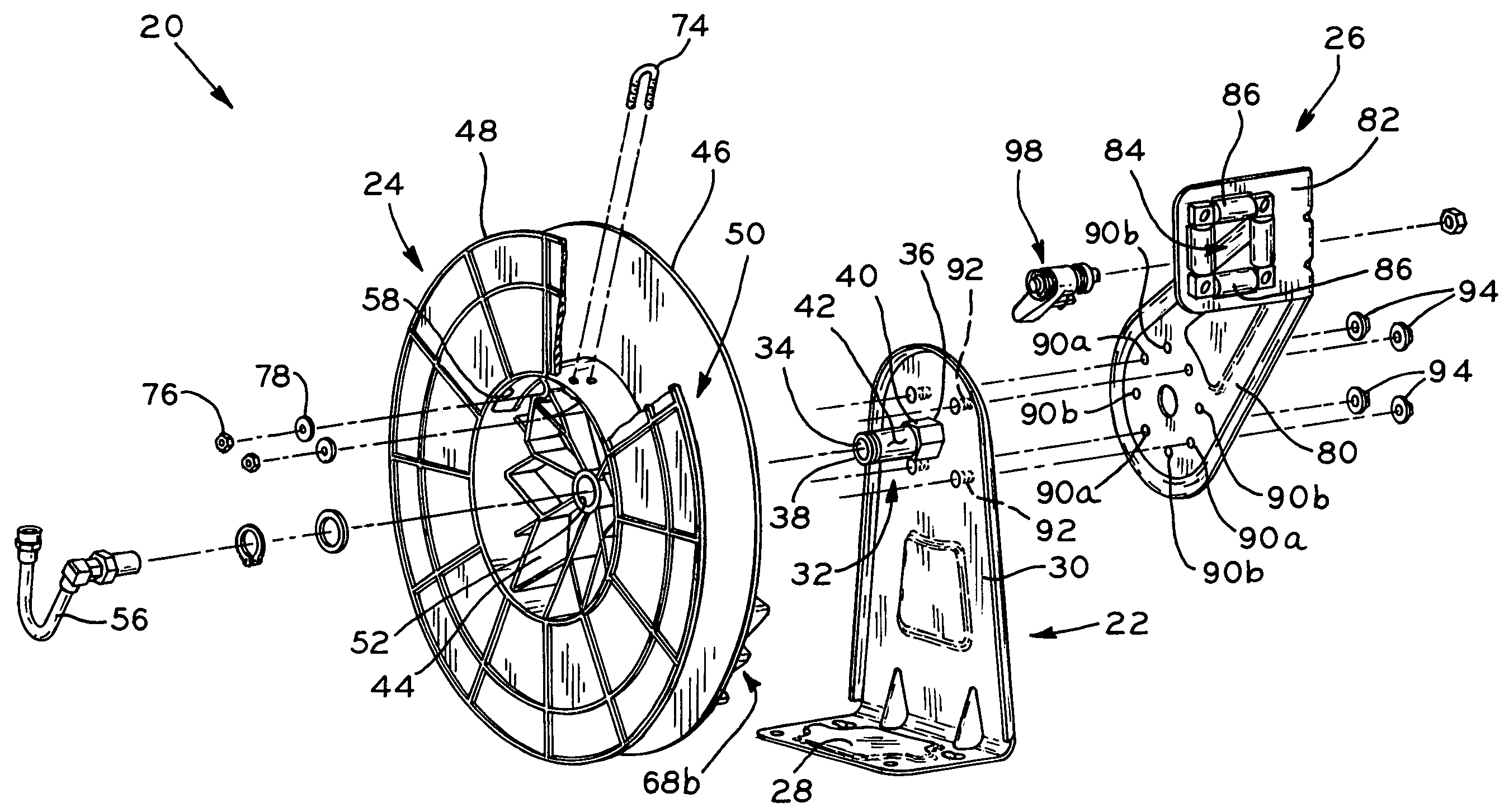

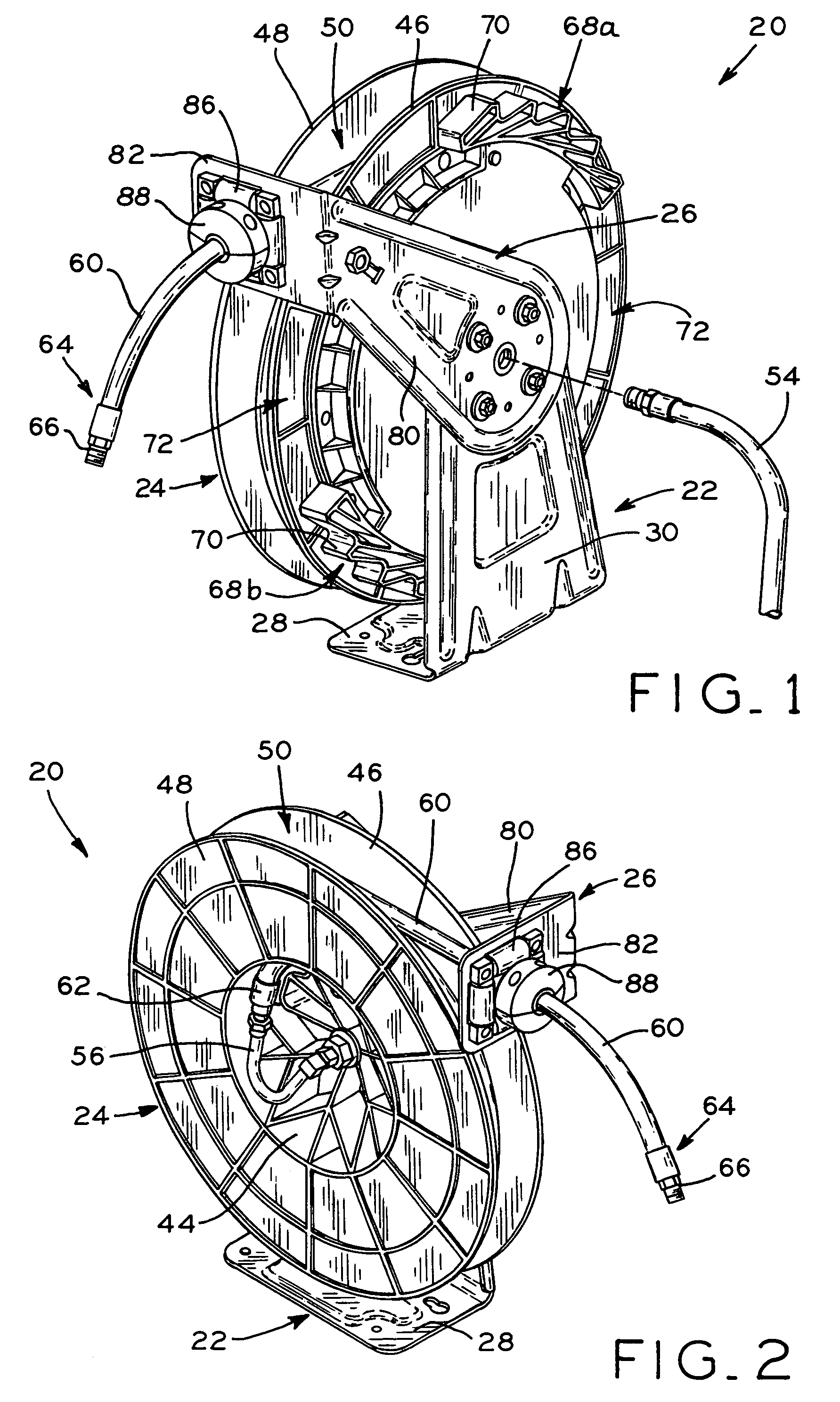

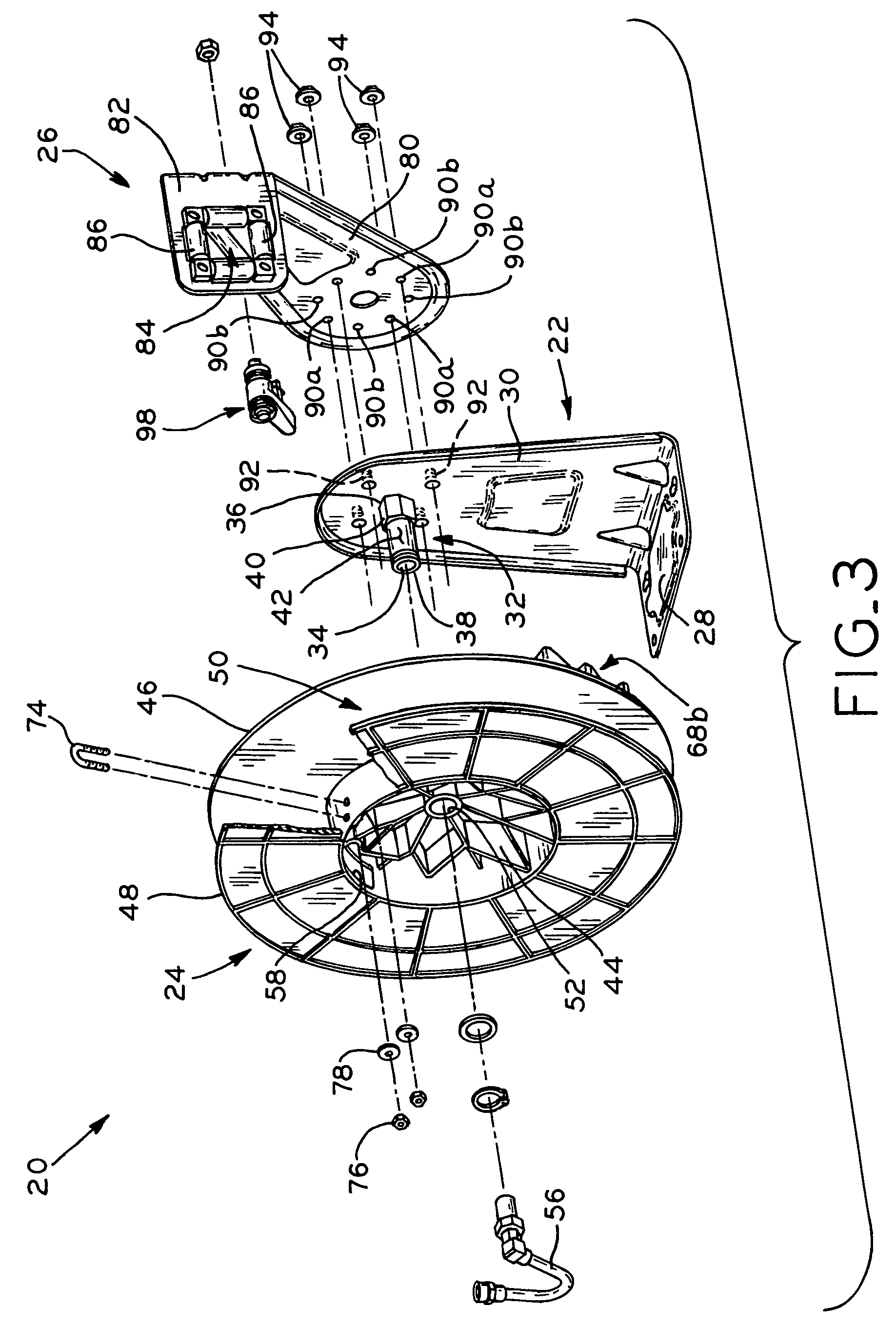

Adjustable reel assembly

A reel assembly for storing a hose, an electrical cord, or other items. The reel assembly includes a base, a spool rotatably mounted to the base, and a guide arm adjustably mounted to the base for guiding the direction in which a hose, for example, is extended from the reel and for guiding the hose onto the reel as the hose is wound upon the reel. A spring is operably connected between the spool and the base to bias the spool in a rotational direction in which the hose is wound onto the spool, thereby automatically retracting the hose after use. A pawl mechanism is mounted to the guide arm, and cooperates with a pair of ratchet teeth sets on the spool to selectively lock the spool against rotation in a hose-winding direction, thereby maintaining the hose in a desired extended position for use. The relative orientation of the ratchet teeth sets and the pawl mechanism, which is mounted to the guide arm, prevents “latch-out” when the hose is disposed in its fully extended position. Also, the spring is permanently enclosed within a spring housing defined between the spool and a cover which is permanently attached to the spool.

Owner:REELCRAFT INDS

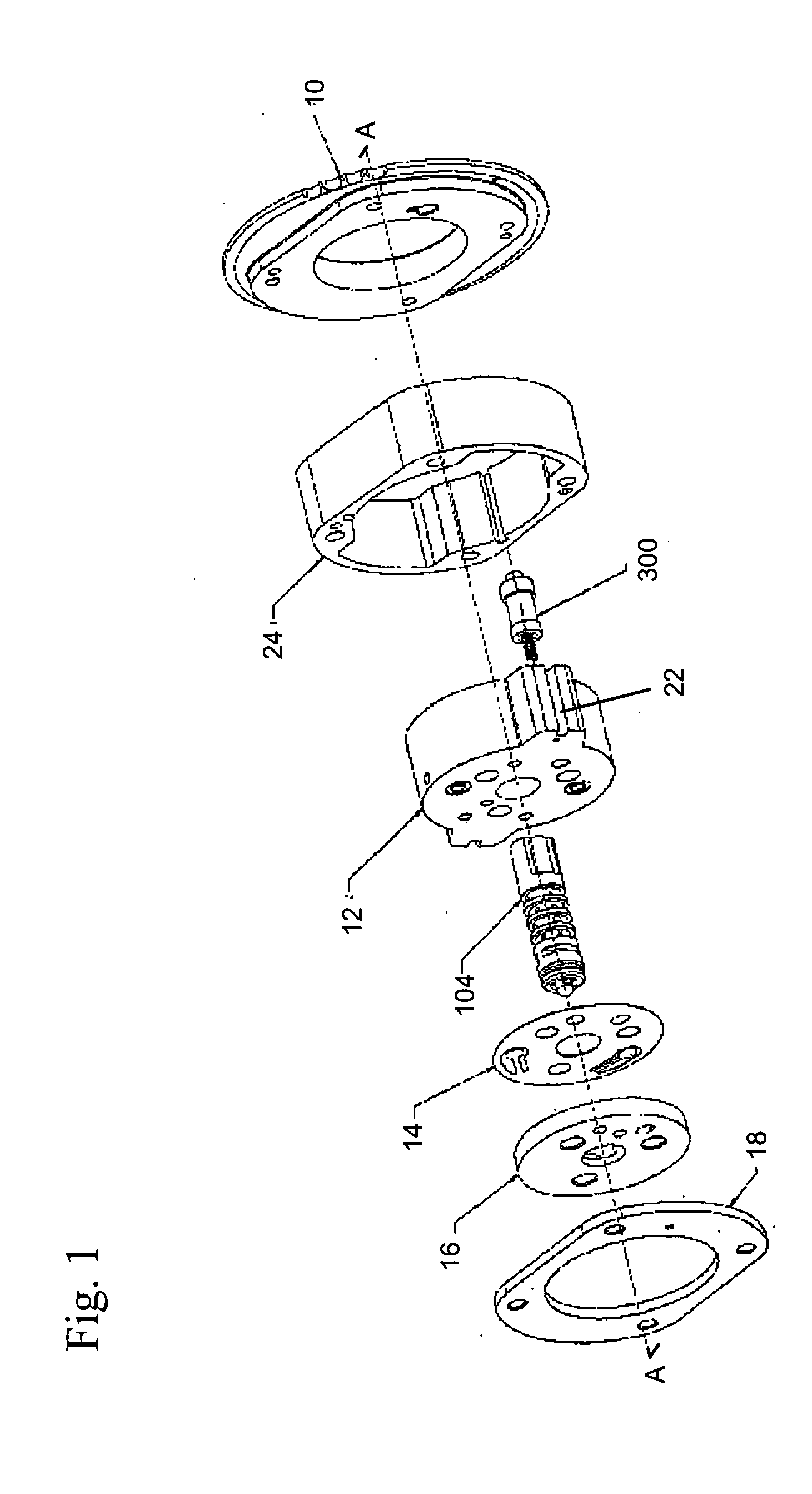

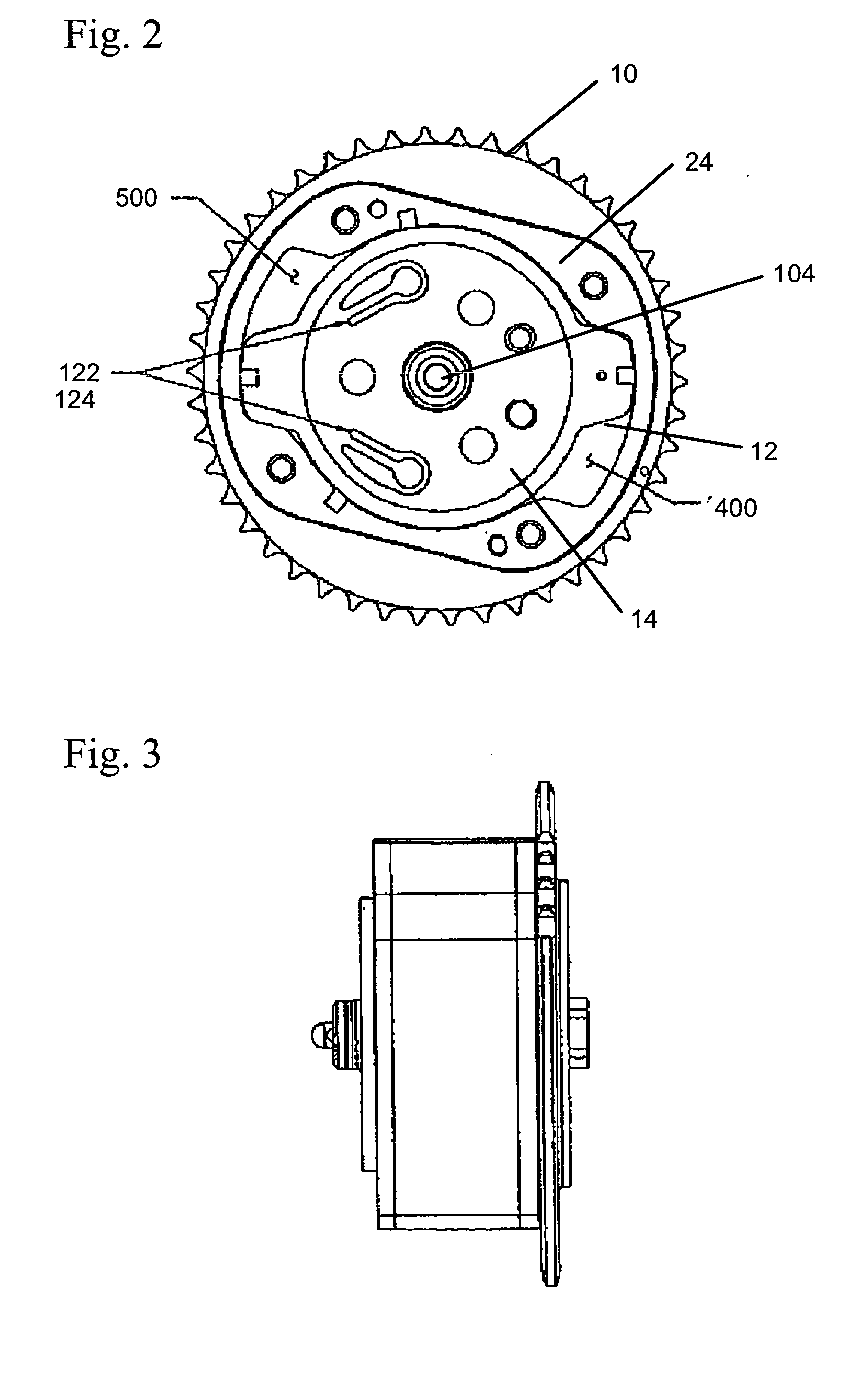

Spool valve controlled VCT locking pin release mechanism

A VCT phaser for an engine having a housing, rotor and a spool valve. The rotor having a bore comprising an open outer end, an inner surface, and inner end having a vent port and arranged along the bore, an advance port, a common port, a retard port, and a lock port. The spool valve comprises a spool with a first land, a first groove, a second land, a second groove, and a third land, with the area between the inner surface of the bore and the first groove defining a first chamber, the area between the bore and the second groove defining a second chamber, and the area between the bore and the inner end of the spool defining a third chamber. A passage between the first groove and the second groove for fluid passage provides fluid communication between the first chamber and the second chamber and lock pin.

Owner:BORGWARNER INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com